Page 1

Operator's Manual

21" SNOW THROWER

Model No. 247.88704

®

CAUTION: using

this product, read this

manua_ and fo_mow am_

safety fumes and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORMNO.769°04080

®SAFETY

®ASSEMBLY

®OPERATION

® MAINTENANCE

® PARTS LIST

® ESPAtIOL

5/28/2008

Page 2

Warranty Statement .................................. Page 2

Safe Operation Practices .......................... Pages 3=5

Safety LabeUs............................................ Page 6

AssemMy .................................................. Pages 7=8

Operation .................................................. Pages 9=11

Service and Maintenance ......................... Pages 12-16

Off=Season Storage .................................. Page 17

Troubb Shooting ....................................... Page 18

Parts List ................................................... Page 20-26

Repair Protection Agreement ................... Page 30

Espa_oU..................................................... Page 31

Service Numbers ...................................... Back Cover

CRAFTSMAN LiMiTED WARRANTY

Two Years on Snow Thrower

Whenoperatedand maintainedaccordingtoaiIsuppibd instructions,ifthis snowthrowerfaibdueto a defectinmaterialorworkmanshipwithin

twoyearsfromthedateor purchase,caiI1=800=4=MY-HOME®toarrangeforfreerepair.

Thiswarrantyappibsforonly90 daysfromthedateof purchaseifthissnowthroweriseverusedforcommercialorrentalpurposes.

Duringthefirstyearofpurchase,there wiiIbenochargeforwarrantyserviceinyourhome.Foryourconvenience,in-homewarrantyservicewill

stillbeavailableafterthefirstyearof purchase,buta tripchargewillapply.Thischargewillbe waivedif youtransportthe snowthrowertoan

authorizedCraftsmandrop-offlocation.Forthe nearestauthorizedlocation,call 1-800-4-MY-HOME®.

Thiswarranty covers ONLYdefects in material andworkmanship. Searswill NOTpayfor:

, Expendableitemsthatbecomewornduringnormaluse,includingbutnotlimitedtoskidshoes,shaveplate,shearpins,sparkplug,air

cleaner,belts,andoil filter.

, Standardmaintenanceservicing,oilchanges,or tune-ups.

, Tire replacementorrepaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,or glass.

, Tireorwheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

, Repairsnecessarybecauseof operatorabuse,includingbutnot limitedtodamagecausedbyimpactingobjectsthat bendtheframeor

crankshaft,orover-speedingtheengine.

, Repairsnecessarybecauseof operatornegligence,includingbutnot limitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeandamountofengineoil,or failureto maintaintheequipmentaccordingto theinstructionscontained

intheoperator'smanual.

, Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

, Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Thiswarrantyappliesonlywhilethisproductis usedinthe UnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

Sears, Roebuckand Co.,Noffman Estates,IL (}0179

EngineOilType:

EngineOilCapacity:

FuelCapacity:

SparkHug:

SparkHug Gap:

@SearsBrands,LLC

SAE 5%30

20 ounces

2 Quarts

Torch F6RTC

.020"-.030"

Model Number.................................................................

Serial Number.................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Page 3

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsinthismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDiTSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothesafeopera-

tionpracticesinthis manualAswithanytypeof powerequipment,

carelessnessorerroron thepartoftheoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethe followingsafety

instructionscouldresultin seriousinjuryor death.

CAUFORNIA PROPOSmON 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm.

, Read,understand,andfollowallinstructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Failuretodosocan resultinseriousinjurytotheoperatorand/

orbystanders.Keepthismanualina safeplaceforfutureand

regularreferenceandfororderingreplacementparts.Forques-

tionscall,1-800-659-5917.

Befamiliarwithallcontrolsandtheirproperoperation.Knowhow

tostopthemachineanddisengagethemquickly.

Neverallowchildrenunder14yearsofagetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesinthismanualandon

themachineandbe trainedandsupervisedbyanadulL

Neverallowadultsto operatethis machinewithoutproper

instruction.

Thrownobjectscan causeseriouspersonalinjury.Planyour

snow4hrowingpatterntoavoiddischargeof materialtoward

roads,bystandersandthelike.

Keepbystanders,petsandchildrenat bast 75feetfromthe

machinewhileitisin operation.Stopmachineifanyoneenters

thearea.

Exercisecautiontoavoidslippingorfalling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict theuseofthis powermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsinthismanualandonthemachine.

SAVE THESE NSTRUCT ONS!

Thoroughlyinspecttheareawheretheequipmentistobeused.

Removealldoormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbetrippedoverorthrownbythe auger/

impeller.

Alwayswearsafetyglassesor eyeshieldsduringoperationand

whileperformingan adjustmentor repairtoprotectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjuryto the

eyes.

, Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjew@y,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

, Usea groundedthree-wireextensioncordand receptaclefor all

machineswithelectricstartengines.

, Disengageall controlleversbeforestartingtheengine.

, Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual

, Letengineandmachineadjusttooutdoortemperaturebefore

startingtoclearsnow.

3

Page 4

SafeHandlingof Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselfor yourclotheswhichcanignite. Washyourskinand

changeclothesimmediately_

, Useonlyanapprovedgasolinecontainer.

, Extinguishallcigarettes,cigars,pipesandothersources

ofignition.

, Neverfuelmachineindoors.

, Neverremovegascaporaddfuel whiletheengineis hot

or running.

, Allowengineto coolat basttwo minutesbeforerefueling.

, Neveroverfill fueltanL Filltanktono morethanY_inch

belowbottomoffillerneckto providespaceforfuel

expansion.

, Replacegasolinecapandtightensecurely.

, ifgasolineisspilled,wipeit offtheengineandequipmenL

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

, Neverstorethemachineorfuelcontainerinsidewhere

thereis anopenflame,sparkor pilotlight(e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

, Allowmachinetocoolatbast 5 minutesbeforestori%

, Neverfillcontainersinsidea vehicleor ona truckor trailer

bedwithaplasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

, if possible,removegas_poweredequipmentfromthetruck

ortrailerand refueliton theground,if thisisnotpossible,

thenrefuelsuchequipmentona trailerwithaportable

container,ratherthanfromagasolinedispensernozzle.

, Keepthenozzleincontactwiththe rimofthefueltankor

containeropeningatalltimesuntilfuelingiscomplete.Do

notuse anozzlelock-opendevice.

, Do notputhandsorfeetnearrotatingparts,in theauger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeel

, Theauger/impellercontrolleverisasafetydevice.Neverbypass

itsoperation.Doingsomakesthemachineunsafeandmaycause

personalinjury.

, Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

, Neveroperatewithamissingor damagedchuteassembly.Keep

all safetydevicesin placeandworki%

, Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

, Do notoperatemachinewhileundertheinfluenceofalcoholor

drugs.

, Mufflerandenginebecomehotandcancausea burn.Do not

toucL Keepchildrenaway.

, Exerciseextremecautionwhenoperatingon orcrossinggravel

surfaces.Stayalertforhiddenhazardsor traffic.

, Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

, Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageorpersonalinjurycausedbya ricocheL

, Neverdirectdischargeatchildren,bystandersand petsor allow

anyoneinfrontofthe machine.

, Donot overloadmachinecapacityby attemptingtoclearsnowat

toofastof a rate.

, Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingand keepafirmholdon thehandles.Walk,

neverrun.

, Disengagepowertotheauger/impellerwhentransportingor not

in use.

, Neveroperatemachineathightransportspeedson slippery

surfaces.Lookdownand behindand usecare whenbackingup.

, ifthe machineshouldstartto vibrateabnormally,stopthe engine,

disconnectthesparkplugwireandgrounditagainsttheengine.

inspectthoroughlyfor damage.Repairanydamagebefore

startingandoperati%

, Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntilthe auger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makinganyadjustments,or inspections.

, Neverputyourhandinthe dischargeor collectoropenings.Do

notunclogchuteassemblywhileengineisrunning.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeuncloggi%

, Useonlyattachmentsandaccessoriesapprovedbythemanufac_

turer(e.g.wheelweights,tirechains,cabsetc.).

, Whenstartingengine,pullcordslowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthan youcan letgo.Broken

bones,fractures,bruisesorsprainscouldresulL

, ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgmenLContactCustomerSupportforassistance

andthenameof yournearestservicingdealer.

CLEARUNG A CLOGGED DUSCHAF{GE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

is themostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobesuretheimpellerbladeshavestopped

rotating_

3_ Alwaysusea clean-outtool,notyourhands.

4

Page 5

MAUNTENANCE& STORAGE

, Nevertamperwithsafetydevices_Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual

, Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntiltheauger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheenginetopreventunintendedstarting.

, Checkboltsandscrewsforpropertightnessatfrequentintervals

tokeepthemachinein safeworkingcondition.Also,visually

inspectmachineforanydamage.

, Do notchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

, Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonly."Useofpartswhichdo notmeettheoriginal

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!"

, Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Referto theadjustment

sectioninthisoperator'smanualforinstructions.

, Maintainorreplacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsand regulationsforgas,oil,etc. to

protecttheenvironment.

, Priorto storing,runmachinea few minutestoclearsnowfrom

machineand preventfreezeupofauger/impeller.

, Neverstorethe machineorfuelcontainerinsidewherethereisan

openflame,sparkorpilotlightsuchasawaterheater,furnace,

clothesdryeretc.

, Alwaysreferto theoperator'smanualforproperinstructionson

off-seasonstorage.

, Checkfuelline,tank,cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

, Do notcrankenginewithsparkplugremoved.

, AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or60 hoursof

operation.AttheendoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failuretodosocanresultinaccidents,injuries

ordeath.

DO NOT MODUFY ENGUNE

Toavoidseriousinjuryor death,do notmodifyengineinany way.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTUOE REGARDUNG EMUSSUONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateon regularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbeusedonornearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwithasparkarrestermeetingapplicablelocalor

statelaws(ifany)

Ifasparkarresterisused,itshouldbemaintainedineffectiveworking

orderbytheoperator.IntheStateofCaliforniatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthemufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

Page 6

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfoflowaftinstructionsonthe machine

beforeattemptingto assembleandoperate.

°

i

\

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine ]s running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine ]s running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, ]n the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICALSHOCK

Do not usethe engine's electric starter in the rain

6

Page 7

NOTE:Referencesto rightorHeftsideof thesnowthrowerare

determinedfrombehindtheunitinthe operatingposition(standing

directlybehindthesnowthrower,facingthe handHepaneH).

REMOVUNG FROM CARTON

1. CutthecornersofthecartonandHaythesidesflaton theground.

RemoveanddiscardaHHpackinginserts.

2. Movethesnowthrowerout ofthecarton.

3. MakecertainthecartonhasbeencompHeteHyemptiedbefore

discardingit.

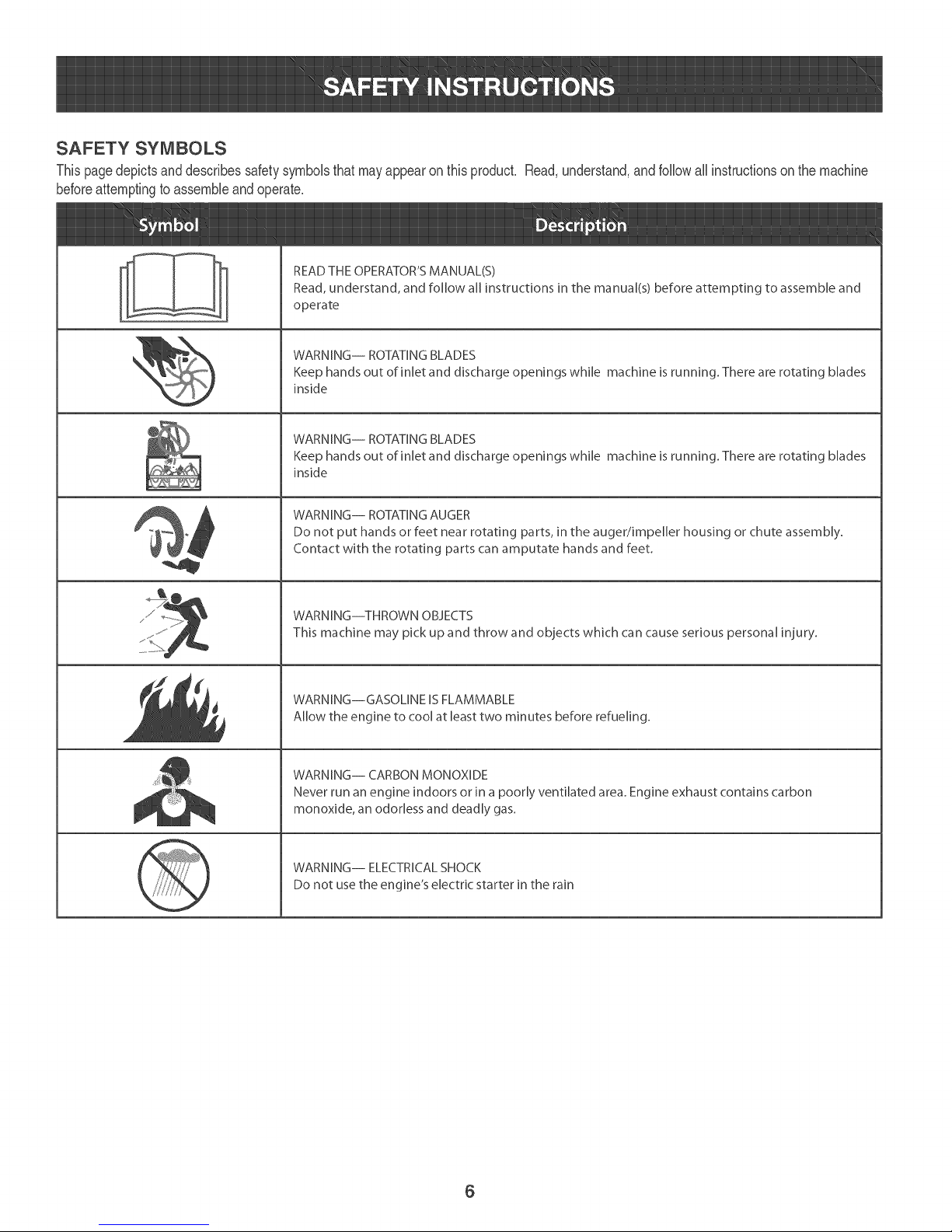

Positioning the Upper Handme

1. PivottheupperhandHeintotheoperatingpositionmakingsurenotto

pinchthe cabHeinthe process,asiHHustratedin Figure1,untiHit

chicksintopHace.

