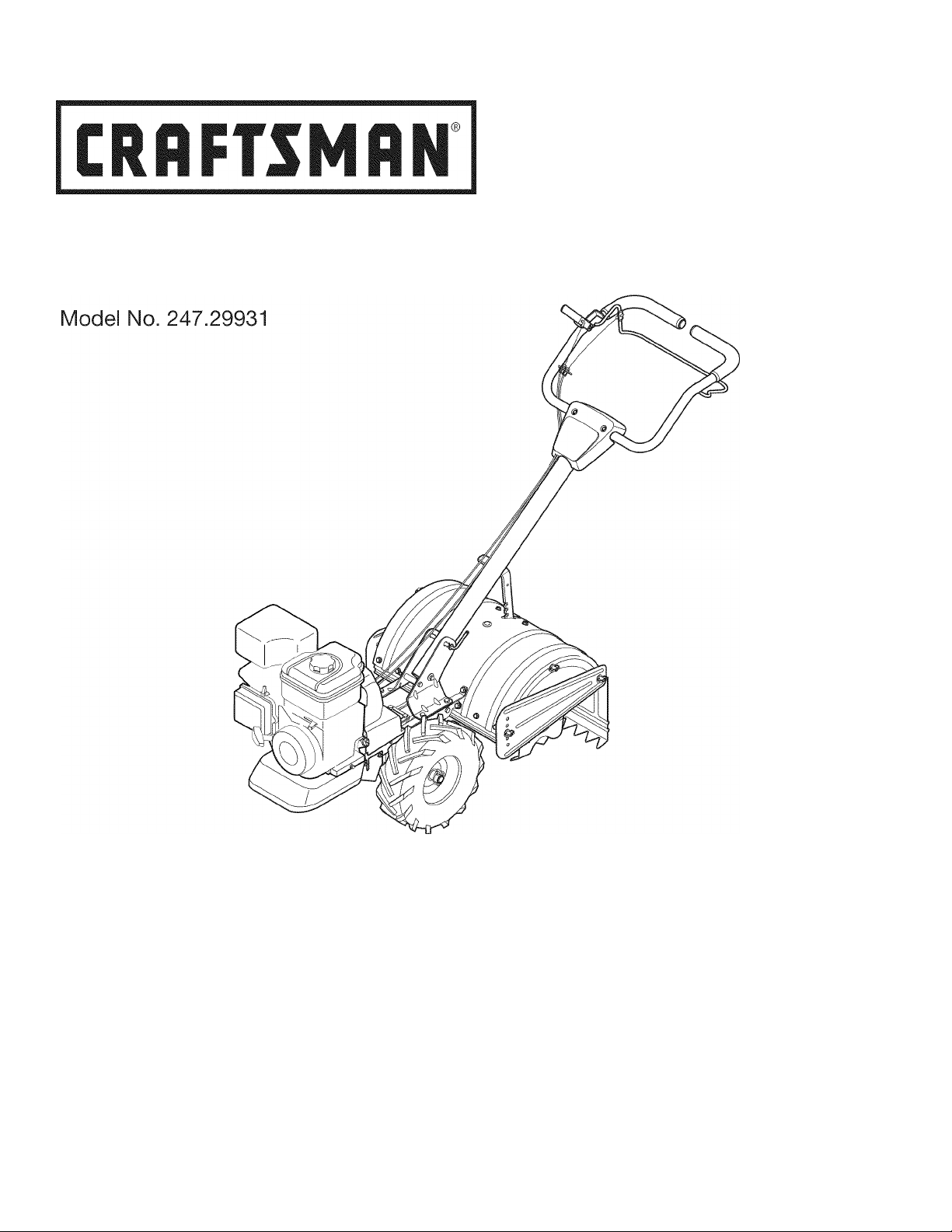

Page 1

Operator's Manual

208cc Engine

Rear Tine Tiller

• SAFETY

• ASSEMBLY

• OPERATION

CAUTION: Before using

this products read this

manual and follow ail

• MAINTENANCE

• PARTS LIST

• ESPAÑOL

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our web site: www.craftsman.com

FORM NO. 769-05526A

12/02/2009

Page 2

TABLE OF CONTENTS

Warranty Statement....................................................Page 2

Safe Operation Practices...........................................Pages 3-6

Safety Labeis................................................................Page 7

Assembiy.......................................................................Pages 8-9

Operation

Service and Maintenance

Off-Season Storage....................................................Page 24

......................................................................

..........................................

Pages 10-17

Pages 18-23

Troubie Shooting...........................................................Page 25

Parts List.......................................................................................Page 26-31

Labei Map.......................................................................Page 32

Repair Protection Agreement.....................................Page 36

Españoi...........................................................................Page 37

Service Numbers...........................................................................Back Oover

WARRANT

CRAFTSMAN FULL WARRANTY

When operated and maintained according to all supplied instructions, it this Craftsman product fails due to a defect in material or workmanship

within two years from the date or purchase, call 1-800-4-MY-HOME® to arrange for free repair (or replacement it repair proves impossible).

This warranty applies for only 90 days from the date of purchase it this product is ever used for commercial or rental purposes.

This warranty covers ONLY defects in material and workmanship. Sears will NOT pay for:

• Expendable items that become worn during normal use, including but not limited to blades, tines, or belts.

• Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or maintenance.

• Repairs necessary because of operator abuse, including but not limited to damage caused by impacting objects that bend the frame or

motor crankshaft.

• Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical damage caused by improper

storage, or failure to maintain the equipment according to the instructions contained in the operator’s manual.

• Repairs necessary due to improper fuel mixture, contaminated or stale fuel.

• Normal deterioration and wear of the exterior finishes, or product label replacement.

I

This warranty applies only while this product is within the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., FI off man Estates, IL 60179

PRODUCT SPECIFICATIONS

Engine Series: 208cc

Engine Oil Type: SAE 30

Engine Oil Capacity: 20 ounces

Fuel: Unleaded Gasoline

Spark Plug: Champion® RC-12YC

Spark Plug Gap: .030”

MODEL NUMBER

Model Number

Serial Number....................................................................

Date of Purchase...............................................................

...................................................................

Record the model number, serial number

and date of purchase above

§ Sears Brands, LLC

Page 3

SAFETY INSTRUCTIONS

J

A WARNING

This symbol points out important safety instructions which, it not

followed, could endanger the personal safety and/or property of

yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with

these instructions may result in personal injury. When you see this

symbol, HEED ITS WARNING!

AWARNING

CALIFORNIA PROPOSITION 65

Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State of California

to cause cancer and birth defects or other reproductive harm. Bat

tery posts, terminals, and related accessories contain lead and lead

compounds, chemicals known to the State of California to cause

cancer and reproductive harm. Wash hands after handling.

TRAINING

• Read, understand, and follow all instructions on the machine and

in the manual(s) before attempting to assemble and operate.

Keep this manual in a safe place for future and regular reference

and for ordering replacement parts.

• Read the Operator’s Manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders. For questions, call 1-800-4MY-HOME.

• Be familiar with all controls and their proper operation. Know how

to stop the machine and disengage them quickly.

• Never allow children under 14 years of age to operate this

machine. Children 14 and over should read and understand the

instructions and safe operation practices in this manual and on

the machine and be trained and supervised by an adult.

• Never allow adults to operate this machine without proper

instruction.

• Keep bystanders, pets, and children at least 75 feet from the

machine while it is in operation. Stop machine it anyone enters

the area.

• Never run an engine indoors or in a poorly ventilated area. Engine

exhaust contains carbon monoxide, an odorless and deadly gas.

A DANGER

This machine was built to be operated according to the safe opera

tion practices in this manual. As with any type of power equipment,

carelessness or error on the part of the operator can result in

serious injury. This machine is capable of amputating fingers, hands,

toes and feet and throwing debris. Failure to observe the following

safety instructions could result in serious injury or death.

___________

AWARNING

Your Responsibility—Restrict the use of this power machine to

persons who read, understand and follow the warnings and instruc

tions in this manual and on the machine.

SAVE THESE INSTRUCTIONS!

PREPARATION

• Thoroughly inspect the area where the equipment is to be used.

Remove all rocks, bottles, cans, or other foreign objects which

could be picked up or thrown and cause personal injury or

damage to the machine.

• Always wear safety glasses or safety goggles during operation

and while performing an adjustment or repair, to protect your

eyes. Thrown objects which ricochet can cause serious injury to

the eyes.

• Wear sturdy, rough-soled work shoes and close-fitting slacks and

shirts. Loose fitting clothes or jewelry can be caught in movable

parts. Never operate this machine in bare feet or sandals.

• Before starting, check all bolts and screws for proper tightness to

be sure the machine is in safe working condition. Also, visually

inspect machine for any damage at frequent intervals.

• Disengage clutch levers and shift (it provided) into neutral (“N”)

before starting the engine.

• Never leave this machine unattended with the engine running.

• Never attempt to make any adjustments while the engine is

running, except where specifically recommended in the operator's

manual.

• Maintain or replace safety and instructions labels, as necessary.

Page 4

SAFETY INSTRUCTION

I

Safe Handling of Gasoline;

To avoid personal injury or property damage use extreme care in

handling gasoline. Gasoline is extremely flammable and the vapors are

explosive. Serious personal injury can occur when gasoline is spilled

on yourself or your clothes which can ignite. Wash your skin and

change clothes immediately.

Use only an approved gasoline container.

Never fill containers inside a vehicle or on a truck or trailer bed

with a plastic liner. Always place containers on the ground away

from your vehicle before filling.

When practical, remove gas-powered equipment from the truck

or trailer and refuel it on the ground. If this is not possible, then

refuel such equipment on a trailer with a portable container, rather

than from a gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete. Do not use

a nozzle lock-open device.

Extinguish all cigarettes, cigars, pipes and other sources of

ignition.

Never fuel machine indoors.

Never remove gas cap or add fuel while the engine is hot or run

ning. Allow engine to cool at least two minutes before refueling.

Never over fill fuel tank. Fill tank to no more than

bottom of filler neck to allow space for fuel expansion.

Replace gasoline cap and tighten securely.

If gasoline is spilled, wipe it off the engine and equipment. Move

unit to another area. Wait 5 minutes before starting the engine.

To reduce tire hazards, keep machine free of grass, leaves, or

other debris build-up. Clean up oil or fuel spillage and remove any

fuel soaked debris.

Never store the machine or fuel container inside where there is an

open flame, spark or pilot light as on a water heater, space heater,

furnace, clothes dryer or other gas appliances.

'/2

inch below

OPERATION

Do not put hands or feet near rotating parts. Contact with the

rotating parts can amputate hands and feet.

Do not operate machine while under the influence of alcohol or

drugs.

Never operate this machine without good visibility or light. Always

be sure of your footing and keep a firm hold on the handles.

Keep bystanders away from the machine while it is in operation.

Stop the machine it anyone enters the area.

Be careful when tilling in hard ground. The tines may catch in the

ground and propel the tiller forward. If this occurs, let go of the

handle bars and do not restrain the machine.

Exercise extreme caution when operating on or crossing gravel

surfaces. Stay alert for hidden hazards or traffic. Do not carry

passengers.

Never operate the machine at high transport speeds on hard or

slippery surfaces.

Exercise caution to avoid slipping or falling.

Look down and behind and use care when in reverse or pulling

machine towards you.

Start the engine according to the instructions found in this manual

and keep feet well away from the tines at all times.

After striking a foreign object or if your machine should start mak

ing an unusual noise or vibration, immediately shut the engine off.

Disconnect the spark plug wire, ground it against the engine and

perform the following steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to assure continued

safe operation.

Disengage all clutch levers (it fitted) and stop engine before you

leave the operating position (behind the handles). Wait until

the tines come to a complete stop before unclogging the tines,

making any adjustments, or inspections.

Never run an engine indoors or in a poorly ventilated area. Engine

exhaust contains carbon monoxide, an odorless and deadly gas.

Muffler and engine become hot and can cause a burn. Do not

touch.

Use caution when tilling near fences, buildings and underground

utilities. Rotating tines can cause property damage or personal

injury.

Do not overload machine capacity by attempting to till soil too

deep at too fast of a rate.

If the machine should start making an unusual noise or vibration,

stop the engine, disconnect the spark plug wire and ground it

against the engine. Inspect thoroughly for damage. Repair any

damage before starting and operating.

Keep all shields, guards, and safety devices in place and operat

ing properly.

Never pick up or carry machine while the engine is running.

Use only attachments and accessories approved by the manu

facturer as listed in the Parts List pages of this operator’s manual.

Failure to do so can result in personal injury.

If situations occur which are not covered in this manual, use care

and good judgement. Contact Customer Support at 1-800-4MY-

HOME for assistance and the name of the nearest service dealer

MAINTENANCE & STORAGE

Keep the machine, attachments and accessories in safe working

order.

Allow the machine to cool at least five minutes before storing.

Never tamper with safety devices. Check their proper operation

regularly.

Check bolts and screws tor proper tightness at frequent intervals

to keep the machine in safe working condition. Also, visually

inspect machine for any damage.

Before cleaning, repairing, or inspecting, stop the engine and

make certain the tines and all moving parts have stopped.

Disconnect the spark plug wire and ground it against the engine to

prevent unintended starting.

Page 5

SAFETY INSTRUCTIONS

J

• Do not change the engine governor settings or over-speed the

engine. The governor controls the maximum safe operating speed

of engine.

• Maintain or replace safety and instruction labels, as necessary.

• Follow this manual for safe loading, unloading, transporting, and

storage of this machine.

• Always refer to the operator’s manual for important details it the

machine is to be stored for an extended period.

• If the fuel tank has to be drained, do this outdoors.

• Observe proper disposal laws and regulations for gas, oil, etc. to

protect the environment.

• According to the Consumer Products Safety Commission (CPSC)

and the U.S. Environmental Protection Agency (EPA), this product

has an Average Useful Life of seven (7) years, or 130 hours of

operation. At the end of the Average Useful Life have the machine

inspected annually by an authorized service dealer to ensure that

all mechanical and safety systems are working properly and not

worn excessively. Failure to do so can result in accidents, injuries

or death.

DO NOT MODIFY ENGINE

To avoid serious injury or death, do not modify engine in any way.

Tampering with the governor setting can lead to a runaway engine and

cause it to operate at unsafe speeds. Never tamper with factory setting

of engine governor.

