Craftsman 247794500 Owner’s Manual

Owner's Manual

[I:RR

/

22 Ton Hydraulic

Log Splitter

Model No.

247.794500

/

/

Ii

CAUTION: Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

Sears, Roebuck And Co., Hoffman Estates, IL 60179, U.S.A.

Printedin U.S.A. 770-10035A

(7/99)

I!

/

U

Content Page

Warranty Information......................................... 2

Safe Operation Practices................................... 3

Accessories ....................................................... 7

Assembly........................................................... 8

Operation........................................................... 10

Content Page

Maintenance...................................................... 14

Service & Adjustment........................................ 17

Off-Season Storage........................................... 19

Trouble-Shooting............................................... 20

Parts List............................................................ 22

ONE-YEAR WARRANTY ON CRAFTSMAN LOG SPLITTER

For one year from the date of purchase, when this Craftsman log splitter is maintained, lubricated, and tuned up

according to the operating and maintenance instructions in the operator's manual, Sears will repair, free of

charge, any defect in material or workmanship.

This warranty excludes the tires, spark plug, oil filter and air cleaner, which are expendable parts and become

worn during normal use.

If this log splitter is used for commercial or rental purposes, this warranty applies for only 30 days from the date

of purchase.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER IN THE

UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED

STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

Horsepower: ......................... 5.0

Engine Oil.............................. SAE 30/1.25 pints

Fuel Capacity: ....................... unleaded/1.25 qts.

Hydraulic Fluid ...................... Dexron III/4 gallons

Tire Pressure ......................... 30 p.s.i, maximum

Spark Plug (Gap .030").......... Champion RJI9LM

Magnetron Ignition Air Gap.....0125"

Model Number..2..4,7.:7..9.4..5.0,0....................................

Serial Number ...........................................................

Date of Purchase ......................................................

Record model number, serial number and date of

purchase ofthe log splitterand keep in a safe place

for future reference.

Thissymbol points out important safety instructions which,ifnot followed,couldendangertheper-

sonalsafetyand/orpropertyof youmelfandothers.Read and follow all instructionsin thismanualbefore

attempting tooperateyour logsplitter.Failuretocomplywiththeseinstructions may resultinpersonal injury.

When you seethissymbol--heed its warning.

Your log splitter was built to be operated according to the rules for safe operation In this

manual, As with any type of power equipment, carelessness or error on the part of the oper-

ator can result in serious injury, if you violate any of these rules, y_u may cause serious

injury to yourself or others,

The engine exhaustfrom this product contains chemicals known to the state of California to cause

cancer, birthdefects or other reproductive harm.

Towing

• This unit should notbe towed on any street,

highway or publicroad withoutchecking the

existing federal, local or state requirements.

Such information may be obtained bycallingyour

state or local bureau of motorvehicles. Any

licensingormodificationsneeded tocomplywith

federal, localor state vehiclerequirements isthe

sole responsibilityofthe purchaser.

• Make sure you follow the wiring diagram color

codes when installing the light kit on the log

splitter. (e.g. ground to ground, left turn to left

turn, etc.). Failure to wire unit correctly may

cause the tow vehicle wiring to overheat and/or

the log splitterlights to operate incorrectly. It may

be necessary to replace the turn signal flasher

unitin your tow vehicle if it is notcapable of

operatingthe additionallightsonthe log splitter.

• Before towing the log splitter on a street, highway

or public road, verify that all lights are functioning

properly and the yellow side reflectors are in

position. Replace bulbs if they are burnt out.

• Before towing, always check to be certain the log

splitter is correctly and securely attached to the

tow vehicle, and safety chains are inplace.

Leave slack in chains for turning allowance.

• Use a class I or higher hitch with a 1-7/8" ball.

Keep ball socketand clamp face lubricated with

chassis grease.

• Be sure the coupleris secured to the hitch ball

and the lock lever isdown tight and locked.

• Check vehicle hitch, ball and coupler for signs of

wear or damage. Replace any parts that are worn

or damaged before towing.

• The coupler must be secured to the log splitter

tongue tube with the original equipment bolts and

nuts. See your authorized service dealer for

replacement parts. Coupler nuts should be

tightened securely (20 foot pounds).

• Make sure beam assembly is securely latched in

the horizontal position andjack stand (if provided)

ispivotedand secured inthe up positionbefore

towing log splitter,Never tow withthe beam in

vertical position.

• Do not tow the log splitterfasterthan 45 MPH.

Higher speeds may damage logsplitter.

Excessive highspeeds may cause the logsplitter

to=fishtail" or otherwise become unstable.

• Check the tire pressure on the logsplittertires. It

must be 30 p.s.i. MAXIMUM for highway travel.

• When parking, storingor usingyour logsplitter,

keep the coupler offthe groundso dirtwillnot

build up inthe ball socket.

• Do not allow anyone to sit or ride on your log

splitter. They can easily fall off and be seriously

injured.

Training

• Beforeoperating this log splitter, read and

understand thisoperator's manual completely.

Become familiar with itfor your ownsafety. To fail

to do somay cause serious injury. Do notallow

anyone to operate yourlog splitterwho has not

read this manual. Keep this manual in a safe

place for future and regular reference and for

ordering replacement parts.

