Craftsman 247298770 Owner’s Manual

Sears

maliiual

f

CAUT :

Read SAFETY

RULESand

iNSTRUCTIONS

carefully

8F__._RS, P, DEBU6-_ AND 03., Cht_I1. 60684 U_.A.

and S_NS-SEARS LI_MYI2!D, Toronto, Canada

i m , i,,,i,ii ...................................... ,,,,.,,?,

PART NO, 770_7763

_RRFTSN_N_

. CHAJ

Ti E

o Assembly

o Operating

®Maintenance

. Repair Parts

IVE

TILLE

........ IIIl/l'

PRINTED IN U,S,A,,

FULL ONE YEAR WARRANTY !

For one year from the date of purchase, Sears will repai_ any defect in material or

workmanship in this TILLER at no charge

If the TtLLER is used for commercial or rental purposes, this warranty applies for onry

thirty days from the date of purchase.

Warranty service is available by contacting the nearest Sears store or Service Center

throughout the United States..

This warranty gives you specific Jegai rights, and you may afso have other rights

which vary from state to state..

Sears, Roebuck and Coo

Sears Tower

BSC 41-3

Chicago, IL 60684

DODOg D Da 0 _J_ Q9_0_0 QD 0 D_ 000001_ D_ 000 QO 0000____90 na _oDa@ ooooooo D_ _

2

IMPORTANT

__is suggested that this manual be read in its entirety before attempting to assemble or operate Keep this

manual in a safe place for future reference and for ordering replacemen! parts

This unit is shipped WITHOUT GASOLINE orO1L After assembly, see operaiing section of this manual

for proper fuel and amount,.

Your tiller is a precision piece of power equipment, not a l::lay thing Therefore exercise extreme caution at

al! times

SAFE OPERATION PRACTICES FOR TILLERS

11,

't. Read the Operating and Service Owner's

Manual carefully, Be thoroughly familiar with

the controls and the proper use of the equip-

ment..

2. Never allow children to operate a power tiller°

Only persons welt acquainted with these rules

of safe operation should be allowed to use

your tiller

Do not fill gasoline tank while engine is

running. Spilling gasoline on hot engine may

cause a fire or explosion,

12.

Do not run the engine while indoors, Exhaust

gases are deadly poisonous.

1;3.

Be careful not to touch the muffler after the

engine has been running, it is hot.

3 Keep the area of operation clear of a]f

persons, particularly small children and pets.

4. Do not operate equipment when barefoot or

wearing open sandals Always wear substan-

tial footwear.

5. Do not wear loose fitting clothing that could

get caught on the tillen

6. Do not start the engine unless the shift tever

is in the neutral (N) position.

7. Do not stand in front of the tiller while

starting the engine.

8. Do not place feet and hands on or near the

tines when starting the engine or while the

engine is running.

9. Do not leave the tiller unattended with the

engine running,,

t0. Do not walk in front of the tiller while the

engine ts running.

14,

Before any maintenance work is performed or

adjustments are made, remove the spark plug

wire and ground it on the engine block for

added safety.

15l&Use caution when tilling near buildings and

fences, rotating tines can cause damage or

injury.

Before attempting to remove rocks, bricks

and other objects from tines, stop the engine

and be sure the tines have stopped

completely. Disconnect t,he spark plug wire

and ground to prevent adctdental starting.

,

Check the tine and engine mounting bolts at

frequent intervals for proper tightness°

t8,

Keep all nuts, bolts and screws tight to be

sure the equipment is in safe working

condition

19.

Never store the equipment with gasoline in

the tank inside of a building where fumes may

reach an open flame or spark, Allow the

engine to coot before storing In any

enclosure°

UNDEX

Warranty .................................... 2

Safe Operation Practices ..................... 3

Introduction ................................... 4

Contents in Hardware Pack ......................... 5

Tiller Identification ................................ 6

Assembly Instructions ......................... 7

Adjustments ..................................... 9

Con trots ....................................... t 0

Engine Preparation ............................... 13

Operation ........................................ 13

Tilling .......................................... 14

Tilling Hints ..................................... 15

Maintenance ................................. 15

Off-Season Storage ............................ ! 9

Transmission--Repair Parts .................. 20

Tiller-- Repair Parts ................................ 22

Parts Information ..................... Back Cover

INTRODUCTION

This Product has been designed, engineered and manufactured to give you the best possible dependability

and performance.

Should you experience any problem you cannot easily remedy, please contact your nearest Sears, or

Simpson-Sears Service Department. They have well qualified, competent trained technicians and the proper

tools to service or repair this unit.

