Craftsman 320.39589 User Manual

Operator's ManuaJ

®

2.5 Amp 1/3 SHEET SANDER

Model No. 320.39589

* WARRANTY

* SAFETY

LISTED

_WARNING: To reduce the risk of injury,

the user must read and understand the

Operator's Manual before using this product.

Sears Brands Management Corporation, Hoffrnan Estates,

IL 60179 U.S.A.

www, craftsman,com

* DESCRiPTiON

* ASSEMBLY

* OPERATION

* MAINTENANCE

* ESPANOL

Warranty Page 2

Safety Symbols Pages 4-5

Safety Instructions Pages 6-8

Description Pages 9-10

Assembly Page 11

Operation Pages 12-16

Maintenance Pages 17-18

Troubleshooting Page 18

Parts List Pages 19-20

CRAFTSMAN ONE YEAR LiMiTED WARRANTY

FOR ONE YEAR from the date of purchase, this product is warranted

against any defects in material or workmanship. With proof of purchase,

defective product will be replaced free of charge.

For warranty coverage, details to obtain free replacement, visit the web

page: www.craftsman.com/warranty

This warranty does not cover the sandpaper, which is an expendable part

that can wear out from normal use within the warranty period.

This ONE YEAR warranty is void if this product is ever used while providing

commercial services or if rented to another person. For 90 DAY commercial

and rental use terms, see the Craftsman warranty web page.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179.

SAVE THESE INSTRUCTIONS!

READ ALL INSTRUCTIONS!

This 1/3 sheet sander has many features for making its use more pleasant and

enjoyable. Safety, performance, and dependability have been given top priority

in the design of this product, making it easy to maintain and operate.

DANGER: People with electronic devices, such as pacemakers, should

consult their physician(s) before using this product. Operation of electrical

equipment in close proximity to a heart pacemaker could cause interference or

failure of the pacemaker.

2 © Sears Brands, LLC

_,WARNING: Some dust created by power sanding, sawing, grinding, drilling

and other construction activities contains chemicals known to the state of

California to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints

Crystalline silica from bricks and cement and other masonry products, and

Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type

of work. To reduce your exposure to these chemical: work in a well ventilated

area, and work with approved safety equipment, such as those dust masks that

are specially designed to filter out microscopic particles.

Thepurposeofsafetysymbolsistoattractyouattentionto possibledangers.

Thesafetysymbolsandtheexplanationswiththemdeserveyourcareful

attentionandunderstanding.Thesymbolwarningsdonot,bythemselves,

eliminateanydanger.Theinstructionsandwarningstheygivearenosubstitutes

forproperaccidentpreventionmeasures.

,_, WARNING: Be sure to read and understand all safety instructions in this

manual, including all safety alert symbols such as "DANGER," "WARNING," and

"CAUTION" before using this tool. Failure to follow all instructions listed in this

manual may result in electric shock, fire, and/or serious personal injury.

SYMBOL SIGNAL MEANING

SAFETY ALERT SYMBOL: Indicates DANGER, WARNING, or CAUTION; may

be used in conjunction with other symbols or pictographs.

DANGER: Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

,_, WARNING: Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

_, CAUTION: Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

Damage prevention and Information Messages

These inform the user of important information and/or instructions that could

lead to equipment or other property damage if they are not followed. Each

message is preceded by the word "NOTICE", as in the example below.

NOTICE" Equipment and/or property damage may result if these instructions are

not followed.

_WARNING: To ensure safety and reliability, all repairs should be performed

by a qualified service technician.

_, WARNING: The operation of any power tools can result in

foreign objects being thrown into your eyes, which can result

in severe eye damage. Before beginning power tool operation,

always wear safety goggles or safety glasses with side shield

and a full face shield when needed. We recommend a Wide

Vision Safety Mask for use over eyeglasses or standard safety

glasses with side shields. Always use eye protection which is

marked to comply with ANSI Z87.1.

