Craftsman 247.290000 Operator's Manual

perator's

I:RnFrSMRN°

REAR ENGINE RiDiNG MOWER

6 Speed, Shift-on=the=Go

30" Deck

Model No. 247.290000

• Espanol, P. 70

This product has a low emission engine which operates differently

from previously built engines. Before you start the engine, read and

understand this Operator's Manual.

For answers to your questions about

Before using this equipment,

read this manual and follow

all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our website: www.craftsman.com FormNo.769-07597C

this product, Call:

1-800=659=5917

CraftsmanTractorHelpLine

7 am =7 pm CT, Mort. =Sun.

(December11,2012)

Warranty Statement ................................... 2

Safety Instructions .................................... 3

Slope Guide .......................................... 8

Assembly ............................................. 9

Operation ........................................... 15

Service and Maintenance ............................ 21

CRAFTSMANFULLWARRANTY

FORTWOYEARSfromthedateofpurchase,allnon-expendablepartsofthisridingequipmentarewarrantedagainstanydefectsinmaterialorworkmanship.

Adefectivenon-expendablepartwill receivefreein-homerepairorreplacementifrepairisunavailable.

BATTERYLIMITEDWARRANTY

FOR90DAYSfromthedateofpurchase,thebattery(anexpendablepart)ofthisridingequipmentiswarrantedagainstanydefectsinmaterialor

workmanship.Anewbatterywillbesuppliedfreeofcharge.Youareresponsibleforthelaborcostofbatteryinstallation.

ADDITIONALLIMITEDWARRANTIES

Inthefollowingadditionalwarranties,youareresponsiblefor thelaborcostof partinstallationafterthesecondyearfromthedateofpurchase.

FORFIVEYEARSfromthedateofpurchase,theframeofthisridingequipmentiswarrantedagainstanydefectsinmaterialorworkmanship.Anewframewill

besuppliedfreeof charge.

FORTENYEARSfromthedateofpurchase,thefrontaxleofthisridingequipmentiswarrantedagainstanydefectsin materialorworkmanship.Anewfront

axlewillbesuppliedfreeofcharge.

FORASLONGASITISUSEDbytheoriginalownerafterthetenthyearfromthedateofpurchase,thecastironfrontaxle(ifequipped)ofthisridingequipment

iswarrantedagainstanydefectsinmaterialorworkmanship.Withproofofpurchase,anewcastironfrontaxlewill besuppliedfreeofcharge.

WARRANTYSERVICE

Forwarrantycoveragedetailsto obtainfreerepairorreplacement,call1-800-659-5917orvisitthewebsite:www.craftsman.com

Inallcasesabove,if partrepairorreplacementisimpossible,the ridingequipmentwill bereplacedfreeofchargewith thesameoranequivalentmodel.

Alloftheabovewarrantycoverageisvoidifthisridingequipmentiseverusedwhileprovidingcommercialservicesorif rentedtoanotherperson.

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.WarrantycoveragedoesNOTinclude:

• Expendableparts(exceptbattery)thatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedtoblades,sparkplugs,air

cleaners,belts,andoilfilters.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementorrepaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireorwheelreplacementorrepairresultingfromnormalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseof operatorabuse,includingbut notlimitedtodamagecausedbytowingobjectsbeyondthecapabilityoftheriding

equipment,impactingobjectsthatbendtheframe,axleassemblyorcrankshaft,orover-speedingtheengine.

• Repairsnecessarybecauseof operatornegligence,includingbut notlimitedto,electricalandmechanicaldamagecausedbyimproperstorage,failureto

usethe propergradeandamountof engineoff,failuretokeepthedeckclearofflammabledebris,orfailuretomaintaintheridingequipmentaccording

totheinstructionscontainedinthe operator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedtobecontaminatedoroxidized(stale).Ingeneral,fuelshouldbeusedwithin30days

ofitspurchasedate.

• Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstateto state.

SearsBrandsManagementCorporation,HoffmanEstates,IL60179

Off-Season Storage ................................... 32

Troubleshooting ..................................... 33

Parts List ............................................. 34

Espaffo[ .............................................. 69

Service Numbers ............................ Back Cover

Engine Oil: SAE30

Fuel: Unleaded Gasoline

Spark Plug: F6RTC (951-10292)

© Sears Brands, LLC

Model Number

Serial Number

Date of Purchase

Record the model number, serial number,

2

and date of purchase above.

Thissymbolpointsout importantsafetyinstructionswhich, ifnot

followed,couldendangerthe personalsafetyand/orproperty of

yourselfandothers.Readandfollow allinstructionsinthismanual

beforeattempting tooperatethismachine.Failuretocomplywith these

instructionsmayresultinpersonalinjury.Whenyouseethissymbol,HEED

ITSWARNING!

Thismachinewasbuilt to beoperatedaccordingto thesafeoperation

practicesinthis manual.Aswith anytype ofpowerequipment,

carelessnessorerroronthe part oftheoperatorcanresultinseriousinjury.

Thismachineiscapableof amputatingfingers, hands,toesandfeet and

throwing debris.Failureto observethefollowing safetyinstructionscould

resultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehiclecomponents

containoremit chemicalsknowntoStateof Californiatocausecancerand

birth defectsorother reproductiveharm.

Batteryposts,terminals,andrelatedaccessoriescontainleadandlead

compounds,chemicalsknowntotheStateof Californiatocausecancerand

reproductiveharm.Washhandsafter handling.

GENERAL OPERATION

Read,understand,andfollowall instructionsonthemachineandinthe

manual(s)beforeattemptingtoassembleandoperate.Keepthismanualin

asafeplaceforfutureandregularreferenceandfororderingreplacement

parts.

Befamiliarwith allcontrolsandtheirproperoperation.Knowhowtostop

themachineanddisengagethemquickly.

Neverallowchildrenunder14yearsold tooperatethismachine.Children14

yearsoldandovershouldreadandunderstandtheoperationinstructions

andsafetyrulesinthismanualandshouldbetrainedandsupervisedbya

parent.

Neverallowadultstooperatethismachinewithout properinstruction.

Tohelpavoidbladecontactorathrownobjectinjury,keepbystanders,

helpers,childrenandpetsatleast75feetfromthemachinewhileitisin

operation.Stopmachineifanyoneentersthearea.

Thoroughlyinspecttheareawheretheequipmentistobeused.Remove

allstones,sticks,wire,bones,toys,andotherforeignobjectswhichcould

bepickedupandthrownbytheblade(s).Thrownobjectscancauseserious

personalinjury.

Planyourmowingpatterntoavoiddischargeof materialtowardroads,

sidewalks,bystandersandthelike.Also,avoiddischargingmaterialagainst

awall orobstructionwhichmaycausedischargedmaterialto ricochetback

towardtheoperator.

Alwayswearsafetyglassesorsafetygogglesduringoperationandwhile

performinganadjustmentor repairto protectyoureyes.Thrownobjects

whichricochetcancauseseriousinjurytotheeyes.

Wearsturdy,rough-soledworkshoesandclose-fittingslacksandshirts.

Loosefitting clothesandjewelrycanbecaughtinmovableparts.Never

operatethis machineinbarefeetorsandals.

Your ResponsibilityiRestrict theuseofthispowermachineto

personswho read,understandandfollow thewarningsand instructionsin

thismanualandonthe machine.

SAVETHESEINSTRUCTIONS!

Beawareof themowerandattachmentdischargedirectionanddonotpoint

it atanyone.Donotoperatethemowerwithoutthedischargecoverorentire

grasscatcherin itsproperplace.

Donotput handsorfeetnearrotatingpartsor underthecuttingdeck.

Contactwiththeblade(s)canamputatehandsandfeet.

Amissingordamageddischargecovercancausebladecontactorthrown

objectinjuries.

Stoptheblade(s)whencrossinggraveldrives,walks,orroadsandwhilenot

cuttinggrass.

Watchfortrafficwhenoperatingnearorcrossingroadways.Thismachineis

not intendedforuseonanypublicroadway.

Donotoperatethemachinewhileunderthe influenceof alcoholordrugs.

Mowonlyindaylightorgoodartificiallight.

Nevercarrypassengers.

Disengageblade(s)beforeshiftingintoreverse.Backupslowly.Alwayslook

clownandbehindbeforeandwhilebackingtoavoidaback-overaccident.

Slowdownbeforeturning.Operatethemachinesmoothly.Avoiderratic

operationandexcessivespeed.

Disengageblade(s),setparkingbrake,stopengineandwaituntilthe

blade(s)cometo acompletestopbeforeremovinggrasscatcher,emptying

grass,uncloggingchute,removinganygrassordebris,or makingany

adjustments.

Neverleavearunningmachineunattended.Alwaysturnoffblade(s),set

parkingbrake,stopengineandremovekeybeforedismounting.

Useextracarewhenloadingor unloadingthemachineintoatrailerortruck.

Thismachineshouldnotbedrivenupordownramp(s),becausethemachine

couldtipover,causingseriouspersonalinjury.Themachinemustbepushed

manuallyonramp(s)to loadorunloadproperly.

Mufflerandenginebecomehotandcancausea burn.Donottouch.

Checkoverheadclearancescarefullybeforedrivingunderlowhangingtree

branches,wires,dooropeningsetc.,wheretheoperatormaybestruckor

pulledfromthemachine,whichcouldresultinseriousinjury.

Disengageallattachmentclutchesanddepressthebrakepedalcompletely

beforeattemptingtostartengine.

Yourmachineisdesignedtocutnormalresidentialgrassofaheightnomore

than10".Donotattempttomowthroughunusuallytall,drygrass(e.g.,

pasture)orpliesofdryleaves.Drygrassorleavesmaycontacttheengine

exhaustand/orbuilduponthemowerdeckpresentingapotentialfire

hazard.

Useonlyaccessoriesandattachmentsapprovedforthismachinebythe

machinemanufacturer.Read,understandandfollowallinstructions

providedwiththeapprovedaccessoryorattachment.Foralistofapproved

accessoriesandattachments,call1-800-659-5917.

Dataindicatesthatoperators,age60yearsandabove,areinvolvedina

largepercentageofridingmower-relatedinjuries.Theseoperatorsshould

evaluatetheirabilitytooperatetheridingmowersafelyenoughtoprotect

themselvesandothersfromseriousinjury.

