Craftsman 351181720 Owner’s Manual

RightFax 8/15/2003 1:18 PAGE 2/11 Righ%Fax

: Colovos

l

Operator's Manual

18 Gauge

- 21/8" Length

BRAD NAILER

Model No.

351.181720

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product, Keep this

manual with tool.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.seors.comlcreftsman

20317.01 Draft (04/24/03}

• Safety

• Operation

• Maintenance

• Parts List

• Espafiol

R±ghtF&× 8/15/2003 1:18 PAGE 3/11 RightFax

• The tool must have a male, free-flow hose coupling so that

all air pressure is renmvad from the tool when the coupling

Warranty ......................................... 2

Safety Rules ...................................... 2

Operation ...................................... 3-5

Maintenance .................................... 5-6

Troubleshooting ................................... 7

Parts IIlustratton and List .......................... 8-9

Espa_ol ...................................... 10-15

FULL ONE YEARWARRANTY

If Dis product falls due to a defect In mateidal or workmanship

wi_ln one year from _ date of pumheae, Sears will at Its

option repair or replace It free of charge. Contact your nearest

Sears Service Center {1-800-4-MY-HOME) to arrange for prod-

uct repair, or return this product to place of purchase for

replacement.

If this product Is used for commercial or rental purposes, this

warranty will apply for 90 days from the date of purchase.

This warranty aepllas only while tlds product is used In the

United States,

This warranty gives you specific legal dghts, and you may also

have other rights which vary from state to state.

Sears, Roobuck and Co., Dept. 817WA, Hoffman Estates,

IL 60179

Read and follow all safety rules and operating instructions

in this manual and on warning label of tool before using

this tool. Keep this manual with the tool.

Keep work area cJean and properly lighted.

• Keep children, bystanders end visitors at a safe distance

from work area while operating this tool.

• Air tool operators and all others In work area should

always wear safety goggles complying with United States

ANSI Z87.1 to prevent eye Injury from fasteners and flying

debris when loading, operating and unloading this tool.

Everyday eyeglasses have only impact resistant lenses.

These are NOT safety glasses. ANSI Z87.1 safety glasses

have permanently attached rigid, hard plastic side shields

and will have "ZBT.I" printed or stamped on them.

• Always wear ear protection. The work area may include

exposure to excessk-_e noise levels which wilt require nec-

essary ear protection. Some enwronmeots will require

head protecBon; use head protection conforming to ANSI

Z89.1.

• DO not alter or modify this tool in any we:( Do not use this

tool for any application other than for which it was

designed,

• Do not use oxygen, carbon dioxide, high-pressure com-

pressed gas or bottled gases as the power source for this

tool. The tool will explode and serious personal injury

could result.

Never connect the tool to air pressure which could potan-

ttatly exceed 200 psi. Use only clean, dry, regulated air

within rated range as marked on tool.

joint is disconnected. Failure to use proper coupling could

cause ac_dente) dlscharge,possibly causing injury.

• Only use air hose that is rated for a maximum working

pressure of 15G ps( or 150% oftbe maximum system pres-

sure, whichever is greater.

• Do not use a hose swivel connector with _is tool.

• Do not putt trigger or depress contact trip white connecting

to the air supply, as the tool may cycle, possibly causing

injury

• When loading tool: Do not puFI trigger or depress contact

trip; DO not point the tool at yourself or others; Do not

place hand or any part of body in the fastener discharge

area of the tool as accidental actuation may occur and

cause thjur_:

* Disconnect tool from air supply betore loading or unload-

ing, performing tool maintenance, clearing a jammed t'as-

tenet, fea_ng work area, moving tool to another location or

handing the tool to another person.

• Use Sears recommended fasteners only.

• Do not load the teal until you are ready to use It.

• Always assume that the tool contains fasteners. Keep _e

tool pointed away from yourself and others at all times.

Never engage Lnhorseplay. Never pull the thgger unless

the contact frfp is In contact wtth the workplace. Keep oth-

ere at a safe distance from the tool while the tool Is In

operation.

• Always remove finger from trigger when not driving fasten-

ers. Never carry the tool with finger on or under the trigger

as accidental actue_lon may oo_ur and cause Injury.

• Always keep hands and body away from the fastener dis-

charge area when air supply is connected to the tool. Grip

too/firmly to maintain control whl_e allowing tco9 to recolJ

away from work surface as fastener Is driven.Ifcontact trip

Is allowed to recontact work surface before trigger Is

released, an unwanted fastener may be driven.

