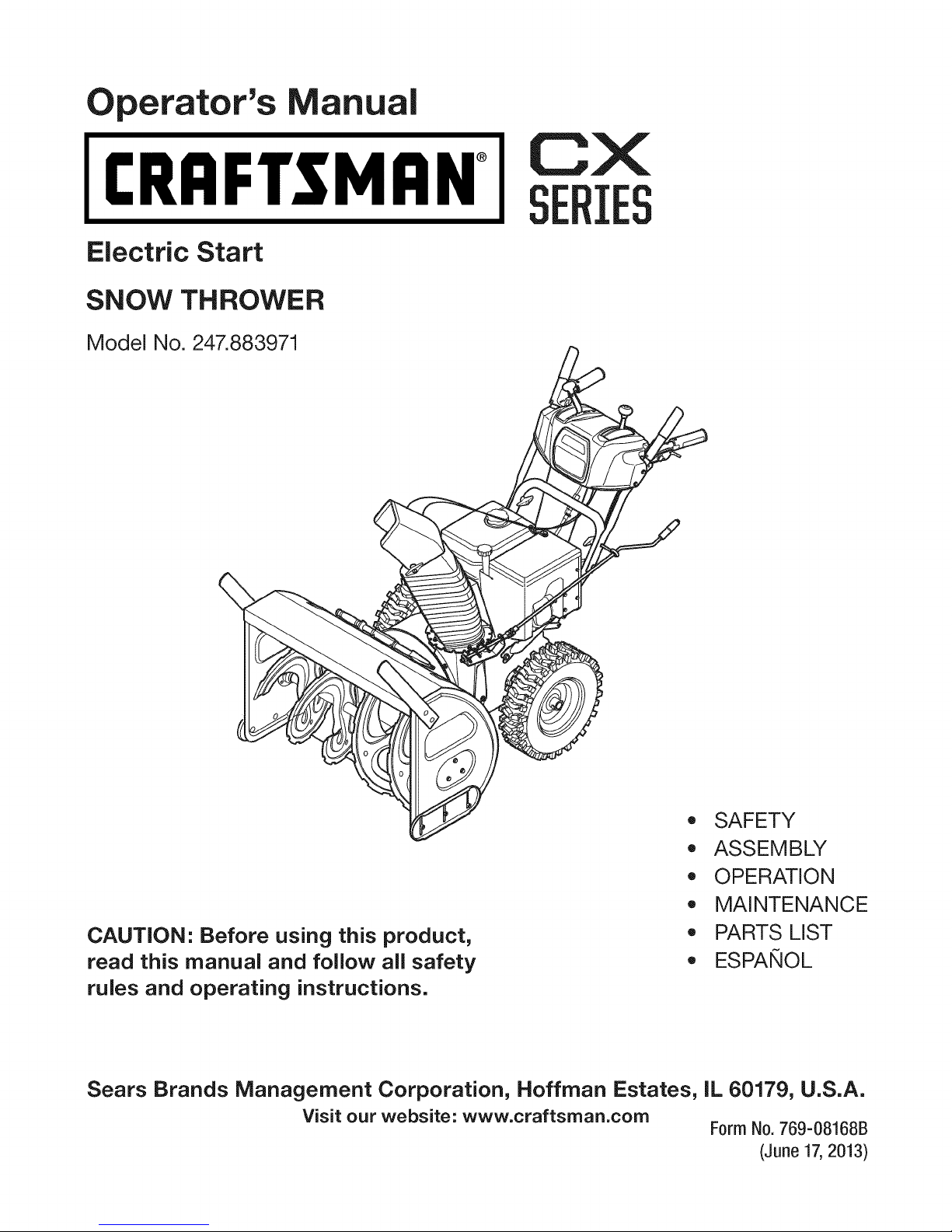

Page 1

perator's nual

I:RRFrSMAN+

Electric Start

SNOW THROWER

Model No. 247.883971

CX

IES

CAUTION" Before using this product,

read this manual and follow all safety

rules and operating instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com

,, SAFETY

o ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

Form No.769-08168B

(June 17,2013)

Page 2

Warranty Statement .................................. Page 2

Safe Operation Practices .......................... Page 3

Assembly .................................................. Page 7

Operation .................................................. Page 12

Service and Maintenance ......................... Page 17

Off-Season Storage .................................. Page 25

Troubleshooting ........................................ Page 27

Parts List ................................................... Page 28

Repair Protection Agreement ................... Page 47

Espa_ol ..................................................... Page 48

Service Numbers ...................................... Back Cover

CRAFTSMANCXTWOYEARFULLWARRANTY

FORTWOYEARSfromthe dateofpurchase,thisproductiswarrantedagainstanydefectsin materialorworkmanship.A defective

productwillreceivefree repairorreplacementif repairisunavailable.

Forwarranty coveragedetails to obtain free repairor replacement,visitthe website: www.craftsman.com

Thiswarranty coversONLYdefects in materialandworkmanship. Warranty coveragedoes NOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedtoaugers,augerpaddles,

driftcutters,skidshoes,shaveplate,shearpins,sparkplug,aircleaner,belts,andoil filter.

• Standardmaintenanceservicing,oilchanges,or tune-ups.

• Tirereplacementorrepaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbutnotlimitedto damagecausedbyover-speedingtheengine,orfrom

impactingobjectsthatbendthe frame,augershaft,etc.

• Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricaland mechanicaldamagecausedby

improperstorage,failureto usethepropergradeandamountof engineoil,or failureto maintaintheequipmentaccordingtothe

instructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfuel determinedtobecontaminatedor oxidized(stale).Ingeneral,fuelshouldbe

usedwithin30 daysofitspurchasedate.

• Normaldeteriorationandwearof theexteriorfinishes,orproductlabelreplacement.

Thiswarrantyisvoidif thisproductiseverusedwhileprovidingcommercialservicesor if rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

SearsBrands ManagementCorporation, Hoffman Estates, IL 60179

EngineOilType: 5W-30

EngineOilCapacity: 37ounces

FuelCapacity: Approx.5 Quarts

SparkPlug: F6RTC(951-10292)

SparkPlugGap: .020"to.030"

© SearsBrands,LLC

Model Number.................................................................

Serial Number.................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Page 3

Thissymbolpointsout importantsafety instructionswhich,if not

followed,couldendangerthe personalsafetyand/orproperty of

yourselfandothers.Readandfollow all instructionsinthis manual

beforeattempting to operatethis machine.Failuretocomplywith these

instructionsmayresultinpersonalinjury.Whenyouseethis symbol,HEED

ITSWARNING!

Thismachinewasbuilt to beoperatedaccordingtothesafeoperation

practicesinthismanual.Aswith anytype of powerequipment,

carelessnessorerroronthe part ofthe operatorcanresultinseriousinjury.

Thismachineiscapableof amputatingfingers, hands,toesandfeet and

throwingdebris.Failuretoobservethefollowing safety instructionscould

resultinseriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someofits constituents,and certainvehiclecomponents

containor emit chemicalsknownto Stateof Californiatocausecancerand

birth defectsorother reproductiveharm.

TRAINING

Read,understand,andfollowall instructionsonthemachineandinthe

manual(s)beforeattemptingtoassembleandoperate.Failuretodosocan

resultinseriousinjurytotheoperatorand/orbystanders.Keepthismanual

inasafeplaceforfutureandregularreferenceandfororderingreplacement

parts.

Befamiliarwith allcontrolsandtheirproperoperation.Knowhowtostop

themachineanddisengagethemquickly.

Neverallowchildrenunder14yearsofagetooperatethismachine.Children

14andovershouldreadandunderstandtheinstructionsandsafeoperation

practicesinthis manualandonthemachineandbetrainedandsupervised

byanadult.

Neverallowadultsto operatethismachinewithout properinstruction.

Thrownobjectscancauseseriouspersonalinjury.Planyoursnow-throwing

patterntoavoiddischargeofmaterialtowardroads,bystandersandthelike.

Keepbystanders,petsandchildrenat least75feetfromthemachinewhileit

isin operation.Stopmachineif anyoneentersthearea.

Exercisecautiontoavoidslippingorfalling,especiallywhenoperatingin

reverse.

PREPARATION

Thoroughlyinspecttheareawheretheequipmentistobeused.Removeall

doormats,newspapers,sleds,boards,wiresandotherforeignobjects,which

couldbetrippedoverorthrownbytheauger/impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationandwhile

performinganadjustmentor repairto protectyoureyes.Thrownobjects

whichricochetcancauseseriousinjuryto theeyes.

Donotoperatewithout wearingadequatewinteroutergarments.Donot

wearjewelry,longscarvesorotherlooseclothing,whichcouldbecome

entangledinmovingparts.Wearfootwearwhichwill improvefootingon

slipperysurfaces.

Usea groundedthree-wireextensioncordandreceptacleforallmachines

with electricstartengines.

Your Responsibility--Restrict theuseofthis powermachineto

personswhoread,understandandfollow thewarningsandinstructionsin

thismanualandonthe machine.

SAVETHESEINSTRUCTIONS!

Disengageallcontrolleversbeforestartingtheengine.

Adjustcollectorhousingheighttocleargravelorcrushedrocksurfaces.

Neverattempttomakeanyadjustmentswhileengineisrunning,except

wherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjusttooutdoortemperaturebeforestartingto

clearsnow.

Safe Handling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecareinhandling

gasoline.Gasolineisextremely flammableandthe vaporsareexplosive.

Seriouspersonalinjurycanoccurwhengasolineisspilledonyourselforyour

clotheswhichcanignite.Washyourskinandchangeclothesimmediately.

Useonlyanapprovedgasolinecontainer.

Neverfill containersinsidea vehicleoronatruckortrailerbedwitha plastic

liner.Alwaysplacecontainersonthegroundawayfromyourvehiclebefore

filling.

Whenpractical,removegas-poweredequipmentfromthetruckor

trailerandrefuelitontheground.Ifthisis notpossible,thenrefuelsuch

equipmentonatrailerwith aportablecontainer,ratherthanfromagasoline

dispensernozzle.

Keepthenozzleincontactwiththerimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Donotuseanozzlelock-opendevice.

Extinguishallcigarettes,cigars,pipesandothersourcesofignition.

Neverfuelmachineindoors.

Neverremovegascaporaddfuelwhiletheengineishotorrunning.Allow

enginetocoolatleasttwominutesbeforerefueling.

Neveroverfill fueltank.Filltankto nomorethan1/2inchbelowbottomof

fillernecktoallowspaceforfuelexpansion.

Replacegasolinecapandtightensecurely.

Ifgasolineisspilled,wipeit offthe engineandequipment.Moveunitto

anotherarea.Wait.5minutesbeforestartingtheengine.

Page 4

Toreducefirehazards,keepmachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillageandremoveanyfuelsoakeddebris.

Neverstorethemachineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlightasonawaterheater,spaceheater,furnace,clothes

dryerorothergasappliances.

OPERATION

Donotputhandsorfeetnearrotatingparts,intheauger/impellerhousing

orchuteassembly.Contactwith therotatingpartscanamputatehandsand

feet.

Theauger/impellercontrolleverisasafetydevice.Neverbypassits

operation.Doingsomakesthemachineunsafeandmaycausepersonal

injury.

Thecontrolleversmustoperateeasilyin bothdirectionsandautomatically

returntothedisengagedpositionwhenreleased.

Neveroperatewith amissingordamagedchuteassembly.Keepallsafety

devicesinplaceandworking.

Neverrunanengineindoorsor inapoorlyventilatedarea.Engineexhaust

containscarbonmonoxide,anodorlessanddeadlygas.

Donotoperatemachinewhileundertheinfluenceof alcoholordrugs.

Mufflerandenginebecomehotandcancauseaburn.Donottouch.Keep

childrenaway.

Exerciseextremecautionwhenoperatingonorcrossinggravelsurfaces.Stay

alertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingonslopes.Do

notoperateonsteepslopes.

Planyoursnow-throwingpatterntoavoiddischargetowardswindows,

walls,carsetc.Thus,avoidingpossiblepropertydamageorpersonalinjury

causedbyaricochet.

Neverdirectdischargeatchildren,bystandersandpetsor allowanyonein

frontofthemachine.

Donotoverloadmachinecapacitybyattemptingtoclearsnowattoofastof

arate.

Neveroperatethismachinewithoutgoodvisibilityorlight.Alwaysbesureof

yourfootingandkeepafirm holdonthehandles.Walk,neverrun.

Disengagepowertotheauger/impellerwhentransportingornotinuse.

Neveroperatemachineathightransportspeedsonslipperysurfaces.Look

downandbehindandusecarewhenbackingup.

Ifthemachineshouldstartto vibrateabnormally,stoptheengine,

disconnectthesparkplugwire andgrounditagainsttheengine.Inspect

thoroughlyfordamage.Repairanydamagebeforestartingandoperating.

Disengageallcontrolleversandstopenginebeforeyouleavetheoperating

position(behindthehandles).Waituntiltheauger/impellercomesto

acompletestopbeforeuncloggingthechuteassembly,makingany

adjustments,orinspections.

Neverputyourhandin thedischargeorcollectoropenings.Donotunclog

chuteassemblywhileengineisrunning.Shutoff engineandremainbehind

handlesuntilallmovingpartshavestoppedbeforeunclogging.

Useonlyattachmentsandaccessoriesapprovedbythemanufacturer(e.g.

wheelweights,tirechains,cabsetc.).

Whenstartingengine,pull cordslowlyuntilresistanceisfelt,thenpull

rapidly.Rapidretractionofstartercord(kickback)will pullhandandarm

towardenginefasterthanyoucanletgo.Brokenbones,fractures,bruisesor

sprainscouldresult.

Ifsituationsoccurwhicharenotcoveredinthismanual,usecareandgood

judgment.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththerotatingimpellerinsidethedischargechuteisthemost

commoncauseof injuryassociatedwithsnowthrowers.Neveruseyourhandto

cleanoutthedischargechute.

Toclearthechute:

a. SHUTTHEENGINEOFF!

b. Wait10secondsto besuretheimpellerbladeshavestopped

rotating.

c. Alwaysuseaclean-outtool,notyourhands.

MAINTENANCE & STORAGE

Nevertamperwithsafetydevices.Checktheirproperoperationregularly.

Refertothemaintenanceandadjustmentsectionsofthismanual.

Beforecleaning,repairing,orinspectingmachinedisengageallcontrol

leversandstoptheengine.Waituntiltheauger/impellercometoacomplete

stop.Disconnectthesparkplugwireandgroundagainsttheengineto

preventunintendedstarting.