Ifsituationsoccurwhicharenotcoveredinthismanual,usecareandgood

judgment.

SLOPE OPERATION

Slopesareamajorfactorrelatedtolossofcontrolandtip-overaccidentswhichcan

resultinsevereinjuryordeath.Allslopesrequireextracaution.Ifyoucannotback

uptheslopeorif youfeeluneasyonit, donotmowit.

Foryoursafety,usetheSlopeGuideincludedaspartofthismanualtomeasure

slopesbeforeoperatingthis machineonaslopedorhilly area.If theslopeisgreater

than12degreesasshownonthe SlopeGuide,donotoperatethis machineonthat

areaorseriousinjurycouldresult.

Do;

Mowupanddownslopes,notacross.Exerciseextremecautionwhen

changingdirectiononslopes.

Watchfor holes,ruts,bumps,rocks,orotherhiddenobjects.Uneventerrain

couldoverturnthemachine.Tallgrasscanhideobstacles.

Useslowspeed.Choosealowenoughspeedsettingsothat youwill nothave

tostoporshiftwhileontheslope.Tiresmaylosetractiononslopeseven

thoughthebrakesarefunctioningproperly.Alwayskeepmachineingear

whengoingdownslopestotakeadvantageof enginebrakingaction.

Followthemanufacturer'srecommendationsfor wheelweightsor

counterweightsto improvestability.

Useextracarewith grasscatchersor otherattachments.Thesecanchange

thestabilityofthemachine.

Keepallmovementontheslopesslowandgradual.Donotmakesudden

changesinspeedordirection.Rapidengagementorbrakingcouldcause

thefrontofthemachineto lift andrapidlyflip overbackwardswhichcould

causeseriousinjury.

Avoidstartingorstoppingona slope.Iftireslosetraction,disengagethe

blade(s)andproceedslowlystraightdowntheslope.

Do Not:

Donotturnonslopesunlessnecessary;then,turnslowlyandgradually

downhill,if possible.

Donotmowneardrop-offs,ditchesorembankments.Themowercould

suddenlyturnoverira wheelisovertheedgeofacliff, ditch,orifanedge

cavesin.

Donottry tostabilizethemachinebyputtingyourfoot ontheground.

Donotuseagrasscatcheron steepslopes.

Donotmowonwetgrass.Reducedtractioncouldcausesliding.

Donotattemptto coastdownhill.Over-speedingmaycausetheoperatorto

losecontrolofthe machineresultinginseriousinjuryordeath.

Donottow heavypull behindattachments(e.g.loadeddumpcart,lawn

roller,etc.)onslopesgreaterthan5degrees.Whengoingdownhill,the

extraweighttendstopushthetractorandmaycauseyoutoloosecontrol

(e.g.tractormayspeedup,brakingandsteeringabilityarereduced,

attachmentmayjack-knifeandcausetractorto overturn).

CHILDREN

Tragicaccidentscanoccurif theoperatoris notalertto thepresenceofchildren.

Childrenareoftenattractedtothemachineandthemowingactivity.Theydonot

understandthedangers.Neverassumethatchildrenwill remainwhereyoulastsaw

them.

Keepchildrenoutofthemowingareaandinwatchfulcareofaresponsible

adultotherthantheoperator.

Bealertandturnmachineoff ifachildentersthearea.

Beforeandwhilebacking,lookbehindanddownforsmallchildren.

Nevercarrychildren,evenwith theblade(s)shutoff.Theymayfall off andbe

seriouslyinjuredorinterferewith safemachineoperation.

Useextremecarewhenapproachingblindcorners,doorways,shrubs,trees

orotherobjectsthatmayblockyourvisionofachildwhomayrunintothe

machine.

Toavoidback-overaccidents,alwaysdisengagethecuttingblade(s)before

shiftinginto Reverse.Ifequipped,the"ReverseCautionMode"(blades

operatewhilemachineridesinreverse)shouldnotbeusedwhenchildrenor

othersarearound.

Keepchildrenawayfromhotorrunningengines.Theycansufferburnsfrom

ahotmuffler.

Removekeywhenmachineisunattendedto preventunauthorized

operation.

Neverallowchildrenunder14yearsofagetooperatethismachine.Children14and

overshouldreadandunderstandtheinstructionsandsafeoperationpracticesin

thismanualandonthemachineandshouldbetrainedandsupervisedbyanadult.

TOWING

Towonlywitha machinethathasahitchdesignedfortowing.Donotattach

towedequipmentexceptat thehitchpoint.

Followthe manufacturersrecommendationforweightlimitsfortowed

equipmentandtowingonslopes.

Neverallowchildrenorothersinorontowedequipment.

4

Onslopes,theweightofthetowedequipmentmaycauselossoftractionand

lossofcontrol.

Alwaysuseextracautionwhentowingwithamachinecapableof making

tight turns(e.g."zero-turn"ride-onmower).Makewideturnstoavoid

jack-knifing.

Travelslowlyandallowextradistanceto stop.

Donotcoastdownhill.

SERVICE

Safe Handling of Gasoline:

Toavoidpersonalinjury orproperty damageuseextremecarein handling

gasoline.Gasolineisextremelyflammableand thevaporsareexplosive.

Seriouspersonalinjurycanoccurwhengasolineisspilled onyourselforyour

clotheswhichcanignite. Washyourskinandchangeclothesimmediately.

Useonlyanapprovedgasolinecontainer.

Neverfill containersinsideavehicleoronatruckortrailerbedwithaplastic

liner.AIwaysplacecontainerson thegroundawayfromyourvehiclebefore

filling.

Whenpractical,removegas-poweredequipmentfromthetruckor

trailerandrefuelitontheground.If thisisnotpossible,thenrefuelsuch

equipmentonatrailerwitha portablecontainer,ratherthanfromagasoline

dispensernozzle.

Keepthenozzlein contactwith therimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Donotuseanozzlelock-opendevice.

Extinguishallcigarettes,cigars,pipesandothersourcesofignition.

Neverfuelmachineindoors.

Neverremovegascaporaddfuelwhiletheengineishotor running.Allow

engineto coolatleasttwo minutesbeforerefueling.

Neveroverfill fueltank.Filltanktonomorethan1/2inchbelowbottomof

fillernecktoallowspaceforfuelexpansion.

Replacegasolinecapandtightensecurely.

Ifgasolineisspilled,wipeit off theengineandequipment.Movemachineto

anotherarea.Wait5minutesbeforestartingtheengine.

Toreducefirehazards,keepmachinefreeof grass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillageandremoveanyfuelsoakeddebris.

Neverstorethe machineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlightasonawaterheater,spaceheater,furnace,clothes

dryerorothergasappliances.

Allowamachineto coolat leastfiveminutesbeforestoring.

General Service

Neverrunanengineindoorsorinapoorlyventilatedarea.Engineexhaust

containscarbonmonoxide,anodorless,anddeadlygas.

Beforecleaning,repairing,orinspecting,makecertaintheblade(s)andall

movingpartshavestopped.Disconnectthesparkplugwireandgroundagainst

theenginetopreventunintendedstarting.

Periodicallychecktomakesurethebladescometo completestopwithin

approximately(5)fivesecondsafteroperatingthe bladedisengagement

control.Ifthebladesdonotstopwithinthethistimeframe,yourmachine

shouldbeservicedprofessionallybyaSearsorotherqualifiedservicedealer.

Checkbrakeoperationfrequentlyasit issubjectedtowearduringnormal

operation.Adjustandserviceasrequired.

Checktheblade(s)andenginemountingboltsatfrequentintervalsfor

propertightness.Also,visuallyinspectblade(s)for damage(e.g.,excessive

wear,bent,cracked).Replacetheblade(s)with theoriginalequipment

manufacturer's(O.E.M.)blade(s)only,listedinthismanual.Useofparts

whichdonotmeettheoriginalequipmentspedficationsmayleadto

improperperformanceandcompromisesafety!

Mowerbladesaresharp.Wrapthebladeorweargloves,anduseextra

cautionwhenservicingthem.

Keepallnuts,bolts,andscrewstight tobesuretheequipmentisinsafe

workingcondition.

Nevertamperwith thesafetyinterlocksystemorothersafetydevices.Check

theirproperoperationregularly.

Afterstrikingaforeignobject,stoptheengine,disconnectthesparkplug

wire(s)andgroundagainsttheengine.Thoroughlyinspectthemachinefor

anydamage.Repairthedamagebeforestartingandoperating.

Neverattemptto makeadjustmentsorrepairstothe machinewhilethe

engineis running.

Grasscatchercomponentsandthedischargecoveraresubjecttowear

anddamagewhichcouldexposemovingpartsorallowobjectstobe

thrown.Forsafetyprotection,frequentlycheckcomponentsandreplace

immediatelywith originalequipmentmanufacturer's(O.E.M.)partsonly,

listedinthismanual.Useofpartswhichdonotmeettheoriginalequipment

specificationsmayleadtoimproperperformanceandcompromisesafety!

Donotchangetheenginegovernorsettingsorover-speedtheengine.The

governorcontrolsthemaximumsafeoperatingspeedof theengine.

Maintainorreplacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsandregulationsforgas,off,etc.toprotectthe

environment.

AccordingtotheConsumerProductsSafetyCommission(CPSC)andtheU.S.

EnvironmentalProtectionAgency(EPA),this producthasanAverageUseful

Lifeof seven(7)years,or 270hoursofoperation.AttheendoftheAverage

UsefulLife,buyanewmachineorhavethemachineinspectedannuallyby

aSearsorotherqualifiedservicedealertoensurethat allmechanicaland

safetysystemsareworkingproperlyandnotwornexcessively.Failuretodo

socanresultin accidents,injuriesordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyengineinanyway.Tampering

with thegovernorsettingcanleadtoarunawayengineandcauseit to

operateat unsafespeeds.Nevertamperwith factory settingof engine

governor.

NOTICE REGARDING EMiSSiONS

Engineswhich arecertified to complywithCaliforniaandfederalEPA

emissionregulationsfor SORE(SmallOffRoadEquipment)arecertified

tooperateonregularunleadedgasoline,andmayincludethefollowing

emissioncontrolsystems:EngineModification (EM),OxidizingCatalyst(0C),

SecondaryAirInjection(SAI)andThreeWayCatalyst(TWC)ifsoequipped.

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollow all instructionsonthemachinebefore

attempting toassembleandoperate.

