Page 1

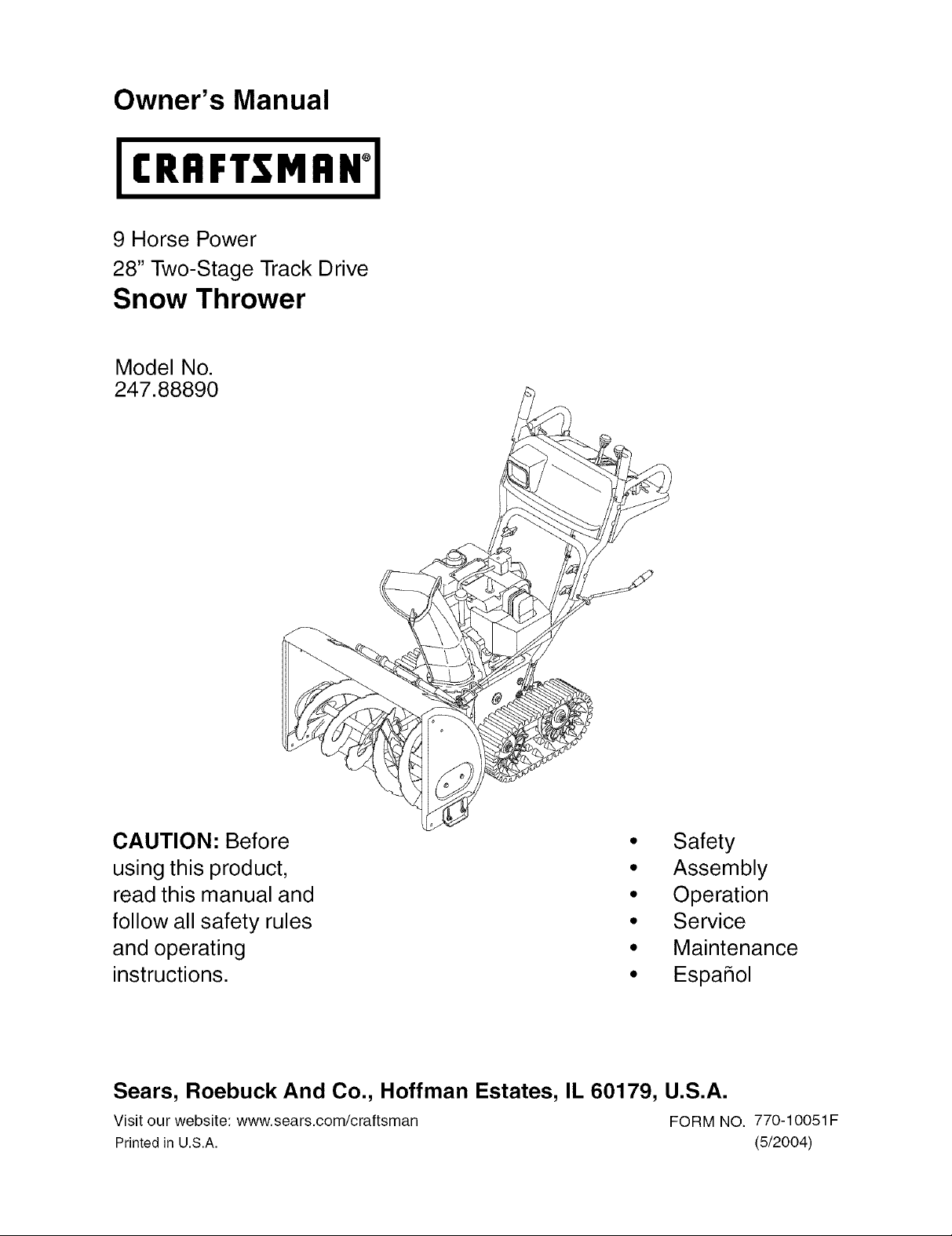

Owner's Manual

9 Horse Power

28" Two-Stage Track Drive

Snow Thrower

Model No.

247.88890

CAUTION: Before

using this product,

read this manual and

follow all safety rules

and operating

instructions.

Sears, Roebuck And Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.sears.com/craftsman FORM NO. 770-10051 F

Printed in U.S.A. (5/2004)

Safety

Assembly

Operation

Service

Maintenance

EspaRol

Page 2

Content Page

Warranty Information .................................... 2

Safe Operation Practices .............................. 3

Assembly ...................................................... 5

Operation ...................................................... 8

Maintenance ................................................. 13

Content Page

Service & Adjustment ....................................... 15

Off-Season Storage ......................................... 19

Trouble-Shooting ............................................. 20

Parts List ......................................................... 22

Espan61 ......................................................... 38

Two -Year Warranty on Craftsman Snow Thrower

For two years from the date of purchase, when this Craftsman Snow Thrower is maintained, lubricated and tuned up according to the instruc-

tions in the owner's manual, Sears will repair, free of charge, any defect in material and workmanship.

If this Craftsman snow thrower is used for commercial or rental purposes, this warranty applies for only 30 days from the date of purchase.

This warranty does not cover:

Expendable items which become worn during normal use, such as skid shoes, shave plate and spark plugs.

Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to maintain the equipment

according to the instructions contained in the owner's manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW THROWER TO THE NEAREST SEARS PARTS & REPAIR

CENTER IN THE UNITED STATES.

This warranty applies only while this product is in use in the United States.

This warranty gives you specific legal rights and you may also have other rights which may vary from state to state.

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES, IL 60179

Repair Protection Agreements

Congratulations on making a smart purchase.Your new Craftsman®

product is designed and manufactured for years of dependable

operation. But like all products, it may require repair from time to

time. That's when having a Repair Protection Agreement can save

you money and aggravation.

Here's what's included in the Agreement:

Expert service by our 12,000 professional repair

_t specialists

Unlimited service and no charge for parts and labor on

all covered repairs

Product replacement ifyour covered product can't be

@P fixed

Discount of 10% from regular price of service and service-

related parts not covered by the agreement; also, 10% off

regular price of preventive maintenance check

Fast help by phone - phone support from a Sears

technician on products requiring in-home repair, plus

convenient repair scheduling

Purchase a Repair Protection Agreement now and protect yourself

from unexpected hassle and expense.

Once you purchase the Agreement, a simple phone call is all that it

takes for you to schedule service. You can call anytime day or night,

or schedule a service appointment online. Sears has over 12,000

professional repair specialists, who have access to over 4.5 million

quality parts and accessories. That's the kind of professionalism you

can count on to help prolong the life of your new purchase for years

to come. Purchase your Repair Protection Agreement today!

Some limitations and exclusions apply. For prices and additional

information call 1-800-827-6655.

Sears Installation Service

For Sears professional installation of home appliances, garage door

openers, water heaters, and other major home items, inthe U.S.A.

call 1-800-4-MY-HOME®.

Horsepower: 9

Engine Oil: SAE 5W30 Capacity: 26 oz.

Fuel: Unleaded Regular Capacity:

Spark Plug: RJ19LM

Eng ne: Tecumseh Mode LH318-156569

Model Number

Serial Number ...........................................................

Date of Purchase ......................................................

Record both serial number and date of purchase and keep in a

safe place for future reference.

Page 3

_, ARNING: This symbol points out important safety instructions which, if not followed, could endangerthe personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with these instructions may result in personal

injury. When you see this symbol--heed its warning.

_L ARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain or emitchemicals known to State of California to cause cancer and birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this manual. As with

any type of power equipment, carelessness or error on the part of the operator can result in serious injury. This

machine is capable of amputating hands and feet and throwing objects. Failure to observe the following safety

instructions could result in serious injury or death,

Training

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place

for future and regular reference and for ordering

replacement parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years old to operate this

machine. Children 14 years old and over should read and

understand the operation instructions and safety rules in

this manual and should be trained and supervised by a

parent.

4. Never allow adults to operate this machine without proper

instruction.

5. Thrown objects can cause serious personal injury. Plan

your snow-throwing pattern to avoid discharge of material

toward roads, bystanders and the like.

6. Keep bystanders, helpers, pets and children at least 75

feet from the machine while it is in operation. Stop

machine if anyone enters the area.

7. Exercise caution to avoid slipping or falling, especially

when operating in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is to be

used. Remove all doormats, newspapers, sleds, boards,

wires and other foreign objects, which could be tripped

over or thrown by the auger/impeller.

2. Always wear safety glasses or eye shields during

operation and while performing an adjustment or repair to

protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

3. Do not operate without wearing adequate winter outer

garments. Do not wear jewelry, long scarves or other

loose clothing, which could become entangled in moving

parts. Wear footwear which will improve footing on

slippery surfaces.

4. Use a grounded three-wire extension cord and

receptacle for all units with electric start engines.

5. Adjust collector housing height to clear gravel or crushed

rock surfaces.

6. Disengage all control levers before starting the engine.

7. Never attempt to make any adjustments while engine is

running, except where specifically recommended in the

operator's manual.

8. Let engine and machine adjust to outdoor temperature

before starting to clear snow.

9. To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes, which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes before

refueling.

f. Never over fill fuel tank. FIll tank to no more than Yz

inch below bottom of filler neck to provide space

for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe itoff the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

(e.g. furnace, water heater, space heater, clothes

dryer etc.).

j. Allow machine to cool at least 5 minutes before

storing.

Operation

1. Do not put hands or feet near rotating parts, in the auger/

impeller housing or chute assembly. Contact with the

rotating parts can amputate hands and feet.

2. The auger/impeller control lever is a safety device. Never

bypass its operation. Doing so makes the machine

unsafe and may cause personal injury.

3. The control levers must operate easily in both directions

and automatically return to the disengaged position when

released.

Page 4

4. Neveroperatewithamissingordamagedchute

assembly.Keepallsafetydevicesinplaceandworking.

5. Neverrunanengineindoorsorinapoorlyventilated

area.Engineexhaustcontainscarbonmonoxide,an

odorlessanddeadlygas.

6. Donotoperatemachinewhileundertheinfluenceof

alcoholordrugs.

7. Mufflerandenginebecomehotandcancauseaburn.Do

nottouch.

8. Exerciseextremecautionwhenoperatingonorcrossing

gravelsurfaces.Stayalertforhiddenhazardsortraffic.

9. Exercisecautionwhenchangingdirectionandwhile

operatingonslopes.

10.Planyoursnow-throwingpatterntoavoiddischarge

towardswindows,walls,carsetc.Thus,avoiding

possiblepropertydamageorpersonalinjurycausedbya

ricochet.

11.Neverdirectdischargeatchildren,bystandersandpets

orallowanyoneinfrontofthemachine.

12.Donotoverloadmachinecapacitybyattemptingtoclear

snowattoofastofarate.

13.Neveroperatethismachinewithoutgoodvisibilityor

light.Alwaysbesureofyourfootingandkeepafirmhold

onthehandles.Walk,neverrun.

14.Disengagepowertotheauger/impellerwhen

transportingornotinuse.

15.Neveroperatemachineathightransportspeedson

slipperysurfaces.Lookdownandbehindandusecare

whenbackingup.

16.Ifthemachineshouldstarttovibrateabnormally,stopthe

engine,disconnectthesparkplugwireandgroundit

againsttheengine.Inspectthoroughlyfordamage.

Repairanydamagebeforestartingandoperating.

17.Disengageallcontrolleversandstopenginebeforeyou

leavetheoperatingposition(behindthehandles).Wait

untiltheauger/impellercomestoacompletestopbefore

uncloggingthechuteassembly,makinganyadjustments,

orinspections.

18.Neverputyourhandinthedischargeorcollector

openings.Alwaysusetheclean-outtoolprovidedto

unclogthedischargeopening.Donotunclogchute

assemblywhileengineisrunning.Shutoffengineand

remainbehindhandlesuntilallmovingpartshave

stoppedbeforeunclogging.

19.Useonlyattachmentsandaccessoriesapprovedbythe

manufacturer(e.g.wheelweights,tirechains,cabsetc.).

20.Ifsituationsoccurwhicharenotcoveredinthismanual,

usecareandgoodjudgment.Contactyourdealerorcall

1-800-800-7310forassistanceandthenameofyour

nearestservicingdealer.

Maintenance & Storage

1. Never tamper with safety devices. Check their proper

operation regularly. Refer to the maintenance and

adjustment sections of this manual.

2. Before cleaning, repairing, or inspecting machine

disengage all control levers and stop the engine. Wait

until the auger/impeller come to a complete stop.

Disconnect the spark plug wire and ground against the

engine to prevent unintended starting.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Do not change the engine governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

5. Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently

check all components and replace with original

equipment manufacturer's (OEM) parts only. "Use of

parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety!"

6. Check controls periodically to verify they engage and

disengage properly and adjust, if necessary. Refer to the

adjustment section in this operator's manual for

instructions.

7. Maintain or replace safety and instruction labels, as

necessary.

8. Observe proper disposal laws and regulations for gas,

oil, etc. to protect the environment.

9. Prior to storing, run machine a few minutes to clear snow

from machine and prevent freeze up of auger/impeller.

10. Never store the machine or fuel container inside where

there isan open flame, spark or pilot light such as a water

heater, furnace, clothes dryer etc.

11. Always refer to the operator's manual for proper

instructions on off-season storage.

Your Responsibility

Restrict the use of this power machine to persons who

read, understand and follow the warnings and

instructions in this manual and on the machine.

Do not modify engine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a

runaway engine and cause it to operate at unsafe speeds.

Never tamper with factory setting of engine governor.

Notice regarding Emissions

Engines which are certified to comply with California and

federal EPA emission regulations for SORE (Small Off Road

Equipment) are certified to operate on regular unleaded

gasoline, and may include the following emission control

systems: Engine Modification (EM) and Three Way Catalyst

(TWC) if so equipped.

Page 5

Unpacking

1. Remove screws/staples from top sides and ends of

the shipping crate. Set panel aside to avoid tire

punctures or personal injury.

2. Remove and discard plastic bag that covers unit.

3. Remove any loose parts includedwith unit (i.e.,

Operator's Manual, Engine Manual, etc.).

