Page 1

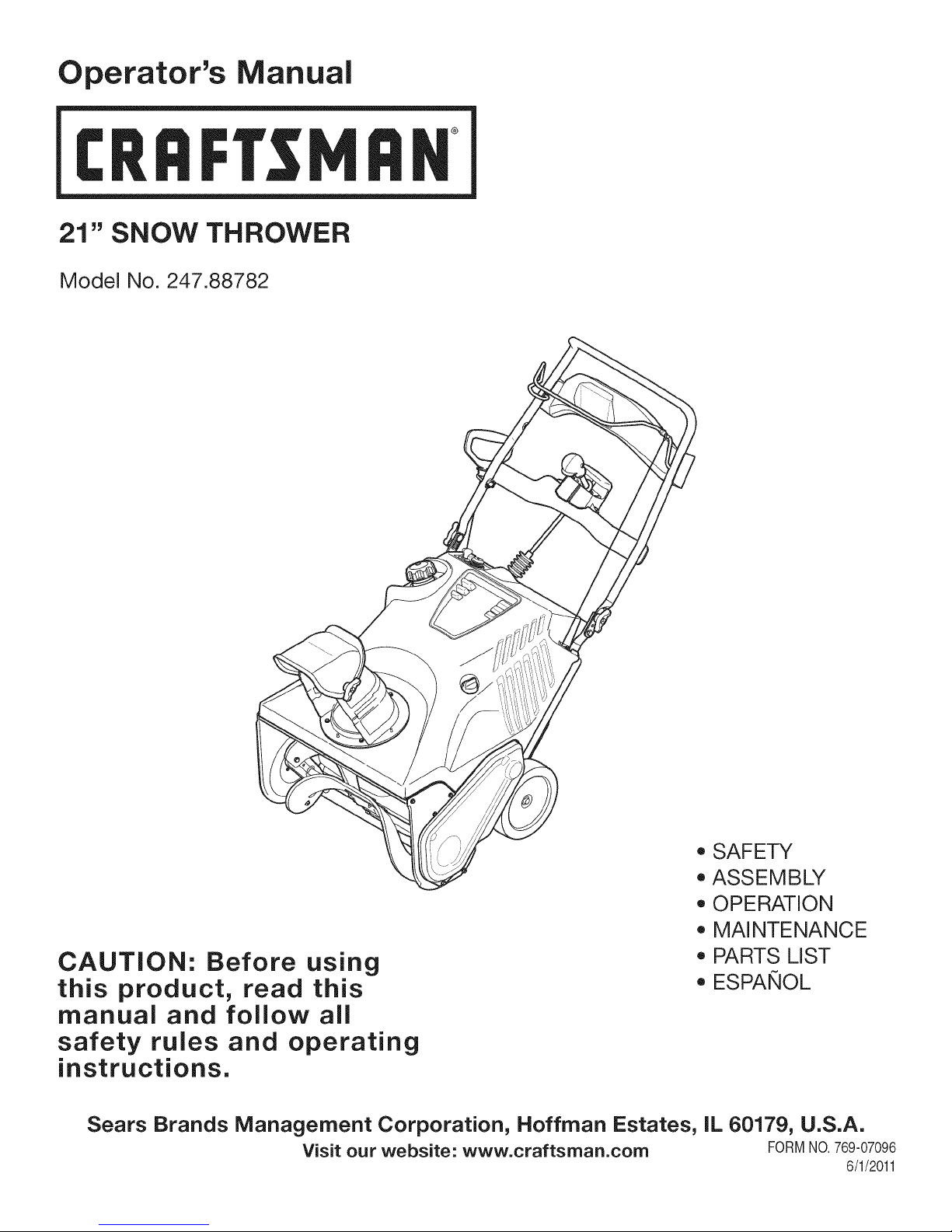

Operator's Manual

CRRFr MRN

21" SNOW THROWER

Model No. 247.88782

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORM1/0.769-07096

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

6/1/2011

Page 2

WarrantyStatement..................................Page2

SafeOperationPractices..........................Pages3-6

Assembly..................................................Pages7-10

Operation..................................................Pages11-13

ServiceandMaintenance.........................Pages14-18

Off-SeasonStorage..................................Page19

Troubleshooting........................................Page20

PartsList...................................................Pages22-25

Labels.......................................................Page26

RepairProtectionAgreement...................Page31

Espafiol.....................................................Page32

ServiceNumbers......................................BackCover

CRAFTSMANTWOYEARFULLWARRANTY

FORTWOYEARSfromthedateofpurchase,thisproductiswarrantedagainstanydefectsinmaterialorworkmanship.Defectiveproductwill

receivefreerepairorfreereplacementifrepairisunavailable.

Thiswarrantyisvoidifthisproductiseverusedwhileprovidingcommercialservicesorifrentedtoanotherperson.

Forwarrantycoveragedetails to obtain repairor replacement,visit the website: www.craftsman.com

This warranty covers ONLYdefects in material andworkmanship.Warrantycoverage does NOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbut not limitedto augers,augerpaddles,drift

cutters,skidshoes,shaveplate,shearpins,sparkplug,aircleaner,belts,andoil filter.

• Standardmaintenanceservicing,oilchanges,or tune-ups.

• Tire replacementorrepaircausedbypuncturesfromoutsideobjects,suchas nails,thorns,stumps,orglass.

Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedtodamagecausedbyover-speedingtheengine,orfromimpacting

objectsthatbendtheframe,augershaft,etc.

• Repairsnecessarybecauseof operatornegligence,includingbutnot limitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeandamountofengineoil,or failureto maintainthe equipmentaccordingtotheinstructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfuel determinedto becontaminatedoroxidized(stale).In general,fuelshouldbeused

within30 daysof itspurchasedate.

Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineOilType: SAE5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 2 Quarts

SparkPlug: F6RTC

SparkPlugGap: .020"-.030"

©KCDIR LLC

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Page 3

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsinthismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothe safeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron thepartoftheoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionsonthemachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Failuretodo socan resultinseriousinjurytothe operatorand/

orbystanders.Keepthismanualina safeplaceforfutureand

regularreferenceandfororderingreplacementparts.Toorder

replacementpartscall,1-800-4MY-HOME.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthemachineanddisengagethemquickly.

• Neverallowchildrenunder14yearsofagetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesinthismanualandon

themachineandbetrainedandsupervisedbyanadult.

Neverallowadultsto operatethis machinewithoutproper

instruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthelike.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileit is in operation.Stopmachineifanyoneenters

thearea.

• Exercisecautiontoavoidslippingorfalling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict theuseofthispowermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandon themachine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentisto beused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbytheauger/

impeller.

• Alwayswearsafetyglassesor eyeshieldsduringoperationand

whileperforminganadjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjuryto the

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

Disengageallcontrolleversbeforestartingtheengine.

• Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjusttooutdoortemperaturebefore

startingtoclearsnow.

3

Page 4

SafeHandlingof Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

onyourselforyourclotheswhichcanignite. Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipesandother sourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuelwhiletheengineis hot or

running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfuel tank.Filltankto nomorethan1/2inchbelow

bottomoffillerneckto providespaceforfuel expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff theengineandequipment.Move

machinetoanotherarea.Wait5 minutesbeforestartingthe

engine.

• Neverstorethe machineorfuel containerinsidewherethereisan

openflame,sparkor pilotlight(e.g.furnace,waterheater,space

heater,clothesdryeretc.).

• Allowmachinetocool at least5 minutesbeforestoring.

• Neverfill containersinsideavehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthegroundaway

fromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruckor

trailerandrefuelit ontheground.Ifthis is not possible,then refuel

suchequipmentona trailerwitha portablecontainer,ratherthan

froma gasolinedispensernozzle.

• Keepthe nozzlein contactwiththerimofthefueltankor

containeropeningatalltimes untilfuelingiscomplete.Donot use

a nozzlelock-opendevice.

OPERATION

• Do not puthandsorfeetnear rotatingparts,in the auger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleveris a safetydevice.Neverbypass

itsoperation.Doingsomakesthemachineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewitha missingor damagedchuteassembly.Keep

all safetydevicesin placeandworking.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Do notoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancausea burn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingonorcrossinggravel

surfaces.Stayalertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc. Thus,avoidingpossibleproperty

damageorpersonalinjurycausedbya ricochet.

Preventpossiblepropertydamageorpersonalinjuryfrom

objectricochetbyplanningyoursnowthrowingpatterntoavoid

dischargetowardswindows,walls,cars,etc.

• Donotoverloadmachinecapacitybyattemptingtoclearsnowat

toofastof a rate.

• Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingandkeepafirmholdon the handles.Walk,

neverrun.

• Disengagepowertotheauger/impellerwhentransportingor not

in use.

• Neveroperatemachineathightransportspeedsonslippery

surfaces.Lookdownand behindand usecarewhenbackingup.

• Ifthemachineshouldstartto vibrateabnormally,stoptheengine,

disconnectthe sparkplugwireandgrounditagainsttheengine.

Inspectthoroughlyfordamage.Repairanydamagebefore

startingandoperating.

• Disengageallcontrolleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntilthe auger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makinganyadjustments,orinspections.

• Neverputyourhandinthedischargeorcollectoropenings.Do

notunclogchuteassemblywhileengineisrunning.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.).

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthan youcanletgo.Broken

bones,fractures,bruisesorsprainscould result.

• Call 1-800-4MY-HOMEfor the locationof the nearestSearsParts

& RepairServiceCenter.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

is themostcommoncauseof injuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,not yourhands.

4

Page 5

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntilthe auger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheengineto preventunintendedstarting.

Checkboltsand screwsfor propertightnessat frequentintervals

tokeepthe machineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingorover-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsandreplacewithoriginalequipmentmanufacturer's

(OEM)partsonlyas listedinthe Partspagesof thisOperator's

Manual.Useofpartswhichdonot meetthe originalequipment

specificationsmayleadto improperperformanceandcompro-

misesafety!

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Referto the adjustment

sectioninthisoperator'smanualforinstructions.

Maintainorreplacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsand regulationsforgas,oil,etc.to

protecttheenvironment.

Priorto storing,runmachinea few minutestoclearsnowfrom

machineandpreventfreezeupofauger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkorpilotlightsuchasa waterheater,furnace,

clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank,cap,andfittingsfrequentlyfor cracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or60 hoursof

operation.At the endoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failuretodo socan resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMiSSiONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateon regularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(ifany)

Ifa sparkarrestorisused,it shouldbe maintainedin effectiveworking

orderbytheoperator.IntheStateof Californiatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthe mufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

Page 6

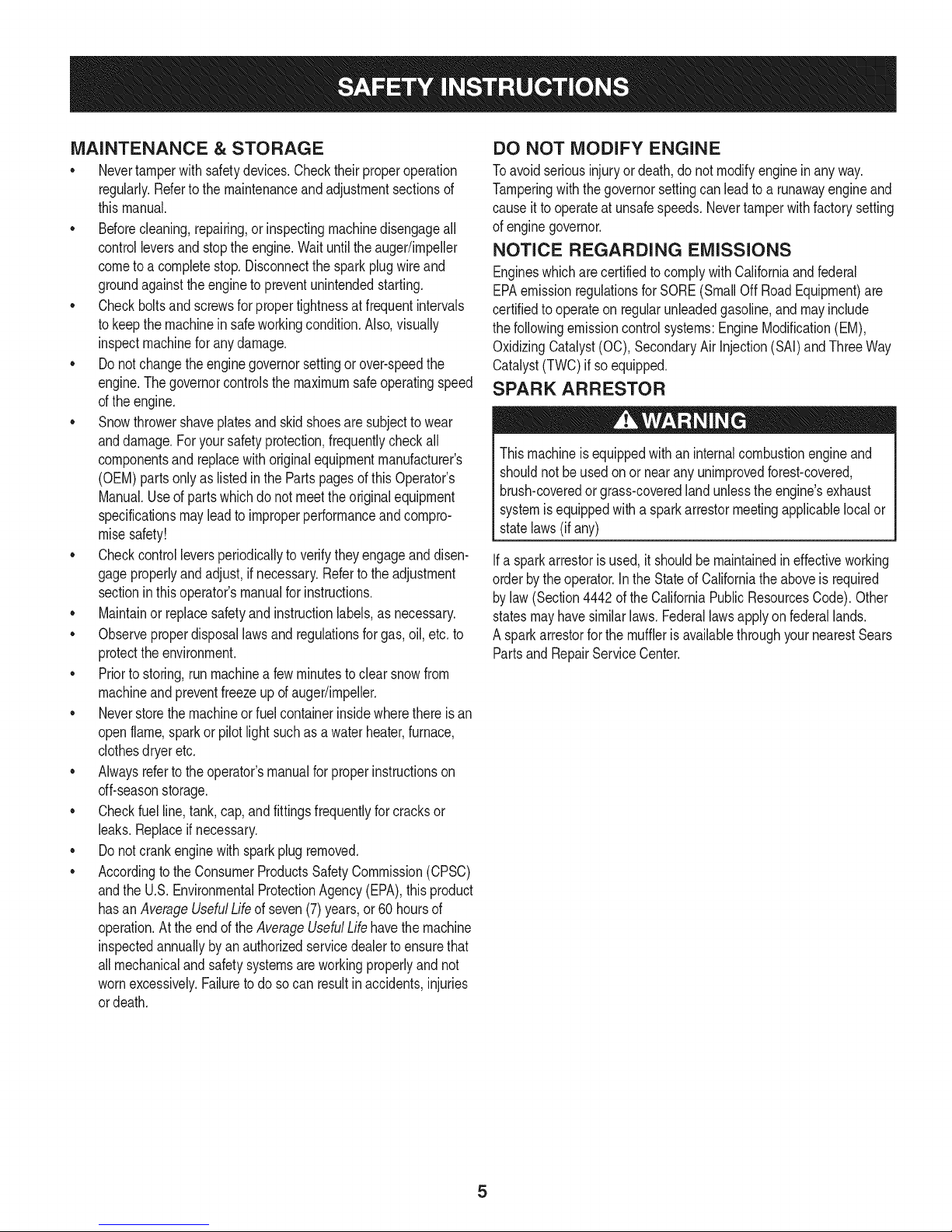

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

. +

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

"JIp

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE ISFLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas+

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

6

Page 7

NOTE:All referencestotheleftor rightsideofthesnowthrowerare

fromtheoperator'sposition.Anyexceptionswill be noted.

UNPACKING THE SNOW THROWER

1. Openthetopofthecarton.

2. Cutdownthecornersonthefrontof thecartonandfolddownthe

frontside.

3. Pullthesnowthroweroutofthecarton.Besurenotto damage

thechute,chuterotationcontrolassemblyoranycablesattached

tothechute.Someofthesepartsareshippedundertheshroud

onthebacksideofthecarton.Checkforanycabletiessecuring

thechuteand removeifnecessary.

