Craftsman 247881900 Owner’s Manual

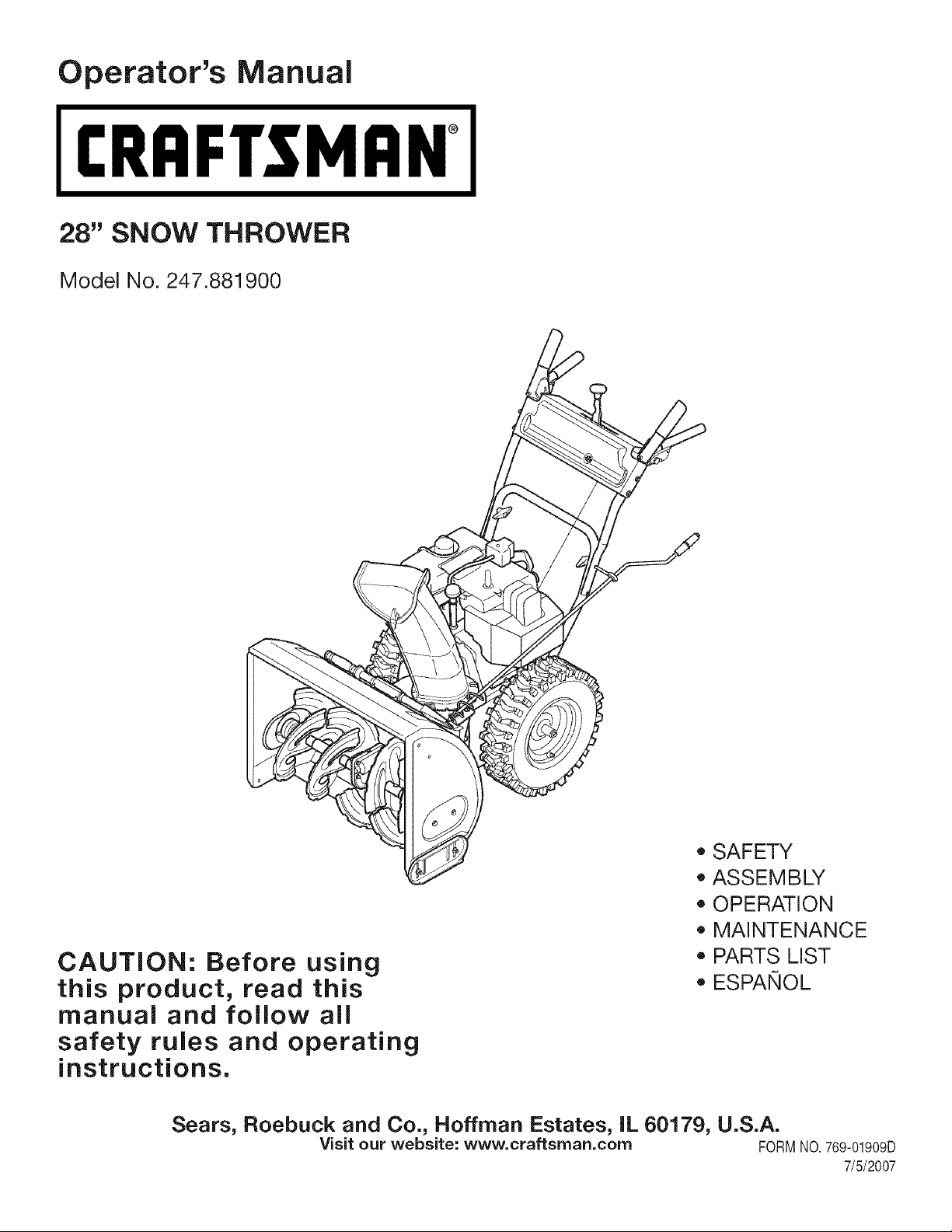

Operator's Manual

CRAFTSMAN°

28" SNOW THROWER

Model No. 247.881900

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www, craftsrnan.corn FORMNO.769-01909D

• SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LiST

ESPAI_OL

7/5/2007

WarrantyStatement.................... Page2

RepairProtectionAgreement............. Page3

SafeOperationPractices.............. Pages4-5

SafetyLabels......................... Page7

Assembly......................... Pages8-11

Service&Maintenance.............. Pages16-23

Off-SeasonStorage................... Page24

Troubleshooting...................... Page25

PartsList......................... Pages26-37

Espa_ol............................. Page40

Operation........................ Pages12-15

Two-YearWarranty on CraftsmanSnowThrower

Thisequipmentiscoveredbyatwo-yearwarranty,providedthatitismaintained,lubricated,andtunedupaccordingtotheinstructionsinthe

operator'smanual.Duringthewarrantyyear,ifthisequipmentexperiencesanyfailureduetodefectsinmaterialorworkmanship,RETURNITTO

YOURNEARESTSEARSPARTS&REPAIRCENTER,andSearswillrepairit,freeofcharge.In-homewarrantyserviceisavailable,butyouwill

havetopayatripcharge.

Thiswarrantydoesnotcover:

Expendableitemswhichbecomewornduringnormaluse,suchasskidshoes,shaveplateandsparkplugs.

Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,bentcrankshafts,failuretousethepropergradeandamountofengineoil,orfailuretomaintaintheequipmentaccordingtothe

instructionscontainedintheoperator'smanual.

Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedtobecontaminatedoroxidized(stale).Ingeneral,fuelshouldbeused

within30daysofitspurchasedate.

Equipmentifusedforcommercialorrentalpurposes.

Thiswarrantyappliesforonly90daysifthisproductiseverusedforcommercialorrentalpurposes.

ThiswarrantyappliesonlywhilethisproductisusedintheUnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

Sears,RoebuckandCo.,HoffmanEstates,IL60179

EngineOilType: SAE5W-30

EngineOilCapacity: 26ounces

FuelCapacity: 4Quarts

SparkPlug: Champion®RJ19LM

SparkPlugGap: .030"

ModelNumber.................................................................

SerialNumber.................................................................

DateofPurchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

©SearsBrands,LLC

Congratulationson makingasmartpurchase.YournewCraftsman®

productisdesignedandmanufacturedforyearsof dependableopera-

tion.Butlikeall products,it mayrequirerepairfromtimeto time.That's

whenhavinga RepairProtectionAgreementcansaveyoumoneyand

aggravation.

Here'swhat'sincludedintheAgreement:

,, Expertserviceby our 12,000professionalrepairspecialists

,, Unlimitedserviceandnochargefor partsandlaboronall covered

repairs

,, Productreplacementifyourcoveredproductcan'tbefixed

,, Discountof 10%fromregularpriceofserviceandservice-related

partsnotcoveredbytheagreement;also,10%off regularpriceof

preventivemaintenancecheck

,, Fasthelpbyphone- phonesupportfromaSearstechnicianon

productsrequiringin-homerepair,plusconvenientrepair

scheduling

Purchasea RepairProtectionAgreementnowandprotectyourself

fromunexpectedhassleandexpense.

Onceyou purchasetheAgreement,a simplephonecall isall thatit

takesfor you toscheduleservice.Youcancall anytimedayornight,or

schedulea serviceappointmentonline.

Searshasover12,000professionalrepairspecialists,who have

accesstoover4.5millionqualitypartsandaccessories.That'sthe

kindof professionalismyoucancounton tohelpprolongthelifeof

yournewpurchaseforyearstocome.PurchaseyourRepairProtection

Agreementtoday!

Somelimitationsandexclusionsapply. For pricesand additional

informationcall 1-800-827-6655.

SearsInstallation Service

ForSearsprofessionalinstallationof homeappliances,garagedoor

openers,waterheaters,andothermajorhomeitems,in theU.S.A.call

1-800-4-MY-HOME®

which,ifnotfollowed,couldendangerthepersonal

__L Thissymbolpointsoutimportantsafetyinstructions

safetyand/orpropertyofyourselfandothers.Read

andfollowallinstructionsinthismanualbefore

attemptingtooperatethismachine.Failuretocomplywiththese

instructionsmayresultinpersonalinjury.Whenyouseethissymbol,

HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtotherulesfor

safeoperationinthismanual.Aswithanytypeofpowerequipment,

carelessnessorerroronthepartoftheoperatorcanresultinserious

injury.Thismachineiscapableofamputatinghandsandfeetand

throwingobjects.Failuretoobservethefollowingsafetyinstructions

couldresultinseriousinjuryordeath.

YourResponsibility:Restricttheuseofthispowermachineto

personswhoread,understand,andfollowthewarningsandinstruc-

tionsinthismanualandonthemachine.

TRAINING

,, Read,understand,andfollowallinstructionsonthemachineandin

the manual(s)beforeattemptingtoassembleandoperate.Keepthis

manualina safeplaceforfuture andregularreferenceandforordering

replacementparts.

,, Be familiarwithallcontrolsandtheirproperoperation.Knowhowto stop

the machineanddisengagethemquickly.

,, Neverallowchildrenunder14yearsoldto operatethismachine.Chil-

dren14yearsoldandovershouldreadandunderstandthe operation

instructionsandsafetyrulesinthis manualand shouldbetrainedand

supervisedbya parent.

,, Neverallowadultsto operatethismachinewithoutproperinstruction.

,, Thrownobjectscancauseseriouspersonalinjury.Planyoursnow-

throwingpatterntoavoiddischargeof materialtowardroads,bystanders

andthe like.

,, Keepbystanders,helpers,petsandchildrenatleast75feetfromthe

machinewhileit is inoperation.Stop machineif anyoneentersthearea.

,, Exercisecautiontoavoidslippingorfalling,especiallywhenoperatingin

reverse.

Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State of California to

1cause cancer and birth defects or other reproductive harm.

PREPARATION

Thoroughlyinspecttheareawheretheequipmentisto beused.Removeall

doormats,newspapers,sleds,boards,wiresandotherforeignobjects,which

couldbetrippedoverorthrownbythe auger/impeller.

,, Alwayswearsafetyglassesoreyeshieldsduringoperationandwhile

performinganadjustmentor repairto protectyoureyes.Thrownobjects

whichricochetcancauseserious injurytothe eyes.

,, Donotoperatewithoutwearingadequatewinteroutergarments.Donot

wearjewelry,longscarvesor otherlooseclothing,whichcouldbecome

entangledinmovingparts.Wearfootwearwhichwill improvefootingon

slipperysurfaces.

,, Usea groundedthree-wireextensioncordand receptacleforall units

with electricstartengines.

,, Adjustcollectorhousingheighttoclear gravelor crushedrocksurfaces.

,, Disengageall controlleversbeforestartingthe engine.

,, Neverattemptto makeanyadjustmentswhileengineis running,except

wherespecificallyrecommendedinthe operator'smanual.

,, Letengineand machineadjustto outdoortemperaturebeforestartingto

clearsnow.

Safe Handling of Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein handling

gasoline.Gasolineisextremelyflammableandthevaporsareexplosive.

Seriouspersonalinjurycanoccurwhengasolineis spilledonyourselforyour

clothes,whichcan ignite.Washyourskinand changeclothesimmediately.

,, Useonlyanapprovedgasolinecontainer.

,, Extinguishall cigarettes,cigars,pipesand othersourcesofignition.

,, Neverfuel machineindoors.

,, Neverremovegascaporaddfuelwhilethe engineishot or running.

,, Allowenginetocoolatleasttwominutesbeforerefueling.

,, Neveroverfill fuel tank.Filltankto nomorethan Y2inchbelowbottomof

fillerneckto providespacefor fuelexpansion.

,, Replacegasolinecapandtightensecurely.

,, Ifgasolineisspilled,wipeit offtheengineandequipment.Move

machineto anotherarea.Wait5 minutesbeforestartingthe engine.