NOTICE REGARDING EMISSIONS

Engines which are certified to comply with California and federal

EPA emission regulations for SCRE (Small Cff Road Equipment) are

certified to operate on regular unleaded gasoline, and may include

the following emission control systems: Engine Modification (EM),

Cxidizing Catalyst (CC), Secondary Air Injection (SAI) and Three Way

Catalyst (TWC) it so equipped.

SPARK ARRESTOR

Awarning

This machine is equipped with an internal combustion engine and

should not be used on or near any unimproved forest-covered,

brushcovered or grass-covered land unless the engine's exhaust

system is equipped with a spark arrester meeting applicable local or

state laws (it any)

If a spark arrester Is used, it should be maintained in effective working

order by the operator. In the State of California the above is required

by law (Section 4442 of the California Public Resources Code). Cther

states may have similar laws. Federal laws apply on federal lands.

A spark arrester for the muffler is available through your nearest Sears

Parts and Repair Service Center.

Page 6

SAFETY INSTRUCTION

I

SAFETY SYMBOLS

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine

before attempting to assemble and operate.

Symbol Description

-

Y i

Ml

O

READ THE OPERATOR’S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING— ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING— ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING—GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING— CARBON MONOXIDE

Never run an engine indoors orin a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING— HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

A

WARNING: Your Responsibility—Restrict the use of this power machine to persons who read, understand and follow the

warnings and instructions in this manual and on the machine.

SAVE THESE INSTRUaiONS!

A

Page 7

SAFETY LABELS

TO AVOID SERIOUS INJURY

Read the operator's manual.

Know location and functions of all controls.

Keep all safety devices and shields in place and working.

Never allow children or uninstructed adults to

operate tiller.

Shut off engine before unclogging tines or

making repairs.

KEEP AWAY FROM

ROTATING TINES.

ROTATING TINES

WILL CAUSE INJURY, the machine towards you.

Operation Of This Equipment May Create Sparks That Can Start Fires Around Dry Vegetation. A Spark

Arrestor May Be Required.The Operator Should Contact Local Fire Agencies For Laws Or Regulations

To Fire Prevention Requirements.

Keep bystanders away from machine.

Keep away from rotating parts.

Use extreme caution when reversing or pulling

I

Page 8

ASSEMBLY

IMPORTANT: This unit is shipped without gasoline or oil in the engine.

Be certain to service engine with gasoline and oil as instructed in the

Operation section of this manual before operating your machine.

NOTE: Reference to right and left hand side of the Tiller is observed

from the operating position.

OPENING CARTON

1. Remove all staples from around the bottom of the perimeter.

2. Remove the carton from the skid.

3. Remove all loose parts.

4. Remove loose packing material.

REMOVING UNIT FROM SKID

1. The tiller is heavy, do not attempt to remove it from the skid until

instructed to do so in these assembly steps.

2. Check carton thoroughly for any other loose parts.

LOOSE PARTS IN CARTON

• Handlebar Assembly

• Tiller

• Engine Oil

• Operator’s Manual

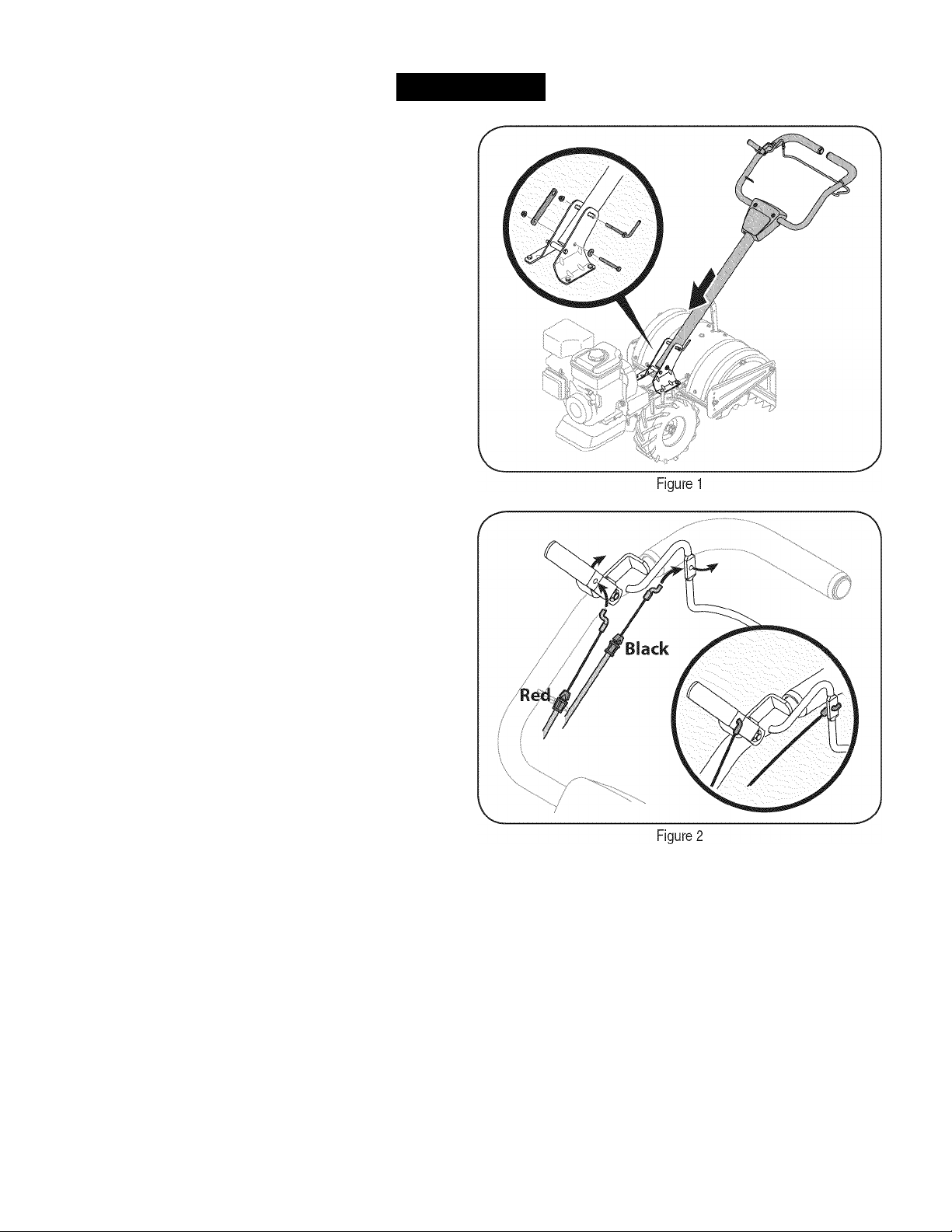

ATTACHING THE HANDLE ASSEMBLY

1. Install the handle onto the tiller using the hardware preinstalled

on the handle mounting brackets. This consists of a 5/16-18 x

3.00” hex bolt, a handle crank assembly, retainer bracket and two

5/16-18 flange lock nuts. Remove this hardware from the handle

mounting brackets on the tiller. Refer to Figure 1 inset.

2. Insert the handle into the handle mounting brackets, lining up the

pre-drilled holes. Insert the 5/16-18 x 3.00” hex bolt in the bottom

hole from the left hand side through to the other side. Place the

round hole end of the hex retainer bracket over the hex bolt and

secure loosely with a bell washer and 5/16-18 flange lock nut

removed earlier. Refer to Figure 1 inset.

NOTE: The bell washer should be positioned with the top of the bell

shape towards the hex nut which will create tension and further secure

the flange lock nut once tightened. Do not tighten this hardware at this

time.

3. Install the handle-crank adjustment rod into the top hole of the

mounting bracket from the left hand side of the handle assembly,

secure with the other flange lock nut previously removed. Fit

the hex end of the retainer bracket over the flange lock nut. See

Figure 1.

4. Tighten the hex bolt installed in Step 2 at this time. Be careful not

to overtighten this hardware.

5. With the handle in the desired position, tighten the handlecrank

adjustment rod at this time.

ATTACHING THE CABLES

1. Route the two cables along the handle assembly on the righthand

side.

2. Connect the reverse cable (Red) to the reverse cable control by

feeding the z-hook through the hole on the reverse cable control

from the inside towards the outside. See Figure 2.

3. Connect the forward drive cable (Black) to the clutch bail by

feeding the z-hook through the hole on the clutch bail from the

outside towards the inside. See Figure 2.

NOTE: Test the function of the reverse clutch by pulling the reverse

handle and releasing it. The handle should return to its neutral

position. If it doesn’t, contact Customer Support for assistance or the

nearest dealer.

To test the function of the forward drive bail, lift the bail to the handle

and release it. The bail should return to its neutral position. If it doesn’t,

contact Customer Support for assistance or the nearest dealer.

Page 9

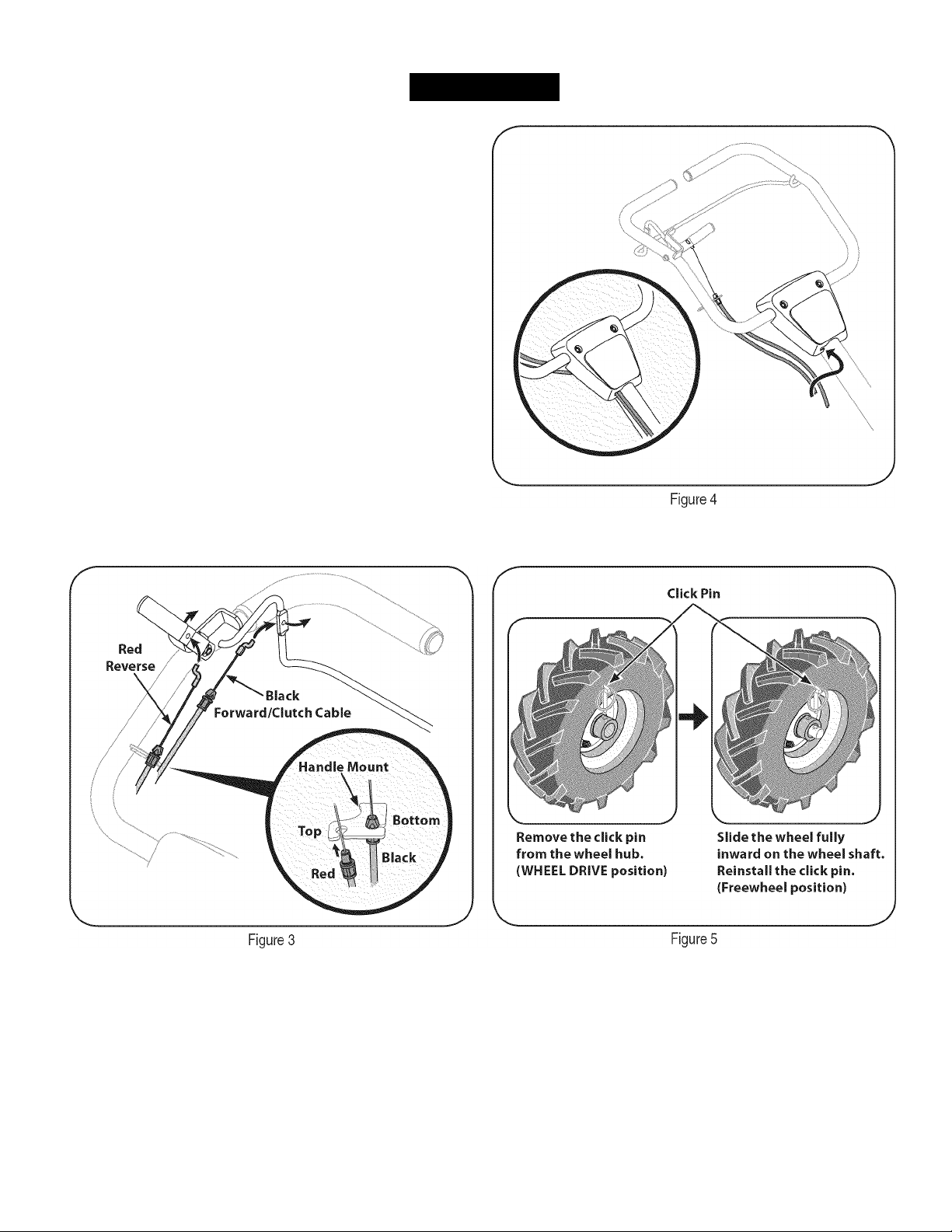

ASSEMBLY

4. Snap the cable housing clips into the handle assembly cable

mount. The red clip (reverse cable) fits into the top position on the

handle assembly, while the black clip (forward/clutch cable) feeds

into the lower position on the handle assembly. See Figure 3.

5. Clip the cables into the cable guides located on the handle

assembly panel as seen in Figure 4.

MOVING THE TILLER OFF THE SKID

To roll the tiller off the shipping platform, put the wheels in freewheel, if

they are not already from the factory, as follows:

1. Place a sturdy block under the transmission to raise one wheel

about 1” off the ground. Remove the click pin from the wheel hub

and wheel shaft. See Figure 5.

Slide the wheel fully inward on the wheel shaft. Reinstall the click

2.

pin through the wheel shaft only (not through the wheel hub). See

Figure 5. The wheel should now spin freely (freewheel) on the

wheel shaft. Repeat with the other wheel.

Use the handlebar to lift and pull the tiller backwards to a flat

3.

area.

NOTE: Before starting the engine, the wheels must be placed in the

WHEEL DRIVE position (pins through wheel hubs and wheel shaft).

This procedure is described in the operation section under wheel drive

pins.

Page 10

OPERATION

Now that you have set up your tiller tor operation, get aquainted with its

controls and features. These are described on the next two pages and

illustrated on this page. This knowledge will allow you to use your new

equipment to its fullest potential.

