Page 1

Operator’s Manual

CRflFTSMHÍr

Wall Mount

DUST COLLECTOR

Model No.

351.223140

■■w

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

s Í I

i

• Safety Rules

• Operation

• Maintenance

• Parts List

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com/craftsman

23962.00 Draft (08/10/05)

• Español

Page 2

TABLE OF CONTENTS

Warranty............................................................................................ 2

Safety Rules

Unpacking..........................................................................................3

Assembly........................................................................................3-5

Installation

Operation...........................................................................................6

Maintenance .....................................................................................6

Troubleshooting.................................................................................7

Parts Illustration and List................................................................8-9

Español

......................................................................................

.........................................................................................

......................................................................................

10-15

• Do not use power tools in dangerous environments. Do not

use power tools in damp or wet locations. Do not expose

power tools to rain.

2

5

• Work area should be properly lighted.

• Proper electrical receptacle should be available for tool.

Three prong plug should be plugged directly into properly

grounded, three-prong receptacle.

• Extension cords should have a grounding prong and the

three wires of the extension cord should be of the correct

gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop childproof.

Use padlocks, master switches or remove switch keys to pre

vent any unintentional use of power tools.

WARRANTY

ONE-YEAR FULL WARRANTY ON CRAFTSMAN TOOL

If this Craftsman tool fails due to a defect in material or

workmanship within one year from the date of purchase CALL

1-800-4-MY-HOME® TO ARRANGE FOR FREE REPAIR.

If this tool is used for commercial or rental purposes, this war

ranty will apply for oniy ninety days from the date of purchase.

This warranty applies oniy while this tool is in the United

States.

This warranty gives you specific legal rights and you may also

have other rights, which vary, from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates,

IL 60179

SAFETY RULES

DANGER; Do not use this dust collector in a flammable or

explosive atmosphere. Do not use to collect metal shavings or

dust. Consult National Fire Protection Association (NFPA)

standards before setting up a dust collection system, espe

cially NFPA 664.

WARNING: For your own safety read all of the instructions

and precautions before operating tool.

CAUTION: Always follow proper operating procedures as

defined in this manual even if you are familiar with use of this

or similar tools. Remember that being careless for even a

fraction of a second can result in severe personal injury

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing, gloves,

neckties, rings, bracelets or other jewelry which may get

caught in moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI

Z87.1. Everyday glasses have only impact resistant lens

es. They are NOT safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools when

tired, intoxicated or when taking medications that cause

drowsiness.

TOOL SHOULD BE MAINTAINED

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjusting

procedures.

• Keep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to see that

adjusting tools are removed before switching machine on.

• Keep all parts in working order. Check to determine that

the guard or other parts will operate properly and perform

their intended function.

• Check for damaged parts. Check for alignment of moving

parts, binding, breakage, mounting and any other condi

tion that may affect a tool’s operation.

• A guard or other part that is damaged should be properly

repaired or replaced. Do not perform makeshift repairs.

(Use parts list provided to order replacement parts.)

KNOW HOW TO USE TOOL

• Use right tool for job. Do not force tool or attachment to do

a job for which it was not designed.

• Disconnect tool when performing service or maintenance.

• Avoid accidental start-up. Make sure that the switch is in

the OFF position before plugging in.

• Do not force tool. It will work most efficiently at the rate for

which it was designed.

• Leave hands free to operate machine. Protect hands from

possible injury.

• Never leave tool running unattended. Turn the power off

and do not leave tool until it comes to a complete stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool is

tipped or if blade is unintentionally contacted.

• Keep hands away from moving parts.

• Know your tool. Learn the tool’s operation, application and

specific limitations.

DANGER: The operation of any power tool can result in for

eign objects being thrown into the eyes, which can result in

severe eye damage. Always wear safety glasses complying

with United States ANSI Z87.1 (shown on package) before

commencing power tool operation.

PREPARE WORK AREA FOR JOB

• Keep work area clean. Cluttered work areas invite

accidents.

© Sears, Roebuck and Co.

