Page 1

Operator's Manual

ROUTER

Double Insulated

Model No.

315.175140

Save this manual for

future reference

CAUTION: Read and

follow all Safety Rules and

Operating Instructions before

first use of this product.

Soars, Roebuck and Co., 3333 Beverly Rd., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

972000-975

5-02

• Safety

• Features

• Adjustments

• Operation

• Maintenance

• Parts List

®

Page 2

• Table Of Contents .......................................................................................................................................... 2

• Warranty ......................................................................................................................................................... 2

• Introduction ..................................................................................................................................................... 2

• Rules for Safe Operation ............................................................................................................................. 3-4

• Product Specifications .................................................................................................................................... 5

• Unpacking ....................................................................................................................................................... 5

• Accessories .................................................................................................................................................... 5

• Features ......................................................................................................................................................... 6

• Adjustments ................................................................................................................................................. 7-9

• Operation ................................................................................................................................................... 9-13

• Maintenance ............................................................................................................................................ 14-15

• Exploded View and Repair Parts List...................................................................................................... 16-17

• Parts Ordering / Service ............................................................................................................................... 18

FULL ONE YEAR WARRANTY ON CRAFTSMANROUTER

Ifthis I:RAFTSMAN Router fails to give complete satisfaction within one year from the date of purchase,

RETURN IT TO THE NEAREST SEARS STORE IN THE UNITED STATES, and Sears will replace it, free of

charge.

Ifthis rRAFT$14AN Router is used for commercial or rental purposes, this warranty applies for only 90 days

from the date of pumhase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

Your router has many features for making routing

operations more pleasant and enjoyable. Safety,

performance and dependability have been given top

pdority in the design of this router making it easy to

maintain and operate.

,_ CAUTION: Carefully road through thisentire

operator's manual before using your new router.

Pay close attention to the Rules for Safe

Operation, Warnings and Cautions. If you use

your router properly and only for what it is

intended, you will enjoy years of safe, reliable

service.

_IL Look for this symbol to point out important safety precautions. It means attentionH! Your

safety is involved.

,_ WARNING:

The operation of any router can result in foreign objects being thrown into your eyes, which

can result insevere eye damage. Before beginning power tool operation, always wear safety

goggles or safety glasses with side shields and a full face shield when needed. We

recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses

with side shields, available at Sears Retail Stores. Always wear eye protection which is

marked to comply with ANSI Z87.1.

Page 3

Thepurposeof safetysymbolsIs to attract your attention to possible dangers. The safety symbols, and

the explanations with them, deserve your careful attention and understanding. The safety warnings do

not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for

proper accident prevention measures.

SYMBOL MEANING

A

A

A

A

SAFETY ALERTSYMBOL:

Indicatesdanger, waming, or_ution. M_ beusedinco_un_ionwith_her_mbolsorpictogrsphs.

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal injury to

yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock

and personal injury.

NOTE: Advises you of information or instructionsvital to the operation or maintenance of the equipment.

DOUBLE INSULATION

Double insulation is a concept in safety, in electric

power tools, which eliminates the need for the usual

thrae-wire grounded power cord. All exposed metal

parts are isolated from internal metal motor

components with protecting insulation. Double

insulated tools do not need to be grounded.

_i WARNING: Do not attempt to operate this tool

until you have read thoroughly and understand

completely all instructions, safety rules, etc.

contained in this manual. Failure to comply can

result in accidents involving fire, electric shock,

or serious personal injury. Save operator's

manual and review frequently for continuing safe

operation, and instructing others who may use

this tool.

READ ALL INSTRUCTIONS

• KNOW YOUR POWER TOOL. Read operator's

manual carefully. Learn its applications and

limitations as well as the specific potential hazards

related to this tool.

• GUARD AGAINST ELECTRICAL SHOCK by

preventing body contact with grounded surfaces.

For example; pipes, radiators, ranges, refrigerator

enclosures.

• KEEP GUARDS IN PLACE and in working order.

• KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

• AVOID DANGEROUS ENVIRONMENT. Do

not use power tools in damp or wet locations or

expose to rain. Keep work area well lit.

IMPORTANT

Servicing of a tool with double insulation requires

extreme care and knowledge of the system and

should be performed only by a qualified service

technician. For service we suggest you return the tool

to your nearest Sears Store for repair. Always use

original factory replacement parts when servicing.

KEEP CHILDREN AND VISITORS AWAY. All

visitors should wear safety glasses and be kept a

safe distance from work area. Do not let visitors

contact tool or extension cord.

• STORE IDLE TOOLS. When not in use, tools

should be stored in a dry and high or locked-up

place - out of the reach of children.

• DO NOT FORCE TOOL. It will do the job better

and safer at the rate for which it was designed.

• USE RIGHT TOOL. Don't force small tool or

attachment to do the job of a heavy duty tool.

Don't use tool for purpose not intended -- for

example -- don't use a circular saw for cutting tree

limbs or logs.

• WEAR PROPER APPAREL. Do not wear loose

clothing or jewelry that can get caught in tool's

moving parts and cause personal injury. Rubber

gloves and nonskid footwear are recommended

when working outdoors. Wear protective hair

covering to contain long hair and keep it from being

drawn into nearby air vents.

• ALWAYS WEAR SAFETY GLASSES. Everyday

eyeglasses have only impact-resistant lenses; they

are not safety glasses.

B PROTECT YOUR LUNGS. Wear a face or dust

mask ifthe operation is dusty.

3

Page 4

• PROTECT YOUR HEARING. Wear hearing

protection during extended periods of operation.

• DO NOT ABUSE CORD. Never carry tool by cord

or yank it to disconnect from receptacle. Keep cord

from heat, oil, and sharp edges.

• SECURE WORK. Use clamps or a vise to hold

work. It is safer than using your hand and it frees

both hands to operate tool.

B DO NOT OVERREACH. Keep proper footing and

balance at all times. Do not use on a ladder or

unstable support. Secure tools when working at

elevated positions.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructions for lubricating and changing accesso-

ries.

• DISCONNECT TOOLS. When not in use, before

servicing, or when changing attachments, tools

should be disconnected from power supply.

B REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

B AVOID ACCIDENTAL STARTING. Do not carry

plugged-in tool with finger on switch. Be sure

switch is off when plugging in.

B MAKE SURE YOUR EXTENSION CORD IS IN

GOOD CONDITION. When using an extension

cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord

will cause a drop in line voltage resulting in loss of

power and overheating. A wire gage size (A.W.G.)

of at least 14 is recommended for an extension

cord 100 feet or less in length. A cord exceeding

100 feet is not recommended. If in doubt, use the

next heavier gage. The smaller the gage number,

the heavier the cord.

• OUTDOOR USE EXTENSION CORDS. When tool

is used outdoors, use only extension cords suitable

for use outdoors. Outdoor approved cords are

marked with the suffix W-A, for example - SJTW-A

or SJOW-A.

B KEEP CUTTERS CLEAN AND SHARP. Sharp

cutters minimize stalling and kickback.

• KEEP HANDS AWAY FROM ROUTING AREA.

Keep hands away from cutters. Donot reach under-

neath work while cutteris rotating.Do notattempt to

remove material while cutteris rotating.

• NEVER USE IN AN EXPLOSIVE

ATMOSPHERE. Normal sparking of the motor

could ignite fumes.

• INSPECT TOOL CORDS PERIODICALLY and if

damaged, have repaired at your nearest Sears

Repair Center. Stay constantly aware of cord

location.

• INSPECT EXTENSION CORDS

PERIODICALLY and replace if damaged.

• KEEP HANDLES DRY, CLEAN, AND FREE

FROM OIL AND GREASE. Always use a clean

cloth when cleaning. Never use brake fluids,

gasoline, petroleum-based products, or any strong

solvents to clean your tool.

• STAY ALERT AND EXERCISE CONTROL. Watch

what you are doing and use common sense. Do

not operate tool when you are tired. Do not rush.

• CHECK DAMAGED PARTS. Before further use of

the tool, a guard or other part that is damaged

should be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and any

other conditions that may affect its operation. A

guard or other part that is damaged should be

properly repaired or replaced by an authorized

service center.

• DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Have defective switches

replaced by an authorized service center.

• INSPECT FOR and remove atl nails from lumber

before routing.

• DO NOT operate this tool while under the influence

of drugs, alcohol, or any medication.

• POLARIZED PLUGS. To reduce the risk of electric

shock, this tool has a polarized plug (one blade is

wider than the other). This plug will fit in a polar-

ized outlet only one way. Ifthe plug does notfit

fully in the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to install the

proper outlet. Do not change the plug in any way.

• WHEN SERVICING USE ONLY IDENTICAL

CRAFTSMAN REPLACEMENT PARTS.

• WHEN USING THIS ROUTER WITH A ROUTER

TABLE, HELP PREVENT POSSIBLE SERIOUS

INJURY BY KEEPING THE CUTTER GUARDED

AT ALL TIMES. Use only router tables, with

guards, that have been designed for use on routers

that are ofthis type, size, and weight.

• DO NOT USE TOOL UNDER "BROWNOUT" OR

OTHER LOW VOLTAGE CONDITIONS. Also, do

not use with any device that could cause the power

supply voltage to change.

• SAVE THESE INSTRUCTIONS. Refer to them

frequently and use them to instruct others who may

use this tool. If youloan someone this tool, loan

them these instructions also.

SAVE THESE INSTRUCTIONS

4

Page 5

,_ WARNING: Some dust created by power

sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known

to cause cancer, birth defects or other

reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies,

depending on howoften you do this type of work.

To reduce your exposure to these chemicals:

work in a well ventilated area, and work with

approved safety equipment, such as those dust

masks that are specially designed to filter out

microscopic particles.

Depth of cut 0 - 1-1/2 in.

Collet 1/4 in.

Horsepower 1-1/2

Rating 120 volts, 60 Hz, AC only

Your router has been shipped completely assembled.

