Craftsman 24729922 Owner’s Manual

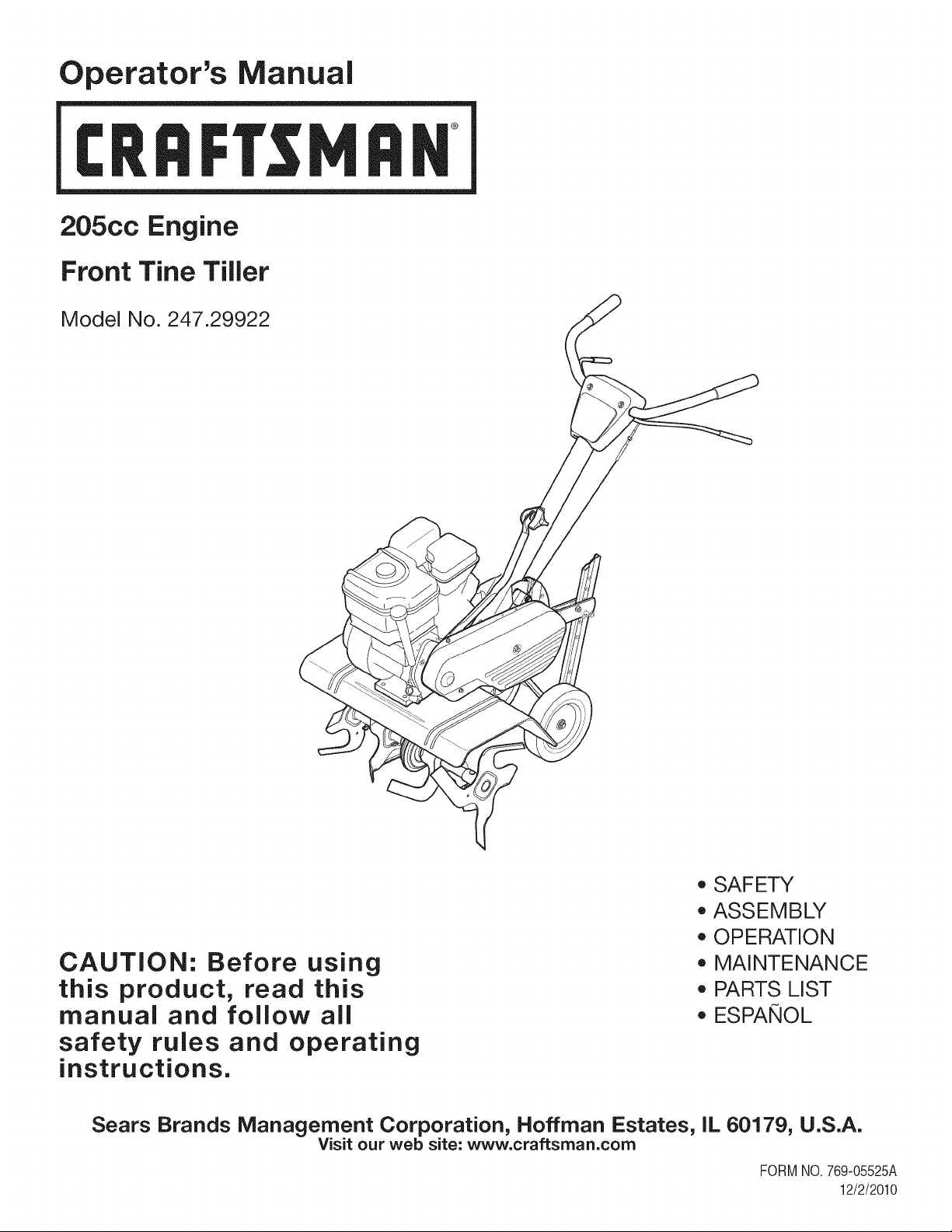

Operator's Manual

I:Rl FI'SlVl N

205cc Engine

Front Tine Tiller

Model No. 247.29922

* SAFETY

* ASSEMBLY

* OPERATION

CAUTION: Before using

this product, read this

manual and follow all

* MAINTENANCE

* PARTS LIST

* ESPANOL

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, iL 60179, U.S.A.

Visit our web site: www.craftsman.com

FORMNO.769-05525A

12/2/2010

WarrantyStatement..................................Pac

Safetyinstructions....................................Pac

SafetyLabels............................................Pac

Assembly..................................................Pac

Operation..................................................Pac

ServiceandMaintenance.........................Pac

Off-SeasonStorage..................................Pac

CRAFTSMAN TWO YEAR FULL WARRANTY

FORTWOYEAR(S)fromthe dateof purchase,thisproductis warrantedagainstanydefectsinmaterialorworkmanship.Defectiveproductwill

receivefreerepairorfree replacementif repairisunavailable,

For warranty coverage details to obtain repair or replacement, visit the web site: www.craftsman.com

This warranty covers ONLY defects in material and workmanship. Warranty coverage does NOT include:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,suchas

blades,tines,orbelts.

Productdamageresultingfromuserattemptsat productmodificationor repairorcausedby productaccessories.

Repairsnecessarybecauseof accidentorfailuretooperateor maintainthe productaccordingtoallsuppliedinstructions.

Preventivemaintenance,or repairsnecessaryduetoimproperfuel mixture,contaminatedor stalefuel.

e2

es3-6

e7

es8-10

es11-17

es18-22

e23

TroubleShooting.......................................Page24

PartsList...................................................Page26-29

LabelMap.................................................Page39

RepairProtectionAgreement...................Page42

Espa_ol.....................................................Page43

ServiceNumbers......................................BackCover

Thiswarrantyisvoidif thisproductisever usedwhileprovidingcommercialservicesorif rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineSeries: 205cc

EngineOilType: SAE30

EngineOilCapacity: 20ounces

Fuel: UnleadedGasoline

SparkPlug: Champion®RC-12YC

SparkPlugGap: .030"

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

©SearsBrands,LLC 2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothe safeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthe partof theoperatorcan resultin

seriousinjury.Thismachineiscapableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm.Bat-

tery posts,terminals,andrelatedaccessoriescontainleadand lead

compounds,chemicalsknownto theStateof Californiato cause

cancerandreproductiveharm.Washhandsafterhandling.

TRAINING

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplaceforfutureand regularreference

andfororderingreplacementparts.

• ReadtheOperator'sManualandfollowallwarningsandsafety

instructions.Failuretodosocanresultin seriousinjurytothe

operatorand/or bystanders.Forquestions,call1-800-4MY-HOME.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsof agetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultstooperatethis machinewithoutproper

instruction.

• Keepbystanders,pets,andchildrenatleast75feetfromthe

machinewhileitisinoperation.Stopmachineif anyoneenters

thearea.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

Your Responsibility=Restrict theuseofthispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall rocks,bottles,cans,or otherforeignobjectswhich

couldbepickedupor thrownandcausepersonalinjuryor

damageto themachine.

• Alwayswearsafetyglassesor safetygogglesduringoperation

andwhileperformingan adjustmentorrepair,to protectyour

eyes.Thrownobjectswhichricochetcancauseseriousinjuryto

theeyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesorjewelrycan becaughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beforestarting,checkallboltsandscrewsfor propertightnessto

besurethe machineisinsafeworkingcondition.Also,visually

inspectmachinefor anydamageatfrequentintervals.

• Disengageclutchleversandshift(if provided)intoneutral("N")

beforestartingtheengine.

• Neverleavethismachineunattendedwiththeenginerunning.

• Neverattempttomakeanyadjustmentswhiletheengineis

running,exceptwherespecificallyrecommendedinthe operator's

manual.

• Maintainor replacesafetyandinstructionslabels,asnecessary.

3

SafeHandling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Neverfill containersinsideavehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthe groundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthe truck

ortrailerand refuelitonthe ground.Ifthisis notpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthe nozzleincontactwiththerimofthe fueltankor

containeropeningatalltimesuntilfuelingiscomplete.Donot use

a nozzlelock-opendevice.

• Extinguishallcigarettes,cigars,pipesandother sourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuel whilethe engineishot or run-

ning.Allowenginetocool atleasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Fill tankto nomorethan1/2inchbelow

bottomoffillerneckto allowspacefor fuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipe itoff theengineandequipment.Move

unitto anotherarea.Wait5 minutesbeforestartingtheengine.

• To reducefirehazards,keepmachinefreeofgrass,leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageand removeany

fuelsoakeddebris.

• Neverstorethe machineorfuelcontainerinsidewherethereis an

openflame,sparkor pilotlightas on awaterheater,spaceheater,

furnace,clothesdryerorothergasappliances.

OPERATION

• Do notputhandsorfeetnear rotatingparts.Contactwiththe

rotatingpartscanamputatehandsandfeet.

• Do notoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Neveroperatethismachinewithoutgoodvisibilityor light.Always

be sureof yourfootingandkeepa firmholdonthehandles.

• Keepbystandersawayfromthe machinewhileitisinoperation.

Stopthe machineif anyoneentersthe area.

• Becarefulwhentillinginhardground.Thetines maycatchinthe

groundandpropelthetillerforward.Ifthis occurs,let goofthe

handlebarsanddo not restrainthemachine.

• Exerciseextremecautionwhenoperatingonor crossinggravel

surfaces.Stayalertforhiddenhazardsortraffic. Donotcarry

passengers.

• Neveroperatethemachineat hightransportspeedsonhardor

slipperysurfaces.

• Exercisecautiontoavoidslippingorfalling.

• Lookdownandbehindandusecarewhenin reverseor pulling

machinetowardsyou.

• Startthe engineaccordingtothe instructionsfoundinthis manual

and keepfeetwell awayfromthetinesat all times.

• Afterstrikingaforeignobjector ifyourmachineshouldstartmak-

inganunusualnoiseor vibration,immediatelyshutthe engineoff.

Disconnectthe sparkplugwire,grounditagainstthe engineand

performthefollowingsteps:

a. Inspectfordamage.

b. Repairorreplaceanydamagedparts.

c. Checkforanyloosepartsandtightento assurecontinued

safeoperation.

• Disengageall clutchlevers(iffitted)andstopenginebeforeyou

leavethe operatingposition(behindthe handles).Waituntil

thetinescometo a completestopbeforeuncloggingthe tines,

makinganyadjustments,or inspections.

• Neverrunanengineindoorsorinapoorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an odorlessanddeadlygas.

• Mufflerandenginebecomehotandcancausea burn.Do not

touch.

• Usecautionwhentillingnearfences,buildingsandunderground

utilities.Rotatingtinescan causepropertydamageorpersonal

injury.

• Donotoverloadmachinecapacitybyattemptingtotillsoil too

deepattoo fastof a rate.

• Ifthemachineshouldstartmakinganunusualnoiseorvibration,

stoptheengine,disconnectthesparkplugwireandgroundit

againsttheengine.Inspectthoroughlyfor damage.Repairany

damagebeforestartingandoperating.

• Keepallshields,guards,and safetydevicesinplaceandoperat-

ing properly.

• Neverpick uporcarrymachinewhiletheengineis running.

• Useonlyattachmentsandaccessoriesapprovedbythemanu-

factureras listedin thePartsListpagesofthisoperator'smanual.

Failuretodosocan resultin personalinjury.

• Ifsituationsoccurwhichare notcoveredinthismanual,usecare

andgoodjudgement.ContactCustomerSupportat 1-800-4MY-

HOMEforassistanceandthe nameof thenearestservicedealer

MAINTENANCE & STORAGE

• Keepthemachine,attachmentsandaccessoriesin safeworking

order.

• Allowthemachinetocoolat leastfiveminutesbeforestoring.

Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.

• Checkboltsandscrewsforpropertightnessat frequentintervals

to keepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

• Beforecleaning,repairing,or inspecting,stoptheengineand

makecertainthetinesandall movingpartshavestopped.

Disconnectthe sparkplugwireandgrounditagainsttheengineto

preventunintendedstarting.

4

• Do notchangetheenginegovernorsettingsor over-speedthe

engine.Thegovernorcontrolsthemaximumsafeoperatingspeed

ofengine.

Maintainor replacesafetyandinstructionlabels,as necessary.

Followthis manualforsafeloading,unloading,transporting,and

storageof thismachine.

Alwaysreferto theoperator'smanualforimportantdetailsifthe

machineisto bestoredforanextendedperiod.

If thefuel tankhasto be drained,do thisoutdoors.

Observeproperdisposallawsandregulationsforgas,oil,etc.to

protecttheenvironment.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 130hoursof

operation.Atthe endof theAverageUsefulLifehavethemachine

inspectedannuallybyanauthorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failureto do socan resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyenginein anyway.

