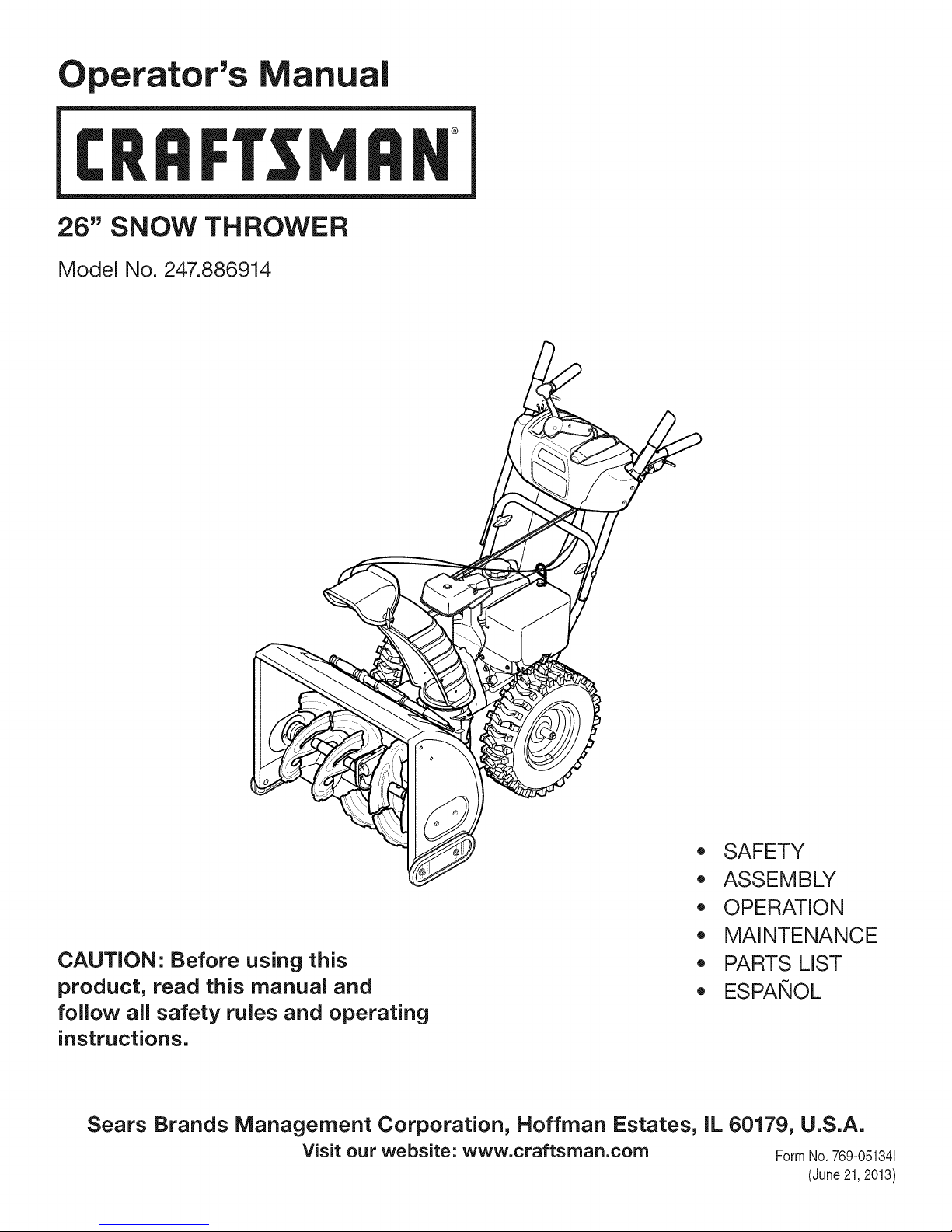

Page 1

Operator's Manual

CRRFr MRN

26" SNOW THROWER

Model No. 247.886914

CAUTION" Before using this

product, read this manual and

follow all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FormNo. 769-051341

,, SAFETY

o ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

(June21,2013)

Page 2

WarrantyStatement.............................. Page2

SafeOperationPractices...................... Pages3-6

Assembly.................................... Pages8-13

Operation.................................. Pages14-17

Service&Maintenance....................... Pages18-23

CRAFTSMANTWOYEARFULLWARRANTY

FORTWOYEARSfromthedateofpurchase,thisproductiswarrantedagainstanydefectsinmaterialorworkmanship.Defectiveproductwillreceivefree

repairorfreereplacementif repairisunavailable.

ADDITIONALLIFETIMELIMITEDWARRANTYon UPPERand LOWERCHUTE

FORASLONGASITISUSEDbytheoriginalownerafterthesecondyearfromthedateofpurchase,theupperandlowerchuteofthissnowthrowerare

warrantedagainstanydefectsinmaterialorworkmanshipasverifiedbyaSearsauthorizedserviceprovider.Withproofofpurchase,youwill receiveanew

chutefreeofcharge.Youareresponsibleforthelaborcostofinstallationandanycostincurredtoverifythedefect.

Forwarrantycoveragedetailstoobtainrepairorreplacement,visitthewebsite:www.craftsman.com

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.WarrantycoveragedoesNOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedto augers,augerpaddles,driftcutters,skid

shoes,shaveplate,shearpins,sparkplug,aircleaner,belts,andoilfilter.

Off-SeasonStorage............................. Page24

Troubleshooting............................ Page26-27

PartsList................................... Pages28-47

RepairProtectionAgreement................... Page50

Espa_ol......................................... Page51

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementorrepaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireorwheelreplacementorrepairresultingfromnormalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbutnotlimitedto damagecausedbyover-speedingtheengine,orfromimpactingobjectsthat

bendtheframe,augershaft,etc.

• Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproperstorage,failureto

usethepropergradeandamountofengineoil,orfailuretomaintaintheequipmentaccordingtotheinstructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedtobecontaminatedoroxidized(stale).Ingeneral,fuelshouldbeusedwithin30days

ofitspurchasedate.

• Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Thiswarrantyisvoidifthisproductiseverusedwhileprovidingcommercialservicesorifrentedto anotherperson.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

SearsBrandsManagementCorporation,NoffmanEstates,IL60179

Engine Oil: 5W-30

Fuel: Unleaded Gasoline

Engine: MTD

Model Number

Serial Number

Date of Purchase

Record the model number, serial number,

and date of purchase above.

© Sears Brands, LLC 2

Page 3

Thissymbolpointsout importantsafetyinstructionswhich, ifnot

followed,couldendangerthe personalsafetyand/orproperty of

yourselfandothers.Readandfollow all instructionsinthis manual

beforeattempting to operatethis machine.Failureto complywith these

instructionsmayresultinpersonalinjury.Whenyouseethis symbol, HEED

ITSWARNING!

Thismachinewasbuilt to beoperatedaccordingtothesafeoperation

practicesinthismanual.Aswith anytypeof powerequipment,

carelessnessorerroronthe part ofthe operatorcanresultinseriousinjury.

Thismachineiscapableof amputating fingers, hands,toesandfeet and

throwingdebris.Failuretoobservethefollowing safety instructionscould

resultinseriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someofits constituents,andcertainvehiclecomponents

containor emit chemicalsknowntoStateof Californiato causecancerand

birth defectsorother reproductiveharm.

TRAINING

Read,understand,andfollowall instructionsonthemachineandinthe

manual(s)beforeattemptingtoassembleandoperate.Failuretodosocan

resultinseriousinjurytotheoperatorand/orbystanders.Keepthis manual

inasafeplaceforfutureandregularreferenceandfororderingreplacement

parts.

Befamiliarwith allcontrolsandtheirproperoperation.Knowhowto stop

themachineanddisengagethemquickly.

Neverallowchildrenunder14yearsof agetooperatethismachine.Children

14andovershouldreadandunderstandtheinstructionsandsafeoperation

practicesinthismanualandonthemachineandbetrainedandsupervised

byanadult.

Neverallowadultsto operatethismachinewithoutproperinstruction.

Thrownobjectscancauseseriouspersonalinjury.Planyoursnow-throwing

patterntoavoiddischargeofmaterialtowardroads,bystandersandthelike.

Keepbystanders,petsandchildrenatleast75feetfromthemachinewhileit

isin operation.Stopmachineif anyoneentersthearea.

Exercisecautiontoavoidslippingorfalling,especiallywhenoperatingin

reverse.

PREPARATION

Thoroughlyinspecttheareawheretheequipmentistobeused.Removeall

doormats,newspapers,sleds,boards,wiresandotherforeignobjects,which

couldbetrippedoverorthrownbytheauger/impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationandwhile

performinganadjustmentor repairto protectyoureyes.Thrownobjects

whichricochetcancauseseriousinjurytotheeyes.

Donotoperatewithout wearingadequatewinteroutergarments.Donot

wearjewelry,longscarvesorotherlooseclothing,whichcouldbecome

entangledinmovingparts.Wearfootwearwhichwill improvefootingon

slipperysurfaces.

Useagroundedthree-wireextensioncordandreceptacleforallmachines

with electricstartengines.

Your Responsibility--Restrict theuseofthis powermachineto

personswhoread,understandandfollow the warningsand instructionsin

thismanualandonthe machine.

SAVETHESEINSTRUCTIONS!

Disengageallcontrolleversbeforestartingtheengine.

Adjustcollectorhousingheighttocleargravelorcrushedrocksurfaces.

Neverattempttomakeanyadjustmentswhileengineisrunning,except

wherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjusttooutdoortemperaturebeforestartingto

clearsnow.

Safe Handling of Gasoline:

Toavoidpersonalinjuryor property damageuseextremecareinhandling

gasoline.Gasolineisextremely flammableandthevaporsareexplosive.

Seriouspersonalinjurycanoccurwhengasolineisspilledon yourselforyour

clotheswhichcanignite.Washyourskinandchangeclothesimmediately.

Useonlyanapprovedgasolinecontainer.

Neverfill containersinsideavehicleoronatruckortrailerbedwitha plastic

liner.Alwaysplacecontainersonthegroundawayfromyourvehiclebefore

filling.

Whenpractical,removegas-poweredequipmentfromthetruckor

trailerandrefuelitontheground.Ifthisis notpossible,thenrefuelsuch

equipmentonatrailerwith aportablecontainer,ratherthanfromagasoline

dispensernozzle.

Keepthenozzleincontactwith therimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Donotusea nozzlelock-opendevice.

Extinguishallcigarettes,cigars,pipesandothersourcesofignition.

Neverfuelmachineindoors.

Neverremovegascaporaddfuelwhiletheengineishotorrunning.Allow

enginetocoolatleasttwominutesbeforerefueling.

Neveroverfill fueltank.Filltankto nomorethan1/2inchbelowbottomof

fillernecktoallowspacefor fuelexpansion.

Replacegasolinecapandtightensecurely.

Ifgasolineisspilled,wipeit offthe engineandequipment.Moveunitto

anotherarea.Wait.5minutesbeforestartingtheengine.

Page 4

Toreducefirehazards,keepmachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillageandremoveanyfuelsoakeddebris.

Neverstorethemachineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlightasonawaterheater,spaceheater,furnace,clothes

dryerorothergasappliances.

OPERATION

Donotputhandsorfeetnearrotatingparts,intheauger/impellerhousing

orchuteassembly.Contactwith therotatingpartscanamputatehandsand

feet.

Theauger/impellercontrolleverisasafetydevice.Neverbypassits

operation.Doingsomakesthemachineunsafeandmaycausepersonal

injury.

Thecontrolleversmustoperateeasilyin bothdirectionsandautomatically

returntothedisengagedpositionwhenreleased.

Neveroperatewith amissingordamagedchuteassembly.Keepallsafety

devicesinplaceandworking.

Neverrunanengineindoorsor inapoorlyventilatedarea.Engineexhaust

containscarbonmonoxide,anodorlessanddeadlygas.

Donotoperatemachinewhileundertheinfluenceofalcoholordrugs.

Mufflerandenginebecomehotandcancauseaburn.Donottouch.Keep

childrenaway.

Exerciseextremecautionwhenoperatingonorcrossinggravelsurfaces.Stay

alertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingonslopes.Do

notoperateonsteepslopes.

Planyoursnow-throwingpatterntoavoiddischargetowardswindows,

walls,carsetc.Thus,avoidingpossiblepropertydamageorpersonalinjury

causedbyaricochet.

Neverdirectdischargeatchildren,bystandersandpetsor allowanyonein

frontofthemachine.

Donotoverloadmachinecapacitybyattemptingtoclearsnowattoofastof

arate.

Neveroperatethismachinewithoutgoodvisibilityorlight.Alwaysbesureof

yourfootingandkeepafirmholdonthehandles.Walk,neverrun.

Disengagepowertotheauger/impellerwhentransportingornotin use.

Neveroperatemachineathightransportspeedsonslipperysurfaces.Look

downandbehindandusecarewhenbackingup.

Ifthemachineshouldstartto vibrateabnormally,stoptheengine,

disconnectthesparkplugwireandgrounditagainsttheengine.Inspect

thoroughlyfordamage.Repairanydamagebeforestartingandoperating.

Disengageallcontrolleversandstopenginebeforeyouleavetheoperating

position(behindthehandles).Waituntil theauger/impellercomesto

acompletestopbeforeuncloggingthechuteassembly,makingany

adjustments,orinspections.

Neverputyourhandin thedischargeorcollectoropenings.Donotunclog

chuteassemblywhileengineisrunning.Shutoff engineandremainbehind

handlesuntilallmovingpartshavestoppedbeforeunclogging.

Useonlyattachmentsandaccessoriesapprovedbythemanufacturer(e.g.

wheelweights,tirechains,cabsetc.).

Whenstartingengine,pull cordslowlyuntil resistanceisfelt,thenpull

rapidly.Rapidretractionofstartercord(kickback)will pullhandandarm

towardenginefasterthanyoucanletgo.Brokenbones,fractures,bruisesor

sprainscouldresult.

Ifsituationsoccurwhicharenotcoveredinthismanual,usecareandgood

judgment.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwith therotatingimpellerinsidethedischargechuteisthemost

commoncauseofinjuryassociatedwith snowthrowers.Neveruseyourhandto

cleanoutthedischargechute.

Toclearthechute:

a. SHUTTHEENGINEOFF!

b. Wait10secondsto besuretheimpellerbladeshavestopped

rotating.

c. Alwaysuseaclean-outtool,notyourhands.

MAINTENANCE & STORAGE

Nevertamperwith safetydevices.Checktheirproperoperationregularly.

Referto themaintenanceandadjustmentsectionsof thismanual.

Beforecleaning,repairing,orinspectingmachinedisengageallcontrol

leversandstoptheengine.Waituntiltheauger/impellercometoacomplete

stop.Disconnectthesparkplugwireandgroundagainsttheengineto

preventunintendedstarting.

Checkboltsandscrewsforpropertightnessatfrequentintervalsto keepthe

machineinsafeworkingcondition.Also,visuallyinspectmachineforany

damage.

Donotchangetheenginegovernorsettingorover-speedtheengine.The

governorcontrolsthemaximumsafeoperatingspeedof theengine.

Snowthrowershaveplatesandskidshoesaresubjecttowearanddamage.

Foryoursafetyprotection,frequentlycheckallcomponentsandreplace

with originalequipmentmanufacturer's(OEM)partsonlyaslistedinthe

Partspagesofthisoperator'smanual.Useofpartswhichdonotmeetthe

originalequipmentspecificationsmayleadtoimproperperformanceand

compromisesafety!

Checkcontrolleversperiodicallyto verifytheyengageanddisengage

properlyandadjust,if necessary.Referto theadjustmentsectioninthis

operator'smanualforinstructions.

Maintainorreplacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsandregulationsforgas,oil,etc.toprotectthe

environment.

Priortostoring,runmachineafewminutestoclearsnowfrommachineand

preventfreezeupof auger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlight suchasawaterheater,furnace,clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionsonoff-season

storage.

4

Page 5

Checkfuelline,tank,cap,andfittingsfrequentlyfor cracksor leaks.Replace

if necessary.

Donotcrankenginewith sparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)andthe

U.S.EnvironmentalProtectionAgency(EPA),thisproducthasanAverage

Useful Lifeof seven(7)years,or60hoursofoperation.Attheendof

theAverage Useful Lifehavethemachineinspectedannuallybyan

authorizedservicedealerto ensurethat allmechanicalandsafetysystems

areworkingproperlyandnotwornexcessively.Failuretodosocanresultin

accidents,injuriesordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donotmodifyengineinanyway. Tampering

with the governorsetting canleadto arunawayengineandcauseit to

operateat unsafespeeds.Nevertamperwith factorysetting ofengine

governor.

NOTICE REGARDING EMiSSiONS

Engineswhichare certifiedto complywith CaliforniaandfederalEPA

emissionregulationsfor SORE(SmallOff RoadEquipment)arecertified

tooperateonregularunleadedgasoline,and mayincludethefollowing

emissioncontrolsystems:EngineModification (EM),OxidizingCatalyst(0C),

SecondaryAirinjection(SAI)andThreeWayCatalyst(TWC)ifsoequipped.

