Page 1

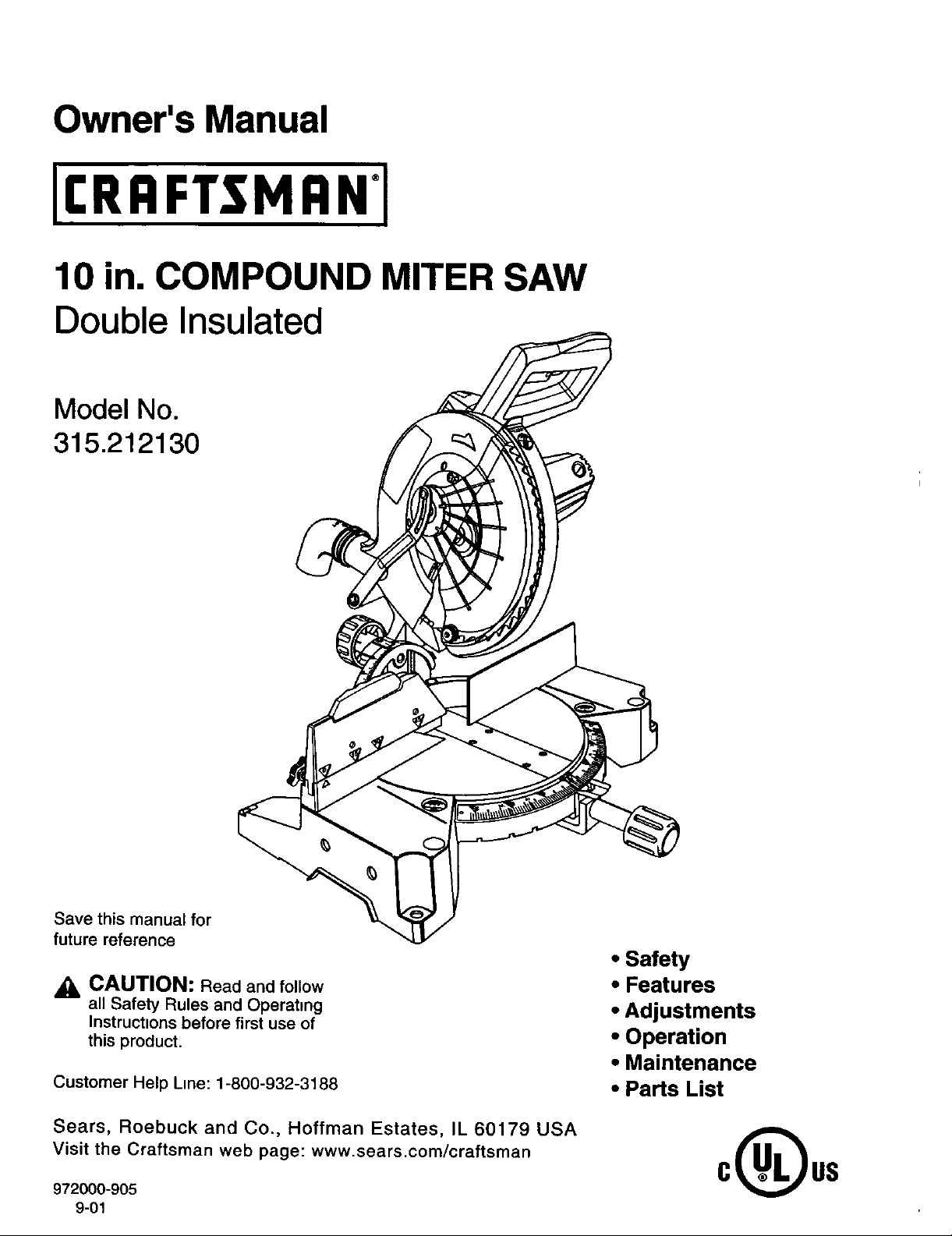

Owner's Manual

IERRFTSMRN'I

10 in. COMPOUND MITER SAW

Double Insulated

Model No.

315.212130

Save this manual for

future reference

_IL CAUTION: Read and follow

all Safety Rules and Operating

Instructions before first use of

this product.

Customer Help Line: 1-800-932-3188

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

972000-905

9-01

• Safety

• Features

• Adjustments

• Operation

• Maintenance

• Parts List

0( us

Page 2

• Table of Contents .............................................................................................................................................. 2

• Warranty and Introduction........ ......................................................................................................................... 2

• Rules For Safe Operation ............................................................................................................................. 3-6

• Glossary ............................................................................................................................................................ 6

• Product Specifications and Unpacking ............................................................................................................. 7

• Labels ................................................................................................................................................................ 8

• Loose Parts and Tools Needed ......................................................................................................................... 9

• Features .................................................................................................................................................... 10-12

• Adjustments ............................................................................................................................................... 13-19

• Operation ................................................................................................................................................... 20-26

• Maintenance .................................................................................................................................................... 27

• Exploded View and Repair Parts List ........................................................................................................ 28-35

• Parts Ordering/Service .................................................................................................................................... 36

FULL ONE YEAR WARRANTY

Ifthis product fails due to a defect in material or workmanship within one year from the date of purchase,

Sears will repair it free of charge.

Contact a Sears Service Center for repair.

If this product is used for commercial or rental purposes, this warranty applies only for 90 days from the date

of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

Your saw has many features for making cutting

operations more pleasant and enjoyable. Safety,

performance and dependability have been given top

priority in the design of this saw making it easy to

maintain and operate.

,_ CAUTION: Carefully read through this entire

owner's manual before using your new saw. Pay

close attention to the Rules For Safe Operation,

and all Safety Alert Symbols including Danger,

Warning and Caution. If you use your saw

properly and only for what it is intended, you will

enjoy years of safe, reliable service.

• ILLook for this symbol to point out important safety precautions. It

means attention!!! Your safety is involved.

WARNING:

The operation of any power tool can result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before beginning tool operation, always wear safety

goggles or safety glasses with side shields and a full face shield when needed. We

recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses

with side shields, available at Sears Retail Stores. Always wear eye protection which is

marked to comply with ANSI Z87.1.

Page 3

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the

explanations with them, deserve your careful attention and understanding. The safety wamings do not by

themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident

prevention measures.

SYMBOL

A

A

A

A

Note: Advises you of information or instructionsvital to the operation or maintenance of the equipment.

DOUBLE INSULATION

Double insulation isa concept in safety, in electric

power tools, which eliminates the need for the usual

three-wire grounded power cord. All exposed metal

parts are isolated from internal metal motor

components with protecting insulation. Double

insulated tools do not need to be grounded.

MEANING

SAFETY ALERT SYMBOL:

Indicates danger, waming or caution. May be used in conjunction with other symbols or picto-

graphs.

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in serious injuryto yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety waming may result in property damage or personal injury to

yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock

and personal injury.

IMPORTANT

Servicing requires extreme care and knowledge of the

system and should be performed only by a qualified

service technician. For service we suggest you return

the tool to your nearest Sears store or repair center for

repair. Always use original factory replacement parts

when servicing.

WARNING: Do not attempt to operate this tool

until you have read thoroughly and understand

completely all instructions, safety rules, etc.

contained in this manual. Failure to comply can

result in accidents involving fire, electrical shock,

or serious personal injury. Save owner's manual

and review frequently for continuing safe

operation, and instructingothers who may use

this tool.

READ ALL INSTRUCTIONS

KNOW YOUR POWER TOOL. Read the owner's

manual carefully. Learn the saw's applications

and limitations as well as the specific potential

hazards related to this tool.

GUARD AGAINST ELECTRICAL SHOCK by

preventing body contact with grounded surfaces

such as pipes, radiators, ranges, refrigerator

enclosures.

• KEEP GUARDS IN PLACE and in good working

order.

REMOVE WRENCHES AND ADJUSTING KEYS.

Get in the habit of checking, before turning on

tool, that hex keys and adjusting wrenches are

removed from tool.

• KEEP THE WORK AREA CLEAN. Cluttered work

areas and work benches invite accidents. DO

NOT leave tools or pieces of wood on the saw

while it is in operation.

• DO NOT USE IN DANGEROUS ENVIRON-

MENTS. Do not use power tools near gasoline or

other flammable liquids, in damp or wet locations,

or expose them to rain, Keep the work area well

lit.

KEEP CHILDREN AND VISITORS AWAY. All

visitors should wear safety glasses and be kept a

safe distance from work area. Do not let visitors

contact tool or extension cord while operating.

MAKE WORKSHOP CHILDPROOF with pad-

locks and master switches or by removing starter

keys.

DO NOT FORCE THE TOOL it will do the job

better and more safely at the rate for which it was

designed.

• USE THE RIGHT TOOL FOR THE JOB. Do not

force the tool or attachment to do a job it was not

designed for. Use it only the way it was intended.

3

Page 4

RULES FOR SAFE OPERATION (Continued)

• USE THE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition.

Use only a cord heavy enough to carry the

current your product will draw. An undersized

cord will cause a drop in line voltage resulting in

loss of power and overheating. A wire gage size

(A.W.G.) of at least 14 is recommended for an

extension cord 25 feet or less in length. If in

doubt, use the next heavier gage. The smaller

the gage number, the heavier the cord.

• INSPECT TOOL CORDS AND EXTENSION

CORDS PERIODICALLY and, if damaged, have

repaired by a qualified service technician at a

Sears store or repair center. Stay constantly

aware of cord location and keep Jtwell away

from the moving blade.

• DRESS PROPERLY. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other

jewelry that can get caught and draw you into

movmg parts. Nonslip footwear is recommended.

Also wear protective hair covering to contain long

hair.

ALWAYS WEAR SAFETY GLASSES WITH

SIDE SHIELDS. Everyday eyeglasses have only

impact-resistant lenses, they are NOT safety

glasses.

WEAR A DUST MASK to keep from inhaling fine

particles.

PROTECT YOUR HEARING. Wear hearing

protection during extended periods of operation.

moving parts, breakage of parts, saw stability, mount-

ing and any other conditions that may affect its

operation. A damaged part must be propedy

repaired or replaced or replaced by a qualified

service techmc_an at a Sears store or repair

center to avoid nsk of personal injury.

mmNEVER LEAVE TOOL RUNNING UNAT-

TENDED. TURN THE POWER OFF. Do not

leave tool untd it comes to a complete stop.

FIRMLY CLAMP OR BOLT your miter saw to a

workbench or table at approximately hip height.

USE ONLY CORRECT BLADES. Use the right

blade size, style and cutting speed for the mate-

nal and the type of cut. Do not use blades with

mcorrect size holes. Never use blade washers or

blade bolts that are defective or incorrect. The

maximum blade capacity of your saw is 10 in.

• KEEP BLADES CLEAN, SHARP, AND WITH

SUFFICIENT SET. Sharp blades minimize

staihng and kickback.

• DO NOT REMOVE THE SAW'S BLADE

GUARDS. Never operate the saw with any guard

or cover removed. Make sure all guards are

operating properly before each use.

• KEEP HANDS AWAY FROM CUl-rlNG AREA.

Do not reach underneath work or in blade cutting

path with your hands and fingers for any reason.

Always turn the power off.

,_ WARNING: Blade coasts after being turned off.

SECURE WORK. Use clamps or a vise to hold

work when practical. It's safer than using your

hand and frees both hands to operate tool

DO NOT OVERREACH. Keep proper footing and

balance at all times.

MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for better and safer perfor-

mance. Follow instructions for lubricating and

changing accessones.

DISCONNECT ALL TOOLS. When not in use,

before servicing, or when changing attachments,

all tools should be disconnected.

AVOID ACCIDENTAL STARTING. Be sure

switch msoff when plugging in any tool.

USE RECOMMENDED ACCESSORIES. Using

improper accessories may risk injury.

NEVER STAND ON TOOL. Senous injury could

occur if the tool is tipped or Ifthe blade is

unintentionally contacted.

CHECK DAMAGED PARTS. Before using the

tool again, check any damaged pads, including

guards, for proper operat=on and performance.

Check alignment of movmg parts, binding of

• DO NOT ABUSE CORD. Never yank cord to

disconnect it from receptacle. Keep cord from

heat, oil, and sharp edges.