Tamperingwiththegovernorsettingcanleadto arunawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,it shouldbe maintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveisrequired

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthemufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

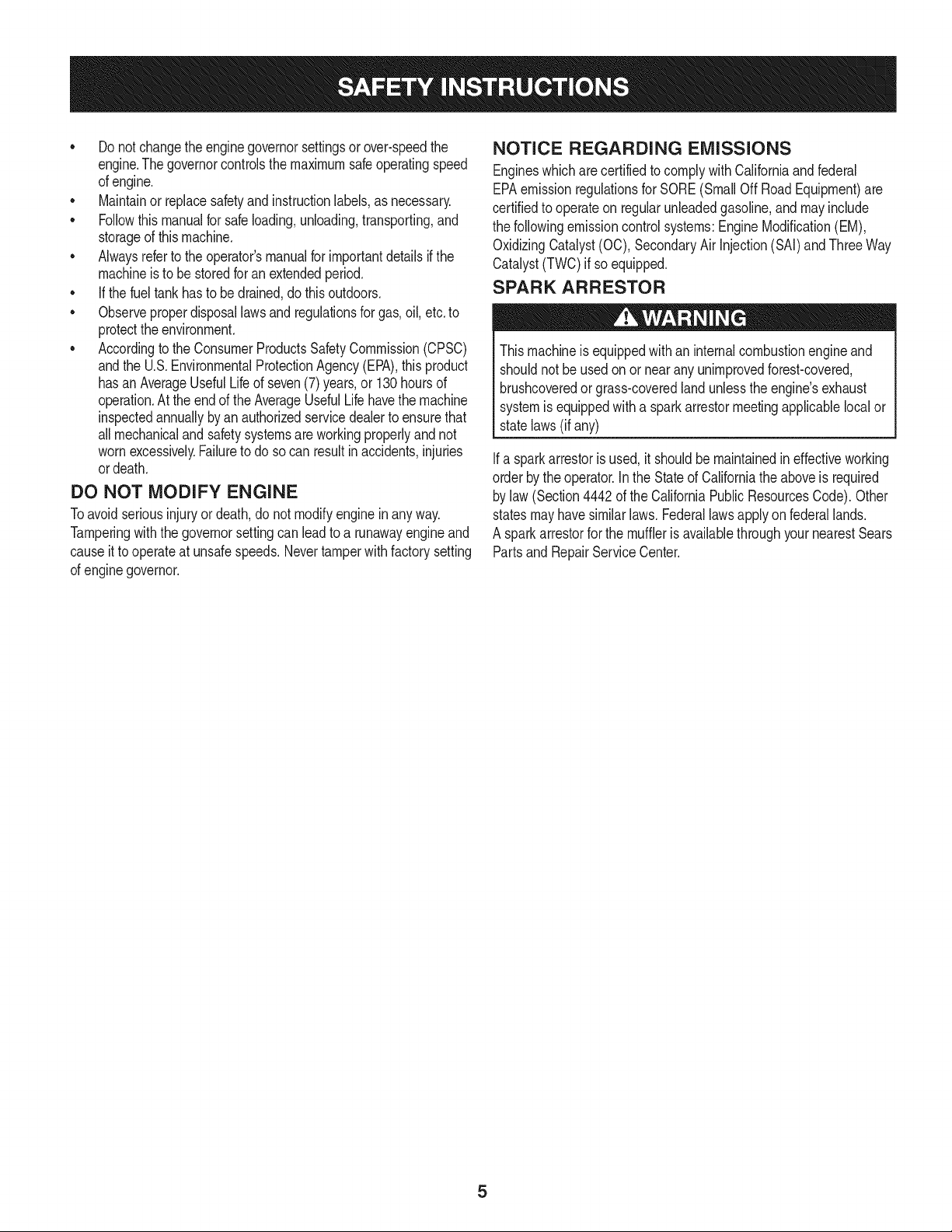

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING: YourResponsibility--Restricttheuse ofthispowermachinetopersonswhoread,understandandfollowthe

warningsand instructionsinthis manualandonthe machine.

SAVETHESEINSTRUCTIONS!

6

7

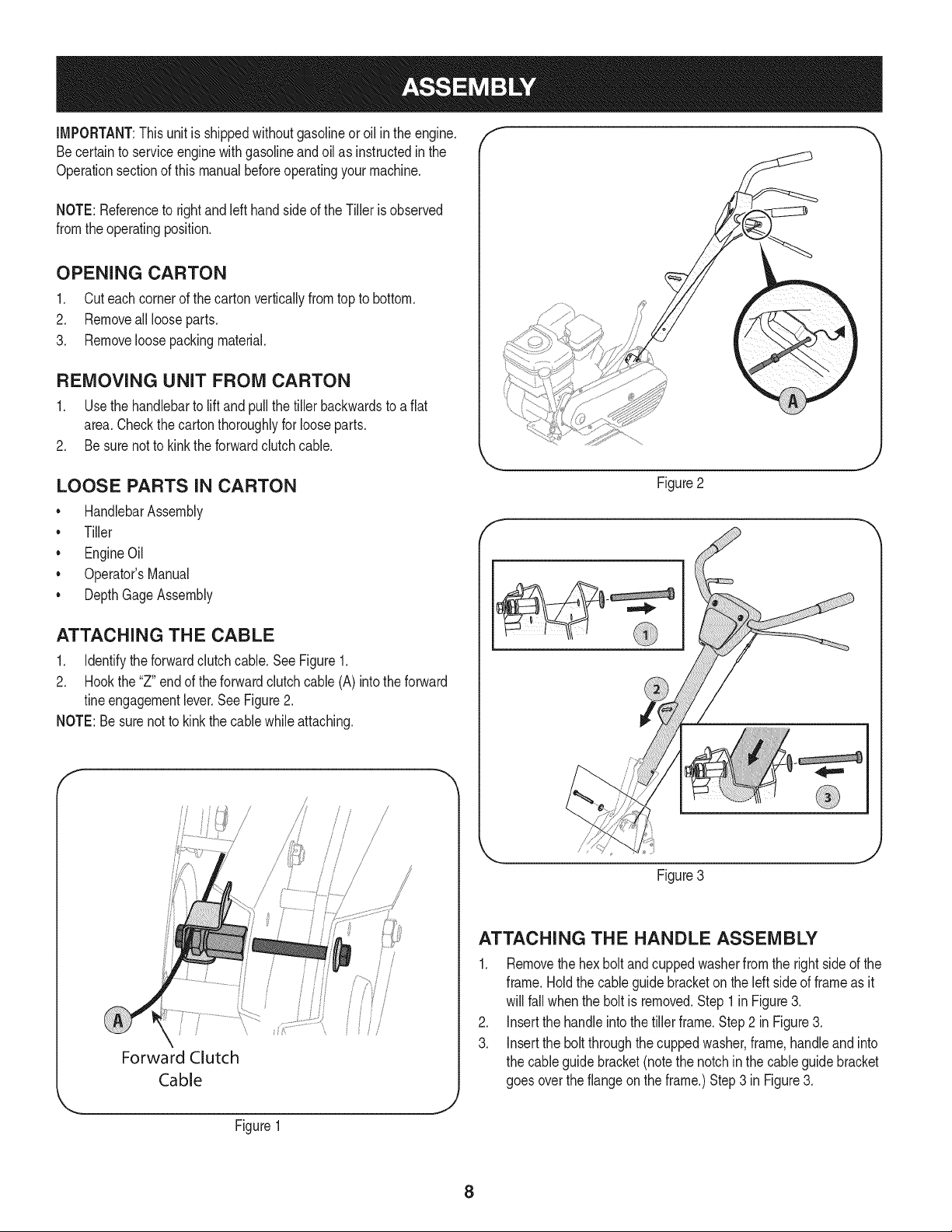

IMPORTANT:Thisunit isshippedwithoutgasolineoroil intheengine.

Becertaintoserviceenginewithgasolineandoilas instructedinthe

Operationsectionofthismanualbeforeoperatingyourmachine.

NOTE:Referenceto rightand lefthandsideofthe Tillerisobserved

fromtheoperatingposition.

OPENING CARTON

1. Cuteachcornerofthe cartonverticallyfromtopto bottom.

2. Removeall looseparts.

3. Removeloosepackingmaterial.

REMOVING UNIT FROM CARTON

1. Usethehandlebartoliftand pullthetiller backwardsto a flat

area.Checkthecartonthoroughlyforlooseparts.

2. Besurenotto kinkthe forwardclutchcable.

LOOSE PARTS IN CARTON

• HandlebarAssembly

• Tiller

• EngineOil

• Operator'sManual

• DepthGageAssembly

f

J

Figure2

f

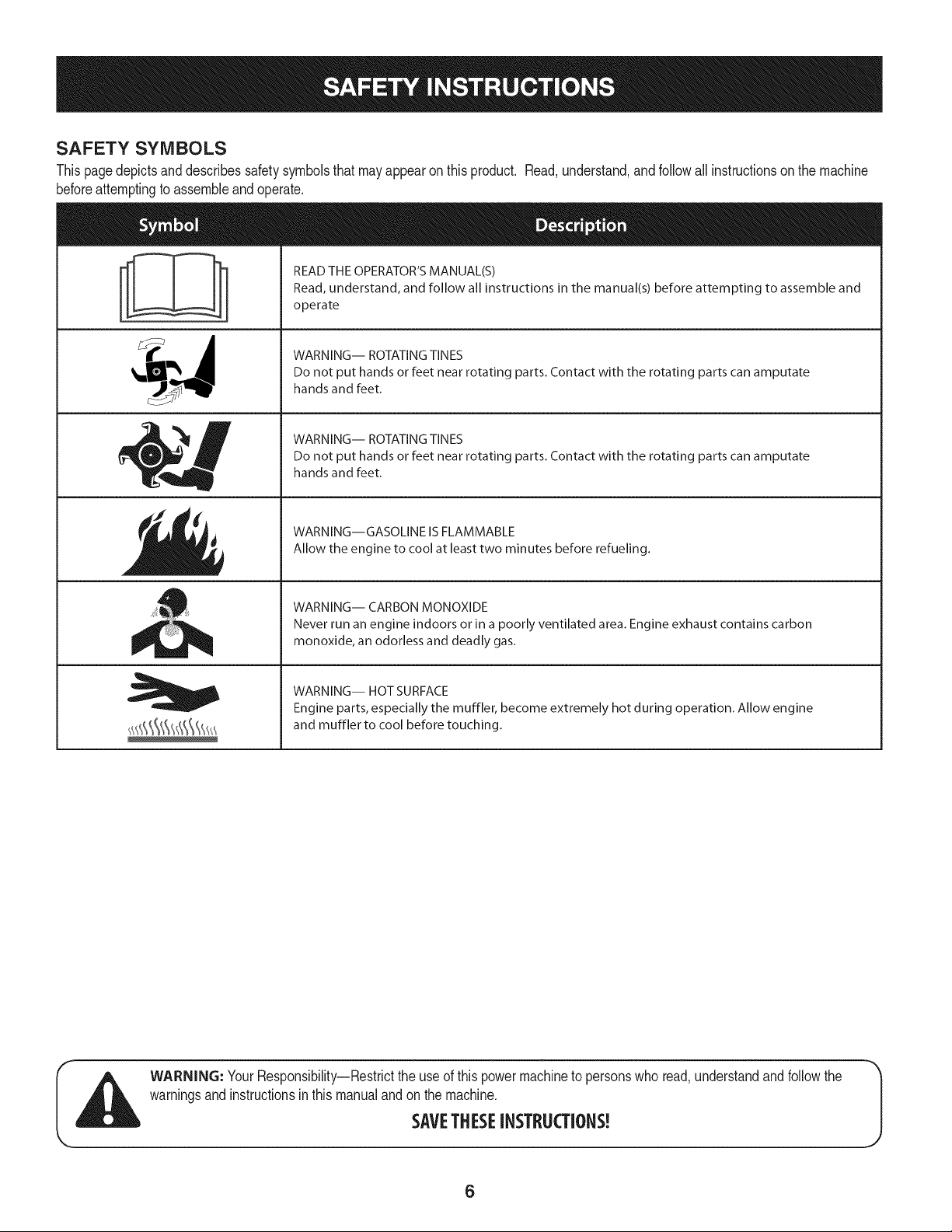

ATTACHING THE CABLE

1. Identifytheforwardclutchcable.SeeFigure1.

2. Hookthe"Z"endoftheforwardclutchcable(A)intotheforward

fineengagementlever.SeeFigure2.

NOTE:Besure notto kinkthecablewhileattaching.