• Never use your splitter for any other purpose than

splitting wood. It is designed for this use and any

other use may cause an injury.Your logsplitteris

a precisionpiece of power equipment, nota toy.

Therefore, exercise extreme caution at all times.

• Never arrow childrento operate your log splitter.

Do not allowadultsto operate itwithoutproper

instruction.Only personswell acquainted with

these rules of safe operationshouldbe allowedto

use your log splitter.

• Only the operatoristo be near your logsplitter

during use. Keep all others, includingpetsand

children,a minimumof20 feet away from your

workzone. Flyingwoodcan be hazardous. If a

helper is assisting in loadinglogs, never activate

3

the control untilthe helper isclear ofthe area,

More accidents occur when more than one

person operates thelogsplitterthan at any other

time.

No one should operate thisunit while intoxicated

or while taking medicationthat impairsthe

senses or reactions.A clear mindisessentialfor

safety. Never allow a person who is tired or

otherwise notalert to use yourlogsplitter.

Preparation

• Never wear loose clothingorjewelry thatcan be

caught by movingparts ofyour log splitterand

pullyou intoit. Keep clothingaway from all

moving partsof your log splitter.

• Wear properhead gear to keep hairaway from

moving parts. Always wear protectivehearing

devices as needed.

• Always wear safety shoes. A dropped logcan

seriouslyinjureyourfoot.

• Always wear safety glasses or goggles while

operatingyour splitter. A piece of splittinglog

couldfly off and hityoureyes.

• Wear leather work gloves. Be sure theyare tight

fitting without loose cuffsor draw strings.

• Use your log splitterin daylight, or undergood

artificial light.

• Never operate your splitter on slippery, wet,

muddy or icy surfaces. Safe footing is essential

in preventing accidents,

• Never operate your splitterwhile attached to a

towingvehicle.

• Only operate your splitter on level ground and

not on the sideof ahill. Itcould tip, or rolling logs

or poor footing could cause an accident.

Operating the splitteron level ground also

prevents the spillage of gasoline from the fuel

tank.

• Never attempt to move the log splitter over hilly

or uneven terrain without a tow vehicle or

adequate help.

• Always block the wheels to prevent movement

of log splitter while in operation.

• Check the fuel before starting the engine.

Gasoline is an extremely flammable fuel. Do not

fill the gasoline tank indoors, when the engine is

running, or while the engine is still hot. Replace

gasoline cap securely and wipe off any spilled

gasoline before startingthe engine as it may

cause a fire or explosion.

• Both ends of each log must be cut as square as

possible to help prevent the log from riding out of

the splitter during operation.

