Craftsman 351.226711 Owner's Manual

SAVE THIS MANUAL

FOR

FUTURE REFERENCE

OWNER'S

MANUAL

MODEL NO.

351.226711

CAUTION:

READ ALL

INSTRUCTIONS

CAREFULLY!

.A/P /CRR FTSMRN

l"x 6" BELT & DISC SANDER

• safety Instructions

• assembly

• operating instructions

• replacement parts

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A. ©

Part NO. 3899.00 May 1991

FULL ONE YEAR WARRANTY ON SEARS/CRAFTSMAN 1" x 6" BELT & 015C SANDER

If Within one full year tom the date of purchase, this Sset_ Cmfleman 1" x 6" Belt & Dlso Sender fells due to

e defect in material or wodunanchlp, Seam will repair It, free of r,hafge,

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS STORE OR SERVICE

CENTER THROUGHOUT THE UNITED STATES.

This warranty glvm; you specific legal rights, and you my have other rigMs which vary from elate to stats.

BEARS, ROEBUCK AND CO., DEPT. 690/'731A SEARS TOWER, CHICAGO, IL 60684

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS

BEFORE ANY WORK IS DONE READ THE CAU-

TIONS LISTED BELOW CAREFULLY. WORKING

SAFELY PREVENTS ACCIDENTS.

OPERATOR SHOULD BE PREPARED FOR JOB:

n. Wear proper IpporeL Do not wear loose clothing,

gloves, neolclles, dngs, mcelsts or other Jewelry

which may get ,-,ught In moving parts el machine.

b. Wear proteoth_ halr layering to contalnlong hair.

c. Wear safety shoes with nOn-slip soles.

d. Wear ealeW glasses. Everyday glasses have only

impact mldstant lenses. They am not safety glass-

as.

e. Wear face mask or dust masklf sanding oberstlon

is dusty.

f. Be alert and Udnk olemty. Never operate power

tools when tired, Immdcm_ or when taking med-

Isatlons that cause drown.

WORK AREA SHOULD BE READY FOR JOB:

S. Keep work area clean. CkJ_.eredwork areas and

workbem:he: _ ecclder_.

=. Do nOt use POWer tools In d-ngeroua em4ron-

menta. Do n_ use power tools In damp or wet

kxmtlona. Do not e:q)oea power toofe to rain.

o, Work am Ihould be ixofxmly llgMed.

d. Proper olectrlccl outlet should be available for

tool Three-prong plug should be plugged directly

Intoprope_f grOUnded,lhrea-p_g re_p_e.

e. Extenefon cords should have • grounding prong

end tha throe wlnm of the e_enelon oord should be

the correc_gauge,

f. Keep vlaimre • safe distance from work area.

g. Keep children out of workplace. Make workshop

chlM-proof. Use padlocks, master switches and

remove starter keyl to prevent any unintanlJonal

useofpo_r ton_.

TOOL SHOULD BE MAINTAINED:

a. Alvmys unplug power tool prior to Inspection.

b. Consult owner'a manual for specific maintaining

end adjusting procedures.

c. Uae clean born end keep me tool clean for safest

operation.

d. Remove adjusting keys end wrenches. Form

I'mblt Of checking to see that keys and adjusting

wrenches ere removed before turning tool on.

e. Keep ell guards In place end In working order.

f, Keep ell parts In woddng order. Check to deter-

mine that the guard or other parts will opamte

propedy end perform their intended fun_on,

g. Check for damaged parts. Check for allgnment of

moving parts, blndlng ofmoving parts, breakage of

parts, mountlng and any other cond#lon that nay

efle¢l a tool's operation.

h, A guard or other pert that [11damaged should be

properly repaked or replaced. Do not perform

makashitt repairs. (Use the part8 list providedto

order replasament parts.)

OPERATOR SHOULD KNOW HOW TO USE TOOL:

e. Use right tool for the Job. Do not force tool or

attachment to do • Job for whk_.hIt was n_ de-

signed,

b. Olsconneot tool when changing ecceseerlal,

such es belt, disc, miter gauge and the like.

