Page 1

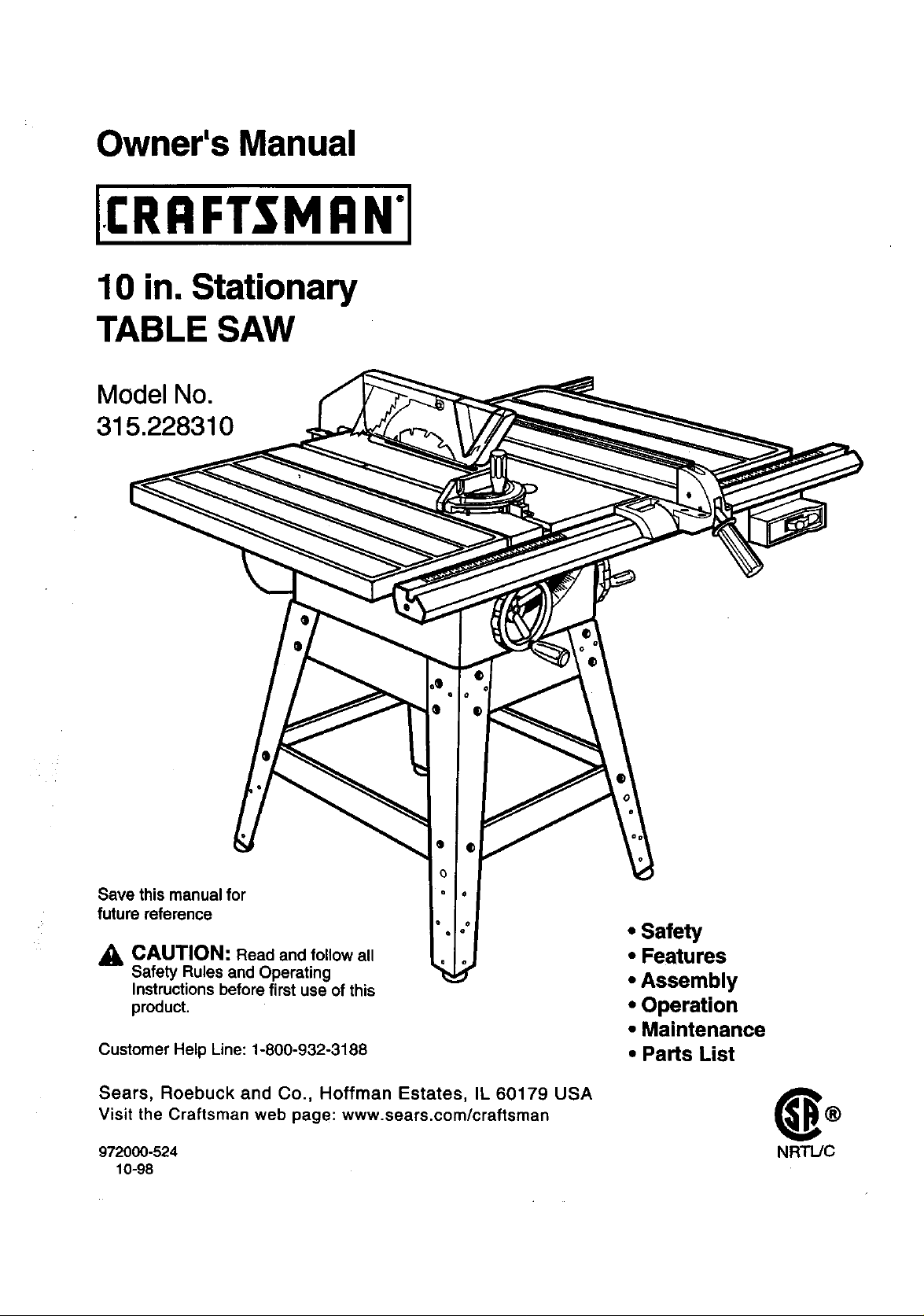

Owner's Manual

10 in. Stationary

TABLE SAW

Model No.

315.228310

Save this manual for

future reference

".I

_, CAUTION: Read and follow all

Safety Rules and Operating

Instructions before first use of this

product.

Customer Help Line: 1-800-932-3188

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

972000-524

10-98

• Safety

• Features

• Assembly

• Operation

• Maintenance

• Parts List

NRTL/C

Page 2

FULLONEYEARWARRANTYONCRAFTSMANTABLESAW

IfthisrRRFTSMRN Table Saw failsdue to a defect in material or workmanshipwithinone year fromthe date of

purchase.Sears will repair it, free ofcharge,

Contacta Sears Service Center for repair.

If this productis used forcommercialor rentalpurposes,thiswarrantyappliesonlyfor 90 days fromthe date of

purchase.

This warranty gives you specificlegal dghts,andyou may also have other rightswhichvary from state to state.

Sears, Roebuck and Co., Dept. 81"IWA, Hoffman Estates, IL 60179

Yoursaw has many features for makingcuttingoperationsmorepleasant and enjoyable. Safety, performance

and dependabilityhave been given top priorityinthe design of thissaw making it easy to maintainand operate.

_, CAUTION: Carefully read throughthis entire owner's manual beforeusingyournew saw. Pay close

attentiontothe Rules For Safe Operation and all Safety Alert Symbols,includingDanger,Wam ng and

Caution. If you useyour saw properlyand onlyfor what it isintended,you will enjoyyears of safe, reliable

service.

._ Look for thissymboltopoint outimportantsafety precautions.It means attention!!!Yoursafetyis involved.

WARNING:

The operationof any powertoolcan resultinforeign objects beingthrowninto youreyes,

whichcan result in severe eye damage. Before beginningpowertool operation, always

wear safety goggles or safety glasses with side shieldsand a full face shieldwhen needed.

We recommenda Wide Vision Safety Mask for use over eyeglasses or standardsafety

glasses withside shields,available at Sears Retail Stores.

• Warranty and Introduction.............................................................................................................................. 2

• Table Of Contents ....................................................................................................................................... 2-3

• Rules For Safe Operation ........................................................................................................................... 4-6

• Electrical......................................................................................................................................................... 7

• Glossaryand ProductSpecifications............................................................................................................. 8

• Unpackingand Accessories........................................................................................................................... 9

• Loose Parts List...................................................................................................... ...................................... 10

• Small Parts List ....................................................................................................................................... 11-12

• Tools Needed ............................................................................................................................................... 13

• Labels...................................................................................................................................................... 14-15

• Features .................................................................................................................................................. 16-17

• Assembly................................................................................................................................................. 18-27

InstallingHandwheels onTable Saw Base .................................................................................................. 18

AssemblingLegStand ............................................................................................................................ 18-19

CRAFTSMAN"TABLESAW315.228310 2

Page 3

MountingtheLegStandontheTableSawBase........................................................................................ 19

AssemblingTable Extensions...................................................................................................................... 20

AligningTable Extensions............................................................................................................................ 20

Installingthe Rear Rail ................................................................................................................................. 21

Installingthe FrontRail ................................................................................................................................ 22

AligningRip Fence and Front Rail ............................................................................................................... 23

Mountingthe Motor ...................................................................................................................................... 23

Installingthe Beltand Belt Guard ................................................................................................................ 24

Checkingthe Throat Plate............................................................................................................................ 24

Installingthe Blade Guard............................................................................................................................ 25

Aligningthe RivingKnifewith the Blade ...................................................................................................... 26

Checking Rip Fence and Blade Alignment .................................................................................................. 27

• Adjustments............................................................................................................................................. 28-32

Replacingthe Blade ..................................................................................................................................... 28

Heeling(Paralleling) the Sawblade to MiterGage Groove........................................ t............................ 29-30

Settingthe Bevel Stops and Indicator..................................................................................................... 30-31

Adjustingthe Miter Gage .............................................................................................................................. 31

Removing/ Replacing the Throat Plate ....................................................................................................... 32

• BasicOperation/bfthe Table Saw .......................................................................................................... 33-40

Causes of Kickback...................................................................................................................................... 33

AvoidingKickback ........................................................................................................................................ 33

Making CuttingAids ..................................................................................................................................... 33

Types of Cuts ............................................................................................................................................... 34

Making a Cross Cut ...................................................................................................................................... 35

Making a Rip Cut .......................................................................................................................................... 35

Making a Miter Cut ....................................................................................................................................... 36

Making a Bevel Cross Cut ............................................................................................................................ 36

Making a Bevel Rip Cut................................................................................................................................ 37

• Making a Compound (Bevel) Miter Cut........................................................................................................ 38

Making a Large Panel Cut ............................................................................................................................ 39

Making a Non-ThroughCut .......................................................................................................................... 39

Making a Dado Cut................................................. _..................................................................................... 40

• Maintenance................................................................................................................................................. 41

• Lubrication.................................................................................................................................................... 41

• Troubleshooting....................................................................................................................................... 42-44

• ExplodedView and Repair Parts List...................................................................................................... 46-63

• PartsOrdering / Service ................................................................................................................... back page

3 CRRFTSMIIN"TABLESAW315.228310

Page 4

The purpose ofsafety symbols isto attract yourattentionto possibledangers.The safety symbols,and the

explanationswiththem, deserve your careful attentionand understanding.The safetywarningsdo not by

themselves eliminateany danger. The instructionsor warnings they give are not substitutesforproperaccident

preventionmeasures.

SYMBOL MEANING

A

SAFETY ALERT SYMBOL

Indicatesdanger, warning,orcaution,May be used inconjunctionwithothersymbolsor

pictographs.

A

A

Note:

DANGER: Failureto obey a safety warningwill resultin seriousinjurytoyourselforto others.

Alwaysfollow the safetyprecautionsto reduce the riskoffire, electdcshockand personalinjury.

WARNING: Failureto obeya safetywarningcan resultinsedousinjuryto yourselfor to others.

Always follow the safetyprecautionsto reduce the riskoffire, electdcshockand personal injury.

CAUTION: Failureto obey a safetywarningmay resultin propertydamageor personalinjuryto

yourselfor to others.Alwaysfollowthe safety precautionsto reducetheriskoffire, electricshock

and personalinjury.

Advisesyou of informationor instructionsvital to the operationor mainienance ofthe equipment.

IMPORTANT

Servicingrequiresextreme care and knowledgeofthe

systemand shouldbe performedonly by a qualified

servicetechnician.For servicewe suggestyoureturn

the toolto yournearest Sears store or repaircenter.

Always use originalfactory replacementpartswhen

servicing.

READ ALL INSTRUCTIONS

KNOW YOUR POWER TOOL. Read the owner's

manual carefully. Learn the saw's applications

and limitationsaswell as the specificpotential

hazards relatedto thistool.

DO NOT USE IN DANGEROUS ENVIRON-

MENT. Do not use powertoolsnear gasolineor

otherflammable liquids,in damp or wet loca-

tions,or expose them to rain. Keep the work

area well lit.

• MAKE WORKSHOP CHILD-PROOF with

padlocksand master switches or by removing

starter keys.

• KEEP CHILDREN AND VISITORS AWAY. All

visitorsshouldwear safety glasses and be kept a

safe distance from work area. Do not let visitors

contacttoolor extensioncord whileoperating,

• KEEP THE WORK AREA CLEAN. Cluttered

work areas and workbenches inviteaccidents,

DO NOT leave toolsorpieces of woodonthe

saw while itis in operation,

_1= WARNING: Do notattemptto operatethistool

untilyouhave readthoroughlyand understand

completelyall instructions,safety rules, etc.

containedin this manual. Failuretocomply can

resultin accidents involvingfire, electricalshock,

or seriouspersonalinjury.Save the owner's

manual and reviewfrequently for continuingsafe

operation,and instructingotherswho may use

this tool.

MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for betterand safer perfor-

mance. Followinstructionsfor lubricatingand

changingaccessories.

USE THE RIGHT TOOL FOR THE JOB. Do not

force the tool or attachmentto do ajob itwas not

designedfor. Use it onlythe way it was intended.

DRESS PROPERLY. Do notwear looseclothing,

gloves, neckties, rings,bracelets,or other

jewelry. They can getcaughtand draw you into

moving parts.Rubberglovesand nonslipfoot-

wear are recommended.Alsowear protective

hair coveringto containlonghair.

ALWAYS WEAR SAFETY GLASSES WITH

SIDE SHIELDS. Everydayeyeglasses have only

impact-resistantlenses;theyare NOT safety

glasses,

NEVER STAND ON TOOL. Seriousinjurycould

occurif the toolis tippedor ifthe blade is unin-

tentionallycontacted.

CRRFTSMRN"TABLESAW315.228310 4

Page 5

BIULES FOR SAFE OPERATION (Continued)

B DO NOT OVERREACH. Keep properfooting and

balance at alltimes.

m

SECURE WORK. Use clampsor a viseto hold

workwhen practical. It'ssaferthan usingyour

handand frees bothhandsto operatetool.

M

USE THE PROPER EXTENSION CORD. Make

sure your extensioncord isin goodcondition.

Use only a cord heavyenoughto carrythe

currentyour productwilldraw. An undersized

cordwillcause a drop in line voltage resultingin

lossof power and overheating. A wire gage size

(A.W.G.) of at least 14 isrecommendedfor an

extensioncord25 feet or less inlength.If in

doubt,use the next heavier gage. The smaller

the gage number,the heavierthe cord.

M

AVOID ACCIDENTAL STARTING. Be sure

switchisoft when pluggingin.

M

REMOVE WRENCHES AND ADJUSTING

KEYS. Get inthe habit of checking- before

turningontool - that hexI_eysand adjusting

wrenchesare removed from tool.

M

CHECK DAMAGED PARTS. Before usingthe

toolagain, checkany damaged parts,including

guards,for proper operationand performance.

Check alignmentofmovingpads, bindingof

movingpads, breakage of pads, saw stability,

mountingand any otherconditionsthat may

affect itsoperation.A damaged part must be

propedyrepairedor replaced bya qualified

servicetechnicianat a Sears storeor repair

center to avoid riskofpersonalinjury.

M

USE ONLY CORRECT BLADES. Use the right

blade size, style and cutting speed for the

material and the type of cut. Blade teeth should

point down toward the front of the table.

M

USE RECOMMENDED ACCESSORIES, Using

improperaccessoriesmay riskinjury.

USE ONLY SEARS REPLACEMENT PARTS,

Allrepairs,whether electdcalor mechanical,

shouldbe made bya qualifiedservicetechnician

at a Sears storeor repaircenter.

M

KEEP GUARDS IN PLACE and in good working

order.This includesthe blade guard, rivingknife,

and anti-kickbackpawls.

M

CHECK DIRECTION OF FEED. Feed work into

a blade or cutteragainst the directionof rotation

ofthe blade or cutter only,

DISCONNECT ALL TOOLS. When notinuse,

before servicing,or when changingattachments,

blades, bits, cutters,etc., all toolsshouldbe

disconnectedfrom power supply.

DO NOT FORCE THE TOOL. It will do tbe job

better and more safely at the ratefor which it

was designed.

M

NEVER LEAVE TOOL RUNNING UNAT-

TENDED. TURN THE POWER OFF. Do not

leave tool untilit comesto a complete stop.

M

BEFORE MOUNTING, DISCONNECTING OR

REMOUNTING THE MOTOR; unplugthesaw

and removethe switchkey.

WARNING: When servicing,useonly identical

A

Craftsman replacementpads. Use ofany other

parts may create a hazard or cause product

damage.

M

NEVER USE THIS TOOL IN AN EXPLOSIVE

ATMOSPHERE. Normal sparkingof the motor

could ignitefumes.

