Craftsman 24788033 Owner’s Manual

Operator's Manual

P R 0 F E S S I 0 N A L

33" SNOW THROWER

Model No. 247.88033

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www, craftsrnan.corn FORMNO.789-03348

,, SAFETY

* ASSEMBLY

o OPERATION

" MAINTENANCE

PARTS LiST

ESPAI_OL

8/28/2007

WarrantyStatement..................................Page2

SafeOperationPractices.........................Pages3-4

SafetyLabels............................................Page5

Assembly..................................................Pages6-9

Operation..................................................Pages10-13

ServiceandMaintenance.........................Pages14-21

Two =Year Limited Warranty on Craftsman Snow Thrower

Whenassembled,operatedand maintainedaccordingtoallsuppliedinstructions,if thisCraftsmanproductfailsduetoadefectinmaterialor

workmanshipwithintwoyearsfromthedateofpurchase,returnit toanySearsstore,SearsParts&RepairServiceCenteror otherCraftsman

outletinthe UnitedStatesforfreerepair.In-homewarrantyserviceisavailable,butyouwillhavetopaya tripcharge.

Thiswarrantycoversonly defectsinmaterialandworkmanship. Searswill NOTpayfor:

• Expendableitemswhichbecomewornduringnormaluse,suchas skidshoes,shaveplateandsparkplugs.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,bentcrankshafts,failuretousethepropergradeandamountofengineoil,orfailuretomaintaintheequipmentaccordingto all

instructionscontainedsuppliedwiththeproduct.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedtobecontaminatedor oxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

Off-SeasonStorage..................................Page22

TroubleShooting......................................Page23

PartsList...................................................Page24-34

RepairProtectionAgreement...................Page38

Espa_ol.....................................................Page39

ServiceNumbers......................................BackCover

Thiswarrantyappliesforonly90 daysif this productiseverusedforcommercialor rentalpurposes.

This warrantyappliesonlywhilethisproductis usedintheUnitedStates.

This warrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstateto state.

Sears, RoebuckandCo.,HoffmanEstates,IL 60179

EngineOil Type: SAE5W-30

EngineOil Capacity: 28 ounces

FuelCapacity: 4 Quarts

SparkPlug: Champion@RJ19LM

SparkPlugGap: .030"

ModelNumber.................................................................

Serial Number.................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

©SearsBrands,LLC

which,if notfollowed,couldendangerthe personal

Thissymbolpointsoutimportantsafetyinstructions

safetyand/orpropertyof yourselfandothers.Read

andfollowallinstructionsinthismanualbefore

attemptingtooperatethismachine.Failuretocomplywiththese

instructionsmayresultin personalinjury.Whenyousee thissymbol,

HEEDITSWARNING!

This machinewasbuilttobeoperatedaccordingtothe rulesfor

safeoperationinthismanual.Aswithanytypeof powerequipment,

carelessnessor erroronthepartoftheoperatorcanresultinserious

injury.Thismachineiscapableofamputatinghandsandfeetand

throwingobjects.Failuretoobservethefollowingsafetyinstructions

couldresultinseriousinjuryor death.

Your Responsibility: Restricttheuseofthispowermachineto

personswhoread,understand,andfollowthewarningsand instruc-

tions inthismanualandonthemachine.

TRAINING

,, Read,understand,andfollowall instructionsonthe machineandin

the manual(s)beforeattemptingto assembleandoperate.Keepthis

manualina safe placefor futureandregularreferenceandfor ordering

replacementparts.

,, Befamiliarwith allcontrolsandtheirproperoperation.Knowhowto stop

the machineanddisengagethemquickly.

,, Neverallowchildrenunder14yearsoldto operatethismachine.Chil-

dren14yearsoldandovershouldreadandunderstandtheoperation

instructionsandsafetyrulesinthis manualandshouldbetrainedand

supervisedbya parent.

,, Neverallowadultstooperatethismachinewithoutproperinstruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyoursnow-

throwingpatternto avoiddischargeofmaterialtowardroads,bystanders

andthe like.

,, Keepbystanders,helpers,petsandchildrenat least75feetfromthe

machinewhileitis in operation.Stopmachineif anyoneentersthearea.

,, Exercisecautiontoavoidslippingorfalling,especiallywhenoperatingin

reverse.

EngineExhaust,someofitsconstituents,andcertainvehicle

componentscontainor emitchemicalsknownto StateofCaliforniato

causecancerand birthdefectsorotherreproductiveharm.

PREPARATION

Thoroughlyinspecttheareawheretheequipmentisto beused.Removeall

doormats,newspapers,sleds,boards,wiresandotherforeignobjects,which

couldbetrippedoverorthrownbythe auger/impeller.

• Alwayswearsafetyglassesor eyeshieldsduringoperationandwhile

performingan adjustmentor repairto protectyoureyes.Thrownobjects

whichricochetcancauseserious injurytothe eyes.

• Donotoperatewithoutwearingadequatewinteroutergarments.Donot

wearjewelry,longscarvesor otherlooseclothing,whichcouldbecome

entangledinmovingparts.Wearfootwearwhichwill improvefootingon

slipperysurfaces.

• Useagroundedthree-wireextensioncordand receptacleforall units

with electricstartengines.

• Adjustcollectorhousingheighttocleargravelor crushedrocksurfaces.

• Disengageall controlleversbeforestartingtheengine.

,, Neverattemptto makeanyadjustmentswhileengineisrunning,except

wherespecificallyrecommendedintheoperator'smanual.

,, Letengineandmachineadjustto outdoortemperaturebeforestartingto

clearsnow.

Safe Handling of Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein handling

gasoline.Gasolineisextremelyflammableandthevaporsareexplosive.

Seriouspersonalinjurycanoccurwhengasolineisspilledonyourselforyour

clothes,whichcan ignite.Washyourskinandchangeclothesimmediately.

,, Useonlyanapprovedgasolinecontainer.

• Extinguishall cigarettes,cigars,pipesand othersourcesof ignition.

• Neverfuelmachineindoors.

,, Neverremovegascapor addfuelwhilethe engineishotorrunning.

,, Allowenginetocoolat least two minutesbefore refueling.

• Neveroverfillfueltank. Filltank to nomorethan Y2inchbelowbottomof

fillernecktoprovidespaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasoline isspilled,wipeit offthe engineandequipment.Move

machineto anotherarea.Wait5 minutesbeforestartingtheengine.

• Neverstorethe machineorfuelcontainerinsidewherethere isanopen

flame,sparkor pilotlight(e.g.furnace,waterheater,spaceheater,

clothesdryeretc.).

• Allowmachinetocoolatleast5minutesbeforestoring.

OPERATION

• Donotput handsorfeet nearrotatingparts,in theauger/impeller

housingor chuteassembly.Contactwiththerotatingpartscanamputate

handsand feet.

• Theauger/impellercontrolleveris a safetydevice.Neverbypassits

operation.Doingso makesthemachineunsafeandmaycausepersonal

injury.

• Thecontrolleversmustoperateeasilyin both directionsand automati-

callyreturnto thedisengagedpositionwhen released.

• Neveroperatewitha missingor damagedchuteassembly.Keepall

safetydevicesin placeand working.

• Neverrunan engineindoorsor in a poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donotoperatemachinewhileunderthe influenceof alcoholordrugs.

• Mufflerand enginebecomehotand cancauseaburn.Donottouch.

• Exerciseextremecautionwhenoperatingon orcrossinggravelsurfaces.

Stayalertfor hiddenhazardsortraffic.

• Exercisecautionwhenchangingdirectionand whileoperatingonslopes.

• Planyoursnow-throwingpatterntoavoiddischargetowardswindows,

walls,cars etc.Thus,avoidingpossiblepropertydamageor personal

injurycausedbyaricochet.

• Neverdirectdischargeatchildren,bystandersand petsorallowanyone

infrontofthe machine.

• Donotoverloadmachinecapacitybyattemptingto clearsnowattoofast

ofa rate.

• Neveroperatethis machinewithoutgoodvisibilityor light.Alwaysbe

sureof your footingandkeepa firm holdonthe handles.Walk,never

run.

• Disengagepowertothe auger/impellerwhentransportingor notinuse.

• Neveroperatemachineat hightransportspeedsonslipperysurfaces.

Lookdownand behindand usecarewhenbackingup.

• Ifthe machineshouldstarttovibrateabnormally,stopthe engine,

disconnectthesparkplugwireandgrounditagainstthe engine.Inspect

thoroughlyfordamage.Repairanydamagebeforestartingandoperat-

ing.

,, Disengageallcontrolleversandstopenginebeforeyou leavethe

operatingposition(behindthe handles).Waituntil the auger/impeller

comesto a completestopbeforeuncloggingthechute assembly,making

anyadjustments,or inspections.

• Neverputyourhandin the dischargeorcollectoropenings.Always

usetheclean-out toolprovidedto unclogthedischargeopening.Do

notunclogchuteassemblywhileengineisrunning.Shutoffengine

andremainbehindhandlesuntilallmovingpartshavestoppedbefore

unclogging.

• Useonlyattachmentsandaccessoriesapprovedbythe manufacturer

(e.g.wheelweights,tirechains,cabs etc.).

• Ifsituationsoccurwhicharenotcoveredinthismanual,usecareand

goodjudgment.ContactyourSearsServiceCenterfor assistance.

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheir properoperation

regularly.Referto the maintenanceandadjustmentsectionsofthis

manual.

• Beforecleaning,repairing,or inspectingmachinedisengageallcontrol

leversandstoptheengine.Waituntilthe auger/impellercometoa

completestop.Disconnectthe sparkplug wireand groundagainstthe

enginetopreventunintendedstarting.

• Checkboltsandscrewsfor propertightnessatfrequentintervalsto keep

the machinein safeworkingcondition.Also,visuallyinspectmachinefor

anydamage.

• Donotchangetheenginegovernorsettingor over-speedthe engine.

Thegovernorcontrolsthe maximumsafeoperatingspeedofthe engine.

• Snowthrowershaveplatesandskid shoesaresubjectto wearand

damage.Foryoursafetyprotection,frequentlycheckallcomponents

andreplacewith originalequipmentmanufacturer's(OEM) partsonly.

"Useof partswhichdonotmeetthe originalequipmentspecifications

mayleadto improperperformanceandcompromisesafety!"

• Checkcontrolsperiodicallytoverifytheyengage anddisengage

properlyandadjust,if necessary.Refertothe adjustmentsectioninthis

operator'smanualfor instructions.

• Maintainorreplacesafetyandinstructionlabels,as necessary.

• Observeproperdisposallawsandregulationsforgas, oil,etc.to protect

the environment.

• Priortostoring, runmachineafewminutestoclearsnowfrom machine

andpreventfreezeup of auger/impeller.

• Neverstorethemachineorfuelcontainerinsidewherethere isan open

flame,sparkor pilotlightsuch asawaterheater,furnace,clothes dryer

etc.

• Alwaysrefertothe operator'smanualforproperinstructionson

off-seasonstorage.

Do not modify engine

Toavoidseriousinjuryor death,do notmodifyenginein anyway.Tampering

withthegovernorsettingcan leadto arunawayengineandcauseitto operate

at unsafespeeds.Nevertamperwithfactorysettingofenginegovernor.

Notice Regarding Emissions

Engineswhichare certifiedtocomplywithCaliforniaandfederalEPAemission

regulationsforSORE(SmallOffRoadEquipment)are certifiedto operateon

regularunleadedgasoline,and mayincludethefollowingemissioncontrolsys-

tems:EngineModification(EM)andThreeWayCatalyst(TWO)if so equipped.

4

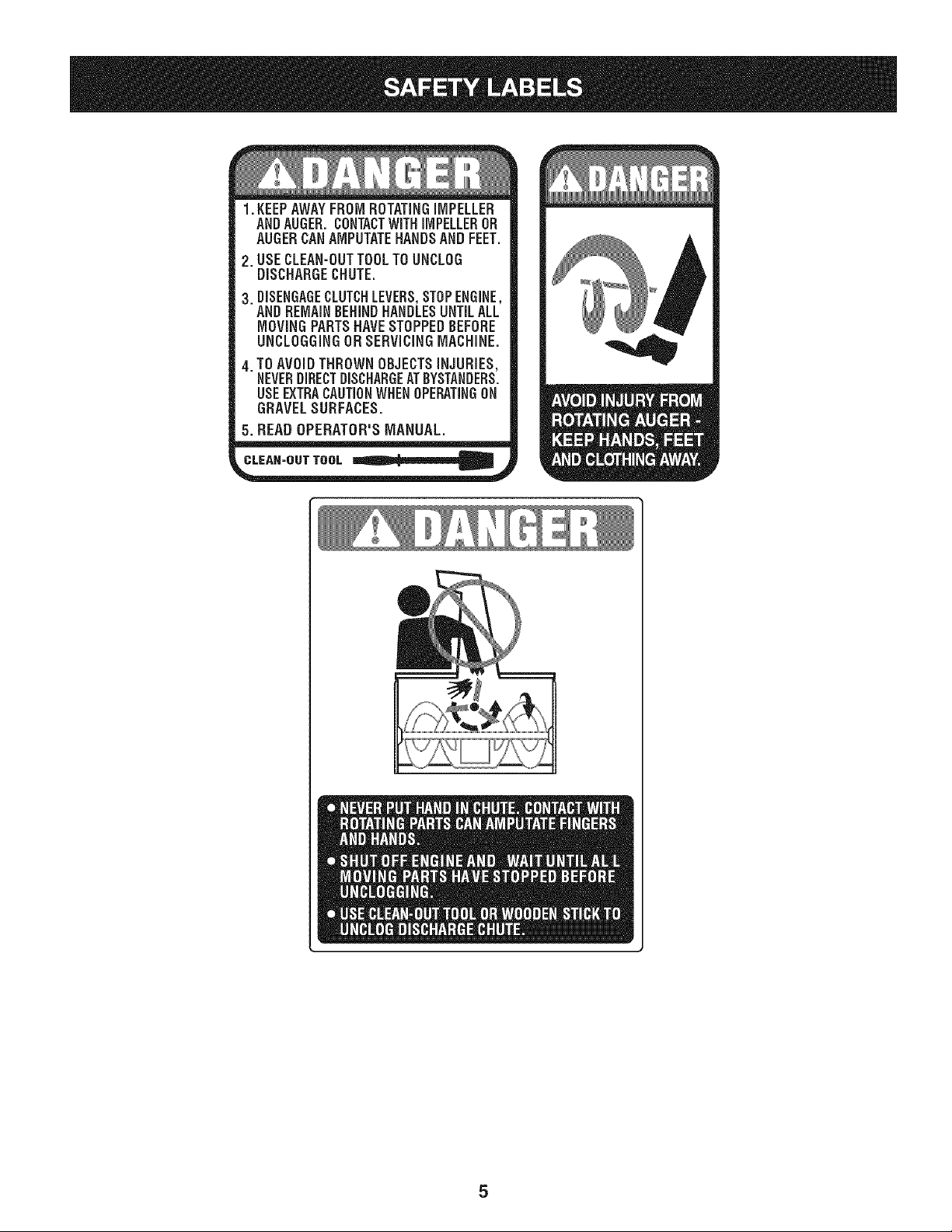

1.KEEPAWAYFROMROTATINGiMPELLER

ANDAUGER.CONTACTWiTHiMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET.