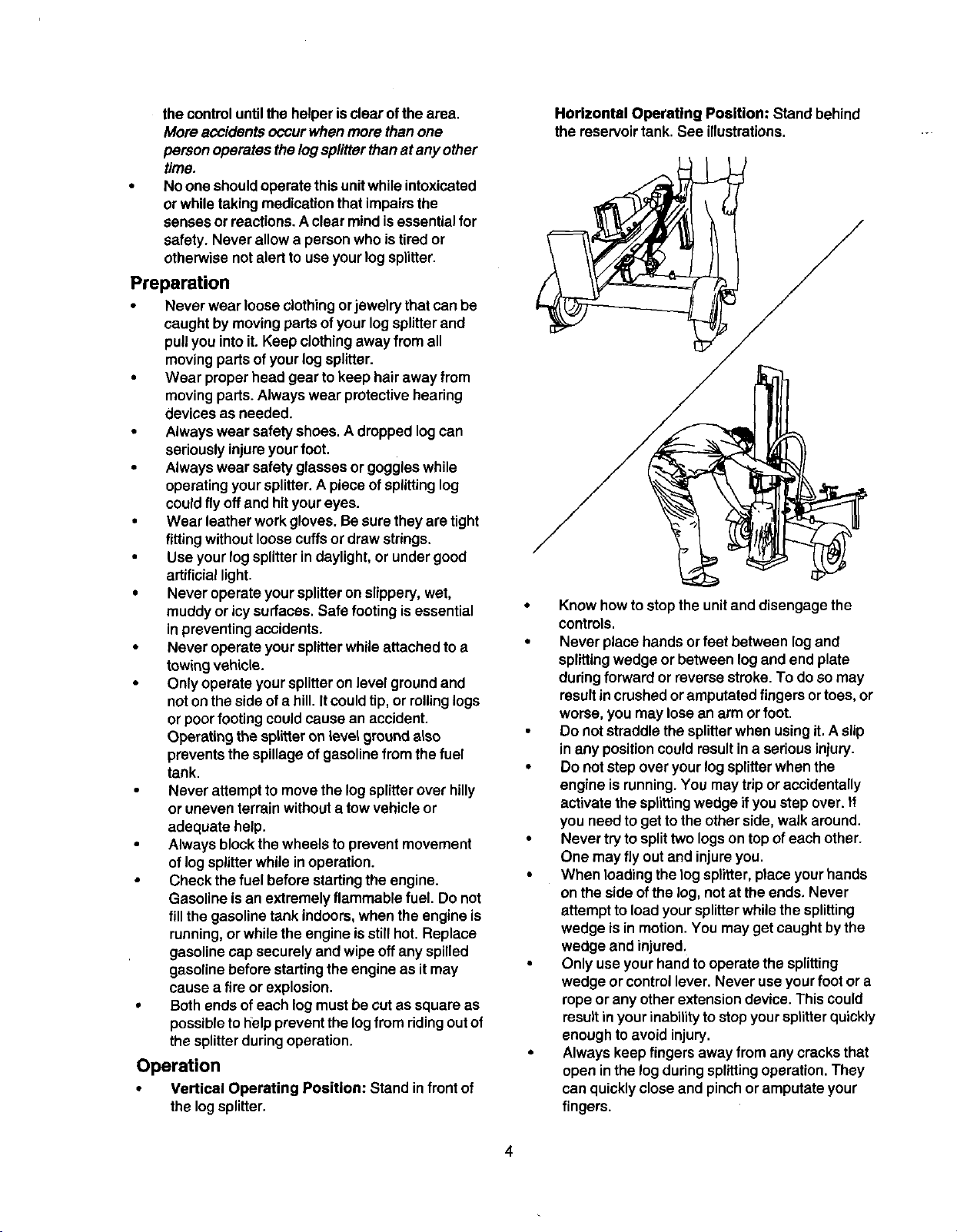

Operation

• Vertical Operating Position: Stand infront of

the logsplitter.

Horizontal Operating Position: Stand behind

the reservoirtank. See illustrations.

Know how to stop the unit and disengage the

controls.

Never place hands or feet between log and

splittingwedge or between log and end plate

during forward or reverse stroke. To do so may

result in crushed or amputated fingers or toes, or

worse, you may lose an arm or foot.

Do not straddle the splitter when using it. A slip

in any position could result in a serious injury.

Do not step over your log splitter when the

engine is running. You may trip or accidentally

activatethe splittingwedge if you step over.If

you need to get to the other side,walk around.

Never try to split two logs on top of each other.

One may fly out and injure you.

When loading the logsplitter, place your hands

on the side of the log, not at the ends. Never

attemptto load your splitter while the splitting

wedge is in motion. You may get caught by the

wedge and injured,

Only use your hand to operate the splitting

wedge or control lever, Never use your foot or a

rope or any other extensiondevice. This could

result in your inability to stopyour splitterquickly

enough to avoid injury.

Always keep fingers away from any cracks that

open inthe log during splitting operation. They

can quickly close and pinch or amputate your

fingers.

• Never attemptto split woods across the grain.

Some types ofwood may burst or fly out ofyour

splitterand result in injuryto you or a bystander.

• For logsthat are notcut square, the longest

portionof the logshould be rotated down and

the most square end placed against the splitting

wedge.

• Keep your work area clean. Immediately

remove splitwoodaround your splittersothat

you do notstumble over it. Clean chipsand dirt

offend plate (wood platform)after each logis

split, orwhenever necessaryto maintain flat

contact between wood and end plate (platform).

• Never move the togsplitterwhile the engine is

running.

• Never leave yourlogsplitterunattended withthe

engine running.Shut off the engine ifyou are

leaving your splitter,even for a short period of

time. Someone couldaccidentally activate the

splittingwedge and be injured.

• Do not run engine in an enclosed area. Exhaust

gases contain carbon monoxide.This odorless

gas can be deadly when inhaled.

• Be careful not to touch the mufflerafter the

engine has been running. It will be HOT!

• Ifthe equipment shouldstarttovibrate

abnormally, stopthe engine and check

immediately for thecause. Vibration is generally

a warning of trouble.

• When cleaning, repairingor inspecting,make

certain all moving parts have stopped.

Disconnectthe spark plugwire and keep the

wire away from the plugto prevent accidental

starting.

Customer Responsibilities

• Do not operate yoursplitter inpoor mechanical

conditionor when in need of repair,

• Periodicallycheck that all nuts, bolts, screws,

hose clamps and hydraulicfittingsare tightto be

sure equipment is insafe workingcondition.

Where appropriate, check all safety guards and

shieldsto be sure they are intheproper position.

Never operate yoursplitterwithsafety guards,

shields orother protectivefeatures removed.

These safety devices are for yourprotection.

• Replace all damaged orworn partssuch as

hydraulichoses and fittingsimmediately with

manufacturer approved replacement parts.

• Do not change the engine governor settingsor

overspeed the engine. This increases the

hazard of personal injury. The maximum engine

speed is preset by the manufacturer and is

within safety limits.

• Do not alter your log splitter in any manner such

as attaching a rope or extension to the control

lever or adding to the width or height of the

wedge. Such alterations may cause yoursplitter

to be unsafe.

• Perform all recommended maintenance

proceduresbefore you use your splitter.

• Do notservice or repair your log splitterwithout

disconnectingthe spark plugwire and movingit

away from the spark plug.

• Never storethe equipmentwithgasoline inthe

tank inside ofa buildingwhere ignitionsources

are present, such as hot water and space

heaters, clothes dryers and the like.Allow the

engineto cool before storinginany enclosure.

• Always storegasoline in an approved, tightly

sealed container. Store the container in a cool,

dryplace. Donot store in a building where

ignitionsources are present.

• To reduce fire hazard, keep engine free ofgrass,

leaves, wood chips, and excessive grease and

oil.

• The hydraulicsystem of yourlogsplitterrequires

carefulinspection,along with the mechanical

parts. Be sure to replace frayed, kinked,or

otherwisedamaged hydrauliccomponents.

