Craftsman 247298780 Owner’s Manual

CAUTION:

I

CRRFT_MRN_

ReQd _FETY

RULESand

BNSTR_TaONS

c=refullv

,, AssembBy

O_rating

oMaintenance

, RepOt Par_s

ROEBLrC"K AND CO., Chl_U. (_0684 U_

PART NO. 770-7764 PRINTED IN US.A,

Am

E TiLL

'rrr_'_:r_ - ... ° ' ._-_'rrr_r_'_r_r___-_qr_rr_

FULL:ONE YEAR WARRANTY !

or one year from tile date (_f pur.chase, Sears will repair any defect i_ material or- ,,

orkmanship in this TILLER at no charge '

the TILLER is used for commercial or rental purposes, this warranty applies for only i

thirty days from [he date of purchase,

Warranty service is available by contacting the nearesi Sears store or Service Center i

throughout the United States.

This warranty gives you specific legal rights, and you may also have other rights _,

Which vary from state to state

Sears, Roebuck and Co."

_. Sea_s Tower _,

I_ BSC-4.14:: ==

_. Chie,.,-i_l.d,,IL 60684

MPORTANT

It is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this

manual in a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see operating section of thts manual

for proper fuel and amount.

Your tiller is a precision piece of power equipmei!.t, not a play thing. Therefore, exercise extreme caution

at all times.

SAFE OPERATION PRACTICES FOR T LLERS

tl.

1, Read the Ope[ating and Service Ownerts

Manual carefully. Be thoroughly familiar with

the controls and the proper use of the

equipment.

2.. Never allow chltdren to operate a power tilter.

Only persons well acquainted with these rules

of safe operation shou}d be allowed to use

your til ler.i

Do not fill gasoline tank while engine is

running. Spilling gasoline on hot engine may

cause a fire or explosion.

12

Do not run the engine while indoors. Exhaust

gases are deadly poisonous.

13,

Be careful not to touch the muffler after the

engine has been rupning, tt is hot°

3, Keep the area of operation clear of all 14,

persons, particularly small children and pets,

4, Do not operate equipment when barefoot or

wearing open sandals_ Always wear substan-

tial footwear,

5. Do not wear loose fitting clothing that could

get caught on the tiller,

6, Do not start the engine unless the shift lever

is in the neutral iN) position,

7, Do n,ot stand tn fi'ont of the tiller while

starttng the :eilgtne.

8, Do not blac_ feet and ha.nd.S,o,n or..near thi_

tines _vhen st_arttng the engine' 5r white {he 18.

eng'lne is i'U_rilng,

9, Do not leave thetll"lar una{t.ended with the

e6gtne running, 19.

l& I)o not.walk :in front of the tiller wh{te the

engine is ru.nntng,

!5_

16_

I 7,

Before any maintenance work iS performed or

adjustments are made, remove the spark plug

wire and ground it on the engine block for

added safety,

Use caution when ti'lling near buildings arid

fences, rotating tines can cause damage oi'

injury.

Before attempting to remove rooks, bricks

and other objects from tines, stop the engine

and be sure the tines have stopped

completely. DisconneCt the spark plug wire

and ground to prevent accidenta! starting.

Check the fine and engine mouhttng bolts at

frequent Intervals for proper tightness.

Keep all nuts, bolts and screws tight to be

sure ,the equipment ts in safe working

condition,

Never store the equlpmetlt with gasoline in

the tank tnstde of a building where fumes may

reach an open flame or spark_ Allow the

engine to cool before storing tn any

enclosure,

A spark arrest muffler is available as an accessory part, "Thepart number is listed in the parts section Of this

