Page 1

Operator's Manual

CRRFTSMRN°

121_"

PLANER/MOLDER

Model No.

351.233831

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

8507.02 Draft(08/10/97)

Page 2

Warranty.................................. 2

Safety Rules.............................. 2-3

Assembly ................................. 3

Installation ............................... 3-5

Operation ............................... 5-12

Maintenance .............................. 12

Troubleshooting ............................ 13

Parts Illustration and List .................. 14-19

EspaSol ............................... 20-31

FULL ONE YEAR WARRANTY ON

CRAFTSMAN 121/="PLANER/MOLDER

If this Craftsman Planer/Molder fails due to a defect in

material or workmanship within one year from the date

of purchase, contact the nearest Sears in-home major

brand repair service in the United States, and Sears will

repair it, free of charge.

If this planer/molder is used for commercial or rental

purposes, this warranty will apply for 90 days from the

date of purchase.

This warranty applies only whilethe product is in the

United States. This warranty gives you specific legal

rightsand you may also have other rightswhichvary

from state to state.

Seam, Roebuck and Co., Dept. 817WA, Hoffman

Estates, IL 60179

WARNING: For your own safety, read all ofthe

instructionsand precautionsbefore operatingtool.

CAUTION: Always followproper operatingprocedures

as defined in this manual even ifyouare familiar with

use ofthis or similartools.Remember that beingcare-

lessfor even a fraction of a second can resultinsevere

personalinjury.

BE PREPARED FOR JOB

• Wear properapparel. Do not wear loose clothing,

gloves, neckties, rings,bracelets or otherjewelry

which may get caught in movingparts of machine.

• Wear protectivehair coveringto containlong hair.

• Wear safety shoeswith non-slipsoles.

• Wear safetyglassescomplyingwithUnited States

ANSI Z87.1. Everydayglasses have only impact

resistantlenses.They are NOT safetyglasses.

• Wear face mask or dust mask if operation isdusty.

• Be alert and thinkclearly.Never operate power tools

when tired, intoxicatedor whentaking medications

that cause drowsiness.

PREPARE WORK AREA FOR JOB

Keep work area clean. Cluttered work areas invite

accidents.

Do not use powertoolsin dangerousenvironments.

Do not use powertoolsin damp or wet locations.Do

not expose powertoolsto rein.

• Work area shouldbe properlylighted.

• Proper electrical receptacleshould be available for

tool.Three prongplug should be pluggeddirectly

intoproperlygrounded,three-prong receptacle.

• Extensioncordsshould havea groundingprongand

the three wires of the extensioncordshouldbe of

the correctgauge.

• Keep visitorsat a safe distancefrom workarea.

• Keep childrenoutof workplace.Make Workshopchild-

proof.Use padlocks,masterswitchesor removeswitch

keysto preventany unintentionaluse of power tools.

TOOL SHOULD BE MAINTAINED

• Always unplugtool prior to inspection.

• Consult manualfor specificmaintainingand adjust-

ing procedures.

• Keep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to

see that adjusting tools are removed before switch-

ing machine on.

• Keep all parts in working order. Check to determine

that the guard or other parts will operate properly

and perform their intended function.

• Check for damaged parts. Check for alignment of

moving parts, binding, breakage, mounting and any

other condition that may affecta tool's operation.

• A guard or other part that is damaged should be

properly repaired or replaced. Do not perform

makeshift repairs. (Use parts list providedto order

replacement parts.)

KNOW HOW TO USE TOOL

• Use righttool forjob. Do notforce tool or attachment

to do a job for which it was not designed.i

• Disconnecttool when changingblades.

• Avoidaccidental start-up. Make sure that_theswitch

is inthe "off"positionbefore pluggingin. =

• Do notforce tool. It willwork mostefficientlyat the

rate for which itwas designed.

• Keep hands away from movingparts'_nd Cutting

surfaces.

Never leave tool running unattended.Turn the power

off and do not leave tool untilit comesto a complete

stop.

Do not overreach.Keep proper footingand balance.

Never standon tool.Seriousinjurycouk:loccurif tool is

tippedor ifblade is unintentionallycon__cted.

Knowyour tool.Learn the tool'soperation,applica-

tionand specificlimitations.

2

Page 3

• Use recommended accessories (refer to page 17).

Use of improperaccessories may cause riskof

injuryto persons.

• Handle workpiece correctly.Protect handsfrom pos-

sibleinjury.

• Turn machine off if it jams. Knifeor bitjams when it

digstoo deeply into workpiece. (Motor force keeps it

stuckin the work.)

• Always keep drive, cutterheedand knife guards in

place and in proper operating condition.

• Feed work into knifeor cutter againstdirectionof

rotation.

CAUTION: Think safety! Safety is a combinationof

operatorcommon sense and alertness at all times

when tool is being used.

WARNING: Do not attempt to operate tool until itis

completely assembled accordingto the instructions.

Refer to Figures 15 and 16, pages 16 and 18.

The planer/molder is shipped assembled except for the

handwheeland handle (Figure 16, KeyNos. 22 and 24).

INSTALL HANDWHEEL AND HANDLE

Refer to Figure 16, page 18.

• Handwheel (KeyNo. 22) must be installedto the left

side of the planer/molder.

• Align handle (Key No. 24) withthe hole on the rim of

the handwheel.

• Insert handle screw (Key No.23) into handle and

tighten to secure.

• Slide handwheel onto crank elevation screw(Key

No. 19) so that the spring pin (Key No. 21) on the

crank elevation screw is positionedbetween the

groovein the handwheel.

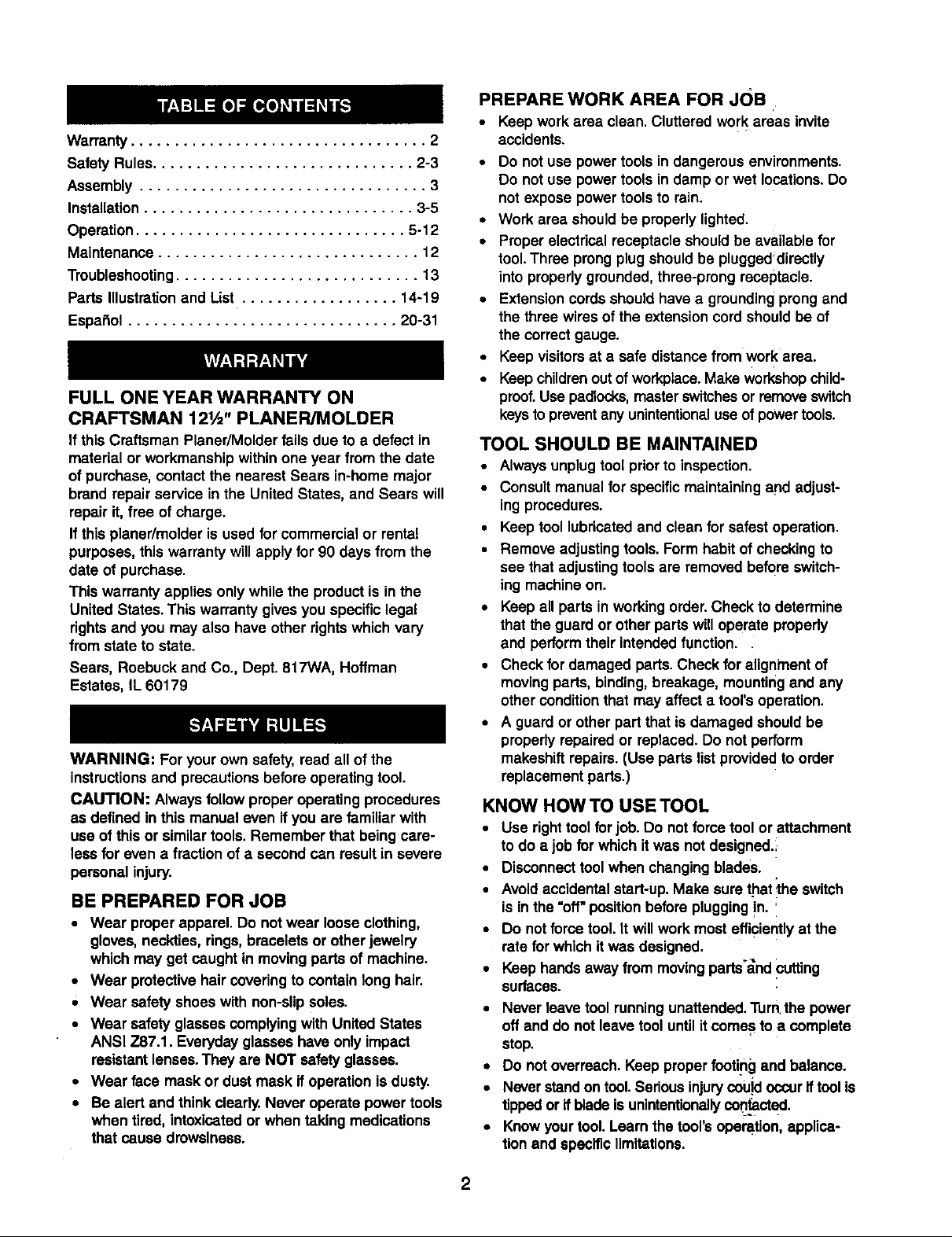

MOUNTING INSTRUCTIONS FOR

OPTIONAL STAND MODEL 22250

Refer to Figure 1.

Material List

• ½ x 15 x 22" particleboard (notsupplied)

• Four 1A-20x 1¼" Bolts withwashers and nuts (not

supplied) for mountingboard to Multi-PurposeStand.

• Four8-1.25 x 30mm boltswith washers (supplied

with planer/molder) for mountingplaner/molder to

board.

A mounting board is needed when mou_ting

planer/molder to Sears Multi-Purpose Stand Model

22250. The mounting board is made from ½" thick ply-

wood or particle board.

• Cut and drill the board using drawing: The 10" diam-

eter hole in the center is used for ventilationonly.

• Secure the mounting board to the stand top first,

using four ¼" bolts, washers and nuts (not provided).

be sure board is centered on stand top and bolted

securely.

• Mount the planer/molderto the mountingboard

using the four 8-1.25 x 30mm boltswithwashers.

Thread the bolts throughthe mountingboard and

intothe base casting from underneath the board.

1

REMOVE CAPS

Refer to Figure 15, page 16.

The planer/molder is shipped with caps (Key No. 13) on

the threaded shafts (Key No. 11) to avoiddamage to

shaftsduring shipping and handling.

• Unscrew and remove caps beforeturning the tool on.

• Save caps forfuture use.

MOUNT PLANER TO WORK SURFACE

Refer to Figure 1.

• Planer is designed to be portable so it can be moved

to job site, butshould be mounted to stable, level

bench or table. See Recommended Accessories,

page 17.

Figure I - Mount Planer/Molder to Optional Multi-Purpose

Stand Model No, 22250

POWER SOURCE

WARNING: Do notconnect planer/molderto the power

sourceuntilall assembly stepshave been completed.

The motor Is designed for operation on the voltage and

frequency specified.Normal loads will be handled safe-

ly on voltages not more than 10% abeve orbelow spec-

ifiedvoltage. Runningthe unit on voltageswhich are not

within range may cause overheatingand motor burn-

out. Heavy loads requirethat voltage at motorterminals

be no less than the voltage specifiedon nameplate.

• Power supplyto the motor iscontrolledby a rocker

switch.Removingthe rockerswitchwill lockthe unit

and prevent unauthorized use.

3

Page 4

GROUNDINGINSTRUCTIONS

WARNING: Improper connectionof equipment

groundingconductorcan resultin the risk of electrical

shock.Equipment should be groundedwhile in use to

protect operatorfrom electricalshock.

• Check with a qualified electricianif grounding

instructions are not understood or if in doubt as to

whether the tool is properly grounded.