Inspect itcarefully to make sure no breakage or

damage has occurred during shipping. If any parts are

damaged or missing, contact your nearest Sears

Retail Store to obtain replacement parts before

attempting to operate router. A wrench and this

Operator's Manual are also included.

THE FOLLOWING RECOMMENDED ACCESSORIES ARE

CURRENTLY AVAILABLE AT SEARS RETAIL STORES

Template Guide Bushings

Dovetail Template

Box Joint Template

Amperes 8

No load speed 25,000 RPM

Power cord 6 ft.

Net weight 8.13 Ibs.

_k WARNING: If any parts are missing, do not

operate this tool until the missing parts are

replaced. Failure to do so could result in possible

serious personal injury.

Butt Hinge Template

Multi-Purpose Router Guide

Rout - A - Form Pantograph

COMBI- VEINING

NATION BIT

PANEL

CUTrER

,_ WARNING: The use of attachments accessories not listed above be hazardous.

COREBOX

BIT

V-GROOVE

CHAMFER

,!,

STRAIGHT

FACE

BIT

COMB-

INATION

STRAIGHT

BEVEL

CUTTER

HINGE

MORTISING

BIT

DOVETAILRABBE1 OGEE,

CUTTER BIT ROMANO

BITS

[

L

*25895FORCARBIDETIPPEDEDGEFORMINGBITS

2589FORHIGHSPEEDSTEELEDGEFORMINGBITS

llll'1 III IIIIII

or

5

L_

*CARBIDETIPPEDBITS I

CHAMFER

might

COVE

BIT,

45°

BIT

BEAD ARBOR

QUARTER. 2589

BITS

ROUND !

wrrH2

BALL

3EARINGS

(1i2IN.&

S/SIN.)

*25895

I

Page 6

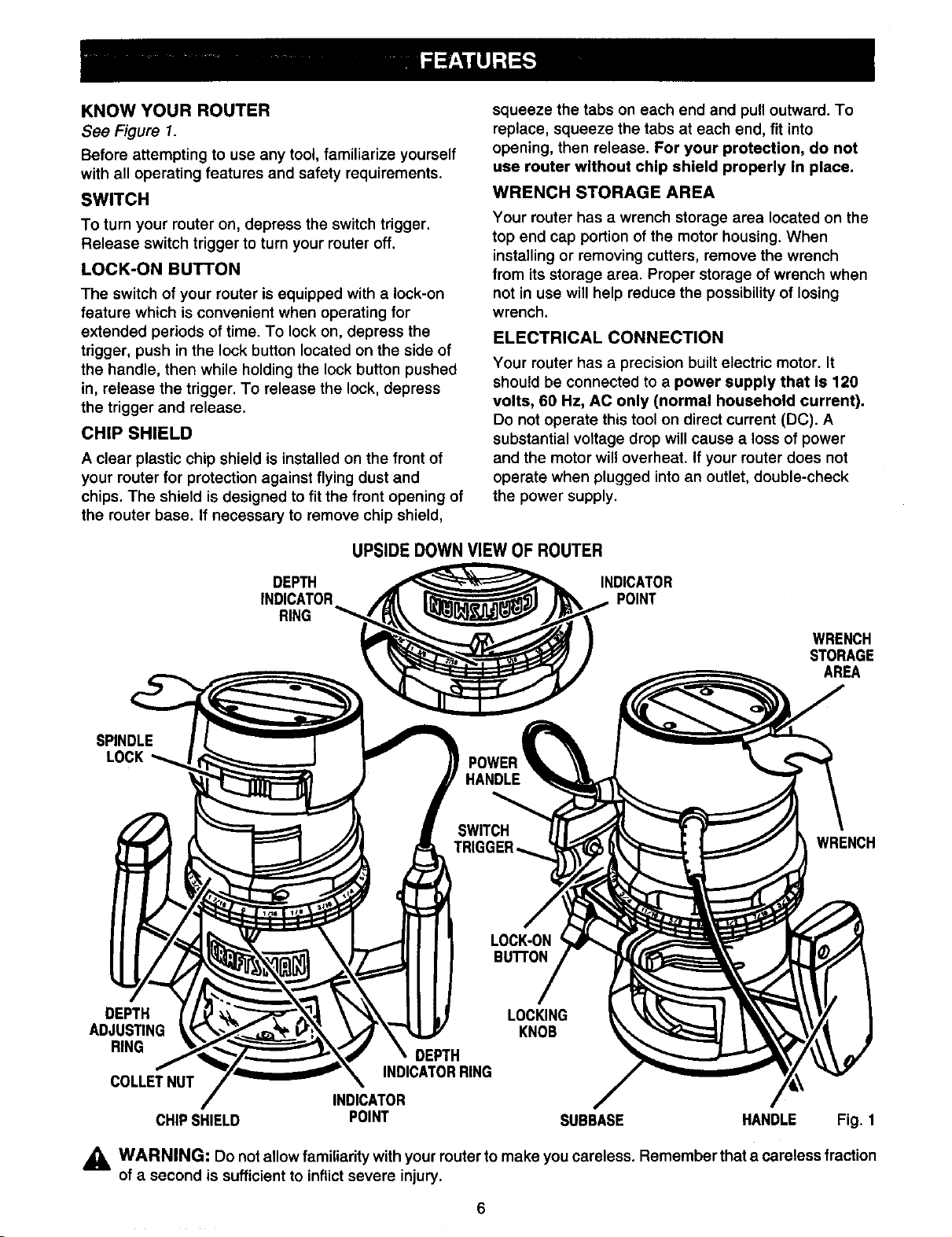

KNOW YOUR ROUTER

See Figure 1.

Before attempting to use any tool, familiarize yourself

with all operating features and safety requirements.

SWITCH

To turn your router on, depress the switch trigger.

Release switch trigger to turn your router off.

LOCK-ON BUTTON

The switch of your router is equipped with a lock-on

feature which is convenient when operating for

extended periods of time. To lock on, depress the

trigger, push in the lock button located on the side of

the handle, then while holding the lock button pushed

in, release the trigger. To release the lock, depress

the trigger and release.

CHIP SHIELD

A clear plastic chip shield is installed on the front of

your router for protection against flying dust and

chips. The shield is designed to fit the front opening of

the router base. If necessary to remove chip shield,

UPSIDEDOWN VIEW OF ROUTER

squeeze the tabs on each end and pull outward. To

replace, squeeze the tabs at each end, fit into

opening, then release. For your protection, do not

use router without chip shield properly In place.

WRENCH STORAGE AREA

Your router has a wrench storage area located on the

top end cap portion of the motor housing. When

installing or removing cutters, remove the wrench

from its storage area. Proper storage of wrench when

not in use will help reduce the possibility of losing

wrench.

ELECTRICAL CONNECTION

Your router has a precision built electric motor. It

should be connected to a power supply that is 120

volts, 60 Hz, AC only (normal household current).

Do not operate this tool on direct current (DC). A

substantial voltage drop will cause a loss of power

and the motor wil! overheat. If your router does not

operate when plugged into an outlet, double-check

the power supply.

SPINDLE

LOCK

DEPTH

ADJUSTING

RING

COLLETNUT

CHIPSHIELD POINT SUBBASE HANDLE Fig. 1

DEPTH

INDICATOR

RING

INDICATOR

POINT

WRENCH

STORAGE

AREA

POWER

WRENCH

LOCKING

KNOB

DEPTH

INDICATORRING

INDICATOR /

_ WARNING: Do not allow familiarity with your router to make you careless. Remember that a careless fraction

of a second is sufficient to inflictsevere injury.

Page 7

_1= WARNING: Your router should never be

connected to power supply when you are

assembling parts, making adjustments,

installing or removing cutters, cleaning,

or when not in use. Disconnecting router

will prevent accidental starting that could

cause serious personal injury.

INSTALLING/REMOVING CUTTERS

See Figures 2 and 3.

• Unplug your router.

_i WARNING: Failure to unplug your router could

result in accidental starting causing serious

injury.

• A spindle lock is located on the front of the motor

housing. To activate lock, push spindle lock in and

slide into lock position. See Figure 2.

,_ WARNING: To prevent damage to the spindle

or spindle lock, always allow motor to come to a

complete stop before engaging spindle lock.

SPINDLELOCK

TOLOCK

SPINDLE

Fig. 2

• Place your router upside down on table, then turn

collet nut with wrench until lock mechanism

interlocks. See Figure 3.

CUTTER

WRENCH

_i, WARNING: If you are changing a cutter

immediately after use, be careful not to touch the

cutter or collet with your hands or fingers. They

will get burned because of the heat buildup from

cutting. Always use the wrench provided.

• Remove cutters by turning collet nut counter-

clockwise enough to allow cutter to slip easily from

collet. See Figure 3. The collet is machined to

precision tolerances to fit cutters with 1/4 in.

diameter shanks.

• With your router still upside down on table, insert

shank of cutter into collet. The shank of your cutter

should be close to but not touching bottom of

collet.

• Tighten the collet nut securely by turning clockwise

with the wrench provided. See Figure 3. Push

spindle lock in and slide into unlock position.

Otherwise, the interlocking mechanism of the

spindle lock will not let you turn your router on.

COLLET

Fig. 3

Note: Spindle lock is spring loaded and will snap into

position when lock mechanism interlocks.

WARNING: Do not use cutters with undersized

shanks. Undersized shanks will not tighten

properly and could be thrown from tool causing

injury.