• Fluidescaping from a very small hole can be

almostinvisible.Do notcheck for leakswithyour

hand. Escapingfluid underpressure can have

sufficientforce to penetrate skin, causing

seriouspersonal injury.Leakscan be locatedby

passinga piece of cardboardor wood over the

suspectedleak and lookingfor discoloration.

• Shoulditbecome necessary to loosenor

remove any hydraulicfitting or line, be sure to

relieveall pressure by shuttingoff the engine

and movingthe control handle back and forth

several times.

• Do not removethe capfrom thehydraulictank or

reservoirwhile your log splitterisrunning.Hot oil

under pressure could cause injury.

• The pressure relief valve on yoursplitteris

preset at the factory. Do notadjustthe valve.

Onlya qualified servicetechnician should

performthisadjustment.

• Completelydrain fuel tank priorto storage. This

guardsagainst accumulationoffuel fumes

which couldresult in a fire hazard.

• Never store log splitteroutsidewithouta

waterproofcover. Rain willcause ruston the

insideof the cylinder.

Important Information

Always:

• Use clean fluid and check fluid level regularly.

• Use Dexron III Automatic Transmission Fluid or

10W non-foaming hydraulic fluid.

• Use a filter (clean or replace regularly).

• Use a breather cap on fluid reservoir.

5

• Make certain pumpis mounted and aligned

properly.

• Use a flexible "spider" type couplingbetween

engine and pump drive shafts.

• Keep hoses clear and unblocked.

• Bleed air out ofhoses before operating.

• Flushand clean hydraulicsystem beforestart-

up after any malfunctionor servicing.

• Use "pipe dope" on all hydraulicfittings.

• Allow time for warm-up before splittingwood,

• Prime the pump before initialstart-up byturning

over the engine with spark plug disconnected.

• Split wood with thegrain (lengthwise) only.

Never:

• Use when fluid is below 20° F, orabove 150° F,

• Use a solidengine/pump coupling.

• Force pump when mounting.

• Operate through reliefvalve.

• Attempt to adjust unloadingor relief valve.

settingswithoutpressure gauges.

• Operate with air in hydraulic system.

• Use Teflon tape on hydraulicfittings.

