Page 1

Operator's Manual !

10"

TILTING HEAD BENCH TOP

BAND SAW WITH DUST COLLECTION

Model No.

351.214600

/

i \,

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www,sears.com/craftsman

20859.01 Draft (05/30/03)

Page 2

Warranty .................................... 2

Safety Rules ............................... 2-3

Unpacking .................................. 3

Assembly ................................... 3

Installation ................................. 4-5

Operation ................................. 5-g

Maintenance ................................. 9

Troubleshooting ............................. 11

Parts Illustrations and Lists.................. 12-15

EspaSol ................................. 16-24

FULL ONE YEAR WARRANTY

If this product fails due to a defect In material or work-

manship within one year from the date of purchase,

Sears will at Its option repair or replace It free of

charge. Contact your nearest Sears Service Center

(1-800-4-MY-HOME) to arrange for product repair, or

return this product to place of purchase for replacement.

If this product is used for commercial or rental purpos-

es, this warranty will apply for 90 days from the date of

purchase.

This warranty applies only while this product is used in

the United States.

This warranty gives you specific legal rights and you may

also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman

Estates, IL 60179

WARNING: For your own safety, read all of the

instructions and precautions before operating tool.

CAUTION: Always follow proper operating procedures

as defined in this manual -- even if you are familiar

with use of this or similar tools. Remember that being

careless for even a fraction of a second can result in

severe personal Injury.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry

which may get caught in moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• WearsafetyglassescomplylngwlthUnitedStates

ANSI Z87.1. Everyday glasses have only impact

resistant lenses. They are NOT safety glasses.

• Wear face mask or dust mask If operation Is dusty.

© Sears, Roebuck and Co.

• Be alert and think clearly. Never operate power tools

when tired, intoxicated or when taking medications

that cause drowsiness,

PREPARE WORK AREA FOR JOB

• Keepwork area clean.Cluttered workareas invite

accidents.

• Do not use power too]s tn da,"_jereus environments.

Do not use pewit tools th damp or wet IocetJonso Do

notexpose power tools to rain.

• Work area should be properly lighted.

• Proper electricet receptacle shoutd be available for

tool.Three-prong plug should be plugged directly

into properly grounded, three-prong receptacle.

• Extension cords should have s grouedlng prong and

the three wires of the extension cord should be of

the correct gauge.

,, Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop

chiJdproof.Use padJesks,master switches or remove

switch keys to prevent any unintentional use of

power tools.

TOOL SHOULD BE MAINTAINED

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjust-

Ing procedures.

• Keep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to

see that adjusting tools are removed before switch-

ing machine on.

• Keep ell parts in working order. Check to determine

that the guard or other parts wllJoperate properly

and perform their intended function.

• Check for damaged parts. Check for alignment of

moving parts, binding, breakage, mounting and any

other cond[t[on that may affect a tool's operation.

• A guard or other part that is damaged shou)d be

properly repaired or replaced. Do not perform

makeshift repairs. (Use parts list provided to order

replacement psrts.)

KNOW HOWTO USE TOOL

• Use right tool for job. Do notforce tool or attachment

to do a job for which it was not designed.

• Disconnect tool when changing btade.

• Avoid accidental start-up. Make sure that the tool is

in the "off"position before plugging in.

• Do not force tool. It will work most effic)ently at the

rate for which itwas designed.

• Keep hands away from moving parts and cutting

surfaces.

• Never leave tool runnin_Junattended. Turn the power

offand do not leave tool until it comes to a complete

stop.

• Do not overreach. Keep proper footing and balance.

2

Page 3

• Never stand on tool. Serious injury could occur if teol

is tipped or If blade Is unintentionally contacted.

• Know your tool. Learn the tool's operation, applica-

tion and specific limitations.

• Use recommended asoeseerles (refer to page 15).

Use of improper accessories may cause risk of

injury to persons.

• Handle workplece correctly. Protect hands from pos-

sible Injury.

• Turn machine off if it iams. Blade jams when it digs

too deeply into work.piece. (Motor force keeps it

stuck in the work.) DO not remove summed or cot off

pieces until the saw is turned off, unplugged and the

blade has stopped.

WARNING: The operation of any power tool can result In

foreign objects being thrown Into the eyes, which can

result in severe eye damage. Always wear safety goggles

complying with United Stete_sANSI 2:87.1 (shown on

package) before commencing power tool operation.

Safety goggles are available through your Sears catalog.

Check for shipping damage. If damage has occurred, a

claim must be filed with carder. Check for complete-

ness. Immediately report missing parts to dealer.

