Craftsman 247882551 Owner’s Manual

Operator's Manual

CRAFTSMAN°

5.5 Horse Power

24-iNCH 4-CYCLE 3-SPEED SNOW THROWER

Model No. 247.88255.1

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www, sears,corn/craftsrnan FORMNO.769-01910B

• SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

ESPANOL R 27

5/30/2006

Warranty Statement ................................................. Page 2 Maintenance and Service ................................. Pages 12-15

Safety Labels ........................................................... Page 3 Off Season Storage & Troubleshooting ............. Page 16-17

Rules of Safe Operation ..................................... Pages 4-5 Parts List .......................................................... Pages 18-25

Set Up & Adjustment .......................................... Pages 6-7 Espa_ol ................................................................... Page 27

Know Your Snow Thrower .................................. Pages 8-9 Service Numbers ............................................... Back Cover

Operation ........................................................ Pages 10-11

Two-YearWarrantyon Craftsman Snow Thrower

Fortwoyearsfromthedateof purchase,whenthis CraftsmanSnowThroweris maintained,lubricatedandtunedupaccordingto theinstructions

intheowner'smanual,Searswillrepair,freeofcharge,anydefectinmaterialandworkmanship.IfthisCraftsmansnowthrowerisusedfor

commercialorrentalpurposes,thiswarrantyappliesforonly30daysfromthedateof purchase.

Thiswarrantydoesnotcover:

• Expendableitemswhichbecomewornduringnormaluse,suchas skidshoes,shaveplateandsparkplugs.

Repairsnecessarybecauseof operatorabuseor negligence,includingbentcrankshaftsandthe failureto maintainthe equipmentaccording

tothe instructionscontainedintheowner'smanual.

WARRANTYSERVICEISAVAILABLEBYRETURNINGTHECRAFTSMANSNOWTHROWERTOTHE NEAREST

SEARSPARTS& REPAIRCENTERINTHEUNITEDSTATES.

This warrantyappliesonly whilethisproductis in useinthe UnitedStates.

TOLOCATETHENEARESTSEARSPARTS& REPAIRCENTERORTOSCHEDULESERVICE,

SIMPLYCONTACTSEARSAT1-800-4-MY-HOME®.

Thiswarrantygivesyouspecificlegalrightsandyoumayalso haveotherrightswhichmayvaryfromstateto state.

SEARS,ROEBUCKANDCO., D/817WA,HOFFMANESTATES,IL 60179

Repair ProtectionAgreements

Congratulationsonmakingasmart purchase.YournewCraftsman®

productisdesignedand manufacturedforyearsofdependableopera-

tion.Butlikeallproducts,it mayrequirerepairfromtimeto time.That's

whenhavinga RepairProtectionAgreementcansaveyoumoneyand

aggravation.

Here'swhat'sincludedintheAgreement:

Expertserviceby our 12,000professionalrepairspecialists

Unlimitedserviceand nochargeforpartsand laboronall covered

repairs

Productreplacementifyourcoveredproductcan'tbe fixed

Discountof 10%fromregularpriceofserviceandservice-related

partsnotcoveredby theagreement;also,10%off regularprice of

preventivemaintenancecheck

Fasthelpby phone- phonesupportfroma Searstechnicianon

productsrequiringin-homerepair,plusconvenientrepair

scheduling

Horse Power:

Engine Oil:

Fuel:

Spark Plug:

Engine:

5.5

SAE 5W-30

Unleaded Gasoline

Champion@ RJ19LM

Tecumseh LH195SP

PurchaseaRepairProtectionAgreementnowandprotectyourself

fromunexpectedhassleandexpense.

Onceyoupurchasethe Agreement,a simplephonecallis all thatit

takesfor youto scheduleservice.Youcancall anytimedayornight,or

schedulea serviceappointmentonline.

Searshasover12,000professionalrepairspecialists,who have

accessto over4.5millionqualitypartsandaccessories.That'sthe

kindof

professionalismyoucancountonto helpprolongthe lifeof yournew

purchaseforyearstocome.PurchaseyourRepairProtectionAgree-

menttoday!

Somelimitationsandexclusionsapply. For pricesandadditional

informationcall 1-800-827-6655.

SearsInstallation Service

ForSearsprofessionalinstallationofhomeappliances,garagedoor

openers,waterheaters,andother majorhomeitems,in theU.S.A.call

1-800-4-MY-HOME®

Model Number .............................................................

Serial Number ..............................................................

Date of Purchase ..........................................................

Record the model number, serial number

and date of purchase above

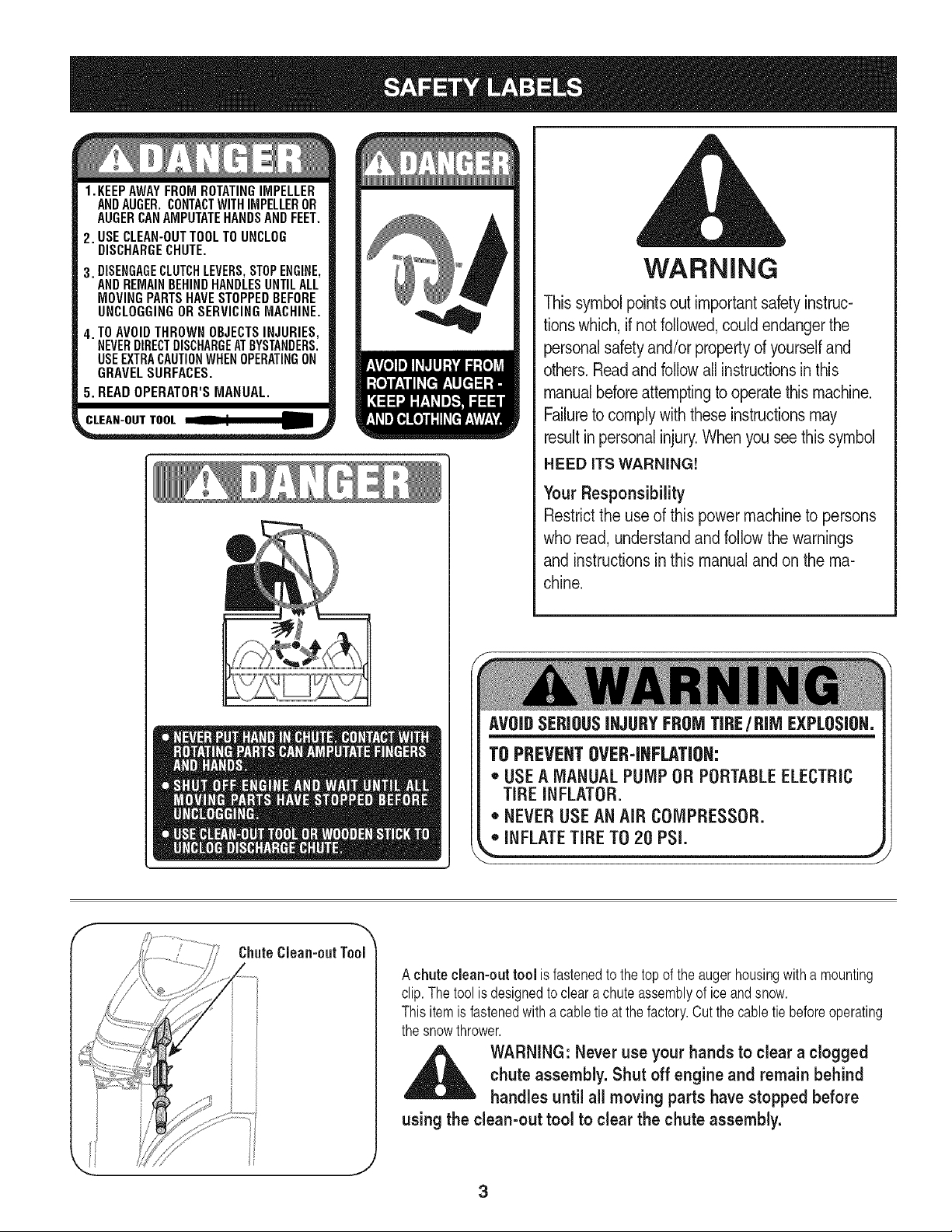

1.KEEPAWAYFROMROTATINGIMPELLER

ANDAUGER.CONTACTWITHIMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET.

2. USECLEAN-OUTTOOLTOUNCLOG

DISCHARGECHUTE.

3. DISENGAGECLUTCHLEVERS,STOPENGINE,

ANDREMAINBEHINDHANDLESUNTILALL

MOVINGPARTSHAVESTOPPEDBEFORE

UNCLOGGINGORSERVICINGMACHINE.

4. TOAVOIDTHROWNOBJECTSINJURIES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHENOPERATINGON

GRAVELSURFACES.

5. READOPERATOR'SMANUAL.

CLEAN-OUTTOOL

WARNING

Thissymbolpointsoutimportantsafetyinstruc-

tionswhich,if notfollowed,could endangerthe

personalsafetyand/or propertyd yourselfand

others.Readand followall instructionsinthis

manualbeforeattemptingto operatethismachine.

Failuretocomplywiththese instructionsmay

resultin personalinjury.Whenyouseethissymbol

HEED iTS WARNING!

Your Responsibility

Restrictthe use of this powermachineto persons

who read, understandand follow the warnings

and instructions in this manualand on the ma-

chine.

ChuteClean-outTool

AVOIDSERIOUSINJURYFROMTIRE/RIM EXPLOSION.

TO PREVENTOVER-INFLATION:

* USEA MANUAL PUMP OR PORTABLEELECTRIC

TIRE INFLATOR.

* NEVERUSEAN AiR COMPRESSOR.

,,"iNFLATETiRE702OPSi, j

A chute clean-out tool isfastenedtothe topof theaugerhousingwitha mounting

clip.Thetool isdesignedtoclear achuteassemblyof iceandsnow.

Thisitemisfastenedwitha cabletie atthe factory.Cutthe cabletie beforeoperating

thesnowthrower.

chute assembly. Shut off engine and remain behind

WARNING: Never use your hands to clear a clogged

handles until all moving parts have stopped before

using the clean-out tool to clear the chute assembly.

chemicalsknown to State of Californiato cause cancer and birth defects or other reproductiveharm.

WARNING: Engine Exhaust,some of its constituents,and certainvehiclecomponentscontain or emit

DANGER: This machine was built to be operatedaccordingto the rulesfor safe operation in this manual.As with any type

of powerequipment,carelessnessorerroron the part of the operator can result in serious injury.This machine is capable

of amputatinghands and feet and throwing objects. Failureto observe the following safety instructionscould resultin

seriousinjuryordeath.

