Page 1

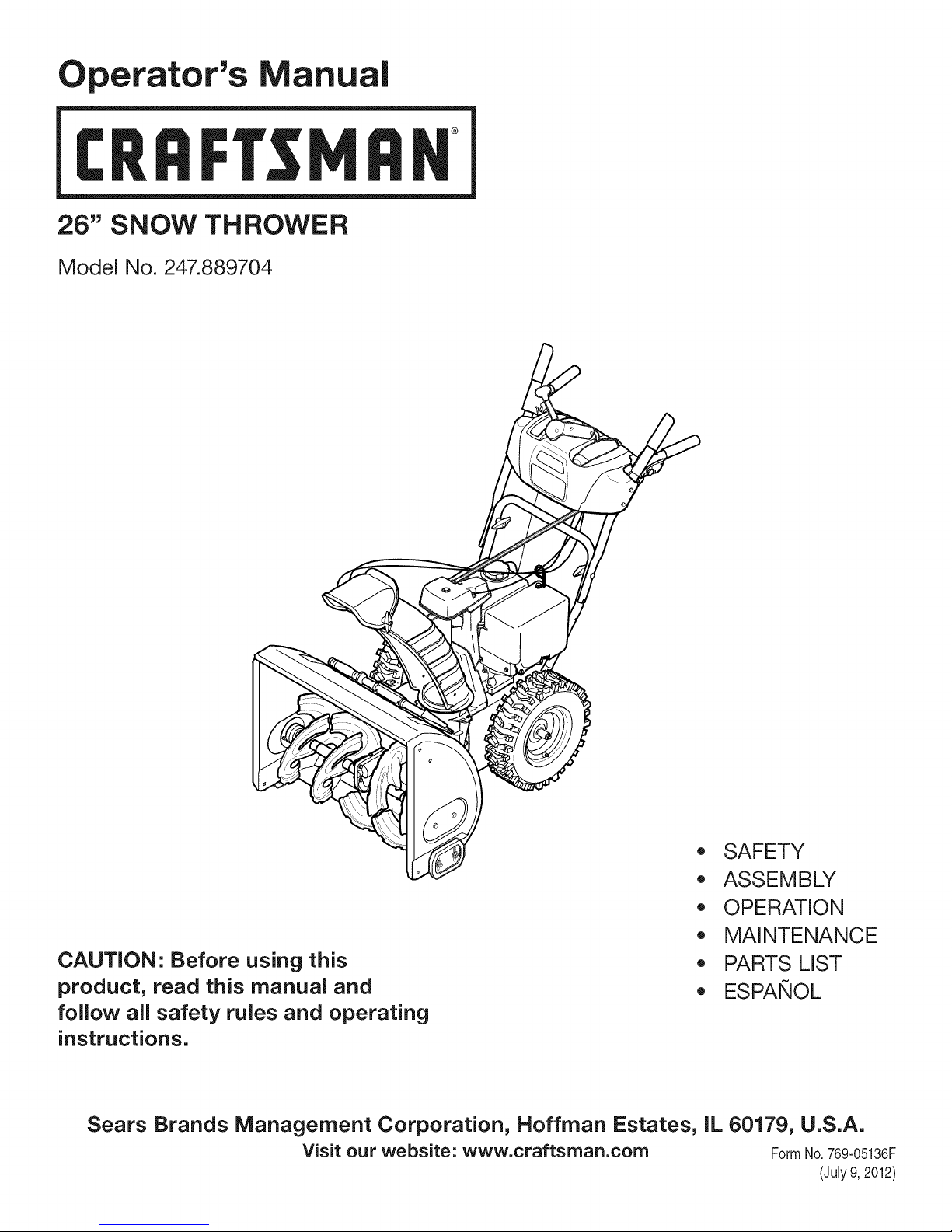

Operator's Manual

CRRFr MRN

26" SNOW THROWER

Model No. 247.889704

\

CAUTION" Before using this

product, read this manual and

follow all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FormNo. 769-05136F

,, SAFETY

o ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

(July9,2012)

Page 2

WarrantyStatement.................... Page2

SafeOperationPractices.............. Pages3-6

Assembly......................... Pages8-13

Operation........................ Pages14-17

Service&Maintenance.............. Pages18-25

Off-SeasonStorage................... Page26

Troubleshooting...................... Page27

PartsList......................... Pages28-45

RepairProtectionAgreement............ Page49

Espadol............................. Page50

CRAFTSMANTWOYEARFULLWARRANTY

FORTWOYEARSfromthedateofpurchase,thisproductiswarrantedagainstanydefectsinmaterialorworkmanship.Defectiveproductwill

receivefreerepairorfreereplacementifrepairisunavailable.

ADDiTiONAL LiFETiME LiMiTED WARRANTY on UPPER and LOWER CHUTE

FORAS LONGAS ITISUSEDbythe originalownerafterthe secondyearfromthedateof purchase,theupperandlowerchuteofthissnow

throwerarewarrantedagainstanydefectsinmaterialorworkmanshipas verifiedby a Searsauthorizedserviceprovider.Withproofofpurchase,

youwill receiveanewchutefree of charge.Youare responsibleforthelaborcostofinstallationandanycostincurredtoverifythedefect.

Forwarrantycoveragedetailsto obtainrepairor replacement,visitthewebsite:www.craftsman.com

ThiswarrantycoversONLYdefectsin materialandworkmanship.Warrantycoveragedoes NOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedtoaugers,augerpaddles,drift

cutters,skidshoes,shaveplate,shearpins,sparkplug,air cleaner,belts,andoil filter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnot limitedto damagecausedbyover-speedingtheengine,orfromimpacting

objectsthatbendtheframe,augershaft,etc.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedby improper

storage,failureto usethepropergradeandamountofengineoil,or failureto maintaintheequipmentaccordingtotheinstructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfueldeterminedto becontaminatedoroxidized(stale).in general,fuelshouldbeused

within30 daysof itspurchasedate.

Normaldeteriorationandwearoftheexteriorfinishes,or productlabelreplacement.

Thiswarrantyisvoid if thisproductiseverusedwhileprovidingcommercialservicesor if rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyou mayalso haveotherrightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineOilType: 5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 2 Quarts

SparkPlug: F6RTC(951-10292)

SparkPlugGap: .020"to .030"

©SearsBrands,LLC

ModelNumber.................................................................

Serial Number.................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Page 3

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingto operatethismachine.Failureto complywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron thepartoftheoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Failuretodo socan resultinseriousinjurytotheoperatorand/

orbystanders.Keepthismanualina safeplaceforfutureand

regularreferenceandfor orderingreplacementparts.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthemachineanddisengagethemquickly.

• Neverallowchildrenunder14yearsofagetooperatethis

machine.Children14andover shouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

Neverallowadultsto operatethis machinewithoutproper

instruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthe like.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileitisin operation.Stopmachineif anyoneenters

thearea.

• Exercisecautiontoavoidslippingor falling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict theuseofthispowermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandon themachine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbytheauger/

impeller.

• Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

Disengageall controlleversbeforestartingtheengine.

Adjustcollectorhousingheighttocleargravelorcrushedrock

surfaces.

• Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjusttooutdoortemperaturebefore

startingtoclearsnow.

3

Page 4

SafeHandlingof Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

onyourselforyourclotheswhichcan ignite. Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuelwhilethe engineis hot or

running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Filltankto nomorethan1/2inchbelow

bottomoffillerneckto providespaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineis spilled,wipe it off theengineandequipment.Move

machinetoanotherarea.Wait5 minutesbeforestartingthe

engine.

• Neverstorethe machineorfuelcontainerinsidewherethereisan

openflame,sparkor pilotlight(e.g.furnace,waterheater,space

heater,clothesdryeretc.).

• Allowmachineto cool at least5 minutesbeforestoring.

• Neverfill containersinsideavehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthegroundaway

fromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthe truckor

trailerandrefuelit ontheground.Ifthis is not possible,thenrefuel

suchequipmenton atrailerwitha portablecontainer,ratherthan

froma gasolinedispensernozzle.

• Keepthe nozzlein contactwiththerimofthefueltankor

containeropeningatalltimes untilfuelingiscomplete.Do not use

a nozzlelock-opendevice.

OPERATION

• Do not puthandsorfeetnearrotatingparts,intheauger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleveris a safetydevice.Neverbypass

itsoperation.Doingsomakesthemachineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewitha missingor damagedchuteassembly.Keep

all safetydevicesin placeandworking.

• Neverrunanengineindoorsor ina poorlyventilatedarea. Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Do notoperatemachinewhileunderthe influenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancauseaburn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingon orcrossinggravel

surfaces.Stayalertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.Do notoperateonsteepslopes.

Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageorpersonalinjurycausedbya ricochet.

Neverdirectdischargeatchildren,bystandersand petsorallow

anyoneinfrontofthemachine.

Donot overloadmachinecapacitybyattemptingto clearsnowat

toofastof a rate.

Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingand keepa firmholdon thehandles.Walk,

neverrun.

Disengagepowerto theauger/impellerwhentransportingor not

in use.

Neveroperatemachineathightransportspeedsonslippery

surfaces.Lookdownand behindand usecarewhenbackingup.

Ifthemachineshouldstartto vibrateabnormally,stoptheengine,

disconnectthesparkplugwire andgrounditagainsttheengine.

Inspectthoroughlyfor damage.Repairanydamagebefore

startingandoperating.

Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntilthe auger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makingany adjustments,or inspections.

Neverputyourhandinthedischargeor collectoropenings.Do

notunclogchuteassemblywhileengineisrunning.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.). Forinformation

concerningtheseitems,call 1-800-469-4663.

Whenstartingengine,pullcordslowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthanyoucan let go. Broken

bones,fractures,bruisesorsprainscouldresult.

Ifsituationsoccurwhichare notcoveredinthismanual,usecare

andgoodjudgment.

Toorderpartsor scheduleservicefor thisproduct,call 1-800-

469-4663.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

is themostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondsto be surethe impellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,not yourhands.

4

Page 5

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstopthe engine.Waituntiltheauger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheenginetopreventunintendedstarting.

Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthe machineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingorover-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonlyas listedinthe Partspagesof thisoperator's

manual.Useofpartswhichdonotmeettheoriginalequipment

specificationsmayleadto improperperformanceandcompro-

misesafety!

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,if necessary.Refertotheadjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsand regulationsfor gas,oil,etc. to

protecttheenvironment.

Priorto storing,runmachineafew minutestoclearsnowfrom

machineand preventfreezeupofauger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkorpilotlightsuchas a waterheater,furnace,

clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank,cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or60 hoursof

operation.Attheendof theAverageUsefulLifehavethe machine

inspectedannuallybyan authorizedservicedealerto ensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failuretodo so can resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMiSSiONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOff RoadEquipment)are

certifiedto operateon regularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)andThreeWay

Catalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(ifany)

Ifa sparkarrestorisused,itshouldbe maintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthemufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

Page 6

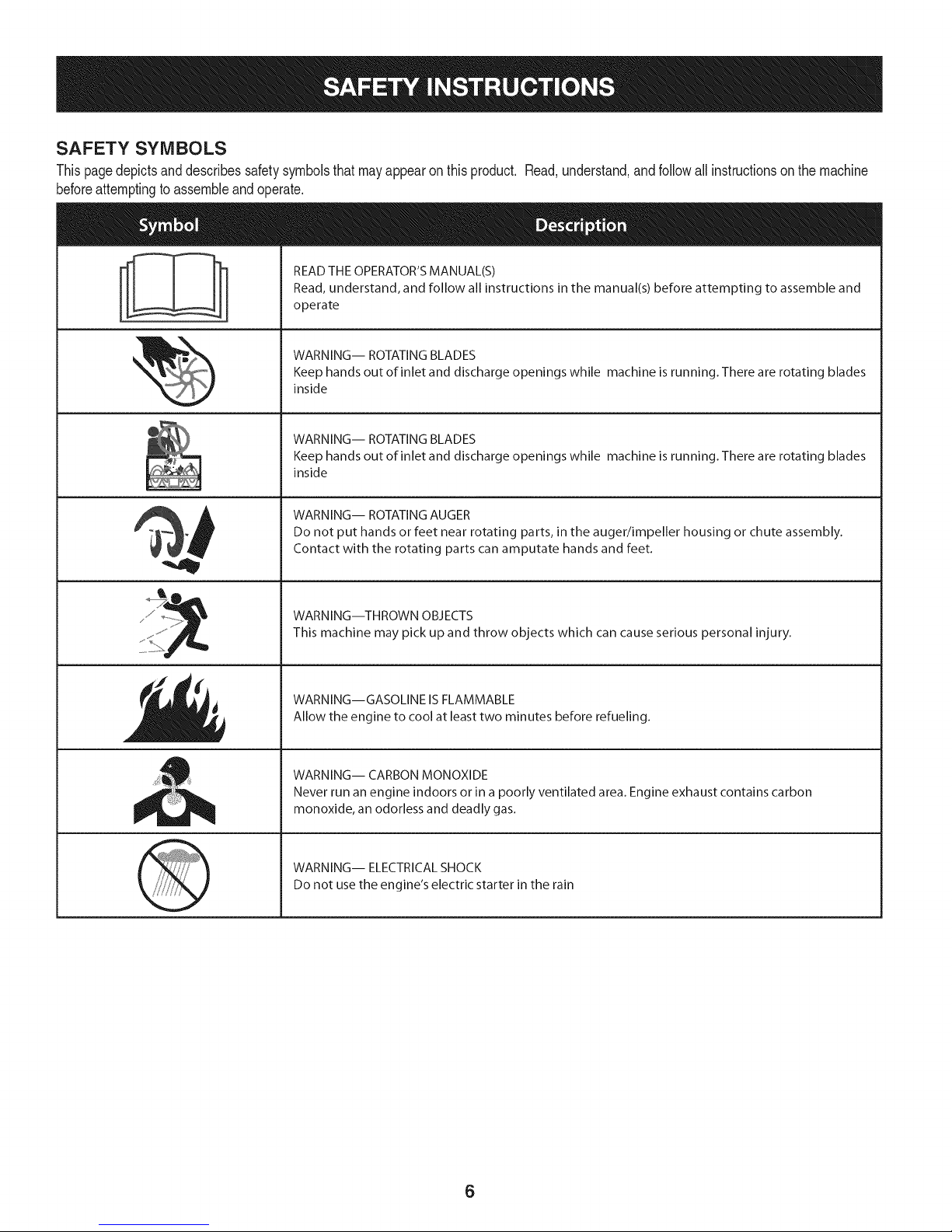

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

. +

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

"JIp

WARNING--THROWN OBJECTS

This machine may pick up and throw objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas+

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

Page 7

Thispageleftintentionallyblank.

7

Page 8

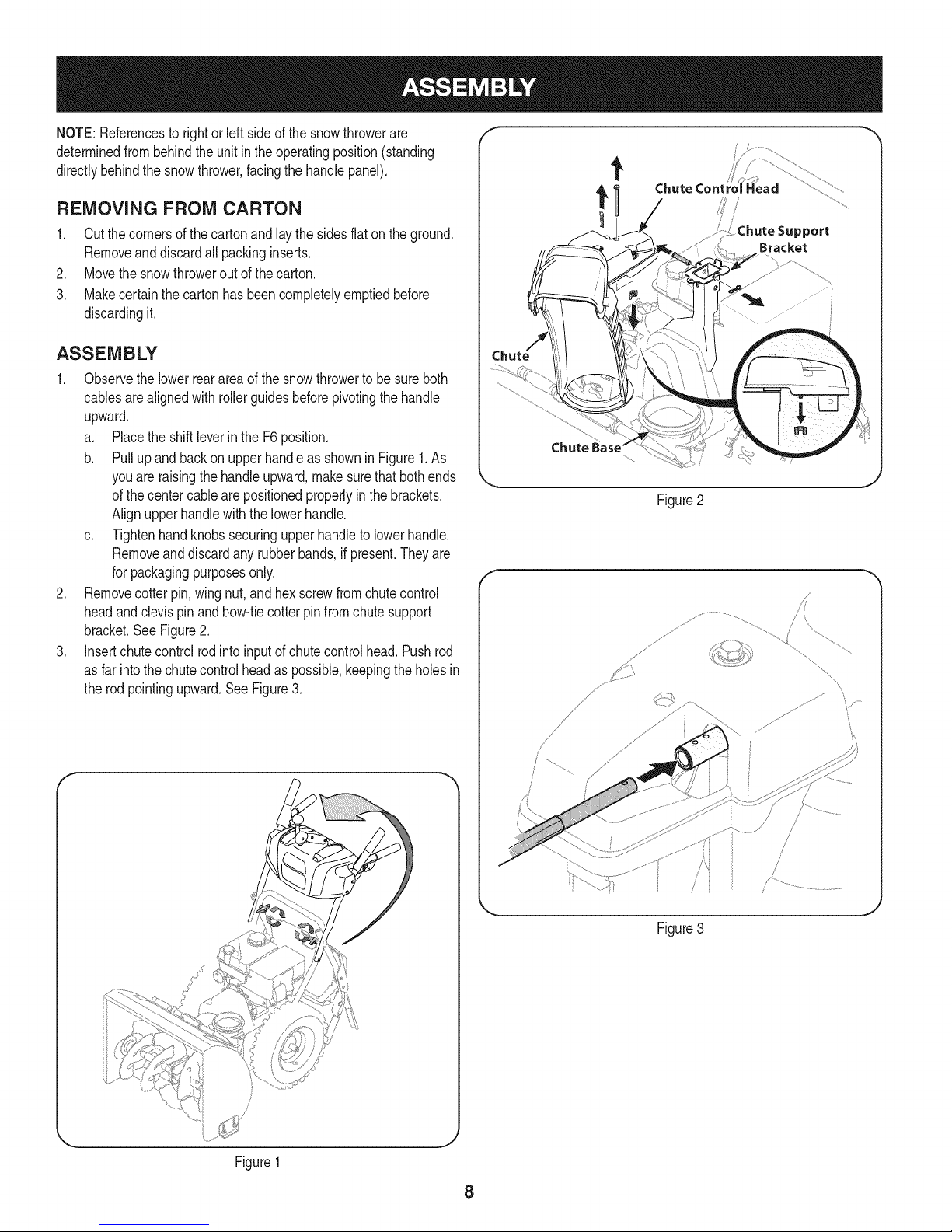

NOTE:Referencesto rightorleft sideof the snowthrowerare

determinedfrombehindtheunitinthe operatingposition(standing

directlybehindthesnowthrower,facingthe handlepanel).