2. USECLEAN-OUTTOOLTOUNCLOG

DISCHARGECHUTE.

3. DISENGAGECLUTCHLEVERS,STOPENGINE,

ANDREMAINBEHINDHANDLESUNTILALL

MOVINGPARTSHAVESTOPPEDBEFORE

UNCLOGGINGDRSERViCiNGMACHINE.

4. TOAVOIDTHROWNOBJECTSiNJURiES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHENOPERATINGON

GRAVELSURFACES.

5. READOPERATOR'SMANUAL.

CLEAN-OUT TOOL

5

NOTE:Referencesto rightor leftsideofthesnowthrowerare

determinedfrombehindtheunitintheoperatingposition(standing

directlybehindthesnowthrower,facingthehandlepanel).

REMOVING FROM CRATE

1. Removescrewsfromthebottomofthecratesecuringthesides,

andendsoftheshippingcrate.

2. Liftoffthe top offofthecrateandsetoutof the wayofthe

assemblyarea.

3. Removeanddiscardplasticbagthatcoversunit.

4. Removeanyloosepartsincludedwithunit(i.e.,Operator's

Manual,etc.).

5. Pushdownonthelowerhandleandpullunitbackoutofcrate.

6. Makecertainthecratehasbeencompletelyemptiedbefore

discardingit.

ASSEMBLY

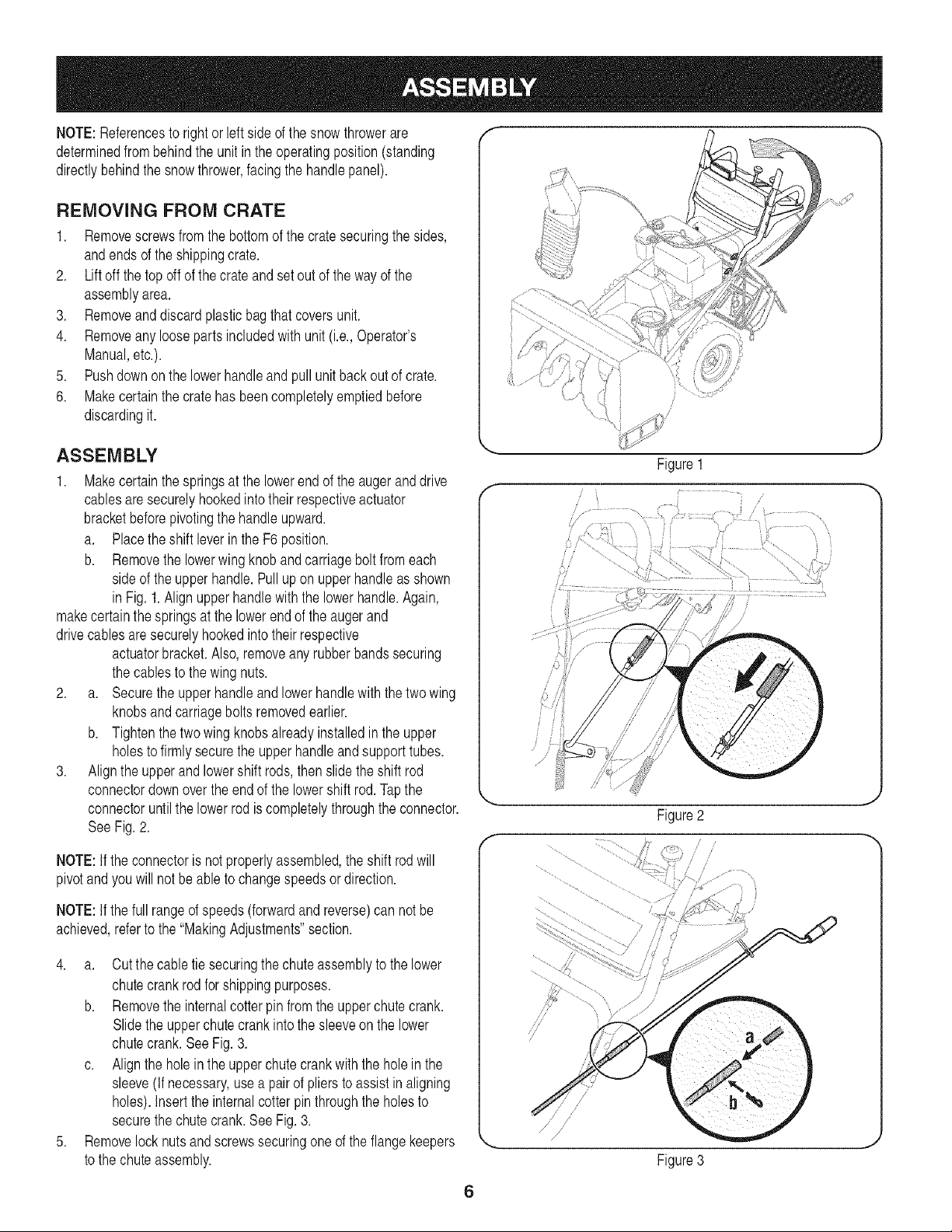

1. Makecertainthespringsat thelowerendoftheaugeranddrive

cablesaresecurelyhookedintotheirrespectiveactuator

bracketbeforepivotingthehandleupward.

a. Placetheshift leverintheF6 position.

b. Removethelowerwingknobandcarriageboltfromeach

sideof theupperhandle.Pulluponupperhandleasshown

in Fig.1.Alignupperhandlewiththelowerhandle.Again,

makecertainthespringsatthe lowerendoftheaugerand

drivecablesaresecurelyhookedintotheir respective

actuatorbracket.Also,removeanyrubberbandssecuring

thecablestothewingnuts.

2. a. Securetheupperhandleandlowerhandlewiththetwo wing

knobsandcarriageboltsremovedearlier.

b. Tightenthetwo wingknobsalreadyinstalledintheupper

holesto firmlysecuretheupperhandleandsupporttubes.

3. Aligntheupperandlowershiftrods,thenslidethe shiftrod

connectordownoverthe endofthe lowershiftrod.Tapthe

connectoruntilthe lowerrodis completelythroughtheconnector.

SeeFig.2.

NOTE:If theconnectoris notproperlyassembled,theshiftrodwill

pivotand youwillnotbe abletochangespeedsordirection.

Figure1

/

/.........

/

ii

J ii

J

Figure2

f

/

NOTE:If thefullrangeofspeeds(forwardandreverse)cannotbe

achieved,refertothe"MakingAdjustments"section.

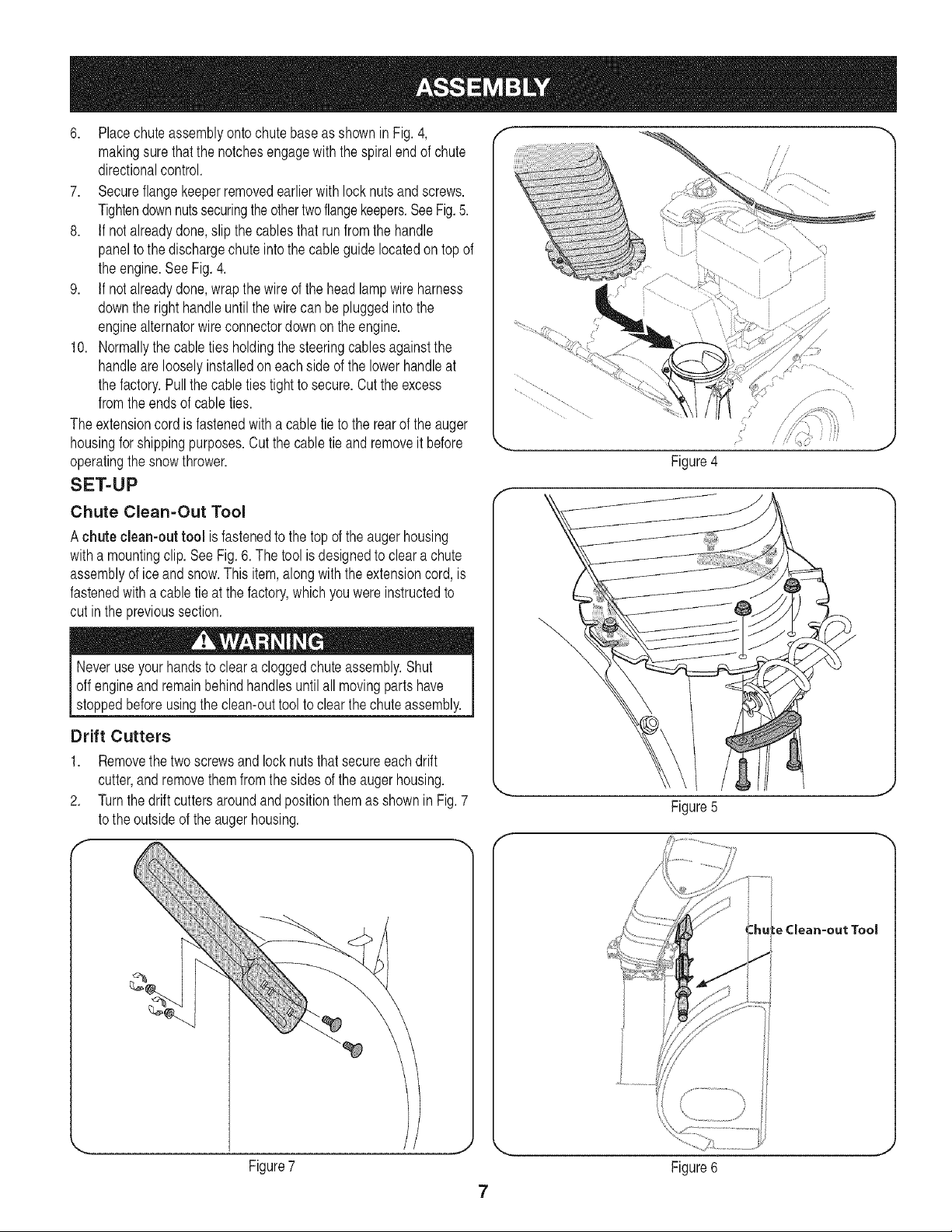

4. a. Cutthecabletie securingthechuteassemblytothelower

chutecrankrodfor shippingpurposes.

b. Removetheinternalcotterpinfromtheupperchutecrank.

Slidetheupperchutecrankintothesleeveon thelower

chutecrank.SeeFig.3.

c. Aligntheholeintheupperchutecrankwiththeholeinthe

sleeve(If necessary,usea pairofplierstoassistinaligning

holes).Insertthe internalcotterpinthroughtheholesto

securethechutecrank.SeeFig.3.

5. Removelocknutsandscrewssecuringoneoftheflangekeepers

tothechuteassembly.

/

/

Figure3

6

6. PlacechuteassemblyontochutebaseasshowninFig.4,

makingsurethatthenotchesengagewiththespiralendofchute

directionalcontrol.

7. Secureflangekeeperremovedearlierwithlocknutsandscrews.

Tightendownnutssecuringtheothertwoflangekeepers.SeeFig.5.

8. If notalreadydone,slipthecablesthat runfromthe handle

paneltothedischargechuteintothe cableguidelocatedontopof

theengine.SeeFig.4.

9. If notalreadydone,wrapthewireoftheheadlampwireharness

downthe righthandleuntilthewire canbepluggedintothe

enginealternatorwireconnectordownon theengine.

10. Normallythecabletiesholdingthesteeringcablesagainstthe

handlearelooselyinstalledoneachsideofthelowerhandleat

thefactory.Pullthecabletiestightto secure.Cutthe excess

fromtheendsofcableties.

Theextensioncordisfastenedwitha cabletietotherearof theauger

housingforshippingpurposes.Cutthe cabletie andremoveitbefore

operatingthesnowthrower.

SET-UP

Chute Clean=Out Tool

Achute clean-out tool is fastenedtothetopoftheaugerhousing

withamountingclip.SeeFig.6. Thetoolisdesignedtocleara chute

assemblyoficeandsnow.Thisitem,alongwiththeextensioncord,is

fastenedwitha cabletieatthefactory,whichyouwereinstructedto

cut intheprevioussection.