WARNING: This symbolpointsout importantsafetyinstructionswhich,if notfollowed,couldendangerthe

personalsafetyand/orpropertyofyourselfand others.Readandfollowall instructionsin thismanualbefore

attemptingto operatethismachine.Failureto complywiththese instructionsmayresultin personalinjury.

Whenyouseethis symbol.HEED ITSWARNING!

Your Responsibility: Restrictthe useof this power machineto personswho read,understandand followthe warnings

and instructionsin this manualand on the machine.

Training

1. Read,understand,andfollowallinstructionsontile machineand inthe

manual(s)beforeattemptingto assembleandoperate.Keepthis manualin

asafeplaceforfutureandregularreferenceandfor orderingreplacement

parts.

2. Befamiliarwithallcontrolsandtheirproperoperation.Knowhowtostop

themachineanddisengagethemquickly.

3. Neverallowchildrenunder14yearsoldto operatethis machine.Children

14yearsold andovershouldreadandunderstandthe operationinstruc-

tionsand safetyrulesinthismanualandshouldbetrainedandsupervised

bya parent.

4. Neverallowadultstooperatethismachinewithoutproperinstruction.

5. Thrownobjectscancauseseriouspersonalinjury.Planyoursnow-throwing

patterntoavoiddischargeofmaterialtowardroads,bystandersandthelike.

6. Keepbystanders,helpers,petsandchildrenatleast75feetfromthe

machinewhileit is inoperation.Stopmachineif anyoneentersthearea.

7. Exercisecautionto avoidslippingor falling,especiallywhenoperatingin

reverse.

Preparation

1. Thoroughlyinspectthe areawheretheequipmentisto beused.Remove

all doormats,newspapers,sleds, boards,wiresand otherforeignobjects,

whichcould betrippedoveror thrownbythe auger/impeller.

2. Alwayswearsafetyglassesor eyeshieldsduringoperationandwhile

performingan adjustmentor repairto protectyoureyes.Thrownobjects

whichricochetcancauseseriousinjuryto theeyes.

3. Donotoperatewithoutwearingadequatewinteroutergarments.Donot

wearjewelry,longscarvesor otherlooseclothing,whichcouldbecome

entangledinmoving parts.Wearfootwearwhichwill improvefootingon

slipperysurfaces.

4. Useagroundedthree-wireextensioncordand receptaclefor all unitswith

electricstart engines.

5. Adjustcollectorhousingheightto cleargravelor crushedrocksurfaces.

6. Disengageall controlleversbeforestartingthe engine.

7. Neverattempttomake anyadjustmentswhileengineis running,except

wherespecificallyrecommendedinthe operator'smanual.

8. Letengineandmachineadjusttooutdoortemperaturebefore startingto

clearsnow.

9. To avoidpersonalinjuryor propertydamageuseextremecarein handling

gasoline.Gasolineisextremelyflammableandthevaporsareexplosive.

Seriouspersonalinjurycanoccurwhen gasolineisspilledonyourself

or yourclothes,whichcanignite.Washyourskin andchangeclothes

immediately.

a. Useonlyan approvedgasolinecontainer.

b. Extinguishall cigarettes,cigars,pipesand othersourcesof ignition.

c. Neverfuel machineindoors.

d. Neverremovegascapor addfuelwhilethe engineis hotor running.

e. Allowengineto coolatleasttwo minutesbeforerefueling.

f. Neveroverfill fuel tank.Filltankto nomorethan_/zinchbelowbottom

offiller neckto providespaceforfuelexpansion.

g. Replacegasolinecapandtightensecurely.

h. Ifgasolineisspilled,wipeit offthe engineandequipment.Move

machinetoanotherarea. Wait5 minutesbeforestartingthe engine.

i. Neverstorethe machineorfuelcontainerinsidewherethere isan open

flame,sparkor pilot light(e.g.furnace,water heater,space heater,

clothesdryeretc.).

j. Allowmachineto coolatleast 5minutesbeforestoring.

4

Operation

1. Do notputhandsorfeetnearrotatingparts,intileauger/impellerhousing

orchuteassembly.Contactwith therotatingpartscan amputatehands

andfeet.

2. Theauger/impellercontrolleverisa safetydevice.Neverbypassits

operation.Doingso makesthemachineunsafeand maycausepersonal

injury.

3. Thecontrolleversmust operateeasilyinbothdirectionsand automatically

returntothe disengagedpositionwhenreleased.

4. Neveroperatewitha missingor damagedchuteassembly.Keepall safety

devicesin placeandworking.

5. Neverrunan engineindoorsor in apoorlyventilatedarea.Engineexhaust

containscarbonmonoxide,anodorlessanddeadlygas.

6. Do notoperatemachinewhileunderthe influenceofalcoholor drugs.

7. Mufflerandenginebecomehotandcancausea burn.Donottouch.

8. Exerciseextremecautionwhenoperatingonorcrossinggravel surfaces.

Stayalertforhiddenhazardsortraffic.

9. Exercisecautionwhenchangingdirectionandwhile operatingon slopes.

10.Planyoursnow-throwingpatterntoavoiddischargetowardswindows,

walls,carsetc.Thus, avoidingpossiblepropertydamageor personal

injurycausedbya ricochet.

11.Neverdirectdischargeatchildren,bystandersand petsorallowanyonein

frontofthe machine.

12.Donotoverloadmachinecapacityby attemptingto clearsnowat toofast

ofa rate.

13.Neveroperatethis machinewithoutgoodvisibilityor light.Alwaysbesure

ofyourfootingandkeepafirm holdonthe handles.Walk,neverrun.

14.Disengagepowertothe auger/impellerwhentransportingor notinuse.

15.Neveroperatemachineat hightransport speedson slipperysurfaces.

Lookdownand behindand usecarewhenbackingup.

16.Ifthe machineshouldstart tovibrateabnormally,stopthe engine,

disconnectthespark plugwireandgroundit againsttheengine.Inspect

thoroughlyfordamage.Repairany damagebeforestartingandoperating.

17.Disengageallcontrolleversandstop enginebeforeyou leavethe operat-

ingposition(behindthe handles).Waituntiltheauger/impellercomes

toa completestopbeforeuncloggingthechuteassembly,makingany

adjustments,or inspections.

18.Neverputyour handinthe dischargeor collectoropenings.Alwaysuse

theclean-outtool providedto unclogthedischargeopening.Donotunclog

chuteassemblywhileengineis running.Shutoff engineand remain

behindhandlesuntilallmovingpartshavestoppedbeforeunclogging.

19.Useonly attachmentsandaccessoriesapprovedbythe manufacturer(e.g.

wheelweights,tirechains,cabsetc.).

20.Ifsituationsoccurwhichare notcoveredinthis manual,usecareand

goodjudgment.ContactyourSearsServiceCenterfor assistance.

Maintenance & Storage

1. Nevertamperwith safetydevices.Checktheir properoperationregularly.

Referto themaintenanceand adjustmentsectionsofthis manual.

2. Beforecleaning,repairing,or inspectingmachinedisengageallcontrol

leversand stoptheengine.Waituntiltheauger/impellercometo a

completestop.Disconnectthespark plugwireand groundagainstthe

enginetopreventunintendedstarting.

3. Checkboltsandscrewsfor propertightnessatfrequentintervalstokeep

the machineinsafeworkingcondition.Also,visuallyinspectmachinefor

anydamage.

4. Donotchangetheenginegovernorsettingor over-speedtheengine.The

governorcontrolsthe maximumsafeoperatingspeedof theengine.

5. Snowthrowershaveplatesandskid shoesaresubjecttowear and

damage.Foryoursafetyprotection,frequentlycheckallcomponentsand

replacewithoriginal equipmentmanufacturer's(OEM)partsonly."Useof

partswhich donotmeetthe originalequipmentspecificationsmayleadto

improperperformanceandcompromisesafety!"

6. Checkcontrolsperiodicallyto verifytheyengageanddisengageproperly

andadjust,if necessary.Refertothe adjustmentsectionin this operator's

manualforinstructions.

7. Maintainorreplacesafetyand instructionlabels,asnecessary.

8. Observeproperdisposallawsand regulationsfor gas, oil,etc.to protect

the environment.

9. Priortostoring,runmachinea fewminutesto clearsnowfrommachine

andpreventfreezeup ofauger/impeller.

10.Neverstorethemachineorfuelcontainerinsidewherethereis anopen

flame,sparkor pilot lightsuchas awater heater,furnace,clothes dryer

etc.

11.Alwaysrefertothe operator'smanualfor properinstructionsonoff-season

storage.

Do not modify engine

Toavoidseriousinjuryor death,do notmodifyengineinanyway.Tampering

withthegovernorsettingcanleadto arunawayengineandcauseitto operate

at unsafespeeds.Nevertamperwithfactorysettingofenginegovernor.

Notice regarding Emissions

Engineswhicharecertifiedto complywithCaliforniaandfederalEPAemission

regulationsfor SORE(SmallOffRoadEquipment)are certifiedtooperateon

regularunleadedgasoline,and mayincludethefollowingemissioncontrolsys-

tems:EngineModification(EM)andThreeWayCatalyst(TWO)ifso equipped.

Engine identification Decal

Thisdecalindicatestheengine'smodelnumber,specificationandthe dateof

manufacture.Pleaselookatthe decalon theengineofyourequipmentand

recordtheseinformationforfuturereference.

Theengineidentificationdecalalsoincludesenginelifespecificationsfor the

emissions-relatedusefullifeperiodofthe engine.This periodrelatestothe

emissioncompliancelifeas certifiedbyEPAand/orCARB.Tofindthe lifeperiod

specificationof the engine,pleasereadthe enginedecalandlocatethe letter

(enclosedbyquotationmarks)betweenthewordsModerateandLifePeriod.

Matchone ofthefollowingletterswiththeletterprintedonyourdecal.For

example,HMSK80modelsaredesignatedas:

"C"-- 250hours

"B"-- 500 hours

"A"-- 1000hours

IMPORTANT:This unitis shippedwiththe enginefullof oil.After

assembly,seepage10for fuelandoildetails.

Removing From Carton

1. Cutthecornersofthecartonandlay thesidesflaton the ground.

Removeall packinginserts.

2. Theupperhandleis packagedunattachedtothe snowthrower,

thoughconnectedby cables.Movethe snowthrowerandupper

handleoutof thecarton.

3. Makecertainthecartonhas beencompletelyemptiedbefore

discardingit.

Before Assembly

R_emoveprotectivewrapp"_g

\

\

,_ WARNING:Disconnectthe spark plugwireand Ground

NOTE:Referenceto right,left,frontor rearof theunitisfromthe

operatingpositionunlessotherwisestated.

itagainstthe engineto prevent unintendedstarting.