7

Page 8

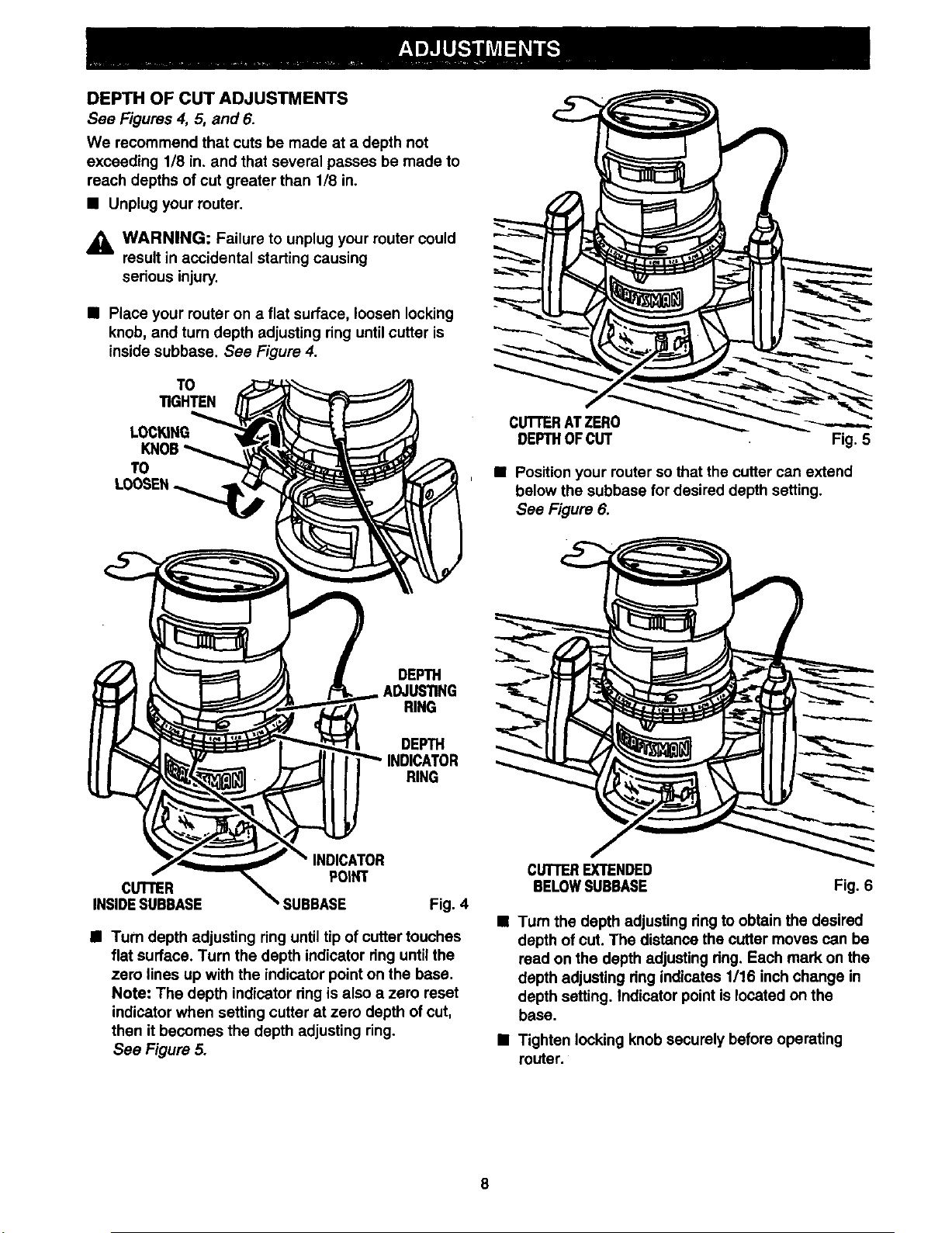

DEPTH OF CUT ADJUSTMENTS

See Figures 4, 5, and 6.

We recommend that cuts be made at a depth not

exceeding 1/8 in. and that several passes be made to

reach depths of cut greater than 1/8 in.

• Unplug your router.

,_i WARNING: Failure to unplug your router could

result in accidental starting causing

serious injury.

• Place your router on a flat surface, loosen locking

knob, and turn depth adjusting ring until cutter is

inside subbase. See Figure 4.

TO

TIGHTEN

LOCKING

KNOB

TO

CUTrERATZERO

DEPTHOFCUT Fig. 5

• Position your router sothat the cutter can extend

below the subbase for desired depth setting.

See Figure 6.

DEPTH

ADJUSllNG

RING

DEPTH

RING

INDICATOR

CUTrER

INSIDESUBBASE ' SUBBASE Fig. 4

• Turn depth adjusting ring untiltip of cutter touches

flat surface. Turn the depth indicator ringuntil the

zero lines up with the indicator point on the base.

Note: The depth indicator ring is also a zero reset

indicator when setting cutter at zero depth of cut,

then it becomes the depth adjusting ring.

See Figure 5.

POIHT

CUTTEREXTENDED

BELOWSUBBASE Fig. 6

•Tum the depth adjusting ring to obtain the desired

depth of cut. The distance the cutter moves can be

read on the depth adjusting dng. Each mark on the

depth adjusting dng indicates 1/16 inch change in

depth setting. Indicator point is located on the

base.

• Tighten locking knob securely before operating

router.

8

Page 9

DEPTHOFCUTADJUSTMENTSWHEN

ROUTERISMOUNTEDTOA ROUTERTABLE

See Figure 7.

The depth of cut is readable from both sides of the depth

indicator ring. The bottom dng is convenient when using

your router mounted upside down to a router table. The

indicator point on the base can also be used when using

your router mounted to a router table.

Set the cutter at zero depth of cut, rotate depth

indicator ring to desired depth of cut on the scale,

then tighten locking knob securely.

FOR ROUTERTABLE USE ONLY

INDICATOR DEPTH

POINT INDICATORRING

Fig. 7

ROUTER TABLES

The use of Craftsman reuters on router tables offered

by other manufacturers has not been investigated for

compliance with applicable safety standards.

_ WARNING: Do not use with router tables that

fail to conform to safe wood working practices

and offer proper guarding for the cutter. Failure

to comply can result in an accident causing

possible serious injury.

HELPFUL HINTS

_/ Always clamp workpiece securely before muting.

_/ A safe operator isone who thinks ahead.

•/ Always wear eye protection when muting.

,/ Make setup adjustments carefully. Then double

check. Measure twice and cut once.

J Keep cutters clean and preperly sharpened.

4' Don't let familiarity make you careless.

J Study all safety rules and do the job safely.

/ Never place your hands in jeopardy.

J Make certain clamps can't loosen while in use.

J Test difficultsetups on scrap -- Don't waste

lumber.

J Pla'neach operation before you begin.

4" Provide for smoother operation by cleaning your

muter frequently. Shake muter or blow with an air

jet to remove sawdust buildup.

Think safety by thinking ahead.

ROUTING

See Figure 8.

For ease of operation and maintaining proper control,

your router has two handles, one on each side of the

router base. When using your router hold it firmly with

both hands as shown in Figure 8.

Turn router on and let motor build to its full speed,

then gradually feed cutter intoworkpiece. Remain

alert and watch what you are doing. Do not operate

router when fatigued.

HANDLE

POWER

HANDLE

PRACTICE BEFORE ACTUAL USE

We suggest that you practice with your router before

installing a cutter and making cuts in wood. Check

the following before connecting your router to

power supply.

• Make sure power supply is 120 volts, 60 Hz, AC

only.

• Make sure the spindle lock isinthe unlocked

position.

• Make sure the tdgger is not in the lock.on position.

• Make sure there is not a cutter in the toilet.

• Make sure the toilet does not extend below the

subbase.

• Plug your routerinto power supply.

• Grasp your routerfirmly with both hands and turn on.

,_ WARNING'- Keep a firm grip on router with both

hands at all times. Failure to do so could result in

loss of control leading to possible serious injury.

9

Fig. 8

Page 10

FREEHAND ROUTING

See Figure 9.

FREEHANDROUTING Fig. 9

When used freehand, your router becomes a flexible

and versatile tool. This flexibility makes it possible to

easily rout signs, relief sculptures, etc.

There are two basic techniques

for freehand routing:

• Routing letters, grooves, and patterns into wood.

See Figure 9.

• Routing out the background, leaving the letters

or pattern raised above the surface.

When freehand routing, we suggest the following:

• Draw or layout the pattern on workpiece.

• Choose the appropriate cutter.

Note: A core box or V-groove bit is often used for

routing letters and engraving objects. Straight bits

and ball mills are often used to make relief

carvings. Veining bitsare used to carve small,

intricate details.

• Rout the pattern in two or more passes. Make the

first pass at 25% of the desired depth of cut. This

will provide better control as well as being a guide

for the next pass.

• Do not rout deeper than 1/8 in. per pass or cut.

WARNING: Do not use large router bits for

A

freehand routing. Use of large router bits when

freehand routing could cause loss of control or

create other hazardous conditions that could

cause possible serious personal injury.When

using a router table, large router bits should be

used for edging only. Do not use router bits that

are larger in diameter than the opening in router

base for any purpose.

RATE OF FEED

IMPORTANT: The whole "secret" of professional

routing and edge shaping lies in making a careful

setup for the cut to be made and in selecting the

proper rate of feed.

PROPER FEEDING

The right feed is neither too fast nor too slow. It is the

rate at which the bit is being advanced firmly and

surely to produce a continuous spiral of uniform chips

-- without hogging into the wood to make large

individual chips or, on the other hand, to create only

sawdust. If you are making a small diameter, shallow

groove in soft, dry wood, the proper feed may be

about as fast as you can travel your router along your

guide line. On the other hand, ifthe bit is a large one,

the cut is deep or the wood is hard to cut, the proper

feed may be a very slow one. A cross-grain cut may

require a slower pace than an identical with grain cut

in the same workpiece.

There is no fixed rule. You will learn by experience

from practice and use. The best rate of feed is

determined by listening to the sound of the router

motor and by feeling the progress of each cut. Always

test a cut on a scrap piece of the workpiece wood,

beforehand.