REMOVING FROM CARTON

1. Cutthe cornersof thecartonandlaythesidesflaton theground.

Removeanddiscardallpackinginserts.

2. Movethesnowthroweroutofthecarton.

3. Makecertainthecartonhas beencompletelyemptiedbefore

discardingit.

ASSEMBLY

1. Observethe lowerrearareaof the snowthrowerto besureboth

cablesarealignedwith rollerguidesbeforepivotingthehandle

upward.

a. Placetheshiftleverin theF6position.

b. Pullupandbackonupperhandleasshownin Figure1.As

youare raisingthehandleupward,makesurethatbothends

ofthecentercablearepositionedproperlyinthe brackets.

Alignupperhandlewiththe lowerhandle.

c. Tightenhandknobssecuringupperhandletolowerhandle.

Removeanddiscardanyrubberbands,ifpresent.Theyare

forpackagingpurposesonly.

2. Removecotterpin,wingnut,and hexscrewfromchutecontrol

headandclevispinandbow-tiecotterpinfromchutesupport

bracket.See Figure2.

3. Insertchutecontrolrodintoinputof chutecontrolhead.Pushrod

asfarintothe chutecontrolheadaspossible,keepingtheholesin

therodpointingupward.SeeFigure3.

Chute Control Head

_ort

Bracket

Figure2

f

/

Figure1

/

/

/

J

Figure3

J

8

Page 9

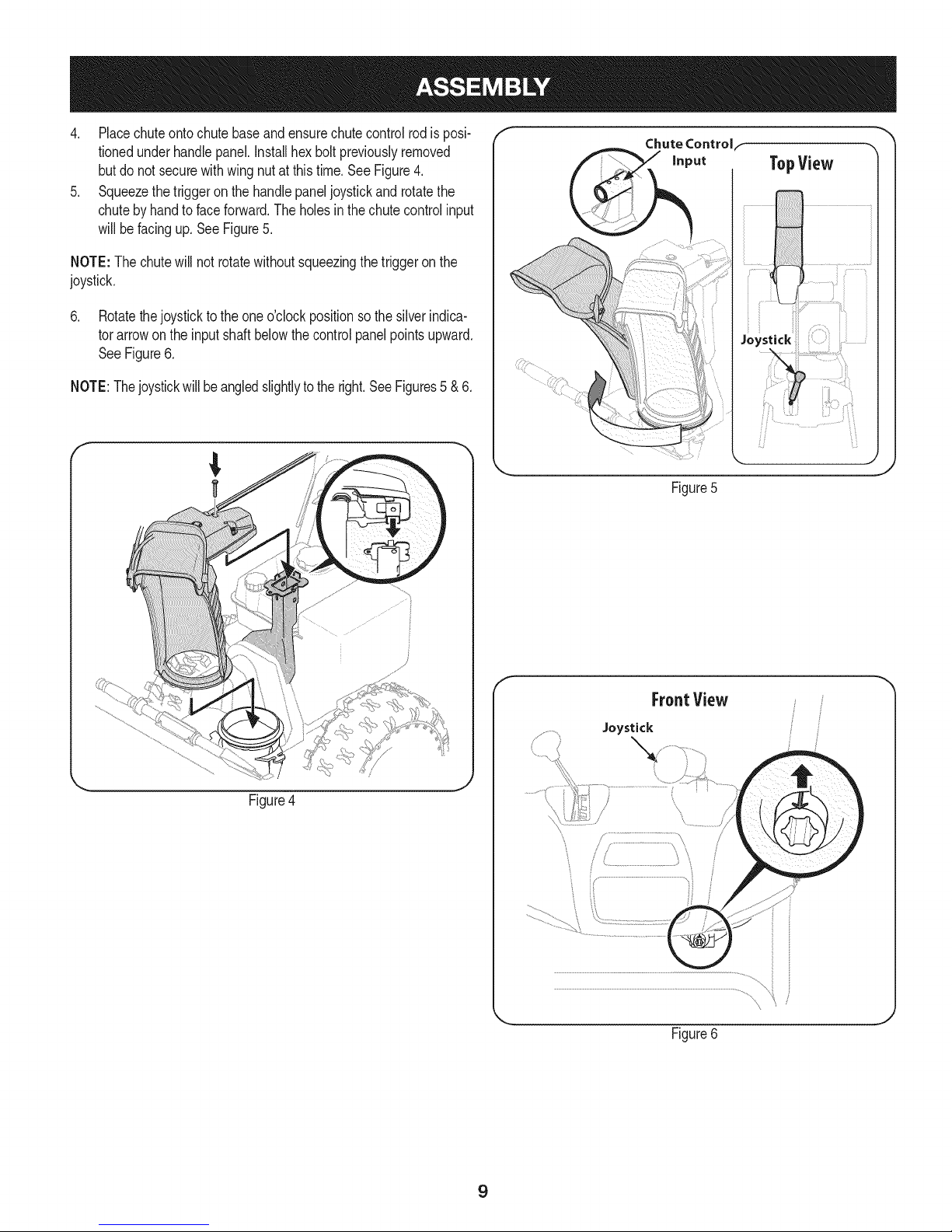

4. Placechuteontochutebaseandensurechutecontrolrodis posi-

tionedunderhandlepanel.Installhexboltpreviouslyremoved

butdonotsecurewithwingnutatthistime.SeeFigure4.

5. Squeezethetriggeron thehandlepaneljoystickand rotatethe

chutebyhandtofaceforward.Theholes inthechutecontrolinput

willbefacingup.SeeFigure5.

NOTE:The chutewill not rotatewithoutsqueezingthetriggeronthe

joystick.

6. Rotatethejoysticktotheoneo'clockpositionsothesilverindica-

torarrowontheinputshaftbelowthecontrolpanelpointsupward.

SeeFigure6.

NOTE:Thejoystickwillbeangledslightlytotheright.SeeFigures5 & 6.

f

Chute Controlf

Figure5

Figure4

f

FroatView

Joystick

J

Figure6

9

Page 10

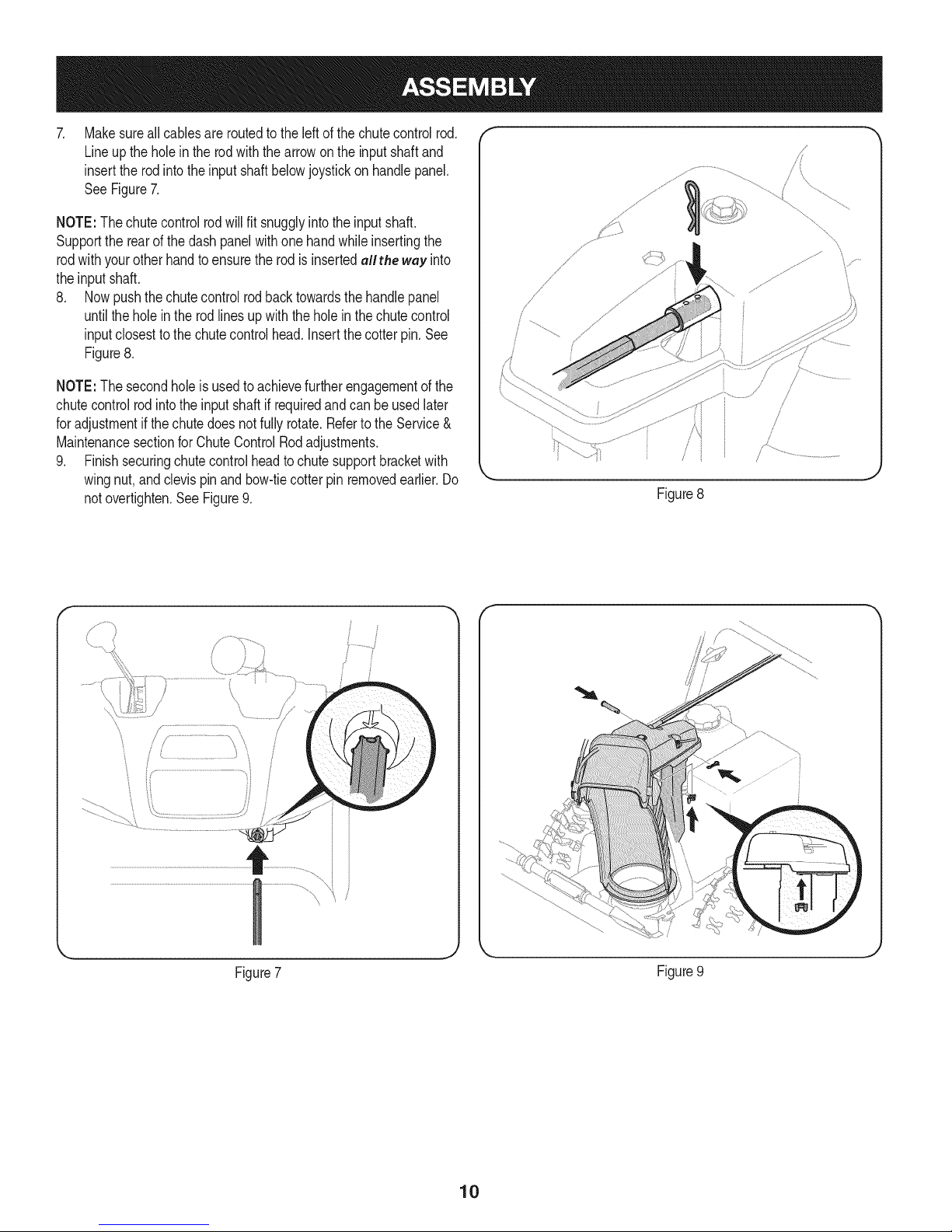

Makesureall cablesare routedtotheleftofthechutecontrolrod.

Lineupthe holein the rodwiththearrowonthe inputshaftand

inserttherodintotheinputshaftbelowjoystickonhandlepanel.

SeeFigure7.

NOTE:The chutecontrolrodwillfit snugglyintotheinputshaft.

Supportthe rearof the dashpanelwithone handwhileinsertingthe

rodwithyourotherhandtoensurethe rodisinsertedallthe way into

theinputshaft.

8. Nowpushthechutecontrolrodbacktowardsthehandlepanel

untilthe holein the rodlinesupwiththeholein thechutecontrol

inputclosestto the chutecontrolhead.Insertthecotterpin.See

Figure8.

NOTE:The secondholeisusedto achievefurtherengagementof the

chutecontrolrodintotheinputshaftifrequiredandcanbe usedlater

foradjustmentif thechutedoesnotfullyrotate.Refertothe Service&

MaintenancesectionforChuteControlRodadjustments.

9. Finishsecuringchutecontrolheadto chutesupportbracketwith

wingnut,andclevispinand bow-tiecotterpinremovedearlier.Do

notovertighten.SeeFigure9.

Figure8

y..................

\

Figure7

Figure9

10

Page 11

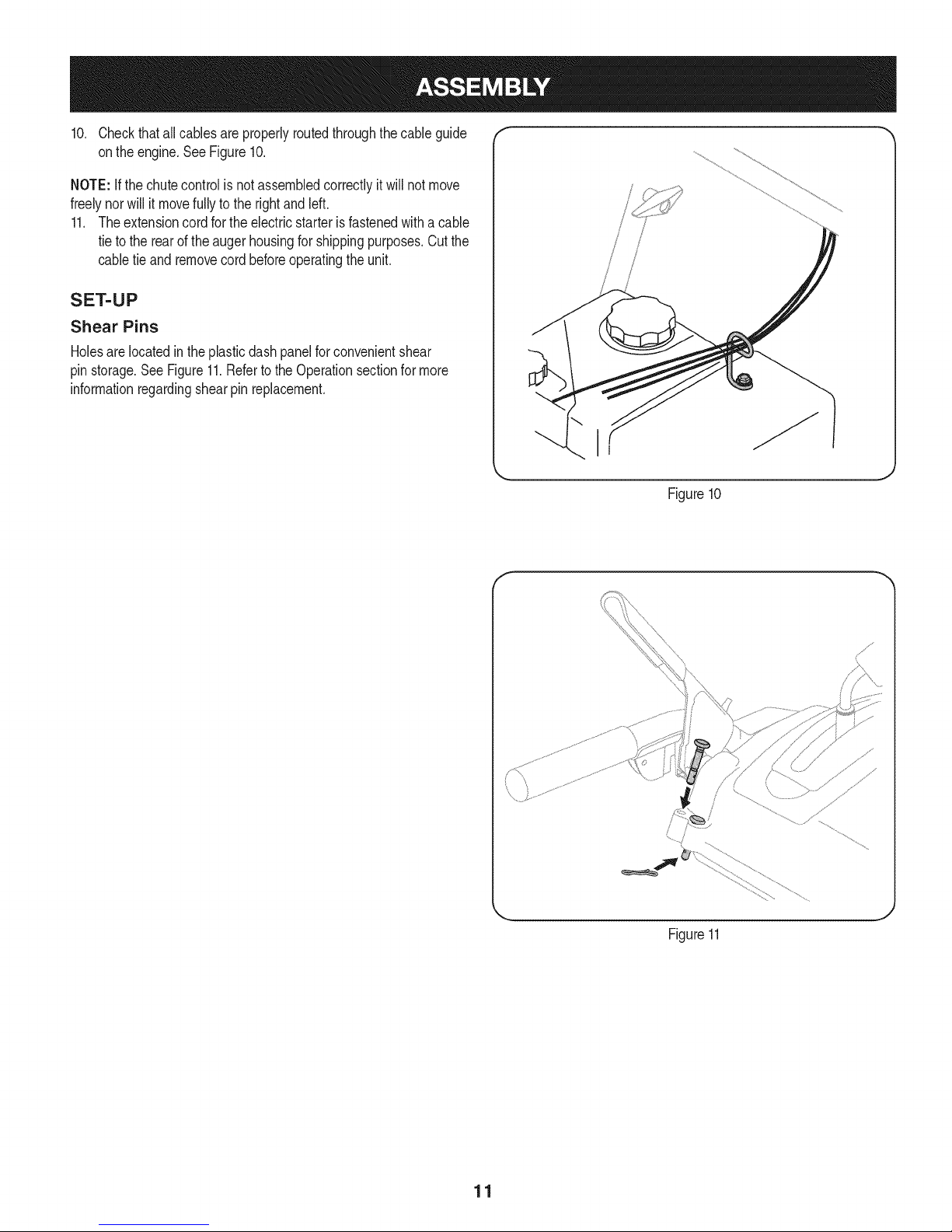

10. Checkthatall cablesareproperlyroutedthroughthecableguide

ontheengine.SeeFigure10.

NOTE:Ifthechutecontrolis notassembledcorrectlyitwillnotmove

freelynorwillit movefullyto the rightandleft.

11. Theextensioncordfortheelectricstarteris fastenedwitha cable

tietotherearoftheaugerhousingforshippingpurposes.Cutthe

cabletie and removecordbeforeoperatingtheunit.