4. Roll unit out of crate.

5. Cut cable tie holding the chute directional control to

the discharge chute.

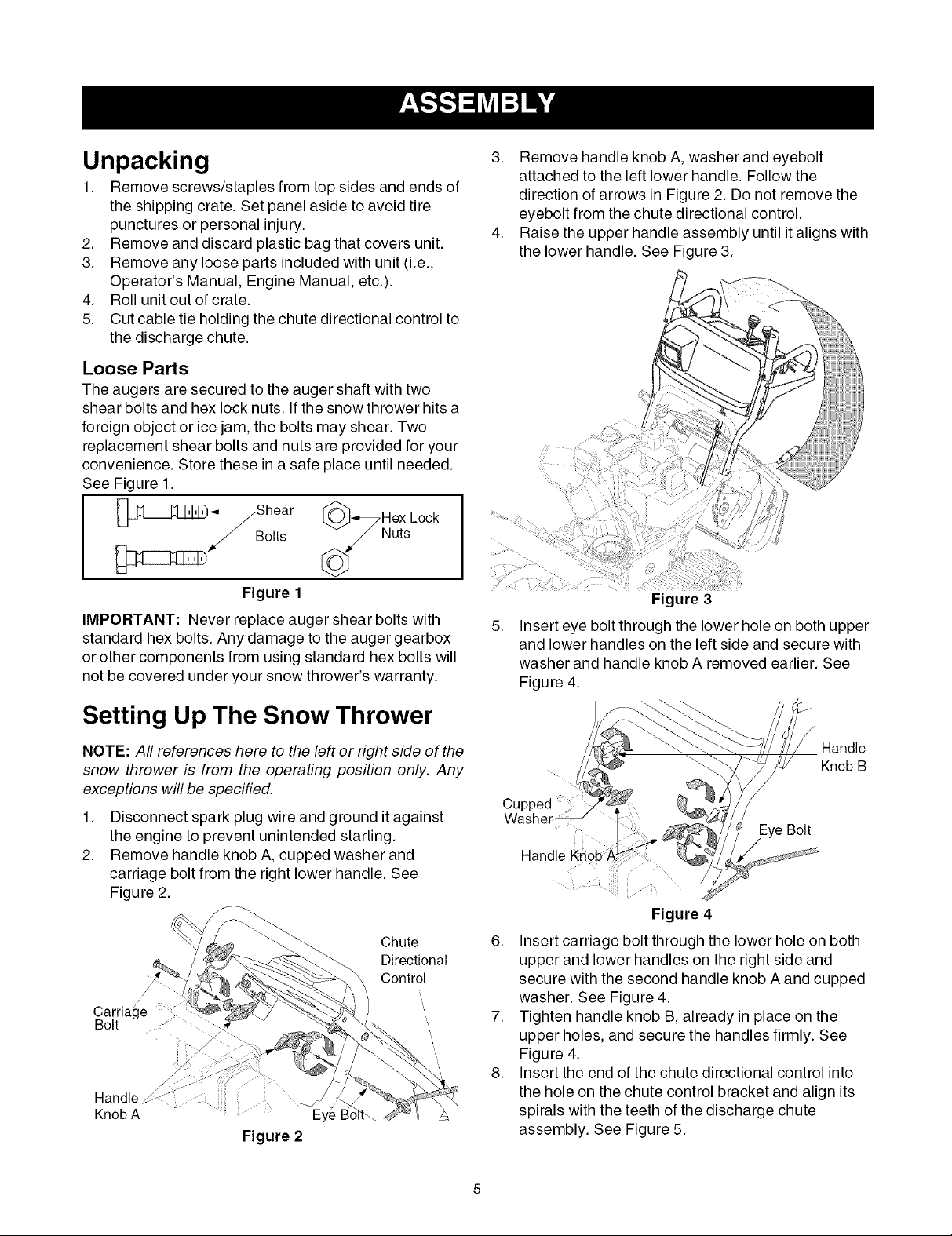

Loose Parts

The augers are secured to the auger shaft with two

shear bolts and hex lock nuts. If the snow thrower hits a

foreign object or ice jam, the bolts may shear. Two

replacement shear bolts and nuts are provided for your

convenience. Store these in a safe place until needed.

See Figure 1.

__Shear _HetXsLOC k

S °'ts

3. Remove handle knob A, washer and eyebolt

attached to the left lower handle. Follow the

direction of arrows in Figure 2. Do not remove the

eyebolt from the chute directional control.

4. Raise the upper handle assembly until it aligns with

the lower handle. See Figure 3.

Figure 1

IMPORTANT: Never replace auger shear Dolts with

standard hex bolts. Any damage to the auger gearbox

or other components from using standard hex bolts will

not be covered under your snow thrower's warranty.

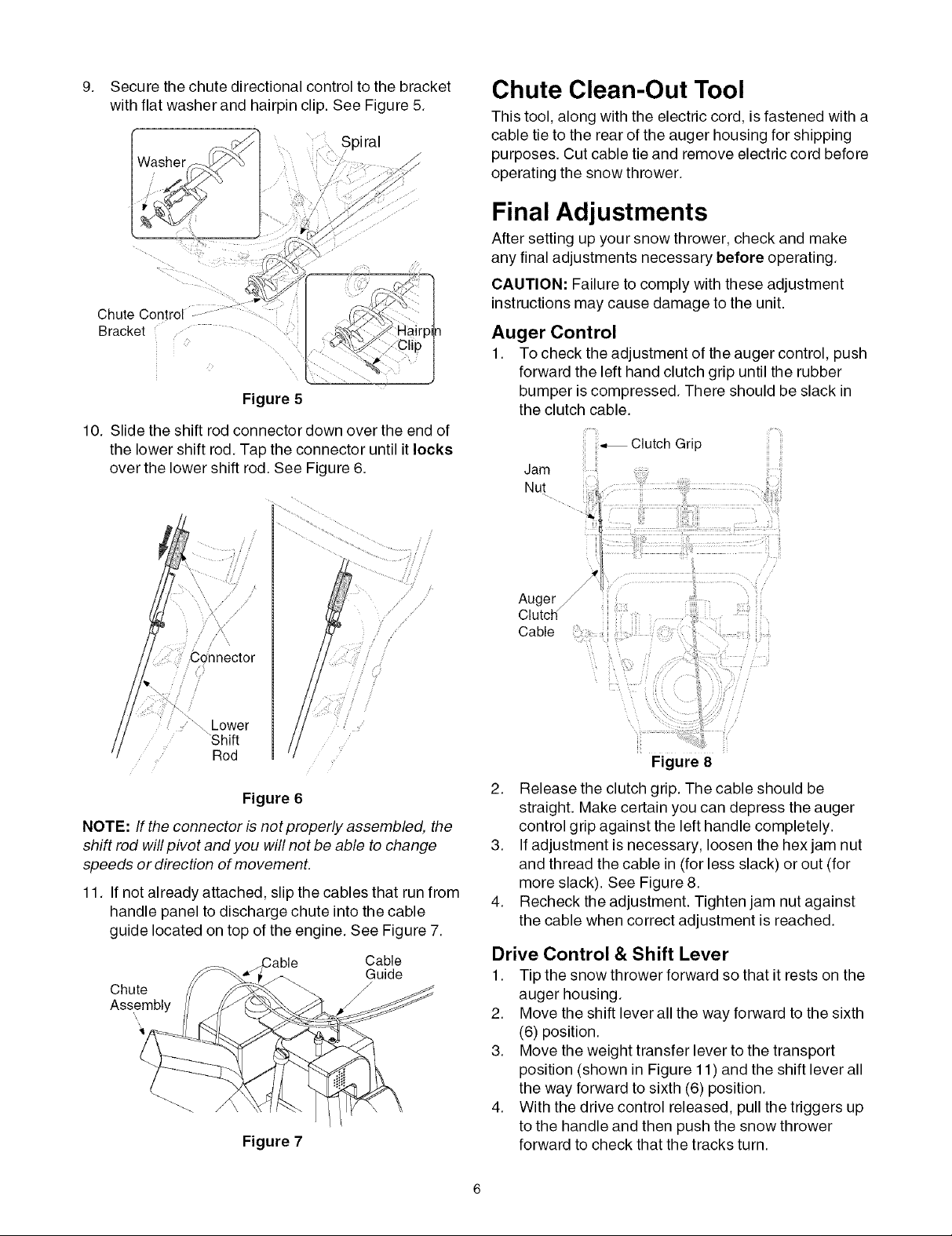

Setting Up The Snow Thrower

NOTE: All references here to the left or right side of the

snow thrower is from the operating position only. Any

exceptions will be specified.

1. Disconnect spark plug wire and ground it against

the engine to prevent unintended starting.

2. Remove handle knob A, cupped washer and

carriage bolt from the right lower handle. See

Figure 2.

Chute

Directional

Control

Handle

Knob A

/

Eye

Figure 2

Figure 3

Insert eye bolt through the lower hole on both upper

and lower handles on the left side and secure with

washer and handle knob A removed earlier. See

Figure 4.

f

Handle

Knob B

Cupped

Handle K_o

Figure 4

6. Insert carriage bolt through the lower hole on both

upper and lower handles on the right side and

secure with the second handle knob A and cupped

washer. See Figure 4.

7. Tighten handle knob B, already in place on the

upper holes, and secure the handles firmly. See

Figure 4.

8. Insert the end of the chute directional control into

the hole on the chute control bracket and align its

spirals with the teeth of the discharge chute

assembly. See Figure 5.

Page 6

9. Securethechutedirectionalcontroltothebracket

withflatwasherandhairpinclip.SeeFigure5.

Spiral

Chute Control

Bracket

Figure 5

10. Slide the shift rod connector down over the end of

the lower shift rod. Tap the connector until it locks

over the lower shift rod. See Figure 6.

J

J

Chute Clean-Out Tool

This tool, along with the electric cord, is fastened with a

cable tie to the rear of the auger housing for shipping

purposes. Cut cable tie and remove electric cord before

operating the snow thrower.

Final Adjustments

After setting up your snow thrower, check and make

any final adjustments necessary before operating.

CAUTION: Failure to comply with these adjustment

instructions may cause damage to the unit.

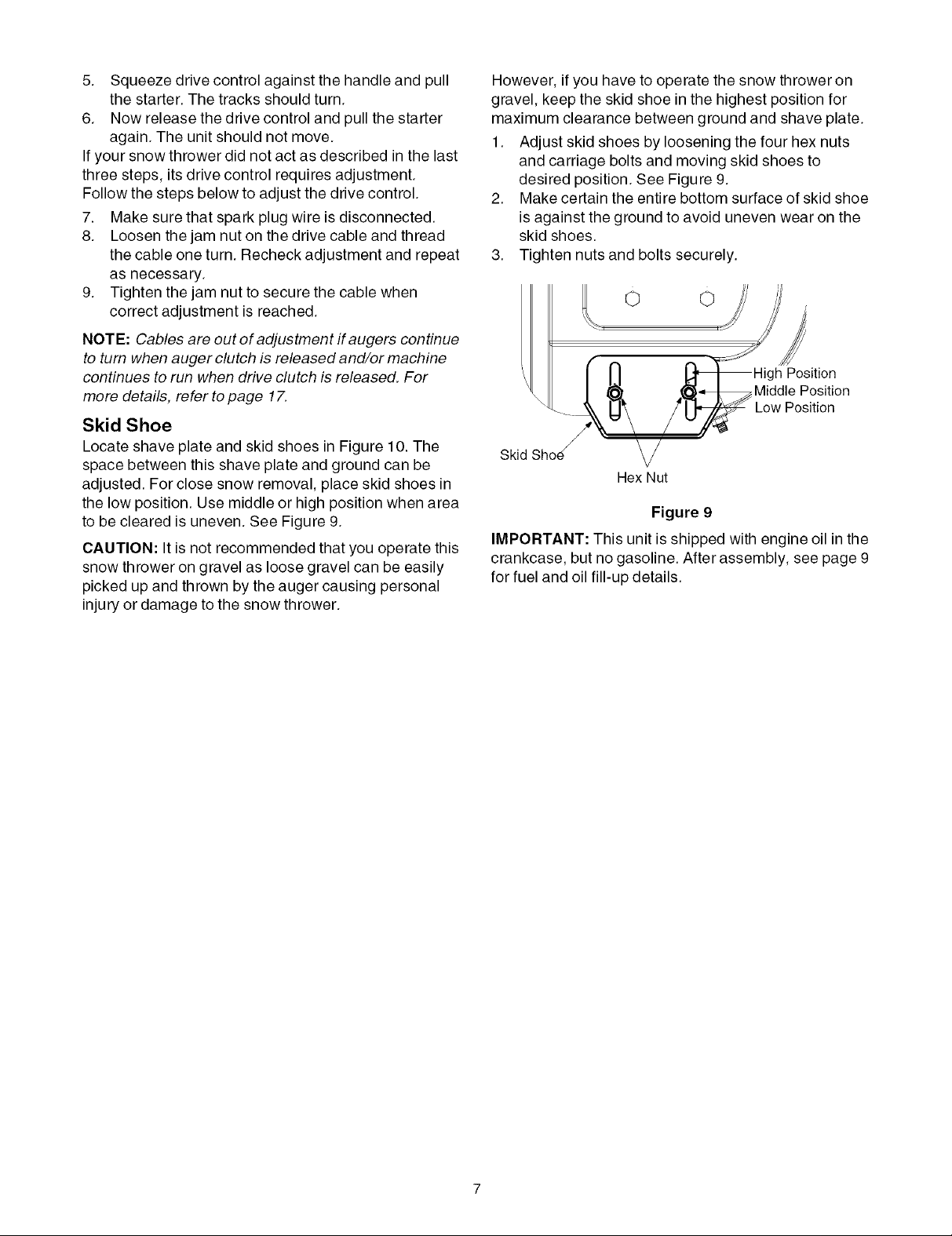

Auger Control

1. To check the adjustment of the auger control, push

forward the left hand clutch grip until the rubber

bumper is compressed. There should be slack in

the clutch cable.