• Check operation of the c_ltact thp frequently. Never use

the tool if the contact thp, trigger or eprlnge have become

Inoperable, mtsslng or damaged. Do not altar or remove

contact tap, trigger or springs. Never use a tool that is leak-

ing air, has missing or damaged parts, or requires repair

• Do not drive fasteners on top of other fasteners or with the

tool at too steep an angle. The fasteners can dcechet and

cause Injury DO not drive fasteners close to the edge of

the workplace. The workpteos is likely to split, allowing the

fastener to tty free and cause injury DO not attempt to

drive fasteners into hard or brittle materials such as con-

crete, steal or tile.

• Do not overreach. Always piece yourself in a firmly bal-

anced position when using or handling the tool. Do not

attach the hose or tool to your body.

• Do not operate tnol w_thout fasteners or damage to too)

may result.

• Do not use tool without safety wamthg label If labe) is

missing, damaged or unreadable, conteot SEARS to

obtain a new label.

• Only qualified repair personnel must perform tool service.

• When servicing a too/. use only JdantJcalrepair parts,

• Store toni out of reach of children and other untrained

persons.

O _ears, Roebuck and Co. 2

KightFax 811512003 1:18 PAGE 4111 RightFax

• Air operated tools require cJesn, dry, lubricated com-

pressed air to ensure top performance, low maintenance

and long life.

DESCRIPTION

The Craftsman 18 Gauge Brad Nailer drives brads from %" to

2%" long. Oiltass design eliminates daily oiling and oil stains

on workpiece. Die cast magnesium body with textured rubber

grip minimizes operator fatigue. I_rga capaoi_ side leading

magazine with posilNe, quick action latch makes loading easy.

Nailer features rear exhaust, single and rapid-fire operation,

adjustable depth of drive control, rubber nose tip and storage

case. Salty feature disabtes toot unless contact tdp is pressed

against workptece. Tapered nosepiece provides operator with

greater visibility for precme fastener placement Rigid nose-

piece reduces jamming. The 18 Gauge Brad Nailer is excellent

for molding, furniture making, and picture fremlng.

SPECIFICATIONS

Capacity .............................. 100 brad nails

Nail size ...................... 18 gauge (.040" x .040 ")

Nail lengths ................................ % to 2_"

Operating pressure ........................ 60-100 PSI

Air inlet.................................... Y,"N.P.T.

Length ........................................ 9Vz"

Height ........................................ 9_ =

Width ......................................... 2_t_,_

Weight ..................................... 2.7 Ibs.

BRAD NAILS

18341 {Box of 5000) ......... 18 gauge brad nails, %" long

19171 {Box of 1000) ......... 18 gauge brad nails, %" long

18342 (Box of 5000) .......... 18 gauge brad nails, 1" long

19172 (Box of 1000) .......... 18 gauge brad nails, 1" long

18343 (Box of 5000) .....

19173 (Box of 1000) .....

18360 [Boo(of 5000) .....

19174 (Box of 1000) .....

18361 (Box of 5000) .....

18362 (Box of 5000) .....

19176 (Box of 1000) .....

