Craftsman 24729935 Owner’s Manual

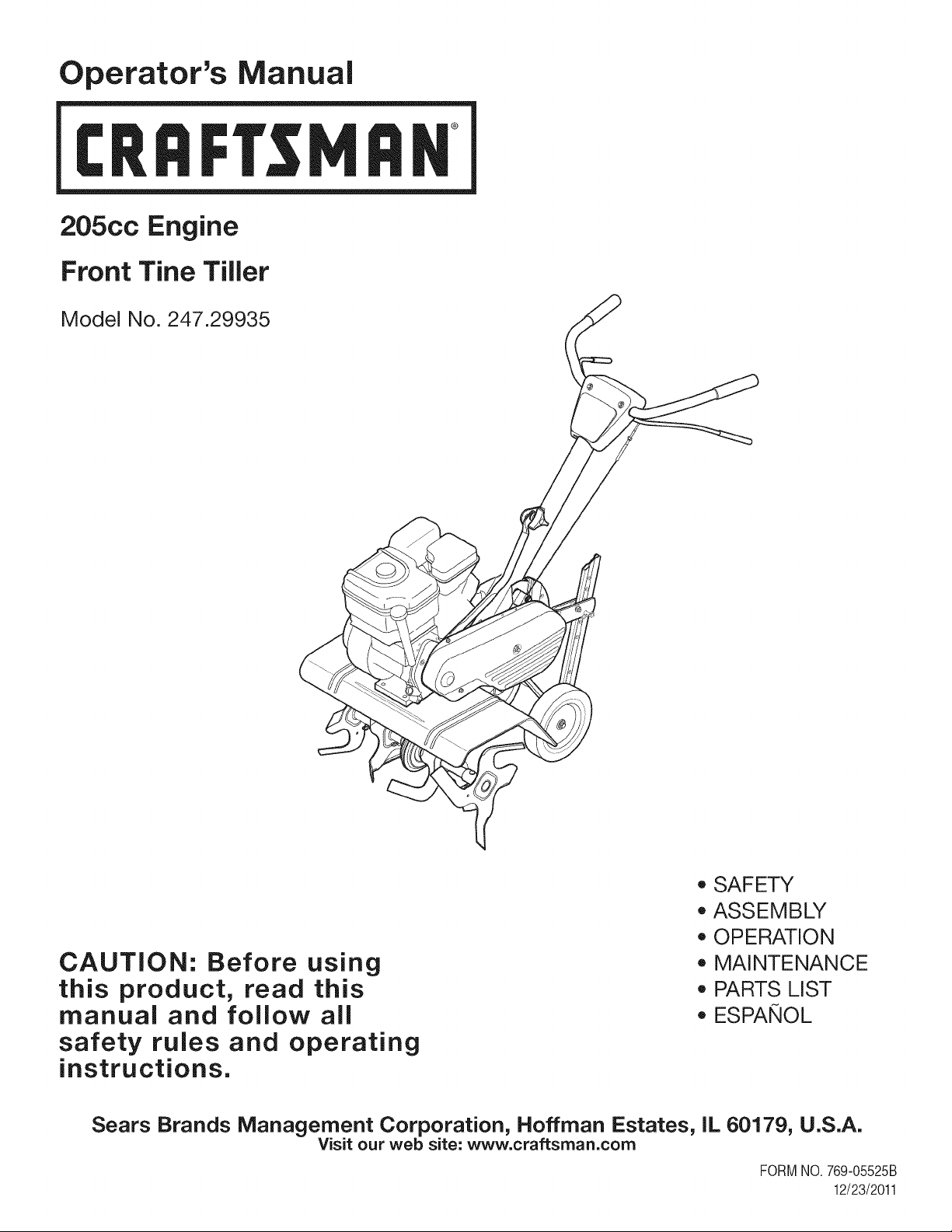

Operator's Manual

I:Rl FI'SlVl N

205cc Engine

Front Tine Tiller

Model No. 247.29935

* SAFETY

* ASSEMBLY

* OPERATION

CAUTION: Before using

this product, read this

manual and follow all

* MAINTENANCE

* PARTS LIST

* ESPANOL

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, iL 60179, U.S.A.

Visit our web site: www.craftsman.com

FORM1/0.769-05525B

12/23/2011

WarrantyStatement..................................Pac

Safetyinstructions....................................Pac

Assembly..................................................Pac

Operation..................................................Pac

ServiceandMaintenance.........................Pac

Off-SeasonStorage..................................Pac

TroubleShooting.......................................Pac

CRAFTSMAN TWO YEAR FULL WARRANTY

FORTWOYEARSfromthe dateof purchase,this productis warrantedagainstanydefectsin materialorworkmanship,A defectiveproductwill

receivefreerepairorreplacementif repairis unavailable,

Forwarranty coverage details to obtain free repairor replacement,visit the web site: www.craftsman.com

This warranty covers ONLYdefects in material andworkmanship. Warrantycoverage does NOTinclude:

• Expendableitemsthatcan wearoutfromnormalusewithinthewarrantyperiod,suchas theblades,tines,orbelts.

• Productdamageresultingfromuserattemptsat productmodificationor repairorcausedby productaccessories.

• Repairsnecessarybecauseof accidentorfailuretooperateor maintaintheproductaccordingtoall suppliedinstructions.

• Preventivemaintenance,or repairsnecessarydueto improperfuelmixture,contaminatedor stalefuel.

e2

es3-6

es7-10

es11-15

es16-19

e20

e21

PartsList...................................................Page22-34

LabelMap.................................................Page35

RepairProtectionAgreement...................Page38

Espa_ol.....................................................Page39

ServiceNumbers......................................BackCover

Thiswarrantyisvoidif thisproductiseverusedwhile providingcommercialservicesorif rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineSeries: 205cc

EngineOilType: SAE30

EngineOilCapacity: 20ounces

Fuel: UnleadedGasoline

SparkPlug: Champion®RC-12YC

SparkPlugGap: .030"

ModelNumber.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

©KCDIP,LLC 2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingto thesafeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthe partof theoperatorcan resultin

seriousinjury.Thismachineiscapableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm.Bat-

tery posts,terminals,andrelatedaccessoriescontainleadand lead

compounds,chemicalsknowntothe Stateof Californiatocause

cancerandreproductiveharm.Washhandsafterhandling.

TRAINING

• Read,understand,andfollowall instructionson the machineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplaceforfutureand regularreference

andfororderingreplacementparts.

• ReadtheOperator'sManualand followallwarningsand safety

instructions.Failuretodosocan resultin seriousinjuryto the

operatorand/or bystanders.Forquestions,call1-800-4MY-HOME.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsof agetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultstooperatethis machinewithoutproper

instruction.

• Keepbystanders,pets,andchildrenatleast75feetfromthe

machinewhileit isin operation.Stopmachineifanyoneenters

thearea.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

Your Responsibility--Restrictthe useof thispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall rocks,bottles,cans,or otherforeignobjectswhich

couldbepickedupor thrownandcausepersonalinjuryor

damageto themachine.

• Alwayswearsafetyglassesor safetygogglesduringoperation

andwhileperformingan adjustmentorrepair,to protectyour

eyes.Thrownobjectswhichricochetcancauseseriousinjuryto

theeyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesorjewelrycan becaughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beforestarting,checkallboltsandscrewsforpropertightnessto

besurethe machineisinsafeworkingcondition.Also,visually

inspectmachinefor anydamageatfrequentintervals.

• Disengageclutchleversandshift(if provided)intoneutral("N")

beforestartingtheengine.

• Neverleavethismachineunattendedwiththeenginerunning.

• Neverattempttomakeanyadjustmentswhiletheengineis

running,exceptwherespecificallyrecommendedinthe operator's

manual.

• Maintainor replacesafetyandinstructionslabels,asnecessary.

3

SafeHandling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Neverfill containersinsidea vehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthe groundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthetruck

ortrailerand refuelitonthe ground.Ifthisis notpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthe nozzleincontactwiththerimofthe fueltankor

containeropeningatalltimes untilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

• Extinguishallcigarettes,cigars,pipesandother sourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuel whilethe engineishot or run-

ning.Allowenginetocool atleasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Fill tankto nomorethan1/2inchbelow

bottomoffillerneckto allowspacefor fuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipe itoff theengineandequipment.Move

unitto anotherarea.Wait5 minutesbeforestartingtheengine.

• To reducefirehazards,keepmachinefreeof grass,leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageand removeany

fuelsoakeddebris.

• Neverstorethe machineorfuelcontainerinsidewherethereis an

openflame,sparkor pilotlightas on awaterheater,spaceheater,

furnace,clothesdryerorothergasappliances.

OPERATION

• Do notputhandsorfeetnear rotatingparts.Contactwiththe

rotatingpartscanamputatehandsandfeet.

• Do notoperatemachinewhileunderthe influenceofalcoholor

drugs.

• Neveroperatethismachinewithoutgoodvisibilityor light.Always

be sureof yourfootingandkeepa firmholdonthehandles.

• Keepbystandersawayfromthe machinewhileit isinoperation.

Stopthe machineif anyoneentersthearea.

• Becarefulwhentillinginhardground.Thetines maycatchinthe

groundandpropelthetillerforward.Ifthis occurs,let goofthe

handlebarsanddo not restrainthemachine.

• Exerciseextremecautionwhenoperatingonor crossinggravel

surfaces.Stayalertforhiddenhazardsortraffic. Donotcarry

passengers.

• Neveroperatethemachineat hightransportspeedsonhardor

slipperysurfaces.

• Exercisecautiontoavoidslippingorfalling.

• Lookdownand behindandusecarewheninreverseorpulling

machinetowardsyou.

• Startthe engineaccordingtothe instructionsfoundinthis manual

and keepfeetwell awayfromthetinesat all times.

• Afterstrikingaforeignobjector ifyourmachineshouldstartmak-

inganunusualnoiseor vibration,immediatelyshutthe engineoff.

Disconnectthe sparkplugwire,grounditagainstthe engineand

performthefollowingsteps:

a. Inspectfordamage.

b. Repairorreplaceanydamagedparts.

c. Checkforanyloosepartsandtightento assurecontinued

safeoperation.

• Disengageall clutchlevers(iffitted)andstopenginebeforeyou

leavethe operatingposition(behindthe handles).Waituntil

thetinescometo a completestopbeforeuncloggingthe tines,

makinganyadjustments,or inspections.

• Neverrunanengineindoorsorinapoorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an odorlessanddeadlygas.

• Mufflerandenginebecomehotandcancauseaburn.Donot

touch.

• Usecautionwhentillingnearfences,buildingsandunderground

utilities.Rotatingtinescan causepropertydamageorpersonal

injury.

• Donotoverloadmachinecapacitybyattemptingtotillsoiltoo

deepattoo fastof a rate.

• Ifthemachineshouldstartmakinganunusualnoiseorvibration,

stoptheengine,disconnectthesparkplugwire andgroundit

againsttheengine.Inspectthoroughlyfordamage.Repairany

damagebeforestartingandoperating.

• Keepallshields,guards,andsafetydevicesinplaceandoperat-

ing properly.

• Neverpick uporcarrymachinewhiletheengineis running.

• Useonlyattachmentsandaccessoriesapprovedbythemanu-

factureras listedin thePartsListpagesofthisoperator'smanual.

Failuretodosocan resultin personalinjury.

• Ifsituationsoccurwhichare notcoveredinthismanual,usecare

andgoodjudgement.ContactCustomerSupportat 1-800-4MY-

HOMEforassistanceandthenameof thenearestservicedealer

MAINTENANCE & STORAGE

• Keepthemachine,attachmentsandaccessoriesinsafeworking

order.

• Allowthemachinetocoolat leastfiveminutesbeforestoring.

Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.

• Checkboltsandscrewsforpropertightnessat frequentintervals

to keepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

• Beforecleaning,repairing,or inspecting,stoptheengineand

makecertainthetinesandall movingpartshavestopped.

Disconnectthe sparkplugwireandgrounditagainsttheengineto

preventunintendedstarting.

4

• Do notchangetheenginegovernorsettingsor over-speedthe

engine.Thegovernorcontrolsthemaximumsafeoperatingspeed

ofengine.

Maintainor replacesafetyandinstructionlabels,as necessary.

Followthis manualfor safeloading,unloading,transporting,and

storageof thismachine.

Alwaysreferto theoperator'smanualforimportantdetailsifthe

machineisto bestoredforan extendedperiod.

If thefuel tankhasto be drained,do thisoutdoors.

Observeproperdisposallawsandregulationsforgas,oil, etc.to

protecttheenvironment.

Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 130hoursof

operation.Atthe endof theAverageUsefulLifehavethemachine

inspectedannuallybyanauthorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failureto do socan resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyenginein anyway.

