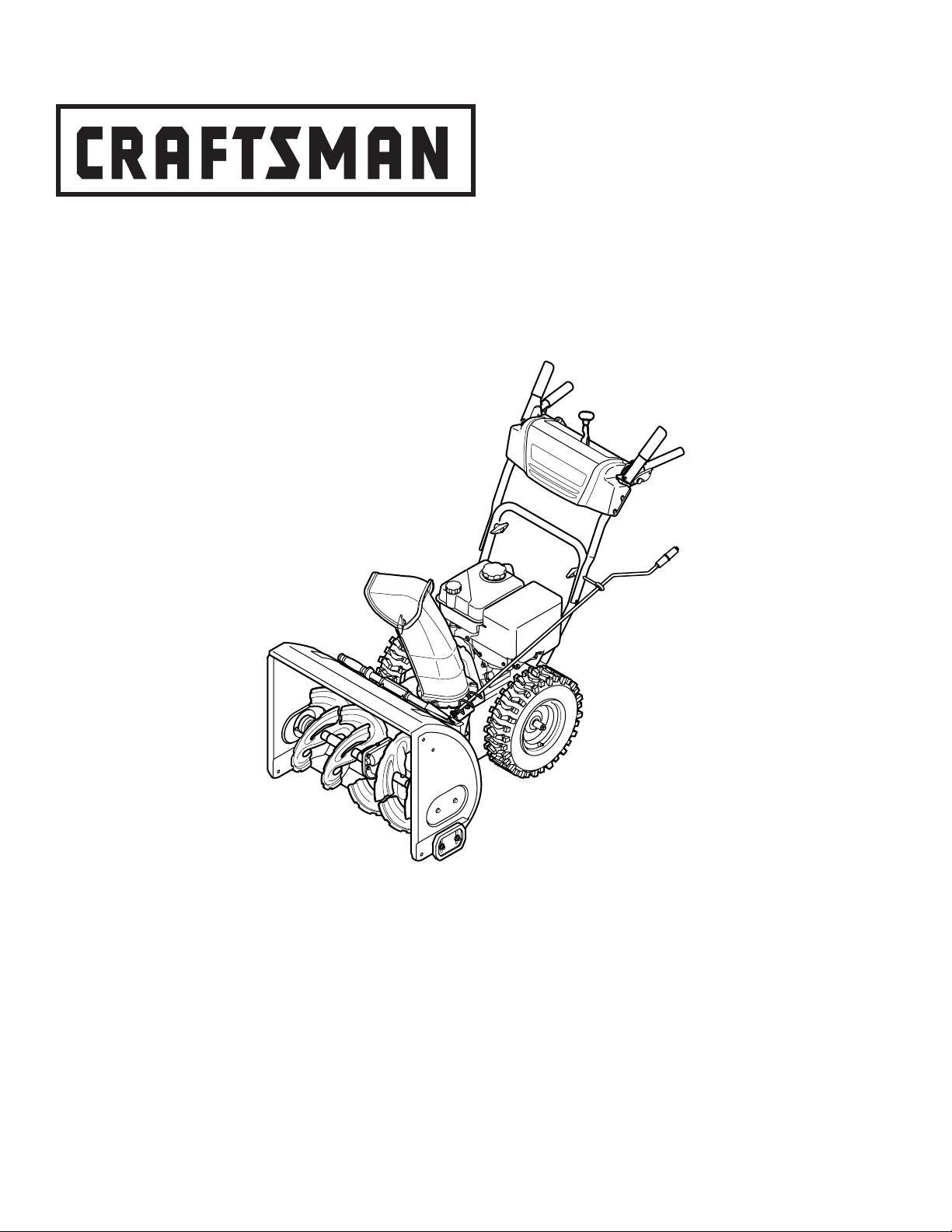

Page 1

Operator’s Manual

24” SNOW THROWER

Model No. 247.88955

®

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com

• SAFETY

• ASSEMBLY

• OPERATION

• MAINTENANCE

• PARTS LIST

• ESPAÑOL

FORM NO. 769-03972

6/3/2008

Page 2

TABLE OF CONTENTS

Warranty Statement . . . . . . . . . . . . . . . . . . . . Page 2

Safe Operation Practices . . . . . . . . . . . . . .Pages 3-6

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

Assembly . . . . . . . . . . . . . . . . . . . . . . . . .Pages 8-11

Operation . . . . . . . . . . . . . . . . . . . . . . . .Pages 12-15

Service &Maintenance . . . . . . . . . . . . . .Pages 16-23

Off-Season Storage . . . . . . . . . . . . . . . . . . . Page 24

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . Page 25

Parts List .........................Pages 26-34

Repair Protection Agreement . . . . . . . . . . . . Page 38

Español ............................. Page 39

WARRANTY STATEMENT

CRAFTSMAN LIMITED WARRANTY

Two Years on Snow Thrower

When operated and maintained according to all supplied instructions, if this snow thrower fails due to a defect in material or workmanship within

two years from the date or purchase, return it to any authorized Craftsman drop-off location for free repair. For the nearest authorized location,

call 1-800-4MYHOME.

This warranty applies for only 90 days from the date of purchase if this snow thrower is ever used for commercial or rental purposes.

This warranty covers ONLY defects in material and workmanship. Sears will NOT pay for:

Expendable items that become worn during normal use, including but not limited to skid shoes, shave plate, shear pins, spark plug, air •

cleaner, belts, and oil filter.

Standard maintenance servicing, oil changes, or tune-ups.•

Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass. •

Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or maintenance.•

Repairs necessary because of operator abuse, including but not limited to damage caused by impacting objects that bend the frame or •

crankshaft, or over-speeding the engine.

Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical damage caused by improper •

storage, failure to use the proper grade and amount of engine oil, or failure to maintain the equipment according to the instructions contained

in the operator’s manual.

Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized (stale). In general, fuel should be used •

within 30 days of its purchase date.

Normal deterioration and wear of the exterior finishes, or product label replacement.•

This warranty applies only while this product is used in the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

PRODUCT SPECIFICATIONS MODEL NUMBER

Engine Oil Type: 5W-30

Engine Oil Capacity: 20 ounces

Fuel Capacity: 2.3 Quarts

Spark Plug: Torch F6RTC (F6TC)

Spark Plug Gap: .020” to .030”

© Sears Brands, LLC

Model Number .................................................................

Serial Number .................................................................

Date of Purchase .............................................................

Record the model number, serial number

and date of purchase above

2

Page 3

SAFETY INSTRUCTIONS

WARNING

This symbol points out important safety instructions which, if not

followed, could endanger the personal safety and/or property of

yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with

these instructions may result in personal injury. When you see this

symbol, HEED ITS WARNING!

WARNING

CALIFORNIA PROPOSITION 65

Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State of California

to cause cancer and birth defects or other reproductive harm.

TRAINING

Read, understand, and follow all instructions on the machine and •

in the manual(s) before attempting to assemble and operate.

Keep this manual in a safe place for future and regular reference

and for ordering replacement parts.

Read the Operator’s Manual and follow all warnings and safety •

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders. For questions call, 1-800-659-5917.

Be familiar with all controls and their proper operation. Know how •

to stop the machine and disengage them quickly.

Never allow children under 14 years of age to operate this •

machine. Children 14 and over should read and understand the

instructions and safe operation practices in this manual and on

the machine and be trained and supervised by an adult.

Never allow adults to operate this machine without proper •

instruction.

Thrown objects can cause serious personal injury. Plan your •

snow-throwing pattern to avoid discharge of material toward

roads, bystanders and the like.

Keep bystanders, pets and children at least 75 feet from the •

machine while it is in operation. Stop machine if anyone enters

the area.

Exercise caution to avoid slipping or falling, especially when •

operating in reverse.

DANGER

This machine was built to be operated according to the safe operation practices in this manual. As with any type of power equipment,

carelessness or error on the part of the operator can result in serious

injury. This machine is capable of amputating fingers, hands, toes

and feet and throwing debris. Failure to observe the following safety

instructions could result in serious injury or death.

WARNING

Your Responsibility—Restrict the use of this power machine to

persons who read, understand and follow the warnings and instructions in this manual and on the machine.

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughly inspect the area where the equipment is to be used.

Remove all doormats, newspapers, sleds, boards, wires and other

foreign objects, which could be tripped over or thrown by the auger/

impeller.

Always wear safety glasses or eye shields during operation and •

while performing an adjustment or repair to protect your eyes.

Thrown objects which ricochet can cause serious injury to the

eyes.

Do not operate without wearing adequate winter outer garments. •

Do not wear jewelry, long scarves or other loose clothing, which

could become entangled in moving parts. Wear footwear which

will improve footing on slippery surfaces.

Use a grounded three-wire extension cord and receptacle for all •

machines with electric start engines.

Adjust collector housing height to clear gravel or crushed rock •

surfaces.

Disengage all control levers before starting the engine. •

Never attempt to make any adjustments while engine is running, •

except where specifically recommended in the operator’s manual.

Let engine and machine adjust to outdoor temperature before •

starting to clear snow.

3

Page 4

SAFETY INSTRUCTIONS

Safe Handling of Gasoline

To avoid personal injury or property damage use extreme care in

handling gasoline. Gasoline is extremely flammable and the vapors are

explosive. Serious personal injury can occur when gasoline is spilled

on yourself or your clothes which can ignite. Wash your skin and

change clothes immediately.

Use only an approved gasoline container.•

Extinguish all cigarettes, cigars, pipes and other sources •

of ignition.

Never fuel machine indoors. •

Never remove gas cap or add fuel while the engine is hot •

or running.

Allow engine to cool at least two minutes before refueling.•

Never over fill fuel tank. Fill tank to no more than ½ inch •

below bottom of filler neck to provide space for fuel

expansion.

Replace gasoline cap and tighten securely.•

If gasoline is spilled, wipe it off the engine and equipment. •

Move machine to another area. Wait 5 minutes before

starting the engine.

Never store the machine or fuel container inside where •

there is an open flame, spark or pilot light (e.g. furnace,

water heater, space heater, clothes dryer etc.).

Allow machine to cool at least 5 minutes before storing.•

Never fill containers inside a vehicle or on a truck or trailer •

bed with a plastic liner. Always place containers on the

ground away from your vehicle before filling.

If possible, remove gas-powered equipment from the truck •

or trailer and refuel it on the ground. If this is not possible,

then refuel such equipment on a trailer with a portable

container, rather than from a gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the fuel tank or •

container opening at all times until fueling is complete. Do

not use a nozzle lock-open device.

OPERATION

Do not put hands or feet near rotating parts, in the auger/impeller •

housing or chute assembly. Contact with the rotating parts can

amputate hands and feet.

The auger/impeller control lever is a safety device. Never bypass •

its operation. Doing so makes the machine unsafe and may cause

personal injury.

The control levers must operate easily in both directions and •

automatically return to the disengaged position when released.

Never operate with a missing or damaged chute assembly. Keep •

all safety devices in place and working.

Never run an engine indoors or in a poorly ventilated area. Engine •

exhaust contains carbon monoxide, an odorless and deadly gas.

Do not operate machine while under the influence of alcohol or •

drugs.

Muffler and engine become hot and can cause a burn. Do not •

touch. Keep children away.

Exercise extreme caution when operating on or crossing gravel •

surfaces. Stay alert for hidden hazards or traffic.

Exercise caution when changing direction and while operating on •

slopes.

Plan your snow-throwing pattern to avoid discharge towards •

windows, walls, cars etc. Thus, avoiding possible property

damage or personal injury caused by a ricochet.

Never direct discharge at children, bystanders and pets or allow •

anyone in front of the machine.

Do not overload machine capacity by attempting to clear snow at •

too fast of a rate.

Never operate this machine without good visibility or light. Always •

be sure of your footing and keep a firm hold on the handles. Walk,

never run.

Disengage power to the auger/impeller when transporting or not •

in use.

Never operate machine at high transport speeds on slippery •

surfaces. Look down and behind and use care when backing up.

If the machine should start to vibrate abnormally, stop the engine, •

disconnect the spark plug wire and ground it against the engine.

Inspect thoroughly for damage. Repair any damage before

starting and operating.

Disengage all control levers and stop engine before you leave •

the operating position (behind the handles). Wait until the auger/

impeller comes to a complete stop before unclogging the chute

assembly, making any adjustments, or inspections.

Never put your hand in the discharge or collector openings. •

Always use the clean-out tool provided to unclog the discharge

opening. Do not unclog chute assembly while engine is running.

Shut off engine and remain behind handles until all moving parts

have stopped before unclogging.

Use only attachments and accessories approved by the manufac-•

turer (e.g. wheel weights, tire chains, cabs etc.).

When starting engine, pull cord slowly until resistance is felt, then •

pull rapidly. Rapid retraction of starter cord (kickback) will pull

hand and arm toward engine faster than you can let go. Broken

bones, fractures, bruises or sprains could result.

If situations occur which are not covered in this manual, use care •

and good judgment. Contact Customer Support for assistance

and the name of your nearest servicing dealer.

4

Page 5

SAFETY INSTRUCTIONS

MAINTENANCE & STORAGE

Never tamper with safety devices. Check their proper operation •

regularly. Refer to the maintenance and adjustment sections of

this manual.

Before cleaning, repairing, or inspecting machine disengage all •

control levers and stop the engine. Wait until the auger/impeller

come to a complete stop. Disconnect the spark plug wire and

ground against the engine to prevent unintended starting.

Check bolts and screws for proper tightness at frequent intervals •

to keep the machine in safe working condition. Also, visually

inspect machine for any damage.

Do not change the engine governor setting or over-speed the •

engine. The governor controls the maximum safe operating speed

of the engine.

Snow thrower shave plates and skid shoes are subject to wear •

and damage. For your safety protection, frequently check all

components and replace with original equipment manufacturer’s

(OEM) parts only. “Use of parts which do not meet the original

equipment specifications may lead to improper performance and

compromise safety!”

Check control levers periodically to verify they engage and disen-•

gage properly and adjust, if necessary. Refer to the adjustment

section in this operator’s manual for instructions.

Maintain or replace safety and instruction labels, as necessary.•

Observe proper disposal laws and regulations for gas, oil, etc. to •

protect the environment.

Prior to storing, run machine a few minutes to clear snow from •

machine and prevent freeze up of auger/impeller.

Never store the machine or fuel container inside where there is an •

open flame, spark or pilot light such as a water heater, furnace,

clothes dryer etc.

Always refer to the operator’s manual for proper instructions on •

off-season storage.

Check fuel line, tank, cap, and fittings frequently for cracks or •

leaks. Replace if necessary.

Do not crank engine with spark plug removed.•

According to the Consumer Products Safety Commission (CPSC) •

and the U.S. Environmental Protection Agency (EPA), this product

has an Average Useful Life of seven (7) years, or 60 hours of

operation. At the end of the Average Useful Life have the machine

inspected annually by an authorized service dealer to ensure that

all mechanical and safety systems are working properly and not

worn excessively. Failure to do so can result in accidents, injuries

or death.

DO NOT MODIFY ENGINE

To avoid serious injury or death, do not modify engine in any way.

Tampering with the governor setting can lead to a runaway engine and

cause it to operate at unsafe speeds. Never tamper with factory setting

of engine governor.

NOTICE REGARDING EMISSIONS

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment) are

certified to operate on regular unleaded gasoline, and may include

the following emission control systems: Engine Modification (EM),

Oxidizing Catalyst (OC), Secondary Air Injection (SAI) and Three Way

Catalyst (TWC) if so equipped.