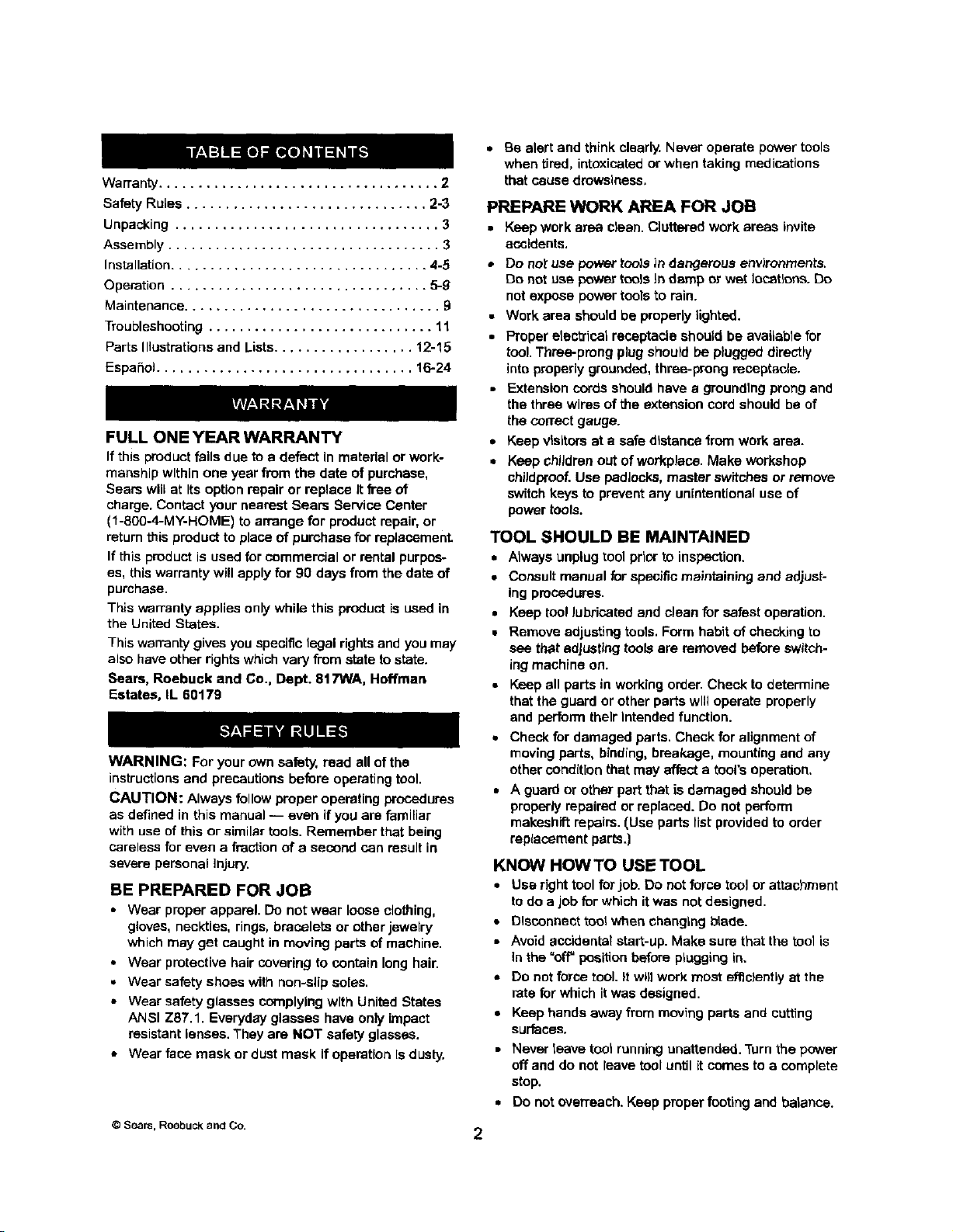

The band saw comes assembled as one unit. Additional

parts which need to be fastened to the saw should be

located and accounted for before assembling:

A Miter Gauge Assembly

B Crank Handle

C Clamp

D Dust Bag

D

IMPORTANT: Table is coated with a protectant. To

ensure proper fit and operation, remove coating.

Coating is easily removed with mild solvents, such as

mineral spirits, and a soft cloth. Avoid getting solution

on paint or any of the rubber or plastic parts. Solvents

may deteriorate these finishes. Use soap and water on

paint, plastic or rubber components. After cleaning,

cover all exposed surfaces with a light coating of oil.

Paste wax is recommended for table top.

WARNING: Never use highly volatile solvents. Non

flammable soNents are recommended to avoid possible

fire hazard.

CAUTION: Do not attempt assembly if parts are miss-

ing. Usa operator's manual to order replacement parts.

MOUNT BAND SAW TO WORK SURFACE

• Band saw is designed to be portable so it can be

moved tojob site, but shou)d be mounted to stable,

level bench or table. See Recommended

Accessories, page 15.

• Base of band saw has four mounting holes.

• If preddlled holes do not exist on work surface, drill

four holes.

• Securely mount band ssw te work sorface by belting

(hardware not supplied) it through the holes.

NOTE: The blade must be tensioned and backed, and

the blade guides must be adjusted before operation of

the sew. Refer to =Tracking Blade" and "Blade Guides" in

the OPERATION section, pages 5, 6 and 7.

INSTALL CRANK HANDLE

• Line up slot on crank handle with pin on the shaft.

• Using maUet or piece of wood with regular hammer,

drive crank handle on the shaft untilthe pin on the

shaft is fully engaged in the slot.

INSTALL DUST COLLECTION BAG

Dust collection system consists of a 30-micren bag and

clamp.

• Place clamp over bag sleeve.

• Slide sleeve with clamp over dust port.

• Secure in position by tightening clamp.

Figure 1 - Unpacking

3

Page 4

Refer to Figures 2 and 3.

MOTOR

The 115 Volt AC motor has the following specifications:

Horsepower (Maximum Developed) ............. 1.0

Voltage ................................... 115

Amps ..................................... 4.6

Hertz ..................................... 60

Phase .................................. Single

RPM .................................... '_725

POWER SOURCE

The motor Is designed for operation on the voltage and

frequency specified, Normal loads will be handled safe-

ly on voltages not more than 10% above or below the

specified voltage.

Running the unit on voltages which are not within the

range may cause overheating and motor burn.out.

Heavy loads require that the voltage at motor terminals

be no less than the voltage specified. Power supply to

the motor is contmllod by a double pole locking rocker

switch. Remove the key to prevent unauthorized use.