,, Neverstorethemachineorfuelcontainerinsidewherethereisan open

flame,sparkor pilotlight(e.g.furnace,waterheater,spaceheater,

clothesdryeretc.).

,, Allowmachineto coolatleast5minutesbeforestoring.

4

OPERATION

. Do notputhandsorfeet nearrotatingparts,intheauger/impeller

housingor chuteassembly.Contactwiththerotatingpartscanamputate

handsand feet.

,, The auger/impellercontrolleverisasafetydevice.Neverbypassits

operation.Doingso makesthe machineunsafeandmaycausepersonal

injury.

,, The controlleversmustoperateeasilyin bothdirectionsandautomati-

callyreturnto thedisengagedpositionwhenreleased.

,, Neveroperatewitha missingor damagedchuteassembly.Keepall

safetydevicesinplaceand working.

,, Neverrunan engineindoorsorin a poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

,, Do notoperatemachinewhileunderthe influenceofalcoholor drugs.

,, Mufflerandenginebecomehotand cancauseaburn.Donottouch.

. Exerciseextremecautionwhenoperatingonorcrossinggravel surfaces.

Stayalertfor hiddenhazardsortraffic.

. Exercisecautionwhenchangingdirectionandwhileoperatingon slopes.

. Planyoursnow-throwingpatterntoavoiddischargetowardswindows,

walls,carsetc.Thus,avoidingpossiblepropertydamageorpersonal

injurycausedbya ricochet.

. Neverdirectdischargeatchildren,bystandersand petsor allowanyone

infrontofthe machine.

. Do notoverloadmachinecapacitybyattemptingto clearsnowattoofast

ofa rate.

. Neveroperatethismachinewithoutgood visibilityorlight.Alwaysbe

sureof your footingandkeepa firm holdon the handles.Walk, never

run.

. Disengagepowertothe auger/impellerwhentransportingor notinuse.

,, Neveroperatemachineat hightransportspeedsonslipperysurfaces.

Lookdownand behindand usecarewhenbackingup.

,, If themachineshouldstart to vibrateabnormally,stopthe engine,

disconnectthesparkplugwireandgrounditagainsttheengine.Inspect

thoroughlyfordamage.Repairanydamagebeforestartingandoperat-

ing.

. Disengageallcontrolleversandstop enginebeforeyouleavethe

operatingposition(behindthe handles).Waituntiltheauger/impeller

comesto a completestopbeforeuncloggingthechute assembly,making

anyadjustments,orinspections.

,, Neverputyourhandinthe dischargeorcollectoropenings.Always

usetheclean-outtoolprovidedto unclogthedischargeopening.Do

not unclogchuteassemblywhileengineisrunning.Shutoffengine

andremainbehindhandlesuntilallmovingpartshavestoppedbefore

unclogging.

,, Useonlyattachmentsandaccessoriesapprovedbythe manufacturer

(e.g.wheelweights,tirechains,cabs etc.).

,, If situationsoccurwhich arenotcoveredinthis manual,usecareand

goodjudgment.ContactyourSearsServiceCenterforassistance.

MAINTENANCE & STORAGE

. Nevertamperwithsafetydevices.Checktheir properoperation

regularly.Refertothe maintenanceandadjustmentsectionsof this

manual.

,, Beforecleaning,repairing,or inspectingmachinedisengageallcontrol

leversand stoptheengine.Waituntiltheauger/impellercometoa

completestop.Disconnectthe sparkplugwireand groundagainstthe

enginetopreventunintendedstarting.

. Checkboltsandscrewsfor propertightnessatfrequentintervalsto keep

the machinein safeworkingcondition.Also,visuallyinspectmachinefor

anydamage.

. Donotchangetheenginegovernorsettingor over-speedthe engine.

Thegovernorcontrolsthe maximumsafeoperatingspeedofthe engine.

. Snowthrowershaveplatesandskidshoesare subjectto wearand

damage.Foryoursafetyprotection,frequentlycheckallcomponents

andreplacewith originalequipmentmanufacturer's(OEM)partsonly.

"Useof partswhichdonotmeetthe originalequipmentspecifications

may leadto improperperformanceandcompromisesafety!"

. Checkcontrolsperiodicallytoverifytheyengageanddisengage

properlyandadjust,ifnecessary.Referto theadjustmentsectionin this

operator'smanualforinstructions.

. Maintainorreplacesafetyandinstructionlabels,as necessary.

. Observeproperdisposallawsandregulationsfor gas, oil,etc.to protect

the environment.

. Priortostoring,runmachineafewminutesto clearsnowfrommachine

andpreventfreezeup ofauger/impeller.

. Neverstorethe machineorfuelcontainerinsidewherethere isanopen

flame,sparkor pilotlightsuch asa waterheater,furnace,clothesdryer

etc.

,, Alwaysreferto the operator'smanualfor properinstructionson

off-seasonstorage.

Do not modify engine

Toavoidseriousinjuryor death,do notmodifyenginein anyway.Tampering

withthegovernorsettingcanleadto a runawayengineandcauseitto operate

at unsafespeeds.Nevertamperwithfactorysettingofenginegovernor.

Notice Regarding Emissions

Engineswhichare certifiedto complywith CaliforniaandfederalEPAemission

regulationsforSORE(SmallOff RoadEquipment)arecertifiedtooperateon

regularunleadedgasoline,and mayincludethefollowingemissioncontrolsys-

tems:EngineModification(EM)andThreeWayCatalyst(TWO)if so equipped.

Thispage left intentionallyblank.

6

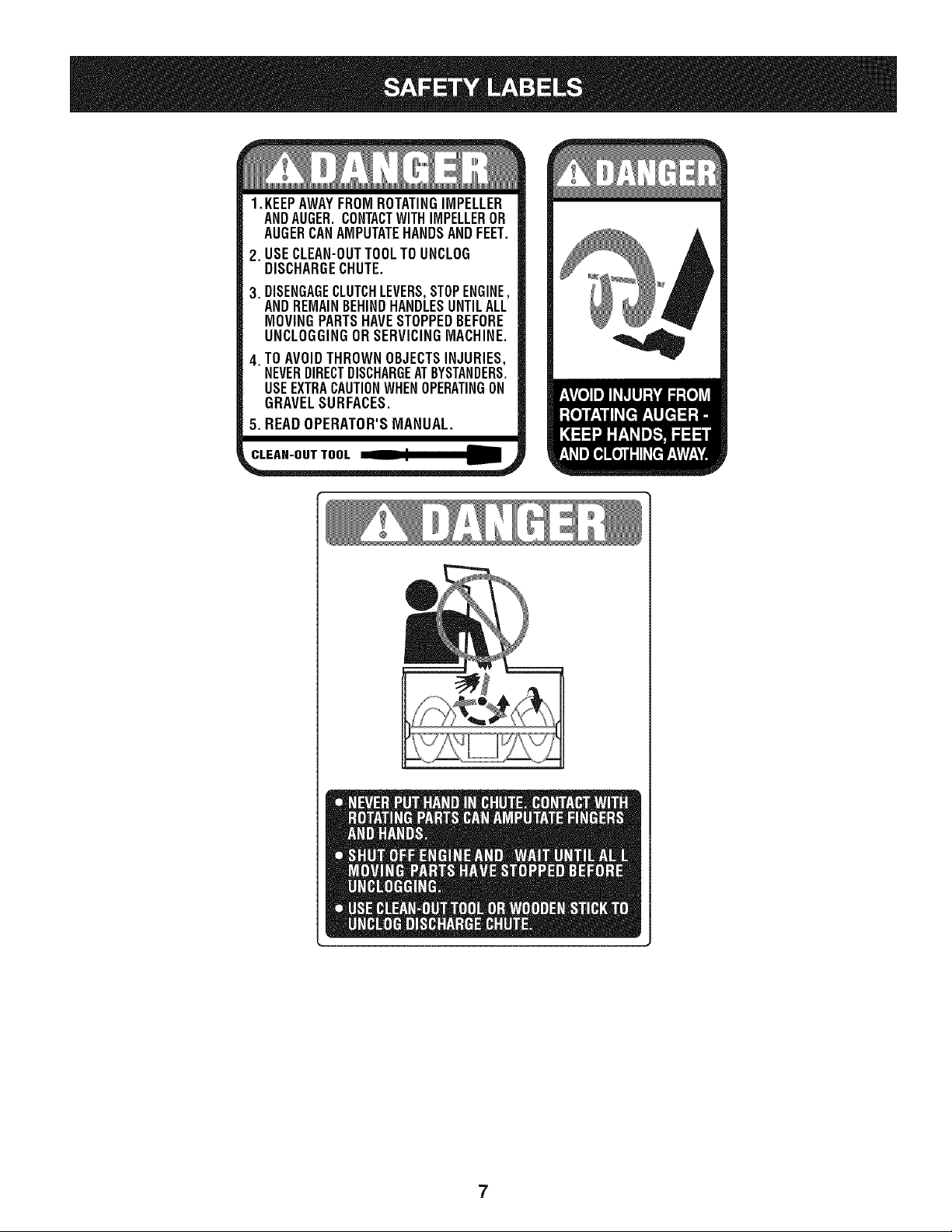

1.KEEPAWAYFROMROTATINGIMPELLER

ANDAUGER.CONTACTWITHIMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET.

2. USECLEAN-OUTTOOLTOUNCLOG

DISCHARGECHUTE.

3. DISENGAGECLUTCHLEVERS,STOPENGINE,

ANDREMAINBEHINDHANDLESUNTILALL

MOVINGPARTSHAVESTOPPEDBEFORE

UNCLOGGINGORSERVICINGMACHINE.

4. TOAVOIDTHROWNOBJECTSINJURIES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHENOPERATINGON

GRAVELSURFACES.

5. READOPERATOR'SMANUAL.

CL_K-O_T_LU___

7

NOTE:Referencesto rightorleftsideofthe snowthrowerare

determinedfrombehindthe unitintheoperatingposition(standing

directlybehindthesnowthrower,facingthehandlepanel).

REMOVING FROM CARTON

1. Cutthecornersofthecartonandlaythesidesflat ontheground.

Removeand discardallpackinginserts.

2. Movethesnowthroweroutofthecarton.

3. Makecertainthecartonhasbeencompletelyemptiedbefore

discardingit.

LOOSE PARTS

Tworeplacementaugershearpinsareincludedwiththis manual.Refer

toReplacingShearPinsintheOperationsectionformoreinformation

regardingshearpin replacement.