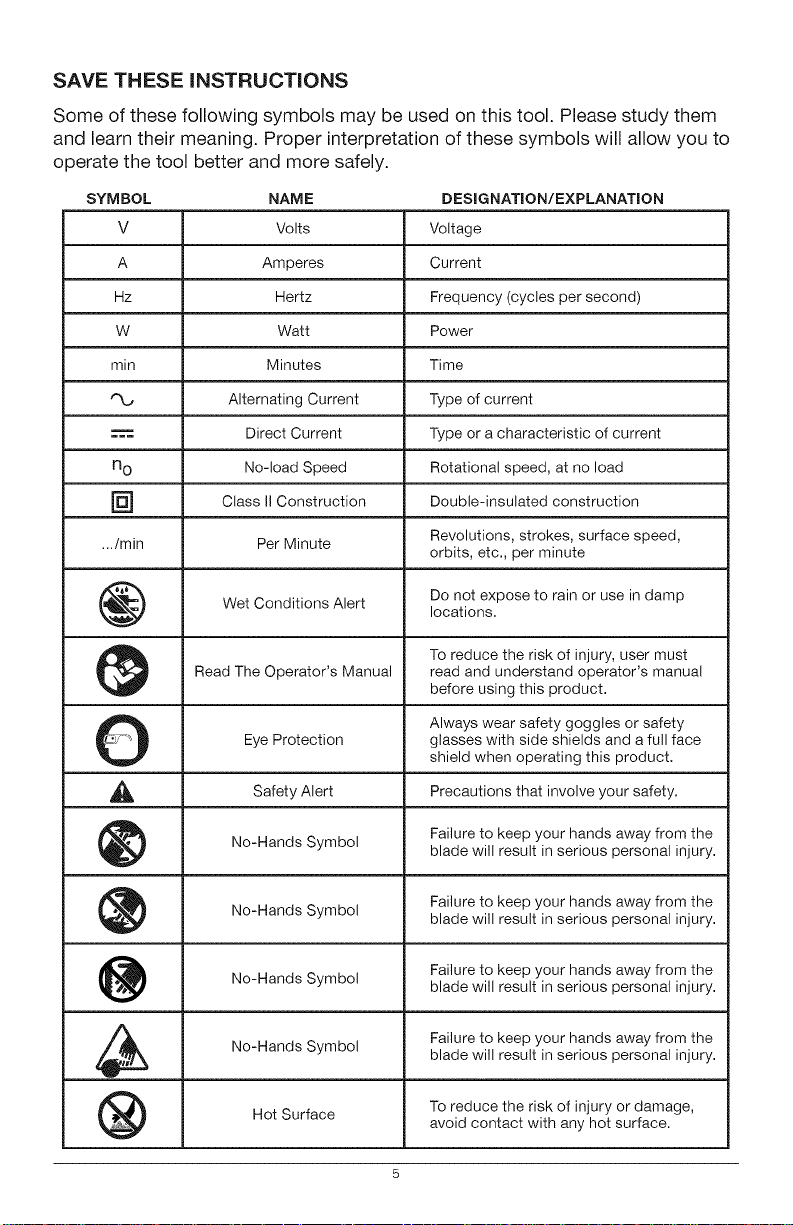

SAVE THESE iNSTRUCTiONS

Some of these following symbols may be used on this tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to

operate the tool better and more safely.

SYMBOL NAME DESIGNATION/EXPLANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

min Minutes Time

Alternating Current Type of current

Direct Current Type or a characteristic of current

n o No-load Speed Rotational speed, at no load

] Class II Construction Double=insulated construction

.../min Per Minute Revolutions, strokes, surface speed,

Wet Conditions Alert Do not expose to rain or use in damp

Read The Operator's Manual read and understand operator's manual

O Always wear safety goggles or safety

Eye Protection glasses with side shields and a full face

Safety your safety.

Alert Precautions that involve

No=Hands Symbol Failure to keep your hands away from theblade will result in serious personal injury.

No=Hands Failure to keep your hands away from the

No=Hands Failure to keep your hands away from the

No=Hands Symbol Failure to keep your hands away from the

Symbol

Symbol

orbits, etc., per minute

locations.

To reduce the risk of injury, user must

before using this product.

shield when operating this product.

blade will result in serious personal injury.

blade will result in serious personal injury.

blade will result in serious personal injury.

Hot Surface To reduce the risk of injury or damage,avoid contact with any hot surface.

5

GENERAL POWER TOOL SAFETY WARNINGS

,_ WARNING: Read all safety warnings and instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and / or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

WORK AREA SAFETY

= Keep work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

= Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adaptor plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock

• Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase the risk of electric shock.

