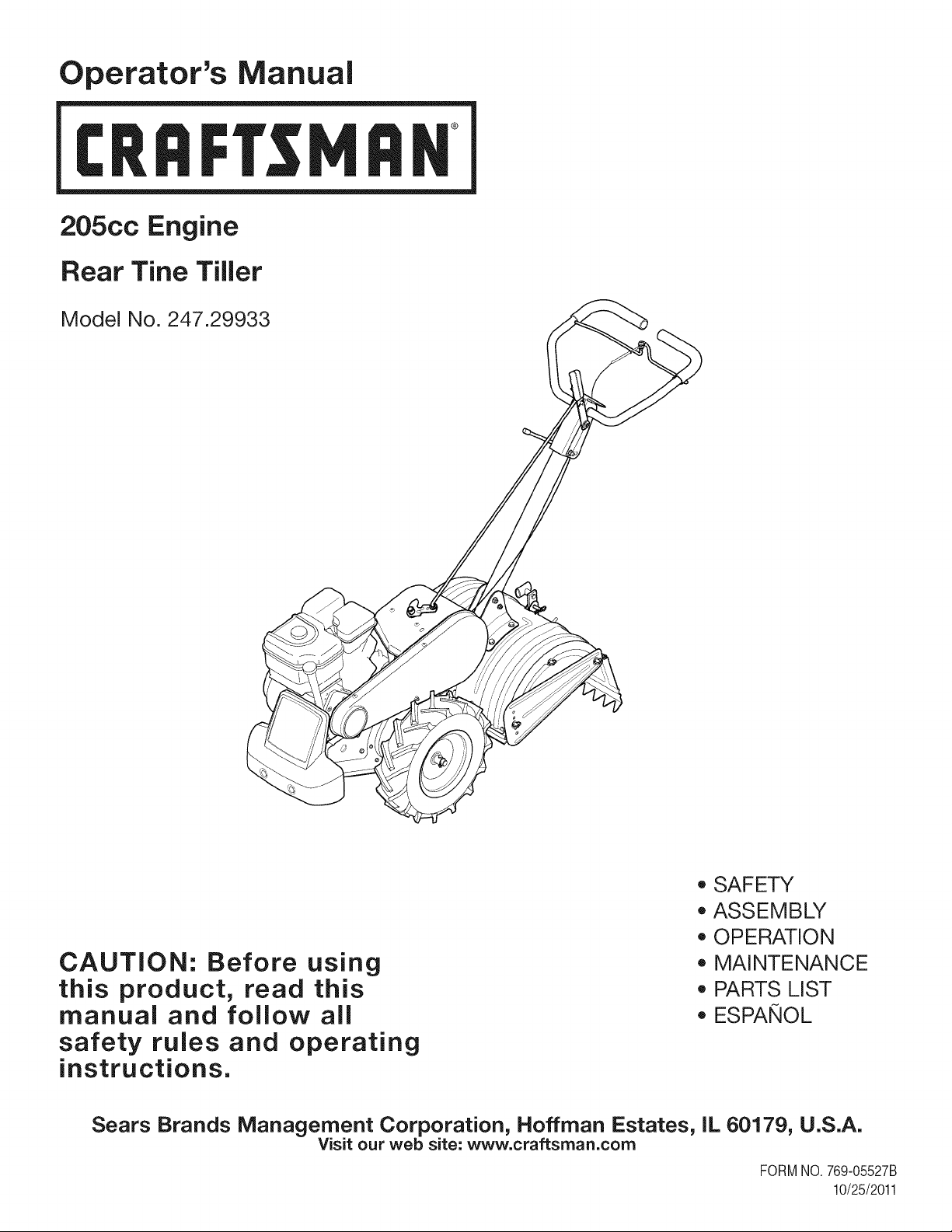

Craftsman 24729933 Owner’s Manual

Operator's Manual

I:Rl FI'SlVl N

205cc Engine

Rear Tine Tiller

Model No. 247.29933

* SAFETY

* ASSEMBLY

* OPERATION

CAUTION: Before using

this product, read this

manual and follow aJl

* MAINTENANCE

* PARTS LIST

* ESPANOL

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, iL 60179, U.S.A.

Visit our web site: www.craftsman.com

FORMNO.769-05527B

10/25/2011

WarrantyStatement..................................Pac

Safetyinstructions....................................Pac

Assembly..................................................Pac

Operation..................................................Pac

ServiceandMaintenance.........................Pac

Off-SeasonStorage..................................Pac

TroubleShooting.......................................Pac

e2

es3-6

es7-10

es11-16

es17-22

e23

e24

PartsList...................................................Page26-40

LabelMap.................................................Page41

RepairProtectionAgreement...................Page44

Espa_ol.....................................................Page45

ServiceNumbers......................................BackCover

CRAFTSMANONEYEAR FULL WARRANTY

FORONEYEARfromthedateofpurchase,this productiswarrantedagainstanydefectsin materialor workmanship.A defectiveproductwill

receivefreerepairorreplacementif repairis unavailable.

Forwarranty coverage details to obtain free repairor replacement,visittheweb site:www.craftsman.com

Thiswarranty isvoidifthis productiseverused while providingcommercialservicesor if rentedto another person.

Thiswarranty coversONLYdefects in material andworkmanship. Warrantycoverage does NOTinclude:

• Expendableitemsthatcan wearoutfromnormalusewithinthewarrantyperiod,includingbutnot limitedtoaugers,augerpaddles,drift

cutters,skidshoes,shaveplate,shearpins,sparkplug,air cleaner,belts,andoil filter.

• Standardmaintenanceservicing,oilchanges,or tune-ups.

Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedtodamagecausedbyover-speedingtheengine,or fromimpacting

objectsthatbendthe frame,augershaft,etc.

• Repairsnecessarybecauseof operatornegligence,includingbutnot limitedto,electricalandmechanicaldamagecausedby improper

storage,failureto usethepropergradeandamountof engineoil,or failureto maintaintheequipmentaccordingtothe instructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfueldeterminedto becontaminatedoroxidized(stale).In general,fuelshouldbeused

within30 daysof itspurchasedate.

Normaldeteriorationandwearof theexteriorfinishes,orproductlabelreplacement.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineSeries: 205cc

EngineOilType: SAE30

EngineOilCapacity: 20ounces

Fuel: UnleadedGasoline

SparkPlug: Champion®RC-12YC

SparkPlugGap: .030"

©KCDIP,LLC 2

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingto thesafeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthe partof theoperatorcan resultin

seriousinjury.Thismachineiscapableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm.Bat-

tery posts,terminals,andrelatedaccessoriescontainleadand lead

compounds,chemicalsknowntothe Stateof Californiatocause

cancerandreproductiveharm.Washhandsafterhandling.

TRAINING

• Read,understand,andfollowall instructionson the machineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplaceforfutureand regularreference

andfororderingreplacementparts.

• ReadtheOperator'sManualand followallwarningsandsafety

instructions.Failuretodosocan resultin seriousinjuryto the

operatorand/or bystanders.Forquestions,call1-800-4MY-HOME.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsof agetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultstooperatethis machinewithoutproper

instruction.

• Keepbystanders,pets,andchildrenatleast75feetfromthe

machinewhileit isin operation.Stopmachineifanyoneenters

thearea.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

Your Responsibility--Restrictthe useof thispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall rocks,bottles,cans,or otherforeignobjectswhich

couldbepickedupor thrownandcausepersonalinjuryor

damageto themachine.

• Alwayswearsafetyglassesor safetygogglesduringoperation

andwhileperformingan adjustmentorrepair,to protectyour

eyes.Thrownobjectswhichricochetcancauseseriousinjuryto

theeyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesorjewelrycan becaughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beforestarting,checkallboltsandscrewsfor propertightnessto

besurethe machineisinsafeworkingcondition.Also,visually

inspectmachinefor anydamageatfrequentintervals.

• Disengageclutchleversandshift(if provided)into neutral("N")

beforestartingtheengine.

• Neverleavethismachineunattendedwiththeenginerunning.

• Neverattempttomakeanyadjustmentswhilethe engineis

running,exceptwherespecificallyrecommendedinthe operator's

manual.

• Maintainorreplacesafetyandinstructionslabels,asnecessary.

3

SafeHandling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Neverfill containersinsidea vehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthe groundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthetruck

ortrailerand refuelitonthe ground.Ifthisis notpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthe nozzleincontactwiththerimofthe fueltankor

containeropeningatalltimes untilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

• Extinguishallcigarettes,cigars,pipesandother sourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuel whilethe engineishot or run-

ning.Allowenginetocool atleasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Fill tankto nomorethan1/2inchbelow

bottomoffillerneckto allowspacefor fuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipe itoff theengineandequipment.Move

unitto anotherarea.Wait5 minutesbeforestartingtheengine.

• To reducefirehazards,keepmachinefreeof grass,leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageand removeany

fuelsoakeddebris.

• Neverstorethe machineorfuelcontainerinsidewherethereis an

openflame,sparkor pilotlightas on awaterheater,spaceheater,

furnace,clothesdryerorothergasappliances.

OPERATION

• Do notputhandsorfeetnear rotatingparts.Contactwiththe

rotatingpartscanamputatehandsandfeet.

• Do notoperatemachinewhileunderthe influenceofalcoholor

drugs.

• Neveroperatethismachinewithoutgoodvisibilityor light.Always

be sureof yourfootingandkeepa firmholdonthehandles.

• Keepbystandersawayfromthe machinewhileit isinoperation.

Stopthe machineif anyoneentersthearea.

• Becarefulwhentillinginhardground.Thetines maycatchinthe

groundandpropelthetillerforward.Ifthis occurs,let goofthe

handlebarsanddo not restrainthemachine.

• Exerciseextremecautionwhenoperatingonor crossinggravel

surfaces.Stayalertforhiddenhazardsortraffic. Donotcarry

passengers.

• Neveroperatethemachineat hightransportspeedsonhardor

slipperysurfaces.

• Exercisecautiontoavoidslippingorfalling.

• Lookdownand behindandusecarewhenin reverseor pulling

machinetowardsyou.

• Startthe engineaccordingtothe instructionsfoundinthis manual

and keepfeetwell awayfromthetinesat all times.

• Afterstrikingaforeignobjector ifyourmachineshouldstartmak-

inganunusualnoiseor vibration,immediatelyshutthe engineoff.

Disconnectthe sparkplugwire,grounditagainstthe engineand

performthefollowingsteps:

a. Inspectfordamage.

b. Repairorreplaceanydamagedparts.

c. Checkforanyloosepartsandtightento assurecontinued

safeoperation.

• Disengageall clutchlevers(iffitted)and stopenginebeforeyou

leavethe operatingposition(behindthe handles).Waituntil

thetinescometo a completestopbeforeuncloggingthe tines,

makinganyadjustments,or inspections.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an odorlessanddeadlygas.

• Mufflerandenginebecomehotandcancausea burn.Do not

touch.

• Usecautionwhentillingnearfences,buildingsandunderground

utilities.Rotatingtinescan causepropertydamageorpersonal

injury.

• Donotoverloadmachinecapacitybyattemptingtotillsoil too

deepattoo fastof a rate.

• Ifthe machineshouldstartmakinganunusualnoiseor vibration,

stoptheengine,disconnectthesparkplugwire andgroundit

againsttheengine.Inspectthoroughlyfordamage.Repairany

damagebeforestartingandoperating.

• Keepallshields,guards,and safetydevicesinplaceandoperat-

ing properly.

• Neverpickuporcarrymachinewhiletheengineis running.

• Useonly attachmentsandaccessoriesapprovedbythe manu-

factureras listedin thePartsListpagesofthisoperator'smanual.

Failuretodosocan resultin personalinjury.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgement.ContactCustomerSupportat 1-800-4MY-

HOMEforassistanceandthenameof thenearestservicedealer

MAINTENANCE & STORAGE

• Keepthemachine,attachmentsandaccessoriesin safeworking

order.

• Allowthemachinetocoolat leastfiveminutesbeforestoring.

Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.

• Checkboltsandscrewsforpropertightnessat frequentintervals

to keepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

• Beforecleaning,repairing,or inspecting,stopthe engineand

makecertainthetinesandall movingpartshavestopped.

Disconnectthe sparkplugwireandgrounditagainsttheengineto

preventunintendedstarting.

4

• Do notchangetheenginegovernorsettingsor over-speedthe

engine.Thegovernorcontrolsthemaximumsafeoperatingspeed

ofengine.

Maintainor replacesafetyandinstructionlabels,as necessary.

Followthis manualfor safeloading,unloading,transporting,and

storageof thismachine.

Alwaysreferto theoperator'smanualforimportantdetailsifthe

machineisto bestoredforan extendedperiod.

If thefuel tankhasto be drained,do thisoutdoors.

Observeproperdisposallawsandregulationsforgas,oil, etc.to

protecttheenvironment.

Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 130hoursof

operation.Atthe endof theAverageUsefulLifehavethemachine

inspectedannuallybyanauthorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failureto do socan resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyenginein anyway.

Tamperingwiththegovernorsettingcan leadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,it shouldbe maintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveisrequired

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthe muffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowallinstructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING: YourResponsibility--Restricttheuseofthispowermachineto personswhoread,understandandfollowthe

warningsand instructionsinthis manualandonthemachine.

SAVETHESEINSTRUCTIONS!

6

NOTE:Thisunitis shippedwithoutgasolineor oil intheengine.Be

certaintoserviceenginewithgasolineandoil as instructedin the

Operationsectionofthis manualbeforeoperatingyourmachine.

NOTE:Referenceto rightand lefthandsideof thetiller isobserved

fromtheoperatingposition.

OPENING CARTON

1. Removethe staples,breaktheglueonthetopflaps,orcutthe

tapeat theendof thecartonand peelit alongthetopflapto open.

2. Removealllooseparts.

3. Cutthecornersandlaythecartondown fiat.

4. Removeloosepackingmaterial.

REMOVING UNIT FROM CARTON

1. Usethehandlebartoliftand pullthetiller backwardstoa flat

area.Checkthecartonthoroughlyforlooseparts.