/

/

/

Forward Clutch

Cable

J

Figure1

Figure3

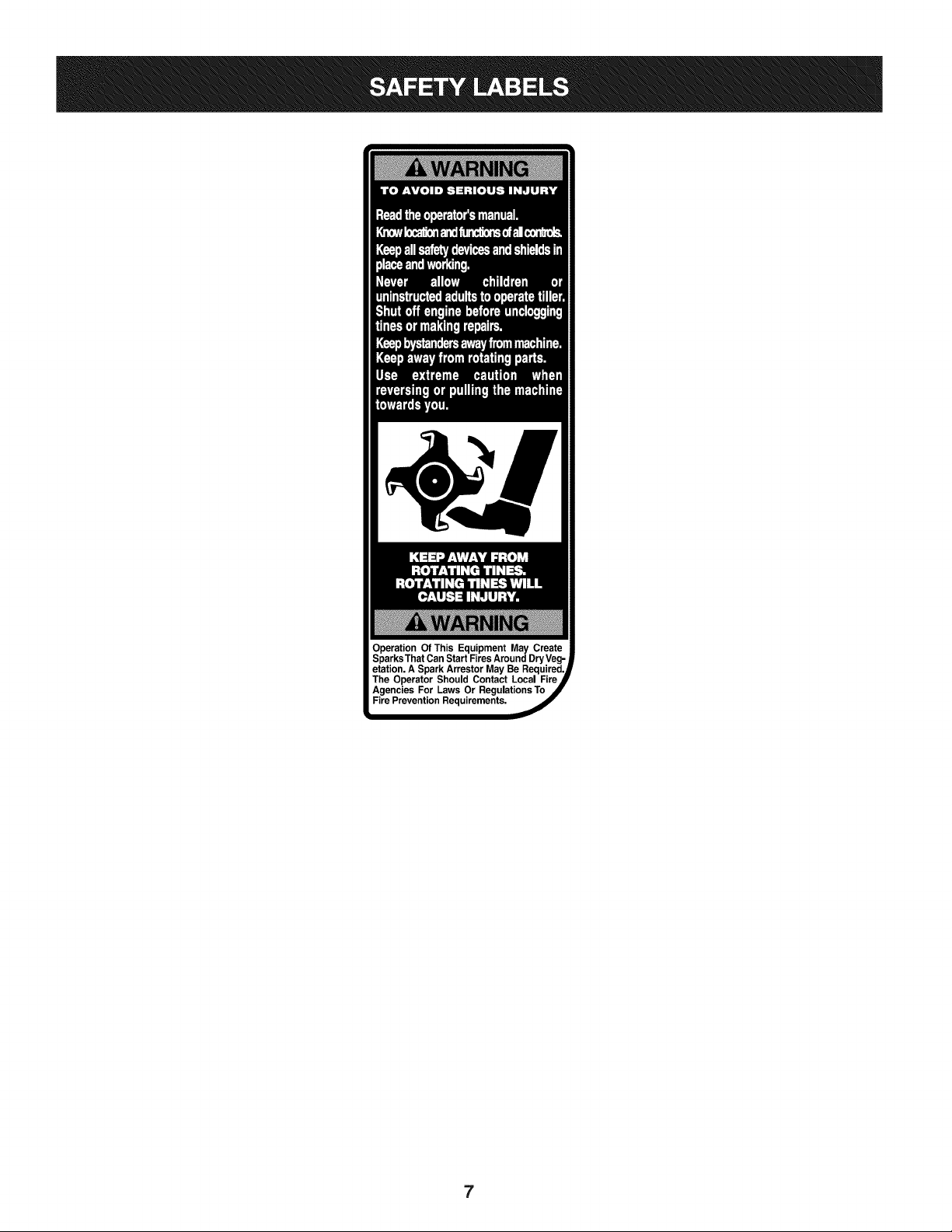

ATTACHING THE HANDLE ASSEMBLY

1. Removethehexboltandcuppedwasherfromtherightsideofthe

frame.Holdthecableguidebracketonthe left sideof frameas it

willfall whenthe boltis removed.Step 1in Figure3.

2. Insertthehandleintothe tillerframe.Step2 in Figure3.

3. Inserttheboltthroughthecuppedwasher,frame,handleandinto

thecableguidebracket(notethenotchinthe cableguidebracket

goesovertheflangeon theframe.)Step3 in Figure3.

8

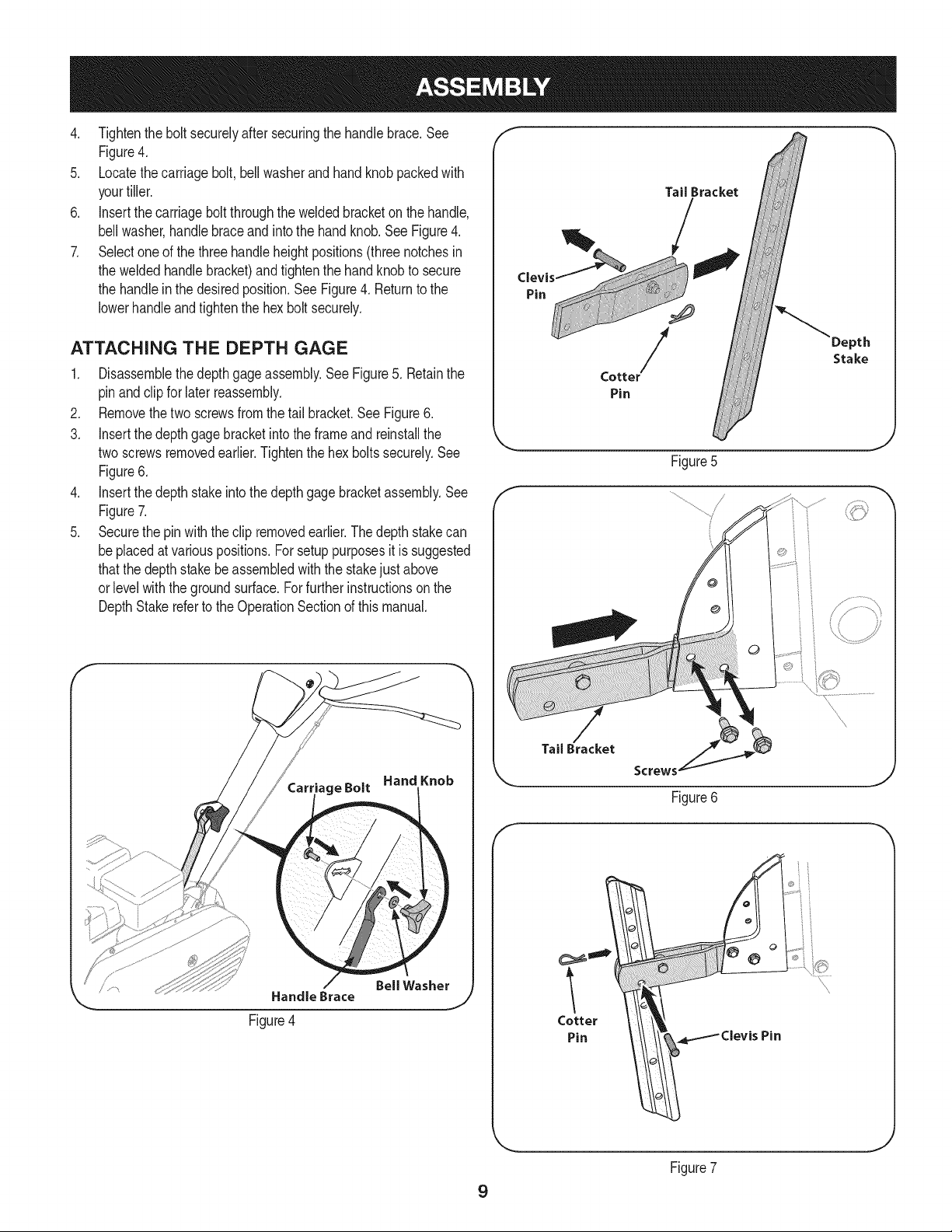

4. Tightentheboltsecurelyaftersecuringthe handlebrace.See

Figure4.

5. Locatethecarriagebolt,bellwasherandhandknobpackedwith

yourtiller.

6. Insertthe carriageboltthroughtheweldedbracketon the handle,

bellwasher,handlebraceandintothe handknob.SeeFigure4.

7. Selectoneofthe threehandleheightpositions(threenotchesin

theweldedhandlebracket)andtightenthe handknobtosecure

thehandleinthe desiredposition.SeeFigure4. Returntothe

lowerhandleandtightenthe hexbolt securely.

Tail Bracket

ATTACHING THE DEPTH GAGE

1. Disassemblethedepthgageassembly.See Figure5.Retainthe

pinandclipfor laterreassembly.

2. Removethetwo screwsfromthe tailbracket.SeeFigure6.

3. Insertthe depthgagebracketintothe frameand reinstallthe

twoscrewsremovedearlier.Tightenthehexboltssecurely.See

Figure6.

4. Insertthe depthstakeintothe depthgagebracketassembly.See

Figure7.

5. Securethepinwiththeclip removedearlier.Thedepth stakecan

beplacedat variouspositions.Forsetuppurposesit issuggested

thatthedepthstakebeassembledwiththestakejust above

orlevelwiththe groundsurface.Forfurtherinstructionsonthe

DepthStakerefertotheOperationSectionofthis manual.

Hand Knob

Depth

Stake

Pin

Figure5

.................. /,

.....................

Tail Bracket

Figure6

f

(:otter

Pin

9

_Clevis Pin

J

Figure7

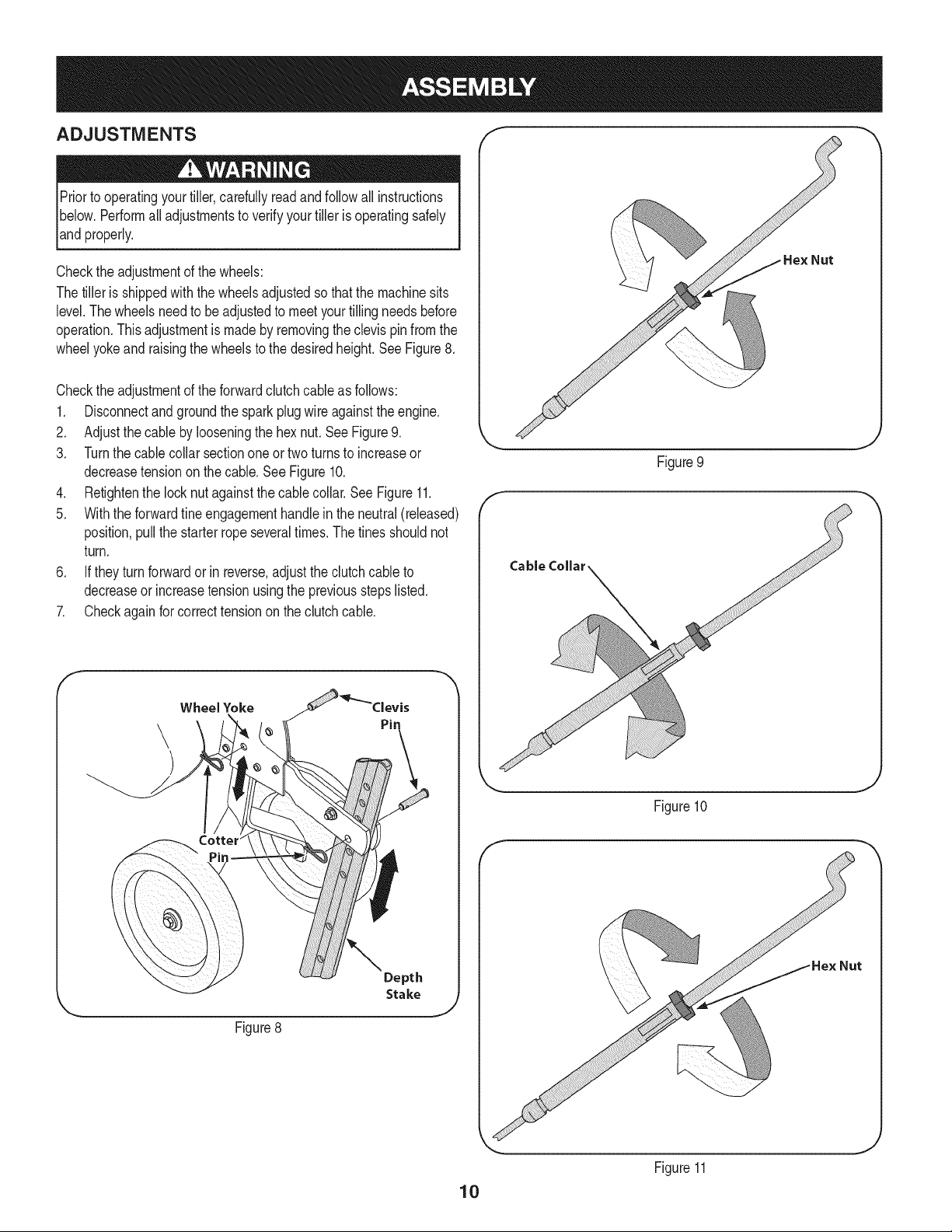

ADJUSTMENTS

Priortooperatingyourtiller,carefullyreadand followall instructions

below.Performall adjustmentstoverifyyourtiller isoperatingsafely

_andpropery.