mendel. Check muffler legal requirements in your area

3

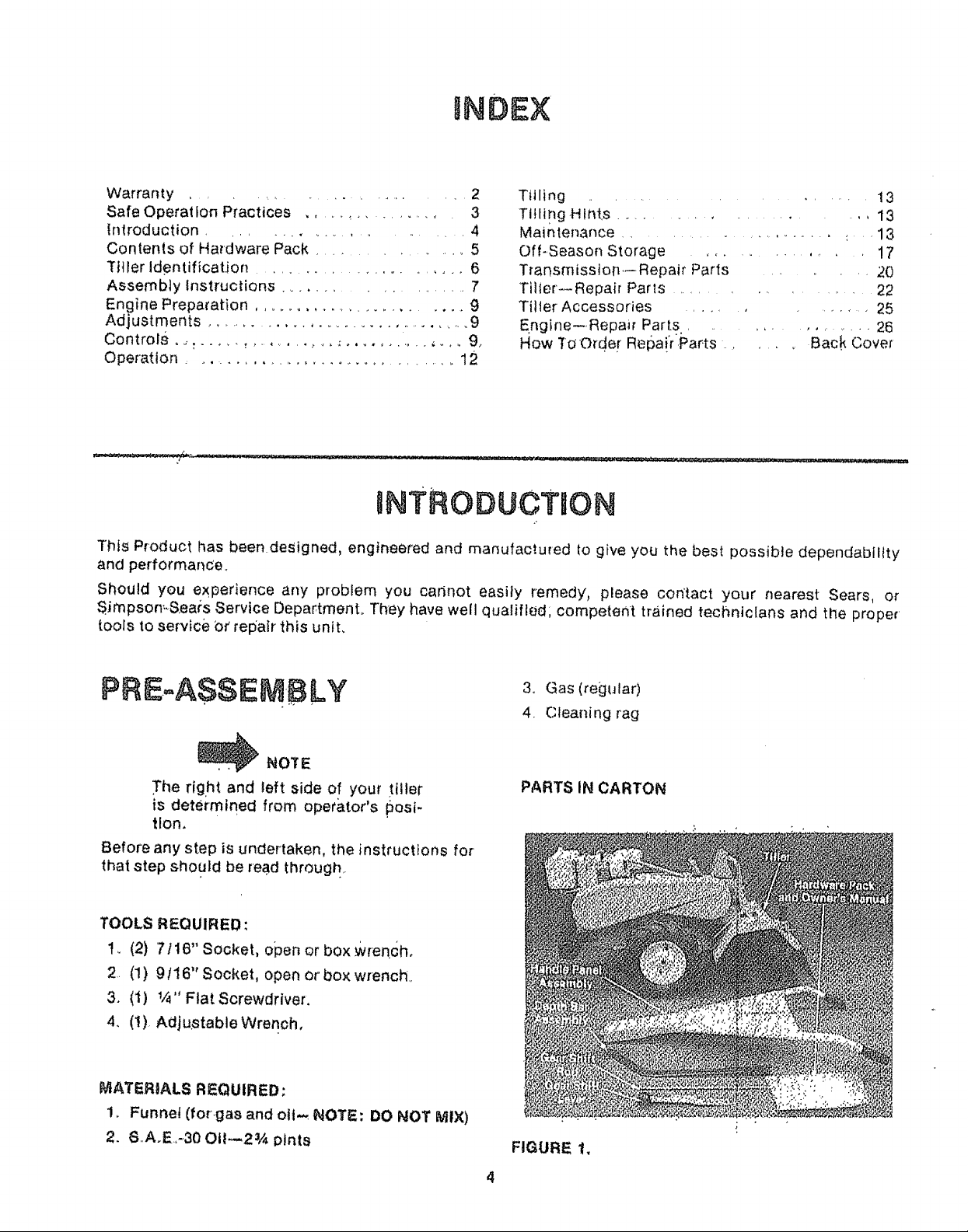

INDEX

Warranty ................. 2

Safe Operat ion Practices ................ 3

Introduction .................. 4

Contents of Hardware Pack ............... 5

Tiller Identificat.ion ..................... 6

Assembly instructions ..................... 7

Engine Preparation ......................... 9

Adjustments .................................... 9

Controls. _.;...... : ............ , ................. 9_

Operation ................................. 12

Tilling ................. 13

Titling Hlttts ......................... 13

Maintenance ................................. 13

Off-Season Storage ............... 17

Transmisstor_,.- Repair Pads .... 20

Tilter--Repair Parts .................... 22

Tiller Accessories .............. 25

Engine--.Repair Parts .................... 26

How "fo Orde.r Repa!'r.Par_ts ...... Back Cover

INTRODUCTION

This Product has been designed, engineered and manufactured to give you the best possible dependability

and performance.

Should you experience any problem you carinot easily remedy, please con'tact your nearest Sears, or

SimpsomSears Service Department° They have well qualified; competent trained technicians and the proper

tools to service Or repair this unit.

PRE...A.SSEMBLY

_ NOlrE

The right and left side of your tiller

is determined from operator's posi-

tion.

Before any step is undertaken, the instructions for

that step should be read through..

TOOLS REQUIRED:

to (2) 7116" Socket, open or bOx Wrench,

2. (1) 9116" Socket, open or box wrench..

3. (1) V4" Flat Screwdriver,

4. (t) AdjustableWrenoh,

MATERIALS REQUIRED:

1. Funnel (for-gas and olt,-_ NOTE: DO NOT MIX)

2. S..A_E.,-30 OtI_2% pints

3. Gas (regular)

4. Cleaning rag

PARTS IN CARTON

FIGURE !,

4

©

K

G j

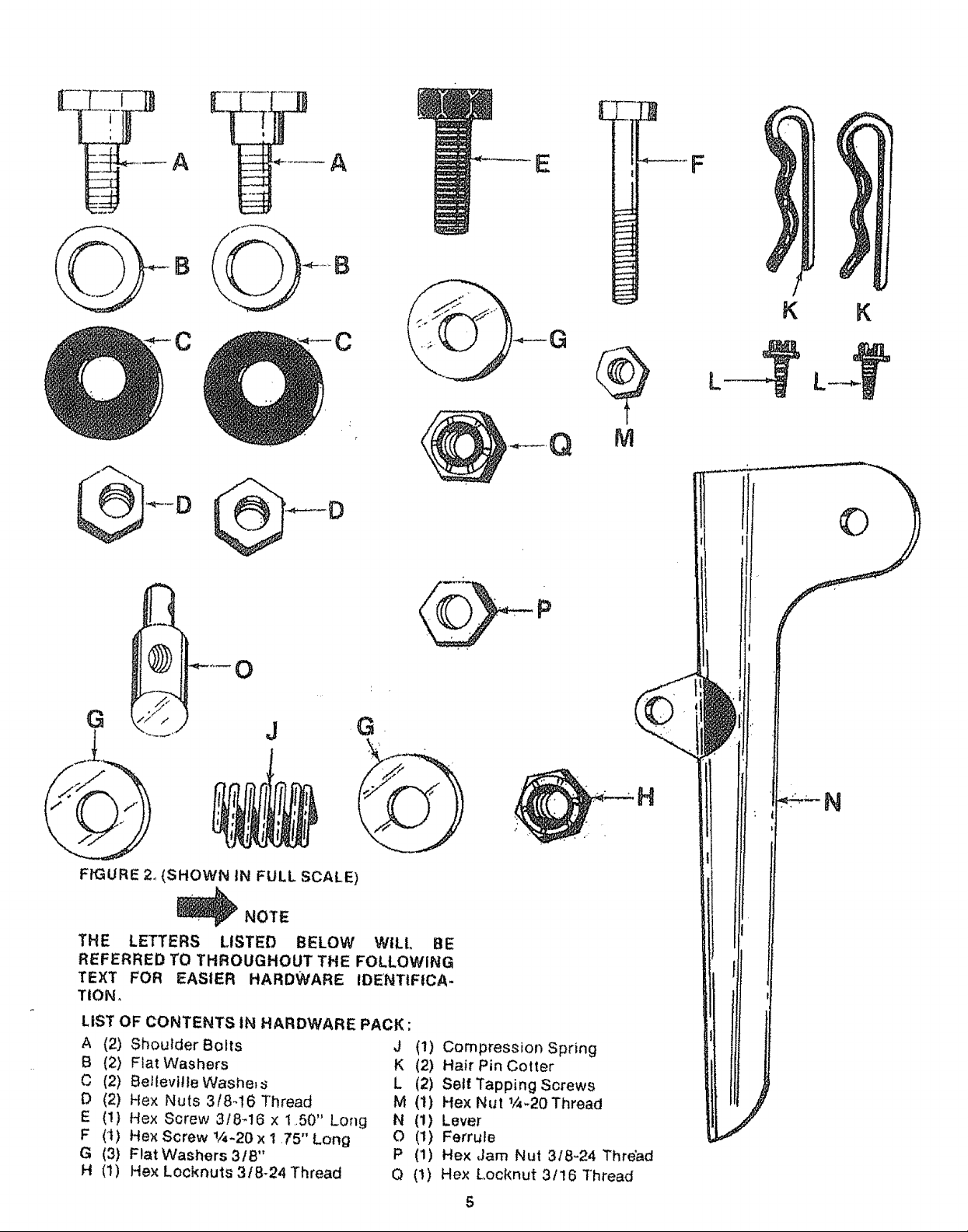

FIGURE 24{SHOWN IN FULL SCALE)

_NOTE

THE LETTERS LISTED BELOW

REFERRED TO THROUGHOUT THE FOLLOWING

TEXT FOR EASIER HARDWARE IDENTIFtCA-

TION,

LiST OF CONTENTS IN HARDWARE PACK :

