Page 1

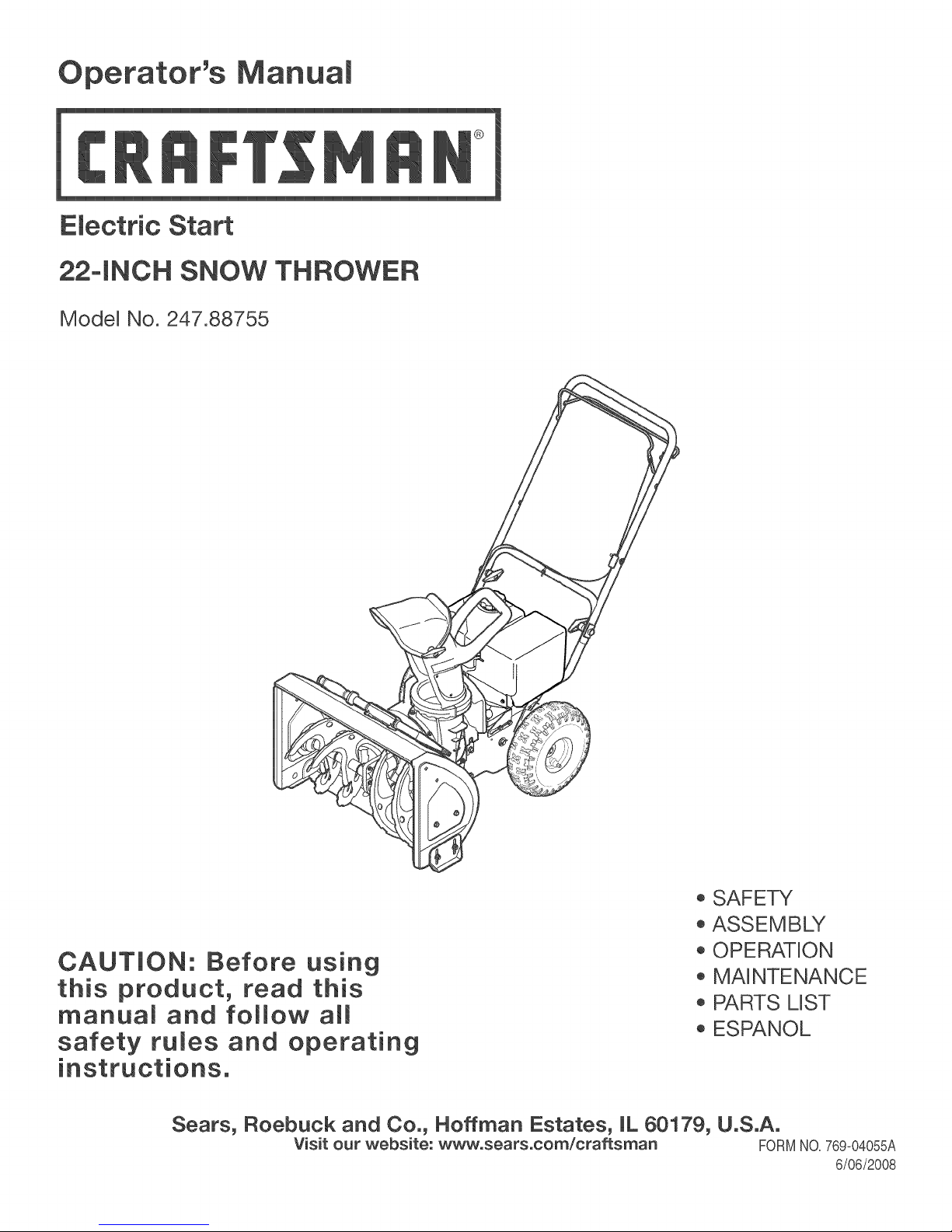

Operator's Manual

Electric Start

°iNCH SNOW THROWER

Model No. 247.88755

®

CAUTION: using

this product, read this

manua_ and folmow aml

safety fumes and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.sears.com/craftsman FORMNO.769-04055A

®SAFETY

®ASSEMBLY

®OPERATION

® MAINTENANCE

® PARTS LIST

® ESPANOL

6/06/2008

Page 2

Warranty Statement .................... Page 2

Safe Operation Practices ................ Page 3

Safety LabeUs ......................... Page 7

Setup & Adjustment .................... Page 8

Operation ........................... Page 12

Maintenance & Service ................. Page 16

Off-Season Storage ................... Page 21

TroubUeshooting ...................... Page 22

Parts List ............................ Page 23

Repair Protection Agreement ............ Page 32

Espa_oU............................. Page 33

Contact Numbers .................. Back Cover

CRAFTSMAN UMUTED WARRANTY

Two Years on Snow Thrower

Whenoperatedandmaintainedaccordingto allsuppliedinstructions,ifthissnowthrowerfailsdueto a defectinmaterialorworkmanshipwithintwoyearsfromthe

dateor purchase,returnitto anyauthorizedCraftsmandrop-offlocationforfree repair. Forthe nearestauthorizedlocation,call 1-800-4MYHOME.

Thiswarrantyappliesforonly90 daysfromthedateof purchaseifthissnowthroweriseverusedforcommercialorrentalpurposes.

Thiswarranty'coversONLYdefectsin materialandworkmanship.Searswill NOTpayfor:

* Expendableitemsthat becomewornduringnormaluse,includingbutnotlimitedto skidshoes,shaveplate,shearpins,sparkplug,air cleaner,belts,

andoilfilter.

, Standardmaintenanceservicing,oil changes,ortuneqps.

* Tirereplacementorrepaircausedbypuncturesfrom outsideobiects,suchasnails,thorns,stumps,orglass.

* Tireorwheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

* Repairsnecessarybecauseofoperatorabuse,includingbutnotlimitedtodamagecausedbyimpactingobiectsthatbendtheframeor crankshaft,or

over-speedingtheengine.

, Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,ebctrical andmechanicaldamagecausedbyimproperstorage,failure

tousethe propergradeand amountof engineoil,or failureto maintaintheequipmentaccordingtothe instructionscontainedinthe operator'smanual.

* Engine(fuelsystem)cleaningor repairscausedbyfueldeterminedto becontaminatedor oxidized(stale).Ingeneral,fuelshouldbe usedwithin30

daysof itspurchasedate.

* Normaldeteriorationandwearof the exteriorfinishes,or productlabelreplacement.

Thiswarrantyappliesonlywhilethisproductiswithinthe UnitedStates.

Thiswarranty'givesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

Sears, Roebuck and Co., Hoffman Estates, JL60179

EngineOilType: 5%30

EngineOilCapacity: 20ounces

FuelCapacity: 2.3Quarts

SparkHug: TorchF6RTC(F6TC)

SparkHug Gap: .020"to.030"

ModeJNumber.................................................................

SeriaJNumber.................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

@SearsBrands,LLC

2

Page 3

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsinthismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDiTSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothesafeopera-

tionpracticesinthis manualAswithanytypeof powerequipment,

carelessnessorerroron thepartoftheoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethe followingsafety

instructionscouldresultin seriousinjuryor death.

CAUFORNIA PROPOSmON 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm.

, Read,understand,andfollowallinstructionson themachineand

in themanual(s)beforeattemptingto assembleandoperate.

Failuretodosocan resultinseriousinjurytotheoperatorand/

orbystanders.Keepthismanualina safeplaceforfutureand

regularreferenceandfororderingreplacementparts.Forques-

tionscall,1-800-659-5917.

Befamiliarwithallcontrolsandtheirproperoperation.Knowhow

tostopthemachineanddisengagethemquickly.

Neverallowchildrenunder14yearsofagetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadulL

Neverallowadultsto operatethis machinewithoutproper

instruction.

Thrownobjectscan causeseriouspersonalinjury.Planyour

snow4hrowingpatterntoavoiddischargeof materialtoward

roads,bystandersandthelike.

Keepbystanders,petsandchildrenatbast75feetfromthe

machinewhileit isin operation.Stopmachineif anyoneenters

thearea.

Exercisecautiontoavoidslippingorfalling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict theuseofthis powermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsinthismanualandon themachine.

SAVE THESE NSTRUCT ONS!

Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbetrippedoverorthrownbythe auger/

impeller.

Alwayswearsafetyglassesor eyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjuryto the

eyes.

, Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjew@y,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

, Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

, Disengageall controlleversbeforestartingtheengine.

, Adjustcollectorhousingheighttocleargravelorcrushedrock

surfaces.

, Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual

, Letengineandmachineadjusttooutdoortemperaturebefore

startingtoclearsnow.

3

Page 4

SafeHandlingof Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselfor yourclotheswhichcanignite. Washyourskinand

changeclothesimmediately_

, Useonlyanapprovedgasolinecontainer.

, Extinguishall cigarettes,cigars,pipesandothersources

ofignition.

, Neverfuelmachineindoors.

, Neverremovegascaporaddfuel whiletheengineis hot

or running.

, Allowengineto coolat bast two minutesbeforerefueling.

, Neveroverfill fueltanL Filltanktono morethanY_inch

belowbottomoffillerneckto providespaceforfuel

expansion.

, Replacegasolinecapandtightensecurely.

, ifgasolineisspilled,wipeit offtheengineandequipmenL

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

, Neverstorethemachineor fuelcontainerinsidewhere

thereis anopenflame,sparkor pilotlight(e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

, Allowmachinetocoolatbast 5 minutesbeforestori%

, Neverfillcontainersinsidea vehicleorona truckortrailer

bedwithaplasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

, if possible,removegas_poweredequipmentfromthetruck

ortrailerand refueliton theground,if thisisnotpossible,

thenrefuelsuchequipmentona trailerwitha portable

container,ratherthanfromagasolinedispensernozzle.

, Keepthenozzleincontactwiththe rimofthefueltankor

containeropeningatalltimesuntilfuelingis complete.Do

notuse anozzlelock-opendevice.

, Do notputhandsorfeetnearrotatingparts,in theauger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeel

, Theauger/impellercontrolleveris a safetydevice.Neverbypass

itsoperation.Doingso makesthemachineunsafeandmaycause

personalinjury.

, Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

, Neveroperatewithamissingor damagedchuteassembly.Keep

all safetydevicesin placeandworki%

, Neverrunanengineindoorsorina poorlyventilatedarea. Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

, Do notoperatemachinewhileundertheinfluenceofalcoholor

drugs.

, Mufflerandenginebecomehotandcancausea burn.Do not

toucL Keepchildrenaway.

, Exerciseextremecautionwhenoperatingonorcrossinggravel

surfaces.Stayalertforhiddenhazardsor traffic.

, Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

, Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc. Thus,avoidingpossibleproperty

damageorpersonalinjurycausedbya ricocheL

, Neverdirectdischargeatchildren,bystandersand petsor allow

anyoneinfrontofthe machine.

, Donot overloadmachinecapacitybyattemptingto clearsnowat

toofastof a rate.

, Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingand keepafirmholdon thehandles.Walk,

neverrun.

, Disengagepowertotheauger/impellerwhentransportingor not

in use.

, Neveroperatemachineathightransportspeedson slippery

surfaces.Lookdownand behindand usecarewhenbackingup.

, ifthemachineshouldstartto vibrateabnormally,stoptheengine,

disconnectthesparkplugwireandgrounditagainsttheengine.

inspectthoroughlyfordamage.Repairanydamagebefore

startingandoperati%

, Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntilthe auger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makinganyadjustments,or inspections.

, Neverputyourhandinthe dischargeor collectoropenings.Do

notunclogchuteassemblywhileengineisrunning.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeuncloggi%

, Useonlyattachmentsandaccessoriesapprovedbythemanufac_

turer(e.g.wheelweights,tire chains,cabsetc.).

, Whenstartingengine,pullcordslowlyuntilresistanceis felt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthan youcan letgo.Broken

bones,fractures,bruisesorsprainscouldresulL

, ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgmenLContactCustomerSupportforassistance

andthenameof yournearestservicingdealer.

CLEARUNG A CLOGGED DUSCHAF{GE CHUTE

Handcontactwiththe rotatingimpellerinsidethe dischargechute

is themostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanout thedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating_

3_ Alwaysusea clean-outtool,notyourhands.

4

Page 5

MAUNTENANCE& STORAGE

, Nevertamperwithsafetydevices_Checktheirproperoperation

regularly.Refertothe maintenanceandadjustmentsectionsof

thismanual

, Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntiltheauger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheenginetopreventunintendedstarting.

, Checkboltsandscrewsfor propertightnessatfrequentintervals

tokeepthemachinein safeworkingcondition.Also,visually

inspectmachineforanydamage.

, Do notchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

, Snowthrowershaveplatesand skidshoesaresubjectto wear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonly."Useofpartswhichdo notmeettheoriginal

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!"

, Checkcontrolleversperiodicallyto verifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Refertothe adjustment

sectioninthisoperator'smanualforinstructions.

, Maintainorreplacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsand regulationsforgas,oil,etc.to

protecttheenvironment.

, Priorto storing,runmachinea few minutestoclearsnowfrom

machineand preventfreezeupofauger/impeller.

, Neverstorethe machineorfuelcontainerinsidewherethereis an

openflame,sparkorpilotlightsuchasa waterheater,furnace,

clothesdryeretc.

, Alwaysreferto theoperator'smanualforproperinstructionson

off-seasonstorage.

, Checkfuelline,tank,cap,andfittingsfrequentlyfor cracksor

leaks.Replaceif necessary.

, Do notcrankenginewithsparkplugremoved.

, AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or60 hoursof

operation.AttheendoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealerto ensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failuretodoso canresultinaccidents,injuries

ordeath.

DO NOT MODUFY ENGUNE

Toavoidseriousinjuryor death,do notmodifyengineinany way.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTUOE REGARDUNG EMUSSUONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateon regularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineis equippedwithaninternalcombustionengineand

shouldnotbeusedonornearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwithasparkarrestermeetingapplicablelocalor

statelaws(ifany)

Ifasparkarresterisused,itshouldbemaintainedineffectiveworking

orderbytheoperator.IntheStateofCaliforniatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterfor themuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

Page 6

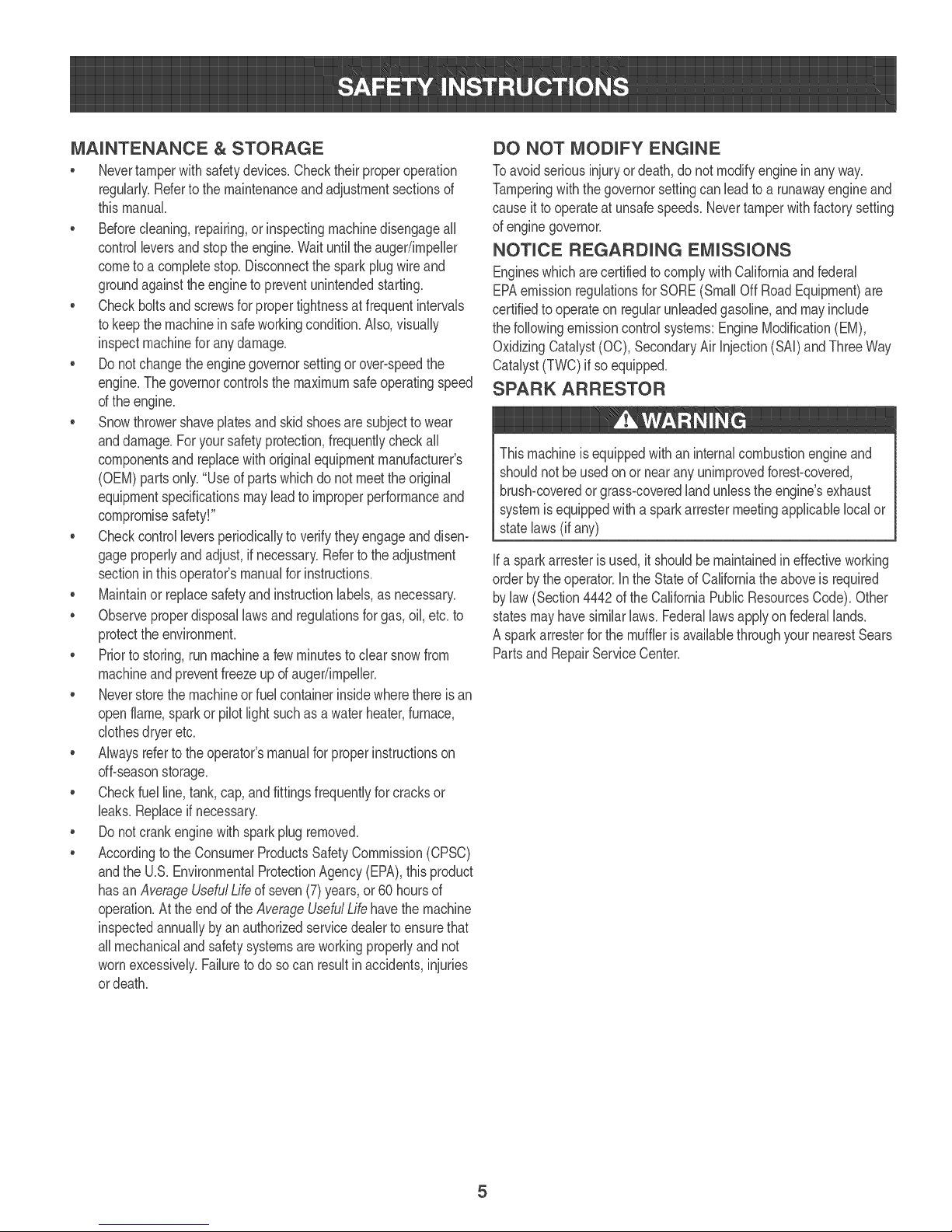

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfoflowaftinstructionson themachine

beforeattemptingtoassembleandoperate.