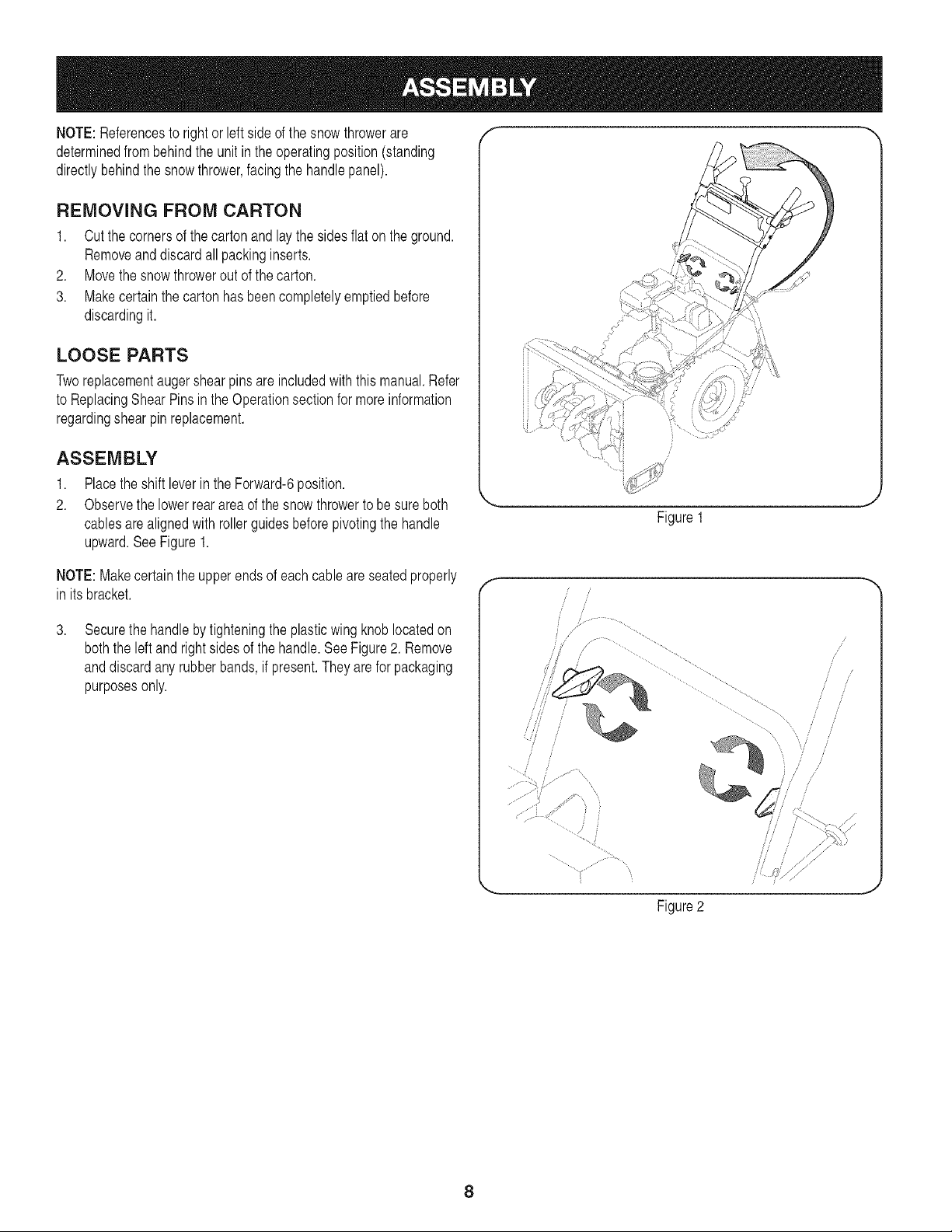

ASSEMBLY

1. Placethe shiftleverin theForward-6position.

2. Observethe lowerrearareaofthesnowthrowertobesureboth

cablesarealignedwithrollerguidesbeforepivotingthe handle

upward.SeeFigure1.

NOTE:Makecertainthe upperendsofeachcableare seatedproperly

in itsbracket.

Figure1

3,

Securethe handlebytighteningtheplasticwingknoblocatedon

boththe left andrightsidesofthehandle.SeeFigure2.Remove

anddiscardanyrubberbands,if present.Theyareforpackaging

purposesonly.

/

/

/

/

/

/

J /

/ /

/

Figure2

8

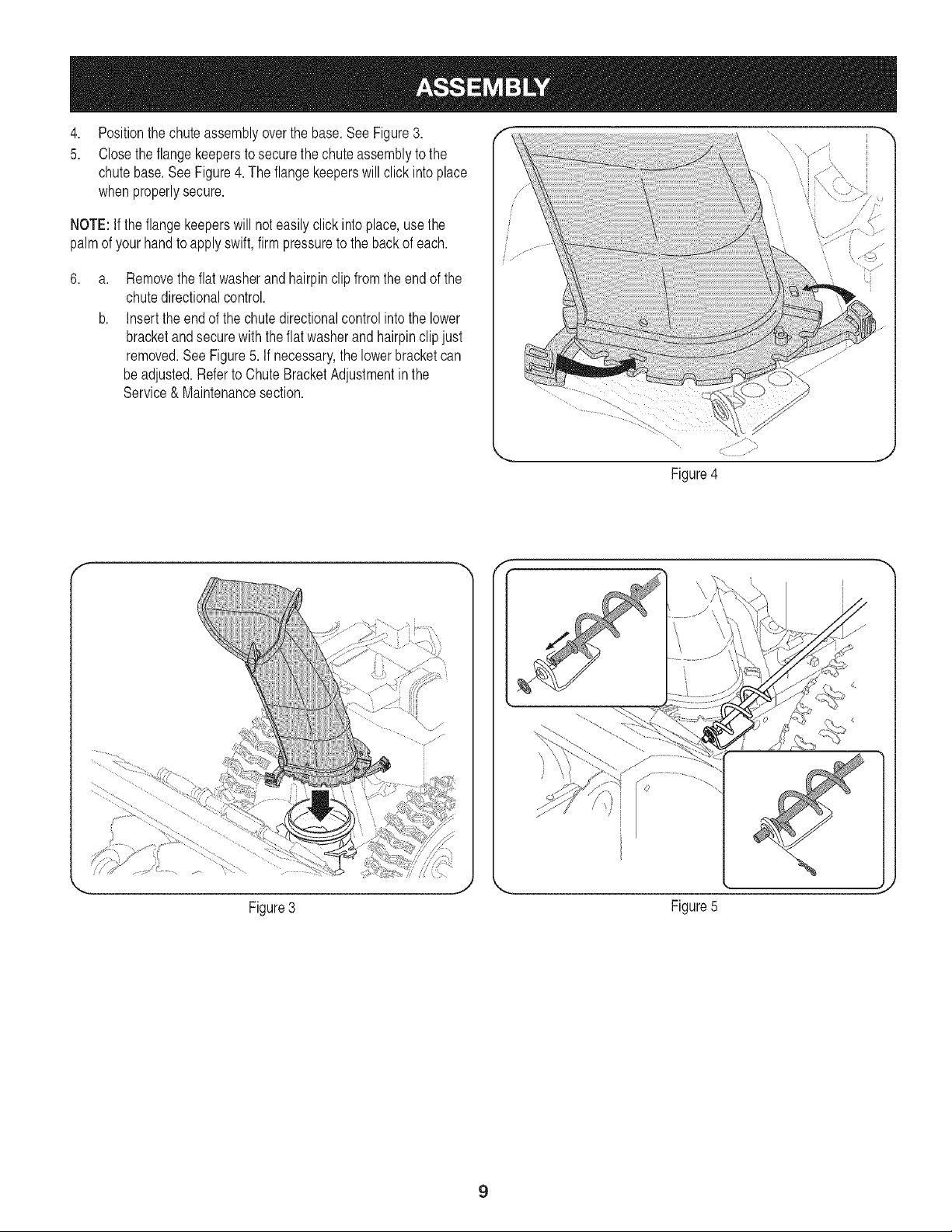

4,

Positionthechuteassemblyoverthebase.SeeFigure3.

5.

Closetheflangekeepersto securethechuteassemblyto the

chutebase.SeeFigure4.Theflangekeeperswillclick into place

whenproperlysecure.

NOTE:If theflangekeeperswillnoteasilyclickintoplace,usethe

palmof your handtoapplyswift,firmpressuretothebackof each.

6,

a.

Removetheflat washerandhairpinclipfromthe endofthe

chutedirectionalcontrol.

b.

Insertthe endofthe chutedirectionalcontrolintothelower

bracketandsecurewiththeflatwasherandhairpinclipjust

removed.SeeFigure5.If necessary,thelowerbracketcan

be adjusted.Referto ChuteBracketAdjustmentinthe

Service&Maintenancesection.

J

Figure4

Figure5

9

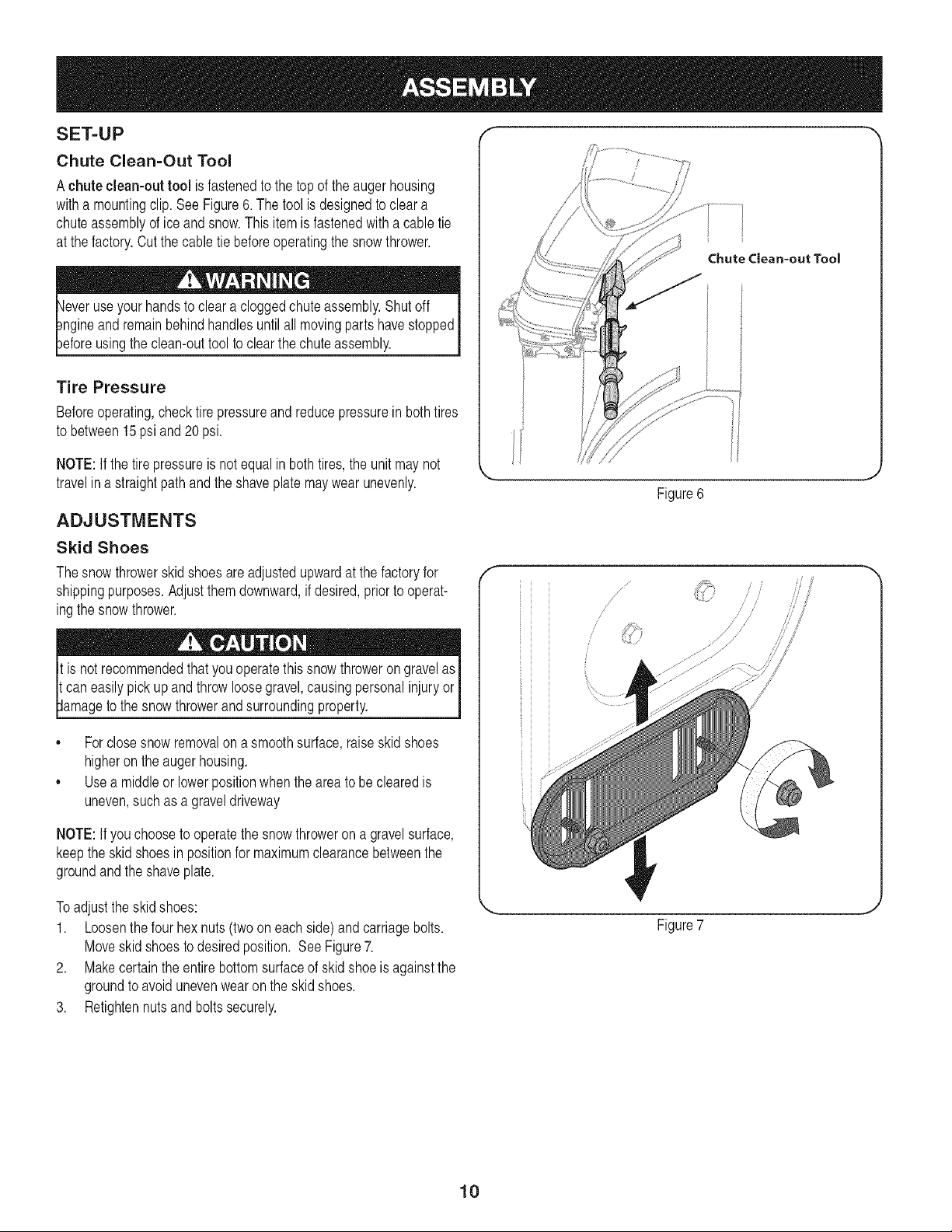

SET-UP

Chute Clean=Out Tool

A chute clean-out tool is fastenedtothetopofthe augerhousing

withamountingclip.SeeFigure6.Thetool is designedtocleara

chuteassemblyoficeandsnow.Thisitemisfastenedwithacabletie

atthefactory.Cutthecabletiebeforeoperatingthesnowthrower.

bever useyourhandstoclearacloggedchuteassembly.Shutoff I

_ngineandremainbehindhandlesuntilallmovingpartshavestoppedI

_oeforeusingthe clean-outtool to clearthechuteassembly. 1

Tire Pressure

Beforeoperating,checktire pressureand reducepressureinbothtires

tobetween15psiand20 psi.