ASSEMBLY

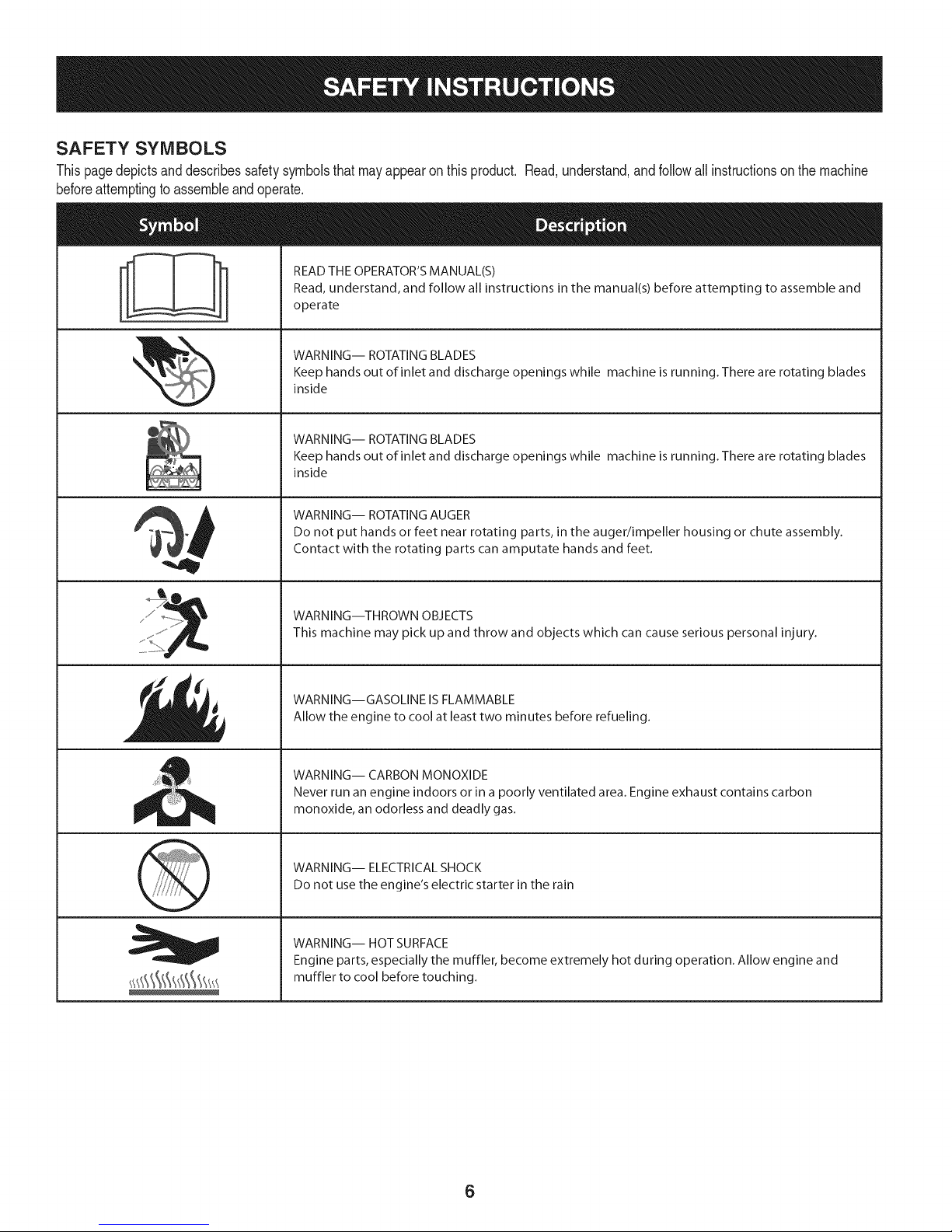

Positioning the Upper Handle

1. Removethewingknobandcarriageboltfromthe top of the lower

handle.SeeFigure1.Itis notnecessarytoremovetheshoulder

screwandflangelocknutbelowthewingknobandcarriagebolt.

g Knob

CarriageBolts

Win(

2. Pivottheupperhandleintotheoperatingposition.Besurenotto

pinchanyof the cablesin theprocess.SeeFigure2.

Wing

/ J'................... Knob

Figure2

.

Thehandlecanbesetin threedifferentposition.Placethehandle

in the desiredpositionandtheninstallwingknobsandcarriage

boltsin theappropriateholeandsecurethehandle.SeeFigure3.

Figure1

.J

ing

Knob

Figure3

7

Page 8

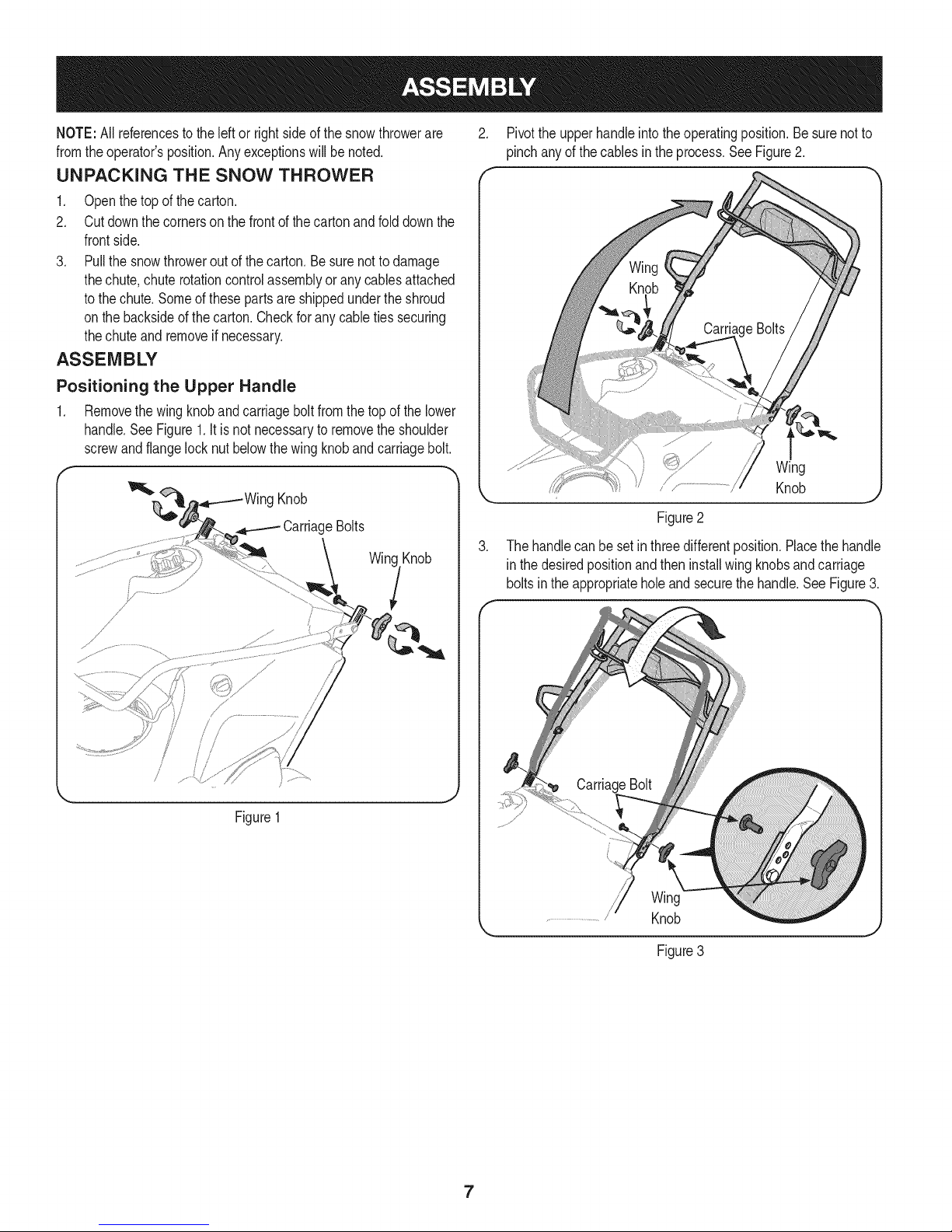

installing the Chute

1. Removethehexwasherscrewsinthechutebase.SeeFigure4.

HexWasher

Screw_,

/

/

Figure4

.

Aligntheholesinthechutebasewiththe holesinthe lowerchute

andsecurewiththepreviouslyremovedhexwasherscrews.See

Figure5.

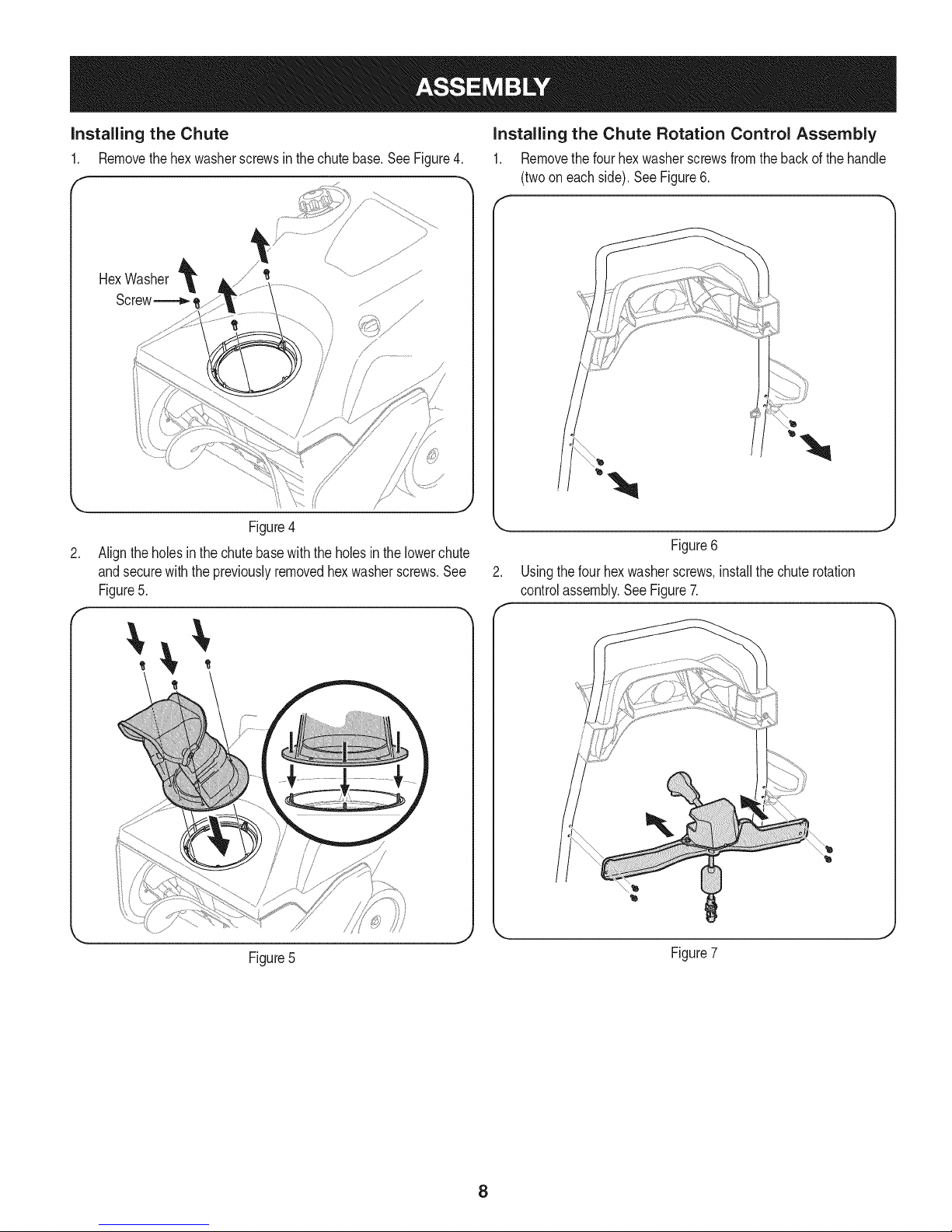

Installing the Chute Rotation Control Assembly

1. Removethefourhexwasherscrewsfromthebackofthehandle

(twoon eachside).SeeFigure6.

Figure6

Usingthefour hexwasherscrews,installthechuterotation

controlassembly.SeeFigure7.

Figure5

Figure7

8

Page 9

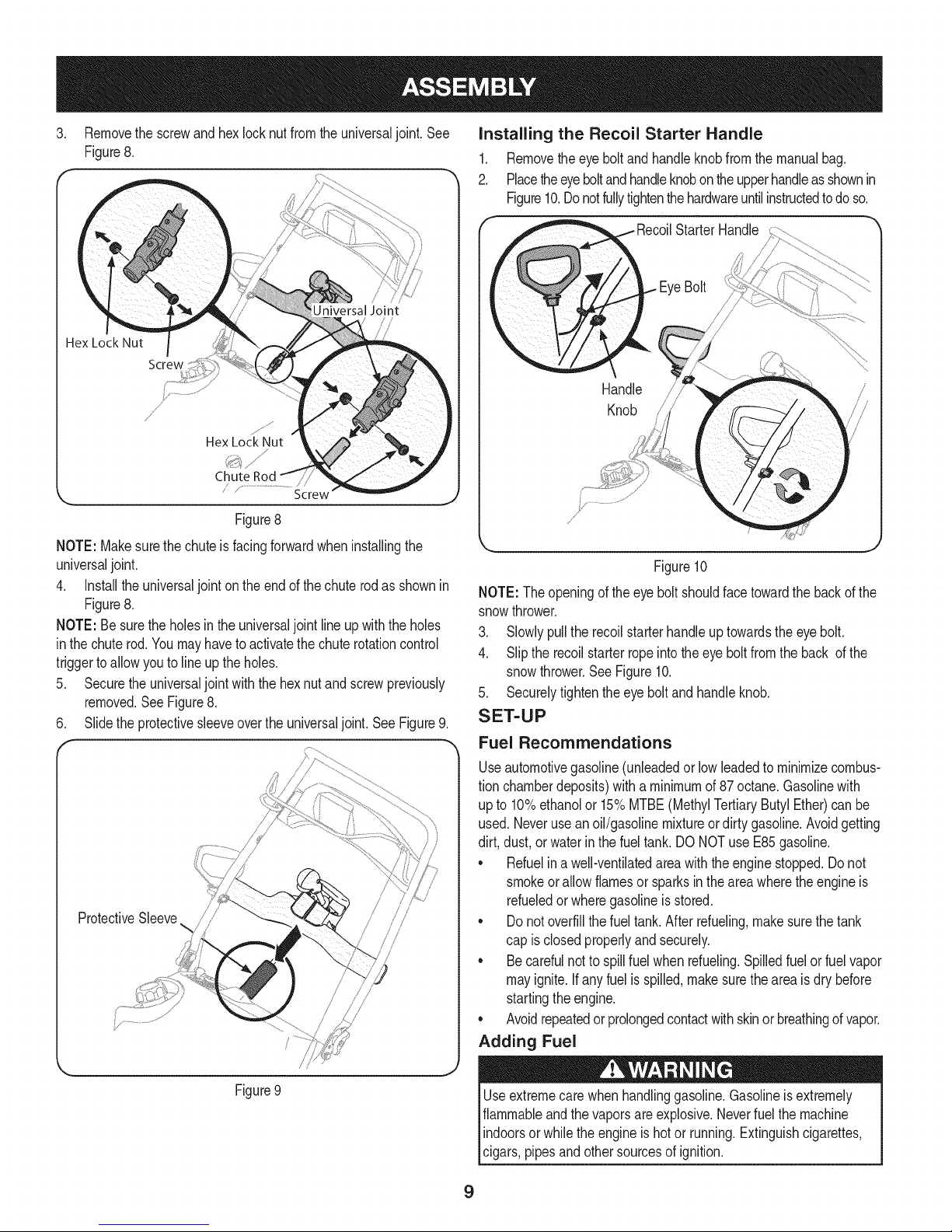

3. Removethe screwandhexlocknutfromtheuniversaljoint.See

Figure8.