• Attempt to cut woodacross the grain,

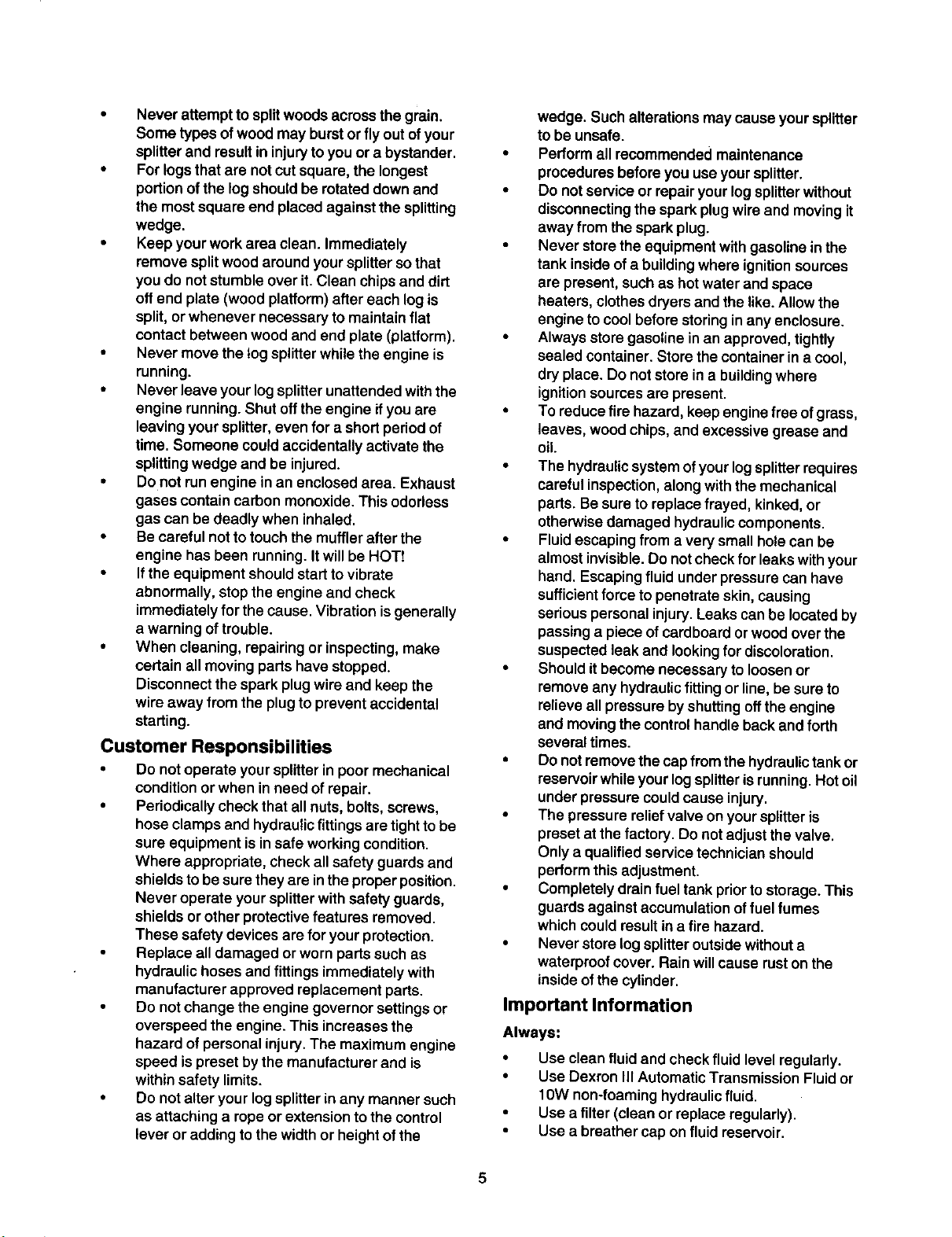

Theseaccessorieswereavailable when the logsplitterwas purchased. These are also available at most Sears

retail outlets, catalog and service centers. Most Sears stores can order repair parts for you when you provide the

model number of your log splitter.

Gasoline Can

Tailight Kit

-<_Fender

IMPORTANT: This unitisshipped without gasoline

in the engine. Afterassembly, see OPERATION

sectionofthis manual for properfuel fill-up.

Tools and Other Items Required

1. Crowbar orLarge Screwdriver

2. A pair of 9/16" Wrenches or a set ofAdjustable

Wrenches

3. Screwdriver

4. Cutters

5. Engine Oil for lubricatingbeam (equipmentis

shippedwith engine oil in the engine forstarting)

6. Unleaded Gasoline

7. Dexron III AutomaticTransmission Fluid or 10W

Non-Foaming Hydraulic Fluid (approximately 4

gallons)

Unpacking from Crate

WARNING: Exercise extreme caution as

parts are very heavy. Mechanical handling

equipment or sufficientmanpower should

beused to prevent injury.

• Prythe top, sides and ends offcrate using a

crowbar or large screwdriver.

• Set panels aside to avoid tire punctures or

personal injury.

• Remove and discard plastic bag that covers

unit.

Note: Do not remove the banding fromaround the

tankuntil the log splitteris assembled.