Checkboltsandscrewsforpropertightnessatfrequentintervalsto keepthe

machineinsafeworkingcondition.Also,visuallyinspectmachineforany

damage.

Donotchangetheenginegovernorsettingorover-speedtheengine.The

governorcontrolsthemaximumsafeoperatingspeedoftheengine.

Snowthrowershaveplatesandskidshoesaresubjecttowearanddamage.

Foryoursafetyprotection,frequentlycheckallcomponentsandreplace

with originalequipmentmanufacturer's(OEM)partsonlyaslistedinthe

Partspagesofthisoperator'smanual.Useof partswhichdonot meetthe

originalequipmentspecificationsmayleadtoimproperperformanceand

compromisesafety!

Checkcontrolleversperiodicallytoverifytheyengageanddisengage

properlyandadjust,ifnecessary.Refertotheadjustmentsectioninthis

operator'smanualfor instructions.

Maintainorreplacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsandregulationsforgas,oil,etc.toprotectthe

environment.

Priortostoring,runmachineafewminutestoclearsnowfrommachineand

preventfreezeupofauger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlight suchasa waterheater,furnace,clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionsonoff-season

storage.

4

Page 5

Checkfuelline,tank,cap,andfittingsfrequentlyforcracksor leaks.Replace

if necessary.

Donotcrankenginewith sparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)andthe

U.S.EnvironmentalProtectionAgency(EPA),thisproducthasanAverage

Useful Lifeofseven(7)years,or60hoursofoperation.Attheendof

theAverage Useful Lifehavethemachineinspectedannuallybyan

authorizedservicedealertoensurethatallmechanicalandsafetysystems

areworkingproperlyandnotwornexcessively.Failureto dosocanresultin

accidents,injuriesordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donotmodifyengineinanyway.Tampering

with the governorsetting canleadto arunawayengineandcauseit to

operateat unsafespeeds.Nevertamperwith factorysetting ofengine

governor.

NOTICE REGARDING EMiSSiONS

Engineswhichare certifiedto complywith Californiaandfederal EPA

emissionregulationsfor SORE(SmallOffRoadEquipment)arecertified

tooperateonregularunleadedgasoline,and mayincludethe following

emissioncontrolsystems:EngineModification (EM),OxidizingCatalyst(0C),

SecondaryAir injection(SAI)andThreeWayCatalyst(TWC)if soequipped.

SPARK ARRESTOR

e

Thismachineisequippedwith an internalcombustionengineandshould

not beusedonornearanyunimprovedforest-covered,brushcoveredor

grass-coveredland unlessthe engine'sexhaustsystemisequippedwith a

sparkarrestormeetingapplicablelocalorstatelaws(if any).

Ira sparkarrestorisused,it shouldbemaintainedin effectiveworking order

bythe operator.IntheState ofCaliforniathe aboveisrequired bylaw (Section

4442ofthe CaliforniaPublicResourcesCode).Otherstates mayhavesimilar

laws.Federallawsapplyonfederal lands.

Asparkarrestorfor the muffler isavailablethroughyournearestSearsParts

andRepairServiceCenter.

Page 6

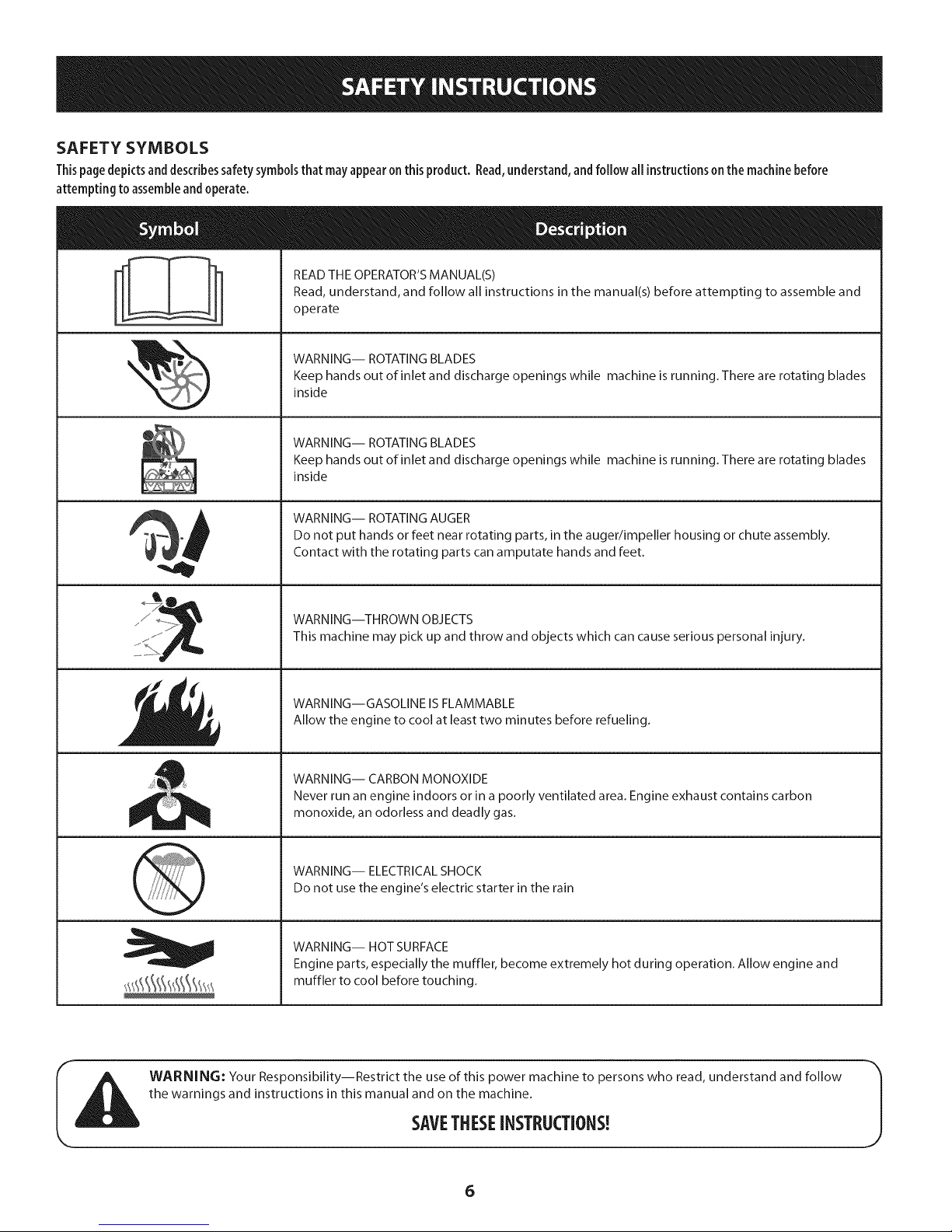

SAFETY SYMBOLS

Thispage depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine before

attempting to assemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

WARNING: Your Responsibility--Restrict the use of this power machine to persons who read, understand and follow

the warnings and instructions in this manual and on the machine.

SAVETHESEiNSTRUCTIONS!

6

Page 7

NOTE:Referencesto rightorleftsideofthesnowthroweraredeterminedfromthe

operatingpositionlookingforwardto thefrontofthemachine.

Removing From (:rate

1. Removescrewsfromthebottomofthecratesecuringthesides,andendsof

theshippingcrate.

2. Liftoff thetopoffofthecrateandsetoutof thewayoftheassemblyarea.

3. Removeanddiscardplasticbagthat coversunit.

4. Removeanyloosepartsincludedwithunit(e.g.,Operator'sManual,etc.).

5. Pushdownonthe lowerhandleandpullunitbackoutofcrate.

6. Makecertainthecratehasbeencompletelyemptiedbeforediscardingit.

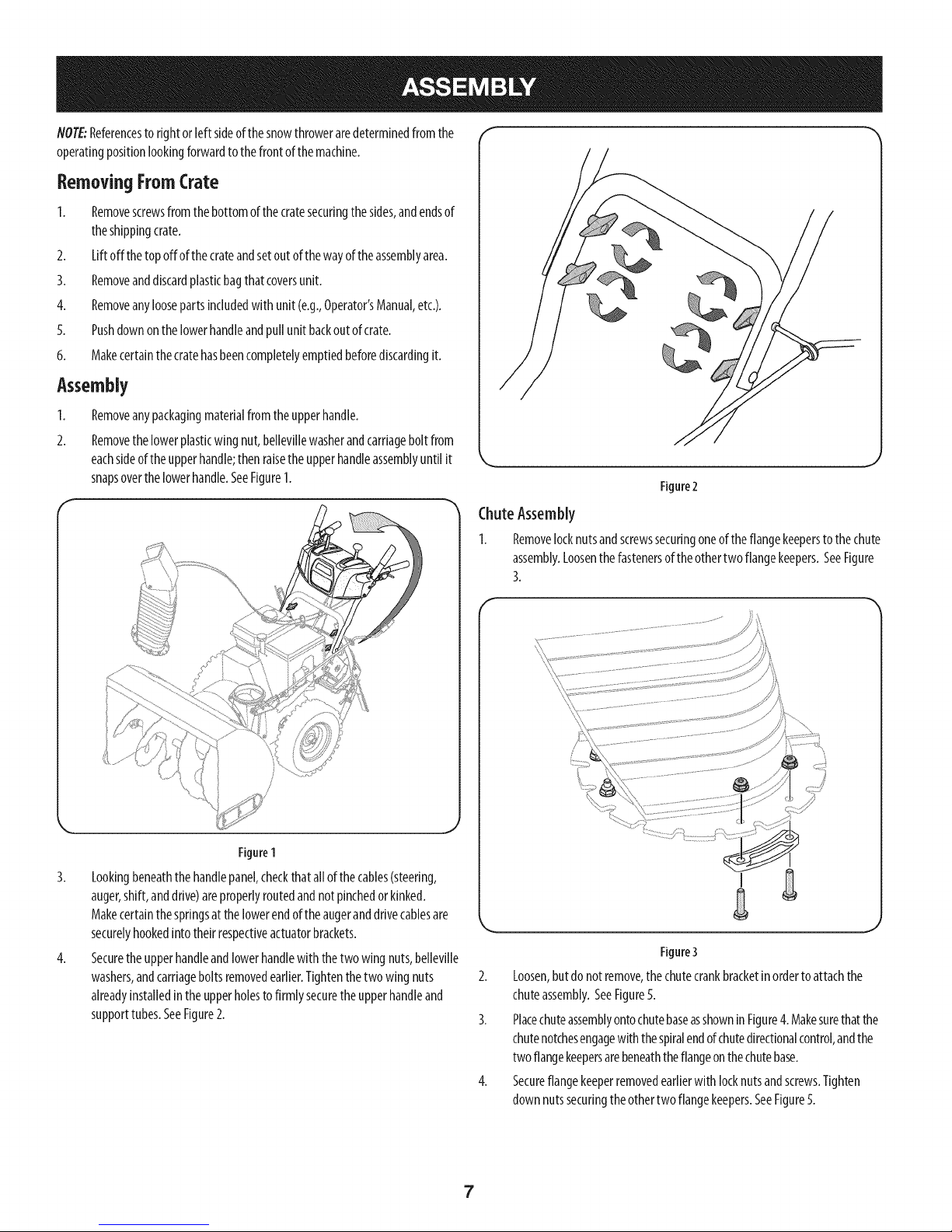

Assembly

1. Removeanypackagingmaterialfromtheupperhandle.

2. Removethelowerplasticwingnut,bellevillewasherandcarriageboltfrom

eachsideoftheupperhandle;thenraisetheupperhandleassemblyuntilit

snapsoverthelowerhandle.SeeFigure1.

"_,r ,,J

Figure2

ChuteAssembly

1. Removelocknutsandscrewssecuringoneoftheflangekeeperstothechute

assembly.Loosenthefastenersoftheothertwoflangekeepers.SeeFigure

3.

Figure1

3. Lookingbeneaththehandlepanel,checkthatallofthecables(steering,

auger,shift,anddrive)areproperlyroutedandnotpinchedorkinked.

Makecertainthespringsatthelowerendoftheaugeranddrivecablesare

securelyhookedintotheirrespectiveactuatorbrackets.

4. Securetheupperhandleandlowerhandlewiththetwo wingnuts,belleville

washers,andcarriageboltsremovedearlier.Tightenthetwowingnuts

alreadyinstalledin theupperholestofirmly securetheupperhandleand

supporttubes.SeeFigure2.

f

Figure3

2. Loosen,butdonotremove,thechutecrankbracketinordertoattachthe

chuteassembly.SeeFigure5.

3. PlacechuteassemblyontochutebaseasshowninFigure4.Makesurethatthe

chutenotchesengagewith thespiralendofchutedirectionalcontrol,andthe

twoflangekeepersarebeneaththeflangeonthechutebase.

4. Secureflangekeeperremovedearlierwith locknutsandscrews.Tighten

downnutssecuringtheothertwoflangekeepers.SeeFigure5.

