Craftsman 351182010, 351182000 Owner’s Manual

Operator's Manual

PALM AIR DRIVER

Model No.

351.182000

351.182010

• Safety

• Operation

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of _is Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

W_W.se_rs,com/_r aft smz_n

16891,02 Draft (06/09/04)

• Parts List

• EspaSol

Warranty ........................ 2 Troubleshooting ................. 5

Safety Rules .................... 2 Parts tilusttation and List ........ 6-7

Operation .................... 2-3 Espafol ..................... 8-11

FULL ONE YEAR WARRANTY

If th_sproduct fails due to a defect in material or workmanship within one year from

the date of purchase. Sears will at its option repair or repines it tree of charge.

Contact your nearest Sears _arvise Cantar (1-BOO-4-MY-HOME) to arrange for

product repair, or return this product to place of pursh_se for replaeemant.

If this product is used for commeroia_ or rental purposes, this warranty will appty for

90 days from the date of purchase.

This warranty applies only while this product is in the United States.

This warranty gives you specific legal rights and you may at_o have other fights

which vary from state to stats.

Sears, Roebuck and Ca., DapL 817WA, Hoffraan Esttates, IL 60179

• Air too_operators and all others in

work area shoutd always wear safety

goggles complying with United

States ANSI Z87.1 to prevent eye

injury from fasteners and flying

debris when loading, operating or

unloa_ng this too!.

• Never exceed operating pressure of

100 PSI.

• Always keep hands and body aWay

from the fastener discharge area

when air euppty is connected to tool

• Always disconnect to01 from air sup-

ply when servicing or a_usting tool

and when tool is not in use.

• Never point tool at yourself or others.

DESCRIPTION

The Craftsman Palm Air Driver (Model

182000) drives 3/4-5%"long nails.

Lightweight die cast aluminum body

provides easy maneuverability where

hammers and other fobls will not work.

© Sears, Roebuck and Co.

Do not use oxygen, combustible g_

or high pressure compressed gas as

the air supply for the too[.

• Always use tool at safe distance

from other people in work area..

• bo not attempt to di._harge fastener

intohard or brittle matefiats such as

Concrete, etse! or tile.

• [30 not connect female quick-connect

coupling to tool side of air line.

• Connect male, free-flow nipple to

tool side of air line so that tool is

deprassunzed when hose is _seon-

neoted.

Do not use a hose swivel with this

tool

Ddver has a magnetic nose to hold

nails for accurate, safe placement. The

Craftsman Palm Air Driver is ideal for

installation of electricat boxes, rafter

bracing, joint hangers, fencing, decking

and framing.

"73_eCraftsman Palm Air Dr_ver Ki_

(Model 182010) includes palm air driver

plus storage case, glove, V," NPT quick

¢ony_ector, rnaintenanee kit, wrenches,

air tool oil, large nail and finish nail

guide bushings.

SPECIFICATIONS

Nail length 3/,. 5V2"(2d-50d)

Nail head size (die.)

18200 .................. V,to _at.

18201 ................... 't, to 't;"

Nail size (die.) ............. % to V,"

Operating pressure ...... 60-100 PSI

Air inlet .................. Y,"N.P.T.

Length ...................... 5YF'

Height ....................... 4=/,"

Width ....................... 331,"

Weight .................... 3.1 Iba.