NOTE:If thetire pressureisnotequalin bothtires,theunitmaynot

travelin a straightpathandtheshaveplatemaywearunevenly.

ADJUSTMENTS

Skid Shoes

Thesnowthrowerskidshoesareadjustedupwardatthefactoryfor

shippingpurposes.Adjustthemdownward,if desired,priorto operat-

ingthesnowthrower.

isnotrecommendedthat this thrower

caneasilypickupandthrowloosegravel,causingpersonalinjuryor I

tt youoperate snow ongravelas

amageto the snowthrowerandsurroundingproperty. 1

Chute Clean-out Tool

Figure6

,//

/

/

/

/

o, / /, ._

/

/_//"

/ /

/ /

/ //

J

• Forclosesnowremovalona smoothsurface,raiseskidshoes

higheron theaugerhousing.

• Useamiddleorlowerpositionwhentheareatobe clearedis

uneven,suchasa graveldriveway

NOTE:If youchoosetooperatethesnowthroweron agravelsurface,

keepthe skidshoesin positionformaximumclearancebetweenthe

groundandtheshaveplate.

Toadjustthe skidshoes:

1. Loosenthefourhexnuts(twooneachside)andcarriagebolts.

Moveskidshoesto desiredposition. SeeFigure7.

2. Makecertaintheentirebottomsurfaceof skidshoeisagainstthe

groundtoavoidunevenwearontheskidshoes.

3. Retightennutsandboltssecurely.

Figure7

10

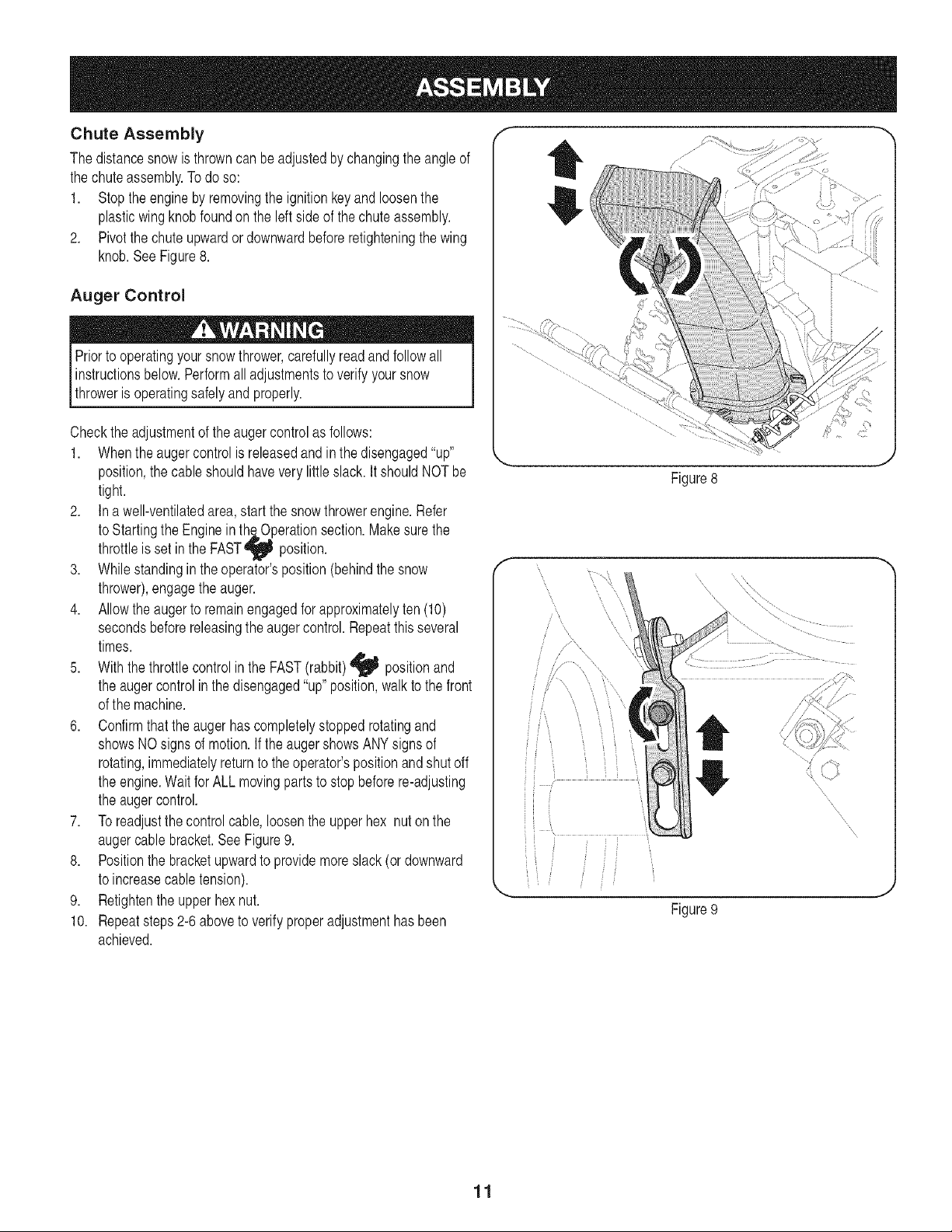

Chute Assembly

Thedistancesnowis throwncanbeadjustedbychangingtheangleof

thechuteassembly.Todoso:

1. Stopthe engineby removingthe ignitionkeyandloosenthe

plasticwingknobfoundon theleftsideof thechuteassembly.

2. Pivotthechuteupwardordownwardbeforeretighteningthe wing

knob.SeeFigure8.

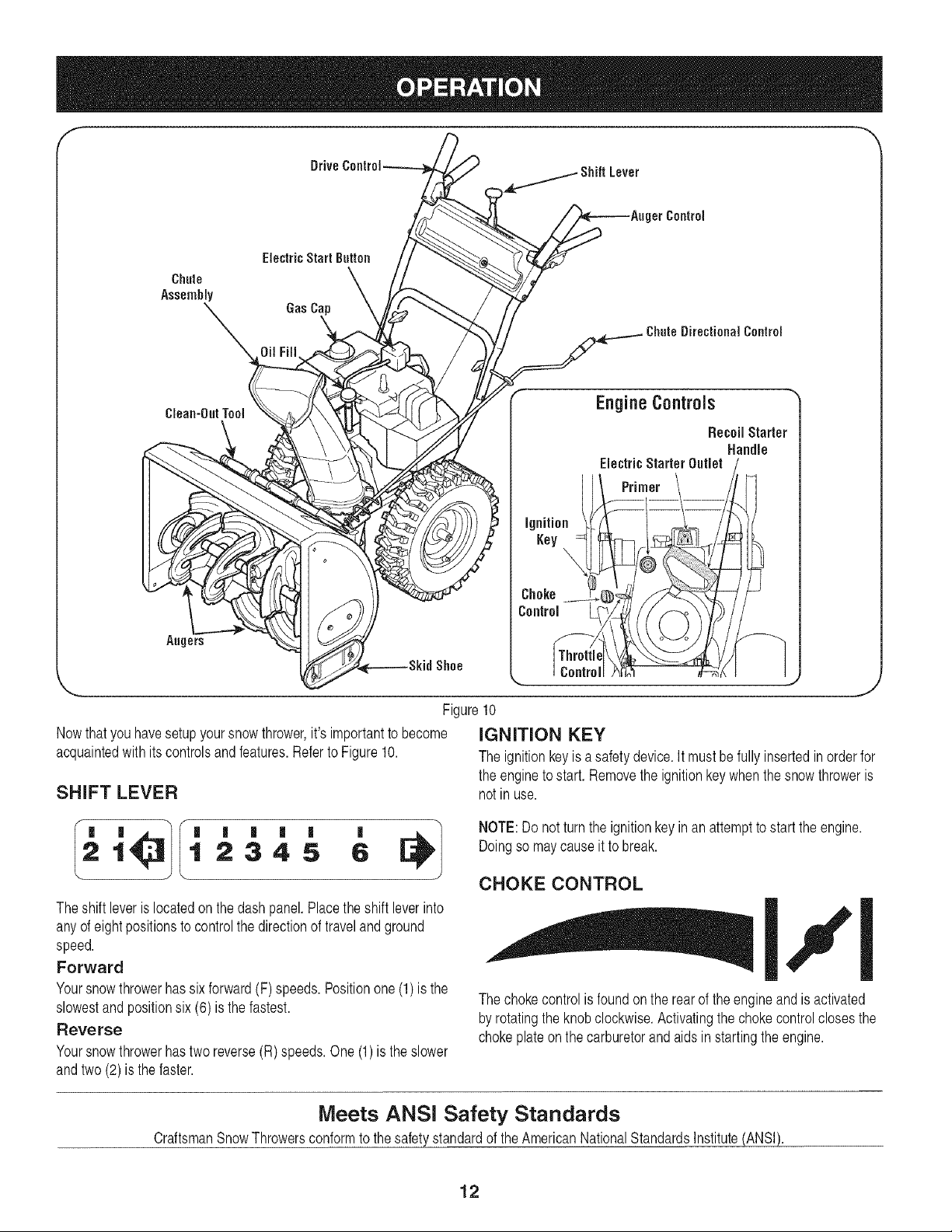

Auger Control

Priorto operatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performalladjustmentstoverifyyoursnow

throwerisoperatingsafelyandproperly.

Checktheadjustmentofthe augercontrolasfollows:

1. Whentheaugercontrolis releasedandinthedisengaged"up"

position,thecableshouldhaveverylittleslack.ItshouldNOTbe

tight.

2. Ina well-ventilatedarea,startthesnowthrowerengine.Refer

toStartingtheEngineinthaiOperationsection.Makesurethe

throttleis setin theFAST_1 position.

3. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagetheauger.

4. Allowthe augerto remainengagedforapproximatelyten(10)

secondsbeforereleasingtheaugercontrol.Repeatthisseveral

times.

5. WiththethrottlecontrolintheFAST(rabbit)_ positionand

theaugercontrolin thedisengaged"up"position,walktothefront

ofthemachine.

6. Confirmthatthe augerhascompletelystoppedrotatingand

showsNOsignsof motion.If the augershowsANYsignsof

rotating,immediatelyreturntotheoperator'spositionandshutoff

theengine.WaitforALL movingpartstostopbeforere-adjusting

theaugercontrol.

7. Toreadjustthecontrolcable,loosentheupperhex nutonthe

augercablebracket.SeeFigure9.

8. Positionthebracketupwardtoprovidemoreslack(or downward

toincreasecabletension).

9. Retightentheupperhexnut.

10. Repeatsteps2-6aboveto verifyproperadjustmenthasbeen

achieved.