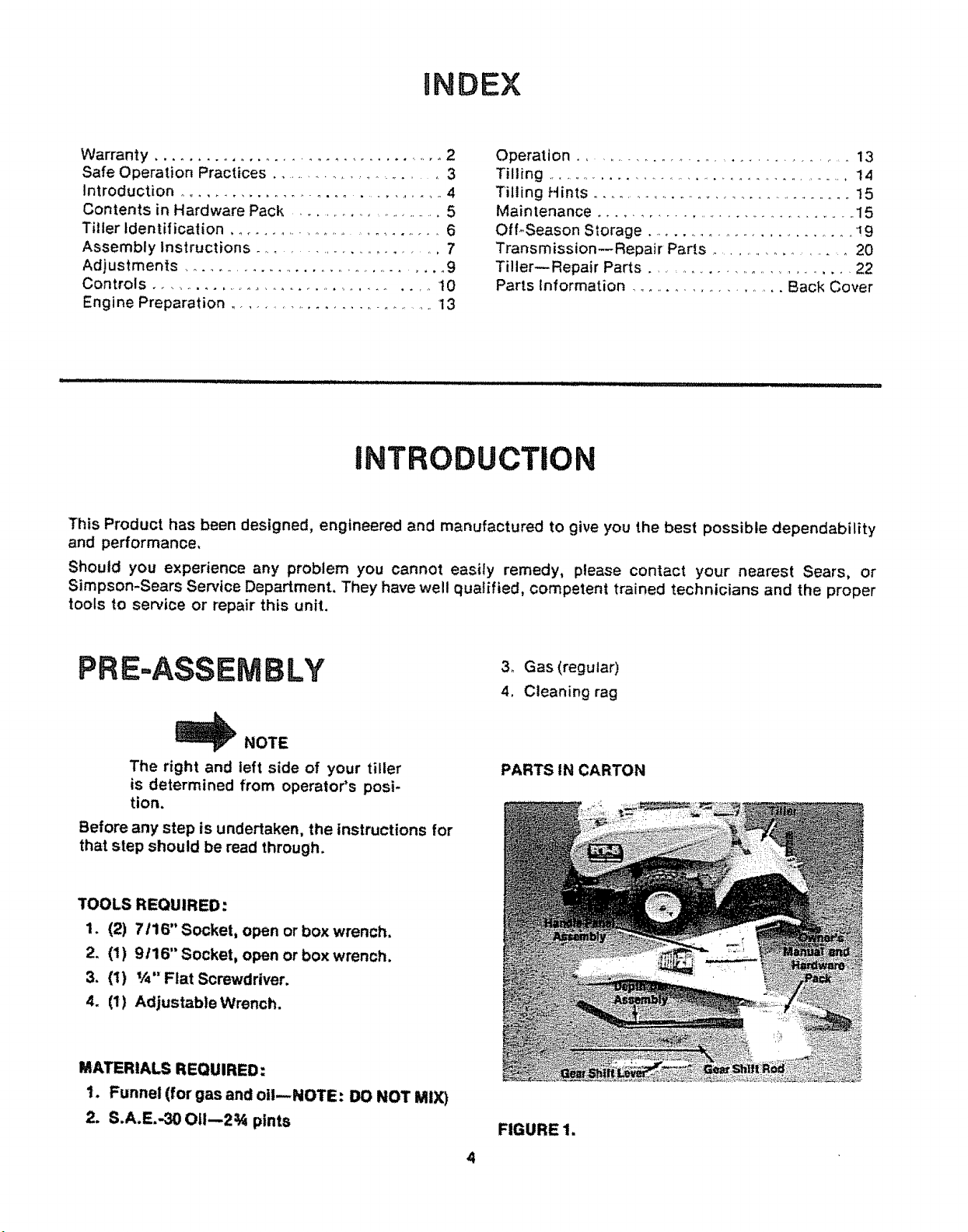

PRE-ASSEMBLY

_NOTE

The right and teft side of your tiller

is determined from operator's posi-

tion.

Before any step is undertaken, the instructions for

that step should be read through.

TOOLS REQUIRED:

1. (2) 7116" Socket, open or box wrench.

2. (1) 9t16" Socket, open or box wrench.

3, (1) V_" Flat Screwdriver.

4. (1) Adjustable Wrench.

MATERIALS REQUIRED:

1. Funnel (for gas and oil--NOTE: DO NOT MIX)

2. S.AoE.-30 O11--2¾ pints

3o Gas (regular)

4. Cleaning rag

PARTS IN CARTON

FIGURE 1.