SPARK ARRESTOR

e

Thismachineisequippedwith aninternalcombustionengineandshould

not beusedonornearanyunimprovedforest-covered,brushcoveredor

grass-coveredland unlesstheengine'sexhaustsystemisequippedwith a

sparkarrestormeetingapplicablelocalorstatelaws(if any).

Ira sparkarrestorisused,it shouldbemaintainedin effective working order

bythe operator.IntheStateof Californiathe aboveisrequiredbylaw (Section

4442ofthe CaliforniaPublicResourcesCode).Otherstatesmayhavesimilar

laws.Federallawsapplyonfederal lands.

Asparkarrestorfor the muffler is availablethroughyour nearestSearsParts

andRepairServiceCenter.

Page 6

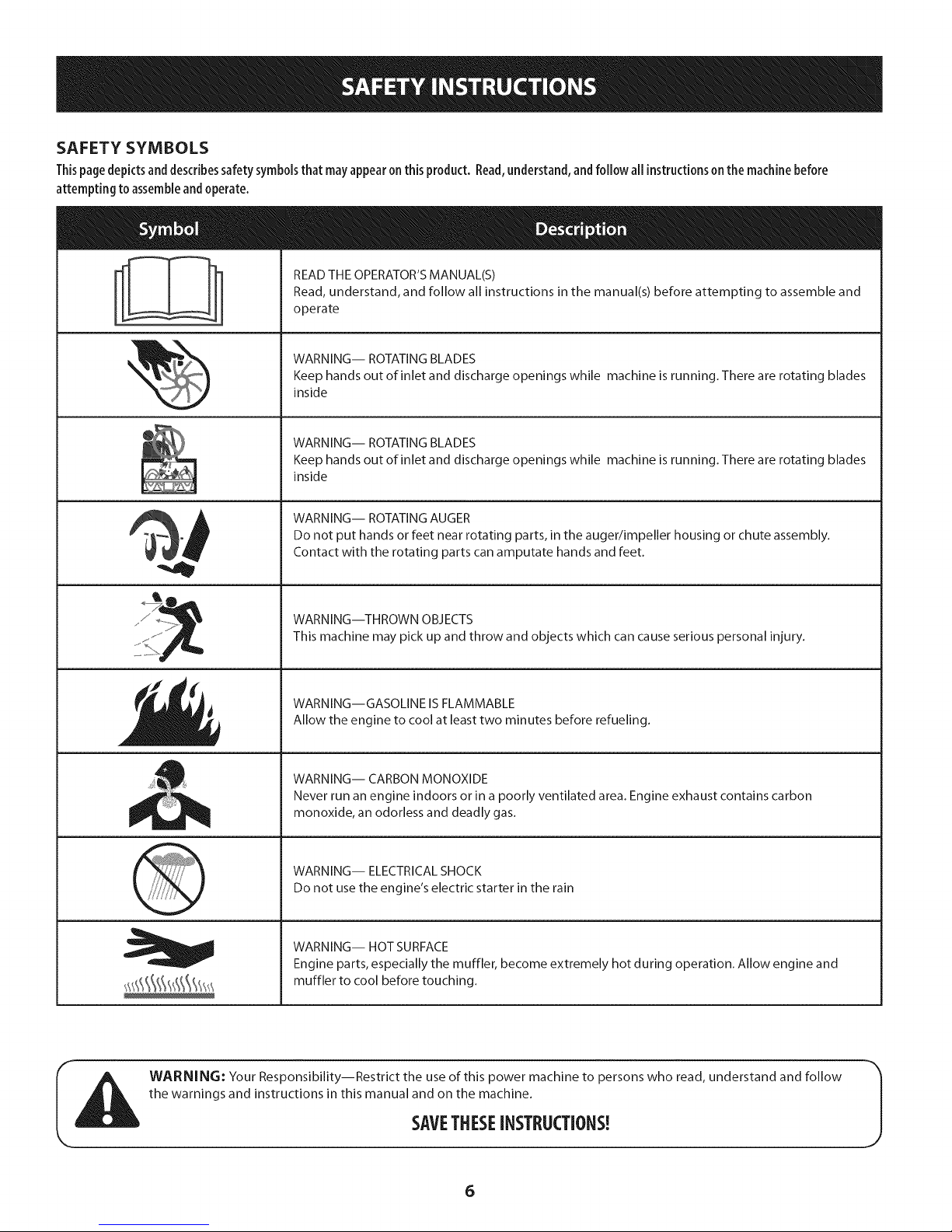

SAFETY SYMBOLS

Thispage depicts and describes safety symbols that may appear on this product. Read,understand, and follow all instructions on the machine before

attempting to assemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

WARNING: Your Responsibility--Restrict the use of this power machine to persons who read, understand and follow

the warnings and instructions in this manual and on the machine.

SAVETHESEiNSTRUCTIONS!

6

Page 7

This page left intentionallyblank.

7

Page 8

NOTE:Referencestorightorleftsideofthesnowthroweraredeterminedfrom

behindtheunitin theoperatingposition(standingdirectlybehindthesnow

thrower,facingthehandlepanel).

Removing FromCarton

1. Cutthecornersofthecartonandlaythesidesflat ontheground.Remove

anddiscardallpackinginserts.

2. Movethesnowthroweroutofthecarton.

3. Makecertainthecartonhasbeencompletelyemptiedbeforediscardingit.

Assembly

Observethelowerrearareaof thesnowthrowerto besurebothcablesare

alignedwith rollerguidesbeforepivotingthehandleupward.

a. Placetheshift [everintheF6position.

b. Pullupandbackonupperhandleasshownin Figure1.Asyouare

raisingthehandleupward,makesurethatbothendsofthecenter

cablearepositionedproperlyinthebrackets.Alignupperhandle

withthelowerhandle.

c. Tightenhandknobssecuringupperhandletolowerhandle.Remove

anddiscardanyrubberbands,if present.Theyarefor packaging

purposesonly.

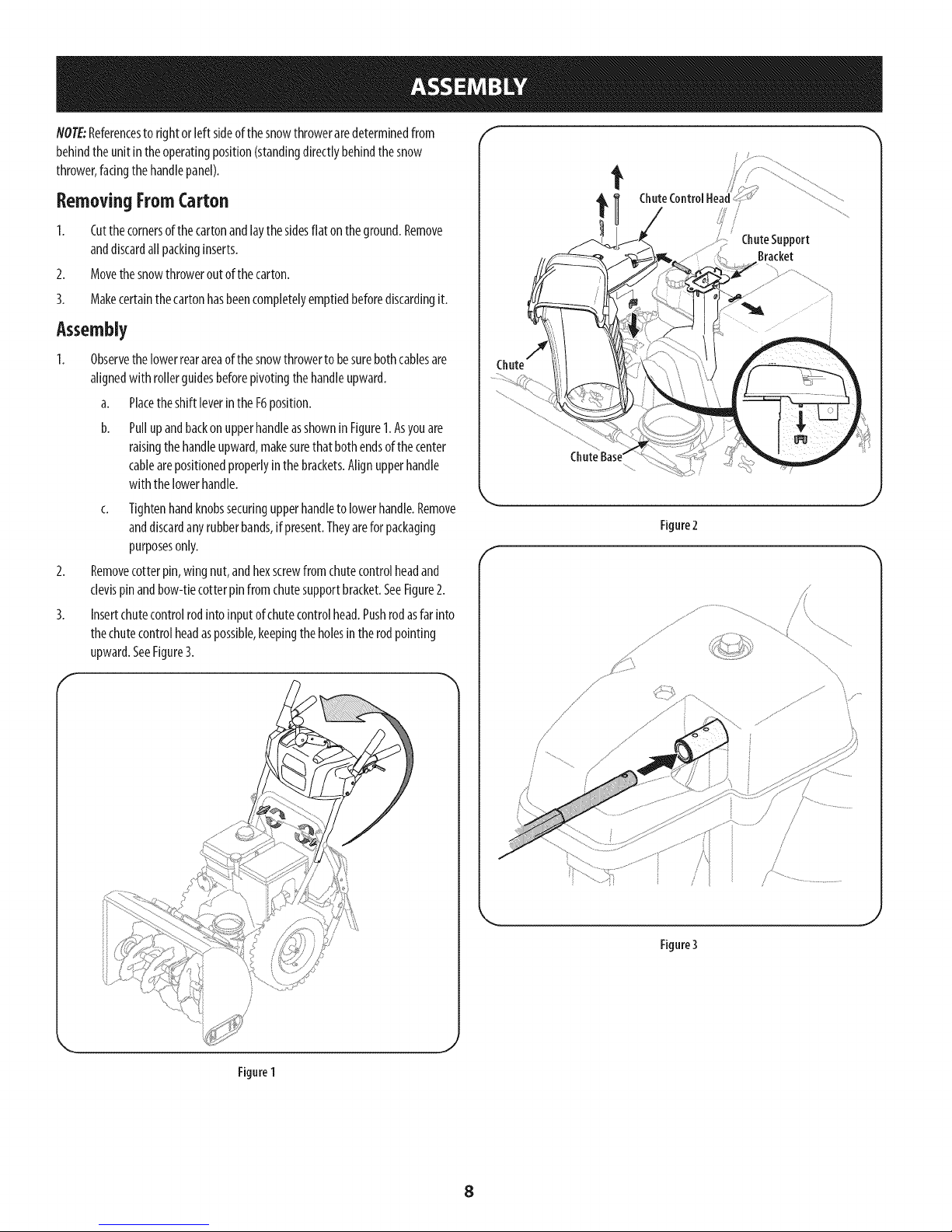

Removecotterpin,wingnut,andhexscrewfromchutecontrolheadand

clevispinandbow-tiecotterpinfromchutesupportbracket.SeeFigure2.

Insertchutecontrolrodintoinputof chutecontrolhead.Pushrodasfarinto

thechutecontrolheadaspossible,keepingtheholesin therodpointing

upward.SeeFigure3.

f

ChuteSupport

Bracket

Chute

.J

Figure2

f

/ .....

Figure1

j

Rgure3

J

8

Page 9

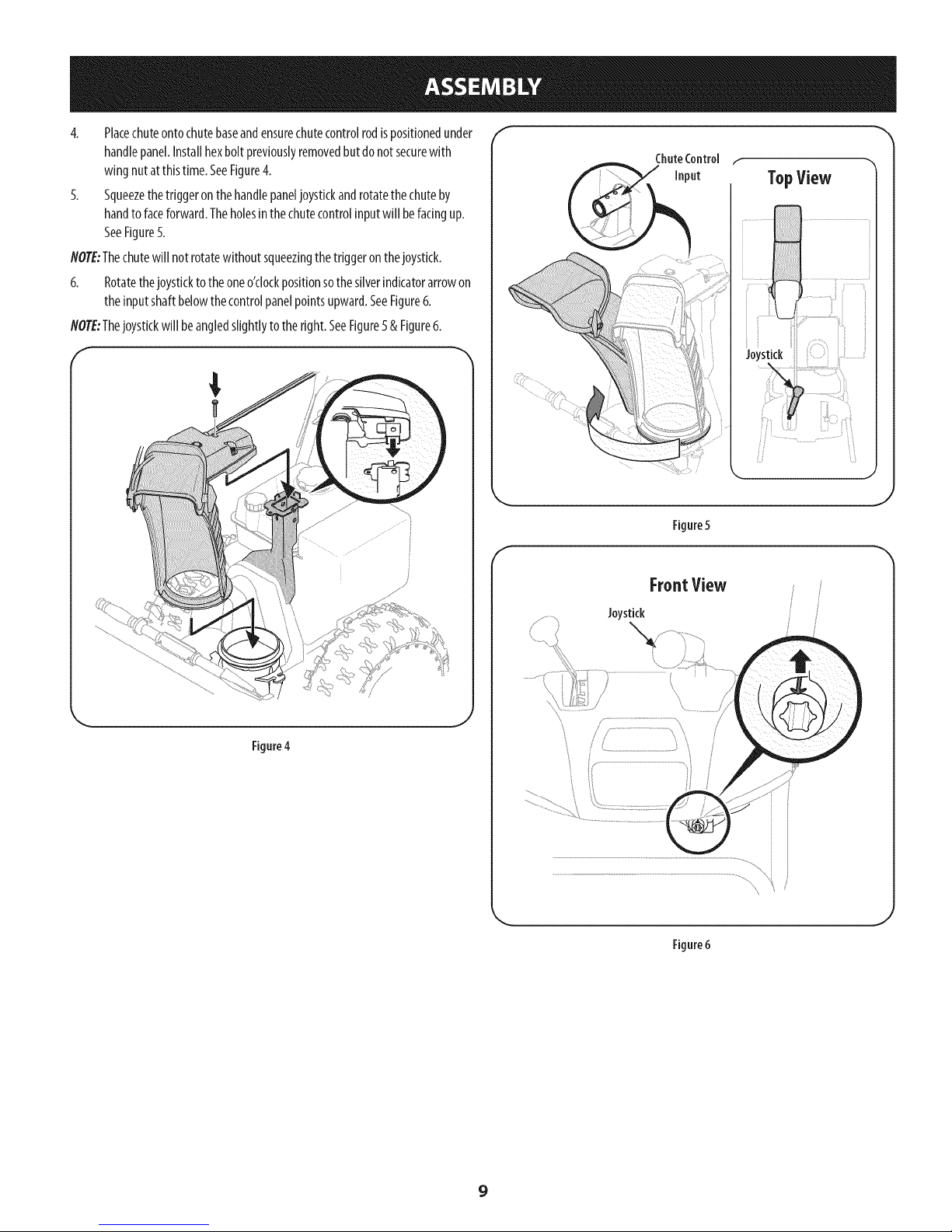

4. Placechuteontochutebaseandensurechutecontrolrodispositionedunder

handlepanel.Installhexboltpreviouslyremovedbutdonotsecurewith

wingnutat thistime.SeeFigure4.

5. Squeezethetriggeronthehandlepaneljoystickandrotatethechuteby

handtofaceforward.Theholesinthechutecontrolinputwillbefacingup.

SeeFigure5.

NOTE:Thechutewillnot rotatewithoutsqueezingthetriggeronthejoystick.

6. Rotatethejoysticktotheoneo'clockpositionsothesliverindicatorarrowon

theinputshaftbelowthecontrolpanelpointsupward.SeeFigure6.

NOTE:Thejoystickwill beangledslightlytotheright.SeeFigure5& Figure6.

f

TopView

_J

Figure5

f

FrontView

//f "_

Joystick

\

Figure6

9

Page 10

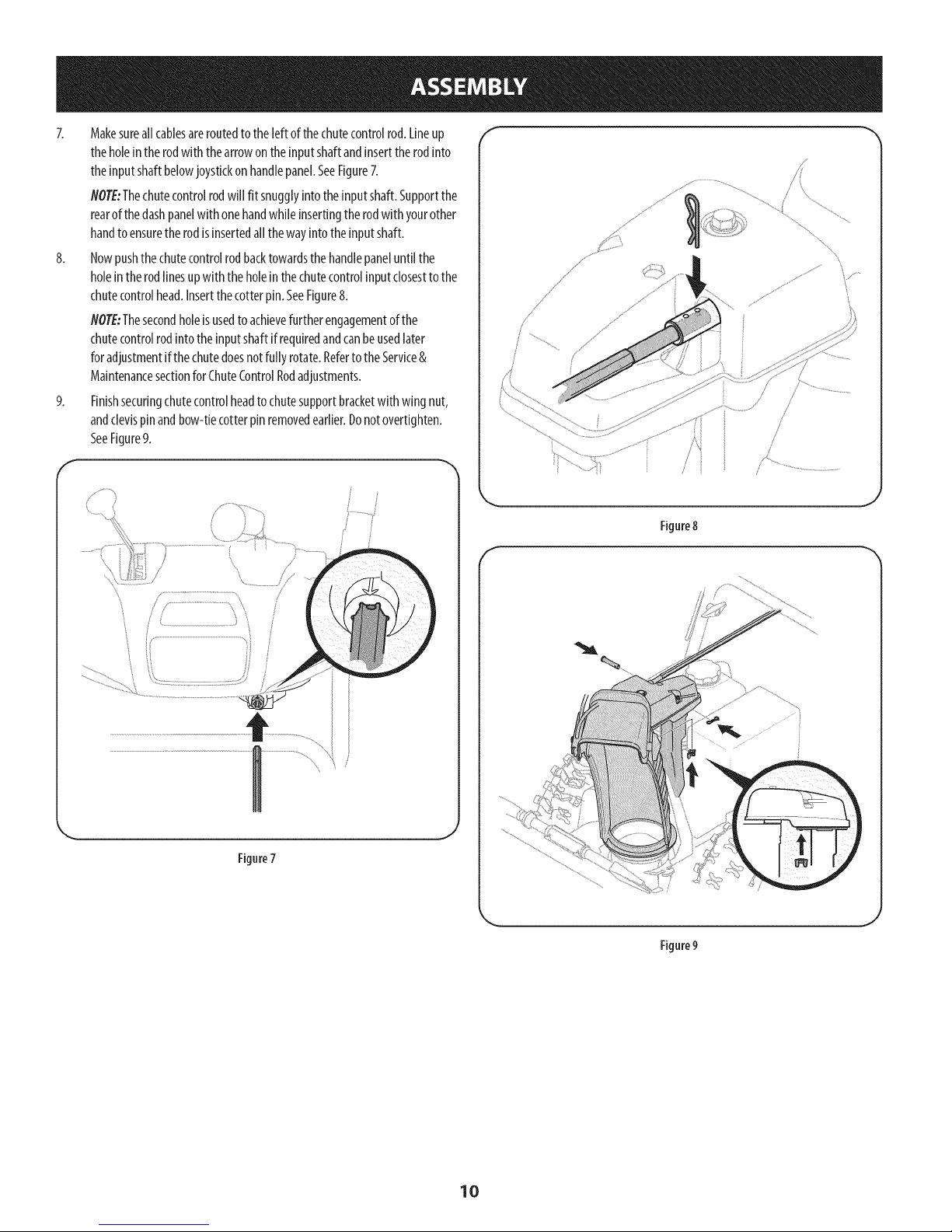

7. Makesureallcablesareroutedtotheleft ofthechutecontrolrod.Lineup

theholeintherodwiththearrowontheinputshaftandinserttherodinto

theinputshaftbelowjoystickonhandlepanel.SeeFigure7.

