Craftsman 3902505 Owner’s Manual

SEARS

OWNER'S

MANUAL

MODEL NO.

390.2505

I:RI:IFTSMRN°

CAUTION:

Readand Follow

All Safety Rulesand

Operating Instructions

BeforeFirstUseof

ThisProduct.

Save ThisManual For

FutureReference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

PRtNTED iN U.S.A. FormNo. F642-04071 (8/3/04)

SHALLOW WELL

JET PUMP

• Safety Instructions

• Installation

• Electrical

• Maintenance

• Repair Parts

CONTENTS

Introduction ............................................................... 2

Warranty ..................................................................... 2

Major System Components ........................................ 3

Installation .................................................................. 4

Electrical .................................................................. 5_5

Maintenance ............................................................ 7-8

Troubleshooting ......................................................... 9

Repair Parts ......................................................... 10-11

INTRODUCTION

Please read our instructions before installing and using

your pump. This will help you obtain the full benefits

of the quality and convenience built into this equip-

ment. It will also help you avoid any needless service

expense resulting from causes beyond our control

which are not covered by our w_ty.

RULES FOR SAFE INSTALLATION AND OPERATION

1. Read the Owners Manual and Rules for Safe

Operation and Installation Instructions carefufiy.

Failure to follow these Rules and Instructions could

cause serious bodily injury, and/or property damage.

2. Check your local electrical wiring codes before in-

stallation. If your local codes are not followed, your

pump will not work to its full rated capacity and

could present a fire hazard. If in doubt, contact your

local power company.

3. BE SURE your pump installation meets all local

plumbing, pump and well codes.

4. While installing your pump, always keep the well

covered to prevent leaves and foreign matter from

falling into the well, contaminating the water

and/or causing possible serious damage to the me-

chanical operation of the pump.

5. Always test the water from web for purity before

using. Check with local health department for test-

ing procedure.

6. Before instaUing or servicing your pump, BE SURE

pump power source is disconnected.

7. BE SURE your pump electrical circuit is properly

grounded.

8. Complete pump and piping system MUST be pre-

tected against below freezing temperature.

Allowing the pump or piping to freeze could cause

severe damage and voids the Warranty.

9. BE SURE the line voltage and frequency of the elec-

trical current supply agree with the motor wiring

as shown on motor nameplate.

10. The correct fusing and wiring sizing is essential to

proper motor operation. Use recommended fusing

and wire size data in the manual (Pages 5 and 6).

11. Pump water only with this pump.

12. Periodically inspect pump and system components.

13. Relief valve must be capable of passing full pump

flow at 75 PSI.

[kWARNIN_ Pump body may explode if used as a

booster pump unless relief valve capable of pass-

ing full pump flow at 75 PSI (517 kPa) is installed.

[a_CAOTION]Motor normally operates at high tempera-

ture and will be too hot to touch. It is protected from

heat damage during operation by an automatic internal

cutoff switch. Before handling pump or motor, stop

motor and allow it to cool for 20 minutes.

2

MAJOR COMPONENTS AND WHAT THEY DO

Tank and Air Volume Control

The tank serves two functions. It provides a reservoir

of water, so that the pump doesn't need to start every

time water is drawn from a fixture in the house, and it

maintains a cushion of air under pressure.

When Captive Air* Tanks are used, no air volume con-

trol is necessary. This tank is precharged with air at the

factory.

When a Standard Tank is used, an air volume control

adds air to the tank when it is needed. See instructions

included with Air Volume Control for details on instal-

lation and operation.

Pressure Switch

The pressure switch provides automatic control.

Model No.

390.2505

When used with a Captive Air* Tank, the precharge

may need adjustment. See the Captive Air* Tank in-

structions for details.

Impeller and Jet

The impeller of the pump rotates with the motor shaft,

causing the water to fly out from its rim by centrifugal

force. The rotation of the impeller creates a partial vac-

uum which pulls in more water. Part of the water is di-

verted back to the jet where it passes through the

nozzle and venturi, reinforcing the vacuum to draw in

more water and delivering it at a high velocity to the

impeller.

Because of the shallow setting, the partial vacuum cre-

ated by the pump is sufficient to pull water to the

pump, therefore, the jet assembly is attached directly

to the pump.