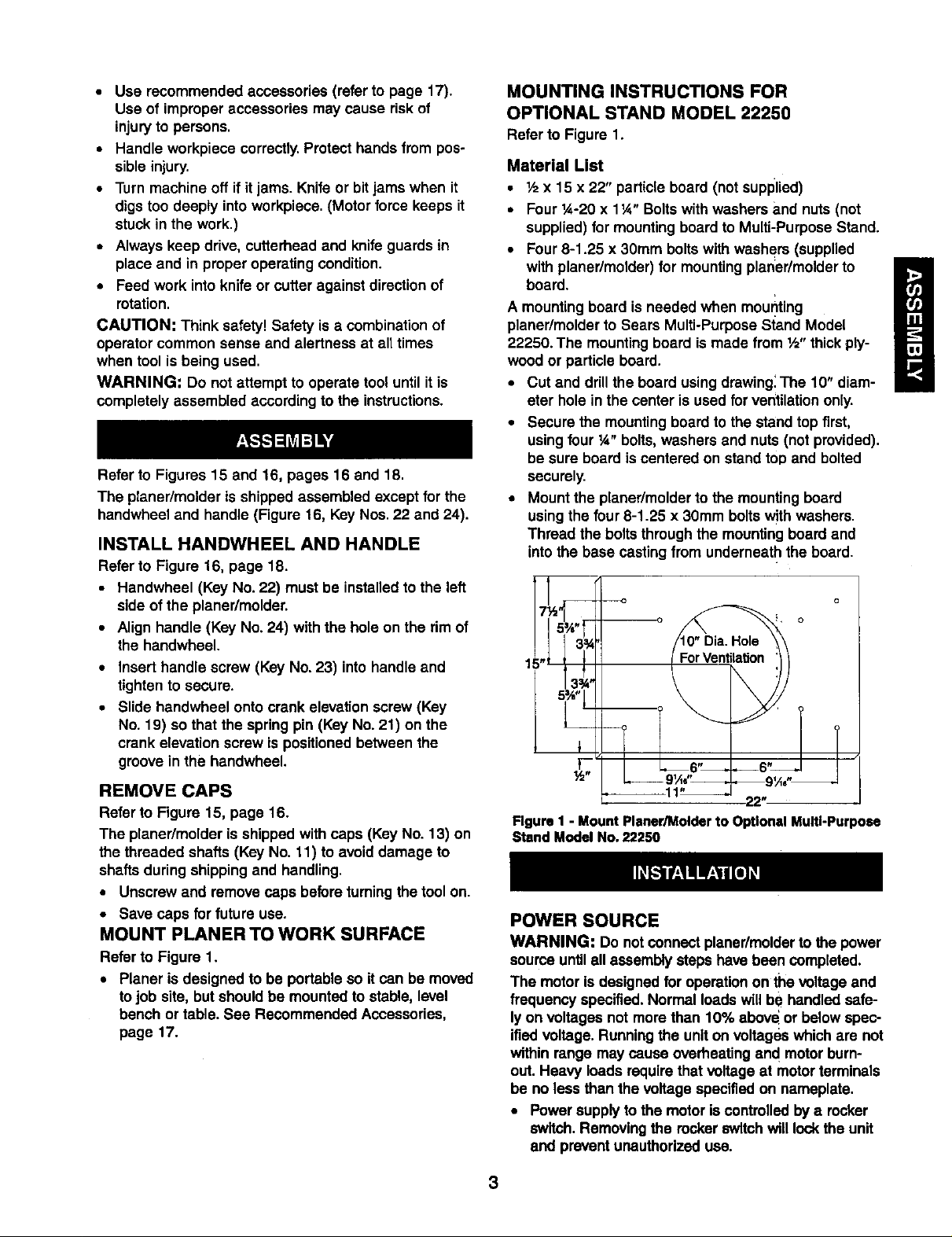

• This tool is equipped with an approved cord rated at

150V and e 3-prong grounding type plug (see Figure

2) for your protection against shock hazards.

• Grounding plug shouldbe plugged directly into a

properly installed and grounded 3-prong grounding-

type receptacle, as shown (see Figure 2).

Properly Grounded Outlet

Grounding Prong

3-Prong Plug__

Figure 2 - 3-Prong Receptacle

• Do notremove or alter grounding prong in any man-

ner. In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electrical shock.

WARNING: Do not permit fingersto touch the termi-

nals ofplug when installingor removingfrom outlet.

• Plug must be pluggedintomatchingoutlet that is

properly installed and groundedin accordance with

all local codes and ordinances•Do not modify plug

provided.If it willnot fit in outlet, have properoutlet

installedby a qualified electrician.

• Inspect toolcords periodically,and if damaged, have

repaired by an authorizedservice facility.

• Green (or green and yellow)conductorin cord isthe

groundingwire. If repair or replacement of the elec-

tric cord or plug is necessary, do not connect the

green (or green and yellow)wire to a live terminal.

• Where a 2-prong wall receptacle is encountered, it

must be replaced with a propedy grounded 3-prong

receptacle installed in accordance with National

ElectricCode and local codes and ordinances.

WARNING: This work should be performedby a quali-

fied electrician.

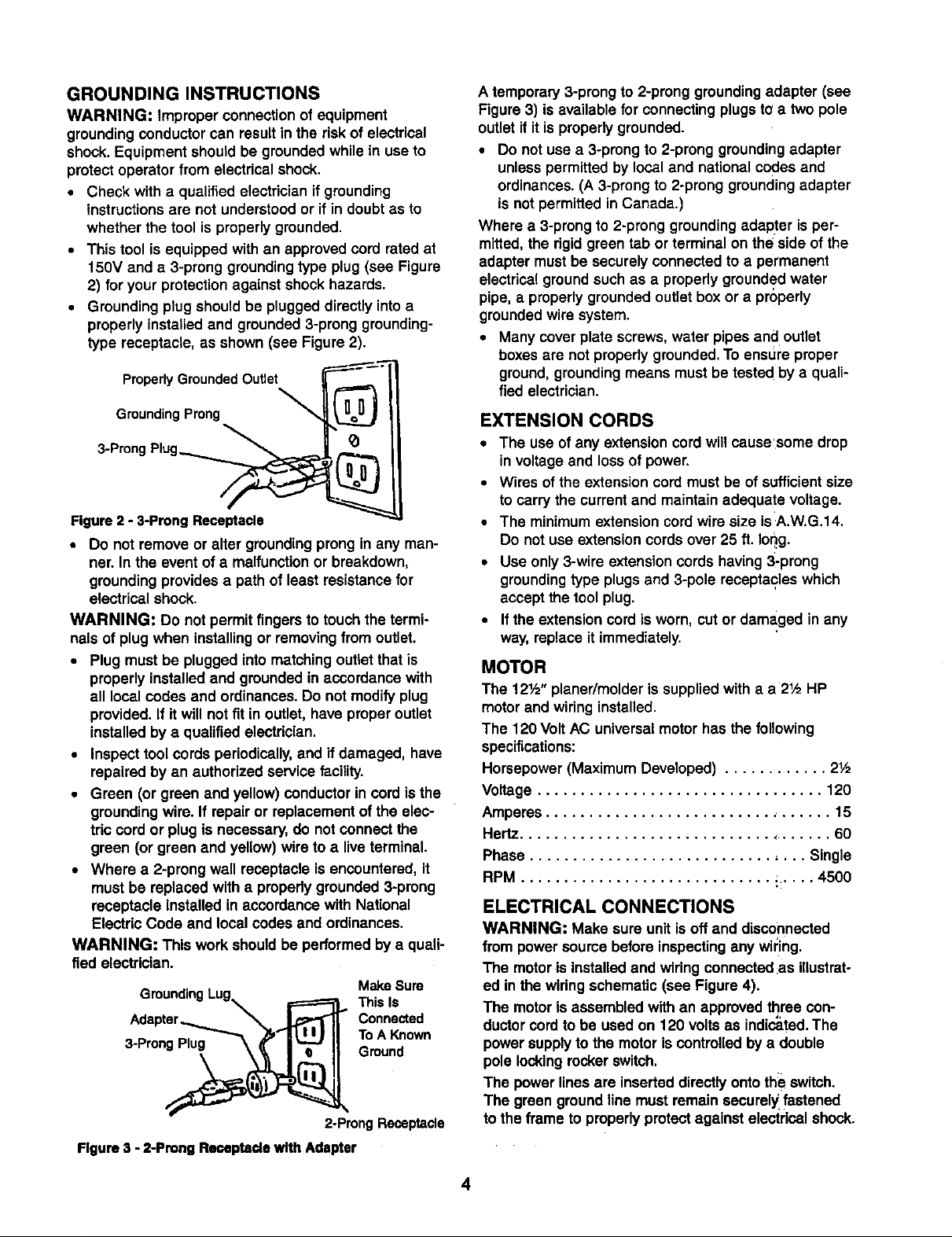

GroundingLug

Figure 3 - 2-Prong Remeptade with Adapter

i=======_ThisIs

MakeSure

c n.oo°

ToA Fm_

2-ProngReceptacle

A temporary 3-prong to 2-prong groundingadapter (see

Figure3) is available for connectingplugs to a two pole

outletif itis properlygrounded.

• Do not use a 3-prongto 2-prong groundingadapter

unless permittedby localand national codes and

ordinances.(A 3-prongto 2-prong groundingadapter

is not permitted in Canada•)

Where a 3-prong to 2-prong groundingadapter is per-

mitted,the rigidgreen tab or terminalon the side ofthe

adapter mustbe securelyconnected to a permanent

electrical groundsuch as a properly groundedwater

pipe, a properlygroundedoutletbox or a properly

groundedwire system.

• Many coverplate screws,water pipes and outlet

boxesare not properly grounded.To ensure proper

ground,groundingmeans must be tested bya quali-

fied electrician.

EXTENSION CORDS

• The use of any extensioncord will cause'some drop

in voltage and lossof power.

• Wires of the extension cord must be of sufficientsize

to carry the currentand maintain adequate voltage.

• The minimum extensioncord wire size is A.W.G.14.

Do not use extensioncords over 25 ft. Ioqg.

• Use only3-wire extensioncordshaving 3-prong

groundingtype plugsand 3-pole receptacleswhich

acceptthe tool plug.

• If the extensioncord isworn, cut or damaged in any

way,replace it immediately.

MOTOR

The 12½" planer/molder is suppliedwith a a2½ HP

motorand wiring installed.

The 120 Volt AC universalmotor has the following

specifications:

Horsepower (Maximum Developed) ............ 2½

Voltage ................................. 120

Amperes ................................. 15

Hertz..................................... 60

Phase ................................ Single

RPM ............................. ;..... 4500

ELECTRICAL CONNECTIONS

WARNING; Make sure unit is off and disconnected

from power source before inspectingany wil:ing.

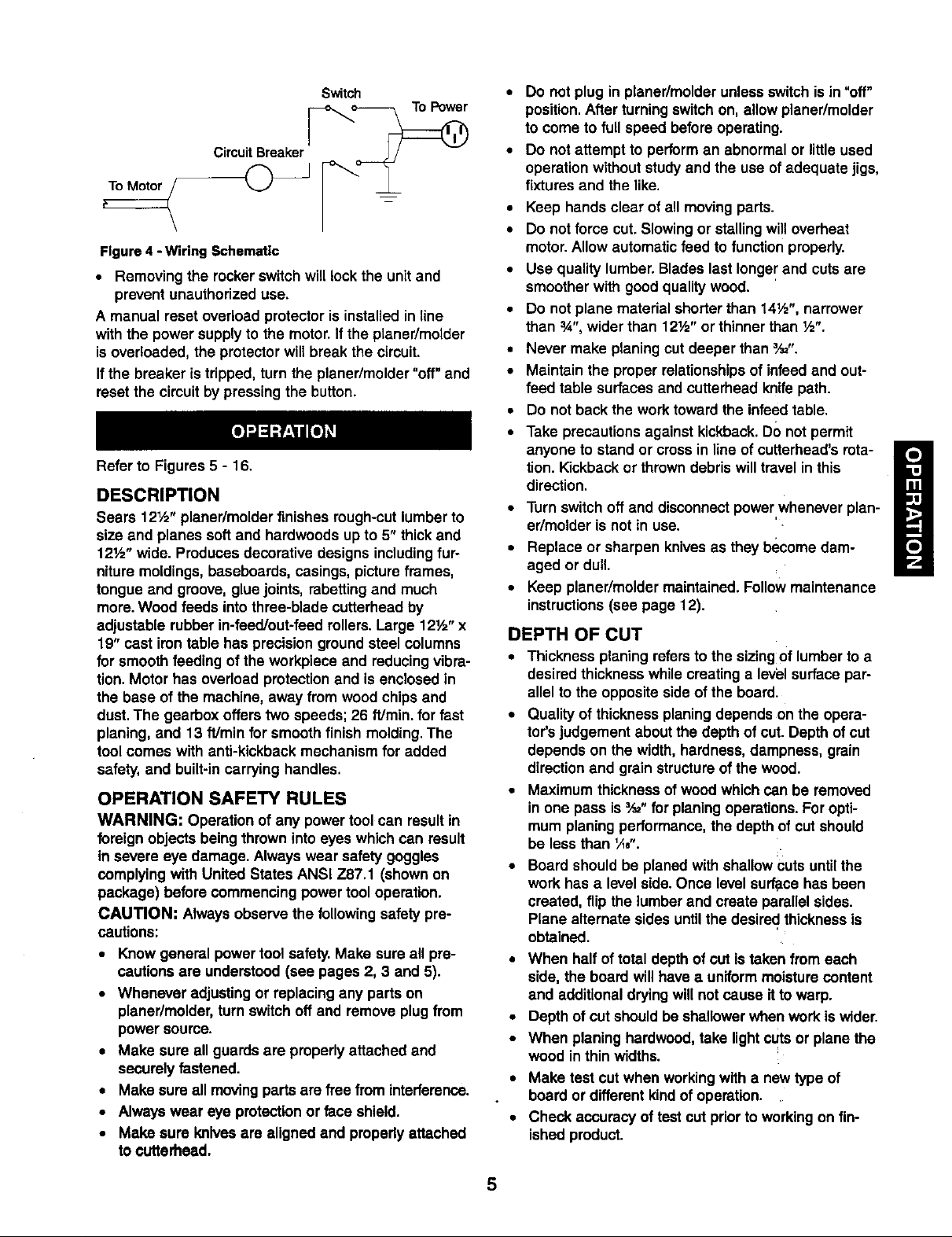

The motor is installedand wiring connected:asillustrat-

ed in the wiring schematic (see Figure 4).

The motor Is assembledwith an approvedthree con-

ductorcordto be used on 120 vo ts as indicated. The

powersupplyto the motoriscontrolledby adouble

pole lockingrocker switch.

The power lines are inserted directlyonto the switch.

The green ground linemust remain securelyfastened

tothe frame to properly protectagainst electricalshock.