Page 3

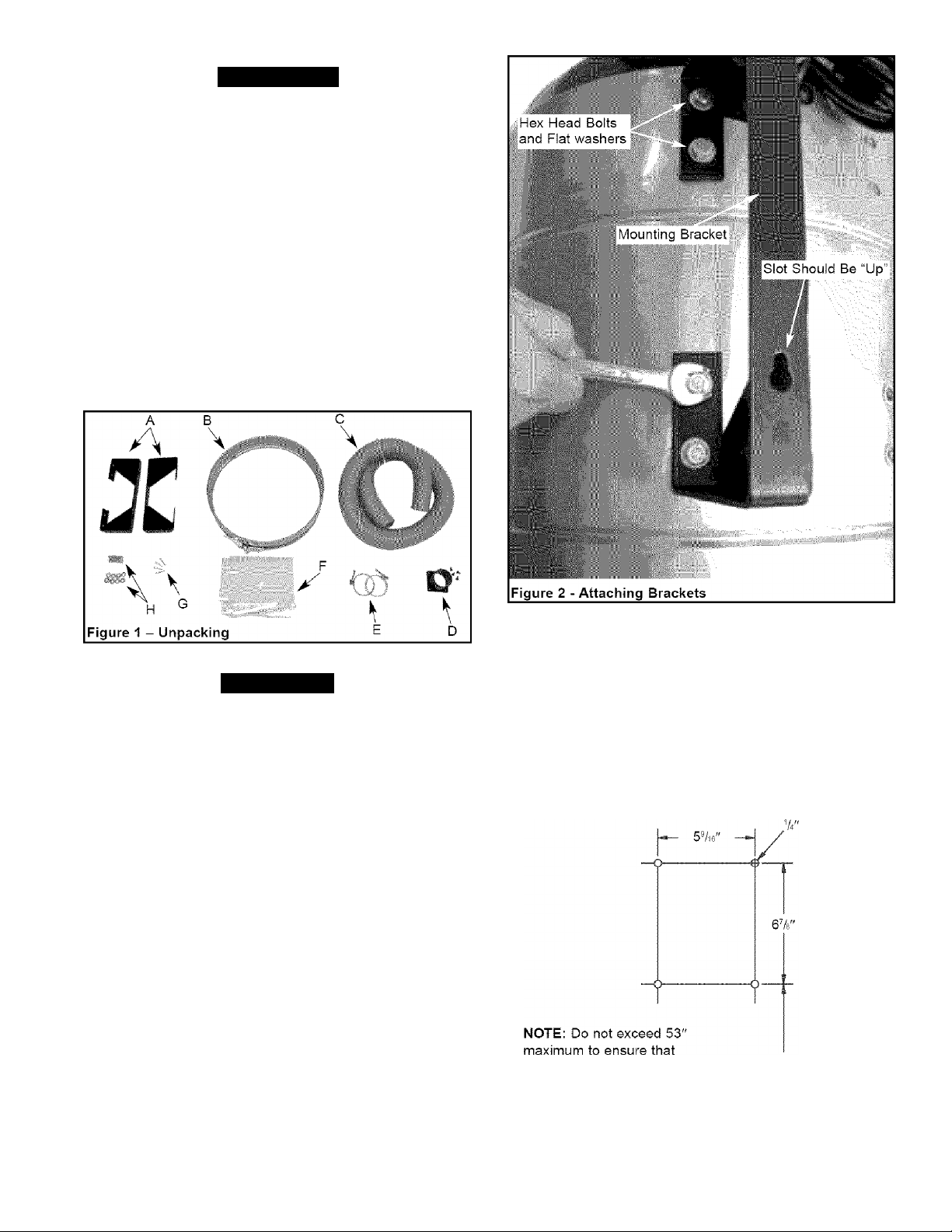

UNPACKING

Check for shipping damage, if damage has occurred, a claim

must be filed with the carrier immediately. Check for complete

ness. Immediately report any missing parts to dealer. Remove

all components of dust collector from shipping carton.

Refer to Figure 1.

The dust collector comes assembled as one unit. Additional

loose parts which need to be fastened to the dust collector

should be located and accounted for before assembly:

A Mounting brackets (2)

B Collar with bag clamp

C Hose

D Inlet and screws (4)

E Hose clamp (2)

F Collector bag (3)

G Mounting screws and anchors (4 each)

H Bolts and washers (8 each)

ASSEMBLY

TOOLS NEEDED

• Vi" Open End Wrench

• Offset or Short Phillips Head Screwdriver

• Portable Drill

• Vt" Drill Bit

• Hammer

NOTE: For masonry walls, use four masonry anchors and

masonry drill bit of proper size for anchors (not supplied).

SELECT SITE FOR DUST COLLECTOR

Site for the dust collector should be located as close to the

woodworking machine(s) as possible. Site should be to the

Left of the machine(s), on the wall.

ATTACH WALL BRACKETS TO DUST COLLECTOR

ASSEMBLY

Refer to Figure 2.

Wall brackets need to be attached to dust collector body. To

attach wall brackets:

• Position wall bracket at set of holes at back of dust

collector body.

• Make sure that the bracket is straight up and down and

that the narrow side of slot is “UP” as shown.

• Secure each wall bracket to dust collector assembly using

four hex head bolts and flat washers.

INSTALL WALL ANCHORS

Refer to Figure 3.

Wall anchors need to be installed at the site selected for the

dust collector. To install wall anchors:

• Mark the location of anchors on the wall according to

Figure 3.

• Drill Va" hole, 1’/4" deep at each of the four marks.

• Hammer anchors into each of four holes so that they are

flush with wall.

• Partially screw in thread-forming screws so that there is

approximately Va" of threads showing.

the collector bag is

supported by the floor

Floor

/77777777777777777"

Figure 3 - Installing Wall Anchors

53" maximum

Page 4

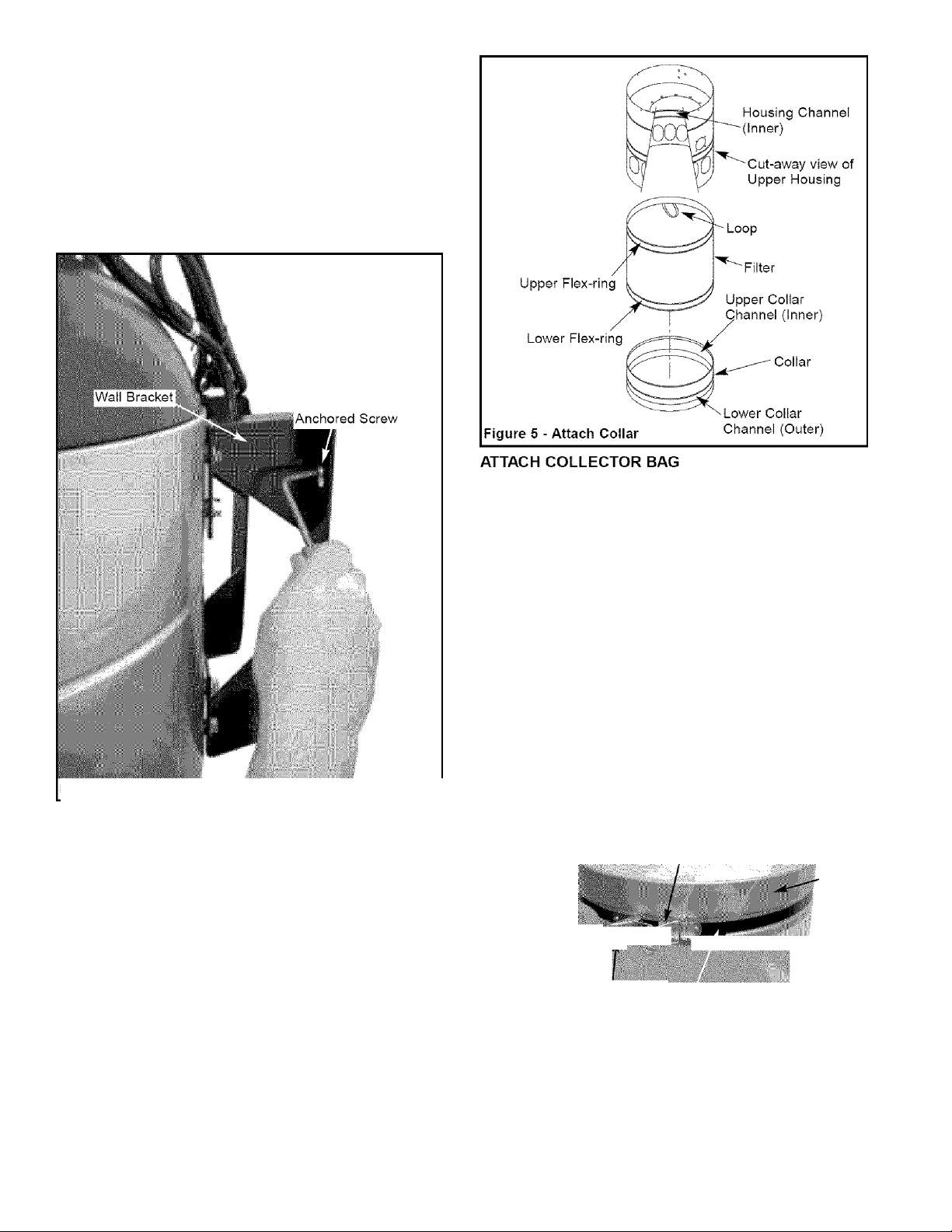

MOUNT DUST COLLECTOR ASSEMBLY TO WALL

Refer to Figure 4,

To mount dust collector assembly:

• Lift dust collector assembly and position slots in wall

brackets over installed anchored screws. Slide dust collec

tor assembly down so that anchored screws rest in narrow

portion of slots.

