Craftsman 351218330 Owner’s Manual

Operator's Manual

CRAFTSMAN

10"

CONTRACTOR TABLE SAW

Model No.

351.218330

CAUTION:

Read and follow all Safety

Rules and Operating

Instructions before First

Use of this Product. Keep

this Manual with Tool.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www, sears.com/craftsman

31105,00 Draft (07/01/09)

Warranty ......................................... 2

Safety Rules .................................... 2-5

Unpacking ....................................... 5

Assembly ...................................... 6-8

Installation ...................................... 8-9

Operation ..................................... 9-13

Maintenance .................................... 13

Repair Protection Agreement ....................... 14

Troubleshooting ............................... 16-17

Parts Illustration and List ........................ 18-29

Espafiol ...................................... 30-47

ONE-YEAR FULL WARRANTY ON CRAFTSMAN

TOOL

if this Craftsman toolfails due to adefect inmaterial or

workmanshipwithinoneyear from thedate ofpumhase,call

1-800-4-MY-HOME®TO ARRANGE FOR FREE REPAIR(or

replacementif repairprovesimpossible).

Thiswarrantydoes notcoverthe blade, whichisan

expendable part.

(fthistooliseverusedfor commercialorrentalpurposes,this

warrantywillapplyfor only90 daysfrom the dateofpurchase.

Thiswarrantygivesyou specific legalrightsandyoumay also

have other rightswhichvaryfrom state to state.

Sears, Roebuck and Co., Hoffman Estates,IL 60179

WARNING: For your own safety, read allof the instructions

and precautions before operating tool.

PROPOSITION 65 WARNING: Some dust created by

power sanding, sawing, grinding, drilling and other construc-

tion activities contains chemicals known to the state of

California to cause cancer, birth defects or other reproductive

harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other

masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures vary, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area and work with

approved safety equipment. Always wear OSHNNIOSH

approved, properly fitting face mask or respirator when using

such tools.

CAUTION: Always follow proper operating procedures as

defined in this manual -- even if you are familiar with use of

this or similar tools. Remember that being careless for even a

fraction of a second can result in severe personal injury'.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing, gloves,

neckties,rings, braceletsor otherjewelrywhichmay get

caughtinmovingpartsof machine.

© Sears, Roebuck and Co.

• Wear protective hair covering to contain long hair.

° Wear safety shoes with non-slip soles.

° Wear safety glasses complying with United States ANSI

Z87.1. Everyday glasses have only impact resistant lens-

es. They are NOT safety glasses.

° Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools when

tired, intoxicated or when taking medications that cause

drowsiness.

PREPARE WORK AREA FOR JOB

• Keep work area clean. Cluttered work areas invite acci-

dents.

• Do not use power toolsindangerous environments. Do not

use powertoolsindamp or wet locations.Do not expose

power toolsto rain.

• Work area should beproperlylighted.

° Keepvisitorsat a safedistancefrom workarea.

• Keep childrenoutof workplace.Make workshopchildproof.

Use padlocks,master switchesor removeswitchkeysto

prevent anyunintentionaluseof powertools.

• Keep power cordsfromcomingin contactwithsharp

objects,oil,greaseandhot surfaces.

TOOL SHOULD BE MAINTAINED

• Always unplugtoolpriorto inspection.

• Consult manual for specificmaintainingand adjusting pro-

cedures.

• Keep tool lubricated and clean for safest operation.

° Remove adjusting tools. Form habit of checking to see that

adjusting tools are removed before switching machine on.

• Keep all parts in working order. Check to determine that

the guard or other parts will operate properly and perform

their intended function.

° Check for damaged parts. Check for alignment of moving

parts, binding, breakage, mounting and any other condi-

tion that may affect a tool's operation.

• A guard or other part that is damaged should be properly

repaired or replaced. Do not perform makeshift repairs.

(Use parts list provided to order replacement parts.)

• Maintain proper adjustment of rip fence and blade guard.

• Never adjust saw while running. Disconnect power to avoid

accidental start-up.

° Have damaged or worn power cords replaced immediately.

° Keep blade sharp for efficient and safest operation.

KNOW HOW TO USE TOOL

• Use right tool for job. Do not force tool or attachment to do

a job for which it was not designed.

• Disconnect tool when changing blade.

• Avoid accidental start-up. Make sure that the tool is in the

"off" position before plugging in, turning on safety discon-

nect or activating breakers.

° Do not force tool. It will work most efficiently at the rate for

which it was designed.

• Keep hands away from blade and moving parts and cutting

surfaces.

° Never leave tool running unattended. Turn the power off

and do not leave tool until it comes to a complete stop.

• Do not overreach. Keep proper footing and balance.

° Never stand on tool. Serious injury could occur if tool is

tipped or if blade is unintentionally contacted.

2

• Know your tool. Learn the tool's operation, application and

specific limitations.

° Handle workpiece correctly. Press firmly against table.

Protect hands from possible injury.

• Turn machine off if it jams. Blade jams when it digs too

deeply into workpiece. (Motor force keeps it stuck in the

work.)

• Feed work into the blade only as recommended in

"Operation"

WARNING: For your own safety, do not operate your saw until it

is completely assembled and installed according to instructions.

STABILITY OF SAW

Ifthere is anytendencyfor the saw to tip overor moveduring

certaincuttingoperations,such as cuttingextremelyheavy

panels or long heavy boards,the saw shouldbe bolteddown.

Ifyouattach anykind ofextensionsover24" wide toeither

end ofthe saw, make sure you either boltthe saw to thefloor,

as appropriate, orsupport theouterend ofthe extension from

the benchor floor, as appropriate.

LOCATION

The saw should be positioned so neither the operator nor a

casual observer is forced to stand in line with the saw blade.

KICKBACKS

A kickback occurs during a rip-type operation when a part or

all of workpiece is thrown back violently toward operator.

Keep your face and body to one side of the saw blade, out of

line with a possible kickback.

Kickbacks and possible injury from them can usually be avoid-

ed by:

• Maintaining rip fence parallel to saw blade.

• Keeping saw blade sharp. Replace or sharpen anti-kick-

back pawls when points become dull.

• Keeping saw blade guard, spreader, and anti-kickback

pawls in place and operating properly. The spreader must

be in alignment with the saw blade and the pawls must

stop a kickback once it has started. Check their action

before ripping.

° Not ripping work that is twisted or warped or does not

have a straight edge to guide along the rip fence.

• Not releasing work until you have pushed it all the way

past the saw blade.

• Using a push stick for ripping widths less than 6 inches.

° Not confining the cutoff piece when ripping or crosscutting.

PROTECTION: EYES, HANDS, FACE, BODY, EARS

• If any part of your saw is missing, malfunctioning, or has

been damaged or broken (such as the motor switch, elec-

tronic controls, other operating control, a safety device or

power cord), cease operating immediately until the partic-

ular part is properly repaired or replaced.

• Wear safety goggles that comply with United States ANSI

Z87.1 and a face shield or dust mask if operation is dusty.