GROUNDING INSTRUCTIONS

WARNING: Improper connection of equipment

grounding conductor can result in the risk of electrical

shock. Equipment should be grounded while In use to

protect operator from electrical shook,

Check with e qualified electrician if grounding instruc-

tions are not understood or if in doubt as to whether the

tool is properly grounded,

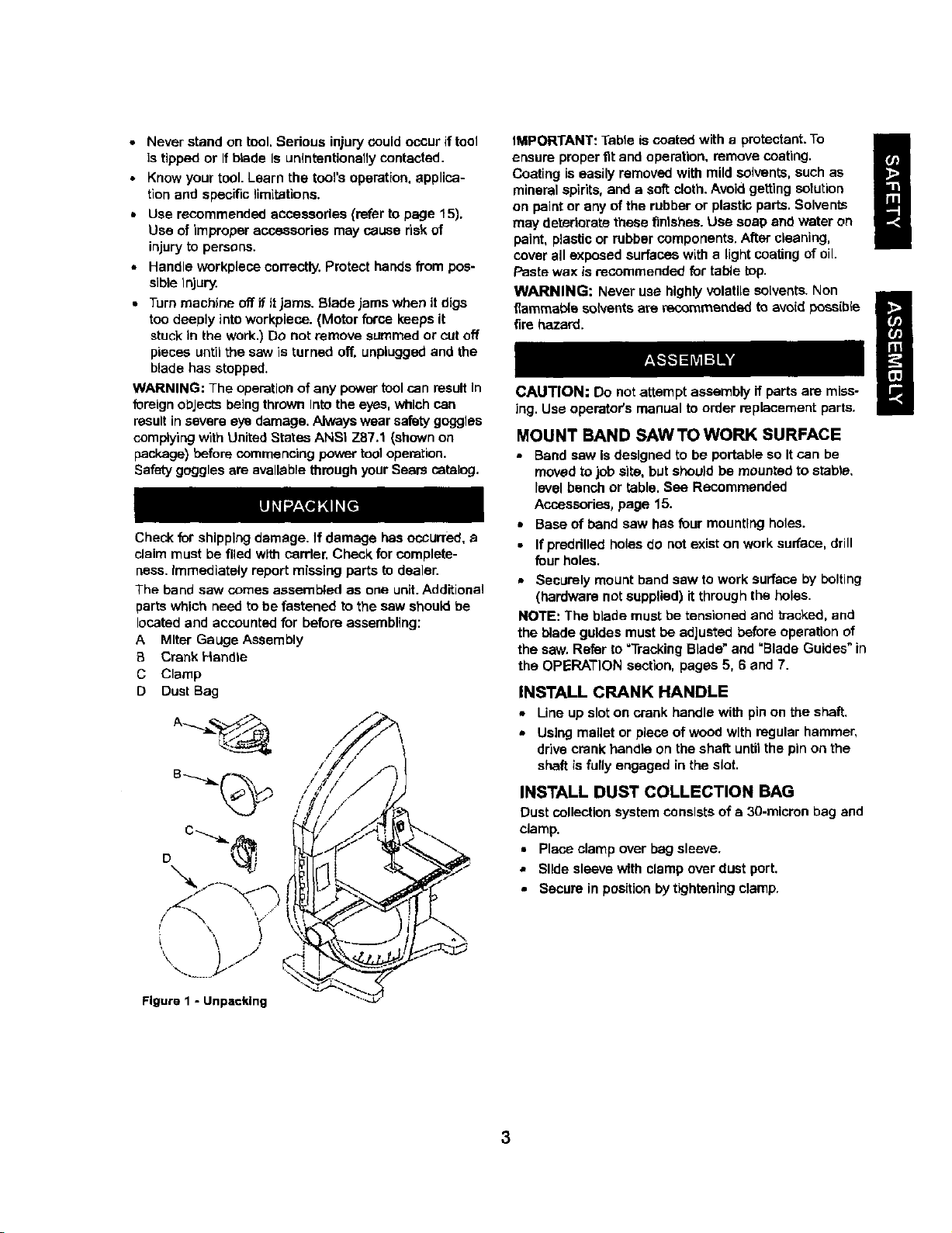

This tool is equipped with an approved 3 conductor

cord rated at 150V and a three prong grounding type

plug for your protection against shock hazards.

Grounding plug should be plugged directly into a prop-

edy installed and grounded 3-prong grounding-type

receptacle, as shown (Figure 2).

Properly Grounded Outlet

Grounding Prong

3-Prong Plug_

Figure 2 - 3-Prong Rocelptade

Do not remove or alter grounding prong in any manner.

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electrical shock.

WARNING: Do not permit fingers to touch the terrnl-

nals of plug when installing or removing from outlet.

Plug must be plugged into matching outlet that is prop-

erly Installed and grounded In accordance with all local

codes and ordinances. Do not modify plug provided. If it

will notfit in ou'dat, have proper outlet installed by a

qualified electrician.

Inspect tool cords periodically, and If damaged, have

them repaired by an authorized service facility.

Green (or green and yellow) conductor in card is the

grounding wire. tf repair or replacement of the electric

cord or plug is necassa_J, do not connect the green (or

green and yellow) wire to a live terminal

Where a 2-prong wall receptacle is encountered, it

must be replaced with a properly grounded 3-prong

receptacle installed in accordance with National Electric

Code and loca] codes and ordinances.

WARNING: This work should be performed by a quali-

fied elestrlc]an.