FORCEFEEDING

Clean, smooth routing and edge shaping can be done

only when the bit is revolving at a relatively high

speed and istaking very small bites to produce tiny,

cleanly severed chips. If your router is forced to move

forward too fast, the RPM of the bit becomes slower

than normal in relation to its forward movement. As a

result, the bit must take bigger bites as it revolves.

"Bigger bites" mean bigger chips, and a rougher

finish. Bigger chips also require more power, which

could result in the router motor becoming overloaded.

Under extreme force-feeding conditions the relative

RPM of the bit can become so slow -- and the bites it

has to take so large -- that chips will be partially

knocked off (rather thanfully cut off), with resulting

splintering and gouging of the workpiece.

See Figure 10.

10

Page 11

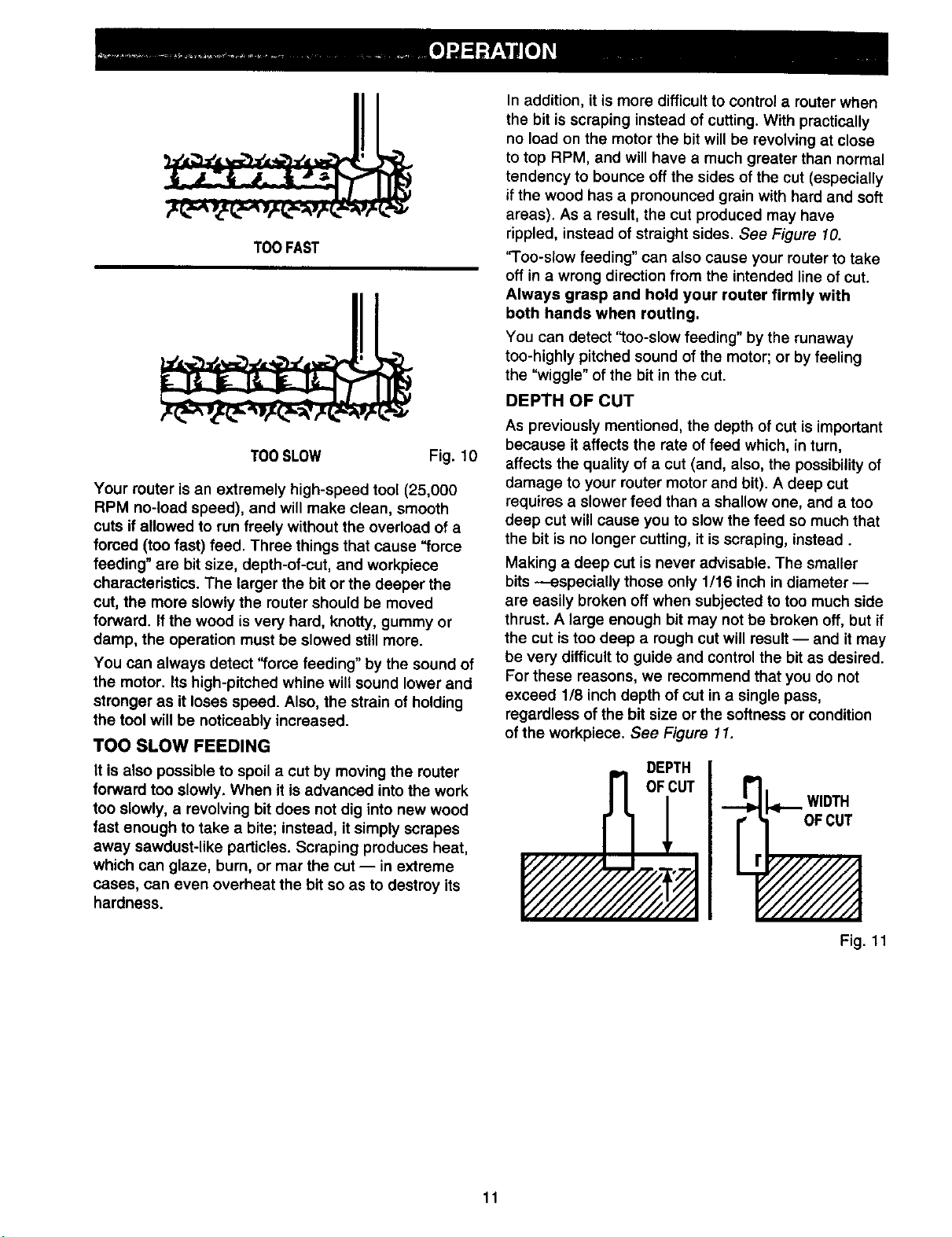

TOOFAST

TOOSLOW Fig.10

Your router is an extremely high-speed tool (25,000

RPM no-load speed), and will make clean, smooth

cuts ifallowed to run freely without the overload of a

forced (too fast) feed. Three things that cause "force

feeding" are bit size, depth-of-cut, and workpiece

characteristics. The larger the bit or the deeper the

cut, the more slowly the router should be moved

forward. If the wood is very hard, knotty, gummy or

damp, the operation must be slowed stillmore.

You can always detect "force feeding" by the sound of

the motor. Its high-pitched whine will sound lower and

stronger as it loses speed. Also, the strain of holding

the tool will be noticeably increased.

TOO SLOW FEEDING

It is also possible to spoil a cut by moving the router

forward too slowly. When it is advanced into the work

too slowly, a revolving bit does not dig into new wood

fast enough to take a bite; instead, it simply scrapes

away sawdust-like particles. Scraping produces heat,

which can glaze, burn, or mar the cut -- in extreme

cases, can even overheat the bit so as to destroy its

hardness.

In addition, it is more difficult to control a routerwhen

the bit is scraping instead of cutting. With practically

no load on the motor the bit will be revolving at close

to top RPM, and will have a much greater than normal

tendency to bounce off the sides of the cut (especially

if the wood has a pronounced grain with hard and soft

areas). As a result,the cut produced may have

rippled, instead of straight sides. See Figure 10.

'q'oo-slow feeding" can also cause your router to take

off in a wrong directionfrom the intended line of cut.

Always grasp and hold your router firmly with

both hands when routing.

You can detect "too-slow feeding" by the runaway

too-highly pitched sound of the motor; or by feeling

the "wiggle" of the bit inthe cut.

DEPTH OF CUT

As previously mentioned, the depth of cut is important

because it affects the rate of feed which, inturn,

affects the quality of a cut (and, also, the possibilityof

damage to your router motor and bit). A deep cut

requires a slower feed than a shallow one, and a too

deep cut will cause you to slow the feed so much that

the bit is no longer cutting, it is scraping, instead.

Making a deep cut is never advisable. The smaller

bits --especially those only 1/16 inch in diameter-

are easily broken off when subjected to too much side

thrust. A large enough bit may not be broken off, but if

the cut is too deep a rough cut will result -- and it may

be very difficult to guide and controlthe bitas desired.

For these reasons, we recommend that you do not

exceed 118inch depth of cut in a single pass,

regardless of the bit size or the softness or condition

ofthe workpiece. See Figure 11.

DEPTH

WIDTH

OFCUT

OFIUT

W/YJ d

11

Fig. 11

Page 12

Tomakedeepercutsitisthereforenecessaryto

makeasmanysuccessivepassesasrequired,

loweringthebit1/8inchfor each new pass. In order to

save time, do all the cutting necessary at one depth

setting, before lowering the bit for the next pass. This

will also assure a uniform depth when the final pass is

completed. See Figure 12.

2ND.PASS

2ND. 1ST.

PASS PASS

Fig. 12

DIRECTION OF FEED AND THRUST

The router motor and bitrevolve in a clockwise direc-

tion. This gives the tool a slight tendency to twist (in

your hands) in a counterclockwise direction, especially

when the motor revs up (as at starting).

Because of the extremely high speed of bit rotation

dudng a "proper feeding" operation, there is very little

kickback to contend with under normal conditions.

However, should the bit strike a knot, hard grain,

foreign object, etc. that would affect the normal

progress of the cutting action, there will be a slight

kickback-- sufficient to spoil the trueness of your cut if

you are not prepared. Such a kickback is always in the

direction opposite to the direction of bit rotation.

To guard against such a kickback, plan your setup and

direction of feed so that you will always be thrusting

the tool -- to hold it against whatever you are using to

guide the cut-- in the same direction that the leading

edge of the bit is moving. In short, the thrust should be

in a direction that keeps the sharp edges of the bit

continuously biting straight into new (uncut) wood.

ROUTING

Whenever you are routing a groove, your travel

should be in a direction that places whatever guide

you are using at the rigHt-handside. In short, when

the guide is positioned as shown in the first part of

Figure 13, tool travel should be left to right and

counterclockwise around curves. When the guide is

positioned as shown in the second part of Figure 13,

tool travel should be right to left and clockwise around

curves. If there is a choice, the first setup is generally

the easiest to use. In either case, the sideways thrust

you use is against the guide.

GUIDEOUTSIDE

ROTATION

THRUST

ROTATION

FEED GUIDE

GUIDEINSIDE

ROTATION_"_

Gu,oE-- '/J

ROTATION_____

_ THRUST

/

FEED

Fig. 13

12

Page 13

STARTING AND ENDING A CUT

INTERNAL ROUTING

Tilt router and place on workpiece, letting edge of

subbase contact workpieoe first. Be careful not to let

router bit contact workpiece. Turn router on and let

motor build to its full speed. Gradually feed cutter into

workpiece until subbase is level with workpiece.

_1 WARNING: Keep a firm grip on router with both

hands at all times. Failure to do so could result in

loss of control leading to possible serious injury.

Upon completion of cut, turn motor off and let it come

to a complete stop before removing router from work

surface.

_1, WARNING: Never pull router out of work and

place upside down on work surface before the

cutter stops.

EDGING WITH PILOT BITS

See Figure 14.

II .ouTE. II

WORKI I I /

Whenever the workpiece thickness together with the

desired depth of cut (as adjusted by router depth

setting) are such that only the top part of the edge is

to be shaped (leaving at least a 1/16 inch thick uncut

portion at bottom), the pilot can ride against the uncut

portion, which will serve to guide it. See Figure 14.

