Craftsman 351.252741, 351.252181, 351.253351 Operator's Manual

Operator's Manual

CRRFT. RN °

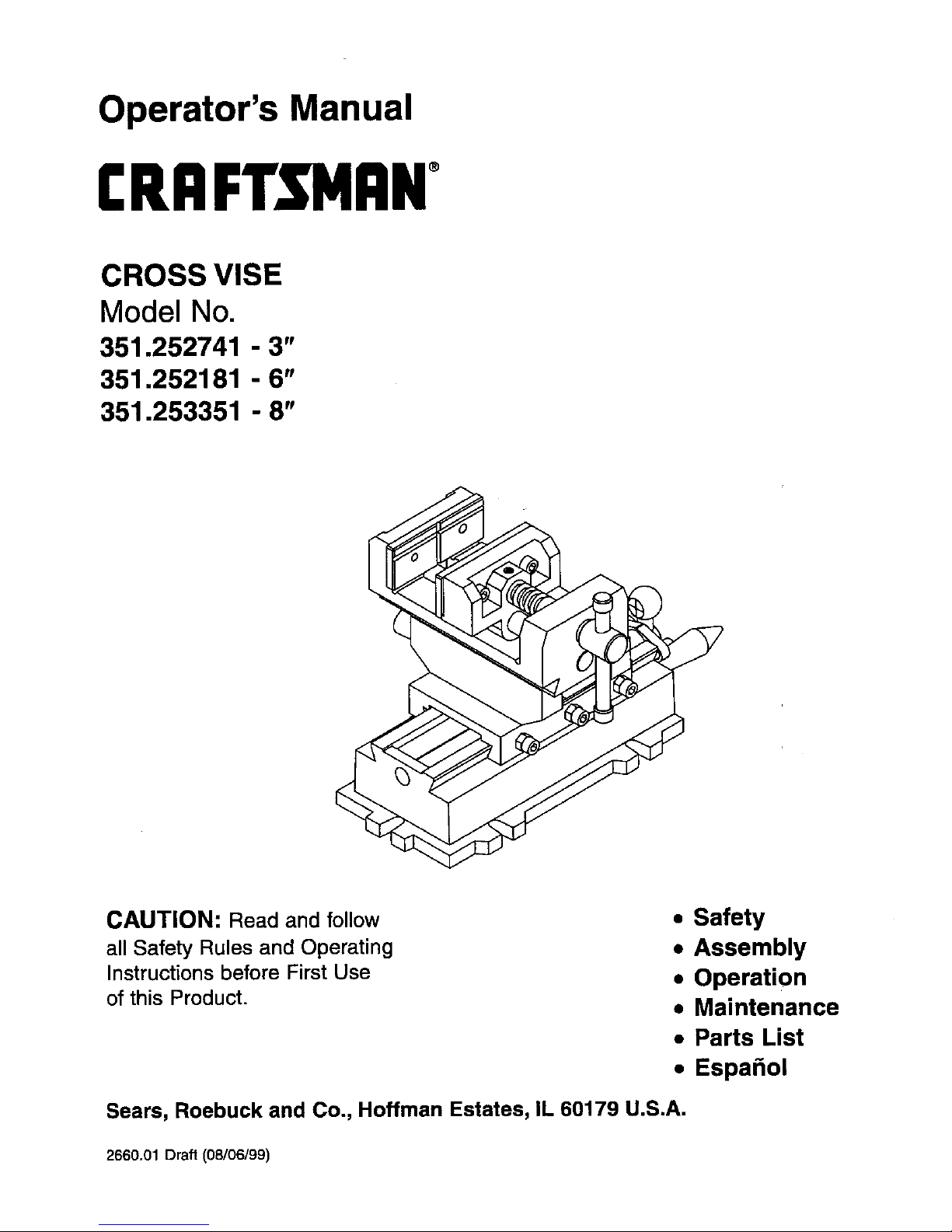

CROSS VISE

Model No.

351.252741 -3"

351.252181 - 6"

351.253351 -8"

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Espa_ol

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

2660.01 Draft (08/06/99)

Warranty....................................... 2

Safety Rules.................................... 2

Assembly ...................................... 2

Operation ...................................... 2

Maintenance.................................... 3

Parts Illustrationand List ......................... 4-5

Espafiol ...................................... 6-7

FULL ONE YEAR WARRANTY ON CRAFTSMAN

CROSS VISES

Ifwithin one full year from the date of purchase, this

Craftsman Cross Vise fails due to a defect in materfel or

workmanship, Sears will repairitfree of charge.

Warranty service is available by simply returningthe Cross

Vise to the nearest Sears Store or Service Center throughout

the United States.

This warranty givesyou specificlegal rightsand youmay

have other rightswhich vary from state to state.