SET-UP

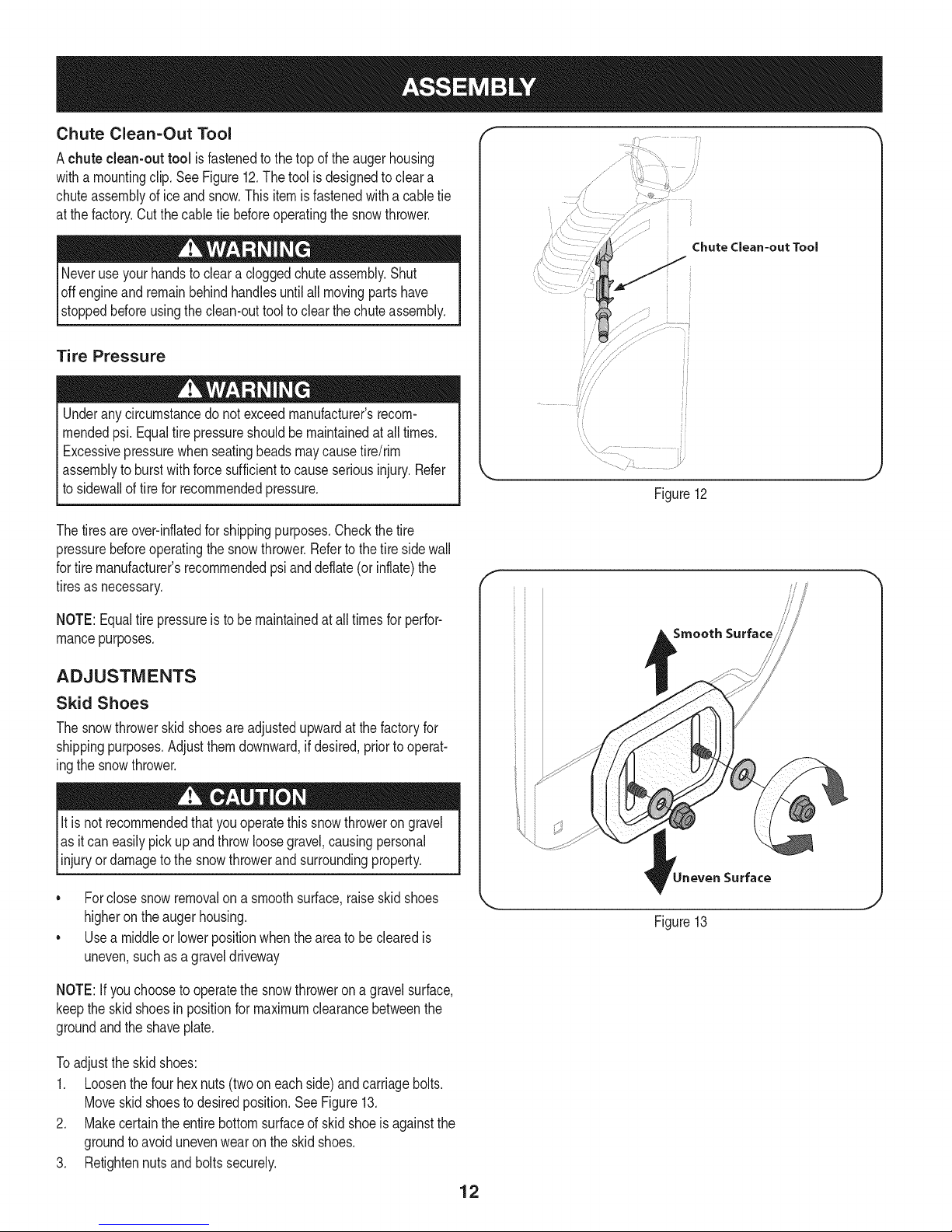

Shear Pins

Holesare locatedintheplasticdashpanelforconvenientshear

pinstorage.SeeFigure11.Referto the Operationsectionformore

informationregardingshearpin replacement.

/

i

i I

iili,

!

Figure10

J

Figure11

11

Page 12

Chute Clean=Out Tool

Achute clean-out tool isfastenedtothe top of the augerhousing

witha mountingclip.SeeFigure12.Thetoolisdesignedtocleara

chuteassemblyoficeandsnow.Thisitemisfastenedwitha cabletie

atthefactory.Cutthecabletiebeforeoperatingthe snowthrower.

loff m=ovingpartshave

stoppedbeforeusingtheclean-outtooltoclearthechuteassembly.

Tire Pressure

Underanycircumstancedo notexceedmanufacturer'srecom-

mendedpsi.Equaltirepressureshouldbemaintainedatall times.

Excessivepressurewhenseatingbeadsmaycausetire/rim

assemblytoburstwithforcesufficienttocauseseriousinjury.Refer

tosidewallof tirefor recommendedpressure.

Thetiresareover-inflatedforshippingpurposes.Checkthetire

pressurebeforeoperatingthe snowthrower.Referto the tire sidewall

fortiremanufacturer'srecommendedpsianddeflate(or inflate)the

tiresasnecessary.

................

Chute Clean-out Tool

_J

Figure12

//'

NOTE:Equaltire pressureistobe maintainedat alltimesfor perfor-

mancepurposes.

ADJUSTMENTS

Skid Shoes

Thesnowthrowerskidshoesareadjustedupwardatthefactoryfor

shippingpurposes.Adjustthemdownward,ifdesired,priorto operat-

ingthesnowthrower.

It is not recommendedthatyouoperatethissnowthrowerongravel

asitcaneasilypickup andthrowloosegravel,causingpersonal

njuryordamageto the snowthrowerandsurroundng property.

• Forclosesnowremovalona smoothsurface,raiseskidshoes

higherontheaugerhousing.

• Usea middleor lowerpositionwhentheareatobe clearedis

uneven,suchas a graveldriveway

NOTE:If youchoosetooperatethesnowthrowerona gravelsurface,

keepthe skidshoesin positionfor maximumclearancebetweenthe

groundandtheshaveplate.

Toadjustthe skidshoes:

1. Loosenthefour hexnuts(twooneach side)andcarriagebolts.

Moveskidshoestodesiredposition.SeeFigure13.

2. Makecertaintheentirebottomsurfaceof skidshoeisagainstthe

groundtoavoidunevenwearontheskidshoes.

3. Retightennutsand boltssecurely.

Smooth Surface

Surface

Figure13

12

Page 13

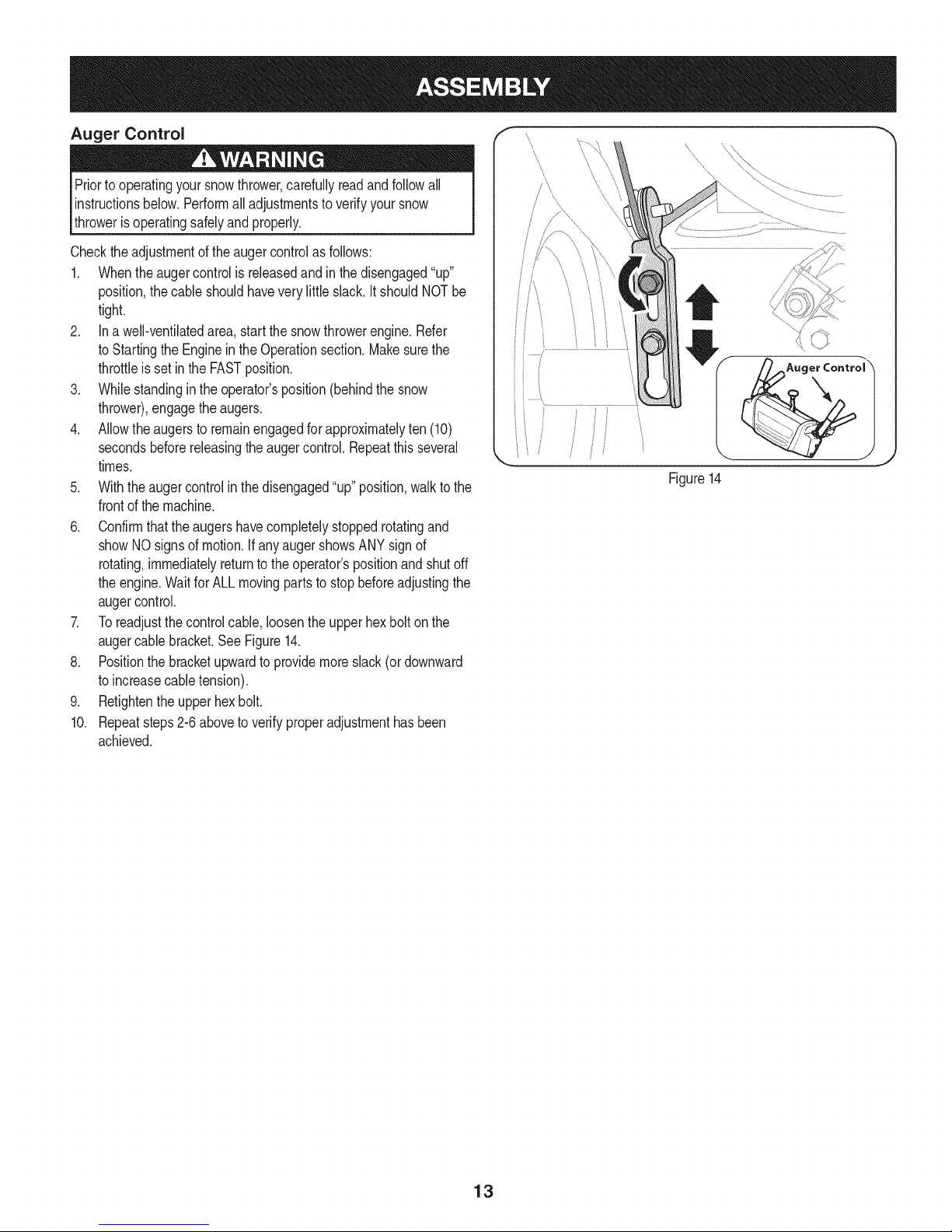

Auger Control

Priortooperatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performalladjustmentsto verifyyoursnow

throwerisoperatingsafelyandproperly.

Checktheadjustmentof the augercontrolas follows:

1. Whentheaugercontrolis releasedandin thedisengaged"up"

position,thecableshouldhavevery littleslack.ItshouldNOTbe

tight.

2. Ina well-ventilatedarea,startthesnowthrowerengine.Refer

toStartingtheEngineintheOperationsection.Makesurethe

throttleis setin the FASTposition.

3. Whilestandingintheoperator'sposition(behindthe snow

thrower),engagethe augers.

4. Allowtheaugersto remainengagedforapproximatelyten(10)

secondsbeforereleasingthe augercontrol.Repeatthisseveral

times.

5. Withtheaugercontrolinthedisengaged"up" position,walkto the

frontofthemachine.

6. Confirmthattheaugershavecompletelystoppedrotatingand

showNOsignsof motion.IfanyaugershowsANYsignof

rotating,immediatelyreturntotheoperator'spositionandshutoff

theengine.WaitforALLmovingpartstostopbeforeadjustingthe

augercontrol.

7. Toreadjustthecontrolcable,loosentheupperhexbolt onthe

augercablebracket.SeeFigure14.

8. Positionthe bracketupwardtoprovidemoreslack(or downward

toincreasecabletension).

9. Retightentheupperhexbolt.

10. Repeatsteps2-6aboveto verifyproperadjustmenthasbeen

achieved.

/_Auger Control \

Figure14

13

Page 14

f

Auger

Chute Assembly

Clean Out

Tool

\

Drive Control

Gas Cap

\

\

Shift Lever

Four-Way Chute ControP (Joystick)

J

J

Auger Control

\

\

\

Muffler Recoil Starter

'\ Handle

Primer FUEL LEVEL

\

\

Hous_

Augers

_ Skid Shoe

Figure15

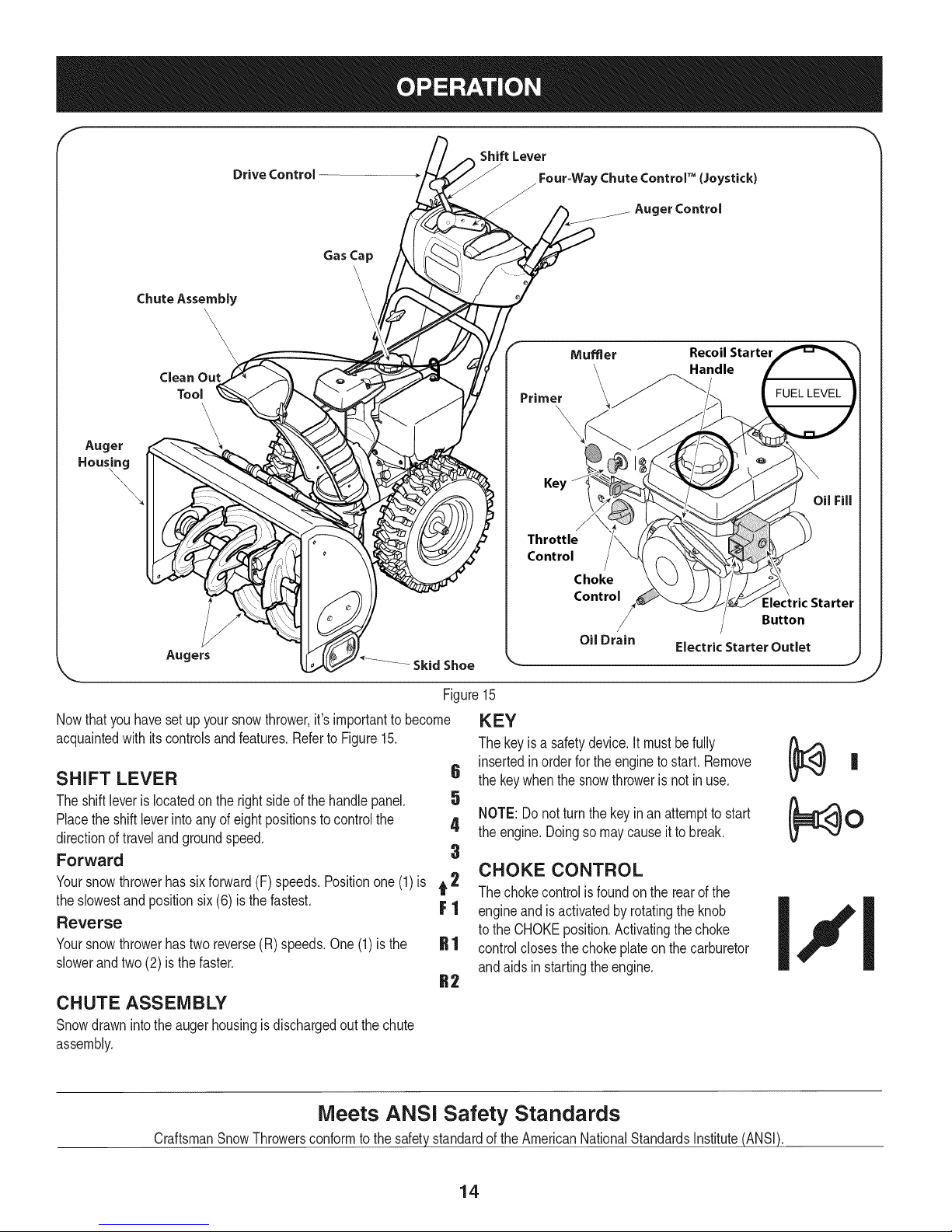

Nowthat youhavesetup yoursnowthrower,it'simportanttobecome

acquaintedwith itscontrolsandfeatures.Referto Figure15.

SHIFT LEVER 6

Theshiftleverislocatedonthe rightsideofthehandlepanel. 5

Placethe shiftleverintoanyof eightpositionstocontrolthe 4

directionoftravelandgroundspeed.

Forward 3

Yoursnowthrowerhassixforward(F)speeds.Positionone(1)is t 2

theslowestand positionsix (6) isthefastest. F 1

Reverse

Yoursnowthrowerhastwo reverse(R)speeds.One(1)is the

slowerandtwo(2) isthefaster.

Key

Throttle

Control

Choke

Control

Oil Drain

Electric Starter Outlet

KEY

Thekeyisa safetydevice.It mustbefully

insertedinorderfortheenginetostart. Remove

thekeywhenthesnowthrowerisnotin use.

NOTE:Donot turnthekeyinan attemptto start

theengine.Doingsomaycauseit tobreak.

CHOKE CONTROL

Thechokecontrolisfoundon therearofthe

engineand is activatedbyrotatingtheknob

totheCHOKEposition.Activatingthe choke

controlclosesthe chokeplateon thecarburetor

andaidsin startingthe engine.

=lectric Starter

Button

CHUTE ASSEMBLY

Snowdrawnintotheaugerhousingisdischargedoutthechute

assembly.

Meets ANSi Safety Standards

CraftsmanSnowThrowersconformto the safetystandardoftheAmericanNationalStandardsInstitute(ANSI).

14

Page 15

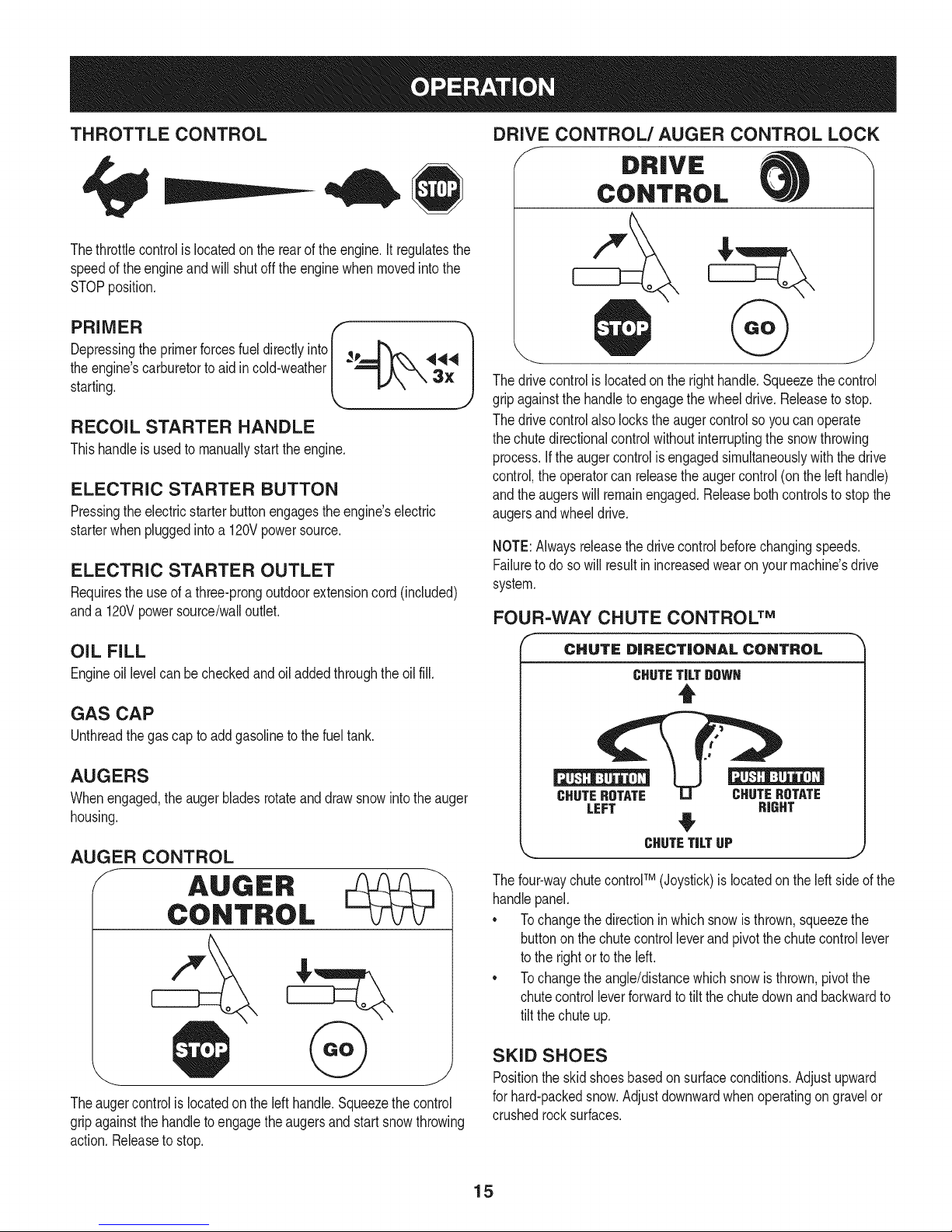

THROTTLE CONTROL

Thethrottlecontrolis locatedon therearoftheengine.It regulatesthe

speedof theengineandwillshutoff the enginewhenmovedintothe

STOPposition.