Piping In The Well

A Shallow well jet pump can be installed on a dug well,

drilled well or with a driven point. SEARS shallow well jet

pumps have a built-in check valve. In a dug or cased well,

a foot valve and strainer is recommended and should be

installed 5 to 10 feet below the lowest level to which the

water will drop while pump is operating (pumping water

level), See Figure 3, Page 4. Your well driller can furnish

this information. The strainer should not be too close to

the bottom, or sediment may clog it. Before installing foot

valve, check to see that it works freely.

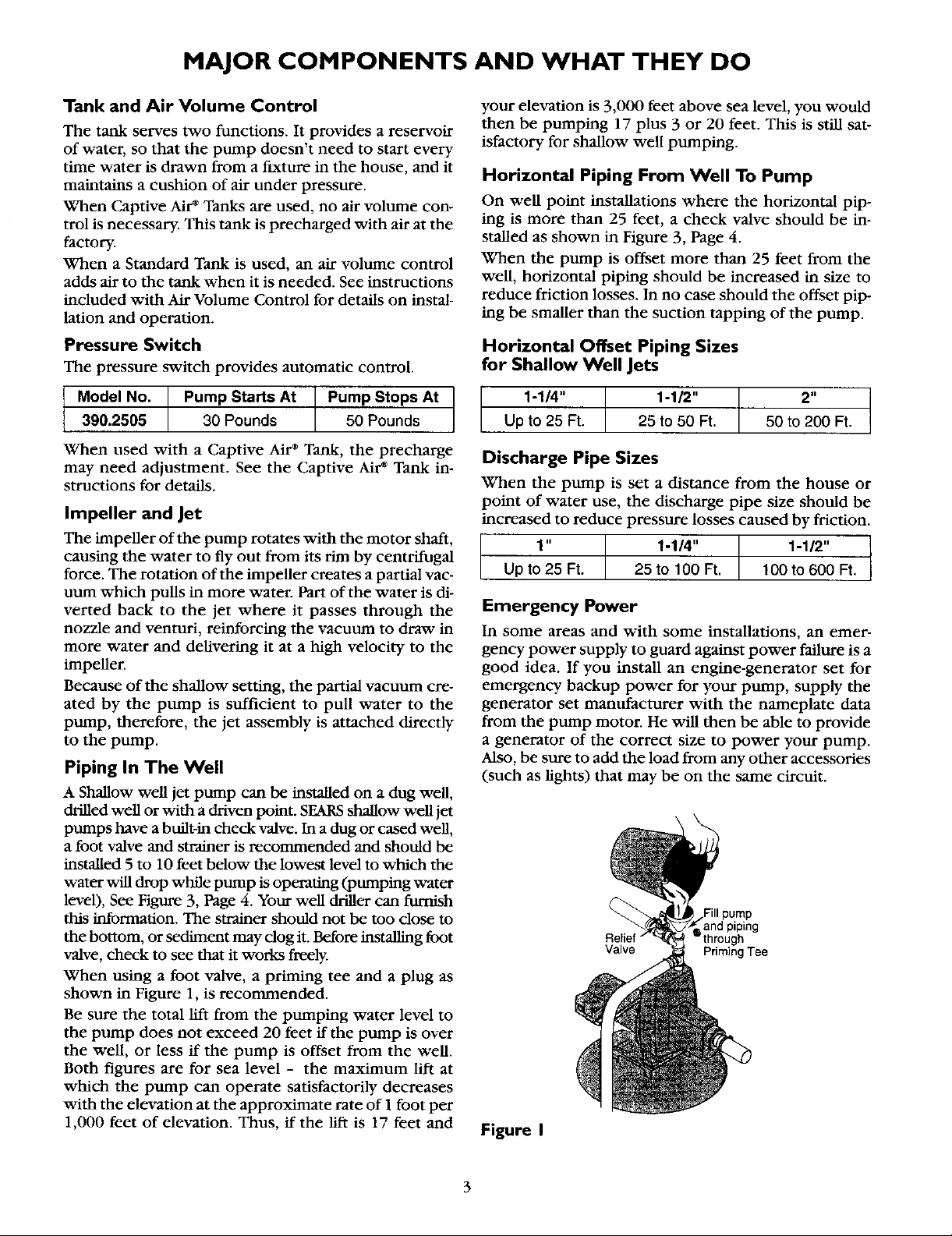

When using a foot valve, a priming tee and a plug as

shown in Figure 1, is recommended.

Be sure the total lift from the pumping water level to

the pump does not exceed 20 feet if the pump is over

the well, or less if the pump is offset from the well.