Clutch Grip

Jam

Nut

",, Lower

"Shift

Rod

Figure 6

NOTE: If the connector is not properly assembled, the

shift rod willpivot and you will not be able to change

speeds or direction of movement.

11. If not already attached, slip the cables that run from

handle panel to discharge chute into the cable

guide located on top of the engine. See Figure 7.

Cable

Guide

Chute

Figure 7

Auger/

Clutch"

Cable

Figure 8

2. Release the clutch grip. The cable should be

straight. Make certain you can depress the auger

control grip against the left handle completely.

3. If adjustment is necessary, loosen the hex jam nut

and thread the cable in (for less slack) or out (for

more slack). See Figure 8.

4. Recheck the adjustment. Tighten jam nut against

the cable when correct adjustment is reached.

Drive Control & Shift Lever

1. Tip the snow thrower forward so that it rests on the

auger housing.

2. Move the shift lever all the way forward to the sixth

(6) position.

3. Move the weight transfer lever tothe transport

position (shown in Figure 11) and the shift lever all

the way forward to sixth (6) position.

4. With the drive control released, pull the triggers up

to the handle and then push the snow thrower

forward to check that the tracks turn.

Page 7

5. Squeezedrivecontrolagainstthehandleandpull

thestarter.Thetracksshouldturn.

6. Nowreleasethedrivecontrolandpullthestarter

again.Theunitshouldnotmove.

Ifyoursnowthrowerdidnotactasdescribedinthelast

threesteps,itsdrivecontrolrequiresadjustment.

Followthestepsbelowtoadjustthedrivecontrol.

7. Makesurethatsparkplugwireisdisconnected.

8. Loosenthejamnutonthedrivecableandthread

thecableoneturn.Recheckadjustmentandrepeat

asnecessary.

9. Tightenthejamnuttosecurethecablewhen

correctadjustmentisreached.

NOTE:Cables are out of adjustment if augers continue

to turn when auger clutch is released and/or machine

continues to run when drive clutch is released. For

more details, refer topage 17.

Skid Shoe

Locate shave plate and skid shoes in Figure 10. The

space between this shave plate and ground can be

adjusted. For close snow removal, place skid shoes in

the low position. Use middle or high position when area

to be cleared is uneven. See Figure 9.

CAUTION: It is not recommended that you operate this

snow thrower on gravel as loose gravel can be easily

picked up and thrown by the auger causing personal

injury or damage to the snow thrower.

However, if you have to operate the snow thrower on

gravel, keep the skid shoe in the highest position for

maximum clearance between ground and shave plate.

1. Adjust skid shoes by loosening the four hex nuts

and carriage bolts and moving skid shoes to

desired position. See Figure 9.

2. Make certain the entire bottom surface of skid shoe

is against the ground to avoid uneven wear on the

skid shoes.

3. Tighten nuts and bolts securely.

Position

Middle Position

Position

Skid Shoe//

Hex Nut

Figure 9

IMPORTANT: This unit is shipped with engine oil in the

crankcase, but no gasoline. After assembly, see page 9

for fuel and oil fill-up details.

Page 8

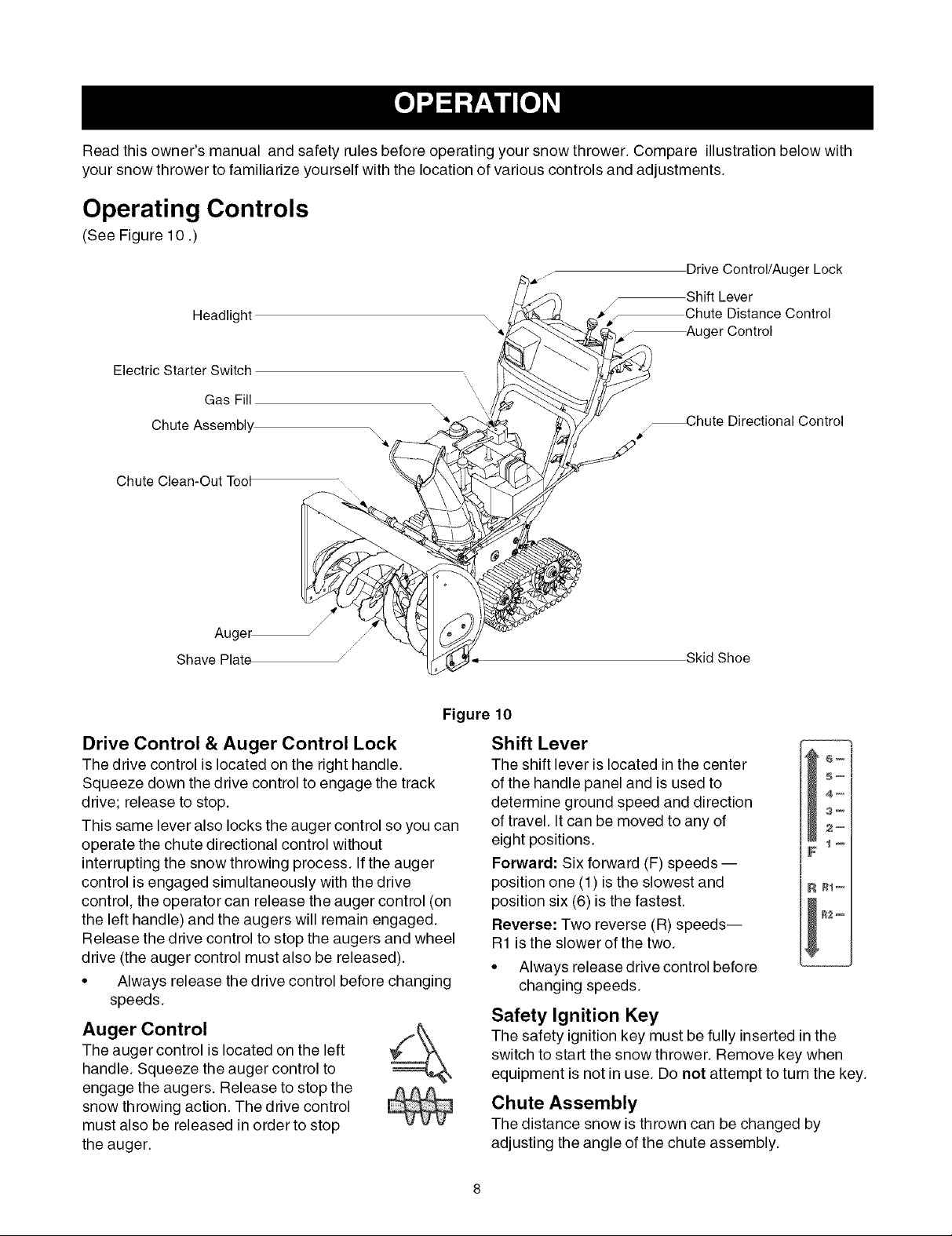

Readthisowner'smanualandsafetyrulesbeforeoperatingyoursnowthrower.Compareillustrationbelowwith

yoursnowthrowertofamiliarizeyourselfwiththelocationofvariouscontrolsandadjustments.

Operating Controls

(See Figure 10 .)

Headlight

Electric Starter Switch

Gas Fill

Chute Assembly

Chute Clean-Out Tool

Auger / ......

Shave Plate J

Figure 10

¢....

Drive Control/Auger Lock

Shift Lever

Chute Distance Control

Auger Control

--Chute Directional Control

Skid Shoe

Drive Control & Auger Control Lock

The drive control is located on the right handle.

Squeeze down the drive control to engage the track

drive; release to stop.

This same lever also locks the auger control so you can

operate the chute directional control without

interrupting the snow throwing process. Ifthe auger

control is engaged simultaneously with the drive

control, the operator can release the auger control (on

the left handle) and the augers will remain engaged.

Release the drive control to stop the augers and wheel

drive (the auger control must also be released).

• Always release the drive control before changing

speeds.

Auger Control

The auger control is located on the left

handle. Squeeze the auger control to

engage the augers. Release to stop the

snow throwing action. The drive control

must also be released in order to stop

the auger.

Shift Lever

The shift lever is located in the center 6-

of the handle panel and is used to 5,-

determine ground speed and direction

4,-

3_

of travel. It can be moved to any of 2,-

eight positions. _,=

Forward: Six forward (F) speeds-

position one (1) is the slowest and _,_

position six (6) is the fastest.

Reverse: Two reverse (R) speeds--

R1 is the slower of the two.

• Always release drive control before

changing speeds.

Safety Ignition Key

The safety ignition key must be fully inserted in the

switch to start the snow thrower. Remove key when

equipment is not in use. Do not attempt to turn the key.

Chute Assembly

The distance snow is thrown can be changed by

adjusting the angle of the chute assembly.

Page 9

Chute Distance Control

The chute distance control lever on

the handle panel adjusts the angle of

the chute. Move this lever forward to

decrease the distance and rearward

to increase the distance that snow is

thrown.

Packed Snow: Locks the front end of the snow thrower

down to the ground for hard-packed or icy snow

conditions.

Chute Directional Control

The chute directional control is

located on the left side of the snow

thrower. Use it to change the

direction in which snow is discharged

from the chute assembly. Avoid by-

standers, animals or cars and

CLOCKWmSE TO

DISCHARGE LEFT

COUNTER CLOCKWISE

TO DISCHARGE RIGHT

buildings by adjusting the direction of

discharge.

Chute Clean-Out Tool

The chute clean-out tool is designed to clear a clogged

discharge chute. Refer to page 12 for instructions on

how to properly use it.

,_ WARNING: Never use your hand to clear aclogged discharge chute. Shut off engine and

remain behind handles until all moving parts

have stopped before unclogging.

Headlight

The headlight is on whenever the engine is running.

Skid Shoe

The skid shoe position is determined by the condition of

the ground from where snow has to be removed. Higher

the snow level, lower will be the skid shoe level. Adjust

it accordingly.

Track Steering Controls

The left and right track steering _ /_/

controls are located on the underside

of the handles and they are used to

assist in steering the snow thrower.

Squeeze the right track control when turning right,

squeeze the left control when turning left. Operate your

snow thrower in open areas until you become familiar

with these controls.

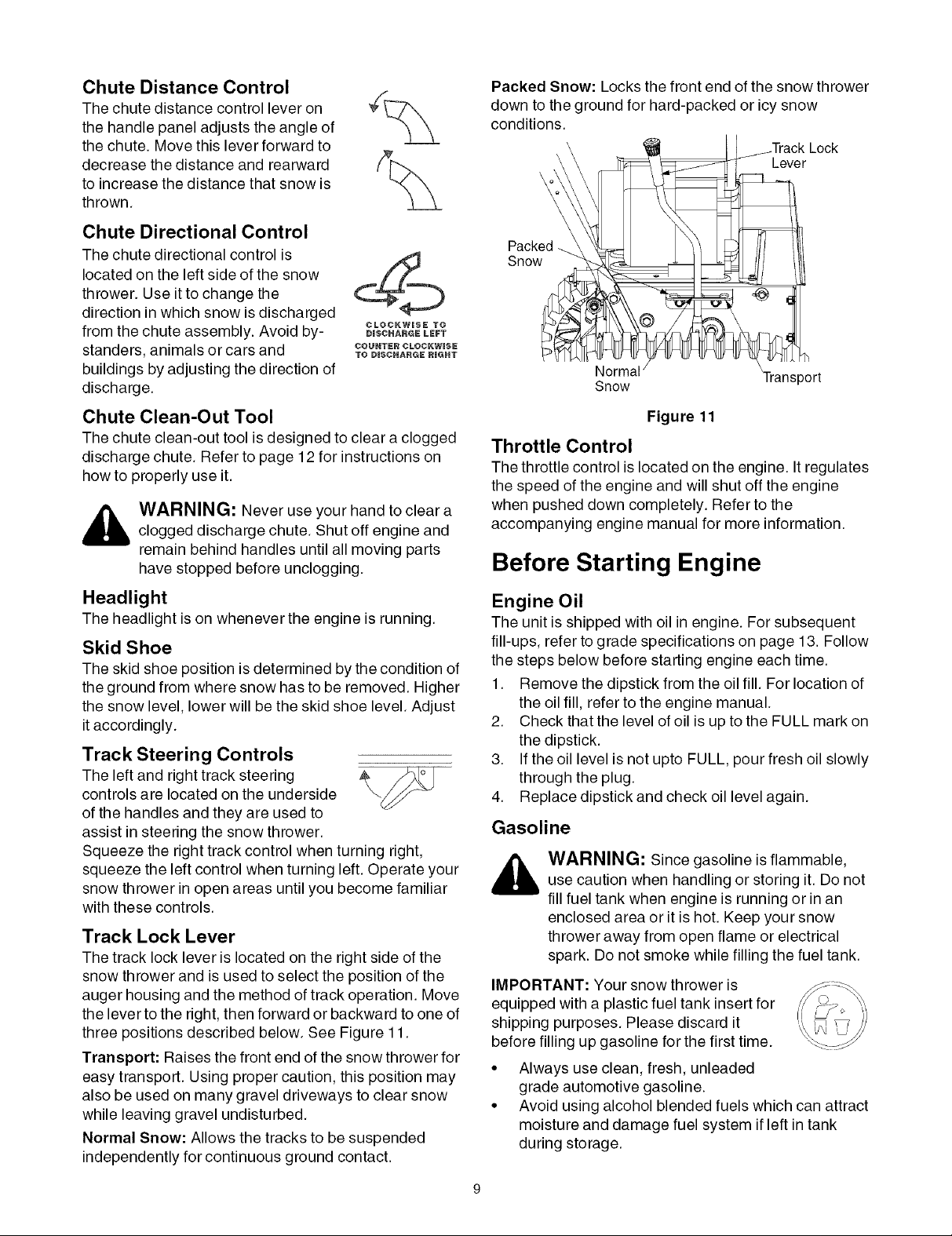

Track Lock Lever

The track lock lever is located on the right side of the

snow thrower and is used to select the position of the

auger housing and the method of track operation. Move

the lever to the right, then forward or backward to one of

three positions described below. See Figure 11.