4

Page 5

Switch

CircuitBreaker

Figure 4 - Wiring Schematic

• Removing the rocker switchwill lock the unit and

prevent unauthorized use.

A manual reset overload protectoris installed in line

with the power supplyto the motor. Ifthe planer/molder

isoverloaded, the protectorwillbreak the circuit.

Ifthe breaker is tripped, turn the planer/molder "off" and

resetthe circuitby pressingthe button.

Refer to Figures 5- 16.

DESCRIPTION

Sears 12½" planer/molder finishes rough-cutlumberto

size and planes softand hardwoods up to 5" thick and

121/="wide. Produces decorative designs includingfur-

niture moldings, baseboards, casings, picture frames,

tongue and groove, gluejoints, rabettingand much

more.Wood feeds intothree-blade cutterhead by

adjustable rubberin-feed/out-feed rollers.Large 12½" x

19" cast irontable has precisionground steel columns

for smoothfeeding ofthe workpiece and reducingvibra-

tion. Motor has overloadprotectionand is enclosed in

the base of the machine,away from wood chipsand

dust.The gearbox offers two speeds; 26 ft/min, for fast

planing, and 13 f!Jminfor smooth finish molding.The

tool comes with anti-kickback mechanism for added

safety, and built-incarrying handles.

OPERATION SAFETY RULES

WARNING: Operation ofany powertool can result in

foreignobjects being thrown intoeyes which can result

in severe eye damage. Alwayswear safety goggles

complyingwith United States ANSi Z87.1 (shown on

package) before commencing power tool operation.

CAUTION: Always observe the following safety pre-

cautions:

• Knowgeneral powertool safety.Make sure all pre-

cautions are understood (see pages 2, 3 and 5).

• Whenever adjusting or replacing any parts on

planer/molder,turn switch off and remove plug from

power source.

• Make sure all guardsare properlyattached and

securelyfastened.

• Make sure all movingpartsare free from interference.

• Always wear eye protectionor face shield.

• Make sure Imlves are aligned and propedyattached

to ¢utterhead.

• Do not plug in planer/molderunlessswitch is in"off"

position.After turningswitchon, allow planer/molder

to come tofull speed beforeoperating.

• Do not attempt to performan abnormalor little used

operationwithout studyand the use of adequate jigs,

fixtures and the like.

• Keep hands clear of all movingparts.

• Do not force cut. Slowingor stallingwilloverheat

motor.Allow automaticfeed to function properly.

• Use qualitylumber.Bladeslast longerand cutsare

smoother with good qualitywood.

• Do not plane material shorterthan 14½", narrower

than 3A",wider than 12Y="or thinnerthan ½".

• Never make planingcutdeeper than _,_".

• Maintain the properrelationshipsof infeed and out-

feed table surfaces and cutterhead knife path.

• Do not backthe work towardthe infeedtable.

• Take precautions against kickback.DOnot permit

anyone to stand or cross in lineof cuttarhead's rota-

tion. Kickback or throwndebris willtravel in this

direction.

• Turn switchoff and disconnectpower whenever plan-

er/molder is not in use.

• Replace or sharpen knivesas they become dam-

aged or dull.

• Keep planer/molder maintained. Followmaintenance

instructions(see page 12).

DEPTH OF CUT

• Thickness planing refersto the sizingOflumber to a

desired thickness while creating a level surface par-

allelto the oppositeside of the board.

• Qualityof thicknessplaning dependson the opere-

tor'sjudgement aboutthe depthof cut. Depth of cut

depends on the width,hardness,dampness, grain

directionand grainstructureof the wood.

• Maximum thicknessof wood whichcan be removed

in one pass is_" forplaning operations.Foropti-

mum planingperformance,the depthof cutshould

be less than _,4,-.

• Board should be planed with shallowcuts untilthe

work has a level side. Once level surlacehas been

created, flip the lumber and create parallelsides.

Plane alternate sides untilthe desired thicknessis

obtained.

• When half oftotal depthof cut is taken from each

side, the board will have a uniformmoisturecontent

and additional drying will not cause itto warp.

• Depthof cut should beshallowerwhen workiswider.

• When planinghardwood,take lightct_tsor plane the

wood in thin widths.

• Make testcut when workingwith a new type of

board or different kind of operation.

• Check accuracy oftest cut priorto workingon fin-

ished product.

5

Page 6

ADJUSTINGTHE DEPTHOF CUT

Refer to Figure 16, page 18.

Board thickness which the planer/molderwillproduce is

indicatedby eitherscale (Key No. 4) on the side.

Thickness is adjusted by rotatingthe handwheel (Key

No.22) clockwise to raise the knifeheight.

To reduce the knife height, rotata the handwheel coun-

terclockwise.

• Do notset knife below %2". Do not plane a board

which isless than a 1,_,thick.

• Knife heightwill be moved 1Ae"with every complete

revolutionof the handwheel.

Make a test cut on a piece of wood and measurethe

thickness produced.

The planer/molder will produce uneven depth of cut

(tapered cut) ifthe cutterhead is not parallel with the table.

To restore parallelism of the cutterhead with the table:

• Clamp a vise plier on the left side of the shaft (Key

No. 6) next to the bevel gear (Key. No. 10).

• Loosen set screws (Key No. 51) and disengage right

bevel gear (Key No. 10) on the elevation screw (Key

No. 18).

• Slowlyrotate handwheel to raise or lower the table.

Rotate clockwise to raise table, counterclockwise to

lower table.Table will be moved by .004" with every

turn of the beveled gear by one tooth.

• After moving table the required distance, make sure

beveled gears (Key Nos. 10 and 12) are engaged

and secured with set screws.

• Release and remove thevise plier

• Make a test cut to make sure the adjustment was

appropriate.

• Add grease to bevel gears if necessary.

When the depth of cut adjustment is operating correctly,

loosen the pan head screw(Key. No.28) and set the

indicator(Key No. 29) to show the thicknessproduced.

Make sure that the indicatoris positionedcorrectly.

TABLE HEIGHT ADJUSTMENT

Refer to Figure 16, page 18.

• The depth of cut ofthe planer/molderis adjusted by

raisingor loweringthe table.

• Rotate the handwheel (Key No.22) to raise or lower

the table to the desired position.

• The scale and indicator(Key Nos. 4 and 29) can be

used when adjusting the table height.

FEED RATE ADJUSTMENT

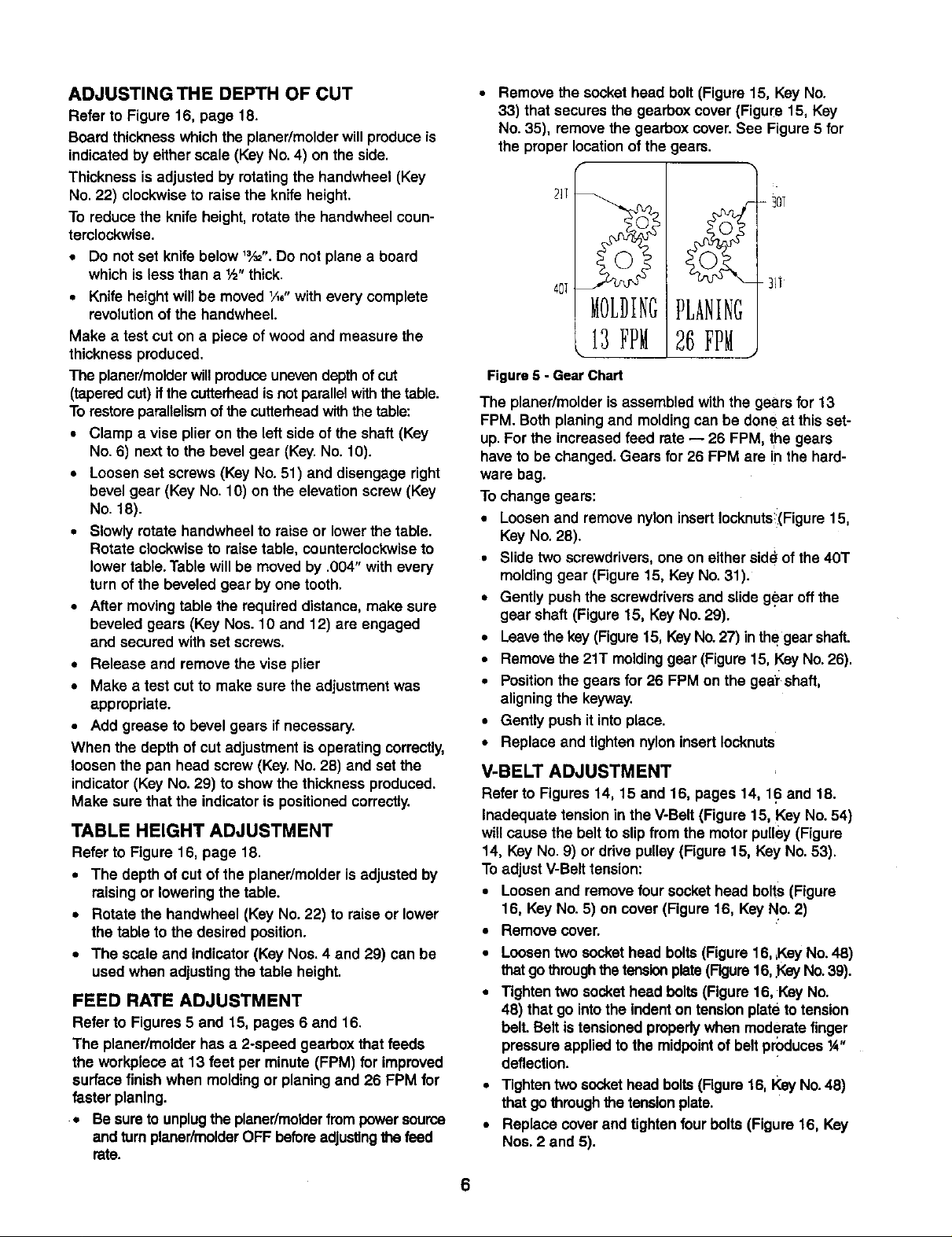

Refer to Figures 5 and 15, pages 6 and 16.

The planer/molder has a 2-speed gearboxthat feeds

the workplace at 13 feet per minute (FPM) for improved

surfacefinish when moldingor planingand 26 FPM for

fester planing.

• Be suretounplugthe planer/mctderfrom powersource

and turnplaner/molderOFF beforeadjustingthe feed

rate.

Remove the socket head bolt(Figure 15, Key No.

33) that secures the gearboxcover (Figure 15, Key

No.35), remove the gearbox cover.See Figure 5 for

the properlocation of the gears.

- 30T

-_i]

26 FPM

Figure 5 - Gear Chart

The planer/molder is assembledwith the gears for 13

FPM. Both planingand moldingcan be done at this set-

up.For the increased feed rate -- 26 FPM, the gears

have to be changed. Gears for 26 FPM are in the hard-

ware bag.

To change gears:

• Loosen and removenyloninsert Iocknutsi(Figure15,

KeyNo. 28).

• Slide two screwdrivers,one on eitherside ofthe 40T

moldinggear (Figure 15, Key No. 31).

• Gently pushthe screwdriversand slide g_ar off the

gear shaft (Figure 15, KeyNo.29).

• Leavethe key (Figure15, KeyNo.27) inthe gear shaft.

• Removethe 21T moldinggear (Figure 15, Key No. 26).

• Positionthe gears for 26 FPM on the gea'rshaft,

aligningthe keyway.

• Gently push it into place.

• Replace andtighten nyloninsertIocknuts

V-BELT ADJUSTMENT

Refer to Figures 14,15 and 16, pages 14, 16 and 18.

Inadequate tension in the V-Belt (Figure 15, Key No. 54)

willcause the belt to slipfrom the motorpulley(Figure

14, Key No. 9) or ddve pulley (Figure 15, Key No.53).

Toadjust V-Belttension:

• Loosen and removefour sockethead bolts (Figure

16, KeyNo. 5) on cover (Figure16, Key No. 2)

• Remove cover.

• Loosen two sockethead bolts(Figure 16, ,KeyNo. 48)

thatgo throughthe tensionplate(Figure16,gay No.39).

• Tightentwo sockethead bolts (Figure 16, Key No.

48) that go intothe indenton tensionplate to tension

belt. Belt istensioned properlywhen moderate finger

pressure applied to the midpointof belt produces_"

deflection.

• Tighten twosockethead bolts (Figure 16, Key No. 48)

that gothroughthe tensionplate.

• Replace coverand tightenfourbolts(Figure 16, Key

Nos. 2 and 5).

6

Page 7

WOODGRAIN

For an improved surface finish with minimaltearout,

always plane or mold the workpiece with the grain. The

workpiece should be fed into the planer/molder so that

the knives or bits are traveling with the grain as the cut-

ters finish the cut. The grain should be angled up

toward the rear of the workpiece as it is fed into the

pLaner/molder.

PLANING

WARNING: Alwaysturn the planer/molder offand dis-

connect it from the power source whenever knife cover

is removed. Never operate planer/molder without the

knife cover properly secured.

The planer/molder is supplied with planing blades mount-

ed in the cutterheedand the infeed and outfeed rollers

adjusted to the correct height. The planer/molder is capa-

ble of working at two different feed rates.Feed rate refers

to rate at which lumber travelsthrough planer/molder.

Planing can be done at 13 FPM for an improved surface

finish or 26 FPM for faster planing (see Feed Rate

Adjustment).

