Page 1

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

www.sears.com/craftsman

31624.00 Draft (10/08/09)

Assembly Instructions

10″

CONTRACTOR TABLE SAW

Model No.

351.218330

Page 2

2

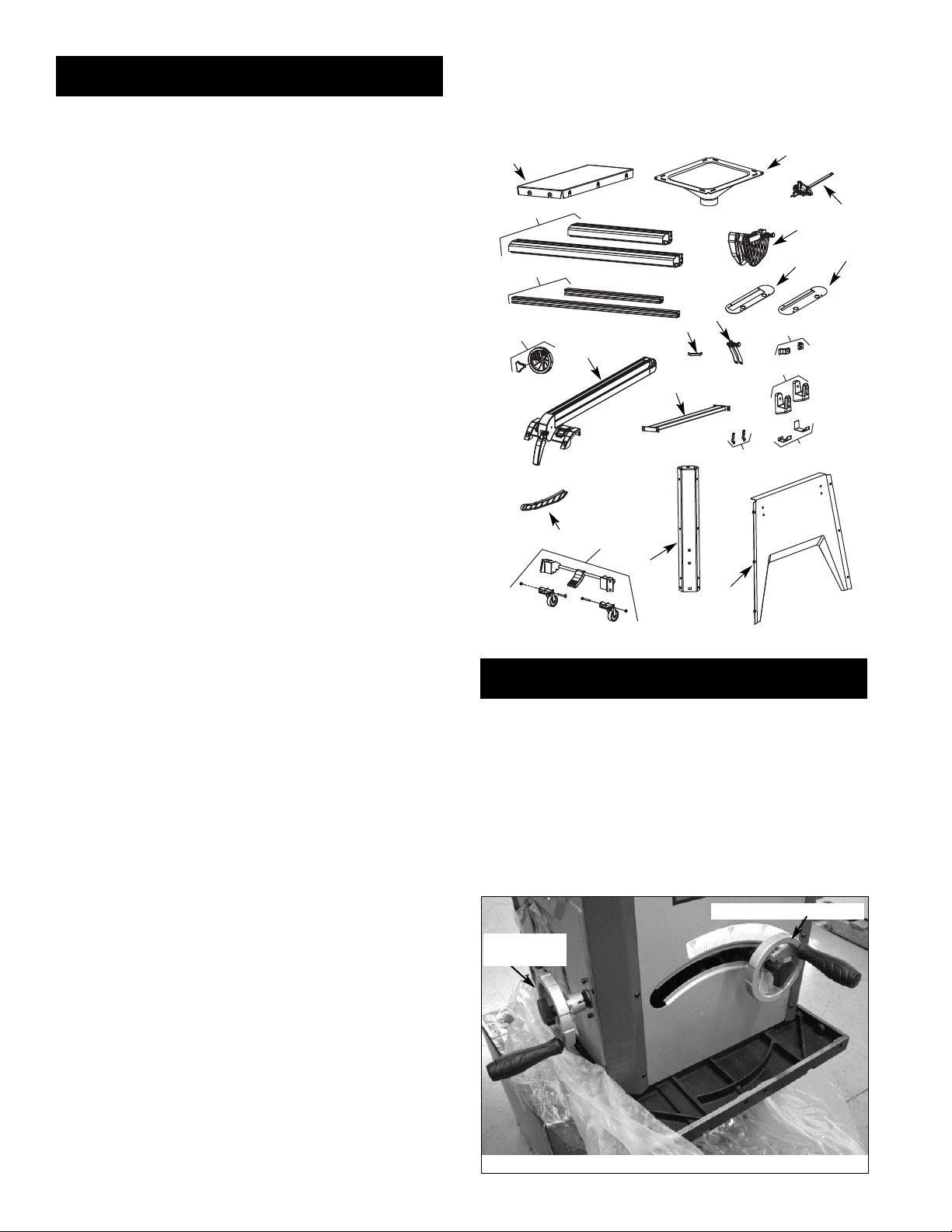

UNPACKING

The table saw body comes assembled as one unit. Additional

parts which need to be fastened to the saw should be located

and accounted for before assembling:

A Extension Table (2)

B Dust Chute

C Front Rail (2)

D Rear Rail (2)

E Miter Gauge Assembly

F Blade Guard Assembly

G Dado Insert

H Table Insert

I Handwheel Assembly with Knob (2)

J Rip Fence Assembly

K Rubber Foot (4)

L Anti-kickback Pawl Assembly

M Line Cord Hooks (2)

N Brace

O Rip Fence Storage Hooks (2)

P Blade Guard Storage Hooks (2)

Q Push Stick Storage Hooks (2)

R Push Stick

S Base Panel (4)

T Corner Support (4)

U Caster Set (2)

Hardware Bag #1

M10 x 25 Socket Head Bolt (6)

M10 Lock Washer (6)

M10 Flat Washer (6)

Hardware Bag #2

M8 x 28 Hex Head Bolt (8)

M8 x 25 Hex Head Bolt (8)

M8 x 20 Hex Head Bolt (4)

M8 Lock Washer (20)

M8 Flat Washer (20)

M8 Hex Nut (16)

M8 Acorn Hex Nut (4)

Hardware Bag #3

M6 x 16 Hex Head Screw (2)

M6 Flat Washer (2)

M6 Hex Nut (2)

M6 Lock Washer (2)

Hardware Bag #4

M10 x 25 Socket Head Bolt (4)

M8 x 16 Socket Pan Head Screw (8)

M6 x 12 Socket Pan Head Screw (24)

M6 x 16 Socket Head Bolt (2)

M5 x 12 Socket Head Bolt (4)

M3 x 10 Pan Head Screw (4)

M10 Lock Washer (4)

M6 Hex Nut (2)

M5 Lock Washer (4)

M3 Lock Washer (4)

M10 Flat Washer (4)

M6 Flat Washer (2)

M5 Flat Washer (4)

M3 Flat Washer (4)

Hardware Bag #5

10/13mm Open End Wrench

4mm Hex Wrench

5mm Hex Wrench

8mm Hex Wrench

STEP 1

INSTALL HANDWHEELS

• Remove saw cabinet and place upside down on carboard

box or cardboard on floor.

• Place one of the handwheels onto the blade raise/lower

shaft located on the front of the cabinet. Align the groove

in the back of the handwheel with the pin.

• Thread the locking knob onto the threaded end of the shaft.

• Repeat the steps above to assemble the remaining handwheel and locking knob onto the blade tilt shaft located on

the side of the cabinet.

© Sears, Roebuck and Co.