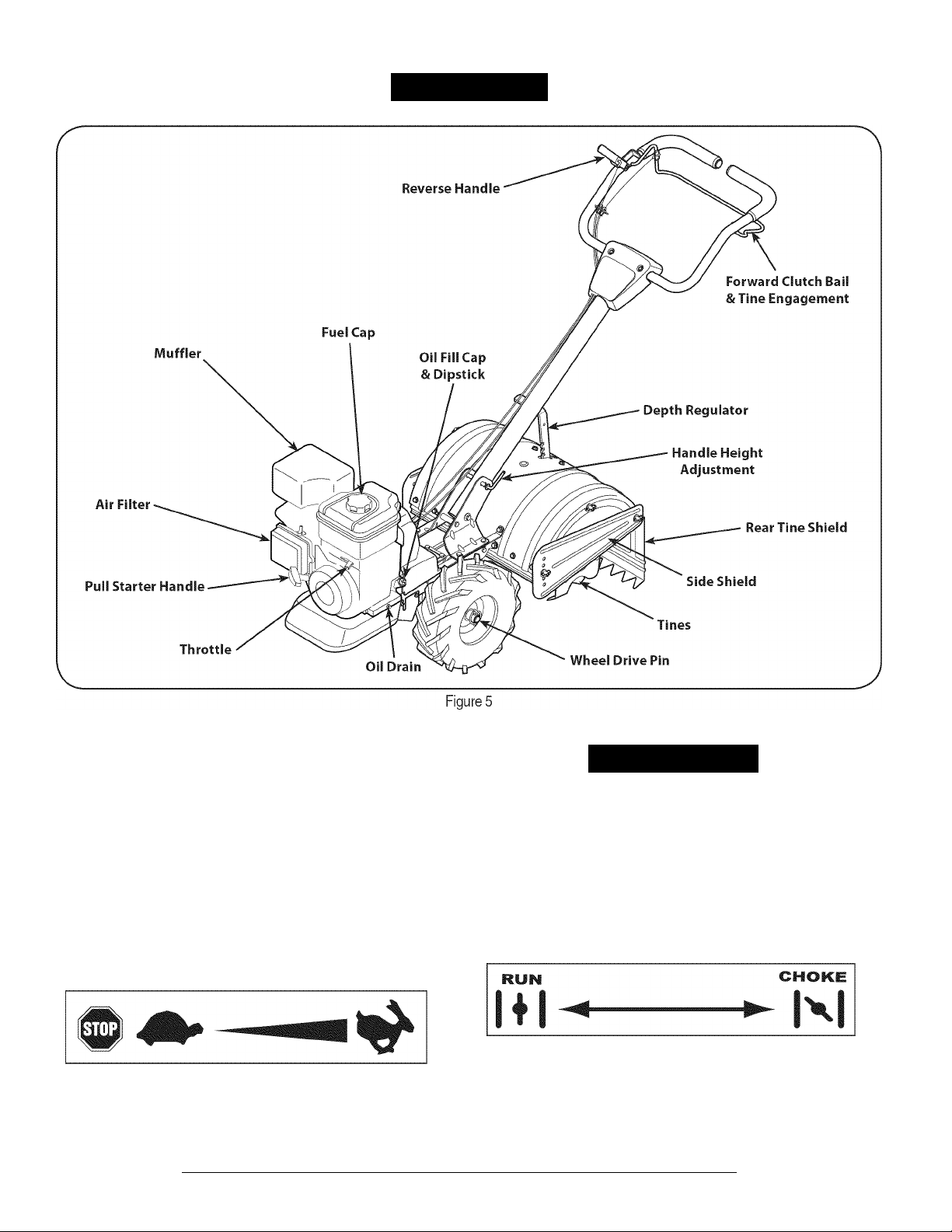

RECOIL STARTER HANDLE

This handle is used to start the engine. See Figure 5.

THROTTLE CONTROL

The throttle control is located on the front of the engine. It regulates the

spread of the engine and will shut off the engine when moved into the

STOP position. See Figure 5.

Meets ANSI Safety Standards

Craftsman Tillers conform to the safety standard of the American National Standards Institute (ANSI).

ik WARNING

The operation of any tiller can result in foreign objects being thrown

into the eyes, which can damage your eyes severely. Always wear the

safety glasses provided with this unit or eye shields before tilling and

while performing any adjustments or repairs.

CHOKE CONTROL

The choke control is activated by moving the lever to the CFIOKE

position. Activating the choke control closes the choke plate on the

carburetor and aids in starting the engine.

10

Page 11

OPERATION

J

AIR FILTER

The air filter is a device on the engine air intake that prevents dust and

dirt entering the engine. See Figure 5.

MUFFLER

Engine exhaust exits the engine via the muffler. See Figure 5.

OIL FILL CAP & DIPSTICK

Engine oil level can be checked and oil added through the oil fill. See

Figure 5.

NOTE: This unit was shipped WITHOUT oil In the engine. Oil Is

Included In the plastic bag packed with the manual In with the unit.

Add the oil as directed in the Gas & Oil Fill Up section. Check the oil

level before each operation to ensure adequate oil is in the engine.

For further instructions, refer to the steps in the Engine Maintenance

section of this manual.

REVERSE HANDLE

The Reverse Handle controls the reverse drive of the wheels and the

tines. See Figure 5.

FORWARD CLUTCH BAIL & TINE ENGAGE

MENT

The forward clutch ball controls the engagement of the forward drive of

the wheels and tines. See Figure 5.

REAR TINE SHIELD

The rear tine shield protects the operator from flying debris while also

smoothing out freshly tilled soil. See Figure 5.

SIDE SHIELD

The side shield is used to maintain clear even rows and may be

adjusted to one of five different positions. See Figure 5.

TINES

Your tiller’s tines are a series of hoes arranged on a revolving powerdriven shaft. See Figure 5.

WHEEL DRIVE PINS

Each wheel is equipped with a wheel drive click pin that secures the

wheel to the wheel shaft. The wheels can be positioned In either a

WHEEL DRIVE ora FREEWHEEL mode. See Figure 5.

OIL DRAIN

Removing the oil drain plug will drain the oil from the engine. See

Figure 5.

DEPTH REGULATOR LEVER

This lever controls the tilling depth of the tines. Pull the lever back and

slide It up or down to engage the notched height. See Figure 5.

HANDLEBAR HEIGHT ADJUSTMENT

The handlebar height is adjustable to three different settings. In

general, adjust the handlebars so they are at waist level when the tines

are 3-4” in the ground. See Figure 5.

11

Page 12

OPERATION

GAS AND OIL FILL-UP

Oil (one bottle shipped with unit)

First Time Use

1. Remove oil fill dipstick.

2. With the tiller on level ground, use a funnel to empty entire

contents of oil bottle provided into the engine.

3. Replace oil fill dipstick and tighten.

Subsequent Uses

Only use high quality detergent oil rated with API service classification

SF, SG, SH, SJ or higher. Select the oil's SAE viscosity grade accord

ing to the expected operating temperature. Follow the chart below.

A

i

Although multi-viscosity oils (5W30,10W30, etc.) improve starting

in cold weather, they will result in increased oil consumption when

used above 32°F. Check your engine oil level more frequently to avoid

possible engine damage from running low on oil.

1. Check the oil level making certain not to rub the dipstick along

the inside walls of the oil fill tube. This would result in a false

dipstick reading. Wipe dipstick clean with cloth. Replace dipstick

into the oil filler neck, but do not screw it in. Remove and check

oil level. Refill to FULL mark on dipstick, it necessary. Capacity is

approximately 20 oz. Cverfilling will cause the engine to smoke

profusely and will result in poor engine performance.

2. Replace oil fill dipstick and tighten.

3. Keep oil level at FULL. Running the engine with too little oil can

result in permanent engine damage.

A

0

o

CO

o

CO

1

o

0)

sz

(fi

Transmission/Gear Oil

First Time Use

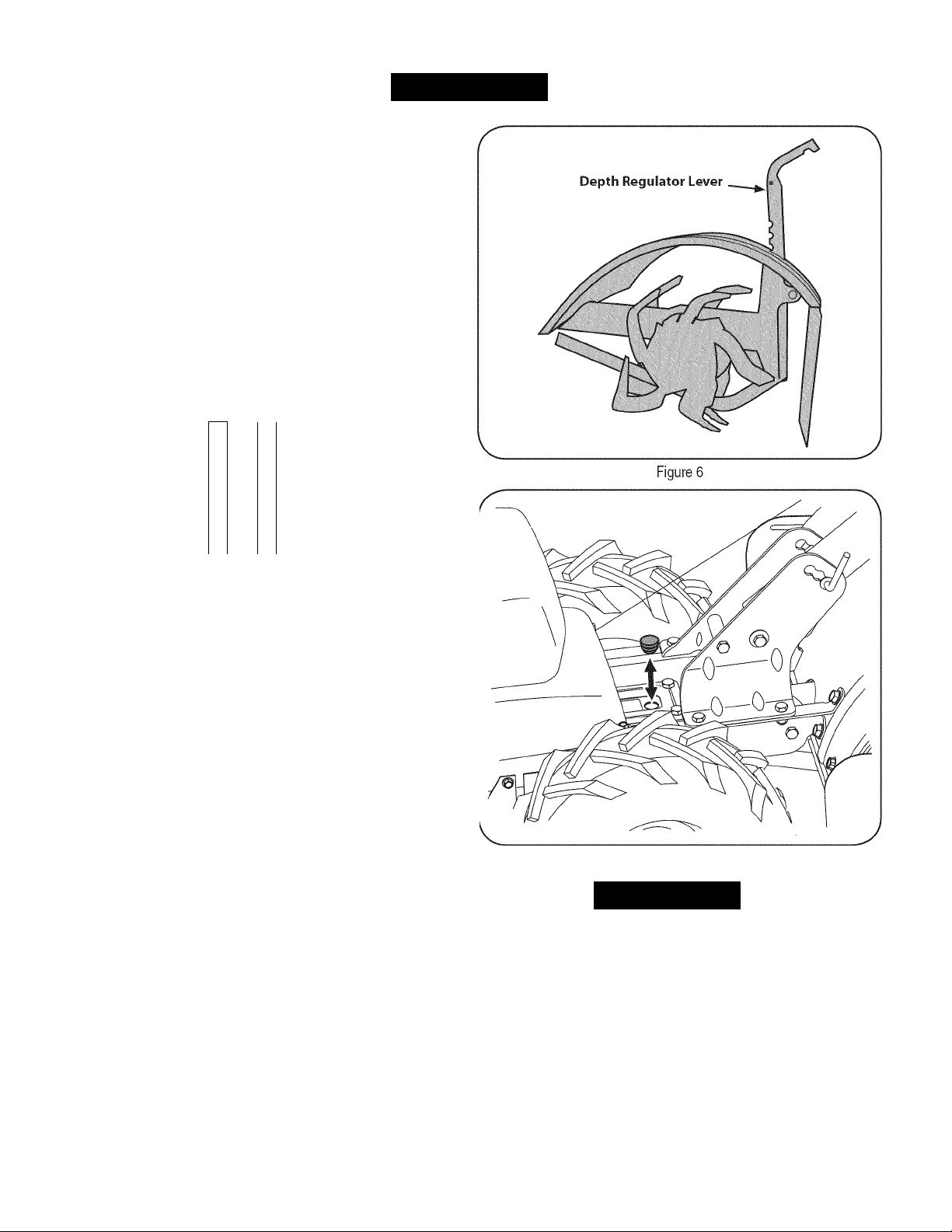

1. With the tiller on level ground, pull the Depth Regulator Lever

back and then all the way up until the lowest notch in the lever is

engaged. See Figure 6.

2. Remove the oil fill plug from the transmission housing cover and

locate the main drive shaft situated inside the housing.

See Figure 7.

3. The gear oil level is correct it the gear oil is approximately halfway

up the side of the main drive shaft.

4. If the oil level is low, refer to the transmission gear oil under the

Maintenance Section.

Figure 7

Awarning

Use extreme care when handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Never fuel machine indoors

or while the engine is hot or running. Extinguish cigarettes, cigars,

pipes, and other sources of ignition.

Gasoline

1. Remove fuel cap from the fuel tank.

2. Make sure the container from which you will pour the gasoline is

clean and free from rust or foreign particles. Never use gasoline

that may be stale from long periods of storage in its container.

Gasoline that has been sitting tor any period longer than four

weeks should be considered stale.

3. Fill fuel tank with clean, fresh, unleaded regular gasoline only. Do

not use gasoline containing METHANOL. Replace fuel cap.

12

Page 13

OPERATIO

J

A CAUTION

Alcohol blended fuels (called gasohol or

can attract moisture which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel system of an engine

while

in

storage.

____________________________________________

using

ethanol or methanol)

A CAUTION

To avoid engine problems, the fuel system should be emptied before

storage for 30 days or longer. Drain the gas tank, start the engine

and let it run until the fuel lines and carburetor are empty. Use fresh

fuel next season. See STORAGE Instructions for additional informa

tion.

A CAUTION

Never use engine or carburetor cleaner products in the fuel tank or

permanent damage may occur.

NOTE: Check the fuel level periodically to avoid running out of

gasoline while operating the tiller.

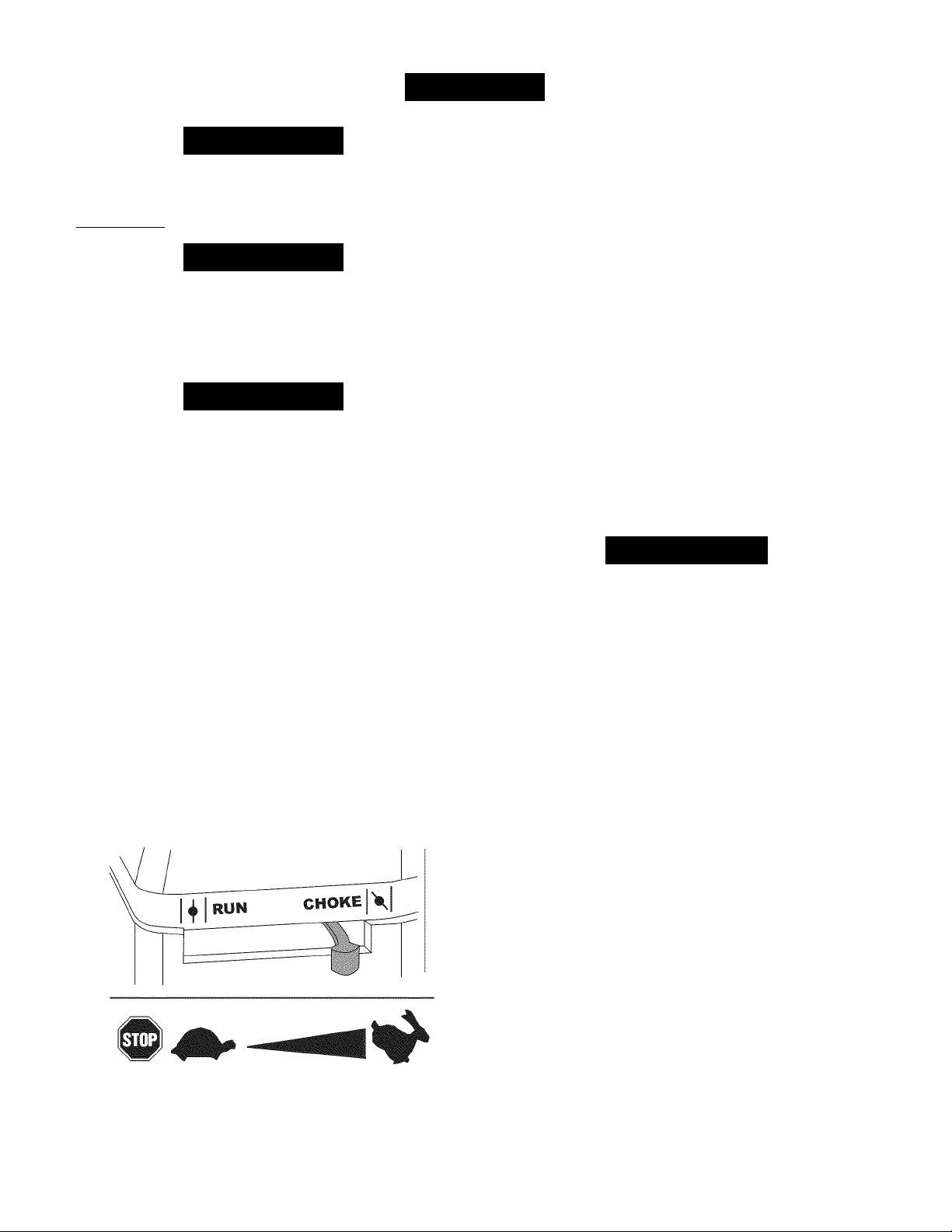

TO START ENGINE

1. Attach spark plug wire and rubber boot to spark plug.

2. Fill tank to no more than 1/2 inch below bottom of filler neck to

provide space for fuel expansion.

