Page 1

Operator's Manual g

PLANER WITH DUST COLLECTION

Model No.

13" I

351.217430

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.con_craftsman

18236.03 Draft (07/01/04)

Page 2

Warranty.................................... 2

Safety Rules ............................... 2-3

Unpacking .................................. 3

Assembly ................................. 3-4

Installation ................................. 4-5

Operation ................................. 6-9

Maintenance .............................. 9-11

Troubleshooting ........................... 12-13

Parts Illustration and List ................... 14-19

Espa_ol ................................. 20-31

FULL ONE YEAR WARRANTY

Ifthis product fails due toa defect inmaterial or work-

manship within oneyear from the date of purchase,

Sears will at its option repair or replace itfree of

charge. Contact your nearest Sears Service Center

(1-800-4-MY-HOME) to arrange for productrepair,or

returnthisproductto place of purchase for replacement.

If this product is used for commercial or rental purpos-

es, this warranty will applyfor 90 days from the date of

purchase.

This warranty applies only while this product is used in

the United States.

This warrantygives you specificlegal dghts and you may

also have other rights which vary from stateto state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman

Estates, IL 60179

WARNING: For yourown safety, read all of the rules

and precautions before operating tool.

CAUTION: Always follow proper operating procedures

as defined in this manual even ifyou are familiar with

use of this or similar tools. Remember that being care-

less for even a fraction of a second can result in severe

personal injury.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry

which may get caught inmoving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States

ANSI Z87.1. Everyday glasses have only impact

resistant lenses. They are NOT safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly Never operate power tools

when tired, intoxicatedor when taking medications

that cause drowsiness.

© Sears, Roebuck and Co.

PREPARE WORK AREA FOR JOB

• Keep work area clean. Cluttered work areas invite

accidents.

• Do not use power tools in dangerous environments.

• Do not use power toots in damp or wet locations.Do

not expose power tools to rain.

• Work area should be properly lighted.

• Proper electrical receptacle shouldbe availablefor

tool. Three prong plug should be plugged directly

into properly grounded, three-prong receptacle.

• Extension cords should have a grounding prong and

the three wires of the extension cord shouldbe of

the correct gauge.

• Keep visitors at a safe distance from work area.

• Keep childrenout of workplace. Make workshop child-

proof. Use padlocks, master switches or remove switch

keys to prevent any unintentional use of power tools.

TOOL SHOULD BE MAINTAINED

• Always unplugtool priorto inspection.

• Consult manual for specificmaintainingand adjust-

ing procedures.

• Keep toollubricatedand clean for safest operation.

• Remove adjustingtools.Form habitof checkingto

see that adjustingtools are removed before switch-

ingmachine on.

• Keep all parts in working order. Check to determine

that the guard or other parts will operate properly

and perform their intended function.

• Check for damaged parts. Check for alignment of

moving parts, binding, breakage, mounting and any

other condition that may affect a tool's operetlon.

• A guard or other part that is damaged should be

properly repaired or replaced. Do not perform

makeshift repairs. (Use parts list provided to order

replacement parts.)

KNOW HOW TO USE TOOL

• Use right tool for job. Do not force tool or attachment

to do a job for which it was not designed.

• Disconnect tool when changing blades.

• Avoid accidental start-up. Make sure that the switch

is in the OFF position before plugging in.

• Do not forcetool. It will work most efficientlyat the

rate for which it was designed.

• Keep hands away from moving parts and cutting

surfaces.

• Never leave tool runningunattended. Turn the power

offand do not leave tool untilit comes to a complete

stop.

• Do notoverreach. Keep proper footingand balance.

• Neverstandontool.Seriousinjurycould occurif tool is

tipped or if blade is unintentionally contacted.

• Know your tool. Learn the tool's operation, applica-

tion and specific limitations.

2

Page 3

• Use recommended accessories (refer to page 15).

Use of improper accessories may cause risk of

injuryto persons.

• Handle workpiece correctly.Protect handsfrom

possible injury.

• Turn machine off if it jams. Blade jams when it digs

too deeply into workpiece. (Motor force keeps it

stuck in the work.)

• Always keep drive, cutterhead and blade guards in

place and in proper operating condition.

• Feed work into blade or cutter against direction of

rotation.

CAUTION: Think safety! Safety is a combinationof

operator common sense and alertness at all times

when tool is being used.

WARNING: Do not attempt to operate tool untit it is

completely assembled according to the instructions.

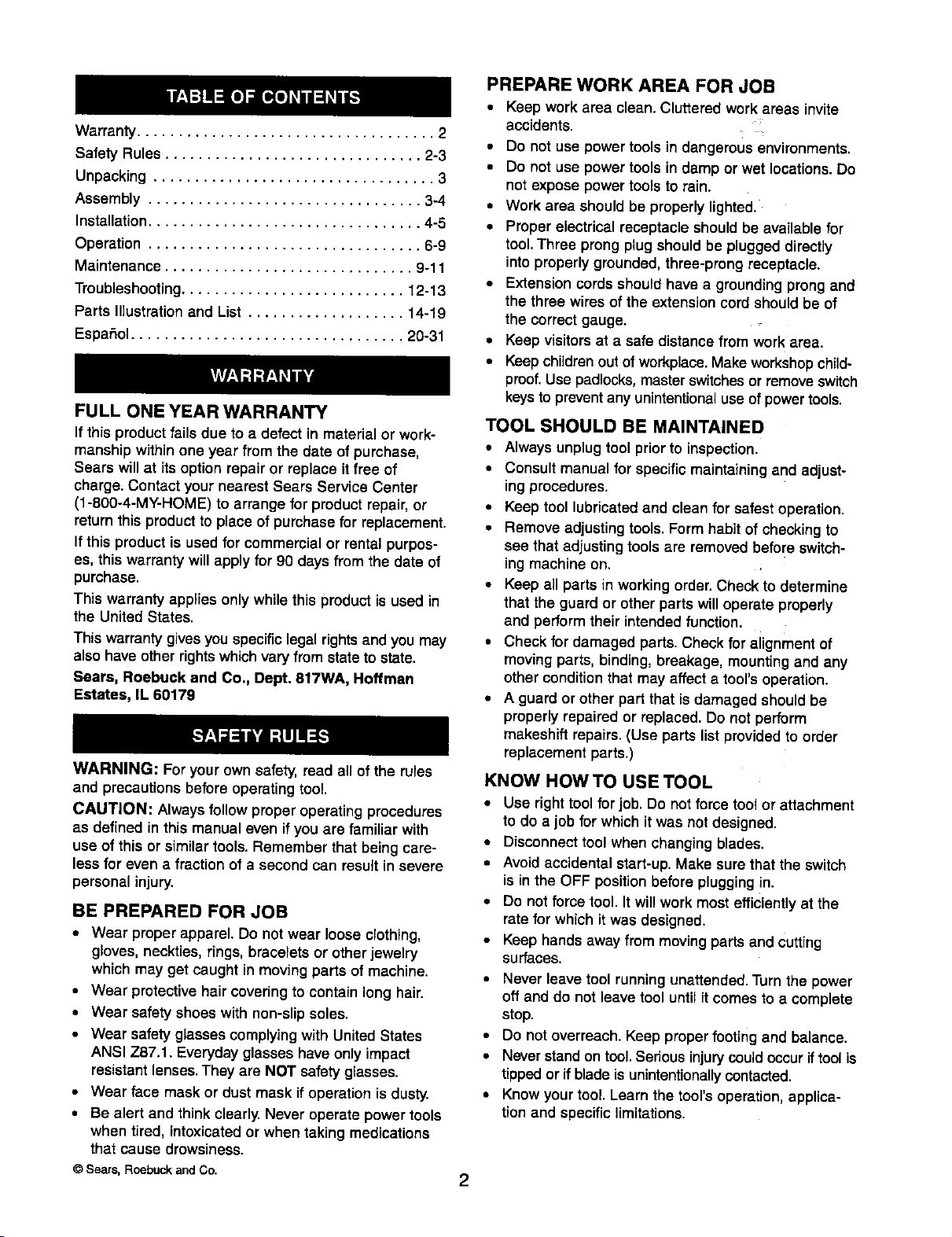

Refer to Figure 1 below.

Check for shipping damage. If damage has occurred, a

claim must be filed with carrier. Check for complete-

ness. immediately report missing partsto dealer,

The planer comes assembled as one unit. Additional

parts which need to be fastened to planer should be

tocated and accounted for before assembling.

A. Planer

B. Handle Assembly

C. 6ram Flat Washer

D. 6-1.0 x 20mm Socket Pan Head Bolt

E. 6-1.0 x 25mm Socket Head Bolt

F. Pointer

G. Magnet (2)

H. 4ram HexWrench

I. Dust Chute

J. Half Bag Dust Collection Set (Not Shown)

WARNING: Do not attempt assembly if parts are

missing. Use this manual to order replacement parts,

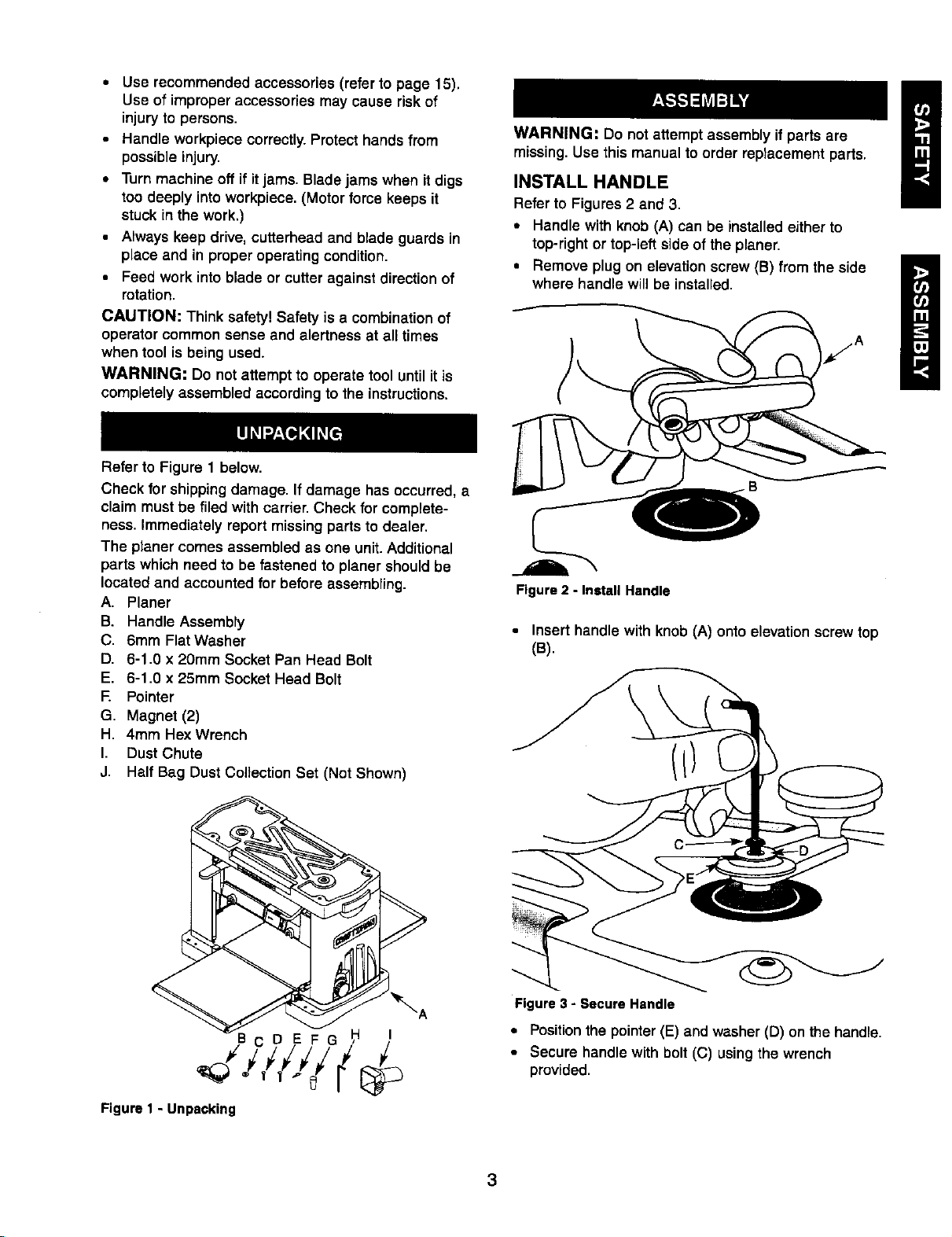

INSTALL HANDLE

Refer to Figures 2 and 3.

• Handle with knob (A) can be installedeither to

top-right or top-left side of the planer,

• Remove plug on elevation screw (B) from the side

where handle will be installed.

Figure 2 - Install Handle

• Insert handle with knob (A) onto elevation screw top

(B).

Figure 1 - Unpacking

Figure3 - Secure Handle

• Positionthe pointer (E) and washer (D) on the handle.

• Secure handle with bolt (C) usingthe wrench

provided,

Page 4

INSTALL DUST CHUTE

Refer to Figure 22.