SPARK ARRESTOR

WARNING

This machine is equipped with an internal combustion engine and

should not be used on or near any unimproved forest-covered,

brushcovered or grass-covered land unless the engine’s exhaust

system is equipped with a spark arrester meeting applicable local or

state laws (if any)

If a spark arrester is used, it should be maintained in effective working

order by the operator. In the State of California the above is required

by law (Section 4442 of the California Public Resources Code). Other

states may have similar laws. Federal laws apply on federal lands.

A spark arrester for the muffler is available through your nearest Sears

Parts and Repair Service Center.

5

Page 6

SAFETY INSTRUCTIONS

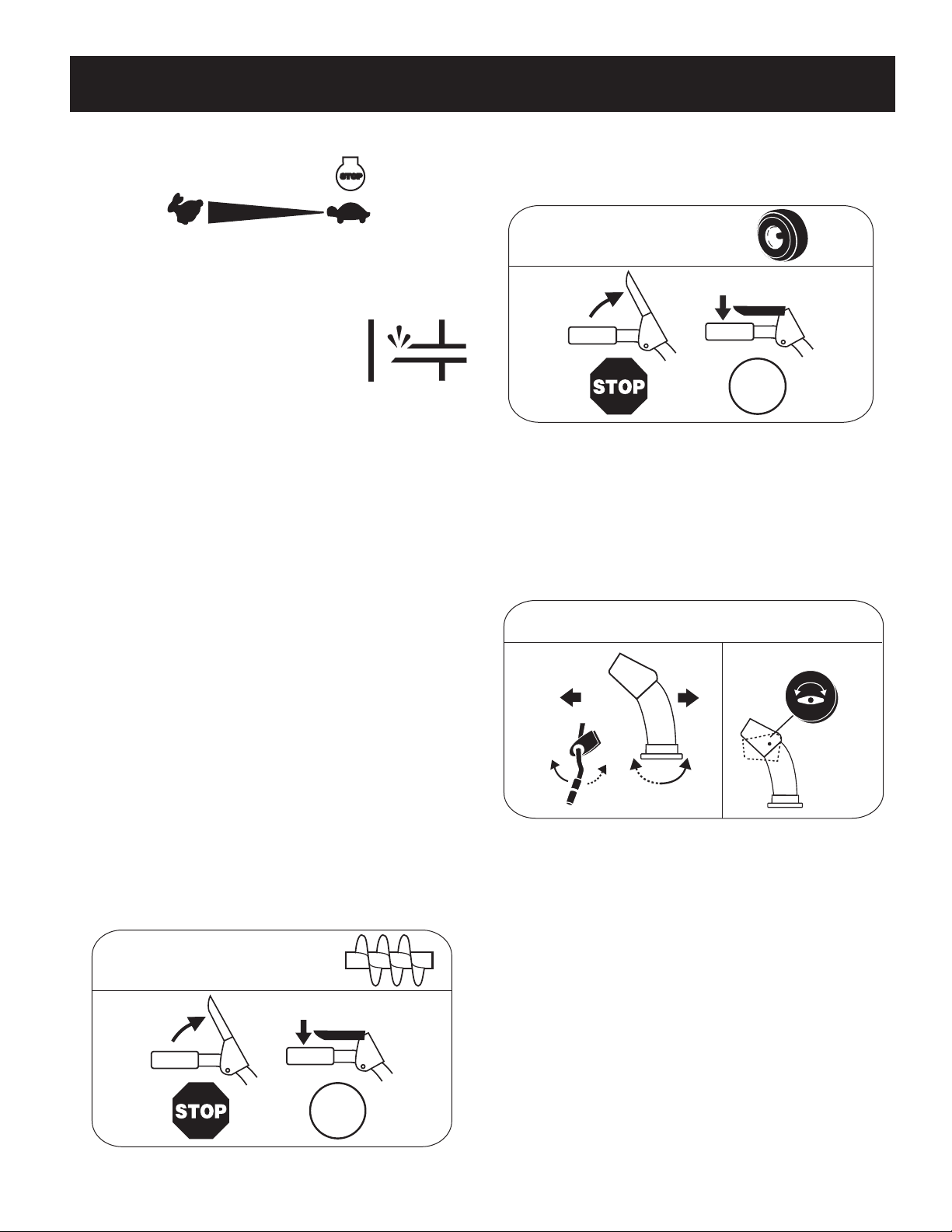

SAFETY SYMBOLS

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine

before attempting to assemble and operate.

Symbol Description

READ THE OPERATOR’S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING— ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING— ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING— ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING—THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING—GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING— CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING— ELECTRICAL SHOCK

Do not use the engine’s electric starter in the rain

6

Page 7

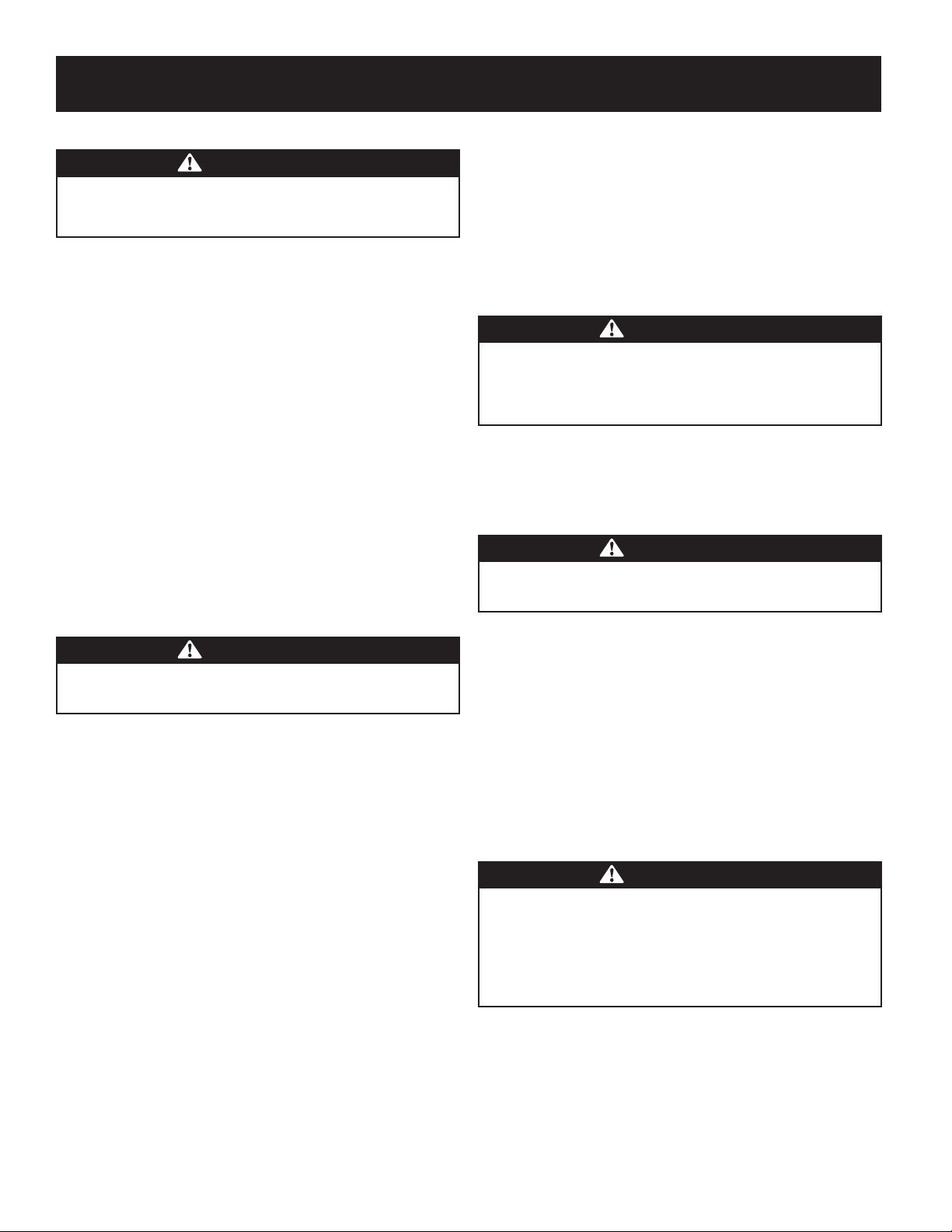

SAFETY LABELS

KEEP AWAY FROM ROTATING IMPELLER

AND AUGER. CONTACT WITH IMPELLER OR

AUGER CAN AMPUTATE HANDS AND FEET

.

USE CLEAN-OUT TOOL TO UNCLOG

DISCHARGE CHUTE.

DISENGAGE CLUTCH LEVERS, STOP ENGINE ,

AND REMAIN BEHIND HANDLES UNTIL ALL

MOVING PARTS HAVE STOPPED BEFORE

UNCLOGGING OR SERVICING MACHINE.

TO AVOID THROWN OBJECTS INJURIES,

NEVER DIRECT DISCHARGE AT BYSTANDERS.

USE EXTRA CAUTION WHEN OPERATING ON

GRAVEL SURFACES.

READ OPERATOR'S MANUAL.

1.

2.

3.

4.

5.

DANGER

CLEAN-OUT TOOL

DANGER

AVOID INJURY FROM

ROTATING AUGER KEEP HANDS, FEET

AND CLOTHING AWA Y.

DANGER

NEVER PUT HAND IN CHUTE. CONTACT WITH

ROTATING PARTS CAN AMPUTATE FINGERS

AND HANDS.

SHUT OFF ENGINE AND WAIT UNTIL AL L

MOVING PARTS HA VE STOPPED BEFORE

UNCLOGGING.

USE CLEAN-OUT TOOL OR WOODEN

UNCLOG DISCHARGE CHUTE.

STICK TO

7

Page 8

ASSEMBLY

NOTE: References to right or left side of the snow thrower are

determined from behind the unit in the operating position (standing

directly behind the snow thrower, facing the handle panel).

REMOVING FROM CARTON

Cut the corners of the carton and lay the sides flat on the ground. 1.

Remove and discard all packing inserts.

Move the snow thrower out of the carton.2.

Make certain the carton has been completely emptied before 3.

discarding it.

LOOSE PARTS

Two replacement auger shear pins are included with this manual. Refer

to Replacing Shear Pins in the Operation section for more information

regarding shear pin replacement.

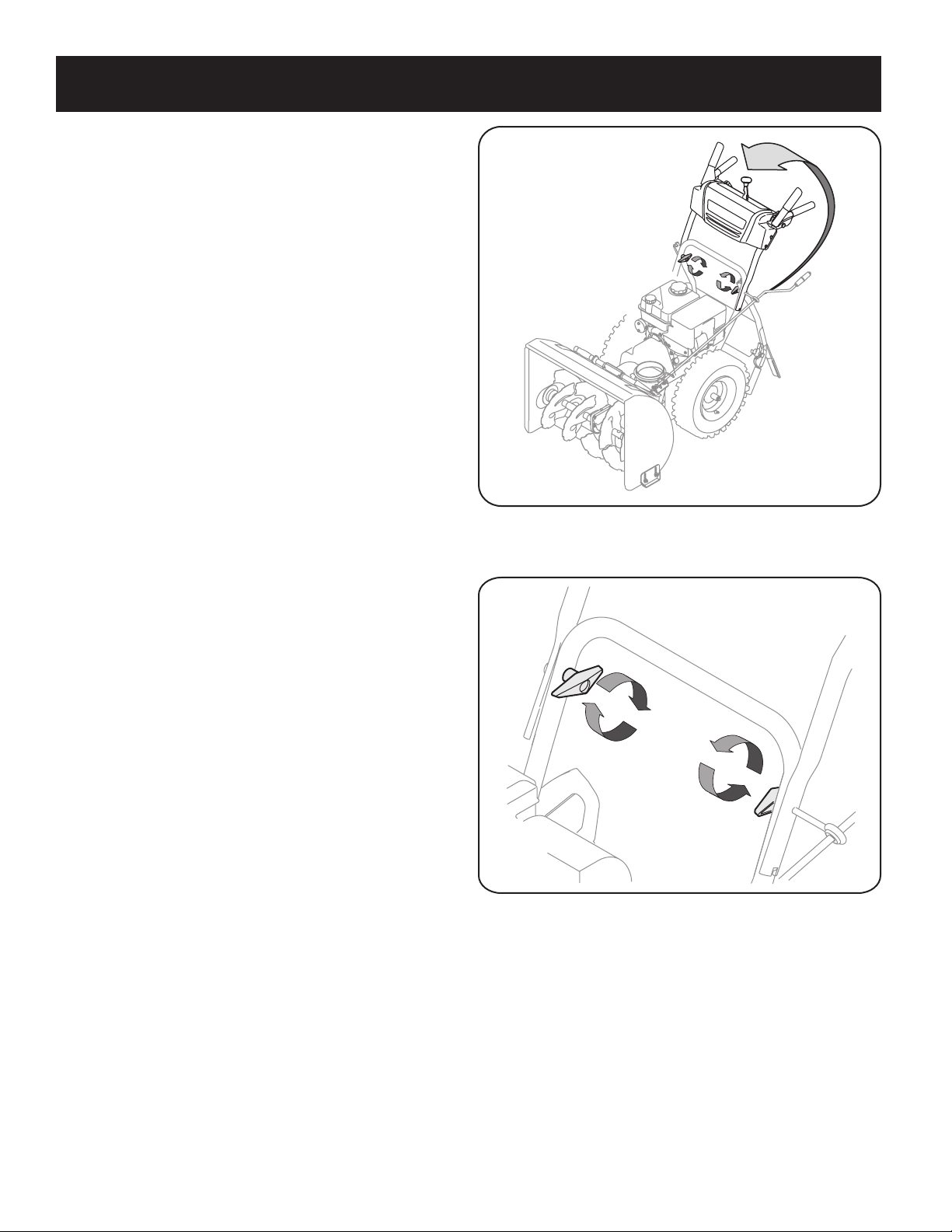

AS SE MBLY

Place the shift lever in the Forward-6 position.1.

Observe the lower rear area of the snow thrower to be sure both 2.

