Page 1

Operator's Manual

CRRFTSMRNo

6V_"

Bench Top

JOINTERJPLANER

Model No.

351,286281

Colovos

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

Sears Canada Inc., Toronto, Ontario M5B 2B8

2602.03 Draft (04/11/01 )

Page 2

Warranty .................................. 2

Safety Rules .............................. 2-3

Unpacking ................................. 3

Assembly ................................. 3

Installation ............................... 4-5

Operetlon ................................ 5-9

Maintenance ............................ 9-10

Troubleshooting ............................ 11

Parts Illustration and List .................. 13-15

FULL TWO YEAR WARRANTY ON

CRAFTSMAN 6'I." JOINTER/PLANER

If within two full years from the date of purcllese, this

Craftsman Jolnterlplener falls due to a defect in matedsl

or workmanship, Sears w_LIrepair it free of charge.

Warranty service is available bycontacting Sears. This

warranty is in addition to any statutory warranty.

If this Jolnter/planer is used for commercial purposes,

this warranty applies for only g0 days from t_a date of

purchase.

Sears Canada, thc., Toronto, Ontario MSB 2B8

WARNING: For your own safety, read all of the rules

and precautions before operating tool.

CAUTION: Always follow proper operating procedures

as defined in this manual even if you are familiar with

use of this or similar tools. Remember that being care-

less for even a fraction of a second can result In severe

personal injury.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing,

gloves, necldles, rings, braceletS or other Jeweify

which may get caught In moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States

ANSI Z87.1. Everyday glasses have only impact

resistant lenses. They are NOT safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools

when tired, intoxicated or when taking medications

that cause drowsiness.

PREPARE WORK AREA FOR JOB

• Keepworkarea clean, Clutteredworkareasinvite

accidents.

• Do not use powertools]ndangerousenvironments.

• Do not use power tools in damp or wet locations. Do

not expose power tools to rein.

• Work area should be properly lighted.

• Proper electrical recepta_e should be avai)aPle for

tool.Three prong plug should be plugged directly

Into proper_ygrounded, three-prong receptacle.

o Extension cords should have a grounding prong and

the three wires of the extension cord should be of

the correct gauge.

* Keep visitors at a safe distance frorn work area.

• Keep children out ofworkplace. Make workshop child-

proof.Use padlocks, master switches or remove switch

keysto preventany unintentional use of power tools.

TOOL SHOULD BE MAINTAINED

• Always unplug toolprior to inspection.

• Consult manual for specific maintaining and adjust-

Ing procedures.

• Keep tool lubricated and clean for safest operation,

• Remove adjusting feoJs. Form habit of checking to

see that adjusting tools are removed before sw{teh-

ing machine on.

• Keep all parts in working order. Check to determine

that the guard or other parts will operate properly

and perform their intended function,

• Check for damaged parts. Check for alignment of

moving parts, binding, breakage, mounting and any

other condition that may affect a tool's operation.

o A guard or other pa_ that is d_'nagsd sh_d be

properly repaired or replaced. Do not perform

makeshift mpalm. (Use parts list provided to order

replacement parts.)

KNOW HOWTO USE TOOL

= Use right toolfor job. Do not force tool or attachment

to do a job for which it was not designed.

• Disconnect too) when changing b}sdes.

• Avoid accidental start-up, Make sure that the switch

is in the OFF position before plugging in.

• Do not force tool. it will work most efficiently a_the

rate for which it was designed.

• Keep hands away from moving parts and cutting

sul'_ces.

• Never leave toot running unattended. Turn the power

off and do not leave tool until it comes to a complete

stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur iftool is

tipped or if blade is unintentionallycontacted.

• Know your tool. Learn the tool's operation, applica-

tion and specific limitations.

• Use recommended accessories (refer to page 15).

Use of improper accessories may cause risk of

injury to persons.

2

Page 3

• Handle workpiece correctly. Protact hands from pos-

sible injury.

• Turn machine off if itjams. Blade jams when It digs

too deeply into workpiece. (Motor force keeps it

stuck in the work.I

• Always keep drive, cutterhesd and blade guards in

place and io proper operating condition.

• Feed work into blade or cutter against direction of

rotation.

CAUTION: Think safety! Safety is a combination of

operator common sense and atar_ess at all times

when tool is being used.

WARNING: Do not attempt to operate tool until It Is

completely essembled according to the instructions.