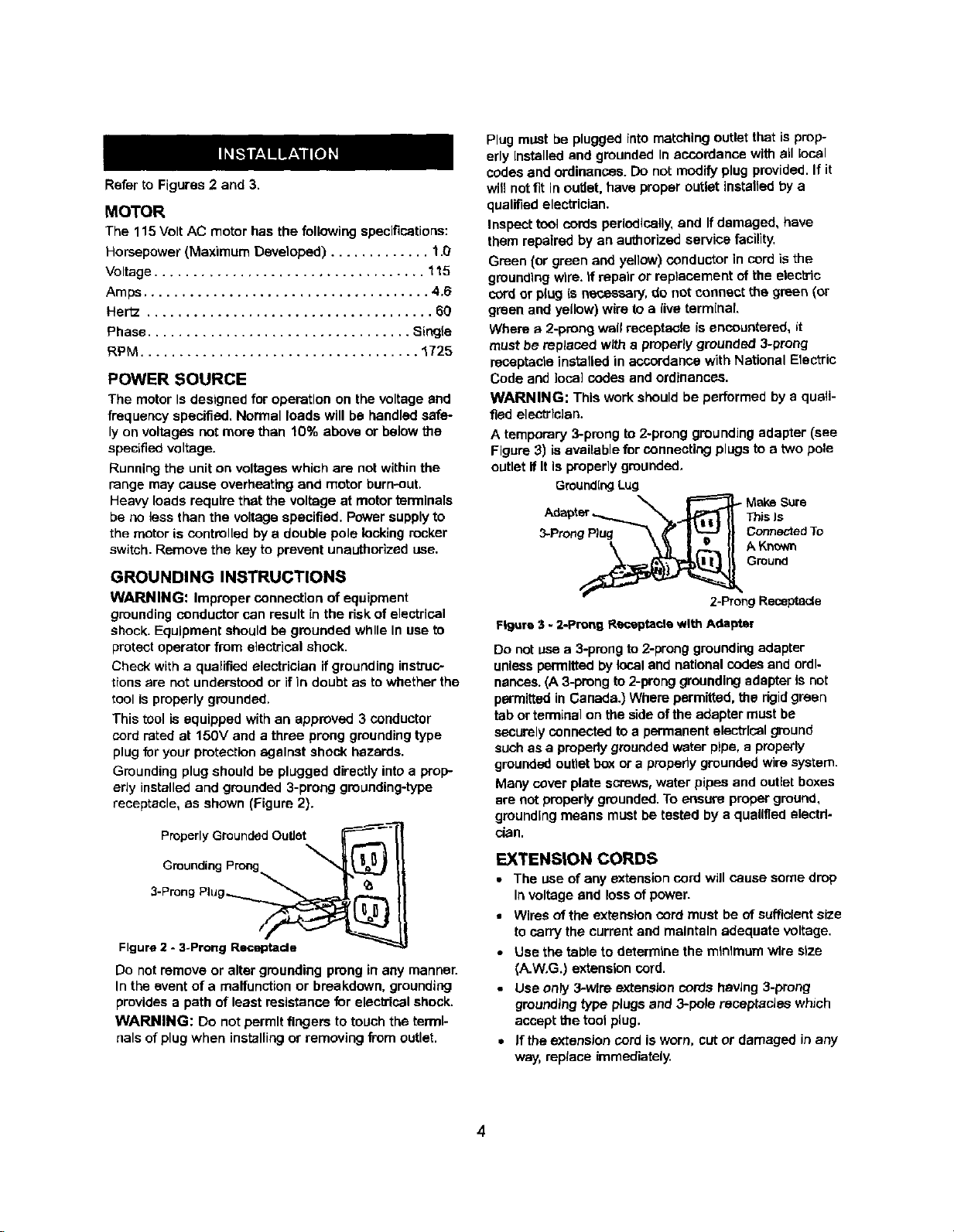

A temporary 3-prong to 2-prong grounding adapter (see

Figure 3) is available for connecting plugs to a two pole

outlet if It Is properly grounded,

GroundingLug

- Make Sure

This Is

3-Prong Plug

Connected To

A Kr_wn

Gmund

2-PrengReceptacle

Figure 3 - 2-prong Receptacle with Adapter

Do not use a 3-prong to 2-prong grounding adapter

unless permitted by local and national codes and ordl-

nancas. (A 3-prong to 2-prong grounding adapter Is not

psrrnitted in Canada.) Where permitted, the rigidgreen

tab or terminal on the side of the adapter must be

securely connected to a permanent electrical ground

suchas a propedy grounded water pipe, a properly

grounded outlet box or a properly grounded wire system.

Many cover plate screws, water pipes and outlet boxes

are not properly grounded. To ensure proper ground,

grounding means must be tested by a qualified electri-

cian.

EXTENSION CORDS

• The use of any extension cord will cause some drop

In voltage and loss of power.

• Wires of the extension cord must be of sufficient size

to carry the current and maintain adequate voltage.

• Use the table to determine the minimum wire size

(A.W.G.) extension cord.

• Use only 3-wire extension cords having 3-preng

grounding type plugs and 3-pole receptacles which

accept the tool plug.

• If the extension cord is worn, cut or damaged in any

way, replace immediately.

Page 5

EXTENSION CORD LENGTH

Wire Size A.W.G.

Up to 50 f_.................................. 16

NOTE: Using extension cords over 50 ft. long Is not

recommended.

Refer to Figures 4 - 13, pages 5-8.

The Craftsman 10" Tilting Head Band Saw features alu-

minum frame construction and a solid cast Iron table

surface to insure durability. It Is designed for cutting

hard and soft woods, as well as nonferrous metals and

plastics. Head of the saw tilts from 90° to 45=while the

table remains in horizontal position for straight line

feeding of the matedal. The saw Is equipped with a

miter gauge for performing many different operations.

The built-in dust collection system helps to keep the

worksurface cleen. A convenient quick tensioning and

comprehensive trackJng mechanism makes blade

changing quick and easy.

SPECIFICATIONS

Depth of throat at 90° . ...................... 9¾"

Maximum depth of cut at 90*. .................. 5"

Depth of throat at 45 ° . ........ 7%" for 1" thick board

3" for 3" thick board

Maximum depth of cut at 45 _. ................. 33/_"

Table size ........................... 133/_x 11%"

Table tilt ............................. 90° to 45 °

Wheel diameter ............................. 8"

Blade length .............................. 83%"

Blade range ........................ 63% - 63%_"

Blade width ............................. 1/,- _/."