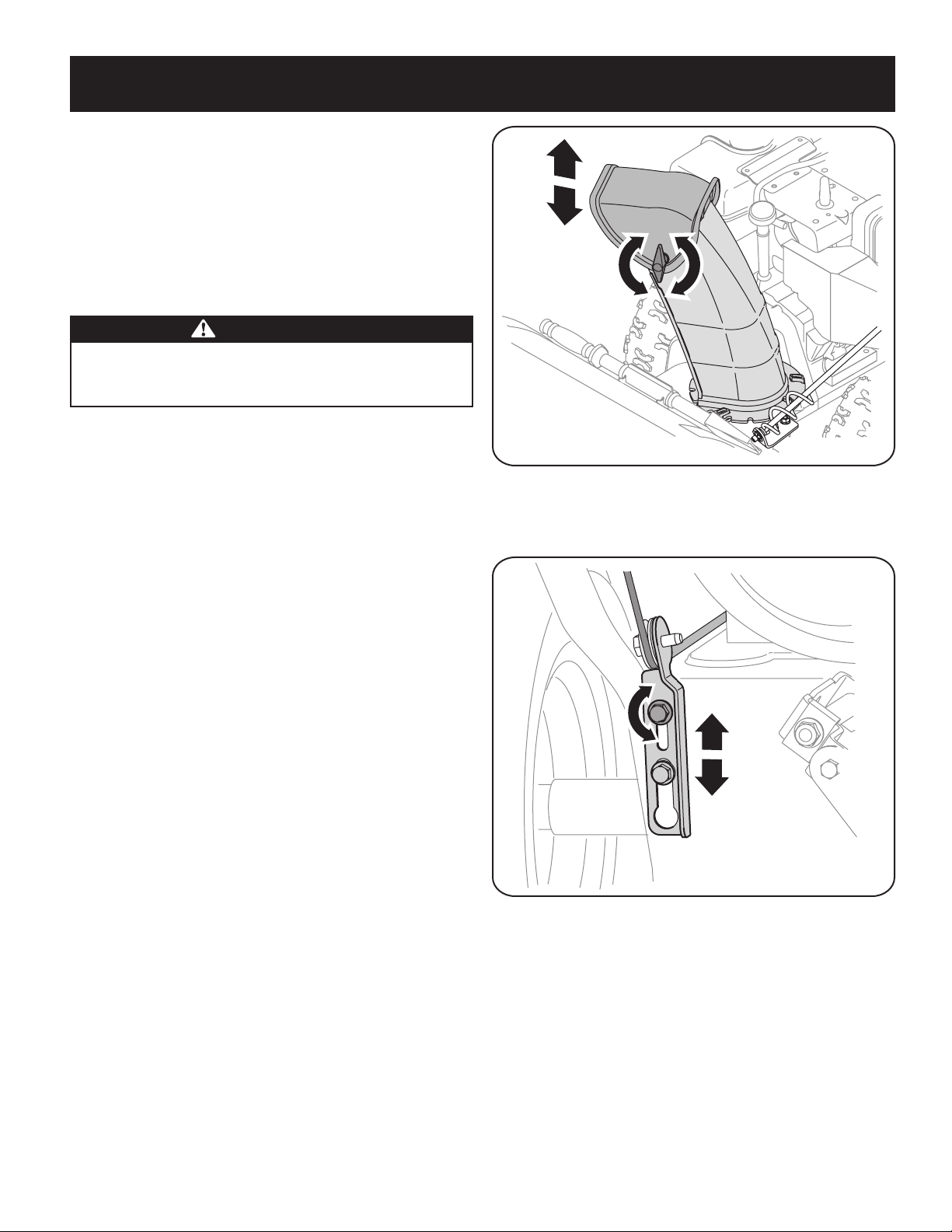

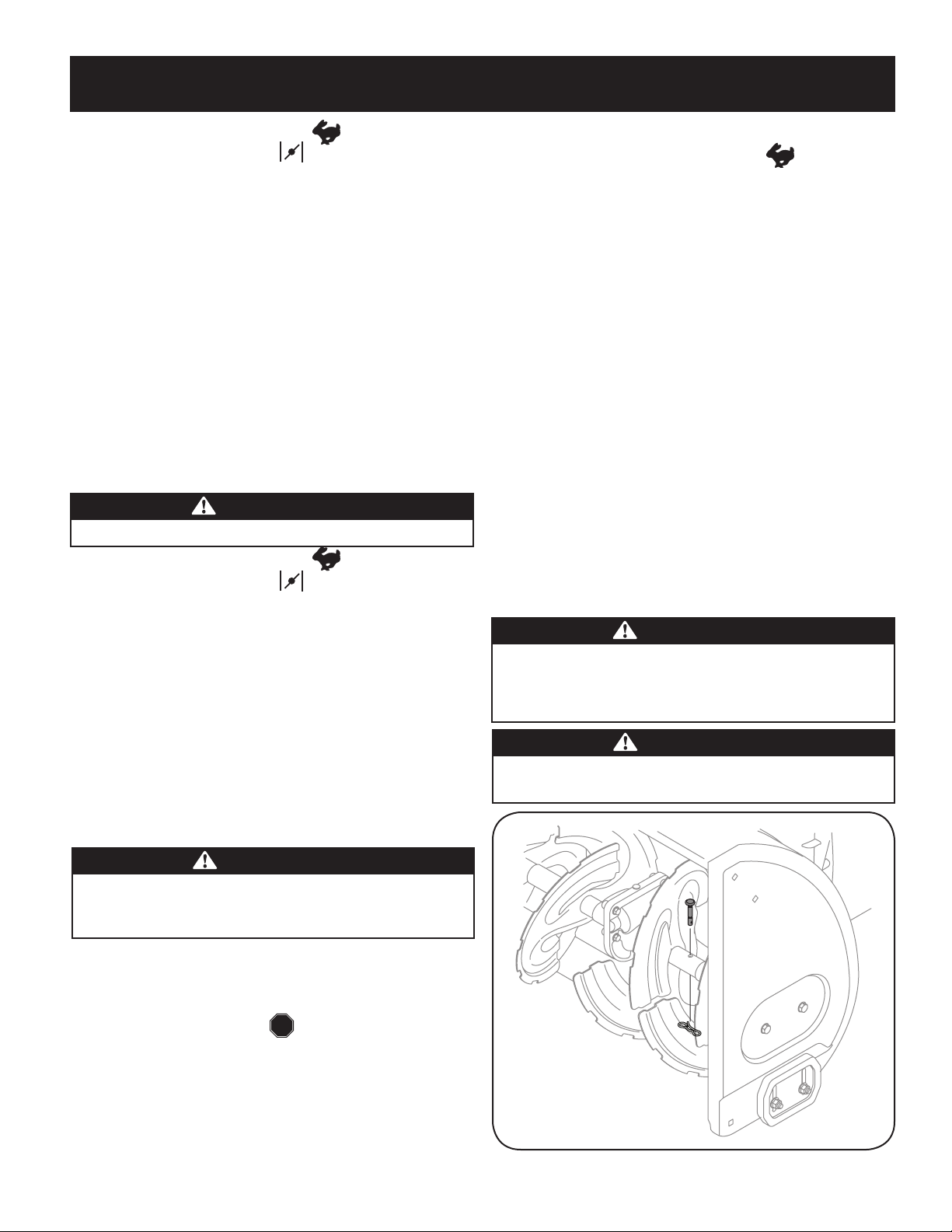

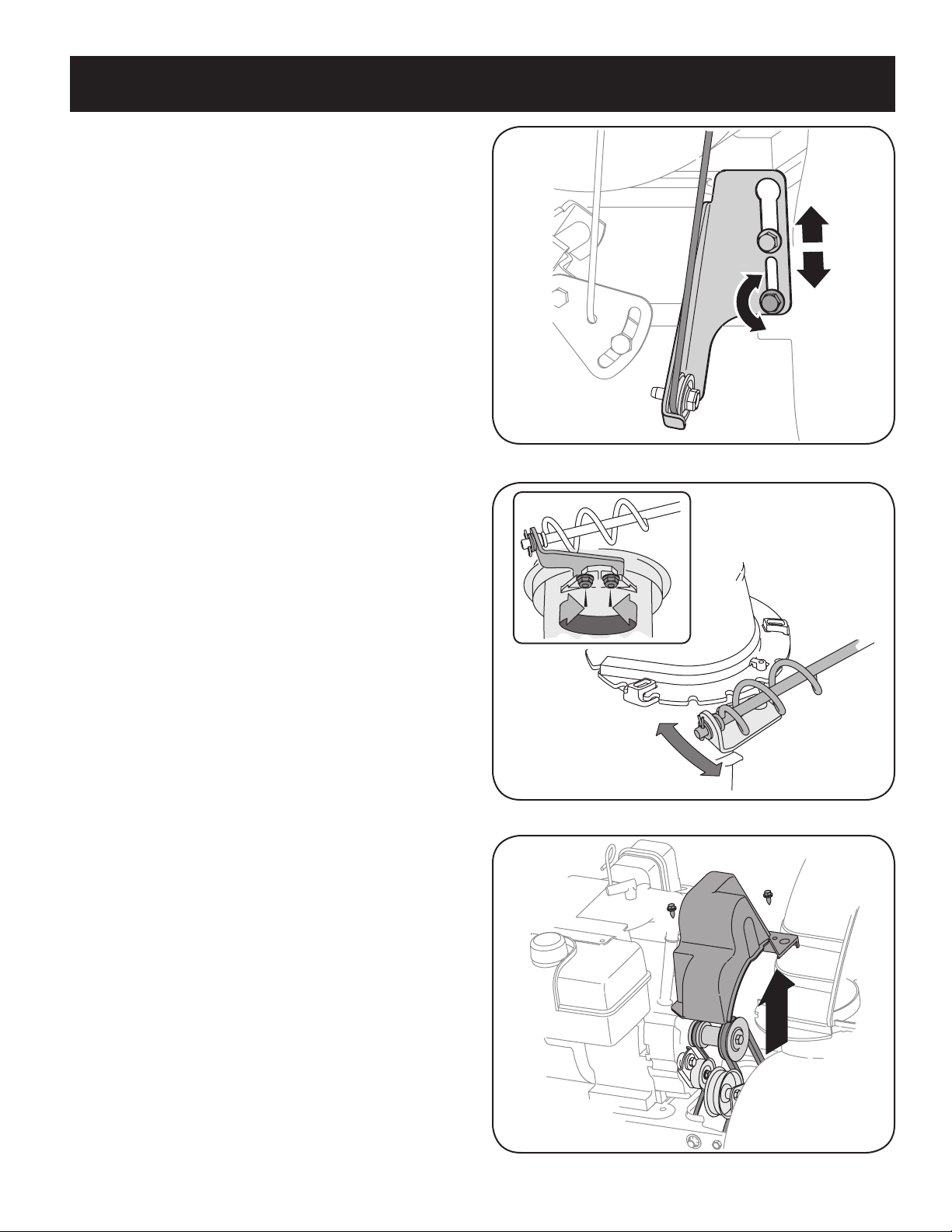

cables are aligned with roller guides before pivoting the handle

upward. See Figure 1.

Figure 1

NOTE: Make certain the upper ends of each cable are seated properly

in its bracket.

3. Secure the handle by tightening the plastic wing knob located on

both the left and right sides of the handle. See Figure 2. Remove

and discard any rubber bands, if present. They are for packaging

purposes only.

Figure 2

8

Page 9

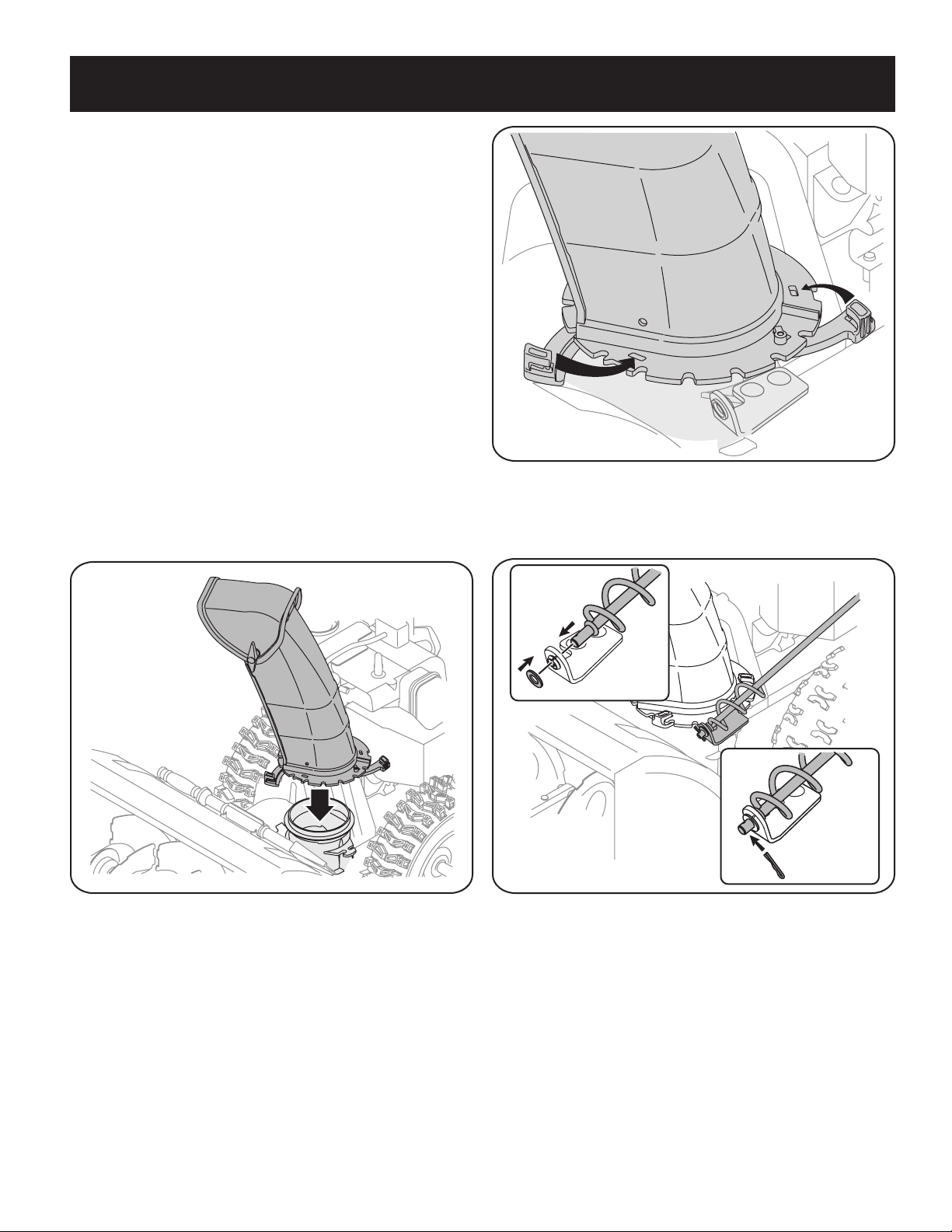

ASSEMBLY

4. Position the chute assembly over the base. See Figure 3.

5. Close the flange keepers to secure the chute assembly to the

chute base. See Figure 4. The flange keepers will click into place

when properly secure.

NOTE: If the flange keepers will not easily click into place, use the

palm of your hand to apply swift, firm pressure to the back of each.

6. a. Remove the flat washer and hairpin clip from the end of the

chute directional control.

b. Insert the end of the chute directional control into the lower

bracket and secure with the flat washer and hairpin clip just

removed. See Figure 5. If necessary, the lower bracket can

be adjusted. Refer to Chute Bracket Adjustment in the

Service & Maintenance section.

