Page 1

Owner's Manual

PROFESSIONAL

10 in. Stationary

RADIAL ARM SAW

Model No.

315.220380

Save this manual for

future reference.

A CAUTION: Read and follow all

Safety Rules and Operating

Instructions before first use of this

product.

Customer Help Line: 1-800-932-3188

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

972000-505

12-98

• Safety

• Features

• Assembly

• Operation

• Maintenance

• Parts List

Page 2

WARRANTY

FULL ONE YEAR WARRANTY ON CRAFTSMAN RADIAL ARM SAW

If this CRRFTSMRN* Radial Arm Saw fails due to a defect in material or workmanship within one year from the

date of purchase, Sears will repair it, free of charge.

Contact a Sears Sen/ice Center for repair.

If this product is used for commercial or rental purposes, this warranty applies only for 90 days from the date of

purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 81 TWA, Hoffman Estates, IL 60179

INTRODUCTION

Your saw has many features for making cutting operations more pleasant and enjoyable. Safety, performance

and dependability have been given top priority in the design of this saw making it easy to maintain and operate.

CAUTION: Carefully read through this entire owner's manual before using your new saw. Pay close

attention to the Rules For Safe Operation, and all Safety Alert Symbols, including Danger, Warning and

Caution. If you use your saw properly and only for what it is intended, you will enjoy years of safe, reliable

service.

^ Look for this symbol to point out important safety precautions. It means attention!!! Your safety is

involved.

WARNING:

The operation of any power tool can result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before beginning power tool operation, always wear

safety goggles or safety glasses with side shields and a full face shield when needed. We

recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses

with side shields, available at Sears Retail Stores.

TABLE OF CONTENTS

Warranty and Introduction.................................................................................................................................. 2

Table of Contents.............................................................................................................................................. 2-3

Rules For Safe Operation....................................................................................................................................

Electrical................................................................................................................................................................

Product Specifications and Glossary..........................................................................................................-(0,11

Unpacking and Accessories........................................................................................................................... 11

...

...

Loose Parts List...............................................................................................................................................12-14

Tools Needed...................................................................................................................................................... 15

Labels............................................................................................................................................................. 16-17

Features

Assembly...........................................................................................................................................................22-36

Assembling Leg Stand........................................................................................................................................ 22

Mounting Saw to Leg Stand.................................................................................................................................23

CRRFTSMIlir RADIAL SAW 315.220380

.......

.................................................................................................................................................. 18-21

Page 3

TABLE OF CONTENTS

Attaching Elevating Handwheel......................................................................................................................................

Instaiiing the Yoke Assembly...........................................................................................................................................24

Removing the Blade........................................................................................................................................................25

Attaching Table Supports.............................................................................................................................................. 25

Setting the Arm Lock Knob..............................................................................................................................................26

Setting the Yoke Clamp...................................................................................................................................................26

Setting the Bevel Lock Lever..........................................................................................................................................

Tightening the Arm and Column......................................................................................................................................28

Adjusting the Column Tube........................................................................................................................................28-29

Adjusting the Carriage Bearings......................................................................................................................................30

Leveling the Table Supports

Installing the Front Table.................................................................................................................................................32

Leveling the Front Table..................................................................................................................................................33

Installing Rear Table, Spacer Table, Fence, and Clamps

Installing Blade and Blade Guard....................................................................................................................................34

Aligning Riving Knife to Blade

Installing Rip Scale Indicators..................................................................................................................................... 36

Adjustments................................................................................................................................................................36-42

Aligning the Arm for Cross Cuts...................................................................................................................................... 37

Aligning the Blade to Table at 0’ Bevel

Squaring Blade to Fence.................................................................................................................................................39

Paralleling Blade to Table................................................................................................................................................40

Aligning the Rip Scale Indicators................................................................................................................................ 41

Installing Control Cut Device................................................................................................................................... 42

.......................................................................................................................................... 31

..........................

........................................................................................................................................

..........................................................................................................................

...............................................................33-34

23

27

35

38

Operation....................................................................................................................................................................43-53

Basic Operation of the Radial Arm Saw

Types of Cuts...................................................................................................................................................................43

Switch and Switch Key................................................................................................................................................ 44

Causes of Kickback....................................................................................................................................................... 44

Avoiding Kickback............................................................................................................................................................44

Cutting Aids..................................................................................................................................................................... 45

Making a Cross Cut

Making a Miter Cut......................................................................................................................................................... 47

Making a Bevel Cut..................................................................................................................................................... 48

Making a Compound Cross Cut......................................................................................................................................49

Rip Cut Hazards and Precautions............................................................................................................................. 50

Setting Up a Rip Cut..................................................................................................................................................50-51

Making a Rip Cut.............................................................................................................................................................51

Making Other Cuts....................................................................................................................................................... 52

Cutting Long Workpieces............................................................................................................................................... 52

Non-Through Cuts....................................................................................................................................................... 53

Maintenance.................................................................................................................................................................. 54

Troubleshooting...................................................................................................................................................... 55-59

Exploded View and Repair Parts List.........................................................................................................................60-81

.................................................................................................................................................... 46

........

................................................................................................................. 43

Parts Ordering / Service.....................................................................................................................................

CROFTlMRir RADIAL SAW 315.220380

back page

Page 4

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

the explanations with them, deserve your careful attention and understanding. The safety warnings do

not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for

proper accident prevention measures.

SYMBOL MEANING

^ SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in conjunction with other symbols or

pictographs.

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

A WARNING: Failure to obey a safety warning can result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

^ CAUTION: Failure to obey a safety warning may result in property damage or personal Injury to

yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock

and personal injury.

Note: Advises you of information or instructions vital to the operation or maintenance of the equipment.

IMPORTANT

Servicing requires extreme care and knowledge of the

system and should be performed only by a qualified

service technician. For service we suggest you contact

your nearest Sears repair center. Always use original

factory replacement parts when servicing.

If you have questions about terms in the following

rules, refer to the Glossary of Terms for Woodworking

or the Features section.

READ ALL INSTRUCTIONS

■ KNOW YOUR POWER TOOL. Read the owner’s

manual carefully. Learn the saw's applications and

limitations as well as the specific potential hazards

related to this tool.

■ DO NOT USE IN DANGEROUS ENVIRONMENT.

Do not use power tools near gasoline or other

flammable liquids, in damp or wet locations, or

expose them to rain. Keep the work area well lit.

■ KEEP CHILDREN AND VISITORS AWAY. All

visitors should wear safety glasses and be kept a

safe distance from work area. Do not let visitors

contact the tool or extension cord while operating.

^ WARNING: Do not attempt to operate this tool

until you have read thoroughly and understand

completely all instructions, safety rules, etc.

contained in this manual. Failure to comply can

result in accidents involving fire, electric shock,

or serious personal injury. Save owner's manual

and review frequently for continuing safe

operation, and instructing others who may use

this tool.

MAKE WORKSHOP CHILD-PROOF with padlocks

and master switches or by removing switch keys.

USE THE RIGHT TOOL FOR THE JOB. Do not

force the tool or attachment to do a job it was not

designed for. Use it only the way it was intended.

DRESS PROPERLY. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry.

They can get caught and draw you into moving

parts. Nonslip footwear is recommended. Also

wear protective hair covering to contain long hair.

ALWAYS WEAR SAFETY GLASSES WITH SIDE

SHIELDS. Everyday eyegiasses have only impactresistant lenses: they are NOT safety glasses.

■ KEEP WORK AREA CLEAN. Cluttered work

areas and work benches invite accidents. DO NOT

leave tools or pieces of wood on the saw while it is

in operation. Keep floors clean and free of saw

dust.

■ MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for better and safer performance. Follow

instructions for lubricating and changing accesso

ries.

CRRFTSMRN' RADIAL SAW 315.220380

NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the blade is uninten

tionally contacted.

DO NOT OVERREACH. Keep proper footing and

balance at all times.

SECURE WORK. Use clamps or a vise to hold

work when practical, it’s safer than using your

hand and frees both hands to operate the tooi.

Page 5

RULES FOR SAFE OPERATION (Continued)

USE THE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition. Use

only a cord heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating. A wire gage size (A.W.G.) of at least

14 is recommended for an extension cord 25 feet

or less in length. If in doubt, use the next heavier

gage. The smaller the gage number, the heavier

the cord.

AVOID ACCIDENTAL STARTING. Be sure switch

is off when plugging in the tool.

REMOVE WRENCHES AND ADJUSTING KEYS.

Get in the habit of checking - before turning on the

tool - that hex keys and adjusting wrenches are

removed from tool. .

CHECK DAMAGED PARTS. Before using the tool

again, check any damaged parts, including guards,

for proper operation and performance. Check

alignment of moving parts, binding of moving parts,

breakage of parts, saw stability, mounting, and any

other conditions that may affect its operation. A

damaged part must be properly repaired or re

placed by a qualified service technician at a Sears

repair center to avoid risk of personal injury.

USE ONLY CORRECT BLADES. Use the right

blade style for the material and the type of cut.

Use only blades marked for at least 5,000 rpm and

10 in. or smaller, with a 5/8 in. arbor hole.

I

KEEP GUARDS IN PLACE and in good working

order. This includes the blade guard, the riving

knife, and the anti-kickback pawls.

i CHECK DIRECTION OF FEED. When ripping,

feed work into a blade or cutter against the direc

tion of rotation of the blade or cutter.

I NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER OFF. Do not leave the tool

until it comes to a complete stop.

I USE RECOMMENDED ACCESSORIES. Using

improper accessories may risk injury. Consult the

Accessories section for recommended accesso

ries.

I USE ONLY SEARS REPLACEMENT PARTS. All

repairs, whether electrical or mechanical, should

be made by a qualified service technician at a

Sears repair center.

■ DISCONNECT ALL TOOLS. When not in use,

before servicing, or when changing attachments,

blades, bits, cutters, etc., all tools should be

disconnected from the power supply.

■ DO NOT FORCE THE TOOL. It will do the job

better and more safely at the rate for which it was

designed.

■ BEFORE MOUNTING, DISCONNECTING OR

REMOUNTING THE MOTOR; unplug the saw and

remove the switch key.

A WARNING: When servicing, use only identical

Craftsman replacement parts. Use of any other

parts may create a hazard or damage product.

■ NEVER USE THIS TOOL IN AN EXPLOSIVE

ATMOSPHERE. Normal sparking of the motor

could ignite fumes.

■ MAKE SURE THE WORK AREA HAS AMPLE

LIGHTING to see the work and that no obstruc

tions will interfere with safe operation BEFORE

performing any work using this tool.

■ DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Have defective switches

replaced by a qualified service technician at a

Sears repair center.

■ GUARD AGAINST ELECTRICAL SHOCK by

preventing body contact with grounded surfaces

such as pipes, radiators, ranges, refrigerator

enclosures.

■ GROUND ALL TOOLS. See Electrical page.

■ WEAR A DUST MASK to keep from inhaling fine

particles. Use wood dust collection systems

whenever possible.

