Craftsman 351184310 Owner’s Manual

Operator's Manual

[RRFTSHRN

16 Gauge

¾ - 21/2" Length

FINISH NAILER

Model No.

351.184310

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

6499.04 Draft (11/02/99)

• Safety

• Operation

• Maintenance

• Parts List

• Espafiol

Warranty ....................................... 2

Safety Rules .................................... 2

Operation .................................... 2-4

Maintenance .................................... 4

Troubleshooting ................................. 5

Parts Illustration and List ......................... 6-7

EspaSol ..................................... 8-11

FULL ONE YEAR WARRANTY ON CRAFTSMAN

FINISH NAILER

If this Craftsman air-drive tool fails due to a defect in material

or workmanship within one full year from the date of purchase,

return it to the nearest Sears Service Center in the United

States, and Sears will repair it free of charge.

If this air-drive tool is used for commercial purposes, this

warranty applies for only 90 days from the date of purchase.

This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL

60179

• Air tool operators and all others in work area should

always wear safety goggles complying with United States

ANSI Z87.1 to prevent eye injury from fasteners and flying

debris when loading, operating or unloading this tool.

• Never exceed operating pressure of 100 PSI.

• Always keep hands and body away from the fastener dis-

charge area when air supply is connected to tool.

• Always disconnect tool from air supply when servicing or

adjusting tool and when tool is not in use.

• Do not operate when contact trip is not in contact with

work.

• Never load the tool until you are ready to use it.

• Never depress tool trigger when loading.

• Always load with nose of tool pointing away from you and

others.

• Never point tool at yourself or others.

• Never carry tool with trigger depressed.

• Do not use oxygen, combustible gas or high pressure

compressed gas as the air supply for the tool.

• Always use tool at safe distance from other people in work

area.

• Do not attempt to discharge fastener into hard or brittle

materials such as concrete, steel or tile.

• Do not connect female quick-disconnect coupling to tool

side of air line.

• Connect male, free-flow nipple to tool side of air line so

that tool is depressurized when disconnected from hose.

• Do not use a hose swivel with this tool.

• Use Sears recommended fasteners only.

Refer to Figures 1,2, 3, 4 and 5.

DESCRIPTION

The Craftsman 16 Gauge Finish Nailer drives nails from 3A"to

2W' long. Die cast aluminum, textured finish body with cush-

ion grip minimizes operator fatigue. Large capacity, top load-

ing magazine makes loading easy. Safety feature disables tool

unless contact trip is pressed against workpiece. Tapered

nosepiece provides operator with greater visibility for precise

fastener placement. Quick release nose cover allows easy

access to jammed fasteners. Adjustment knob controls depth

of fastener. Air deflector can be adjusted to any direction. The

16 Gauge Finish Nailer is excellent for interior and exterior

trim work, door and window manufacturing, furniture making

and cabinetry.

SPECIFICATIONS

Capacity ............................ 110 finish nails

Nail size ..................... 16 gauge (.062" x .052")

Nail lengths ............................... 3Ato 21/2''

Operating pressure ....................... 60-100 PSI

Air inlet ................................. W' N.RT.F.

Length....................................... 12"

Height ..................................... 111/2"

Width ........................................ 3"

Weight.................................... 4.1 Ibs.