Figure 4

Figure 3

Figure 5

9

Page 10

ASSEMBLY

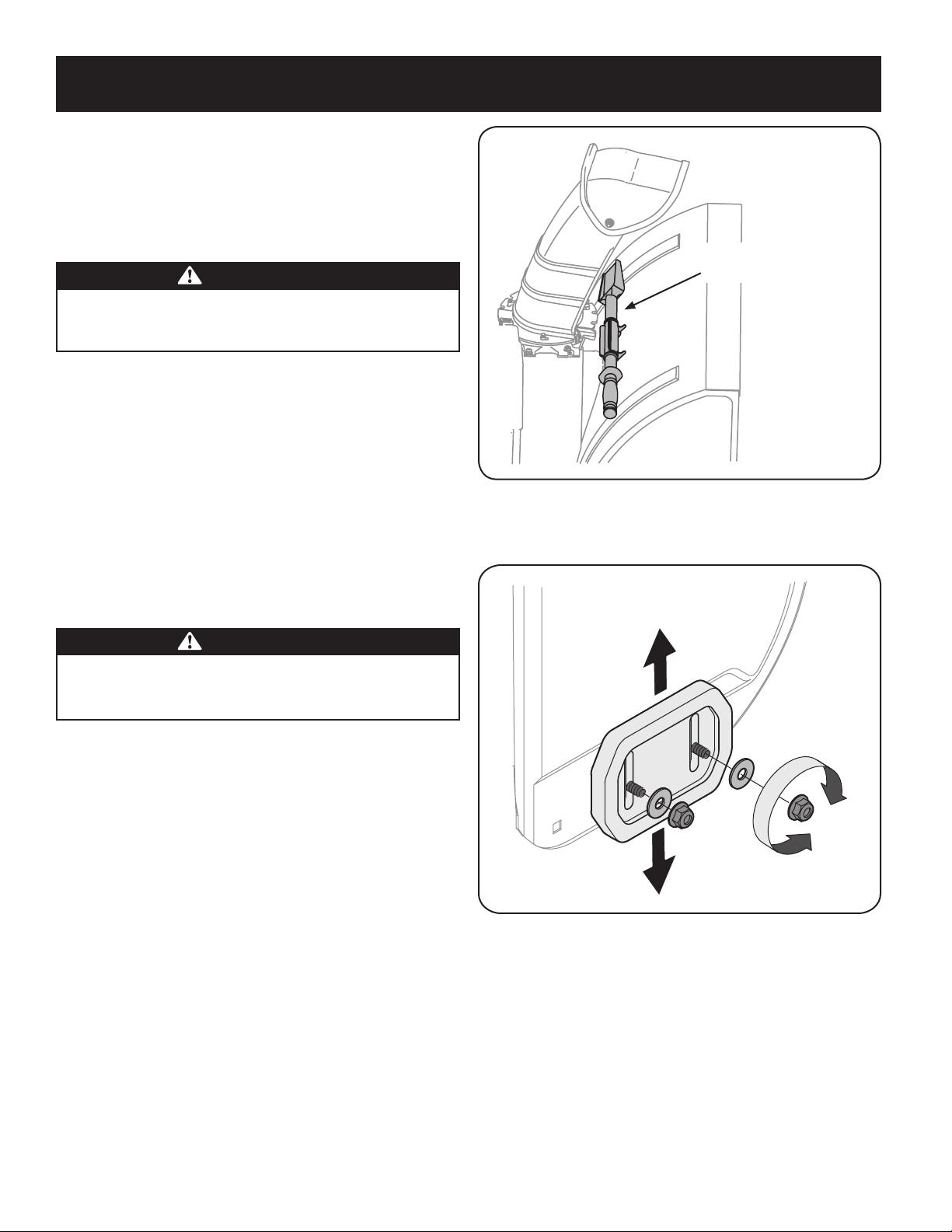

Chute Clean-out Tool

SET-UP

Chute Clean-Out Tool

A chute clean-out tool is fastened to the top of the auger housing

with a mounting clip. See Figure 6. The tool is designed to clear a

chute assembly of ice and snow. This item is fastened with a cable tie

at the factory. Cut the cable tie before operating the snow thrower.

WARNING

Never use your hands to clear a clogged chute assembly. Shut

off engine and remain behind handles until all moving parts have

stopped before using the clean-out tool to clear the chute assembly.

Tire Pressure

Before operating, check tire pressure and reduce pressure in both tires

to between 15 psi and 20 psi.

NOTE: If the tire pressure is not equal in both tires, the unit may not

travel in a straight path and the shave plate may wear unevenly.

ADJUSTMENTS

Skid Shoes

The snow thrower skid shoes are adjusted upward at the factory for

shipping purposes. Adjust them downward, if desired, prior to operating the snow thrower.

Figure 6

CAUTION

It is not recommended that you operate this snow thrower on gravel

as it can easily pick up and throw loose gravel, causing personal

injury or damage to the snow thrower and surrounding property.

For close snow removal on a smooth surface, raise skid shoes •

higher on the auger housing.

Use a middle or lower position when the area to be cleared is •

uneven, such as a gravel driveway

NOTE: If you choose to operate the snow thrower on a gravel surface,

keep the skid shoes in position for maximum clearance between the

ground and the shave plate.

To adjust the skid shoes:

Loosen the four hex nuts (two on each side) and carriage bolts. 1.

Move skid shoes to desired position. See Figure 7.

Make certain the entire bottom surface of skid shoe is against the 2.

ground to avoid uneven wear on the skid shoes.

Retighten nuts and bolts securely.3.

Figure 7

10

Page 11

ASSEMBLY

Chute Assembly

The distance snow is thrown can be adjusted by changing the angle of

the chute assembly. To do so:

Stop the engine by removing the ignition key and loosen the 1.

plastic wing knob found on the left side of the chute assembly.

Pivot the chute upward or downward before retightening the wing 2.

knob. See Figure 8.

Auger Control

WARNING

Prior to operating your snow thrower, carefully read and follow all

instructions below. Perform all adjustments to verify your snow

thrower is operating safely and properly.

Check the adjustment of the auger control as follows:

When the auger control is released and in the disengaged “up” 1.

position, the cable should have very little slack. It should NOT be

tight.

In a well-ventilated area, start the snow thrower engine. Refer to 2.

Starting the Engine in the Operation section.

While standing in the operator’s position (behind the snow 3.

thrower), engage the auger.

Allow the auger to remain engaged for approximately ten (10) 4.

seconds before releasing the auger control. Repeat this several

times.

With the auger control in the disengaged “up” position, walk to the 5.

front of the machine.

Confirm that the auger has completely stopped rotating and 6.

shows NO signs of motion. If the auger shows ANY signs of

rotating, immediately return to the operator’s position and shut off

the engine. Wait for ALL moving parts to stop before adjusting the

auger control.

To readjust the control cable, loosen the upper hex bolt on the 7.

auger cable bracket. See Figure 9.

Position the bracket upward to provide more slack (or downward 8.

to increase cable tension).

Retighten the upper hex bolt.9.

Repeat steps 2-6 above to verify proper adjustment has been 10.

achieved.

Figure 8

Figure 9

11

Page 12

OPERATION

Oil Drain

Electric Starter Outlet

Primer

Throttle

Control

Choke

Control

Electric Start

Button

Recoil Starter

Handle

Ignition

Key

Drive Control

Chute Assembly

Oil Fill

Gas Cap

Shift Lever

Auger Control

Chute Directional Control

Clean Out

To ol

Augers

Skid Shoe

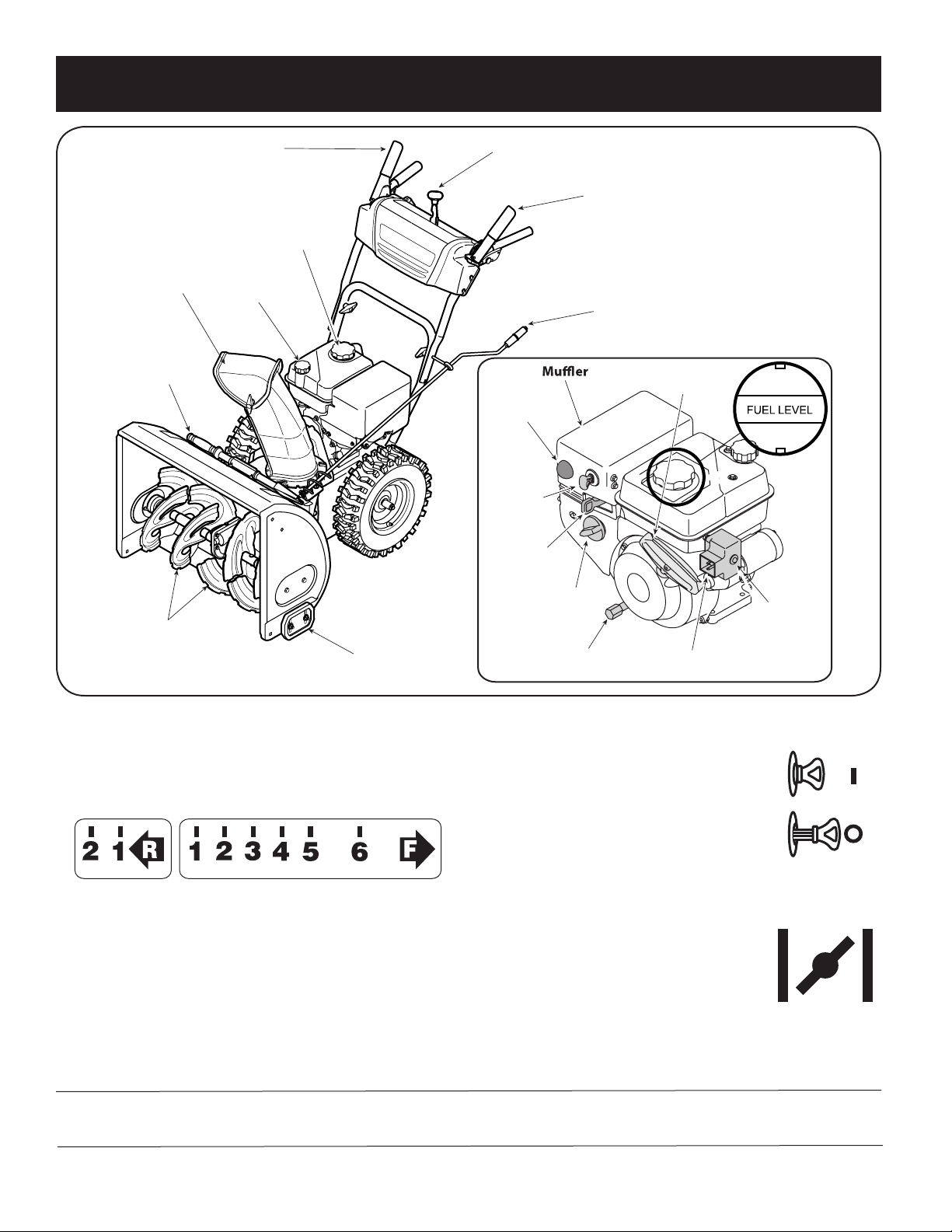

Now that you have set up your snow thrower, it’s important to become

acquainted with its controls and features. Refer to Figure 10.

SHIFT LEVER

The shift lever is located on the dash panel. Place the shift lever into

any of eight positions to control the direction of travel and ground

speed.

Forward

Your snow thrower has six forward (F) speeds. Position one (1) is the

slowest and position six (6) is the fastest.

Reverse

Your snow thrower has two reverse (R) speeds. One (1) is the slower

and two (2) is the faster.

Meets ANSI Safety Standards

Craftsman Snow Throwers conform to the safety standard of the American National Standards Institute (ANSI).

Figure 10

IGNITION KEY

The ignition key is a safety device. It must be

fully inserted in order for the engine to start.

Remove the ignition key when the snow thrower

is not in use.

NOTE: Do not turn the ignition key in an attempt

to start the engine. Doing so may cause it to

break.

CHOKE CONTROL

The choke control is found on the rear of the

engine and is activated by turning the rotary

choke knob to the ON position. Activating the

choke control closes the choke plate on the

carburetor and aids in starting the engine.

12

Page 13

OPERATION

THROTTLE CONTROL

The throttle control is located on the rear of the engine. It regulates the

speed of the engine and will shut off the engine when moved into the

STOP position.

PRIMER

Depressing the primer forces fuel directly into the

engine’s carburetor to aid in cold-weather starting.

RECOIL STARTER HANDLE

This handle is used to manually start the engine.

ELECTRIC STARTER BUTTON

Pressing the electric starter button engages the engine’s electric

starter when plugged into a 120V power source.

ELECTRIC STARTER OUTLET

Requires the use of a three-prong outdoor extension cord (included)

and a 120V power source/wall outlet.

The auger control is located on the left handle. Squeeze the control

grip against the handle to engage the augers and start snow throwing

action. Release to stop.

DRIVE CONTROL/ AUGER CONTROL LOCK

DRIVE

CONTROL

GO

The drive control is located on the right handle. Squeeze the control

grip against the handle to engage the wheel drive. Release to stop.

Release both controls to stop the augers and wheel drive.

NOTE: Always release the drive control before changing speeds.

Failure to do so will result in increased wear on your machine’s drive

system.

CHUTE DIRECTIONAL CONTROL

OIL FILL

Engine oil level can be checked and oil added through the oil fill.

GAS CAP

Unthread the gas cap to add gasoline to the fuel tank.

AUGERS

When engaged, the augers rotate and draw snow into the auger

housing.

CHUTE ASSEMBLY

Snow drawn into the auger housing is discharged out the chute

assembly.

AUGER CONTROL

AUGER

CONTROL

CHUTE DIRECTIONAL CONTROL

ADJUSTABLE

DISCHARGE

LEFT

The chute directional control is located on left side of the snow thrower.

To change the direction in which snow is thrown, turn chute directional

control as follows:

Crank clockwise to discharge to the left.•

Crank counterclockwise to discharge to the right.•

DISCHARGE

RIGHT

SKID SHOES

Position the skid shoes based on surface conditions. Adjust upward

for hard-packed snow. Adjust downward when operating on gravel or

crushed rock surfaces.

CHUTE TILT

GO

13

Page 14

OPERATION

CLEAN-OUT TOOL

WARNING

Never use your hands to clear a clogged chute assembly. Shut

off engine and remain behind handles until all moving parts have

stopped before using the clean-out tool to clear the chute assembly.

The chute clean-out tool is conveniently fastened to the rear of the

auger housing with a mounting clip. Should snow and ice become

lodged in the chute assembly during operation, proceed as follows to

safely clean the chute assembly and chute opening:

Release both the Auger Control and the Drive Control.1.

Stop the engine by removing the ignition key. 2.

Remove the clean-out tool from the clip which secures it to the 3.

rear of the auger housing.

Use the shovel-shaped end of the clean-out tool to dislodge and 4.

scoop any snow and ice which has formed in and near the chute

assembly.

Refasten the clean-out tool to the mounting clip on the rear of 5.

the auger housing, reinsert the ignition key and start the snow

thrower’s engine.

While standing in the operator’s position (behind the snow 6.

thrower), engage the auger control for a few seconds to clear any

remaining snow and ice from the chute assembly.

Refuel in a well-ventilated area with the engine stopped. Do not •

smoke or allow flames or sparks in the area where the engine is

refueled or where gasoline is stored.

Do not overfill the fuel tank. After refueling, make sure the tank •

cap is closed properly and securely.

Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor •

may ignite. If any fuel is spilled, make sure the area is dry before

starting the engine.

Avoid repeated or prolonged contact with skin or breathing of •

vapor.

WARNING

Use extreme care when handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Never fuel the machine

indoors or while the engine is hot or running. Extinguish cigarettes,

cigars, pipes and other sources of ignition.

Clean around fuel fill before removing cap to fuel.1.

A fuel level indicator is located in the fuel tank. Fill tank until fuel 2.

reaches the fuel level indictor. See Figure 10 inset. Be careful not

to overfill.

STARTING THE ENGINE

WARNING

Always keep hands and feet clear of moving parts. Do not use a

pressurized starting fluid. Vapors are flammable.