A (2) Shoulder Bolts J (!) Compression Spring

B (2) Fiat Washers K (2) Hair Pin Cotter

C (2) Bellevilte Washe, s L (2) Self Tapping Sorews

P (2) Hex Nuts 3/8-16 Thread M (t) Hex Nut 1/4-20Thread

E (!) Hex Screw 3f8_t6 x 1..50" Lo_g N (1) Lever

F (1) HexScrewl/4.20xl.75"Long O (1) Ferrule

G (3) Flat Washers 31B" P (1) Hex ,Jam Nut 318-24 Thread

H (1) Hex Locknuts3t8-24Thread Q (1) Hex Locknut 3/16 Thread

Gk

WILt, BE

H

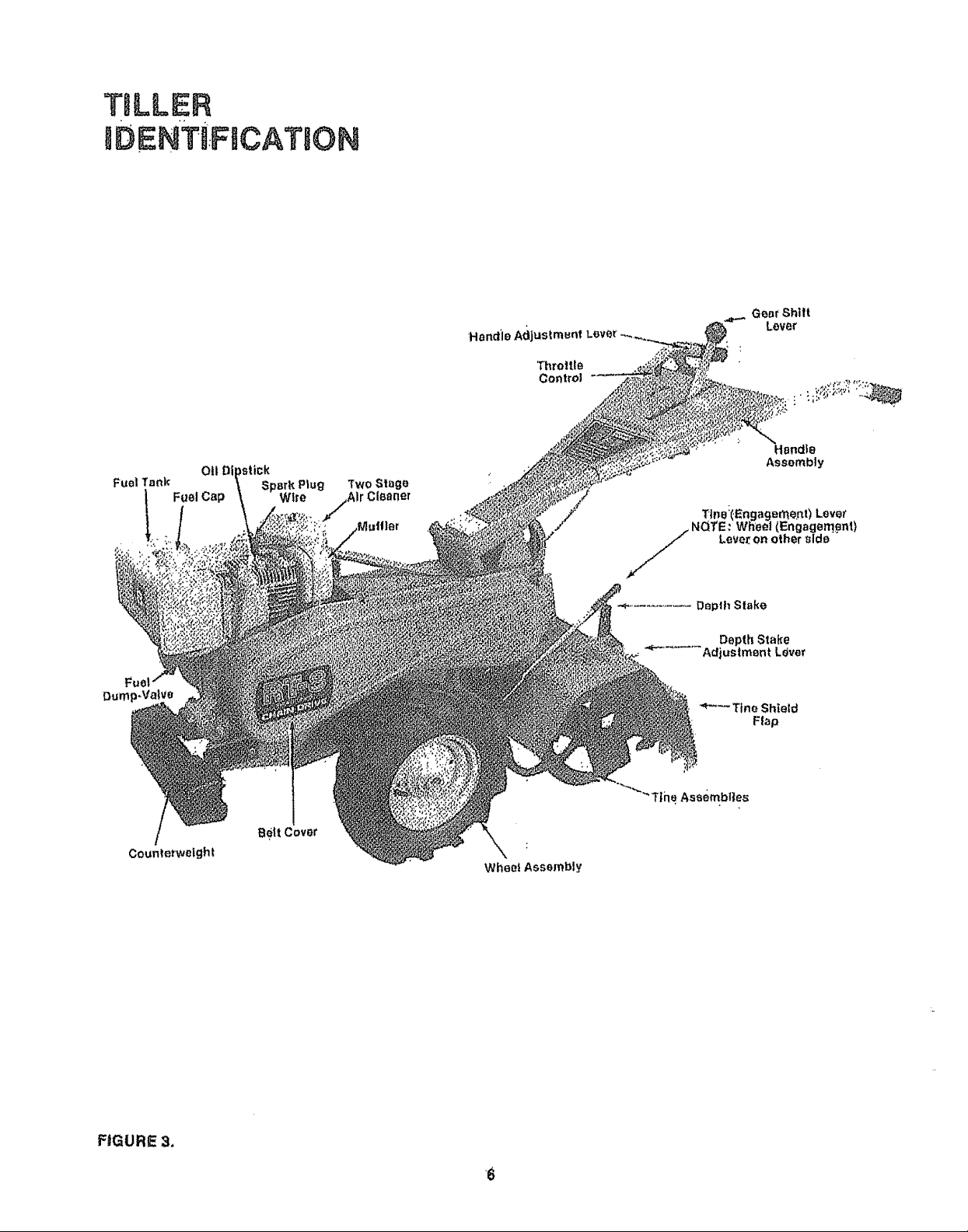

TBLLER

mDENTi:F6CAT ON

GearShill

Lover

Fuel Tank

.=-

Dum

Counterweight

011Di

Fuel Cap

Spsrk Plug

Wire

B_|t Cover

, " ,die

Assembly

Tine:(,Enga_er_e.nt) Lever

i NQTE: Wheel (Engagempn_)