Wear ear plugs or muffs during extended periods of oper-

ation.

Small loose pieces of wood or other objects that contact

the rear of the revolving blade can be thrown back at the

operator at excessive speed. This can usually be avoided

by keeping the guard and spreader in place for all thru-

sawing operations (sawing entirely thru work) and by

removing all loose pieces from the table with a long stick

of wood immediately after they are cut off.

• Use extra caution when the guard assembly is removed for

resawing, dadoing, or rabbeting--replace guard as soon

as that operation is completed.

• Never turn the saw ON before clearing the table of all

tools, wood scraps, etc., except the workpiece and related

feed or support devices for the operation planned.

• Never place your face or body in line with the cutting tool.

• Never place your fingers or hands in path of saw blade or

other cutting tool.

• For rip or rip-type cuts, the following end of a workpiece to

which a push stick or push board is applied must be

square (perpendicular to the fence) in order that feed

pressure applied to the workpiece by the push stick or

block does not cause the workpiece to come away from

the fence, and possibly cause a kickback.

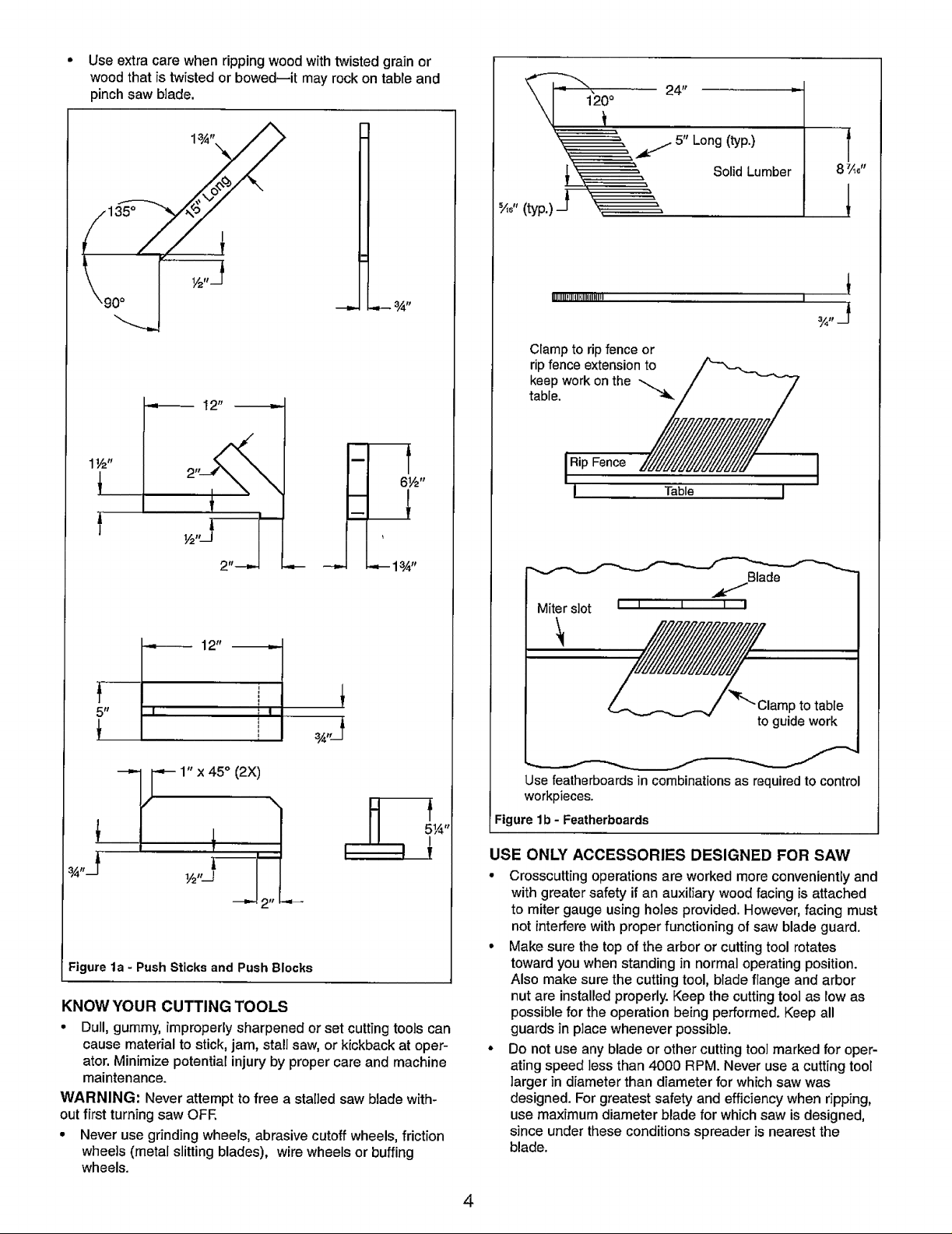

• During rip and rip-type cuts, workpiece must be herd down

on table and against fence with a push stick, push block,

or featherboards, as applicable (see Figures l a and lb,

page 4).

The push stick and push block examples shown below are use-

ful for keeping hands and fingers away from saw blade during

ripping, rabbeting and dadoing. Apply downward pressure and

push workpiece through the cut and past the blades. Several

other configurations may be suitable for safe operation.

Featherboards are used to keep the work in contact with the rip

fence or table during the cutting operation. Use of featherboards

can help to prevent kickbacks and binding. Featherboards

should be used for all "non thru-sawing" operations.

• Never reach in back of the cutting tool with either hand to

hold down or support the workpiece, remove wood scraps,

or for any other reason. Avoid awkward operations and

hand positions where a sudden slip could cause fingers or

hand to move into a saw blade or other cutting tool.

• Do not perform layout, assembly, or setup work on the

table while the cutting tool is rotating.

• Do not perform any operation freehand--always use either

rip fence or miter gauge to position and guide the work.

• Never use the rip fence when cross-cutting or the miter gauge

when ripping. Do not use rip fence as a length stop. Never

hold onto ortouch free-end of workpiece or a free-piece that

is cut off, while power is ON and/or saw blade is rotating.

• Shut the saw OFF and disconnect power source when

removing the table insert, changing the cutting too],

removing or replacing the blade guard, or making adjust-

ments.

Provide adequate support to the rear and sides of the saw

table for wide or long workpieces.

ib

Plastic and composition materials (like hardboard) may be

cut on your saw. However, since these are usually quite

hard and slippery, the anti-kickback pawls may not stop a

kickback. Therefore, be especially attentive to following

proper setup and cutting procedures for ripping. Do not

stand, or permit anyone else to stand, in line with a poten-

tial kickback.

• If you stall or jam the saw blade in the workpiece, turn saw

OFF and remove the workpiece from the saw blade.

Check to see if the saw blade is parallel to the miter

gauge grooves and if the spreader is in proper alignment

with the saw blade. If ripping at the time, check to see if

the rip fence is parallel with the saw blade. Readjust as

required.