FINISH NAILS

18345 ................... 16 gauge finish nails, 3A"long

18344 .................. 16 gauge finish nails, 1W' long

18346 .................. 16 gauge finish nails, 1W' long

18347 ................... 16 gauge finish nails, 2" long

18368 .................. 16 gauge finish nails, 2W' long

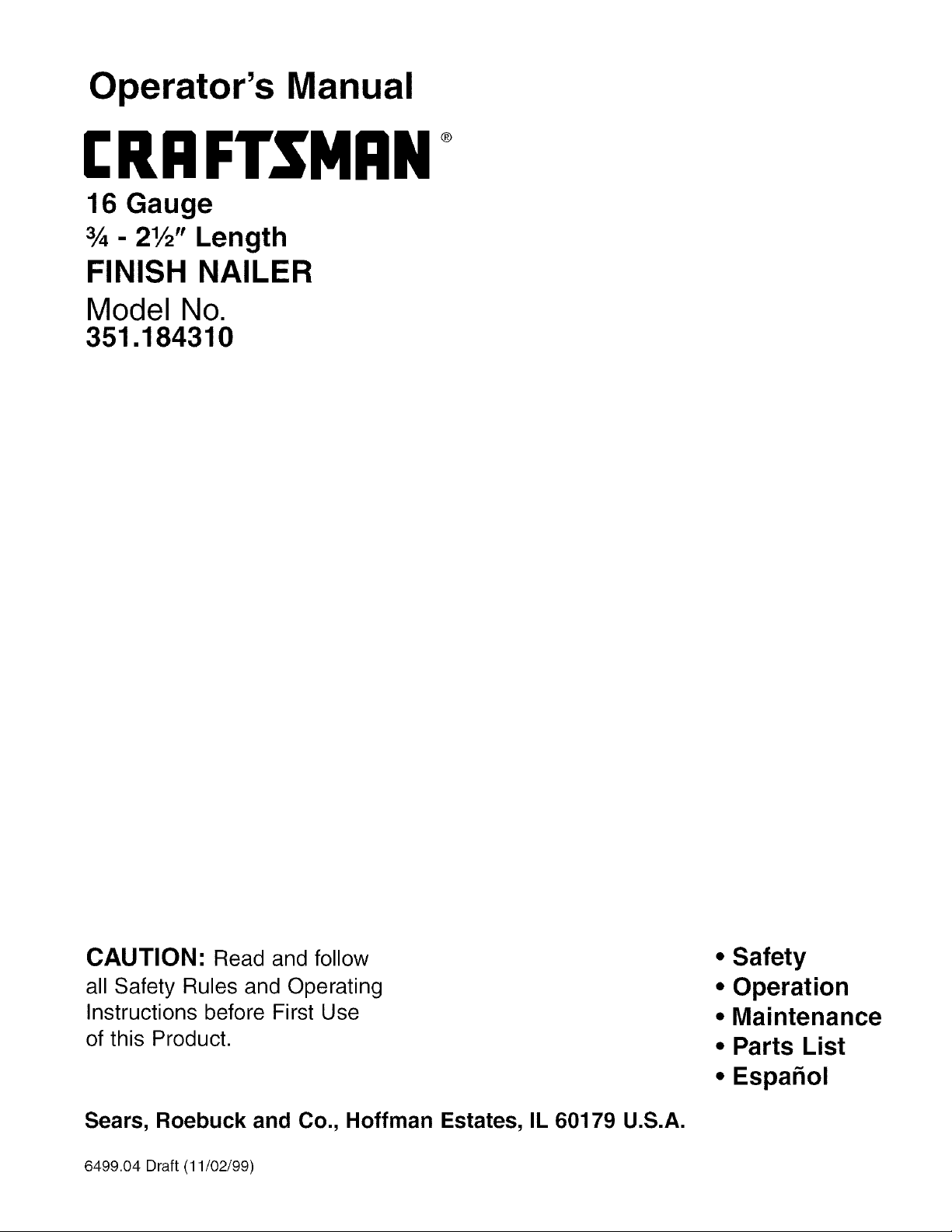

AIR SUPPLY LINE

Refer to Figure 1 (page 3).

° The air tool operates on compressed air at pressures from

60 to 100 PSI.

° Never exceed maximum pressure.

Air Delivery Required: 1.41 SCFM @ 90 PSI

(30 shots per minute).

WARNING: Keep hands and body away from discharge area

of tool when connecting air supply. Always disconnect tool

from air supply when servicing or adjusting tool and when tool

is not in use.

° Air operated tools require clean, dry, lubricated com-

pressed air to ensure top performance, low maintenance

and long life.

° Dirt and abrasive materials present in all air lines will dam-

age tool O-rings, valves and cylinders.

° Moisture will reduce tool performance and life if not

removed from compressed air.

° A filter-regulator-lubricator system is required and should be

located as close to tool as possible (see Figure 1, page 3).

A distance of less than 15 feet is recommended.

° Keep air filter clean. A dirty filter will reduce the air pressure

to the tool causing a reduction in power and efficiency.

2

• The air supply system must be able to provide air pressure

of 60 to 100 pounds per square inch at tool.

• The lubricator should be filled with a non-detergent air tool

oil.

• All hoses and pipes in the air supply system must be clean

and free of moisture and foreign particles.

• Do not mount swivel connector in air supply line.

• The air pressure should be properly regulated.

