Craftsman 351182930 Owner’s Manual

Operator's Manual

ERRFTSHRNo

PALM NAILER

Model No.

351.182930

• Safety

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

2698.01 Draft (06/21/00)

• Operation

• Parts List

Warranty ...................... 2 Troubleshooting ................ 5

Safety Rules ................... 2 Parts Illustration and List ........ 6-7

Operation ................... 2-3

FULL ONE YEAR WARRANTY ON CRAFTSMAN AIR-DRIVE TOOLS

If this Craftsman air-drive tool fails due to a def_=ctin material or workmanship

withinone full year from the date of purchase, return it to the nearest Sears

Service Center in the United States, and Sears will repair it free of charge.

If this air-drive tool is used for commercial purposes, this warranty applies for

only 90 days from the date of purchase.

This warranty gives you specific legal rights and you may also have other

rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

• Air tool operators and all othersin

work area should always wear safety

gogglescomplyingwith United

States ANSI Z87.1 to preventeye

injuryfromfasteners and flying

debris when loading, operating or

unloadingthis tool,

• Never exceed operating pressure of

100 PSI.

• Always keep hands end body away

from the fastener discharge area

when air supply is connected to tool.

• Always disconnect tool from air sup-

ply when servicing or adjusting tool

and when tool is not in use.

• Never pointtool at yourselfor others.

DESCRIPTION

The Craftsman Palm Nailer drives 2-5"

long nails. Lightweight die cast alu-

minum body with handle provides easy

maneuverability in where hammers and

other tools will not work. Nailer has a

• Do net use oxygen,combustiblegas

or high pressure compressed gas as

the air supply forthe tool.

• Alwaysuse tool at safe distance

fromother people in work area.

Do not attempt to dischargefastener

intohard or brittle materials such as

concrete, steel or tile.

• Do not connect female quick-discon-

nect coupling to tool side of air line.

• Connect male, frae-fiow nipple to

tool side of air line so that tool is

depressurized when hose is discon-

nected.

Do not use a hose swivelwiththis

tool,

magnetic noseto hold nails for accu-

rate, safe placement and includes a belt

hook. Craftsman nailer is ideal for

installation of electrical boxes, rafter

bracing, joint hangers, fencing, decking

and framing.

SPECIFICATIONS

Nail length ........... 2_5" (5d-40d)

Nail head size (dia.)........ V,to ,3/=,,

Nail size (dia.) ............ %, to 3/_,,

Operating pressure ...... 60-100 PSI

Air inlet................. V,"N.RT.

Length....................... 8"

Height...................... 51/2,'

Width ...................... 33/,"

Weight.................. 1.50 Ibs.