DRIVE CONTROL/AUGER CONTROL LOCK

f DRIVE

CONTROL

Depressingthe primerforcesfuel directlyinto _p

theengine'scarburetortoaid incold-weather

starting.

RECOIL STARTER HANDLE

Thishandleisusedto manuallystarttheengine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

ELECTRIC STARTER OUTLET

Requirestheuseof athree-prongoutdoorextensioncord(included)

anda 120Vpowersource/walloutlet.

OIL FILL

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill.

GAS CAP

Unthreadthegascaptoaddgasolinetothe fuel tank.

AUGERS

Whenengaged,theaugerbladesrotateanddrawsnowintotheauger

housing.

AUGER CONTROL

f AUGER

CONTROL

@

Thedrivecontrolis locatedontherighthandle.Squeezethecontrol

gripagainstthehandletoengagethewheeldrive.Releaseto stop.

Thedrivecontrolalso lockstheaugercontrolsoyoucanoperate

thechutedirectionalcontrolwithoutinterruptingthesnowthrowing

process.If theaugercontrolis engagedsimultaneouslywiththedrive

control,the operatorcanreleasetheaugercontrol(onthelefthandle)

andtheaugerswillremainengaged.Releasebothcontrolstostopthe

augersandwheeldrive.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.

Failureto dosowillresultinincreasedwearon yourmachine'sdrive

system.

FOUR-WAY CHUTE CONTROL TM

f

CHUTE DiRECTiONAL CONTROL

CHUTETiLTDOWH

t

CHUTEROTATE CHUTEROTATE

LEFT RIGHT

CHUTETiLTUP

Thefour-waychutecontroFM(Joystick)islocatedon theleft sideofthe

handlepanel.

* Tochangethe directioninwhichsnowisthrown,squeezethe

buttononthechutecontrolleverand pivotthe chutecontrollever

tothe rightortotheleft.

* Tochangethe angle/distancewhichsnowisthrown,pivotthe

chutecontrolleverforwardtotiltthechutedownandbackwardto

tilt the chuteup.

Theaugercontrolislocatedontheleft handle.Squeezethecontrol

gripagainstthehandletoengagetheaugersandstartsnowthrowing

action.Releasetostop.

SKID SHOES

Positiontheskidshoesbasedonsurfaceconditions.Adjustupward

forhard-packedsnow.Adjustdownwardwhenoperatingon gravelor

crushedrocksurfaces.

15

Page 16

CLEAN-OUT TOOL

Neveruseyourhandsto cleara cloggedchuteassembly.Shut

off engineandremainbehindhandlesuntilall movingpartshave

stoppedbeforeusingtheclean-outtoolto clear thechuteassembly.

Thechuteclean-outtoolisconvenientlyfastenedtothe rearofthe

augerhousingwitha mountingclip. Shouldsnowandice become

lodgedin thechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. ReleaseboththeAugerControlandtheDriveControl.

2. Stoptheenginebyremovingtheignitionkey.

3. Removetheclean-outtoolfromtheclipwhichsecuresit to the

rearoftheaugerhousing.

4. Usethe shovel-shapedendof theclean-outtooltodislodgeand

scoopanysnowand icewhichhasformedin andnearthechute

assembly.

5. Refastenthe clean-outtooltothemountingclip ontherearof

theaugerhousing,reinserttheignitionkeyandstartthe snow

thrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagethe augercontrolfora fewsecondstoclear any

remainingsnowandice fromthechuteassembly.

BEFORE STARTING ENGINE

Read,understand,andfollowall instructionsandwarningsonthe

machineand inthismanualbeforeoperating.

Oil

Theunit wasshippedwith oil inthe engine.Checkoillevelbefore

eachoperationtoensureadequateoil intheengine.Forfurther

instructions,refertothe stepson page18.

NOTE:Besureto checktheengineon alevelsurfacewiththeengine

stopped.

1. Removetheoil fillercap/dipstickandwipethe dipstickclean.

2. insertthecap/dipstickintothe oilfillerneck,andtightenthecap

untilseated.

3. Removetheoil fillercap/dipstick,ifthelevelislow,slowlyadd

oil (5%30, witha minimumclassificationof SF/SG)untiloil level

registersbetweenhigh(H) andlow(L).

NOTE:Do notoverfill.Overfillingwithoilmayresultinenginesmoking,

hardstartingorsparkplugfouling.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Gasoline

Useautomotivegasoline(unleadedor low leadedto minimizecombus-

tionchamberdeposits)witha minimumof 87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureordirtygasoline.Avoidgetting

dirt,dust,or waterinthefuel tank. DO NOTuse E85gasoline.

• Refuelina well-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksin theareawherethe engineis

refueledor wheregasolineisstored.

• Donot overfillthe fueltank.After refueling,makesurethe tank

capisclosedproperlyandsecurely.

• Becarefulnotto spillfuel whenrefueling.Spilledfuelorfuel vapor

mayignite,ifany fuelis spilled,makesuretheareaisdrybefore

startingthe engine.

• Avoidrepeatedorprolongedcontactwithskinor breathingof

)or.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsare explosive.Neverfuelthemachine

indoorsorwhiletheengineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

1. Cleanaroundfuel fill beforeremovingcaptofuel.

2. A fuellevelindicatorislocatedinthe fueltank.SeeFigure15

inset.Becarefulnottooverfill.Filltank untilfuel reachesthefuel

levelindicatortoallowspaceforfuelexpansion.

STARTING THE ENGINE

Alwayskeephandsandfeetclearof movingparts.Donotusea

pressurizedstartingfluid.Vaporsareflammable.

NOTE:Allowtheenginetowarmupfora fewminutesafter starting.

Theenginewillnotdevelopfullpoweruntilitreachesoperating

temperatures.

1. Makecertainboththeaugercontrolanddrivecontrolarein the

disengaged(released)position.

2. insertignitionkeyinto slot.Makesure itsnapsintoplace.Donot

attempttoturnthekey.

NOTE:Theenginecannotstartwithoutthekeyisfully insertedintothe

ignitionswitch.

Electric Starter

Theoptionalelectricstarterisequippedwitha groundedthree-wire

powercordand plug,andis designedtooperateon120voltAC

householdcurrent.Itmustbe usedwitha properlygroundedthree-

prongreceptacleat all timesto avoidthepossibilityof electricshock.

Followall instructionscarefullypriortooperatingtheelectricstarter.

DONOTuseelectricstarterinthe rain.

Determinethatyourhome'swiringisa three-wiregroundedsystem.

Aska licensedelectricianif you arenotcertain.

Ifyou havea groundedthree-prongreceptacle,proceedasfollows.

Ifyou donothavethe properhousewiring,DONOTusetheelectric

starterunderanyconditions.

1. Plugtheextensioncordintothe outletlocatedon theengine's

surface.Plugtheotherendof extensioncord intoa three-prong

120-volt,grounded,ACoutletina well-ventilatedarea.

16

Page 17

2. MovethrottlecontroltoFAST(rabbit)_ position.

3. MovechoketotheCHOKEI,"1pos t /co denginestart).If

engineiswarm,placechokein RUNposition.

4. Pushprimerthree(3)times,makingsuretocoverventholewhen

pushing.Ifengineiswarm,pushprimeronlyonce.Alwayscover

ventholewhenpushing.Coolweathermayrequireprimingtobe

repeated.

5. Pushstarterbuttonto start engine.Oncethe enginestarts,im-

mediatelyreleasestarterbutton.Electricstarteris equippedwith

thermaloverloadprotection;systemwilltemporarilyshut-downto

allowstartertocoolifelectricstarterbecomesoverloaded.

6. Astheenginewarms,slowlyrotatethe chokecontroltoRUN

position.Iftheenginefalters,restartengineandrunwithchoke

athalf-chokepositionfor a shortperiodoftime,andthenslowly

rotatethechokeintoRUNposition.

7. Afterengineis running,disconnectpowercordfromelectric

starter.Whendisconnecting,alwaysunplugtheendatthewall

outletbeforeunpluggingtheoppositeendfromthe engine.

Recoil Starter

Donotpullthestarterhandlewhiletheenginerunning.

1. Movethrottlecontrolto FAST(rabbit)_ position.

2. MovechoketotheCHOKEJ..#Jposition(coldenginestart).If

engineiswarm,placechokein RUNposition.

3. Pushprimerthree(3)times,makingsuretocoverventholewhen

pushing.Ifengineiswarm,pushprimeronlyonce.Alwayscover

ventholewhenpushing.Coolweathermayrequireprimingtobe

repeated.

4. Pullgentlyonthe starterhandleuntilitbeginstoresist,then

pullquicklyandforcefullytoovercomethecompression.Engine

shouldstart.Donot releasethehandleandallowittosnapback.

ReturnropeSLOWLYtooriginalposition.If required,repeatthis

step.

5. Astheenginewarms,slowlyrotatethe chokecontroltoRUN

position.Iftheenginefalters,restartengineandrunwithchoke

athalf-chokepositionfor a shortperiodoftime,andthenslowly

rotatethechokeintoRUNposition.

TO ENGAGE DRIVE

1. Withthethrottlecontrolinthe Fast(rabbit)'_ position,move

shiftleverintooneof thesix forward(F) positionsortwo reverse

(R)positions.Selecta speedappropriateforthesnowconditions

anda paceyou'recomfortablewith.

NOTE:Whenselectinga DriveSpeed,usethe slowerspeedsuntil

youarecomfortableandfamiliarwiththeoperationofthesnow

thrower.

2. Squeezethedrivecontrolagainstthehandleandthesnow

throwerwillmove.Releaseitanddrivemotionwillstop.

NOTE:NEVERrepositionthe shiftlever(changespeedsordirection

oftravel)withoutfirst releasingthedrivecontrolandbringingthesnow

throwertoa completestop.Doingsowill resultin prematurewearto

thesnowthrower'sdrivesystem.

TO ENGAGE AUGERS

1. Toengagethe augersandstartthrowingsnow,squeezethe

augercontrolagainstthelefthandle.Releasetostoptheaugers.

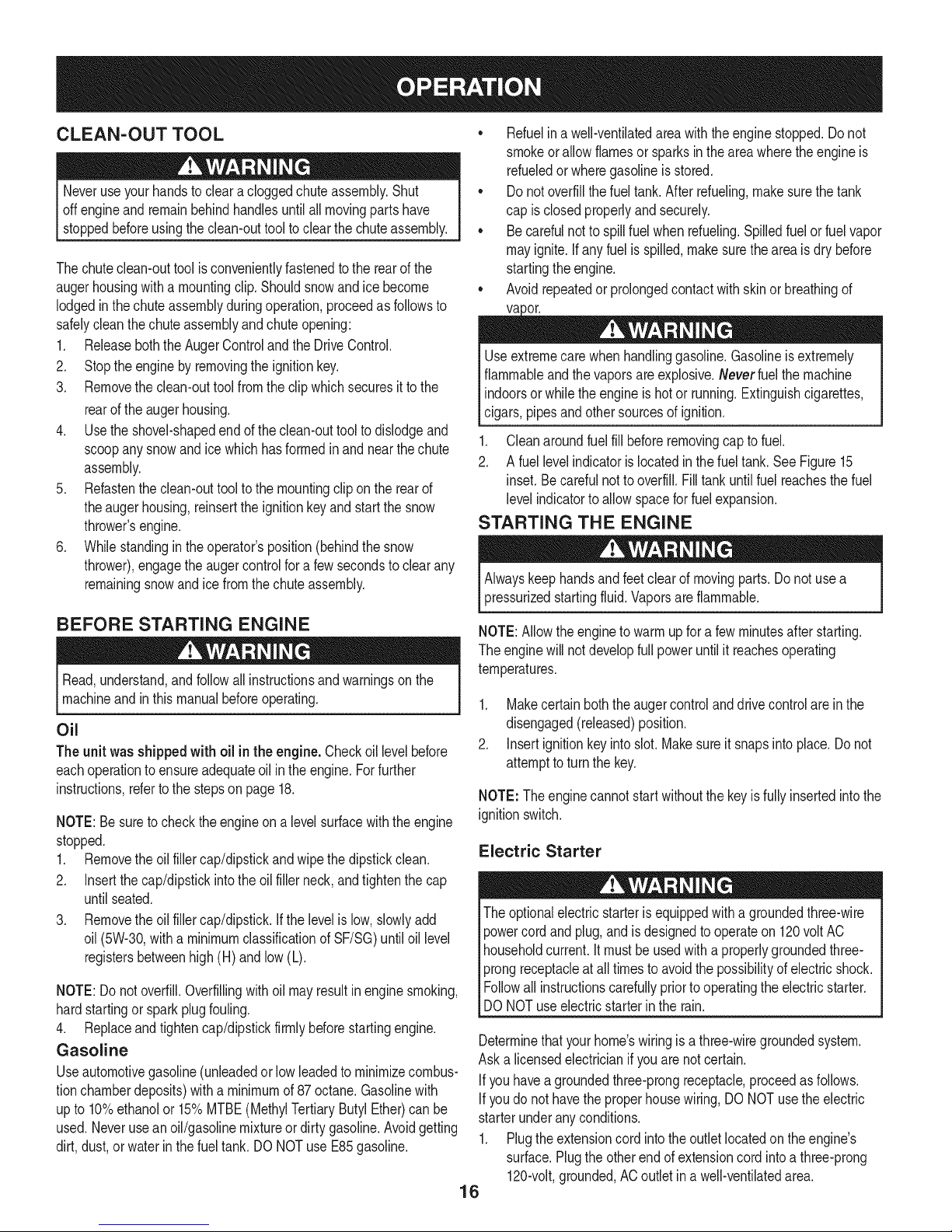

REPLACING SHEAR PINS

Theaugersaresecuredtothespiralshaftwith shearpinsandcotter

pins.If the augersshouldstrikeaforeignobjectoricejam,the snow

throwerisdesignedsothatthe pins mayshear.If theaugerswillnot

turn,checktoseeifthepinshavesheared.SeeFigure16.

NEVERreplacethe augershearpinswithanythingotherthanSears

SKU#88389/0EMPartNo.738-04124Areplacementshearpins.

Anydamagetotheaugergearboxorothercomponentsas a resultof

[fa ngto dosow NOTbe coveredby yoursnowthrowerswarranty.

Alwaysturnoff the snowthrower'sengineandremovethekeypriorto

replacingshearpins.

o

Toavoid unsupervisedengineoperation,neverleavethemachine

unattendedwiththeenginerunning.Turntheengineoffafteruseand

removeignitionkey.

STOPPING THE ENGINE

Afteryouarefinishedsnow-throwing,runenginefora fewminutes

beforestoppingtohelpdry offanymoistureonthe engine.

1. Movethrottlecontrolto OFFposition.

2. Removetheignitionkey.Removingthekeywill reducethepos-

sibilityof unauthorizedstartingof theenginewhileequipmentis

notinuse.Keepthe keyin a safeplace.Theenginecannotstart

withouttheignitionkey.

