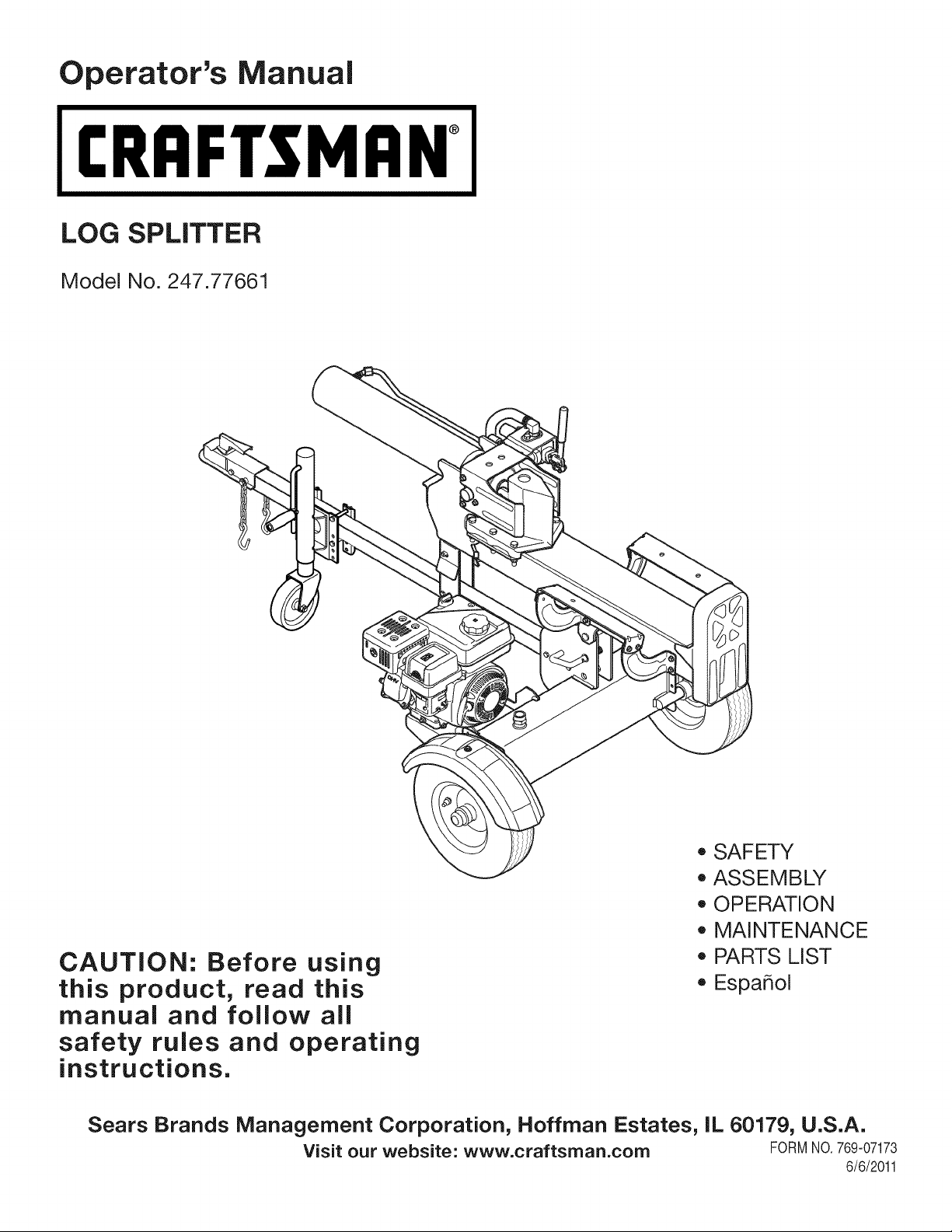

Operator's Manual

CRRF[SM ®

LOG SPLITTER

Model No. 247.77661

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

CAUTION: Before using

this product, read this

PARTS LIST

Espa_ol

manual and follow all

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, iL 60179, U.S.A.

Visit our website: www.craftsman.corn FORMNO.769-07173

6/6/2011

WarrantyStatement..................................Page2

SafeOperationPractices..........................Pages3-6

Assembly..................................................Pages7-10

Operation..................................................Pages11-15

Service&Maintenance...............................Pages16-20

PartsList.....................................................Pages24-33

Labels.......................................................Page34

RepairProtectionAgreement...................Page35

Espa_ol.....................................................Page36

ServiceNumbers......................................BackCover

OffSeasonStorage..................................Page21

Troubleshooting........................................Page22-23

CRAFTSMANONEYEARFULLWARRANTY

FORONEYEARfromthedateofpurchase,thisproductiswarrantedagainstanydefectsinmaterialorworkmanship.Adefectiveproductwill

receivefreerepairorreplacementifrepairisunavailable,

Forwarrantycoveragedetailstoobtainfreerepairorreplacement,visitthewebsite:www.craftsman.com

Thiswarranty coversONLYdefects in materialandworkmanship. Warranty coveragedoes NOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,suchasthespark plug, air cleaner, belts, and oil

filter.

• Productdamageresultingfromuserattemptsat productmodificationorrepairorcausedbyproductaccessories.

• Repairsnecessarybecauseof accidentorfailureto operateor maintainthe productaccordingtoallsuppliedinstructions.

• Preventivemaintenance,or repairsnecessaryduetoimproperfuel mixture,contaminatedor stalefuel.

Thiswarrantyisvoidif thisproductiseverusedwhileprovidingcommercialservicesor ifrentedtoanotherperson,

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstateto state,

Sears Brands Management Corporation, Hoffman Estates, IL 60179

Engine Series: 752Z170-L0

Engine Oil: SAE 30

Engine Oil Capacity: 20 Ounces

Fuel Capacity: 1.5 Quarts

Spark Plug (.030" Gap): Champion® RJ19LM

Hydraulic Fluid/Capacity: Dexron® Ill/3.0 gal.

Model Number .............................................................

Serial Number ..............................................................

Date of Purchase ..........................................................

Record the model number, serial number

and date of purchase above

2

4_ Thissymbolpointsout importantsafetyinstructions

which,if notfollowed,couldendangerthepersonal

safetyand/orpropertyof yourselfandothers.Read

andfollowall instructionsinthismanualbefore

attemptingto operatethismachine.Failuretocomply

withtheseinstructionsmayresultin personalinjury.

Whenyouseethissymbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothe safeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthepartoftheoperatorcan resultin

seriousinjury.Thismachineis capableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto StateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm.

TRAINING

1. Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplaceforfutureandregularreference

andfororderingreplacementparts.

2. Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

3. Neverallowchildrenunder16yearsofageto operatethis

machine.Children16andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

4. Neverallowadultsto operatethis machinewithoutproper

instruction.

5. Manyaccidentsoccurwhenmorethanonepersonoperatesthe

machine.Ifa helperisassistinginstackinglogs,neveractivate

thecontroluntilthehelperis aminimumof 10feetfromthe

machine.

6. Keepbystanders,pets,andchildrenatleast10feetfromthe

machinewhileitisin operation.

7. Neverallowanyonetorideon thismachine.

8. Nevertransportcargoonthis machine.

9. Hydrauliclogsplittersdevelophighfluidpressuresduringopera-

tion.Fluidescapingthrougha pinholeopeningcanpenetrate

yourskinandcausebloodpoisoning,gangrene,ordeath.Give

attentiontothefollowinginstructionsatall times:

a. Donotcheckforleakswithyourhand.

b. Donotoperatemachinewithfrayed,kinked,cracked,or

damagedhoses,fittings,ortubing.

c. Stoptheengineandrelievehydraulicsystempressureby

cyclingthevalvecontrolleverfromforwardto reverseseveral

timeswhileengineis notrunning;returningto neutralbefore

repairingoradjustingfittings,hoses,tubing,orothersystem

components.

d. Donotadjustthepressuresettingsofthepumporvalve.

Your Responsibility -- Restricttheuseofthispowermachine

to personswhoread,understandandfollowthewarningsand

instructionsinthis manualandonthe machine.

SAVE THESE INSTRUCTIONS!

10. Leakscanbe detectedbypassingcardboardorwood,while

wearingprotectiveglovesand safetyglasses,overthesuspected

area.Lookfordiscolorationof cardboardorwood.

11. Ifinjuredbyescapingfluid,seeadoctorimmediately.Serious

infectionor reactioncandevelopifpropermedicaltreatmentisnot

administeredimmediately.

12. Keeptheoperatorzoneandadjacentareaclearforsafe,secure

footing.

13. Ifyourmachineisequippedwithaninternalcombustionengine

and isintendedforusenearanyunimprovedforest,brush,or

grasscoveredland,theengineexhaustshouldbeequippedwith

a sparkarrestor.Makesureyoucomplywithapplicablelocal,

state,andfederalcodes.Takeappropriatefirefightingequipment

withyou.

14. Thismachineshouldbeusedforsplittingwoodonly,do notuseit

foranyotherpurpose.

15. Followthe instructionsinthemanual(s)providedwithany

attachment(s)forthismachine.

PREPARATION

1. Alwayswearsafetyshoesor heavyboots.

2. Alwayswearsafetyglassesorsafetygoggleswhenoperatingthis

machine.

3. Neverwearjewelryor looseclothingthatmightbecomeentangled

inmovingor rotatingpartsofthemachine.

4. Makesuremachineisona flat,dry,solid groundbeforeoperating.

5. Alwaysblockwheelstopreventunintendedmovement,andlock

beamineitherthehorizontalorverticalposition.

3

.