0. Avoid accidental start-up. Make sure that the

machine Is In the *off" posItion before plugging In.

d. DO nOt force • tool, Kwe11work most affldently at

the rata for whlch It was designed.

e. Usa rscommended eok-easorlea. Refer to page

1t. Use of improper e_sorles may cause riskof

Inlmytopersons.

I. Handle theworkpleceOorreotly. Use alter gauge

when requlred. Protect hands from passlMe Injury.

g, Dlreotlon of feed. Feed work Into • bar or dlso

against dlro_lon of rotation of the ben or dlso.

h. Turn the ma¢hlne off If It Jams. Disconnect plug

from power _uroe before servicing tool.

I. Never leave • too4 running unattended. Turn the

power offend do not leave sander until itcomes to

e complete atop.

J. Do not overreach. Keep proper footing and

Imlanoe.

k. Never stead on tool. Serious Injury oould occur If

tool Is Upped or If abraslve belt or dlsc Is unlnten-

tlonally contacted,

I. Keep hands away from moving parts and earKllng

surfaces,

m. Know your power tool. team its operation, ap-

plk:ation end specific limitations.

-2-

CONTENTS

Wmmmty ................................ a

Goal 8eloty Immmotkme

for Power Tcolo ...................... 2

Salety InIWmotlene

for Bolt & Disc Sender ................. S

Motor Speclfk:atlone

end Ei$Ctlrlsal Requirements ............ 4

Eieotrk:al ConnecUone .................. 4 & S

Unpaeldng end Checking Contents ........... 8

TOOLSNeeded ............................ $

As_mb_ ............................... s

Operetlon ............................... 0

Malntermr_e .......................... 0 & 0

Trouble Shooting ......................... 9

RepMcament Perta Illustration .............. 10

Roplasement Parts Usl ................... 11

WARNING LABEL

The bolt and d_ sander has beam marked with •

warning lehegma_ seeds to be obs_ved for esfe opera-

floe, The operator should be aware of the locatlon end

contents of this label.

This wemlng label Is placed In • speclflc looatlon so It

Is vislble to the operator when stanlng and operating

the belt and disc sander.

SAFETY INSTRUCTIONS FOR l"x 6" BELT & DISC SANDER

WARNING: IX) NOT ATI"EMPT TO OPERATE BELT

& DISC SANDER UNTIL IT IS COM-

PLETELY ASSEMBLED ACCORDING

TO THE INSTRUCTIONS.

1. Know general power toot sefety. Make sum all

precautlorm am understood end provided to(

Loa0oz).

2. Secure aU Motener$. FmquenW check that nuts

and bo_,4are tight and heve not viaroted Iocoe.

3. _et_mdlonlnwuotl_e. Operateme be_

end dis(: sander eel deserl1>ed In this manual

(r.,0es 6 through 8),

4, Be eure motor rum €lockwise on dllm side.

Abrasiveb_ mu,,t_1 down.

5. Perform dhm eandlng on down ekle (right side).

The dl_ should p_l work towards the table.

6. Support worlq:lece. Use baelmop orwork _t_.

The backstop forthe abrssJve_ isthe bell platen

(Key No. 25) as described In "Oper-sflng Instruc-

tions" (page 7),

7. Do not forse work. Slowing or stallIng the motor

wUloverhset

8. DO not overlmot work. Move metal across the

abmslve end (:xx_Itwhen It becomes hot.

9. DO not wet grind or polish. Never use a steady

stream of water on thewodq_eca. Only quench the

wod(pleca in water to cool It.

10.

11.

12.

Do not grind or polish magnesium, k could catch

on fire.

Koep sender maintained. Follow "Maintenance

Instructions" (Page 9).

Dleconneot IX:.wor. Tum swRch off and discon-

nec_power whenever sender Is not In use.

CAUTION: Be certain to follow proper operating

proeedursa decpfle familiarity gelned

from frequent uso of your lea end disc

sander. Always remember that beklg

careleec for even m fraotlon of • second

IS sufll_ent time to Inflict severe InJu_,.

The operation of any power tool can result in foreign

being thrown into the eyes, whloh can result In

e(wom eys damage.