3. Put the wheels in the WHEEL DRIVE position.

4. Move the Depth Regulator Lever all the way down to the “trans

port” position, so that the tines clear the ground.

5. Release all of the controls on the tiller.

6.

Turn

the fuel shut-off valve to the ON position.

7. Move the choke lever on the engine to CHOKE N position. (A

warm engine may not require choking.) See Figure 8.

8. Move throttle control to START/RUN (Rabbit) JL m position. See

Figure 8.

9. Standing on the side of the unit, grasp starter handle and pull

rope out until you feel a drag.

10. Pull the rope with a rapid, continuous, full arm stroke. Keep a firm

grip on the starter handle. Let the rope rewind slowly.

11. Repeat, if necessary, until engine starts. When engine starts,

move choke control gradually toward the RUN 111 position..

12. If engine falters, move choke control back toward the CHOKE

N position and repeat steps 5 though 8.

13. ALWAYS keep the throttle control in the START/RUN (Rabbit

position when operating the tiller.

TO STOP ENGINE

1. To stop the wheels and tines, release the Forward Clutch Bail.

2. Move throttle control lever to slow (turtle) position.

Whenever possible, gradually reduce engine speed before

stopping engine.

3. Move throttle control lever to STOP or OFF position.

4.

Turn

the fuel shut-off valve to the OFF position.

5. Disconnect spark plug wire and ground it against the engine to

prevent accidental starting while the equipment is unattended.

AWARNING

Do not push down on the handlebars, especially in unfilled soil. This

could allow the tines to rapidly propel the tiller rearward, which can

result in loss of control, property damage, or personal injury.

TO ENGAGE DRIVE & TINES

1. For forward motion of the wheels and power to the tines pull the

Forward Clutch Bail up against the handlebar.

NOTE: In forward mode, the tines will rotate in reverse.

2. Walk slowly behind the tiller allowing It to move at its own pace

while keeping a secure grip on the handlebar with your elbows

flexed.

3. Release the bail to stop the rotation of the wheels and tines.

To move tiller in reverse: (Do not till in reverse)

a. Release the Forward Clutch Bail.

b. Lift the handlebar until the tines are off the ground.

c. Slowly pull back on the Reverse Lever, and carefully walk

backwards with the machine.

NOTE: In reverse mode, the tines will rotate forward.

d. If longer distances need to be covered in reverse, shut off the

Figure 8

13

Page 14

OPERATION

engine, then place the two wheels in FREEWHEEL.

TURNING THE TILLER

1. Practice turning the tiller in a level, open area. Be very careful to

keep your feet and legs away from the tines.

2. To begin a turn, lift the handlebars until the tines are out of the

ground and the engine and tines are balanced over the wheels.

3. With the tiller balanced, push sideways on the handlebar to steer

in the direction of the turn. After turning, slowly lower the tines into

Awarning

Be certain spark plug wire is disconnected and grounded against the

engine when performing any adjustments.

the soil to resume tilling.

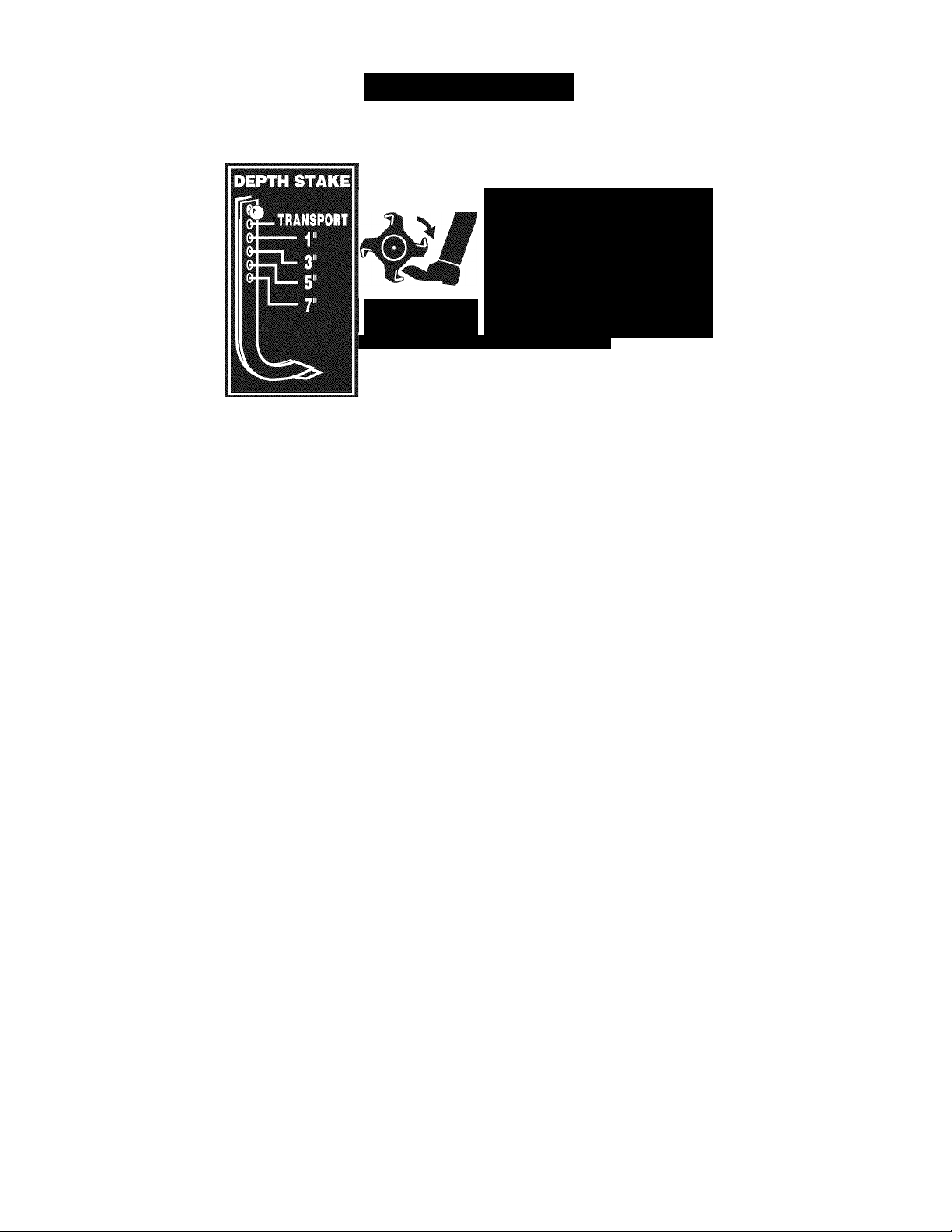

SETTING THE DEPTH

Tilling depth is controlled by the depth stake which can be adjusted to

five different settings. Adjust the side shields as you adjust the depth

stake.

• When using the tiller for the first time, use the second adjustment

hole from the top (1” of tilling depth).

• When breaking up sod and tor shallow cultivation, use the setting

which gives 1” of tilling depth (second hole from the top). Place

the side shields in their lowest position.

• For further depth, raise the depth stake and side shields and also

make one or two more passes over the area.

• When tilling loose soil, the depth stake may be raised to its

highest position (use bottom adjustment hole) to give the deepest

tilling depth. Raise the side shields to their highest position.

• To transport tiller, lower the depth stake (use top adjustment

hole).

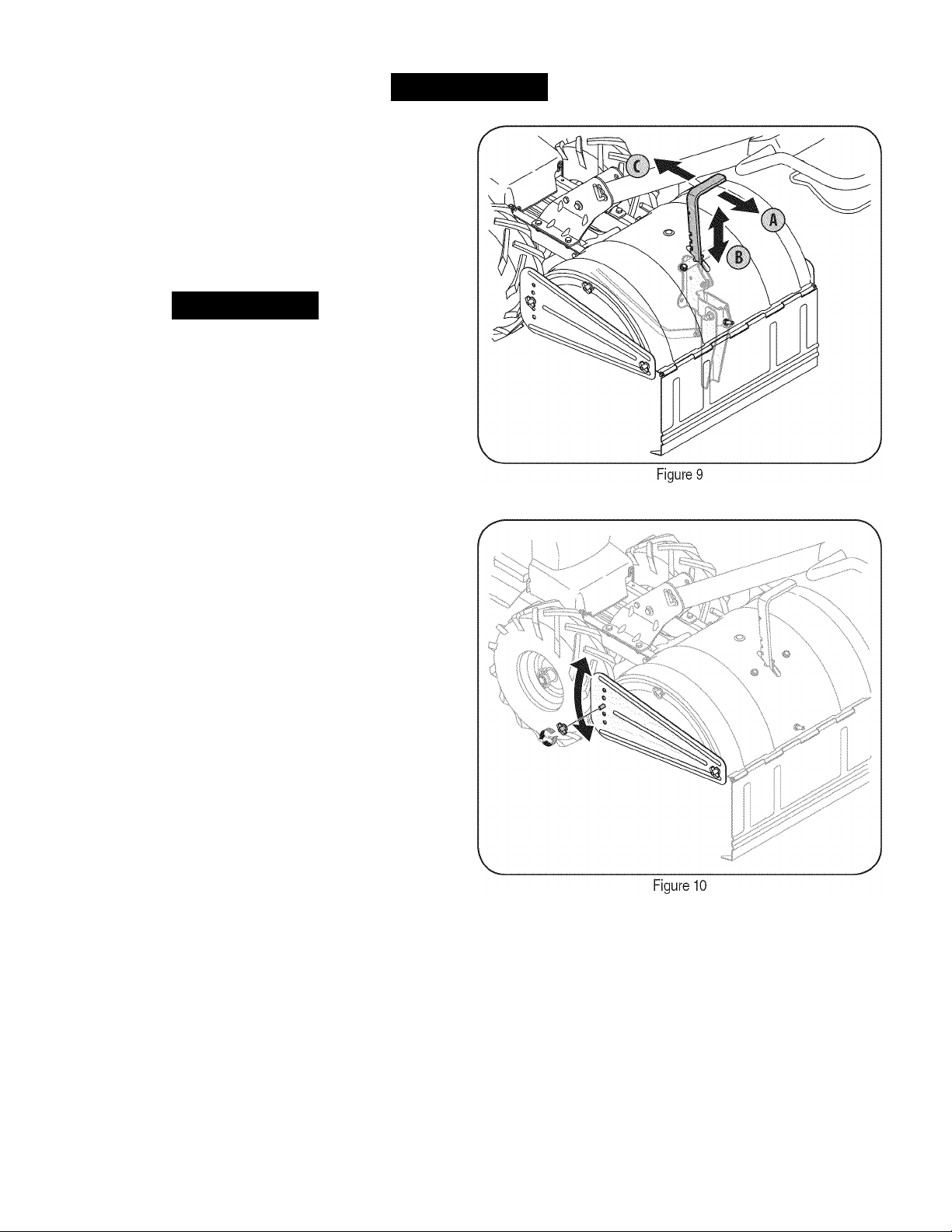

To adjust the depth stake, pull back on the depth adjustment bracket

(A) and push up or down (B) until the bracket reaches the desired

position, then release the bracket (C). See Figure 9.

To adjust the side shields, remove the wing nuts. Move the side shield

14

Page 15

OPERATION

to the desired position and replace the wing nuts. Tighten securely.

See Figure 10.