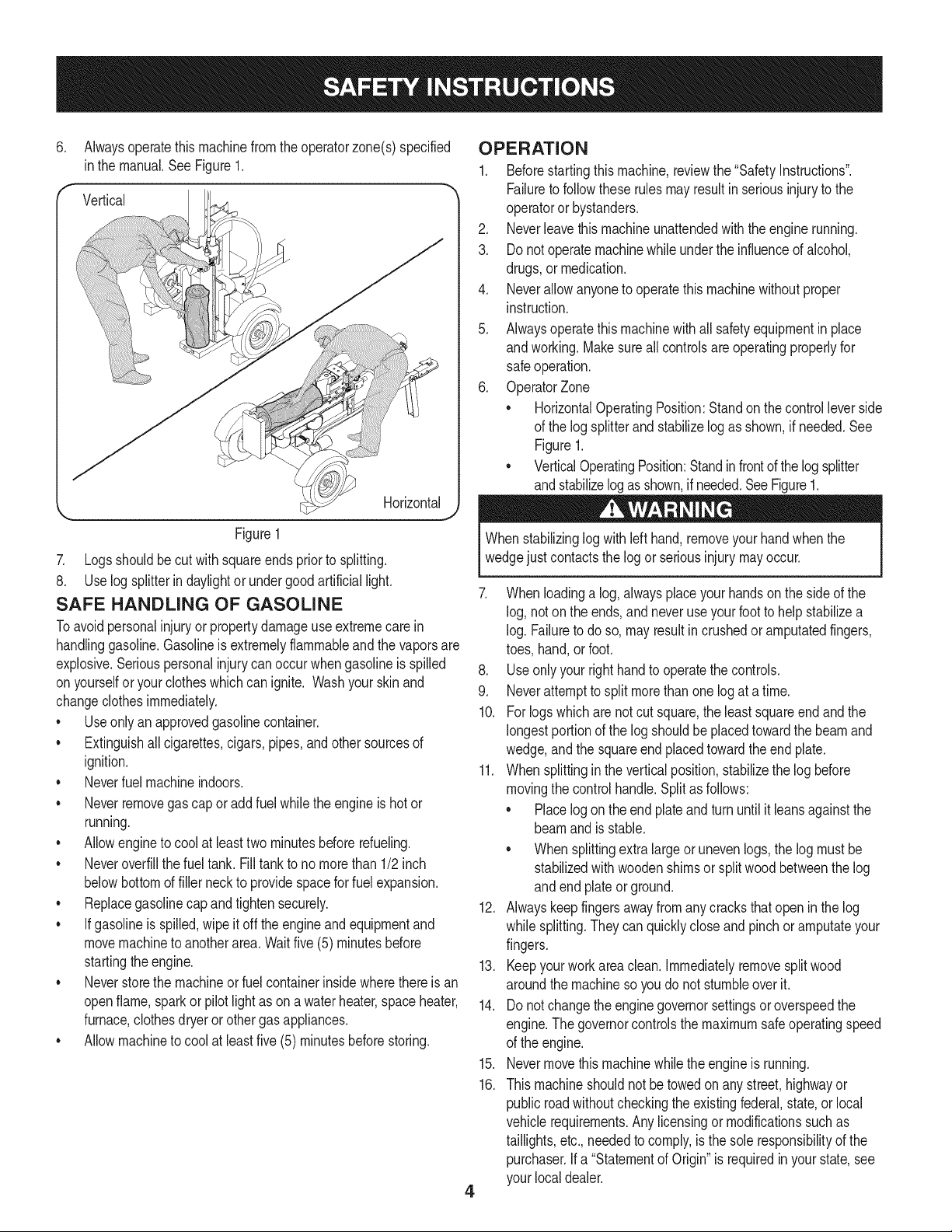

Alwaysoperatethismachinefromtheoperatorzone(s)specified

inthe manual.SeeFigure1.

Vertical

OPERATION

1. Beforestartingthis machine,reviewthe"SafetyInstructions".

Failuretofollowtheserulesmayresultin seriousinjuryto the

operatororbystanders.

2. Neverleavethismachineunattendedwiththe enginerunning.

3. Donotoperatemachinewhile undertheinfluenceofalcohol,

drugs,ormedication.

4. Neverallowanyonetooperatethismachinewithoutproper

instruction.

5. Alwaysoperatethismachinewithall safetyequipmentin place

andworking.Makesureall controlsareoperatingproperlyfor

safeoperation.

6. OperatorZone

• HorizontalOperatingPosition:Standonthecontrolleverside

ofthe logsplitterand stabilizelogasshown,if needed.See

Figure1.

• VerticalOperatingPosition:Standinfrontof thelogsplitter

andstabilizelogasshown,if needed.SeeFigure1.

Figure1

7. Logsshouldbecut withsquareendspriortosplitting.

8. Uselogsplitterin daylightor undergoodartificiallight.

SAFE HANDLING OF GASOLINE

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

onyourselforyourclotheswhichcan ignite.Washyour skinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipes,andothersourcesof

ignition.

• Neverfuelmachineindoors.

• Neverremovegas capor addfuelwhiletheengineishotor

running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillthefueltank.Filltanktono morethan 1/2inch

belowbottomoffiller neckto providespaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff theengineandequipmentand

movemachineto anotherarea.Waitfive (5)minutesbefore

startingtheengine.

• Neverstorethemachineorfuelcontainerinsidewherethereis an

openflame,sparkor pilotlightason awaterheater,spaceheater,

furnace,clothesdryer orothergasappliances.

• Allowmachinetocoolatleastfive(5) minutesbeforestoring.

Whenstabilizinglog withlefthand,removeyour handwhenthe

wedgejustcontactsthelogor seriousinjurymayoccur.

7. Whenloadinga log,alwaysplaceyourhandsonthesideof the

log,noton theends,and neveruseyourfoottohelpstabilizea

log.Failuretodo so,mayresultin crushedor amputatedfingers,

toes,hand,or foot.

8. Useonlyyourrighthandtooperatethe controls.

9. Neverattemptto splitmorethan onelogata time.

10. Forlogswhicharenotcutsquare,theleastsquareendandthe

longestportionof thelog shouldbe placedtowardthebeamand

wedge,andthesquareend placedtowardtheendplate.

11. Whensplittingintheverticalposition,stabilizethelogbefore

movingthecontrolhandle.Splitas follows:

• Placelogon theendplateandturnuntilit leansagainstthe

beamand isstable.

• Whensplittingextralargeorunevenlogs,thelogmustbe

stabilizedwithwoodenshimsor splitwoodbetweenthelog

andend plateorground.

12. Alwayskeepfingersawayfromanycracksthatopenin thelog

whilesplitting.Theycanquicklycloseandpinchor amputateyour

fingers.

13. Keepyourworkareaclean.Immediatelyremovesplitwood

aroundthemachineso youdo notstumbleoverit.

14. Donotchangethe enginegovernorsettingsoroverspeedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

15. Nevermovethismachinewhiletheengineis running.

16. Thismachineshouldnotbe towedonanystreet,highwayor

publicroadwithoutcheckingtheexistingfederal,state,orlocal

vehiclerequirements.Anylicensingormodificationssuchas

taillights,etc.,neededto comply,isthesoleresponsibilityofthe

purchaser.Ifa "Statementof Origin"is requiredinyour state,see

yourlocaldealer.

4

17.Donottowmachineover45mph.

18.SeeTransportingtheLogSplittersectioninthismanualforproper

towinginstructionsonceallfederal,local,orstaterequirements

aremet.

MAINTENANCE AND STORAGE

1. Stoptheengine,disconnectthesparkplugandgroundit against

theenginebeforecleaning,orinspectingthemachine.

2. Stopthe engineandrelievehydraulicsystempressurebycycling

thevalvecontrolleverfromforwardto reverseseveraltimeswhile

engineisnot running;returningto neutralbeforerepairingor

adjustingfittings,hoses,tubing,orothersystemcomponents.

3. Topreventfires,cleandebrisandchaff fromthe engineand

mufflerareas.Ifthe engineis equippedwitha sparkarrestor

muffler,cleanand inspectit regularlyaccordingtomanufacturers

instructions.Replaceif damaged.

4. Periodicallycheckthatall nutsandbolts,hoseclamps,and

hydraulicfittingsaretightto besureequipmentis insafeworking

condition.

5. Checkallsafetyguardsandshieldstobe suretheyarein the

properposition.Neveroperatewithsafetyguards,shields,or

otherprotectivefeaturesremoved.

6. Thepressurereliefvalveispresetat thefactory.Donot adjustthe

valve.

7. Neverattempttomovethismachineoverhillyor uneventerrain

withoutatowvehicleor adequatehelp.

8. Foryoursafety,replaceall damagedorwornpartsimmediately

withoriginalequipmentmanufacturer's(O.E.M)partsonly.Useof

partswhichdo notmeettheoriginalequipmentspecificationsmay

leadtoimproperperformanceandcompromisesafety!

9. Donotalterthismachinein anymanner,alterationssuchas

attachingaropeorextensiontothe controlhandle,or addingto

thewidthor heightof thewedgemayresultinpersonalinjury.

10. Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan Average UsefulLifeofseven(7)years,or 130hoursof

operation.At theendoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failuretodo socanresultinaccidents,injuries

ordeath.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,brush

coveredorgrass-coveredlandunlesstheengine'sexhaustsystem

isequippedwitha sparkarrestormeetingapplicablelocalor state

laws(ifany).

Ifa sparkarrestorisused,itshouldbe maintainedineffectiveworking

orderbytheoperator.Inthe Stateof Californiathe aboveis required

bylaw (Section4442of theCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthemuffleris availablethroughyournearest

engineauthorizedservicedealeror contacttheservicedepartment,

RO.Box361131Cleveland,Ohio44136-0019.