• Do not remove small pieces of cutoff material that may

become trapped inside the blade guard while the saw is

running. This could endanger your hands or cause kick-

back. Turn saw OFF and wait until blade stops.

3

Use extra care when ripping wood with twisted grain or

wood that is twisted or bowed--it may rock on table and

pinch saw blade.

4 It

5" Long (typ.)

Solid Lumber

1½"

+

12"

- t

6½"

,-- 13A,,

%+"(typ.) J "_

IIIIIll}[IlUHIIilIlUlI" I

Clamp to rip fence or

rip fence extension to

keep work on the

table.

I Rip Fence

I Table

Miter slot

•_,;,,,, ,,

+

¾,,J

Blade

I I .........,I I I

i ' +

5 +1

!I_12"

+ i

2

Figure la - Push Sticks and Push Blocks

KNOW YOUR CUTTING TOOLS

• Dull, gummy, improperly sharpened or set cutting tools can

cause material to stick, jam, stall saw, or kickback at oper-

ator. Minimize potential injury by proper care and machine

maintenance.

WARNING: Never attempt to free a stalled saw blade with-

out first turning saw OFE

• Never use grinding wheels, abrasive cutoff wheels, friction

wheels (metal slitting blades), wire wheels or buffing

wheels.

p to table

to guide work

Use featherboards in combinations as required to control

workpieces.

Figure lb - Featherboards

USE ONLY ACCESSORIES DESIGNED FOR SAW

• Crosscutting operations are worked more conveniently and

with greater safety if an auxiliary wood facing is attached

to miter gauge using holes provided. However, facing must

not interfere with proper functioning of saw blade guard.

° Make sure the top of the arbor or cutting tool rotates

toward you when standing in normal operating position.

Also make sure the cutting tool, blade flange and arbor

nut are installed properly. Keep the cutting tool as low as

possible for the operation being performed. Keep all

guards in place whenever possible.

• Do not use any blade or other cutting tool marked for oper-

ating speed less than 4000 RPM. Never use a cutting tool

larger in diameter than diameter for which saw was

designed. For greatest safety and efficiency when ripping,

use maximum diameter blade for which saw is designed,

since under these conditions spreader is nearest the

blade.

4

• Adjust table inserts flush with table top. Never operate saw

unless proper insert is installed.

• Never feed material into the cutting tool from the rear of

the saw. An accident and serious injury could result.

THINK SAFETY

Safety is a combination of operator common sense and alert-

ness at all times when the saw is being used.

Never use another person as a substitute for a table exten-

sion, or as additional support for a workpiece that is longer or

wider than basic saw table, or to assist in feeding, supporting

or pulling the workpiece.

Do not pull the workpiece through the saw blade--position

your body at the infeed side of the guard; start and complete

the cut from that same side. This will require added table sup-

port for long or wide workpieces that extend beyond the

length or width of the saw table.

CAUTION: Follow safety instructions that appear on the front

of your saw.

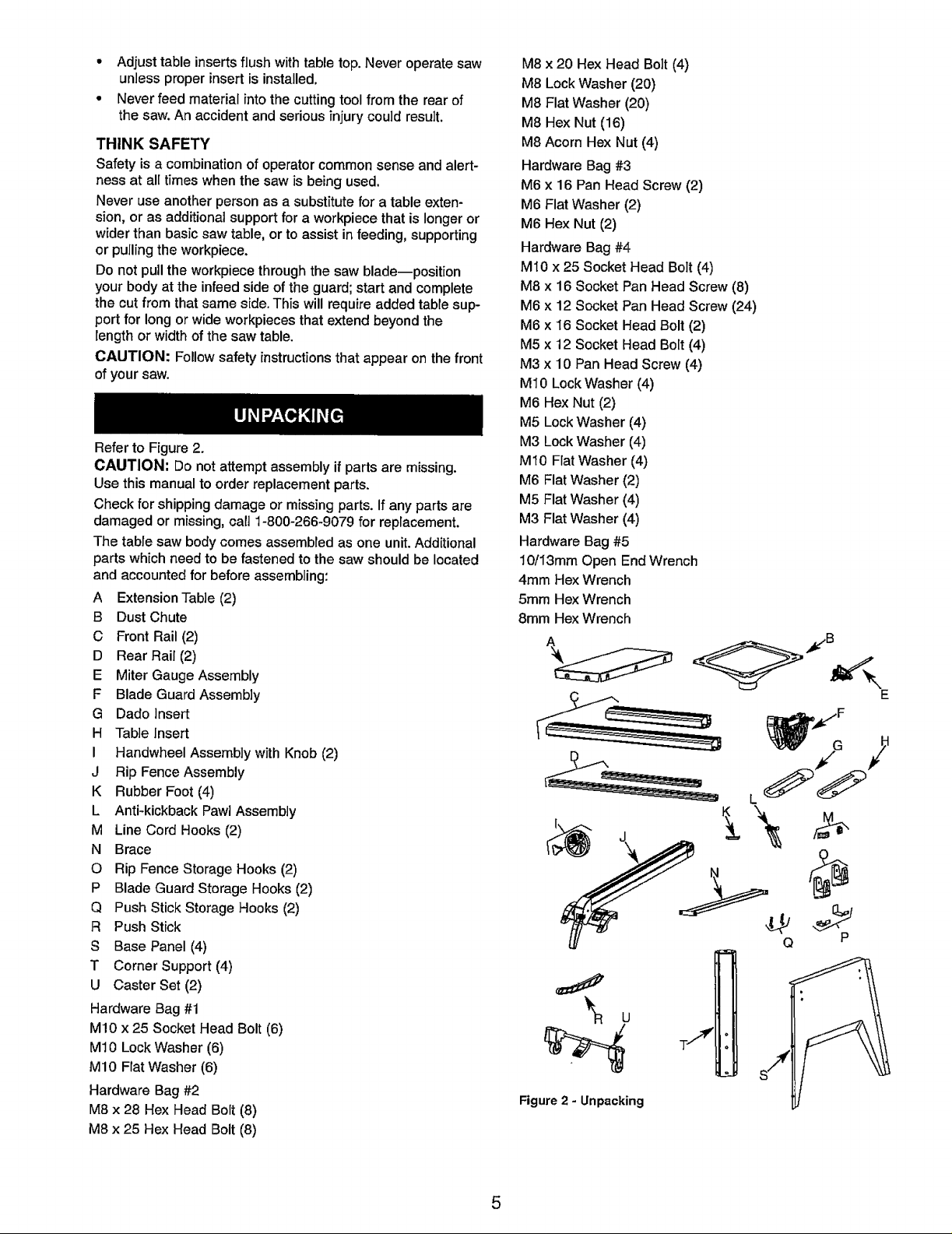

Refer to Figure 2.

CAUTION: Do not attempt assembly if parts are missing.

Use this manual to order replacement parts.

Check for shipping damage or missing parts. If any parts are

damaged or missing, calt 1-800-266-9079 for replacement.