2. Extendthecontrolcableandlayit on thefloor.Becarefulnot to

bendor kinkthecontrolcable.

LOOSE PARTS IN CARTON

• HandlebarAssembly

• Tiller

• EngineOil

• Operator'sManual

• ShiftRod

• DepthStake

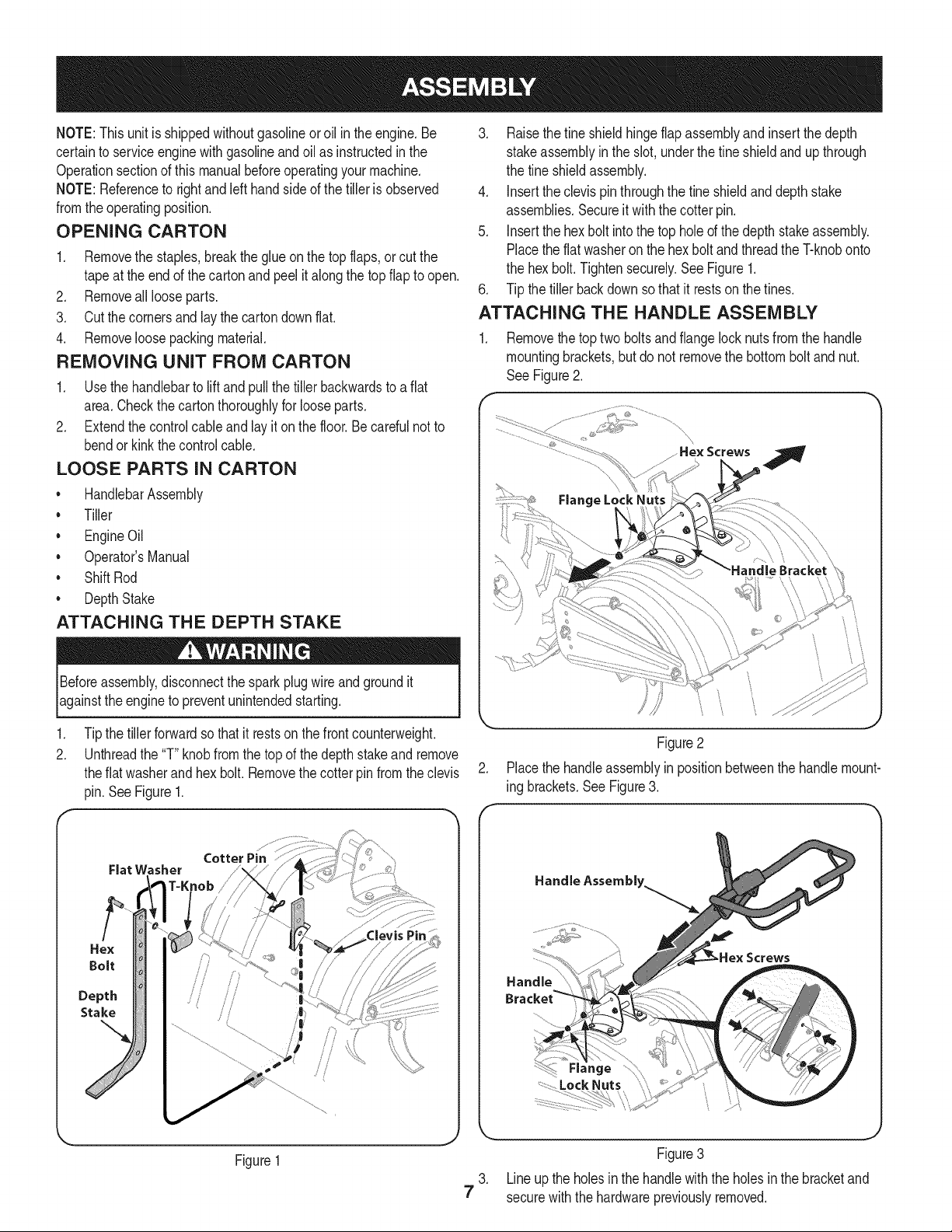

ATTACHING THE DEPTH STAKE

3. Raisethefine shieldhingeflapassemblyand insertthedepth

stakeassemblyinthe slot,underthe fineshieldandup through

thetine shieldassembly.

4. Inserttheclevispinthroughthefineshieldanddepthstake

assemblies.Secureitwiththe cotterpin.

5. Insertthehexbolt intothe topholeofthedepthstakeassembly.

Placetheflatwasheronthehex boltandthreadtheT-knobonto

thehex bolt.Tightensecurely.SeeFigure1.

6. Tipthetillerbackdownsothatit restsonthe tines.

ATTACHING THE HANDLE ASSEMBLY

1. Removethetoptwoboltsandflangelocknutsfromthehandle

mountingbrackets,but do notremovethebottomboltandnut.

See Figure2.

f

He× Screws

Beforeassembly,disconnectthesparkplugwireandgroundit

againsttheengineto preventunintendedstarting.

1. Tipthetillerforwardso thatitrestson thefrontcounterweight.

2. Unthreadthe"T"knobfromthetopofthedepthstakeand remove

theflat washerandhexbolt. Removethecotterpinfromtheclevis

pin.SeeFigure1.

Flat Washer

Hex

Cotter Pin

Bolt

Depth

Stake

Figure1

\

Figure2

.

Placethehandleassemblyin positionbetweenthe handlemount-

ing brackets.See Figure3.

Handle Assembly.

Figure3

3. Lineup theholesinthehandlewiththeholesin thebracketand

7

securewiththehardwarepreviouslyremoved.

J

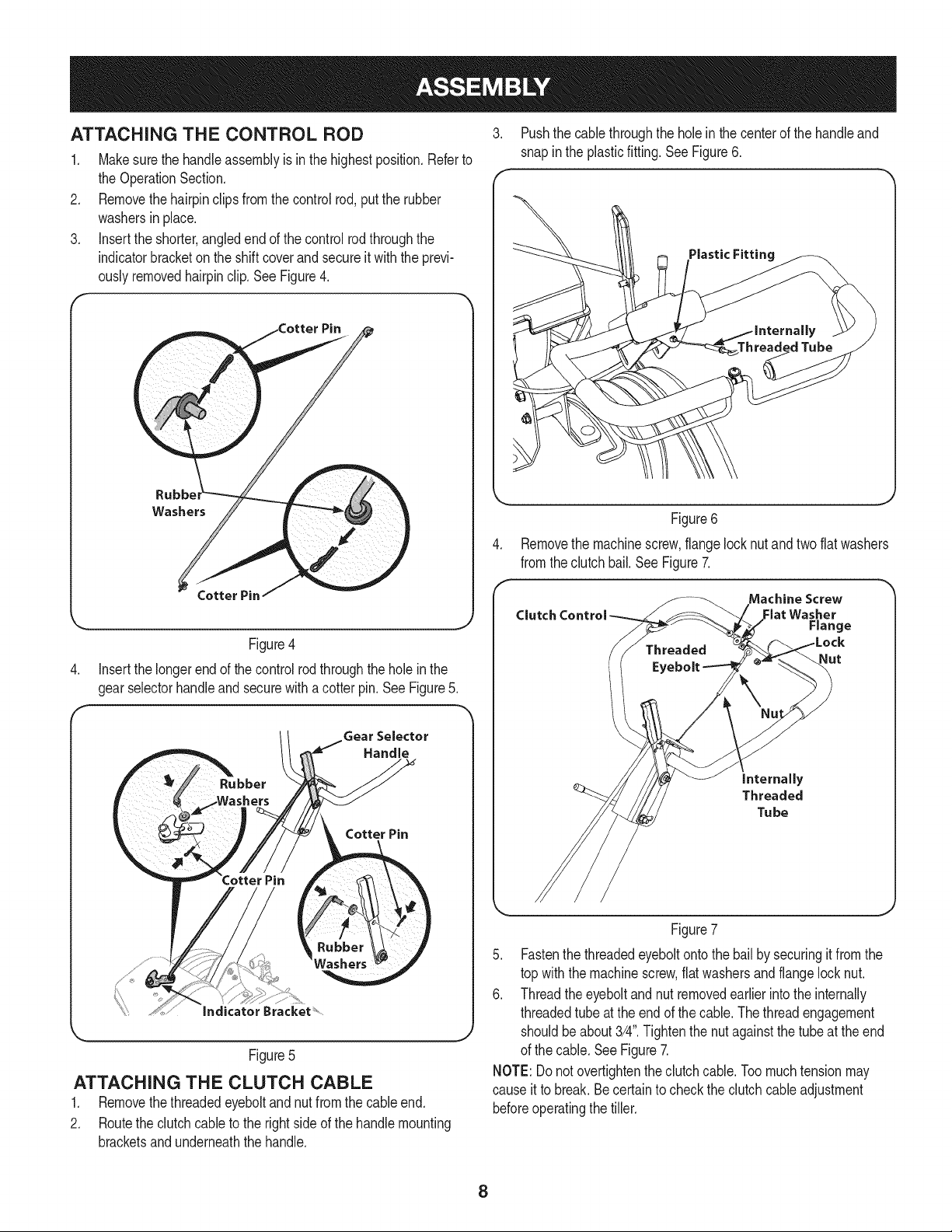

ATTACHING THE CONTROL ROD

1. Makesurethehandleassemblyis inthehighestposition.Referto

theOperationSection.

2. Removethehairpinclipsfromthecontrolrod,putthe rubber

washersinplace.

3. Insertthe shorter,angledendof thecontrolrodthroughthe

indicatorbracketonthe shiftcoverandsecureit withtheprevi-

ouslyremovedhairpinclip.SeeFigure4.

Rubb_

Washers

3. Pushthecablethroughthe holein thecenterofthehandleand

snapinthe plasticfitting.SeeFigure6.

Threaded Tube

Figure6

Removethe machinescrew,flangelocknut andtwoflatwashers

fromtheclutchbail.See Figure7.

Figure4

4. Insertthe longerendofthe controlrodthroughthe holeinthe

gearselectorhandleandsecurewitha cotterpin.SeeFigure5.

Gear Selector

Handle

Cotter Pin

Figure5

ATTACHING THE CLUTCH CABLE

1. Removethethreadedeyeboltandnutfromthe cableend.

2. Routetheclutchcableto therightsideof thehandlemounting

bracketsandunderneaththe handle.

Machine Screw

Clutch Control Flat Washer

Range

Nut

internally

Threaded

Tu be

Figure7

5. Fastenthe threadedeyeboltontothebailbysecuringitfromthe

topwiththe machinescrew,flatwashersandflangelocknut.

6. Threadtheeyeboltandnutremovedearlierintotheinternally

threadedtubeatthe endof thecable.Thethreadengagement

shouldbeabout3/4".Tightenthenutagainstthetubeattheend

ofthe cable.SeeFigure7.

NOTE:Donotovertightentheclutchcable.Toomuchtensionmay

causeitto break.Becertaintochecktheclutchcableadjustment

beforeoperatingthetiller.

8

SET-UP

Tire Pressure

Checktheair pressureinbothtires.Theairpressureshouldbe

between15-20PSI.Keepbothtiresequallyinflatedtohelpprevent

machinefrompullingtoone side.

Checking and Adding Oil

Theengineis shippedwithoutoil in theengine.Youmustfill the

enginewithoil beforeoperating.Runningtheenginewithinsufficient

_o cancauseserous engnedamageandvod the productwarranty.

Initial Use

1. Removetheoil filldipstick.

2. Placethetilleron levelground,usea funnelto emptyentire

contentsofthe oil bottleprovidedwiththe tillerintotheengine.

3. Replacetheoilfilldipstickandtighten.

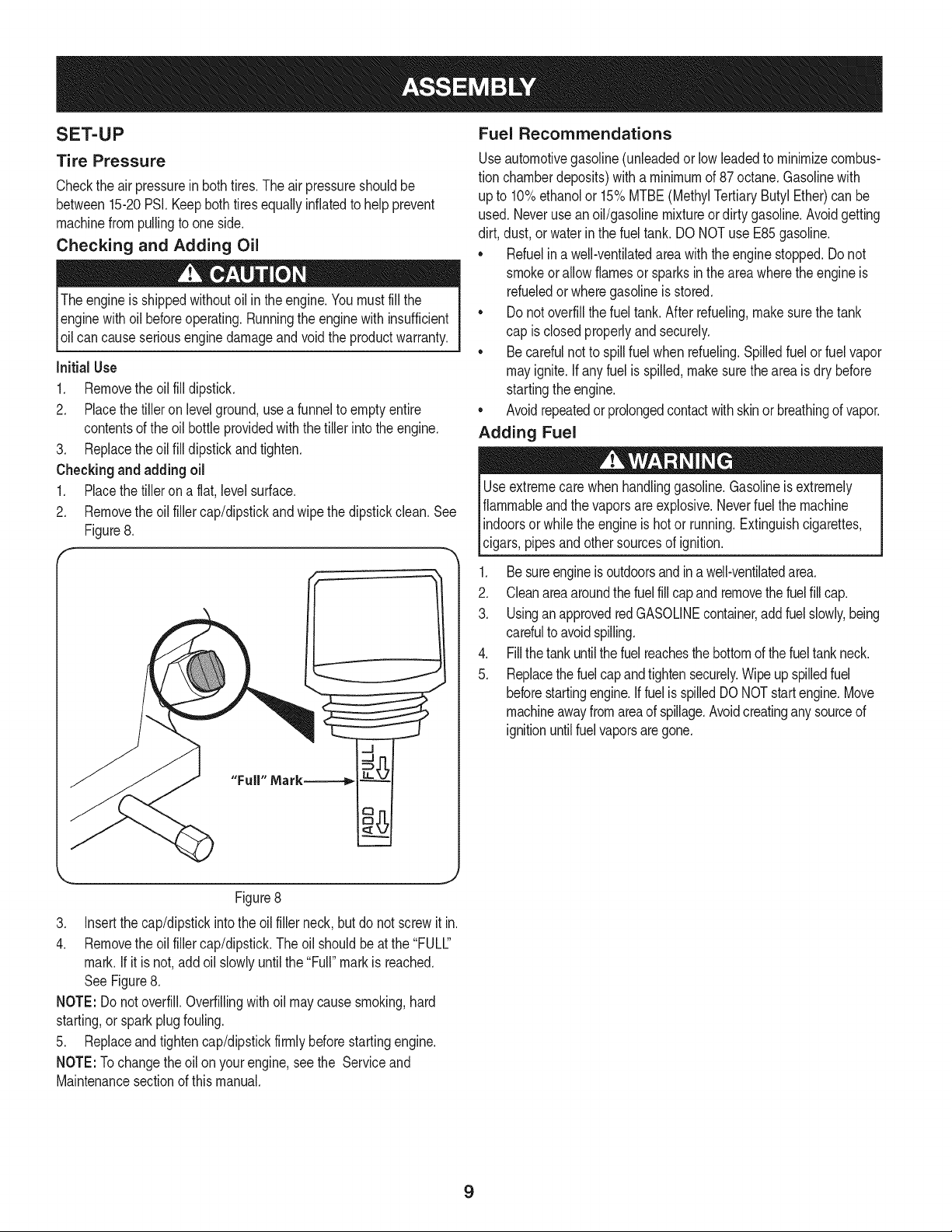

Checkingand adding oil

1. Placethetillerona flat, levelsurface.

2. Removetheoil fillercap/dipstickandwipethedipstickclean.See

Figure8.