7

Page 8

/ /

/ /

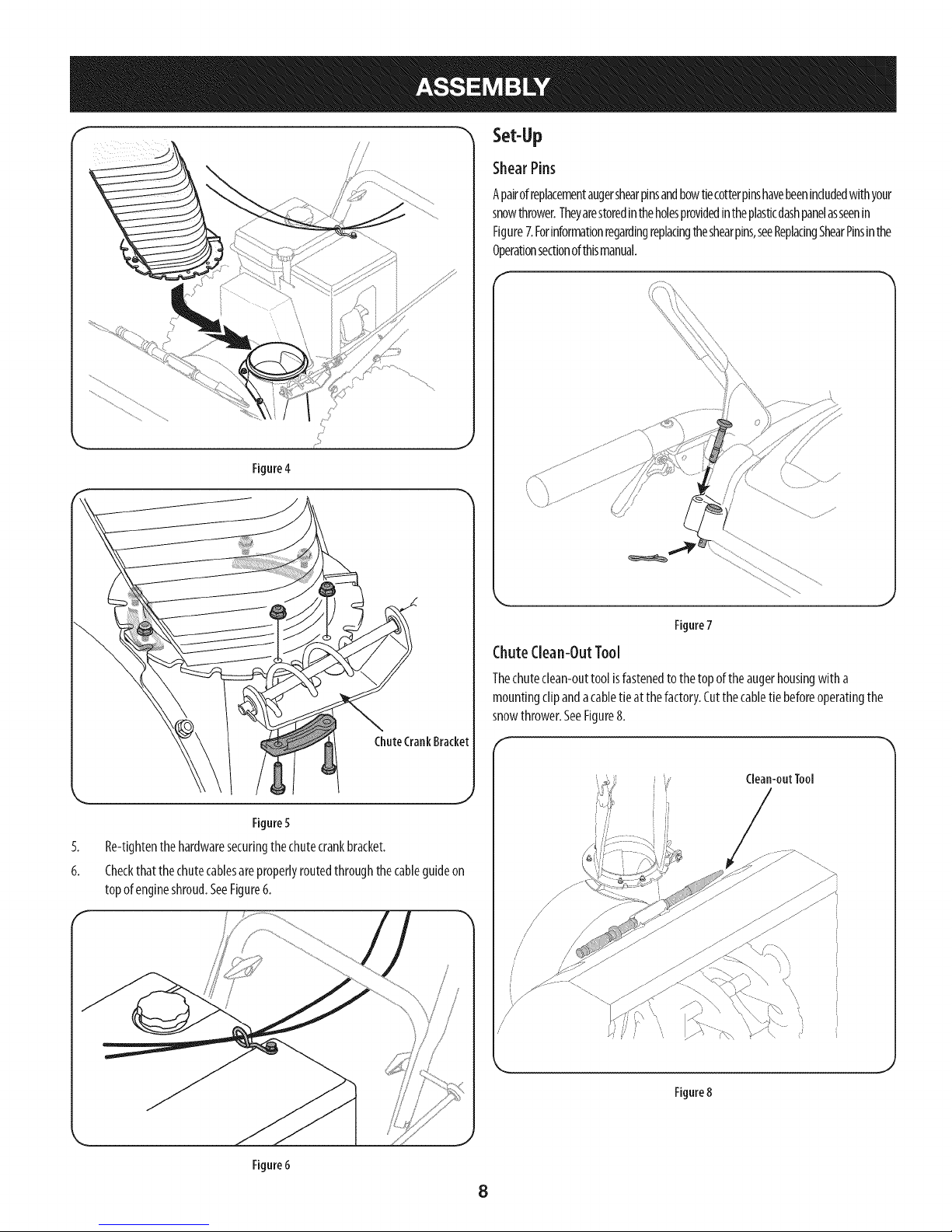

Set-Up

ShearPins

Apairofreplacementaugershearpinsandbowtiecotterpinshavebeenincludedwithyour

snowthrower.Theyarestoredintheholesprovidedintheplasticdashpanelasseenin

Figure7.Forinformationregardingreplacingtheshearpins,seeReplacingShearPinsinthe

Operationsectionofthismanual.

Figure4

Figure5

5.

Re-tightenthehardwaresecuringthechutecrankbracket.

6.

Checkthatthechutecablesareproperlyroutedthroughthecableguideon

topofengineshroud.SeeFigure6.

......

Figure7

ChuteClean-OutTool

Thechutedean-outtool isfastenedtothetopof theaugerhousingwitha

mountingclipandacabletieat thefactory.Cutthecabletie beforeoperatingthe

snowthrower.SeeFigure8.

Clean-outTool

Figure6

/

/

/

/

/

J

Figure8

8

Page 9

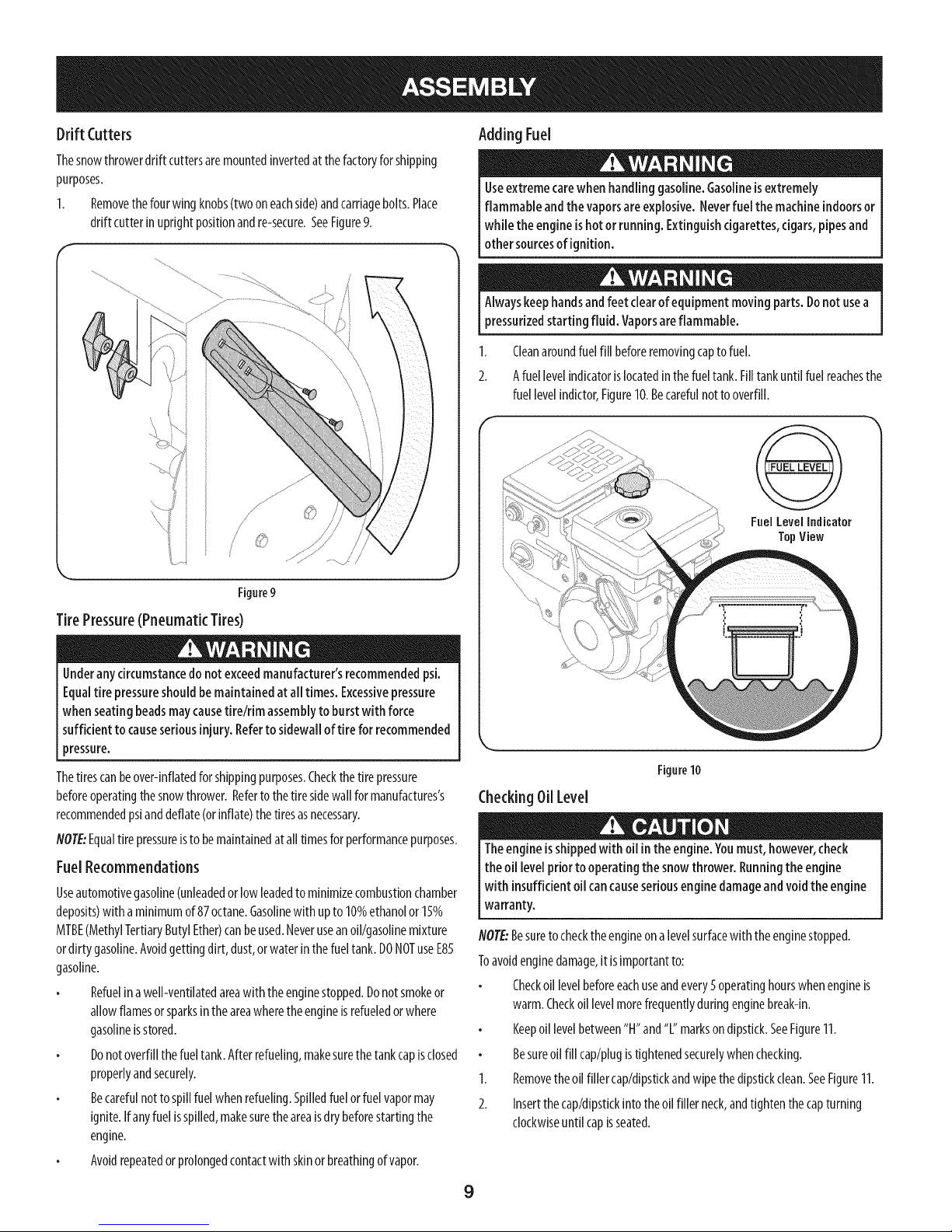

DriftCutters

Thesnowthrowerdrift cuttersaremountedinvertedatthefactoryforshipping

purposes.

1. Removethefourwing knobs(twooneachside)andcarriagebolts.Place

driftcutterinuprightpositionandre-secure.SeeFigure9.

Figure9

Adding Fuel

Useextremecarewhen handlinggasoline.Gasolineisextremely

flammable andthe vaporsareexplosive.Neverfuel the machineindoorsor

whiletheengineishotorrunning.Extinguishcigarettes,cigars,pipesand

othersourcesofignition.

Alwayskeephandsandfeet clearof equipmentmovingparts.Donot usea

pressurizedstarting fluid. Vaporsareflammable.

1. Cleanaroundfuelfillbeforeremovingcaptofuel.

2. Afuellevelindicatorislocatedinthefueltank.Filltankuntilfuelreachesthe

fuellevelindictor,Figure10,Becarefulnotto overfill,

FuelLevelIndicalor

TopView

J

TirePressure(Pneumatic Tires)

Underanycircumstancedonotexceedmanufacturer'srecommendedpsi.

Equaltire pressureshould bemaintainedatall times.Excessivepressure

whenseatingbeadsmaycausetire/rim assemblyto burstwithforce

sufficientto causeseriousinjury.Referto sidewalloftire forrecommended

pressure.

Thetirescanbeover-inflatedfor shippingpurposes.Checkthetire pressure

beforeoperatingthesnowthrower.Referto thetiresidewallformanufactures's

recommendedpsianddeflate(orinflate)thetiresasnecessary.

NOTE:Equaltire pressureisto bemaintainedat alltimesforperformancepurposes.

FuelRecommendations

Useautomotivegasoline(unleadedorlowleadedtominimizecombustionchamber

deposits)withaminimumof87octane.Gasolinewith upto10%ethanolor1__%

MTBE(MethylTertiaryButylEther)canbeused.Neveruseanoil/gasolinemixture

ordirtygasoline.Avoidgettingdirt, dust,orwaterinthefueltank.DONOTuseE85

gasoline.

Refuelinawell-ventilatedareawith theenginestopped.Donotsmokeor

allowflamesorsparksintheareawheretheengineisrefueledorwhere

gasolineisstored.

Donotoverfillthefueltank.Afterrefueling,makesurethetankcapisclosed

properlyandsecurely.

Becarefulnottospillfuelwhenrefueling.Spilledfuelorfuelvapormay

ignite.Ifanyfuelisspilled,makesuretheareaisdrybeforestartingthe

engine.

Avoidrepeatedorprolongedcontactwith skinorbreathingofvapor.

Figure10

CheckingOil Level

Theengineisshippedwithoilintheengine.Youmust, however,check

the oiilevel priorto operatingthesnowthrower. Runningthe engine

with insufficientoilcancauseseriousenginedamageandvoidthe engine

warranty.

NOTE:Besuretochecktheengineona levelsurfacewith theenginestopped.

Toavoidenginedamage,it isimportantto:

Checkoil levelbeforeeachuseandevery5operatinghourswhenengineis

warm.Checkoillevelmorefrequentlyduringenginebreak-in.

Keepoil levelbetween"H"and"L"marksondipstkk.SeeFigure11.

Besureoil fillcap/plugistightenedsecurelywhenchecking.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.SeeFigure11.

2. Insertthecap/dipstickintotheoil fillerneck,andtightenthecapturning

clockwiseuntil capisseated.

9

Page 10

f

Figure11

NOTE:Onsomeengines,athreadedscrewcapwill bepresentinsteadofthequarter

turnlockingcap.Intheinstanceofathreadedoilcap/dipstkk,DONOTscrewthe

cap/dipstkkintocheck.Checktheoilbyrestingthecap/dipstkkonthethreads,but

notscrewingit in.

3. Removetheoilfillercap/dipstick.Ifthelevelislow,slowlyaddoil untiloil

levelregistersbetweenhigh(H)andlow(L),Figure11.

4. Replaceandtightencap/dipstkkfirmlybeforestartingengine.

NOTE:Donotoverfill.Overfillingwith oilmaycausesmoking,hardstarting,or

sparkplugfouling.

NOTE:DONOTallowoilleveltofall belowthe"L" markonthedipstick.Doingso

mayresultinequipmentmalfunctionsordamage.

NOTE"Tochangetheoilonyourengine,seetheMaintenanceSectionoftheengine

operator'smanualincludedwith thesnowthrower.

Adjustments

SkidShoes

Thesnowthrowerskidshoesareadjustedupwardat thefactoryforshipping

purposes.Adjustthemdownwardpriortooperatingthesnowthrower.

It isnotrecommendedthat you operatethis snowthrowerongravelas

it caneasilypickupand throw loosegravel,causingpersonalinjury or

damagetothe snowthrower andsurroundingproperty.

Forclosesnowremovalonasmoothsurface,adjusttheskidshoessothattheshaveplate

onthebottomofthe augerhousingisjustofftheground.

Adjusttheskidshoesto alowerpositionto raisetheshaveplateoffthe ground

whenclearingunevenareas,suchasa ribbontypedrivewayoragraveldriveway

NOTE:Ifyouchoosetooperatethesnowthroweronagravelsurface,keeptheskid

shoesin positionformaximumclearancebetweenthegroundandtheshaveplate.

2. Whileobservingthedistancebetweentheshaveplateandtheground,

adjusttheskidsshoesupordowntoachievethedesiredshaveplateheight.

SeeFigure12.

3. Makecertaintheentirebottomsurfaceofskidshoesareagainsttheground

toavoidunevenwearontheskidshoes;thentightennutsandboltssecurely.

Lower

Shave

ShavePlate

Figure12

Plate

Raise

Shave

Plate

_J

Augerand DriveControl Cables

Priorto operatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performall adjustmentsto verifyyoursnowthroweris

operatingsafelyandproperly.

TestingAugerDrive Control

1. Whentheaugercontrolis releasedandinthedisengaged"up"position,the

cableshouldhaveverylittle slack.It shouldNOTbetight. Referto Figure13.

2. Inawell-ventilatedarea,startthesnowthrowerengineasinstructedinthe

Operationsectionofthis manual.MakesurethethrottleissetintheFAST

position.

3. Whilestandingintheoperator'sposition(behindthesnowthrower),engage

theauger.

4. Allowtheaugertoremainengagedforapproximatelyten(10)seconds

beforereleasingtheaugercontrol.Repeatthisseveraltimes.

NOTE:Whenengagingtheauger,youmayheara"chirp"sound.Thisis

normal,it isthe beltengagingthepulley.Asthebeltwears,thissoundwill

not beheardwhenengagingtheauger.

5. WiththethrottlecontrolintheFAST(rabbit)positionandtheaugercontrol

in thedisengaged"up"position,walktothefrontof themachine.

Toadjust the skidshoes:

1. Adjustskidshoesbylooseningthesix(threeoneachside)hexnutsand

carriageboltssecuringtheskidshoesto theaugerhousing.RefertoFigure

12.

10

Page 11

6.

ConfirmthattheaugerhascompletelystoppedrotatingandshowsNOsigns

ofmotion.IftheaugershowsANYsignsof rotating,immediatelyreturnto

theoperator'spositionandshutoffthe engine.WaitforALLmovingpartsto

stopbeforere-adjustingtheaugercontrol.