• Adjust the table height to produce the depth of cut

desired.

• Stand to side whichthe handwheel was attached.

• Lift edge to infeed side ofthe table by grasping

edges of board at approximately middleof length.

• Boards longer than 24" should have additional sup-

port from free standing material stands.

• Position the workpiece with the face to be planed on

top.

• Gently slidethe workpiece into the infeed side of the

planer/molder until the infeed roller begins to

advance the workpiece.

• Let go of the workpiece and allow automatic feed to

advance the workpiece.

• Do not push/pull on workpiece.

• Move to the rear and receive planed lumber by

grasping it in same manner as it was fed.

CAUTION: Do not stand directly in line withfront or

rear of planer/molder.

• Do notgrasp any portion ofboard which has not

gone past out-feed roller.

• Repeat this operation on all boards which need to be

same thickness.

• Move to the rear and receive planed board by gently

pushing itup when the infeed rollerlooses contact

with the board.

• When planing more than one board of the same

thickness, butt boards togetherto avoidsnipe.

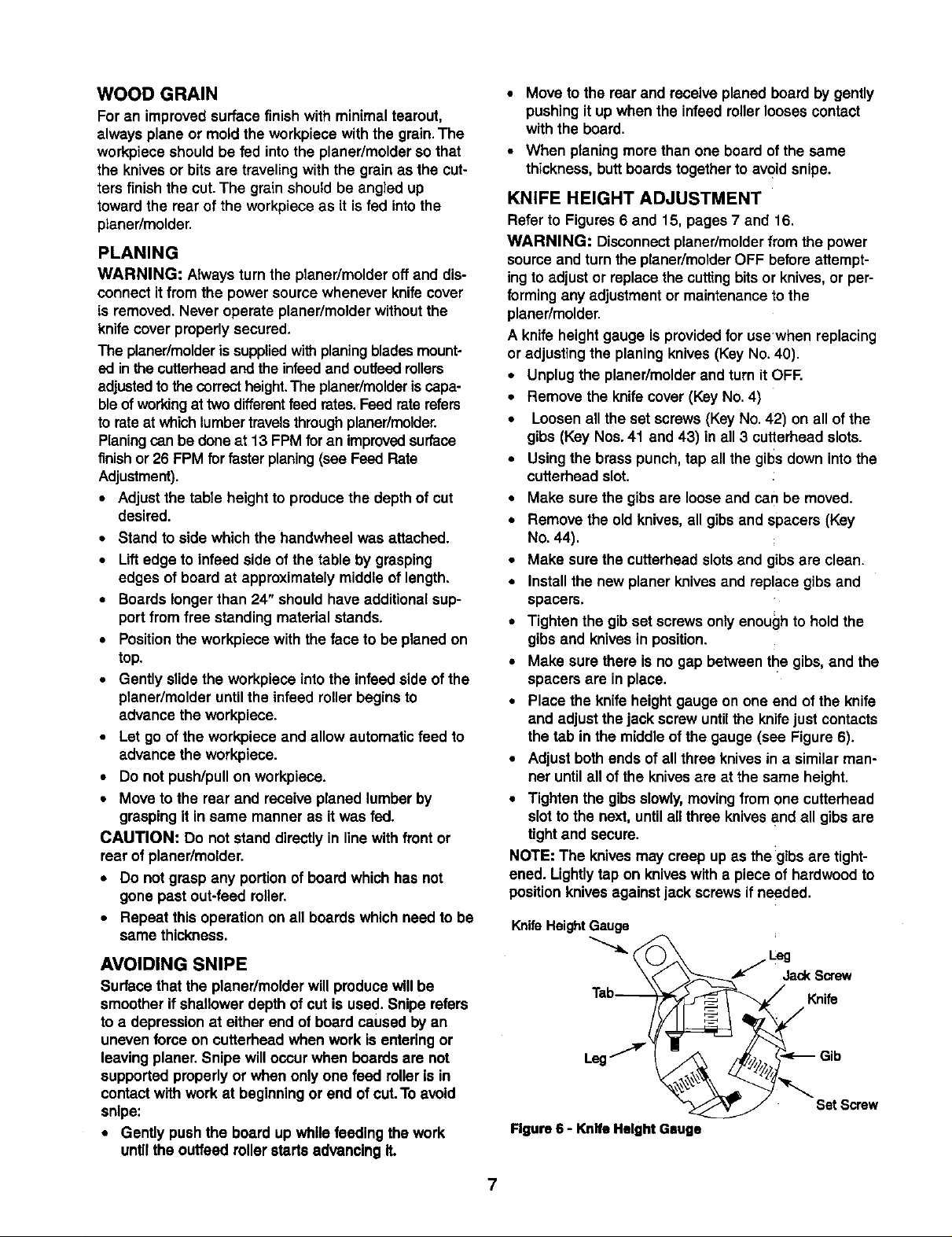

KNIFE HEIGHT ADJUSTMENT

Refer to Figures 6 and 15, pages 7 and 16.

WARNING: Disconnect planer/molderfrom the power

sourceand turn the planer/molderOFF before attempt-

ingto adjustor replacethe cuttingbitsor knives,or per-

forming any adjustment or maintenanceto the

planer/molder.

A knife height gauge is providedfor usewhen replacing

or adjusting the planingknives (Key No. 40).

• Unplugthe planer/molderand turn itOFF.

• Remove the knifecover (Key No.4)

• Loosen all the set screws(Key No. 42) on all ofthe

gibs (Key Nos.41 and 43) inall 3 cutterhead slots.

• Using the brass punch,tap all the gibsdown intothe

cutterhead slot.

• Make sure the gibs are loose and can be moved.

• Remove the old knives, all gibs and spacers (Key

No. 44).

• Make sure the cutterhead slots and gibs are clean.

• Install the new planer knives and replace gibs and

spacers.

• Tighten the gibset screws only enough to holdthe

gibs and knivesin position.

• Make sure there is nogap betweenthe gibs,and the

spacers are in place.

• Place the knifeheightgauge on one end of the knife

and adjust the jack screw untilthe knife justcontacts

the tab in the middle ofthe gauge (see Figure 6).

• Adjust both ends ofall three knives in a similar man-

ner untilall of the knivesare at the same height.

• Tighten the gibs slowly,movingfrom one cutterhead

slot to the next, until allthree knivesand all gibsare

tightand secure.

NOTE: The knivesmay creep up as the:gibsare tight-

ened. Lightlytap on kniveswith a piece of hardwoodto

positionknivesagainst jack screws if needed.

Knife Height Gauge

AVOIDING SNIPE

Surface that the planer/molder will produce will be

smootherif shallowerdepth of cut is used.Snipe refers

toa depressionat eitherend of board caused by an

unevenforce on cutterheadwhen work is enteringor

leaving planer. Snipe will occur when boards are not

supported properlyor when only one feed rolleris in

contactwith work at beginningor end of cuLTo avoid

snipe:

• Gently push the board upwhile feeding the work

untilthe outfeed roller starts advancing It.

Tab_ Knife

Figure6 - KnifeHeightGsuge

7

Page 8

POSITIONTHE CHIPBREAKER

Refer to Figure 15, page 16.

The chipbreaker (Key No.2) is used to help remove

wood chipsfrom the cutter bitsand kniveswhile planing

or molding. Adjustthe chipbreaker every time the cut-

tingtoolsare changed or adjusted.

The chipbreakershould be positionedas closeto the

cutterheadas possiblewithoutcontactingthe cutter bits

or knives. Loosen the three hex head bolts (Key No.3)

that hold the chip breaker and position itas close to the

cutterhead as possible, rotate the cutterhead by hand to

ensurethat there is no interference with the chipbreaker.

Secure the chipbreaker by tightening the three hex head

bolts. Replace and secure knife cover.

MOLDING

Molding, also knownas miliworkor trim,can be defined

as a stripof wood milled with a plain or decorative sur-

face which is continuousthroughoutits length.

• To get superior moldingfinish, workpiece must be

planed and presized priorto molding.Always presize

the workpiece to '/_,"of the final thicknessprior to

molding.

Certain moldingprofilesrequireouter edge clean-up.

When usingsuch profilesthe workpiece must be pre-

sizedto ¼" larger than the final width.This will allow ',_,"

for clean-up on either side.

Certain molding profilescut only the edge of the work-

piece.When using such profilesworkpiece mustbe pre-

sizedto the same width as the final width.

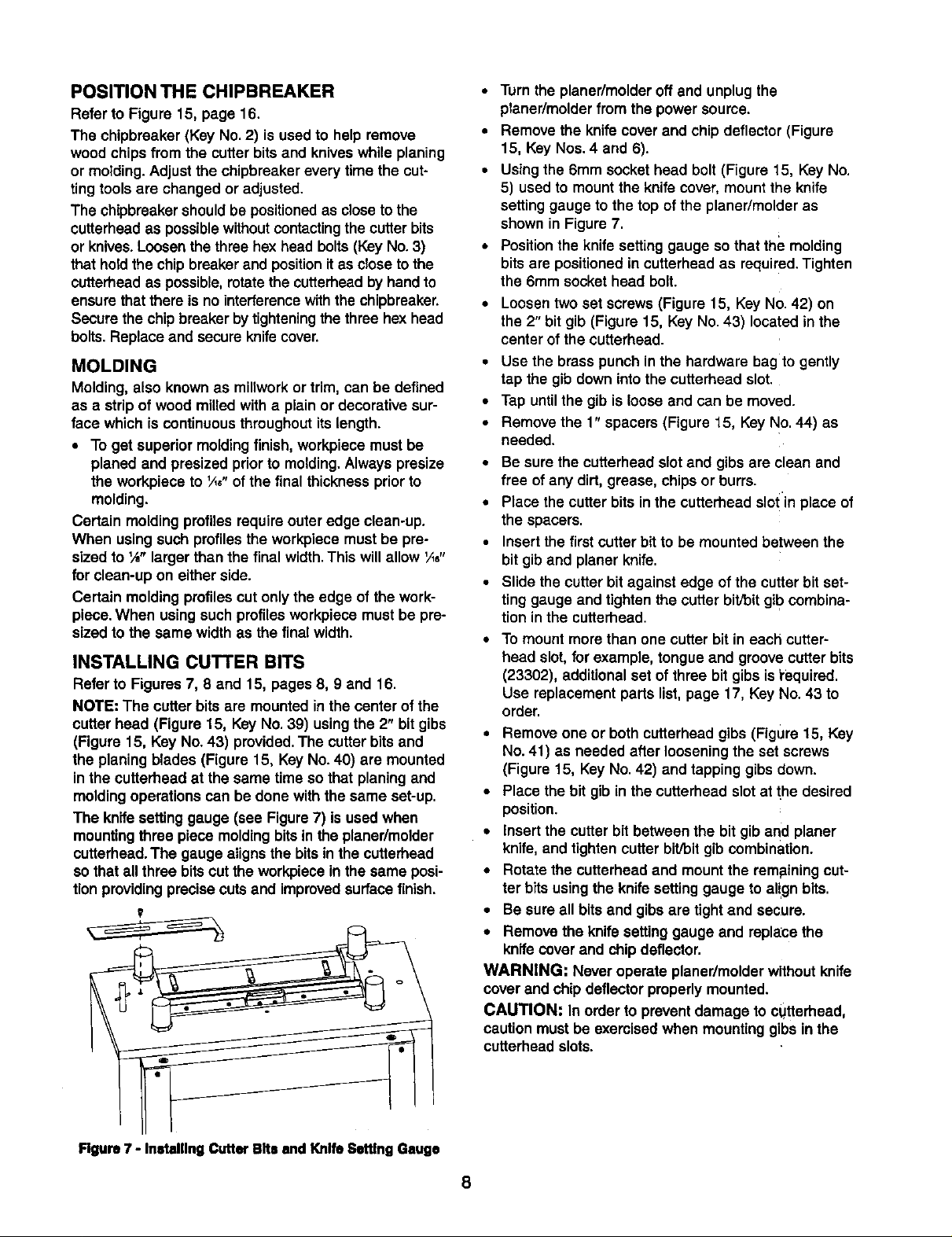

INSTALLING CUTTER BITS

Refer to Figures 7, 8 and 15, pages 8, 9 and 16.

NOTE: The cutter bits arc mounted in the center of the

cutter head (Figure 15, Key No. 39) usingthe 2" bit gibs

(Figure 15, Key No.43) provided.The cutterbits and

the planing blades (Figure 15, KeyNo. 40) are mounted

in the cutterhead at the same time so that planingand

moldingoperations can be done with the same set-up.

The knife settinggauge (see Figure 7) isused when

mountingthree piecemoldingbitsin the planer/molder

cutterhead.The gauge alignsthe bits inthe cutterhead

so that all three bitscutthe workpiece inthe same posi-

tionprovidingprecisecutsand improvedsurfacefinish.

• Turn the planer/molder off and unplugthe

planer/molderfrom the power source.

• Remove the knife cover and chip deflector (Figure

15, Key Nos. 4 and 6).

• Using the 6mm socket head bolt (Figure 15, Key No.

5) used to mount the knife cover, mount the knife

setting gauge to the top of the planer/molder as

shown in Figure 7.

• Position the knife setting gauge so that the molding

bits are positioned incutterhead as required. Tighten

the 6mm socket head bolt.

• Loosen two set screws (Figure 15, KeyNo. 42) on

the 2" bit gib (Figure 15, Key No. 43) locatedin the

center of the cutterhead.