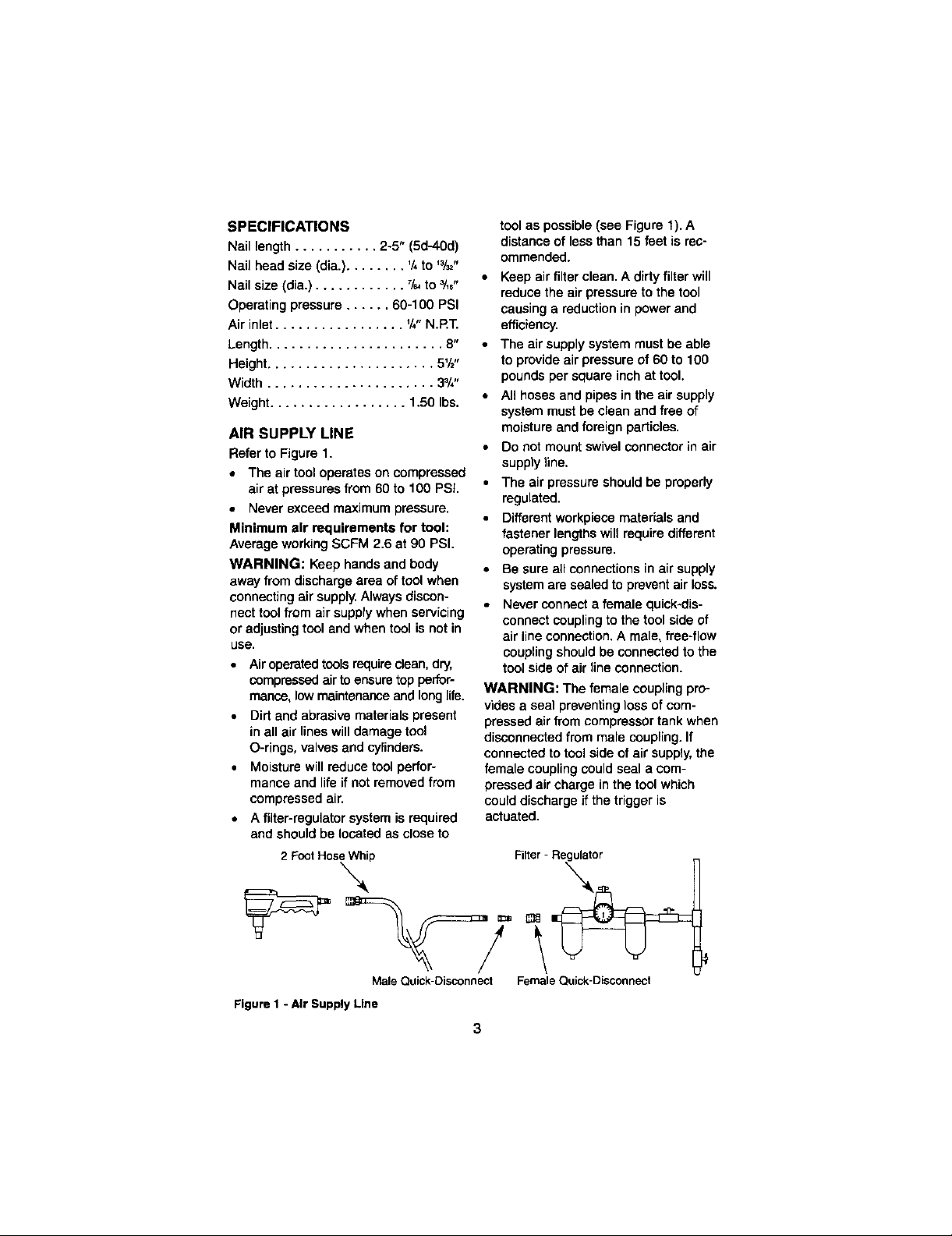

AIR SUPPLY LINE

Referto Figure 1.

• The air tooloperates on compressed

air at pressures from 60 to 100 PSI.

• Never exceed maximum pressure.

Minimum air requirements for tool:

Averageworking SCFM 2.6 at 90 PSI.

WARNING: Keep handsand body

away from discharge area of toolwhen

connectingair supply.Alwaysdiscon-

necttool from air supplywhen servicing

or adjustingtooland whentool is not in

use.

• Airoperatedtools require clean, dry,

compressedairto ensuretop perfor-

mance, lowmaintenance and long life.

• Dirt and abrasive materials present

in all air lines will damage tool

O-rings,valves and cylinders.

• Moisturewill reduce tool perfor-

mance and lifeif not removed from

compressed air.

• A filter-regulatorsystem is required

and shouldbe located as closeto

2Foot HoseWhip

tool as possible (see Figure 1). A

distance of lessthan 15 feet is re(:-

ommended.

• Keep air filter clean. A dirtyfilter will

reduce the air pressureto the tool

causing a reductionin powerand

efficiency.

• The air supplysystem must be able

to provide air pressureof 60 to 100

pounds per squareinchat tool.

• All hoses and pipes in the air supply

system must be clean and free of

moistureand foreign particles.

• Do not mountswivel connector in air

supplyline.

• The air pressura shouldbe properly

regulated.

• Differentworkpieco materials and

fastener lengths willrequire different

operatingpressure.

• Be sure all connectionsin air supply

systemare sealed to preventair loss.

Never connecta female quick*dis-

connectcouplingto the tool side of

air line connection.A male,free-flow

coupling shouldbe connected tothe

tool side of air lineconnection.

WARNING: The female couplingpro-

vides a seal preventingloss of com-

pressedair from compressortank when

disconnectedfrom male coupling. If

connected to toolside of air supply,the

female couplingcould seal a com-

pressedair charge in the tool which

coulddischarge if the trigger is

actuated.

Filter- Regulator

Figure 1 - Air Supply Line

Male Quick-Disconnect

Female Quick-Disconnect

3

Loading...

Loading...