3. Wipeanymoistureawayfromthecontrolsontheengine.

iJ

Figure16

17

Page 18

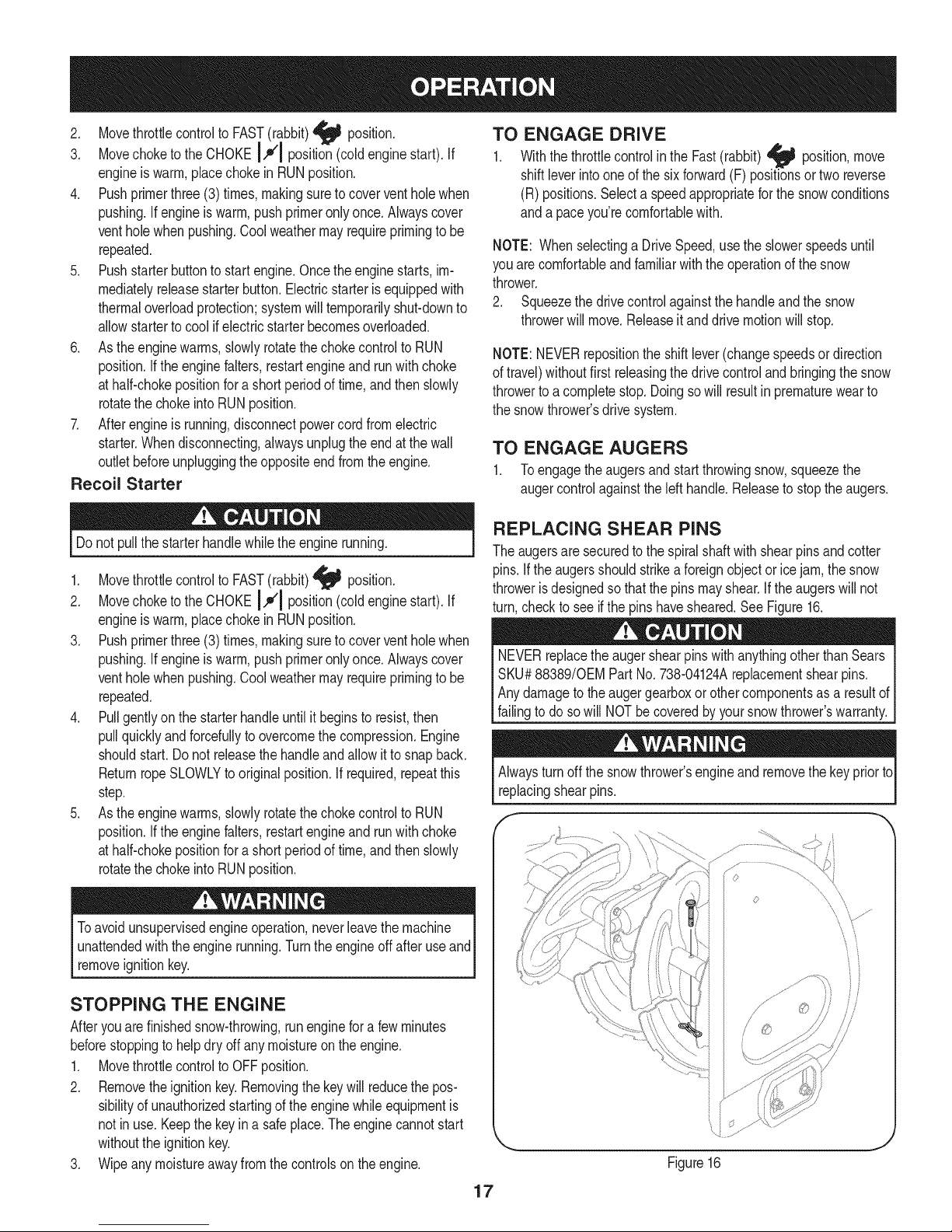

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationor whileperforminganyadjustmentsorrepairs.

EachUseandevery5

hours

1st5 hours

Annuallyor25hours

Annuallyor50hours

Annuallyor100hours

BeforeStorage

1. Engineoillevel

2. Looseormissinghardware

3. Unitandengine.

1. Engineoil

1. Sparkplug

2. Controllinkagesand pivots

3. Wheels

4. GearshaftandAugershaft

5. 4-WayChuteControlTM

1. Engineoil

1. Sparkplug

1. Fuelsystem

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Check

2. Lubewithlightoil

3. Lubewithmultipurposeautogrease

4. Lubewithlightoil

5. Checkforcableslackness

1. Change

1. Change

1. Runengineuntilit stopsfromlack

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.To locate the nearestSearsService

Centeror toscheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

offuel

ENGINE MAINTENANCE

Beforelubricating,repairing,or inspecting,disengageall controls

Iandstopengine.Waituntilall movingpartshavecometo a complete

_stop.

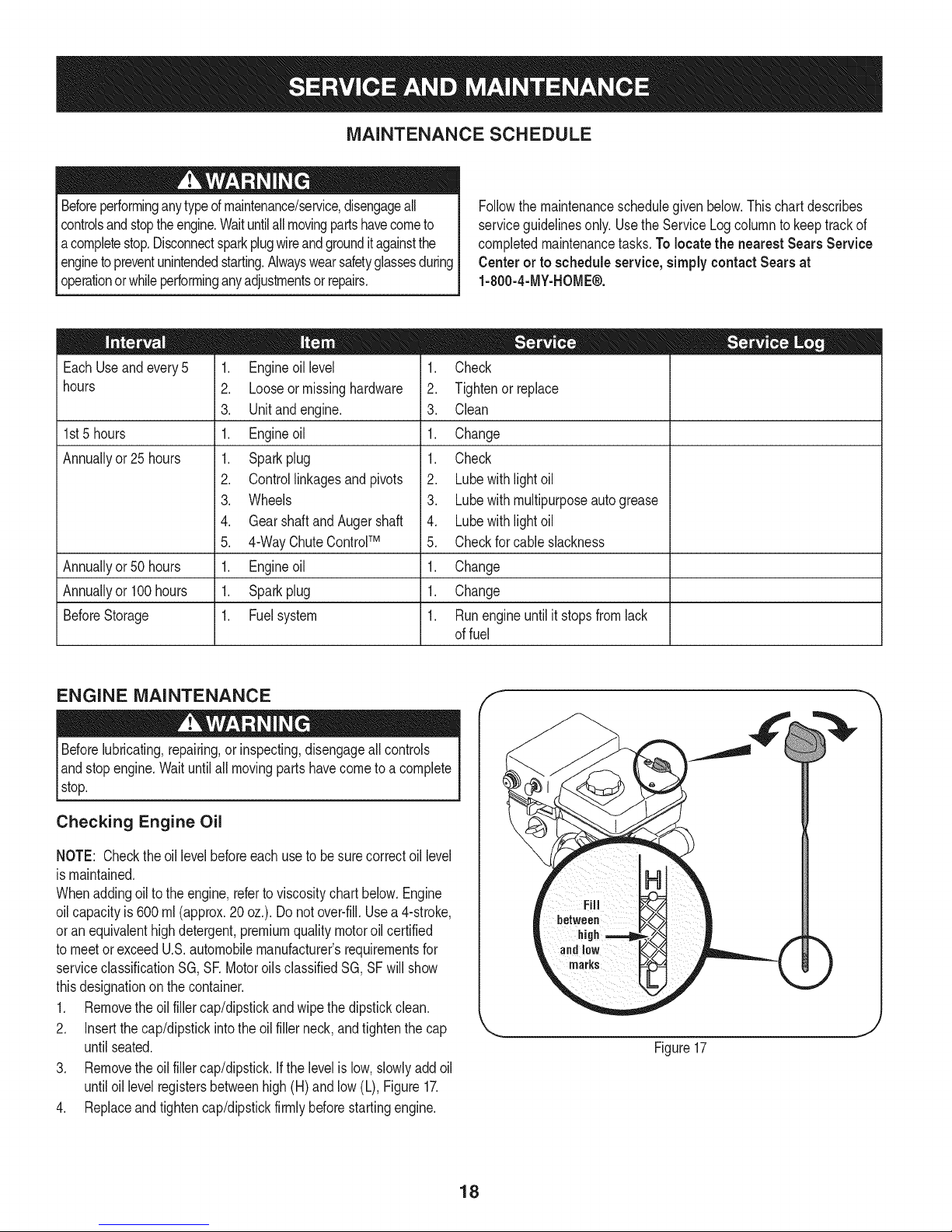

Checking Engine Oil

NOTE: Checktheoil levelbeforeeachuseto besurecorrectoil level

ismaintained.

Whenaddingoiltotheengine,referto viscositychart below.Engine

oilcapacityis 600ml (approx.20oz.).Donot over-fill.Usea 4-stroke,

oran equivalenthighdetergent,premiumqualitymotoroilcertified

tomeetorexceedU.S.automobilemanufacturer'srequirementsfor

serviceclassificationSG, SR MotoroilsclassifiedSG,SFwillshow

thisdesignationonthecontainer.

1. Removetheoil fillercap/dipstickandwipethe dipstickclean.

2. Insertthecap/dipstickintothe oilfillerneck,andtightenthecap

untilseated.

3. Removetheoil fillercap/dipstick.Ifthe levelislow,slowlyaddoil

untiloil levelregistersbetweenhigh(H) and low(L), Figure17.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

f

Figure17

18

Page 19

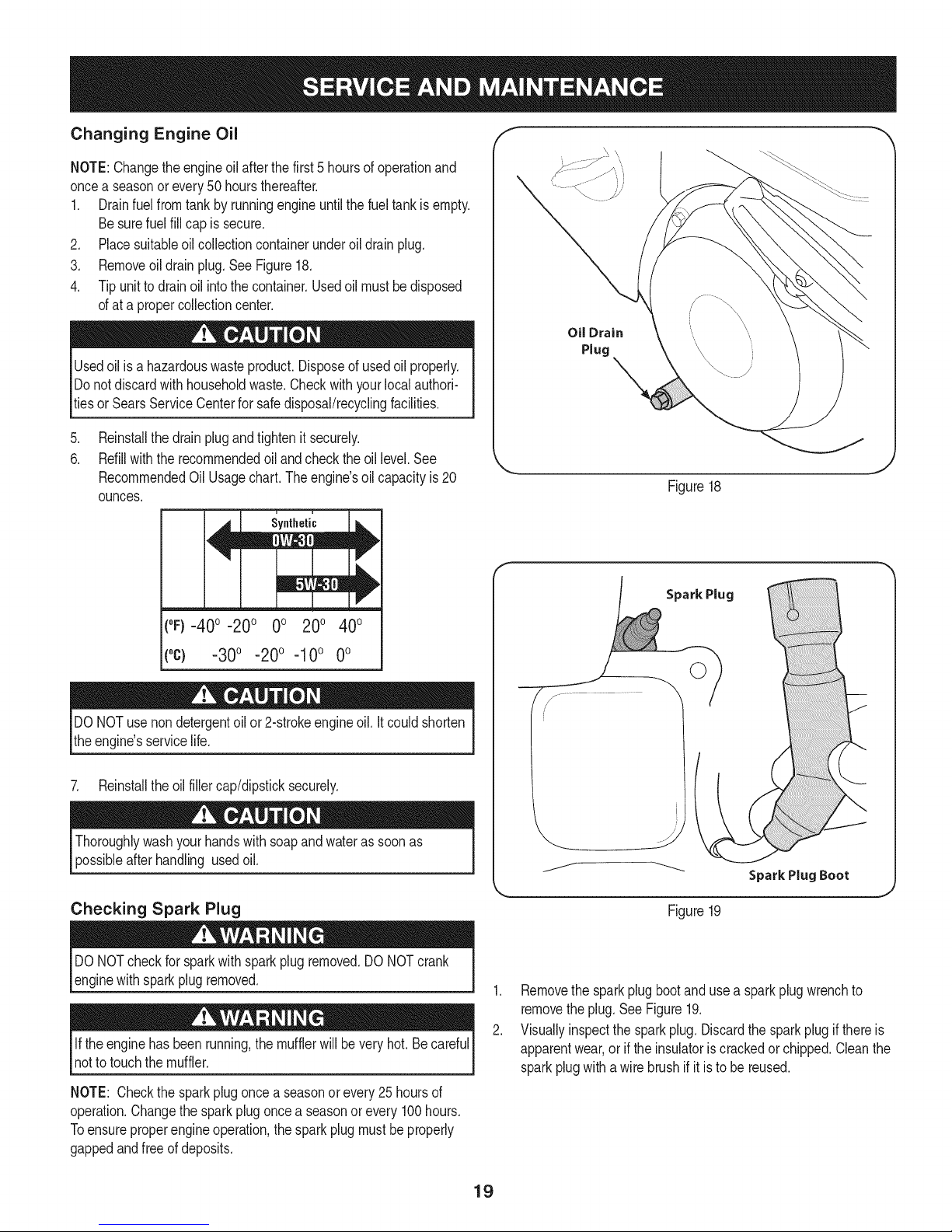

Changing Engine Oil

NOTE:Changetheengineoilafterthe first 5hoursof operationand

oncea seasonorevery50hoursthereafter.

1. Drainfuelfromtankbyrunningengineuntilthe fuel tankisempty.

Besurefuelfillcapissecure.

2. Placesuitableoil collectioncontainerunderoildrainplug.

3. Removeoildrainplug.SeeFigure18.

4. Tipunittodrainoil intothecontainer.Usedoil mustbe disposed

ofata propercollectioncenter.

Usedoil isa hazardouswasteproduct.Disposeof usedoil properly.

Donotdiscardwith householdwaste.Checkwithyourlocalauthori-

tiesor SearsServiceCenterforsafedisposal/recyclingfacilities.

.

Reinstallthedrainplugandtightenit securely.

6.

Refillwiththerecommendedoilandchecktheoil level.See

RecommendedOil Usagechart.Theengine'soilcapacityis20

ounces.

u i

Synthetic

Oil Drain

Plug

_=, ,J

Figure18

(0F)-40o-20 o 0o 200 400

("c) -30° -20° -10° 0°

DONOTuse nondetergentoilor 2-strokeengineoil.It couldshorten

theengine'sservicelife.

7. Reinstalltheoilfillercap/dipsticksecurely.

Thoroughlywashyourhandswithsoapandwaterassoonas

possibleafterhandling usedoil.

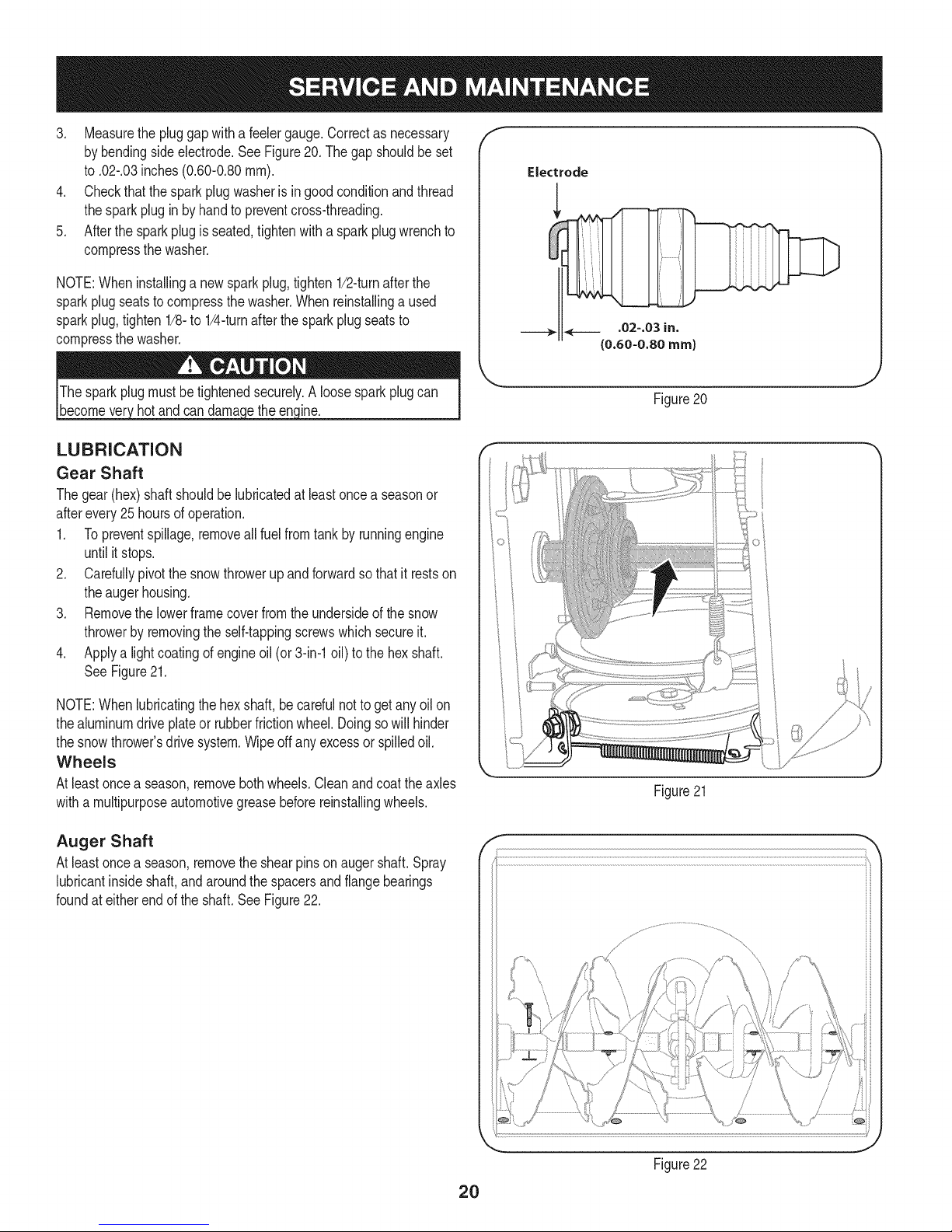

Checking Spark Plug

DONOTcheckfor sparkwithsparkplugremoved.DONOTcrank

enginewithsparkplugremoved.

Iftheenginehasbeenrunning,themufflerwillbevery hot.Becareful

notto touchthemuffler.

NOTE: Checkthe sparkplugoncea seasonorevery25hoursof

operation.Changethesparkplugoncea seasonor every100hours.

Toensureproperengineoperation,thesparkplugmustbe properly

gappedandfreeofdeposits.

Spark Plug

©

J

Figure19

1. Removethesparkplugbootand usea sparkplugwrenchto

removetheplug.SeeFigure19.

2. Visuallyinspectthesparkplug.Discardthe sparkplugifthereis

apparentwear,oriftheinsulatoriscrackedorchipped.Cleanthe

sparkplugwithawirebrushif it is to be reused.