Tamperingwiththegovernorsettingcan leadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,it shouldbe maintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthe muffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

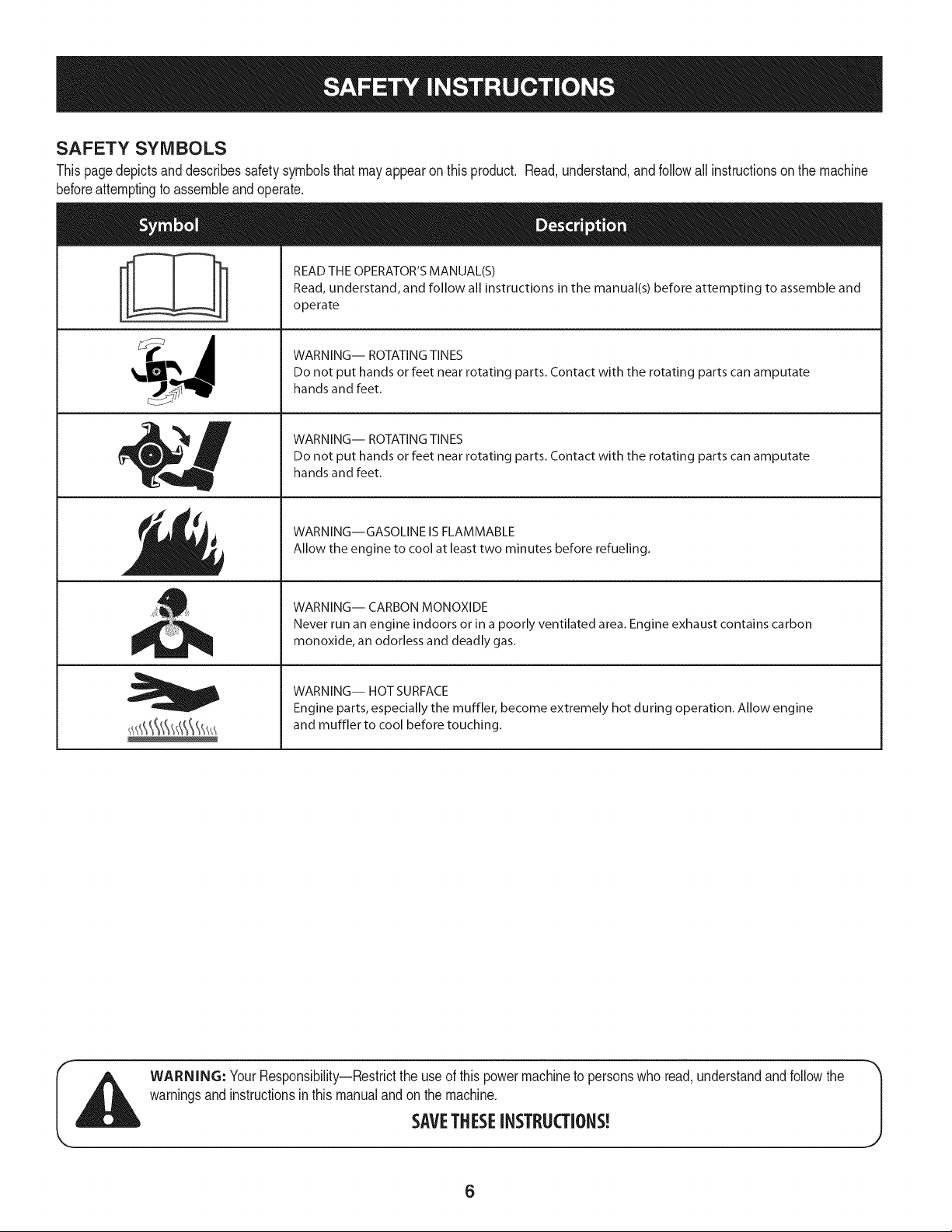

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowallinstructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING: YourResponsibility--Restricttheuseofthispowermachineto personswhoread,understandandfollowthe

warningsand instructionsinthis manualandonthemachine.

SAVETHESEINSTRUCTIONS!

6

NOTE:Thisunit isshippedwithoutgasolineor oilin theengine.Be

certaintoserviceenginewithgasolineandoil as instructedin the

Operationsectionofthis manualbeforeoperatingyourmachine.

NOTE:Referenceto rightand lefthandsideof theTillerisobserved

fromtheoperatingposition.

OPENING CARTON

1. Cuteachcornerofthe cartonverticallyfromtopto bottom.

2. Removealllooseparts.

3. Removeloosepackingmaterial.

REMOVING UNIT FROM CARTON

1. Usethehandlebartoliftand pullthetiller backwardstoa flat

area.Checkthecartonthoroughlyforlooseparts.

2. Besurenotto kinkthe forwardclutchcable.

LOOSE PARTS IN CARTON

• HandlebarAssembly

• Tiller

• EngineOil

• Operator'sManual

• DepthGageAssembly

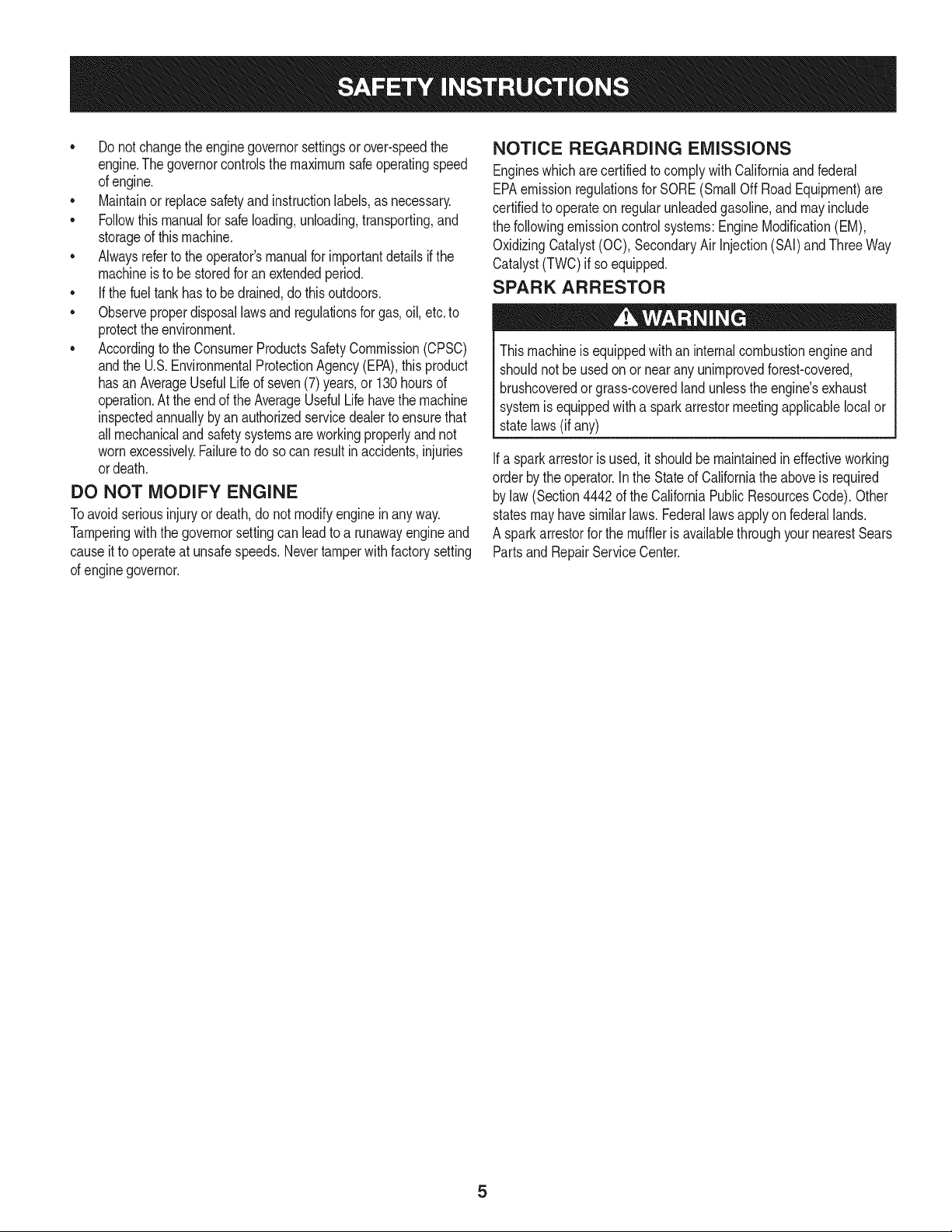

ATTACHING THE CABLE

1. Identifytheforwardclutchcable(A). SeeFigure1.

2. Hookthe"Z"endof theforwardclutchcable(A)intotheforward

fineengagementlever.SeeFigure2.

f

Figure2

NOTE:Besurenotto kinkthecable whileattaching.

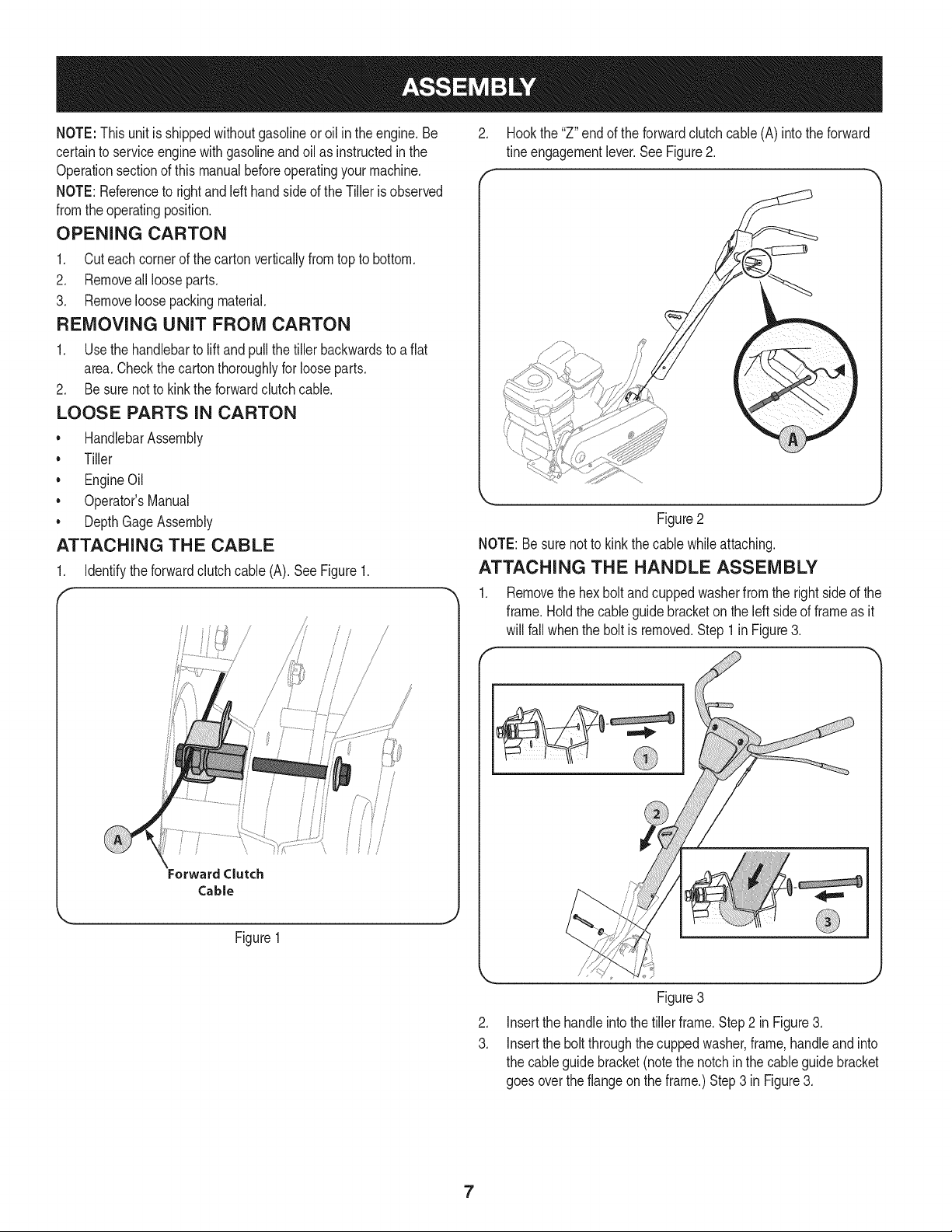

ATTACHING THE HANDLE ASSEMBLY

1. Removethehexbolt andcuppedwasherfromthe rightside ofthe

frame.Holdthecableguidebracketonthe left sideof frameas it

willfall whenthe boltis removed.Step 1inFigure3.

Forward Clutch

Cable

Figure1

//': , "-d,.......

Figure3

.

Insertthehandleintothe tillerframe.Step2 in Figure3.

3.

Inserttheboltthroughthecuppedwasher,frame,handleandinto

thecableguidebracket(notethenotchinthe cableguidebracket

goesovertheflangeon theframe.)Step3 in Figure3.

