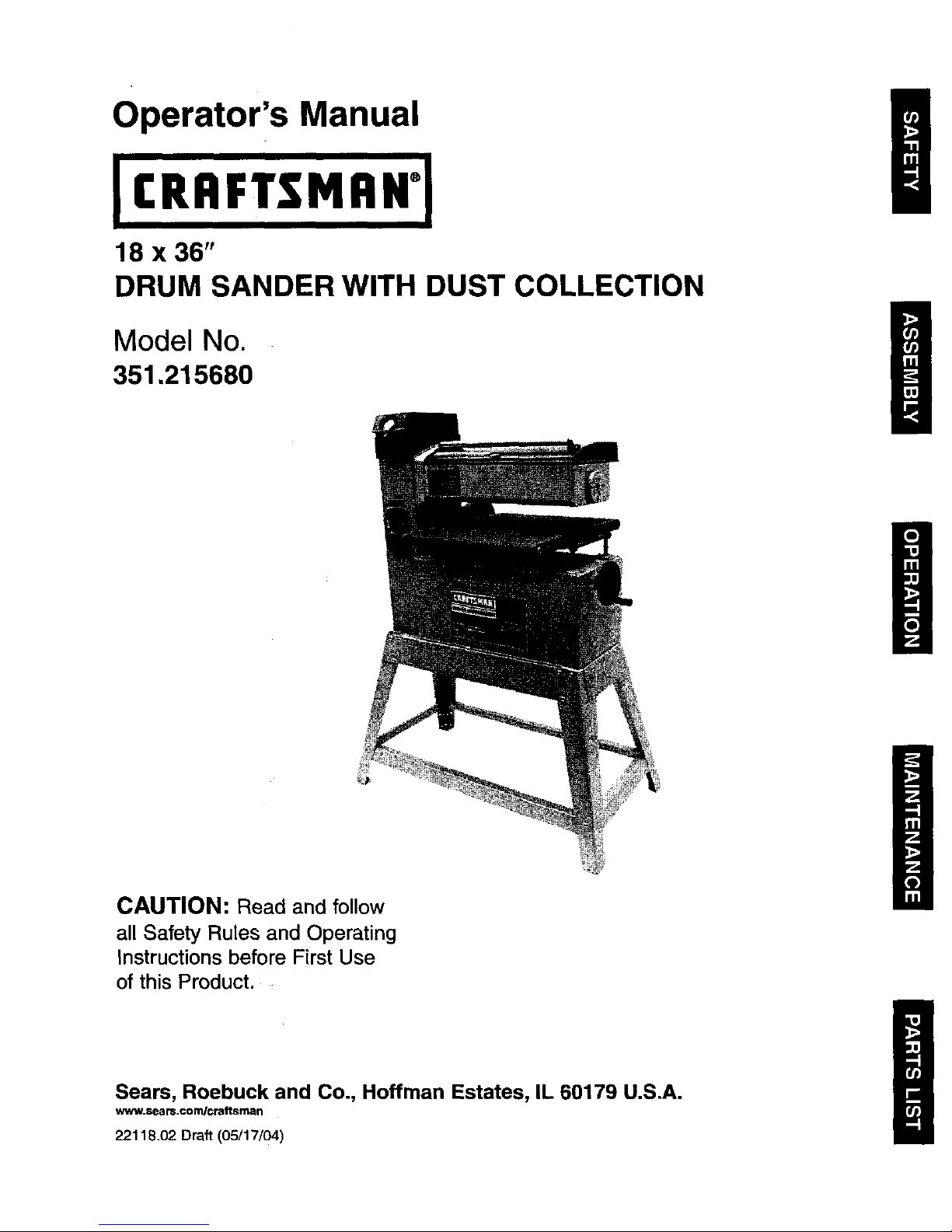

Craftsman 351.215680 Operator's Manual

Operator's Manual

CRRFTSMRN°I

8 x 36"

DRUM SANDER WITH DUST COLLECTION

Model No.

351.21 5680

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.seam.com/craftsman

22118.02 Draft (05/17/04)

Warranty......................................... 2

Safety Rules...................................... 2

Unpacking ....................................... 3

Assembly ...................................... 3-4

Installation ...................................... 4-5

Operation ...................................... 5-9

Maintenance .................................. 10-11

Troubleshooting .................................. 12

Parts Illustration and List ........................ 14-19

FULL ONE YEAR WARRANTY ON CRAFTSMAN

DRUM SANDER

If this product failsdue to a defect in material or workmanship

within one year from the date of purchase, Sears will at its

option repair or replace it free of charge. Contact your nearest

Sears Service Center (1-80O-4-MY-HOME) to arrange for

product repair, or return this product to place of purchasefor

replacement.

If this product is used for commercial or rental purposes, this

warranty will apply for 90 days from the date of purchase.

This warranty applies only while this product is used in the

United States.

This warranty gives you specific legal rights, and you may

also have other dghts which vary from state to state.

