Craftsman 351183220 Owner’s Manual

SAVE THiS MANUAL

FOR

FUTURE REFERENCE

OWNER'S

MANUAL

MODEL NO.

351.183220

4"

FIN®

CAUTION:

READ ALL

INSTRUCTIONS

CAREFULLY!

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A. ©

Part No. 75_3.01 SEPTEMBER 1993

An le Finishin ailer

®safety instructions

• operating instructions

®replacement parts

DESCRIPTION

The Sears Angle Finishing Nailer drives 15 gauge nails

from 1 1/2 to 2 1/4" long and 14 gauge nails 2 1/2" long

Magazine is angled for nailing in tight spots.. Tapered

nose makes precise nail placement easy. Die cast

aluminum body is light weight and balanced to reduce

operator fatigue_ Contact safety disables nailer uritil

nosepiece is in contact with workpiece. Convenient

rear load magazine makes loading nails easy. The

Sears Angle Finishing Nailer-is ideal for interior and

exterior molding, furniture making and cabinetry°

SPECIFICATIONS

Capacity ...................... I00 nails, 15 gauge

.................................... 90 nails, 14 gauge

Finish nail lengths ..................... 1 1/2 to 2 1/2"

Operating pressure ....................... 60-100 PSIG

Air inlet .................................. 1/4" N..RTE

Length ..................................................... 13"

Height ........................................ 11 1/2"

Width .......................................... 3 3/4"

Weight .......................................... 5 3/4 tbs.

Always disconnect tool from air supply when servicing

or adjusting tool and when tool is not in use,,

Do not operate tool when contact trip is not in contact

with work

Never load the tool untUyou are ready to use it,,

Never depress tool trigger when Ioading_

Always load tool with tool pointing away from you arid

others.

Never' point tool at yourself or others.

Never carry tool with trigger depressed.

Do not use oxygen, combustible gases or high pres-

sure compressed gas as the air'supply for the toot,

Always use tool at safe distance from other people in

work area,,

Do not attempt to discharge fastener into hard or brittle

materials such as concrete, steel or tile.

Do not connect female quick-disconnect coupling to

tool side of air'line_

Connect male free-flow nipple to tool side of air line so

that tool is depressurized when disconnected from

hose°

Use Sears recommended fasteners only,

FINISH NAILS

918348 ................ 15 gauge finish nails, 1 t/2" long

9.18349 .................. 15 gauge finish nails, 2" long

918350 .............. 14 gauge finish nails, 2 1/2" long

SAFETY INSTRUCTIONS

Air tool operators and all others in work area should

always wear safety goggles (must comply with ANSI

Z87.t) to prevent eye injury from fasteners and flying

debris when loading, operating or unloading this tool

Never exceed operating pressure of 100 PSIG (7.1

kg/cm3).