Setting Up The Handle

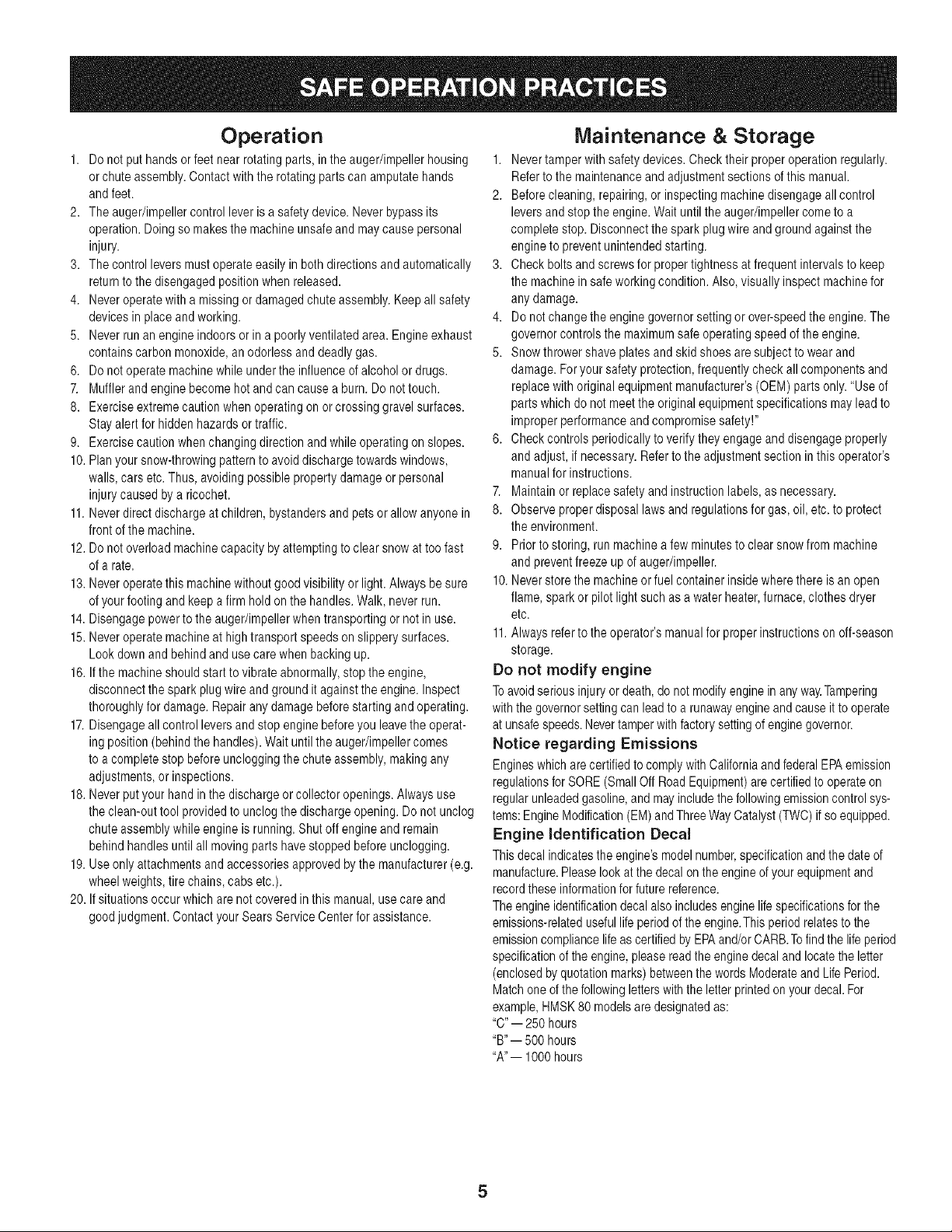

1. If applicable,removecabletiesecuringupperhandleto lower

handleforshippingpurposes.Removeall protectiveplasticwrap-

pingfromhandlesasshownin Figure1.

NOTE: BecarefulNOTto removethethreelooselyfittedcableties

thatwillbeutilizedlatertosecurecables.

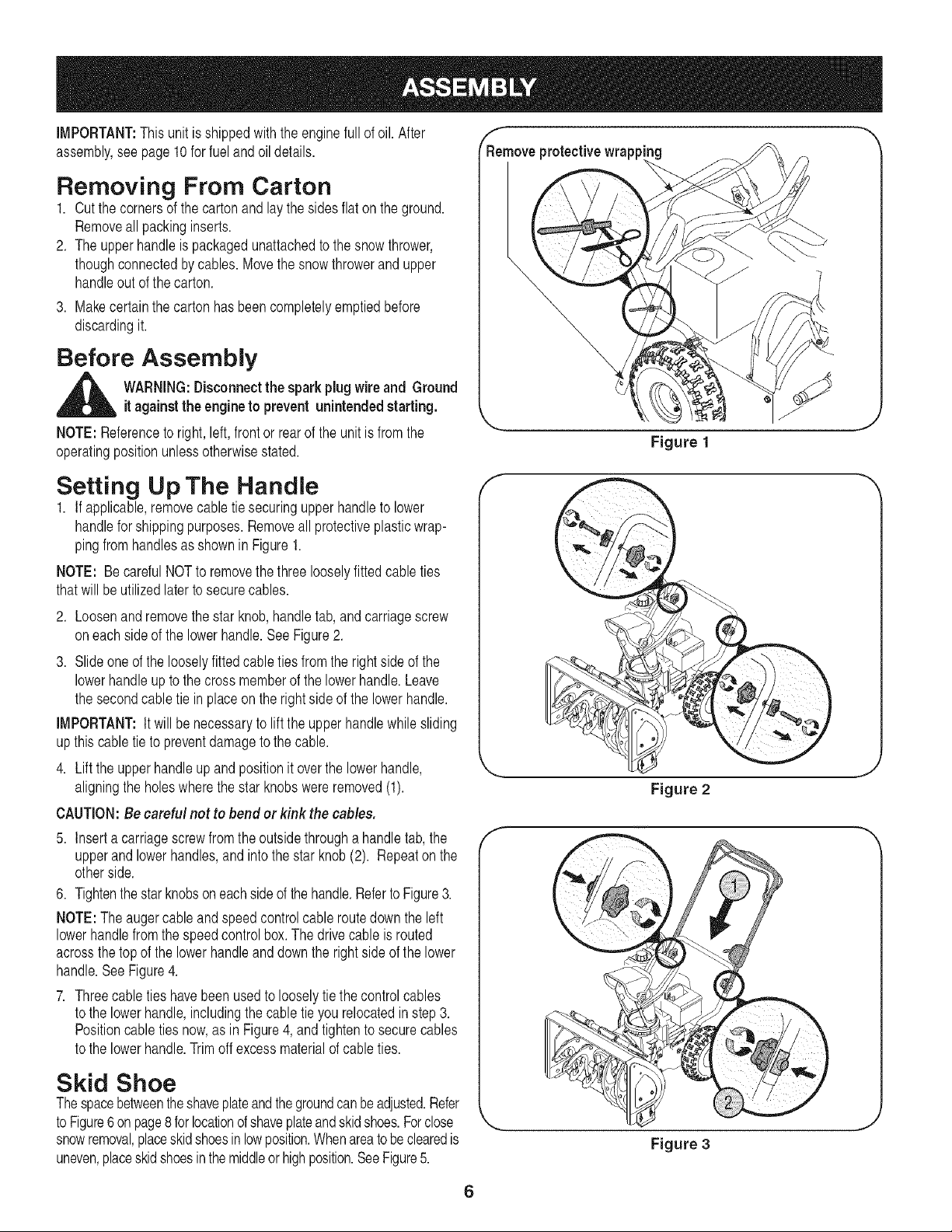

2. Loosenandremovethe starknob,handletab,andcarriagescrew

oneachsideofthe lowerhandle.SeeFigure2.

3. Slideoneofthe looselyfittedcabletiesfromtherightsideof the

lowerhandleupto thecross memberof thelowerhandle.Leave

thesecondcabletiein placeontherightsideof thelowerhandle.

IMPORTANT:It will benecessaryto lifttheupperhandlewhilesliding

upthis cabletie topreventdamagetothe cable.

4. Liftthe upperhandleupandpositionit overthelowerhandle,

aligningtheholeswherethe starknobswereremoved(1).

CAUTION:Be careful not to bend or kink the cables,

5. Inserta carriagescrewfromtheoutsidethroughahandletab,the

upperand lowerhandles,andintothestar knob(2). Repeatonthe

otherside.