Figure 1 - Unpacking

F

G

H

I

J

K

M

N

L

A

B

P

S

U

T

Q

R

O

C

E

D

Figure 2

Blade Raise Handwheel

Blade Tilt

Handwheel

Page 3

3

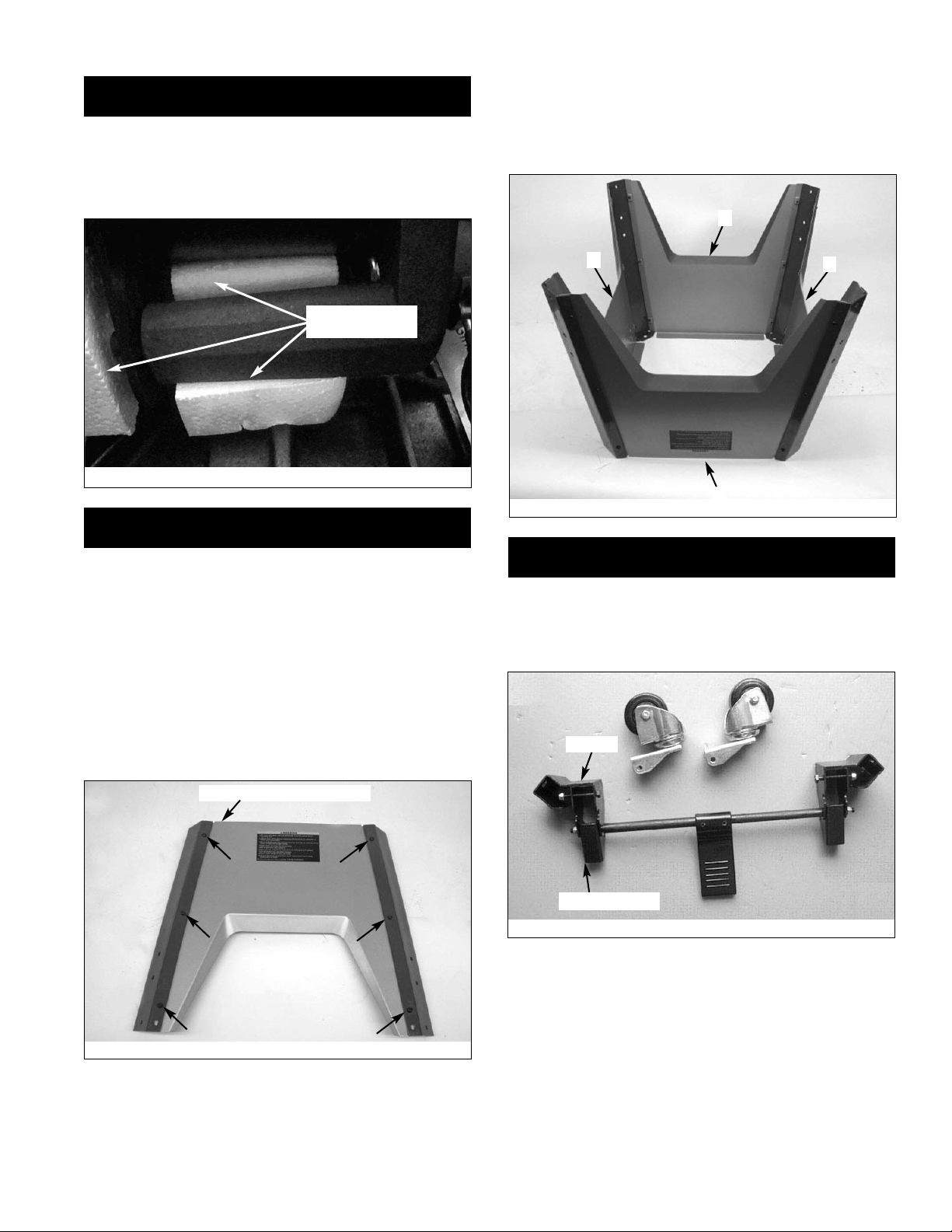

STEP 2

• Use the blade tilt handwheel to tilt the blade completely to

45°.

• Remove the packing material from behind the motor.

• Return blade to the 0° position.

STEP 3

ASSEMBLE MOBILE BASE PANELS

Tools Required: 4mm Hex Wrench

Hardware Required: Twenty-four M6 x 12 socket pan head

bolts (Hardware bag #4).

• Attach the front panel between the two corner supports

using six M6 x 12 socket pan head bolts.

Note: Place the panel edges INSIDE the corner support

surfaces.

Note: Front panel and rear panel are both stamped ‘A’.

Front panel has warning label.

• Repeat above step for the rear panel.

• Set both panel assemblies upside down on bench and

attach the left side panel (stamped ‘B’) to the assemblies

made above.

• Attach the right side panel (stamped ‘C’) to the assembly.

Below is completed base assembly.

STEP 4

ASSEMBLE CASTER SETS

Tools Required: Two 1⁄2″ Open End Wrenches

• Refer to Figure 6; remove casters (4) and supports (2)

from carton.