2_ TightenthewingknobstosecurethehandHeinpHace.

See Figure2,

if

Figure2

Figure1

Fuem Recommendations

UseautomotivegasoHine(unHeadedorHowHeadedtominimizecombus-

tionchamberdeposits)withaminimumof87 octane.GasoHinewith

up to 10%ethanoHor 15%MTBE(MethyHTertiaryButyHEther)canbe

used.Neverusean oiH/gasoHinemixtureordirtygasoHine.Avoidgetting

dirt, dust,or waterinthefueHtank.DONOTuseE85gasoHine.

, RefueHina weHH-ventiHatedareawiththeenginestopped.Donot

smokeoraHHowflamesor sparksin theareawheretheengineis

refuelledor wheregasoHineis stored.

, Donot overfiHHthefueHtank.After refuelling,makesurethetank

capisdosed properHyandsecureHy.

, BecarefuHnotto spiHHfueHwhenrefuelling.SpiHHedfueHorfueHvapor

J

mayignite.HfanyfueHis spiHHed,makesurethe areaisdrybefore

startingthe engine.

, AvoidrepeatedorproHongedcontactwithskinor breathingof

vapor.

Adding Fuem

UseextremecarewhenhandHinggasoHine.GasoHineisextremeHy

fHammabHeandthevaporsareexpHosive.NeverfueHthe machine

indoorsorwhiHetheengineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesofignition.

AHwayskeephandsandfeetcHearofequipmentmovingparts.Do not

usea pressurizedstartingfluid.VaporsarefHammabHe.

1. Removethegascap,checkthefueHHeveHandaddfueHif neces-

sary.

7

Page 8

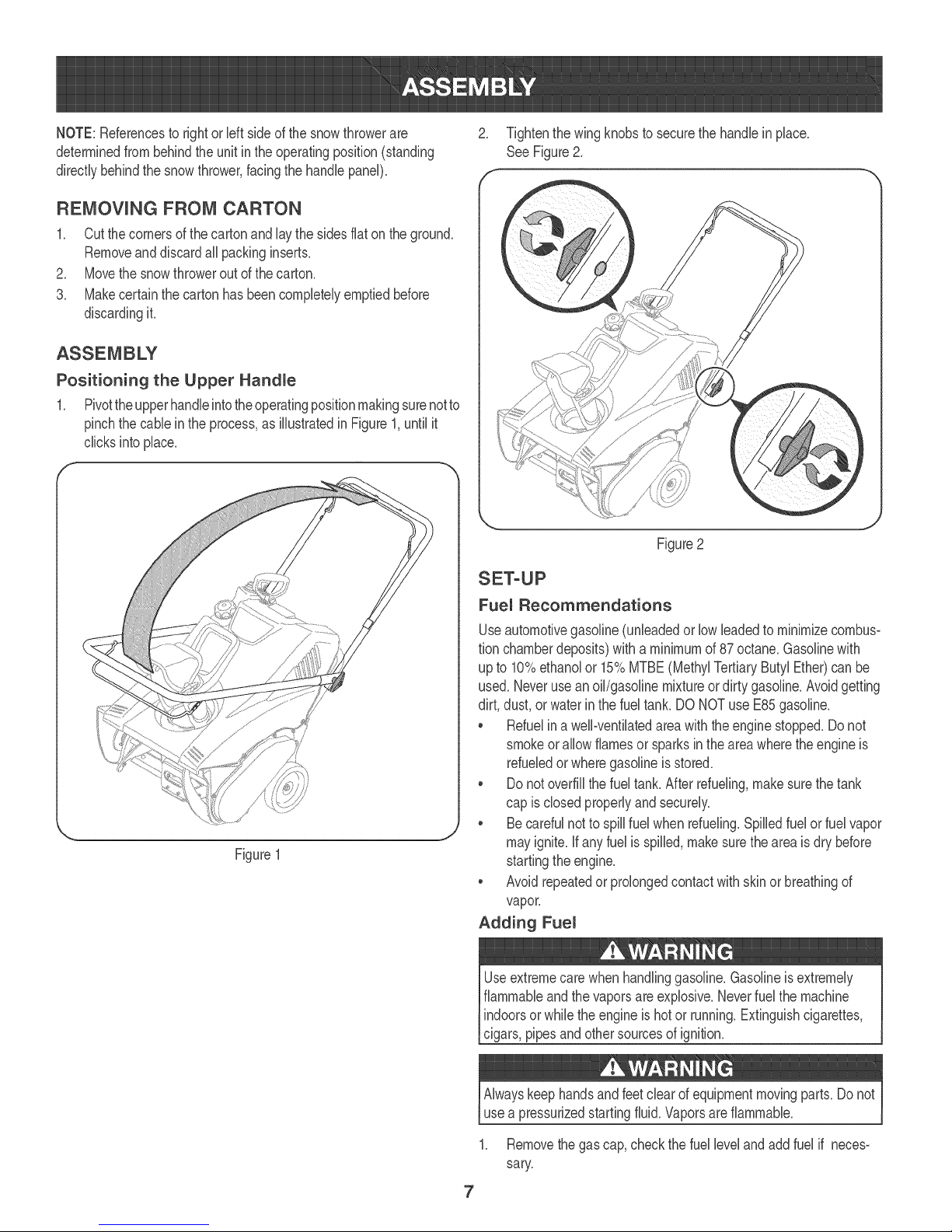

Adding Oim

Theengineis shippedwithoutoilin theengine.Youmustfillthe

enginewithoilbeforeoperating.Runningtheenginewithinsufficient

oilcancauseseriousenginedamageandvoid theproductwarranty.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.See

Figure3.

f

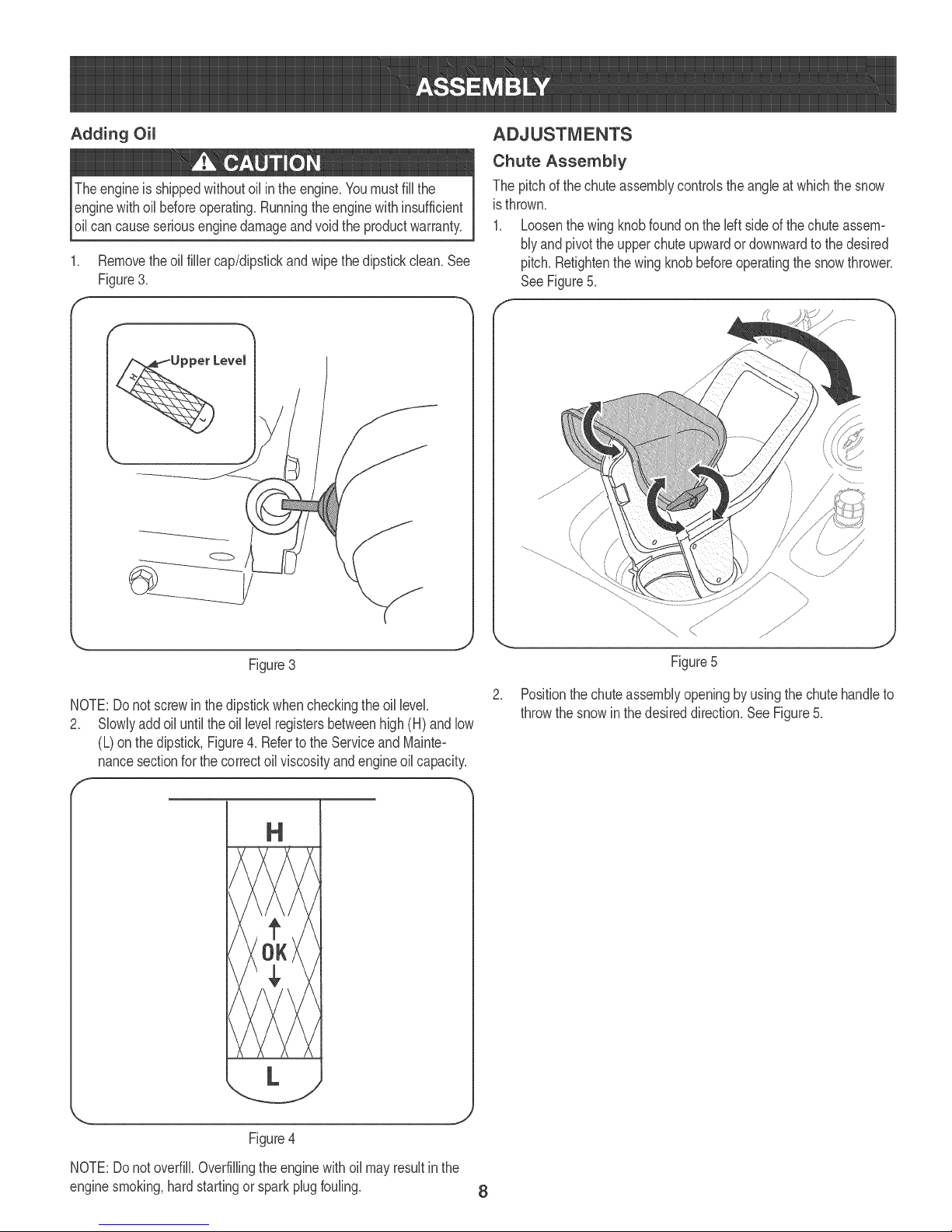

Chute Assembmy

Thepitchofthechuteassemblycontrolstheangleat whichthesnow

isthrown.

1. Loosenthewingknobfoundontheleft sideofthechuteassem-

blyandpivottheupperchuteupwardordownwardtothedesired

pitch.Retightenthewingknobbeforeoperatingthesnowthrower.

SeeFigure5.

/

J

Figure3

NOTE:Donotscrewinthe dipstickwhencheckingtheoil level

2. Slowlyaddoil untiltheoillevelregistersbetweenhigh(H)andlow

(L)onthedipstick,Figure4. Referto theServiceandMainteo

nancesectionforthecorrectoil viscosityandengineoilcapacity.

f

Figure5

Positionthechuteassemblyopeningbyusingthechutehandleto

throwthesnowin thedesireddirection.SeeFigure5_

Figure4

NOTE:Donotoverfill Overfillingtheenginewithoil mayresultinthe

enginesmoking,hardstartingor sparkplugfouling.

8

Page 9

Gas Cap

Chute Assembl

Shave Plate

Nowthatyouhavesetupyour snowthrower,it'simportanttobecome

acquaintedwith itscontrolsandfeatures.RefertoFigure10.

CHOKE LEVER

Activatingthechokecontrolclosesthechokeplateoncarburetorand

aidsin startingengine.

Pressingprimerforcesfueldirectlyintoengine'scarburetor

PRUMER @

toaidin cold=weatherstarting.

UGNUTUONKEY

Theignitionkeyisa safetydevice_it mustbefully I_:"_}

insertedinorderfortheenginetostart.Removethe

ignitionkeywhenthesnowthroweris notinuse.

Figure10

RECOUL STARTER

Thestarterhandleisusedto starttheengine_

GASOLINE CAP

Removethegascaptoaddfuel

AUGER

Whenengaged,theaugersrotationdrawssnowintotheaugerhousing

andthrowsitoutthedischargechute.Rubberpaddiesontheaugers

alsoaidin propellingthesnowthrowerastheycomeincontactwith

thepavemenL

AUGER CONTROL

Locatedontheupperhandle,theaugercontrolhandleis usedto

engageanddisengagedrivetotheauger.Squeezethe controlhandle

againsttheupperhandleto engagetheauger;releaseittodisengage.

NOTE:Donotturnthe ignitionkeyinanattemptto start

theengine.Doingsomaycauseit tobreaL

CraftsmanSnowThrowersconformtothesafetystandardoftheAmericanNationalStandardsinstitute(ANSI).

Meets ANSi Safety Standards

9

Page 10

CHUTE ASSEMBLY

Rotatethedischargechutetotheleftor rightusingthechutehandb.

Thepitchofthedischargechutecontrolstheangleatwhichthesnow

isthrown.Loosenthewingknobonthesideofthedischargechute

beforepivotingthedischargechuteupwardordownwar&Retighten

theknoboncethedesiredpositionhasbeenachbve&

SHAVE PLATE

Theshaveplatemaintainscontactwiththepavementasthesnow

throwerispropelled,allowingsnowcloseto thepavement'ssurfaceto

bedischarge&

BEFORE STARTING THE ENGUNE

machineand inthismanualbefore

1. Thesparkplugwirewasdisconnectedforsafety.Attachthespark

plugwiretothesparkplugbeforestarting.

STARTUNG THE ENGUNE

3ressurizedstarfinc areflammabb.

5. Iftheengineis warm,pushtheprimerbuttononlyonce.

NOTE:Alwayscovertheventholeintheprimerbuttonwhenpushing.

Additionalprimingmaybe necessaryforthefirst startifthetempera-

tureisbelow15° R

6. Graspthe starterhandleandpulltheropeoutslowly,untilitpulls

slightlyharder.Lettheroperewindslowly.

7. Pullthestarterhandlerapidly.Donotallowthehandletosnap

back.Allow ittorewindslowlywhilekeepingafirmholdonthe

handle.