Both figures arc for sea level - the maximum lift at

which the pump can operate satisfactorily decreases

with the elevation at the approximate rate of 1 foot per

1,000 feet of elevation. Thus, if the lift is 17 feet and

Pump Starts At

30 Pounds

Pump Stops At

50 Pounds

your elevation is 3,000 feet above sea level, you would

then be pumping 17 plus 3 or 20 feet. This is still sat-

isfactory for shallow well pumping.

Horizontal Piping From Well To Pump

On well point installations where the horizontal pip-

ing is more than 25 feet, a check valve should be in-

stalled as shown in Figure 3, Page 4.

When the pump is offset more than 25 feet from the

well, horizontal piping should be increased in size to

reduce friction losses. In no case should the offset pip-

ing be smaller than the suction tapping of the pump.

Horizontal Offset Piping Sizes

for Shallow Well Jets

1-1/4" 1-1/2" 2"

Up to 25 Ft. 25 to 50 Ft. 50 to 200 Ft.

Discharge Pipe Sizes

When the pump is set a distance from the house or

point of water use, the discharge pipe size should be

Increased to reduce pressure losses caused by friction.

1" 1-1/4" 1-1/2"

Up to 25 Ft. 25 to 100 Ft. t 00 to 600 Ft.

Emergency Power

In some areas and with some installations, an emer-

gency power supply to guard against power failure is a

good idea. If you install an engine-generator set for

emergency backup power for your pump, supply the

generator set manufacturer with the nameplate data

from the pump motor. He will then be able to provide

a generator of the correct size to power your pump.

Also, be sure to add the load from any other accessories

(such as lights) that may be on the same circuit.

Relief "