• When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

if operating a power tool in a damp location is unavoidable, use a

ground fault circuit interrupter (GFCl} protected supply. Use of a GFCI

reduces the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use tool while tired or under the

influence of drugs, alcohol, or medication. A moment of inattention while

operating power tools may result in serious personal injury.

• Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch is in the off-position

before connecting to power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your finger on the switch or

energizing in power tools that have the switch on invites accidents.

• Remove any adjusting key or wrench before turning the power tool

on. A wrench or a key left attached to a rotating part of the power tool may

result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or

long hair can be caught in moving parts.

• If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used. Use

of these devices can reduce dust-related hazards.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at the

rate for which it was designed.

• Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and must

be repaired.

• Disconnect the plug from the power source and/or the battery pack

from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to operate

the power tool. Power tools are dangerous in the hands of untrained users.

• Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool's operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly maintained power tools.

Keepcuttingtoolssharpandclean.Properlymaintainedcuttingtoolswith

sharpcuttingedgesarelesslikelytobindandareeasiertocontrol.

Usethepower tool, accessories and tool bits etc., in accordance with

these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for operations different from

those intended could result in a hazardous situation.

SERVICE

Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained.

Follow instructions in the Maintenance section of this manual. Use of

unauthorized parts or failure to follow Maintenance instructions may create

a risk of shock or injury.

SPECiFiC SAFETY RULES FOR SHEET SANDER

Hold power tools by insulated gripping surfaces, because the

sandpaper may contact its own cord. Cutting a "live" wire may make

exposed metal parts of the power tool "live" and could give the operator an

electric shock.

* A suitable breathing respirator must be worn while sanding lead paint,

some woods and metal to avoid breathing the harmful/toxic dust or air.

* Always wear safety goggles and a dust mask when sanding, especially

sanding over-head.

* The machine is not suitable for wet sanding.

* Secure the workpiece. A workpiece clamped with clamping devices or in a

vice is held more secure than by hand.

* Make sure the sandpaper is not contacting the workpiece before the

on/off trigger switch is depressed.

* Do not leave the tool running. Operate the tool only when hand-held.