Universal Join{

Hex Lock Nut

Screw

f

/

//

Hex Lock Nut

Chute

/_ "..............................................Screw

Figure8

NOTE:Makesurethe chuteis facingforwardwheninstallingthe

universaljoint.

4. Installthe universaljointon theend ofthechuterodasshownin

Figure8.

NOTE:Besuretheholesinthe universaljointlineup withthe holes

inthechuterod.Youmayhavetoactivatethechuterotationcontrol

triggerto allowyoutoline uptheholes.

5. Securetheuniversaljointwiththehexnutandscrewpreviously

removed.See Figure8.

6. Slidethe protectivesleeveovertheuniversaljoint.See Figure9.

/

ProtectiveSleeve%/ ,

/

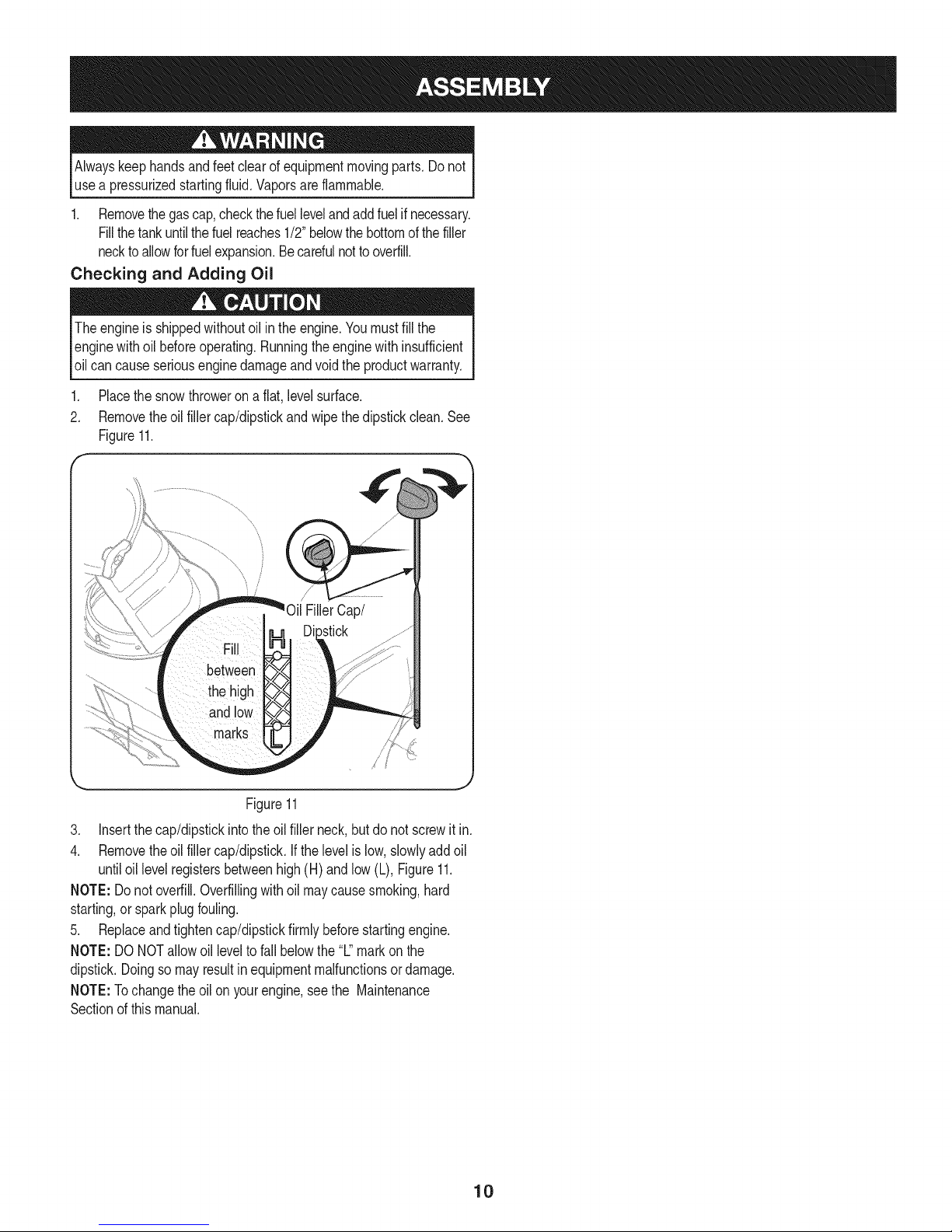

Installing the Recoil Starter Handle

1. Removetheeyeboltandhandleknobfromthemanualbag.

2. Placetheeyeboltandhandleknobonthe upperhandleas shownin

Figure10.Donotfullytightenthehardwareuntilinstructedtodoso.

Handle /

Knob

J

j

Figure10

NOTE:Theopeningof the eyeboltshouldfacetowardthe backofthe

snowthrower.

3. Slowlypullthe recoilstarterhandleuptowardstheeyebolt.

4. Slipthe recoilstarterropeinto theeyeboltfromtheback of the

snowthrower.See Figure10.

5. Securelytightentheeyebolt andhandleknob.

SET-UP

Fuel Recommendations

Useautomotivegasoline(unleadedorlowleadedtominimizecombus-

tionchamberdeposits)witha minimumof87 octane.Gasolinewith

up to 10%ethanolor15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureordirty gasoline.Avoidgetting

dirt, dust,or waterinthe fuel tank.DONOTuseE85gasoline.

• Refuelina well-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksintheareawheretheengineis

refueledor wheregasolineisstored.

• Donotoverfillthe fueltank.After refueling,makesurethetank

capisclosedproperlyandsecurely.

• Becarefulnotto spillfuel whenrefueling.Spilledfuelorfuelvapor

mayignite.Ifany fuelis spilled,makesuretheareaisdrybefore

startingthe engine.

• Avoidrepeatedor prolongedcontactwithskinorbreathingofvapor.

Adding Fuel

Figure9

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuelthemachine

indoorsorwhilethe engineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

9

Page 10

Alwayskeephandsandfeetclearof equipmentmovingparts.Do not

usea pressurizedstartingfluid.Vaporsare flammable.

1. Removethegascap,checkthefuellevelandaddfuel if necessary.

Fillthetankuntilthefuel reaches1/2"belowthebottomofthefiller

necktoallowforfuelexpansion.Becarefulnottooverfill.

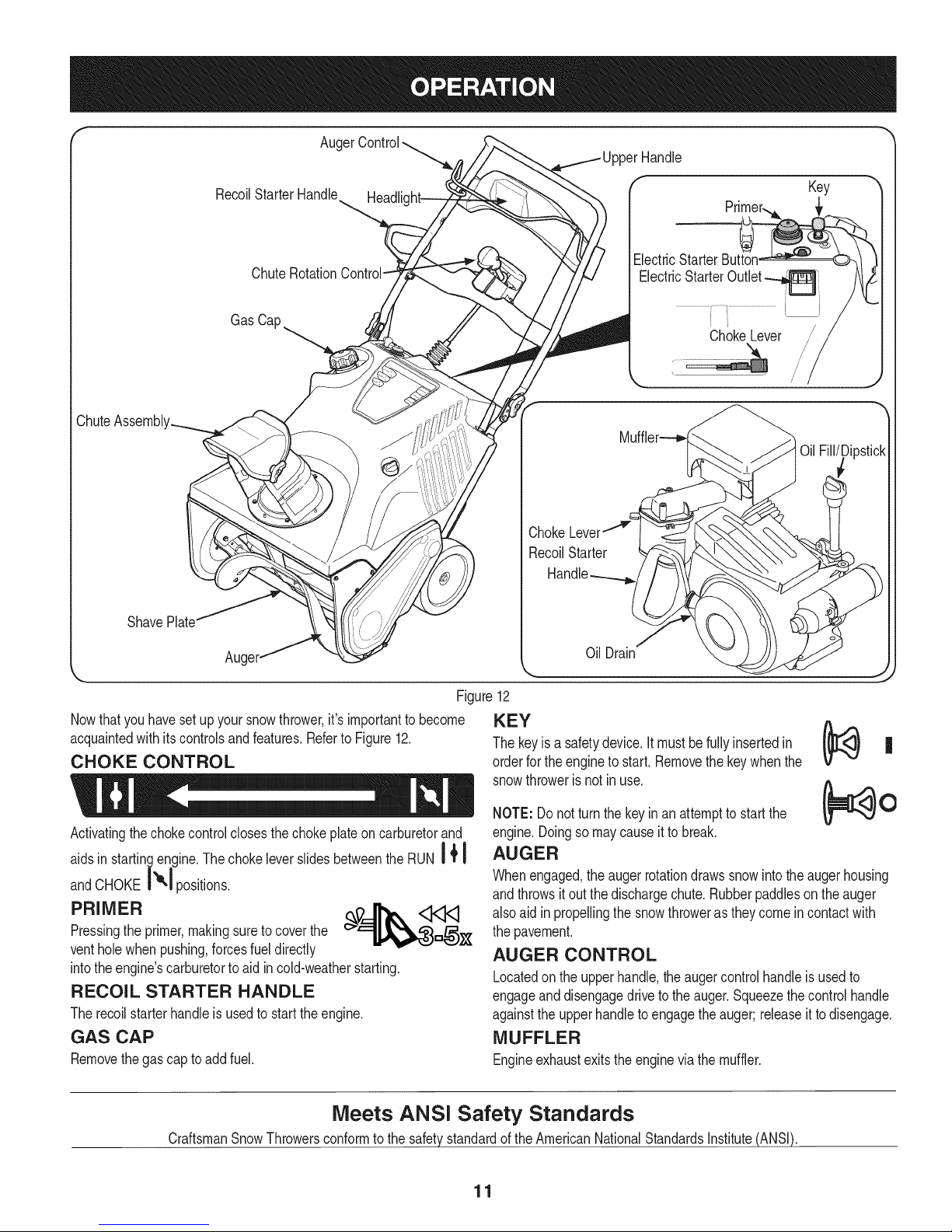

Checking and Adding Oil

Theengineis shippedwithoutoil in theengine.Youmustfill the

enginewithoilbeforeoperating.Runningtheenginewithinsufficient

oilcancauseseriousenginedamageandvoid the productwarranty.

Placethe snowthrowerona flat, levelsurface.

2. Removetheoil fillercap/dipstickandwipethedipstickclean.See

Figure11.

\

Figure11

.

Insertthe cap/dipstickintotheoilfillerneck,butdo notscrewit in.

4.

Removetheoil fillercap/dipstick.Ifthelevelis low,slowlyaddoil

untiloil levelregistersbetweenhigh(H) andlow(L), Figure11.

NOTE:Donot overfill.Overfillingwithoil maycausesmoking,hard

starting,or sparkplugfouling.

5. Replaceandtightencap/dipstickfirmlybeforestartingengine.

NOTE:DONOTallowoil leveltofallbelowthe"L"markonthe

dipstick.Doingsomayresultin equipmentmalfunctionsordamage.

NOTE:Tochangetheoilon yourengine,seethe Maintenance

Sectionofthismanual.

10

Page 11

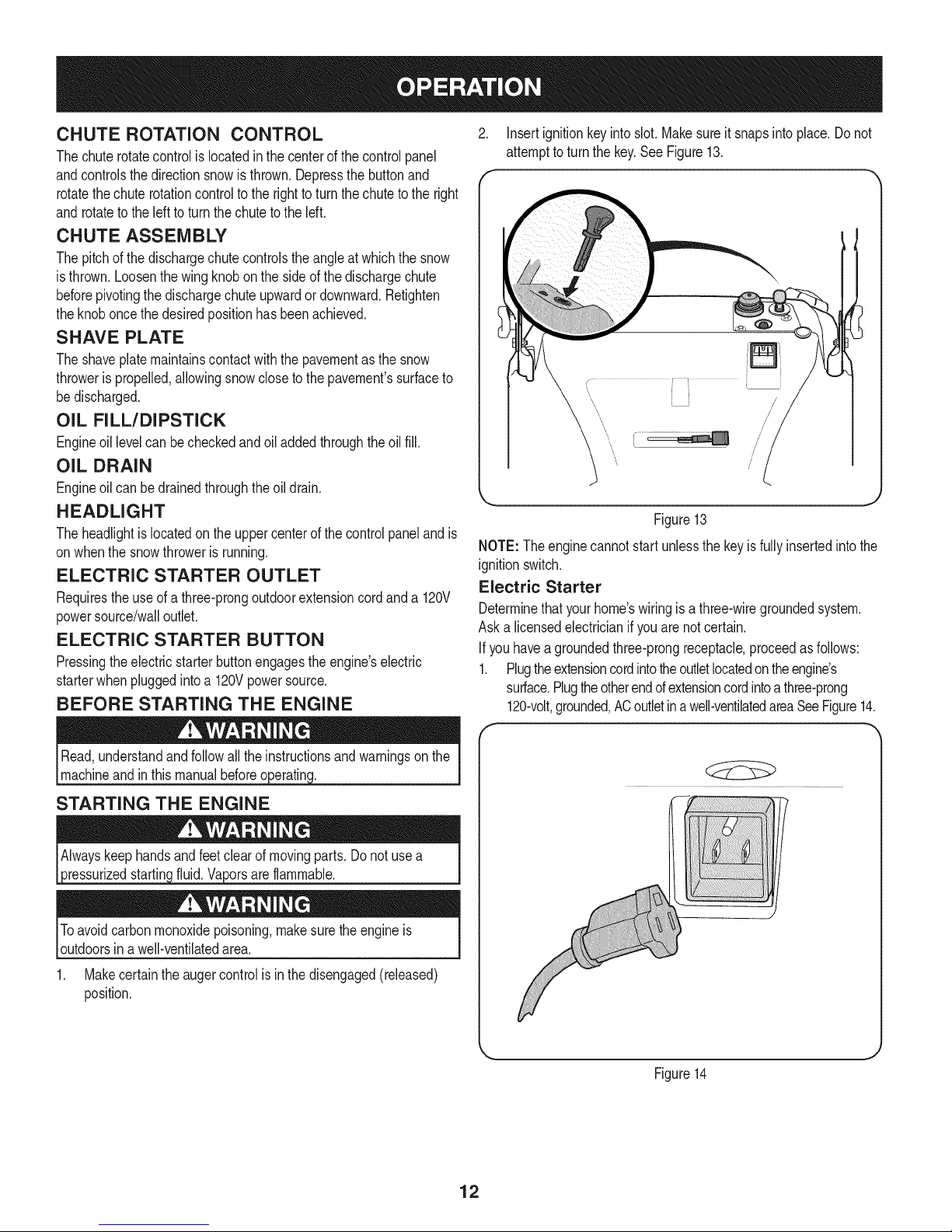

f Auger

ChuteAssembl'

Shave

RecoilStarterHandle

ChuteRotation

GasCap

Key

ElectricStarterButton

ElectricStarterOutlet

Aug

Nowthatyouhavesetupyoursnowthrower,it'simportanttobecome

acquaintedwithitscontrolsandfeatures.RefertoFigure12.

CHOKE CONTROL

Activatingthechokecontrolclosesthechokeplateoncarburetorand

aidsin startingengine.ThechokeleverslidesbetweentheRUNI { I

|

andCHOKEi'_ positions.

Pressing the primer, making sure to cover the

ventholewhenpushing,forcesfueldirectly

intothe engine'scarburetorto aidin cold-weatherstarting.