Valve Priming Tee

Figure I

and piping

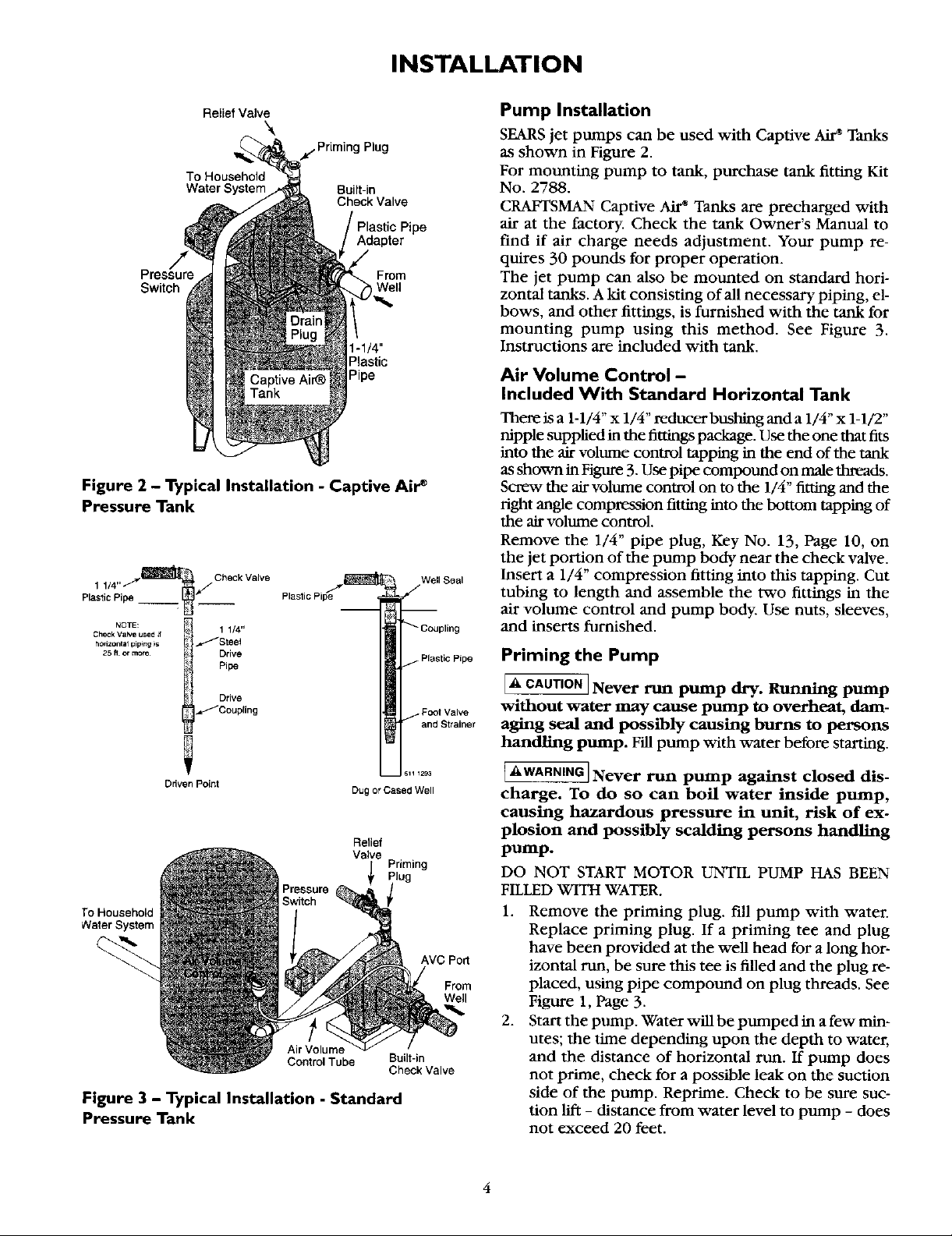

INSTALLATION

ReliefValve

Plug

To Household

Water System Built-in

Switch

Tank

Check Valve

Adapter

From

Weft

Plastic

Pipe

Figure 2 - Typical Installation - Captive Air e

Pressure Tank

Plastic P

NOTE: _ 1 1/4"

Check Va_e used if

h°dz°ntal piping is _t /Stee_

25. o_more _{ Drive

_'Coupling

o.ockvo,vo

Pipe

Drive

Well Seal

Foot Valve

Pump Installation

SEARS jet pumps can be used with Captive _ Tanks

as shown in Figure 2.

For mounting pump to tank, purchase tank fitting Kit

No. 2788.

CRAFTSMAN Captive Air* Tanks are precharged with

air at the factory. Check the tank Owner's Manual to

find if air charge needs adjustment. Your pump re-

quires 30 pounds for proper operation.

The jet pump can also be mounted on standard hori-

zontal tanks. A kit consisting of all necessary piping, el-

bows, and other fittings, is furnished with the tank for

mounting pump using this method. See Figure 3.

Instructions are included with tank.

Air Volume Control -

Included With Standard Horizontal Tank

There is a 1-1/4" x 1/4" reducer bushing and a 1/4" x 1-1/2"

nipple supplied in the fittings package. Use the one that fits

into the air volume control tapping in the end of the tank

as shown in Figure 3. Use pipe compound on male threads.

Screw the air volume control on to the 1/4" fitting and the

right angle compression fitting into the bottom tapping of

the air volume control.

Remove the 1/4" pipe plug, Key No. 13, Page 10, on

the jet portion of the pump body near the check valve.

Insert a 1/4" compression fitting into this tapping. Cut

tubing to length and assemble the two fittings in the

air volume control and pump body. Use nuts, sleeves,

and inserts furnished.

Priming the Pump

I_' CAUTIONI Never run pump dry. Running pump

without water may cause pump to overheat, dam-

aging seal and possibly causing burns to persons

handling pump. Fill pump with water before starting.

Ddven Point

To Household

Water System

Air Volume

Control Tube Built-in

Dug or Cased Well

Relief

Valve

Figure 3 - Typical Installation - Standard

Pressure Tank

Priming

AVC Port

Check Valve

From

Well

[AWA_ Never run pmnp against closed dis-

charge. To do so can boil water inside pump,

causing hazardous pressure in unit, risk of ex-

plosion and possibly scalding persons handling

pump.

DO NOT START MOTOR UNTIL PUMP HAS BEEN

FILLED WITH WATER.

1. Remove the priming plug. fill pump with water.

Replace priming plug. If a priming tee and plug

have been provided at the well head for a long hor-

izontal run, be sure this tee is filled and the plug re-

placed, using pipe compound on plug threads. See

Figure 1, Page 3.

2. Start the pump. Water win be pumped in a few min-

utes; the time depending upon the depth to water,

and the distance of horizontal run. If pump does

not prime, check for a possible leak on the suction

side of the pump. Reprime. Check to be sure suc-

tion lift - distance from water level to pump - does

not exceed 20 feet.

4

Loading...

Loading...