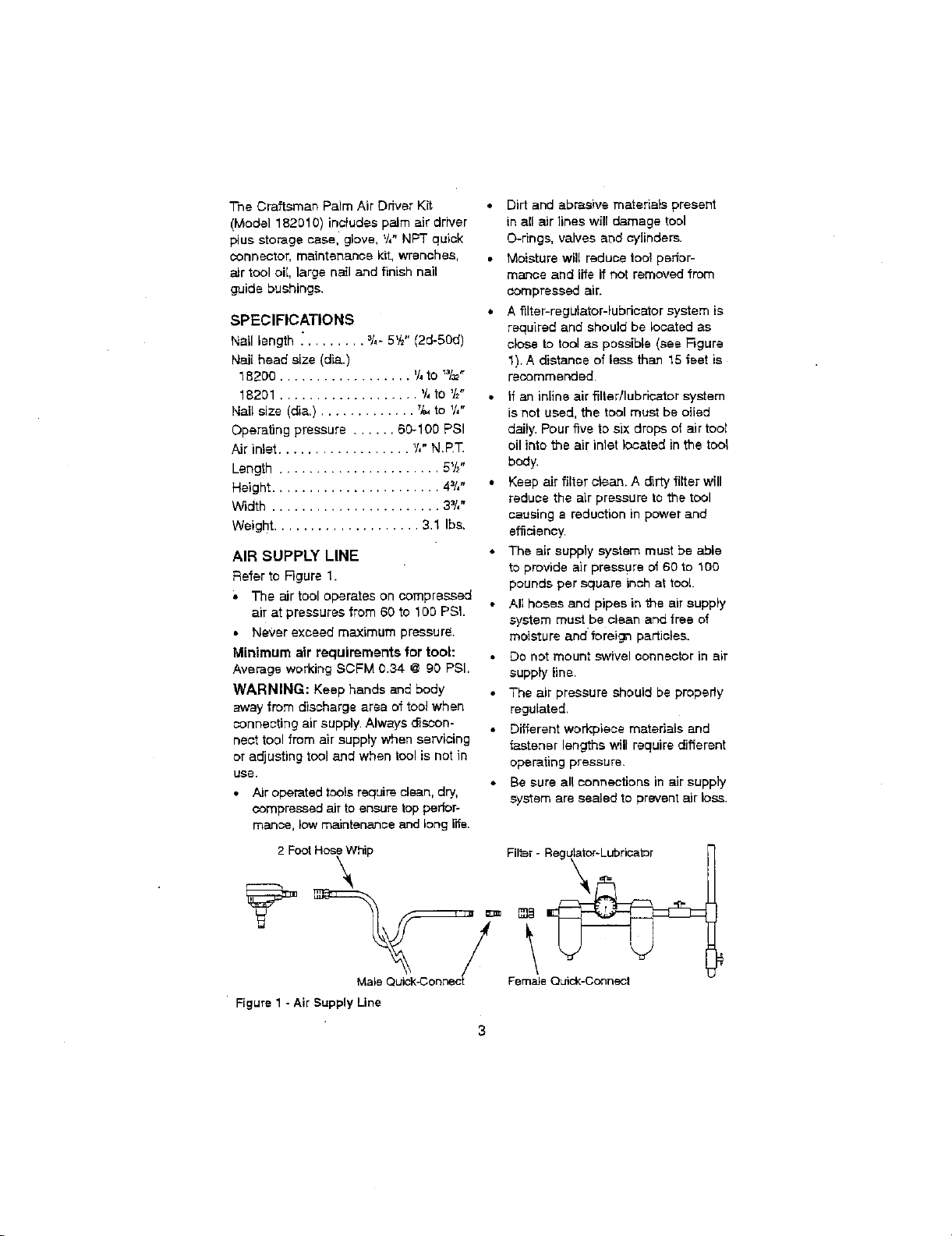

AIR SUPPLY LINE

Refer to Pqgure1.

• The air tool operates on compressed

air at pressures from 60 to 100 PSI.

• Never exceed maximum pressure.

Minimum air requirements for tool:

Average workingSCFM 0.34 @ 90 PSI.

WARNING: Keep hands and body

away from discharge area _f tool when

connecting air supply. Always discon.

nect tool from air supply when servicing

or adjusting tool and when tool is not in

use.

• Air operated tools require clean, dry,

compressed air to ensure top perf_F

mar=re, low maintenance and long life.

2 FootHoseWhip

• Did and abra_ve materials present

in all air lines will damage tool

O-rings, valves add cylinders.

Moisture will reduce toot perfor-

mance and life if not removed from

compreseed air.

• A fiifer-regulatorqubricator system is

required and should be located as

close to tool as possible (see F'lgura

1). A d}etance of less than 15 feet is

recommended.

If an inline air filterllubricator system

is not used, the tool must be oiIed

daily. Pour five to six drops of air tool

oil into the air inlet located in the toot

body.

• Keep air filter clean. A dirty filter will

reduce the air pressure to the tool

causing a reduction in power and

efficlanay.

The air supply system must be able

to provide air press#re of 60 to 100

pounds per square inch at tool.

AI; hoses and pipes in the air supply

system must be clean and free of

moisture and foreign particles.

Do not mount swivel connector in air

supply line.

• The air pressure should be property

regulated.

Different workplace materials and

fastener lengths will require different

operating pressure.

• Be sure al! connections in air supply

system are sealed to prevent air loss.

\ =

Figure 1 - Air Supply Line

F

FernaJeQuick-Connect

Neverconnecta femsie quick-

connect coupling to the-reel side of

air line connection. A male, free-flow

coupling should be connected to the

tool side of air line connection.

WARNING: The female coupling pro-

vides a sea_preventing toss oi corm

pressed air from compressor tank when

disconnected fn3m male coupling. If con-

nected to tool side of air supply, the

female coupling could seal a compresssd

air charge in the tool which could _s-

charge ifthe trigger is actuated.