19

Page 20

3. Measurethe pluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure20.Thegap shouldbe set

to.02-.03inches(0.60-0.80ram).

4. Checkthatthesparkplugwasheris ingoodconditionandthread

thesparkplugin byhandto preventcross-threading.

5. Afterthe sparkplugis seated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatstocompressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-to 1/4-turnafterthesparkplugseatsto

compressthewasher.

hotandcan ine.

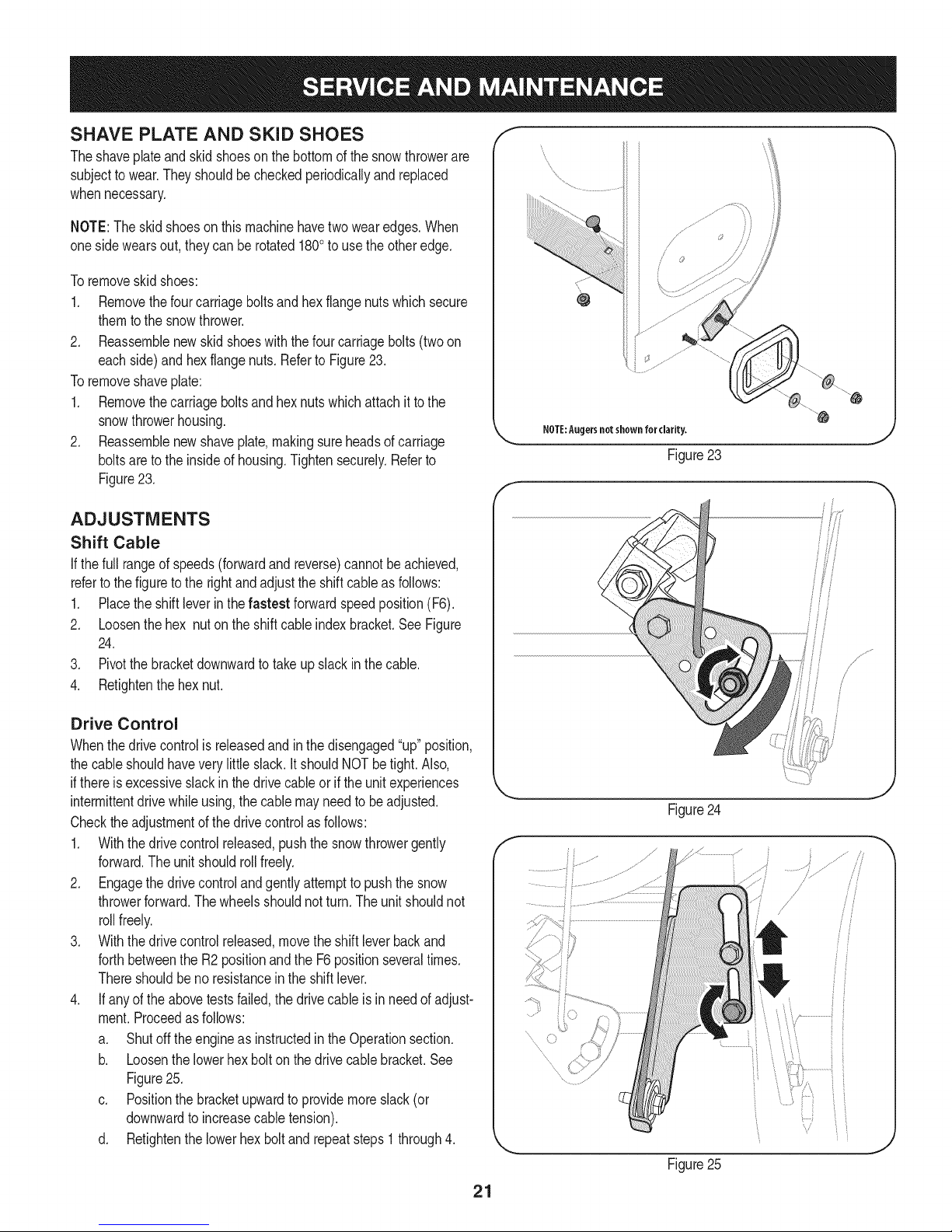

LUBRICATION

Gear Shaft

Thegear(hex)shaft shouldbe lubricatedatleastoncea seasonor

afterevery25 hoursof operation.

1. Topreventspillage,removeallfuel fromtank byrunningengine

untilitstops.

2. Carefullypivotthesnowthrowerupandforwardsothat itrestson

theaugerhousing.

3. Removethe lowerframecoverfromthe undersideofthesnow

throwerbyremovingtheself-tappingscrewswhichsecureit.

4. Applya lightcoatingofengineoil (or3-in-1oil) to the hexshaft.

SeeFigure21.

f

J

Figure20

NOTE:Whenlubricatingthehexshaft,be carefulnottogetanyoilon

thealuminumdriveplateor rubberfrictionwheel.Doingsowillhinder

thesnowthrower'sdrivesystem.Wipeoff anyexcessor spilledoil.

Wheels

Atleastoncea season,removebothwheels.Cleanandcoattheaxles

witha multipurposeautomotivegreasebeforereinstallingwheels.

Auger Shaft

Atleastoncea season,removetheshearpinson augershaft.Spray

lubricantinsideshaft,andaroundthespacersandflangebearings

foundat eitherendof the shaft.SeeFigure22.

Figure21

f

\

J

Figure22

2O

Page 21

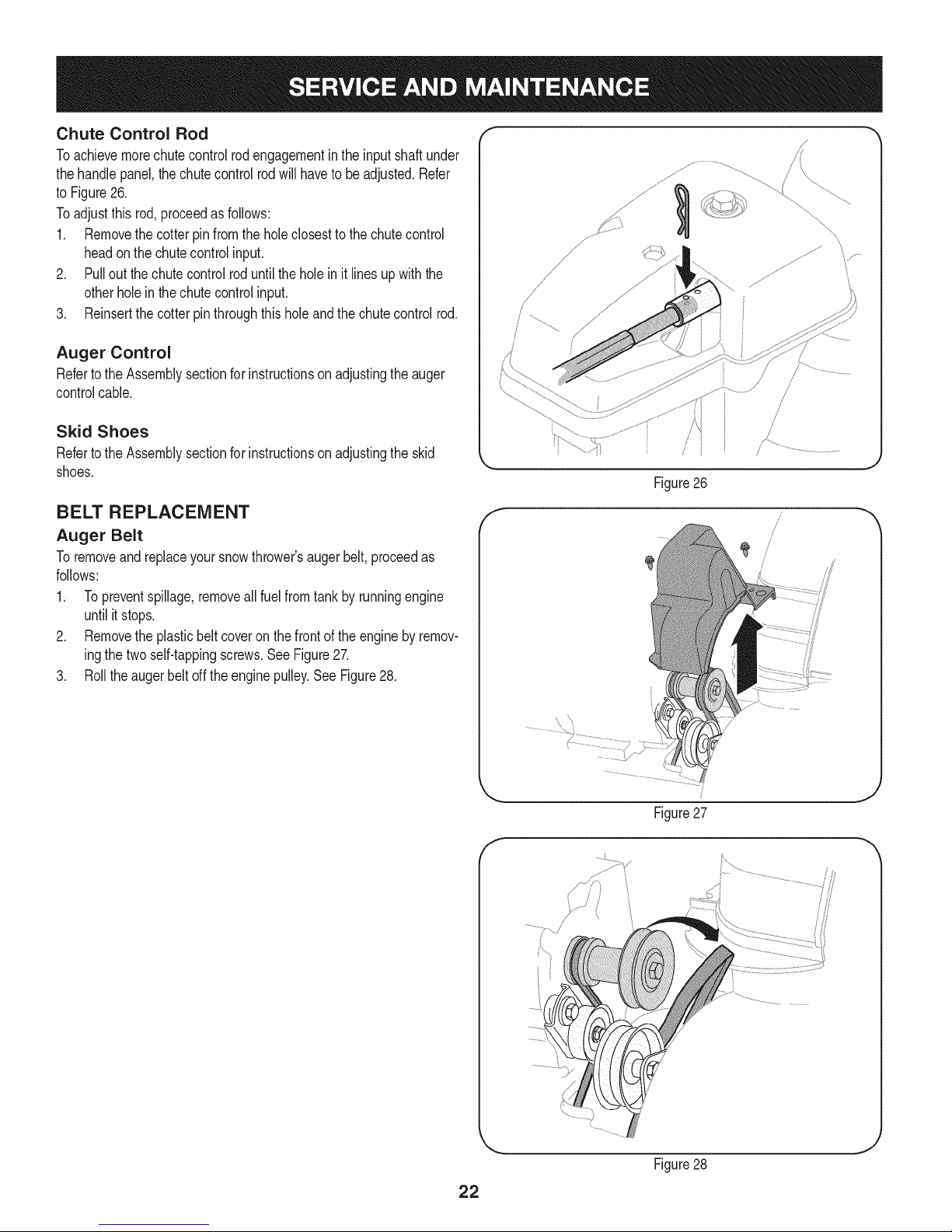

SHAVE PLATE AND SKiD SHOES

Theshaveplateand skidshoesonthebottomofthesnowthrowerare

subjectto wear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

NOTE:Theskidshoesonthismachinehavetwowearedges.When

onesidewearsout, theycan be rotated1800to usethe otheredge.

Toremoveskidshoes:

1. Removethefourcarriageboltsandhexflangenutswhichsecure

themtothe snowthrower.

2. Reassemblenewskidshoeswiththefour carriagebolts(twoon

eachside)and hexflangenuts.Referto Figure23.

Toremoveshaveplate:

1. Removethecarriageboltsand hexnutswhichattachit tothe

snowthrowerhousing.

2. Reassemblenewshaveplate,makingsureheadsof carriage

boltsareto the insideofhousing.Tightensecurely.Referto

Figure23.

ADJUSTMENTS

Shift Cable

If thefull rangeofspeeds(forwardandreverse)cannotbeachieved,

referto the figuretotherightandadjusttheshiftcableasfollows:

1. Placethe shiftleverin thefastest forwardspeedposition(F6).

2. Loosenthehex nutontheshiftcableindexbracket.SeeFigure

24.

3. Pivotthebracketdownwardtotakeupslack inthecable.

4. Retightenthehexnut.

NOTE:Augersnotshown for clarity.

Figure23

fj

Drive Control

Whenthedrivecontrolisreleasedandinthedisengaged"up"position,

thecableshouldhaveverylittle slack.It shouldNOTbetight.Also,

ifthereisexcessiveslackinthedrivecableor if the unitexperiences

intermittentdrivewhileusing,the cable mayneedtobeadjusted.

Checktheadjustmentof the drivecontrolasfollows:

1. Withthedrivecontrolreleased,pushthesnowthrowergently

forward.Theunitshouldrollfreely.

2. Engagethe drivecontrolandgentlyattempttopushthe snow

throwerforward.Thewheelsshouldnotturn.The unitshouldnot

rollfreely.

3. Withthedrivecontrolreleased,movetheshiftleverbackand

forthbetweenthe R2positionandthe F6 positionseveraltimes.

Thereshouldbeno resistanceintheshiftlever.

4. If anyoftheabovetestsfailed,thedrivecable isinneedof adjust-

ment.Proceedasfollows:

a. Shutoff theengineas instructedintheOperationsection.

b. Loosenthelowerhexboltonthe drivecablebracket.See

Figure25.

c. Positionthebracketupwardtoprovidemoreslack(or

downwardto increasecabletension).

d. Retightenthelowerhex boltand repeatsteps1 through4.

21

Figure24

f

/

/

........

Figure25

Page 22

Chute Control Rod

Toachievemorechutecontrolrodengagementinthe inputshaftunder

thehandlepanel,thechutecontrolrodwillhaveto beadjusted.Refer

toFigure26.

Toadjustthis rod,proceedasfollows:

1. Removethecotterpinfromtheholeclosestto the chutecontrol

headon the chutecontrolinput.

2. Pullout thechutecontrolroduntiltheholein it linesupwiththe

otherholein thechutecontrolinput.

3. Reinsertthecotterpinthroughthisholeandthechutecontrolrod.

Auger Control

RefertotheAssemblysectionforinstructionsonadjustingtheauger

controlcable.

Skid Shoes

RefertotheAssemblysectionforinstructionsonadjustingtheskid

shoes.

BELT REPLACEMENT

Auger Belt

Toremoveandreplaceyoursnowthrower'saugerbelt,proceedas

follows:

1. Topreventspillage,removeallfuel fromtank byrunningengine

untilitstops.

2. Removethe plasticbeltcoveronthe frontoftheenginebyremov-

ingthetwoself-tappingscrews.SeeFigure27.

3. Rolltheaugerbeltoff theenginepulley.SeeFigure28.

/

/

/

/

/

/

Figure26

f

J

Figure27

f

/

Figure28

22

Page 23

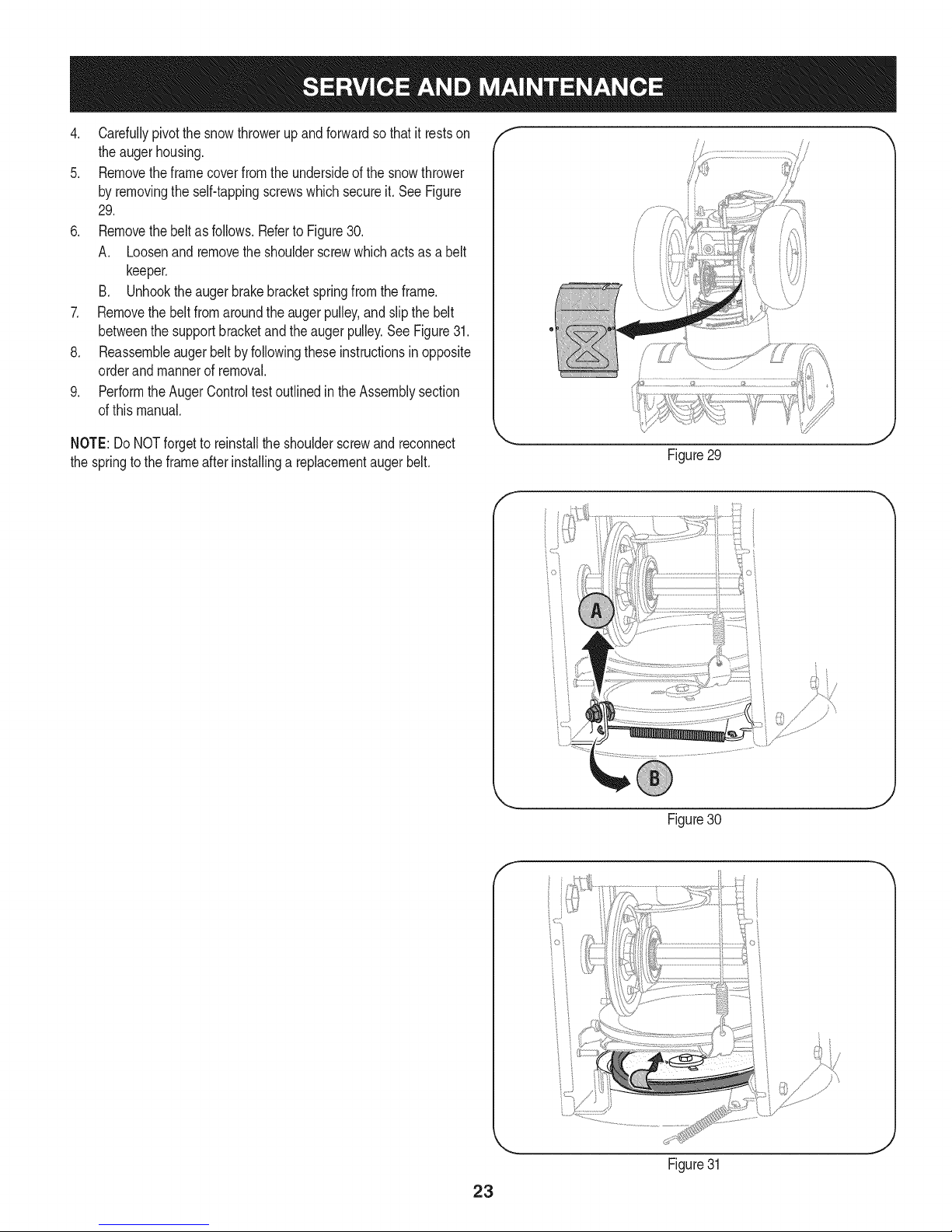

4. Carefullypivotthesnowthrowerupandforwardsothatitrestson

theaugerhousing.

5. Removetheframecoverfromtheundersideofthesnowthrower

byremovingtheself-tappingscrewswhichsecureit.SeeFigure

29.

6. Removethebeltasfollows.RefertoFigure30.

A. Loosenandremovetheshoulderscrewwhichactsasabelt

keeper.

B. Unhooktheaugerbrakebracketspringfromtheframe.

7. Removethebeltfromaroundtheaugerpulley,andslipthebelt

betweenthesupportbracketandtheaugerpulley.SeeFigure31.

8. Reassembleaugerbeltbyfollowingtheseinstructionsinopposite

orderandmannerofremoval.

9. PerformtheAugerControltestoutlinedintheAssemblysection

ofthismanual.

/

NOTE:Do NOTforgetto reinstalltheshoulderscrewandreconnect

thespringtotheframeafterinstallinga replacementaugerbelt.