" "i READTHEOPERATOR'SMANUAL(S)

i Read,understand, and follow all instructions in the manual(s) before attempting to assemble and

i

' operate

I

SPARK ARRESTOR

Thismachineisequippedwith aninternal combustionengineand should

not beusedonor nearanyunimprovedforest-covered,brusbcoveredor

grass-coveredland unlessthe engine'sexhaustsystemisequippedwith a

sparkarrestor meetingapplicablelocalorstate laws(ifany).

Ira sparkarrestorisused,it shouldbemaintainedin effectiveworking order

bythe operator.Inthe StateofCaliforniathe aboveisrequiredbylaw (Section

4442ofthe CaliforniaPublicResourcesCode).Otherstatesmayhavesimilar

laws.Federallawsapplyonfederal lands.

Asparkarrestorfor the muffler isavailablethroughyournearestSearsParts

andRepairServiceCenter.

DANGER-- ROTATINGBLADES

Never carry passengers. Never carry children, even with the blades off.

O_, DANGER-- ROTATINGBLADES

_j WARNING-- ROTATINGBLADES

..........._ •

,,,/_ WARNING--THROWN OBJECTS

JJ .

ii_;iil._',_....... This machine may pick up and throw and objects which can causeserious personal injury.

Toavoid a back-over accident, keep children awayfrom the machine while it isin operation.

Do not put hands or feet near rotating parts or under the cutting deck.Contact with the blade(s)canamputate hands and feet.

DANGER-- ROTATINGBLADES

Always look down and behind before and while backing to avoid a back-over accident.

/ WARN,NG--T.ROWNOBJECTS

Thismachinemaypickupandthrowandobjectswhichcancauseseriouspersona,injury

_f

6

®

O

BYSTANDERS

Keep bystanders, helpers, children and pets at least 75 feet from the machine while it is in operation.

WARNING-- SLOPEOPERATION

Do not operate this machine on a slope greater than 12 degrees.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

DANGER- ROTATING BLADES

To reduce the risk of injury, keep hands and feet away. Do not operate unless discharge cover or grass

catcher is in its proper place. If damaged, replace immediately.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

DANGER-- ROTATING BLADES

Do not step on the cutting deck.

WARNING: Your Responsibility--Restrict the use of this power machine to persons who read, understand and follow

the warnings and instructions in this manual and on the machine.

SAVETHESEINSTRUCTIONS!

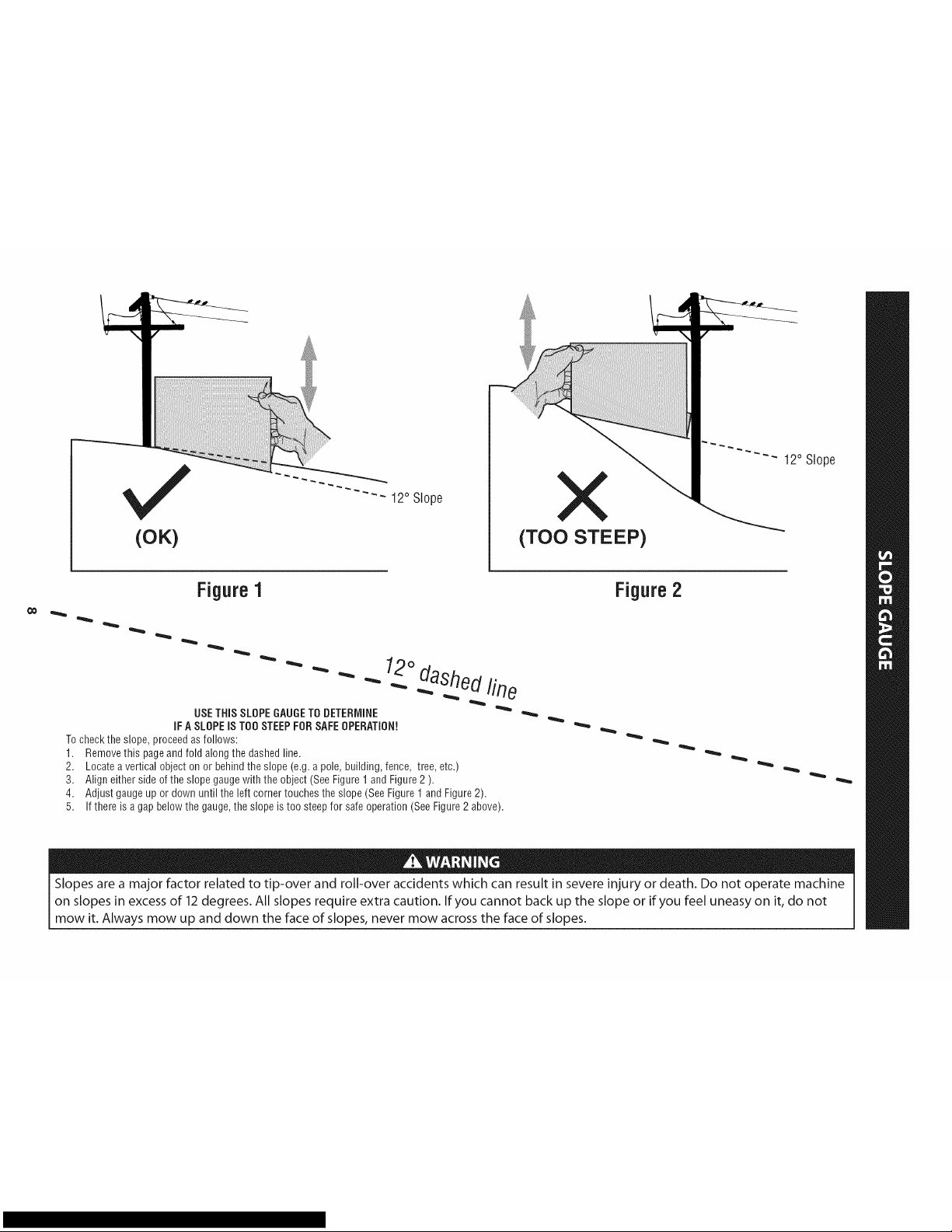

,/

(OK)

"'- 12° Slope

X

(TOO STEEP)

- 12° Slope

Figure1

USETHiSSLOPEGAUGE TO DETERMINE

iFA SLOPE iSTOOSTEEPFOB SAFEOPERATION!

Tochecktheslope,proceedas follows:

1. Removethis pageandfoldalongthe dashedline.

2. Locateaverticalobjecton or behindtheslope (e.g.a pole,building,fence, tree,etc.)

3. Aligneithersideoftheslopegaugewith the object(SeeFigure1andFigure2 ).

4. Adjustgaugeupor downuntil theleftcornertouchestheslope(SeeFigure1 andFigure2).

5.

Ifthereisagapbelowthegauge,theslopeis toosteepfor safeoperation(SeeFigure2above).

Figure2

Slopes are a major factor related to tip-over and roll-over accidents which can result in severe injury or death. Do not operate machine

on slopes in excess of 12 degrees. All slopes require extra caution. If you cannot back up the slope or if you feel uneasy on it, do not

mow it. Always mow up and down the face of slopes, never mow across the face of slopes.

Contents of Crate

OneRidingMower

OneSteeringWheel/ShaftAssembly

OneRearHitchPlate

OneRidingMowerOperator'sManual

OneSeatAssembly

OneRearEngineCover

OneOilDrainSleeve

OneEngineOperator'sManual

Contents of Hardware Pack

Beforebeginninginstallation,removeallthecontentsfromthecrateandallthe

hardwarefromthepackfromto makesureeverythingispresent.Hardwareislisted

below.Partnumbersareshowninparentheses.

HitchPlate

SeatMountingBracket(withtwo shoulderbolts&locknutsinstalled)

EecommendedToolsfor Assembly

3/8"Wrench(orsocket) 9/16"Socket

1/2"Wrench(orsocket) 7/16"wrench

5/8"Wrench(orsocket) PhillipsScrewDriver

1/4"DriveRatchet

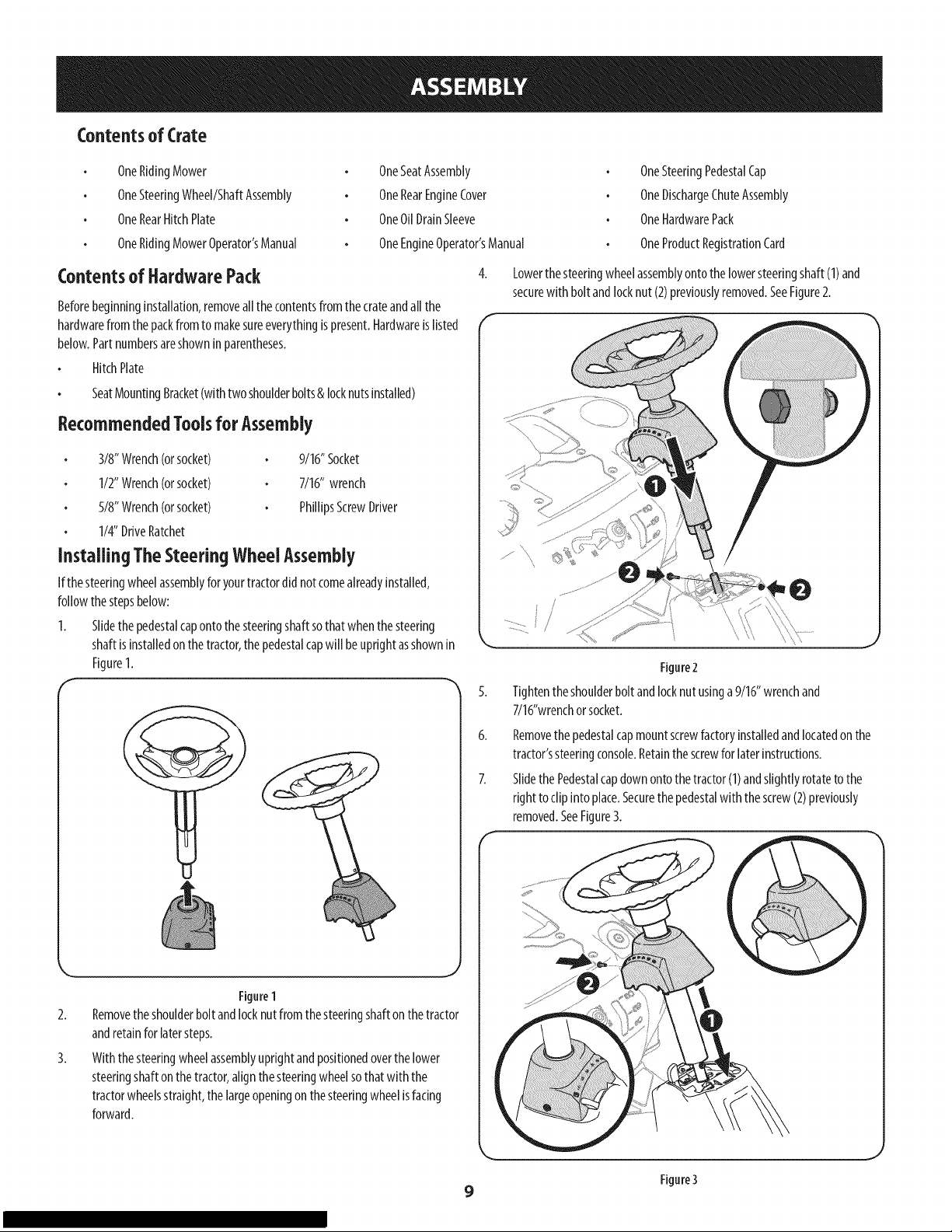

InstallingTheSteeringWheelAssembly

Ifthesteeringwheelassemblyforyourtractordidnotcomealreadyinstalled,

followthestepsbelow:

1. Slidethe pedestalcapontothesteeringshaftsothatwhenthesteering

shaftisinstalledonthetractor,thepedestalcapwillbeuprightasshownin

Figure1.

OneSteeringPedestalCap

OneDischargeChuteAssembly

OneHardwarePack

OneProductRegistrationCard

Lowerthesteeringwheelassemblyontothelowersteeringshaft(1)and

securewith boltandlocknut(2)previouslyremoved.SeeFigure2.

Figure2

Tightentheshoulderboltandlocknutusinga9/16"wrenchand

7/16"wrenchorsocket.

6. Removethepedestalcapmountscrewfactoryinstalledandlocatedonthe

tractor'ssteeringconsole.Retainthescrewforlaterinstructions.

7. SlidethePedestalcapdownontothetractor(1)andslightlyrotatetothe

rightto clipintoplace.Securethepedestalwith thescrew(2)previously

removed.SeeFigure3.

Figure1

Removetheshoulderboltandlocknutfromthesteeringshaftonthetractor

andretainforlatersteps.

Withthesteeringwheelassemblyuprightandpositionedoverthelower

steeringshaftonthetractor,alignthesteeringwheelsothatwith the

tractorwheelsstraight,thelargeopeningonthesteeringwheelisfacing

forward.

9 Figure3

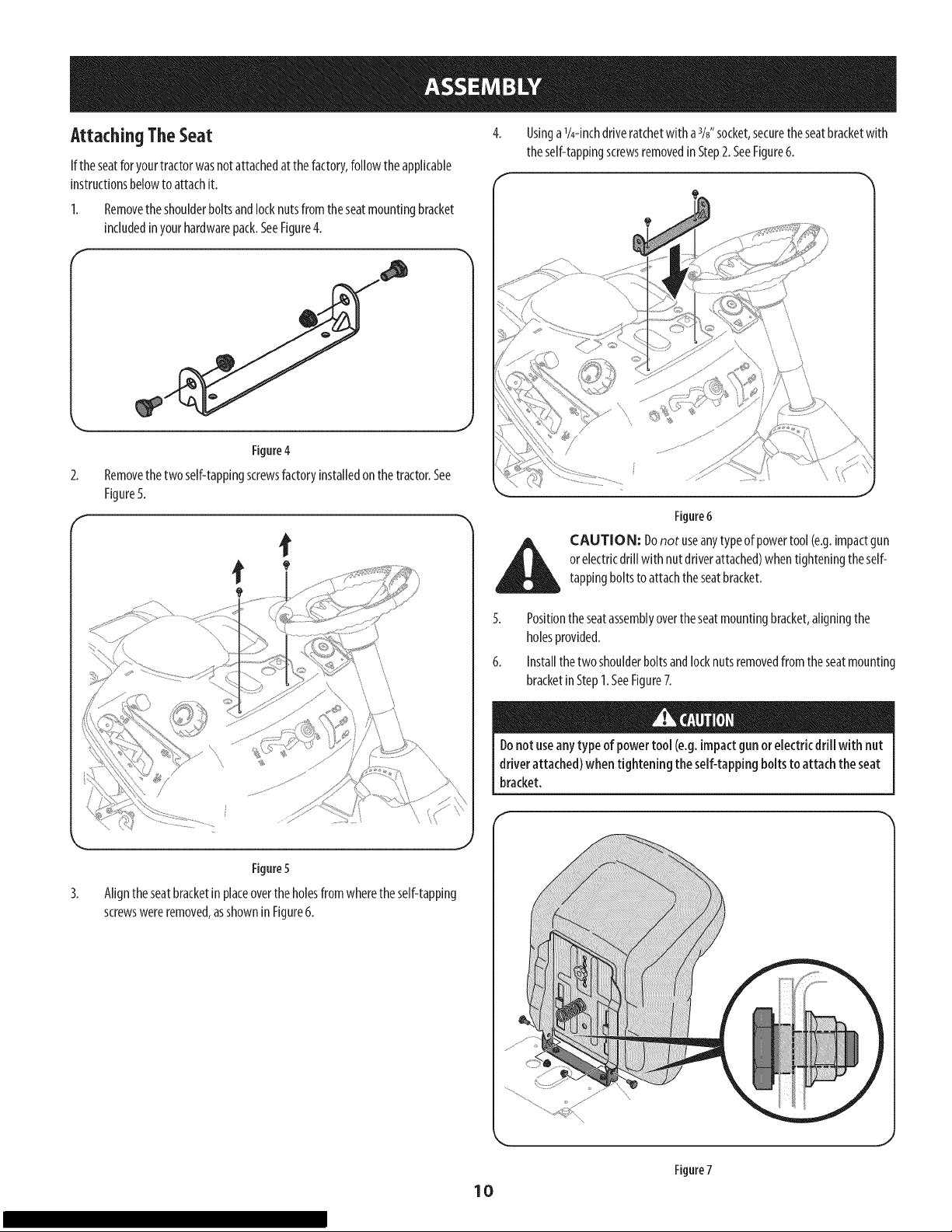

AttachingTheSeat

Iftheseatforyourtractorwasnotattachedatthefactory,followtheapplicable

instructionsbelowtoattachit.

2. Removetheshoulderboltsandlocknutsfromtheseatmountingbracket

includedinyourhardwarepack.SeeFigure4.

f

Figure4

2. Removethetwo self-tappingscrewsfactoryinstalledonthetractor.See

Figure5.

Usinga1/4-inchdriveratchetwith a%" socket,securetheseatbracketwith

theself-tappingscrewsremovedin Step2.SeeFigure6.

Figure6

Figure5

3.

Aligntheseatbracketinplaceovertheholesfromwheretheself-tapping

screwswereremoved,asshowninFigure6.

i_ll CAUTIO N: Donot useanytypeofpowertool(e.g.impactgun

5. Positiontheseatassemblyovertheseatmountingbracket,aligningthe

6. Installthetwo shoulderboltsandlocknutsremovedfromtheseatmounting

Donotuseanytype of powertool (e.g.impactgunor electricdrill with nut

driverattached)whentightening theself-tappingboltsto attachthe seat

bracket°

orelectricdrill with nutdriverattached)whentighteningtheself-

tappingboltstoattachtheseatbracket.

holesprovided.

bracketin Step1.SeeFigure7.

Figure7

I0

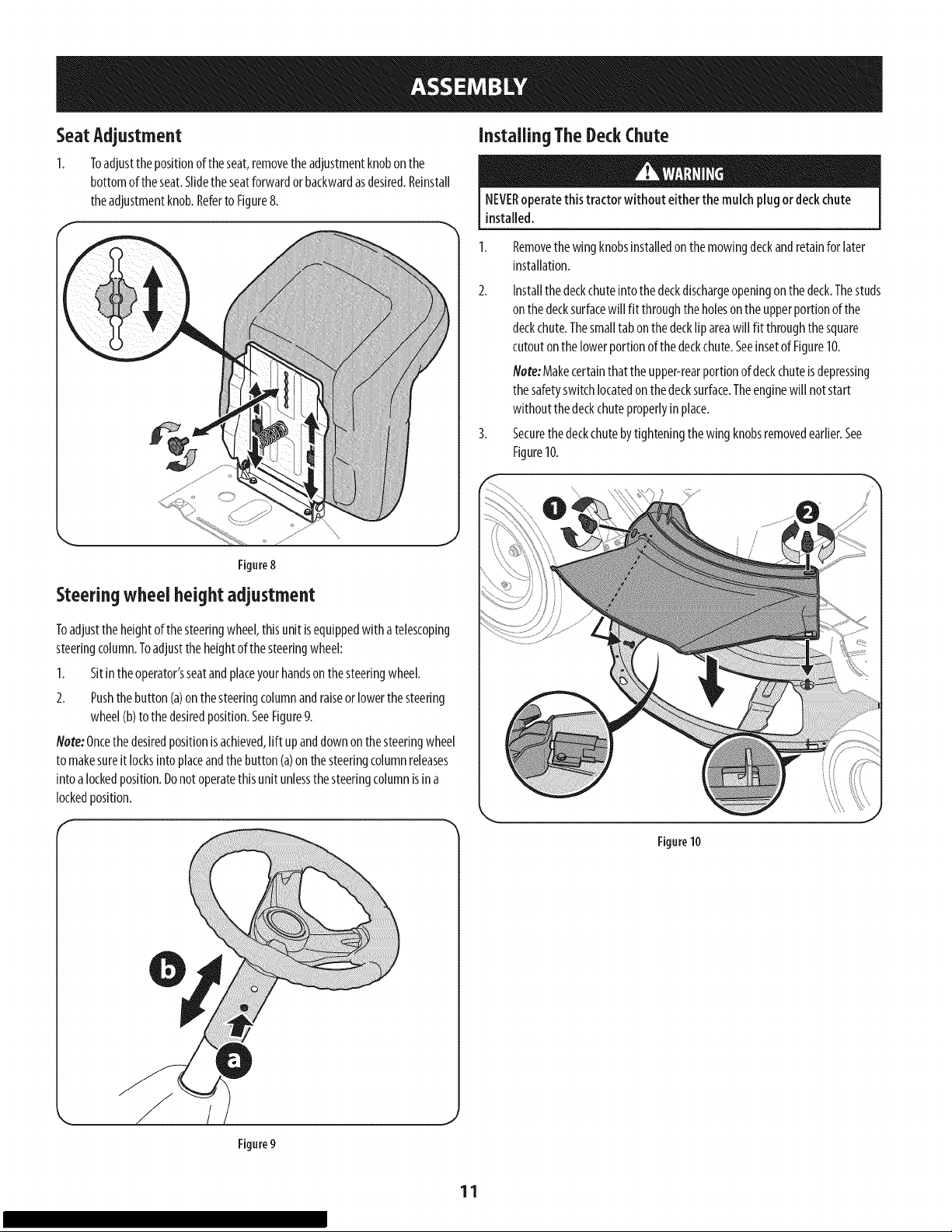

1. Toadjustthepositionoftheseat,removetheadjustmentknobonthe

bottomoftheseat.Slidetheseatforwardorbackwardasdesired.Reinstall

theadjustmentknob.RefertoFigure8.

f

s j_

Figure8

InstallingTheDeckChuteSeatAdjustment

NEVERoperatethis tractor without either the mulchplugordeckchute

installed.