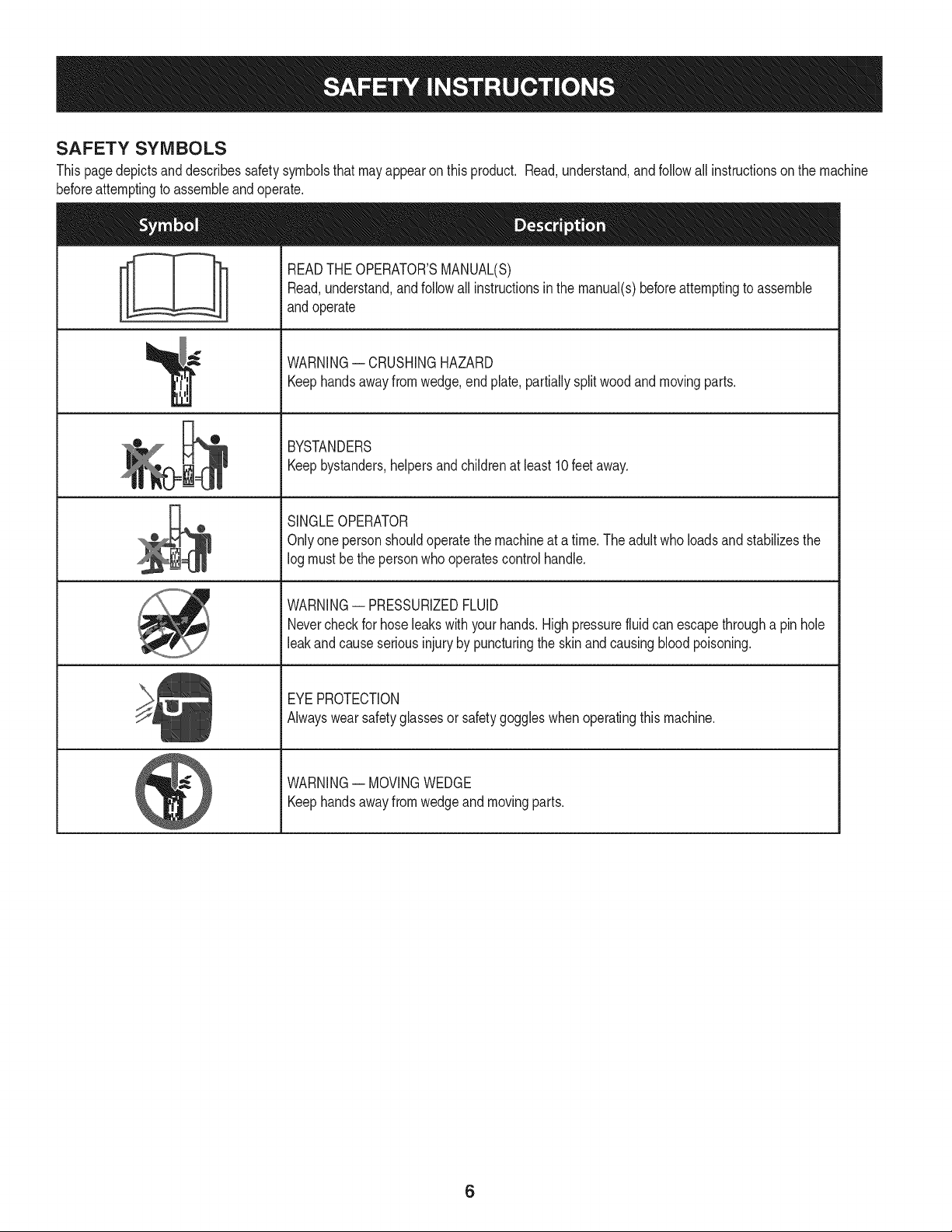

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingtoassembleandoperate.

READTHEOPERATOR'SMANUAL(S)

i

i

'lI

Read,understand,andfollowall instructionsinthe manual(s)beforeattemptingtoassemble

andoperate

WARNING-- CRUSHINGHAZARD

Keephandsawayfromwedge,endplate,partiallysplitwood andmovingparts.

BYSTANDERS

Keepbystanders,helpersandchildrenat least10feetaway.

SINGLEOPERATOR

Onlyonepersonshouldoperatethemachineata time.Theadultwholoadsand stabilizesthe

logmustbethe personwhooperatescontrolhandle.

WARNING-- PRESSURIZEDFLUID

Nevercheckforhoseleakswithyourhands.High pressurefluidcanescapethroughapinhole

leakandcauseseriousinjurybypuncturingtheskinandcausingbloodpoisoning.

EYEPROTECTION

Alwayswearsafetyglassesorsafetygoggleswhenoperatingthismachine.

WARNING-- MOVINGWEDGE

Keephandsawayfromwedgeandmovingparts.

6

Useextremecautionunpackingthismachine.Somecomponentsare

veryheavyandwillrequireadditionalpeopleor mechanicalhandling

equipment.

NOTE:Yourlogsplitteris shippedwithmotoroilintheengine.However,

youMUSTchecktheoillevelbeforeoperating.Becarefulnottooverfill.

SeeGasandOilFill-Upinthissection.

NOTE:All referencesin thismanualtotheleftor rightsideofthelog

splitterarefromtheoperatingpositiononly.SeeOperatorZonein the

Operationsectionof theSafetyinstructions.

UNPACKING & ASSEMBLING THE LOG

SPLITTER

TOOLS NEEDED: Safetyglasses,leathergloves,wirecutters,prybar

and/orclawhammer.

1. Usea prybarorclawhammertoloosenandremovethetopof

thecrate.

2. Usea prybarorclawhammertoremovethesidesofthecrate,

beginningwiththe shortsides(orleftandrightsideof thelog

splitter).Setthe sidesof thecrateasidetoavoidinjury.

3. Onthefrontsideofthecratethetongueassemblyisattachedonthe

insideofthecratewitha cabletie.Cutthecabletietoremovetongue.

4. Removethe largeplasticcoveranddiscard.

9. Insertthehexboltsthroughtopholesinthejackstandmounting

bracketsandholesinthe adjustablejackstand.Securewith lock

nuts.

10. Insertthehexboltsthroughtheupperholesin thebottomofthe

mountingbracketsandadjustablejack stand.Securewith lock

nuts.

11. Theadjustablejack standisraisedbyturningthecrankclockwise

and loweredbyturningcounter-clockwise.

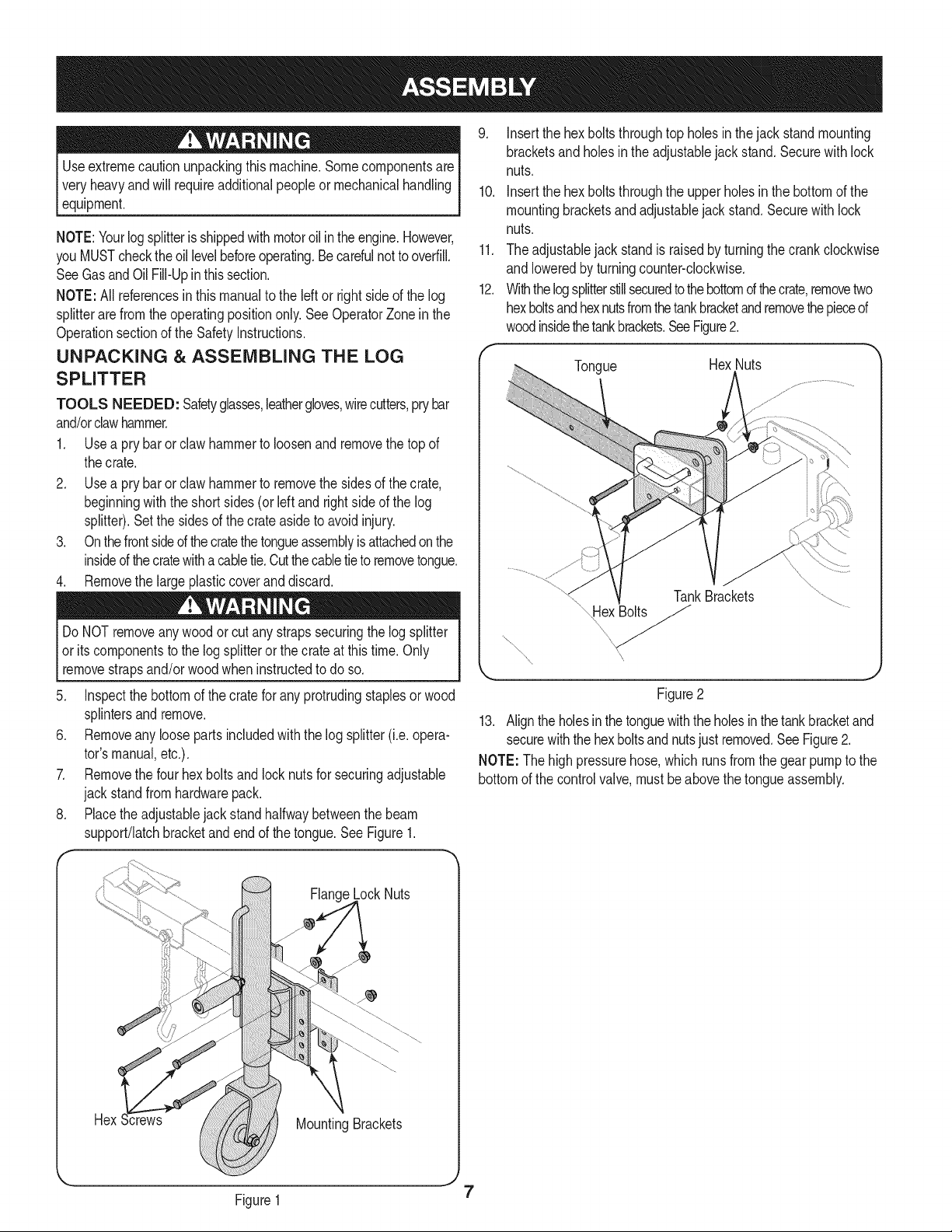

12. Withthelogsplitterstillsecuredtothebottomofthecrate,removetwo

hexboltsandhexnutsfromthetankbracketandremovethepieceof

woodinsidethetankbrackets.SeeFigure2.

Tongue HexNuts

TankBrackets ...............................

DoNOTremoveanywoodor cutanystrapssecuringthelogsplitter

Iorits componentstothelogsplitteror thecrateatthistime.Only

removestrapsand/orwoodwheninstructedtodoso.

5. inspectthe bottomofthecrateforanyprotrudingstaplesor wood

splintersandremove.

6. Removeanyloosepartsincludedwiththe logsplitter(i.e.opera-

tot'smanual,etc.).

7. Removethefourhexboltsandlocknutsfor securingadjustable

jack standfromhardwarepack.

8. Placetheadjustablejack standhalfwaybetweenthebeam

support/latchbracketandendof thetongue.SeeFigure1.

FlangeLockNuts

\Hex_

_ J

Figure2

13. Aligntheholesin thetonguewiththeholesinthetankbracketand

securewiththehexboltsandnutsjust removed.SeeFigure2.