°

i

\

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine ]s running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine ]s running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, ]n the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICALSHOCK

Do not usethe engine's electric starter in the rain

6

Page 7

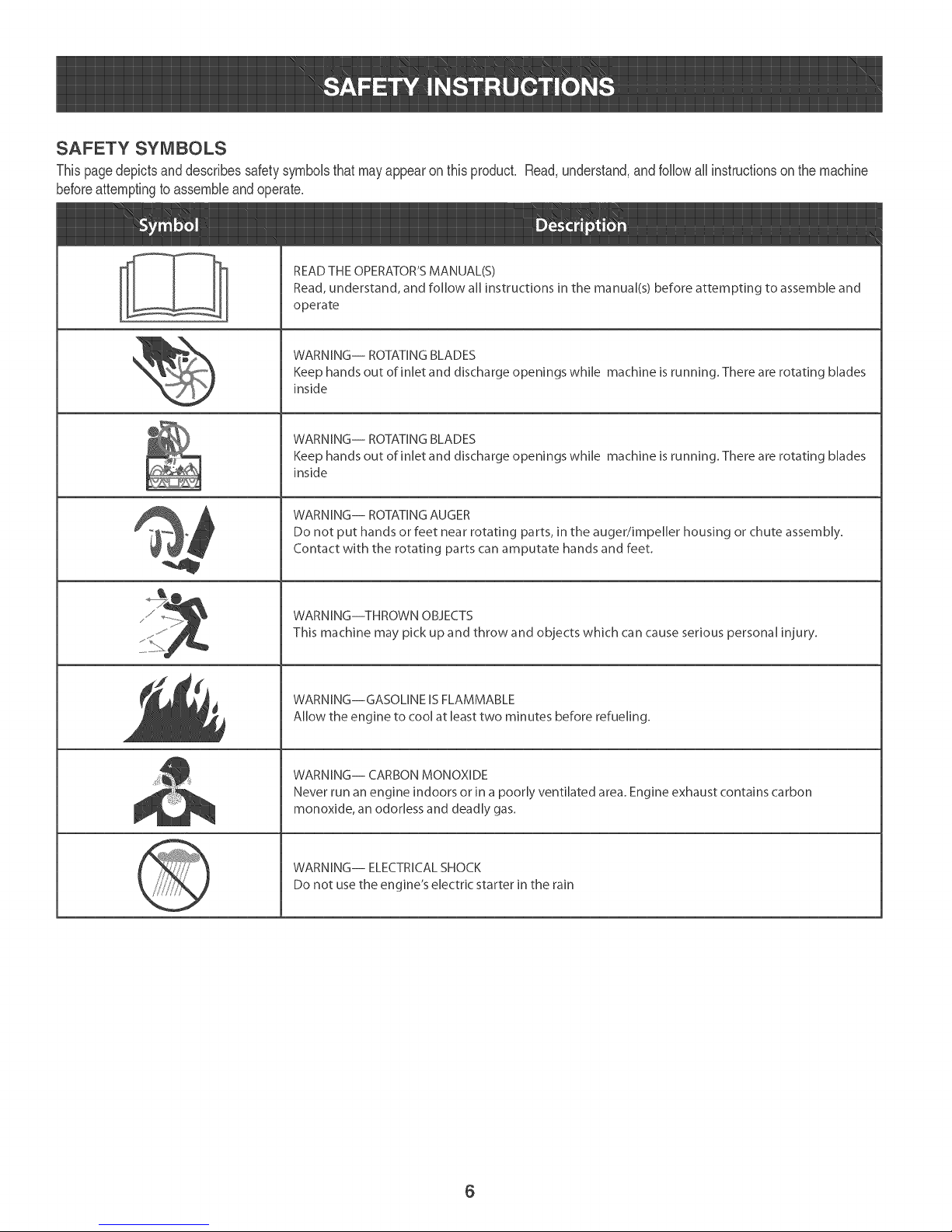

I,KEEPAWAY FROM ROTATINGiMPELLER

ANDAUGER.CONTACTWiTHiMPELLEROR

AUGER CAN AMPUTATEHANDSAND FEET.

2.USE CLEAN-OUTTOOLTO UNCLOG

DISCHARGECHUTE.

3.DISENGAGECLUTCHLEVERS,STOPENGINE,

AND REMAINBEHINDHANDLESUNTILALL

MOVING PARTSHAVE STOPPEDBEFORE

UNCLOGGING OR SERVICINGMACHINE.

4.TO AVOIDTHROWN OBJECTSiNJURIES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHENOPERATINGON

GRAVEL SURFACES.

5, READOPERATOR'SMANUAL.

7

Page 8

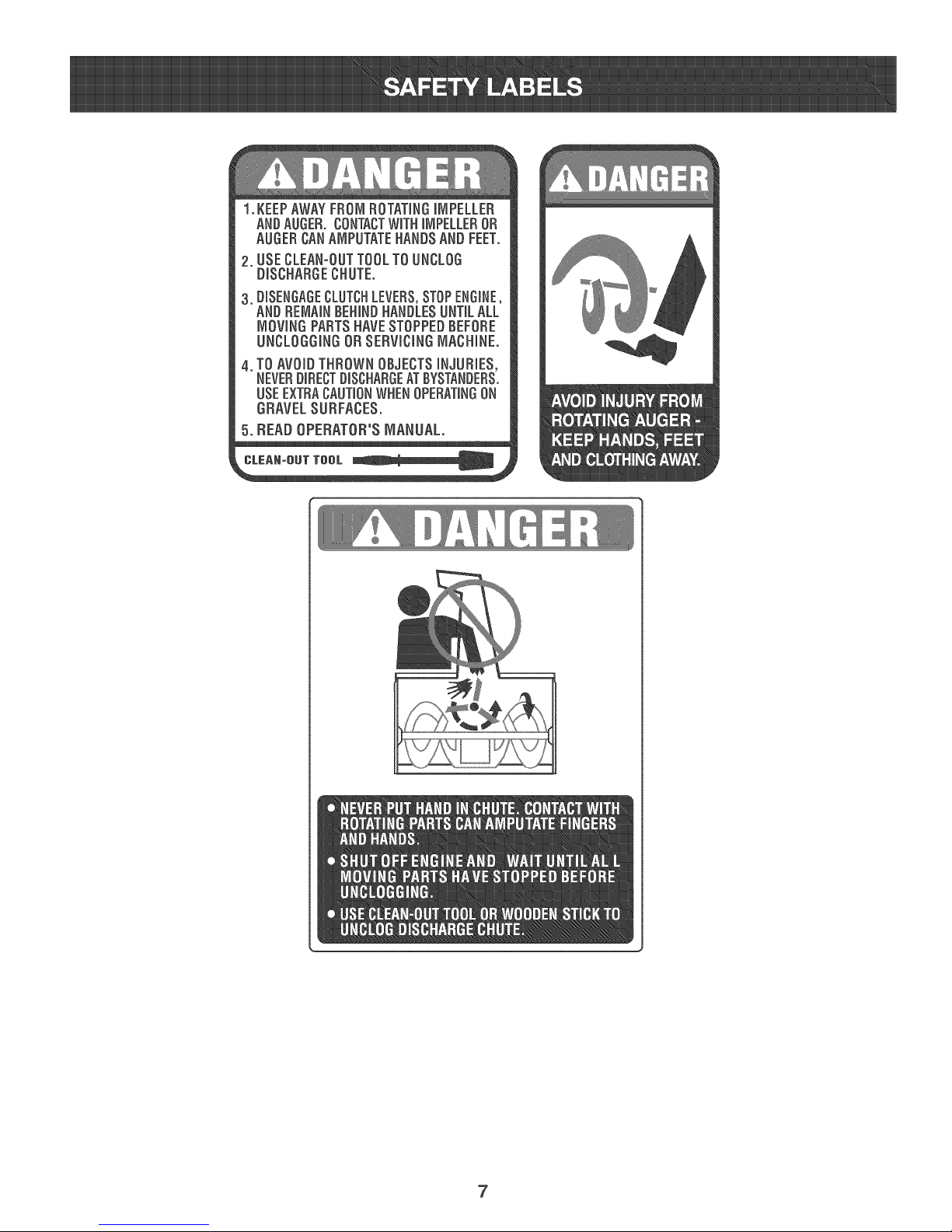

iMPORTANT:Thisunitis shippedwiththeenginefullofoil.After

assembly,seepage10for fuelandoildetails.

Removing From Carton

1. Cutthecornersofthecartonandlaythesidesflaton theground.

Removeall packinginserts.

2_ Movethesnowthroweroutof thecarton.

3. Makecertainthecartonhasbeencompletelyemptiedbefore

discardingit.

DO NOTliftthesnowthrowerbythechutehandle.

Before Assembly

NOTE:Referenceto right,left, frontorrearof theunitis fromthe

operatingpositionunlessotherwisestated.

Setting Up The Handme

NOTE: Beawareofthethreelooselyfitted cabletiesattachedtothe

lowerhandlethatwillbeutilizedlatertosecurethecables.

1. Loosenandremovethewing knob,saddlewasher,handletab and

carriagescrewoneachside ofthe lowerhandle.See Fig.1.

2. Slideone of thelooselyfitted cabletiesfromthe rightsideofthe lower

handleuptothecrossmemberofthe lowerhandle.Leavethesecond

cabletiein placeon the rightsideofthe lowerhandle.See Fig.3 for

reference.

IMPORTANT: Itwillbenecessarytolifttheupperhandlewhileslidingup

thiscabletietopreventdamagetothecable.

3. Lifttheupperhandleupandpositionit overthelowerhandle,align-

ingtheholeswherethewing knobswereremoved(1).SeeFig.2.

f

Becarefulnottobendor kinkthecables.

4_ Inserta carriagescrewfromtheoutsidethroughahandletab,the

upperand lowerhandles,a saddlewasherandintothewingknob

(2)_Repeatontheotherside.

5_ Tightenthewingknobsoneach sideofthe handle.Referto Fig.2_

NOTE:The augercableroutesdowntheleftlowerhandleandthe

drivecableis routedacrossthetop ofthelowerhandleanddownthe

rightside ofthelowerhandle.SeeFig.3_

.

Threecabletieshavebeenusedto looselytiethecontrolcables

tothelowerhandle,includingthecabletieyourelocatedinstep2_

Positioncabletiesnow,asin Fig.3,andtightento securecablesto

thelowerhandle.Trimoffexcessmaterialofcableties.

Figure 2

DriveCable

\

get Cable

Figure 3

8

Page 9

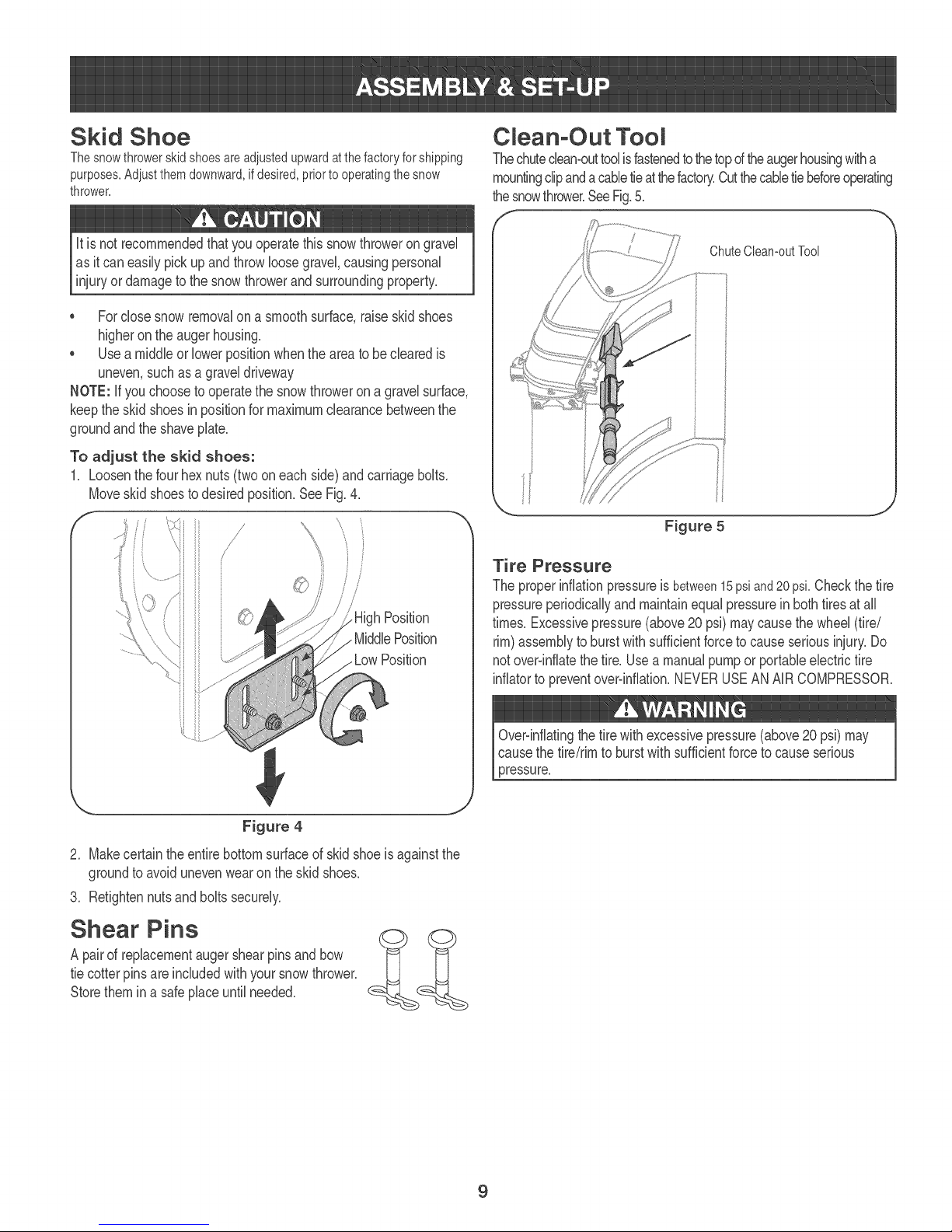

Skid Shoe

Thesnowthrowerskidshoesareadiustedupwardatthefactoryforshipping

purposes.Adiustthemdownward,ifdesired,priortooperatingthesnow

thrower.