Figure 4

Figure 5

Letter Stamp On Top Edge

Figure 3

Remove this

packing material

A

A

Kick Plate Cam

Bracket

B

C

Figure 6

Page 4

4

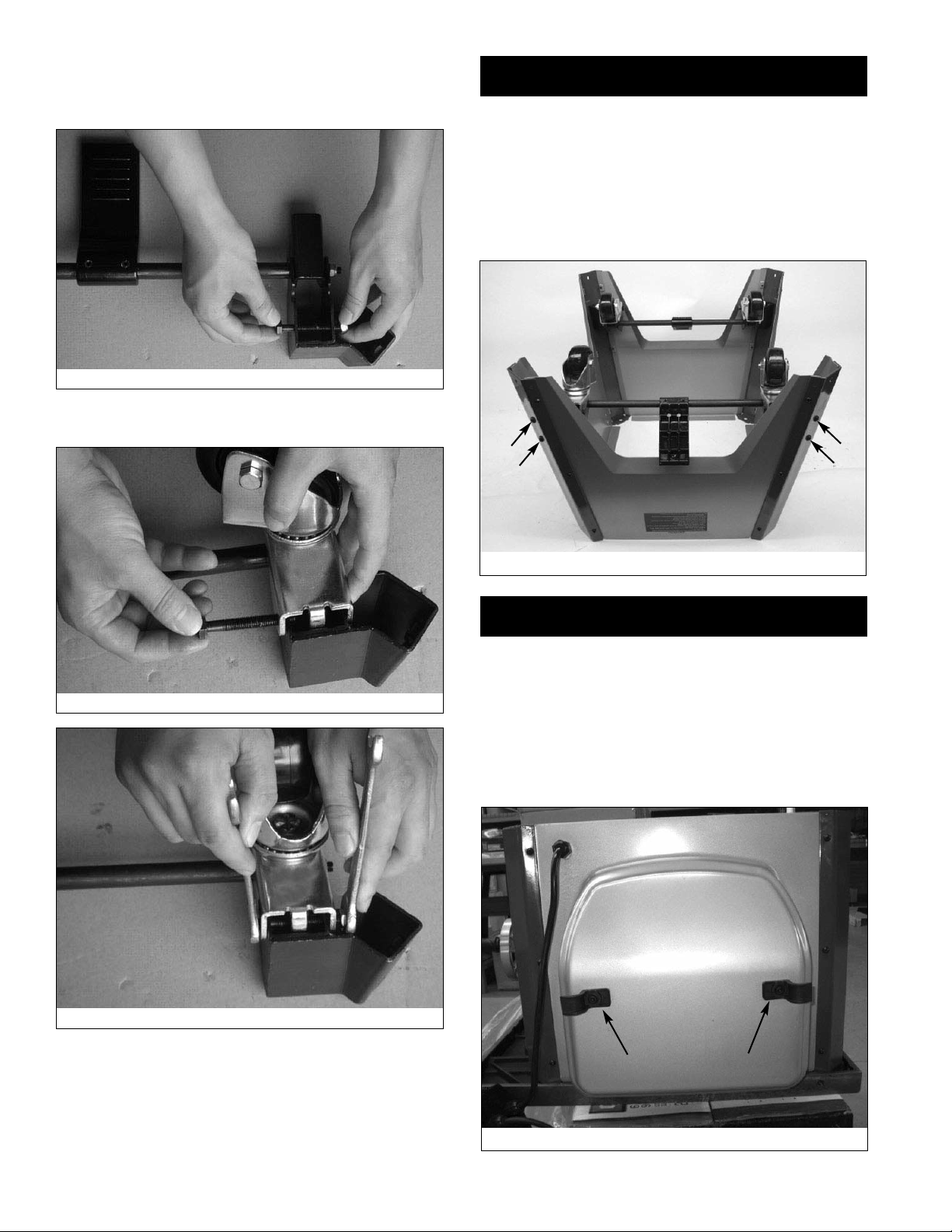

• Refer to Figure 7; loosen and remove the bolt and hex nut

from the support. Rotate foot pedal bar so that kick plate

cam is inside bracket. The kick plate cam must be underneath the caster to function properly.

• Refer to Figure 8 and 9; place caster onto the support and

secure in position with bolt and hex nut.