• Slide dust chute (Key No. 10) over fan housing(Key

No. 8). Secure in positionwith bolt (Key No 9).

• Attachthe Half Bag Dust CollectionSet (included)

after mounting planer to work surface.

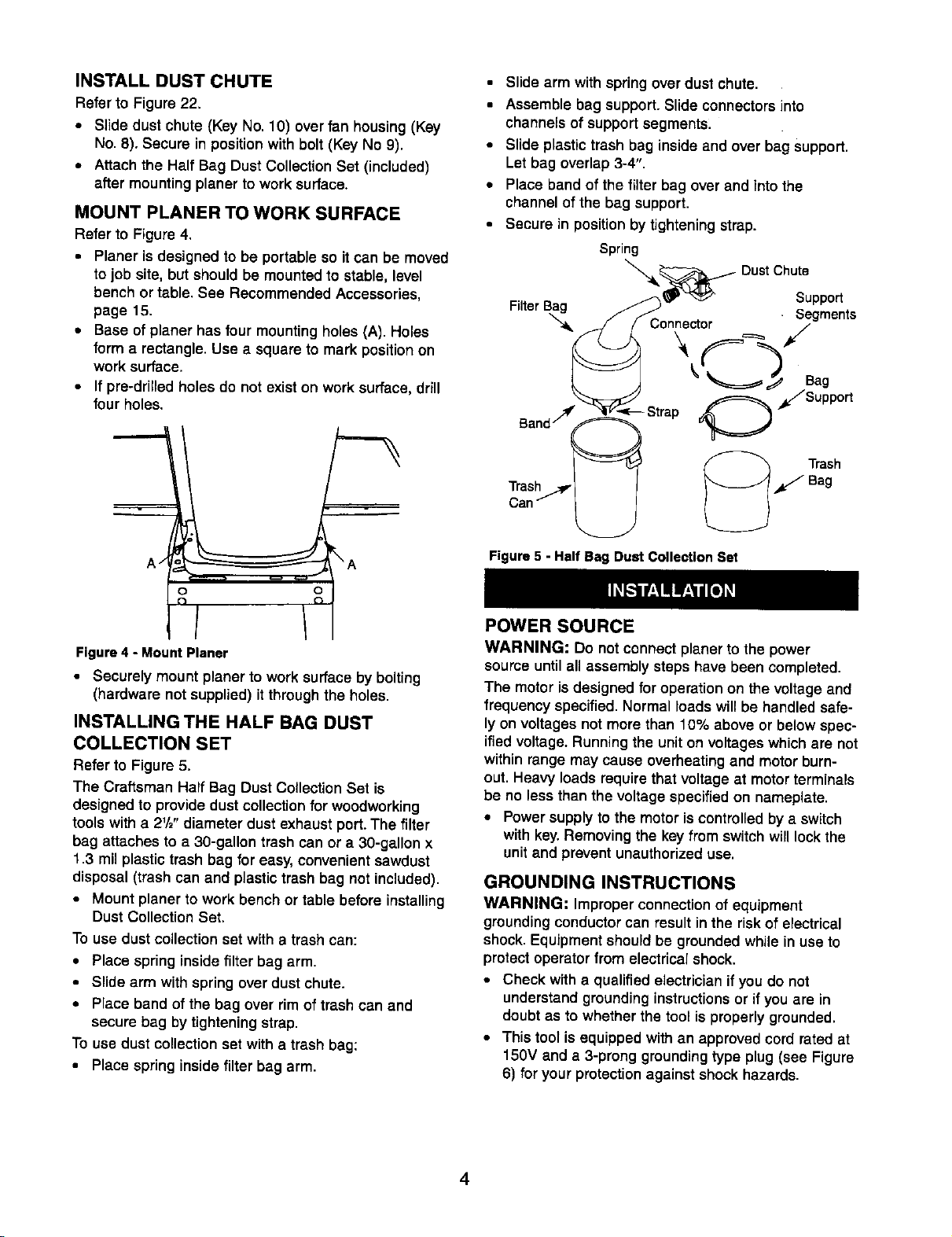

MOUNT PLANER TO WORK SURFACE

Refer to Figure 4.

• Planer is designed to be portable so itcan be moved

to job site, butshould be mountedto stable, level

bench or table. See Recommended Accessories,

page 15.

• Base of planer has four mounting holes (A). Holes

form a rectangle. Use a square to mark position on

work surface.

• If pre-drilled holes do not exist on work surface, drill

four holes.

• Slide arm withspring over dust chute.

• Assemble bag support. Slide connectorsinto

channels of support segments:

• Slide plastic trash bag inside and over bag support.

Let bag overlap 3-4".

• Place band of the filter bag over and into the

channel of the bag support.

• Secure in position by tightening strap.

Figure4 - MountPlaner

• Securely mount planer towork surface by bolting

(hardware not supplied) itthrough the holes.

INSTALLING THE HALF BAG DUST

COLLECTION SET

Refer to Figure 5.

The Craftsman Half Bag Dust CoUection Set is

designed to provide dust collection for woodworking

tools with a 2%" diameter dust exhaust port. The filter

bag attaches to a 30-gaUon trash can or a 30-gallon x

1.3 mil plastic trash bag for easy, convenient sawdust

disposal (trash can and plastic trash bag not included).

• Mount planer to work bench ortable before installing

Dust Collection Set,

To use dust collection set with a trash can:

• Place spring insidefilter bag arm.

• Slide arm with spring over dust chute.

• Place band of the bag over rim oftrash can and

secure bag by tightening strap.

To use dust collection set with a trash bag:

• Place spring inside filter bag arm.

Figure 5 - Half Bag Dust Collection Set

POWER SOURCE

WARNING: Do not connectplaner to the power

source untilall assembly steps have been completed.

The motoris designedfor operationon the voltage and

frequency specified. Normal loads willbe handledsafe-

lyon voltages not more than 10% above or below spec-

ified voltage. Running the uniton voltageswhichare not

within range may cause overheating and motor burn-

out. Heavy loads require that voltage at motor terminals

be no less than the voltage specifiedon nameplate.

• Power supply to the motor is controlled by a switch

with key.Removing the key from switch will lock the

unit and prevent unauthorized use.

GROUNDING INSTRUCTIONS

WARNING: Improper connection of equipment

groundingconductorcan result in the riskof electrical

shock.Equipment shouldbe groundedwhile in use to

protectoperatorfrom electrical shock.

• Check with a qualified electricianifyou do not

understand groundinginstructionsor if you are in

doubt as to whether the tool is properlygrounded.

• This tool isequipped withan approved cord rated at

150V and a 3-prong groundingtype plug (see Figure

6) for your protectionagainst shockhazards.

Page 5

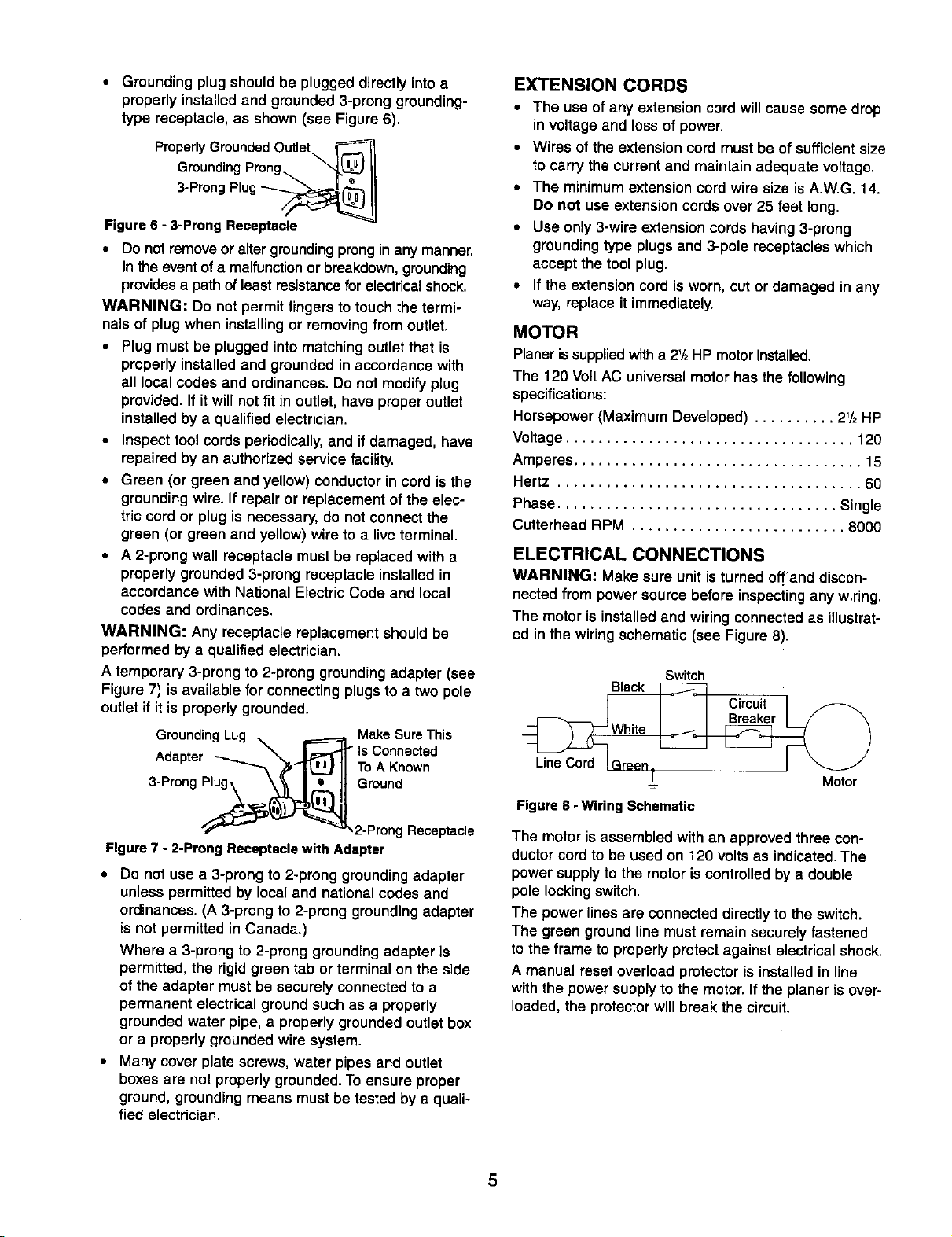

• Grounding plug should be plugged directly into a

properly installed and grounded 3-prong grounding-

type receptacle, as shown (see Figure 6).

Properly Grounded Outlet _

Grounding Prong ®11

3-Prong Plug __

Figure 6 - 3-Prong Receptacle

• Do not remove or alter grounding prong in any manner.

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electrical shock.

WARNING: Do not permit fingers to touch the termi-

nals of plug when installing or removing from outlet.

• Plug must be plugged into matching outlet that is

properly installed and grounded in accordance with

all local codes and ordinances. Do not modify plug

provided. If it will not fit in outlet, have proper outlet

installed by a qualified electrician.

• Inspect tool cords periodically, and if damaged, have

repaired by an authorized service facility.

• Green (or green and yellow) conductor in cord is the

grounding wire. If repair or replacement of the elec-

tric cord or plug is necessary, do not connect the

green (or green and yellow) wire to a live terminal.

• A 2-prong wall receptacle must be replaced with a

properly grounded 3-prong receptacle installed in

accordance with National Electric Code and local

codes and ordinances.

WARNING: Any receptacle replacement should be

performed by a qualified electrician.

A temporary 3-prong to 2-prong grounding adapter (see

Figure 7) is available for connecting plugs to a two pole

outlet if it is properly grounded.

Grounding Lug _ Make Sure This

-- - _ m.--..---rr is Connected

P,oapTer _''"_ _'t"_-J[I ToAKnown

3-Prong __ _.. J Ground

"/'_ _;_v't_'l _"_2-Prong Receptacle

Figure 7 - 2-Prong Receptacle with Adapter

• Do not use a 3-prong to 2-prong grounding adapter

unless permitted by local and national codes and

ordinances. (A 3-prong to 2-prong grounding adapter

is not permitted in Canada.)

Where a 3-prong to 2-prong grounding adapter is

permitted, the rigid green tab or terminal on the side

of the adapter must be securety connected to a

permanent electrical ground such as a properly

grounded water pipe, a properly grounded outlet box

or a properly grounded wire system.

• Many cover plate screws, water pipes and outlet

boxes are not properly grounded. To ensure proper

ground, grounding means must be tested by a quali-

fied electrician.

EXTENSION CORDS

• The use of any extensioncord will cause some drop

involtage and loss of power.

• Wires ofthe extensioncord mustbe of sufficientsize

to carry the current and maintain adequate voltage.

• The minimum extension cord wire size is A.W.G. 14.

Do not use extension cords over 25 feet long.

• Use only 3-wire extension cords having 3-prong

grounding type plugs and 3-pole receptacles which

accept the tool plug.

• If the extension cord is worn, cut or damaged in any

way, replace it immediately.

MOTOR

Planeris suppliedwith a 2+/2HP motorinstalled.