Removethewingknobsinstalledonthemowingdeckandretainfor later

installation.

2. Installthedeckchuteintothedeckdischargeopeningonthedeck.Thestuds

onthedecksurfacewill fit throughtheholesonthe upperportionofthe

deckchute.Thesmalltabonthedecklip areawill fit throughthesquare

cutoutonthe lowerportionofthedeckchute.SeeinsetofFigure10.

Note:Makecertainthat theupper-rearportionofdeckchuteisdepressing

thesafetyswitchlocatedonthedecksurface.Theenginewill notstart

withoutthedeckchuteproperlyin place.

3. Securethedeckchutebytighteningthewingknobsremovedearlier.See

Figure10.

Steering wheel height adjustment

Toadjusttheheightofthesteeringwheel,thisunitisequippedwith atelescoping

steeringcolumn.Toadjusttheheightofthesteeringwheel:

1. Sitintheoperator'sseatandplaceyourhandsonthesteeringwheel.

2. Pushthebutton(a)onthesteeringcolumnandraiseorlowerthesteering

wheel(b)tothedesiredposition.SeeFigure9.

flete:Oncethedesiredpositionisachieved,lift upanddownonthesteeringwheel

tomakesureit locksintoplaceandthebutton(a)onthesteeringcolumnreleases

intoalockedposition.Donotoperatethisunitunlessthesteeringcolumnisina

lockedposition.

Figure10

Figure9

11

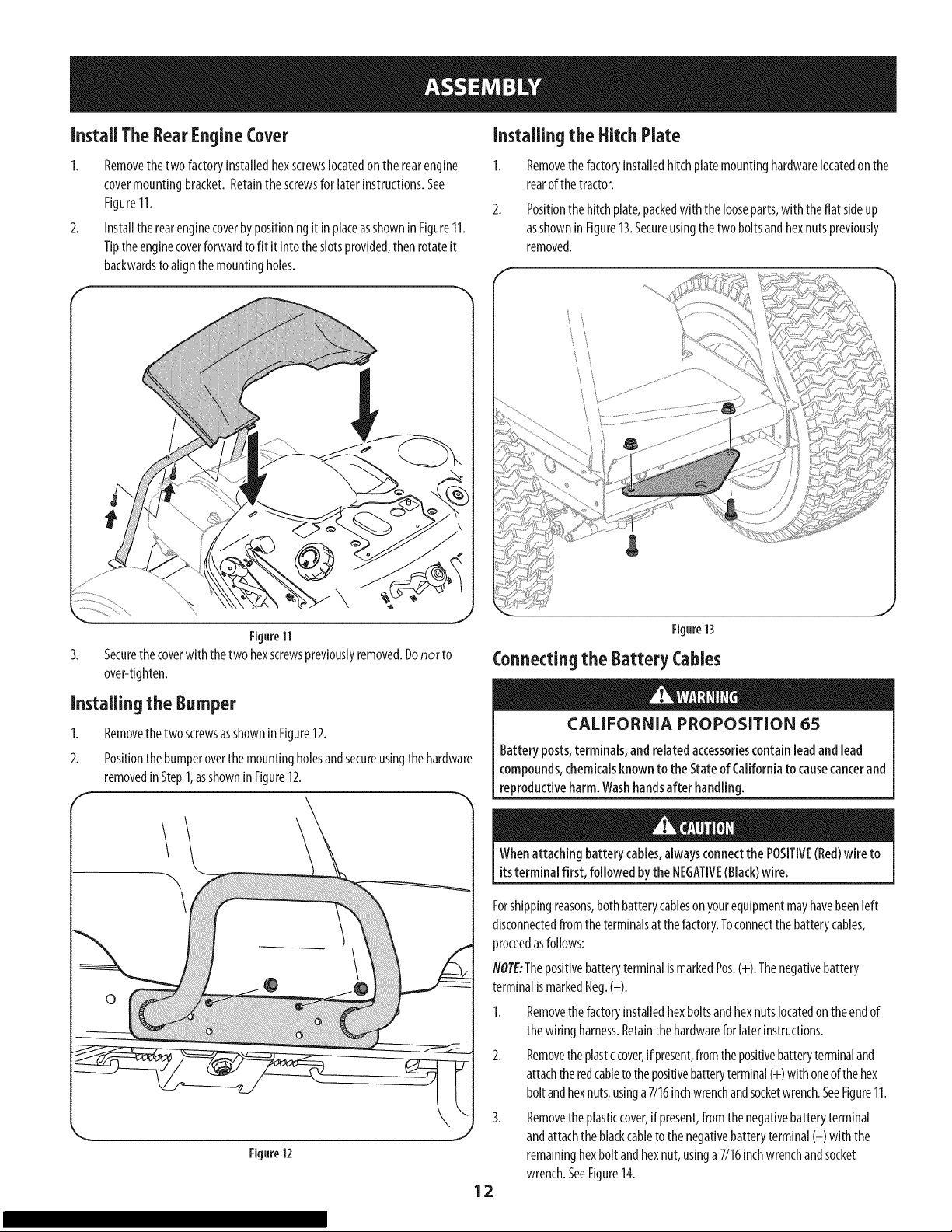

InstallTheRearEngineCover

Installingthe HitchPlate

1. Removethetwofactoryinstalledhexscrewslocatedontherearengine

covermountingbracket.Retainthescrewsfor later instructions.See

Figure11.

2. Installtherearenginecoverbypositioningitin placeasshowninFigure11.

Tiptheenginecoverforwardtofit it intotheslotsprovided,thenrotateit

backwardstoalignthemountingholes.

F

Removethefactoryinstalledhitchplatemountinghardwarelocatedonthe

rearofthetractor.

Positionthehitchplate,packedwiththe looseparts,with theflat sideup

asshowninFigure13.Secureusingthetwoboltsandhexnutspreviously

removed.

Figure11

3.

Securethecoverwith thetwohexscrewspreviouslyremoved.Donot to

over-tighten.

Installingthe Bumper

1. Removethetwo screwsasshownin Figure12.

2. Positionthebumperoverthemountingholesandsecureusingthehardware

removedinStep1,asshownin Figure12.

\

Figure12

Figure13

Connecting the Battery Cables

CALIFORNIA PROPOSITION 65

Batteryposts,terminals,andrelatedaccessoriescontainleadandlead

compounds,chemicalsknownto theStateof Californiato causecancerand

reproductiveharm.Washhandsafter handling.

Whenattachingbatterycables,alwaysconnectthe POSITIVE(Red)wire to

itsterminal first, followed bythe NEGATIVE(Black)wire.

Forshippingreasons,bothbatterycablesonyourequipmentmayhavebeenleft

disconnectedfromtheterminalsatthefactory.Toconnectthebatterycables,

proceedasfollows:

NOTE:ThepositivebatteryterminalismarkedPos.(+).Thenegativebattery

terminalismarkedNeg.(-).

1. Removethefactoryinstalledhexboltsandhexnutslocatedontheendof

thewiringharness.Retainthehardwarefor laterinstructions.

Removetheplasticcover,if present,fromthepositivebatteryterminaland

attachtheredcableto thepositivebatteryterminal(+)withoneofthehex

boltandhexnuts,usinga7/16inchwrenchandsocketwrench.SeeFigure11.