8. Asthe enginewarmsupandbeginsto operateevenly,slidethe

chokeleverslowlytothe 1/2chokeposition.Whentheengine

I I

beginsto runsmoothly,movethechoketo theOFF_ _position.

Iftheenginefails,returnto FULL1"_1choke,thenslowlymoveto

| I

1/2chokethenthe OFF_ _position.

STOPPING THE ENGINE

1. Runtheenginefora fewminutesbeforestoppingto helpdryoffany

moistureontheengine.

2. Tostopthe engineremovetheignitionkeyandstoreitin a safe

place.

3. Wipeallthesnowandmoistureawayfromtheenginecontrols

area.

Toavoidcarbonmonoxidepoisoning,makesuretheengineis

outdoorsin awelPventilatedarea.

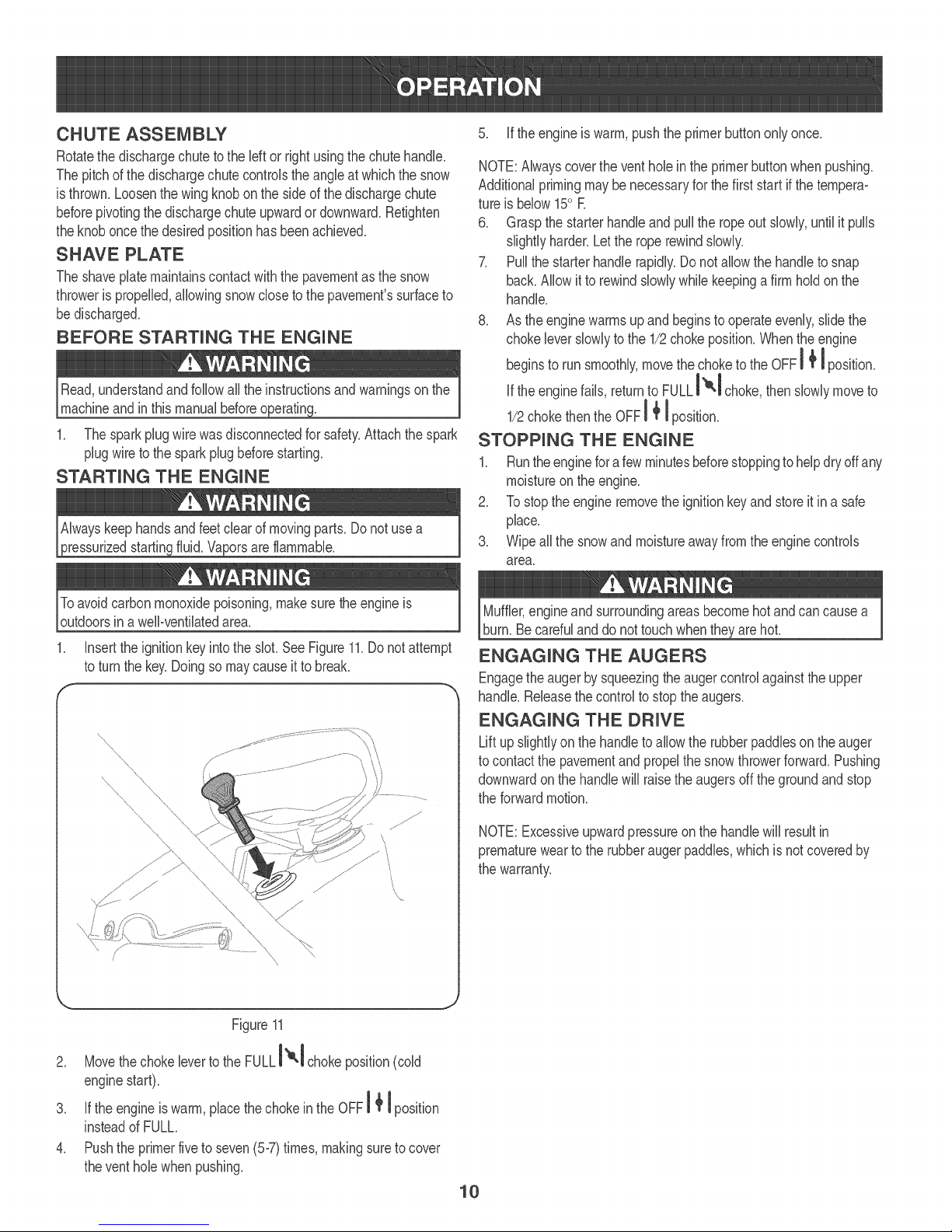

1. inserttheignitionkeyintotheslot.SeeFigure11.Donotattempt

toturnthekey.Doingsomaycauseittobreak.

x

\

\

\,

\

....\

Figure11

Muffler,engineandsurroundingareasbecomehotandcancausea

burn.BecarefulanddonottouchwhentheyarehoL

ENGAGUNG THE AUGERS

Engagetheaugerbysqueezingtheaugercontrolagainsttheupper

handle.Releasethecontroltostoptheaugers.

ENGAGUNG THE DRUVE

Liftupslightlyonthehandletoallowtherubberpaddlesonthe auger

tocontactthe pavementand propelthesnowthrowerforwar&Pushing

downwardonthehandlewill raisetheaugersoffthegroundandstop

theforwardmotion.

NOTE:Excessiveupwardpressureonthe handlewillresultin

prematurewearto therubberaugerpaddies,whichisnotcoveredby

thewarranty.

2. MovethechokelevertotheFULL1'_'1chokeposition<cold

enginestart).

3. ifthe engineiswarm,placethechokeintheOFF! I position

insteadofFULL.

4. Pushthe primerfiveto seven(5_7)times,makingsureto cover

theventhob whenpushing.

A

{,

10

Page 11

ThispageUeftintentionallybUank.

11

Page 12

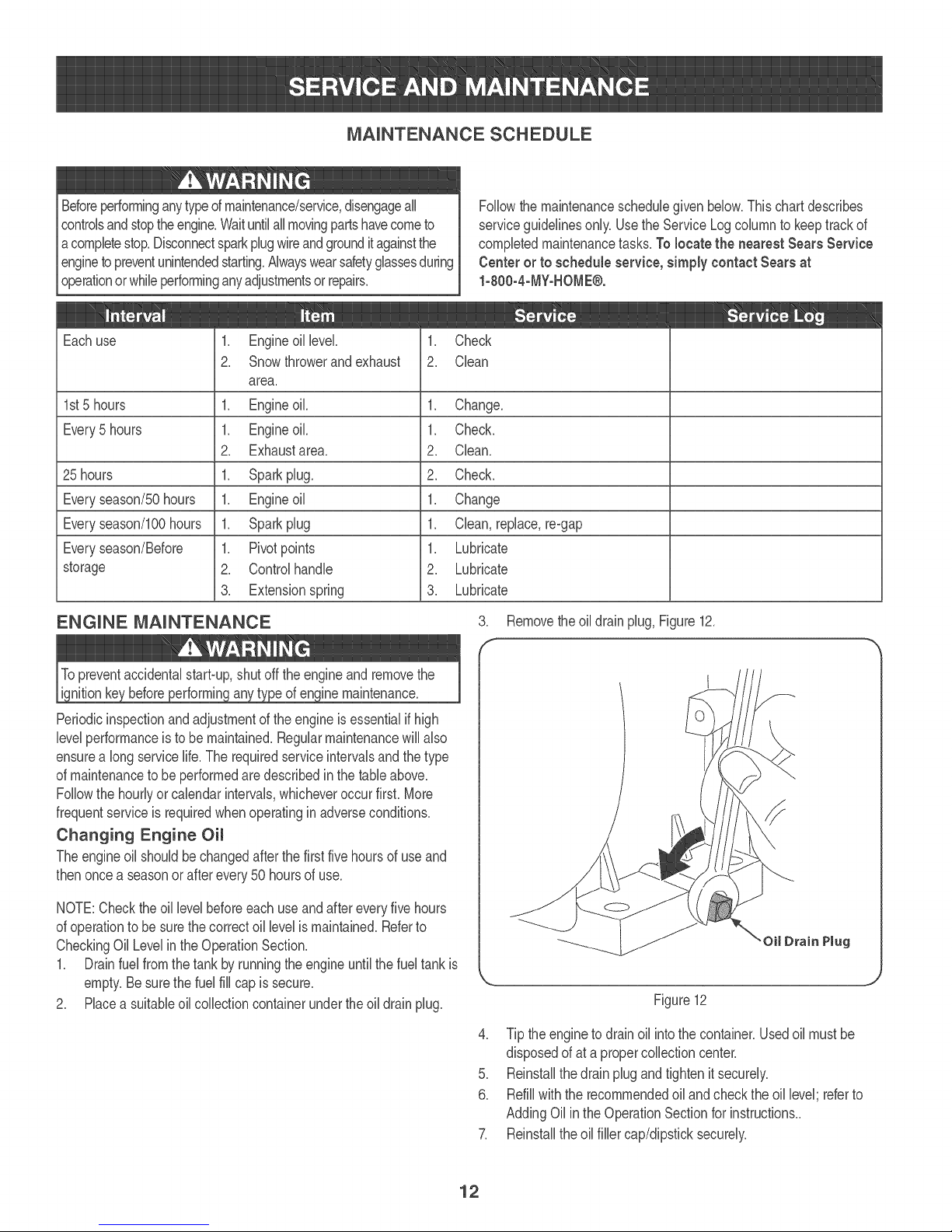

MAUNTENANCESCHEDULE

Followthemaintenanceschedubgivenbeiow.Thischartdescribes

serviceguidelinesoniy.UsetheServiceLogcoBmntokeeptrackof

compbtedmaintenancetasks.To locatethe nearest SearsService

Centeror to schedule service,simply contact Searsat

1-800-4-MY-HOME®.

'I m [d_.] _d_t _=

Eachuse 1. 1. Check

1st5 hours 1. 1. Change.

Every5hours 1. 1. Check.

25 hours 1. 2. Check.

Everyseason/50hours 1. 1. Change

Everyseason/lO0hours 1. 1. Cban, replace,re-gap

Everyseason/Before 1. 1. Lubricate

storage 2. 2. Lubricate

EngineoilbveI.

2. 2. Cban

Snowthrowerandexhaust

area.

Engineoil

Engineoil

2. 2. Cban.

Exhaustarea.

SparkpBg.

Engineoil

SparkpBg

Pivotpoints

Controlhandle

3. 3. Lubricate

ENGINE MAINTENANCE

ine maintenance.

Periodicinspectionandadjustmentoftheengineis essentialifhigh

levelperformanceistobemaintaine&Regularmaintenancewill also

ensurealongservicelife.The requiredserviceintervalsandthetype

ofmaintenanceto beperformedaredescribedinthetableabove.

Followthehourlyorcalendarintervals,whicheveroccurfirst.More

frequentserviceis requiredwhenoperatinginadverseconditions.

Changing Engine Oim

Theengineoil shouldbechangedafterthefirstfivehoursof useand

thenoncea seasonorafterevery50 hoursof use.

NOTE:Checktheoil levelbeforeeachuse andaftereveryfivehours

ofoperationtobesurethe correctoil levelis maintaine&Referto

CheckingOilLevelintheOperationSection.

1. Drainfuelfromthetankbyrunningtheengineuntilthefueltankis

empty.Besurethefuel fillcapissecure.

2. Race a suitableoilcollectioncontainerundertheoil drainplug.

.

Removetheoildrainplug,Figure12.

f

/

Figure12

4. Tipthe enginetodrainoilintothecontainer.Usedoil mustbe

disposedofata propercollectioncenter.

5. Reinstallthedrainplugandtightenitsecurely.

6. Refillwiththerecommendedoilandchecktheoil level;referto

AddingOilintheOperationSectionforinstructions_

7. Reinstalltheoil fillercap/dipsticksecurely.

12

Page 13

Thoroughiywashyourhandswithsoapandwaterassoonas

possibieafterhandBgusedoil

NOTE:Pieasedisposeofusedmotoroiiina mannerthatis frbndHyto

theenvironment.Takeit toa recycBgcenteror othercoiiecfioncenter.