NOTE: Mounting dust collector will be easier and safer if done

by two people.

• Tighten four screws using offset or short Phillips head

screwdriver.

Refer to Figure 6.

Collector bag needs to be attached to collar using collector

bag clamp. To attach collector bag:

• Remove collector bag clamp from collar.

• Slide collector bag over collar. Position bag approximately

T'h" above lower edge of collar.

NOTE: The bottom of collector bag should rest flat on the

floor, so that the floor supports the weight of wood dust and

chips.

• Position bag clamp in lower channel of collar over bag.

• Position the spring connector into one of the slots on the

latch and lock the clamp handle.

• Make sure collector bag is secure.

NOTE: The top of collector bag should NOT block the filter. If

collector bag does block filter, fold excess bag over bag

clamp.

Figure 4 - Mounting Dust Collector Assembly

ATTACH COLLAR

Refer to Figure 5.

Collar needs to be attached to lower flex-ring of filter. To

attach lower collar:

• Pull filter down from dust collector housing.

• Make sure that filter is straight and there are no folds or

creases.

• Bend and insert lower flex-ring of filter into upper collar

channel.

• Pull down on collar to make sure that flex-ring is entirely in

channel.

Spring Connector

JClamp ,

Collecx Вас

Figure 6 - Attaching Collector Bag

-a"d ■■ -'Otlector Bag Clamp

Filter

Collar

Page 5

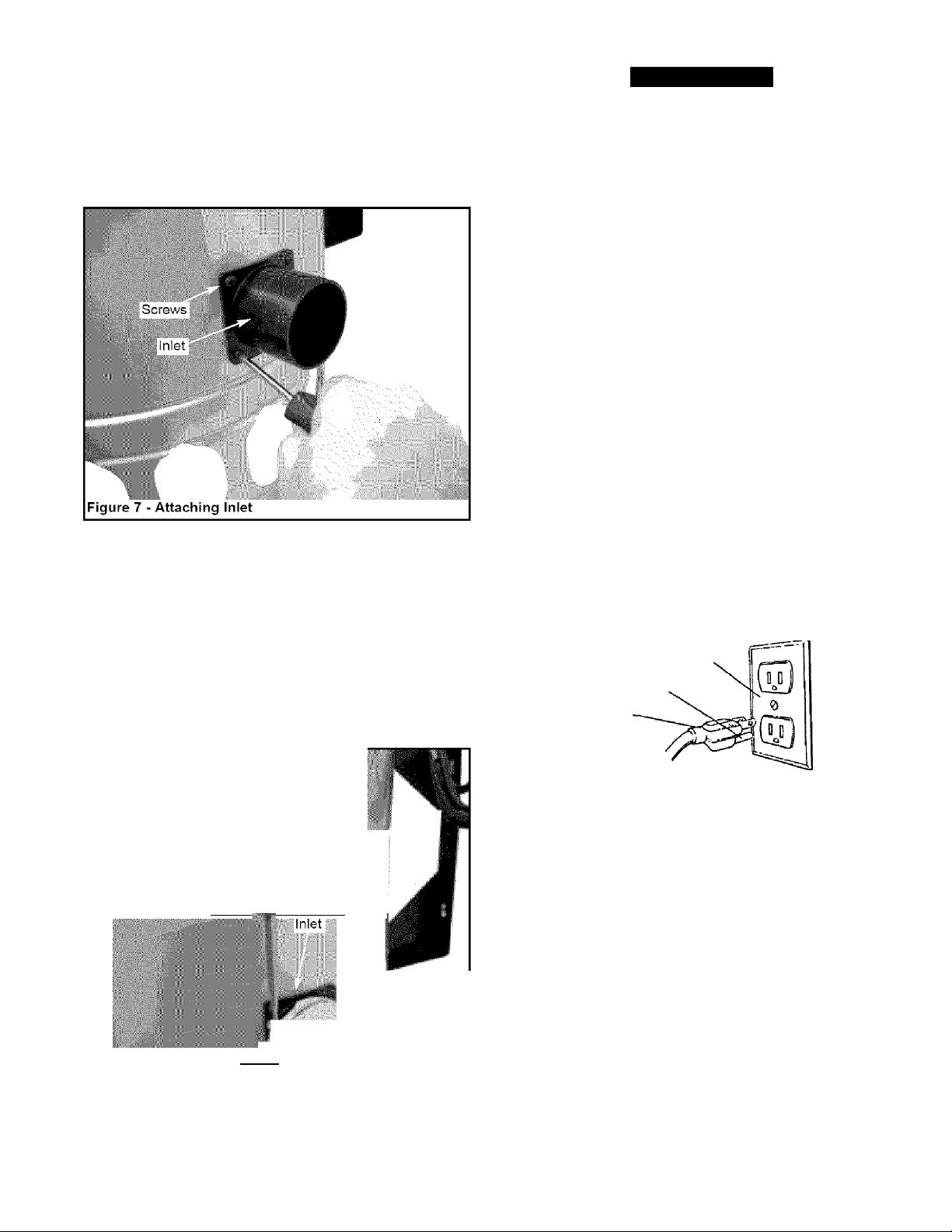

ATTACH INLET

Refer to Figure 7.

Inlet needs to be attached to right side of dust collector

assembly. To attach inlet:

• Position inlet over 2'h" hole on right side of dust collector

assembly.

• Secure inlet using four 4.2-1.4 x 12mm thread-forming

screws.

ATTACH HOSE

Refer to Figure 8.

Hose needs to be attached to the inlet using hose clamp.

To attach hose:

• Slide hose clamp onto one end of hose. Loosen clamp

screw if required to slide hose clamp onto hose.

• Position the hose clamp wires on the hose grooves.

• Slide hose with clamp onto inlet.

• Tighten hose clamp screw to secure hose with inlet.

• Slide other hose clamp onto the opposite hose end. This

end will be connected to the dust producing machine

INSTALLATION

DANGER; Do not permit fingers to touch terminals of plug

when installing or removing the plug to or from the outlet.

WARNING: Do not connect to power source until unit is

completely assembled.

