Craftsman 351.275210 Operator's Manual

Operator's Manual

CRAFTSMAN®

12Y2''

PLANER/MOLDER

Model

351.275210

No.

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

Sears Canada Inc., Toronto, Ontario MSB

8507.03 Draft (08/10/97)

288

TABLE

OF

CONTENTS

Warranty

..................................

2

Safety Rules

..............................

2-3

Assembly

...............

..

............

....

. 3

Installation . .

.............................

3-5

Operation

...........

.

.............

.

.....

5-12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Troubleshooting

.... , .......................

13

Parts Illustration and List

......

....

........

14-19

WAR.RANTY

FULL ONE YEAR WARRANTY ON

CRAFTSMAN 12%" PLANER/MOLDER

If within one full year from the date

of

purchase, this

Craftsman planer/molder

fails due to a defect

in

materi-

al

or

workmanship, Sears will repair it, free

of

charge.

Warranty service is available

by

contacting Sears. This

warranty is in addition

to

any statutory warranty.

If this planer/molder is used for commercial purposes,

this warranty applies for only

90 days from the date

of

purchase.

Sears Canada, Inc., Toronto, Ontario

M58

288

SAFETY

RULES

WARNING: For your own safety, read all of the

instructions and precautionsbefore operating

tool.

CAUTION: Always follow proper operating procedures

as defined

in

this manual even if you are familiar with

use

of

this

or

similar tools. Remember that being care-

less for even a fraction

of

a second can result in severe

personal injury.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry

which may get caught in moving parts

of

machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States

ANSI Z87.1. Everyday glasses have only impact

resistant lenses. They are

NOT safety glasses.

• Wear face mask

or

dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools

when tired, intoxicated or when taking medications

that cause drowsiness.

2

PREPARE WORK AREA FOR JOB

• Keep work area clean. Cluttered work areas invite

accidents.

• Do not use power tools in dangerous env ironments.

Do not use power tools

in

damp

or

wet locations. Do

not expose power tools to rain.

• Work area should be properly lighted.

• Proper electrical receptacle should be available for

tool. Three prong plug should be plugged directly

into properly grounded, three-prong receptacle.

• Extension cords should have a grounding prong and

the three wires

of

the extension cord should be of

the correct gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop childproof. Use padlocks, master switches or remove switch

keys

to

prevent any unintentional use

of

power tools.

TOOL SHOULD

BE

MAINTAINED

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjusting procedures.

• Keep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to

see that adjusting tools are removed before switching machine on.

• Keep all parts

in

working order. Check to determine

that the guard or other parts will operate properly

and perform the ir intended function.

• Check for damaged parts. Check for alignment of

moving parts, bi

nd

ing, breakage, mounting and any

other condition that may affect a tool's operation.

• A guard

or

other part that is damaged should be

properly repaired or rep laced. Do not perfo

rm

makeshift repairs. (Use parts list provided to order

replacement parts.)

KNOW HOW TO USE TOOL

• Use right tool for job. Do not force tool or attachment

to do a job for 'which it was not designed.

• Disconnect tool when changing blades.

• Avoid accidental start-up. Make sure that the switch

is

in

the "off" position before plugging

in.

• Do not force tool. It will work most efficiently at the

rate for which it was designed.

• Keep hands away from moving parts and cutting

surfaces.

• Never leave tool running unattended. Turn the power

off

and do not leave tool until

it

comes to a complete

stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool

is

tipped or if blade is unintentionally contacted.

• Know your tool. Learn the tool's operation, applica-

tion and specific limitation

s.

• Use recommended accessories (refer to page 17).

Use

of

improper accessories may cause risk of

injury to persons.

• Handle workpiece correctly. Protect hands from possible

injury.

• Turn machine off if it jams. Knife or bit jams when it

digs too deeply into workpiece. (Motor force keeps it

stuck

in

the work.)

• Always keep drive. cutterhead and knife guards in

place and

in

proper operating condition.

• Feed work into knife or cutter against direction of

rotation.

CAUTION: Think safety! Safety is a combination

of

operator common sense and alertness at all times

when tool is being used.

WARNING:

Do

not attempt to operate tool until

it

is

completely assembled according to the instructions.

ASSEMBLY

'

Refer to Figures 15 and 16, pages 16 and 18.

The planer/molder

is

shipped assembled except for the

handwheel and handle (Figure

16,

Key Nos. 22 and 24).

INSTALL HANDWHEEL

AND

HANDLE

Refer to Figure 16, page 18.

• Handwheel (Key

No.

22) must be installed to the left

side

of

the planer/molder.

• Align handle (Key No. 24) with the hole on the rim

of

the handwheel.

• Insert handle

screw (Key

No.

23) into handle and

tighten to secure.

• Slide handwheel onto crank elevation screw (Key

No.

19) so that the spring pin (Key

No.

21) on the

crank elevation screw

is

positioned between the

groove

in

the handwheel.