NOTE:Thehighpressurehose,whichrunsfromthe gearpumptothe

bottomof thecontrolvalve,mustbeabovethetongueassembly.

mex

MountingBrackets

Figure1 7

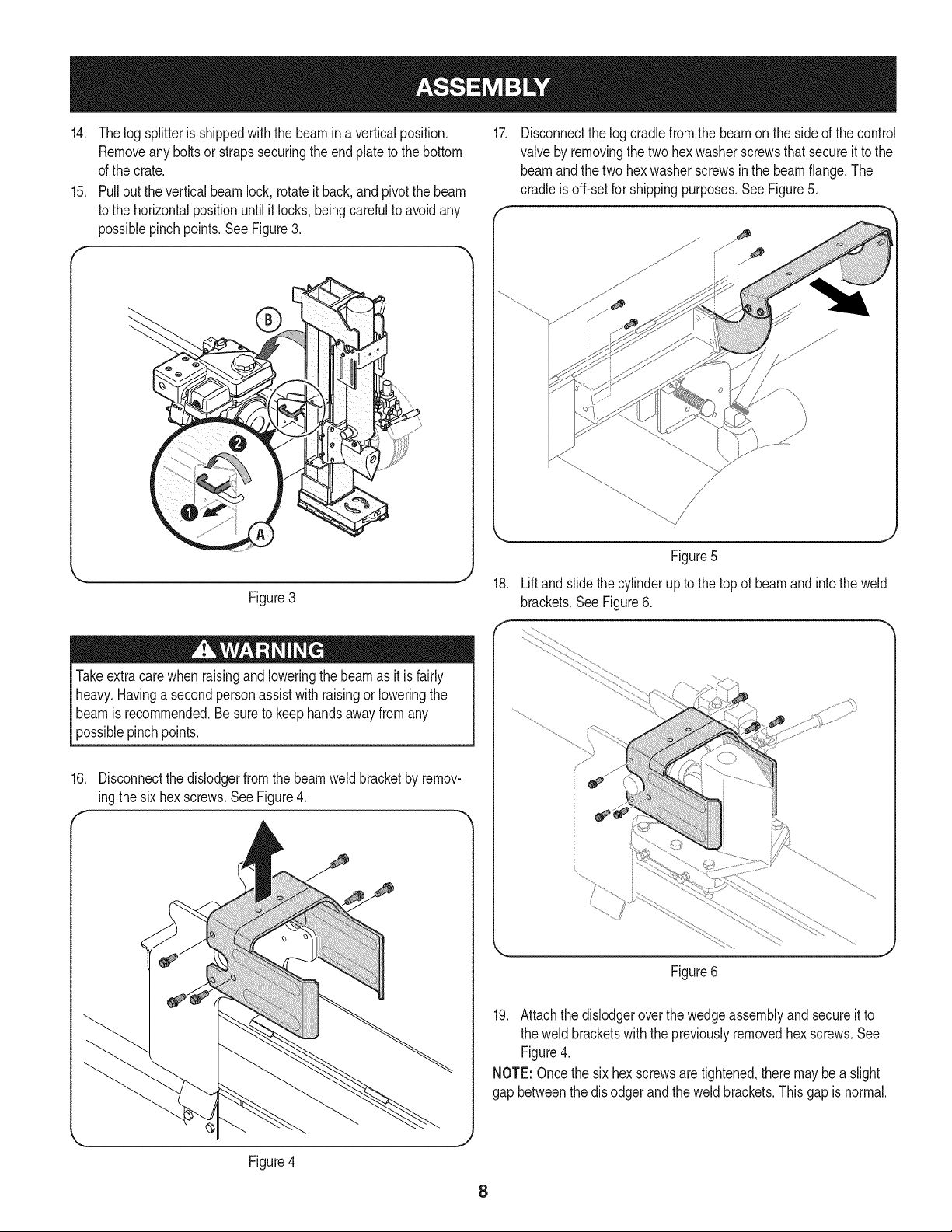

14, Thelog splitterisshippedwiththebeaminaverticalposition,

Removeanyboltsor strapssecuringtheendplatetothe bottom

ofthe crate.

15. Pulloutthe verticalbeamlock,rotateitback,andpivotthebeam

tothe horizontalpositionuntilit locks,beingcarefultoavoidany

possiblepinchpoints.See Figure3.

j

Figure3

17.

Disconnectthelogcradlefromthebeamon thesideofthecontrol

valvebyremovingthetwohexwasherscrewsthatsecureittothe

beamandthe twohex washerscrewsin thebeamflange.The

cradleis off-setfor shippingpurposes.SeeFigure5.

Figure5

18.

Liftandslidethe cylinderupto thetopofbeamandintotheweld

brackets.SeeFigure6.

Takeextracarewhen raisingandloweringthebeamas itisfairly

heavy.Havingasecondpersonassistwithraisingorloweringthe

beamis recommended.Besuretokeephandsawayfromany

possiblepinchpoints.

16. Disconnectthedislodgerfromthebeamweldbracketbyremov-

ingthesixhex screws.SeeFigure4.

f -,

Figure6

19. Attachthe dislodgeroverthewedgeassemblyandsecureit to

theweldbracketswiththepreviouslyremovedhexscrews.See

Figure4.

NOTE:Oncethesixhex screwsaretightened,theremaybea slight

gap betweenthedislodgerandtheweldbrackets.Thisgapisnormal.

\

Figure4

8

20.

Reattachthe logcradletothesideof the beamwiththecontrol Oil

valve,aligningtheholesin thecradlewiththeholesin thebeam. 1.

SeeFigure7. 2.

J

Figure7

21. Checkforandremoveanystaplesonthebottomofthe cratethat

maypuncturethetire.

22. Cutthemetalstrapsecuringthelogsplittertothebottomofthe

crateand removethewoodundertheengineand/oranyother

wood,thenrollthe logsplitteroffthebottomofthe shippingcrate.

SET-UP

Tire Pressure

Themaxrecommendedoperatingpressureis30 psi. Donot,under

anycircumstances,exceedthemanufacturer'srecommendedpsi.

Maintainequalpressureon alltires.

Excessivepressurewhenseatingbeadsmaycausetire/rim

toburstwithforcesufficienttocauseseriousinjury.

Gas and Oil Fill-Up

Servicetheenginewithgasolineandoil asinstructedbelow.Readthe

instructionscardully.

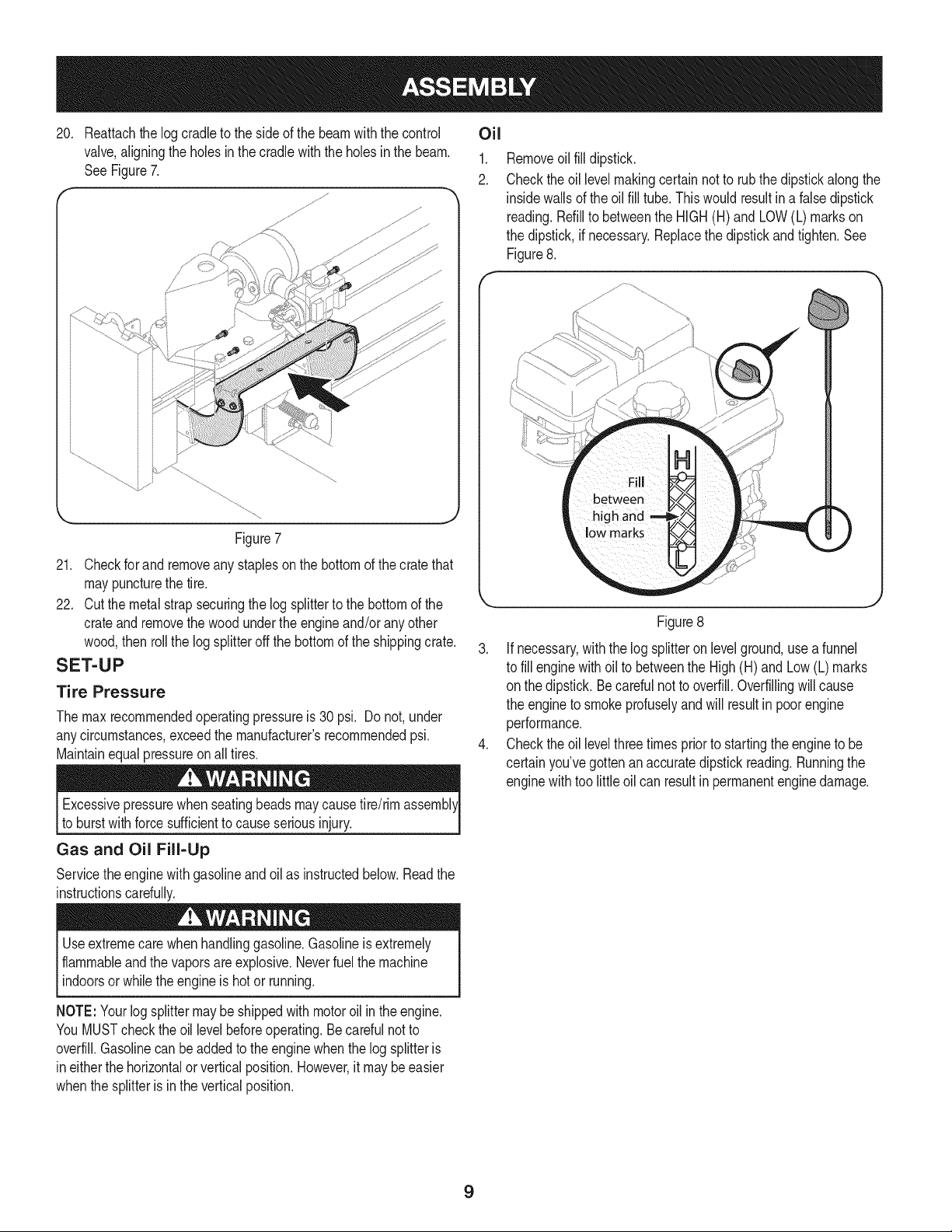

Removeoil filldipstick.

Checkthe oillevelmakingcertainnotto rubthedipstickalongthe

insidewallsof theoilfilltube.Thiswouldresultinafalsedipstick

reading.Refilltobetweenthe HIGH(H)and LOW(L) markson

thedipstick,ifnecessary.Replacethe dipstickandtighten.See

Figure8.

Figure8

3. Ifnecessary,withthelog splitteronlevelground,useafunnel

tofill enginewithoiltobetweentheHigh(H)and Low(L)marks

on thedipstick.Becarefulnottooverfill.Overfillingwillcause

theengineto smokeprofuselyandwill resultinpoorengine

performance.

4. Checkthe oillevelthreetimespriorto startingtheengineto be

certainyou'vegottenanaccuratedipstickreading.Runningthe

enginewithtoolittleoil canresultin permanentenginedamage.

Useextremecarewhenhandlinggasoline.Gasolineis extremely

flammableandthevaporsareexplosive.Neverfuelthemachine

indoorsorwhiletheengineis hotor running.

NOTE:Yourlogsplittermaybe shippedwithmotoroil intheengine.

YouMUSTchecktheoil levelbeforeoperating.Becarefulnotto

overfill.Gasolinecanbeaddedto theenginewhenthe logsplitteris

ineitherthe horizontalor verticalposition.However,it maybeeasier

whenthe splitterisinthe verticalposition.