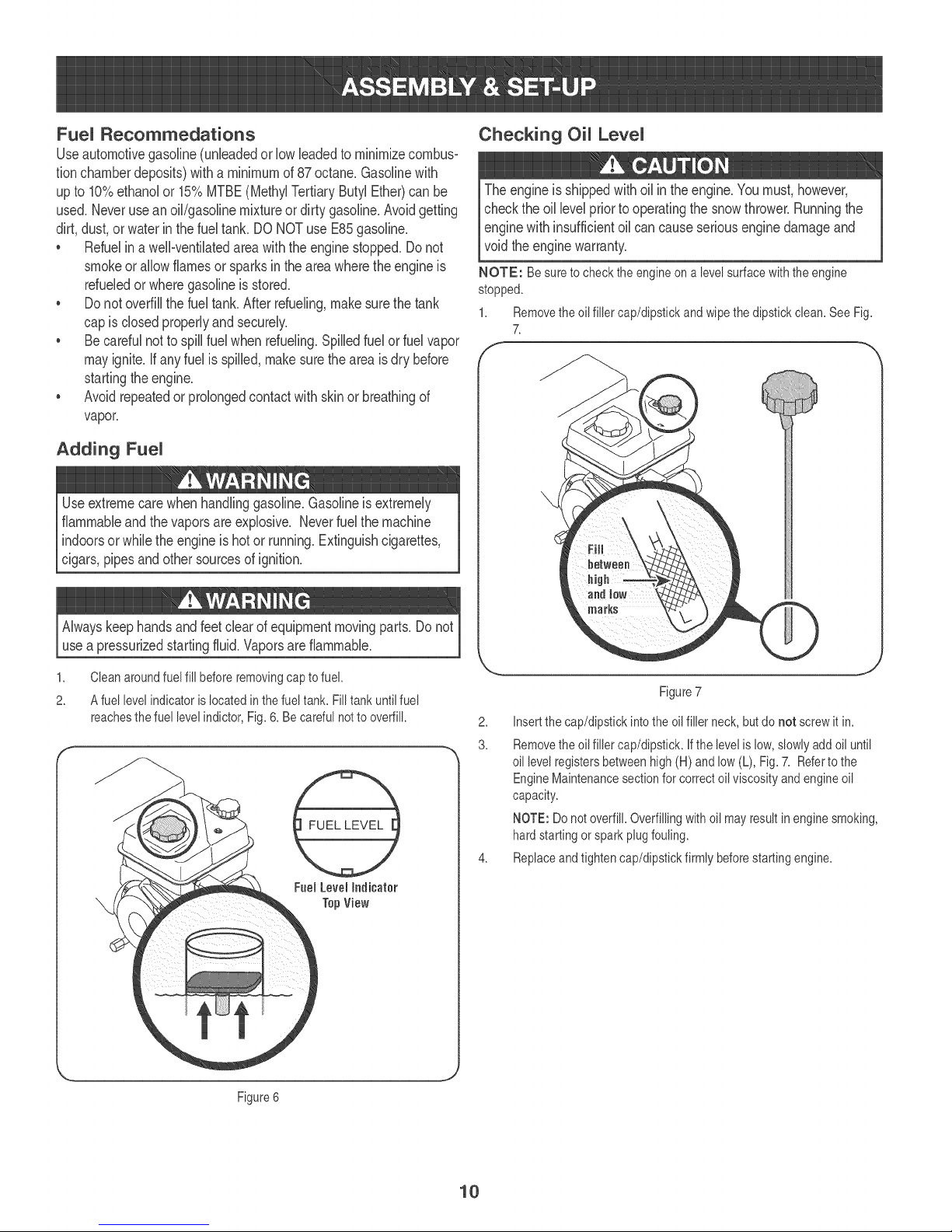

Clean-Out Tool

Thechuteclean-outtoolisfastenedto thetopd theaugerhousingwitha

mountingdipandacabletieatthefactory.Cutthecabletiebeforeoperating

thesnowthrower.SeeFig.5.

f

It isnotrecommendedthatyouoperatethis snowthrowerongravel

as itcaneasilypickupandthrowloosegravel,causingpersonal

injuryordamagetothesnowthrowerand surroundingproperty.

, Fordose snowremovalona smoothsurface,raiseskidshoes

higherontheaugerhousing.

, Useamiddleor lowerpositionwhentheareatobe clearedis

uneven,suchasa graveldriveway

NOTE:Ifyouchooseto operatethe snowthroweronagravelsurface,

keepthe skidshoesinpositionfor maximumclearancebetweenthe

groundandtheshaveplate.

To adjust the skid shoes:

1. Loosenthefourhexnuts(twooneachside)andcarriagebolts.

Moveskidshoestodesiredposition.See Fig.4.

/

/

/

.MiddlePosition

ChuteCleamoutTool

Figure 5

Tire Pressure

Theproperinflationpressureisbetween15psiand20psi.Checkthetire

pressureperiodicallyandmaintainequalpressurein bothtiresatall

times.Excessivepressure(above20psi)maycausethewheel(tire/

rim)assemblytoburstwithsufficientforcetocauseseriousinjury.Do

notovePinflatethe tire.Usea manualpumpor portableelectrictire

inflatorto preventover-inflation.NEVERUSEANAIRCOMPRESSOR.

2_ Makecertaintheentirebottomsurfaceof skidshoeisagainstthe

groundtoavoidunevenwearonthe skidshoes.

3. Retightennutsandboltssecurely.

Shear Pins

A pairof replacementaugershearpinsandbow

tiecotterpinsare includedwithyoursnowthrower.

Storethemina safeplaceuntilneeded.

Over-inflatingthetirewithexcessivepressure(above20psi) may

causethetire/rimto burstwithsufficientforcetocauseserious

pressure.

9

Page 10

FueURecommedations

Useautomotivegasoline(unleadedor lowleadedtominimizecombus-

tionchamberdeposits)withaminimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureordirtygasoline.Avoidgetting

dirt,dust,or waterin thefuel tank.DONOTuse E85gasoline.

, Refuelin awelFventilatedareawiththeenginestopped.Donot

smokeorallowflamesorsparksintheareawheretheengineis

refueledorwheregasolineisstored.

, Do notoverfillthefueltank.Afterrefueling,makesurethetank

capisclosedproperlyandsecurely.

, Becarefulnottospillfuel whenrefueling.Spilledfuelorfuelvapor

mayignite.Ifanyfuelisspilled,makesuretheareaisdrybefore

startingtheengine.

, Avoidrepeatedor prolongedcontactwithskinorbreathingof

vapor.

Adding FueU

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuel themachine

indoorsorwhile theengineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesofignition.

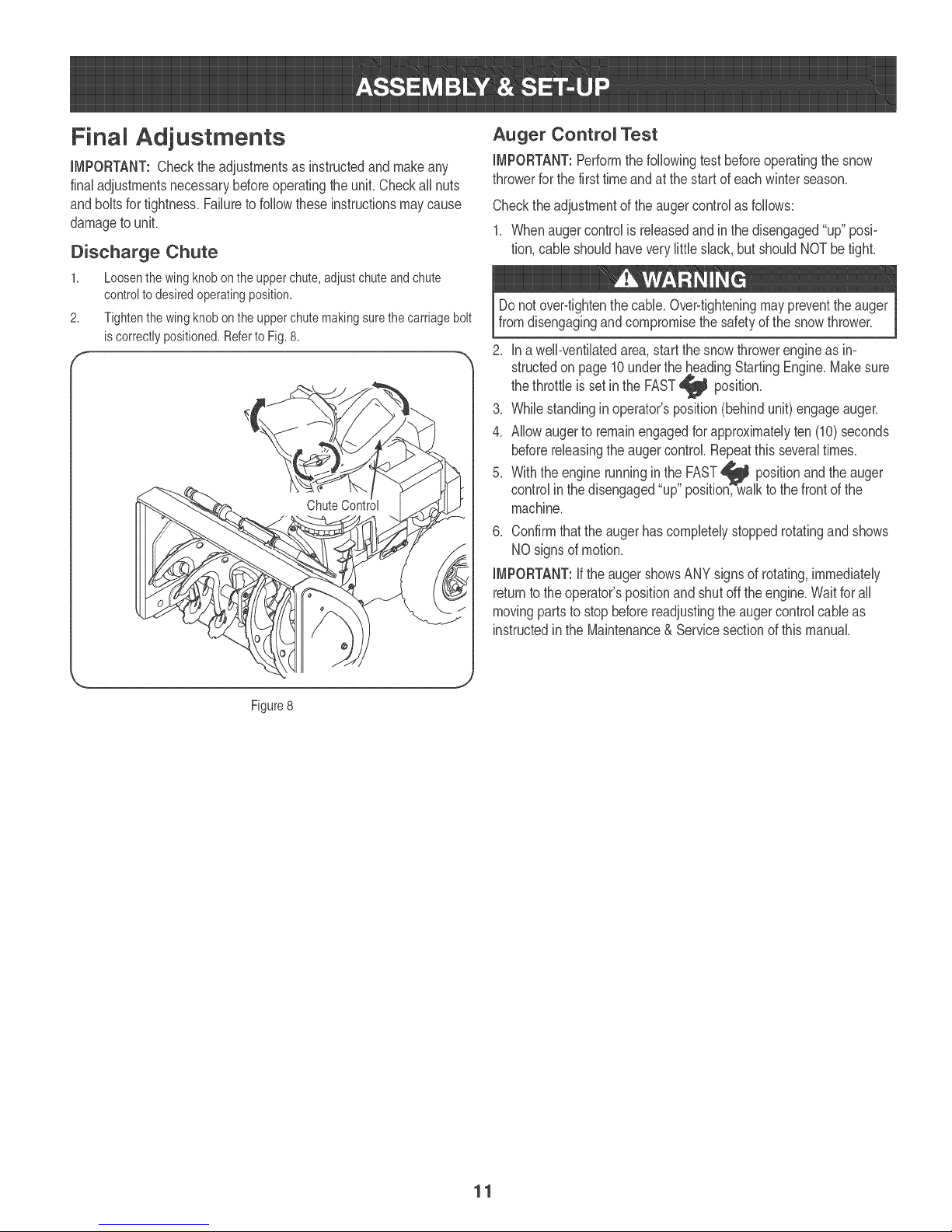

Checking OiU LeveU

Theengineisshippedwithoil intheengine.Youmust,however,

checkthe oillevelpriortooperatingthesnowthrower.Runningthe

enginewithinsufficientoil cancauseseriousenginedamageand

voidtheenginewarranty.

NOTE: Besuretochecktheengineonalevelsurfacewiththeengine

stopped.

1. Removetheoilfillercap/dipstickandwipethedipstickclean.SeeFig.

7.

Alwayskeephandsandfeetclearof equipmentmovingparts.Do not

usea pressurizedstartingfluid.Vaporsareflammable.

1. Cleanaroundfuel fill beforeremovingcaptofuel.

2. A fuellevelindicatorislocatedinthefuel tank. Filltankuntil fuel

reachesthefuellevel indictor,Fig.6.Becarefulnotto overfill.

Figure7

2. Insertthe cap/dipstickintotheoilfillerneck,butdo not screwit in.

3. Removetheoil fillercap/dipstick.Ifthe levelis low,slowlyadd oiluntil

oil levelregistersbetweenhigh(H) andlow(L), Fig.7. Refertothe

EngineMaintenancesectionfor correctoil viscosityandengineoil

capacity.

NOTE:Do notoverfill.Overfillingwith oil mayresultin enginesmoking,

hardstartingorsparkplugfouling.

4. Replaceandtightencap/dipstickfirmly beforestartingengine.

Figure6

10

Page 11

Final Adjustments

iMPORTANT:Checktheadjustmentsasinstructedandmakeany

finaladjustmentsnecessarybeforeoperatingtheunit.Checkallnuts

andboltsfortightness.Failureto followtheseinstructionsmaycause

damagetounit.

Discharge Chute

1. Loosenthewingknobontheupperchute,adiustchuteandchute

controlto desiredoperatingposition.

2. Tightenthewingknobontheupperchutemakingsurethecarriagebolt

iscorrectlypositioned.RefertoFig.8.

f, -,

Auger ControU Test

IMPORTANT:Performthefollowingtestbeforeoperatingthesnow

throwerforthefirsttimeandatthestartof eachwinterseason.

Checktheadjustmentof theaugercontrolasfollows:

1. Whenaugercontrolis releasedandinthedisengaged"up"posi=

tion,cableshouldhaveverylittleslack,butshouldNOTbetight.

Donot over4ightenthecane. Overqighteningmaypreventtheauger

fromdisengagingandcompromisethesafetyofthesnowthrower.

2. inaweIFventilatedarea,startthesnowthrowerengineasin-

structedon page10underthe_.headingStartingEngine.Makesure

thethrottleissetintheFAST position.

3. Whilestandinginoperator'sposition(behindunit)engageauger.

4. Allowaugerto remainengagedforapproximatelyten(10)seconds

beforereleasingtheaugercontrol.Repeatthisseveraltimes.

5. Withtheenginerunninginthe FAST_ positionandtheauger

controlinthedisengaged"up"position,w-alkto thefrontofthe

machine.

6. Confirmthattheaugerhascompletelystoppedrotatingand shows

NOsignsofmotion.

IMPORTANT:ifthe augershowsANYsignsof rotating,immediately

returntotheoperator'spositionand shutofftheengine.Waitfor all

movingpartstostopbeforereadjustingtheaugercontrolcane as

instructedinthe Maintenance& Servicesectionofthismanual.