Sears, Roebuck and Co,, Dept. 817WA, Hoffman Estates,

IL 60179

WARNING: For your own safety, read all of the instructions

and precautions before operating tool,

CAUTION: Always followproper operating procedures as

definedin this manual even if you are familiar with use of this

or similartools. Remember that being caraleesfor even a

fraction of a second can result in severe personal injury.

BE PREPARED FOR JOB

• Wear proper apparel.Do not wear looseclothing, gloves,

neckties, rings, bracelets or other jewelry which may get

caught in moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slipsoles.

• Wear safety glasses complyingwith United States ANSI

Z87.1. Everyday glasses have only impact resistant lenses.

They are NOT safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and thinkcieady. Never operate power toolswhen

tired, intoxicatedor when taking medications that cause

drowsiness.

PREPARE WORK AREA FOR JOB

• Keep work area clean. Cluttered work areas inviteaccidents.

• Do not use power tools in dangerous environments,Do not

use power tools in damp or wet locations.Do not expose

power tools to rain.

• Work area should be properly lighted.

• Proper electrical receptacle should be available for tool.

Three prong plug should be plugged directly into properly

grounded, three-prong receptacle.

• Extension cords should have a grounding prong and the three

wiresof theextensioncord shouldbe of the correctgauge.

• Keep visitorsat a safe distance from work area.

• Keep childrenout of workplace. Make workshop childproof.

Use padlocks, master switches or remove switch keys to

prevent any unintentionaluse of power tools.

TOOL SHOULD BE MAINTAINED

• Always unplugtool prior to inspection.

• Consult manual for specific maintaining and adjusting

procedures.

• Keep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to see that

adjustingtools are removed before switching machine on.

• Keep all parts in working order. Check to determine that the

guard or other parts will operate properly and perform their

intended function.

• Check for damaged parts. Check for alignment of moving

parts, binding, breakage, mounting and any other condition

that may affect a tool's operation.

• A guard or other part that is damaged should be properly

repaired or replaced. Do not perform makeshift repairs.

(Use parts list provided to order replacement parts.)

KNOW HOWTO USETOOL

• Use right tool for job. Do notforce tool or attachment to do

a job for which it was not designed.

• Disconnecttool when changing belt.

• Avoid accidental start-up.Make sure that the tool is in the

"OFF" positionbeforepluggingin.

• Do notforce tool. It will work mostefficiently at the rate for

which it was designed.

• Keep hands away from moving parts and sanding surfaces.

• Never leave tool running unattended.Turnthe power off

and do not leave tooluntilit comes to a complete stop.

• Do not overreach. Keep properfooting and balance.

• Never stand on tool. Serious injury could occurif tool is

tipped or if belt is unintentionallycontacted.

• Know your tool. Learn the tool'soperation, applicationand

specificlimitations.

• Use of improper accessories may cause risk of injuryto

persons.

• Handle the work,piece correctly.Protect hands from possi-

ble injury.

CAUTION: Think safety! Safety is a combination of operator

common sense and alertness at all times when tool is being

used.

WARNING: Do not attempt tooperate tooluntilit is com-

pletely assembled according to the instructions.