USE ONLY OUTDOOR EXTENSION CORDS.

Use only extension cords with the marking

"Acceptable for use with outdoor appliances;

store cords mdoors whde not m use'. Use exten-

sion cords with an electncal rabng not less than

the saw's rating. Always disconnect the extension

cord from the outlet before disconnecting the

product from the extension cord.

m DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Have defective switches

replaced by a qualified service technician at a

Sears store or repair center.

KEEP TOOL DRY, CLEAN, AND FREE FROM

OIL AND GREASE. Always use a clean cloth

when cleanmg. Never use brake fluids, gasoline,

petroleum-based products, or any solvents to

clean tool.

ALWAYS SUPPORT LONG WORKPIECES

while cutting to mimmize risk of blade pmching

and kickback. Saw may slip, walk or slide whde

cuttmg long or heavy boards.

4

Page 5

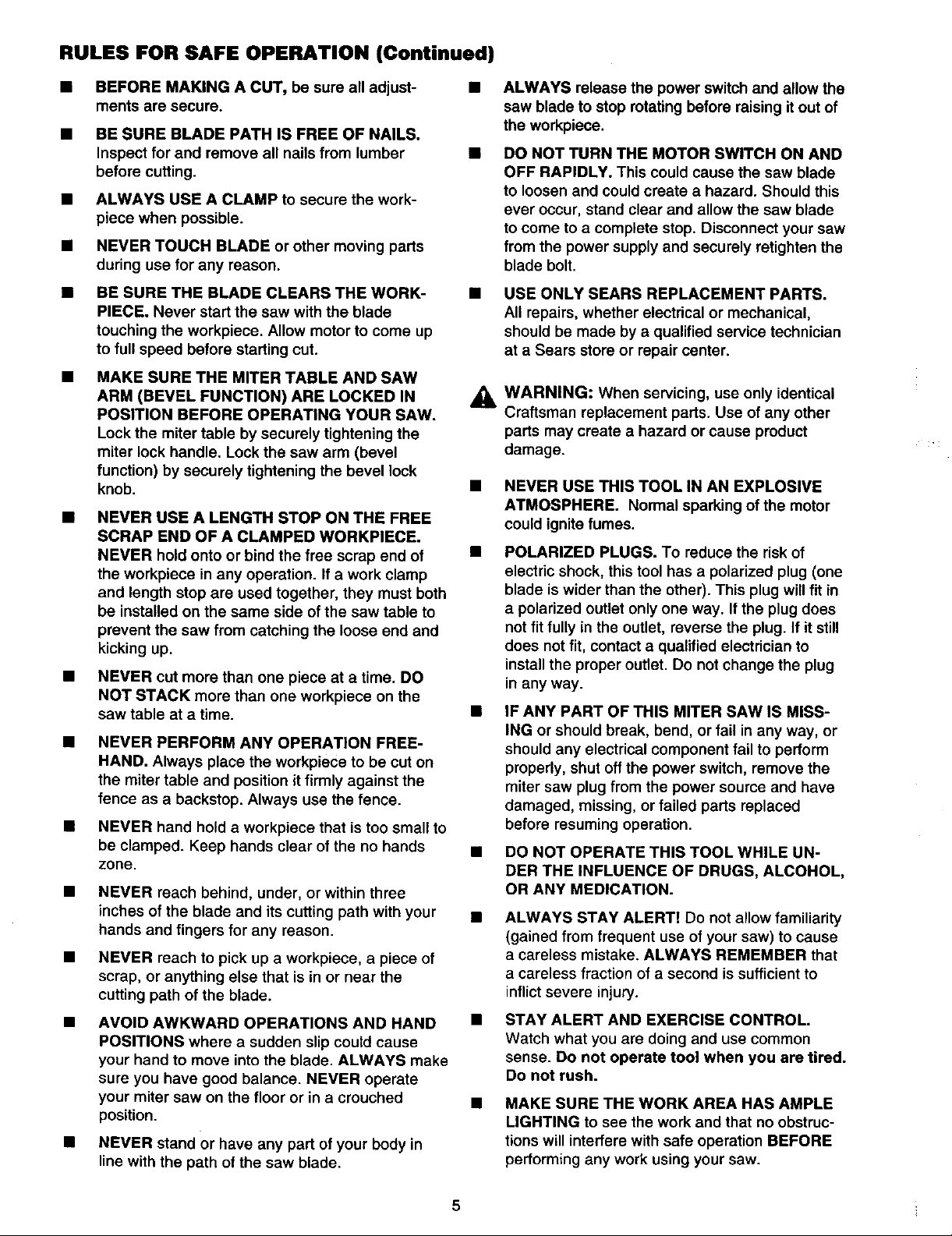

RULES FOR SAFE OPERATION (Continued)

BEFORE MAKING A CUT, be sure all adjust-

ments are secure.

BE SURE BLADE PATH IS FREE OF NAILS.

Inspect for and remove all nails from lumber

before cutting.

ALWAYS USE A CLAMP to secure the work-

piece when possible.

NEVER TOUCH BLADE or other moving parts

during use for any reason.

BE SURE THE BLADE CLEARS THE WORK-

PIECE. Never start the saw with the blade

touching the workpiece. Allow motor to come up

to full speed before starting out.

MAKE SURE THE MITER TABLE AND SAW

ARM (BEVEL FUNCTION) ARE LOCKED IN

POSITION BEFORE OPERATING YOUR SAW.

Lock the miter table by securely tightening the

miter lock handle. Lock the saw arm (bevel

function) by securely tightening the bevel lock

knob.

NEVER USE A LENGTH STOP ON THE FREE

SCRAP END OF A CLAMPED WORKPIECE.

NEVER hold onto or bind the free scrap end of

the workpiece in any operation. If a work clamp

and length stop are used together, they must both

be installed on the same side of the saw table to

prevent the saw from catching the loose end and

kicking up.

NEVER cut more than one piece at a time. DO

NOT STACK more than one workpiece on the

saw table at a time.

NEVER PERFORM ANY OPERATION FREE-

HAND. Always place the workpiece to be cut on

the miter table and position it firmly against the

fence as a backstop. Always use the fence.

NEVER hand hold a workpiece that is too small to

be clamped. Keep hands clear of the no hands

zone.

NEVER reach behind, under, or within three

inches of the blade and itscutting path with your

hands and fingers for any reason.

n

NEVER reach to pick up a workpiece, a piece of

scrap, or anything else that is in or near the

cutting path of the blade.

n AVOID AWKWARD OPERATIONS AND HAND •

POSITIONS where a sudden slip could cause

your hand to move into the blade. ALWAYS make

sure you have good balance. NEVER operate

your miter saw on the floor or in a crouched •

position.

• NEVER stand or have any part of your body in

line with the path of the saw blade.

l

ALWAYS release the power switch and allow the

saw blade to stop rotating before raising itout of

the workpiece.

DO NOT TURN THE MOTOR SWITCH ON AND

OFF RAPIDLY. This could cause the saw blade

to loosen and could create a hazard. Should this

ever occur, stand clear and allow the saw blade

to come to a complete stop. Disconnect your saw

from the power supply and securely retighten the

blade bolt.

USE ONLY SEARS REPLACEMENT PARTS.

All repairs, whether electrical or mechanical,

should be made by a qualified service technician

at a Sears store or repair center.

WARNING: When servicing, use only identical

A

Craftsman replacement parts. Use of any other

parts may create a hazard or cause product

damage.

NEVER USE THIS TOOL IN AN EXPLOSIVE

ATMOSPHERE. Normal sparking of the motor

could ignite fumes.

POLARIZED PLUGS. To reduce the risk of

electric shock, this tool has a polarized plug (one

blade is wider than the other). This plug will fit in

a polarized outlet only one way. Ifthe plug does

not fit fully in the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician to

install the proper outlet. Do not change the plug

in any way.

IF ANY PART OF THIS MITER SAW IS MISS-

ING or should break, bend, or fail in any way, or

should any electrical component fail to perform

properly, shut off the power switch, remove the

miter saw plug from the power source and have

damaged, missing, or failed parts replaced

before resuming operation.

DO NOT OPERATE THIS TOOL WHILE UN-

DER THE INFLUENCE OF DRUGS, ALCOHOL,

OR ANY MEDICATION.

ALWAYS STAY ALERT! Do not allow familiarity

(gained from frequent use of your saw) to cause

a careless mistake. ALWAYS REMEMBER that

a careless fraction of a second is sufficient to

inflictsevere injury.

STAY ALERT AND EXERCISE CONTROL.

Watch what you are doing and use common

sense. Do not operate tool when you are tired.

Do not rush.

MAKE SURE THE WORK AREA HAS AMPLE

LIGHTING to see the work and that no obstruc-

tions will interfere with safe operation BEFORE

performing any work using your saw.

5

Page 6

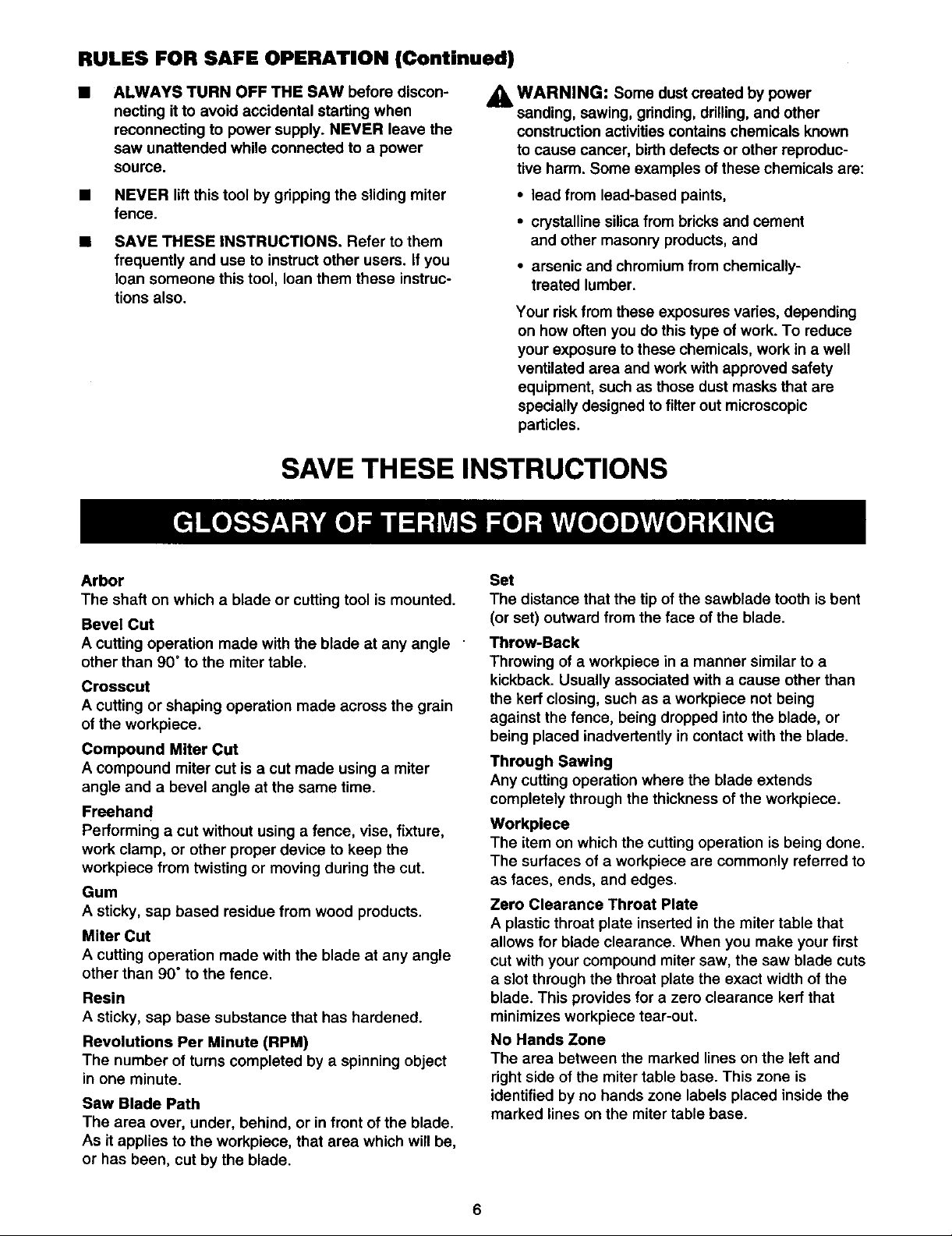

RULES FOR SAFE OPERATION (Continued)

ALWAYS TURN OFF THE SAW before discon-

necting itto avoid accidental starting when

reconnecting to power supply. NEVER leave the

saw unattended while connected to a power

source.