Blade speed ......................... 3800 FPM

Overafl dimensions ............... 283/,x 161/sx 34"

Shipping weight .......................... 95 I_

Dust collection port ......................... 2'/_"

CAUTION: Always observe the following safety

precautions:

• Make sure that blade guides and thrust bearings are

positioned and adjusted correctty to prevent side-

ways and rearward movement of the blade, Adjust

upper guide to just clear workplece.

• Check to make sure blade is tensioned and I_acking

property.Do not over tension the blade In order to

prevent premature blade wear and breakage. Avoid

under tensioning to etiminate back and forth, side to

side blade movement as it outs.

• Use proper blade for the curing operation.

• After turning saw on, allow blade to come to full

speed before attempting any cutting operation.

• Support workplace properly and use a smooth

steady feed to guide work through the cut, Use push

sticks or push blocks when required,

• Keep hands away and out of line with moving parts,

• Atways wear eye protection.

REMOVING BLADE

WARNING: Disconnect bend saw from power source

when changing or adjusting blades, Wear leather groves

when handling band saw blades, Never wear gloves

when operating saw.

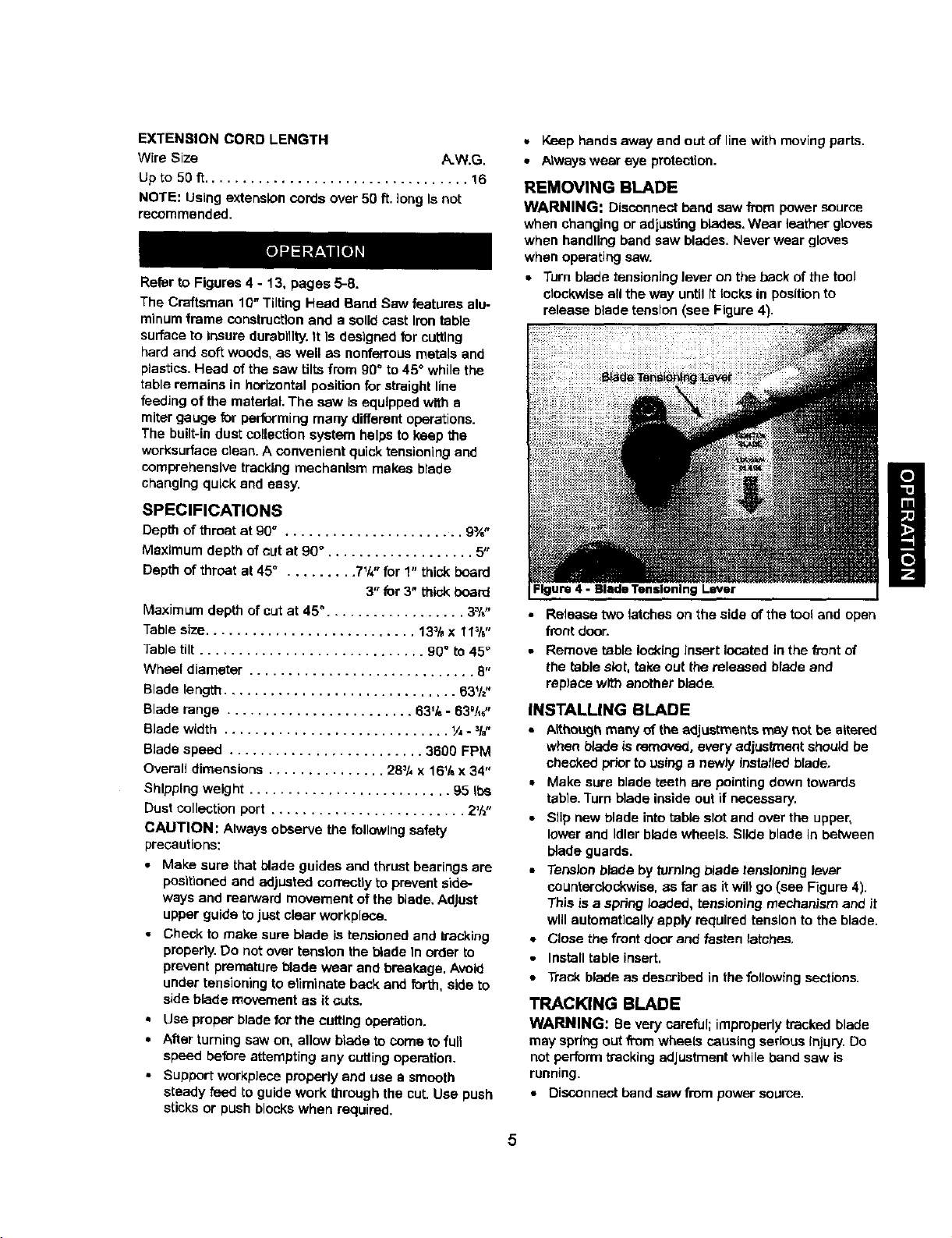

• Turn blade tensioning lever on the beck of the tooJ

clockwise all the way until it rocks in position to

release blade tension (see Figure 4).

Flgura 4 - Blade Tensioning Lever

• Releese two latches on the side of the tool and open

front dear,

• Remove table locking insert located in the front of

the table slot, take out the released blade arid

rep)aco with another blade.

INSTALLING BLADE

• Although many of the adjustments may not be altered

when blade is removed, every adjustment should be

checked prior to using a newly installed blade,

• Make sure blade teeth are pointing dawn towards

table. Turn blade inside out if necessary,

• Slip new blade into table slot and over the upper,

loWer and Idler blade wheels. Slide blade in betWeen

blade guards.

• Tension blade by turning blade tensioning taver

counterclockwise, as far as it wilt go {see Figure 4).

This is a spring loaded, tensioning mechanism and it

will auiomatlcally apply required teeslon to the blade.