9

Gasoline

Operatingtheenginewith E85fuel,anoil/gasolinemixture,dirty

gasoline,or gasolineover30daysoldthathasnotbeenstabilizedus-

ingafuel additive,mayresultindamageto yourengine'scarburetor.

Subsequentdamagewouldnot becoveredunderthemanufacturer's

warranty.

Useautomotivegasoline(unleadedorlowleadedtominimizecombus-

tionchamberdeposits)witha minimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureordirtygasoline.Avoidgetting

dirt,dust,or waterinthefueltank.DONOTuseE85gasoline.

An adultshouldfuelthisengine.NEVERallowchildrento refuelthis

engine.Gasoline(fuel)vaporsare highlyflammableandcanexplode.

Fuelvaporscan spreadandbe ignitedbya sparkor flamemanyfeet

awayfromengine.Topreventinjuryordeathfromfuelfires, DONOT

useleadedfuel, Fuelmustbefreshandclean.NEVERusefuel left

overfromlastseasonorstoredfor longperiods,NEVERmixoil with

fueland DONOTuse fuelcontainingMethanol(WoodAlcohol).

Beforerefueling,allowthe enginetocoolfortwominutes.

2. Besureengineis outdoorsand ina well-ventilatedarea.

3. Cleanareaaroundthe fuelfill capand removethefuelfillcap.

4. UsinganapprovedredGASOLINEcontainer,addfuelslowly,

beingcarefultoavoidspilling.

5. Fillthetankuntilthefuel reachesthe"fuelfull"indicatormark.

SeeFigure9.

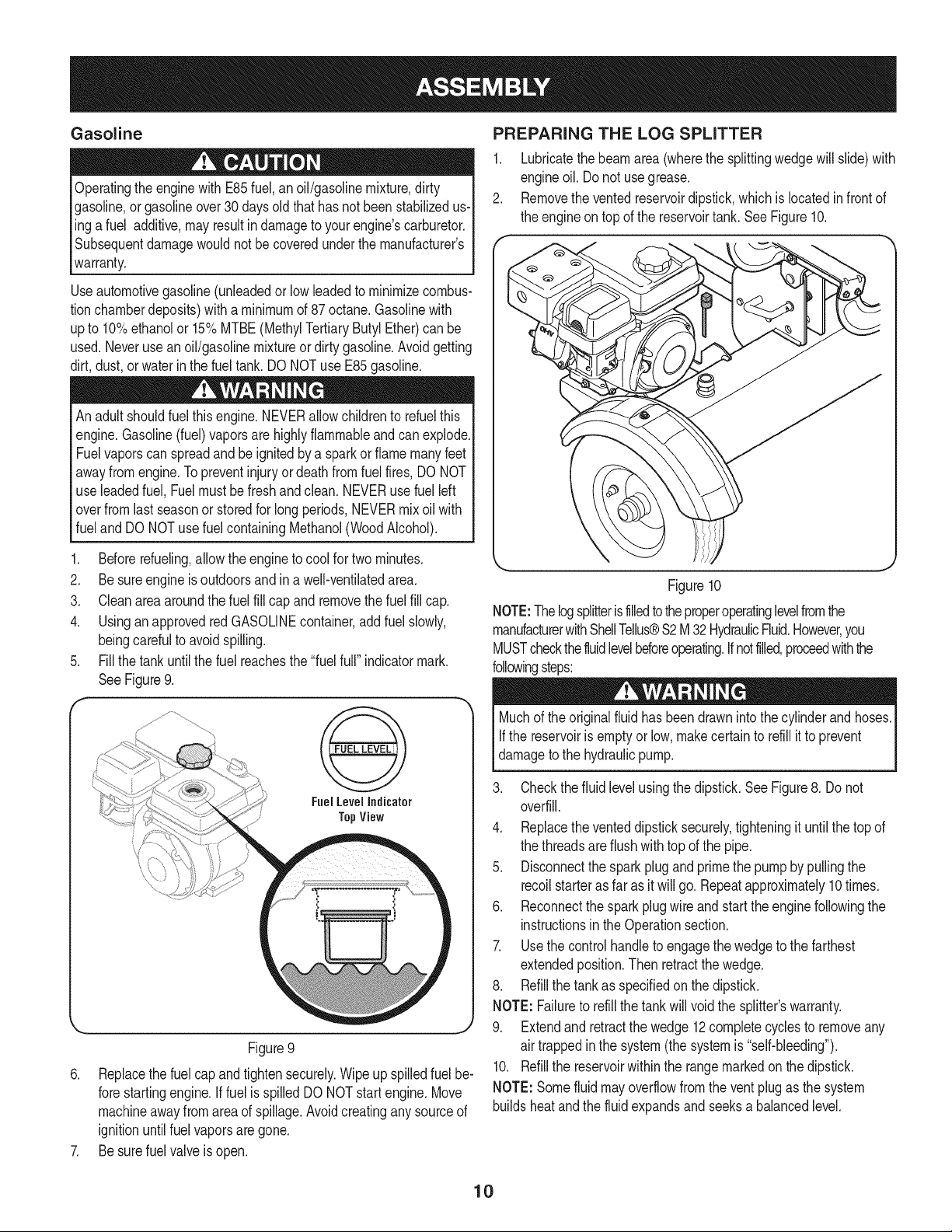

PREPARING THE LOG SPLITTER

1. Lubricatethebeamarea(wherethe splittingwedgewill slide)with

engineoil. Donot usegrease.

2. Removetheventedreservoirdipstick,whichis locatedin frontof

theengineon topof the reservoirtank.SeeFigure10.

Figure10

NOTE:Thelogsplitterisfilledtotheproperoperatinglevelfromthe

manufacturerwithShellTellus®$2M32HydraulicFluid.However,you

MUSTcheckthefluidlevelbeforeoperating.Ifnotfilled,proceedwiththe

followingsteps:

Figure9

6. Replacethefuel capandtightensecurely.Wipeupspilledfuelbe-

forestartingengine.Iffuel isspilledDO NOTstartengine.Move

machineawayfromareaofspillage.Avoidcreatinganysourceof

ignitionuntilfuelvaporsare gone.

7. Besurefuel valveisopen.

Muchofthe originalfluidhasbeendrawnintothecylinderandhoses.

Ifthereservoirisemptyorlow,makecertainto refillitto prevent

damagetothehydraulicpump.

3. Checkthefluidlevelusingthedipstick.SeeFigure8.Donot

overfill.

4. Replacethe venteddipsticksecurely,tighteningituntilthetopof

thethreadsareflushwithtopofthe pipe.

5. Disconnectthesparkplugandprimethepumpbypullingthe

recoilstarterasfar asitwillgo.Repeatapproximately10times.

6. Reconnectthesparkplugwireandstarttheenginefollowingthe

instructionsintheOperationsection.

7. Usethecontrolhandleto engagethewedgeto thefarthest

extendedposition.Thenretractthewedge.

8. Refillthetankas specifiedonthedipstick.

NOTE:Failuretorefillthetankwill voidthesplitter'swarranty.

9. Extendand retractthewedge12completecyclestoremoveany

air trappedin thesystem(thesystemis"self-bleeding").

10. Refillthereservoirwithinthe rangemarkedonthedipstick.

NOTE:Somefluidmayoverflowfromtheventplugas thesystem

buildsheatandthefluid expandsand seeksabalancedlevel.

10

Coupler

Hitch

AdjustableStand

Assembly

Choke

EngineControls

Cont_

Cylinder

Tongue

ControlHandle

LogDi:;lodger

Horizontal

BeamLock

Assembly

Plate

FuelValve

\

, RecoilStarterHandle

Fi.

Readthisoperator'smanualandthesafetyrulesbeforeoperating

yourlogsplitter.Comparetheillustrationsbelowwithyourequipment

tofamiliarizeyourselfwiththelocationofvariouscontrolsandadjust-

ments.Savethismanualforfuturereference.

BEAM LOCKS

Thesetwolocksare usedto securethebeaminthehorizontalor

theverticalposition.Theverticalbeamlockislocatedonthe tanks

bracket.Thehorizontalbeamlockislocatedonthebeamsupportlatch

bracket.

WEDGE

Thewedgeisusedto splitthewood.

COUPLER HITCH

Thecouplerhitchisat theend ofthetongueandattachesto atowball

fortransportationpurposes.

Tray

Beam

Lock Reservoir

Tank

ure 11

Befamiliarwithallthecontrolsandtheir properoperation.Knowhow

tostopthe machineanddisengagethemquickly.

Alwayswearsafetyglasseswhenoperatingthisequipmentorwhile

performinganyadjustmentsor repairsonit.

CONTROL HANDLE

Thecontrolhandleis usedtomovethewedgeup anddowntosplit

wood.Thecontrolhandlehas threepositions;Forward,Neutraland

Reverse.Seethe "Usingthe LogSplitter"sectionforinstructions.

LOG DISLODGER

Thelogdislodgerisdesignedto removeanypartiallysplitwoodfrom

thewedge.Thismayoccurwhilesplittinglargediameterwoodor

freshlycutwood.

RECOIL STARTER HANDLE

Usedtostarttheengine.

MEETS ANSI SAFETY STANDARDS

CraftsmanLogSplittersconformtothesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

11

LOG TRAY

Thelogtrayisdesignedtocatchthelogafteritis split,

END PLATE

Theend plateholdsthelog in placewhilethewedgesplitsthe log.

TONGUE

Thetongueisusedtoattachtoa towingvehiclefortransportation.