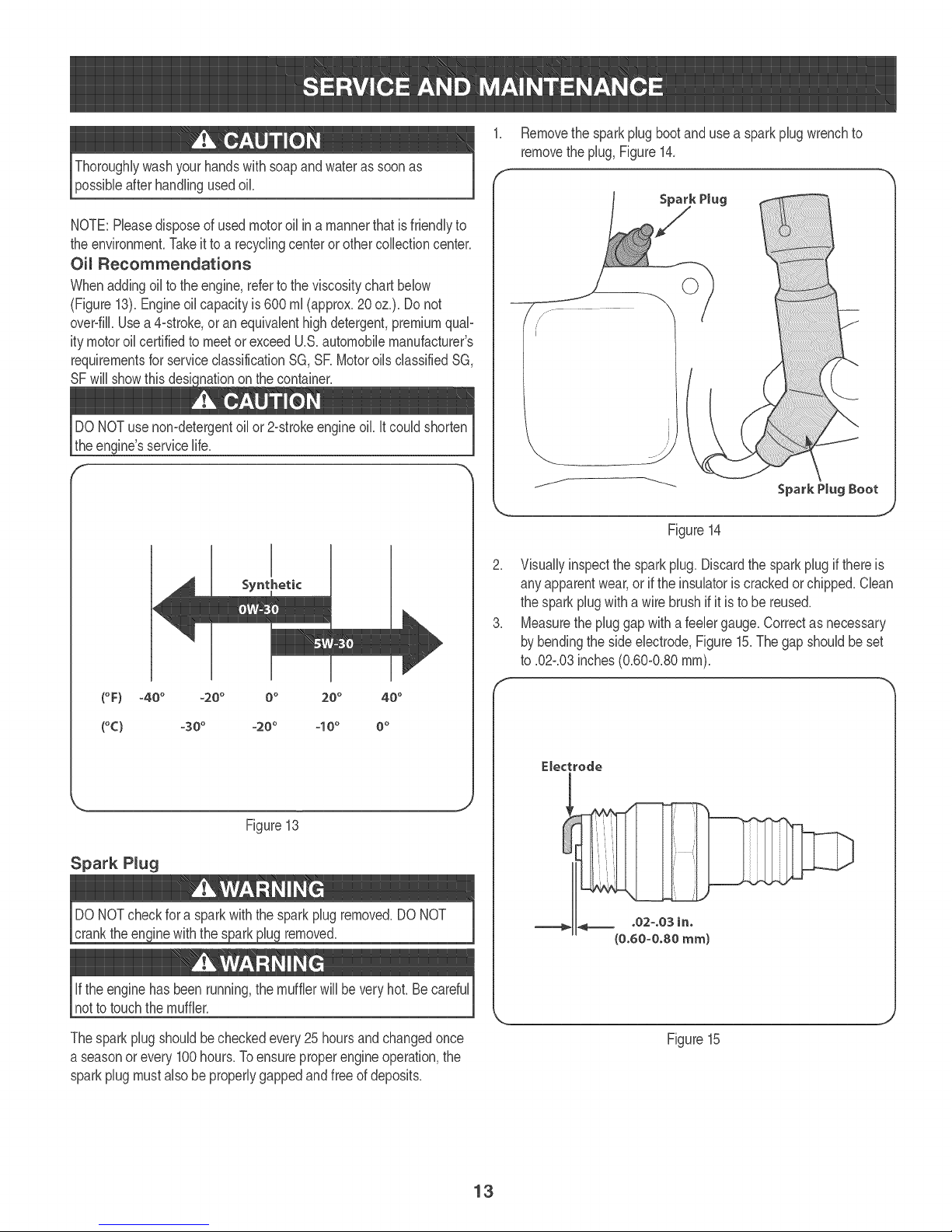

OimRecommendations

Whenaddingoiitothe engine,refertotheviscositychartbellow

(Figure13).Engineoiicapacityis600 mi(approx.20 oz.).Donot

overqiLUsea 4-stroke,or anequivaienthighdetergent,premiumquai-

ity motoroiicertifiedtomeetor exceedU.S.automoWemanufacturer's

requirementsfor serviceciassifbafionSG,SRMotoroiis ciassifbdSG,

SFwiiishowthisdesicnationonthecontainer.

DONOTusenonqetergentoilor bstroke engineoil itcouldshorten

theengine'sservicelife.

f -,

Removethesparkplugbootand usea sparkplugwrenchto

removetheplug,Figure14.

Figure14

Visuallyinspectthe sparkplug.Discardthe sparkplugifthereis

anyapparentwear,oriftheinsulatoriscrackedorchipped.Clean

thesparkplugwitha wirebrushifit isto bereused.

Measurethepluggapwitha feelergauge.Correctasnecessary

bybendingthe sideelectrode,Figure15.Thegap shouldbeset

to .02-.08inches(0.60-0.80ram).

(°F) 40 ° -20° 0o 20 ° 40°

(°C) -30 ° -20 ° qO ° 0 °

Figure13

Spark Plug

cranktheen(inewiththe_ removed.

iftheenginehasbeenrunning,themufflerwillbe veryhoLBecareful

notto touchthemuffler.

Thesparkplugshouldbecheckedevery25 hoursandchangedonce

a seasonorevery100hours.Toensureproperengineoperation,the

sparkplugmustalsobeproperlygappedandfreeofdeposits.

Electrode

_ o02=o03in,

(0,60=0,80 ram)

Figure15

13

Page 14

4. CheckthatthesparkpBgwasheris ingoodconditionandthread

thesparkplugin byhandtopreventcross4hreading.

5. Afterthe sparkpBg isseated,tightenwitha sparkpBgwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkpBg,tighten1/24urnafterthe

sparkpBgseatstocompressthewasher.Whenreinstallinga used

sparkpBg,tighten1/8-to 1/44urnafterthe sparkpBgseatsto

corn)ressthe washer.

becomever hotandcan damac une.

Cmeaning the Engine

iftheenginehasbeenrunning,allowittocoolforatbast halfanhour

beforecbaning.Periodballyremovedirtbuild-upfromengine.

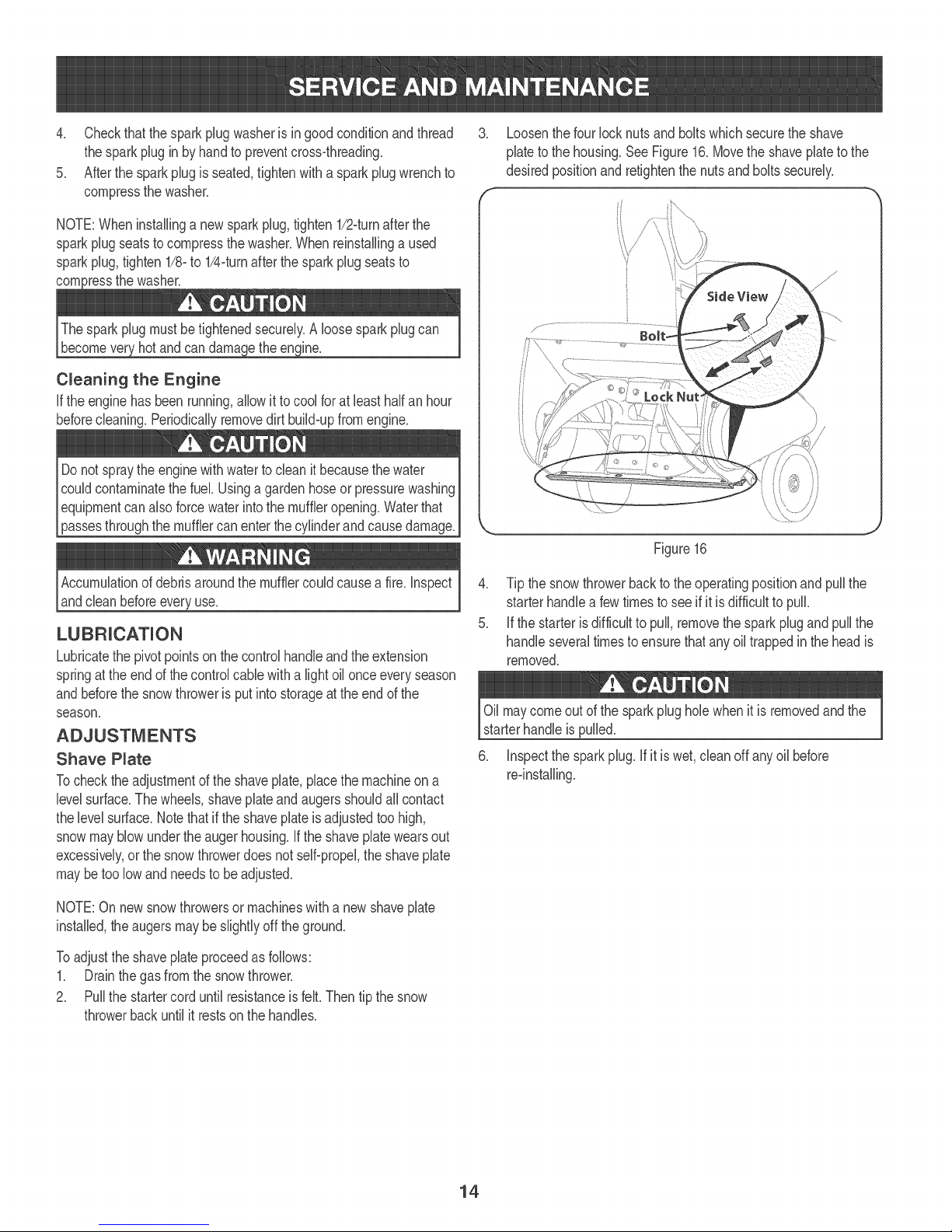

3_ Loosenthefour locknutsandboltswhichsecuretheshave

phte tothehousing.SeeFigure16_Movethe shaveplatetothe

desiredpositionandretightenthenutsandboltssecurely.

Figure16

Accumulationofdebrisaroundthemufflercouldcausea fire. Inspect

andcleanbeforeeveryuse.

Lubricatethepivotpointsonthecontrolhandleandtheextension

springat theendofthecontrolcablewithalightoil onceeveryseason

andbeforethesnowthroweris putintostorageattheendof the

season.

Shave Plate

Tochecktheadjustmentof theshaveplate,placethe machineona

levelsurface.Thewheels,shaveplateandaugersshouldallcontact

thelevelsurface.Notethatif theshaveplateisadjustedtoohigh,

snowmayblowundertheaugerhousing.Iftheshaveplatewearsout

excessively,orthe snowthrowerdoesnotseBpropel,theshaveplate

maybetoolowandneedsto beadjusted.

NOTE:Onnewsnowthrowersor machineswitha newshaveplate

installed,theaugersmaybeslightlyoffthe ground.

Toadjustthe shaveplateproceedasfollows:

1. Drainthegasfromthesnowthrower.

2. Pullthestartercorduntilresistanceisfelt.Thentipthesnow

throwerbackuntilitrestson thehandles.

4_ Tipthesnowthrowerbacktotheoperatingpositionandpullthe

starterhandlea fewtimesto seeifit isdifficulttopull.

5_ if thestarterisdifficultto pull,removethesparkplugandpullthe

handleseveraltimestoensurethatanyoil trappedinthe headis

remove&

Oilmaycomeoutofthesparkplughob whenitis removedandthe

starterhandleis pulled.

6. inspectthesparkplug.if itiswet, cleanoffanyoil before

14

Page 15

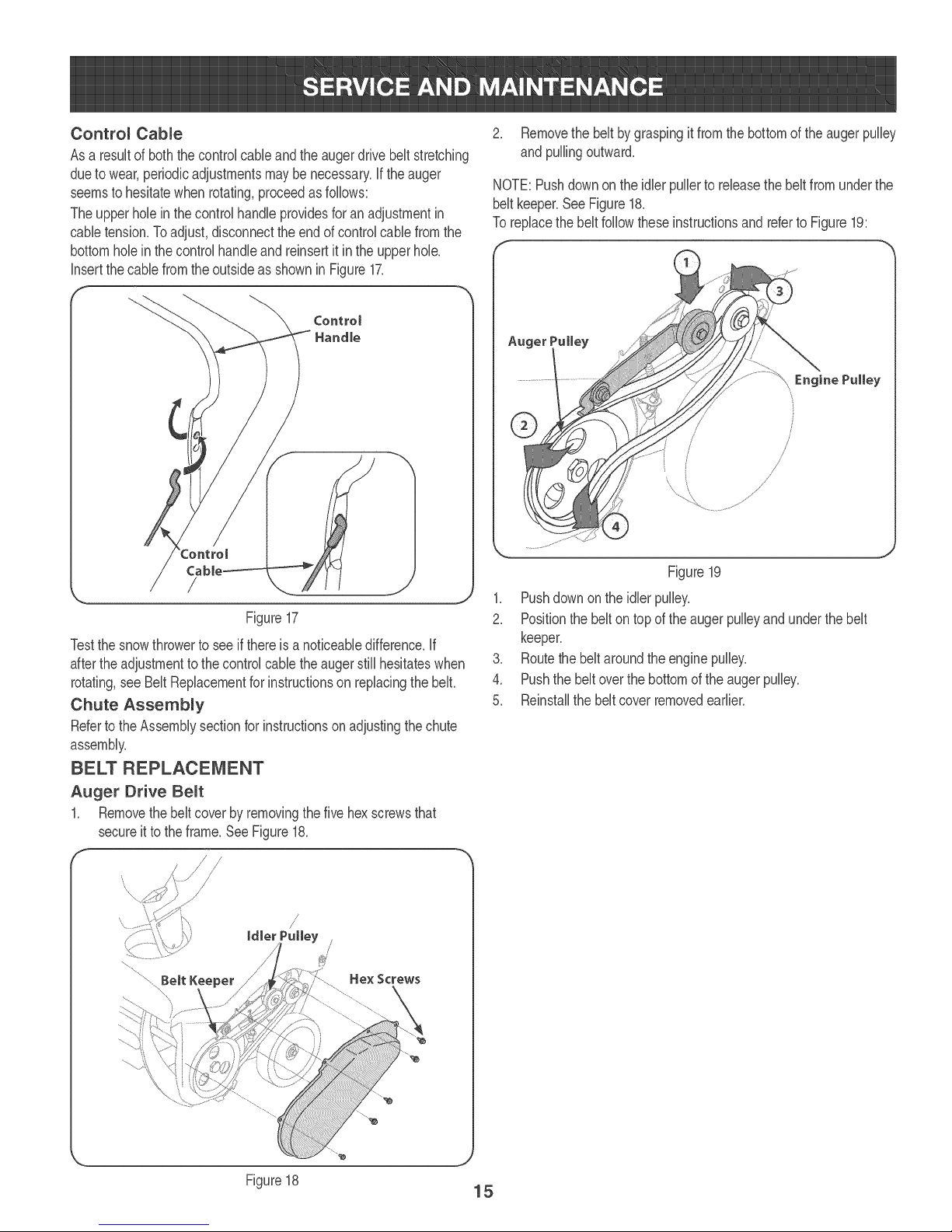

Controm Cabme

Asa resultofboth thecontrolcane andthe augerdrivebeltstretching

duetowear,periodicadjustmentsmaybenecessary,iftheauger

seemsto hesitatewhenrotating,proceedasfollows:

Theupperhob inthecontrolhandleprovidesforanadjustmentin

cane tension.Toadjust,disconnecttheendofcontrolcane fromthe

bottomhob in thecontrolhandleand reinsertit intheupperhob.

insertthecane fromtheoutsideas shownin Figure17.