• Close the front door and fasten latches,

• Install table insert.

• Track blade as described in the foflowing sections.

TRACKING BLADE

WARNING: Be very careful; improperly tracked blade

may spring out from wheels causing serious injury. Do

not perform tracking adjustment while band saw is

running.

• Disconnect bend saw from power source.

Page 6

• To check the blade tracking rotate drive wheel by

hand in clockwise direction.

• Proper tracking is achieved when drive and idler

wheels are aligned. Tracking plate (see Figure 5) on

the hack of the tool frame is used to tilt upper idler

wheel and align all three blade wheels.

Set Screw

Figure 5. Tracking Plate

• Loosen up hex nut.

• Loosen up socket head bolts. There are four socket

head bolts holding tracking plate. Bottom socket

head bolts should be loosened just enough to allow

ttitlngof the plate. If the bottom socket head bolt Is

loosened too much, the plate will not tilt.

• Using set screws, tilt the plate In vertical (up and

down) plane until proper tracking is achieved. Upper

idler blade wheel will tilt in the same direction as

tracking plate.

• Most of the time tracking plate should be tilted to the

desired degree as shown in Figure 6 (top of tracking

plate should be pulled away from cabinet wall, while

bottom part of tracking plate should be touching

cabinet wall).

• When blade is tracking properly, tighten up hex nut

and all four socket head bolts.

• Properly tracked blade shoutd ride at the center

height on all three wheels (drive and idlers).

BLADE GUIDES

NOTE_ Adjust blade guides only after blade has been

properly tensioned and tracked.

• Blade guides support blade at sides and rear of

blade, and prevent twisting or deflactlon.

• Blade guides should not touch blade when no work-

piece is in contact with blade. Adjust guides as

described In following section.

UPPER BLADE GUIDES

• Upper blade guides employ guide pins for side

support and a ball bearing for rear support.

• Loosen set screws and adjust guide pins to sides of

the b_ade (see Figure 7). Use a feeler gauge to

check that guide pins are 0.002" away from blade.

• Lock adjustment by tightening set screws.

Ba_Beadng

GuidePin

Set Screw

Figure7. Upper Blade Guides

:igure 6 -Tracking Plate

If blade rides away from cabldet, Increase gap

between tracking plate and cabinet wall. If the blade

rldas into cabinet, decrease the gap.

• AdjUst ball bearing at rear of blade by loosening hex

nutand turning bearing shaft (see Figure 8).

6

Page 7

• Position ball bearing 0.002" away from back of

blade.

• Secure pesition of thrust bearing by tightening hex

nut.

• Adjust the height of upper guide to clear the work-

piece by W'. Loosen upper guide knob (see Figure 9)

and adjust height of upper guide until it clears

workplace by W'. Tighten upper guide knob.

• Loosen socket head bolts (see Figure 11) and adjust

lower guide bracket position so that rear of blade is

positioned inside the groove of roller (see Figure 10).

There should be 0.002" clearance between blade

and roller.

Figure 9 - Upper Blade Guide

LOWER BLADE GUIDES

• Lower blade guides employ guide pins for side sup-

port and grooved roller for rear support.

• Loosen set screws (see Figure 10) and move guide

pins away from blade sides.

Figure 10 - Lower Blade Guides

Figure 11 - Lower Blade Guide

• Tighten socket head bolts (see Figure 11).

• ,_djust guide pins (see Figure 10) to sides of the

blade. Use a feeler gauge to check that guide pins

are 0.002" away from blade.

• Lock adjustment by tightening set screws.

BLADE SELECTION

• Blades vary depending on type of material, size of

workplace and type of cut that is being performed.

• Characteristics which make blades different are

width, thickness end pitch.

BLADE WIDTH

• Width of blade describes distance from tip of a tooth

to back of blade.

• Width of blade will affect rigidity of blade. A wider

blade will wander less and produce a straighter cut.

• Width of blade a!so limitsthe smallest radius which can

be cut. A ¼" wide blade can cut about a ½" radius.

BLADE THICKNESS

• Blade thickness describes the distance between

sides of blade. A thicker blade has more rigidity end

stronger teeth.

• A narrow thick blade would be used to cut curves

while a wide thin blade would be used to make long,

straight cuts,

7

Page 8

BLADE PITCH

• Pitch describes number of teeth per inch or tooth

size. A blade with more teeth per inch will produce a

smoother cut.

• The type of material being cut determines number of

teeth which should be in contact with work.

• For soft materials, the proper blade has between 6

to 8 teeth per Inch.

• When cutting hard materials, where shocking is

more detrimental, use a blade with B to 12 teeth per

inch.

• There should always be at least three teeth In

contact with cut to avoid shocking blade.

• Blade shocking occurs when pitch is too large and

blade tooth encounters too much material This can

strip teeth from blade.

• Blade manufacturers are prepared to supply

information about blades for specific applications.

TYPE OF CUT

• Contour cutting is done by guiding werkpiece

free-handed to produce curved shapes.

• Beveled cutting can be done by filling saw head and

using proper work guide method.

- Regardless of which work guiding method is used, a

workpiece which overhangs table by more than 5"

should be properly supported

CONTOUR SAWING

• When contour sawing, use both hands to keep work-

piece fiat against table and guided along desired

path.

• Avoid positioning hands In line with blade. If hands

slip they could contact blade.

• Try to stand to front of the saw and use hands over

the portion of table which Is to right of blade and

before cut.

• Cut small corners by sawing around them. Saw to

remove scrap until desired shape Is obtained.

BEVEL CUTTING

Refer to Figure 10.

• Perform bevel cutting by tilting head to desired

degree,

• Unlock head by loosening locking handle located on

the backside of the unit (see Figure 12).

• Tilt head to desired position by rotating crank handle

(see Flgura 13).