Sears, Roebuck and Co., Dept 817WA, Hoffman Estates, IL

60179

• Understand and obey all safety instructionssuppliedwith

drillpress, mill,or other machines on which vise is used.

• Bolt orclamp vise to work surface in at least two mounting

locations usingmounting flanges provided on base.

• Be sure workpiece isclamped securely between jaws

before starting machining operation.

• Do not over tighten--vise can develop a large damping

force.Use only force which is needed.

• Do not pound or hammer on workpiece.This vise is

designed to clamp the workpiece in a desired positionfor

machining operations only.

MODEL 252741, 3" VISE

Refer to Figure 1.

• Mount crank handles (Fig. 1, No. 12) to longitudinaland

cressfeed leadscrews (Fig. 1, Nos. 9 and 23) using acorn

nuts (Fig. 1, No. 13).

• This vise is shipped with a protective coating.This coating

should be removedbefore operation. Remove protective

coating with penetratingoil.

MODELS 252181 AND 253351,6" AND 8" VISES

Refer to Figure 1.

• Thread movablejaw leadscrew (Fig. 1, No. 14) through end

ofbody (Fig. 1, No. 16) and into holein movablejaw (Fig. 1,

No. 18).

• Secure with dog point set screw (Fig. 1, No. 19)

• Mount crank handles (Fig. 1, No. 12) to longitudinaland

crossfeed leadscrews (Fig. 1, Nos. 9 and 23) usingacorn

nuts (Fig. 1, No. 13).

• This vise is shipped with a protectivecoating. This coating

should be removed before operation.Remove protective

coatingwithpenetrating oil.

2

DESCRIPTION

Cross Vises travel ontwo separate axes_ongitudinal and

crossfeed, to permit accurate positioningof workpiece. Body,

saddle, base and jaws are made ofhigh strength cast iron.

Vise feadserew, longitudinaland crossfeed leadsorews are

precisfenground carbon steel.A prismaticjaw isprovided for

clamping roundstock.

Refer to Figure 1.

• Mount vise towork surface indesired location by securing at

least two mounting flanges located on base (Fig. 1, No. 1).

• Move saddle (Fig. 1, No. 3) by rotating longitudinal crank

handle (Fig. 1, No. 12). Tighten center set screw (Fig. 1,

No.6) to secure position.

• Move body to desired position by rotating crossfeed crank

handle (Fig. 1, No. 12). Tighten center set screw (Fig. 1,

No. 6) to secure position.

• Open jaws of vise. Place workpiece between jaws in

desired position. Rotate movable jaw leadscrew (Fig. 1, No.

14) to secure workpiese between jaws. Be sure workpiece

is secure in vise before starting machining operation.

SPECIFICATIONS

Longitudinaltravel (left to right).............. 5" (252741)

..................................... 8" (252180)

..................................... 8" (253351)

Cress travel (frontto back) ................. 5" (252741)

..................................... 8" (252180)

..................................... 8" (253351)

Jaw Width.............................. 3_ (252741)

..................................... 6" (252180)

..................................... 8" (253351)

Maximum Jaw Opening ................... 3" (252741)

..................................... 6" (252180)

..................................... 6" (253351)

Value of One Division ................ 0.0039" (252741)

................................. 0.0039"(252180)

................................. 0,0039" (253351)

Cross Travelper One Revolution........ 0.1181" (252741)

................................. 0.1575" (252180)

................................. 0.1575"(253351)

LongitudinalTravelper One Revolution... 0.1181" (252741)

................................. 0.1575" (252180)

................................. 0.1575"(253351)

MOUNTING PRISMATIC JAW

One prismatic jaw is provided. This prismatic jaw can be sub-

stitutedfor either flat jaw plate.

• Attach prismaticjawto work on roundstock. Deep V-slots

allow both horizontaland verticaldamping.

• Remove jaw plate by unscrewing socket head bolts (Fig. 1,

No. 17).

• Switch jaw plates and securely fasten prismatic jaw to vise,

using socket head bolts (Fig. 1, No. 17).

Particles of metal or wood can damage machined surfaces,

causing difficultor inaccurate operation.

• Keep machined surfaces and all moving parts clean and

free of dirt, chips and foreign materials.

• Keep machined surfaces and leadscrews lubricated with

medium weight machine oil.

GIB ADJUSTMENT

Refer to Figure 1.

• Adjustgibs (Fig. 1, No. 4) by tighteningthe set screws (Fig.

1, No. 6) at each end of the gibs.

• Adjustthe screws untila slight drag is felt when rotatingthe

crank handles (Fig. 1, No. 12). Secure screws by tightening

nuts(Fig. 1, No. 5).

3

Loading...

Loading...