,.. j

Figure8

11

Page 12

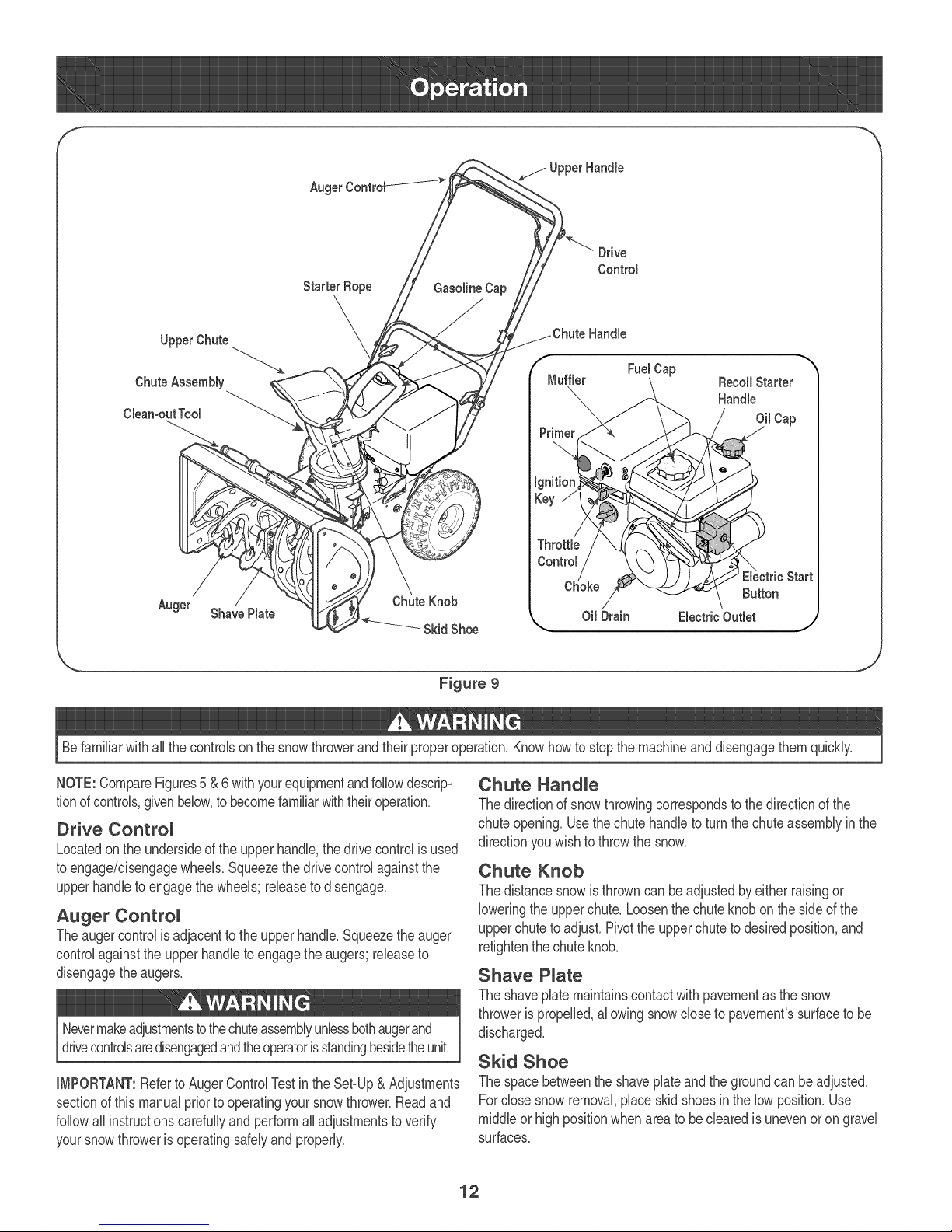

AugerContr_

S UpperHandle

Ddve

Control

StarterRope GasolineCap

UpperChute _",, Handle

"_ FuelCap

ChuteAssembly

Clean-outTool

Recoil Starter

Handle

Figure 9

Befamiliarwithallthecontrolsonthesnowthrowerand theirproperoperation.Knowhowto stopthemachineanddisengagethemquickly.

NOTE:CompareFigures5 &6withyourequipmentandfollowdescrip-

tionof controls,givenbelow,tobecomefamiliarwiththeiroperation.

Drive ControU

Locatedon theundersideof the upperhandle,thedrivecontrolis used

toengage/disengagewheel&Squeezethedrivecontrolagainstthe

upperhandleto engagethe wheels;releasetodisengage.

Auger Control

Theaugercontrolisadjacentto theupperhandle.Squeezetheauger

controlagainsttheupperhandletoengagethe augers;releaseto

disengagetheauger&

Chute HandUe

Thedirectionof snowthrowingcorrespondsto thedirectionofthe

chuteopening.Usethechutehandleto turnthechuteassemblyinthe

directionyouwishtothrowthe snow.

Chute Knob

Thedistancesnowisthrowncanbeadjustedbyeither raisingor

loweringtheupperchute.Loosenthechuteknobontheside ofthe

upperchutetoadjust.Pivotthe upperchutetodesiredposition,and

retightenthechuteknob.

Shave PUate

Theshaveplatemaintainscontactwithpavementas thesnow

throwerispropelled,allowingsnowclosetopavement'ssurfacetobe

Nevermakeadjustmentstothechuteassemblyunlessbothaugerand

discharged.

ddvecontrolsaredisengagedandtheoperatorisstandingbesidetheunit.

Skid Shoe

IMPORTANT:RefertoAugerControlTestintheSebUp& Adjustments

sectionofthismanualpriortooperatingyoursnowthrower.Readand

followall instructionscarefullyandperformalladjustmentsto verify

yoursnowthroweris operatingsafelyandproperly.

Thespacebetweentheshaveplateand thegroundcan beadjusted.

Forclosesnowremoval,placeskidshoesin thelowposition.Use

middleor highpositionwhenareato beclearedis unevenorongravel

surfaces.

J

12

Page 13

Whenengaged,theaugersrotateanddrawsnowintotheauger

housing.

Chute AssembUy

Snowdrawnintotheaugerhousingisdischargedoutthechute

assemNy.

Choke ControU

Activatingchokecontrolbyturningitall theway

tothebft doses thechokeplateoncarburetor

andaidsin startingthe engine.Forinformationon

chokeusage,seeStartingTheEnginelaterin this

section.

RecoiU Starter & Starter HandUe

Thismotorisfittedwitha recoilactionpullstart andamittengrip

handb foreasyaccesswhib wearingglovesormitten&

Ugnition Key

Theignitionkeyisa safetydevice,it mustbefully ___,,_

insertedinorderfortheenginetostart.Remove

theignitionkeywhenthesnowthroweris notin

use.

NOTE:Do notturnthe ignitionkeyin anattemptto

startthe engine.Doingsomaycauseittobreak.

,O

EUectric Starter Button

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

EUectric Starter OutUet

Requirestheuseof athree-prongoutdoorextensioncord(included)

anda120Vpowersource/walloutleL

Thethrottlecontrolislocatedontheengine,it regulatesthe speedof

theengineandwillshutofftheenginewhen pusheddowncompletely.

Theimagetotherightrepresentsthe speedsofthethrottlecontroland

correspondswiththelabelontheengine.Theimagesbelowillustrate

thedefinitionofeachsymbol.

CUean=Out TooU

Neveruseyour handstoclearacloggedchuteassembly.Shutoff

engineandremainbehindhandlesuntilall movingpartshavestopped

beforeusingthecleamouttooltoclear thechuteassembly.

Thechutecleamouttoolisconvenientlyfastenedtotherearofthe

augerhousingwitha mountingcliF Shouldsnowand icebecome

lodgedinthechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1_ ReleaseboththeAugerControlandtheDriveControl

2_ Stoptheenginebyremovingthe ignitionkey.

3_ Removethecleamouttoolfromtheclipwhichsecuresitto the

rearoftheaugerhousing.

4_ Usethe shovePshapedendoftheclean-outtoolto dislodgeand

scoopanysnowandicewhichhas formedinandnearthe chute

assembly.

5_ Refastenthecleamouttoolto themountingclipon therearof

theaugerhousing,reinserttheignitionkeyandstartthesnow

thrower'sengine.

6_ Whilestandingintheoperator'sposition(behindthesnow

thrower),engagetheaugercontrolfora fewsecondstoclearany

remainingsnowand icefromthe chuteassembly.

Before Starting Engine

Depressingprimerforcesfueldirectlyintoengine's

carburetorto aidincold-weatherstarting_Referto _k1_)_,,,,,,,,a,,,,,m

thestartinginstructionsinthe Operationsection

ofthismanualforproperprimerusage.The image

belowleft,correspondswiththelabelonthe

engineidentifyingtheprimer.

Oil Fill

Removeoilcap toaddoil Referto the Maintenance&Servicesection

forcheckingandaddingoilinstruction&

GasoUine Cap

Removegascaptoaddfuel.Unitrunson regulargas.

NOTE:Thisunitmayincludea fuelplug,whichisonlyusedduring

assemblytokeepdirtanddebrisout offueltank. Discardthefuel plug

beforefillingthefueltank.

ThrottUe ControU

1

Read,understand,andfollowallinstructionsandwarningsonthe

machineandinthismanualbeforeoperating.

Engine OiU

Theunitwasshippedwith oilinthe engine.Checkoillevelbeforeeach

operationtoensureadequateoil intheengine.Forfurtherinstructions,

refertothe Maintenance& Servicesectionofthismanual.

NOTE:Besuretocheckthe engineonalevelsurfacewiththeengine

stoppe&

1_ Removetheoilfillercap/dipstickandwipe thedipstickclean.

2_ insertthe cap/dipstickintotheoilfiller neck,butdonot screwit in.

3_ Removetheoilfillercap/dipsticL ifthe levelislow,slowlyadd

oil (5%30, witha minimumclassificationofSF/SG)untiloillevel

registersbetweenhigh(H)andlow(L).

NOTE:Donotoverfill.Overfillingwithoil mayresultin enginesmoking,

hardstartingor sparkplugfouling.

4_ Replaceandtightencap/dipstickfirmlybeforestartingengine.

13

Page 14

Gasolne

Useautomotivegasoline(unleadedor lowleadedtominimizecombus-

tionchamberdeposits)withaminimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureordirtygasoline.Avoidgetting

dirt,dust,or waterin thefuel tank.DONOTuse E85gasoline.

, Refuelin awell-ventilatedareawiththe enginestopped.Donot

smokeorallowflamesorsparksintheareawheretheengineis

refueledorwheregasolineisstored.

, Do notoverfillthefueltank.Afterrefueling,makesurethetank

capisclosedproperlyandsecurely.

, Becarefulnottospillfuel whenrefueling.Spilledfuelorfuelvapor

mayignite.Ifanyfuelisspilled,makesuretheareaisdrybefore

startingtheengine.

, Avoidrepeatedor prolongedcontactwithskinorbreathingof

vapor.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuel themachine

indoorsorwhiletheengineishotorrunning.Extinguishcigarettes,

cigars,pipesandothersourcesofignition.

.

Cleanaroundfuelfill beforeremovingcaptofuel.

2.

Afuellevelindicatorislocatedinthefueltank.Filltankuntilfuel

reachesthefuel levelindictor.SeeFigure10inset.Becarefulnot

tooverfill.

Starting The Engine

Determinethatyourhome'swiringisathree-wiregroundedsystem.

Askalicensedelectricianifyou arenotcertain.

Ifyouhaveagroundedthree-prongreceptacle,proceedasfollows.

Ifyoudonothavetheproperhousewiring,DONOTusetheelectric

starterunderanyconditions.

1. Plugtheextensioncordintotheoutletlocatedon theengine's

surface.Plugtheotherendof extensioncordintoathree-prong

120-volt,grounded,AC outletinawell-ventilatedarea.

2. Movethrottlecontrolto FAST(rabbit)_ position.

3. MovechoketotheONposition1,,#'1(coldenginestart).Ifengine

is warm,placechokeinOFFposition.

4. Pushprimerthreeto five(3-5)times,makingsuretocovervent

holewhenpushing.If engineiswarm,pushprimeronlyonce.

Alwayscoverventholewhenpushing.Coolweathermayrequire

primingto berepeated.

5. Pushstarterbuttonto startengine.Oncetheenginestarts,im-

mediatelyreleasestarterbutton.Electricstarterisequippedwith

thermaloverloadprotection;systemwilltemporarilyshut-downto

allowstartertocoolif electricstarterbecomesoverloaded.

6. Asthe enginewarms,slowlyrotatethechokecontroltoOFF

position.Iftheenginefalters,restartengineand runwithchoke

at half-chokepositionfor a shortperiodoftime,andthenslowly

rotatethechokeintoOFFposition.

Afterengine

Whendisconnecting,alwaysunplugtheendatthewall outlet

beforeunpluggingtheoppositeendfromtheengine.

Recoil Starter

Alwayskeephandsandfeetclearof movingparts.Do notusea

pressurizedstartingfluid.Vaporsareflammable.

NOTE:Forlocationofalltheenginecontrolsreferredto inthis section,

referto Fig.9onpage 12.

NOTE:Allowtheengineto warmupfor afewminutesafterstarting.

Theenginewill notdevelopfullpoweruntilit reachesoperating

temperatures.

1. Makecertainboththe augercontrolanddrivecontrolare inthe

disengaged(released)position.

2. insertignitionkeyinto slot.Makesureitsnapsintoplace.Donot

attempttoturnthekey.

NOTE:The enginecannotstartwithoutthekeyfullyinsertedintothe

Electric Starter

Theoptionalelectricstarterisequippedwitha groundedthree-wire

powercordandplug,andisdesignedtooperateon 120voltAC

householdcurrent,it mustbeusedwitha properlygroundedthree-

prongreceptacleatalltimestoavoidthe possibilityofelectricshock.

Followall instructionscarefullypriortooperatingtheelectricstarter.

DONOTuseelectricstarterinthe rain.

Donot pullthestarterhandlewhiletheenginerunning.

1. Movethrottlecontrolto FAST(rabbit)_ position.

2. MovechoketotheONpositionlJ 1(coldenginestart),ifengineis

warm,placechokeinOFFposition.

3. Pushprimerthreeto five(3-5)times,makingsuretocovervent

hob whenpushing,if engineis warm,pushprimeronlyonce.

Alwayscoverventhob whenpushing.Coolweathermayrequire

primingto berepeated.

4. Pullgentlyonthestarterhandleuntil itbeginsto resist,thenpull

quicklyandforcefullyto overcomethecompression.Do notrelease

thehandleandallowit tosnapback.ReturnropeSLOWLYto

originalposition,if required,repeatthisstep.

5. Astheenginewarms,slowlyrotatethechokecontrolto OFF

position,if theenginefalters,restartengineandrunwith chokeat

hal-choke positionfora shortperiodoftime,andthenslowlyrotate

thechokeintoOFFposition.

Toavoidunsupervisedengineoperation,neverleavethemachine

unattendedwiththeenginerunning.Turntheengineoff afteruseand

removeignitionkey.

14

Page 15

Stopping The Engine

Runenginefor afewminutesbeforestoppingtohelpdryoff any

moistureonthe engine.

1. MovethrottlecontroltoSTOP position.

2. Removetheignitionkey.Removingthekeywill reducethepos-

sibilityof unauthorizedstartingof theenginewhileequipmentis

notinuse.Keepthekeyin a safeplace.Theenginecannotstart

withouttheignitionkey.

Positioning Discharge Chute

Loosenthechuteknobandpivotupperchuteto desiredposition.Tighten

thechuteknobmakingsurethecarriageboltiscorrectlypositioned.

Rotatechutehandletodesiredoperatingposition.

Donot liftthe snowthroweratany timebythechutehandle.

3. Wipeanymoistureawayfromthecontrolsontheengine.

Before Stopping

1. Runenginefor afewminutestohelpdry offanymoistureonengine.

2. Toavoidpossiblefreeze-upof therecoilstarter,followthisstep:

RecoiU Starter

a. Withtheenginerunning,pullthe starterropewitha rapid,

continuousfullarm strokethreeor fourtimes.

To Stop The Snow Thrower

1. Tostopthewheels,releasethe drivecontrok

2. Tostopthrowingsnow,releasetheaugercontrok

3. Tostopengine,pushthrottlecontrollevertoOFF @ and pullout

thekey.Donotturn key.

Thetemperatureofmufflerandthesurroundingareasmayexceed

1500F.Avoidtheseareas.

Clearing The Snow

CAUTION:Checktheareatobe clearedfor foreignobjects.Remove

foreignobjects,if any.

1. Starttheenginefollowingstartinginstructions.

2. Allowtheenginetowarmupfora fewminutesastheenginewillnot

developfullpoweruntilit reachesoperatingtemperature.

3. Rotatethechuteassemblyto thedesireddirection,awayfrom

bystandersand/or buildings.

4. Makingcertainno bystandersor obstaclesarein frontoftheunit,

squeezetheaugercontrolcompletelyagainsttheupperhandleto

fullyengagetheaugers.

5. Whiletheaugercontrolisengaged,squeezethedrivecontrol

completelyagainstthe upperhandleto engagethewheels.Donot

"feather"thedrivecontrok

6. Asthesnowthrowerstartsto move,maintaina firmholdonthe

handle,andguidethesnowthroweralongthe pathto becleared.

7. Releasetheaugerand drivecontrolstostopthesnowthrowing

actionandforwardmotion.

NOTE:Yourunit isequippedwitha clutchin thetransmission,if the

wheelsstopturningwhiletryingtodischargelargevolumesofsnow,

immediatelydisengagethedrivecontrolandallowtherotatingaugers

todischargesnowfromthehousing.Reducetheclearingwidthand

continueoperation.