Figure29

f

Figure30

f

Figure31

23

Page 24

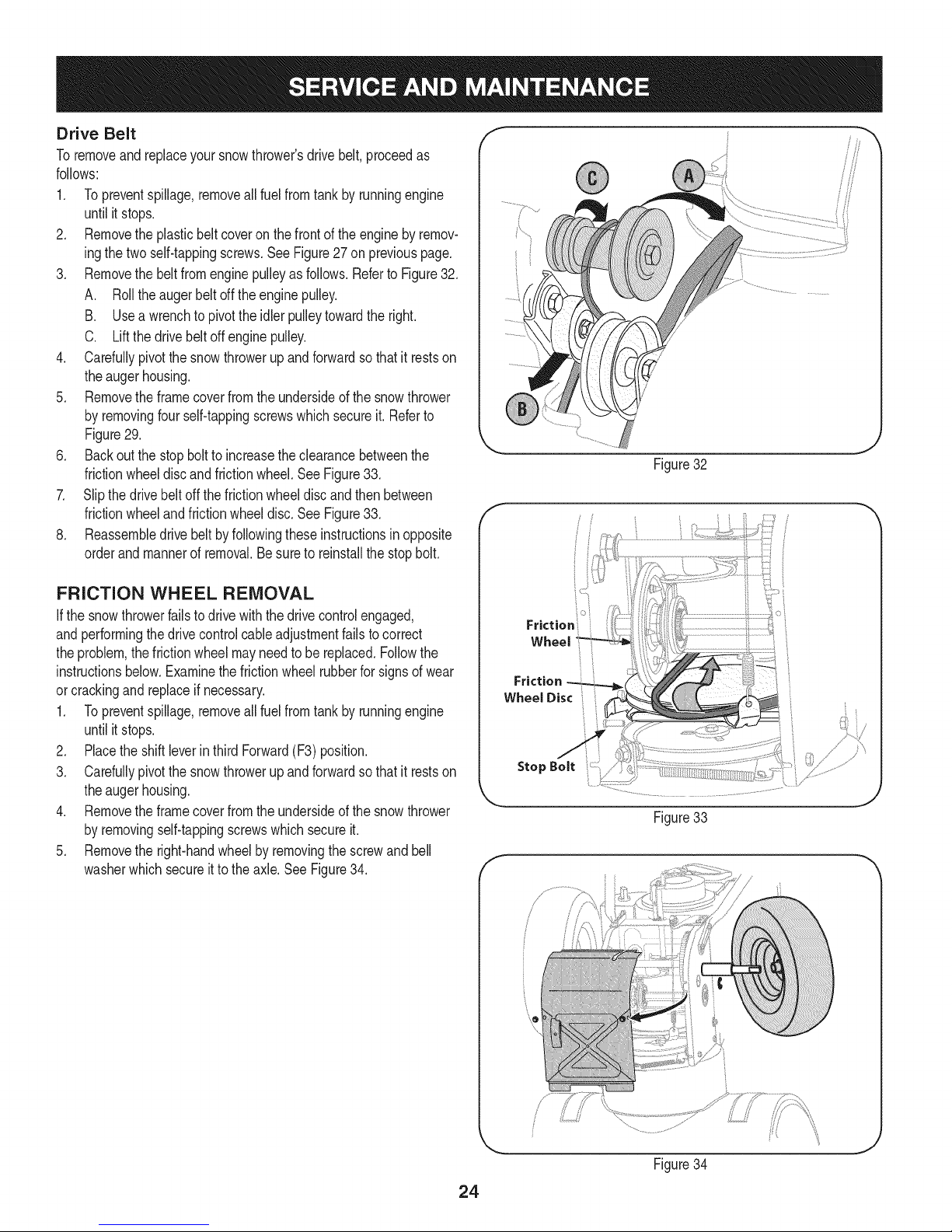

Drive Belt

Toremoveandreplaceyoursnowthrower'sdrivebelt,proceedas

follows:

1. Topreventspillage,removeallfuel fromtank byrunningengine

untilitstops.

2. Removethe plasticbeltcoveronthe frontoftheenginebyremov-

ingthetwoself-tappingscrews.SeeFigure27on previouspage.

3. Removethe beltfromenginepulleyas follows.Referto Figure32.

A. Rollthe augerbeltoff theenginepulley.

B. Usea wrenchto pivottheidlerpulleytowardthe right.

C. Liftthedrivebeltoffenginepulley.

4. Carefullypivotthesnowthrowerup andforwardsothat itrestson

theaugerhousing.

5. Removetheframecoverfromtheundersideof thesnowthrower

byremovingfourself-tappingscrewswhichsecureit.Referto

Figure29.

6. Backoutthestopboltto increasetheclearancebetweenthe

frictionwheeldiscandfrictionwheel.SeeFigure33.

7. Slipthedrivebeltoffthefrictionwheeldiscandthenbetween

frictionwheelandfrictionwheeldisc.SeeFigure33.

8. Reassembledrivebeltbyfollowingtheseinstructionsin opposite

orderandmannerof removal.Besureto reinstallthestopbolt.

J

Figure32

FRICTION WHEEL REMOVAL

Ifthe snowthrowerfailstodrivewiththedrivecontrolengaged,

andperformingthe drivecontrolcableadjustmentfailstocorrect

theproblem,thefrictionwheelmayneedtobe replaced.Followthe

instructionsbelow.Examinethefrictionwheelrubberfor signsof wear

orcrackingandreplaceif necessary.

1. Topreventspillage,removeallfuel fromtank byrunningengine

untilitstops.

2. Placetheshiftleverin thirdForward(F3)position.

3. Carefullypivotthesnowthrowerupandforwardsothat itrestson

theaugerhousing.

4. Removetheframecoverfromtheundersideof the snowthrower

byremovingself-tappingscrewswhichsecureit.

5. Removethe right-handwheelbyremovingthe screwandbell

washerwhichsecureitto theaxle.SeeFigure34.

Friction

Wheel

Friction

WheelDisci i

Figure33

f

J

Figure34

24

Page 25

.

Carefullyremovethe hexnutandwasherwhichsecuresthehex

shaftto the snowthrowerframeand lightlytaptheshaft'send _;!

todislodgetheballbearingfromtherightsideoftheframe.See

Figure35. .]_j

NOTE:Becarefulnottodamagethethreadson theshaft.

7. Carefullypositionthehexshaftdownwardandto the left before

carefullyslidingthefrictionwheelassemblyoff theshaft.See

Figure36.

NOTE:Ifyou'rereplacingthefrictionwheelassemblyasa whole,

discardthewornpartand slidethenewpartontothe hexshaft.

8. Followthestepsaboveinreverseorderto reassemblecompo-

nents.

9. Performthe DriveControlTestoutlinedearlierintheServiceand

Maintenancesection.

If you'redisassemblingthefrictionwheeland replacingonlytherubber

ring,proceedasfollows:

1. Removethefourscrewswhichsecurethe frictionwheel'sside

platestogether.SeeFigure37.

2. Removetherubberringfrombetweentheplates.

3. Reassemblethesideplateswitha newrubberring.

Figure36

NOTE: Whenreassemblingthefrictionwheelassembly,makesure

thattherubberringis centeredandseatedproperlybetweenthe side

plates.Tighteneachscrewonlyone rotationbeforeturningthewheel

clockwiseandproceedingwiththe nextscrew.Repeatthisprocess

severaltimestoensurethe platesaresecuredwithequalforce

(between6 ft-lbsand 9ft-lbs).

4. Slidethefrictionwheelassemblybackontothehexshaftand

reassemblecomponentsbyfollowingtheseinstructionsin

oppositeorderand mannerofremoval.

5. Performthe DriveControlTestoutlinedearlierintheServiceand

Maintenancesection.

f

J

Figure37

Figure35

Page 26

Ifthesnowthrowerwillnotbeusedfor30daysorlonger,orifitistheendofthesnowseasonwhenthelastpossibilityofsnowisgone,the

equipmentneedstobestoredproperly.Followstorageinstructionsbelowtoensuretopperformancefromthesnowthrowerformanymoreyears.

PREPARING ENGINE

Enginesstoredover30daysneedtobedrainedoffueltoprevent

deteriorationandgumfromforminginfuelsystemoronessential

carburetorparts.If thegasolineinyourenginedeterioratesduring

storage,youmayneedto havethecarburetor,andotherfuelsystem

components,servicedor replaced.

1. Removeall fuel fromtank byrunningengineuntilitstops.Donot

attempttopourfuelfromtheengine.

2. Changetheengineoil.

3. Removesparkplugandpourapproximately1oz.(30 rnl)ofclean

engineoil intothecylinder.Pullthe recoilstarterseveraltimesto

distributetheoil,and reinstallthesparkplug.

4. Cleandebrisfromaroundengine,andunder,around,andbehind

muffler.Applya lightfilmof oilon anyareasthatare susceptible

torust.

• Storeina clean,dry andwellventilatedareaawayfromanyap-

pliancethatoperateswithaflameor pilotlight,suchasa furnace,

waterheater,or clothesdryer.Avoidanyareawitha spark

producingelectricmotor,orwherepowertoolsareoperated.

Neverstoresnowthrowerwithfuelintank indoorsor inpoorlyventi-

latedareas,wherefuelfumesmayreachanopenflame,sparkor pilol

lightas ona furnace,waterheater,clothesdryerorgasappliance.

PREPARING SNOW THROWER

Whenstoringthe snowthrowerin anunventilatedormetalstor-

age shed,careshouldbetakentorustprooftheequipment.Using

a light oilor silicone,coattheequipment,especiallyanychains,

springs,bearingsandcables.

• Removealldirt fromexteriorofengineandequipment.

• Followlubricationrecommendations.

• Storeequipmentin a clean,dry area.

• Inflatethetirestothe maximumPSi. Referto tiresidewall.

• If possible,avoidstorageareaswithhighhumidity.

• Keepthe enginelevelin storage.Tiltingcan causefuel oroil

leakage.

26

Page 27

Enginefailsto start

Enginerunningerratically/

inconsistentRPM(huntingor

surging)

Excessivevibration

Lossofpower

Unitfailstopropelitself

Unitfailstodischargesnow

1. ChokecontrolnotinCHOKEposition.

2. Sparkplugwiredisconnected.

3. Faultysparkplug.

4. Fueltankemptyor stalefuel.

5. Enginenotprimed.

6. Keynotinserted.

7. Extensioncordnotconnected(when

usingelectricstartbutton,on modelsso

equipped).

1. EnginerunningonCHOKE.

2. Stalefuel.

3. Waterordirt infuelsystem.

4. Over-governedengine.

1. Loosepartsor damagedauger.

1. Sparkplugwireloose.

2. Gascapventholeplugged.

1. Drivecableinneedofadjustment.

2. Drivebeltlooseor damaged.

3. Wornfrictionwheel.

1. Chuteassemblyclogged.

2. Foreignobjectlodgedin auger.

3. Augercablein needof adjustment.

4. Augerbeltlooseordamaged.

5. Shearpin(s)sheared.

1. Movechokecontrolto CHOKEposition.

2. Connectwireto sparkplug.

3. Clean,adjustgap,or replace.

4. Filltankwith clean,freshgasoline.

5. Primeengineasinstructedinthe OperationSection.

6. Insertkeyfully intotheswitch.

7. Connectoneendoftheextensioncordtotheelectric

starteroutletandtheotherendtoa three-prong

120-volt,grounded,ACoutlet.

1. Movechokecontrolto RUNposition.

2. Filltankwith clean,freshgasoline.

3. Drainfueltankby runningengineuntilitstops.Refill

withfreshfuel.

4. ContactyourSearsParts& RepairCenter.

1. Stopengineimmediatelyand disconnectsparkplug

wire.Tightenall boltsand nuts.Ifvibrationcontinues,

haveunit servicedbya SearsParts& RepairCenter.

1. Connectandtightensparkplugwire.

2. Removeiceand snowfromgascap. Becertainvent

holeisclear.

1. Adjustdrivecontrolcable.RefertoServiceand

Maintenancesection.

2. Replacedrive belt.Referto Serviceand Mainte-

nancesection.

3. Havefrictionwheelreplacedata SearsParts&

RepairCenter.

1. Stopengineimmediatelyand disconnectsparkplug

wire.Cleanchuteassemblyandinsideofauger

housingwithclean-outtoolor astick.

2. Stopengineimmediatelyand disconnectsparkplug

wire.Removeobjectfromaugerwith clean-outtool

ora stick.

3. Adjustaugercontrolcable.Referto Assembly

section.

4. Replaceaugerbelt.RefertoServiceand Mainte-

nancesection.

5. Replacewith newshearpin(s).

Chutefailstoeasilyrotate180 1. Disassemblechutecontroland reassembleas

1. Chuteassembledincorrectly.

degrees directedintheAssemblysection.

NEED HORE HELP?

Yot,Fttfind. th_ answer a!ld mo_e on ma_age_y_ifeocom _ for free]

Find this and att your other product manua[s ontine.

Get answers from our team of home experts.

Get a personalized maintenance p[an for your home.

Find information and tools to he[p with home projects.

managemylife

b_e'_g_t_/_eyeu by Sea_s

27

Page 28

Craftsman Snow Thrower Model 247.889704

i )

t

_39_

- _' ',_1;f

28

Page 29

Craftsman Snow Thrower IViodel 247.889704

D = 0

931-2643 Clean-OutTool

2. 712-04065 FlangeLockNut

3. 756-04224 FiatidlerPulley

4. 710-0347 HexBolt,3/8-16x 1.75

5. 790-00080B AugerIdlerBracket

6. 736-0174 WaveWasher

7. 938-0281 ShoulderScrew

8. 738-0143 ShoulderScrew

9. 790-00075 BearingHousing

10. 926-04012 PushNut

11. 712-04063 FlangeLockNut,5/16-18

12. 941-0309 BallBearing

13. 732-04460 ExtensionSpring

14. 710-04484 Screw,5/16-18x0.750

15. J731-07525 J ChuteAdapter

16. 710-0703 CarriageScrew,1/4-20x 0.75

17. 731-2635 Clean-outToolMtg.Bracket

18. 684-04264-4044 AugerHousingAssembly,26-inch

19. 712-04064 FlangeLockNut,1/4-20

20. 918-04172B GearboxAssembly,26-inch

21. 731-06439 SlideShoe

22. 710-0451 CarriageBolt

23. 790-00121-4044 ShavePlate

24. 684-04057A-0637 ImpellerAssembly

25. 917-04126 WormShaft

26. 721-0327 OilSeal

27. 741-0662 FlangeBearing

28. 718-04071 ThrustCollar

D = B

741-0663 FlangeBearing

30. 710-0642 Screw,1/4-20x0.75

31. 790-00087A-0637 BearingHousing

32. 721-0325 Plug

33. 736-3084 FiatWasher

34. 715-04021 DowelPin

35. 684-04108-0637 SpiralAssembly-RH

36. 918-0123A ReducerHsg.-RH

37. 917-04861 WormGear,20T

38. 725-0157 CableTie

39. 738-04124A ShearPin

40. 914-0161 Key

41. 936-0351 FiatWasher

42. 921-0338 OilSeal

43. 741-0661A FlangeBearing

44. 918-0124A ReducerHsg.-LH

45. 711-04284 Axle,Auger,26"

46. 684-04107-0637 SpiralAssembly-LH

47. 714-04040 BowTieCotterPin

48. 731-04870 Spacer

49. 741-0493A FlangeBushing

50. 736-0188 FiatWasher

51. 941-0245 HexFlangeBearing

52. 736-0242 BellWasher

53. 929-0071A ExtensionCord

54. 946-04230A AugerClutchCable

55. 710-0276 Screw,Carriage,5/16-18x 1.00

56. 936-0159 Washer,Fiat,.349x .879x .063

29

Page 30

Craftsman Snow Thrower IViodel 247.889704

_'.'X

'J2_\

=

<

3O

......................................................,_!:...........................¢o_......................

Page 31

Craftsman Snow Thrower Model 247.889704

D = 0 0

684-04112C HandleEngagementAssemblyRH

2. _ 738-04367 _FlangeShoulderScrew

3. 731-04894D LockPlate

4. 684-04250 PivotRod

5. 935-0199A RubberBumper

6. 710-3069 Screw,1/4-20x.500

7. 731-04896B ClutchLockCam

8. 712-04081A ShoulderNut,1/4-20

9. 710-0627 HexScrew,5/16-24x .750

10. 731-06440A LowerChute

11. 720-0274 HandleGrip

12. 710-1233 Screw,#10-24x 0.375

13. 738-04348 ShoulderScrew,1/4-20

14. 710-04586 Screw,1/4-20x 1.625

15. 749-04190A-0637 UpperHandleRH

16. 710-0572 CarriageScrew,5/16-18x2.25

17. 720-04039 ShiftKnob

18. 753-06438 HandlePanel

19. 731-05324 Lens

20. 710-04071 CarriageBolt,5/16-18x 1.0

21. 631-04134B HandleClutchLockRHAssy

22. 914-0101 CotterPin

23. 712-04064 FlangeLockNut, 1/4-20

24. 732-0193 CompressionSpring

25. 790-00311A-0637 ShiftLever

26. 790-00248C-0637 PanelBracket

27. 738-04125 ShoulderScrew

28. 684-04311A-0637 ChuteSupportBracket

29. 946-04396A SpeedSelectorCable

30. 736-04446 FiatWasher,.25x.630x .0515

31. 710-0895 Hi-LoScrew,1/4-15x .75

32. 710-04370 HexScrew,1/4-20x 3.00

33. 731-04427A UpperChute

34. _918-04801A _4-WayChuteGearboxAssembly

35. 710-04187 Hi-LoScrew,1/4-15x0.5

36. 984-04338A 4-WayChuteControlTM Assembly

D = O

749-04191A-0637 UpperHandleLH

38. 710-04326 Screw,#8-16x0.50

39. 732-04219C ClutchLockSpring

40. 712-3087 WingNut, 1/4-20

41. 714-04040 BowTie CotterPin

42. 710-0262 CarriageBolt,5/16-18x 1.50

43. 631-04133A HandleClutchLockLHAssy

44. 684-04111B HandleEngagementAssemblyLH

45. 784-5594-0637 CableBracket

46. 920-0284 WingKnob

47. 712-04063 FlangeLockNut,5/16-18

48. 731-06451 ChuteTiltCableGuide

49. 711-04469A ClevisPin

50. 710-04484 Screw,5/16-18x 0.75

51. 749-04138A-0637 LowerHandle

52. 732-04238 TorsionSpring

53. 936-0267 FiatWasher

54. 914-0145 ClickPin

55. 936-0159 FiatWasher,.349x .879x .063

56. 747-05116 ChuteRod

57. 753-06151 HandleAssembly

58. 946-04528A 4-WayCable

946-04477 4-WayCablew/Clip(NotShown)

59. 731-04893A HandlePlunger

60. 710-04879 Screw,Mach.,#8-32x .750

61. 710-04353 Screw,#8x 1.00

62. 731-07031 HandleLever

63. 984-04324A ShiftAssembly

64. 753-06152 GearSetAssembly

65. 753-06153 HandleHousingAssembly

66. 710-1256 Screw,#8-18x 1.250

67. 684-04350 JointBlockAssembly

68. 715-04095 Pin

69. 715-0150 RollPin

-- 753-080181- ChuteKit(Incl.Ref.#10&33)

1-Availableforwarrantycoverageonly.Contacta Searsauthorized

serviceproviderfordetails.