NOTE:Thechutecontrolrodwill fit snugglyintotheinputshaft.Supportthe

rearofthedashpanelwithonehandwhileinsertingtherodwith yourother

handtoensuretherodisinsertedallthewayintotheinputshaft.

8. Nowpushthechutecontrolrodbacktowardsthehandlepaneluntilthe

holeintherodlinesupwith theholeinthechutecontrolinputclosesttothe

chutecontrolhead.Insertthecotterpin.SeeFigure8.

NOTE:Thesecondholeisusedtoachievefurtherengagementof the

chutecontrolrodintotheinputshaftifrequiredandcanbeusedlater

foradjustmentifthechutedoesnotfully rotate.RefertotheService&

Maintenancesectionfor ChuteControlRodadjustments.

9. Finishsecuringchutecontrolheadto chutesupportbracketwith wingnut,

andclevispinandbow-tiecotterpinremovedearlier.Donotovertighten.

SeeFigure9.

f

f

/ /

Figure8

f

Figure7

\

Figure9

10

Page 11

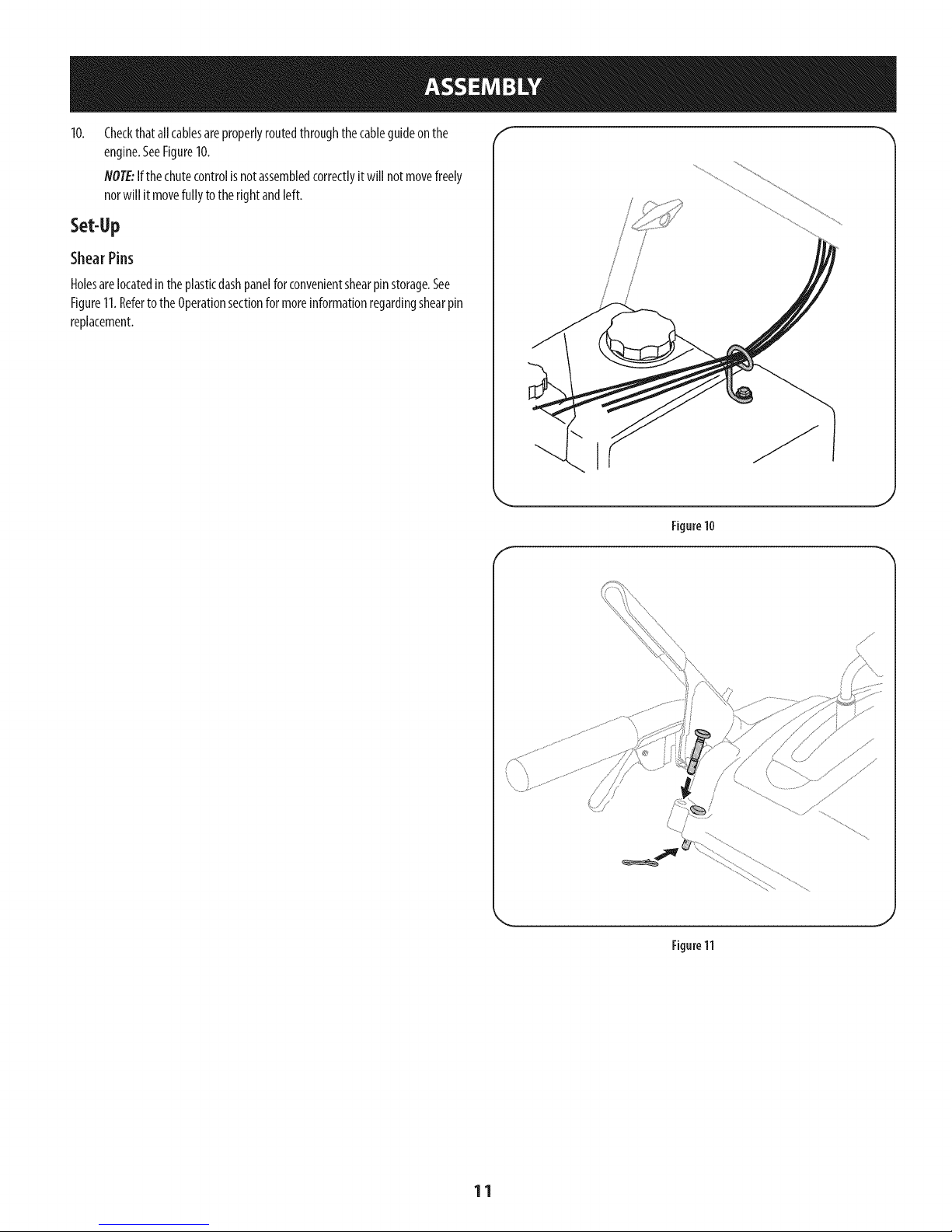

Checkthatallcablesareproperlyroutedthroughthecableguideonthe

engine.SeeFigure10.

NOTE:Ifthechutecontrolisnotassembledcorrectlyitwill notmovefreely

norwill it movefully totherightandleft.

Set-Up

ShearPins

Holesarelocatedintheplasticdashpanelforconvenientshearpinstorage.See

Figure11.RefertotheOperationsectionfor moreinformationregardingshearpin

replacement.

I

J

Figure10

f

J

Figure11

11

Page 12

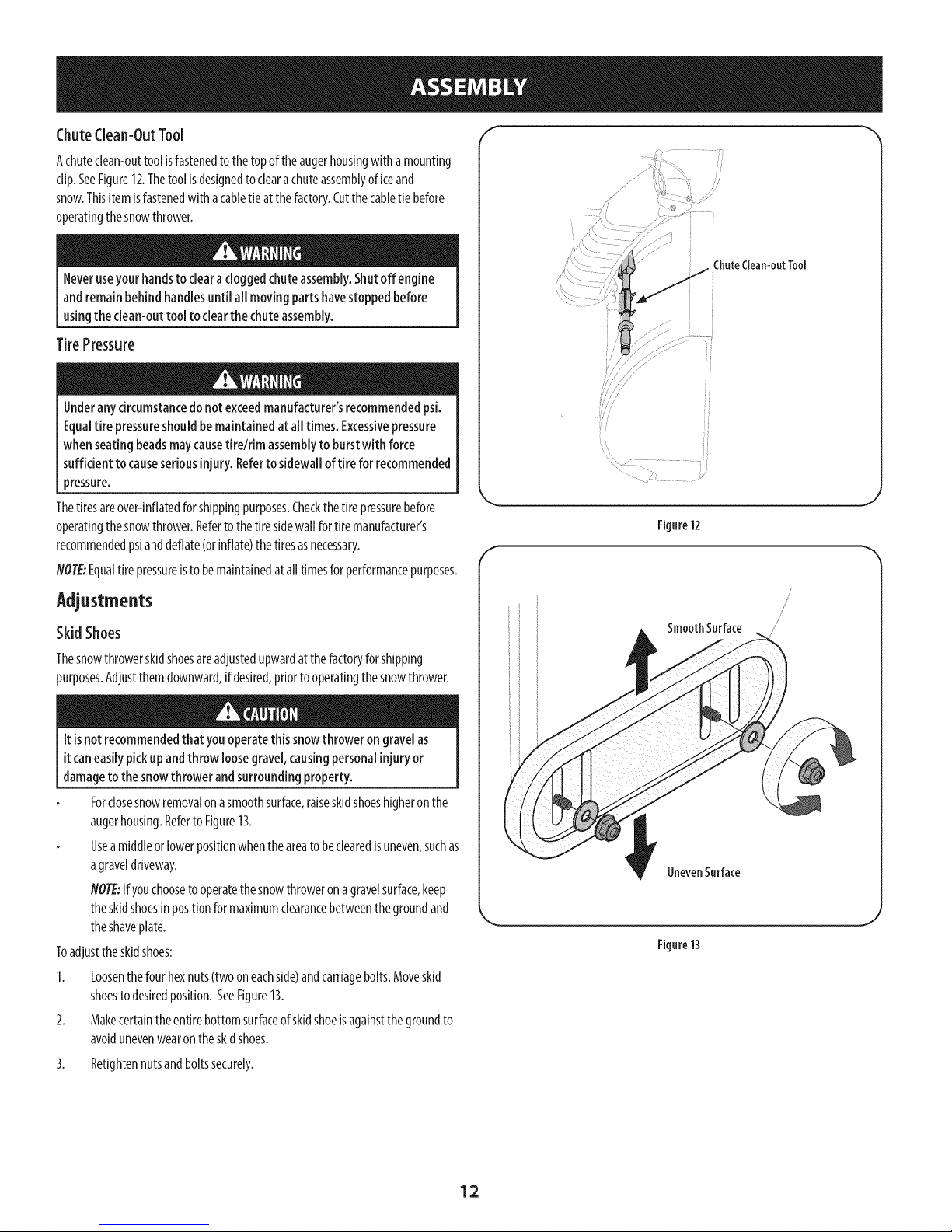

ChuteClean-OutTool f _

Achuteclean-outtoolisfastenedtothetopoftheaugerhousingwithamounting

clip.SeeFigure12.Thetoolisdesignedtoclearachuteassemblyoficeand

snow.Thisitemisfastenedwith acabletieat thefactory.Cutthecabletiebefore

operatingthesnowthrower.

ChuteClean-outTool

Neveruseyour handstoclearacloggedchuteassembly.Shutoff engine

andremainbehindhandlesuntil all movingpartshavestoppedbefore

usingthe clean-outtool to clearthe chuteassembly.

TirePressure

Underanycircumstancedo notexceedmanufacturer'srecommendedpsi.

Equaltire pressureshouldbemaintainedat alltimes. Excessivepressure

when seatingbeadsmaycausetireldm assemblyto burstwith force

sufficient tocauseseriousinjury. Refertosidewallof tire for recommended

pressure.

Thetiresareover-inflatedforshippingpurposes.Checkthetire pressurebefore

operatingthesnowthrower.Refertothetiresidewallfor tiremanufacturer's

recommendedpsianddeflate(orinflate)thetiresasnecessary.

NOTE:Equaltirepressureisto bemaintainedatalltimesforperformancepurposes.

Adjustments

SkidShoes

Thesnowthrowerskidshoesareadjustedupwardatthefactoryforshipping

purposes.Adjustthemdownward,ifdesired,priortooperatingthesnowthrower.

Itis notrecommendedthat youoperatethissnowthroweron gravelas

itcaneasilypickupandthrow loosegravel,causingpersonalinjuryor

damageto thesnowthrower andsurroundingproperty.

Forclosesnowremovalonasmoothsurface,raiseskidshoeshigheronthe

augerhousing.Referto Figure13.

Useamiddleorlowerpositionwhentheareatobeclearedisuneven,suchas

agraveldriveway.

NOTE:Ifyouchoosetooperatethesnowthroweronagravelsurface,keep

theskidshoesinpositionformaximumclearancebetweenthegroundand

theshaveplate.

Toadjusttheskidshoes:

1. Loosenthefourhexnuts(twooneachside)andcarriagebolts.Moveskid

shoestodesiredposition.SeeFigure13.

2. Makecertaintheentirebottomsurfaceofskidshoeisagainstthegroundto

avoidunevenwearontheskidshoes.

3. Retightennutsandboltssecurely.

///

.J

Figure12

f

SmoothSurface

UnevenSurface

\

Figure13

12

Page 13

AugerControl F

Priortooperatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performalladjustmentstoverifyyoursnowthroweris

operatingsafelyandproperly.

Checktheadjustmentoftheaugercontrolasfollows:

1. Theaugercontrolislocatedontheleft handle.SeeFigure14inset.When

theaugercontrolisreleasedandinthedisengaged"up"position,thecable

shouldhaveverylittle slack.ItshouldNOTbetight.

2. Ina well-ventilatedarea,startthesnowthrowerengine.Referto Starting

theEngineintheOperationsection.

3. Whilestandingintheoperator'sposition(behindthesnowthrower),engage

theauger.

4. Allowtheaugerto remainengagedforapproximatelyten(10)seconds

beforereleasingtheaugercontrol.Repeatthisseveraltimes.

5. Withtheaugercontrolinthedisengaged"up" position,walkto thefrontof

themachine.

6.

Toreadjustthecontrolcable,loosentheupperhexboltontheaugercable

bracket.SeeFigure14.

Positionthebracketupwardtoprovidemoreslack(ordownwardtoincrease

cabletension).

8. Retightentheupperhexbolt.

9. Repeatsteps2-6aboveto verifyproperadjustmenthasbeenachieved.

10. Confirmthat theaugerhascompletelystoppedrotatingandshowsNOsigns

ofmotion.IftheaugershowsANYsignsofrotating,immediatelyreturnto

theoperator'spositionandshutofftheengine.WaitforALLmovingpartsto

stopbeforeadjustingtheaugercontrol.

AugerControl

J

/

f

J

Figure14

13

Page 14

Chute Assembly

Clean Out

Tool

Drive Control

Gas Cap

Shift Lever

J

Four=WayChute ControP (Joystick)

J

Auger Control

\

MUfti\er i_e;:_lleStarte_

Primer

Key

Throttle

Control

Wheel Steering Control

IF ELLEVEL'

Choke

Control

/ Button

Oil Drain Electric Starter Outlet

Electric Start

Figure15

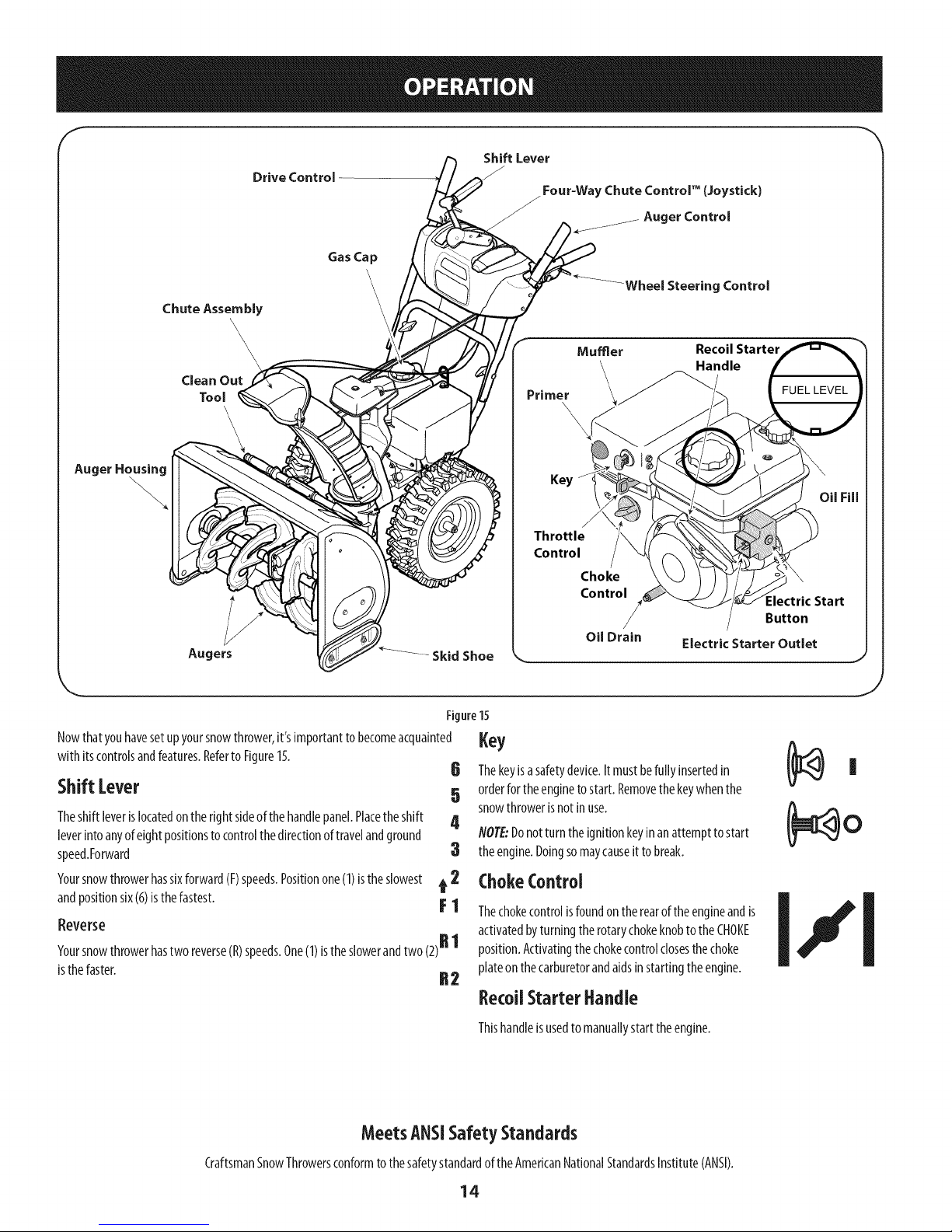

Nowthatyouhavesetupyoursnowthrower,it'simportanttobecomeacquainted

with itscontrolsandfeatures.Referto Figure15.