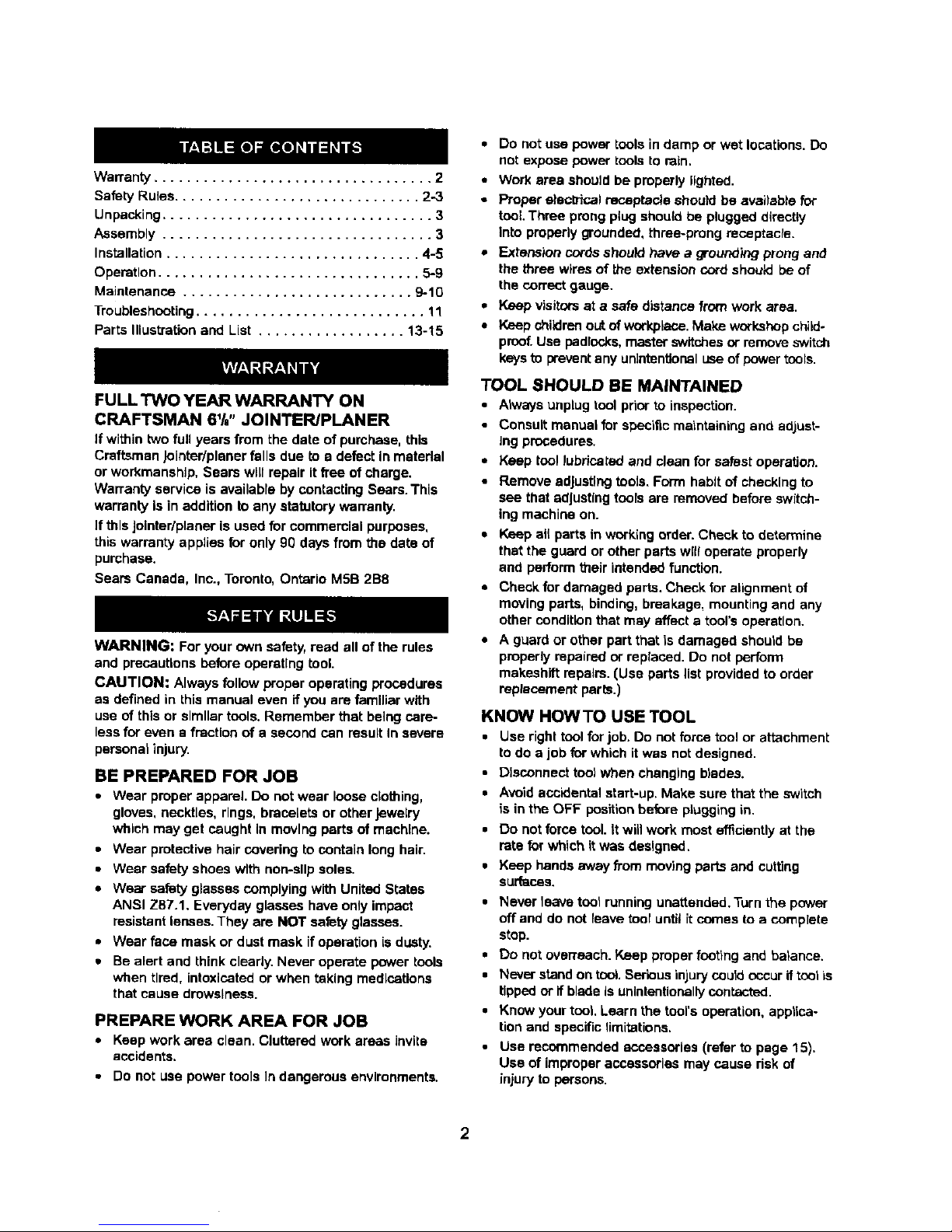

Refer to Figure 1.

Check for shipping damage. If damage has occurred, a

claim must be filed with carder. Check for complete-

ness. Immadtately report missing parts to dealer.

The jointer/planer is shipped complete in one carton.

Additional parts which need to be fastened to

jolnterlptaner should be located end accounted for

before assembling.

A Jointer Bed Assembly

B Fence

C Fence Bracket Assembly

D Push Blocks (2)

Hardware bag includes:

• 6-1.0 x 16ram Socket Head Bolts (2)

• 6mm Lock washer (2)

• 1/4-20 x 1/2" Socket Head Bo)ts (4)

• 1/4"-20 Square Nuts (4)

• 3, 4, 5 L-Wrench

• 8-10 Open Wrench

• Screw Driver

Figure I - Unpacking

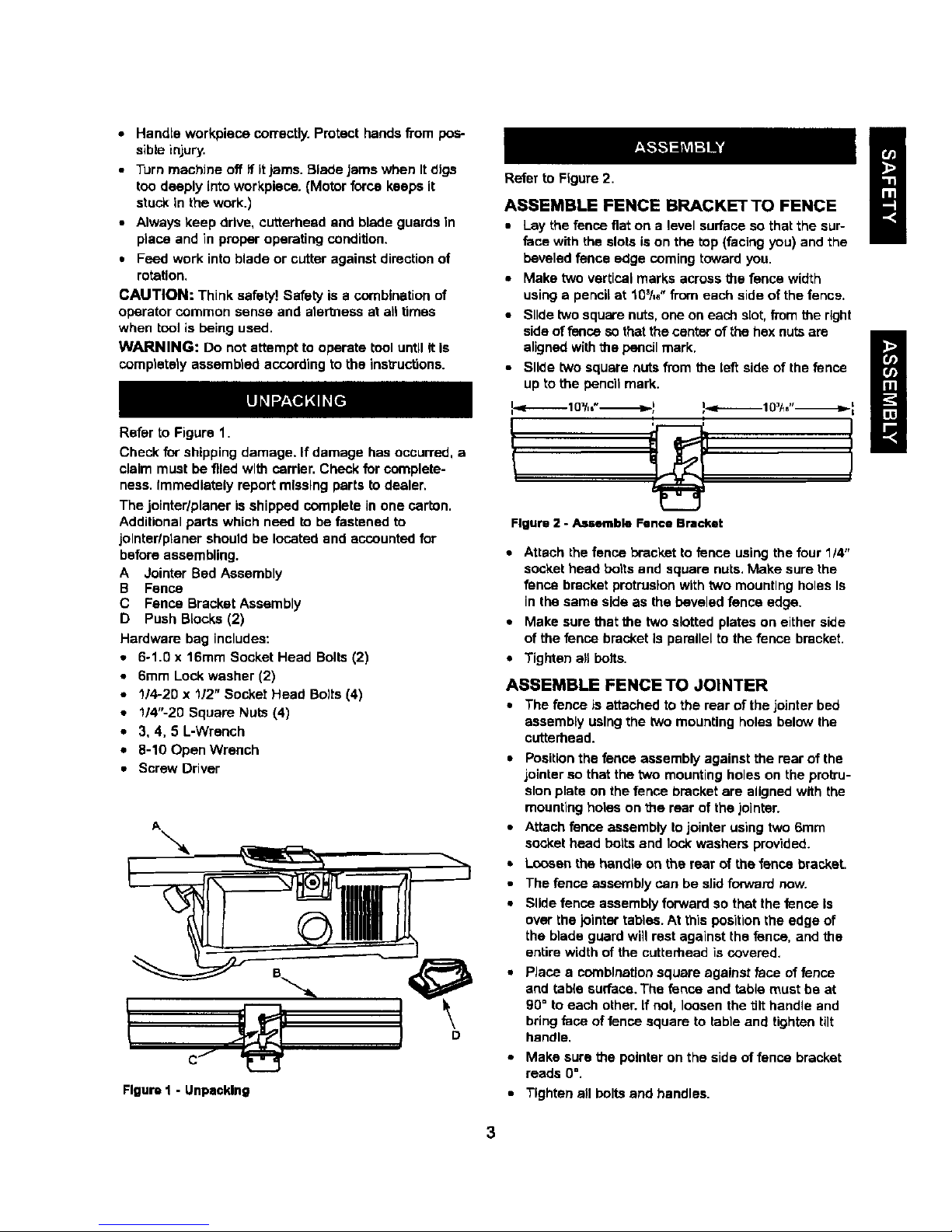

Refer to Figure 2.

ASSEMBLE FENCE BRACKET TO FENCE

• Lay the fence fiat on a level surface so that the sur-

face with the slots is on the top (facing you) and the

beveled fence edge coming toward you.

• Make two vertical marks across the fence width

using a penci_at t0_/,e" from each side of the fence.

• Slide two square nuts, one on each slot, from the right

side of fence so that the center of the hex nutsare

aligned with the pencil mark.

• Slide two square nutsfrom the left side of the fence

up to the pencil mark.

Figure 2 - Assemble Fence Bracket

• Attach the fence bracket to fence using the four 1/4"

socket head bolts and square nuts. Make sure the

fence bracket protrusion with two mounting holes Is

in the same side as the beveled fence edge.

• Make sure that the two slotted plates on either side

of the fence bracket is parallel to the fence bracket.

• Tighten all bolts.

ASSEMBLE FENCETO JOINTER

• The fenceisattachedto therear of thejointerbed

assemblyusingthe twomounting holesbelowthe

cutterhead.

• Position the fence assembly against the mar of the

jointer so that the two mounting holes on the protru-

sion plate on the fence bracket are aligned with the

mounting holes on the rear of the )ointer.