NEVER liftthis tool by gripping the sliding miter

fence.

SAVE THESE INSTRUCTIONS. Refer to them

frequently and use to instruct other users, if you

loan someone this tool, loan them these instruc-

tions also.

SAVE THESE INSTRUCTIONS

_ WARNING: Some dust created by power

sanding, sawing, grinding, drilling,and other

construction activities contains chemicals known

to cause cancer, birth defects or other reproduc-

tive harm. Some examples ofthese chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well

ventilated area and work with approved safety

equipment, such as those dust masks that are

specially designed tofilter out microscopic

particles.

Arbor

The shaft on which a blade or cutting tool is mounted.

Bevel Cut

A cutting operation made with the blade at any angle

other than 90" to the miter table.

Crosscut

A cutting or shaping operation made across the grain

of the workpiece.

Compound Miter Cut

A compound miter cut is a cut made using a miter

angle and a bevel angle at the same time.

Freehand

Performing a cut without using a fence, vise, fixture,

work clamp, or other proper device to keep the

workpiece from twisting or moving during the cut.

Gum

A sticky, sap based residue from wood products.

Miter Cut

A cutting operation made with the blade at any angle

other than 90" to the fence.

Resin

A sticky, sap base substance that has hardened.

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object

in one minute.

Saw Blade Path

The area over, under, behind, or in front of the blade.

As it applies to the workpiece, that area which will be,

or has been, cut by the blade.

Set

The distance that the tip of the sawblade tooth is bent

(or set) outward from the face of the blade.

Throw-Back

Throwing of a workpiece in a manner similar to a

kickback. Usually associated with a cause other than

the kerr closing, such as a workpiece not being

against the fence, being dropped into the blade, or

being placed inadvertently in contact with the blade.

Through Sawing

Any cutting operation where the blade extends

completely through the thickness of the workpiece.

Workpiece

The item on which the cutting operation is being done.

The surfaces of a workpiece are commonly referred to

as faces, ends, and edges.

Zero Clearance Throat Plate

A plastic throat plate inserted in the miter table that

allows for blade clearance. When you make your first

cut with your compound miter saw, the saw blade cuts

a slot through the throat plate the exact width ofthe

blade. This provides for a zero clearance kerr that

minimizes workpiece tear-out.

No Hands Zone

The area between the marked lines on the left and

right side of the miter table base. This zone is

identified by no hands zone labels placed inside the

marked lines on the miter table base.

6

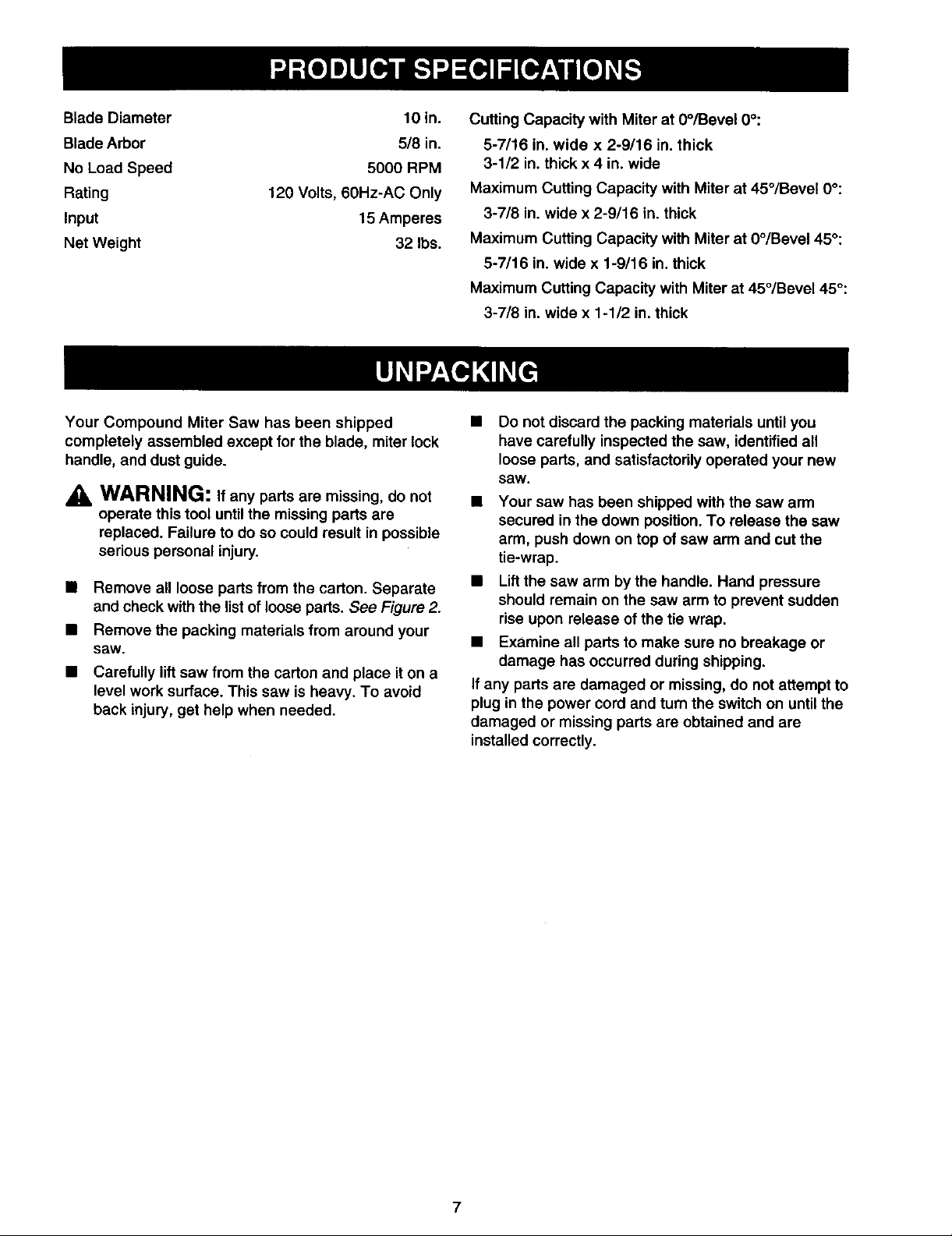

Page 7

BladeDiameter 10in.

BladeArbor 518in.

No Load Speed 5000 RPM

Rating 120 Volts, 60Hz-AC Only

Input 15 Amperes

Net Weight 32 Ibs.

Cutting Capacity with Miter at 0°/Bevel 0°:

5-7/16 in. wide x 2-9/16 in. thick

3-1/2 in. thick x 4 in. wide

Maximum Cutting Capacity with Miter at 45°/Bevel 0°:

3-7/8 in. wide x 2-9/16 in. thick

Maximum Cutting Capacity with Miter at 0°/Bevel 45°:

5-7/16 in.wide x 1-9/16 in. thick

Maximum Cutting Capacity with Miter at 45°/Bevel 45°:

3-7/8 in. wide x 1-1/2 in. thick

Your Compound Miter Saw has been shipped

completely assembled except for the blade, miter lock

handle, and dust guide.

WARNING: If any parts are missing, do not

operate this tool until the missing parts are

replaced. Failure to do so could result in possible

serious personal injury.

• Remove all loose parts from the carton. Separate

and check withthe list of loose parts. See Figure 2.

• Remove the packing materials from around your

saw.

• Carefully lift saw from the carton and place it on a

level work surface. This saw is heavy. To avoid

back injury, get help when needed.

Do not discard the packing materials untilyou

have carefully inspected the saw, identified all

loose parts, and satisfactorily operated your new

saw.

Your saw has been shipped with the saw arm

secured in the down position. To release the saw

arm, push down on top of saw arm and cut the

tie-wrap.

• Lift the saw arm by the handle. Hand pressure

should remain on the saw arm to prevent sudden

rise upon release of the tie wrap.

• Examine all parts to make sure no breakage or

damage has occurred during shipping.

If any parts are damaged or missing, do not attempt to

plug in the power cord and turn the switch on until the

damaged or missing parts are obtained and are

installed correctly.

7

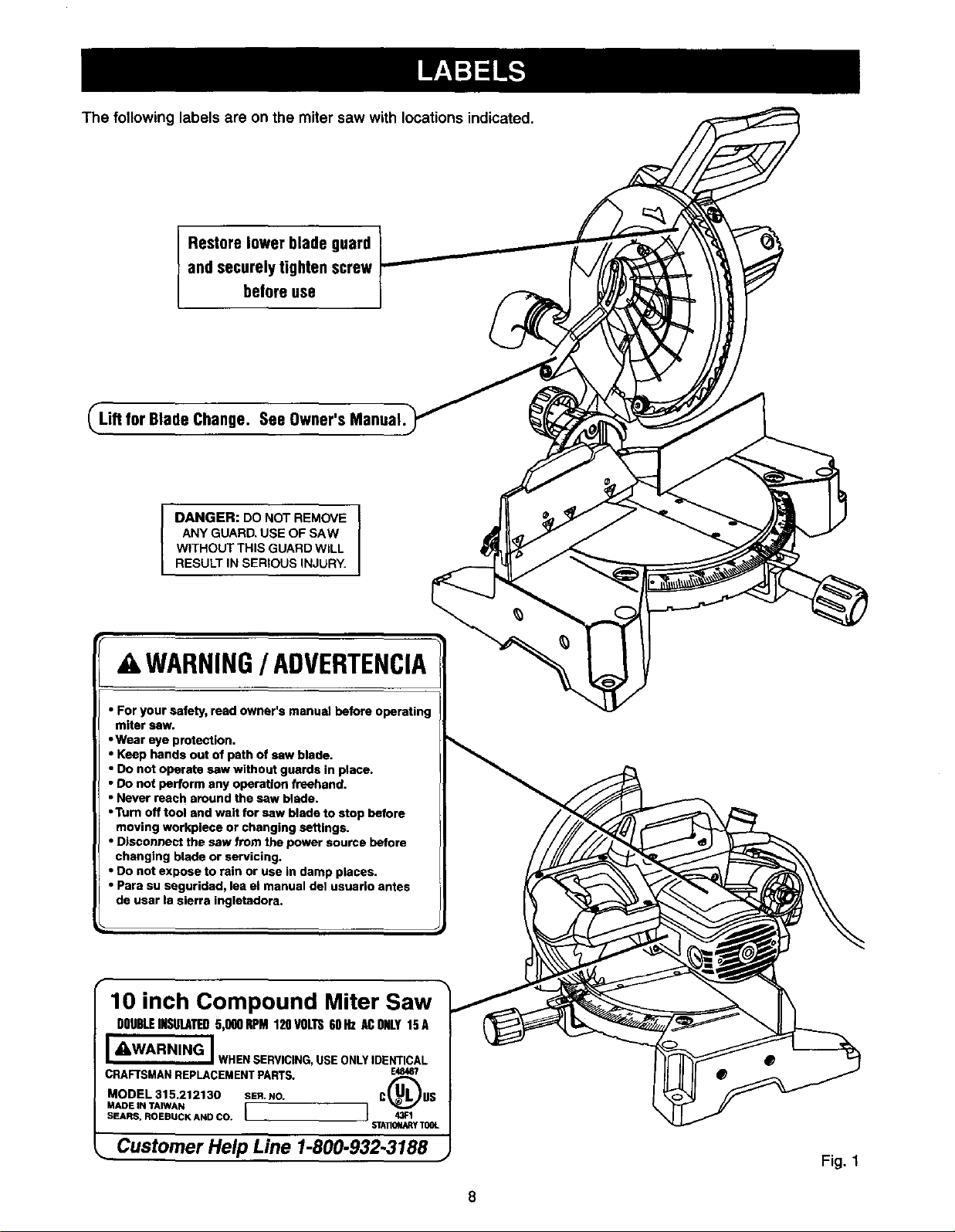

Page 8

The following labels are on the miter saw with locations indicated.

andsecurelytightenscrew

I Restorelowerbladeguard

beforeuse

CUlt for Blade Change. See

DANGER: DO NOT REMOVE

ANY GUARD, USE OF SAW

WITHOUT THIS GUARD WILL

RESULT IN SERIOUS INJURY.