■ PROTECT YOUR HEARING. Wear hearing

protection during extended periods of operation.

■ DO NOT OPERATE THIS TOOL WHILE UNDER

THE INFLUENCE OF DRUGS, ALCOHOL, OR

ANY MEDICATION.

■ STAY ALERT AND EXERCISE CONTROL. Watch

what you are doing and use common sense. Do

not operate tool when you are tired. Do not

rush.

■ AVOID AWKWARD OPERATIONS AND HAND

POSITIONS where a sudden slip could cause your

hand to move into the blade. ALWAYS make sure

you have good balance.

CRRFTSMmr RADIAL SAW 315.220380

Page 6

RULES FOR SAFE OPERATION (Continued)

I GUARD AGAINST KICKBACK. Kickback can

occur when the blade stalls, driving the work piece

back toward the operator. It can cause your hand

to contact the blade, resulting in serious personai

injury. Stay out of the blade path and turn switch

off immediately if blade binds or stalls.

I

DO NOT USE A PERSON AS A SUBSTITUTE

FOR A TABLE if additional support is needed. Use

a support the same height as the table.

I

USE A SUPPORT FOR THE SIDES AND BACK

OF THE SAW TABLE when sawing wide or long

workpieces to minimize the risk of blade pinching

and kickback. Use a sturdy “outrigger" support to

prevent tipping if a table extension more than 24

inches long is attached to the saw.

CUT ONLY WOOD, PLASTIC OR WOOD-LIKE

MATERIALS. Do not cut metal.

BEFORE MAKING A CUT, be sure all adjustments

are secure.

NEVER cut more than one piece at a time. DO

NOT STACK more than one workpiece on the saw

table at a time.

DO NOT REMOVE THE SAW'S BLADE GUARD.

Never operate the saw with the blade guard

removed. Make sure all guards are operating

properly before each use.

NEVER PERFORM ANY OPERATION FREE

HAND. Always place the workpiece to be cut on

the saw table and position it firmly against the

fence as a backstop.

USE THE RIP FENCE. Always use a fence or

straight edge guide when ripping.

BE SURE THE BLADE PATH IS FREE OF

NAILS. Inspect for and remove all nails from

lumber before cutting.

BE SURE THE BLADE CLEARS THE WORK

PIECE. Never start the saw with the blade touching

the stock.

KEEP HANDS AWAY FROM CUTTING AREA.

Do not reach underneath work or in biade cutting

path with your hands and fingers for any reason.

Always turn the power off when cut is complete.

USE A PUSHBLOCK OR PUSHSTICK in rip mode

for workpieces so small that your fingers go under

the blade guard. NEVER TOUCH BLADE or other

moving parts during use, for any reason.

■ ALLOW THE MOTOR TO COME UP TO FULL

SPEED before starting a cut to avoid blade binding

or stailing.

■ ALWAYS PUSH THE WORKPIECE when ripping;

never pull it toward the saw.

■ DO NOT FEED THE MATERIAL TOO QUICKLY.

Do not force the workpiece against the blade.

■ ALWAYS TURN OFF SAW before disconnecting

it, to avoid accidental starting when reconnecting

to the power supply. NEVER leave the saw

unattended while connected to a power source.

■ BEFORE CHANGING THE SETUP, REMOVING

COVERS, GUARDS, OR BLADE; unplug the saw

and remove the switch key.

■ KEEP TOOL DRY, CLEAN, AND FREE FROM

OIL AND GREASE. Always use a clean cloth

when cleaning. Never use brake fluids, gasoline,

petroleum-based products, or any solvents to

clean tool.

■ KEEP BLADES CLEAN, SHARP AND WITH

SUFFICIENT SET. Sharp blades minimize stalling

and kickback. Keep blades free of rust, grease,

and pitch.

WARNING: Blade coasts after being turned off.

■ USE ONLY OUTDOOR EXTENSION CORDS.

Use only extension cords with the marking “Ac

ceptable for use with outdoor appliances; store

indoors while not in use.” Use extension cords with

an electrical rating not less than the saw’s rating.

Always disconnect the extension cord from the

outlet before disconnecting the product from the

extension cord.

■ INSPECT TOOL CORDS AND EXTENSION

CORDS PERIODICALLY and, if damaged, have

repaired by a qualified service technician at a

Sears repair center. Stay constantly aware of cord

location and keep it well away from the moving

biade.

■ DO NOT ABUSE CORD. Never yank the cord to

disconnect it from receptacle. Keep the cord from

heat, oil, and sharp edges.

■ SAVE THESE INSTRUCTIONS. Refer to them

frequently and use to instruct other users. If you

loan someone this tool, loan them these instruc

tions also.

CRRFTIMflN* RADIAL SAW 315.220380

SAVE THESE INSTRUCTIONS

Page 7

ADDITIONAL SAFETY RULES FOR RADIAL SAWS

SECURE THE SAW. Firmly bolt the saw to the leg

stand to keep the saw from tipping, walking, or

sliding.

DO NOT SET UP WORK WITH THE BLADE

SPINNING. Keep the saw power off until you are

ready to use it.

RIP ONLY WORKPIECES LONGER THAN THE

BLADE’S DIAMETER. Never rip a piece of wood

that is shorter than the diameter of the blade.

NEVER LOWER AN UNLOCKED REVOLVING

CUTTING TOOL. Always lock the carriage lock

knob before lowering the blade.

SHUT OFF THE POWER TO FREE A JAMMED

GUARD. Press the switch off before putting your

hands near the blade. Wait for the blade to stop,

then free the guard.

I LOCK THE SAW BEFORE MOVING IT. Secure

the radial arm with the arm lock knob. Secure the

carriage with the carriage lock knob.

I POSITION THE WORKPIECE WITH THE FIN

ISHED SIDE DOWN. If the anti-kickback pawls

catch the wood to stop kickback, they could mar

the top surface or cause splintering.

I POSITION THE WORKPIECE SO NO ONE MUST

STAND IN LINE WITH THE BLADE. If kickback or

climb occurs, a helper, operator, or observer in the

sawblade path could be seriously injured.

I POSITION THE CUT SO THE WASTE PART

FALLS OFF. Never use a length stop on the free

end of the workpiece. Never apply force to the free

end or hold it while the sawblade is rotating.

A WARNING: In a rip cut. holding the cut-off edge

behind the blade can cause the cut edges to

pinch, risking kickback. It could cause the blade

to climb over the front edge of the wood and

contact your hand.

■ BEFORE CUTTING, position and tighten the blade

guard and anti-kickback pawls. Test the pawls to

make sure they would stop kickback if it started.

Keep the points sharp.

■ KEEP THE SAW BLADE PATH CLEAR. Position

the saw to allow enough room on all sides so

neither the operator nor a visitor stands in line with

the sawblade.

■ AVOID HEELING by adjusting the saw blade so it

exactly parallels the fence during ripping opera

tions.

■ AVOID GRABBING in rip mode by keeping the

. saw blade correctly adjusted and by feeding the

work from the infeed side (opposite the anti-

^ kickback pawls).

■ AVOID PINCHING by using a riving knife and

sharp saw blade. Keep the work positioned firmly

against the fence.

■ USE IN-RIP WHENEVER POSSIBLE by position

ing the work so the blade is between (inside) the

column and the motor.

■ NEVER ADJUST GUARD, PAWLS, OR BLADE

WITHOUT DISCONNECTING THE POWER.

Always turn off the switch and unplug the cord

before freeing a jammed blade, tightening a loose

blade, or repositioning the guard or pawls.

yy CAUTION: Do not turn the motor switch on and

off rapidly. This can loosen the sawblade. .

■ NEVER CUT MORE THAN ONE PIECE OF

WOOD AT A TIME. The feed will be uneven and

could cause the blade to pick up one or more

pieces and cause serious injury.

■ TURN OFF SAW IF A STRANGE NOISE OR

HEAVY VIBRATION OCCURS. Immediately turn

off the saw, locate the source, and correct the

problem before using the saw further.

I BEFORE STARTING EACH CUT, check that no

play exists in the carriage. Be sure the arm, yoke

and bevel locks and clamps are tight. Verify the

blade, all handles, blade washers, and blade nuts

are secure.

I BEFORE MAKING A CUT, test the upper and

lower blade guards for free movement up and

down. Position the nose of the guard to just clear

the workpiece.

■ AVOID KICKBACK AND POSSIBLE INJURY by

preventing heeling, grabbing, and pinching.

■ POSITION THE CUT SO THE BLADE WILL NOT

EXTEND BEYOND THE EDGE OF THE TABLE.

■ KEEP THE GUARDS IN PLACE AND THE WORK

SURFACE CLEAR DURING A CUT. Small objects

or wood slivers can ricochet from the blade into the

fence and back toward the operator. If the blade

loosens slivers, remove them with a stick, not your

hand.

■ IN A RIP CUT, DO NOT LET GO OF THE WORK

PIECE UNTIL THE CUT IS COMPLETE. When the

workpiece is fed into the blade, push the workpiece

all the way past the blade.

CRRFTSMflM' RADIAL SAW 315.220380

Page 8

ELECTRICAL

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug. When using a power tool at a consider

able distance from the power source, use an exten

sion cord heavy enough to carry the current that the

tool will draw. An undersized extension cord will

cause a drop in line voltage, resulting in a loss of

power and causing the motor to overheat. Use the

chart provided below to determine the minimum wire

size required in an extension cord. Only round jack

eted cords listed by Undenwriter's Laboratories (UL)

should be used.

Length of Extension Cord Wire Size (A.W.Q.)

Up to 25 feet 14

26-100 feet 12

When working with the tool outdoors, use an exten

sion cord that is designed for outside use. This is

indicated by the letters WA on the cord's jacket.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

CAUTION: Keep the cord away from the cutting

area and position the cord so that it wili not be

caught on lumber, tools, or other objects during

cutting operations.

ELECTRICAL CONNECTION

Your Sears Craftsman Radial Arm Saw is powered by

a precision built electric motor. It should be connected

to a power supply that is 120 volts, 60 Hz, AC only

(normal household current), it should be connected

to a 240 volt power supply only If it has been reset

according to the instructions in this manual. The

motor has been set at the factory for 120 volts; if it is

reconnected to operate at 240 volts, the main power

cord plug and any receptacle must be replaced with

devices rated for 240 volts. This tool will not operate

on direct current (DC). A substantial voltage drop will

cause a loss of power and the motor will overheat. If

the saw does not operate when plugged into an outlet,

double check the power supply.

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current

to reduce the risk of electric shock. This tool is

equipped with an electric cord having an equipment

grounding conductor and a grounding plug. The plug

must be plugged into a matching outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Do not modify the plug provided. If it will not fit the

outlet, have the proper outlet installed by a qualified

electrician. Improper connection of the equipment

grounding conductor can result in a risk of electric

shock. The conductor with insulation having an outer

surface that is green with or without yellow stripes is

the equipment-grounding conductor. If repair or

replacement of the electric cord or plug is necessary,

do not connect the equipment-grounding conductor to

a live terminal.

