Page 1

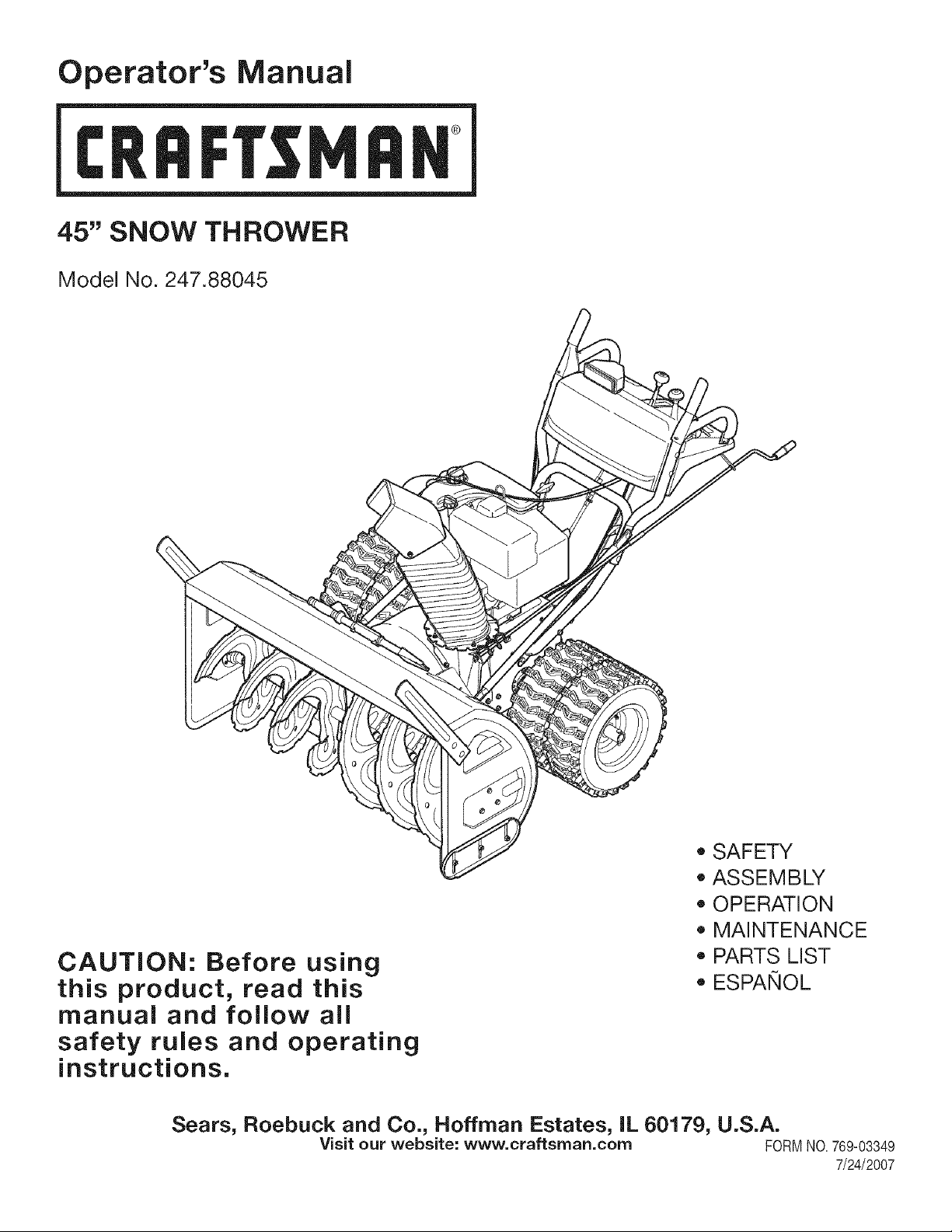

Operator's Manual

CNNFTSMNN

45" SNOW THROWER

Model No. 247.88045

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www, craftsrnan.corn FORMNO.769-03349

• SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

ESPANOL

7/24/2007

Page 2

WarrantyStatement..................................Page2

RepairProtectionAgreement...................Page3

SafeOperationPractices.........................Pages4-5

SafetyLabels............................................Page7

Assembly..................................................Pages8-11

Operation..................................................Pages12-15

ServiceandMaintenance.........................Pages16-23

Off-SeasonStorage..................................Page24

TroubleShooting......................................Page25

PartsList...................................................Page26-36

Espa_ol.....................................................Page40

ServiceNumbers......................................BackCover

Two-YearWarranty on CraftsmanSnowThrower

Thisequipmentiscoveredbyatwo-yearwarranty,providedthatitismaintained,lubricated,andtunedupaccordingtotheinstructionsinthe

operator'smanual.Duringthewarrantyyears,ifthisequipmentexperiencesanyfailureduetodefectsinmaterialorworkmanship,RETURNIT

TOYOURNEARESTSEARSPARTS&REPAIRCENTER,andSearswillrepairit,freeofcharge.In-homewarrantyserviceisavailable,butyou

willhavetopayatripcharge.

Thiswarrantydoesnotcover:

• Expendableitemswhichbecomewornduringnormaluse,suchasskidshoes,shaveplateandsparkplugs.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,bentcrankshafts,failuretousethepropergradeandamountofengineoil,orfailuretomaintaintheequipmentaccordingto the

instructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedtobecontaminatedor oxidized(stale). Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

• Equipmentifusedforcommercialorrentalpurposes.

Thiswarrantyappliesforonly90 daysif this productis everusedforcommercialorrentalpurposes.

This warrantyappliesonlywhilethisproductis usedintheUnitedStates.

This warrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstateto state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

EngineOil Type: SAE5W-30

EngineOil Capacity: 28 ounces

FuelCapacity: 4 Quarts

SparkPlug: Champion@RJ19LM

SparkPlugGap: .030"

ModelNumber.................................................................

Serial Number.................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

©SearsBrands,LLC

Page 3

Congratulationson makingasmartpurchase.YournewCraftsman®

productisdesignedandmanufacturedfor yearsofdependableopera-

tion.Butlikeall products,it mayrequirerepairfromtimetotime.That's

whenhavinga RepairProtectionAgreementcansaveyou moneyand

aggravation.

Here'swhat'sincludedintheAgreement:

,, Expertserviceby our 12,000professionalrepairspecialists

,, Unlimitedserviceandnochargefor partsandlaboronallcovered

repairs

,, Productreplacementif yourcoveredproductcan'tbe fixed

,, Discountof 10%fromregularpriceof serviceandservice-related

partsnotcoveredbytheagreement;also,10%offregularpriceof

preventivemaintenancecheck

,, Fasthelpbyphone- phonesupportfromaSearstechnicianon

productsrequiringin-homerepair,plusconvenientrepair

scheduling

Purchasea RepairProtectionAgreementnowandprotectyourself

fromunexpectedhassleandexpense.

Onceyou purchasetheAgreement,a simplephonecallisall thatit

takesfor you toscheduleservice.Youcan call anytimedayornight,or

schedulea serviceappointmentonline.

Searshasover12,000professionalrepairspecialists,whohave

accesstoover4.5millionqualitypartsandaccessories.That'sthe

kindof professionalismyoucan counton to helpprolongthelifeof

yournewpurchaseforyearstocome.PurchaseyourRepairProtection

Agreementtoday!

Somelimitationsand exclusionsapply. For pricesand additional

informationcall 1-800-827-6655.

SearsInstallation Service

ForSearsprofessionalinstallationof homeappliances,garagedoor

openers,waterheaters,andothermajorhomeitems,in the U.S.A.call

1-800-4-MY-HOME®

Page 4

which,ifnotfollowed,couldendangerthepersonal

__L Thissymbolpointsoutimportantsafetyinstructions

safetyand/orpropertyofyourselfandothers.Read

andfollowallinstructionsinthismanualbefore

attemptingtooperatethismachine.Failuretocomplywiththese

instructionsmayresultinpersonalinjury.Whenyouseethissymbol,

HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtotherulesfor

safeoperationinthismanual.Aswithanytypeofpowerequipment,

carelessnessorerroronthepartoftheoperatorcanresultinserious

injury.Thismachineiscapableofamputatinghandsandfeetand

throwingobjects.Failuretoobservethefollowingsafetyinstructions

couldresultinseriousinjuryordeath.

YourResponsibility:Restricttheuseofthispowermachineto

personswhoread,understand,andfollowthewarningsandinstruc-

tionsinthismanualandonthemachine.

TRAINING

,, Read,understand,andfollowallinstructionsonthemachineandin

the manual(s)beforeattemptingtoassembleandoperate.Keepthis

manualina safeplacefor future andregularreferenceandfor ordering

replacementparts.

,, Be familiarwithallcontrolsandtheirproperoperation.Knowhowto stop

the machineanddisengagethemquickly.

,, Neverallowchildrenunder14yearsoldto operatethis machine.Chil-

dren14yearsoldandovershouldreadandunderstandtheoperation

instructionsandsafetyrulesinthis manualand shouldbetrainedand

supervisedbya parent.

,, Neverallowadultsto operatethismachinewithout properinstruction.

,, Thrownobjectscancauseseriouspersonalinjury.Planyoursnow-

throwingpatterntoavoiddischargeof materialtowardroads,bystanders

andthe like.

,, Keepbystanders,helpers,petsandchildrenat least 75feet fromthe

machinewhileit is inoperation.Stop machineif anyoneentersthearea.

,, Exercisecautiontoavoidslippingorfalling,especiallywhenoperatingin

reverse.

Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to Stateof California to

1cause cancer and birth defects or other reproductive harm.

PREPARATION

Thoroughlyinspecttheareawheretheequipmentisto beused.Removeall

doormats,newspapers,sleds,boards,wiresandotherforeignobjects,which

couldbetrippedoverorthrownbythe auger/impeller.

,, Alwayswearsafetyglassesoreyeshieldsduringoperationandwhile

performinganadjustmentor repairto protectyoureyes.Thrownobjects

whichricochetcancauseserious injurytothe eyes.

,, Donotoperatewithoutwearingadequatewinteroutergarments.Donot

wearjewelry,longscarvesor otherlooseclothing,whichcouldbecome

entangledinmovingparts.Wearfootwearwhichwill improvefootingon

slipperysurfaces.

,, Usea groundedthree-wireextensioncordand receptacleforall units

with electricstartengines.

,, Adjustcollectorhousingheighttoclear gravelor crushedrocksurfaces.

,, Disengageallcontrolleversbeforestartingtheengine.

,, Neverattemptto makeanyadjustmentswhileengineis running,except

wherespecificallyrecommendedintheoperator'smanual.

,, Letengineandmachineadjustto outdoortemperaturebeforestartingto

clearsnow.

Safe Handling of Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein handling

gasoline.Gasolineisextremelyflammableandthevaporsareexplosive.

Seriouspersonalinjurycanoccurwhengasolineis spilledonyourselforyour

clothes,whichcan ignite.Washyourskinandchangeclothesimmediately.

,, Useonlyan approvedgasolinecontainer.

,, Extinguishall cigarettes,cigars,pipesandothersourcesofignition.

,, Neverfuelmachineindoors.

,, Neverremovegascaporaddfuel whilethe engineishot or running.

,, Allowenginetocoolatleasttwominutesbeforerefueling.

,, Neveroverfillfuel tank.Filltankto nomorethan Y2inch belowbottomof

fillerneckto providespacefor fuelexpansion.

,, Replacegasolinecapandtightensecurely.

,, Ifgasolineisspilled,wipeit offthe engineandequipment.Move

machineto anotherarea.Wait5 minutesbeforestartingtheengine.

,, Neverstorethemachineorfuelcontainerinsidewherethere isan open

flame,sparkor pilotlight(e.g.furnace,waterheater,spaceheater,

clothesdryeretc.).

,, Allowmachineto coolatleast5minutesbeforestoring.

4

Page 5

OPERATION

. Do notputhandsorfeet nearrotatingparts,intheauger/impeller

housingor chuteassembly.Contactwiththerotatingpartscanamputate

handsand feet.

,, The auger/impellercontrolleverisasafetydevice.Neverbypassits

operation.Doingso makesthe machineunsafeandmaycause personal

injury.

,, The controlleversmustoperateeasilyin bothdirectionsandautomati-

callyreturnto thedisengagedpositionwhenreleased.

,, Neveroperatewitha missingor damagedchuteassembly.Keepall

safetydevicesinplaceand working.

,, Neverrunan engineindoorsorin apoorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

,, Do notoperatemachinewhileunderthe influenceofalcoholordrugs.

,, Mufflerandenginebecomehotand cancauseaburn.Donottouch.

. Exerciseextremecautionwhenoperatingonorcrossinggravel surfaces.

Stayalertfor hiddenhazardsortraffic.

. Exercisecautionwhenchangingdirectionand whileoperatingon slopes.

. Planyoursnow-throwingpatterntoavoiddischargetowardswindows,

walls,carsetc.Thus,avoidingpossiblepropertydamageorpersonal

injurycausedbya ricochet.

. Neverdirectdischargeatchildren,bystandersand petsorallowanyone

infrontofthe machine.

. Do notoverloadmachinecapacitybyattemptingto clearsnowattoofast

ofa rate.

. Neveroperatethis machinewithoutgoodvisibilityor light.Alwaysbe

sureof your footingandkeepa firm holdonthe handles.Walk, never

run.

. Disengagepowertothe auger/impellerwhentransportingor notinuse.

,, Neveroperatemachineat hightransportspeedsonslipperysurfaces.

Lookdownand behindand usecarewhenbackingup.

,, If the machineshouldstarttovibrateabnormally,stoptheengine,

disconnectthesparkplugwireandgrounditagainsttheengine.Inspect

thoroughlyfordamage.Repairanydamagebeforestartingandoperat-

ing.

. Disengageallcontrolleversandstop enginebeforeyouleavethe

operatingposition(behindthe handles).Waituntilthe auger/impeller

comesto a completestopbeforeuncloggingthe chute assembly,making

anyadjustments,orinspections.

,, Neverputyourhandinthe dischargeor collectoropenings.Always

usetheclean-outtoolprovidedto unclogthedischargeopening.Do

not unclogchuteassemblywhileengineisrunning.Shutoffengine

andremainbehindhandlesuntilallmovingpartshavestoppedbefore

unclogging.

,, Useonlyattachmentsandaccessoriesapprovedbythemanufacturer

(e.g.wheelweights,tirechains,cabs etc.).

,, If situationsoccurwhich arenotcoveredinthismanual,usecareand

goodjudgment.ContactyourSearsServiceCenterforassistance.

MAINTENANCE & STORAGE

. Nevertamperwithsafetydevices.Checktheir properoperation

regularly.Referto the maintenanceandadjustmentsectionsofthis

manual.

,, Beforecleaning,repairing,or inspectingmachinedisengageallcontrol

leversand stoptheengine.Waituntiltheauger/impellercometoa

completestop.Disconnectthe sparkplug wireand groundagainstthe

enginetopreventunintendedstarting.

. Checkboltsandscrewsfor propertightnessatfrequentintervalsto keep

the machinein safeworkingcondition.Also,visuallyinspectmachinefor

anydamage.

. Donotchangetheenginegovernorsettingor over-speedthe engine.

Thegovernorcontrolsthe maximumsafeoperatingspeedoftheengine.

. Snowthrowershaveplatesandskidshoesare subjectto wearand

damage.Foryoursafetyprotection,frequentlycheckallcomponents

andreplacewith originalequipmentmanufacturer's(OEM) partsonly.

"Useof partswhichdonotmeetthe originalequipmentspecifications

may leadto improperperformanceandcompromisesafety!"

. Checkcontrolsperiodicallytoverifytheyengageanddisengage

properlyandadjust,ifnecessary.Referto theadjustmentsectionin this

operator'smanualfor instructions.

. Maintainorreplacesafetyandinstructionlabels,as necessary.

. Observeproperdisposallawsandregulationsforgas, oil,etc.to protect

the environment.

. Priortostoring,runmachineafewminutesto clearsnowfrom machine

andpreventfreezeup of auger/impeller.

. Neverstorethe machineorfuelcontainerinsidewherethere isanopen

flame,sparkor pilotlightsuch asawaterheater,furnace,clothes dryer

etc.

,, Alwaysreferto the operator'smanualfor properinstructionson

off-seasonstorage.

Do not modify engine

Toavoidseriousinjuryor death,do notmodifyenginein anyway.Tampering

withthegovernorsettingcanleadto a runawayengineandcauseitto operate

at unsafespeeds.Nevertamperwithfactorysettingofenginegovernor.

Notice Regarding Emissions

Engineswhichare certifiedtocomplywithCaliforniaandfederalEPAemission

regulationsforSORE(SmallOffRoadEquipment)are certifiedto operateon

regularunleadedgasoline,and mayincludethefollowingemissioncontrolsys-

tems:EngineModification(EM)andThreeWayCatalyst(TWO)if soequipped.

Page 6

Thispage left intentionallyblank.