Lever on other sld_

*'_........... Depth Stake

Depth Stake

.... Adjustment Lever

Tine Shield

Flap

FIGURE 3,

S

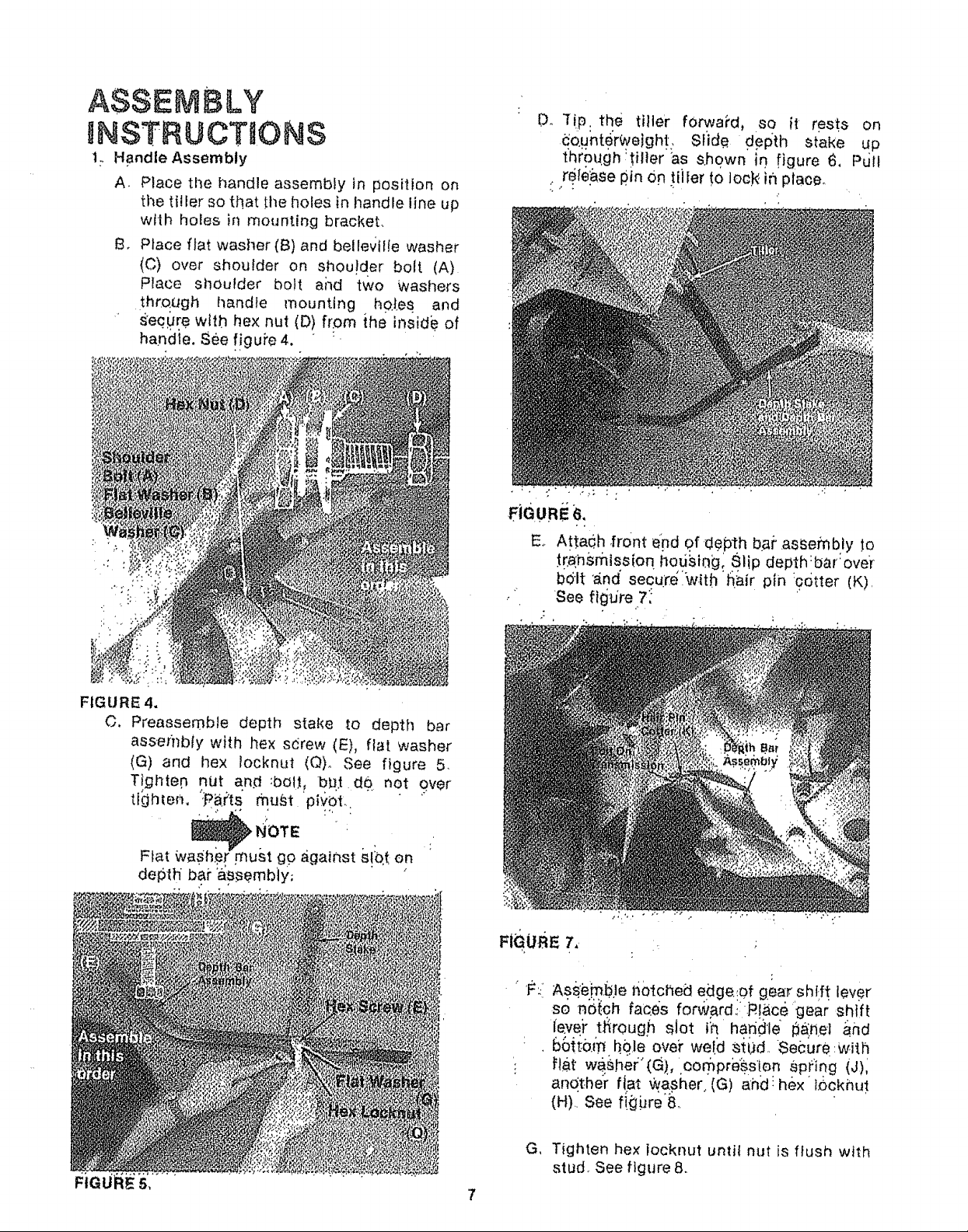

ASSEMBLY

INSTRUCTIONS

1. Handle Assembly

A. Place the handle assembty tn position on

the tiller so that tile holes in Ilandle line up

with holes in nqounting bracket..

B. Place flat washer (B) and belleviIte washer

(C) over shoulder on shou!der bolt (A)

Place sl]oufder bolt ai_d two Washers

thro, ugh handle mounting hot.es and

s'eq.Ure wH.h he× nut (D) from ihe inside of

handle. See !!guPe 4. :

