Craftsman 351182140 Owner’s Manual

Operator's Manual

11/4- 21/2" Length

COIL UTILITY NAILER

Model No.

351.182140

®

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product. Keep this

manual with tool.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com/craftsman

21662.00 Draft (01/12/04)

• Safety

• Operation

• Maintenance

• Parts List

• Espa5ol

Warranty ......................................... 2

Safety Rules ...................................... 2

Operation ...................................... 3-6

Maintenance ..................................... 6

Troubleshooting ................................... 7

Parts Illustration and List .......................... 8-9

EspaSol ...................................... 10-15

FULL ONE YEAR WARRANTY

If this product fails due to a defect in material or workmanship

within one year from the date of purchase, Sears will at its

option repair or replace it free of charge. Contact your nearest

Sears Service Center (1-800-4-MY-HOME) to arrange for

product repair, or return this product to place of purchase for

replacement.

If this product is used for commercial or rental purposes, this

warranty will apply for 90 days from the date of purchase.

This warranty applies only while this product is used in the

United States.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates,

IL 60179

* Read and follow all safety rules and operating instructions

in this manual and on warning label of tool before using

this tool. Keep this manual with the tool.

* Keep work area clean and properly lighted.

* Keep children, bystanders and visitors at a safe distance

from work area while operating this tool.

* Air tool operators and all others in work area should

always wear safety goggles complying with United States

ANSI Z87.1 to prevent eye injury from fasteners and flying

debris when loading, operating and unloading this tool.

Everyday eyeglasses have only impact resistant lenses.

These are NOT safety glasses. ANSI Z87.1 safety glasses

have permanently attached rigid, hard plastic side shields

and will have "Z87.1" printed or stamped on them.

* Always wear ear protection. The work area may include

exposure to excessive noise levels which will require nec-

essary ear protection. Some environments will require

head protection; use head protection conforming to ANSI

Z89.1.

* Do not alter or modify this tool in any way. Do not use this

tool for any application other than for which it was

designed.

* Do not use oxygen, carbon dioxide, high-pressure com-

pressed gas or bottled gases as the power source for this

tool. The tool will explode and serious personal injury

could result.

* Never connect the tool to air pressure which could poten-

tially exceed 200 psi. Use only clean, dry, regulated air

within rated range as marked on tool.

* The tool must have a male, free-flow hose coupling so that

all air pressure is removed from the tool when the coupling

joint is disconnected. Failure to use proper coupling could

cause accidental discharge, possibly causing injury.

* Only use air hose that is rated for a maximum working

pressure of 150 psi or 150% of the maximum system pres-

sure, whichever is greater.

* Do not use a hose swivel connector with this tool.

* Do not pull trigger or depress contact trip while connecting

to the air supply, as the tool may cycle, possibly causing

injury.

* When loading tool: Do not pull trigger or depress contact

trip; Do not point the tool at yourself or others; Do not

place hand or any part of body in the fastener discharge

area of the tool as accidental actuation may occur and

cause injury.

* Disconnect tool from air supply before loading or unload-

ing, performing tool maintenance, clearing a jammed fas-

tener, leaving work area, moving tool to another location or

handing the tool to another person.

* Use Sears recommended fasteners only.

* Do not load the tool until you are ready to use it.

* Always assume that the tool contains fasteners. Keep the

tool pointed away from yourself and others at all times.

Never engage in horseplay. Never pull the trigger unless

the contact trip is in contact with the workpiece. Keep oth-

ers at a safe distance from the tool while the tool is in

operation.

* Always remove finger from trigger when not driving fasten-

ers. Never carry the tool with finger on or under the trigger

as accidental actuation may occur and cause injury.

* Always keep hands and body away from the fastener dis-

charge area when air supply is connected to the tool. Grip

tool firmly to maintain control while allowing tool to recoil

away from work surface as fastener is driven. If contact trip

is allowed to recontact work surface before trigger is

released, an unwanted fastener may be driven.

* Check operation of the contact trip frequently. Never use

the tool if the contact trip, trigger or springs have become

inoperable, missing or damaged. Do not alter or remove

contact trip, trigger or springs. Never use a tool that is leak-

ing air, has missing or damaged parts, or requires repair.