M

MAKE SURE THE WORK AREA HAS AMPLE

LIGHTING to see the workand that noobstruc-

tionswillinterferewithsafe operation BEFORE

performingany workusingthistool.

M

DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Have defective switches

replaced by a qualifiedservicetechnician at a

Sears store or repaircenter.

M

GUARD AGAINST ELECTRICAL SHOCK by

preventingbodycontactwith grounded surfaces

such as pipes, radiators,ranges,refrigerator

enclosures.

M

GROUND ALL TOOLS. See Electricalpage.

WEAR A DUST MASK to keep from inhalingfine

particles.

PROTECT YOUR HEARING. Wear hearing

protectiondudngextended periodsof operation.

M

DO NOT OPERATE THIS TOOL WHILE UN-

DER THE INFLUENCE OF DRUGS, ALCOHOL,

OR ANY MEDICATION.

M

STAY ALERT AND EXERCISE CONTROL,

Watch whatyou are doingand use common

sense, Do not operate tool when you ere tired.

Do not rush.

M

AVOID AWKWARD OPERATIONS AND HAND

POSITIONS where asudden slip couldcause

your hand to moveintothe blade.ALWAYS

make sureyou have goodbalance,

M

ALWAYS SUPPORT LARGE WORK PIECES

while cuttingto minimize riskof blade pinching

and kickback.Saw may slip,walk or slide while

cuttinglarge or heavy boards.

5 CRAFTSMAN"TABLESAW315,228310

Page 6

RULES FOR SAFE OPERATION (Continued)

• GUARD AGAINST KICKBACK. Kickbackcan

occurwhen the blade sta$$s,ddvingthe work

piece back towardthe operator. It can pullyour

hand intothe blade, resultingin sedous personal

injury.Stay out of the blade pathand turn switch

off immediatelyifblade bindsor stalls.

USE A SUPPORT FOR THE SIDES AND BACK

OF THE SAW TABLE when sawingwide or long

workpieces. Use a sturdy"outrigger" supportif a

table extensionis morethan 24 incheslong and

is attached to the saw, to preventtipping.

CUT ONLY WOOD, PLASTIC OR WOOD-LIKE

MATERIALS. Do not cut metal.

• NEVER cutmore than one piece at a time. DO

NOT STACK more than one workpieceon the

saw table at a time.

DO NOT REMOVE THE SAW'S BLADE

GUARDS. Never operate the saw with any guard

or cover removed.Make sureall guardsare

operating propedybefol'eeach use.

NEVER PERFORM ANY OPERATION FREE-

HAND. Always place the workpieceto be cut on

the saw table and position itfirmly againstthe

fence as a backstop.

USE THE RIP FENCE. Always use afence or

straightedgeguide when ripping.

BEFORE MAKING A CUT, be sureall adjust-

mentsare secure.

• BE SURE THE BLADE PATH IS FREE OF

NAILS. Inspect for and remove all nails from

lumber before cutting.

• BE SURE THE BLADE CLEARS THE

WORKPIECE. Never startthe saw with the blade

touchingtheworkplace.

• KEEP HANDS AWAY FROM CUTTING AREA.

Do notreach underneathworkor inblade cutting

path withyourhands and fingersfor any reason.

Alwaysturnthe power off.

• USE A PUSHBLOCK OR PUSH STICK for

workpiecessosmall that yourfingersgounder

the blade guam:d.NEVER TOUCH BLADE or

other movingpartsduringuse, for any reason.

ALLOW THE MOTOR TO COME UP TO FULL

SPEED before startinge cutto avoidblade

bindingor stalling.

ALWAYS PUSH THE WORKP|ECE; never pullit

towardthe saw.

DO NOT FEED THE MATERIAL TOO QUICKLY.

Do notfome the workpieceagainstthe blade.

ALWAYS TURN OFF SAW beforedisconnecting

it,to avoidaccidental startingwhen reconnecting

to powersupply. NEVER leave the table saw

unattendedwhileconnectedto a powersource.

BEFORE CHANGING THE SETUP, REMOVING

COVERS, GUARDS, OR BLADE; unplugthe

saw andremove the switchkey.

KEEP TOOL DRY, CLEAN, AND FREE FROM

OIL AND GREASE. Alwaysuse a clean cloth

when cleaning. Never use brakefluids, gasoline,

petroleum-basedproducts,or any solvents to

clean tool.

KEEP BLADES CLEAN, SHARP AND WITH

SUFFICIENT SET. Sharp blades minimize

stallingand kickback.

USE ONLY OUTDOOR EXTENSION CORDS.

Use only extensioncordswiththe marking

=Acceptable for use with outdoorappliances;

store cordsindoorswhilenot in use." Use

extensioncordswith an electricalratingnot less

than the saw's rating.Always disconnectthe

extensioncordfrom the outletbeforedisconnect-

ingthe productfrom the extensioncord.

• INSPECT TOOL CORDS AND EXTENSION

CORDS PERIODICALLY and, ifdamaged, have

repairedbya qualifiedsewice technicianat a

Sears store or repaircenter. Stay constantly

aware of cord locationand keep itwell away

fromthe movingblade.

• DO NOT ABUSE CORD, Never yank cord to

disconnectit from receptacle. Keep cord from

heat, oil,and sharp edges.

SAVE THESE INSTRUCTIONS. Referto them

frequently and use to instructother users. If you

loansomeonethis tool, loanthem these instruc-

tionsalso.

_k WARNING: Blade coasts after beingtumed off.

SAVE THESE INSTRUCTIONS

[RAFTSMRW TABLESAW316,228310 6

Page 7

EXTENSION CORDS

Use only 3-wire extensioncordsthat have 3-prong

groundingplugsand 3-pole receptaclesthat accept

thetool's plug. When usinga power tool at a consid-

erable distance fromthe power source, use an

extensioncord heavyenoughto carrythe current that

thetool will draw.An undersizedextensioncordwill

cause a drop in linevoltage, resultingin a loss of

powerand causingthe motorto overheat. Use the

chart providedbelowto determinethe minimumwire

size requiredinan extensioncord. Only roundjack-

eted cords listed by Underwriter'sLaboratories(UL)

shouldbe used.

Length of Extension Cord Wire Size (A.W.G.)

Up to 25 feet 14

26-100 feet 12

When workingwiththetool outdoors,use an exten-

sioncordthat isdesignedfor outsideuse. This is

indicatedbythe lettersWA on the cord's jacket.

Beforeusing an extensioncord, inspect it for looseor

exposedwires and cut or worninsulation.

_k CAUTION: Keep the cord away from the cutting

area and positionthe cord sothat it willnot be

caughton lumber,tools,or otherobjectsdudng

cuttingoperations.

ELECTRICAL CONNECTION

YourSears Craftsman Table Saw is powered bya

precisionbuiltelectricmotor. It should be connected

to a power supply that Is 120 volts, 60 Hz, AC only

(normal household current). Do not operate thistool

ondirectcurrent (DC). A substantialvoltagedropwill

causea lossofpower and the motorwilloverheat. If

the saw does not operatewhen plugged intoan

outlet,doublecheckthe power supply.

SPEED AND WIRING

The no-loadspeed of your table saw is approximately

3,600 rpm.This speed is not constantand decreases

undera load or with lowervoltage. For voltage, the

wiringin a shopis as importantas the motor'shorse-

powerrating.A lineintendedonlyfor lightscannot

properlycarry a power tool motor. Wire that isheavy

enoughfor a short distance willbe too lightfor a

greaterdistance. A line thatcan supportone power

tool may not be ableto supporttwo or three tools.

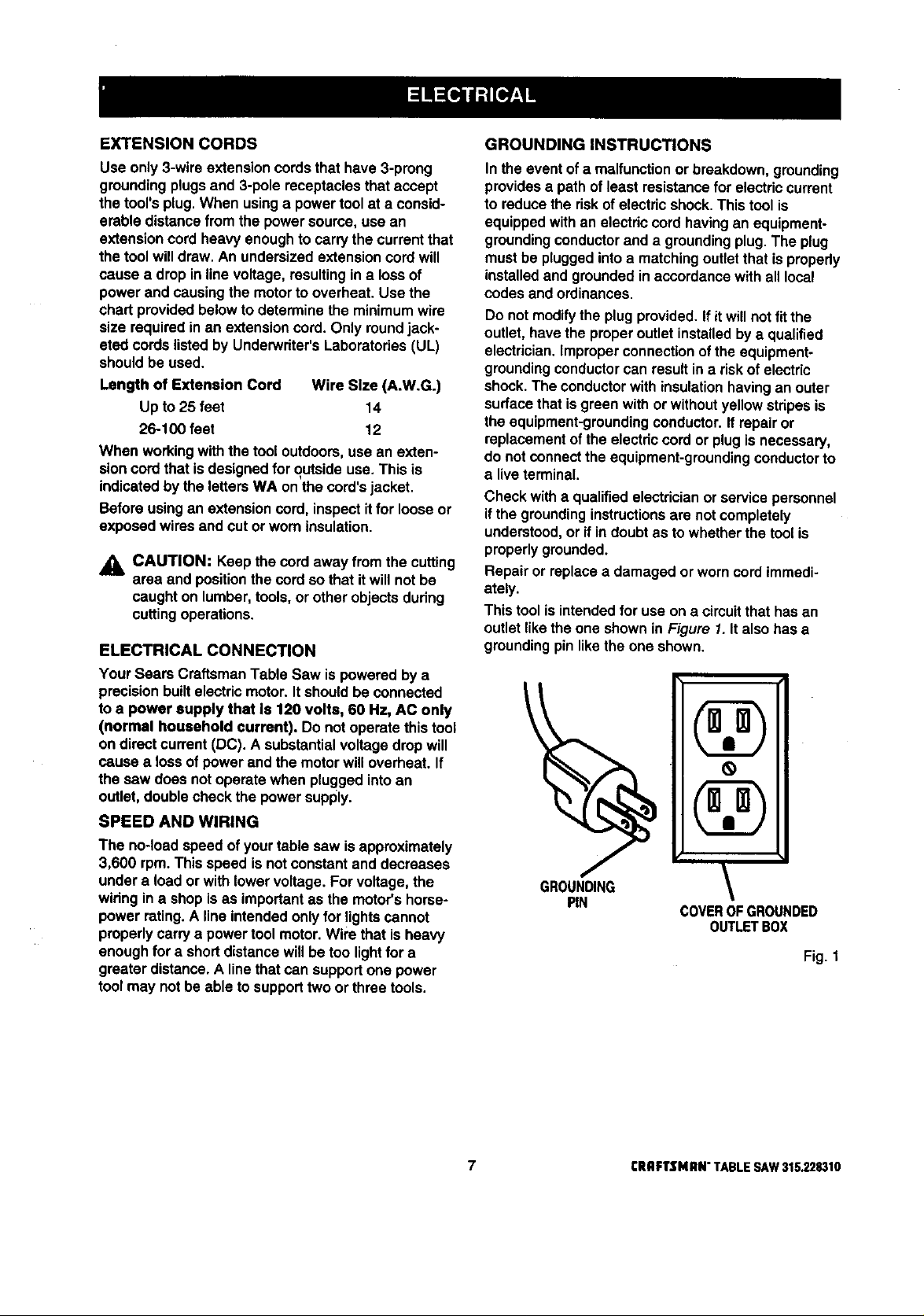

GROUNDING INSTRUCTIONS

In the event ofa malfunctionorbreakdown, grounding

providesa path ofleast resistancefor electriccurrent

to reduce the riskofelectricshock.Thistool is

equippedwithan electric cord having an equipment-

groundingconductorand a groundingplug.The plug

mustbe pluggedintoa matchingoutletthat ispropedy

installedand grounded in accordancewith all local

codes and ordinances.

Do not modifythe plug provided. If itwillnot fit the

outlet,have the proper outletinstalledby a qualified

electrician.Improperconnectionof the equipment-

groundingconductorcan resultin a riskof electric

shook.Theconductorwith insulationhavingan outer

surfacethat isgreen withor withoutyellowstripes is

the equipment-groundingconductor. If repairor

replacementofthe electdc cordor plug isnecessary,

do not connect the equipment-groundingconductorto

a liveterminal.

Check witha qualifiedelectricianor service personnel

ifthe groundinginstructionsare notcompletely

understood,or if indoubt as to whether the toolis

properlygrounded.

Repair or replace a damaged or worncord immedi-

ately.

This tool is intendedfor use on a circuitthathas an

outletlikethe one shownin Figure 1. Italso hasa

groundingpinlikethe oneshown.

GROUNDING

PIN

COVEROFGROUNDED

0UTLETBOX

Fig. 1

7 rRRFTSNRN"TABLESAW31S.228310

Page 8

Anti-Kickback Pawls

Toothedsafety devicesbehindthe bladedesignedto

stop a workpiece from beingkicked back at the

operatorduringa rippingoperation.

Arbor

The shafton which a bladeor cuttingtoolis mounted.

Bevel Cut

A cuttingoperationmade withthe blade at any angle

otherthan 90"to the saw table.

Compound Cut

A cut with both a miterangle and a bevel angle.

Crosscut

A cuttingoperation made acrossthe grainor the width

ofthe workpiece.

Dsdo

A non-throughcut that gives a square notchortrough;

requiresa specialblade.

Featherboard

A device to helpguide workpiecesduring ripcuts.

Freehand (for table saw)

Dangerous practice ofmaking s cut withoutusingdp

or miterfences.See Safety Rules.

Gum

A sticky, sap-based residuefromwood products.

Heel

Alignmentof the blade.

Kerf

The materialremovedby the blade in a through cut or

the slotproducedby the blade in a non-throughcut.

Kickback

A hazard that can occurwhen blade bindsor stalls,

throwingworkpiece back towardoperator.

Leading End

The endof the workpiecepushed into the cuttingtool

first.

Miter Cut

A cuttingoperationmade with the miter gage at any

angle other than 0".

Molding

A non-throughcutthat givesa varied shapeto the

workpiece and requires e specialblade.

Push Stick

A device usedto feed the workpiecethroughthe saw

blade duringnarrowcuttingoperations.It helps keep

the operator'shandswellaway from the blade,

Rabbet

A notch inthe edge of a workpiece.

Resaw

A cuttingoperationto reduce the thicknessofthe

workpieceinorder to make thinner pieces.

Resin

A sticky,sap-based substance.

RIp Cut

A cut made withthethe grainof the workpiece.

Sswblade Path

The area directlyin line withthe blade-- over, under,

behind, orin front of it. Also, theworkpiecearea

whichwillbe or has been cutby theblade.

Set

The distancethat the tip ofthe saw blade tooth is bent

(or set) outwardfromthe faceof the blade.

Throw-Back

Saw throwingback a workpiece;similarto kickback,

Through Sawing

Any cuttingoperationwhere the blade extends

completelythroughthe workpiece.

Trailing End

The workpieceend last cut by the blade in a dp cut.

Workp|ece

The itemon whichthe cutting operationis beingdone.

The surfacesof a workpieceare commonlyreferredto

as faces,ends, and edges.

Worktable

The surfaceonwhichthe wodq_ecerestswhile

performinga cuttingoperation.

BladeArbor 5/8 in.

Blade Diameter 10 in.

Blade Tilt 0"- 45"

TableSize withouttableextensions 20 in. x 27 in.

Table Size with table extensions 44 in. x 27 in.

rRRFTSNlUI" TABLESAW$1G,228310 8

Rating 120 V,60 Hz -AC only

Input 13 Amperes

No LoadSpeed 3,600 RPM

CuttingCapacitywithMiter at 0"/Bevel0": 3-3/8 in.