REMOVE CAPS

Refer to Figure 15, page 16.

The planer/molder is shipped with caps (Key

No.

13) on

the threaded shafts (Key

No.

11) to avoid damage to

shafts during shipping and handling.

• Unscrew and remove caps before turning the tool on.

• Save caps for future use.

MOUNT PLANER

TO

WORK

SURFACE

Refer to Figure

1.

• Planer is designed to be portable so

it

can be moved

to job site, but

should be mounted to stable, level

bench

or

table. See Recommended Accessories,

page

17.

3

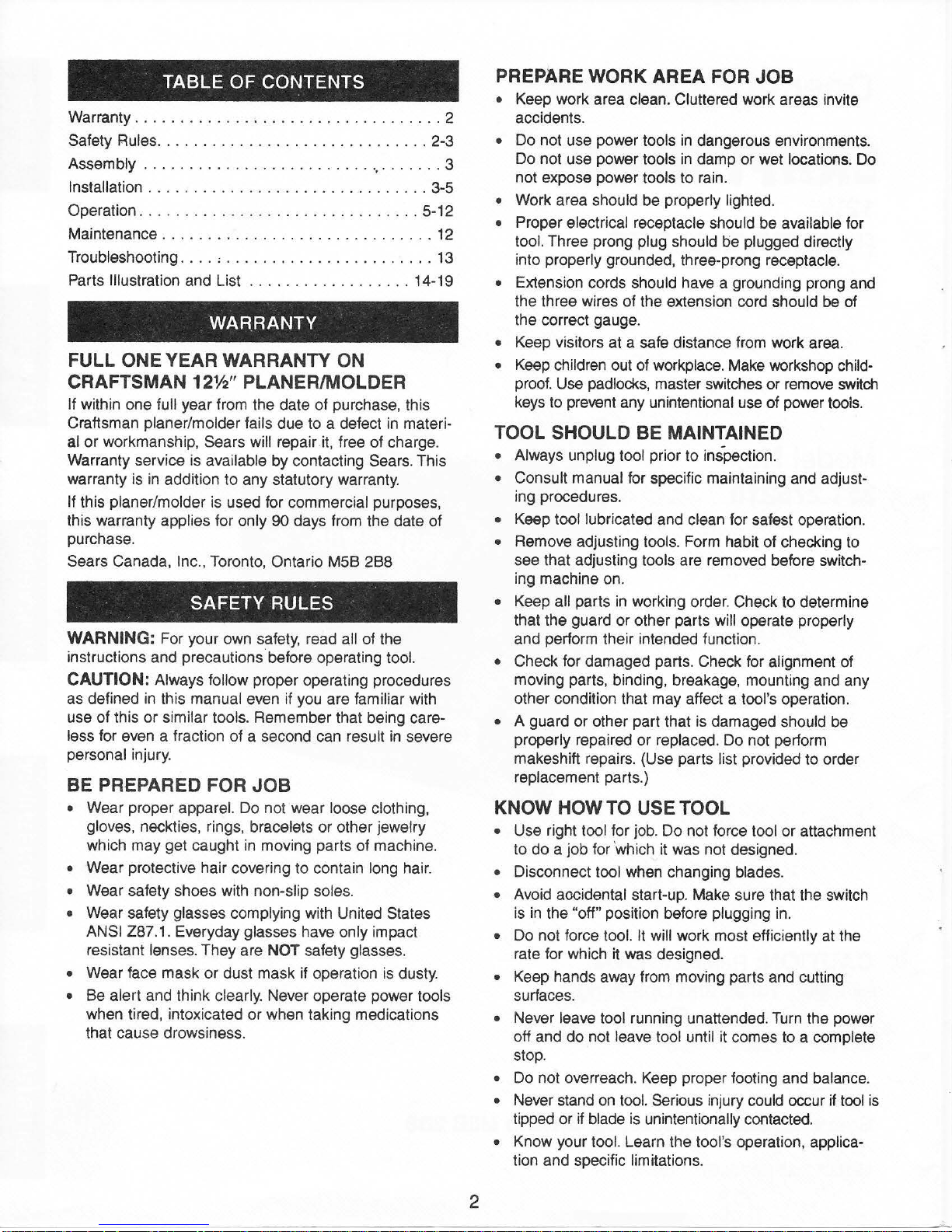

MOUNTING

INSTRUCTIONS FOR

OPTIONAL

STAND

MODEL

22250

Refer to Figure

1.

Material List

•

Y2

x 15 x 22" particle board (not supplied)

• Four

14-20

x 1

1.1.1''

Bolts wi

th

washers and nuts (not

supplied) for mounting board to

Multi-Purpose Stand.

• Four 8-1.25 x 30mm bolts with washers (supplied

with planer/molder) for mounting planer/molder

to

board.

A mounting board is needed when mounting

planer/molder

to

Sears Multi-Purpose Stand Model

22250. The mounting board is made from

W'

thick ply-

wood or particle board.