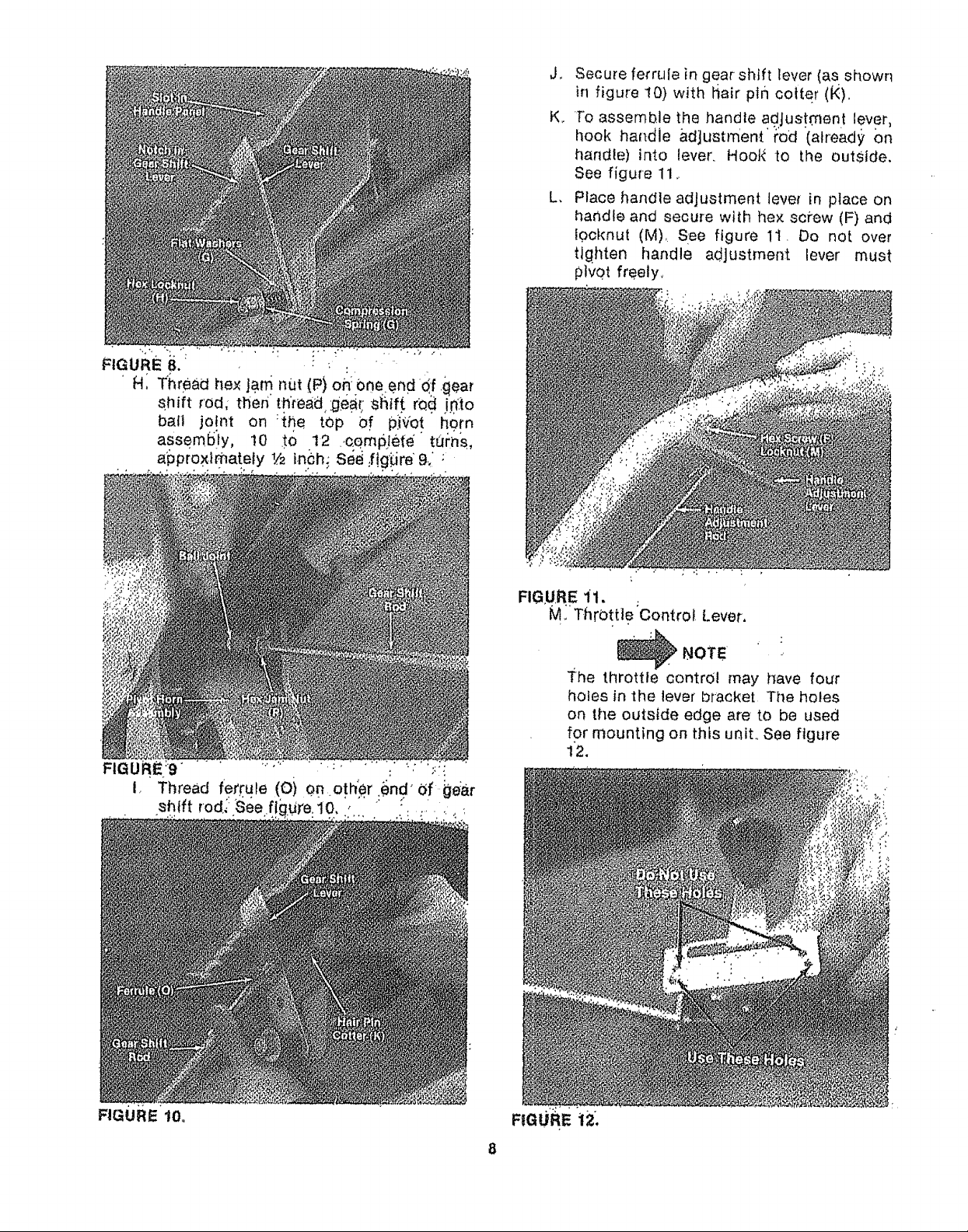

Dr "l!p. the tilte'r fOrwa?d, so it rests on

_o.unter_ejghl, $Iide d.ePth stake up

thrpughUl}er as s.ho,wn in, .figure 6, Pdll

rele&se #in On tiJier to loc_4 in place.

,+FJOURE6,

E. At.ta_.h ,front epd of d@pt.h bai" .assembly !o

tr_ni_mlssion hodsiag: Slip depth:bar:over

bolt _,nd secu_te w.fth hair ptn :9otter (K).

See l.0.re,7:

FIGURE 4.

C. Preassemble depth stake .to depth bar

assembly with hex sdrew (E), flat washer

(G) and hex locknut (Q)o See figure 5.

T_gl_tep nut an.d :boU, b_J.t d0. net over

tlOhtem ':P_,i.hsmu_t 'pivOt.

Flat W_Sh.er must go against s!:qt on

depth bai" assembly,

" 'I_::Ass..i_mB.ler_0tched edge:of gear shi-.ft lever

so n0(o.h faces forwa[d._:: P.!ac6gear shift

ie.vej" tl_rough slot th handle #An.el a.nd

66{t0._ h0.,leove_"we!d s{bd,-Secure:Wiih

: t=l_t w_,ller'(G)., oompre_s!e n .Sp(iog (J)i

andt.her fiat washer,(G) ahd: hex IOckhui

(H). See f!Ljbre'8.

G, Tighten hex tocknut until nut is Mush with

stud. See figure 8.

J_

Secure ferrule in gear shift lever (as shown

in figure 10) with hair p_n cotter (_),

K,

To assemble the handle adjustment lever,

hook handle ad]ustmen.t' t:od '(already on

handle) into lever, Hoot_ to the outside.

See figure 11,.

L.

Place handle adjustment tevet in place on

handle and secure with he× sci'ew (F) and

f0cl{nut (M), See figure 1t. Do not over

ttgilten handle adjustment lever must

pivot freely,

F GU.REi1.

M., ThrOttl e Control [.ever,

]_he throttle control may have four

holes in the lever bracket The holes

on the outside edge are to be used

for mounting on this unit., See figure

12.

NOTE -,

FIGURE 10.