The table saw body comes assembled as one unit. Additional

parts which need to be fastened to the saw should be located

and accounted for before assembling:

A Extension Tab]e (2)

B Dust Chute

C Front Rail (2)

D Rear Rail (2)

E Miter Gauge Assembly

F Blade Guard Assembly

G Dado Insert

H Tab]e Insert

I Handwheel Assembly with Knob (2)

J Rip Fence Assembly

K Rubber Foot (4)

L Antkkickback Pawi Assembly

M Line Cord Hooks (2)

N Brace

O Rip Fence Storage Hooks (2)

P Blade Guard Storage Hooks (2)

Q Push Stick Storage Hooks (2)

R Push Stick

S Base Panel (4)

T Corner Support (4)

U Caster Set (2)

Hardware Bag #1

M!0 x 25 Socket Head Bolt (6)

M10 Lock Washer (6)

M10 Flat Washer (6)

Hardware Bag #2

M8 x 28 Hex Head Bolt (8)

M8 x 25 Hex Head Bolt (8)

M8 x 20 Hex Head Bolt (4)

M8 Lock Washer (20)

M8 Flat Washer (20)

M8 Hex Nut (16)

M8 Acorn Hex Nut (4)

Hardware Bag #3

M6 x 16 Pan Head Screw (2)

M6 Flat Washer (2)

M6 Hex Nut (2)

Hardware Bag #4

MI0 x 25 Socket Head Bolt (4)

M8 x 16 Socket Pan Head Screw (8)

M6 x 12 Socket Pan Head Screw (24)

M6 x 16 Socket Head Bolt (2)

M5 x 12 Socket Head Bolt (4)

M3 x 10 Pan Head Screw (4)

M10 Lock Washer (4)

M6 Hex Nut (2)

M5 Lock Washer (4)

M3 Lock Washer (4)

M10 Flat Washer (4)

M6 Flat Washer (2)

M5 Flat Washer (4)

M3 Flat Washer (4)

Hardware Bag #5

10/I3mm Open End Wrench

4mm Hex Wrench

5mm Hex Wrench

8mm Hex Wrench

S

a

L._

Figure 2 - Unpacking

E

_F

L

Q P

5

IMPORTANT: Table is coated with a protectant. To ensure

proper fit and operation, remove coating. Coating is easily

removed with mild solvents, such as mineral spirits, and a soft

cloth. Avoid getting solution on paint or any of the rubber or

plastic parts. Solvents may deteriorate these finishes. Use

soap and water on paint, plastic or rubber components. After

cleaning, cover all exposed surfaces with a light coating of oil.

Paste wax is recommended for table top.

WARNING: Never use highly volatile solvents. Non flamma-

ble solvents are recommended to avoid possible fire hazard.

Refer to Figures 3, 4, 5, 7, 8, 9 and 10.

CAUTION: Do not attempt assembly if parts are missing.

Use this manual to order replacement parts.

Be certain all parts are clean and free of shipping preserva-

tive. Also, completely remove all parts of packing. Saw cabinet

should be directly on the floor.

SAW INSTALLATION

Positioning the saw on a level surface (shimming may be

required) will improve stability and accuracy and prevent

warpage and failure of cast components and welds.

WARNING; Make certain that the saw is disconnected from

the power source.

ASSEMBLE THE MOBILE BASE

Refer to Figure 12, page 24.

NOTE: Finger tighten bolts and nuts until assembly of mobile

base is complete. Then tighten all fasteners securely.

• Use two M8 x 16 socket pan head bolts (Key No. 1) to

attach a corner support bracket (Key No. 3) to each fixed

support (Key Nos. 9 and 29) at the ends of one of the

caster sets.

• Repeat for the other caster set.

° Attach the front panel (Key No. 8 - stamped 'A') between

the two corner supports attached to one of the caster sets

using six M6 x I2 socket pan head bolts (Key No. 2).

Note: Place the panel edges INSIDE the corner support

surfaces.

• Attach the rear panel (Key No. 8) between the two corner

supports attached to the remaining caster set.

= Attach the left side panel (Key No. 25 - stamped 'B') to the

assemblies made in the previous two steps.

• Attach the right side panel (Key No. 33 - stamped 'C') to

the assembly made in the previous step.

ASSEMBLE BASE TO CABINET

Refer to Figures i0 and 12, pages 20 and 24.

NOTE: Saw cabinet and base are very heavy. Two people are

required to assemble this saw.

° Place a large sheet of cardboard or carpet on the floor to

protect the table top.

• Carefully place the saw cabinet upside down on the floor.

° Remove the six bolts and the back panel (Fig. 10, Key

Nos. 2 and 24). This will allow you to adjust the cabinet

holes to align with the base holes.

° Place the dust chute (Fig. 12, Key No. 30) on the cabinet

with the chute facing upwards.

° Place the mobile base assembly onto the cabinet and dust

chute and secure in position with four socket head bolts,

lock washers and flat washers (Fig. 12, Key Nos. 10, 11

and 12).

NOTE: The foot pedals of the caster sets face towards front

and rear of cabinet, the push stick is attached to the left side

of the base and rip fence hooks are on the right side of the

base.

• Press the four rubber feet (Fig. 12, Key No. 4) to the base

legs.

° Turn the saw upright, reattach the back panel of the

cabinet.

HANDWHEEL ASSEMBLY

Refer to Figure 13, page 26.

WARNING: Make certain that the saw is disconnected from

the power source.

• Place one of the handwheels (Key No. 30) onto the blade

raise/lower shaft (Key No. 56) located on the front of the

cabinet. Align the groove in the back of the handwheel

with the pin.

° Thread the locking knob (Key No. 27) onto the threaded

end of the shaft.

° Repeat the steps above to assemble the remaining hand-

wheel and locking knob onto the bevel shaft located on

the right side of the cabinet.

ATTACH LINE CORD HOOKS

Refer to Figure 10, page 20.

° Tilt the tableto 45°.

° Installthe linecordhooks(KeyNo.9)usingsockethead

bolts, washersand nuts(KeyNos.10, 12 and 13) to the

leftside of thesaw cabinet.

ASSEMBLE BLADE GUARD STORAGE BRACKETS

Referto Figure 12, page 24.

Installthe blade guardstorage brackets(KeyNos. 18 and 19)

to the leftside pane[ (KeyNo.25) of the base usingfour

screws, lock washers and fiat washers(Key Nos.15, 16

and 17).

ASSEMBLE PUSH STICK STORAGE BRACKETS

Refer to Figure 12, page 24.

Installthepush stickstorage brackets (KeyNo.23) tothe left

side panel(Key No.25) ofthebase usingfour screws, lock

washersandflat washers(KeyNos.20, 2t and 22).

ASSEMBLE RIP FENCE STORAGE BRACKETS

Refer to Figure 12, page 24.

Install the rip fence storage brackets (Key No. 34) to the right

side panel (Key No. 33) of the base using two screws, flat

washers and hex nuts (Key Nos. 14, 31 and 32).