However, if the workpiece is too thin or the bit set too

low so that there will be no uncut edge to ridethe pilot

against, an extra board to act as a guide must be

placed under the workpiece. This "guide" board must

have exactly the same contour -- straight or curved

-- as the workpiece edge. If it is positioned so that its

edge is flush with the workpiece edge, the bit will

make a full cut (in as far as the bit radius). On the

other hand, if the guide is positioned as shown in

Figure14 (out from the workpiece edge), the bit will

make less than a full cut -- which will alter the shape

of the finished edge.

Note: Any of the piloted bits can be used without a

pilot for edge shaping with guides, as preceding. The

size (diameter) of the pilot that is used determines the

maximum cut width that can be made with the pilot

against the workpiece edge - the small pilot exposes

all ofthe bit; the large one reduces thisamount by

1/16 inch.

TOPEDGESHAPING

|

PILOT

WHOLE EDGESHAPING Fig. 14

Arbor-type bits with pilots are excellent for quick,

easy, edge shaping, They will follow workpiece edges

that are either straight or curved. The pilot prevents

the bit from making too deep a cut; and holding the

pilot firmly in contact with the workpiece edge

throughout prevents the cut from becoming too

shallow.

EDGE ROUTING

Place router on workpiece, making sure the router bit

does not contact workpiece. Turn router on and let

motor build to its full speed. Begin your cut, gradually

feeding cutter into workpiece.

_k WARNING: Keep a firm grip on router with both

hands at all times. Failure to do so could result in

loss of control leading to possible serious injury.

Upon completion of cut, turn motor off and let it come

to a complete stop before removing router from work

surface.

d_i WARNING: Never pull router out of work and

place upside down on work surface before the

cutter stops.

ROUTING WITH GUIDE BUSHINGS

When using the Template Guide Bushings Item No.

9-25082 with your router, you must visually center the

bit with the bushing before beginning your cut. Your

router subbase may be adjusted by loosening the

screws holding the subbase to your router. Be sure

locking knob is tightened before centering bit in

bushing. After centedng bit with bushing, tighten

screws securely.

13

Page 14

,_ WARNING: When servicing, use only identical

Craftsman replacement parts. Use of any other

part may create a hazard or cause product

damage.

GENERAL

Only the parts shown on parts list, page 17, are

intended to be repaired or replaced by the customer.

All other parts represent an important part of the

double insulation system and should be serviced only

by a qualified Sears service technician.

Avoid using solvents when cleaning plastic parts.

Most plastics are susceptible to damage from various

types of commercial solvents and may be damaged

by their use. Use clean cloths to remove dirt, carbon

dust, etc.

_k WARNING: Do not at any time let brake fluids,

gasoline, petroleum-based products, penetrating

oils, etc. come in contact with plastic parts. They

contain chemicals that can damage, weaken or

destroy plastic.

It has been found that electric tools are subject to

accelerated wear and possible premature failure when

they are used on fiberglass boats, sports cars,

wallboard, spackling compounds, or plaster. The

chips and grindings from these materials are highly

abrasive to electric tool parts such as bearings,

brushes, commutators, etc. Consequently, it is not

recommended that this tool be used for extended

work on any fiberglass material, wallboard, spackling

compounds, or plaster. During any use on these

materials it is extremely important that the tool is

cleaned frequently by blowing with an air jet.

LUBRICATION

All of the bearings in this tool are lubricated with a

sufficient amount of high grade lubricant for the life of

the unit under normal operating conditions. Therefore,

no further lubrication is required.

EXTENSION CORDS

The use of any extension cord will cause some loss of

power. To keep the loss to a minimum and to prevent

tool overheating, use an extension cord that is heavy

enough to carry the current the tool will draw.

A wire gage size (A.W.G.) of at least 14 is

recommended for an extension cord 100 feet or less

in length. When working outdoors, use an extension

cord that is suitable for outdoor use. The cord's jacket

will be marked WA.

CAUTION: Keep extension cords away from the

A

cutting area and position the cord so that it will

not get caught on lumber, tools, etc., during

cutting operation.

_ WARNING: Check extension cords before each

use. If damaged replace immediately. Never use

tool with a damaged cord since touching the

damaged area could cause electrical shock

resulting in serious injury.

Extension cords suitable for use with your router are

available at your nearest Sears Retail Store.

,_ WARNING: Always wear safety goggles or

safety glasses with side shields during power

tool operation or when blowing dust. If operation

is dusty, also wear a dust mask.

PROPER CARE OFCU'n'ERS

Get faster more accurate cutting results by keeping

cutters clean and sharp. Remove all accumulated

pitch and gum from cutters after each use.

When sharpening cutters, sharpen only the inside of

the cutting edge. Never grind the outside diameter. Be

sure when sharpening the end of a cutter to grind the

clearance angle the same as originally ground.

PROPER CARE OFCOLLET

From time to time, it also becomes necessary to clean

your collet and collet nut. To do so, simply remove

collet nut from collet and clean the dust and chips that

have collected. Then return conet nut to its original

position.

14

Page 15

SWITCH REPLACEMENT

See Figures 15and 16.

• Unplug your router.

_k WARNING: Failure to unplug your router could

result in accidental starting causing

serious injury.

• Remove screws (A) and handle cover (B).

See Figure 15.

• Make lead connections to new switch. Push each

lead as far as possible into proper switch

receptacle. Pull on leads to check lead connections

with lead receptacles.

• Locate switch in handle and place leads so they

won't be pinched or contact screws when handle

cover is replaced.

• Make sure molded bend relief (C) is correctly

positioned in switch handle, then replace handle

cover and screws.

• Tighten all screws securely.

LIGHT BULB REPLACEMENT

See Figure 17.

• Unplug your router.

A

Fig. 15

Note the location of the molded bend relief (C)

on the power handle cord. Also note all wiring

In the handle end how each lead is connected

to the switch. Connections and wiring position

must be identical when installing new switch.

See Figure 15.

Remove leads from switch (D) by inserting a 1/32

in. diameter nail or pin into switch lead receptacle

and pulling on lead as shown in Figure 16.

Remove nail or pin with a twisting, pulling motion.

LEAD

_ WARNING: Failure to unplug router could

result in accidental starting causing serious

injury.

• Remove cutter from router. Refer to page 7 to

remove cutter.

• Adjust router to maximum height.

• Remove screws (A) and subbase (B).

See Figure 17.

A

C

D I

your

B

E

POWER

HANDLE

CORD

WHITE

1/32In, DIAMETER

NAILORPIN

RED

WORK

LIGHT

Fig. 17

• Remove screw (C) and work light lens (D).

• With bulb (E) pointing toward you, push bulb in and

turn to the left to remove from bulb socket.

Note: Light bulb removal and installation is similar

to removing and installing a standard automotive

bulb.

• Install new bulb by reversing the above procedure.

• Reassemble all parts and tighten screws securely.

Fig. 16

15

Page 16

CRAFTSMAN ROUTER - MODEL NUMBER 315.175140

I I

SEE NOTE "A"

24 25

21

9

10

NOTE: "A" - The assembly shown represents an Important part of the Double Insulated System. To avoid

the possibility of alteration or damage to the System, service should be performed by your near-

est Sears Repair Center. Contact your nearest Sears Retsll Store for Service Center Information.

16

Page 17

CRAFTSMAN ROUTER- MODEL NUMBER 315.175140

The model number will be found on a plate attached to the motor housing. Always mention the model number |

in all correspondence regarding your ROUTER or when ordering repair parts,

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

PARTS LIST

Key Pad

No. Number

1 983256-001

2 970692-001

3 989985-903

4 983217-001

5 974131-002

6 623166-006

7 622832-014

8 606066-004

9 617966-030

10 970697-000

11 973735-002

12 606688-002

13 998586-001

14 612191-004

15 989684-001

16 975041-001

17 610930-001

18 970696-000

19 610951-001

20 998895-001

21 623173-006

22 999603-001

23 931744-059

24 999053-003

25 989935-006

972000-975

Description Quan.

Data Plate .............................................................................................. 1

Label ...................................................................................................... 1

Collet Nut (1/4 in.) ................................................................................. 1

Depth Adjusting Ring Assembly (Includes Key No. 24) ........................ 1

Depth Indicator Ring.............................................................................. 1

* Square Head Bolt(#1/4-20 x 1-1/4 in.).................................................. 1

Roll Pin .................................................................................................. 1

* Screw (#10-32 x 3/4 in. Pan Hd.) .......................................................... 4

* Screw (#8-10 x 5/8 in. Pan Hd.) ............................................................ 8

Handle Assembly .................................................................................. 1

Base ...................................................................................................... 1

Chip Shield ............................................................................................ 1

* Screw (#10-32 x 1/4 in. Pan Hd.) .......................................................... 3

Subbase ................................................................................................ 1

* Screw (#6-32 x 1/4 in. T. C. Pan Hd.) ................................................... 1

Work Light Lens .................................................................................... 1

Light Housing ........................................................................................ 1

Power Handle Assembly ....................................................................... 1

Light Bulb .............................................................................................. 1

Switch .................................................................................................... 1

Wire Nut ................................................................................................ 1

Knob ...................................................................................................... t

Washer .................................................................................................. 3

* Screw (#5-10 x 1/2 in. Fil. Hd.) .............................................................. 2

Wrench (9/16 in.) ................................................................................... 1

Operator's Manual

I

* Standard Hardware Item - May Be Purchased Locally

17

Page 18

For repair of major brand appliances in your own home...

no matter who made it, no matter who sold it!

1-800-4-MY-HOM EsMAnytime,dayornight

(1-800-469-4663)

www.sears.com

To bring in products such as vacuums, lawn equipment and electronics

for repair, call for the location of your nearest Sears Parts & Repair Center

1-800-488-1222 Anytime, day or night

www.sears.com

For the replacement parts, accessories and owner's manuals

that you need to do-it-yourself, call Sears PartsDirect sM!