6

Page 7

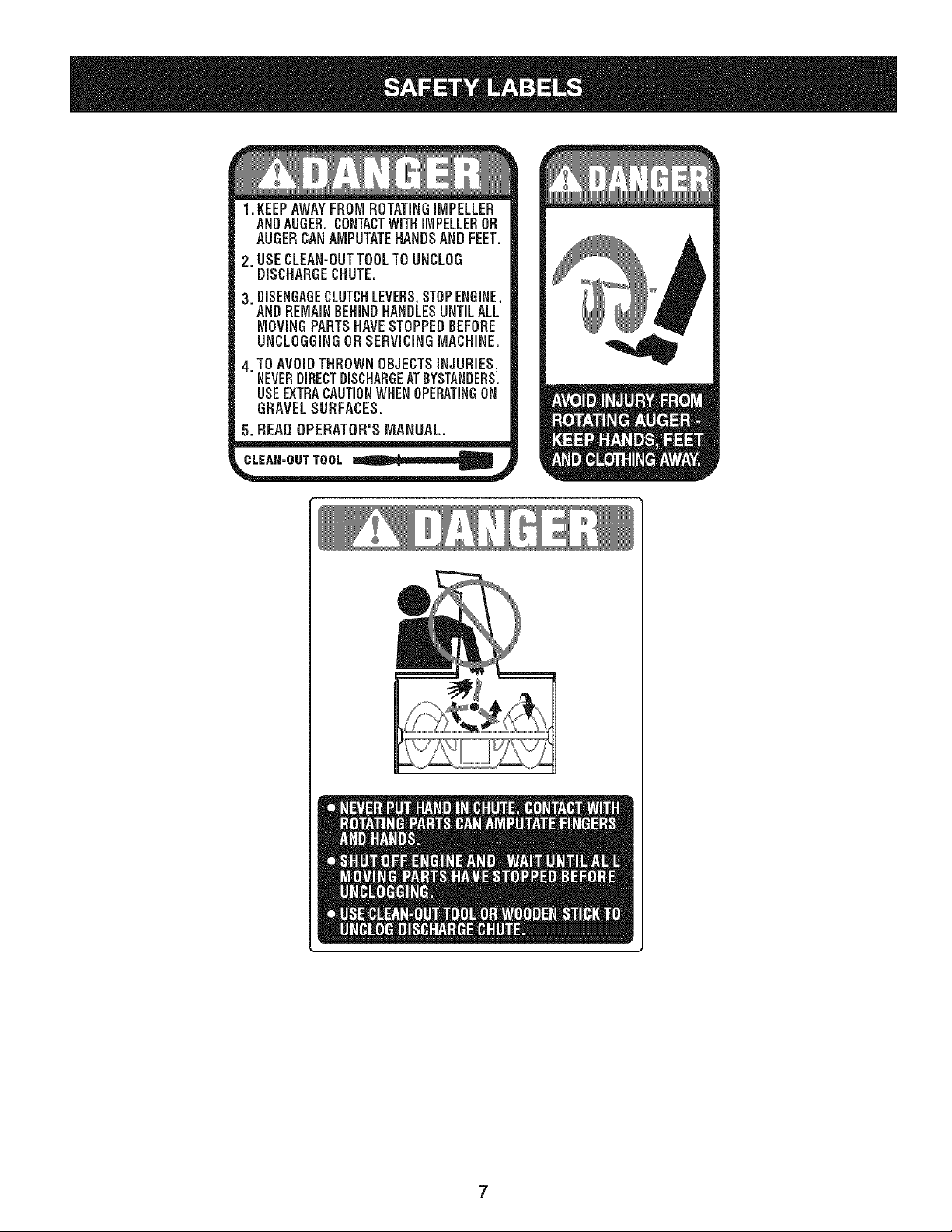

1.KEEPAWAYFROMROTATINGiMPELLER

ANDAUGER.CONTACTWiTHiMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET.

2. USECLEAN-OUTTOOLTOUNCLOG

DISCHARGECHUTE.

3. DISENGAGECLUTCHLEVERS,STOPENGINE,

ANDREMAINBEHINDHANDLESUNTILALL

MOVINGPARTSHAVESTOPPEDBEFORE

UNCLOGGINGDRSERViCiNGMACHINE.

4. TOAVOIDTHROWNOBJECTSiNJURiES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHENOPERATINGON

GRAVELSURFACES.

5. READOPERATOR'SMANUAL.

CLEAN-OUT TOOL

7

Page 8

NOTE:Referencesto rightor leftsideof thesnowthrowerare

determinedfrombehindtheunitintheoperatingposition(standing

directlybehindthesnowthrower,facingthehandlepanel).

REMOVING FROM CRATE

1. Removescrewsandstaplesfromthetop,sides,andendsofthe

shippingcrate.

2. Setpanelsasidetoavoidtirepuncturesorpersonalinjury.

3. Removeanddiscardplasticbagthatcoversunit.

4. Removeanyloosepartsincludedwithunit(i.e.,Operator's

Manual,etc.).

5. Pushdownonhandlesand pullunitbackout of crate.

6. Makecertainthecratehasbeencompletelyemptiedbefore

discardingit.

ASSEMBLY

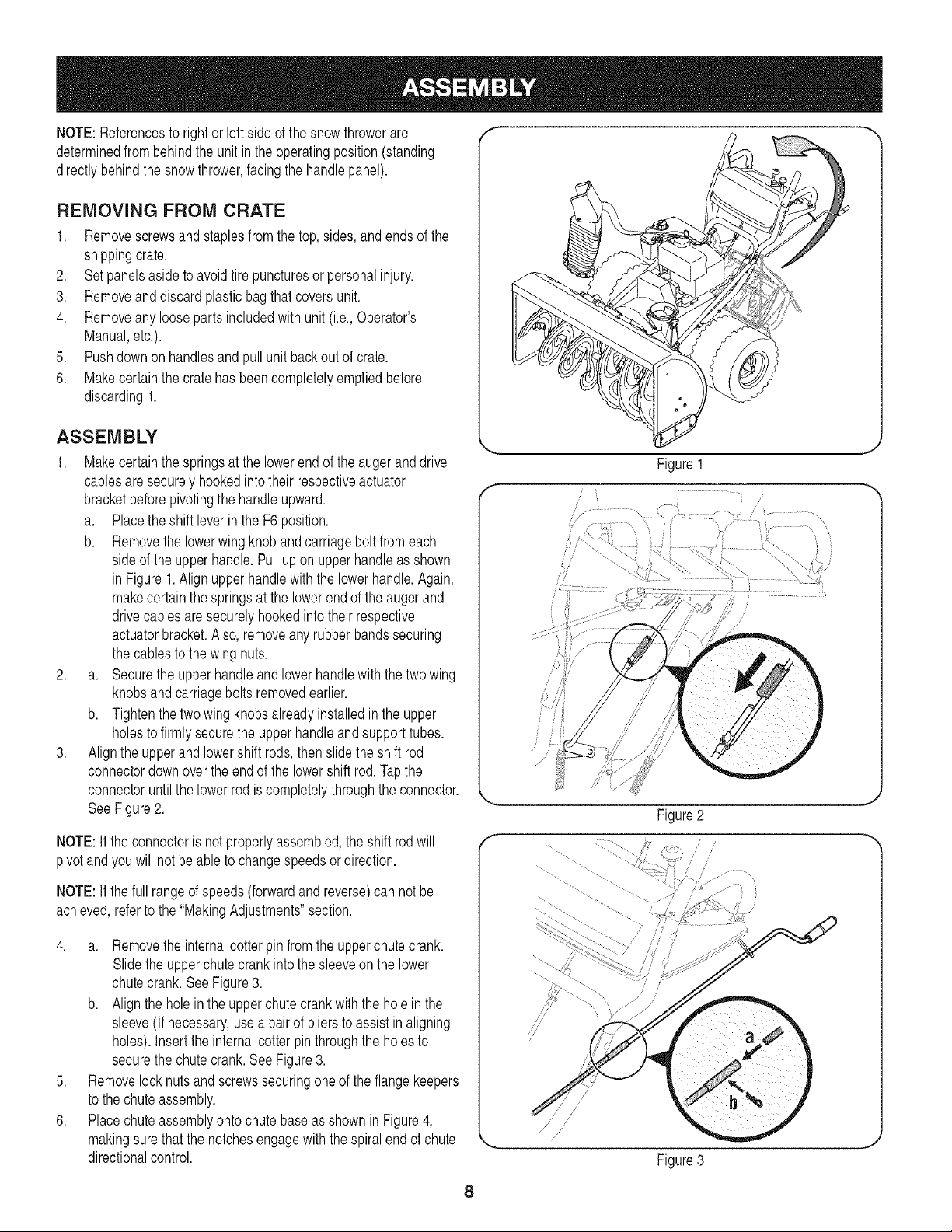

1. Makecertainthespringsat the lowerendof the augeranddrive

cablesaresecurelyhookedintotheirrespectiveactuator

bracketbeforepivotingthehandleupward.

a. Placetheshift leverintheF6 position.

b. Removethelowerwingknobandcarriageboltfromeach

sideof theupperhandle.Pullupon upperhandleasshown

in Figure1.Alignupperhandlewiththelowerhandle.Again,

makecertainthespringsatthe lowerendoftheaugerand

drivecablesaresecurelyhookedintotheir respective

actuatorbracket.Also,removeanyrubberbandssecuring

thecablestothewingnuts.

2. a. Securetheupperhandleandlowerhandlewiththetwowing

knobsandcarriageboltsremovedearlier.

b. Tightenthetwowingknobsalreadyinstalledintheupper

holesto firmlysecuretheupperhandleandsupporttubes.

3. Alignthe upperand lowershiftrods,thenslidetheshiftrod

connectordownoverthe endofthe lowershiftrod.Tapthe

connectoruntilthe lowerrodis completelythroughtheconnector.

SeeFigure2.

NOTE:If theconnectoris notproperlyassembled,theshiftrodwill

pivotand youwillnotbe abletochangespeedsordirection.

NOTE:If thefullrangeof speeds(forwardandreverse)can notbe

achieved,refertothe"MakingAdjustments"section.

Figure1

/

/

//

i/ ..........

/'-_F .......

Figure2

f

/

4. a. Removetheinternalcotterpinfromtheupperchutecrank.

Slidetheupperchutecrankintothesleeveon thelower

chutecrank.SeeFigure3.

b. Aligntheholein theupperchutecrankwiththeholein the

sleeve(If necessary,usea pairofplierstoassistin aligning

holes).Insertthe internalcotterpinthroughtheholesto

securethechutecrank.SeeFigure3.

5. Removelocknutsandscrewssecuringoneoftheflangekeepers

tothechuteassembly.

6. Placechuteassemblyontochutebaseasshownin Figure4,

makingsurethat thenotchesengagewiththespiralend ofchute

directionalcontrol.

/

/

Figure3

8

Page 9

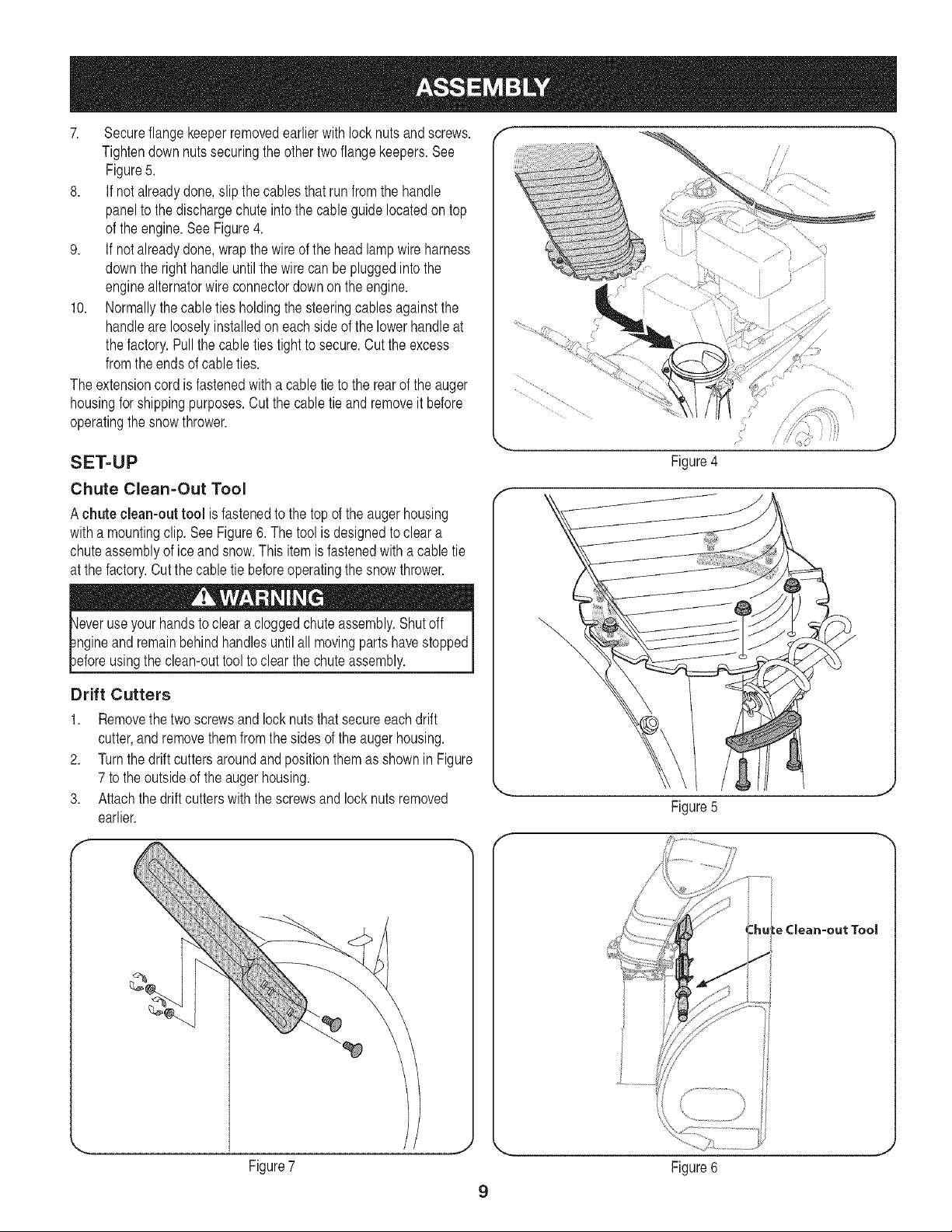

7. Secureflangekeeperremovedearlierwithlocknutsandscrews.

Tightendownnutssecuringtheothertwoflangekeepers.See

Figure5.

8. Ifnotalreadydone,slipthecablesthatrunfromthehandle

paneltothedischargechuteintothe cableguidelocatedontop

of theengine.SeeFigure4.

9. Ifnotalreadydone,wrapthewireoftheheadlampwireharness

downtherighthandleuntilthewirecanbepluggedintothe

enginealternatorwireconnectordownonthe engine.

10. Normallythecableties holdingthesteeringcablesagainstthe

handlearelooselyinstalledoneachsideofthelowerhandleat

thefactory.Pullthecabletiestighttosecure.Cuttheexcess

fromtheendsofcable ties.

Theextensioncordisfastenedwitha cabletietotherearof theauger

housingforshippingpurposes.Cutthe cabletie andremoveitbefore

operatingthesnowthrower.

1/

ii

..............

SET-UP

Chute Clean-Out Tool

Achute clean-out tool isfastenedtothetop oftheaugerhousing

withamountingclip.SeeFigure6.The toolisdesignedtocleara

chuteassemblyoficeandsnow.Thisitemisfastenedwitha cabletie

atthefactory.Cutthecabletiebeforeoperatingthesnowthrower.

Drift Cutters

1. Removethetwoscrewsandlocknutsthatsecureeachdrift

cutter,andremovethemfromthesidesoftheaugerhousing.

2. Turnthedriftcuttersaroundandpositionthemasshownin Figure

7 to theoutsideoftheaugerhousing.

3. Attachthe driftcutterswiththe screwsandlocknutsremoved

earlier.

Figure4

\

Figure5

Figure7

:hule Clean-out Tool

Figure6

9

Page 10

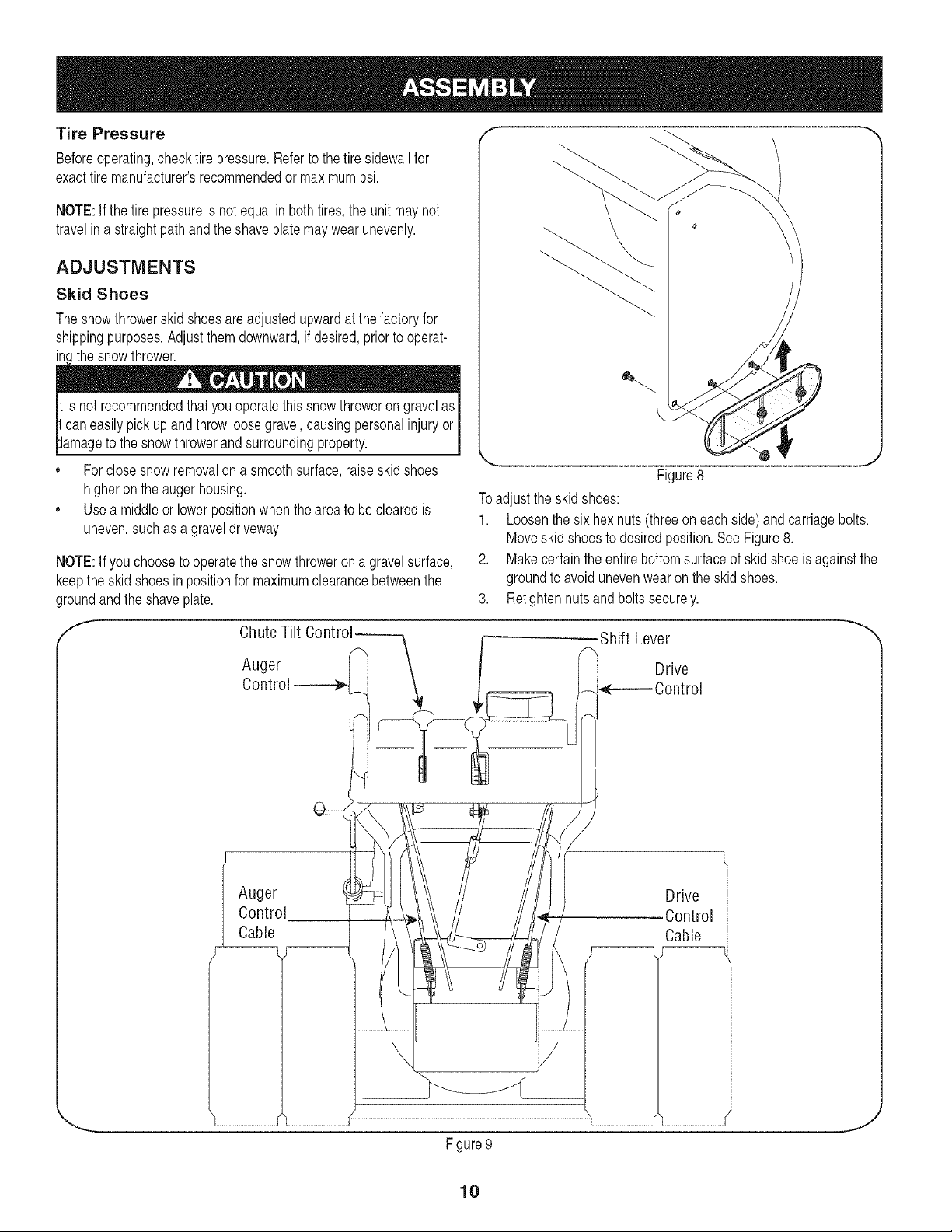

Tire Pressure f

Beforeoperating,checktirepressure.Refertothetiresidewallfor

exacttiremanufacturer'srecommendedor maximumpsi.