• Cut and drill the board using drawing. The 1 0" diameter hole in the center is used for ventilation only.

•

Secure the mounting board to the stand top first,

using four

14"

bolts, washers and nuts (not provided).

be sure board is centered on stand top and bolted

securely.

• Mount the planer/molder to the mounting board

using the four 8-1.25 x 30mm bolts with washers.

Thread the

bolts through the mounting board and

into the base casting from underneath the board.

r---H--

0 0

0

I

%"

6

~'

--+---

9'Ae"

...._-------2

2"

Figure 1 - Mount Planer/Molder to Optional Multi-Purpose

Stand Model No. 22250

INSTALLATION

POWER

SOURCE

WARNING: Do not connect planer/molder to the power

source until all assembly steps have been completed.

The motor is designed for operation on the voltage and

frequency specified. Normal loa

ds

will be handled safe-

ly

on voltages not more than 1

0%

above

or

below specified voltage. Running the unit on voltages which are not

within range may cause overheating and motor burnout. Heavy loads require that voltage

at

motor terminals

be

no

less than the voltage specified on nameplate.

• Power supply to t

he

motor is contro lled by a rocker

switch. Removing the rocker switch

will lock the unit

and prevent unauthorized us

e.

GROUNDING INSTRUCTIONS

WARNING:

Improper connection of equipment

grounding conductor can result in the risk of electrical

shock. Equipment should be grounded while

in

use to

protect operator from electrical shock.

• Check with a qualified electrician if grounding

instructions are not understood or if

in

doubt as to

whether the tool is properly grounded.

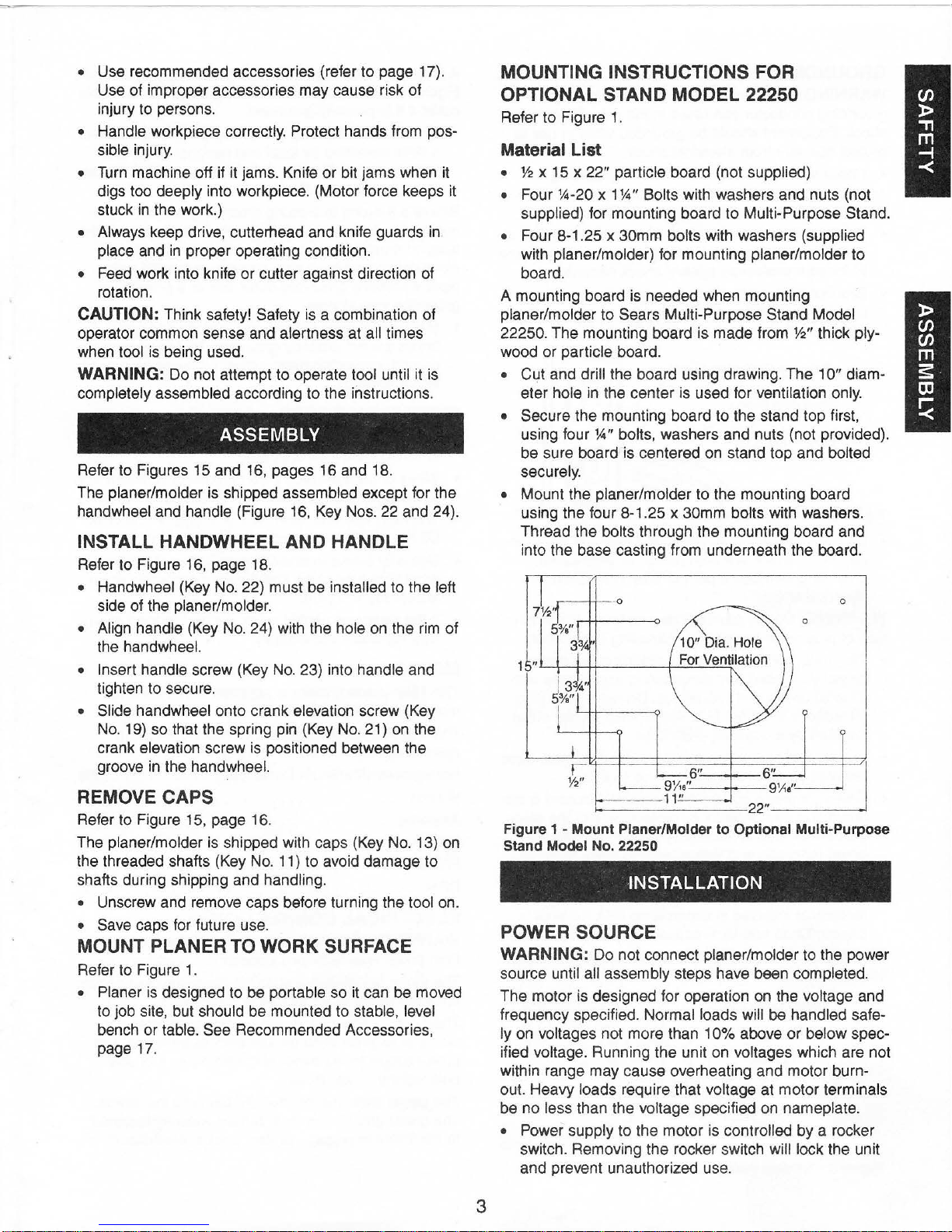

• This tool is equipped with

an

approved cord rated at

150V and a 3-prong grounding type plug (see Figure

2) for your protection against shock hazards.