• Use the brass punch in the hardware bag to gently

tap the gibdown into the cutterheadslot.

• Tap untilthe gib isloose and can be moved.

• Remove the 1" spacers (Figure 15, Key No.44) as

needed.

• Be surethe cutterhead slotand gibs arc clean and

free ofany dirt, grease, chipsor burrs.

• Place the cutter bits in the cutterhead slo! in place of

the spacers.

• Insertthe first cutter bitto be mounted between the

bit gib and planer knife.

• Slide thecutter bit against edge of the cutter bit set-

ting gauge and tightenthe cutter bit/bitgib combina-

tion in the cutterhead.

To mount more than one cutter bit ineach cutter-

head slot, for example, tongue and groovecutter bits

(23302), additionalset of three bit gibs isi'equired.

Use replacement parts list,page 17, Key No. 43 to

order.

• Remove oneor both cutterhead gibs (Figure 15, Key

No.41) as needed after looseningthe set screws

(Figure 15, KeyNo. 42) and tapping gibs down.

• Place the bit gibin thecutterheed slot at the desired

position.

• insert the cutter bitbetween the bitgib and planer

knife,and tightencutter bit]bitgibcombination.

• Rotate the outterhead and mountthe remainingcut-

ter bits usingthe knifesettinggauge to align bits.

• Be sure all bits and gibsare tight and secure.

• Remove the knife settinggauge and replace the

knifecoverand chipdeflector.

WARNING: Never operate planer/molder withoutknife

cover and chip deflectorproperly mounted.

CAUTION: In order to preventdamage to cUtterhead,

caution must be exercisedwhen mountinggibs in the

cutterhead slots.

Figure 7 - Installing Cutter Bits and Knife Setttng Gauge

8

Page 9

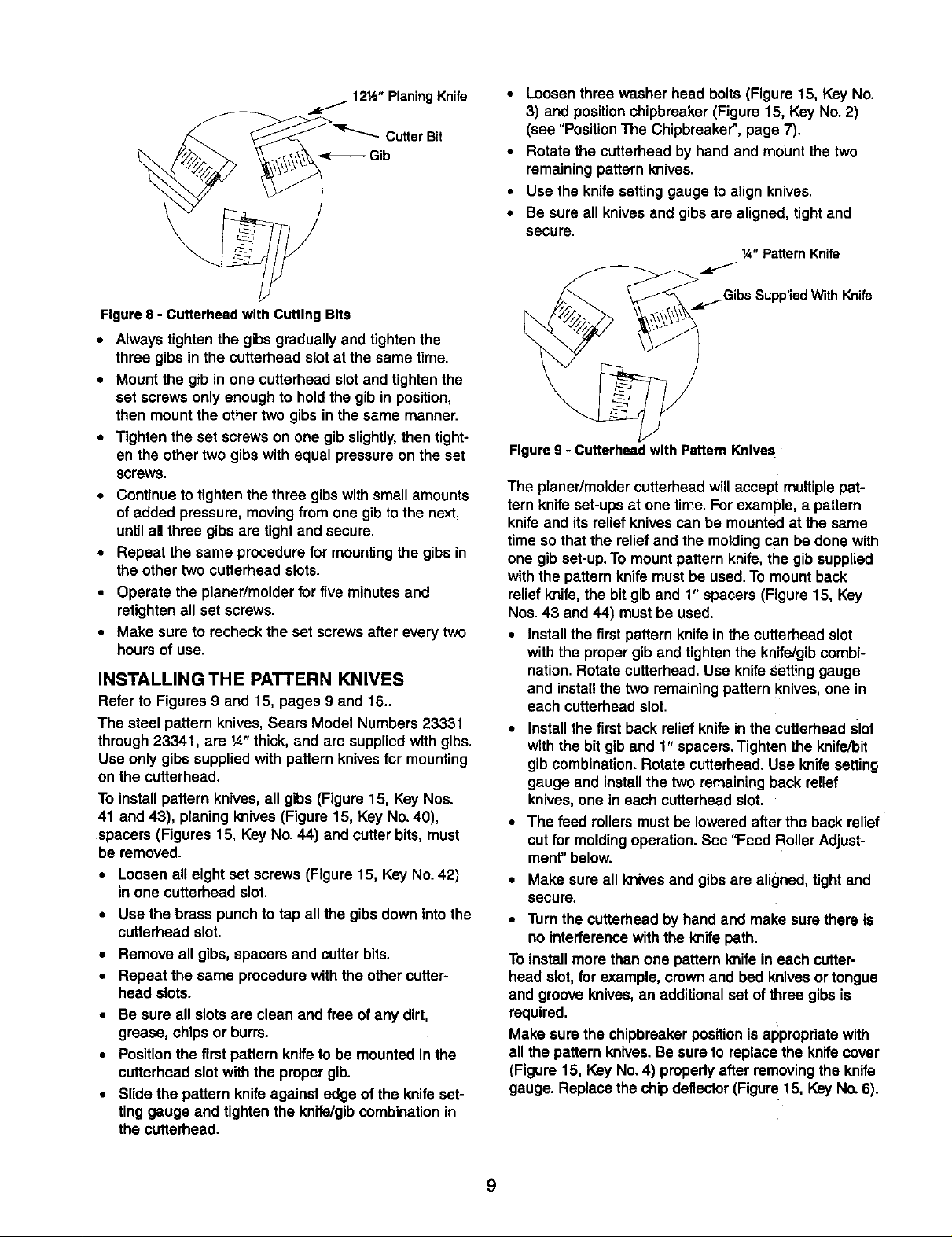

12½" Planing Knife

Cutter Bit

Gib

• Loosen three washerhead bolts (Figure 15, Key No.

3) and positionchipbreaker (Figure 15, Key No. 2)

(see "Position The Chipbreaker",page 7).

• Rotate the cutterhead by hand and mount the two

remaining pattern knives.

• Use the knifesettinggauge to align knives.

• Be sureall knivesand gibsare aligned, tightand

secure.

ix="PatternKnife

Figure 8 - Cutterhead with Cutting Bits

• Always tighten the gibs gradually and tightenthe

three gibs in the cutterhead slotat the same time.

• Mount the gib in onecutterhead slotand tightenthe

set screws only enough to hold the gib in position,

then mount the other two gibsin the same manner.

• Tighten the set screws on one gib slightly, then tight-

en the other two gibs with equal pressure on the set

screws.

• Continueto tightenthe three gibswith small amounts

ofadded pressure,movingfrom one gibto the next,

untilall three gibs are tight and secure.

• Repeat the same procedurefor mountingthe gibs in

the other two cutterhead slots.

• Operate the planer/molder for five minutes and

retightenall set screws.

• Make sure to recheck the set screwsafter every two

hours of use.

INSTALLING THE PATTERN KNIVES

Refer to Figures 9 and 15, pages 9 and 16_

The steel pattern knives,Sears Model Numbers 23331

through 23341, are ¼" thick, and are suppliedwith gibs.

Use onlygibs supplied with pattern knives for mounting

on the cutterhead.

To installpattern knives, all gibs (Figure 15, Key Nos.

41 and 43), planing knives (Figure 15, Key No. 40),

spacers (Figures 15, Key No. 44) and cutter bits, must

be removed.

• Loosen all eightset screws (Figure 15, Key No. 42)

in one cutterhead slot.

• Use the brass punch to tap all the gibsdown into the

cutterhead slot.

• Remove all gibs,spacers and cutter bits.

• Repeat the same procedure with the other cutter-

head slots.

• Be sureall slotsare clean andfree ofany dirt,

grease, chips or burrs.

• Positionthe first pattern knifeto be mounted inthe

cutterhead slot with the proper gib.

• Slide the pattern knifeagainst edge of the knife set-

tinggauge and tightenthe knife/gibCOmbinationin

the cutterhead.

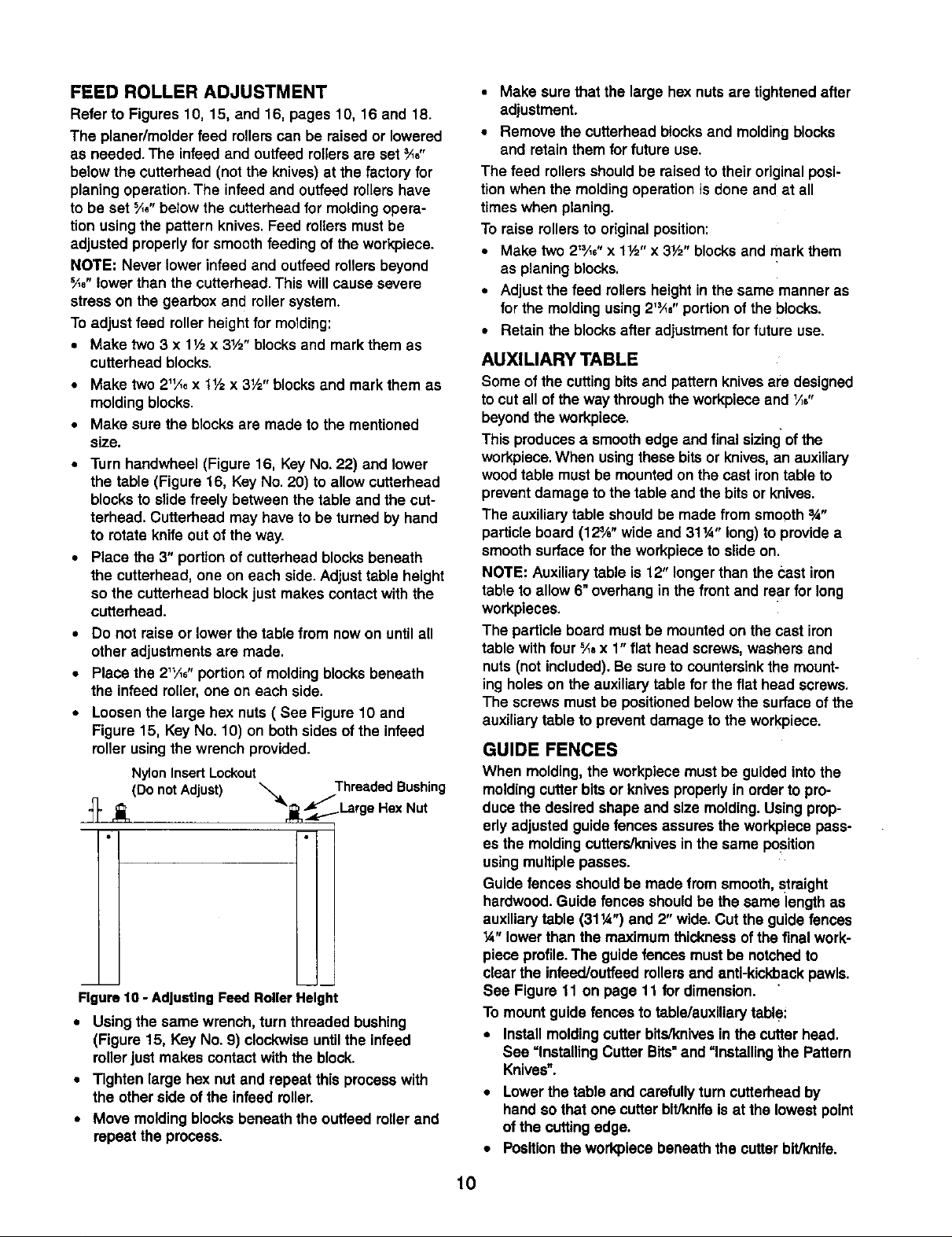

,_,.j.Gibs SuppnedWith Knife

Figure 9 - Cutterhead with Pattern Knives

The planer/molder cutterheadwill accept multiplepat-

tern knife set-ups at one time. For example, a pattern

knife and its relief knives can be mounted at the same

time so that the relief and the molding can be done with

one gib set-up.To mount pattern knife, the gib supplied

with the pattern knife must be used. To mount back

relief knife, the bit gib and 1" spacers (Figure 15, Key

Nos. 43 and 44) must be used.

• Installthe firstpattern knife inthe cutterhead slot

withthe propergib and tighten the knife/gibcombi-

nation.Rotate cutterhead. Use knifeSettinggauge

and installthe two remainingpattern knives, one in

each cutterhead slot.

• Installthe first back relief knifein the cutterhead slot

withthe bit gib and 1"spacers.Tightenthe knife/bit

gib combination.Rotate cutterhead. Use knifesetting

gauge and installthe two remaining back relief

knives,one in each cutterhead slot.

• The feed rollersmustbe lowered after the back relief

cut for moldingoperation.See "Feed Roller Adjust-

ment"below.

• Make sure all knivesand gibs are aligned,tightand

secure.

• Turn the cutterhead by handand make surethere is

no interference withthe knifepath.

To installmore than one pattern knife in each cutter-

head slot, for example, crown and bed knivesor tongue

and groove knives, an additional set of three gibs is

required.

Make sure the chipbreakerpositionisappropriatewith

all the pattern knives. Be sure to replacethe knife cover

(Figure 15, Key No.4) properly after removingthe knife

gauge. Replace the chip deflector(Figure 15, Key No. 6).

9

Page 10

FEEDROLLERADJUSTMENT

Refer to Figures 10, 15, and 16, pages 10, 16 and 18.

