Craftsman 351.264271 Operator's Manual

Operator's Manual

MORTISING CHISEL KIT

351.264271

CAUTION:

Read and follow all Safety

Rules and Operating

Instructions before First Use

of this Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com/craftsman

17350.01 Draft (11/11/02)

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Espahol

Warranty ....................... 2

Safety Rules .................. 2-3

Assembly ...................... 3

Installation .................... 3-4

Operation .................... 4-5

Maintenance .................... 5

Parts Illustration and List ........ 6-7

EspaSol ..................... 8-11

FULL ONE YEAR WARRANTY

If this product fails due to a defect in material or workmanship within one year from

the date of purchase, Sears will at its option repair or replace it free of charge.

Contact your nearest Sears Service Center (1-800-4-MY-HOME) to arrange for

product repair, or return this product to place of purchase for replacement.

If this product is used for commercial or rental purposes, this warranty will apply for

90 days from the date of purchase.

This warranty applies only while this product is used in the United States.

This warranty gives you specific legal rights and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

WARNING: For your own safety, read

all of the instructions and precautions

before operating tool.

CAUTION: Always follow proper operat-

ing procedures as defined in this manual

even if you are familiar with use of this or

similar tools. Remember that being care-

less for even a fraction of a second can

result in severe personal injury.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear

loose clothing, gloves, neckties,

rings, bracelets or other jewelry

which may get caught in moving

parts of machine.

° Wear protective hair covering to

contain long hair.

° Wear safety shoes with non-slip soles.

° Wear safety glasses complying with

United States ANSI Z87.1. Everyday

© Sears, Roebuck and Co. 2

glasses have only impact resistant

lenses. They are NOT safety glasses.

Wear face mask or dust mask if

operation is dusty.

Be alert and think clearly. Never

operate power tools when tired,

intoxicated or when taking medica-

tions that cause drowsiness.

PREPARE WORK AREA FOR JOB

° Keep work area clean. Cluttered

work areas invite accidents.

° Work area should be properly lighted.

° Keep visitors at a safe distance from

work area.

° Keep children out of workplace.

Make workshop childproof. Use pad-

locks, master switches or remove

switch keys to prevent any uninten-

tional use of power tools.

KNOW HOW TO USE TOOL

• Use right tool for job. Do not force

tool or attachment to do a job for

which it was not designed.

• Do not force tool. It wilt work most

efficiently at the rate for which it was

designed.

• Keep hands away from moving parts

and cutting surfaces.

• Know your toot. Learn the tool's

operation, application and specific

limitations.

• Use of improper accessories may

cause risk of injury to persons.

• Handle workpiece correctly. Protect

hands from possible injury.

• Turn machine off if it jams. Chisel or

bit jams when it digs too deeply into

workpiece. (Motor force keeps it

stuck in the work.)

CAUTION: Think safety! Safety is a

combination of operator common sense

and alertness at all times when tool is

being used.