• Attach fence assembly to jointer using two 6mm

socket head bolts and lock washers provided.

• Loosen the handle on the rear of the fence bracket.

• The fence assembly can be slid forward now.

• Slide fence assembly forward so that the fence Is

over the jointar tables. At this position the edge of

the blade guard will rest against the fence, and the

entire width of the cutterhead is covered.

PJace a combination square against face of fence

and tab(e surface. The fence and table must be at

90=to each other, if not, loosen the tilt handle and

bring face of fence square to table and tighten tilt

handle.

Make sure the pointer on the side of fence bracket

reads O'.

Tighten all bolts and handles.

Page 4

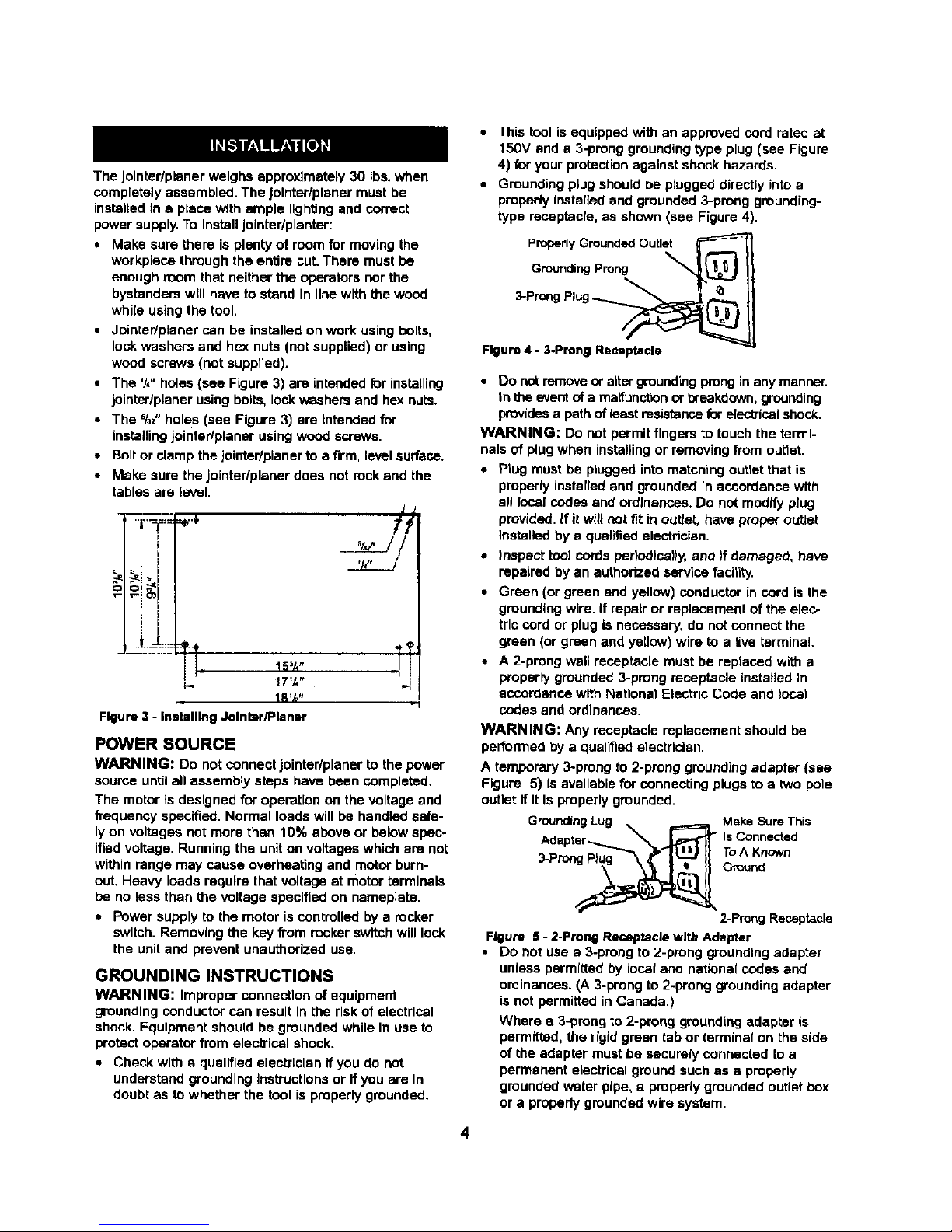

TheJolnter/pienerweighsapproximately30Ibs. when

completely assembled. The Jolnter/plener must be

installed In a piece with ample IlghUng and correct

power supply. To Install Jolntar/planter:

• Make sure there is plenty of room for moving the

workplace through the entire cut. There must be

enough room that neither the operators nor the

bystanders will have to stand In line with the wood

while using the tool.

• Jointer/planer can be installed on work using bolts,

lock washers and hex nuts (not supplied) or using

wood screws (not supplied).

• The %" holes (see Figure 3) are intended for installing

jointer/planer using boils, lock washers and hex nuts.

• The %="holes (see Figure 3) are Intended for

installing jointer/planer using wood screws.

• Bolt or clamp the iointedplaner to a firm, levelsurface.

• Make sure the jointer/planer does not rock and the

tables are level.

•-|-._:_===:r.$,

,'e-= O) I

_1 .t...:t:::=

/

,,T

I I " 15_A"

i_ la_h"

Figure 3 - InmtalllngJointar/Planar

POWER SOURCE

WARNING: Do not connect jointer/pianer to the power

source until all assembly steps have been completed.

The motor is designed for operation on the voltage and

frequency specified. Normal loads will be handled safe-

ly on voltages not more than 10% above or below spec-

ified voltage. Running the unit on voltages which are not

within range may cause overheating and motor burn-

out, Heavy loads require that voltage at motor terminals

be no less than the voltage specified on nameplate,

• Power supply to the motor is controlled by a rocker

switch. Removing the key from rocker switch will lock

the unit and prevent unauthorized use,

GROUNDING INSTRUCTIONS

WARNING: Improper connection of equipment

grounding conductor can result In the risk of electrical

shock. Equipment should be grounded while In use to

protect operator from electrical shock.

• Check with a qualified electrician if you do not

understand grounding Ins_'uctlons or if you are In

doubt as to whether the tool is properly grounded.

4

• This tool is equipped with an approved cord rated at

150V and a 3-prong grounding type plug (see Figure

4) for your protection against shock hazards.

• Grounding plug should be plugged directly into a

properly installed and grounded 3-prong grounding-

type receptacle, as shown (see Figure 4).

Properly Grounded Outlet

Grounding Pr_ _

Plu -

3-Prong g __

Figure 4 - 3.Prong Receptacle

• Do not remove or alter groundingprong in any manner.

In the event of a maitunotlonor breakdown, grounding

provides a path of least resistancefor efec_ical shock.

WARNING: Do not permit fingers to touch the termi-

nals of plug when installing or removing from outlet.