• Grounding plug should be plugged directly into a

properly installed and grounded 3-prong grounding-

type receptacle, as shown (see Figure 2).

Properly Grounded Outlet

Grounding Prong

3-Prong

Plug

Figure 2 - 3-Prong Receptacle

•

Do

not remove

or

alter grounding prong

in

any man-

ner.

In

the event of a malfunction

or

breakdown,

grounding provides a path of least resistance for

electrical shock.

WARNING:

Do

not permit fingers to touch the termi-

nals

of

plug when installing or removing from outlet.

• Plug must be plugged into matching outlet that is

properly installed and grounded in accordance with

all local codes and ordinances.

Do

not modify plug

provided.

If it will not fit in outlet, have proper outlet

installed by a qualified electrician.

• Inspect tool cords periodically, and if damaged, have

repaired by

an

authorized service facility.

• Green (or green and yellow) conductor

in

cord is the

grounding wire.

If repair or replacement of the elec-

tric cord or plug is necessary,

do

not conneCt the

green (or green and yellow) wire to a live terminal.

• Where a 2-prong wall receptacle is encountered,

it

must be replaced with a properly grounded 3-prong

receptacle installed in accordance with National

Electric Code and local codes and ordinances.

WARNING:

This work should be performed by a quali-

fied electrician.