Figure8

x

Figure9

11

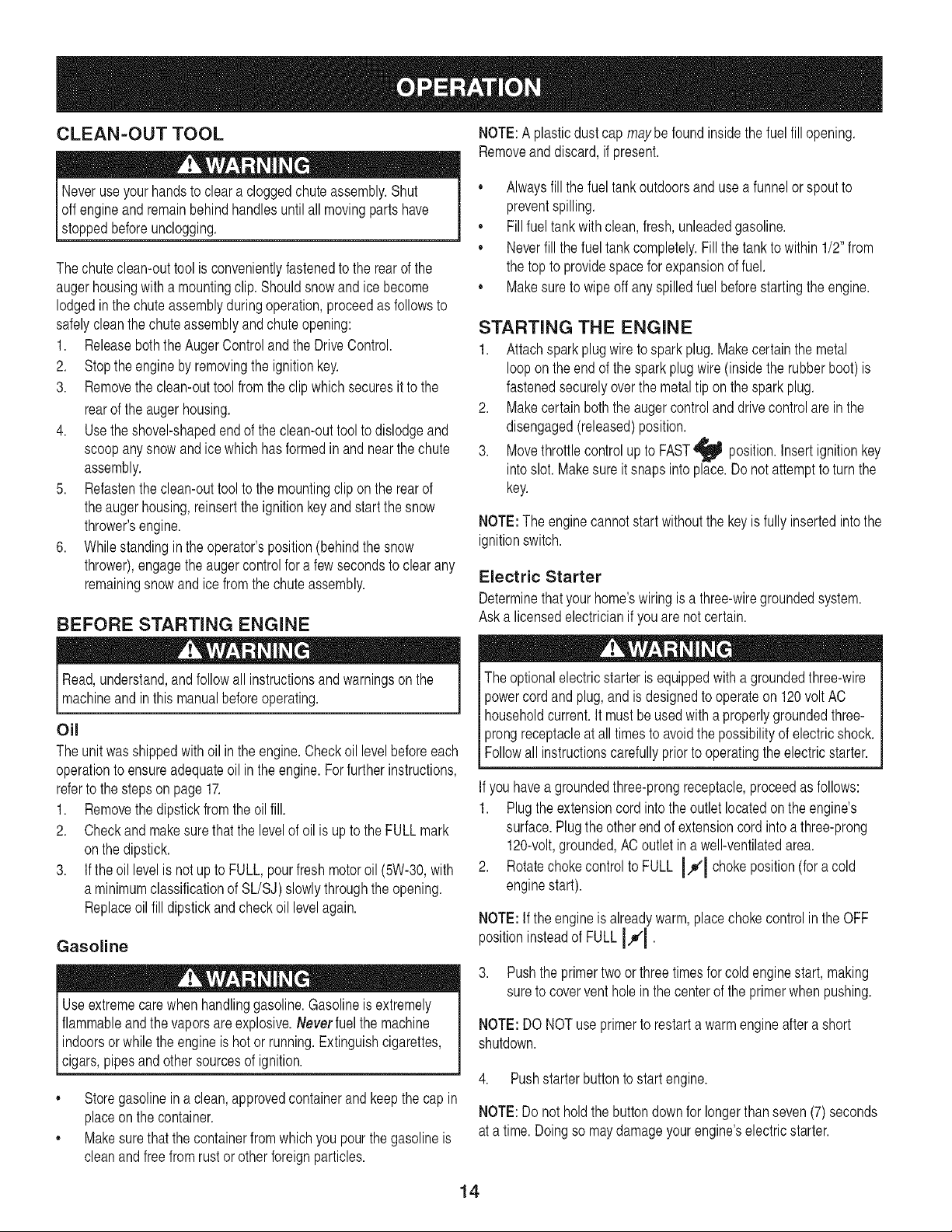

Chute

Assembly

get Control

ElectricStart Button

DirectionalControl

EnGineControls

RecoilStarter

Handle

ElectricStarterOutlet /

Ignition 1\ /_/'

\ J

%. ,j

Figure10

Nowthatyouhavesetupyoursnowthrower,it'simportanttobecome [GNITION KEY

acquaintedwithitscontrolsandfeatures.RefertoFigure10. Theignitionkeyis asafetydevice.It mustbefullyinsertedinorderfor

theenginetostart. Removetheignitionkeywhenthesnowthroweris

SHIFT LEVER notin use.

|

6

NOTE:Donotturntheignitionkeyinan attempttostartthe engine.

Doingso maycauseit tobreak.

CHOKE CONTROL

Theshift leverislocatedon thedashpanel.Placetheshiftleverinto

anyof eightpositionstocontrolthe directionof travelandground

speed.

Forward

Yoursnowthrowerhassix forward(F)speeds.Positionone(1)isthe

slowestandpositionsix (6)is thefastest.

Reverse

Yoursnowthrowerhastwo reverse(R)speeds.One(1)is the slower

andtwo(2)is thefaster.

Thechokecontrolisfoundontherearof theengineandisactivated

byrotatingthe knobclockwise.Activatingthechokecontrolclosesthe

chokeplateonthecarburetorandaidsinstartingthe engine.

III

Meets ANSi Safety Standards

CraftsmanSnowThrowersconformto thesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

12

THROTTLE CONTROL

Thethrottlecontrolis locatedontherearoftheengine.

It regulatesthespeedofthe engineandwillshutoff the

enginewhenmovedintotheSTOPposition.

RECOIL STARTER HANDLE

This handleisusedto manuallystarttheengine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagesthe engine's

electricstarterwhenpluggedintoa 120Vpowersource.

ELECTRIC STARTER OUTLET

Requirestheuseofa three-prongoutdoorextensioncord

(included)anda 120Vpowersource/walloutlet.

AUGERS

Whenengaged,theaugersrotateanddrawsnowintotheauger

housing.

CHUTE ASSEMBLY

Snowdrawnintotheaugerhousingisdischargedout thechute

assembly.

PRIMER

Depressingtheprimerforcesfueldirectlyintotheengine'scarburetor

toaidincold-weatherstarting.

OIL FILL

Engineoil levelcanbecheckedandoiladdedthroughtheoilfill.

GAS CAP

Unthreadthegascapto addgasolineto thefuel tank.

DRIVE CONTROL/AUGER CONTROL LOCK

f-

DRIVE

CONTROL

@

J

Thedrivecontrolis locatedonthe righthandle.Squeezethe control

gripagainstthehandletoengagethewheeldrive.Releaseto stop.

Thedrivecontrolalso lockstheaugercontrolso you canoperate

thechutedirectionalcontrolwithoutinterruptingthe snowthrowing

process.Iftheaugercontrolis engagedsimultaneouslywiththedrive

control,the operatorcanreleasetheaugercontrol(onthelefthandle)

andtheaugerswillremainengaged.Releasebothcontrolstostopthe

augersandwheeldrive.

NOTE:Alwaysreleasethedrive controlbeforechangingspeeds.

Failuretodoso willresultinincreasedwearon yourmachine'sdrive

system.

CHUTE DIRECTIONAL CONTROL

f

CHUTE DiRECTiONAL CONTROL

ADJUSTABLE

DISCHARGE

LEFT

CHUTETiLT

AUGER CONTROL

f_

Theaugercontrolislocatedonthe lefthandle.Squeezethecontrol

gripagainstthehandletoengagetheaugersandstart snowthrowing

action.Releasetostop.

Thechutedirectionalcontrolislocatedonleftsideof the snowthrower.

Tochangethedirectioninwhichsnowisthrown,turnchutedirectional

controlasfollows:

,, Crankclockwisetodischargetotheleft.

,, Crankcounterclockwisetodischargetotheright.

SKID SHOES

Positiontheskidshoesbasedonsurfaceconditions.Adjustupward

forhard-packedsnow.Adjustdownwardwhenoperatingongravelor

crushedrocksurfaces.

13

CLEAN-OUT TOOL NOTE:Aplasticdustcapmaybefoundinsidethefuelfillopening.

Removeanddiscard,ifpresent.

Neveruseyourhandstoclearacloggedchuteassembly.Shut

off engineand remainbehindhandlesuntilallmovingpartshave

stoppedbeforeunclogging.

Thechuteclean-outtoolis convenientlyfastenedto the rearofthe

augerhousingwitha mountingclip.Shouldsnowandicebecome

lodgedin the chuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. ReleaseboththeAugerControlandtheDriveControl.

2. Stopthe engineby removingthe ignitionkey.

3. Removetheclean-outtoolfromthe clip whichsecuresit tothe

rearoftheaugerhousing.

4. Usetheshovel-shapedendof the clean-outtooltodislodgeand

scoopanysnowandicewhichhasformedin andnearthechute

assembly.

5. Refastenthe clean-outtool to themountingclip onthe rearof

theaugerhousing,reinsertthe ignitionkeyandstartthe snow

thrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagetheaugercontrolfora fewsecondsto clearany

remainingsnowandicefromthechuteassembly.

BEFORE STARTING ENGINE

,, Alwaysfill thefueltankoutdoorsanduseafunnelorspoutto

preventspilling.

,, Fillfuel tankwithclean,fresh,unleadedgasoline.

,, Neverfill thefuel tankcompletely.Fillthetanktowithin1/2"from

thetoptoprovidespaceforexpansionoffuel.

,, Makesureto wipeoff anyspilledfuelbeforestartingtheengine.

STARTING THE ENGINE

1. Attachsparkplugwireto sparkplug.Makecertainthe metal

loopon theendof the sparkplugwire(insidethe rubberboot) is

fastenedsecurelyoverthemetaltip onthesparkplug.

2. Makecertainboththe augercontrolanddrivecontrolarein the

disengaged(released)position.

3. MovethrottlecontroluptoFAST_ position.Insertignitionkey

intoslot. Makesureitsnapsintoplace.Donotattemptto turn the

key.

NOTE:Theenginecannotstartwithoutthekeyis fullyinsertedintothe

ignitionswitch.

Electric Starter

Determinethatyourhome'swiringisa three-wiregroundedsystem.

Askalicensedelectricianifyouarenotcertain.

Read,understand,andfollowallinstructionsandwarningsonthe

machineandinthis manualbeforeoperating.

Oil

Theunit wasshippedwithoilintheengine.Checkoil levelbeforeeach

operationtoensureadequateoil intheengine.Forfurtherinstructions,

referto the stepsonpage 17.

1. Removethedipstickfromtheoilfill.

2. Checkandmakesurethatthelevelofoilis upto theFULLmark

onthedipstick.

3. If theoillevelis notupto FULL,pourfreshmotoroil (5W-30,with

a minimumclassificationof SL/SJ)slowlythroughtheopening.

Replaceoilfilldipstickandcheckoil levelagain.

Gasoline

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuel the machine

indoorsorwhilethe engineishotor running.Extinguishcigarettes,

[c gars,ppesandothersourcesof gnt on.

,, Storegasolinein aclean,approvedcontainerandkeepthecap in

placeonthecontainer.

,, Makesurethatthecontainerfromwhichyou pourthegasolineis

cleanandfreefromrustor otherforeignparticles.

Theoptionalelectricstarteris equippedwitha groundedthree-wire

powercordandplug,andis designedtooperateon120voltAC

householdcurrent.It mustbeusedwithaproperlygroundedthree-

prongreceptacleatall timestoavoidthepossibilityofelectricshock.

Followall instructionscarefullypriortooperatingtheelectricstarter.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows:

1. Plugtheextensioncordintotheoutletlocatedontheengine's

surface.Plugtheotherend ofextensioncordinto athree-prong

120-volt,grounded,ACoutletinawell-ventilatedarea.

2. RotatechokecontroltoFULL I,.#'1chokeposition(foracold

enginestart).

NOTE:If theengineisalreadywarm,placechokecontrolintheOFF

positioninsteadofFULLIJl •

3. Pushtheprimertwoor threetimesforcoldenginestart,making

sureto coverventholeinthecenterofthe primerwhenpushing.

NOTE:DO NOTuse primertorestarta warmengineaftera short

shutdown.

4. Pushstarterbuttontostartengine.

NOTE:Donotholdthebuttondownforlongerthanseven(7)seconds

ata time.Doingso maydamageyourengine'selectricstarter.