Check with a qualified electrician or senrice personnel

if the grounding instructions are not completely

understood, or if in doubt as to whether the tool is

properly grounded.

Repair or replace a damaged or worn cord immedi

ately.

This tool is intended for use on a circuit that has an

outlet like the one shown in Figure 1. It also has a

grounding pin like the one shown.

SPEED AND WIRING

The no-load speed of your saw is approximately 3,600

ipm. This speed is not constant. For voltage, the

wiring in a shop is as important as the motor’s horse

power rating. A line intended only for lights cannot

properly carry a power tool motor. Wire that is heavy

enough for a short distance will be too light for a

greater distance. A line that can support one power

tool may not be able to support two or three tools.

CRRFnMRN* RADIAL SAW 315.220380

COVER OF GROUNDED

OUTLET BOX

Fig. 1

Page 9

ELECTRICAL

CHANGING VOLTAGE

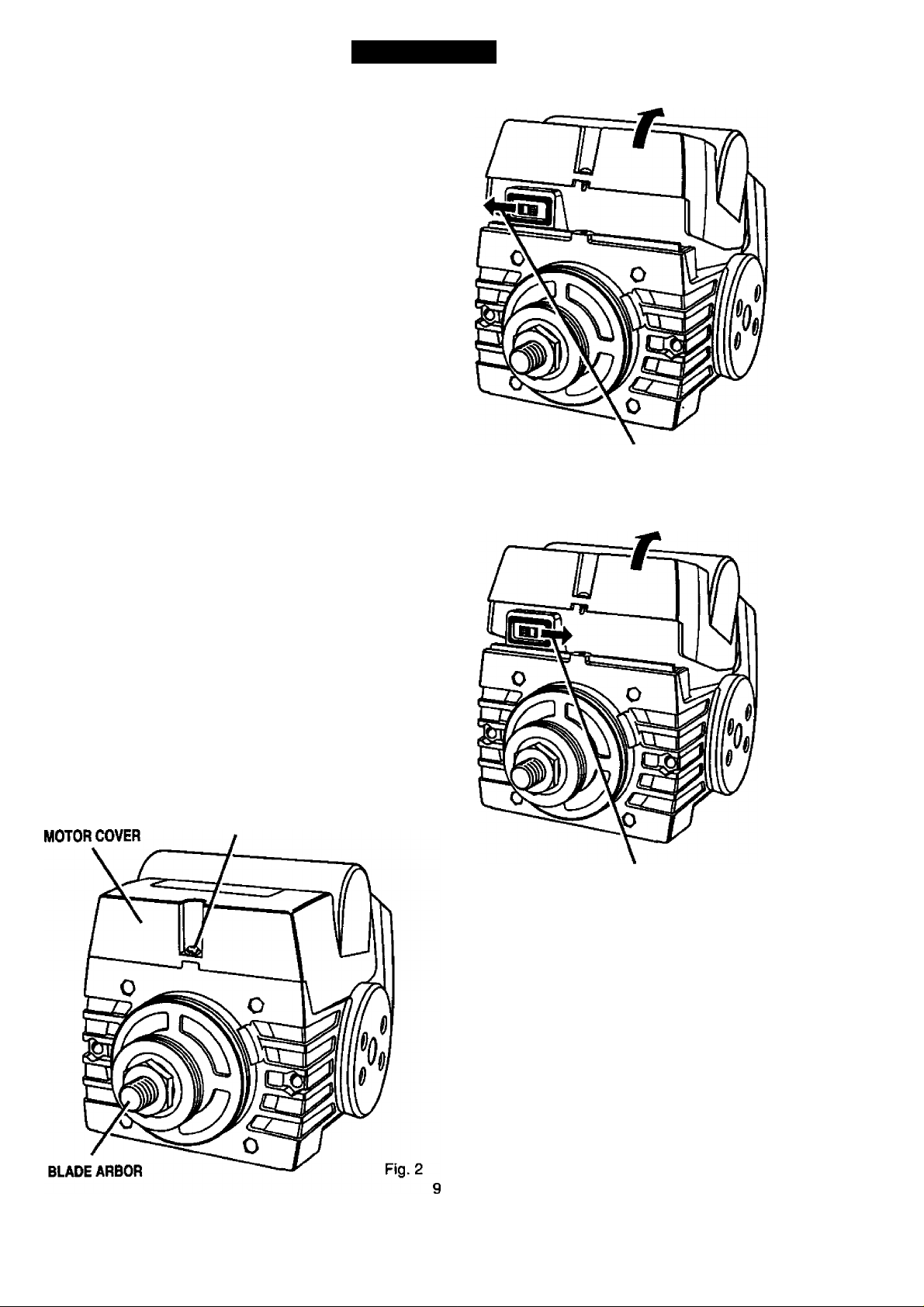

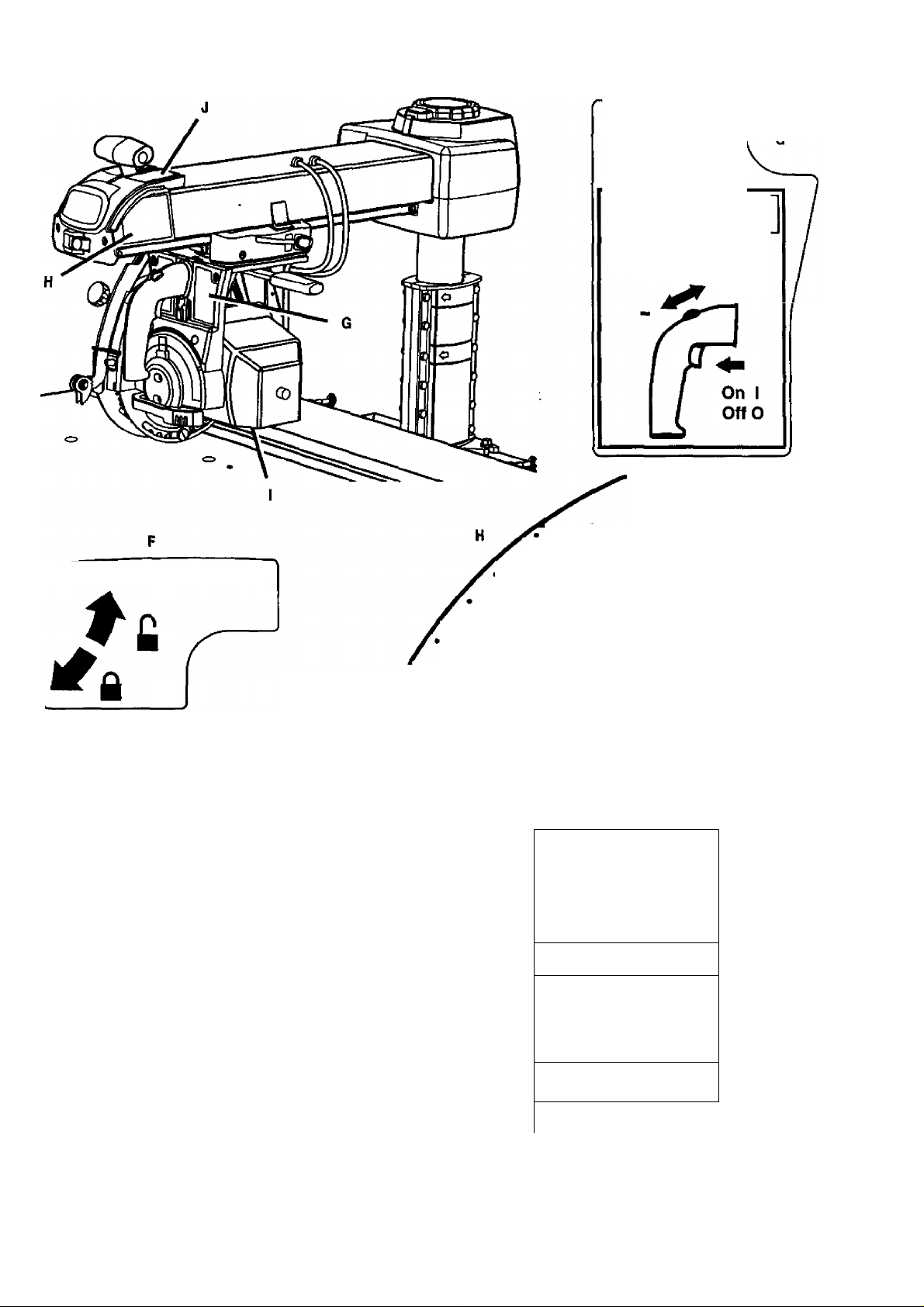

See Figures 2-4.

Your radial saw has been set up at the factory to

operate efficiently on a 120V AC single voltage circuit.

However, if heavy duty operation is required, the

circuits are overloaded, or the circuit is low voltage,

have a qualified electrician change the voltage on the

main power system to a 240V AC voltage circuit.

A WARNING: The control cut device is set up for

a 120V AC single voltage circuit. Do not modify

the control cut cord. Identify the control cut

cord and tie it back out of the way.

■ Correctly identify the control cut cord, unplug it,

and set it aside.

■ Unplug the main power cord.

■ Remove the blade following the procedure in the

Assembly section.

■ Remove the pan head screw above the blade

arbor on the motor cover. Lift motor cover to

expose switch. See Figure 2.

■ Use a small screwdriver to slide the dual voltage

switch to the 240V position. See Figures 3 and 4.

■ Reinstall motor cover.

■ Replace the 120V plug on the main cord with a UL

listed 240V, 15 amp, 3-prong plug.

■ Follow the instructions provided with the UL listed

plug.

■ Plug the cord into a 240V, 15 amp, 3-blade recep

tacle. Make sure the receptacle is connected to a

240V AC power supply through a 240V branch

circuit that has a 15 amp fuse or circuit breaker.

Note: No adapter is available for this type of plug or

receptacle.