@Sears, Roebuck and Co. 2

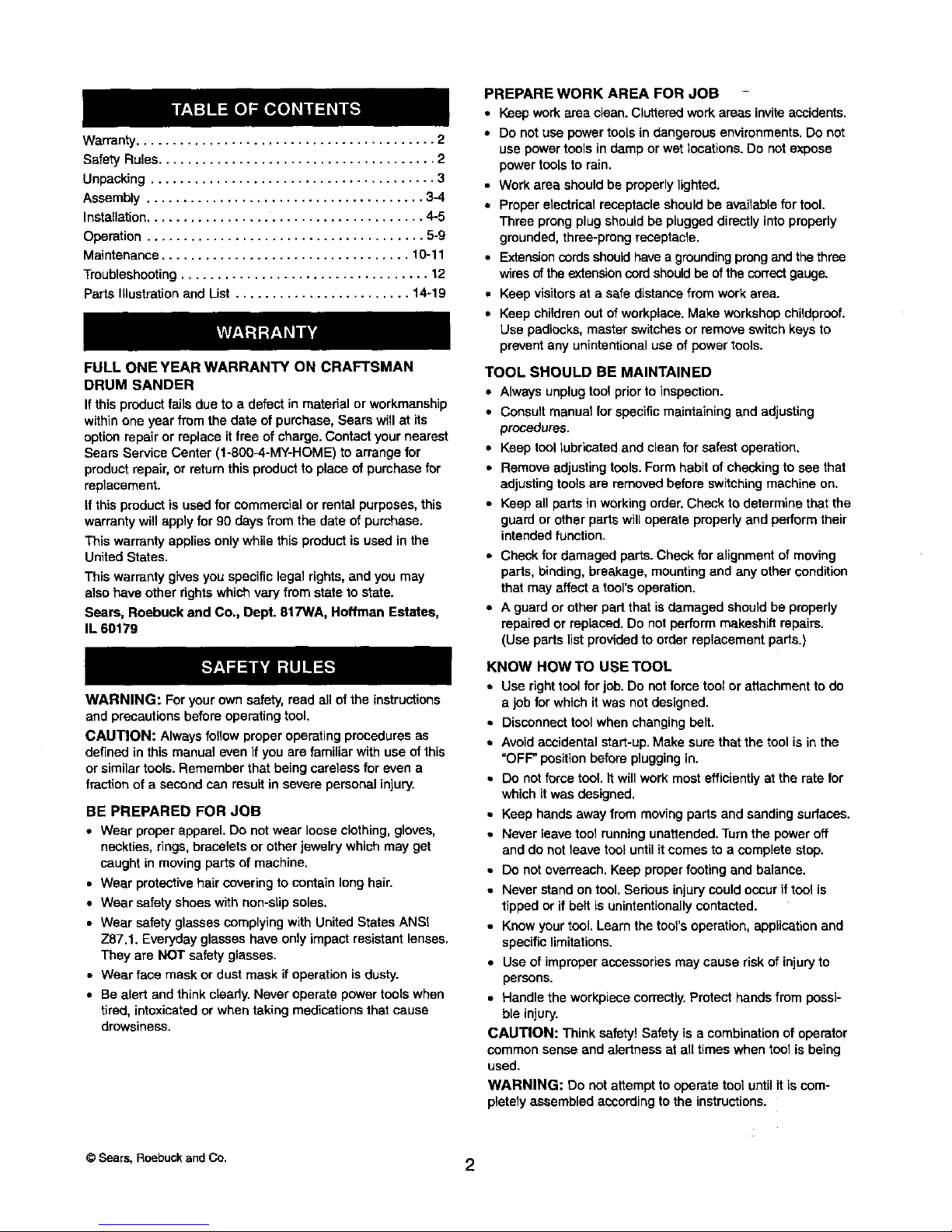

Referto Figure 1.

CAUTION: Do not attempt assembly if parts are missing.

Use this manual to order replacement parts.

Check for shipping damage. If damage has occurred, a claim

mustbe filled with cartier. Check for completeness.

immediately report missingparts to dealer.

The drum sander comes assembled as one unit. Additional

parts which need to be fastened to the drum sander, should

be Iccated and accountedfor before assembling(see Figure 1).

A Leg (4)

B Small Support (2)

C Small Brace (2)

D Large Brace (2)

E Large Support (2)

F Dust Chute

G Handwheel

H Half Bag Dust Collection Bet

I Hardware Bag (Part No. 22119.00)