2. Removethebeltbygraspingitfromthebottomofthe augerpulley

and pullingoutward.

NOTE:Pushdownontheidler )ullerto releasethebeltfromunderthe

beltkeeper.SeeFigurel&

Toreplacethebeltfollowtheseinstructionsand referto Figure19:

Figure17

Testthesnowthrowerto seeif thereisa noticeabledifference,if

aftertheadjustmenttothecontrolcane theaugerstill hesitateswhen

rotating,seeBeltReplacementfor instructionson replacingthebell

Chute Assembmy

RefertotheAssemblysectionforinstructionsonadjustingthechute

assembly.

BELT REPLACEMENT

Auger Drive Beret

1. Removethebeltcoverby removingthefivehexscrewsthat

secureittotheframe.SeeFigure18.

f* j /

/

\

//

/

/ /

/

/

/

/

Figure19

1. Pushdownon theidlerpulley.

2. Positionthebelton topof theaugerpulleyand underthebelt

keeper.

3. Routethebeltaroundtheenginepulley.

4. Pushthebeltoverthebottomoftheaugerpulley.

5. Reinstallthebeltcoverremovedearlier.

Figure18 15

Page 16

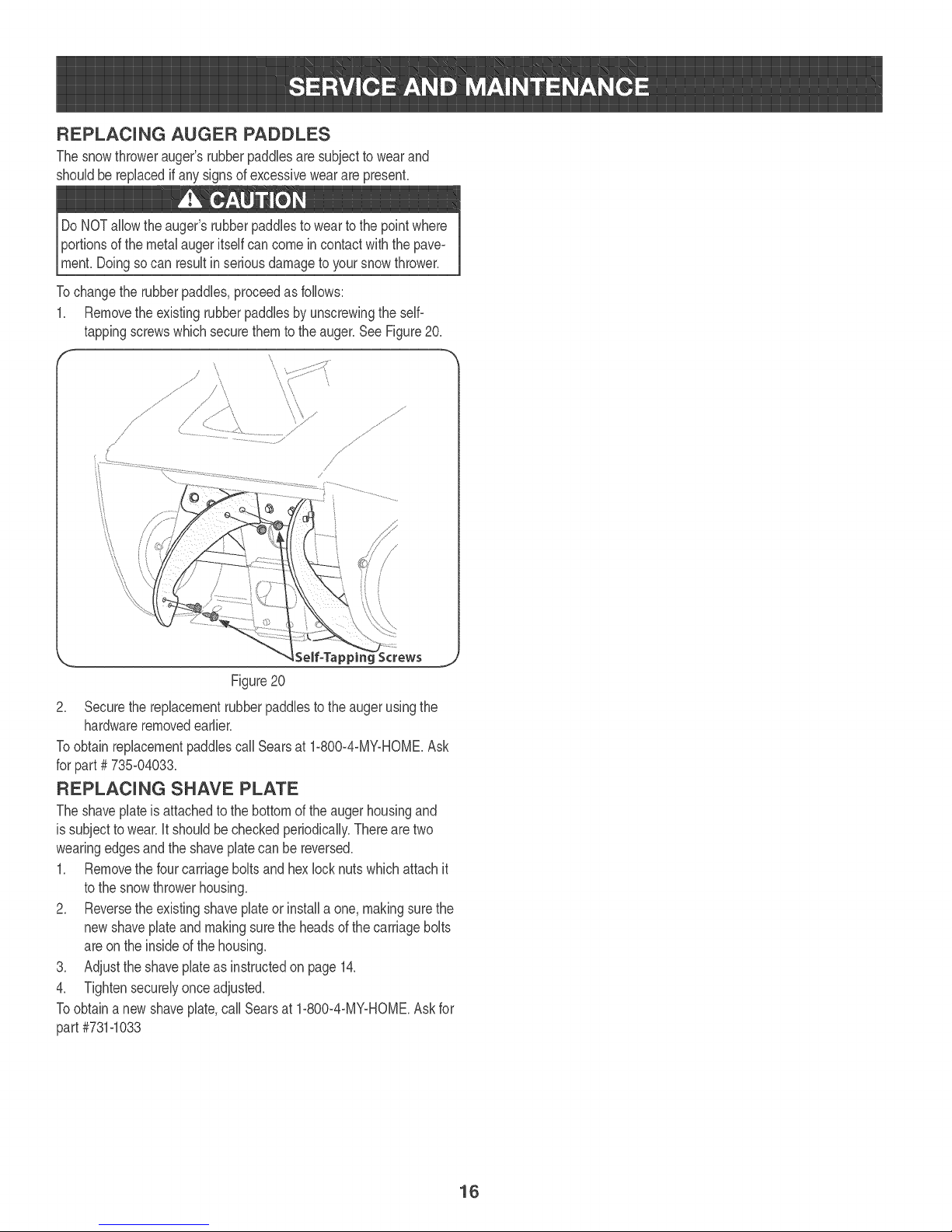

REPLACUNGAUGER PADDLES

Thesnowthrowerauger'srubberpaddiesaresubjecttowearand

shouldbereplacedifanysignsof excessiveweararepresent.

DoNOTallowtheauger'srubberpaddiesto weartothepointwhere

Tochangethe rubberpaddies,proceedasfollows:

1. Removetheexistingrubberpaddiesbyunscrewingtheself-

tappingscrewswhichsecurethemto theauger.SeeFigure20_

_,_ $etf-Tappir j

Figure20

2. Securethereplacementrubberpaddiestothe augerusingthe

hardwareremovedearlier.

ToobtainreplacementpaddiescallSearsat 1-800-4-MY-HOME.Ask

forpart#735-04033.

REPLACUNG SHAVE PLATE

Theshaveplateis attachedtothebottomoftheaugerhousingand

issubjecttowear.it shouldbecheckedperiodically.Therearetwo

wearingedgesandtheshaveplatecanbe reversed.

1. Removethefourcarriageboltsandhexlocknutswhichattachit

tothesnowthrowerhousing.

2. Reversetheexistingshaveplateor installaone,makingsurethe

newshaveplateandmakingsuretheheadsofthecarriagebolts

areontheinsideof thehousing.

3. Adjusttheshaveplateasinstructedon page14.

4. Tightensecurelyonceadjusted.

Toobtainanewshaveplate,callSearsat 1-800-4-MY-HOMEAskfor

part#731-1033

16

Page 17

ifthe snowthrowerwillnotbe usedfor30 daysor longer,or ifit istheendofthesnowseasonwhenthe lastpossibilityof snowisgone,the

equipmentneedsto bestoredproperly.Followstorageinstructionsbelowtoensuretop performancefromthesnowthrowerfor manymoreyears.

PREPARUNG ENGUNE

Enginesstoredover30daysneedto bedrainedoffuelto prevent

deteriorationandgumfromforminginfuelsystemor onessential

carburetorparts,if thegasolineinyourenginedeterioratesduring

storage,youmayneedto havethecarburetor,andotherfuelsystem

components,servicedor replace&

1_ Removeallfuelfromtank byrunningengineuntilit stops.

2_ Changetheengineoil.

3_ Removesparkplugandpourapproximately1oz.(% ml)of clean

engineoil intothecylinder.Pullthe recoilstarterseveraltimesto

distributetheoil,and reinstallthesparkplug.

4_ Cleandebrisfromaroundengine,andunder,around,andbehind

muffler.Applya lightfilmofoilonanyareasthatare susceptible

torusL

, Storeinaclean,dry andwellventilatedareaawayfromanyapo

pliancethatoperateswithaflameor pilotlight,suchasa furnace,

waterheater,or clothesdryer.Avoidanyareawitha spark

producingelectricmotor,orwherepowertoolsareoperate&

latedareas,wherefuelfumesmayreachan openflame,

lightas onafurnace,waterheater,clothesdryerorgasappliance.

PREPARUNG SNOW THROWER

, Whenstoringthesnowthrowerin anunventilatedormetalstop

age shed,careshouldbetakento rustprooftheequipmenLUsing

a lightoilor silicone,coattheequipment,especiallyanychains,

springs,bearingsandcables.

, Removealldirt fromexteriorofengineandequipmenL

, Followlubricationrecommendations.

, Storeequipmentinaclean,dry area.

, if possible,avoidstorageareaswithhighhumidity.

, Keepthe enginelevelin storage.Tiltingcancausefueloroil

leakage.

17

Page 18

or

This section addressesminor service issues.Tolocatethe nearestSears ServiceCenteror to scheduleservice, simply contact Sears

at 1-800-4-MYoHOME®.

"o1_1'£'_:

Enginefaib to start

Enginerunserratically

Engineoverheats

Lossof power

Excessivevibration

1. Fueltankempty,or stab fuel

2. Blockedfuelline.

3. Keynotinsertedalltheway.

4. Sparkplugwiredisconnecte&

5. Faultysparkplug.

6. Enginenotprime&

7. Enginefloodedfromexcessivepriming.

1. Enginerunningonchoke.

2. Fuellineblocked,or stab fuek

3. Wateror dirtinfuelsystem.

4. CarburetoroutofadjustmenL

1. CarburetoroutofadjustmenL

1. Sparkplugwireloose.

2. Ventin gascapplugge&

1. Loosepartsordamagedauger.

1. Filltankwithcleanfreshgasoline.

2. Cleanfuel line.

3. insertkeyall theway.

4. Connectwiretosparkplug.

5. Cleansparkplug,readjustgap,or replace.

6. Primeenginefivetoseventimes.

7. Waitatbast tenminutesbeforestarting.

1. Movechokeleverto OFFposition.

2. Cleanfuel lineandfilltankwithfresh,cleangasoline.

3. Drainfueltank.Refillwithfreshfuel

4. Contacta SearsServiceCenter.

1. Contacta SearsServiceCenter.

1. Firmlyconnectsparkplugwire.

2. ClearvenL

1. Stopengineimmediatelyanddisconnectsparkplug

wire.Checkforpossibledamage.Tightenallbolts

andnuts.Repairasnee@&if problempersists,take

snowthrowertoa SearsServiceDealer.

Snowthrowerfailsto selh 1. AugercontrolcableoutofadjustmenL 1.

propel

2. Augerdrivebeltlooseor damage& 2.

Augerscontinueto rotate 1. AugercontrolcableoutofadjustmenL 1.

Adjustaugercontrolcableasshownin Serviceand

Maintenancesection.

Replaceaugerdrivebell

Adjustaugercontrolcableasshownin Serviceand

Maintenancesection.

Unitfailstodischargesnow 1. Chuteassemblyclogge& 1.

Stopengineanddisconnectsparkplugwire.Clean

chuteand insideof augerhousingwithcleamouttool

or sticL

2. Foreignobjectlodgedinauger.

2. Stopengineimmediatelyanddisconnectthespark

plugwire.Removeobjectfromauger.

3. AugercontrolcableoutofadjustmenL

4. Augerbeltlooseordamage&

3. Adjustaugercontrolcable.

4. ReplaceaugerbelL

You'H fred the answer" and more o_'1manaoemyho_'y_e corn - kw I_'ee

Find this and all your other product manuals online.

Get answers from our team of home experts_

Get a personalized maintenance plan for your home,

Find information and tools to help with home projects,

NEED MORE HELP?

otagt e y@ by Sear,

18

Page 19

19

Page 20

Craftsman Snow Thrower Modem 247.88704

/

/

/

2O

Page 21

Craftsman Snow Thrower Modem 247.88704

1. 684-04236A Shroud

2. 710-04669 HexScrew,10-16x .625

3. 710-1090 HexFlangeScrew,5/16-18x 1.25

4. 712-04063 FlangeLockNut,5/16-18

5. 710-1882 HexFlangeScrew,5/16-18x 1.50

6. 984-04127 HexScrew,1/4-15x .750

7. 720-0284 WingNut,5/16-18

8. 710-04071 CarriageBolt,5/16-18x 1.00

9. 712-04063 FlangeLockNut,5/16-18

10. 710-0451 CarriageBolt,5/16-18x .750

11. 731-04426A UpperChute

12. 731-04388A ChuteHandle

13. 684-04127 LowerChute

14. 749-04459 UpperHandle

15. 747-04165 BailControl

16. 725-0157 CableTie,3/16x .05x 7.4

17. 746-04237 ClutchCable

18. 710-04532 CarriageBolt,5/16-18x 2.00

19. 731-1033 ShavePlate,21"

20. 710-0134 CarriageScrew,1/4o20x .62

21. 712-04064 FlangeLockNut,1/4-20

22. 710-3008 HexScrew,5/16-18x .75

23. 736-0176 FlatWasher,.265x .938x .120

24. 750-04297B Spacer,.875x.320x 1.027

25. 749-04114 LowerHandle

26. 731-04353 LowerChuteRing

27. 731-04886 ChuteAdapter

28. 732-04111 ChuteAdjustmentSpring

21

Page 22

/- ¸\

3

O

O

-4

Page 23

Craftsman Snow Thrower Modem 247.88704

1. 751-10487 FuelCap

2. 751-10023 FuelTank,2 Qt.