POWER SOURCE

• Motor is designed for operation on the voltage and fre

quency specified on motor nameplate.

• Normal loads will be handled safely on voltages not more

than 10% above or below the specified voltage.

• Running unit on voltages not within range may cause over

heating and motor burnout.

GROUNDING INSTRUCTIONS

Refer to Figure 9.

• This tool is equipped with a 3-conductor cord.

• Do not remove or alter grounding prong in any manner. In

the event of malfunction or breakdown, grounding provides

path of least resistance for electrical current to reduce risk

of electrical shock.

• Plug must be plugged into a matching outlet that is proper

ly installed and grounded in accordance with all local

codes and ordinances.

• The conductor with insulation having an outer surface

which is green is equipment grounding conductor. If repair

or replacement is necessary, make sure equipment

grounding conductor is not connected to line terminal.

• If power cord is worn, cut or damaged in any way, have it

replaced immediately.

Properly Grounded Outlet

Grounding Prong

3-Prong Plug

^^^^^■ClampJ

Hose

■

Figure 8 - Attaching Hose

. Jl,

Ill®

-os:

Figure 9 - 3-Prong Receptacle

CAUTION: Improper connection of the equipment-grounding

conductor can result in a risk of electrical shock.

EXTENSION CORDS

• The use of any extension cord will cause some drop in the

voltage and loss of power.

• Wires of the extension cord must be sufficient in size to

carry the current and maintain adequate voltage.

• Use the table below to determine the minimum wire size

(A.W.G.) extension cord.

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool

plug.

• If extension cord is worn, cut or damaged in any way, have

it replaced immediately.

Extension Cord Length

Wire Size A.W.G.

Up to 50 ft

Note; Using extension cords over 50 ft. long is not

recommended.

........................................................................................

16

Page 6

OPERATION MAINTENANCE

DESCRIPTION

The Craftsman Dust Collector is designed to remove and coilect wood dust and wood chips from woodworking machinery.

Collector bag collects dust and chips, and makes disposal of

dust and chips easy. Collector features 2V2 x 72” intake hose.

SPECIFICATIONS

Motor Horsepower (Max. Developed)............................................

Voltage......................................................................................115 V

Amperes..........................................................................................9.0

Hertz................................................................................................60

Phase........................................................................................Single

RPM............................................................................................ 3450

Certification

Air Flow Rate..........................................................................150 CFM

Air Velocity............................................................................4400 FPM

Maximum Static Pressure

Sound Level

Inlet................................................................................................2'H'

Collector Bag Capacity........................................36 gal. (4.9 cu. ft.)

Collector Bag Rating

Weight......................................................................................

Overall Size

.................................................................................

............................

.............................................................................

....................................................... 1 micron

...

............................................... 17% x 19 x 72"

3.75" of water column

1V2

CSA

76 dB A

55 lbs

WARNING; Turn switch off and remove plug from power

source outlet before maintaining your dust collector.

Refer to Figure 10.

• Clean motor of dust, chips or other particles. If operation is

excessively dusty or dirty, frequent inspection of motor is

required. Vacuum any particles that may have entered the

motor.

• Replace worn, cut or damaged line cord.

• Replace worn or damaged collector hose.

• Replace worn or damaged collector bag.

• Clean or replace filter on a regular basis.

• Frequently check that all nuts, bolts, screws, etc. have not

loosened due to collector vibration.

CLEANING OR REPLACING FILTER

DANGER: Turn switch off and remove plug from power

source outlet before maintaining your dust collector.

Refer to Figure 5, Page 4.

• Remove collector bag.

• Remove collar by pushing flex-ring away from collar.

• Reach into collector housing and pull down on loop at top

of filter.

• Clean inside of filter using vacuum.

• Reinstall filter.

• Reinstall collector bag.

DUST COLLECTOR

DANGER: Do not use this dust collector in a flammable or

explosive atmosphere. Do not use to collect metal shavings or

dust Consult National Fire Protection Association (NFPA)

standards before setting up a dust collection system, espe

cially NFPA 664,

• Connect collector hose to dust producing machine using

hose clamp.

NOTE: For installations with more than one machine, it is rec

ommended that Craftsman 22313 Shop Dust Collection

System be used for best performance.

NOTE: A longer hose may be used (maximum length is 40' of

I'll" diameter hose). A larger diameter hose may be used, but

length will be decreased.

• Turn dust collector on before starting dust producing

machine.

EMPTYING COLLECTOR BAG

Refer to Figure 10.

DANGER:Turn switch off and remove plug from power

source outlet before emptying collector bag.

• Empty collector bag by lifting bag clamp handle and

releasing spring connector from latch. Slide bag away from

collar. Dispose of dust properly.

• Mount collector bag by sliding bag over opening on collar.

Position the spring connector into one of the slots on the

latch and lock the clamp handle. Make sure collector bag

is secure and rests flat on floor, so that floor supports the

weight of wood dust and chips.

Page 7

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor will not run 1. Defective plug, cord, switch or motor 1.Check wiring, replace defective parts

2. Blown fuse or circuit breaker 2. Check fuse or breaker, replace

Excessive dust in air 1. Leaking bag or hose connection 1. Check filter and collector bag connections.

Check collector hose connections

2. Filter or collector bag leaks 2. Dust trapped under bag clamp or collector bag not

sealed on collar

Excessive impeller noise 1. Large debris or piece or wood in I.D0 not vacuum metal materials. Turn

impeller housing collector off and let debris settle in

collector bag.

2. Loose impeller 2. Disconnect collector from power source.

Remove four screws holding motor/fan assembly to

upper blower housing. Carefully lift out motor/fan

assembly and lay on workbench. Hold motor shaft from

turning using vise grips and tighten bolt holding impeller.

Excessive motor noise Defective motor Have motor checked by qualified motor

service technician

Motor fails to develop full I.Low voltage to collector caused by 1. Remove other electric machines or

power or motor stalls circuit overload appliances from circuit

2. Low voltage to collector caused by 2. Increase wire gauge size of extension

undersized extension cords cords or shorten extension cords

3.L0W voltage from power source 3. Request voltage check from power

company

4. Defective motor capacitor 4. Replace motor capacitor

Motor slow to start or fails

to reach full speed

Motor overheats 1. Motor overload 1. Reduce lead by slowing dust production

Tripping circuit breaker or 1. Motor overloaded 1. Reduce load by slowing dust production

fuses

1. Burned or defective motor 1. Check motor, replace if necessary

2. Defective motor capacitor switch 2.Check switch, replace if necessary

2. Improper motor cooling 2. Clean sawdust from motor

2. Improper capacity of circuit breaker 2. Use proper capacity circuit breaker or

or fuses fuse

Page 8

Model 351.223140

Figure 10 - Replacement Parts Illustration for Dust Collector

8

Page 9

REPLACEMENT PARTS LIST FOR DUST COLLECTOR

KEY

NO. PART NO. DESCRIPTION QTY.