Figure4

1i

ii

Neveruseyour handsto clearacloggedchuteassembly.Shut

off engineandremainbehindhandlesuntilallmovingpartshave

stoppedbeforeusingtheclean-outtoolto clearthechuteassembly.

Drift Cutters

1. Removethetwoscrewsandlocknutsthatsecureeachdrift

cutter,andremovethemfromthesidesoftheaugerhousing.

2. Turnthedriftcuttersaroundandpositionthemasshownin Fig.7

totheoutsideofthe augerhousing.

\

Figure5

-=hule Clean-out Tool

Figure7

Figure6

7

3. Attachthedriftcutterswiththescrewsandlocknutsremoved

earlier.

TirePressure

Beforeoperating,checktirepressure.Refertothetiresidewallfor

exacttiremanufacturer'srecommendedor maximumpsi.

NOTE:Ifthetirepressureis notequalinbothtires,theunitmaynot

travelinastraightpathandtheshaveplatemaywearunevenly.

ADJUSTMENTS

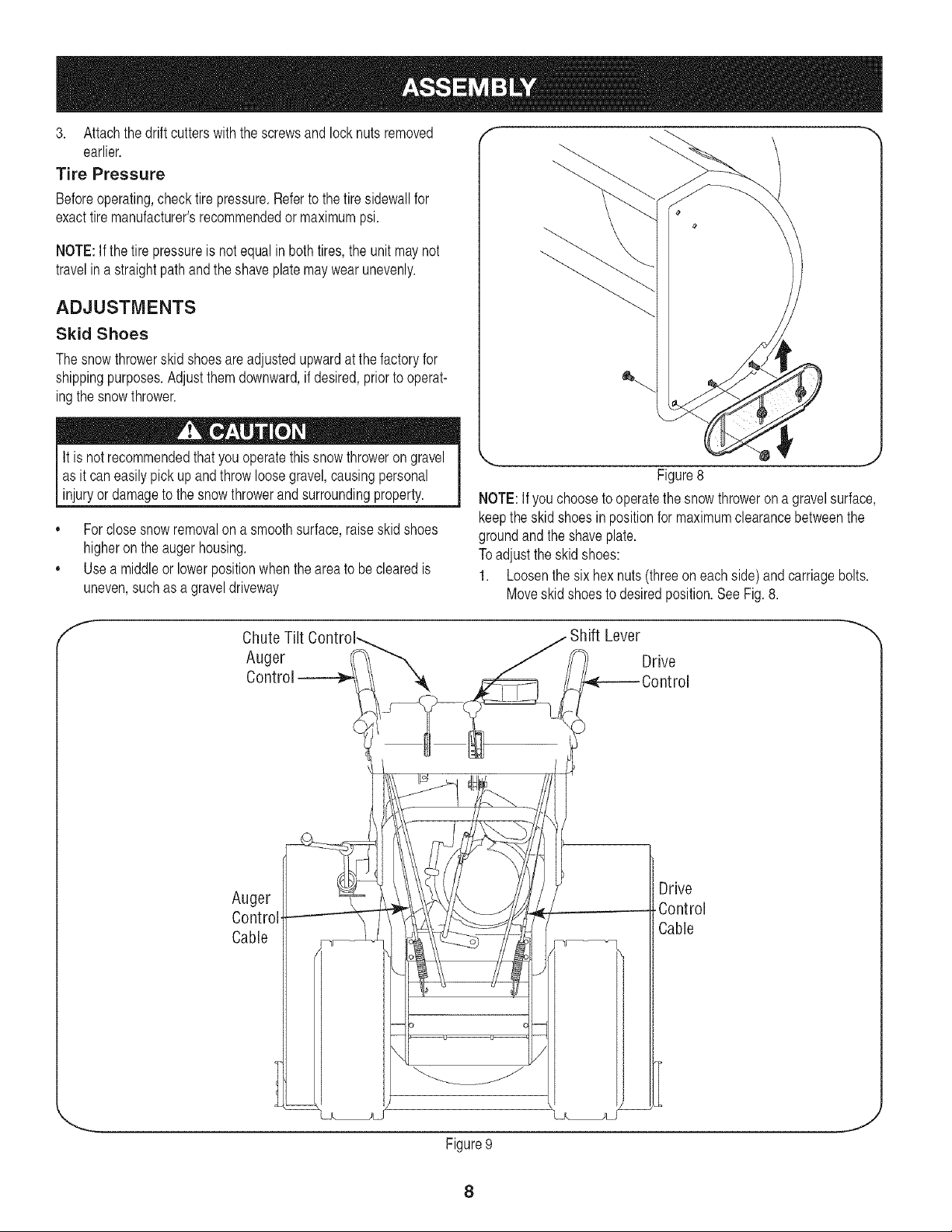

Skid Shoes

Thesnowthrowerskidshoesareadjustedupwardatthefactoryfor

shippingpurposes.Adjustthemdownward,if desired,priorto operat-

ingthesnowthrower.

It is notrecommendedthatyouoperatethissnowthrowerongravel

asitcaneasilypick upandthrowloosegravel,causingpersonal

injuryor damagetothesnowthrowerandsurroundingproperty.

,, Forclosesnowremovalon a smoothsurface,raiseskidshoes

higherontheaugerhousing.

,, Usea middleorlowerpositionwhentheareatobeclearedis

uneven,suchasagraveldriveway

Figure8

NOTE:Ifyouchoosetooperatethesnowthroweronagravelsurface,

keeptheskidshoesinpositionformaximumclearancebetweenthe

groundandtheshaveplate.

Toadjusttheskidshoes:

1. Loosenthesix hexnuts(threeoneachside)andcarriagebolts.

Moveskid shoestodesiredposition.SeeFig.8.

f

Chute Tilt

Auger

Control --

Auger

Control

Cable

Shift Lever

Drive

Drive

Control

Cable

z

J

Figure9

8

2. Makecertaintheentirebottomsurfaceofskidshoe isagainstthe

groundtoavoidunevenwearontheskidshoes.

3. Retightennutsandboltssecurely.

Testing Auger Drive Control

Priortooperatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performalladjustmentsto verifyyoursnow

throwerisoperatingsafelyandproperly.

Whentheaugercontrolisreleasedand inthedisengaged"up"posi-

tion,thecableshouldhaveverylittleslack,butshouldNOTbetight.

1. Ina well-ventilatedarea,startthesnowthrowerengineas

instructedin theO_erationsection.Makesurethethrottle issetin

thefastposition_. ,

2. Whilestandingintheoperators position(behindthesnow

thrower),engagethe augercontrolandallowthe augerto remain

engagedforapproximatelytensecondsbeforereleasingthe

augercontrol.Repeatthisseveraltimes.

3. Withtheenginerunninginthefastposition_ andtheauger

controlin thedisengaged"up"position,walktothefrontofthe

machine.Confirmthattheaugerhascompletelystoppedrotating

andshowsnosignsof motion.

4. If theaugershowsanysignsof rotating,immediatelyreturntothe

operator'spositionandshutoffthe engine.Waitforallmoving

partstostopbeforereadjustingtheaugercontrolcable.

Testing Drive Control & Shift Lever

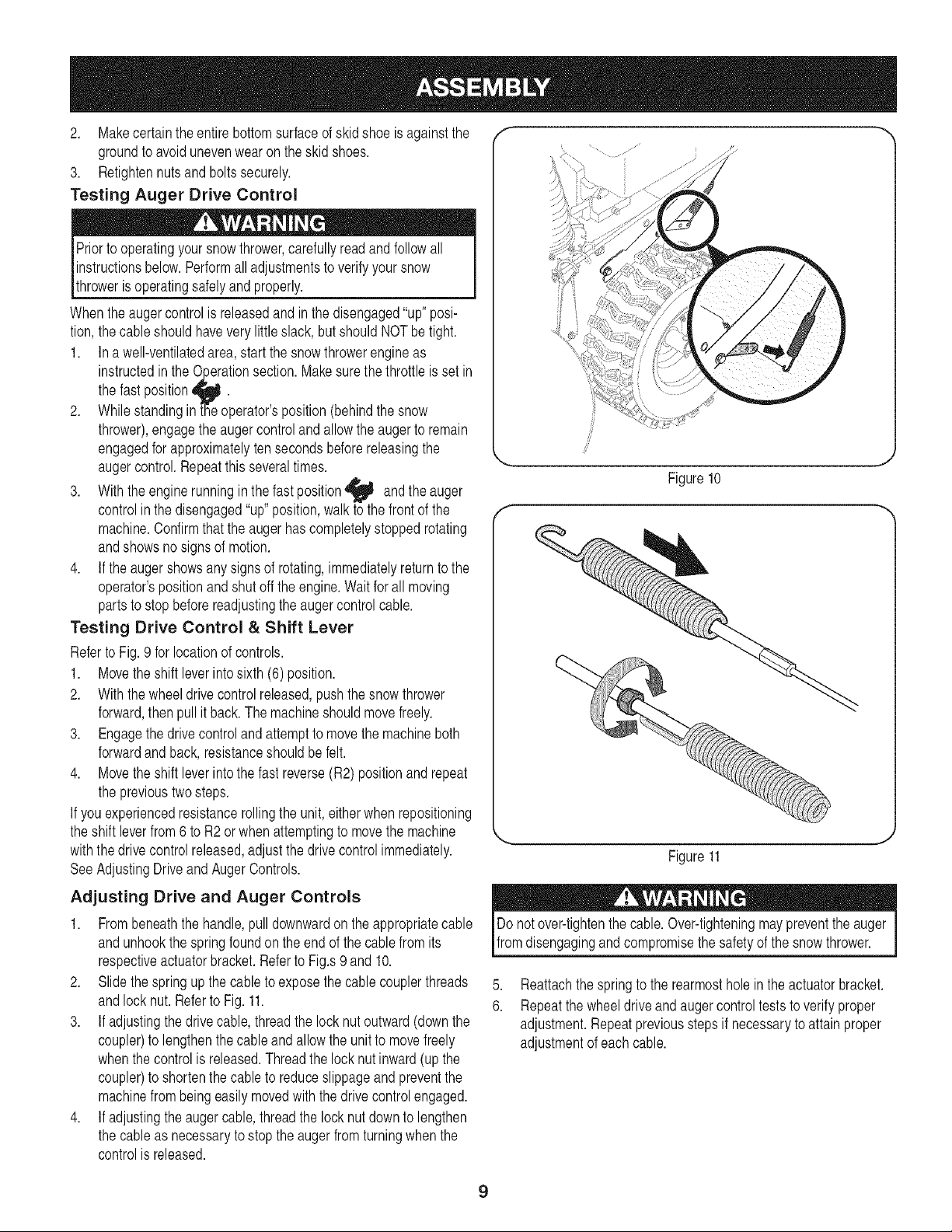

RefertoFig.9for locationof controls.

1. Movetheshiftleverintosixth(6)position.

2. Withthewheeldrivecontrolreleased,pushthesnowthrower

forward,thenpullit back.The machineshouldmovefreely.

3. Engagethedrivecontrolandattempttomovethemachineboth

forwardandback,resistanceshouldbefelt.

4. Movetheshiftleverintothefastreverse(R2)positionandrepeat

theprevioustwosteps.

If youexperiencedresistancerollingtheunit,eitherwhenrepositioning

theshiftleverfrom6toR2orwhenattemptingto movethemachine

withthedrivecontrolreleased,adjustthedrive controlimmediately.

SeeAdjustingDriveandAugerControls.

4

,,.,,

Figure10

f

Figure11

Adjusting Drive and Auger Controls

1. Frombeneaththehandle,pulldownwardon theappropriatecable

andunhookthespringfoundontheendofthecablefromits

respectiveactuatorbracket.RefertoFig.s9 and10.