• Different workpiece materials and different fastener lengths

will require different operating pressure.

2 Foot Hose Whip

° Be sure all connections in air supply system are sealed to

prevent air loss.

° Never connect a female quick-disconnect coupling to the

tool side of air system. A male, free-flow coupling should

be connected to the tool side of air system.

WARNING: The female coupling provides a seal preventing

loss of compressed air from compressor tank when discon-

nected from male coupling. If connected to tool side of air

supply, the female coupling could seal a compressed air

charge in the tool which could discharge if the tool trigger is

actuated.

Filter - Regulator - Lubricator

MaleQuick-Disconnect

Figure 1 - Air Supply Line

Female Quick-Disconnect

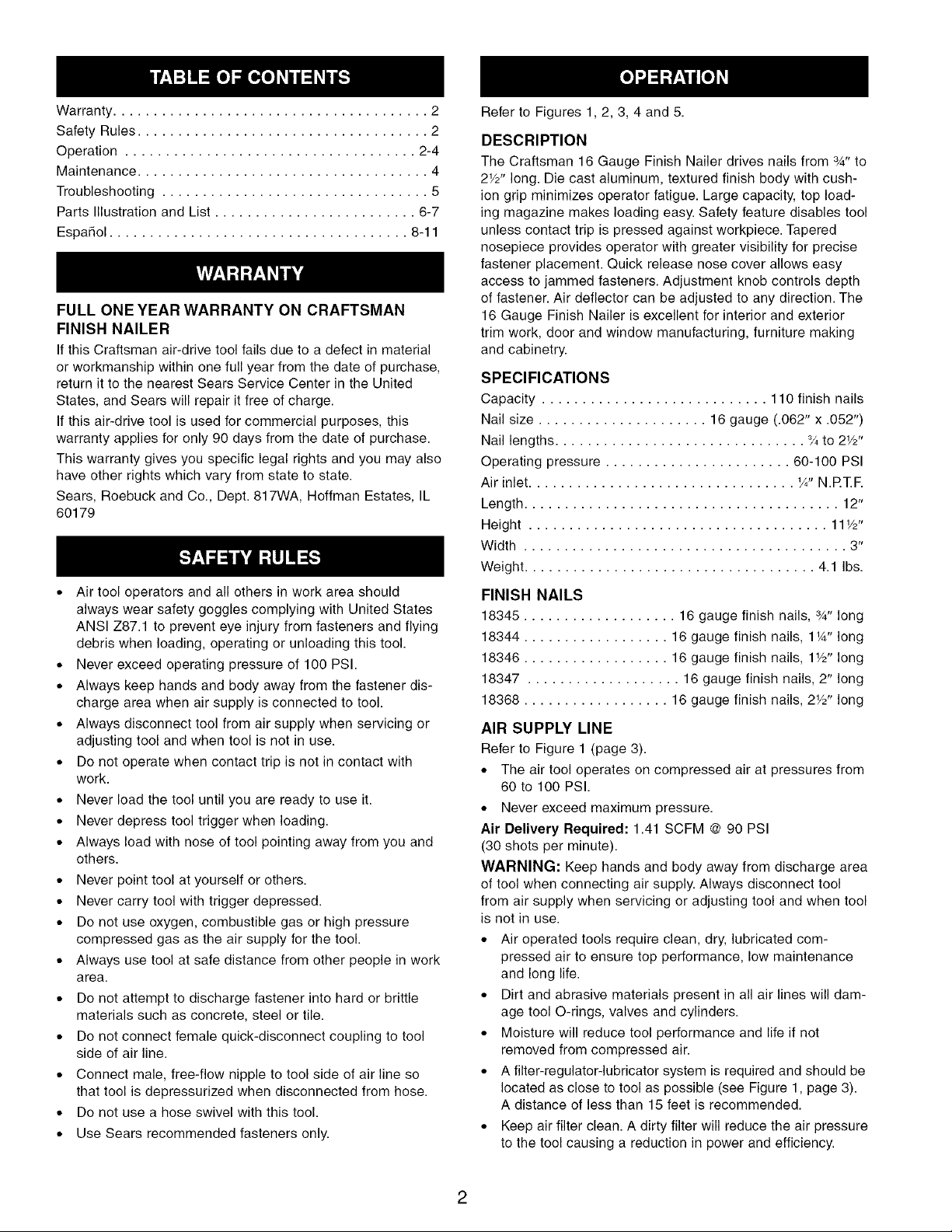

LOADING

Refer to Figures 2 & 5 (pages 3 and 6).