• Repeat above steps for the second caster set.

STEP 5

ATTACH CASTER SETS TO BASE

Tools Required: 5mm Hex Wrench

Hardware Required: Eight M8 x 16 socket pan head bolts

(Hardware bag #4).

• Attach one caster set to the two front corner supports

using four M8 x 16 socket pan head bolts.

• Attach the remaining caster set to the two rear corner

supports.

STEP 6

ATTACH LINE CORD HOOKS

Tools Required: 4mm Hex Wrench

Hardware Required: Two M6 x 16 socket pan head screws,

two M6 flat washers and two M6 hex nuts (Hardware bag #4).

• Insert a screw into a line cord hook and place against the

holes on the left side of the saw cabinet.

• Secure hook in position using flat washer and hex nut.

• Repeat for other hook.

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Page 5

5

STEP 7

ATTACH BASE TO CABINET

Tools Required: 8mm Hex Wrench

Hardware Required: Four M10 x 25 socket head bolts, four M10

lock washers and four M10 flat washers (Hardware bag #4).

• Place dust chute over the cabinet as shown. Make sure

the holes in the corners are aligned with the slots in the

dust chute.

• Place the base assembly over the dust chute and secure

the base assembly to the cabinet using the flat washers,

lock washers and bolts.

• Secure all fasteners in the base assembly fully tight.

STEP 8

ATTACH RIP FENCE BRACKETS

Tools Required: 4mm Hex Wrench

Hardware Required: Two M6 x 16 socket head bolts, two M6

flat washers and two M6 hex nuts (Hardware bag #4).

Install the rip fence storage brackets to the right side panel of

the base using two screws, flat washers and hex nuts.

STEP 9

BLADE GUARD AND PUSH STICK STORAGE

BRACKETS

Tools Required: Phillips screwdriver and 4mm hex wrench

Hardware Required: Four M3 x 10 pan head screws, four M3

lock washers, four M3 flat washers, four M5 x 12 socket head

bolts, four M5 lock washers and four M5 flat washers

(Hardware bag #4).

• Install the push stick storage brackets to the left side panel

of the base using four screws, lock washers and flat washers.

• Install the blade guard storage brackets to the left side

panel of the base using four screws, lock washers and flat

washers.

• Press the four rubber feet to the base legs.

• Turn the saw upright.

Figure 12

Figure 13

Figure 14

Rubber Feet

Blade Guard

Bracket

Push Stick

Bracket

Figure 15

Page 6

STEP 10

ATTACH EXTENSION TABLES

Tools Required: 13mm Open End Wrench and Straight Edge

Hardware Required: Six M10 x 25 hex head bolts, six M10

lock washers and six M10 flat washers (Hardware bag #1).

• Assemble extension table to the table using hex head

bolts, lock washers and flat washers.

• Hand tighten only. Do not tighten completely until tables

are level. Use a straightedge to level tables.

• Repeat above procedure for the other extension table.

• Use a straight edge to check level and flatness between

main and extension tables.

• After tables are adjusted level and flat, secure the extension tables by tightening the hex nuts completely.

STEP 11

INSTALL BLADE

Tools Required: 13mm Open end Wrench

• Loosen knob on right side of cabinet.

• Remove blade and wrench. Replace knob.

• Depress arbor lock and use wrench to loosen flange nut.

Remove flange and nut from arbor.

• Place blade on arbor. Make sure arrow on blade and teeth

point towards front of saw.

• Replace flange and nut on arbor and securely snug blade

in position.

STEP 12

CHECK TABLE ALIGNMENT

• Saws are shipped from the factory with the table adjusted

so the miter gauge slots are parallel to the saw blade.

However, in order to obtain the best results from the saw, it

is suggested this adjustment be checked before operating.

• A simple method of checking alignment is as follows: Bolt

or clamp a dowel rod or similar object to miter gauge (a

combination square can be substituted). Pick out a tooth

on front of blade and set the dowel to it so it is just touching. Move same tooth to back of blade.