Removetheplasticcover,if present,fromthenegativebatteryterminal

andattachtheblackcabletothenegativebatteryterminal(-) with the

remaininghexboltandhexnut,usinga 7/16inchwrenchandsocket

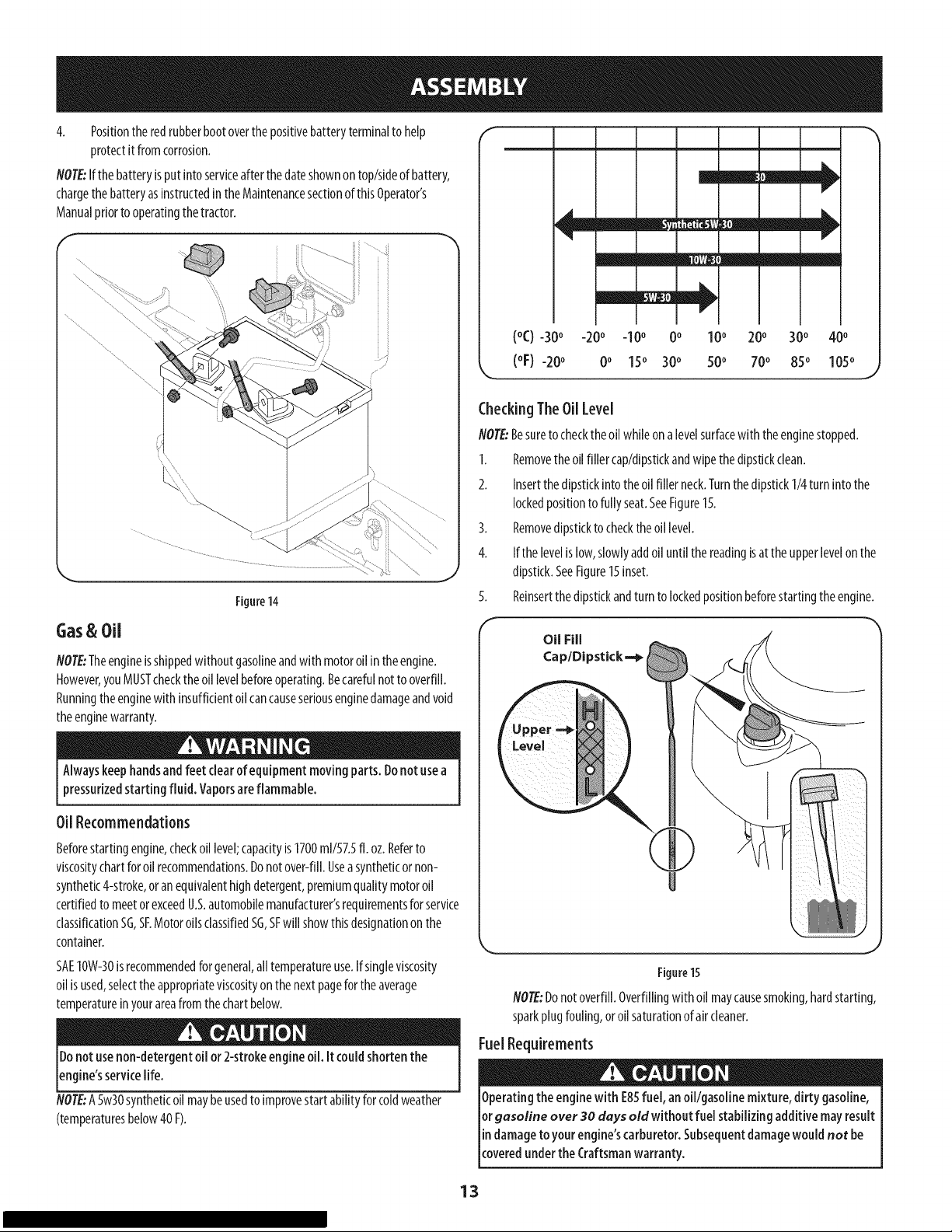

wrench.SeeFigure14.

12

4. Positiontheredrubberbootoverthepositivebatteryterminaltohelp

protectitfromcorrosion.

NOTE:Ifthe batteryisput intoserviceafterthedateshownontop/sideofbattery,

chargethe batteryasinstructedintheMaintenancesectionofthisOperator's

Manualpriortooperatingthetractor.

Figure14

m///=lllb

v

v

mm mm

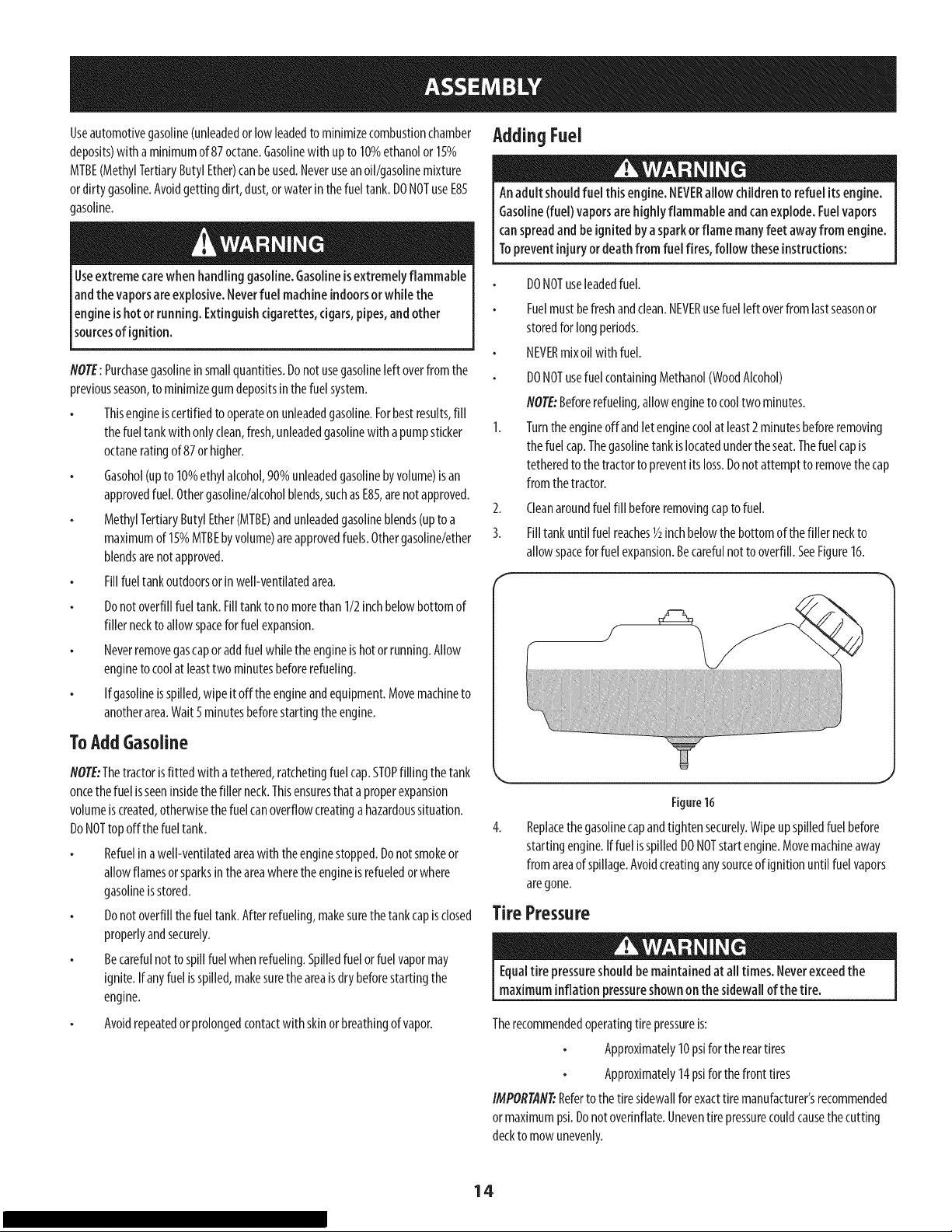

(°C)-30 ° -20° -10° 0° 10° 200 300

(°F)-20 ° 0° 150 300 50o 70o 85o 105o

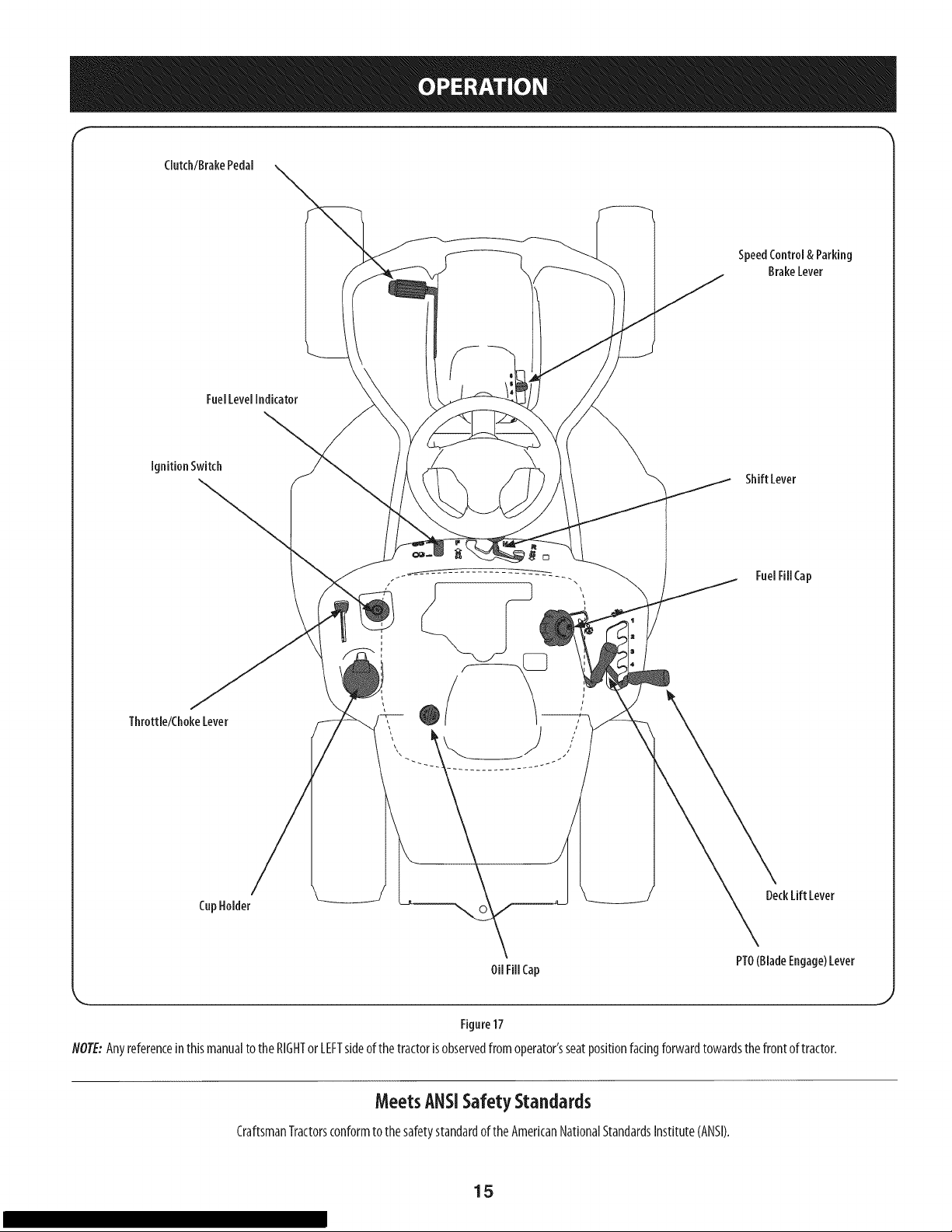

CheckingThe Oil Level

NOTE:Besuretochecktheoilwhileonalevelsurfacewith theenginestopped.