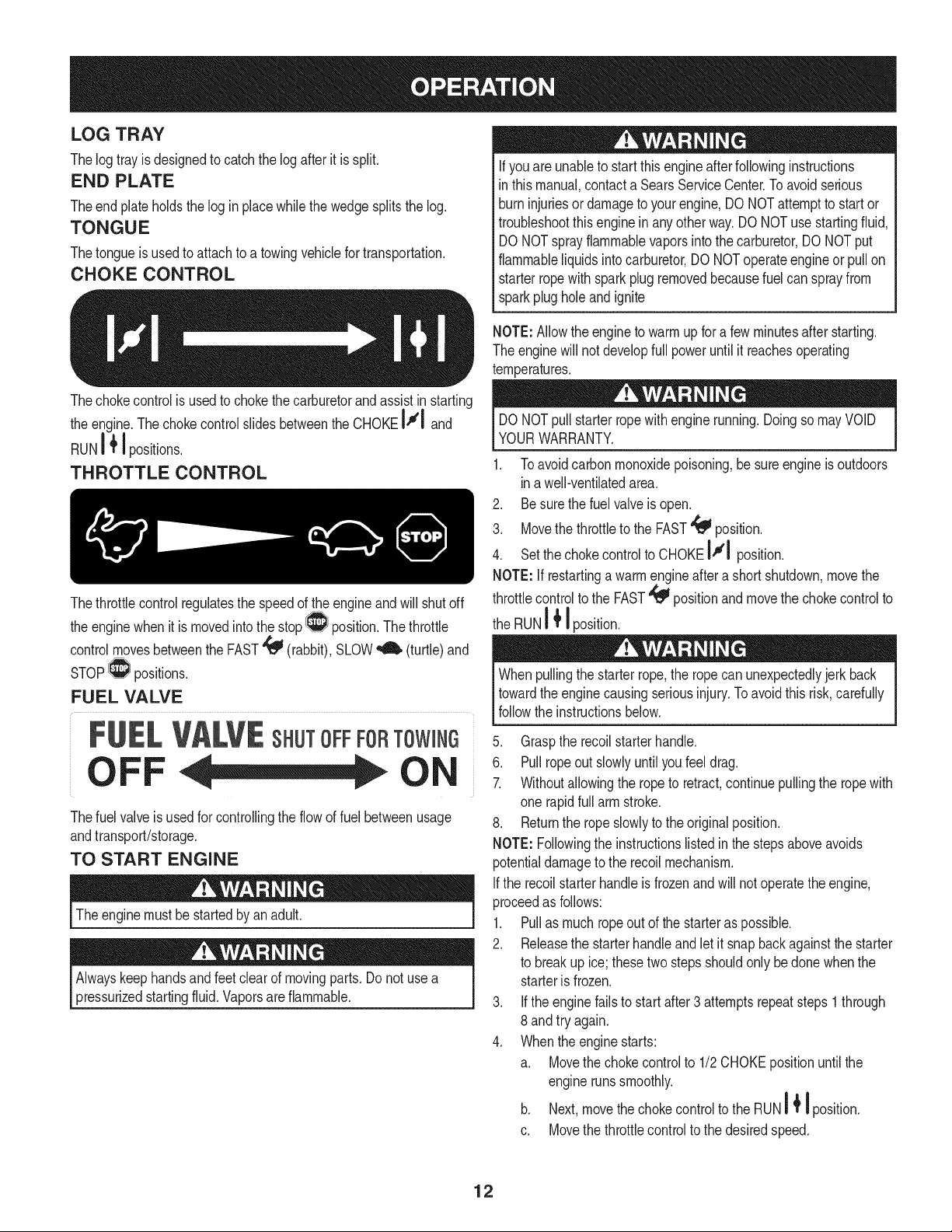

CHOKE CONTROL

Thechokecontrolis usedtochokethe carburetorandassistinstarting

theenqine.ThechokecontrolslidesbetweentheCHOKEIJl and

RUNI_'}! positions.

THROTTLE CONTROL

Thethrottlecontrolregulatesthespeedof theengineandwillshutoff

theenginewhenitis movedintothestop_ position.Thethrottle

controlmovesbetweentheFAST'_ (rabbit),SLOW_ (turtle)and

STOP_ positions.

FUEL VALVE

FUELVALVESHUTOFFFORTOWmNG

OFF

Thefuel valveis usedforcontrollingtheflowof fuelbetweenusage

andtransport/storage.

TO START ENGINE

Theenginemust bestartedbyan adult.

Alwayskeephandsandfeetclearofmovingparts.Donot usea

pressurizedstartingfluid.Vaporsareflammable.

Ifyouare unabletostartthisengineafterfollowinginstructions

in thismanual,contactaSearsServiceCenter.Toavoidserious

burninjuriesordamagetoyourengine,DO NOTattempttostartor

troubleshootthisenginein anyotherway.DO NOTusestartingfluid,

DONOTsprayflammablevaporsintothecarburetor,DONOTput

flammableliquidsintocarburetor,DO NOToperateengineor pullon

starterropewithsparkplugremovedbecausefuelcan sprayfrom

sparkplugholeand ignite

NOTE:Allowtheengineto warmupfor afewminutesafterstarting.

Theenginewill notdevelopfull poweruntilitreachesoperating

temperatures.

DONOTpull starterropewithenginerunning.DoingsomayVOID

YOURWARRANTY.

.

Toavoidcarbonmonoxidepoisoning,be sureengineisoutdoors

ina well-ventilatedarea.

2.

Besurethe fuelvalveisopen.

3.

MovethethrottletotheFAST'_ position.

4.

Setthe chokecontroltoCHOKEIJl position.

NOTE:If restartingawarmengineaftera shortshutdown,movethe

throttlecontrolto the FAST'_ positionandmovethe chokecontrolto

theRUN! _'Jposition.

Whenpullingthe starterrope,the ropecanunexpectedlyjerkback

towardtheenginecausingseriousinjury.Toavoidthisrisk,carefully

followtheinstructionsbelow.

5. Grasptherecoilstarterhandle.

6. Pullropeoutslowlyuntilyoufeeldrag.

7. Withoutallowingtheropeto retract,continuepullingtheropewith

one rapidfullarmstroke.

8. Returnthe ropeslowlytotheoriginalposition.

NOTE:Followingtheinstructionslistedinthestepsaboveavoids

potentialdamagetothe recoilmechanism.

Iftherecoilstarterhandleis frozenandwill notoperatetheengine,

proceedas follows:

1. Pullasmuchropeoutof thestarteras possible.

2. Releasethe starterhandleandletit snapbackagainstthestarter

to breakupice;thesetwostepsshouldonlybedonewhenthe

starterisfrozen.

3. Iftheenginefailstostartafter3 attemptsrepeatsteps1through

8 andtry again.

4. Whenthe enginestarts:

a. Movethe chokecontrolto 1/2CHOKEpositionuntilthe

enginerunssmoothly.

b. Next,movethechokecontrolto the RUN! I position.

c. Movethethrottlecontroltothedesiredspeed.

m i

12

Iftheenqinestartsbutfalterswhenthechokecontrolis movedtothe

RUN! _1 position:

1. Momentarilymovechokecontrolbackto theCHOKEIJl

position.

2. Next,movethechokecontrolto 1/2CHOKEpositionuntilengine

runssmoothly.

3. Finally,movethechokecontroltothe RUNI I position.

II÷It

IIt,i

4. Iftheenginediesafterchokecontrolis movedto RUN! I

position,repeatstepsfor startingtheengineon page12.

It÷II

5. iftheenginefailsto startafter3 attemptsinthe RUN! I

position,movethechokecontrolto CHOKEIJl positionand

startengine.

6. Ifenginedoesnot startafterfollowingtheseinstructions,contact

a SearsServiceCenter.DONOTattempttotroubleshootthis

enginein anyotherway.

TO STOP ENGINE

1. Ifoperatingtheenginein thesnowor rain,runthe enginefora

fewminutestohelpdryoffany moisture.

2. Movethethrottlecontrolleverto theSTOP_ position.

3. Movetheenginechokebackandforthseveraltimesand leavein

theCHOKEIJl position.

4. Besurethe FuelShut-OffValveisoff.

5. Disconnectsparkplugwireandgrounditto preventaccidental

startingwhiletheequipmentis unattended.

USING THE LOG SPLITTER

5. Placethelogagainsttheendplateandonlysplitwood alongthe

grain(lengthwise).

6. Tostabilizethe log,placeyourleft handonthesideof thelog.

Neverplacea handbetweenthelog andthe splittingwedgeor

thelogandend plate.

Onlyoneoperatoris permitted.Theadultwholoadsandstabilizes

thelogmustbe thepersonwhooperatesthecontrolhandle.

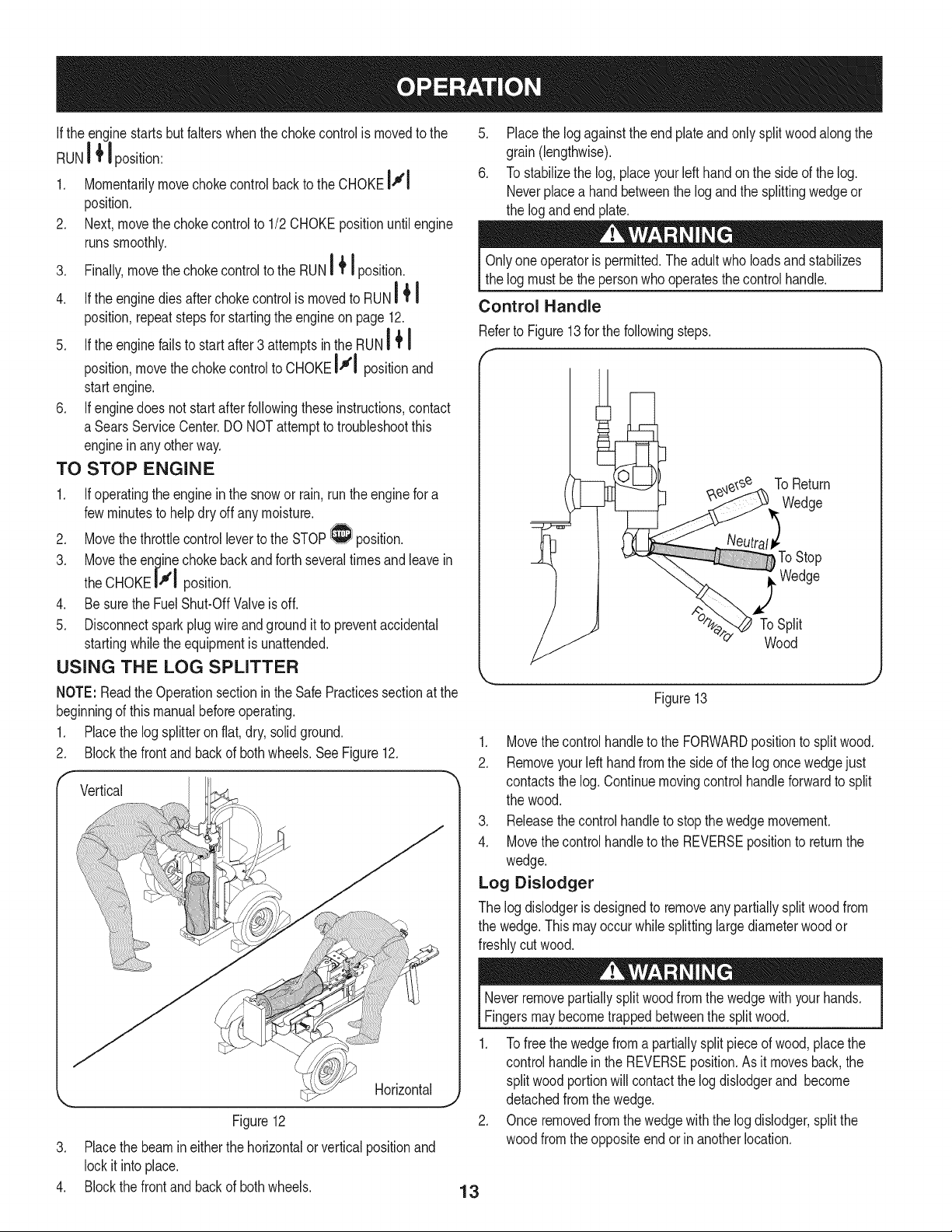

Control Handle

RefertoFigure13forthe followingsteps.

o,e.,le_s_._ToReturn

_'e-e_"_-'-/7ToSplit

o" Wood

NOTE:ReadtheOperationsectioninthe SafePracticessectionat the

beginningof thismanualbeforeoperating.