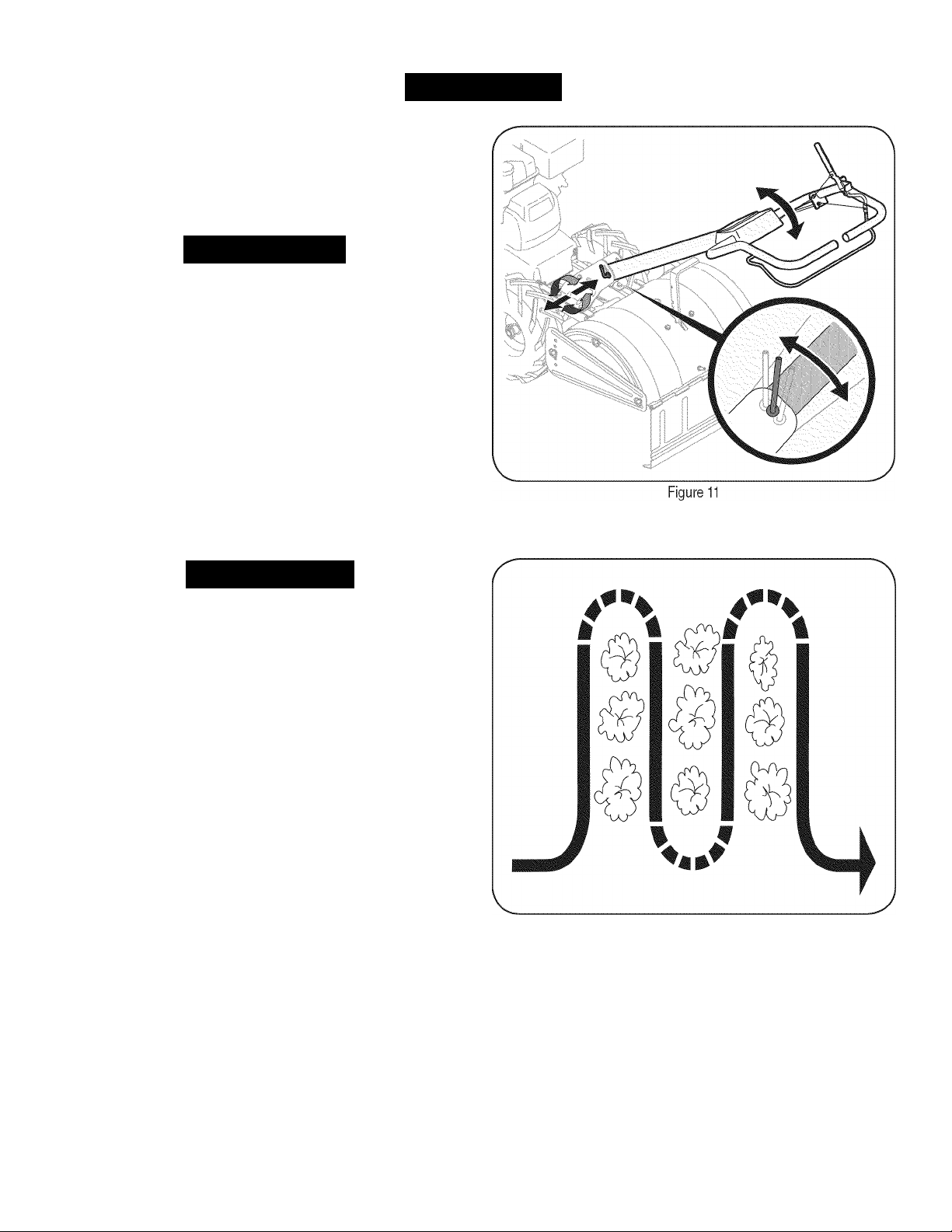

ADJUSTING THE HANDLE HEIGHT

The handle should be adjusted so that when the tiller is digging 3-4”

into the soil, the handle falls to about waste-high. To adjust handle,

AWARNING

Before clearing the tines by hand, stop the engine, allow all moving

parts to stop and disconnect the spark plug wire. Failure to follow this

warning could result in personal injury.

simply loosen the handle adjustment crank, move the handle to the

desired height and retighten the adjustment crank. See Figure 11.

CLEARING THE TINES

• The tines have a self-clearing action which eliminates most of the

tangling of debris. Flowever, occasionally dry grass, stringy stalks

or tough vines may become tangled. Follow these procedures to

help avoid tangling and to clear the tines, it necessary.

• To reduce tangling, set the depth regulator deep enough to get

maximum “chopping” action as the tines chop the material against

the ground. Also, try to till under crop residues or cover crops

while they are green, moist and tender.

AWARNING

Before tilling, contact your telephone or utilities company and inquire

it underground equipment or lines are used on your property. Do not

till near buried electric cables, telephone lines, pipes or hoses.

• While tilling, try swaying the handlebars from side to side (about

6” to 12”). This “fishtailing” action often clears the tines of debris.

TILLING TIPS & TECHNIQUES

Tilling Depth

• This is a CRT (counter-rotating tine) tiller. As the wheels pull

forward, the tines rotate backward. This creates an “uppercut”

tine action which digs deeply, uprooting soil and weeds. Don’t

overload the engine, but dig as deeply as possible on each pass

On later passes, the wheels may tend to spin in the soft dirt. Help

them along by lifting up slightly on the handlebar (one hand, palm

up, works most easily).

• Avoid the temptation to push down on the handlebars in an

attempt to force the tiller to dig deeper. Doing so takes the weight

off the powered wheels, causing them to lose traction. Without the

wheels to hold the tiller back, the tines will attempt to propel the

tiller backward, towards the operator.

• When cultivating (breaking up the surface soil around the plants

to destroy weeds. See Figure 12), adjust the tines to dig only 1”

to 2” deep. Using the shallow tilling depth helps prevent injury to

the plants whose roots often grow close to the surface. If needed,

lift up on the handlebars slightly to prevent the tines from digging

too deeply. (Cultivating on a regular basis not only eliminates

weeds, it also loosens and aerates the soil for better moisture

absorption and faster plant growth.) Watering the garden area a

few days prior to tilling will make tilling easier, as will letting the

Figure 12

15

Page 16

OPERATION

newly worked soil set for a day or two before making a final, deep

tilling pass.

Choosing the Correct Wheel & Tine Speeds

With experience, you will find the tilling depth and tilling speed

combination that is best for your garden. Set the engine throttle lever at

a speed to give the engine adequate power and yet allow it to operate

at the slowest possible speed until you have achieved the maximum

tilling depth you desire. Faster engine speeds may be desirable

when making final passes through the seedbed or when cultivating.

Selection of the correct engine speed, in relation to the tilling depth,

will ensure a sufficient power level to do the job without causing the

engine to labor.

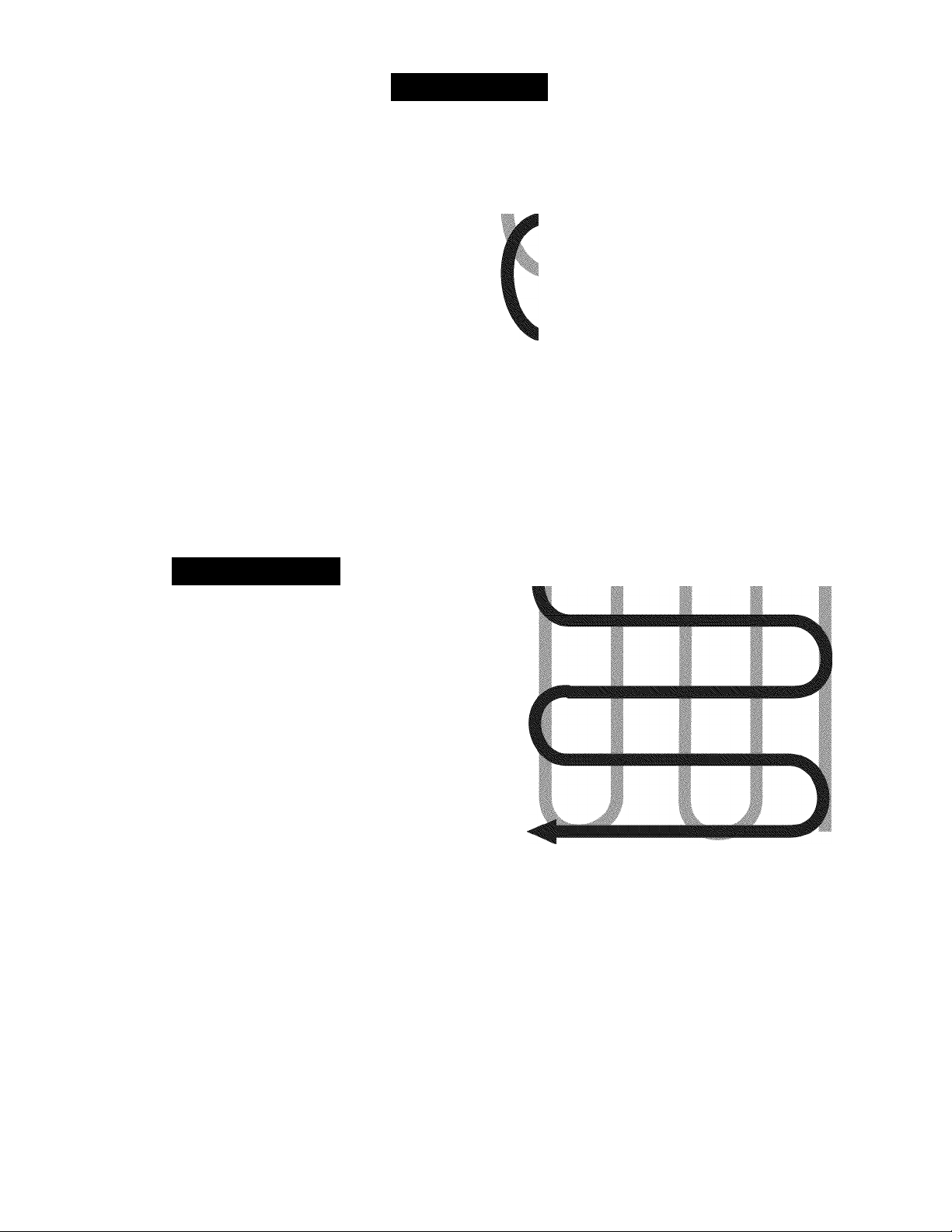

Suggested Tilling Patterns

• When preparing a seedbed, go over the same path twice in the

first row, then overlap one-half the tiller width on the rest of the

passes. See Figure 13.

• When finished in one direction, make a second pass at a right

angle. See Figure 14. Overlap each pass for the best results (in

very hard ground, it may take three or four passes to thoroughly

pulverize the soil.)

• If the garden size will not permit lengthwise and then crosswise

Figure 13

A

AWARNING

Do not operate the tiller on a slope too steep for safe operation. Till

slowly and be sure you have good footing. Never permit the tiller to

freewheel down slopes. Failure to follow this warning could result in

personal injury.

tilling, then overlap the first passes by one-half a tiller width, fol

lowed by successive passes at one-quarter width. See Figure 15.

Tilling on a Slope

1. Till only on moderate slopes, never on steep ground where the

footing is difficult.

2. Tilling up and down slopes is recommended over terracing. Tilling

vertically on a slope allows maximum planting area and also

leaves room for cultivating.

NOTE: When tilling on slopes, be sure the correct oil level is main

tained in the engine (check every one-half hour of operation). The

incline of the slope will cause the oil to slant away from its normal

level and this can starve engine parts of required lubrication. Keep the

motor oil level at the full point at all times.

Tilling Up and Down a Slope

1. To keep soil erosion to a minimum, be sure to add enough organic

matter to the soil so that it has good moistureholding texture and

try to avoid leaving footprints or wheel marks.

2. When tilling vertically, try to make the first pass uphill as the tiller

digs more deeply going uphill than it does downhill. In soft soil or

weeds, you may have to lift the handlebars slightly while going up-

Figure 14

A

OB

m

16

B

Figure 15

Page 17

OPERATION

hill. When going downhill, overlap the first pass by about one-half

the width of the tiller.

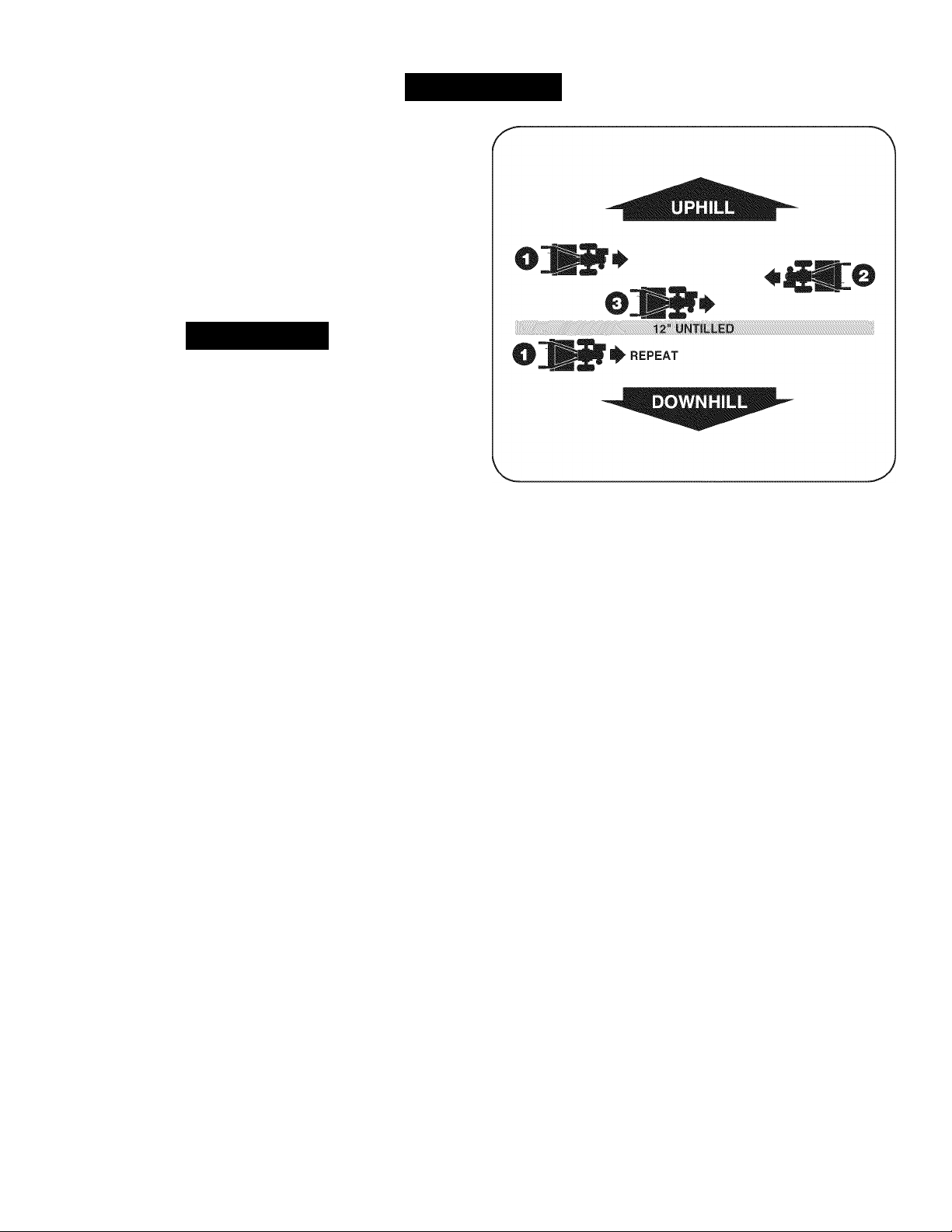

Terrace Gardening

1. To create a terrace, start at the top of the slope and work down

Go back and forth across the first row. See Figure 16.