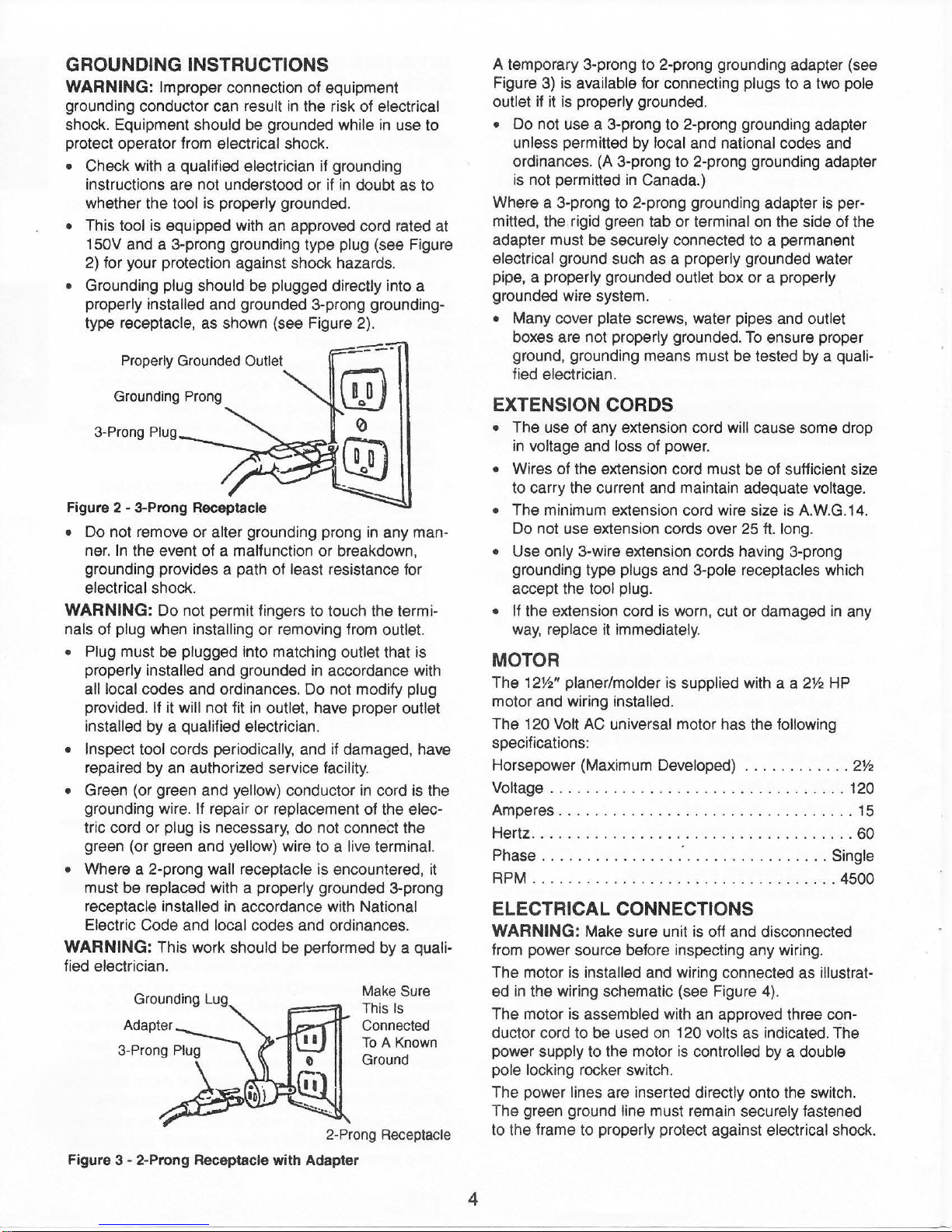

Grounding Lug

Make

Sure

This

IS

Connected

To

A Known

Ground

2-Prong Receptacle

Figure

3 - 2-Prong Receptacle with Adapter

4

A temporary 3-prong to 2-prong grounding adapter (see

Figure

3)

is available for connecting plugs to a two pole

outlet if it is properly grounded.

•

Do

not use a 3-prong to 2-prong grounding adapter

unless permitted by local and national codes and

ordinances. (A 3-prong to 2-p

ro

ng grounding adapter

is not permitted

in

Canada.)

Where a 3-prong to 2-prong ground ing adapter is

per-

mitted, the rigid green tab

or

terminal on the side of the

adapter must be securely connected to a permanent

electrical ground such as a properly grounded water

pipe, a properly grounded outlet box or a properly

grounded wire system.

• Many cover plate screws, water pipes and outlet

boxes are not properly grounded.

To

ensure proper

ground, grounding means must be tested by a

quali-

fied electrician.

EXTENSION CORDS

• The use of any extension cord will cause some drop

in voltage and loss of power.

• Wires of the extension cord must be of sufficient size

to

carry the current and maintain adequate voltage.

• The minimum extension cord wire size

is

A.W.G.14.

Do not use extension cords over 25 ft. long.

• Use only 3-wire extension cords having 3-prong

grounding type plugs and 3-pole receptacles which

accept the tool plug.

• If the extension cord is worn, cut or damaged

in

any

way,

replace it immediately.

MOTOR

The 12W' planer/molder is supplied with a a

2%

HP

motor and wiring installed.

The

120 Volt AC universal motor has the following

specifications:

Horsepower (Maximum Developed) .

...........

2%

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Amperes

.....

. .

......

...........

.

........ 15

Hertz .

....

. .

.. ................

.

.......

.

..

60

Phase

....

..

.........

."

. .

........

......

Single

RPM

.....

.......

.

......

..

. .

...

......

. . 4500

ELECTRICAL CONNECTIONS

WARNING:

Make sure unit

is

ott and disconnected

from power source before inspecting any wiring.