ATTACH EXTENSION TABLES

Refer to Figure 11, page 22.

° Assemble extension table (Key No. 35) to the table using

hex head bolts, lock washers and fiat washers (Key Nos.

36, 37 and 38).

° Hand tighten only. Do not tighten completely until tables

are level.

° Repeat above procedure for the other extension table.

6

• Use a straight edge to check level and flatness between

main and extension tables.

• After tables are adjusted level and flat, secure the exten-

sion tables by tightening the hex nuts completely.

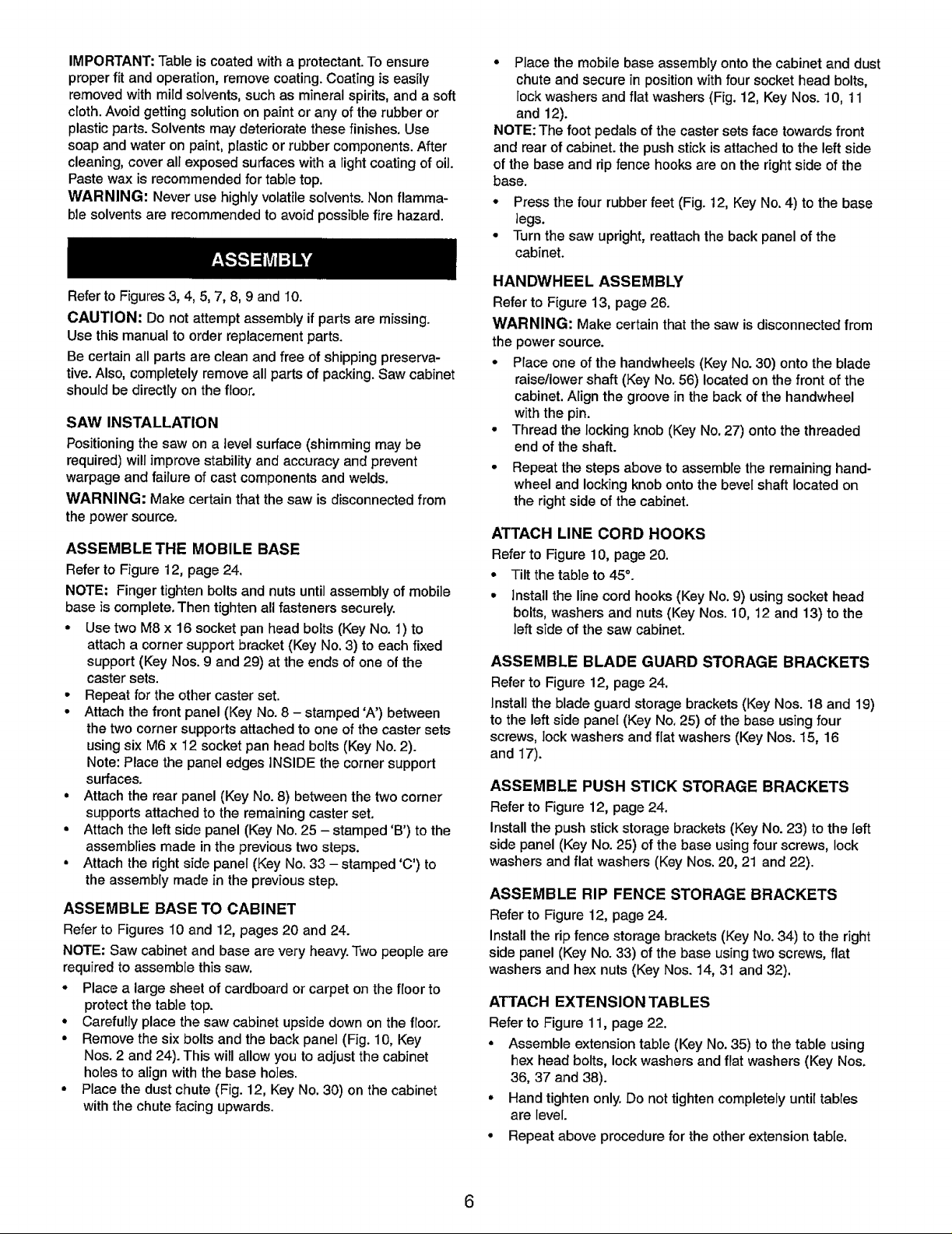

CHECK TABLE ALIGNMENT

Refer to Figures 3 and 13, pages 7 and 26.

• Saws are shipped from the factory with the table adjusted

so the miter gauge slots are parallel to the saw blade.

However, in order to obtain the best results from the saw, it

is suggested this adjustment be checked before operating.

° A simple method of checking alignment is as follows: Bolt

or clamp a dowel rod or similar object to miter gauge (a

combination square can be substituted). Pick out a tooth

on front of blade and set the dowel to it so it is just touch-

ing. Move same tooth to back of blade.

• Gauge this tooth with the dowel rod. If the tooth is in the

same position, relative to the miter gauge, the table is par-

allel with the blade. In short, the miter gauge slots must be

parallel with the blade. This means that when measuring

distance between blade and slot at the front and rear of

the blade, the distances will be equal (see Figure 3).

NOTE: Be positive to measure the distance or make the test

on the same tooth of the saw blade in both front and rear

positions.

• If an adjustment is necessary, proceed as follows: (Refer

to Figure 13). Loosen the hex head bolts and lock wash-

ers (Nos. 36, 37 and 38) of the trunnion. Shift trunnion

until a position is found where the saw blade is parallel to

the miter gauge slots.

NOTE: Saw blade should also be centered within its table

insert opening.

__'1",j_,

Rear

t

I

1

I

i

I

i

I

i

I

i

1

1

I

i

I

i

, r_Y

_aw :

_Blade :

RAIL ASSEMBLY

Refer to Figure 11, page 22.

° Insert two M8 x 28 hex head bolts and two M8 x 25 hex

head bolts into the T-slot of the right front guide rail (Key

Nos. 16, 21, and 22) (The two longer bolts will attach to

the table; the two shorter bolts attach to the table

extension.)

• Attach rail to the table and right table extension using flat

washers, lock washers and hex nuts (Key Nos. 23, 24 and

25).

NOTE: Hand tighten all hardware during rail assembly. Do not

completely tighten hardware until all rails are mounted.

• Attach the left front rail and both rear rails (Key Nos. 18, 32

and 34) in the same manner.

• Position rails so that rails are butted together and the joint

between rails is aligned with the blade.

• Secure all hardware completely.

• Use a straight edge to check level and flatness between

right and left rail and make certain that both front rails are

parallel to the table surface.

• After front rails are adjusted level and flat, tighten the

screws completely.

• Repeat above steps for rear rails.

• Attach the brace (Key No. 30) to the far right end of the

rails using four hex head bolts, flat washers, lock washers

and cap nuts (Key Nos. 26-29).