2. Each succeeding lower terrace is started by walking below the

terrace you are preparing. For added stability of the tiller, always

keep the uphill wheel in the soft, newly tilled soil. Do not till the

last 12” or more of the downhill outside edge of each terrace. This

untilled strip helps prevent the terraces from breaking apart and

Awarning

Loading and unloading the tiller into a vehicle is potentially hazard

ous and doing so is not recommended unless absolutely necessary,

as this could result in personal injury or property damage.

washing downhill. It also provides a walking path between the

rows.

Loading & Unloading the Tiller

If you must load or unload the tiller, follow the guidelines given below:

• Before loading or unloading the tiller, stop the engine, wait for all

parts to stop moving, disconnect the spark plug wire and let the

engine and muffler cool.

• Put the wheels in freewheel by putting the click pins through the

wheel shaft only (not through the wheel hub).

• The tiller is too heavy and bulky to be safely lifted by one person.

Two or more people should share the load.

• Use sturdy ramps and manually — with the engine shut off — roll

the tiller into and out of the vehicle. Two or more people are

needed to do this.

• The ramps must be strong enough to support the combined

weight of the tiller and any handlers. The ramps should provide

good traction to prevent slipping; they should also have side rails

to guide the tiller along the ramps; and they should have a locking

device to secure them to the vehicle.

• The handlers should wear sturdy footwear that will help to prevent

slipping.

• Position the loading vehicle so that the ramp angle is as flat

as possible (the less incline to the ramp, the better).

vehicle's engine off and apply the parking brake.

• When going up the ramps, stand in the normal operating position

and push the tiller ahead of you. Have a person at each side to

turn the wheels.

• When going down the ramps, walk backward with the tiller

following you. Keep alert tor any obstacles behind you. Position a

person at each wheel to control the speed of the tiller. Never go

down the ramps tiller-first, as the tiller could tip forward.

• Place wooden blocks on the downhill side of the wheels it you

need to stop the tiller from rolling down the ramp. Also, use the

blocks to temporarily keep the tiller in place on the ramps (if

necessary), and to chock the wheels in place after the tiller is in

the vehicle.

• After loading the tiller, prevent it from rolling by engaging the

wheels in the WHEEL DRIVE position. Chock the wheels with

Turn

the

Figure 16

17

Page 18

SERVICE AND MAINTENANCE

MAINTENANCE SCHEDULE

Awarning

Before performing any type of maintenance/service, disengage all

controls and stop the engine. Wait until all moving parts have come to

a complete stop. Disconnect spark plug wire and ground it against the

engine to prevent unintended starting. Always wear safety glasses during

operation or while performing any adjustments or repairs.

Interval

Each Use 1. Engine oil level 1. Check

2. Loose or missing hardware 2. Tighten or replace

3. Engine and around muffler 3. Clean

4. Air cleaner 4. Check

1st 2 hours 1. Drive belt tension 1. Check

2. Nuts and Bolts 2. Check

1st 5 hours 1. Engine oil 1. Change

Every 10 hours 1. Drive belt tension 1. Check

2. Unit 2. Lubricate

Every 25 hours 1. Spark plug 1. Check

Every 30 hours 1. Transmission oil level 1. Check

2. Tines for wear 2. Check

3. Tire pressure 3. Check

Annually or Every 50 hours 1.

Annually or Every 100 hours 1. Air cleaner 1. Change

Before Storage 1. Fuel system 1. Run engine until it stops from lack of

t Change oil every twenty five hours when operating engine under heavy load or in high temperatures

Engine oilf

2. Spark Plug 2. Change

Item

Follow the maintenance schedule given below. This chart describes

service guidelines only. Use the Service Log column to keep track of

completed maintenance tasks. To locate the nearest Sears Service

Center or to schedule service, simply contact Sears at

1-800-4-MY-HOME®.

Service Service Log

1. Change

fuel or add a gasoline additive to the

gas in the tank.

GENERAL RECOMMENDATIONS

• Always observe all safety rules found on product labels and in

this operator's manual when performing any maintenance. Safety

rules can be found on the product labels and in this Operator’s

Manual beginning on page 3.

• The warranty on this tiller does not cover items that have been

subjected to operator abuse or negligence. To receive full value

from warranty, operator must maintain the equipment as

instructed here.

• Some adjustments will have to be made periodically to maintain

your unit properly.

• Periodically check all fasteners and make sure these are tight.

If the engine has been running, the muffler will be very hot. Be careful

not to touch the muffler.

A CAUTION

The spark plug must be securely tightened. An improperly tightened

spark plug can become very hot and may damage the engine.

Checking the Spark Plug

To ensure proper engine operation, the spark plug must be properly

gapped and free of deposits. Check the spark plug every 25 hours and

replace it every 100 hours.

18

Page 19

SERVICE AND MAINTENANCE

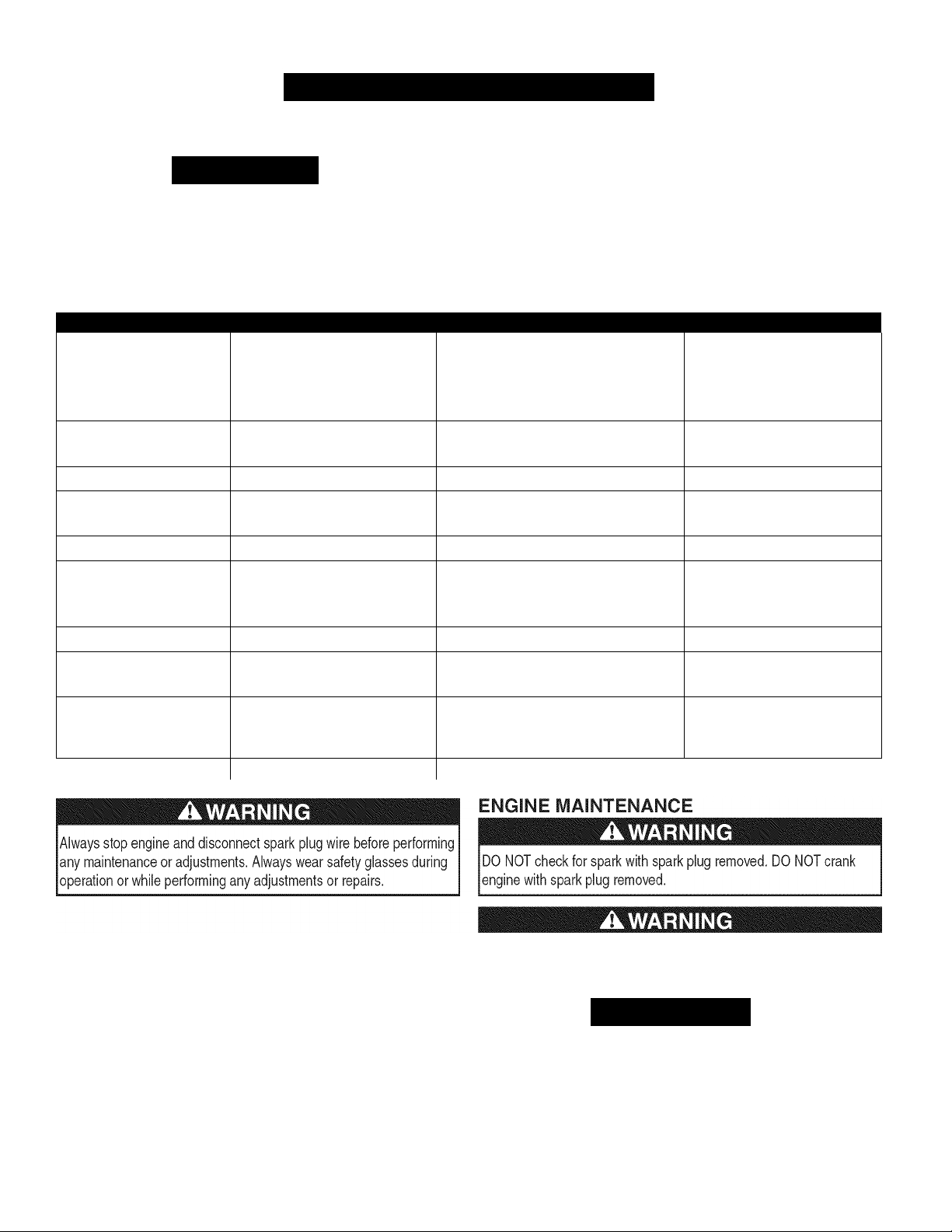

1. Remove the spark plug boot and use a spark plug wrench to

remove the plug. See Figure 17.

2. Visually inspect the spark plug. Discard the spark plug it there is

apparent wear, or if the insulator is cracked or chipped. Clean the

spark plug with a wire brush if it is to be reused.

3. Measure the plug gap with a feeler gauge. Correct as necessary

by bending side electrode. See Figure 18. The gap should be set

to 0.030 in.

4. Check that the spark plug washer is in good condition and thread

the spark plug in by hand to prevent crossthreading.

5. After the spark plug is seated, tighten with a spark plug wrench to

compress the washer.

NOTE: When installing a new spark plug, tighten 1/2

spark plug seats to compress the washer. When reinstalling a used

spark plug, tighten 1/8-1/4 turn after the spark plug seats to compress

the washer.

turn

after the

Spark Plug

Boot

Spark Plug

AWARNING

Never use gasoline or low flash point solvents for cleaning the air

cleaner element. A fire or explosion could result.

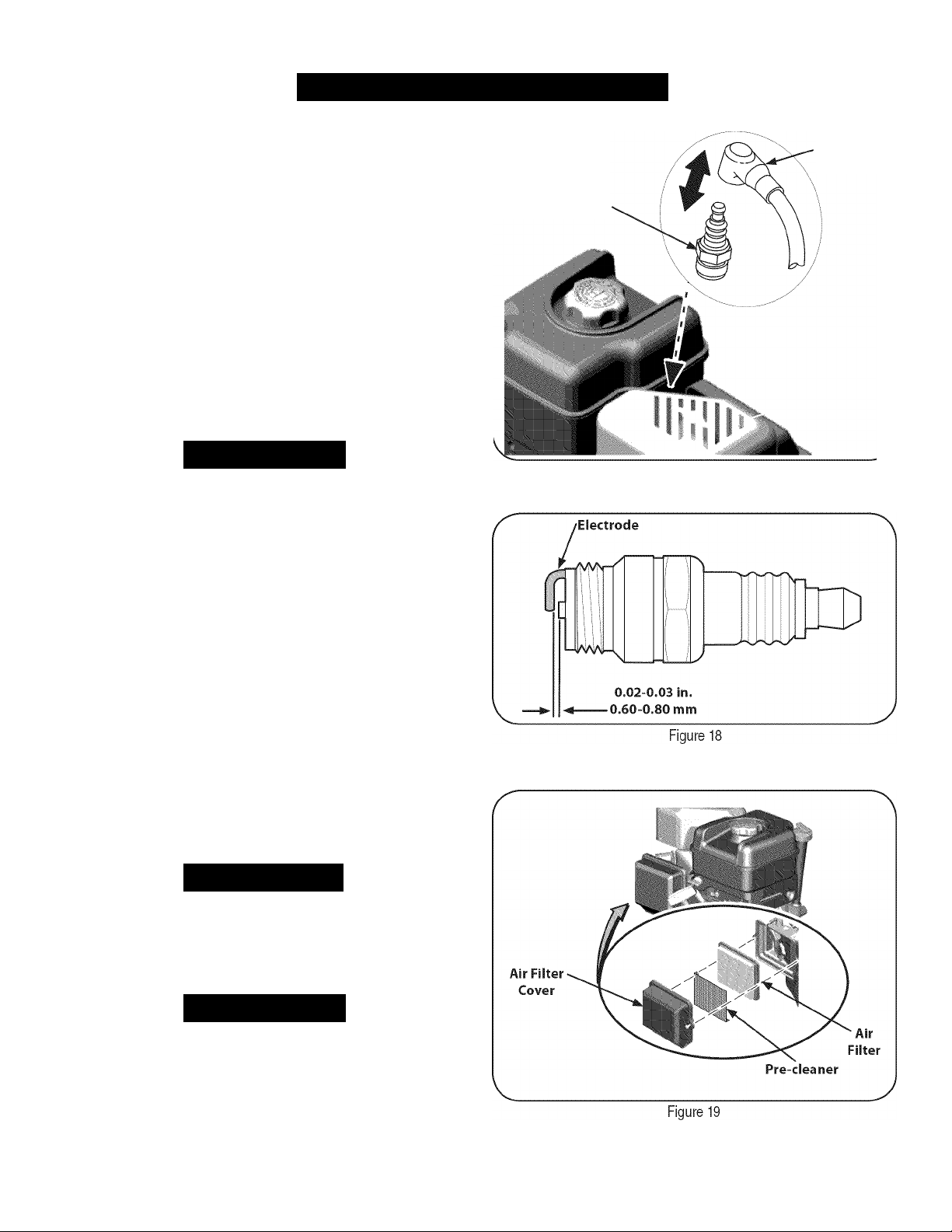

Servicing the Air Cleaner

The air cleaner prevents damaging dirt, dust, etc., from entering the

carburetor and being forced into the engine and is important to engine

life and performance. Never run the engine without an air cleaner

completely assembled. Check the air cleaner before each use.

Paper filters cannot be cleaned and must be replaced once a year

or every 100 operating hours; more often it used in extremely dusty

conditions.

1.

Loosen screws that hold the air filter cover. See Figure 19.

Open the cover and remove the pre-cleaner and air filter.

2.

Wash the pre-cleaner and allow to dry.

3.

4.

Discard old air filter.

5.

Install new air filter and washed pre-cleaner.

6.

Close the cover and tighten the screws.

NOTE: If the filter is torn or damaged in any way, replace it.

A CAUTION

Do not spray engine with water to clean because water could

contaminate fuel. Using a garden hose or pressure washing equip

ment can also force water into the muffler opening. Water that passes

through the muffler can enter the cylinder, causing damage.

Figure 17

AWARNING

Accumulation of debris around muffler could cause a fire. Inspect and

clean before every use.

Cleaning the Engine

If the engine has been running, allow it to cool for at least half an hour

before cleaning. Periodically remove dirt build-up from the engine.

Clean around the muffler. Clean with a brush or compressed air.

19

Page 20

SERVICE AND MAINTENANCE

Check Engine Oil

1. Check oil before each use. Stop engine and wait several minutes

before checking oil level. With the tiller on level ground, the oil

must be to FULL mark on dipstick.