NOTE:If thetirepressureis notequalinbothtires,theunitmaynot

travelinastraightpathandtheshaveplatemaywearunevenly.

ADJUSTMENTS

Skid Shoes

Thesnowthrowerskidshoesareadjustedupwardatthefactoryfor

shippingpurposes.Adjustthemdownward,if desired,priorto operat-

ingthesnowthrower.

isnotrecommendedthat this thrower

It youoperate snow on gravelas

it.caneasilypickupandthrowloosegravel,causingpersonalinjuryor i

_damageto the snowthrowerandsurroundingproperty, j

,, Forclosesnowremovalon a smoothsurface,raiseskidshoes

higherontheaugerhousing.

,, Usea middleorlowerpositionwhentheareatobeclearedis

uneven,suchasagraveldriveway

NOTE:Ifyouchoosetooperatethesnowthroweronagravelsurface,

keeptheskidshoesin positionfor maximumclearancebetweenthe

groundand theshaveplate.

Figure8

Toadjusttheskidshoes:

1. Loosenthesix hexnuts(threeon eachside)andcarriagebolts.

Moveskid shoestodesiredposition.SeeFigure8.

2. Makecertaintheentirebottomsurfaceof skidshoeisagainstthe

groundtoavoidunevenwearon theskidshoes.

3. Retightennutsandboltssecurely.

Chute Tilt Controi_

Auger

Control----4_ .

Auger !

Control

Cable

-Shift Lever

i Drive

_e--_ Contro

Drive

Control

Cable

7

Figure9

10

J

Page 11

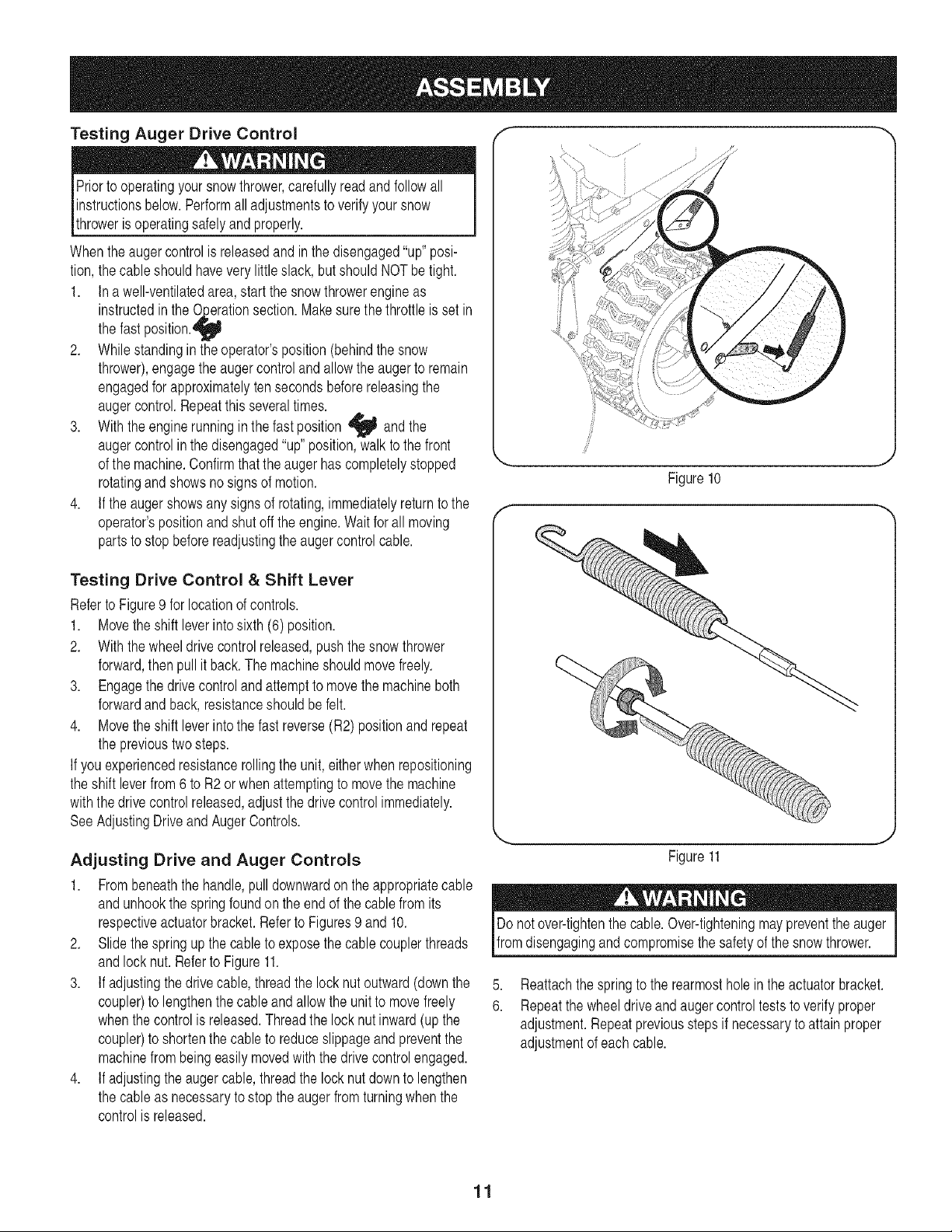

Testing Auger Drive Control "*

Priortooperatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performalladjustmentsto verifyyoursnow

throwerisoperatingsafelyandproperly.

Whentheaugercontrolisreleasedand inthedisengaged"up"posi-

tion,thecableshouldhaveverylittleslack,butshouldNOTbetight.

1. Ina well-ventilatedarea,startthesnowthrowerengineas

instructedin the O_erationsection.Makesurethethrottleissetin

thefastposition.G_p

2. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagethe augercontrolandallowthe augerto remain

engagedforapproximatelytensecondsbeforereleasingthe

augercontrol.Repeatthisseveraltimes.

3. Withtheenginerunninginthefastposition '_ andthe

augercontrolinthe disengaged"up"position,walktothefront

ofthemachine.Confirmthattheaugerhascompletelystopped

rotatingandshowsnosignsof motion.

4. If theaugershowsanysignsof rotating,immediatelyreturntothe

operator'spositionandshutoffthe engine.Waitforallmoving

partstostopbeforereadjustingtheaugercontrolcable.

Testing Drive Control & Shift Lever

RefertoFigure9 for locationofcontrols.

1. Movetheshiftleverintosixth(6)position.

2. Withthewheeldrivecontrolreleased,pushthesnowthrower

forward,thenpullit back.The machineshouldmovefreely.

3. Engagethedrivecontrolandattempttomovethemachineboth

forwardandback,resistanceshouldbefelt.

4. Movetheshiftleverintothefastreverse(R2)positionandrepeat

theprevioustwosteps.

If youexperiencedresistancerollingtheunit,eitherwhenrepositioning

theshiftleverfrom6toR2orwhenattemptingto movethemachine

withthedrivecontrolreleased,adjustthedrive controlimmediately.

SeeAdjustingDriveandAugerControls.

4

Figure10

f

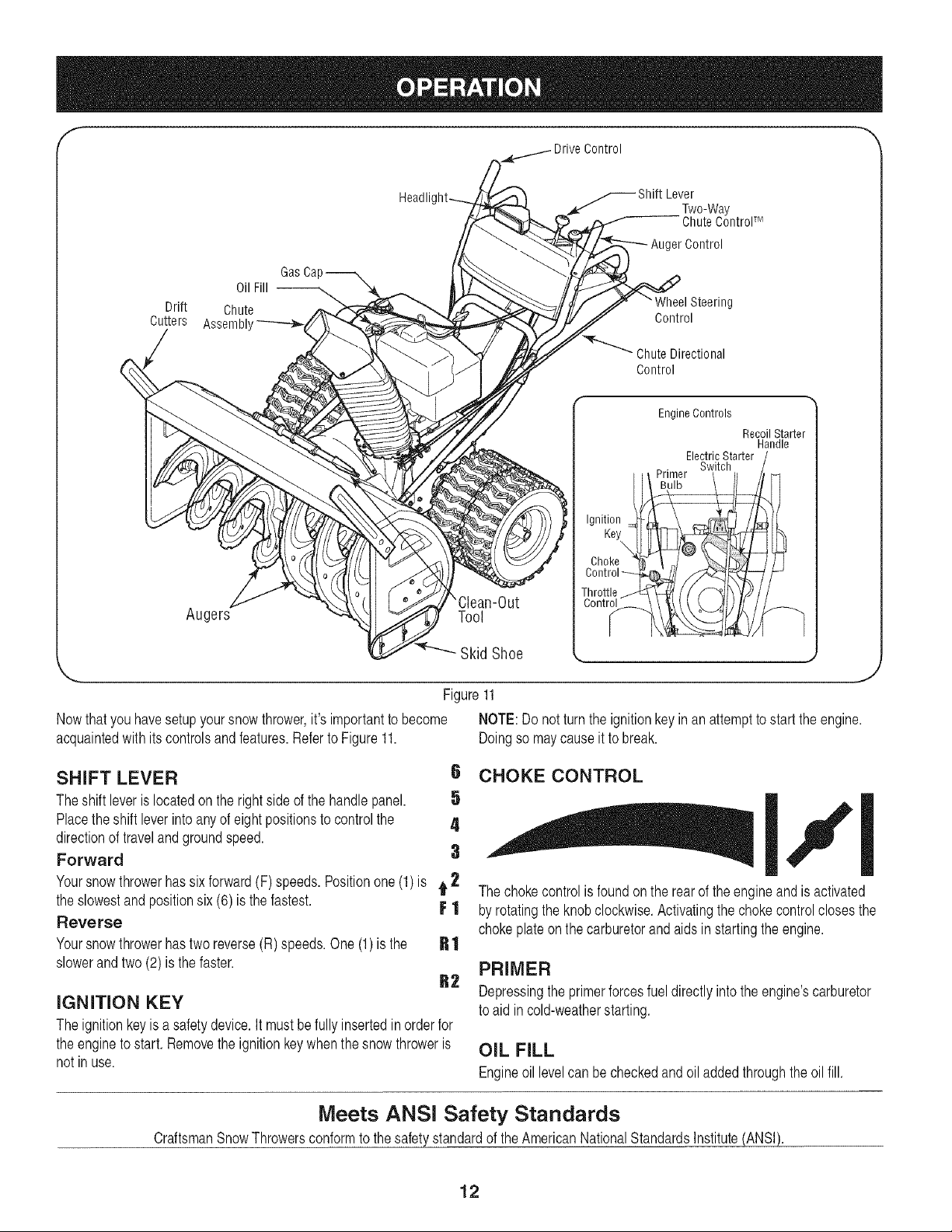

Adjusting Drive and Auger Controls

1. Frombeneaththehandle,pulldownwardon theappropriatecable

andunhookthespringfoundontheendofthecablefromits

respectiveactuatorbracket.RefertoFigures9and10.

2. Slidethespringupthecabletoexposethecablecouplerthreads

andlocknut.Referto Figure11.

3. If adjustingthedrivecable,threadthelocknut outward(downthe

coupler)tolengthenthecableandallowtheunittomovefreely

whenthe controlis released.Threadthe locknutinward(upthe

coupler)toshortenthecableto reduceslippageandpreventthe

machinefrombeingeasilymovedwiththedrivecontrolengaged.

4. If adjustingtheaugercable,threadthelocknutdowntolengthen

thecableas necessarytostoptheaugerfromturningwhenthe

controlis released.

Figure11

Donotover-tightenthecable.Over-tighteningmaypreventtheauger I

Ifromdsengagngandcompromsethesafetyof the snowthrower. J

5,

Reattachthespringto therearmostholeintheactuatorbracket.

6.

Repeatthewheeldriveandaugercontrolteststo verifyproper

adjustment.Repeatpreviousstepsifnecessarytoattainproper

adjustmentofeachcable.

11

Page 12

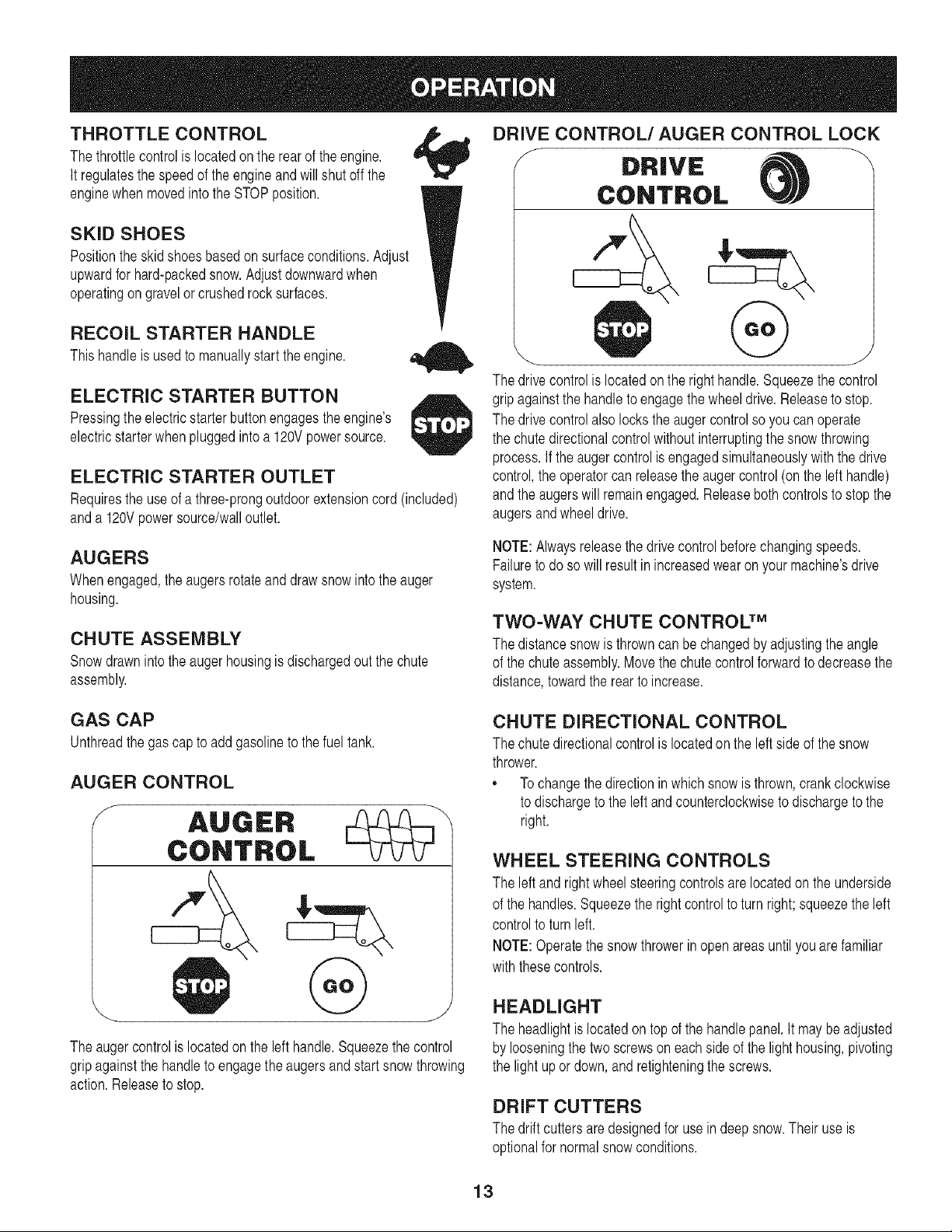

f

DriveControl

Drift

Cutters

/

Assembl

Augers

OilFill

Chute

/

GasCa

Headlk

Lever

Two-Way

Chute ControP

Control

I Steering

ol

•ChuteDirectional

Control

Tool

Skid Shoe

Figure11

Nowthatyouhavesetupyoursnowthrower,it'simportanttobecome NOTE:Donotturntheignitionkeyinan attempttostartthe engine.

acquaintedwith itscontrolsandfeatures.RefertoFigure11. Doingso maycauseit tobreak.

SHIFT LEVER

Theshift leverislocatedon the rightsideofthehandlepanel.

Placetheshift leverintoanyofeightpositionsto controlthe

directionof travelandgroundspeed.

Forward

Yoursnowthrowerhassix forward(F)speeds.Positionone(1)is t 2 Thechokecontrolis foundonthe rearof theengineandisactivated

theslowestand positionsix (6)is thefastest.

Reverse

Yoursnowthrowerhastwo reverse(R)speeds.One(1)is the

slowerandtwo(2) is thefaster.