The planer/molder feed rollerscan be raisedor lowered

as needed. The infeedand ouffeed rollersare set _6"

below the cutterheed (not the knives)at the factory for

planingoperation.The infeed and ouffeedrollers have

to be set _e" below the cutterheed for moldingopera-

tion usingthe pattern knives.Feed rollers must be

adjusted properlyfor smoothfeeding of the work.piece.

NOTE: Never lower infeedand oufteed rollersbeyond

_o" lowerthan the cutterheed.This willcause severe

stresson the gearbox and rollersystem.

To adjust feed roller heightfor molding:

• Make two 3 x 1½ x 3½" blocks and mark them as

cutterhead blocks.

• Make two 2"A, x 11/2x 3½" blocks and mark them as

molding blocks.

• Make sure the blocks are made to the mentioned

size.

• Turn handwheel (Figure 16, Key No.22) and lower

the table (Figure 16, Key No. 20) to allow cutterhead

blocks to slidefreely between the table and the cut-

terhead. Cutterhead may have to be turned by hand

to rotate knife out of the way.

• Place the 3" portion of cutterhead blocks beneath

the cutterhead, one on each side. Adjust table height

so the cutterhead block just makes contact with the

cutterhead.

• Do not raiseor lower the tablefrom nowon untilall

other adjustmentsare made.

• Place the 2"/_6"portionof moldingblocksbeneath

the infeed roller,one on each side.

• Loosen the large hex nuts ( See Figure 10 and

Figure 15, Key No. 10) on both sides ofthe infeed

roller using the wrench provided.

Nylon Insert Lockout

Threaded Bushing

(Do not Adjust) "_'r_Large Hex Nut

Figure10 - AdjustingFeed RollerHeight

• Using the same wrench,turn threaded bushing

(Figure 15, Key No. 9) clockwiseuntilthe infeed

rollerjust makes contactwith the block.

• Tighten large hex nutand repeat this process with

the other side of the infeed roller.

• Move moldingblocks beneath the outfeed roller and

repeat the process.

• Make sure that the large hex nutsare tightenedafter

adjustment.

• Remove the cutterhead blocksand moldingblocks

and retain them for future use.

The feed rollers should be raised to their original posi-

tion when the moldingoperationis done and at all

times when planing.

To raise rollersto original position:

• Make two 21'Ae" x 1½" x 3½" blocksand mark them

as planing blocks.

• Adjust the feed rollersheightin the same manneras

for the moldingusing 2'_" portionof the blocks.

• Retain the blocksafter adjustmentfor future use.

AUXILIARY TABLE

Some of the cuttingbits and pattern knives are designed

tocut all of the way throughthe workpiece and _/;,"

beyondthe workpiece.

Thisproducesa smooth edge and final sizing of the

workpiece.When usingthese bitsor knives,an auxiliary

woodtable must be mountedon the cast irontable to

preventdamage to the table and the bits or knives.

The auxiliary table shouldbe made from smooth 3A"

particle board (12¾" wide and 31W' long) to providea

smoothsurface for the workpiece to slideon.

NOTE: Auxiliarytable is 12" longerthan the bast iron

table to allow 6" overhangin the front and rearfor long

workpieces.

The particle board must be mountedon the cast iron

table with four _a x 1"flat head screws,washers and

nuts(not included).Be sureto countersinkthe mount-

ingholeson the auxiliary table for the flat head screws.

The screws must be positionedbelow the surface of the

auxiliary table to preventdamage tothe workpiece.

GUIDE FENCES

When molding,the workpiece mustbe guided into the

moldingcutterbits or knives properlyin order to pro-

duce the desired shape and size molding. Using prop-

erly adjusted guidefences assures the workplece pass-

es the moldingcutters/knivesinthe same position

usingmultiplepasses.

Guide fences shouldbe made from smooth,straight

hardwood.Guide fences should be the same lengthas

auxiliarytable (311/4")and 2" wide.Cut the guide fences

14"lower than the maximum thicknessof the final work-

piece profile.The guidefences must be notchedto

clear the infeed/ouffeedrollersand anti-kickbackpawls.

See Figure 11 on page 11for dimension.

To mount guide fences to table/auxiliary table:

• Installmoldingcutter bits/knivesinthe cutterhead.

See =Installing CutterBits=and =Installing the Pattern

Knives".

• Lowerthe table and carefullyturn cutterheadby

handso that one cutterbitJknlfeis at the lowest point

of the cuttingedge.

• Positionthe workplece beneath the cutter bit/knife.

10

Page 11

• Slide in first guide fence and positioninside edge of

guide rail to outside edge of workpiece.

• Clamp the guidefence to table/auxiliarytable using

"C"clamps on bothends,

• Positionsecond guide fence onthe otherside of the

workpiece and clamp it to table/auxiliarytable,

• Make sure workpiece slidesbetween guide fences

smoothlyand withoutbinding.

9½" 9½"

121/'" _'_

"A"willchangedependinguponthicknessoffinishedworkpiece.

Figure 11 - Guide Fence (Side View)

RELIEF KNIVES

Many of the ¼" pattern knivesare suppliedwith relief

knives. The relief knives are used to cut a relief on the

back side of the molding so that the molding will better

fit irregular surfaces such as plastered walls.

Always cut the relief first before molding the workpiece,

sothat there is a flat surface for the workpiece to slide

on during the molding operation. If the molding is done

first, the workpieca will not lie flat on the feed table and

therefore the relief cannot be cut.

SE'n'ING UP FOR MOLDING

• Mount auxiliary table ontocast iron table.

• Install the required molding cutter bits/knives in the

cutterhead.

• Lower the table and insertthe workpiece relativeto

the positionof cutter bits/knives.

• Install the guide fences relativeto the positionof the

workpiece.

• Raise the table untilthe workpiece just contactsthe

infeed roller.

• Record the height ofthe table as indicatedon the

scale.

• Lowerthe table and removeworkpiece.

• Raise the table back to the recorded measurement.

Continue to raise the table one fullturn ofthe hand-

wheel. Record the measurement -- this is the first

pass measurement.

• Switch on the planer/molderand insertthe work-

piece untilthe feed rollerbegins to advance the

workpiece.

NOTE: When usingcertain cutter bite/knives,the

workpiece may feed ina jerky motion.If this hap-

pens, turn the handwheel and raise thetable until

the workplece advances smoothly.Revise the first

pass measurement with the current reading.

• If your moldingrequiresseveral passes, make sure

you run all yourstockbefore changingthe set-up for

each pass. This will assure conformityof shape

between workpieces.

FACE MOLDING

Refer to Figure 12 below.

NOTE: Alwayscut the relief first before moldingthe

workpiece.

• Mount the requiredcutter bits or pattern knives in

the planer/moldercutterhead.(See =Installing Cutter

Bits or Mounting Pattern Knives",pages 8 and 9.)

• Positionthe guide fences on each sideof the bitsor

knife in the desired position.(See "Guide Fences",

page 10.)

mini

Figure 12 - Face Molding

EDGE MOLDING

Refer to Figure 13 below.

The workpiece edges can be molded by feeding the

workpieceon edge intothe planer/molder.

Guide fences that are 3A"shorterthan the workpiece

mustbe positionedon the sides of the workpiece. Be

sure the workpiece is supportedrigidlyon bothsides by

the guide fences directlyunder the cutter bitsor knives.

JJ J J

Rgure 13 - Edge Molding

ANTI-KICKBACK PAWLS

The planer/molder is suppliedwith anti-kickbackpawls

that help preventthe cutterheadfrom kickingback the

workplece.

CAUTION." Never standin front of infeed or outfeed

side of planer/molder,Always stand to one side of plan-

er/molderto avoid injuryif a kickbackof the workpleco

shouldoccur.

11

Page 12

DUST COLLECTOR CHIP CHUTE

Refer to Figure 15, page 16.

A dust collector chip chute (notshown) isavailable as

an optionalaccessory.

The dust collectorchip chute is mountedto the plan-

er/molder in place of the chip deflector. To mount dust

collectorchip chute:

• Switch off and unplugthe planer/molder.

• Unscrew and remove three socket head bolts and

washers (Key Nos. 7 and 8).

• Remove chipdeflector (Key No.6).

• Slide dustcollectorchip chute along the edges of

knife cover (Key No.4) so that the slotson the knife

cover are aligned above the holes on the dust collec-

tor chute and the slots onthe dust collectorchute

align with the holes on the rear side of rollercase

(Key No. 1).

• Reuse three sockethead boltsand washers (Key

Nos.7 and 8) to fasten dust chute with knife cover.

• Use three6-1.0 x 8mm socket head boltsand three

6mm flat washers (suppliedwith dust chute) to fas-

ten dust chute with roller case.

The dust chute has a fitting for attaching a vacuum

hose.Attach a 2!._"O.D.weVdry vacuum hose to the fit-

ting. Be sure to turn the vacuum on beforeoperating

the planer/molder.

• Clean the four steel columns (Key No.32) to prevent

the table from bindingwhen raised and lowered.

• Keep elevating lead screws (Key Nos. 18 and 19)

clean and properlylubricatedwith grease.

• Keep the anti-kickbackpawls clean and operating

smoothlyto prevent injury due to kickback.

• After each ten hours ofoperation, clean the

chain/gear drive mechanism.

• Using a clean, drycloth, clean all of the chainsand

gears of wood chips, dust, and old grease.

• Use common automotive bearing grease to lubricate

all chains and gears. Be sure all chainsand gears

have plenty of grease.

LUBRICATION

The table surface can be coated witha lubricant,such

as furniturewax, to make the workpiecefeed smoother.

Be sure that the lubricantused does not affect the abili-

ty to finish the work.piecewithvarnish, sealer, etc.

'Forexample, do not usa any silicone base kJbricants

because they will ruin any attempt tofinishthe wood.

Replace feed rollersif damaged. Replace blades,cutter

bitsand pattern knives ifworn or damaged.

OVERLOAD RESET

The planer/molderis suppliedwithan overloadprotection

circuitbreaker to prevent damage to theplaner/molder

motor.

If the planer/molder stopsworking during a planing or

moldingoperation, unplugthe planar/molder and turn

the switch OFF. Press the reset buttonnext tothe

switch to enable the planer/molderto be restarted.

LIFTING BARS

Refer to Figure 16, page 18.

Four liftingbars (Key No. 25) are providedto make relo-

cation ofthe planer/moldereasy,

Slide the fourhandles out of the infeedand outfeed

ends of the table and use them to carry the

planer/molder to the desired location.

CAUTION: The planer/molder is top-heavy and will

tend to tip when moved. Exemise caution whenever

movingthe planer/molder.

Refer to Figure 16, page 18,

WARNING: Be sure planer/molder is unpluggedfrom

any power sourceand turned off before attempting any

maintenance.

• Keep planer/molder clean of any wood chips, dust,

dirt or debris.

12

Page 13

SYMPTOM

Excessivesnipe

(gougingat ends of board)

Fuzzy grain

POSSIBLE CAUSE(S)

1. Dull knives

2. Inadequate supportof longboards

3. Unevenfeed rollerpressure

4.Table not aligned

5. Lumber not buttedproperly

6. Support rollersmisaligned

Planing woodwith a high moisture

content

CORRECTIVE ACTION

1. Replace knives per instructions,see

"Operation"

2. Support longboards

3. Check feed roller operation

4. Check positionon elevationscrews

5. Butt end to end each piece of stockas

boards pass throughplaner/molder

6. Adjustsupport rollers i

Remove high moisturecontentfrom wood by

drying

Torngrain

Rough raised grain

Difficultto raise/lowertable

Uneven depth of cut

(tapered cut)

Belt slipping

Planer/Molder will not operate

Board slips,will not feed

Board feeds, but does notcut

Board feeds inside,but stops

moving past the ouffeed miler

Planing/moldingknife cannot

be removed

1.Too heavy a cut

2. Knives cuttingagainst grain

3. Dull knives

1.Dull knives

2. Too heavya cut

3. Moisturecontenttoo high

Cutterhead not parallel with table

Cutterhead not parallel with table

Loose belt

1. No power to planer/molder

2. Motor overload protectiontripped

3. Defective or looseswitch or wiring

Feed rollerstoo high

Feed rollerstoo low

1.Outfeed rollerstoo high

2. Outfeed rollerscannot rotatedue

to cloggingof chips

Gibs not loose

1. Review "Depth of Cut"

2. Review "Wood Grain"

3. Replace knives per instructions,

see =Knife Height Adjustment'

1.Replace knives per instructions,

see =KnifeHeightAdjustment"

2. Review "Depth of Cut"

3. Dry the wood or use dried wood

_.djust elevationscrews,see =Adjusting Depth

of Cut"

,

tkdjust elevationscrews,see "Adjusting Depth

of Cut"

Tensionor replace belt, see "V-Belt

Adjustment"

1.Check power source byqualified electrician

2.Reset motoroverload protection,

see "Overload Reset=

3.Check switchand wiring by qualified

electrician

Lower feed rollers,see "Feed RollerAdjustment"

Raisefeed rollers,see "Feed Rol!erAdjustment"

1. Loweroutfeed rollersin level.withinfeed

rollers,see "Feed Roller Adjustment"

2.Clear the clogging,use dust collectorchip

chute, see "Recommended Accessories",

page 17

Loosenset screwson gibsand tap downallthe

gibs

13

Page 14

12 5

Model 351.233831

21

16

19

26

11

Figure 14 - Replacement Paris Illustration for Motor

26

Page 15

KEY

NO,

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

PART NO.