7

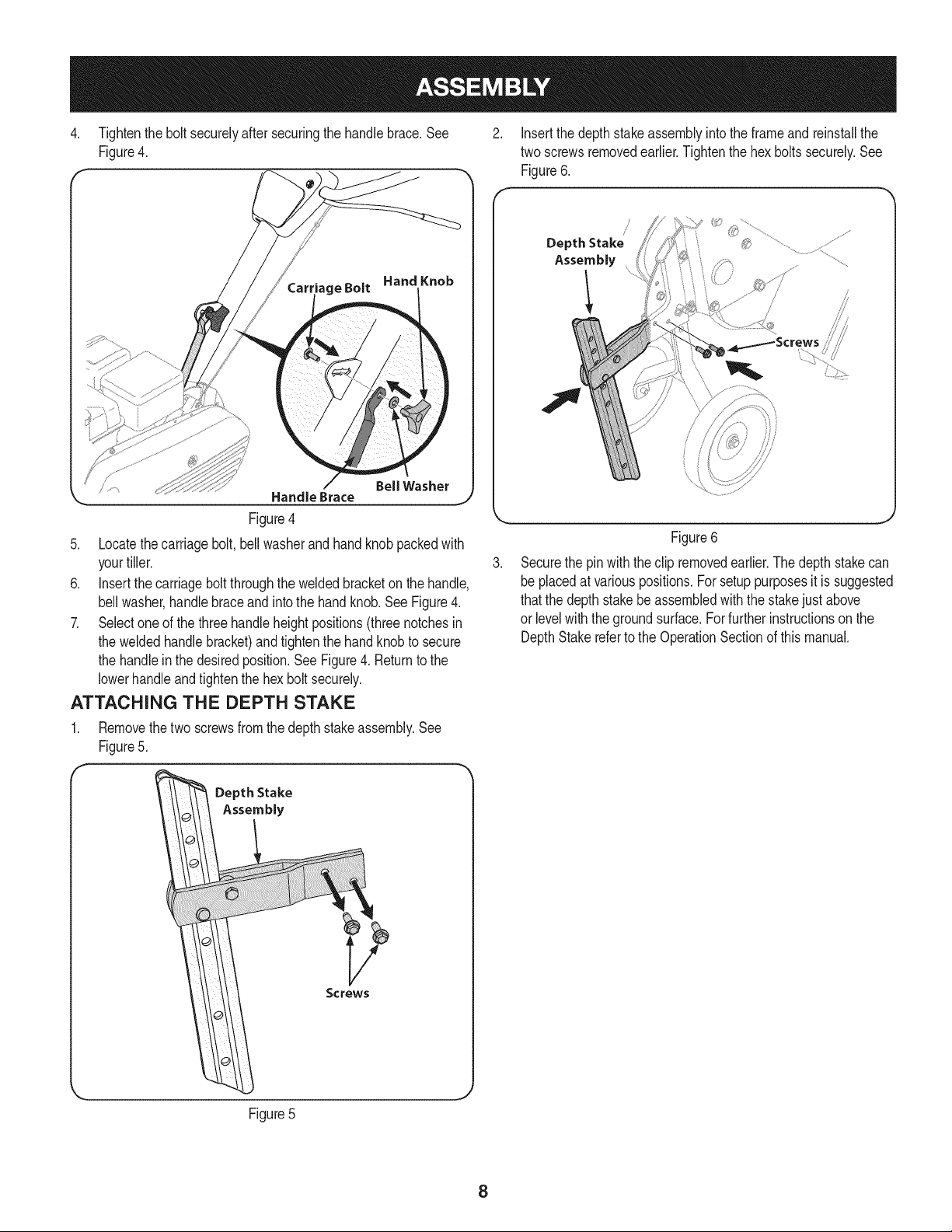

4. Tightentheboltsecurelyaftersecuringthe handlebrace.See

Figure4.

Insertthedepthstakeassemblyintothe frameandreinstallthe

two screwsremovedearlier.Tightenthehexboltssecurely.See

Figure6.

DepthStake

Assembly

/ /

Handle Brace

Bell Washer

Figure4

5. Locatethecarriagebolt,bellwasherandhandknobpackedwith

yourtiller.

6. Insertthe carriageboltthroughtheweldedbracketon thehandle,

bellwasher,handlebraceandintothe handknob.SeeFigure4.

7. Selectoneofthe threehandleheightpositions(threenotchesin

theweldedhandlebracket)andtightenthe handknobtosecure

thehandleinthe desiredposition.SeeFigure4. Returntothe

lowerhandleandtightenthe hexbolt securely.

ATTACHING THE DEPTH STAKE

1. Removethetwo screwsfromthe depthstakeassembly.See

Figure5.

Depth Stake

Assembly

Figure6

Securethepinwiththeclip removedearlier.Thedepthstakecan

beplacedat variouspositions.Forsetuppurposesit issuggested

thatthedepthstakebeassembledwiththestakejustabove

or levelwiththe groundsurface.Forfurtherinstructionsonthe

DepthStakereferto theOperationSectionof thismanual.

Figure5

Screws

8

SET-UP

Tire Pressure

Checktheair pressureinbothtires.Theairpressureshouldbe

between15-20PSI.Keepbothtiresequallyinflatedtohelpprevent

machinefrompullingtoone side.

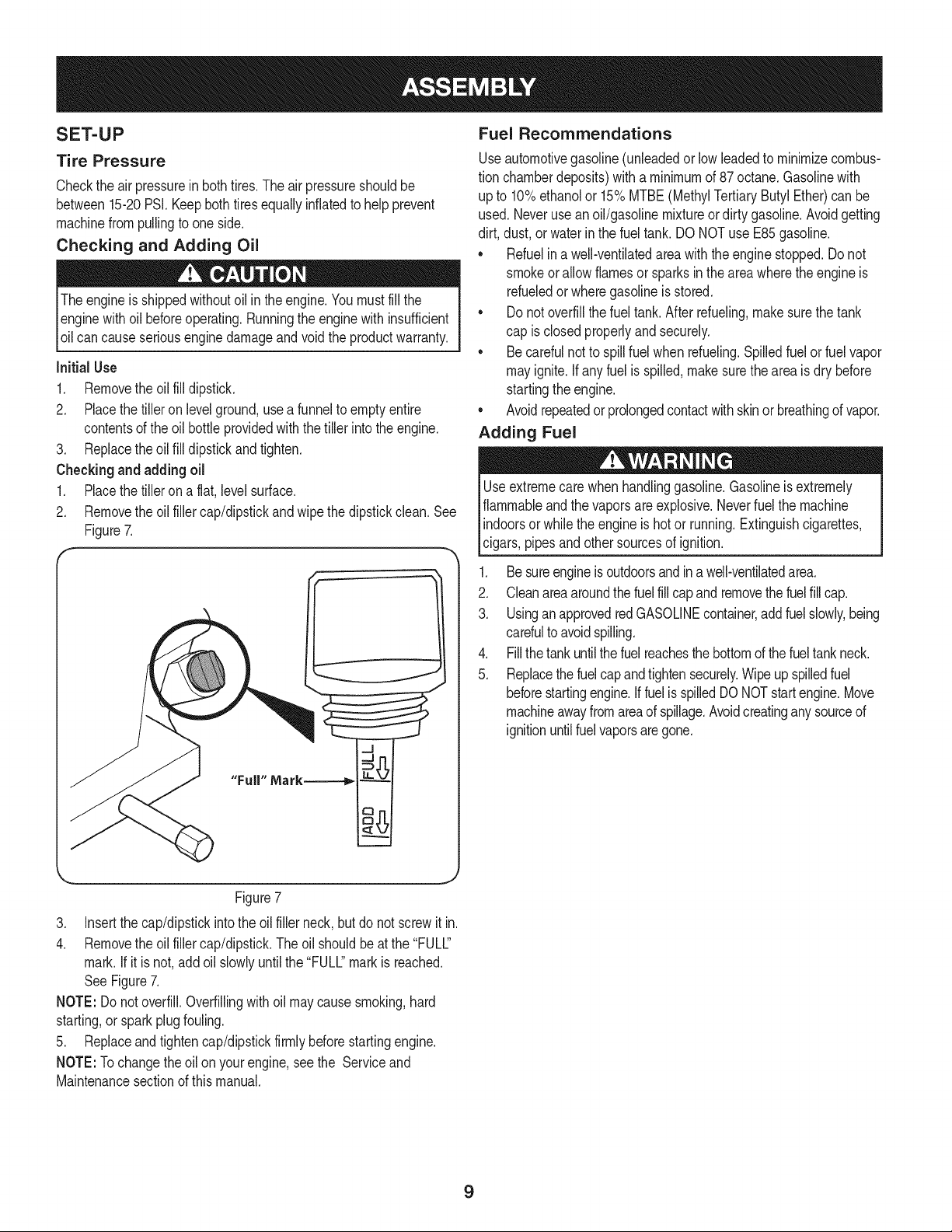

Checking and Adding Oil

Theengineis shippedwithoutoil in theengine.Youmustfill the

enginewithoil beforeoperating.Runningtheenginewithinsufficient

_o cancauseserous engnedamageandvod the productwarranty.

Initial Use

1. Removetheoil filldipstick.

2. Placethetilleron levelground,usea funnelto emptyentire

contentsofthe oil bottleprovidedwiththe tillerintotheengine.

3. Replacetheoil fill dipstickandtighten.

Checkingand adding oil

1. Placethetillerona flat, levelsurface.

2. Removetheoil fillercap/dipstickandwipethedipstickclean.See

Figure7.

Fuel Recommendations

Useautomotivegasoline(unleadedorlowleadedtominimizecombus-

tionchamberdeposits)witha minimumof 87 octane.Gasolinewith

up to 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neverusean oil/gasolinemixtureordirty gasoline.Avoidgetting

dirt, dust,or waterinthe fueltank.DONOTuse E85gasoline.

• Refuelina well-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksin theareawheretheengineis

refueledor wheregasolineisstored.

• Donotoverfillthefueltank.Afterrefueling,makesurethetank

capis closedproperlyandsecurely.

• Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuelvapor

mayignite.Ifany fuelis spilled,makesurethe areaisdry before

startingthe engine.

• Avoidrepeatedor prolongedcontactwithskinorbreathingofvapor.

Adding Fuel

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuelthe machine

indoorsorwhilethe engineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

1. Besureengineisoutdoorsandina well-ventilatedarea.

2. Cleanareaaroundthefuelfill capandremovethefuelfill cap.

3. UsinganapprovedredGASOLINEcontainer,addfuelslowly,being

carefultoavoidspilling.

4. Fillthetankuntilthefuelreachesthe bottomofthefueltankneck.

5. Replacethefuelcapandtightensecurely.Wipeupspilledfuel

beforestartingengine.IffuelisspilledDONOTstartengine.Move

machineawayfromareaofspillage.Avoidcreatinganysourceof

ignitionuntilfuelvaporsaregone.

Figure7

3. Insertthe cap/dipstickintothe oilfillerneck,butdo not screwitin.

4. Removetheoil fillercap/dipstick.Theoilshouldbeatthe "FULC'

mark.If itisnot,addoil slowlyuntilthe "FULL"markisreached.

SeeFigure7.

NOTE:Donotoverfill.Overfillingwithoil maycausesmoking,hard

starting,or sparkplugfouling.

5. Replaceandtightencap/dipstickfirmlybeforestartingengine.

NOTE:Tochangethe oilon yourengine,seethe Serviceand

Maintenancesectionofthismanual.

9

ADJUSTMENTS

Priortooperatingyourtiller,carefullyreadandfollowall instructions

below.Performall adjustmentsto verifyyourtilleris operatingsafely

andpropery.

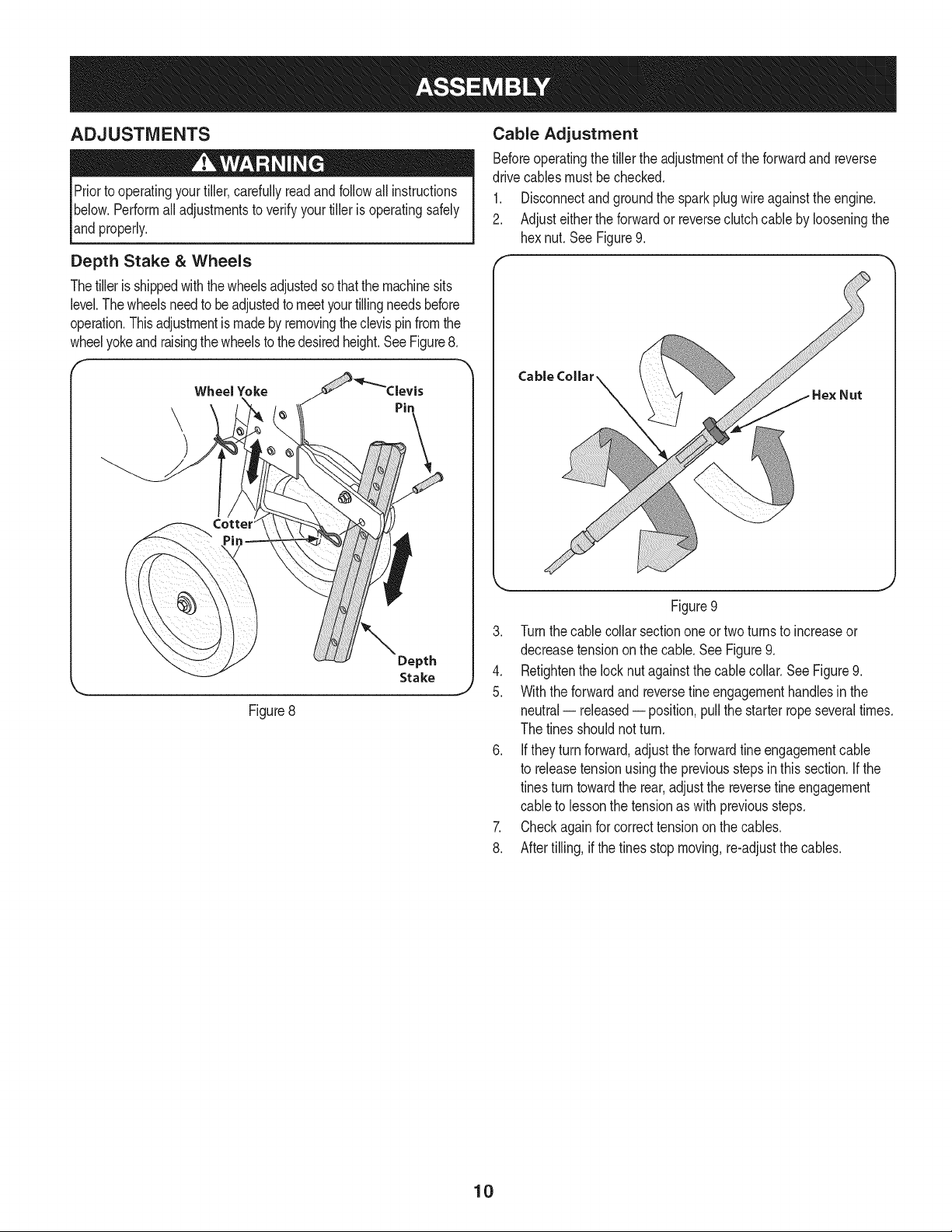

Depth Stake & Wheels

Thetillerisshippedwiththewheelsadjustedsothatthemachinesits

level.Thewheelsneedto beadjustedtomeetyourtillingneedsbefore

operation.Thisadjustmentismadebyremovingtheclevispinfromthe

wheelyokeandraisingthewheelstothedesiredheight.SeeFigure8.