8. Oneachsucceedingpass,readjustthechuteassemblytothe

desiredpositionandslightlyoverlapthepreviouslyclearedpath.

Operating Tips

1. Formostefficientsnowremoval,removesnowimmediatelyafteritfalls.

2. Dischargesnowdownwindwheneverpossible.Slightlyoverlap

eachpreviouspath.

3. Setthe skidshoes1/4"belowtheshaveplatefornormalusage.

Theskidshoesmaybeadjustedupwardfor hard-packedsnow.

NOTE:it isnotrecommendedthatyouoperatethis snowthroweron

gravelas loosegravelcanbe easilypickedupandthrownbytheauger

causingpersonalinjuryand/ordamagetothesnowthrower.

4. ifforsomereason,youhaveto operatethesnowthrowerongravel,

keeptheskidshoeinthehighestpositionformaximumclearance

betweenthegroundandtheshaveplate.

5. Cleanthesnowthrowerthoroughlyaftereachuse.

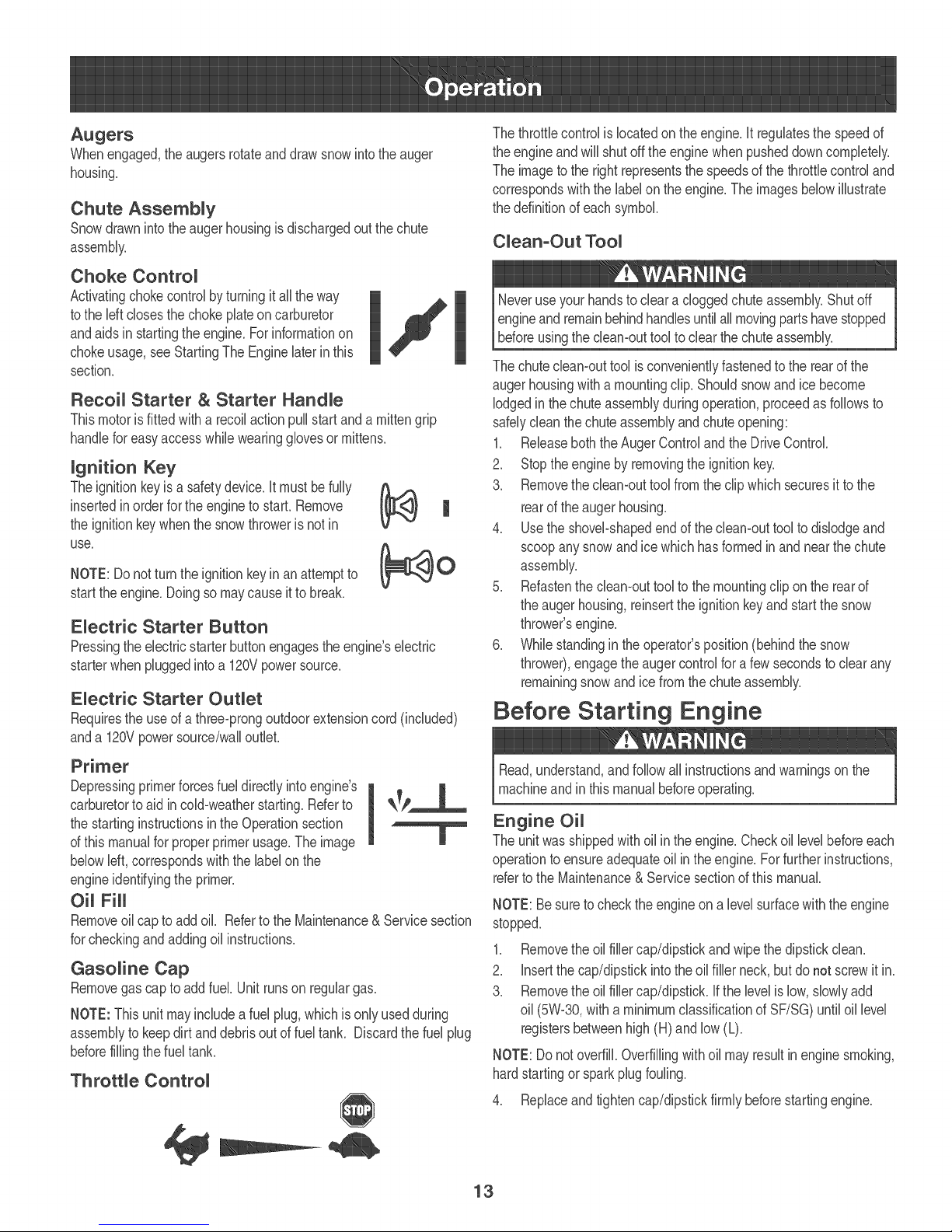

REPLACUNG SHEAR PUNS

Theaugersaresecuredtothespiralshaftwithtwo shearpinsand

bow-tieclips,if theaugershouldstrikea foreignobjector icejam,the

snowthrowerisdesignedsothatthe shearpinsmayshear,if augers

willnotturn,checkto seeif thepinshavesheared.SeeFig. 10.

NEVERreplacetheaugershearpinswithanythingotherthanOEM 1

PartNo.0EM-738-04124replacementshearpins.Anydamageto the1

augergearboxorothercomponentsasaresultof failingtodosowill j

NOTbecoveredbyyoursnowthrowerswarranty.

Alwaysturnoffthesnowthrower'sengineand removethekeypriorto

replacingshearpins.

f "-,

// @

/

Figure10

15

Page 16

ENGUNE MAUNTENANCE f _,

Beforelubricating,repairing,or inspecting,disengageall controls

andstopengine.Waituntilall movingpartshavecometo a complete

stop,

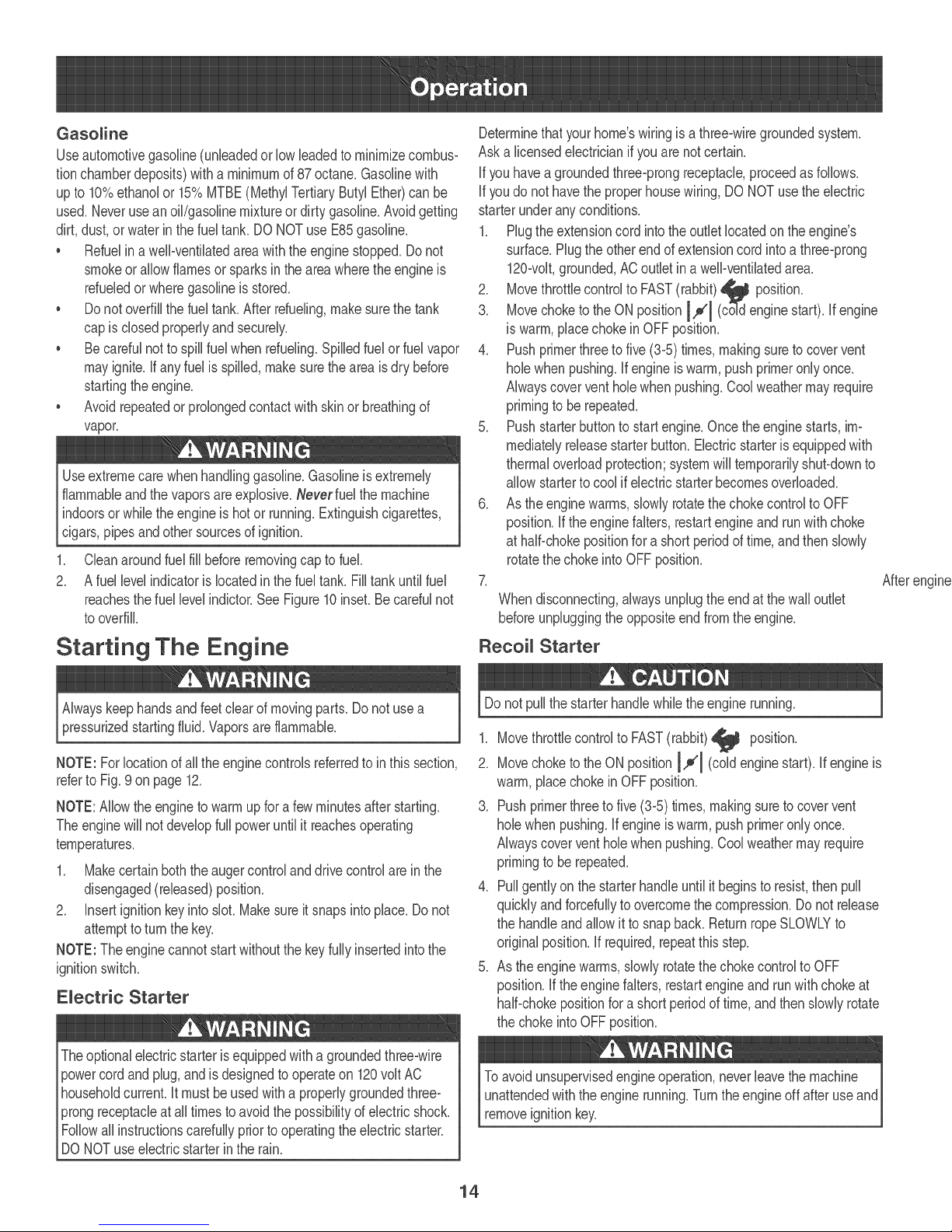

Checking Engine Oim

NOTE: Checktheoil levelbeforeeachuseandaftereveryfivehours

ofoperationtobesurecorrectoillevelismaintained.

Whenaddingoiltothe engine,referto viscositychart below.Engine

oilcapacityis 600ml(approx.20oz.).Donotover-fill.Usea4-stroke,

oranequivalenthighdetergent,premiumqualitymotoroilcertified

tomeetorexceedU.S.automobilemanufacturer'srequirementsfor

serviceclassificationSG,SR MotoroilsclassifiedSG, SFwillshow

thisdesignationonthe container.

1. Removethe oilfillercap/dipstickandwipethe dipstickclean.

2. insertthecap/dipstickintotheoilfillerneck,butdo notscrewitin.

3. Removethe oilfillercap/dipsticL if levelislow,slowlyadd oiluntil

oil levelregistersbetweenhigh(H) andlow(L).SeeFigure11.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Figure11

J

f

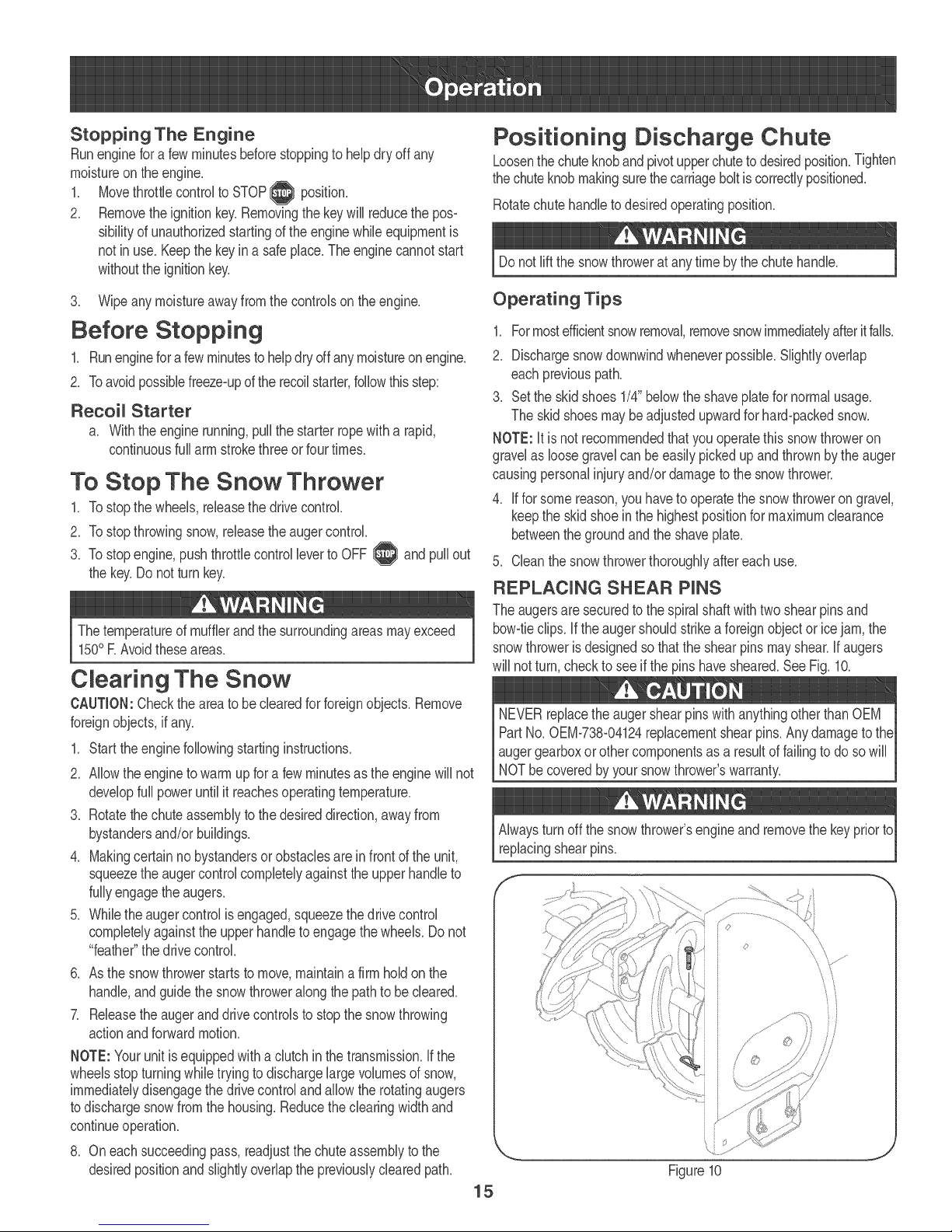

Changing Engine Oim

NOTE:Changetheengineoilafterthefirst5 hoursof operationand

oncea seasonorevery50 hoursthereafter,

1. Drainfuelfromtankbyrunningengineuntilthe fueltankisempty.

Besurefuelfillcapissecure,

2. Placesuitableoilcollectioncontainerunderoildrainplug.

3. Removeoil drainplug.SeeFigure12.

4. Tipengineto drainoil intothecontainer,Usedoil mustbe

disposedofat apropercollectioncenter,

Usedoil isa hazardouswasteproducLDisposeofusedoilproperly.

Donotdiscardwithhouseholdwaste.Checkwithyour localauthori-

tiesorSearsServiceCenterforsafedisposal/recyclingfacilities.

.

Reinstallthedrainplugandtightenit securely.

6.

Refillwiththe recommendedoil andchecktheoillevel See

RecommendedOilUsage charL The engine's oilcapacity is 20

ounces.