The 120 Volt AC universalmotorhas the following

specifications:

Horsepower (Maximum Developed) .......... 2V2HP

Voltage ................................... 120

Amperes................................... 15

Hertz ..................................... 60

Phase.................................. Single

Cutterhead RPM .......................... 8000

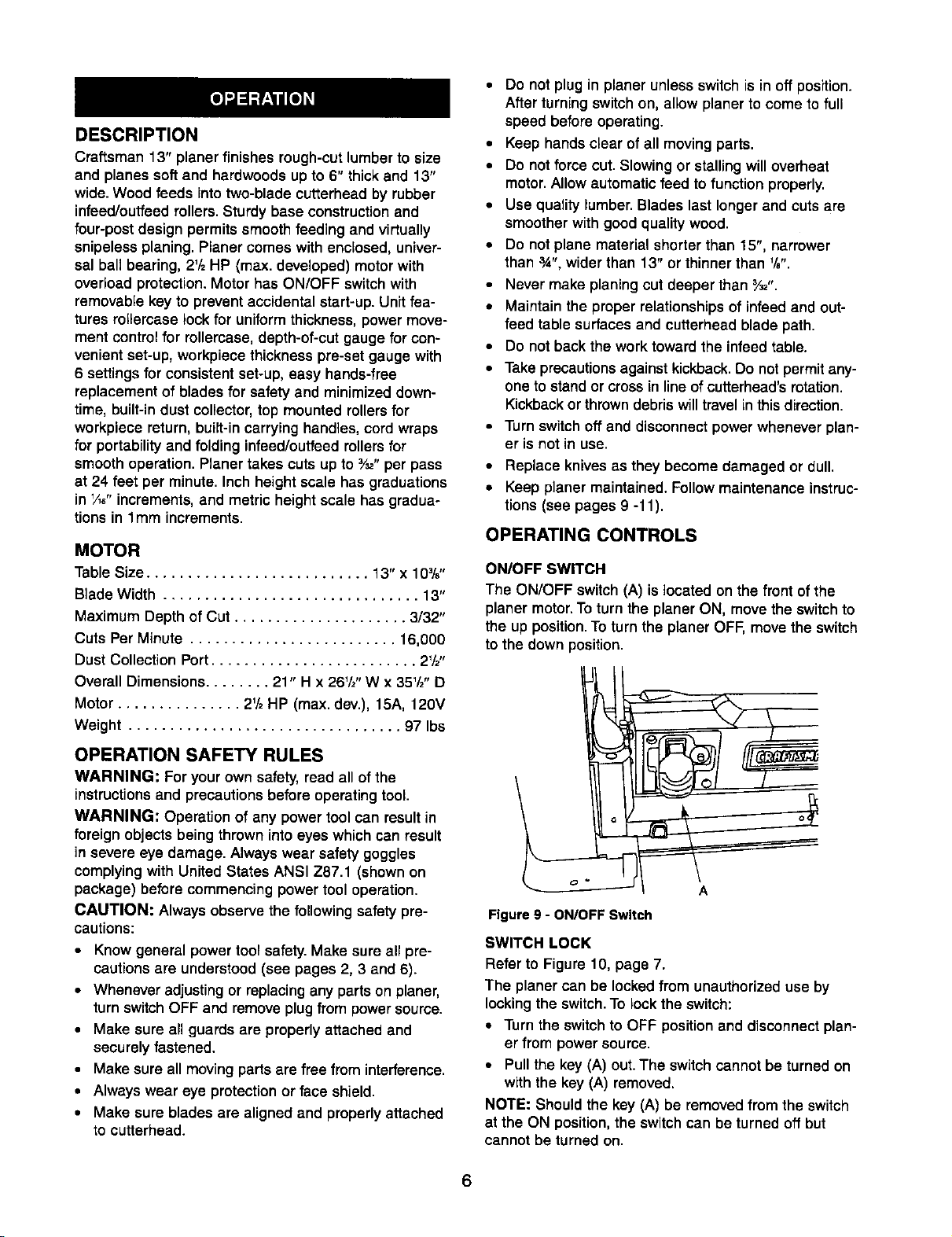

ELECTRICAL CONNECTIONS

WARNING: Make sure unit is turned offand discon-

nected from power source before inspectingany wiring.

The motoris installedand wiringconnected as illustrat-

ed in the wiringschematic (see Figure 8).

Black

Switch

Circuit

Breaker

Line Cord

Motor

Figureg- WiringSchematic

The motor is assembled with an approved three con-

ductor cord to be used on 120 volts as indicated. The

power supply to the motor is controlled by a double

pole locking switch.

The power lines are connected directly to the switch.

The green ground line must remain securely fastened

to the frame to properly protect against electrical shock.

A manual reset overload protector is installed in line

with the power suppry to the motor. If the planer is over-

loaded, the protector will break the circuit.

5

Page 6

DESCRIPTION

Craftsman 13" planer finishes rough-cutlumber to size

and planes soft and hardwoods up to 6" thick and 13"

wide. Wood feeds into two-blade cutterhead by rubber

infeed/outfeed rollers. Sturdy base construction and

four-post design permits smooth feeding and virtually

snipeless planing. Planer comes with enclosed, univer-

sal ball bearing, 2_/2HP (max. developed) motor with

overload protection. Motor has ON/OFF switch with

removable key to prevent accidental start-up. Unit fea-

tures rollercase lock for uniform thickness, power move-

ment control for rollercase, depth-of-cut gauge for con-

venient set-up, workpiece thickness pre-set gauge with

6 settings for consistent set-up, easy hands-free

replacement of blades for safety and minimized down-

time, built-in dust collector, top mounted rollers for

workpiece return, built-in carrying handles, cord wraps

for portability and folding infeed/outfeed rollers for

smooth operation. Planer takes cuts up to _/_"per pass

at 24 feet per minute. Inch height scale has graduations

in _A6"increments, and metric height scale has gradua-

tions in lmm increments.

MOTOR

Table Size ........................... 13" x 10%"

Blade Width ............................... 13"

Maximum Depth of Cut ..................... 3/32"

Cuts Per Minute ......................... 16,000

Dust Collection Port......................... 2V2"

Overall Dimensions........ 21" H x 26_/2" W x 35V2"D

Motor ............... 2V2HP (max, dev,), 15A, 120V

Weight ................................. 97 Ibs

• Do not plug in planer unless switch is in off position.

After turning switch on, allow planer to come to full

speed before operating.

• Keep hands clear of all moving parts.

• Do not force cut. Slowing or stalling will overheat

motor. Allow automatic feed to function properly.

• Use quality lumber. Blades last longer and cuts are

smoother with good quality wood.

• Do not plane material shorter than 15", narrower

than 3A",wider than 13" or thinner than '/8".

• Never make planing cut deeper than 3/,,.

• Maintain the proper relationships of infeed and out-

feed table surfaces and cutterhead blade path.

• Do not back the work toward the infeed table.

• Take precautions against kickback. Do not permit any-

one 1ostand or cross in line of cutterhead's rotation.

Kickback or thrown debris will travel in this direction.

• Turn switch off and disconnect power whenever plan-

er is not in use.

• Replace knives as they become damaged or dull.

• Keep planer maintained. Follow maintenance instruc-

tions (see pages 9 -11).

OPERATING CONTROLS

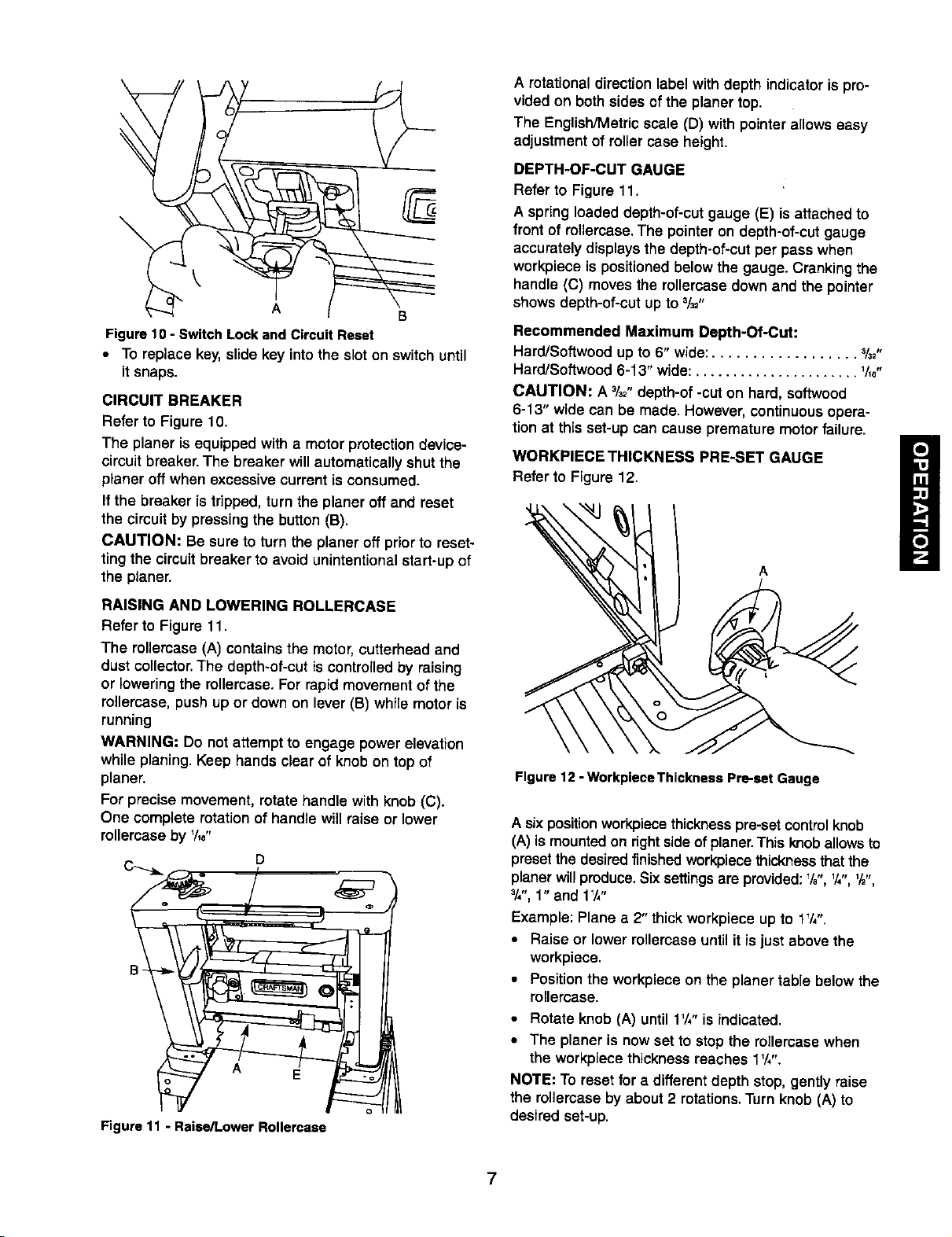

ON/OFF SWITCH

The ON/OFF switch (A) is located on the front of the

planer motor. To turn the planer ON, move the switch to

the up position. To turn the planer OFF, move the switch

to the down position.

OPERATION SAFETY RULES

WARNING: For yourown safety,read all of the

instructions and precautionsbefore operatingtool

WARNING: Operation of any power toolcan resultin

foreignobjectsbeing thrown into eyes whichcan result

in severe eye damage. Always wear safety goggles

complying with United States ANSI Z87.1 (shown on

package) before commencing power tool operation.

CAUTION: Always observe the following safety pre-

cautions:

• Know general power tool safety.Make sure all pre-

cautions are understood (see pages 2, 3 and 6).

• Whenever adjusting or replacing any parts on planer,

turn switch OFF and remove plug from power source.

• Make sure all guards are properly attached and

securely fastened.

• Make sure all moving parts are free from interference.

• Always wear eye protection or face shield.

• Make sure blades are aligned and properly attached

to cutterhead.

Figure 9 - ON/OFF Switch

SWITCH LOCK

Refer to Figure 10, page 7.

The planer can be lockedfrom unauthorizeduse by

lockingthe switch.To lock the switch:

• Turnthe switchto OFF positionand disconnect plan-

er from powersource.

• Pull the key (A) out.The switch cannot be turned on

with the key (A) removed.

NOTE: Shouldthe key (A) be removedfrom the switch

at the ON position,the switchcan be turned offbut

cannot be turned on.

Page 7

B

Figure10 - Switch Lockand Circuit Reset

• Toreplace key, slidekey intothe slot on switch until

it snaps.

CIRCUIT BREAKER

Refer to Figure 10.

The planer isequipped with a motor protection device-

circuitbreaker. The breaker will automaticallyshut the

planer off when excessive current is consumed.

Ifthe breaker is tripped, turn the planer off and reset

the circuitby pressingthe button(B).

CAUTION: Be sure to turn the planer off priorto reset-

tingthe circuitbreaker to avoid unintentionalstart-up of

the planer.

A rotationaldirection label with depth indicatoris pro-

vided on bothsides of the planer top.

The English/Metricscale (D) with pointerallowseasy

adjustment of relier case height.

DEPTH-OF-CUT GAUGE

Refer to Figure 11.