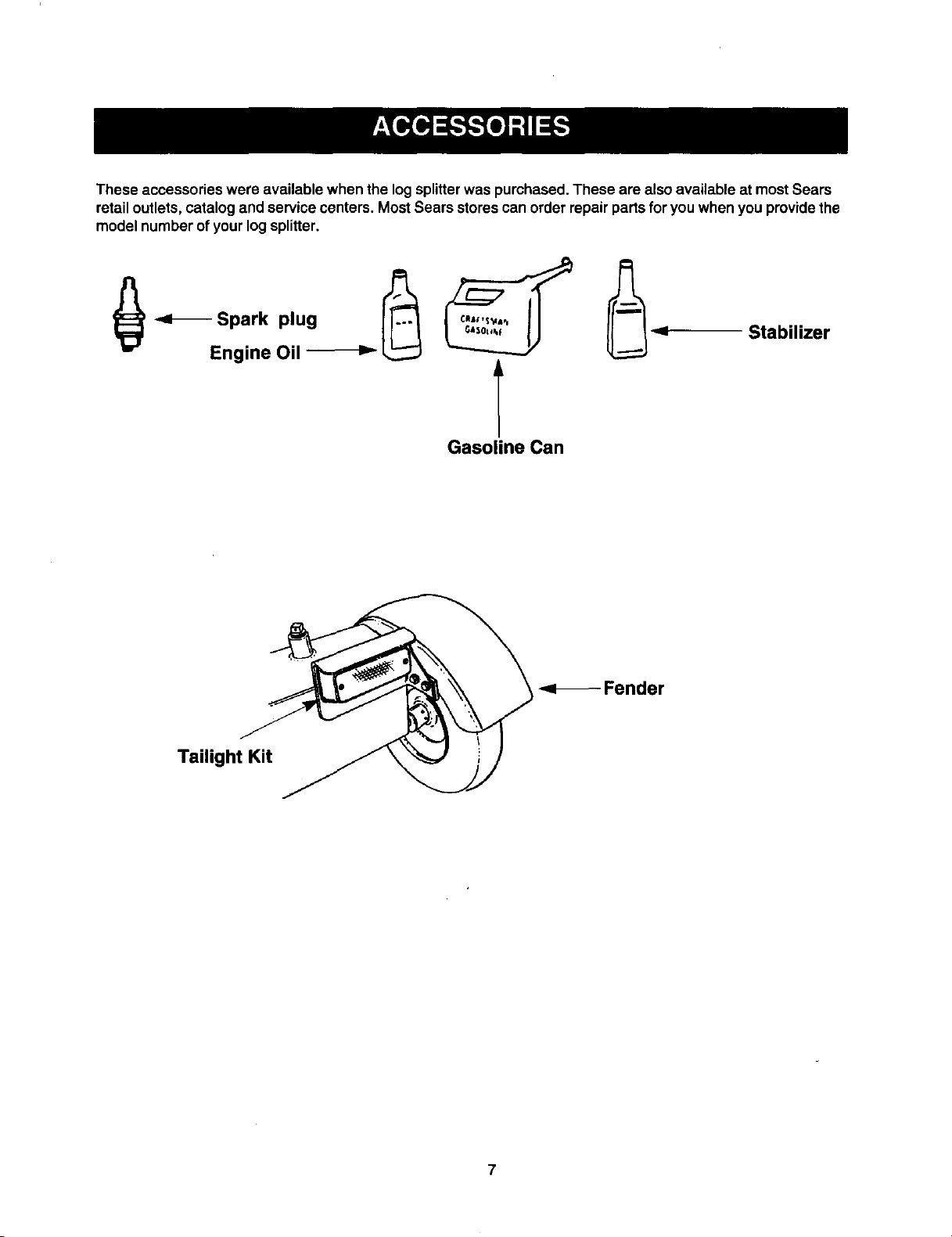

Disconnecting Spark Plug

• Before you proceed withthe assembly

procedure, disconnectthe sparkplugwire from

the spark plug on the logsplitterengine and

move the wire away from the spark plug. This

willprevent accidental starting.See Figure 1.

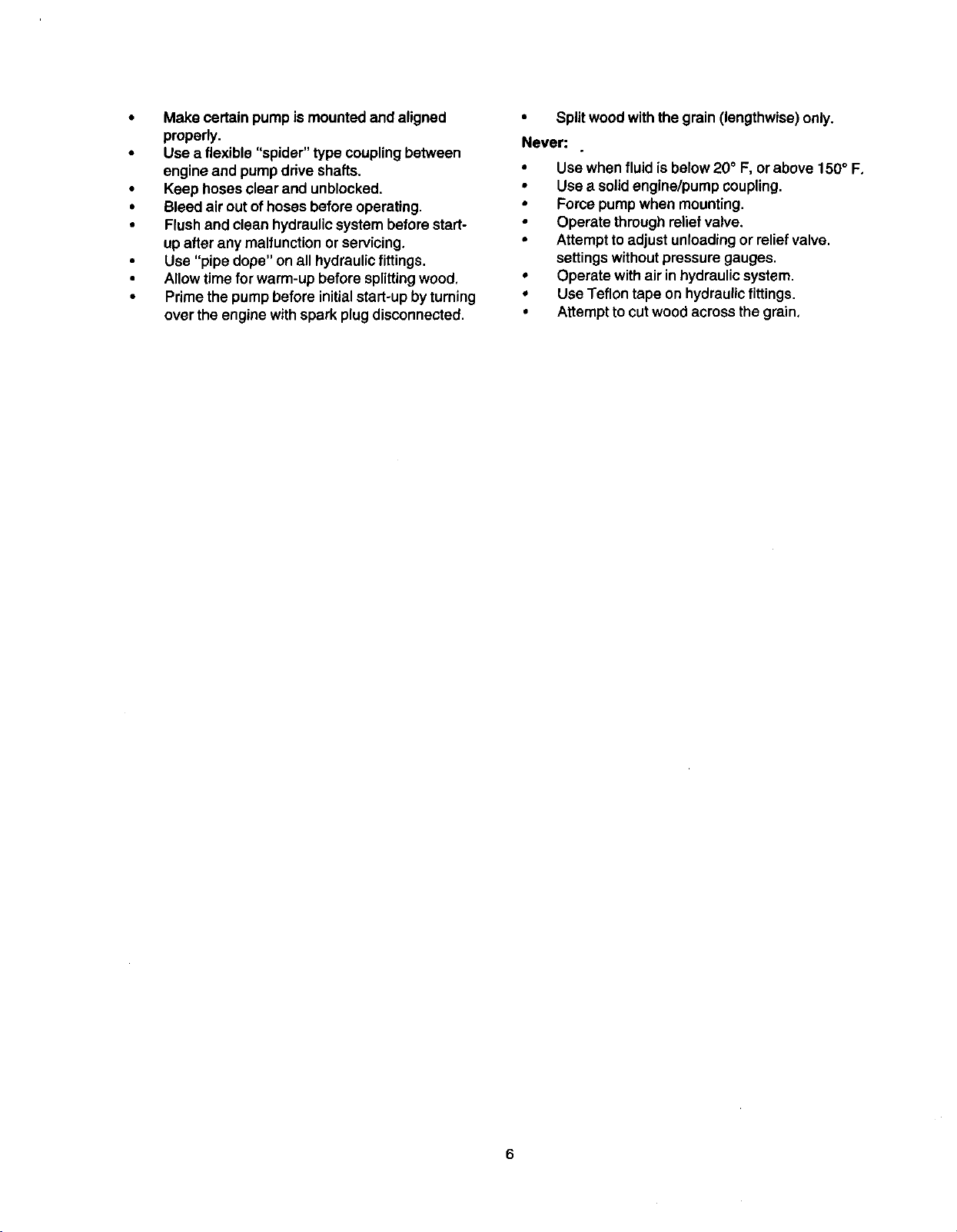

• Remove the two bolts, lock washers and hex

nutsthat secure the tongue assembly to the

beam assembly. See Figure 2.

• Unlockthe two beam locksby pullingouton the

beam locksand pivotingthem down. Remove

thetongue assembly.