Transport: Raises the front end of the snow thrower for

easy transport. Using proper caution, this position may

also be used on many gravel driveways to clear snow

while leaving gravel undisturbed.

Normal Snow: Allows the tracks to be suspended

independently for continuous ground contact.

Packed

Snow

Normal /

Snow

Figure 11

Throttle Control

The throttle control is located on the engine. Itregulates

the speed of the engine and will shut off the engine

when pushed down completely. Refer to the

accompanying engine manual for more information.

Before Starting Engine

Engine Oil

The unit is shipped with oil in engine. For subsequent

fill-ups, refer to grade specifications on page 13. Follow

the steps below before starting engine each time.

1. Remove the dipstick from the oilfill. For location of

the oil fill, refer to the engine manual.

2. Check that the level of oil is up to the FULL mark on

the dipstick.

3. If the oil level is not upto FULL, pour fresh oil slowly

through the plug.

4. Replace dipstick and check oil level again.

Gasoline

_ ARNING: Since gasoline is flammable,use caution when handling or storing it. Do not

fill fuel tank when engine is running or in an

enclosed area or it is hot. Keep your snow

thrower away from open flame or electrical

spark. Do not smoke while filling the fuel tank.

IMPORTANT: Your snow thrower is

equipped with a plastic fuel tank insert for

shipping purposes. Please discard it

before filling up gasoline for the first time.

• Always use clean, fresh, unleaded

grade automotive gasoline.

• Avoid using alcohol blended fuels which can attract

moisture and damage fuel system if left in tank

during storage.

Page 10

CAUTION:Neveruseengineorcarburetorcleaner

productsinthefueltank.

• Fillthefueltankoutdoorsanduseafunnelorspout

topreventspilling.Thegasolinecontainershould

becleanandfreeofrustorotherforeignparticles.

• Neverfillthefueltankcompletely.Fillthetankto

within1/4"-1/2"fromthetoptoprovidespacefor

expansionoffuel.

• Wipeoffanyspilledfuelbeforestartingtheengine.

To Start Engine

_ ARNING: Be sure no one other than theoperator is standing near the snow thrower

while starting or operating. Do not operate this

snow thrower unless the discharge chute

assembly has been properly installed.

9. Plug the other end of the power cord into a three-

hole, grounded 120 volt A.C. receptacle.

10. Push primer button three times,

making sure to cover vent hole

when pushing.

11. Push down on the electric starter

button until the engine starts. Do

not crank for more than 20

seconds at a time. Allow the

starter to cool down before cranking again.

Vent Hole

_ ARNING: Severe damage to electricstarter is possible if you continue to crank for

more than 20 seconds without a cool-down.

12. When engine starts, release the starter button and

slowly rotate choke to OFF position. If the engine

falters, rotate choke to FULL and then to OFF.

• For location of engine controls, see engine manual.

A. Electric Starter

The snow thrower engine is equipped with a 120 volt

A.C. electric starter and recoil starter. The electric

starter is equipped with a three-wire power cord and

plug and is designed to operate on 120 volt AC

household current.

Cold Start

1. Determine whether your house wiring is a three-

wire grounded system. Ask a licensed electrician if

you are not certain.

_ ARNING: The electric starter must beproperly grounded at all times to avoid the

possibility of electric shock to the operator. If

your house wiring system is not a three-wire

grounded system, do not use this electric starter

under any conditions.

2. If your house wiring system is grounded and a

three-hole receptacle is not available at the point

the snow thrower starter will normally be used, one

should be installed by a licensed electrician.

NOTE: When connecting the power cord, always

connect cord to starter on engine first, then plug the

other end into a three-hole grounded 120 Volt

receptacle. When disconnecting the power cord,

always unplug the end from the three-hole, grounded

receptacle first.

3. Attach spark plug wire to spark plug.

4. Make sure that the auger control bail and the drive

control bail are disengaged.

5. Remove the keys from the plastic bag. Push key

into the ignition slot. Do not turn the key. Keep

second key in a safe place.

6. Move the choke knob to FULL choke position.

7. Move throttle control to the FAST position.

8. Connect power cord to the switch box on engine.

NOTE: When engaging the electric starter, a slight

hesitation of a few seconds may occur before the

engine starts to turn. This is normal.

13. Disconnect the power cord from the receptacle first

and then from the switch box on the engine.

14. Allow the engine to warm up fora few minutes

because the engine will not develop full power until

it reaches operating temperature. Operate at FULL

throttle when throwing snow.

Warm Start

If restarting a warm engine, rotate choke to OFF

instead of FULL and press the starter button. Do not

push the primer button.

B. Recoil Starter

Make sure that the auger control bail and the drive

control bail are released.

Cold Start

1. Move throttle control to FAST position.

2. Push key into the ignition slot so that it snaps into

place. Do not turn key. Remove plastic bag and

keep the second key in a safe place.

3. Rotate choke control to FULL choke position.

4. Push primer button while covering

the vent hole. Remove your finger

from the primer between primes.

Do not prime if temperature is

above 50° F. Prime two times

when temperature is between Vent Hole

50°F and 15°F and four times

below 15°F.

5. Pull the starter handle rapidly. Do not allow the

handle to snap back, but allow it to rewind slowly

while keeping a firm hold on the starter handle.

6. As the engine warms up and begins to operate

evenly, rotate the choke knob slowly to OFF

position. If the engine falters, return to FULL choke,

then slowly move to OFF choke position.

10

Page 11

7. Allow the engine to warm up for a few minutes

because the engine will not develop full power until

it reaches operating temperature.

8. Operate the engine at full throttle (FAST) when

throwing snow.

NOTE: If the starter motor runs but the engine does not

turn over, the starter gear may have frozen. Place the

snow thrower in a warmer part of the garage till the gear

is free of accumulated ice.

Frozen Recoil Starter

If the starter is frozen and will not turn the engine,

proceed as follows:

1. Pull as much rope out of the starter as possible.

2. Release the starter handle and let it snap back

against the starter.

3. If the engine still fails to start, repeat the first two

steps. Ifcontinued attempts do not free starter,

follow the electric starter procedures to start.

Avoid freezing of the recoil starter by referring to

instructions in the next column.

Warm Start

If restarting an engine after a temporary shut- down,

rotate choke to OFF instead of FULL and do not prime.

Pull the starter handle as instructed before.

Before Stopping

1. Run engine for a few minutes to help dry off any

moisture on engine.

2. To avoid possible freeze-up of the starter, follow

these steps:

Recoil Starter

a. With the engine running, pull the starter rope

with a rapid, continuous full arm stroke three

or four times.

Electric Starter

a. Connect power cord to switch box, then to

120 Volt AC receptacle.

b. While engine is running, push starter button

and spin the starter for several seconds.

c. Disconnect power cord from the receptacle

first, then from the snow thrower.

NOTE: The unusual sound from pulling the starter rope

or from spinning the starter will not harm the engine.

To Stop The Snow Thrower

1. While standing in the operator's position (behind the

snow thrower), engage theauger control bail fora few

secondsto clear any remaining snow and ice from the

discharge chute.

2. To stop the track, release the drive control bail.

3. To stop throwing snow, release the auger control bail.

4. To stop engine, push throttle control lever to OFF

and pull out the key. Do not turn key.

5. Wipe off all snow and moisture from the carburetor

area and around the engine.

_ ARNING: The temperature of muffler and

surrounding areas may exceed 150° F. Avoid

these areas.

Clearing the Snow

CAUTION: Check the area to be cleared for foreign

objects. Remove, if any.

1. Start the engine following earlier instructions.

2. Rotate discharge chute to the desired direction,

away from bystanders and/or buildings.

3. Making certain no bystanders or obstacles are in

front of the unit, squeeze the auger control bail

completely against the upper handle to fully engage

the augers.

4. Keeping auger control engaged, squeeze the drive

control against the upper handle to engage tracks.

5. As the snow thrower starts to move, maintain a firm

hold on the handle, and guide the snow thrower

along the path to be cleared.

6. Release auger control to stop snowthrowing action

and drive control to stop forward motion.

NOTE: Your unit is equipped with a clutch in the

transmission. If the tracks stop turning while trying to

discharge large volumes of snow, disengage drive

control and allow rotating augers to discharge snow

from the housing. Continue operation on narrower

stretch with less volume of snow.

7. On each succeeding pass, readjust the chute

deflector to the desired position and slightly overlap

the previously cleared path.

Operating Tips

NOTE: Allow the engine to warm up for a few minutes

as the engine will not develop full power until it reaches

operating temperature.

_ ARNING: The temperature of muffler and

• For most efficient snow removal, remove snow

• Discharge snow downwind whenever possible.

• Set the skid shoes 1/4" below the scraper bar for

CAUTION: Operating this snow thrower on gravel is not

recommended.

surrounding areas may exceed 150° F. Avoid

these areas.

immediately after it falls.

Slightly overlap each previous swath.

normal usage. The skid shoes may be adjusted

upward for hard-packed snow.

11

Page 12

• If, however, you have to operate the snow thrower

on gravel, keep the skid shoe in the highest position

for maximum clearance between the ground and

the shave plate.

• Clean the snow thrower thoroughly after each use.

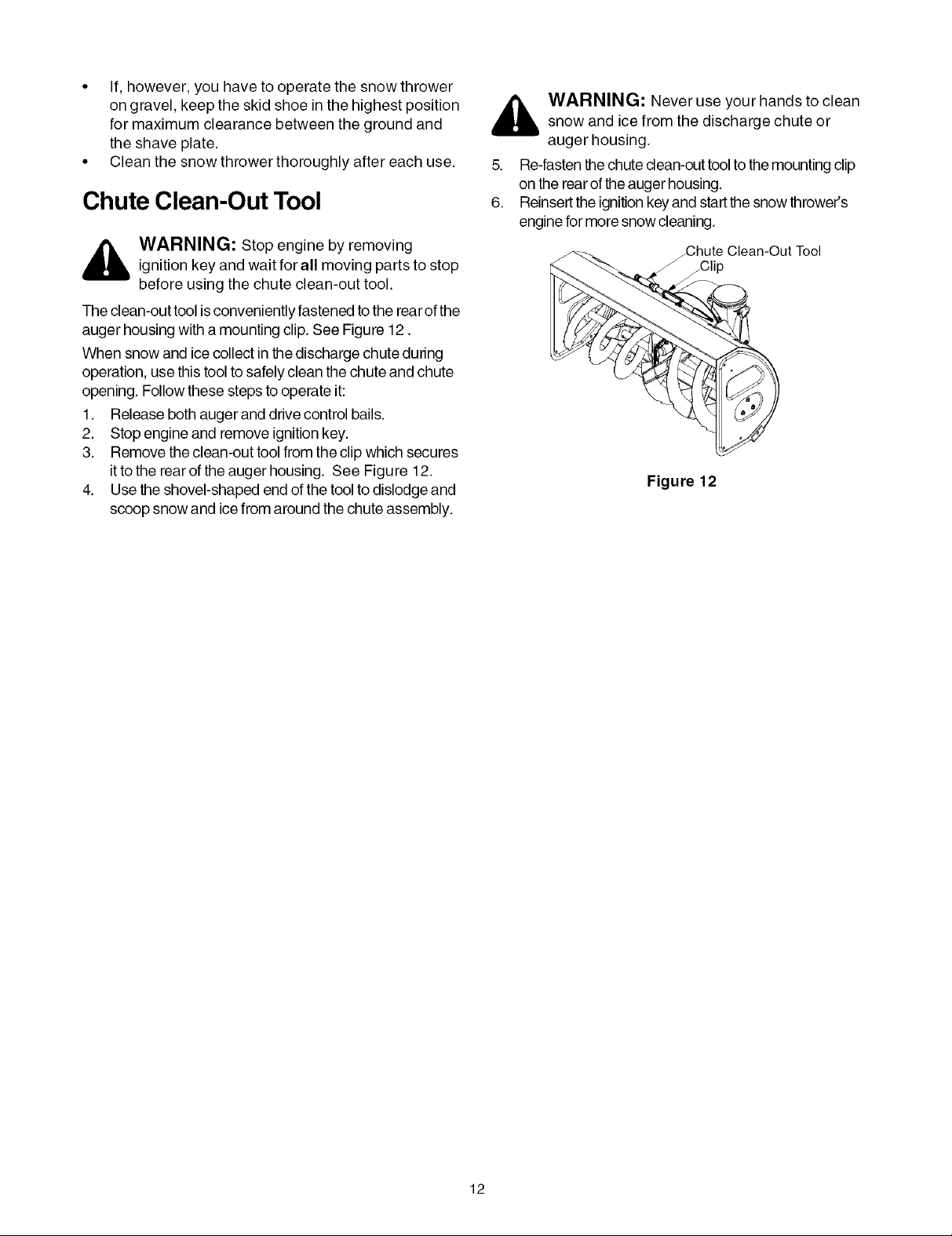

Chute Clean-Out Tool

_ ARNING: Stop engine by removing

The clean-out tool isconveniently fastened to the rear ofthe

auger housing with a mounting clip. See Figure 12.

When snow and ice collect in the discharge chute during

operation, use this tool to safely clean the chute and chute

opening. Follow these steps to operate it:

1. Release both auger and drive control bails.

2. Stop engine and remove ignition key.

3. Remove the clean-out tool from the clip which secures

4. Use the shovel-shaped end of the tool to dislodge and

ignition key and wait for all moving parts to stop

before using the chute clean-out tool.

itto the rear of the auger housing. See Figure 12.

scoop snow and ice from around the chute assembly.

_ ARNING: Never use your hands to cleansnow and ice from the discharge chute or

auger housing.

5. Re-fasten the chute clean-out tool tothe mounting clip

on the rearof the auger housing.

6. Reinsertthe ignition keyand startthe snow thrower's

engine formore snow cleaning.

Chute Clean-Out Tool

_Clip

Figure 12

12

Page 13

General Recommendations

• Always observe safety rules when performing any

maintenance.

• The warranty on this snow thrower does not cover

items that have been subjected to operator abuse

or negligence. To receive full value from the

warranty, operator must maintain the snow

thrower as instructed in this manual.

• All adjustments listed inthis manual should be

checked at least once each season.