3. 790-00134 FuelTankBracket

4. 747-04236 FuelTankSupportWire

5. 726-0205 HoseClamp,.490

6. 751-0535 FuelLineHose

7. 712-04064 HangeLockNut,1/4-20

8. 710-0751 HexBolt, 1/4-20x .620

9. 710-0654A SeresScrew,3/8-16x 1.000

10. 790-00216 EngineBracket

11. 726-0233 PushNut,.25IDx .50OD

12. 726-0154 CableTie,7.5"

13. 756-0416B PulleyHalf,.625IDx .225OD

14. 736-0242 BellWasher,.340x .872x.060

15. 710-0627 HexBolt,5/16-24x .750

16. 756-04232 Pulley,1/2x 6.00

17. 754-0101A V-Belt

18. 790-00045B BeltCover

19. 710-0653 HexScrew,1/4-20x.375

20. 710-0896 HexScrew,1/4-14x .625

21. 710-1005 HexScrew,1/4-14x .500

22. 790-00249 BearingCup

23. 741-04188A BallBearing,.625x 37x 12

24. 712-04063 HangeLockNut,5/16-18

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

748-0234

790-00238A

684-04168

750-04571

710-0106

726-0299

738-0924A

756-0625

684-04253

750-04757

750-04758

710-0642

736-0329

736-0176

732-0357A

712-0896

684-04227

710-0896

735-04033

735-04032

734-04063

710-0409

736-0119

750-04297B

ShoulderSpacer

IdlerBracket

IdlerPulleyAssembly,1.917

ShoulderSpacer,.280x .785x .538

HexScrew,1/4-20x 1.25

PushCap,1/2

ShoulderScrew,

CableRoller

AugerAssembly,21"

LHSpacer

RHSpacer

HexScrew,1/4-20x .750

LockWasher,1/4

FlatWasher,.265x .938x .120

ExtensionSpring,.33x 1.12

HexLockNut,1/4-28

AugerHousingAssembly,21"

HexScrew,1/4-14x .625

RubberPaddle

SpiralCrescent

Wheel,7 x 1.5

HexBolt,5/16-24x 1.75

LockWasher,5/16

Spacer,.875x .320xl.027

23

Page 24

59

81

79

17

16

67

84

21

66 64

22

20

3

O

O

45

42

@ ,@

Page 25

Craftsman Snow Thrower Modem 247.88704

751-10950

O-RingGowShaft

751-10949

751-10951

751-10952

CylinderHeadAssembly

HeadCoverGasket

RockerArm&BoltAssembly(Incl.50-53)

PivotBolt

RockerArm

ValveAdjustingNut

PivotLockingNut

ValveSpring

intakeValveSpringSeat

ExhaustValveSpringSeat

ExhaustValveAdjuster

PushRodGuidePlate

CarburetorInsulator

CarburetorInsulatorGasket

CylinderHead-Complete

CylinderHeadGasket

GasketKit- Complete

O-Ring

CrankcaseCoverGasket

O-Ring,52 x 1.9

OilSeal,22x 35x 7

Washer,10x 16x 1.5

CylinderHeadGasket

MufflerGasket

HeadCoverGasket

CarburetorInsulatorGasket

Packing

CarburetorGasket

GasketKit- External

O-Ring

Washer,10x 16x 1.5

MufflerGasket

HeadCoverGasket

CarburetorInsulatorGasket

CarburetorGasket

E

7O

49

5O

51

52

53

56

57

58

59

62

4O

79

74

76

2

9

11

84

17

76

9O

7O

79

81

45

2

17

9O

7O

79

45

25

Page 26

751q0948

751q0292

751q0953

751q0954

751o10955

731@5696

751q0657

751q0307

751q0908

751q0910

751q0956

751q0961

751q0962

751q0912

751q0913

751q0948

751q0957

751q0958

751q0370

751q0959

751q0901

751q0639

751q0307

CarburetorKitMajor

SparkPlug

GovernorReturnSpring

ThrottleReturnSpring

RecoilStarterAssembly

RecoilStarterHandle

MufflerStudAssembly

FlywheelKey

Flywheel

CoolingFan

CarburetorAssembly

intakeHeaterBox

intakeHeaterBoxBase

ValveKit

PushRodKit

CarburetorKit- Major

DipstickAssembly

ignitionCoil

Oil DrainPlugandWasherAssembly

MufflerGasket

MufflerAssembly

Primer

Flywheel

NS

73

34

32

91

27

75

92

21

22

47

43

42

54,55

61

NS

2,3

18

16,17

90

39

43

92

26

Page 27

MTD CONSUMER GROUP mNC(MTD), the California Air Resources Board (CARD)

and the United States Environment Protection Agency (U. S. EPA)

Emission Contro_ System Warranty Statement

(Owner's Defect Warranty Rights and Obligations)

EMiSSiONCONTROLSYSTEMCOVERAGEIS APPLICABLETOCERTiFiEDENGINESPURCHASEDiNCALiFORNiAiN2005ANDTHERE-

AFTER,WHICHAREUSEDiNCALiFORNiA,ANDTOCERTiFiEDMODELYEAR2005ANDLATERENGINESWHICHAREPURCHASEDAND

USEDELSEWHEREiN THEUNITEDSTATE&

CaliforniaandelsewhereintheUnitedStatesEmissionControlDefectsWarrantyCoverage

TheCaliforniaAir ResourcesBoard(CARB),U.S.EPAandMTDarepleasedtoexplaintheemissionscontrolsystemwarrantyonyourmodelyear

2006andlatersmalloff-roadengine,in California,newsmalloff-roadenginesmustbe designed,builtand equippedtomeettheStatesanti-smog

standards.ElsewhereintheUnitedStates,newnon-road,spark=ignitionenginescertifiedformodel2005andlater,mustmeetsimilarstandardsset

forthbytheU.S.EPA.MTDmustwarrantytheemissioncontrolsystemonyourengineforthe periodoftimelistedbelow,providedtherehasbeen

noabuse,neglectorimpropermaintenanceofyoursmalloff-roadengine.

Youremissioncontrolsystemmayincludepartssuchasthe carburetor,fuel-injectionsystem,theignitionsystem,andcatalyticconverter,fuel

tanks,fuellines,fuelcaps,valves,canisters,filters,vaporhoses,clamps,connectors,andotherassociatedemission-relatedcomponents.

Whereawarrantableconditionexists,MTDwillrepairyoursmalloff-roadengineat nocostto yourincludingdiagnosis,partsand labor.

MANUFACTURER'S WARRANTY COVERAGE:

Thisemissionscontrolsystemiswarrantedfortwoyears,if anyemission-relatedpartonyourengineisdefective,thepartwill berepairedor

replacedbyMTD.

OWNER'S WARRANTY RESPONSIBIUTmES:

Asthesmalloff=roadengineowner,youareresponsibleforthe performanceofthe requiredmaintenancelistedinyour Owner'sManuakMTD

recommendsthatyouretainallyourreceiptscoveringmaintenancesonyoursmalloff=roadengine,butMTDcannotdenywarrantysolelyforthe

lackofreceiptsorforyourfailureto ensuretheperformanceto allscheduledmaintenance.

Asthesmalloff=roadengineowner,youshouldhoweverbeawarethatMTDmaydenyyourwarrantycoverageif yoursmalloff=roadengineorpart

hasfailedduetoabuse,neglect,impropermaintenanceor unapprovedmodifications.

Youare responsibleforpresentingyour smalloff=roadenginetoan AuthorizedMTDServiceDealerassoonasa problemexists.Thewarranted

repairsshouldbe completedina reasonableamountof time,nottoexceed30 days.

ifyouhaveanyquestionsregardingyourwarrantyrightsand responsibilities,youshouldcontacta MTDServiceRepresentativeat 1-800-800-7310

andaddressisMTDCONSUMERGROURRO.Box361131,ClevelandOH,44136-0019_

DEFECTS WARRANTY REQUmREMENTS FOR 1995 AND LATER SMALL OFF-ROAD ENGmNES:

Thissectionappliesto 1995andlatersmalloff-roadengines.Thewarrantyperiodbeginsonthedatetheengineor equipmentisdeliveredtoan

ultimatepurchaser.

!a) GeneralEmissionsWarrant_

MTDmustwarranttotheultimatepurchaserandeachsubsequentpurchaserthattheengineis:

(1)Designed,built,andequippedsoas to conformwithallapplicableregulationsadoptedbytheAirResourcesBoardpursuantto itsauthorityin

Chapters1and2,Part5,Division26of theHealthandSafetyCode;and

(2) Freefromdefectsin materialsandworkmanshipthatcausethe failureofawarrantedparttobeidenticalin all materialrespectstothepartas

describedin theenginemanufacturer'sapplicationforcertificationfora periodoftwoyears.

!b)Thewarrantyonemissions-relatedpartswillbe interpretedasfollows:

(1)Anywarrantedpartthatisnotscheduledforreplacementas requiredmaintenanceinthewritteninstructionsrequiredbySubsection(c)

mustbewarrantedforthewarrantyperioddefinedinSubsection(a)(2).ifanysuchpartfailsduringthe periodof warrantycoverage,it mustbe

repairedor replacedbyMTDaccordingto Subsection(4)below.Anysuchpartrepairedorreplacedunderthewarrantymustbewarrantedfor

theremainingwarrantyperiod.

(2)Anywarrantedpartthatisscheduledonlyfor regularinspectioninthewritteninstructionsrequiredbySubsection(c)mustbewarrantedfor

thewarrantyperioddefinedin Subsection(a)(2).A statementinsuchwritteninstructionstothe effectof"repairor replaceasnecessary"will

notreducetheperiodofwarrantycoverage.Anysuchpartrepairedor replacedunderwarrantymustbe warrantedfortheremainingwarranty

period.

(3) Anywarrantedpartthatwhichis scheduledfor replacementas requiredmaintenanceinthewritteninstructionsrequiredbySubsection(c)

mustbewarrantedfortheperiodoftimepriortothefirstscheduledreplacementpointforthat part.ifthe partfailspriorto thefirstscheduled

replacement,thepart mustbe repairedor replacedbyMTDaccordingto Subsection(4) below.Anysuchpartrepairedorreplacedunder

warrantymustbewarrantedfortheremainderoftheperiodpriortothefirstscheduledreplacementpointfortheparL

Page 28

(4)Repairorreplacementofanywarrantedpartunderthewarrantyprovisionsofthisarticlemustbeperformedatnochargetotheownerata

warrantystation.

(5)NotwithstandingtheprovisionsofSubsection(4)above,warrantyservicesorrepairsmustbeprovidedatallMTDdistributioncentersthat

arefranchisedtoservicethesubjectengines.

(6)Theownermustnotbechargedfordiagnosticlaborthatleadstothedeterminationthatawarrantedpartisinfactdefective,providedthat

suchdiagnosticworkisperformedatawarrantystation.

(7)Theenginemanufacturerisliablefordamagestootherenginecomponentsproximatelycausedbyafailureunderwarrantyofanywarranted

part.

(8)Throughouttheengine'swarrantyperioddefinedinSubsection(a)(2),MTDwillmaintainasupplyofwarrantedpartssufficienttomeetthe

expecteddemandforsuchparts.

(9)Anyreplacementpartmaybeusedintheperformanceofanywarrantymaintenanceorrepairsandmustbeprovidedwithoutchargetothe

owner.SuchusewillnotreducethewarrantyobligationsofMTD.

(10)Add-onormodifiedpartsthatarenotexemptedbytheAirResourcesBoardmaynotbeused.Theuseofanynon-exemptedadd-onor

modifiedpartsshallbegroundsfordisallowingawarrantyclaimmadeinaccordancewiththisarticle.Theenginemanufacturershallnotbe

liableunderthisarticletowarrantfailuresofwarrantedpartscausedbytheuseofnon-exemptedadd-onormodifiedpart.

__)MTDwill includeaco_yofthefollowingemissionwarrantyLpartslistwitheach newen_q thoseportionsofthelistap#licabletothe

(1)FuelMeteringSystem

, Coldstartenrichmentsystem(softchoke)

•Carburetorandinternalparts

, FuelPump

, FuelTank

(2)AirinductionSystem

, Aircleaner

, Intakemanifold

(3) ignitionSystem

, Sparkplug(s)

, MagnetoIgnitionSystem

(4)ExhaustSystem

, Catalyticconverter

, SAI(Reedvalve)

(5) MiscellaneousItemsUsedin AboveSystem

, Vacuum,temperature,position,timesensitivevalvesandswitches

, Connectorsandassemblies

(6) Evaporativecontrol

, FuelHosecertifiedforARBevaporativeemissionof2006.

, FuelHoseClamps

, Tetheredfuel cap

, Carboncanister

, Vaporlines

GDOC-100174Rev,B

Page 29

Look For ReUevant Emissions DurabiUity Period and

Air Unde× Unformation On Your Engine Emissions LabeU

Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must

display information regarding the Emissions Durability Period and the Air index. Sears, Roebuck and Co., U.S.A.

makes this information available to the consumer on our emission labels.

The Emissions Durability Period describes the number of hours of actua_ running time for which the engine is

certified to be emissions compliant, assuming proper maintenance in accordance with the Operating & Mainte-

nance Instructions. The following categories are used:

Moderate: Engine is certified to be emission compliant for 125 hours of actual engine running time.

mntermediate: Engine is certified to be emission compliant for 250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore, the Emissions

Durabimity Period of an engine with an intermediate rating would equate to 10 to 12 years.

The Air mndexis a calculated number describing the relative level of emissions for a specific engine family. The

lower the Air Index, the cleaner the engine. This information is displayed in graphical form on the emissions label.

After July 1,2000, Look For Emissions Compliance Period

On Engine Emissions CompUiance LabeU

After July 1, 2000 certain Sears, Roebuck and Co., U.S.A. engines will be certified to meet the United States

Environmental Protection Agency (USEPA) Phase 2 emission standards. For Phase 2 certified engines, the Emis-

sions Compliance Period referred to on the Emissions Compliance _abei indicates the number of operating hours

for which the engine has been shown to meet Federal emission requirements.

For engines less than 225 cc displacement, Category C = 125 hours, B = 250 hours and A = 500 hours.

For engines of 225 cc or more, Category C = 250 hours, B = 500 hours and A = 1000 hours.

This is a generic representation of the emission labe_typically found on a certified engine.