14

5. Oncetheenginestarts,releasestarterbutton.

6. Astheenginewarms,slowlyrotatechokecontrolto theOFF

position.Iftheenginefalters,quicklyrotatechokecontrolbackto

FULL 14D"Ithenslowlyintothe OFFpositionagain.

7. Whendisconnectingtheextensioncord,alwaysunplugtheend

atthethree-prongwall outletbeforeunpluggingthe oppositeend

fromthesnowthrower.

Recoil Starter

1. Rotatechokecontrolto FULL IJl chokeposition(coldengine

start).

NOTE:Iftheengineisalreadywarm,placechokecontrolinthe OFF

position

2. Pushthe primertwoorthreetimesforcoldenginestart,making

NOTE:DONOTuseprimertorestartawarmengineafterashort

shutdown.

NOTE:Additionalprimingmaybe necessaryifthetemperatureis

below15°Fahrenheit.

insteadofFULLIJ|.

sureto coverventholeinthecenterof the primerwhenpushing.

NOTE:Whenselectinga DriveSpeed,usethe slowerspeedsuntil

youarecomfortableandfamiliarwiththeoperationofthesnow

thrower.

2. Squeezethedrivecontrolagainstthehandlethesnowthrower

will move.Releaseitanddrivemotionwillstop.

NOTE:NEVERrepositiontheshiftlever(changespeedsor direction

of travel)withoutfirstreleasingthedrive controlandbringingthesnow

throwertoa completestop.Doingsowillresultin prematurewearto

thesnowthrower'sdrivesystem.

TO ENGAGE AUGERS

1. Toengagetheaugersandstartthrowingsnow,squeezethe

augercontrolagainstthelefthandle.Releaseto stoptheaugers.

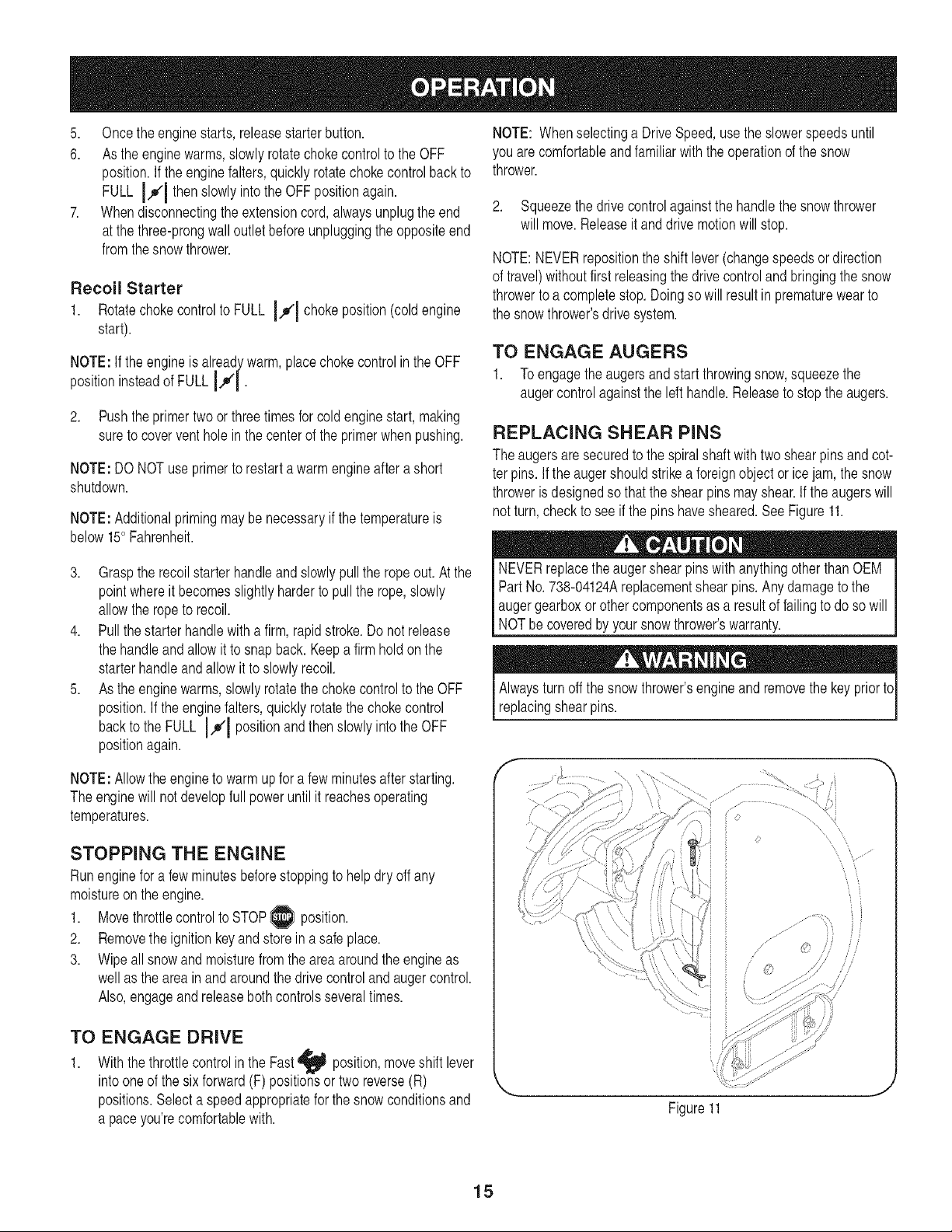

REPLACING SHEAR PiNS

Theaugersaresecuredto thespiralshaft withtwoshearpinsandcot-

terpins.if theaugershouldstrikea foreignobjector icejam,thesnow

throwerisdesignedsothattheshearpinsmayshear.Iftheaugerswill

notturn,checkto seeifthepinshavesheared.SeeFigure11.

3. Graspthe recoilstarterhandleandslowlypulltheropeout.Atthe

pointwhereitbecomesslightlyharderto pullthe rope,slowly

allowthe ropetorecoil.

4. Pullthestarterhandlewitha firm,rapidstroke.Donotrelease

thehandleandallowit to snapback.Keepa firmholdon the

starterhandleandallowitto slowlyrecoil.

5. Astheenginewarms,slowlyrotatethechokecontroltotheOFF

position.Iftheenginefalters,quicklyrotatethechokecontrol

backtotheFULL I,_1 positionandthenslowlyintotheOFF

positionagain.

NOTE:Allowtheenginetowarmupfor afewminutesafterstarting.

Theenginewill notdevelopfull poweruntilit reachesoperating

temperatures.

STOPPING THE ENGINE

Runenginefor a fewminutesbeforestoppingto helpdryoff any

moistureonthe engine.

Movethrottlecontrolto STOP1.position.

2. Removethe ignitionkeyandstoreinasafeplace.

3. Wipeall snowandmoisturefromtheareaaroundtheengineas

wellas the areainand aroundthedrivecontrolandaugercontrol.

Also,engageandreleasebothcontrolsseveraltimes.

NEVERreplacetheaugershearpinswith anythingotherthan OEM

PartNo.738-04124Areplacementshearpins.Anydamagetothe

augergearboxorothercomponentsasaresultof failingtodoso will

NOTbecoveredbyyoursnowthrower'swarranty.

Alwaysturnoffthe snowthrower'sengineand removethekeypriortc

replacingshearpins.

f

\

TO ENGAGE DRIVE

1. WiththethrottlecontrolintheFast_ position,moveshiftlever

intooneofthesix forward(F)positionsortworeverse(R)

positions.Selecta speedappropriateforthe snowconditionsand

a paceyou'recomfortablewith.

Figure11

15

ENGINE MAINTENANCE

Beforelubricating,repairing,orinspecting,disengageallcontrols

land stopengine.Waituntilall movingpartshavecometoacomplete

|stop.

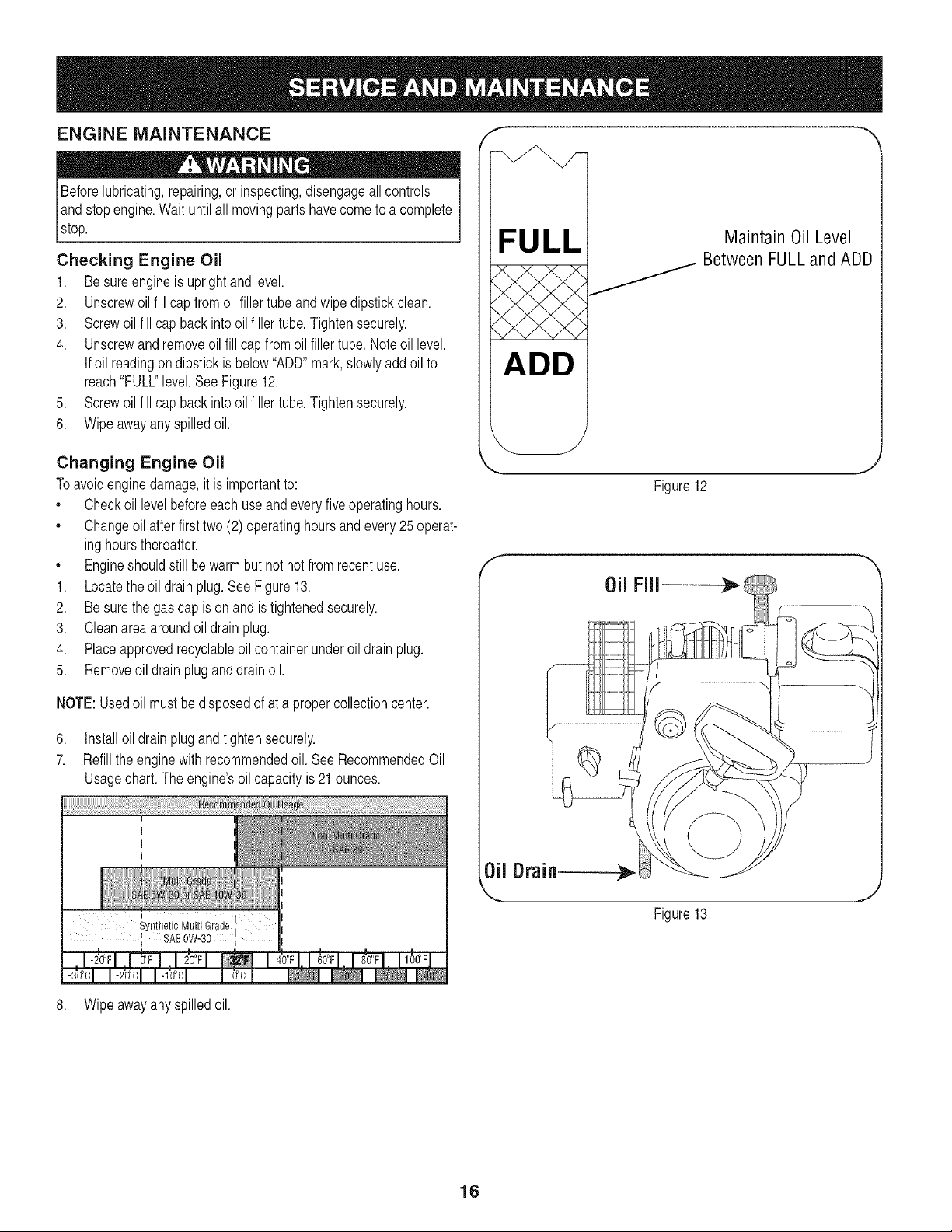

Checking Engine Oil

1. Besureengineisuprightandlevel.

2. Unscrewoil fillcapfromoil fillertubeandwipedipstickclean.

3. Screwoil fill capbackintooilfillertube.Tightensecurely.

4. Unscrewandremoveoilfillcapfromoilfillertube.Noteoillevel.

ifoil readingondipstickisbelow"ADD"mark,slowlyaddoilto

reach"FULL"level.SeeFigure12.