1-800-366-PART 6 a.m. - 11 p.m. CST,

(1-800-366"7278) 7 days a week

www.sears.condpartsdirect

To purchase or inquire about a Sears Service Agreement:

1-800-827-6655

7 a.m. - 5 p.m. CST, Mon.- Sat.

Para pedir servicio de reparacibn a domicilio,

y para ordenar piezas con entrega a domicilio:

1-888-SU-HOGAR sM

(1-888-784"6427)

® Registered Trademark / TM Trademark of Sears, Roebuck and Co.

O Sears, Roebuck and Co. ® Mama Reglstrada / _'_ Mama de Fdbdca de Sears, Roebuck and Co.

Au Canada pour serviceen fran_ais:

1-877-LE-FOYER sM

(1-877-533-6937)

Page 19

Manual del Usuario

TUPI

Aislamiento Doble

Modelo No

315.175140

Conserve este manual

para referencia futura

ATENClON: Lea cuidadosamente

todas las Reglas de Seguridad y las

Instruccionesantes de usar esta

herramienta.

Sears, Roebuck and Co., 3333 Beverly Rd., Hoffman Estates, IL 60179 USA

Visite la p_gina Web de Craftsman: www.sears.com/craftsman

972000-975

5-02

• Seguridad

• Caracter|sticas

• Ajustes

• Funcionamiento

• Mantenimiento

• Lista de Repuestos

®

Page 20

• Tabla de Materias ........................................................................................................................................... 2

• Garantia .......................................................................................................................................................... 2

• Introducci6n .................................................................................................................................................... 2

• Reglas para Funcionamiento Seguro ......................................................................................................... 3-4

• Especificaciones del Producto ....................................................................................................................... 5

• Desempaque .................................................................................................................................................. 5

• Accesodos ...................................................................................................................................................... 5

• Caracteristicas ............................................................................................................................................... 6

• Ajustes ......................................................................................................................................................... 7-9

• Funcionamiento ......................................................................................................................................... 9-13

• Mantenimiento ......................................................................................................................................... 14-15

• Vista Esquemdtica y Lista de Repuestos ................................................................................................ 16-17

• Pedidos de Repuestos / Servicio ................................................................................................................. 18

GARANTIA COMPLETA DE UN AI_IO DEL TUPI [RRFTSMRN

Si este Tupf £RRFTSMRN no le proporciona completa satisfacci6n a partir de un aSo desde la fecha de compra,

DEVUELVALO AL ALMACEN SEARS MAS CERCANO EN LOS ESTADOS UNIDOS y Sears Io reemplazard

gratuitamente.

Si este Tupf CRRFTSMRNse usa para prop6sitos comerciales o de alquiler, esta garantfa es vdlida solamente

durante 90 dlas desde la fecha de compra.

Esta garant{a le otorga derechos legales especfficos y usted puede ademds tener otros derechos que varfan de

un estado a otro.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

Su tupf tiene muchas caracterfsticas que contribuyena

facilitar y hacer rods agradable su trabajo. Se ha dado

prioridad mdxima a la seguridad, rendimiento y '

dependabilidad en el diseSo de este tupi por Io cual es

fdcil de mantener y operar.

Este sfmbolo le indica de

su seguridad.

_k ADVERTENCIA:

La utilizaci6n de cualquier tup{ puede causar la proyeccibn de objetos extraSos a sus ojos, Io

cual puede ocasionar daSos oculares severos. Antes de comenzar a usar la herramienta

mecdnica, siempre use sus lentes protectores o gafas de seguridad con protecci6n lateral y

una mdscara completa cuando sea necesario. Recomendamos una M_.scara de Visibn Amplia

para usar sobre sus lentes protectores o lentes de seguridad estdndar, con protecci6n lateral,

disponible en los Almacenes Sears. Siempre use lentes protectores que ¢umplan con la

norma ANSI Z87.1 y que esten asi marcados.

importantes reglas seguridad, iSignifica atenciSn! Existe riesgo para

_ ATENCION: Lea cuidadosamente todoeste

manual antes de usar su nuevo tupf. Preste mucha

atenci6na las Reglas para FuncionamientoSeguro

asi como alas Advertencias y Avisos. Si usted

utitizaeltupfdebidamente y solamente para el

prop6sitoque ha sido disefiado, usted disfrutardde

muchosaSos de servicio seguro.

2

Page 21

Estoss|mbolosdesegurldadseutilizanpareadvertirlesobreclertosrlesgosposibles.Lossimbolosde

segurldadylasexpllcaclonesqueacompafianestossimbolosmerecencuidadosaatencibnycomprenslbn.

Lasadvertenclasporelmismasnoelimlnannlngdnpeligro.LasInstruccloneso lasadvertenclasquese

proporclonannoreemplazanalasmedidasadecuadasdeprevenclbndeaccldentes.

SIMBOLO SIGNIFICADO

A

A

SIMBOLO DE ALERTA SOBRE SEGURIDAD: Indica atenci6n, advertenciao peligro. Puede

usarseconjuntamentecon otrossfmboloso pictogramas.

PELIGRO: Si no se obedece una advertenciade seguridadpuede lesionarse esi mismo y a otros.

Siempresiga las precaucionesde seguridad para reducirel riesgode incendio,choque electrico y

lesibn personal.

ADVERTENCIA: Si no se obedece una advertencia de seguridad puede lesionarse a si mismoy a

otros.Siempre siga las precaucionesde seguridad para reducirel riesgode incendio,choque el(_ctrico

y lesi6n personal.

ATENClON: Si no se obedece una advertencia de seguridad puede lesionarse a si mismo y a otros.

Siempre siga las precaucionesde seguridadpara reducir el riesgode incendio,choque el_ctricoy

lesibn personal.

NOTA: Informaci6n o instrucciones vitalespara el funcionamiento o mantenimiento de la herramienta.

AISLAMIENTO DOBLE

El aislamientodobte es un concepto de seguridad, en las

herramientas rnecdnicas electricas, que elimina la

necesidad del cord6n normal trifilar puesto a tierra.

Todas las piezas met&licas expuestas est_.naisladas de

los componentes internesdel motor con aislamiento

protector. Las herramientascon dobleaislamiento no

necesitan ser puestasa tierra.

IMPORTANTE

La reparacibn de las herramientas con aislamiento doble

requiere extremo cuidado y conocimiento del sistema y

debe ser realizada solarnente pot un t_cnico de servicio

calificado. Para toda reparaci6n, le sugerimos que neve

la herramienta a su Almac_n Sears m&s cercano.

Siempre use repuestos de f&brica originales cuando

efect0e alguna reparacibn.

ADVERTENCIA: No intentehacerfuncionar

esta herramienta sin antes haber leido y

oomprendido bien todas las instrucciones, las reglas

de seguridad, etc. indicadas en este manual. El

incumplimiento de estas instrucciones puede

ooasionar accidentes, incendio, choque el_ctrico o

lesiones personales graves. Conserve el manual

del usuario y estt_dielo frecuentemente para poder

utilizar el equipo con seguridad y poder comunicar

las instrucciones apropiadas a otras personas que

utilicen esta herramienta.

LEA TODAS LAS INSTRUCCIONES

• CONOZCA SU HERRAMIENTA MECANICA. Lea

cuidadosamente el manual del usuario. Aprenda sus

aplicaciones y limitaciones asi como tambi_n los riesgos

potenciales especificos relacionados con esta

herramienta.

• PROTEJASE CONTRA CHOQUE ELECTRICO evitando

contacto del cuerpo con las superficies puestas a tierra.

Por ejemplo: las cajas de las tuberias, radiadores,

estufas, refrigeradores.

• MANTENGA LOS PROTECTORES EN SU LUGAR yen

buen estado de funcionamiento.

• MANTENGA EL AREA DE TRABAJO LIMPIA. Los

lugares y bancos de trabajo desordenados invitan a los

accidentes.

• EVITE TODOS LOS AMBIENTES PELIGROSOS. No

use su herramienta mec&nica donde haya humedad, en

lugares mojados o donde est6 expuesta ala Iluvia.

Mantenga el lugar de trabajo bien iluminado.

• MANTENGA A LOS NIl;lOS Y A LOS ESPECTADORES

ALEJADOS, Todos los espectadores deben usar lentes

de seguridad y ser mantenidos a una distancia prudente

del _rea de trabajo. No deje que los espectadores

toquen la herramienta o el cordbn de extensi6n,

• ALMACENAMIENTO DE LAS HERRAMIENTAS QUE

NO SE USAN. Cuando no est_n en uso las

herramientas deben ser guardadas en un lugar seco, alto

o bajo Ilave - fuera del alcance de los nifios.

• NO FUERCE LA HERRAMIENTA. El trabajo quedar&

hecho mejor y de manera m&s segura si la herramienta

trabaja ala velocidad a la cual fu6 disefiada.

• USE LA HERRAMIENTA CORRECTA. No fuerce a una

herramienta o a un accesorio pequer_o que haga el

trabajo de una herramienta de servicio pesado. No use

ia herramienta para prop6sitos que no ha sido diseflada.

Por ejemplo, no use una sierra circular pare cortar

troncos o ramas de _rboles.

• USE VESTIMENTA ADECUADA. No use ropa o joyas

sueltas, pues pueden quedar atrapadas en las piezas

m6viles de la herramienta y causar lesibn personal. Se

recomienda usar guantes de gorna y calzado

antirresbaladizo cuando se trabaja al aire libre. Tambi6n,

prot_jase el cabello largo y suj_telo a fin de evitar que

quede atrapado en los respiraderos cercanos.

• USE SIEMPRE LENTES PROTECTORES. Los anteojos

regulares tienen solamente lentes resistentes al impacto;

ellos no son lentes de seguridad.