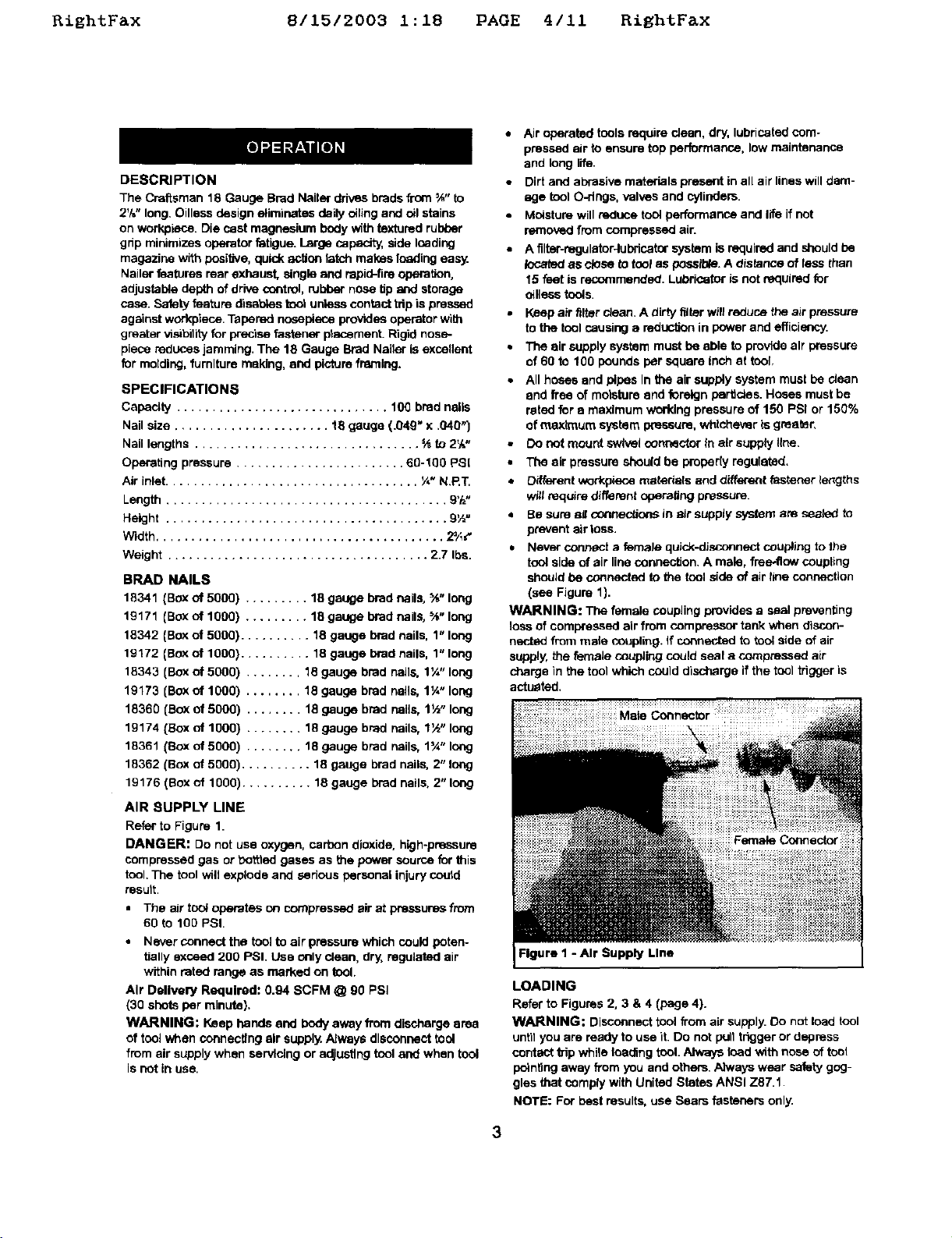

AIR SUPPLY LINE

Rater to Figure 1.

DANGER: Do not use oxygen, carbon dioxide, high-pressure

compressed gas or hotttad gases as the power source for this

tool. The tool will explode and serious personal injury coutd

resutt.

The air tool operates on compressed sir at pressures from

60 to 100 PSI.

Never connect the tool to air pressure which could poten-

tially exceed 200 PSI. Use only clean, dry, regulated air

within rated range as marked on tool.

Air Delivery Required: 0.94 SCFM @ 90 PSI

(30 shots per minute),

WARNING; Keep hands and _ away from discharge area

of tool when connecting air supply. Always disconnect tool

from air supply when servicing or adjusting tool and when tool

Is not in use.

.18 gauge brad nails, 1%" long

18 gauge bred nails, 1%" long

.18 gauge bred nails, 1%" long

• 18 gauge bred nails, 1½" long

• 18 gauge brad nails, 1%" long

... 18 gauge brad nails, 2" long

... 18 gauge brad nails, 2" long

Dirt and abrasive materials present in all air lines will dam-

age tool O-rings, valves and cylinders.

Moisture will reduce tool performance and life if not

removed from cornprassecl air.

• A filter-ragulator-lubricator system is required and should be

located as dose to tool as possible. A distance of tess than

15 feet is recommended. Lubricator is not required for

oittess tools.

• Keep air filter clean. A dirty filter will reduce the air pressure

to the tool causing a reduction in power and efficiency.

• The air supply system must ha able to provide air pressure

of 60 to 100 pounds per square Inch st tool

• All hoses and pipes In the air supply system must be clean

and free of moisture end foreign pertisies. Hoses must be

rated for s maximum woddng pressure of 150 PSI or 150%

of maximum system pressure, whichever is greater,

• Do n_ mou_ swivel contractor in air supply line.

• The air pressure should be properly regulated,

• Oifferent workptece mate_ls and different fastener lengths

will require different operating pressure.

• Be sure a= conneoitons in air supply system are sealed to

prevent air toss.

• Never connect a female quick-disconnect coupling to the

tool side of air line connection. A male, free-tim coupling

should be connected to the tool side of air freeconnection

(see Figure 1).

WARNING: The female coupling provides a seal preventing

loss of compressed air from compressor tank when discon-

net.fad from msie coupling, if connected to tool s{de of air

supply, the farnate ooupling could seal a compressed air

charge in the tool which could discharge if the tool trigger is

actuated.

Figure I -Air Supply Line

LOADING

Refer to Figures 2, 3 & 4 (page 4).

WARNING: Disconnect tool from air supply. Oo not load tool

until you are ready to use it. Do not ppll trigger or depress

contact tripwhile loading tool. Always load with nose of tool

pointing away from you and others. Always wear ssfaly gog-

gles that comply with United States ANSI Z87.1.

NOTE: For best results, use Sears fasteners only.

3

Loading...

Loading...