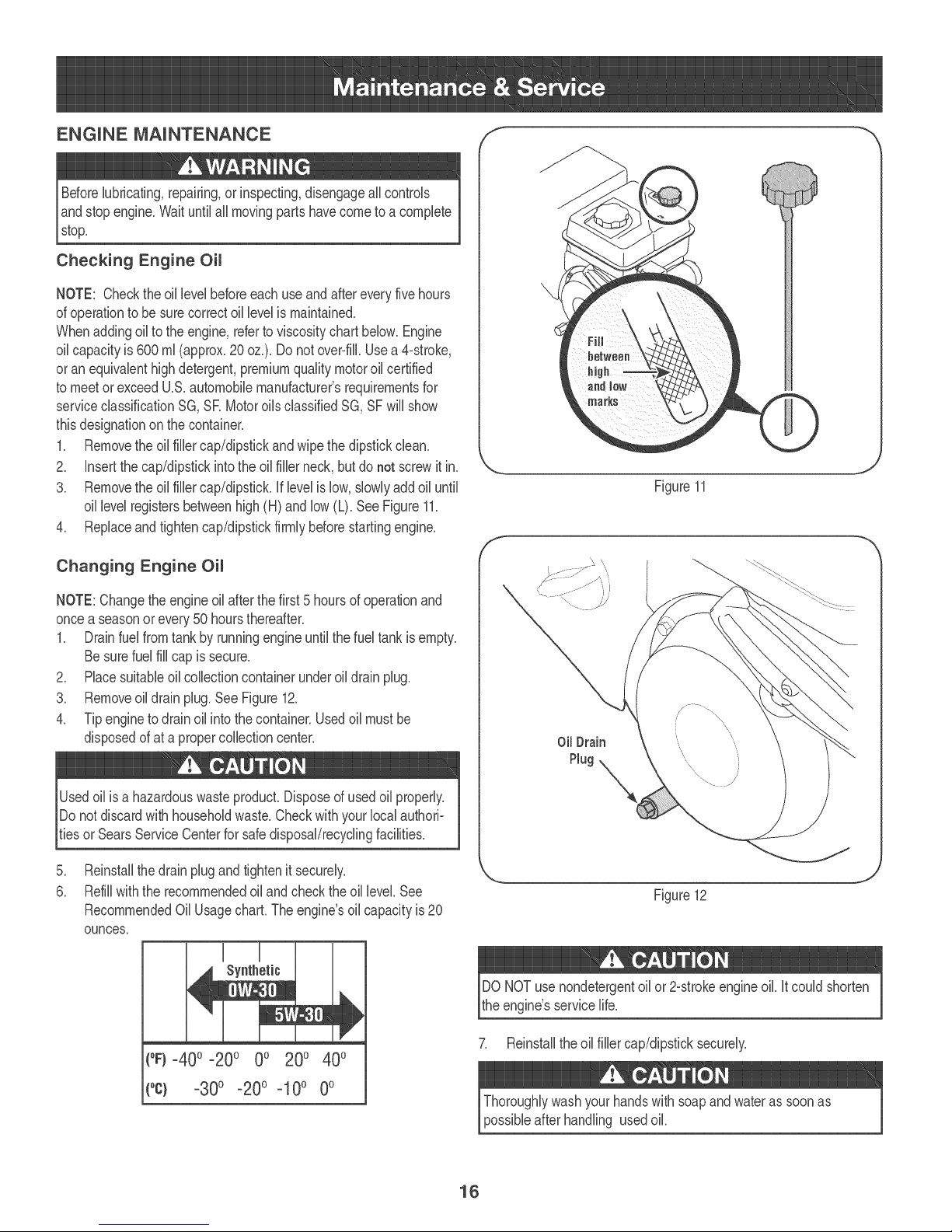

Synthetic

H

(°F)-400 -200 0o 200 400

J

Figure12

DONOTusenondetergentoilor 2_strokeengineoil.it couldshorten

theengine'sservicelife.

7. Reinstalltheoil fillercap/dipsticksecurely.

(oc) -300 -200 -10° 0°

Thoroughlywashyourhandswithsoapandwaterassoonas

possibleafterhandlingusedoil.

16

Page 17

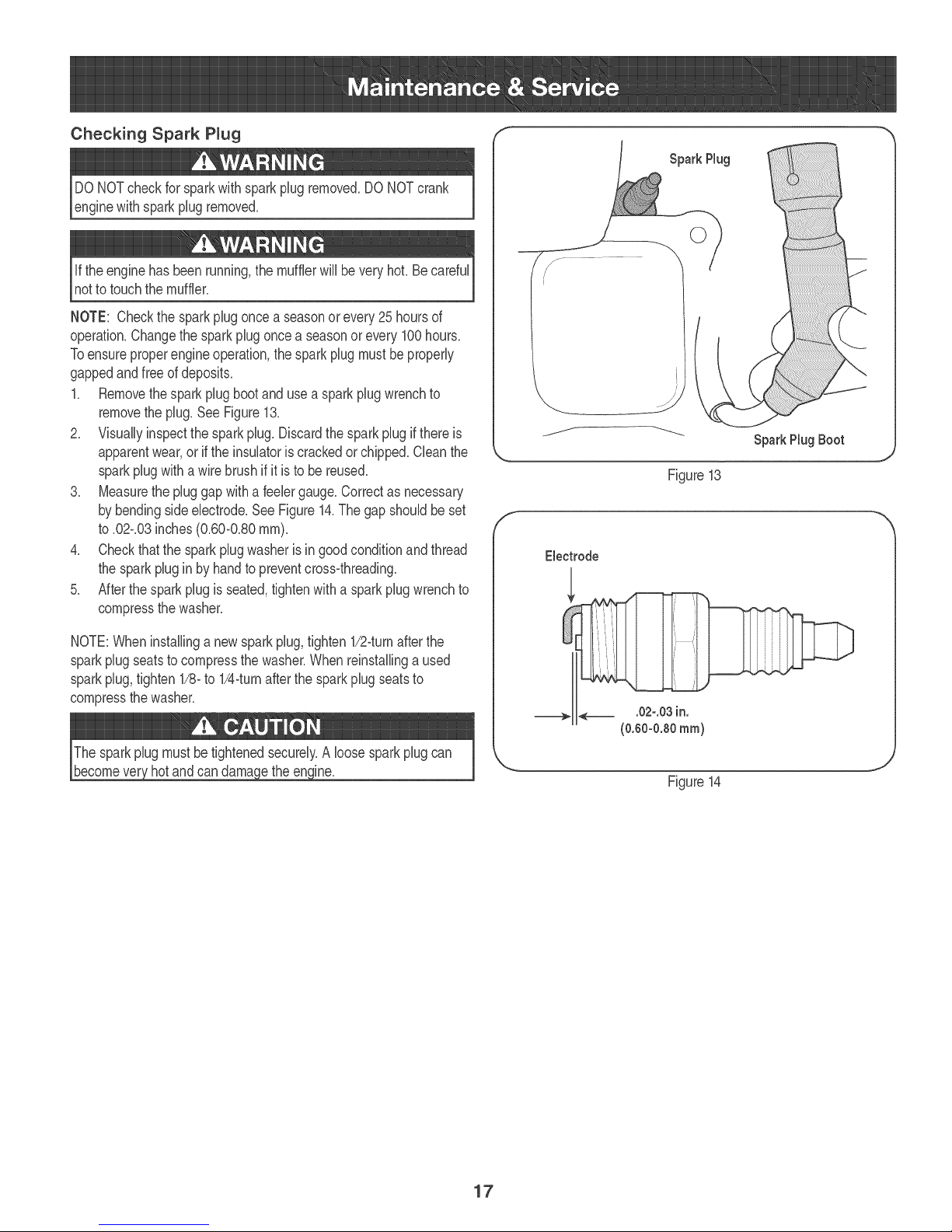

Checking Spark Pmug "

DONOTcheckforsparkwithsparkpBgremoved.DONOTcrank

enginewithsparkplugremoved.

iftheenginehasbeenrunning,themufflerwillbeveryhoLBecareful

notto touchthemuffler.

NOTE: Checkthesparkplugoncea seasonorevery25hoursof

operation.Changethesparkplugoncea seasonor every100hours.

Toensureproperengineoperation,thesparkplugmustbe properly

gappedandfreeofdeposits.

1_ Removethesparkplugbootanduse asparkplugwrenchto

removetheplug.SeeFigure13_

2_ Visuallyinspectthesparkplug.Discardthesparkplugifthereis

apparentwear,orif the insulatoriscrackedor chipped.Cleanthe

sparkplugwithawirebrushifit isto be reuse&

3_ Measurethepluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure14_Thegapshouldbeset

to_02_03inches(0_60@_80mm).

4_ Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin byhandtopreventcross-threadi%

5_ Afterthesparkplugis seated,tightenwitha sparkplugwrenchto

compressthewasher.

SparkPlug

©

SparkPlugBoot

Figure13

Electrode

NOTE:Wheninstallinga newsparkplug,tighten1/2_turnafterthe

sparkplugseatstocompressthewasher.Whenreinstallinga used

sparkplug,tighten1/8_to 1/4-turnafterthesparkplugseatsto

compressthewasher.

Thesparkplugmustbe tightenedsecurely.A loosesparkplugcan

becomeveryhotandcandama ethe en ine.

Figure14

17

Page 18

General Recommendations

.

Alwaysobservesafetyrubs whenperforminganymaintenance.

2_

Thewarrantyon thissnowthrowerdoesnotcoveritemsthathave

beensubjectedtooperatorabuseor negligence.Toreceivefull

valuefromthe warranty,operatormustmaintainthe snowthrower

asinstructedin thismanual.

3. Periodicallycheckallfastenersandhardwaretomakesurethese

aretighL

Beforeservicing,repairing,lubricatingorinspecting,disengageallcontrols

andstopengine.WaituntilallmovingpartshavecometoacompletestoF

Disconnectsparkplugwireandgroundit againsttheenginetoprevent

unintendedstarting.Alwayswearsafetyglassesduringoperationorwhile

performinganyadjustmentsor repair&

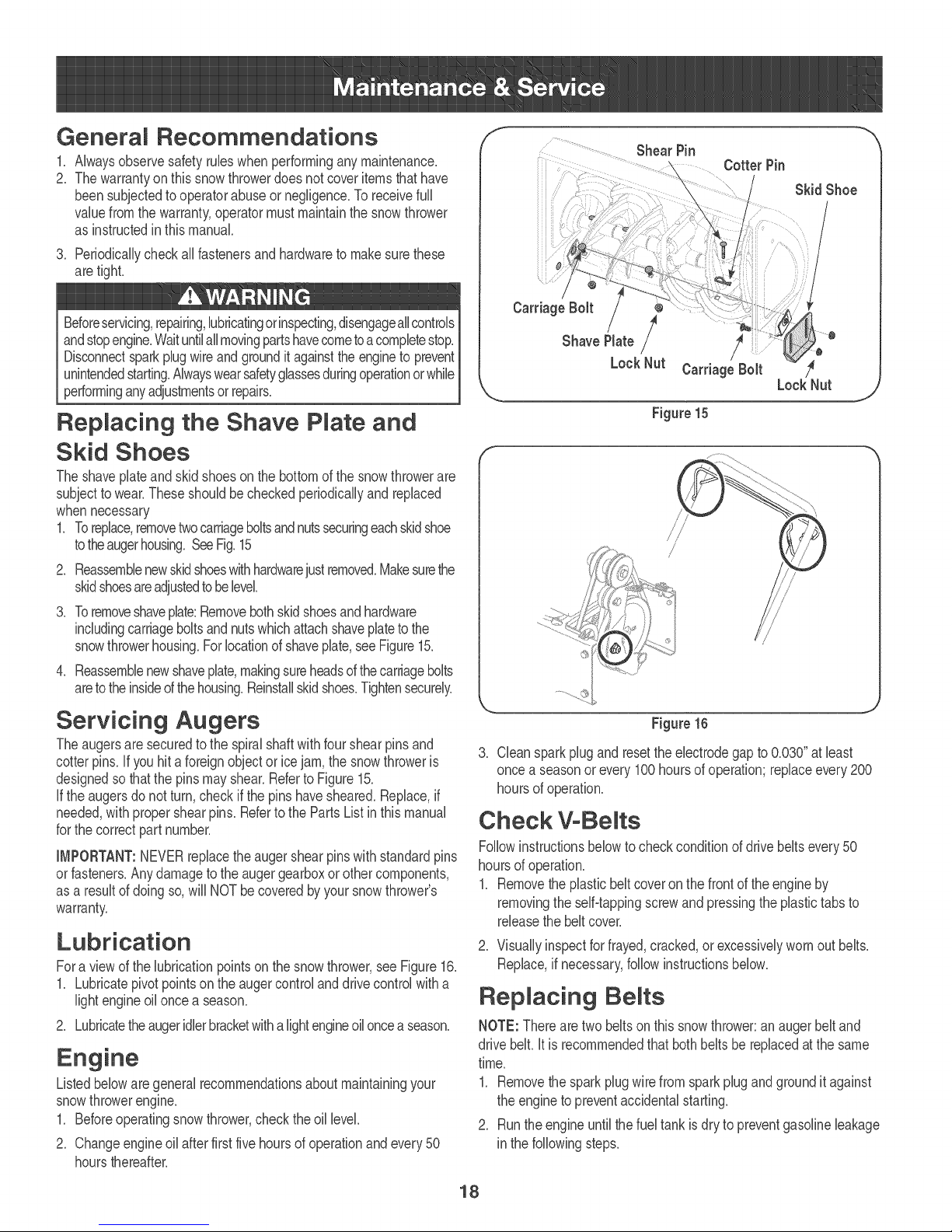

Replacing the Shave Pmateand

Skid Shoes

Theshaveplateandskidshoesonthebottomofthesnowthrowerare

subjecttowear.Theseshouldbe checkedperiodicallyandreplaced

whennecessary

1. Toreplace,removetwocarriageboltsandnutssecuringeachskidshoe

totheaugerhousing_SeeFig_15

.

Reassemblenewskidshoeswithhardwarejustremove&Makesurethe

skidshoesareadjustedtobelevel

3_

Toremoveshaveplate:Removebothskidshoesandhardware

includingcarriageboltsandnutswhichattachshaveplatetothe

snowthrowerhousing.Forlocationof shaveplate,see Figurel&

.

Reassemblenewshaveplate,makingsureheadsof thecarriagebolts

aretotheinsideof thehousing.Reinstallskidshoe&Tightensecurely.

S Shear Pin

CarriageBolt

ShavePlate /

Lock Nut

CarriageBolt

Figure 15

Cotter Pin

!

Skid Shoe

!

Lock Nut

J

Servicing Augers

Theaugersaresecuredtothespiralshaftwithfourshearpinsand

cotterpin& ifyouhita foreignobjectorice jam,thesnowthroweris

designedsothatthepinsmayshear_RefertoFigurel&

iftheaugersdo notturn,checkifthepinshavesheare&Replace,if

needed,withpropershearpin&Referto thePartsListinthismanual

forthecorrectpartnumber_

iMPORTANT:NEVERreplacetheaugershearpinswithstandardpins

orfastener&Anydamagetothe augergearboxor othercomponents,

asa resultofdoingso,willNOTbe coveredbyyoursnowthrower's

warranty_

Lubrication

Fora viewofthe lubricationpointson the snowthrower,seeFigure16.

1. Lubricatepivotpointsontheaugercontrolanddrivecontrolwitha

lightengineoil onceaseason.

2. Lubricatetheaugeridlerbracketwithalightengineoilonceaseason.

Engine

Listedbelowaregeneralrecommendationsaboutmaintainingyour

snowthrowerengine.

1. Beforeoperatingsnowthrower,checktheoillevel.

2_ Changeengineoil afterfirstfivehoursofoperationandevery50

hoursthereafter.

Figure16

3. Cleansparkplugandresettheelectrodegapto 0.030"at bast

oncea seasonor every100hoursof operation;replaceevery200

hoursof operation.

Check VoBemts

Followinstructionsbelowtocheckconditionofdrivebeltsevery50

hoursof operation.

1_ Removetheplasticbeltcoveron thefrontoftheengineby

removingthe self4appingscrewandpressingtheplastictabsto

releasethebeltcover.

2_ Visuallyinspectforfrayed,cracked,or excessivelywornoutbelts.

Replace,if necessary,followinstructionsbelow.

Replacing Berets

NOTE:Therearetwobeltsonthis snowthrower:anaugerbeltand

drivebelt.itis recommendedthatbothbeltsbe replacedatthe same

time.

1. Removethesparkplugwirefromsparkplugandgrounditagainst

theenginetopreventaccidentalstarting.

2. Runtheengineuntilthefueltankisdryto preventgasolineleakage

in thefollowingstep&

18

Page 19

Performbeltmaintenanceoutdoorsassomegasmaypossibly

leakfromthecarburetoreventhoughyouplaceda sheetofphsfic

underneaththegas capto preventthegascapfromleaking.