1. Removetheoilfillercap/dipstickandwipethedipstickclean.

2. Insertthedipstickintotheoilfiller neck.Turnthedipstick1/4turnintothe

lockedpositiontofullyseat.SeeFigure15.

3. Removedipstickto checktheoil level.

4. Ifthelevelislow,slowlyaddoiluntilthereadingisattheupperlevelonthe

dipstick.SeeFigure15inset.

5. Reinsertthedipstickandturnto lockedpositionbeforestartingtheengine.

Gas&Oil

NOTE:Theengineisshippedwithoutgasolineandwithmotoroil intheengine.

However,youMUSTchecktheoil levelbeforeoperating.Becarefulnotto overfill.

Runningtheenginewithinsufficientoilcancauseseriousenginedamageandvoid

theenginewarranty.

Alwayskeephandsandfeet clearofequipment movingparts. Donot usea

pressurizedstarting fluid. Vaporsareflammable.

Oil Recommendations

Beforestartingengine,checkoillevel;capacityis1700ml/57.5ft. oz.Referto

viscositychartfor oilrecommendations.Donotover-fill.Useasyntheticornon-

synthetic4-stroke,oranequivalenthighdetergent,premiumqualitymotoroil

certifiedtomeetorexceedU.S.automobilemanufacturer'srequirementsforservice

classificationSG,SEMotoroilsclassifiedSG,SFwill showthisdesignationonthe

container.

SAE10W-30isrecommendedforgeneral,alltemperatureuse.Ifsingleviscosity

oilisused,selecttheappropriateviscosityonthe nextpagefortheaverage

temperatureinyourareafromthechartbelow.

Donotusenon-detergentoil or 2-strokeengineoil. It couldshortenthe

engine'sservicelife.

NOTE:A5w30syntheticoilmaybeusedtoimprovestartabilityforcoldweather

(temperaturesbelow40F).

Oil Fill

Cap/Dipstick-==_

Level

Figure15

NOTE:Donotoverfill.Overfillingwithoil maycausesmoking,hardstarting,

sparkplugfouling,oroilsaturationof aircleaner.

FuelRequirements

Operatingthe enginewith ESSfuel, anoil/gasolinemixture, dirty gasoline,

or gasoline over 30 days old without fuel stabilizingadditivemayresult

[indamagetoyourengine'-scarburetor.Subsequentdamagewouldnot be

coveredunderthe Craftsmanwarranty.

13

Useautomotivegasoline(unleadedorlowleadedtominimizecombustionchamber

deposits)witha minimumof87octane.Gasolinewith upto10%ethanolor15%

MTBE(MethylTertiaryButylEther)canbeused.Neveruseanoil/gasolinemixture

ordirtygasoline.Avoidgettingdirt,dust,orwaterinthefueltank.DONOTuseE85

gasoline.

AddingFuel

Anadult shouldfuel this engine.NEVERallow childrentorefuel itsengine.

Gasoline(fuel)vaporsarehighlyflammable andcanexplode.Fuelvapors

canspreadandbeignitedbyasparkor flamemanyfeetawayfrom engine.

Topreventinjuryor deathfrom fuel fires, follow theseinstructions:

Useextremecarewhen handling gasoline.Gasolineisextremelyflammable

andthevaporsare explosive.Neverfuel machineindoorsorwhile the

engineishot or running.Extinguishcigarettes,cigars,pipes,andother

sourcesofignition.

NOTE:Purchasegasolineinsmallquantities.Donotusegasolineleftoverfromthe

previousseason,to minimizegumdepositsinthefuelsystem.

Thisengineiscertifiedtooperateonunleadedgasoline.Forbestresults,fill

thefueltankwith onlyclean,fresh,unleadedgasolinewith apumpsticker 1.

octaneratingof 87orhigher.

Gasohol(upto10%ethylalcohol,90%unleadedgasolinebyvolume)isan

approvedfuel.Othergasoline/alcoholblends,suchasE85,arenotapproved.

MethylTertiaryButylEther(MTBE)andunleadedgasolineblends(uptoa

maximumof 15_ MTBEbyvolume)areapprovedfuels.Othergasoline/ether 3.

blendsarenotapproved.

Fillfueltankoutdoorsorinwell-ventilatedarea. f

Donotoverfillfueltank.Filltankto nomorethan1/2inchbelowbottomof

fillernecktoallowspaceforfuelexpansion.

Neverremovegascaporaddfuelwhiletheengineishotor running.Allow

engineto coolatleasttwo minutesbeforerefueling.

Ifgasolineisspilled,wipeit offtheengineandequipment.Movemachineto

anotherarea.Wait5minutesbeforestartingtheengine.

o

DONOTuseleadedfuel.

Fuelmustbefreshandclean.NEVERusefuelleftoverfromlastseasonor

storedforlongperiods.

NEVERmixoilwith fuel.

DONOTusefuelcontainingMethanol(WoodAlcohol)

NOTE:Beforerefueling,allowenginetocooltwominutes.

Turntheengineoffandlet enginecoolatleast2minutesbeforeremoving

thefuelcap.Thegasolinetankislocatedundertheseat.Thefuelcapis

tetheredtothetractortopreventitsloss.Donotattempttoremovethecap

fromthetractor.

2.

Cleanaroundfuelfill beforeremovingcaptofuel.

Filltankuntilfuelreaches1/2inchbelowthebottomof thefillerneckto

allowspaceforfuelexpansion.Becarefulnotto overfill.SeeFigure16.

ToAddGasoline

NOTE:Thetractorisfittedwith a tethered,ratchetingfuelcap.STOPfillingthetank

oncethefuelisseeninsidethefillerneck.Thisensuresthataproperexpansion

volumeiscreated,otherwisethefuelcanoverflowcreatinga hazardoussituation.

DoNOTtopoffthe fueltank.

Refuelin awell-ventilatedareawiththeenginestopped.Donotsmokeor

allowflamesorsparksintheareawheretheengineisrefueledorwhere

gasolineisstored.

Donotoverfillthefueltank.Afterrefueling,makesurethetankcapisclosed

properlyandsecurely.

Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuelvapormay

ignite.Ifanyfuelisspilled,makesuretheareaisdrybeforestartingthe

engine.

Avoidrepeatedorprolongedcontactwith skinorbreathingofvapor.

,. j

Figure16

4. Replacethegasolinecapandtightensecurely.Wipeupspilledfuelbefore

startingengine.IffuelisspilledDONOTstartengine.Movemachineaway

fromareaof spillage.Avoidcreatinganysourceof ignitionuntilfuelvapors

aregone.

TirePressure

Equaltire pressureshouldbemaintainedat alltimes. Neverexceedthe

maximuminflation pressureshownonthe sidewall of the tire.

Therecommendedoperatingtirepressureis:

Approximately10psiforthereartires

Approximately14psiforthefronttires

IMPORTANT:Refertothetiresidewallforexacttire manufacturer'srecommended

ormaximumpsi.Donotoverinflate.Uneventirepressurecouldcausethecutting

deckto mowunevenly.

14

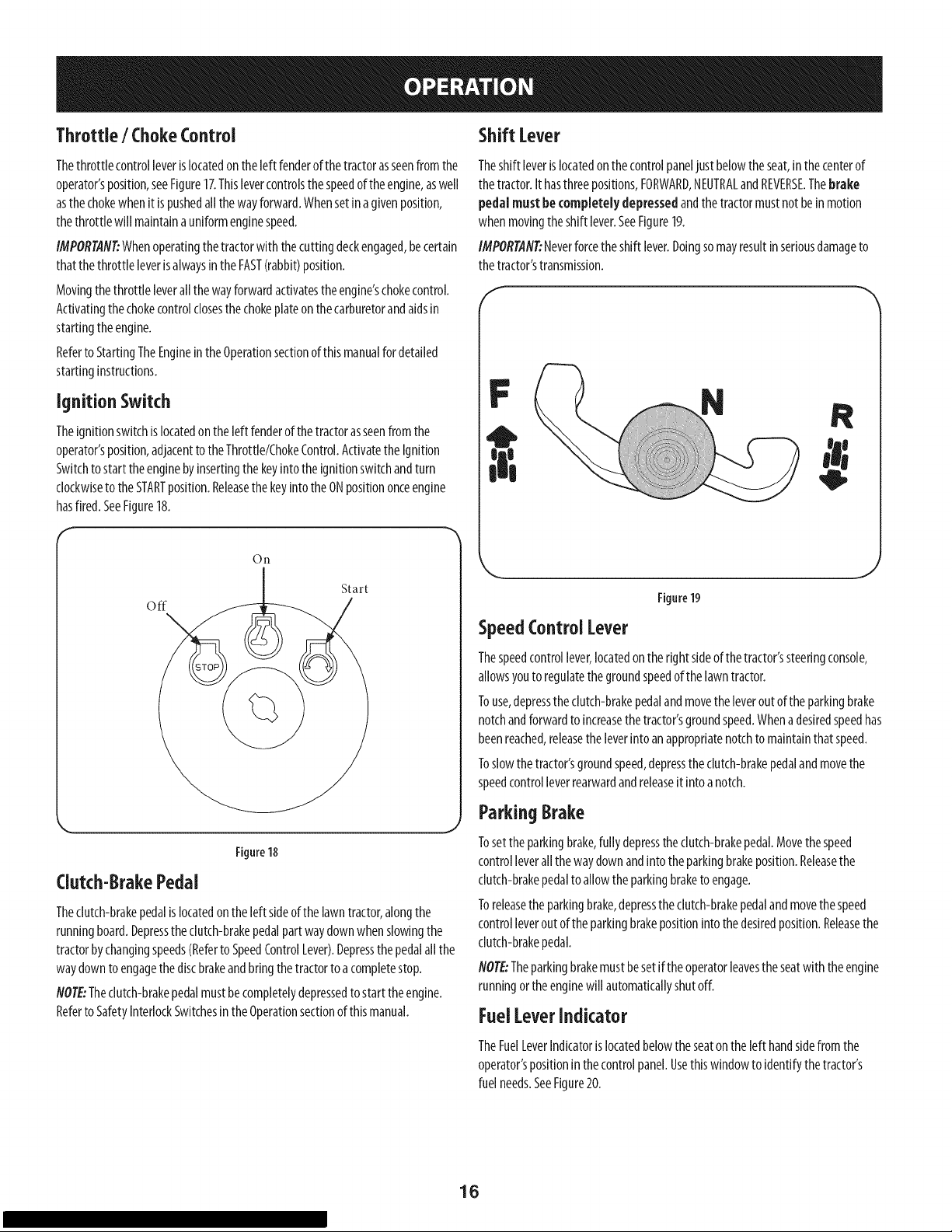

Clutch/BrakePedal

FuelLevelindicator

SpeedControl&Parking

BrakeLever

IgnitionSwitch

Throttle/ChokeLever

CupHolder

Shift Lever

FuelFillCap

DeckLift Lever

OilFillCap

Figure17

NOTE:Anyreferenceinthismanualto theRIGHTorLEFTsideofthetractorisobservedfromoperator'sseatpositionfacingforwardtowardsthefrontoftractor.