A

Figure 1 - Unpacking

D

c\

G

E

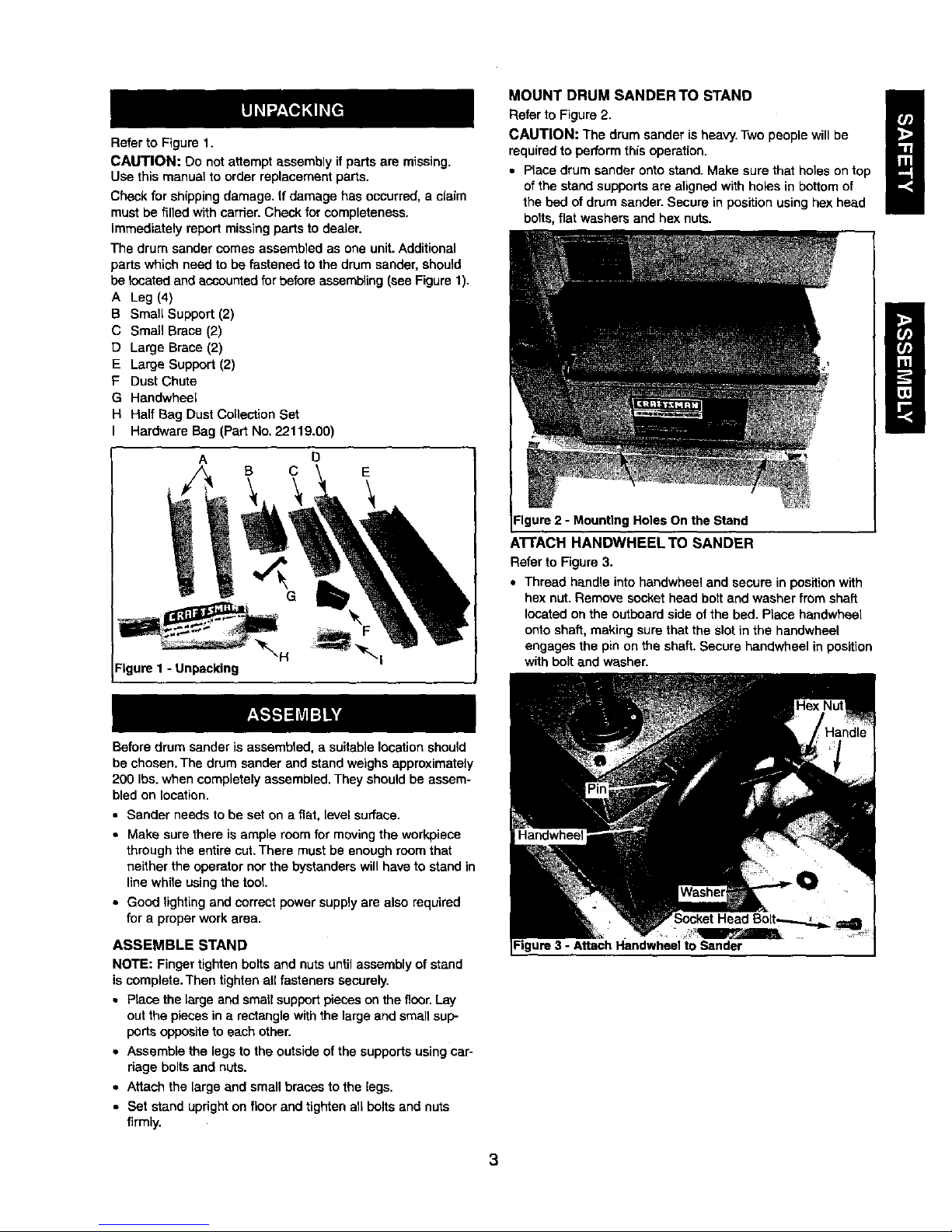

MOUNT DRUM SANDERTO STAND

B

Referto Figure 2.

CAUTION: The drum sander is heavy.Two people will be

requiredto perform this operation.

• Place drum sander onto stand. Make sure that holes on top

ofthe stand supports are aligned with holes in bottom of

the bed ofdrum sander.Secure in position using hex head

bolts, flat washers and hex nuts.

=Igure2 - Mounting Holes On the Stand

AI-rACH HANDWHEELTO SANDER

Refer to Figure 3.

• Thread handle into handwheel and secure in positionwith

hex nut. Remove socket head boltand washer from shaft

locatedon the outboard side of the bed. Place handwheel

onto shaft, making sure that the slot in the handwheel

engages the pin on the shaft. Secure handwheel in position

with bolt and washer.

Before drum sander is assembled, a suitable location should

be chosen. The drum sander and stand weighs approximately

200 Ibs, when completely assembled. They should be assem-

bled on location.

• Bander needs to be set on a flat, level surface.

• Make surethere is ample room for moving the workpiece

through the entire cut, There must be enough room that

neLther the operator nor the bystanders will have to stand in

line while using the tool

• Good lightingand correct power supplyare also required

for a proper work area.

ASSEMBLE STAND

NOTE: Finger tighten bolts end nutsuntilassemblyof stand

iscomplete. Then tightenall fasteners securely.

• PLacethe Largeandsmall supportpieces on the floor.Lay

outthe pieces in a rectangle withthe large and small sup-

portsoppositeto each other.

• Assemble the legsto the outside of the supports usingcar-

riage boltsand nUts.

• Attach the large and smallbraces to the [egs.

• Set stand uprighton floor and tighten all bolts and nuts

firmly.