Cutting Capacity withMiter at O'/Bevel45": 2-1/4 in.

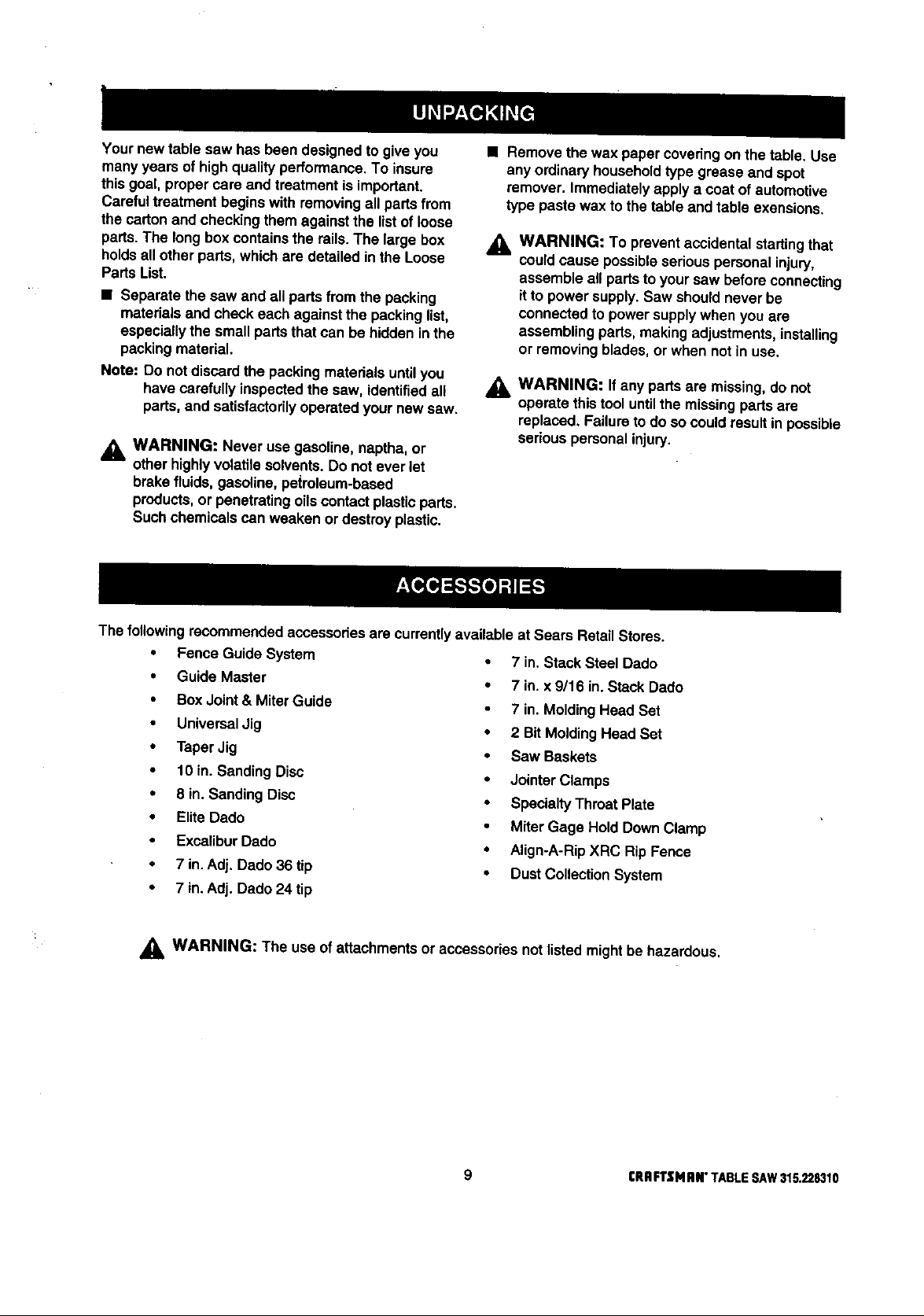

Page 9

Your new table saw has been designed to give you

manyyears of high qualityperformance.To insure

thisgoal, proper care and treatment is important.

Careful treatment beginswith removingall pads from

the cartonand checkingthem against the listof loose

parts.The long box containsthe rails. The large box

holdsall other parts,which are detailed inthe Loose

PartsList.

• Separate the sawand all partsfrom the packing

materialsand checkeach against the packing list,

especiallythe small partsthat can be hidden inthe

packingmaterial

Note: Do notdiscardthe packingmaterialsuntilyou

have carefullyinspectedthe saw, identifiedall

parts,and satisfactorily operated your new saw.

_IL WARNING: Never use gasoline,naptha, or

other highlyvolatilesolvents.Do not ever let

brake fluids, gasoline,petroleum-based

products,or penetratingoilscontact plasticparts.

Such chemicalscan weaken ordestroy plastic.

II Remove the wax paper covering on the table. Use

anyordinary household type grease and spot

remover. Immediatelyapply a coat of automotive

typepaste wax to the table and table exensions.

,_ WARNING: To preventaccidental startingthat

couldcause possibleseriouspersonalinjury,

assemble all partsto your saw before connecting

it to power supply.Saw should never be

connected to power supplywhen you are

assemblingparts,making adjustments, installing

or removingblades, or when notin use.

,_ WARNING: If any partsare missing,do not

operate thistool untilthe missingpartsare

replaced. Failure to do so could result inpossible

seriouspersonalinjury.

The following recommendedaccessoriesare currentlyavailable

• Fence Guide System

• Guide Master

• Box Joint & Miter Guide

• Universal Jig

• Taper Jig

• 10 in. Sanding Disc

• 8 in. SandingDisc

• Elite Dado

• ExcaliburDado

• 7 in. Adj. Dado 36 tip

at Sears RetailStores.

• 7 in.Stack Steel Dado

• 7 in.x 9/16 in.Stack Dado

• 7 in. MoldingHead Set

• 2 BitMoldingHead Set

• Saw Baskets

• JointerClamps

• SpecialtyThroat Plate

• Miter Gage Hold Down Clamp

• Align-A-RipXRC Rip Fence

• Dust CollectionSystem

• 7 in.Adj. Dado 24 tip

,_ WARNING: The use of attachmentsor accessoriesnot listed mightbe hazardous.

9 [RAFTSMAN" TABLESAW315.228310

Page 10

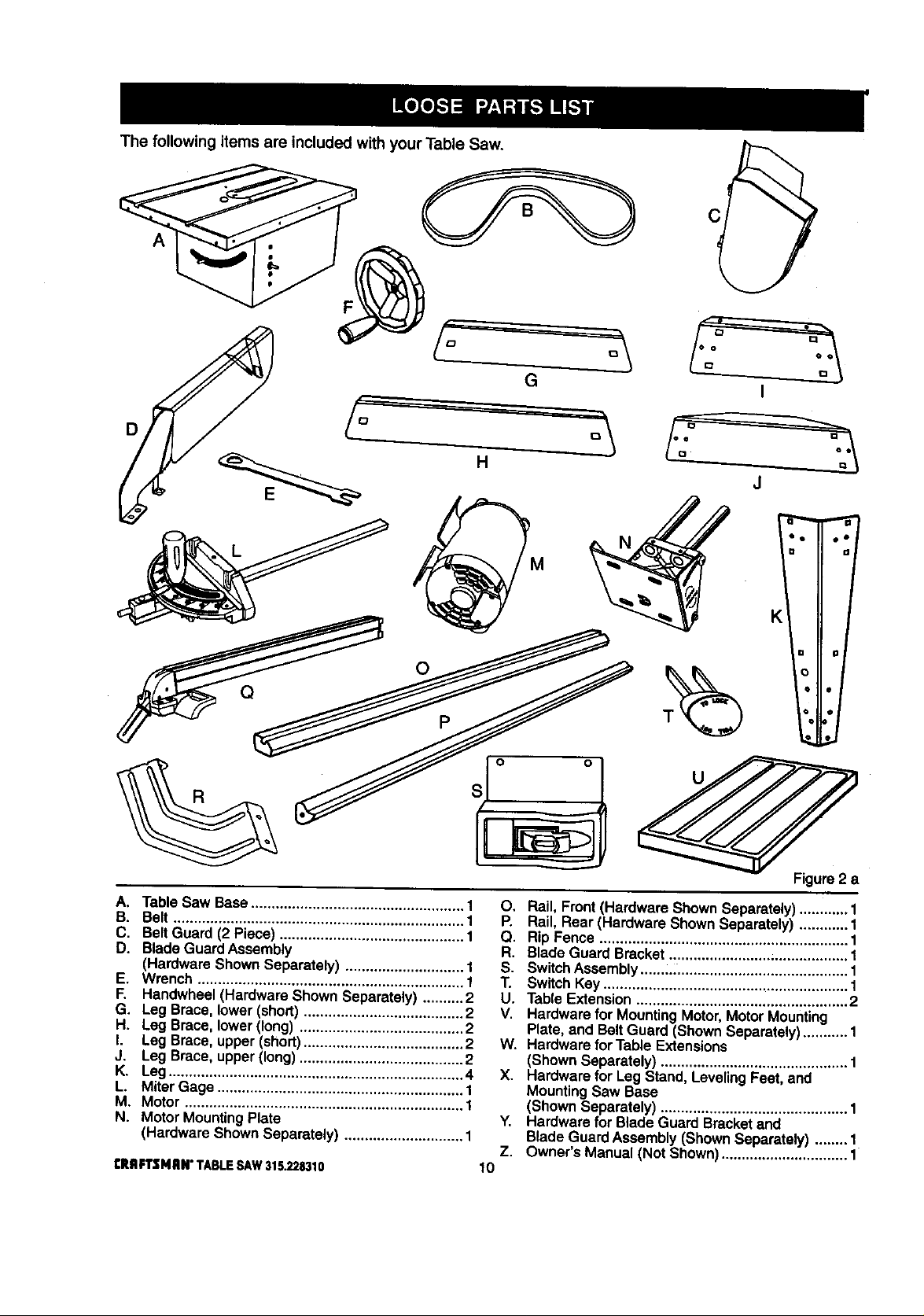

The following items are included with your Table Saw.

A

G

I

D

J

o

Q

A. Table SawBase .................................................... 1

B. Belt ....................................................................... 1

C. Belt Guard (2 Piece) ............................................. 1

D. Blade GuardAssembly

(Hardware Shown Separately) ............................. 1

E. Wrench ................................................................. 1

F. Handwheel(Hardware Shown Separately) ..........2

G. LegBrace, lower(short)....................................... 2

H. Leg Brace, lower(long) ........................................ 2

I. Leg Brace, upper(short)....................................... 2

J. Leg Brace, upper (long) ........................................ 2

K. Leg........................................................................ 4

L. MiterGage ............................................................ 1

M. Motor .................................................................... 1

N. Motor MountingPlate

(Hardware Shown Separately) ............................. 1

tRRFTZMRI¢ TABLE SAW 315.228310

Figure2 a

O. Rail, Front(Hardware ShownSeparately)............ 1

P. Rail,Rear (Hardware Shown Separately) ............ 1

Q. RipFence ............................................................. 1

R. Blade Guard Bracket ......................... ;.................. 1

S. SwitchAssembly ......,, ......................................... 1

T. SwitchKey ............................................................ 1

U. Table Extension.................................................... 2

V. Hardwarefor MountingMotor,MotorMounting

Plate, and BeltGuard (Shown Separately)...........1

W. Hardware for Table Extensions

(ShownSeparately) .............................................. 1

X. Hardwarefor Leg Stand, LevelingFeet, and

MountingSaw Base

(ShownSeparately) .............................................. 1

Y. Hardwarefor Blade Guard Bracketand

Blade Guard Assembly (ShownSeparately) ........ 1

Z. Owner's Manual (Not Shown)............................... 1

10

Page 11

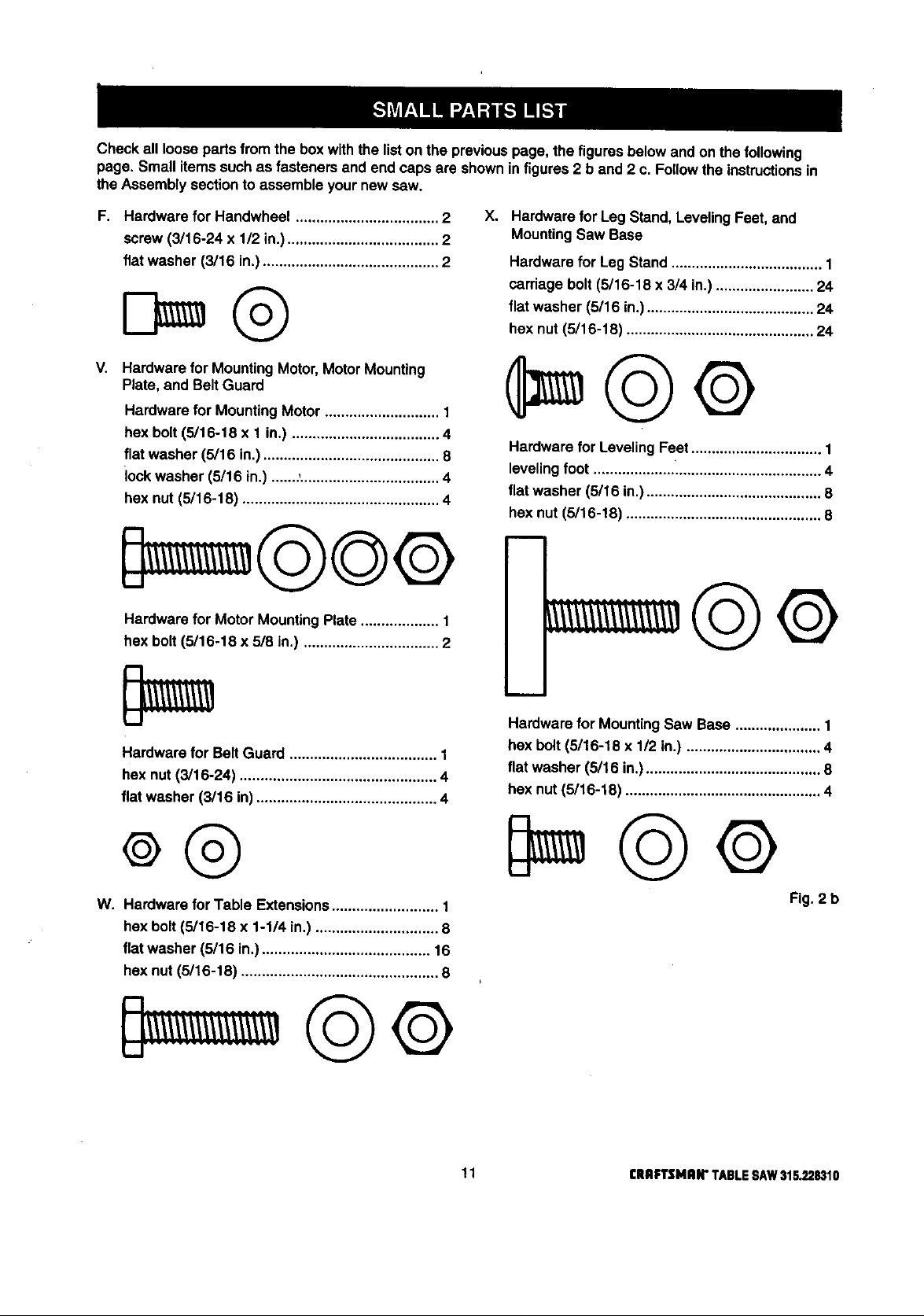

Checkallloosepartsfromtheboxwiththelistonthepreviouspage,thefiguresbelowandonthefollowing

page,Smallitemssuchasfastenersandendcapsareshowninfigures2band2c.Followtheinstructionsin

theAssemblysectiontoassembleyournewsaw.