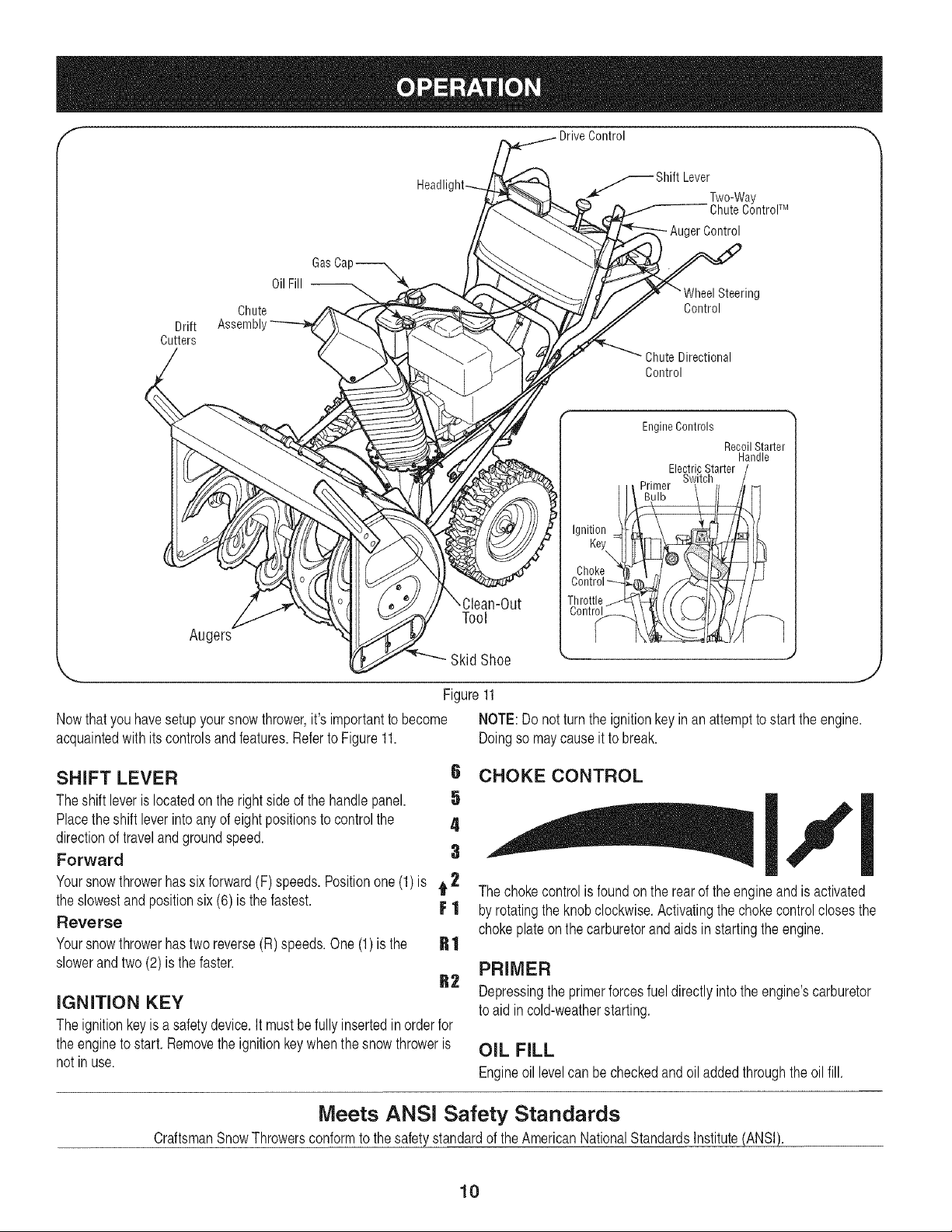

2. Slidethespringupthecabletoexposethecablecouplerthreads

andlocknut.Referto Fig.11.

3. If adjustingthedrivecable,threadthelocknutoutward(downthe

coupler)tolengthenthecableandallowtheunittomovefreely

whenthe controlis released.Threadthe locknutinward(upthe

coupler)toshortenthecableto reduceslippageandpreventthe

machinefrombeingeasilymovedwiththedrivecontrolengaged.

4. If adjustingtheaugercable,threadthelocknut downtolengthen

thecableas necessarytostoptheaugerfromturningwhenthe

controlis released.

Donotover-tightenthecable.Over-tighteningmaypreventtheauger I

Ifromdsengagngandcompromsethesafetyof the snowthrower. J

5,

Reattachthespringto therearmostholeintheactuatorbracket.

6.

Repeatthewheeldriveandaugercontrolteststo verifyproper

adjustment.Repeatpreviousstepsifnecessarytoattainproper

adjustmentofeachcable.

9

Headlk

GasCa

OilFill

Chute

Drift Assembl

Cutters

Augers

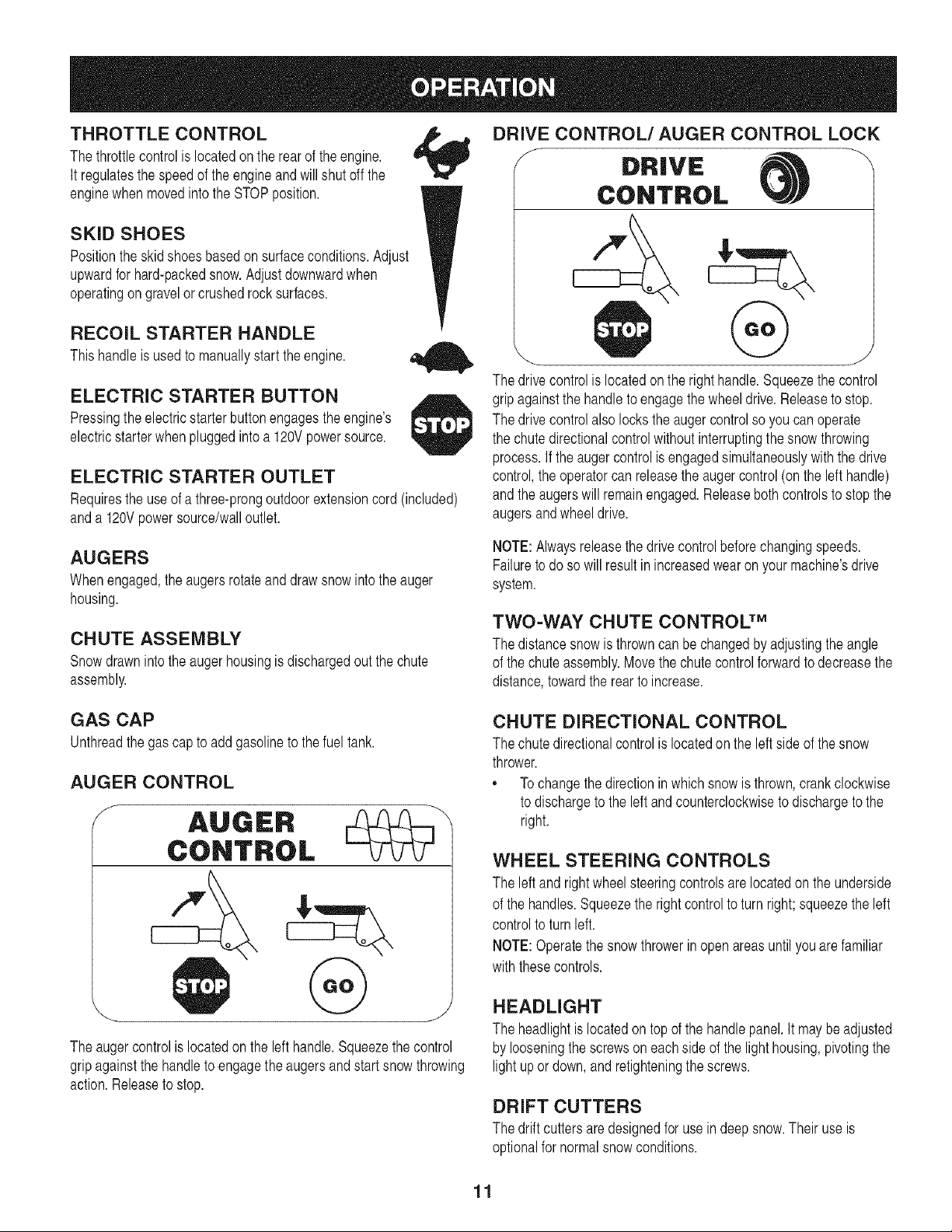

Nowthatyouhavesetupyoursnowthrower,it'simportanttobecome

acquaintedwith itscontrolsandfeatures.RefertoFigure11.

s Shift LeverTwo_Way

Chute ControlTM

Auger Control

Control

Chute Directional

Control

EngineControls

ElectricStarter /

. Switch /

Ignition =

Key

\

Choke

Control

Throttle/

Tool

SkidShoe

Figure11

NOTE:Donotturntheignitionkeyinan attempttostarttheengine.

Doingso maycauseit tobreak.

Contr_t_

g

RecoilStarter

Handle

,J

SHIFT LEVER

Theshift leverislocatedon the rightsideofthehandlepanel.

Placetheshift leverintoanyofeightpositionsto controlthe

directionof travelandgroundspeed.

Forward

Yoursnowthrowerhassix forward(F)speeds.Positionone(1)is t 2 Thechokecontrolisfoundontherearof theengineandisactivated

theslowestand positionsix (6) is thefastest.

Reverse

Yoursnowthrowerhastwo reverse(R)speeds.One(1)is the

slowerandtwo(2) is thefaster.

6 CHOKE CONTROL

I,,'l

FI

byrotatingthe knobclockwise.Activatingthechokecontrolclosesthe

chokeplateonthecarburetorandaidsinstartingtheengine.

R1

PRIMER

R2

IGNITION KEY

The ignitionkeyis a safety device. Itmust be fullyinsertedinorderfor

the engine tostart. Remove the ignitionkey when thesnow throweris

not in use.

Depressingthe primerforcesfueldirectlyintotheengine'scarburetor

toaid incold-weatherstarting.

OIL FILL

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill.

Meets ANSI Safety Standards

CraftsmanSnowThrowersconformto thesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

10

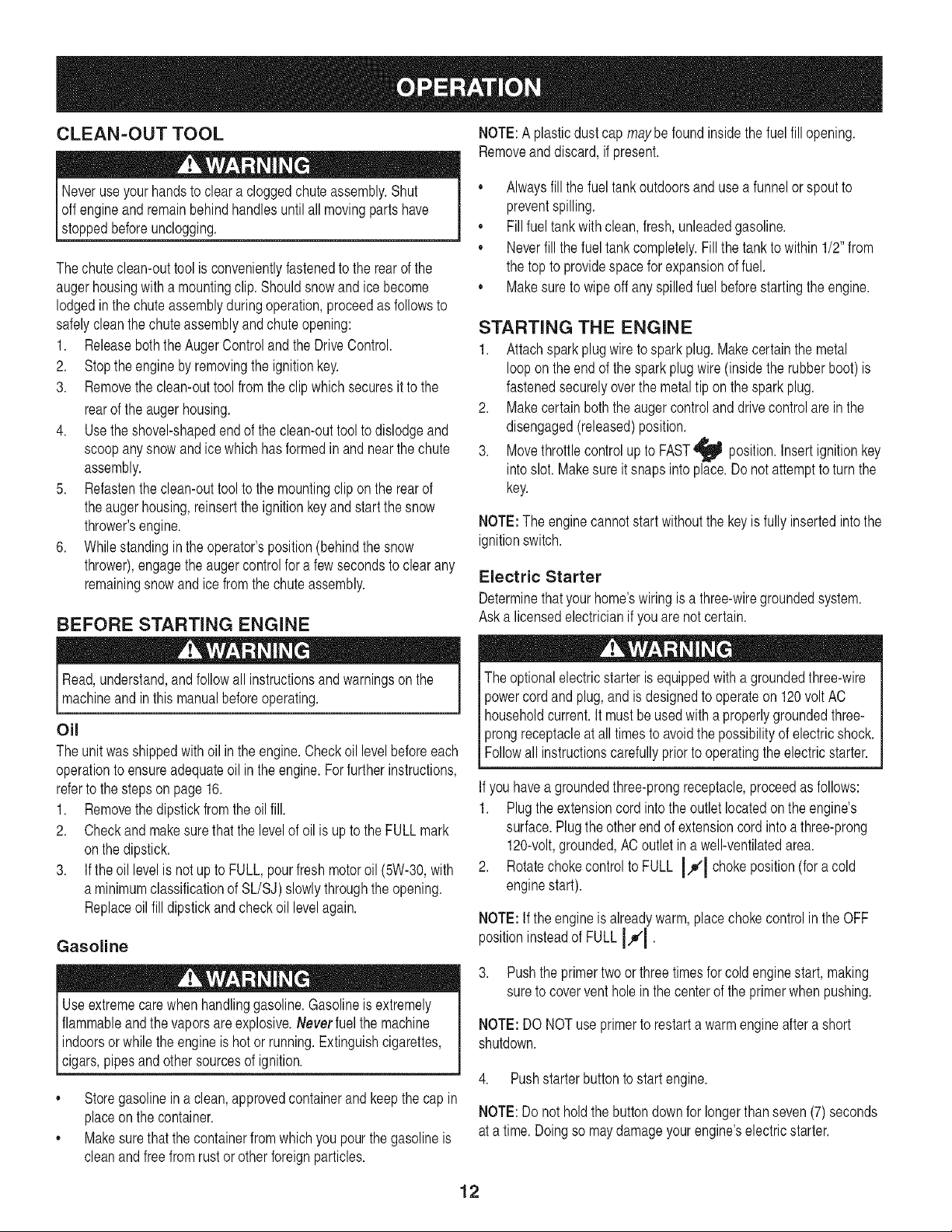

THROTTLE CONTROL

Thethrottlecontrolis locatedontherearof theengine.

It regulatesthespeedofthe engineandwillshutoff the

enginewhenmovedintotheSTOPposition.

SKID SHOES

Positiontheskidshoesbasedon surfaceconditions.Adjust

upwardforhard-packedsnow.Adjustdownwardwhen

operatingongravelorcrushedrocksurfaces.

DRIVE CONTROL/AUGER CONTROL LOCK

f

DRIVE

CONTROL

RECOIL STARTER HANDLE

This handleisusedto manuallystarttheengine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine's

electricstarterwhenpluggedintoa 120Vpowersource.

ELECTRIC STARTER OUTLET

Requirestheuseofathree-prongoutdoorextensioncord(included)

anda120Vpowersource/walloutlet.

AUGERS

Whenengaged,the augersrotateanddrawsnowintotheauger

housing.

CHUTE ASSEMBLY

Snowdrawnintotheaugerhousingisdischargedoutthechute

assembly.

GAS CAP

Unthreadthegascap toaddgasolinetothefueltank.

AUGER CONTROL

S

@

Thedrivecontrolis locatedonthe righthandle.Squeezethecontrol

gripagainstthehandletoengagethewheeldrive.Releaseto stop.

Thedrivecontrolalso locksthe augercontrolsoyoucanoperate

thechutedirectionalcontrolwithoutinterruptingthesnowthrowing

process.If the augercontrolisengagedsimultaneouslywiththedrive

control,the operatorcanreleasetheaugercontrol(onthelefthandle)

andtheaugerswillremainengaged.Releaseboth controlstostopthe

augersandwheeldrive.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.