=igure3 - Attach Handwheel to Sander

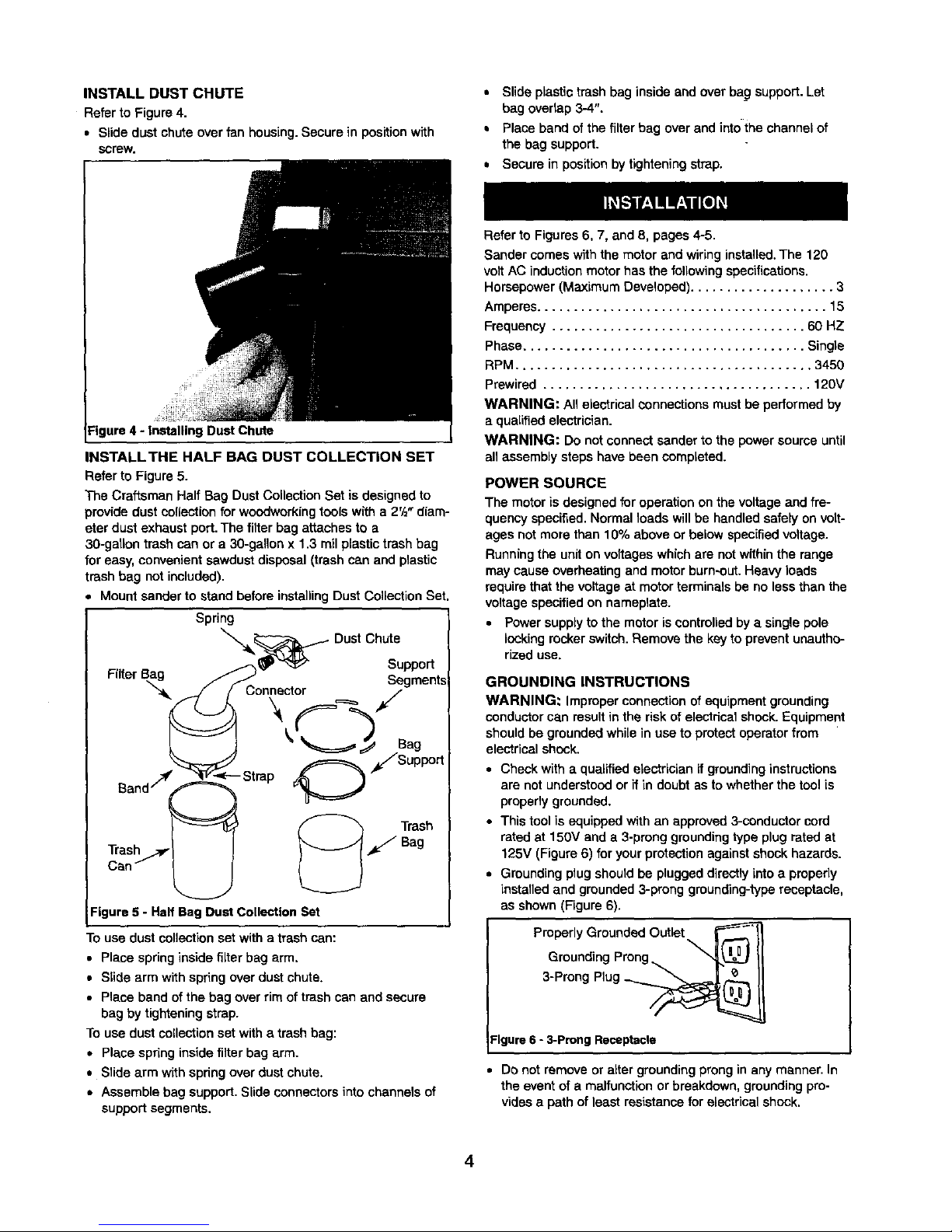

INSTALLDUSTCHUTE

RefertoFigure4.

• Slidedustchuteoverfanhousing.Securein positionwith

screw.

• Slide plastic trash bag inside end over bag support.Let

bag ovedap 3-4",

• Place band of the filter bag overand into the channel of

the bag support.

• Secure in positionby tighteningstrap.

igure 4 - Installing Duet Chute

INSTALL THE HALF BAG DUST COLLECTION SET

Refer to Figure 5.

The Craftsman Half Bag Dust Collection Set isdesigned to

providedust collectionfor woodworkingtools with a 2'/="diam-

eter dust exhaust port. The filter bag attaches to a

30-gatlon trash can or a 30-gallon x 1,3 rail plastictrash bag

foreasy, convenient sawdust disposal (trash can and plastic

trash bag not included).

Mount sander to stand before installingDust Collection Set.

Spring

DustChute

• _-,_ _ Support

Filter Bag /_..> Segments

j / Connector i

_' Sag

O */Support

Can _._

Figure 5 - Half Bag Dust Collection Set

Touse dust collectionset with a trash can:

• Place spring inside filter bag arm,

• Slide arm with spring over dust chute.

• Place band of the bag over rim of trash can and secure

bag by tightening strap.

Touse dust collection set with a trash bag:

• Place spring inside filter bag arm.

• Slide arm with spdng over dust chute.

• Assemble bag support. Slide connectors into channels of

supportsegments.

Refer to Figures 6, 7, and 8, pages 4-5.

Sander comes with the motor and wiringinstalled.The 120

volt AC induction motor has the following specifications.

Horsepower (Maximum Developed) .................... 3

Amperes ........................................ 15

Frequency ................................... 60 HZ

Phase....................................... Single

RPM ......................................... 3450

Prewired ..................................... 120V

WARNING: All electrical connections mustbe performed by

a qualified electrician.

WARNING: Do not connect sander to the power source until

an assembly steps have been completed.

POWER SOURCE

The motor is designed for operation on the voltageand fre-

quency specified.Normal loads willbe handled safely onvolt-

ages not more than 10% above or below specifiedvoltage.

Runningthe unit onvoltages whichare not withinthe range

may cause overheating and motorburn-out.Heavy loads

require that the voltage at motor terminals be no less than the

voltage specifiedon nameplate.

• Power supply to the motor iscontrolledby a single pole

looking rocker switch.Remove the key to prevent unautho-

rized use,

GROUNDING INSTRUCTIONS

WARNING: Improper connection of equipment grounding

conductorcan resultinthe risk of electricalshock. Equipment

should be grounded while in use to protect operator from

electricalshock.

• Check with a qualified electrician if groundinginstructions

are not understood or if in doubt as to whether the tool is

propedy grounded.

• This tool is equipped with an approved3-conductor cord

rated at 150V and a 3-prong groundingtype plug rated at

125V (Figure 6) for your protectionagainst shock hazards.

• Grounding plug should be plugged directly into a properly

installed and grounded 3-prong greunding-type receptacle,

as shown (Figure 6).

Preperly Grounded Outlet F/_

Grounding Prong_ II

3-Prong Plug _

Figure 6 - 3-prong Receptacle

• De not remove or alter groundingprong in any manner. In

the eventof a malfunction or breakdown, groundingpro-

videsa path of least resistancefor electrical shock.

4

WARNING: Do not permit fingers to touch the terminals of

plug when installing or removing from outlet.

• Plug must be plugged into matching outlet that is properly

installedand grounded in accordance with all local codes

and ordinances. Do not modify plugprovided. If itwill not fit

in outlet, have proper outlet installed by a qualified

electrician.