4

C

E

F

G

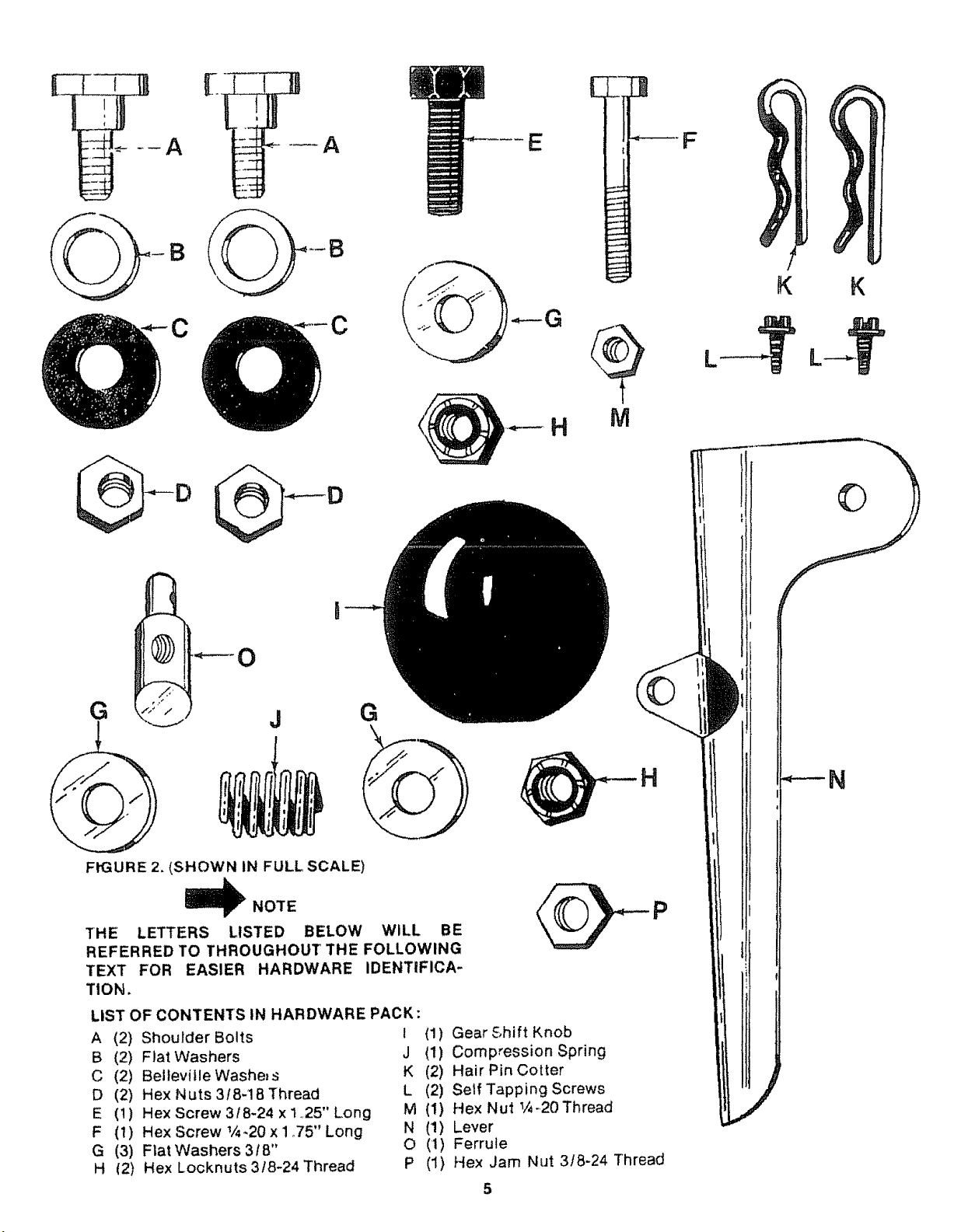

FIGURE 2, (SHOWN IN FULL SCALE)

THE LETTERS LISTED BELOW WILL BE

REFERRED TO THROUGHOUT THE FOLLOWING

TEXT FOR EASIER HARDWARE IDENTiFICA-

TION,

LIST OF CONTENTS IN HARDWARE PACK:

A (2) Shoulder Bolts

B (2) Flat Washers

C (2) BeltevitleWashe_s

D (2) Hex Nuts 318-18 Thread

E (t) Hex Screw 318-24 xi.,25" Long

F (t) Hex Screw !/4,20 x 1 ,,75" Long

G (3) Flat Washers 318"