Failuretodoso willresultinincreasedwearonyourmachine'sdrive

system.

TWO=WAY CHUTE CONTROL TM

Thedistancesnowis throwncanbechangedbyadjustingtheangle

of thechuteassembly.Movethechutecontrolforwardtodecreasethe

distance,towardtherearto increase.

CHUTE DIRECTIONAL CONTROL

Thechutedirectionalcontrolislocatedontheleftsideofthesnow

thrower.

,, Tochangethedirectioninwhichsnowisthrown,crankclockwise

todischargetotheleftandcounterclockwisetodischargetothe

right.

Theaugercontrolislocatedonthe lefthandle.Squeezethe control

gripagainstthehandletoengagetheaugersandstart snowthrowing

action.Releasetostop.

WHEEL STEERING CONTROLS

Theleftandrightwheelsteeringcontrolsarelocatedontheunderside

of thehandles.Squeezetherightcontroltoturn right;squeezetheleft

controlto turnleft.

NOTE:Operatethesnowthrowerinopenareasuntilyouarefamiliar

withthesecontrols.

HEADLIGHT

Theheadlightislocatedontopofthehandlepanel.It maybeadjusted

bylooseningthe screwson eachside of thelighthousing,pivotingthe

lightupor down,andretighteningthescrews.

DRIFT CUTTERS

Thedriftcuttersaredesignedforusein deepsnow.Theiruseis

optionalfor normalsnowconditions.

11

CLEAN-OUT TOOL NOTE:Aplasticdustcapmaybefoundinsidethefuelfillopening.

Removeanddiscard,if present.

Neveruseyourhandstoclearacloggedchuteassembly.Shut

off engineand remainbehindhandlesuntilallmovingpartshave

stoppedbeforeunclogging.

Thechuteclean-outtoolis convenientlyfastenedto the rearofthe

augerhousingwitha mountingclip.Shouldsnowandicebecome

lodgedin the chuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. ReleaseboththeAugerControlandthe DriveControl.

2. Stopthe enginebyremovingtheignitionkey.

3. Removetheclean-outtoolfromtheclipwhichsecuresittothe

rearoftheaugerhousing.

4. Usetheshovel-shapedendof theclean-outtoolto dislodgeand

scoopanysnowandicewhichhasformedin andnearthechute

assembly.

5. Refastentheclean-outtoolto the mountingclipon therearof

theaugerhousing,reinsertthe ignitionkeyandstartthesnow

thrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagethe augercontrolforafewsecondsto clearany

remainingsnowandicefromthechuteassembly.

BEFORE STARTING ENGINE

,, Alwaysfill thefueltankoutdoorsanduseafunnelorspoutto

preventspilling.

,, Fillfueltankwithclean,fresh,unleadedgasoline.

,, Neverfill thefuel tankcompletely.Fillthetanktowithin1/2"from

thetoptoprovidespaceforexpansionoffuel.

,, Makesuretowipeoff anyspilledfuelbeforestartingtheengine.

STARTING THE ENGINE

1. Attachsparkplugwire tosparkplug.Makecertainthe metal

loopon theendof the sparkplugwire(insidethe rubberboot)is

fastenedsecurelyoverthe metaltip onthesparkplug.

2. Makecertainboththeaugercontrolanddrivecontrolarein the

disengaged(released)position.

3. MovethrottlecontroluptoFAST_ position.Insertignitionkey

intoslot. Makesureitsnapsintoplace.Donotattemptto turn the

key.

NOTE:Theenginecannotstartwithoutthekeyis fullyinsertedintothe

ignitionswitch.

Electric Starter

Determinethatyourhome'swiringis a three-wiregroundedsystem.

Askalicensedelectricianifyouarenotcertain.

Read,understand,andfollowall instructionsandwarningsonthe

machineand inthis manualbeforeoperating.

Oil

Theunit wasshippedwithoilintheengine.Checkoil levelbeforeeach

operationtoensureadequateoilintheengine.Forfurtherinstructions,

referto the stepsonpage 16.

1. Removethedipstickfromtheoilfill.

2. Checkandmakesurethatthe levelofoil is upto theFULLmark

onthedipstick.

3. If theoil levelis notupto FULL,pourfreshmotoroil(5W-30,with

a minimumclassificationofSL/SJ)slowlythroughtheopening.

Replaceoil fill dipstickandcheckoil levelagain.

Gasoline

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuel themachine

indoorsorwhilethe engineishotor running.Extinguishcigarettes,

[c gars,ppesandothersourcesof gnt on.

,, Storegasolinein aclean,approvedcontainerandkeepthe capin

placeonthecontainer.

,, Makesurethatthe containerfromwhichyoupourthe gasolineis

cleanandfreefromrustor otherforeignparticles.

Theoptionalelectricstarteris equippedwithagroundedthree-wire

powercordandplug,andis designedtooperateon120voltAC

householdcurrent.It mustbeusedwith aproperlygroundedthree-

prongreceptacleatall timestoavoidthepossibilityof electricshock.

Followall instructionscarefullypriortooperatingtheelectricstarter.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows:

1. Plugtheextensioncordintothe outletlocatedontheengine's

surface.Plugtheotherend of extensioncordintoathree-prong

120-volt,grounded,ACoutletinawell-ventilatedarea.

2. RotatechokecontroltoFULL I,.#'1chokeposition(foracold

enginestart).

NOTE:If theengineis alreadywarm,placechokecontrolin theOFF

positioninsteadofFULL IJl •

3. Pushtheprimertwoor threetimesforcoldenginestart, making

sureto coverventholeinthecenterofthe primerwhenpushing.

NOTE:DO NOTuse primerto restartawarmengineafterashort

shutdown.

4. Pushstarterbuttontostartengine.

NOTE:Donotholdthebuttondownforlongerthanseven(7)seconds

ata time.Doingso maydamageyourengine'selectricstarter.

12

5. Oncetheenginestarts,releasestarterbutton.

6. Astheenginewarms,slowlyrotatechokecontrolto theOFF

position.Iftheenginefalters,quicklyrotatechokecontrolbackto

FULL 14D"Ithenslowlyintothe OFFpositionagain.

7. Whendisconnectingthe extensioncord,alwaysunplugtheend

atthethree-prongwalloutletbeforeunpluggingtheoppositeend

fromthesnowthrower.

Recoil Starter

1. Rotatechokecontrolto FULL IJl chokeposition(coldengine

start).

NOTE:Iftheengineisalreadywarm,placechokecontrolintheOFF

position

2. Pushthe primertwoorthreetimesforcoldenginestart,making

NOTE:DONOTuseprimertorestartawarmengineafterashort

shutdown.

NOTE:Additionalprimingmaybe necessaryifthetemperatureis

below15°Fahrenheit.

insteadofFULLIJ|.

sureto coverventholeinthecenteroftheprimerwhenpushing.

NOTE:Whenselectinga DriveSpeed,usetheslowerspeedsuntil

youarecomfortableandfamiliarwiththeoperationofthesnow

thrower.

2. Squeezethedrivecontrolagainstthehandlethe snowthrower

will move.Releaseitanddrivemotionwillstop.

NOTE:NEVERrepositiontheshiftlever(changespeedsordirection

of travel)withoutfirstreleasingthedrivecontrolandbringingthesnow

throwertoa completestop.Doingso willresultin prematurewearto

thesnowthrower'sdrivesystem.

TO ENGAGE AUGERS

1. Toengagetheaugersandstartthrowingsnow,squeezethe

augercontrolagainstthelefthandle.Releasetostoptheaugers.

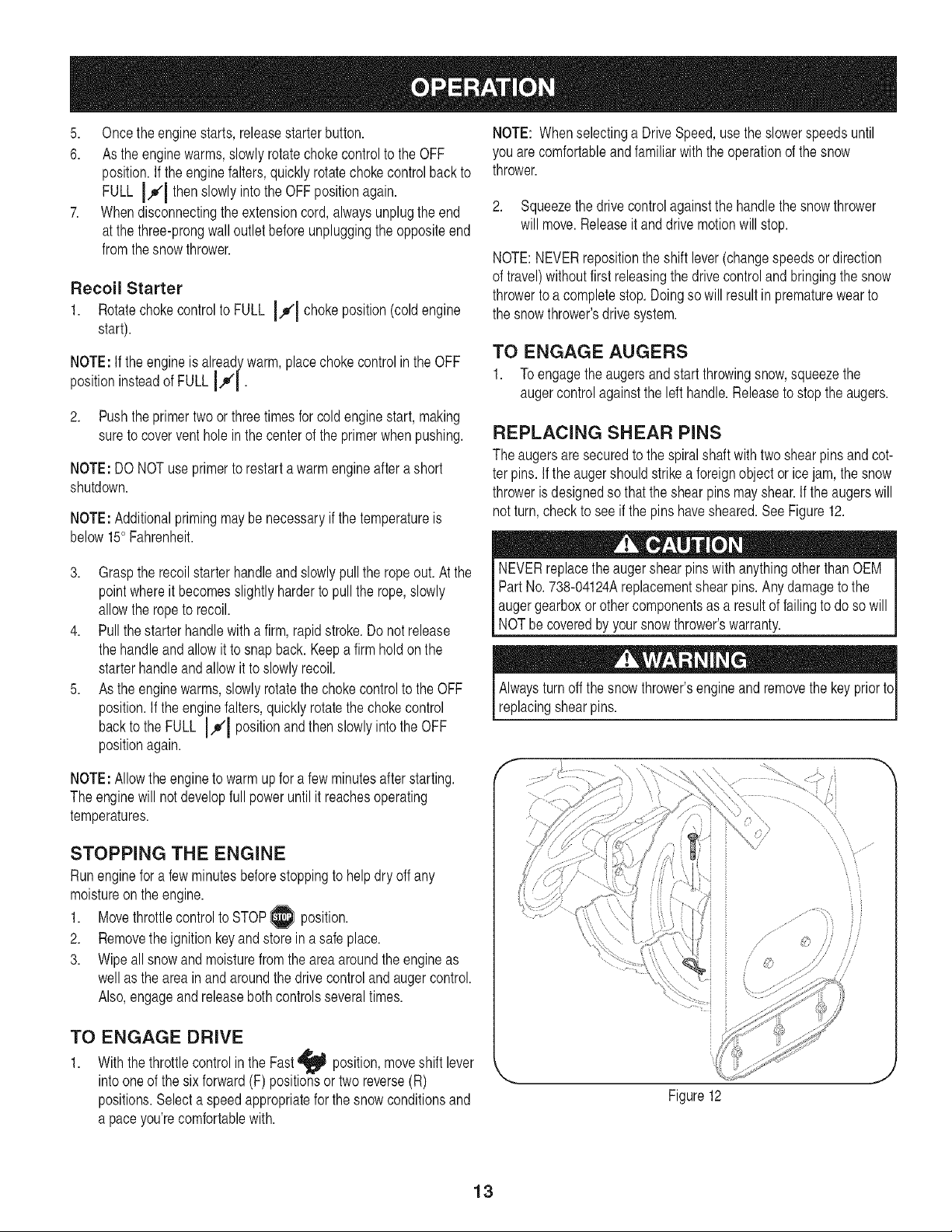

REPLACING SHEAR PiNS

Theaugersaresecuredto thespiralshaftwithtwoshearpinsandcot-

terpins.if theaugershouldstrikea foreignobjector icejam,thesnow

throwerisdesignedsothattheshearpinsmayshear.Iftheaugerswill

notturn,checkto seeifthepins havesheared.SeeFigure12.

3. Graspthe recoilstarterhandleandslowlypulltheropeout.Atthe

pointwhereitbecomesslightlyhardertopullthe rope,slowly

allowthe ropetorecoil.

4. Pullthestarterhandlewitha firm,rapidstroke.Donotrelease

thehandleandallowit tosnapback.Keepa firmholdonthe

starterhandleandallowitto slowlyrecoil.

5. Astheenginewarms,slowlyrotatethechokecontroltotheOFF

position.Iftheenginefalters,quicklyrotatethechokecontrol

backtotheFULL I,_1 positionandthenslowlyintotheOFF

positionagain.

NOTE:Allowtheenginetowarmupfor afewminutesafterstarting.

Theenginewill notdevelopfullpoweruntilit reachesoperating

temperatures.

STOPPING THE ENGINE

Runenginefor a fewminutesbeforestoppingto helpdry off any

moistureonthe engine.

Movethrottlecontrolto STOP1.position.

2. Removethe ignitionkeyandstoreinasafeplace.

3. Wipeallsnowandmoisturefromtheareaaroundtheengineas

wellas the areainandaroundthedrivecontrolandaugercontrol.

Also,engageandreleasebothcontrolsseveraltimes.

NEVERreplacetheaugershearpinswith anythingotherthanOEM

PartNo.738-04124Areplacementshearpins.Anydamagetothe

augergearboxorothercomponentsasaresultof failingtodoso will

NOTbecoveredbyyoursnowthrower'swarranty.

Alwaysturnoffthe snowthrower'sengineand removethekeypriortc

replacingshearpins.

//

TO ENGAGE DRIVE

1. WiththethrottlecontrolintheFast_ position,moveshiftlever

intooneofthesix forward(F)positionsor tworeverse(R)

positions.Selecta speedappropriatefor thesnowconditionsand

a paceyou'recomfortablewith.

Figure12

13

ENGINE MAINTENANCE

Beforelubricating,repairing,orinspecting,disengageallcontrols

land stopengine.Waituntilall movingpartshavecometoacomplete

[stop.