A WARNING/ ADVERTENCIA

• For your safety, road owner's manual before operating

miter saw.

• Wear eye protection.

• Keep hands out of path of saw blade.

• Do not operate saw without guards in place.

• Do not perform any operation freehand.

• Never roach around the sew blade.

• "hJmoff tool and wait for sew blade to stop before

moving workpiece or changing settings.

• Disconnect the saw from the power source before

changing blade or servicing.

• Do not expose to rain or use in damp places.

• Para su seguridad, lea el manual del usuario antes

de usar la sierra ingletadora.

10 inch Compound Miter Saw

DOUBLEINSULATED5,000 RPM 120 VOLTS60HZ ACONLY15A

r AWARNING I WHENSERVICING,USE ONLYIDENTICAL

CRAFTSMANREPLACEMENTPARTS. s48467

MODEL 315.212130 SER.,O. C(_UL)us

MADE IN TAIWAN

SEARS, ROEBUCK A.D CO. L l 43F1

STAnONARYTOOl_

,.,,,Customer Help Line 1-800-932-3188

Fig. 1

Page 9

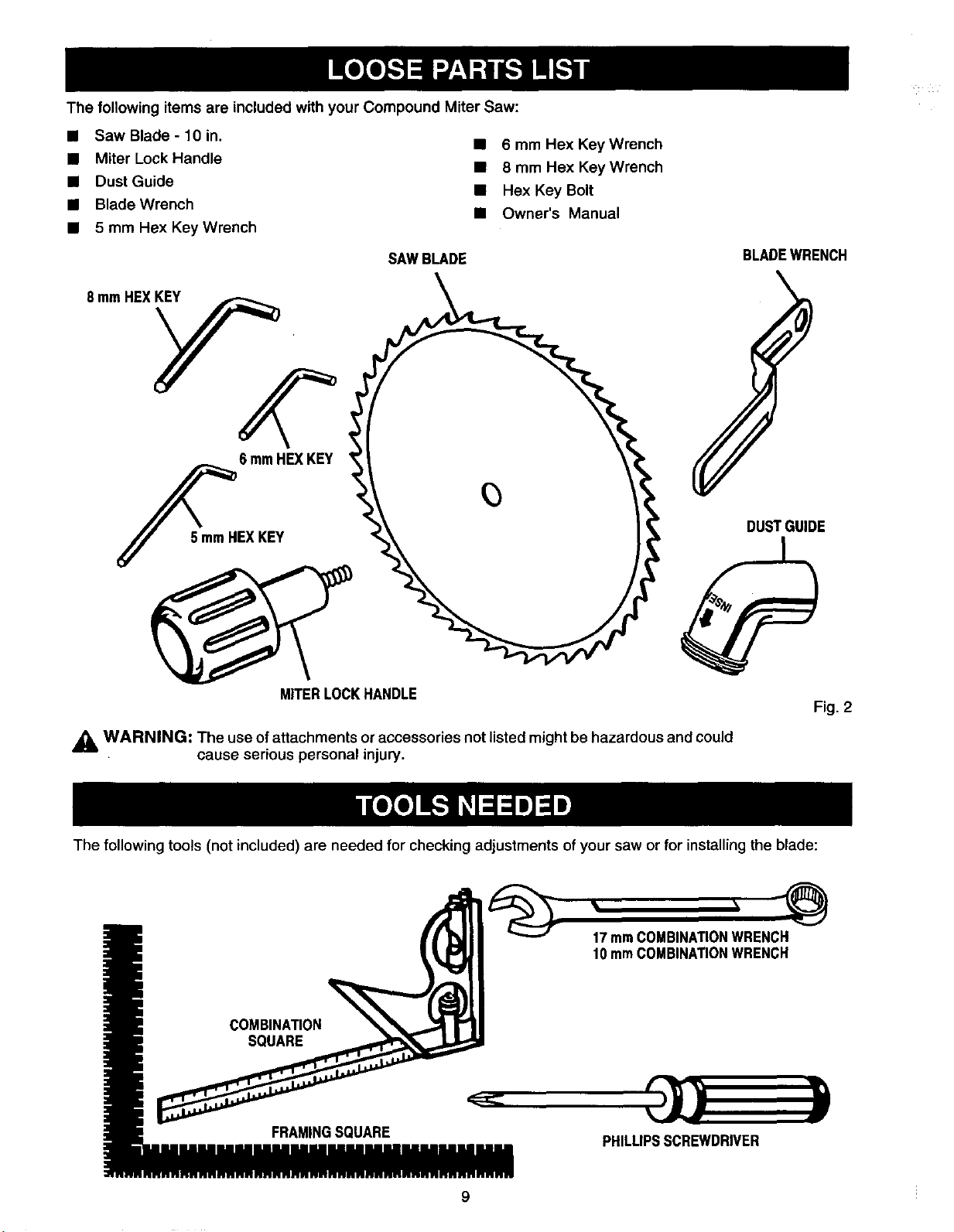

The following items are included with your Compound Miter Saw:

Saw Blade - 10 in. • 6 mm Hex Key Wrench

Miter Lock Handle : 8 mm Hex Key Wrench

Dust Guide Hex Key Bolt

Blade Wrench • Owner's Manual

5 mm Hex Key Wrench

SAWBLADE BLADEWRENCH

8 mmHEXKEY

6 mmHEXKEY

(b

5 mmHEXKEY

b DUSTGUIDE

k

MITERLOCKHANDLE

_1= WARNING: The use of attachments or accessories not listed might be hazardous and could

The following tools (not included) are needed for checking adjustments of your saw or for installingthe blade:

cause serious personal injury.

COMBINATION

SQUARE

FRAMINGSQUARE

17mmCOMBINATIONWRENCH

10mmCOMBINATIONWRENCH

PHILLIPSSCREWDRIVER

Fig. 2

9

Page 10

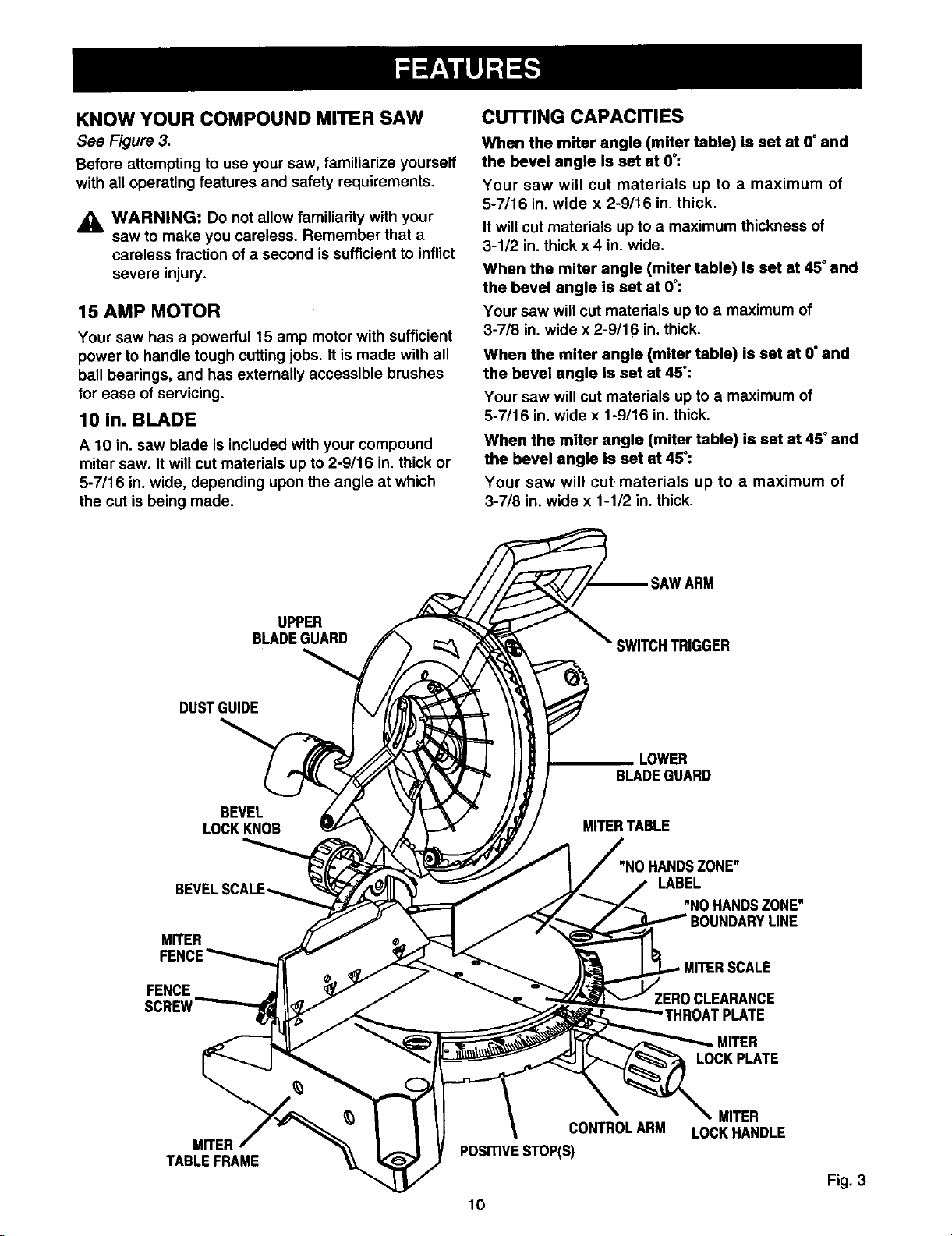

KNOW YOUR COMPOUND MITER SAW

See Figure 3.

Before attempting to use your saw, familiarize yourself

with all operating features and safety requirements.

_1, WARNING: Do not allow familiarity with your

saw to make you careless. Remember that a

careless fraction of a second issufficient to inflict

severe injury.

15 AMP MOTOR

Your saw has a powerful 15 amp motor with sufficient

power to handle tough cutting jobs. It is made with all

ball bearings, and has externally accessible brushes

for ease of servicing.

10 in. BLADE

A 10 in. saw blade is included with your compound

miter saw. It will cut materials up to 2-9/16 in. thick or

5-7/16 in. wide, depending upon the angle at which

the cut is being made.

CUTTING CAPACITIES

When the miter angle (miter table) is set at O° and

the bevel angle Is set at O°:

Your saw will cut materials up to a maximum of

5-7/16 in. wide x 2-9/16 in. thick.

It will cut materials up to a maximum thickness of

3-1/2 in. thick x 4 in. wide.

When the miter angle (miter table) is set at 45 +and

the bevel angle is set at O°:

Your saw will cut materials up to a maximum of

3-7/8 in. wide x 2-9/16 in. thick.

When the miter angle (miter table) is set at 0° and

the bevel angle is set at 450:

Your saw will cut materials up to a maximum of

5-7/16 in. wide x 1-9/16 in. thick.

When the miter angle (miter table) is set at 4S° and

the bevel angle is set at 45+:

Your saw will cut materials up to a maximum of

3-7/8 in. wide x 1-1/2 in. thick.

DUSTGUIDE

BEVEL!