3857.00

4283.00

4284.00

3860.00

3861.00

STD315215

4285.00

STD815205

3865.00

3866.00

3867.00

3868.00

1838.00

3869.00

3870.00

3874.00

3875.00

3873.00

3871.00

3872.00

3846.00

3876,00

DESCRIPTION

Motor Housing

Stator

Fan Casing

Fan

AligningBushing

6201 Bearing*

Armature With Fan

6200 Bearing*

Motor Pulley

BrushHolder

Carbon Brush(Set of 2)

BrushCap

5-0.8 x 10mm Set Screw

Gearbox Bracket

Gearbox

PinionShaft

Gear

4 x 4 x 8mm Key

PinionShaft

Gear

3 x 3 x 7mm Key

Gear

QTY.

1

1

1

1

4

1

1

1

1

2

1

2

2

1

1

1

1

1

1

1

1

1

KEY

NO.

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

4O

41

42

43

PART NO.

8575.00

STD315225

1531.00

0533.00

STD315525

3853.00

3885.00

4286.00

8576.00

1766.00

8580.00

1474.00

1643.00

2434.00

4288.00

5156.00

1544.00

3888.00

8578.00

8577.01

0781.00

DESCRIPTION

Gear Shaft

6202 Bearing*

4 x 4 x 10mm Key

3AM1-15 Retaining Ring

6002 Bearing*

Chain Sprocket

4-1.5 x 16ram Pan Head Screw

Gearbox Housing

Cord Plate

6-0.8 x 8mm Pan Head Screw

Motor Cord

5mm Serrated Washer

5-1.6 x 60mm Pan Head Screw

Strain Relief

5-1.6 x 70mm Pan Head Screw

4mm Serrated Washer

5-1.6 x 50ram Pan Head Screw

4mm Flat Washer

Gearbox Assembly

MotorAssembly

4-0.7 x 8mm Pan Head Screw

QTY.

1

1

1

4

1

1

2

1

1

1

1

1

1

1

2

2

3

2

1

1

2

Standard hardware item available locally

Page 16

Model351.233831

63

4

f

50

53

57

54

52

57

5O

55 46

/T

51

47

63

39

25

29

2

16

7 23

37

\

59

67

Rgure 15 - Replacement Parts Illustration for Roller case

16

Page 17

KEY

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

2O

21

22

23

24

25

26

27

28

i29

30

31

32

33

34

PART NO. DESCRIPTION

8508.00

8509,00

7317.00

Roller Case

Chipbreaker

6-1.0 x 12mm Washer

Head Bolt

8510.00

8662.00

Knife Cover

6-1.0 x 8mm Socket

Head Bolt

8512.00

6086.00

Chip Deflector

4-0.7 x 8turn Socket

Head Bolt

STD851004

8613.00

8514.00

8516.00

8516.00

4mm Flat Washer*

Threaded Bushing

22-1.5mm Hex Nut

Threaded Shaft

10-1.5mm Nylon Insert

Locknut

8517.00

3844.00

8519.00

$520.00

3853.00

3856.00

0533.00

8522.00

8523.00

8524.00

8525.00

8526.00

8527.00

8528.00

3873.00

8529,00

Cap

Spring

Retaining Bracket

Roller

Chain Sprocket

Spacer

3AM1-15 Retaining Ring

Roller Chain

Gearbox Chain

Motor Chain

Chain Sprocket

Gear Shaft

Gearbox

21T Molding Gear

4 x 4 x 8mm Key

8-1.25mm Nylon Insert

Locknut

8530.00

STD851005

8532.00

1775.00

Gear Shaft

5mm Flat Washer*

40T Molding Gear

6-1.0 x 25mm Socket

Head Bolt

6270.00

5-0.8 x 8ram Socket

Head Bolt

STD851006

6mm Flat Washer*

QTY.

1

1

3

1

3

1

3

3

4

4

4

4

4

4

4

2

4

2

3

1

1

1

1

1

1

1

2

2

1

1

2

2

3

KEY

NO. PART NO, DESCRIPTION QTY.

35 8534.00 Gearbox Cover 1

36 1441.00 3BMI-34 Retaining Ring 3

37 8535,00 Spacer 35

38 STD315225 6202ZZ Bearing* 2

39 8536.00 Cutterhead 1

40 8537.00 Planer/Knife (Set) 1

41 8538.00 Cutterhead Gib 6

42 8560.00 l 8-1,25 x 16mmSet Screw 18

43 8539.00 BitGib 3

44 8540,00 Spacer 6

45 8541.00 Jack Screw 6

46 STD315535 6203ZZ Bearing* 1

47 3838.00 3BMI-40 Retaining Ring 1

48 8542.00 Spur Gear 1

49 3839.00 5 x5 x 10ram Key 2

50 3829,00 16-1.5mm Hex Nut 2

51 8544.00 Spur Gear Shaft Assembly 1

!52 8545.00 Gearbox 1

53 3840.00 DrivePulley 1

54 8547.00 PolyV-belt 1

55 6511.00 4 x 16mm Dowel Pin 2

56 8548,00 6-1.0 x 35ram Pan' 1

Head Screw

57 6182.00 6-1.0 x 30ram Socket 3

Head Bolt

58 8549.00 Anti-KickbackPawl Shaft 1

59 8550.01 Anti-KickbackPawl 34

60 8551 .O0 Bracket 2

61 3855.00 5-0.8 x 10mm Socket 4

Head Bolt

62 1822.00 6-1.25 x 20mm Socket 4

Head Bolt

63 8552.00 30T Planing Gear _ 1

64 8553.00 31T Planing Gear 3

65 STD852005 5mm LockWasher* 4

66 8664,00 8 x 45mm Spring Pin 1

67 9575.00 Brass Punch 1

A 8507.02 Owner's Manual 1

A 8581.00 Blade HeightGauge 1

A 8755.00 Cutter Bit SettingGauge 1

t_ 8760.01 Wrench 1

Standard hardware

,% Not Shown

item available locally

Recommended Accessories

A E)ustCollectorChipChute 8582.00

& _ulti-Purpose Stand 351.22250

A HorizontalRollerStand 351.21417

17

Page 18

Model 351.233831

27

29 '_ I

30..._

32

i

28

2O

18

41

,.<-_32

46

25

3

41

45

4

3\

50

38

Figure 16 - Replacement Parts illustration for Base

18

Page 19

KEY

PART NO. DESCRIPTION

NO.

1 9598.00

2 8555.00

3 8556.00

4 8557.00

5 }662.00

9510.00

6

7

8559.00

8

8529.00

9 1510.00

10 3818.00

11 1531.00

12 8531.00

13 3873.00

14 8561.00

15 1505.00

16 STD852016

17 8562.00

18 8563.00

19 8564.00

20 8565.00

21 6164.00

22 8566.00

23 3821.00

24 3820,00

25 7365.00

26 B568.00

27 _812.00

28 0781.00

Base

Cover (LeftSide)

Cover (Right Side)

Scale (Set)

6-1.0 x 8mm Socket

Head Bolt

Shaft

Bracket

8-1.25mm Nylon Insert

Locknut

3CM1-15 E-Ring

Bevel Gear

4 x 4 x 10mm Key

Bevel Gear

4 x4 x8mm Key

Retaining Plate

6-1.0 x 12ram Socket

Head Bolt

6mm Lock Washer*

Right Guide Plate

Elevation Screw

Crank Elevation Screw

Table

3 x 25mm Spring Pin

Handwheel

Handle Screw

Handle

Lifting Bar

LeftGuide Plate

6-1.0 x 10ram Pan

Head Screw

4-0.7 x 8ram Pan

Head Screw

QTY.

1

1

1

1

8

1

2

2

4

2

2

2

2

2

4

2O

1

1

1

1

1

1

1

1

4

1

4

KEY

NO.

29

30

31

32

33

34

35

36

37

38

39

4O

41

42

43

144

45

46

47

48

49

50

51

PART NO. DESCRIPTION

8569.00

8570.00

8571.00

8572.00

1822.00

Indicator

V-belt Guard

Chain Guard

Column

8-1.25 x 20mm Socket

Head Bolt

STD852008

0423.00

4287.00

9511.00

3855.00

8mm Lock Washer*

Switch With Key

Circuit Breaker

Bracket

5-0.8 x 10mm Socket

Head Bolt

8574.01

0179.00

ITension Plate

6-1.0 x 20ram Socket

Head Bolt

STD851006

STD851010

8579.00

3886.00

8533.00

3984.00

13180.0O

6mm Flat Washer*

8mm Flat Washer*

Shaft

Aligning Pin

LineCord

Strain Relief

6-1.6 x 20mm Thread

FormingScrew

1775.00

6-1.0 x 25mm Socket

Head Bolt

1760.00

6-1.0 x 16mm Socket

Head Bolt

STD852005

1043.00

5mm LockWasher*

6-1.0 x 8mm Set Screw

QTY.

1

1

1

4

4

4

1

1

2

4

1

2

12

4

1

2

1

1

2

Standard hardware item available locally

19

Page 20

CEPILLADORA/MOLDEADORA

DE 121/="

Modelo No.

351.233831

PRECAUClON: Lea este manual y siga las

Reglas de Seguridad y las Instrucciones de

Operaci6n, antes de user este producto por la

primera vez.

Ingl6s ............................................ 2-19

Ilustraci6n y lista de partes ........................... 14-19

Garant_a............................................ 20

Reglas de seguridad ................................ 20-21

Montaje ............................................ 21

Instalaci6n ........................................ 21-23

Oparaci6n ........................................ 23-30

Mantenimiento ....................................... 30

Idantif'w.ati6nde problemas .............................. 31

UN A_IO ENTERO DE GARANTIA PARA LA CEPILLA-

DORA/MOLDEADORA DE 31,8 CM CRAFTSMAN

Si la cepilladora/moldeadora Craftsman falla debido a un defecto

en el material o en la mano de obrs, dentro de un aRo a partir

de la fecha de compra, p6ngase en contacto con el servicio de

reparaciones de rsareas principeles, interno, Sears en Estados

Unidos, y Sears la reparard sin costo.

SI esta cepitladora/moldeadora se usa pars fines cornerciales o

pars arriendo, esta garsntfa se aplica por 90 dfas a partir de la

fecha de comprs.

Esta garantfa se apllce solamente cuando el producto estd an

Estados Unidos. Esta garsntfa le otorga derschos legales especf-

ficos y tambidn puede tener otros derschos qua varfan de estado

a estado.

Sears, Roebuck and Co., Dept, 817WA, Hoffman Estates, IL

60179

ADVERTENClA: Pars su prop[a seguridad, lea todas las

Instruodones y las prscauciones antes de operar la herrsmienta.

PRECAUClON: Siempre siga los procedimientos de operack_'l

correctos, tel como se definen en esta manuel, aun cuando estd

familla.dzado con el uso de dsta o de otras herramientas similares.

Recuerde quesi no se t;ene cuida.do por aunque sea.una frscci6n

de un segundo se pueden producir lesicoes personeles graves.

ESTE PREPARADO PARA EL TRABAJO

Use rope. aproplada. No use ropa suelta, guantes, corbatas,

anlllos pulsera.s u otres |oyas que pueda.n quedar cogidas en

la.spartes rs6viles de la rsdquina.

Use una cubierta protectora, pare el cabelto, pa.rs suJetar el

cabello largo.

• Use zapatos de seguddad con suelas sntldesnzantes.

• Use gafa.s de segurided, que cumplan con ANSI Z87.1 de

Estados Unidos, Los enteojos cordentaa tienen solarsente

tentes resistentes al impacto. NO son anteoJos de seguridad.

• Use una mdscara pare la cara o una mdscara pars el poivo,

si ia operaci6n produce polvo.

• Estd alerta y piense claramente. Nunca opers herramientas

rsecdnicas cuando est_ cansado, intoxicado o cuando estd

tomando medicamentos que causan mareos.

PREPARACION DEL AREA PARA EJECUTAR EL

TRABAJO

• Mantenga el drsa limpia.Las drsas de trabajodesordenadas

atraenaccidentes.

• No use herramientas mecdnicas en amblentes peligrssos. No

use herramientas mecdnicas en lugares ht_medos o mojados.

No exponga las herramientas mecdnicas ala Iluvia.

• El drsa de trabajo debe estar iluminada adecuadamente.

• Tiene qua heber disponlble un rsceptdcoto el_ctdco adecuado

para la herramienta. El enchufe de tres puntas se tiene qua

enchufar dirsctamente en un recept_leulo de trss puntas

conectado a tierra corrsctamente.

Los cordones de extensi6n deben tenet una punta de co-

nexi6n a tierra y los tree alambres del cord6n de exlensi6n

deben ser del calibre correcto.

Ma.ntenga. a los visitantes a una distancia prudente del drea

de traba.jo.

Mantenga a los niRos fuera del lugar de trabejo. Haga que

su teller sea a prueba, de ni5os. Use ca.ndados, interruptores

principales o remueve las I[aves del interruptor para evitar el

uso no intencional de las herramientas mecdnicas.

ES IMPORTANTE MANTENER I.AS HERRAMIENTAS

Desenchufe siersprs ta herramienta antes de inspeccionarla.

Consulte el manual pa.ra,informarse sobre los procedimientos

de mantenlmiento y ajuste espec_'ficos.

Ma.ntenga la herrarsienta lubdcada y limpia, pare o_ener una

opersci6n rods segura.