H (2) Hex Locknuts 3/8-24 Thread

J

NOTE

G

I (1) Gear Shift Knob

J (1) Compression Spring

K (2) Hair Pin Cotter

L (2) Serf Tapping Screws

M (1) Hex Nut _-.20Thread

N (1) Lever

O (1) Ferruie

P

(1) Hex Jam Nut 3f8-24 Thread

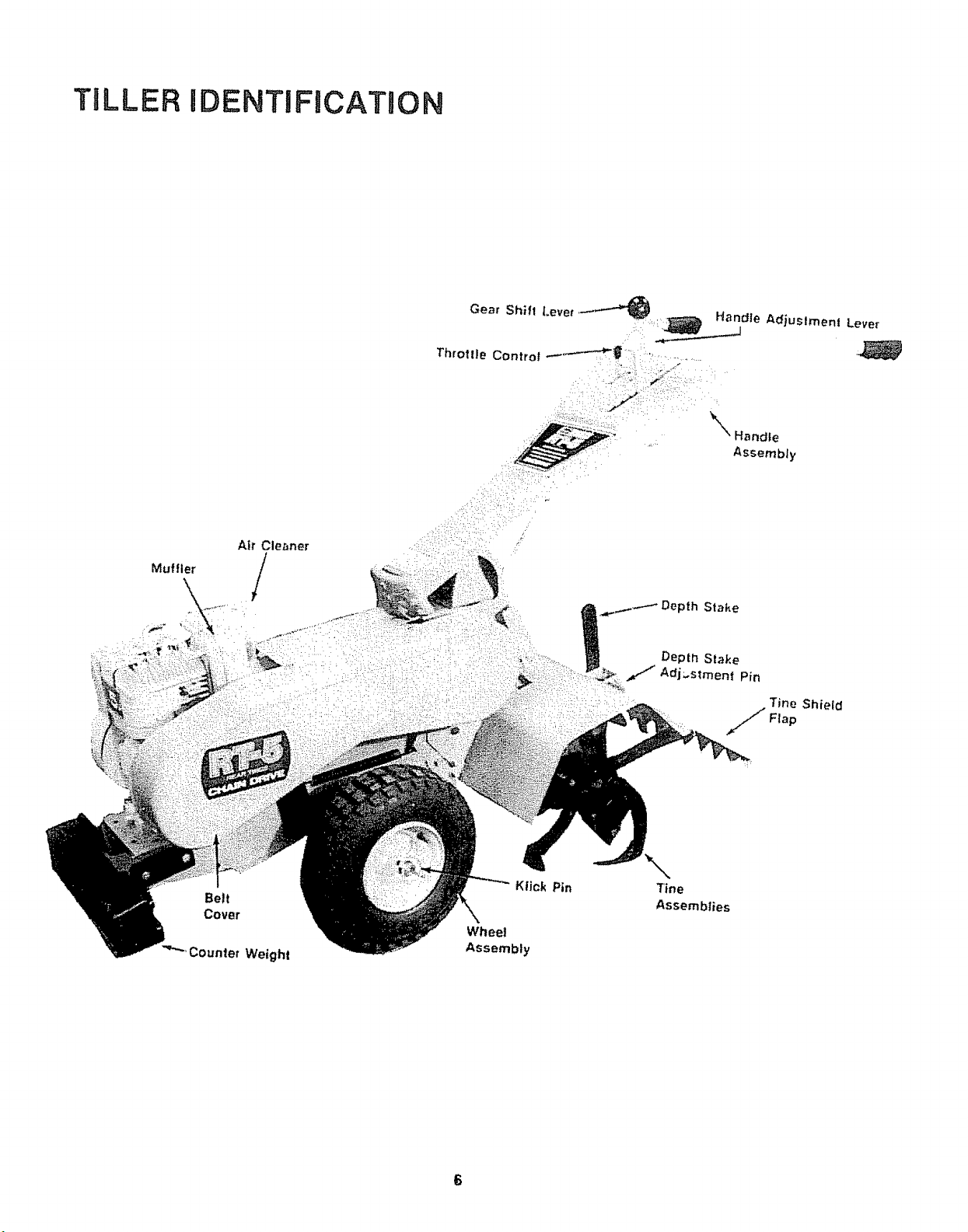

TILLER IDENTIFICATION

Belt

Cover

3ounter Weight

Klick Pin

Depth Slake