Shift [ever

Theshift leverislocatedontheright sideofthehandlepanel.Placetheshift

leverintoanyofeightpositionstocontrolthedirectionoftravelandground

speed.Forward

Yoursnowthrowerhassixforward(F)speeds.Positionone(1)isthe slowest

andpositionsix(6)isthefastest.

t 2 ChokeControl

Reverse

Yoursnowthrowerhastwo reverse(R)speeds.One(1)istheslowerandtwo(2)R 1

isthefaster. R2

MeetsANSiSafetyStandards

CraftsmanSnowThrowersconformtothesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

,ey6 Thekeyisasafetydevice.It mustbefully insertedin Ii

5 orderfortheenginetostart.Removethekeywhenthe

4 NOTE:Donotturntheignitionkeyinanattempttostart

snowthrowerisnotinuse. (_ O

:3 theengine.Doingsomaycauseitto break.

activated byturning the rotarychokeknobto the CHOKE

position.Activatingthe choke controlclosesthe choke

plateon the carburetorandaids instarting the engine.

RecoUStarterHandle

Thishandleisusedtomanuallystarttheengine.

14

Page 15

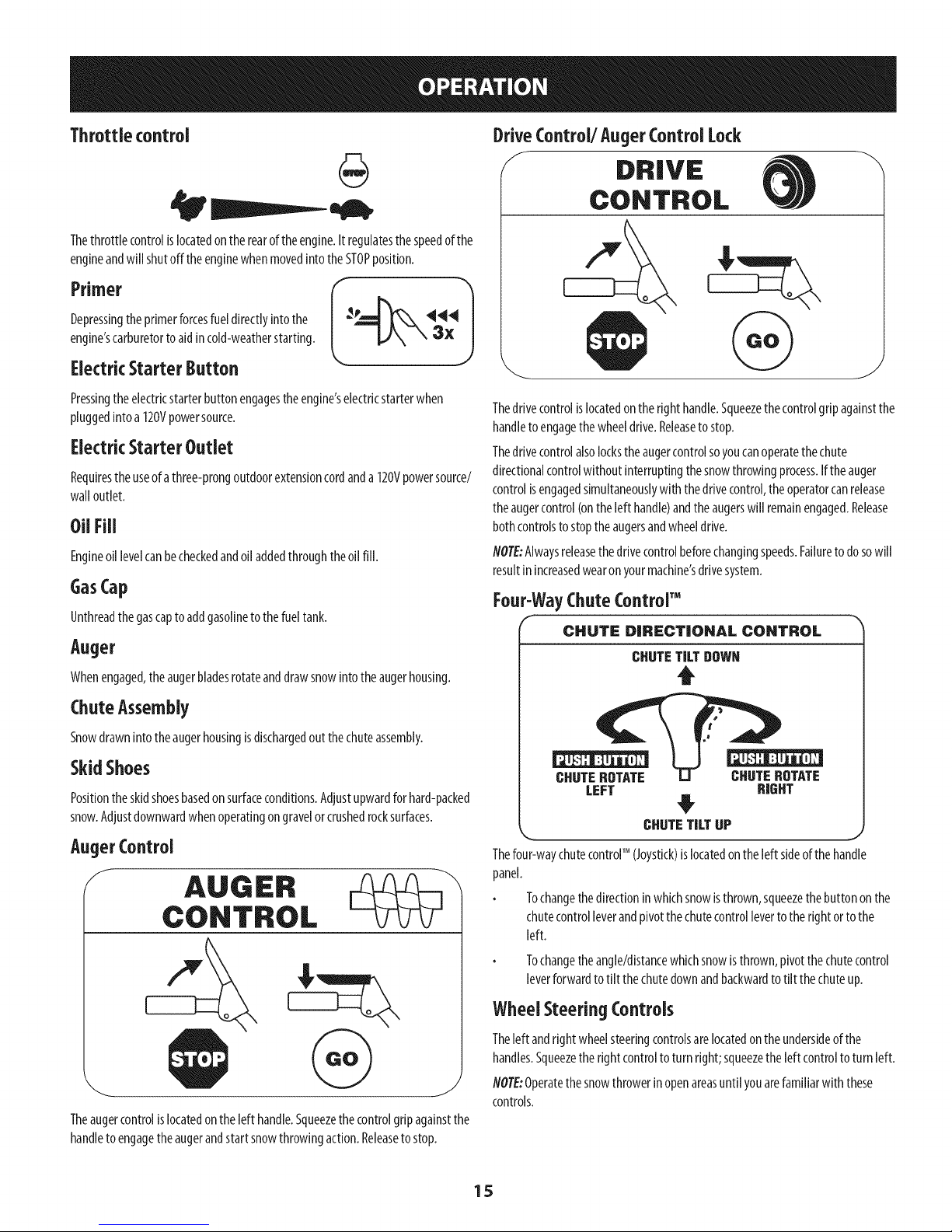

Throttlecontrol

Thethrottlecontrolislocatedontherearoftheengine.It regulatesthespeedofthe

engineandwillshutoffthe enginewhenmovedintotheSTOPposition.

Primer

Depressingtheprimerforcesfueldirectlyintothe

engine'scarburetortoaidincold-weatherstarting.

ElectricStarter Button

DriveControl/Auger Control Lock

/ DRIVE

CONTROL

Pressingtheelectricstarterbuttonengagestheengine'selectricstarterwhen

pluggedintoa 120Vpowersource.

ElectricStarter Outlet

Requirestheuseofathree-prongoutdoorextensioncordanda 120Vpowersource/

walloutlet.

OilFill

Engineoillevelcanbecheckedandoiladdedthroughtheoil fill.

GasCap

Unthreadthegascaptoaddgasolinetothefueltank.

Auger

Whenengaged,theaugerbladesrotateanddrawsnowintotheaugerhousing.

ChuteAssembly

Snowdrawnintotheaugerhousingisdischargedoutthechuteassembly.

SkidShoes

Positiontheskidshoesbasedonsurfaceconditions.Adjustupwardforhard-packed

snow.Adjustdownwardwhenoperatingongravelorcrushedrocksurfaces.

AugerControl

f

Thedrivecontrolislocatedontheright handle.Squeezethecontrolgripagainstthe

handletoengagethewheeldrive.Releasetostop.

Thedrivecontrolalsolockstheaugercontrolsoyoucanoperatethechute

directionalcontrolwithoutinterruptingthesnowthrowingprocess.Iftheauger

controlisengagedsimultaneouslywiththedrivecontrol,theoperatorcanrelease

theaugercontrol(ontheleft handle)andtheaugerswill remainengaged.Release

bothcontrolstostoptheaugersandwheeldrive.

flOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.Failuretodosowill

resultinincreasedwearonyourmachine'sdrivesystem.

Four-WayChuteControrM

CHUTe: DIRECTIONAL CONTROL

CHUTETILTDOWN

t

CHUTEROTATE CHUTEROTATE

LEFT RIGHT

CHUTETILTUP

_r n_

Thefour-waychutecontrolTM (Joystick)is locatedontheleft sideofthehandle

panel.

Tochangethedirectioninwhichsnowisthrown,squeezethebuttononthe

chutecontrolleverandpivotthechutecontrollevertotherightortothe

left.

Theaugercontrolislocatedontheleft handle.Squeezethecontrolgripagainstthe

handletoengagetheaugerandstartsnowthrowingaction.Releasetostop.

Tochangetheangle/distancewhichsnowisthrown,pivotthechutecontrol

leverforwardtotilt thechutedownandbackwardtotilt thechuteup.

Wheel Steering Controls

Theleft andrightwheelsteeringcontrolsarelocatedontheundersideofthe

handles.Squeezetherightcontroltoturnright;squeezetheleftcontroltoturn left.

NOTE:Operatethesnowthrowerinopenareasuntilyouarefamiliarwith these

controls.

15

Page 16

Clean-OutTool

Neveruseyour handstoclearacloggedchuteassembly.Shutoff engine

andremainbehindhandlesuntilall movingparts havestoppedbefore

usingthe clean-outtool to clearthe chuteassembly.

Thechutedean-outtoolisconvenientlyfastenedtotherearoftheaugerhousing

with amountingclip.Shouldsnowandicebecomelodgedin thechuteassembly

duringoperation,proceedasfollowstosafelycleanthechuteassemblyandchute

opening:

1. ReleaseboththeAugerControlandtheDriveControl.

2. Stoptheenginebyremovingtheignitionkey.

3. Removetheclean-outtoolfromtheclipwhichsecuresit totherearofthe

augerhousing.

4. Usetheshovel-shapedendoftheclean-outtooltodislodgeandscoopany

snowandicewhichhasformedinandnearthechuteassembly.

5. Refastentheclean-outtooltothemountingdipontherearoftheauger

housing,reinserttheignitionkeyandstartthesnowthrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnowthrower),engage

theaugercontrolforafewsecondstoclearanyremainingsnowandicefrom

thechuteassembly.

BeforeStartingEngine

Read,understand,andfollow all instructionsandwarningsonthe

machineandinthis manualbeforeoperating.

Oil

Theunitwasshippedwithoilintheengine.Checkoillevelbeforeeachoperationto

ensureadequateoilintheengine.

flO?E:Besuretochecktheengineonalevelsurfacewiththeenginestopped.

1. Removetheoilfillercap/dipstickandwipethedipstickclean.

2. Insertthecap/dipstickintotheoilfillerneck,butdoNOTscrewitin.

3. Removetheoilfillercap/dipstick.Ifthelevelislow,slowlyaddoil(5W-30,

with aminimumclassificationof SF/SG)untiloillevelregistersbetweenhigh

(H)andlow(L).

flOTE:Donotoverfill.Overfillingwithoilmayresultinenginesmoking,hard

startingorsparkplugfouling.

4.

Replaceandtightencap/dipstickfirmlybeforestartingengine.

Gasoline

Useautomotivegasoline(unleadedorlowleadedto minimizecombustionchamber

deposits)witha minimumof87octane.Gasolinewithupto 10%ethanolor15%

MTBE(MethylTertiaryButylEther)canbeused.Neveruseanoil/gasolinemixture

ordirtygasoline.Avoidgettingdirt, dust,orwaterinthefueltank.DONOTuseE85

gasoline.

Refuelinawell-ventilatedareawith theenginestopped.Donotsmokeor

allowflamesorsparksin theareawheretheengineisrefueledorwhere

gasolineisstored.

Donotoverfillthefueltank.Afterrefueling,makesurethetankcapisclosed

properlyandsecurely.

Becarefulnottospillfuelwhenrefueling.Spilledfuelorfuelvapormay

ignite.Ifanyfuelisspilled,makesuretheareaisdry beforestartingthe

engine.

Avoidrepeatedorprolongedcontactwithskinorbreathingofvapor.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuel the machineindoorsor

while the engineishotor running. Extinguishcigarettes,cigars,pipesand

othersourcesof ignition.

1.

Cleanaroundfuelfill beforeremovingcaptofuel.

2.

Afuel levelindicatorislocatedinthefueltank.SeeFigure15inset.Be

carefulnottooverfill.Filltankuntil fuelreachesthefuellevelindicatorto

allowspacefor fuelexpansion.

Starting TheEngine

Alwayskeephandsandfeet clearof movingparts.Donot useapressurized

starting fluid. Vaporsareflammable.

flOTE:Allowtheengineto warmupfor afewminutesafterstarting.Theenginewill

notdevelopfull poweruntilit reachesoperatingtemperatures.

1. Makecertainboththeaugercontrolanddrivecontrolarein thedisengaged

(released)position.

2. Insertkeyintoslot.Makesureit snapsintoplace.Donotattempttoturnthe

key.

NOTE:Theenginecannotstartwithoutthekeyfullyinsertedinto the

ignitionswitch.

ElectricStarter

Theelectric starterisequippedwith agroundedthree-wirepowerplug,

andisdesignedtooperateon 120voltAChouseholdcurrent.It must be

usedwith aproperlygroundedthree-prongreceptacleatall timesto avoid

the possibilityof electrk shock.Followall instructionscarefullypriorto

operatingthe electricstarter. DONOTuseelectric starterinthe rain.

Determinethatyourhome'swring isathree-wiregroundedsystem.Askalicensed

electricianifyouarenotcertain.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows.Ifyoudonot

havetheproperhousewiring,DONOTusetheelectricstarterunderanyconditions.

1. Pluganextensioncordintotheoutletlocatedontheengine'ssurface.Plug

theotherendofextensioncordintoathree-prong120-volt,grounded,AC

outletinawell-ventilatedarea.

Theextensioncordcan beanylength, but must beratedfor 15ampsat

125volts,groundedand ratedforoutdoor use.

16

Page 17

2. Movethrottle controlto FAST(rabbit)_Jl__ position.

3 MovechoketotheCHOKEI,'Ipos t on co,deng nestart),fengine s

warm,placechokein RUNposition.

4. Pushprimerthree(3)times,makingsureto coverventholeinprimerbulb

whenpushing.Ifengineiswarm,pushprimeronlyonce.Alwayscovervent

holewhenpushing.Coolweathermayrequireprimingto berepeated.

5. Pushstarterbuttonto startengine.Oncetheenginestarts,immediately

releasestarterbutton.Electricstarterisequippedwith thermaloverload

protection;systemwilltemporarilyshut-downtoallowstartertocoolif

electricstarterbecomesoverloaded.

6.

Astheenginewarms,slowlyrotatethechokecontroltoRUNposition.Ifthe

enginefalters,restartengineandrunwith chokeathalf-chokepositionfora

shortperiodoftime,andthenslowlyrotatethechokeinto RUNposition.

Afterengineisrunning,disconnectextensioncordfromelectricstarter.

Whendisconnecting,alwaysunplugtheendatthewalloutletbefore

unpluggingtheoppositeendfromtheengine.

RecoilStarter

ToEngageDrive

1. Withthethrottlecontrolinthe Fast(rabbit)_ _1 position,moveshift lever

intooneofthesixforward(F)positionsortwo reverse(R)positions.Selecta

speedappropriatefor thesnowconditionsanda paceyou'recomfortable

with.

flOTE:WhenselectingaDriveSpeed,usetheslowerspeedsuntilyouare

comfortableandfamiliarwiththeoperationofthesnowthrower.

2. Squeezethedrivecontrolagainstthehandleandthesnowthrowerwill

move.Releaseit anddrivemotionwill stop.

NOTE:NEVERrepositiontheshiftlever(changespeedsordirectionoftravel)

withoutfirst releasingthedrivecontrolandbringingthesnowthrowertoa

completestop.Doingsowillresultinprematureweartothesnowthrower'sdrive

system.

ToEngageAuger

Toengagetheaugerandstartthrowingsnow,squeezetheaugercontrol

againstthelefthandle.Releaseto stoptheauger.

ReplacingShearPins

Eachaugerbladeissecuredtothespiralshaftwithashearpinandbow-tieclip.If

Donotpull the starter handlewhilethe enginerunning.

1. Movethrottle controlto FAST(rabbit)_ _j position.

2. Movechoketo theCHOKEI,*'1position(coldenginestart).If engineis

warm,placechokein RUNposition.

3. Pushprimerthree(3)times,makingsureto coverventholewhenpushing.

Ifengineiswarm,pushprimeronlyonce.Alwayscoverventholewhen

pushing.Coolweathermayrequireprimingtoberepeated.

4. Pullgentlyonthestarterhandleuntil it beginsto resist,thenpullquickly

andforcefullytoovercomethecompression.Donotreleasethe handleand

allowit tosnapback.ReturnropeSLOWLYto originalposition.If required,

repeatthisstep.