• Plug must be plugged into matching outlet that is

properly Installed and grounded In accordance with

a!l local codes end ordinances. Do not modify plug

provided. If it will not/_t in outlet, have proper outlet

installed by a qualified eLsctdcian.

• Inspect tool cords ber)odlca)Iy, and )f damaged, have

repaired by an authorized service facility.

• Green (or green and yellow) conductor in cord is the

grounding wire. It repair or replacement of the elec-

tric cord or plug Is necessary, do not connect the

green (or green and yellow) wire to a live terminal

• A 2-prong wall receptacle must be replaced with a

properly grounded 3-prong receptacle installed In

accordance with National Electric Code and local

codes and ordinances.

WARNING: Any receptacle replacement should be

performed by a quailed electrician.

A temporary 3-prong to 2-prong grounding adapter (see

Figure 5) is available for connecting plugs to a two pole

outlet if It is properly grounded.

GroundingLug _ _ Make SureThis

Adapter_'_'_ IsConnected

3.Prong_ ToA Known

Ground

2-Prong Receptacle

Figure 5- 2-Prong Receptacle with Adapter

• DO not use a 3-prong to 2-prong grounding adapter

unlass permitted by focal and national codes and

ordinances. (A 3-prong to 2-prong grounding adapter

is not permitted in Canada.)

Where a 3-prong to 2-prong grounding adapbsr is

permitted, the rigid green tab or terminal on the side

of the adapter must be securely connected to a

permanent electrical ground such as e properly

gmunded water pipe, a properly grounded outlet box

or a properly grounded wire system.

Page 5

• Many cover plate screws, water pipes and outlet

boxes are not properly grounded. To ensure proper

ground, grounding means must be tested by a quali-

fied electrician.

EXTENSION CORDS

• The use of any extension cord wJlJcause some drop

In voltage and loss of power.

• Wires of the extension cord must be of sufficient size

to carry the current and maintain adequate voltage.

• Use the table to determine the minimum wire size

(A.W.G._ extension cord.

• Use only 3-wire extension cords having 3-.prong

grounding type plugs and 3-pele receptacles which

accept the tool plug.

• If the extension cord is worn, cut or damaged in any

way, replace it immediately.

EXTENSION CORD LENGTH

Wire Size A.W.G.

Up to 50 ft................................ 16

50-100 ft.................................. 14

NOTE'. Using extension cords over 100 ft. long Is not

recommended.

MOTOR

Jointer/pianer is supplied with a 1% HP (max devel-

oped) motor.

The 120 Volt AC universal motor has the following

specifications:

Horsepower (Maximum Developed) ............. l_h

Voltage ................................. 120

Amps ................................... 10

Hertz .................................... 60

Phase ................................ Single

RPM .................................. 8000

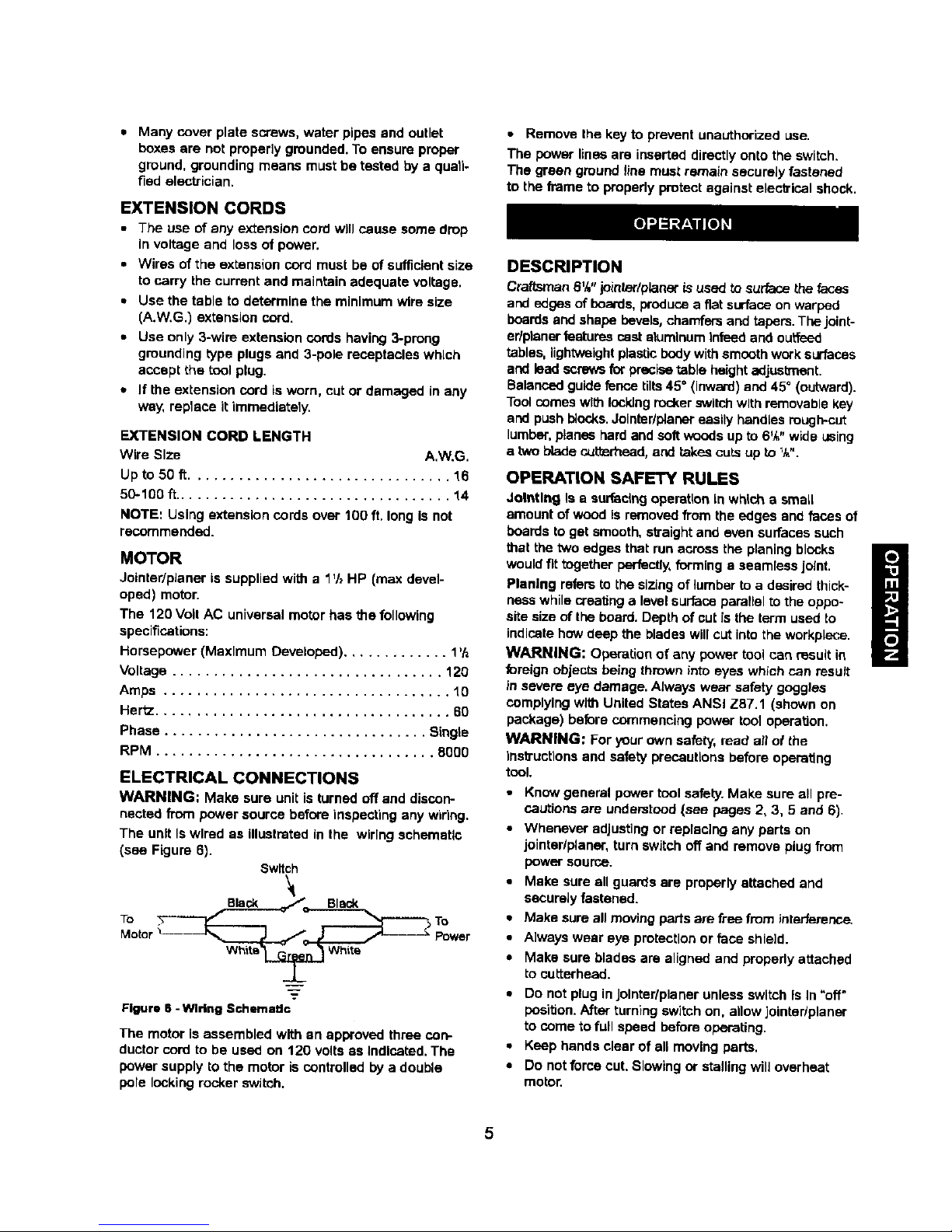

ELECTRICAL CONNECTIONS

WARNING: Make sure unit is turned off and discon-

nected from power source before inspecting any widng.

The unit Is wired as illustrated in the wiring schematic

(see Figure 6).

Switch

Whi_l _ White

Figure 6 - Wiring SchemaUc

The motor is assembled with an approved three con-

ductor cord to be used on 120 volts as Indicated. The

power supply to the motor is controlled by a double

pole locking rocker switch.

• Remove the key to prevent unauthorized use.