• Inspect tool cords periodically, and if damaged, have

repaired by an authorized service facility.

• Green (or green and yellow) conductor in cord is the

groundingwire. If repair or replacement of the electric cord

or plug is necessary, do not connect the green (or green

and yellow) wire to a live terminal.

• Where a 2-prong wall receptacle is encountered, it must be

replaced with a properly grounded 3-prong receptacle

installed in accordance with National Electric Cede and

local codes and ordinances.

WARNING: This work shouldbe performed by a qualified

electrician.

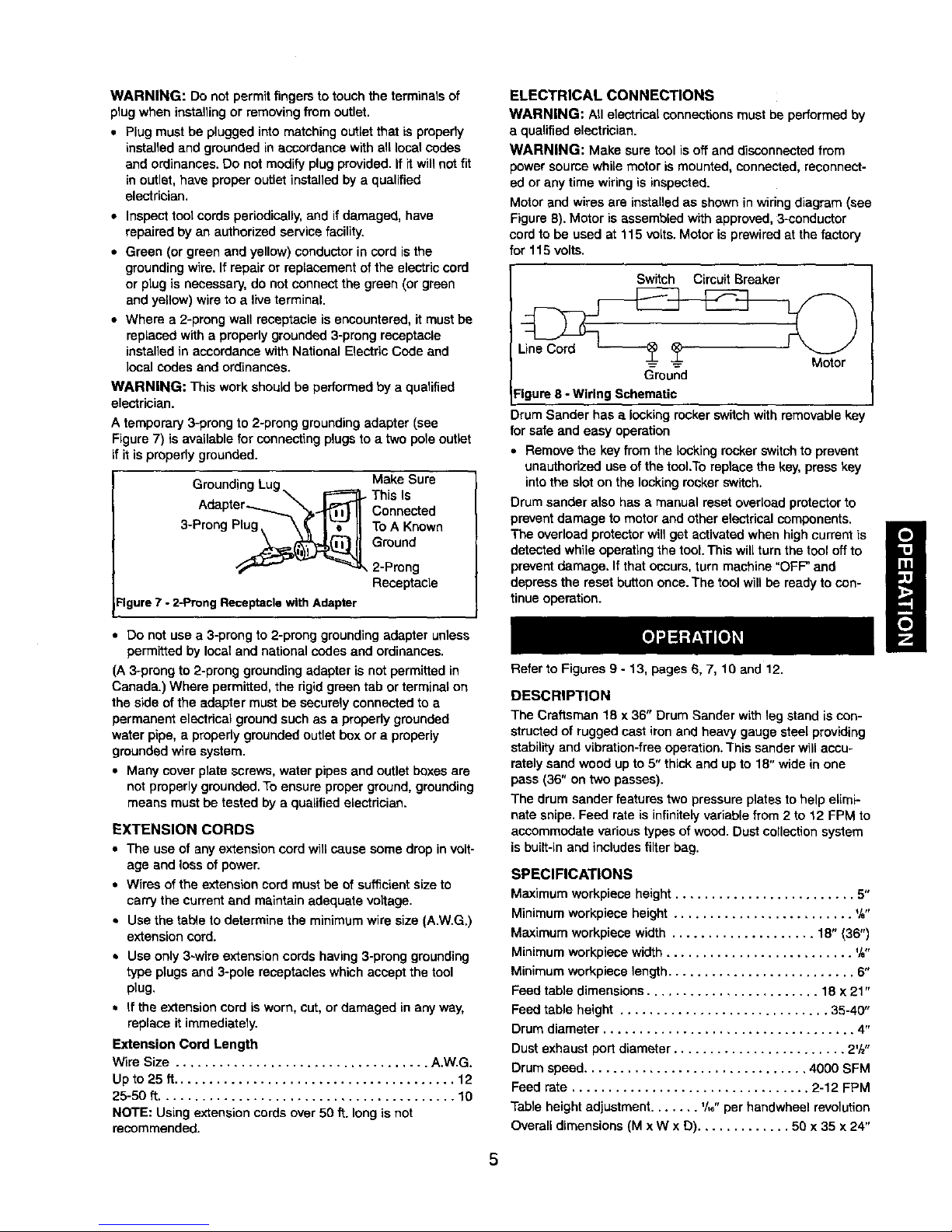

A temporary 3-prong to 2-prong groundingadapter (see

Figure 7) is available for connecting plugs to a two pole outlet

if it is properly grounded.

Grounding Make Sure

This Is

Connected

3-Prong Plug ToA Known

Ground

,2-Prong

Receptacle

Figure7 - 2-Preng ReceptaclewithAdapter

• Do not use a 3-prong to 2-prong grounding adapter unless

permittedby local and national codes and ordinances.

(A 3-prong to 2-preng grounding adapter is not permitted in

Canada.) Where permitted, the rigid green tab or terminal on

the side of the adapter must be securely connected to a

permanent electrical groundsuch as a properly grounded

water pipe, a properly grounded outlet box or a properly

grounded wire system.

• Many cover plate screws, water pipes and outlet boxes are

not properly grounded. To ensure proper ground, grounding

means must be tested by a qualified electrician.