MITER

FENCE

SCREW

BLADEGUARD

BEVEL

LOCKKNOB

SAWARM

UPPER

SWITCHTRIGGER

LOWER

BLADEGUARD

MITERTABLE

"NOHANDSZONE"

LABEL

"NOHANDSZONE"

SCALE

ZEROCLEARANCE

THROATPLATE

lITER

LOCKPLATE

MITER

TABLEFRAME

POSITIVESTOP(S)

10

CONTROLARM

MITER

LOCKHANDLE

Fig. 3

Page 11

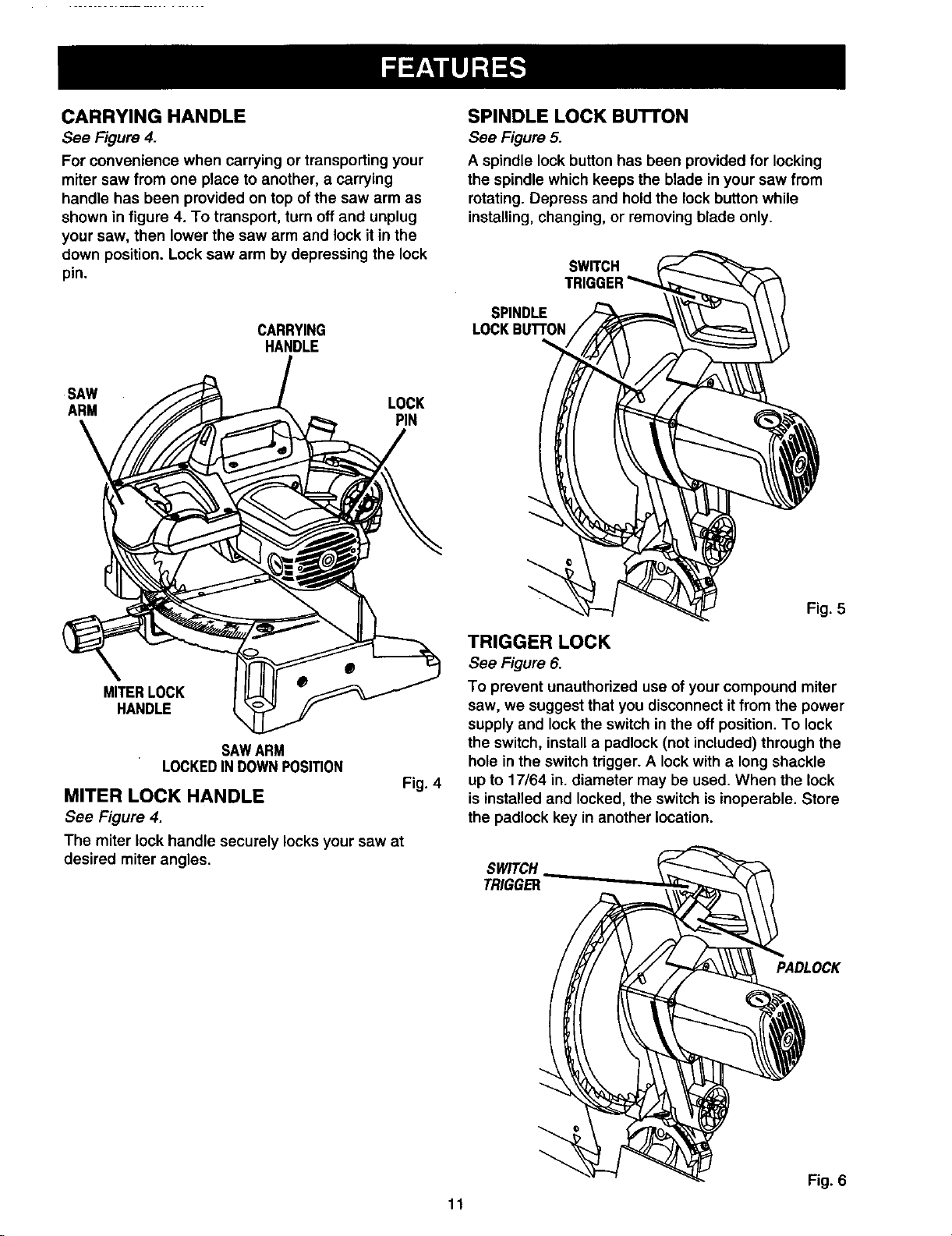

CARRYING HANDLE

See Figure 4.

For convenience when carrying or transporting your

miter saw from one place to another, a carrying

handle has been provided on top of the saw arm as

shown in figure 4. To transport, turn off and unplug

your saw, then lower the saw arm and lock it in the

down position. Lock saw arm by depressing the lock

pin.

CARRYING

HANDLE

SAW

ARM LOCK

PIN

SPINDLE LOCK BUTTON

See Figure 5.

A spindle lock button has been provided for locking

the spindle which keeps the blade in your saw from

rotating. Depress and hold the lock button while

installing, changing, or removing blade only.

SWRCH

SPINDLE

LOCKBUI"rON

MITERLOCK

HANDLE

SAWARM

LOCKEDIN DOWNPOSITION

MITER LOCK HANDLE

See Figure 4.

The miter lock handle securely locks your saw at

desired miter angles.

Fig. 4

Fig. 5

TRIGGER LOCK

See Figure6.

To prevent unauthorized use of your compound miter

saw, we suggest that you disconnect it from the power

supply and lock the switch in the off position. To lock

the switch, install a padlock (not included) through the

hole in the switch trigger. A lock with a long shackle

up to 17/64 in. diameter may be used. When the lock

is installed and locked, the switch is inoperable. Store

the padlock key in another location.

SWITCH

TRIGGER

PADLOCK

11

Fig. 6

Page 12

POSITIVE STOPS ON MITER TABLE

Positive stops have been provided at 0°, 22-1/2 ° and

45°. The 22-1/2 ° and 45 °positive stops have been

provided on both the left and right side of the miter

table.

BEVEL LOCK KNOB

_w

173/16"

l

The bevel lock knob securely locks your compound

miter saw at desired bevel angles. Positive stop

adjustment screws have been provided on each side

of the saw arm. These adjustment screws are for

making fine adjustments at 0°and 45°. See pages 17

and 18.

ELECTRIC BRAKE

An electric brake has been provided to quickly stop

blade rotation after the switch is released.

MITER FENCE

The miter fence on your compound miter saw has

been provided to hold your workpiece securely

against when making all cuts; the left side is also

larger providing additional support. It has a sliding

feature for clearance of the saw arm when making

bevel or compound cuts.

Loosen the fence screw before attempting to slide the

miter fence. Once the desired position of the miter

fence is determined, tighten the fence screw to secure

the sliding fence.

SELF-RETRACTING LOWER BLADE

GUARD

The lower blade guard is made of shock-resistant,

see-through plastic that provides protection from each

side of the blade. It retracts over the upper blade

guard as the saw is lowered into the workpiece.

103/16"

___ 7tt6"DIAHOLE

173/16"

24"

313_"

Fig. 7

noted, secure the workbench to the floor before

operating.

_, WARNING: Always make sure your compound

miter saw is securely mounted to a workbench or

an approved workstand. Failure to do so could

result in an accident resulting in possible serious

personal injury.

ELECTRICAL CONNECTION

Your saw has a precision built electric motor. It should

be connected to a power supply that Is 120 volts,

60Hz, AC only (normal household current). Do not

operate this tool on direct current (DC). A substantial

voltage drop will cause a loss of power and the motor

will overheat. If your tool does not operate when

plugged into an outlet, double-check the power

supply.

MOUNTING HOLES

See Figure 7.

Your compound miter saw should be permanently

mounted to a firm supporting surface such as a

workbench. Four bolt holes have been provided in the

saw base for this purpose. Each of the four mounting

holes should be bolted securely using 3/8 in. machine

bolts, lock washers, and hex nuts (not included). Bolts

should be of sufficient length to accommodate the

saw base, lock washers, hex nuts, and the thickness

of the workbench.

Tighten all four bolts securely.

The hole pattern for an 18 in. x 24 in. workbench is

shown in Figure 7. Carefully check the workbench

after mounting to make sure that no movement can

occur during use. If any tipping, sliding, or walking is

WARNING: The operation of any saw can

A

result in foreign objects being thrown into your

eyes, which can result in severe eye damage.

Before starting power tool operation, always

wear safety goggles or safety glasses with side

shields and a full face shield when needed. We

recommend wide vision safety mask for use over

eyeglasses or standard safety glasses with side

shields.

_i, WARNING: Do not attempt to modify this tool or

create accessories not recommended for use

with this tool. Any such alteration or modification

is misuse and could result in a hazardous

condition leading to possible serious personal

injury.

12

Page 13

_, WARNING: To prevent accidental starting that

could cause possible serious personal injury,

assemble all parts to your saw before connecting

itto power supply. Saw should never be

connected to power supply when you are

assembling parts, making adjustments, installing

or removing blades, or when not in use.

As mentioned previously your saw has been factory

assembled and adjusted. The miter lock handle, dust

guide, and blade are the only parts that have to be

installed.

MITER LOCK HANDLE

See Figure 8.

To install the miter lock handle, place the threaded

stud on the end of the miter lock handle intothe

threaded hole in the control arm. Turn clockwise to

tighten.

TO

LOOSEN

TO INSTALL BLADE

See Figures 10, 11, and 12.

WARNING: A 10 in. blade is the maximum

A

blade capacity of your saw. Never use a blade

that is too thick to allow outer blade washer to

engage with the flats on the spindle. Larger

blades will come in contact with the blade

guards, while thicker blades will prevent the

blade screw from securing the blade on the

spindle. Either of these situations could result in

a serious accident and can cause serious

personal injury.

• Unplug your saw.

,_ WARNING: Failure to unplug your saw could

result in accidental starting causing possible

serious personal injury.

• Push down on the saw arm and pull out the lock

pin to release saw arm. Raise saw arm to its full

raised position. Be cautious, saw arm is spring

loaded to raise.

• Loosen the phillips screw on the blade bolt

cover until blade bolt cover can be raised.

See Figure 10 and 11.

• Gently raise the lower blade guard bracket,

releasing lower blade guard from notch so that

lower blade guard and blade bolt cover can be

rotated up and back to expose the blade bolt. See

Figures lOand 11.

TIGHTEN

CONTROL

MITER ARM MITER

LOCKHANDLE TABLE

DUST GUIDE

See Figure 9.

To install the dust guide, place the end marked

INSERT over the exhaust port in the upper blade

guard. Turn the guide so that the open end isfacing

down or toward the rear of the saw.

EXHAUST

PORT

DUSTGUIDE

Fig. 8

Fig. 9

PHILLIPSSCREW

LOWER

BLADEGUARD

NOTCH

LOWERBLADE

GUARDBRACKET

Fig. 10

13

Page 14

LOWER PHILLIPS

BLADEGUARD SCREW

BLADE

BOLTCOVER

FLAT(S)

ONSPINDLE

TO WASHERWITH

LOOSEN DOUBLE"D" FLATS

BLADE

TIGHTEN

BLADEBOLT

• Depress the spindle lock button and rotate the

blade bolt until the spindle locks. See Figure 12.

• Using the blade wrench provided, loosen and

remove the blade bolt.

Note: The blade bolt has left hand threads. Turn

blade bolt clockwise to loosen.

• Remove outer blade washer. Do not remove

inner blade washer.

OUTERBLADEWASHER

WITHDOUBLE"D" FLATS

Fig. 11

• Fit saw blade inside lower blade guard and onto

spindle. The blade teeth point downward at the

front of saw as shown in figure 11.

CAUTION: Always install the blade with the

A

blade teeth and the arrow printed on the side of

the blade pointing down at the front of the saw.

The direction of blade rotation is also stamped

with an arrow on the upper blade guard.

• Replace outer blade washer. The double "D" flats

on the blade washers align with the flats on the

spindle.

• Depress spindle lock button and replace blade

bolt.

Note: The blade bolt has left hand threads. Turn

blade bolt counterclockwise to tighten.

• Tighten blade bolt securely.

• Remove the blade wrench and store it in a safe

place for future use.

• Replace the lower blade guard and blade bolt

cover.

• Retighten phillips screw securing blade bolt cover.

Tighten screw securely. See Figure 11.

_lL WARNING: Failure to tighten the phillips screw

can result in serious personal injury.

WARNING: Make sure the spindle lock button is

A

not engaged before reconnecting saw into power

source. Never engage spindle lock button when

blade is rotating.

SPINDLE

BuI"rON

Fig. 12

• Wipe a drop of oil onto inner blade washer and

outer blade washer where they contact the blade.