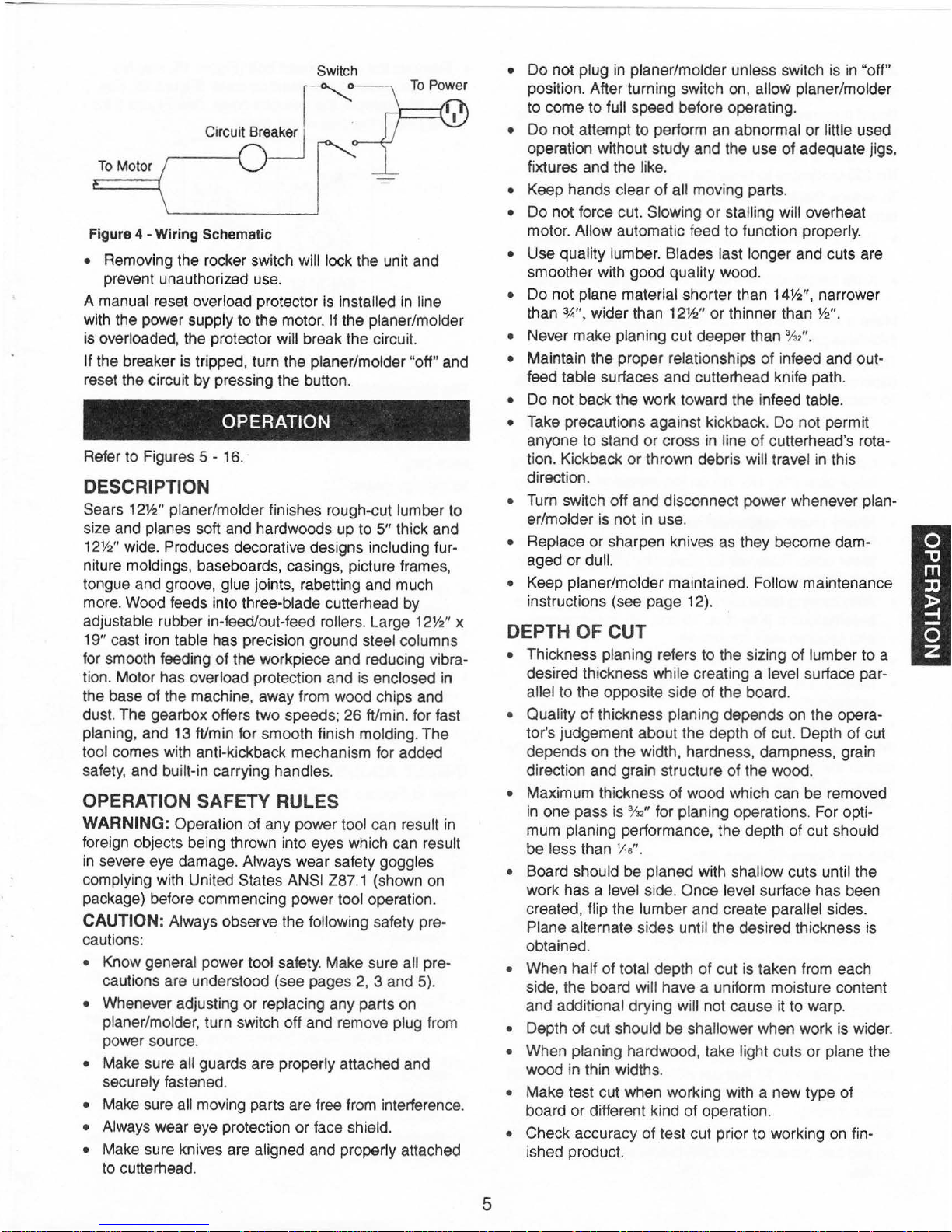

The motor is installed and wiring connected as

illustrat-

ed in the wiring schematic (see Figure 4

).

The motor is assembled with

an

approved three con-

duc

tor

cord to

be

used on 120 volts as indicated. The

power supply to the motor is controlled by a double

pole locking rocker switch.

The power lines are inserted directly onto the switch.

The green ground

line must rema

in

securely fastened

to the frame to properly protect against electrical shock.

Switch

To

Motor

Figure 4 -Wiring Schematic

• Removing the rocker switch will lock the unit and

prevent unauthorized use.

A manual reset overload protector is installed in line

with the power supply to the motor.

If the planer/molder

is overloaded, the protector

will break the circuit.

If the breaker is tripped, turn the planer/molder "off" and

reset the circuit

by

pressing the button.

OPERATION

Refer to Figures 5 - 16.

DESCRIPTION

Sears 12W' planer/molder finishes rough-cut lumber to

size and planes soft and hardwoods up to

5" thick and

12W' wide. Produces decorative designs including furniture moldings, baseboards, casings, picture frames,

tongue and groove, glue joints, rabetting and much

more. Wood feeds into three-blade cutterhead by

adjustable rubber in-feed/out-feed rollers. Large

12W' x

19" cast iron table has precision ground steel columns

for smooth feeding of the workpiece and reducing vibration. Motor has overload protection and is enclosed

in

the base of the machine, away from wood chips and

dust. The gearbox offers two speeds; 26

ftlmin. for fast

planing, and

13ft/min

for smooth finish molding. The

tool comes with anti-kickback mechanism for added

safety, and

bu

ilt-in carrying handles.

OPERATION SAFETY RULES

WARNING: Operation of any power tool can result

in

foreign objects being thrown into eyes which can result

in severe eye damage. Always wear safety goggles

complying with United States

ANSI Z87.1 (shown on

package) before commencing power tool operation.

CAUTION: Always observe the following safety pre-

cautions:

• Know general power tool safety. Make sure all pre-

cautions are understood (see pages 2, 3 and 5).

• Whenever adjusting

or

replacing any parts on

planer/molder, turn switch off and remove plug from

power source.

• Make sure all guards are properly attached and

securely fastened.

• Make sure all moving parts are free from interference.

• Always wear eye protection or face shield.

• Make sure knives are aligned and properly attached

to cutterhead.

5

• Do not plug in planer/molder unless switch is in "o ff"

position. After turning switch on, allow planer/molder

to come to

full speed before operating.

• Do not attempt to perform an abnormal

or

little used

operation without study and the use

of

adequate jigs,

fixtures and the like.

• Keep hands clear

of

all moving parts.

• Do not force cut. Slowing or stalling will overheat

motor.

Allow automatic feed to function properly.

• Use quality lumber. Blades last longer and cuts are

smoother with good quality wood.

• Do not plane material shorter than

14Y2'',

narrower

than

3

.4"

, wider than 12W'

or

thinner than W'.

• Never make planing cut deeper than % ".

•

Maintain the proper relationships of infeed and outfeed table surfaces and cutterhead knife path.

•

Do

not back the work toward the infeed table.

• Take precautions against kickback. Do not permit

anyone

to

stand or cross in line of cutterhead's rota-

tion . Kickback

or

thrown debris will travel in this

direction.