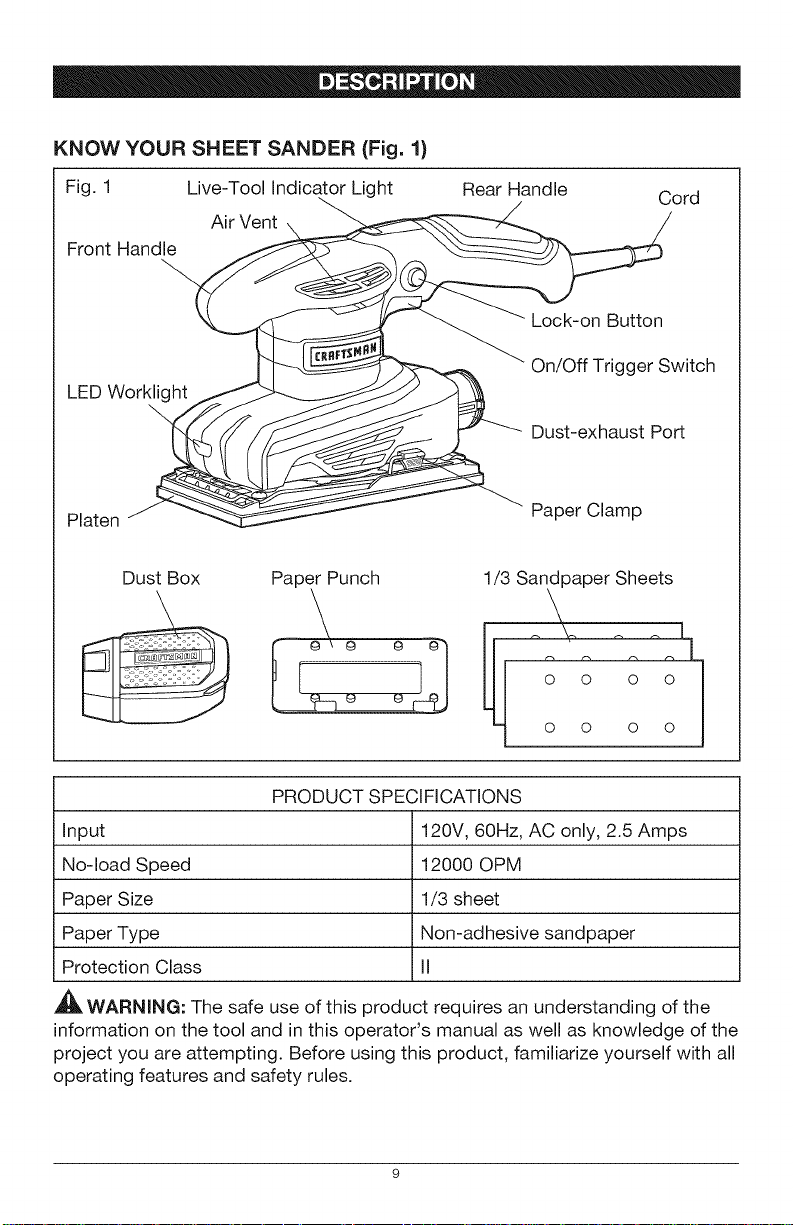

KNOWYOUR SHEET SANDER (Fig. 1)

Fig. 1 Live-Tool Indicator Light

Air Vent

Front Handle

LED Worklight

\

Platen

Dust Box

Paper Punch 1/3 Sandpaper Sheets

Rear Handle

Lock-on Button

On/Off Trigger Switch

Dust-exhaust Port

Paper Clamp

Cord

ooJ

o o

PRODUCT SPECIFICATIONS

Input 120V, 60Hz, AC only, 2.5 Amps

No-load Speed 12000 OPM

Paper Size 1/3 sheet

Paper Type Non-adhesive sandpaper

Protection Class II

,_ WARNING: The safe use of this product requires an understanding of the

information on the tool and in this operator's manual as well as knowledge of the

project you are attempting. Before using this product, familiarize yourself with all

operating features and safety rules.

ORBITAL MOTION

Orbital motion is ideal for fast cutting action when removing old finishes,

smoothing rough wood, cutting stock down to required dimensions or for

finishing surfaces to be painted. The sandpaper moves in tiny circles at a very

high speed, allowing the sander to move easily.

LOCK=ON BUTTON

Locks the tool ON for continuous work.

DUST BOX

Translucent dust box with micro-fine filter provides for efficient dust control

and extraction.

LED WORKLIGHT

The LED worklight, located in the front of the tool, illuminates when the trigger

switch is depressed. This feature provides extra light for increased visibility.

PAPER CLAMP

The sander has two paper clamps designed to secure standard sandpaper to

the platen.

PAPER PUNCH

The paper punch can be used to punch holes in sandpapers, to allow sanded

material to pass through the sheet sander into the dust box or through a vacuum.

LIVE-TOOL INDICATOR LIGHT

The LED indicator light illuminates green when the tool is plugged into a

power source.

10

,&

,_b, WARNING: If any parts are broken or missing, do not attempt to plug or

operate the sheet sander until the broken or missing parts are replaced. Failure

to do so could result in possible serious injury.

_, WARNING: Do not attempt to modify this sander or create accessories not

recommended for use with this sheet sander. Any such alteration or modification is

misuse and could result in a hazardous condition leading to possible serious injury.

,_, WARNING: To prevent accidental starting that could cause serious personal

injury, always disconnect the sander from the power source when assembling

parts, making adjustments, installing or removing sandpaper, cleaning, or when

it is not in use.

UNPACKING

* Carefully remove the tool and any accessories from the carton. Make sure

that all items listed in the packing list are included.

* Inspect the tool carefully to make sure no breakage or damage occurred

during shipping.

* Do not discard the packing material until you have carefully inspected and

satisfactorily operated the tool.

* If any parts are damaged or missing, please return the tool to the place of

purchase.

PACKING LiST

1/3 sheet sander, 3 sandpapers (grit 60,120,220), dust box, paper punch and

operator's manual.

11

,&

,d_ WARNING: To prevent accidental starting that could cause serious personal

injury, always disconnect the sander from the power source when assembling

parts, making adjustments, installing or removing sandpaper, cleaning, or when

it is not in use.