Tongue

Assembly

Beam

Lock Washers

and Hex Nuts

Figure 2

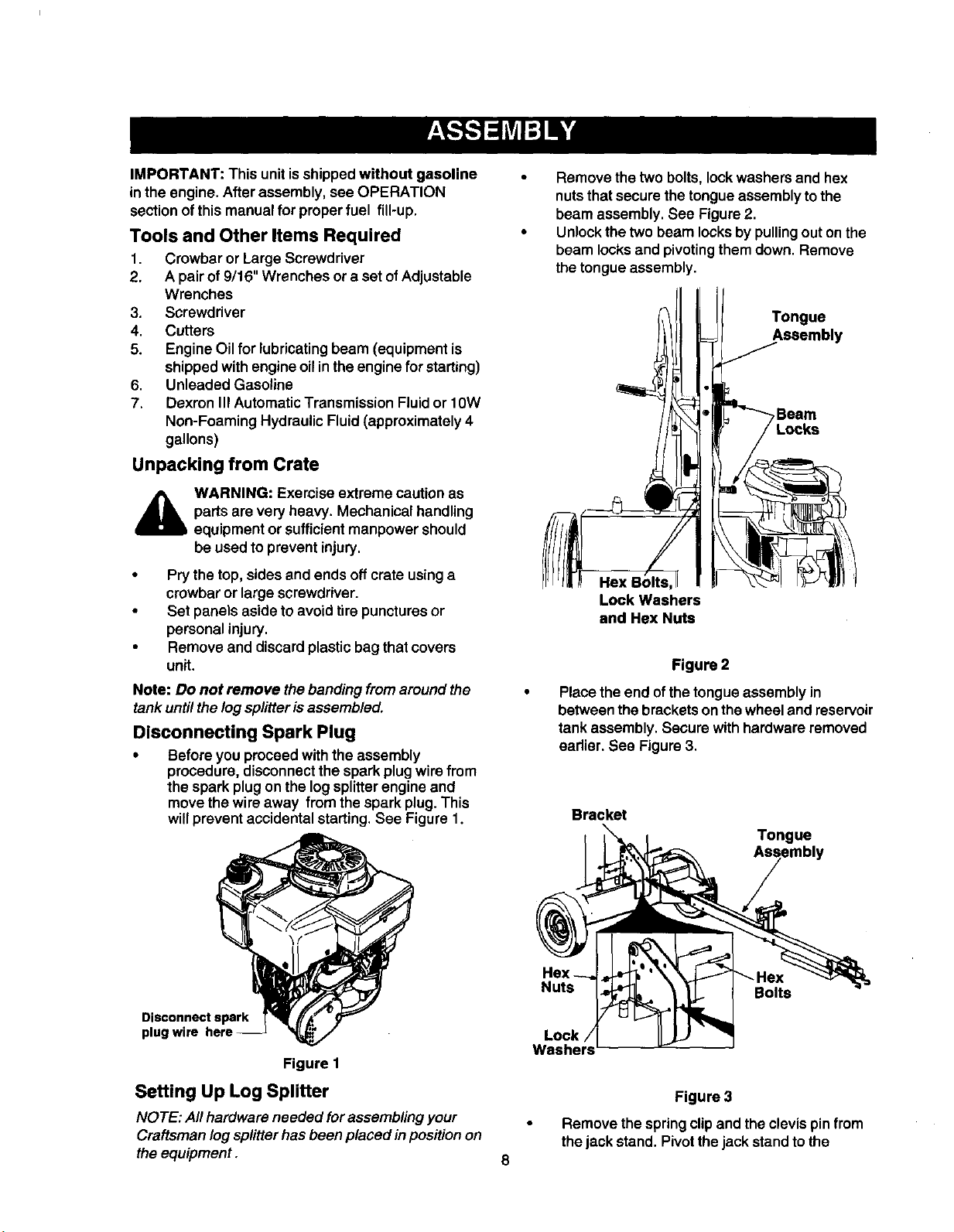

Place the end ofthe tongue assembly in

between the bracketson thewheel and reservoir

tankassembly. Secure with hardware removed

eadier. See Figure3.

Bracket

Tongue

Disconnect spark

plug wire here

Figure 1

Setting Up Log Splitter

NOTE: All hardware needed for assembling your

Craftsman log splitterhas been placed in positionon

the equipment.

Nuts

Lock

Figure 3

Remove the spring clipand the clevispin from

the jack stand. Pivot thejack stand tothe

8

Bolts

operatingposition (90°), and secure with the

springclipand clevispin. See Figure4.

Final Assembly

Tire Pressure

Tongue

Jack Stand

Figure 4

• Cut the twostraps fromaround the reservoir

tankassembly

• Remove lag screw and washer whichsecures

the beam assembly tothe bottom of thecrate.

• Lower the beam assembly to its horizontal

position. Make certain the beam is locked

securely with the horizontal beam lock. See

Figure 5.

• Puilthelogsplitteroffthepallet.

The tiresmay have been over-inflated for shipping

purposes. Maximum tirepressure should not exceed

30 p.s.i. Check tirepressure regularly.

Preparing the Engine

• Place the log splitteron a firm, level surface.

• Check engine oilas instructed on page 11.

• Fill engine withgasoline as instructedon

page 11.

Preparing the Log Splitter

• Lubricate the beam area where the splitting

wedge will slide withengine oil (do not use

grease). Make certain to oil both front and back

of the beam face.