A spring loaded depth-of-cut gauge (E) is attached to

front of rollercase. The pointer on depth-of-cut gauge

accurately displays the depth-of-cut per pass when

workpieca is positioned below the gauge. Cranking the

handle (C) moves the rollercase down and the pointer

shows depth-of-cut up to 3/=,,

Recommended Maximum Depth-Of-Cut:

Hard/Softwood up to 6" wide:.................. %2"

Hard/Softwood 6-13" wide: ...................... V_e"

CAUTION: A 3/_,,depth-of -cuton hard, softwood

6-13" wide can be made. However, continuousopera-

tion at this set-up can cause premature motorfailure.

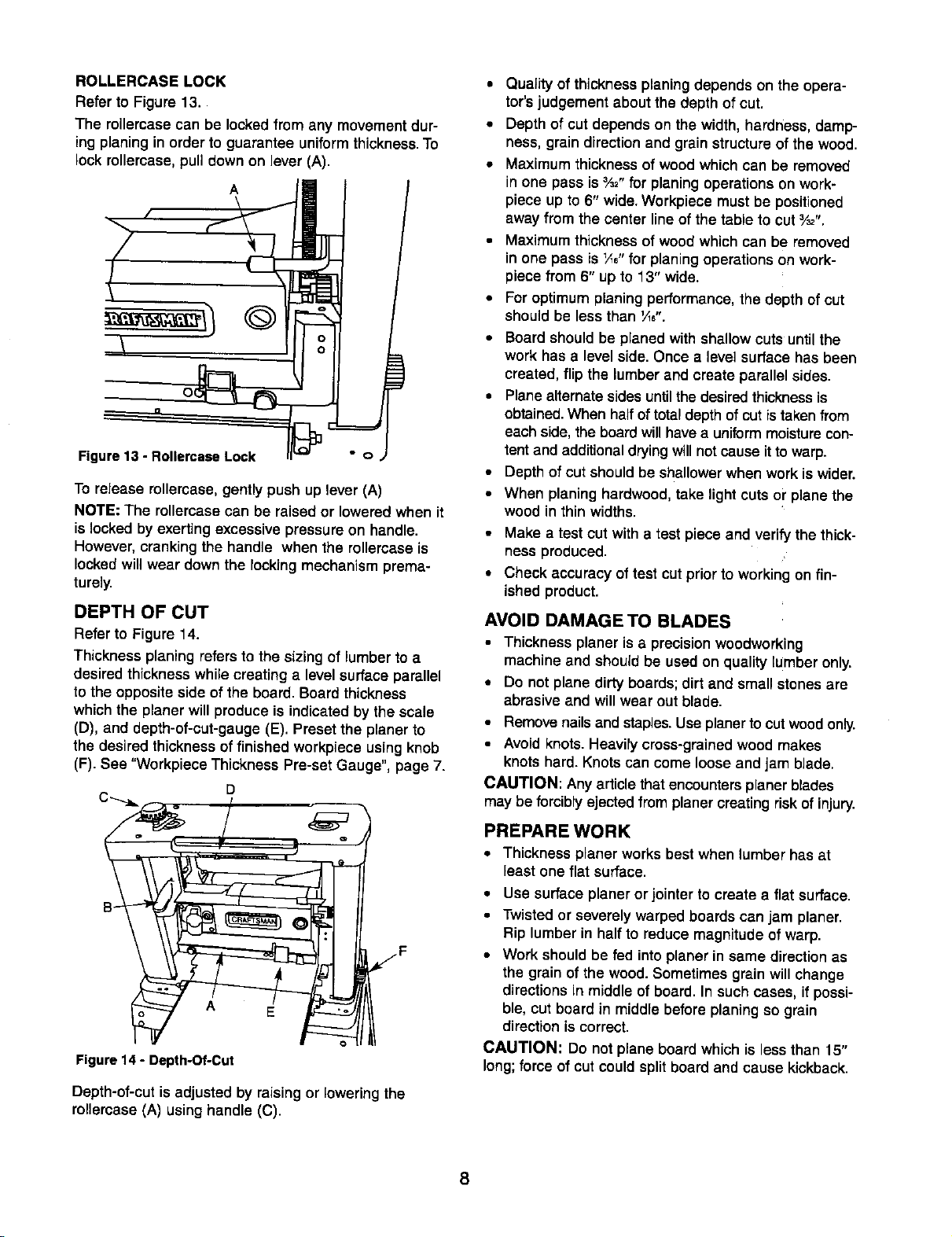

WORKPIECE THICKNESS PRE-SET GAUGE

Refer to Figure 12.

A

RAISING AND LOWERING ROLLERCASE

Refer to Figure 11.

The rellercase (A) containsthe motor,cutterhead and

dust collector.The depth-of-cut is controlledby raising

or lowering the rellercase. For rapid movementof the

rellercase, push up or down on lever (BI while motor is

running

WARNING: Do notattempt to engage power elevation

while planing.Keep handsclear of knobon top of

planer.

For precise movement, rotate handle with knob (C).

One complete rotationof handle will raise or lower

rollercaseby %6"

Figure 11 - Raise/Lower Rollercase

Figure 12 -Workpisce Thickness Pre-set Gauge

A six position workpiecethickness pre-setcontrolknob

(A) ismountedon rightside of planer.This knoballowsto

presetthe desiredfinished workpiecathicknessthatthe

planerwillproduce.Sixsettingsare provided:%", Y,",'/_",

_/,",1" and 1W'

Example: Plane a 2" thickworkpiece up to 1_/,".

• Raise or lowerrollercase until it is just above the

workpiece.

• Positionthe workpiece on the planer table belowthe

rollercase.

• Rotate knob (A) until 1V,"is indicated.

• The planer is nowset to stopthe roilercase when

the workpiecethickness reaches 1V,".

NOTE: To reset for a differentdepth stop,gently raise

the rollercase byabout 2 rotations.Turnknob (A) to

desired set-up.

7

Page 8

ROLLERCASELOCK

Refer to Figure 13.

The rollercase can be locked from any movementdur-

ing planing in order to guarantee uniform thickness. To

lock rollercase, pull down on lever (A).

Figure 13 - Ronercase Lock

To release rollercase, gently push up lever (A)

NOTE: The rollercasecan be raised or lowered when it

is locked by exerting excessivepressure on handle.

However, cranking the handle when the rollercaseis

lockedwillwear down the locking mechanism prema-

turely.

DEPTH OF CUT

Refer to Figure 14.

Thickness planing refers to the sizing of lumber to a

desired thicknesswhile creating a level surface parallel

to the opposite side of the board. Board thickness

whichthe planer will produce is indicated by the scale

(D), and depth-of-cut-gauge (El. Preset the planer to

the desired thickness of finished workpiece using knob

(F). See "Workpiece Thickness Pre-set Gauge", page 7.

D

• Quality of thickness planing depends on the opera-

tor's judgement about the depth of cut.

• Depth of cut depends on the width, hardness, damp-

ness, grain direction and grain structure of the wood.

• Maximum thickness of wood which can be removed

in one pass is 3/=,,for planing operations on work-

piece up to 6" wide. Workpiece must be positioned

away from the center line of the table to cut _/=".

• Maximum thickness of wood which can be removed

in one pass is _," for planingoperations on work-

piece from 6" up to 13" wide.

• For optimum planing performance, the depth of cut

should be less than '/1,".

• Board should be planed with shallow cuts until the

work has a level side. Once a level surface has been

created, flip the lumber and create parallel sides.

• Planealternatesides until the desired thickness is

obtained.When halfof totaldepth of cut istaken from

each side,the boardwillhavea uniformmoisturecon-

tentand additionaldryingwill notcause ittowarp.

• Depth of cut shouldbeshallowerwhen work is wider.

• When planing hardwood, take lightcuts or plane the

wood in thin widths.

• Make a test cut with a test piece and verifythe thick-

ness produced.

• Check accuracy of test cut prior to working on fin-

ished product.

AVOID DAMAGE TO BLADES

• Thickness planer is a precisionwoodworking

machine and shouldbe used on quality lumber only,

• Do not plane dirtyboards;dirt and small stones are

abrasive and willwear out blade,

• Removenailsand staples.Useplanerto cutwoodonly.

• Avoidknots.Heavilycress-grethedwood makes

knots hard. Knotscan come loose and jam blade.

CAUTION: Anyarticlethat encountersplaner blades

may be forciblyejected from planercreating riskofinjury,

Figure 14 - Depth-Of-Cut

Depth-of-cutis adjusted by raisingor lowering the

rollercase (A) using handle (C).

PREPARE WORK

• Thickness planer works best when lumber has at

least one flat surface.

• Use surface planer orjointerto create a flat surface.

• Twistedor severely warped boards can jam planer.

Rip lumber in half to reduce magnitude of warp.

• Work shouldbe fed intoplaner in same directionas

the grain of the wood. Sometimes grain will change

directions in middle of board. In such cases, if possi-

ble, cut board in middle before planing so grain

direction is correct.

CAUTION: Do not plane board which is less than 15"

long;force of cut couldsplitboard and cause kickback.

8

Page 9

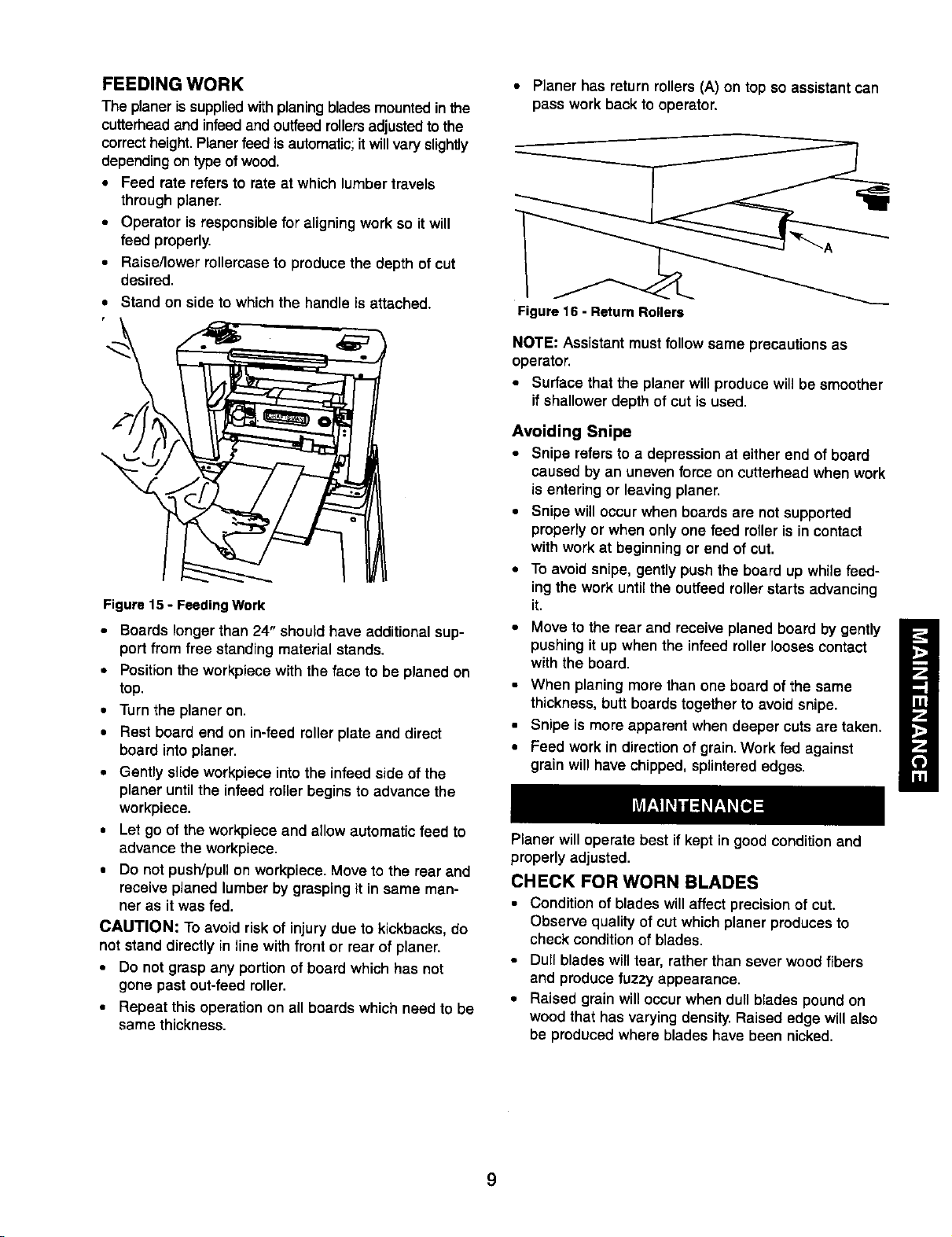

FEEDINGWORK

The planerissuppliedwithplaningbladesmountedinthe

cutterheadand infeedandoutfeedrollersadjustedtothe

correctheight.Planerfeed isautomatic;itwillvary slightly

depending on typeofwood.

• Feed rate refers to rate at which lumber travels

through planer.

• Operator is responsiblefor aligning work so it will

feed properly.

• Raise/lower rottercaseto produce the depth ol cut

desired.