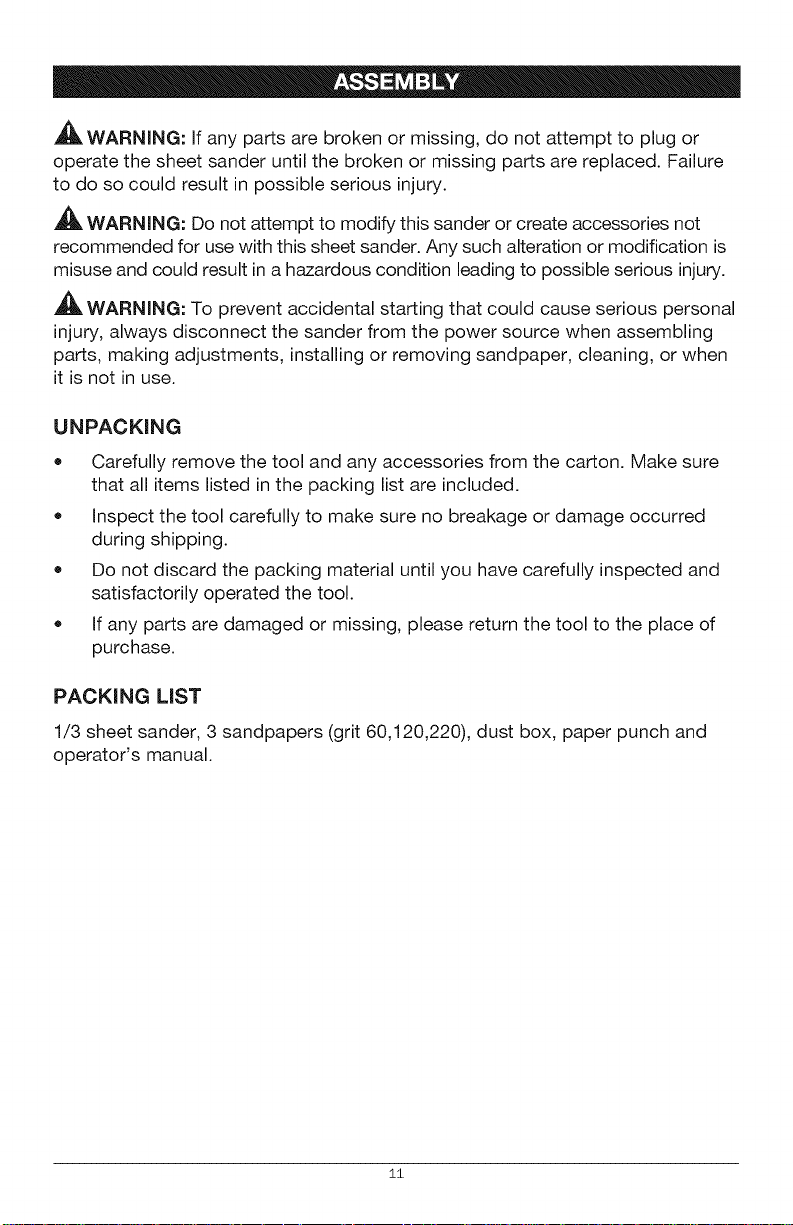

TURNING THE SANDER ON/OFF (Fig. 2)

To turn on the sander, connect the plug to an electrical outlet, and depress the

on/off trigger switch.

To turn it off, release the trigger switch.

LOCK-ON BUTTON (Fig. 2)

The lock-on button allows the

operator to keep the sheet sander

running without continuously

depressing the trigger switch.

To engage the lock-on function:

depress and hold the trigger

switch, depress the lock-on button,

and then release both.

To release the lock-on button,

depress and then release the

trigger switch.

LED WORKLIGNT (Fig. 3}

The LED worklight, located in

the front of the tool, will turn on

when the on/off trigger switch

is depressed. This provides

additional lighting on the surface

of the workpiece for operation.

The LED worklight will turn off

when the switch is released.