BEFORE STARTING ENGINE

WARNING

Read, understand, and follow all instructions and warnings on the

machine and in this manual before operating.

Oil

The unit was shipped with oil in the engine. Check oil level before each

operation to ensure adequate oil in the engine. For further instructions,

refer to the steps on page 16.

NOTE: Be sure to check the engine on a level surface with the engine

stopped.

Remove the oil filler cap/dipstick and wipe the dipstick clean.1.

Insert the cap/dipstick into the oil filler neck, but do 2. not screw it in.

Remove the oil filler cap/dipstick. If the level is low, slowly add 3.

oil (5W-30, with a minimum classification of SF/SG) until oil level

registers between high (H) and low (L).

NOTE: Do not overfill. Overfilling with oil may result in engine smoking,

hard starting or spark plug fouling.

Replace and tighten cap/dipstick firmly before starting engine.4.

Gasoline

Use automotive gasoline (unleaded or low leaded to minimize combustion chamber deposits) with a minimum of 87 octane. Gasoline with

up to 10% ethanol or 15% MTBE (Methyl Tertiary Butyl Ether) can be

used. Never use an oil/gasoline mixture or dirty gasoline. Avoid getting

dirt, dust, or water in the fuel tank. DO NOT use E85 gasoline.

NOTE: Allow the engine to warm up for a few minutes after starting.

The engine will not develop full power until it reaches operating

temperatures.

Make certain both the auger control and drive control are in the 1.

disengaged (released) position.

Insert ignition key into slot. Make sure it snaps into place. Do not 2.

attempt to turn the key.

NOTE: The engine cannot start without the key is fully inserted into the

ignition switch.

Electric Starter

WARNING

The optional electric starter is equipped with a grounded three-wire

power cord and plug, and is designed to operate on 120 volt AC

household current. It must be used with a properly grounded threeprong receptacle at all times to avoid the possibility of electric shock.

Follow all instructions carefully prior to operating the electric starter.

DO NOT use electric starter in the rain.

Determine that your home’s wiring is a three-wire grounded system.

Ask a licensed electrician if you are not certain.

If you have a grounded three-prong receptacle, proceed as follows.

If you do not have the proper house wiring, DO NOT use the electric

starter under any conditions.

Plug the extension cord into the outlet located on the engine’s 1.

surface. Plug the other end of extension cord into a three-prong

120-volt, grounded, AC outlet in a well-ventilated area.

14

Page 15

OPERATION

Move throttle control to FAST (rabbit) 2. position.

Move choke to the ON position 3. (cold engine start). If

engine is warm, place choke in OFF position.

Push primer three to five (3-5) times, making sure to cover vent 4.

hole when pushing. If engine is warm, push primer only once.

Always cover vent hole when pushing. Cool weather may require

priming to be repeated.

Push starter button to start engine. 5. Once the engine starts, immediately release starter button. Electric starter is equipped with

thermal overload protection; system will temporarily shut-down to

allow starter to cool if electric starter becomes overloaded.

As the engine warms, slowly rotate the choke control to OFF 6.

position. If the engine falters, restart engine and run with choke

at half-choke position for a short period of time, and then slowly

rotate the choke into OFF position.

After engine is running, disconnect power cord from electric 7.

starter. When disconnecting, always unplug the end at the wall

outlet before unplugging the opposite end from the engine.

Recoil Starter

CAUTION

Do not pull the starter handle while the engine running.

Move throttle control to FAST (rabbit) 1. position.

Move choke to the ON position 2. (cold engine start). If

engine is warm, place choke in OFF position.

Push primer three to five (3-5) times, making sure to cover vent 3.

hole when pushing. If engine is warm, push primer only once.

Always cover vent hole when pushing. Cool weather may require

priming to be repeated.

Pull gently on the starter handle until it begins to resist, then 4.

pull quickly and forcefully to overcome the compression. Do

not release the handle and allow it to snap back. Return rope

SLOWLY to original position. If required, repeat this step.

As the engine warms, slowly rotate the choke control to OFF 5.

position. If the engine falters, restart engine and run with choke

at half-choke position for a short period of time, and then slowly

rotate the choke into OFF position.

TO ENGAGE DRIVE

With the throttle control in the Fast (rabbit) 1. position, move

shift lever into one of the six forward (F) positions or two reverse

(R) positions. Select a speed appropriate for the snow conditions

and a pace you’re comfortable with.

NOTE: When selecting a Drive Speed, use the slower speeds until

you are comfortable and familiar with the operation of the snow

thrower.

2. Squeeze the drive control against the handle and the snow

thrower will move. Release it and drive motion will stop.

NOTE: NEVER reposition the shift lever (change speeds or direction

of travel) without first releasing the drive control and bringing the snow

thrower to a complete stop. Doing so will result in premature wear to

the snow thrower’s drive system.

TO ENGAGE AUGERS

To engage the augers and start throwing snow, squeeze the 1.

auger control against the left handle. Release to stop the augers.

REPLACING SHEAR PINS

The augers are secured to the spiral shaft with two shear pins and

bow-tie clips. If the auger should strike a foreign object or ice jam, the

snow thrower is designed so that the shear pins may shear. If augers

will not turn, check to see if the pins have sheared. See Figure 11.

CAUTION

NEVER replace the auger shear pins with anything other than Sears

SKU# 88389/OEM Part No. 738-04124A replacement shear pins.

Any damage to the auger gearbox or other components as a result of

failing to do so will NOT be covered by your snow thrower’s warranty.

WARNING

Always turn off the snow thrower’s engine and remove the key prior to

replacing shear pins.

WARNING

To avoid unsupervised engine operation, never leave the machine

unattended with the engine running. Turn the engine off after use and

remove ignition key.

STOPPING THE ENGINE

After you have finished snow-throwing, run engine for a few minutes

before stopping to help dry off any moisture on the engine.

Move throttle control to STOP 1. position.

Remove the ignition key. Removing the key will reduce the pos-2.

sibility of unauthorized starting of the engine while equipment is

not in use. Keep the key in a safe place. The engine cannot start

without the ignition key.

Wipe any moisture away from the controls on the engine.3.

STOP

Figure 11

15

Page 16

SERVICE AND MAINTENANCE

Fill

between

high

and low

marks

Oil Drain

Plug

ENGINE MAINTENANCE

WARNING

Before lubricating, repairing, or inspecting, disengage all controls

and stop engine. Wait until all moving parts have come to a complete

stop.

Checking Engine Oil

NOTE: Check the oil level before each use to be sure correct oil level

is maintained.

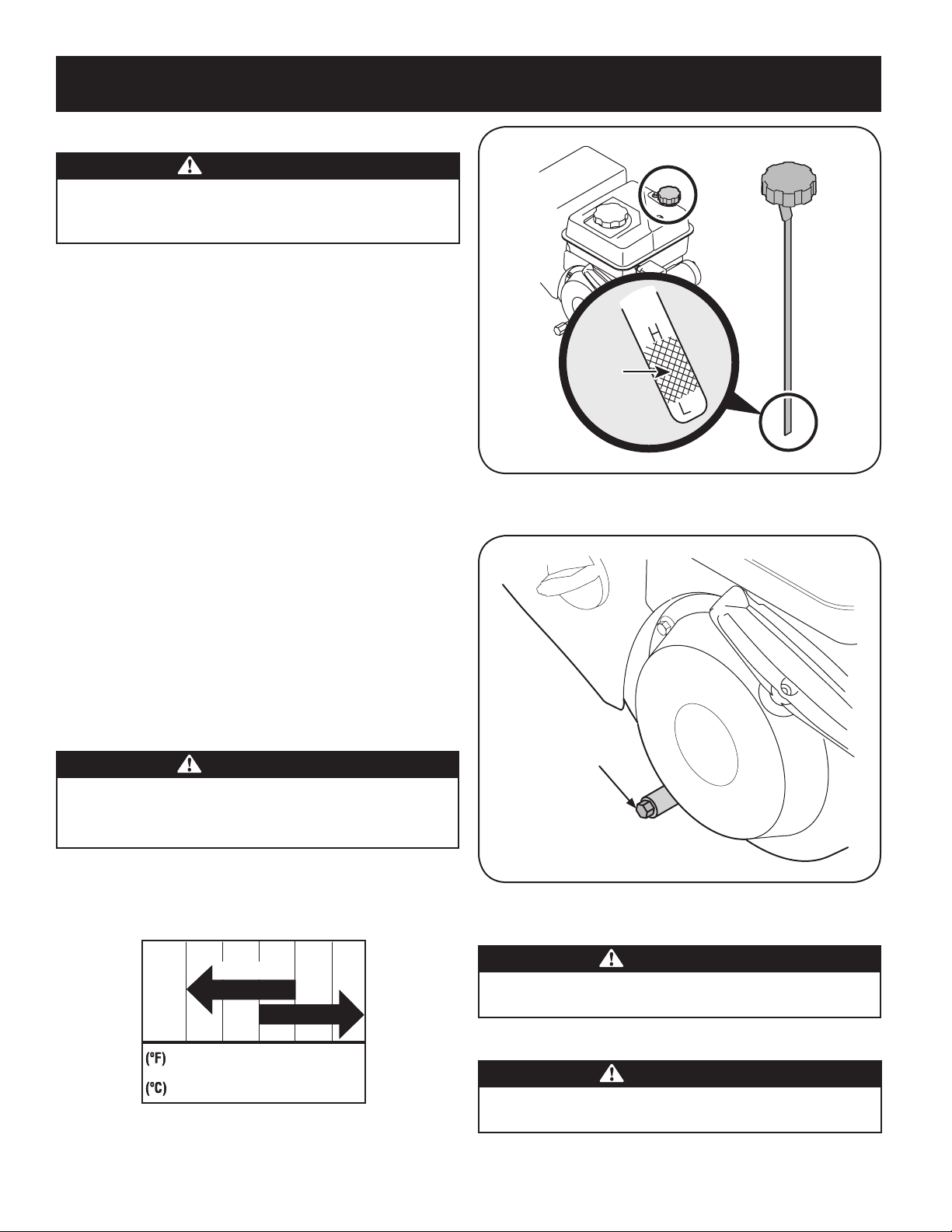

When adding oil to the engine, refer to viscosity chart below. Engine

oil capacity is 600 ml (approx. 20 oz.). Do not over-fill. Use a 4-stroke,

or an equivalent high detergent, premium quality motor oil certified

to meet or exceed U.S. automobile manufacturer’s requirements for

service classification SG, SF. Motor oils classified SG, SF will show

this designation on the container.

Remove the oil filler cap/dipstick and wipe the dipstick clean.1.

Insert the cap/dipstick into the oil filler neck, but do 2. not screw it in.

Remove the oil filler cap/dipstick. If level is low, slowly add oil until 3.

oil level registers between high (H) and low (L). See Figure 12.

Replace and tighten cap/dipstick firmly before starting engine.4.

Figure 12

Changing Engine Oil

NOTE: Change the engine oil after the first 5 hours of operation and

once a season or every 50 hours thereafter.

Drain fuel from tank by running engine until the fuel tank is empty. 1.

Be sure fuel fill cap is secure.

Place suitable oil collection container under oil drain plug. 2.

Remove oil drain plug. See Figure 13.3.

Tip engine to drain oil into the container. Used oil must be 4.

disposed of at a proper collection center.

CAUTION

Used oil is a hazardous waste product. Dispose of used oil properly.

Do not discard with household waste. Check with your local authorities or Sears Service Center for safe disposal/recycling facilities.

Reinstall the drain plug and tighten it securely. 5.

Refill with the recommended oil and check the oil level. 6. See

Recommended Oil Usage chart. The engine’s oil capacity is 20

ounces.

Synthetic

Synthetic

0W-30

0W-30

5W-30

5W-30

Figure 13

CAUTION

DO NOT use nondetergent oil or 2-stroke engine oil. It could shorten

the engine’s service life.

-40º

-40º

-30º -20º -10º 0º

-30º -20º -10º 0º

0º 20º 40º-20º

0º 20º 40º-20º

Reinstall the oil filler cap/dipstick securely.7.

CAUTION

Thoroughly wash your hands with soap and water as soon as

possible after handling used oil.

16

Page 17

SERVICE AND MAINTENANCE

.02-.03 in.

(0.60-0.80 mm)

Electrode

Spark Plug

Spark Plug Boot

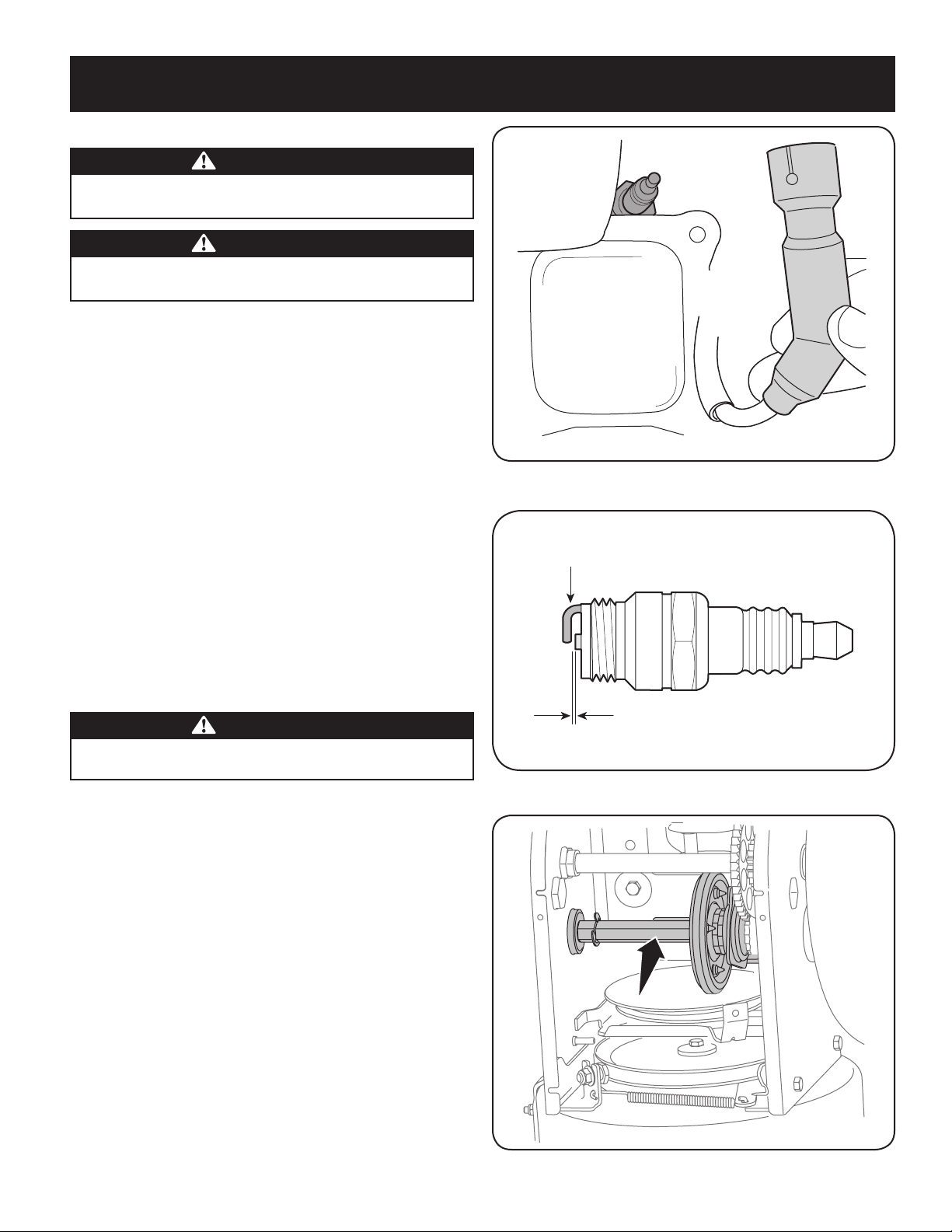

Checking Spark Plug

WARNING

DO NOT check for spark with spark plug removed. DO NOT crank

engine with spark plug removed.