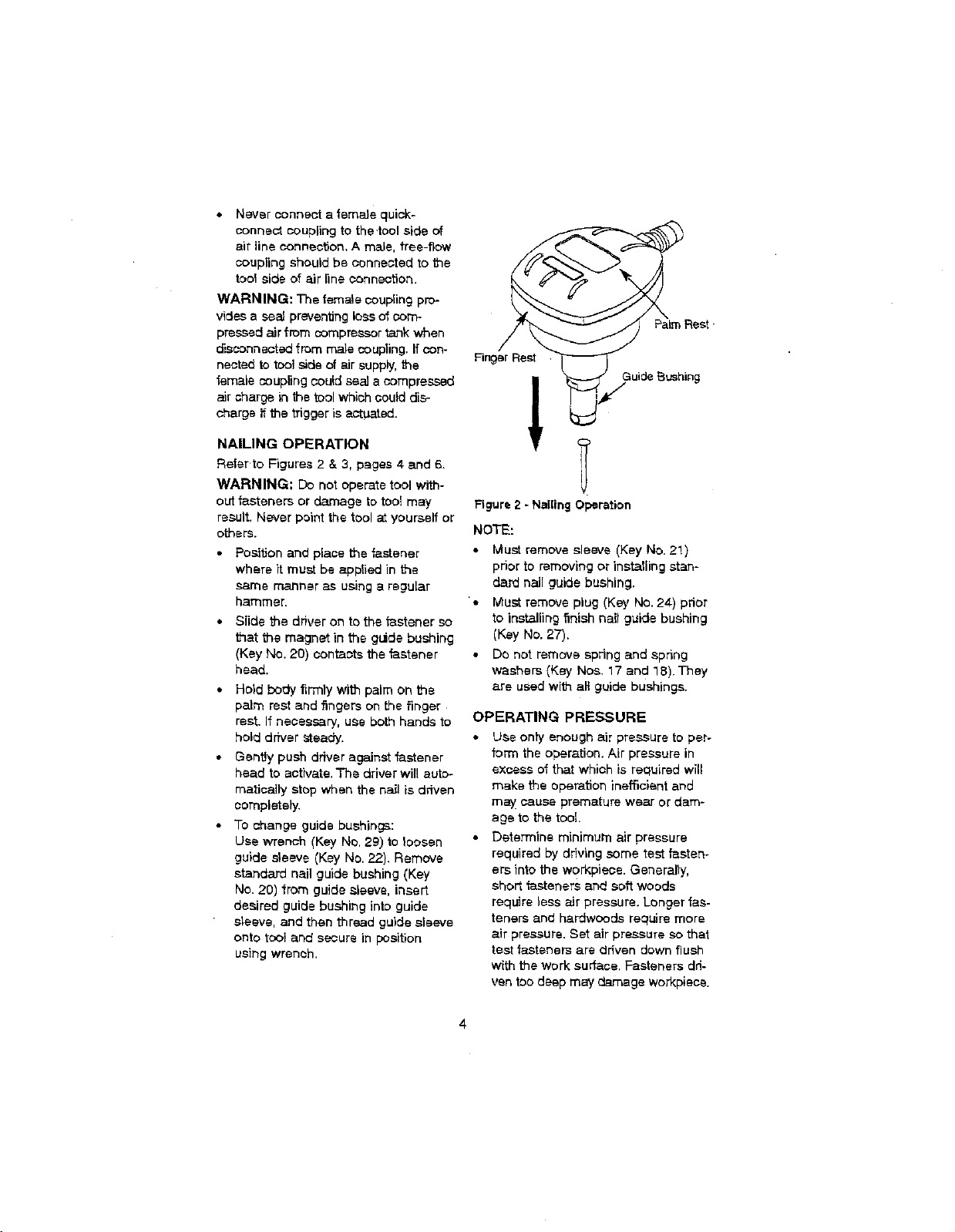

NAILING OPERATION

Retsr to Figures 2 & 3, pages 4 and 6.

WARNING; Do not operate tool with-

out fasteners or damage to too[ may

result. Never point the tool at yourself or

others.

Position and place the fastener

where it must be applied in the

same manner as using a regular

hammer.

Slide the driver on to the fastener so

that the magnet in the glide bushing

(Key No. 20) contants the fastener

head.

• Hold body firmly with palm on the

palm rest and fingers on the finger

rest. If necessary, use both hands to

hold driver steady.

Gently push driver againstfastener

head to activate. The driver wil! auto°

maritally stop when the na_ is driven

completely.

• To change guide bushings:

Use wrench {Key No. 29) to }oossn

guide sleeve (Key No. 22). Remove

standard nail guide bushing (Key

No. 20) from guide sleeve, insert

desired guide bushing into guide

sleeve, and then thread guide sleeve

onto toot and secure in position

using wrench.

_Rest

Finger Rest

w

GLiC'e_U_hing

Figure 2 - NailingOperation

NOTE:

Must remove sleeve (Key No. 2!)

prior to removing or installing stan-

dard nail guide bushing.

'o

Must remove plug (Key No.24-)prior

to installing finish nail guide bushing

(Key No. 27).

Do net remove spring and spring

washers (Key Nos. 17 and 18). They

are used with aE guide bushings.

OPERATING PRESSURE

Use only enough air pressure to per-

form the operation. Air pressure in

excess of that which is required will

make the operation inefficient and

may cause premature wear or dam-

age to the tool.

Determine minimum air pressure

required by driving some test fasten-

ers into the work;piece.Generally,

short fasteners and soft woods

require less air pressure. Longer fas-

teners and hardwoods require more

air pressure. Set air pressure so that

test fasteners are driven down flush

with the work surface. Fasteners dri-

ven too deep may damage workpiece.

Loading...

Loading...