2. Remove oil fill dipstick and wipe clean with cloth.

3. Replace dipstick into the oil filler neck, but do not screw it in.

Remove and check oil level. Level should be at FULL mark.

4. If needed, add oil slowly - recheck. Do not overfill.

5. Wipe dipstick clean, replace but do not tighten. Remove and

check oil level. Oil level should be at FULL line on dipstick.

6. Replace and tighten dipstick firmly before starting engine.

A CAUTION

DO NOT use non-detergent oil or 2-stroke engine oil. It could shorten

the engine’s service life.

Change Engine Oil

• SAE 30 is recommended for general, all temperature use. When

adding oil to the engine, refer to viscosity chart in the operation

section. Use a 4-stroke, or an equivalent high detergent, premium

quality motor oil certified to meet or exceed U.S. automobile

manufacturer’s requirements for service classification SF, SG, SH,

SJ or higher. Motor oils classified SF, SG, SH, SJ will show this

designation on the container.

• Change engine oil after the first five to eight hours of operation,

and every fifty hours or every season thereafter. Change oil every

twenty five hours when operating engine under heavy load or in

high temperatures.

Oil

Drain

Figure 20

4. Replace and tighten the oil drain end cap.

5. When engine is drained of all oil, place engine level. Refill with

approximately 20 oz. of fresh oil. Fill to FULL line on dipstick.

Do not overfill. Refer to Check Engine Oil in this SERVICE &

MAINTENANCE section.

6. Replace spark plug wire before starting.

AWARNING

Before tipping engine or equipment to drain oil, drain fuel from tank by

running engine until fuel tank is empty.

AWARNING

Used motor oil may cause skin cancer it repeatedly left in contact with

the skin for prolonged periods. Although this is unlikely unless you

handle used oil on a daily basis, it is still advisable to thoroughly wash

your hands with soap and water as soon as possible after handling

used oil.

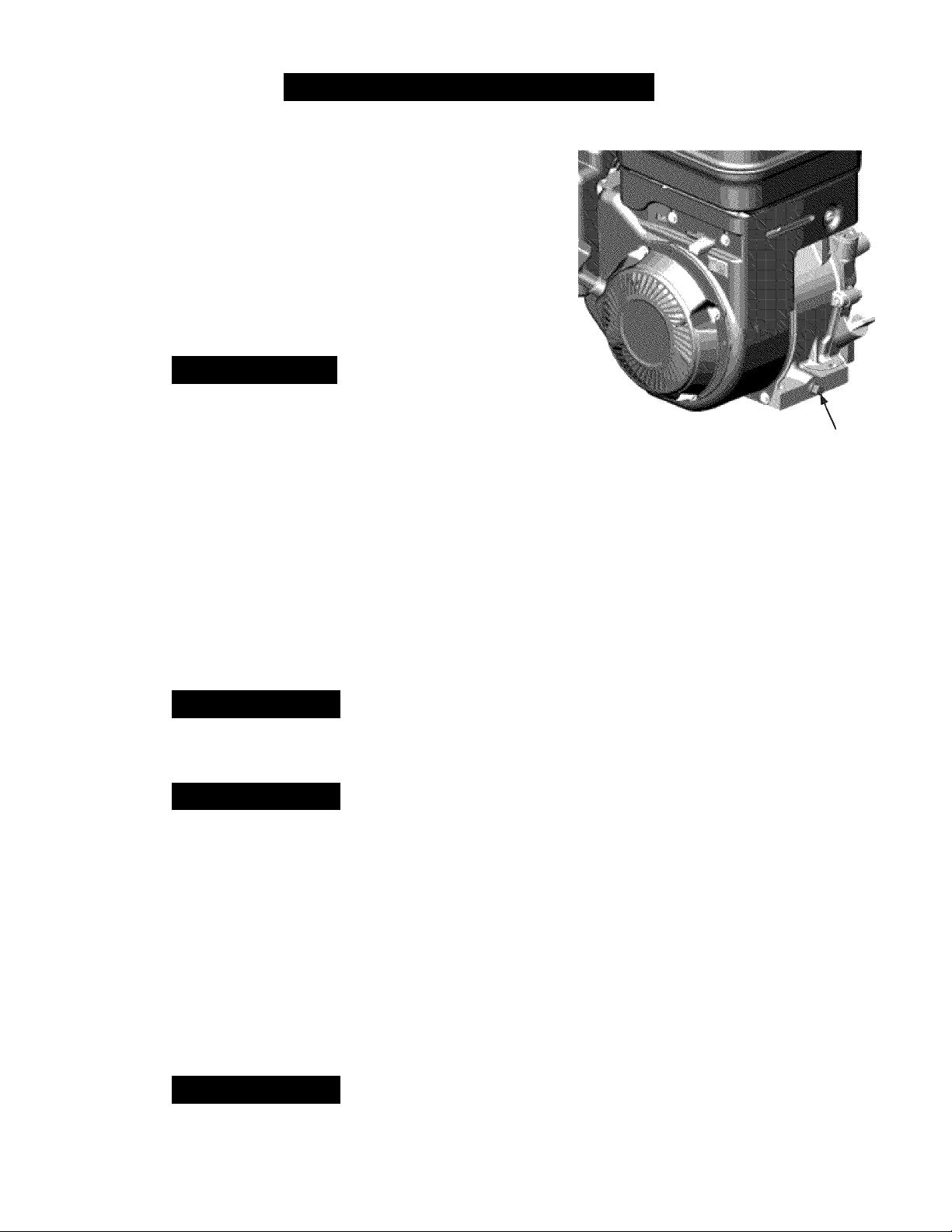

To Drain Oil

1. Drain the fuel from the tank by running the engine until the fuel tank is

empty. Be sure fuel fill cap is secure.

2. With engine OFF but still warm, disconnect spark plug wire and

keep it away from spark plug.

3. Remove oil drain end cap located at the base of the engine, and

drain oil into an appropriate receptacle. See Figure 20.

AWARNING

Used oil is a hazardous waste product. Dispose of used oil properly

Do not discard with household waste. Check with your local authori

ties or Sears Service Center for safe disposal/recycling facilities.

20

Page 21

SERVICE AND MAINTENANCE

Check Transmission Gear Oil

Check the transmission gear oil after every 30 hours of operation

or whenever you notice any oil leak. Operating the tiller when the

transmission is low on oil can result in severe damage.

To Check the Transmission Gear Oil Level:

1. Check the gear oil level when the transmission is cool. Gear oil

will expand in warm operating temperatures and this expansion

will provide an incorrect oil level reading.

2. With the tiller on level ground, pull the Depth Regulator Lever all

the way up.

3. Remove the oil fill plug from the transmission housing and look

inside the oil fill hole to locate the main drive shaft situated below

the hole. See Figure 21.

4. The gear oil level is correct it the gear oil is approximately halfway

up the side of the main drive shaft.

5. If the gear oil level is low, add gear oil as described next. If the

gear oil level is okay, securely replace the oil fill plug.

6. If adding only a few ounces of gear oil, use API rated GL-4 or

GL-5 gear oil having a viscosity of SAE 140, SAE 85W-140 or SAE

80W-90. If refilling an empty transmission, use only GL-4 gear oil

having a viscosity of SAE 85W-140 or SAE 140.

7. While checking frequently to avoid overfilling, slowly add gear oil

into the oil fill hole until it reaches the halfway point on the drive

shaft.

8. Securely replace the oil fill plug.

Change Transmission Gear Oil

The transmission gear oil does not need to be changed unless it has

been contaminated with dirt, sand or metal particles. See an autho

rized Sears Service Center to have the transmission gear oil changed

or to schedule service, simply contact Sears at 1-800-4-MY-HOME®.

LUBRICATION

After every 10 operating hours, oil or grease the lubrication points. Use

clean lubricating oil (#30 weight motor oil is suitable) and clean general

purpose grease (grease containing a metal lubricant is preferred, if

available). See Figure 22.

• Remove the wheels, clean the wheel shaft and apply a thin

coating of grease.

• Grease the back, front and sides of the depth regulator lever.

• Remove the tines and clean the tine shaft. Use a file or sandpa

per to gently remove any rust, burrs or rough spots (especially

around the holes in the shaft). Apply grease to the ends of the

shaft before installing the tines.

• Oil the threads on the handlebar height adjustment screws and

the handlebar attaching screws.

TIRE PRESSURE

Check the air pressure in both tires. The air pressure should be betwen

15-20 PSI. Keep both tires equally inflated to help prevent machine

from pulling to one side.

HARDWARE

Check for loose or missing hardware after every 10 operating hours

and tighten or replace — as needed — before reusing the tiller. Be

sure to check the screws underneath the tiller hood that secure the

transmission cover and the Depth Regulator Lever to the transmission.

21

Page 22

SERVICE AND MAINTENANCE

Awarning

Before performing any type of maintenance on the machine, wait for

all parts to stop moving and disconnect the spark plug wire. Failure

to follow this instruction could result in personal injury or property

damage.

BELT REPLACEMENT

If the drive belt or reverse belt needs to be replaced, it is best to

replace both belts

belt as an “over- the-counter” belt may not perform satisfactorily.

The procedure requires average mechanical ability and commonly

available tools.

To replace the Drive and Reverse belts, follow these steps:

1. Make sure the tiller is on a flat surface, with the engine turned

off and the spark plug wire unplugged and grounded to prevent

unintended firing of the engine.

2. Remove the belt cover by first removing the two 1/4-20 self

tapping hex screws. See Figure 23. Lift the belt cover up and

away from the tiller and set in a safe location until reinstallation.

3. Remove the four 1/4-20 self-tapping hex screws that secure the

pulley shield to the frame and remove the pulley shield and set

aside in a safe location until reinstallation. See Figure 24.

4. Remove the idler bracket extension spring. See Figure 25. It is

recommended to use a pair of needle-nosed pliers, and grab the

spring by the end that hooks over the frame. Simply grab it and

pull it away from the frame, then up wards and carefully relieve

the tension of the spring.

5. Remove the idler pulley bracket by removing the 5/16-24 hex

head screw, flat washer and lock washer. See Figure 26.

NOTE: It will be necessary to remove the belt from around the idler

pulley by working it off the pulley and from underneath each belt

keeper.

at

the same time. Use only a factory authorized

Remove the

belt from the

idler pulley

by working it

under the belt

keepers.

Figure 23 Figure 26

Remove the

idler pulley

bracket by

removing the

hex head screw,

fiat and lock

washers

Page 23

SERVICE AND MAINTENANCE

Remove the hex bolts securing the transmission drive pulley, then

remove the pulley along with the two belts. See Figure 27.

Replace the old belts with the new belts in the same order they

7.

were removed. The longer belt (1916658) belongs closer to the

engine (V-side out), with the shorter belt (1916657) positioned

closer to the tines.

8. Reinstall the transmission drive pulley with the new belts.

9. Reassemble the tiller in the reverse order in which it was disas

sembled.

IMPORTANT: When reinstalling the belt cover, be sure to engage

the bail and hold it so that the drive belt is tight before attempting to

reinstall the belt cover. This will enable the belt to fall under the belt

keeping mechanism built into the belt cover. Failure to do so could

damage the belt and/or belt cover.

TINES

The tines will wear with use and should be inspected at the beginning

of each tilling season and after every 30 operating hours. The tines

can be replaced. Refer to the Parts List section of this manual for part

numbers.

Tine Inspection

With use, the tines will become shorter, narrower and pointed. Badly

worn tines will result in a loss of tilling depth, and reduced effective

ness when chopping up and turning under organic matter.

Removing/lnstalling a Tine Assembly

1. Remove the tine shield end covers and side shields by removing

the three wing nuts on each side that secure them.

2. A tine assembly consists of a left hand tine and a right hand tine.

NOTE: The tine assembly moves in a counter-rotating motion with

the sharp edges of the tines positioned to enter the soil first when

counter-rotating. Note this position of the tines for reinstallation of the

new tine assemblies.

3. To remove a tine assembly, simply remove the cotter pin securing

the clevis pin. See Figure 28.

4. Remove the clevis pin and slide the assembly to the outside of

the unit and off of the tine shaft.

5. Before reinstalling the tine assembly, inspect the tine shaft tor

rust, rough spots or burrs. Lightly file or sand, as needed. Apply a

thin coat of grease to the shaft.

6. Install each tine assembly so that the cutting (sharp) edge of the

tines will enter the soil first when the tiller moves forward. Keep

in mind that these tines are counter-rotating, so secure the tine

assembly to the tine shaft using the clevis pin and cotter pin.

23

Page 24

OFF-SEASON STORAG

AWARNING

Never store tiller with fuel in tank indoors or in poorly ventilated areas

where fuel fumes may reach an open flame, spark, or pilot light as on

a furnace, water heater, clothes dryer, or gas appliance.

I

AWARNING

[ Never leave engine unattended while

PREPARING THE ENGINE

Engines stored between 30 and 90 days need to be treated with a

gasoline stabilizer and engines stored over 90 days need to be drained

of fuel to prevent deterioration and gum from forming in fuel system or

on essential carburetor parts. If the gasoline in your engine deterio

rates during storage, you may need to have the carburetor, and other

fuel system components, serviced or replaced.

1. Remove all fuel from tank by running engine until it stops from

lack of fuel.

2. Change the oil. See Change Engine Oil in SERVICE AND

MAINTENANCE section.

3. Remove spark plug and pour about a 1/2 ounce of engine oil into

the cylinder. Replace spark plug and crank it slowly to distribute

oil.

4. Clean debris from around the engine and the muffler. Touch up

any damaged paint, and coat other areas that may rust with a light

film of oil.

5. Store in a clean, dry and well ventilated area away from any ap

pliance that operates with a flame or pilot light, such as a furnace,

water heater, or clothes dryer. Also avoid any area with a spark

producing electric motor, or where power tools are operated.

6. If possible, also avoid storage areas with high humidity, because

that promotes rust and corrosion.

7. Keep the engine level in storage. Tilting can cause fuel or oil

leakage.

it is

running.

_________________

PREPARING THE TILLER

When the tiller won’t be used for an extended period, prepare it for

|

storage as follows:

1. Clean the tiller and engine.

2. Follow the lubrication recommendations and check for loose parts

and hardware.

3. Store the tiller in a clean, dry area.

4. Never store the tiller with fuel in the fuel tank in an enclosed area

where gas fumes could reach an open flame or spark, or where

ignition sources are present (space heaters, hot water heaters,

furnaces, etc.).