Checktheadjustmentofthewheels:

Thetiller isshippedwiththewheelsadjustedso thatthe machinesits

level.Thewheelsneedto beadjustedto meetyourtillingneedsbefore

operation.Thisadjustmentismadeby removingtheclevispinfromthe

wheelyokeand raisingthewheelsto thedesiredheight.SeeFigure8.

Checktheadjustmentoftheforwardclutchcableasfollows:

1. Disconnectandgroundthesparkplugwire againsttheengine.

2. Adjustthecablebylooseningthe hexnut.SeeFigure9.

3. Turnthecablecollar sectiononeor twoturnsto increaseor

decreasetensionon thecable.SeeFigure10.

4. Retightenthelocknut againstthecablecollar.SeeFigure11.

5. Withtheforwardfine engagementhandlein theneutral(released)

position,pullthe starterropeseveraltimes.Thetinesshouldnot

turn.

6. Iftheyturnforwardor in reverse,adjustthe clutchcableto

decreaseor increasetensionusingthepreviousstepslisted.

7. Checkagainfor correcttensiononthe clutchcable.

f

J

Figure9

f

WheelYoke

Pin

\

Figure10

f

Depth

Stake

J

Figure8

Nut

10

J

Figure11

f

Muffler Forward Tine

Fuel Cap Adjustment

Oil Fill Cap

& Dipstick

Tiller Tines

Figure12

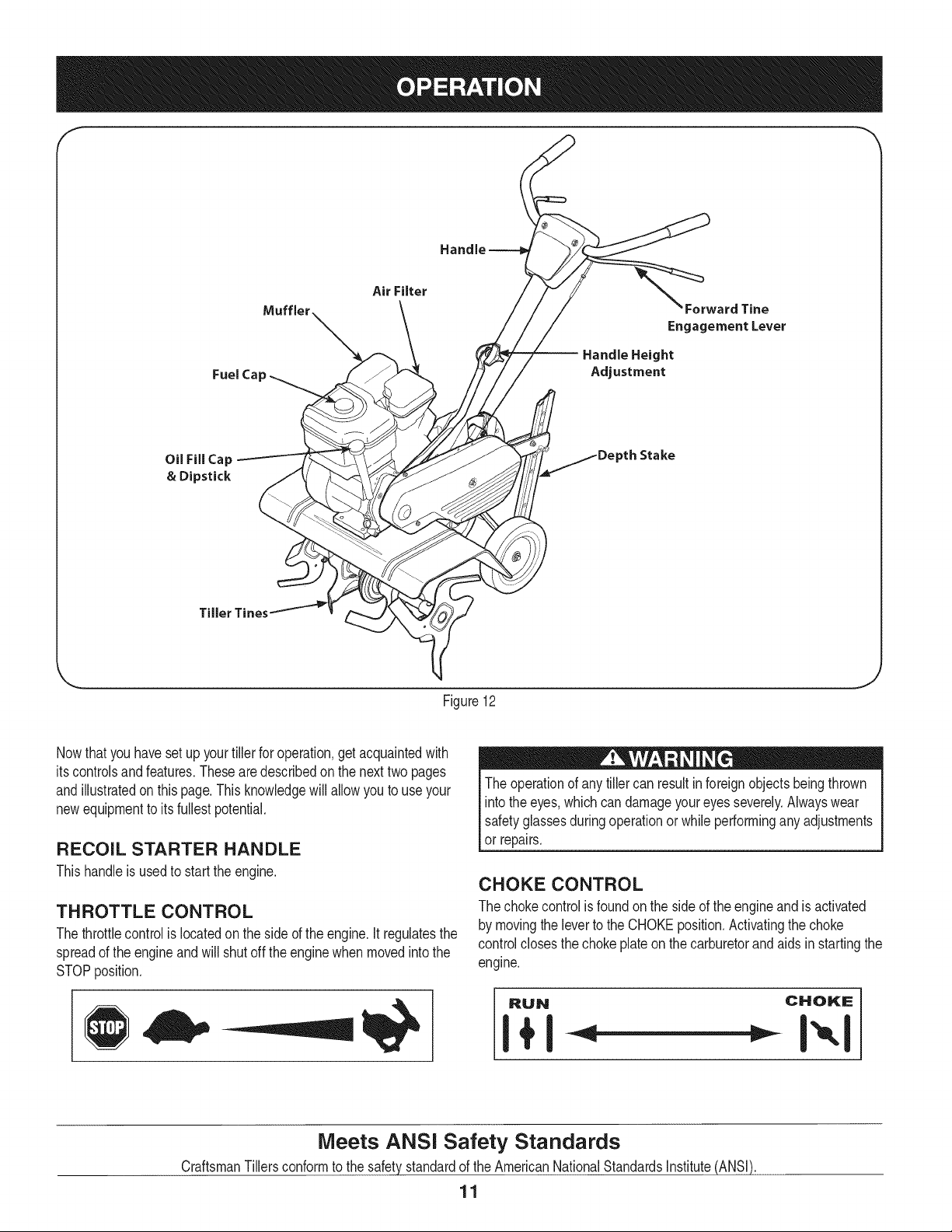

Nowthat youhavesetup yourtillerforoperation,getacquaintedwith

itscontrolsandfeatures.Thesearedescribedonthe nexttwopages

andillustratedon thispage.Thisknowledgewillallowyouto useyour

newequipmenttoits fullestpotential.

RECOIL STARTER HANDLE

Thishandleisusedto starttheengine.

THROTTLE CONTROL

Thethrottlecontrolis locatedonthe sideof theengine.Itregulatesthe

spreadoftheengineandwill shutoff theenginewhen movedintothe

STOPposition.

Handle Height

Theoperationofanytillercan resultinforeignobjectsbeingthrown

intothe eyes,whichcan damageyoureyesseverely.Alwayswear

safetyglassesduringoperationor whileperforminganyadjustments

or repairs.

Engagement Lever

Stake

.J

CHOKE CONTROL

Thechokecontrolis foundon the sideof theengineandis activated

bymovingthe leverto theCHOKEposition.Activatingthe choke

controlclosesthe chokeplateon the carburetorandaidsin startingthe

engine.

@

RUN CHOKE

Meets ANSi Safety Standards

CraftsmanTillersconformtothesafetystandardof theAmericanNationalStandardsInstitute(ANSI).

11

AiR FILTER

Theair filteris a deviceontheengineair intakethatpreventsdustand

dirtenteringtheengine.SeeFigure12.

MUFFLER

Engineexhaustexitstheenginevia themuffler.SeeFigure12.

DEPTH STAKE

Thedepthstakecontrolsthetillingdepth.SeeFigure12.

HANDLEBAR HEIGHT ADJUSTMENT

Thehandleheightmaybeadjusted.Loosentheknobtochangethe

position.Tightenhardwarewhencomplete.SeeFigure12.

OIL FILL CAP & DIPSTICK

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill. See

Figure12.

NOTE:ThisunitwasshippedWITHOUToil inthe engine.Oilis

includedintheplasticbagpackedwiththe manualinwiththe unit.

Addtheoil as directedin theGas & OilFillUp section.Checktheoil

levelbeforeeachoperationtoensureadequateoil is intheengine.

Forfurtherinstructions,refertothestepsintheEngineMaintenance

sectionof thismanual.

FORWARD TINE ENGAGEMENT LEVER

Theforwardtine engagementlevercontrolstheengagementof the

tines.Releasetheleverto stopthetines.SeeFigure12.

TINES

Tillingtinesareusedtocultivate,furrowandprepareyourgardenfor

seeding.SeeFigure12.

12

GAS AND OIL FILL-UP

Oil (one bottle shipped with unit)

FirstTimeUse

1. Removeoilfilldipstick.

2. Withthetilleron levelground,usea funneltoemptyentire

contentsofoil bottleprovidedintothe engine.

3. Replaceoilfilldipstickandtighten.

Subsequent Uses

Onlyusehighqualitydetergentoil ratedwithAPIserviceclassification

SF,SG,SH,SJor higher.Selecttheoil'sSAEviscositygradeaccord-

ingtothe expectedoperatingtemperature.Followthe chartbelow.

°F °C

Althoughmulti-viscosityoils (5W30,10W30,etc.)improvestarting

incoldweather,theywillresultinincreasedoilconsumptionwhen

usedabove32°RCheckyourengineoillevelmorefrequentlyto avoid

possibleenginedamagefromrunninglowon oil.

1. Checktheoillevelmakingcertainnotto rubthedipstickalongthe

insidewallsoftheoil filltube.Thiswould resultina falsedipstick

reading.Wipedipstickcleanwithcloth. Replacedipstickinto

theoilfiller neck,but donotscrewitin.Removeandcheckoil

level.RefilltoFULLmarkondipstick,ifnecessary.Capacityis

approximately20oz.Overfillingwillcausetheenginetosmoke

profuselyandwill resultin poorengineperformance.

2. Replaceoilfilldipstickandtighten.

3. Keepoil levelat FULL.Runningtheenginewithtoo littleoilcan

resultinpermanentenginedamage.

Alcoholblendedfuels(calledgasoholorusingethanolormethanol)

canattractmoisturewhichleadsto separationandformationofacids

duringstorage.Acidicgascandamagethefuel systemofanengine

whilein storage.

Toavoidengineproblems,the fuelsystemshouldbeemptied

beforestoragefor30daysor longer.Drainthegas tank,start the

engineandletit rununtilthe gastank, fuellinesand carburetorare

empty.Usefreshfuelnextseason.SeeSTORAGEInstructionsfor

additionalinformation.

Neveruseengineor carburetorcleanerproductsinthefueltankor

permanentdamagemayoccur.

NOTE:Checkthefuellevelperiodicallytoavoidrunningoutof

gasolinewhileoperatingthetiller.

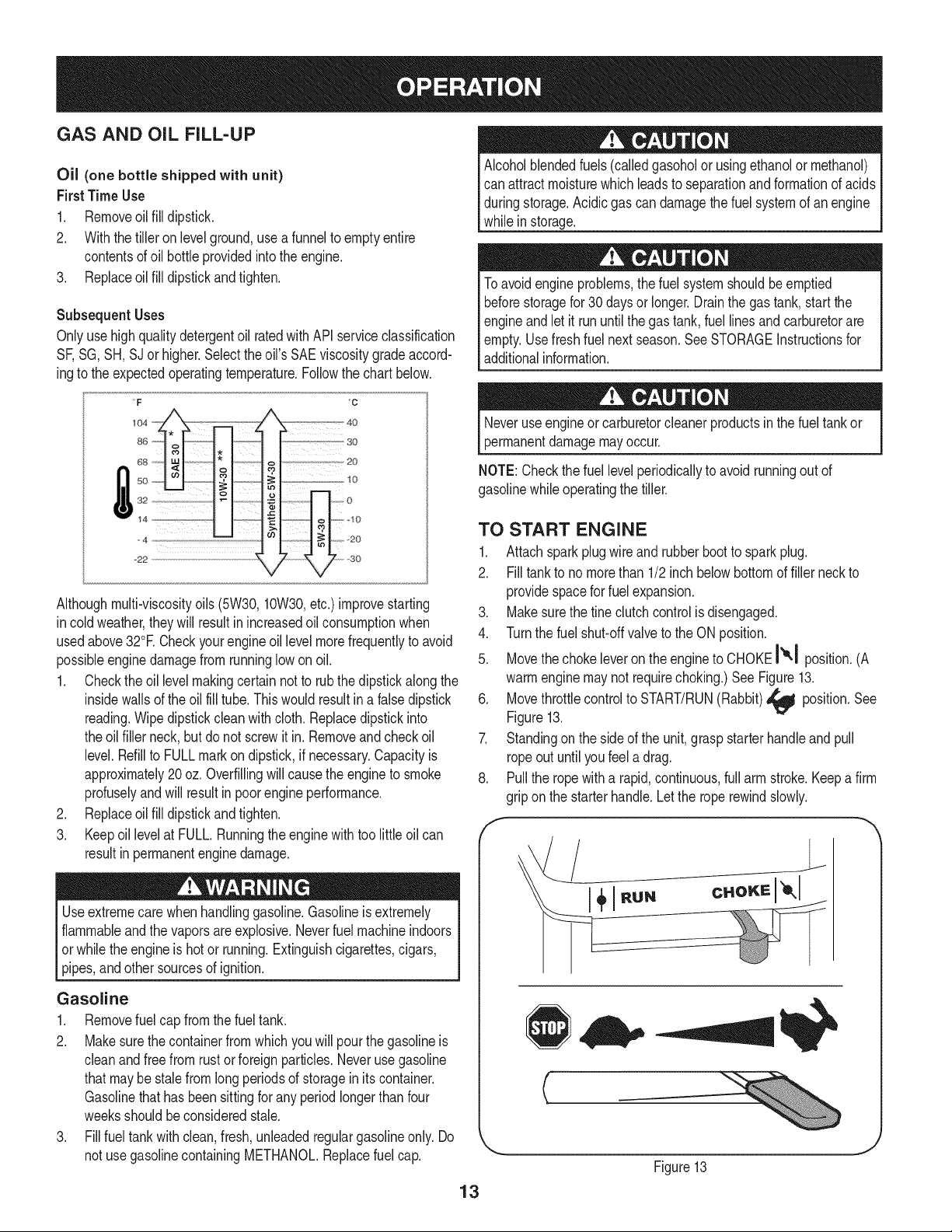

TO START ENGINE

1. Attachsparkplugwireandrubberbootto sparkplug.

2. Filltankto no morethan 1/2inch belowbottomoffiller neckto

providespacefor fuelexpansion.