* Do not drive fasteners on top of other fasteners or with the

tool at too steep an angle. The fasteners can ricochet and

cause injury. Do not drive fasteners close to the edge of

the workpiece. The workpiece is likely to split, allowing the

fastener to fly free and cause injury. Do not attempt to

drive fasteners into hard or brittle materials such as con-

crete, steel or tile.

* Do not overreach. Always place yourself in a firmly bal-

anced position when using or handling the tool. Do not

attach the hose or tool to your body.

* Do not operate tool without fasteners or damage to tool

may result.

* Do not use tool without safety warning label. If label is

missing, damaged or unreadable, contact SEARS to

obtain a new label.

* Only qualified repair personnel must perform tool service.

* When servicing a tool, use only identical repair parts.

* Store tool out of reach of children and other untrained

persons.

© Sears, Roebuck and Co. 2

DESCRIPTION

The Craftsman Coil Utility Nailer drives full head nails from

1_/4"to 2W' long. Magazine will hold a coil of 400 wire

collated nails. Safety feature disables tool unless contact trip

is pressed against workpiece. Sequential trigger switch allows

selection of rapid-fire or single-fire mode. Contact trip can be

adjusted for setting nail depth. Plastic protector on the end of

contact trip prevents marring of workpiece. Air deflector can

be adjusted to any direction. Die cast aluminum body with

textured rubber grip minimizes operator fatigue and makes

nailer lightweight and durable. The coil utility nailer is excellent

for siding, sheathing, exterior trim, subflooring, decking and

fencing.

SPECIFICATIONS

Capacity ..................... 400 wire collated coil nails

Nail size ....................... 0.082 to .110" diameter

Nail lengths ............................... 1_ to 2_/2''

Operating pressure ........................ 65-110 PSI

Air inlet ................................... W' N.P.T.

Length ....................................... 103/4''

Height ....................................... 11%"

Width .......................................... 5"

Weight ..................................... 4.2 Ibs.