• Stand on side towhich the handle is attached.

-!

Figure15 - FeedingWork

• Boards longerthan 24" shouldhave additionalsup-

port from free standing materiat stands.

• Positionthe workpiece with the face to be planed on

top,

• Turnthe planer on.

• Rest board end on in-feed roller plate and direct

board into planer.

• Gently slide workpiece into the infeed side of the

planer until the infeed roller begins to advance the

workpiece.

• Let go of the workpieca and allow automatic feed to

advance the workpieca.

• Do not push/pull on workpiece. Move to the rear and

receive planed lumber by grasping itin same man-

ner as it was fed.

CAUTION: To avoid risk of injury due to kickbacks, do

not stand directly in line with front or rear of planer,

• Do not grasp any portion of board which has not

gone past out-feed roller.

• Repeat this operation on all boards which need to be

same thickness.

• Planer has return rollers (A) on top so assistant can

pass work back to operator.

Figure 16 - Return Rollers

NOTE: Assistantmustfollow same precautions as

operator.

• Surface thatthe planer willproducewill be smoother

ifshallowerdepth of cut is used.

Avoiding Snipe

• Snipe refers to a depression at either end of board

caused by an uneven force on cutterhead when work

is entering or leaving planer.

• Snipe will occur when boards are not supported

properly or when only one feed roller is in contact

with work at beginning or end of cut.

• To avoid snipe, gently push the board up while feed-

ing the work until the outfeed rotterstarts advancing

it.

Move to the rear and receive planed board by gently

pushing it up when the infeed roller looses contact

with the board.

• When planing more than one board of the same

thickness, butt boards together to avoid snipe.

• Snipe is more apparent when deeper cuts are taken.

• Feed work in direction of grain. Work fed against

grain will have chipped, splintered edges.

Planer willoperate best if kept in good conditionand

properly adjusted.

CHECK FOR WORN BLADES

• Conditionof blades willaffect precisionof cut.

Observe quality of cutwhich planer producesto

check conditionof blades.

• Dull bladeswilltear, rather than sever woodfibers

and producefuzzy appearance.

• Raised grain willoccurwhen dull blades poundon

wood that has varying density.Raised edge willalso

be prm:luced where blades have been nicked.

9

Page 10

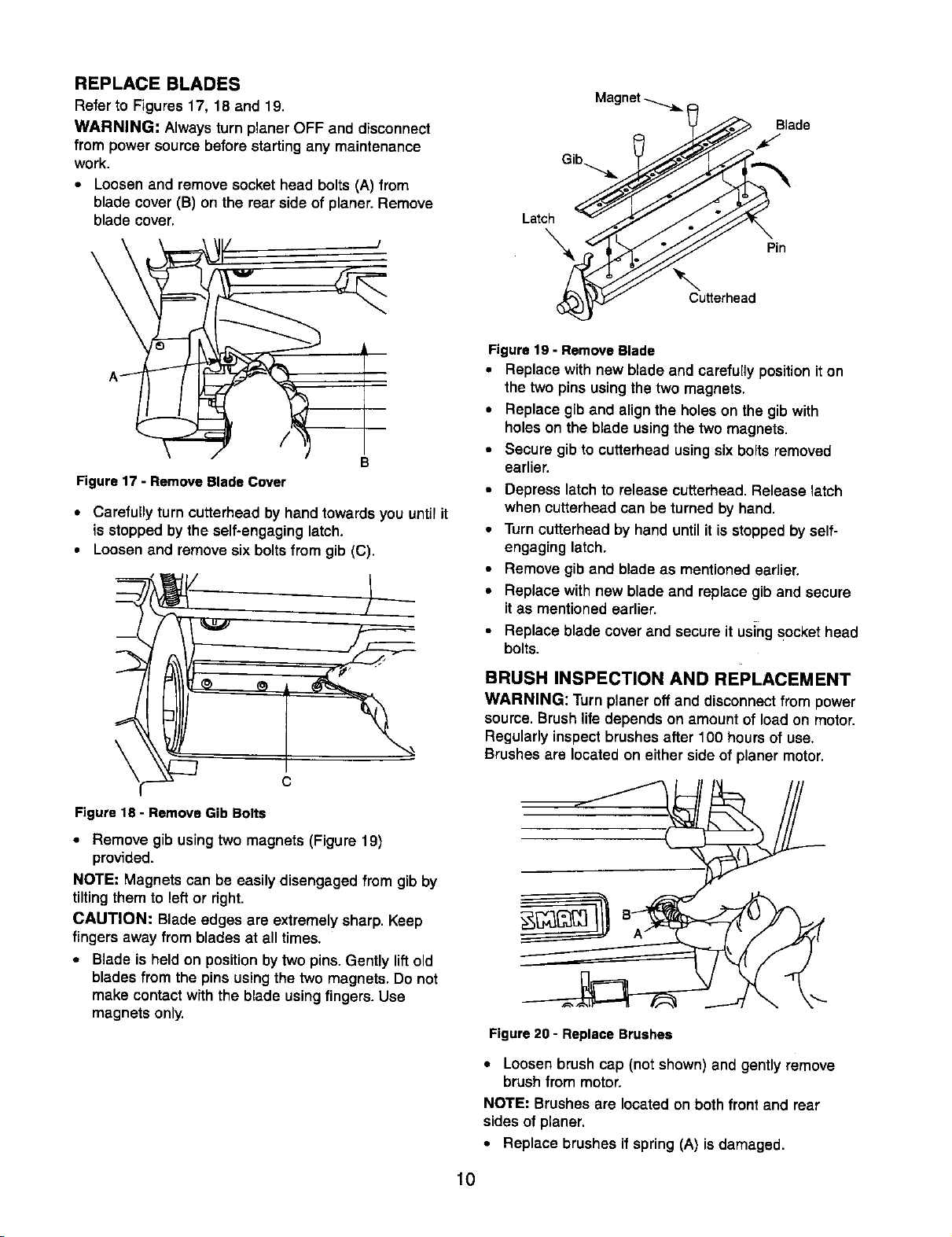

REPLACE BLADES

Refer to Figures 17, 18 and 19.

WARNING: Always turn planer OFF and disconnect

from power source before starting any maintenance

work.

• Loosen and remove socket head bolts (A) from

blade cover (B) on the rear side of planer.Remove

blade cover.

A/

B

Figure17 - RemoveBlade Cover

• Carefully turn cutterhead by hand towards you until it

is stopped by the self-engaging latch.

• Loosen and remove six bolts from gib (C).

Magnet

Blade

Latcx_kS

Figure19 - RemoveBlade

• Replace with new blade and carefullyposition it on

the two pins using thetwo magnets.

• Replace gib and align the holeson the gib with

holeson the blade using the two magnets,

• Secure gib to cutterhead usingsix boltsremoved

earlier.

• Depress latch to release cutterhead. Release latch

when cutterhead can be turned by hand.

• Turncutterhead by hand until it is stopped by self-

engaging latch,

• Remove gib and blade as mentioned earlier.

• Replace with new blade and replace giband secure

itas mentioned earlier.

• Replace blade cover and secure it usingsockethead

bolts.

Figure 18 - Remove Gib Bolts

• Remove gib using two magnets (Figure 19)

provided.

NOTE: Magnets can be easily disengaged from gib by

tiltingthem to leftor right.

CAUTION: Blade edges are extremely sharp. Keep

fingers away from blades at all times.

• Blade is held on position by two pins. Gently lift old

blades from the pins using the two magnets. Do not

make contact with the blade using fingers. Use

magnets only.

BRUSHINSPECTION AND REPLACEMENT

WARNING: Turn planer off and disconnect from power

source. Brushlife depends on amount of load on motor,

Regularly inspect brushes after 100 hours of use.

Brushes are located on either side of planer motor.

Figure 20 - Replace Brushes

• Loosen brush cap (not shown) and gently remove

brush from motor.

NOTE: Brushes are located on both front and rear

sides of planer.

• Replace brushes if spring (A) is damaged.

10

Page 11

• Replace brushes if carbon (B) is worn.

• Replace brushes and tighten brush cap.

ADJUSTING ROLLERCASE LEVEL

Refer to Figures 21 and 22, pages 14and 16.

The planer will produceuneven depthof cut (tapered

cut) if rollemase (Fig. 22, Key No. 59) is not parallel

with base (Fig. 21, Key No. 48). To restore parallelism of

rollercasewith base:

• Using a test piece, measure height of the taper.

• Turnplaner offand disconnect from power source.

• Fold front and rear extensiontables.

• Lay planer carefully on itsback so that bottom side

of base is facing you.

• Loosentwo socket head bolts (Fig.21, Key No. 62).

Loosen chain (Fig. 21, Key No.67) bysliding idler

bracket (Fig. 21, KeyNo. 60).

• Rotate elevationscrews as needed. Each turn of

screw will movethat side of rollercase by _Aa".

• Retighten chain using idler bracket.Tighten socket

head bolts securely.

• Set planer back on itsbase.

• Make a test cut toverify adjustment.

REPLACING V-BELT

Refer to Figures 21, 22 and 23, pages 14, 16 and 18.

Inadequate tension in V-belts (Fig 22, Key No. 28 and

Fig. 23, Key No.78) will cause belts to slip from the pul-

leys. Loose belts must be replaced. To replace V-belts:

• Remove socket pan head screw and flat washer

(Fig. 21, Key Nos. 1 and 2). Pull handle off. Pull knob

(Fig. 21, Key No. 40) off.

• Remove four pan head screws (Fig. 21, Key No. 15)

from cover (Fig. 21, Key No. 10). Remove cover.

Remove right side cover (Fig. 21, Key No. 39).

• Remove V-belt (Fig. 22, Key No. 28) by walkingthe

belt from both pulleys alternately. Gently pull the belt

while turning the pulleys at the same time. Repeat

with V-belt (Fig. 23, Key No. 78).

• Replace with new belts. Walk each belt onto the pul-

leys in the reverse manner as when removingthe

belts.

Make sure each of the belts are evenly seated all

the way on both pulleys.

Replace right side panel and knob. Replace cover

and secure with pan head screws. Replace handle

and secure with flat washer and pan head screw.

LUBRICATION

• Motorand cutterhead bearings are sealed and need

no lubrication.

Gears and elevation screws should be cleaned of

debris and greased.

The table and extension tables can be coated with a

lubricant such as paste wax, to make the workpiece

feed smoother. Be sure the lubricant used does not

affect the ability to finish the workpiece with varnish,

sealer, etc. Do not use any siliconebase lubricants.

CLEAN PLANER

• Keepplaner cleanof any wood chips,dust,dirt ordebris.

• After 10 hours of operation, the chains and gears

should have wood chips, dust and old grease

removed.

• Use common automotive bearing grease to lubricate

all chains and gears. Be sure all chains and gears

have plenty of grease.

11

Page 12

SYMPTOM

Snipe

(gouging at ends of board)

Fuzzy grain Planing wood with a high moisture Remove high moisture content from woodby

Torn grain 1.Too heavy a cut 1.Review "Depth of Cut"

Rough raised grain 1.Dull blades 1.Replace blades per instructions.

Uneven depth of cut Rollercase not level with planer Rollercase not level

side to side) base See "Adjusting Table Level"

Rollercase elevation adjusts

with difficulty

POSSIBLE CAUSE(S)

1.Dull blades

2.Inadequate supportof long boards

3.Uneven force on cutterhead

4.Rollercase not level with base

5.Lumber not butted properly

content drying

2.Blades cutting against grain 2.Review "Feeding Work"

3.Dull blades 3.Replace blades per instructions

2.Too heavy a cut 2.Review "Depth of Cut"

3.Moisture content too high 3.Dry the wood or use dried wood

1.Sprockets or chain dirty

2.Elevation screws, columns dirty

3.Elevation screws worn

4.Friction between rollercase and

covers

5.Rollercase not parallel with planer

base

6.Rollercase lockengaged

CORRECTIVE ACTION

1.Replace bladesper instructions,

See "Maintenance"

2,Support long boards.See "Avoiding Snipe"

3,Gently push board when board is in contact

withonlyonefeed roller,See "AvoidingSnipe"

4,Adjust rollercase

See "Adjusting Table Level"

5,Butt end to end each piece of stock as

boards pass through planer

See "Maintenance"

See "Maintenance"

1.Clean and lubricate sprocketsand chain

2.Clean and lubricateelevationscrews, columns

3.Replace elevation screws

4.Clean and lubricate

5.Adjust rollercase

See "Adjusting Table Level"

6.Release rollercase lock

Board feeds inside, but stops 1.Outfeed rollers cannot rotate due 1.Clear the clogging, cleandust collector

moving past the outfeed roller to clogging of chips system. See "Clean Planer"

2.Too much pressure on the 2.Use support stands to support workpiece

cutterhead from long workpiece longer than 24". See "Recommended

Accessories"

Board thickness does not Indicator not set correctly Adjust indicator and tighten securely

match depth of cut scale

Chain jumping 1.Sprockets worn 1.Replace sprockets

2.Chain worn 2.Replace chain

Planer will not operate 1.No power to planer 11.Check power source by qualified electrician

2.Motor overload protection tripped !2.Turn planer off. Reset motor overload

3.Defective or loose switch or wiring 3.Check switchand wiring by qualified

Belt slipping Loose belt Replace belt, see "Replacing V-Belt"

Rollercase connect be lowered Workpiece thickness gauge setting Reset thickness gauge setting,

restricts rollercase movements see "Workpiece Thickness Gauge"

I

protection. See "Overload Reset"

electrician

12

Page 13

SYMP/uM

Excessive dust in air

(gougingat ends of board)

Excessive fan noise

Motor overheats

Tripping circuit breaker or fuses

POSSIBLE CAUSE(S)

1.Leaking bag or hose connection

2.Collector bag leaks

1.Large debris or piece of wood in

fan housing

2.Loose fan

1.Motor overload

2.Improper motor cooling

1.Motor overload

2.Improper capacity of circuit breaker

or fuses

3.Dull blades

CORRECTIVE ACTION

1.Check collector bagconnections. Check

collectorhose connections

2.Dust trapped under bag clamp or collector

bag not sealed on flange

1.Turn collector off and let debris settlein

collector bag. Remove blade guard and

clear chamber

2.Remove blade cover and tighten bolt

(Fig. 22, Key No. 19)

1.Reduce depth ofcut

2.Clean sawdustfrom motor

1.Reduce depth of cut

2.Use proper capacity circuitbreaker or fuse

3.Replace blades

13

Page 14

Model 351.217430

Figure 21 - Replacement Parts Illustration for Base

9,

19 20 7 1_

-_1

,, 22

26 27/4

j°

56

35 36

58

38

28/_

65

68

66

54

14

Page 15

KEY

NO.