3. Makesurethe tineclutchcontrolisdisengaged.

4. Turnthe fuelshut-offvalveto theONposition.

5. Movethechokeleveron theengineto CHOKEI'_1 position.(A

warmenginemaynotrequirechoking.)SeeFigure13.

6. Movethrottlecontrolto START/RUN(Rabbit)_ position.See

Figure13.

7. Standingonthe sideof theunit,graspstarterhandleandpull

ropeoutuntilyoufeela drag.

8. Pulltheropewitha rapid,continuous,fullarm stroke.Keepa firm

gripon thestarterhandle.Letthe roperewindslowly.

f

extreme when Gasolineis

flammableandthe vaporsareexplosive.Neverfuelmachineindoors

or whilethe engineishotor running.Extinguishcigarettes,cigars,

l Use care handlinggasoline, extremely

pipes,andothersourcesofignition.

Gasoline

1. Removefuelcap fromthefuel tank.

2. Makesurethecontainerfromwhichyouwill pourthegasolineis

cleanandfreefrom rustorforeignparticles.Neverusegasoline

thatmaybestalefromlongperiodsofstorageinitscontainer.

Gasolinethathas beensittingfor anyperiodlongerthan four

weeksshouldbeconsideredstale.

3. Fillfueltankwithclean,fresh,unleadedregulargasolineonly.Do

notusegasolinecontainingMETHANOL.Replacefuelcap.

C

J

Figure13

13

9. Repeat,if necessary,untilenginestarts.Whenenginestarts,

movechokecontrolgraduallytowardthe RUNI _'I position..

10. Ifenginefalters,movechokecontrolbacktowardtheCHOKE

I'_1 positionand repeatsteps5 though8.

11. ALWAYSkeepthethrottlecontrolintheSTART/RUN(Rabbit)

positionwhenoperatingthetiller.

TO STOP ENGINE

1. Tostopthewheelsandtines,releasethe ForwardClutchBail.

2. Movethrottlecontrollevertoslow(turtle)_ position.

Wheneverpossible,graduallyreduceenginespeedbefore

stoppingengine.

3. MovethrottlecontrollevertoSTOP_ orOFFposition.

4. Turnthefuelshut-offvalveto theOFFposition.

5. Disconnectsparkplugwireandgrounditagainsttheengineto

preventaccidentalstartingwhiletheequipmentis unattended.

Wheel Wheel Yoke

J

Figure14

TO ENGAGE DRIVE & TINES

1. Forforwardmotionof thewheelsand powertothetinespullthe

ForwardClutchBailupagainstthehandlebar.

2. Whentilling,relaxandletthewheelspullthemachinewhilethe

tinesdig.Walkslowlybehindthetiller allowingitto moveat its

ownpacewhilekeepinga securegriponthehandlebarwithyour

elbowsflexed.

3. Releasethebailtostoptheforwardmotionofwheelsandtines.

TURNING THE TILLER

1. Practiceturningthetillerinalevel,openarea.Beverycarefultokeep

yourfeetandlegs awayfromthetines.

2. Tobeginaturn, liftthe handlebarsuntil thetinesareout ofthe

groundandtheengineandtinesarebalancedoverthewheels.

3. Withthetillerbalanced,push sidewayson thehandlebartosteer

in thedirectionof theturn.Afterturning,slowlylowerthe tinesinto

thesoilto resumetilling.

Becertainsparkplugwireis disconnectedandgroundedagainstthe

enginewhenperformingany adjustments.

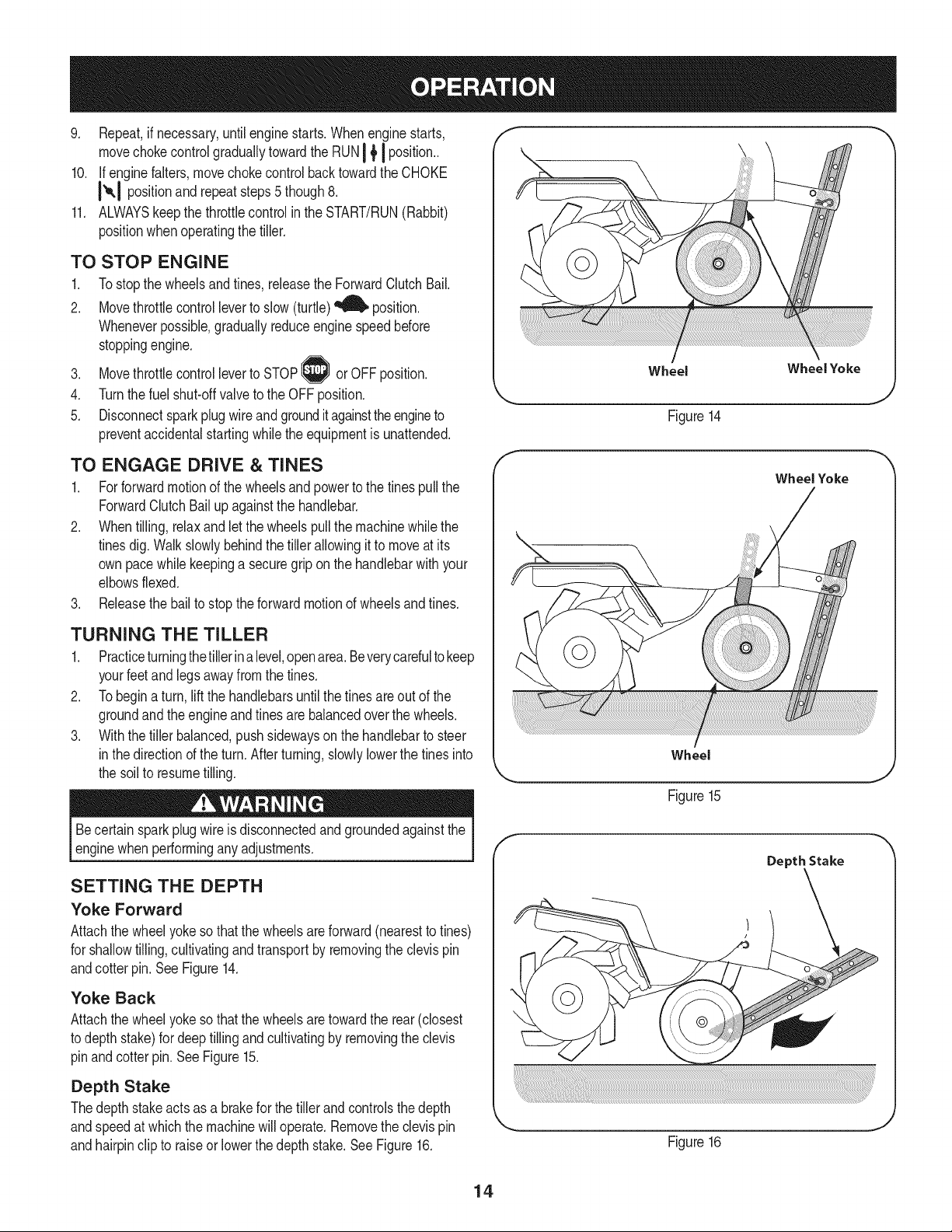

SETTING THE DEPTH

Yoke Forward

Attachthe wheelyokeso thatthewheelsareforward(nearesttotines)

forshallowtilling,cultivatingandtransportbyremovingthe clevispin

andcotterpin. SeeFigure14.

Wheel Yoke

Wheel

.J

Figure15

f

Depth Stake

Yoke Back

Attachthe wheelyokeso thatthewheelsaretowardthe rear(closest

todepthstake)for deeptillingandcultivatingbyremovingtheclevis

pinandcotterpin.SeeFigure15.

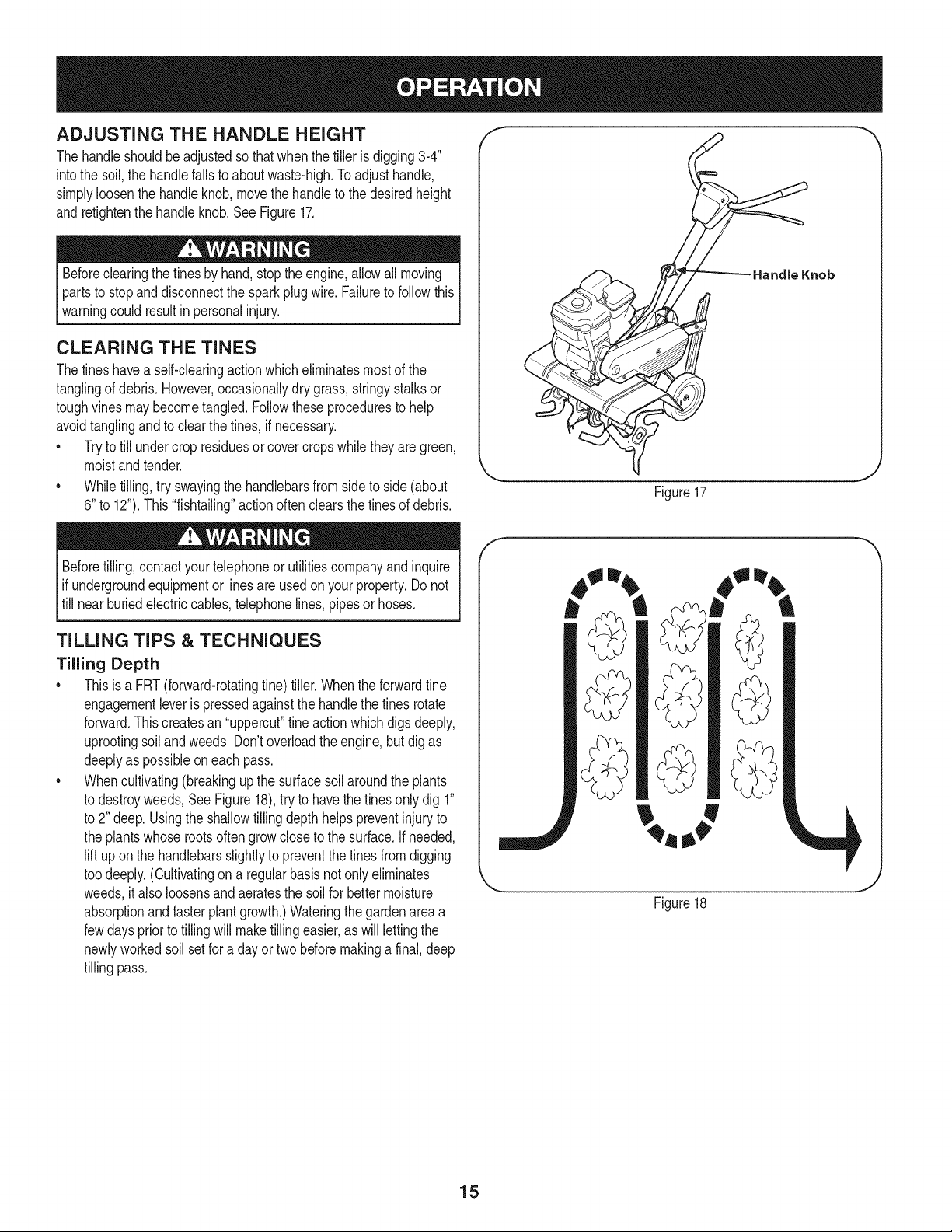

Depth Stake

Thedepth stakeactsasa brakeforthe tillerandcontrolsthedepth

andspeedat whichthemachinewill operate.Removetheclevispin

andhairpinclipto raiseorlowerthedepth stake.SeeFigure16.