NAILS

18081 (Box of 8000) ........... Galvanized nails, 13/4'' long

18082 (Box of 6000) ............ Galvanized nails, 2" long

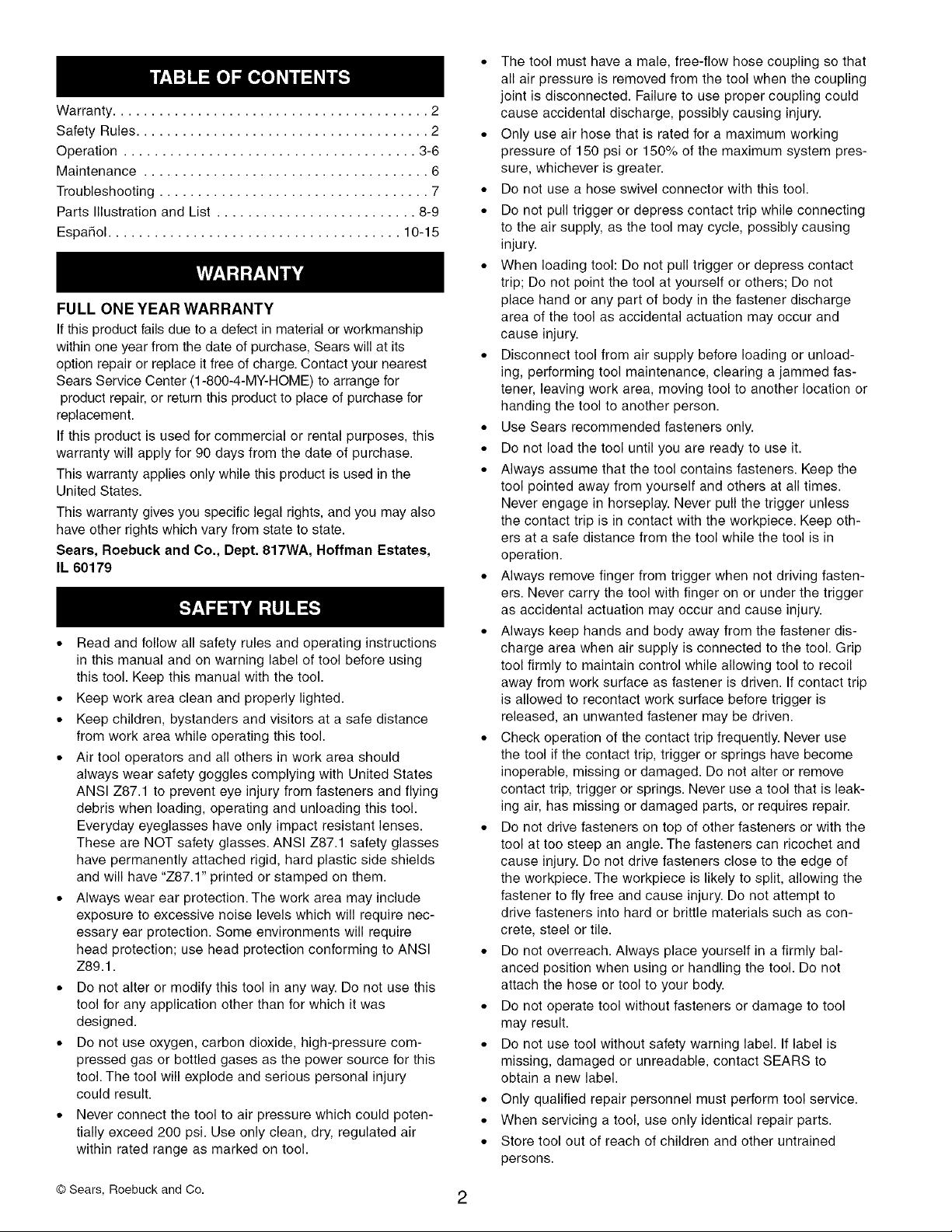

AIR SUPPLY LINE

Refer to Figure 1.

DANGER: De not use oxygen, carbon dioxide, high-pressure

compressed gas or bottled gases as the power source for this

tool. The tool will explode and serious personal injury could

result.

• The air tool operates on compressed air at pressures from

65 to 110 PSI.

• Never connect the tool to air pressure which could poten-

tially exceed 200 PSI. Use only clean, dry, regulated air

within rated range as marked on tool.

Air Delivery Required: 1.87 SCFM @ 90 PSI

(30 shots per minute).

WARNING: Keep hands and body away from discharge area

of tool when connecting air supply. Always disconnect tool

from air supply when servicing or adjusting tool and when tool

is not in use.

• Air operated tools require clean, dry, lubricated com-

pressed air to ensure top performance, low maintenance

and long life.

• Dirt and abrasive materials present in all air lines will dam-

age tool O-rings, valves and cylinders.

• Moisture will reduce tool performance and life if not

removed from compressed air.

• A filter-regulator-lubricator system is required and should be

located as close to tool as possible. A distance of less than

15 feet is recommended.

• Keep air filter clean. A dirty filter will reduce the air pressure

to the tool causing a reduction in power and efficiency.

• The air supply system must be able to provide air pressure

of 65 to 110 pounds per square inch at tool.

° All hoses and pipes in the air supply system must be clean

and free of moisture and foreign particles. Hoses must be

rated for a maximum working pressure of 150 PSI or 150%

of maximum system pressure, whichever is greater.

° Do not mount swivel connector in air supply line.

° The air pressure should be properly regulated.

° Different workpiece materials and different fastener lengths

will require different operating pressure.

° Be sure all connections in air supply system are sealed to

prevent air loss.

° Never connect a female quick-disconnect coupling to the

tool side of air line connection. A male, free-flow coupling

should be connected to the tool side of air line connection

(see Figure 1).

WARNING: The female coupling provides a seal preventing

loss of compressed air from compressor tank when discon-

nected from male coupling. If connected to tool side of air

supply, the female coupling could seal a compressed air

charge in the tool which could discharge if the tool trigger is

actuated.