ATTACH SWITCH ASSEMBLY

Refer to Figure 11, page 22.

• Attach the switch assembly (Key Nos. 1-10) to the bottom of

the left side of the front rail using two flat washers, lock-

washers and hex head bolts. (Key Nos. 11, 12, 13 and 14).

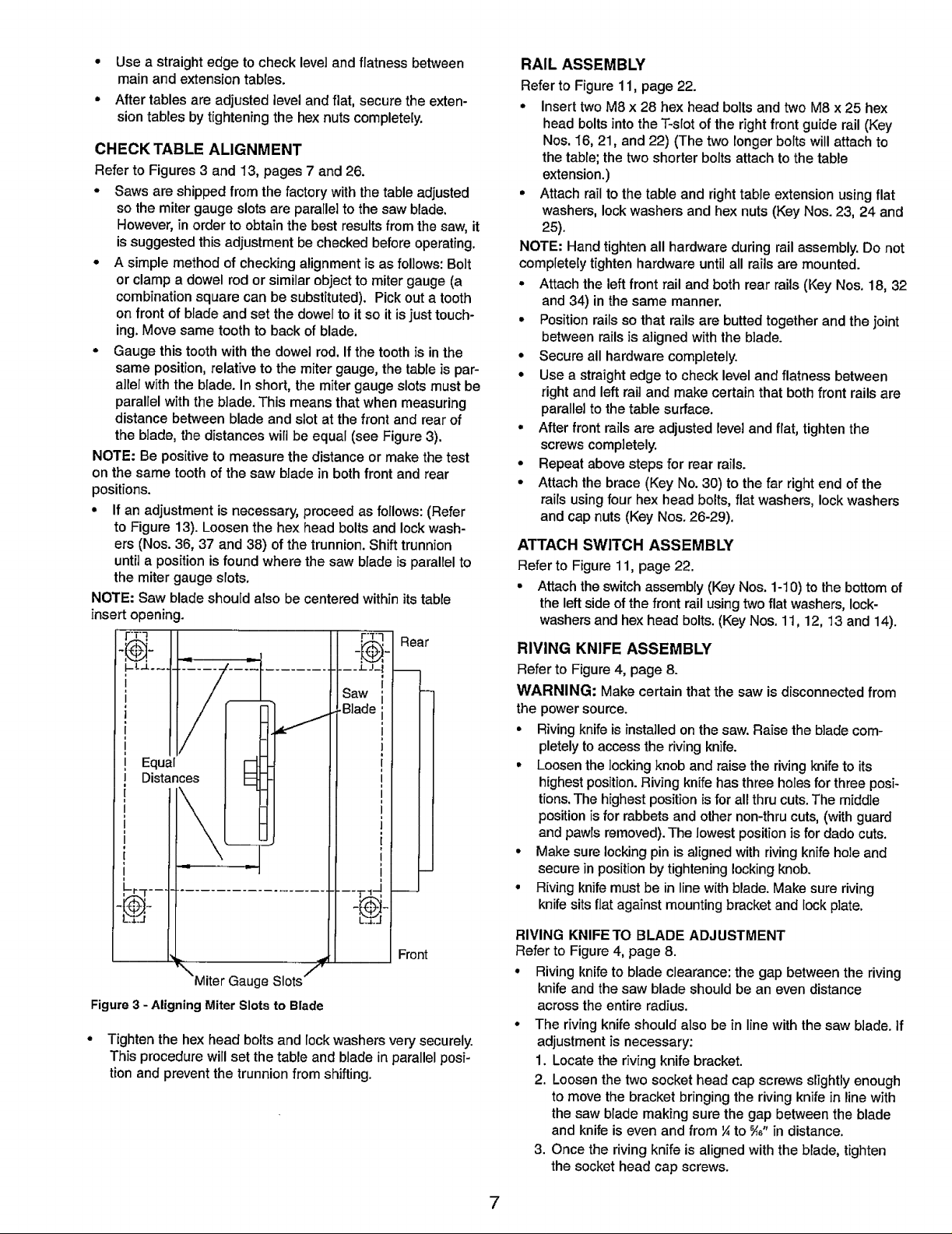

RIVING KNIFE ASSEMBLY

Refer to Figure 4, page 8.

WARNING: Make certain that the saw is disconnected from

the power source.

• Riving knife is installed on the saw. Raise the blade com-

pletely to access the riving knife.

• Loosen the locking knob and raise the riving knife to its

highest position. Riving knife has three holes for three posi-

tions. The highest position is for all thru cuts. The middle

position is for rabbets and other non-thru cuts, (with guard

and pawls removed). The lowest position is for dado cuts.

• Make sure locking pin is aligned with riving knife hole and

secure in position by tightening locking knob.

• Riving knife must be in line with blade. Make sure riving

knife sits flat against mounting bracket and lock plate.

Front

"'Miter Gauge Slots ''f

Figure 3 - Aligning Miter Slots to Blade

° Tighten the hex head bolts and lock washers very securely.

This procedure will set the table and blade in parallel posi-

tion and prevent the trunnion from shifting.

RIVING KNIFETO BLADE ADJUSTMENT

Refer to Figure 4, page 8.

• Riving knifetoblade cJearance:thegap betweenthe riving

knife and thesaw blade should be an even distance

across the entireradius.

• The rivingknifeshouldalso bein linewiththe saw blade, if

adjustmentis necessary:

1. Locatetheriving knife bracket.

2. Loosenthe twosockethead capscrews slightlyenough

to move the bracketbringing the rivingknifein linewith

thesaw blademakingsure the gap betweentheblade

and knifeiseven and from¼to _," in distance,

3. Once the riving knife isalignedwiththe blade, tighten

thesocket headcap screws.

7

Locking

Pin

Figure 4 - Riving Knife

INSTALL TABLE INSERT

Referto Figure 11, page 22.

° Place table insert (Key No.41) into throat of table.

• Insert is held in position by magnet in table.

• To adjust insert level with table, adjust leveling screws (Key

No. 42) up or down.