Ii CHOKE CONTROL

I11

FI

byrotatingthe knobclockwise.Activatingthechokecontrolclosesthe

chokeplateonthecarburetorandaidsinstartingtheengine.

R1

PRIMER

R2

IGNITION KEY

Theignitionkeyisa safetydevice.It mustbefullyinsertedinorderfor

theenginetostart,Removetheignitionkeywhenthesnowthroweris

notinuse.

Depressingthe primerforcesfueldirectlyintotheengine'scarburetor

toaid incold-weatherstarting.

OIL FILL

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill.

Meets ANSI Safety Standards

CraftsmanSnowThrowersconformto thesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

12

Page 13

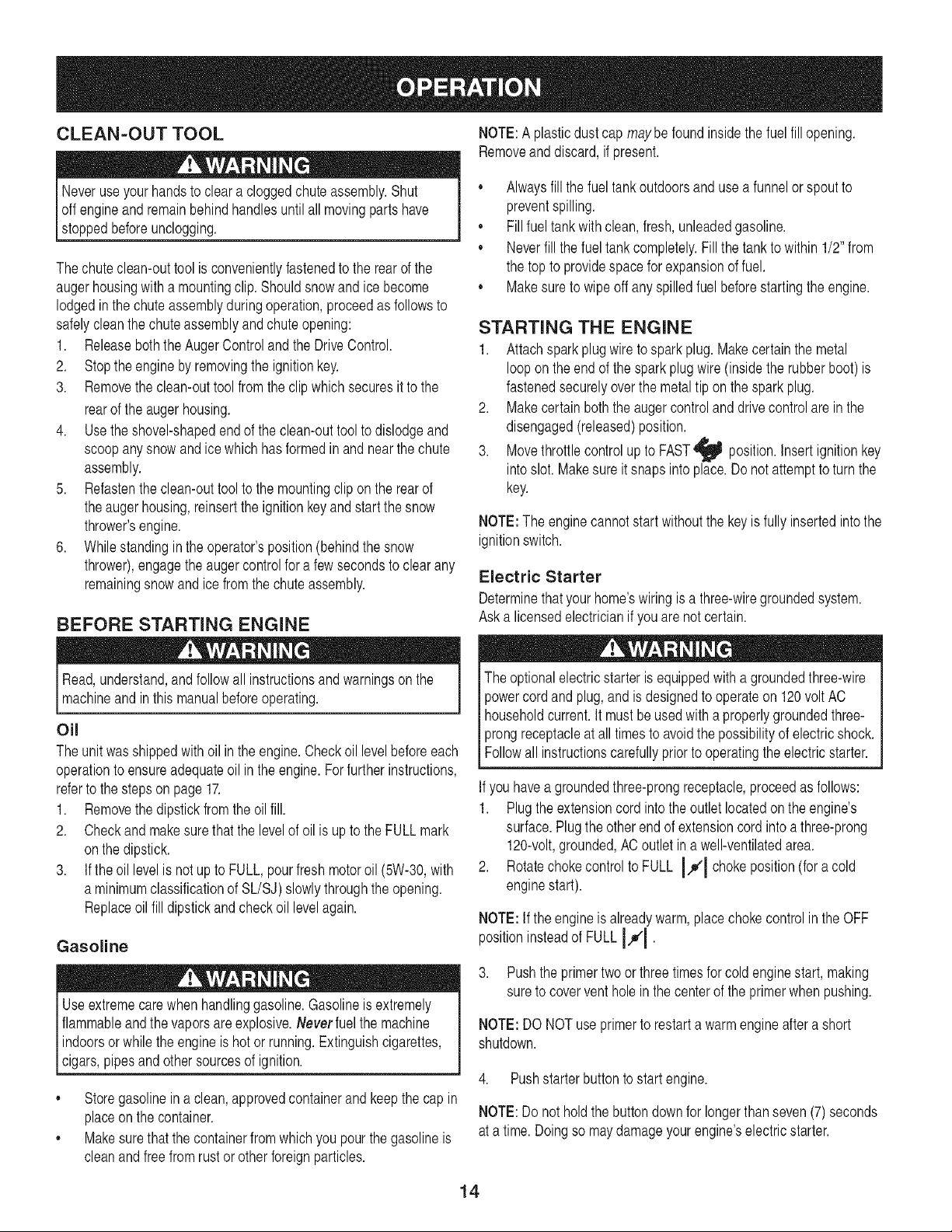

THROTTLE CONTROL

Thethrottlecontrolis locatedontherearoftheengine.

It regulatesthespeedofthe engineandwillshutoff the

enginewhenmovedintotheSTOPposition.

SKID SHOES

Positiontheskidshoesbasedon surfaceconditions.Adjust

upwardforhard-packedsnow.Adjustdownwardwhen

operatingongravelorcrushedrocksurfaces.

DRIVE CONTROL/AUGER CONTROL LOCK

f

DRIVE

CONTROL

RECOIL STARTER HANDLE

This handleisusedto manuallystarttheengine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine's

electricstarterwhenpluggedintoa 120Vpowersource.

ELECTRIC STARTER OUTLET

Requirestheuseofathree-prongoutdoorextensioncord(included)

anda120Vpowersource/walloutlet.

AUGERS

Whenengaged,the augersrotateanddrawsnowintotheauger

housing.

CHUTE ASSEMBLY

Snowdrawnintotheaugerhousingisdischargedoutthechute

assembly.

GAS CAP

Unthreadthegascap toaddgasolineto thefueltank.

AUGER CONTROL

S

@

Thedrivecontrolis locatedon therighthandle.Squeezethecontrol

gripagainstthehandletoengagethewheeldrive.Releaseto stop.

Thedrivecontrolalso locksthe augercontrolso youcanoperate

thechutedirectionalcontrolwithoutinterruptingthesnowthrowing

process.If the augercontrolisengagedsimultaneouslywiththedrive

control,the operatorcanreleasetheaugercontrol(onthelefthandle)

andtheaugerswillremainengaged.Releaseboth controlstostopthe

augersandwheeldrive.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.

Failuretodoso willresultinincreasedwearonyourmachine'sdrive

system.

TWO=WAY CHUTE CONTROL TM

Thedistancesnowis throwncanbechangedbyadjustingtheangle

of thechuteassembly.Movethechutecontrolforwardtodecreasethe

distance,towardtherearto increase.

CHUTE DIRECTIONAL CONTROL

Thechutedirectionalcontrolislocatedontheleftsideofthesnow

thrower.

,, Tochangethedirectioninwhichsnowis thrown,crankclockwise

todischargetotheleftandcounterclockwisetodischargetothe

right.

Theaugercontrolislocatedonthe lefthandle.Squeezethe control

gripagainstthehandletoengagetheaugersandstart snowthrowing

action.Releasetostop.

WHEEL STEERING CONTROLS

Theleftandrightwheelsteeringcontrolsarelocatedontheunderside

of thehandles.Squeezetherightcontrolto turnright;squeezetheleft

controlto turnleft.

NOTE:Operatethesnowthrowerinopenareasuntilyouarefamiliar

withthesecontrols.

HEADLIGHT

Theheadlightislocatedontopofthehandlepanel.It maybeadjusted

bylooseningthe twoscrewsoneachsideofthelighthousing,pivoting

thelightupor down,andretighteningthescrews.

DRIFT CUTTERS

Thedriftcuttersaredesignedforusein deepsnow.Theiruseis

optionalfor normalsnowconditions.

13

Page 14

CLEAN-OUT TOOL NOTE:Aplasticdustcapmaybefoundinsidethefuelfillopening.

Removeanddiscard,if present.

Neveruseyourhandstoclearacloggedchuteassembly.Shut

off engineand remainbehindhandlesuntilallmovingpartshave

stoppedbeforeunclogging.

Thechuteclean-outtoolis convenientlyfastenedto the rearofthe

augerhousingwitha mountingclip. Shouldsnowandicebecome

lodgedin the chuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. ReleaseboththeAugerControlandthe DriveControl.

2. Stopthe enginebyremovingtheignitionkey.

3. Removetheclean-outtoolfromtheclipwhichsecuresittothe

rearoftheaugerhousing.

4. Usetheshovel-shapedendof theclean-outtoolto dislodgeand

scoopanysnowandicewhichhasformedin andnearthechute

assembly.

5. Refastentheclean-outtoolto the mountingclipon therearof

theaugerhousing,reinsertthe ignitionkeyandstartthesnow

thrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagethe augercontrolforafewsecondsto clearany

remainingsnowandicefromthechuteassembly.

BEFORE STARTING ENGINE

,, Alwaysfill thefueltankoutdoorsand usea funnelorspoutto

preventspilling.

,, Fillfuel tankwithclean,fresh,unleadedgasoline.

,, Neverfill thefueltankcompletely.Fillthe tanktowithin1/2"from

thetoptoprovidespaceforexpansionoffuel.

,, Makesureto wipeoff anyspilledfuelbeforestartingtheengine.

STARTING THE ENGINE

1. Attachsparkplugwiretosparkplug.Makecertainthe metal

loopon theendof the sparkplugwire(insidethe rubberboot)is

fastenedsecurelyoverthe metaltip onthesparkplug.

2. Makecertainboththeaugercontrolanddrivecontrolarein the

disengaged(released)position.

3. MovethrottlecontroluptoFAST_ position.Insertignitionkey

intoslot. Makesureitsnapsintoplace.Donotattemptto turn the

key.

NOTE:Theenginecannotstartwithoutthekeyis fullyinsertedintothe

ignitionswitch.

Electric Starter

Determinethatyourhome'swiringis a three-wiregroundedsystem.

Askalicensedelectricianifyouarenotcertain.

Read,understand,andfollowall instructionsandwarningsonthe

machineand inthis manualbeforeoperating.

Oil

Theunit wasshippedwithoilintheengine.Checkoil levelbeforeeach

operationtoensureadequateoilintheengine.Forfurtherinstructions,

referto the stepsonpage 17.

1. Removethedipstickfromtheoilfill.

2. Checkandmakesurethatthe levelofoil is upto theFULLmark

onthedipstick.

3. If theoil levelis notupto FULL,pourfreshmotoroil (5W-30,with

a minimumclassificationofSL/SJ)slowlythroughtheopening.

Replaceoil fill dipstickandcheckoil levelagain.

Gasoline

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuel themachine

indoorsorwhilethe engineishotor running.Extinguishcigarettes,

[c gars,ppesandothersourcesof gnt on.

,, Storegasolinein aclean,approvedcontainerandkeepthe capin

placeonthecontainer.

,, Makesurethatthecontainerfromwhichyoupourthegasolineis

cleanandfreefromrustor otherforeignparticles.

Theoptionalelectricstarteris equippedwithagroundedthree-wire

powercordandplug,andis designedtooperateon120voltAC

householdcurrent.It mustbeusedwith aproperlygroundedthree-

prongreceptacleatall timestoavoidthepossibilityof electricshock.

Followall instructionscarefullypriortooperatingtheelectricstarter.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows:

1. Plugtheextensioncordintothe outletlocatedontheengine's

surface.Plugtheotherend of extensioncordinto athree-prong

120-volt,grounded,ACoutletinawell-ventilatedarea.

2. RotatechokecontroltoFULL I,.#'1chokeposition(foracold

enginestart).

NOTE:If theengineis alreadywarm,placechokecontrolinthe OFF

positioninsteadofFULL IJl •

3. Pushtheprimertwoor threetimesforcoldenginestart, making

sureto coverventholeinthecenterofthe primerwhenpushing.

NOTE:DO NOTuse primerto restartawarmengineafterashort

shutdown.

4. Pushstarterbuttontostartengine.

NOTE:Donotholdthebuttondownforlongerthanseven(7)seconds

ata time.Doingso maydamageyourengine'selectricstarter.

14

Page 15

5. Oncetheenginestarts,releasestarterbutton.

6. Astheenginewarms,slowlyrotatechokecontrolto theOFF

position.Iftheenginefalters,quicklyrotatechokecontrolbackto

FULL 14D"Ithenslowlyintothe OFFpositionagain.

7. Whendisconnectingthe extensioncord,alwaysunplugtheend

atthethree-prongwalloutletbeforeunpluggingtheoppositeend

fromthesnowthrower.

Recoil Starter

1. Rotatechokecontrolto FULL IJl chokeposition(coldengine

start).

NOTE:Iftheengineisalreadywarm,placechokecontrolintheOFF

position

2. Pushthe primertwoorthreetimesforcoldenginestart,making

NOTE:DONOTuseprimertorestartawarmengineafterashort

shutdown.

NOTE:Additionalprimingmaybe necessaryifthe temperatureis

below15°Fahrenheit.

insteadofFULLIJ|.

sureto coverventholeinthecenterof the primerwhenpushing.

NOTE:Whenselectinga DriveSpeed,usethe slowerspeedsuntil

youarecomfortableandfamiliarwiththeoperationofthesnow

thrower.

2. Squeezethedrivecontrolagainstthehandlethe snowthrower

will move.Releaseitanddrivemotionwillstop.

NOTE:NEVERrepositiontheshiftlever(changespeedsordirection

of travel)withoutfirstreleasingthedrivecontrolandbringingthesnow

throwertoa completestop.Doingso will resultin prematurewearto

thesnowthrower'sdrivesystem.

TO ENGAGE AUGERS

1. Toengagethe augersandstartthrowingsnow,squeezethe

augercontrolagainstthelefthandle.Releasetostoptheaugers.

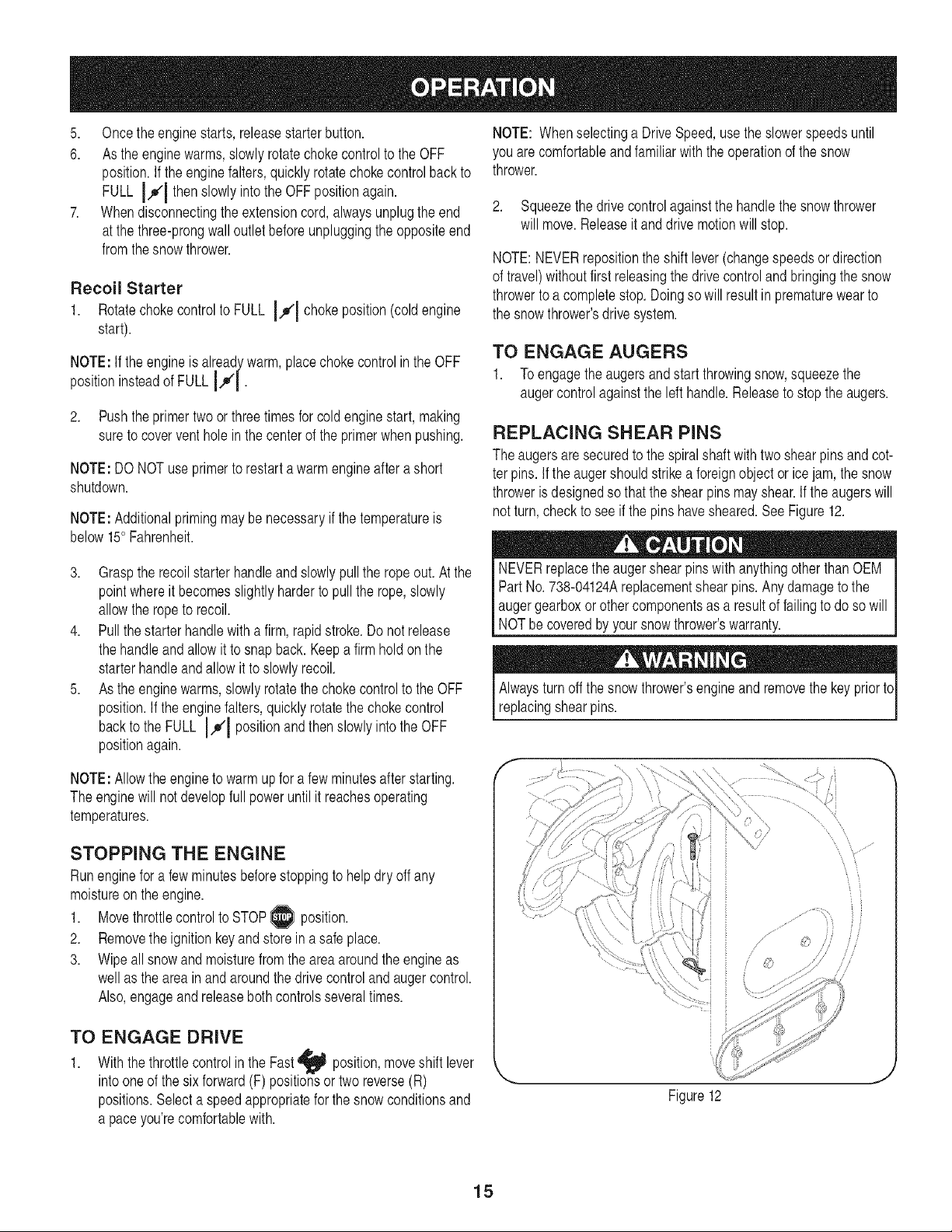

REPLACING SHEAR PiNS

Theaugersaresecuredto thespiralshaft withtwoshearpinsandcot-

terpins.if theaugershouldstrikea foreignobjectorice jam,thesnow

throwerisdesignedsothattheshearpinsmayshear.Iftheaugerswill

notturn,checkto seeifthepins havesheared.SeeFigure12.

3. Graspthe recoilstarterhandleandslowlypulltheropeout.Atthe

pointwhereitbecomesslightlyhardertopullthe rope,slowly

allowthe ropetorecoil.

4. Pullthestarterhandlewitha firm,rapidstroke.Donotrelease

thehandleandallowit to snapback.Keepafirmholdonthe

starterhandleandallowitto slowlyrecoil.

5. Astheenginewarms,slowlyrotatethechokecontroltotheOFF

position.Iftheenginefalters,quicklyrotatethechokecontrol

backtotheFULL I,_1 positionandthenslowlyintotheOFF

positionagain.