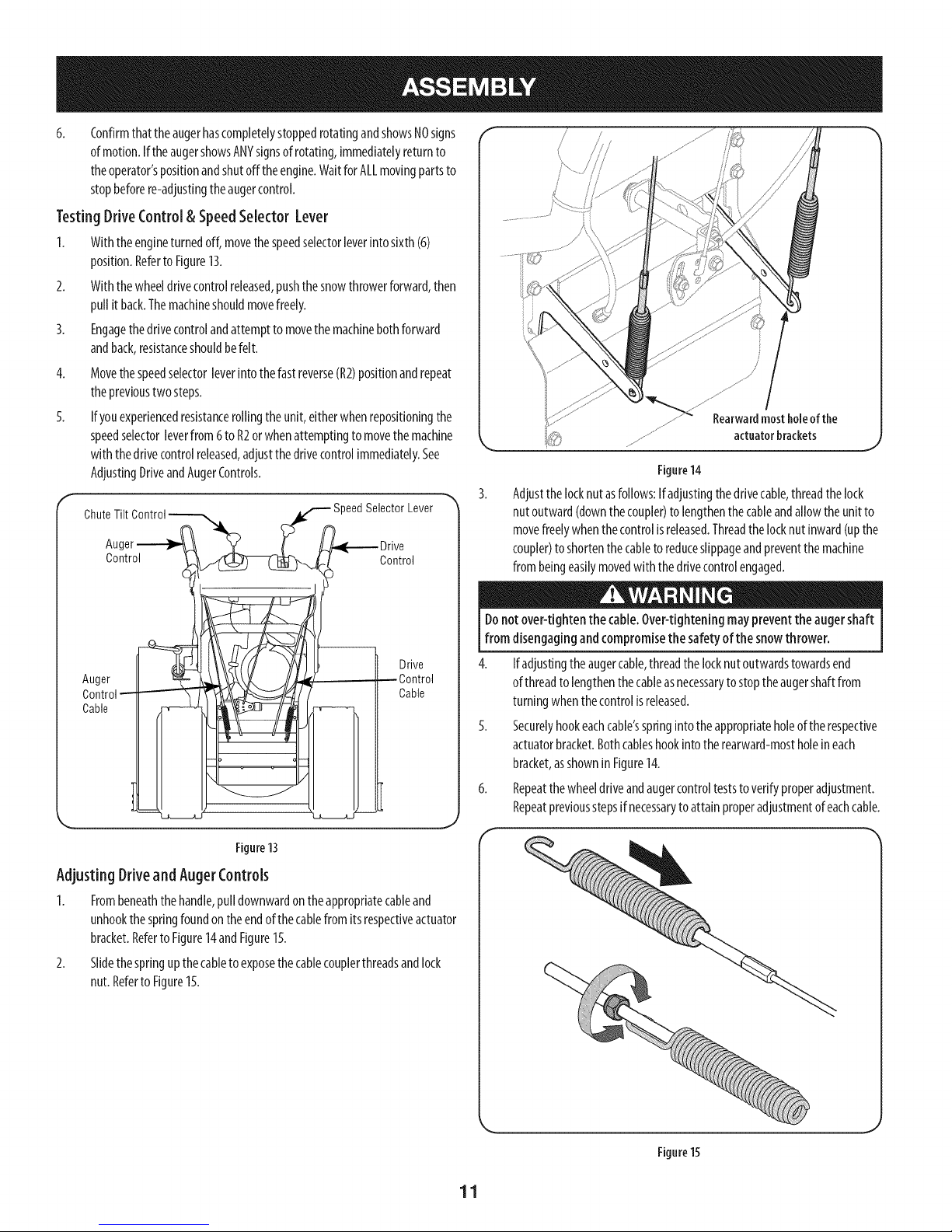

TestingDriveControl& SpeedSelector Lever

1. Withtheengineturnedoff,movethespeedselectorleverintosixth(6)

position.Referto Figure13.

2. Withthewheeldrivecontrolreleased,pushthesnowthrowerforward,then

pullit back.Themachineshouldmovefreely.

3. Engagethedrivecontrolandattempttomovethemachinebothforward

andback,resistanceshouldbefelt.

4.

Movethespeedselectorleverintothefastreverse(R2)positionandrepeat

theprevioustwosteps.

5.

Ifyouexperiencedresistancerollingtheunit,eitherwhenrepositioningthe

speedselectorleverfrom6toR2orwhenattemptingtomovethemachine

with thedrivecontrolreleased,adjustthedrivecontrolimmediately.See

AdjustingDriveandAugerControls.

ChuteTilt

Auc

Control Control

_eedSelectorLever

/

Figure14

Adjustthelocknutasfollows:If adjustingthedrivecable,threadthelock

nutoutward(downthecoupler)tolengthenthecableandallowtheunit to

movefreelywhenthecontrolisreleased.Threadthelocknutinward(upthe

coupler)toshortenthecabletoreduceslippageandpreventthemachine

frombeingeasilymovedwith thedrivecontrolengaged.

Drive

Auger

Control

Cable

Figure13

--Control

Cable

Adjusting Drive and AugerControls

1. Frombeneaththehandle,pulldownwardontheappropriatecableand

unhookthespringfoundontheendofthecablefromitsrespectiveactuator

bracket.Referto Figure14andFigure15.

2. Slidethespringupthecabletoexposethecablecouplerthreadsandlock

nut.RefertoFigure15.

Donotover-tightenthe cable.Over-tighteningmaypreventthe augershaft

from disengagingandcompromisethe safetyof the snowthrower.

4. Ifadjustingtheaugercable,threadthelocknutoutwardstowardsend

ofthreadtolengthenthecableasnecessarytostoptheaugershaftfrom

turningwhenthecontrolisreleased.

5. Securelyhookeachcable'sspringintotheappropriateholeoftherespective

actuatorbracket.Bothcableshookintotherearward-mostholeineach

bracket,asshownin Figure14.

6. Repeatthewheeldriveandaugercontrolteststo verifyproperadjustment.

Repeatpreviousstepsif necessarytoattainproperadjustmentofeachcable.

Figure15

11

Page 12

WheelDriveControl

Headlight _eedSelectorLever

FuelTank

ChutePitch Control"

erControl

FuelCap

OilFill WheelSteeringControl

ChuteAssemb[

DriftCutter

AugerHousing

Auger

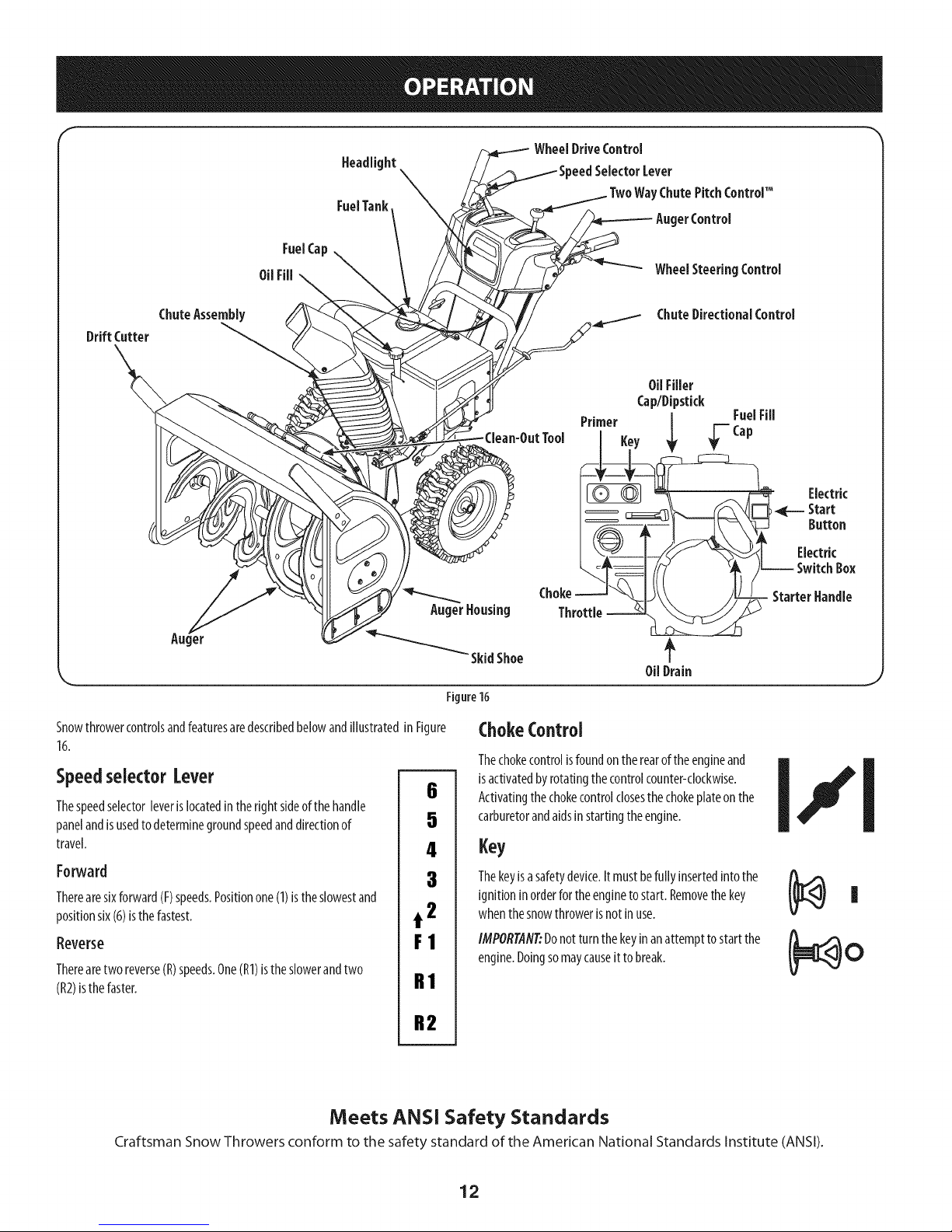

SnowthrowercontrolsandfeaturesaredescribedbelowandillustratedinFigure

16.

Speedselector Lever

Thespeedselectorleverislocatedintheright sideofthe handle

panelandisusedtodeterminegroundspeedanddirectionof

travel.

Forward

Therearesixforward(F)speeds.Positionone(1)istheslowestand

positionsix(6)isthe fastest.

Reverse

Therearetwo reverse(R)speeds.One(R1)isthe slowerandtwo

(R2)isthefaster.

6

5

4

3

t 2

F1

R1

ChuteDirectionalControl

OilFiller

Cap/Dipstick

Primer I ,-- FuNFill

Ch_ - StarterHandle

_Skid Shoe

OilDrain

Figure16

ChokeControl

Thechokecontrolisfoundontherearoftheengineand

isactivatedbyrotatingthecontrolcounter-clockwise.

Activatingthechokecontrolclosesthechokeplateonthe

carburetorandaidsinstartingtheengine.

Key

Thekeyisasafetydevice.Itmustbefully insertedintothe

ignitioninorderfortheenginetostart.Removethekey

whenthesnowthrowerisnotin use.

IMPORTANT:Donotturnthekeyinanattempttostartthe

engine.Doingsomaycauseit tobreak.

_ Electric

_ Start

Button

f Bectric

tL_ Switch Box

Craftsman Snow Throwers conform to the safety standard of the American National Standards institute (ANSI).

R2

Meets ANSi Safety Standards

12

Page 13

ThrottleControl

===..__

Thethrottlecontrolislocatedontherearoftheengine.Itregulatesthespeedofthe

engineandwillshutoffthe enginewhenmovedintotheSTOPposition.

Primer

carburetortoaidinstartinga"Cold"engine,orrestartinga

Pressingtheprimerforcesfueldirectlyintotheengine's I _,_P_.._.L

warmengine.

OilFill

Engineoillevelcanbecheckedandoiladdedthroughtheoil fill.

OilDrain

Engineoilcanbedrainedthroughtheoil drain.

FuelCap

Un-threadthegascaptoaddgasolinetothefueltank.

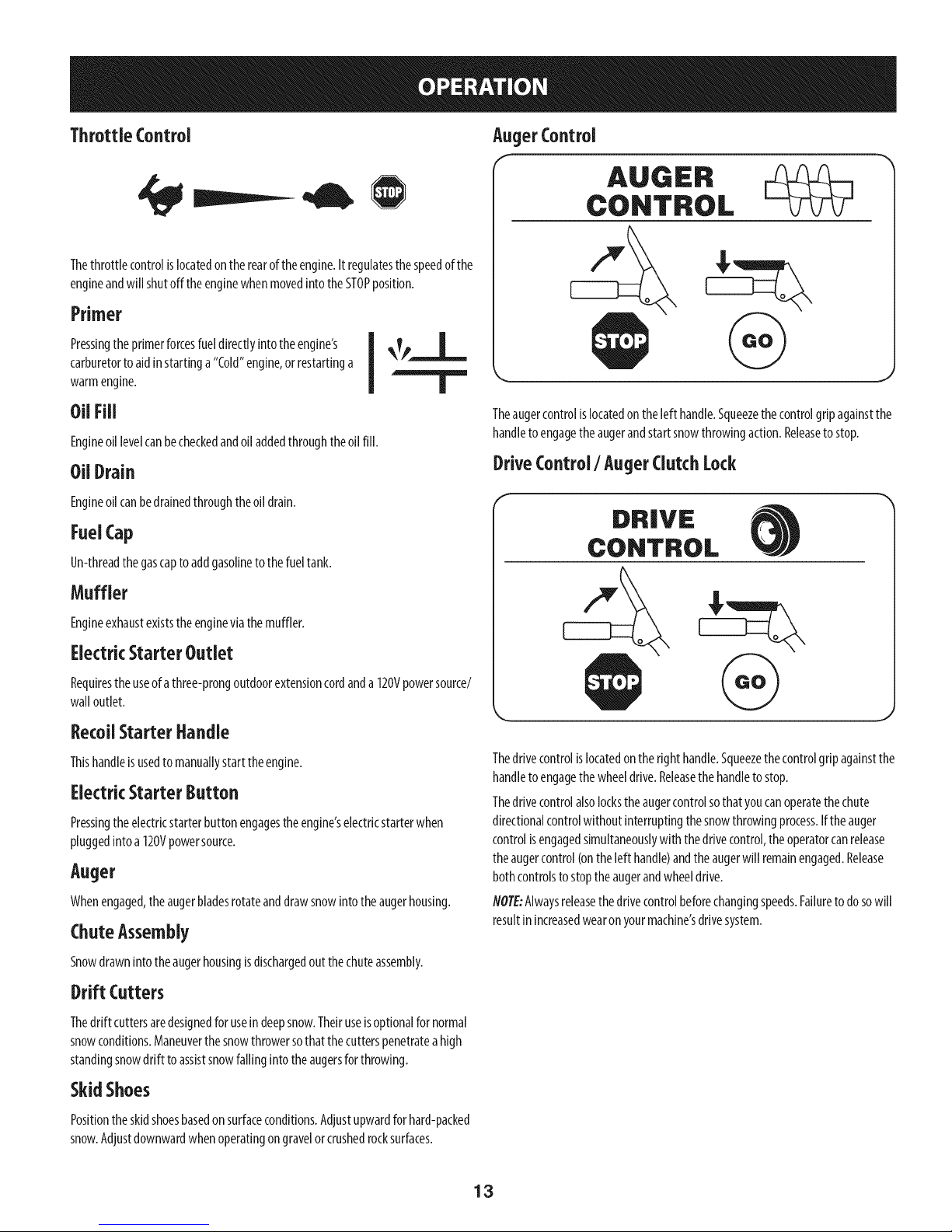

AugerControl

Theaugercontrolislocatedontheleft handle.Squeezethecontrolgripagainstthe

handletoengagetheaugerandstartsnowthrowingaction.Releasetostop.