5. Screwoil fill capbackintooilfillertube.Tightensecurely.

6. Wipeawayany spilledoil.

f --,,

FULL

_ Between FULLand ADD

Maintain Oil Level

ADD

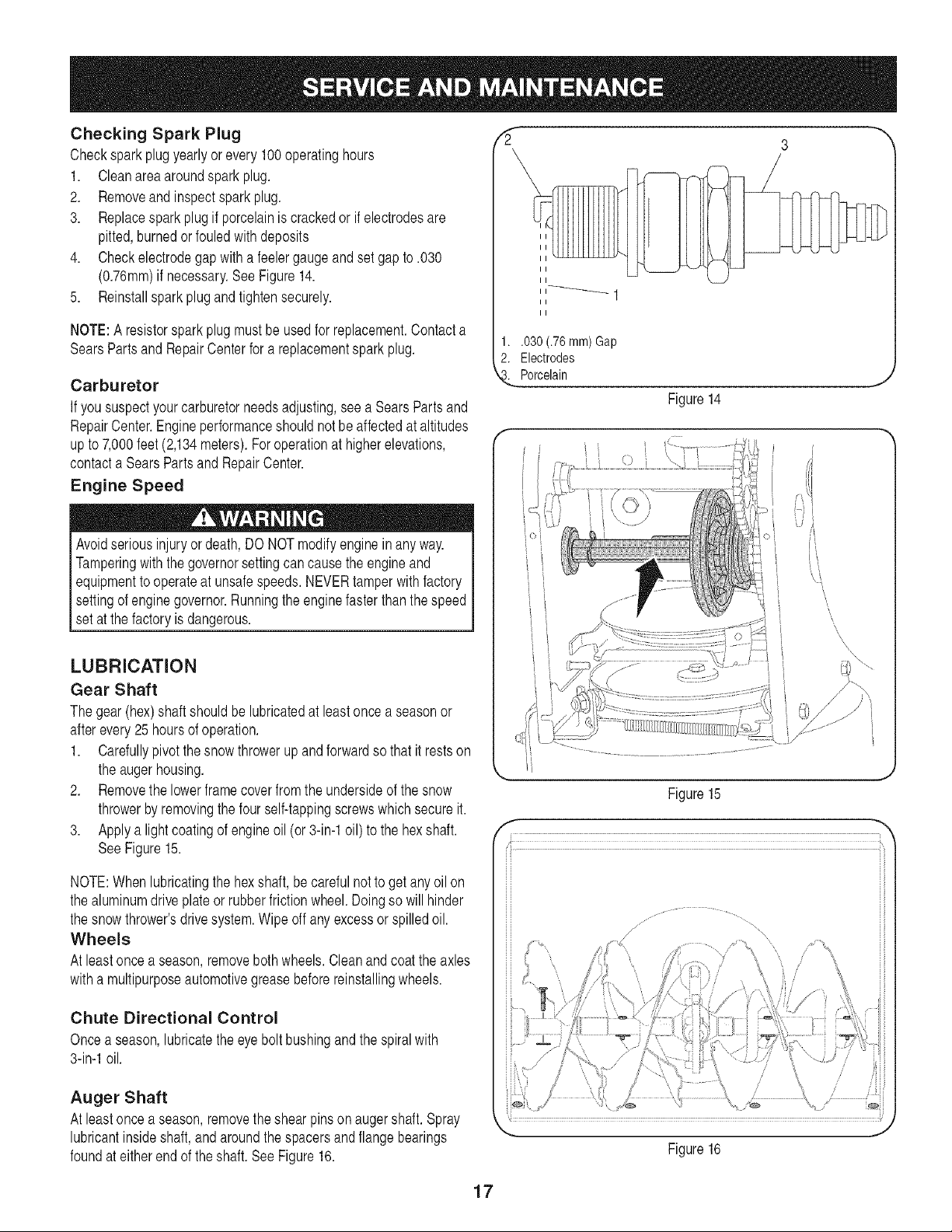

Changing Engine Oil

Toavoidenginedamage,itisimportantto:

,, Checkoil levelbeforeeachuse andeveryfiveoperatinghours.

,, Changeoilafterfirsttwo (2)operatinghoursandevery25 operat-

inghoursthereafter.

,, Engineshouldstillbewarmbut nothot fromrecentuse.

1. Locatetheoildrainplug.SeeFigure13.

2. Besurethegascap is onandistightenedsecurely.

3. Cleanareaaroundoil drainplug.

4. Placeapprovedrecyclableoilcontainerunderoildrainplug.

5. Removeoil drainpluganddrainoil.

NOTE:Usedoil mustbedisposedofat a propercollectioncenter.

6. Installoildrain plugandtightensecurely.

7. Refilltheenginewithrecommendedoil.SeeRecommendedOil

Usagechart.The engine'soilcapacityis21ounces.

Synthetic Multi Grade i

SAE0W-30 *

J

Figure12

0il FIll -_

0il Draia_

Figure13

8. Wipeawayany spilledoil.

16

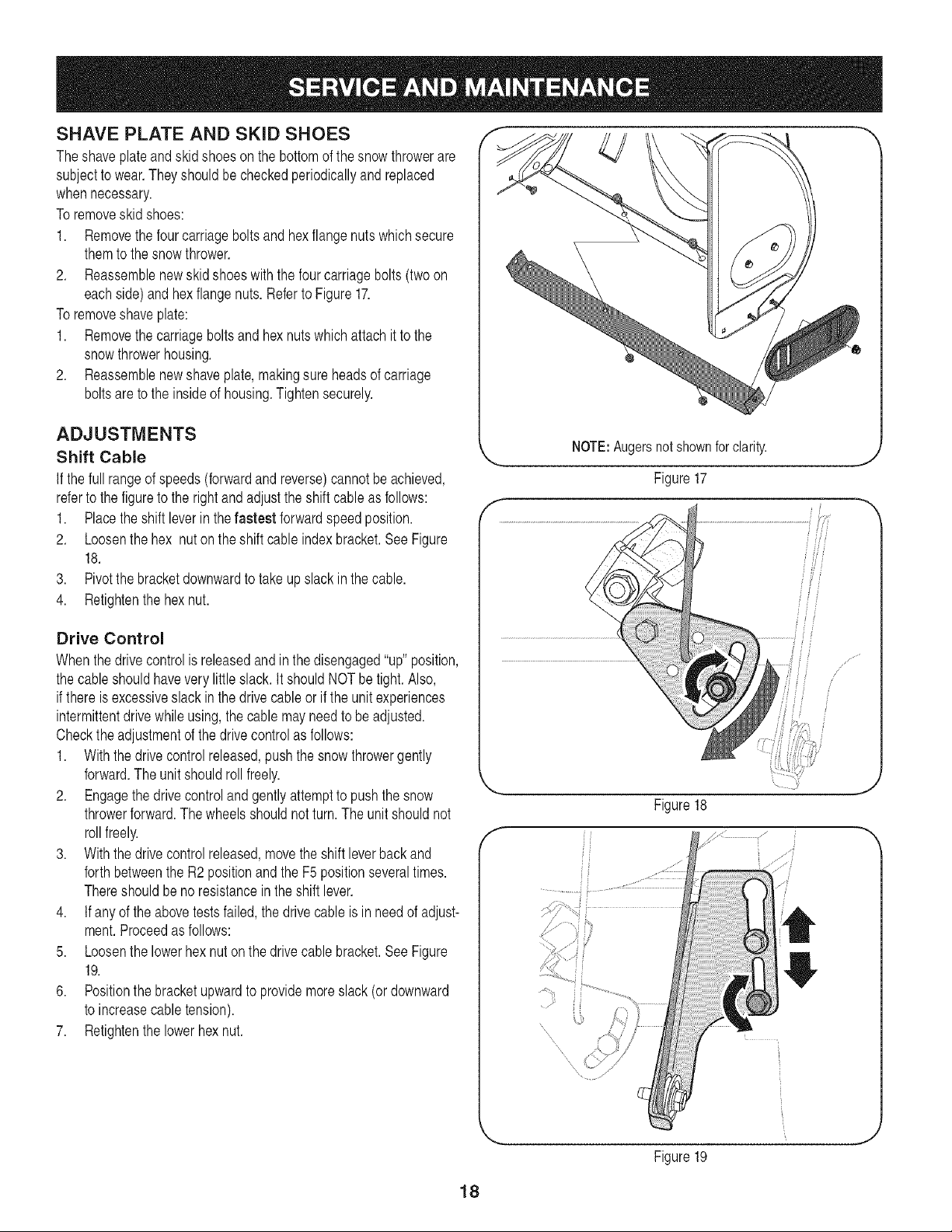

Checking Spark Plug

Checksparkplugyearlyor every100operatinghours

1. Cleanareaaroundsparkplug.

2. Removeand inspectsparkplug.

3. Replacesparkplugif porcelainiscrackedorifelectrodesare

pitted,burnedorfouledwithdeposits

4. Checkelectrodegapwitha feelergaugeandsetgapto.030

(0.76ram)ifnecessary.SeeFigure14.

5. Reinstallsparkplugandtightensecurely.

NOTE:A resistorsparkplugmust beusedforreplacement.Contacta

SearsPartsand RepairCenterforareplacementsparkplug.

Carburetor

If yoususpectyourcarburetorneedsadjusting,seea SearsPartsand

RepairCenter.Engineperformanceshouldnotbeaffectedataltitudes

upto7,000feet(2,134meters).Foroperationathigherelevations,

contacta SearsPartsandRepairCenter.

Engine Speed

Avoidseriousinjuryordeath,DONOTmodifyengineinanyway.

Tamperingwiththegovernorsettingcancausethe engineand

equipmentto operateatunsafespeeds.NEVERtamperwithfactory

settingof enginegovernor.Runningtheenginefasterthanthe speed

set at thefactoryisdangerous.

LUBRICATION

Gear Shaft

Thegear(hex)shaftshouldbelubricatedatleastoncea seasonor

afterevery25hoursofoperation.

1. Carefullypivotthesnowthrowerup andforwardso thatit restson

theaugerhousing.

2. Removethe lowerframecoverfromtheundersideofthesnow

throwerbyremovingthefourself-tappingscrewswhichsecureit.

3. Applya lightcoatingof engineoil(or 3-in-1oil)tothehexshaft.

SeeFigure15.

II

II

1..030 (.76 ram)Gap

2. Electrodes

Porcelain

3

J

Figure14

\\\\

\,, ........

Figure15

NOTE:Whenlubricatingthe hexshaft,be carefulnottogetanyoilon

thealuminumdriveplateorrubberfrictionwheel.Doingso willhinder

thesnowthrower'sdrivesystem.Wipeoff anyexcessorspilledoil.

Wheels

Atleastoncea season,removebothwheels.Cleanandcoatthe axles

withamultipurposeautomotivegreasebeforereinstallingwheels.

Chute Directional Control

Oncea season,lubricatetheeyeboltbushingandthespiralwith

3-in-1oil.