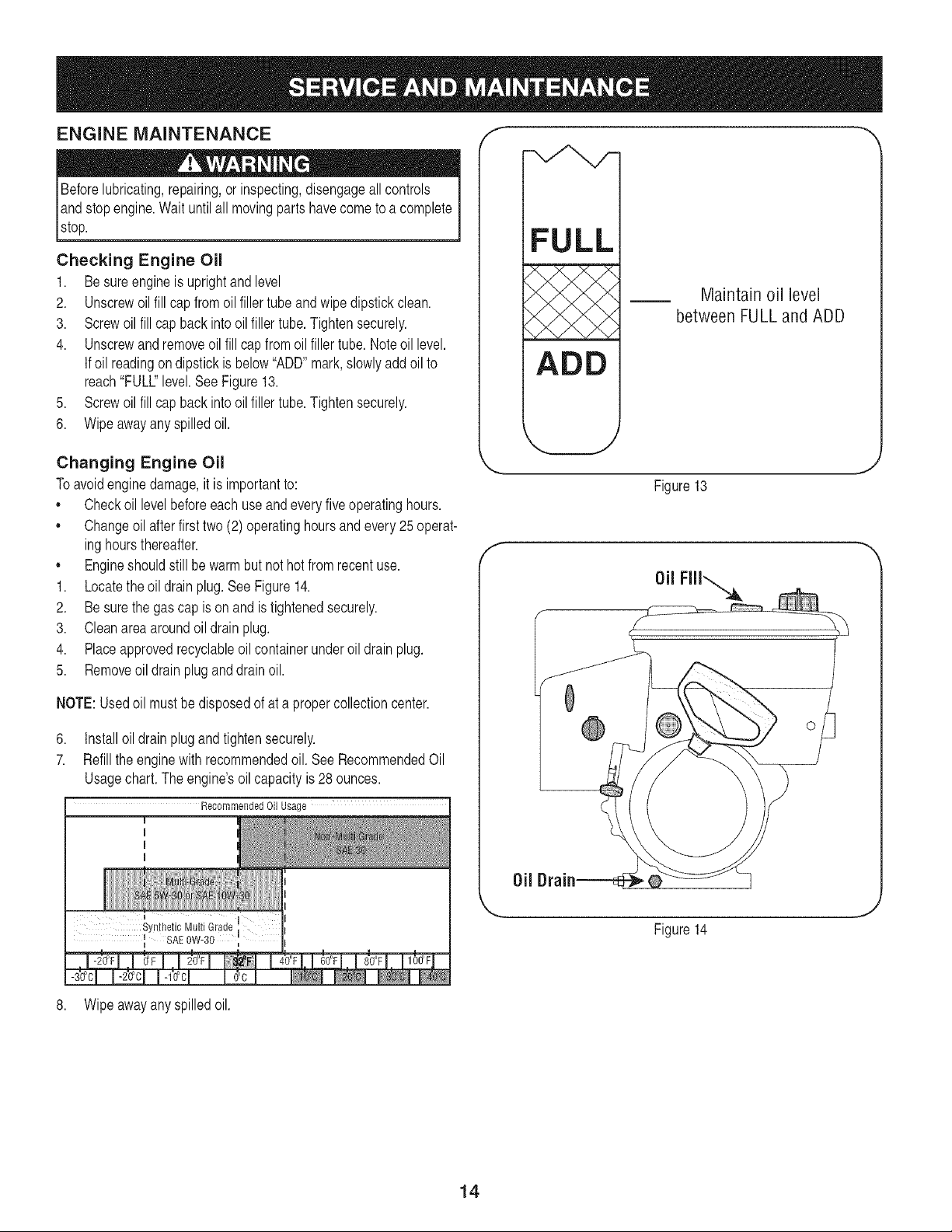

Checking Engine Oil

1. Besureengineisuprightandlevel

2. Unscrewoil fillcapfromoil fillertubeandwipedipstickclean.

3. Screwoil fillcapbackintooilfillertube.Tightensecurely.

4. Unscrewandremoveoilfillcapfromoilfiller tube.Noteoil level.

ifoil readingondipstickisbelow"ADD"mark,slowlyaddoil to

reach"FULL"level.SeeFigure13.

5. Screwoil fillcapbackintooilfillertube.Tightensecurely.

6. Wipeawayanyspilledoil.

f

FULL

Maintain oil level

between FULLand ADD

ADD

Changing Engine Oil

Toavoidenginedamage,itisimportantto:

,, Checkoillevelbeforeeachuse andeveryfiveoperatinghours.

,, Changeoilafterfirst two (2)operatinghoursandevery25operat-

inghoursthereafter.

,, Engineshouldstillbewarmbut nothotfromrecentuse.

1. Locatetheoildrainplug.SeeFigure14.

2. Besurethegas cap isonandistightenedsecurely.

3. Cleanareaaroundoil drainplug.

4. Placeapprovedrecyclableoilcontainerunderoil drainplug.

5. Removeoildrainpluganddrainoil.

NOTE:Usedoil mustbedisposedof ata propercollectioncenter.

6. Installoildrain plugandtightensecurely.

7. Refilltheenginewithrecommendedoil. SeeRecommendedOil

Usagechart.The engine'soilcapacityis28 ounces.

Recommended Oil Usage

I

Synthetic Multi Grade

_ SAE 0W-30

J

Figure13

f

Oil

',,_ _,

Figure14

8. Wipeawayanyspilledoil.

14

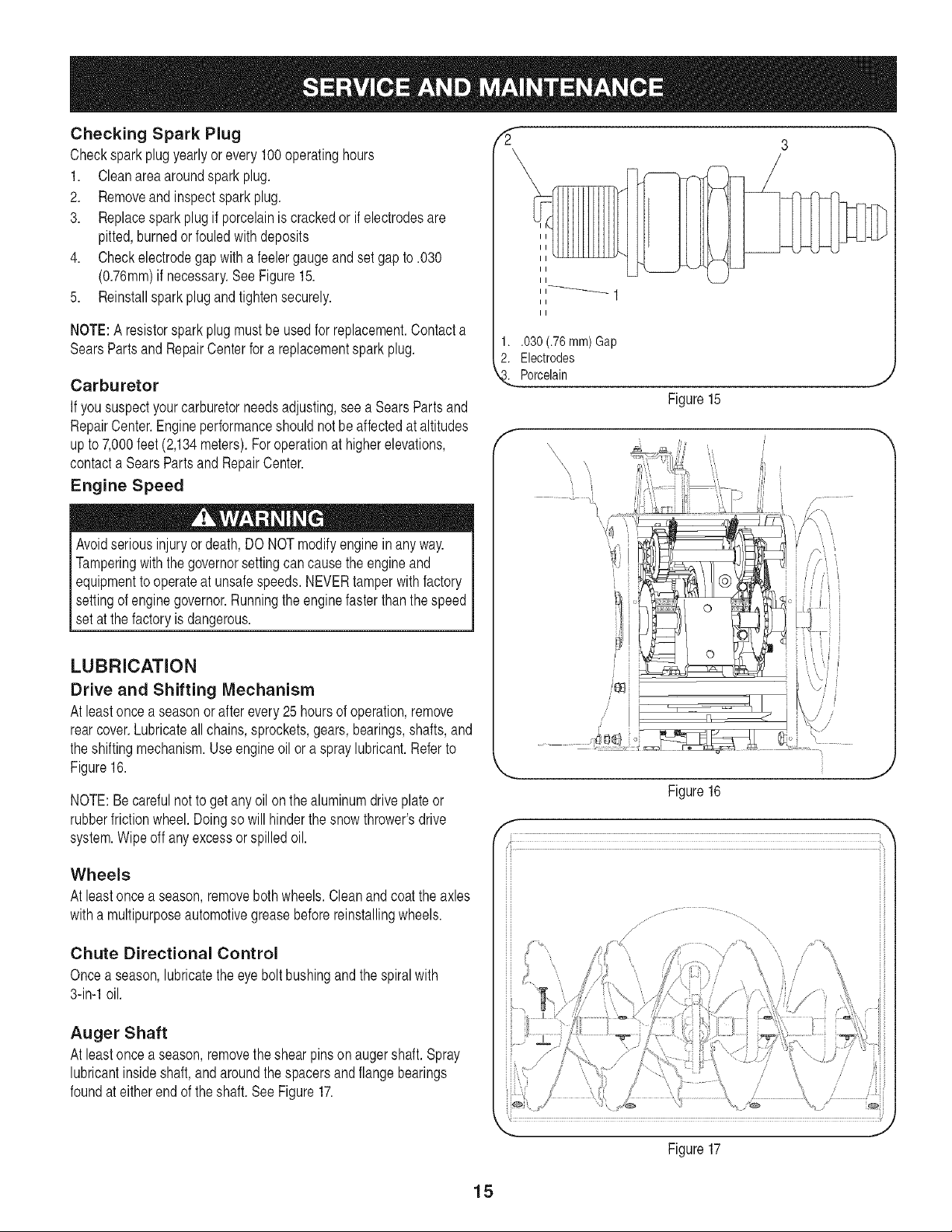

Checking Spark Plug

Checksparkplugyearlyor every100operatinghours

1. Cleanareaaroundsparkplug.

2. Removeand inspectsparkplug.

3. Replacesparkplugif porcelainiscrackedorifelectrodesare

pitted,burnedorfouledwithdeposits

4. Checkelectrodegapwitha feelergaugeandset gapto.030

(0.76ram)ifnecessary.SeeFigure15.

5. Reinstallsparkplugandtightensecurely.

NOTE:A resistorsparkplugmustbeusedforreplacement.Contacta

SearsPartsand RepairCenterfora replacementsparkplug.

Carburetor

If yoususpectyourcarburetorneedsadjusting,seea SearsPartsand

RepairCenter.Engineperformanceshouldnotbe affectedataltitudes

upto7,000feet(2,134meters).Foroperationathigherelevations,

contacta SearsPartsandRepairCenter.

Engine Speed

Avoidseriousinjuryordeath,DONOTmodifyengineinanyway.

Tamperingwiththegovernorsettingcancausetheengineand

equipmenttooperateat unsafespeeds.NEVERtamperwithfactory

settingof enginegovernor.Runningtheenginefasterthanthespeed

set at thefactoryisdangerous.

LUBRICATION

Drive and Shifting Mechanism

Atleastoncea seasonorafterevery25hoursof operation,remove

rearcover.Lubricateall chains,sprockets,gears,bearings,shafts,and

theshiftingmechanism.Useengineoil or aspraylubricant.Referto

Figure16.

NOTE:Becarefulnotto getanyoilon thealuminumdriveplateor

rubberfrictionwheel.Doingsowillhinderthesnowthrower'sdrive

system.Wipeoff anyexcessorspilledoil.

II

II

1..030 (.76ram)Gap

2. Electrodes

Porcelain

f

•••L.i,

Figure15

,,, <¢_._ , , ,

i,, _ ',, i

,,,, _,,,

,,,, _ ,,, _ [

i

,, ,_ [

f

Figure16

3

J

,ji

|¢

J

Wheels

Atleastoncea season,removebothwheels.Cleanandcoattheaxles

withamultipurposeautomotivegreasebeforereinstallingwheels.

Chute Directional Control

Oncea season,lubricatetheeyeboltbushingandthespiralwith

3-in-1oil.

Auger Shaft

Atleastoncea season,removetheshearpinsonaugershaft.Spray

lubricantinsideshaft,andaroundthespacersandflangebearings

foundat eitherendoftheshaft.SeeFigure17.

15

Figure 17

/ 7

/

/

J

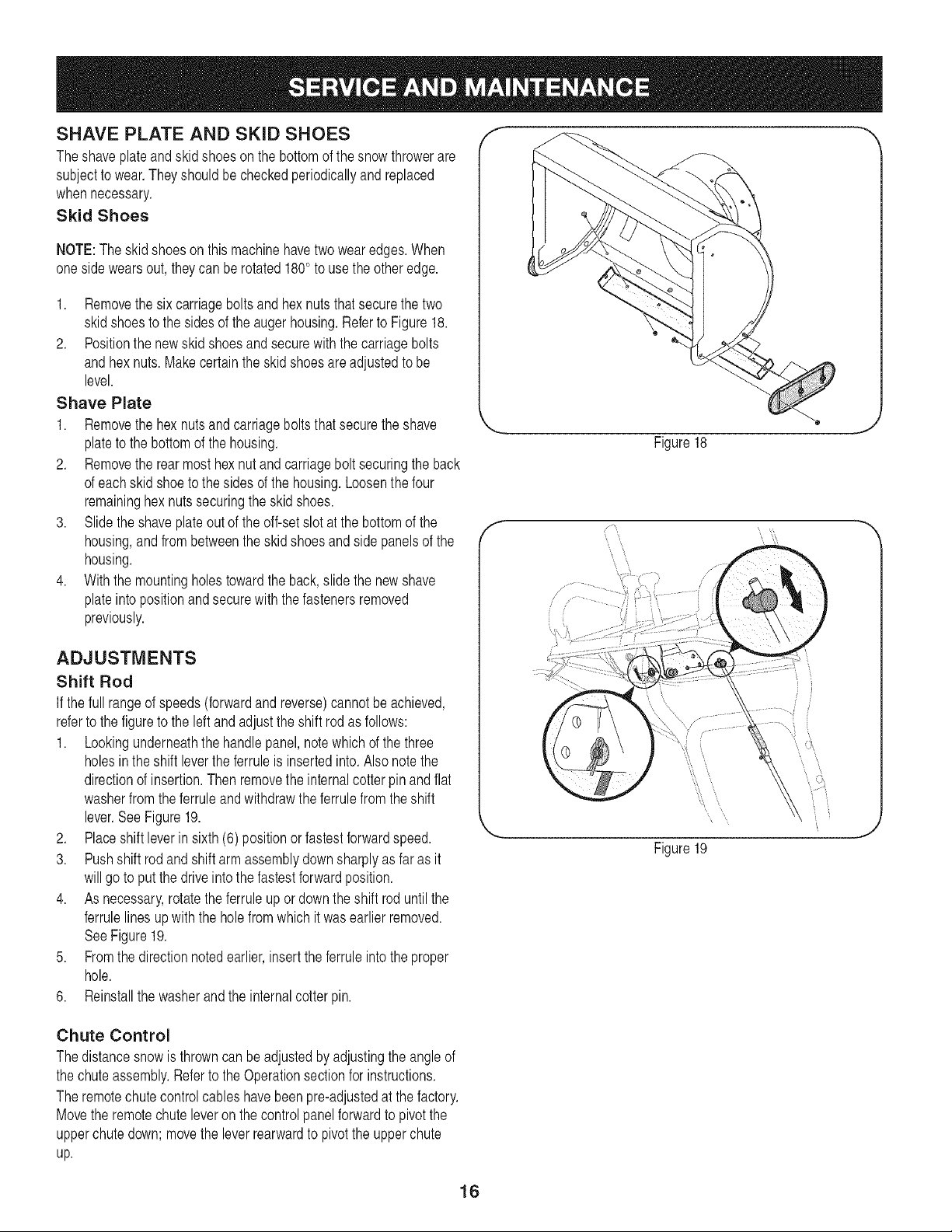

SHAVE PLATE AND SKID SHOES

Theshaveplateandskidshoesonthe bottomofthesnowthrowerare

subjectto wear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

Skid Shoes

NOTE:Theskidshoesonthismachinehavetwowearedges.When

onesidewearsout,theycan berotated180° to usethe otheredge.