DriveControl/ AugerClutchLock

Muffler

Engineexhaustexiststheengineviathemuffler.

ElectricStarterOutlet

Requirestheuseofathree-prongoutdoorextensioncordanda120Vpowersource/

walloutlet.

RecoilStarter Handle

Thishandleisusedto manuallystarttheengine.

ElectricStarterButton

Pressingtheelectricstarterbuttonengagestheengine'selectricstarterwhen

pluggedintoa 120Vpowersource.

Auger

Whenengaged,theaugerbladesrotateanddrawsnowintotheaugerhousing.

ChuteAssembly

Snowdrawnintotheaugerhousingisdischargedoutthechuteassembly.

Drift Cutters

Thedrift cuttersaredesignedforusein deepsnow.Theiruseisoptionalfornormal

snowconditions.Maneuverthesnowthrowersothatthecutterspenetratea high

standingsnowdriftto assistsnowfallingintotheaugersforthrowing.

Thedrivecontrolislocatedontheright handle.Squeezethecontrolgripagainstthe

handletoengagethewheeldrive.Releasethehandleto stop.

Thedrivecontrolalsolockstheaugercontrolsothatyoucanoperatethechute

directionalcontrolwithoutinterruptingthesnowthrowingprocess.Iftheauger

controlisengagedsimultaneouslywiththedrivecontrol,theoperatorcanrelease

theaugercontrol(ontheleft handle)andtheaugerwill remainengaged.Release

bothcontrolstostoptheaugerandwheeldrive.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.Failuretodosowill

resultinincreasedwearonyourmachine'sdrivesystem.

SkidShoes

Positiontheskidshoesbasedonsurfaceconditions.Adjustupwardforhard-packed

snow.Adjustdownwardwhenoperatingongravelorcrushedrocksurfaces.

13

Page 14

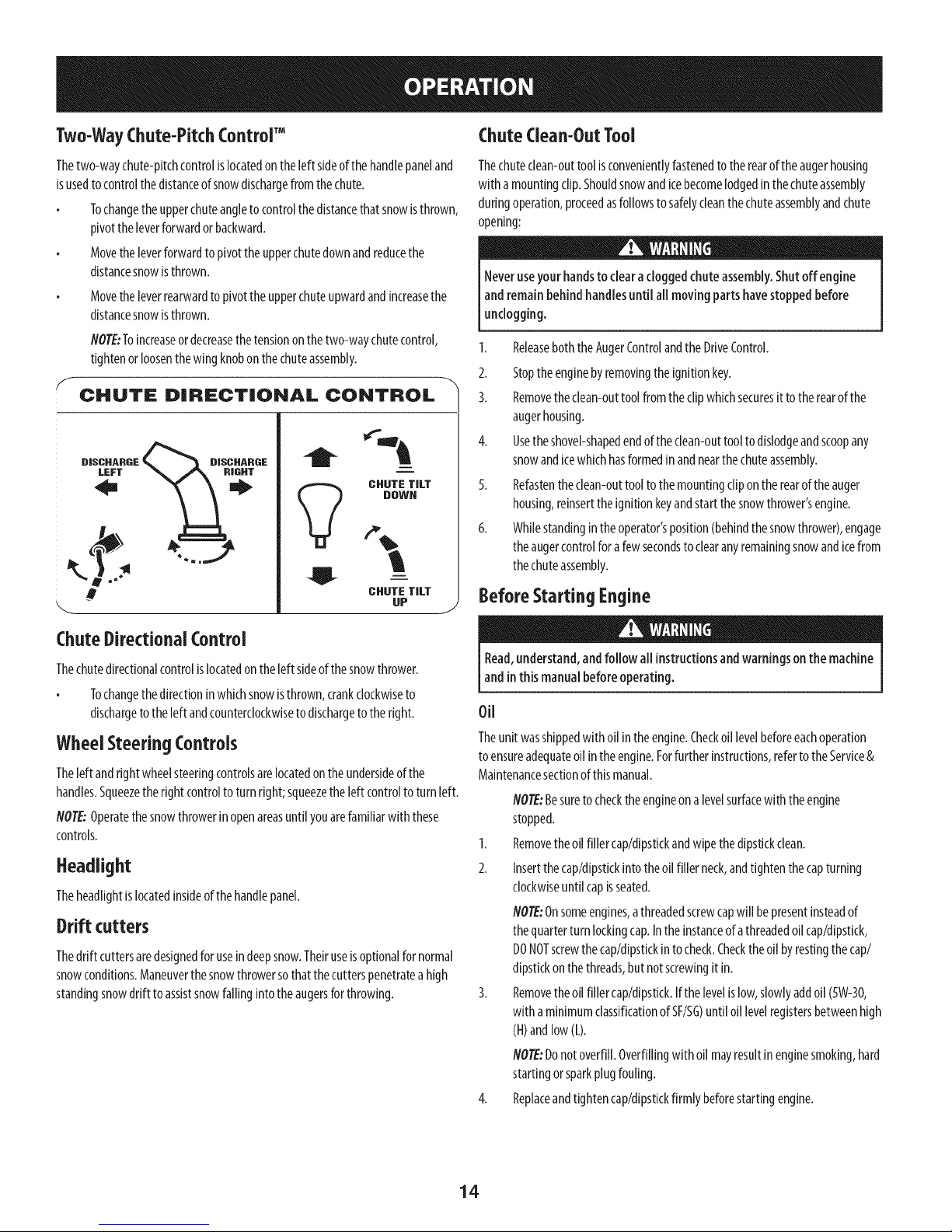

Two-WayChute-PitchControlTM

Chute Clean-Out Tool

Thetwo-waychute-pitchcontrolislocatedonthe[eftsideofthe handlepaneland

isusedto controlthedistanceof snowdischargefromthechute.

Tochangetheupperchuteangletocontrolthedistancethatsnowisthrown,

pivotthe[everforwardorbackward.

Movethe[everforwardtopivotthe upperchutedownandreducethe

distancesnowisthrown.

Movetheleverrearwardtopivottheupperchuteupwardandincreasethe

distancesnowisthrown.

NOTE:Toincreaseordecreasethetensiononthetwo-waychutecontrol,

tightenorloosenthewingknobonthechuteassembly.

CHUTE DiRECTiONAL CONTROL

D|SCHABGE _ D|SCHARGE

m

i

CHUTE TILT

DOWN

CHUTE TILT

UP

J

Thechuteclean-outtoolisconvenientlyfastenedtotherearoftheaugerhousing

with amountingclip.Shouldsnowandicebecomelodgedinthechuteassembly

duringoperation,proceedasfollowstosafelycleanthechuteassemblyandchute

opening:

Neveruseyourhandsto clearacloggedchuteassembly.Shutoff engine

andremainbehindhandlesuntilall movingpartshavestoppedbefore

unclogging.

1. ReleaseboththeAugerControlandtheDriveControl.

2. Stoptheenginebyremovingtheignitionkey.

3. Removetheclean-outtool fromtheclipwhichsecuresit totherearof the

augerhousing.

4. Usetheshovel-shapedendoftheclean-outtooltodislodgeandscoopany

snowandicewhichhasformedinandnearthechuteassembly.

5. Refastentheclean-outtoolto themountingclipontherearoftheauger

housing,reinserttheignitionkeyandstartthesnowthrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnowthrower),engage

theaugercontrolforafewsecondstoclearanyremainingsnowandicefrom

thechuteassembly.

Before Starting Engine

ChuteDirectional Control

Thechutedirectionalcontrolislocatedontheleft sideof thesnowthrower.

Tochangethedirectioninwhichsnowisthrown,crankclockwiseto

dischargetotheleftandcounterclockwiseto dischargeto theright.

Wheel Steering Controls

Theleftandrightwheelsteeringcontrolsarelocatedontheundersideofthe

handles.Squeezetheright controlto turnright;squeezetheleft controltoturnleft.

NOTE:Operatethesnowthrowerinopenareasuntilyouarefamiliarwith these

controls.

Headlight

Theheadlightis locatedinsideofthehandlepanel.

Drift cutters

Thedrift cuttersaredesignedfor useindeepsnow.Theiruseisoptionalfornormal

snowconditions.Maneuverthesnowthrowersothatthecutterspenetratea high

standingsnowdriftto assistsnowfallingintotheaugersforthrowing.

Read,understand,andfollow all instructionsandwarningsonthe machine

andinthis manualbeforeoperating.

Oil

Theunitwasshippedwithoil intheengine.Checkoil levelbeforeeachoperation

toensureadequateoil intheengine.Forfurtherinstructions,refertotheService&

Maintenancesectionofthismanual.

NOTE:Besureto checktheengineonalevelsurfacewith theengine

stopped.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.

2. Insertthecap/dipstickintotheoil fillerneck,andtightenthecapturning

clockwiseuntil capisseated.

NOTE:Onsomeengines,athreadedscrewcapwill bepresentinsteadof

thequarterturnlockingcap.Inthe instanceof athreadedoilcap/dipstick,

DONOTscrewthecap/dipstkkintocheck.Checktheoil byrestingthecap/

dipstickonthethreads,but notscrewingit in.

3. Removetheoil fillercap/dipstick.Ifthe levelislow,slowlyaddoil (5W-30,

with aminimumclassificationofSF/SG)untiloil levelregistersbetweenhigh

(H)andlow(L).

NOTE:Donotoverfill.Overfillingwithoil mayresultinenginesmoking,hard

startingorsparkplugfouling.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

14

Page 15

Gasoline

Useextremecarewhenhandling gasoline.Gasolineisextremelyflammable

andthevaporsareexplosive.Neverfuelthe machineindoorsor while the

engine ishot or running.Extinguishcigarettes,cigars,pipesand other

sourcesof ignition.

Useautomotivegasoline(unleadedorlowleadedto minimizecombustionchamber

deposits)withaminimumof87octane.Gasolinewith upto10%ethanolor15%

MTBE(MethylTertiaryButylEther)canbeused.Neveruseanoil/gasolinemixture

ordirtygasoline.Avoidgettingdirt,dust,orwaterinthefueltank.DONOTuseE85

gasoline.

Refuelin awell-ventilatedareawiththeenginestopped.Donotsmokeor

allowflamesorsparksintheareawheretheengineisrefueledorwhere

gasolineisstored.

Donotoverfillthefueltank.Afterrefueling,makesurethetankcapisclosed

properlyandsecurely.

Becarefulnottospillfuel whenrefueling.Spilledfuelorfuelvapormay

ignite.Ifanyfuelisspilled,makesuretheareaisdrybeforestartingthe

engine.

Avoidrepeatedorprolongedcontactwith skinorbreathingofvapor

1. Cleanaroundfuelfill beforeremovingcaptofuelto preventdebrisfrom

enteringfueltank..

2. Afuellevelindicatorislocatedin thefueltank.Filltankuntil fuelreachesthe

fuellevelindictor.SeeFigure10inset.Becarefulnottooverfill.

Starting TheEngine

Alwayskeephandsandfeet clearof movingparts.Donot usea pressurized

starting fluid. Vaporsareflammable.

flOTE:Allowtheenginetowarmupforafewminutesafterstarting.Theenginewill

notdevelopfull poweruntilit reachesoperatingtemperatures.

1. Makecertainboththeaugercontrolanddrivecontrolareinthedisengaged

(released)position.

2. Insertkeyintoslot.Makesureit snapsintoplace.Donotattempttoturnthe

key.

NOTE:Theenginecannotstartwithout thekeyisfullyinsertedintothe ignition

switch.

ElectricStarter

Theoptional electricstarter isequippedwith agroundedthree-wire power

plug,and isdesignedtooperateon120volt AChouseholdcurrent. It mustbe

usedwith a properlygroundedthree-prongextensioncordandreceptacle

atall timesto avoidthe possibilityof electricshock.Followall instructions

carefullypriorto operatingthe electricstarter.DONOTuseelectricstarterin

the rain.

Determinethatyourhome'swiringisathree-wiregroundedsystem.Aska licensed

electricianifyouarenotcertain.

Theextensioncordcanbeany length,but must beratedfor 15ampsat 125

volts,groundedand ratedfor outdooruse.

Ifyouhaveagroundedthree-prongreceptacle,proceedasfollows.Ifyoudonot

havethe properhousewiring,DONOTusetheelectricstarterunderanyconditions.

1. Plugtheextensioncordintotheoutletlocatedontheengine'ssurface.Plug

theotherendofextensioncordintoa three-prong120-volt,grounded,AC

outletinawell-ventilatedarea.

2. Movethrottlecontrolto FAST(rabbit)_j_ position.

3. MovechoketotheCHOKEposition[,j €[ (coldenginestart).

4. NOTE:Iftheengineisalreadywarm,placechokecontrolintheRUNposition

insteadofCHOKEI."1

5. Pushprimerthreetimes(3x),makingsuretocoverventholeinprimerbulb

whenpushing.If engineiswarm,pushprimeronlyonce.Alwayscovervent

holewhenpushing.Coolweathermayrequireprimingtoberepeated.

6. Pushstarterbuttonto startengine.Oncetheenginestarts,immediately

releasestarterbutton.Electricstarterisequippedwith thermaloverload

protection;systemwill temporarilyshut-downtoallowstarterto coolif

electricstarterbecomesoverloaded.

Toprolongstarter life, useshortstarting cycles(5secondsmaximum,then

wait oneminute).