NOTE:Allowtheenginetowarmupfor afewminutesafterstarting.

Theenginewill notdevelopfullpoweruntilit reachesoperating

temperatures.

STOPPING THE ENGINE

Runenginefor a fewminutesbeforestoppingto helpdry off any

moistureonthe engine.

Movethrottlecontrolto STOP1.position.

2. Removethe ignitionkeyandstoreinasafeplace.

3. Wipeallsnowandmoisturefromtheareaaroundtheengineas

wellas the areainandaroundthedrivecontrolandaugercontrol.

Also,engageandreleasebothcontrolsseveraltimes.

NEVERreplacetheaugershearpinswith anythingotherthanOEM

PartNo.738-04124Areplacementshearpins.Anydamagetothe

augergearboxorothercomponentsasaresultof failingtodoso will

NOTbecoveredbyyoursnowthrower'swarranty.

Alwaysturnoffthe snowthrower'sengineand removethekeypriortc

replacingshearpins.

//

TO ENGAGE DRIVE

1. WiththethrottlecontrolintheFast_ position,moveshiftlever

intooneofthesix forward(F)positionsor tworeverse(R)

positions.Selecta speedappropriatefor thesnowconditionsand

a paceyou'recomfortablewith.

Figure12

15

Page 16

ENGINE MAINTENANCE

Beforelubricating,repairing,orinspecting,disengageallcontrols

land stopengine.Waituntilall movingpartshavecometoacomplete

[stop.

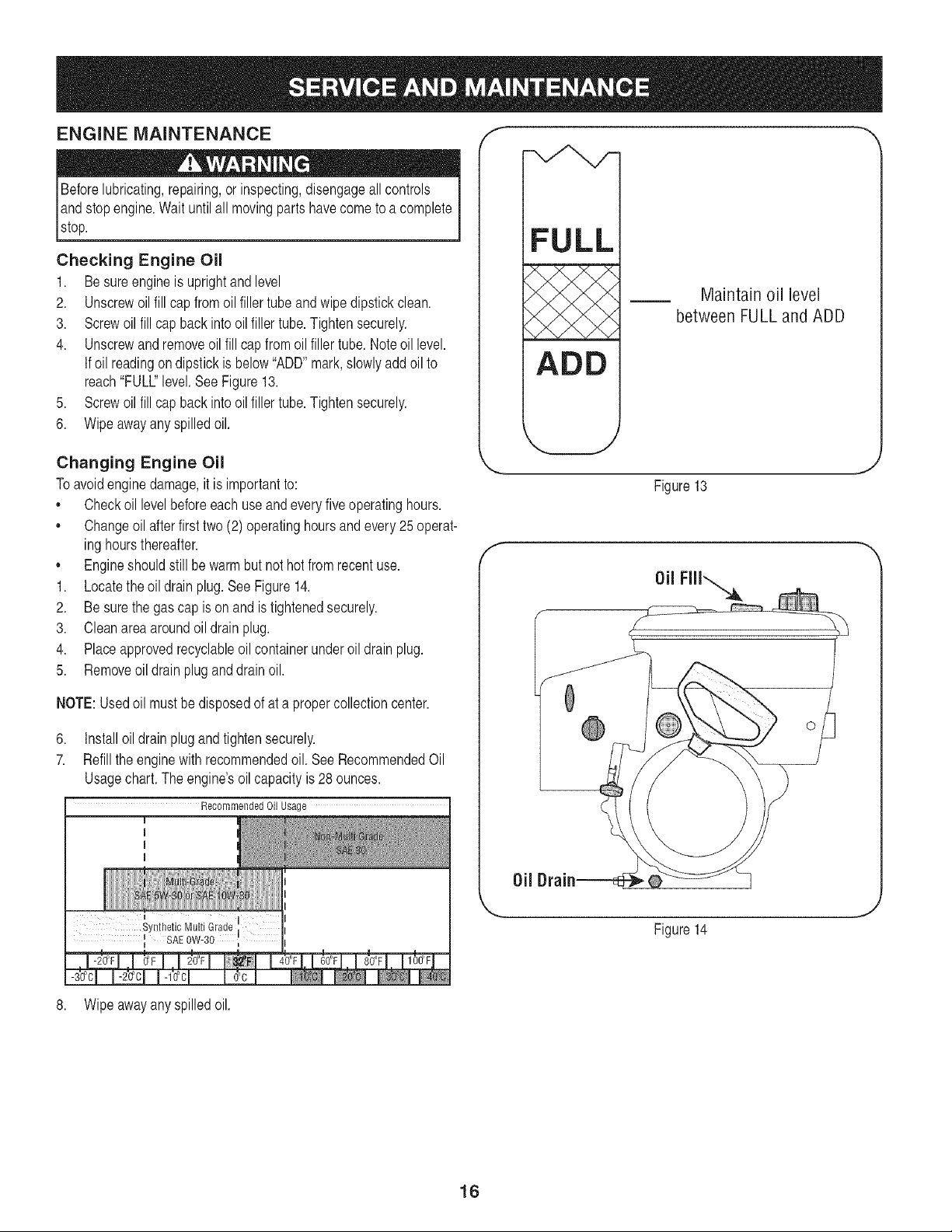

Checking Engine Oil

1. Besureengineisuprightandlevel

2. Unscrewoil fillcapfromoil fillertubeandwipedipstickclean.

3. Screwoil fillcapbackintooilfillertube.Tightensecurely.

4. Unscrewandremoveoilfillcapfromoilfiller tube.Noteoil level.

If oil readingondipstickisbelow"ADD"mark,slowlyaddoilto

reach"FULL"level.SeeFigure13.

5. Screwoil fillcapbackintooilfillertube.Tightensecurely.

6. Wipeawayanyspilledoil.

f --,,

FULL

Maintain oil level

between FULLand ADD

ADD

Changing Engine Oil

Toavoidenginedamage,itisimportantto:

,, Checkoil levelbeforeeachuseandeveryfiveoperatinghours.

,, Changeoilafterfirsttwo (2)operatinghoursandevery25 operat-

inghoursthereafter.

,, Engineshouldstillbewarmbut nothot fromrecentuse.

1. Locatetheoildrainplug.SeeFigure14.

2. Besurethegas cap isonandistightenedsecurely.

3. Cleanareaaroundoil drainplug.

4. Placeapprovedrecyclableoilcontainerunderoil drainplug.

5. Removeoildrainpluganddrainoil.

NOTE:Usedoil mustbedisposedof at a propercollectioncenter.

6. Installoildrain plugandtightensecurely.

7. Refilltheenginewithrecommendedoil.SeeRecommendedOil

Usagechart.The engine'soilcapacityis28 ounces.

Recommended Oil Usage

J

Figure13

f

SAE0W-30

I

8. Wipeawayanyspilledoil.

16

Page 17

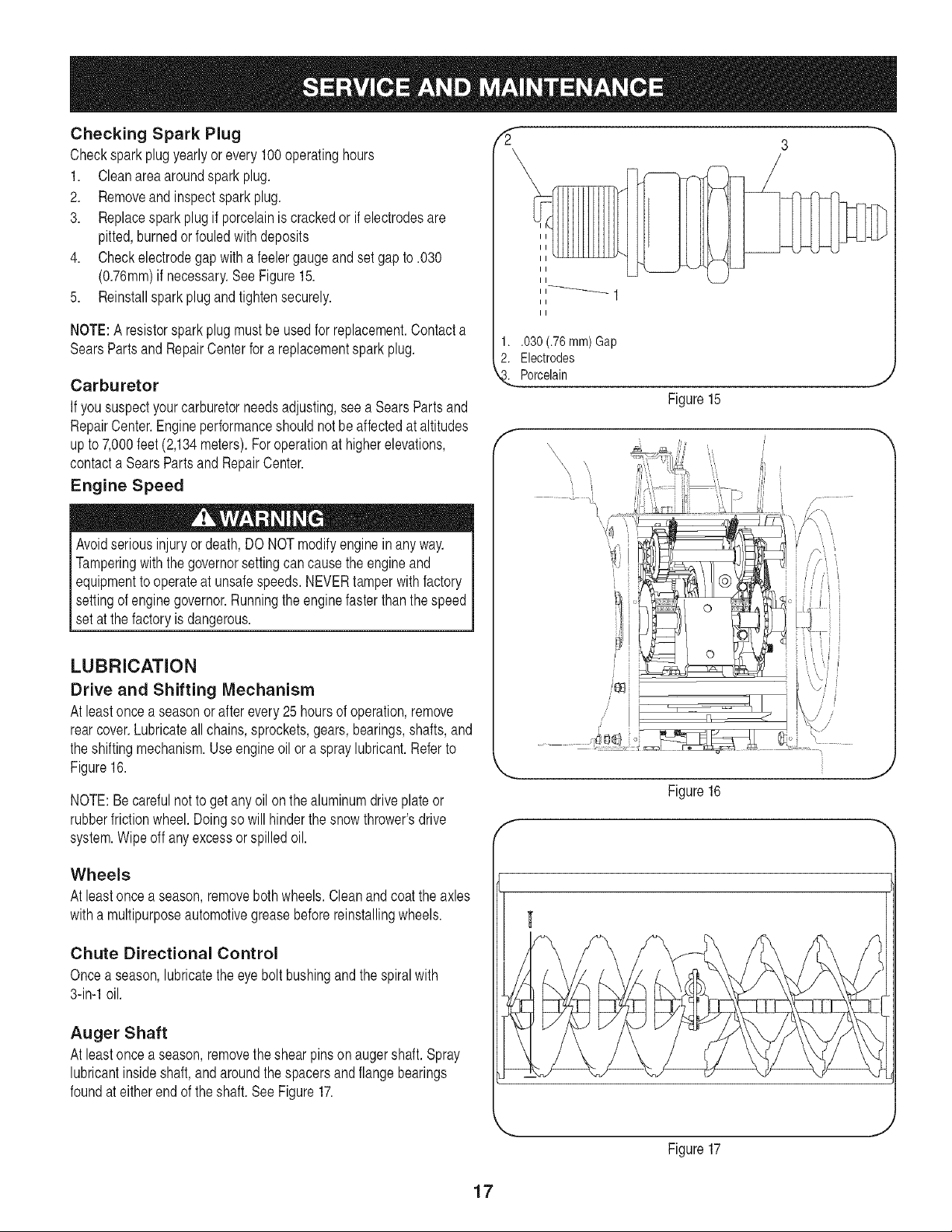

Checking Spark Plug

Checksparkplugyearlyor every100operatinghours

1. Cleanareaaroundsparkplug.

2. Removeand inspectsparkplug.

3. Replacesparkplugif porcelainiscrackedorifelectrodesare

pitted,burnedorfouledwithdeposits

4. Checkelectrodegapwitha feelergaugeandset gapto.030

(0.76ram)ifnecessary.SeeFigure15.

5. Reinstallsparkplugandtightensecurely.

NOTE:A resistorsparkplugmustbeusedforreplacement.Contacta

SearsPartsand RepairCenterfora replacementsparkplug.

Carburetor

If yoususpectyourcarburetorneedsadjusting,seea SearsPartsand

RepairCenter.Engineperformanceshouldnotbe affectedataltitudes

upto7,000feet(2,134meters).Foroperationathigherelevations,

contacta SearsPartsandRepairCenter.

Engine Speed

Avoidseriousinjuryordeath,DONOTmodifyengineinanyway.

Tamperingwiththegovernorsettingcancausetheengineand

equipmenttooperateat unsafespeeds.NEVERtamperwithfactory

settingof enginegovernor.Runningtheenginefasterthanthespeed

set at thefactoryisdangerous.

LUBRICATION

Drive and Shifting Mechanism

Atleastoncea seasonorafterevery25hoursof operation,remove

rearcover.Lubricateall chains,sprockets,gears,bearings,shafts,and

theshiftingmechanism.Useengineoil or aspraylubricant.Referto

Figure16.

NOTE:Becarefulnotto getany oilonthealuminumdriveplateor

rubberfrictionwheel.Doingsowillhinderthesnowthrower'sdrive

system.Wipeoff anyexcessorspilledoil.

3

II

II

1..030 (.76ram)Gap

2. Electrodes

Porcelain

Figure15

f -'-,

,,, <¢_._ , , ,

,,,, _,,,

•••L.i,

,,,, _ ,,, _ [

,, ,_ [

f

I

Figure16

|¢

J

Wheels

Atleastoncea season,removebothwheels.Cleanandcoattheaxles

withamultipurposeautomotivegreasebeforereinstallingwheels.

Chute Directional Control

Oncea season,lubricatetheeyebolt bushingandthespiralwith

3-in-1oil.

Auger Shaft

Atleastoncea season,removethe shearpinsonaugershaft.Spray

lubricantinsideshaft,andaroundthespacersandflangebearings

foundat eitherendoftheshaft.SeeFigure17.

J

Figure17

17

Page 18

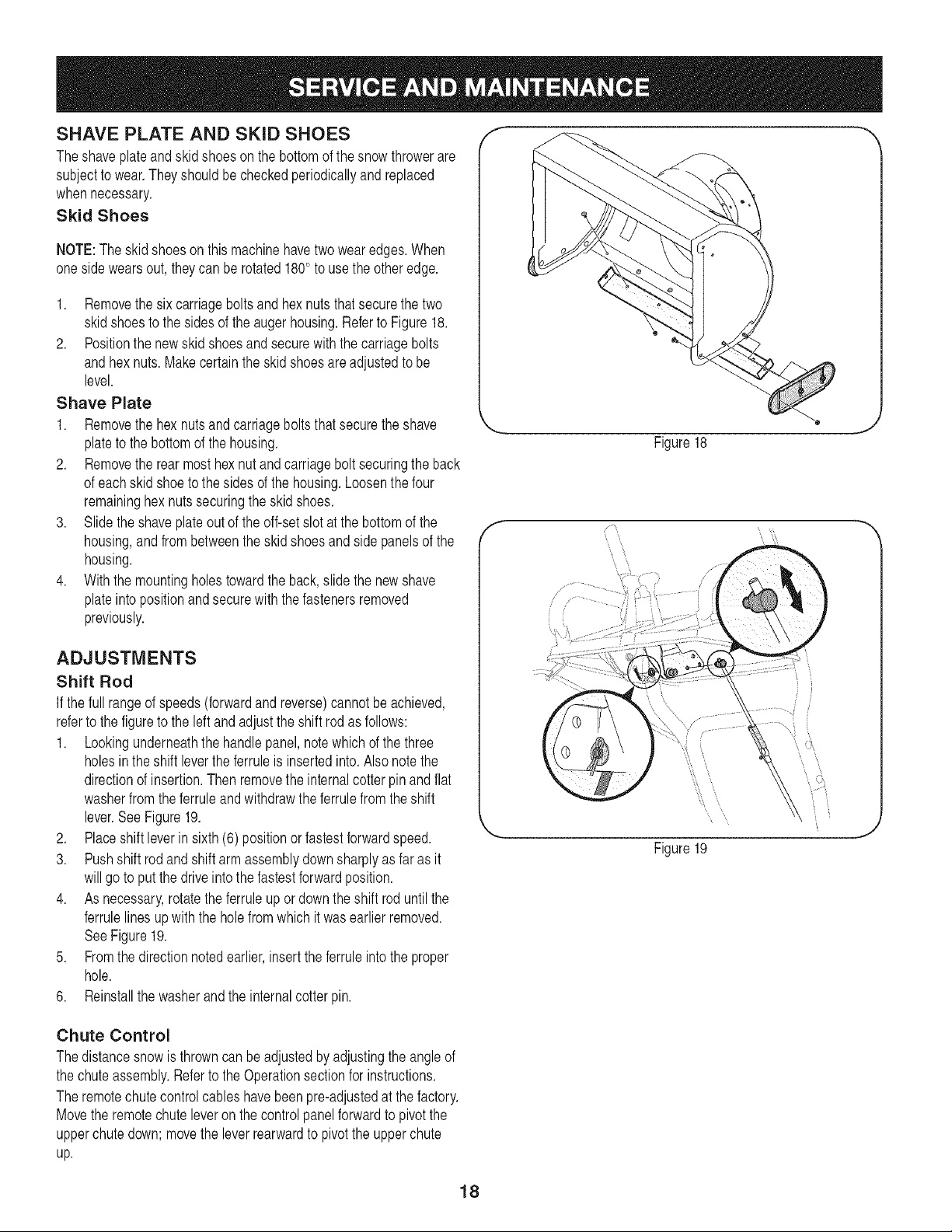

SHAVE PLATE AND SKID SHOES

Theshaveplateandskidshoesonthebottomofthesnowthrowerare

subjectto wear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

Skid Shoes

NOTE:Theskidshoesonthismachinehavetwowearedges.When

onesidewearsout,theycan berotated180° to usetheotheredge.

1. Removethesixcarriageboltsandhexnutsthatsecurethe two

skidshoestothesidesoftheaugerhousing.RefertoFigure18.

2. Positionthenewskidshoesandsecurewiththecarriagebolts

andhexnuts.Makecertaintheskidshoesareadjustedtobe

level.

Shave Plate

1. Removethe hexnutsandcarriageboltsthatsecuretheshave

plateto the bottomof the housing.

2. Removethe rearmosthexnutandcarriageboltsecuringthe back

ofeachskidshoetothesidesofthehousing.Loosenthefour

remaininghexnutssecuringthe skidshoes.

3. Slidetheshaveplateoutoftheoff-setslot at thebottomofthe

housing,andfrombetweentheskidshoesandsidepanelsofthe

housing.