5. Astheenginewarms,slowlyrotatethechokecontroltoRUNposition.Ifthe

enginefalters,restartengineandrunwith chokeathalf-chokepositionfora

shortperiodoftime,andthenslowlyrotatethechokeinto RUNposition.

anaugerbladestrikesaforeignobjectoricejam,thepinwill shearoff toprevent

damagetotheblade.Ifanaugerbladedoesnotturn,checktoseeif itspinhas

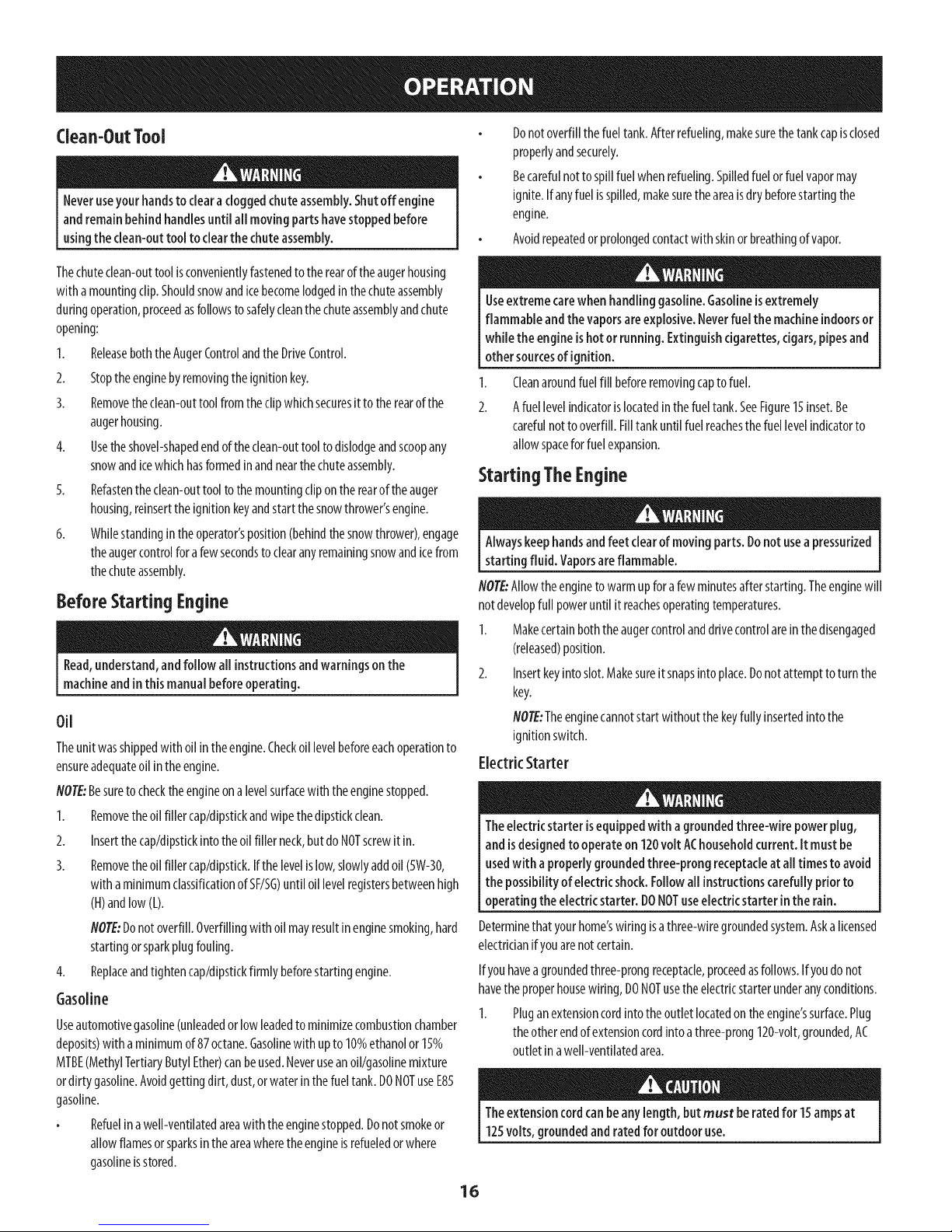

shearedoff. SeeFigure16.

NEVERreplacetheaugershearpinswith anything otherthan SearsSKU#

88389/0EMPartNo.738-04124Areplacementshearpins.Anydamageto

the augergearboxorother componentsasaresultof failing to dosowill

NOTbecoveredbyyoursnowthrower'swarranty.

Alwaysturn off the snowthrower'sengineandremovethekeypriorto

replacingshearpins.

Toavoidunsupervisedengineoperation,neverleavethe machine

unattendedwith theenginerunning. Turntheengineoff after useand

removekey.

Stopping TheEngine

Afteryouhavefinishedsnow-throwing,runengineforafewminutesbefore

stoppingto helpdryoffanymoistureontheengine.

1. Movethrottle controlto OFFposition.

2. Removethekey.Removingthe keywillreducethepossibilityof

unauthorizedstartingoftheenginewhileequipmentisnotinuse.Keepthe

keyina safeplace.Theenginecannotstartwithoutthekey.

3. Wipeanymoistureawayfromthecontrolsontheengine.

17

J

Figure16

Page 18

MAINTENANCESCHEDULE

Beforeperforminganytypeof maintenance/service,disengageallcontrols

andstopthe engine.Wait until allmovingpartshavecometo a complete

stop.Disconnectsparkplug wireand grounditagainsttheengineto

preventunintendedstarting.

Followthemaintenanceschedulegivenbelow.Thischartdescribesservice

guidelinesonly.UsetheServiceLogcolumntokeeptrackofcompleted

maintenancetasks.TolocatethenearestSearsServiceCenterorto scheduleservice,

simplycontactSearsat1-800-4-MY-HOME®.

EachUseandevery5hours

Ist5hours

Annuallyor25hours

Annuallyor50hours

Annuallyor100hours

BeforeStorage

1. Engineoil level

2. Looseormissinghardware

3. Unitandengine.

1. Engineoil

1. Sparkplug

2. Controllinkagesandpivots

3. Wheels

4. GearshaftandAugershaft

5. 4-WayChuteControlTM

1. Engineoil

1. Sparkplug

1. Fuelsystem

EngineMaintenance

CheckingEngineOil

Beforelubricating, repairing,or inspecting,disengageall controlsandstop

engine.Waituntil all movingparts havecometo acompletestop.

NOTE:Checktheoillevelbeforeeachuseto besurecorrectoillevelismaintained.

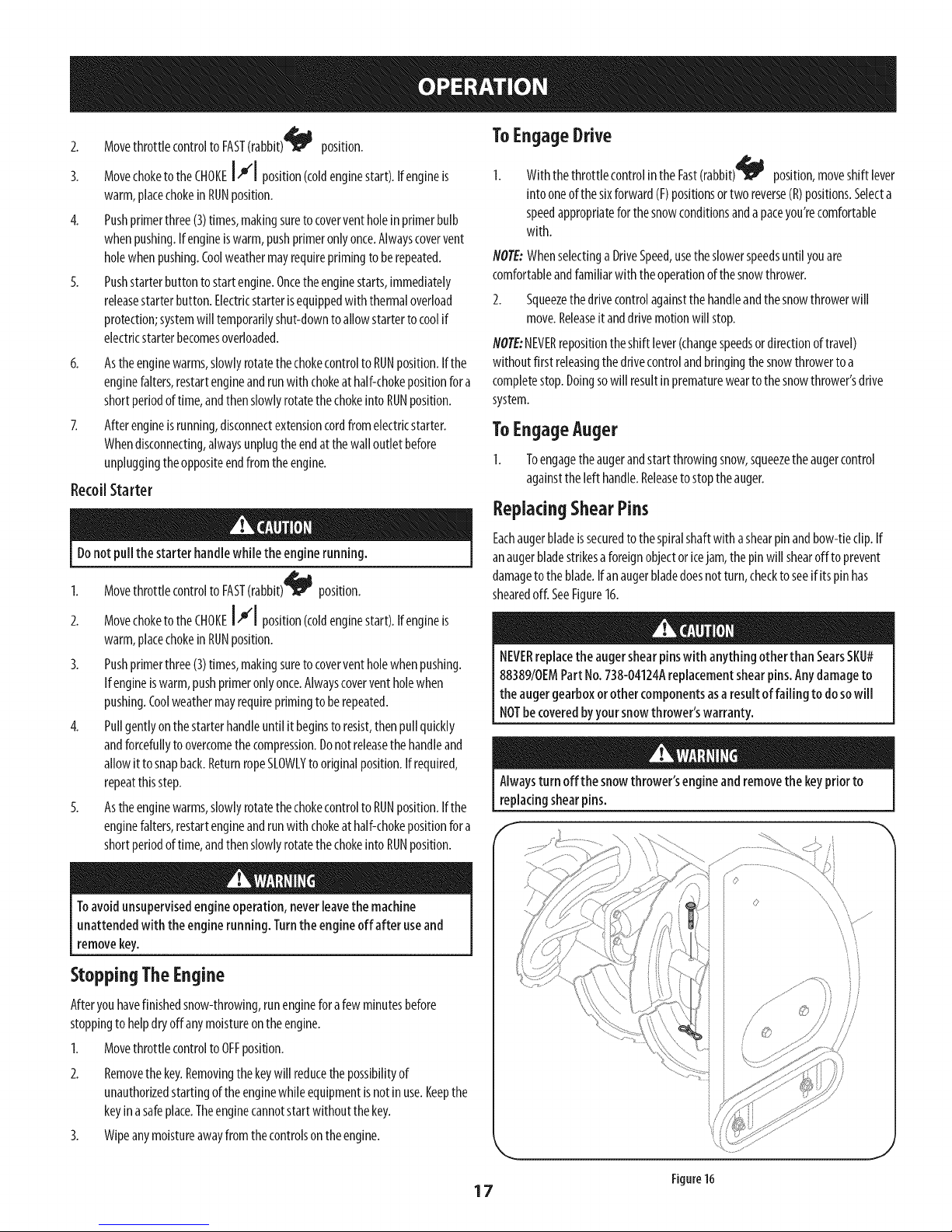

Whenaddingoiltotheengine,refertoviscositychartbelow.Engineoilcapacity

is600ml(approx.20oz.).Donotover-fill.Usea4-stroke,oranequivalenthigh

detergent,premiumqualitymotoroilcertifiedtomeetorexceedU.S.automobile

manufacturer'srequirementsforserviceclassificationSG,SF.Motoroilsclassified

SG,SFwillshowthisdesignationonthecontainer.

1. Removetheoilfillercap/dipstkkandwipethedipstkkclean.

2. Insertthecap/dipstkkintotheoilfillerneck,butdoNOTscrewit in.

3. Removetheoilfillercap/dipstick.Iflevelislow,slowlyaddoiluntiloillevel

registersbetweenhigh(H)andlow(L).SeeFigure17.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

ChangingEngineOil

NOTE:Changetheengineoilafterthefirst5 hoursofoperationandoncea season

orevery50hoursthereafter.

1. Drainfuelfromtankbyrunningengineuntil thefueltankisempty.Besure

fuelfill capissecure.

2. Placesuitableoilcollectioncontainerunderoil drainplug.

3. Removeoildrainplug.SeeFigure18onnextpage.

1. Check

2. Tightenorreplace

3. Clean

1. Change

1. Check

2. Lubewith lightoil

3. Lubewith multipurposeautogrease

4. Lubewith lightoil

5. Checkfor cableslackness

1. Change

1. Change

1. Runengineuntilitstopsfromlackoffuel

f

J

Figure17

Tipunittodrainoil intothecontainer.Usedoil mustbedisposedof ata

propercollectioncenter.

Usedoil isahazardouswasteproduct.Disposeofusedoil properly.Donot

discardwith householdwaste.Checkwithyour localauthorities or Sears

ServiceCenterforsafedisposal/recyclingfacilities.

5. Reinstallthedrainplugandtightenitsecurely.

18

Page 19

Refillwith therecommendedoilandchecktheoil level.SeeRecommended

OilUsagechart.Theengine'soilcapacityis20ounces.

(oF)-40o-20 o 0o 20o 40o

(oc) -30° -20° -10° 0°

DONOTusenondetergentoil or 2-strokeengineoil. it couldshorten the

engine'sservicelife.

7. Reinstalltheoilfillercap/dipsticksecurely.

Thoroughlywashyour handswith soapandwater assoonaspossibleafter

handlingusedoil.

CheckingSparkPlug

OilDrain

Plug \

Figure18

E

SparkPlug

DONOTcheckforsparkwith sparkplugremoved.DONOTcrankenginewith

sparkplug removed.

Ifthe enginehasbeenrunning,the muffler will beveryhot. Becarefulnot

to touchthe muffler.

NOTE:Checkthe sparkplugonceaseasonor every25hoursofoperation.Change

thesparkplugonceaseasonorevery100hours.Toensureproperengineoperation,

thesparkplugmustbeproperlygappedandfreeofdeposits.

1. Removethesparkplugbootanduseasparkplugwrenchtoremovethe

plug.SeeFigure19.

2. Visuallyinspectthesparkplug.Discardthesparkplugifthereisapparent

wear,orif theinsulatoriscrackedorchipped.Cleanthesparkplugwitha

wirebrushifit istobereused.

3.

Measurethepluggapwith afeelergauge.Correctasnecessarybybending

sideelectrode.SeeFigure20.Thegapshouldbesetto.02-.03inches(0.60-

0.80mm).

4. Checkthatthesparkplugwasherisin goodconditionandthreadthespark

pluginbyhandtopreventcross-threading.

5. Afterthesparkplugisseated,tightenwithasparkplugwrenchtocompress

thewasher.

NOTE:Wheninstallinganewsparkplug,tighten1/2-turnafterthesparkplug

seatstocompressthewasher.Whenreinstallingausedsparkplug,tighten1/8-to

1/4-turnafterthesparkplugseatsto compressthewasher.

SparkPlugBoot

Figure19

Electrode

Thesparkplug mustbe tightened securely.Aloosesparkplugcanbecome

very hotandcandamagethe engine.

Figure20

19

Page 20

Lubrication "I

GearShaft

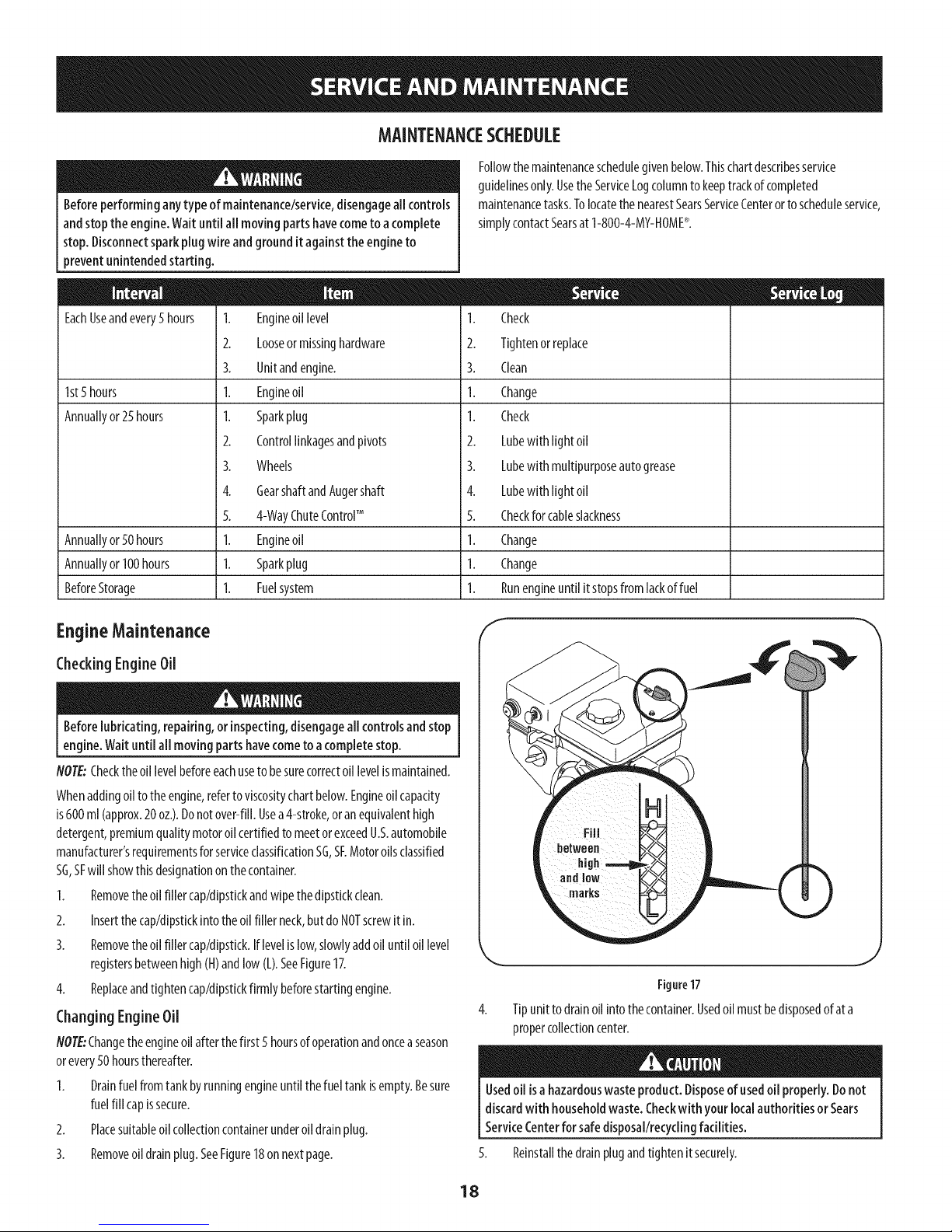

Thegear(hex)shaftshouldbelubricatedatleastonceaseasonorafterevery25

hoursofoperation.

I. Topreventspillage,removeallfuelfromtankbyrunningengineuntilit

stops.

2. Carefullypivotthesnowthrowerupandforwardsothatit restsontheauger

housing.