1. Placethe logsplitteronflat,dry,solidground.

2. Blockthefrontandbackof bothwheels.SeeFigure12.

Vertical

Horizontal

Figure12

.

Placethe beamineitherthe horizontalorverticalpositionand

lockit intoplace.

4.

Blockthefrontandbackof bothwheels.

Figure13

1. Movethecontrolhandleto theFORWARDpositiontosplitwood.

2. Removeyourleft handfromthesideofthe logoncewedgejust

contactsthelog.Continuemovingcontrolhandleforwardto split

thewood.

3. Releasethe controlhandletostopthewedgemovement.

4. Movethecontrolhandleto theREVERSEpositionto returnthe

wedge.

Log Dislodger

Thelogdislodgerisdesignedto removeanypartiallysplitwoodfrom

thewedge.Thismayoccurwhilesplittinglargediameterwoodor

freshlycutwood.

Neverremovepartiallysplitwoodfromthewedgewithyourhands.

Fingersmaybecometrappedbetweenthesplitwood.

1. Tofreethewedgefroma partiallysplitpieceofwood,placethe

controlhandleintheREVERSEposition.As itmovesback,the

splitwoodportionwillcontactthe logdislodgerand become

detachedfromthewedge.

2. Onceremovedfromthewedgewiththe logdislodger,splitthe

woodfromthe oppositeendorin anotherlocation.

13

Vertical Position

1. Pullthehorizontalbeamlockout to releasethebeamandpivot

thebeamtothe verticalposition.

2. Tolockthebeaminthe verticalposition,pulloutonthevertical

beamlockandrotateit to securethebeam.SeeFigure14.

f

iVertical BeamLock]

Figure14

.

Standin frontof thelogsplittertooperatethecontrolhandleand

tostabilizethelog.See Figure12.

Horizontal Position

1. Pulltheverticalbeamlockoutand rotateit down.SeeFigure

15.Pivotthebeamto thehorizontalposition.Thebeamwilllock

automaticallyinthehorizontalposition.

TRANSPORTING THE LOG SPLITTER

3. Lowerthebeamtoitshorizontalposition.Makecertainthebeam

islockedsecurelywiththehorizontalbeamlock.

4. Raisetheadjustablejack standbyturningthecrankclockwise.

SeeFigure16.

Adjustment

Nut

Crank

J

Figure16

5. Attachthe couplerhitchtoaclass Ior higher2"ballona towing

vehicle.Latchsecurely.

6. Ifthecouplerhitchdoesnotfitonthe ball:Turntheadjustment

nutoneturn counter-clockwise.

7. Ifthecouplerhitchistoo looseon theball:Turntheadjustment

nutoneturn clockwise.Thenrecheckandadjustaccordingly.

8. Connectthe safetychainstothe towingvehicle.

HorizontalBeamLock

Figure15

.

Standbehindthe reservoirtanktooperatethe controlhandleand

tostabilizethelog.See Figure12.

Donot towfasterthan45mph andchecklocal,state,and federal

requirementsbeforetowingonanypublic road.

NOTE:Usecautionwhenbackingup.Usinga spotteroutsideof the

vehicleis recommended.

14

OPERATING TIPS

Always:

1. Usecleanfluidandcheckthe fluidlevelregularly.

2. Useanapprovedhydraulicfluid.ApprovedfluidsincludeShell

Tellus®$2M32HydraulicFluid,Dexron®III/Mercon®automatic

transmissionfluid, Pro-SelectTM AW-32HydraulicOilor 10WAW-

ISOviscositygrade32 hydraulicoil.

NOTE:Itis notrecommendedthathydraulicfluidsbe mixed.

3. Alwaysensurethatthefilteris inplace.Cleanorreplacethefilter

regularly.

4. Thisunitcomeswitha breathercaponthefluidreservoir.Donot

useany othertypeofreservoircap.

5. Makesurethe pumpismountedandalignedproperly.

6. Thisunitcomeswitha flexible"spider"type couplingbetween

theengineandpumpdriveshafts.Donot useanyothertypeof

coupling.

7. Keepthehosesclearand unblocked.

8. Bleedtheairout ofthehosesbyfullyextendingand retracting

thewedge 12completecyclesto removeanyair trappedinthe

systembeforeoperating.

9. Flushandcleanthehydraulicsystembeforerestartingafterservicing.

SeeServiceandMaintenancesection.

10. Use"pipedope"onall hydraulicfittings.

11. Allowtimefortheenginetowarm-upbeforesplittingwood.

12. Primethepumpbeforetheinitialstart-upby turningoverthe

enginewithsparkplugdisconnected.

13. Splitthewoodalongthegrain(lengthwise)only.

Never:

1. Usewhenfluidisbelow200For above1500E

2. Usea solidengine/pumpcoupling.

3. Operatethroughreliefvalveformorethan 5seconds.Ifthe

wedgestopsmovingor reachestheendof itsstroke,releasethe

controlhandleor REVERSEitwithin5 secondstoavoidputting

stresson thehydraulicsystemandengine.

4. Attemptto adjustunloadingor reliefvalvesettings.

5. Operatewithairinthe hydraulicsystem.

6. Useteflontapeonthe hydraulicfittings.

7. Attemptto cutwoodacrossthegrain.

8. Attemptto removepartiallysplitwoodfromthe wedgewithyour

hands.Fullyretractthewedgetodislodgethewoodwiththe log

dislodger.

15

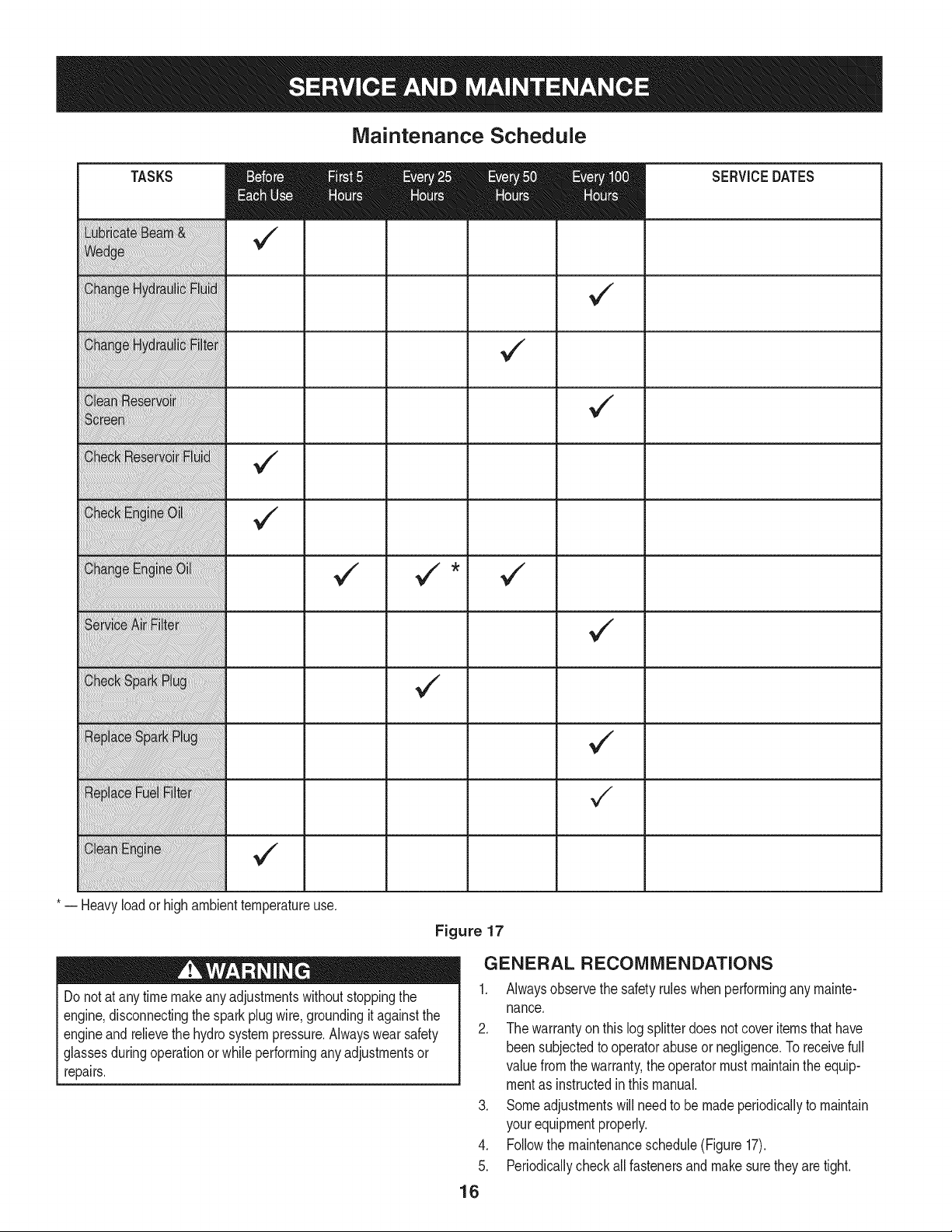

Maintenance Schedule

TASKS

SERVICEDATES

v"

,/

*-- Heavyloador highambienttemperatureuse.