7. Astheenginewarms,slowlyrotatethechokecontroltothe RUNposition.If

theenginefalters,restartengineandrunwith chokeathalf-chokeposition

fora shortperiodoftime,andthenslowlyrotatethechokeintotheRUN

position.

8. Afterengineisrunning,disconnectpowercordfromelectricstarter.When

disconnecting,alwaysunplugtheendatthewalloutletbeforeunplugging

theoppositeendfromtheengine.

position.

RecoilStarter

Donotpull the starter handlewhilethe enginerunning.

1. Movethrottlecontrolto FAST(rabbit)_ position.

2. MovechoketotheCHOKEI,"lpos t on co,denginestart).Ifengineis

warm,placechokeintheRUNposition.

3. Pushprimerthreetimes,makingsuretocoverventholewhenpushing.

Ifengineiswarm,pushprimeronlyonce.Alwayscoverventholewhen

pushing.Coolweathermayrequireprimingtoberepeated.

4. Pullgentlyonthestarterhandleuntilit beginsto resist,thenpullquicklyand

forcefullytoovercomethecompression.Engineshouldstart.Donotreleasethe

handleandallowit tosnapback.ReturnropeSLOWLYto originalposition.If

required,repeatthisstep.

5. Astheenginewarms,slowlyrotatethechokecontroltothe RUNposition.If

theenginefalters,restartengineandrunwith chokeathalf-chokeposition

fora shortperiodoftime,andthenslowlyrotatethechokeintotheRUN

position.

15

Page 16

ReplacingShearpins

Toavoidunsupervisedengineoperation,neverleavethe machine

unattendedwith the enginerunning.Turnthe engineoff afteruseand

removekey.

StoppingTheEngine

Afteryouhavefinishedsnow-throwing,runengineforafewminutesbefore

stoppingto helpdryoffany moistureontheengine.

1. MovethrottlecontroltoSTOP@ position.

ine.Backfireoreric ,occur.

2. Removethekey.Removingthe keywill reducethepossibilityof

unauthorizedstartingoftheenginewhileequipmentisnotinuse.Keepthe

keyinasafeplace.Theenginecannotstartwithoutthe key.

3. Wipeallsnowandmoisturefromtheareaaroundtheengineaswellasthe

areainandaroundthewheeldrivecontrolandaugercontrol.Also,engage

andreleasebothcontrolsseveraltimes.

ToEngageDrive

1. Withthethrottle controlin theFast(rabbit)_ position,movespeed

selectorleverintooneofthesixforward(F)positionsortworeverse(R)

positions.Selecta speedappropriateforthesnowconditionsandapace

you'recomfortablewith.

Theaugersaresecuredtothespiralshaftwith shearpinsandbow-tiecotterpins.

Iftheaugershouldstrikeaforeignobjectoricejam,thesnowthrowerisdesigned

sothatthepinsmayshear.Iftheaugerswill notturn,checktoseeif thepinshave

sheared.SeeFigure17.

NOTE:Twoextrashearpinsaresuppliedinthemanualbag.

NEVERreplacetheaugershearpinswith anything otherthanSearsSKU#

88389/0EMPartNo.738-0415Sreplacementshearpins.Anydamageto the

augergearboxorother componentsasaresult offailing todosowill NOTbe

coveredbyyoursnowthrower'swarranty.

Alwaysturn off thesnowthrower's engineandremovethe key priorto

replacingshearpins.

NOTE: WhenselectingaDriveSpeed,usetheslowerspeeds

untilyouare comfortableandfamiliarwiththe operationofthe

snowthrower.

2. Squeezethedrivecontrolagainstthehandleandthesnow

throwerwill move.Releaseit anddrivemotionwillstop.

NOTE:NEVERrepositionthespeedselectorlever(changespeedsordirectionof

travel)without firstreleasingthedrivecontrolandbringingthe snowthrowertoa

completestop.Doingsowillresultinprematureweartothesnowthrower'sdrive

system.

ToEngageAuger

1. Toengagetheaugerandstartthrowingsnow,squeezetheaugercontrol

againstthelefthandle.Releasetostoptheauger.

J

Figure17

16

Page 17

MAINTENANCE SCHEDULE

Beforeperforminganytypeof maintenance/service,disengageall controls

andstoptheengine.Waituntil all movingpartshavecometoacomplete

stop.Removethe keyto preventunintendedstarting. Alwayswearsafety

glassesduringoperationorwhile performinganyadjustmentsor repairs.

EachUse

1st5-8 hours

25hours

50hours

Annuallyor100hours

1.

Engineoil level

2.

Looseormissinghardware

3.

Unitandengine.

1.

Engineoil

1.

Engineoilf

2.

Controllinkagesandpivots

1.

Engineoil

1.

Sparkplug

1.

2.

3.

1.

1.

2.

1.

1.

BeforeStorage 1. Fuelsystem 1.

Under heavy load or inhigh temperatures

Followthemaintenanceschedulegivenbelow.Thischartdescribesservice

guidelinesonly.UsetheServiceLogcolumntokeeptrackofcompleted

maintenancetasks.TolocatethenearestSearsServiceCenterorto scheduleservice,

simplycontactSearsat1-800-4-MY-HOME®.

Check

Tightenorreplace

Clean

Change

Change

Lubewith lightoil

Change

Cleanandre-gap,orelsereplacewith

newplug.

Runengineuntilitstopsfromlackoffuel

oraddagasolineadditivetothegasin

thetank.

EngineMaintence

CheckingEngine0il

Beforelubricating, repairing,orinspecting,disengageallcontrolsand stop

Iengine.Waituntil allmoving partshavecometoa completestop.Remove

_thekeytopreventunintendedfiring of theengine.

NOTE:Checktheoillevelbeforeeachusetobesurecorrectoillevelismaintained.

Whenaddingoiltotheengine,refertoviscositychartbelow.Engineoilcapacity

isapproximately37ounces.Donotover-fill.Usea4-stroke,oranequivalenthigh

detergent,premiumqualitymotoroilcertifiedtomeetorexceedU.S.automobile

manufacturer'srequirementsforserviceclassificationSG,SF.Motoroilsclassified

SG,SFwill showthisdesignationonthecontainer.

1. Removetheoilfillercap/dipstickandwipethedipstickclean.

2. Insertthecap/dipstickintotheoilfiller neck,butdonot screwitin.

NOTE:Onsomeengines,athreadedscrewcapwill bepresentinsteadof

thequarterturnlockingcap.Intheinstanceof athreadedoilcap/dipstick,

DONOTscrewthecap/dipstickintocheck.Checktheoilbyrestingthecap/

dipstickonthethreads,butnotscrewingitin.

3. Removetheoilfillercap/dipstick.Iflevelislow,slowlyaddoiluntiloillevel

registersbetweenhigh(H)andlow(L).SeeFigure18.

4.

Replaceandtightencap/dipstickfirmlybeforestartingengine.

Figure18

ChangingEngineOil

NOTE:Changetheengineoilafterthefirst5 hoursofoperationandonceaseason

orevery50hoursthereafter.

1. Drainfuelfromtankbyrunningengineuntilthefueltankisempty.Besure

fuelfill capissecure.

2. Placesuitableoil collectioncontainerunderoildrainplug.

3. Removeoildrainplug.SeeFigure19.

4. Tipenginetodrainoilintothecontainer.Usedoil mustbedisposedofata

17

propercollectioncenter.

J

Page 18

f

Oil Drain

Plug

Figure19

Usedoil isahazardouswasteproduct.Disposeof usedoil properly.Donot

discardwith householdwaste.Checkwithyourlocalauthoritiesor Sears

ServiceCenterfor safedisposal/recyclingfacilities.

Ifthe enginehasbeenrunning,the muffler willbeveryhot.Becarefulnot

to touchthe muffler.

NOTE:Checkthesparkplugonceaseasonorevery25hoursof operation.Change

thesparkplugonceaseasonorevery100hours.

Toensureproperengineoperation,thesparkplugmustbeproperlygappedand

freeofdeposits.

1. Removethesparkplugbootanduseasparkplugwrenchtoremovethe

plug.SeeFigure20.

Spark Plug

5. Reinstallthedrainplugandtightenitsecurely.

6. Refillwiththerecommendedoilandchecktheoil level.SeeRecommended

Oil Usagechart.Theengine'soilcapacityis37ounces.

DONOTusenon-detergentoil or2-strokeengineoil. It couldshortenthe

engine'sservicelife.

(°F)-40o-20o 0o 200 400

(oc) -30o -20o -10o 0o

7. Reinstalltheoilfillercap/dipsticksecurely.

Thoroughlywashyour handswith soapandwater assoonas

possibleafterhandling usedoil.

CheckingSparkPlug

DONOTcheckforsparkwith sparkplugremoved.DONOTcrankenginewith

sparkplugremoved.

Spark Plug Boot

Figure20

Visuallyinspectthesparkplug.Discardthesparkplugifthereisapparent

wear,oriftheinsulatoriscrackedorchipped.Cleanthesparkplugwith a

wirebrushifitistobereused.

Measurethepluggapwith afeelergauge.Correctasnecessarybybending

sideelectrode.SeeFigure21.Thegapshouldbesetto.02-.03inches(0.60-

0.80mm).

1..030 (.76 mm) Gap

2. Electrodes

3. Porcelain

Figure21

18

Page 19

4. Checkthatthesparkplugwasherisingoodconditionandthreadthespark

pluginbyhandtopreventcross-threading.

5. Afterthesparkplugisseated,tightenwith asparkplugwrenchtocompress

thewasher.

NOTE:Wheninstallinganewsparkplug,tighten1/2-turnafterthespark

plugseatsto compressthewasher.Whenreinstallingausedsparkplug,

tighten1/8-to1/4-turnafterthesparkplugseatsto compressthewasher.

'hot andcandamagetheengine.

Carburetor Adjustment

Thecarburetorisnotuseradjustable.ContactSearsParts& Repairforadjustment.

Lubrication

Driveand Shifting Mechanism

Atleastonceaseasonorafterevery25hoursofoperation,removerearcover.

Lubricateallchains,sprockets,gears,bearings,shafts,andtheshiftingmechanism.

Useengineoiloraspraylubricant.RefertoFigure22.

NOTE:Beforetippingthe unitonthefronthousing,runthefueltankempty

sofueldoesnotleakoutof thefuelcap.

1. Carefullypivotthesnowthrowerupandforwardsothatit restsontheauger

housing.

2. Removetheframecoverfromtheundersideof thesnowthrowerby

removingtheself-tappingscrewswhichsecureit. RefertoFigure27.

3. Applyalightcoatingofengineoil(or3-in-1oil)tothehexshaft.SeeFigure

22.

Wheels

Atleastonceaseason,removebothwheels.Cleanandcoattheaxleswith a

multipurposeautomotivegreasebeforereinstallingwheels.

Chute Directional Control

Onceaseason,lubricatetheeyeboltbushingandthespiralwith 3-in-1oil.

Auger Shaft

Atleastonceaseason,oneatatime,removealloftheshearpinsfromthe auger

shaft.Spraylubricantinsidethehubofeachaugerspiralassemblyandaroundthe

spacersontheaugershaft.

Greasefittingscanalsobefoundat eachendoftheaugershaft.Lubricatewitha

greasegunonceaseason.SeeFigure23.

GearCase

Theaugergearcaseisequippedwith agreasefitting. Lubricatewith greaseoncea

season(orderpartnumber737-0168).SeeFigure23.

NOTE:Torelievepressure,removetheventplugbeforelubricatingthegearcase.

SeeFigure23.Failuretodosocouldresultindamagetothegearcaseseals.

Augers

Eachof theaugerspiralassembliesissecuredtothespiralshaftwithashearpinand

cotterpin.Iftheaugershouldstrikeaforeignobjectoricejam,thesnowthroweris

designedsothatthepinsmayshear.

1. Ifaugersdonotturn,checktoseeifpinshavesheared.

2. Replacethepinsifneeded.Tworeplacementshearpinsandcotterpins

havebeenprovidedwiththesnowthrower.Sprayanoil lubricantintoshaft

beforeinsertingnewpinsandsecuringwithnewcotterpins.SeeFigure23.

NOTE:Becarefulnotto getanyoilonthealuminumdriveplateorrubber

frktion wheel.Doingsowill hinderthesnowthrower'sdrivesystem.Wipe

offanyexcessorspilledoil.

4.

AtleastonceaseasongreasethewheelaxlewithArcticgrease,partnumber

737-0318.Thegreasefitting islocatedonthewheelaxletubebehindthe

wheelaxlesupportbracket.

f

Rubber Friction

Wheel

Aluminum

Drive

Wheel Axle

Support Bracket

Bow-Tie Pins Spacers

Figure23

Figure22

19

Page 20

ShavePlateand SkidShoes

Theshaveplateandskidshoesonthebottomofthesnowthroweraresubjectto

wear.Theyshouldbecheckedperiodicallyandreplacedwhennecessary.

SkidShoes

NOTE:Theskidshoesonthismachinehavetwo wearedges.Whenoneside

wearsout,theycanberotated180°to usetheotheredge.

Removethesixcarriageboltsandhexnutsthatsecurethetwoskidshoesto

thesidesoftheaugerhousing.Referto Figure24.

2.

Positionthenewskidshoesandsecurewith thecarriageboltsandhexnuts.

Makecertaintheskidshoesareadjustedtobelevel.

ShavePlate

1. Removethehexnutsandcarriageboltsthatsecuretheshaveplatetothe

bottomofthe housing.Referto Figure24.

2. Removetherearmosthexnutandcarriageboltsecuringthebackof each

skidshoetothesidesofthehousing.Loosenthefourremaininghexnuts

securingthe skidshoes.

3. Slidetheshaveplateoutoftheoff-setslotatthebottomofthehousing,and

frombetweentheskidshoesandsidepanelsofthehousing.

4. Withthemountingholestowardthe backoftheunit,slidethenewshave

plateintopositionandsecurewiththefastenersremovedpreviously.

f

Figure25

ChuteBracketAdjustment

Ifthespiralatthebottomofthechutedirectionalcontrolisnotfully engagingwith

thechuteassembly,thechutebracketcanbeadjusted.Todoso:

I. Loosenthetwonutswhichsecurethechutebracketandrepositionit

slightly.SeeFigure26.