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

PART NO.

16099.00

STD851006

16098.00

16100.00

00964.00

STD652005

20042.00

16610.00

18578.00

18623.00

18524.00

09637.00

16742.00

02783.00

16096.00

16101.00

18500.00

01903.00

18566.00

05285.00

18603.00

18581.00

18565.00

07339.00

18525.00

03069.00

18583.00

18580.00

07482.00

18554.00

18516.00

18555.00

00389.00

18564,00

18619.00

18344.00

DESCRIPTION

QTY.

6-1.0 x 20ram Socket Pan Head 2

Screw

6ram Flat Washer* 2

Pointer 1

Handle Assembly 1

6-1.0 x 6ram Set Screw 1

5ram LockWasher* 4

6 x 24ram Knurled Dowel Pin 2

Spring 1

Plug 1

Upper Cover 1

6 x 21mm Knurled Dowel Pin 2

Bushing 4

Roller 2

4 x 18mm Spring Pin 1

8-1.25 x 16ram Socket Pan Head 4

Screw

Grip 2

4-1.59 x 6ram Threadforming 8

Screw

4-0.7 x 10ram Pan Head Screw 2

Bracket 1

5-0.8 x 6ram Pan Head Screw 4

Spring 1

Pointer Bracket 1

Cable 1

6mm Steel Ball 1

Collar 2

5-0.8 x 6ram Set Screw 2

Pointer Guide 1

Pointer 1

5-0.8 x 18ram Socket Head Bolt 2

Pulley Bracket 1

Bushing 2

Cable Pulley 1

5-9.8 x 12mm Pan Head Screw 1

Left Side Cover 1

Tool Storage Case 1

5-1.6 x 12ram Threadforming 4

Screw

Shaft37 18597.00 1

KEY

! NO. PART NO.

38 16115.00

39 18591.00

40 18560.00

41 18616,00

42 18547.00

43 03855.00

44 00256.00

45 18526.00

46 18527.00

47 18534.00

48 18507.00

49 STD841217

50 STD833020

51 STD840610

52 18601.00

53 08662.00

54 09658.00

55 18615.00

56 00781.00

57 18563.00

58 18535.00

59 18590.00

60 18299.00

61 STD851005

62 05331.00

63 18339.00

64 18333.00

65 05148.00

66 18618.00

67 18522.00

68 18540.00

69 STD315505

70 18510.00

71 18332.00

72 18338.00

73 STD851004

74 20036.00

75 STD841015

76 18505.00

DESCRIPTION

Magnet

RightSide Cover

Knob

Table

Guide Plate

5-0.8 x 10ram Socket Head Bolt

3AMI-20 Retaining Ring

FrontColumn

Rear Column

ElevatingScrew

Base

12-1.75mm Hex Nut*

6-1.0 x 20ram Hex Head Bolt*

6-1.0ram Hex Nut*

Spacer

6-1.0 x 8ram Socket Head Bolt

Bushing

Support Roller

4-0.7 x 8ram Pan Head Screw

Left Roller Plate

ExtensionTable

Right Roller Plate

Idler Bracket

5mm FlatWasher*

5-0.8 x 12mm Socket Head Bolt

Sprocket

Spacer

3AMI-8 Retaining Ring

Thickness Gauge

Chain

Gauge Bracket

6000ZZ Ball Bearing*

Bearing Retainer

Spacer

Sprocket

4ram Flat Washer*

4-0.7 x 12ram Socket Pan Head

Screw

10-1.5ram Hex Nut*

AdjustScrew

QTY.

2

1

1

1

2

8

2

2

2

2

1

4

4

4

4

4

4

2

12

2

2

2

1

2

6

1

1

1

1

1

1

2

2

2

2

2

2

4

4

Standard hardware item available locally

A Not Shown

Recommended Accessories

A Multi-Purpose Stand

A Horizontal Roller Stand

A Three-Roller Stand

15

9-22224

9-21417

9-22265

Page 16

Model 351.217430

Figure 22 - Replacement Parts Illustration for Rollercase

51

36

35

11 12

13

14 15

21 25

23

f

40

33

\

47 48

32

12

11

2

69

73

2-_--'P--/

43

16

34

.d,--- 41

f,

Page 17

KEY

NO.

1

2

3

4

5

6

7

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

PART NO.

18506.00

03855.00

18514.00

18499.00

01784.00

18523.00

06731.00

18537.00

18349.00

18288.00

STD840812

STD852008

16383.00

06821.00

06396.00

18568.00

16129.00

16351.00

06346.00

STD851006

18536,00

18539.00

STD315505

18599.00

18533.00

00964.00

18538.00

18495.00

16125.00

16124.00

16123.00

16382.00

03069.00

20039.00

18573.00

00964.00

DESCRIPTION

Air Duct

5-0.8 x 10mm Socket Head Bolt

Blade Cover

4-1.4 x 12mm Flat Head

ThreadformingScrew

5-0,8 x 10ram Pan Head Screw

Chip Deflector

5-0.8 x 10ram Socket Pan Head

Screw

Fan Housing

6-1.0 x25ram Socket Pan Head

Screw

Dust Chute

8-1.25mm Hex Nut*

8mm Lock Washer*

Left Cam

3CM1-12 E-Ring

3 x 12mm Spring Pin

LockLever

Spring

LockLever Cap

6-1.0 x 12mm Socket Pan Head

Screw

6ram Flat Washer*

!Ean

i Fan Shaft

6000ZZ Ball Bearing*

Spacer

Dust Cover

6-1.0 x 6mm Set Screw

Fan Pulley

135J2 V-Belt

Rod

Spring

Pad

Right Cam

5-0,8 x 6ram Set Screw

Spring

Nut

6-1.0 x 6ram Set Screw

QTY.

1

16

1

3

4

1

2

1

2

2

1

2

2

1

1

1

1

1

1

1

2

1

1

1

1

1

4

4

4

1

1

2

1

1

KEY

NO.

37

38

39

4O

41

42

43

44

45

46

47

48

49

5O

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

7O

71

72

73

74

75

PART NO.

18562.00

STD851005

08551,00

00814.00

18612.00

02702.00

18593.00

18513.00

18595.00

18589.00

05383.00

STD540501

00361.00

01474.00

18582.00

01548.00

STD851004

18579.00

18520.00

00781.00

18584.00

18574.00

18594.00

18494.00

18587.00

18636.00

18570.00

18571,00

02614,00

STD841015

18614.00

!18611.00

00533.00

STD851008

00483.00

18567.00

03853.00

03843.00

18585,00

DESCRIPTION QTY.

Left Elevating Nut 1

5ram Flat Washer* 1

Retainer Plate 1

5-0.8 x 16ram Socket Head Bolt 2

Outfeed Spring 2

Cord Clamp 1

Roller 2

Belt Guard 1

Screw 1

Right Elevating Nut 1

5-9.8 x 16mm Hex Head Bolt 5

5-0.8ram Hex Nut* 5

5-0.8 x 8ram Pan Head Screw 2

5ram Serrated Lock Washer 2

Pointer Cover 1

4-0.7 x 12ram Pan Head Screw 1

4mm Flat Washer* 1

Pointer 1

Bushing 1

4-0.7 x 8ram Pan Head Screw 2

PointerHousing 1

Nut 1

Rollercase 1

12mm Steel Ball 1

Retaining Plate 1

3-1.0 x 8ramThreadforming Screw 2

Magnet 4

Magnet Seat 4

5-0.8 x 10ram Flat Head Screw 4

10-1.5mm Hex Nut* 1

Stop Rod 1

InfeedSpring 2

3AM1-15 Retaining Ring 2

8ram Fiat Washer* 1

8-1.25 x 25mm Socket Head Bolt 1

Cable Clamp 1

Sprocket 2

RetainingBracket 4

Retainer 4

Standard hardware itemavailable locally

17

Page 18

Model 351.217430

Figure 23 - Replacement Parts Illustration for Cutterhead and Gearing

48 55

51

67

68

\

63

64

65

2-.._

3

83 84

82

@ _X 87

69

71

\7 3

.76

77 78 79

86

85

7 46

4O

44

45

35

36

37

59

J

!

26

47

18

Page 19

KEY

NO. PART NO.

1 18517.00

2 18548.00

3 00221.00

4 03855.00

8 18516.00

6 16515.00

7 18545.00

8 18551.00

9 00256.00

10 03069.00

11 18546.00

12 ST0852005

13 18598.00

14 05331.00

15 STD315505

16 18510.00

17 18332.00

18 18338.00

19 ST0851004

20 20036.00

21 18606.00

22 06182.00

23 18549.00

24 18541.00

25 18622.00

26 ST0315525

27 18542.00

28 18613.00

29 18607.00

30 97339.00

31 18519.00

32 18621.00

33 06252.00

34 18553,00

35 18497.0O

36 22548,00

37 03853.00

38 06045.00

39 ST0851005

40 18608.00

41 18617.O0

42 18600.00

43 18502.00

44 15105.00

45 18575.00

Standard hardware item available locally

A Not Shown

DESCRIPTION

Bushing

Guide Rod

3AMI-10 Retaining Ring

5-0.8 x 10rnrn Socket Head Bolt

Bushing

Bracket

Grip

Handle

3AMI-20 Retaining Ring

6-0.8 x 6ram Set Screw

Guide Bracket

5mm Lock Washer*

Sliding Bar

5-0.8 x 12rnrn Socket Head Bolt

6000ZZ Ball Bearing"

Bearing Retainer

Spacer

Sprocket

4rnrn Flat Washer*

4-0.7 x 12turn Socket Pan Head

Screw

Spring

6-1.0 x 30rnm Socket Head Bolt

Guide Rod

Gear

Transmission Seat

6002ZZ Ball Bearing"

Gear

Spring Holder

Spring

6mm Steel Ball

Bushing

Transmission Collar

5-0.8 x 14rnrn Socket Head Bolt

Holder

3AMI-24 Retaining Ring

Chain

Sprocket

5-0.8 x 20rnm Socket Head Bolt

5mrn Flat Washer*

Spring

Tension Wheel Assembly

Spacer

5-0.8 x 30turn Socket Head Bolt

5-0.8 x 35rnrn SocketHead Bolt

Outside Gear Plate

QTY.

1

1

1

4

1

1

1

1

3

2

1

2

1

2

1

1

1

1

1

1

2

2

1

2

1

2

1

4

4

4

4

1

2

1

1

1

1

1

1

1

1

1

2

4

1

KEY

NO.

PART NO. DESCRIPTION

46

20038.00

47

18596.00

48

18267.00

49

18351.00

5O

18329.00

51

20020.00

52

18577.00

53

STD315225

54

18572.00

55

18266.00

56

18277.00

57

18330.00

58

18528.00

59

19069.00

60

16529.00

61

03839.00

62

18557.00

63

18602.00

64

9-29459

65

18543,00

66

09789.00

67

18512.00

68

ST0315245

69

18509.00

7O

05331.00

71

18609.00

72

18531.00

73

20040,00

74

01784,00

75

18824,00

76

18832,00

77

18552,00

78

93841.00

79

00964,00

8O

18530.00

81

18493,00

82

20041,00

83

16080,00

84

94287,00

85

20043,00

86

20044.00

87

20045.00

A

18625,00

20026,00

18236,03

QTY.