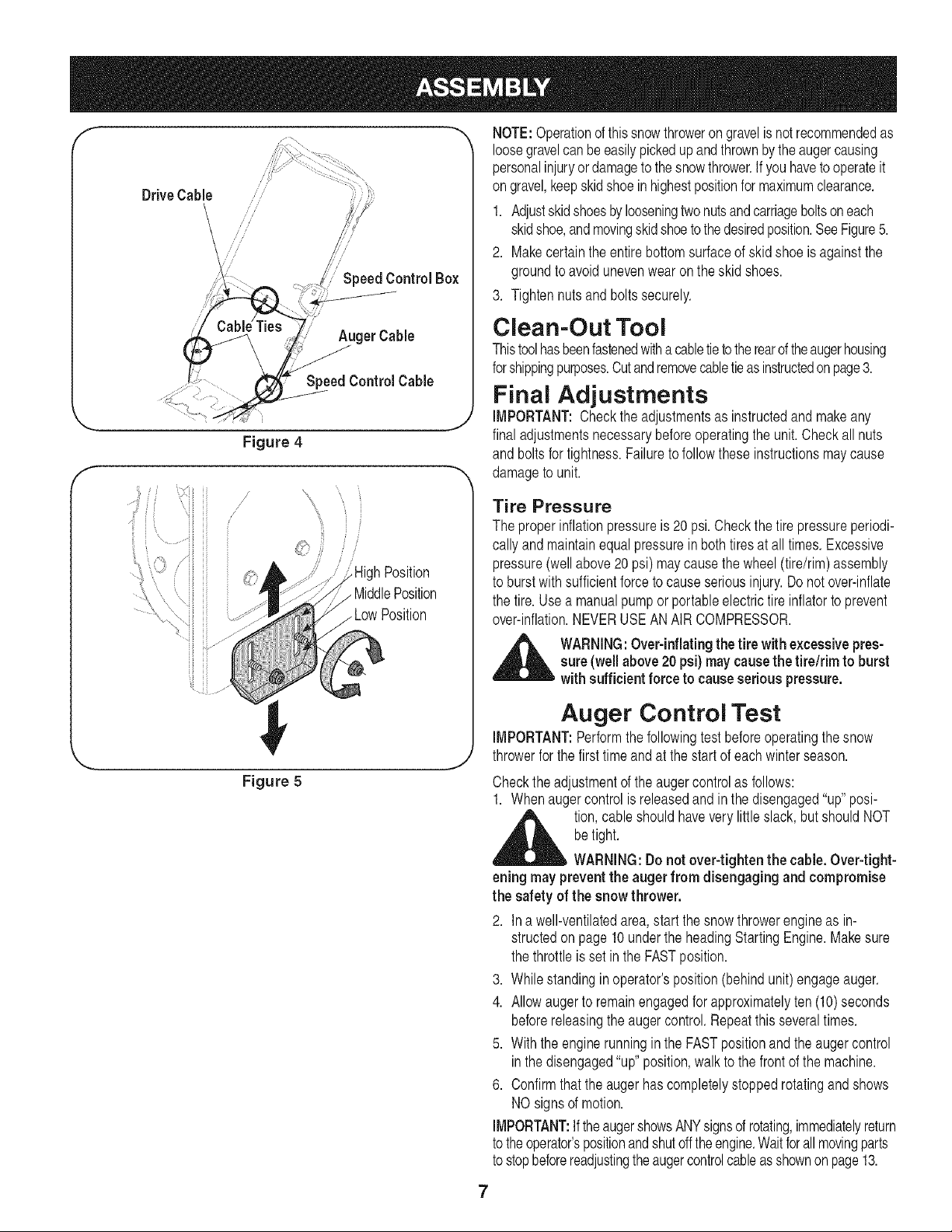

6. Tightenthestarknobsoneachsideof thehandle.Referto Figure3.

NOTE:The augercableandspeedcontrolcableroutedownthe left

lowerhandlefromthe speedcontrolbox.The drivecableisrouted

acrossthetopof thelowerhandleanddownthe rightside ofthe lower

handle.SeeFigure4.

7. Threecabletieshavebeenusedtolooselytie thecontrolcables

tothe lowerhandle,includingthecabletie yourelocatedinstep3.

Positioncabletiesnow,as in Figure4,and tightentosecurecables

tothe lowerhandle.Trimoff excessmaterialof cableties.

Figure 1

Figure 2

Skid Shoe

Thespacebetweentheshaveplateandthegroundcanbeadjusted.Refer

toFigure6onpage8forlocationofshaveplateandskidshoes.Forclose

snowremoval,placeskidshoesin lowposition.Whenareatobeclearedis

uneven,placeskidshoesinthemiddleor highposition.SeeFigure5.

Figure 3

6

Drive Cable

NOTE:Operationof thissnowthrowerongravelisnot recommendedas

loosegravelcanbeeasilypickedupandthrownbytheaugercausing

personalinjuryordamagetothesnowthrower.Ifyouhavetooperateit

on gravel,keepskidshoeinhighestpositionformaximumclearance.

/

Speed Control Box

1. Adjustskidshoesbylooseningtwonutsandcarriageboltsoneach

skidshoe,andmovingskidshoetothedesiredposition.SeeFigure5.

2. Makecertaintheentirebottomsurfaceofskidshoeisagainstthe

groundtoavoidunevenwearon theskid shoes.

3. Tightennutsandboltssecurely.

AugerCable

SpeedControl Cable

Clean-Out Tool

Thistoolhasbeenfastenedwithacabletietotherearoftheaugerhousing

forshippingpurposes.Cutandremovecabletieasinstructedonpage3.

Final Adjustments

IMPORTANT:Checktheadjustmentsas instructedand makeany

Figure 4

f

/

/

J

J

Position

MiddlePosition

finaladjustmentsnecessarybeforeoperatingtheunit.Checkall nuts

and boltsfortightness.Failuretofollowtheseinstructionsmaycause

damageto unit.

Tire Pressure

Theproperinflationpressureis20 psi.Checkthetirepressureperiodi-

callyandmaintainequalpressureinbothtiresat alltimes.Excessive

pressure(wellabove20psi) maycausethewheel(tire/rim)assembly

to burstwithsufficientforcetocauseseriousinjury.Donotover-inflate

thetire.Usea manualpumporportableelectrictire inflatortoprevent

over-inflation.NEVERUSEANAIRCOMPRESSOR.

,_ WARNING:Over-inflating thetire with excessivepres-

sure(well above20psi)may causethe tire/rim to burst

with sufficient forceto cause serious pressure.

Auger Control Test

IMPORTANT:Performthefollowingtestbeforeoperatingthesnow

throwerforthe firsttimeandat thestart ofeachwinterseason.

Figure 5

Checkthe adjustmentof theaugercontrolas follows:

1. Whenaugercontrolis releasedandin thedisengaged"up"posi-

,_ tion,cableshouldhaveverylittleslack,but shouldNOT

eningmay preventthe auger from disengaging and compromise

the safety of the snow thrower.

2. Inawell-ventilatedarea,startthesnowthrowerengineas in-

structedon page10undertheheadingStartingEngine.Makesure

thethrottleisset inthe FASTposition.

3. Whilestandinginoperator'sposition(behindunit)engageauger.

4. Allowaugerto remainengagedforapproximatelyten (10)seconds

beforereleasingthe augercontrol.Repeatthisseveraltimes.

5. Withtheenginerunningin the FASTpositionandtheaugercontrol

inthedisengaged"up"position,walkto thefrontof themachine.

6. Confirmthattheaugerhascompletelystoppedrotatingandshows

NOsignsof motion.

IMPORTANT:IftheaugershowsANYsignsofrotating,immediatelyreturn

totheoperator'spositionandshutofftheengine.Waitforallmovingparts

tostopbeforereadjustingtheaugercontrolcableasshownonpage13.

betight.

WARNING:Donot over-tighten the cable.Over-tight-

7

Gasoline Cap -_

Upper Chute

Drive

Control

Starter Rope

Shave Plate

Chute Assembly_

Chute Handle

Chute Knob

/

Anger "_ Skid Shoe

Clean-out Tool

'-.... ,J

Figure 6

_ ARNING:Be familiar with all the controls on the snow thrower and their properoperation. Know how to stop the machine

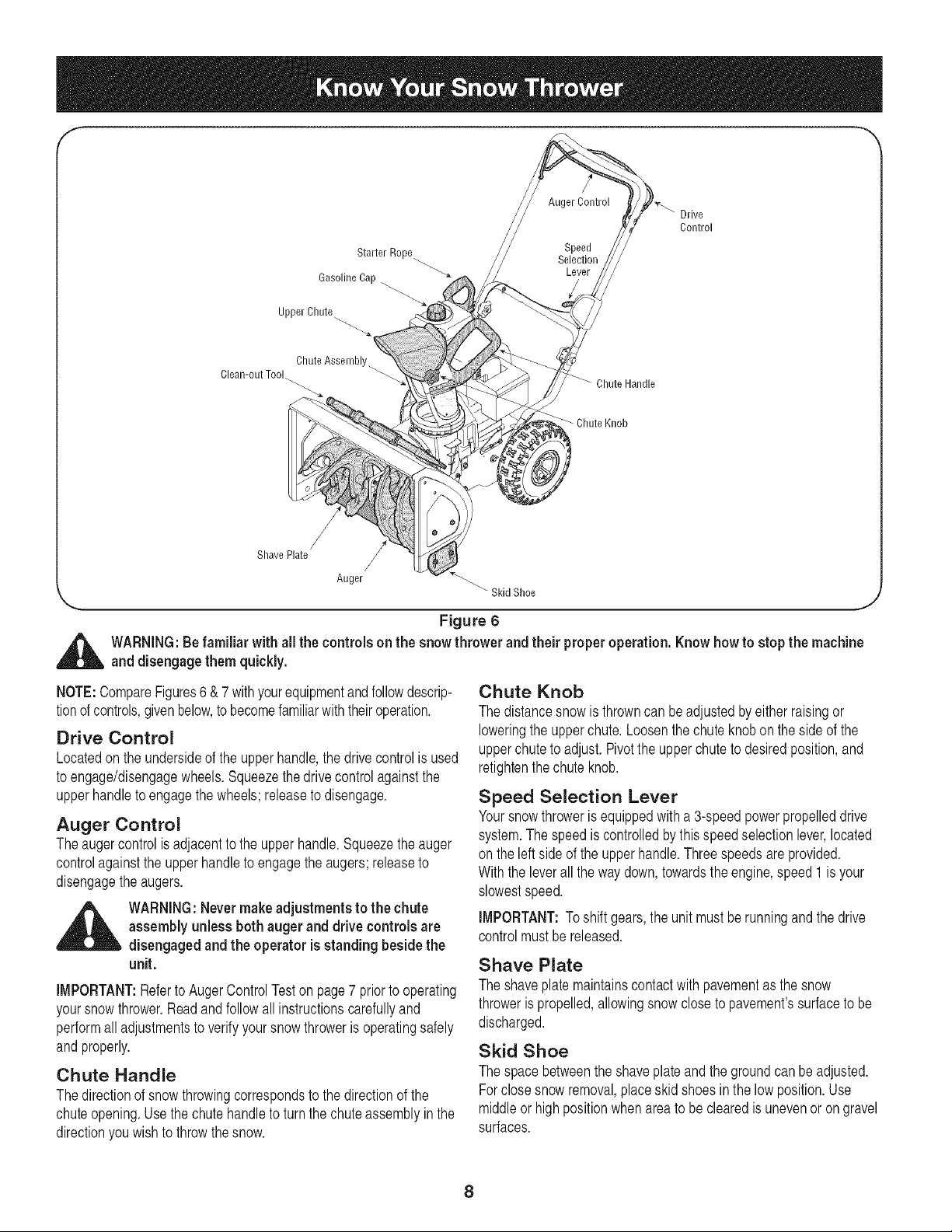

NOTE:CompareFigures6 &7 withyourequipmentandfollowdescrip-

tionof controls,givenbelow,to becomefamiliarwiththeiroperation.

Drive Control

Locatedon the undersideof the upperhandle,thedrivecontrolis used

toengage/disengagewheels.Squeezethedrivecontrolagainstthe

upperhandletoengagethe wheels;releasetodisengage.

Auger Control

Theaugercontrolis adjacenttothe upperhandle.Squeezethe auger

controlagainsttheupperhandleto engagetheaugers;releaseto

disengagetheaugers.

_ ARNING:Nevermakeadjustments to the chute

iMPORTANT:Referto AugerControlTeston page7 priorto operating

yoursnowthrower.Readandfollowall instructionscarefullyand

performalladjustmentstoverifyyoursnowthroweris operatingsafely

andproperly.

Chute Handle

Thedirectionof snowthrowingcorrespondsto thedirectionof the

chuteopening.Usethe chutehandletoturnthechuteassemblyinthe

directionyou wishtothrowthe snow.

and disengagethem quickly.

assembly unless both auger and drive controls are

disengaged and the operator isstanding besidethe

unit.