4. Withthemountingholestowardthe back,slidethenewshave

plateintopositionandsecurewith thefastenersremoved

previously.

f m

Figure18

ADJUSTMENTS

Shift Rod

If the fullrangeofspeeds(forwardandreverse)cannotbeachieved,

referto the figureto the leftandadjustthe shiftrodasfollows:

1. Lookingunderneaththehandlepanel,notewhichofthethree

holesintheshiftlevertheferruleisinsertedinto.Also notethe

directionofinsertion.Thenremovetheinternalcotterpin andflat

washerfromtheferruleandwithdrawtheferrulefromtheshift

lever.SeeFigure19.

2. Placeshift leverinsixth(6)positionor fastestforwardspeed.

3. Pushshift rodandshiftarmassemblydownsharplyas far asit

willgo toput thedriveintothefastestforwardposition.

4. Asnecessary,rotatetheferruleupor downtheshiftroduntilthe

ferrulelinesupwiththeholefromwhichitwasearlierremoved.

SeeFigure19.

5. Fromthedirectionnotedearlier,inserttheferruleintotheproper

hole.

6. Reinstallthewasherandtheinternalcotterpin.

Chute Control

Thedistancesnowisthrowncanbeadjustedbyadjustingtheangleof

thechuteassembly.Referto theOperationsectionfor instructions.

Theremotechutecontrolcableshavebeenpre-adjustedatthe factory.

Movetheremotechuteleveron thecontrolpanelforwardto pivotthe

upperchutedown;movethe leverrearwardto pivottheupperchute

up.

\\

\

\ \

18

Page 19

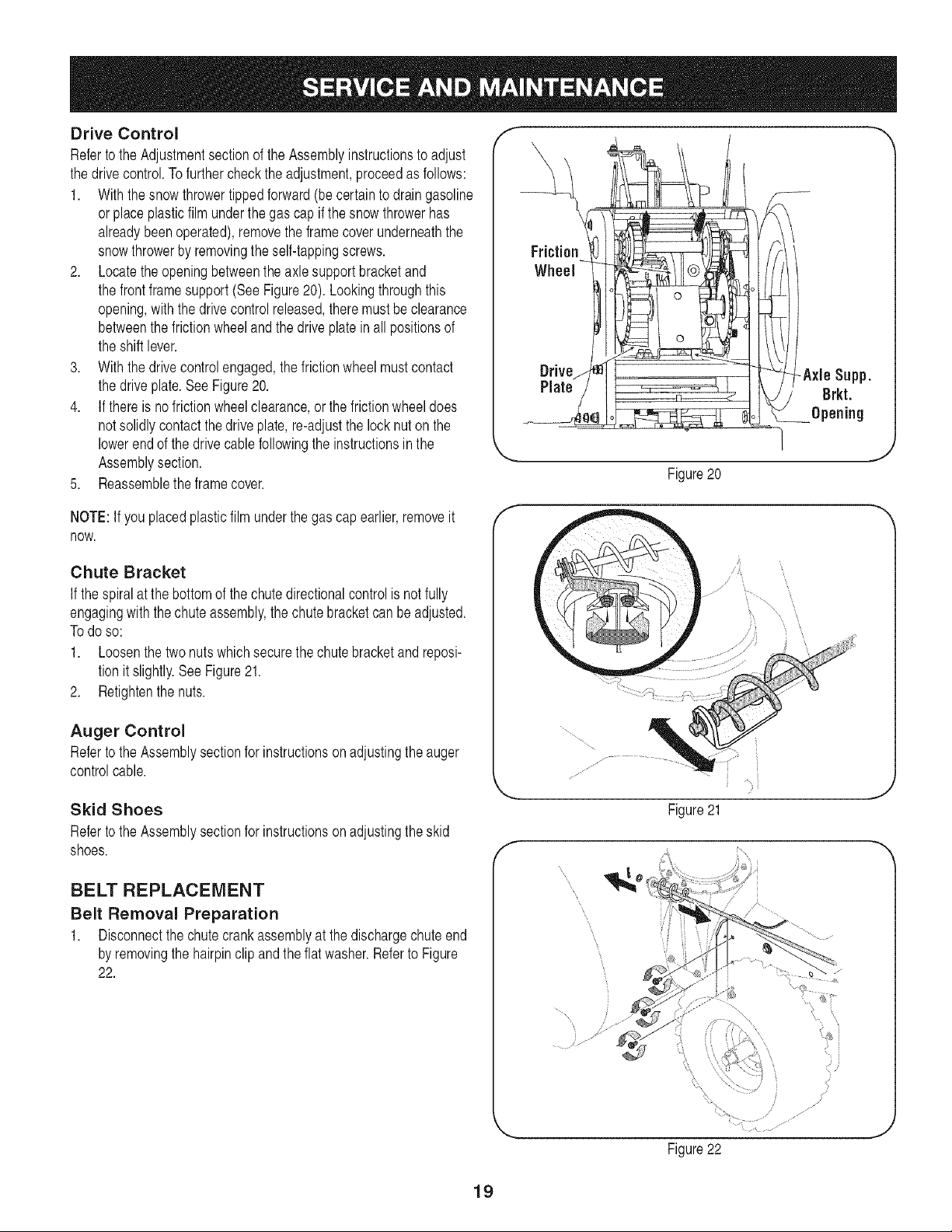

Drive Control

RefertotheAdjustmentsectionoftheAssemblyinstructionsto adjust

thedrivecontrol.Tofurtherchecktheadjustment,proceedasfollows:

1. Withthesnowthrowertippedforward(becertaintodraingasoline

orplaceplasticfilm underthegascapifthesnowthrowerhas

alreadybeenoperated),removetheframecoverunderneaththe

snowthrowerbyremovingtheself-tappingscrews.

2. Locatetheopeningbetweentheaxlesupportbracketand

thefrontframesupport(SeeFigure20). Lookingthroughthis

opening,withthe drivecontrolreleased,theremustbeclearance

betweenthefrictionwheelandthedriveplatein allpositionsof

theshiftlever.

3. Withthedrivecontrolengaged,thefrictionwheelmustcontact

thedriveplate.SeeFigure20.

4. If thereis nofrictionwheelclearance,orthefrictionwheeldoes

notsolidlycontactthedriveplate,re-adjustthelocknutonthe

lowerendofthedrivecablefollowingtheinstructionsinthe

Assemblysection.

5. Reassembletheframecover.

f --,,

Friction

Wheel

Drive_qj

Plate!

J

Figure20

NOTE:If youplacedplasticfilmunderthegascapearlier,removeit

now.

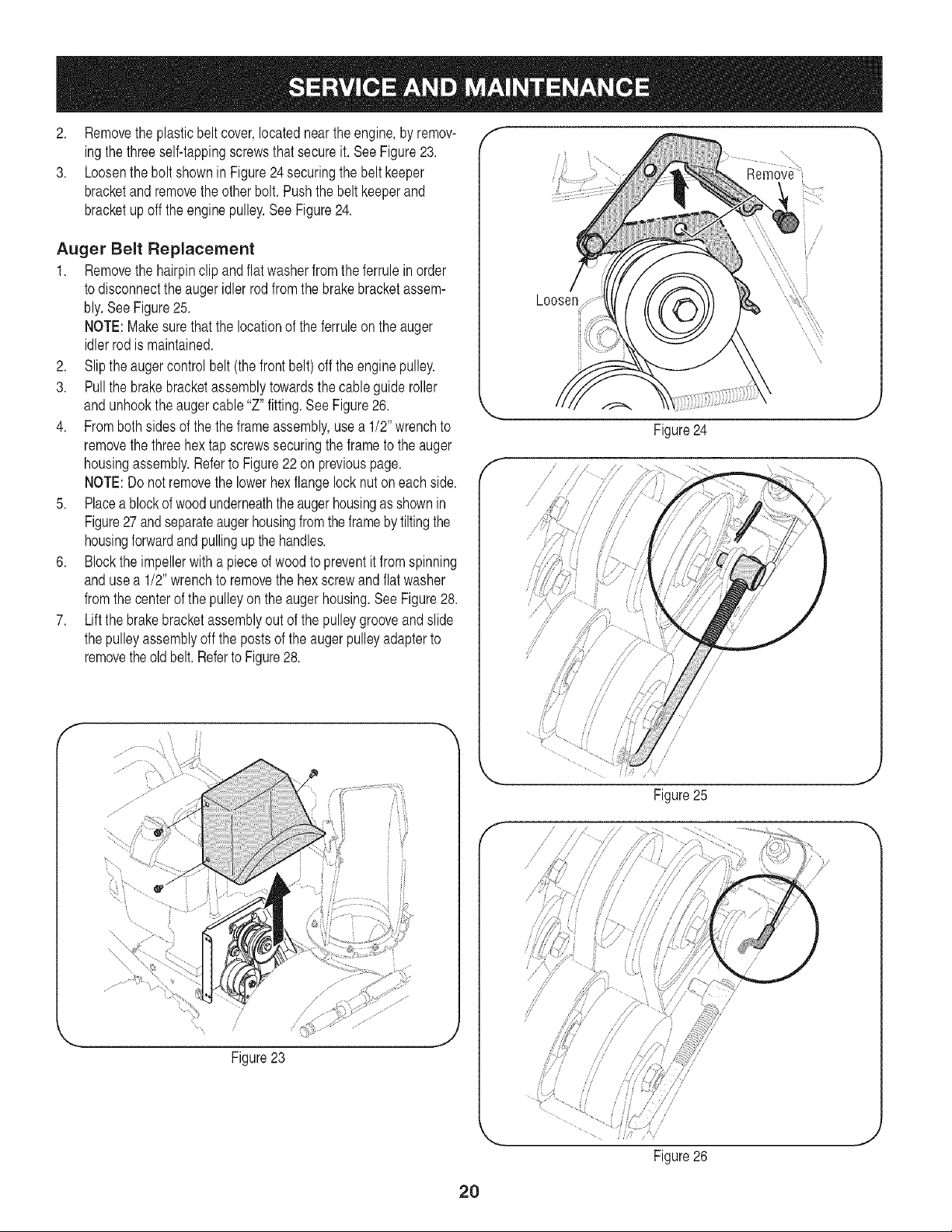

Chute Bracket

If thespiralatthebottomofthechutedirectionalcontrolisnotfully

engagingwiththechuteassembly,thechutebracketcanbeadjusted.

Todoso:

1. Loosenthetwonutswhichsecurethechutebracketandreposi-

tionitslightly.SeeFigure21.

2. Retightenthenuts.

Auger Control

RefertotheAssemblysectionforinstructionsonadjustingtheauger

controlcable.

Skid Shoes

RefertotheAssemblysectionforinstructionsonadjustingtheskid

shoes.

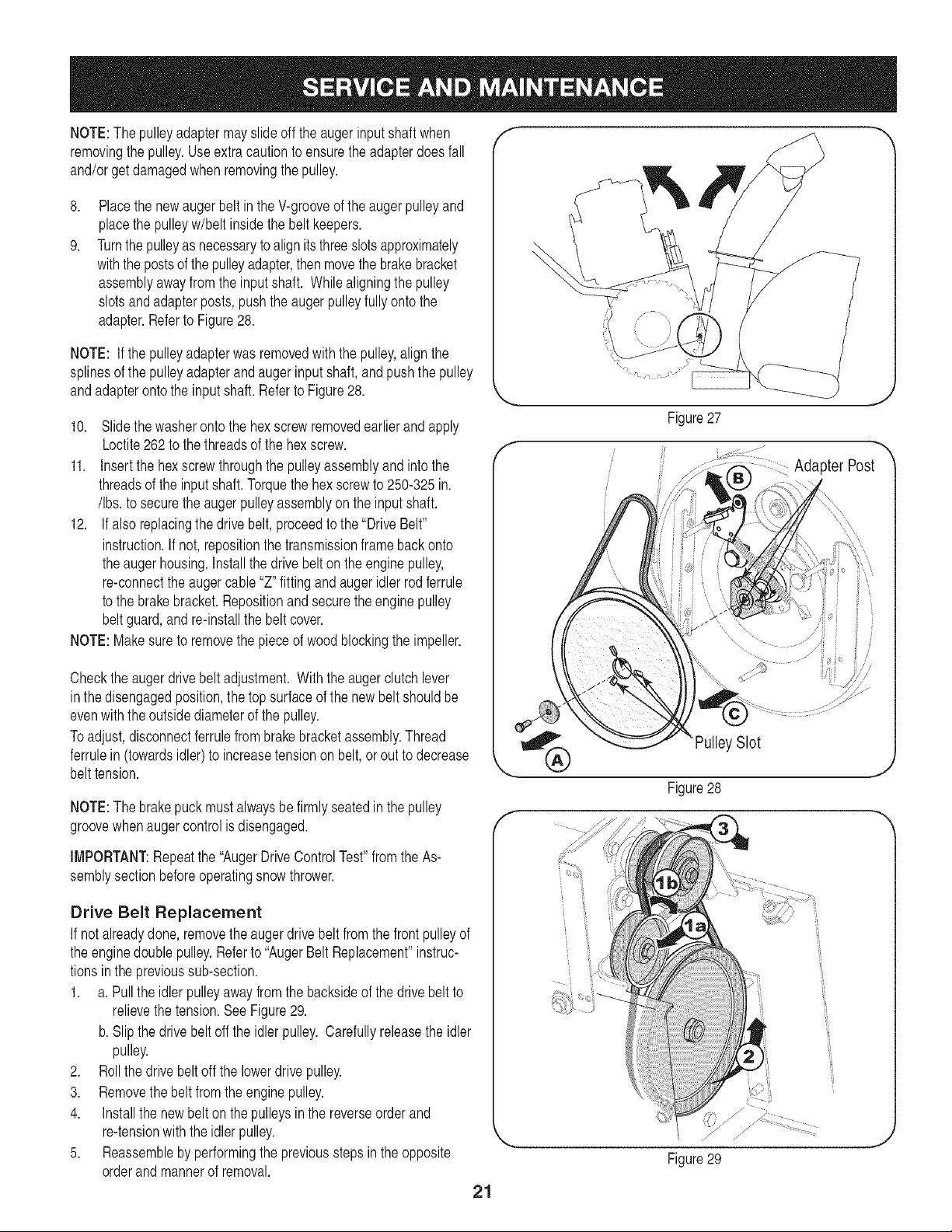

BELT REPLACEMENT

Belt Removal Preparation

1. Disconnectthechutecrankassemblyat the dischargechuteend

byremovingthehairpinclipandtheflat washer.RefertoFigure

22.

f

/

J

Figure21

f

19

Figure22

....JJ

i/

jl

J

Page 20

2. Removethe plasticbeltcover,locatedneartheengine,byremov-

ingthethreeself-tappingscrewsthatsecureit.SeeFigure23.

3. Loosentheboltshownin Figure24securingthebeltkeeper

bracketandremovetheotherbolt. Pushthe beltkeeperand

bracketupofftheenginepulley.SeeFigure24.

Auger Belt Replacement

1. Removethe hairpinclipandflatwasherfromthe ferruleinorder

todisconnecttheaugeridlerrodfromthe brakebracketassem-

bly.SeeFigure25.

NOTE:Makesurethatthe locationoftheferruleonthe auger

idlerrodis maintained.

2. Sliptheaugercontrolbelt(thefrontbelt)offtheenginepulley.

3. Pullthebrakebracketassemblytowardsthecableguideroller

andunhooktheaugercable"Z"fitting.SeeFigure26.

4. Frombothsidesofthe the frameassembly,usea 1/2" wrenchto

removethethreehex tapscrewssecuringtheframetothe auger

housingassembly.Referto Figure22on previouspage.

NOTE:Do notremovethelowerhexflangelocknutoneachside.

5. Placeablockofwoodunderneaththe augerhousingasshownin

Figure27andseparateaugerhousingfromtheframebytiltingthe

housingforwardandpullingupthehandles.

6. Blockthe impellerwithapieceofwoodtopreventitfromspinning

andusea 1/2"wrenchto removethehexscrewandflatwasher

fromthecenterofthe pulleyon theaugerhousing.SeeFigure28.

7. Liftthebrakebracketassemblyoutofthepulleygrooveandslide

thepulleyassemblyoffthe postsof the augerpulleyadapterto

removetheoldbelt.RefertoFigure28.

f --,,

/

/

Loosen

/

//

Figure24

i

,,.-/"

Figure23

20

//

Figure25

f

/" /, //

// //

// ,/

/

J

Figure26

Page 21

NOTE:Thepulleyadaptermayslideoffthe augerinputshaftwhen

removingthepulley.Useextracautiontoensuretheadapterdoesfall

and/orget damagedwhenremovingthepulley.

8,

Placethe newaugerbeltin the V-grooveof the augerpulleyand

placethe pulleyw/beltinsidethe beltkeepers.

9.

Turnthepulleyasnecessarytoalignitsthreeslotsapproximately

withthepostsofthepulleyadapter,thenmovethe brakebracket

assemblyawayfromtheinputshaft. Whilealigningthepulley

slotsandadapterposts,pushtheaugerpulleyfullyontothe

adapter.Referto Figure28.

NOTE: If thepulleyadapterwasremovedwiththepulley,alignthe

splinesofthepulleyadapterandaugerinputshaft,andpushthepulley

andadapterontothe inputshaft.Referto Figure28.

10. Slidethewasherontothe hexscrewremovedearlierandapply

Loctite262to the threadsofthehexscrew.

11. Insertthe hexscrewthroughthepulleyassemblyandintothe

threadsoftheinputshaft.Torquethe hexscrewto 250-325in.

/Ibs.tosecuretheaugerpulleyassemblyontheinputshaft.

12. If alsoreplacingthedrivebelt,proceedtothe"DriveBelt"

instruction.If not,repositionthetransmissionframebackonto

theaugerhousing.Installthedrivebelton theenginepulley,

re-connectthe augercable "Z"fittingandaugeridlerrodferrule

tothebrakebracket.Repositionandsecuretheenginepulley

beltguard,andre-installthe beltcover.