Always wear safety goggles complying with ANSI Z87.t

(shOwn on package) before commencing power tool

operation. Safety goggles am available at Sears ro_H

or cetslog _ores,

THINK SAFETY: Safety is • combination Of operator

common sense and alertness st ell

times when the belt & disc sander is

being used.

--3-

MOTOR SPECIFICATIONS AND ELECTRICAL REQUIREMENTS

MOTOR

The belt and disc lander Is mmembled with motor 8nd

wiringreadied ,., an _eTal i_t of the tool

The 120 Volt AC permanent epla €_q_c_ motor has

therenewingqx_ncatk_:

M_ Devek¢_ Horsepower................ 1/t

Voltage .................................. 120

Amperes .................... ............... 3

Phase ................................ Single

RPM ................................... 34S0

Rotation (viewed from left side) ......... Clockwise

POWER SOURCE

CAUTION: Do not _nneot the heft and dlso sender

to the power source until ,,11ummmly

steps hsve been completed.

1. The motor b designed for operatton on the voftage

and frequor_y spodfled on motor nsmel_te.

2. Normal loadswll be hendled safeb/on vdtages nof

more than 10% el)ova or below nameplate voltage.

3. Running the unlt on vo#ages whleh 8re not within

range may cause overhaadng and motor bum-out.

4, Heavy loads require thst voltage lit motor ter-

mlr.ds be not less than voltage specified on

nameplate.

GROUNDING INSTRUCTIONS

This tool Io equipped v/_th 8 _€onduc_o_ (x)rd end

7ot_J t_e pl_ w_dd_hee e gu_ncJ_g jx_O 8p-

provedby Unden_ere Labondodu end theCanadian

StandardaA_lodmUon.

Do not remove or _er the grounding prong in any

mmrmer.In.the m_nt of 8 _ o4"Ixmlkclown.

7oond_g IXovldese pethofIse= rudmmcaforqdoc_

sel ¢ummt to reduce the rbk of electrical shock.

The plug mu= be plugged Into e mmddng ouUetth=

• prop_ _ and70undod_ ===xde,x_w=h

nglocal€odes amdordlrmno_

Do nof modifyme plugixovlded,ff = v41not _ Inme

o_let, hero the proper outlet _ by a qualH_l

electtfcbR Improper OOnnectlonOf _.g_)und-

Ing conductor can re_JIt In a risk of dectrkmJ ohock.

The ¢ondu(_x wlh Insu_tlon having an outer surface

whichb omen 18the equipmentgroundingconductor.

If repair or re_(_mlent of the e/octlrk_ cord or i_ug IS

_, rnako m the equipment g_ndlng c,on-

ductor 18no( connected to a line terminal.

WARNING: CHECK WITH A QUALIFIED ELECTRI-

ClAN OR SERVICE PERSONNEL IF THE

GROUNDING INSTRUCTIONS ARE

NOT UNDERSTOOD OR IF IN DOUBT

A8 TO WHETHER TOOL I$ PROPERLY

GROUNDED.