Fig. 2

__ sOwn_Ochgg

Fig. 3

LED

worklight

Lock-on button

12

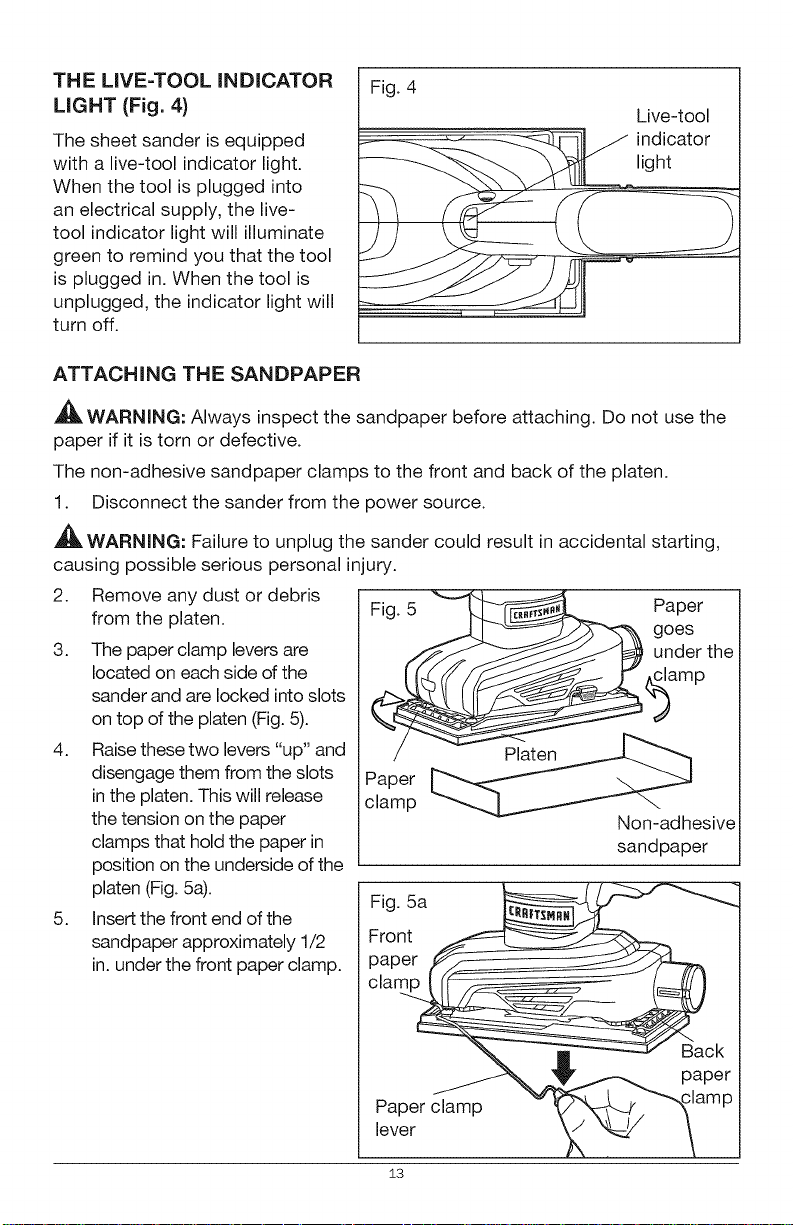

THE LIVE=TOOL iNDiCATOR

LIGHT (Fig. 4}

The sheet sander is equipped

with a live-tool indicator light.

When the tool is plugged into

an electrical supply, the live-

tool indicator light will illuminate

green to remind you that the tool

is plugged in. When the tool is

unplugged, the indicator light will

turn off.

Fig. 4

Live-tool

indicator

ATTACHING THE SANDPAPER

_, WARNING: Always inspect the sandpaper before attaching. Do not use the

paper if it is torn or defective.

The non-adhesive sandpaper clamps to the front and back of the platen.

1. Disconnect the sander from the power source.

WARNING: Failure to unplug the sander could result in accidental starting,

causing possible serious personal injury.

2. Remove any dust or debris

from the platen.

3. The paper clamp levers are

located on each side of the

sander and are locked into slots

on top of the platen (Fig. 5).

4. Raise these two levers "up" and

disengage them from the slots

in the platen. This will release

the tension on the paper

clamps that hold the paper in

position on the underside of the

platen (Fig. 5a).

5. Insert the front end of the

sandpaper approximately 1/2

in. under the front paper clamp.