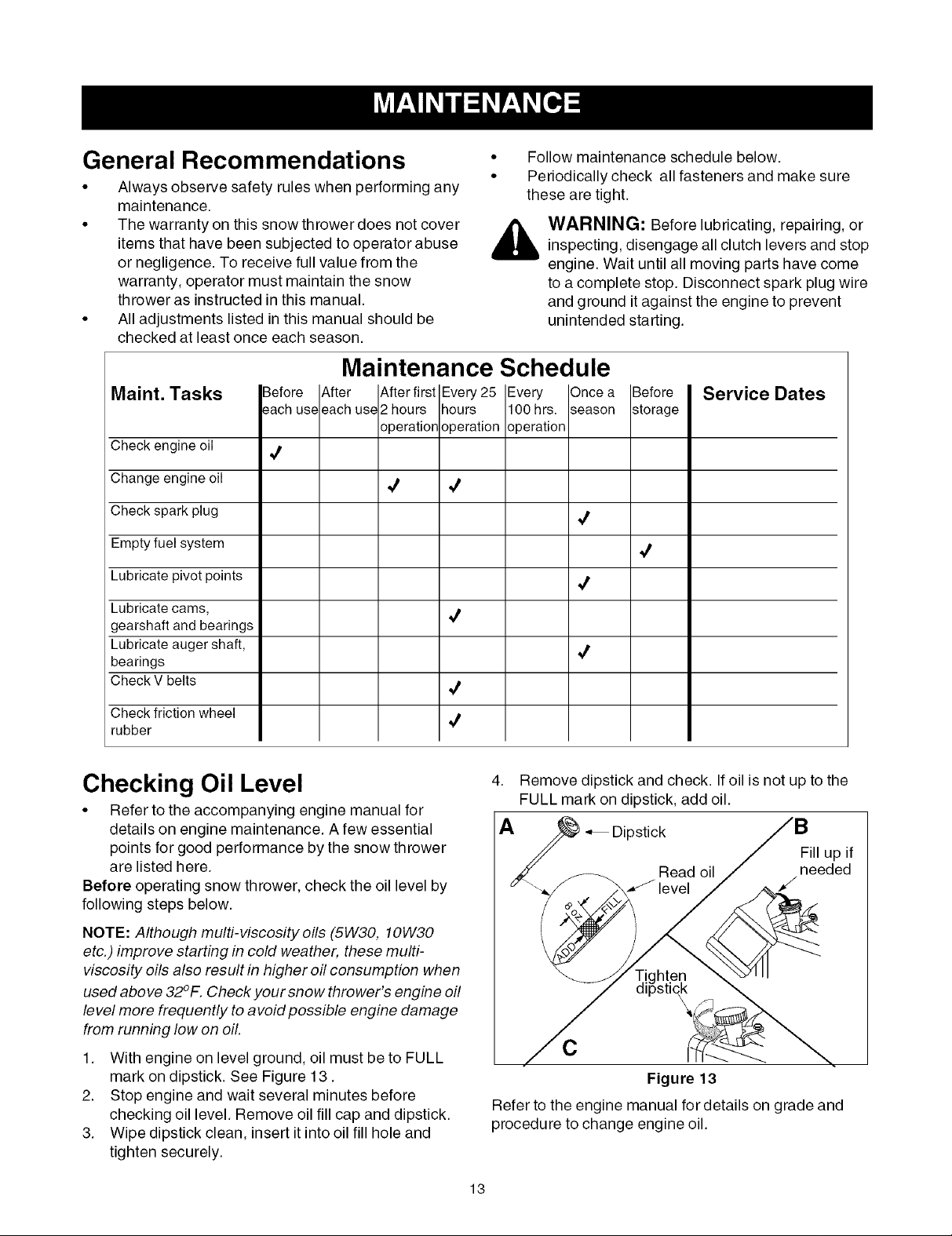

Maintenance Schedule

Maint. Tasks

Check engine oil

Change engine oil

Check spark plug

Empty fuel system

Lubricate pivot points

Lubricate cams,

gearshaft and bearings

Lubricate auger shaft,

bearings

Check V belts

Check friction wheel

rubber

4

./

Every 25

hours

operation

• Follow maintenance schedule below.

• Periodically check all fasteners and make sure

these are tight.

_ ARNING: Before lubricating, repairing, orinspecting, disengage all clutch levers and stop

engine. Wait until all moving parts have come

to a complete stop. Disconnect spark plug wire

and ground it against the engine to prevent

unintended starting.

Every

100 hrs.

operation

Service Dates

./

4

4

4

4

4

4

4

Checking Oil Level

• Refer to the accompanying engine manual for

details on engine maintenance. A few essential

points for good performance by the snow thrower

are listed here.

Before operating snow thrower, check the oil level by

following steps below.

NOTE: Although multi-viscosity oils (5W30, 10W30

etc.) improve starting in cold weather, these multi-

viscosity oils also result in higher oil consumption when

used above 32°F. Check your snow thrower's engine oil

level more frequently to avoid possible engine damage

from running low on oil.

1. With engine on level ground, oil must be to FULL

mark on dipstick. See Figure 13.

2. Stop engine and wait several minutes before

checking oil level. Remove oil fill cap and dipstick.

3. Wipe dipstick clean, insert itinto oil fill hole and

tighten securely.

Remove dipstick and check. If oil is not up to the

FULL mark on dipstick, add oil.

pstick

Fill up if

Read oil needed

J

C

Figure 13

Refer to the engine manual for details on grade and

procedure to change engine oil.

13

Page 14

Lubrication

Engine

Refer to the separate engine manual packed with your

unit for all engine lubrication instructions.

Gear Shaft

Lubricate the gear shaft with 6-n-1 grease at least once

a season or after every 25 hours of operation (available

at automotive stores). Refer to Figure 26.

IMPORTANT: Keep all grease and oil off the rubber

friction wheel and aluminum drive plate.

Chute Directional Control

The worm gear on the chute directional control should

be greased with multipurpose automotive grease.

Gear Case

The gear case is lubricated with grease at the factory

and does not require checking. If it is disassembled for

any reason, lubricate with 2 ounces of Shell Alvania

grease EPR00. Before reassembling, remove old

sealant and apply new sealant.

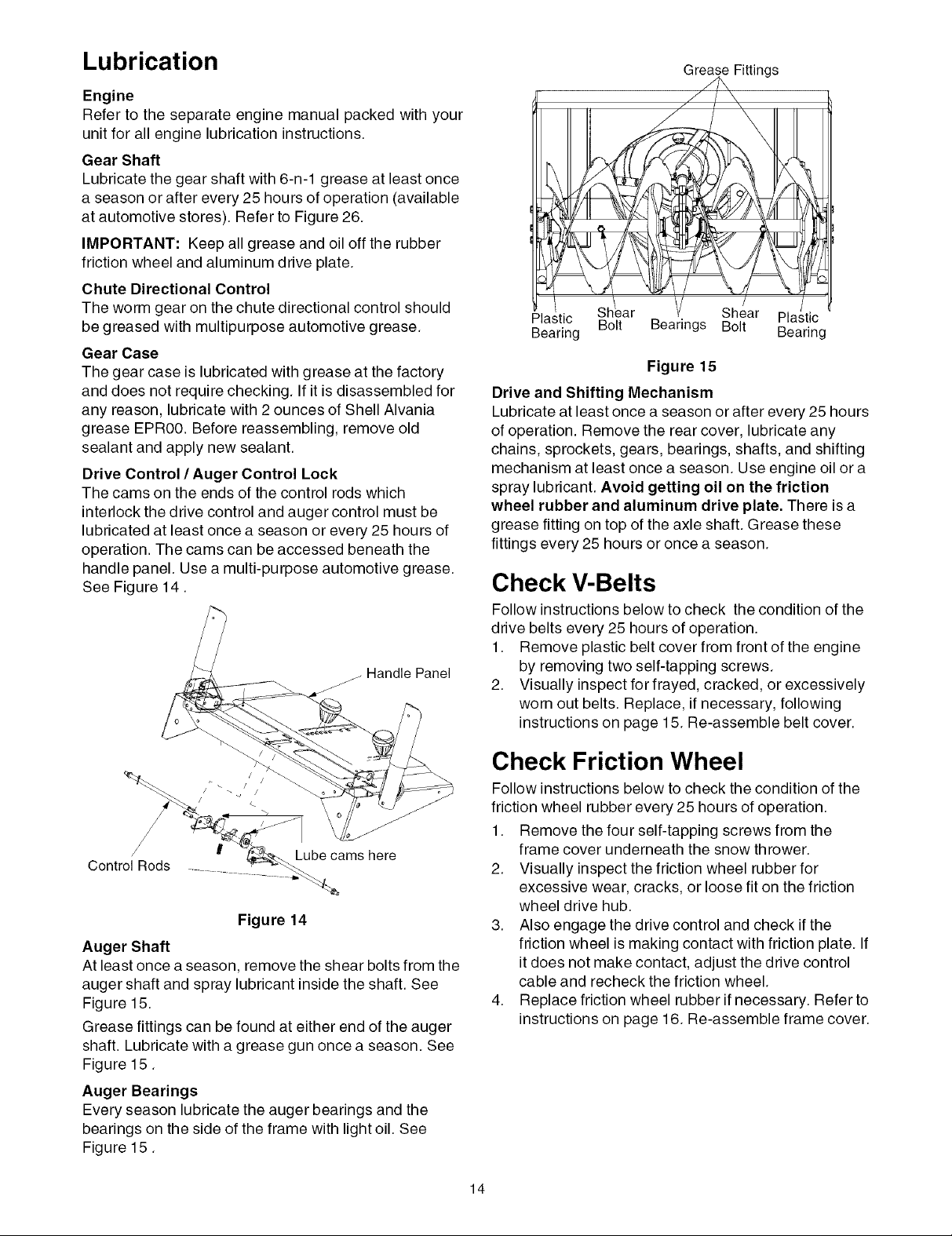

Drive Control / Auger Control Lock

The cams on the ends of the control rods which

interlock the drive control and auger control must be

lubricated at least once a season or every 25 hours of

operation. The cams can be accessed beneath the

handle panel. Use a multi-purpose automotive grease.

See Figure 14.

Handle Panel

Grease Fittings

Plastic Bolt

Bearing

Drive and Shifting Mechanism

Lubricate at least once a season or after every 25 hours

of operation. Remove the rear cover, lubricate any

chains, sprockets, gears, bearings, shafts, and shifting

mechanism at least once a season. Use engine oil or a

spray lubricant. Avoid getting oil on the friction

wheel rubber and aluminum drive plate. There is a

grease fitting on top of the axle shaft. Grease these

fittings every 25 hours or once a season.

St_ear

Bearings Bolt Bearing

Figure 15

Shear Plastic

Check V-Belts

Follow instructions below to check the condition of the

drive belts every 25 hours of operation.

1. Remove plastic belt cover from front of the engine

by removing two self-tapping screws.

2. Visually inspect for frayed, cracked, or excessively

worn out belts. Replace, if necessary, following

instructions on page 15. Re-assemble belt cover.

Figure 14

Auger Shaft

At least once a season, remove the shear bolts from the

auger shaft and spray lubricant inside the shaft. See

Figure 15.

Grease fittings can be found at either end of the auger

shaft. Lubricate with a grease gun once a season. See

Figure 15.

Auger Bearings

Every season lubricate the auger bearings and the

bearings on the side of the frame with light oil. See

Figure 15.

Check Friction Wheel

Follow instructions below to check the condition of the

friction wheel rubber every 25 hours of operation.

1. Remove the four self-tapping screws from the

frame cover underneath the snow thrower.

2. Visually inspect the friction wheel rubber for

excessive wear, cracks, or loose fit on the friction

wheel drive hub.

3. Also engage the drive control and check if the

friction wheel is making contact with friction plate. If

it does not make contact, adjust the drive control

cable and recheck the friction wheel.

4. Replace friction wheel rubber if necessary. Refer to

instructions on page 16. Re-assemble frame cover.

14

Page 15

,_ WARNING: Always stop engine, disconnectspark plug wire and move it away from the

spark plug before performing any adjustments

or repairs on the snow thrower.

WARNING: Never attempt to clean the

discharge chute or make any adjustments

while the engine is running.

Augers

The augers are secured to the spiral shaft with two

shear bolts and hex lock nuts. If snow thrower hits a

hard foreign object or ice jam, the bolts may shear.

Refer to Figure 15. If the augers will not turn, check to

see if the bolts have sheared.

Use replacement shear bolts and lock nuts provided

with the snow thrower. When replacing bolts, spray an

oil lubricant into shaft before inserting new bolts.

IMPORTANT: Never replace auger shear bolts with

standard hex bolts. Any damage to the auger gearbox

or other components from hex bolt usage will not be

covered by the snow thrower's warranty.