WARNING: Disconnect tool from air supply. Always load with

nose of tool pointing away from you and others. Always wear

safety goggles that comply with United States ANSI Z87.1.

NOTE: For best results use Sears fasteners only.

• Slide pusher handle (Fig. 5, No. 72) towards rear of tool

until it locks into position.

• Insert fasteners into magazine (see Figure 2).

• Hold pusher handle firmly and release by pushing latch

bracket (Fig. 5, No. 82) towards bracket (Fig. 5, No. 83).

Allow pusher to gently slide forward against fasteners.

This operating procedure provides rapid-fire fastener dri-

ving. Never operate tool unless contact trip is in contact

with workpiece.

° The driven depth of the fastener can be changed by turning

the adjusting knob (Fig. 5, No. 54) in either direction.

° The tool is equipped with a rotating switch that can change

the operating mode from rapid-fire to single-fire. When the

switch assembly (Fig. 5, No. 48) is rotated to the single-fire

position, the tool will fire one fastener only. To fire the next

fastener, both the trigger (Fig. 5, No. 35) and the contact

trip (Fig. 5, No. 58) must be released.

WARNING: All air power fastening tools recoil when operat-

ed. This recoil is caused by rapid driving of the fastener. Tool

may bounce from recoil causing a second, unwanted fastener

to be driven. Reduce tool bounce by holding tool firmly in

hand and pressing tool gently against workpiece. This will

allow recoil of tool to bounce away from workpiece preventing

the driving of second fastener.