GDOC-100182Rev.A

29

Page 30

Congratulationsonmakingasmartpurchase.YournewCraftsman®

productisdesignedandmanufacturedforyearsofdependabbopera-

tion.ButlikeaiIproducts,itmayrequirerepairfromtimetotime.That's

whenhavingaRepairProtectionAgreementcansaveyoumoneyand

aggravation.

Here'swhattheRepairProtectionAgreement*incBdes:

, Expertservicebyour10,000professionalrepairspecialists

, Unlimitedserviceandnochargeforpartsandlaboronall

coveredrepairs

, Productreplacementupto$1500ifyourcoveredproductcan'tbe

fixed

, Discountof10%fromregularpriceofserviceandrelatedinstalled

partsnotcoveredbytheagreement;also,10%offregularpriceof

preventivemaintenancecheck

, FastheJpbyphone=wecallitRapidResolution=phonesupport

fromaSearsrepresentative.Thinkofusasa"talkingowner's

manual/'

OnceyoupurchasetheAgreement,asimplephonecall isall thatit

takesfor youto scheduleservice.Youcancallanytimedayor night,or

schedulea serviceappointmentonline.

TheRepairProtectionAgreementisarisk-freepurchase,if youcancel

foranyreasonduringtheproductwarrantyperiod,wewillprovideafull

refund.Or,a proratedrefundanytimeaftertheproductwarrantyperiod

expires.Purchaseyour RepairProtectionAgreementtoday!

SomeJimitations andexclusions apply. Forprices and additional

information in the U.S.A.call 1-800-827-6655.

*Coveragein Canadavaries on some items.Forfull detaib call

SearsCanadaat 1-800-361-6665.

SearsInstallation Service

ForSearsprofessionalinstallationofhomeappliances,garagedoor

openers,waterheaters,andothermajorhomeitems,inthe U.S.A.or

Canadacall1-800-4-MY-HOME®.

3O

Page 31

DedaraciOn de garantia ........................ Pagina 31

Medidas importantes de seguridad .....Paginas 32=34

Etiquetas de seguridad ......................... Pagina 35

Montaje ................................................. Paginas 36=37

Funcionambnto .................................... Paginas 38=40

Servicio y Mantenimbnto ..................... Paginas 41=45

AImacenambnto fuera de temporada..Pagina 46

SoluciOn de problemas ......................... Pagina 47

Acuerdo de protecci6n para

reparaciones .................................... Pagina 51

NOmero de servido .............................. Cubbrta

posterior

GARANTJA UMITADA CRAFTSMAN

Dos ASos en Lanzador de Nieve

Cuandohechofuncionary mantenidoseg_ntodaslasinstruccionessuministradas,siestelanzadordenievefalladebidoa undefectoenmate°

rialohabilidaddentrode dosaSosde lafechaocompra,llameI=800=4MYHOMEhacerlosarreglosparareparaci6nlibre.

Estagarantias61oten@b,validezdurante90dias siesteproductoseutilizaen cualquiermomentoparafinescomercialeso de alquiler.

Duranteel primeraSodela compra,nohabrb,ningOnprecioparael serviciodegarantiaen sucasa. Parasuconveniencia,ende casaelservicio

degarantiatodaviaestarb,disponibledespu_sdel primeraSode lacompra,perounpreciodeviajese aplicarb_Esteprecioseth.renunciado

siustedtransportaallanzadorde nieveaunaposici6nde bajadade Artesanoautorizada.Parala posici6nautorizadamb.scercana,llame

1=8004-MY-HOME@.

Esta gatantiacubre SOLOdefectosen material y habilidad. Searsno pagar_pata:

, Losarficulosprescindibbsquese hacenIbvadospuestosduranteeluse normal,incBso,perono limitadosparapatinarzapatos,platode

afeitado,esquilanalfibres, bujia,filtrodeaire,cinturones,yfiltrodel aceite.

, Revisi6ndemantenimientoest_.ndar,cambiosdeaceite,opuestasa punto.

, Reemplazodeneumb@oo reparaci6ncausadaporpinchazosdesdefueradeobjetos,comeuSas,espinas,tocones,ocristal.

, Neumb@ooreemplazode ruedao reparaci6nqueresultade ropanormal,accidente,uoperaci6nimpropiao mantenimiento.

, Las reparacionesnecesarias@bideal abusedeoperador,incBsoperonolimitadoparadaSarcausadoafectandoobjetosquedoblanel

marcoo elcigOeSal,oel sobreexcesode velocidaddelmotor.

, Reparacionesnecesarias@bidea negligenciadeloperador,induyendoentreotros,daSosmecb.nicoyel@triceocasionadoporun

almacenamientonoapropiado,falla porelusede aceitedegradey/o cantidadnoapropiadao fallaper nodarmantenimientoal equipode

acuerdoconlasinstruccionescontenidasenel manualdeloperador.

, Limpiezaoreparacionesal motor(sistemadecombustible)provocadasporuncombustiblecontaminadouoxidado(viejo).Engeneral,el

combustibledebeutilizarseenunperiodono mayorde 30diasa partirde suadquisici6n.

, Elempejoramientonormaly laropadelosfinesexteriores,oproductoetiquetanelreemplazo.

Estagarantias61oten@b,validezmientraselproductoseutiliceenlos EstadosUnidos.

Estagarantialeotorgaderechoslegalesespecificos,peroustedpodriagozarde otrosderechosen raz6ndesulugarde residencia.

Sears, Roebuckand Co.,Hoffman Estates,IL (}0179

Tipode aceitedelmotor:

Capacidaddeaceitedelmotor:

Capacidaddecombustible:

Bujiadeencendido

Separaci6nde lasbujias:

@SearsBrands,LLC

SAE5W=30

20onzas

2 Cuartosdegal6n

TorchF6RTC

.020"=.030"

N(_metode mode!o.........................................................

Nemero de serie ............................................................

Fecha de compra.........................................................................

RegistreelnOmerodemodelo,nQmerode serie

y fechade compramb.sarriba

31

Page 32

La presenda de este simbolo indica que se trata

de instrucciones importantes de seguridad que

se deben respetar para evitar poner en peligro

su seguddad personal y/o material y la de otras

personas. Lea y siga todas las instrucdones de

este manual antes de poner en funcionamiento

esta rna'quina. Si no respeta estas instrucciones

podria provocar lesiones personales. Cuando

vea este simbolo, ipreste atenci6n a la

advertencia!

PROPOSUCU6N 65 DE CAL_FORNUA

Elescapedelmotordeesteproducto,algunosdesuscomponentes

y algunoscomponentesdelvehicWocontieneno liberansustandas

quimicasqueelestadode Californiaconsideraque puedenprodudr

cancer,defectosdenacimientouotrosproNemasreproductivos.

Esta ma'quina fue construida para ser operada de acuerdo

con las reglas de seguddad contenidas en este manual.

AI igual que con cualquier tipo de equipo motorizado, un

descuido o error pot parte del operador puede producir

lesiones graves. Esta m_iquina es capaz de amputar manos y

pies y de arrojar objetos con gran fuerza. De no respetar las

instrucciones de seguridad siguientes se pueden _roducir

lesiones graves o la muerte.

Su responsabilidad--Restrinja el uso de esta maquina

motorizada a las personas que lean, comprendan y respeten

las advertencias e instrucdones que aparecen en este

manual y en la ma'quina.

6gARgI:BTA$ INSTRg(:(:IONE$

, Leer,entendery seguirtodaslasinstruccionesenlamaquina

yen elmanual(s)antesdeintentarmontary operar.No

hacerlopuederesWtaren lesionesgravesparaeloperadory/

otranseOntes.Guardeestemanualenunlugarseguroparael

futurey regularde referenciayparapedirpiezasde repuesto.

ParapreguntasIlameal, 1-800-659-5917.

, Familiaricesecontodosloscontrolesyconel useadecuado

de losmismos.Sepac6modetenerlamaquinaydesactivarlos

controlesrapidamente.

, No permitanuncaque losnifiosmenoresde14ariesutilicen

estamaquina.Losnifiosde 14ariesenadelantedebenleery

entenderlasinstruccionesde operaci6nynormasdeseguridad

contenidasen estemanualyen lamaquinay debenser

entrenadosy supervisadosporun adWto.

, NuncapermitaquelosadWtosoperenestamaquinasinrecibir

antesla instrucci6napropiada.

, Losobjetosarrojadosporla maquinapuedenproducirlesiones

graves.Planifiqueel patr6nenel quevaa irarrojandonievepara

evitarqueladescargadematerialse realicehacialoscaminos,

losobservadores,etc.

, MantengaalostranseOntes,mascotasynifiosalmenosa 75

piesde la maquinamientrasestaen funcionamiento.Detengala

maquinasialguienseacerca.

, Seaprecavidoparaevitarpatinarseo caerseespecialmente

cuandooperala maquinaenmarchaatras.

Inspeccioneminuciosamenteelareadondeutilizarael equipo.Saque

todoslosfelpudos,peri6dicos,trineos,taNas,cablesy otrosobjetos

extrafiosconlosquepodriatropezaro quepodrianserarrojadospor

la barrena/impWsor.

1. Paraprotegerselosojosutilicesiempreanteojosoantiparras

de seguridadmientrasoperalamaquinao mientraslaajusta

o repara.Losobjetosarrojadosquerebotanpuedenproducir

lesionesocWaresgraves.

2. Nooperelamaquinasinla vestimentaadecuadaparaestaral

aire libreeninvierno.Noutilicealhajas,bufandaslargasuotras

prendassueltasquepodrianenredarseenlaspartesm6viles.

Utiliceuncalzadoespecialparasuperficiesresbaladizas.

3. Useun prolongadory untomacorrientedetrescablescon

conexi6natierraparatodaslasmaquinasconmotoresde

encendidoel_ctrico.

4. Desengranetodaslaspalancasdecontrolantesde arrancarel

motor.

5. Nuncaintenterealizarajustesmientraselmotorest,.enmarcha

exceptoenloscasosespecificamenterecomendadosenel

manualdeloperador.

6. Dejequeelmotory lam_.quinaseadaptenalatemperatura

exteriorantesdecomenzara sacarla nieve.

32

Page 33

MANEJO SEGURO DE LA GASOUNA

Paraevitarlesionespersonaleso daSosmaterialestengamucho

cuidadocuandotrabajecongasolina.Lagasolinaessumamente

infiamableysusvaporespuedencausarexplosiones.Si sederrama

gasolinaendmaosobrela ropasepuedelesionargravementeyaque

sepuedeencender.L_.veselapM y cb.mbiesede ropade inmediato.

, Ufilices61olos recipientesparagasolinaautorizados.

, Apaguetodoslos cigarrillos,dgarros, pipasyotrasfuentesde

combusti6n.

, Nuncacarguecombustibleen lamb.quinaenunespadocerrado.

, Nuncasaquelatapade lagasolinani agreguecombustible

mientraselmotorestacalienteo en marcha.

, Dejequeelmotorse enfriepot Iomenosdosminutosantesde

volvera cargarcombustible.

, NuncaIleneenexcesoeldep6sitodecombustible.Lleneel

tanqueano mb.sdeY2pulgadapotdebajode la basedelcuello

deIlenadodejandoespacioparaladilataci6ndelcombustible.

, Vuelvaa colocarlatapadelcombustibleyajOstelabien.

, Limpieelcombustiblequesehayaderramadosobreel motoryel

equipo.Trasladela mb.quinaa otrazona.Espere5 minutosantes

deencenderel motor.

, Nuncaalmacenelamb.quinao el recipientede combustibleen

unespaciocerradodondehayafuego,chispaso luzpiloto(pot

ejemplo,hornos,calentadoresdeagua,calefactores,secadores

de ropa,etc.).

, Dejequelamb.quinaseenfriepot Iomenos5 minutosantesde

guardarla.

, NuncaIlenelosrecipientesenelinteriordeunvehiculoocami6n

o caiade remolqueconrecubrimientoplb.stico.Coloquesiempre

losrecipientesenelpiso ylejosdelvehiculoantesdeIlenarlos.

, Sies posible,retireel equipoa gasolinadelcami6no remolque

y116neloen el suelo.Siestono es posible,Ileneel equipoen un

remolqueconun contenedorportatil,envezde conunaboquilla

dispensadoradegasolina.

, Mantengalaboquilladispensadoraen contactoconelbordedel

dep6sitode combustibleoconla aberturadelrecipienteen todo

momento,hastaterminarlacarga.Noutiliceundispositivode

apertura/cierredeboquilla.

FUNCUONAMUENTO

1. Nopongalasmanoso lospiescercadelaspiezasrotatorias,

enlacajade la barrena/ impulsoro en elmontajedelcanalde

descarga.Elcontactocon laspiezasgiratoriaspuederesultaren

la amputaci6ndemanoso pies.

2. La palancadecontrolde la barrena/ impulsores undispositivo

deseguridad.Nuncaevitesufuncionamiento.De hacerlola

operaci6ndela mS.quinaesriesgosay puedeocasionarlesiones.

3. Laspalancasdecontroldebenfuncionarbienen ambas

direccionesy regresarautomb.ticamentea laposici6nde

desengranecuandose lassuelta.

4. Nuncaoperelamaquinasifaltaunmontajedelcanalosi

el mismoestada_ado.Mantengatodoslosdispositivosde

seguridadensulugaryen funcionamiento.

5. Nuncaenciendaelmotoren espacioscerradosoenunazona

conpocaventilaci6n.Elescapedelmotorcontienemon6xidode

carbono,ungasinodoroyletal.

6. Noutilicela mb.quinabajola infiuenciadelalcohololas drogas.

7. Elsilenciadoryel motorsecalientany puedencausar

quemaduras.No lostoque.Mantengaa losniSosalejados.