F. Hardware for Handwheel ................................... 2

screw (3/16-24 x 1/2 in.)..................................... 2

flat washer (3/15 in.)........................................... 2

V.

Hardware for MountingMotor, MotorMounting

Plate, andBelt Guard

Hardware for Mounting Motor ............................ 1

hex bolt (5/16-18 x 1 in.) .................................... 4

flat washer (5/16 in.) ........................................... 8

lock washer (5/16 in.) .......,.................................. 4

hex nut (5/16-18) ................................................ 4

Hardware for Motor MountingPlate ................... 1

hex bolt (5/16-18 x 5/8 in.) ................................. 2

Xo

Hardware for Leg Stand, LevelingFeet, and

MountingSaw Base

Hardware for Leg Stand ..................................... 1

carriage bolt (5/16-18 x 3/4 in.) ........................ 24

flat washer (5/16 in.)......................................... 24

hex nut(5/16-18) .............................................. 24

Hardware for LevelingFeet ................................ 1

leveling foot ........................................................ 4

flatwasher (5/16 in.)........................................... 8

hex nut (5/16-18) ................................................ 8

Hardware for Belt Guard .................................... 1

hex nut (3/16-24) ................................................ 4

flat washer (3/16 in) ............................................ 4

W. Hardware forTable Extensions.......................... 1

hex bolt (5/16-18 x 1-1/4 in.) .............................. 8

flatwasher (5/16 in.) ......................................... 16

hex nut (5/16-18) ................................................ 8

m

Hardware for MountingSaw Base ..................... 1

hex belt (5116-18 x 1/2 in.) ................................. 4

flat washer (5/16 in°)........................................... 8

hex nut (5116-18) ................................................ 4

Fig. 2 b

11 [IIRFrSMRIr TABLESAW31S.228310

Page 12

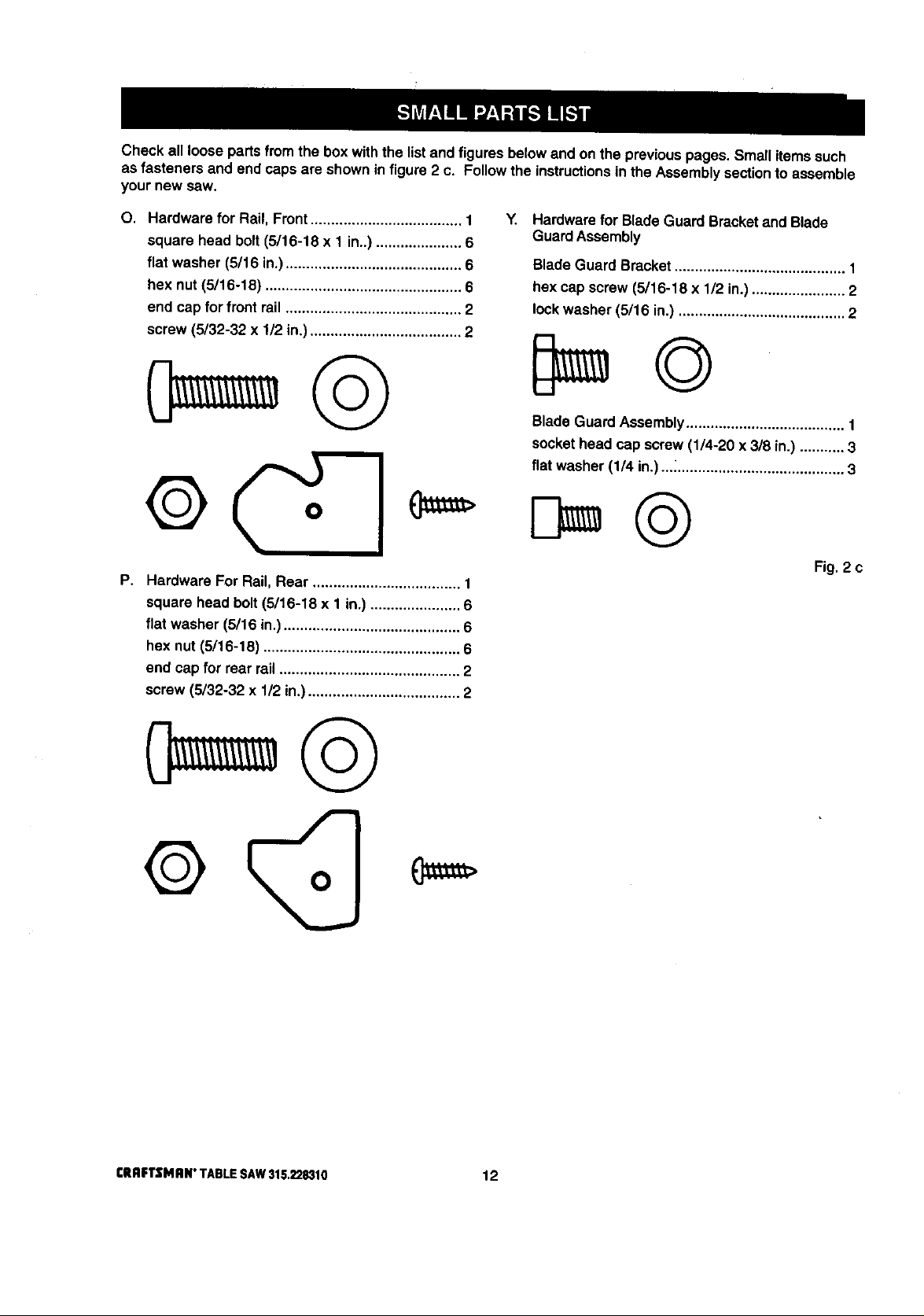

Check allloose partsfrom the box with the listand figuresbelowand on the previouspages, Small itemssuch

as fasteners and endcapsare shown in figure2 c. Followthe instructionsin the Assemblysectionto assemble

your new saw.

O. Hardwarefor Rail, Front..................................... 1

square head bolt (5/16-18 x 1 in..) ..................... 6

flat washer (5/16 in.) ........................................... 6

hex nut (5/16-18) ................................................ 6

end cap for front rail ........................................... 2

screw (5/32-32 x 1/2 in.) ..................................... 2

Y. Hardwarefor Blade GuardBracketand Blade

GuardAssembly

BladeGuard Bracket.......................................... 1

hex cap screw (5/16-18 x 1/2 in.) ....................... 2

lock washer (5/16 in.) ......................................... 2

©

F,

Hardware For Rail, Rear .................................... 1

square head bolt (5/16-18 x 1 in.) ...................... 6

flat washer (5/16 in.) ........................................... 6

hex nut (5/16-18) ................................................ 6

end capfor rear rail ............................................ 2

screw (5/32-32 x 1/2 in.) ..................................... 2

Blade Guard Assembly....................................... 1

socket head cap screw (1/4-20 x 3/8 in.) ........... 3

flat washer (1/4 in.) ..._......................................... 3

Fig. 2c

CRAFTSMAN"TABLESAW315.228310 12

Page 13

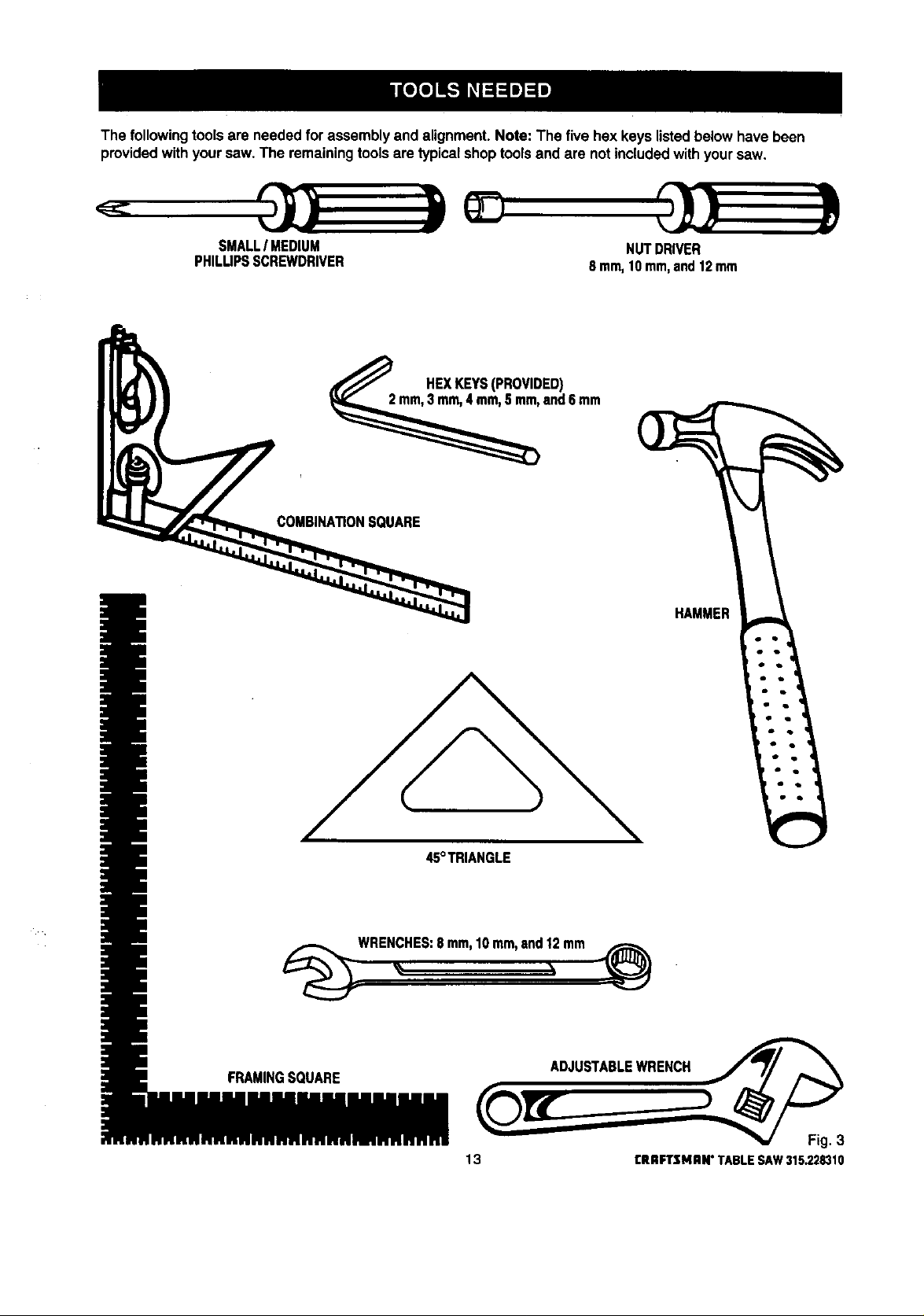

The followingtoolsare neededfor assemblyandalignment. Note: The fivehex keyslistedbelow have been

providedwith your saw.The remainingtoolsare typicalshoptoolsand are notincludedwithyour saw.

SMALLI MEDIUM

PHILUPSSCREWDRIVER

COMBINA_ONSOUARE

NUTDRIVER

8 mm,10mm,and12mrn

HEXKEYS(PROVIDED)

and6 mm

HAMMER

FRAMINGSQUARE

45°TRIANGLE

WRENCHES:8 mm,10mm,and12mm

ADJUSTABLEWRENCH

13 rRRFTSMRN"TABLESAW315.228310

Page 14

/

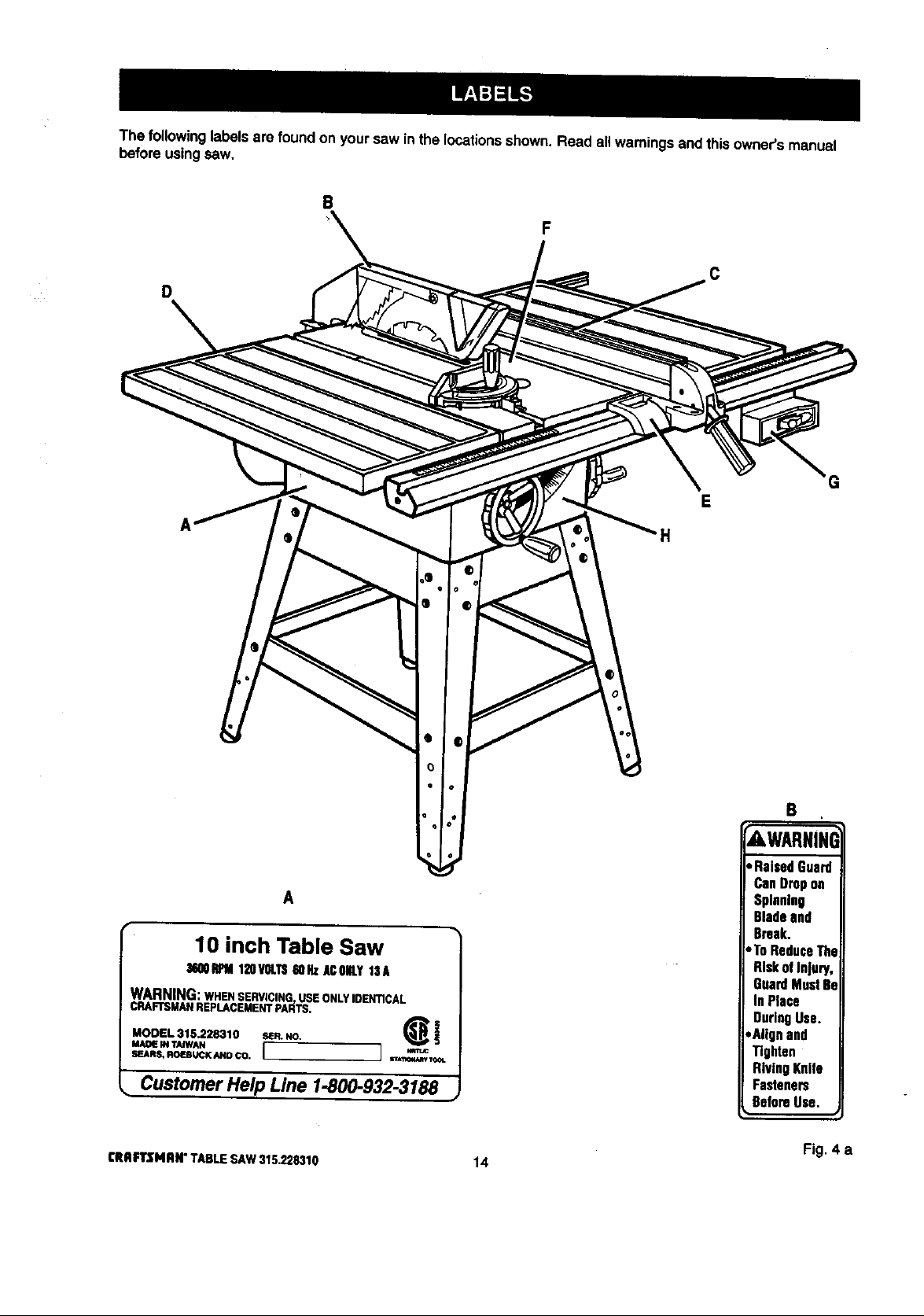

The followinglabelsare foundon yoursaw inthe locationsshown.Read allwarningsand thisowner'smanual

before using saw,

B

F

C

D

G

H

e

o

o

A

10 inch Table Saw

36QOIh_M120VOLTS60HzACONLY13A

WARNING:WHEN SERVICING, USE ONLY IDENTICAL

CRAFTSMANREPLACEMENTPARTS.