• Turn switch off and disconnect power whenever planer/molder is not

in

use.

• Replace

or

sharpen knives as they become dam-

aged

or

dull.

•

Keep planer/molder maintained. Follow maintenance

instructions (see page 12}.

DEPTH

OF

CUT

• Thickness planing refers to the sizing of lumber to a

desired thickness while creating a

level surface par-

allel

to

the opposite side of the board.

• Quality

of

thickness planing depends on the operator's judgement about the depth of cut. Depth of cut

depends on the width, hardness, dampness, grain

direction and grain structure of the wood.

• Maximum thickness of wood which can be removed

in

one pass is

%2''

for planing operations . For optimum planing performance, the depth of cut should

be

less than

~6,.

• Board should be planed with shallow cuts until the

work has a

level side. Once level surface has been

created, flip the lumber and create

parallel sides.

Plane alternate sides until the desired thickness is

obtained.

• When half of total depth of cut is taken from each

side, the board

will have a uniform moisture content

and additional drying

will not cause

it

to warp.

• Depth of cut should be shallower when work is wider.

• When planing hardwood, take light cuts or plane the

wood in thin widths.

• Make test cut when working with a new type

of

board or different kind

of

operation.

• Check accuracy of test cut prior to working

on

fin-

ished product.

ADJUSTING THE DEPTH

Refer

to

Figure 16, page 18.

Board thickness which

indicated by either scale (Key No.4) on the side.

Thickness is adjusted

No. 22) clockwise to raise the knife height.

To reduce the knife height, rotate the handwheel counterclockwise.

• Do not set knife below '

which is less than a

• Knife height will be moved

revolution of the

Make a test cut on a piece

thickness produced.

The planer/molder will produce uneven depth of cut

(tapered cut)

To

restore parallelism of the cutterhead with the table:

• Clamp a vise plier on the left side

No.6)

• Loosen set screws (Key No. 51) and disengage right

bevel gear (Key No. 1

No. 18).

• Slowly rotate

Rotate clockwise to raise table, counterclockwise to

lower table. Table will be moved

turn

• After mov ing table the required distance, make sure

beveled gears (Key Nos. 1

and secured with set screws.

• Release and remove the vise plier

Make a test cut to make sure the adjustment was

•

appropriate.

• Add grease to bevel gears if necessary.

When the depth

loosen the pan head screw (Key.

indicator (Key No. 29) to show the thickness produced.

Make sure that the indicator is positioned correctly.

if

the cutterhead is not parallel with the table.

next to the bevel gear

of

the beveled gear by one tooth.

t~e

by

rotating the handwheel (Key

W'

handwheel.

O)

ha~dwheel

of

cut adjustment is operating correctly,

OF

CUT

planer/molder will produce

o/32".

Do not plane a board

thick.

Y.s"

with every complete

of

wood and measure the

of

the shaft (Key

(Key.

No.

10).

on the elevation screw (Key

to raise or lower the table.

by

.004" with every

0 and 12) are engaged

No.

28) and set the

is

TABLE HEIGHT ADJUSTMENT

Refer to Figure 16, page 18.

• The depth

raising or lowering the table .

• Rotate the handwheel (Key

the table

• The scale and indicator (Key Nos. 4 and 29) can be

used when adjusting the table height.

of

cut

of

the planer/molder

to

the desired position.

No.