Fuel Recommendations

Useautomotivegasoline(unleadedorlowleadedtominimizecombus-

tionchamberdeposits)witha minimumof 87 octane.Gasolinewith

up to 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neverusean oil/gasolinemixtureordirty gasoline.Avoidgetting

dirt, dust,or waterinthe fueltank.DONOTuse E85gasoline.

• Refuelina well-ventilatedareawiththe enginestopped.Donot

smokeorallowflamesor sparksin theareawheretheengineis

refueledor wheregasolineisstored.

• Donotoverfillthe fueltank.After refueling,makesurethe tank

capis closedproperlyandsecurely.

• Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuel vapor

mayignite.Ifany fuelis spilled,makesurethe areaisdry before

startingthe engine.

• Avoidrepeatedor prolongedcontactwithskinorbreathingofvapor.

Adding Fuel

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuelthe machine

indoorsorwhilethe engineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

1. Besureengineisoutdoorsandina well-ventilatedarea.

2. Cleanareaaroundthefuelfill capandremovethefuelfill cap.

3. UsinganapprovedredGASOLINEcontainer,addfuelslowly,being

carefultoavoidspilling.

4. Fillthetankuntilthefuelreachesthe bottomofthefueltankneck.

5. Replacethefuelcapandtightensecurely.Wipeupspilledfuel

beforestartingengine.IffuelisspilledDONOTstartengine.Move

machineawayfromareaofspillage.Avoidcreatinganysourceof

ignitionuntilfuelvaporsaregone.

Figure8

3. Insertthe cap/dipstickintothe oilfillerneck,butdo not screwitin.

4. Removetheoil fillercap/dipstick.Theoilshouldbeatthe"FULC'

mark.If itisnot,addoil slowlyuntilthe "Full"markisreached.

SeeFigure8.

NOTE:Donotoverfill.Overfillingwithoil maycausesmoking,hard

starting,or sparkplugfouling.

5. Replaceandtightencap/dipstickfirmlybeforestartingengine.

NOTE:Tochangethe oilon yourengine,seethe Serviceand

Maintenancesectionofthismanual.

9

ADJUSTMENTS

Priortooperatingyourtiller,carefullyreadandfollowall instructions

below.Performall adjustmentsto verifyyourtilleris operatingsafely

andpropery.

Clutch Cable

NOTE:Servicethe enginewithoil andgasolinebeforecheckingthis

adjustment.Referto theseparateEngineOperator'sManualpacked

withyourtillerforproperfuel andengineoil recommendations.

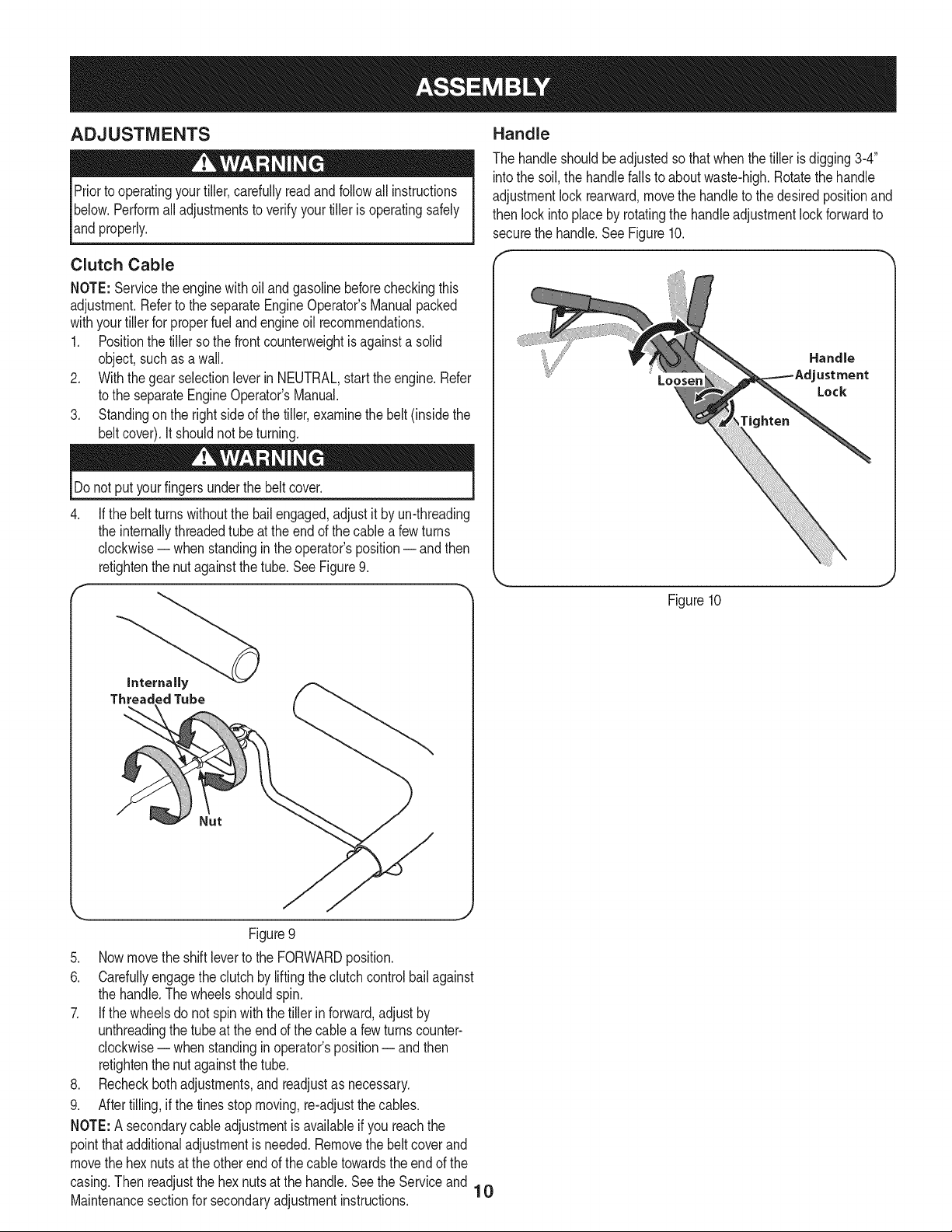

1. Positionthetillerso thefrontcounterweightis againsta solid

object,suchas a wall.

2. WiththegearselectionleverinNEUTRAL,starttheengine.Refer

tothe separateEngineOperator'sManual.

3. Standingonthe rightsideofthe tiller,examinethebelt (insidethe

beltcover).It shouldnotbeturning.

Donot putyourfingersunderthebelt cover.

.

If thebeltturnswithoutthebailengaged,adjustitbyun-threading

theinternallythreadedtubeat theendof thecablea fewturns

clockwise-- when standingin theoperator'sposition-- andthen

retightenthenut againstthetube.SeeFigure9.

f

Handle

Thehandleshouldbeadjustedsothatwhenthetillerisdigging3-4"

intothe soil,the handlefallsto aboutwaste-high.Rotatethehandle

adjustmentlock rearward,movethe handleto thedesiredpositionand

thenlockintoplaceby rotatingthehandleadjustmentlockforwardto

securethehandle.SeeFigure10.

Handle

Loosen

tighten

ustment

Lock

Figure10

Internally

ThreadedTube

Figure9

,

Nowmovetheshiftleverto theFORWARDposition.

6.

Carefullyengagethe clutchby liftingtheclutchcontrolbailagainst

thehandle.Thewheelsshouldspin.

7.

If thewheelsdo not spinwiththe tillerinforward,adjustby

unthreadingthe tubeat theendof thecablea fewturnscounter-

clockwise-- when standingin operator'sposition-- andthen

retightenthenut againstthetube.

,

Recheckbothadjustments,andreadjustas necessary.

9.

Aftertilling,ifthe tinesstopmoving,re-adjustthe cables.

NOTE:A secondarycableadjustmentisavailableifyoureachthe

pointthatadditionaladjustmentisneeded.Removethebeltcoverand

movethehexnutsatthe otherendof thecabletowardstheendofthe

casing.Thenreadjustthehex nutsatthe handle.Seethe Serviceand

Maintenancesectionforsecondaryadjustmentinstructions.

10

Gear

Handle Adjustment

Clutch Control

Muffler

\

I

Fuel Cap

Air Filter. _ I__

Shift Lever indicator

Stake

Recoil!ta_

Rear Tine Shield

Figure11

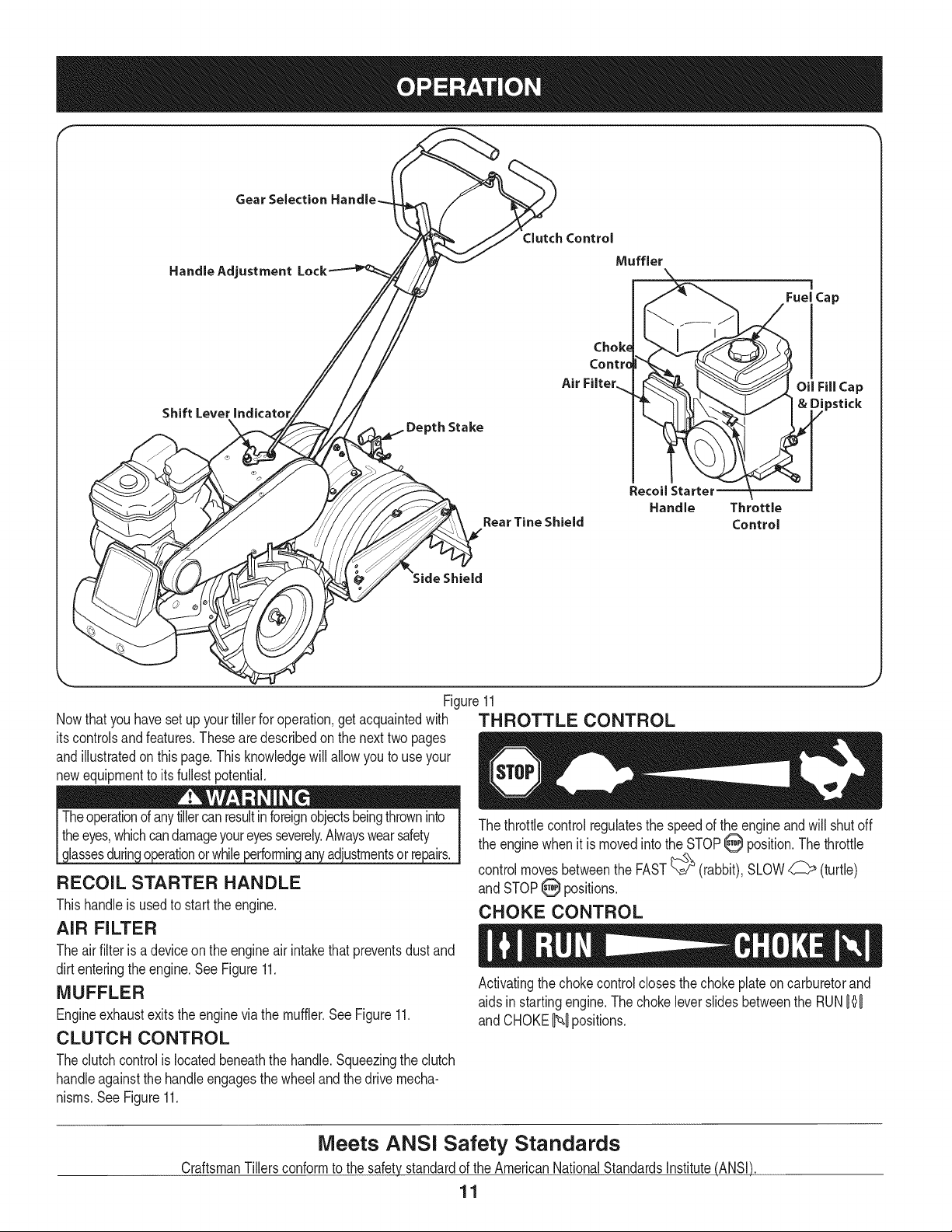

Nowthat youhavesetup yourtillerforoperation,getacquaintedwith TH ROTTLE CONTROL

itscontrolsandfeatures.Thesearedescribedonthe nexttwopages

andillustratedonthispage.Thisknowledgewillallowyouto useyour

newequipmenttoitsfullestpotential.

Theoperationofanytillercanresultinforeignobjectsbeingthrowninto

theeyes,whichcandamageyoureyesseverely.Alwayswearsafety

assesdurn o eratonorwh e erformn an adustmentsorre a rs.

Thethrottlecontrolregulatesthespeedofthe engineandwill shutoff

theenginewhenit is movedintothe STOPO position.Thethrottle

controlmovesbetweenthe FAST_ (rabbit),SLOW_ (turtle)

RECOIL STARTER HANDLE

Thishandleisusedto starttheengine.

and STOPO positions.