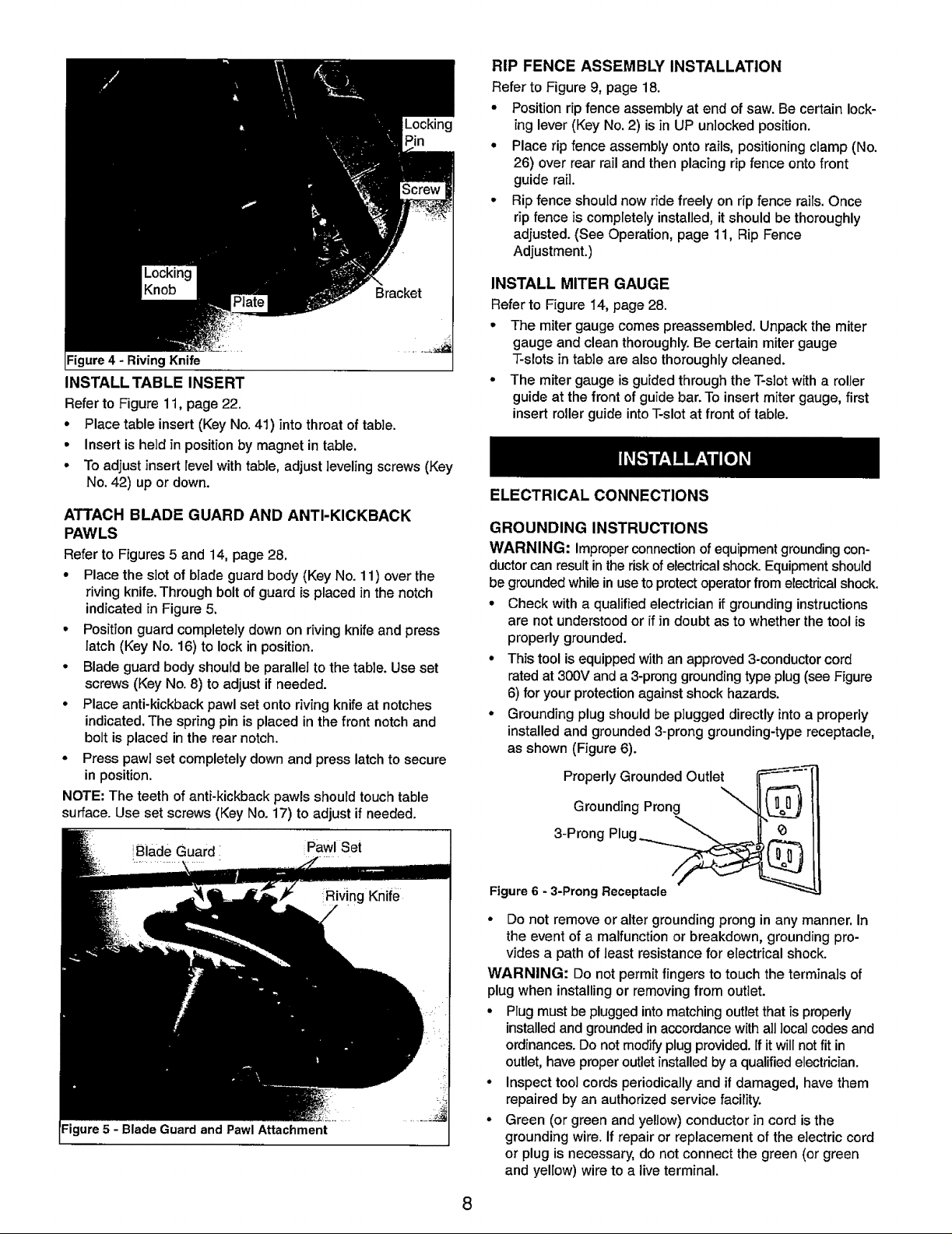

ATTACH BLADE GUARD AND ANTI-KICKBACK

PAWLS

Refer to Figures5 and 14, page 28.

• Placethe slot ofbladeguardbody (Key No.11) overthe

riving knife.Throughbolt ofguardis placed inthe notch

indicatedinFigure5.

• Positionguardcompletelydownon rivingknifeand press

latch (KeyNo. 16) to lockin position.

° Bladeguardbody should be parallel tothe table.Useset

screws(Key No.8) toadjustifneeded.

• Place anti-kickbackpawlset ontorivingknifeat notches

indicated.The springpinisplacedin thefront notchand

bolt isplaced inthe rearnotch.

° Presspawlset completelydownand presslatchtosecure

in position.

NOTE:The teethofanti-kickback pawls should touchtable

surface. Use set screws (KeyNo. 17) to adjust if needed.

RIP FENCE ASSEMBLY INSTALLATION

Refer to Figure 9, page 18.

° Positionrip fenceassembly at end ofsaw.Be certainlock-

ing lever(KeyNo.2) is in UP unlockedposition.

° Placerip fenceassembly ontorails,positioningclamp(No.

26) overrear rail and thenplacingripfence ontofront

guide rail.

° Ripfence should now ride freely on ripfence rails. Once

rip fence is completely installed, it should be thoroughly

adjusted. (See Operation, page 11, Rip Fence

Adjustment.)

INSTALL MITER GAUGE

Referto Figure 14, page 28.

° The mitergauge comespreassembled.Unpackthe miter

gaugeand cleanthoroughly.Be certain mitergauge

T-slotsin tableare alsothoroughlycleaned.

° The mitergaugeisguidedthroughtheT-slotwitha roller

guideat the frontofguidebar. To insertmiter gauge,first

insertrollerguideintoT-slotat front oftable.

ELECTRICAL CONNECTIONS

GROUNDING INSTRUCTIONS

WARNING: improperconnectionofequipmentgroundingcon-

ductorcanresultintheriskofelectricalshock.Equipmentshould

begroundedwhileinusetoprotectoperatorfrom electricalshock.

• Check witha qualifiedelectrician ifgroundinginstructions

are not understoodor if in doubtas towhetherthetool is

properlygrounded.

• Thistoolisequippedwithan approved3-conductorcord

ratedat 300V anda 3-pronggroundingtypeplug(see Figure

6) for yourprotectionagainst shock hazards.

• Grounding plug should be pluggeddirectlyintoa properly

installedand grounded3-pronggrounding-typereceptacle,

as shown (Figure6).

Properly Grounded Outlet

Grounding Prong

iBlade Guard Pawl Set

3-Prong Plug ___

Figure 6 - 3-Prong Receptacle

° Do not remove or alter grounding prong in any manner. In

the event of a malfunction or breakdown, grounding pro-

vides a path of least resistance for electrical shock.

WARNING: Do not permit fingers to touch the terminals of

plug when installing or removing from outlet.

• Plug must be plugged into matching outlet that is properly

installed and grounded in accordance with all local codes and

ordinances. Do not modify plug provided. If it will not fit in

outlet, have proper outlet installed by a qualified electrician.

° Inspect tool cords periodically and if damaged, have them

repaired by an authorized service facility.

• Green (or green and yellow) conductor in cord is the

grounding wire. If repair or replacement of the electric cord

or plug is necessary, do not connect the green (or green

and yellow) wire to a live terminal.

8

Where a 2-prong wall receptacle is encountered, it must be

replaced with a properly grounded 3-prong receptacle

installed in accordance with National Electric Code and

local codes and ordinances.

WARNING: This work should be performed by a qualified

electrician.