Depress Trigger

Figure2 __

Loading Nails

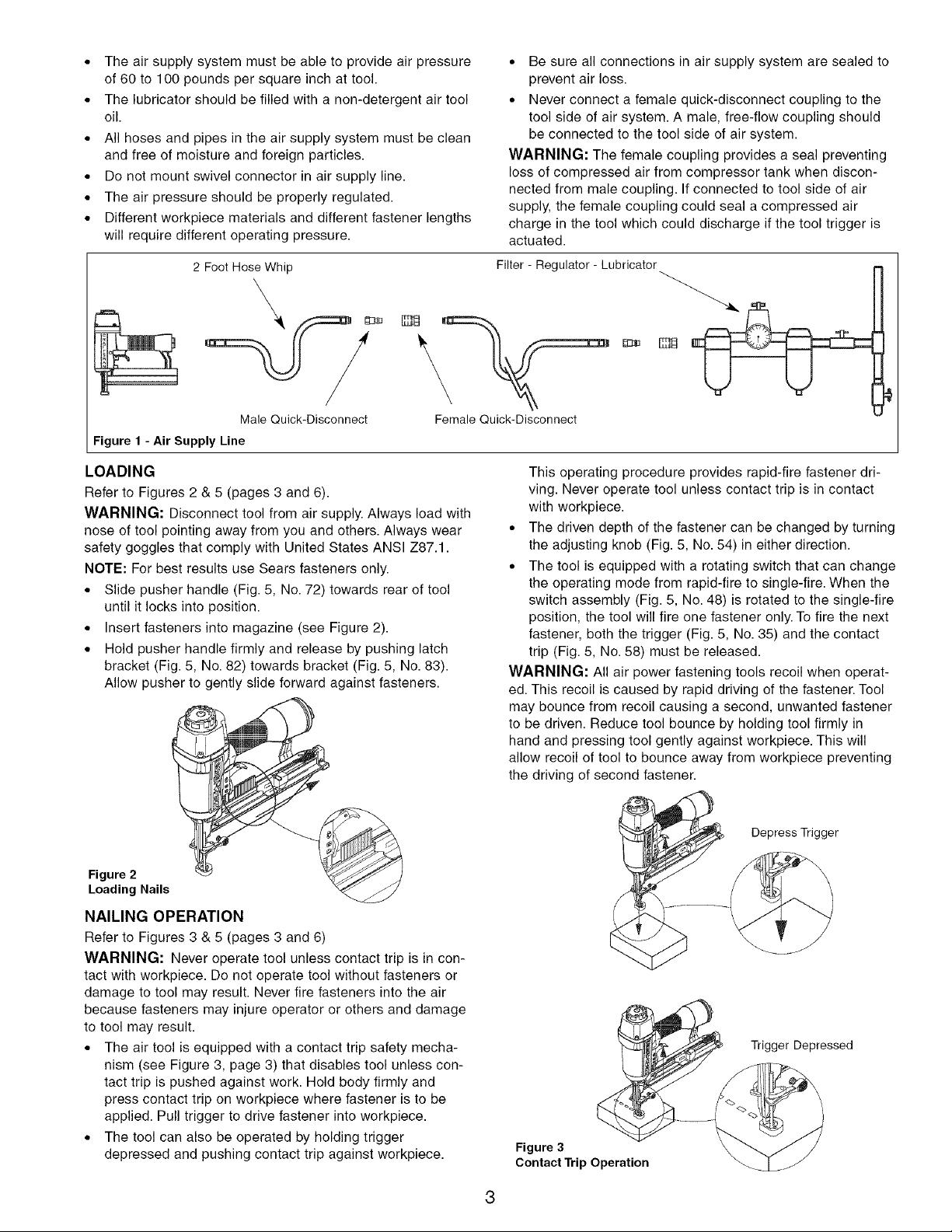

NAILING OPERATION

Refer to Figures 3 & 5 (pages 3 and 6)

WARNING: Never operate tool unless contact trip is in con-

tact with workpiece. Do not operate tool without fasteners or

damage to tool may result. Never fire fasteners into the air

because fasteners may injure operator or others and damage

to tool may result.

• The air tool is equipped with a contact trip safety mecha-

nism (see Figure 3, page 3) that disables tool unless con-

tact trip is pushed against work. Hold body firmly and

press contact trip on workpiece where fastener is to be

applied. Pull trigger to drive fastener into workpiece.

• The tool can also be operated by holding trigger

depressed and pushing contact trip against workpiece.

Trigger Depressed

Figure 3

Contact Trip Operation

QUICK RELEASE NOSE

Refer to Figure 5 (page 6).

The tool is equipped with a quick release nose for clearing

jammed fasteners.

° If a fastener jams in the tool, disconnect the air supply

from the tool. Open the magazine and remove any fasten-

ers. Squeeze the nose cover latches (Fig. 5, No. 63) and

release the nose cover. Remove the jammed fastener and

secure the latches. Reload the fasteners and reconnect

the air supply.

OPERATING PRESSURE

° Use only enough air pressure to perform the operation. Air

pressure in excess of that which is required will make the

operation inefficient and may cause premature wear or

damage to the tool.

° Determine minimum air pressure required by driving some

test fasteners into the workpiece. Set air pressure so that

test fasteners are driven down flush with the work surface.

Fasteners driven too deep may damage workpiece.