MODEL 315.228310 S_R.NO. _i

MAD_ IN TAJWAN

SEARS, ROEBUCK AND CO. i I

• Customer Help Line 1-800-932-3188 ,

CRAFTSMAN"TABLESAW315.228310 14

sr_l_4_ TOOL

B

AWARNINI

• RaisedGuard

CanDropon

Spinning

Bladeand

Break.

•ToReduceThe

RiskofInjury,

GuardMust81

InPlace

DuringUse.

,Alignand

Tighten

RivingKnife

Fasteners

BeforeUse.

Fig, 4 a

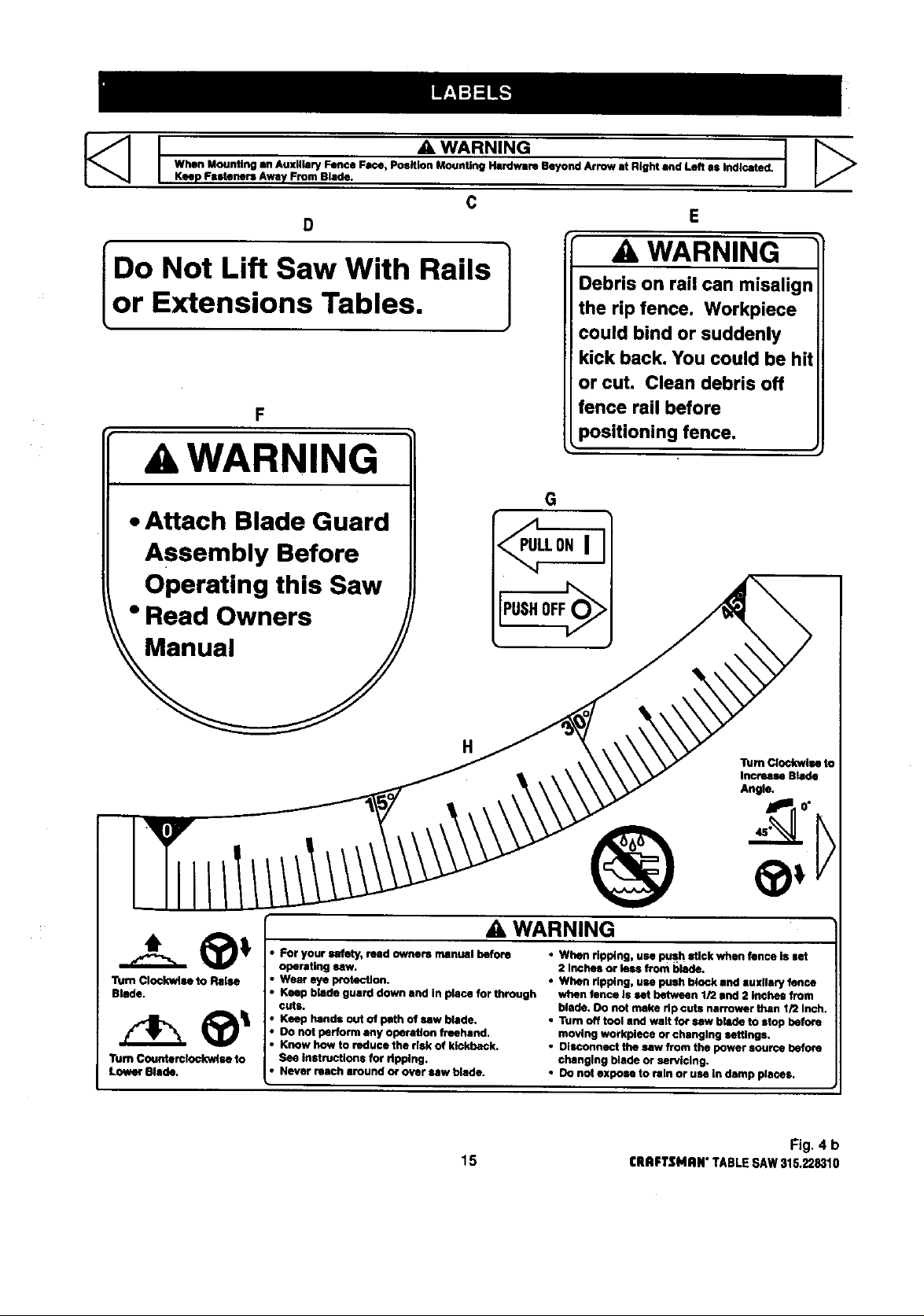

Page 15

When Mounting an Auxiliary Fence Face, Position Mounting Hardware Beyond Arrow at Bight and Left as Indicated.

I _ WARNING

Keep Fasteners Away From Blade.

C

D E

Do Not Lift Saw With Rails Debris on rail can misalign

I ] ,A,WARNING

Lor Extensions Tables. the rip fence. Workpiece

could bind or suddenly

kick back. You could be hit

or cut. Clean debris off

F

fence rail before

positioning fence.

A WARNING

G

• Attach Blade Guard

Assembly Before

Operating this Saw

• Read Owners

• For your safety, read owners manual before

Turn Clockwise to Raise

Blade.

"rumCounterclockwise to

Lower Blade.

operating saw.

• Wear eye p_otection.

• Keep blade guard down and In place for through

cuts.

• Keep hands out of path of saw blade.

• Do not perform any operation freehand.

• Know how to reduce the risk of kickback.

See instructions for ripping.

• Never reach around o¢ over/Niw blade.

,_LLONI

PUSHOFF

H

A WARNING

Turn Clockwise to

Increase Blade

Angle.

®

• When ripping, use push stick when fence is set

2 Inches or lees from blade.

• When ripping, use push block and auxllary fence

when fence Is set between 1/2 and 2 inches from

blade. Oo nut make rip cuts narrower than 1/2 Inch.

•Tum off tool and walt for saw blade to stop before

moving workplece or changing settings.

• Disconnect the saw from the power source before

changing blade or se_icing.

• Do not expose to rbln or use in damp places.

15 I:RRFTSMIIN"TABLESAW315.228310

Fig. 4 b

Page 16

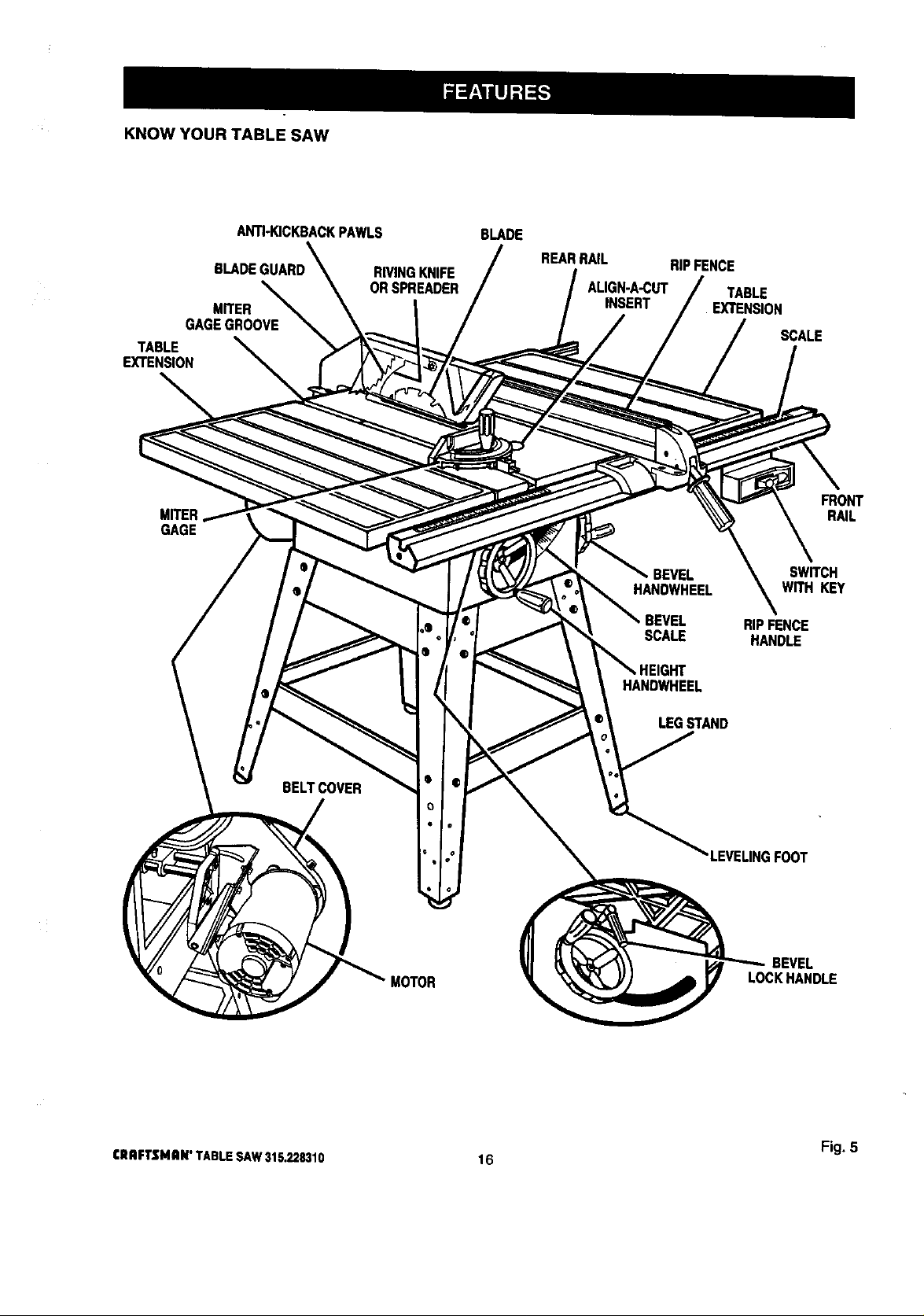

KNOW YOUR TABLE SAW

EXTENSION

TABLE

GAGE

ANTI-KICKBACKPAWLS

BLADE

MITER

GAGEGROOVE

BLADE

RIVINGKNIFE

REARRAIL RIPFENCE

ORSPREADER ALIGN-A-CUT TABLE

INSERT EXTENSION

BEVEL SWITCH

HANDWHEEL WITH KEY

RIPFENCE

SCALE HANDLE

HANDWHEEL

SCALE

FRONT

RAIL

BELTCOVER

MOTOR

CRAFTSMAN"TABLESAW315.228310 16

LEGSTAND

'LEVELINGFOOT

BEVEL

LOCKHANDLE

Fig. 5

Page 17

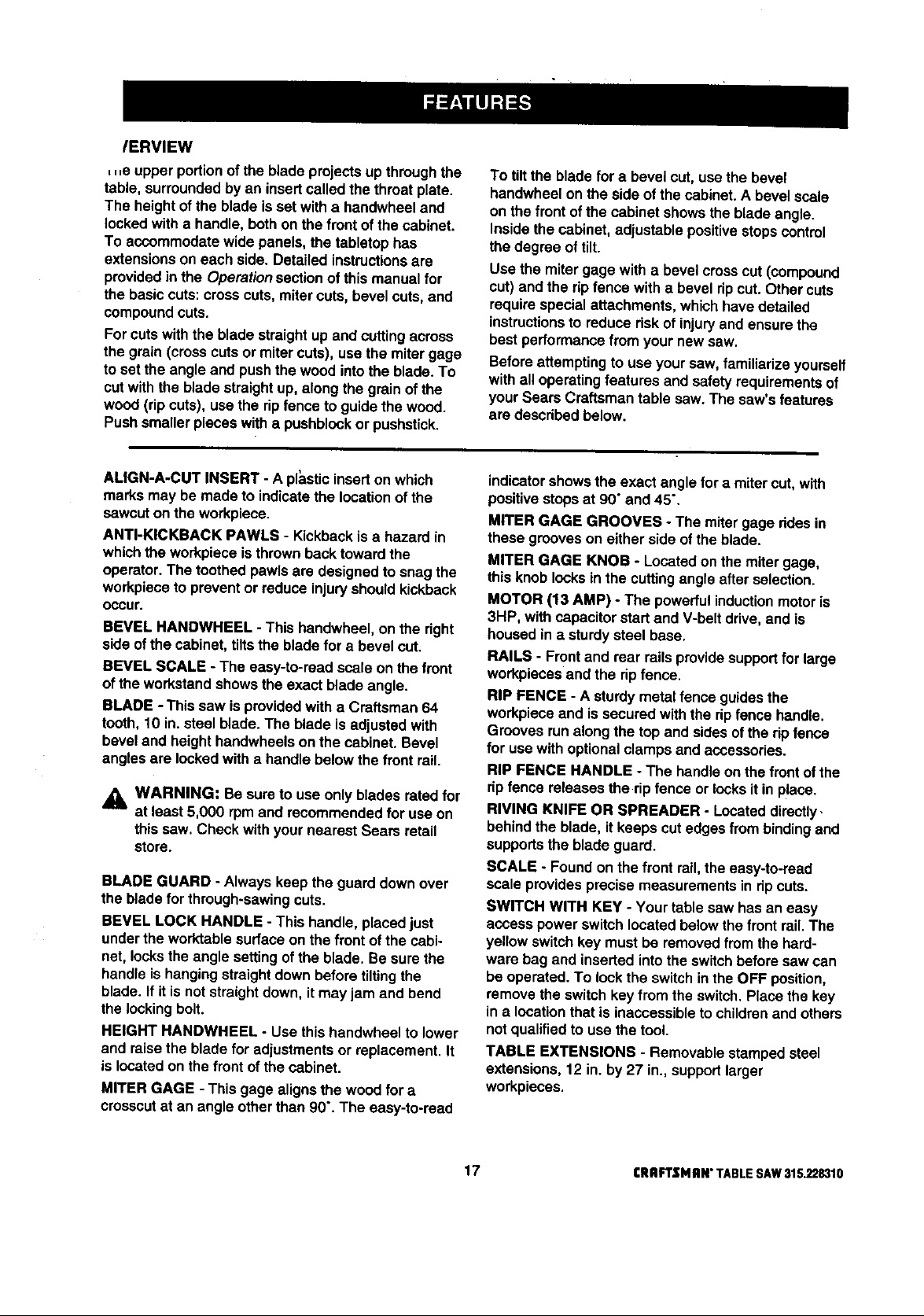

/ERVIEW

,,,e upper portionof the blade projectsup throughthe

table, surroundedbyan insertcalled thethroat plate.

The heightof the blade is set witha handwheel and

lockedwith a handle, both on the front of the cabinet.

To accommodatewide panels, the tabletop has

extensionsoneach side. Detailed instructionsare

providedinthe Operationsection of this manual for

the basiccuts:crosscuts,mitercuts, bevel cuts,and

compoundcuts.

Forcutswith the blade straightupand cuttingacross

the grain(cross cuts or mitercuts), use the mitergage

to set the angle and pushthe wood into the blade. To

cut with the blade straight up, along the grain of the

wood (rip cuts), use the ripfence to guide the wood.

Push smallerpieces with a pushblockorpushstick.

To tiltthe blade for a bevel cut, usethe bevel

handwheelon the side of the cabinet. A bevel scale

on the front of the cabinet showsthe bladeangle.