_l, WARNING: If inner blade washer has been

removed, replace it before placing blade on

spindle. Failure to do so could cause an accident

since blade will not tighten properly.

Your compound miter saw has been adjusted at the

factory for making very accurate cuts. However, some

of the components might have been jarred out of

alignment during shipping. Also, over a period of time,

readjustment will probably become necessary due to

wear. After unpacking your saw, check the following

adjustments before you begin using saw. Make any

readjustments that are necessary and periodically

check the parts alignment to make sure that your saw

is cutting accurately.

WARNING: Your saw should never be

connected to power supply when you are

assembling pans, making adjustments, installing

or removing blades, or when not in use.

Disconnecting your saw will prevent accidental

starting that could cause serious injury.

14

Page 15

Note: Many of the illustrations in this manual show

only portions of your compound miter saw. This is

intentional so that we can clearly show points being

made in the illustrations. Never operate your saw

without all guards securely in place and in good

operating condition.

SQUARING THE MITER TABLE

TO THE FENCE

See Figures 13 - 16.

• Unplug your saw.

MITERFENCE

MITERTABLE

_i, WARNING: Failure to unplug your saw could

result in accidental starting causing possible

serious personal injury.

• Push down on the saw arm and pull out the lock

pin to release the saw arm.

• Raise saw arm to its full raised position.

• Loosen the miter lock handle approximately one-

half turn.

Depress the miter lock plate and rotate the miter

table until the pointer on the control arm is posi-

tioned at 0°.

Release the miter lock plate and securely tighten

the miter lock handle.

Lay a framing square flat on the miter table. Place

one leg of the square against the fence. Place the

other leg of the square beside the zero clearance

throat plate in the miter table. The edge of the

square and the zero clearance threat plate in

the miter table should be parallel as shown in

figure 13.

If the edge of the framing square and the zero

clearance throat plate in the miter table are not

parallel as shown in figures 14 and 15, adjust-

ments are needed.

FRAMING MITER

SQUARE FENCE

MITERTABLE

FRAMING ZEROCLEARANCE

SQUARE THROATPLATE

VIEWOF MITERTABLENOTSQUAREWITH

FENCE,ADJUSTMENTSARE REQUIRED

Fig. 14

MITER

FRAMING ZEROCLEARANCE

SQUARE THROATPLATE

VIEWOFMITERTABLENOTSQUAREWITH

FENCE,ADJUSTMENTSAREREQUIRED

Fig. 15

• Using a 6 mm key, loosen the socket head screws

securing the fence. See Figure 16.Adjust the

fence left or right until the framing square and

zero clearance throat plate are parallel.

• Retighten the screws securely and recheck the

fence-to-table alignment.

LOCKPLATE

VIEWOF MITERTABLESQUAREWITHFENCE

ANDCORRECTLYADJUSTED Fig. 13

THROATPLATE

MITER

LOCKHANDLE

6 mmSOCKETHEAD 6 mmSOCKETHEAD

SCREW(S) SCREW(S)

Fig. 16

15

Page 16

SQUARING THE SAW BLADE TO THE

FENCE

See Figures 17 - 20.

• Unplug your saw.

_k WARNING: Failure to unplug your saw could

result in accidental starting causing possible

serious personal injury.

Pull the saw arm all the way down and engage

the lock pin to hold the saw arm in transport

position.

Loosen the miter lock handle approximately

one-half turn.

Depress the miter lock plate and rotate the miter

table until the pointer on the control arm is

positioned at O°.

Release the miter lock plate and securely tighten

the miter lock handle.

Lay a framing square flat on the miter table. Place

one leg of the square against the fence. Slide the

other leg of the square against the flat part of saw

blade.

Note: Make sure that the square contacts the flat

part of the saw blade, not the blade teeth.

The edge of the square and the saw blade should

be parallel as shown in figure 17.

If the front or back edge of the saw blade angles

away from the square as shown in figures 18 and

19, adjustments are needed.

Using the 8 mm hex key provided, loosen the

socket head screws that secure the mounting

bracket to the miter table. See Figure 20.

Rotate the mounting bracket left or right until the

saw blade is parallel with the square.

MITER

FENCE

\

• Retighten the screws securely and recheck the

blade-to-fence alignment.

MITER

FENCE

X

MITER FRAMING

TABLE SQUARE

VIEWOF BLADENOTSQUAREWITH

FENCE,ADJUSTMENTSAREREQUIRED Fig. 18

MITER

FENCE

BLADE

MITER FRAMING

TABLE SQUARE

VIEWOF BLADENOTSQUAREWITH

FENCE,ADJUSTMENTSAREREQUIRED

Fig. 19

FRAMING

MITER SQUARE

TABLE

VIEWOF BLADE

SQUAREWITHFENCE

BLADE

MITER

LOCK

PLATE

MITER

LOCKHANDLE

Fig. 17

16

8 mmHEXKEY

WRENCH

MITER

MOUNTING TABLE

BRACKET

Fig. 20

Page 17

SQUARING THE BLADE TO THE

MITER TABLE

See Figures 21 - 24.

• Unplug your saw.

,_ WARNING: Failure to unplug your saw could

result in accidental starting causing possible

serious personal injury.

Pull the saw arm all the way down and engage

the lock pin to hold the saw arm in transport

position.

Loosen the miter lock handle approximately one-

half turn.

Depress the miter lock plate and rotate the miter

table until the pointer on the control arm is posi-

tioned at 0".

Release the miter lock plate and securely tighten

the miter lock handle.

Loosen bevel lock knob and set saw arm at O°

bevel (blade set 90 ° to miter table). Tighten bevel

lock knob.

Place a combination square against the miter

table and the flat part of saw blade.

Note" Make sure that the square contacts the flat

part of the saw blade, not the blade teeth.

• Rotate the blade by hand and check the blade-to-

table alignment at several points.

• The edge of the square and the saw blade should

be parallel as shown in figure 21.

• Ifthe top or bottom of the saw blade angles away

from the square as shown in figures 22 and 23,

adjustments are needed.

MITER

FENCE

BLADE

COMBINATION

MITER SQUARE

TABLE

VIEWOFBLADENOTSQUAREWITHMITER

TABLE,ADJUSTMENTSAREREQUIRED

Fig. 22

•MITER

FENCE

MITER

FENCE

TABLE

LOCKHANDLE

CORRECTVIEWOF BLADE

SQUAREWITHMITERTABLE

MITER

Fig. 21

BLADE

COMBINA_ON

MITER SQUARE

TABLE

VIEWOFBLADENOTSQUAREWITHMITER

TABLE,ADJUSTMENTSAREREQUIRED

Using a 10 mm wrench or adjustable wrench,

loosen the lock nut securing positive stop adjust-

ment screw. Also loosen bevel lock knob.

Adjust positive stop adjustment screw to bring

saw blade intoalignment with the square. See

Figures 24 and 25.

Fig. 23

17

Page 18

POSITIVESTOP

ADJUSTMENT

SCREWFOR

TRAVEL PIVOT ADJUSTMENT

The saw arm should rise completely to the up

position by itself.

Ifthe saw arm does not raise by itself or if there is

play in the pivot joints, have saw repaired by a

qualified service technician at your nearest Sears

store or repair center to avoid risk of personal

injury.

BEVEL PIVOT ADJUSTMENT

• Your compound miter saw should bevel easily by

loosening the bevel lock knob and tilting the saw

arm to the left.

If movement is tight or if there is play in the pivot,

have saw repaired by a qualified service techni-

cian at your nearest Sears store or repair center

to avoid risk of personal injury.

Fig. 24

Retighten bevel lock knob. Next, retighten lock nut

securing the positive stop adjustment screw.

Recheck blade-to-table alignment.

Note: The above procedure can be used to check

blade squareness of the saw blade to the miter

table at both O°and 45°angles,

Your saw has three scale indicators, two on either

side of the bevel scale and one on the miter scale.

After squaring adjustments have been made, it may

be necessary to loosen the indicators screws and

reset them to zero.

cu'n'ING A SLOT IN THE ZERO

CLEARANCE THROAT PLATE

In order to use your compound miter saw, you must

cut a slot through the zero clearance throat plate to

allow for blade clearance. To cut the slot, set your

saw at 0° miter, turn saw on and allow the blade to

reach full speed, then carefully make a straight cut as

far as it will go through the throat plate. Turn your saw

off and allow the blade to come to a complete stop

before raising the saw arm.

Next, adjust the bevel angle to 45 °,turn your saw on

and allow the blade to reach full speed, then carefully

make another cut through the zero clearance throat

plate. The slot in the throat plate will then be wide

enough to allow the blade to pass through it at any

angle from O° to 45°.

PIVOT ADJUSTMENTS

Note: These adjustments were made at the factory

and normally do not require readjustment.

DEPTH STOP

The depth stop limits the blade's downward travel. It

allows the blade to go below the miter table enough to

maintain full cutting capacities. The depth stop

positions the blade 1/4 in. from the miter table

support.

Note: The miter table support is located inside miter

table.

The depth stop is factory set to provide maximum

cutting capacity for the 10 in. saw blade provided with

your saw. Therefore, the saw blade provided should

never need adjustments.

However, when the diameter of the blade has been

reduced due to sharpening, it may be necessary to

adjust the depth stop to provide maximum cutting

capacity. Also, when a new blade is installed, it is

necessary to check the clearance of the blade to the

miter table support before starting the saw. Make

adjustments if needed.

DEPTH STOP ADJUSTMENTS

See Figure 25.

• Unplug your saw,

_I, WARNING: Failure to unplug your saw could

result in accidental starting causing possible

sedous personal injury.

To adjust the depth stop use a 17 mm wrench or

adjustable wrench and loosen the hex nut at the

rear of the miter saw arm.

Use the 5 mm hex key wrench provided to adjust

the depth stop adjustment screw. The saw blade

is lowered by turning the screw counter-clockwise

and raised by turning the screw clockwise.

18

Page 19

DEPTHSTOP

ADJUSTMENT

SCREW

)

_h, WARNING: Before starting any cutting

operation, clamp or boltyour compound miter

saw to a workbench. Never operate your miter

saw on the floor or in a crouched position.

Failure to heed this warning can result in serious

personal injury.

BEVEL

TABLE

POSITIVE

STOPADJUSTMENT LOCKNUT(S)

SCREWFOR0°ANGLES

• Lower the blade into the zero clearance throat

plate of the miter table. Check blade clearance

and maximum cutting distance (distance from

fence where blade enters) to front of miter table

slot.

• Readjust if necessary.

_k, WARNING: Do not start your compound miter

saw without checking for interference between

the blade and the miter table support. Damage

could result to the blade if it strikes the miter

table support during operation of the saw.

Tighten the hex nut with a 17 mm wrench or

adjustable wrench.

To prevent the depth stop adjustment screw from

turning while tightening the hex nut, carefully hold

it with the hex key wrench while tightening the

hex nut.

Fig. 25

APPLICATIONS

(Use only for the purposes listed below)

• Cross cutting wood and plastic.

• Cross cutting miters, joints, etc. for picture frames,

moldings, door casings, and fine joinery.

Note: The blade provided is fine for most wood

cutting operations, but for fine joinery cuts or cutting

plastic, use one of the accessory blades available

from your nearest Sears store.

CUTTING WITH YOUR COMPOUND

MITER SAW

WARNING: When using a work clamp or

A

C-clamp to secure your workpiece, clamp

workpiece on one side of the blade only. The

workpiece must remain free on one side of the

blade to prevent the blade from binding in

workpiece. The workpiece bindingthe blade will

cause motor stalling and kickback. This situation

could cause an accident resulting in possible

sedous personal injury.

CROSSCUTTING

See Figure 26.

A crosscut is made by cutting across the grain of the

workpiece. A straight crosscut is made with the miter

table set at the 0° position. Miter crosscuts are made

with the miter table set at some angle other than zero.

TO CROSSCUT WITH YOUR MITER SAW

• Pull out the lock pin and liftsaw arm to itsfull

height.

• Loosen the miter lock handle. Rotate the miter

lock handle approximately one-half turn to the left

to loosen.

• Press the miter lock plate down with your thumb

and hold.