J

Figure16

14

ADJUSTING THE HANDLE HEIGHT

Thehandleshouldbe adjustedsothatwhenthetillerisdigging3-4"

intothe soil,thehandlefallsto aboutwaste-high.To adjusthandle,

simplyloosenthehandleknob,movethe handletothe desiredheight

andretightenthehandleknob.SeeFigure17.

Beforeclearingthetinesbyhand,stoptheengine,allowall moving

partsto stopanddisconnectthe sparkplugwire.Failureto followthis

warningcouldresultin personalinjury.

CLEARING THE TINES

Thetineshavea self-clearingactionwhicheliminatesmostofthe

tanglingofdebris.However,occasionallydrygrass,stringystalksor

toughvinesmaybecometangled.Followtheseprocedurestohelp

avoidtanglingandtoclearthetines,if necessary.

• Tryto tillundercrop residuesor covercropswhiletheyaregreen,

moistandtender.

• Whiletilling,try swayingthehandlebarsfromsidetoside (about

6"to12").This"fishtailing"actionoftenclearsthetinesofdebris.

Beforetilling,contactyourtelephoneor utilitiescompanyandinquire

l ifundergroundequipmentorlinesareusedonyour property.Donot

|till nearburiedelectriccables,telephonelines,pipesor hoses.

[

TILLING TIPS & TECHNIQUES

Tilling Depth

• Thisisa FRT(forward-rotatingfine) tiller.Whenthe forwardtine

engagementleveris pressedagainstthehandlethe tinesrotate

forward.Thiscreatesan"uppercut"tineactionwhichdigsdeeply,

uprootingsoilandweeds.Don'toverloadthe engine,butdigas

deeplyas possibleon eachpass.

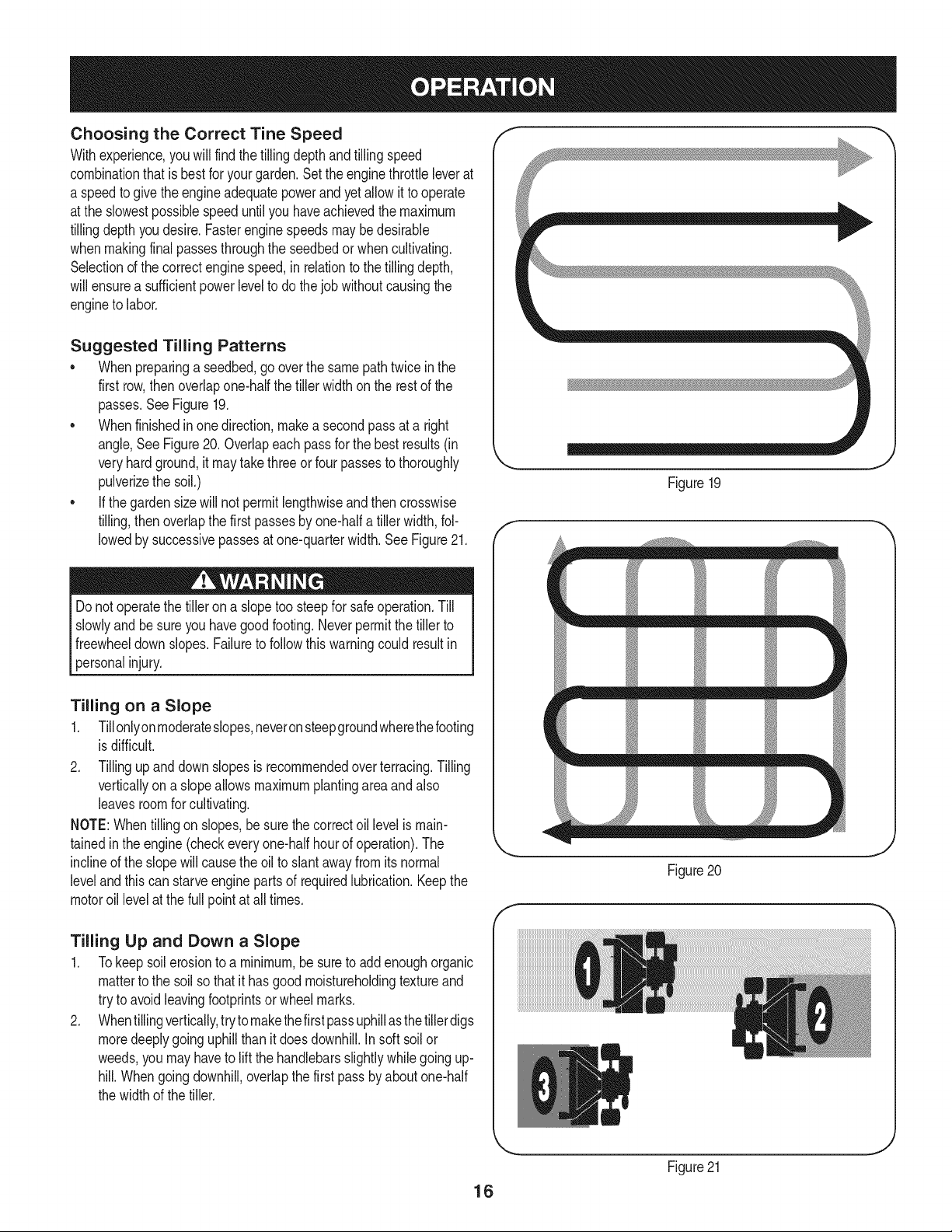

• Whencultivating(breakingupthesurfacesoilaroundtheplants

todestroyweeds,SeeFigure18),tryto havethetinesonlydig 1"

to2" deep.Usingtheshallowtilling depthhelpspreventinjuryto

theplantswhoserootsoftengrow closetothe surface.If needed,

lift uponthe handlebarsslightlytopreventthetinesfromdigging

toodeeply.(Cultivatingona regularbasisnotonlyeliminates

weeds,it alsoloosensandaeratesthe soilfor bettermoisture

absorptionandfasterplantgrowth.)Wateringthegardenareaa

fewdayspriortotillingwillmaketillingeasier,aswill lettingthe

newlyworkedsoilsetfora dayortwo beforemakinga final,deep

tillingpass.

Figure17

f

J

Figure18

15

Choosing the Correct Tine Speed

Withexperience,you willfindthetillingdepthandtilling speed

combinationthatisbestforyourgarden.Settheenginethrottleleverat

a speedtogivethe engineadequatepowerandyetallowittooperate

atthe slowestpossiblespeeduntilyouhaveachievedthe maximum

tillingdepthyoudesire.Fasterenginespeedsmaybedesirable

whenmakingfinalpassesthroughtheseedbedorwhencultivating.

Selectionofthecorrectenginespeed,inrelationto thetillingdepth,

willensurea sufficientpowerlevelto dothejob withoutcausingthe

enginetolabor.

Suggested Tilling Patterns

• Whenpreparinga seedbed,go overthesamepathtwiceinthe

firstrow,thenoverlapone-halfthetillerwidthontherestof the

passes.SeeFigure19.

• Whenfinishedinonedirection,makeasecondpassat a right

angle,SeeFigure20.Overlapeachpassfor thebest results(in

veryhardground,itmaytakethreeorfour passestothoroughly

pulverizethesoil.)

• If thegardensizewillnot permitlengthwiseandthen crosswise

tilling,thenoverlapthefirstpassesby one-halfatillerwidth,fol-

lowedby successivepassesat one-quarterwidth.SeeFigure21.

Figure19

Donot operatethetilleron a slopetoosteepfor safeoperation.Till

slowlyandbe sureyouhavegoodfooting.Neverpermitthetillerto

freewheeldownslopes.Failuretofollowthiswarningcouldresultin

personalinjury.

Tilling on a Slope

1. Tillonlyonmoderateslopes,neveronsteepgroundwherethefooting

isdifficult.

2. Tillingupanddownslopesisrecommendedoverterracing.Tilling

verticallyon a slopeallowsmaximumplantingareaandalso

leavesroomforcultivating.

NOTE:Whentillingonslopes,besurethe correctoil levelismain-

tainedinthe engine(checkeveryone-halfhourofoperation).The

inclineof theslopewillcausethe oiltoslantawayfromitsnormal

levelandthiscan starveenginepartsof requiredlubrication.Keepthe

motoroil levelatthefullpointatalltimes.

Tilling Up and Down a Slope

1. Tokeepsoil erosiontoa minimum,be suretoaddenoughorganic

mattertothe soilsothatit hasgoodmoistureholdingtextureand

tryto avoidleavingfootprintsor wheelmarks.

2. Whentillingvertically,trytomakethefirstpassuphillasthetillerdigs

moredeeplygoinguphillthanit doesdownhill.Insoftsoil or

weeds,youmayhavetolift thehandlebarsslightlywhilegoingup-

hill.Whengoingdownhill,overlapthefirstpassbyaboutone-half

thewidthof thetiller.

[

m_m_

t j

Figure20

16

Figure21

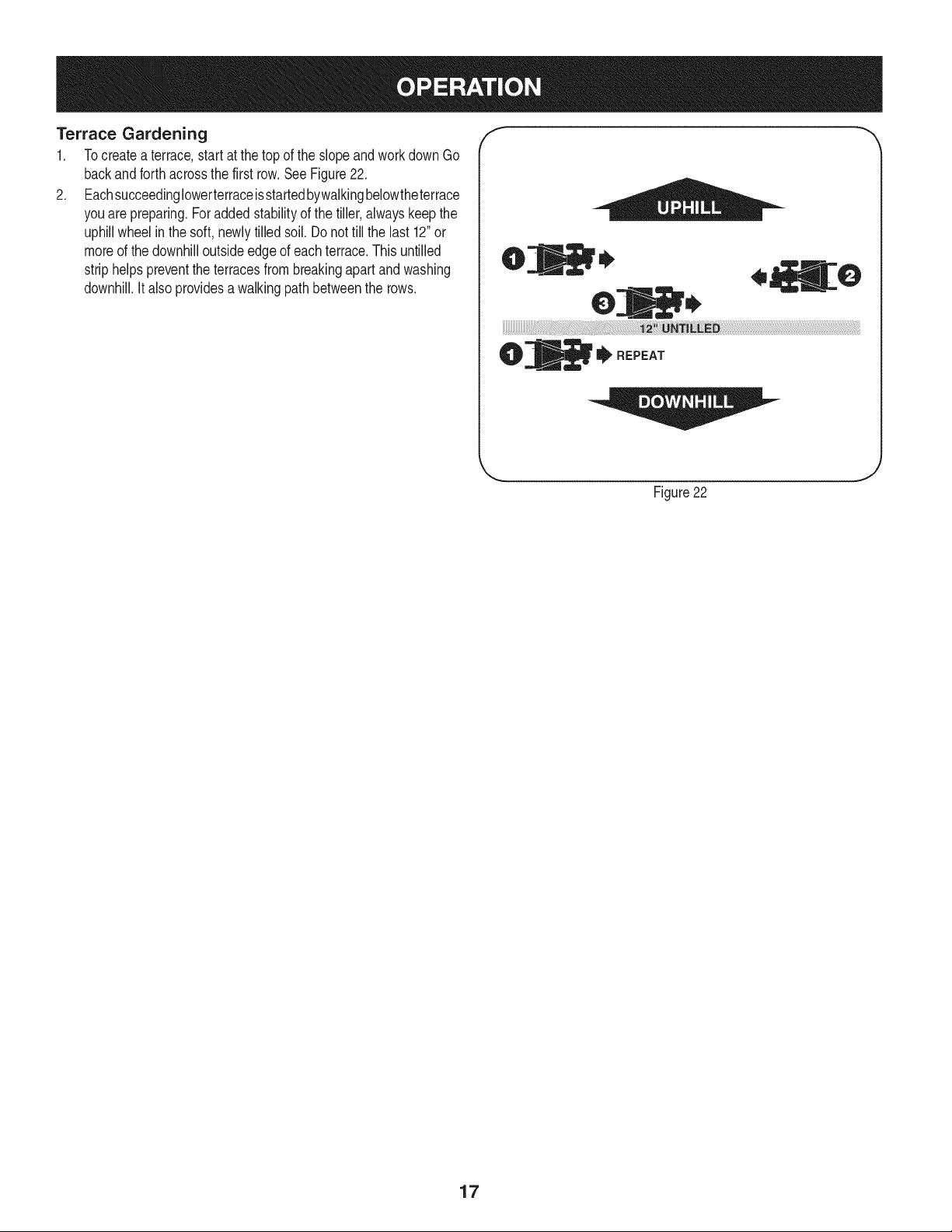

Terrace Gardening

1. Tocreateaterrace,startat thetop ofthe slopeandworkdownGo

backand forthacrossthe firstrow.SeeFigure22.