Insidethe cabinet, adjustable positivestopscontrol

the degree of tilt.

Use the miter gage with a bevel crosscut (compound

cut)and the rip fence with a bevel ripcut. Other cuts

requirespecialattachments, which have detailed

instructions to reduce risk of injury and ensurethe

best performance from your new saw.

Before attemptingto use your saw, familiarize yourself

withall operating features and safety requirements of

your Sears Craftsman table saw. The saw's features

are described below.

ALIGN-A-CUT INSERT - A pt_,sticinsert onwhich

marks may be made to indicate the locationofthe

sawcuton the workpiece.

ANTI-KICKBACK PAWLS - KickbackIs a hazard in

whichthe workpiece is thrownbacktoward the

operator. The toothed pawls are designedto snag the

workpieceto preventor reduceinjury should kickback

Occur.

BEVEL HANDWHEEL - This handwheel,on the right

side of the cabinet, tiltsthe blade for a bevel cut.

BEVEL SCALE - The easy-to-road scale on the front

ofthe work.standshowsthe exact blade angle.

BLADE -This saw is providedwith a Craftsman 64

tooth, 10 in. steel blade. The blade is adjustedwith

bevel and heighthandwheels on the cabinet. Bevel

anglesare locked with a handlebelow the front rail.

WARNING: Be sure to use onlyblades rated for

at least 5,000 rpmand recommended for useon

this saw. Check with yournearest Sears retail

store.

BLADE GUARD - Always keepthe guard down over

the bladefor through-sawingcuts.

BEVEL LOCK HANDLE - This handle, placedjust

under theworktable surfaceonthe frontof the cabi-

net, locksthe anglesettingof theblade. Be surethe

handle is hangingstraightdownbeforetiltingthe

blade. If itis notstraightdown, it may jam and bend

thelockingbolt.

HEIGHT HANDWHEEL - Use thishandwheel to lower

and raise the blade for adjustmentsor replacement. It

is locatedonthe front of the cabinet.

MITER GAGE - This gage alignsthe wood for a

crosscutat an angle other than 90". The easy-to-road

indicator showsthe exact angle for a mitercut,with

positivestopsat 90" and 45".

MITER GAGE GROOVES - The miter gage ddes in

these grooves on either side ofthe blade.

MITER GAGE KNOB - Located on themiter gage,

this knoblocksinthe cuttingangleafter selection.

MOTOR (13 AMP) - The powerfulinductionmotor is

3HP, withcapacitorstartand V-belt drive,and is

housedina sturdysteel base.

RAILS - Front and rear railsprovidesupportfor large

workpiecesendthe ripfence.

RiP FENCE - A sturdy metalfence guidesthe

workpieceand is secured withthe rip fence handle.

Grooves run alongthe top and sidesof the ripfence

for usa withoptionalclampsand accessories.

RIP FENCE HANDLE -The handleon the front ofthe

rip fence releasesthe ripfence or locksitin place.

RIVING KNIFE OR SPREADER - Locateddirectly.

behindthe blade, itkeeps cutedges frombindingand

supportsthe blade guard.

SCALE - Found on the frontrail,the easy-to-road

scale providesprecise measurementsin dp cuts.

SWITCH WITH KEY - Your table saw has an easy

access power switchlocatedbelowthe front rail.The

yellowswitchkey mustbe removedfromthe hard-

ware bag and inserted intothe switchbefore saw can

be operated. To lockthe switchinthe OFF position,

remove the switch key fromthe switch. Place the key

in a locationthatis inaccessibleto childrenand others

notqualifiedto use the tool.

TABLE EXTENSIONS - Removablestampedsteel

extensions,12 in.by 27 in., supportlarger

workpieces,

17 CRAFTSHAN"TABLESAW315.228310

Page 18

Assembly is best done inthe area where the saw will be used. When you remove the table saw base, loose

parts, and hardware fromthe packingmatedals, check allitemswith the looseparts listand drawing. Ifyou are

unsure about thedescriptionof any part, referto the drawing. Ifany parts are missing,delay assemblinguntil

you have obtainedthe missingpart(s).

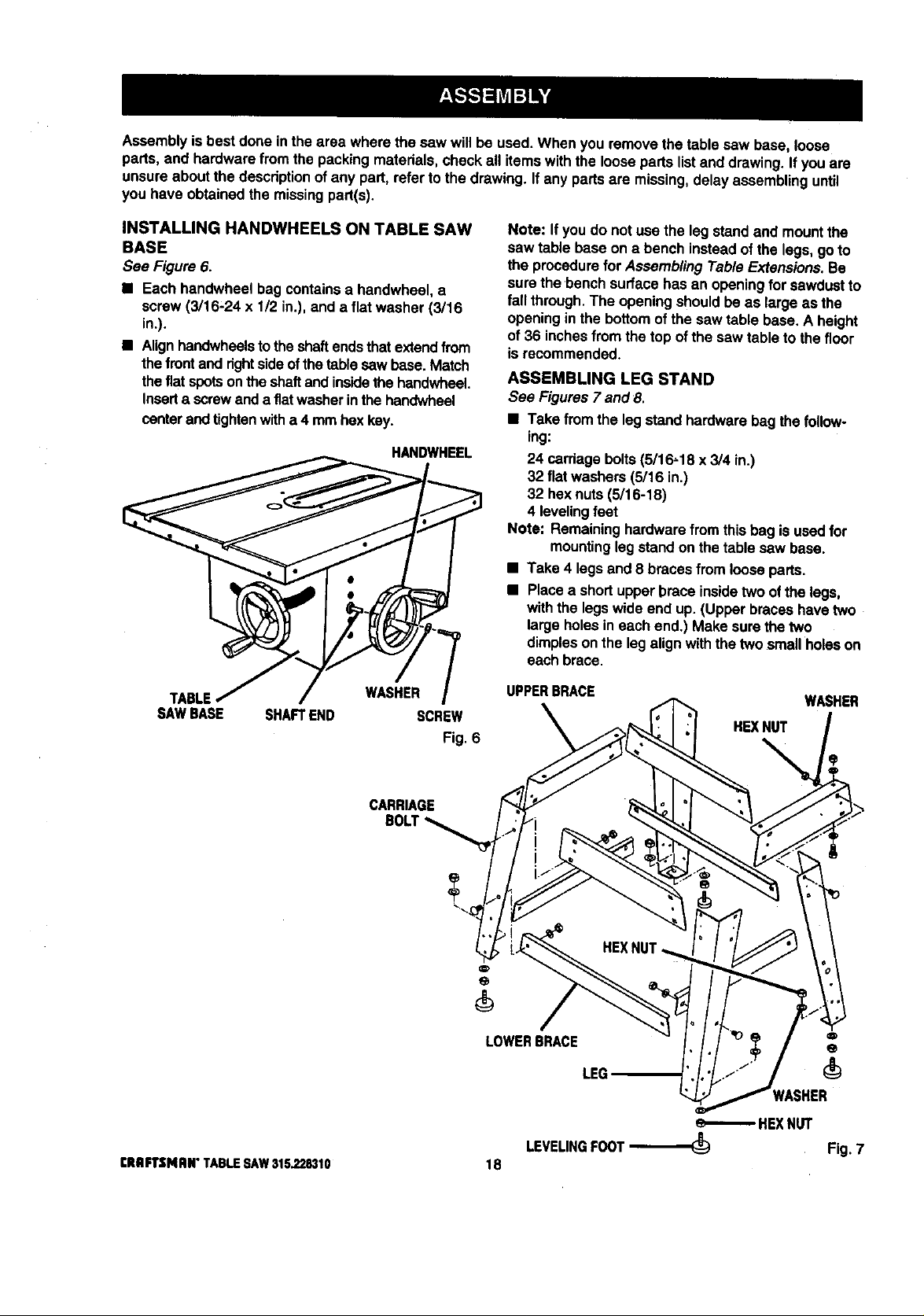

INSTALLING HANDWHEELS ON TABLE SAW

BASE

See Figure 6.

• Each handwheel bag containsa handwheel,a

screw (3/16-24 x 1/2 in.), and a flat washer (3/16

in.).

• Alignhandwheelstotheshaftendsthatextendfrom

thefrontandrightsideofthetable sawbase. Match

thefiatspotsonthe shaftandinsidethe handwheeL

Inserta screwanda fiatwasherin thehandwheel

centerandtightenwitha 4 mmhex key.

HANDWHEEL

Note: Ifyou do not usa the legstand and mountthe

saw tablebase ona bench instead ofthe legs, goto

the procedurefor Assembling TableExtensions. Be

sure the 'bench surfacehas an openingforsawdustto

fall through.The opening shouldbe as large as the

opening in the bottomof the saw table base, A height

of 36 inchesfromthe top of the saw table to the floor

is recommended.

ASSEMBLING LEG STAND

See Figures 7 and 8.

• Take fromthe legstandhardware bag the follow-

ing:

24 carriagebolts(5/16,18 x 3/4 in.)

32 flatwashers (5/16 in.)

32 hex nuts(5/16-18)

4 levelingfeet

Note: Remaininghardwarefromthisbagis usedfor

mountingleg standonthe tablesaw base.

• Take 4 legsand 8 bracesfromloose parts.

• Place a shortupperbrace insidetwo of the legs,

withthe legswideend up.(Upper braceshavetwo

largeholesin each end.) Make sure the two

dimplesonthe leg alignwith thetwo small holes on

each brace.

TABLE WASHER

SAWBASE SHAFTEND SCREW

CARRIAGE

[RRFTSMIIN" TABLESAW315,228310

Fig. 6

UPPERBRACE

HEXNUT

%

LOWERBRACE

LEG

HEXNUT

LEVELINGFOOT_ Fig. 7

18

WASHER

Page 19

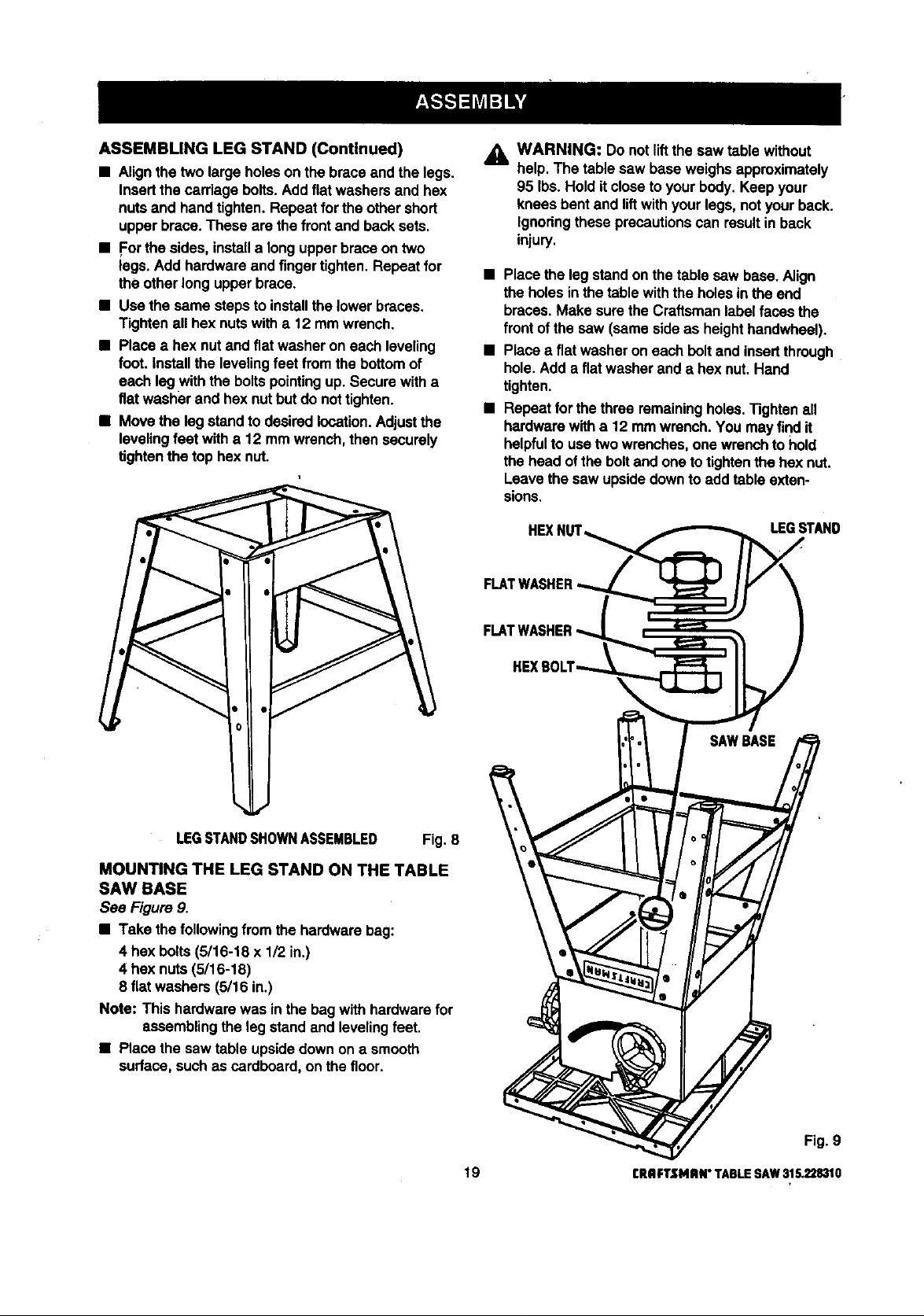

ASSEMBLINGLEGSTAND(Continued)

• Alignthetwo large holeson the brace and the legs.

Insertthe cardage bolts.Addflatwashersand hex

nuts and hand tighten. Repeat forthe other short

upper brace. These are the frontand backsets.

• For the sides,installalong upperbraceon two

legs.Add hardware and fingertighten.Repeat for

the other long upperbrace.

• Use the same steps to installthe lowerbraces.

Tightenall hex nutswith a 12 mm wrench.

• Place a hex nut and flat washer on each leveling

foot.installthe levelingfeet fromthe bottomof

each legwith the boltspointingup.Securewitha

fiatwasher and hex nutbut do nottighten.

• Move the leg standto desiredlocation.Adjustthe

levelingfeet witha 12 mmwrench, then securely

tightenthe top hexnut.

_k WARNING: Do notliftthe saw table without

help. The table saw base weighs approximately

95 Ibs.Hold it closeto yourbody. Keep your

kneesbent and liftwith your legs, notyourback.

Ignoringthese precautionscan resultin back

injury.

• Place the legstandon the table saw base. Align

the holes inthe tablewith the holesin theend

braces.Make surethe Craftsman labelfaces the

front ofthesaw (same sideas heighthandwheel).

• Place a flat washeron each bolt and insertthrough

hole. Add a flat washerand a hex nut.Hand

tighten.

• Repeat for thethree remainingholes.Tighten all

hardwarewitha 12 mmwrench.You may find it

helpfulto usetwo wrenches,onewrenchtohold

the head of the boltand one to tightenthe hex nut.

Leavethe saw upsidedownto add table exten-

sions.

HEXI, LEGSTAND

LEGSTANDSHOWNASSEMBLED Fig. 8

MOUNTING THE LEG STAND ON THE TABLE

SAW BASE

See Figure 9.

• Take thefollowingfrom the hardwarebag:

4 hex bolts(5/16-18 x 1/2 in.)

4 hex nuts (5/18-18)

8 flatwashers (5/16 in.)

Note: This hardwarewas inthe bagwithhardwarefor

assemblingthe legstand and levelingfeet.