• Rotate the control arm until the pointer aligns with

the desired angle on the miter scale.

• Release the miter lock plate.

Note: You can quickly locate 0°,22-1/2 ° left or

right, and 45° left or right by releasing the lock

plate as you rotate the control arm. The lock plate

will seat itself in one of the positive stop notches,

located in the miter table frame.

• Tighten the miter lock handle securely.

WARNING: To avoid serious personal injury,

always tighten the miter lock handle securely

before making a cut. Failure to do so could result

in movement of the control arm or miter table

while making a cut.

19

Page 20

STRAIGHT

CROSSCUT

• C-CLAMP Fig, 26

Slowly lower the blade into and through the

workpiece. See Figure 26.

Release the switch trigger and allow the saw

blade to stop rotating before raising the blade out

of workpiece. Wait until the electric brake stops

blade from turning before removing the workpiece

from the miter table.

BEVEL CUT

See Figures 27 and 28.

A bevel cut is made by cutting across the grain ofthe

workpiece with the blade angled to the workpiece. A

straight bevel cut is made with the miter table set at

the zero degree position and the blade set at an angle

between 0° and 45°.

LEFTSIDE RIGHTSIDE

LEFT RIGHT

INDICATOR INDICATOR

POINT

Place the workpiece flat on the miter table with

one edge securely against the fence. If the board

is warped, place the convex side against the

fence. If the concave edge of a board is placed

against the fence, the board could collapse on the

blade at the end of the cut, jamming the blade.

See Figures 33 and 34.

• When cutting long pieces of lumber or molding,

support the opposite end of the stock with a roller

stand or with a work surface level with the saw

table. See Figure 31.

• Align cutting line on the workpiece with the edge

of saw blade.

Grasp the stock firmly withone hand and secure

it against the fence. Use the optional work clamp

or a C-clamp to secure the workpiece when

possible. See Figure 26.

_, WARNING: To avoid serious personal injury,

keep your hands outside the no hands zone; at

least 3 in. from blade. Never perform any cutting

operation freehand (without holding workpiece

against the fence). The blade could grab the

workpiece if it slips or twists.

Before turning on the saw, perform a dry run of the

cutting operation just to make sure that no

problems win occur when the cut is made.

Grasp the saw handle firmly then squeeze the

switch trigger. Allow several seconds for the blade

to reach maximum speed.

SCALE

MOUNTINGBRACKET

Fig. 27

TO BEVEL CUT WITH YOUR MITER SAW

• Pull out the lock pin and liftsaw arm to its full

height.

• Loosen the miter lock handle. Rotate the miter

lock handle approximately one-half turn to the left

to loosen.

• Press the miter lock plate down with your thumb

and hold.

• Rotate the control arm until the pointer aligns with

zero on the miter scale.

• Release the miter lock plate.

Note: You can quickly locate zero by releasing

the lock plate as you rotate the control arm. The

lock plate will seat itself in one of the built-in

positive stop notches, located in the miter table

frame.

• Tighten the miter lock handle securely.

_L, WARNING: To avoid serious personal injury,

always tighten the miter lock handle securely

before making a cut. Failure to do so could result

in movement of the control arm or miter table

while making a cut.

2O

Page 21

FENCE

SCREW

BEVELCUT

C-CLAMP Fig. 28

When cutting long pieces of lumber or molding,

support the opposite end of the stock with a roller

stand or with a work surface level with the saw

table. See Figure 31.

Align the cutting line on the workpiece with the

edge of saw blade.

Grasp the stock firmly with one hand and secure it

against the fence. Use the optional work clamp or

a C-clamp to secure the workpiece when pos-

sible. See Figure 28.

_, WARNING: To avoid serious personal injury,

keep your hands outside the no hands zone; at

least 3 in. from blade. Never perform any cutting

operation freehand (without holding workpiece

against the fence). The blade could grab the

workpiece if it slips or twists.

• Before turning on the saw, perform a dry run of

the cutting operation just to make sure that no

problems will occur when the cut is made.

• Grasp the saw handle firmly then squeeze the

switch trigger. Allow several seconds for the blade

to reach maximum speed.

• Adjustments of the miter fence must be made to

correspond to the desired angle of the bevel cut

prior to tilting the saw arm. The fence is marked

for 15°, 30°, or 45°. Loosen the fence screw on the

miter fence, slide the fence to the desired position,

and retighten the fence screw. See Figure 28.

• The 45° triangle on the miter fence provides for

the maximum clearance required for adjusting the

miter saw's angle when making a bevel or com-

pound cut.

• Loosen the bevel lock knob and move the saw

arm to the left to the desired bevel angle.

• Bevel angles can be set from 0°to 45°.

• For your convenience there is a double scale

located on the mounting bracket. See Figure 27. If

one side becomes difficult to read as you move

the saw arm to the left, simply refer to the other

side. Align the indicator point for the side you

choose with the desired angle.

• Once the saw arm has been set at the desired

angle, securely tighten the bevel lock knob.

Place the workpiece flat on the miter table with

one edge securely against the fence. If the board

is warped, place the convex side against the

fence. If the concave edge of a board is placed

against the fence, the board could collapse on the

blade at the end of the cut, jamming the blade.

See Figures 33 and 34.

• Slowly lower the blade into and through the

workpiece. See Figure 28.

Release the switch tdgger and allow the saw

blade to stop rotating before raising the blade out

of workpiece. Wait until the electric brake stops

blade from turning before removing the workpiece

from miter table.

COMPOUND MITER CUT

A compound miter cut is a cut made using a miter

angle and a bevel angle at the same time. This type of

cut is used to make picture frames, cut molding, make

boxes with sloping sides, and for certain roof framing

cuts.

To make this type of cut the control arm on the miter

table must be rotated to the correct angle and the saw

arm must be tilted to the correct bevel angle. Care

should always be taken when making compound miter

setups due to the interaction of the two angle settings.

Adjustments of miter and bevel settings are interde-

pendent with one another. Each time you adjust the

miter setting you change the effect of the bevel

setting. Also, each time you adjust the bevel setting

you change the effect of the miter setting.

It may take several settings to obtain the desired cut.

The first angle setting should be checked after setting

the second angle, since adjusting the second angle

affects the first.

Once the two correct settings for a particular cut have

been obtained, always make a test cut in scrap

matedal before making a finish cut in good matedal.

21

Page 22

TO MAKE A COMPOUND CUT WITH YOUR

MITER SAW

• Recheck miter angle setting. Make a test cut in

scrap matedal.

• Pull out the lock pin and liftsaw arm to its full

height.

• Loosen the miter lock handle. Rotate the miter lock

handle approximately one-half turn to the left to

loosen.

• Press the miter lock plate down with your thumb

and hold.

• Rotatethe control arm until the pointer aligns with

the desired angle on the miter scale.

• Release the miter lock plate.

Note: You can quickly locate 0°, 22-1/2" leftor

dght, and 45" left or right by releasing the miter

lock plate as you rotate the control arm. The miter

lock plate will seat itself in one of the positive stop

notches, located in miter table frame.

• Tighten the miter lock handle securely.

WARNING: To avoid serious personal injury,

A

always tighten the miter lock handle securely

before making a cut. Failure to do so could result

in movement of the control arm or miter table

while making a cut.

Place the workpiece flat on the miter table with

one edge securely against the fence. If the board

iswarped, place the convex side against the

fence. If the concave edge of a board could

collapse on the blade at the end of the cut,

jamming the blade. See Figures 33 and 34.

When cutting long pieces of lumber or molding,

support the opposite end ofthe stock with a roller

stand or with a work surface level with the saw

table. See Figure 31.

• Align the cutting line on the workpiece with the

edge of saw blade.

• Grasp the stock firmly withone hand and secure it

against the fence. Use the optional work clamp or

a C-clamp to secure the workpiece when _ossible.

See Figure 29.

,_ WARNING: To avoid serious personal injury,

always keep your hands outside the no hands

zone; at least 3 in. from blade. Never perform any

cutting operation freehand (without holding

workpiece against the fence). The blade could

grab the workpiece ifit slips or twists.

Adjustments of the miter fence must be made to

correspond to the desired angle of the bevel cut

prior to tilting the saw arm. The fence is marked

for 15°, 30°, or 45°. Loosen the fence screw on the

miter fence, slide the fence to the desired position,

and retighten the fence screw. See Figures 28

and 29.

The 45° triangle on the miter fence provides for the

maximum clearance required for adjusting the

miter saw's angle when making a bevel or com-

pound cut.

• Loosen the bevel lock knob and move the saw

arm to the left to the desired bevel angle.

• Bevel angles can be set from 0° to 45".

For your convenience there is a double scale

located on the mounting bracket. See Figure 27. If

one side becomes difficult to read as you move the

saw arm to the left, simply refer to the other side.

Align the indicator point for the side you choose

with the desired angle.

• Once the saw arm has been set at the desired

angle, securely tighten the bevel lock knob.

C&LAMP

COMPOUND

MITERCUT

Fig. 29

22

Page 23

• Before turning on the sew, perform a dry run of the

cutting operation just to make sure that no

problems will occur when the cut is made.

• Grasp the saw handle firmly then squeeze the

switch trigger. Allow several seconds for the blade

to reach maximum speed.

Slowly lower the blade into and through the work-

piece. See Figures 29 and 30.

Release the switch trigger and allow the saw

blade to stop rotating before raising the blade out

of workpiece. Wait until the electric brake stops

blade from turning before removing the workpiece

from miter table.

SUPPORT LONG WORKPIECES

See Figure 31.

Long workpieces need extra supports. Supports

should be placed along the workpiece so itdoes not

sag. The support should let the workpiece lay flat on

the base of the saw and work table during the cutting

operation. Use the optional work clamp or a C-clamp

to secure the workpiece.

45"x45"COMPOUNDMITERCUT

Fig. 30

,_ WARNING: To avoid serious personal injury,

always keep your hands outside the no hands

zone; at least 3 in. from blade. Never perform

any cutting operation freehand (without holding

workpiece against the fence). The blade could

grab the workpiece if it slips or twists.

LONGWORKPIECE

WORKPIECESUPPORTS

23

Fig. 31

Page 24

cu'n'ING COMPOUND MITERS

To aid in making the correct settings, the compound angle setting chart below has been provided. Since com-

pound cuts are the most difficult to accurately obtain, trial cuts should be made in scrap material, and much

thought and planning made, pdor to making your required cut.