CHOKE CONTROL

AIR FILTER

Theair filteris adeviceontheengineair intakethatpreventsdustand

dirtenteringtheengine.SeeFigure11.

MUFFLER

Engineexhaustexitstheenginevia themuffler.SeeFigure11.

Activatingthechokecontrolclosesthechokeplateon carburetorand

aidsin startingengine.ThechokeleverslidesbetweentheRUN0{'0

and CHOKEN positions.

CLUTCH CONTROL

Theclutchcontrolislocatedbeneaththehandle.Squeezingtheclutch

handleagainstthehandleengagesthewheelandthedrivemecha-

nisms.SeeFigure11.

Oil Fill Cap

& Dipstick

Handle Throttle

Control

Meets ANSI Safety Standards

CraftsmanTillersconformtothe safetystandardofthe AmericanNationalStandardsInstitute(ANSI)

11

OiL FiLL CAP & DIPSTICK

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill. See

Figure11.

NOTE:ThisunitwasshippedWITHOUToil inthe engine.Oilis

includedintheplasticbag packedwiththemanualinwiththetiller.

Addtheoil as directedintheGas & OilFillUp section.Checktheoil

levelbeforeeachoperationtoensureadequateoil is intheengine.

Forfurtherinstructions,refertothestepsintheEngineMaintenance

sectionof thismanual.

GEAR SELECTION HANDLE

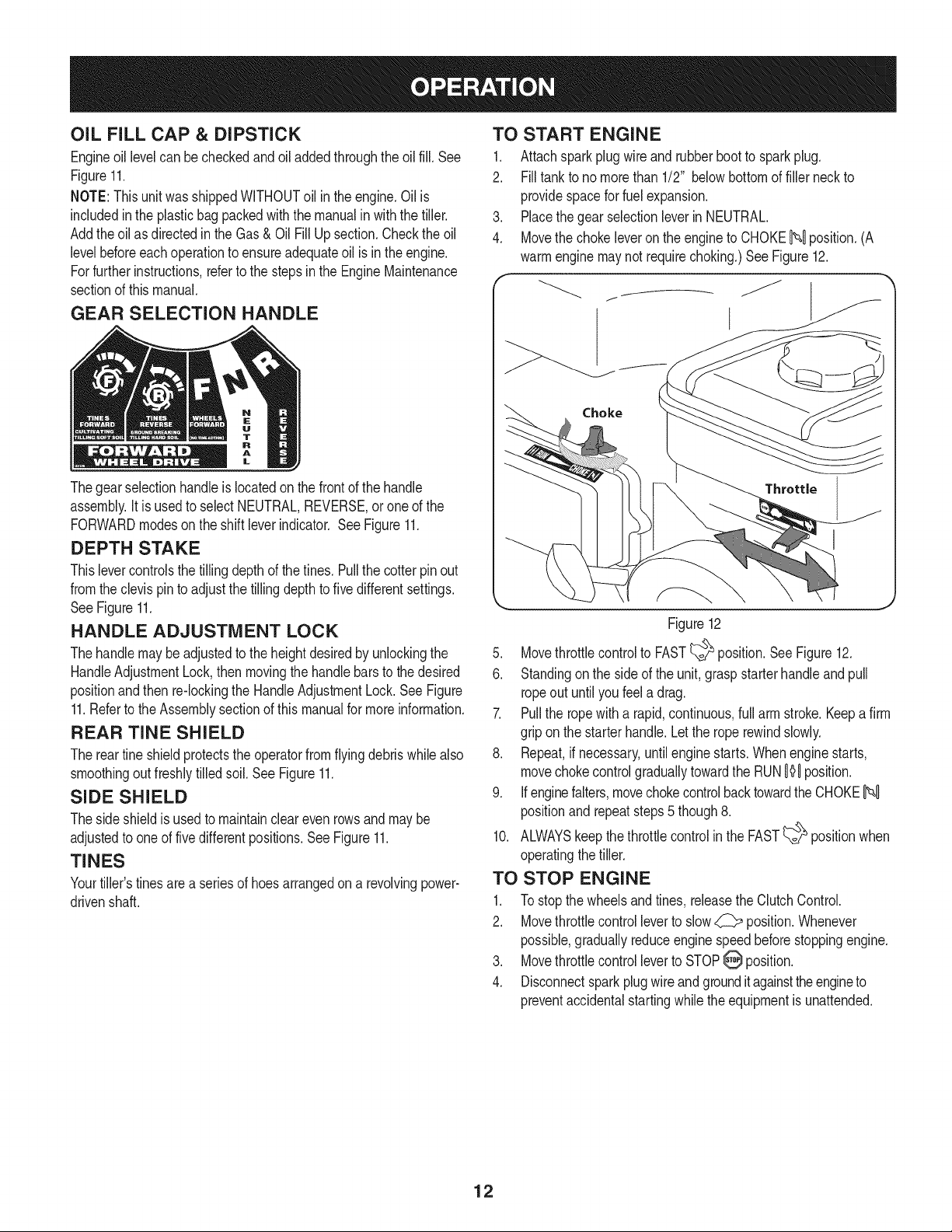

TO START ENGINE

1. Attachsparkplugwireandrubberboot tosparkplug.

2. Filltankto no morethan 1/2" belowbottomoffillerneckto

providespaceforfuelexpansion.

3. Placethegearselectionleverin NEUTRAL.

4. Movethechokeleveron theengineto CHOKEN position.(A

warmenginemaynotrequirechoking.)SeeFigure12.

Choke

Thegearselectionhandleislocatedonthe frontof thehandle

assembly.It is usedto selectNEUTRAL,REVERSE,oroneof the

FORWARDmodeson the shiftleverindicator.SeeFigure11.

DEPTH STAKE

Thislevercontrolsthetillingdepthof thetines.Pullthecotter pinout

fromtheclevis pintoadjustthe tillingdepthtofivedifferentsettings.

SeeFigure11.

HANDLE ADJUSTMENT LOCK

Thehandlemaybe adjustedtotheheightdesiredbyunlockingthe

HandleAdjustmentLock,thenmovingthehandlebarsto thedesired

positionandthenre-lockingtheHandleAdjustmentLock.SeeFigure

11.Referto theAssemblysectionofthis manualformoreinformation.

REAR TIME SHIELD

Thereartine shieldprotectstheoperatorfromflyingdebriswhilealso

smoothingout freshlytilledsoil.SeeFigure11.

SIDE SHIELD

Theside shieldis usedto maintainclearevenrowsandmaybe

adjustedtooneof fivedifferentpositions.SeeFigure11.

TINES

Yourtiller'stinesarea seriesof hoesarrangedona revolvingpower-

drivenshaft.

Throttle

Figure12

5. Movethrottlecontrolto FAST_ position.SeeFigure12.

6. Standingon the sideof theunit,graspstarterhandleandpull

ropeoutuntilyoufeela drag.

7. Pullthe ropewitha rapid,continuous,fullarm stroke.Keepafirm

gripon thestarterhandle.Letthe roperewindslowly.

8. Repeat,ifnecessary,untilenginestarts.Whenenginestarts,

movechokecontrolgraduallytowardthe RUN0'_0position.

9. Ifenginefalters,movechokecontrolbacktowardtheCHOKEN

positionand repeatsteps5 though8.

10. ALWAYSkeepthethrottlecontrolin theFAST_ positionwhen

operatingthetiller.

TO STOP ENGINE

1. To stopthewheelsandtines, releasetheClutchControl.

2. Movethrottlecontrolleverto slow_ position.Whenever

possible,graduallyreduceenginespeedbeforestoppingengine.

3. Movethrottlecontrolleverto STOPO position.

4. Disconnectsparkplugwireandgrounditagainsttheengineto

preventaccidentalstartingwhilethe equipmentisunattended.

12

TO ENGAGE DRIVE & TINES

Donot pushdownon thehandlebarstotry to makethetillertill more

deeply.This preventsthe wheelsfromholdingthetiller backandcan

allowthe tinesto rapidlypropelthetiller,whichcould resultin lossof

control,propertydamage,orpersonalinjury.

Tomoveforward:

1. Forforwardmotionofthewheelsusethe gearselectionhandle

andforpowertothe tinespulltheclutchcontrolupagainstthe

handlebar.

2. Whentilling,letthewheelspullthe machinewhilethetinesdig.

Walkslowlybehindthetillerallowingitto moveatits ownpace

whilekeepinga securegripon thehandlebarwithyourelbows

flexed.

3. Releasethebailto stopthewheelsandtines.

Tomoveinreverse:(Donot tillin reverse)

1. Releasethe ClutchControl.Thenliftthe handlebaruntilthe tines

areoff theground.

2. Pullbackonthegearselectionhandle,andwalkbackwardswith

themachine.

NOTE:In reversemode,thetineswill reverserotation.

TURNING THE TILLER

1. Practiceturningthetillerin a level,openarea.Beverycarefulto

keepyourfeetandlegsawayfromthe tines.

2. Tobeginaturn,liftthe handlebarsuntilthetinesareout ofthe

groundandtheengineandtinesarebalancedoverthewheels.

3. Withthetillerbalanced,pushsidewayson the handlebartosteer

in thedirectionoftheturn.Afterturning,slowlylowerthe tinesinto

thesoil toresumetilling.

SETTING THE DEPTH

Tillingdepthiscontrolledbythedepthstakewhichcan be adjustedto

fivedifferentsettings.Adjustthesideshieldsasyou adjustthedepth

stake.

• Whenusingthe tillerfor thefirsttime,usethesecondadjustment

holefromthetop (1"oftillingdepth).

• Whenbreakingupsodandforshallowcultivation,usethe setting

whichgives1"oftillingdepth(secondholefromthetop).Place

thesideshieldsintheirlowestposition.

• Forfurtherdepth,raisethedepthstakeandsideshieldsandalso

makeoneor twomorepassesoverthearea.

• Whentillingloosesoil,thedepthstakemayberaisedtoits

highestposition(usebottomadjustmenthole)to givethedeepest

tillingdepth.Raisethe sideshieldsto theirhighestposition.

• Totransporttiller,lowerthedepth stake(usetopadjustment

hole).

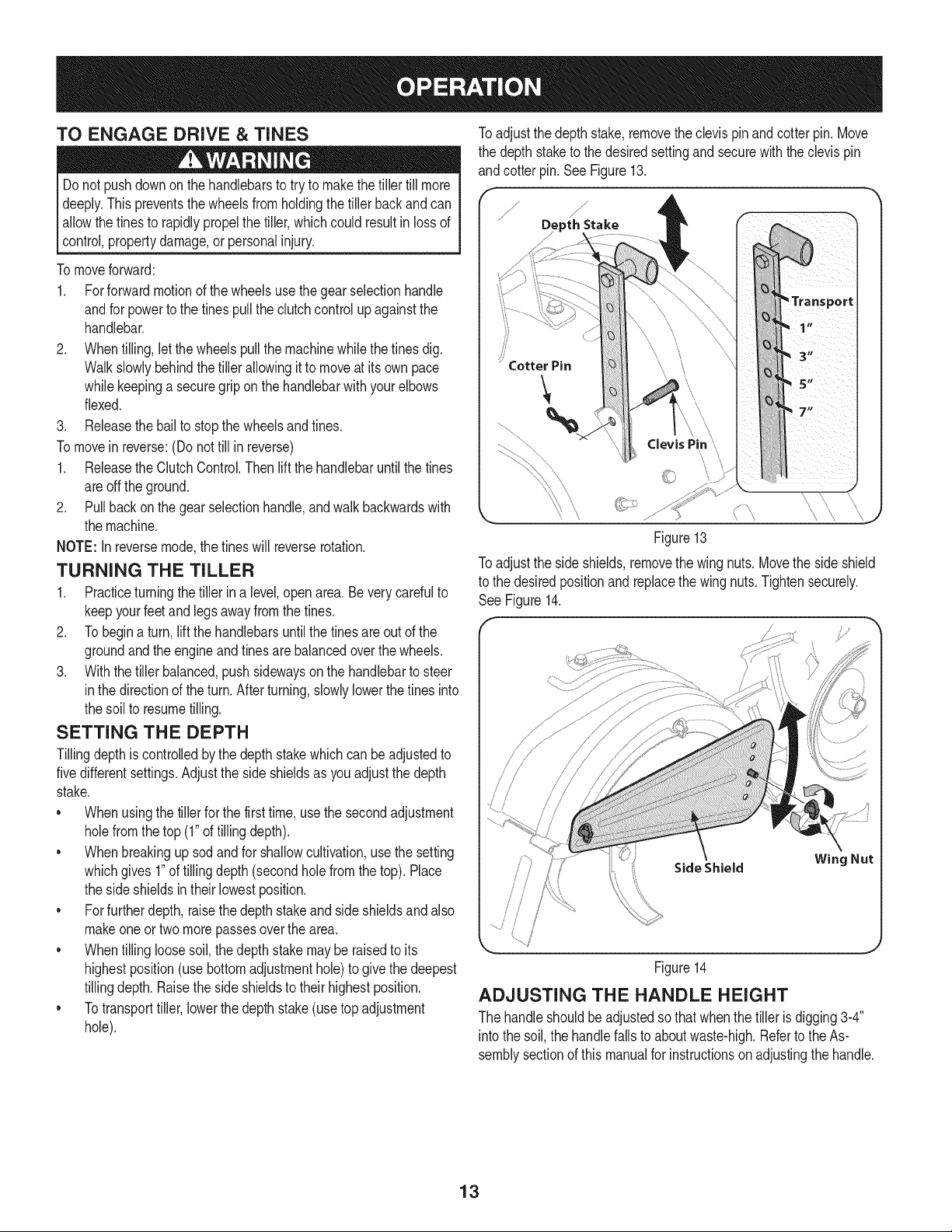

Toadjustthedepthstake,removetheclevispinandcotterpin.Move

thedepthstaketo thedesiredsettingandsecurewiththeclevispin

andcotterpin.SeeFigure13.