UFT MOTOR COVER TO EXPOSE SWITCH

SUDE AS SHOWN FOR SINGLE VOLTAGE CIRCUITS

SWITCH SHOWN IN 110-120 VOLT POSITION

Fig.3

LIFT MOTOR COVER TO EXPOSE SWITCH

PAN HEAD SCREW

SUDE AS SHOWN FOR DUALVOLTAGE CIRCUITS

SWITCH SHOWN IN 220-240 VOLT POSITION

Fig. 4

CRRFTSMRN* RADIAL SAW 315.220380

Page 10

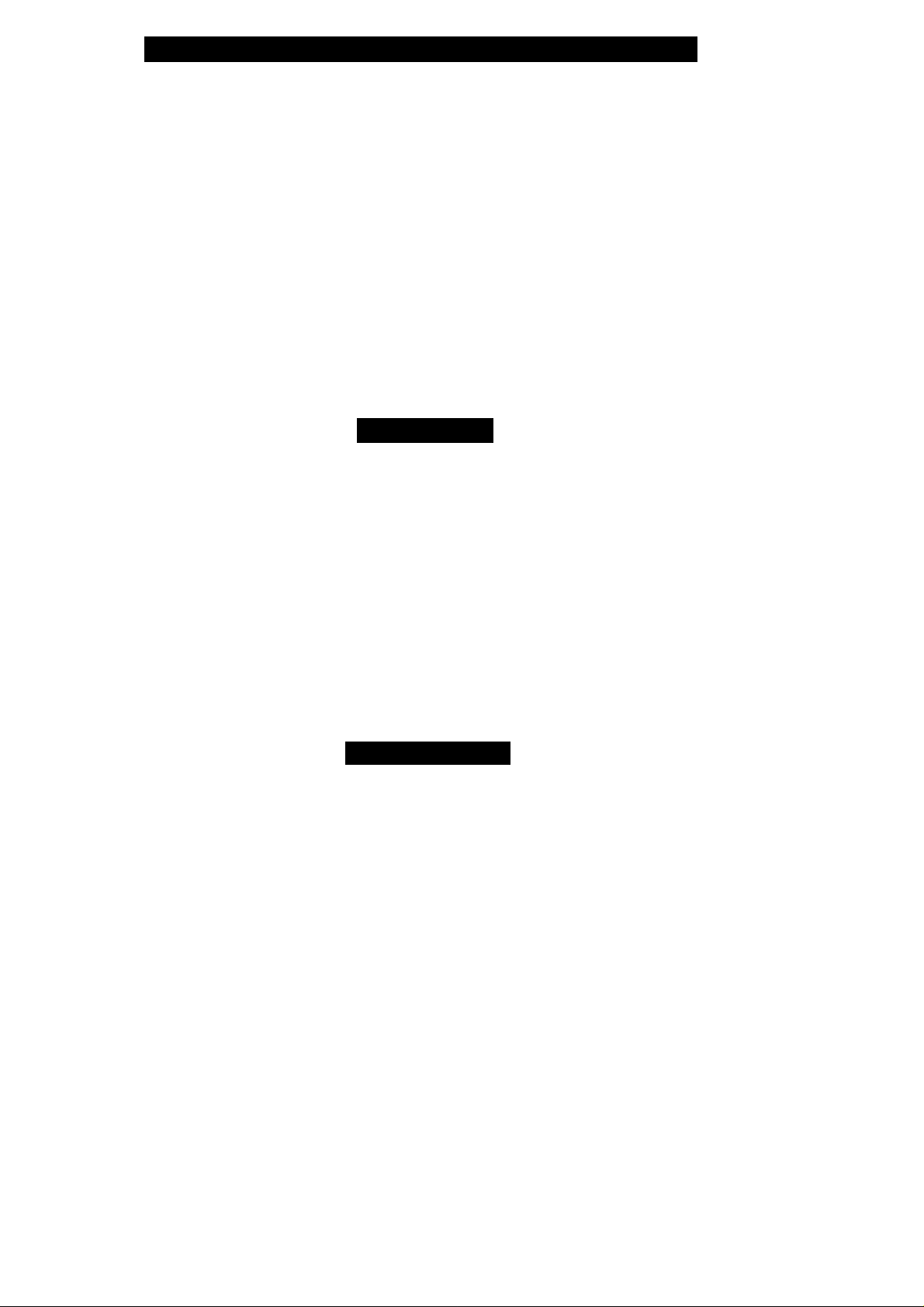

PRODUCT SPECIFICATIONS

Blade Arbor

Blade Diameter

Blade Bevel Angle

Radial Arm Swing Range

Blade Height Adjust

Carriage Travel

Cutting Capacity - Maximum Cross Cut 15.50 in.

Cutting Capacity - Maximum Out-Rip 26 in.

50* left - 90’ right

5/8 in.

10 in.

O’ - 90*

5.35 in.

17.25 in.

GLOSSARY OF TERMS FOR WOODWORKING

Bevel Cut

A cut made across a workpiece with the blade at any

angle other than 90’ to the table surface.

Chamfer

A cut removing a wedge from a block so the end (or

part of it) is angled rather than at 90 degrees.

Climb

A hazard in which the blade “climbs” over and out of

the workpiece, pulling the stock out of the operator's

hands or running across the wori<piece.

Compound Cut

A cross cut with both a miter angle and a bevel angle.

Cross Cut

A cutting operation with the blade parallel to the

carriage arm and the blade teeth pointing down. It can

be across or with the grain, normally across the grain

or width of the workpiece.

Dado Cut

A non-through cut that leaves a square notch dr

trough; requires a special blade.

Featherboard

A device to help guide workpieces during rip cuts.

Fence

A piece of wood used as a edge guide for the

workpiece. Located perpendicular to the carriage arm.

Can be placed at different distances from the rear

table edge in combination with the other table pieces

and is secured with table clamps.

Freehand

Dangerous practice of making a cut without using a

fence.

Gum

A sticky, sap-based residue from wood products.

Heel

Alignment of the blade to the fence.

Cutting Capacity - Maximum In-Rip

Depth of Cut at 90*

Depth of Cut at 45’

Table Size

Table Height

Rating

Input

No Load Speed

120V/240V 60 Hz - AC only

40 x 27.75 x 1 in.

13.0/6.5 Amperes

3,600 RPM

Infeed

The side of the blade where the blade teeth point up,

opposite the anti-kickback pawls.

In-Rip

A type of rip cut in which the blade is between the

column and the motor.

Kerf

The space left by the removal of material in a cut or

the slot produced by the blade in a non-through cut.

Kickback

A hazard that can occur when blade binds or stalls,

throwing workpiece back toward operator.

Leading End

The end of the workpiece pushed into the cutting tool

first.

Miter Cut

A vertical cut made at any angle other than 0’ across

the workpiece.

Molding

A shaping cut that gives a varied shape to the

workpiece and requires a special blade.

Out-Rip

A type of rip cut in which the motor is between the

blade and the column. (The blade is "outside” the

motor).

Pushstick

A device used to feed the workpiece through the saw

blade during cutting operations. It helps keep the

operator's hands well away from the blade.

Rabbet

A type of cut that gives a notch in the edge of a

workpiece.

Resaw

A cutting operation to reduce the thickness of the

workpiece to make thinner pieces.

16 in.

3 in.

2.25 in.

36 in.

CRRFTSMRN’ RADIAL SAW 315.2203S0

10

Page 11

GLOSSARY OF TERMS FOR WOODWORKING (Cont.)

Resin

A sticky, sap-based substance.

Rip Cut .

In a radial saw, a cut made with the blade parallel to

the fence and perpendicular to the arm. Can be

across or with the grain. The teeth point up at the

point of contact with the wood.

Sawblade Path

The area directly in line with the blade — over, under,

behind, or in front of it. Also, the workpiece area which

will be or has been cut by the blade.

Set

The distance that the tip of the saw blade tooth is off

set from the face of the blade.

UNPACKING

WARNING: To prevent accidental starting that

could cause possible serious personal injury,

assemble all parts to your saw before connecting

it to power supply. The saw should never be

connected to the power supply when you are

assembling parts, making adjustments, installing

or removing blades, or when not in use.

WARNING: if any parts are missing, do not

operate this tool until the missing parts are

replaced. Failure to do so could result in possible

serious personal injury.

Throw-Back

Saw throwing back a workpiece similar to kickback.

Through Sawing

Any cutting operation where the blade extends

completely through the workpiece.

Trailing End

The workpiece end last cut by the blade in a rip cut.

Workpiece

The item on which the cutting operation is being done.

The surfaces of a workpiece are commonly referred to

as faces, ends, and edges.

Worktable

The surface on which the workpiece rests while

performing a cutting operation.

■ Carefully remove all parts from the carton and

place the saw on a level work surface. Separate

and check against the list of loose parts.

■ Do not discard the packing materials until you have

carefully inspected the saw, identified all parts, and

satisfactorily operated your new saw.

Note: If any parts are damaged or missing, do not

attempt to plug in the power cord and turn the

switch on until the damaged or missing parts

are obtained and are installed correctly.

ACCESSORIES

The following recommended accessories are currently available at Sears Retail Stores.

■ Steel and carbide tipped circular saw blades ■ Adjustable taper jig

■ Hold down clamps ■ Sawdust collector shroud

■ Saw baskets

^ WARNING: The use of attachments or accessories not listed might be hazardous.

11

CRRFnMRir RADIAL SAW 31S.220380

Page 12

LOOSE PARTS LIST

Check ail loose parts from the box with the list below. Use the instructions on the following pages to assemble.

All fasteners are shown actual size.

1. Saw Assembly

...........................................................

SAW ASSEMBLY SHOWN AS PACKED

1

2. Elevating Handwheel

A. Handwheel

B. Screw {10-24 X 5/8 in. Soc. Hd.)

C. Star Washer..........................................................

ummmii

.............................................................

...........................

B

□

o

Fig. 5

3. Blade Wrench.

.....

2

1

1

1

4. Hex Key

A. 3/16 in. Hex Key.

B. 1/4 in. Hex Key...

CRUFTSHIIN* RADIAL SAW 315.220380

Fig. 6A

12

Page 13

LOOSE PARTS LIST

Check all loose parts from the box with the list below. Use the instructions on the following pages to assemble.

All fasteners are shown actual size.

5. Saw Base To Leg Stand Assembly

A. Saw Assembly (not shown).............................1

B. Leg Stand Assembly (not shown)

C. Hex bolt (5/16-18 X 5/8 in. Hex Head)

D. Washer (5/16 in.)

E. Lock washer (5/16 in.)......................................4

F. Hex Nut (5/16-18)..............................................4

..............................................

..................

(o) @ ©

Hardware for Front Table

6.

A. Front table

B. Screw (1/4-20 x 1 in.)..................................... 4

C. Washer (1/4 in.)................................................4

D. Lock washer (1/4 in.)

E. Hex nut (1/4-20)

.......................................................

......................................

...............................................

.............

1

4

8

1

4

4

9. Fence.

10. Leveling Hardware for Front Table

A. Screw (1/4-20 x 1-3/4 in.)............

B. Washer.........................................

C. U-clip

D. Setscrew......................................

E. Tee nut.........................................

...........................................

^mmm @ (Q) ©

B

7. Rear Table.................................................................1

11. Scale Indicator

A. Screw

B. Speed Nut

C. Indicator

D. Switch Key.......................................................2

...............................................................

........................................................

..........................................................

inroTF

B

4

2

2

Fig. 6B

CRRFTSMRN* RADIAL SAW 315.220380

Page 14

LOOSE PARTS LIST

Check all loose parts from the box with the list below. Use the instructions on the following pages to assemble.

All fasteners are shown actual size.

12. Table Support

A. Table Support Rails

B. Square head bolt (5/16-18 x 3/4 in.)

C. Flat washer (5/16 in.)

D. Lock washer (5/16 in.)

E. Hex nut (5/16-18)

13. Table Clamp

A. Thumb screw (2)

B. Square nut........................................................2

C. Table clamp bracket

D. Cup washer......................................................2

........................................................

........................................

...............

......................................

....................................

.............................................

.............................................

.......................................