2. Retightenthe nuts.

Figure24

Adjustments

Shift Cable

Ifthefull rangeof speeds(forwardandreverse)cannotbeachieved,refertothe

Figure25andadjusttheshiftcableasfollows:

I. Placetheshiftleverinthefastestforwardspeedposition.

2. Loosenthehex nutontheshiftcableindexbracket.SeeFigure25.

3. Pivotthebracketdownwardtotakeupslackinthecable.

4. Retightenthehexnut.

Figure26

ChuteControl

Thedistancesnowisthrowncanbeadjustedbyadjustingtheangleofthechute

assembly.RefertotheOperationsectionforinstructions.

Theremotechutecontrolcableshavebeenpre-adjustedat thefactory.Movethe

remotechuteleveronthecontrolpanelforwardto pivottheupperchutedown;

movetheleverrearwardtopivottheupperchuteup.

2O

Page 21

Wheeldrivecontrol

RefertotheAdjustmentsectionoftheAssemblyinstructionstoadjustthewheel

drivecontrol.Tofurtherchecktheadjustment,proceedasfollows:

1. Withthe snowthrowertippedforward(be certainto runthe

fueltankdry beforetippingtheunitforward),removetheframe

coverunderneaththesnowthrowerbyremovingtheself-tapping

screws.SeeFigure27.

f

_ ___11/_...... _ !........ ..........

%

Figure27

.

Locatetheopeningbetweentheaxlesupportbracketand

thefrontframesupport(SeeFigure28). Lookingthroughthis

opening,withthe wheeldrivecontrolreleased,theremustbe

clearancebetweenthefrictionwheelandthe driveplateinall

positionsofthespeedselectorlever.

.

Withthewheeldrivecontrolengaged,thefrictionwheelmust

contactthedrive plate.SeeFigure28.

f

Auger Control

RefertotheAssemblysectionforinstructionsonadjustingtheaugercontrolcable.

SkidShoes

RefertotheAssemblysectionforinstructionsonadjustingtheskidshoes.

Tire Pressure

RefertotheAssemblysectionforinstructionsonadjustingthetirepressure.

Beltreplacement

Belt RemovalPreparation

I. Removethechutecrankrodfromthechutecrankassemblyby

removingthehairpinclip shownin Figure29.Movethechute

crankrodawayfromtheassemblyasshown.

2. Removethreeself-tapscrewsonbothsidesofthe transmission

housingasshownin Figure29.

Figure28

4. Ifthereis nofrictionwheelclearance,or thefrictionwheeldoes

notsolidlycontactthe driveplate,re-adjustthelocknuton the

lowerendof thedrivecablefollowingtheinstructionsinthe

Assemblysection.

5. Reassembletheframecover.

Figure29

3. Removethe plasticbeltcover,locatedneartheengine,by remov-

ing thethreeself-tappingscrewsthatsecureit.See Figure30.

21

Figure30

J

Page 22

4. LoosentheboltshowninFigure31securingthebeltkeeper

bracketandremovetheotherbolt.Pushthebeltkeeperand

bracketupofftheenginepulley.

f

Loosen

Figure31

Auger Belt Replacement

1. Removethebow-tieclipandflatwasherfromtheferruleinorder

todisconnecttheaugeridlerrodfromthebrakebracketassem-

bly.SeeFigure32.

z-fitting

Figure33

5. Placeablockofwoodunderneaththeaugerhousingas shownin

Figure34andseparateaugerhousingfromtheframebytiltingthe

housingforwardandpullingupthehandles.

6. Blocktheimpellerwitha pieceofwoodtopreventitfromspinningand

usea1/2"wrenchto removethehexscrewandflatwasherfromthe

centerofthe pulleyontheaugerhousing.SeeAin Figure35.

7. Liftthebrakebracketassemblyoutofthe pulleygroove(B in

Figure35)andslide thepulleyassemblyoff the postsoftheauger

pulleyadapter(C)to removethe oldbelt.

Figure32

NOTE:Makesurethat thelocationoftheferruleontheaugeridlerrodis

maintained.

2. Sliptheaugercontrolbelt (thefrontbelt) offtheenginepulley.

3. Pullthebrakebracketassemblytowardsthecableguideroller

andunhooktheaugercablez-fitting.SeeFigure33.

4. Frombothsidesof thethe frameassembly,usea 1/2"wrenchto

removethethreehextap screwssecuringthe frametothe auger

housingassembly.Referbackto Figure29.

NOTE:Do notremovethelowerhexflangelocknutoneachside.

ger IdlerRod

Figure34

NOTE:Thepulleyadaptermayslideofftheaugerinputshaftwhenremoving

thepulley.Useextracautiontoensuretheadapterdoesfalland/orget

damagedwhenremovingthepulley.

8. Placethenewaugerbeltin theV-grooveofthe augerpulleyand

placethepulleyw/belt insidethebeltkeepers.

Turnthepulleyasnecessarytoalignitsthreeslotsapproximately

withthepostsofthepulleyadapter,thenpivotthe brakebracket

assemblyawayfromthepulleygroove. Whilealigningthepulley

slotsandadapterposts,pushtheaugerpulleyfullyontothe

adapter.RefertoFigure35.Ensurethebrakepuckofthebrake

bracketassemblyalignsandisfullyseatedin thepulleygroove.

22

Page 23

!

/

Brake

pterPost

PulleySlot

J \ J

Figure35

NOTE: If thepulleyadapterwas removedwiththepulley,alignthe

splinesofthe pulleyadapterandaugerinputshaft,andpushthepulley

andadapterontotheinputshaft.Referto Figure36.

9. Slidethewasherontothehex screwremovedearlierandapply

Loctite262to thethreadsofthehexscrew.

10. Insertthehexscrewthroughthepulleyassemblyandintothe

threadsofthe inputshaft.Torquethehexscrewto250-325in.

Ibs.to securetheaugerpulleyassemblyon the inputshaft.

11. Ifalsoreplacingthedrivebelt,proceedtothe"DriveBelt"instruc-

tions.If not,repositionthetransmissionframebackonto

theaugerhousing.

12. Installthedrivebeltontheenginepulley,re-connecttheauger

cablez-fittingandaugeridler rodferruletothebrakebracket.

Repositionand securetheenginepulleybeltguard,and re-install

thebeltcover.

NOTE:Makesureto removethepieceofwoodblockingtheimpeller.

Checktheaugerdrivebeltadjustment.Withthe augerclutchlever

inthedisengagedposition,thetopsurfaceofthenewbeltshouldbe

evenwiththeoutsidediameterofthe pulley.

Toadjust,disconnectferrulefrombrakebracketassembly.Threadferrulein

(towardsidler)toincreasetensiononbelt,orouttodecreasebelttension.

NOTE:Thebrakepuckmustalwaysbefirmly seatedinthepulley

groovewhenaugercontrolisdisengaged.

IMPORTANT:Repeatthe"AugerDriveControlTest"fromthe As-

semblysectionbeforeoperatingsnowthrower.

%

Figure36

2. Rollthedrivebeltoff thelowerdrivepulley.

3. Removethe beltfromtheenginepulley.

4. Installthe newbelton thepulleysinthereverseorderand

re-tensionwiththeidlerpulley.

5. Reassemblebyperformingthepreviousstepsin theopposite

orderand mannerofremoval.

CHANGING FRICTION WHEEL

Therubberonthefrictionwheelissubjecttowearandshouldbechecked

periodically.Replacethefrictionwheelifanysignsofwearorcrackingarefound.

1. Runthe unit'sfueltankdry beforeperformingStep2. Donot

attempttopourfuel fromtheengine.

2. Tipthesnowthrowerupand forward,sothatit restsonthe

housing.

3. Removescrewsfromtheframecoverunderneaththesnow

thrower(referto Figure37).Removetherightwheelfromthe axle.

Drive Belt Repla(ement

Ifnotalreadydone,removetheaugerdrivebeltfromthefrontpulleyoftheengine

doublepulley.Referto"AugerBeltReplacement"instructionsintheprevious

sub-section.

a.Pullthe idlerpulleyawayfromthebacksideofthedrivebeltto

relievethetension.SeeFigure36.

b.Slipthe drivebeltofftheidlerpulley. Carefullyreleasetheidler

pulley.

J

Figure37

23

Page 24

.

Usinga 3/4"wrench,holdthe hexshaftandremovethehex

screwandbellevillewasherand bearingfromleft sideofthe

frame.Referto Figure38.

f RemoveHexScrew

BellevilleWasher

l.

Figure38

5. Holdingthefrictionwheelassembly,slidethehexshaftoutof

thefrictionwheelassemblyandthe rightsideof theframe.The

spacerontheleft sideofthehexshaftwillfallandthe sprocket

shouldremainhanginglosein thechain.

6. Liftthefrictionwheelassemblyoutbetweentheaxle shaftand

thedriveshaftassemblies.

7. Removefourscrewssecuringthefrictionwheelto thehub

assembly(referto Figure39).Discardoldfrictionwheel.

f

FrictionWheelAss'y.

/

SlideHex

ShaftOut

RightSide

©

Figure40

10. Slidethehexshaftthroughtherightsideoftheframetowardthe

Idt sideandthroughthefrictionwheelassembly.

11. Aftermakingcertainthatthe chainisonboththelargeandthe

smallsprocket,alignthehexshaftwiththehexhubofthesmall

sprocket,andslidethe shaftthroughthesprocket.

NOTE:Ifthe sprocketfell fromthesnowthrowerwhileremoving

thehex shaft,placethesprocketonthechain.Realignthe

sprocketonthechainwiththehex hubfacingtherightsideof

unit.Positionthehexhubofthe sprockettowardthe frictionwheel

whenslidingthesprocketonto thehexshaft.

12. Slidethespacerontotheendofthehexshaft.

Note:The spaceristobeplacedon thehexshaftbetweenthe

sprocketandbearingpreviouslyremovedonthe Idt sideofthe

frame.

Figure39

.

Reassemblethenewfrictionwheelontothehubassembly,tighten-

ingthefourscrewsinrotationandwithequalforce,itisimportantto

assemblethefrictionwheelsymmetricallyforproperfunctioning.

.

Repositionthefrictionwheelassemblyinthe snowthrowerframe.

insertthepinfromthe speedselector armassemblyintothe

frictionwheelassemblyandholdassemblyinposition.Referto

Figure40.

13. Alignthe bearingontherightendof thehexshaftwiththe hole

intherightsideof theframe,thenpushthehexshafttotheleft

intopositioninthe frame.

14. Slidethebearingontotheleftendofthehexshaftandpressinto

theholeon theleftsidetheframe.

15. Placethebellevillewasher(roundedsidetowardhead)ontothe

hexscrewremovedearlier,andinsertthescrewinto thethreaded

holeofthe hexshaft.

16. Graduallytightenthehexscrewto fullyseatthebearingsineach

sideof theframeandtosecurethehexshaft.

17. Positionthe framecoveron thebottomoftheframeandsecure

withtheself-tappingscrews.Pivotthe snowthrowerdownto it

normaloperatingposition.

IMPORTANT:Repeatthedrivecontroltestfromthe Assemblysection

ofthis manualbeforeoperatingthe snowthrower.

24

Page 25

Ifthesnowthrowerwill notbeusedfor 30daysorlonger,orifit istheendofthesnowseasonwhenthelastpossibilityof snowisgone,theequipmentneedstobestored

properly.Followstorageinstructionsbelowtoensuretopperformancefromthesnowthrowerformanymoreyears.

PreparingEngine

Enginesstoredover30daysneedtobedrainedoffueltopreventdeteriorationand

gumfromforminginfuelsystemoronessentialcarburetorparts.If thegasolinein

yourenginedeterioratesduringstorage,youmayneedtohavethecarburetor,and

otherfuelsystemcomponents,servicedorreplaced.

1. Removeallfuelfromtankbyrunningengineuntilit stops.Donotattemptto

pourfuelfromtheengine.

2. Changetheengineoil.

3. Removesparkplugandpourapproximately1oz.(30ml)ofcleanengineoil

intothecylinder.Pulltherecoilstarterseveraltimesto distributetheoil, and

reinstallthesparkplug.

4. Cleandebrisfromaroundengine,andunder,around,andbehindmuffler.

Applyalightfilm ofoilon anyareasthat aresusceptibletorust.

Storeinaclean,dryandwellventilatedareaawayfromanyappliancethat

operateswith aflameorpilotlight,suchasa furnace,waterheater,or

clothesdryer.Avoidanyareawithasparkproducingelectricmotor,orwhere

powertoolsareoperated.

Ifpossible,avoidstorageareaswith highhumidity.

Keeptheenginelevelinstorage.Tiltingcancausefueloroil leakage.

!

Neverstoresnowthrowerwith fuel intank indoorsor inpoorlyventilated J

areas,where fuel fumesmayreachanopenflame, sparkor pilotlight asonaJ

fumace,water heater,cothesdryerorgasapp ante. j

PreparingSnowThrower

Whenstoringthe snowthrowerinanunventilatedormetalstorageshed,

careshouldbetakento rustprooftheequipment.Usingalightoil orsilicone,

coattheequipment,especiallyanychains,springs,bearingsandcables.

Removealldirtfromexteriorofengineandequipment.

Followlubricationrecommendations.

Storeequipmentinaclean,dryarea.

InflatethetirestothemaximumPSI.Refertotire sidewall.

I

25

Page 26

Enginefailstostart

Enginerunningerratically/

inconsistentRPM(huntingor

surging)

Excessivevibration

Lossofpower

Unitfailstopropelitself

Unitfailstodischargesnow

1. ChokecontrolnotinCHOKEposition.

2. Sparkplugwire disconnected.

3. Faultysparkplug.

4. Fueltankemptyor stalefuel.

5. Enginenotprimed.

6. Keynot inserted.

7. Extensioncordnotconnected(when

usingelectricstartbutton,on modelsso

equipped).

1. EnginerunningonCHOKE.

2. Stalefuel.

3. Waterordirt infuel system.

4. Over-governedengine.

1. Loosepartsor damagedauger.

1. Sparkplugwire loose.

2. Gascap ventholeplugged.

1. Drivecableinneedof adjustment.

2. Drivebeltlooseor damaged.

3. Wornfrictionwheel.

1. Chuteassemblyclogged.

2. Foreignobjectlodgedin auger.

3. Augercablein needof adjustment.

4. Augerbeltlooseordamaged.

5. Shearpin(s)sheared.

1. Movechokecontrolto CHOKEposition.

2. Connectwireto sparkplug.

3. Clean,adjustgap,or replace.

4. Filltankwithclean,freshgasoline.

5. PrimeengineasinstructedintheOperationSection.

6. Insertkeyfully intotheswitch.

7. Connectoneendof theextensioncordto theelectric

starteroutletandthe otherendtoathree-prong

120-volt,grounded,ACoutlet.