RECOIL STARTER HANDLE

Therecoilstarterhandleisusedtostarttheengine.

GAS CAP

Removethegascaptoaddfuel.

Oil Drain

12

Figure

KEY

Thekeyisa safetydevice.Itmustbefullyinsertedin

orderfortheengineto start.Removethekeywhenthe

snowthrowerisnotinuse.

NOTE:Do notturnthekeyinan attemptto startthe

engine.Doingsomaycauseittobreak.

AUGER

Whenengaged,theaugerrotationdrawssnowintothe augerhousing

andthrowsitout the dischargechute.Rubberpaddlesontheauger

alsoaidin propellingthesnowthrowerastheycomein contactwith

thepavement.

AUGER CONTROL

Locatedontheupperhandle,theaugercontrolhandleis usedto

engageanddisengagedrivetotheauger.Squeezethecontrolhandle

againsttheupperhandletoengagetheauger;releaseittodisengage.

MUFFLER

Engineexhaustexitstheengineviathemuffler.

CraftsmanSnowThrowersconformto the safetystandardoftheAmericanNationalStandardsInstitute(ANSI).

Meets ANSI Safety Standards

11

Page 12

CHUTE ROTATION CONTROL

Thechuterotatecontrolis locatedin thecenterof the controlpanel

andcontrolsthedirectionsnowisthrown.Depressthe buttonand

rotatethechuterotationcontroltothe rightto turnthe chuteto the right

androtatetothelefttoturnthechutetotheleft.

CHUTE ASSEMBLY

Thepitchofthedischargechutecontrolstheangleatwhichthe snow

isthrown.Loosenthe wing knobonthe side of the dischargechute

beforepivotingthedischargechuteupwardordownward.Retighten

theknoboncethedesiredpositionhasbeenachieved.

SHAVE PLATE

Theshaveplatemaintainscontactwiththepavementasthesnow

throwerispropelled,allowingsnowcloseto thepavement'ssurfaceto

bedischarged.

OIL FILL/DIPSTICK

Engineoillevelcanbecheckedandoil addedthroughtheoil fill.

OIL DRAIN

Engineoilcanbedrainedthroughtheoil drain.

HEADLIGHT

Theheadlightislocatedon the uppercenterof the controlpanelandis

onwhenthesnowthroweris running.

ELECTRIC STARTER OUTLET

Requirestheuseofa three-prongoutdoorextensioncordanda 120V

powersource/walloutlet.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa120Vpowersource.

BEFORE STARTING THE ENGINE

2. Insertignitionkeyinto slot.Makesureitsnapsintoplace.Donot

attempttoturnthekey.SeeFigure13.

Figure13

NOTE:Theenginecannotstartunlessthe keyis fullyinsertedintothe

ignitionswitch.

Electric Starter

Determinethatyourhome'swiringisa three-wiregroundedsystem.

Aska licensedelectricianifyou arenotcertain.

Ifyouhaveagroundedthree-prongreceptacle,proceedasfollows:

1. Plugtheextensioncordintotheoutletlocatedontheengine's

surface.Plugtheotherendofextensioncordintoathree-prong

120-volt,grounded,ACoutletinawell-ventilatedareaSeeFigure14.

f

machineandinthismanualbefore

STARTING THE ENGINE

3ressurizedstartinc areflammable.

Toavoidcarbonmonoxidepoisoning,makesuretheengineis

outdoorsin awell-ventilatedarea.

1. Makecertaintheaugercontrolisin thedisengaged(released)

position.

Figure14

12

Page 13

2. PushthechokelevertotheCHOKEI'e,I position.

a

3. If theengineiswarm,placethechokeinthe RUNi ! position

insteadof CHOKEI_1.

4. Pushthe primerthree(3) times,makingsuretocoverthe vent

holewhenpushing.

5. If theengineiswarm,pushthe primerbuttononlyonce.

6. Pushstarterbuttontostartengine.

7. Oncethe enginestarts,releasestarterbutton.

8. Allowtheengineto warmup severalminutes,adjustingchoke

| |

towardRUN| _position.Waituntilenginerunssmoothlybefore

eachchokeadjustment.

9. Whendisconnectingtheextensioncord,alwaysunplugtheend

atthethree-prongwalloutletbeforeunpluggingtheoppositeend

fromthesnowthrower.

Recoil Starter

1. Pushthechokeleverto the CHOKEI_1 position.

2. If theengineiswarm,placethechokeinthe RUNI_1 position

insteadof CHOKEI"_1.

3. Pushthe primerthree(3) times,makingsuretocoverthe vent

holewhenpushing.

4. If theengineiswarm,pushthe primerbuttononlyonce.

5. Graspthe recoilstarterhandleandslowlypullthe ropeout.At

thepointwhereitbecomesslightlyhardertopulltherope,slowly

allowthe ropeto recoil.

6. Pullthestarterhandlewitha firm, rapidstroke.Donot release

thehandleandallowitto snap back.Keepa firmholdonthe

starterhandleandallowit to slowlyrecoil.

7. Allowtheengineto warmup severalminutes,adjustingchoke

| |

towardRUN| _position.Waituntilenginerunssmoothlybefore

eachchokeadjustment.

STOPPING THE ENGINE

1. Runthe enginefora fewminuteswithoutloadbeforestoppingto

helpdryoff anymoistureontheengine.

2. Tostoptheengineremovethekeyand storeit in asafeplace.

3. Wipeallthesnowandmoistureawayfromtheenginecontrols

area.

Muffler,engineandsurroundingareasbecomehotandcan causea

burn.Becarefulanddonot touchwhentheyare hot.

ENGAGING THE AUGER

Engagethe augerby squeezingtheaugercontrolagainsttheupper

handle.Releasethecontroltostoptheauger.

ENGAGING THE DRIVE

Liftup slightlyontheupperhandletoallowthe rubberpaddleson the

augertocontactthepavementandpropelthe snowthrowerforward.

Pushingdownwardonthe handlewill raisetheaugeroff theground

and stopthe forwardmotion.

NOTE:Excessiveupwardpressureonthehandlewillresultin

prematureweartotherubberaugerpaddles,whichwillnotbecovered

bythe warranty.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

isthe mostcommoncauseof injuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanoutthe dischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtoolor stick,notyourhands.

13

Page 14

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilall movingpartshavecome

toa completestop.Disconnectsparkplugwireandgrounditagainst

theenginetopreventunintendedstarting.Alwayswearsafetyglasses

duringoperationorwhileperforminganyadjustmentsor repairs.

Eachuse .

Engineoillevel.

2.

Snowthrowerandexhaust

1. Check

2. Clean

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumntokeeptrackof

completedmaintenancetasks.To locate the nearestSearsService

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

= =

area.

1st5 hours 1. 1. Change.

Every5hours 1. 1. Check.

25 hours 1. 2. Check.

Everyseason/50hours 1. 1. Change

Everyseason/100hours 1. 1. Clean,replace,re-gap

Everyseason/Before 1. 1. Lubricate

storage 2. 2. Lubricate

ENGINE MAINTENANCE

Engineoil.

Engineoil.

Exhaustarea.

2. 2. Clean.

Sparkplug.

Engineoil

Sparkplug

Pivotpoints

Controlhandle

3. 3. Lubricate

Extensionspring

Engineoilcapacityis600ml (approx.20oz.). Do notover-fill.Usea

4-stroke,oran equivalenthighdetergent,premiumqualitymotoroil

certifiedto meetor exceedU.S.automobilemanufacturer'srequire-

mentsfor serviceclassificationSG,SE MotoroilsclassifiedSG,SF

usedoil.

Oil Recommendations

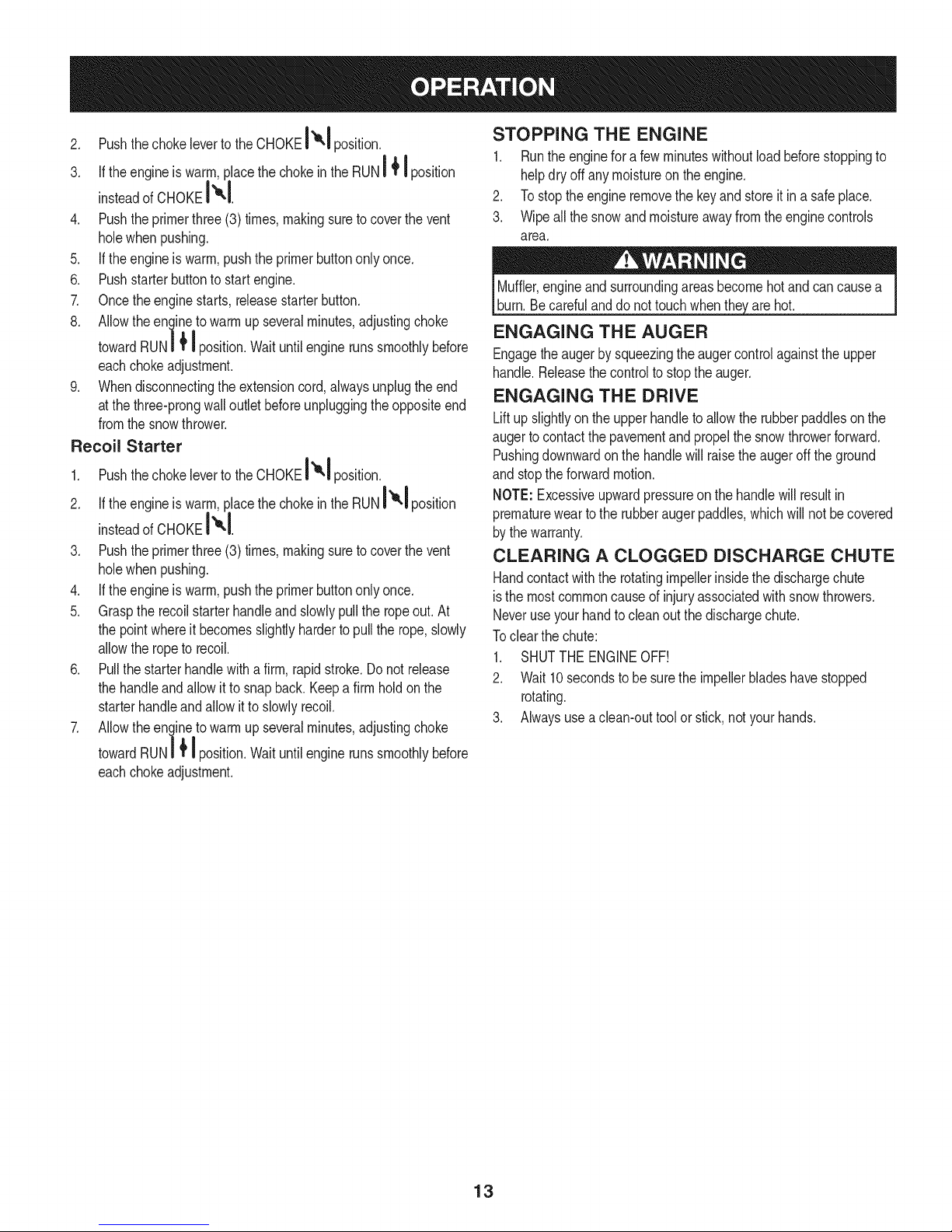

Whenaddingoiltotheengine,referto theviscositychartbelow

willshowthis designationon thecontainer.

NOTE:Pleasedisposeofusedmotoroilin amannerthatisfriendlyto

theenvironment.Takeittoa recyclingcenteror othercollectioncenter.

(Figure15).

DONOTusenon-detergentoil or2-strokeengineoil.It couldshorten

I

£

F-

O

Lf_

- r I ] [

theengine'sservicelife.

Changing Engine Oil

Shutofftheengineand removetheignitionkeybeforeperforming

anymaintenance.Topreventaccidentalstart-up,disconnectthe

mW/==b,

Iv

sparkplugboot.

Periodicinspectionandadjustmentoftheengineisessentialifhigh

levelperformanceis to bemaintained.Regularmaintenancewillalso

oJ t'_

CL

mm /m!

V

ensurea longservicelife.The requiredserviceintervalsandthetype

of maintenancetobe performedaredescribedinthe tableabove.

Followthehourlyorcalendarintervals,whicheveroccurfirst.More

mm mlb,

I-=

(°C) =30° -20o =10o 0o 100 200 300 400

(oF)-20 o 0o 150 300 500 700 850 1050

frequentserviceis requiredwhenoperatinginadverseconditions.

Checkoil levelbeforeeachuseandevery5 operatinghourswhenthe

engineiswarm.RefertoCheckingandAddingOilintheAssembly

Section.

Changetheoil afterthe first5 operatinghoursandevery50 operating

Figure15

hoursthereafter.EngineshouldstillbewarmbutNOThotfrom recent

use.

14

Page 15

.

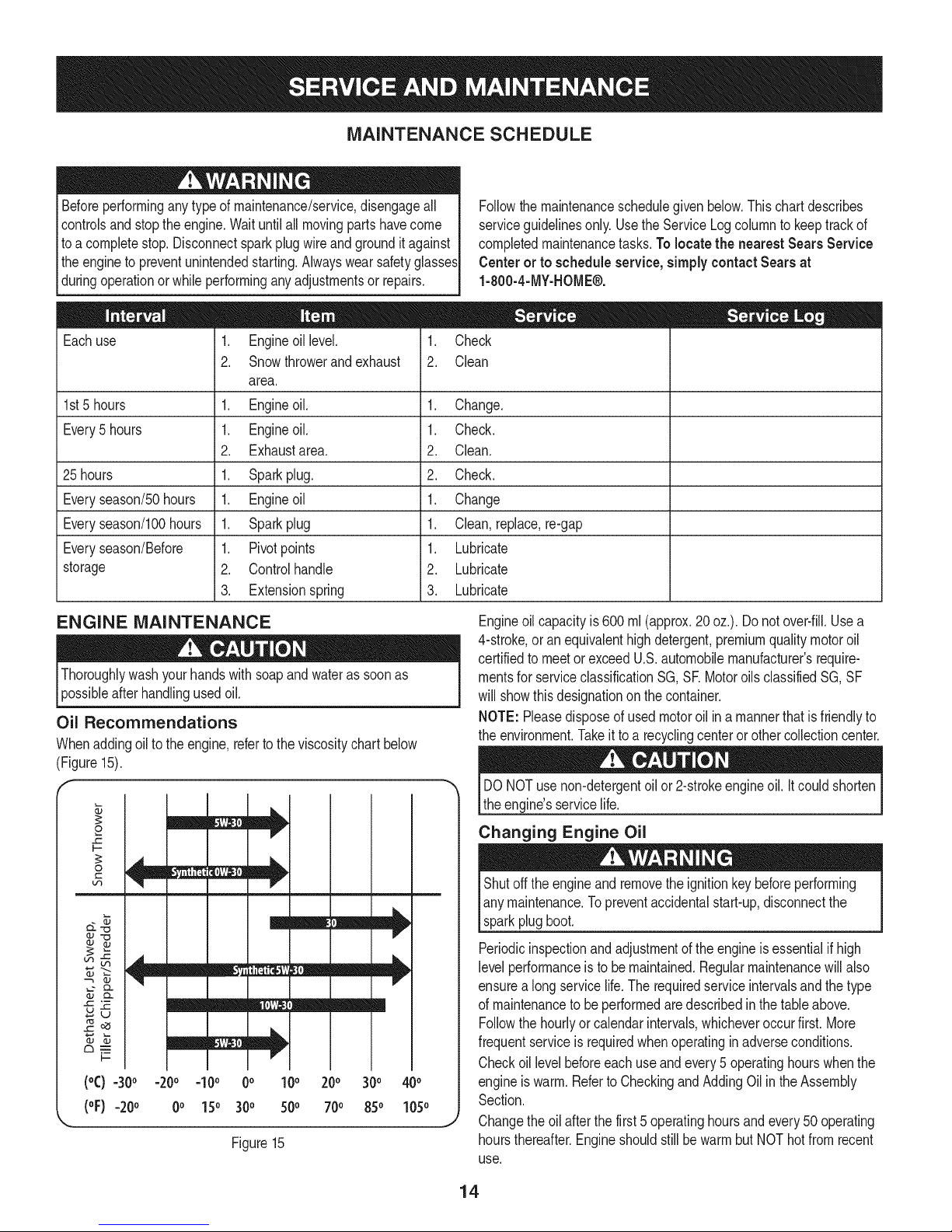

Drainfuelfromthe tankby runningtheengineuntilthefueltankis

empty.Besurethefuel fill capis secure.