PITCH

NUMBEROFSIDES

OFSIDE 4 I 5 I 6 I 7 I 8 I 9 10

0o M-45.00 ° M- 36.00 ° M- 30.00 ° M- 25.71° M- 22.50 ° M- 20.00 ° M- 18.00 °

5o

10°

15°

20°

25°

30° M-40.89 ° M-32.18 ° M- 26.57 ° M-22.64 ° M- 19.73° M- 17.50 ° M- 15.72 °

35°

40 °

45 °

50° B-32.80 ° B-26.76 ° B-22.52 ° B-19.41° B-17.05 ° B-15.19 ° B-13.69 °

55 °

60 °

65°

70o

B- 0.00 ° B- 0.00 ° B- 0.00 ° B- 0.00 ° B- 0.00° B- 0.00 ° i B- 0.00°

M-44.89 ° M- 35.90 ° M-29.91 ° M-25.63 ° M- 22.42 ° M- 19.93 ° M- 17.94°

B- 3.53 ° B- 2.94 ° B- 2.50 ° B- 2.17 ° B- 1.91° B- 1.71° B- 1.64°

M-44.56 ° M-35.58 ° M- 29.62 ° M- 25.37 ° M-22.19 ° M- 19.72 ° M- 17.74 °

B- 7.05 ° B- 5.86 ° B- 4.98 ° B- 4.32 ° B- 3.81 ° B- 3.40° B- 3.08 °

_-44.01 ° M-35.06 ° M-29.15 ° M-24.95 ° M-21.81 ° M-19.37 ° M-17.42 °

B-10.55 ° B- 8.75 ° B- 7.44° B- 6.45 ° B- 5.68 ° B- 5.08 ° B- 4.59 °

M-43.22 ° M-34.32 ° M-28.48 ° M-24.35 ° ! M-21.27 ° M- 18.88 ° M- 16.98 °

B-14.00 ° B-11.60 ° B- 9.85 ° B- 8.53 ° B- 7.52 ° B- 6.72 ° B- 6.07 °

M-42.19 ° M-33.36 ° M-27.62 ° M-23.56 ° M-20,58 °' M-18.26 ° M-16.41°

B- 17.39 ° B- 14.38 ° B- 12.20 ° B- 10.57 ° B- 9.31 ° B- 8.31 ° B- 7.50 °

B-20.70 ° B-17.09 ° B-14.48 ° B-12.53 ° B-11.03 ° B- 9.85° B- 8.89 °

M- 39.32 ° !M- 30.76 ° _M- 25.31 ° M- 21.53 ° M- 18.74 ° M- 16.60 ° M- 14.90°

B- 23.93 ° B- 19.70 ° B- 16.67 ° B- 14.41 ° B- 12.68 ° B- 11,31 ° B- 10.21 °

M- 37,45 ° M-29.10 ° M-23.86 ° M-20.25 ° M- 17.60 ° M- 15.58 ° M- 13.98 °

B-27.03 ° B-22,20 ° B-18.75 ° B-16.19 ° iB-14.24 ° B-12.70 ° B-11.46 °

M- 35.26 ° _1-27.19 ° M-22.21 ° M- 18.80 ° M- 16.32 ° M- 14.43 ° M- 12.94 °

B- 30.00 ° B- 24.56 ° B- 20.70 ° B- 17.87° B- 15.70° i B- 14.00 ° B- 12.62°

M-32.73 ° M-25.03 ° M- 20.36 ° M- 17.20° M- 14.91 ° M- 13.17° M- 11.80 °

M. 29.84 o M-22.62 ° M-18.32 ° M-15.44 ° M-13.36 ° M-11.79 ° M-10.56 °

B-35.40 ° B-28.78 ° B-24.18 ° B- 20.82 ° B-18.27 ° B-16.27 ° B-14.66 °

M-26.57 ° M-19.96 ° M-16.10 ° M-13.54 ° M-11.70 ° M-10.31 ° M- 9.23 °

B- 37.76 ° B- 30.60 ° B- 25.66 ° B- 22.07 ° B- 19.35 ° B- 17.23 ° B- 15.52°

M-22.91 ° M-17.07 ° M-13.71 ° M-11.50 ° M- 9.93 ° M- 8.74 ° M- 7.82 °

B- 39.86 ° B-32.19 ° B-26.95 ° B-23.16 ° B-20.29 ° B- 18.06° B-16.26 °

M-18.88 ° M-13.95 ° M-11.17 ° M- 9.35 ° M- 8.06 ° M- 7.10 ° M- 6.34 °

B-41.64 ° B-33.53 ° B- 28.02 ° B- 24.06 ° B-21.08 ° B- 18,75 ° B- 16.88°

75 ° M-14.51 ° M-10.65 ° M- 8.50 ° M- 7.10 ° M- 6.12° M- 5.38 ° M- 4.81 °

80 °

85° B- 44.78 ° B- 35.84 ° B- 29.87 ° B- 25.61 ° B- 22.41 ° B- 19.92 ° B- 17.93 °

90° B- 45.00 ° B- 36.00 ° B- 30.00 ° B- 25.71° B- 22.50 ° B- 20.00 ° B- 18.00 °

B- 43.08 ° B- 34.59 ° B- 28.88 ° B- 24.78 ° B- 21.69 ° B- 19.29 ° B- 17.37°

M- 9.85° M- 7.19 ° M- 5.73 ° M- 4.78 ° M- 4.11° M- 3.62 ° M- 3.23 °

B-44.14 ° B-35.37 ° B- 29.50 ° B- 25.30 ° B-22.14 ° B- 19.68 ° B- 17.72 °

M- 4.98° M- 3.62 ° M- 2.88 ° M- 2,40° M-2.07 ° M-1.82 ° M- 1.62°

M- 0.00 ° M- 0.00 ° M- 0,00 ° M- 0.00 ° M- 0.00 ° M- 0.00° M- 0.00°

Each B (Bevel) and M (Miter) Setting is Given to the Closest 0.005 °.

COMPOUND-ANGLE SETTINGS FOR POPULAR STRUCTURES

24

Page 25

CUTTING CROWN MOLDING

Your compound miter saw does an excellent job of

cutting crown molding. In general, compound miter

saws do a better job of cutting crown molding than

any other tool made.

In order to fit properly, crown molding must be com-

pound mitered with extreme accuracy.

The two contact surfaces on a piece of crown molding

that fit flat against the ceiling and the wall of a room

are at angles that, when added together, equal

exactly 90". Most crown molding has a top rear angle

(the section that fits flat against the ceiling) of 52°and

a bottom rear angle (the section that fits flat against

the wall) of 38 °.

LAYING MOLDING FLAT ON THE

MITER TABLE

See Figure 32.

To use this method for accurately cutting crown

molding for a 90" inside or outside comer, lay the

molding with its broad back surface flat on the miter

table and against the fence.

When setting the bevel and miter angles for com-

pound miters, remember that the settings are interde-

pendent; changing one angle changes the other angle

as well.

Keep in mind that the angles for crown moldings are

very precise and difficult to set. Since it is very easy

for these angles to shift, all settings should first be

tested on scrap molding. Also most walls do not have

angles of exactly 90°, therefore, you will need to fine

tune your settings.

When cutting crown molding by this method the bevel

angle should be set at 33.85 °`The miter angle should

be set at 31.62 °either right or left, depending on the

desired cut for the application. See the chart below for

correct angle settings and correct positioning of crown

molding on miter table.

The settings inthe chart below can be used for cutting

All Standard (U.S.) crown molding with 52°and 38°

angles. The crown molding is placed flat on the miter

table using the compound features of your miter saw.

38:,,

L

LING

FENCE

TOPEDGEAGAINSTFENCE=

• LEFTSIDE,INSIDECORNER

• RIGHTSIDE,OUTSIDECORNER

© ©

CORNER

MITERTABLE

CROWNMOLDINGFLATONMITERTABLE

FENCE

OUTSIDE

CORNER

BOTFOMEDGEAGAINSTFENCE=

• RIGHTSIDE,INSIDECORNER

OUTSIDECORNER

MITERTABLE

Fig. 32

25

Page 26

Bevel

Angle Type of Cut

Setting

Left side, inside corner

1. Top edge of molding against fence

33"85° 2. Miter table set right 31.62 °

3. Save left end of cut

Right side, inside corner

1. Bottom edge ofmolding against fence

33.85* 2. Miter table set left 31.62"

3. Save left end of cut

Left side, outside corner

1. Bottom edge of molding against fence

33.85" 2. Miter table set left 31.62*

3. Save right end of cut

Right side, outside corner

1. Top edge of molding against fence

33.85" 2. Miter table set right 31.62 °

3. Save right end of cut

WRONG Fig. 34

_lb WARNING: To avoid a kickback and to avoid

serious personal injury, never position the

concave edge of bowed or warped material

against the fence.

CUTTING WARPED MATERIAL

See Figures 33 and 34.

When cutting warped material, always make sure it is

positioned on the miter table with the convex side

against the fence as shown in figure 33.

If the warped material is positioned the wrong way as

shown in figure 34, it will pinch the blade near the

completion of the cut.

CLAMPING WIDE WORKPIECES

See Figure 35.

When cutting wide workpieces such as a 2 in. x 6 in.,

boards should be clamped with a C-clamp as shown in

figure 35.

WIDE

BOARD

RIGHT Fig. 33

Fig. 35

26

Page 27

WARNING:Whenservicing,useonlyidentical

Craftsmanreplacementpads.Useofanyother

partmay create a hazard or cause product

damage.

GENERAL

Avoid using solvents when cleaning plastic parts.

Most plastics are susceptible to damage from various

types of commercial solvents and may be damaged

by their use. Use clean cloths to remove dirt, carbon

dust, etc.

_1= WARNING: Do not at any time let brake fluids,

gasoline, petroleum-based products, penetrating

oils, etc. come in contact with plastic parts. They

contain chemicals that can damage, weaken or

destroy plastic.

It has been found that electric tools are subject to

accelerated wear and possible premature failure when

they are used on fiberglass boats, sports cars, wall-

board, spackling compounds, or plaster. The chips

and grindings from these materials are highly abrasive

to electric tool parts such as bearings, brushes,

commutators, etc. Consequently, it is not recom-

mended that this tool be used for extended work on

any fiberglass material, wallboard, spackling com-

pounds, or plaster. During any use on these materials

it is extremely important that the tool is cleaned

frequently by blowing with an air jet.

LUBRICATION

All of the bearings in this tool are lubricated with a

sufficient amount of high grade lubricant for the life of

the unit under normal operating conditions. Therefore,

no further lubrication is required.

EXTENSION CORDS

The use of any extension cord will cause some loss of

power. To keep the loss to a minimum and to prevent

tool overheating, use an extension cord that is heavy

enough to carry the current the tool will draw.

A wire gage size (A.W.G.) of at least 14 is recom-

mended for an extension cord 25 feet or less in

length. When working outdoors, use an extension

cord that is suitable for outdoor use. The cord's jacket

will be marked WA.

_i, CAUTION: Keep extension cords away from the

cutting area and position the cord so that it will

not get caught on lumber, tools, etc., during

cutting operation.

,_ WARNING: Check extension cords before each

use. If damaged, replace immediately. Never use

tool with a damaged cord since touching the

damaged area could cause electrical shock

resulting in serious injury.

WARNING: Always wear safety goggles or

A

safety glasses with side shields during power

tool operation or when blowing dust. If operation

is dusty, also wear a dust mask.

_k WARNING: To ensure safety and reliability, all

repairs -- with the exception of the externally

accessible brushes -- should be performed by a

qualified service technician at a Sears store to

avoid risk of personal injury.

BRUSH

ASSEMBLY

BRUSH

CAP

BRUSH BRUSH

CAP ASSEMBLY

BRUSH REPLACEMENT

See Figure 36.

Your saw has externally accessible brush assemblies

that should be periodically checked for wear.

Proceed as follows when replacement Is required:

• Unplug your saw.

_i, WARNING: Failure to unplug your saw could

result in accidental starting causing serious

injury.

• Remove brush cap with a screwdriver. Brush

assembly is spring loaded and will pop out when

you remove brush cap.

• Remove brush assembly.

• Check for wear. Replace both brushes when

either has less than 1/4 in. length of carbon

remaining. Do not replace one side without

replacing the other.

• Reassemble using new brush assemblies. Make

sure curvature of brush matches curvature of

motor and that brush moves freely in brush tube.

• Make sure brush cap is oriented correctly

(straight) and replace.

• Tighten brush cap securely. Do not overtighten.

Fig. 36

27

Page 28

L 3

CRAFTSMAN COMPOUND MITER SAW - MODEL NUMBER 315.212130

FigureA

Page 29

CRAFTSMAN COMPOUND MITER SAW- MODEL NUMBER 315.212130

MITER SAW or when ordering repair parts.

I The model number will be found on a plate attached to the motor housing. Always mention the model number in all correspondence regarding your

PARTS LIST FOR FIGURE A

KEY PART

NO. NUMBER DESCRIPTION QUAN.

1 710308-045

2 ** STD852008

3 511101000

4 511102000

5 980117-001

6 976516-001

7 160030-400

8 976569-001

9 976605-001

10 982611-001

11 976568-001

12 976598-001

13 976601-001

14 976531-001

15 977434-001

16 977435-001

* Bolt (M8 x 45 Soc. Hd.) ................................... 2

* Lock Washer (M8) ........................................... 4

Fence .............................................................. 1

Miter Fence ..................................................... 1

* Bolt (M8 x 25 Soc. Hd.) ................................... 2

Zero Clearance Throat Plate ........................... 1

* Screw (M4 x 8 Flat Hd.) ................................... 4

8 mm Hex Key ................................................. 1

6 mm Hex Key ................................................. 1

5 mm Hex Key ................................................. 1

Blade Wrench .................................................. 1

Cover Plate ...................................................... 1

* Screw (M4 x 9 Pan Hd.) .................................. 2