15. Leg Stand.................................................................i

2

4

4

4

4

2

2

2

A. Leg.......................................................................

B. Long bottom brace................................................2

C. Long top brace.....................................................

D. Short bottom brace

E. Short top brace

F. Foot..........................................................................

G. Screw (1/4-20 x 5/8 in.)

H. Star washer

I. Hex nut (1/4-20)..................................................

J. Hex nut (3/8-16)

oTo

..............................................

....................................................

......................................

.....................................................

....................................................

40

40

40

4

2

2

2

4

8

14. Owner’s Manual (not shown)

CRRFTSMRN' RADIAL SAW 315.220380 14

0 0

o ©

H

Fig. 6C

Page 15

TOOLS NEEDED

The following tools are needed for assembly and alignment. They are not included with this saw.

LEVEL

HEX KEYS:

S/32in.AND 1/B1n.

MEDIUM FLAT BUDE SCREWDRIVER

Fig. 7

CRRFTSMRN* RADIAL SAW 315.220380

Page 16

Control Cut Settings

Crosscut

Wood

Type

Hard A

Medium

Soft

Wood

Type

All Types A

Wood

Type

Hard A

Medium

Soft C 0-35

Com

Wood

Type

All Types A 0-6

Setting

Position

B 0-20

C 0-35

evel brnssc

%

Setting

Position

iter Crosscut 1

1 w

Setting

Position

B

pound Crosscut

Setting

Position

Feet

Minute

0-6

ut

Feet

Minute

0-6

Feet

Minute

0-6

0-20

Feet

Minute

A WARNING / ADVERTENCIA

^ 10 inch Radial Arm Saw ^

3,600 RPM 120/240 VOLTS 13/6.5Aiiw 60Hz AC ONLY

WARNING: when servicing, use only identical

CRAFTSMAN REPLACEMENT PARTS.

MODEL 315.220380

MADE IN U.S.A.

SEABS, ROEBUCK AND CO.

SER. NO.

®!

\Customer Help Line 1-800-932-318S J

PROFESSIONAL

Rip Feed Direction

• For your own safety, Read and understand

owner's manual before operating saw.

• This tool has more than one connection to the

power source.

• To reduce the risk of electrical shock or injury,

disconnect all power connections

• When servicing, use only identical

replacement parts.

• Para su seguridad, lea y entlenda el manual del

propietario antes de operar la sierra.

A WARNING/ADVERTENCIA

• For your nfcty, <to net food rip material Into

law from thit direction.

• Pan tn ugnridad, no introducá «1 matarial qua

vayi a cortaran la clam daada actaa diracción.

CRRFT3Miir RADIAL SAW 315.220380

Fig. 8A

16

Page 17

Carriage Lock

Control Cut

Speed Adjustment

+

A WARNING

ADVERTENCIA

For your salety, road owners manual before operating

saw.

Wear salety goggles.

Do not perform freehand cuts.

• Return carriage to full rear position after each cross cut.

See Instructions on how to reduce the risk of kickback.

Whan ripping, use pushstickwhen blade Is set 2 inches or more from

fence.

When ripping, use puAhlock and auxiliary fence when blade is set between

1/2 and 2 incNs from fence. Do not make rip cuts narrower than 1/2 inch.

• Keep hands out of path of blade.

• Do not reach around saw blade.

• Turn power off and wait tor blade to stop betnra moving workpiece or

changing settings.

• Unplug saw before changing the blade or servicing.

• Para su seguridad, lea y entiendi el manual del pmpietarlo antes de operar la sierra,

▲ WARNING

ADVERTENCIA

• Read and understand owners manual

before operating saw.

• For your safety, do not use

accessories without proper guarding.

• Provide proper workpiece support

• Position cutting tool behind the

fence.

• With power off and switch key

removed, turn cutting tool by hand to

make sure it does not strike guard,

fence or any other saw parts.

• Para su seguridad, lea y entienda el

manual del propietario antes de

operar la sierra.

17

LOCKED

UNLOCKED

■ PIVOT 1b

CRRFnHRir RADIAL SAW 315.220380

\

i

fi

Fig. 8B

Page 18

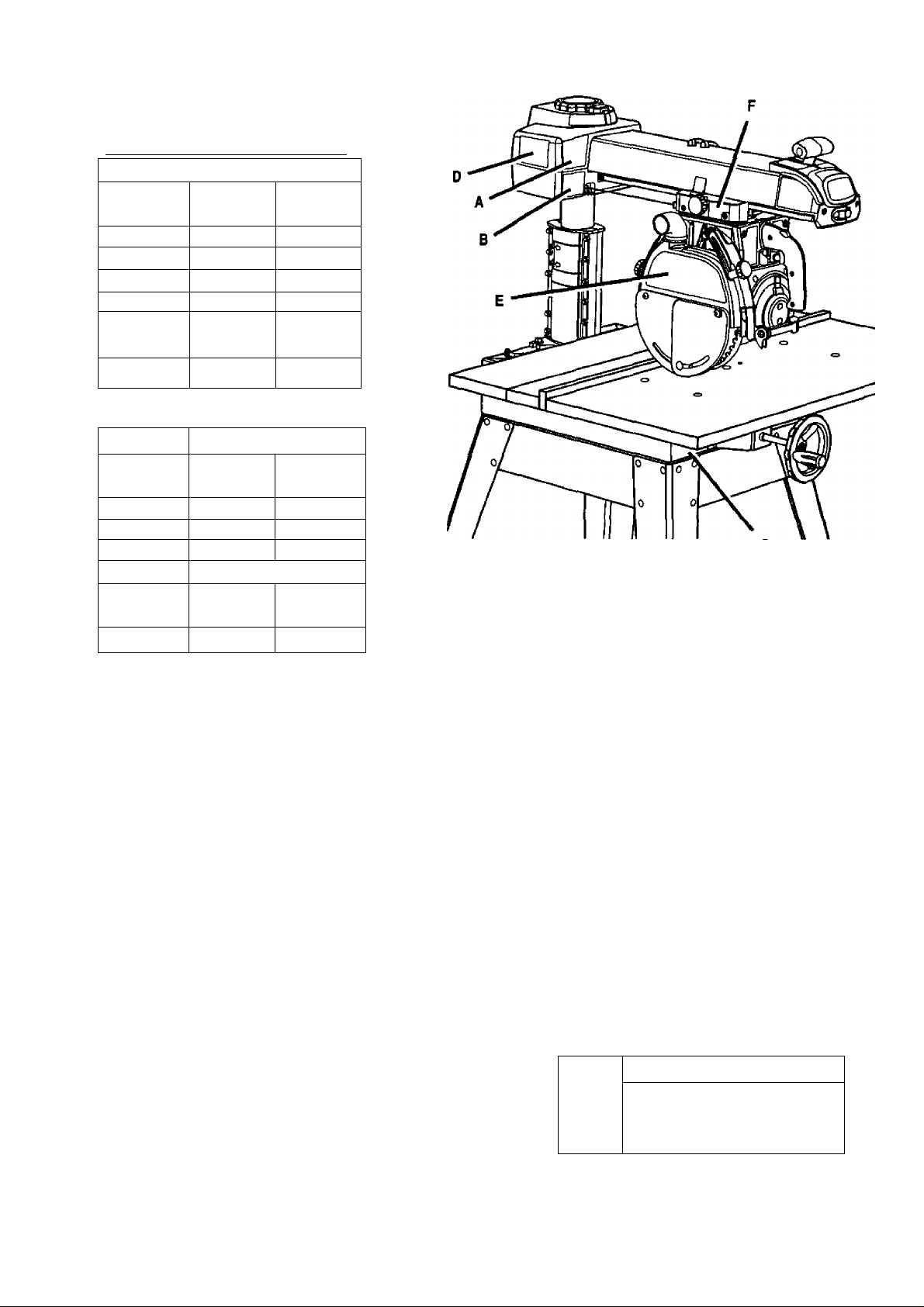

FEATURES

KNOW YOUR RADIAL SAW

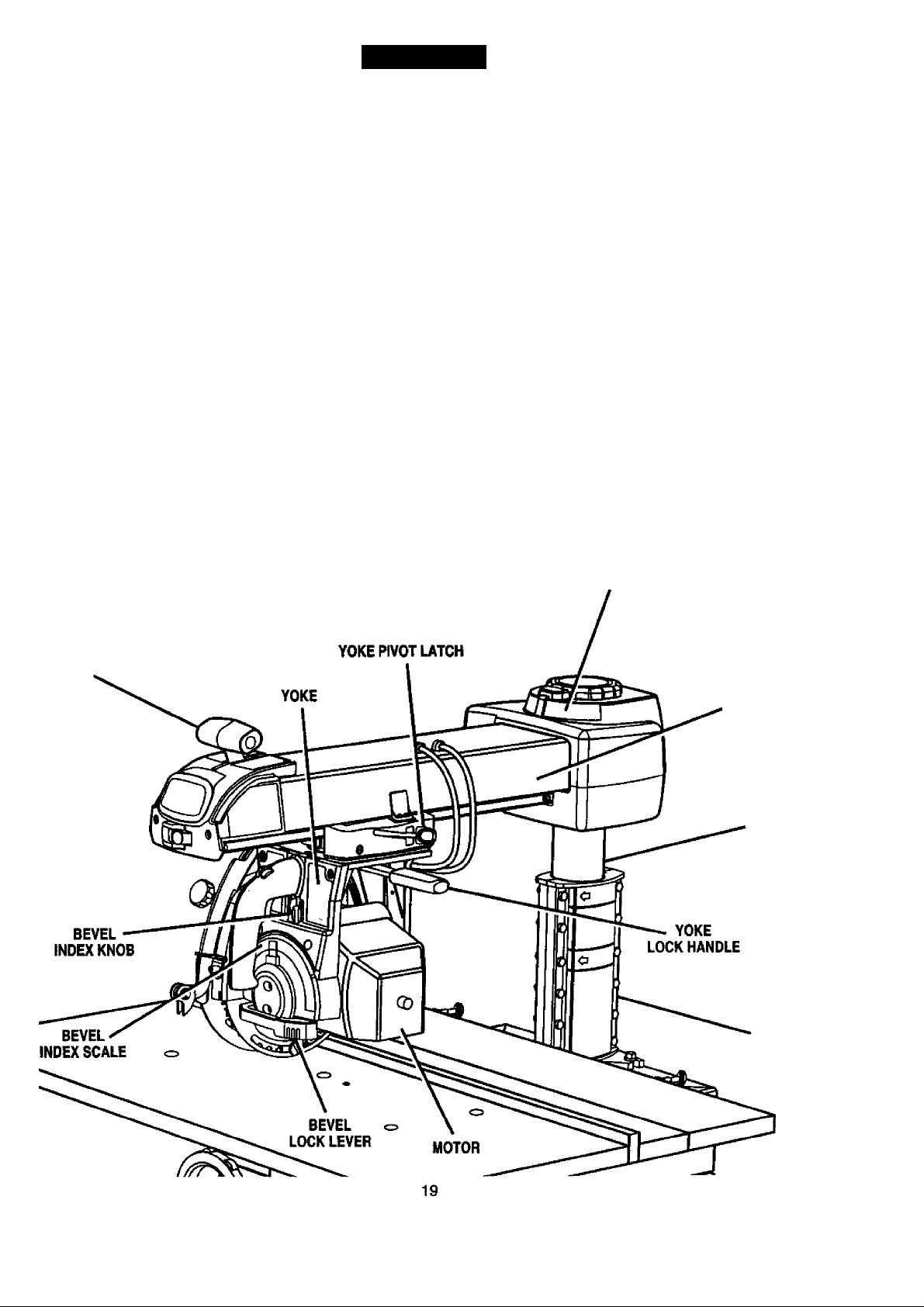

See Figure 9A.