2.

Removethethreescrewsthatsecurethelowerpanel.Removethe

lowerpanelbyliftinguponthe paneltofreethetabsatthe bottom

d thepanelfromthetab slotsandthenpullback.SeeFigure16.

f

7. Refillwiththerecommendedoiland checktheoil level;referto

CheckingandAddingOil intheAssemblySection.

8. Reinstallthe oil fillercap/dipsticksecurely.

9. Re-installthe lowerpanelbyplacingthetabs inthe tab slots,

liftingthepanelintoplaceandsecurewiththethreescrews

removedinstep2.

Spark Plug

DONOTcheck fora sparkwiththesparkplugremoved.DONOT

cranktheenginewiththesparkplugremoved.

Iftheenginehasbeenrunning,the mufflerwillbeveryhot. Becareful

nottotouchthemuffler.

/

k. j

Figure16

NOTE:The bottomofthepanelhastabsthathelpholdit inplace.

NOTE:An oildrainextensionkitisavailableseparately.Contacta

SearsPartsand RepairCenterforkit#753-06684.

3. Placea suitableoilcollectioncontainerundertheoildrainplug.

4. Removetheoil drainplug,Figure17.

F 1

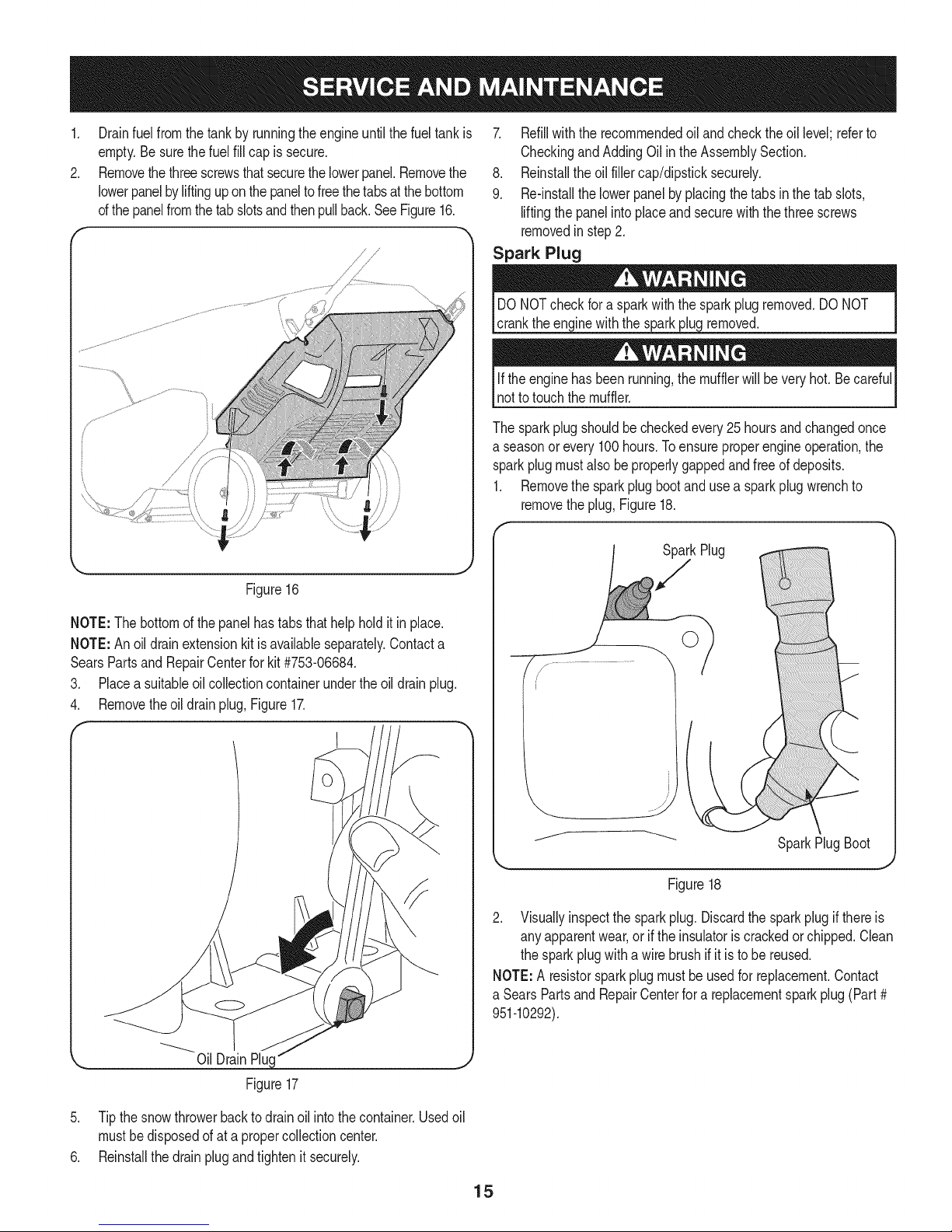

Thesparkplugshouldbecheckedevery25hoursandchangedonce

a seasonor every100hours.Toensureproperengineoperation,the

sparkplugmustalsobeproperlygappedandfreeof deposits.

1. Removethesparkplugbootand usea sparkplugwrenchto

removetheplug,Figure18.

SparkPlugBoot

k_ Oil DrainPlug

Figure17

5. Tipthesnowthrowerbacktodrainoil intothecontainer.Usedoil

mustbedisposedofata propercollectioncenter.

6. Reinstallthedrainplugandtightenit securely.

Figure18

2. Visuallyinspectthe sparkplug. Discardthe sparkplugifthereis

anyapparentwear,or if theinsulatoriscrackedorchipped.Clean

thesparkplugwitha wirebrushifit istobe reused.

NOTE:A resistorsparkplugmustbeusedforreplacement.Contact

a Sears PartsandRepairCenterfora replacementsparkplug(Part#

951-10292).

15

Page 16

.

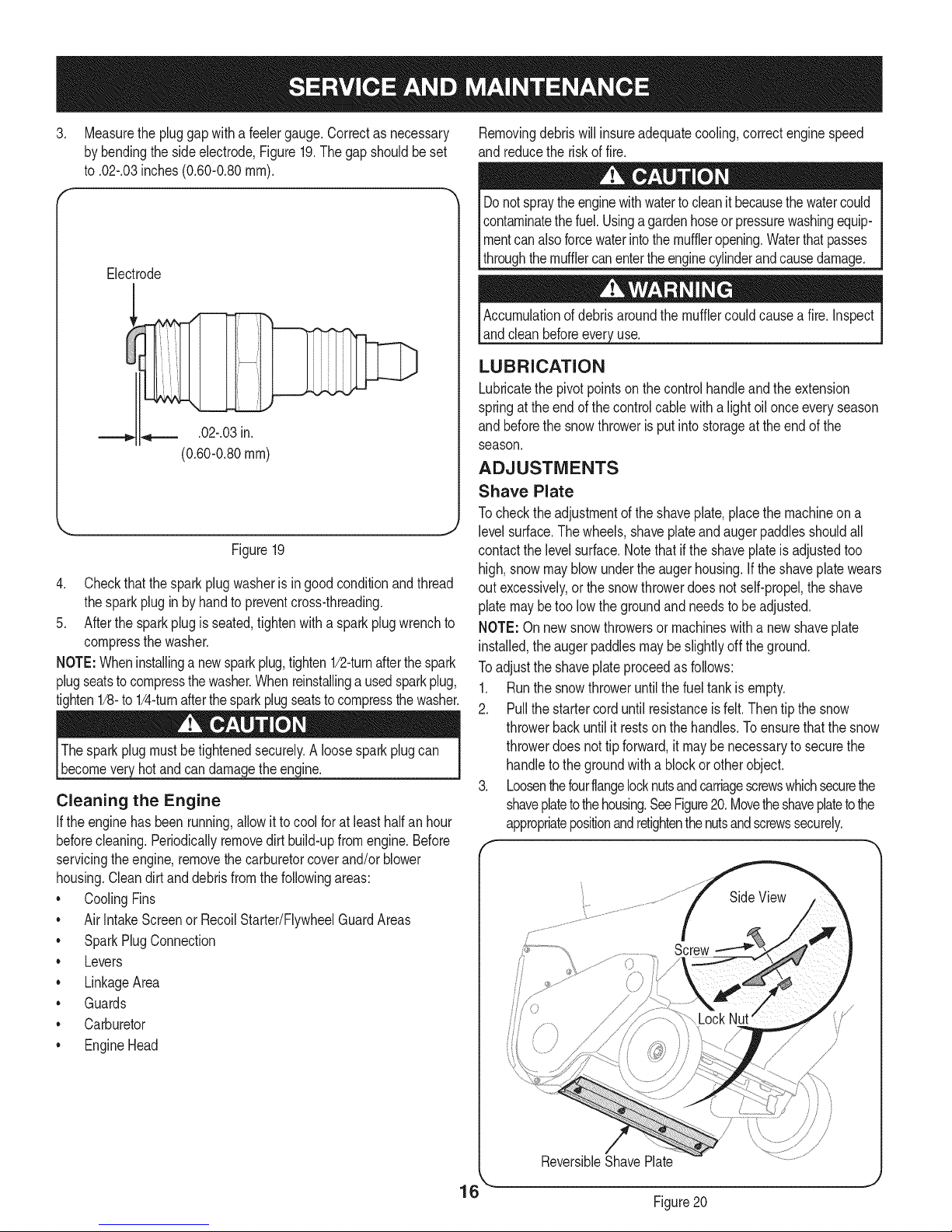

Measurethepluggapwitha feelergauge.Correctasnecessary

bybendingthe side electrode,Figure19.Thegapshouldbeset

to.02-.03inches(0.60-0.80ram).

Electrode

.02-.03in.

(0.60-0.80ram)

Figure19

4. Checkthatthesparkplugwasherisingoodconditionandthread

thesparkplugin byhandtopreventcross-threading.

5. Afterthe sparkplugisseated,tightenwithasparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinganewsparkplug,tighten1/2-turnafterthespark

plugseatstocompressthewasher.Whenreinstallingausedsparkplug,

tighten1/8-to1/4-turnafterthesparkplugseatstocompressthewasher.

Thesparkplugmustbetightenedsecurely.Aloosesparkplugcan

becomeveryhotandcandamagetheengine.

Cleaning the Engine

Iftheenginehasbeenrunning,allowittocoolforatleasthalfan hour

beforecleaning.Periodicallyremovedirtbuild-upfromengine.Before

servicingtheengine,removethecarburetorcoverand/orblower

housing.Cleandirtanddebrisfromthefollowingareas:

• CoolingFins

• AirIntakeScreenorRecoilStarter/FlywheelGuardAreas

• SparkPlugConnection

• Levers

• LinkageArea

• Guards

• Carburetor

• EngineHead

Removingdebriswillinsureadequatecooling,correctenginespeed

and reducetheriskoffire.

Donotspraytheenginewithwatertocleanitbecausethewatercould

contaminatethefuel.Usingagardenhoseorpressurewashingequip-

mentcanalsoforcewaterintothemuffleropening.Waterthatpasses

throughthemufflercanentertheenginecylinderandcausedamage.

Accumulationofdebrisaroundthemufflercouldcausea fire.Inspect

andcleanbeforeevery_use.

LUBRICATION

Lubricatethe pivotpointson thecontrolhandleandtheextension

springat the endofthecontrolcablewitha light oilonceeveryseason

and beforethesnowthrowerisputintostorageat the endof the

season.

ADJUSTMENTS

Shave Plate

Tochecktheadjustmentofthe shaveplate,placethemachineon a

levelsurface.Thewheels,shaveplateandaugerpaddlesshouldall

contactthelevelsurface.Notethat ifthe shaveplateisadjustedtoo

high,snowmayblowundertheaugerhousing.Iftheshaveplatewears

outexcessively,or thesnowthrowerdoesnotself-propel,the shave

platemaybetoolowthegroundandneedstobeadjusted.

NOTE:Onnewsnowthrowersormachineswitha newshaveplate

installed,theaugerpaddlesmaybeslightlyofftheground.

Toadjusttheshaveplateproceedasfollows:

1. Runthe snowthroweruntilthefueltankisempty.

2. Pullthestartercorduntil resistanceisfelt.Thentip the snow

throwerbackuntilit restsonthe handles.Toensurethatthe snow

throwerdoesnot tip forward,it maybenecessarytosecurethe

handletothegroundwitha blockorotherobject.

3. Loosenthefourflangelocknutsandcarriagescrewswhichsecurethe

shaveplatetothehousing.SeeFigure20.Movetheshaveplatetothe

appropriatepositionandretightenthenutsandscrewssecurely.

16 ``.¸

ReversibleShavePlate

J

Figure20

Page 17

4. Tipthesnowthrowerbacktotheoperatingpositionandpullthe

starterhandleafewtimestoseeifitisdifficulttopull.

5. Ifthestarterisdifficulttopull,removethesparkplugandpullthe

handleseveraltimestoensurethatanyoiltrappedintheengine

headisremoved.

Oilmaycomeoutofthesparkplugholewhenitisremovedandthe

starterhandleispulled.

6. Inspectthesparkplug.Ifitiswet,cleanoffanyoilbefore

re-installing.

Control Cable

Asaresultofboththecontrolcableandtheaugerdrivebeltstretching

duetowear,periodicadjustmentsmaybenecessary.Iftheauger

seemstohesitatewhenrotating,proceedasfollows:

Theupperholeinthecontrolhandleprovidesforanadjustmentin

cabletension.Toadjust,disconnecttheendofcontrolcablefromthe

bottomholeinthecontrolhandleandreinsertitintheupperhole.