Donotatany timemakeanyadjustmentswithoutstoppingthe

engine,disconnectingthe sparkplugwire,groundingitagainstthe

engineandrelievethehydrosystempressure.Alwayswearsafety

glassesduringoperationor whileperforminganyadjustmentsor

repairs.

,/

Figure 17

GENERAL RECOMMENDATIONS

1. Alwaysobservethesafetyruleswhenperforminganymainte-

nance.

2. Thewarrantyonthis logsplitterdoesnotcoveritemsthathave

beensubjectedtooperatorabuseor negligence.Toreceivefull

valuefromthe warranty,theoperatormustmaintaintheequip-

mentasinstructedinthismanual.

3. Someadjustmentswillneedto bemadeperiodicallytomaintain

yourequipmentproperly.

.

Followthemaintenanceschedule(Figure17).

5.

Periodicallycheckallfastenersandmakesuretheyaretight.

16

HYDRAULIC FLUID AND iNLET FILTER

Stopthe engineandrelievehydraulicsystempressurebeforechang-

ingor adjustingfittings,hoses,tubing,or othersystemcomponents.

Checkthehydraulicfluid levelin thelogsplitterreservoirtankbefore

eachuse.Maintainthefluidlevelwithintherangespecifiedon the

dipstickatalltimes.

Changethehydraulicfluid inthereservoirevery100hoursof opera-

tion.Followthestepsbelow:

1. Placeasuitableoil collectioncontainerunderthetank.

2. Disconnectthesuctionhosefromthe bottomofthe reservoirtank.

SeeFigure18.

f *-

4. Allowthefluidto drainintoa suitablecontainer.

NOTE:The reservoirtankhasacapacityof3 gallonsandtheentire

hydraulicsystemhasacapacityofapproximately4.7gallons.

5. Reinstallthefilterinletscreenand hose.Tightenthe hoseclamp.

6. Checkthefluidlevelusingthedipstick.Donotoverfill.

NOTE:ApprovedfluidsincludeShellTellus®$2 M32HydraulicFluid,

Dexron®III/ Mercon®automatictransmissionfluid,Pro-SelectTM

AW-32HydraulicOilor IOWAW-lSOviscositygrade32 hydraulicoil. It

isrecommendedthatfluidsnotbe mixed.

7. Replacetheventeddipsticksecurely,tighteningituntilthetopof

thethreadsareflushwithtopofthe pipe.

8. Disconnectthesparkplugandprimethepumpbypullingthe

recoilstarterasfar asitwillgo.Repeatapproximately10times.

9. Reconnectthesparkplugwireandstarttheenginefollowingthe

instructionsintheOperationsectionofthis manual.

10. Usethecontrolhandletoengagethewedgeto thefarthest

extendedposition.Thenretractthewedge.

11. Ifnecessaryrefillthereservoirwithinrangemarkedonthe

dipstick.SeeFigure20.

Dipstick

Suction

Hose

3. Carefullyunthreadtheinletfilterandcleanitwithpenetratingoil.

SeeFigure19.

InletFilter

Inlet

Filter

Figure18

Figure19

HydraulicFluid

Only

Figure20

12. Extendand retractthewedge12completecyclestoremove

trappedairin thesystem(thesystemis"self-bleeding").

Muchofthe originalfluidhasbeendrawnintothe cylinderandhoses.

Makecertaintorefillthereservoirtopreventdamagetothehydraulic

pump.Failureto refillthetankwillvoidthelogsplitter'swarranty.

NOTE:Somefluidmayoverflowfromtheventplugas thesystem

buildsheatandthefluid expandsand seeksabalancedlevel.Do

notoperatethelog splitterwithouttheproperamountof fluidinthe

reservoir tank.

13. Maintainthefluidlevelwithintherangespecifiedonthedipstickat

alltimes.Whencheckingthefluid,alwaysmakesuretotightenthe

dipstickuntilthetopof thethreadsareflushwiththetopofthe pipe.

NOTE:Alwaysdisposeofanyusedhydraulicfluidandengineoil at

approvedrecyclingcentersonly.

17

14.

Contaminantsinthefluidmaydamagethe hydrauliccomponents.

Flushingthereservoirtankandhoseswithkerosenewhenever

serviceisperformedonthetank,hydraulicpumporvalveisrecom-

mended.ContactaSearsor otherauthorizedservicedealer.

Useextremecautionwhenworkingwith kerosene.It isanextremely

flammablefluid.

Hydraulic Filter

Changethehydraulicfilterevery50 hoursofoperation.Useonlya 10

micronhydraulicfilter.Orderpartnumber723-0405.

BEAM AND SPLITTING WEDGE

Beforeeachuse,lubricatebothsidesof thebeam(whereitcomesinto

contactwiththesplittingwedge)withengineoil. Thewedgeplateon

thelogsplitterisdesignedsothe gibson thesideofthewedgeplate

canberemovedandrotatedand/orturnedoverforevenwear.Seethe

GibAdjustmentsection.

Makecertainto readjusttheadjustmentboltssothewedgemoves

freely,butnoexcessspaceexistsbetweenthe wedgeplateandthe

beam.

ENGINE

Iftheenginehasbeenrunning,themuffler,engineheadandspark

plugwill beveryhot.Becarefulnotto touchanyofthesecomponents

untiltheyhavecooled.

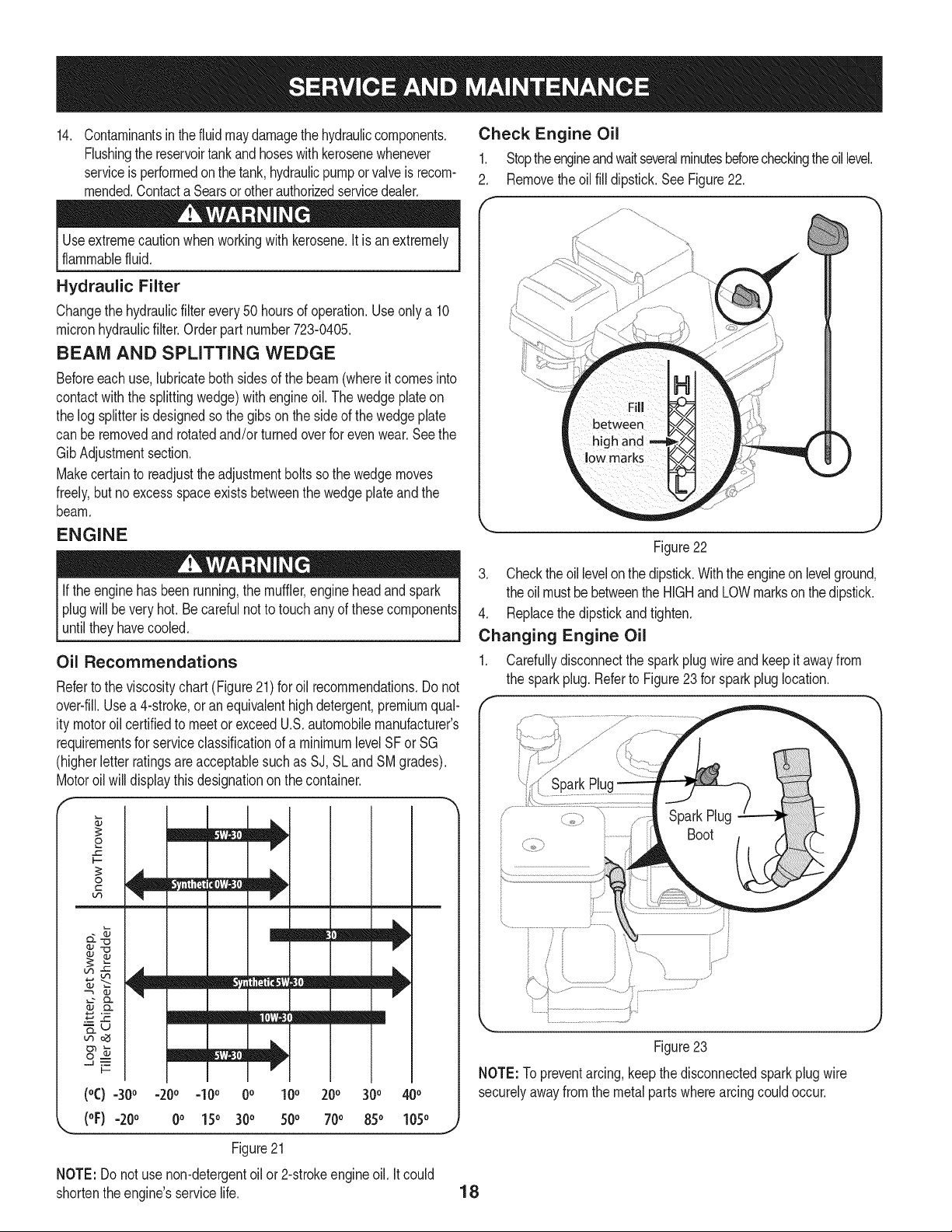

Oil Recommendations

Refertothe viscositychart(Figure21)foroil recommendations.Donot

over-fill.Usea4-stroke,oranequivalenthighdetergent,premiumqual-

ity motoroilcertifiedtomeetorexceedU.S.automobilemanufacturer's

requirementsfor serviceclassificationofa minimumlevelSFor SG

(higherletterratingsareacceptablesuchasSJ, SLandSMgrades).

Motoroil willdisplaythisdesignationon thecontainer.

Check Engine Oil

1. Stoptheengineandwaitseveralminutesbeforecheckingtheoillevel.

2. Removetheoilfill dipstick.SeeFigure22.

Figure22

3. Checktheoillevelonthe dipstick.Withtheengineonlevelground,

theoilmustbebetweentheHIGHandLOWmarksonthe dipstick.

4. Replacethe dipstickandtighten.

Changing Engine Oil

1. Carefullydisconnectthesparkplugwire andkeepitawayfrom

thesparkplug.Referto Figure23for sparkpluglocation.

I

o

©

®"o V

cu

4,,.., _

.__z __ _:__lm

_u

cqo_

b-

(°C) =30° "20° =10° 0° 10° 200 300 400

(oF)-20 ° 0o 150 300 500 700 850 105o

NOTE:Donotuse non-detergentoil or2-strokeengineoil. Itcould

shortentheengine'sservicelife.

mm/mlb,

Figure21

Figure23

NOTE:Topreventarcing,keepthedisconnectedsparkplugwire

securelyawayfromthe metalpartswherearcingcouldoccur.

J

18