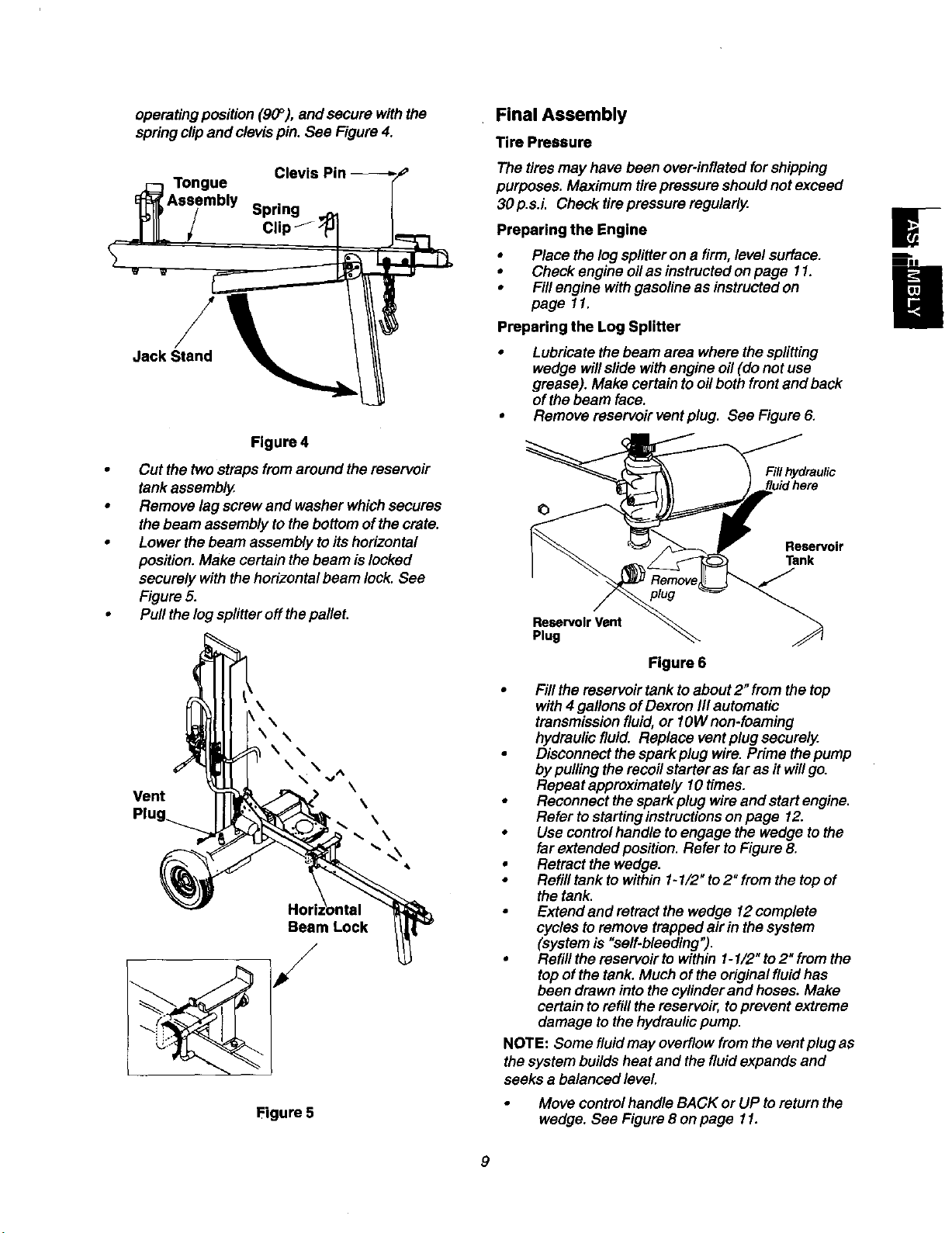

• Remove reservoir vent plug. See Figure 6.

Fill hydraulic

Reservoir

Tank

Reservoir Vent

Plug

Figure 6

W

m

I|l

Vent

Plu

\

\

\ \

\ \

\\\_^

Beam Lock

,/

Figure 5

• Fill the reservoir tank to about 2" from the top

with4 gallons of Dexron III automatic

transmission fluid, or lOW non-foaming

hydraulic fluid. Replace ventplug securely

• Disconnect the spark plug wire. Prime the pump

by pulling the recoil starter as far as it will go.

\

\

Repeat approximately 10 times.

• Reconnect the sparkplug wire and start engine.

Refer to starting instructions on page 12.

• Use control handle to engage the wedge to the

far extended position. Refer to Figure 8.

• Retract the wedge.

• Refilltanktowithin 1-1/2"to2"fromthetopof

the tank.

• Extendandretractthewedge 12complete

cycles to remove trapped air in the system

(system is "self-bleeding").

• Refillthereservoirtowithin 1-1/2"to2"fromthe

top of the tank. Much of the original fluid has

been drawn into the cylinder and hoses. Make

certain to refill the reservoir, to prevent extreme

damage to the hydraulic pump.

NOTE: Some fluid may overflow from the ventplug as

the system builds heat and the fluid expands and

seeks a balanced level.

Move control handle BACK or UP to return the

wedge. See Figure 8 on page 11.

9

Loading...

Loading...