Always keep hands and body away from the fastener

discharge area when air' supply is connected to tool

OPERATING INSTRUCTIONS

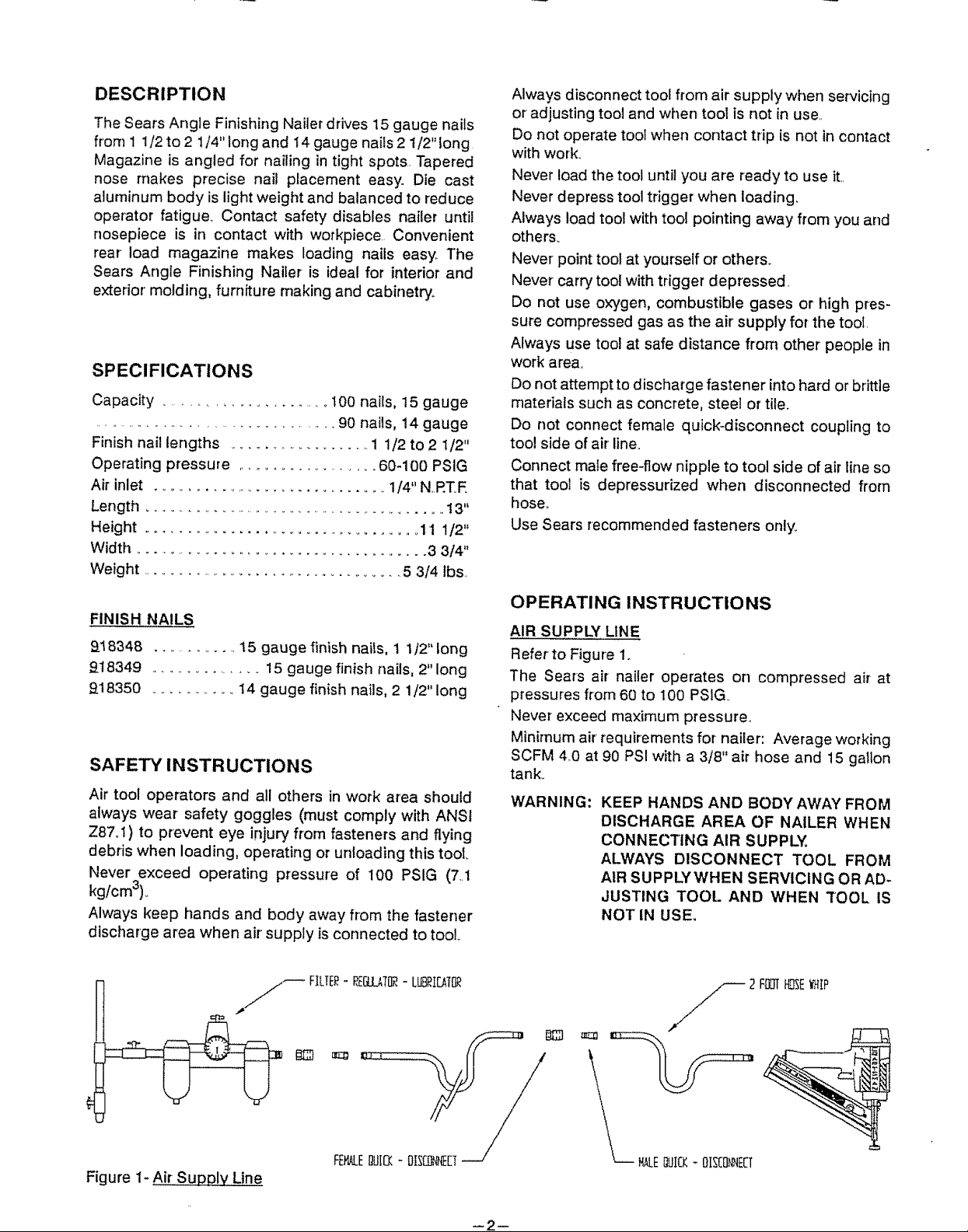

AIR SUPPLY LINE

Refer to Figure I.

The Sears air nailer operates on compressed air at

pressures from 60 to 100 PSIG.

Never exceed maximum pressure.

Minimum air requirements for nailer: Average working

SCFM 40 at 90 PSI with a 3/8" air hose and 15 gallon

tank..

WARNING:

KEEP HANDS AND BODY AWAY FROM

DISCHARGE AREA OF NAILER WHEN

CONNECTING AIR SUPPLY.

ALWAYS DISCONNECT TOOL FROM

AIR SUPPLY WHEN SERVICING OR AD-

JUSTING TOOL AND WHEN TOOL IS

NOT IN USE,

Figure 1-

_j_ FILTE_- P,EELLAI_- LL(BP,I_IOR

FEHkLEDUI_- OISCI)N)IE[T

HALEOUICK-OISCOhrrECT

--2--

OPERATING INSTRUCTIONS (Continued)

AIR SUPPLY LINE (Continued)

Clean dry air is essential to the operation of the Sears

nailer, Air operated tools require clean, dry, lubricated

compressed air to ensure top performance, tow main-

tenance and long life.

Dirt and abrasive materials present in all air lines will

damage tool O-rings, valves and cylinders,

Moisture wilt reduce tool performance and life if not

removed from compressed air,.

A _ter-regulator-lubricator system is required and

should be located as close to tool as possible (see

Figure 1), a distance of less than 15 feet is recom-

mended.

Keep air filter clean. A dirty filter will reduce the air

pressure tothe nailer causing a reduction in power and

efficiency.

The air supply system must be able to provide air

pressure of 60 to 100 pounds per square inch at tool..

The lubricator should be filled with a nomdetergent air

tool oil.

All hoses and pipes in the air supply system must be

clean and free of all moisture and foreign particles,.

Never connect a female quick-disconnect coupling

to the tool side of air system. A male, free-flow cou -

piing should be connected to the tool side of air

system° The female coupling provides a sea! prevent-

ing loss of compressed air frorn compressor tankwhen

disconnected from male coupling.. If connected to tool

side of air supply, the female coupling could seal a

compressed air charge in the naiter which could dis-

charge ifthe tool trigger is actuated,

The air pressure should be properly regulated_ Do not

mount swivel connector in air suppiy line.

Different workpiece materials and different nail lengths

will require different operating pressure..