1 23937.00 Cover 1

2 08066.00 Switch 1

3 23938.00 Motor Cord 1

4 23939.00 Motor 1

5 STD861313 4.2-1.4 X 12mm Threadforming Screw* 16

6 21166.00 Motor Gasket 1

7 23942.00 Blower Cover 1

8 STD523107 =/i6-18 x%" Hex Head Bolt* 13

9 STD551031 Flat Washer* 12

10 21167.00 Impeller 1

11 05662.00 Tie" Flat Washer (wide)* 1

12 23941.00 '/4-20 X "/4" Socket Pan Head Screw* 4

13 STD551025 '/4" Flat Washer* 4

14 23946.00 Strain Relief 1

15 23947.00 Line Cord 1

16 23948.00 Inlet 1

17 23949.00 Upper Blower Housing 1

18 23950.00 Bracket, LH 1

19 23951.00 Bracket, RH 1

20 23943.00 #8-18 X 1’/4” Threadforming Screw* 4

21 23944.00 '/4 X T/4” Wall Anchor* 4

22 23954.00 Filter 1

23 23955.00 Collar 1

24 23956.00 Collector Bag Clamp 1

25 23957.00 Collector Bag 3

26 23958.00 2Vi X 72" Flexible Hose 1

27 23959.00 Hose Clamp 2

A 24010.00 Screwdriver, L-shape 1

A 23962.00 Operator’s Manual 1

* standard hardware item available locally

A Not Shown

Page 10

COLECTOR DE POLVO

de Montaje en Pared

Modelo No.

351.223140

PRECAUCION: Lea y siga todas las Reglas

de Seguridad e Instrucciones de Operación

antes de utilizar este producto por primera vez.

• Use una cubierta protectora para el cabello, para sujetar el

cabello largo.

• Use zapatos de seguridad con suelas antideslizantes.

• Use gafas de seguridad que cumplan con la norma ANSI Z87.1

de los Estados Unidos. Los anteojos comunes tienen lentes

que sólo son resistentes al impacto. NO son anteojos de

seguridad.

• Use una máscara para la cara o una máscara contra el polvo,

si al utilizar la herramienta se produce mucho polvo.

• Esté alerta y piense claramente. Nunca maneje herramientas

mecánicas cuando esté cansado, intoxicado o bajo la influencia

de medicación que produzca somnolencia.

CONTENIDO

Inglés..............................................................................................2-7

Ilustración y Lista de Partes............................................................8-9

Garantía...........................................................................................10

Reglas de Seguridad

Desempaque...................................................................................11

Montaje.......................................................................................11-13

Instalación..................................................................................13-14

Operación........................................................................................14

Mantenimiento.................................................................................14

Identificación de Problemas

.................................................................

............................................................

10-11

15

GARANTIA

GARANTIA COMPLETA DE UN ANO PARA

HERRAMIENTA CRAFTSMAN

Si esta herramienta Craftsman fallara por causa de defectos en el

material o en la mano de obra en un lapso de un año a partir de la

fecha de compra. LLAME al 1-800-4-MY-HOME® PARA SOLICITAR

LA REPARACION GRATUITA DEL PRODUCTO.

Si esta herramienta se usa para fines comerciales o de alquiler, esta

garantía es válida únicamente por noventa días a partir de la fecha

de compra.

Esta garantía aplica únicamente si la herramienta se encuentra

en los Estados Unidos.

Esta garantía le otorga derechos legales específicos y también

puede usted tener otros derechos que varíen de estado a estado.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, !L 60179

REGLAS DE SEGURIDAD

PELIGRO: No utilice este colector de polvo en un ambiente

inflamable o explosivo. No lo utilice para recolectar polvo o virutas

metálicas. Consulte las normativas de la Asociación Nacional de

Protección contra Incendios (National Pire Protection Assooiation,

NFPA) antes de instalar un sistema de recolección de polvo,

especialmente la NFPA 664.

ADVERTENCIA: Por su propia segundad, lea todas las

instrucciones y precauciones antes de manejar la herramienta.

PRECAUCION: Siempre siga los procedimientos de operación

correctos, tal como se definen en este manual, aun cuando esté

familiarizado con el uso de ésta o de otras herramientas similares.

Recuerde que descuidarse aunque sólo sea por una fracción de

segundo puede ocasionarle graves lesiones.

EL OPERADOR DEBE ESTAR PREPARADO PARA

ELTRABAJO

• Use ropa apropiada. No use ropa holgada, guantes, corbatas,

anillos, pulseras ni otras joyas que puedan atascarse en las

piezas móviles de la máquina.

PREPARE EL AREA DE TRABAJO PARA LA TAREA

A REALIZAR

• Mantenga el área de trabajo limpia. Las áreas de trabajo

desordenadas atraen accidentes.

• No use herramientas mecánicas en ambientes peligrosos. No

use herramientas mecánicas en lugares húmedos o mojados.

No exponga las herramientas mecánicas a la lluvia.

• El área de trabajo debe estar iluminada adecuadamente.

• Debe haber disponible una toma de corriente adecuada para

la herramienta. El enchufe de tres puntas debe enchufarse

directamente a un receptáculo para tres puntas puesto a

tierra correctamente.

• Los cordones de extensión deben tener una punta de conexión

a tierra y los tres conductores del cordón de extensión deben

ser del calibre correcto.

• Mantenga a los visitantes a una distancia prudente del área

de trabajo.

• Mantenga a los niños fuera del lugar de trabajo. Haga que

su taller sea a prueba de niños. Use candados, interruptores

maestros y extraiga las llaves del arrancador para impedir

cualquier uso involuntario de las herramientas mecánicas.

SE DEBE DAR MANTENIMIENTO A LA HERRAMIENTA

• Desenchufe siempre la herramienta antes de inspeccionarla.

• Consulte el manual para informarse sobre los procedimientos

de mantenimiento y ajuste específicos.

• Mantenga la herramienta lubricada y limpia de modo que

funcione de la manera más segura.

• Retire las herramientas de ajuste. Desarrolle el hábito de verificar

que hayan sido retiradas las herramientas de ajuste antes de

encender la máquina.

• Mantenga todas las partes listas para funcionar. Revise el protector

u otras piezas para determinar si funcionan correctamente y

hacen el trabajo que deben hacer.