Sleeve 2

Shaft 1

58"1"/12TGear 1

70T Gear 1

Spacer 2

Inside Gear Plate 1

Pinion Gear 1

6202ZZ Ball Bearing* 1

Motor Pulley 1

52T/12T Gear 1

Bushing 5

Spacer 4

Cover 1

4 x4x 19mm Key 1

Cutterhead 1

5 x5x 10mm Key 1

Cutterhead Pin 4

Spring 4

Blade (Set of 2) 1

Gib 2

6-1.0 x 16turn Socket Pan Head 12

Screw

Bearing Retainer 1

6204ZZ Bail Bearing* 1

Bearing Cover 1

5-0.8 x 12mm Socket Head Bolt 3

Spring 1

Cutterhead Lock 1

Bushing 1

5-0.8 x 10mm Pan Head Screw 1

Spacer 1

Cutterhead Pulley 1

Pulley Retaining Nut 1

135J6 V-Belt 1

6-1.0 x 6rnrnSet Screw 1

Cutterhead Fan Pulley 1

Motor Assembly 1

Line Cord 1

Switch 1

Circuit Breaker 1

Brush Holder 2

Brush (set of 2) 1

Brush Cap 2

Half-Bag Dust Collection Set 1

Parts Bag 1

Operator's Manual 1

19

Page 20

CEPILLADORA CON RECOLECTOR

DE POLVO de 13"

Modelo No.

351.217430

PRECAUClON: Lea y acate todas las normas

de seguridad e instrucciones de operaci6n

antes de usar pot prirnera vez este producto,

Ingl(_s........................................ 2-19

Garantfa ........................................ 20

Reglas de seguridad............................ 20-21

Desempaque .................................... 21

Montaje ...................................... 21-22

Instalaci6n.................................... 22-24

Operaci6n .................................... 24-28

Mantenimiento ................................ 28-29

Identificaci6n de problemas ...................... 30-31

GARANTIA COMPLETA DE UN AI_O

Si fallare este producto pot causa de defectos en el material

o en la mano de obra en un lapso de un a_o a partir de la

fecha de compra, Sears Io reparar_,o reemplazard, a su

elecci6n, sin oostoadicional. Solioiteal Centro de servicio

Sears (1-800-4-MY-HOME) rods cercano la repareci6n del

productoo devu_lvalo al establecimientodonde Io adquiri6.

Si este procluctose usa para fines comerciales o de alquiler,

esta garantfa es v_.lida por 90 d(as a partir de la fecha de

compra.

Esta garentfa aplica _nicamente cuando el produotose utiliza

en los Estados Unidos.

Esta garentfa le otorga derechos legales especfficosy

tambidn puede usted tener otros derechos que varfen de

estado a estado.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates,

IL 60179

ADVERTENCIA: Pot su propia seguridad, lea todas las

normas y precauciones antes de manejar la herramienta.

PRECAUClON: Siempre siga los procedimientos de

operaci6n correctos,tal como se definen en este manual,

aun cuando estd familiarizado con el uso de _sta o de otres

herramientas similares. Recuerde que descuidarse aunque

s61osea pot una fraccibn de segundo puede ocasionarle

graves ]esiones.

EL OPERADOR DEBE ESTAR PREPARADO

PARA ELTRABAJO

Use ropa apropiada. No use ropa holgada, guantes,

corbatas, anillos, pulseras ni otras joyas que puedan

atascarse en las piezas rn6viles de la mdquina.

Use una cubierta protectora para el cabello, para sujetar el

cabello largo. ,

Use zapatos de seguridad con suelas antidesllzantes.

Use gafas de seguridad que cumplan con la norma ANSI

Z87.1 de los Estados Unidos. Los anteojos comunes

tienen lentes que s61oson resistentes al impacto,NO son

anteojos de seguridad.

Use una mdscara para la care o una m_.scaracontra el

polvo,sial utilizarla herramienta se produce mucho polvo.

Estd alerta y piense claremente. Nunca opere herramien-

tas mec_.nicascuando est_ cansado, intoxicado o bajo la

influenciade medicaci6n que produzca somnolencia.

PREPARE EL AREA DETRABAJO PARA LA

TAREA A REALIZAR

Mantenga el drea de trabajo limpia. Las dreas de trabajo

desordenadas atraen accidentes.

No use herremientas mec_.nicas en ambientes peligrosos.

No use herramientas mec_.nicas en lugares hOmedos

o mojados. No exponga las herramientas mec_.nicas

a la Iluvia.

Eldrea de trabajo debe estar iluminada adecuadamente.

Debe haber disponibleuna toma de corriente adecuada

para la herramienta. El enchufe de tres puntas debe en-

chufarse directamente a un recept_.culopara tres puntas

puesto a tierra correctamente.

Los cordones de extensi6n deben tener una puntade

conexi6n a tierra y los tres alambres del cord6n de

extensiSn deben ser del calibre correcto.

Mantenga a losvisitantes a una distancia prudente del

_.rea de trebajo.

Mantenga a los niSosfuere del lugar de trabajo. Haga que

su taller sea a prueba de ni_os, Use candados, interrup-

tores maestros y remueva las Ilaves del arrencador para

impedir cualquier uso involuntariode ]as herramientas

mecdnicas.

SE DEBE DAR MANTENIMIENTO A

LA HERRAMIENTA

Desenchufesiemprela herramientaantesdeinspec-

cionarla.

Consulte el manual para informarse sobre los proce-

dimientosde mantenimientoy ajuste especfflcos.

Mantenga la herramienta lubricaday limpia de modo que

funcione de la manere m_.ssegure.

Retire las herremientas de ajuste. Desarrolle el hdbito de

verificarque hayan sido retiradas las herramientasde

ajuste antes de encender la mdquina.

Mantenga todas las partes listas para funcionar. Revise

el protector u otras piezas para determinar si funcionan

eorrectamente y hacen el trabajo que deben hacer.

Revise que no haya partes daSadas. Verifique el alinea-

miento de las partes m6viles, si hay atascamiento, roturas

y montaje o cualquier otre condici6n que pudiera afectar el

funeionamiento de la herramienta.

Si hay una protecci6n o cualquier otra parte daSada, dstas

deberdn repararse correctamente o ser reemplazadas. No

haga reparaciones provisionales(v&lgase de la listade

piezas incluida para solicitarpiezas de reemplazo).

20

Page 21

EL OPERADOR DEBE SABER COMO USAR

LA HERRAMIENTA

• Use la herramienta corractapara cada trabajo. No fuerce

la herramienta o el accesorio ni los use para una tarea

para la que no fueron diseSados.

• Cuando cambie las cuchillas,desconecte la herramienta.

• Evite que ]a herramienta se encienda por accidente,

Aseg0rese de que el interruptorest_ en la posici6n

OFF (apagado) antes de enchufar.

• No fuerce la herramienta. Funcionar_ en la forma rods

eficiente a la velocidad para la cu_l se disefi6.

• Mantenga las manos alejadas de las partes movibles y

de las superficiescortadoras.

• Nunca deje desatendidauna herramientaen funcionamiento.

Descon_etela y no abandone el lugar hasta que se haya

detenido por completo.

• No trate de alcanzar demasiado lejos. Mant_ngase firme y

equilibrado.

• Nunca se pare sobre la herramienta. Se pueden producir

lesiones graves si la harramienta se vuelca o hace contac-

to con la cuchilla sin intencibn.

• Conozca su herramienta. Aprenda a manejar la herramienta,

su aplicacibn y limitaeiones especfficas.

• Use los accesorios recomendados (eonsulte la pdgina 15).

Si se usan accesorios incorreetos, puede sufrirlesiones o

lesionar a alguien.

• Maneje la pieza de trabajo en forma eorrecta. Prot_jase

las manos de posibles lesiones.

• Apague la mdquina si se atasca. La hoja se atasca si se

introduce muy profundamente en la pieza de trabajo (la

fuerza del motor la mantiene trabada en la pieza de trabajo).

• Siempre mantenga los protectores de la transmisibn, el

portacuchilla y la euehilla en su lugar yen adecuadas

condicionesde funcionamiento.

• Introduzca la pieza de trabajo en la cuchilla o cortadora en

sentidocontrario al de rotaci6n,

PRECAUCION: iPiense en [a seguridad! La seguridad es

una combinaei6n del sentido com_n del operador y un estado

de alerta permanente al usar la herramienta.

ADVERTENClA: No trate de operar la herramienta hasta

que haya sido completamente armada seg_n las instruc-

cionas.

F. Indicador

G. Imanes (2)

H. Llave hexagonal de 4 mm

I. Canal para polvo

J. Equipo recolector de polvo de media bolsa (no se muestra)

Flgura 1 - Desempaque

ADVERTENCIA: No intente hacer el montaje sihay partes

que faltan. V&lgase de este manual para solicitarpartes de

repuesto.

INSTALE LA MANIVELA

Consulte [as Figuras 2 y 3.

Se puede instalar la manivela con perilla (A) ya sea en el

ladosuperior derecho o izquierdode la cepilladora,

Retire el obturadordel tornillode elevaei6n (B) del lade

donde se instalar_ la manivela.

Consulte la Figura 1 a continuaci6n.

Verifique que no hayan ocurrido dafios durante el envro. Si

hay dados, se deber_, presentar un reclamo a la eompaSfa de

transporte. Verifique que est6 completa. Avise inmediata-

mente al distribuidor si faltan partes.

La cepilladora viene armada como una unidad. Es neeesario

Iocalizar y tomar en cuenta las piezas adicionales que daben

asegurarse a la herramienta antes de armada:

A. Cepilladora

B. Conjunto del volante

C. Arandela plana de 6 mm

D. Perno de cabeza hueca, 6-1.0 x 20 mm

E. Perno de eabeza hueca, 6-1,0 x 25 mm

Figura2 - Instale la Manlvela

Introduzca la manivela con perilla (A) en la parte superior

del tornillode elevaci6n (B),

21

Page 22

• Coloque el indicador (E) y ia arandela (D) en la manivela.

• Asegure la manivela mediante el perno (C) y la Ilave que

se incluye.

Figure 3 -Asegure le Menlvela

INSTALE EL CANAL PARA POLVO

Consulte la Figura 22, pdgina 16.

• Deslice el canal para polvo (Clave No. 10) sobre el

alojamiento del ventilador (Clave No.8). Fije en su

lugarcon el perno (Clave No 9).

• Instale el Equipo Recolector de Polvo de Media Bolsa

(ineluido) despuds de montar ia cepiliadora on la

superficiede trabajo.

MONTAJE DE LA CEPILLADORA EN

LA SUPERFICIE DE TRABAJO

Consulte la Figura 4.

La cepilladora ha sido dise_ada para ser portdtilde modo

que puada Ilevarse ai lugar de trabajo, pero se debe men-

tar en un banco o mesa estable y nivelada. Vdase

Accesorios Recomendados on la pdgina 15.

La base do la cepil]adoratiene cuatro agujeros do montaje

(A). Los orificiosforman un rectdngulo.Use una escuadra

pare marcar la posici6nsobre la supefficie de trabajo.

Si la superfieiede trabajo no tiene ya hechos los orificios,

perforecuatro con un taladro.

Monte firmemente la cepilladora en la superficie de

trabajo aperndndola (pernos no ineluidos) a travds

de los agujeros.

COMO INSTALAR EL EQUIPO RECOLECTOR

DE POLVO DE MEDIA BOLSA

Consulte la Figura 5.

El Equipo Recolector de Polvo de Media Bolsa Craftsman

estddise_ado para recolectar el polvo residualde herramien-

tas de cerpinterfa que tengan un orificiodo escape de polvo

do 2V2"de didmetro. La bolsa de filtrar se une a un cubo de

basura de 30 galones o una boise pidstica para basura do 30

galones x 1.3 milipuigadas para permitirel desecho sencilloy

prdcticode aserdn (no se incluyeel cubo de basura nila

bolsa pldstica para basura).

Monte la copilladora en un banco de trabajo o mesa antes

de instalar el Equipo Recolector de PoIvo.

Pare usar el equipo recolector de polvocon un cube de

basura:

Coloque el resorte dentro del braze de la bolsa do filtrar.

Dos]ice el braze con el resorte sobre el canal para polvo.

Ponga la banda de la bolsa sobre el reborde del cube de

basura y ajuste la bolsa apretando la cinta.

Para usar el equipo recolector de polvocon una boise para

basura:

Coloque el resorte dentro del brazo de la bolsa de filtrar.

Deslice el brazo con el resorte sobre el canal para polvo.

Arme el soporle de la bolsa. Deslice los conectores por

las ranuras de los segmentos del soporte,

Deslice la bolsa pldstica por dentro del soporte. Deje sola-

par la bolsa entre 3 y 4".

Ponga la banda de la bolsa de filtrar sobre el soporte de la

bolsa y dentro de la ranura.

Fije on su lugar apretando la cinta.

Resorte

"__ Canal pare polvo

Boisepara ._ _ Segmentos

tiltrar "_ S_onecto r _oporte

Figura 4 - Monte la Cepilladora

Cubodo 2;L12

basura / _

Figure 5 - Equlpo Recolectorde Polvode MediaBoise

FUENTE DE ALIMENTACION

ADVERTENCIA: No conecte la cepilladora a la fuente de

alimentacibn hasta haber cumplido todos los pasos del

ensamblaje.