j_

DepthStake

Figure13

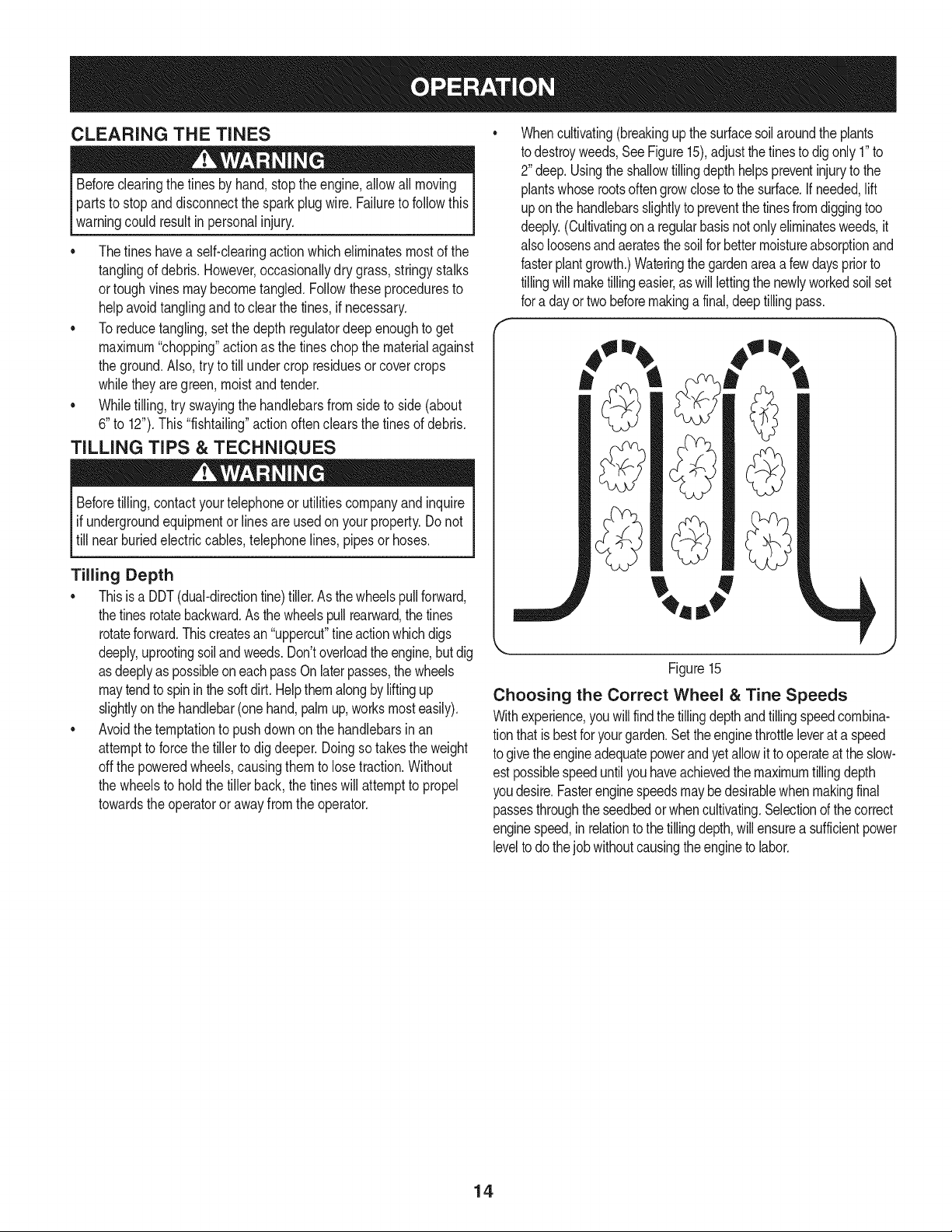

Toadjustthe sideshields,removethewingnuts.Movethesideshield

tothe desiredpositionandreplacethewingnuts.Tightensecurely.

See Figure14.

f J

/

!

_h J

Side Shield Wing Nut

Figure14

ADJUSTING THE HANDLE HEIGHT

Thehandleshouldbeadjustedsothat whenthetillerisdigging3-4"

intothe soil,thehandlefallsto aboutwaste-high.RefertotheAs-

semblysectionofthis manualforinstructionson adjustingthehandle.

13

CLEARING THE TINES

Beforeclearingthetinesby hand,stoptheengine,allowallmoving

partstostopanddisconnectthesparkplugwire.Failuretofollowthis

warningcouldresultinpersonalinjury.

• Thetines haveaself-clearingactionwhicheliminatesmostofthe

tanglingofdebris.However,occasionallydrygrass,stringystalks

ortoughvinesmaybecometangled.Followtheseproceduresto

helpavoidtanglingandtoclearthetines, ifnecessary.

• To reducetangling,setthedepthregulatordeepenoughtoget

maximum"chopping"actionasthetineschopthe materialagainst

theground.Also,trytotill undercropresiduesorcovercrops

whiletheyaregreen,moistandtender.

• Whiletilling,try swayingthehandlebarsfromsideto side(about

6"to 12").This"fishtailing"actionoftenclearsthetinesof debris.

TILLING TiPS & TECHNIQUES

Beforetilling,contactyourtelephoneor utilitiescompanyandinquire

l ifundergroundequipmentorlinesareusedon yourproperty.Donot

[till nearburiedelectriccables,telephonelines,pipesor hoses.

Tilling Depth

• Thisisa DDT(dual-directiontine)tiller.Asthewheelspullforward,

thetinesrotatebackward.As thewheelspullrearward,the tines

rotateforward.Thiscreatesan "uppercut"fineactionwhichdigs

deeply,uprootingsoilandweeds.Don'toverloadtheengine,butdig

asdeeplyaspossibleoneachpassOnlaterpasses,thewheels

maytendto spininthe softdirt.Helpthemalongbyliftingup

slightlyonthehandlebar(onehand,palmup,worksmosteasily).

• Avoidthetemptationto pushdownonthehandlebarsinan

attempttoforcethetillerto digdeeper.Doingsotakestheweight

off thepoweredwheels,causingthemto losetraction.Without

thewheelsto holdthetillerback,the tineswillattemptto propel

towardstheoperatororawayfromthe operator.

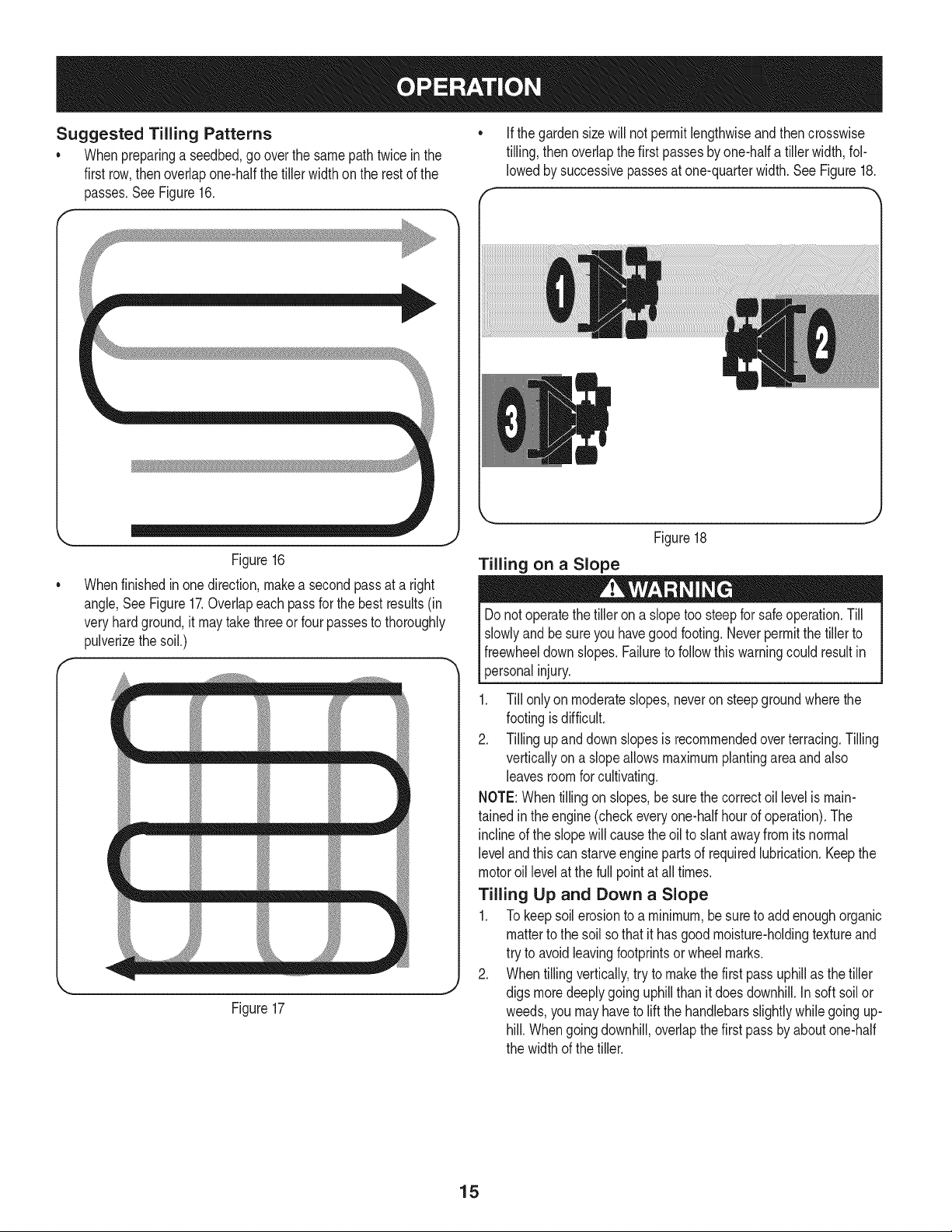

Whencultivating(breakingupthesurfacesoilaroundtheplants

todestroyweeds,SeeFigure15),adjustthe tinestodigonly1"to

2"deep.Usingtheshallowtillingdepthhelpspreventinjurytothe

plantswhoserootsoftengrowclosetothesurface.Ifneeded,lift

uponthehandlebarsslightlyto preventthetinesfromdiggingtoo

deeply.(Cultivatingona regularbasisnotonlyeliminatesweeds,it

alsoloosensandaeratesthesoilforbettermoistureabsorptionand

fasterplantgrowth.)Wateringthegardenareaafewdayspriorto

tillingwillmaketillingeasier,as willlettingthenewlyworkedsoilset

fora dayortwobeforemakingafinal,deeptillingpass.

,j

Figure15

Choosing the Correct Wheel & Tine Speeds

Withexperience,you willfindthetillingdepthandtillingspeedcombina-

tionthatisbestforyourgarden.Settheenginethrottleleverata speed

togivetheengineadequatepowerandyetallowittooperateattheslow-

estpossiblespeeduntilyouhaveachievedthemaximumtillingdepth

youdesire.Fasterenginespeedsmaybedesirablewhenmakingfinal

passesthroughtheseedbedor whencultivating.Selectionofthe correct

enginespeed,inrelationto thetillingdepth,willensurea sufficientpower

leveltodothejobwithoutcausingtheenginetolabor.

14

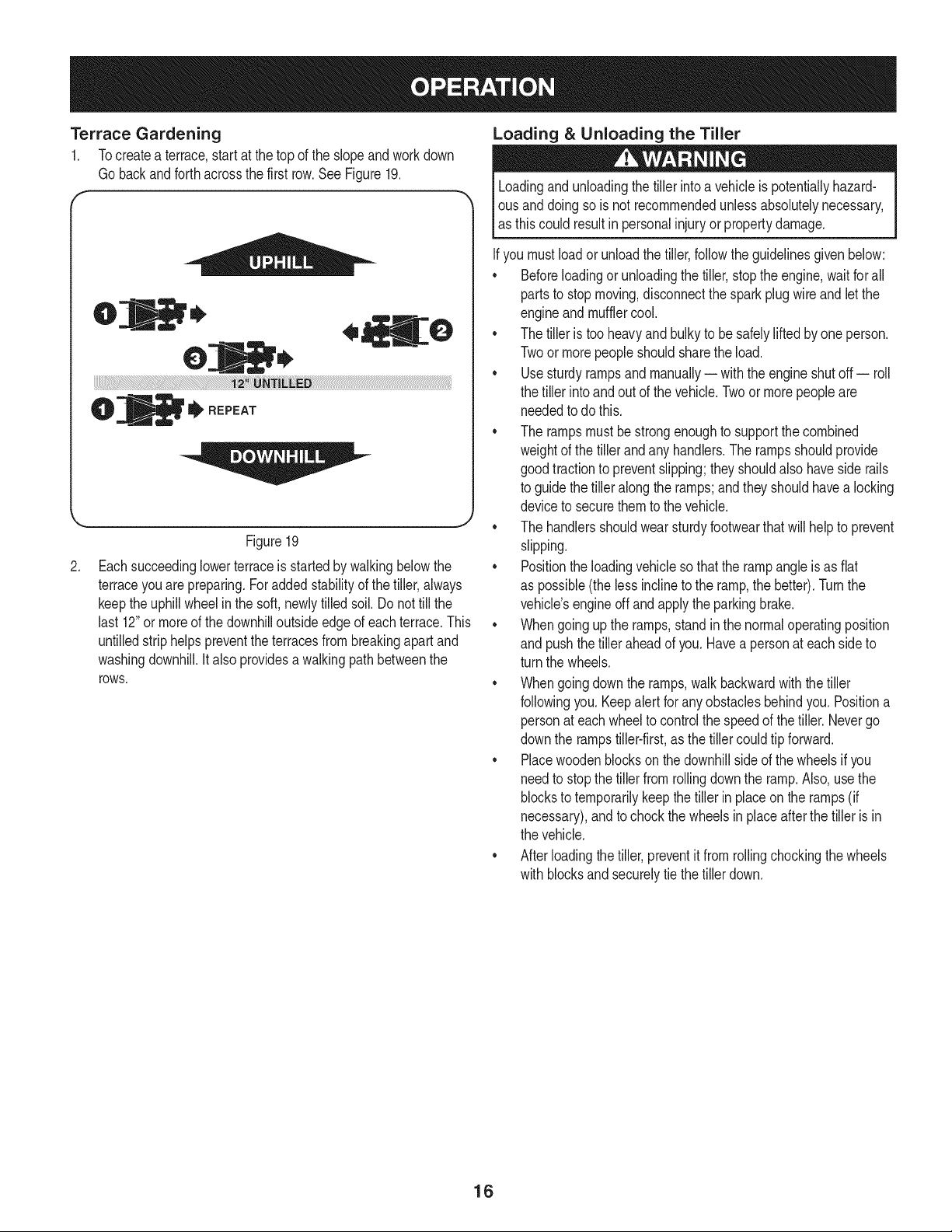

Suggested Tilling Patterns

• Whenpreparinga seedbed,gooverthe samepathtwice inthe

firstrow,thenoverlapone-halfthetiller widthontherestof the

passes,SeeFigure16,

• Ifthe gardensizewillnotpermitlengthwiseandthencrosswise

tilling,thenoverlapthefirst passesbyone-halfatiller width,fol-

lowedby successivepassesatone-quarterwidth.SeeFigure18.