• Revise que no haya partes dañadas. Verifique el alineamiento

de las partes móviles, si hay atascamiento, roturas y montaje o

cualquier otra condición que pudiera afectar el funcionamiento

de la herramienta.

• Si hay una protección o cualquier otra parte dañada, éstas

deberán repararse correctamente o ser reemplazadas. No

haga reparaciones provisionales. (Válgase de la lista de piezas

incluida para solicitar piezas de reemplazo.)

EL OPERADOR DEBE SABER COMO USAR

LA HERRAMIENTA

• Use la herramienta correcta para cada trabajo. No fuerce la

herramienta o el accesorio ni los use para una tarea para la

que no fueron diseñados.

• Desconecte la herramienta cuando le dé servicio o mantenimiento

a la misma.

• Evite que la herramienta se encienda accidentalmente. Asegúrese

que el interruptor esté en la posición OFF (apagado) antes de

enchufar la herramienta.

10

Page 11

• No fuerce la herramienta. Funcionará en la forma más eficiente

a la velocidad para la cuál se diseñó.

• Mantenga las manos libres para poder operar la máquina.

Protéjase las manos de posibles lesiones.

• Nunca deje desatendida una herramienta en funcionamiento.

Desconéctela y no la abandone hasta que se haya detenido

por completo.

• No trate de alcanzar demasiado lejos. Manténgase firme y

equilibrado.

• Nunca se coloque de pie sobre la herramienta. Se pueden

producir lesiones graves si la herramienta se vuelca o se hace

contacto con la hoja sin intención.

• Mantenga las manos alejadas de las partes móviles.

• Conozca su herramienta. Aprenda a manejar la herramienta,

su aplicación y limitaciones específicas.

PELIGRO: La operación de toda herramienta mecánica puede hacer

que salgan arrojados objetos extraños hacia los ojos y les causen

graves heridas. Antes de comenzar a utilizar la herramienta mecánica,

póngase siempre gafas de seguridad {mostradas en el empaque)

que cumplan con la norma ANSI Z87.1 de los Estados Unidos.

DESEMPAQUE

NOTA: Para las paredes de mampostería, utilice cuatro anclas para

mampostería y una broca para mampostería del tamaño adecuado

para las brocas (no suministradas).

SELECCIONE UN LUGAR PARA INSTALAR

EL COLECTOR DE POLVO

El colector de polvo debe situarse lo más cerca posible a la(s)

máquina(s) de carpintería. Se debe seleccionar un lugar en la

pared que esté a la Izquierda de la(s) máquina(s).

INSTALE LOS SOPORTES PARA LA PARED EN

EL CONJUNTO DEL COLECTOR DE POLVO

Consulte la Figura 2.

Los soportes para la pared deben instalarse en el cuerpo del colector

de polvo. Para instalar los soportes para la pared:

• Sitúe el soporte para la pared en la serie de agujeros que están

en la parte posterior del cuerpo del colector de polvo.

• Asegúrese que la pieza de soporte esté en posición vertical

(de arriba hacia abajo) y que el lado angosto de la ranura esté

“ARRIBA”, como se muestra.

• Fije cada soporte para la pared en el conjunto del colector de polvo

usando cuatro pernos de cabeza hexagonal y arandelas planas.

Verifique que no hayan ocurrido daños durante el envío. De ser

así, deberá enviarse de inmediato una reclamación a la compañía

transportista. Verifique que esté completa. Avísele inmediatamente

al distribuidor si faltan partes. Retire de la caja de envío todos los

componentes del colector de polvo.

Consulte la Figura 1.

El colector de polvo viene armado como una unidad. Será necesario

localizar y ver que no falten las partes adicionales que deben

montarse en el colector de polvo, antes de instalarlas:

A Soportes de montaje (2)

B Collar con abrazadera de bolsa

C Manguera

D Entrada y tornilios (4)

E Abrazadera de ¡a manguera (2)

F Bolsa del colector (3)

G Anclas y tornillos de montaje (4 de cada uno)

H Pernos y arandelas (8 de cada uno)

Pernos de

cabeza hexagonal

y ararde as planas

Soporte ae montaje

* •

La ranura debe estar “Arriba”

MONTAJE

HERRAMIENTAS NECESARIAS

Llave de extremo abierto de 'h"

Destornillador con cabeza acodada o Phillips corto

Taladro portátil

Broca de Vn"

Martillo

Figura 2 - Instalación de los Soportes

INSTALE ANCLAS PARA PARED

Consulte la Figura 3. página 12.

Las anclas para pared deben instalarse en el lugar seleccionado para

el colector de polvo. Para instalar las anclas para pared en la pared:

• Marque la posición de las anclas en la pared de acuerdo con la

Figura 3.

• Taladre un agujero de 'U" de diámetro y 1W de profundidad en

cada una de las cuatro posiciones marcadas.

• Con un martillo, clave las anclas en cada uno de los cuatro

agujeros hasta que estén al ras con la pared.

• Atornille parcialmente tornillos autorroscantes hasta que haya

aproximadamente 'W de las roscas visibles.

11

Page 12

MONTE EL CONJUNTO DEL COLECTOR DE POLVO

EN LA PARED

Consulte la Figura 4.

Para montar el conjunto del colector de polvo:

• Levante el conjunto del colector de polvo y coloque las ranuras en

los soportes para la pared sobre los tornillos anclados instalados.

Deslice el conjunto del colector de polvo hacia abajo de manera

que los tornillos anclados descansen en las porciones angostas

de las ranuras.

NOTA: La operación de montaje del colector de polvo será más fácil

y más segura si es realizada por dos personas.

• Apriete los cuatro tornillos usando el destornillador de cabeza

acodada o Phillips.

■

ara a pa^ed ■

Tornillo anclado

INSTALE EL COLLAR

Consulte la Figura 5.

El collar debe instalarse en el aro flexible inferior del filtro. Para

instalar el collar Inferior:

• Tire del filtro hacia abajo para sacarlo de la caja del colector.

• Cerciórese de que el filtro esté recto y no esté doblado ni plegado.

• Doble e inserte el aro flexible inferior del filtro en el canal del

collar superior.

• Tire del collar hacia abajo para asegurarse que el aro flexible

esté totalmente dentro del canal.

INSTALE LA BOLSA DEL COLECTOR

Consulte la Figura 6.

La bolsa del colector debe instalarse en el collar usando la abraza

dera para la bolsa del colector. Para instalar la bolsa del colector:

• Retire del collar la abrazadera de la bolsa del colector.

• Deslice la bolsa del colector sobre el collar. Coloque la bolsa a

aproximadamente 2V2" por encima del borde inferior del collar.

NOTA: La parte inferior de la bolsa del colector deberá descansar

plana sobre el piso, para que el piso soporte el peso del polvo y de

las virutas de madera.