Adj..stmen{ Pin

Shield

Tine

Assemblies

6

ASSEMBLY

INSTRUCTIONS

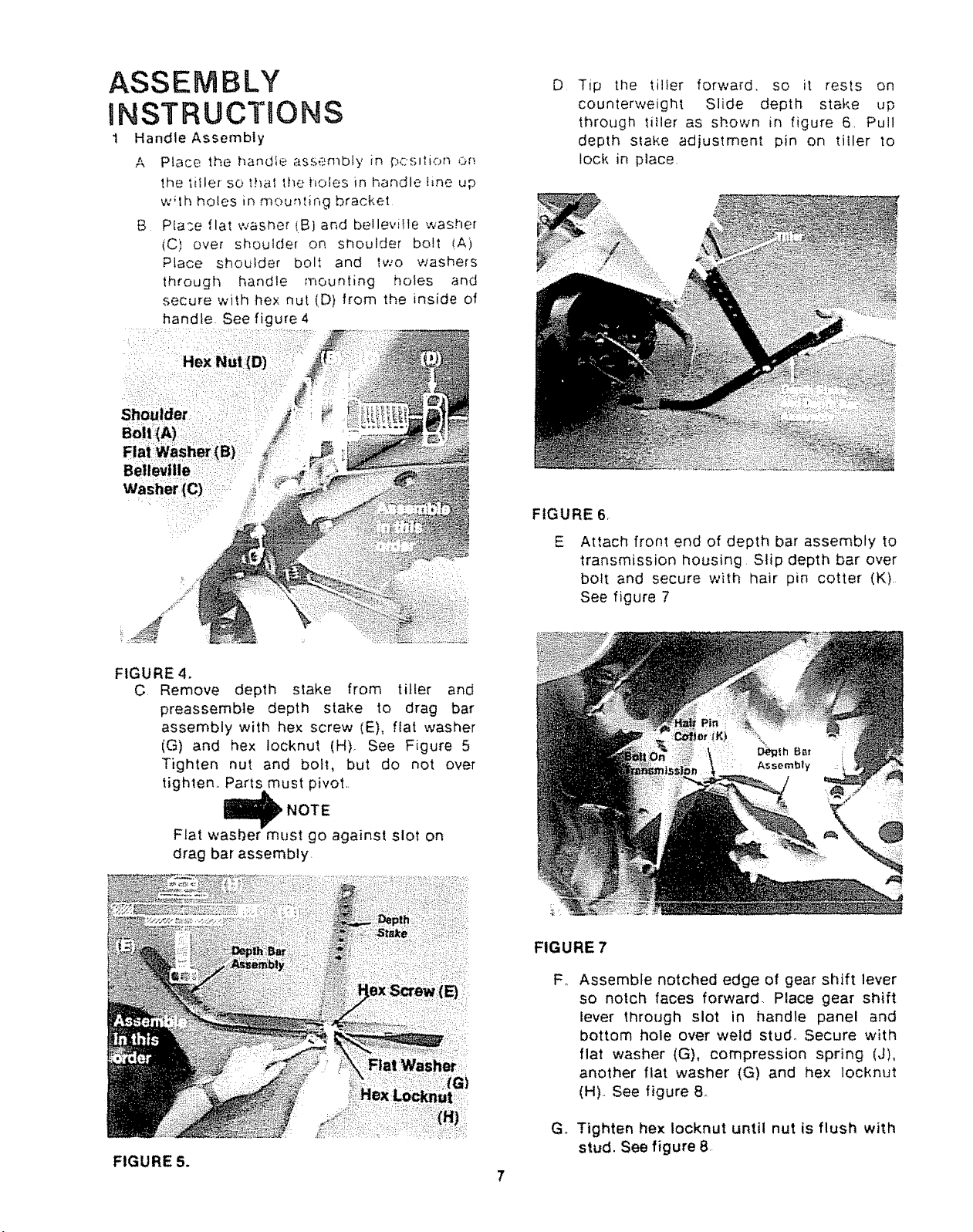

1 Handle Assembly

A Place the handle assembly in p,:;s,'",k)n Or:

the tiller so that the holes in handle Ime up

w_th holes in mountir, g bracket

g Place flat washer (B} and bellevi_le washer

(C) over shoulder on shoulder bolt (A)