Wheel Yoke

Pin

Cable Adjustment

Beforeoperatingthetiller theadjustmentof theforwardandreverse

drivecablesmustbechecked.

1. Disconnectandgroundthe sparkplugwireagainstthe engine.

2. Adjusteithertheforwardor reverseclutchcablebylooseningthe

hexnut.SeeFigure9.

Figure8

Depth

Stake

Figure9

3. Turnthecablecollarsectiononeortwoturnsto increaseor

decreasetensiononthecable.See Figure9.

4. Retightenthe locknutagainstthe cablecollar.SeeFigure9.

5. Withtheforwardandreversefineengagementhandlesinthe

neutral-- released-- position,pullthe starterropeseveraltimes.

Thetinesshouldnotturn.

6. Iftheyturnforward,adjusttheforwardfineengagementcable

to releasetensionusingthe previousstepsinthis section.Ifthe

tinesturntowardthe rear,adjustthereversefineengagement

cableto lessonthetensionaswith previoussteps.

7. Checkagainforcorrecttensiononthe cables.

8. Aftertilling,ifthe tinesstopmoving,re-adjustthe cables.

10

f

Air Filter

Fuel Ca

Oil Fill Cap

& Dipstick

Tiller Tines

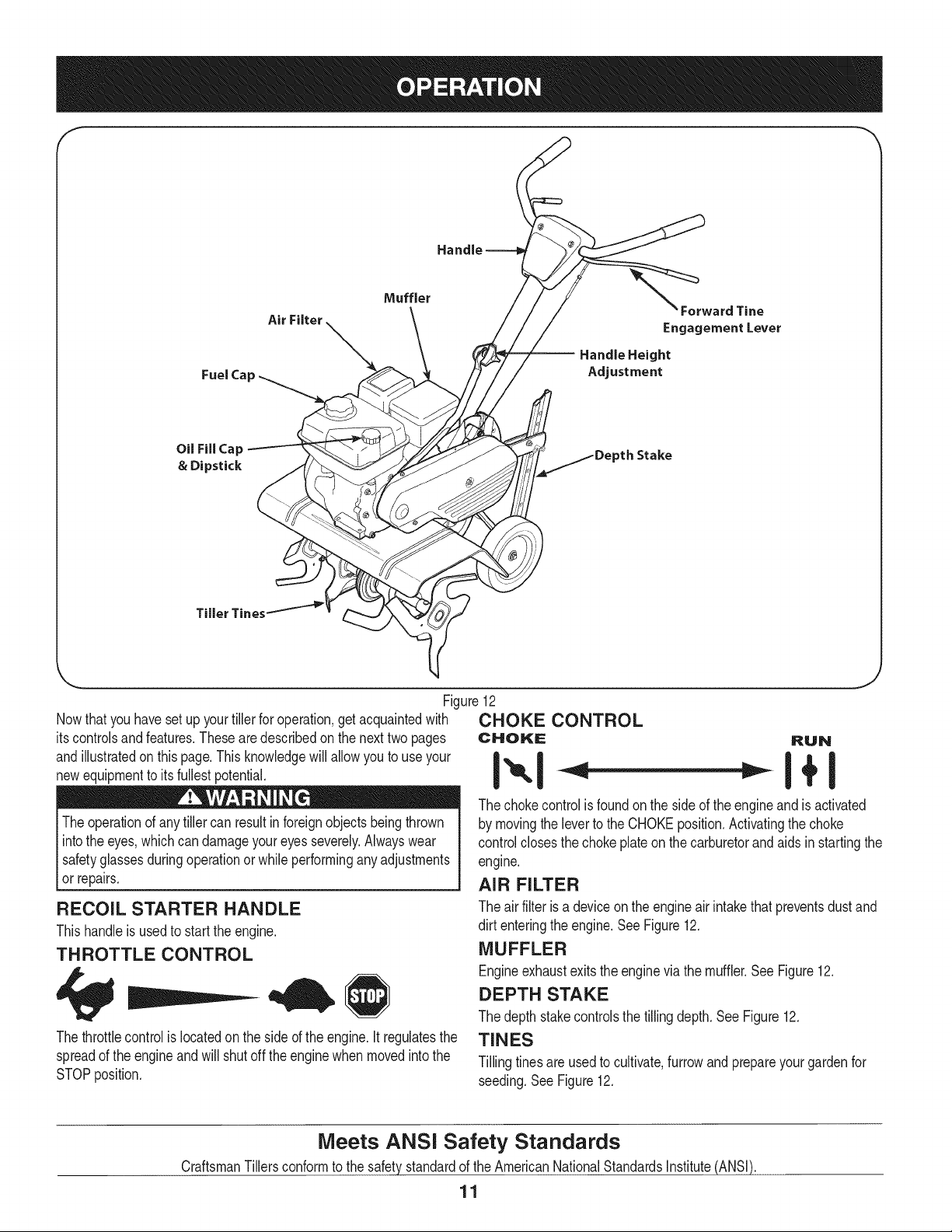

Nowthat youhavesetup yourtillerforoperation,getacquaintedwith

itscontrolsandfeatures.Thesearedescribedon thenexttwopages

andillustratedonthispage.Thisknowledgewillallowyouto useyour

newequipmenttoitsfullestpotential.

Forward Tine

Engagement Lever

-- Handle Height

Adjustment

)th Stake

.J

Figure12

CHOKE CONTROL

CHOKE RUN

Theoperationofanytillercan resultinforeignobjectsbeingthrown

intothe eyes,whichcan damageyoureyesseverely.Alwayswear

Isafetyglassesduringoperationor whileperforminganyadjustments

[or repairs.

RECOIL STARTER HANDLE

Thishandleisusedto starttheengine,

THROTTLE CONTROL

Thethrottlecontrolis locatedonthe sideof theengine.Itregulatesthe

spreadoftheengineandwill shutoff theenginewhen movedintothe

STOPposition.

Meets ANSi Safety Standards

CraftsmanTillersconformtothe safetystandardofthe AmericanNationalStandardsInstitute(ANSI).

The choke control is found on the side of the engine and is activated

bymovingthe leverto theCHOKEposition.Activatingthechoke

controlclosesthe chokeplateon the carburetorandaidsin startingthe

engine.

AIR FILTER

Theairfilterisa deviceon theengineairintakethatpreventsdustand

dirtenteringtheengine.SeeFigure12.

MUFFLER

Engineexhaustexitstheenginevia themuffler.SeeFigure12.

DEPTH STAKE

Thedepthstakecontrolsthetillingdepth.See Figure12.

TINES

Tillingtinesareusedtocultivate,furrowandprepareyourgardenfor

seeding.SeeFigure12.

11

HANDLEBAR HEIGHT ADJUSTMENT

Thehandleheightmaybeadjusted.Loosenthe knobto changethe

position.Tightenhardwarewhencomplete.SeeFigure12.

OIL FILL CAP & DIPSTICK

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill. See

Figure12.

NOTE:ThisunitwasshippedWITHOUToil intheengine.Oilisincluded

intheplasticbagpackedwiththemanualinwiththeunit.Addtheoilas

directedintheGas& OilFillUpsection.Checktheoil levelbeforeeach

operationtoensureadequateoilisinthe engine.Forfurtherinstructions,

refertothestepsintheEngineMaintenancesectionofthismanual.

FORWARD TINE ENGAGEMENT LEVER

Theforwardtine engagementlevercontrolstheengagementof the

tines.Releasetheleverto stopthetines.SeeFigure12.

TO START ENGINE

1. Attachsparkplugwireand rubberboottosparkplug.

2. Filltankto nomorethan1/2inchbelowbottomof fillerneckto

providespaceforfuelexpansion.

3. Makesurethe fineclutchcontrolisdisengaged.

4. Movethechokeleverontheengineto CHOKEI'_1 position.(A

warmenginemaynotrequirechoking.)SeeFigure13.

f

jL

TO STOP ENGINE

1. To stopthewheelsandtines, releasetheForwardClutchBail.

2. Movethrottlecontrolleverto slow(turtle)_ position.

Wheneverpossible,graduallyreduceenginespeedbefore

stoppingengine.

3. Movethrottlecontrolleverto STOP or OFFposition.

4. Disconnectsparkplugwireandgrounditagainsttheengineto

preventaccidentalstartingwhilethe equipmentisunattended.

TO ENGAGE DRIVE & TINES

1. Forforwardmotionofthewheelsandpowertothe tinespullthe

ForwardClutchBailupagainstthe handlebar.

2. Whentilling,relaxandletthe wheelspullthemachinewhilethe

tinesdig.Walkslowlybehindthetillerallowingit tomoveat its

ownpacewhilekeepinga securegripon thehandlebarwithyour

elbowsflexed.

3. Releasethebailto stoptheforwardmotionof wheelsandtines.

TURNING THE TILLER

1. Practiceturningthetiller ina level,openarea.Beverycarefulto

keepyourfeetand legsawayfromthetines.

2. Tobeginaturn,liftthe handlebarsuntilthetinesare outofthe

groundandtheengineandtinesarebalancedoverthewheels.

3. Withthetillerbalanced,pushsidewaysonthe handlebartosteer

inthedirectionof theturn.Afterturning,slowlylowerthetinesinto

thesoil toresumetilling.

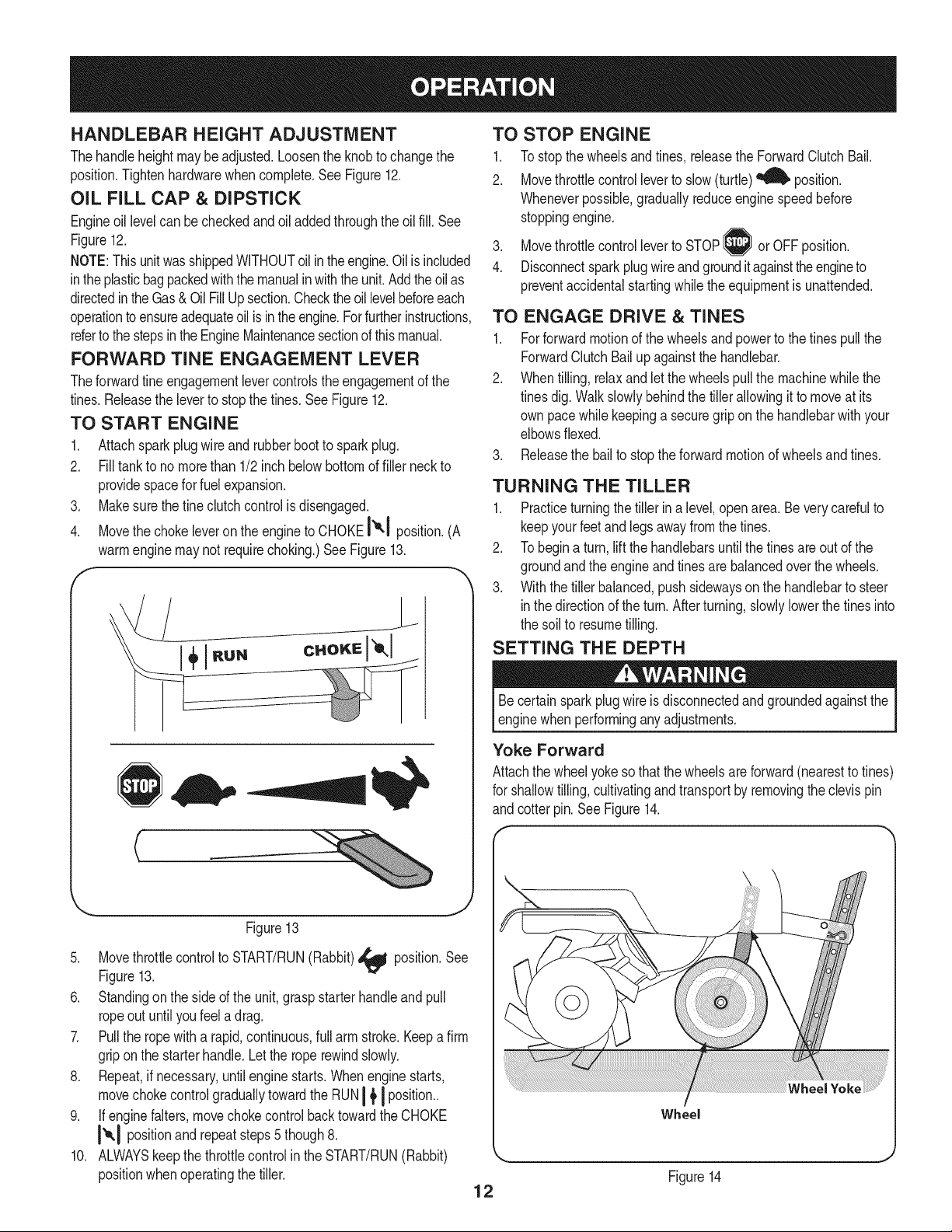

SETTING THE DEPTH

C

Figure13

5. Movethrottlecontrolto START/RUN(Rabbit)_ position.See

Figure13.