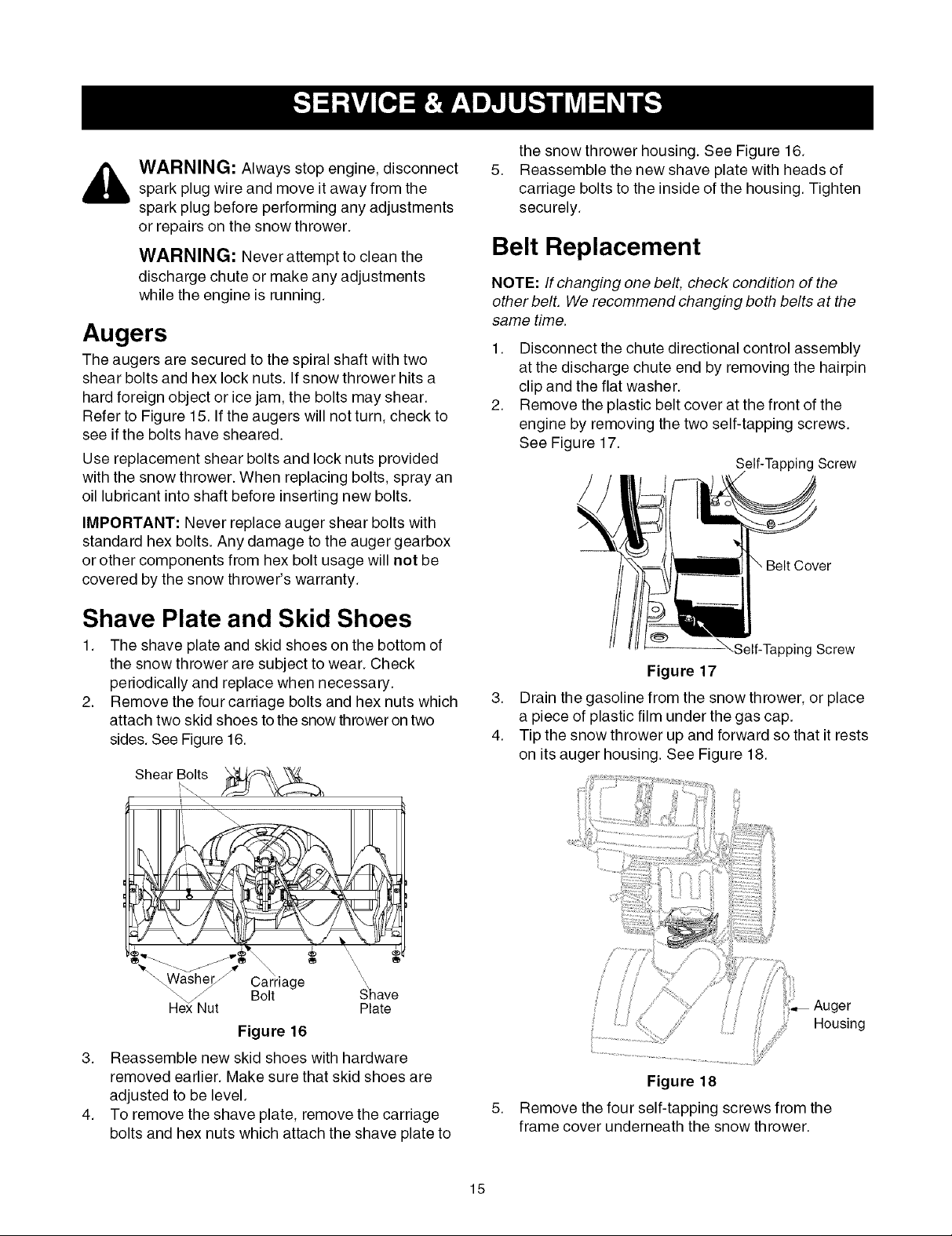

the snow thrower housing. See Figure 16.

5.

Reassemble the new shave plate with heads of

carriage bolts to the inside of the housing. Tighten

securely.

Belt Replacement

NOTE: If changing one belt, check condition of the

other belt. We recommend changing both belts at the

same time.

1. Disconnect the chute directional control assembly

at the discharge chute end by removing the hairpin

clip and the flat washer.

2. Remove the plastic belt cover at the front of the

engine by removing the two self-tapping screws.

See Figure 17.

Self-TappingScrew

Shave Plate and Skid Shoes

1. The shave plate and skid shoes on the bottom of

the snow thrower are subject to wear. Check

periodically and replace when necessary.

2. Remove the four carriage bolts and hex nuts which

attach two skid shoes to the snow thrower on two

sides. See Figure 16.

Shear Bolts _

i \

_Wa;her_ Carriage \_

.._... Bolt Shave

MexNut Plate

Figure 16

3.

Reassemble new skid shoes with hardware

removed earlier. Make sure that skid shoes are

adjusted to be level.

4.

To remove the shave plate, remove the carriage

bolts and hex nuts which attach the shave plate to

%_Self-TappingScrew

Figure 17

3.

Drain the gasoline from the snow thrower, or place

a piece of plastic film under the gas cap.

4.

Tip the snow thrower up and forward so that it rests

on its auger housing. See Figure 18.

Housing

Figure 18

5. Remove the four self-tapping screws from the

frame cover underneath the snow thrower.

15

Page 16

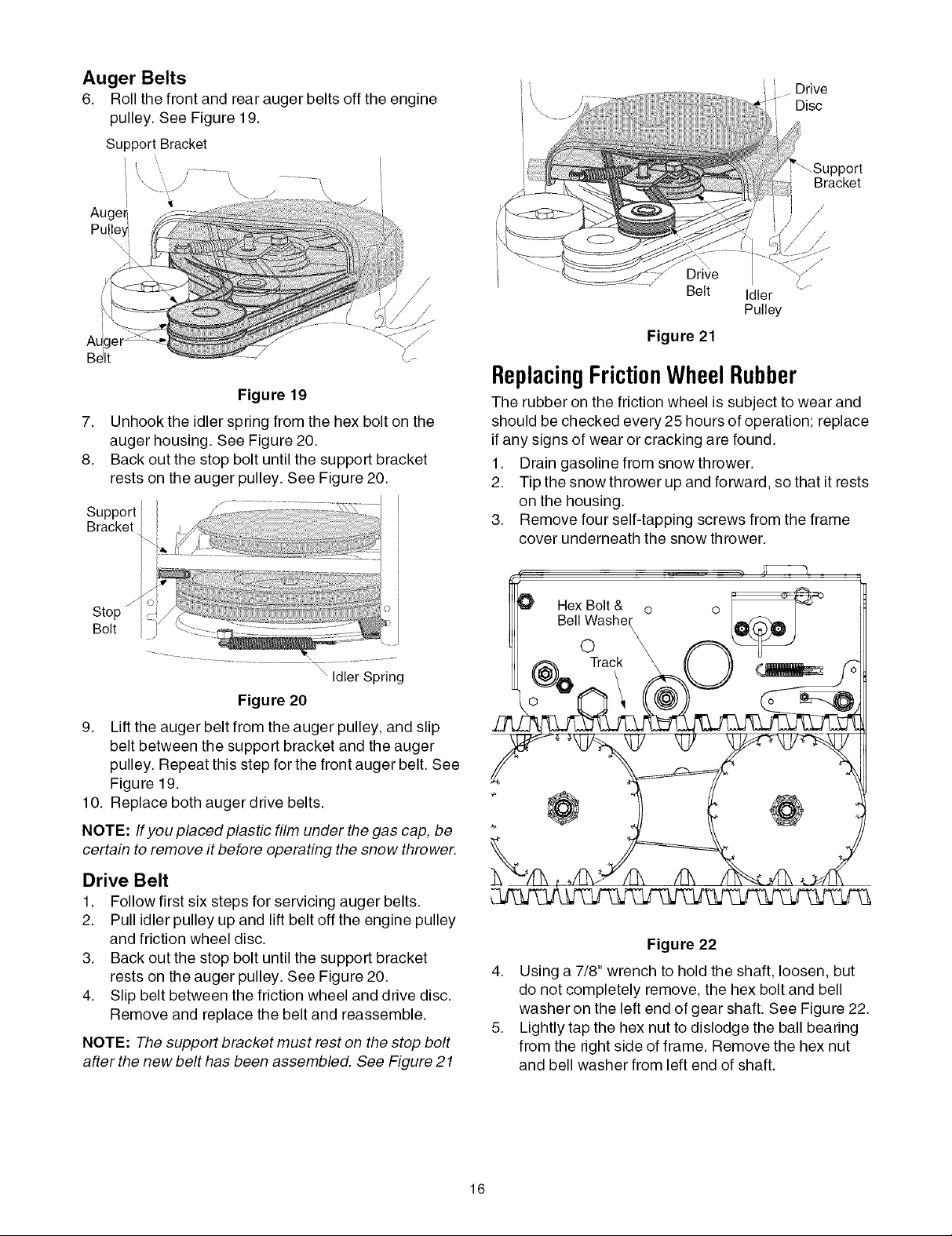

Auger Belts

6. Roll the front and rear auger belts off the engine

pulley. See Figure 19.

Support Bracket

Drive

Disc

oort

Bracket

Auger

Figure 19

7. Unhook the idler spring from the hex bolt on the

auger housing. See Figure 20.

8. Back out the stop bolt until the support bracket

rests on the auger pulley. See Figure 20.

Support

Bracket

Stop j

Bolt

Idler Spring

Figure 20

9. Lift the auger belt from the auger pulley, and slip

belt between the support bracket and the auger

pulley. Repeat this step for the front auger belt. See

Figu re 19.

10. Replace both auger drive belts.

/

/

/

Dri,_e

j_

Belt Idler

Pulley

Figure 21

ReplacingFrictionWheelRubber

The rubber on the friction wheel is subject to wear and

should be checked every 25 hours of operation; replace

if any signs of wear or cracking are found.

1. Drain gasoline from snow thrower.

2. Tip the snow thrower up and forward, so that it rests

on the housing.

3. Remove four self-tapping screws from the frame

cover underneath the snow thrower.

Hex Bolt &

Bell Washel

O

Track

NOTE: If you placed plastic film under the gas cap, be

certain to remove it before operating the snow thrower.

Drive Belt

1. Follow first six steps for servicing auger belts.

2. Pull idler pulley up and lift belt off the engine pulley

and friction wheel disc.

3. Back out the stop bolt until the support bracket

rests on the auger pulley. See Figure 20.

4. Slip belt between the friction wheel and drive disc.

Remove and replace the belt and reassemble.

NOTE: The support bracket must rest on the stop bolt

after the new belt has been assembled. See Figure 21

Figure 22

4. Using a 7/8" wrench to hold the shaft, loosen, but

do not completely remove, the hex bolt and bell

washer on the left end of gear shaft. See Figure 22.

5. Lightly tap the hex nut to dislodge the ball bearing

from the right side of frame. Remove the hex nut

and bell washer from left end of shaft.

16

Page 17

ShiftRod

Spacer

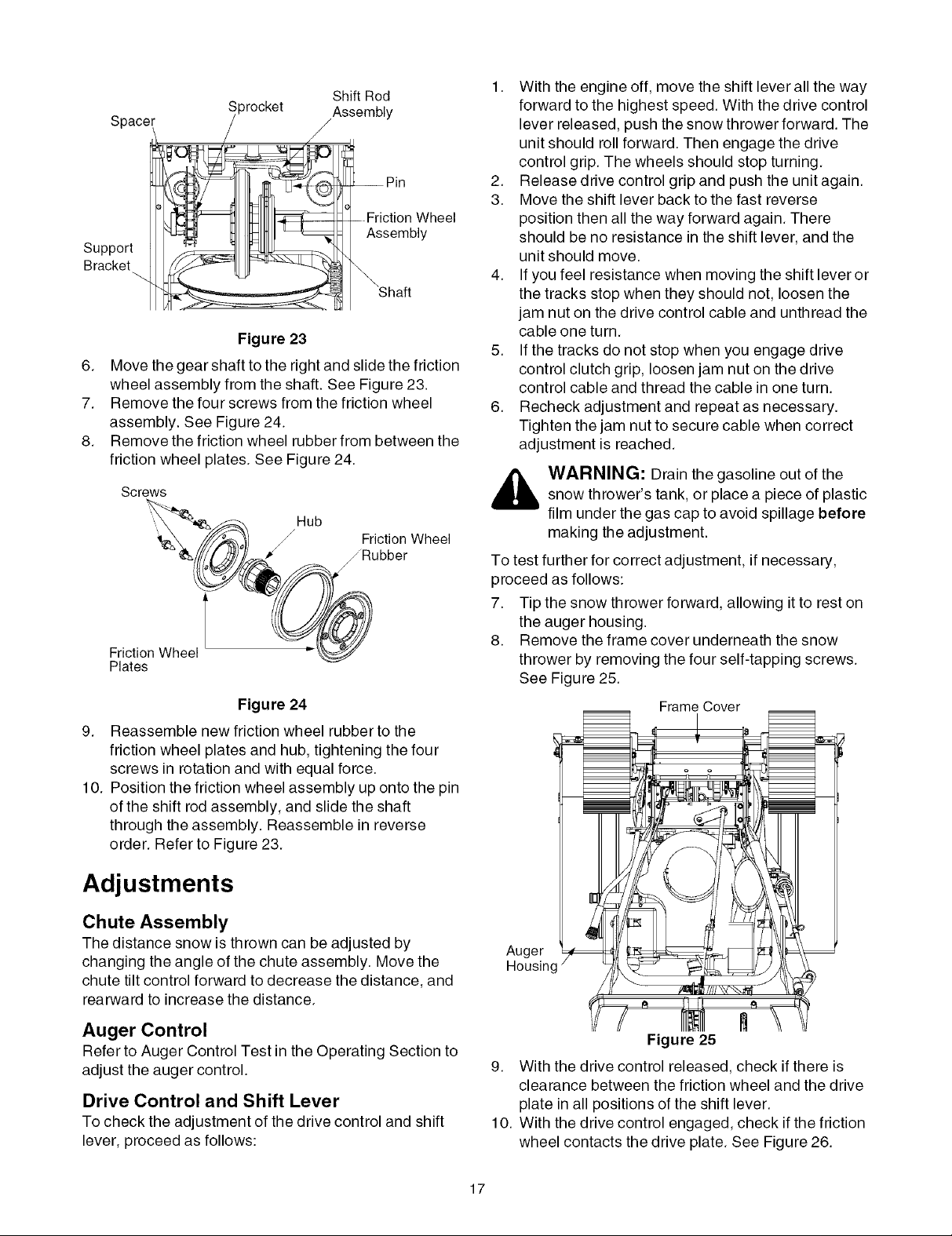

6. Move the gear shaft to the right and slide the friction

wheel assembly from the shaft. See Figure 23.

7. Remove the four screws from the friction wheel

assembly. See Figure 24.

8. Remove the friction wheel rubber from between the

friction wheel plates. See Figure 24.

_procket Assembly

/

--Pin

Friction Wheel

Assembly

_S haft

Figure 23

1. With the engine off, move the shift lever all the way

forward to the highest speed. With the drive control

lever released, push the snow thrower forward. The

unit should roll forward. Then engage the drive

control grip. The wheels should stop turning.