Place shou}der bolt and two washers

through handle mounting holes and

secure with lie× nut (D) from the inside of

handle. See figure 4

D

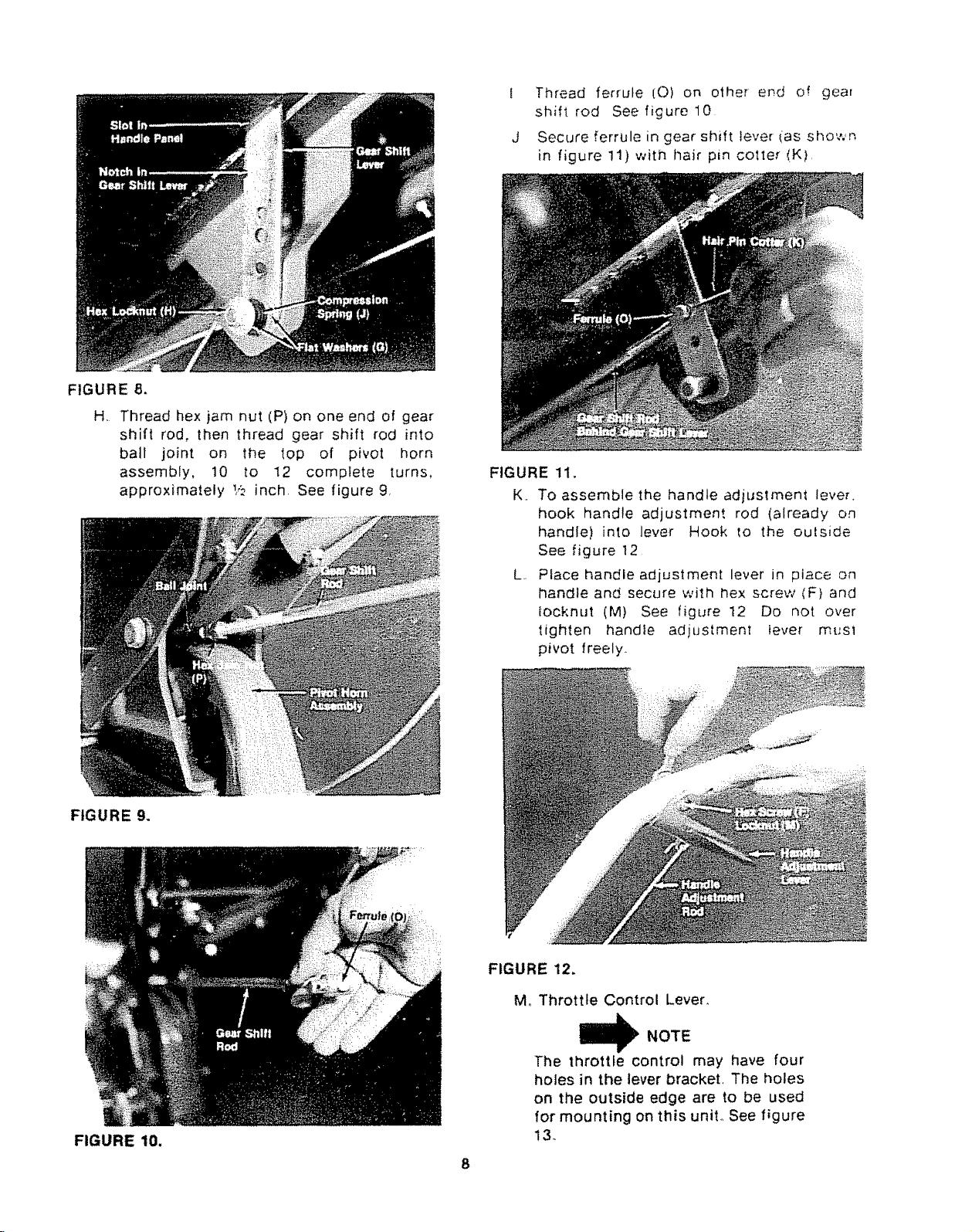

Tip the tiller forward, so it rests on

counterweight Slide depth stake up

through titler as shown in figure 6, Pull

depth stake adjustment pin on tiller to

lock in place

FIGURE 6,

FIGURE 4.

C Remove depth stake from tiller and

preassemble depth stake to drag bar

assembly with hex screw (E), flat washer

(G) and hex Iocknut (H). See Figure 5

Tighten nut and bolt, but do not over

tightem Parts must pivot.

NOTE

Flat washer must go against slot on

drag bar assembly

E

Attach front end of depth bar assembly to

transmission housing Slip depth bar over

bolt and secure with hair pin cotter (K).

See figure 7

FIGURE 7

F_

Assemble notched edge of gear shift lever

so notch faces forward. Place gear shift

lever through slot in handle panel and

bottom hole over weld stud_ Secure with

flat washer (G), compression spring (J),

another flat washer (G) and hex locknut

(H)° See figure 8,

@

FIGURE 5.

G. Tighten hex Iocknut until nut is flush with

stud. See figure 8

7

FIGURE 8.

H. Thread hex jam nut (P) on one end of gear

shift rod, then thread gear shift rod into

ball joint on the top of pivot horn

assembly, 10 to 12 complete turns,

approximately 1,,t,inch. See figure 9,

Thread ferrule [0) on other er_.d of gear

shift rod See figure 10

Secure ferrule in gear shift lever (as shown

in figure 11) with llair pin cotter (K),

FIGURE 11.

K,,

To assemble the handle adjustment lever.

hook handle adjustment rod (already on

handle) into lever Hook to the outside

See figure 12

L,,

Place handle adjustment lever in place on

handle and secure with hex screw (F) and

tocknut (M) See figure 12 Do not over

tighten handle adjustment iever mt'sl

pivot freely.

FIGURE 9.

FIGURE 10.

FIGURE 12.

M. Throttle Control Lever_

NOTE

The throttle control may have four

holes in the lever bracket, The holes

on the outside edge are to be used

for mounting on this unit° See figure

!3.