Chute Knob

Thedistancesnowisthrowncan beadjustedbyeitherraisingor

loweringtheupperchute.Loosenthechuteknobonthe sideof the

upperchutetoadjust.Pivottheupperchutetodesiredposition,and

retightenthechuteknob.

Speed Selection Lever

Yoursnowthrowerisequippedwitha 3-speedpowerpropelleddrive

system.Thespeediscontrolledbythis speedselectionlever,located

on theleftside ofthe upperhandle.Threespeedsareprovided.

Withtheleverallthewaydown,towardstheengine,speed1is your

slowestspeed.

iMPORTANT:Toshift gears,theunit mustbe runningandthedrive

controlmustbereleased.

Shave Plate

Theshaveplatemaintainscontactwithpavementas thesnow

throwerispropelled,allowingsnowcloseto pavement'ssurfacetobe

discharged.

Skid Shoe

Thespacebetweentheshaveplateandthe groundcan be adjusted.

Forclosesnowremoval,placeskidshoesin the lowposition.Use

middleorhighpositionwhenareatobe clearedisunevenor on gravel

surfaces.

8

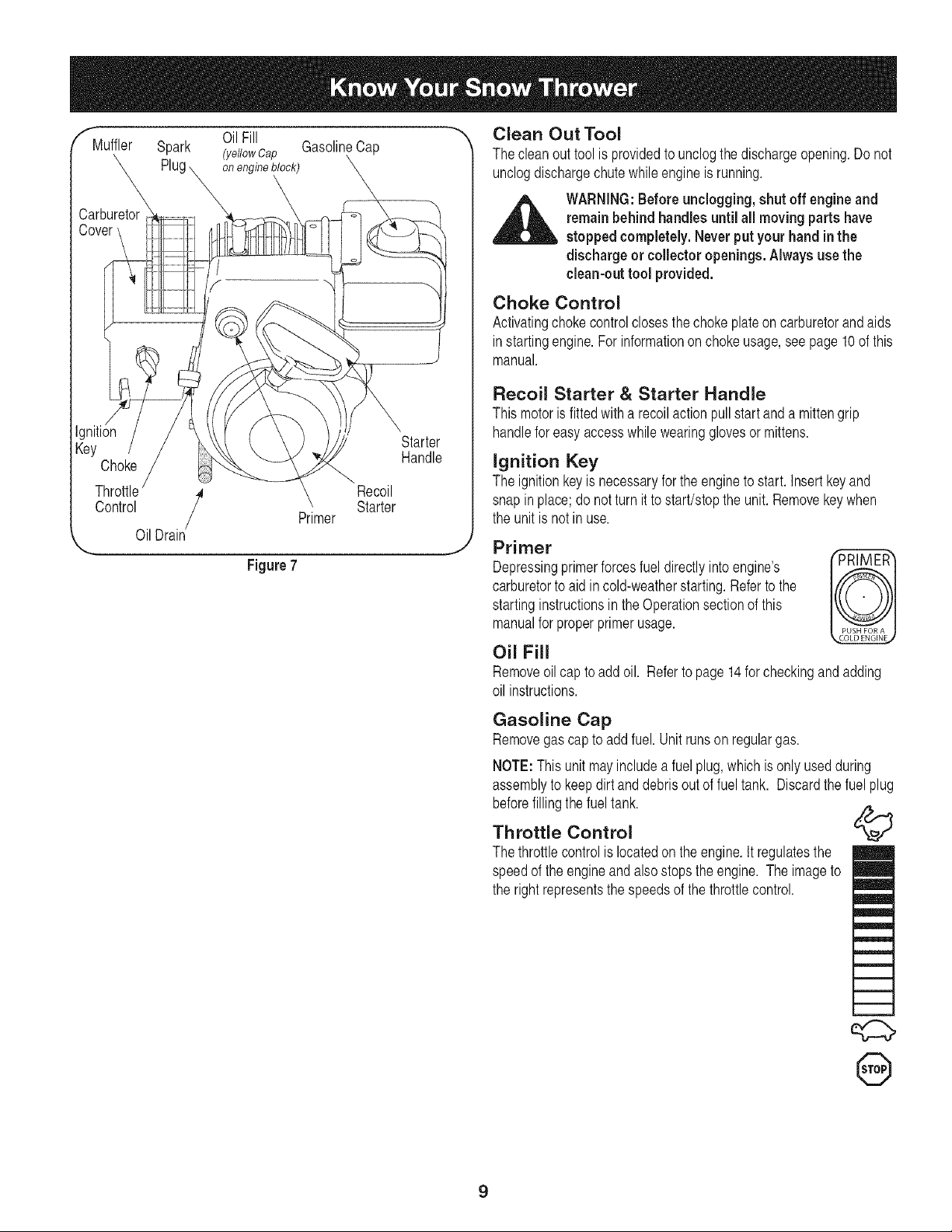

f"fMuffler Spark (ydlowCap GasolineCap

OilFill

onengineblock) \

x

X

Carburetor

Cow

Ignition

Key Starter

Choke

Control Primer Starter

Throttle / Recoil

OilDrain

,._ j

Figure7

Handle

"_ Clean Out Tool

Thecleanouttool isprovidedtounclogthedischargeopening.Donot

unclogdischargechutewhileengineis running.

_ ARNING:Before unclogging, shut off engineand

Choke Control

Activatingchokecontrolclosesthechokeplateoncarburetorandaids

instartingengine.Forinformationonchokeusage,seepage10ofthis

manual.

Recoil Starter & Starter Handle

Thismotorisfittedwitha recoilactionpullstartanda mittengrip

handlefor easyaccesswhilewearingglovesor mittens.

Ignition Key

Theignitionkeyis necessaryfortheengineto start.Insertkeyand

snapinplace;do notturnit tostart/stopthe unit. Removekeywhen

theunit isnot in use.

Primer

Depressingprimerforcesfueldirectlyintoengine's Iv_KI

carburetorto aid incold-weatherstarting.Refertothe

startinginstructionsintheOperationsectionofthis

manualforproperprimerusage.

remainbehind handles until all moving partshave

stopped completely. Never put your hand inthe

discharge or collector openings. Always usethe

clean-out tool provided.

Oil Fill

Removeoil capto addoil. Refertopage14forcheckingandadding

oil instructions.

Gasoline Cap

Removegascaptoadd fuel.Unitrunsonregulargas.

NOTE:Thisunit mayincludeafuel plug,whichis onlyusedduring

assemblyto keepdirtanddebrisoutof fueltank. Discardthefuel plug

beforefillingthefueltank.

Throttle Control

Thethrottlecontrolislocatedonthe engine.It regulatesthe

speedof theengineandalso stopsthe engine.The imageto

theright representsthespeedsof thethrottlecontrol.

,:d:::>

@

9

Before Starting Engine

Engine Oil

Theengineisshippedwithoil init.Checktheoil levelbeforefirst use.

Forsubsequentfill-ups,usethe gradeofengineoil specifiedon page

14.Toaddoil:

1. Removethedipstickfromtheoilfill. Pourfreshoilslowlythrough

theplug.Replacedipstick.

2. Checkandmakesurethatthelevelofoil is upto the FULLmarkon

thedipstick.

Gasoline

,_ WARNING:Gasolineisflammable and cautionmust

,_ WARNING:Keepyour snow thrower awayfrom any

1. Neverfillthefueltankcompletely.Fillthe tanktonomorethan1/2

inchbelowbottomof fillerneckto providespaceforexpansionof

fuel.

NOTE:Thisunit mayincludeafuel plug,whichisonlyusedduring

assemblyto keepdirt anddebrisout offuel tank. Discardthefuelplug

beforefillingthefuel tank.

2. Alwaysuseclean,fresh,unleadedgradeautomotivegasoline.Fill

thefueltankoutdoorsandusea funnelor spouttopreventspilling.

Makesurethatthe containerfromwhichyou pourthegasolineis

cleanandfreefromrustor otherforeignparticles.Makesureto

wipeoff anyspilledfuel beforestartingtheengine.

3. Atthe endofthejob,emptythefueltank ifthe snowthrowerisnot

goingto beusedfor30 daysor longer.Storegasolinein aclean

containerand keepthecap in placeonthe container.

CAUTION:Never useengineor carburetor cleanerproducts in

the fuel tank.

be used when handlingor storingit. Donot fill fuel

tank while the snow thrower is running, whenit is

hot or whenit is inanenclosedarea.

open flame or an electricalspark and do not smoke

during fueling.

To Start Engine

6. Pushprimerbuttonwhilecoveringthe venthole.Removeyour

fingerfromthe primerbetweenprimes.Donot primeif temperature

is above500F;primetwo timesbetween500F and 150F;and

primefour timesbelow150R

7. Graspstarterhandleandpull ropeoutslowlyuntilenginereaches

startof compressioncycle (ropewillpullslightlyharderatthis

point).Letthe roperewindslowly.

8. Pull ropewitha rapid,continuous,fullarmstroke.Keepinga firm

gripon thestarterhandle,lettheropereturnto thestarterslowly.

Repeatuntilenginestarts.

9. Astheenginewarmsup,rotatethechokeknobslowlyto OFF

position.If theenginefalters,returnto FULLchoke,thenslowly

moveto OFFchokeposition.

10.Allowthe enginetowarmupfor a fewminutesbecausetheengine

willnot developfullpoweruntilit reachesoperatingtemperature.

11.Operatetheengineat fullthrottle(FAST)whenthrowingsnow.

For A Warm Start:

1. If restartinganengineafteratemporaryshut-down,rotatechoke

toOFFinsteadof FULLanddo notprime.Pullstarterhandleas

instructedbefore.

Before Stopping

1. Runenginefora fewminutestohelpdryoff anymoistureonengine.

2. Toavoidpossiblefreeze-upofthe starter,followthesesteps:

Recoil Starter

a. Withtheenginerunning,pullthestarterropewitha rapid,

continuousfullarmstrokethreeorfour times.

To Stop The Snow Thrower

1. Tostopthe wheels,releasethedrivecontrol.

2. Tostopthrowingsnow,releasetheaugercontrol.

3. Tostopengine,pushthrottlecontrolleverto OFFandpulloutthe

key.Do notturn key.

temperature

,_ WARNING:The of muffler and the

rounding areas mayexceed150° F.Avoidtheseareas

sur-

,_ WARNING:Besure no oneother than the operator

NOTE:Forlocationofallthe enginecontrolsreferredtointhis section,

referto Figure7.

isstanding nearthe snow thrower while starting or

operating. Do not operate this snow thrower unless

the chute assembly hasbeen properly installedand

issecured.

For A Cold Start

1. Makesurethataugeranddrivecontrolsarereleased.Attachspark

plugwireto sparkplug.