• Lock head in position by tightening locking handle

(see Figure 12).

- Head Locldng Handle

Figure 13 - HL_KI TIIUng M_hanlem

MITER GAUGE

• Use miter gauge for securing and holding werkpiece

at desired angle to produce angled cuts. Use scale

to ad._ustgauge to desired angle.

WARNING: Never use miter gauge and rip fence at

the same lime. The blade might bind in the workpiece.

Operator could be injured and/or workpiece could be

damaged.

BLADE CLEANING BRUSH

Refer to Figure 14.

• Make sure that brush (Key No. 13) is in contact with

blade to properly remove foreign particles from drive

wheel.

8

Page 9

WARNING: Make certain that unit is disconnected

from power source before attempting to service or

remove any component.

CLEANING

• Keepmachineandworkshopclean.Do not allow

sawdustto accumulateon bandsaw.

• Keep wheels clean. Debris on wheels will cause

poor tracking and blade slippage.

• Keep mechanisms and threaded or sliding surfaces

clean and free of foreign particles.

• Operate band saw with a dust collector to minimize

clean up.

LUBRICATION

• The shielded bali bearings are permanentJy lubricat-

ed and require no further lubrication.

• Small amounts of machine oil can be applied to belt

tension mechanisms and threaded or sliding sur-

faces.

• Occasionally applya coat of automobiletype wax to

tabletop to keep itslick and corrosion free.

KEEP BAND SAW IN REPAIR

• If power cord is worn or cut in any way, have It

replaced.

• Replace any damaged or missing part.

• Use parts list to order parts.

Page 10

Service Record

Craftsman 10"Tilting Head Bench Top Band Saw with Dust Collection

IDATE MAINTENANCE PERFORMED REPLACEMENT PARTS REQUIRED 1

10

Page 11

SYMPTOM

Excessive blade breakage

Premature blade dulling

Crookedcuts

Rough cuts

Blade istwisting or unusual

wear on side/back of blade

Teeth ripping from blade

Motor running too hot

Saw will not start

POSSIBLE CAUSE(S)

1. Material not secure on table

2. Blade too coarse for material

3.Teeth in contact with work before

sawing

4. Misaligned guides

5. Blade too thick for wheel diameter

6. Cracking at weld

1.Blade too coarse

2. Inadequate feed pressure

3. Hard spots or scala in or on

material

4. Blade installed backwards

1.Work: not square

2. Rate of feed too great

3. Blade guides not adjusted properly

4. Upper blade guide too far

from workplace

5. Dull blade

6. Blade guide assembly loose or

blade thrust bearing loose

1.Too muchfeed

2.Blade toocoarse

1.Cut is binding blade

2. Blade guides or bearing worn

3. Blade guides or bearings not

adjusted propedy

4. Blade guide brackets loose

1.Teeth too coarse for work

2. Rate of feed too great

3.Vibrating workpiece

4.Teeth filling with material

1. Blade too coarse for work:

(typical when cutting pipe)

2. Blade too fine for work (typical

when cutting slick or soft material}

3. Excessive dirt and chips

Loose electrical connections

CORRECTIVE ACTION

1. Squarely place work:on table

2. Usa finer pitch blade

3. Placa blade in contact with work after saw is

started and has reached full speed

4. Adjust blade guides properly

5. Use thinner blade

6. Replace blade

1. Use finer tooth blade

2. Gently increase pressure

3. Reduce speed; ineR_se rate of feed for

scale and change blades for hard spots

4. Remove blade, twist inside out and reinstall

blade

1.Use miter gauge; adjust tilt of head at 90°

2. Reduce rate of feed

3. Move beth guide block:s within .002" from

blade (use gauge)

4. Adjust upper guide to just clear work:piece

by¼"

5. Replace blade

6. Tighten blade thrust bearing within .002"

behind blade back

1.Reducefeed

2.Replace withfinerblade

1. Decrease feed pressure

2. Replace

3. Adjust blade guides; see "Operation"

4. Tighten properly

1. Use blade with finer teeth

2. Decrease feed rate

3. Hold work:piece firmly

4. Use blade with coarser teeth

1. Use blade with finer teeth

2. Use blade with coarser teeth

3. Clean thoroughly

Have qualified electrician check electrical

connections

11

Page 12

Model 351.214600

Figure 14 - Replacement Parts Illustration for Frame

31 32

p,_33_ 4 35

5

29

5

22

2a 5

\

\

30

51

52

J

21

19

17

B1

IO

58

12

Page 13

KEY

NO. PART NO.

1 20803.00

2 16080.00

3 00781.00

4 20804.00

5 05331.00

6 STD851005

7 20805.00

8 20806.00

9 20807.00

10 20808.00

11 20862.00

12 STD840610

13 20810.00

14 20811,00

15 00090.00

18 02702.00

17 20812.00

18 20993.00

19 ST0852008

20 01760.00

21 20814.00

22 20815.00

23 20816.00

24 01680.00

25 20817.00

26 20818.00

27 STD841217

28 00351.00

29 20819.00

3O

20820.00

31

20821.00

32

20822.00

DESCRIPTION QTY.

Front Door 1

Switch with Key 1

4-0.7 x 8mm Pan Head Scra_ 11

Switch Plate 1

5-0.8 x 12ram Socket 18

Head Bolt

5mm Flat Washer*

Wheel Band

Ddve Wheel Assembly

Small Idler Wheel Band

Small Idler Wheel Assembly

Blade 63.5" x _,_"x 6 Hook

6-1.0ram Hex Nut*

Blade Brush

Frame

Line Cord

Cord Clamp

Reck

5 x 15ram Dowel Pin

6rnm Lock Washer*

6-1.0 x 16mm Socket

Head Bolt

Motor

4 x 4 x 20ram Key

Bushing

Strain Relief

Tracking Plate

Strain Relief

12-1.75mm He_ Nut*

6-1.0 x 10ram Set Screw

Blade Tensioning

Cam Assembly

Upper Blade Guide Assembly

Knob

Upper Guide Seat

KEY

NO.