OVERVIEW - The main operating components include

the coiumn, the arm, and the yoke assembiy (yoke,

motor, and blade), and their operation is summarized

in the paragraph below. Safety features and control

functions are given also. Spending a few minutes

reviewing the illustrations and features list below and

on the following pages to locate these items will make

assembly easier.

METHOD OF OPERATION: The column at the back

of the saw supports the radial arm. The arm can be

raised or lowered to change the blade height or

swiveled left and right for a miter cut. A yoke fits into

a carriage on the arm, which can travel back and

fonivard. The yoke supports the yoke assembly

(motor, blade, and blade guard) and can be pivoted

so the blade faces right, front, or left. The motor can

be rotated to change the blade angle.

Control functions include 1) column height (elevating

handwheel), 2) arm angle (arm lock knob), 3) yoke

movement on arm (‘carriage iock knob) 4) yoke

rotation {‘yoke pivot latch and ‘yoke lock handle), and

5) blade bevel (‘bevel index lever and ‘bevel lock

knob).

Safety features include the control cut device, the

removable switch key, and the blade guard assembly.

Never operate the saw without ensuring these safety

features are in place and functioning correctly.

On a radial saw, “cross cut” means a cut parallel to

the arm, and a “rip cuf is perpendicular to the arm.

There are several ways to make cuts, depending on

the size and material of the workpiece and the end

result desired.

Before attempting to use your saw, familiarize yourself

with all operating features and safety requirements of

your Sears Craftsman Radial Arm Saw.

‘Shown on following pages

CRHFTSMRN’ RADIAL SAW 315.220380

Fig. 9A

18

Page 19

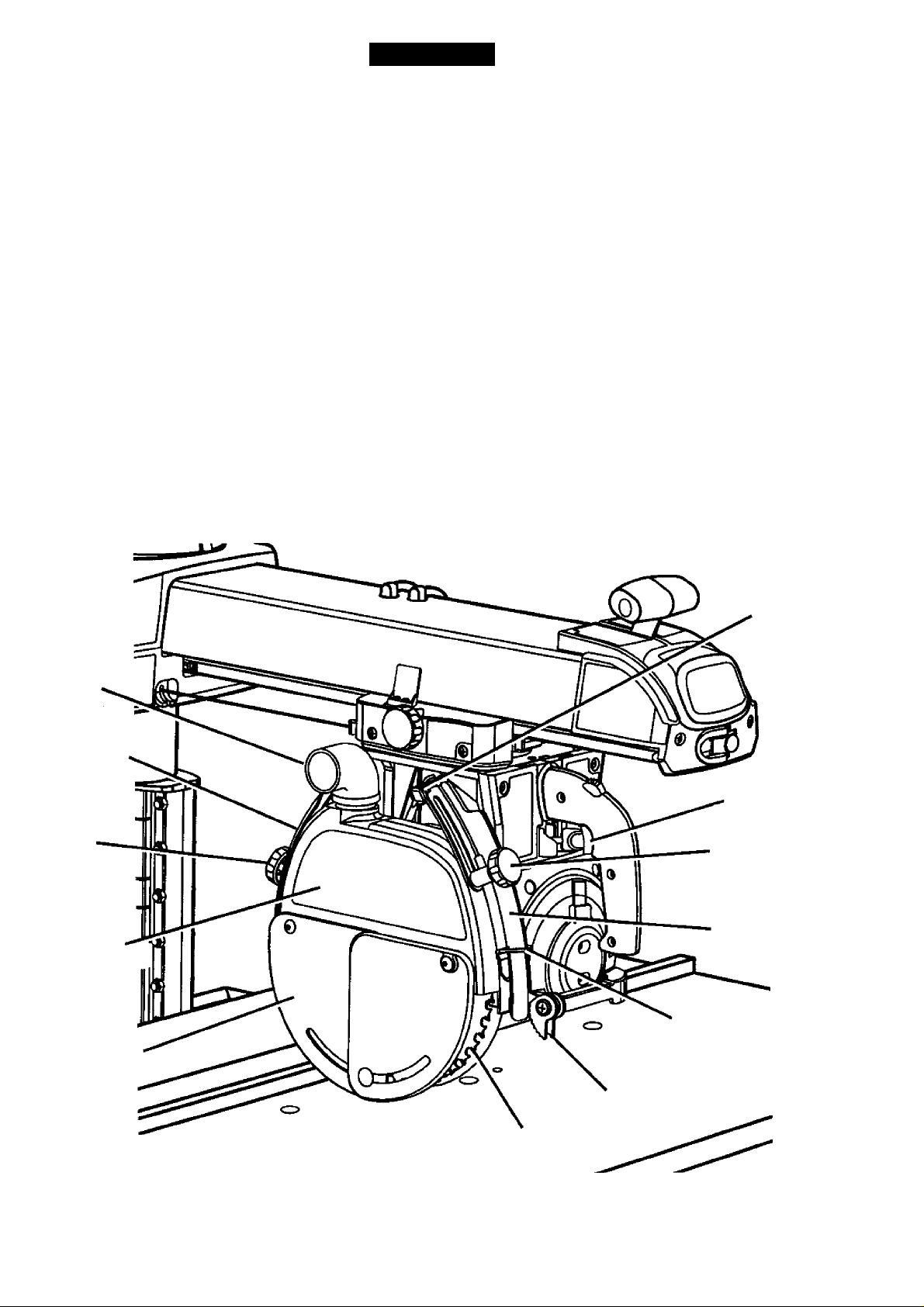

FEATURES

FEATURES LIST

See Figures 9A-9D.

ADJUSTABLE TABLES - A narrow spacer table and

wider rear table that can be repositioned or even

replaced with different tables. See Figure 9C.

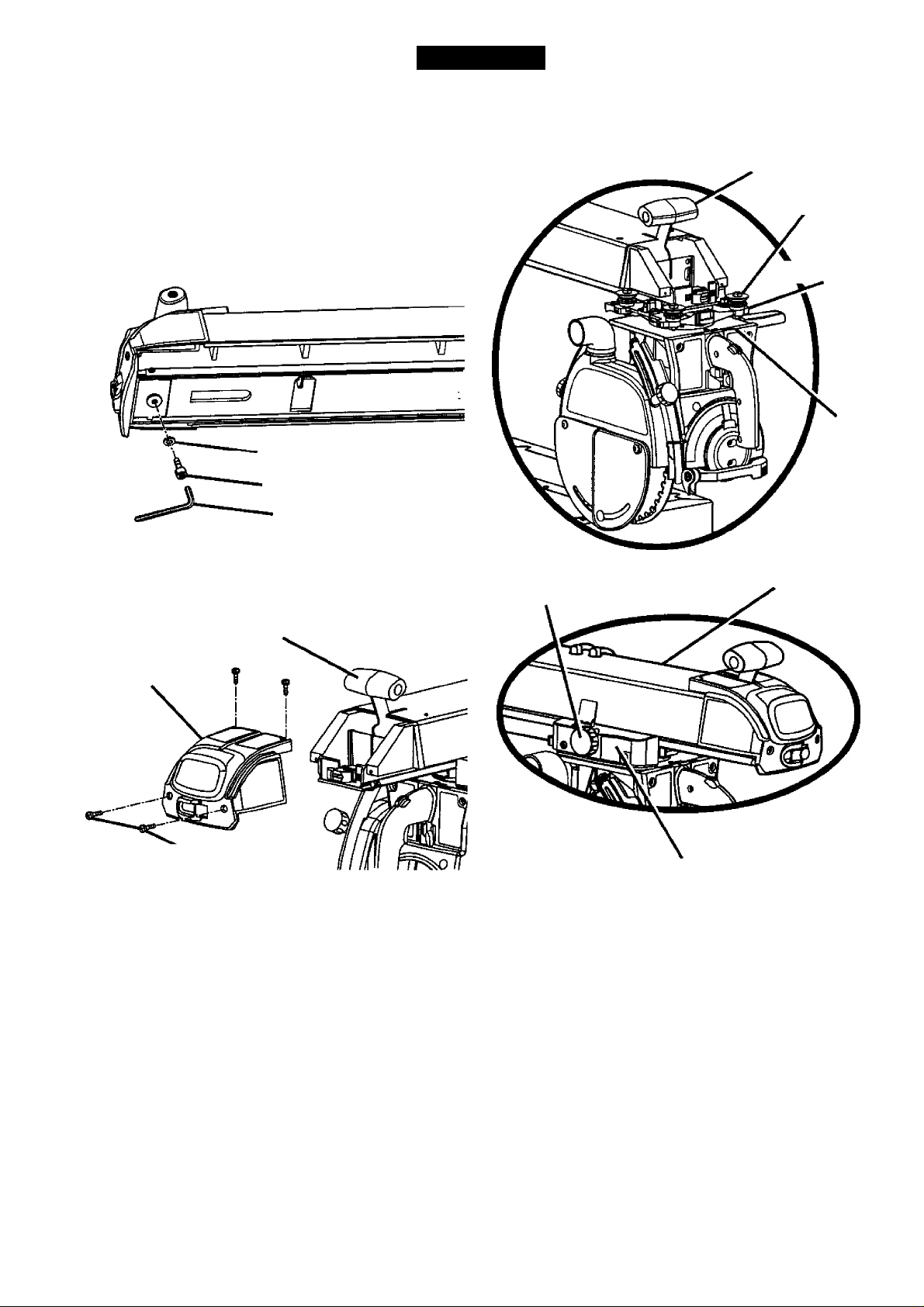

ANTI-KICKBACK PAWLS - Toothed pawls that snag

the work in case of kickback during rip cuts. (When

the blade is parallel to the arm, the pawls are in front

of the blade.) Keep the pawls in place to reduce risk

of injury. See Figure 9D.

ARM - The assembly extending from the column,

which supports the yoke, the motor, and the blade.

See Figure 9A.

ARM LOCK KNOB - Controls arm angle. Use to set

the arm to the positive stops at 0", 45' left, and 45'

right and to lock the arm in place. Located on top of

arm at front. See Figures 9A and 9B.

BEVEL INDEX KNOB - Controls the blade angle

between positive stops at O', 45', and 90'. Located

behind the handle. See Figure 9B.

BEVEL INDEX SCALE - Shows the blade angle for

bevel cuts and is located behind the handle. See

Figure 9B.

BEVEL LOCK LEVER - Sets and locks blade angle, it

is located below the handle. See Figure 9B.