The power lines are inserted directly onto the switch.

The green ground line must remain securely fastened

to the frame to properly protect against elecVical shock.

DESCRIPTION

Craftsman 6%" jointer/planer is used tos_Jrfacethe faces

and edges of boards, produce a fiat surface on warped

boards and shape bevels, chamfers and tapers. The joint-

er/ptaner features cast aluminum iofeed and ouffeed

tables, lightweightplastic body withsmooth work surfaces

and lead screws for precise table height adjustment.

Balanced guide fence tilts 45° (Inw_d) and 45° (outward).

Tool comes wlt_ iockJng ro_er switch with removable key

and push blocks.Jointer/placer easily handles rough-cut

lumber,planes hard and soft woods up to 6_ " wide using

a two blade cuttorhead, and takes cuts up to %".

OPERATION SAFETY RULES

dothtlng Is a surfeclng operatLonin which a smaLL

amount of wood is removed from the edges and feces of

boards to get smooth, straight and even surfaces such

that the two edges that run across the planing blocks

would fit together perfectly, forming a seamless joint.

Planing refers to the sizing of lumber toa desired thick-

hess while creating a level surface parallel to the oppo-

site size of the board. Depth of cut is the term used to

iedlcete how deep the blades will cut into the workplece.

WARNING: Operation of any power tool Can result in

foreign objects being thrown into eyes which can result

in severe eye damage. Always wear safety goggles

cemplylng with United States ANSi Z87.1 (shown on

package) before commencing power tool operation.

WARNING: For your own safety,,read art of _he

insb'uctlonsand safety precautions before operating

tool.

• Know general power tool safety. Make sure all pre-

cautions are understood (see pages 2, 3, 5 and 6).

• Whenever adjusting or replacing any parts on

jointer/planer, turn switch off and remove plug from

power source.

• Make sure all guards ere properly attached and

securely fastened.

• Make sure all moving parts are free from interference.

• Always wear eye protection or face shield.

• Make sure blades are aligned and properly attached

to cutterhead.

• Do not plug inJolnter/planer unless switch is in -off-

position. After turning switch on, allow jointer/planer

to come to full speed before operating.

• Keep hands clear of all moving parts.

• Do not force cut. Slowing or stalling will overheat

motor.

5

Page 6

• Use quality lumber. Blades last longer and cuts are

smoother with good quality wood.

• Do not perform jointing/planing operations on materi-

al shorter than 8%", narrower than _/4",or !ess than

I/_,,thick

• Never make jointing cut deeper than 'k".

• Always keep cutterhead and blade guards in proper

working condition.

• Maintain the proper relationships of infeed and out-

feed table surfaces and cutterhead blade path.

• Do not back the work toward the Infeed table,

• Support the workplace adequately at all times during

operation; maintain control of the workplace.

• Use hold-down/push blocksfor jolntlng material nar-

rower than 3" or planing material thinner than 3".

• Take precautions against kickback. Do not permit any-

one to stand or cross in line of cotterbead's rotation.

Kickback or thrown debris will travel In this direction.

• Turn switch offand disconnect power whenever

jointer/planer is not in use.

• Replace or sharpen blades as they become damaged

ordull.

• Do not attempt to perform an abnormal or little used

operation without study and the use of adequate hold-

down/push blocks, jigs, fixtures, stops and the like.

• Keep jointer/planer maintained. Follow maintenance

instructions (see pages g-lO).

DEPTH OF CUT

Refer to Figure 7.

The depth of cut is adjusted by the relative positioning

of the infeed table with respect to the cutterhead. Infeed

table can be raised or lowered using the handwheel.

Turning the handwheel counterclockwise will lower the

infeed table causing more wood to be removed from

workplece. Turning the handwhool clockwise will raise

the Infeed table causing less wood to be removed from

workpleca.

Do not make jointing or planing cuts deeper than V#.

[nfeed Table

Depth of Cut

Hand Knob

Figure 7 - Depth of Cut

CHECK DEPTH OF CUT

Refer to Figure 8.

• Place a straight edge on the ouffeed table extending

over the Infeed table.

• Measure from the surface ofthe infsed tableto the bet-

tom of the straight edge. This will be the depth of cut.

Outfeed

Table

Max Depth

of Cut _/_"

FIgura e - Check Depth of Cut

NOTE: This jointar/planer willmake a maximum %"

deep cut. To reduce the danger of kickback and possi-

ble injury, the depth of cut should not exceed _/_".

CAUTION: Make sure the switch is in the "off positJon

and the cord is unplugged from power source before

perform)rig this check.

POSITIONING FENCE

The fence can be adjusted to cut various angles from

0°-45 ° inward and outward. The fence can be tilted

idward up to 45" (toward the cutterhead) to maintain

greater stability of a narrow workplece or up to 45° out-

ward (away from cutterhead) for larger angle cutting

operations.

To adjust tiltangle:

• Loosen fence tilt handle.

• The fence tilt handle is spring loaded. To continue

turning the handle, gently pull the handle away from

the fence and return It to the odglnal position.

• Release the handle and continue loosening.

• Manually tilt fence Inward/outward to the desired

angle. Use the scale on the left side offence bracket

to measure tilt angle.

NOTE: The fence has positive stops at 0 ° (g0° from

table) and at 45" Inward.

• Tighten fence tilthandle.

• To continue tightening, gently pull the handle away

from fence and return the handle to the original posi-

tion.

• Re)ease the handle and continue tightening.

• Make sure the fence )s tight and secure.

The slotted plates on the fence bracket prevent the

btadas from being exposed. Do not remove the ptatas

at any time. The fence can be positioned so that the

desired width of the blade is exposed.

To adjust fence position:

• Loosen fence slide hand)e.

• S)ide fence forward to the desired position.

• Tighten tense slide beadle.

• Make sure fence Is tight and secure,

• Loosen fence rock handle.

CAUTION: Do not remove blade guard and slotted

plates. Make sure that the cutterhead Is covered all the

time.

6

Page 7

CAUTION: Do not slide fence away from the jointer

body. All sides of the cutterhead must be covered all the

time.

BLADE GUARD

The blade guard provides protection over the cuttar-

head. It must always be in place and function properly.

Check the guard to make sure it functions properly. To

check:

• Pass a V*"thick piece of wood over the cutter'head

between the guard and the fence. The guard will

spread and leave way for the wood piece to pass.

The guard must return to the original position auto-

matically when the wood piece is removed.

• Open the blade guard all the way until Itstops, and

release it several times. It should always return to its

original position by spring action.

CAUTION: If the blade guard fails to operate properly,

the spring must be replaced or adjusted.

• To replace spring, contact your nearest Rears store

or service center.

= To adjust or to assemble spring see "Adjus'dngBlade

Guard", page 9.

ADJUSTING BLADE HEIGHT

Refer to Figures 9 and 10,

CAUTION: Make sure the switch is in the "OFF" posi-

tion and cord is unplugged before proceeding with

checking blades.