2. EachsucceedingIowerterraceisstartedbywalkingbelowtheterrace

youare preparing.Foraddedstabilityofthetiller,alwayskeepthe

uphillwheelinthe soft,newlytilledsoil.Donottill thelast 12"or

moreof thedownhilloutsideedgeofeachterrace.Thisuntilled

striphelpspreventtheterracesfrombreakingapartandwashing

downhill.Italsoprovidesawalkingpathbetweenthe rows.

f

,O

' REPEA'

J

Figure22

17

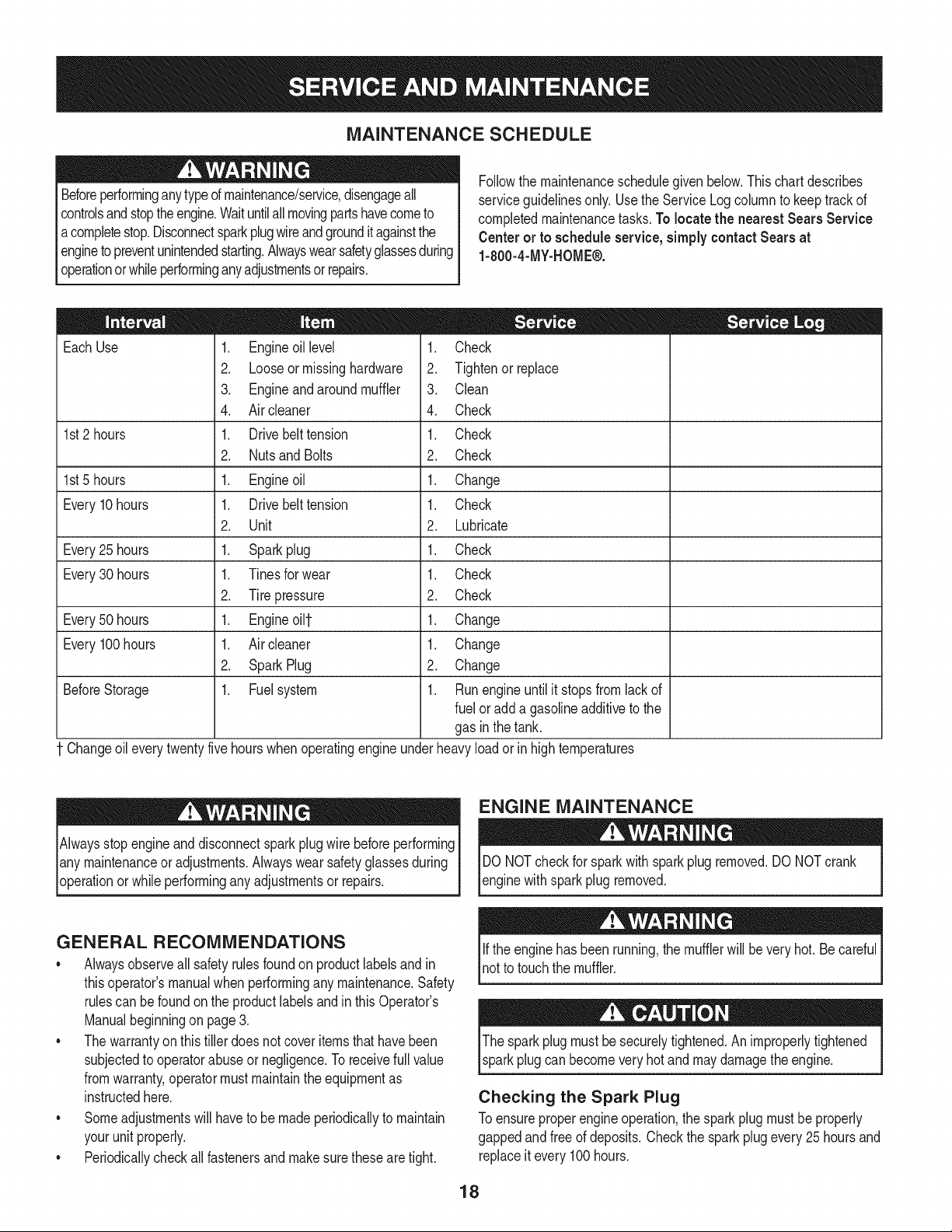

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.To locate the nearest Sears Service

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

operationorwhileperforminganyadjustmentsorrepairs.

Followthemaintenanceschedulegivenbelow.Thischartdescribes

= =

EachUse

1st2 hours

1st5 hours

Every10hours

Every25 hours

Every30 hours

Every50 hours

Every100hours

BeforeStorage

.

Engineoillevel

2.

Looseormissinghardware

3.

Engineandaroundmuffler

4.

Aircleaner

1.

Drivebelttension

2.

Nutsand Bolts

1.

Engineoil

1.

Drivebelttension

2.

Unit

1.

Sparkplug

1.

Tinesforwear

2.

Tirepressure

1.

Engineoill-

1.

Aircleaner

2.

SparkPlug

1.

Fuelsystem

1. Check

2. Tightenor_place

3. Clean

4. Check

1. Check

2. Check

1. Change

1. Check

2. Lubricate

1. Check

1. Check

2. Check

1. Change

1. Change

2. Change

1. Runengineuntilit stopsfromlackof

fueloradda gasolineadditivetothe

gasin thetank.

Changeoileverytwentyfivehourswhenoperatingengineunderheavyloadorinhightemperatures

Alwaysstopengineanddisconnectsparkplugwirebeforeperforming

lanymaintenanceor adjustments.Alwayswearsafetyglassesduring

[operationorwhileperforminganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

• Alwaysobserveallsafetyrulesfoundonproductlabelsandin

thisoperator'smanualwhenperforminganymaintenance.Safety

rulescan befoundonthe productlabelsandin thisOperator's

Manualbeginningon page3.

• Thewarrantyonthistillerdoesnotcoveritemsthathavebeen

subjectedto operatorabuseor negligence.Toreceivefullvalue

fromwarranty,operatormustmaintainthe equipmentas

instructedhere.

• Someadjustmentswillhaveto be madeperiodicallytomaintain

yourunit properly.

• Periodicallycheckall fastenersand makesurethesearetight.

ENGINE MAINTENANCE

DONOTcheckforsparkwithsparkplugremoved.DONOTcrank

enginewithsparkplug removed.

Iftheenginehas beenrunning,themufflerwillbeveryhot. Becareful

notto touchthemuffler.

Thesparkplugmustbesecurelytightened.Animproperlytightened

sparkplugcanbecomeveryhot andmaydamagetheengine.

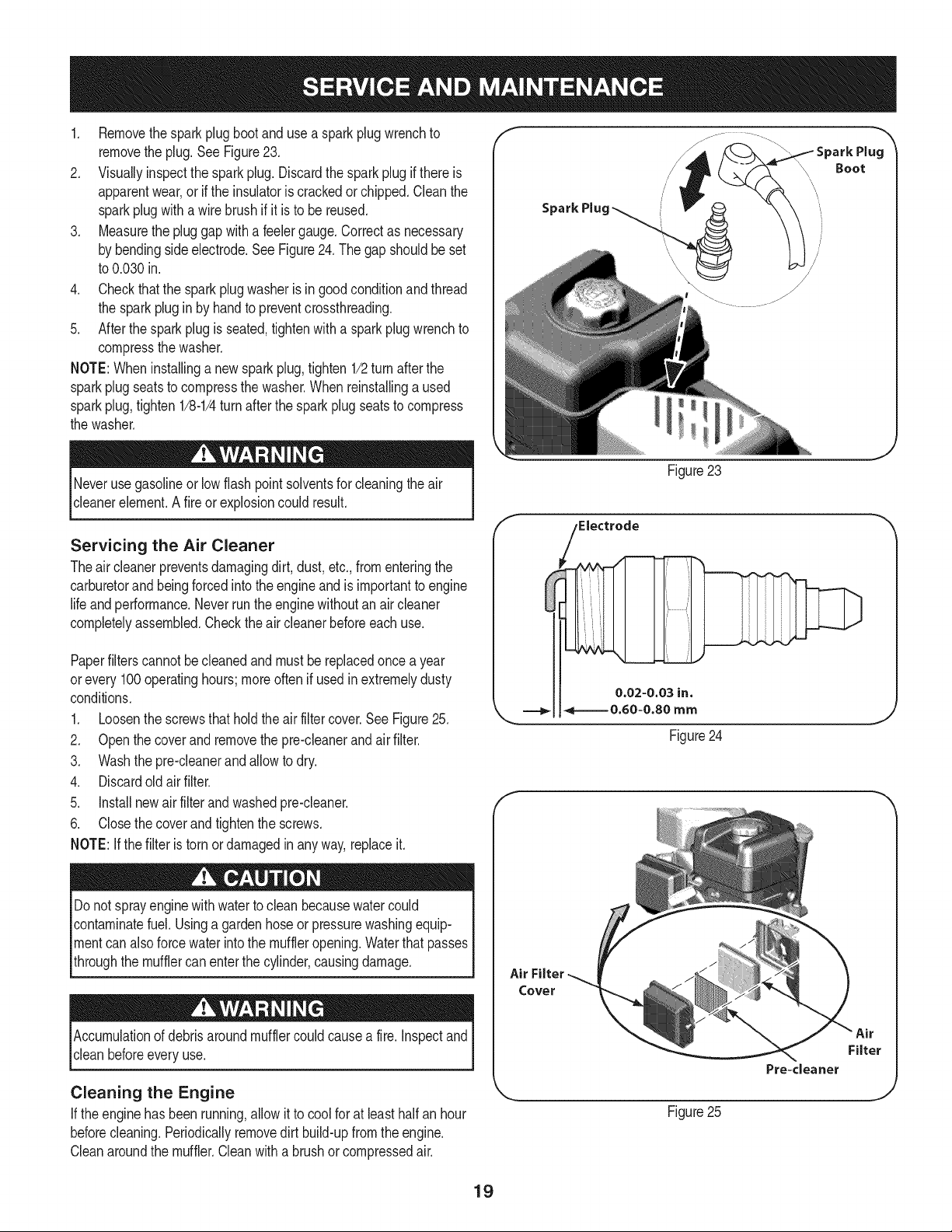

Checking the Spark Plug

Toensureproperengineoperation,thesparkplugmustbeproperly

gappedandfreeof deposits.Checkthe sparkplugevery25hoursand

replaceitevery100hours.

18

1. Removethesparkplugbootandusea sparkplugwrenchto

removetheplug.See Figure23.

2. Visuallyinspectthesparkplug.Discardthesparkplugif thereis

apparentwear,orif the insulatoriscrackedorchipped.Cleanthe

sparkplugwitha wirebrush ifit isto be reused.

3. Measurethe pluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure24.The gapshouldbeset

to0.030in.

4. Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin by handtopreventcrossthreading.

5. Afterthesparkplugis seated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2turnafterthe

sparkplugseatsto compressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-1/4turnafterthesparkplugseatsto compress

thewasher.

Boot

Neverusegasolineorlowflashpointsolventsforcleaningthe air

ceanereement. A fre orexposoncou d resut.

Servicing the Air Cleaner

Theair cleanerpreventsdamagingdirt, dust,etc.,fromenteringthe

carburetorand beingforcedintothe engineandisimportanttoengine

lifeandperformance.Neverrunthe enginewithoutanaircleaner

completelyassembled.Checktheaircleanerbeforeeachuse.

Paperfilterscannotbecleanedandmustbe replacedonceayear

orevery 100operatinghours;moreoftenifusedin extremelydusty

conditions.

1. Loosenthescrewsthatholdtheair filtercover.SeeFigure25.

2. Openthecoverand removethepre-cleanerandairfilter.

3. Washthepre-cleanerandallowto dry.

4. Discardoldairfilter.

5. Installnewairfilterandwashedpre-cleaner.

6. Closethecoverandtightenthe screws.

NOTE:Ifthe filteristorn ordamagedinanyway,replaceit.

Donot sprayenginewithwatertoclean becausewatercould

contaminatefuel. Usinga gardenhoseorpressurewashingequip-

mentcanalso forcewaterintothe muffleropening.Waterthat passes

throughthemufflercanenterthe cylinder,causingdamage.

,Electrode

0.02-0.03 in.

===_1_====0.60=0.80 mm

E

Air Filter

Cover

Figure23

J

Figure24

Accumulationofdebrisaroundmufflercouldcausea fire.Inspectand

cleanbeforeeveryuse.

Cleaning the Engine

If theenginehasbeenrunning,allowitto coolfor atleasthalfan hour

beforecleaning.Periodicallyremovedirtbuild-upfromtheengine.

Cleanaroundthe muffler.Cleanwithabrushor compressedair.