3. Removethelowerframecoverfromtheundersideofthesnowthrowerby

removingtheself-tappingscrewswhichsecureit.

4. Applyalightcoatingofengineoil(or3-in-1oil)to thehexshaft.SeeFigure

21.

NOTE:Whenlubricatingthe hexshaft,becarefulnottogetanyoilonthealuminum

driveplateorrubberfrictionwheel.Doingsowill hinderthesnowthrower'sdrive

system.Wipeoffanyexcessorspilledoil.

Wheels

Atleastonceaseason,removebothwheels.Cleanandcoattheaxleswitha

multipurposeautomotivegreasebeforereinstallingwheels.

AugerShaft

Atleastonceaseason,removetheshearpinsonaugershaft.Spraylubricantinside

shaft,andaroundthespacersandflangebearingsfoundat eitherendoftheshaft.

SeeFigure22.

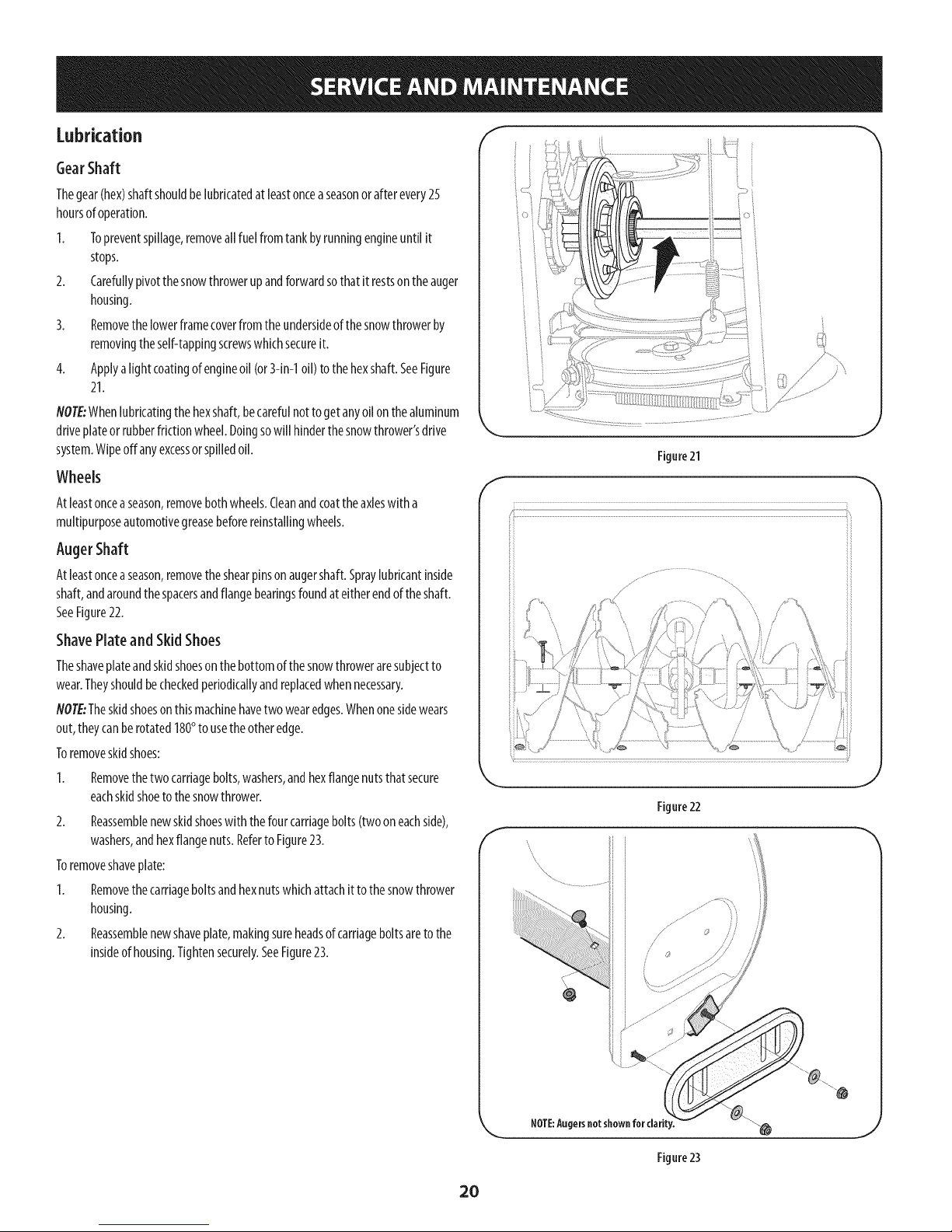

ShavePlateand SkidShoes

Theshaveplateandskidshoesonthebottomofthesnowthroweraresubjectto

wear.Theyshouldbecheckedperiodkallyandreplacedwhennecessary.

flOT£:Theskidshoesonthismachinehavetwo wearedges.Whenonesidewears

out,theycanberotated180°tousetheotheredge.

Toremoveskidshoes:

Removethetwocarriagebolts,washers,andhexflangenutsthatsecure

eachskidshoetothesnowthrower.

2. Reassemblenewskidshoeswith thefourcarriagebolts(twooneachside),

washers,andhexflangenuts.Referto Figure23.

Toremoveshaveplate:

1. Removethecarriageboltsandhexnutswhichattachittothesnowthrower

housing.

2. Reassemblenewshaveplate,makingsureheadsof carriageboltsaretothe

insideof housing.Tightensecurely.SeeFigure23.

f

J

Figure21

f

NOTE:Augersnot shownfor clarity.

Figure23

20

Page 21

Adjustments

Shift Cable

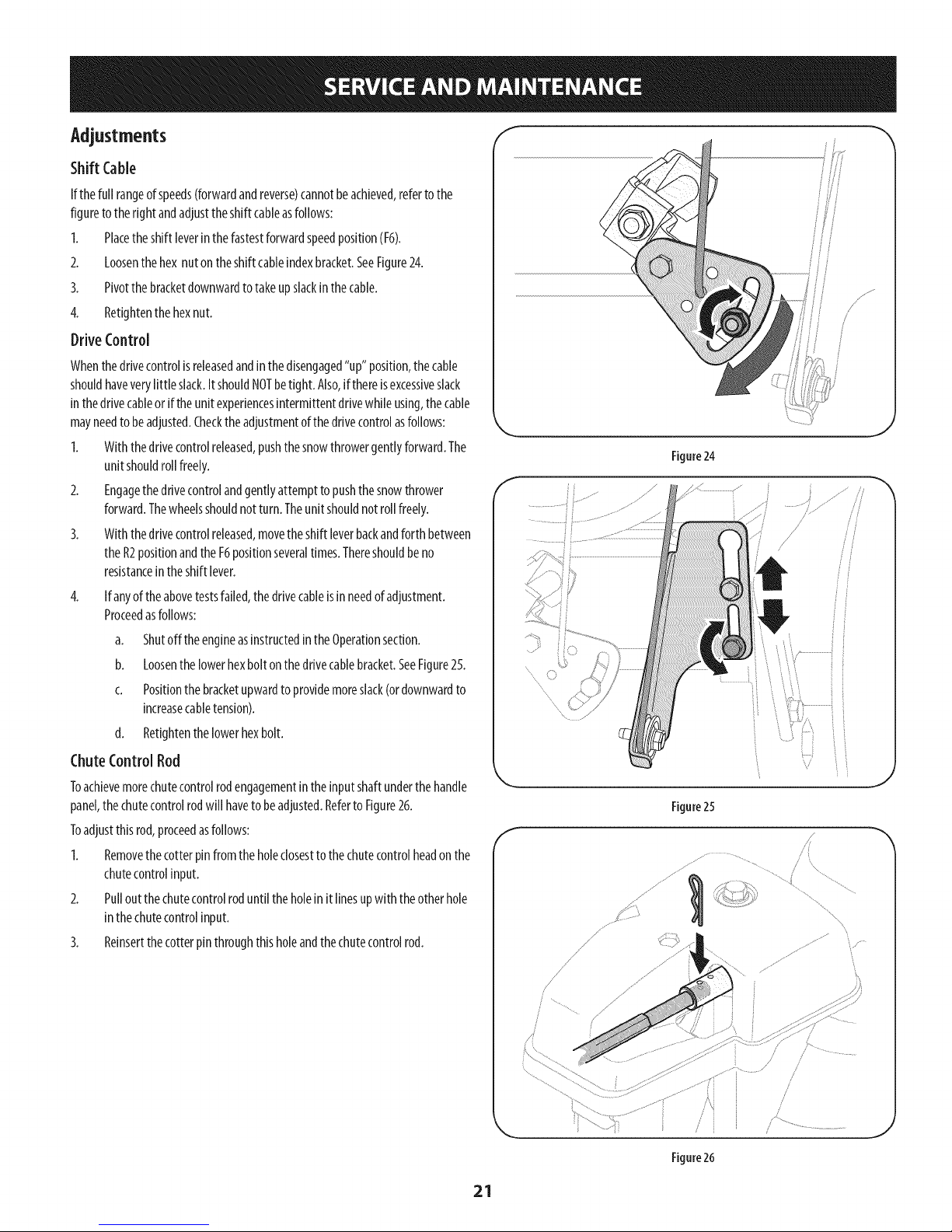

Ifthefull rangeofspeeds(forwardandreverse)cannotbeachieved,refertothe

figuretothefight andadjusttheshiftcableasfollows:

I. Placetheshift leverinthefastestforwardspeedposition(F6).

2. Loosenthehex nutontheshiftcableindexbracket.SeeFigure24.

3. Pivotthebracketdownwardtotakeupslackinthecable.

4. Retightenthehexnut.

DriveControl

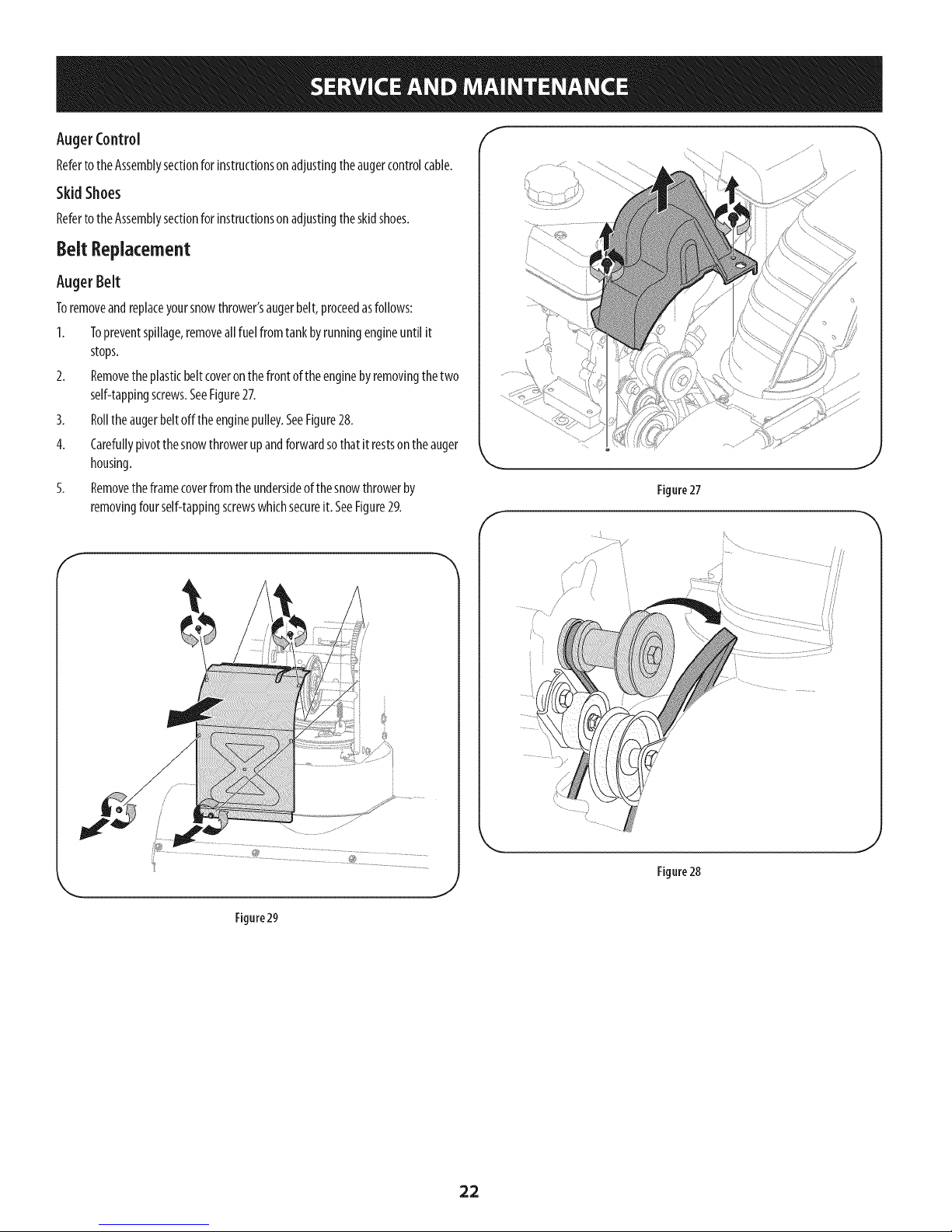

Whenthedrivecontrolisreleasedandinthedisengaged"up"position,thecable

shouldhaveverylittle slack.ItshouldNOTbetight. Also,ifthereisexcessiveslack

inthedrivecableor iftheunitexperiencesintermittentdrivewhileusing,thecable

mayneedtobeadjusted.Checktheadjustmentofthedrivecontrolasfollows:

I. Withthedrivecontrolreleased,pushthesnowthrowergentlyforward.The

unitshouldrollfreely.

2. Engagethedrivecontrolandgentlyattemptto pushthesnowthrower

forward.Thewheelsshouldnotturn.Theunitshouldnotrollfreely.

3. Withthedrivecontrolreleased,movetheshift leverbackandforthbetween

theR2positionandtheF6positionseveraltimes.Thereshouldbeno

resistanceintheshiftlever.

f

Figure24

4. Ifanyoftheabovetestsfailed,thedrivecableisinneedofadjustment.

Proceedasfollows:

a. Shutoff theengineasinstructedinthe Operationsection.

b. Loosenthelowerhexboltonthedrivecablebracket.SeeFigure25.

c. Positionthebracketupwardto providemoreslack(ordownwardto

increasecabletension).

d. Retightenthelowerhexbolt.

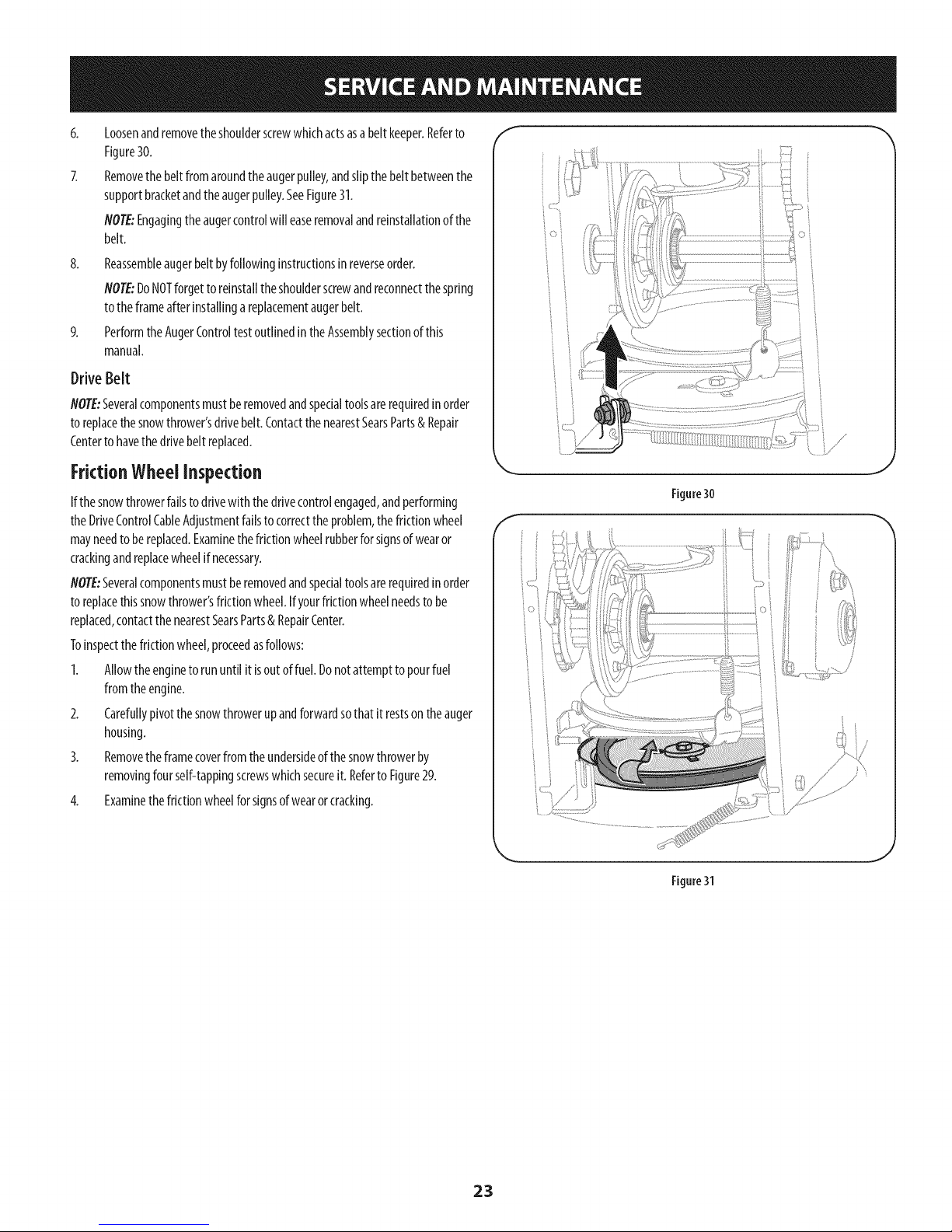

ChuteControlRod

Toachievemorechutecontrolrodengagementintheinputshaftunderthe handle

panel,thechutecontrolrodwill havetobeadjusted.RefertoFigure26.