The blades have been adjusted at the factory to assure

proper operation and should require no adjusb'nent,

However, shipping and handling may have caused rues-

alignment. For accurate cutting, the blades must be

0.003" higher than the outfeed table when positioned at

the highest point. To check blade height:

• Block the blade guard from closing using a scrap

piece of wood about 6V_"long between the fence

and blade guard.

Blade Clamp I I

Cutter H:mad__Wad°de°_e Bl°ck

..__r"_ Cuttar Guard

Figure g - Block Blade Guard

• Turn the cutterhead so that one of the blades is at

the highest position.

CAUTION: The cuttarhead blades are extremely

sharp. Do not let your fingers contact the cutting edge

at any time.

• Place a straightedge over the outfeed table and the

blade.

BackSideof Machine

Straightedge /_L_"_

t I

GIll

OutfeedTable

Figure 10 - Adjust Blade Height

• The straight edge must touch evenly on the outfeed

table at both ends of the blade.

• Turn the cuttarhead slowly, and check if the blade

lightlytouches the straight edge.

• If the straightedge raises, loosen the blade lock

screws and gently tap the blade with a piece of

scrap wood. If the blade does not touch the straight-

edge, loosen the blade lock screws and raise the

blade by prying the lower edge of the blade against

the outfeed table using a screwdriver.

• Tighten blade lock screws.

AVOID DAMAGE TO BLADES

3oW_arlpLanerisa precLsion_ing mechlne and

should only be used on quality lumber.Using bad lumber

could resultin a poor qualitycut on subsequent pieces.

For proper operation, itis preferable touse the jblnter with

a dust collectingsystem (see "Using a Vacuum Hose",

page 9) aL'tachadto the exhaust port inthe rear ofthe join-

tel'.Attaching a dust collecting system isespecially

required when taking deeper cuts io prevent clogging of

wood chll_.

• DO not use dirty boards. Dirt and stones are abrasive

and will wear blade.

,, Remove narisand staples.Jothtershou_ ontycut wood.

• Avoid knots. Heavy cross-grain makes knots hard

and they can come toose and jam the jointar.

• Assess value ofbadly warped boards. Operator can

be tempted to usa too deep of cut tu square boards

quickly.Use several passes to maintain a levelsurface.

ON-OFF SWITCH

Refer to Figure 11, page 8.

The operating positionsof the "On-Off" switch are locat-

ed on the front of your jointar/planer.

• Push the switch up to turnjointar/planer On and

push down to turn the unit Off.

• The switch has a removabJa kay that alJowsthe unit

to be locked in the "Off" position.

To activate locking mechanism:

• Push the switch to'Off" position.

• Puff switch key.

To deactivate locking mechanism:

• Insert and press switch key in the slot on switch.

Page 8

Feed with the grain whenever possible.

_._ With theGrain

Rotation

Key

Figure 11 • On-Off Switch

WARNING: Be sure the switch Is In "OFF" position

and the cord is unplugged from the power source

before removing switch key.

FEEDING WORKPIECE

Refer to Figures 12, 13, 14 and 15.

Feed rate refers to rate at which wood is passed over

blades. An even feed will produce a uniform service. To

feed workpiece:

• Hold the board firmly down on both tables and

against the fence.

• Keep fingers close together.

• Feed the board at a continuous even rate of speed.

Any hesitation or stopping could cause a "step"to be

cut on the edge of the board.

Againstthe Grain

Rotation

Figure 14 - Dlrecttan of Feed

• If the nature of the workpiece issuch that ]t must be

fed against the grain, take very light cuts and feed

siowiy.

• When using long workpiscas, to avoid injuryfrom slips

or kickbacksand to exer_ even pressure on the cuiter-

heed, use extra supports (see Recommended

Accessodas, page 15) at both infeed and outfeed ends.

USING HOLD DOWN/PUSH BLOCKS

Refer to Figure 15.

• Always use hold-down/push-blocks when jolndng, or

rabbeting wood that is narrower than 3", planing

wood thinner than 3".

Figure 12 - Feeding Workplace

• As the b'alllng hand passes over the cutterheed,

remove the leading hand.

• Continue feeding while placing the leading hand

behind the trslllng hand until the entire length of the

board is cut.

Figure 13 - Guiding Workplace

Figure 15,- Feeding with Push Blocks

• Grasp the hoio-down/push-blocks firmly.

• Position the push-blocks flat on top of workpiece and

push the workpieco down against the table.

• Use a hand-over-hand motion to maintain control

over the workpiece at all times.

• When planing workplace between _ - _J_"and nar-

rower than the push-blocks, tilt the push-blocks so

that It clears the cutterhead guard while feedtng.

BEVELING AND CHAMFERING

Rear to Figure 16, page 9.

• The fenco on the Jolnter/plener le adJusta_e from

45" Inward to 45" outward. Adjust the fence to the

desired angle and tighten fence lock knobs. You may

require to lift the positive pin to move fence.

8

Page 9

• Beveling refers to cutting the entire edge of a board

at an angle. Beveling may require several passes

due to the depth of cut needed.

• Chamfering refers to removing only the comer of the

edge of a board. Normally a chamfer Is made on one

pass; so a '/,e" depth of cut Is marie.

Charnfer_ Edge

Figure 16 - Beveling and Chamfering

USING A VACUUM HOSE

A standard dust collection hose can be attached to the

exhaust port (2 _h"Die.) on the rear of the Jointer.Jolnter

will perform properly at all depths of cuts up to '/," when

used with a dust collecting system. {See "Avoid Damage

to Blades', page 7.) To attach a dust collecting system:

• Insert the dust collection hose to the exhaust port on

the rear of the jointer.

• Turn the dust coJlecting system on.

• Turn the Jotnter on.

• Periodicallyreplace/empty bag in dustcollection system.

If the blades are nicked they must be replaced or

reground. They can be reground several times until they

become '_lte"wide.

NOTE: Many shops do not have capabilities to resur-

face blades. Yellow pages should list"Sharpening

Services" or "Tool Grinding:

Figure 17 • Sharpening Blades

Never Install unbalanced blades or reground blades

less than '_/." wide.

REPLACING BLADES

Refer to Figures 18 and "_g.pages g _nd 10.

• Unplug the jolnter/planer from power source and turn

the switch to "OFF" position.

• Block the blade guard from closing down.

• Loosen and remove three blade lock screws secur-

ing blade and blade clamp.

WARNING: Turn the switch to "Off" position and

unplug jointerlptaner from power source before pro-

ceeding to do maintenance work,

CHECKING FOR WORN BLADES

Condition of blades will affect precision of cut. If blade

wear is not observed when checking the btade height,

the quality of cut will indicate the blade condition. Dull

blades will tear rather than sever wood fiber. A raised

grain will occur when dull blades pound on wood where

there is difference in density, A raised ridge will be pro-

duced where the blades have been nicked.