6. Standingonthe sideof theunit,graspstarterhandleand pull

ropeoutuntilyoufeel adrag.

7. Pulltheropewitha rapid,continuous,fullarmstroke.Keepa firm

griponthestarterhandle.Lettheroperewindslowly.

8. Repeat,if necessary,untilenginestarts.Whenenginestarts,

movechokecontrolgraduallytowardtheRUNI/t Iposition..

9. Ifenginefalters,movechokecontrolbacktowardthe CHOKE

i'_1 positionand repeatsteps5though8.

10. ALWAYSkeepthethrottlecontrolintheSTART/RUN(Rabbit)

positionwhenoperatingthetiller.

Becertainsparkplugwireis disconnectedandgroundedagainstthe

enginewhenperforminganyadjustments.

Yoke Forward

Attachthe wheelyokeso thatthewheelsareforward(nearestto tines)

forshallowtilling,cultivatingandtransportbyremovingtheclevispin

andcotterpin.SeeFigure14.

Wheel

J

Figure14

12

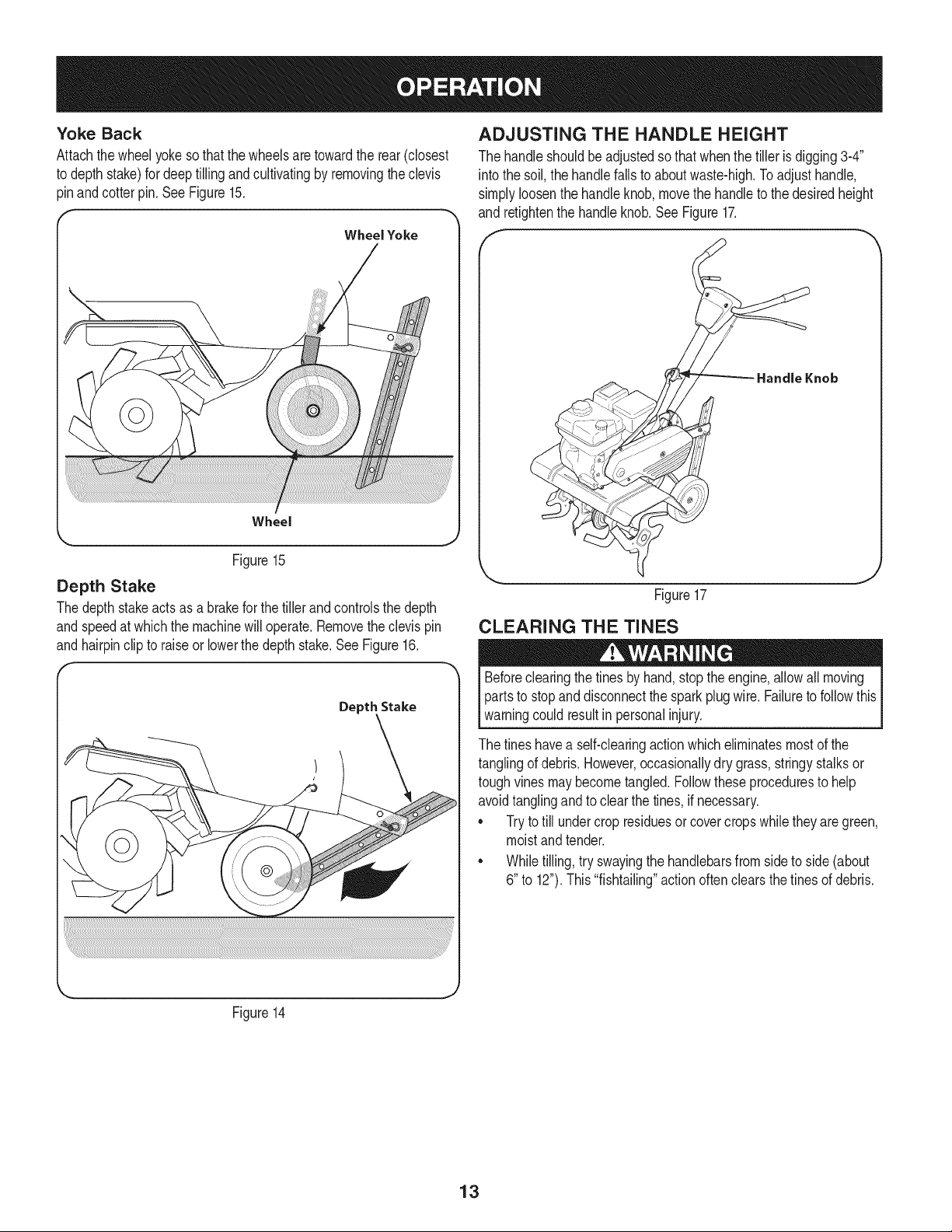

Yoke Back

Attachthe wheelyokeso thatthewheelsaretowardthe rear(closest

todepthstake)for deeptillingandcultivatingby removingtheclevis

pinandcotterpin,SeeFigure15,

Wheel Yoke

Wheel

Figure15

Depth Stake

Thedepthstakeactsasa brakeforthe tillerand controlsthedepth

andspeedat whichthe machinewilloperate.Removetheclevispin

andhairpinclipto raiseor lowerthedepth stake.SeeFigure16.

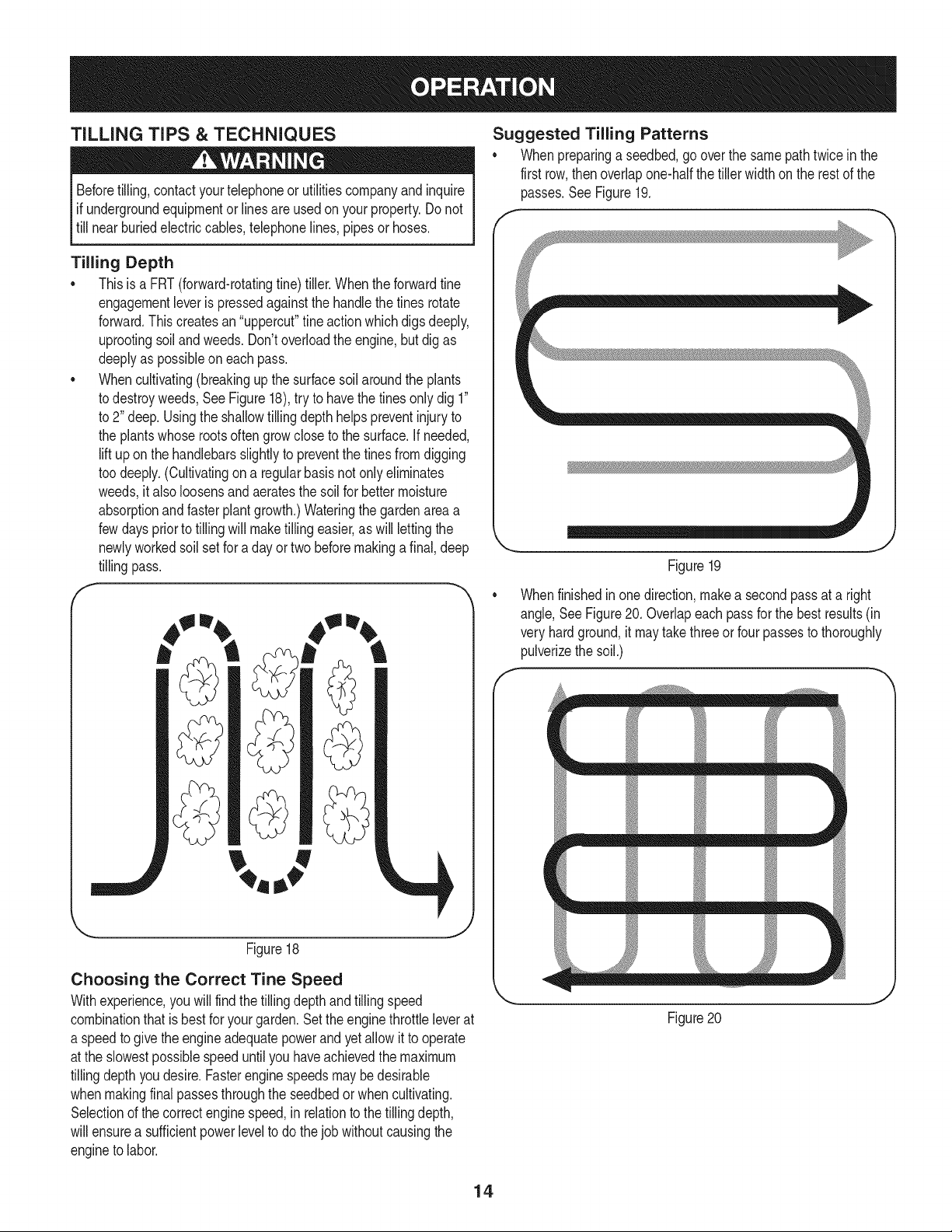

ADJUSTING THE HANDLE HEIGHT

Thehandleshouldbeadjustedsothat whenthetiller isdigging3-4"

intothe soil,thehandlefallsto aboutwaste-high.Toadjusthandle,

simplyloosenthehandleknob,movethe handletothe desiredheight

and retightenthehandleknob.SeeFigure17.

J

J

Figure17

CLEARING THE TINES

Figure14

Depth Stake

Beforeclearingthetinesby hand,stopthe engine,allowall moving

partstostopanddisconnectthesparkplugwire.Failuretofollowthis

warningcouldresultin personalinjury.

Thetineshavea self-clearingactionwhicheliminatesmostof the

tanglingof debris.However,occasionallydrygrass,stringystalksor

toughvinesmaybecometangled.Followtheseproceduresto help

avoidtanglingandtoclear thetines,ifnecessary.

• Tryto till undercrop residuesorcovercropswhiletheyaregreen,

moistandtender.

• Whiletilling,try swayingthe handlebarsfromsideto side(about

6"to 12").This"fishtailing"actionoftenclearsthetinesofdebris.

13

TiLLiNG TIPS & TECHNIQUES

Beforetilling,contactyourtelephoneor utilitiescompanyandinquire

l ifundergroundequipmentorlinesareusedon yourproperty.Donot

[till nearburiedelectriccables,telephonelines,pipesor hoses.

Tilling Depth

o Thisisa FRT(forward-rotatingfine) tiller.Whenthe forwardtine

engagementleveris pressedagainstthehandlethe tinesrotate

forward.Thiscreatesan "uppercut"fine actionwhichdigsdeeply,

uprootingsoiland weeds.Don'toverloadtheengine,butdigas

deeplyas possibleon eachpass.

Whencultivating(breakingupthesurfacesoilaroundthe plants

todestroyweeds,SeeFigure18),try to havethetinesonlydig1"

to2" deep.Usingtheshallowtillingdepthhelpspreventinjuryto

theplantswhoserootsoftengrowcloseto the surface.If needed,

lift upon thehandlebarsslightlyto preventthetinesfromdigging

toodeeply.(Cultivatingona regularbasisnot onlyeliminates

weeds,italsoloosensandaeratesthe soilfor bettermoisture

absorptionandfasterplantgrowth.)Wateringthe gardenareaa

fewdayspriortotillingwill maketillingeasier,aswill lettingthe

newlyworkedsoilsetfor a dayortwo beforemakinga final,deep

tillingpass.