I

Male Connector

Female Connector

Figure 1 - Air Supply Line

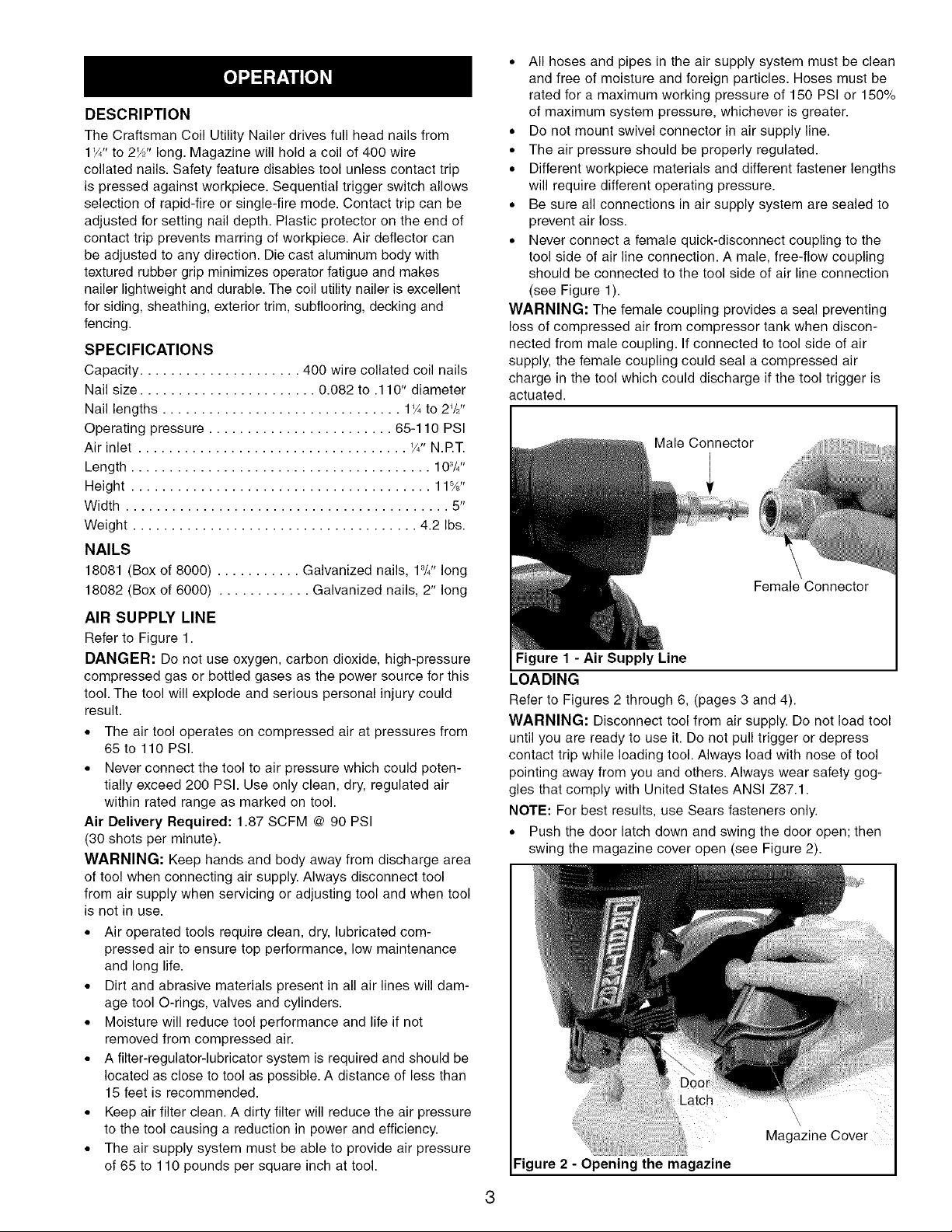

LOADING

Refer to Figures 2 through 6, (pages 3 and 4).

WARNING: Disconnect tool from air supply. Do not load tool

until you are ready to use it. Do not pull trigger or depress

contact trip while loading tool. Always load with nose of tool

pointing away from you and others. Always wear safety gog-

gles that comply with United States ANSI Z87.1.

NOTE: For best results, use Sears fasteners only.