1. Removethesixcarriageboltsandhexnutsthatsecurethe two

skidshoestothesidesoftheaugerhousing.RefertoFigure18.

2. Positionthenewskidshoesandsecurewiththecarriagebolts

andhexnuts.Makecertaintheskidshoesareadjustedtobe

level.

Shave Plate

1. Removethe hexnutsandcarriageboltsthatsecuretheshave

plateto the bottomof thehousing.

2. Removethe rearmosthexnutandcarriageboltsecuringthe back

ofeachskidshoetothesidesofthehousing.Loosenthefour

remaininghexnutssecuringthe skidshoes.

3. Slidetheshaveplateoutoftheoff-setslot at thebottomofthe

housing,andfrombetweentheskidshoesandsidepanelsofthe

housing.

4. Withthemountingholestowardthe back,slidethenewshave

plateintopositionandsecurewith thefastenersremoved

previously.

f --,,

Figure18

ADJUSTMENTS

Shift Rod

If the fullrangeofspeeds(forwardandreverse)cannotbe achieved,

referto the figureto theleftandadjusttheshiftrodasfollows:

1. Lookingunderneaththehandlepanel,notewhichofthethree

holesintheshiftlevertheferruleisinsertedinto.Also notethe

directionofinsertion.Thenremovetheinternalcotterpin andflat

washerfromtheferruleandwithdrawtheferrulefromtheshift

lever.SeeFigure19.

2. Placeshift leverinsixth(6)positionor fastestforwardspeed.

3. Pushshift rodandshiftarmassemblydownsharplyas farasit

willgo toput thedriveintothefastestforwardposition.

4. Asnecessary,rotatetheferruleupor downtheshiftroduntilthe

ferrulelinesupwiththeholefromwhichitwasearlierremoved.

SeeFigure19.

5. Fromthedirectionnotedearlier,inserttheferruleintotheproper

hole.

6. Reinstallthewasherandtheinternalcotterpin.

Chute Control

Thedistancesnowisthrowncanbeadjustedbyadjustingtheangleof

thechuteassembly.Referto theOperationsectionforinstructions.

Theremotechutecontrolcableshavebeenpre-adjustedatthe factory.

Movetheremotechuteleveron thecontrolpanelforwardto pivotthe

upperchutedown;movethe leverrearwardto pivottheupperchute

up.

\\

\

\ \

16

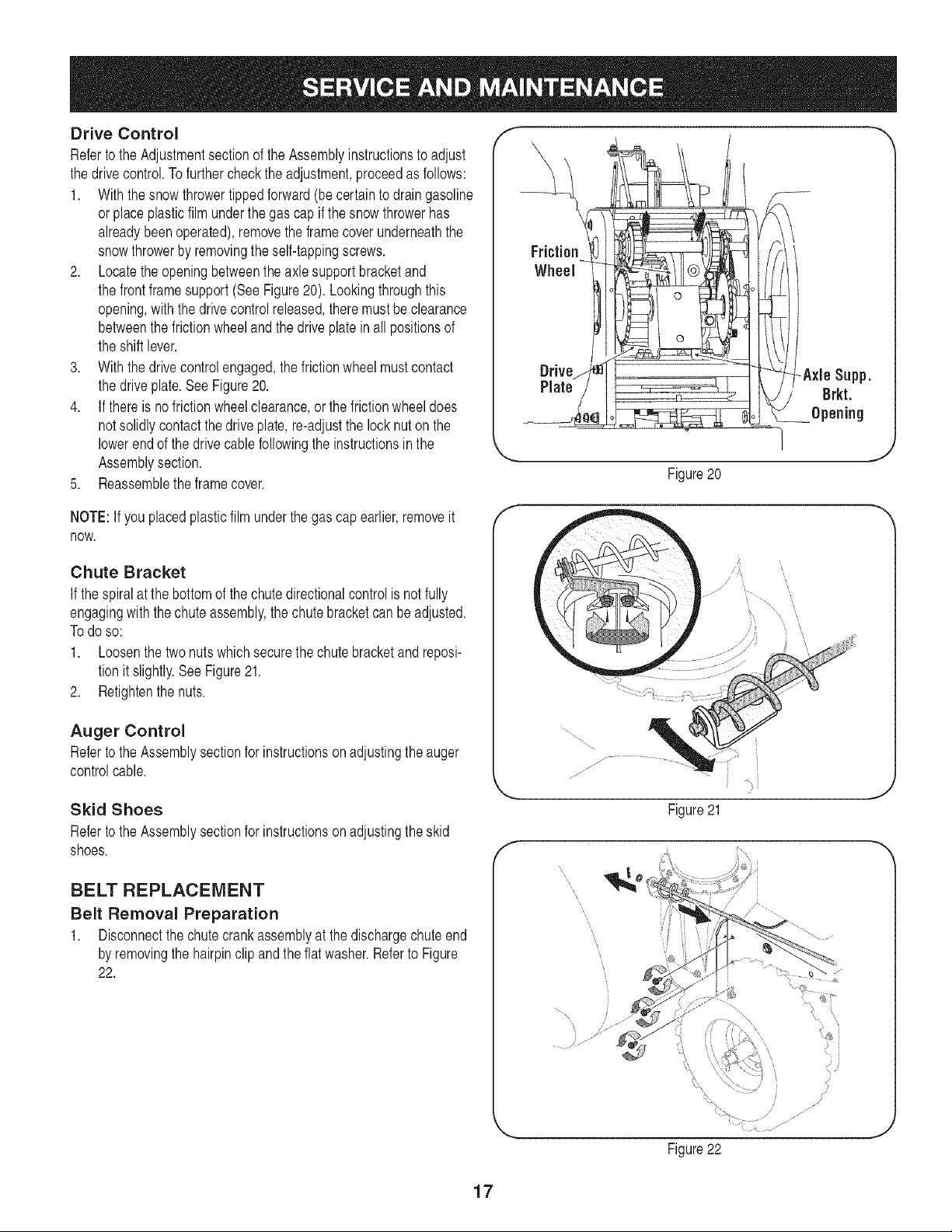

Drive Control

RefertotheAdjustmentsectionoftheAssemblyinstructionsto adjust

thedrivecontrol.Tofurtherchecktheadjustment,proceedasfollows:

1. Withthesnowthrowertippedforward(becertaintodraingasoline

orplaceplasticfilm underthegascapifthesnowthrowerhas

alreadybeenoperated),removetheframecoverunderneaththe

snowthrowerbyremovingtheself-tappingscrews.

2. Locatetheopeningbetweentheaxlesupportbracketand

thefrontframesupport(SeeFigure20). Lookingthroughthis

opening,withthe drivecontrolreleased,theremustbeclearance

betweenthefrictionwheelandthedriveplatein allpositionsof

theshiftlever.

3. Withthedrivecontrolengaged,thefrictionwheelmustcontact

thedriveplate.SeeFigure20.

4. If thereis nofrictionwheelclearance,orthefrictionwheeldoes

notsolidlycontactthedriveplate,re-adjustthelocknutonthe

lowerendofthedrivecablefollowingtheinstructionsinthe

Assemblysection.

5. Reassembletheframecover.

f --,,

Friction

Wheel

DriveN

Plate!

J

Figure20

NOTE:If youplacedplasticfilmunderthegascapearlier,removeit

now.

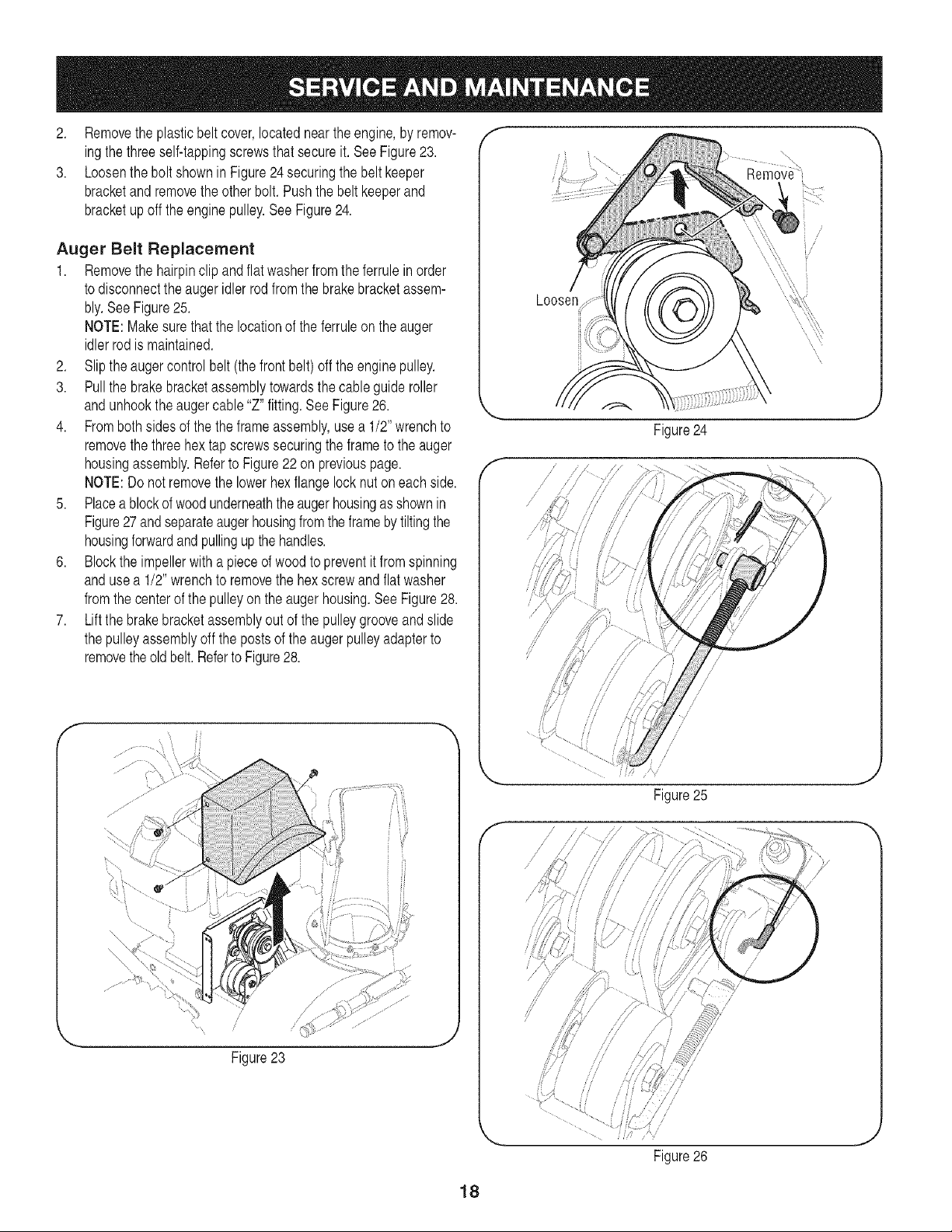

Chute Bracket

If thespiralatthebottomofthechutedirectionalcontrolisnotfully

engagingwiththechuteassembly,thechutebracketcanbeadjusted.

Todoso:

1. Loosenthetwonutswhichsecurethechutebracketandreposi-

tionitslightly.SeeFigure21.

2. Retightenthenuts.

Auger Control

RefertotheAssemblysectionforinstructionsonadjustingtheauger

controlcable.

Skid Shoes

RefertotheAssemblysectionforinstructionsonadjustingtheskid

shoes.