2. Turnfuelvalveon,if soequipped.

3. Movethrottlecontrolto FASTposition.

4. Pushkeyintotheignitionslotsothatitsnapsintoplace.Donotturnkey.

5. Rotatechokecontrolto FULLchokeposition.

Clearing The Snow

CAUTION:Checkthe areato beclearedforforeignobjects.Remove

foreignobjects,if any.

1. Starttheenginefollowingstartinginstructions.

2. Allowtheenginetowarmupfor a fewminutesastheenginewill

notdevelopfullpoweruntilit reachesoperatingtemperature.

3. Rotatethe chuteassemblytothe desireddirection,awayfrom

bystandersand/or buildings.

4. Makingcertainnobystandersorobstaclesareinfrontof the unit,

squeezetheaugercontrolcompletelyagainsttheupperhandleto

fullyengagetheaugers.

5. Whiletheaugercontrolisengaged,squeezethe drivecontrol

completelyagainstthe upperhandletoengagethe wheels.Do not

"feather"thedrivecontrol.

10

6. Asthesnowthrowerstartsto move,maintaina firm holdon the

handle,andguidethe snowthroweralongthepathto becleared.

7. Releasetheaugeranddrivecontrolstostopthesnowthrowing

actionandforwardmotion.

NOTE:Yourunitisequippedwithaclutch inthetransmission.If the

wheelsstopturningwhiletryingtodischargelargevolumesofsnow,

immediatelydisengagethedrivecontrolandallowtherotatingaugers

todischargesnowfromthe housing.Reducetheclearingwidthand

continueoperation.

8. Oneachsucceedingpass,readjustthechuteassemblyto the

desiredpositionandslightlyoverlapthepreviouslyclearedpath.

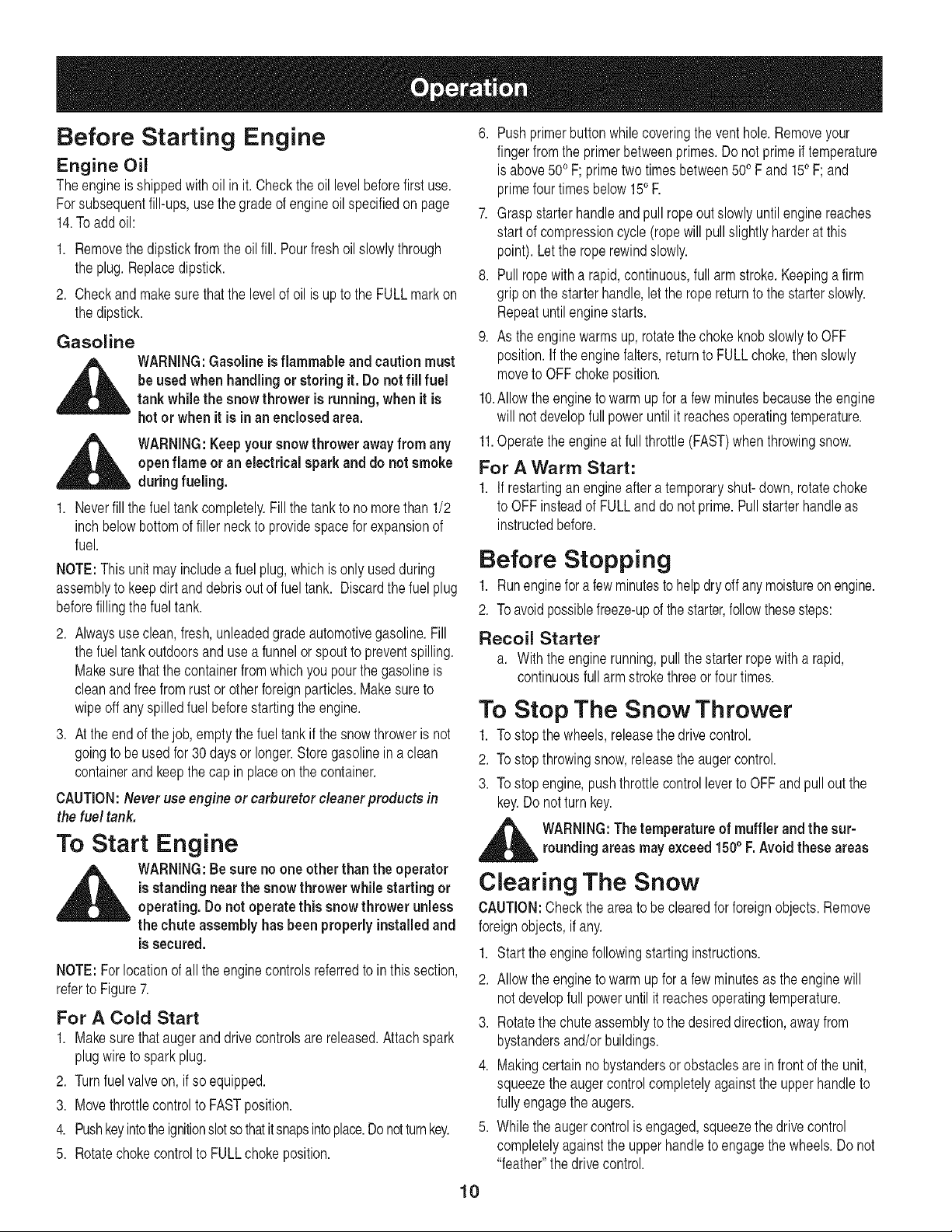

Speed Selector Lever

Yourunitis equippedwitha 3-speedpowerpropelleddrivesystem.

Speedposition1,whentheleverisdepressedall thewaydowntoward

themotor,isSlow. Speedposition2 isalittlefasterand3 isthe

fastest. SeeFigure8.

Speed

Selector

Lever

NOTE:It is notrecommendedthatyouoperatethissnowthroweron

gravelas loosegravelcanbeeasilypickedup andthrownbytheauger

causingpersonalinjuryand/ordamagetothe snowthrower.

4. Ifforsomereason,you haveto operatethesnowthrowerongravel,

keeptheskidshoeinthe highestpositionformaximumclearance

betweenthe groundandtheshaveplate.

5. Cleanthe snowthrowerthoroughlyaftereachuse.

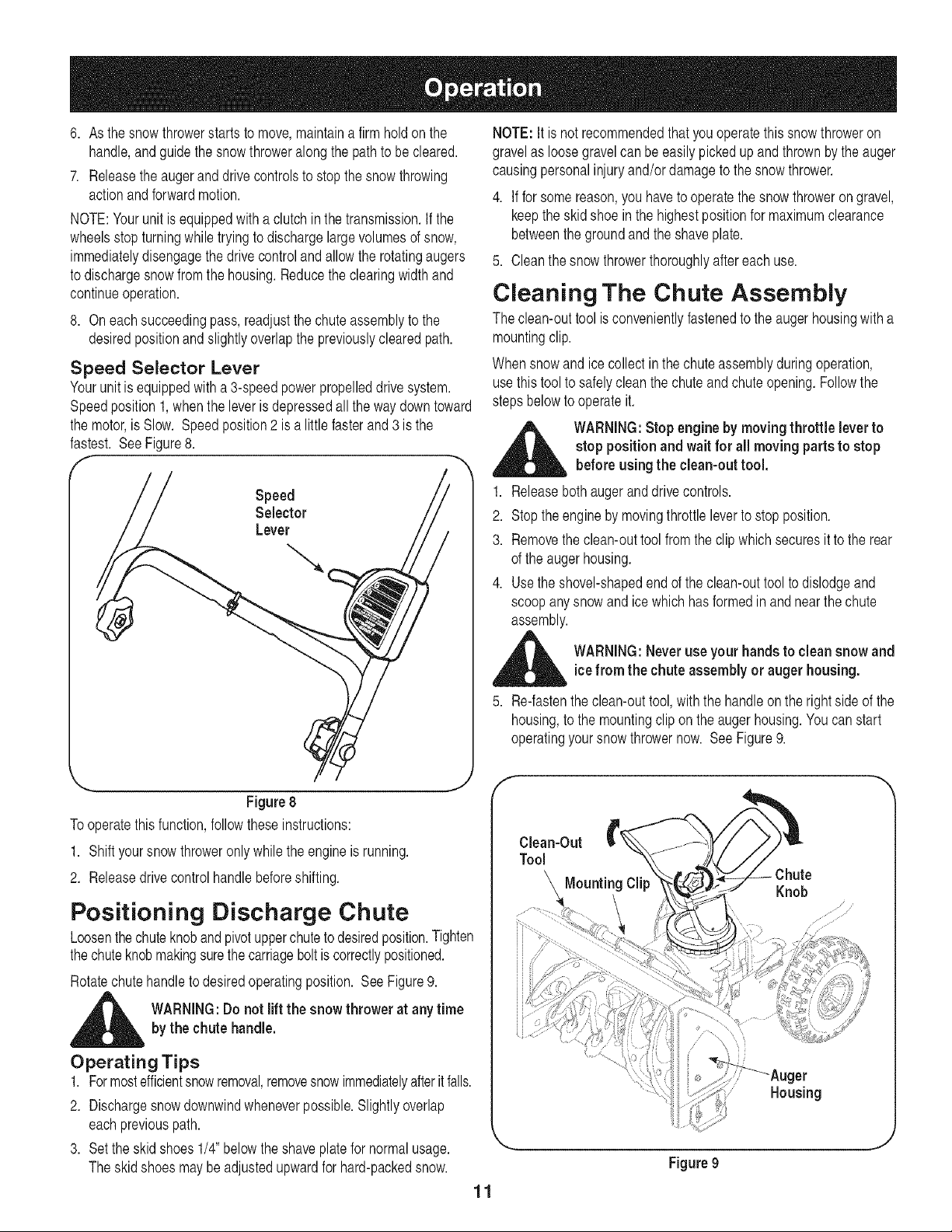

Cleaning The Chute Assembly

Theclean-outtoolisconvenientlyfastenedtotheaugerhousingwitha

mountingclip.

Whensnowandice collectinthe chuteassemblyduringoperation,

usethistool tosafelycleanthechuteandchuteopening.Followthe

stepsbelowtooperateit.

_ WARNING:Stopenginebymoving throttle leverto

1. Releasebothaugeranddrivecontrols.

2. Stoptheenginebymovingthrottlelevertostopposition.

3. Removethe clean-outtool fromtheclipwhichsecuresitto the rear

ofthe augerhousing.

4. Usetheshovel-shapedendoftheclean-outtooltodislodgeand

scoopanysnowandice whichhasformedin andnearthe chute

assembly.

stoppositionand wait for all moving partsto stop

before using the clean-outtool.

Figure 8

Tooperatethisfunction,followtheseinstructions:

1. Shiftyoursnowthroweronlywhilethe engineisrunning.

2. Releasedrivecontrolhandlebeforeshifting.

Positioning Discharge Chute

Loosenthechuteknobandpivotupperchutetodesiredposition.Tighten

thechuteknobmakingsurethecarriageboltis correctlypositioned.