BLADE - For maximum performance, use the Crafts

man 40-tooth, 10 in. carbide-tipped blade provided

with your saw. It is a high-quality combination blade

suitable for ripping and crosscut operations. Blades

recommended for other operations are listed in the

Accessory section of this manual. The blade is

powered by the main motor and turned off by the

switch. See Figure 9D.

WARNING: Use only blades rated for at least

5,000 rpm and recommended for use on this

saw. Check with your nearest Sears retail store.

BLADE GUARD ASSEMBLY • Protective unit over

the blade, with a riving knife, anti-kickback pawls, an

upper blade guard, a lower outer blade guard, and a

lower inner blade guard. Always keep each item in

place unless specifically instructed to move it. See

Figures 9A and 9D.

BLADE GUARD CLAMP SCREW - Secures the

blade guard to the motor. Located between the blade

and the motor. See Figure 9D.

ARM LOCK KNOB

MITER SCALE

RIP

SCALE(S)

COLUMN TUBE

COLUMN SUPPORT

Fig. 9B

CRDFT^MRN' RADIAL SAW 315.220380

Page 20

FEATURES

CARRIAGE - Slides along track under arm and

supports yoke. Contained in two carriage covers, one

on each side of the arm. See Figure 9C.

CARRIAGE LOCK KNOB - Controls whether the

carriage is locked or can travel. Located on the left

side of the arm on the carriage cover. See Figure 9C.

COLUMN - Upright housing at the back of the saw,

consisting of a column support and a column tube.

The column tube can be raised or lowered with the

elevating handwheel at the front of the saw. See

Figures 9A and 9B.

CONTROL CUT DEVICE - Limits carriage speed to

prevent climb, using a cable from the carriage to the

column. Has a separate motor on left side, which is

activated by the switch trigger in the handle. The

cable returns the carriage to the column when the

motor is not activated. Speed is adjusted with a

thumbwheel on the handle. It runs on a separate

120V AC single voltage circuit. See Figure 9C.

WARNING: When connecting only one of the

cords, squeeze the switch trigger in the handle. If

the main motor cord alone is connected, the

switch trigger in the handle will not operate the

control cut device. The carriage cannot be

advanced without power to the control cut device.

DUAL VOLTAGE - If needed, your main power

source may be rewired by a qualified electrician to

provide a 240V AC circuit. See the E/ecir/ca/section.

DUST GUIDE - Directs sawdust, created from the cut

being made, in the direction you set. Located at the

rear of the upper blade guard. See Figure 9D.

ELEVATING HANDWHEEL - The handwheel below

the worktable (in front) that changes the height of the

arm and the blade. See Figure 9C.

FENCE - Removable guide for work, which extends

across width of table. See Figure 9C,

FRONT TABLE - Fixed portion of the worktable that

supports the work. See Figure 9C.

HANDLE - Used to pull the yoke assembly. Mounted

on the yoke to the right of the blade. See Figure 9C.

HOLD DOWN - A metal guard to control workpiece

climb during rip cuts. When blade parallels arm, hold

down is over the back of the blade. See Figure 9D.

HOLD DOWN KNOB - Controls placement of the hold

down and locks it in place. See Figure 9D.

MITER SCALE - Shows the miter angle setting of the

arm. See Figure 98.

CONTROL

CUT MOTOR

SPACER

TABLE

FENCE

TRACK

CARRIAGE

LOCK KNOB

CARRIAGE

AND COVER

SWITCH

AND KEY

FRONT TABLE

ELEVATING

HANDWHEEL

CRRFTSMRN* RADIAL SAW 315.220380

Fig. 9C

Page 21

FEATURES

MOTOR (13/6.5 AMP) - Powers the blade and is

controlled by the switch and key at the front of the

arm. The powerful induction motor has a capacitor

start. It is mounted in the yoke and rotated with the

bevel index knob and bevel lock lever. See Figure 9B.

RIP SCALES - Show the distance from the fence to.

the blade. (In-rip scales are on the right side of the

arm, and out-rip scales are on the left side.) Upper

scales show the distance with the fence beside the

front table. Lower scales show the distance with the

fence in farthest back position. See Figure 9B.

RIVING KNIFE OR SPREADER - Located directly in

front of the blade and beside the anti-kickback pawls,

the riving knife keeps cut edges from binding during

rip cuts. See Figure 9D.

RIVING KNIFE BRACKET - Allows adjustment of the

riving knife. Located midway along the riving knife.

See Figure 9D.

RIVING KNIFE KNOB - Adjusts the riving knife and

locks both the pawls and the riving knife in place.

Located toward the top and front of the blade guard.

See Figure 9D.

SWITCH TRIGGER - Used to power the control cut

device to allow yoke assembly to be pulled forward.

Mounted in the handle. See Figure 9D.

SWITCH WITH KEY - Powers the blade motor.

Placed on the front of the arm for easy access. To

lock the switch once it has been pressed to OFF,

remove the yellow key. Place the key in a location that

is inaccessible to children and others not qualified to

use the tool.

See Figures 9A and 9C.

YOKE - Supports the blade and motor. Can be

pivoted to index the blade between rip and cross cuts.

Located between the carriage and the motor. See

Figure 9B.

YOKE PIVOT LATCH - Indexes the yoke (after it is

released) to position the blade to face right (out-rip

cut), front (cross cut), or left (in-rip cut). Located on

the right carriage cover. See Figure 9B.

YOKE LOCK HANDLE - Releases the yoke to allow

indexing for rip cut or cross cut. Located below the

yoke, on the right. See Figure 9B.

DUST GUIDE

HOLD DOWN

HOLD

DOWN KNOB

UPPER

BLADE GUARD

LOWER

BLADE GUARD

BLADE GUARD

CLAMP SCREW

SWITCH

TRIGGER

RIVING

KNIFE KNOB

RIVING KNIFE

RIVING

KNIFE BRACKET

21

ANTI-KICKBACK

PAWLS

BLADE

Fig. 9D

CRAFTSMAN' RADIAL SAW 315.220380

Page 22

ASSEMBLY

Assembly is best done in the area where the saw will

be used. When you remove the saw and hardware

from the packing materials, carefully check the items

with the Loose Parts list. If you are unsure about the

description of any part, refer to their illustrations. For

your convenience, all fasteners have been drawn

actual size. If any parts are missing, delay assembling

until you have obtained the missing part(s).

Your radiai arm saw is capable of a wide variety of

operations, and thus requires a number of initiai setup

adjustments. However, once the saw is set up, you

can check your saw in about ten minutes and correct

any misalignment with the procedures in the Adjust

ment section.

CAUTION: Perform ail the procedures in both

the Assembly and Adjustments sections before

using the saw. Run a check on your saw

frequently, referring to the Adjustments section.

Failure to perform the adjustments in the initiai

set up or on a frequent basis can result in poor

performance or machine damage.

ASSEMBLING LEG STAND

See Figures 10A - IOC.

■ Take the following hardware from the hardware

bags in the leg stand carton:

40 truss head screws (1/4-20 x 5/8 in.)

40 star washers (1/4 in.)

40 hex nuts (1/4-20)

■ Take the foliowing hardware from the remaining

hardware bags in the leg stand carton:

4 leveling feet

8 large hex nuts (3/8-16)

■ Obtain four legs and eight braces from the leg

stand carton. See the Loose Parts section.

Place a 3/8-16 hex nut on each leveling foot and

insert leveling feet into the bottom of the legs. Cap

with remaining 3/8-16 hex nuts but only finger

tighten. See Figure 10A.

Place a short upper brace inside two of the legs

(wide end of legs up) and align the three holes in

the brace with the holes in the legs.

Insert the screws. Add the star washers and 1/4-20

hex nuts. Finger tighten.

Instali a short lower brace on the legs.

See Figure 10A.

Repeat for the other end assembly.

Connect the leg sets with a long upper brace. Add

the hardware and finger tighten. Repeat for the

other side brace, then install the long lower braces.

See Figure 10B.

Tighten all screws, washers, and nuts with a 7/16

in. wrench and as needed a #2 phillips screwdriver.

Move the leg stand to the desired location. Using a

level, adjust the leveling feet by raising or iowering

the bolts with a 9/16 in. wrench.

When the leg stand is ievel, securely tighten all four

nuts with the wrench.

Your leg stand is now completely assembled and

ready for use. See Figure IOC.

Fig. 10C

Page 23

ASSEMBLY

MOUNTING SAW TO LEG STAND

See Figure 11.

A WARNING: Firmly bolt the saw to the leg stand

to keep the saw from tipping, walking, or sliding.

■ Locate the following hardware from a small hard

ware bag:

4 hex bolts {5/16-18 x 5/8 in.)

4 iockwashers (5/16 in.)

8 flat washers (11/32 in.)

4 hex nuts (5/16-18)

■ Place the saw on top of the leg stand so the holes

in the saw base line up with the holes on top of the

teg stand braces.

■ Put a washer on a screw, and put the screw and

washer into the hole in the saw base. Cap with

another washer, then a lockwasher and a hex nut.

Hand tighten the set.

■ install the other three sets and securely tighten all

four sets with a 1/2 in. wrench.

ATTACHING ELEVATING HANDWHEEL

See Figure 12.

A WARNING: Be sure the main power cord of

your saw is unplugged. Ignoring this precaution

could result in serious injury. Do not perform the

following steps unless the saw is unplugged.

The elevating handwheel adjusts the height of the

radial arm and the blade.

■ Take the handwheel, star washer, and screw

(10-24 X 5/8 in. Soc. Hd.) from the hardware bag.

■ Place the handwheel on the end of the elevating

shaft, which extends from the front of the saw base.

■ Place the star washer on the screw and thread

screw into the end of the shaft.

■ Securely tighten the screw with a 5/32 in. hex key.

■ Raise or lower the arm by turning the handwheel.

ELEVATING

SHAFT

SAW_

BASE

SCREW

LEG

STAND

WASHER

Fig. 12

FLAT

WASHER

LEG STAND

LOCKWASHER

HEX NUT

Fig. 11

23

CRDFTSMIIN’ RADIAL SAW 315.220380

Page 24

ASSEMBLY

INSTALLING THE YOKE ASSEMBLY

See Figures 13A - 13C.

The yoke rides in the carriage below the arm and

supports the motor, the biade guard, and the biade.

Install the yoke assembly from the front of the arm.

■ Remove the carriage stop screw and lockwasher

from below the front of the arm with a 1/4 in. hex

key. See Figure 13A.

ARM ViEWED FROM BELOW

LOCKWASHER

CARRIAGE STOP SCREW

1/4 in. HEX KEY

Remove the arm cap screws and arm cap from the

front of the arm with a phillips screwdriver. See

Figure 13B.

Fig. 13A

FOR CLARITY, CARRIAGE COVERS AND CARRIAGE LOCK

KNOB ARE NOT SHOWN IN ILLUSTRATION

ARM LOCK KNOB

BEARINGS (4)

CARRIAGE

YOKE

CARRIAGE

LOCK KNOB

ARM

ARM LOCK KNOB

ARM CAP

ARM

CAP SCREWS

Fig. 13B

Remove and discard the two motor setscrews in

the bottom of the motor. They are for shipping

purposes only.