Be sure all connections in air supply system are sealed

to prevent air Iosso

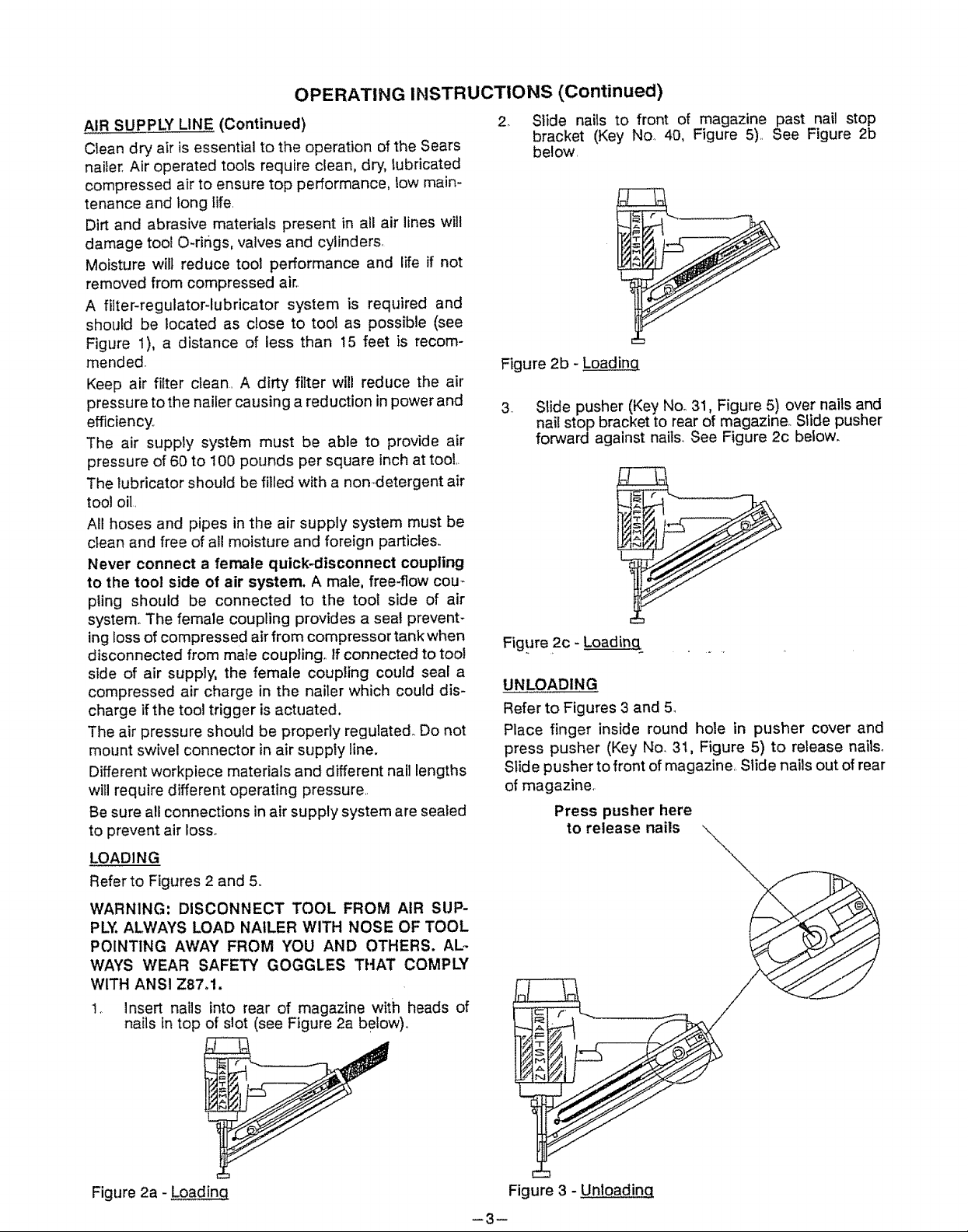

LOADING

Refer to Figures 2 and 5,.

WARNING; DISCONNECT TOOL FROM AIR SUP-

PLY.ALWAYS LOAD NAILER WITH NOSE OF TOOL

POINTING AWAY FROM YOU AND OTHERS. AL_

WAYS WEAR SAFETY GOGGLES THAT COMPLY

WITH ANSI Z87°1.

1. Insert nails into rear of magazine with heads of

nails in top of slot (see Figure 2a below)..

2_ Slide nails to front of magazine past nail stop

bracket (Key No_ 40, Figure 5).. See Figure 2b

below.

Figure 2b - LoadinCl

3. Slide pusher (Key Noo31, Figure 5) over nails and

nail stop bracket to rear of magazine_ Slide pusher

forward against nails_See Figure 2c below.

Figure 2c - Loadinq .....

UNLOADING

Refer to Figures 3 and 5.

Place finger inside round hole in pusher cover and

press pusher (Key No. 31, Figure 5) to release nails_

Slid e pusher to front of magazine, Slide nails out of rear

of magazine_

Press pusher here

to release nails

Figure 2a - Loadinq

Figure 3 - Unloadinq

-3-

Loading...

Loading...