Rotatechutehandleto desiredoperatingposition. SeeFigure9.

,_ WARNING:Do not liftthe snowthrower at anytimebythe chutehandle.

Operating Tips

1. Formostefficientsnowremoval,removesnowimmediatelyafteritfalls.

2. Dischargesnowdownwindwheneverpossible.Slightlyoverlap

eachpreviouspath.

3. Settheskidshoes1/4"belowtheshaveplatefornormalusage.

Theskidshoesmaybeadjustedupwardforhard-packedsnow.

_ ARNING:Neveruse your handsto cleansnowand

5. Re-fastentheclean-outtool,withthehandleontherightsideofthe

housing,to themountingclipontheaugerhousing.Youcanstart

operatingyoursnowthrowernow. SeeFigure9.

icefrom the chuteassembly or auger housing.

f --,,,

Knob

_er

Housing

Figure9

11

J

General Recommendations

1. Alwaysobservesafetyruleswhenperforminganymaintenance.

2. Thewarrantyon thissnowthrowerdoesnot coveritemsthat have

beensubjectedtooperatorabuseor negligence.Toreceivefull

valuefromthe warranty,operatormustmaintainthesnowthrower

asinstructedinthismanual.

3. Periodicallycheckallfastenersandhardwareto makesurethese

aretight.

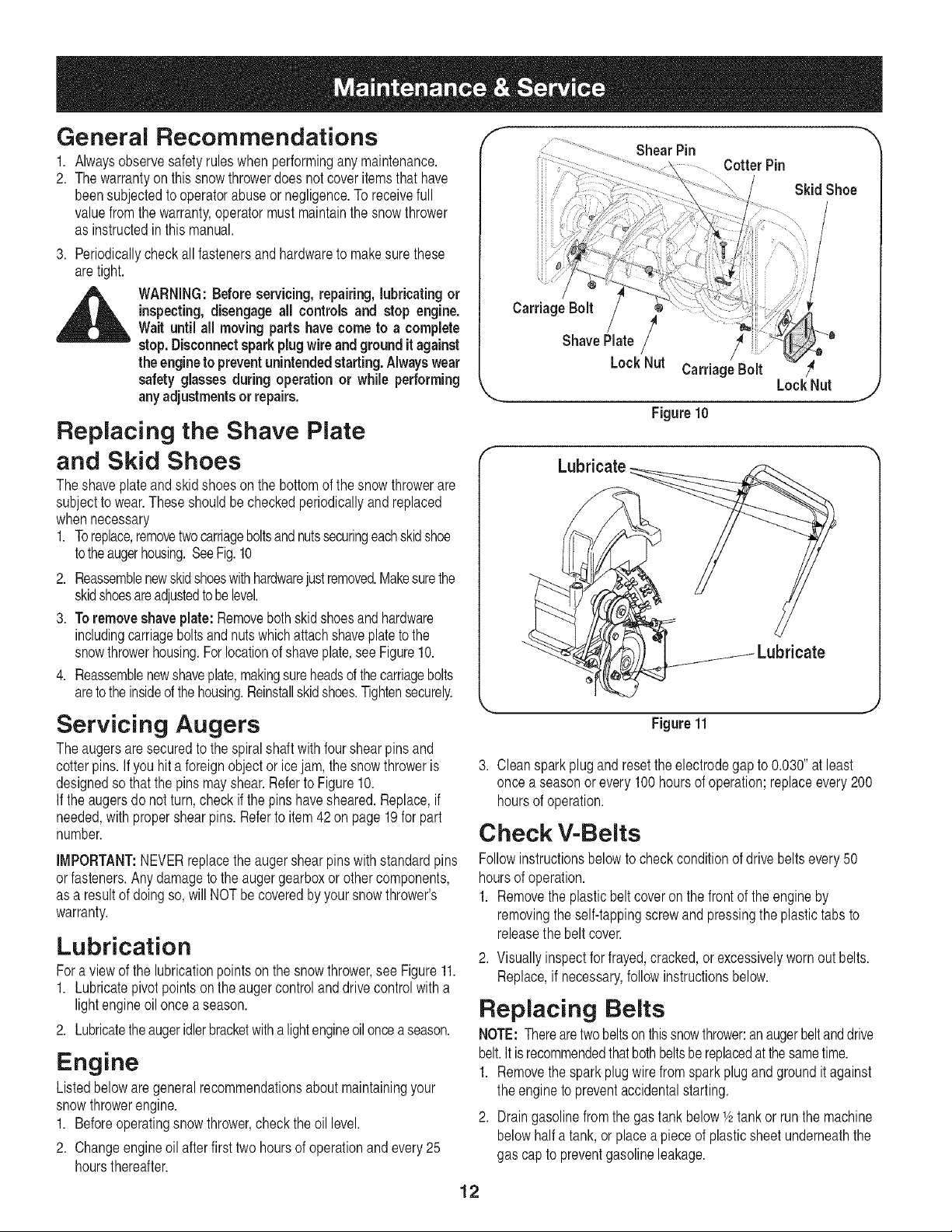

f

ShearPin

ill .

iii/

iiiii

iiiii

CotterPin

Skid Shoe

_ WARNING: Beforeservicing,repairing,lubricatingor

inspecting,disengageall controlsand stop engine.

Wait until all moving partshavecometo a complete

stop.Disconnectsparkplugwireandground itagainst

the engineto preventunintendedstarting.Alwayswear

safetyglassesduringoperation or while performing

anyadjustmentsor repairs.

Replacing the Shave Plate

and Skid Shoes

Theshaveplateandskidshoesonthe bottomofthe snowthrowerare

subjectto wear.Theseshouldbecheckedperiodicallyandreplaced

whennecessary

1. Toreplace,removetwocarriageboltsandnutssecuringeachskidshoe

totheaugerhousing.SeeFig.10

2. Reassemblenewskidshoeswithhardwarejustremoved.Makesurethe

skidshoesareadjustedtobelevel.

3. Toremoveshaveplate:Removebothskidshoesandhardware

includingcarriageboltsandnutswhichattachshaveplatetothe

snowthrowerhousing.Forlocationof shaveplate,see Figure10.

4. Reassemblenewshaveplate,makingsureheadsof thecarriagebolts

aretothe insideofthehousing.Reinstallskidshoes.Tightensecurely.

Servicing Augers

Theaugersaresecuredtothe spiralshaftwithfourshearpinsand

cotterpins.Ifyou hita foreignobjector icejam,the snowthroweris

designedsothatthepinsmayshear.RefertoFigure10.

If theaugersdo notturn,checkifthe pinshavesheared.Replace,if

needed,withpropershearpins.Referto item42on page19for part

number.

IMPORTANT:NEVERreplacetheaugershearpinswithstandardpins

orfasteners.Anydamagetotheaugergearboxorothercomponents,

asa resultof doingso,willNOTbe coveredbyyoursnowthrower's

warranty.

Lubrication

Fora viewof thelubricationpointsonthe snowthrower,see Figure11.

1. Lubricatepivotpointsontheaugercontrolanddrivecontrolwitha

lightengineoiloncea season.

2. Lubricatetheaugeridlerbracketwithalightengineoiloncea season.

Engine

Listedbelowaregeneralrecommendationsabout maintainingyour

snowthrowerengine.

1. Beforeoperatingsnowthrower,checkthe oil level.

2. Changeengineoilafterfirst two hoursof operationandevery25

hoursthereafter.

Carriage Bolt

ShavePlate /

LockNut CarriageBolt

LockNut

Figure10

Lubricate

Figure11

3. Cleansparkplugand resetthe electrodegap to0.030"atleast

oncea seasonorevery100hoursofoperation;replaceevery200

hoursof operation.

Check V-Belts

Followinstructionsbelowto checkconditionofdrivebeltsevery50

hoursofoperation.

1. Removetheplasticbeltcoveron thefrontof theengineby

removingthe self-tappingscrewand pressingtheplastictabsto

releasethe beltcover.

2. Visuallyinspectfor frayed,cracked,or excessivelywornoutbelts.

Replace,if necessary,followinstructionsbelow.

Replacing Belts

NOTE:Therearetwobeltsonthissnowthrower:anaugerbeltanddrive

belt.It isrecommendedthatbothbeltsbereplacedat thesametime.

1. Removethesparkplugwirefromsparkplugandgroundit against

theengineto preventaccidentalstarting.

2. Draingasolinefromthegas tankbelowV2tankor runthemachine

belowhalf a tank,or placeapieceof plasticsheetunderneaththe

gascap topreventgasolineleakage.

12

J

f

"-... HousingScrew ,j

Figure12

F ....

Figure13

AugerCabi_"_

Adjustment

Bracket

Wood Block

WARNING:Performbeltmaintenanceoutdoorsas

somegasmaypossiblyleakfrom thecarburetoreven

thoughyou placedasheetofplasticunderneaththe

gascap topreventthe gascapfrom leaking.

Adjusting The Auger Cable

Periodicadjustmenttothe augercontrolcablemayberequireddue

to normalstretchandwearonthe belt.Adjustmentis neededif the

augersseemto hesitatewhileturning,buttheenginemaintainsspeed,

or continueturningwiththe augercontroldisengaged.