WARNING

If the engine has been running, the muffler will be very hot. Be careful

not to touch the muffler.

NOTE: Check the spark plug once a season or every 25 hours of

operation. Change the spark plug once a season or every 100 hours.

To ensure proper engine operation, the spark plug must be properly

gapped and free of deposits.

Remove the spark plug boot and use a spark plug wrench to 1.

remove the plug. See Figure 14.

Visually inspect the spark plug. Discard the spark plug if there is 2.

apparent wear, or if the insulator is cracked or chipped. Clean the

spark plug with a wire brush if it is to be reused.

Measure the plug gap with a feeler gauge. Correct as necessary 3.

by bending side electrode. See Figure 15. The gap should be set

to .02-.03 inches (0.60-0.80 mm).

Check that the spark plug washer is in good condition and thread 4.

the spark plug in by hand to prevent cross-threading.

After the spark plug is seated, tighten with a spark plug wrench to 5.

compress the washer.

Figure 14

NOTE: When installing a new spark plug, tighten 1⁄2-turn after the

spark plug seats to compress the washer. When reinstalling a used

spark plug, tighten 1⁄8- to 1⁄4-turn after the spark plug seats to

compress the washer.

CAUTION

The spark plug must be tightened securely. A loose spark plug can

become very hot and can damage the engine.

LUBRICATION

Gear Shaft

The gear (hex) shaft should be lubricated at least once a season or

after every 25 hours of operation.

To prevent spillage, remove all fuel from tank by running engine 1.

until it stops.

Carefully pivot the snow thrower up and forward so that it rests on 2.

the auger housing.

Remove the lower frame cover from the underside of the snow 3.

thrower by removing the four self-tapping screws which secure it.

Apply a light coating of engine oil (or 3-in-1 oil) to the hex shaft. 4.

See Figure 16.

NOTE: When lubricating the hex shaft, be careful not to get any oil on

the aluminum drive plate or rubber friction wheel. Doing so will hinder

the snow thrower’s drive system. Wipe off any excess or spilled oil.

Figure 15

Figure 16

17

Page 18

SERVICE AND MAINTENANCE

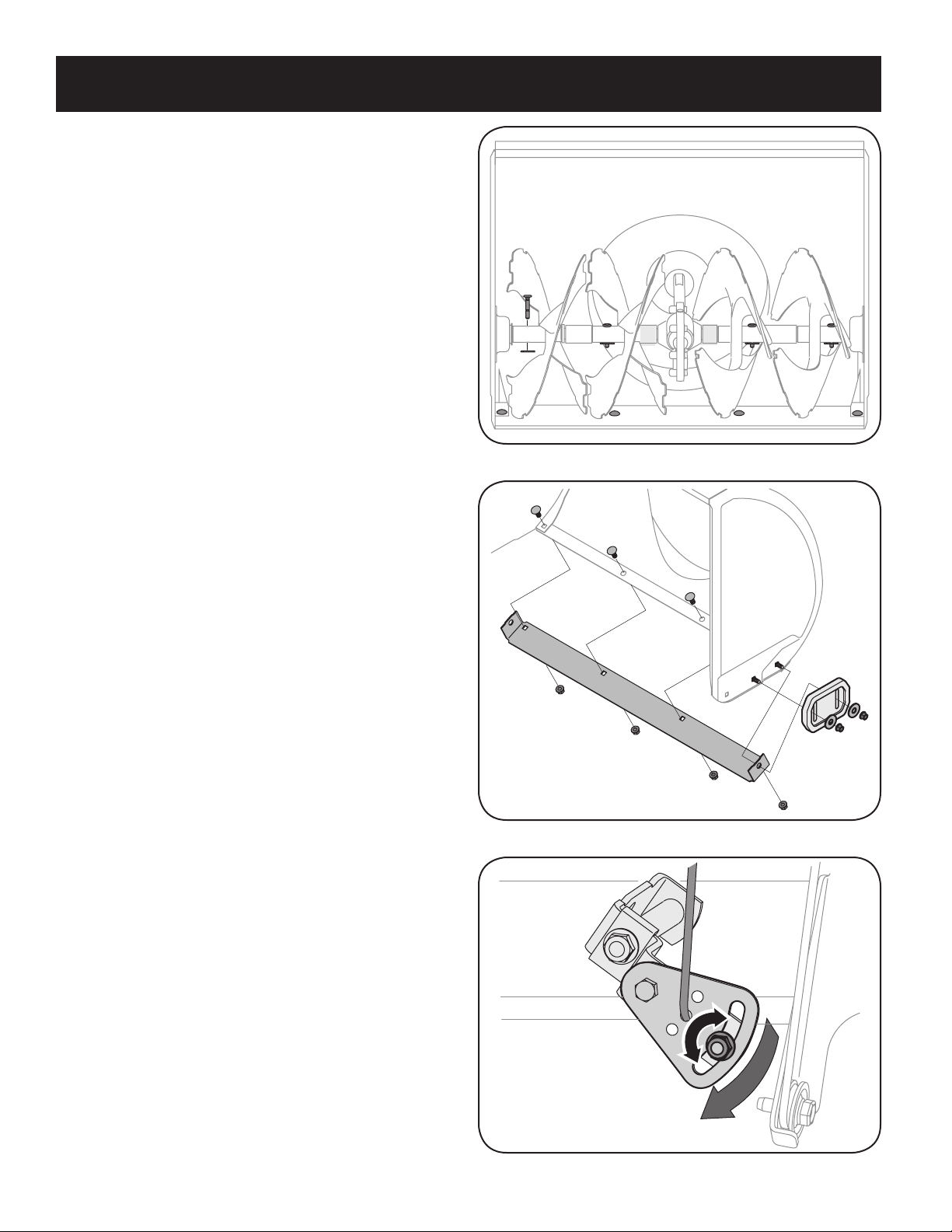

NOTE: Augers not shown for clarity.

Wheels

At least once a season, remove both wheels. Clean and coat the axles

with a multipurpose automotive grease before reinstalling wheels.

Chute Directional Control

Once a season, lubricate the eye bolt bushing and the spiral with 3-in-1

oil.

Auger Shaft

At least once a season, remove the shear pins on auger shaft. Spray

lubricant inside shaft, and around the spacers and flange bearings

found at either end of the shaft. See Figure 17.

SHAVE PLATE AND SKID SHOES

The shave plate and skid shoes on the bottom of the snow thrower are

subject to wear. They should be checked periodically and replaced

when necessary.

To remove skid shoes:

Remove the four carriage bolts, washers, and hex flange nuts 1.

which secure them to the snow thrower.

Reassemble new skid shoes with the four carriage bolts (two on 2.

each side), washers, and hex flange nuts. Refer to Figure 18.

To remove shave plate:

Remove the carriage bolts and hex nuts which attach it to the 1.

snow thrower housing.

Reassemble new shave plate, making sure heads of carriage 2.

bolts are to the inside of housing. Tighten securely. See Figure 18.

Figure 17

ADJUSTMENTS

Shift Cable

If the full range of speeds (forward and reverse) cannot be achieved,

refer to the figure to the right and adjust the shift cable as follows:

Place the shift lever in the 1. fastest forward speed position (F6).

Loosen the hex nut on the shift cable index bracket. See Figure 2.

19.

Pivot the bracket downward to take up slack in the cable. 3.

Retighten the hex nut.4.

Drive Control

When the drive control is released and in the disengaged “up” position,

the cable should have very little slack. It should NOT be tight. Also,

if there is excessive slack in the drive cable or if the unit experiences

intermittent drive while using, the cable may need to be adjusted.

Check the adjustment of the drive control as follows:

With the drive control released, push the snow thrower gently 1.

forward. The unit should roll freely.

Engage the drive control and gently attempt to push the snow 2.

thrower forward. The wheels should not turn. The unit should not

roll freely.

With the drive control released, move the shift lever back and 3.

forth between the R2 position and the F6 position several times.

There should be no resistance in the shift lever.

Figure 18

Figure 19

18

Page 19

SERVICE AND MAINTENANCE

If any of the above tests failed, the drive cable is in need of adjust-4.

ment. Proceed as follows:

Loosen the lower hex bolt on the drive cable bracket. See Figure 5.

20.

Position the bracket upward to provide more slack (or downward 6.

to increase cable tension).

Retighten the lower hex bolt.7.

Chute Bracket

If the spiral at the bottom of the chute directional control is not fully

engaging with the chute assembly, the chute bracket can be adjusted.

To do so:

Loosen the two nuts which secure the chute bracket and reposi-1.

tion it slightly. See Figure 21.

Retighten the nuts.2.

Auger Control

Refer to the Assembly section for instructions on adjusting the auger

control cable.

Skid Shoes

Refer to the Assembly section for instructions on adjusting the skid

shoes.

BELT REPLACEMENT

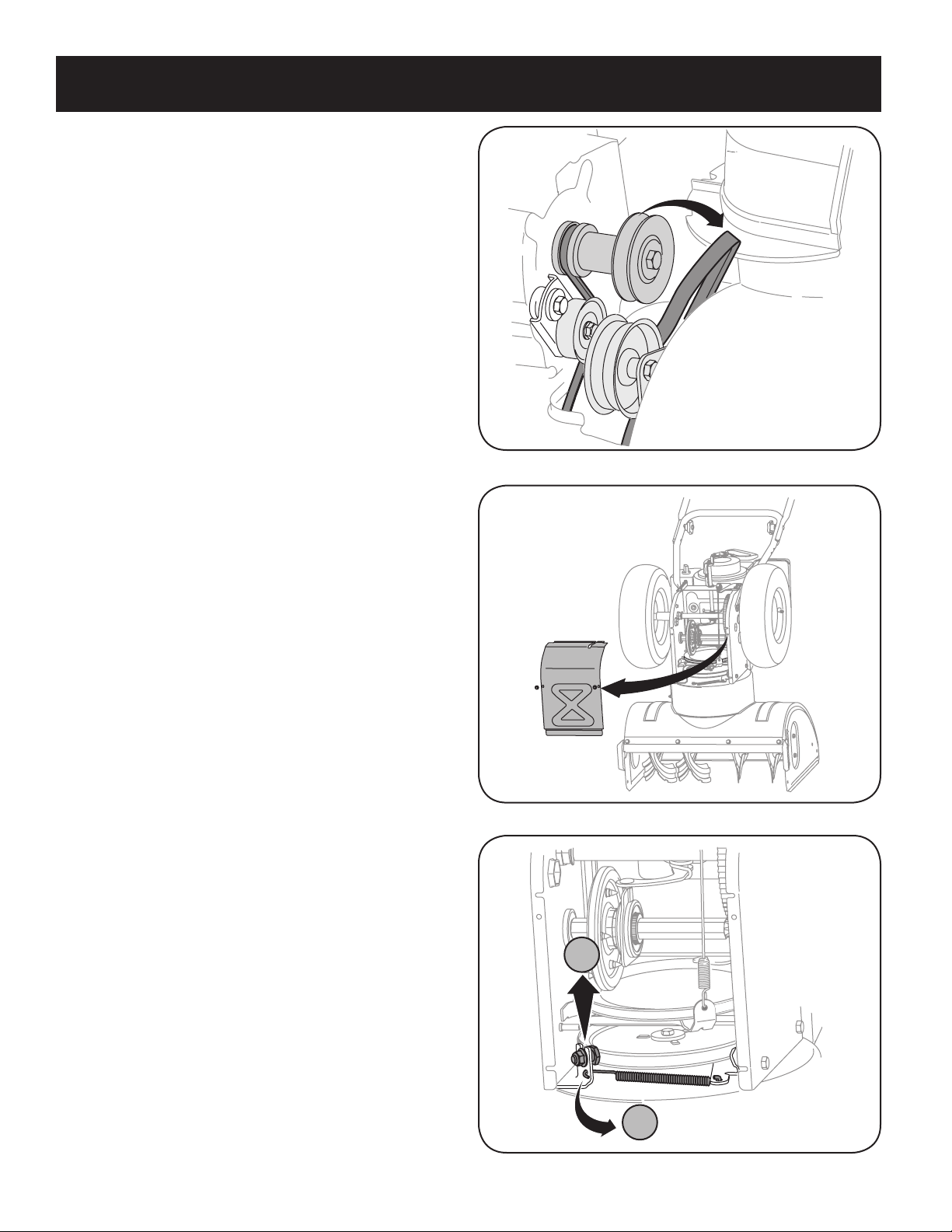

Auger Belt

To remove and replace your snow thrower’s auger belt, proceed as

follows:

To prevent spillage, remove all fuel from tank by running engine 1.

until it stops.

Remove the plastic belt cover on the front of the engine by remov-2.

ing the two self-tapping screws. See Figure 22.

Figure 20

Figure 21

19

Figure 22

Page 20

SERVICE AND MAINTENANCE

Roll the auger belt off the engine pulley. See Figure 23.3.

Carefully pivot the snow thrower up and forward so that it rests on 4.

the auger housing.

Remove the frame cover from the underside of the snow thrower 5.

by removing four self-tapping screws which secure it. See Figure

24.

Remove the belt as follows. Refer to Figure 25.6.

a. Loosen and remove the shoulder screw which acts as a belt

keeper.

b. Unhook the support bracket spring from the frame.