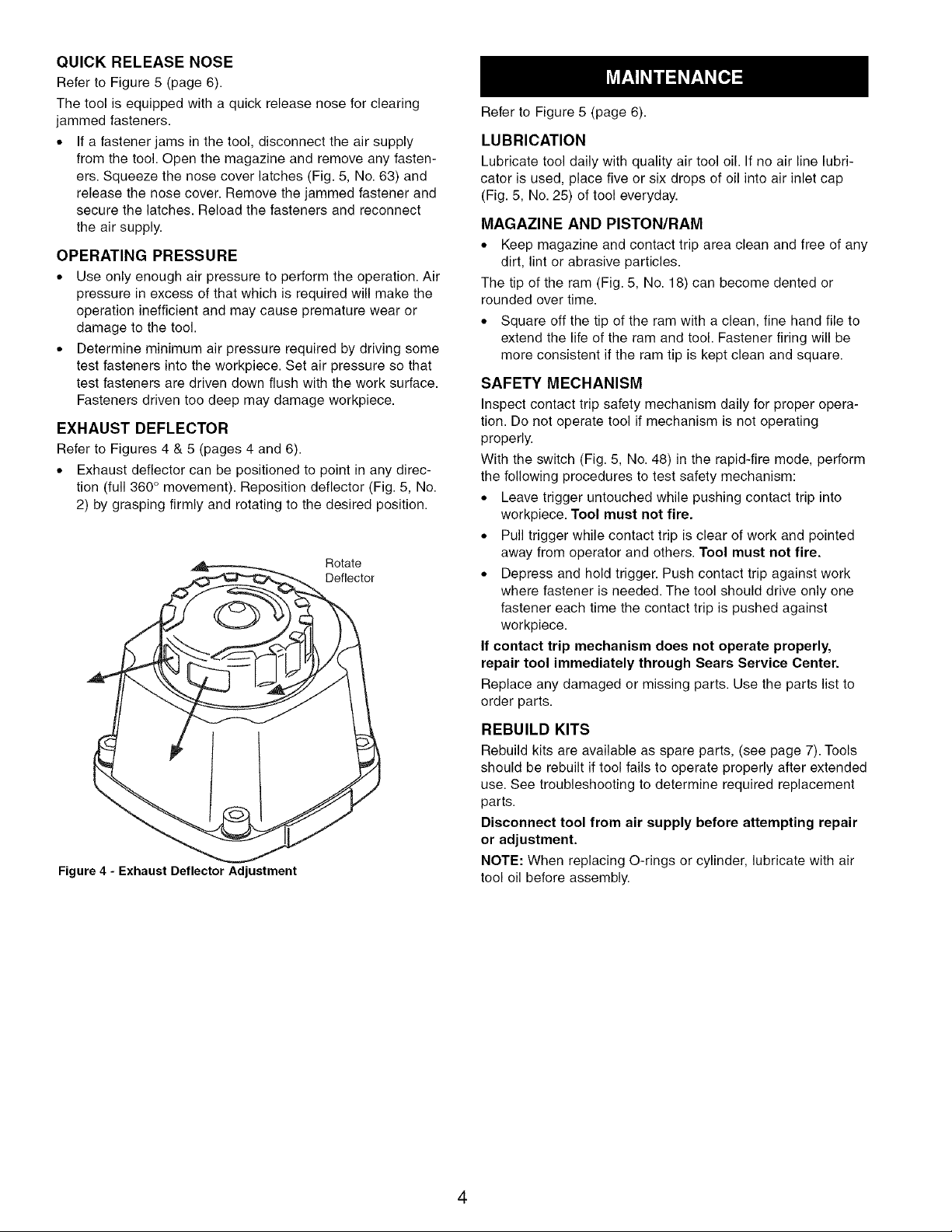

EXHAUST DEFLECTOR

Refer to Figures 4 & 5 (pages 4 and 6).

° Exhaust deflector can be positioned to point in any direc-

tion (full 360 ° movement). Reposition deflector (Fig. 5, No.

2) by grasping firmly and rotating to the desired position.

Rotate

Figure 4 - Exhaust Deflector Adjustment

Refer to Figure 5 (page 6).

LUBRICATION

Lubricate tool daily with quality air tool oil. If no air line lubri-

cator is used, place five or six drops of oil into air inlet cap

(Fig. 5, No. 25) of tool everyday.

MAGAZINE AND PISTON/RAM

° Keep magazine and contact trip area clean and free of any

dirt, lint or abrasive particles.

The tip of the ram (Fig. 5, No. 18) can become dented or

rounded over time.

• Square off the tip of the ram with a clean, fine hand file to

extend the life of the ram and tool. Fastener firing will be

more consistent if the ram tip is kept clean and square.

SAFETY MECHANISM

Inspect contact trip safety mechanism daily for proper opera-

tion. Do not operate tool if mechanism is not operating

properly.

With the switch (Fig. 5, No. 48) in the rapid-fire mode, perform

the following procedures to test safety mechanism:

° Leave trigger untouched while pushing contact trip into

workpiece. Tool must not fire.

° Pull trigger while contact trip is clear of work and pointed

away from operator and others. Tool must not fire.

° Depress and hold trigger. Push contact trip against work

where fastener is needed. The tool should drive only one

fastener each time the contact trip is pushed against

workpiece.

If contact trip mechanism does not operate properly,

repair tool immediately through Sears Service Center.

Replace any damaged or missing parts. Use the parts list to

order parts.

REBUILD KITS

Rebuild kits are available as spare parts, (see page 7). Tools

should be rebuilt if tool fails to operate properly after extended

use. See troubleshooting to determine required replacement

parts.

Disconnect tool from air supply before attempting repair

or adjustment.

NOTE: When replacing O-rings or cylinder, lubricate with air

tool oil before assembly.

4

Loading...

Loading...