3. Removetheself-tappingscrewshowninFigure17,and pressthe

plastictabsto releasethe beltcover.Pullthebeltcoverupandout

fromaroundtheengineandchuteassembly.Setit asideandsave.

Auger Belt

IMPORTANT:Gascould leakfromthecarburetoratthis point,the

engineshouldhavebeenrununtilthefueltankwasdry,aspreviously

instructed.

1. Tipthesnowthrowerupandforwardsothat itrestsonthe auger

housing. RemovethebeltkeeperascalledoutinFigure19.Return

thesnowthrowertoits uprightpositionto completethefollowing

Figure17

f

er Belt

steps.

2. Slipthefrontaugerbeltoffof theenginepulleypushingitforward

and rollinginoffof thepulley.SeeFigure18.

3. Squeezetheaugercontrolhandleto releasetheaugerbrake,

whichisthetab thatholdsthebeltontotheaugerpulley.Remove

Drive

thebelt.

4, Replacewithnewbeltafterreplacingthedrive belt.

Drive Belt

NOTE:Replacethedrivebeltbeforereassemblingthenewaugerbelt.

1.Tip thesnowthrowerupandforwardsothatit restsontheauger

housing.

IMPORTANT:Gascould leakfromthecarburetoratthis point,the

engineshouldhavebeenrununtilthefueltankwasdry,aspreviously

instructed.

J

Figure18

f

2. Removethe springthatconnectsthetransmissionto a bolton the

engineframe.SeeFigure19.

NOTE:it maybeeasiertofirst removetheflangelocknut,thenuse

needle-nosedpliersto firmlygripspringand removefrombolt.

.

Pivotthetransmissionforwardto releasepressureonthe drivebelt.

Removebeltfromtransmissionpulley.

4,

Removethedrivebeltfromaroundtheenginepulley,andaway

fromtheunit.

5,

Placethenewdrivebeltintothe grooveon theenginepulley.See

Figure18.

6.

Tilt thetransmissionforwardandpositionthedrivebeltontothe

transmissionpulley.

7,

Reconnectthe springtothe bolton theengineframeand secure

thetransmission.Reinstalltheflangelocknut.

.

Installnewaugerbelt.

9.

Reassemblethebeltcoveron thesnowthrower.

Figure19

10.Reassemblethebelt keepertothehousing.

19

Page 20

Adjusting The Auger Cable

Periodicadjustmenttotheaugercontrolcabb mayberequireddue

tonormalstretchandwearonthe beL Adjustmentis neededifthe

augersseemto hesitatewhib turning,buttheenginemaintainsspeed,

orcontinueturningwiththeaugercontroldisengaged.

1. Loosentherearhexbolton the cabb adjustmentbracket.See

Figure20.

2. Slidethecabb adjustmentbracketbackwardstakingoutthe slack

in theaugercabb.

3. Refightentherearhexbolt

4. Startengineandverifyaugercontrolengagesanddisengages

properly.

NOTE:ifaugercontinuesto rotatewiththe controldisengaged,shut

offtheengineand readjustthecablebracketforward.Thenrecheck

theaugeroperation.

f

Bottom Auger

Housing Screw

Auger Cabb_

Adjustment

Bracket

TopAuger

"" Housing Screw

Figure20

J

Followthe maintenancescheduie given below. Someadjustmentswiii have to be madeperiodicaliyto maintainyour unit

properiy. Periodicaliycheck aii fastenersandmakesure these aretight. Keeptrack of your scheduiedservice by fiiiing in

theService Dates fieid below.

Beforeservicing,repairing,lubricatingor inspecting,disengageallcontrolsandstopengine.Waituntilallmovingpartshavecometoa completestop.

Disconnectsparkplugwireandgroundit againsttheengineto preventunintendedstarting.Alwayswearsafetyglassesduringoperationor while

performinganyadjustmentsorrepairs.

Maintenance Schedule

'I _ _'d_R-1i

BeforeEachUse

AfterEachUse

1st5 hours

After25hours

BeforeStorage

Oncea Season

1. CheckengineoilleveL

1. CheckequipmenL

2. Checkskidshows.

1. Engineoil

1. CheckWbelts.

1. Fuelsystem.

1. Pivotpoints.

2. Drivesystem&hex gear

shafL

3. Wheelshall

4. Sparkplug.

1. Filloiliflow

1. Clean

2. Clean

1. Change.

2. Adjustor replaceif necessary.

1. Empty.

1. Lubricate.

2. Lubricate.

3. Grease.

4. Changeifnecessary.

20

Page 21

ifthe snowthrowerwillnotbe usedfor30 daysor longer,or ifit istheendof thesnowseasonwhenthe lastpossibilityof snowisgone,the

equipmentneedsto bestoredproperly.Followstorageinstructionsbelowtoensuretopperformancefromthesnowthrowerformanymoreyear&

PREPARUNG ENGUNE

Short-Terns Storage

it isimportanttopreventgumdepositsfromforminginessentialfuel

systempartsof theenginesuchasthecarburetor,fuel filter,fuelhose,

ortankduringshortqermstorage(15_30days).Topreventthis,treat

thefuel systemusingafuel stabilizer.

Fuelstabilizer(suchas STA-BILTM or ULTRA-FRESWM)isanaccepb

ablealternativein minimizingtheformationoffuel gumdepositsduring

storage.Addstabilizertogasolineinfueltankorstoragecontainer.

Alwaysfollowmixratiofoundonstabilizercontainer.Runengineat

bast 10minutesafteraddingstabilizertoallowittoreachthecarbure-

tor.

latedareas,wherefuelfumesmayreachan openflame,

lightas onafurnace,waterheater,clothesdryerorgasappliance.

PREPARUNG SNOW THROWER

, Whenstoringthesnowthrowerin anunventilatedormetalstop

age shed,careshouldbetakento rustprooftheequipmenLUsing

a lightoilor silicone,coattheequipment,especiallyanychains,

springs,bearingsandcables.

, Removealldirt fromexteriorof engineandequipmenL

, Followlubricationrecommendation&

, Storeequipmentin a clean,dryare&

Long-Term Storage

Toavoidengineproblems,thefuelsystemshouldbeemptiedbefore

storagefor30 daysor longer.

Fuelleftin engineduringwarmweatherdeterioratesandwillcause

seriousstartingproblems.

1. Runthe engineuntilthefuel tankisemptyandit stopsdueto lack

offuel.Donotattempttopourfuelfromtheengine.

Neveruseengineor carburetorcleaningproductsinthefueltankor

permanentdamagemayoccur.

,

Removethe sparkplugandpourone (1)ounceofengineoil

throughthesparkplughob into thecylinder.Coversparkplughob

witharagandcrankthe engineseveraltimestodistributetheoil.

Replacesparkplug.

21

Page 22

Beforeperforminganytyped maintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

a completestop.Disconnectsparkplugwireandgroundit againstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsorrepairs.

This section addressesminor service issues. Tolocate the nearest SearsServiceCenteror to seheduJeservice, simpJycontact Sears

at 1-800-4-MYoHOME®.

1. Chokecontrolnotin ONposition.

Enginerunserratically

Engineoverheats

Excessivevibration

2. Sparkplugwiredisconnected.

3. Faultysparkplug.

4. Fueltankemptyorstab fuel.

5. Enginenotprimed.

6. Safetykeynot inserted.

1. EnginerunningonCHOKE.

2. Stab fuel.

3. Wateror dirtinfuelsystem.

4. Carburetoroutofadjustment.

1. Carburetornotadjustedproperly.

1. Loosepartsordamagedauger.

2. Connectwireto sparkplug.

3. Clean,adjustgap,or replace.

4. Filltankwithclean,freshgasoline.

5. Primeengineasinstructedin theOperationSection.

6. insertkeyfullyintothe switch.

2. Filltankwithclean,freshgasoline.

3. Drainfueltank.Refillwithfreshfuel.

4. ContactyourSearsParts& RepairCenter.

Lossof power 1. Sparkplugwireloose. 1.

2. Gascapventhob plugged. 2.

Unitfailsto propelitself 1. Drivecane inneedof adjustment. 1.

2. Drivebeltlooseordamaged. 2.

Unitfailsto dischargesnow 1. Chuteassemblyclogged. 1.

2. Foreignobjectlodgedin auger.

3. Augercane inneedofadjustment.

4. Augerbeltlooseor damaged.

5. Shearpin(s)sheared.

2. Stopengineimmediatelyanddisconnectsparkplug

3. Adjustaugercontrolcable.RefertoAssembly

4. Replaceaugerbelt.Referto Serviceand Mainte-

5. Replacewith newshearpin(s).

1. MovechokecontroltoON position.

1. MovechokecontroltoOFFposition.

1. ContactyourSearsParts&RepairCenter.

1. Stopengineimmediatelyanddisconnectsparkplug

wire.Tightenall boltsandnuts.if vibrationcontinues,

haveunit servicedby aSearsParts& RepairCenter.

Connectandtightensparkplugwire.

Removeiceandsnowfromgascap.Becertainvent

hob isclear.

Adjustdrivecontrolcable.RefertoServiceand

Maintenancesection.

Replacedrivebelt.Referto Service&Maint.section.

Stopengineimmediatelyanddisconnectsparkplug

wire.Cleanchuteassemblyandinsideofauger

housingwithclean-outtoolora stick.

wire.Removeobjectfromaugerwithclean-outtool

or astick.

section.

nancesection.

NEED MORE HELP?

_£}u_11_indt_e ;_nswe_a_Idl:Iloreon _a_age_ryhe_e4_e_ o fenf_÷e!

o Find this and at[ your other product raanua[s on[_ne

o Get answers from our team of home experts,

o Get a persorla[ized maintenance p[an fo_"your home,

o Find information and too[s to help with home projects,

22

Page 23

Craftsman Snow Thrower Modem 247.88755

23

Page 24

Craftsman Snow Thrower Modem 247.88755

1 684-04037 ChuteAssembly

2 710-04071 CarriageBolt5/16-18x1.0"

3 710-0451 CarriageBolt5/16-18

4 710-0280A CarriageBolt5/16-18x.62

5 720-0284 WingKnob5/16-18

6 731-04388A ChuteHandle

7 731-04426A UpperChute

8 736-0287 FlatWasher.385x .87x .06

9 731-04127 LowerChute

10 731-04353 ChuteRing

11 731-2836A ChuteAdapter5"Dia.

12 732-04111 ChuteAdiustmentSpring

13 712-04064 FlangeLockNut1/4-20

14 731-2843 Clean-outTool

15 731-2835 Clean-outToolMount

16 725-0157 CableTie

17 710-0134 CarriageScrew1/4-20x0.62"

18 710-0520 HexBolt3/8-16x 1.50"

19 710-04484 AB Screw5/16-18x .750

20 712-04063 FlangeLockNut,5/16-18

21 712-04065 FlangeLockNut,3/8-16

22 750-04852 ShoulderSpacer

23 715-04020 SpiralPin

24 728-04012 PushOnNut

25

28

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

731-04218B

732-0611

736-0174

738-0281

741-0245

741-0309

750-04191

741-0919

784-0434

790-00075

618-04292A

684-04113A

684-04114A

684-04166A

714-04040

731-04870

736-0351

738-04124A

741-0493A

790-00087A

790-00117

784-5580

710-04606

Impeller

ExtensionSpring

WaveWasher

ShoulderScrew3/8-16

HexFlangeBearing

BallBearing

Spacer

FlatIdler

AugerIdlerBracket

BearingHousing

AugerGearboxAssembly

AugerAssembly- LH

AugerAssembly- RH

AugerHousing,22"

BowTieCotterPin72

Spacer,1.25x.75x 1.00

FlatWasher

ShearPin,.25x 1.50

FlangeBushing

HexBearingHousing

ShavePlate2.25x 21.66LG

SkidShoe

BeltKeeper

24

Page 25

Craftsman Snow Thrower Modem 247.88755

25

Page 26

Craftsman Snow Thrower Modem 247.88755

1 710-0449 CarriageScrew5/16-18x2.25

2 710-0605 Mach.Screw1/4-20x1.825

3 710-04484 Screw5/16-18x .75

4 712-04064 Range LockNut1/4-20

5 720-0284 WingKnob5/16-18

6 725-0157 CableTie

7 748-04256 DriveCable

8 748-04236 AugerCable

9 747-1161A AugerControl

10 747-1214 DriveControl

11 749-04147 LowerHandle

12 749-04459 UpperHandle

13 790-00053 HandleTab

14 618-04296A TransmissionAssembly

15 710-0809 TTScrew1/4-20x 1.25

16 710-1652 Screw1/4-20x .625

17 711-1364 ClevisPin

18 714-0115 CotterPin1/8 x 1.0

19 714-04040 BowTieCotter Pin 72

20 715-0249 RollPin

21 717-04066A Pinion14T

22 717-04073A Gear70T

23 732-0429A ExtensionSpring

24 i 736-0192 FlatWasher

25 738-04184A ShoulderScrewl/4-20

26 J738-0924A ShoulderScrew1/4-28

27 741-0245 HexFlangeBearing

28 741-04108 HexFlangeBearing

29

3O

31

32

33

34

35

36

37

38

39

4O

41

42

43

44

45

46

47

48

49

5O

51

52

53

54

55

756-0625

784-0419C

790-00223A

790-00224

634-04282A

710-0627

736-0242

738-04321

710-0224

710-0654A

710-0696

710-1245B

731-04162A

736-0247

736-0505

748-04067A

750-1355

750-1356

754-04013

754-04014

756-04024

756-0569

729-04035

731-05672A

736-0160

736-0451

750-04913

CableRoller

DriveHousingFrame

AugerCable Bracket

AugerCableAdi. Bracket

WheelAssy SnowHogGray

LockBolt5/16-24x .75

BellWasher.34x.872x.06

Axle

HexScrew#10-16x.500

TTSeresScrew3/8-16x 1.0

HexBolt3/8-24x .875

LockBolt5/16-24x .875

BeltCover

FlatWasher.406IDx 1.25OD

FlatWasher.34IDx1.50OD

Pulley:Adapter.75Dia.

Spacer.876x 1.25x .19

Spacer.876x 1.25x .86

V-Belt3/8 x21.108Lg.

V-Belt3/8 x26.680Lg.