SHARPENING BLADES

Refer to Figure 17.

The blades can be honed individually by whetting them

with a fine sharpening stone. Make sure oilstone is fiat

and is cot worn. To sharpen blades:

• Partially cover the stone with paper to protect the

table top.

• Position in_=ed table so stone will contact blade

along its beveled surface.

• Stroke the stone across blade from one side to other

while stone is also moved slightly in the direction of

feed.

• Make sure to do the same number of atTokeson

each place.

_usrd

Figure 1B • Block Blade Guard

• Lift blade and blade clamp from cutterhead

• Clean any sawdust and resin buildup from cutter-

head and blade clamp.

• Place blade clamp against the replacement blade

and replace In cutterhead.

• Secure blade and blade clamp using three blade

lock screws. Do nottighten blade lock screws.

NOTE: Check blade height at both ends of blade (see

Adjusting Blade Height, page 7).

• Tighten blade lock screws.

• Recheck blade edJus_nent and make sure blade is

still level with ou_eed table.

• Repeat the procedure to replace the other blade.

• Remove the scrap wood and release blade guard.

• Make sure allthe i_ada lock screws are tight and snug.

9

Page 10

Blade • Replace with now timing belt by maintaining inward

Cutterhead f pressure.

Figure lg - Replacing Bladu Replace

ADJUSTING BLADE GUARD

CAUTION: Do not lubricate the pivot point of the b_ade

guard, Oil and lubricating products may contain chemi-

cats that can damage and/or destroy blade guard or

other plastic parts.

The blade guard needs adjustment or swing replace-

ment if it does not cover the cutterhead when released.

To adjust or replace spring:

• Lay the jointedpidner on the side so that the switch

is facing the roof,

• Loosen and remove screw and wavy washer on the

base that secure the blade guard.

• Slide out brads guard.

• If the spring Is out of tension, it must be replaced.

Slide out spring from the dimple. Contact your near-

est Sears store or service center for replacement.

• Replace new spring so that the short arm of the

swing is inside the hole on the body.

• Position blade guard so that the long arm of the

spring is aoathst the wal_of the blade gumd.

• Secure blade guard using pan head screw and

washer,

• Make sure blade guard functions appropriately.

REPLACING TIMING BELT

Refer to Figures 20 and 21.

• Turn the switch to "OFF" position and unplug the tool

from power source.

• Lay the jointer/planer on the side so that the switch

faces the roof,

• Remove old ttmtng bert by torntng belt and maintain-

ing pressure.

Rerno_

Figure 21 - Raplacthg Tlmtsg Belt

NOTE: Make sure that the full width of bert is on both

pulleys.

GENERAL MAINTENANCE

Jointadplaner will operate best if it is kept in good oper-

ating condition. Keep unit adjusted as described in

"Operation."

• Do not allow gum end pitch to accumulate Onthe

tabtes, fence, blades and blade guard,

• Apply e thin coat of paste type wax to the tables and

the fence so that the wood slides easily while feed-

ing.

• Do not allow chips to accumuJate on the underside

of the Jointer/planer,

• Keep blades sharp (see "Sharpening Blades," page

9). Sometimes replacing blades is less expensive

than resurfacing them. Keeping a spare set of blades

on hand is recommended. Blades should always be

sherpene_:lor replaced In sets of two,

LUBRICATION

WARNING: Make sure the switch is in the "OFF" posi-

tion and the tool is disconnected _om the power

source.

WARNING: Do not at any time let brake fluids, gaso-

tthe, penetrating oils, etc. come in contact with plastic

parts.They contain chernlcals that can damage and/or

destroy plastics.

• Motor and cutterhead bearings are sealed and need

no lubrication,

• Fence, trunnion, trunblon cover and elevation screws

should be cleaned of debris and greased as needed,

MACHINED SURFACES

• Surfaceof tables and fence must be kept smoothand

clean for easy work fe_.

• Apply a paste wax to surfaces to keep them slick

and prevent cowosidn.

Figure 20 - Rm-novlng Timing Belt

10

Page 11

SYMPTOM

Motor does notstart

Motor stalls (resulting in blown

fuses or tripped circuit

breakers)

Motor starts slowly or fails to

coma to full speed

Motor running too hot

Frequent opening of fuses or

circuit breakers

Snipe

(gouging at end of boards)

Uneven depth of cut

45 = cuts inaccurate

Fuzzy grain

Torn grain

POSSIBLE CAUSE(S_)

1. Defective switch

2. Defective motor

3. Low line voltage

1. Circuit overloaded

2. Low line voltage

3. Motor overloaded

4. Incorrect fuses on circuit breakers

5. Short circuit in motor; loose

connections or worn insulation

on lead wires

1.Defective motor windings

2. Clogged wood chips

1.Motor overloaded

2. Restricted air circulation due to

dust accumulation

1.Motor overloaded

2. Fuses or cimult breakers do not

have sufficient capacity

3. Clmuit overloaded

1. Dull blades

2. Inadequate support of long boards

3. Uneven feed

1. Blade height not uniform

2. Fence not perpendicular to

Jointerbed

3. Feeding wood too fast

1. Fence stops not adjusted propedy

2. Fence bottom not even with

outfeed table due to wood chips

under fence

Planing wood with high moisture

1. Too heavy a cut

2. Blades cutting against grain

3. Dull blades

CORRECTIVE ACTION

1. Have switch replaced.

2. Have motor replacedlrepaired.

NOTE: 1 and 2 must be done by a qualified

service technician; Consult Sears service.

3.Correct low line voltage condition.

1. Reduce circuit load

(turn off other appliances).

2.Correct low line voltage conditions.

3.Reduce load on motor.

4.Have correct fuses on circuit breakers

installed.

5.Inspect terminals in motor for damaged

insulation and shorted wires and have

them replaced.

1.Have motor replaced/repaired.

2.Take shallow depth of cut and attach a

dust coUecting system to exhaust port.

1.Reduce load on motor.

2.Clean dust and restore normal air circulation.

1.Reduce load on motor

2.Have correct fuses or circuit breakers

installed.

3.Reduce circuit load

(turn off other appliances).

1.Replace or sharpen blades.

See "Sharpening Blades," page 9.

2.Support long boards.

See =Recommended Accessories" page 15.

3.See "Feeding Workpfece," page 8.

I1.Adjust blade height.

See "Adjusting Blade Height," page 7.

2.See =Positioning Fence," page 6.

13.Feed wood slower.

11. Adjust fence stops.

See "Positioning Fence:', page 6.

12.Clean wood chips from underside of fence.

IRemove high moisture content from wood by

drying.

1. Reduce depth of cut.

2. Feed work along grain.

3. Replace or sharpen blades.

11

Page 12

NOTES

12

Page 13

Model 351.286281

Figure 22 - Replacement Parts Illustration for Motor

t

2

17

7

KEY

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

18

17

PART NO.