• Gauge this tooth with the dowel rod. If the tooth is in the

same position, relative to the miter gauge slot, the table is

parallel with the blade. In short, the miter gauge slots must

be parallel with the blade. This means that when measuring distance between blade and slot at the front and rear

of the blade, the distances will be equal (see Figure 20).

NOTE: Be positive to measure the distance or make the test

on the same tooth of the saw blade in both front and rear

positions.

• If an adjustment is necessary, proceed as follows: (Refer

to Figure 13 in operator’s manual). Loosen the hex head

bolts and lock washers (Nos. 36, 37 and 38) of the trunnion. Shift trunnion until a position is found where the saw

blade is parallel to the miter gauge slots.

NOTE: Saw blade should also be centered within its table

insert opening.

6

Figure 17

Flange

Straight Edge

Nut

Figure 18

Arbor Lock

Figure 19

Page 7

• Tighten the hex head bolts and lock washers very securely.

This procedure will set the table and blade in parallel position and prevent the trunnion from shifting.

STEP 13

RAIL ASSEMBLY

Tools Required: 13mm Open end Wrench

Hardware Required: Eight M8 x 28 hex head bolts, eight M8 x

25 hex head bolts, four M8 x 20 hex head bolts, twenty M8

lock washers, twenty M8 flat washers, sixteen M8 hex nuts

and four M8 acorn nuts. (Hardware bag #2).

• Insert two M8 x 28 hex head bolts and two M8 x 25 hex

head bolts into the T-slot of the right front guide rail. (The

two longer bolts will attach to the table; the two shorter

bolts attach to the table extension.)

• Attach right front rail to the table and right table extension

using flat washers, lock washers and hex nuts.

NOTE: Hand tighten all hardware during rail assembly. Do not

completely tighten hardware until all rails are mounted.

• Attach left front rail in the same manner. (The two longer

bolts attach to the table; the two shorter bolts attach to

table extension.)

• Position rails so that rails are butted together and the joint

between rails is aligned with the blade. You may need a

mallet to lightly tap rails together. Make sure rails are completely butted together at the joint.

• Use a straight edge to check level and flatness between

right and left rail and make certain that both front rails are

parallel to the table surface..

• After front rails are adjusted level and flat, tighten the

screws completely.

• Secure all hardware completely.

• Loosen and remove six socket pan head screws and the

back panel. This will allow easier attachment of the rear rails.

• Install the rear rails in the same manner as the front rails

and align the rail joint to the blade.

• Replace back panel of the cabinet.

7

Figure 22 - Use Straight Edge to Align Rail Joint to Blade

Figure 24

Figure 20 - Aligning Miter Slots to Blade

Equal

Distances

Saw

Blade

Rear

Miter Gauge Slots

Front

M8 x 28 Bolts

M8 x 25 Bolts

Figure 21 - Right Front Rail

Figure 23

Page 8

• Attach brace to the far right end of the rails.

Simultaneously slide brace with hex bolts into the rail Tslots and secure in position using lock washers, flat washers and acorn nuts.

STEP 14

ATTACH SWITCH ASSEMBLY

Tools Required: 10mm Open end Wrench

Hardware Required: Two M6 x 16 hex head bolts, two M6 flat

washers, two M6 lock washers and two M6 hex nuts.

(Hardware bag #3).

• Insert the two M6 x 16 hex head bolts into the T-slot on the

bottom of the left front rail. Position bolts approximately 6 to

8″ from the left end of the rail.

• Attach switch assembly to bolts and secure in position with

flat washers, lock washers and hex nuts.

STEP 15

POSITION AND ADJUST RIVING KNIFE

• Riving knife is installed on the saw. Raise the blade completely to access the riving knife.

• Loosen the locking knob and raise the riving knife to its

highest position. Riving knife has three holes for three positions. The highest position is for all thru cuts. The middle

position is for rabbets and other non-thru cuts, (with guard

and pawls removed). The lowest position is for dado cuts.