AugerPulley

PulleyHalf

AmpSealedConnector

Spacer

FlatWasher.53x.93x .05

SaddleWasher

Spacer

26

Page 27

Craftsman Engine Modem ZS385oSU For Snow Thrower Modem 247.88755

(,0

_ . _-_i_!¸

27

Page 28

Craftsman Engine Modem ZS385oSU For Snow Thrower Modem 247.88755

751q0645

751q0646

751q0663

751q0658

751q0654

751q0664

751q0665

751q0655

751q0656

751q0662

751q0652

751q0653

751q0642

751q0666

751q0292

751q0639

751q0638

751q0635

751q0637

751q0630

751q0636

751q0634

751q0643

751q0640

751q0651

751o10307

731@5696

952Z365_

ElectricStarter 84

ignitionCoil 22

FanCoverComplete 112

RecoilStarterAssembly 121

GovernorSpring 77

ThrottleReturnSpring 78

GovernorRod 79

Dipstick 107

DipstickTube 108

Cover_Engine/Dipstick 110

FuelFilter 113

FuelTank 115

MufflerShroud 37

MufflerGasket 59

SparkPlug 58

Primer 64

CarburetorAssembly 65

Air FilterHeatingPipeCover 69

ignitionSwitch 70

ignitionKey 71

ChokeLever 73

EngineShroud 72

MufflerShield 40

ChokePushRod 66

FuelTankNipple 116

FlywheelKey N/A

StarterHandle N/A

EngineComplete N/A

751q0660

751q0661

751q0668

GasketKitComplete

OilSeal

CrankcaseCoverGasket

O_Ring

CylinderHeadGasket

MufflerGasket

HeadCoverGasket

CarbInsulatorGasket

CarburetorInsulator

CarburetorGasket

PaperGasket

OilDrainWasher

GasketKitExternal

OilDrainWasher

MufflerGasket

CarbInsulatorGasket

CarburetorInsulator

CarburetorGasket

HeadCoverGasket

CylinderHeadAssembly

RockerArm

intakeValve

ExhaustValve

ValveSpring

ValveSpringRetainers_Exhaust

PivotAdjustingNut

RockerArmLockNut

RockerArmStuds

PushRodGuide

ValveCoverGasket

CarburetorInsulatorPlateGasket

CarburetorInsulatorPlate

MufflerGasket

CylinderHeadGasket 170

CylinderHead

ExhaustValveAdjuster

ValveSpringRetainer_ intake

4

10

15

55

59

47

61

62

63

42

19

19

59

61

62

63

47

51

103

98

100

101

52

53

5O

49

47

61

62

59

55

N/A

102

104

28

Page 29

Craftsman Engine Modem ZS385oSU For Snow Thrower Modem 247.88755

751_10659 ShortBlock

CrankcaseComplete 17

Oil PipeReserve N/A

CrankcaseCover 5

Piston 93

PistonRingSet_Complete 95

PistonPin 94

PistonPinClip 92

ConnectingRodAssemblyComplete 91

ValveLifter(Tappet) 96

CamshaftAssembly 7

CarbInsulatorplategasket 61

CrankshaftAssembly 11

CarburetorInsulatorHate 62

MufflerGasket 59

GovernorArmShaft 16

Pin Lock 14

GovernorAssembly 12

CaseCoverGasket 10

CylinderHeadGasket 55

ValveCoverGasket 47

Oil DrainBolt 20

Oil DrainPlugWasher 19

DowelPin 9

DowelPin 8

DowelPin 56

751_10641

751_10647

751_10648

751_10649

751_10650

751_10657

751_10669

751_10644

OilDrainAssembly

OilDrainPipe

DrainBolt

ValveKit

ExhaustValve

intakeValve

PushRodKit

PushRod

FuelCapAssembly

FuelCapComplete

Packing( Gasket )

Clip ( GasketRetainer)

FuelLineKit

FuelLineClamp

FuelLine

MufflerStudAssembly

MufflerStud

OilFillPlugAssembly

OilFillHug

O-Ring

MufflerAssemblyComplete

MufflerAssembly

ExhaustPipe

18

2

98

103

97

111

N/A

N/A

117

118

6O

2

3

41

43

Bearing 13

Bolt 1

Oil Seal 4

O-Ring- GovernorArm 15

Oil FillerPlug 2

O-Ring- Oil FillerPlug 3

Oil DrainPipe 18

29

Page 30

MTD CONSUMER GROUP (NC (MTD), the Caifornia Air Resources Board (CARD)

and the United States Environment Protection Agency (UoSoEPA)

Emission Contro( System Warranty Statement

(Owner's Defect Warranty Rights and Obigations)

EMISSIONCONTROLSYSTEMCOVERAGEISAPPLICABLETOCERTIFIEDENGINESPURCHASEDINCALIFORNIAIN2005ANDTHERE-

AFTER,WHIOHAREUSEDINCALIFORNIA,ANDTOCERTIFIEDMODELYEAR2005ANDLATERENGINESWHICHAREPURCHASEDAND

USEDELSEWHEREINTHEUNITEDSTATES.

Californiaandelsewherein theUnitedStatesEmissionControlDefectsWarrantyCoverage

TheCaliforniaAir ResourcesBoard(CARB),U.S.EPAandMTDarepleasedtoexplaintheemissionscontrolsystemwarrantyonyourmodelyear

2006andlatersmalloff-roadengine,in California,newsmalloff-roadenginesmustbe designed,builtandequippedtomeettheStatesanti-smog

standards.ElsewhereintheUnitedStates,newnon-road,spark-ignitionenginescertifiedformodel2005andlater,mustmeetsimilarstandardsset

forthbytheU.S.EPA.MTDmustwarrantytheemissioncontrolsystemonyourengineforthe periodoftimelistedbelow,providedtherehasbeen

noabuse,neglectorimpropermaintenanceofyour smalloff-roadengine.

Youremissioncontrolsystemmayincludepartssuchasthe carburetor,fuel-injectionsystem,theignitionsystem,andcatalyticconverter,fuel

tanks,fuellines,fuelcaps,valves,canisters,filters,vaporhoses,clamps,connectors,andotherassociatedemission-relatedcomponents.

Whereawarrantableconditionexists,MTDwillrepairyoursmalloff-roadengineat nocosttoyourincludingdiagnosis,partsandlabor.

MANUFACTURER'S WARRANTY COVERAGE:

Thisemissionscontrolsystemiswarrantedfortwoyears,if anyemission-relatedpartonyourengineisdefective,thepart willberepairedor

replacedbyMTD.

OWNER'S WARRANTY RESPONSlBILmES:

Asthesmalloff-roadengineowner,youare responsibleforthe performanceofthe requiredmaintenancelistedinyourOwner'sManual.MTD

recommendsthatyouretainall yourreceiptscoveringmaintenanceson yoursmalloff-roadengine,butMTDcannotdenywarrantysolelyfor the

lackofreceiptsorfor yourfailureto ensuretheperformancetoallscheduledmaintenance.

Asthesmalloff-roadengineowner,youshouldhoweverbeawarethat MTDmaydenyyourwarrantycoverageifyoursmalloff-roadengineorpart

hasfailedduetoabuse,neglect,impropermaintenanceorunapprovedmodifications.

Youare responsibleforpresentingyoursmalloff-roadenginetoan AuthorizedMTDServiceDealerassoonasa problemexists.Thewarranted

repairsshouldbe completedin a reasonableamountof time,nottoexceed80 days.

if youhaveanyquestionsregardingyourwarrantyrightsand responsibilities,youshouldcontacta MTDServiceRepresentativeat 1-800-800-7310

andaddressisMTDCONSUMERGROURRO.Box361131,ClevelandOH,44136@019.

DEFECTS WARRANTY REQU(REMENTS FOR 1995 AND LATER SMALL OFF-ROAD ENG(NES:

Thissectionapples to 1995andlatersmalloff-roadengines.The warrantyperiodbeginsonthe datethe engineorequipmentisdeliveredtoan

ultimatepurchaser.

!a) GeneralEmissionsWarrant_

MTDmustwarranttotheultimatepurchaserandeachsubsequentpurchaserthatthe engineis:

(1)Designed,built,andequippedsoasto conformwithallapplicableregulationsadoptedbytheAirResourcesBoardpursuantto itsauthorityin

Chapters1and2,Part5,Division26of theHealthandSafetyCode;and

(2) Freefromdefectsin materialsandworkmanshipthatcausethefailureofa warrantedpartto be identicalin all materialrespectstothepartas

describedin theenginemanufacturer'sapplicationforcertificationfora periodof twoyears.

!b)Thewarrantyonemissions-relatedpartswillbe interpretedasfollows:

(1)Anywarrantedpart thatisnotscheduledforreplacementas requiredmaintenanceinthewritteninstructionsrequiredbySubsection(c)

mustbewarrantedfor thewarrantyperioddefinedinSubsection(a)(2).ifanysuchpartfailsduringthe periodof warrantycoverage,it mustbe

repairedor replacedbyMTDaccordingto Subsection(4)below.Anysuchpartrepairedor replacedunderthewarrantymustbewarrantedfor

theremainingwarrantyperiod.

(2)Anywarrantedpartthatis scheduledonlyfor regularinspectioninthewritteninstructionsrequiredbySubsection(c) mustbewarrantedfor

thewarrantyperioddefinedin Subsection(a)(2).A statementinsuchwritteninstructionstotheeffectof"repairor replaceasnecessary"will

notreducetheperiodofwarrantycoverage.Anysuchpartrepairedor replacedunderwarrantymustbe warrantedfortheremainingwarranty

period.

(3) Anywarrantedpartthatwhichis scheduledforreplacementas requiredmaintenancein thewritteninstructionsrequiredbySubsection(c)

mustbewarrantedfor theperiodoftimepriortothe firstscheduledreplacementpointforthat part.ifthepart failspriortothefirst scheduled

replacement,the partmustbe repairedor replacedbyMTDaccordingtoSubsection(4) below.Anysuchpartrepairedor replacedunder

warrantymustbewarrantedfor theremainderof theperiodpriortothefirstscheduledreplacementpointforthepart.

Page 31

(4)Repairorreplacementofanywarrantedpartunderthewarrantyprovisionsofthisarticlemustbeperformedatnochargetotheownerata

warrantystation.

(5)NotwithstandingtheprovisionsofSubsection(4)above,warrantyservicesorrepairsmustbeprovidedatallMTDdistributioncentersthat

arefranchisedtoservicethesubjectengines.

(6)Theownermustnotbechargedfordiagnosticlaborthatleadstothedeterminationthatawarrantedpartisinfactdefective,providedthat

suchdiagnosticworkisperformedatawarrantystation.

(7)Theenginemanufacturerisliablefordamagestootherenginecomponentsproximatelycausedbyafailureunderwarrantyofanywarranted

part.

(8)Throughouttheengine'swarrantyperioddefinedinSubsection(a)(2),MTDwillmaintainasupplyofwarrantedpartssufficienttomeetthe

expecteddemandforsuchparts.

(9)Anyreplacementpartmaybeusedintheperformanceofanywarrantymaintenanceorrepairsandmustbeprovidedwithoutchargetothe

owner.SuchusewillnotreducethewarrantyobligationsofMTD.

(10)Add-onormodifiedpartsthatarenotexemptedbytheAirResourcesBoardmaynotbeused.Theuseofanynon-exemptedadd-onor

modifiedpartsshallbegroundsfordisallowingawarrantyclaimmadeinaccordancewiththisarticle.Theenginemanufacturershallnotbe

liableunderthisarticletowarrantfailuresofwarrantedpartscausedbytheuseofnon-exemptedadd-onormodifiedpart.

__)MTDwillincludea co_yofthefollowingemissionwarrantyLpartslistwitheachnewen_q thoseportionsofthe listap#licabletothe

(1)FuelMeteringSystem

, Coldstartenrichmentsystem(softchoke)

•Carburetorandinternalparts

, FuelPump

, FuelTank

(2)AirinductionSystem

, Aircleaner

, Intakemanifold

(3) ignitionSystem

, Sparkplug(s)

, MagnetoIgnitionSystem

(4)ExhaustSystem

, Catalyticconverter

, SAI(Reedvalve)

(5) MiscellaneousItemsUsedin AboveSystem

, Vacuum,temperature,position,timesensitivevalvesand switches

, Connectorsandassemblies

(6) Evaporativecontrol

, FuelHosecertifiedforARBevaporativeemissionof2006.

, FuelHoseClamps

, Tetheredfuelcap

, Carboncanister

, Vaporlines

GDOC-100174Rev,B

Page 32

Look For ReUevant Emissions DurabiUity Period and

Air Unde× Unformation On Your Engine Emissions LabeU

Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must

display information regarding the Emissions Durability Period and the Air index. Sears, Roebuck and Co., U.S.A.

makes this information available to the consumer on our emission labels.

The Emissions Durability Period describes the number of hours of actua_ running time for which the engine is

certified to be emissions compliant, assuming proper maintenance in accordance with the Operating & Mainte-

nance Instructions. The following categories are used:

Moderate: Engine is certified to be emission compliant for 125 hours of actual engine running time.

mntermediate: Engine is certified to be emission compliant for 250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore, the Emissions

Durabimity Period of an engine with an intermediate rating would equate to 10 to 12 years.

The Air mndex is a calculated number describing the relative level of emissions for a specific engine family. The

lower the Air Index, the cleaner the engine. This information is displayed in graphical form on the emissions label.

After July 1,2000, Look For Emissions Compliance Period

On Engine Emissions CompUiance LabeU

After July 1, 2000 certain Sears, Roebuck and Co., U.S.A. engines will be certified to meet the United States

Environmental Protection Agency (USEPA) Phase 2 emission standards. For Phase 2 certified engines, the Emis-

sions Compliance Period referred to on the Emissions Compliance _abei indicates the number of operating hours

for which the engine has been shown to meet Federal emission requirements.

For engines less than 225 cc displacement, Category C = 125 hours, B = 250 hours and A = 500 hours.

For engines of 225 cc or more, Category C = 250 hours, B = 500 hours and A = 1000 hours.

This is a generic representation of the emission labe_typically found on acertified engine.

GDOC-100182Rev.A

32

Page 33

Congratulationsonmakingasmartpurchase.YournewCraftsman®

productisdesignedandmanufacturedforyearsofdependabbopera-

tion.ButlikeaiIproducts,itmayrequirerepairfromtimetotime.That's

whenhavingaRepairProtectionAgreementcansaveyoumoneyand

aggravation.

Here'swhattheRepairProtectionAgreement*incBdes:

, Expertservicebyour10,000professionalrepairspecialists

, Unlimitedserviceandnochargeforpartsandlaboronall

coveredrepairs

, Productreplacementupto$1500ifyourcoveredproductcan'tbe

fixed

, Discountof10%fromregularpriceofserviceandrelatedinstalled

partsnotcoveredbytheagreement;also,10%offregularpriceof

preventivemaintenancecheck

, FastheJpbyphone=wecallitRapidResolution=phonesupport

fromaSearsrepresentative.Thinkofusasa"talkingowner's

manual/'

Onceyoupurchasethe Agreement,a simplephonecallisallthatit

takesfor youto scheduleservice.Youcancallanytimedayor night,or

schedulea serviceappointmentonline.

TheRepairProtectionAgreementisa risk-freepurchase,if youcancel

foranyreasonduringtheproductwarrantyperiod,wewillprovideafull

refund.Or,a proratedrefundanytimeafterthe productwarrantyperiod

expires.PurchaseyourRepairProtectionAgreementtoday!

SomeJimitations andexclusions apply. Forprices and additional

information in the U.S.A.call 1-800-827-6655.

*Coveragein Canadavaries on some items.Forfull detaib call

SearsCanadaat 1-800-361-6665.

SearsInstallation Service

ForSearsprofessionalinstallationofhomeappliances,garagedoor

openers,waterheaters,andothermajorhomeitems,inthe U.S.A.or

Canadacall1-800-4-MY-HOME®.

33

Page 34

DecUaraci6n de garantia ............................ Pagina 33

Practicas operaciOn seguras ..................... Pagina 34

Montaje ...................................................... Pagina 38

OperaciOn .................................................. Pagina 42

Servicio y Mantenimiento .......................... PAgina 46

SoUuci6n de proMemas .............................. Pagina 52

Etiquetas de segundad .............................. Pagina 7

Lista de piezas ........................................... Pagina 23

Acuerdo de protectiOn para reparaciones .... Pagina 55

N0mero de servicio ................................... Cubierta posterior

AUmacenamiento fuera de temporada ....... Pagina 51

CRAFTSMAN GARANT[A L_MUTADA

Dos ASos en Lanzador de Nieve

Cuandohechofuncionary mantenidosegOntodaslas instruccionessuministradas,si estelanzadordenievefalladebidoa undefectoen matedalohabilidadden-

tro dedosaSosdela fechao compra,vueltaestoaalgunoautoriz6Craftsmanposici6ndeba]adaparareparaci6nlibre.Parala posici6nautorizadam&scercana,

Ilamar1-800-4MYHOME.

EstagaranfiasoIMtas61o90d[asde lafechade lacomprasiestelanzadorde nieveesusadoalgunavezparaob]efivosdealquileropublicidad.

EstagaranfiacubreSOLOdefectosen matedalyhabilidad.Chamuscano pagar¶:

• LosarficulosprescindiblesquesehacenIlevadospuestosduranteel uso normal,incluso,perono Iimitadosparapafinarzapatos,platodeafeitado,