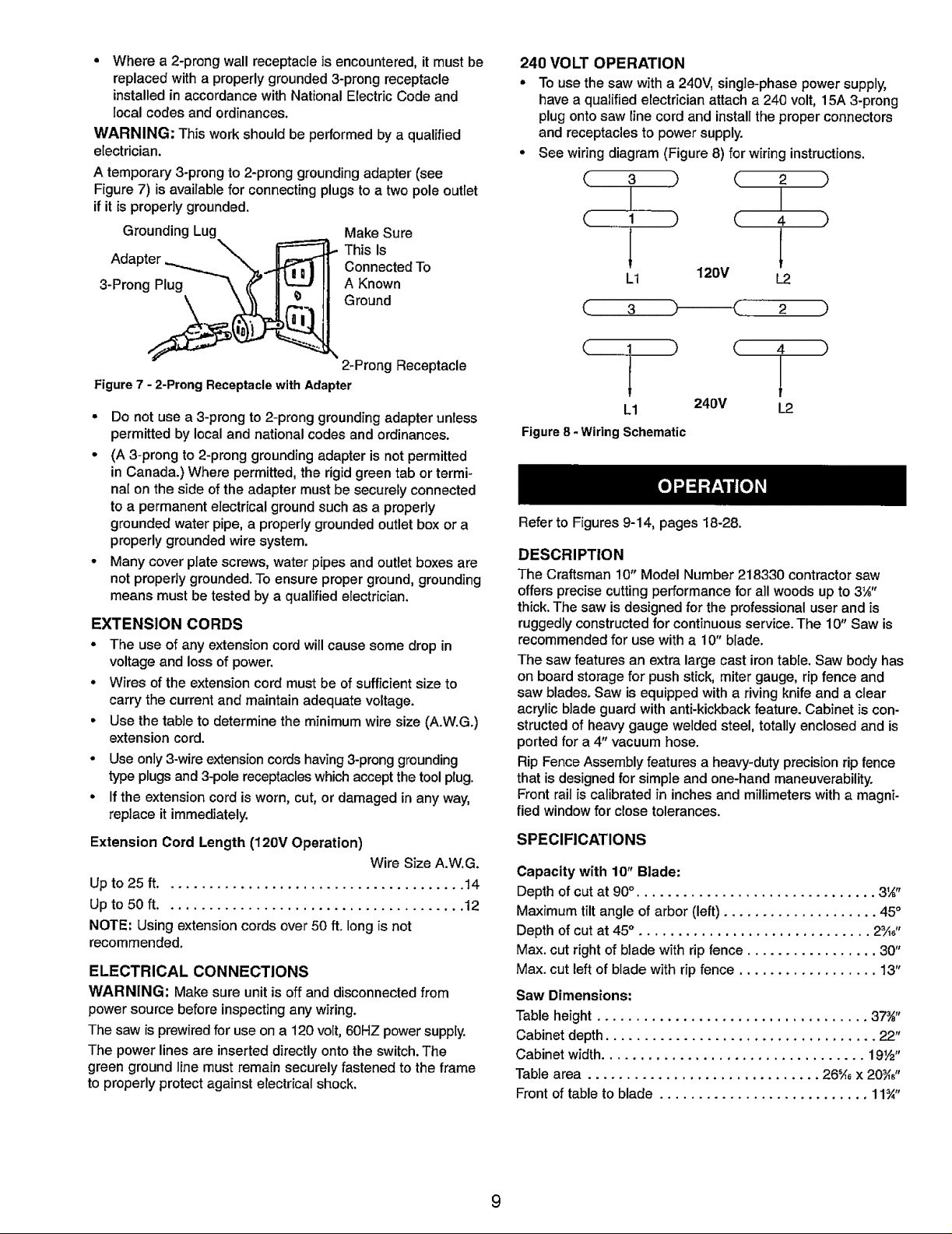

A temporary 3-prong to 2-prong grounding adapter (see

Figure 7) is available for connecting plugs to a two pole outlet

if it is properly grounded.

Grounding Lug Make Sure

This Is

Adapter Connected To

3-Prong Plug A Known

Ground

240 VOLT OPERATION

° To use the saw with a 240V, single-phase power supply,

have a qualified electrician attach a 240 volt, 15A 3-prong

plug onto saw line cord and install the proper connectors

and receptacles to power supply.

• See wiring diagram (Figure 8) for wiring instructions.

3 ) ( 2 )

I I

1 ) (. 4 )

L

L1 120V L2

(.. 3

2 )

2-Prong Receptacle

Figure 7 - 2-Prong Receptacle with Adapter

° Do not use a 3-prong to 2-prong grounding adapter unless

permitted by local and national codes and ordinances.

° (A 3-prong to 2-prong grounding adapter is not permitted

in Canada.) Where permitted, the rigid green tab or termi-

nal on the side of the adapter must be securely connected

to a permanent electrical ground such as a properly

grounded water pipe, a properly grounded outlet box or a

properly grounded wire system.

° Many cover plate screws, water pipes and outlet boxes are

not properly grounded. To ensure proper ground, grounding

means must be tested by a qualified electrician.

EXTENSION CORDS

° The use of any extension cord will cause some drop in

voltage and loss of power.

° Wires of the extension cord must be of sufficient size to

carry the current and maintain adequate voltage.

• Use the table to determine the minimum wire size (A.W.G.)

extension cord.

° Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

• If the extension cord is worn, cut, or damaged in any way,

replace it immediately.

Extension Cord Length (120V Operation)

Wire Size A.W.G.

Up to 25 ff....................................... 14

Up to 50 ft....................................... 12

NOTE: Using extension cords over 50 ft. long is not

recommended.

ELECTRICAL CONNECTIONS

WARNING: Make sure unit is off and disconnected from

power source before inspecting any wiring.

The saw is prewired for use on a 120 volt, 60HZ power supply.

The power lines are inserted directly onto the switch. The

green ground line must remain securely fastened to the frame

to properly protect against electrical shock.

( 1 )

( 4 )

1

kl

Figure 8 -Wiring Schematic

Refer to Figures 9-14, pages 18-28.

DESCRIPTION

The Craftsman 10" Model Number 218330 contractor saw

offers precise cutting performance for all woods up to 3_"

thick. The saw is designed for the professional user and is

ruggedly constructed for continuous service. The 10" Saw is

recommended for use with a 10" blade.

The saw features an extra large cast iron table. Saw body has

on board storage for push stick, miter gauge, rip fence and

saw blades. Saw is equipped with a riving knife and a clear

acrylic blade guard with anti-kickback feature. Cabinet is con-

structed of heavy gauge welded steel, totally enclosed and is

ported for a 4" vacuum hose.

Rip Fence Assembly features a heavy-duty precision rip fence

that is designed for simple and one-hand maneuverability.

Front rail is calibrated in inches and millimeters with a magni-

fied window for close tolerances.

240V

SPECIFICATIONS

Capacity with 10" Blade:

Depth of cut at 90°. .............................. 3'_"

Maximum tilt angle of arbor (left) .................... 45°

Depth of cut at 45° . ............................. 2¾,"

Max. cut right of blade with rip fence ................. 30"

Max. cut left of blade with rip fence .................. 13"

Saw Dimensions:

Table height ................................... 37¾"

Cabinet depth ................................... 22"

Cabinet width.................................. 19Y2"

Table area .............................. 26'/, x 20_,"

Front of table to blade ........................... 11¾"

L2

9

Loading...

Loading...