8. SeasumamenteprecavidocuandooperelamS.quinasobreuna

superficiecongravao cuandolacruce.Mant_ngasealerta porsi

sepresentanpeligrosocultoso tr_.nsito.

9. Tenga cuidado cuando cambie de direcci6n ocuando opere la mSquina en

pendientes.

10. Planifique el patr6n en el que vaa ir arrojando nieve para evitar que

la descarga de material se produzca hacia lasventanas, las paredes,

losautom6viles, etc. y evitar asi posiblesdahos matedales o lesiones

producidas por los rebotes.

11. Nunca diriia la descarga hacia los nihos, losebservadores o las mascotas ni

deie que nadie se pare delante de lamb,quina.

12. No sebrecargue la capacidad de lamSquina tratando de sacar la nieve muy

rApidamente.

13. Nunca opere esta mb,quina sin buena visibilidad o iluminaci6n. Siempre

debe estar seguro de que est5 bien afirmado y sujetando firmemente las

maniias. Camine, nunca corra.

14. Corte la corriente a la barrena/impulsor cuando transporte la mSquinao

cuando lamisma no estA en use.

15. Nunca opere la mAquina aalta velocidad de desplazamiento sobre

superficies resbaladizas. Mire hacia abajo y hacia atrb,sy tenga cuidado

cuando vaya marcha atrb,s.

16. Si la mSquina comenzara a vibrar de manera anormal, detenga elmotor,

desconecte el cable de la buiia y p6ngala de manera que haga masa contra

el motor. Inspeccione lamb,quina minuciosamente para vet siest_ dahada.

Reparetodos los dahos antes de encender yoperar lamAquina.

17. Desengrane todas laspalancas de control ydetenga el motorantes dedeiar

la pesici6n de operaci6n (detr_s de las manijas). Espere aque la barrena/

impulsor se detenga por completo antes de destapar el montajedel canal o

realizar ajustes e inspecciones.

18. Nunca penga las manos en las aberturas de descarga o de recelecci6n.

Nodestape el montaje del canal mientras elmotor estb,enfuncionamiento.

Antes de destaparlo, apague elmotor y permanezca detrb,s de las manijas

hasta quetodas las partes m6vilesse hayan detenido.

19. Use s61ounionesy accesodos aprobados per el fabricante (porejemplo,

pesaspara las ruedas, cadenas para los neumaficos, cabinas, etc.).

20. Paraencender elmotor,iale de la cuerda lentamente hasta que sienta

resistencia, luegojale r_pidamente. El repliegue rSpido de la cuerda de

arranque (tensi6n de retroceso) le jalarb_lamano y el braze hacia el motor

ragsr_pido de Io que usted puede soltar. El resultado pueden ser huesos

rotos, fracturas, hematomas oesguinces.

21. Sise presentan situaciones que no est_n previstas en este manual,sea

cuidadoso y use elsenfido cemOn.P6ngase en contacto con Asistencia

al Cliente para solicitar ayuda y el hombre del distribuidor de servicio mSs

cercano.

33

Page 34

DESPEJE DE UN CANAL DE DESCARGA

OBSTRUiDO

EIcontactodelasmanoscon eIirnpuborrotatorioqueest&dentrodeI

canaldedescargaesla causarrlb.scorrl_ndebsionesasodadascon

lasmb.quinasquitanbve.Nuncause sumanoparalimpiareIcanal de

descarga.

ParadespejareIcanak

1. iAPAGUEELMOTOR!

2. Espere10segundosparaestarsegurode quelascucHias deI

motorhandejadoderotar.

3. Utilicesiempreunaherramientadelimpieza,nouselasmanos.

MANTENUMUENTO Y ALMAOENAMUENTO

1. Nuncaalterelos dispositivosdeseguridad.Controb

peri6dicamentequefuncionencorrectamente.Remitasealas

seccionesde mantenimientoyajustede estemanual.

2, Antes de realizar lalimpieza, reparar o revbar la mAquina,desengrane

todas las palancas de control y detenga el motor, Espere a que la barrena/

impulsor se detenga per cempleto, Desconecte el cane de la buiia y

p6ngale hacbndo masa contra el motor para evitar quese encbnda

accidentalmente,

3, Controle frecuentemente que todos los pernos y tornillos est6n bien

ajustados para comprobar que la mAquinase encuentra encondiciones

seguras de funcionambnto, AdemAs,haga una inspecci6n visual de la

mAquinapara verificar si estAdahada,

4, No cambb la configuraci6n del reguladordel motor ni acelere demasiado

el mismo, El regulador del motorcontrola la velocidad maxima segura de

funcionambnto del motor,

5, Las placas de raspado y las zapatasantideslizantes quese usan con la

mAquinaquitanbve sedesgastan y se dahan, Para proteger su seguridad,

verifique frecuentemente todos los componentes y reemplAcelos s61ocon

partes de los fabricantes de equipos originales (OEM), "iEI use de piezas

que nocumplen con las especificaciones del equipo original puede resultar

en rendimiento inadecuado ademAs de poneren rbsgo la seguridad!"

6, Revise las palancas de control peri6dbamente para verificar queengranen

y desengranen adecuadamente y ajOstelossi es necesario, Consulte la

seccidn de aiustes de este manual del operador paraobtener instrucciones,

7, Mantenga o reemplace las etiquetas de seguridad e instrucciones segOn

sea necesario,

8, Respete las normas referentes a la disposbi6n correcta y las

reglamentaciones sobre gasolina, aceite, etc, para proteger el medio

ambiente,

9, Antes de almacenar la mAquina enci6ndala unos minutos para sacar la

nbve que haya quedado en la misma y paraevitar asi que secongele la

barrena/impulsor,

10, Nunca almacene la maquina oel recipiente de combustible en un espacio

cerrade donde hayafuego, chbpas o Bz piloto come per ejemplo,

cabntadores de agua, hornos, secadores de ropa, etc,

11, Consulte sbmpre el manual del eperador para obtener instrucciones

adecuadas para el almacenambnto fuera de temporada,

12, Verifique frecuentemente la linea de combustibb, el tanque, el tapdn,y los

accesofios buscando rajaduras o p6rdidas, Reemplace de ser necesario,

13, No de arranque al motorsi no estA la bujia de encendido.

14. SegOnlaComisidndeSeguridaddeProductosparael

ConsumidordelosEstadosUnidos(CPSC)yla Agencia

de ProteccidnAmbientaldelosEstadosUnidos(EPA),este

productotieneunavidadtflmediadesiete(7)aSos660horasde

funcionamiento.AI finalizarla vidadfilmedia hagainspeccionar

anualmenteestaunidadporundistribuidordeservicioautorizado

paracerciorarsede quetodoslossistemasmecb.nicosy de

seguridadfuncionancorrectamentey notienenexcesivo

desgaste.SinoIohace,puedenproducirseaccidentes,bsiones

o lamuerte.

NO MODUFUQUE EL MOTOR

Paraevitarbsiones gravesolamuerte,nomodifiqueelmotorbajo

ningunacircunstancia.Si cambialaconfiguracidndel reguladordel

motor,_stepuededescontrolarsey operaravelocidadesinseguras.

Nuncacambielaconfiguraci6ndefb.bricadelreguladordelmotor.

AWSO REFERUDO A EMUSUONES

Losmotoresqueestancertificadosycumpbn con lasregulaciones

de emisionesfederalesEPAy deCaliforniaparaSORE(Equipos

pequeSostodoterreno)estancertificadosparaoperarcongasolina

comOnsinplomoy puedenincluirlossiguientessistemasde control

de emisiones:Modificaci6nde motor(EM),catalizadoroxidante(OC),

inyecci6ndeaire secundaria(SAI) ycatalizadordetresvias(TWC)si

estanequipadosde esamanet&

Amertiguader de chispas

Estambquinaestaequipadaconunmotorde combusti6ninternoy

nodebesetutilizadaenocercade unterrenoagrestecubiertopot

bosque,malezaso hierbaexceptoque elsistemadeescapedel

motorest_equipadoconunamortiguadordechispasquecumpla

conlasbyeslocaleso estatalescorrespondientes(encasode

existir)

Si seutilizaunamortiguadorde chispaseloperadorIodebemantener

en condicionesde usoadecuadas.Enel Estadode Californialas

medidasanteriormentemencionadassonexigidaspot ley(Articulo

4442delC6digode RecursosPOblicosde California).Esposible

queexistanbyes similaresenotrosestados.Lasbyesfederalesse

aplicanenterritoriosfederales.

Puedeconseguirelamortiguadordechispasparael silenciadora

tray,s desudistribuidorde mantenimientode motoresautorizadomb.s

cercanoo poni_ndoseencontactoconeldepartamentode servicios,

ApartadoPostal361131Cleveland,Ohio44136@019.

34

Page 35

S mbe[esdeseguridad

En esta p_igina se presentan y descr]ben los simboJos de seguridad que pueden aparecer en este producto. Lea, entJenda y cump[a todas [as

]nstrucc]ones ]ncluidas en [a m_iquina antes de [ntentar realJzar el montaje de [a un]dad y uti[Jzar[a.

i u E Bl _ E _m E E illl_

LEA EL(LOS) MANUAL(ES) DEL OPERADOR

Lea, ent]enda y cumpla todas [as ]nstrucc]ones ]nclu]das en el(los) manuales antes de ]ntentar

real]zar el montaje de [a un]dad y ut]l]zarla.

ADVERTENCIA- CUCHILLAS GIRATORIAS

MJentras [a m_iquina est.1 en fundonamJento mantenga [as manos fuera de [as aberturas de entrada y

de descarga. En el interior hay cuch]lhs g]rator]as

ADVERTENCIA- CUCHILLAS GIRATORIAS

M]entras la m_iquina est.1 en fundonam]ento mantenga [as manos fuera de [as aberturas de entrada y

de descarga. En el interior hay cuch]llas g]rator]as

ADVERTENCIA- CUCHILLAS GIRATORIAS

No ponga [as manos o los pies cerca de [as pJezas rotatorias, en [a caja de [a barrena/motor o

en el montaje de[ canal de descarga. El contacto con [as p]ezas g]ratodas puede resultar en [a

amputad6n de manos o pies.

ADVERTENCIA- OBJETOS ARROJADOS

Esta m_iquina puede [evantar y arrojar objetos [o cua[ puede causar [esiones personales graves.

ADVERTENCIA- LA GASOONA ESINFLAMABLE

Deje que el motor se enfrie por Io menos dos m]nutos antes de cargar combustible.

ADVERTENCIA- MONOXIDO DE CARBONO

Nunca encienda el motor en espados cerrados o en una zona con poca vent][ad6n. El escape de[

motor cont]ene mon6x]do de carbono, un gas ]nodoro y [etaL

ADVERTENCIA- DESCARGAS ELECTRICAS

No use el arranque el@ctrJco del motor bajo la [[uv]a

35

Page 36

NOTA:LasreferendasaHadoderechooizquierdodeHamb.quina

quitanievesedeterminansitu_.ndosedetr_.sdeHaunidaden posici6n

deoperad6n(permanedendodirectamentedetrb.sdeHamb.quina

quitanieve,mirandohaciaeHpaneHdeHamanija).

EXTRACCI6N DE LA UNIDAD DE LA CAJA

1. Cortelasesquinasdela cajade cart6ny exfiendalosladosde

maneraquequedenpianossobreeipisoQuiteydescartetodos

losinsertosdeempaque.

2. SaqueHamb.quinaquitanievedeHacaja.

3. AsegOresedevadarcompHetamenteHacajaantesdetirarHa.

Colocaci6n de la barra de control superior

1. GireHabarradecontroHsuperiorhastaHaposM6ndeoperad6n,

comeseiHustraenHaFigura1hastaquequedeen suHugar,

cuidandodenopeHHizcareHcabHeeneHproceso.

f- ,,

2. AjusteHasperiHHasdeaHetasparasujetarHabarraensuHugar.

VeaHaFigura2.

Figura2

Figura1

Recomendaciones sobre el combustible

UtiHicegasoHinaparaautom6viHes(sinpHomoobajopHomopara

minimizarHosdep6sitosenHac_.marade combusti6n)conun minimo

de 87octanes.SepuedeusargasoHinacon hastaun 10%deetanoH

o un15%deMTBE(6termetiHicoterciario-butiHico).Nuncauseuna

mezcHadeaceitey gasoHinani gasoHinasucia.Evitequeseintroduzca

suciedad,poHvoo aguaeneHdep6sitodecombustibHe.NOutiHice

gasoHinaE85.

, CarguecombustibHeen unb.reabienventiHadayconeHmotor

apagado.NofumenipermitaHHamaso chispaseneHHugardonde

secargacombustibHeo seaHmacenaHagasoHina.

, NoHHeneenexcesoeHdep6sitodecombustibHe.Despu6sde

cargarcombustibHe,asegOresedequeeHtap6ndelldep6sitoest_

biencerradoy asegurado.

, Tengacuidadodeno derramarcombustibHeaMcargarHo.EH

combustibHederramadoosusvaporesse puedenincendiar.Si se

derramacombustibHe,asegOresedequeeHb.reaest_secaantes

de arrancareHmotor.

, EviteeHcontactorepetidoo proHongadoconHapieHo HainhaHaci6n

de Hosvapores.

Carga de combustible

TengamuchocuidadoaMtrabajarcongasoHina.LagasoHinaes

sumamenteinfHamabHey susvaporespuedencausarexpHosiones. I

NuncaagreguecombustibHea Hamb.quinaeninterioresnimientraseHI

motorest,.caHienteoen funcionamiento.ApaguecigarriHHos,cigarros,I

pipasy otrasfuentesde combusti6n. J

SiempremantengaHasmanosy lospiesaiejadosdeHaspiezas

m6viiesdeiequipo.Noutiiicefiuidoscomprimidosparaarrancar.Los

vaporessoninfiamabies.

36

Page 37