2. Release drive control grip and push the unit again.

3. Move the shift lever back to the fast reverse

position then all the way forward again. There

should be no resistance in the shift lever, and the

unit should move.

4. If you feel resistance when moving the shift lever or

the tracks stop when they should not, loosen the

jam nut on the drive control cable and unthread the

cable one turn.

5. If the tracks do not stop when you engage drive

control clutch grip, loosen jam nut on the drive

control cable and thread the cable in one turn.

6. Recheck adjustment and repeat as necessary.

Tighten the jam nut to secure cable when correct

adjustment is reached.

Screws

Hub

/

Friction Wheel

Plates

Friction Wheel

_Rubber

Figure 24

9. Reassemble new friction wheel rubber to the

friction wheel plates and hub, tightening the four

screws in rotation and with equal force.

10. Position the friction wheel assembly up onto the pin

of the shift rod assembly, and slide the shaft

through the assembly. Reassemble in reverse

order. Refer to Figure 23.

Adjustments

Chute Assembly

The distance snow is thrown can be adjusted by

changing the angle of the chute assembly. Move the

chute tilt control forward to decrease the distance, and

rearward to increase the distance.

_ WARNING: Drain the gasoline out of the

snow thrower's tank, or place a piece of plastic

film under the gas cap to avoid spillage before

making the adjustment.

To test further for correct adjustment, if necessary,

proceed as follows:

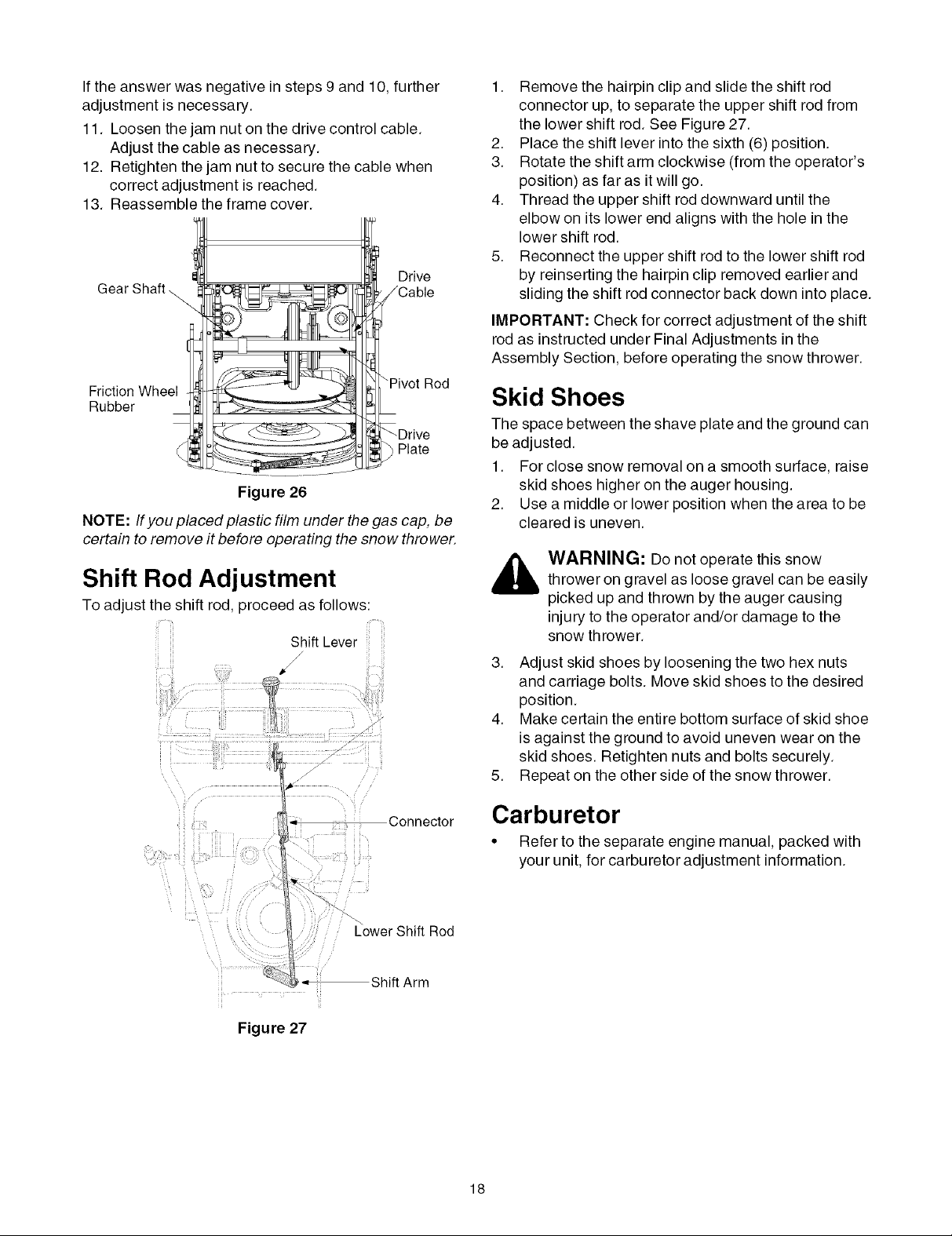

7. Tip the snow thrower forward, allowing it to rest on

the auger housing.

8. Remove the frame cover underneath the snow

thrower by removing the four self-tapping screws.

See Figure 25.

Frame Cover

Auger

Housing

Auger Control

Refer to Auger Control Test in the Operating Section to

adjust the auger control.

Drive Control and Shift Lever

To check the adjustment of the drive control and shift

lever, proceed as follows:

Figure 25

9. With the drive control released, check if there is

clearance between the friction wheel and the drive

plate in all positions of the shift lever.

10. With the drive control engaged, check if the friction

wheel contacts the drive plate. See Figure 26.

17

Page 18

If the answer was negative in steps 9 and 10, further

adjustment is necessary.

11. Loosen the jam nut on the drive control cable.

Adjust the cable as necessary.

12. Retighten the jam nut to secure the cable when

correct adjustment is reached.

13. Reassemble the frame cover.

Drive

Cable

\Pivot Rod

_Drive

Plate

Figure 26

NOTE: Ifyou placed plastic film under the gas cap, be

certain to remove it before operating the snow thrower.

1. Remove the hairpin clip and slide the shift rod

connector up, to separate the upper shift rod from

the lower shift rod. See Figure 27.

2. Place the shift lever into the sixth (6) position.

3. Rotate the shift arm clockwise (from the operator's

position) as far as it will go.

4. Thread the upper shift rod downward until the

elbow on its lower end aligns with the hole in the

lower shift rod.

5. Reconnect the upper shift rod to the lower shift rod

by reinserting the hairpin clip removed earlier and

sliding the shift rod connector back down into place.

IMPORTANT: Check for correct adjustment of the shift

rod as instructed under Final Adjustments in the

Assembly Section, before operating the snow thrower.

Skid Shoes

The space between the shave plate and the ground can

be adjusted.

1. For close snow removal on a smooth surface, raise

skid shoes higher on the auger housing.

2. Use a middle or lower position when the area to be

cleared is uneven.

Shift Rod Adjustment

To adjust the shift rod, proceed as follows:

Shift_Lever

_-,_ Shift Arm

Figure 27

_ ARNING: Do not operate this snowthrower on gravel as loose gravel can be easily

picked up and thrown by the auger causing

injury to the operator and/or damage to the

snow th rowe r.

3. Adjust skid shoes by loosening the two hex nuts

and carriage bolts. Move skid shoes to the desired

position.

4. Make certain the entire bottom surface of skid shoe

is against the ground to avoid uneven wear on the

skid shoes. Retighten nuts and bolts securely.

5. Repeat on the other side of the snow thrower.

Carburetor

• Refer to the separate engine manual, packed with

your unit, for carburetor adjustment information.

Lower Shift Rod

18

Page 19

If your snow thrower is left unused for 30 days or longer,

it needs to be prepared for storage. Also, at the end of

the snow season, you should follow the same set of

instructions and store the snow thrower properly for the

off-season. Proper storage ensures longer life of the

snow thrower.

Preparing For Storage

_ ARNING: Never store snow thrower withfuel in tank indoors or in poorly ventilated

areas, where fuel fumes may reach an open

flame, spark or pilot light as on a furnace, water

heater, clothes dryer or gas appliance.

WARNING: Drain fuel into approved

container outdoors, away from any open flame.

Be certain engine is cool. Do not smoke.

WARNING: Do not drain carburetor if using

fuel stabilizer. Never use engine or carburetor

cleaning products in the fuel tank or permanent

damage may occur.

It is important to prevent gum deposits from forming in

essential fuel system parts of the engine such as the

carburetor, fuel filter, fuel hose or tank during storage.

Fuel left in engine during warm weather deteriorates

and will cause serious starting problems. To avoid such

problems, the fuel system shouldbe emptiedbefore

storage for 30 days or longer.

NOTE: Also experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which leads to separation and

formation of acids during storage. Acidic gas can

damage the fuel system of an engine while in storage.

1. Remove gasoline from the carburetor and the fuel

tank to prevent gum deposit in the engine.

2. Run the engine until the fuel tank is empty and it

stops due to lack of fuel.

3. Remove the spark plug and pour one (1) ounce of

engine oil through the spark plug hole into the

cylinder. Place a rag over the hole. Crank the

engine several times to distribute the oil. Replace

spark plug.

NOTE: Follow the engine manual to further prepare the

snowthrower engine for storage.

4. When storing the snow thrower in an unventilated or

metal storage shed, rustproof the equipment. Using

a light oil or silicone, coat the equipment, especially

any chains, springs, bearings and cables.

5. Remove all dirt from exterior of engine and

equipment.

6. Follow lubrication recommendations on page 14.

7. Store snowthrower in a clean, dry area.

19

Page 20

Problem Cause

Engine fails to start 1. Fueltank empty, or stale fuel.

2. Blocked fuel line.

3. Choke not in the ON position

4. Faulty spark plug.

5. Safety key not in ignition switch on engine.

6. Spark plug wire disconnected.

7. Primer button not being used properly.

Engine runs erratic

Loss of power 1. Spark plug wire loose.

Excessive vibration 1. Loose parts or damaged auger.

Unit fails 1. Drive control cable in need of adjustment.

to propel itself

Unit fails 1.

to discharge snow

1. Unit running on choke.

2. Blocked fuel line or stale fuel.

3. Water or dirt in the fuel system.

2. Gas cap vent hole plugged.

Discharge chute clogged.

Shear bolt sheared.

2,

3.

Foreign object lodged in auger.

4. Auger control cable in need of adjustment. 4. Adjust auger control cable. Refer to page 17.

5. Auger belt looseor damaged. 5. Replace auger belt. Refer to page 16.

Remedy

1. Fill tank with clean, fresh gasoline. Fuel

becomes stale after thirty days.

2. Clean the fuel line.

3. Move switch to the ON position

4. Clean, adjust gap or replace.

5. Insert the key fully into the switch.

6. Connect spark plug wire.

7. Refer to the engine manual.

1. Move the choke lever to OFF position.

2. Clean fuel line; fill tank with fresh gasoline.

3. Drain fuel tank and carburetor. Refill with

fresh fuel.

1. Connect and tighten spark plug wire.

2. Remove ice/snow from gas cap vent hole.

1. Stop engine immediately and disconnect

spark plug wire. Tighten all bolts and nuts. If

vibration continues, have the unit serviced by

Sears service center.

1. Adjust drive control cable. Refer to page 17

for instructions.

1. Stop engine and disconnect spark plug wire.

Clean discharge chute and inside of auger

housing with chute clean-out tool.

2. Replace shear bolt.

3. Stop engine immediately and disconnect

spark plug wire. Remove object from auger.

line by calling 1-800-4-MY-HOME.

NOTE: This section addresses minor service issues. For further details, contact Sears service information

2O

Page 21

777122363

SAFETY& DECORATIVELABELS

777D08420

777120324

777S32066

777122386 777122387 777122388

REF. 777S32236

i

777D08419

21

Page 22

Craftsman Snowthrower Model 247.88890

25

i. _ Part of handle panel

9

for reference only

78

/ 24

66 t, .-20

3- ........

!

/'

/

/

64

77

81j

80 /

79/

76

75

/

13

22_ /

T;9 , .......

11 ,_'/_ "i 5

23

....10 12

16 66

69

/

/

\

2

22

18

Page 23

Craftsman Snowthrower Model 247.88890

Ref.

No.

1. 684-0008A

2. 705-5204A

3. 710-0449

4. 710-0458

5. 710-0643

6. 710-0788

7. 710-1880

8. 711-0677

9. 712-04063

10. 712-3010

11. 714-0104

12. 720-0201A

13. 720-0274

14. 720-0284

15. 726-0100

16. 735-0234

17. 736-0119

18. 736-0185

19. 736-0275

20. 736-0451

21. 747-0620A

22. 747-0621

23. 747-0697

24. 749-0951

25. 749-0952A

26. 749-0953A

27. 750-0963

28. 629-0058

29. 684-0111B

30. 684-0112A

31. 710-1003

32. 712-0271

33. 712-0415

34. 720-0300

35. 725-1300

36. 731-1317

37. 731-1773A

38. 684-0102

39. 710-0459A

40. 710-0599

41. 711-0653

Part No.

Ref.

Part Description No. Part No.