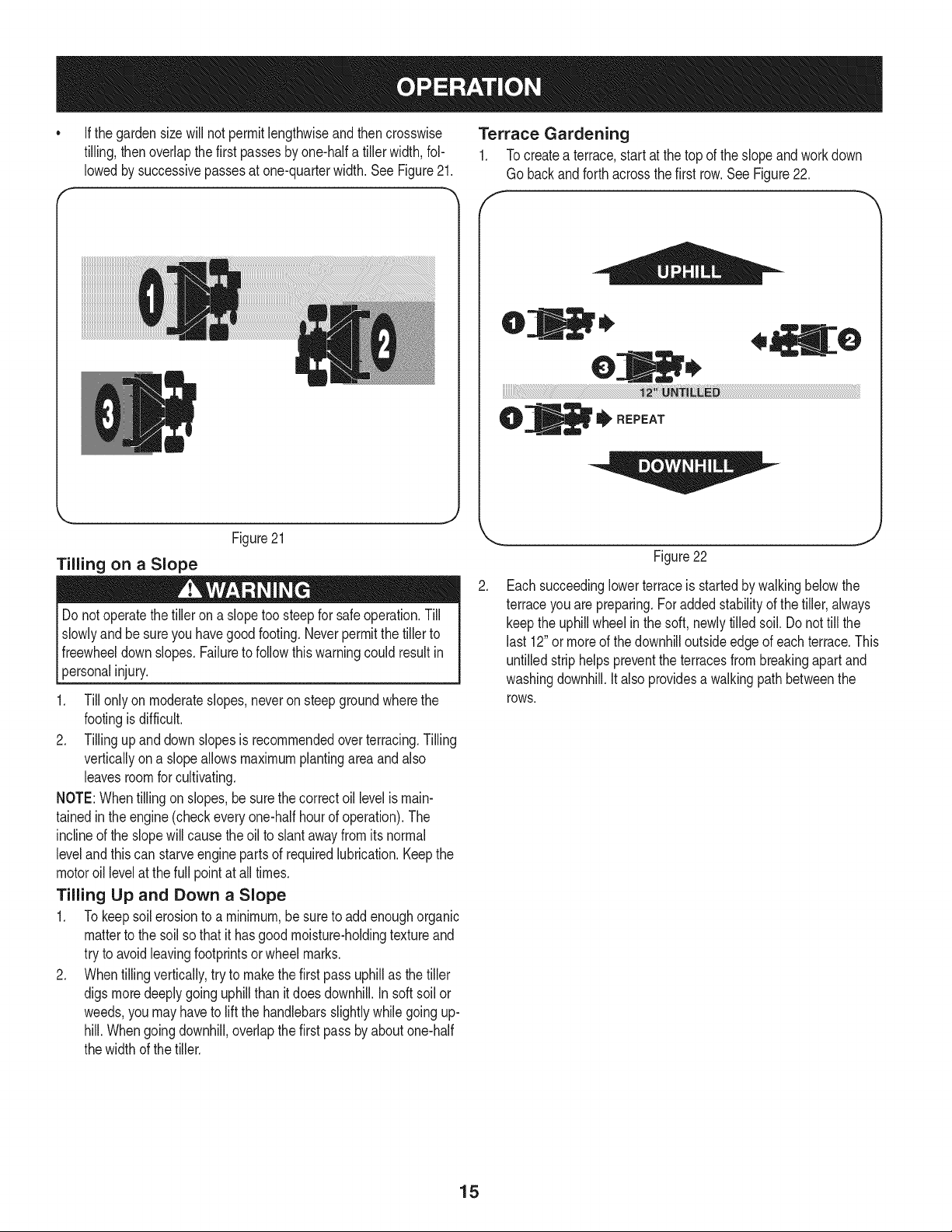

Suggested Tilling Patterns

• Whenpreparinga seedbed,go overthe samepathtwice inthe

firstrow,then overlapone-halfthetiller widthon therestof the

passes.See Figure19.

f -

_ J

Figure18

Choosing the Correct Tine Speed

Withexperience,youwillfind thetillingdepthand tillingspeed

combinationthatis bestforyourgarden.Settheenginethrottleleverat

a speedto givethe engineadequatepowerandyetallowit tooperate

atthe slowestpossiblespeeduntilyouhaveachievedthemaximum

tillingdepthyoudesire.Fasterenginespeedsmaybedesirable

whenmakingfinal passesthroughtheseedbedor whencultivating.

Selectionofthecorrectenginespeed,in relationto thetillingdepth,

willensurea sufficientpowerlevelto dothejobwithoutcausingthe

enginetolabor.

Whenfinishedin onedirection,makea secondpassata right

angle,SeeFigure20.Overlapeachpassfor thebestresults(in

very hardground,itmaytakethreeor fourpassesto thoroughly

pulverizethesoil.)

f

r

J

Figure 20

14

Ifthegardensizewill notpermitlengthwiseandthencrosswise

tilling,thenoverlapthefirst passesbyone-halfa tillerwidth,fol-

lowedby successivepassesat one-quarterwidth.See Figure21.

J

Figure21

Tilling on a Slope

Donotoperatethetilleron a slopetoosteepfor safeoperation.Till

slowlyandbe sureyouhavegoodfooting.Neverpermitthetillerto

freewheeldownslopes.Failuretofollowthis warningcouldresultin

lPersona njury.

1. Tillonlyon moderateslopes,neveronsteepgroundwherethe

footingisdifficult.

2. Tillingupanddownslopesisrecommendedoverterracing.Tilling

verticallyona slopeallowsmaximumplantingareaandalso

leavesroomfor cultivating.

NOTE:Whentillingonslopes,besurethe correctoil levelismain-

tainedinthe engine(checkeveryone-halfhourofoperation).The

inclineof theslopewillcausetheoil toslantawayfromitsnormal

levelandthiscan starveenginepartsof requiredlubrication.Keepthe

motoroil levelat thefull pointat alltimes.

Tilling Lip and Down a Slope

1. Tokeepsoilerosiontoa minimum,besuretoaddenoughorganic

matterto thesoil sothatit hasgoodmoisture-holdingtextureand

try toavoidleavingfootprintsorwheel marks.

2. Whentillingvertically,tryto makethefirst passuphillasthe tiller

digsmoredeeplygoinguphillthan itdoesdownhill.Insoft soilor

weeds,youmayhaveto lift thehandlebarsslightlywhilegoingup-

hill.Whengoingdownhill,overlapthefirstpassbyaboutone-half

thewidthof thetiller.

Terrace Gardening

1. Tocreatea terrace,startatthe topof theslopeandworkdown

Go backandforthacrossthe firstrow.SeeFigure22.

/- -,

Q

I .REPEAT

Figure22

.

Eachsucceedinglowerterraceisstartedbywalkingbelowthe

terraceyouarepreparing.Foraddedstabilityof thetiller,always

keepthe uphillwheelinthe soft,newlytilledsoil.Do nottill the

last 12"ormoreofthedownhilloutsideedgeofeachterrace.This

untilledstriphelpspreventtheterracesfrombreakingapartand

washingdownhill.Italsoprovidesawalkingpathbetweenthe

rows.

15

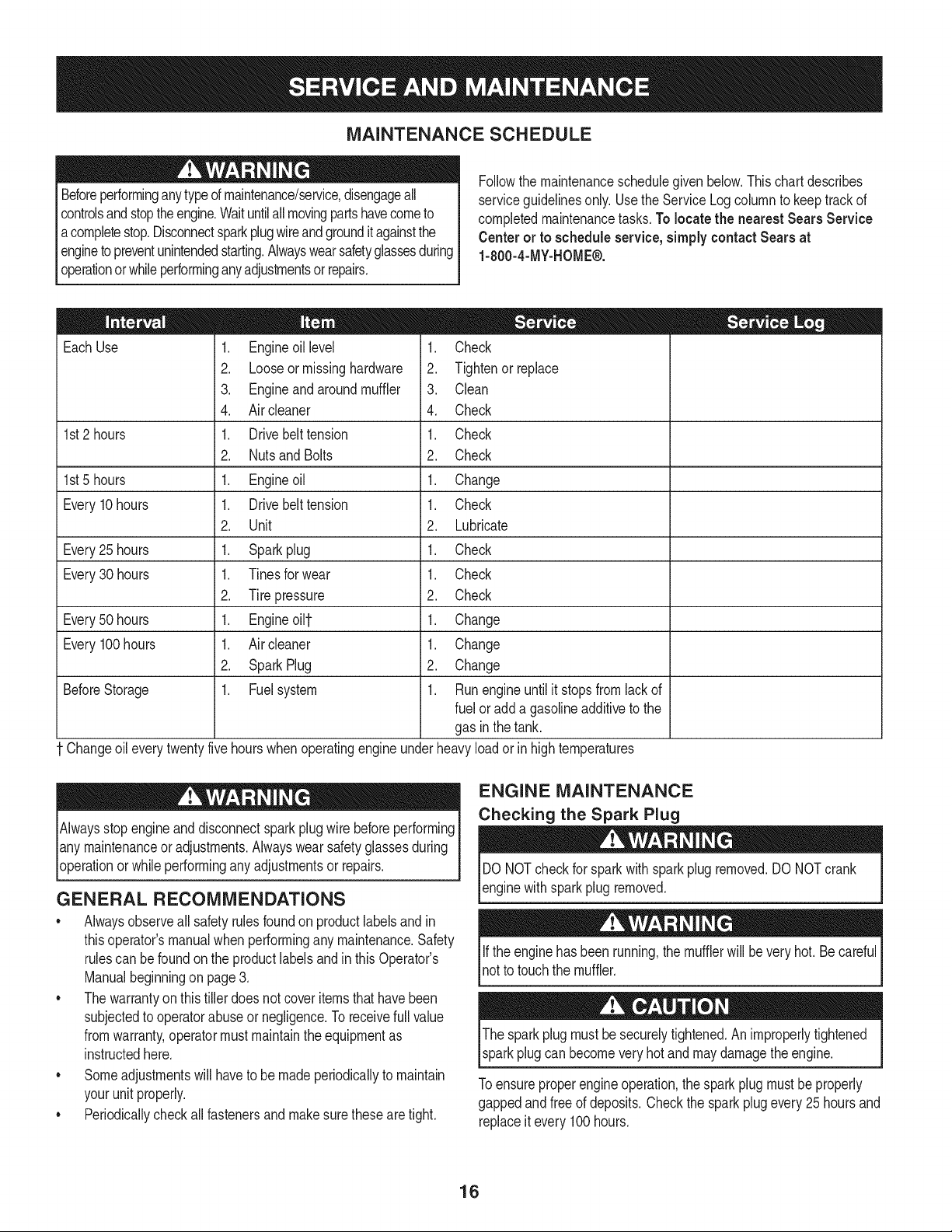

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.To locate the nearest Sears Service

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

operationor whileperforminganyadjustmentsor repairs.

Followthemaintenanceschedulegivenbelow.Thischartdescribes

= =

EachUse

1st2 hours

1st5 hours

Every10hours

Every25 hours

Every30 hours

Every50 hours

Every100hours

BeforeStorage

.

Engineoillevel

2.

Looseormissinghardware

3.

Engineandaroundmuffler

4.

Aircleaner

1.

Drivebelttension

2.

Nutsand Bolts

1.

Engineoil

1.

Drivebelttension

2.

Unit

1.

Sparkplug

1.

Tinesforwear

2.

Tirepressure

1.

Engineoill-

1.

Aircleaner

2.

SparkPlug

1.

Fuelsystem

1. Check

2. Tightenor_place

3. Clean

4. Check

1. Check

2. Check

1. Change

1. Check

2. Lubricate

1. Check

1. Check

2. Check

1. Change

1. Change

2. Change

1. Runengineuntilit stopsfromlackof

fueloradda gasolineadditivetothe

gasin thetank.

Changeoileverytwentyfivehourswhenoperatingengineunderheavyloadorinhightemperatures

Alwaysstopengineanddisconnectsparkplugwirebeforeperforming

lanymaintenanceor adjustments.Alwayswearsafetyglassesduring

_operationorwhile performinganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

• Alwaysobserveallsafetyrulesfoundonproductlabelsandin

thisoperator'smanualwhenperforminganymaintenance.Safety

rulescan befoundonthe productlabelsandin thisOperator's

Manualbeginningon page3.

• Thewarrantyonthistillerdoesnotcoveritemsthathavebeen

subjectedto operatorabuseor negligence.Toreceivefullvalue

fromwarranty,operatormustmaintaintheequipmentas

instructedhere.

• Someadjustmentswillhaveto be madeperiodicallytomaintain

yourunit properly.

• Periodicallycheckall fastenersand makesurethesearetight.

ENGINE MAINTENANCE

Checking the Spark Plug

DONOTcheckforsparkwithsparkplugremoved.DONOTcrank

enginewithsparkplug removed.

Iftheenginehas beenrunning,themufflerwillbeveryhot. Becareful

notto touchthemuffler.

Thesparkplugmustbesecurelytightened.Animproperlytightened

sparkplugcanbecomeveryhot andmaydamagetheengine.

Toensureproperengineoperation,thesparkplugmustbeproperly

gappedandfreeof deposits.Checkthe sparkplugevery25hoursand

replaceitevery100hours.