22) to raise

is

adjusted by

or

lower

FEED RATE ADJUSTMENT

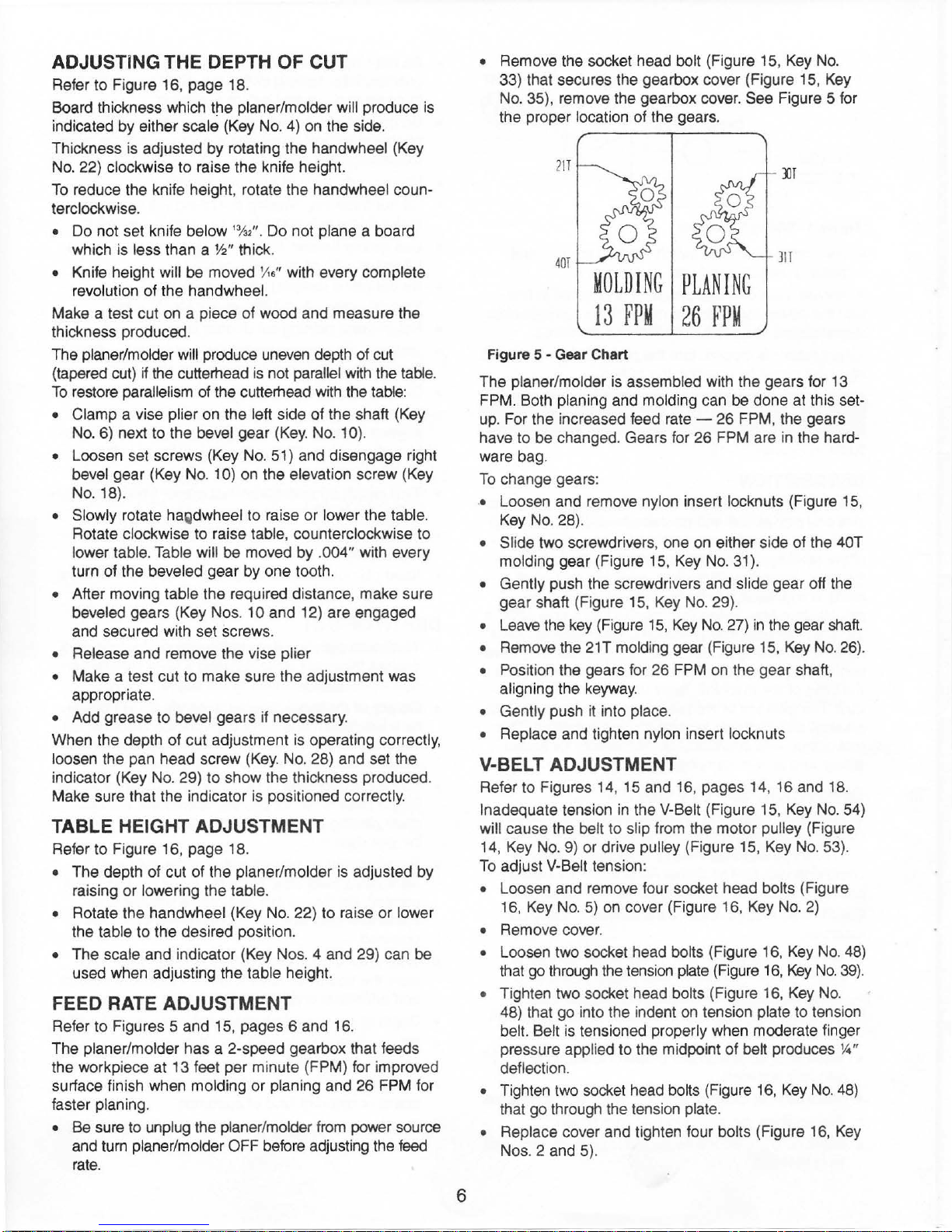

Refer to Figures 5 and 15, pages 6 and 16.

The planer/molder has a 2-speed gearbox that feeds

the workpiece

surface finish when molding or planing and

faster planing.

• Be sure to unplug the planer/molder from power source

and turn planer/molder

rate.

at

13 feet per minute (FPM) for improved

26

FPM for

OFF before adjusting the feed

• Remove the socket head bolt (Figure 15, Key No.

33) that secures the gearbox cover (Figure

No.

35), remove the gearbox cover. See Figure 5 for

the proper location of the gears.

21T

40T

MOLDING

13

FPM

Figure 5 - Gear Chart

The planer/molder is assembled with the gears for 13

FPM. Both planing and molding can be done at this set-

up. For the increased feed rate - 26 FPM, the gears

have to be changed. Gears for 26

ware bag.

To

change gears:

• Loosen and remove nylon insert locknuts (Figure

Key No. 28).

• Slide two screwdrivers, one on either side of the 40T

molding gear (Figure 15, Key No.

• Gently push the screwdrivers and slide gear off the

gear shaft (Figure 15, Key No. 29).

• Leave the key (Figure

• Remove the 21T molding gear (Figure

• Position the gears for 26 FPM on the gear shaft,

aligning the keyway.

• Gently push it into place.

• Replace and tighten nylon insert locknuts

PLANING

26

FPM

FPM are in the hard-

31

15,

Key

No.

27)

).

llT

]11

in

the gear

15,

Key

15

, Key

shaft.

No.

15,

26).

V-BELT ADJUSTMENT

Refer to Figures 14, 15 and 16, pages 14, 16 and 18.

Inadequate tension

will cause the belt to slip from the motor pulley (Figure

14, Key

To adju st

• Loosen and remo

• Remo

• Loosen two socket head bolts (Figure 16, Key

• Tighten two socket head bolts (Figure 16, Key No.

• Tighten two socket head bolts (Figure 16,

• Replace cover and tighten four bolts (Figure 16,

No.9)

V-Belt tension:

16, Key

that

48) that go into the indent on tension plate to tension

belt. Belt is tensioned properly when moderate finger

pressure applied to the midpoint of

deflection.

that go through the tension plat

Nos. 2 and 5).

No.

ve

cover.

go

through the tension plate (Figure 16,

in

the V-Belt (Figure 15, Key No. 54)

or drive pulley (Figure 15, Key

ve

four socket head bolts (Figure

5)

on

cover (Figure 16, Key No.

belt produces W'

Key

e.

No.

Key

2)

No.

53).

No.

No.

48)

39)

48)

Key

.

6

Loading...

Loading...