InsertthecablefromtheoutsideasshowninFigure21.

f

Control

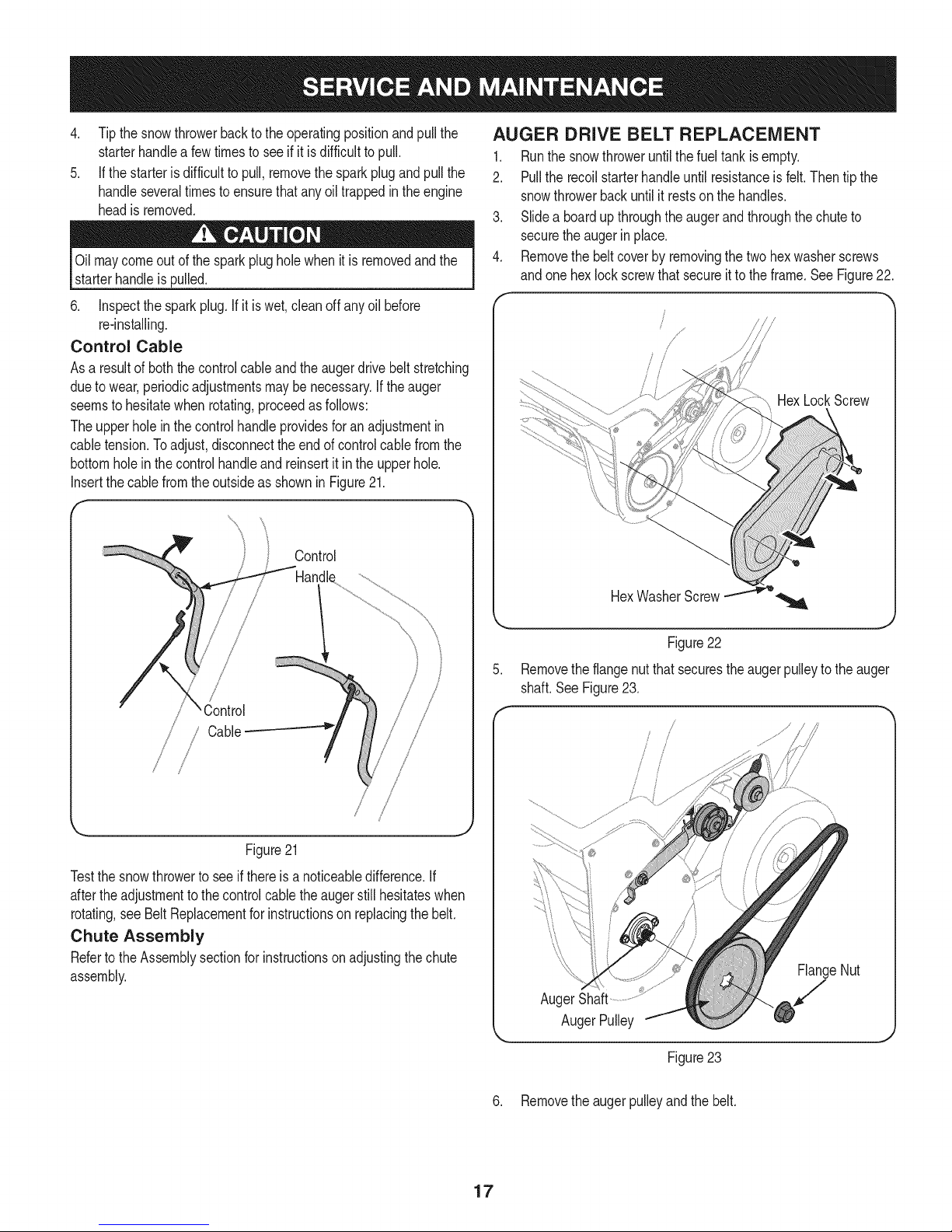

AUGER DRIVE BELT REPLACEMENT

1. Runthe snowthroweruntilthefueltankisempty.

2. Pullthe recoilstarterhandleuntilresistanceisfelt.Thentipthe

snowthrowerbackuntilitrestson thehandles.

3. Slidea boardupthroughtheaugerandthroughthechuteto

securetheaugerinplace.

4. Removethe beltcoverbyremovingthetwohexwasherscrews

andone hexlockscrewthatsecureittotheframe.SeeFigure22.

HexLockScrew

/

Cable

Figure21

Testthesnowthrowertoseeifthereisa noticeabledifference.If

aftertheadjustmentto the controlcabletheaugerstill hesitateswhen

rotating,seeBeltReplacementforinstructionson replacingthebelt.

Chute Assembly

RefertotheAssemblysectionforinstructionsonadjustingthechute

assembly.

j

/

/

/

Figure22

.

Removetheflangenutthat securestheaugerpulleytotheauger

shaft.SeeFigure23.

/

FlangeNut

AugerShaft

AugerPulley

Figure23

J

J

6. Removethe augerpulleyandthebelt.

17

Page 18

Toreplacethebeltfollowtheseinstructionsandreferto Figure24:

Drive

js

Figure24

1. Routethebeltaroundthe drivepulleyandundertheidlerpulley.

2. Routetheendofthebeltaroundtheaugerpulleyandslidethe

pulleybackon tothe augershaft.It maybe necessaryto push

downontheidlerpulleytoget theaugerpulleyunderthebelt

keeper.

3. Replacetheflangenutandtightensecurely.

4. Reinstallthebeltcoverremovedearlier.

5. Removethe boardfromtheaugerandchute.

REPLACING AUGER PADDLES

Thesnowthrowerauger'srubberpaddlesaresubjectto wearand

shouldbereplacedifanysignsof excessiveweararepresent.

DoNOTallowthe auger'srubberpaddlesto weartothepointwhere

Iportionsof the metalaugeritselfcancomein contactwiththepave-

_ment.Doingsocan resultin seriousdamageto yoursnowthrower.

Tochangetherubberpaddles,proceedasfollowsandreferto Figure

25:

HexWasherScrew

HexWasherScrew

Figure25

1. Runthe snowthroweruntilthefueltankisempty.

2. Pulltherecoilstarterhandleuntil resistanceisfelt.Then tip the

snowthrowerbackuntilitrestson thehandles.

3. Removethe existingrubberpaddlesbyunthreadingthehex

washerscrewswhichsecurethemtotheauger.SeeFigure25.

NOTE:Theaugerpaddlesshouldbereplacedoneat a timesothat

theaugerstillattachedcanbeusedas anexampleforpositioningand

re-installingthenewauger.

4. Securethe replacementrubberpaddlestotheaugerusingthe

hardwareremovedearlier.

Toobtaina fullaugerreplacementkitincludingrubberpaddlesand

hexwasherscrews,callSearsat 1-800-4-MYHOME.Askforpart

753-06469.

REPLACING OR REVERSING SHAVE PLATE

Theshaveplateis attachedtothebottomof the augerhousingand

is subjecttowear.Itshouldbecheckedperiodically.Therearetwo

wearingedgesandtheshaveplatecan be reversed.

1. Runthe snowthroweruntilthefueltankisempty.

2. Pulltherecoilstarterhandleuntil resistanceisfelt.Then tip the

snowthrowerbackuntilitrestson thehandles.

3. Removethe fourcarriageboltsandflangelocknutswhichattach

it tothe snowthrowerhousing.Referto Figure20on page14.

4. Reversethe existingshaveplateor installanewone,makingsure

thenewshaveplateandthe headsofthe carriageboltsareon

theinsideof the housing.

5. Adjustthe shaveplateas instructedon page14.

6. Tightensecurelyonceadjusted.

Toobtaina newshaveplate,callSearsat 1-800-4-MY-HOME.Askfor

part#731-08171.

18

Page 19

Ifthe snowthrowerwillnot be usedfor30 daysor longer,orif it is the endofthesnowseasonwhenthe lastpossibilityof snowisgone,the

equipmentneedstobestoredproperly.Followstorageinstructionsbelowtoensuretopperformancefromthe snowthrowerfor manymoreyears.

PREPARING THE ENGINE

Enginesstoredover30daysneedto bedrainedoffueltoprevent

deteriorationandgumfromforminginthefuelsystemoronessential

carburetorparts.If thegasolineinyourenginedeterioratesduring

storage,youmayneedto havethecarburetor,andotherfuelsystem

components,servicedorreplaced.

1. Removeall fuelfromthetankby runningtheengineuntilit stops.

2. Changetheengineoil.

3. Removethe sparkplugandpourapproximately1oz.(30 ml)of

cleanengineoil intothecylinder.Pullthe recoilstarterseveral

timesto distributetheoil,and reinstallthe sparkplug.

4. Cleantheexterioroftheenginebywipingdirtanddebrisfromthe

followingareas:

• CoolingFins

• AirIntakeScreenorRecoilStarter/FlywheelGuardAreas

• SparkPlugConnection

• Levers

LinkageArea

Guards

Carburetor

EngineHead

!

PREPARING SNOW THROWER

Ifthesnowthrowerwillnotbeusedfor30daysor longer,followthe

instructionsbelow.

1. Storetheequipmentinaclean,dryarea.

2. Wipedownthesnowthrowerwitha ragand removeanydirtor

debris.

3. Ifstoringthe snowthrowerin anunventilatedarea,rustproofthe

metalpartsof the machinewitha lightoil orsiliconecoating.

Donotspraytheenginewithwatertocleanitbecausethewatercould

contaminatethefuel.Usinga gardenhoseorpressurewashingequip-

Imentcanalsoforcewaterintothemuffleropening.Waterthatpasses

[throughthe mufflercanentertheenginecylinderandcausedamage.

5. Storeina clean,dry andwellventilatedareaawayfromany

appliancethatoperateswitha flameorpilotlight,suchas a

furnace,waterheateror clothesdryer.Avoidanyareawitha spark

producingelectricmotor,or wherepowertoolsareoperated.

Neverstoresnowthrowerwithfuelintank indoorsorinpoorlyventi-

latedareas,wherefuelfumesmayreachanopenflame,sparkor pilol

lightas ona furnace,waterheater,clothesdryerorgasappliance.

6. If possible,avoidstorageareaswithhighhumidity.

7. Keeptheenginelevelin storage.Tiltingtheengine can cause

fuelor oilleakage.

19

Page 20

Beforeperforminganytypeof maintenance/service,disengageallcontrolsandstoptheengine.Waituntilall

movingpartshavecometo acompletestop.Disconnectsparkplugwireandgrounditagainsttheengineto

Ipreventunintendedstarting.Alwayswearsafetyglassesduringoperationorwhileperforminganyadjustmentsor

[repairs.

This section addresses minor service issues. Tolocate the nearestSearsService Centeror to schedule service, simply contact Sears

at 1-800-4-MY-HOME®.

Enginefailsto start 1. Fueltankempty,or stalefuel.

2. Blockedfuelline.

3. Keynotinsertedalltheway.

4. Sparkplugwiredisconnected.

5. Faultysparkplug.

6. Enginenotprimed.

7. Enginefloodedfromexcessivepriming.

Enginerunningerratically/

inconsistentRPM(huntingor

surging)

1. Enginerunningonchoke.

2. Fuellineblocked,or stalefuel.

3. Wateror dirtinfuel system.

1. Filltankwithcleanfreshgasoline.

2. Contacta SearsServiceCenter.

3. Insertkeyalltheway.

4. Connectwireto sparkplug.

5. Cleansparkplug,readjustgap,or replace.

6. Pushtheengineprimerbuttonfivetoseventimes.

7. Waitatleasttenminutesbeforestarting.

1. MovechokecontroltoRUNposition.

2. Contacta SearsServiceCenter.

3. Runengineuntilthefueltank isempty.Rdill with

freshfuel.

4. Carburetoroutofadjustment.

5. Over-governedengine

Engineoverheats Contacta SearsServiceCenter.

Lossof power Firmlyconnectsparkplugwire.

1. Carburetoroutofadjustment.

1. Sparkplugwireloose.

2. Ventin gascap plugged.

Excessivevibration Stopengineimmediatelyandremovekey.Checkfor

1. Loosepartsordamagedauger.

4. Contacta SearsServiceCenter.

5. Contacta SearsServiceCenter.

1.

1.

2.

Clearvent.

1.

possibledamage.Tightenall boltsand nuts.Repair

asneeded.Ifproblempersists,takesnowthrowerto

a SearsServiceCenter.

Snowthrowerfailsto self- 1. Augercontrolcableoutofadjustment. 1. Adjustaugercontrolcableasshownin Serviceand

propel Maintenancesection.

2. Augerdrivebeltlooseor damaged. 2. Replaceaugerdrivebelt.

Augercontinuesto rotate 1. Augercontrolcableoutof adjustment. 1. Adjustaugercontrolcableasshownin Serviceand

Maintenancesection.

Unitfailstodischargesnow 1. Chuteassemblyclogged. 1.

Stopengineanddisconnectsparkplugwire.Clean

chuteand insideof augerhousingwithclean-outtool

or stick.

2. Foreignobjectlodgedin auger.

2. Stopengineimmediatelyanddisconnectthespark

plugwire.Removeobjectfromauger.

3. Augercontrolcableoutof adjustment.

4. Augerbeltlooseor damaged.

3. Adjustaugercontrolcable.

4. Replaceaugerbelt.

lqg_/1 find the a_swez a[_d z[_or{÷on maztagemy[£e,,,_om - [0[ [ree!

Find this and all your other product manual.sonl.ine.

Get answers from our team of home experts.

Get a personaLized maintenance pl.anfor your home.

Find information and tools to hel.pwith home projects.

_ managemylife

b_g_t t_ ye_ By S_a_'s

2O

Page 21

This page intentionally left blank. Use this page to make any notes regarding your snow thrower.

21

Page 22

Craftsman Snow Thrower Model 247.88782

i

i (

_31)

22

Page 23

Craftsman Snow Thrower IViodel 247.88782

|= 0 =

684-04168 IdlerPulleyAssembly

2. 984-04393 AugerAssembly

-- 753-06469 Rubber Auger Paddle Kit (Includes 2

paddles and 12hexwasher screws)