Shift Arm Assembly 42. 712-0116

Chute Directional Control 43. 712-04063

Carriage Screw 5/16-18 x 2.25 44. 714-0104

Carriage Bolt 5/16-18 x 1.75 45. 714-0507

Hex Bolt 5/16-18 x 1.0 46. 732-0145

Tt Screw 1/4-20 x 1.0 47. 732-0193

Hex Bolt 5/16-18 x 0.75 48. 732-0746

Ferrule 49. 735-0199A

Flange Lock Nut 50. 736-0105

Hex Nut 5/16-18 51. 736-0509

Hairpin Clip 52. 746-0778

Knob: Chute Directional Control 53. 747-0877

Grip 54. 748-0362

Handle Knob Assembly 55. 748-0363

Push Cap 56. 784-5619A

Rubber Grommet 57. 784-5679

Lock Washer 58. 784-5680

Fiat Washer 59. 784-5681

Fiat Washer 60. 784-5682

Saddle Washer 61. 710-0805

Upper Shift Rod 62. 746-0901

Lower Shift Rod 63. 746-0896

Eye Bolt 64. 731-1313C

Lower Handle 65. 784-5604

Upper Handle RH 66. 712-04063

Upper Handle LH 67. 736-0506A

Connector: Shift Red 68. 710-0895

Harness: Light 69. 731-1379C

Handle Engagement Assembly LH 70. 741-0475

Handle Engagement Assembly RH 71. 784-5647

B Screw #10-16 x 0.625 72. 710-0451

Hex Seres Nut 1/4-20 73. 710-0597

Hex Nut 74. 731-0851A

Shift Knob 75. 712-04064

Headlight 76. 731-1300B

Headlight Bezel 77. 731-04427A

Handle Panel 78. 784-5594

Handle Panel Assembly w/Tilt 79. 710-04071

Hex Bolt 3/8-24 x 1.5 80. 710-0895

TT Screw 1/4-20 x 0.5 81. 710-0262

Clevis Pin

Part Description

Jam Lock Nut 3/8-24

Flange Lock Nut

Cotter Pin

Cotter Pin

Compression Spring

Compression Spring

Torsion Spring

Rubber Bumper

Bell Washer

Flat Washer

Z Fitting: Clutch Cable

Cam Rod

Cam: Handle Lock

Pawl: Handle Lock

Shift Handle

Handle Support Bracket LH

Handle Support Bracket RH

Support Bracket LH

Support Bracket RH

Hex Bolt 5/16-18 x 1.5

Chute Deflector Cable w/Clip

Chute Deflector Control Cable

Chute Cable Guide

Chute Distance Control

Flange Lock Nut 5/16-18

Special Washer

Hi-Lo Screw 1/4-15 x 0.75

Chute Adapter

Plastic Bushing

Bracket: Chute Directional Control

Carriage Bolt 5/16-18 x 0.75

Hex Bolt 1/4-20 x 1.0

Flange Keeper

Flange Lock Nut 1/4-20

Lower Chute

Upper Chute

Cable Bracket

Carriage Bolt 5/16-18 x 1.0

Hi-Lo Screw 1/4-15 x 0.75

Carriage bolt 5/16-18 x 1.5

NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable color code, wherever

needed, to the part number to order a replacement part. For instance, if a part, numbered 700-xxxx, is painted red, the part

number to order would be 700-xxxx-0721.

Sears Red: 0721

Powder Black: 0637

23

Page 24

Craftsman Snowthrower Model 247.88890

3 2 4

15

\

38

\

\

\

14

16

12

\. ....... :30

" -32

36

37

40

41

33

16

42

\

\43

24

Page 25

Craftsman Snowthrower Model 247.88890

Ref.

No.

1. 712-0116

2. 756-0178

3. 784-5632B

4. 710-0459A

5. 738-0281

6. 736-0174

7. 732-0611

8. 712-3068

9. 710-0276

11. 05931A

12. 741-0309

13. 710-0451

14. 705-5226

15. 684-04131

16. 712-04063

19. 736-0320

21. 731-2635

22. 731-2643

Part No.

Ref.

Part Description No. Part No.

Lock Jam Nut 3/8-24 24. 790-00087

Flat Idler 26. 710-0726

Auger Idler Arm 27. 725-0157

Hex Cap Screw 3/8-24 x 1.50 28. 712-04065

Shoulder Screw 29. 741-0245

Wave Washer 30. 784-5580

Extension Spring 32. 712-04063

Hex Nut 5/16-18 33. 790-00121

Carriage Bolt, 5/16-18 x 1.00 34. 710-0451

Housing 35. 684-0065

Ball Bearing 36. 715-0114

Carriage Bolt, 5/16-18 x.75 37. 618-0122B

Chute Reinforcement 38. 605-5196A

Auger Housing Assembly 28" 39. 736-0188

Flange Lock Nut 5/16-18 40. 741-0493A

Flat Washer 41. 605-5197A

Clean-Out Tool Mount 42. 710-0890A

Clean-Out Tool 43. 737-3000

Part Description

Bearing Housing

Hex Screw 5/16-12

Cable Tie (not shown)

Flange Lock Nut 3/8-16

Hex Flange Bearing

Skid Shoe

Flange Nut 5/16-18

Shave Plate

Carriage Bolt 5/16-18 x 1.00

Impeller Assembly

Pin

Gear Assembly Complete, 28"

Spiral Assembly RH

Fiat Washer

Flange Bushing

Spiral Assembly LH

Shear Bolt 5/16-18 x 1.5

Lube Fitting

NOTE: For painted parts, please refer to the

list of color codes below. Please add the

applicable color code, wherever needed, to

the part number to order a replacement part.

For instance, if a part, numbered 700-xxxx, is

painted red, the part number to order would

be 700-xxxx-0721.

Sears Red: 0721

Powder Black: 0637

25

Page 26

Craftsman Snowthrower Model 247.88890

Suppli_

on engine

29

27

23

21 16

22 \

\

x

x

26

\

\

\

\

\

\

19 16 _

I

I

L

\

\

\

11 10

16

19

16

\

12\

15

13

14

17

24

25

20

/

26

Page 27

Craftsman Snowthrower Model 247.88890

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

Part No. Part Description

710-1652

731-1324

732-0710

710-0627

710-3005

05896A

748-0234

756-0987

754-0346

756-0986

736-0270

710-0230

756-0313

710-1245B

712-0181

756-0569

736-0242

736-0505

754-0430B

756-0967

736-0247

736-0331

710-0696

748-0360

710-0654A

629-0071

OEM-390-987

751428974

75142896

7511A173106

684-04014A

710-04082

712-3004A

Hex Washer Screw 1/4-20 x.625

Belt Cover

Extension Spring

Hex Screw 5/16-24 x.75

Hex Cap Screw 3/8-16 x 1.25

Drive Clutch Idler Bracket

Shoulder Spacer

Pulley Half

V-Belt

Pulley Half

Bell Washer

Hex Cap Screw 1/4-28 x.50

Flat Idler

Lock Hex Cap Screw 5/16-24

Lock Jam Nut 3/8-16

Pulley Half

Bell Washer

Flat Washer

Belt

Auger Pulley

Flat Washer 3/8 x 1.25 OD

Bell Washer

Hex Cap Screw 3/8-24

Adapter Pulley

Hex Screw 3/8-16 x 1.0

Extension Cord

Electric Start Kit

Hex Screw #6-32 x 2.5

Hex Screw 1/4-20 x.500

Electric Starter

Engine Shroud Assembly

Screw #10-16 x.75

Flange Lock Nut 5/16-18

NOTE: For painted parts, please refer to the

list of color codes below. Please add the

applicable color code, wherever needed, to

the part number to order a replacement part.

For instance, if a part, numbered 700-xxxx, is

painted red, the part number to order would

be 700-xxxx-0721.

Sears Red: 0721

Powder Black: 0637

27

Page 28

Craftsman Snowthrower Model 247.88890

20

33

34

32

3O

\

28

12

40

38

28

2

37

NOTE: For painted parts, please refer to the

list of color codes below. Please add the

applicable color code, wherever needed, to

the part number to order a replacement part.

For instance, if a part, numbered 700-xxxx, is

painted red, the part number to order would

be 700-xxxx-0721.

Sears Red: 0721

Powder Black: 0637

Page 29

Craftsman Snowthrower Model 247.88890

Ref.

No.

1. 784-5648

2. 710-0896

3. 748-0190

4. 732-0264

5. 712-0711

6. 736-0105

7. 684-0021

8. 746-0898B

9. 656-0012A

10. 784-5689A

11. 713-0413

12. 746-0897

13. 750-0997

14. 711-1042

15. 684-0042C

16. 736-0160

17. 714-0474

18. 741-0563

19. 736-0242

20. 710-0538

21. 710-0875

Part No.

Part Description

Frame Cover

AB Screw 1/4-14 x.625

Spacer

Extension Spring

Jam Nut 3/8-24

Bell Washer

Friction Whl Support Bracket

Drive Cable

Friction Disc

Front Support Guide Bracket

10T Sprocket

Auger Cable

Spacer

Hex Track Shaft

Friction Wheel Assembly

Flat Washer

Cotter Pin

Ball Bearing

Bell Washer

Hex Cap Screw 5/16-18 x.625

Tap Screw 1/4-20 x.75

Ref,

No.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

Part No.

736-0270

736-0176

741-1111

710-0643

748-0234

710-0604A

684-0031

738-0924

756-0625

784-5688

710-0599

784-5590

684-0014B

784-5687A

710-0809

618-0063A

718-0301A

735-0243B

790-00011

790-00010

Part Description

Bell Washer.265 ID x.75 OD

Flat Washer 1/4 ID x.93 OD

Hex Flange Bearing

Hex Cap Screw 5/16-18 x 1"

Shoulder Spacer

Tap Screw 5/16-18 x.625

Frame Assembly

Hex Screw 1/4-28 x.375

Cable Roller

Drive Cable Guide Bracket

Tap Screw 1/4-20 x.5

Shift Frame Bracket

Shift Rod Assembly

Auger Cable Guide Bracket

Tap Screw 1/4-20 x 1.250

Friction Wheel Bearing

Friction Wheel Hub

Friction Wheel Rubber

Friction Plate

Friction Plate

REF.

NO.

1.

8

10

/

17 3

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

PART

NO.

618-0123

618-0418

710-0642

711-0910A

714-0161

715-0143

717-0526A

717-0526

718-0186

721-0325

721-0327

736-0351

736-0369

736-0445

741-0662

741-0663

737-3000

618-0416A

DESCRIPTION

RH Housing

LH Housing

Self Tapping Screw, 1/4-20 x.75

Spiral Axle

Hi-Pro Key

Spring Spiral Pin

Worm Gear, 20-tooth

Worm Shaft

Thrust Collar

Grease Plug

Grease Seal

Flat Washer

Flat Washer

Flat Washer

Flange Bearing

Flange Bearing

Lube Fitting

Gear Assembly Complete

29

Page 30

Craftsman Snowthrower Model 247.88890

5

10

/12

16

20

/ /

15....... _"_"

26

/

44

W

41

14

21 e

22 _ ^

/

/

/.

\ //

/

\\17

\

14

30

Page 31

Craftsman Snowthrower Model 247.88890

Ref.

No.

1. 720-0223

2. 710-0604A

3. 784-5642

4. 710-0157

5. 736-0242

6. 684-0038

7. 710-0459A

8. 712-0214

9. 748-0353A

10. 750-0547

11. 784-5609

12. 684-0009

13. 712-0346

14. 731-1292

15. 736-0272

16. 731-1538A

17. 631-0032

18. 750-0995

19. 738-0140

20. 736-0406

21. 750-0909

22. 712-04063

23. 618-0044

24. 684-0024

25. 710-1231

26. 784-5639

27. 711-0911

Part No.

Ref.

Part Description No. Part No.

Grip 28. 713-0233

Tap Screw, 5/16-18 x.625 29. 618-0169A

Track Lockout Plate 30. 683-0024

Hex Cap Screw, 5/16-24 x.75 31. 713-0437

Bell Washer 32. 741-0339

Track Lock Handle Assembly 33. 736-0287

Hex Cap Screw, 3/8-24 x 1.5 34. 611-0053

Hex Nut, 3/8-24 35. 750-0904

Lift Shaft Drive 36. 618-0043

Spacer 37. 750-0903

Steering Cable Bracket 38. 732-0209

Track Pivot Rod Assembly 39. 710-0602

Jam Nut, 1/2-20 40. 719-0295A

Snow Track 41. 746-0948

Flat Washer 42. 746-0950

Track Drive Wheel 44. 710-1233

Track Idler Wheel 45. 716-0114

Spacer 46. 618-0046B

Screw,.435 x.178-5/16 x.56 47. 717-1211B

Flat Washer 48. 716-0115

Spacer 49. 713-0414

Flange Lock Nut, 5/16-18 50. 711-0912

LH Dogg Assembly 51. 736-0502

Idler Axle Assembly 52. 736-0336

Eye Bolt 53. 715-0120

Track Side Plate 54. 717-1209A

Actuator Shaft 55. 717-1210A

Part Description

Chain

Track/Steering Shaft Assembly

Track Hub Assembly

Chain

Flange Bearing

Flat Washer

Axle Assembly

Spacer

RH Degg Assembly

Spacer

Extension Spring

Tap Screw, 5/16-18 x 1

Track Housing

Steering Cable

Steering Trigger

Screw, #10-24 x 1.375

Retaining Ring

Carrier Assembly

Ring Gear

Retaining Ring

13-Tooth Sprocket

Track Steering Drive Shaft

Fiat Washer

Flat Washer

Spiral Pin

12-Tooth Gear

18-Tooth Gear

NOTE: For painted parts, please refer to the

list of color codes below. Please add the

applicable color code, wherever needed, to

the part number to order a replacement part.

For instance, if a part, numbered 700-xxxx, is

painted red, the part number to order would

be 700-xxxx-0721.

Sears Red: 0721

Powder Black: 0637

31

Page 32

Tecumseh Engine HMSK90-156569G For Craftsman Snow Thrower Model 247.88890

83

87

70

182

69

30

173

207

"169

25

26

322

/

323

f

370C

32

285

93 _.,. /

390 /

_420

370K

287

Page 33

Tecumseh Engine HMSK90-156569G For Craftsman Snow Thrower Model 247.88890

Key No.

1.

2.

3.

5.

14.

15.

15B.

16.

17.

18.

19.

20.

25.

26.

28.

30.

35.

36.

37.

38.

40.

40.

41.

41.

42.

42.

43.

45.

47.

48.

49.

50.

60.

65.

69.

70.

71.

72.

75.

76.

80.

81.

82.

83.

84.

86.

87.

89.

90.

PaN No.

35385

27652

650820

30969

28277

30699C

650494

33454A

29916

651028

34663

35319

37853

650561

30322

35980A

29826

29918

29216

29642