24

Page 25

TROUBLESHOOTING

Awarning

Before performing any type of maintenance/service, disengage all controls and stop the engine. Wait until all

moving parts have come to a complete stop. Disconnect spark plug wire and ground it against the engine to prevent

unintended starting. Always wear safety glasses during operation or while performing any adjustments or repairs.

I

Problem

Engine fails to start 1. Spark plug wire disconnected.

2. Engine Throttle Control Lever Incorrectly set.

3. Fuel tank empty or stale fuel.

4. Dirty air filter.

5. Defective or Incorrectly gapped spark plug.

6. MIsadjusted throttle control.

7. Dirt or water In fuel tank.

Engine runs erratically 1. Defective or incorrectly gapped spark plug.

2. Dirty air fllter(s).

3. Carburetor out of adjustment.

4. Stale gasoline.

5. Dirt or water In fuel tank.

6. Engine cooling system clogged.

Engine overheats 1. Engine cooling system clogged.

2. Carburetor out of adjustment.

3. Oil level Is low.

Engine does

Wheels/Tines will not turn 1. Improper use of controls.

Tines turn, but wheels don’t 1. Wheel Drive Pins not In WHEEL DRIVE.

Wheels

Poor tilling performance 1. Worn tines.

not

shut off 1. MIsadjusted throttle control or Ignition switch. 1. Contact your Sears Parts & Repair Center.

2. Worn, broken, or misadjusted drive belt(s).

3. Internal transmission wear or damage.

4. Bolt loose In transmission pulley.

2. Bolt loose in transmission pulley.

3. Internal transmission wear or damage.

turn,

but tines don’t 1. Tine holder mounting hardware missing.

2. Bolt loose in transmission pulley.

3. Internal transmission wear or damage.

2. Improper Depth Regulator setting.

3. Incorrect throttle setting.

4. Forward Drive Belt slipping.

Cause Remedy

1. Reconnect wire.

2. Put lever In START position.

3. Fill tank with clean, fresh gasoline.

4. Clean or replace filter.

5. Clean, adjust gap, or replace.

6. Contact your Sears Parts & Repair Center.

7. Contact your Sears Parts & Repair Center.

1. Clean, adjust gap, or replace.

2. Clean or replace.

3. Contact your Sears Parts & Repair Center.

4. Replace with fresh gasoline.

5. Contact your Sears Parts & Repair Center.

6. Clean air cooling system.

1. Clean air cooling area.

2. Contact your Sears Parts & Repair Center.

3. Check oil level.

1. Review Operation section.

2. Replace or adjust belts.

3. Contact your Sears Parts & Repair Center.

4. Tighten bolt.

1. Inserts Drive Pins properly.

2. Tighten bolt.

3. Contact your Sears Parts & Repair Center.

1. Replace hardware.

2. Tighten bolt.

3. Contact your Sears Parts & Repair Center.

1. Replace Tines.

1. See “Tilling Tips & Techniques.”

1. See Service & Maintenance Section.

1. See Service & Maintenance Section.

NEED MORE HELP?

' Find this and all your other product manuals online.

' Get answers from our team of home experts.

' Get a personalized maintenance plan for your home.

' Find information and tools to help with home projects.

25

Page 26

Craftsman Tiller — Model No. 247.29931

PARTS LIS

J

26

Page 27

Craftsman Tiller — Model No. 247.29931

Ref. No. Part No. Description

1 686-0044B-0721 End Cover Assembiy

2 710-0597 Hex Head Screw, 1/4-20 x 1

3 710-0604A Seif Tapping Screw, 5/16-18 x .625

4 710-1238 Hex Head Screw, 5/16-18 x .875

5 710-3008 Hex Head Screw, 5/16-18 x .75

6 712-04063 Nyion Hex Lock Nut, 5/16-18

7 712-04064 Nyion Hex Lock Nut, 1/4-20

8 712-04065 Flange Lock Nut, 3/8-16

9 712-0421 Wing Nut, 5/16-18

10 715-0108 Spirol Pin

11 926-0106 Cap Nut, 1/4 Rod

12 731-05512 Hole Plug

13 732-04320 Torsion Spring

14 738-04320 Shoulder Screw, .405 x .435 5/16-18

15 938-0533 Shoulder Screw, .498 x 1.635

16 938-0849 Stop Screw

17 747-0432 Tiller Flap Rod

18 750-05349 Spacer

19 786-0090A-0721 Side Shield

20 786-0113A-0721 Rear Tine Shield

21 786-04092-0721 Reverse Stop Arm

22. 786-04104-0721 Drag Bar

23 786-04352A-0721 Tine Shield Mounting Bracket

24 786-04355A-0721 Tine Shield

25 786-04356-0721 Adjustable Depth Bar

26 786-04363-0721 Tail Bracket, LH

I

PARTS LIS

J

Ref. No. Part No. Description

27 786-04364-0721 Tail Bracket, RH

28 649-04054-0721 Upper Handle Assembly

29 686-04098-0721 Reverse Handle Assembly

30 710-0189 Hex Head Screw, 5/16-18 x 3.00

31 710-0599 Self-Tapping Screw, 1/4-20 x 1/2

32 720-0270A Reverse Handle Grip

33 720-0278A Foam Handle Grip

34 726-0135 Cap Nut, .3125 dia.

35 731-06253A Handle Cover

36 735-04105 Plug End

37 736-0242 Bell Washer, .340 x .872 x .060

38 946-04504 Reverse Cable

39 946-04506 Forward Cable

40 747-04789-0637 Clutch Bail

41 750-0885A Spacer, .322 x .625 x 2.00

42 786-0340A Handle Crank

43 786-04344-0721 Handle Bracket, RH

44 786-04345-0721 Handle Bracket, LH

45 786-04358 Retainer Nut Bracket

46 786-04360-0721 Front Bumper

47 731-06529 Belt Cover

48 736-0173 Flat Washer, .28 x .74 x .063

49 710-0502A SEMS Screw, 3/8-16

50 710-0805 Hex Head Screw, 5/16-18 x 1.50

51 736-04193 Bell Washer, .827 x .331 x .098

52 710-1307 Stub, 5/16-18 X .75

Page 28

Craftsman Tiller — Model No. 247.29931

PARTS LIS

J

28

Page 29

Craftsman Tiller — Model No. 247.29931

I

PARTS LIS

J

Ref. No. Part No. Description

1 634-04652 Complete WhI. Ass., 13x5x6(6, C)

2 714-0143A Click Pin

3 684-04168 Idler Pulley Assembly

4 710-0331 Hex Head Screw, 3/8-24 x 2.25

5 710-0170 Hex Head Screw, 5/16-24 x .625

6 710-0599 Self Tapping Screw, 1/4-20 x .500

7 710-0606 Hex Head Screw, 1/4-20 x 1.50

8 710-0672 Hex Head Screw, 5/16-18 x 1.25

9 710-1880 Hex Head Screw, 5/16-18 x .75, Patch

10 710-3008 Hex Head Screw, 5/16-18 x .75, STD

11 712-04064 Nylon Hex Lock Nut, 1/4-20

12 712-0700 Nut, 9/16-18, Flange Lock

13 718-04407 Hub, 5/8 Spline

14 732-04085 Extension Spring, .480 OD X 5.00 LG

15 732-04276A Extension Spring, LT5 PTO

16 936-0119 Lock Washer, 5/16

17 736-0173 Washer, .28 x .74 x .063

18 714-04043 Internal Cotter Pin

19 736-0343 Flat Washer, .330 X 1.25 X .120

20 936-0452 Bell Washer, .396 x 1.140 x .095

21 736-3092 Flat Washer, .265 x 1.0 x .030

Ref. No. Part No. Description

22 738-04425 Shoulder Screw, .342 x .335 1/4-28

23 748-04087A Pivot Idler Spacer

24 750-04571 Shoulder Spacer, .260 x .785 x .538

25 750-04907 Pivot Idler Spacer

26 1916657 V-Belt,4Lx 25.375 Long

27 1916658 V-Belt,3Lx 29.125 Long

28 756-04198A Engine Pulley

29 756-04355 Transmission Pulley

30 756-0625 Cable Roller

31 786-04312 Idler Bracket, Forward

32 786-04343-0721 Cover Plate

33 786-04346 Idler Bracket, Reverse

34 786-04416-0721 Mounting Frame, RH

35 786-04415A-0721 Mounting Frame, LH

36 786-04357-0721 Pulley Bracket

37 786-04371-0721 Pulley Shield

38 642-04071-0721 Tine Assembly, LH

39 642-04072-0721 Tine Assembly, RH

40 911-0415 Clevis Pin, .375 x 1.75

41 918-04815A Transmission Assembly

29

Page 30

Craftsman Tiller — Model No. 247.29931

12

PARTS LIS

J

30

Page 31

Craftsman Tiller — Model No. 247.29931

Ref. No. Part No. Description

918-04815A Transmission Assembly

1 919-04184A Housing, Transmission

2 710-3008 Hex Screw, 5/16-18, .75, Gr5

3 911-04844 Shaft, Tiller

4 911-04854 Shaft, Wheel

5 911-05028 Shaft, Worm

6 714-04059 Key, Hi Pro .25x 1.062

7 716-0204 Retaining Ring

8 716-04102 Retaining Ring, Int

9 917-04380 Worm Gear, 61t, RH

10 917-04381 Worm Gear, 30t, LH

11 918-04435 Bearing Cover

12 921-04030 Seal, Oil, .750 Shaft x 1.783 Bore

13 921-04229 Gasket, Gear Housing

14 721-04232 Seal, Oil, 1.00 Shaft x 2.00 Bore

15 721-04271 Rubber Plug, Oil

16 732-0614 Wire Ring

17 736-04305 * Washer, Flat, 1.50x 1.75X.062

736-04306 * Washer, Flat, 1.50x 1.75X.005

736-04307 * Washer, Flat, 1.50 x 1.75 x .03

736-04308 * Washer, Flat, 1.50x 1.75X.010

18 736-0745 Washer, Flat, 1.01 Ox 1.56X.060

19 941-04298 Cone Bearing

20 941-04299 Bearing Cup

21 741-3114 Ball Bearing

22 786-04366 Cover, Transmission

23 786-04392 Cover, Transmission

* The flat washers listed

in allowable end play on

I

PARTS LIS

J

are used as required to obtain .005 to .015

the drive shaft.

31

Page 32

Craftsman Tiller Model No. 247.29931

Parts Li

J

777S33496

Keep all safety devices and shields in place and vrarking.

Never allow children or uninstructed adults to

operate tiller.

Shut off engine before unclogging tines or

making repairs.

Keep bystanders away from machine.

Keep away from rotating parts.

Operation Of This Equipment May Create Sparks That Can Start Fires Around Dry Vegetation. A Spark

Arrestor May Be Required. The Operator Should Contact Local Fire Agencies For Laws Or Regulations

To Fire Prevention Requirements.

777D14197

777I22969

777X43688

iiiof

USE E85 OR FUEL'

CONTAINING MORE'

I THAN 10% ETHANOL I

M.

777I20358

777I22968

' TILL "

COUNTER

ROTATING

TIN

ii

WHEELS

FORWARD

Page 33

NOTE

J

Page 34

(This page applicable in the U.S.A. and Canada only.)

Sears, Roebuck and Co., U.S.A. (Sears), the California Air Resources Board (CARB)

and the United States Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner’s Defect Warranty Rights and Obligations)

EMISSION CONTROL WARRANTY COVERAGE IS APPLICABLE TO CERTI- YEAR 1997 AND LATER ENGINES WHICH ARE PURCHASED AND USED

PIED ENGINES PURCHASED IN CALIFORNIA IN 1995 AND THEREAF- ELSEWHERE IN THE UNITED STATES (AND AFTER JANUARY 1,2001 IN

TER, WHICH ARE USED IN CALIFORNIA, AND TO CERTIFIED MODEL CANADA).

California and United States Emission Control Defects Warranty Statement

The California Air Resources Board (CARB), U.S. EPA and Sears are pleased engine for the periods of time listed below, provided there has been no abuse,

to explain the Emission Control System Warranty on your model year 2000 and neglect or improper maintenance of your small off-road engine. Your emislater small off-road engine (SORE). In California, new small off-road engines

must be designed, built and equipped to meet the State’s stringent anti-smog

standards. Elsewhere in the United States, new non-road, spark-ignition

engines certified for model year 1997 and later must meet similar standards set

forth by the U.S. EPA. Sears must warrant the emission control system on your

sion control system includes parts such as the carburetor, air cleaner, ignition

system, muffler and catalytic converter. Also included may be connectors and

other emission related assemblies. Where a warrantable condition exists. Sears

will repair your small off-road engine at no cost to you including diagnosis, parts

and labor.

Sears Emission Control Defects Warranty Coverage

Small off-road engines are warranted relative to emission control parts defects part on your engine is defective, the part will be repaired or replaced by Sears,

for a period of one year, subject to provisions set forth below. If any covered

Owner’s Warranty Responsibilities

As the small off-road engine owner, you are responsible for the performance of

the required maintenance listed in your Operating and Maintenance Instruc

tions. Sears recommends that you retain all your receipts covering maintenance

on your small off-road engine, but Sears cannot deny warranty solely for the

lack of receipts or for your failure to ensure the performance of all scheduled

maintenance. As the small off-road engine owner, you should however be

aware that Sears may deny you warranty coverage if your small off-road engine

or a part has failed due to abuse, neglect, improper maintenance or unap

proved modifications. You are responsible for presenting your small off-road

engine to an Authorized Sears Service Dealer as soon as a problem exists. The

undisputed warranty repairs should be completed in a reasonable amount of

time, not to exceed 30 days. If you have any questions regarding your warranty

rights and responsibilities, you should contact a Sears Service Representative

at 1 -800-469-4663. The emission warranty is a defects warranty. Defects are

judged on normal engine performance. The warranty is not related to an in-use

emission test.

Sears Emission Control Defects Warranty Provisions

The following are specific provisions relative to your Emission Control Defects Warranty Coverage. It is in addition to the Sears engine warranty for non-regulated

engines found in the Operating and Maintenance Instructions.

1. Warranted Parts

Coverage under this warranty extends only to the parts listed below (the

emission control systems parts) to the extent these parts were present on

the engine purchased.

a. Fuel Metering System

• Cold start enrichment system

• Carburetor and internal parts

• Fuel Pump

b. Air Induction System

• Air cleaner

• Intake manifold

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive valves