2856.00

STD315215

2857.00

STD315205

2858.00

2859.00

STD852005

2860.00

1413.00

STD651005

5383,00

2861.00

2862.00

2863.00

1838.00

2864.00

1474.00

DESCRIPTION

Motor Cover

6201ZZ Ball Bearing

Armature with Fan

6200ZZ Ball Bearing*

Wavy Washer

Thread Forming Screw

5r'nmLock Washer*

Stator

Strain Relief

5mm Flat Washer*

5-0,8 x 18ram Hex Head Bolt

QTY.

1

1

1

1

1

2

6

1

1

4

4

Brush Cap

Carbon Brush (set of 2)

Brush Holder

5-0.8 x 10ram Bet Screw

Motor Housing

5ram Serrated V_asher

* Standard hardware item available _ocalty

2

1

2

2

1

1

13

Page 14

Model 351.286281

Figure 23 - Replacement Parts Illustration for Jointer

41 42

,\

48

59

6O

3O

81

19

32

82

33

56

2O

24

78

79

14

Page 15

KEY

NO.

1

2

3

4

5

6

7

8

9

10

11

PART NO.

Z693.01

4135.00

1553.00

Z895.00

3850.00

_722.00

]423.00

2892.00

3729.00

Z894.00

)361.00

QTY.

1

4

1

8

18

DESCRIPTION

Base

Foot Pad

Cord Clamp

Thread Forming Screw

5-1.0 x 16ram

Socket Head Bolt

7mm SpecialWasher

Switch

Spflng

Thread Forming Screw

Cover

5-0.8 x 8mm

Pan Head Screw

5mm Flat Washer*

7mm SpecialWasher

Wavy Washer

Blade Guard

Access Cover

Belt

Drive Pulley

6-1.0 x 6ram Set Screw

6200ZZ Ball Beadng"

Cutterhead

Blade Clamp

6-1.0 x 12mm

Socket Pan Head Screw

Blade(set of 2)

Shaft

5-0.5 x 12ram

Flat Head Screw

6-1.0 x 12ram Bet Screw

5-0.8 x lOmm

Socket Head Bolt

5mm Lock Washer*

Motor Mounting Plate

Motor Pulley

Motor

Outfeed Table

Fence

V,-20" Square Nut

Scale

Rivet

4-0.7 x 6mm Pan Head Screw

Indicator

Right Side Slotted Plate

lO

1

1

1

1

1

12 3TD851005 4

13 _723.00 1

14 3499.00 1

15 2891.00 1

16 4128.00 1

17 _887.00 1

18 Z886.00 1

19 )964.00 2

20 3TD315205 2

21 Z885.00 1

22 Z883.00 2

23 3346.0D 9

24 !9-73667 1

25 =2881.00 1

26 !3535.O0 4

27 2803.00 2

28 3855.00 4

29 BTD851005 4

30 2866.01 1

31 2889.00 1

32 2890.00 1

33 2880.02 1

34 2865.00 1

35 2866.00 4

36 2898.00 1

37 1286.00 2

38 0781.00 3

39 2896.00 1

40 2997.00 1

Standa_ hardware i_m availa_elocal_

NotShown

KEY

NO.

41

42

43

44

45

PART NO.

2872.00

9725.00

2869.00

1993.00

1903.00

46 9720.00

47 ST0840508

48 2873.00

49 9724.00

50 2874.00

51 2870.00

52 9727.00

53 2671.00

54 5383.00

55 2867.00

56 STD852006

57 2576.00

58 2875.OO

59 9726.00

90 2579.01

61 3267.00

62 9728.00

63 5461.00

64 !5223.00

65 2877.00

66 0221.00

67 ISTD840610

68 9721.00

69 2879.00

70 0761.00

71 3270.00

72 3271.00

73 3272.00

74 16780.00

75 0351.00

76 5156.00

77 STD851004

78 4137.00

79 1412.01

80 9-73666

81 16404.00

82 16405.00

2602.03

DESCRIPTION QTY.

ShoulderBolt 2

WavyWasher 3

TrunnionHolder 1

V,-20x V_" 4

Socket Head Bdt

4-0.7 x lOmm 2

Pan Head Screw

5-0.8 x 10ram He=<Head Bolt 1

5-0.8mm Hex Nut* 3

Fence Bracket 1

6mm BpecialWasher 2

Handle 2

Trennlon 1

Bpdng 1

Plate 1

5-0.8 x 16ram Hex H_d Bolt 1

Support Nut 1

6ram LockWasher* 6

T-Nut 1

Fence Support 1

Left Bide Slotted Plate 1

!InfeedTable 1

Bracket 4

8ram Special Washer 4

3CM1-8Retaining Ring 4

5--0.8x 30ram Set Screw 1

Table Frame 1

3AMI-10 Ratainimj Rin9 1

8-1.0ram Hex Nut* 1

6-1.0 x30ram Set Screw 1

Support Plate I.

4-0.7 x 8ram Pan Head Screw 2

Spring 1

Elevation Screw 1

Knob 1

Shoulder Bolt 1

6-1.0 x 10mm Set Screw 4

4ram Serrated Washer 2

4ram Flat Washer* 2

Grommet 1

Line Cord 1

Push Block (set) 1

Baffle 1

Thread Forming Screw 5

Owner's Manual 1

Recommended Accessories

Blade(sat of 2) / 9-73667

T

t_ Push 91o{_k(set) J 9-73666

15

Page 16

SEARS

Owner's Manual

Sears service is available at or through

your Sears Retail Store

or Catalogue Sales Office

How to order repair parts

SERVICE AND REPAIR PARTS

CALL 1-800-4-MY-HOME*

(%800-469-4663)

Keep this number handy should you require a

service call or need to order repair parts.

If ordering parts make sure you have the name, make and

model no. of the merchandise and the name and number

of the part you wish to order.

When ordering repair perts

always give:

1.The Part Number

2, The Part Description

3, The Model Number:

4. The name of the item:

*if callin9 lOCally,please use one of the following numbers:

Regina - 566-5124 Montreal - 333-5740

Toronto - 744-4900 Halifax. 454-2444

Kitchener - 894-7590 Ottawa - 738-4440

_ancouver - 420-8211

WE SERVICE WHAT WE SELL.

WE MAKETHIS PLEDGE BECAUSE OUR CONCERN FOR OUR CUSTOMERS DOES NOT

ENDWITH THE SALE. TO HONOR OUR PLEDGE, WE HAVE DEVELOPED ATOP-NOTCH

SERVICE PROGRAM STAFFED BY HIGHLY TRAINED SPECIALISTS. THEIR KNOWLEDGE

OF OUR NEW PRODUCTS IS CONSTANTLY UPGRADED. THEY USE ONLY

PARTS SPECIFICALLY DESIGNED FORYOUR FINE SEARS PRODUCTS.

Sold by: SEARS CANADA INC.,TORONTO, ONTARIO, CANADA M5B 2B8

Loading...

Loading...