Figure 23

20

Figure 24

A

B

Figure 25

Page 21

SERVICE AND MAINTENANCE

Stop Bolt

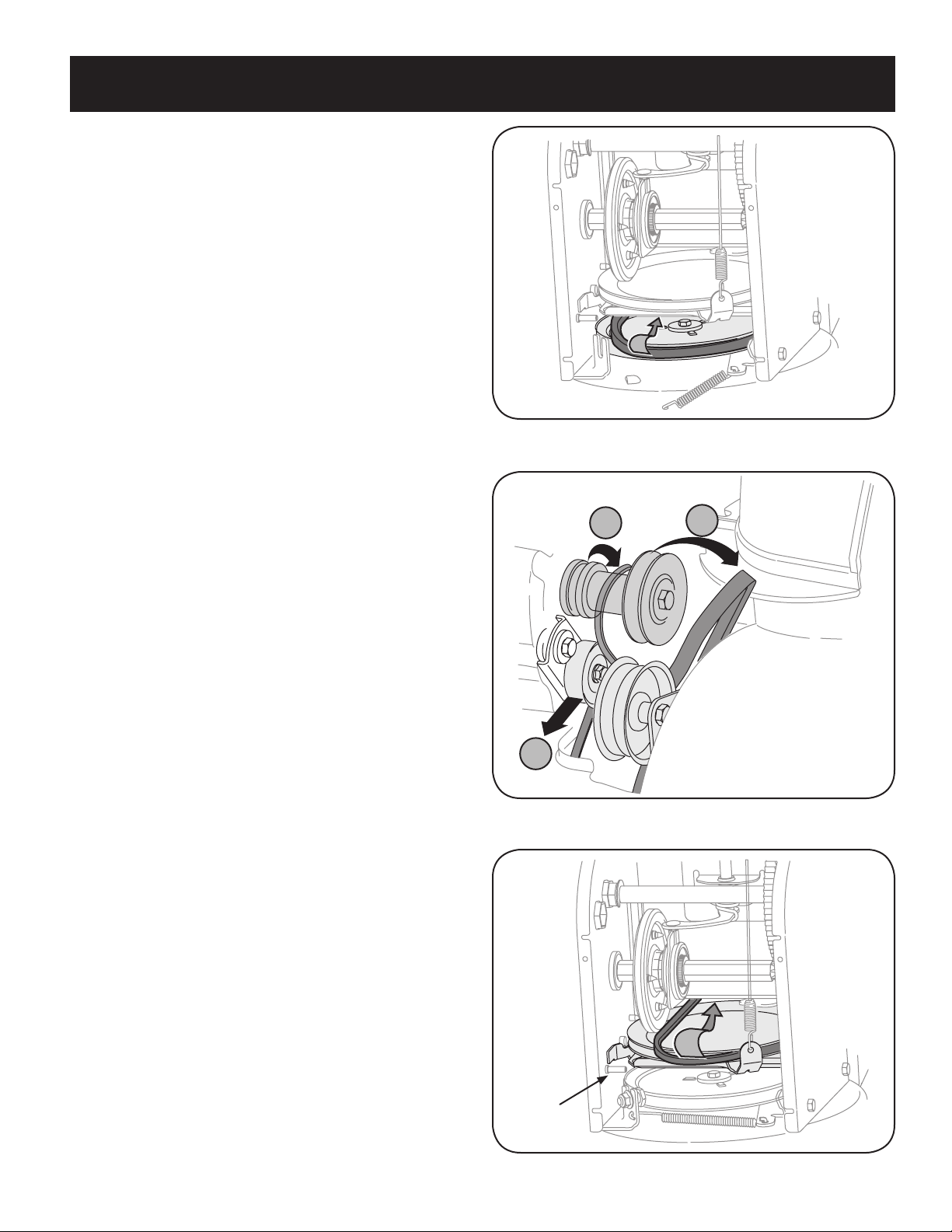

7. Remove the belt from around the auger pulley, and slip the belt

between the support bracket and the auger pulley. See Figure 26.

8. Reassemble auger belt by following instructions in reverse order.

9. Perform the Auger Control test outlined in the Assembly section

of this manual.

NOTE: Do NOT forget to reinstall the shoulder screw and reconnect

the spring to the frame after installing a replacement auger belt.

Drive Belt

To remove and replace your snow thrower’s drive belt, proceed as

follows:

To prevent spillage, remove all fuel from tank by running engine 1.

until it stops.

Remove the plastic belt cover on the front of the engine by remov-2.

ing the two self-tapping screws. See Figure 22 on previous page.

Remove the belt as follows. Refer to Figure 27.3.

a. Roll the auger belt off the engine pulley.

b. Use a wrench to pivot the idler pulley toward the right.

c. Lift the drive belt off engine pulley.

4. Carefully pivot the snow thrower up and forward so that it rests on

the auger housing.

5. Remove the frame cover from the underside of the snow thrower

by removing four self-tapping screws which secure it. Refer to

Figure 24.

6. Back out the stop bolt to increase the clearance between the

friction wheel disc and friction wheel. See Figure 28.

7. Slip the drive belt off the pulley and between friction wheel and

friction wheel disc. See Figure 28.

8. Remove and replace belt in the reverse order.

Figure 26

C

A

NOTE: Engaging the drive control will ease reassembly of the belt.

B

Figure 27

Figure 28

21

Page 22

SERVICE AND MAINTENANCE

FRICTION WHEEL REMOVAL

If the snow thrower fails to drive with the drive control engaged,

and performing the drive control cable adjustment fails to correct

the problem, the friction wheel may need to be replaced. Follow the

instructions below. Examine the friction wheel for signs of wear or

cracking and replace if necessary.

To prevent spillage, remove all fuel from tank by running engine 1.

until it stops.

Place the shift lever in third Forward (F3) position.2.

Carefully pivot the snow thrower up and forward so that it rests on 3.

the auger housing.

Remove the frame cover from the underside of the snow thrower 4.

by removing four self-tapping screws which secure it.

Remove the right-hand wheel by removing the screw and bell 5.

washer which secure it to the axle. See Figure 29.

Carefully remove the hex nut and washer which secures the hex 6.

shaft to the snow thrower frame and lightly tap the shaft’s end

to dislodge the ball bearing from the right side of the frame. See

Figure 30.

NOTE: Be careful not to damage the threads on the shaft.

Figure 30

7. Carefully position the hex shaft downward and to the left before

carefully sliding the friction wheel assembly off the shaft. See

Figure 31.

Figure 29

Figure 31

22

Page 23

SERVICE AND MAINTENANCE

NOTE: If you’re replacing the friction wheel assembly as a whole,

discard the worn part and slide the new part onto the hex shaft.

Follow the steps above in reverse order to reassemble components. If

you’re disassembling the friction wheel and replacing only the rubber

ring, proceed as follows:

Remove the four screws which secure the friction wheel’s side 1.

plates together. See Figure 32.

Remove the rubber ring from between the plates.2.

Reassemble the side plates with a new rubber ring.3.

NOTE: When reassembling the friction wheel assembly, make sure

that the rubber ring is centered and seated properly between the side

plates. Tighten each screw only one rotation before turning the wheel

clockwise and proceeding with the next screw. Repeat this process

several times to ensure the plates are secured with equal force

(between 6 ft-lbs and 9 ft-lbs).

4. Slide the friction wheel assembly back onto the hex shaft and

follow the steps above in reverse order to reassemble

components.

5. Perform the Drive Control Test outlined earlier in the Service and

Maintenance section.

Figure 32

MAINTENANCE SCHEDULE

WARNING

Before performing any type of maintenance/service, disengage all

controls and stop the engine. Wait until all moving parts have come to

a complete stop. Disconnect spark plug wire and ground it against the

engine to prevent unintended starting. Always wear safety glasses during

operation or while performing any adjustments or repairs.

Interval Item Service Service Log

Each Use and every 5

hours

1st 5 hours Engine oil1. Change1.

Annually or 25 hours Spark plug1.

Annually or 50 hours Engine oil1. Change1.

Annually or 100 hours Spark plug1. Change1.

Before Storage Fuel system1. Run engine until it stops from lack 1.

Engine oil level1.

Loose or missing hardware2.

Unit and engine.3.

Control linkages and pivots2.

Wheels3.

Gear shaft and Auger shaft4.

Follow the maintenance schedule given below. This chart describes

service guidelines only. Use the Service Log column to keep track of

completed maintenance tasks. To locate the nearest Sears Service

Center or to schedule service, simply contact Sears at

1-800-4-MY-HOME®.

Check1.

Tighten or replace2.

Clean3.

Check1.

Lube with light oil2.

Lube with multipurpose auto grease3.

Lube with light oil4.

of fuel

23

Page 24

OFF-SEASON STORAGE

If the snow thrower will not be used for 30 days or longer, or if it is the end of the snow season when the last possibility of snow is gone, the

equipment needs to be stored properly. Follow storage instructions below to ensure top performance from the snow thrower for many more years.

PREPARING ENGINE

Engines stored over 30 days need to be drained of fuel to prevent

deterioration and gum from forming in fuel system or on essential

carburetor parts. If the gasoline in your engine deteriorates during

storage, you may need to have the carburetor, and other fuel system

components, serviced or replaced.

Remove all fuel from tank by running engine until it stops.1.

Change the engine oil.2.

Remove spark plug and pour approximately 1 oz. (30 ml) of clean 3.

engine oil into the cylinder. Pull the recoil starter several times to

distribute the oil, and reinstall the spark plug.

Clean debris from around engine, and under, around, and behind 4.

muffler. Apply a light film of oil on any areas that are susceptible

to rust.

Store in a clean, dry and well ventilated area away from any ap-•

pliance that operates with a flame or pilot light, such as a furnace,

water heater, or clothes dryer. Avoid any area with a spark

producing electric motor, or where power tools are operated.

WARNING

Never store snow thrower with fuel in tank indoors or in poorly ventilated areas, where fuel fumes may reach an open flame, spark or pilot

light as on a furnace, water heater, clothes dryer or gas appliance.

PREPARING SNOW THROWER

When storing the snow thrower in an unventilated or metal stor-•

age shed, care should be taken to rustproof the equipment. Using

a light oil or silicone, coat the equipment, especially any chains,

springs, bearings and cables.

Remove all dirt from exterior of engine and equipment.•

Follow lubrication recommendations.•

Store equipment in a clean, dry area.•

If possible, avoid storage areas with high humidity.•

Keep the engine level in storage. Tilting can cause fuel or oil •

leakage.

24

Page 25

TROUBLESHOOTING

Problem Cause Remedy

Engine fails to start Choke control not in ON position1.

Spark plug wire disconnected2.

Faulty spark plug3.

Fuel tank empty or stale fuel4.

Engine not primed.5.

Safety key not inserted.6.

Engine runs erratically Engine running on CHOKE1.

Stale fuel2.

Water or dirt in fuel system3.

Carburetor out of adjustment4.

Engine overheats Carburetor not adjusted properly1. Contact your Sears Parts & Repair Center.1.

Excessive vibration Loose parts or damaged auger1. Stop engine immediately and disconnect spark plug 1.

Loss of power Spark plug wire loose.1.

Gas cap vent hole plugged.2.

Unit fails to propel itself Drive cable in need of adjustment 1.

Drive belt loose or damaged 2.

Worn friction wheel.3.

Unit fails to discharge snow Chute assembly clogged. 1.

Foreign object lodged in auger. 2.

Auger cable in need of adjustment. 3.

Auger belt loose or damaged. 4.

Shear pin(s) sheared.5.

Move choke control to ON position.1.

Connect wire to spark plug.2.

Clean, adjust gap, or replace.3.

Fill tank with clean, fresh gasoline.4.

Prime engine as instructed in the Operation Section.5.

Insert key fully into the switch.6.

Move choke control to OFF position.1.

Fill tank with clean, fresh gasoline.2.

Drain fuel tank. Refill with fresh fuel.3.

Contact your Sears Parts & Repair Center.4.

wire. Tighten all bolts and nuts. If vibration continues,

have unit serviced by a Sears Parts & Repair Center.

Connect and tighten spark plug wire.1.

Remove ice and snow from gas cap. Be certain vent 2.

hole is clear.

Adjust drive control cable. Refer to Service and 1.

Maintenance section.

Replace drive belt. Refer to Service and Mainte-2.

nance section.

Change friction wheel.3.

Stop engine immediately and disconnect spark plug 1.

wire. Clean chute assembly and inside of auger

housing with clean-out tool or a stick.

Stop engine immediately and disconnect spark plug 2.

wire. Remove object from auger with clean-out tool

or a stick.

Adjust auger control cable. Refer to Assembly 3.

section.

Replace auger belt. Refer to Service and Mainte-4.

nance section.

Replace with new shear pin(s).5.

NEED MORE HELP?

managemyhome.com – for free!

Find this and all your other product manuals online.

Get answers from our team of home experts.

Get a personalized maintenance plan for your home.

Find information and tools to help with home projects.

25

Page 26

Craftsman Snow Thrower Model 247.88955

11

54

55

9

PARTS LIST

1

18

4

4

13

3

6

25

23

28

12

16

8

26

9

24

20

15

17

7

5

14

30

37

39

50

53

46

43

38

5

56

2

7

7

36

35

48

52

42

51

41

44

31

47

33

40

49

45

33

31

33

21

29

34

919

26

10

33

32

22

Page 27

Craftsman Snow Thrower Model 247.88955

PARTS LIST

Ref. No. Part No. Description

1. 731-2635 Snow Removal Tool Mount

2. 684-04057A Impeller Assembly, 12” Dia.

3. 710-0347 Hex Screw, 3/8-16, 1.75, Gr5

4. 710-0451 Bolt, Carriage, 5/16-18, .750 Gr1

5. 710-04484 Screw, 5/16-18, 0.750

6. 710-0703 Screw, Carriage, 1/4-20, .750, Gr5

7. 712-04063 Nut, Flange Lock, 5/16-18, Nylon

8. 712-04064 Nut, Flange Lock, 1/4-20, Nylon

9. 712-04065 Nut, Flange Lock, 3/8-16, Nylon

10. 714-04040 Cotter Pin, Bow-tie

11. 725-0157 Cable, Tie, 3/16 x .05 x 7.4

12. 726-04012 Nut, Push-on, .25 Dia

13. 731-04705 Chute, Adapter 5” Dia

14. 732-04460 Spring, Extension, .38 OD x 4.59

15. 736-0174 Washer, Wave, .625 x .885 x .015

16. 736-0242 Washer, Bell, .340 x .872 x .060

17. 746-04230 Clutch Cable, Auger, 47.23”

18. 731-2643 Snow Removal Tool

19. 738-0143 Screw, Shoulder, .498 x .34, 3/8-16

20. 738-0281 Screw, Shoulder, .625 x .17, 3/8-16

21. 738-04124A Shear Pin, .25 x 1.50

22. 741-0245 Bearing, Hex Flange x .75 ID

23. 741-0309 Bearing, Ball, .75 ID x 1.85 OD

24. 756-0981B Flat Pulley, Idler, 2.75 OD

25. 790-00075 Housing, Bearing, 1.85 ID

26. 790-00080A Bracket, Auger Idler w/ Brake

2 7. 618-04171A Gearbox Assembly, Auger, 24”

28. 684-04265 Housing Assembly, Auger 24”

Ref. No. Part No. Description

29. 684-04107 Spiral Assembly, LH

30. 684-04108 Spiral Assembly, RH

31. 731-04870 Spacer, 1.25 OD x .75 ID x 1.00

32. 736-0188 Washer, Flat, .76 x 1.49 x .06

33. 741-0493A Bushing, Flange, .80 ID x .91 OD

34. 790-00087A Housing, 1” Hex Bearing

35. 790-00120 Shave Plate, 2.25 x 23.66

36. 731-06439 Slide Shoe

3 7. 618-0123A Housing, Auger, RH

38. 618- 0124A Housing, Auger, LH

39. 721- 0338 Seal, Oil, .750 x 1.00 x .125

40. 741-0662 Bearing, Flange, .75 x 1.0 x .59

41. 710-0642 Screw, Self-tapping, 1/4-20, 0.750

42. 711 -0 428 5 Axle, Auger, 24”