Figure16

Whenfinishedinonedirection,makea secondpassata right

angle,SeeFigure17.Overlapeachpassfor thebestresults(in

veryhardground,it maytakethreeorfour passestothoroughly

pulverizethesoil.)

== ==== ==d

Figure17

J

Tilling on a Slope

Donotoperatethetillerona slopetoosteepfor safeoperation.Till

slowlyandbesureyouhavegoodfooting.Neverpermitthetillerto

freewheeldownslopes.Failuretofollowthiswarningcouldresultin

personalinjury.

1. Till onlyon moderateslopes,neveronsteepgroundwherethe

footingisdifficult.

2. Tillingupand downslopesisrecommendedoverterracing.Tilling

verticallyon aslopeallowsmaximumplantingareaandalso

leavesroomforcultivating.

NOTE:Whentillingon slopes,be surethe correctoillevelismain-

tainedin theengine(checkeveryone-halfhourofoperation).The

inclineof theslopewillcausethe oilto slantawayfromitsnormal

levelandthis canstarveenginepartsof requiredlubrication.Keepthe

motoroil levelat thefull pointat all times.

Tilling Up and Down a Slope

1. To keepsoilerosionto a minimum,besureto addenoughorganic

matterto thesoil sothat it hasgoodmoisture-holdingtextureand

try toavoidleavingfootprintsor wheelmarks.

2. Whentillingvertically,tryto makethefirst passuphillasthetiller

J

digsmoredeeplygoinguphillthanit doesdownhill.Insoft soilor

weeds,youmayhaveto liftthehandlebarsslightlywhilegoingup-

hill.Whengoingdownhill,overlapthefirstpassby aboutone-half

thewidthof thetiller.

Figure18

15

Terrace Gardening

1. Tocreatea terrace,startatthetopof theslopeandworkdown

Gobackandforthacrossthefirstrow.See Figure19.

f

to,

O

tI'REPEAT

Figure19

.

Eachsucceedinglowerterraceis startedby walkingbelowthe

terraceyouarepreparing.Foraddedstabilityof thetiller,always

keepthe uphillwheelin the soft,newlytilledsoil.Donottill the

last 12"ormoreof thedownhilloutsideedgeofeachterrace.This

untilledstriphelps preventtheterracesfrombreakingapart and

washingdownhill.Italsoprovidesawalkingpathbetweenthe

rOWS.

Loading & Unloading the Tiller

Loadingandunloadingthetillerintoa vehicleis potentiallyhazard-

Ious anddoingsois notrecommendedunlessabsolutelynecessary,

las thiscould resultin personalinjuryorpropertydamage.

Ifyoumustloadorunloadthetiller,followthe guidelinesgivenbelow:

• Beforeloadingorunloadingthetiller,stopthe engine,waitfor all

partsto stopmoving,disconnectthesparkplugwireandletthe

engineand mufflercool.

• The tilleris tooheavyand bulkyto besafelyliftedbyone person.

Twoor morepeopleshouldsharethe load.

• Usesturdyrampsand manually-- withtheengineshutoff-- roll

thetiller intoandout ofthe vehicle.Twoormorepeopleare

neededtodo this.

• The rampsmustbe strongenoughto supportthecombined

weightofthe tillerandanyhandlers.The rampsshouldprovide

goodtractionto preventslipping;theyshouldalsohaveside rails

toguidethe tilleralongthe ramps;andtheyshouldhavea locking

deviceto securethemto thevehicle.

J

• The handlersshouldwearsturdyfootwearthatwill helptoprevent

slipping.

• Positiontheloadingvehiclesothatthe rampangleis asflat

as possible(thelessinclineto theramp,the better).Turnthe

vehicle'sengineoffandapplytheparkingbrake.

• Whengoinguptheramps,standin thenormaloperatingposition

and pushthetilleraheadof you.Havea personateachsideto

turnthe wheels.

• Whengoingdownthe ramps,walkbackwardwiththetiller

followingyou.Keepalertfor anyobstaclesbehindyou.Positiona

personateachwheeltocontrolthe speedof thetiller.Nevergo

downthe rampstiller-first,asthetillercouldtip forward.

• Placewoodenblockson thedownhillsideof thewheelsif you

needtostopthe tillerfromrollingdowntheramp.Also,usethe

blockstotemporarilykeepthetiller in placeonthe ramps(if

necessary),andto chockthe wheelsin placeafterthe tilleris in

thevehicle.

• Afterloadingthe tiller,preventitfromrollingchockingthewheels

with blocksandsecurelytiethe tillerdown.

16

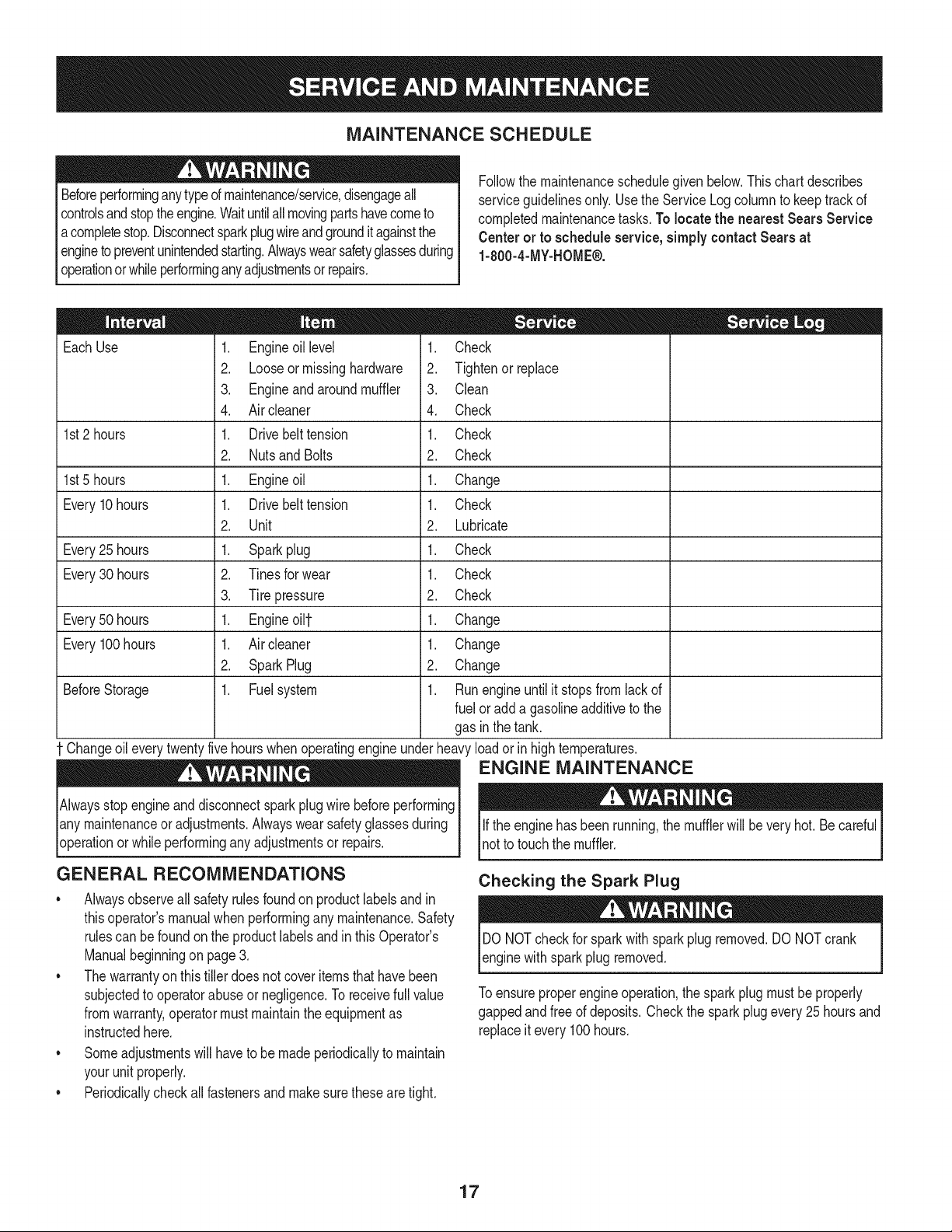

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.To locate the nearest Sears Service

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

operationor whileperforminganyadjustmentsor repairs.

Followthemaintenanceschedulegivenbelow.Thischartdescribes

= =

EachUse

1st2 hours

1st5 hours

Every10hours

Every25 hours

Every30 hours

Every50 hours

Every100hours

BeforeStorage

1. Engineoillevel

2. Looseormissinghardware

3. Engineandaroundmuffler

4. Aircleaner

1. Drivebelttension

2. Nutsand Bolts

1. Engineoil

1. Drivebelttension

2. Unit

1. Sparkplug

2. Tinesforwear

3. Tirepressure

1. Engineoilf

1. Aircleaner

2. SparkPlug

1. Fuelsystem

1. Check

2. Tightenor_place

3. Clean

4. Check

1. Check

2. Check

1. Change

1. Check

2. Lubricate

1. Check

1. Check

2. Check

1. Change

1. Change

2. Change

1. Runengineuntilit stopsfromlackof

fueloradda gasolineadditivetothe

gasin thetank.

Changeoileverytwentyfivehourswhenoperatingengineunderheavyloadorinhightemperatures.

ENGINE MAINTENANCE

Alwaysstopengineanddisconnectsparkplugwirebeforeperforming

lanymaintenanceor adjustments.Alwayswearsafetyglassesduring

_operationorwhile performinganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

• Alwaysobserveallsafetyrulesfoundonproductlabelsandin

thisoperator'smanualwhenperforminganymaintenance.Safety

rulescan befoundonthe productlabelsandin thisOperator's

Manualbeginningon page3.

• Thewarrantyonthistillerdoesnotcoveritemsthathavebeen

subjectedto operatorabuseor negligence.Toreceivefullvalue

fromwarranty,operatormustmaintaintheequipmentas

instructedhere.

• Someadjustmentswillhaveto be madeperiodicallytomaintain

yourunit properly.

• Periodicallycheckall fastenersand makesurethesearetight.

Iftheenginehas beenrunning,themufflerwillbeveryhot.Becareful

notto touchthemuffler.

Checking the Spark Plug

DONOTcheckforsparkwithsparkplugremoved.DONOTcrank

enginewithsparkplug removed.

Toensureproperengineoperation,thesparkplugmustbeproperly

gappedandfreeof deposits.Checkthe sparkplugevery25hoursand

replaceitevery100hours.

17

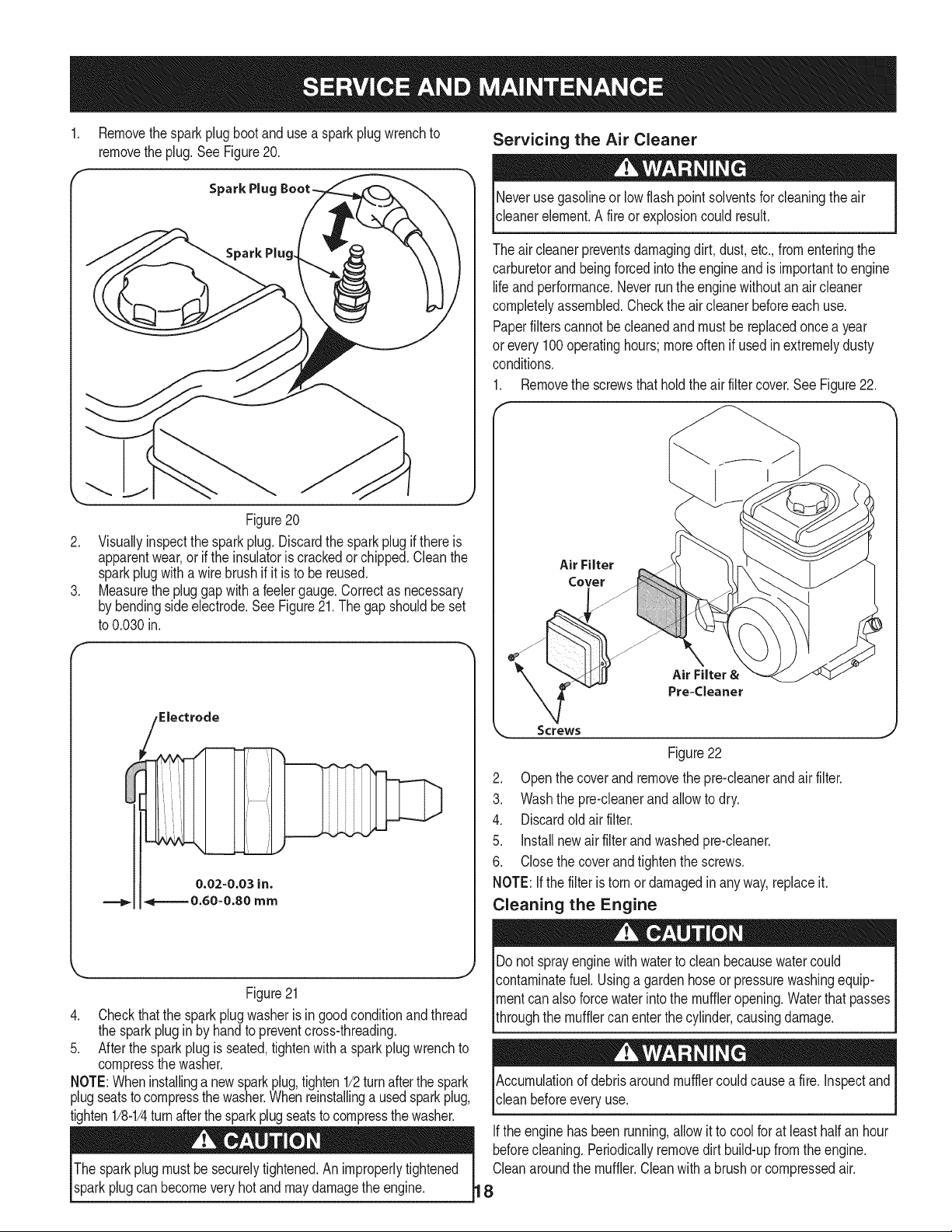

Removethesparkplugbootanduse a sparkplugwrenchto

removetheplug.See Figure20.