22

Page 23

Elmotor ha sidodiseSado para funcionar al voltaje y frecuen-

cia espeeificados. Las cargas normales se pueden manejar

sinriesgos dentro de un intervalo del 10% respecto al voltaje

espeeificado. Si se haee funeionar la unidad a un voltaje fuera

de este intervalo, se puede recalentar y quemar el motor.Las

cargas pesadas exigen que el voltaje en los terminales del

motor no sea inferior al especificado.

La fuente de alimentaeidn del motor se controla mediante

un interruptor de Ilave. Si sa extrae la llave del interruptor,

se bloquea la unidad e impide el uso no autorizado.

INSTRUCCIONES PARA LA CONEXION A TIERRA

ADVERTENCIA: Si no sa conecta correctamente el con-

ductor a tierra del equipo,sa corre el riesgo de un electro-

choque. El equipo debe ester conectado a tierra mientras se

usa para proteger al operador de un electrochoque.

• Si no entiende lee instrucciones de conexidn a tierra o

dude que la herramienta haya quedado efectivamente

puesta a tierra, consulte un electrieista calificado,

Esta herramienta viene equipada con un cable especifica-

do para 150Vy un enchufe de 3 puntas para conexibna

tierra (vdase la Figura 6) que Io protegen a usted de un

electrochoque.

El enchufe de eonexidn a tierra debera coneetarsa directa-

mente a un zbcalo para 3 clavijas instalado y conectado

debidamente a tierra, tal como se muestra (vdase la

Figura 6).

Tomacorrientepuesto __-_1

atierra adecuadamente_ _t-"3 II

Puntade conexidnatierra.,rra_ _'L_ _I

Enchufede 3 puntas _r._ I_

Figure6 - Recept_culopare 3Puntsa

• No retire ni modifique en forma alguna la punta de cone-

xi6n a tierra. En caso de un mal funcionamiento o una

descompostura, la conexidn a tierra proporciona una ruta

de menor resisteneia pare la descarga eldctrica.

ADVERTENClA: AI conectar o desconectar el enchufe del

tomacorriente, no permita que los dedos toquen los termi-

nales o el enchufe.

• El enehufe debe conectarse en el tomacorriente corres-

pondiente que haya sido instalado y conectado a tierra

debidamente, de acuerdo con todoslos cddigos y regula-

clones locales. No modifique el enchufe que se ineluye. Si

nocabe en el tomacorriente, solicite a unelectricista califi-

cado que instale un tomacorriente adecuado.

• Revise peri6dicamente los cordones de la herramienta y si

estdn da_ados, II_velos a un eentro de servicio autorizado

pare que los reparen.

• El conductorverde (o verde y amarillo) del corddn es el

cable de eonexidn a tierra. Si es necasario reparar o reem-

plazar el corddn eldctrico o el enchufe, no conecte el cable

verde (o verde y amarillo) a unterminal cargado.

• Un zbcalo para dos clavijasdeber_ ser reemprazado con

un zdcalo para tree elavijas debidamente conectado a

tierra e instalado de acuerdo con las Normas para

Instalaciones Eldctricas (National ElectricCode) y los

c6digos y regulaciones locales.

ADVERTENClA: $51o un electricista califlcado debe cam-

biar los recept_culos.

Se puede user temporalmente un adaptador de 3 puntas a 2

puntas con conexibn a tierra (vdase la Figura 7) para eonec-

tar los enchufes a un tomacorriente bipolar que estd correcta-

mente puesto a tierra.

Orejetaterminalde tierra AsegOreseque

Adaptador eunatierra

Enchufe conocida

"_'_ _'_ 2 puntas

Figure7 - Recept#iculoconAdaptadorpara Enchufe

de 2 Punta

• No utiliceeste tipo de adaptadores a menos que estd per-

mitido por loscbdigos y regulacionesnacionales y locales,

(En Canadd no se permite usar adaptadores de conexi6n

a tierra de 3 puntas a 2 puntas).

Si se permite el uso de un adaptador de 3 a 2 punt.s con

conexi6n a tierra, sa debe eonectar firmemente la leng_e-

ta verde o terminal dgido en un lado der adaptador a una

toma de tierra permanente, por ejemplo, una tuberla de

agua puesta a tierra, una caja de tomacorriente puesta a

tierra o un sistema de cables puesto a tierra.

• Muchos de los tornillosde la plancha de cubierta, las

tuberfas de agua y las cajas de tomacorriente no est_.n

debidamente conectados a tierra. Para garantizar que la

conexidn a tierra sea efectiva, un electricistacaliflcado

debe verificar los medios de conexidn a tierra.

CORDONES DE EXTENSION

El uso de cualquier tipo de cordbn de extensidn ocasio-

nard.una cafda en el voltaje y una pdrdida de potencia.

Los cables del cordbnde extensibn deben tenet el tamaSo

sufieiente pare conducir la corriente adecuada y mantener

el voltaje correcto.

El tamaSo mfnimo de los hilos del cable de extensidn es

14 A.W.G. No use cables de extensidn cuya Iongitudsea

mayorde 25 pies.

Utilicednicamente cordonesde extensibn trifilaresque

tengan enehufes tipo eonexidn a tierra de tree puntas y

receptdeulostripolares que aeepten el enchufe de la

herramienta.

Si el cordbn de extensidn estd desgastado, roto o daSado

en cualquier forma, reempldeelo inmediatamente.

MOTOR

La cepinadora viene con un motor de 2Y2HP.

El motor universal de CA de 120 voltiostiene las siguientes

especificaciones:

Caballaje (m_ximo desarrollado) ................. 2Y2HP

Voltaje ........................................ 120

Amperaje ....................................... 15

Frecuencia (Hz) .................................. 60

Fase.................................... Monofdsico

Velocidaddel portacuchilla(rpm) .................. 8000

CONEXIONES ELECTRICAS

ADVERTENCIA: Cercidrese de que la unidad estd apagada

ydesconectada de la fuente de alimentacidn antes de inspec-

cionar el cableado.

23

Page 24

Se instala el motor y se conecta el cableado segL_n]a ilus-

traci6n del diagrama de cableado (v8ase la Figura 8).

Interruptor

Cord6nde

la Iinea

Figura8 - Dlagremade Csblesdo

El motor se ensambla con un cable de tres conductores,

aprobado para usarse con 120 voltios comose indica. La

fuente de alimentaci6n del motor estd controlada per un con-

mutador enclavador bipolar.

Las Ifneas de energfa el6ctrica se conectan directamente al

interruptor.La Iinea de conexibn a tierra verde debe per-

manecer firmemente sujeta al bastidor para ofrecer la ade-

cuada proteeci6n eontra un electrochoque.

Estd instalado un protectorde sobrecarga de reajuste manual

en Iinea con la fuente de alimentaci6n del motor. Si se sobre-

carga la cepilladora, el protectorinterrumpe el circuito.

Motor

DESCRIPCION

La cepi[ladora de 13" de Craftsman acaba la madera tosca y

la deja del tama_o correctoy cepilla las maderas duras de

hasta 6" de grosory 13" de ancho. La madera se alimenta al

portacuchillade dos hojas per medio de los redillos de goma

de entradaJsalida.Su fuerte construcci6nde base y dise5o de

euatre soportes permite una alimentaeibn uniforme y un cepi-

Ilado virtualmente sin redondeo.La cepil]adoraviene con un

redamiento de bola universal,encerrado, y un motor de 2'/2 HP

(desarrollo mdximo) con protecci6n contra sobrecarga. El

motortiene un interruptor de ON OFF (encendido/apagado)

con Ilave removiblepara impedir un arranque accidental. La

unidad incluye un dispositivo de traba de la caja de rodillos

para un espesor uniforms, controlmec&nico del movimiento

de la caja de ro-dillos,calibrador de profundidad del corte

para una eonfiguraci6n m,_sseneilla, calibrador preajustado

del espesor de la pieza de trabajo con 6 valores de ajuste

para obtener siempre una misma configuraci6n, cuehillas

fdciles de reemplazar sin intervenei6n manual para mayor

seguridad y menor tiempo improductivo,recolsctor de polvo

incorporado,redil_os de montaje superior para el retomo de la

pieza de trabajo, asas de transporte incorporadas, cable

arrollabls para mayor portabilidad y redillos de alimentaci6n y

salida plegables para un funcionamiento fluido.La cepilladora

acepta cortes de hasta 3/_,,por pasada a 24 pies por minuto.

La escala de altura en pulgadas, tiene gredaeiones en incre-

mentos de _/_6"y la escala mdtrica decimal tiene incrementos

de 1 mm.

MOTOR

Tama_o de la mesa ......................... 13 x 103/8"

Anchode la cuchilia.............................. 13"

Profundidad de corte mdxima ...................... 3/_,,

Cortes per minuto ............................. 16,000

Orificio rocolector de polvo ........................ 2V2"

Dimensiones generales ......... 21" A x 26V2"A x 35'/2" P

Motor .............. 2V2HP (desarrollo mdx.), 15 A, 120 V

Peso ........................................ 97 Ibs

REGLAS DE SEGURIDAD DE OPERACION

ADVERTENCIA: Para su propia seguridad, lea todas

las instruceionesy las precauciones antes de operar la

herramienta.

ADVERTENCIA: El funcionamiento de todas las herramientas

mec_nicas puede hacer que sean lanzados a losojoscuer-

pos extra_os, Io cual puede lesionarlos gravemente. Siempre

use galas de seguridad que cumplan con los requisitosde la

norma estadounidense ANSI Z87.1 (se indica en el paquete)

antes de comenzar a usar la herramienta mecdnica.

PRECAUClON: Tenga siempre en cuenta las siguientes

precauciones:

• Aprenda las reglas de seguridad generales para el uso de

herramientas mecdnicas. Aseg_rese de comprender todas

las precauciones (vdanse las pdginas 20, 21 y 24).

• Cuando ajusts o reemplace cualquier parte de la cepilla-

dora, Ileve el interruptora la posici6n OFF (apagado) y

retire el enehufe de la fuente de alimentaci6n.

• Asegdrese que todos los protectoresestdn eorrectamente

acopladosy firmemente sujetos.

• Asegdrese que nada obstaeulice ninguna parte movible.

• Siempre use protecci6n para los ojos o para la cara.

• Asegdrese que las euchillasestdn alineadas y correcta-

mente acopladas al portacuchUla.

• No enehufe la cepilladora a menos que el interruptorest_

en la posicibnde apagado. Despuds de encender el inte-

rruptor,permita que la cepilladora alcance toda la veloci-

dad antes de usar.

Mantenga las manos alejadas de las partes movibles.

No fuerce el corte. Si disminuye la velocidad o se queda

atascado, se recalienta el motor.Permita que la ali-

mentaci6n automdticafuncione correctamente.

• Use madera de calidad. Las cuchiUasduran rods y los

cortes resultan rods uniformes si la madera es de buena

calidad.

No cspille material qus tenga menos de 15" de Iongitud,

menos de 3/,,,de aneho, rods de 13" de ancho o menos de

Va"de grosor.

Nunca haga un corte de cepillado mayor de 3/_, de pre-

fundidad.

Mantenga la proporei6n adecuada entre las superficiesde

las planchas de alimentaci6n y salida y la trayectoriade

las cuchillas del portacuchilla.

No haga retreceder la pieza hacia la plancha de ali-

mentaci6n.

Tome las precaueionesnecesarias en caso de con-

tragolpes. No permita que nadie cruce ni est_ de pie en la

trayectoria de rotacibn del portacuchilla.Los contragolpes

o los residuosarrojados irdn en esta direccibn.

Abra el interruptory desconecte la alimentaci6n si no se

estd usando la cepilladora.

Reemplaee las navajas si se daSan o desafilan.

Dele mantenimiento a la cepilladora. Siga ]as instruc-

ciones de mantenimiento (v_ase las p&ginas28-29).

24

Page 25

CONTROLES DE ACCIONAMIENTO

INTERRUPTOR DE ON/OFF (ENCENDIDO/APAGADO)

El interruptorde ON OFF (encendido/apagado) (A) se halla

en la parte delantera del motor de la cepilladora. Para

ENCENDERLA, Ileve el interruptora la posici6n superior.

Para APAGARLA, Ileve el interruptora la posici6n inferior.

Flgura9 - Interruptorde ON OFF(Encendldo/Apagado)

TRABA DEL INTERRUPTOR

Consulte la Figura 10.

Se puede impedir el uso no auterizado de la copinadora tra-

bando el interruptor. Para trabar el interruptor:

• Lleve el interruptor a la posici6n OFF (apagado) y

desconecte la cepilladora de la fuente de alirnentacibn.

• Extraiga la Ilave (A), No se puede Ilevar el interruptor a la

posici6n de encendido sin la Ilave (A).

AVISO: Si se extrae [a Ilave con el interrupter en la posiciSn

ON (encendido), se puede Ilevar a la posici6n de apagado Flgura11- Suba/Bajela CaJade Rodlllos

pero no a la de encendido.

A

Figura 10-Traba del Interruptor y Reajuste del Clrculto

Para volver a insertarla llave, deslfcela al interior de la

ranura del interruptorbasra que se acople.

CORTACIRCUITO

Consulte la Figura 10.

La cepiliadora estd equipada con un cortacircuito que sirve

de proteeei6n al motor. Elcortacircuito apaga autom._tica-