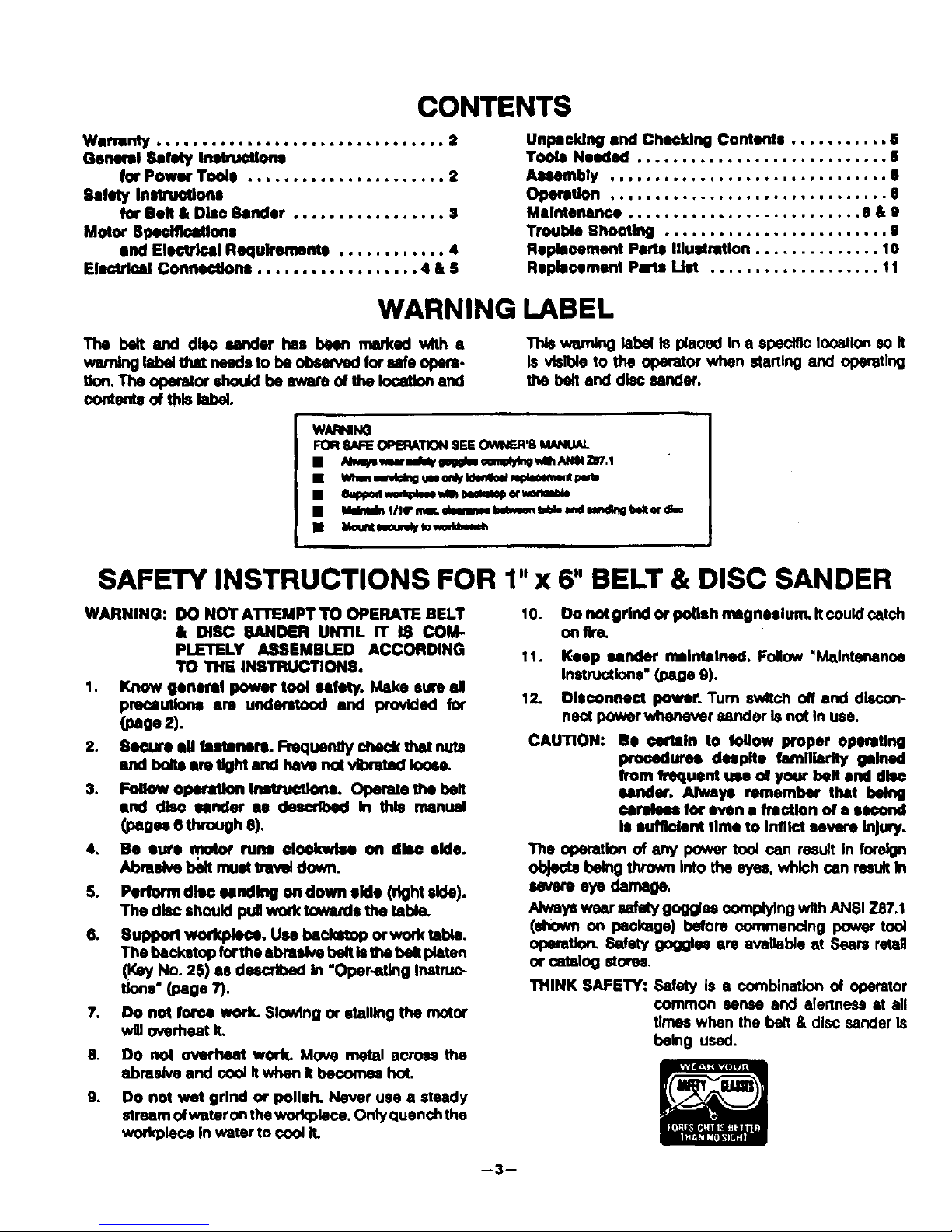

PROPERLY

GROUNDED

This tOOl Is Intended for use on clrcult having e

nominal mtlng lee8 than 150 volts whl,',hhss an outlot

that looks like the one ll=ed above.