Servicing the Air Cleaner

Spark Plug

Figure20

2. Visuallyinspectthesparkplug.Discardthesparkplugif thereis

apparentwear,orif the insulatoriscrackedorchipped.Cleanthe

sparkplugwitha wirebrush ifit isto be reused.

3. Measurethepluggapwithafeelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure21.The gapshouldbeset

to0.030in.

Neverusegasolineor lowflashpoint solventsforcleaningtheair

cleanerelement.A fireor explosioncouldresult.

Theaircleanerpreventsdamagingdirt,dust,etc.,fromenteringthe

carburetorandbeingforcedintothe engineandis importanttoengine

lifeandperformance.Neverruntheenginewithoutanair cleaner

completelyassembled.Checktheair cleanerbeforeeachuse.

Paperfilterscannotbecleanedand mustbereplacedoncea year

or every100operatinghours;moreoftenif usedinextremelydusty

conditions.

1. Removethescrewsthatholdtheairfiltercover.SeeFigure22.

Air Filter

Cover

Figure21

4. Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin by handtopreventcross-threading.

5. Afterthesparkplugisseated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2turnafterthespark

plugseatstocompressthewasher.Whenreinstallinga usedsparkplug,

tighten1/8-1/4turnafterthesparkplugseatstocompressthewasher.

Thesparkplugmustbe securelytightened.An improperlytightened

sparkplugcanbecomeveryhot andmaydamagetheengine.

Air Filter &

Pre=Cleaner

Screws

Figure22

2. Openthecoverandremovethepre-cleanerandairfilter.

3. Washthe pre-cleanerandallowtodry.

4. Discardoldair filter.

5. installnewair filterandwashedpre-cleaner.

6. Closethecoverandtightenthe screws.

NOTE:Ifthe filteristornor damagedinany way,replaceit.

Cleaning the Engine

Donotsprayenginewithwatertocleanbecausewatercould

contaminatefuel.Usinga gardenhoseor pressurewashingequip-

mentcanalsoforcewaterintothe muffleropening.Waterthatpasses

throughthe mufflercanenterthe cylinder,causingdamage.

Accumulationofdebrisaroundmufflercouldcausea fire. inspectand

cleanbeforeeveryuse.

Iftheenginehas beenrunning,allow itto coolfor at leasthalf anhour

beforecleaning.Periodicallyremovedirt build-upfromtheengine.

Cleanaroundthemuffler.Cleanwitha brushor compressedair.

8

Check Engine Oil

1. Checkoilbeforeeachuse.Stopengineandwaitseveralminutes

beforecheckingoil level.Withengineon levelground,theoilmust

beto FULLmarkon dipstick.

2. Refertothe Assemblysectionofthismanualforinstructionson

checkingtheoil.

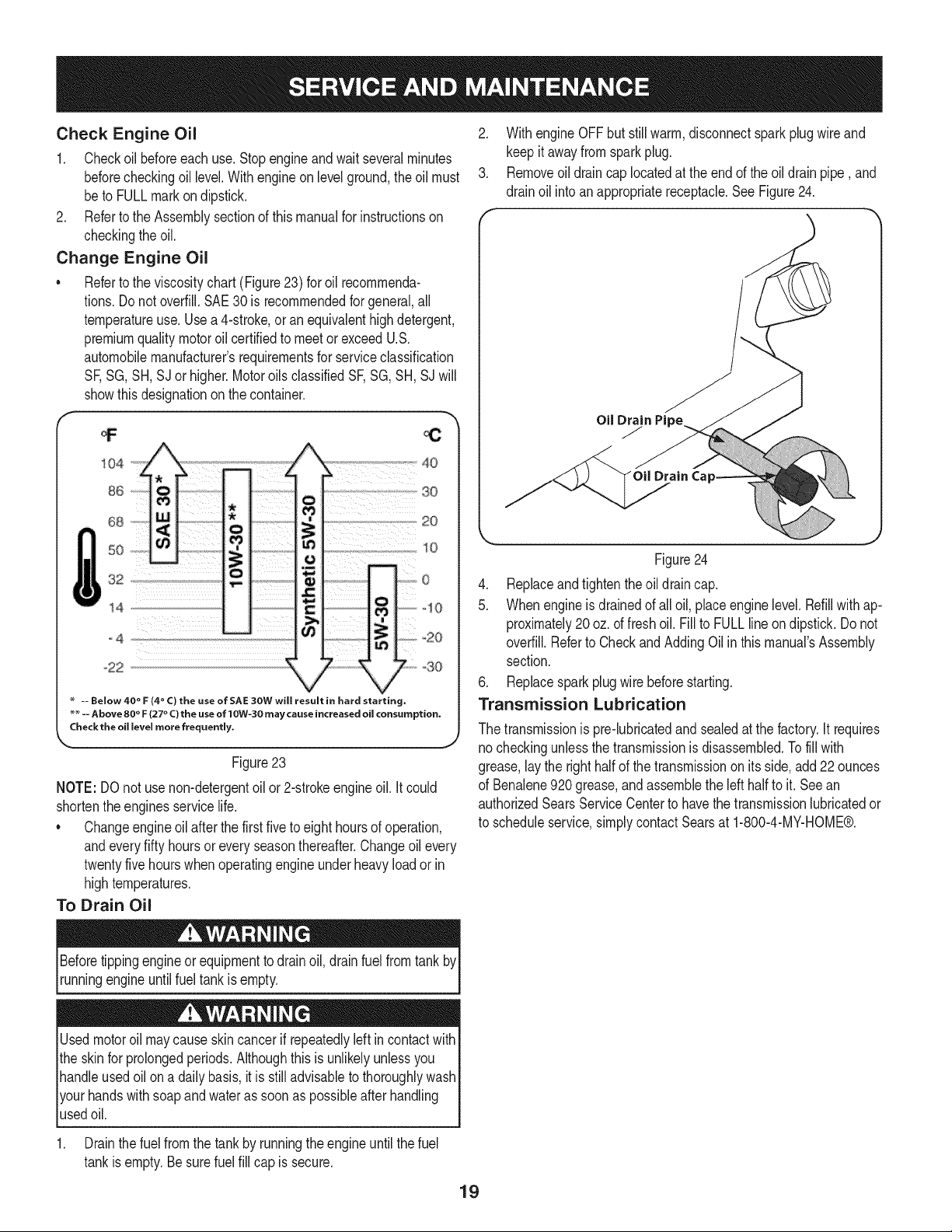

Change Engine Oil

Refertothe viscositychart(Figure23)for oil recommenda-

tions.Do notoverfill.SAE30 is recommendedforgeneral,all

temperatureuse.Usea 4-stroke,oranequivalenthighdetergent,

premiumqualitymotoroilcertifiedto meetorexceedU.S.

automobilemanufacturer'srequirementsforserviceclassification

SF,SG,SH,SJ or higher.MotoroilsclassifiedSF,SG,SH,SJ will

showthisdesignationon thecontainer.

2. WithengineOFFbutstillwarm,disconnectsparkplugwireand

keepit awayfromsparkplug.

3. Removeoil draincap locatedatthe endofthe oildrainpipe, and

drainoil intoanappropriatereceptacle.See Figure24.

OilDrain

J

104

86

68

50

32

14

o4

,-22

-- Below 40 ° F (4 ° C) the use of SAE 30W will result in hard starting,

_ -- Above 80 ° F (27 ° C) the use of 10W-30 may cause increased oil consumption,

Check the oil level more frequently,

Figure23

NOTE:DOnotusenon-detergentoil or2-strokeengineoil.it could

shortentheenginesservicelife.

• Changeengineoil afterthefirst fivetoeight hoursofoperation,

andeveryfifty hoursoreveryseasonthereafter.Changeoil every

twentyfivehourswhenoperatingengineunderheavyloadorin

hightemperatures.

To Drain Oil

ii

4O

2O

_10

_20

I°

o30

ain Ca

Figure24

4. Replaceandtightentheoildraincap.

5. Whenengineis drainedofall oil, placeenginelevel.Refillwithap-

proximately20oz.offreshoil. Fillto FULLlineondipstick.Do not

overfill.Referto CheckandAddingOilin thismanual'sAssembly

section.

6. Replacesparkplugwirebeforestarting.

Transmission Lubrication

Thetransmissionispro-lubricatedandsealedatthefactory,it requires

no checkingunlessthetransmissionis disassembled.Tofill with

grease,laythe righthalfof thetransmissionon itsside,add22ounces

of Benalene920grease,andassemblethelefthalftoit. Seean

authorizedSearsServiceCenterto havethe transmissionlubricatedor

to scheduleservice,simplycontactSearsat 1-800-4-MY-HOME®.

Beforetippingengineor equipmenttodrainoil, drainfuelfromtank by

runningengineuntilfuel tankisempty.

Usedmotoroil maycauseskincancerifrepeatedlyleftin contactwith

theskinfor prolongedperiods.Althoughthis is unlikelyunlessyou

handleusedoil ona daily basis,it isstilladvisableto thoroughlywash

yourhandswithsoapandwateras soonas possibleafter handling

usedoil.

1. Drainthefuelfromthe tankbyrunningtheengineuntilthefuel

tankisempty.Besurefuelfill capis secure.

19

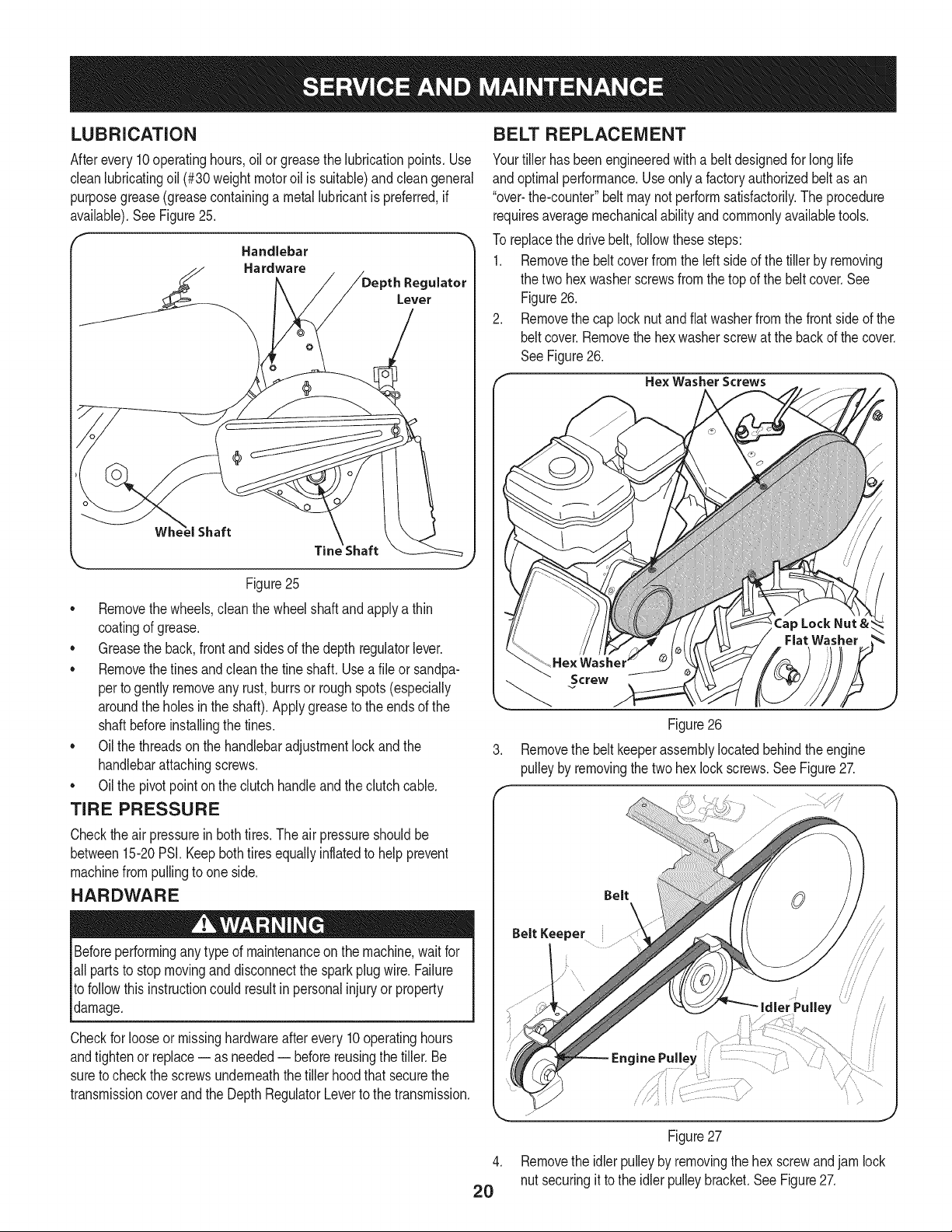

LUBRiCATiON

Afterevery10operatinghours,oilor greasethelubricationpoints.Use

cleanlubricatingoil(#30weightmotoroil is suitable)andcleangeneral

purposegrease(greasecontaininga metallubricantis preferred,if

available).SeeFigure25.