Lock the arm with the arm lock knob, located on top

of the front of the arm, so the arm doesn’t swing

while you are mounting the yoke assembly.

Pick up the yoke assembly and carefully slip it onto

the carriage track below the arm. Keep it parallel

with the arm so bearings slide in smoothly. See

Figure 13C.

CARRIAGE COVER

Fig. 13C

Reinstall the carriage stop screw, the lockwasher,

arm cap, and arm cap screws. Tighten all screws

securely.

^ WARNING: Once the yoke assembly is on the

carriage track, reinstall the arm cap, the arm cap

screws, the carriage stop screw, and the

lockwasher. Do not risk serious injury or damage

to the saw by failing to replace these parts.

Tighten the carriage lock knob, on the carriage

cover on the left of the arm. to lock the yoke

assembly in place.

CRRFTSHRN’ RADIAL SAW 315.220380

24

Page 25

ASSEMBLY

REMOVING THE BLADE

See Figure 14.

Remove the blade and blade guard assembly during

setup for safety and better access. The blade guard

includes an upper blade guard, an outer lower guard,

and an inner lower guard. The lower inner guard

consists of two overlapping slotted metal strips. The

strips are held together with a retaining screw and a

nut. Locate these items before beginning the proce

dure.

iV WARNING: To prevent accidental contact with

^ the blade that could result in injury, remove the

blade and blade guard before making setups

involving the blade arbor and work stand. Use

the blade wrenches provided with your saw.

■ Remove the retaining screw and nut at the bottom

of the lower inner blade guard.

■ Loosen the guard clamp screw, a long thumbscrew

between the blade guard and the motor.

■ Rotate and lift the guard assembly up and over the

blade, then remove it.

■ Hold the blade arbor (motor shaft) with one of the

two blade wrenches provided. Put the other blade

wrench on the blade nut and turn it clockwise

(down), since the blade arbor has left hand threads.

■ Remove the blade nut. outer blade washer, saw

blade, and inner blade washer. Set these items

aside until all the tables have been installed and the

front table Is level.

ATTACHING TABLE SUPPORTS

See Figure 15.

The table supports are a base for the three wooden

table sections and fence.

■ Locate the two table supports and the following

hardware: •

4 square head bolts (5/16-18 x 3/4 in.)

4 lockwashers (5/16 in.)

4 hex nuts (5/16-18)

4 flat washers (5/16 in.)

■ Attach the supports to the side of the saw base.

There are holes in both sides of each support. The

long side of each support (with the slotted holes)

fits against the saw base.

■ Use two square head bolts per support. Inserted

from within the saw base outward.

■ Place a flat washer, a lock washer, and a hex nut

on the end of each screw,

■ Position table supports so that bolts are approxi

mately centered in slotted holes.

■ Finger tighten or snug with a 1/2 in. wrench only at

this time. Final adjustments will be made later in

Leveling The Table Supports section.

TABLE

SUPPORT

SQUARE

HEAD BOLT

THUMBSCREW

RETAINING

SCREW AND NUT

BUDE

ROTATION

BUDE

ARBOR

BUDE GUARD

OUTER BUDE

WASHER

INNER BUDE

TO

TIGHTEN

BLADE

WRENCH (2)

BUDE

WASHER

MOUNTTABLE SUPPORTS

Fig. 14 USING THESE HOLE LOCATIONS Fig. 15

25 CRBFTSMflH* RADIAL SAW 315.220380

Page 26

ASSEMBLY

SETTING THE ARM LOCK KNOB

See Figure 16.

It may be possible to move the arm when locked, if

the arm lock knob is too loose. If the arm does not

move freely when unlocked, the arm lock knob may

be too tight. Use this procedure to check and set the

arm lock knob by turning the arm lock wheel (under

the carriage arm).

■ Release the arm lock knob, located on top of the

arm at the front.

■ Swing the arm 30* to the left or the right, referring

to the miter scale on top of the column.

■ Lock the arm in place with the arm lock knob.

■ Apply a reasonable amount of pressure. The arm

can be forced but if it moves easily, it needs

adjustment.

■ Locate the arm lock wheel.

■ Release the arm lock knob and turn the lock wheel

clockwise to tighten or counterclockwise to loosen.

■ Repeat above steps until the arm movement is

minimized when locked.

ARM LOCK KNOB

ARM

ARM CAP

MOTOR

YOKE

ASSEMBLY

Lock the yoke lock handle. Grasp the motor with

both hands and apply reasonable pressure to see if

it slips. If it moves, reset the yoke lock handle as

follows.

Remove the arm cap screws and arm cap at the

front of the arm with a phillips screwdriver. See

Figure 13B.

Remove the carriage stop screw and lockwasher

with a 1/4 in. hex key. Carefully slide the yoke

assembly forward and off the carriage.

Place the yoke assembly in a spot where it will be

secure as you work on the top of the yoke.

Release the yoke lock handle. Tighten the center

nut with a 15/16 in. wrench until the lock handle is

centered between the two legs of the yoke.

Carefully replace the yoke assembly on the car

riage arm track. Slide it back about halfway.

Replace the carriage stop screw and lockwasher,

followed by the arm cap and arm cap screws.

Lock and test the yoke again. If it can be moved,

repeat the procedure until it is secure.

YOKE LOCK

HANDLE

Fig. 17A

SETTING THE YOKE CLAMP

See Figures 17A and 17B.

The yoke clamp keeps the yoke from rotating on the

carriage when you want the saw blade to be station

ary. Use this procedure to check and set the yoke

clamp.

■ Release the yoke lock handle (below the arm on

the right side) so the motor can be rotated.

■ Swivel the motor slightly, it should be at an angle in

between one of the preset positive stop angles.

CRRFTSMflN* RADIAL SAW 315.2203S0

CENTER NUT

YOKE LOCK

HANDLE

YOKE LEG

Fig. 17B

26

Page 27

SETTING THE BEVEL LOCK LEVER

See Figures 18A -18C.

The bevel lock lever locks the blade at desired angles

other than the preset positive stop angles. The bevel

lock lever is preset at the factory but may need

readjustment after shipping or extended use. Check

for overtightness or looseness and make any neces

sary adjustments as follows:

The bevel lock lever is located on the front of the yoke

assembly, near the bottom. It is attached to a clamp

bolt that controls the amount of tightness.

■ Pull the bevel lock lever fonward to unlock it. Use

the bevel index knob (just under the handle) to

rotate the motor approximately 30*. Lock the bevel

lock lever. ■

■ If the bevel lock lever is difficult to lock, the clàmp

bolt needs to be loosened. If the motor can bé

forced out of position, the clamp bolt needs to be

tightened.

■ Remove the socket screw (under the bevel lock

lever) and star washer with a 1/8 in. hex key.

■ Use the bevel lock handle as a wrench to tighten or

loosen the clamp bolt. The clamp bolt has a right

handed thread. Tighten it left to right.

■ When the bolt is correctly set, remove the bevel

lock lever from the clamp bolt and place it roughly

parallel to the yoke assembly.

■ Replace the socket screw and star washer. Re

check the tightness of the bevel lock lever. Repeat

the steps above until the motor is secure when

locked, and the bevel lock lever fits squarely

against the yoke assembly.

ASSEMBLY

STAR WASHER

SOCKET SCREW

1/8 in. HEX KEY

CLAMP BOLT

BEVEL

LOCK LEVER

Fig. 188

BEVEL ' BEVEL

LOCK LEVER INDEX KNOB MOTOR Fig. 18A

27

BEVEL LOCK LEVER IN

CORRECT LOCKED POSITION

Fig. 18C

CRRFTSMRN* RADIAL SAW 315.220380

Page 28

ASSEMBLY

TIGHTENING THE ARM AND COLUMN

See Figure 19.

There should be no play, vertical or horizontal, in the

arm relative to the column. If you can move the arm

up, down or sideways when it is unlocked, use the

following steps to tighten it. •

■ Using a Phillips screwdriver, remove the rear cover

screws (2) and rear cover from the back of the arm.

This uncovers the bolts on the column .

■ Tighten the top two bolts evenly until the arm is firm

and there is no vertical or horizontal movement.

■ Also check the two bottom hex nuts. It is not

necessary to tighten them as tight as the upper

■bolts. However they should be tightened even and

snug.

■ -Replace the rear cover and rear cover screws.

■ Tighten screws securely.

REAR

COVER SCREWS

REAR

COVER

ADJUSTING THE COLUMN TUBE

See Figures 20A - 200.

The purpose of this procedure is to check whether the

inner column tube is snug in the housing and to

remove any looseness. Looseness could result in a

poor cut or difficulty in elevating the carriage. The

column tube is the upper portion of the column and

extends from the column support.

Note: It is criticaiXo remove all looseness with this

procedure. If this procedure is not done cor

rectly, following adjustments will be wrong and

could result in machine damage.

This procedure checks both the elevating action and

the rotating action. If a check does not show loose

ness, do not perform the adjustment.

■ If the arm is not at 0' (straight forward), release the

arm lock knob, set the arm, and re-lock the arm

lock knob.

■ Elevation check: To check the elevation movement,

place your hand under the front of the radial arm.

Press upward on the radial arm. There should be

no play between the column tube and the column

support. The whole assembly should move as one.

See Figure 20A.

HEX NUT (2)

Fig. 19

SUPPORT

COLUMN

TUBE

ARM

Fig. 20A

CRRFTSMRN* RADIAL SAW 315.220380 28

Page 29

ASSEMBLY

Rotation check: To check the rotation, hold the front

of the arm with one hand and grasp the top of the

column support with the other. Press the arm to the

side. If there is play between the column support

and the column tube, it needs to be adjusted. See

Figure 20B.

COLUMN TUBE

COLUMN SUPPORT

Fig. 20B

Elevation Adjustment: If the elevation check did not

show any play between the column tube and the

support, go to the rotation adjustment. Othenwise,

raise and lower the arm with the elevating hand

wheel. Tighten the black screws on the right side of

the column support by 1/16th to 1/8th of a turn.

Tighten the two silver screws on the left side

slightly more. You will need two 1/2 in. wrenches or

sockets. Turn the elevating handwheel again. If the

column tube binds, loosen the silver and black

screws and turn the handwheel again. See Figure

20C.

When the elevation is smooth, check for looseness

again by pressing upward on the front of the arm.

Repeat the previous step until elevation is smooth

with no play between the column tube and the

column support.

Elevation Adjustment

COLUMN

TUBE

BUCK

SCREWS

Fig. 20C

Rotation Adjustment: Using a 3/16 in. hex key,

slightly tighten the two cap screws at the back of

the column support (left side) until no play shows

between the radial arm and the column. The cap

screws are indicated by arrows. See Figure 20D.

Recheck the rotation by holding the front of the

arm, grasping the top of the column support with

the other, and pressing the arm to the side.

Rotation Adjustment