• Coloque la abrazadera de la bolsa en el canal inferior del collar

sobre la bolsa.

Figura 4 - Montaje del Conjunto del Colector de Polvo

12

Page 13

• Coloque el conectar rápido en una de las ranuras del pestillo y

fije la manija de la abrazadera.

• Asegúrese que la bolsa del colector esté fija.

NOTA; La parte superior de la bolsa del colector NO deberá bloquear

el filtro. Si la bolsa del colector bloquea el filtro, doble el exceso de la

bolsa sobre la abrazadera de la bolsa.

INSTALE LA ENTRADA

Consulte la Figura 7.

La entrada debe instalarse en el lado derecho del conjunto del

colector de polvo. Para instalar la entrada:

• Coloque la entrada sobre el agujero de 2V2" que está en

el lado derecho del conjunto del colector de polvo.

• Fije la entrada usando cuatro tornillos autorroscantes de

4.2-1.4 X 12 mm

Figura 7 - Instalación de la Entrada

INSTALE LA MANGUERA

Consulte la Figura 8.

La manguera debe conectarse en la entrada usando la abrazadera

para la manguera.

Para conectar la manguera:

• Deslice la abrazadera de la manguera por un extremo de la

manguera. Afloje el tornillo de la abrazadera si es necesario

para deslizar la abrazadera de la manguera sobre la manguera.

Coloque los cables de la abrazadera de la manguera en las

ranuras de la manguera.

Deslice y monte la manguera con la abrazadera en la entrada.

Apriete el tornillo de la abrazadera de la manguera para fijar la

manguera en la entrada.

Deslice la otra abrazadera de la manguera por el extremo opuesto

de la manguera. Este extremo se conectará a la máquina

productora de polvo.

INSTALACION

PELIGRO: Al conectar o desconectar el enchufe del zócalo, no

permita por ningún motivo que sus dedos toquen las clavijas.

ADVERTENCIA: No conecte la fuente de alimentación hasta que

la unidad esté totalmente armada.

FUENTE DE ALIMENTACION

• El motor ha sido diseñado para funcionar al voltaje y frecuencia

especificados en la placa del fabricante.

• Las cargas normales se pueden manejar con seguridad con

voltajes no mayores de un 10% por encima o por debajo del

voltaje especificado.

• Si se hace funcionar la unidad a un voltaje fuera de este intervalo,

se puede recalentar y quemar el motor.

INSTRUCCIONES PARA LA CONEXION A TIERRA

Consulte la Figura 9.

• La herramienta está equipada con un cable de 3 conductores.

• No retire ni modifique en forma alguna la punta de conexión a

tierra. En caso de un mal funcionamiento o una descompostura, la

conexión a tierra proporciona una ruta de menor resistencia para la

corriente eléctrica a fin de reducir el riesgo de descarga eléctrica.

• El enchufe debe conectarse en el tomacorriente correspondiente

que haya sido instalado y conectado a tierra debidamente, de

acuerdo con todos los códigos y regulaciones locales.

• El conductor con aislamiento cuya superficie exterior es verde es

el conductor a tierra del equipo. Si es necesario llevar a cabo una

reparación o un reemplazo, asegúrese que el conductor a tierra

del equipo no se encuentre conectado al terminal de línea.

• Si el cordón de corriente eléctrica está desgastado, cortado

o dañado en cualquier manera, cámbielo inmediatamente.

Tomacorriente puesto

a tierra adecuadamente

Punta de conexión a tierra

Acrazade^a de : rré';

■'la mangje''a

Figura 8 - Instalación de la Manguera

Entrada

Manquera

Enchufe de 3 puntas

Figura 9 - Receptáculo para 3 Puntas

PRECAUCION: Si no se conecta correctamente el conductor a

tierra del equipo, se corre el riesgo de un electroohoque.

CORDONES DE EXTENSION

• El uso de cualquier tipo de cordón de extensión ocasionará una

caída en el voltaje y una pérdida de potencia.

• Los alambres del cordón de extensión deben tener el tamaño

suficiente para transportar la corriente adecuada y mantener el

voltaje correcto.

• Utilice la tabla que se da abajo para determinar el tamaño mínimo

del alambre (según la norma AWG) del cordón de extensión.

• Utilice únicamente cordones de extensión irifilares que tengan

enchufes tipo conexión a tierra de tres puntas y receptáculos

tripolares que acepten el enchufe de la herramienta.

• Si el cordón de extensión está desgastado, cortado o dañado

en cualquier manera, cámbielo inmediatamente.

13

Page 14

Longitud del cordón de extensión

Tamaño del alambre Norma AWG

Hasta 50 pies....................................................................................16

NOTA: No se recomienda utilizar cordones de extensión de más de

50 pies.

OPERACION

DESCRIPCION

El Colector de Polvo Craftsman ha sido diseñado para extraer y

recolectar las astillas de madera de las máquinas utilizadas para

trabajar maderas. La bolsa del colector recolecta las astillas de

madera y el polvo de la madera y facilita el desecho de los mismos.

El colector tiene una manguera de entrada de 2'h" x 72”.

ESPECIFICACIONES

Caballaje del motor (máximo desarrollado)...................................1V2

Voltaje...........................................................................................115V

Amperaje..........................................................................................9.0

Hertzios.............................................................................................60

Fase

...................................................................................

RPM............................................................................................. 3450

Certificación...................................................................................CSA

Velocidad de flujo de aire.......................................................150 PGM

Velocidad del aire.................................................................4400 PPM

Presión estática máxima

Nivel de sonido.........................................................................76 dB A

Entrada..........................................................................................2V2"

Capacidad de la bolsa del colector.... 36 galones (4.9 pies cúbicos)

Capacidad de la bolsa del colector

Peso.............................................................................................55 Ibs

Tamaño total.................................................................17^4 x 19 x 72”

COLECTOR DE POLVO

PELIGRO: No utilice este colector de polvo en un ambiente

inflamable o explosivo. No lo utilice para recolectar polvo o virutas

metálicas. Consulte las normativas de la Asociación Nacional de

Protección contra Incendios (National Fire Protection Association,

NFPA) antes de instalar un sistema de recolección de polvo,

especialmente la NFPA 664.

• Conecte la manguera del colector a la máquina productora de

polvo usando la abrazadera de la manguera.

NOTA: En las instalaciones donde hay más de una máquina, se

recomienda utilizar el Sistema de Recolección de Polvo para

Talleres 22313 Craftsman para obtener los mejores resultados.

NOTA: Si lo desea, puede utilizar una manguera más larga (la

máxima longitud es 40 pies para una manguera de 2V2" de diámetro).