PART NO.

20823.00

133:

20824.00

35

20825.00

36

20826.00

37

20827.00

4

2

1

1

1

1

3

1

1

1

4

1

2

3

3

1

1

1

1

1

2

1

4

1

1

1

1

38

39

40

41

42

43

44

45

46

47

48

49

5O

51

52

53

54

55

56

57

58

59

60

20828.00

20829.00

20830.00

01474.00

00361.00

STD85200E

01822.00

20831.00

20832.00

03806.00

20833.00

20834.00

20835.00

20836.00

06270.00

20837.00

20838.00

20839.00

20840.00

20841.00

20842.00

20994.00

20995.00

DESCRIPTION

Spring

Locking Insert

Upper Guide Bracket

Blade Guard with

Lamp Assembly

Lamp Switch

Lamp Bulb

Cord Clamp

Lower Blade

Guide Assembly

5ram Serrated Washer

5-0.8 x 8mm Pan

Head Screw

8ram LockWasher*

8-1.25 x 20ram Socket

Head Bolt

Hinge Pivot

Cover

6-1.0 x 10ram Socket

Head Bolt

6 x 16 x 1.5ram Flat Washer

Shaft

Link

Bracket

5-0.8 x 8ram Socket

Head Bolt

Teeslonlng Rod

Teeslonlng Nut

Idler Wheel Assembly

8 x 23 x 2mm FlatWasher

Tensioning Spring

Door Latch

Sleeve

Special Washer

QTY,

1

1

1

1

1

1

2

1

2

2

4

4

1

1

1

1

1

1

1

12

1

1

1

1

1

2

1

* Standard hardware item available _oeaW.

13

Page 14

Model 351.214600

Figure 15 - Replacement Parts Illustration for Base

23

\

25

t

27

28

14

3

Page 15

KEY

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

!20

21

22

23

24

25

26

27

28

PART NO.

20843.00

20844.00

20845.00

8TD851005

05331.00

01081.00

STD851008

20776.00

20777.00

20847.00

20848.00

08182.00

STD833020

STD852006

02783.00

20849.00

STD852005

20850.00

20851.00

20852.00

8TD851006

03812.00

20853.00

20854.00

20855.00

20856.00

20857.00

20858.00

&

20859.00

DESCRIPTION

Head Mounting Bracket

Base

Pointer Assembly

5ram Flat Washer*

5-0,8 x 12ram Socket Head Bolt

6-1,25 x 25ram Hex Head Bolt

8ram Flat Washer*

Dust Collection Bag

Bag Clamp

Bushlr_

Lock Handle

6-1.0 x 30ram Socket Head Bolt

6-1.0 x 20ram Hex Head Bolt*

6mm Lock Washer*

4 x 18ram Spring Pin

Worm Cover

5mm Lock Washer*

Worm Shaft Assembly'

Bearing Flange

Swivel Beadn_g

6ram Flat Washer*

6-1.0 x 10ram Pan Head Screw

Crank Handle

Table with Scale

Table Insert

Table Locking Insert

6-1.0 x 28mm Wing Bolt

Miter Gauge Assembly

Operator's Manual

QTY.

1

1

1

2

4

2

2

1

1

3

1

2

2

3

1

1

2

1

2

1

2

2

1

1

1

1

1

1

1

* Standard hardware item available locally.

Recommended Accessories Model No.

6 Multi-Purpose Stand 9-'22224

6 Blade 63.5" x '/4"x 10R 20860.00

& Blade 63.5" x '/4"x 6 Hook 20861.00

A Blade 83.5" x 3/,,,,x 6 Hook 20862.00

15

Page 16

:¸

:::::: Your Home

:::::::: For repair-in your home-of all major brand appliances,

::......... lawn and garden equipment, or heating and cooling systems,

noma.erwhoma eit.nomatterwhoso, ,t,

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation ........

of home appliances

...... and items like garage door openers and water heaters. ::::_::..............

• :::::

............ 1 800 4 MY ...........

........ HOME ® (1-800 469-4663)

.......... Call anytime day or night (U S A. and Canada) ;:::..........:

www.sears.com www.sears.ca

.... Our Home :::

:_:_:;.... For repair of carry-in items like vacuums, lawn equipment, :_:;.........

.......... and electronics, call or go on-line for the location of your nearest :::......

: Sears Parts & Repair Center.

.........: 1-800-488-1222

::;:::::

:::::..:

:' Call anytime, day or night (U.S.A. only)

_,se_rs,_t_t

!!!!

To purchase a protection agreement (U,S.A.)

........... or maintenance agreement (Canada) on a product serviced by Sears: ......

_:::; 1-800-827-6655 (U.S.A.) 1-800-361- Canada)

............._...... _, .....-_ ........-..........._ ..-..............._..................,.....,...,...._.......... ,, ....

;::::: Para pedir servicio de reparacibn Au Canada pour service en fran_pais:

........... a domicilio, y para ordenar pieT.as: :,:

............. 1-800-LE-FOYER _

6665 ( :;i::

1-888-SU-HOGAR _ (1-800-533-6937)

- V_NW.Se_FS.Ca ; :

(1 888-784--6427) .......

!! ! i

® Registered Trademark / Trademark / Service Mark of 5earn, Roebuck and Co

® Mama Regis_ada / _MMama de F&brlca / su Marca de Seevldo de Sears, Roebuc_ and Co,

ac Marque de cernrnerce /no Marque depo_de de Seam. Roebuck and Co. ® Sears, Roebuck and Co.

TM 8M

Loading...

Loading...