NOTE:Makesureto removethepieceof woodblockingthe impeller.

f

Adapter Post

Checktheaugerdrivebeltadjustment.Withtheaugerclutchlever

inthedisengagedposition,thetopsurfaceof thenewbelt shouldbe

evenwiththeoutsidediameterof thepulley.

Toadjust,disconnectferrulefrombrakebracketassembly.Thread

ferrulein (towardsidler)toincreasetensiononbelt,orouttodecrease

belttension.

NOTE:Thebrakepuckmustalwaysbefirmlyseatedinthe pulley

groovewhenaugercontrolisdisengaged.

IMPORTANT:Repeatthe "AugerDriveControlTest"fromtheAs-

semblysectionbeforeoperatingsnowthrower.

Drive Belt Replacement

If notalreadydone,removethe augerdrivebeltfromthefrontpulleyof

theenginedoublepulley.Referto"AugerBeltReplacement"instruc-

tionsinthe previoussub-section.

1. a.Pulltheidlerpulleyawayfromthebacksideofthedrivebelt to

relievethetension.SeeFigure29.

b.Slipthedrivebelt offtheidler pulley.Carefullyreleasetheidler

pulley.

2. Rollthedrivebeltoff thelowerdrivepulley.

3. Removethebeltfromtheenginepulley.

4. Installthenewbelton thepulleysinthereverseorderand

re-tensionwith theidler pulley.

5. Reassembleby performingthepreviousstepsintheopposite

orderandmannerof removal.

,ySlot

Figure28

// ,/ j

Figure29

21

Page 22

CHANGING FRICTION WHEEL

Therubberonthefrictionwheelissubjecttowearandshouldbe

checkedafterthefirst25hoursofoperation,andperiodicallythere-

after.Replacethefrictionwheelifanysignsofwearorcrackingare

found.

1. Drainthegasolinefromthesnowthrower,or placea pieceof

plasticunderthe gas cap.

2. Tipthesnowthrowerupandforward,sothat itrestsonthe

housing.

3. Removescrewsfromtheframecoverunderneaththesnow

thrower(referto Figure30). Removetherightwheelfromthe

axle.

4. Usinga 3/4"wrench,holdthe hex shaftandremovethe hex

screwandbellevillewasherand bearingfromleft sideofthe

frame.Referto Figure31.

5. Holdingthefrictionwheelassembly,slidethe hex shaftout of

thefriction wheelassemblyandtherightside oftheframe.The

spacerontheleftsideofthehexshaft will falland thesprocket

shouldremainhanginglosein thechain.

6. Liftthefrictionwheelassemblyout betweentheaxleshaftand

thedrive shaftassemblies.

7. Removefourscrewssecuringthefrictionwheeltothehub

assembly(referto Figure32).Discardoldfrictionwheel.

8. Reassemblethenewfrictionwheelontothehubassembly,

tighteningthefourscrewsin rotationandwithequalforce.It is

importanttoassemblethefrictionwheelsymmetricallyforproper

functioning.

f --,,

[_ ?q ,gr

i f f _

Figure30

f

RemoveHexScrew

BellevilleWasher

[,

FrictionWheelAss'y.

SlideHex

ShaftOut

RightSide

22

RexShaft

,J

Figure31

,J

Figure32

Page 23

9. Repositionthefrictionwheelassemblyinthe snowthrowerframe.

Insertthe pinfromtheshiftarm assemblyintothe frictionwheel

assemblyandholdassemblyinposition.RefertoFigure33.

10. Slidethehexshaftthroughtherightsideoftheframetowardthe

leftsideandthroughthefrictionwheelassembly.

11. Aftermakingcertainthatthechainison boththe largeandthe

smallsprocket,alignthe hexshaftwiththehexhubofthesmall

sprocket,andslidetheshaftthroughthesprocket.

NOTE:If thesprocketfellfromthesnowthrowerwhile removingthe

hexshaft,placethe sprocketon thechain.Realignthesprocketon the

chainwiththehexhubfacingtherightsideof unit.Positionthehex

hubofthesprockettowardthefrictionwheelwhenslidingthesprocket

ontothe hexshaft.

12. Slidethespacerontotheendofthe hexshaft.

13. Alignthebearingon therightendof the hexshaftwiththe hole

in the rightside oftheframe,thenpushthehexshafttotheleft

intopositionintheframe.

14. Slidethebearingontotheleftendof the hexshaftandpressinto

theholeontheleftside theframe.

15. Placethe bellevillewasher(roundedsidetowardhead)ontothe

hexscrew removedearlier,and insertthescrewintothethreaded

holeofthehexshaft.

16. Graduallytightenthehexscrewto fullyseatthe bearingsineach

sideof theframeandtosecurethehexshaft.

MAINTENANCE SCHEDULE

©

Figure33

17. Positionthe framecoveron thebottomoftheframeand secure

withtheself-tappingscrews.Pivotthesnowthrowerdowntoit

normaloperatingposition.

NOTE:Ifyouplacedplasticfilmunderthegascap,becertainto

removeit.

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsorrepairs.

EachUse

1st5- 8hours

25 hours

50 hours

Annuallyor100hours

BeforeStorage

' Underheavyloador inhightemperatures

1. Engineoillevel

2. Looseormissinghardware

3. Unitandengine.

1. Engineoil

1. Engineoi11

2. Aircleaner

3. Controllinkagesand pivots

1. Engineoil

1. Sparkplug

1. Fuelsystem

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Change

2. Cleanor replace

3. Lubewithlightoil

1. Change

1. Clean,replace,re-gap

1. Runengineuntil itstopsfromlackof

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumntokeeptrackof

completedmaintenancetasks.To locate the nearest Sears Service

Center or to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

fueloraddagasolineadditivetothe

gasin thetank.

23

Page 24

If the snowthrowerwill notbeusedfor30daysor longer,or if itistheendofthesnowseasonwhenthelastpossibilityof snowisgone,the

equipmentneedsto bestoredproperly.Followstorageinstructionsbelowto ensuretopperformancefromthesnowthrowerformanymoreyears.

PREPARING ENGINE

Short=Term Storage

It is importanttopreventgumdepositsfromforminginessentialfuel

systempartsof the enginesuchasthecarburetor,fuel filter,fuelhose,

ortankduringshort-termstorage(15-30days).Topreventthis,treat

thefuelsystemusingafuelstabilizer.

Fuelstabilizer(suchasSTA-BILTM or ULTRA-FRESHTM) is anaccept-

ablealternativein minimizingthe formationof fuelgumdepositsduring

storage.Addstabilizertogasolineinfueltankorstoragecontainer.

Alwaysfollowmixratiofoundonstabilizercontainer.Runengineat

least10minutesafteraddingstabilizertoallowitto reachthecarbure-

tor.

Neverstoresnowthrowerwithfuelin tankindoorsorin poorlyventi-

latedareas,wherefuelfumesmayreachanopenflame,sparkor pilo

ghtason afurnace,waterheater,clothesdryerorgas appliance.

Alcoholblendedfuels(calledgasoholor usingethanolor methanol)

canattractmoisturewhichleadstoseparationandformationofacids

duringstorage.Acidicgascandamagethefuelsystemofan engine

[wh e nstorage.

PREPARING SNOW THROWER

,, Whenstoringthe snowthrowerin anunventilatedor metalstor-

ageshed,careshouldbetakentorustprooftheequipment.Using

a light oilorsilicone,coattheequipment,especiallyanychains,

springs,bearingsandcables.

,, Removealldirt fromexteriorof engineand equipment.

,, Followlubricationrecommendations.

,, Storeequipmentin a clean,dryarea.

Long=Term Storage

Toavoidengineproblems,thefuel systemshouldbeemptiedbefore

storagefor 30daysor longer.

Fuelleft inengineduringwarmweatherdeterioratesandwillcause

seriousstartingproblems.

1. Runtheengineuntilthefueltankisemptyanditstops duetolack

offuel.Donotattemptto pourfuelfromtheengine.

carburetor inthefueltank

pNeveruseengineor cleaningproducts or

ermanentdamagemayoccur, j

2. Removethesparkplugandpourone (1)ounceof engineoil

throughthesparkplugholeintothe cylinder.Coversparkplughole

witharagandcranktheengineseveraltimestodistributetheoil.

Replacesparkplug.

J

/

24

Page 25

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

a completestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesdurin(

operationorwhileperforminganyadjustmentsorrepairs.

Thissectionaddressesminor serviceissues,Tolocatethe nearestSears ServiceCenter or to scheduleservice,simply contactSears

at 1-800-4-MY-HOME®.

o =

Enginefailsto start

Enginerunserratically

Engineoverheats

Excessivevibration

1. Chokecontrolnotin ONposition

2. Sparkplugwiredisconnected

3. Faultysparkplug

4. Fueltankemptyorstalefuel

5. Enginenotprimed.

6. Safetykeynotinserted.

1. Enginerunningon CHOKE

2. Stalefuel

3. Wateror dirtinfuelsystem

4. Carburetoroutof adjustment

1. Carburetornotadjustedproperly

1. Loosepartsordamagedauger

1. MovechokecontroltoONposition.

2. Connectwiretosparkplug.

3. Clean,adjustgap,or replace.

4. Filltankwithclean,freshgasoline.

5. PrimeengineasinstructedintheOperationSection.

6. Insertkeyfullyintothe switch.

1. MovechokecontroltoOFFposition.

2. Filltankwithclean,freshgasoline.

3. Drainfueltank.Refillwith freshfuel.

4. ContactyourSearsParts&RepairCenter.

1. ContactyourSearsParts& RepairCenter.

1. Stopengineimmediatelyanddisconnectsparkplug

wire.Tightenall boltsandnuts.If vibrationcontinues,

haveunit servicedbya SearsParts& RepairCenter.

Lossof power 1. Sparkplugwireloose.

2. Gascapventholeplugged.

1. Connectandtightensparkplugwire.

2. Removeiceandsnowfromgas cap.Becertainvent

holeisclear.

Unitfailsto propelitself 1. Drivecablein needofadjustment

1. Adjustdrivecontrolcable.Referto Serviceand

Maintenancesection.

2. Drivebeltlooseordamaged

2. Replacedrivebelt.RefertoServiceand Mainte-

nancesection.

Unitfailsto dischargesnow 1. Chuteassemblyclogged.

1. Stopengineimmediatelyanddisconnectsparkplug

wire.Cleanchuteassemblyandinsideofauger

housingwithclean-outtool ora stick.

2. Foreignobjectlodgedinauger.

2. Stopengineimmediatelyanddisconnectsparkplug

wire.Removeobjectfromaugerwithclean-outtool

or astick.

3. Augercableinneedofadjustment.

3. Adjustaugercontrolcable.Referto Assembly

section.

4. Augerbeltlooseordamaged.

4. Replaceaugerbelt.Referto ServiceandMainte-

nancesection.

5. Shearpin(s)sheared.

5. Replacewithnewshearpin(s).

25

Page 26

Craftsman Snow Thrower Model 247.88045

26

Page 27

Craftsman Snow Thrower Model 247.88045

D" Q 0

05244B Housing,Bearing

2. 05845C Housing,Bearing

3. 618-04515 GearBoxAssembly,Auger

4. 618-0281A BracketAssy,AugerBrake

5. 684-0090B Impellar,16"

6. 684-04224 Housing,Auger- 45"

7. 684-04151 SpiralAssy,LH

8. 684-04152 SpiralAssy,RH

9. 710-1245B Screw,5/16-24x.875

10. 710-0389 Bolt,Carriage,3/8-16x .750

11. 710-0451 Screw,Carriage,5/16-18x .75

12. 710-0459A Scr,HexCap,3/8-24x1.5

13. 710-0376 Scr,HexCap,5/16-18x 1.00

14. 710-04484 Screw,5/16-18x .750

15. 726-04012 Nut,Push

16. 629-0071 ExtensionCord,110V

17. 710-3168 Bolt,Carriage,3/8-16x 1.0

18. 710-04606 Screw,5/16-18x .4300

19. 711-0677 Ferrule

20. 712-0116 Nut,HexLock,3/8-24

21. 712-04063 Nut,FlngeLk,5/16-18

22. 712-04065 Nut,Fig Lk,3/8-16

23. 741-0217 Sleeve

24. 714-0104 Pin,InternalCotter

25. 714-0126 Key,HiPro,3/16x3/4

26. 714-0135 Key,Woodruff,I/4x 3/4

27. 714-04040 Pin,BowtieCotter

28. 715-0118 Pin,Spirol,5/16x 1.75

29. 725-0157 Tie,Cable

30. 731-1696A Adapter,Chute,6"

31. 738-0275 Shf,Gear,Worm

32. 731-05163 Spacer,1.0x 1.5x 1

33. 731-2635 Clip,Mounting

34. 731-2643 Tool,Cleanout

35. 732-0858 Spring,Extension

36. 736-0159 Washer,.349x .879x.063

37. 736-0174 Washer,.625x .885x.015

38. 736-0505 Washer,Flat,.34x 1.50x .150

D _ 0 Q

750-04020 Spacer,1.004x 1.375x .25

40. 721-0146 OilSeal

41. 736-3008 Washer,.344x .75x.12

42. 736-3046A Washer,1.01x 1.86x.06

43. 738-0281 Screw,Shoulder,.625x.17

44. 738-04155 Pin,Shear,.25x 1.75

45. 738-04159 Axle,Spiral,45"

46. 741-0192 Bearing,Flangew/Flats

47. 741-04024 Bearing,SelfAligning

48. 741-0475 Bushing,Nylon

49. 741-0494 Bushing,Flange,1.051x 1.16

50. 747-0980A Rod,AugerIdler

51. 721-0325 Plug

52. 754-0222A V Belt,l/2 x44

53. 756-0178 Pulley,FlatIdler,2.75OD

54. 756-04244A Pulley,AugerDrive,10.0

55. 784-0385B Bracket,AugerIdler

56. 790-00264A Bracket,GearBox Support

57. 784-5123 Bracket,ChuteCrank

58. 710-0276 Screw,Carriage,5/16-18x 1.00

59. 790-00181 DriftCutter

60. 790-00280 Plate,Shave,45"

61. 741-0184 Brg,Thrust

62. 784-5697 Shoe,Skid

63. 749-04384 SupportTube

64. 710-3008 Screw,5/16-18x.75

65. 748-04067A Pulley,Adapter,.75Dia.

66. 618-0246 HsgAssyAugerRH(Inc.40&70)

67. 618-0247 HsgAssyAugerLH(Inc.40&70)

68. 710-1260A Screw,LD,5/16-18x .750

69. 711-04714 Shf,Drive,Auger

70. 741-0670 FlangeBearing

71. 716-0111 Ext,Ret,Ring

72. 717-1425 Gear,Worm,LH

73. 721-0145 Seal,Oil

74. 736-0266 Washer,Flat,1.52IDx 2.00D

75. 736-0291 Washer,Flat,.88IDx.38OD

76. 717-0299 Gear,Worm,DblThread

27

Page 28

Craftsman Snow Thrower Model 247.88045

®

\

28

Page 29

Craftsman Snow Thrower Model 247.88045

D" i Q

625-0007A Assembly,Light

2. 646-0012 CableAss'y,Auger/Drive

3. 684-0053B Crank,Chute,26.0

4. 705-5218 Handle,Engage,RH

5. 705-5219 Handle,Engage,LH

6. 705-5266 Bracket,ChuteCrank

7. 710-0458 Screw,Cam, 5/16-18x 1.75

8. 710-0572 Screw,Cam, 5/16-18x 2.5

9. 710-1003 Screw,#10-16x .625

10. 710-1625 Screw,#10-24x 1.75

11. 710-04682 Screw,Hex,3/8-16x2.00

12. 710-3118 Screw,Hex,3/8-16x 1.00

13. 710-3015 Screw,Hex,1/4-20x.75

14. 711-0677 Ferrule,5/16-18x.312Dia

15. 784-5679 Brkt.,HandleSupport- LH

16. 712-04064 Nut,HexFlange,1/4-20

17. 712-3068 Nut,HexLock,5/16-18GR5

18. 714-0101 Pin,InternalCotter

19. 714-0104 Pin,InternalCotter

20. 720-0201A Knob,Crank

21. 720-04039 Knob,Shift

22. 720-0284 Knob,Wing,5/16-18

23. 725-0157 Tie,Cable

24. 784-5682 Brkt.,HandleSupport- RH

25. 784-5681 Brkt.,HandleSupport- LH

26. 726-0100 Cap,Push,3/8

27. 731-2298 Panel,Handle

28. 736-0105 Wash,Bell,.375x .87x .063

29. 736-0185 Wash,Fl.,.375x .738x.063

30. 736-0242 Wash,Bell,.34x .872x .06

31. 736-0275 Wash,FI,.344x .688x .065

32. 741-0475 Bushing,Plastic,.38ID

33. 746-0950A CableAssembly,Trigger

34. 747-0624 Rod,ChuteCrank

35. 747-0983A Rod,LowerShift

36. 747-0997 Rod,UpperShift

37. 784-5680 Brkt.,HandleSupport- RH

38. 749-0989A Handle,UpperLH

39. 749-0990A Handle,UpperRH

40. 749-0991 Handle,Lower

41. 750-0963 Connector,ShiftRod

D _ O Q

684-0102A Panel,Handle

43. 710-0276 Screw,Carr,5/16-18x1.0

44. 710-0458 Screw,Carr.,5/16-18x 1.75

45. 710-0459A Screw,Hex,3/8-24x 1.5

46. 710-0597 Screw,Hex,1/4-20x 1.0

47. 710-0599 Screw,Hx,1/4-20x.5

48. 710-0805 Screw,Hex,5/16-18x 1.5

49. 710-0895 Screw,Hx,1/4-15x.75

50. 711-0653 Pin,Clevis,.312x1.0

51. 712-0116 Nut,Insert,3/8-24

52. 712-04063 Nut,FlngeLk,5/16-18

53. 714-0507 Pin,Cotter,3/32x .75

54. 731-08460 Chute,Upper,6.0

55. 731-0851A FlangeKeeper,Chute

56. 731-0903D Chute,Lower

57. 731-13130 Cbl.Guide,ChuteTilt

58. 732-0145 Spring,Compression

59. 732-0193 Spring,Compression

60. 732-0746 Spring,Torsion

61. 735-0199A Bumper,Rubber

62. 784-5619B Handle,Shift

63. 736-0231 Wash,FI,.344x 1.125x.12

64. 736-0119 Washer,Lock,5/16

65. 736-0509 Wash,FI,.35Sqx .72x .134

66. 746-0902 Cable,ChuteControl,66"

67. 746-0903 Cable,ChuteControlw/Clip,

68. 747-0877 Rod,Cam

69. 748-0362 Cam,HandleLock

70. 748-0363 Pawl,HandleLock

71. 784-5594 Bracket,Cable

72. 784-5604A Handle,ChuteTilt

73. 736-0159 Washer,Flat,.349x .879x .063

74. 705-5217 Bracket,Mount,Lamp

75. 710-0451 Bolt,Carriage,5/16-18x.750

76. 710-1240 Screw,M4x.7

77. 725-1658 Lamp

78. 725-1669 Housing,Lamp

79. 725-04220 Harness

80. 731-1364 Housing

81. 735-0225 Grommet

29

Page 30

3O

Page 31

Craftsman Snow Thrower Model 247.88045

I _ O Q

05244B Housing,Bearing

2. 618-0279 Dogg,SteeringDrive,LH

3. 618-0280 Dogg,SteeringDrive,RH

4. 618-0282E ShaftAssembly,Steering

5. 618-04178 Assembly,FrictionWheel

718-04034 Wheel,Friction,Bonded

710-0896 Screw,HexWash

6. 684-0118B Bracket,AugerActuator

7. 684-0119B Bracket,DriveActuator

8. 684-04235 Sprocket,32T

9. 684-0161 Arm,Shift

10. 684-04212 Brkt, FrictionDriveSuprt.