• Push the door latch down and swing the door open; then

swing the magazine cover open (see Figure 2).

Figure 2 - Opening the magazine

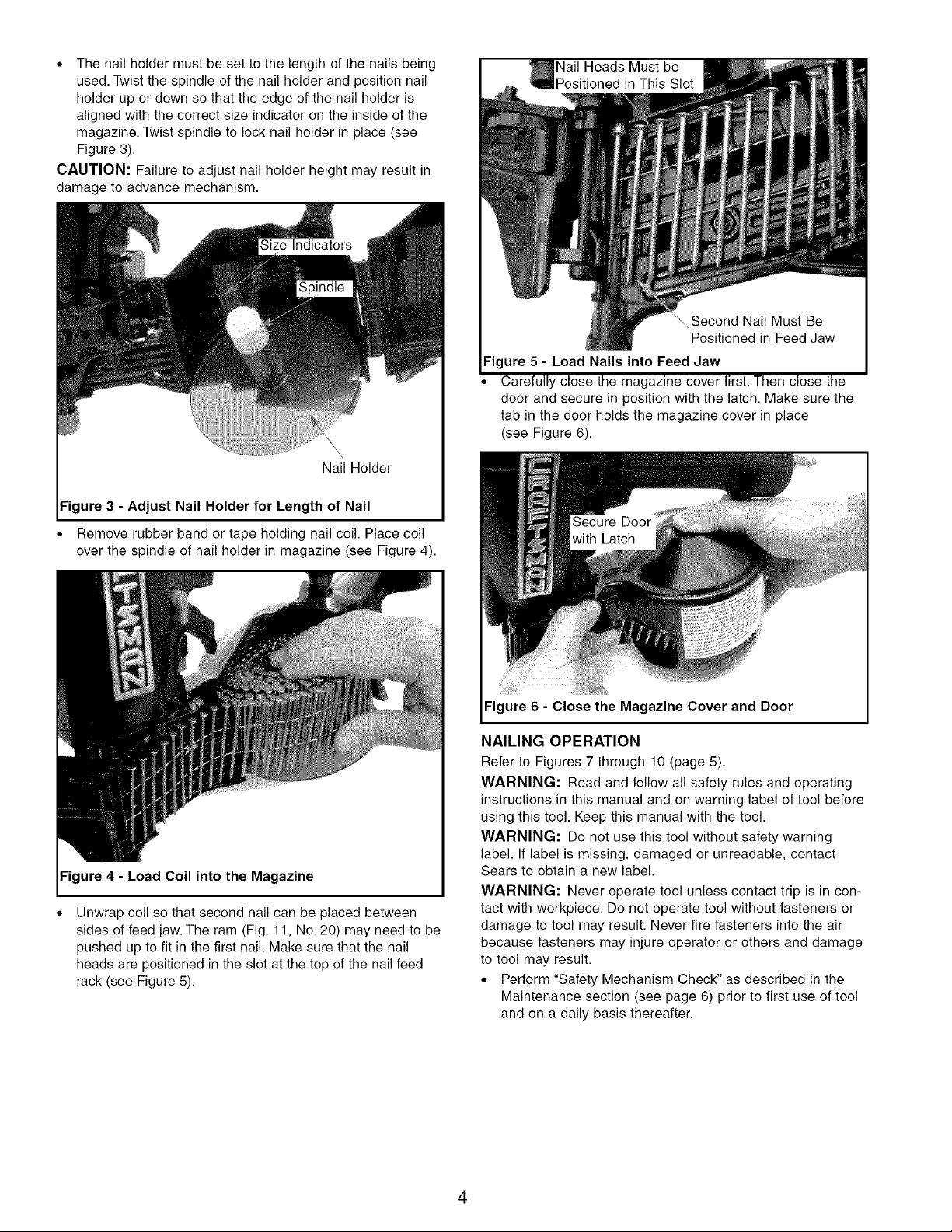

° The nail holder must be set to the length of the nails being

used. Twist the spindle of the nail holder and position nail

holder up or down so that the edge of the nail holder is

aligned with the correct size indicator on the inside of the

magazine. Twist spindle to lock nail holder in place (see

Figure 3).