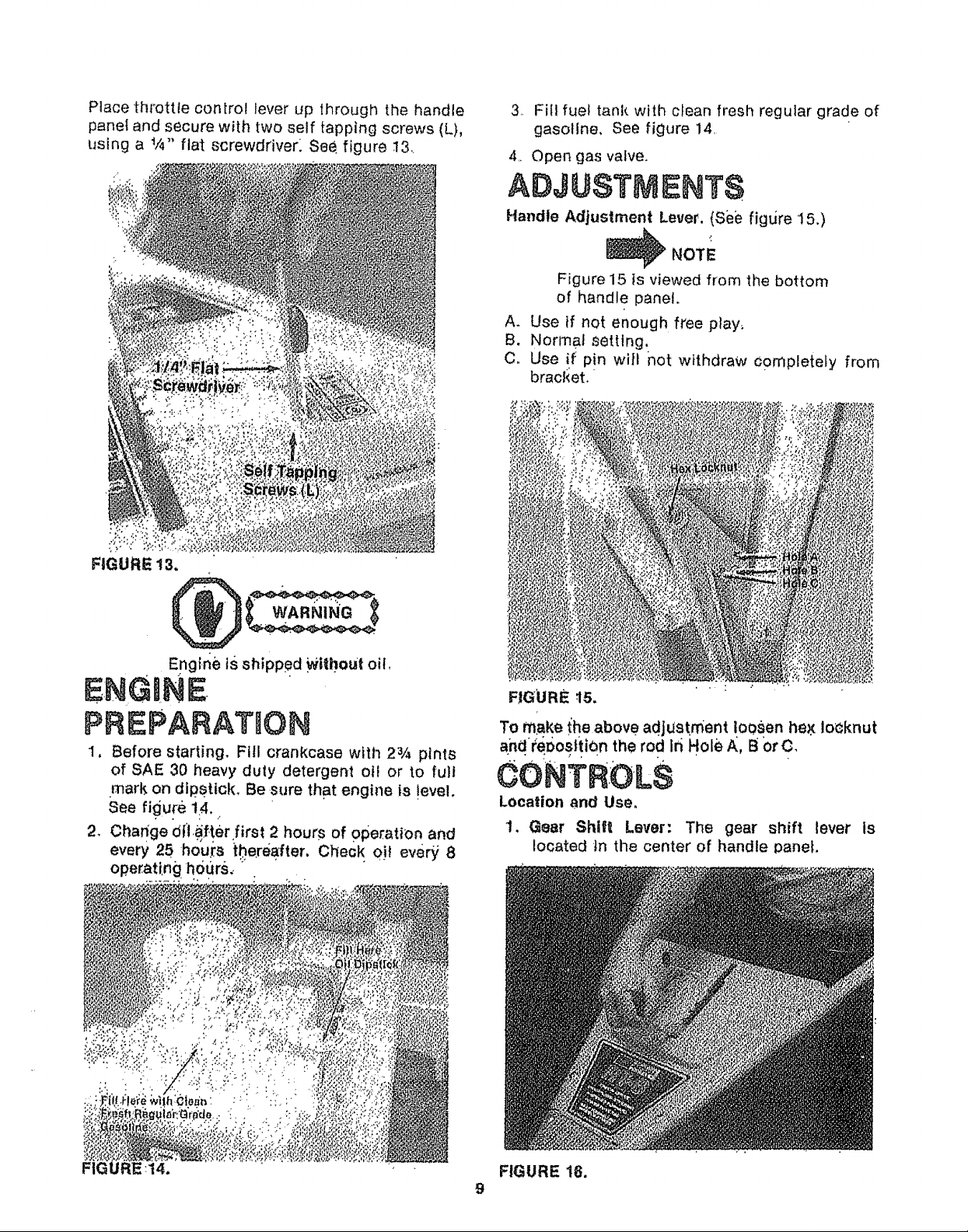

Placethrottle controlleverup throughthehandle

panelandsecurewith twoself tappingscrews(L),

usinga t/4" flat screwdriver: See figure !3

3 Fill fuel tank with c_ean fresh regular grade of

gasoline, see figure 14

4 Open gas valve.

ADJUSTNgNTS

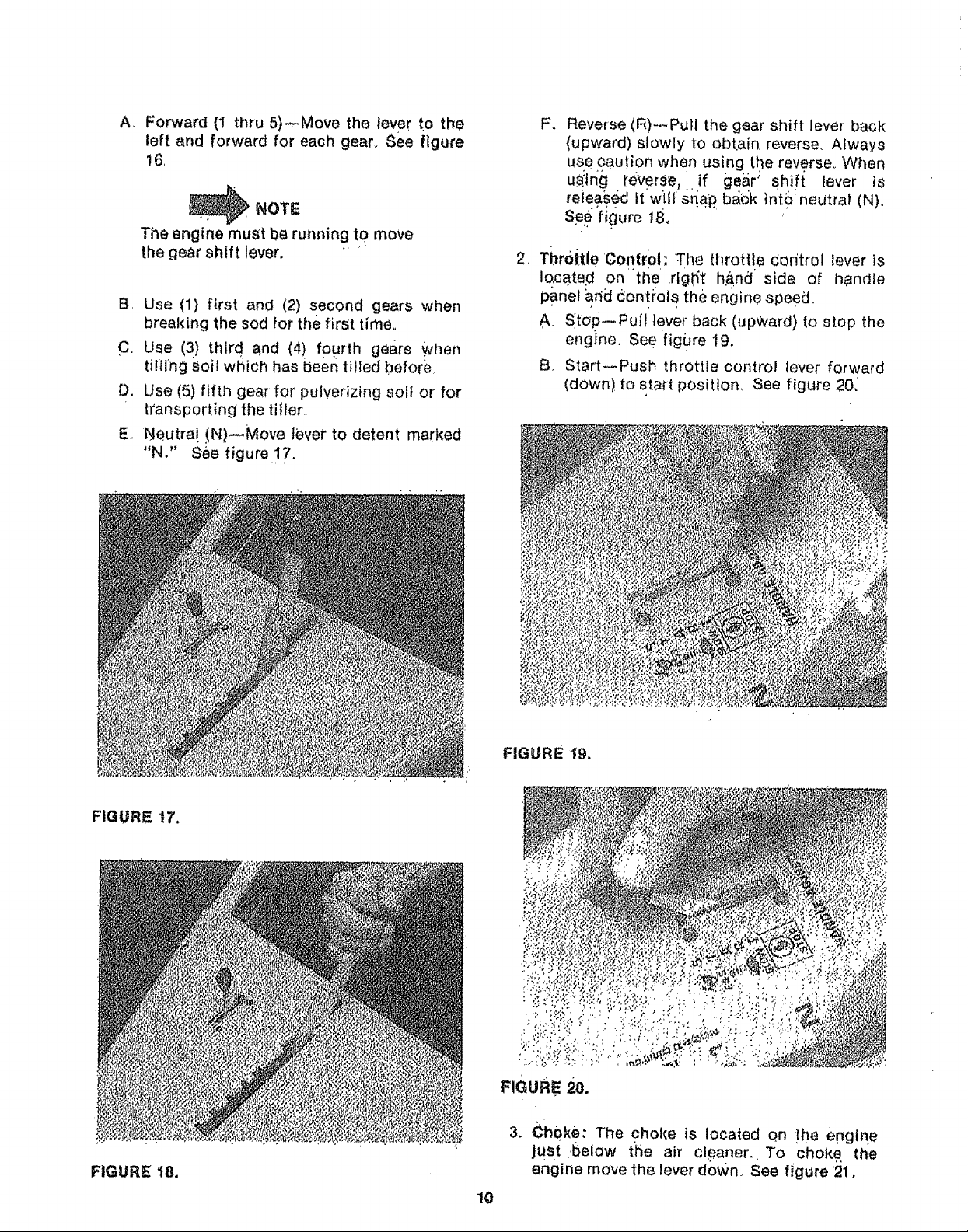

Handle Adjustment Lever. (See figure 15.)

NOTE

Figure 15 is viewed from the bottom

of handle panet.

A. Use if not enough free play;

B. Normal setting.

C. Use _f pin wi{t not withdraw c0mpletely from

bracl<et_ *

FIGURE 13,

Engine tsshipped Wi{bout oil,

ENGINE

PREPARATION

1, Before starting. Fill crankcase with 23/4 pints

of SAE 30 heavy duty detergent oit or to full

mark on dipstick, Be sure that engine is !evet,

See figure 14, ..

2. Change 0(l._ter first 2 hours of operation and

every 25 hours the.re_ter, CheGk 0)_ eve_ 8

operati.ng h0grs, _ •

FIGURE .15.

To make the above adjustment !o0sen hex io_knut

a_nd'_e_os|!iOn the rod Ifi Hole A, B Or C,

CONTROLS

Location and Use.

1. Gear Shilt Lever: The gear shift lever is

located in the center of handle panel,

FIG

FIGURE 16.

9

A. Forward (1 thru 5)--. Move the lever t.o the

left and forward for each gear, See figure

16,

_NOTE

The engine must be running tO move

the gear shift lever, ".....

B_

Use (1) first and (2) second gears when

breaking the sod for the first time_

Use (3) third and (4! f0,urth gears when

till!ng soil which has been tilled before_

D.

Use (5) fifth gear for pulverizing solt or for

transporting the tiller,

E

Neutra! ,(N)_Move lever to detent marked

"N," See figure 17.

F, Reverse (R) ....Pull the gear shift lever back

(upward) slowly to obtain, reverse, Always

use caution when using the reverse_ When

u_tng {:everSe, .if gear' shift lever is

re}eased It'w[tl sqap. ba_k int_: neutral (N),

Se_'figure 18,

2 Throttle Control: The throttle con'trol iever is

IQcated on the right' h_nd side of handle

panel arid _ontrels the engine speed,

A. St_op--Pull lever back (upWard) to stop the

engine, See fig0re 19,

B, Start_Push throttle oontrol lever forward

(down) to start position.. See figure 20,

FIGURE t7,

FIGURE 18.

FIGURE 19.

3. Ch0ke: The choke is located on the e.ng{qe

Jus.t .l_elow t'tle air cleaner. To choke the

engine move the lever down, See figure '21,

10