3. 684-04398-4044

4. 710-0134

5. 710-04484

6. 710-05183

710-0599

FrameAssembly

CarriageScrew,1/4-20x .62

HexWasherScrew,5/16-18x .750

HexScrew,5/16-24x 1.25

HexWasherScrew,1/4-20x .500

8. 710-0627 HexLockScrew,5/16-24x .750

9. 710-0778 HexWasherScrew,1/4-20x 1.500

10. 710-0817 HexWasherScrew,5/16-18x 1.250

L

11. 710-0895

12. 710-1652

13. 712-04064

14. 712-04065

HexWasherScrew,1/4-15x .750

HexWasherScrew,1/4-20x .625

FlangeLockNut, 1/4-20

FlangeLockNut,3/8-16

15. L71804836 LPulleyHub

16. 726-0233 PushNut,.25x .50

17. 731-07737A BeltCover

18. 731-08171 ShavePlate

19. 732-04748

20. 738-04456

21. 741-04517

22. 747-05360A

23. 748-0234

24. 749-04810-0637

ExtensionSpring,.70x 3.035

ShoulderBolt,5/16-24x .496x2.18

BallBearing,.5000x 1.375x.4375

DriveCableWireSupport

ShoulderSpacer

LowerHandle

D = O 0

750-04571 ShoulderSpacer

26. 790-00426-0637 IdlerCableBracket

27. 790-00444-4044 RHSidePlate

28. 790-00445-4044 LHSidePlate

29. 790-00457-4044 BearingCup

30. 790-00461-0637 IdlerBracket

31. 726-0299 PushCap,1/2

32. 734-1781 Wheel,8 x 1.7

33. 750-05417 SleeveSpacer,.525x .78x 1.07

34. 929-0071A ExtensionCord

35. 710-0627 HexLockScrew,5/16-24x .750

36. 710-0654A HexWasherScrew,3/8-16x 1.000

37. 710-0895 HexWasherScrew,1/4-15x .750

38. 912-0702 FlangeNut,7/16-20

39. 726-0205 HoseClamp,.490

40. 731-07664 ChokeExtensionLever

41. 736-0371 ThrustWasher,.343x .880x.062

42. 747-05513 GasTankWireSupport

43. 751-10487A FuelCap

44. 751-11648 FuelTank

45. 954-04050 Belt,.500x 35.06

46. 956-0416B PulleyHalf,.625x 2.25

47. 756-04443 Pulley,1/2x 6.00

48. 946-04782 ClutchCable

49. 952Z370-JU-11 ReplacementEngine

23

Page 24

Craftsman Snow Thrower Model 247.88782

/

/

/

Ix • _

\

24

Page 25

Craftsman Snow Thrower IViodel 247.88782

|= 0 =

631-04526P ChuteRotationControlAssembly

2. 684-04350 JointBlockAssembly

3. _684-04383-0637_indicatorBracketAssembly

4. 710-0451

5. 710-05108

6. 710-05179A

7. 710-0599

8. 710-0895

9. 712-04035

10. 712-04263

11. 714-04003

CarriageBolt,5/16-18x .750

HexWasherScrew,1/4x .750

MachineScrew,#8-32x .88

HexWasherScrew,1/4-20x0.500

HexWasherScrew,1/4-15x 0.750

HexLockNut,#8-32

HexLockNut,#8-32

CotterPin,.125x2.5

12. 715-04095 SpringPin,.156x .85

13. 917-04844B BevelGear,95T

14. 717-04940 SpurGear,35T

15. 717-04941 SpurGear,40T/11T

16. 720-04122 WingKnob,5/16-18

17. 720-04174 Grip,1.18x 3.33

18. 731-04426A UpperChute

19. .931-07626A J ChuteAdapter

20. 731-07708 ChutePlug

21. 931-07753A LowerChute

22. 731-07957 ChuteRotationCover

23. 736-04161 FiatWasher,.75x 1.00x .06

24. 941-0475 PlasticBushing,.380

25. 747-05299A ChuteRotationRod,3/8

26. 790-00416 GearMountingPlate

27. 790-00471 GearRetainerBracket

m

28. 731-07784 HandlePanelLens

D = O O

631-04504 HandlePanel

-- 777X44559 LightLabel

30. 710-04998 CarriageScrew,5/16-18x1.00

31. 710-05348 EyeBolt,1/4-20

32. 712-04064 FlangeLockNut, 1/4-20

33. 720-0279 WingKnob,1/4-20

34. 720-04122 WingKnob,5/16-18

35. 725-0157 CableTie,3/16x .05x 7.4

36. 725-1629 Lamp,#1141

37. 738-04419A ShoulderScrew,1/4-20x .375x .148

38. 747-05327B-0637AugerControl

39. 749-04693B-0637UpperHandle

40. 931-04579 BottomCoverAssembly

41. 631-04607 CoverAssembly

42. 710-04187 HexWasherScrew,1/4-15x .50

43. 732-04789 CompressionSpring,.460x 1.469

44. 731-08018 ChuteRotationRod

45. 925-04031A IgnitionSwitchAssembly

46. 951-10645A ElectricStarter

47. 951-10639A Primer

48. 684-04381-0637 ChuteRotationRodAssembly

49. 710-04352 Screw,#6x .375

50. 710-04353 Screw,#8x 1.00

51. 731-04904 RHControlKnob

52. 731-04905 LHControlKnob

53. 731-06525 JoystickTrigger

54 715-0150 RollPin,3/16x 1.1

NS 925-04139 WiringHarness

25

Page 26

Craftsman Snow Thrower Model 247.88782

777D16367 777X43688

777S34027 777i22139

g0 N_r 777S33731

USEE85 ORFUEL

CONTAININGMORE

THAN10% ETHANOL

777122992

777S32236

777S33118

777D16345

777123463

777123574

26

Page 27

This page intentionally left blank. Use this page to make any notes regarding your snow thrower.

27

Page 28

MTD CONSUMER GROUP (MTD), the California Air Resources Board (CARB)

and the United States Environment Protection Agency (U. S. EPA)

Emission Control System Warranty Statement

(Owner's Defect Warranty Rights and Obligations)

EMiSSiONCONTROLSYSTEMCOVERAGEISAPPLICABLETOCERTiFiEDENGINESPURCHASEDINCALIFORNIAIN2005ANDTHERE-

AFTER,WHICHAREUSEDINCALiFORNiA,ANDTOCERTiFiEDMODELYEAR2005ANDLATERENGINESWHICHAREPURCHASEDAND

USEDELSEWHEREINTHEUNITEDSTATES.

CaliforniaandelsewhereintheUnitedStatesEmissionControlDefectsWarrantyCoverage

TheCaliforniaAirResourcesBoard(CARB),U.S. EPAandMTDarepleasedtoexplaintheemissionscontrolsystemwarrantyonyour modelyear

2006andlatersmalloff-roadengine.In California,newsmalloff-roadenginesmustbe designed,builtand equippedtomeettheStatesanti-smog

standards.ElsewhereintheUnitedStates,newnon-road,spark-ignitionenginescertifiedformodel2005and later,mustmeetsimilarstandardsset

forthbytheU.S. EPA.MTDmustwarrantytheemissioncontrolsystemonyourengineforthe periodof timelistedbelow,providedtherehasbeen

noabuse,neglector impropermaintenanceofyoursmalloff-roadengine.

Youremissioncontrolsystemmayincludepartssuchasthecarburetor,fuel-injectionsystem,theignitionsystem,andcatalyticconverter,fuel

tanks,fuellines,fuelcaps,valves,canisters,filters,vaporhoses,clamps,connectors,andotherassociatedemission-relatedcomponents.

Whereawarrantableconditionexists,MTDwill repairyoursmalloff-roadengineat nocost to yourincludingdiagnosis,partsandlabor.

MANUFACTURER'S WARRANTY COVERAGE:

Thisemissionscontrolsystemiswarrantedfortwoyears.If anyemission-relatedpartonyourengineis defective,thepart will berepairedor

replacedbyMTD.

OWNER'S WARRANTY RESPONSIBILITIES:

Asthesmalloff-roadengineowner,youare responsibleforthe performanceofthe requiredmaintenancelistedinyourOwner'sManual.MTD

recommendsthatyou retainall yourreceiptscoveringmaintenancesonyoursmalloff-roadengine,but MTDcannotdenywarrantysolelyforthe

lackofreceiptsorforyourfailureto ensuretheperformancetoallscheduledmaintenance.

Asthesmalloff-roadengineowner,youshouldhoweverbeawarethatMTDmaydenyyourwarrantycoverageif yoursmalloff-roadengineorpart

hasfaileddue toabuse,neglect,impropermaintenanceor unapprovedmodifications.

Youare responsibleforpresentingyoursmalloff-roadengineto an AuthorizedMTDServiceDealerassoonasa problemexists.Thewarranted

repairsshouldbe completedina reasonableamountof time,notto exceed30 days.

Ifyouhaveanyquestionsregardingyourwarrantyrightsand responsibilities,youshouldcontacta MTDServiceRepresentativeat 1-800-800-7310

andaddressisMTDCONSUMERGROUP,RO.Box361131,ClevelandOH,44136-0019.

DEFECTS WARRANTY REQUIREMENTS FOR 1995 AND LATER SMALL OFF=ROAD ENGINES:

Thissectionappliesto 1995andlatersmalloff-roadengines.Thewarrantyperiodbeginsonthe datetheengineor equipmentisdeliveredtoan

ultimatepurchaser.

(a) GeneralEmissionsWarrantyCoverage

MTDmustwarranttotheultimatepurchaserandeachsubsequentpurchaserthattheengineis:

(1)Designed,built,andequippedsoasto conformwithallapplicableregulationsadoptedbythe AirResourcesBoardpursuantto itsauthorityin

Chapters1and2,Part5,Division26of theHealthandSafetyCode;and

(2) Freefromdefectsin materialsandworkmanshipthatcausethe failureofa warrantedparttobeidenticalin allmaterialrespectstothepartas

describedintheenginemanufacturer'sapplicationfor certificationfora periodoftwoyears.

(b)Thewarrantyonemissions-relatedpartswill be interpretedasfollows:

(1)Anywarrantedpart thatisnotscheduledforreplacementas requiredmaintenanceinthe writteninstructionsrequiredby Subsection(c)

mustbewarrantedforthewarrantyperioddefinedinSubsection(a)(2).Ifanysuchpartfailsduringtheperiodof warrantycoverage,it mustbe

repairedorreplacedbyMTDaccordingto Subsection(4)below.Anysuchpartrepairedorreplacedunderthewarrantymustbewarrantedfor

theremainingwarrantyperiod.

(2)Anywarrantedpartthat isscheduledonlyfor regularinspectioninthewritteninstructionsrequiredbySubsection(c)mustbewarrantedfor

thewarrantyperioddefinedinSubsection(a)(2).A statementinsuchwritteninstructionsto the effectof "repairor replaceasnecessary"will

notreducetheperiodofwarrantycoverage.Anysuchpart repairedorreplacedunderwarrantymustbe warrantedfortheremainingwarranty

period.

(3) Anywarrantedpartthat whichisscheduledfor replacementas requiredmaintenancein the writteninstructionsrequiredbySubsection(c)

mustbewarrantedfortheperiodoftimepriortothefirstscheduledreplacementpointforthat part.Ifthepartfailspriorto thefirst scheduled

replacement,thepartmustbe repairedor replacedbyMTDaccordingtoSubsection(4) below.Any suchpart repairedor replacedunder

warrantymustbewarrantedforthe remainderofthe periodpriortothefirstscheduledreplacementpointforthepart.

Page 29

(4)Repairorreplacementofanywarrantedpartunderthewarrantyprovisionsofthisarticlemustbeperformedatnochargetotheownerata

warrantystation.

(5)NotwithstandingtheprovisionsofSubsection(4)above,warrantyservicesorrepairsmustbeprovidedatallMTDdistributioncentersthat

arefranchisedtoservicethesubjectengines.

(6)Theownermustnotbechargedfordiagnosticlaborthatleadstothedeterminationthatawarrantedpartisinfactdefective,providedthat

suchdiagnosticworkisperformedatawarrantystation.

(7)Theenginemanufacturerisliablefordamagestootherenginecomponentsproximatelycausedbyafailureunderwarrantyofanywarranted

part.

(8)Throughouttheengine'swarrantyperioddefinedinSubsection(a)(2),MTDwillmaintainasupplyofwarrantedpartssufficienttomeetthe

expecteddemandforsuchparts.

(9)Anyreplacementpartmaybeusedintheperformanceofanywarrantymaintenanceorrepairsandmustbeprovidedwithoutchargetothe

owner.SuchusewillnotreducethewarrantyobligationsofMTD.

(10)Add-onormodifiedpartsthatarenotexemptedbytheAirResourcesBoardmaynotbeused.Theuseofanynon-exemptedadd-onor

modifiedpartsshallbegroundsfordisallowingawarrantyclaimmadeinaccordancewiththisarticle.Theenginemanufacturershallnotbe

liableunderthisarticletowarrantfailuresofwarrantedpartscausedbytheuseofnon-exemptedadd-onormodifiedpart.

(c)MTDwill includea copyofthefollowingemissionwarrantypartslistwitheachnewengine,usingthoseportionsofthelistapplicabletothe

e__&gine.

(1)FuelMeteringSystem

•Coldstartenrichmentsystem(softchoke)

,,Carburetorandinternalparts

•FuelPump

•FuelTank

(2)Air InductionSystem

•Aircleaner

•Intakemanifold

(3) IgnitionSystem

•Sparkplug(s)

•MagnetoIgnitionSystem

(4)ExhaustSystem

Catalyticconverter

•SAI(Reedvalve)

(5) MiscellaneousItemsUsedin AboveSystem

Vacuum,temperature,position,timesensitivevalvesand switches

Connectorsandassemblies

(6) Evaporativecontrol

•FuelHosecertifiedforARBevaporativeemissionof2006.

•FuelHoseClamps

Tetheredfuelcap

Carboncanister

Vaporlines

GD0C-100174Rev.A

Page 30

Look For Relevant Emissions Durability Period and

Air index information On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must

display information regarding the Emissions Durability Period and the Air Index. Sears Brands Management

Corporation makes this information available to the consumer on our emission labels.

The Emissions Durability Period describes the number of hours of actual running time for which the engine is

certified to be emissions compliant, assuming proper maintenance in accordance with the Operating & Mainte-

nance Instructions. The following categories are used:

Moderate: Engine is certified to be emission compliant for 125 hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant for 250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore, the Emissions

Durability Period of an engine with an intermediate rating would equate to 10 to 12 years.

The Air index is a calculated number describing the relative level of emissions for a specific engine family. The

lower the Air Index, the cleaner the engine. This information is displayed in graphical form on the emissions label.

After July 1,2000, Look For Emissions Compliance Period

On Engine Emissions Compliance Label

After July 1, 2000 certain Sears Brands Management Corporation engines will be certified to meet the United

States Environmental Protection Agency (USEPA) Phase 2 emission standards. For Phase 2 certified engines, the

Emissions Compliance Period referred to on the Emissions Compliance label indicates the number of operating

hours for which the engine has been shown to meet Federal emission requirements.

For engines less than 225 cc displacement, Category C = 125 hours, B = 250 hours and A = 500 hours.

For engines of 225 cc or more, Category C = 250 hours, B = 500 hours and A = 1000 hours.

This isa generic representation of the emission label typically found on a certified engine.

FAMILYYBSXS.3192VA 274812

GDOC-100182Rev.B

38

Page 31

Congratulations on making a smart purchase. Your new Craftsman® product is designed and

manufactured for years of dependable operation. But like all products, it may require repair

from time to time. That's when having a Repair Protection Agreement can save you money and

aggravation.

Here's what the Repair Protection Agreement* includes:

[] Expert service by our 10,000 professional repair specialists

[] Unlimited service and no charge for parts and labor on all covered repairs

[] Product replacement up to $1500 if your covered product can't be fixed

[] Discount of 25% from regular price of service and related installed parts not covered by the

agreement; also, 25% off regular price of preventive maintenance check

[] Fast help by phone - we call it Rapid Resolution - phone support from a Sears representative.

Think of us as a "talking owner's manual."

Once you purchase the Repair Protection Agreement, a simple phone call is all that it takes for you

to schedule service. You can call anytime day or night, or schedule a service appointment online.

The Repair Protection Agreement is a risk-free purchase. If you cancel for any reason during the

product warranty period, we will provide a full refund. Or, a prorated refund anytime after the

product warranty period expires. Purchase your Repair Protection Agreement today!

Some limitations and exclusions apply. For prices and additional information in the U.S.A.

call 1=800=827=6655.

*Coverage in Canada varies on some items. For full details call Sears Canada at 1=800=361=

6665.

Sears Installation Service

For Sears professional installation of home appliances, garage door openers, water heaters, and

other major home items, inthe U.S.A. or Canada call 1=800=4=MY=HOME®.

39

Page 32

Declaraci6n de garantia ............ Pagina 32

Medidas de seguridad ............. Paginas 33-36

Montaje ......................... Paginas 37-40

Funcionamiento .................. Paginas 41-43

Servicio y Mantenimiento ........... Paginas 44-49

GARANTiA COMPLETA CRAFTSMAN POR DOS AltOS

PORDOSANOSapartirdela fechadelacornpra,esteproductoest_garantizadopotdefectosen los rnaterialesyla rnanodeobra.

Losproductosdefectuososser_nreparadossincostooreernplazadossincostosi la reparaci6nnoest_disponible.

La presentegarantiase anulasiseutilizaesteproductoalgunavezparaprestarservicioscornercialeso siseIoalquilaa otrapersona.