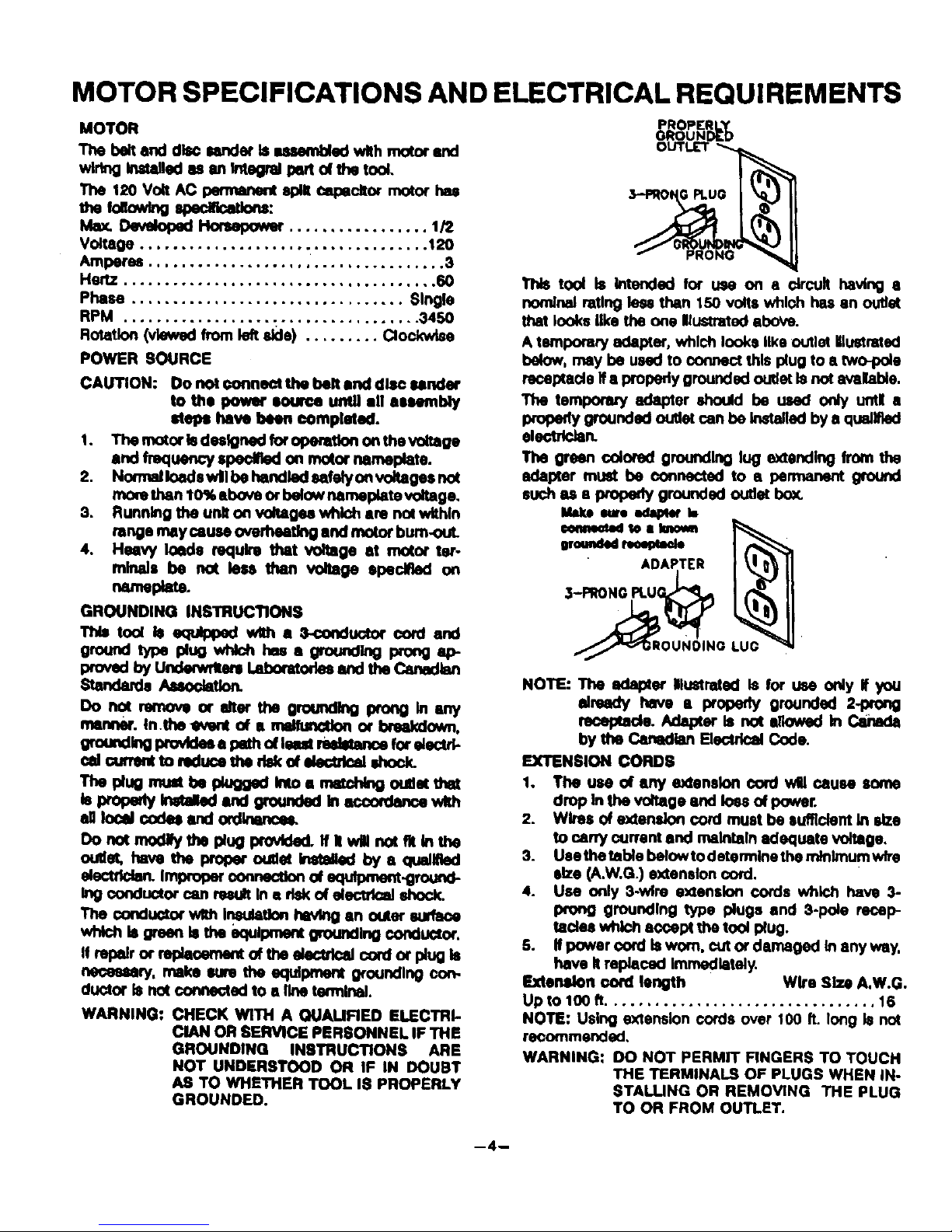

A temporary adapter, which looks like outlet lilustr_ed

below, may be used to connect this plug to 8 two-pole

recalXa_le If a propedy grounded outlet ISnot avdable.

The temporary adapter _lould be used only untl a

pmpedy grounded outlet can be Installed by 8 qua,fled

eleofrldan.

The green colored groundlng luo extending from the

edalXer must be connected to a permanent Qfound

such its 8 properly grounded outlet box.

Mslm sine _IN_w Is

NOTE: The adapter llu_nded IS for use only If you

81rcady have • properly grounded 2-Wong

ru=epmde. ,,_la_er IS not ellowed In Cshada

by the Canadian Eleotrlcal Code.

EXTENSION CORD8

1. The use of amy e_enslon cord wRI cause some

drop In the voltage end Io_ of power.

2. Wires of extension cord must be sufficient In idze

to carry current and malnlaln 8dequste voltage,

3. Use the tame belowto determlne the minlmum wlre

she (A.W.G.) extension cord.

4. Use only 3-wire extension cords whlcl_ haw 3-

prong grounding type plugs and 3-po_e recep-

tacles which accept the tool plug.

S. ff power €ord b worn, cut or damaged In any why,

have Itmpk_ced Immediately.

Extonslon oon:l length Wlre Slze A.W.G.

Upto 100 ft................................. 16

NOTE: Using extension cords over 100 ft. long b no_

recommended.

WARNING: DO NOT PERMIT FINGERS TO TOUCH

THE TERMINALS OF PLUG(= WHEN IN-

$TALUNG OR REMOVING THE PLUG

TO OR FROM OUTLET.

--4--

Loading...

Loading...