CAUTION: Failure to adjust nail holder height may result in

damage to advance mechanism.

\

Nail Holder

Figure 3 - Adjust Nail Holder for Length of Nail

° Remove rubber band or tape holding nail coil. Place coil

over the spindle of nail holder in magazine (see Figure 4).

Nail Heads Must be

Positioned in This Slot

....,Second Nail Must Be

Positioned in Feed Jaw

Figure 5 - Load Nails into Feed Jaw

° Carefully close the magazine cover first. Then close the

door and secure in position with the latch. Make sure the

tab in the door holds the magazine cover in place

(see Figure 6).

Figure 4 - Load Coil into the Magazine

Unwrap coil so that second nail can be placed between

sides of feed jaw. The ram (Fig. 11, No. 20) may need to be

pushed up to fit in the first nail. Make sure that the nail

heads are positioned in the slot at the top of the nail feed

rack (see Figure 5).

Figure 6 - Close the Magazine Cover and Door

NAILING OPERATION

Refer to Figures 7 through 10 (page 5).

WARNING: Read and follow all safety rules and operating

instructions in this manual and on warning label of tool before

using this tool. Keep this manual with the tool.

WARNING: Do not use this tool without safety warning

label. If label is missing, damaged or unreadable, contact

Sears to obtain a new label.

WARNING: Never operate tool unless contact trip is in con-

tact with workpiece. Do not operate tool without fasteners or

damage to tool may result. Never fire fasteners into the air

because fasteners may injure operator or others and damage

to tool may result.

° Perform "Safety Mechanism Check" as described in the

Maintenance section (see page 6) prior to first use of tool

and on a daily basis thereafter.