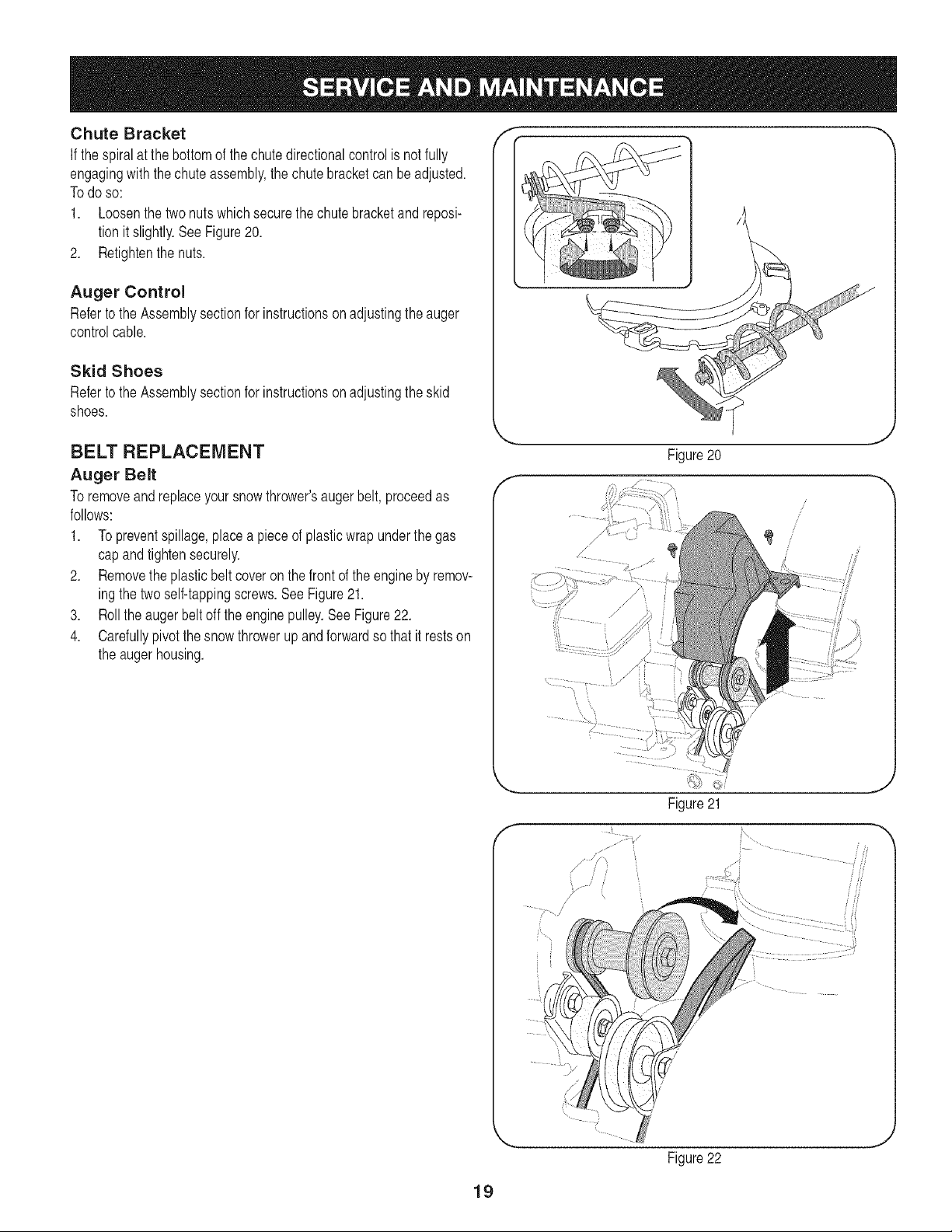

Auger Shaft

Atleastoncea season,removetheshearpinson augershaft.Spray

lubricantinsideshaft,andaroundthespacersandflangebearings

foundat eitherendoftheshaft.SeeFigure16.

17

Figure 16

/ 7

/

/

J

SHAVE PLATE AND SKID SHOES

Theshaveplateandskidshoesonthe bottomofthesnowthrowerare

subjectto wear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

Toremoveskidshoes:

1. Removethefourcarriageboltsandhexflangenutswhichsecure

themto thesnowthrower.

2. Reassemblenewskidshoeswiththe fourcarriagebolts(twoon

eachside) andhexflangenuts.Referto Figure17.

Toremoveshaveplate:

1. Removethecarriageboltsandhexnutswhichattachitto the

snowthrowerhousing.

2. Reassemblenewshaveplate,makingsure headsofcarriage

boltsareto theinsideof housing.Tightensecurely.

ADJUSTMENTS

Shift Cable

If the fullrangeofspeeds(forwardandreverse)cannotbe achieved,

referto the figuretothe rightandadjusttheshiftcableasfollows:

1. Placethe shiftleverin thefastest forwardspeedposition.

2. Loosenthehex nutontheshiftcable indexbracket.SeeFigure

18.

3. Pivotthebracketdownwardtotakeupslackinthecable.

4. Retightenthehexnut.

Figure17

Drive Control

Whenthe drivecontrolisreleasedandin thedisengaged"up"position,

thecableshouldhavevery littleslack.It shouldNOTbe tight.Also,

ifthereisexcessiveslackin thedrivecableorifthe unitexperiences

intermittentdrivewhileusing,thecablemayneedtobeadjusted.

Checktheadjustmentofthe drivecontrolasfollows:

1. Withthedrivecontrolreleased,pushthe snowthrowergently

forward.Theunitshouldrollfreely.

2. Engagethe drivecontrolandgentlyattempttopushthesnow

throwerforward.Thewheelsshouldnot turn.The unitshouldnot

rollfreely.

3. Withthedrivecontrolreleased,movetheshiftleverbackand

forthbetweentheR2 positionandtheF5 positionseveraltimes.

Thereshouldbenoresistanceintheshiftlever.

4. If anyoftheabovetestsfailed,thedrivecableisin needof adjust-

ment.Proceedasfollows:

5. Loosenthelowerhexnutonthedrivecablebracket.SeeFigure

19.

6. Positionthe bracketupwardtoprovidemoreslack(ordownward

toincreasecabletension).

7. Retightenthelowerhexnut.

,J

Figure18

f

--,,,

18

J

Figure19

Chute Bracket

If thespiralatthebottomofthechutedirectionalcontrolis not fully

engagingwiththechuteassembly,the chutebracketcan beadjusted.

Todoso:

1. Loosenthetwonutswhichsecurethechutebracketandreposi-

tionitslightly.SeeFigure20.

2. Retightenthenuts.

Auger Control

RefertotheAssemblysectionfor instructionsonadjustingtheauger

controlcable.

Skid Shoes

RefertotheAssemblysectionfor instructionsonadjustingtheskid

shoes.

f --,,

BELT REPLACEMENT

Auger Belt

Toremoveandreplaceyoursnowthrower'saugerbelt, proceedas

follows:

1. Topreventspillage,placea pieceofplasticwrapunderthegas

capand tightensecurely.

2. Removetheplasticbeltcoveronthefrontof the enginebyremov-

ingthetwoself-tappingscrews.SeeFigure21.

3. Rollthe augerbelt offthe enginepulley.SeeFigure22.

4. Carefullypivotthesnowthrowerup andforwardso thatit restson

theaugerhousing.

Figure20

f

/

19

J

Figure22

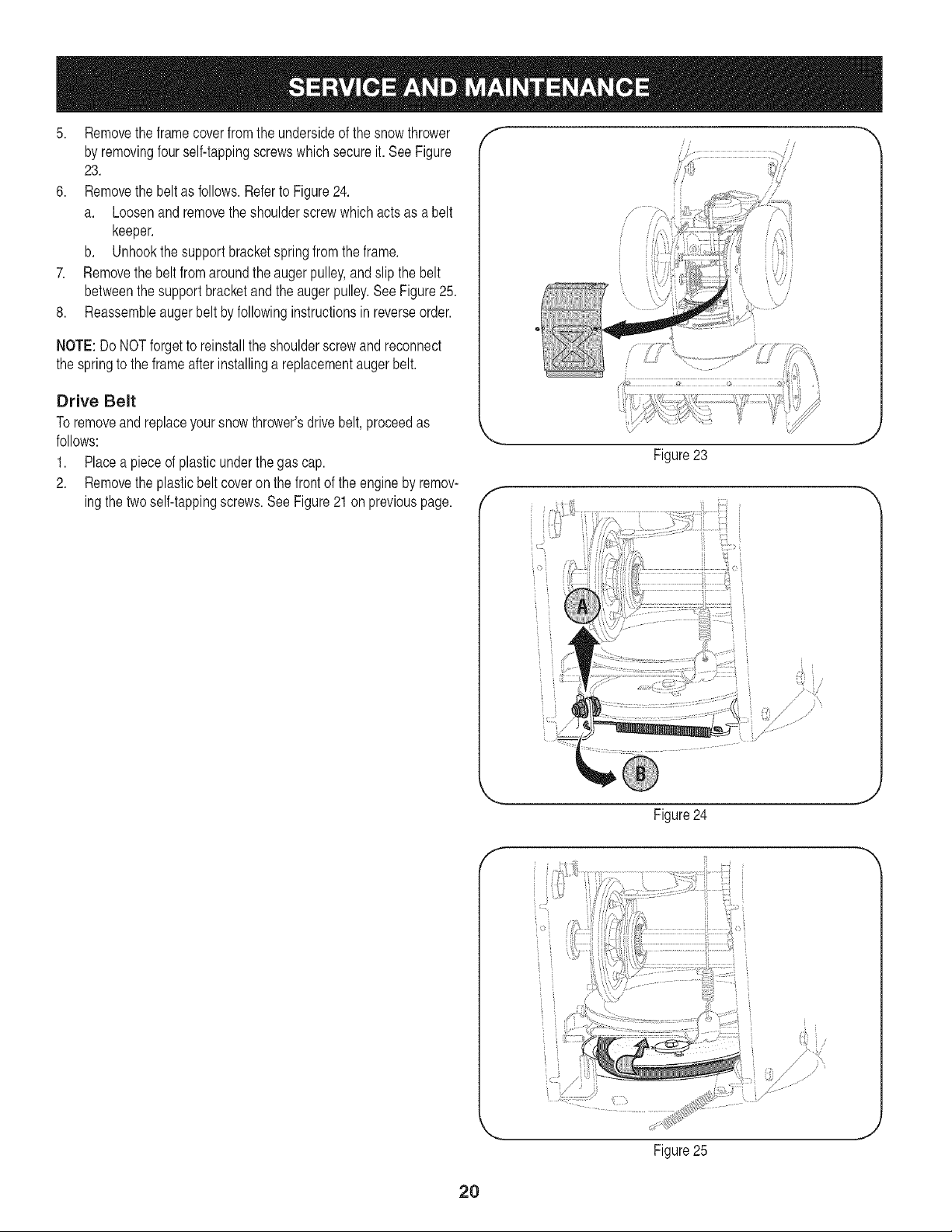

5. Removetheframecoverfromtheundersideofthesnowthrower

byremovingfourself-tappingscrewswhichsecureit. SeeFigure

23.

6. Removethe beltasfollows.RefertoFigure24.

a. Loosenandremovetheshoulderscrewwhichactsas abelt

keeper.

b. Unhookthesupportbracketspringfromtheframe.

7. Removethebeltfromaroundtheaugerpulley,andslipthebelt

betweenthesupportbracketandthe augerpulley.SeeFigure25.

8. Reassembleaugerbeltbyfollowinginstructionsin reverseorder.

NOTE:Do NOTforgetto reinstalltheshoulderscrewandreconnect

thespringto theframeafterinstallinga replacementaugerbelt.

Drive Belt

Toremoveandreplaceyoursnowthrower'sdrivebelt,proceedas

follows: "_.

1. Placea pieceof plasticunderthegas cap.

2. Removethe plasticbeltcoveronthefrontoftheenginebyremov-

ingthetwoself-tappingscrews.SeeFigure21onpreviouspage. f-

J

Figure23

--,,,,

Figure24

ii_ii

/

2O

Figure25

Loading...

Loading...