1. Movechokecontrolto RUNposition.

2. Filltankwithclean,freshgasoline.

3. Drainfueltankby runningengineuntilitstops.Refill

withfreshfuel.

4. ContactyourSearsParts& RepairCenter.

1. Stopengineimmediatelyand disconnectsparkplug

wire.Tightenall boltsandnuts.Ifvibrationcontinues,

haveunit servicedbya SearsParts& RepairCenter.

1. Connectandtightensparkplugwire.

2. Removeiceand snowfromgascap. Becertainvent

holeisclear.

1. Adjustdrivecontrolcable.Referto Serviceand

Maintenancesection.

2. Replacedrivebelt.Referto Serviceand Mainte-

nancesection.

3. Havefrictionwheelreplacedata SearsParts&

RepairCenter.

1. Stopengineimmediatelyand disconnectsparkplug

wire.Cleanchuteassemblyandinsideofauger

housingwithclean-outtoolor astick.

2. Stopengineimmediatelyand disconnectsparkplug

wire.Removeobjectfromaugerwith clean-outtool

ora stick.

3. Adjustaugercontrolcable.RefertoAssembly

section.

4. Replaceaugerbelt.RefertoServiceand Mainte-

nancesection.

5. Replacewith newshearpin(s).

Chutefailstoeasilyrotate180 1. Disassemblechutecontroland reassembleas

1. Chuteassembledincorrectly.

degrees directedintheAssemblysection.

NEED HORE HELP?

Yot,Fttfind. th_ answer a!ld mo_e on ma_age_y_ifeocom _ for free]

Find this and att your other product manua[s ontine.

Get answers from our team of home experts.

Get a personalized maintenance p[an for your home.

Find information and tools to he[p with home projects.

managemylife

b_e'_g_t_/_eyeu by Sea_s

26

Page 27

Craftsman Snow Thrower Model 247.883971

22

20.

\

19

65

6660

2

10

14

4

42

J

64

43 41

60

64

66

27

Page 28

Craftsman Snow Thrower Model 247.883971

! = 0 0

918-0281A Bracket Assy, Auger Brake

2. 684-0090B-0637 Impellar, 16"

3. 931-2643 Tool, Cleanout

4. 710-0376 Scr,Hex Cap, 5/16-18 x 1.00

5. 710-04484 Screw, 5/16-18 x .750

6. 710-0451 Screw, Carriage, 5/16-18 x .75

7. 710-04606A Screw, 5/16-18 x .4300

8. 710-1245B Screw, 5/16-24 x .875

9. 911-0677 Ferrule

10. 712-04063 Nut, Flnge Lk, 5/16-18

11. 712-04065 Nut, Fig Lk, 3/8-16

12. 914-0135 Key, Woodruff, l/4 x 3/4

13. 714-04040 Pin, Bowtie Cotter

14. 915-0118 Pin, Spirol, 5/16 x 1.75

15. 725-0157 Tie, Cable

16. 926-04012 Nut, Push

17. 731-1696B Adapter, Chute, 6"

18. 732-0858 Spring, Extension

19. 936-0159 Washer, .349 x .879 x .063

20. 736-0174 Washer, .625 x .885 x .015

21. 736-0505 Washer, Flat, .34 x 1.50 x .150

22. 936-3008 Washer, .344 x .75 x .12

23. 736-3046A Washer, 1.01 x 1.86 x .06

24. 731-2635 Clip, Mounting

25. 938-0281 Screw, Shoulder, .625 x .17

26. 738-04155 Pin, Shear, .25 x 1.75

27. 741-0192 Bearing, Flange w/Flats

28. 941-04024 Bearing, Self Aligning

29. 747-0980A Rod, Auger Idler

30. 748-04067A Pulley, Adapter, .75 Dia.

31. 950-04020 Spacer, 1.004 x 1.375 x .25

32. 756-04244A Pulley, Auger Drive, 10.0

33. 790-00264A-0637 Bracket, Gear Box Support

34. 05244B Housing, Bearing

35. 784-0315A-0637 Housing, Bearing

36. 918-04514 Gear Box Assembly, Auger

D = B II

684-04151-4028 Spiral Assy, LH

38. 684-04152-4028 Spiral Assy, RH

39. 684-04214-0691 Housing, Auger - 33"

40. 731-05162 Spacer, 1.0 x 1.5 x 2

41. 731-05163 Spacer, 1.0 x 1.5 x 1

42. 938-04158 Axle, Spiral, 33"

43. 741-0494 Bushing, Flange, 1.051 x 1.16

44. 784-5714B-0637 Shave Plate

45. 710-3168 Bolt, Carriage, 3/8-16 x 1.0

46. 710-3034 Bolt, Carriage, 3/8-16 x 1.25

47. 731-06007 Shoe, Skid

48. 790-00181-0637 Drift Cutter

49. 736-0262 Washer, Flat, .385 x .870

50. 918-0246 Hsg Assy Auger RH (Inc. 65 & 66)

51. 918-0435 Hsg Assy Auger LH (Inc. 65 & 66)

52. 710-1260A Screw, LD, 5/16-18 x .750

53. 711-04714 Shf, Drive, Auger

54. 914-0126 Key, Hi Pro, 3/16 x 3/4

55. 716-0111 Ext, Ret, Ring

56. 917-0299 Gear, Worm, Dbl Thread

57. 917-1425 Gear, Worm, LH

58. 921-0145 Seal, Oil

59. 721-0325 Plug

60. 936-0266 Washer, Flat, 1.52 ID x 2.00D

61. 936-0291 Washer, Flat, .88 ID x .38 OD

62. 738-0275 Shf, Gear, Worm

63. 741-0184 Brg, Thrust

64. 941-0217 Sleeve

65. 921-0146 Oil Seal

66. 741-0670 Flange Bearing

67. 954-04194A V Belt,4L x 44.60 Lg.

68. 937-3000 Lube Fitting, 3/16 #70

69. 736-0188 Washer, Flat, .78 x 1.49 x .08

70. 720-0284 Wing Knob

71. 712-3007 Jam Nut, 5/16-18

72.

28

Page 29

Craftsman Snow Thrower Model 247.883971

65

57

66

_\ 7 58

5O

64

3O

21

15

79

79

40

/

/

/

/

38

3 39

\

29

Page 30

m _ O O

684-04308A ChuteCrankAssembly

2 684-04350 JointBlockAssembly

3 710-0276

4 710-04682

5 710-0572

6 710-3118

7 712-04063

8 912-3010

9 914-0101

10 914-04040

Screw,Carriage,5/16-18x 1.0

Screw,Hex,3/8-16x 2.00Lock,Gr5

Screw,Carriage,5/16-18x2.5

Screw,Hex,3/8-16x 1.0Lock,Gr5

FlangeLockNut,5/16-18

HexNut,5/16-18

internalCotterPin

internalCotterPin

11 715-04095 SpringPin

12 720-0201A Knob,Crank

13 720-0284 Knob,WingNut, 5/16-18

14 926-0100 Cap,Push,3/8

15 735-0234 Grommet,Rubber

16 736-0105 Washer,Bel,.375x .87x .063

17 936-0159 Washer,Fiat,.349x .879.063

18 936-0185 JWasher,.375x .738x .063

19 736-0242 Washer,Belleville,.34x .872x .06

20 941-0475 PlasticBushing,.380I.D.

21 747-04747 _ EyeBolt

22 747-04925A-0637 ChuteRod

23 749-04675-0691 Handle,Upper- LH

24 749-04674-0691 Handle,Upper- RH

25 749-0991-0691 Handle,Lower

26 790-00329-0637 ChuteCrankBracket

27 716-04036 Ring,Retainer

28 725-0157 CableTie

29 731-06113 . Trigger

30 738-04126 Pin,3/16

31 710-04022 HexHeadScrew,MB1.25

32 732-04677 CableGuide

33 936-0264 FiatWasher,.330x .630x .0635

34 984-04230 J 2-WayChuteControl Assy

TM

35 710-04187 Hi-LoScrew,1/4-15x 0.5

36 710-0458 Bolt,Carriage,5/16-18x 1.75

37 710-0597 Screw,1/4-20x 1.00

38 710-0895 Hi-LoScrew,1/4-15x .75

39 712-04064 FlangeLockNut,1/4-20

40 731-0846C UpperChute

41 731-0851A Chute,FlangeKeeper

D _ O

731-0903E LowerChute

43 731-1313C ChuteTiltCableGuide

44 936-0231 FiatWasher

45 784-5594-0637 CableBracket

46 631-04133A HandleClutchLock- LH

47 631-04134B HandleClutchLock- RH

48 931-04187A HandlePanel

49 646-0012 CableAssembly,Auger/Drive

746-0952 Cable,Clutch

732-0184 Spring,Extension

50 684-04111B HandleEngageAssy- LH

51 684-04112C HandleEngageAssy- RH

52 684-04250 RodAss'y,ClutchLockPivot

53 710-04326 Screw,#8-16x0.50

54 710-04586 Screw,1/4-20x 1.625

55 710-0837 ABScrew,#10-16

56 710-1233 Screw,#10-24x 0.375

57 710-3069 Screw,1/4-20x.375

58 712-04081A ShoulderNut,1/4-20

59 720-04039 ShiftKnob

60 736-0159 FiatWasher,.349x .879x .063

61 725-05148 WiringHarness(NotShown)

62 725-04393 Htd.HandGripon/offSwitch

63 725-06095 LightSocket

64 725-05149 HeatedHandGrip

65 731-04894D LockPlate

66 731-04896B ClutchLockCam

67 732-0193 CompressionSpring

68 732-04219C ClutchLockSpring

69 732-04238 TorsionSpring

70 935-0199A RubberBumper

71 936-0267 FiatWasher,.385x .87x .06

72 738-04125 ShoulderScrew

73 738-04348 ShoulderScrew,1/4-20x 1.345

74 746-04341 SpeedSelectorCable

75 790-00248C-0637 PanelBracket

76 790-00281B-0637 ShiftLever

77 731-05324 LensPanel

78 777X41804 ReflectorLabel

79 746-04338 Cable,ChuteTilt

3O

Page 31

Craftsman Snow Thrower Model 247.883971

91

"93 78

92

100

102

104

23

36

88

45

/7

18

18

34 74

33

67

17

15

25 32

32

_3 56

19 55

72

77

27

1j

11

31

11

z

112

24

111 10

31

Page 32

Craftsman Snow Thrower Model 247.883971

|= o e

05244B

2. 618-0279P

3. 618-0280P

4. 918-0282E

5. 918-04178

718-04034

710-0896

6. 684-0118B-0637

684-0119B-0637

8. 684-04212-0637

9. 684-04229

Housing,Bearing

Dogg,SteeringDrive,LH

Dogg,SteeringDrive,RH

ShaftAssembly,Steering

Assembly,FrictionWheel

Wheel,Friction,Bonded

Screw,HexWash

Bracket,AugerActuator

Bracket,DriveActuator

Brkt,FrictionDriveSuprt.

RodAssembly,Shift

10. 684-04235 Sprocket,32T

11. 710-04484 TTScrew,5/16-18x .750

12. 710-0538 Screw,HexCapLock,

13. 710-0599 HexScrew,1/4-20x .50

14. 710-0751 HexHeadScrew,1/4-20

15. 710-1652 Screw,HexWash.

16. 710-3001 Screw,HexCap,3/8-16

17. 911-04279 Shaft,HexDrive

18. 711-04605 Shaft,Actuator

19. 912-0116 Nut,HexInsertJamLock

20. 912-0138 Nut,Hex,1/4-28GR5

21. 712-04063 FlangeLockNut,5/16-18

22. 712-04064 FlangeLockNut,1/4-20

23. 712-04065 FlangeLockNut,3/8-16

24. 912-0413 HexNut,5/8-18

25. 712-0717 Nut,Insert3/8-16

26. 713-0284 Chain,Endless,#41x 36L

27. 713-0286 Chain,#420x 40L

28. 913-04015 Sprocket,#41x lOT

29. 914-0104 Pin,InternalCotter

30. 914-0135 Key,Woodruff

31. 914-0388 Key,Hi-Pro,3/16x5/8

32. 916-0104 E-Ring

33. 716-0136 Ring,Retaining

34. 716-04048 Ring,Retainer

35. 917-0302 Plate,Drive

36. 726-0221 SpeedNut,.500

37. 932-0121 Spring,Extension

38. 932-0209 Spring,Extension

D = Q m

732-04385 TorsionSpring,.750I.D.x .968 Lg.

40. 936-0158 Washer,Lock,5/8

41. 736-0242 Wsh,Bell.,.34x .872x .06

42. 936-0864 Wash,.375x .812x .060

43. 936-0329 Washer,Lock,1/4

44. 936-3015 FiatWasher,.469x .875x .105

45. 790-00257-0691 Cover,UpperFrame

46. 790-00259-0691 Cover,LowerFrame

47. 937-3000 Fitting,Lube,3/16Drive

48. 738-0143 Screw,Shldr.,.498x .34

49. 738-0279 Spindle,DrivePlate

50. 738-04184A ShoulderScrew,.368x .113,1/4-20

51. 738-0924A Screw,HexShldr.,1/4-28

52. 741-0163A Ass'y,Bearing/Housing

53. 941-04025 Bearing,SelfAligning

54. 741-04108 Bearing,HexFlange

55. 941-0563 Bearing,Ball

56. 741-0747 Bush,Fig,.5625x1.375x .4375

57. 741-0748 Bush,Fig,.5 IDx .627OD

58. 746-04337A SteeringCable,35.97"Long

59. 946-0951A Cable,AugerIdler

60. 747-0973 Rod,DriveClutch

61. 750-04703 Spcr.,1.0IDx 1.50OD

62. 750-04717 Spcr.,.51IDx 7.895Lg.

63. 750-04718 Spcr.,.51IDx 3.66Lg.

64. 750-04719 Spcr.,.5151ID x.750ODx .220

65. 750-05342 Spcr.,.566IDx .87ODx .190

66. 750-05343 Spcr.,.566IDx .87ODx 1.25

67. 750-0903B Spcr.,.514x .632x 2.44

68. 950-0997 Spacer,.675x 1.0x .23

69. 750-1302B Spcr,.6725x 1.125x 2.48

70. 756-0344 Pulley,Auger

71. 756-0625 Roller,Cable

72. 784-0404 BearingRetainingBracket

73. 784-0406A-0637 Bracket,FrameSupport