Handlebar

Hardware

Regulator

Lever

Shaft

Tin_

R

Figure25

• Removethewheels,cleanthewheelshaft andapplya thin

coatingofgrease.

Greasetheback,frontandsidesof thedepth regulatorlever.

Removethetinesandcleanthe fineshaft.Usea file or sandpa-

pertogentlyremoveanyrust,burrsor roughspots(especially

aroundtheholesintheshaft).Applygreasetotheendsofthe

shaftbeforeinstallingthetines.

Oilthethreadsonthe handlebaradjustmentlockandthe

handlebarattachingscrews.

Oilthepivotpointontheclutchhandleandtheclutchcable.

TIRE PRESSURE

Checktheair pressureinbothtires.Theairpressureshouldbe

between15-20PSI.Keepbothtiresequallyinflatedtohelpprevent

machinefrompullingtoone side.

HARDWARE

BELT REPLACEMENT

Yourtillerhasbeenengineeredwith a beltdesignedforlonglife

andoptimalperformance.Useonlya factoryauthorizedbeltasan

"over-the-counter"beltmaynotperformsatisfactorily.The procedure

requiresaveragemechanicalabilityandcommonlyavailabletools.

Toreplacethedrivebelt,followthesesteps:

1. RemovethebeltcoverfromtheIdt sideofthetillerbyremoving

thetwo hexwasherscrewsfromthetopof the beltcover.See

Figure26.

2. Removethe caplocknutandflatwasherfromthefrontsideofthe

beltcover.Removethehexwasherscrewat thebackofthe cover.

SeeFigure26.

Hex Washer Screws

Figure26

Removethe beltkeeperassemblylocatedbehindtheengine

pulleybyremovingthetwohex lockscrews.SeeFigure27.

Beforeperformingany typeofmaintenanceonthemachine,waitfor

all partsto stopmovinganddisconnectthesparkplugwire.Failure

tofollowthis instructioncouldresultinpersonalinjuryor property

damage.

Checkfor looseormissinghardwareafterevery10operatinghours

andtightenor replace-- as needed-- beforereusingthetiller.Be

sureto checkthe screwsunderneaththe tillerhoodthatsecurethe

transmissioncoverandthe DepthRegulatorLeverto thetransmission.

2O

v/*

Figure27

.

Removethe idlerpulleyby removingthehex screwandjamlock

nutsecuringittothe idlerpulleybracket.SeeFigure27.

5. Removetheoldbeltandinstallthenewbelt.Followtheinstruc-

tionsinreverseordertore-installthebeltkeeperandbeltcover.

SeeFigure27.

NOTE:Uponreassembly,makecertainthebeltisroutedovertheidler

pulleyandinsideofthebeltkeepersbytheenginepulley.

TINES

Thetineswillwearwithuseandshouldbeinspectedatthebeginningof

eachtillingseasonandafterevery30operatinghours.Thetinescanbe

replaced.RefertothePartsListsectionof thismanualforpartnumbers.

Tine Inspection

Withuse,thetineswill becomeshorter,narrowerandpointed.Badly

worntineswill resultina lossof tillingdepth,andreducedeffective-

nesswhenchoppingupandturningunderorganicmatter.

Removing/Installing a Tine Assembly

1. Removethetineshieldendcoversandsideshieldsbyremoving

thethree wingnutsoneach sidethatsecurethem.

2. Afineassemblyconsistsofa lefthandfineanda righthandfine.

NOTE:Thefineassemblymovesina counter-rotatingmotionwith

thesharpedgesof thetinespositionedtoenterthesoilfirstwhen

counter-rotating.Notethis positionof thetinesfor reinstallationof the

newfine assemblies.

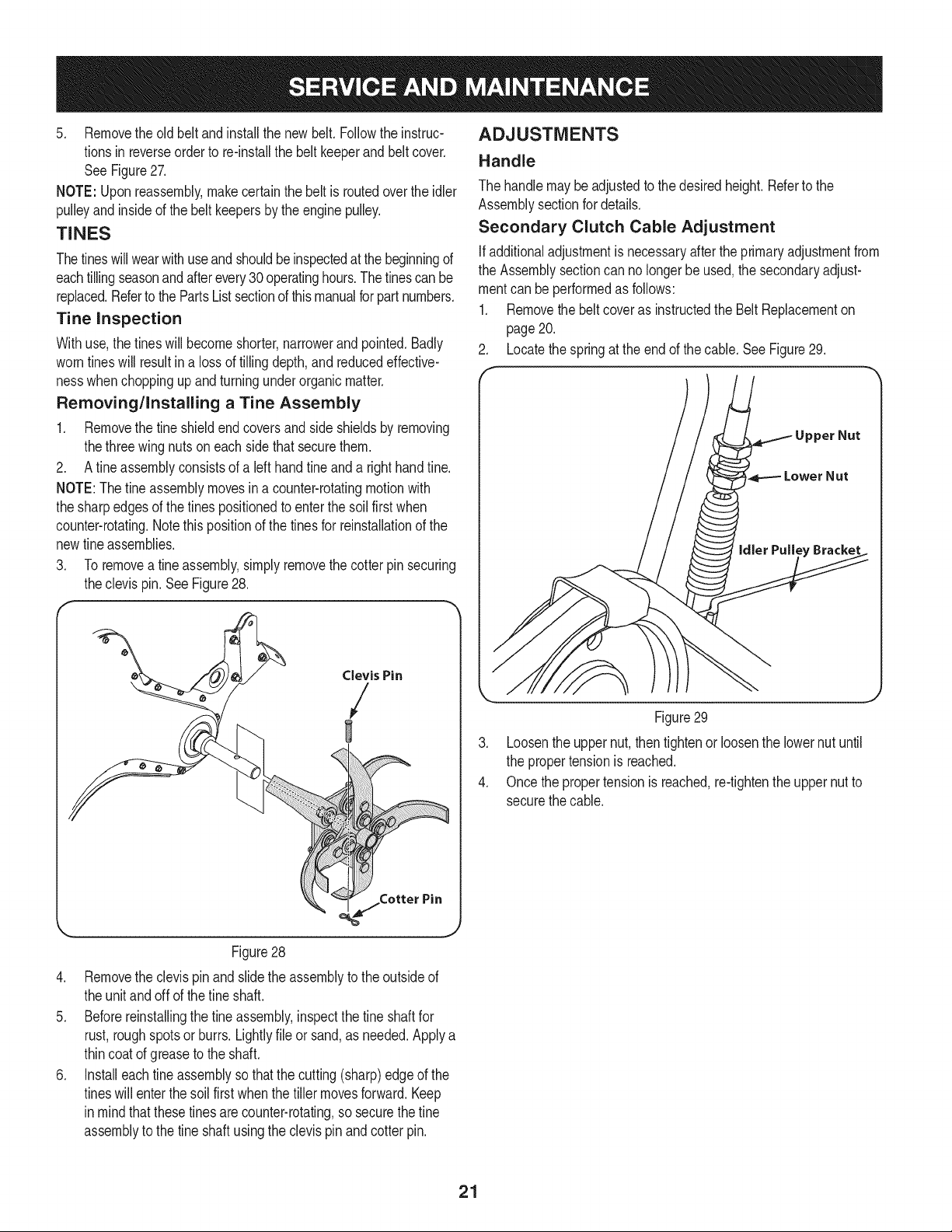

3. Toremoveafineassembly,simplyremovethecotterpin securing

theclevis pin.SeeFigure28.

ADJUSTMENTS

Handle

Thehandlemaybeadjustedto thedesiredheight.Refertothe

Assemblysectionfordetails.

Secondary Clutch Cable Adjustment

Ifadditionaladjustmentis necessaryaftertheprimaryadjustmentfrom

theAssemblysectioncannolongerbe used,the secondaryadjust-

mentcanbeperformedasfollows:

1. RemovethebeltcoverasinstructedtheBeltReplacementon

page20.

2. Locatethespringatthe endofthe cable.SeeFigure29.

Clevis Pin

/

C

Figure28

4. Removetheclevispinandslidetheassemblytotheoutsideof

theunitandoff ofthe fineshaft.

5. Beforereinstallingthe fineassembly,inspectthetineshaftfor

rust,roughspotsorburrs.Lightlyfileor sand,as needed.Applya

thincoatof greaseto theshaft.

6. Installeachtineassemblysothatthecutting(sharp)edgeof the

tineswillenterthesoil firstwhenthetiller movesforward.Keep

in mindthatthesetinesarecounter-rotating,sosecurethe fine

assemblytothe tineshaftusingthe clevispinandcotterpin.

Figure29

,

Loosentheuppernut,thentightenor loosenthelowernutuntil

thepropertensionis reached.

4.

Oncethepropertensionisreached,re-tightenthe uppernutto

securethecable.

21

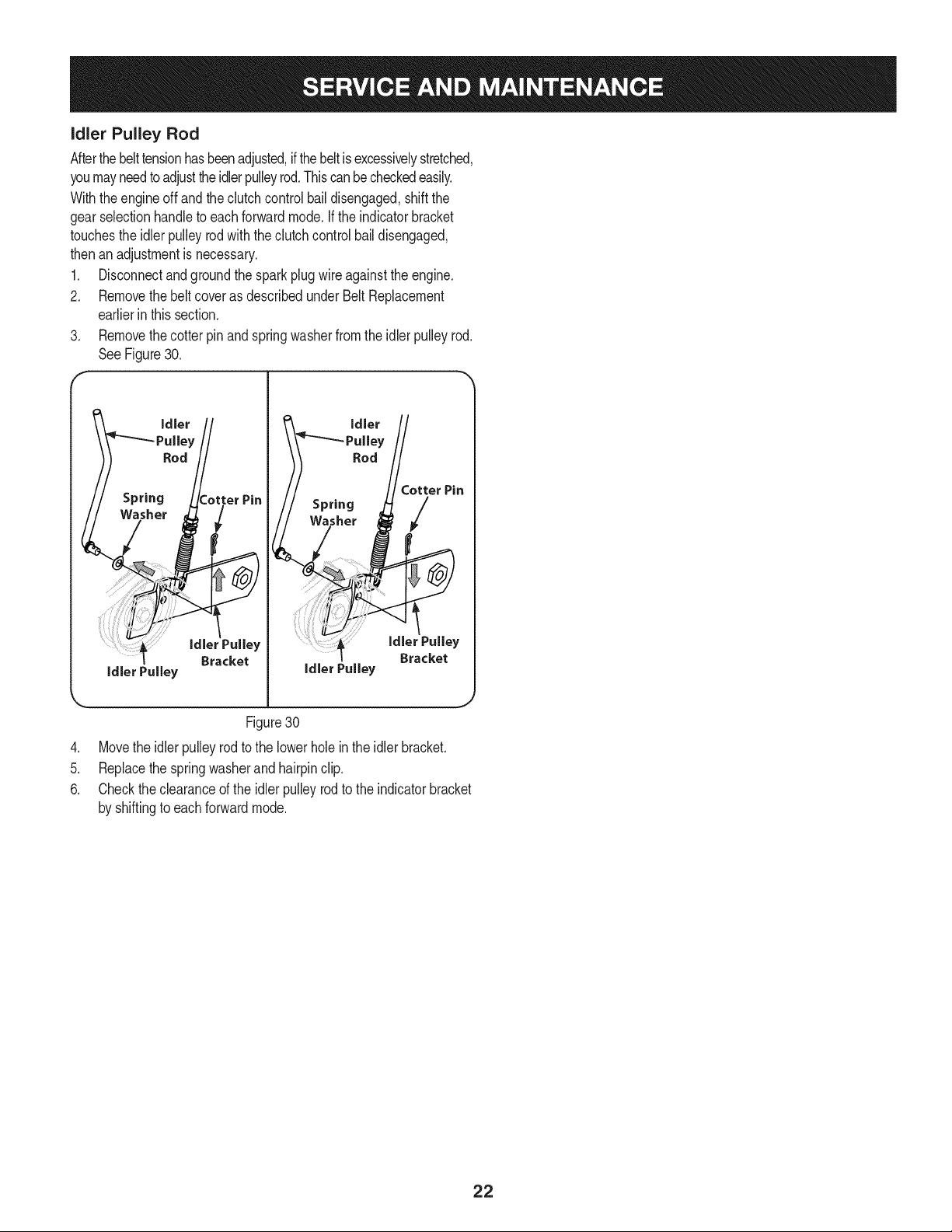

idler Pulley Rod

Afterthebelttensionhasbeenadjusted,ifthebeltis excessivelystretched,

youmayneedtoadjusttheidlerpulleyrod.Thiscanbecheckedeasily.

Withtheengineoff andthe clutchcontrolbaildisengaged,shiftthe

gearselectionhandletoeachforwardmode.Ifthe indicatorbracket

touchestheidlerpulleyrodwiththeclutchcontrolbaildisengaged,

thenan adjustmentisnecessary.

1. Disconnectandgroundthesparkplugwire againsttheengine.

2. Removethebeltcoveras describedunderBeltReplacement

earlierin thissection.

3. Removethecotterpin andspringwasherfromtheidlerpulleyrod.

SeeFigure30.

F

idler IRod t otter Pin

gROdllotter Pin

Washer _[ /

Spring /Washer

idlerPulley

idlerPulley

Bracket

idler Pulley

Bracket

Figure30

.

Movetheidlerpulleyrodtothe lowerholeinthe idlerbracket.

5.

Replacethespringwasherandhairpinclip.

6.

Checktheclearanceofthe idlerpulleyrodto theindicatorbracket

byshiftingtoeach forwardmode.

J

22

Loading...

Loading...