3

Page 22

• PROTEJA SUS PULMONES. Utiliceuna m_L_cara

contrael polvosi laoperacibnde cortevaa despedir

mucho polvo.

• PROTEJA SU AUDIClON. Utiliceproteccibnparalos

oidosdurantepeHodosprolongadosde funcionamiento.

• NO ABUSE DEL CORDON. Nuncatransportela

herramientaporel cordbno latiredet cordbnpara

desconectadadeltomacorriente.Mantengaelcord6n

alejadodelcalor,del aceitey de loshordesafilados.

• SUJETE EL TRABAJO. Use mordazas oun tornillode

bancopara sujetarel trabajo. Es m_sseguroque usar

su manoy ledejaambasmanes libresparautilizarla

herramienta.

• NO USE LA HERRAMIENTA A UNA DISTANCIA

DEMASIADO ALEJADA. Mantengasiempreunbuen

equilibrioy una posicibnfirme. No lautiliceen una

escalerao enun apoyoinestable.Asegurelas

herramientascuandotrabajeen posicionesaltas.

• MANTENGA BIEN CUIDADA LA HERRAMIENTA.

Mantengala herramientaafiladaen todomomento y

limpiapara unrendimientomejory m_sseguro. Siga las

instruccionesdelubricacibny de cambiode accesorios.

• DESCONECTE I.AS HERRAMIENTAS. Cuandono

est_nen uso,antesdelservicioocuandocambia

accesorios, todaslas herramientasdebende estar

desconectadasde lafuente de alimentacibn.

• SAQUE LAS LLAVES DE AJUSTE Y LLAVES

INGLESAS. Acost0mbresea verificarsise han sacado

todaslasIlavesde laherramientaantesde ponerlaen

marcha.

• EVITE LA PUESTA EN MARCHA ACCIDENTAL. No

transporte las herramientas que est&n enchufadas con

dedo sobre el interruptor. AsegOrese de que el

interruptor est_ en la posicibn "OFF" (apagado) al

enchufarla.

• ASEGURESE DE QUE SU CORDON DE EXTENSION

ESTE EN BUEN ESTADO. Cuando use un cord6n de

extensi6n, aseg_rese de qua su di_.metro sea suficiente

para portar la cordente qua necesita su herramienta. Un

cordbn de calibre inferior causaret una p_rdida en el

voltaje de linea resultando en p_rdida de potencia y

sobrecalentamiento. Se recomienda un cord6n de pot Io

menos calibre 14 (A.W.G.) para un cordbn de extensi6n

de lOg pies o menos de largo. No se recomienda'el uso

de un cord6n qua sobrepase los 100 pies de largo.

Mientras mds pequet_o es el n_mero del calibre, mayor

es el di_metro del cord6n.

• USE CORDONES DE EXTENSION APROPIADOS

PARA EL EXTERIOR. Cuando la herramienta es usada

al aire libre use solamente cordones de extensi6n

adecuados para uso al aire libra. Los cordones

aprobados para uso al aire libra est_n marcados con el

sufijo W-A, por ejemplo - SJTW-A o SJOW-A.

• MANTENGA LAS FRESAS LIMPIAS Y AFILADAS. Las

fresas afiladas reducen a un mfnimo la p_rdida de

velocidad y ei contragolpe.

• MANTENGA LAS MANOS ALEJADAS DEL AREA DE

CORTE. Mantenga las manos alejadas de las fresas.

No trate de alcanzar por debajo del trabajo cuando la

fresa est_ girando. No intente sacar material, pedazos o

astillas cuando el cortador est_ girando.

• NUNCA USE EN UNA ATMOSFERAEXPLOSIVA. I-as

chispasnormalesdel motorpueden hacerexplotar los

vapores.

• INSPECCIONE PERIODICAMENTELOS CORDONES

DE LA HERRAMIENTAy si est_n dahados,hdgalos

repararpot el centrodeservicioSears. Siempreestd

atentode la ubicaci6ndelcord6n.

• INSPECCIONE LOSCORDONES DE EXTENSION

PERIODICAMENTE yreempl_lcelossiest._nda_ados.

• MANTENGA LAS MANIJAS SECAS, LIMPIAS YSIN

ACEITE NI GRASA. Siempreuse unpaso limpiopara

efectuar la Iimpieza.Nuncause I{quidode frenos,

gasolina,productosa base de petrbleoo solventespara

limpiar suherramienta.

• MANTENGASE ALERTAY EN CONTROL. Ponga

atenci6na Ioqua est_ haciendoy usesentidocom,',n.

No hagafuncionarla herramientacuandoest_cansado.

No se apresurepararealizarel trabajo.

• INSPECClON DE PIEZAS DAI[IADAS. Antesde seguir

utilizandola herramienta, inspeccioneparadeterminarsi

alg0nprotector ocualquierpiezaqueest_ da_ada

funcionar_ debidamente.Verifiqueelalineamientode las

piezasm6viles, si est_matascadaso si hay roturade

piezas,reviseadem_isel montaje ycualquierotroestado

que puedaafectarsufuncionamiento. Si seda_a un

protectoro cualquierotrapiezadebeser reparadao

reemplazadapotun centrodeservicioautorizado.

• NO USE LA HERRAMIENTASI EL INTERRUPTOR NO

FUNClONA DEBIDAMENTE. Haga reemplazarel

interruptordefectuosopor undistribuidorautorizado.

• INSPECClONE y saquetodoslosclavosde lamadera

el

antesde ranurar.

• NO hagafuncionaresta herramientacuandoestd bajola

influenciade drogas,alcoholo hayatornadomedicina.

• ENCHUFES POLARIZADOS. Para reducirel riesgode

choqueelectrico,laherramientatiene unenchufe

polarizado(unahoja de contactoes m_lsanchaqua la

otra). EsteenchufepuedecoFocarseen un

tomacorrientepolarizado enunasola direccibn

solamente. Si etenchufenocalza bienenel

tomacorriente,inviertaelenchufe. Si todaviano calza,

pbngaseencontactoconun electricistacalificadopara

que instaleuntomacorrienteadecuado. Nomodifique el

enchufede ningunamanera.

• CUANDO EFECTUE LABORESDE MANTENIMIENTO

USESOLAMENTE REPUESTOSCRAFTSMAN

AUTENTICOS.

• CUANDO USE ESTE TUPI CON UNA MESA PARA

TUPI, AYUDE A EVITAR POSlBLES LESIONES

GRAVES MANTENIENDO LA FRESA PROTEGIDA EN

TODO MOMENTO. Use solamente mesas para tupis,

con protectores, qua ban sido dise_lados para usar con

tupfs de este tipo, tama_o y peso.

• NO USE LA HERRAMIENTA SI SE PRODUCE

PERDIDA DE TENSION U OTRAS SITUAClONES EN

QUE EL VOLTAJE SEA BAJO. Tampoco use con

ningL_notro dispositivoqua pueda provocar cambio en el

voltaje de la fuente de energ{a.

• CONSERVE ESTAS INSTRUCClONES. Cons01telas

con frecuencia y _seLas para ayudar a otros que puedan

usar esta herramienta. Si usted presta esta herramienta

a otra persona, entregue tambi_n las instrucciones.

CONSERVE ESTAS INSTRUCCIONES

4

Page 23

_ ADVERTENClA: El polvo creado por el lijado

mec_nico, aserrado, rectificado, taladrado y otras

actividades empleadas en construcci6n contiene

productos qufmicos que se sabe causan cdncer,

defectos cong6nitos u otros dafios al sistema

reproductor. Algunos de estos productos

qufmicos son:

• plomo proveniente de pinturas a base de plomo

• sl'licecristalizada de laddllos y cemento y

otros productos de albafiileda y,

• ars6nico y cromo de madera tratada

qufmicamente.

Su desgo de exposici6n a estos productos varfa

dependiendo de cuan a menudo usted hace este

tipo de trabajo. Para reducir su exposici6n a

estos productos quimicos: trabaje en lugares

bien ventilados y utilice equipo de seguddad

aprobado, tal como mdscaras contra el polvo

especialmente disefiadas para filtrar partfculas

microscbpicas.

Profundidad del Corte 0 - 1-1/2 pulg.

Portafresa 1/4 pulg.

HP 1-1/2

Alimentacibn 120 voltios, 60 Hz, CA solamente

Su tup{ ha sido embarcado completamente armado.

Inspecci6nelo cuidadosamente para asegurarse de

que no ha ocurddo daho o rotura durante el transporte.

Si hay partes dafiadas o faltantes, Ilame a su Almac_n

Sears mds cercano para obtener piezas de repuesto

Amperios 8

Velocidad sin Carga 25.000 RPM

Cord6n El_ctrico 6 pies

Peso Neto 8,13 libras

ADVERTENClA: Si falta cualquiera de las

piezas, no haga funcionar esta herramienta hasta

que las piezas faltantes no hayan sido

reemplazadas. De Io contrario puede resoltar en

una posible lesi6n personal grave.

antes que intente utilizar el tupL Tambi_n se incluye

una Ilave y este Manual del Usuario.

LOS SIGUIENTES ACCESORIOS RECOMENDADOS

ESTAN DISPONIBLES EN LOS ALMACEN SEARS

Bujes de Gu|a de Plantilla PlanUlla para Bisagra de Puerta

Plantilla para Cola de Milano Guia de Tupf para Prop6sitos Mdltiples

Plantllla de Ensamblaje de Cajas Pant6grafo "Rout - A - Form"

FRESA FRESADE

COMBI- ACANALAR

NADA

PARA

PANEL

FRESADE

CAJADE

MACHOS

BISEL PARA

RANURA

ENV

BROCA

DERECHA

COMBINADA

DEFRESA

DERECHAY

ANGULO

ESCO-

PLEADORA

DEBISAGRA

[

COLADE REBA- GOLA CONCAVA,

MILANO JADORA ROMANA BISELADO

DE45°

L

i *FRESASCONPUNTADE CARBURO I

"25895- PARA FRESASPERFILADORASDEBORDESCON PUNTADE CARBURO

2589 - PARAFRESASPERFILADORASDEBORDESDE ACERODE ALTAVELOCIDAD

!:..... ! _--J!L!':.........................!LLZ_-=:- ........ "_

_L ADVERTENCIA: El uso de accesorios que no estdn incluidos en la lista anterior puede ser peligroso.