16

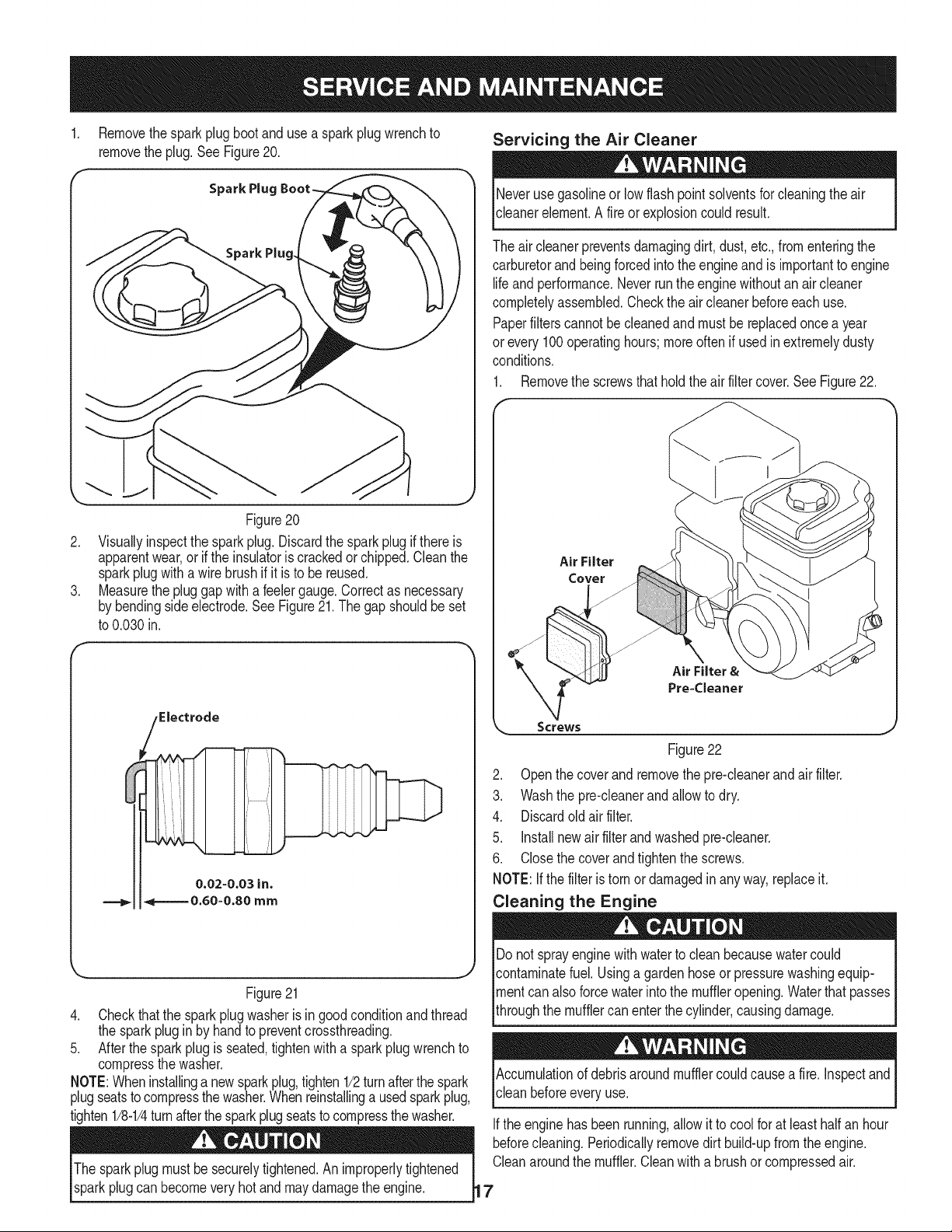

Removethesparkplugbootanduse a sparkplugwrenchto

removetheplug.See Figure20.

Servicing the Air Cleaner

Spark Plug

Figure20

2. Visuallyinspectthesparkplug.Discardthesparkplugif thereis

apparentwear,orif the insulatoriscrackedorchipped.Cleanthe

sparkplugwitha wirebrush ifit isto be reused.

3. Measurethepluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure21.The gapshouldbeset

to0.030in.

Neverusegasolineor lowflashpoint solventsforcleaningtheair

cleanerelement.A fireor explosioncouldresult.

Theaircleanerpreventsdamagingdirt,dust,etc.,fromenteringthe

carburetorandbeingforcedintothe engineandis importanttoengine

lifeandperformance.Neverruntheenginewithoutanair cleaner

completelyassembled.Checktheair cleanerbeforeeachuse.

Paperfilterscannotbecleanedand mustbereplacedoncea year

or every100operatinghours;moreoftenif usedinextremelydusty

conditions.

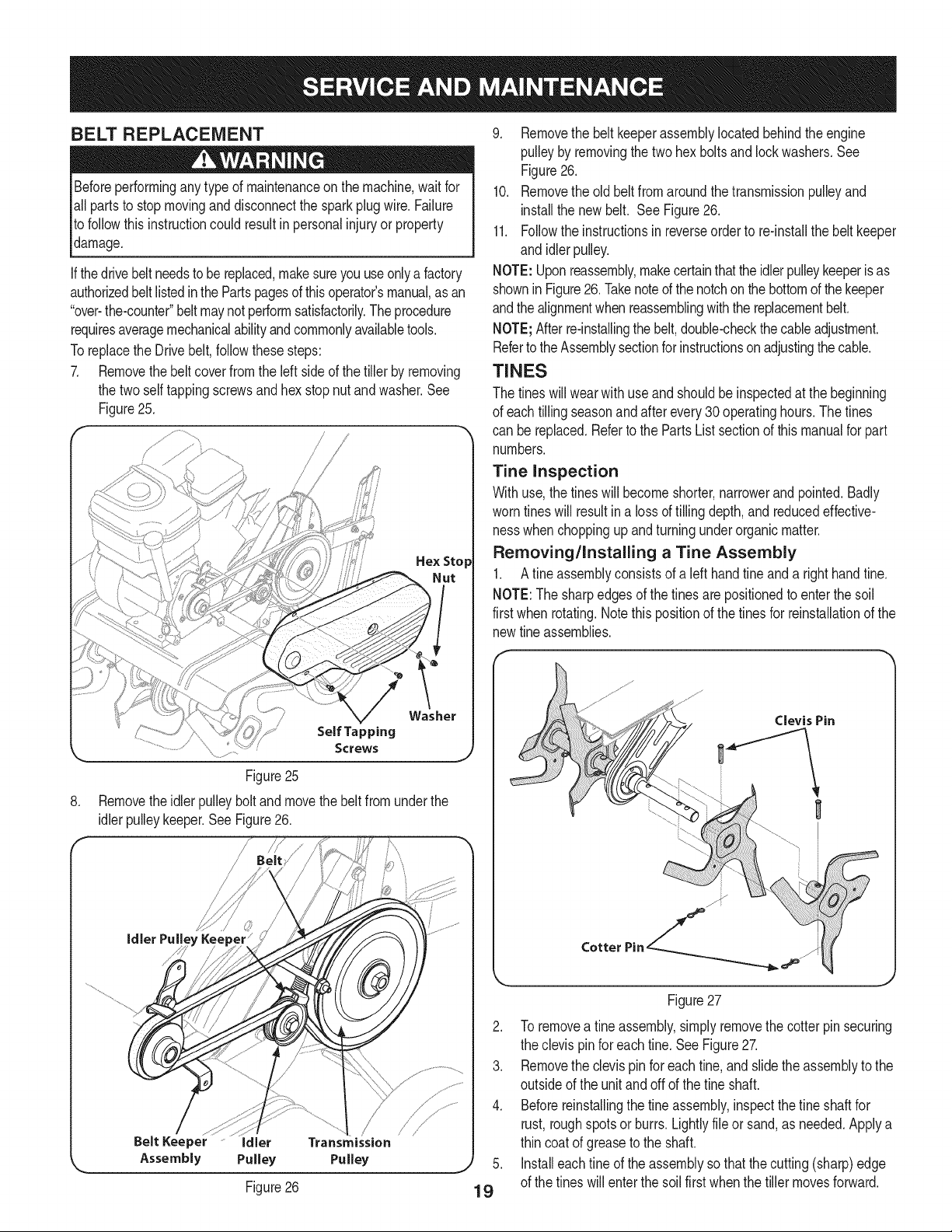

1. Removethescrewsthatholdtheair filtercover.SeeFigure22.

Air Filter

Cover

Figure21

4. Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin by handtopreventcrossthreading.

5. Afterthesparkplugisseated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2turnafterthespark

plugseatstocompressthewasher.Whenreinstallinga usedsparkplug,

tighten1/8-1/4turnafterthesparkplugseatstocompressthewasher.

Thesparkplugmustbe securelytightened.An improperlytightened

sparkplugcanbecomeveryhot andmaydamagetheengine.

Air Filter &

Pre=Cleaner

Screws

Figure22

2. Openthecoverandremovethepre-cleanerandairfilter.

3. Washthe pre-cleanerandallowto dry.

4. Discardoldair filter.

5. installnewair filterandwashedpre-cleaner.

6. Closethecoverandtightenthe screws.

NOTE:Ifthe filteristornor damagedinany way,replaceit.

Cleaning the Engine

Donotsprayenginewithwatertocleanbecausewatercould

contaminatefuel.Usinga gardenhoseor pressurewashingequip-

mentcanalsoforcewaterintothe muffleropening.Waterthatpasses

throughthe mufflercanenterthe cylinder,causingdamage.

Accumulationofdebrisaroundmufflercouldcausea fire. inspectand

cleanbeforeeveryuse.

Iftheenginehas beenrunning,allow itto coolfor at leasthalf anhour

beforecleaning.Periodicallyremovedirt build-upfromtheengine.

Cleanaroundthemuffler.Cleanwitha brushor compressedair.

17

Check Engine Oil

1. Checkoilbeforeeachuse.Stopengineandwaitseveralminutes

beforecheckingoil level.Withengineon levelground,theoilmust

beto FULLmarkon dipstick.

2. Refertothe Assemblysectionof thismanualforinstructionson

checkingtheoil.

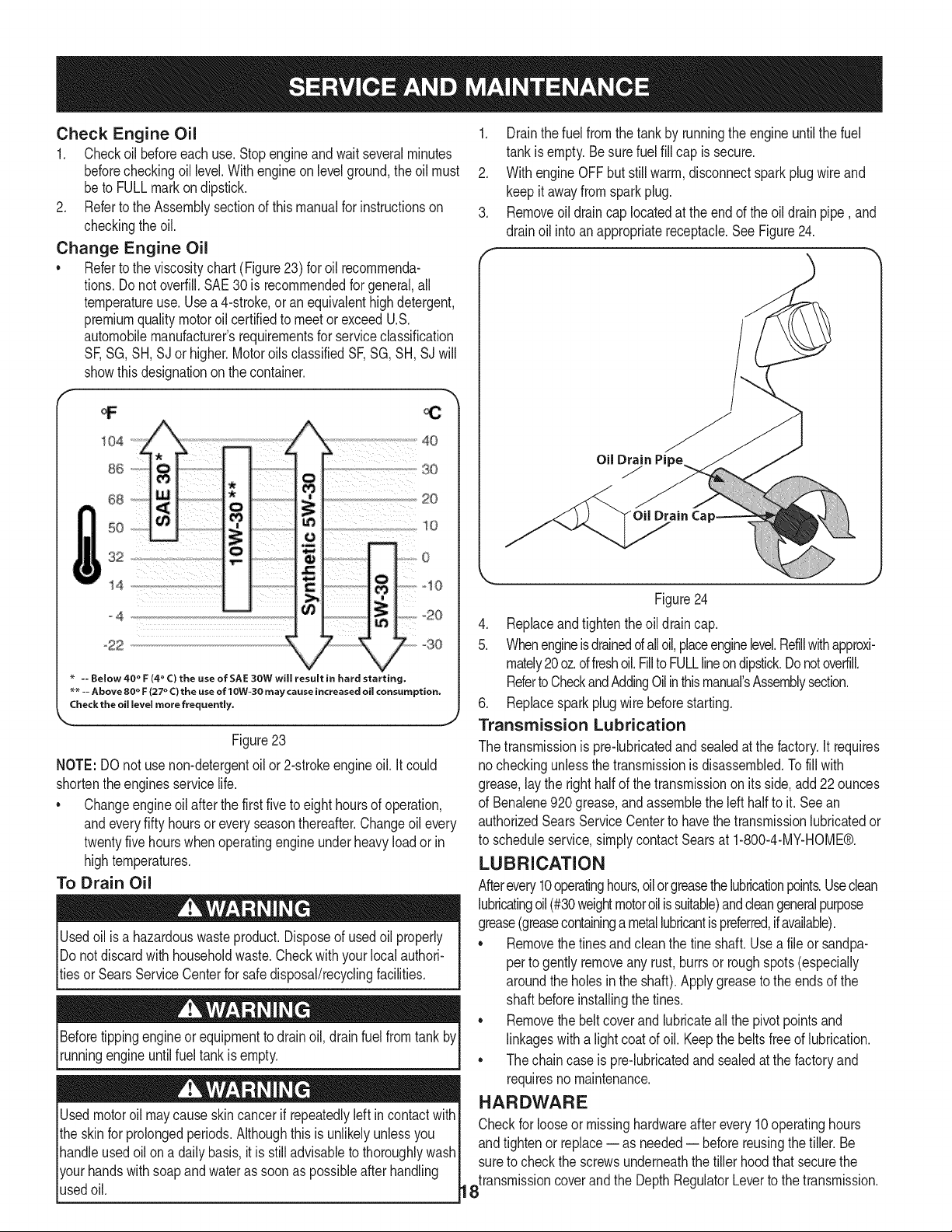

Change Engine Oil

• Referto theviscositychart(Figure23) foroil recommenda-

tions.Do notoverfill.SAE30 isrecommendedforgeneral,all

temperatureuse.Usea 4-stroke,oranequivalenthighdetergent,

premiumqualitymotoroilcertifiedto meetorexceedU.S.

automobilemanufacturer'srequirementsforserviceclassification

SF,SG,SH,SJ or higher.MotoroilsclassifiedSF,SG,SH,SJ will

showthisdesignationon thecontainer.