Se puede utilizar una manguera de mayor diámetro, pero la longitud

será menor.

............................

...........................................

3.75" de columna de agua

Monofásico

1 miera

• Encienda el colector de polvo antes de arrancar la máquina

que produce polvo.

COMO VACIAR LA BOLSA DEL COLECTOR

Consulte la Figura 10, página 8.

PELIGRO: Apague el interruptor y retire el enchufe del tomacorriente de la fuente de alimentación antes de vaciar la bolsa

del colector.

• Vacie la bolsa del colector levantando la manija de la abrazadera

de la bolsa y soltando el conector rápido del pestillo. Deslice la

bolsa y sepárela del collar. Deseche adecuadamente el polvo.

• Monte la bolsa del colector. Para hacer esto, deslice la bolsa

sobre la abertura en el collar. Coloque el conector rápido en

una de las ranuras del pestillo y fije la manija de la abrazadera.

Asegúrese que la bolsa del colector esté bien sujetada y

descanse plana sobre el piso, a fin de que el piso soporte

el peso del polvo y de las astillas de madera.

MANTENIMIENTO

ADVERTENCIA: Apague el Interruptor y retire el enchufe del

tomacorriente de la fuente de alimentación antes de realizar el

mantenimiento del colector.

Consulte la Figura 10, página 8.

• Limpie del motor iodo polvo, astillas u otras partículas. Si

la operación levanta mucho polvo o suciedad, deberá inspec

cionarse el motor con frecuencia. Aspire las partículas que

puedan haber ingresado en el motor.

• Reemplace los cables desgastados, cortados y dañados.

• Reemplace las mangueras del colector desgastadas o dañadas.

• Reemplace las bolsas del colector desgastadas o dañadas.

• Limpie o reemplace el filtro en forma regular.

• Verifique con frecuencia todas las tuercas, pernos, tornillos, etc.

para asegurarse que no se hayan aflojado debido a la vibración

del colector.

LIMPIEZA O REEMPLAZO DEL FILTRO

PELIGRO: Apague el interruptor y retire el enchufe del toma-

corriente de la fuente de alimentación antes de realizar el

mantenimiento del colector.

Consulte la Figura 5, página 12.

• Retire la bolsa del colector.

• Empuje y saque el aro flexible del collar, luego retire el collar.

• Inserte la mano en la caja del colector y tire del bucle, en la

parte superior del filtro, hacia abajo.

• Limpie el interior del filtro con una aspiradora.

• Vuelva a instalar el filtro.

• Vuelva a instalar la bolsa del colector.

14

Page 15

IDENTIFICACION DE PROBLEMAS

SINTOMA CAUSAS{S) POSIBLE(S) MEDIDA CORRECTIVA

El motor no funciona 1. Enchufe, cable, interruptor o motor defectu

oso

2. Fusible 0 interruptor de circuito quemado

1. Revise el cableado, reemplace las partes defectuosas

2. Revise el fusible o el interruptor, reemplácelos

Demasiado polvo

en el aire

El impulsor hace

demasiado ruido

El motor hace

demasiado ruido

El motor no desarrolla

su máxima potencia o

el motor se detiene

El motor arranca

lentamente o no alcanza

su máxima potencia

1. Fuga en la bolsa o conexión de la manguera

2. La bolsa del colector o del filtro tiene

una fuga

1. Restos grandes de material o pedazo

de madera en el alojamiento del impulsor

2. Rueda móvil suelta

Motor defectuoso Haga que un técnico calificado de mantenimiento

1. Bajo voltaje en el colector debido a una

sobrecarga en el circuito

2. Bajo voltaje en el colector debido a

cordones de extensión demasiado cortos

3. Bajo voltaje proveniente de la fuente

de alimentación

4. Capacitor del motor defectuoso

1. Motor quemado o defectuoso

2. Interruptor del capacitor del motor

defectuoso

1. Revise las conexiones de la bolsa del colector y del filtro.

Verifique las conexiones de la manguera del colector

2. Hay polvo atrapado debajo de la abrazadera de la bolsa o

la bolsa del colector no está sellada en el collar

1. No aspire materiales metálicos. Apague el colector y deje

que los residuos se asienten en la bolsa del colector

2. Desconecte el colector de la fuente de alimentación.

Extraiga los cuatro tornillos que sujetan el conjunto del

motor y ventilador en el alojamiento del soplador superior.

Levante cuidadosamente el conjunto del motor y ventilador y

tiéndalo en la mesa de trabajo. Sujete el eje del motor con

una prensa para inmovilizarlo, y apriete el perno que

sujeta el impulsor

de motores revise el motor

1. Desconecte del circuito toda máquina eléctrica

0 electrodoméstico

2. Aumente el calibre del alambre de los cordones

de extensión o acorte los cordones de extensión

3. Solicítele a la compañía de energía eléctrica

que revise el voltaje

4. Reemplace el capacitor del motor

1. Revise el motor, reemplácelo de ser necesario

2. Revise el interruptor, reemplácelo de ser necesario

El motor se recalienta 1. Sobrecarga del motor

2. Enfriamiento inadecuado del motor

Se dispara el

cortocircuito

0 los fusibles

1. Motor sobrecargado

2. Capacidad inadecuada del cortacircuito

0 los fusibles

1. Disminuya la producción de polvo, para reducir

la carga

2. Elimine el aserrín acumulado en el motor

1. Reduzca la carga disminuyendo la producción

de polvo

2. Use cortacircuito o fusibles de la capacidad

adecuada

15

Page 16

Get it fixed, at your home or ours!

Your Home

For repair-in your home-of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made It, no matter who sold It!

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME® (1-800-469-4663)

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call or go on-line for the location of your nearest

Sears Parts & Repair Center.

1-800-488-1222

Call anytime, day or night (U.S.A. only)

www.sears.com

To purchase a protection agreement (U.S.A.)

or maintenance agreement (Canada) on a product serviced by Sears:

1-800-827-6655 (U S A ) 1-800-361-6665 (Canada)

Para pedir servicio de reparación

a domicilio, y para ordenar piezas:

1-888-SU-HOGAR®“

(1-888-784-6427)

Au Canada pour service en français:

1-800-LE-FOYER“^

(1-800-533-6937)

www.sears.ca

® Registered Trademark / ™ Trademark / ®’''’ Service Mark of Sears, Roebuck and Co.

® Marca Registrada / ™ Marca de Fábrica / Marca de Servicio de Sears, Roebuck and Co.

Marque de commerce / Marque déposée de Sears. Roebuck and Co.

©Sears, Roebuck and Co.

Loading...

Loading...