Toadjustthisrod,proceedasfollows:

I. Removethecotterpinfromtheholeclosesttothechutecontrolheadonthe

chutecontrolinput.

2. Pulloutthechutecontrolroduntiltheholeinit linesupwith theotherhole

inthechutecontrolinput.

3. Reinsertthecotterpinthroughthisholeandthechutecontrolrod.

Figure25

"',,,%

............................/ ....

21

Figure26

/

/

/

/

/

/

Page 22

AugerControl

RefertotheAssemblysectionforinstructionsonadjustingtheaugercontrolcable.

SkidShoes

RefertotheAssemblysectionforinstructionsonadjustingtheskidshoes.

Belt Replacement

Auger Belt

Toremoveandreplaceyoursnowthrower'saugerbelt,proceedasfollows:

I. Topreventspillage,removeallfuelfromtankbyrunningengineuntilit

stops.

2. Removetheplasticbeltcoveronthefrontof theenginebyremovingthetwo

self-tappingscrews.SeeFigure27.

3. Rolltheaugerbeltoffthe enginepulley.SeeFigure28.

4. Carefullypivotthesnowthrowerupandforwardsothatit restsontheauger

housing.

5. Removetheframecoverfromtheundersideofthesnowthrowerby

removingfourself-tappingscrewswhichsecureit. SeeFigure29.

f

J

Figure27

Figure29

J

22

Page 23

Loosenandremovetheshoulderscrewwhichactsasabeltkeeper.Referto

Figure30.

Removethebeltfromaroundtheaugerpulley,andslipthebeltbetweenthe

supportbracketandtheaugerpulley.SeeFigure31.

NOTE:Engagingtheaugercontrolwill easeremovalandreinstallationof the

belt.

8.

Reassembleaugerbeltbyfollowinginstructionsinreverseorder.

NOTE:DoNOTforgettoreinstalltheshoulderscrewandreconnectthespring

totheframeafterinstallingareplacementaugerbelt.

PerformtheAugerControltestoutlinedintheAssemblysectionofthis

manual.

Drive Belt

NOTE:Severalcomponentsmustberemovedandspecialtoolsarerequiredinorder

toreplacethesnowthrower'sdrivebelt.ContactthenearestSearsParts& Repair

Centerto havethedrivebeltreplaced.

FrictionWheelInspection

Ifthesnowthrowerfailstodrivewiththedrivecontrolengaged,andperforming

theDriveControlCableAdjustmentfailstocorrectthe problem,thefrictionwheel

mayneedtobereplaced.Examinethefrictionwheelrubberforsignsofwearor

crackingandreplacewheelifnecessary.

NOTE:Severalcomponentsmustberemovedandspecialtoolsarerequiredin order

toreplacethissnowthrower'sfrictionwheel.Ifyourfrictionwheelneedsto be

replaced,contactthe nearestSearsParts& RepairCenter.

Toinspectthefrictionwheel,proceedasfollows:

1. Allowtheengineto rununtil itisoutof fuel.Donotattemptto pourfuel

fromtheengine.

2. Carefullypivotthesnowthrowerupandforwardsothatit restsontheauger

housing.

3. Removetheframecoverfromtheundersideofthesnowthrowerby

removingfourself-tappingscrewswhichsecureit. Referto Figure29.

4. Examinethefrictionwheelforsignsofwearorcracking.

J

Figure30

Figure31

23

Page 24

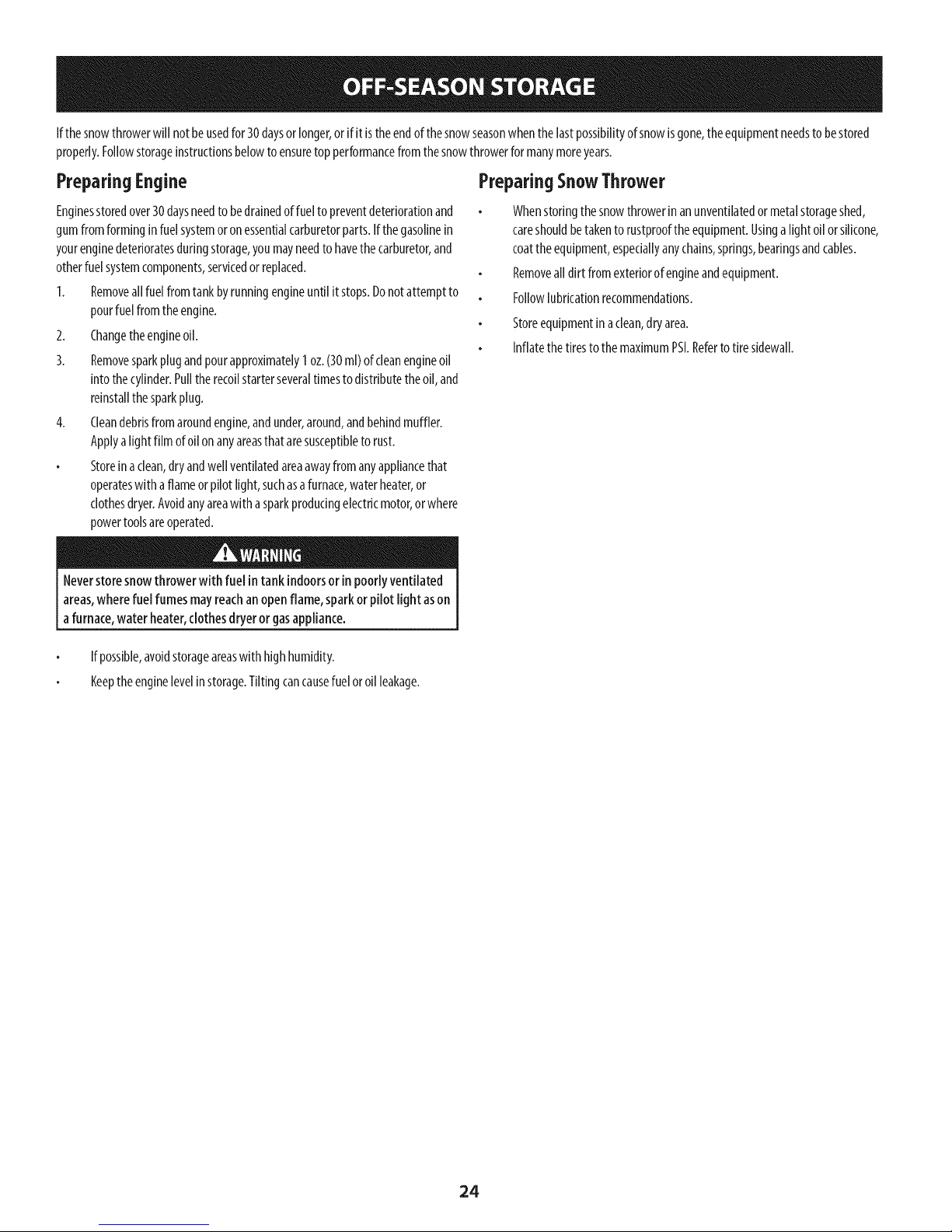

Ifthesnowthrowerwill notbeusedfor 30daysorlonger,orifit istheendofthesnowseasonwhenthelastpossibilityofsnowisgone,theequipmentneedsto bestored

properly.Followstorageinstructionsbelowtoensuretopperformancefromthesnowthrowerformanymoreyears.

PreparingEngine

Enginesstoredover30daysneedtobedrainedoffueltopreventdeteriorationand

gumfromforminginfuelsystemoronessentialcarburetorparts.Ifthegasolinein

yourenginedeterioratesduringstorage,youmayneedtohavethecarburetor,and

otherfuelsystemcomponents,servicedorreplaced.

1. Removeallfuelfromtankbyrunningengineuntil it stops.Donotattemptto

pourfuelfromtheengine.

2. Changetheengineoil.

3. Removesparkplugandpourapproximately1oz.(30ml)ofcleanengineoil

intothecylinder.Pulltherecoilstarterseveraltimestodistributetheoil, and

reinstallthesparkplug.

4. Cleandebrisfromaroundengine,andunder,around,andbehindmuffler.

Applyalightfilm ofoilonanyareasthat aresusceptibleto rust.

Storeinaclean,dryandwellventilatedareaawayfromanyappliancethat

operateswith aflameorpilot light,suchasafurnace,waterheater,or

clothesdryer.Avoidanyareawitha sparkproducingelectricmotor,orwhere

powertoolsareoperated.

Neverstoresnowthrowerwith fuel intank indoorsorin poorlyventilated

areas,wherefuelfumesmayreachanopenflame,sparkor pilotlight ason

afurnace,water heater,clothesdryeror gasappliance.

PreparingSnowThrower

Whenstoringthe snowthrowerin anunventilatedormetalstorageshed,

careshouldbetakento rustprooftheequipment.Usinga lightoilorsilicone,

coattheequipment,especiallyanychains,springs,bearingsandcables.

Removealldirt fromexteriorofengineandequipment.

Followlubricationrecommendations.

Storeequipmentinaclean,dryarea.

InflatethetirestothemaximumPSI.Refertotire sidewall.

Ifpossible,avoidstorageareaswith highhumidity.

Keeptheenginelevelinstorage.Tiltingcancausefueloroil leakage.

24

Page 25

25

Page 26

Disconnectthe sparkplugwireandgrounditagainstthe engineto prevent

unintendedstarting. Beforeperforminganytypeofmaintenance/service,

disengageallcontrolsandstoptheengine.Waituntil aHmovingparts

havecometoa completestop.Alwayswear safetyglassesduringoperation

or while performinganyadjustmentsorrepairs.

Thissectionaddressesminorserviceissues.Tolocatethe nearestSearsServiceCenterorto scheduleservice,simplycontactSearsat1-800-4-MY=HOMP.

Engine fails to start 1.

Engine running erratically/

inconsistent RPM (hunting

or surging)

Excessive vibration

Lossof power

Unit fails to propel itself

Choke control not in CHOKE position.

2.

Spark plug wire disconnected.

3.

Faulty spark plug.

4.

Fuel tank empty or stale fuel.

5.

Engine not primed.

6.

Key not inserted.

7.

Extension cord not connected (when

using electric start button, on models so

equipped).

1. Engine running on CHOKE.

2. Stale fuel.

3. Water or dirt in fuel system.

4. Carburetor out of adjustment.

5. Over-governed engine.

1. Loose parts or damaged auger.

1. Spark plug wire loose.

2. Gas cap vent hole plugged.

1. Drive cable in need of adjustment.

2. Drive belt loose or damaged.

3. Worn friction wheel.

1. Move choke control to CHOKE position.

2. Connectwire to spark plug.

3. Clean, adjust gap, or replace.

4. Fill tank with clean, fresh gasoline.

5. Prime engine as instructed in the Operation Section.

6. Insert key fully into the switch.

7. Connect one end of the extension cord to the

electric starter outlet and the other end to a three-

prong 120-volt, grounded, ACoutlet.

1. Move choke control to RUN position.

2. Fill tank with clean, fresh gasoline.

3. Drain fuel tank by running engine until it stops. Refill

with fresh fuel.

4.

Contact your Sears Parts & Repair Center.

5.

Contact your Sears Parts & Repair Center.

1.

Stop engine immediately and disconnect spark

plug wire. Tighten all bolts and nuts. If vibration

continues, have unit serviced by a Sears Parts &

Repair Center.

1.

Connect and tighten spark plug wire.

2.

Remove ice and snow from gas cap. Be certain vent

hole is clear.

1.

Adjust drive control cable. Refer to Service and

Maintenance section.

2.

Have drive belt replaced. Contact your Sears Parts &

Repair Center.

3.

Have friction wheel replaced at a Sears Parts &

Repair Center.

NEED MORE HELP?

Find this and a[[ your other product manuals online,

Get answers from our team of home experts.

Get a personalized maintenance plan for your home.

Find information and tools to help Mth home projects.

26

Page 27

Unit fails to discharge snow

1. Chute assembly clogged. 1. Stop engine immediately and disconnect spark

plug wire. Clean chute assembly and inside of auger

housing with clean-out tool or a stick.

2. Foreign object lodged in auger.

2. Stop engine immediately and disconnect spark plug

wire. Remove object from auger with clean-out tool

or a stick.

3. Auger cable in need of adjustment.

3. Adjust auger control cable. Refer to Assembly

section.

4. Auger belt loose or damaged.

4. Replace auger belt. Refer to Service and

Maintenance section.

5. Shearpin(s) sheared.

5. Replace with new shear pin(s).

Chute fails to easily rotate

180 degrees

1. Chuteassembled incorrectly.

1. Disassemble chute control and reassemble as

directed in the Assembly section.

NEED MORE HELP?

YotJU,fir_}the _: swe a_] :m,_"Yeo_:__._a_,a_emy[f_eo_@_,,,,,,,fo_'free!

o Find this and a[[ your other product manuals online.

Get answers from our team of home experts,

o Get a personalized maintenance plan for your home_

Find information and tools to help with home projects.

27

Page 28

CraftsmanSnowThrower Model247.886914

15

20

17

31

54

' 32

10j_

i27

28

Page 29

CraftsmanSnowThrowerModel 247.886914

N

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

731-2635

684-04057A-0637

710-0347

710-0451

710-04484

710-0703

712-04063

712-04064

712-04065

714-04040

936-0159

926-04012

731-07525

732-04460

736-0174

736-0242

946-04230A

931-2643

738-0143

938-0281

738-04124A

941-0245

941-0309

756-04224

790-00075

790-00080A-0637

918-04172B

Snow Removal Tool Mount

Impeller Assembly, 12" Dia.

Hex Screw, 3/8-16, 1.75, Gr5

Bolt, Carriage, 5/16-18, .750 Grl

Screw, 5/16-18, 0.750

Screw, Carriage, 1/4-20, .750, Gr5

Nut, Flange Lock, 5/16-18, Nylon

Nut, Flange Lock, 1/4-20, Nylon

Nut, Flange Lock, 3/8-16, Nylon

Cotter Pin, Bow-tie

Washer, Flat, .349 x .879 x .063

Nut, Push-on, .25 Dia

Chute, Adapter 5" Dia

Spring, Extension, .38 OD x 4.59

Washer, Wave, .625 x .885 x .015

Washer, Bell, .340 x .872 x .060

Clutch Cable, Auger, 47.23"

Snow Removal Tool

Screw, Shoulder, .498 x .34, 3/8-16

Screw, Shoulder, .625 x .17, 3/8-16

Shear Pin, .25 x 1.50

Bearing, Hex Flange x .75 ID

Bearing, Ball, .75 ID x 1.85 OD

Flat Pulley, Idler, 2.75 OD

Housing, Bearing, 1.85 ID

Bracket, Auger Idler w/Brake

Gearbox Assembly, Auger, 26"

m

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

684-04264-4044

684-04107-0637

684-04108-0637

731-04870

736-0188

741-0493A

790-00087A-0637

790-00121-4044

731-05984A

918-0123A

918-0124A

921-0338

741-0662

710-0642

711-04284

914-0161

715-04021

917-04126

917-04861

718-04071

721-0325

721-0327

936-0351

736-3084

741-0663

741-0661 B

710-0276

Housing Assembly, Auger 26"

Spiral Assembly, LH

Spiral Assembly, RH

Spacer, 1.25 OD x .75 ID x 1.00

Washer, Flat, .76 x 1.49 x .06

Bushing, Flange, .80 ID x .91 OD

Housing, I" Hex Bearing

Shave Plate, 2.25 x 25.66

Slide Shoe

Housing, Auger, RH Reduced

Housing, Auger, LH Reduced

Seal, Oil, .750 x 1.00 x .125

Bearing, Flange, .75 x 1.0 x .59

Screw, Self-tapping, I/4-20, 0.750

Axle, Auger, 26"

Key, Hi-pro 3/16 x 5/8

Pin, Dowel, .25 OD x 1.2

Shaft, Worm .75 OD

Gear, Worm 20T

Collar, Thrust

Plug, I/4 x .437

Seal, Oil, .75 x I x .131

Washer, Flat, .760 ID x 1.50D

Washer, Flat, .51 x 1.12

Bearing, Flange, .75 x 1.0 x .925

Bearing, Flange, .75 x 1.00 x .975

Screw, Carriage, 5/16-18 x 1.00

29

Page 30

CraftsmanSnowThrower Model247.886914

27

/

15 ///

/

/

/

/

27

1

/

/

28

f

30

29

3O

Page 31

CraftsmanSnowThrower Model247.886914

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

3Z

± Available for warranty coverage only. Contact a Sears authorized

service provider for details.