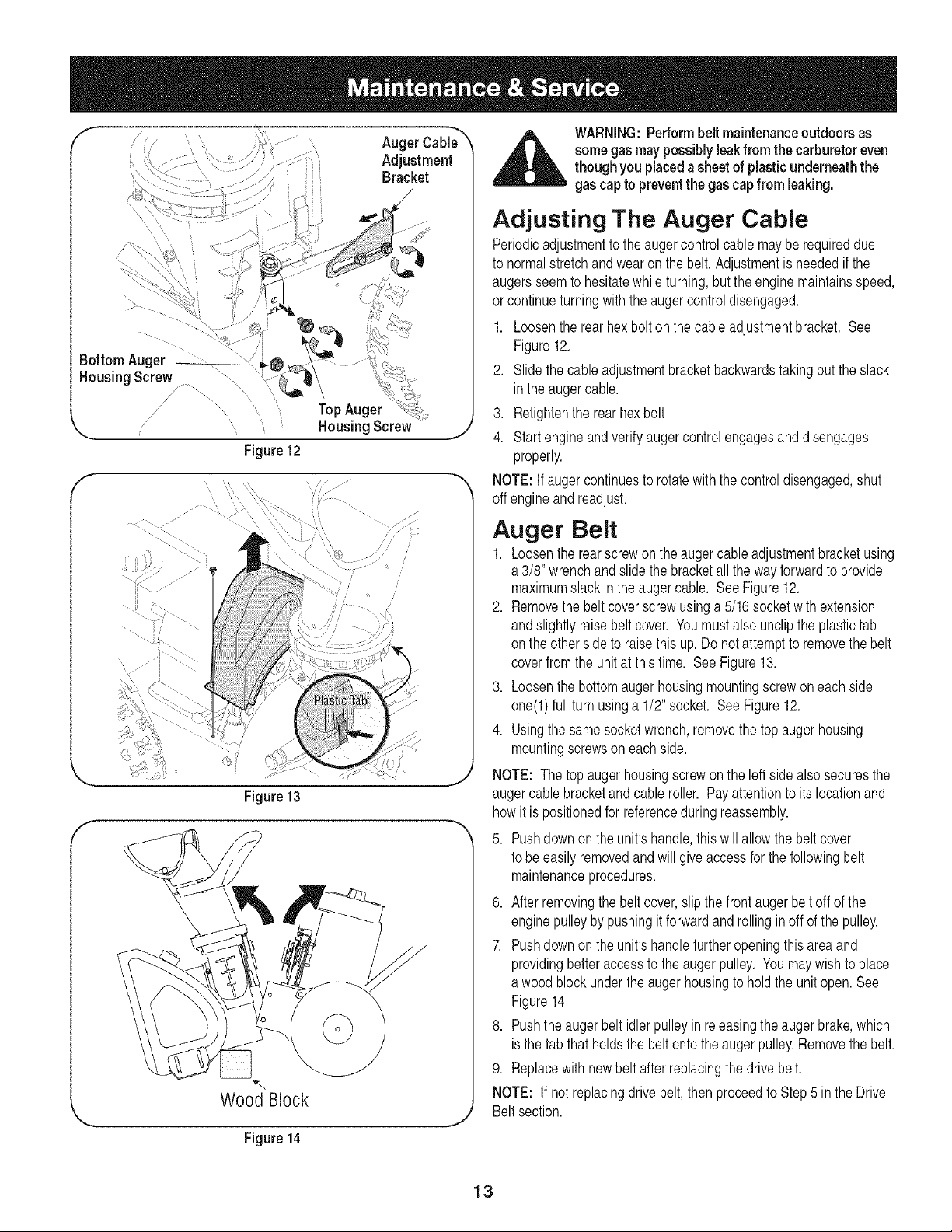

1. Loosentherearhexboltonthecableadjustmentbracket.See

Figure12.

2. Slidethecableadjustmentbracketbackwardstakingouttheslack

intheaugercable.

3. Retightenthe rearhexbolt

4. Startengineandverifyaugercontrolengagesand disengages

properly.

NOTE:If augercontinuestorotatewiththe controldisengaged,shut

off engineandreadjust.

Auger Belt

1. Loosentherearscrewonthe augercableadjustmentbracketusing

a 3/8' wrenchandslidethebracketallthewayforwardtoprovide

maximumslack intheaugercable. SeeFigure12.

2. Removethe beltcoverscrewusinga5/16socketwithextension

andslightlyraise beltcover. Youmustalso uncliptheplastictab

on theothersideto raisethisup.Donotattempttoremovethebelt

coverfromtheunit atthistime. SeeFigure13.

3. Loosenthebottomaugerhousingmountingscrewoneachside

one(l) fullturnusinga 1/2"socket. SeeFigure12.

4. Usingthesamesocketwrench,removethetopaugerhousing

mountingscrewsoneachside.

NOTE: The topaugerhousingscrewonthe leftsidealsosecuresthe

augercablebracketandcableroller. Payattentionto itslocationand

howit is positionedforreferenceduringreassembly.

5. Pushdownon theunit'shandle,thiswillallowthe beltcover

tobe easilyremovedandwillgiveaccessfor thefollowingbelt

maintenanceprocedures.

6. Afterremovingthebelt cover,slipthefrontaugerbelt off ofthe

enginepulleybypushingit forwardandrollingin offofthe pulley.

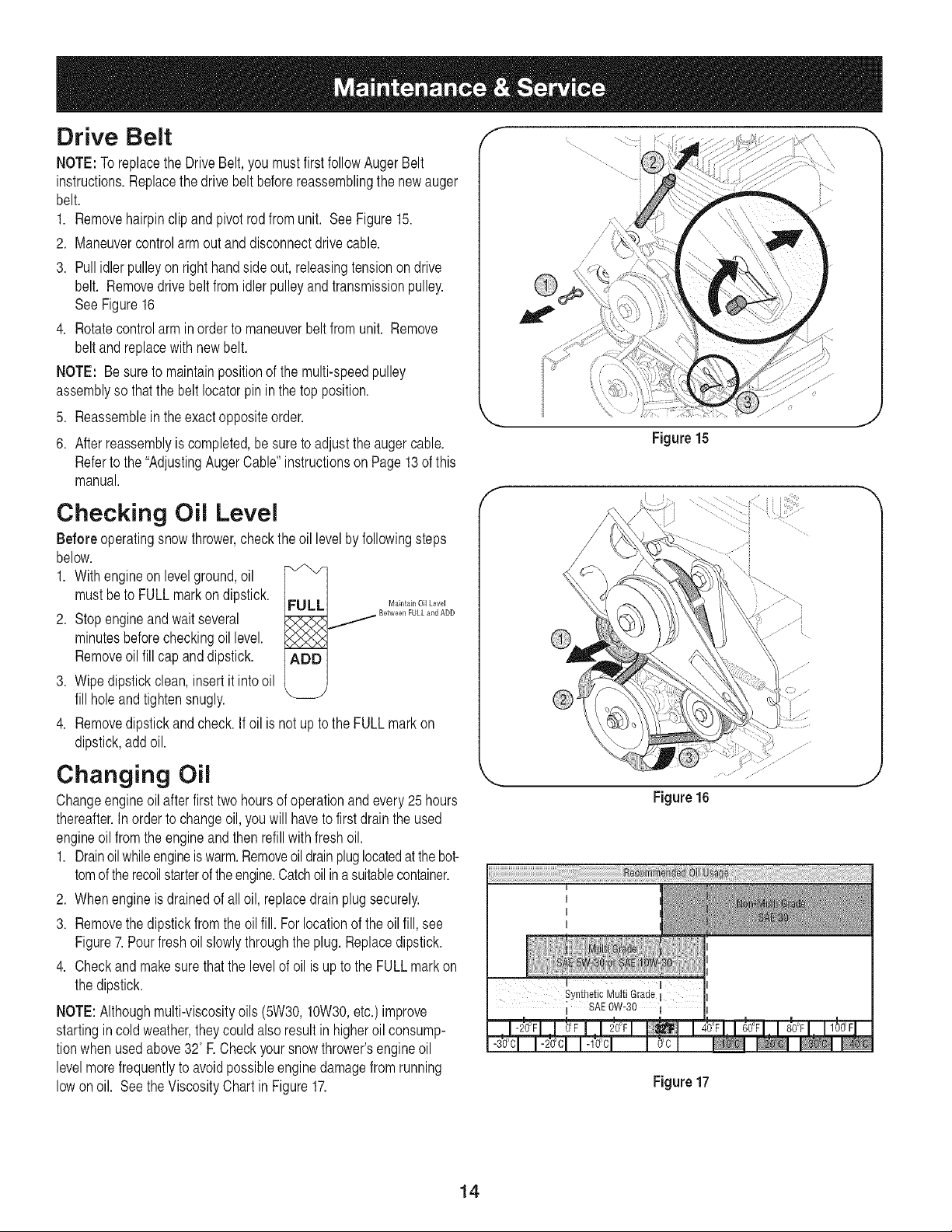

7. Pushdownon theunit'shandlefurtheropeningthisareaand

providingbetteraccesstothe augerpulley. Youmaywishtoplace

a woodblockunderthe augerhousingtoholdtheunitopen.See

Figure14

8. Pushtheaugerbeltidlerpulleyin releasingtheaugerbrake,which

isthe tabthat holdsthe beltontothe augerpulley.Removethebelt.

9. Replacewithnewbeltafterreplacingthedrivebelt.

NOTE: If not replacingdrivebelt,thenproceedto Step5 intheDrive

Beltsection.

Figure14

13

Drive Belt

NOTE:ToreplacetheDriveBelt,youmustfirstfollowAugerBelt

instructions.Replacethedrivebeltbeforereassemblingthenewauger

belt.

1. Removehairpinclipand pivotrodfromunit. SeeFigure15.

2. Maneuvercontrolarmout anddisconnectdrivecable.

3. Pullidlerpulleyonright handsideout, releasingtensionon drive

belt. Removedrivebeltfromidlerpulleyandtransmissionpulley.

SeeFigure16

4. Rotatecontrolarmin orderto maneuverbeltfromunit. Remove

beltand replacewithnewbelt.

NOTE: Besureto maintainpositionofthemulti-speedpulley

assemblyso thatthebelt Iocatorpinin thetop position.

5. Reassemblein theexactoppositeorder.

6. Afterreassemblyis completed,be sureto adjusttheaugercable.

Refertothe "AdjustingAugerCable"instructionson Page13of this

manual.

Checking Oil Level

Beforeoperatingsnowthrower,checkthe oil levelbyfollowingsteps

below.

1. Withengineonlevelground,oil

mustbeto FULLmarkon dipstick.

2. Stopengineandwaitseveral

minutesbeforecheckingoillevel.

Removeoil fillcap anddipstick.

3. Wipedipstickclean,insertit intooil

fillholeandtightensnugly.

4. Removedipstickandcheck.If oil isnotuptotheFULLmarkon

dipstick,addoil.

FULLJ M_int_inOilLevel

_ Between FULL and ADD

ADD

Figure15

Changing Oil

Changeengineoilafterfirsttwo hoursofoperationandevery25hours

thereafter.Inordertochangeoil,you willhavetofirstdraintheused

engineoil fromtheengineandthen refillwithfreshoil.

1. Drainoilwhileengineis warm.Removeoildrainpluglocatedatthebot-

tomoftherecoilstarteroftheengine.Catchoilina suitablecontainer.

2. Whenengineis drainedofalloil, replacedrainplugsecurely.

3. Removethedipstickfromtheoilfill. Forlocationof theoil fill,see

Figure7.Pourfreshoilslowlythroughtheplug. Replacedipstick.

4. Checkandmakesurethatthelevelofoil is upto the FULLmarkon

thedipstick.

NOTE:Althoughmulti-viscosityoils (5W30,10W30,etc.)improve

startingincold weather,theycouldalso resultin higheroilconsump-

tionwhen usedabove32°RCheckyoursnowthrower'sengineoil

levelmorefrequentlyto avoidpossibleenginedamagefromrunning

lowon oil. Seethe ViscosityChartin Figure17.

14

Synthetic Multi Grade

; SAE0W-30

I

Figure16

1

Figure17

Loading...

Loading...