11. 684-04103 RodAssembly,Shift

12. 784-0385B Brkt.,Idler,Auger

13. 710-0538 Screw,HexCapLock,

14. 756-0178 Idler,Flat,2.75OD

15. 754-0222A V-Belt,1/2x 44.0

16. 750-04718 Spcr.,.51IDx 3.66Lg.

17. 710-1652 Screw,HexWash.

18. 750-04717 Spcr.,.51IDx 7.895Lg.

19. 710-3001 Screw,HexCap,3/8-16

20. 750-04703 Spcr.,1.0IDx 1.50OD

21. 710-0788 Screw,Hex,1/4-20x 1.00

22. 710-0459A Screw,3/8-24x 1.50

23. 711-04279 Shaft,HexDrive

24. 711-04605 Shaft,Actuator

25. 716-04048 Ring,Retainer

26. 712-0116 Nut,HexInsertJamLock

27. 712-0138 Nut,Hex,1/4-28GR5

28. 784-5726 Bracket,Idler,Drive

29. 712-04065 Nut,HxFlngeInsertLk

30. 712-0413 Nut,HxInsertJamLk

31. 710-04484 TT Screw,5/16-18x .750

32. 712-0717 Nut,Insert3/8-16

33. 713-0284 Chain,Endless,#41x36L

34. 713-0286 Chain,#420x40L

35. 713-04015 Sprocket,#41x lOT

36. 714-0135 Key,Woodruff

37. 714-0104 Pin,InternalCotter

D _ O i

716-0104 E-Ring

39. 714-0388 Key,Hi-Pro,3/16x 5/8

40. 716-0136 Ring,Retaining

41. 717-0302 Plate,Drive

42. 732-0121 Spring,Extension

43. 732-0209 Spring,Extension

44. 756-0241B Pulley,Dbl,3.25OD

45. 736-0158 Washer,Lock,5/8

46. 756-0240 Pulley,FlatIdler,3.00D

47. 634-0225A WheelAss'y.- LH

634-0226A WheelAss'y.-RH

734-2031 Tire

734-0255 Valve

741-0246A Bearing

48. 711-04615 Pin,Clevis

49. 736-0242 Wsh,Bell.,.34x.872x.06

50. 736-0300 Wash,.406x .875x .059

51. 736-0329 Washer,Lock,1/4

52. 714-0149B Pin,InternalCotter

53. 737-3000 Fitting,Lube,3/16Drive

54. 738-0143 Screw,Shldr.,.498 x .34

55. 738-0279 Spindle,DrivePlate

56. 738-0924A Screw,HexShldr.,1/4-28

57. 741-0163A Ass'y,Bearing/Housing

58. 741-04108 Bearing,HexFlange

59. 741-04025 Bearing,SelfAligning

60. 741-04076 Bearing,Ball

61. 741-0563 Bearing,Ball

62. 741-0748 Bush,Fig,.5IDx .627OD

63. 746-0949A Cable,Steering

64. 746-0951 Cable,AugerIdler

65. 747-0973 Rod,DriveClutch

66. 750-0903B Spcr.,.514x .632x2.44

67. 750-0997 Spacer,.675x 1.0x.23

68. 750-1302B Spcr,.6725x1.125x 2.48

69. 756-0344 Pulley,Drive

70. 756-0625 Roller,Cable

71. 790-00257 Cover,UpperFrame

72. 790-00259 Cover,LowerFrame

31

Continuedonfollowingpage

Page 32

Craftsman Snow Thrower Model 247.88045

Continuedfrom previouspage

711-04606 Axle,Wheel,45"

74. 790-00255A Frame,Transmission

75. 784-0406A Bracket,FrameSupport

76. 784-0407 Bracket,AxleSupport

77. 790-00254 Bracket,BeltCover

78. 710-0191 Screw,3/8-14x 1.25GR8

79. 710-0237 Screw,5/16-24x .625

80. 710-0607 Screw,HxWashHdTapp

81. 710-1245B Screw,HxCap5/16-24

82. 710-0654A Screw,3/8-16x 1.00

83. 736-0173 Wsh,Flat,.28 x .74x .063

84. 714-0118 Key,Square,1/4x 1.5

85. 790-00167A Brkt.,Belt,Keeper

86. 731-2531 Cover,Belt

87. 732-0303 Spring,Extension

88. 732-0705 Guide,ChuteCable

89. 736-0247 Washer,Flat,.406x 1.25

90. 748-0234 Spacer,Shoulder

91. 736-0159 Washer,Flat,.349x .879

92. 754-0131 V-Belt,3/8 x35.5

93. 712-04064 Nut,FigLk, 1/4-20

94. 726-0221 Nut,Spd.

95. 735-04099 Plug,3/8 ID

D _ J Q

32

Page 33

Craftsman Engine Model OH358SA=223828 For Snow Thrower Model 247.88045

154A

342A

300A

335A,

47

169,

220 / / '''_" _" "

"._ _ ""-.206

328 420 "_" 92'

186B

33

35O

!

351

37O

- 203

,178

/

990

Page 34

Craftsman Engine IVlodel OH358SA=223828 For Snow Thrower IVlodel 247.88045

37083

2 27652

3 650820

4 0

5 30969

14 28277

14A 651057

15 35685

16 35686A

17 29916

18 651028

19 35688

20 35319

25 37861

26 650561

28 30322

30 35680A

31 35327

35 29826

36 29918

37 29216

38 29642

40 35777A

40 35776A

42 35780

42 35779

43 35772

45 36898A

47 651033A

48 35313A

50 35682A

51 35315A

60 35316A

65 30200

69 35683

D _ J m

Cylinder(Incl.2, 20, 72&80)

DowelPin

Screw,1/4-20x 1/2"(UpperMountingScrews

for120-VoltElectricStarterMotor)

Oil DrainExtensionNotAvailable

ExtensionCap,1/4-18NPT

FlatWasher

Washer

GovernorRod (Incl.14& 38)

GovernorLever(Incl.212A)

GovernorLeverClamp

Screw,T-15,8-32x7/16"

ExtensionSpring

Oil Seal

BlowerHousingBaffle(Incl.325)

Screw1/4-20x 19/32"

LockNut,8-32

Crankshaft

CounterbalanceGear

Screw,10-32x 3/4"

LockWasher#8

LockNut,10-32

RetainingRing

Piston,Pin&RingSet(.010"OS)(Incl.41,42

& 43)

Piston,Pin&RingSet(Std) (Incl.41,42& 43)

RingSet (.010"OS)

RingSet (Std.)(3-5/16")

PistonPinRetainingRing

ConnectingRodAssembly(incl.47& 49)

ConnectingRodBolt(1/4-20x 1-5/16")

ValveLifter

Camshaft(MCR)

CounterbalanceWeight

BlowerHousingExtension

Screw,10-24x9/16"

CylinderCoverGasket

35684A

71 35377

80 35751

81 35479A

82 35321

83 35322

84 29193

86 650833

87 650832

89 32589

90 611093

92 650880

93 650881

100 35135A

101 611289

102 651024

103 651007

110 35187

110A 37047

119 36932

120 37491

125 36936

125 36934

126 36937

126 36935

127 650691

128 650690

130 650697A

135 34645

150 33507

151 33508

151A 35862

153 35949

154 651105

D _ e ID

CylinderCover(Incl.14,15,20,38

CrankshaftBushing

GovernorShaft

Washer

GovernorGearAssembly

GovernorSpool

RetainingRing

Screw1/4-20x 1-3/16"

Screw,1/4-20x 1- 11/16"

FlywheelKey

Flywheel(3Amp,w/ringgear)

BellevilleWasher

FlywheelNut(5/8-18)

SolidStateIgnition(Incl. 101)

SparkPlugCover

SolidStateMountingStud

Screw,T-15,10-24x 15/16"

GroundWire(13.65"long- darkgreen- 90°

female&2 maleblades)

GroundWire(10.50"withmale&femaleflag

terminals)

CylinderHeadGasket

CylinderHead(Incl. 151A&270A)

ExhaustValve(1/32"OS)

ExhaustValve(Std)

IntakeValve(1/32"OS)

IntakeValve(Std.)

FlatWasher

BellevilleWasher

Screw,5/16-18x2-1/2"

ResistorSparkPlug(RN4C)alsoavailablein

PackagedPart#740069

ValveSpring

ValveSpringKeeper

IntakeValveSeal

PushRod Guide

RockerArmStud

34

Page 35

Craftsman Engine IVlodel OH358SA=223828 For Snow Thrower IVlodel 247.88045

D _ Q ®

35950 RockerArm

156 37843 RockerArmBearing

157 650586 JamNut,5/16-24

158 35466 PushRod

159 35952 RockerArmCoverGasket

160 35953A RockerArmCover

161 30063 Screw,T-30,1/4-20x 1/2"

161A 651034 ValveCoverMountingStud

169 27896A ValveCoverGasket

170 28423 BreatherBody

171 28424 BreatherElement

172 28425 ValveCover

173 35350 BreatherTube

174 650128 Screw,10-24x 1/2"

178 29752 Nut&LockWasher1/4-28

180 37101 BlowerHousingExtension

183 34583A ChokeBracket

184 33263 Carburetor-to-IntakePipeGasket

185 37085 IntakePipe

186 35691 GovernorLink

186B 36653 ChokeSpring

200 35702 ManualControlBracket(Incl.203,204&206)

203 31342 CompressionSpring

204 651029 Screw,T-IO,5-40x 7/16"

206 610973 Terminal

207 35692 ThrottleLink

212 30773A Bushing(Incl.14A&213)

212A 36288 Bushing

212B 651017 Washer

213 650930 Screw,10-32x 5/8"

215 35440 ControlKnob

216 35679 R.RM.AdjustingLever

219 35689 ChokeRod

220 35438 ControlKnob

223 650971 Screw,T-30,5/16-18x7/8"

224 33515A IntakePipeGasket

238 28820 Screw,10-32x 1/2"

260 37092A BlowerHousing

D _ O Q

651084 Screw,5/16-18x9/16"

265 37086 CylinderHeadCover

266 650876 Screw,5/16-18x 1-9/32"

269 35762 ExhaustManifoldGasket

270 37263 ExhaustManifold

270A 35829A ExhaustPortLiner

271 35293 LockingPlate(Manifold)

275 37264 Muffler

276 35348 LockingPlate

277A 650877 Screw,5/16-18x4-1/2"

280 37265 HeatShield

285 35985C StarterCup

290 37964 FuelLine(32.0"length)

292 26460 FuelLineClamp

293A 650517 Screw,T-30,1/4-20x 27-32"

298 650665 Screw,1/4-15x3/4"

300A 37099A FuelTank(Incl.292&301)

301 37845 FuelCap(RedPlastic)(1-1/2"I.D.)

302 37098 FuelTankExtension

305 35574 Oil FillTube

307 35499 O-Ring

308 35539 FillTubeClip

309 651011 Screw,10-32x5/16"

310 35700 Dipstick

314 650873 Screw,1/4-20x 3/4"

315 611111 AlternatorCoil(18Watt)

328 35062 IgnitionKey(alsoavailablein PackagedPart

#740077)

329A 651060 Screw,8-32x23/64"

335 37096A CarburetorCover

335A 37087 CarburetorCover

338 650821 Screw,10-32x 1/2"

341 37093 FuelTankBracket

342A 792028 Screw,5/16-18x7/8"

343 35079A KeySwitchBracket(Incl.329A)

345 37097 HeatBaffle

350 570682A PrimerAssembly(alsoavailableinPackaged

Part#740101)

35

Page 36

Craftsman Engine IVlodel OH358SA=223828 For Snow Thrower IVlodel 247.88045

32180C

355 590574

361 650990

369 651032

370 37119

370 36695

370

36534

370

36501

370

37226

380

640105

390

590749

396

37105

4OO

36947B

42O

730226A

704 650738

710 36482

711 651019

-- 730286

PrimerLine

StarterHandle(MittenGrip)alsoavailablein

PackagedPart#740053B

Screw,T-30,1/4-20x 15/32"(ElectricStarter

MountingScrews)

Screw,12-16x 5/8"

WarningDecal(Bilingual)

Decal- TecumsehLogoforTopof Recoil

Starter

WarningDecal

Decal- Primer-InternationalSymbol

Decal- SpeedControl,Choke,& Key

Carburetor(Incl.184)

RewindStarter

ElectricStarterMotor(120Volt)(Optional)

GasketSet(Incl.itemsmarked*) (Incl.items

marked*)

SAE5W304-CycleEngineOil(Quart)

(Winter)

Screw,1/4-20x5/8"

CompressionSpring

Screw,T-IO,6-32x41/64"

WinterMaintenanceKitincludes32 oz.

- SAE5W30Oil,sparkplug,switchkey,fuel

stabilizer

EnginePartNumber

913300B

ShortBlockPartNumber

758216

36

Page 37

37

Page 38

(ThispageapplicableintheU.S.A.and Canadaonly.)

Sears, Roebuck and Co., U.S.A. (Sears), the California Air Resources Board (CARB)

and the United States Environmental Protection Agency (U.S. EPA)

Emission ControJ System Warranty Statement (Owner's Defect Warranty Rights and ObJigations)

EMISSIONCONTROLWARRANTYCOVERAGEISAPPLICABLETOCERTI- YEAR1997ANDLATERENGINESWHICHARE PURCHASEDANDUSED

FlEDENGINESPURCHASEDINCALIFORNIAIN 1995ANDTHEREAF- ELSEWHEREINTHE UNITEDSTATES(ANDAFTERJANUARY1,2001 IN

TER,WHICHAREUSEDINCALIFORNIA,ANDTOCERTIFIEDMODEL CANADA).

California and United States Emission Control Defects Warranty Statement

TheCaliforniaAirResourcesBoard(CARB),U.S.EPAandSearsarepleased

toexplaintheEmissionControlSystemWarrantyonyourmodelyear2000and

latersmalloff-roadengine(SORE).InCalifornia,newsmalloff-roadengines

mustbe designed,builtand equippedto meettheState'sstringentanti-smog

standards.ElsewhereintheUnitedStates,newnon-road,spark-ignition

enginescertifiedformodelyear1997andlatermustmeetsimilarstandardsset

forthbythe U.S.EPA.Searsmustwarranttheemissioncontrolsystemonyour

engineforthe periodsoftimelistedbelow,providedtherehasbeenno abuse,

neglector impropermaintenanceof your smalloff-roadengine.Youremis-

sioncontrolsystemincludespartssuchas thecarburetor,aircleaner,ignition

system,mufflerandcatalyticconverter.Alsoincludedmaybeconnectorsand

otheremissionrelatedassemblies.Wherea warrantableconditionexists,Sears

will repairyoursmalloff-roadengineatnocosttoyouincludingdiagnosis,parts

andlabor.

Sears Emission Control Defects Warranty Coverage

Smalloff-roadenginesarewarrantedrelativeto emissioncontrolpartsdefects

fora periodofoneyear,subjecttoprovisionssetforthbelow,Ifanycovered

Owner's Warranty

Asthe smalloff-roadengineowner,youareresponsiblefortheperformanceof

therequiredmaintenancelistedinyour OperatingandMaintenanceInstruc-

tions.Searsrecommendsthatyouretainallyourreceiptscoveringmaintenance

onyoursmalloff-roadengine,butSearscannotdenywarrantysolelyforthe

lackofreceiptsorfor yourfailuretoensuretheperformanceofallscheduled

maintenance.Asthe smalloff-roadengineowner,youshouldhoweverbe

awarethat Searsmaydenyyouwarrantycoverageifyoursmalloff-roadengine

ora parthasfaileddueto abuse,neglect,impropermaintenanceor unap-

partonyourengineisdefective,thepartwillbe repairedor replacedbySears.

Responsibilities

provedmodifications.Youareresponsibleforpresentingyoursmalloff-road