EXTENSION CORDS

• The use of anyextension cord will cause some drop in volt-

age and lossof power.

• Wires ofthe extension cord mustbe of sufficientsize to

carry the current end maintain adequate voltage.

• Use the ta_e to determine the minimumwire size (A,W.G.)

extension cord.

Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool

plug,

If the extensioncord is worn, cut, or damaged in any way,

replace it immediately.

Extension Cord Length

Wire Size ................................... A.W,G.

Up to 25 tt....................................... 12

25-50 ft......................................... 10

NOTE: Using extension cords over 50 ft. long is not

recommended.

ELECTRICAL CONNECTIONS

WARNING: All electrical connectionsmust be performedby

a qualified electrician.

WARNING: Make sure tool is off and disconnected from

power soume while motor is mounted, connected, reconnect-

ed or any time wiring is inspected.

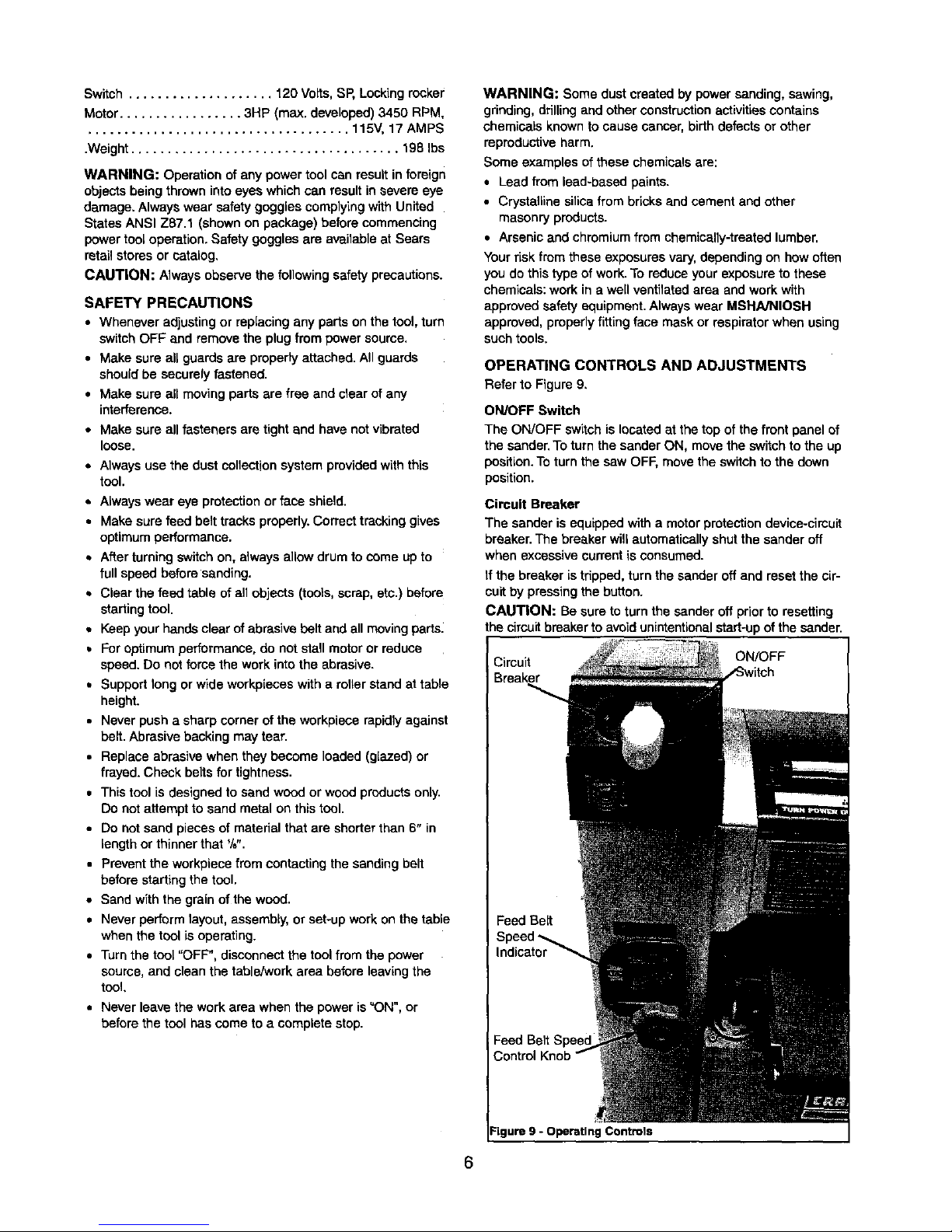

Motor and wires are installed as shown in wiringdiagram (see

Figure 6). Motor is assembled with approved, 3-oonductor

cordto be used at 115 volts. Motor is prewired at the factory

for 115 volts.

Switch CircuitBreaker

Ground

:igure 8 - Wiring Schematic

Drum Sander has a locking rocker switchwith removable ke

for safe and easy operation

• Remove the key from the Iook_]ngrocker switch to prevent

unauthorized use of the tool.Toreplace the key, press key

into the slot on the locking rocker switch.