5

REBORDE ARBOL

DE 2589

CUARTO

BOCEL !c

CON2

COJINETES

DE BOLAS

(1/2'ySR')

"2S8_

I

Page 24

CONOZCA SU TUPI

Ver Figura 1.

Antes de intentar usarsu tupf,familiarfcese con todaslas

caracteristicasde operaci6n y los requerimientosde

seguridad.

INTERRUPTOR

Para poner en MARCHA (ON) su tupf, aprieteel gatillo.

Para APAGAR (OFF) el tupi,suelte el gatillo.

BOTON DE BLOQUEO EN MARCHA

El interruptordel tup{ est_l equipado con una

caracter{stica de bloqueo en marcha que es conveniente

cuando se trabaja durante perfodos prolongados de

tiempo. Para bloquear en marcha, apriete el gatillo,

oprima el bot6n de bloqueo en marcha situado en el lado

de ia manija, luego manteniendo oprimido el bot6n de

bloqueo en marcha, suelte el gatillo. Para desenganchar

el bloqueo en marcha, apriete y suelte el gatillo.

PROTECTOR CONTRA ASTILLAS

En la parte delantera de su tup{ se ha instalado un

protector contra astillas, de pl&stico transparente, para

protecci6n contra el potvo y las astillas que saltan. Ha

sido diseSado para que calce en la abertura delantera en

VISTA DELTUPI AL REVES

la base del tupf. Si es necesario sacarel protector contra

astillas, apriete laslengOetasen cada extremo y tire

hacia afuera. Para volvera colocarapriete las lengOetas

de cada extremo, para que calce en la abertura y

su61telas.Pare su protecclbn, no use el tupl sin tener

el protector contra astlllas en su lugar.

AREA DEL GUARDALLAVE

Su tupf tiene una &rea para guardar las Ilaves situada en

la parte superiorde la tapa del motor. Cuando instaleo

saque fresas, saque la Ilave de su_rea de

almacenamiento. Coloque la Ilave en el guardallave tan

prontocomo termine de usarlaa fin de reducirla

posibilidadde que se pierda.

CONEXlON ELECTRICA

Su tup{tiene un motor el_ctrico construido a precisibn.

Debe set conectado a una fuente de allmentacl6n de

120 voltios, 60 Hz, CA solamente (la corrlente normal

del hogar). No haga funcionar esta herramientacon

corrientecontinua(CC). Una cafda significativade

voltajepuede causar p6rdidade potenciay

sobrecalentamiento del motor. Si sutupi con efecto de

_mbolo no funciona cuando est&enchufado,vuelva a

verificarla fuente de alimentacibn.

ANILLOINDICADOR

DEPROFUNDIDAD

BLOQUE0

DEL

HUSILL0

ANILLODE BOTONDE

AJUSTEDE BLOQUEO

PROFUNDIDAD

TUERCA DEPROFUNDIOAD

PORTAFRESA

PROTECTOR PUNTO

CONTRAASTILLAS INDICADOR SUBBASE MANIJA

ANILLOINDICADOR

MANIJADE

PUESTAEN

BOTONDE

BLOQUEO

ENMARCHA

PUNTO

INDICADOR

GUARDALLAVE

L_VE

Fig. 1

_. ADVERTENCIA: No permita que su familiaridad con su tupf Io haga descuidado. Recuerde que un

descuido de una fraeci6n de segundo es suficiente para ocasionar una lesi6n grave.

6

Page 25

,_ ADVERTENClA: Su tupf no debe estar

enchufado en la fuente de alimentacibn cuando

est_ instalando piezas, haciendo ajustes,

instalando o sacando fresas, Ifmpibndoloo

cuando no est', en uso. AI desenchufar el tupf

evitard la puesta en marcha accidental que

podrfa provocar una lesibn personal grave.

INSTALACION/CAMBIO DE FRESAS

Ver Figuras 2 y 3.

• Desenchufe su tupf.

_ ADVERTENClA: Si no se desenchufa el tupf,

se puede producir la puesta en marcha

accidental causando una lesibn grave.

En el frente de la caja del motor se encuentra un

bloqueo del husillo. Para activar el bloqueo,

oprima el bloqueo del husillo y deslicelo a la

posici6n de bloqueo. Ver Figura 2.

,_ ADVERTENClA: Para evitar que se daSe el

husillo o el bloqueo del husillo, espere hasta

que el motor se detenga completamente antes

de enganchar el bloqueo del husillo.

BLOQUEODEL

HUSILLO

PARA

BLOQUEAR

DEL HUSILLC

Fig. 2

• Coloque su tupi al rev_s sobre una mesa, luego

gire la tuerca del portafresa con una Ilave hasta

que el mecanismo de bloqueo se enganche.

Ver Figura 3.

Nota: El bloqueo del husillo es a resorte y se

acomodar& en su posicibn cuando el mecanismo de

bloqueo se enclave.

TUERCADEL

PORTAFRESA

.LLAVE_

ADVERTENCIA: Si usted est,. cambiando una

A

fresa inmediamente despu6s de haber usado la

herramienta, tenga cuidadode no tocarla fresa o

el portafresa consusmanos o con losdedos. Se

puede quemar debidoa la acumulacibn de calor

producidapor el corte.Siempre use la Ilave que

se proporciona.

Saque las fresas girandola tuerca del portafresa a

la izquierda Io suficiente para permitir que la fresa

se deslice f&cilmente fuera del portafresa. Ver

Figura 3. El portafresa est,. labrado a tolerancias

muy precisas para poder recibir fresas con espigas

de 1/4 pulg. de diametro.

Con su tupi todavfa al rev_s sobre la mesa, inserte

la espiga de la fresa en el portafresa. La espiga de

la fresa debe estar cerca pero sin tocar el fondo del

portafresa.

Apriete firmemente la tuerca del portafresa gir&ndola

a la derecha con la Ilave provista. Ver Figura 3.

Coloque el bloqueo del husillo nuevamente en la

posici6n de desbloqueo. De Io contrario, el

mecanismo de enclavamiento del bloqueo del

husillo le impedir& poner en marcha su tupf.

ADVERTENCIA: No use fresas que tengan

A

v&stagos demasiado pequeSos. Losv_stagos

m_.spequeSos noquedar&ndebidamente

apretados y puedansalirse de la herramienta

causando lesiones.

FRESA

AFLOJARLA

TUERCADEL

PORTAFRESA

PARA

Fig. 3

Page 26

AJUSTES DE LA PROFUNDIDAD DE CORTE

Ver Figuras 4, 5 y 6.

Recomendamos que loscortes sean hechos a

prefundidades no mayores de 1/8 pulg. y que se

hagan varias pasadas para hacer cortes m&s

profundos de 1/8 pulg.

• Desenchufe su tupf.

_i, ADVERTENCIA: Si no se desenchufa el tupi,

se puede producir la puesta en marcha

accidental causando una lesibn grave.

• Coloque su tup{ sobre una superficie plana, afloje

el bot6n de bloqueo y gire el anillo de ajuste de

profundidad hasta que la fresa est6 dentro de la

subbase. Ver Figura 4.

PARAAPRETAR

BOTONDE

BLOQUEO_

PARA

AFLOJAR

FRESAENLA

PROFUNDIDAD -_.,....,._

DECORTECERO Fig. 5

• Coloque su tup{ de modo que la fresa pueda

extenderse m_.s all& de la subbase para el ajuste

de profundidad deseado. Ver Figura 6.

ANILLODE "_

AJUSTEDE

PROFUNDIDAD

ANILLO

•INDICADORDE

PROFUNDIDAD

_" PUNTO

INDICADOR

SUBBASE Fig. 4

• Gire el anillo de ajuste de profundidad hasta que la

punta de ta fresa toque la superficie plana. Gire el

anillo de ajuste de profundidad hasta que el cero se

alinee con el punto indicador en la base.

Nota: El anilto indicador de profundidad tambi_n es

un indicador de reposici6n a cero cuando se est&

ajustando la fresa a la profundidad de corte zero,

despu_s pasa a ser el anillo de ajuste de

profundidad. Ver Figura 5.

FRESAEXTENDIDAMAS

ABAJODELASUBBASE

Fig. 6

• Gire el anillo de ajuste de profundidad para obtener

la profundidad de corte deseada. La distancia a

que Ilega la fresa puede leerse en el anillo de

ajuste de profundidad. Cada marca en el anillo de

ajuste de profundidad indica un cambio de

1/16 pulg. en el ajuste de la profundidad. Punto

indicador est& situado en la base.

• Apriete firmemente el bot6n de bloqueo antes de

poner en marcha el tupL

R

Page 27

AJUSTES DE LA PROFUNDIDAD DE CORTE

CUANDO EL TUPI ESTA INSTALADO EN UNA

MESA DE TUPI

Ver Figura 7.

La profundidad de corte puede leerse desde ambos tados

del anillo de ajuste de profundidad. Elanillo infedor es

conveniente cuando se usa el tupf instalado en una mesa

de tupL El punto indicador en la base tambi6n debe usarse

cuando trabaje con el tupi instalado en una mesade tupL

Ajuste la fresa a la profundidad de corte cero, gire el aniile

indicador de ajuste a )a profundidad de corte deseada en la

escala, luego apriete firmemente el botbn de bloqueo.

SOLAMENTE PARA USO EN LA MESA DE TUPI

PUNTO

INDICADOR

ANILLOINDICADOR

DEPROFUNDIDAD Fig. 7

MESAS DE TUPI

No se ha investigadoel use de un tupi Craftsman en mesas