Paraobtener informaci6nsobre el alcancede la garantiay solieitar la reparaci6noelreemplazo,visite elsitio Web:www.craftsman.com

Esta garanfia eubre0NiCAMENTElosdefectos en los rnaterialesy en lamanode obra. Estagaranfia NOcubre:

• Elernentosno renovablesquepuedendesgastarsepor elusonormal,duranteeiplazodela garantia,incluyendoentreotros,las barrenas,

laspaletasdelasbarrenas,loscortadoresdedesplazarniento,laszapatasantideslizantes,la placade raspado,lospasadoresdecuchilla,

la bujia,elfiltrode aire,las correasy el filtrodeaceite.

• Serviciosde rnantenirnientoestandar,carnbiosdeaceiteo afinaci6n.

• Carnbiode neurn_ticoso reparacionesporpinchadurasconobjetosexternoscornoclavos,espinas,toconesovidrios.

• Reernplazoo reparaci6ndeneurn_ticoso ruedascornoresultadodel desgastenormal,unaccidente,o funcionarniento

o rnantenirnientoincorrectos.

• Reparacionesrequeridascornoresultadodel uso inadecuadopot partedeloperador,incluyendoentreotrosel dafioocasionadoporobjetos

queirnpactanlarnaquinay quetuercenel bastidor,elejede labarrena,etc.,odebidoa queel motorrueaceleradoenexceso.

• Reparacionesnecesariasdebidoanegligenciadeloperador,incluyendoentreotros,dafiosrnec_nicoyel@tricoocasionadopor

unalrnacenarnientonoapropiado,fallaporel usodeaceitede gradoy/o cantidadnoapropiadoso fallapornodar rnantenirniento

alequipodeacuerdoconlasinstruccionescontenidasenel manualdeloperador.

• Lirnpiezao reparacionesdelmotor(sisternade combustible)debidasa combustiblequesedeterrninaest_contarninadouoxidado(viejo).

Engeneral,elcombustibledebeutilizarseenunperiodono mayorde 30dias a partirde suadquisici6n.

• Eldeterioroydesgastenormalde losacabadosexteriores,oreernplazode laetiquetadelproducto.

Almacenamiento fuera de temporada . Pagina 50

Solucion de problemas ............. Pagina 51

Acuerdo de protecci6n

para reparaciones ................. Pagina 55

NOmeros de servicio ............... Contratapa

Estagarantialeotorgaderechoslegalesespecificos,peroustedpodriagozardeotrosderechosenraz6ndesulugarde residencia.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

Tipodeaceitedelmotor:

Capacidaddeaceitedel motor:

Capacidaddecombustible:

Bujfas:

Separaci6ndelasbujias:

©KCDIP,LLC

SAE5W-30

20onzas

2 Cuartosdegai6n

F6RTC

0.020"-0.030"

NSrnerodernodelo ...............................

N_rnerode serie .................................

Feehadeeompra ................................

RegistrearribaelnQrnerodelrnodeio,elnQrnero

deserie yla fechadecornpra

32

Page 33

Lapresenciade estesfmboloindicaque setratade instruccionesde

seguridadimportantesquedeberespetarparaevitarponeren riesgosu

seguridadpersonaly/o materialy la de losdemos.Leay cumplatodas las

instruccionesdeestemanualantesde intentaroperarestam_quina.Si no

respetaestas instruccionespuedeprovocarlesionespersonales.Cuando

veaestesfmbolo,iTENGAENCUENTALAADVERTENClA!

Estam_quinaest_dise_adaparasetutilizadarespetandolasnormas

de seguridadcontenidaseneste manual.AIigualquecon cualquiertipo

de equipomotorizado,un descuidoo errorporpartedeloperadorpuede

producirlesionesgraves.Estam_quinaescapaz deamputardedos,

manosy piesy dearrojarresiduos.Deno respetarlasinstruccionesde

seguridadsiguientessepuedenproducirlesionesgraveso la muerte.

PROPOSICl6N 05 DE CALIFORNIA

Elescapedelmotorde esteproducto,algunosde suscomponentesy

algunoscomponentesdelvehfculocontieneno liberansustanciasqufmicas

queel estadode Californiaconsideraque puedenproducirc_ncer,

defectosdenacimientouotrosproblemasreproductivos.

CAPAClTACl6N

• Lea,entienday cumplatodaslas instruccionesinchidas en lam_quina

yen el(los)manual(es)antesde intentarrealizarel montajede launidad

y utilizarla.Si no Iohace,sepuedenprovocarlesionespersonalesal

operadoroalos transeQntes.Guardeestemanualenun lugarseguro

paraconsultasfuturasy peri6dicas,asfcomo parasolicitarrepuestos.

Antecualquierduda,Ilameal 1-800-4MY-HOME.

• Familiarfcesecontodosloscontrolesy conel usoadecuadode

los mismos.Sepac6modetenerla m_quinay desengancharlos

controlesrapidamente.

• Nopermitanuncaque losniSosmenoresde 14aSosutilicenesta

m_quina.LosniSosde14aSosen adelantedebenleer yentenderlas

instruccionesdeoperaci6ny normasde seguridadcontenidaseneste

manualyen la m_quinay debensetentrenadosysupervisadospot

unadulto.

• Nuncapermitaquelos adultosoperenesta m_quinasinrecibirantesla

instrucci6napropiada.

• Losobjetosarrojadosporlam&quinapuedencausarlesionesgraves.

Planifiqueelpatr6nenel queva air arrojandonieveparaevitar que

la descargadematerialse realicehacialos caminos,

losobservadores,etc.

• Mantengaa losobservadores,mascotasyniSosporIomenosa 75pies

dela m_quinasiemprequeestefuncionando.Detengala m_quinasi

alguiense acerca.

• Seaprecavidoparaevitarpatinarseo caerseespecialmentecuando

operala m_quinaenmarchaarras.

Su Responsabilidad -- Estam_quinamotorizadas61opuedenusarlalas

personasque lean,comprendanyrespetenlasadvertenciaseinstruc-

clonesque apareceneneste manualyen la m_quina.

iGUARDE ESTAS INSTRUCClONES!

PR E PARATIVO S

Inspeccioneminuciosamenteel_readondeutilizar_el equipo.Saquetodos

losfelpudos,peri6dicos,trineos,tablas,cablesy otrosobjetosextraSoscon

losquepodrfatropezaroque podrfanset arrojadosporla barrena/impulsor.

• Paraprotegerselos ojosutilicesiempreanteojoso antiparrasde

seguridadmientrasoperalam_quinao mientrasla ajustao repara.Los

objetosarrojadosquerebotanpuedencausarlesionesocularesgraves.

• Nooperela m&quinasin lavestimentaadecuadaparaestaral aire libre

en invierno.No utilicealhajas,bufandaslargasuotrasprendassueltas

quepodrfanenredarseen laspartesm6viles.Utiliceuncalzadoespecial

parasuperficiesresbaladizas.

• Useunprolongadoryuntomacorrientedetres cablesconconexi6na

tierra paratodas las m_quinasconmotoresde encendidoelectrico.

• Desengranetodas laspalancasde controlantesde arrancarel motor.

• Nuncaintenterealizarajustesmientrasel motorest#,enmarchaexcepto

en loscasos especfficamenterecomendadosen elmanualdeloperador.

• Dejequeel motory lam_quinaseadaptena latemperaturaexterior

antesde comenzarasacar lanieve.

33

Page 34

Manejo seguro de la gasolina

Paraevitarlesionespersonalesoda_osmaterialessea sumamentecuida-

dosoal manipularlagasolina.La gasolinaessumamenteinflamableysus

vaporespuedencausarexplosiones.Sise derramagasolinaencimao sobre

la ropase puedelesionargravementeyaquese puedeencender. Lavesela

piely c_mbiesederopade inmediato.

• Utilices61olos recipientesparagasolinaautorizados.

• Apaguetodos los cigarrillos,cigarros,pipasyotrasfuentes

decombusti6n.

• Nuncacarguecombustibleen lam_quinaenun espaciocerrado.

• Nuncasaquela tapadel combustibleniagreguecombustiblemientrasel

motorest&calienteo en marcha.

• Dejeque el motorse enfriepot Iomenosdosminutosantesde volvera

cargarcombustible.

• NuncaIleneenexcesoeldep6sitodecombustible.Lleneeltanque a no

m&sdeV2pulgadapordebajodela basedel cuellode Ilenadodejando

espacioparala dilataci6ndel combustible.

• Vuelvaacolocar la tapadel combustibley ajL]stelabien.

• Limpieel combustiblequese hayaderramadosobreelmotory el

equipo.Trasladelam_quinaa otrazona. Espere5 minutosantesde

encenderelmotor.

• Nuncaalmacenelam_quinao el recipientede combustibleen un

espaciocerradodondehayafuego,chispaso luz piloto(porejemplo,

hornos,calentadoresdeagua,calefactores,secadoresde ropa,etc.).

• Dejeque la m_quinaseenfrie potIomenos5 minutosantes

deguardarla.

• NuncaIlenelosrecipientesen el interiordeunvehiculoocami6no

cajaderemolquecon recubrimientopl_stico.Coloquesiemprelos

recipientesenel pisoy lejos delvehiculoantesde Ilenarlos.

• Sies posible,retireelequipoa gasolinadel cami6noremolquey Ilenelo

enel suelo.Siesto noesposible,Ileneel equipoen unremolquecon un

recipienteport_til,en vezde hacerlocon unaboquilladispensadora

degasolina.

• Mantengala boquillade Ilenadoencontactoconel hordedeldep6sito

decombustibleo conla aberturadelrecipienteen todo momento,hasta

terminarlacarga.No utiliceundispositivodeboquilladeapertura/cierre.

FUNCIONAIVIIENTO

• Nopongalasmanoso los piescercadelas piezasgiratorias,en la

cajadela barrena/impulsor oen el montajedelcanalde descarga.El

contactocon laspiezasgiratoriaspuederesultaren la amputaci6nde

manoso pies.

• Lapalancadecontrolde la barrena/impulsor es undispositivode

seguridad.Nuncaevitesu funcionamiento.Dehacerlolaoperaci6nde la

m&quinaes riesgosay puedeocasionarlesiones.

• Laspalancasde controldebenfuncionarbienen ambasdirecciones

y regresarautom_ticamentea la posici6ndedesengranecuandose

lassuelta.

• Nuncaoperela m&quinasi falta unmontajedelcanalo si el mismo

est_daSado.Mantengatodoslosdispositivosde seguridadensu lugar

yen funcionamiento.

• Nuncaenciendael motoren espacioscerradoso enunazonaconpoca

ventilaci6n.Elescapedel motorcontienemon6xidode carbono,ungas

inodoroy letal.

• Noutilicela m_quinabajola influenciadelalcoholo lasdrogas.

• Elsilenciadoryel motorse calientany puedencausarquemaduras.

No lostoque.Mantengaa losniSosalejados.

• Seasumamenteprecavidocuandooperela m&quinasobreuna

superficiecongravao cuandola cruce.Mantengasealerta pot si se

presentanpeligrosocultosotr_nsito.

• Tengacuidadocuandocambiededirecci6no cuandooperela m_quina

enpendientes.

• Planifiqueelpatr6nen elque vaair arrojandonieveparaevitarque

la descargade materialseproduzcahacialasventanas,las paredes,

los autom6viles,etc.y evitarasi posiblesdaSosmaterialesolesiones

producidasporlos rebotes.

• Nuncadirijala descargahacialos niSos,losobservadoresolas

mascotasnideje quenadiese paredelantede lam&quina.

• Nosobrecarguela capacidadde la m_quinatratandodesacarla nieve

muy r_pidamente.

• Nuncaopereesta m_quinasinbuenavisibilidado iluminaci6n.Siempre

debeestarsegurodeque est&bienafirmadoy sujetandofirmementelas

manijas.Camine,nuncacorra.

• Cortela corrientea la barrena/impulsorcuandotransportela m_quina

ocuandola mismanoest&enuso.

• Nuncaopere lam&quinaaalta velocidaddedesplazamientosobre

superficiesresbaladizas.Mire haciaabajo y haciaarrasy tengacuidado

cuandovayamarchaatr&s.

• Sila m&quinacomenzaraa vibrarde maneraanormal,detengael motor,

desconecteel cabledela bujiay p6ngalademaneraquehaga masa

contrael motor.Inspeccionelam_quinaminuciosamenteparaver si

est&daSada.ReparetodoslosdaSosantesdeencendery operar

la m&quina.

• Desengranetodas las palancasde controly detengael motorantesde

dejarla posici6ndeoperaci6n(detr&sde las manijas).Espereaquela

barrena/impulsorsedetengaporcompletoantesdedestaparel montaje

delcanalo realizarajustese inspecciones.

• Nuncapongalas manosenlasaberturasdedescargao derecolecci6n.

No destapeel montajedelcanal mientrasel motorest&enfunciona-

miento.Antesdedestaparlo,apagueelmotory permanezcadetr_s

de las barrasdecontrolhastaquetodaslas partesm6vilesse

hayandetenido.

• Uses61ounionesyaccesoriosaprobadosporelfabricante(porejemplo,

pesasparalasruedas,cadenasparalosneum_ticos,cabinas,etc.).

• Paraencenderel motor,jaledela cuerdalentamentehastaquesienta

resistencia,luegojale r_pidamente.Elreplieguer&pidode lacuerda

de arranque(tensi6nde retroceso)lejalar&la manoy el brazohaciael

motorm_sr&pidode Io que ustedpuedesoltar.PuedeIlegara causar

huesosrotos,fracturas,hematomasyesguinces.

• Llameal 1-800-4MY-HOMEparalaubicaci6nm_scercanade Sears

Parts& ServiceCenterdereparaci6n.

DESPEJE DE UN CANAL DE DESCARGA

OBSTRUIDO

Elcontactode las manosconel impulsorrotatorioqueest_dentro del canal

de descargaeslacausam_scomL]nde lesionesasociadascon lasm_quinas

quitanieve.Nuncausesu manoparalimpiarel canaldedescarga.

Paradespejarel canal:

1. iAPAGUEELMOTOR!

2. Espere10segundosparaestarsegurode quelas cuchillasdelmotor

handejadode rotar.

3. Utilicesiempreunaherramientadelimpieza,nouselas manos.

34

Page 35

MANTENIMIENTO Y ALMACENAMIENTO

,, Nuncaalterelosdispositivosdeseguridad.Controleperi6dicamenteque

funcionencorrectamente.Remitasealas seccionesdemantenimientoy

ajustede estemanual.

• Antesde realizarla limpieza,repararo revisarlam_quina,

desengranetodas las palancasde controly detengaelmotor.Esperea

quelabarrena/impulsorsedetenga porcompleto.Desconecteel cable

dela bujia y p6ngalohaciendomasacontrael motorparaevitar quese

enciendaaccidentalmente.

• Controlefrecuentementeque todoslos pernosytornillosesten bien

ajustadosparacomprobarquelam_quinaseencuentraen condiciones

segurasdefuncionamiento.Adem_s,hagauna inspecci6nvisualdela

m_quinaparaverificarsi est_da_ada.

• Nocambielaconfiguraci6ndel reguladordel motorniacelerede-

masiadoelmismo.Elreguladordel motorcontrolalavelocidadm_xima

defuncionamientosegurodelmotor.

• Quitanievesafeitarplacasy patinesest_nsujetosa desgasteyda_os.

Parasuprotecci6nde seguridad,verifiquefrecuentementetodoslos

componentesy con(OEM)delfabricantedel equipooriginals61o