31

Page 32

Craftsman Snow Thrower Model 247.889704

i,73/

<

32

Page 33

Craftsman Snow Thrower IViodel 247.889704

|= 0 =

656-04055 DiscAssembly,FrictionWheel

2. 684-04153 FrictionWheelAssembly,5.50D

3_ L684-04154B-0637_Supp°rtBracket,Friction Wheel

4. 684-04156A ShiftAssembly,Rod

5. 710-0627 HexScrew,5/16-24,.750,Gr5

6. 710-0788 Screw,1/4-20,1.000

7. 710-1652 Screw,1/4-20x .625

8. 712-04065 Nut,FlangeLock,3/8-16,Nylon

9. 712-0417A Nut,JamLock,5/8-18,Gr5,Nylon

10. 914-0126 Key,Hi Pro,3/16x3/4 Dia.

11. 916-0104 E-ring,.500Dia.

12. 716-0136 E-ring,Retaining,.875Dia.

13. 916-0231 E-ring,.750Dia.

14. 917-04209A HexShaft,.8125,7-Tooth

15. 917-04230A Gear,80-Tooth

16. 726-0221 SpeedNut, .500

17. 932-0264 ExtensionSpring

18. 736-0242 Washer,Bell, .340x.872x .060

19. .936-0287 Washer, Flat,.793x 1.24x .060

20. 736-04161 Washer,Flat,.75x 1.00x .060

21. 748-04112B Spacer,Shldr.,.3175IDx .500x .094

22. 735-04100 Plug,1/2 ID

23. 738-04184A Screw,Shoulder,.37x.105,1/4-20

24. 738-0924A Screw,1/4-28,.375

25. 941-0245 Bearing,HexFlangex .75ID

26. 941-0563 Bearing,Ball,17x40x 12

27. ,946-04229B _ClutchCable,Wheel,44.95"

28. 790-00289A-0637 Plate,Cover

29. 748-0190 Spacer,.508IDx .75ODx .68

30. 756-0625 Roller,Cable

31. 790-00096-0637 FrontGuideBracket,AugerCable

32. 790-00180A-4044 Frame

33. 790-00206A-0637 GuideBracket,AugerCable

34. 790-00207B GuideBracket,DriveCable

35. 790-00316-0637 Cover,Frame

36. 634-04148A-0911 WheelAssembly- RH

634-04147A-0911 WheelAssembly-LH

37. 731-04873 Spacer,1.25x .75x 3.0

38. 938-04168 Axle,.75x22"

D = O O

735-04099 Plug,3/8 ID

40. 710-0809 HexScrew,1/4-20,1.25,Gr5

41. 710-0191 HexScrew,3/8-24,1.25,Gr8

42. 710-0672 HexScrew,5/16-24,1.25,Gr5

43. 710-0654A Screw,Seres,3/8-16,1.00

44. 710-1245B HexScrew,5/16-24,.875,Gr8

45. 712-04064 Nut,FlangeLock,1/4-20,Nylon

46. 926-04012 Nut,Push-on,.25Dia.

47. 731-05353 Cover,Belt

48. 732-04308A Spring,Torsion,.850IDx .354

49. 736-0247 Washer,Flat,.406x 1.25x .157

50. 936-0119 Washer,Lock.3125

51. 736-0505 Washer,Flat,.34x 1.50x .150

52. 748-04053A Pulley,Adapter,.75Dia.

53. 936-0329 LockWasher

54. 750-04303 Spacer,.875IDx 1.185OD

55. 750-04477A Spacer,.340x .750x .360

56. 954-04050 Belt,AugerDrive

57. 954-04260 Belt,WheelDrive

58. 756-04109

59. 756-04113

60. 756-04252

61. 790-00208C

62. 684-04169

63. 750-04571

64. 935-04054

65. 710-0751

66. 732-04311A

67. 712-04063

68. 936-3015

69. 790-00217A-0637

70. 790-00218A-0637

71. 936-0264

72. 732-0705

73. 710-04022

Pulley,AugerDrive,8.1x .5

Pulley,Half,Vx 2.600OD

Pulley,Half,3/8-Vx 1.7160OD

IdlerBracket,WheelDrive

IdlerPulleyAssembly

Spacer,Shoulder,.26x .79x .538

Rubber,FrictionWheel,5.50D

HexScrew,1/4-20,.620,Gr5

Spring,Torsion,.750IDx .968

Nut,FlangeLock,5/16-18,Nylon

Washer,Flat,.469x .875x .105

PivotBracket,SpeedSelector

ShiftBracket,SpeedSelector

Washer,Fiat,.330x .630x .0635

CableControlWire

Screw,M8-1.25

74. 738-04439 ShoulderScrew

75. 710-0599 Screw,AB, 1/4-20x .500

76. 952Z270-SUA ReplacementEngine

33

Page 34

Craftsman Engine Model 270=SUA For Snow Model 247.889704

24

23

23

m

l

i

i19

!

i

120

i

i

i

i20

!

!

i

121

i

i

122

i

i

i

i23

!

i

i

124

i

951-11282

710-05001

951-14190

951-11289

712-04214

710-04915

951-10642B

2

21

m = 0 O

MufflerAssembly

MufflerStud

MufflerStudKit

MufflerGasket

Nut- M8

Bolt- M6X 12Zin

MufflerShroud

34

Page 35

Craftsman Engine Model 270=SUA For Snow Model 247.889704

41 _42

m

34

35

36

37

39

4O

41

42

43

951-10634

712-04213

951-11284

951-10757

951-10637

731-05632

951-10640

951-10635

710-04943

°0

Shroud-Engine

Nut

ChokeKnob

ThrottleKnob

Switch-Ignition

IgnitionKeySwitch

PushRod-Choke

Air FilterHeating

Bolt-M61X28MSpec

37

35

D = O O

35

Page 36

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.889704

131-6asketKit-Complete

132-6asketKit-External

133- CompleteEngine

36

Page 37

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.889704

m

5O

51

52

53

54

55

56

57

58

59

6O

61

62

63

64

65

66

67

68

69

951-12111

951-11632

951-12007

951-11633

710-04915

951-11113

951-11573

951-14053

736-04461

951-11902

714-04078

951-11575

951-11369

951-10307

951-11247A

951-11576

715-04092

715-04096

951-11371

951-12125

951-11246

D = O

PistonRingSet

PistonPinSnapRing

Piston

PistonPin

Bolt- M6X 12Zin

Shield- Air

ConnectingRodAssembly

GovernorShaft

Washer

GovernorSeal

CotterPin

CamshaftAssembly

Bearing

Key:Flywheel

CrankshaftKit

(Incl.62,63,64,74,79)

GovernorGear/Shaft

Pin-Dowel

DowlPin9X14

CrankcaseCoverGasket

CrankcaseCover

CrankcaseCoverKit

(Incl.62,68-74)

m

7O

71

73

74

75

76

77

78

79

130

131

132

133

710-04932

951-11283

951-11577

951-11368

951-11249

951-11060B

951-11350

736-04440

710-04906

951-11370

951-10641

951-11059A

951-10661B

952Z270-SUA

D = O O

Bolt

Oil FillPlugAssembly

O-Ring15.8X 2.5

OilSeal

CrankcaseKit

(Incl.59,62,74,75,79)

ShortblockAssembly

(Incl.4,21,27-29,44,46,

47,50-53,56-79)

Oil DrainPipe

Washer

Bolt- DrainPlug

OilSeal

Oil DrainAssembly

GasketKit-Complete

(Incl.4,21,27-29,32,44,

58,59,68,74,77,79)

GasketKit-External

(Incl.4,21,27-29,32,77)

CompleteEngine

37

Page 38

Craftsman Engine Model270-SUAForSnow Model 247.889704

18

15

13

44 _p 49 46 _46

129

_ U" -"45

17

131-GasketKit-Complete

132-GasketKit-External

133-CompleteEngine

38

Page 39

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.889704

m

1

2

3a

3b

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

44

45

46

47

48

49

129

131

132

133

710-04968

951-11054A

731-07059

726-04101

951-11565

951-12000

951-11892

751-11124

751-11123

951-11893

710-04902

951-12002

951-12003

951-12004

951-11894

710-04933

951-11895

951-10722B

951-10292

951-11572

951-10648

951-11899

715-04108

951-10647A

951-10647A

951-12626

951-11059A

951-10661B

952Z270-SUA

D = O O

FlangeBoltM6

ValveCover

Hose-Breather

Clamp-BreatherHose

ValveCoverGasket

IntakeValveSpringRetainer

RockerArmAssembly

Nut- PivotLockin

Nut- ValveAdjust

RockerArm

Bolt- Pivot

ExhaustValveAdjuster

ExhaustValveSpringRetainer

ValveSpring

IntakeValveSeal

Bolt- M8X 55Zin

PushRodGuide

CylinderHeadAssembly

(Incl.4-14,16,17,21,27-29,

44,48,49)

Plug:Spark

Gasket-CylinderHead

Kit-PushRod

Tappet

Pin-Dow110X 16

ValveKit

ValveKit

ValveCoverKit

GasketKit-Complete

(Incl.4,21,27-29,32,44,

58,59,68,74,77,79)

GasketKit-External

(Incl.4,21,27-29,32,77)

CompleteEngine

39

Page 40

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.889704

134-CarburetorKit- Deni

135- CarburetorKit- Huayi

27

w

4O

Page 41

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.889704

m

25

26

27

28

29

30

30

31

31

32

33

134

135

a

b

C

d

e

f

g

h

I

J

k

I

I1q

n

o

P

q

r

s

t

U

V

W

X

Y

710-04939

710-04910

951-11567

951-11896

951-11569A

951-10639A

951-11824

951-14026A

951-14027A

951-11897

951-11112

951-14154

951-12788A

n/a

n/a

n/a

n/a

710-05469

736-04638

n/a

n/a

n/a

n/a

951-11699

951-11906

n/a

n/a

n/a

951-12875

n/a

n/a

n/a

951-11589

n/a

951-11348

710-04945

951-11349

710-04938

D = W O

Stud-Carb

Stud- M6X 105

Gasket-CarbInsulator

CarburetorInsuiat

CarburetorGasket

Primer

PrimerBulb

CarburetorAssembly- Huayi

CarburetorAssembly- Deni

CarburetorGasket

Bracket-ChokeControl

CarburetorKit- Deni

(Incl.h,n,o,p,q,r,s,t,u,x)

CarburetorKit- Huayi

(Incl.h,n,o,p,q,r,s,t,u,x)

ChokeShaft

ChokePlate

ThrottleShaft

ThrottlePlate

ScrewM3x5

LockWasher

Gasket,ThrottlePlate

IdleJet Assembly

IdleSpeedAdjustingScrew

MixtureScrew

PrimerHose

HoseClamp

CarburetorBody

FloatPin

EmulsionTube

FloatNeedleValve

MainJet

NeedleValveSpring

Float

FuelBowlGasket

FuelBowl

FuelBowlGasket

FuelBowlMountingBolt

FuelDrainPlugGasket

FuelDrainPlug

41

Page 42

Craftsman Engine IViodel 270-SUA For Snow IViodel 247.889704

82

84

85

m

8O

81

82

83

84

85

86

87

88

90

91

92

93

951-10646

951-11110

710-04940

710-04919

951-12416

951-10934

951-10911

712-04209

710-04915

951-10663A

736-04455

710-04974

951-14151

D = O O

IgnitionCoil

Shield- Air Flow

Bolt

Bolt- FlangeM6

Flywheel

CoolingFan

StarterCup

Nut- M14

Bolt- M6X 12Zin

FanCoverComplete

FlatWasher-Recoil

FlangeBoltM6

RecoilStartAssembly

42

Page 43

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.889704

95 102 _---115

,114

115

m

94

95

96

97

98

99

101

102

103

104

105

106

9s- 97 9s

94

951-10758

710-05103

951-11108

951-11935

951-10664

951-10665

951-11106

712-04212

710-04908

951-11700

951-10650

710-04915

ThrottleControlAssembly

Bolt-M6X 12

Shield- Governor

GovernorSpring

Spring-ThrottleReturn

Rod-Governor

Bracket-Governor

Nut- M6

Bolt- M6X 21Gov

HoseClamp-Oarb

Kit-FuelLine

Bolt- M6X 12Zin

D = O 0

105

104

105

m

107

108

109

110

111

112

113

114

115

116

117

951-11914

710-04905

710-04915

951-11913

951-11381

951-10656

951-11904

951-12482

951-12533

951-11933

951-10653B

D = O 0

Engine/DipstickCover

Bolt

Bolt- M6X 12Zin

Oil FillTubeAssembly

O-Ring

DipstickTube

O-RingDipstick

DipstickAssy

FuelCap

FuelLevelIndicator

FuelTank

43

Page 44

Craftsman Engine IViodel 270=SUA For Snow IViodel 247.889704

23

m

i

1118

1

1

1

i119

!

i

i 120

1

1

1

1121

1

1

1

i 122

!

i

i 123

1

1

1

i 124

!

!

i

i 125

1

1

i 126

1

1

1

i 127

!

i

1

i 128

1

710-04914

951-11680

951-11114

712-05015

710-04965

710-04935

710-05182

715-04088

951-10645A

710-04915

951-11109

D = O !

Bolt- FlangeM6

FlexibleClamp

Bracket-SwitchHousingMount

Nut

ScrewM4X 55

Screw- M4X 60

Bolt-M6X 32

Pin- Dowel

ElectricStarter

Bolt- M6X 12Zin

Shield- BlowerHousing

44

Page 45

Craftsman Snow Thrower Model 247.889704

777S32636

_m _ lool zflO-NV:Zlo

"=IVflNVW S,EIO/VEI3dO QV:IEI"_

N3HM NOIlnV3 VSIX_ 3sn "SU3ON¥1S_8lV 39UVHOSIG

IO]UIO U3A]N 'S31UflrNI $103r80 NMOUHI QIOAV01 "1

]H0_38 Q3ddOiS 3AVH SIHVd 9NIAOW 11VlllNfl S31QNVH

gNIH39 NIV_3_ ONV'3NION3 dOiS 'SU3A31HOlfl13 30VON3SIQ"I

']lflH3 ]9UVHOSIO 9010Nfl 01 ]OO1 lflO-NY313 _Sfl ";

"133_ ONVSQNVH ]lVlfld_V NVOU3OflV UOU3]]3dWI HIIM

lOVlNO3 "U]gflV QNVU3113dWI 9NIIVIOU _OUJ AVMVd33X"

"S33V-IEInS 13AVEI9 NO9NIIVEI3dO

"3NIHOV_ 9NIOIAU3S UO 9NI9901ONfl

777S32236

777D16339

777122339

777D16338

STARTING INSTRUCTIONS:

777D16341

!

777122363

AUGER CONTROL

777122435

777D16340

777X43688

USEE85ORFUEL

CONTAININGMORE

THAN10%ETHANOL

DRIVE CONTROL _)

777D18042

45

Page 46

MTD CONSUMER GROUP INC (MTD), the California Air Resources Board (CARB)

and the United States Environment Protection Agency (U. S. EPA)

Emission Control System Warranty Statement

(Owner's Defect Warranty Rights and Obligations)

EMISSIONCONTROLSYSTEMCOVERAGEISAPPLICABLETOCERTIFIEDENGINESPURCHASEDINCALIFORNIAIN2005ANDTHERE-

AFTER,WHICHAREUSEDINCALIFORNIA,ANDTO CERTIFIEDMODELYEAR2005ANDLATERENGINESWHICHAREPURCHASEDAND

USEDELSEWHEREINTHEUNITEDSTATES.

CaliforniaandelsewhereintheUnitedStatesEmissionControlDefectsWarrantyCoverage

TheCaliforniaAir ResourcesBoard(CARB),U.S.EPAandMTDarepleasedtoexplaintheemissionscontrolsystemwarrantyonyour modelyear