43. 714-0161 Key, Hi-pro 3/16 x 5/8

44. 715-04021 Pin, Dowel, .25 OD x 1.2

45. 717- 04126 Shaft, Worm .75 OD

46. 717-04449 Gear, Worm 20T

47. 718-04071 Collar, Thrust

48. 721-0325 Plug, 1/4 x .437

49. 721-0327 Seal, Oil, .75 x 1 x .131

50. 736-0351 Washer, Flat, .760 ID x 1.5 OD

51. 736-3084 Washer, Flat, .51 x 1.12

52. 741-0663 Bearing, Flange, .75 x 1.0 x .925

53. 741- 06 61A Bearing, Flange, .75 x 1.00 x .975

54. 629-0071 Extension Cord, 110V

55. 710-0276 Screw, Carriage, 5/16-18 x 1.00

56. 736- 0159 Washer, Flat, .349 x .879 x .063

27

Page 28

Craftsman Snow Thrower Model 247.88955

15

PARTS LIST

4

41

26

13

36

10

11

23

31

12

16

3

9

6

6

1

29

30

15

18

21

8

44

12

28

7

19

25

24

12

35

17

32

34

20

5

20

27

33

39

12

38

42

37

22

14

43

40

28

Page 29

Craftsman Snow Thrower Model 247.88955

PARTS LIST

Ref. No. Part No. Description

1. 631- 04133A Handle Assembly, Clutch Lock, LH

2. 631- 04134B Handle Assembly, Clutch Lock, RH

3. 684-04105B Handle Ass’y, Engage, Black, LH

4. 684-04106B Handle Ass’y, Engage, Black, RH

5. 631-04131B Chute Assembly (Includes Ref. # 27)

6. 712- 04064 Nut, Flglk, 1/4-20

7. 714-0145 Click Pin

8. 710-0136 Screw, 1/4-20, 1.75, Gr5

9. 790-00219 Panel, Handle, (no cutout)

10. 710 -123 3 Screw, Machine, #10-24, 1.375

11. 731-06471 Handle Panel Cover

12. 712-04063 Nut, Flange Lock, 5/16-18, Nylon

13. 749- 0419 0A Handle, Upper, RH

14. 736-0185 Washer, Flat, .375 x .738 x .063

15. 720-0274 Grip, 1.0 ID x 5.0

16. 720-04039 Knob, Shift, Black

17. 735-0234 Grommet, .44 ID x .94 OD x .50

18. 726-0100 Cap, Push, 3/8 Rod

19. 732-0193 Spring, .39 x .60 x .88

20. 720-0284 Knob, 5/16-18, Black

21. 720-0201A Crank Knob, 1.0 Dia. x 3.2, Black

22. 749-04138A Handle, Lower

Ref. No. Part No. Description

23. 735-0199A Bumper, Rubber, .62 OD x .22

24. 736-0262 Washer, Flat, .385 x .870 x .092

25. 738-04118 Bolt, Shoulder, 5/16-18 x 0.905

26. 738-04348 Screw, Shoulder, .43 x 1.3, 1/4-20

2 7. 731-04869 Chute, Flange Keeper

28. 746-04397 Cable, Speed Selector

29. 749-04191A Handle, Upper, LH

30. 747-04263 Eye Bolt, Chute Crank

31. 790-00313 Shift Lever

32. 731-04912B Chute, Lower, 5.0 Dia.

33. 710-0276 Bolt, Carriage, 5/16-18, 1.0

34. 710-04071 Bolt, Carriage, 5/16-18, 1.0

35. 710-0451 Bolt, Carriage, 5/16-18, .750

36. 731-04426A Chute, Upper, w/ Label

3 7. 736 -0159 Washer, .349 x .879 x .063

38. 741- 047 5 Bushing, Plastic, .380

39. 784-5647 Bracket, Chute Crank

40. 684-04104 Crank Assembly, Chute

41. 710-0449 Screw, Carriage, 5/16-18, 2.25

42. 710-04484 Screw, 5/16-18, 2.25, Gr5

43. 714-0104 Pin, Cotter, .072 x 1.13

44. 736-0463 Washer, Flat, .25 x .630 x .0515

29

Page 30

Craftsman Snow Thrower Model 247.88955

53

22

21

50

62

42

63

40

33

30

24

36

18

5

25

37

19

6

31

7

30

24

26

13

23

47

44

23

43

39

2

7

5

34

24 30

51

58

52

61

35

27

7

14

55

48

46

7

59

59

49

41

2

1

11

4

A

B

B

A

8

26

16

28

45

29

17

3

9

54

32

60

57

56

60

20

10

15

12

38

65

64

68

67

72

71

66

23

69

70

PARTS LIST

30

Page 31

Craftsman Snow Thrower Model 247.88955

PARTS LIST

Ref. No. Part No. Description

1. 656-04025A Disc Assembly, Friction Wheel

2. 684-04153 Friction Wheel Assembly, 5.5 OD

3. 684-04154 Support Bracket, Friction Wheel

4. 684-04156A Shift Assembly, Rod

5. 710-0627 Hex Screw, 5/16-24, .750, Gr5

6. 710-0788 Screw, 1/4-20, 1.000

7. 710 -1652 Screw, 1/4-20 x .625

8. 712-04065 Nut, Flange Lock, 3/8-16, Nylon

9. 712- 0417A Nut, Flange, 5/8-18

10. 714-0126 Key, Hi Pro, 3/16 x 3/4 Dia.

11. 716-0104 E-ring, .500 Dia.

12. 716-0136 E-ring, Retaining, .875 Dia.

13. 716-0231 E-ring, .750 Dia.

14. 717-04209A Hex Shaft, .8125, 7-Tooth

15. 717-04230 Gear, 80-Tooth

16. 726-0221 Speed Nut, .500

17. 732-0264 Extension Spring

18. 736-0242 Washer, Bell, .340 x .872 x .060

19. 736-0287 Washer, Flat, .793 x 1.24 x .060

20. 736-04161 Washer, Flat, .75 x 1.00 x .060

21. 790-00289A Plt., Cvr.

22. 748 -02 34 Shoulder Spacer

23. 738-04184A Screw, Shoulder, .37 x .105, 1/4-20

24. 738-0924A Screw, 1/4-28, .375

25. 741- 024 5 Bearing, Hex Flange x .75 ID

26. 741- 0563 Bearing, Ball, 17 x 40 x 12

2 7. 746-04229 Clutch Cable, Wheel, 44.95”

28. 735-04054 Rubber, Friction Wheel, 5.5 OD

29. 748-0190 Spacer, .508 ID x .75 OD x .68

30. 756-0625 Roller, Cable

31. 790-00096 Front Guide Bracket, Auger Cable

32. 790-00180A Frame

33. 790-00206A Guide Bracket, Auger Cable

34. 790-00207A Guide Bracket, Drive Cable

35. 790-00316 Cover, Frame

36. 634-04167A LH Wheel Assembly

634-04168A RH Wheel Assembly

Ref. No. Part No. Description

3 7. 731-04873 Spacer, 1.25 x .75 x 3.0

38. 738-04168 Axle, .75 x 22”

39. 729-04035 Conn., Amp

40. 710-0809 Hex Screw, 1/4-20, 1.25, Gr5

41. 710-0191 Hex Screw, 3/8-24, 1.25, Gr8

42. 710-0672 Hex Screw, 5/16-24, 1.25, Gr5

43. 710-0654A Screw, Sems, 3/8-16, 1.00

44. 710-124 5B Hex Screw, 5/16-24, .875, Gr8

45. 710-0896 Screw, 1/4-20 x .625

46. 726-04012 Nut, Push-on, .25 Dia.

47. 731-04792A Cover, Belt

48. 732-04308A Spring, Torsion, .850 ID x .354

49. 736-0247 Washer, Flat, .406 x 1.25 x .157

50. 73 6- 011 9 Washer, Lock .3125

51. 736-0505 Washer, Flat, .34 x 1.50 x .150

52. 748 -04 05 3A Pulley, Adapter, .75 Dia.

53. 74 8- 0 4112 A Spacer, Shoulder, .317 x .50 x .102

54. 750-04303 Spacer, .875 ID x 1.185 OD

55. 750-04477 Spacer, .340 x .750 x .360

56. 754-04050 Belt, Auger Drive

5 7. 754-0367 Belt, Wheel Drive

58. 756-04109 Pulley, Auger Drive, 8.1 x .5

59. 756 -0 4113 Pulley, Half, V x 2.600 OD

60. 756-04252 Pulley, Half, 3/8-V x 1.7160 OD

61. 790-00208C Idler Bracket, Wheel Drive

62. 684-04169 Idler Pulley Assembly

63. 750-04571 Spacer, Shoulder, .26 x .79 x .538

64. 735-04099 Plug, 3/8 ID

65. 73 5- 04100 Plug, 1/2 ID

66. 712-04064 Nut, Flange Lock, 1/4-20, Nylon

6 7. 710-0751 Hex Screw, 1/4-20, .620, Gr5

68. 73 2- 0 43 11 Spring, Torsion, .750 ID x .968

69. 712-04063 Nut, Flange Lock, 5/16-18, Nylon

70. 736-3015 Wash., Flat, .469 x .875 x .105

71. 790-00217A Pivot Bracket, Speed Selector

72. 790-00218A Shift Bracket, Speed Selector

31

Page 32

PARTS LIST

Craftsman Engine Model ZS365-SUA For Snow Thrower Model 247.88955

32

Page 33

PARTS LIST

Craftsman Engine Model ZS365-SUA For Snow Thrower Model 247.88955

Part No. Description Ref. No.

751-10645A Electric Starter 84

751-10646 Ignition Coil 22

751-10663 A Fan Cover 112

751-10658 Recoil Starter Assembly 121

751-10654 Governor Spring 77

751-10664 Throttle Return Spring 78

751-10665 Governor Rod 79

751-10655 Dipstick 107

751-10656 Dipstick Tube 108

751-10662 Cover - Engine/Dipstick 110

751-10652 Fuel Filter 113

751-10653 A Fuel Tank 115

751-10642A Muffler Shroud 37

751-10666 Muffler Gasket 59

751-1029 2 Spark Plug 58

751-10639 Primer 64

751-10 974 Carburetor Assembly 65

751-10635 Air Filter Heating Pipe Cover 69

751-10637 Ignition Switch 70

731-05632 Ignition Key 71

751-10636 Choke Knob 73

751-10634 Engine Shroud 72

751-10643 Muffler Shield 40

751-10640 Choke Push Rod 66

751-10651 Fuel Tank Nipple 116

751-10307 Flywheel Key 149

731-05696 Starter Handle N/A

752Z365- Engine Complete N/A

SUA

751-10719 Stator 28

75 1-10911 Starter Cup 32

751-10909 Cooling Fan 31

751-10805 Flywheel 30

751-10757 Throttle Control Knob 82

751-10758 Throttle Control Assembly 81

Part No. Description Ref. No.

751-10723 Gasket Kit Complete

Oil Seal 4

Crankcase Cover Gasket 10

O-Ring 15

Oil Seal 21

Cylinder Head Gasket 55

Muffler Gasket 59

Valve Cover Gasket 47

Carburetor Insulator Gasket 61

Carburetor Insulator 62

Carburetor Gasket 63

Paper Gasket 42

Oil Drain Washer 19

751-10661 Gasket Kit External

Oil Drain Washer 19

Muffler Gasket 59

Carburetor Insulator Gasket 61

Carburetor Insulator 62

Carburetor Gasket 63

Valve Cover Gasket 47

751-1072 2 Cylinder Head Assembly

Rocker Arm 51

Intake Valve 103

Exhaust Valve 98

Valve Spring 100

Valve Spring Retainers - Exhaust 101

Valve Adjusting Nut 52

Pivot Locking Nut 53

Pivot Bolt 50

Push Rod Guide Plate 49

Valve Cover Gasket 47

Carburetor Insulator Gasket 61

Carburetor Insulator 62

Muffler Gasket 59

Cylinder Head Gasket 55

Cylinder Head 54

Exhaust Valve Adjuster 102

Valve Spring Retainer- Intake 104

Valve Seal 99

33

Page 34

PARTS LIST

Craftsman Engine Model ZS365-SUA For Snow Thrower Model 247.88955

Part No. Description Ref. No.

751-10724 Short Block Assembly

Crankcase Complete 17

Oil Pipe Reserve N/A

Crankcase Cover 5

Piston 93

Piston Ring Assembly 95

Piston Pin 94

Piston Pin Clip 92

Connecting Rod Assembly 91

Tappet 96

Camshaft Assembly 7

Carburetor Insulator Gasket 61

Crankshaft Complete 11

Carburetor Insulator 62

Muffler Gasket 59

Governor Arm 16

Lock Pin 14

Governor Kit 12

Crankcase Cover Gasket 10

Cylinder Head Gasket 55

Oil Drain Bolt 20

Oil Drain Plug Washer 19

Dowel Pin 9

Dowel Pin 8

Dowel Pin 56

Radial Ball Bearing 13

Bolt 1

Oil Seal 4

O-Ring - Governor Arm 15

Oil Filler Plug 2

O-Ring - Oil Filler Plug 3

Oil Drain Pipe 18

Radial Ball Bearing 6

Oil Seal 21

Part No. Description Ref. No.

751-10641 Oil Drain Assembly

Oil Drain Pipe 18

Drain Bolt 20

751-10647 Valve Kit

Exhaust Valve 98

Intake Valve 103

751-10648 Push Rod Kit

Push Rod 97

751-10649 Fuel Cap Assembly

Fuel Cap Complete 111

Packing ( Gasket ) N/A

Clip ( Gasket Retainer ) N/A

751-10650 Fuel Line Kit

Fuel Line Clamp 117

Fuel Line 118

751-10657 Muffler Stud Assembly

Muffler Stud 57

751-10669 Oil Fill Plug Assembly

Oil Fill Plug 2

O-Ring 3

751-10644 Muffler Assembly Complete

Muffler Assembly 41

Exhaust Pipe 43

34

Page 35

MTD CONSUMER GROUP (MTD) and the United States Environment Protection Agency (U. S. EPA)

Emission Control System Warranty Statement

(Owner’s Defect Warranty Rights and Obligations)

The U. S. EPA and MTD are pleased to explain the emissions control system warranty on your model year 2005 and later small off-road engine.

New small off-road engines must be designed, built and equipped to meet the stringent anti-smog standards. MTD must warranty the emission

control system on your engine for the period of time listed below, provided there has been no abuse, neglect or improper maintenance of your small

off-road engine.

Your emission control system may include parts such as the carburetor, air cleaner, ignition system, exhaust system, and other associated emission-related components.

Where a warrantable condition exists, MTD will repair your small off-road engine at no cost to your including diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

This emissions control system is warranted for two years. If any emission-related part on your engine is defective, the part will be repaired or

replaced by MTD.

OWNER’S WARRANTY RESPONSIBILITIES:

As the small off-road engine owner, you are responsible for the performance of the required maintenance listed in your Owner’s Manual. MTD

recommends that you retain all your receipts covering maintenances on your small off-road engine, but MTD can not deny warranty solely for the

lack of receipts or for your failure to ensure the performance to all scheduled maintenance.

As the small off-road engine owner, you should however be aware that MTD may deny your warranty coverage if your small off-road engine or part

has failed due to abuse, neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your small off-road engine to an Authorized MTD Service Dealer as soon as a problem exists. The warranted

repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should contact a MTD Service Representative at 1-800-800-7310

and address is MTD LLC, P.O. Box 361131, Cleveland OH, 44136-0019.

DEFECTS WARRANTY REQUIREMENTS FOR 1995 AND LATER SMALL OFF-ROAD ENGINES:

This section applies to 1995 and later small off-road engines. The warranty period begins on the date the engine or equipment is delivered to an

ultimate purchaser.

(a) General Emissions Warranty Coverage

MTD must warrant to the ultimate purchaser and each subsequent purchaser that the engine is:

(1) Designed, built, and equipped so as to conform with all applicable regulations adopted by the Air Resources Board pursuant to its authority in

Chapters 1 and 2,Part 5, Division 26 of the Health and Safety Code; and