• Make sure locking pin is aligned with riving knife hole and

secure in position by tightening locking knob.

• Riving knife must be in line with blade. Make sure riving

knife sits flat against mounting bracket and lock plate.

RIVING KNIFE TO BLADE ADJUSTMENT

• Riving knife to blade clearance: the gap between the riving

knife and the saw blade should be an even distance

across the entire radius.

• The riving knife should also be in line with the saw blade. If

adjustment is necessary:

1. Locate the riving knife bracket.

2. Loosen the two socket head cap screws slightly enough

to move the bracket bringing the riving knife in line with

the saw blade making sure the gap between the blade

and knife is even and from

1

⁄4 to 5⁄16″ in distance.

3. Once the riving knife is aligned with the blade, tighten

the socket head cap screws.

STEP 16

INSTALL TABLE INSERT

• Place table insert into throat of table.

• Insert is held in position by magnet in table.

• To adjust insert level with table, adjust leveling screws up

or down.

8

Figure 25

Figure 26

Figure 28

Figure 27 - Riving Knife

Locking

Pin

Bracket

Plate

Locking

Knob

Screw

Leveling Screws

Page 9

STEP 17

ATTACH BLADE GUARD AND ANTI-KICKBACK

PAWLS

• Place the slot of blade guard body over the riving knife.

Slot of bushing is placed in the notch indicated in Figures

29 and 30.

• The bushings have a beveled edge and must be located in

the center of the slot to lock properly.

• Position guard completely down on riving knife and press

latch to lock in position.

• Blade guard body should be parallel to the table. Use set

screws to adjust if needed.

• Place anti-kickback pawl set onto riving knife at notches

indicated. The spring pin is placed in the front notch and

bolt is placed in the rear notch.

• Press pawl set completely down and press latch to secure

in position.

NOTE: The teeth of anti-kickback pawls should touch table

surface. Use set screws to adjust if needed.

STEP 18

INSTALL MITER GAUGE

• The miter gauge comes preassembled. Unpack the miter

gauge and clean thoroughly. Insert into storage slots on

right side of cabinet.

9

Figure 29 - Blade Guard and Pawl Attachment

Blade Guard

Pawl Set

Riving Knife

Figure 30

Bushing

Figure 31 - Latches Lock and Unlock Blade Guard and Pawls

to Riving Knive

Set Screws

Latches

Figure 32

Page 10

STEP 19

INSTALL PUSH STICK

• Insert the push stick into brackets on left side of base.

STEP 20

INSTALL RIP FENCE

• Position rip fence assembly at end of saw. Be certain locking lever is in UP unlocked position.

• Place rip fence assembly onto rails, positioning clamp over

rear rail and then placing rip fence onto front guide rail.

• Rip fence should now ride freely on rip fence rails. Once

rip fence is completely installed, it should be thoroughly

adjusted.

STEP 21

SAW COMPLETELY ASSEMBLED

10

Figure 33

Figure 35

Figure 34

Page 11

11

NOTES

Page 12

Get it fixed, at your home or ours!

Your Home

For expert troubleshooting and home solutions advice:

www.managemyhome.com

For repair – in your home – of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

®

(1-800-469-4663)

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call anytime for the location of your nearest

Sears Parts & Repair Service Center

1-800-488-1222 (U.S.A.) 1-800-469-4663 (Canada)

www.sears.com www.sears.ca

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655 (U.S.A.) 1-800-361-6665 (Canada)

Para pedir servicio de reparación

a domicilio, y para ordenar piezas:

1-888-SU-HOGAR

(1-888-784-6427)

®

Au Canada pour service en français:

1-800-LE-FOYER

(1-800-533-6937)

www.sears.ca

MC

® Registered Trademark / TM Trademark /SM Service Mark of Sears Brands, LLC

® Marca Registrada / TM Marca de Fábrica / SM Marca de Servicio de Sears Brands, LLC

MC

Marque de commerce / MD Marque déposée de Sears Brands, LLC © Sears Brands, LLC

Loading...

Loading...