Filter

Pre+cleaner

J

Figure25

19

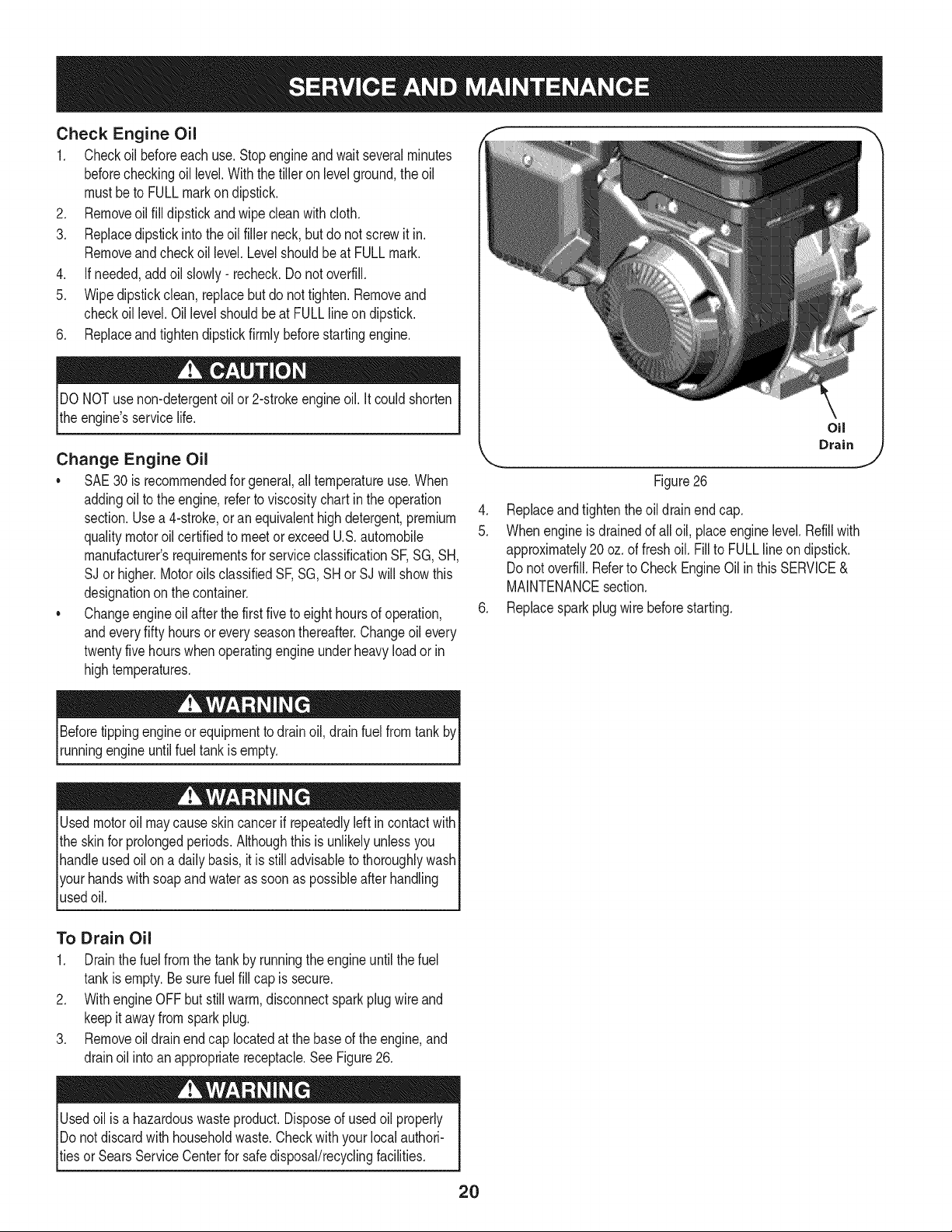

Check Engine Oil

1. Checkoilbeforeeachuse.Stopengineandwaitseveralminutes

beforecheckingoil level.Withthetilleron levelground,the oil

mustbeto FULLmarkon dipstick.

2. Removeoil filldipstickandwipe cleanwithcloth.

3. Replacedipstickintotheoilfiller neck,but donotscrewitin.

Removeandcheckoil level.Levelshouldbeat FULLmark.

4. If needed,addoil slowly- recheck.Do notoverfill.

5. Wipedipstickclean,replacebutdonot tighten.Removeand

checkoil level.Oillevelshouldbeat FULLlineondipstick.

6. Replaceandtightendipstickfirmlybeforestartingengine.

DONOTuse non-detergentoilor 2-strokeengineoil.Itcouldshorten

theengine'sservicelife.

Change Engine Oil

• SAE30 is recommendedforgeneral,alltemperatureuse.When

addingoilto theengine,refertoviscositychartinthe operation

section.Usea4-stroke,oran equivalenthighdetergent,premium

qualitymotoroil certifiedto meetor exceedU.S.automobile

manufacturer'srequirementsforserviceclassificationSF,SG,SH,

SJor higher.MotoroilsclassifiedSF,SG, SHor SJ willshowthis

designationon thecontainer.

• Changeengineoil afterthefirst fivetoeight hoursofoperation,

andeveryfifty hoursoreveryseasonthereafter.Changeoil every

twentyfivehourswhenoperatingengineunderheavyloadorin

hightemperatures.

Figure26

4. Replaceandtightentheoildrainendcap.

5. Whenengineisdrainedofall oil, placeenginelevel.Refillwith

approximately20oz.offreshoil. Fillto FULLlineondipstick.

Donot overfill.Referto CheckEngineOilinthis SERVICE&

MAINTENANCEsection.

6. Replacesparkplugwirebeforestarting.

Beforetippingengineor equipmenttodrainoil,drainfuelfromtankby

runningengineuntilfuel tankisempty.

Usedmotoroil maycauseskincancerifrepeatedlyleftincontactwith

theskinfor prolongedperiods.Althoughthis isunlikelyunlessyou

handleusedoil ona daily basis,itisstilladvisableto thoroughlywash

yourhandswithsoapandwateras soonas possibleafter handling

usedoil.

To Drain Oil

1. Drainthefuelfromthe tankbyrunningtheengineuntilthefuel

tankisempty.Besurefuelfill capissecure.

2. WithengineOFFbutstillwarm,disconnectsparkplugwire and

keepitawayfromsparkplug.

3. Removeoil drainendcaplocatedatthebaseofthe engine,and

drainoil intoanappropriatereceptacle.SeeFigure26.

Usedoilisa hazardouswasteproduct.Disposeofusedoil properly

IDonotdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

_tiesor SearsServiceCenterfor safedisposal/recyclingfacilities.

2O

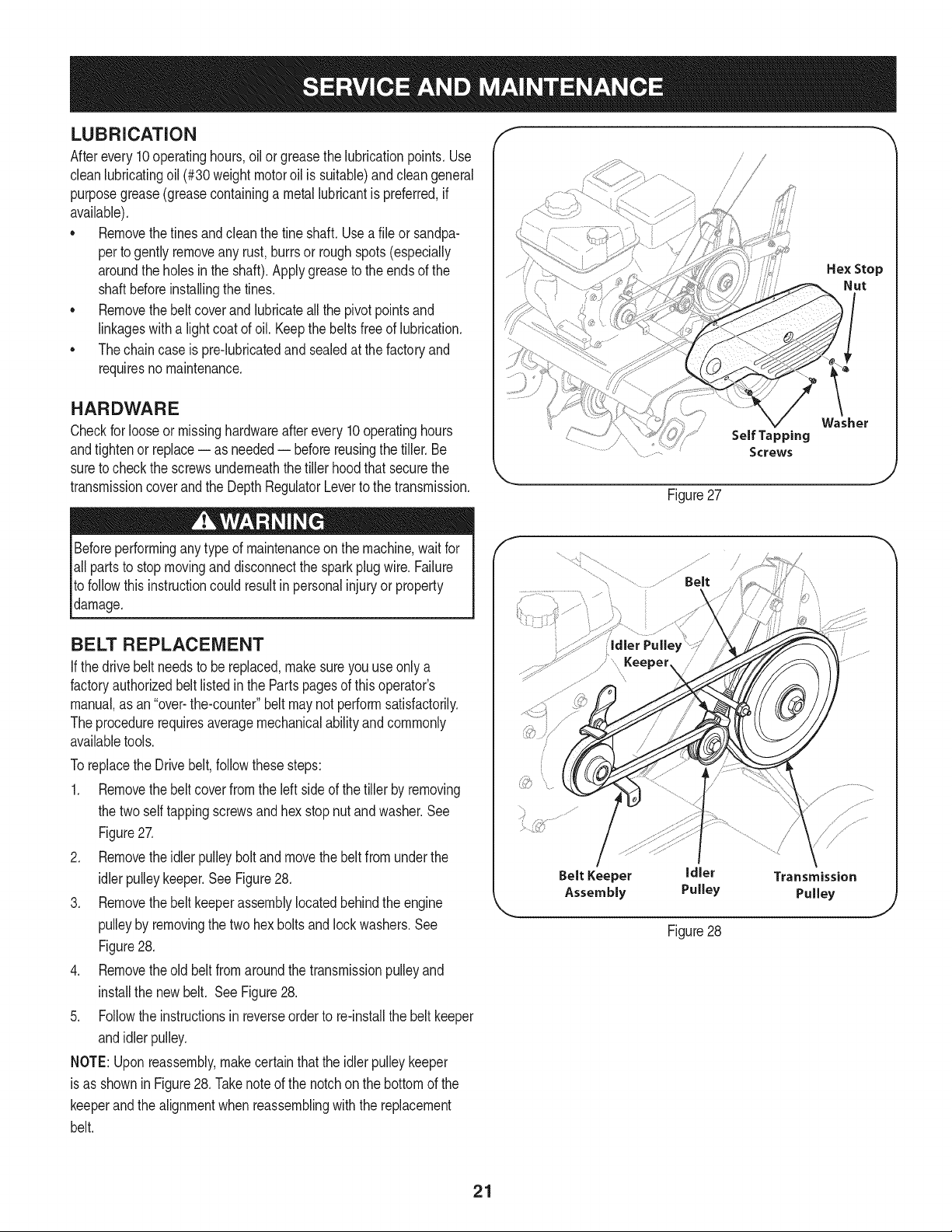

LUBRiCATiON

Afterevery10operatinghours,oilor greasethelubricationpoints.Use

cleanlubricatingoil(#30weightmotoroil is suitable)andcleangeneral

purposegrease(greasecontaininga metallubricantis preferred,if

available).

* Removethetinesandcleanthe fineshaft.Usea file or sandpa-

pertogentlyremoveanyrust,burrsor roughspots(especially

aroundtheholesintheshaft).Applygreasetotheendsofthe

shaftbeforeinstallingthetines.

, Removethebeltcoverandlubricateallthepivotpointsand

linkageswitha lightcoatofoil.Keepthebeltsfreeoflubrication.

* Thechaincaseis pre-lubricatedandsealedat thefactoryand

requiresnomaintenance.

f

J

HexStop

Nut

HARDWARE

Checkfor looseormissinghardwareafterevery10operatinghours

andtightenor replace= asneeded= beforereusingthetiller.Be

sureto checkthe screwsunderneaththe tillerhoodthatsecurethe

transmissioncoverandthe DepthRegulatorLeverto thetransmission.

Beforeperformingany typeofmaintenanceonthemachine,waitfor

all partsto stopmovinganddisconnectthesparkplugwire.Failure

tofollowthis instructioncouldresultinpersonalinjuryor property

damage.

BELT REPLACEMENT

If thedrive beltneedstobe replaced,makesureyouuseonlya

factoryauthorizedbeltlistedinthePartspagesofthisoperator's

manual,asan"over-the-counter"beltmaynotperformsatisfactorily.

Theprocedurerequiresaveragemechanicalabilityandcommonly

availabletools.

Toreplacethe Drivebelt,followthesesteps:

1. Removethebelt coverfromtheleftside ofthe tillerby removing

thetwoselftappingscrewsandhexstopnutandwasher.See

Figure27.

2. Removetheidlerpulleyboltandmovethe beltfromunderthe

idlerpulleykeeper.SeeFigure28.

3. Removethebeltkeeperassemblylocatedbehindtheengine

pulleyby removingthetwo hexboltsandlockwashers.See

Figure28.

4. Removetheold beltfromaroundthe transmissionpulleyand

installthenew belt. SeeFigure28.

5. Followtheinstructionsinreverseorderto re-installthebeltkeeper

andidlerpulley.

NOTE:Uponreassernbly,makecertainthattheidlerpulleykeeper

isas showninFigure28.Takenoteof thenotchon the bottomofthe

keeperandthe alignmentwhenreassemblingwiththereplacement

belt.

Washer

Figure27

Transmission

Pulley

J

Figure28

21

Loading...

Loading...