Front

paper y_

clam_

"_ _ Back

Paperdamp

,ow Y,W /

13

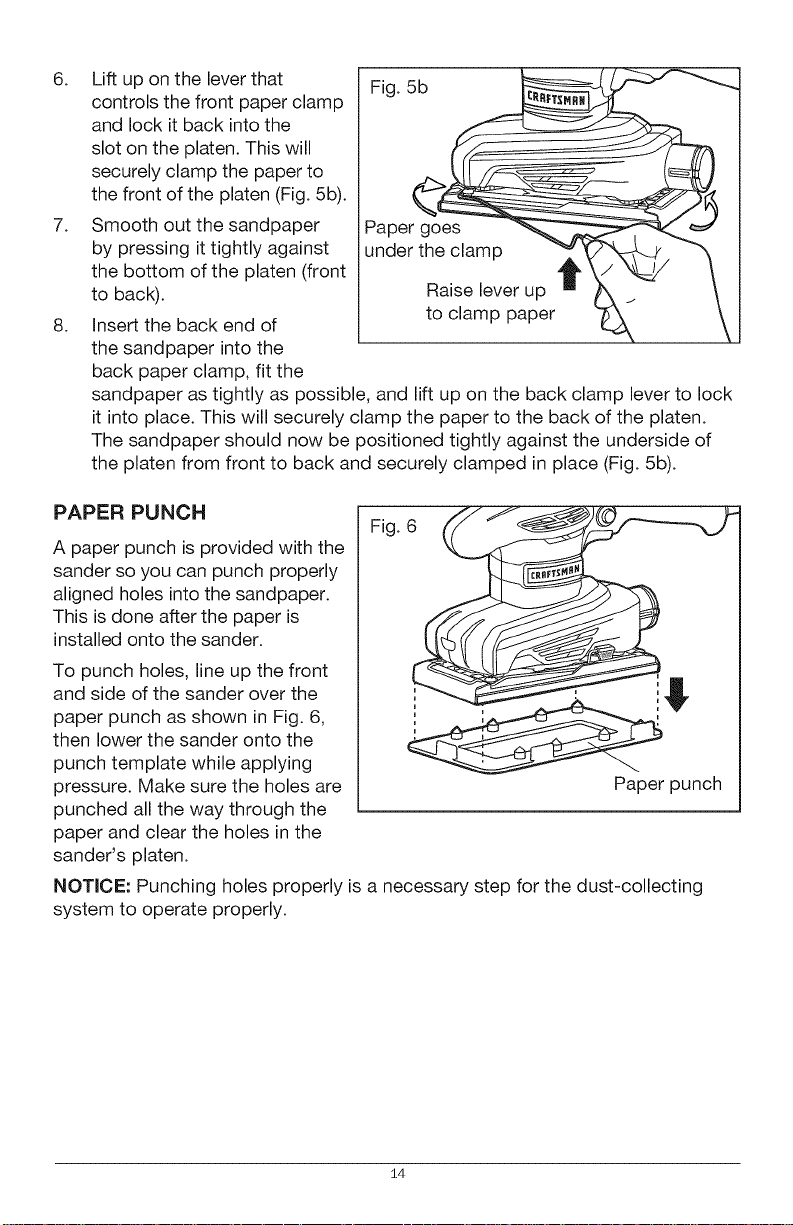

6. Lift up on the lever that

controls the front paper clamp

and lock it back into the

slot on the platen. This will

securely clamp the paper to

the front of the platen (Fig. 5b).

7. Smooth out the sandpaper

by pressing it tightly against

the bottom of the platen (front

to back).

8. Insert the back end of

the sandpaper into the

back paper clamp, fit the

sandpaper as tightly as possible, and lift up on the back clamp lever to lock

it into place. This will securely clamp the paper to the back of the platen.

The sandpaper should now be positioned tightly against the underside of

the platen from front to back and securely clamped in place (Fig. 5b).

Fig. 5b

Paper g__

under the clamp ,_'__ -"_

PAPER PUNCH

A paper punch is provided with the

sander so you can punch properly

aligned holes into the sandpaper.

This is done after the paper is

installed onto the sander.

To punch holes, line up the front

and side of the sander over the

paper punch as shown in Fig. 6,

then lower the sander onto the

punch template while applying

pressure. Make sure the holes are

punched all the way through the

paper and clear the holes in the

sander's platen.

NOTICE: Punching holes properly is a necessary step for the dust-collecting

system to operate properly.

Paper punch

,

Z4

Loading...

Loading...