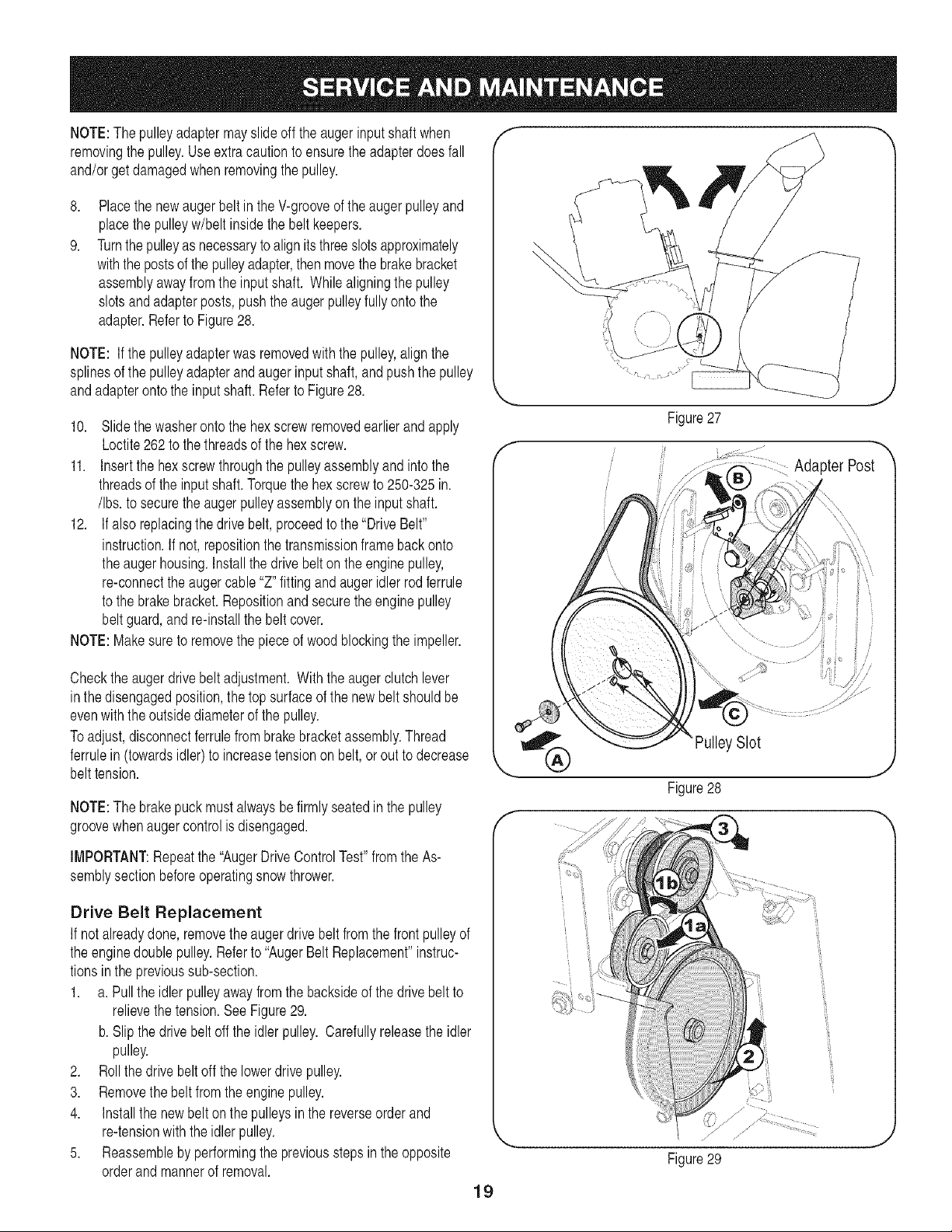

BELT REPLACEMENT

Belt Removal Preparation

1. Disconnectthechutecrankassemblyat the dischargechuteend

byremovingthehairpinclipandtheflat washer.RefertoFigure

22.

f

/

J

Figure21

f

17

Figure22

....JJ

,/

j,

J

2. Removethe plasticbeltcover,locatedneartheengine,byremov-

ingthethreeself-tappingscrewsthatsecureit.SeeFigure23.

3. Loosentheboltshownin Figure24securingthebeltkeeper

bracketandremovetheotherbolt. Pushthe beltkeeperand

bracketupofftheenginepulley.SeeFigure24.

Auger Belt Replacement

1. Removethe hairpinclipandflatwasherfromthe ferruleinorder

todisconnecttheaugeridlerrodfromthe brakebracketassem-

bly.SeeFigure25.

NOTE:Makesurethatthe locationoftheferruleonthe auger

idlerrodis maintained.

2. Sliptheaugercontrolbelt(thefrontbelt)offtheenginepulley.

3. Pullthebrakebracketassemblytowardsthecableguideroller

andunhooktheaugercable"Z"fitting.SeeFigure26.

4. Frombothsidesofthe the frameassembly,usea 1/2"wrenchto

removethethreehex tapscrewssecuringtheframetothe auger

housingassembly.Referto Figure22on previouspage.

NOTE:Do notremovethelowerhexflangelocknutoneachside.

5. Placeablockofwoodunderneaththe augerhousingasshownin

Figure27andseparateaugerhousingfromtheframebytiltingthe

housingforwardandpullingupthehandles.

6. Blockthe impellerwithapieceofwoodtopreventitfromspinning

andusea 1/2"wrenchto removethehexscrewandflatwasher

fromthecenterofthe pulleyon the augerhousing.SeeFigure28.

7. Liftthebrakebracketassemblyoutofthepulleygrooveandslide

thepulleyassemblyoffthe postsof theaugerpulleyadapterto

removetheoldbelt.RefertoFigure28.

f --,,

/

/

Loosen

/

//

Figure24

i

,,J

Figure23

18

Figure25

f

/" /, //

// //

// ,/

/

J

Figure26

NOTE:Thepulleyadaptermayslideoffthe augerinputshaftwhen

removingthepulley.Useextracautiontoensuretheadapterdoesfall

and/orget damagedwhenremovingthepulley.

8,

Placethe newaugerbeltin the V-grooveof theaugerpulleyand

placethe pulleyw/beltinsidethe beltkeepers.

9.

Turnthepulleyasnecessarytoalignitsthreeslotsapproximately

withthepostsofthepulleyadapter,thenmovethe brakebracket

assemblyawayfromtheinputshaft. Whilealigningthe pulley

slotsandadapterposts,pushtheaugerpulleyfullyontothe

adapter.Referto Figure28.

NOTE: If thepulleyadapterwasremovedwiththepulley,alignthe

splinesofthepulleyadapterandaugerinputshaft,andpushthepulley

andadapterontothe inputshaft.Referto Figure28.

10. Slidethewasherontothehexscrewremovedearlierandapply

Loctite262tothethreadsof the hexscrew.

11. Insertthe hexscrewthroughthepulleyassemblyandintothe

threadsoftheinputshaft.Torquethe hexscrewto 250-325in.

/Ibs.tosecuretheaugerpulleyassemblyontheinputshaft.

12. Ifalso replacingthe drivebelt,proceedtothe"DriveBelt"

instruction.Ifnot,repositionthetransmissionframebackonto

theaugerhousing.Installthedrivebelton theenginepulley,

re-connecttheaugercable"Z"fittingandaugeridlerrodferrule

tothebrakebracket.Repositionandsecuretheenginepulley

beltguard,andre-installthe beltcover.

NOTE:Makesureto removethepieceofwoodblockingtheimpeller.

f

Adapter Post

Checktheaugerdrivebeltadjustment.Withtheaugerclutchlever

inthedisengagedposition,thetopsurfaceofthenewbeltshouldbe

evenwiththeoutsidediameterof thepulley.

Toadjust,disconnectferrulefrombrakebracketassembly.Thread

ferrulein (towardsidler)toincreasetensiononbelt,orouttodecrease

belttension.

NOTE:Thebrakepuckmustalwaysbefirmlyseatedinthe pulley

groovewhenaugercontrolisdisengaged.

IMPORTANT:Repeatthe "AugerDriveControlTest"fromtheAs-

semblysectionbeforeoperatingsnowthrower.

Drive Belt Replacement

If notalreadydone,removethe augerdrivebeltfromthefrontpulleyof

theenginedoublepulley.Referto"AugerBeltReplacement"instruc-

tionsinthe previoussub-section.

1. a.Pulltheidlerpulleyawayfromthebacksideofthedrivebelt to

relievethetension.SeeFigure29.

b.Slipthedrivebelt offtheidler pulley.Carefullyreleasetheidler

pulley.

2. Rollthedrivebeltoff thelowerdrivepulley.

3. Removethebeltfromtheenginepulley.

4. Installthenewbeltonthepulleysin thereverseorderand

re-tensionwith theidlerpulley.

5. Reassemblebyperformingthepreviousstepsintheopposite

orderandmannerof removal.

,ySlot

Figure28

// ,/ j

Figure29

19

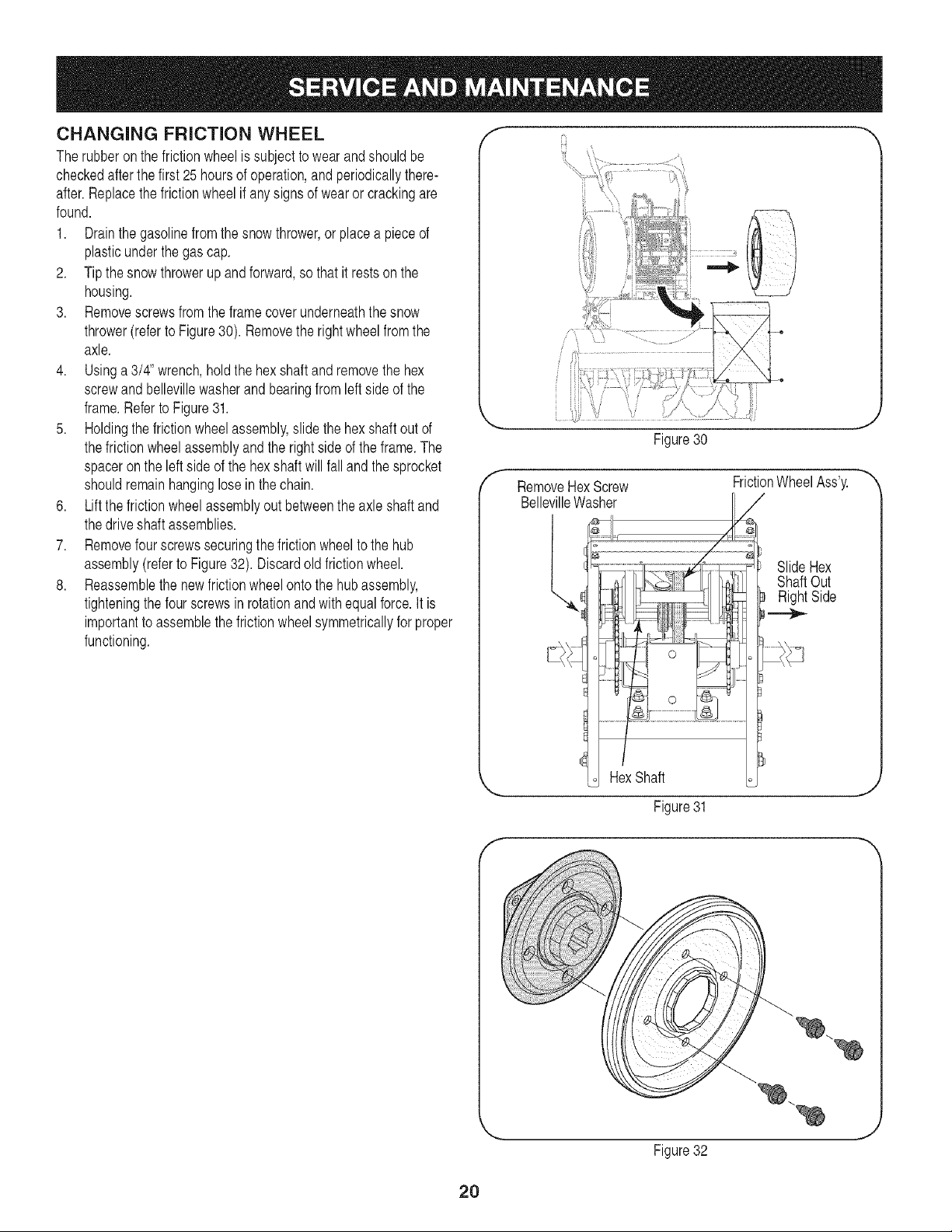

CHANGING FRICTION WHEEL

Therubberonthefrictionwheelissubjecttowearandshouldbe

checkedafterthefirst25hoursofoperation,andperiodicallythere-

after.Replacethefrictionwheelifanysignsofwearorcrackingare

found.

1. Drainthegasolinefromthesnowthrower,or placeapieceof

plasticunderthe gas cap.

2. Tipthesnowthrowerupandforward,sothat itrestsonthe

housing.

3. Removescrewsfromtheframecoverunderneaththesnow

thrower(referto Figure30). Removetherightwheelfromthe

axle.

4. Usinga 3/4"wrench,holdthe hex shaftandremovethe hex

screwandbellevillewasherand bearingfromleft sideofthe

frame.Referto Figure31.

5. Holdingthefrictionwheelassembly,slidethe hex shaftout of

thefriction wheelassemblyandtherightside oftheframe.The

spacerontheleftsideofthehexshaft will falland thesprocket

shouldremainhanginglosein thechain.

6. Liftthefrictionwheelassemblyout betweentheaxleshaftand

thedrive shaftassemblies.

7. Removefourscrewssecuringthefrictionwheeltothehub

assembly(referto Figure32).Discardoldfrictionwheel.

8. Reassemblethenewfrictionwheelontothehubassembly,

tighteningthefourscrewsin rotationandwithequalforce.It is

importanttoassemblethefrictionwheelsymmetricallyforproper

functioning.

f --,,

{_ ?q ,gr

Figure30

f

RemoveHexScrew

BellevilleWasher

l,

FrictionWheelAss'y.

SlideHex

ShaftOut

RightSide

2O

RexShaft

,J

Figure31

,J

Figure32

Loading...

Loading...