• Place the sawtable upsidedownon a smooth

surface,such as cardboard, on thefloor.

Fig. 9

19 CRAFTSMRN"TABLESAW315.228310

Page 20

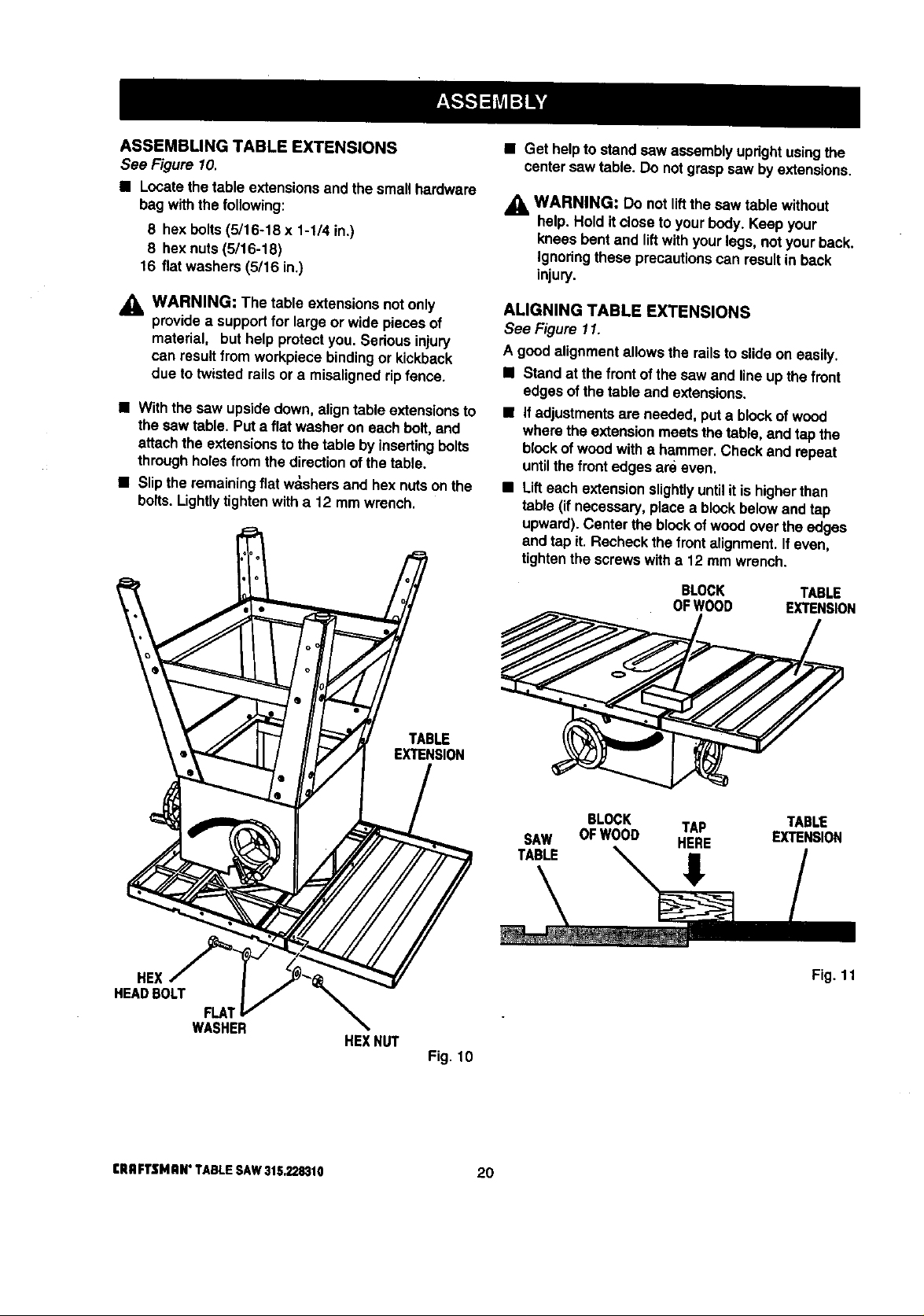

ASSEMBLING TABLE EXTENSIONS

See Figure 10.

• Locatethetable extensionsand the smal_hardware

bag withthe following:

8 hex bolts(5/16-18 x 1-1/4 in.)

8 hex nuts (5/16-18)

16 fiatwashers (5/16 in.)

• Get help to standsawassemblyupdghtusingthe

centersawtable. Do notgraspsaw by extensions.

_i, WARNING: Do not lift the saw table without

help. Hold it closeto yourbody. Keep your

kneesbent and liftwithyour legs, not your back.

Ignoringthese precautionscan resultin back

injury.

,_ WARNING: The table extensions notonly

providea supportfor large orwide pieces of

material, but help protect you.Serious injury

can result from workpiece bindingor kickback

due to twisted rails or a misaligned rip fence.

• With the sawupsidedown, align table extensionsto

the sawtable. Put a flat washer on each bolt,and

attachthe extensionsto thetable byinsertingbolts

throughholes from thedirectionofthe table.

• Slipthe remaining flat w_shers and hex nuts on the

bolts. Lightly tighten with a 12 mm wrench.

TABLE

EXTENSION

ALIGNING TABLE EXTENSIONS

See Figure 11.

A good alignment allowsthe railsto slideon easily.

• Standat the frontof the saw and line up the front

edgesof thetable and extensions.

• ifadjustmentsare needed, puta blockof wood

wherethe extensionmeetsthe table, and tap the

blockof woodwith a hammer.Check and repeat

untilthe frontedgesare even.

• Lifteach extensionslightlyuntilit is higherthan

table (if necessary,placea blockbelowand tap

upward).Center the blockof wood overthe edges

and tapit. Recheckthe front alignment.Ifeven,

tightenthe screwswith a 12 mm wrer,_h.

BLOCK TABLE

OFWOOD EXTENSION

HEX

HEAD BOLT

FLA;

WASHER

HE](NUT

Fig. 10

eRRFTSMRI_ TABLESAW3152.28310 20

SAW

TABLE

BLOCK TAP TABLE

OFWOOD HERE EXTENSION

Fig. 11

Page 21

INSTALLING THE REAR RAIL

See Figures 12- 14.

SQUARE

HEADBOLTS

,_ WARNING: Frontand rear railsmustbe

installedand carefullyalignedto reduce the risk

of kickback. Kickbackcan resultin seriousinjury.

• Fromthe carton,removethe rearrail andthe

followinghardware:

6 squarehead bolts(5/16-18 x 1 in.)

6 flatwashers (5/16 in.)

6 hex nuts(5/16-18)

Right and leftend caps for rear rail

2 screws(5/32-32 x 1/2 in.)

Note: Remaininghardware from thishardware bag is

used for installingthe front rail and end caps.

• At the back of the table, put the square head bolts

inthe holesin theedge of the table and extensions

so the boltheadsextendoutward 1/2 in.

• Underthe table, looselyattach washers and hex

nutsontobolts.Slidethe sloton the rearrail over

the bolts.Adjusteach boltto fit the railcloselyto

the table.

• Positionrailsothat righthandedge extends 2-1/2

inchesbeyondtable extension.

• Pushthe railagainsttable and tighteneach nutwith

a 12 mmwrench.

• Ifthe railjams and does notslideeasily over the

bolts,re-alignthe table extensions.

• Putthe end caps onthe rail ends. Insertthe screws

and tightenwitha phillipshead screwdriver.

NUT

FLAT

WASHER

TABLE

REARRAIL

Fig. 13

SLOT

REARRAIL

EXTENSION

SQUARE HEXNUT

HEADBOLTS FLAT

WASHER Fig. 12

TABLE

ENDCAP

SCREW

REAROF SAW Fig. 14

21 CRRFTSNAN" TABLE SAW 315.228310

Page 22

INSTALLING THE FRONT RAIL

See Figures 15and 16.

• Getthe front rail the switchassembly, and the

followinghardware:

6 squarehead botts(5/16-18 x 1 in.)

6 fiatwashers (5/16 in.)

6 hex nuts (5/16-18)

2 screws(1/4-20 x 3/8 in.) (locatedon switch plate)

2 squarenuts (1/4-20) (located on switchplate)

Rightandleft end capsfor front rail

2 screws(5/32-32 x 1/2 in.)

• Set aside end capsand screwsuntilyouhave

alignedthe dpfence and front rail.

• Insertthe six square head boltsintothe tableand

extensions,so the boltheads extend outward 112

in.

• Looselyattach a washer and a hex nut to each bolt.

• The back of the rail hastwo slots.Slidethe upper

slotoverthe bolts. (Bottomslotisfor switch.)

• Alignthe railleft to fight- Matchthe 7-1/8 in. mark

on the dghtscale tothe dghtedge of the table saw

base (main table). See Figure 16.

• Snugthe rail against table. Finger-tighteneach nut

onthetable and extensions.

• Locatethe switchassembly.The two screws are

installedthroughthe backofthe switchplate with

thesquarenuts extendingouttowardthe front.

Note: The square nutsare loose on the switchplate.

• Slidethesquare nuts intothe lower slotof therail.

• Slidetheswitchassemblytoa convenientposition,

leavingample clearancefor the haedwheeLTighten

securelywitha screwdriver. Do nottightenthe rail

bolts.

SOUARE

HEADBOLTS

TABLE

EXTENSION

SCALE

FRONTRAIL

HEXNUT

FLAT

WASHER

Fig.!5

ENDCAP

SCREW

A_ WARNING: Place the switchoutof the

immediatework area to avoidaccidentally

turningitoffdudng operation.

TABLE

EXTENSION

_IRIn.MARK

R_HTBCALE

TABLE

TABLE

EXTENSION

SWITCH.

WITHKEY

Page 23

ALIGNINGTHERIPFENCEANDFRONTRAIL

See Figures 17and 18.

The ripfence scale indicatoris installedonthe right

side ofthe rip fence but can be removedand rein-

stalledon the left side if needed. If a cuttingoperation

requiresplacing the ripfence on the left side ofthe

blade, andyou find relocatingthe scale indicator

necessary,simplyunscrewand re-attach it.

• Hookthe backof the ripfenceover the rear rail.

Lowerthe frontof therip fence intothe grooveon

thefrontrail.

• Slidethe ripfence backandforth. It should move

freely withabout 1/16 in.clearance between the rip

fence and table surface. If itdoesn't,loosenthe

nuts holdingthe front rail and adjust it up or down.

• Remove the rip fence and repeat on other side of

the blade. When the fence rides smoothly,

tighten all rail hex nuts with a 12 mm wrench.

• Attachthe end caps and s_rews witha phillips

screwdriver.

NCE

MOUNTING THE MOTOR

See Figure 19.

• Locatethe motorassembly,the motor mounting

plate and the followinghardware:

4 hex bolts (5/16-18 x 1 in.)

8 flat washers (5/16 in,)

4 lockwashers(5/16 in.)

4 hex nuts(5/16-18)

2 hex bolts(5/16-18 x 5/8 in.)

Note: Remaininghardwarefromthis bag isused for

installingthe belt guard.

• Release the bevellock handle (frontof cabinet)

and turnthe bevel handwheel (sideof cabinet) until

the blade isfullyvertical. Retightenthe bevel lock

handle.

• Alignthe holes inthe motormountingplate and the

motorbracketso thetop edges are even. Place a

flat washer on the 1 in. boltsand insertintothe

holes.

• Installa flatwasher, lockwasher, and a hex nut on

each belt. Hand tightenonly.This isthe motor

supportassembly.

• Center the motorsideto sideon themotor mount-

ingplate.Tighten the nutswitha 12 mm wrench.

• Insertthe two rodsonthe motorsupportassembly

intoholesin the cradle.Pushthe motor in as far as

itwillgo. Threadthe two hexboltsintothe cradle

to clamp down on the rods.Do not securely

tighten bolts yet.

oo

TOINSTALL

SCALEINDICATOR

ONLEFT

REARRAIL Fig. 17

RIPFENCE

FRONTRAIL

Fig. 18 Fig. 19

HEXBOLTS

RODS

MOTOR

BRACKET

1 In.HEXBOLTS

23 CRRFTSNRN"TABLESAW315.228310

MOTOR

ASSEMBLY

WASHER

Page 24

INSTALLINGTHEBELTANDBELTGUARD

See Figures20 and 21.

• Getthe belt, belt guard, 4 flatwashers(3/16 in.)

and 4 smallhex nuts (3/16-24).

• Lowerthe bladeby turningthe heighthandwheel.

• Slipthe belton the saw pulley(insidecabinet). Lift

the motorforwardand place the belt on the motor

pulley.

• Checkthatthe beltis straightand both pulleysare

aSgned. If not, adjustthe motoron the motor

supportassembly. Referto MountingtheMotor.

• Raisethe saw blade all the way up.

• Pullthe motorout untilthebelt istaut. Securely

tightenthe hex boltsabove the rodswitha 12 mm

wrench.

• Putyourhandaroundthe belthalfwaybetween the

two pulleysand squeeze the be_tuntil bothsidesof

the belt touch.The motorshouldmove freelyas

you squeeze the belt. If i_doesnot,loosenthe hex

boltsand readjustthe belttension.

• Lowerthe bladewith the heighthandwheel.Liftthe

motorforwardand remove the belt.

• Openthe hinged belt guard and place it over the

motorscrews on the motorpulley. Secure withfiat

washers and hex nuts.Securelytightenthe hex

nuts witha 10 mm wrench.

• Replace the belt and snap the guardclosed.

• Checkthe clearances byindexingthe blade.Turn

the bevel hendwheel to 45" and back. Usethe

heighthandwheelto fully lower and raise the blade.

SAWPULLEY

BELT

BELTI

Fig. 21

CHECKING THE THROAT PLATE

See Figure22.

j_ CAUTION: The throatplate mustbe even with

the table surface. If itistoo highor too low,the

workpiece can catchon unevenedges and

cause kickback.

• Make surethe throatplate is flush withthe table

top.To change heightofthethroat plate, loosenthe

flathead screwthatsecuresthethroatplate and

adjustthe four setscrewswitha 2 mm hex key. Do

not allow the throatplate to bow up above the table

surface.

MOTORSUPPORT

ASSEMBLY

MOTORSCREWS

rRRFTSMRN"TABLESAW315,228310

MOTOR

Fig. 20

2mm

HEXKEY SETSCREW

TABLETOP

HEIGHT

HANDWHEEL

BEVEL

HANDWHEEL

24

FRAMINGSQUARE

IROATPLATE

Fig. 22

Page 25

INSTALLING THE BLADE GUARD

See Figures23 - 25.

WARNING: Ifthe blade isnot fully lowered, tum

the heighthandwheel to lowertheblade to

preventinjury.

• Locatethe blade guard,the blade guardbracket,

and the followinghardware:

2 hex bolts(5/16-18 x 1/2 in.)

2 lockwashers (5/16 in.)

3 sockethead screws(1/4-20 x 3/8 in.)

3 fiatwashers (1/4 in.)

• Alignthe lower end of the blade guard bracketand

the threaded holes of thecradle and insertthe hex

boltsand _ockwashers.Securely tk3htanwith a 12

mm wrench.

• Remove the throat plate. See page 32.

• Put the bladeguard assemblyin place on the table

top,aligningthe screw holes inthe rivingknifeto

the holesin the bracket. Alignthe hole inthe front

of the rivingknifebase withthe screw hole in the

saw table.

Note: The screwhole is located undertheslot in back

ofthe throat plate.

• Inserttwo socket head screws and two flat washers

inthe two holesat the beckofthe dyingknifebase.

Securelytightenwith a 5 mmhex key.