Remueva la.s herra.mlentas de ajuste. F6rmese el hdbito de

reviser para verificar el la.s herra.rsientas de ajuste se ha.n

removido antes de encender la mdquina..

Mantenga todas las partes Iistas pare funcionar. Revise pare

determiner que el protector u otras pa.rtes opersrdn correcta-

mente y hardn el trsbajo que deben hacer.

Revise pars verificar sl hay partes de_adas. Revise pars

vedficar el elineamiento de lea partes moviblea, sl hay atas-

camiento, rcturas y rsontaje o cuelquler otra condici6n qua

pudiers afectar laopersci6n de la herramienta,

• Si hay una protecciSn o cuelquier otra parte dafiadaa, tienen

que rsparsrse corrsctamente o semblarse. No haga rspars-

clones provisodas. (Use la lista de partes qua viene incluida

pare ordenar las partes de rspuesto.)

EL OPERADOR DEBE SABER COMO USAR LA

HERRAMIENTA

• Use la herramientacorrecta pars eltrabajo,No fuerce la

herramlenta,oel accesodo,nl los use pars untrabaJopare

el cualnohartsidediseRados.

• Desconectela herrsrslentacoando camblelash_Jas.

• Evlte el arranquapor accldentes,Asegdmseque el Interruptor

de leherramlentaestden lapoelcl6n"apaga.do"(off) antesdo

enchufada.

• No fuercela herramlenta.TrabaJarden la formamSsafidente

ala veloddadpera lacuel sa diseftS.

20

Page 21

Mantenga las manos alejadas de las partes m6viles y de las

superficies cortadoras.

Nunca deje que una herramienta funcione cola. Descon6ctela

y no se vaya hasta que se defenga completamente.

No trate de alcanzar demasiado lejos. Mant6ngase firme

y equilibredo.

Nunca se pare en la herramienta. Se pueden producir

lesiones graves si la herramienta se incline, o sise tcoa

el disco o la correa pot accidente.

• Conozca su herramienta. Aprenda la operaci6n de la herra-

mienta, aplicacibn y lim_taeiones especfficas.

• Use los acoesorios que se recomienda. (Refri6rase a la pdgi-

na 17.) Si se usan accesodos iecorrectos, se puede producir

riesgo de lesiones personales.

• Deje las manos libres para operar la mdquina. Prot_jalas de

posibles lesionea.

• Desconecte la mdquina si ae atassa. La cuchillo o la hoja se

atassa cuando penetra demasiedo profundamente en la pleza

de trabajo. (La fuerza del motor la mantiene pegada ala pieza

de trabajo.)

• Siempre mantenga el impulsor, el portacochilla y tas protec-

ciones de las cuchUlas en su lugar y en condiciones de

operaci6n adecuadas.

• Alimente el trabajo en la euchilla o en la cortedora en contra

de la direcci6n de rotaci6n.

PRECAUClON: IPiense en la seguridadt La seguddad es una

combinacibn de sentido com0n del operador y de ester alerta

en todo mornento cuando se estd usando la herramienta.

ADVERTENCIA: No trate de operarla herramlentahasteque

est_ completamentemontadasegt_nlas Instrucciones.

Refidrase a las Figuras 15 y 16, pdginas 16 y 18.

La ospilladora/moideadora se envfa montada, exospto por el

velante y el mango (Figura 16, Clave Nos. 22 y 24).

MONTAJE DE LA CEPILLADORA EN LA

SUPERFICIE DE TRABAJO

Refi6mseala Figure 1.

La cepl[ladorahasidodise_edapara que sea portdtilde

modoque se puedaIlevaral lugar de trabajo,pero setiene

que montaren un banco o mesaestable y nivelada.Vea

"AccesoriosRecomendados",pdgina17.

INSTRUCCIONES DE MONTAJE PARA EL

PEDESTAL OPCIONAL MODELO 22250

Refidrasea Ia Figura1,

Llste de Materiales

Tabla de partfculas de 1,3 x 38,1 x 55,9 cm(no viene inclui-

da)

Cuatro pernos de 1/4 - 20 x 11A"con arandelas y tuercas (no

vienen incluidos) pare e[ montaje de la tabla en el pedestal de

prop6sffo mdltiple.

Cuatro pernos de 8 - 1,25 x 30 mm con arandelas (vienen

incluidos con la ospilladora/moldeadora) para montar la cepi-

IladoraJmoldeedora en la tabta.

Se necesita una tabla de montaje cuando se monte la ospilla-

doraJmoldeadom en el pedestal de prop6sito mdltiple, modelo

22250 Sears. La table de montaje estd hecha de madem lamb-

neda de 11,3 cm de espesor o de partfcu[as.

Corte y perfore la tabla usando el dibujo. Elagujero de

25,4 cm de didmetro en el centro se usa Data ventilaci6n

solamente.

Asngure primero la tabla de montaje en la I_arte superior del

pedestal, usando cuatro pernos de ¼", arandelas y tuercas

(no vienen inctuidos). Asegdrese que la tabla quede osntrada

en la parte superior del pedestal y apernad a en forma segura.

Monte la cepilladora/moldeedora en la tabla de montaje usan-

do los cuatro pernos de 8 - 1,25 x 30 mm con las arandelas.

Atomille los pernos a travds de ta tabla de montaje yen la

pleza fundida de la base desde la parte inferior de la tabla.

INSTALACION DEL VOLANTE Y EL MANGO

Refidrasea la Figure 16, pdglna 15.

El volante(Clave No.22) se tieneque Instalar af 1adoizquier-

do de[a ospilladora/moldeadora.

Anneeel mango(Clave No.24) conel aguJeroen el aro del

volante.

Inserteel tomUlodelmango (Clave No.23) en el mango y

apri6tetoen forma segura.

Desliceel velante en el tornillode eteved6n de la mantvela

(Clave No. 19) de modo queel pasadorde resorte(ClaveNo.

21) en eltornillode eleveci6nde lamanivela quede colocado

entrela ranuray el volante.

REMOClON DE LAS TAPAS

Refldrasea la Figure 15, p=_gina16.

La ospllladora/moldeadora se envfacon lastapas (Clave No.13)

en los ejes roscados(ClaveNo. 11) para evitarel dafioen los

ejesduranteel envfoy el manejo.

Desatomilley remuevalas tapesantesde enosnderla herra-

mienta.

Guarde las tapespara usoen el futuro.

cm

13,7915

.I Cmcm

cm

13,7 crnI

1,3 crn 2im!_ _

9 cm

Figure 1 - Monte la Ceplgedora/Moldndom en el Pedestal de

Propdelto Mdltlple Opclonal Modelo No. 22250

55 9 cm _-

FUENTE DE ENERGIA

ADVERTENCIA: No conectela cepilladoraJmoldeadoraala

fuentede energfaslno haste despu6sde que _e hayan comple-

tadotodos lospesosdel montaje.

21

Page 22

Elmotorhasidodisefiedoparaoperarconelvoftafeylafre-

cuenc_aespecificedos,Lasca_gasnorrnalessepueden rnanejar

conseguridadconvoltajesde norndsde 10°/oporsobreo bajo

delvoltajeespecificado.SI se hace funcionar la unidadconvol-

tajes que no estdn dentrode la garna,se puedepraducirun

calentamientoexcasivoy quernarseel rnctor.LOScargaspesa-

des exigenque elvoltaje en los terminalesdel motorno scan

menosque el voltajeespedficado.

Elabasteeirnlento de energfaque va admotorestdcontrolado

por el interruptoroscilante. Si se remueveel ir_erruptorosci-

lantese asegura la unidady se impideel usonoautorizado.

INSTRUCCIONES PARA LA CONEXION A TIERRA

ADVERTENCIA: Si se conectaincorractamenteelconductor

de conexidnatierra de1equlpo,se puedeproducirundesgo de

choqueeldctdco.El equipodabe estar conectadoatierra mien-

trasse estd usando,para protegeral operadorcontraun choque

eldctdco.

• SI las Instrucoiones para la conexidn a tierra no se ent[enden

o si se tienen dudes de que la herrarnienta estd conectada a

tierm correctamente, consulte a un electdcista calificado.

• Esta herramienta vlene equlpada con un corddn de 3 conduc-

totes, aprobado, con capacldad de 150V y con un enchufe

de 3 puntas del tipo de conexibn a tierra (yea la Figure 2) para

su prateccidn en contra de los peligros de choque el_ctrico.

• El enchufe de eonexl_,n a tierra se dabe enchufar directa-

mente en un receptdculo de conexidn a tierra de 3 puntas,

conectado a tierra e Instalado correctamente, como se

rnuestra (Figure 2).

Tornacorrlente conectado

a tierra correctamente

Punta de conexidn a tierra

ADVERTENCIA: Este trabajodebe serejecutadoporun elec-

tdcistacalificado.

Se puedeobtenerun adaptadorde conexibn atierraproviso-

riode 3 puntasa 2 puntas(veala Figura3) pare conectarlos

enchufesa untomacorrientebipolar,siestd conectadoa tierra

correctamente.

Tal6nde tierra_ ,======_ Asegdrese

A _ IF _ que este

dap dor , J TII co°ectedoa

.... _ _ I_ II unaconexidn

P_ncnulrede \ ! II atierra

3 pun__ concoido

'*_ _'/ _Recapt_culo

de 2 puntas

Figure3 - Receptdculode 2 Puntascon Adaptador

No use un adaptador de conexi_,n a tierra de 3 puntas a

2 puntas a menos que sea permitido por los cddigos y regia-

rnentos locales y nacionales, (En Canadd no se perrnite usar

un adaptador de conexidn • tierra de 3 puntas a 2 puntas.)

En donde se permite el uso de un adaptador de conexidn a tierra

de 3 puntas a 2 puntas, la lengOeta verde rlgida o el terminal en

el lado del adaptador debe ester conectado firmernente a una

conexidn a tierra eldctrica perrnanente, tadcorno una tuberla de

ague conectada a tierra correctamente, una caja de tomacorden-

te conectada a tierra correctarnente o un sistema de cables

conectado a tierra correctarnente.

Muchos de lostornillosdela planchade cubierta, lastube-

rfasde ague y lascajas de tornacorrienteno estdnconecta-

dos a tierra correctamente,Pareaseguraruna conexidna tie-

rracorrecta, un e[ectricistacalificadodabe probai"losmedios

de conexidna tlerra.

3En;uhntufaesde __

Figure 2 - Recapt_culo de 3 Puntas

No remuevanialtere la punta de conexidna t{erradeninguna

manera.En el casode una fallao de unadescargadisruptive,

la conexi_ a tlerra proporcionael caminode menorrasisten-

cla al choqueeldctdco.

ADVERTENClA: No perm;taque los dedostoquenlostermi-

haleso elenchufe cuandose estdninstalandoo rernoviendodel

tomaeordente.

El enchufe se debe enchufar en el tomacorriente correspon-

dlente, que dabe estar instadadocorrectarnente y conectedo

a tierra segOn todos los cddigos y reglarnentos locales. No

modiflque el enehufe que se propornlona. SI no calza en

el tomacordente, haga que un electrlcista oslificado instale

uno osrrecto.

Inspeccloneloscordones de la herramlentaped_llcamente y,

sl est_.nda_ados, hdgalosreparar porunservido autodzado.

El conductor verde (o verdey amarillo)del corddn es el cable

de conexldn a tlerra.Si es necasadoreparar ocarnbiarel cor-

ddn eldctdcoo el enehufe,no conecte el cableverde (o verde

y amadUo)a un terminalosrgado.

Cuandoca eneuentraun recaptdcolode paredde 2 puntas,

se debe reemplazarpor un reosptdoslode 3 puntasconecta-

do atlerracorrectament_ee Instaladode acuerdocon loscddt-

gosy raglarnentos delNationalElectdcCodey con losc_:ll-

gos locales.

CORDONES DE EXTENSION

Eluso de cualquiercorddnde extensidnproducir_,cierta

carda de voltajey pdrdidade energ[a.

Loscablesdel corddn de exlensi(_ntienen que aer del tama_o

suficientecomo para conducircorrientey rnantener el voltaje

adecuado.

EltamaRomfnimodel cable delcordbnde extensidnes 14

A.W.C.No usecordonesde extensidncon mdsde 7,6 rn de

Iongitud.

• Usecordones de extensidnde 3 cables,con enchufesdel Upo

de conexi_n a tierra de tres puntasy receptdculosde tripola-

resque acepten el enchufe de la unidad.

• Si el corddnde extensi6nestd desgastado,cortedoo daSado

en algunaforma, cdrnbieloinrnediatamente,

MOTOR

La capilladora/rnoldeadora de 31,8 cm viene con un motorde 21,_

caballos de fuerza y conel osbleado instalado.

Elmotoruniversaldecorriente alternade 120 voltiostiene las

especificacionessiguientes:

Caballos de fuerza (mdximo desarrollado) ............ 2½

Voltaje ............................ ;.. : ...... 120

Ampedos ........................ ; ..... ' ....... 15

Hertz ........................................ 60

Fase ................................. i Monofdslco

RPM ............................ _........... 4500

22

Page 23

CONEXIONES ELECTRICAS

ADVERTENCIA: Asegt_raseque la unidadastd apagada y

dasconectadade la fuante de energfaantes de inspeccionar

el cableado.

El motor se instala y se conecta el cableado segt_nla ilustreci6n

en el diagrama de cablaado (vea la Flgura 4, pagina 23).