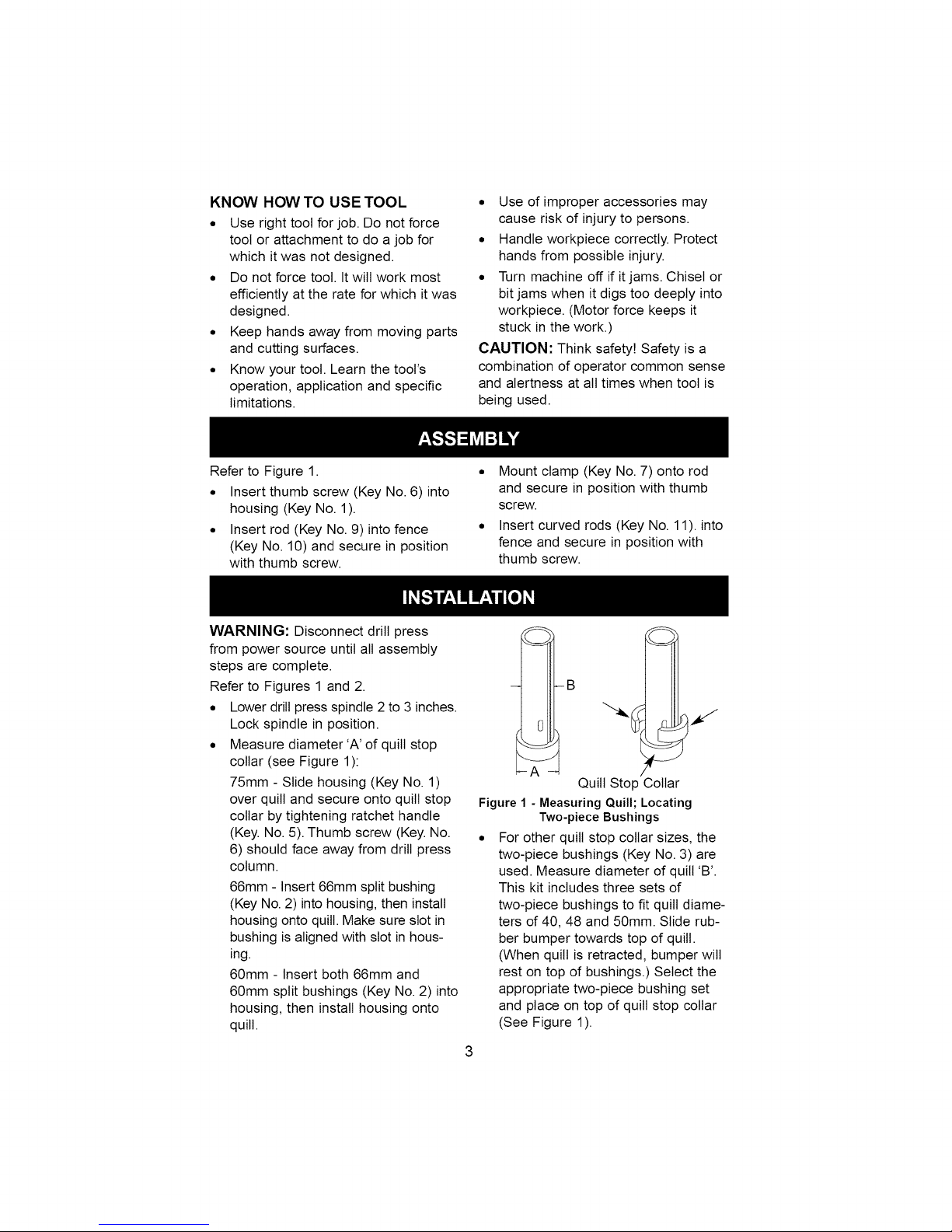

Refer to Figure 1.

• Insert thumb screw (Key No. 6) into

housing (Key No. 1).

• Insert rod (Key No. 9) into fence

(Key No. 10) and secure in position

with thumb screw.

WARNING: Disconnect drill press

from power source until all assembly

steps are complete.

Refer to Figures 1 and 2.

• Lower drill press spindle 2 to 3 inches.

Lock spindle in position.

• Measure diameter'A' of quill stop

collar (see Figure 1):

75mm - Slide housing (Key No. 1)

over quill and secure onto quill stop

collar by tightening ratchet handle

(Key. No. 5). Thumb screw (Key. No.

6) should face away from drill press

column.

66mm - Insert 66mm split bushing

(Key No. 2) into housing, then install

housing onto quill. Make sure slot in

bushing is aligned with slot in hous-

ing.

60mm - Insert both 66mm and

60mm split bushings (Key No. 2) into

housing, then install housing onto

quill.

• Mount clamp (Key No. 7) onto rod

and secure in position with thumb

screw.

• Insert curved rods (Key No. 11). into

fence and secure in position with

thumb screw.

- B

1

Quill Stop Collar

Figure 1 - Measuring Quill; Locating

Two-piece Bushings

• For other quill stop collar sizes, the

two-piece bushings (Key No. 3) are

used. Measure diameter of quill 'B'.

This kit includes three sets of

two-piece bushings to fit quill diame-

ters of 40, 48 and 50mm. Slide rub-

ber bumper towards top of quill.

(When quill is retracted, bumper will

rest on top of bushings.) Select the

appropriate two-piece bushing set

and place on top of quill stop collar

(See Figure 1).

3

Loading...

Loading...