• Insertthe thirdsockethead screwand flat washer

intoscrewhole in saw table underthroatplate.

Securelytightenwith a 5 mmhex key.

• Replacethe throatplate.

SOCKET

HEADSCREWS

FLM

WASHER

SOCKET

HEADSCREW

FLAT

BLADE

Fig. 24

BLADE

RIVING

KNIFE

BLADE

GUARD

BRACKET

LOCK

WASHER

HEX

_NTI-KICKBACK

PAWLS

Fig. 25

Fig. 23

25 CRRFTSNnN"TABLESAW315.228310

Page 26

ALIGNINGTHERIVINGKNIFEWITHTHE

BLADE

See Figures26 - 28.

BLADEGUARD

_l, WARNING: Make sure the switchis off, the

switchkeyis removed,and yoursaw is

unplugged.Failure to do so could result in

accidental starting, causing serious personal

injury.

The rivingknife must be alignedwithend centered

overthe blade.

_I, WARNING: It is importantto installand adjust

the riving knifecorrectly.Poor alignment could

cause kLckbackand throw the workpiece at the

operator.

• Raisethe blade guard.

• Placea framing squareor straightedgebesidethe

bladeon the left. See Figure26.

• Loosen the front screw on the riving knife with a

5 mm hex key. See Figure 27.

• Center the rivingknifeoverthe blade.See Figure

28.

• Securelytightenthe screwwitha 5 mm hex key.

RMNGKNIFE

BLADE

RIVINGKNIFE

BLADE

/

Fig. 27

RIVINGKNIFE

SAW

TABLE

FRAMINGSQUARE Fig. 26

rRIIfTSMRN" TABLESAY/315.22S310 26

I

/

FRAMING

SQUARE

BLADE

TOPVIEWOFSAWWITHRIVING

KNIFESHOWNCENTEREDOVERBLADE

/

_ROAT

PLA_

Fig. 28

Page 27

CHECKING RIP FENCE AND BLADE

ALIGNMENT

See Figures29 - 31.

The ripfence is self-aligningbut shouldbe checked

before first use.

_, WARNING: Failure to align the ripfence to the

blade can causejams and kickback,resultingin

seriouspersonal injury.

• Slidethe ripfence to the mitergage groove,which

isparallelto blade. Do not lockthe rip fence.

• Place a framing square againstthe blade,with the

longendunderthe ripfence. Note the distance.

• Movethe square tothe back and measure the

lengthfrom the other end of the fence.

• Ifthe distancesare different, loosenthefour screws

aroundthe ripfence handlewitha 6 mmhex key.

Alternatethe order (loosenthe screwopposite,not

nexttothe first one).

• Holdthe fence handle againstthe front railand

alignthe ripfence withthe blade.

• Retightenthe screws in alternatingorderand check

thealignment.

• Repeat untilthe rip fence is aligned.

BLADE

MITERGAGE

GROOVE

RIPFENCE

FRAMING

SOUARE

Fig. 30

RIP FENCE

To completeassemblyof the saw, plugthe motorcord

intothe back of the switch.Run the cordaroundthe

side of the cabinet. Secure itto the side of the cabinet

withthe cordclipand screwprovided. Use care with

thecord around sharpedges. Your saw is now set up

toprovideyears of highqualityperformance.

RIPFENCE

MITERGAGE

GROOVE

BLADE

FRAMING

SQUARE

€

Fig. 29

RIPFENCEHANDLE Fig. 31

Note: To insureproperselfalignmentwhen positiOn-

ingripfence, push sidesofscale indicator

housingagainstfront railbefore lookingrip

fence handle.

27 CRaFTSMRN"TABLESAW315.228310

Page 28

To avoid unnecessarysetupsand adjustments,a

goodpracticeisto check yoursetupscarefullywith a

framing squareand make practicecuts inscrapwood

beforemakingfinish cuts in goodworkpieces.Do not

startany adjustmentsuntilyou have checkedw_tha

squareand made test cuts to be sure adjustmentsare

needed.

REPLACING THE BLADE

See Figures32 - 34.

_1, WARNING: Make surethe switchis off,the

switchkeyis removed,and yoursaw is

unplugged.Failureto doso could result in

accidentalstarting,resultinginseriouspersonal

injury.

• Raise the blade guard and remove the throat plate.

TOremove, loosenthe screwat the frontwitha

phillipsscrewddverand I!ftthe front end. Pullitout

towardthe front end.

• Raise the blade to itshighestpositionby turning

the height handwheel clockwise.Angle the blade

straightup by looseningthe bevel lockhandle and

turningthe bevel handwheet.Wedge a piece of

scrapwood againstthe frontof the blade. See

Figure32.

• Loosenthe blade nut withthe bible wrench

providedwithyour saw. Remove the blade nut and

bladewasher. Carefully remove the scrap wood

and blade.

• To replacethe bladewith an accessoryblade,

follow the instructionsprovidedwiththeaccessory.

• To install a standard blade, place the newblade on

thearbor shaft,withteeth pointing downtowardthe

front of thesaw, Wedge a pieceof scrap woodat

the back of the blade. See Figure34.

T0

LOOSEN

BLADE

SCRAPWOOD

BLADE

GUARD

BLADE

I

BLADE

BLADE

WASHER

I

/

BLADEHUT

CAUTION: The teeth mustpointdowntoward

thefrontof the saw towork properly.Otherwise,

damage to the blade, saw, or workpiececan

occur.

• Place the bladewasher and the blade nut over

the blade arbor. Be sure thedome side of the

bladewasher faces out from the blade and that

all items are snug againstthe arbor housing.

Tightensecurely.

• Remove the scrapwood and rotate the blade by

handto make sure it turns freely.

• Slipthethroat plateintothe openingandpushit

towardtheback of thesaw to engage the spring

clip,Securelytightenthe screw. If thethroatplate

isnotflush withthe table,adjustthe setscrews

with a 2 mrn hex key. [3o not allow the throat

plateto bow up above the table surface.

[RRFTSMRW TABLESAW$15.2283t0 28

ARBORSHAFT

/

Fig. 33

Page 29

SCRAPWOOD

BLADEGUARD

FRAMINGSQUARE

BLADE

TOTIGHTEN

BLADENUT Fig. 34

HEELING (PARALLELING) THE SAWBLADE

TO THE MITER GAGE GROOVE

See Figures 35 - 37.

DO NOT loosen any screws for this adjustment

until you have checked with a square and made

test cuts to be sure adjustments are necessary.

Once the screws are loosened, these Items must

be reset.

_k WARNING: Make sure the switchis off, the

switchkeyis removed,and your saw is un-

plugged.Failureto doso couldresult in acciden-

tal starting, resultingin seriouspersonalinjury.

_l, WARNING: The sawblade mustbe parallelto

the mitergage groove so the wood does not

bind,resultingin kickback.You couldbe hitor

cut.

• Liftthe blade guard.Raise the blade all the way by

turning the height handwheel.

• Mark one of the sawblade teeth at the front of the

blade. Place a framing square beside the blade and

just touching the marked tooth. Measure the

distance to the right miter gage groove.

• Turn the sawblade so the marked tooth is at the

back.

• Move the square to the rearand again measurethe

distanceto the rightmitergagegroove. If the

distancesare the same, the blade and the miter

gage groove are parallel.

NUT

WASHER

/

MITERGAGEGROOVE

(_ FRAMING

SQUARE

f

MITERGAGEGROOVE

• Ifthe distancesmeasuredare different,adjustthe

mechanismunderneaththesaw.

j_ WARNING: When reaching under the saw

table, wear glovesor firstremove the blade.

Accidentalcontactwith the blade couldcause a

cut resultingin seriouspersonalinjury.

• Remove thethroat plate by loosening the front

screwwitha phillips screwdriver.Liftthe throat

plateand pull itout by the front end.

• Lowerthe blade completelywiththe height

handwheel.Youcan thenaccess thetable brackets

throughthethroatplate opening.

• Fromthe back,loosenthethree rear screws

holdingreartable bracketusinga 12 mm wrench.

• Ifthe toothwas too far from the square's blade,

movethe rear brackettowardthe mitergage

groove.Tap with a blockof wood and hammer.

Fig. 35

Fig. 36

29 CRRFTSNRN"TABLESAW315.228310

Page 30

• If thetoothwas too close tothe square,backthe

bracket away withthe block of woodand hammer.

• Tightenthe screws,raise the blade and recheck.

• Repeat untilblade is parallel to mitergage groove.

• If the blade Is not parattel,adjust the front table

bracket.Tilt the blade to45" with the bladelock

handleand bevel handwheel.

• From the back of the saw, toosenthe bolts holding

the front table bracket,as well as the reartable

bracket.

• Repositionthe bladeto 90"with the bevel hand-

wheel and blade lock handle.

• Lowerthe blade and movethe bracketsas needed.

Retightenall bracket screws.

• Raise the blade and recheck. Repeat untilthe

bladeis parallelto the miter gage groove.

• Place the throatplate in the openingand pushit

towardthe rearof saw baseto engage the spring

clip.

Note: The keyslotinthe throat plate willdrop overthe

frontscrew.

• Tightenthe screw. Do not allow the throat plateto

bow up above the table surface.

SAWTABLEVIEWFROMBELOW

REAR SAWTABLE

SETTING THE BEVEL STOPS AND INDICATOR

See Figures38 and 39.

,_ WARNING: Make sure the switchis off,the

switchkey is removed, and your saw is

unplugged.Failureto doso could result in

accidentalstarting,resultingin serious personal

injury.

The bevel scale shouldshow0" whenthe blade isset

verticalat 90" to table, and 45" when blade isat 45" tilt.

• Raise the blade all the wayup by turningthe height

handwheel. Liftthe bladeguard.

• Loosenbevel lookhandleand turnthe bevel

handwheelclockwiseto tiltthe blade, Reverse it

and turnthe handwheel counterclockwiseuntilit

stops.

• Check the blade angle witha combinationsquare.

Don't let the squaretoucha bladetooth.The blade

shouldbe at 90"and th_ scaleindicatorat 0".

Note: The scaleindicatoristhe plasticplateon the

scaleat thefront ofthe cabinet.

• Ifthe scale indicatordoes notpointto 0", loosenthe

scale indicatorwitha screwdriver,adjustit within

the s_ot,and retightenthe screw.

• If the bladeangle is wrong,adjustthe 90"stop

screw (left of the blade, lookingfrom the front). Start

byturningthe 90" stopscrewthreeor four turns

with a 4 mm hexkey.

TABLEBRACKET /

REAR

BRACKET

SCREW(S)

FRON

FRONT BRACKET

TABLEBRACKET SCREW(S)

90_STOPSCREW

45_STOPSCREW

4 mm

HEXKEY

Fig. 38

Fig. 37

• Turn the bevel handwhee]clockwiseonce, then

back counterclockwiseto square blade withtable.

• Tightenthe 90" stopscrewand recheckthatthe

blade is square in a 90" position,If not, repeat,

When theblade issquare, check the scale indica-

tor. If itis notat zero, resetthe scale indicatoras

before.

CRAFTSMAN*TABLESAW315.228310 30

Page 31

• Check the45" setting.Tiltthe bladewiththe bevel

handwheelas far as itwill go to the left.Place the

squareagainstthe blade (be surethe square is not

againstone ofthe saw teeth). Ifthe bladeisnot at

45", unscrewthe 45"stop screw(rightofblade),

turnthe handwheel untilthe blade iscorrect,and

tightenthe screw. Recheck and repeat if neces-

sary.

• Check thatthe scale indicatorisat 45°.

• If not, loosen the scale indicatorwith a screwdriver,

adjustitwithinthe slot,and retightenthe screw.

• Loosenknoband pullouton stoppinto rotatemiter

gage base paststop screws.

• Loosenthe locknutof the0" stop screw at the stop

pin witha 8 mm wrench.

• Place a 90" squareagainstthe mitergage rodand

the mitergage base.

• If the rodis notsquare, loosen theknob, adjust the

rod, and tightenthe knob.

• Adjustthe 0" stop screwuntilitrestsagainst the

stop pin.

• Adjustthe plus and minus45" stopscrewsusinga

45"tdangle and the stepsabove.

SCALE

INDICATOR

Fig. 39

ADJUSTING THE MITER GAGE

See Figure40.

You can set the mitergage at O"and plus or minus45"

withthe miter gage stop pin and adjustable stop

screws

Note: The mitergage providesclose accuracyin

angled cuts. For very cloSetolerances,test

cutsare recommended.

MITER

GAGEROD MITER

STOPSCREW

0° ADJUSTABLE

KNOB

GAGEBASE

STOPSCREW

LOCKNUT

STOPPIN

Fig. 40

31 rRRFTSMRN"TABLESAW315.228310

Page 32

REMOVING / REPLACING THE THROAT

PLATE

See Figure41.

,_ WARNING: Make surethe switch is off,the

switchkeyis removed,and yoursaw is

unplugged.Failureto do socould result in

accidentalstarting,resultingin sadous personal

injury.

• To removethe throat plate, firstloosenthe screw in

the throat platewith a phillipsscrewdriverand lift

the frontend. Pullitouttowardthe frontofthe saw.

• To re-installthethroat plate, placeIt inthe opening.

Push ittowardthe rear of saw base toengage the

spdngclip.

Note: The keyslotinthe throatplate willdropover the

screw.

• Check that the throat plate is even withthe table

top. If not, adjustthe foursetscrewswitha 2

mm hex key. See the procedureinthe Assam-

b/ysection.

• Socure_ytightenthroatplate screw. Do not allow

the throat plateto bowup above thetable surface.

THROATPLATE

KEYSLOT

SPRINGCLIP

TABLE

Fig. 41

CRIIFI3MAN" TABLESAW31tL_8310 32

Page 33

BASIC OPERATION OF THE TABLE SAW

A table saw can be used for straight-linecutting

operationssuchas crosscutting,ripping,mitering,

beveling,and compoundcutting.It can make dado or

moldingcutswith optionalaccessories.

The three-prongplug must be pluggedintoa match-

ingoutletthat is propeityinstalledand grounded

accordingto all localcodes and ordinances.Improper

connectionofthe equipment can resultin electdc

shock.Check with an electrician or service personnel

if you are unsure about proper grounding, Do not

modifythe plug;if it will notfit the outlet, have the

correctoutlet installed by a qualifiedelectrician.Refer

tothe Electricalpage of this manual.

Note: Thistable sew is designed to cut wood and

woodcompositionproductsonly.

CAUSES OF KICKBACK

Kickbackcan occurwhen the blade stallsorbinds,

kickingthe workpieceback toward you with great

force end speed, if yourhands are near the sewblade,

they may be jerked loose fromthe workpieceand may

contactthe blade. Obviously, kickbackcan cause

seriousinjury, and it is well worthusing precautionsto

avoidthe risks.

Kickbackcan be caused by any actionthat pinches

the blade in the wood, such as thefollowing:

• Makinga cut with incorrectblade depth

• Sawingintoknotsor nailsin the workpiece

• Twistingthe woodwhilemakinga cut

• Failingto supportwork

• Forcinga cut

• Cuttingwarpedor wet lumber

• Usingthe wrongblade for the type of cut

• Not following correct operatingprocedures

• Misusingthe saw

• Fai{ingto use the ant'vkickback pawls

• Cutting witha dull, gummed-up, orimproperlyset

blade

AVOIDING KICKBACK

• Always use the correct blade depth setting. The

top of the blade teeth should clear the workpiece

by 1/8 in. to 1/4 in.

• Inspectthe work for knotsor nailsbefore beginning