4O

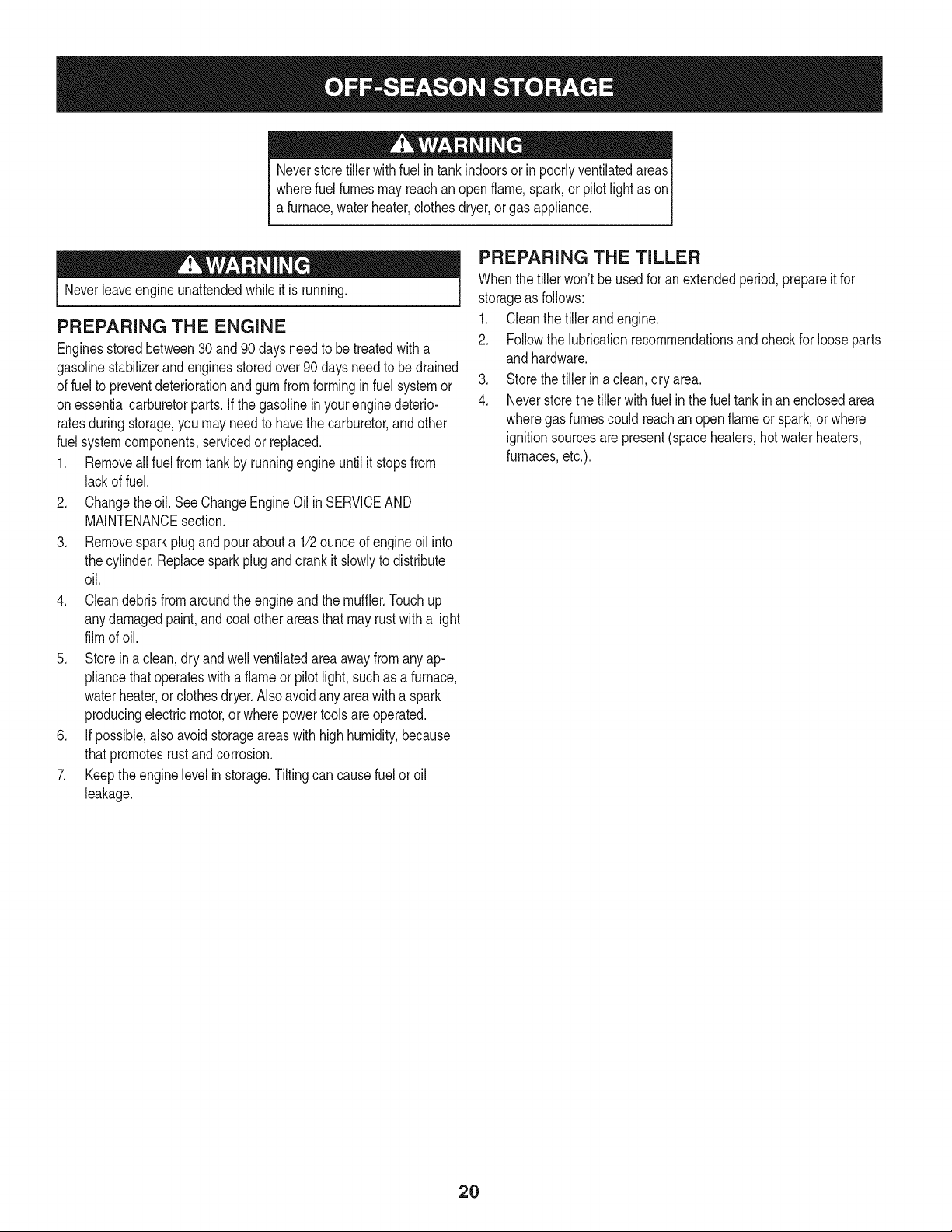

1. Drainthefuelfromthe tankbyrunningthe engineuntl the fuel

tankisempty.Besurefuelfill capis secure.

2. WithengineOFFbutstillwarm,disconnectsparkplugwireand

keepitawayfromsparkplug.

3. Removeoil draincap locatedatthe endofthe oildrainpipe, and

drainoil intoanappropriatereceptacle.See Figure24.

OilDrain

ain Ca

-- Below 40 ° F (4 ° C) the use of SAE 30W will result in hard starting.

_ -- Above 80 ° F (27 °C) the use of 10W-30 may cause increased oil consumption.

Check the oil level more frequently.

Figure23

NOTE:DOnotusenon-detergentoil or2-strokeengineoil.It could

shortentheenginesservicelife.

Changeengineoilafterthefirstfiveto eighthoursofoperation,

andeveryfifty hoursoreveryseasonthereafter.Changeoil every

twentyfivehourswhenoperatingengineunderheavyloadorin

hightemperatures.

To Drain Oil

Usedoilisa hazardouswasteproduct.Disposeofusedoil properly

IDonotdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

_tiesor SearsServiceCenterfor safedisposal/recyclingfacilities.

Beforetippingengineor equipmenttodrainoil, drainfuelfromtank by

runningengineuntilfuel tankisempty.

Usedmotoroil maycauseskincancerifrepeatedlyleftincontactwith

theskinfor prolongedperiods.Althoughthis isunlikelyunlessyou

handleusedoil ona daily basis,itisstilladvisableto thoroughlywash

yourhandswithsoapandwateras soonas possibleafter handling

usedoil.

Figure24

4. Replaceandtightentheoildraincap.

5. Whenengineisdrainedd alloil,placeenginelevel.Refillwithapproxi-

mately20oz.d freshoil.Fillto FULLlineondipstick.Donotoverfill.

RefertoCheckandAddingOilinthismanual'sAssemblysection.

6. Replacesparkplugwirebeforestarting.

Transmission Lubrication

Thetransmissionispro-lubricatedandsealedatthefactory.It requires

no checkingunlessthetransmissionisdisassembled.Tofill with

grease,laythe righthalfof thetransmissionon itsside,add22ounces

of Benalene920grease,andassemblethelefthalf toit. Seean

authorizedSearsServiceCenterto havethe transmissionlubricatedor

to scheduleservice,simplycontactSearsat 1-800-4-MY-HOME®.

LUBRICATION

Afterevery10operatinghours,oilorgreasethelubricationpoints.Useclean

lubricatingoil(#30weightmotoroilissuitable)andcleangeneralpurpose

grease(greasecontaininga metallubricantispreferred,ifavailable).

• Removethetinesand cleanthetineshaft.Useafileor sandpa-

pertogentlyremoveanyrust,burrsor roughspots(especially

aroundtheholesin theshaft).Applygreaseto theendsofthe

shaftbeforeinstallingthetines.

• Removethebeltcoverandlubricateallthepivotpointsand

linkageswitha lightcoatof oil.Keepthe beltsfreeof lubrication.

• The chaincaseis pro-lubricatedandsealedat thefactoryand

requiresnomaintenance.

HARDWARE

Checkfor looseor missinghardwareafterevery10operatinghours

andtightenor replace= as needed= beforereusingthetiller.Be

sureto checkthe screwsunderneaththe tillerhoodthat securethe

8transmissioncoverandthe DepthRegulatorLevertothetransmission.

BELT REPLACEMENT

Beforeperformingany typeofmaintenanceonthemachine,waitfor

all partsto stopmovinganddisconnectthesparkplugwire.Failure

tofollowthis instructioncouldresultinpersonalinjuryor property

damage.

Ifthedrivebeltneedstobe replaced,makesureyouuseonlyafactory

authorizedbeltlistedinthe Partspagesofthisoperator'smanual,asan

"over-the-counter"beltmaynotperformsatisfactorily.Theprocedure

requiresaveragemechanicalabilityandcommonlyavailabletools.

Toreplacethe Drivebelt,followthesesteps:

7. Removethebeltcoverfromthe leftsideof thetillerbyremoving

thetwoselftappingscrewsandhexstopnutandwasher.See

Figure25.

9. Removethe beltkeeperassemblylocatedbehindtheengine

pulleybyremovingthetwohex boltsand lockwashers.See

Figure26.

10. Removetheoldbeltfromaroundthe transmissionpulleyand

installthenewbelt. SeeFigure26.

11. Followtheinstructionsinreverseorderto re-installthebeltkeeper

and idlerpulley.

NOTE:Uponreassembly,makecertainthattheidlerpulleykeeperisas

shownin Figure26.Takenoted the notchonthebottomofthekeeper

andthealignmentwhenreassemblingwiththe replacementbelt.

NOTE;Afterre-installingthebelt,double-checkthe cableadjustment.

RefertotheAssemblysectionforinstructionsonadjustingthe cable.

TINES

Thetineswillwearwithuse andshouldbeinspectedatthe beginning

ofeach tillingseasonandafterevery30operatinghours.Thetines

canbe replaced.RefertothePartsListsectionofthis manualforpart

numbers.

Tine Inspection

Withuse,thetineswill becomeshorter,narrowerandpointed.Badly

worntineswill resultina lossoftillingdepth,and reducedeffective-

nesswhenchoppingup andturningunderorganicmatter.

Removing/Installing a Tine Assembly

1. A fine assemblyconsistsofa left handtineanda righthandfine.

NOTE:Thesharpedgesof thetinesare positionedto enterthesoil

firstwhenrotating.Notethispositionof thetinesfor reinstallationof the

newfineassemblies.

Screws

Figure25

Removetheidlerpulleybolt andmovethebeltfromunderthe

idlerpulleykeeper.SeeFigure26.

Clevis Pin

Figure27

Toremoveafineassembly,simplyremovethecotterpinsecuring

theclevispinforeachtine.SeeFigure27.

Removethe clevispinfor eachfine,andslidetheassemblytothe

outsideofthe unitandoffof thefine shaft.

Beforereinstallingthe tineassembly,inspectthefineshaftfor

rust,roughspotsor burrs.Lightlyfileor sand,as needed.Applya

thincoatof greasetotheshaft.

Installeachfineof theassemblysothatthecutting(sharp)edge

ofthe tineswillenterthesoilfirstwhenthetillermovesforward.

NeverstoretillerwithfuelintankindoorsorinpoorlyventilatedareasI

wherefuelfumesmayreachanopenflame,spark,orpilotlightason

a furnace,waterheater,cothesdryer,orgasapp ance. 1

Neverleaveengineunattendedwhileitis running.

PREPARING THE ENGINE

Enginesstoredbetween30and 90daysneedto betreatedwitha

gasolinestabilizerandenginesstoredover90daysneedto bedrained

offuel topreventdeteriorationandgumfromforminginfuelsystemor

on essentialcarburetorparts.Ifthegasolineinyourenginedeterio-

ratesduringstorage,youmayneedtohavethecarburetor,andother

fuelsystemcomponents,servicedor replaced.

1. Removeallfuel fromtankbyrunningengineuntilit stopsfrom

lackoffuel.

2. Changetheoil.SeeChangeEngineOil inSERVICEAND

MAINTENANCEsection.

3. Removesparkplugand pourabouta 1/2ounceof engineoilinto

thecylinder.Replacesparkplugandcrankit slowlytodistribute

oil.

4. Cleandebrisfromaroundtheengineandthe muffler.Touchup

anydamagedpaint,andcoatotherareasthatmayrustwitha light

filmofoil.

5. Storein aclean,dry andwellventilatedareaawayfromanyap-

pliancethatoperateswitha flameorpilot light,suchasa furnace,

waterheater,orclothesdryer.Alsoavoidany areawitha spark

producingelectricmotor,orwherepowertoolsare operated.

6. Ifpossible,alsoavoidstorageareaswithhighhumidity,because

that promotesrustandcorrosion.

7. Keeptheenginelevelinstorage.Tiltingcancausefuelor oil

leakage.

PREPARING THE TILLER

Whenthe tillerwon'tbeusedforanextendedperiod,prepareitfor

storageasfollows:

1. Cleanthetillerandengine.

2. Followthelubricationrecommendationsandcheckforlooseparts

and hardware.

3. Storethe tillerinaclean,dryarea.

4. Neverstorethetillerwithfuelinthe fueltankinan enclosedarea

wheregas fumescouldreachanopenflameor spark,or where

ignitionsourcesare present(spaceheaters,hotwaterheaters,

furnaces,etc.).

2O

Loading...

Loading...