4

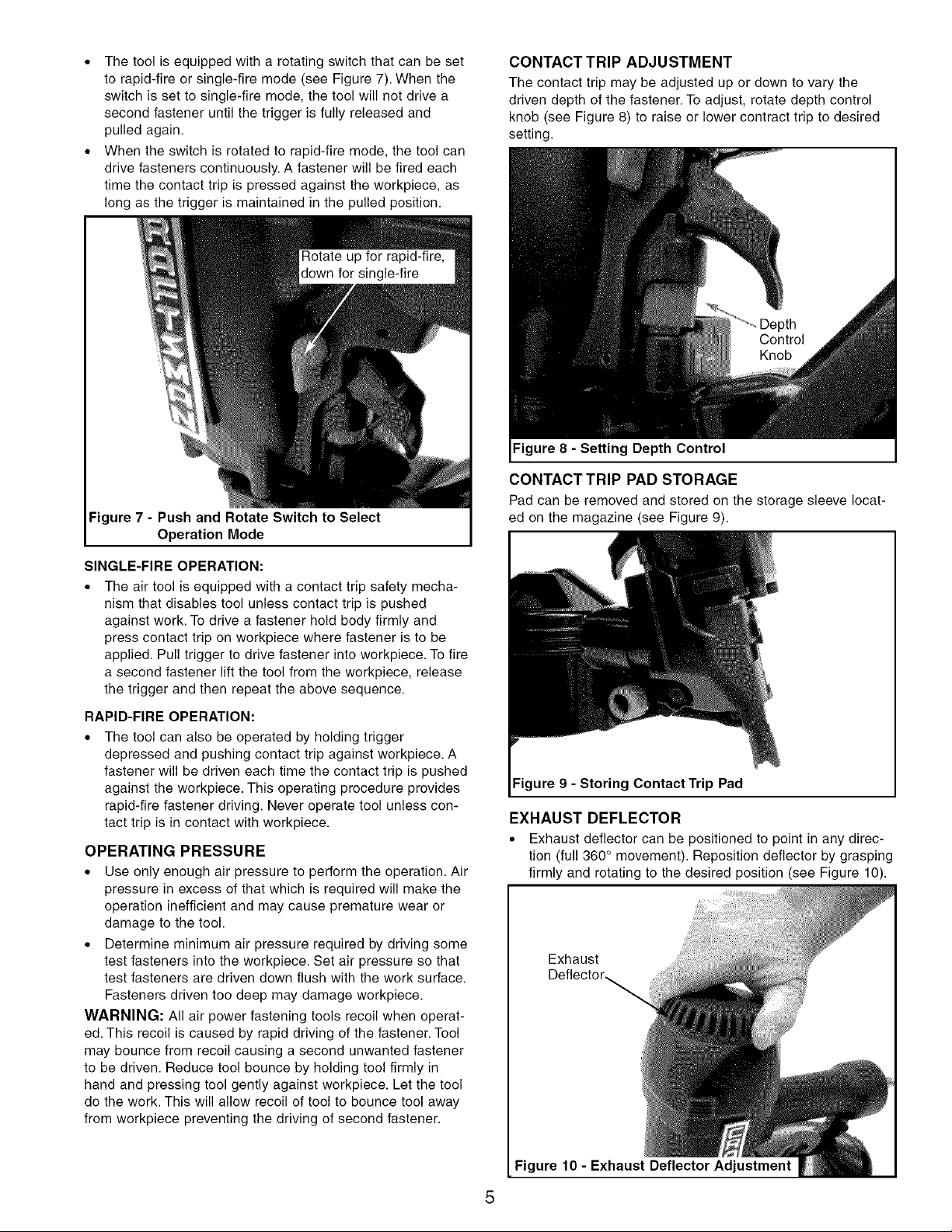

• The tool is equipped with a rotating switch that can be set

to rapid-fire or single-fire mode (see Figure 7). When the

switch is set to single-fire mode, the tool will not drive a

second fastener until the trigger is fully released and

pulled again.

• When the switch is rotated to rapid-fire mode, the tool can

drive fasteners continuously. A fastener will be fired each

time the contact trip is pressed against the workpiece, as

long as the trigger is maintained in the pulled position.

Figure 7 - Push and Rotate Switch to Select

Operation Mode

CONTACT TRIP ADJUSTMENT

The contact trip may be adjusted up or down to vary the

driven depth of the fastener. To adjust, rotate depth control

knob (see Figure 8) to raise or lower contract trip to desired

setting.

Control

Knob

Figure 8 - Setting Depth Control

CONTACT TRIP PAD STORAGE

Pad can be removed and stored on the storage sleeve locat-

ed on the magazine (see Figure 9).

SINGLE-FIRE OPERATION:

• The air tool is equipped with a contact trip safety mecha-

nism that disables tool unless contact trip is pushed

against work. To drive a fastener hold body firmly and

press contact trip on workpiece where fastener is to be

applied. Pull trigger to drive fastener into workpiece. To fire

a second fastener lift the tool from the workpiece, release

the trigger and then repeat the above sequence.

RAPID-FIRE OPERATION:

• The tool can also be operated by holding trigger

depressed and pushing contact trip against workpiece. A

fastener will be driven each time the contact trip is pushed

against the workpiece. This operating procedure provides

rapid-fire fastener driving. Never operate tool unless con-

tact trip is in contact with workpiece.

OPERATING PRESSURE

• Use only enough air pressure to perform the operation. Air

pressure in excess of that which is required will make the

operation inefficient and may cause premature wear or

damage to the tool.

• Determine minimum air pressure required by driving some

test fasteners into the workpiece. Set air pressure so that

test fasteners are driven down flush with the work surface.

Fasteners driven too deep may damage workpiece.

WARNING: All air power fastening tools recoil when operat-

ed. This recoil is caused by rapid driving of the fastener. Tool

may bounce from recoil causing a second unwanted fastener

to be driven. Reduce tool bounce by holding tool firmly in

hand and pressing tool gently against workpiece. Let the tool

do the work. This will allow recoil of tool to bounce tool away

from workpiece preventing the driving of second fastener.

Figure 9 - Storing Contact Trip Pad

EXHAUST DEFLECTOR

° Exhaust deflector can be positioned to point in any direc-

tion (full 360 ° movement). Reposition deflector by grasping

firmly and rotating to the desired position (see Figure 10).

Exhaust

Deflector.

Figure 10- Exhaust Deflector Adjustment

5

Loading...

Loading...