8

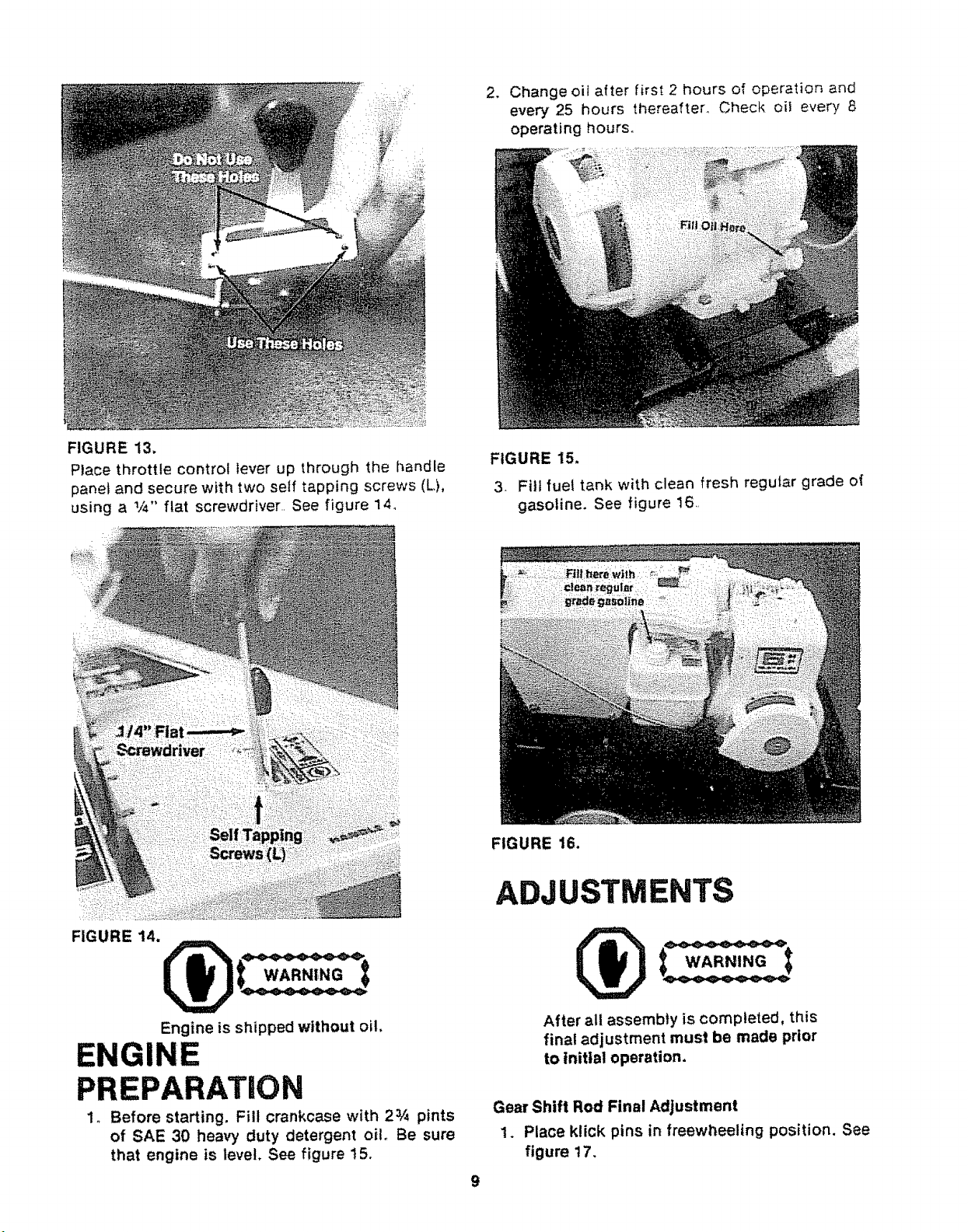

FIGURE 13.

Place throttle control lever up through the handle

panel and secure with two self tapping screws (L),

using a 1/4" fiat screwdriver.. See figure 14_

2, Change oil after first 2 hours of operation and

every 25 hours thereafter_ Check oil every 8

operating hours.

FIGURE 15.

3- Fill fuel tank with clean fresh regular grade of

gasoline. See figure 16..

FIGURE 14.

Engine is shipped without oil,

ENGINE

PREPARATION

1o Before starting, Fill crankcase with 2_A pints

of SAE 30 heavy duty detergent oil, Be sure

that engine is level, See figure 15,

FIGURE 16.

ADJUSTMENTS

After all assembly is completed, this

final adjustment must be made prior

to initial operation.