984-04338A

710-04187

715-0150

747-05116

710-04370

738-04367

918-04801A

736-04446

920-0284

936-0159

731-04427A

914-0101

711-04469A

712-3087

684- 0431IA-0637

714-04040

712-04064

712-04063

784-5594-0637

731-06451

710-0262

710-0895

710-04071

731-06440A

710-0627

946-04528A

946-04477

753-06151

731-04893A

710-04879

710-04353

731-07031

984-04324A

753-06152

753-06153

710-1256

684-04350

715-04095

753-08018f

4-Way Chute Control TM Assembly

Hi-Lo Screw, 1/4-15 x 0.5

Roll Pin

Chute Rod

Hex Screw, 1/4-20 x 3.00

Flange Shoulder Screw

4-Way Chute Gearbox Assembly

Flat Washer, .25 x .630 x .0515

Wing Knob

Flat Washer, .349 x .879 x .063

Upper Chute

Cotter Pin

Clevis Pin

Wing Nut, 1/4-20

Chute Support Bracket

Bow Tie Cotter Pin

Flange Lock Nut, 1/4-20

Flange Lock Nut, 5/16-18

Cable Bracket

Chute Tilt Cable Guide

Carriage Bolt, 5/16-18 x 1.50

Hi-Lo Screw, 1/4-15 x .75

Carriage Bolt, 5/16-18 x 1.0

Lower Chute

Hex Screw, 5/16-24 x .750

4-Way Cable

4-Way Cable w/Clip (Not Shown)

Handle Assembly

Handle Plunger

Screw, Mach., #8-32 x .750

Screw, #8 x 1.00

Handle Lever

Shift Assembly

Gear Set Assembly

Handle Housing Assembly

Screw, #8-18 x 1.250

Joint Block Assembly

Pin

Chute Kit (Incl. Ref.# 11 & 24)

31

Page 32

CraftsmanSnowThrower Model247.886914

12

2

3

31

/

61/_

32

Page 33

CraftsmanSnowThrowerModel247.886914

M

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

684-04112C

732-04238

731-04894D

684-04250

935-0199A

710-3069

731-04896B

712-04081A

684- 04111 B

631-04133A

720-0274

710-1233

738-04348

710-04586

749-04190A-0637

710-0572

720-04039

753-06437

731-05324

731-06113

631-04134B

725-0157

712-04064

732-0193

790-00311B-0637

790-00248C-0637

738-04125

920-0284

946-04396A

936-0267

914-0145

749-04138B-0637

710-04484

710-04022

936-0264

Handle Engagement Ass'y RH

Torsion Spring

Lock Plate

Pivot Rod

Rubber Bumper

Screw, 1/4-20 x .500

Clutch Lock Cam

Shoulder Nut, 1/4-20

Handle Engagement Assembly LH

Handle Clutch Lock LH Assembly

Handle Grip

Screw, #10-24 x 0.375

Shoulder Screw, 1/4-20

Screw, 1/4-20 x 1.625

Upper Handle RH

Carriage Screw, 5/16-18 x 2.25

Shift Knob

Handle Panel

Lens

Steering Control

Handle Clutch Lock RH Assembly

Cable Tie

Flange Lock Nut, 1/4-20

Compression Spring

Shift Lever

Panel Bracket

Shoulder Screw

Wing Knob

Speed Selector Cable

Flat Washer

Click Pin

Lower Handle

Screw, 5/16-18 x 0.75

Screw, M8-1.25

Flat Washer, .330 x .630 x .0635

m

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.

65.

66.

67.

68.

N/A

732-0705

749-04191A-0637

710-04326

732-04219C

738-04126

716-04036

936-0329

710-1652

731-05353

926-04012

756- 04109

736-0505

738-04439

936-0119

684-04169

790-00289A-0637

750-04571

732-04308A

710-0672

756-04252

954-04260

710-0809

790-00208D

748-04112B

750-04477A

710-0654A

750-04303

756- 04113

736-3082A

710-0191

748-04053A

710-1245B

954-04050

Cable Control Wire

Upper Handle LH

Screw, #8-16 x 0.50

Clutch Lock Spring

Pin, 3/16

Retainer Ring

Lock Washer

AB Screw, 1/4-20 x 0.625

Belt Cover

Push-on Nut

Auger Pulley

Flat Washer

Shoulder Screw

Lock Washer

Idler Pulley Assembly

Pit., Cvr.

Spacer

Torsion Spring

Hex Screw, 5/16-24 x 1.25

Pulley Half

Belt, Wheel Drive

TT Screw, 1/4-20 x 1.25

Drive Clutch Idler Bracket

Shoulder Spacer

Spacer

TT Seres Screw, 3/8-16 x 1.0

Spacer

Pulley Half

Flat Washer

Hex Bolt, 3/8-24 x 1.25

Pulley Adapter

Hex Bolt, 5/16-24 x 0.875

V-Belt,.500 x 35.00 Lg

Engine (see breakdown)

MTD Model No. 952Z270-SUA

33

Page 34

CraftsmanSnowThrower Model247.886914

43

45

42

2

I

36

20

10

22

14 i

13

2O

26 45 24

I

28

57

62

58

56

59i

I

35

34

Page 35

CraftsmanSnowThrowerModel 247.886914

N

I.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

735-04099

711-1268B

946-05067

732-04345

790-00207C

684- 04156A

750-04474

914-0126

735-04100

917-04210

941-0245

790-00206A-0637

756-0625

738-0924A

618-06988

618-06987

936-3015

732-04311A

731-05297

916-0104

736-0188

750-06087

941-0563

938-04180

731-04873

710-0788

790-00527-4044

634-04147A-091 l

634-04148A-0911

710-05339

684-04154B-0637

790-00096A-0637

748-0190

Plug, 3/8 ID

Actuator Shaft

Drive Clutch Cable

Extension Spring

Drive Clutch Cable Guide Bracket

Shift Rod Assembly

Axle Support Tube

Hi Pro Key

Plug, 1/2 ID

Gear, 56T

Hex Flange Bearing

Auger Clutch Cable Guide Bracket

Cable Roller

C Screw, 1/4-28 x 0.375

Dogg Assembly - LH

Dogg Assembly - RH

Washer, Flat

Torsion Spring, .750 ID x .968 Lg.

Spacer

E Ring

Flat Washer, .76 x 1.49 x .06

Spacer

Ball Bearing

Axle

Spacer

TT Screw, 1/4-20 x 1.0

Shaft Retainer- LH

Wheel Complete - LH

Wheel Complete - RH

Screw, 5/16-24 x 0.75

Friction Wheel Support Brkt. Assy.

Auger Cable Guide Bracket

Spacer

N

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

738-04184A

790-00316-4044

656-04055

918-06072

684-04153C

716-0136

726-0221

790-00183C-4044

932-0264

712-0417A

946-0956C

790-00528-4044

750-0767

712-04065

710-0751

790-00217A-0637

790-00218A-0637

712-04063

712-04064

618-0063A

935-04054

790-00174C

710-04484

710-1652

918-06054

918-06056

711-06117

916-0231

717-05146

717-1209A

736-04581

736-05031

Shoulder Screw

Frame Cover

Friction Wheel Disc Assembly

Drive Shaft Assembly

Friction Wheel Assembly

Retainer Ring

Speed Nut

Wheel Drive Frame

Extension Spring

Flange Nut, 5/8-18

Steering Cable

Shaft Retainer- RH

Axle Spacer

Flange Lock Nut, 3/8-16

Hex Screw, 1/4-20 x .620

Speed Selector Pivot Bracket

Speed Selector Shift Bracket

Flange Lock Nut, 5/16-18

Flange Lock Nut, 1/4-20

Friction Wheel Bearing Assembly

Friction Wheel

Friction Plate

Screw, 5/16-18 x .750

AB Screw, 1/4-20 x 0.625

Gear Assembly, Plantry Ring

Carrier Assembly, Plantry Ring

Shaft, Strbl Drv Hex, .812

E-Ring

Gear, Sun, 18T

Gear, 12T

Washer, Thrust, .75 x 1.25 x .03

Washer, Flat, .67 x 1.174 x .02

3S

Page 36

CraftsmanEngineModel270-SUAForSnowModel247.886914

23

24

23

2

21

D - o ii

19

951-11282

20

710-05001

20

951-14190

21

951-11289

22

712-04214

23

710-04915

24

951-I0642B

Muffler Assembly

Muffler Stud

Muffler Stud Kit

Muffler Gasket

Nut- M8

Bolt- M6 X 12 Zin

Muffler Shroud

36

Page 37

CraftsmanEngineModel270-SUAForSnowModel247.886914

41 _42

34

35

36

37

39

4O

41

42

43

951-10634

712-04213

951-11284

951-10757

951-10637

731-05632

951-10640

951-10635

710-04943

°0

Shroud-Engine

Nut

Choke Knob

Throttle Knob

Switch-Ignition

Ignition Key Switch

Push Rod-Choke

Air Filter Heating

Bolt-M6 1X28M Spec

37

35

D _ o o

37

Page 38

CraftsmanEngineModel270-SUAForSnowModel247.886914

7O

131-GasketKit-Complete

70---_

70-_%

132-GasketKit-External

133- CompleteEngine

63

62

38

Page 39

CraftsmanEngineModel270-SUAForSnowModel247.886914

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

73

74

75

76

77

78

79

130

131

132

133

951-12111

951-11632

951-12007

951-11633

710-04915

951-11113

951-11573

951-14053

736-04461

951-11902

714-04078

951-11575

951-11369

951-10307

951-11247A

951-11576

715-04092

715-04096

951-11371

951-12125

951-11246

710-04932

951-11283

951-11577

951-11368

951-11249

951-11060B

951-11350

736-04440

710-04906

951-11370

951-10641

951-11059A

951-10661B

952Z270-SUA

Piston Ring Set

Piston Pin Snap Ring

Piston

Piston Pin

Bolt- M6 X 12Zin

Shield - Air

Connecting Rod Assembly

Governor Shaft

Washer

Governor Seal

Cotter Pin

Camshaft Assembly

Bearing

Key:Flywheel

Crankshaft Kit (Incl. 62,63,64,74,79)

Governor Gear/Shaft

Pin-Dowel

Dowl Pin 9X14

Crankcase Cover Gasket

Crankcase Cover

Crankcase Cover Kit (Incl. 62,68-74)

Bolt

Oil Fill Plug Assembly

O-Ring 15.8 X2.5

Oil Seal

Crankcase Kit (Incl. 59,62,74,75,79)

Shortblock Assembly

(Incl. 4,21,27-29,44,46, 47, 50-53,56-79)

Oil Drain Pipe

Washer

Bolt- Drain Plug

Oil Seal

Oil Drain Assembly

Gasket Kit-Complete

(Incl. 4,21,27-29,32,44,58,59,68,74,77,79)

Gasket Kit-External (Incl. 4,21,27 29,32,77)

Complete Engine

D _ o 0

39

Page 40

CraftsmanEngineModel270-SUAForSnowModel247.886914

18

44 _p 49 46 _46

129

_ U" -"45

17

131-GasketKit-Complete

132-GasketKit-External

133- CompleteEngine

40

Page 41

CraftsmanEngineModel270-SUAForSnowModel247.886914

1

710-04968

2

951-11054A

3a

731-07059

3b

726-04101

4

951-11565

5

951-12000

6

951-11892

7

751-11124

8

751-11123

9

951-11893

10

710-04902

11

951-12002

12

951-12003

13

951-12004

14

951-11894

15

710-04933

16

951-11895

17

951-10722B

18

951-10292

44

951-11572

45

951-10648

46

951-11899

47

715-04108

48

951-10647A

49

951-10647A

129

951-12626

131

951-11059A

132

951-10661B

133

952Z270-SUA

ID - o 0

Flange Bolt M6

Valve Cover

Hose-Breather

Clamp-Breather Hose

Valve Cover Gasket

Intake Valve Spring Retainer

Rocker Arm Assembly

Nut - Pivot Lockin

Nut - Valve Adjust

Rocker Arm

Bolt - Pivot

Exhaust Valve Adjuster

Exhaust Valve Spring Retainer

Valve Spring

Intake Valve Seal

Bolt - M8 X 55 Zin

Push Rod Guide

Cylinder Head Assembly

(Incl. 4-14,16,17,21,27-29, 44,48,49)

Plug:Spark

Gasket-Cylinder Head

Kit-Push Rod

Tappet

Pin-Dow110 X 16

Valve Kit

Valve Kit

Valve Cover Kit

Gasket Kit-Complete

(Incl. 4,21,27-29,32,44,58,59,68,74,77,79)

Gasket Kit-External (Incl. 4,21,27 29,32,77)

Complete Engine

41

Page 42

CraftsmanEngineModel270-SUAForSnowModel247.886914

27

28

134-CarburetorKit-Deni

135-CarburetorKit-Huayi

d\

e_

w

42

Page 43

CraftsmanEngineModel270-SUAForSnowModel247.886914

25

710-04939

26

710-04910

27

951-11567

28

951-11896

29

951-11569A

30

951-10639A

30

951-11824

31

951-14026A

31

951-14027A

32

951-11897

33

951-11112

134

951-14154

135

951-12788A

a

n/a

b

n/a

C

n/a

d

n/a

e

710-05469

f

736-04638

n/a

g

h

n/a

I

n/a

n/a

J

k

951-11699

I

951-11906

m

n/a

n

n/a

o

n/a

951-12875

P

n/a

q

r

n/a

s

n/a

t

951-11589

U

n/a

V

951-11348

710-04945

W

951-11349

X

710-04938

Y

II _ o w

Stud-Carb

Stud- M6X 105

Gasket-Carb Insulator

Carburetor Insulat

Carburetor Gasket

Primer

Primer Bulb

Carburetor Assembly - Huayi

Carburetor Assembly - Deni

Carburetor Gasket

Bracket- Choke Control

Carburetor Kit- Deni

(Incl. h,n,o,p,q,r,s,t,u,x)

Carburetor Kit- Huayi

(Incl. h,n,o,p,q,r,s,t,u,x)

Choke Shaft

Choke Plate

Throttle Shaft

Throttle Plate

Screw M3x5

LockWasher

Gasket, Throttle Plate

Idle Jet Assembly

Idle Speed Adjusting Screw

Mixture Screw

Primer Hose

Hose Clamp

Carburetor Body

Float Pin

Emulsion Tube

Float Needle Valve

Main Jet

Needle Valve Spring

Float

Fuel Bowl Gasket

Fuel Bowl

Fuel Bowl Gasket

Fuel Bowl Mounting Bolt

Fuel Drain Plug Gasket

Fuel Drain Plug

43

Page 44

CraftsmanEngineModel270-SUAForSnowModel247.886914

82

86

84

85

92

8O

81

82

83

84

85

86

87

88

9O

91

92

93

951-10646

951-11110

710-04940

710-04919

951-12416

951-10934

951-10911

712-04209

710-04915

951-10663A

736-04455

710-04974

951-14151

D - ® ®

Ignition Coil

Shield - Air Flow

Bolt

Bolt - Flange M6

Flywheel

Cooling Fan

Starter Cup

Nut- M14

Bolt- M6X 12 Zin

Fan Cover Complete

Flat Washer-Recoil

Flange Bolt M6

Recoil Start Assembly

44

Page 45

CraftsmanEngineModel270-SUAForSnowModel247.886914

,114

115

94

95

96

97

98

99

101

102

103

104

105

106

951-10758

710-05103

951-I 1108

951-I 1935

951-10664

951-I0665

951-l I 106

712-04212

710-04908

951-I1700

951-I0650

710-04915

94

D - o o

Throttle Control Assembly

Bolt-M6 X 12

Shield - Governor

Governor Spring

Spring-Throttle Return

Rod-Governor

Bracket- Governor

Nut- M6

Bolt - M6 X 21 Gov

Hose Clamp-Carb

Kit-Fuel Line

Bolt - M6 X 12 Zin

105

104

107

108

109

110

111

112

113

114

115

116

117

951-11914

710-04905

710-04915

951-11913

951-11381

951-10656

951-11904

951-12482

951-12533

951-11933

951-10653B

D - o

Engine/Dipstick Cover

Bolt

Bolt- M6 X 12 Zin

Oil Fill Tube Assembly

O-Ring

Dipstick Tube

O-Ring Dipstick

Dipstick Assy

Fuel Cap

Fuel Level Indicator

Fuel Tank

45

Page 46

CraftsmanEngineModel270-SUAForSnowModel247.886914

118

119

120

121

m

118

119

120

121

122

123

124

125

126

127

128

121

710-04914

951-11680

951-11114

712-05015

710-04965

710-04935

710-05182

715-04088

951-I0645A

710-04915

951-11109

123

124

D - o e

Bolt- Flange M6

Flexible Clamp

Bracket- Switch Housing Mount

Nut

Screw M4 X 55