Drum sander also has a manual reset overload protectorto

prevent damage to motor and other electrical components.

The overload protector will get activated when high current is

detected while operating the tool. This will turn the tool off to

prevent damage. If that occurs, turn machine "OFF" and

depress the reset button once. The tool will be ready to con-

tinue operation.

Refer to Figures 9 - 13, pages 6, 7, 10 and 12.

DESCRIPTION

The Craftsman 18 x 36" Drum Sander with leg stand is con-

strocted of rugged cast iron and heavy gauge steel providing

stability and vibration-free operation. This sander will accu-

rately sand wood up to 5" thick and up to 18" wide in one

pass (36" on two passes).

The drum sander features two pressure plates to help elimi-

nate snipe. Feed rate is infinitely variable from 2 to 12 FPM to

accommodate various types of wood. Dust collection system

is built-in and includes filter bag.

SPECIFICATIONS

Maximum workplace height ......................... 5"

Minimumworkplace height ......................... %"

Maximum workplace width .................... 18" (36")

Minimumworkpiece width .......................... %"

Minimumworkpiece length .......................... 6"

Feed table dimensions ........................ 18 x 21"

Feed table height ............................. 35-40"

Drum diameter ................................... 4"

Dust exhaust port diameter ........................ 2'/z"

Drum speed............................... 4000 SFM

Feed rate ................................. 2-12 FPM

Table height adjustment....... _/,6"per handwheel revolution

Overall dimensions (M x W x D) ............. 50 x 35 x 24"

Switch.................... 120 Volts, SP,Locking rocker

Motor ................. 3HP (max, developed) 3450 RPM,

.................................... 115V,17 AMPS

.Weight ..................................... 198 Ibs

WARNING: Operation of any power tool can result in foreign

objectsbeingthrown into eyes which can result in severe eye

damage. Always wear safety goggles complyingwith United

States ANSI Z87.1 (shown on package) before commencing

powertooloperation. Safety goggles are available at Sears

retail stores or catalog,

CAUTION: Alwaysobserve the following safety precautions.

SAFETY PRECAUTIONS

• Whenever adjustingorreplacing any parts on the tool,turn

switchOFF and remove the plug from power source.

• Make sure all guards are properlyattached. All guards

should be securely fastened.

• Make sure all moving parts are free and clear of any

interference.

• Make sure all fasteners are tight and have not vibrated

loose.

• Always use the dust collection system provided with this

tool.

• Always wear eye protection or face shield.

• Make sure feed belt tracks properly. Correct tracking gives

optimumperformance.

• After turning switchon, always allow drum to come up to

full speed before sanding.

• Clear the feed table of aUobjects (tools,scrap, etc.) before

starting tool.

• Keep yourhands clear of abrasive belt and allmovingparts.

• For optimum performance, do not stall motor or reduce

speed. Do not force the work into the abrasive.

• Support long or wide workpieces with a roller stand at table

height.

• Never push a sharp corner of the workpiece rapidly against

belt. Abrasive backing may tear.

• Replace abrasive when they become loaded (glazed) or

frayed. Check belts fortightness.

• This tool is designed to sand wood or wood productsonly.

Do not attempt to sand metal on thistool.

• Do not sand pieces ofmaterial that are shorter than 6" in

length or thinnerthat Ys".

• Prevent the workpiece from contacting the sandingbelt

before starting the tool.

• Sand with the grain of the wood.

• Never perform layout, assembly,or set-up workon the table

when the tool is operating.

• Turn the tool"OFF", disconnectthe tool from the power

source,and clean the table/work area before leaving the

tool,

• Never leave the work area when the power is =ON", or

before the tool has come to a complete stop.

WARNING: Some dust created by power sanding, sawing,

grinding,drillingand other constructionactivitiescontains

chemicals known to cause cancer, birth defects or other

reproductiveharm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silicafrom bricksand cement and other

masonry products.

• Arsenic and chromium from chemically-traatedlumber.

Yourrisk from these exposures vary,depending on how often

you do this type ofwork.To reduce your exposureto these

chemicals:work in a web ventilated area and work with

approved safety equipment.Always wear MSHA/NIOSH

approved, properlyfitting face mask or respiratorwhen using

such tools.

OPERATING CONTROLS AND ADJUSTMENTS

RefartoFigure9,

ON/OFF Switch

The ON/OFF switch is located at the top of the front panel of

the sander.To turnthe sander ON, move the switch to the up

position. To turn the saw OFF, move the switchto the down

position.

Circuit Breaker

The sander is equipped with a motor protectiondevice-cireuit

breaker.The breaker will automatically shutthe sander off

when excessivecurrent is consumed.

if the breaker is tripped, turn the sander off and reset the cir-

cuit by pressing the button.

CAUTION: Besure to turnthe sander off prior to resetting

the circuitbreakerto avoidunintentionalstart-up of the sander.

Cimuit

Breaker

ON/OFF

Feed Belt

Indicator

Feed Belt

Control

Figure 9 - Operating Controls

Loading...

Loading...