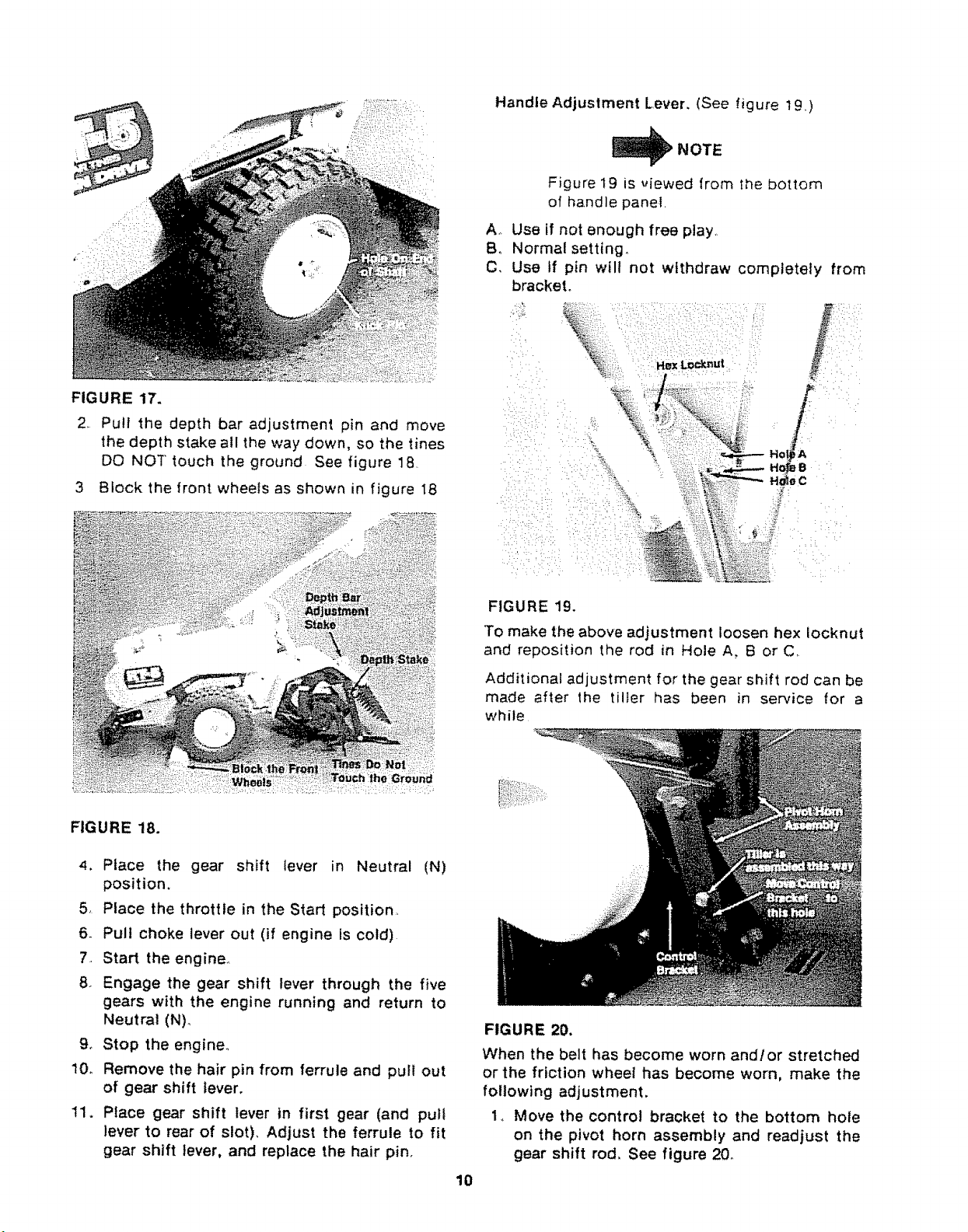

Gear Shift Rod Final Adjustment

1. Place ktick pins in freewheeling position. See

figure 17,

FIGURE 17.

2 Pull the depth bar adjustment pin and move

the depth stake all the way down. so the tines

DO NOT" touch the ground See figure 18

3 Block the front wheels as shown in figure 18

Handle Adjustment Lever. (See figure t9 )

NOTE

Figure 19 is _,iewed from the bottom

of handle panel

A_ Use if not enough free play

B. Normal setting°

C, Use If pin wilt not withdraw completely from

bracket.

FIGURE 18.

4. Place the gear shift lever in Neutral (N)

position.

5, Place the throttle in the Start position

6. Pull choke lever out (if engine Is cold)

7. Start the engine_

8 Engage the gear shift lever through the five

gears with the engine running and return to

Neutral (N)_

9. Stop the engine,

10o Remove the hair pin from ferrule and pull out

of gear shift lever,

11. Place gear shift lever in first gear (and pull

lever to rear of slot), Adjust the ferrule to fit

gear shift lever, and replace the hair pin,

FIGURE 19.

To make the above adjustment loosen hex iocknut

and reposition the rod in Hole A, B or C.

Additional adjustment for the gear shift rod can be

made after lhe tiller has been in service for a

while

FIGURE 20.

When the belt has become worn and/or stretched

or the friction wheel has become worn, make the

following adjustment.

1. Move the control bracket to the bottom hole

on the pivot horn assembly and readjust the

gear shift rod, See figure 20_

10

Loading...

Loading...