PTO(BladeEngage)Lever

MeetsANSiSafetyStandards

CraftsmanTractorsconformtothesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

15

Throttle/ ChokeControl

ShiftLever

Thethrottlecontrolleverislocatedontheleftfenderofthetractorasseenfromthe

operator'sposition,seeFigure17.Thislevercontrolsthespeedoftheengine,aswell

asthechokewhenit ispushedallthewayforward.Whensetinagivenposition,

thethrottlewill maintainauniformenginespeed.

IMPORTAfl#Whenoperatingthetractorwiththecuttingdeckengaged,becertain

thatthethrottle leverisalwaysintheFAST(rabbit)position.

Movingthethrottleleverallthewayforwardactivatestheengine'schokecontrol.

Activatingthechokecontrolclosesthechokeplateonthecarburetorandaidsin

startingtheengine.

RefertoStartingTheEnginein theOperationsectionofthis manualfordetailed

startinginstructions.

ignitionSwitch

Theignitionswitchislocatedontheleftfenderofthetractorasseenfromthe

operator'sposition,adjacentto theThrottle/ChokeControl.Activatethe Ignition

Switchtostarttheenginebyinsertingthekeyintothe ignitionswitchandturn

clockwisetotheSTARTposition.ReleasethekeyintotheONpositiononceengine

hasfired.SeeFigure18.

On

Start

off

Theshiftleverislocatedonthecontrolpaneljustbelowtheseat,inthecenterof

thetractor.Ithasthreepositions,FORWARD,NEUTRALandREVERSE.Thebrake

pedalmustbe completely depressedandthetractormustnotbeinmotion

whenmovingtheshift lever.SeeFigure19.

IMPORTANT:Neverforcetheshift lever.Doingsomayresultin seriousdamageto

thetractor'stransmission.

f

Figure19

SpeedControl Lever

Figure18

Clutch-BrakePedal

Thedutch-brakepedalislocatedonthe leftsideofthe lawntractor,alongthe

runningboard.Depressthedutch-brakepedalpartwaydownwhenslowingthe

tractorbychangingspeeds(Referto SpeedControlLever).Depressthepedalallthe

wayclownto engagethediscbrakeandbringthetractorto acompletestop.

NOTE:Thedutch-brakepedalmustbecompletelydepressedto starttheengine.

RefertoSafetyInterlockSwitchesintheOperationsectionofthismanual.

Thespeedcontrollever,locatedontherightsideofthetractor'ssteeringconsole,

allowsyoutoregulatethegroundspeedofthelawntractor.

Touse,depressthedutch-brakepedalandmovetheleveroutoftheparkingbrake

notchandforwardtoincreasethetractor'sgroundspeed.Whenadesiredspeedhas

beenreached,releasetheleverintoanappropriatenotchtomaintainthat speed.

Toslowthetractor'sgroundspeed,depressthedutch-brakepedalandmovethe

speedcontrolleverrearwardandreleaseit intoa notch.

ParkingBrake

Tosettheparkingbrake,fullydepresstheclutch-brakepedal.Movethespeed

controlleverallthewaydownandintotheparkingbrakeposition.Releasethe

clutch-brakepedaltoallowtheparkingbraketoengage.

Toreleasetheparkingbrake,depresstheclutch-brakepedalandmovethespeed

controlleveroutoftheparkingbrakepositionintothedesiredposition.Releasethe

clutch-brakepedal.

NOTE:Theparkingbrakemustbesetiftheoperatorleavestheseatwith theengine

runningortheenginewill automaticallyshutoff.

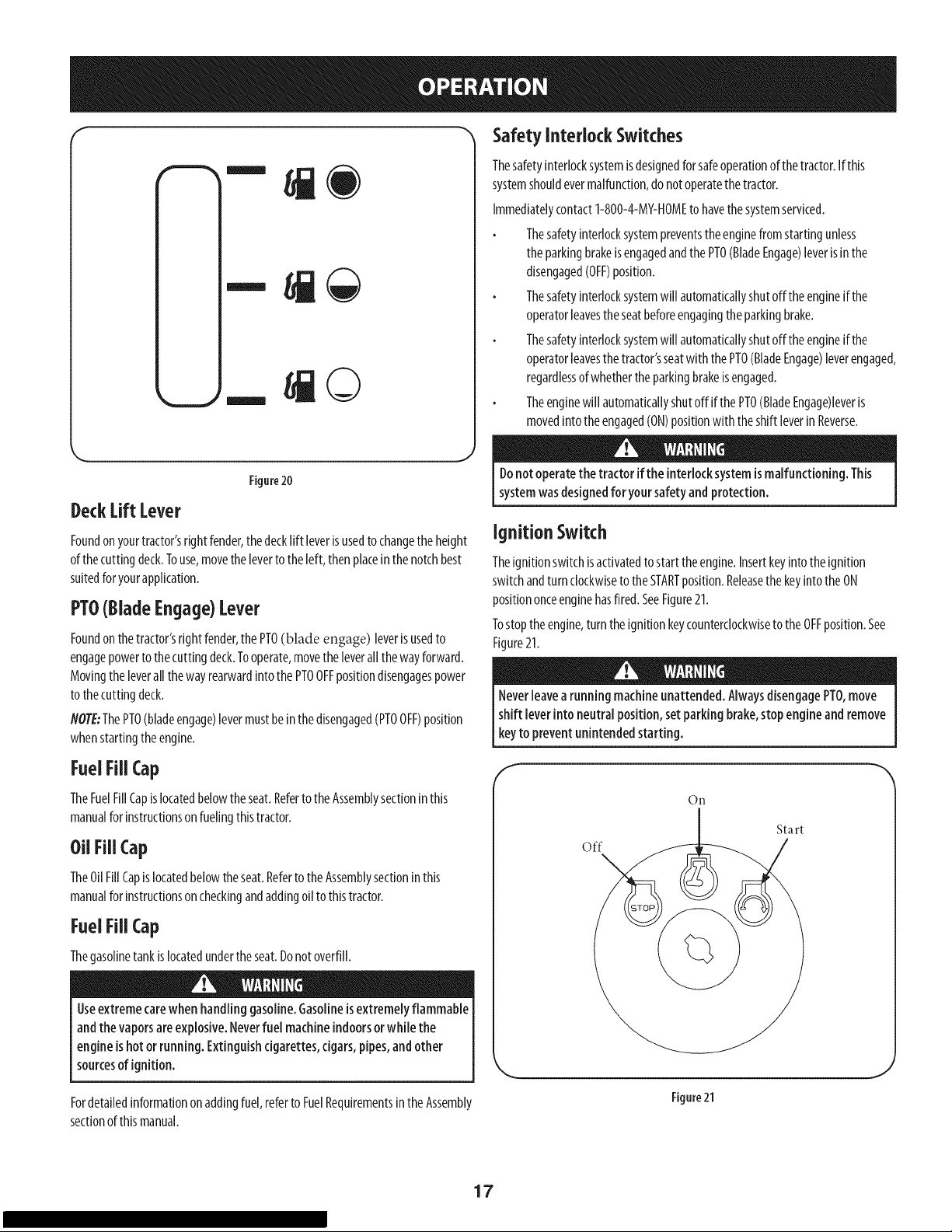

FuelLeverIndicator

TheFuelLeverIndicatorislocatedbelowtheseatontheleft handsidefromthe

operator'spositioninthecontrolpanel.Usethiswindowtoidentifythetractor's

fuelneeds.SeeFigure20.

16

©

Safety Interlock Switches

Thesafetyinterlocksystemisdesignedfor safeoperationofthetractor.Ifthis

systemshouldevermalfunction,do notoperatethetractor.

Immediatelycontact1-800-4-MY-HOMEto havethesystemserviced.

Thesafetyinterlocksystempreventstheenginefromstartingunless

theparkingbrakeisengagedandthePTO(BladeEngage)leverisinthe

disengaged(OFF)position.

Thesafetyinterlocksystemwill automaticallyshutofftheengineifthe

operatorleavestheseatbeforeengagingtheparkingbrake.

Thesafetyinterlocksystemwill automaticallyshutofftheengineifthe

operatorleavesthetractor'sseatwiththe PTO(BladeEngage)leverengaged,

regardlessofwhethertheparkingbrakeisengaged.

Theenginewill automaticallyshutoff ifthe PTO(BladeEngage)leveris

movedintotheengaged(ON)positionwiththeshiftleverin Reverse.

Figure20

DeckLiftLever

Foundonyourtractor'srightfender,thedecklift leverisusedto changetheheight

ofthecuttingdeck.Touse,movethelevertotheleft,then placeinthenotchbest

suitedfor yourapplication.

PTO(BladeEngage)Lever

Foundonthetractor'srightfender,the PTO(blade engage) leveris usedto

engagepowertothecuttingdeck.Tooperate,movetheleverallthewayforward.

Movingtheleverallthewayrearwardintothe PTOOFFpositiondisengagespower

tothecuttingdeck.

NOTE:ThePTO(bladeengage)levermustbeinthedisengaged(PTOOFF)position

whenstartingtheengine.

FuelFillCap

TheFuelFillCapislocatedbelowtheseat.RefertotheAssemblysectioninthis

manualforinstructionsonfuelingthistractor.

OilFill Cap

TheOilFillCapislocatedbelowtheseat.RefertotheAssemblysectioninthis

manualforinstructionsoncheckingandaddingoiltothistractor.

Donotoperatethetractor if the interlocksystemismalfunctioning. This

systemwasdesignedfor your safetyandprotection.

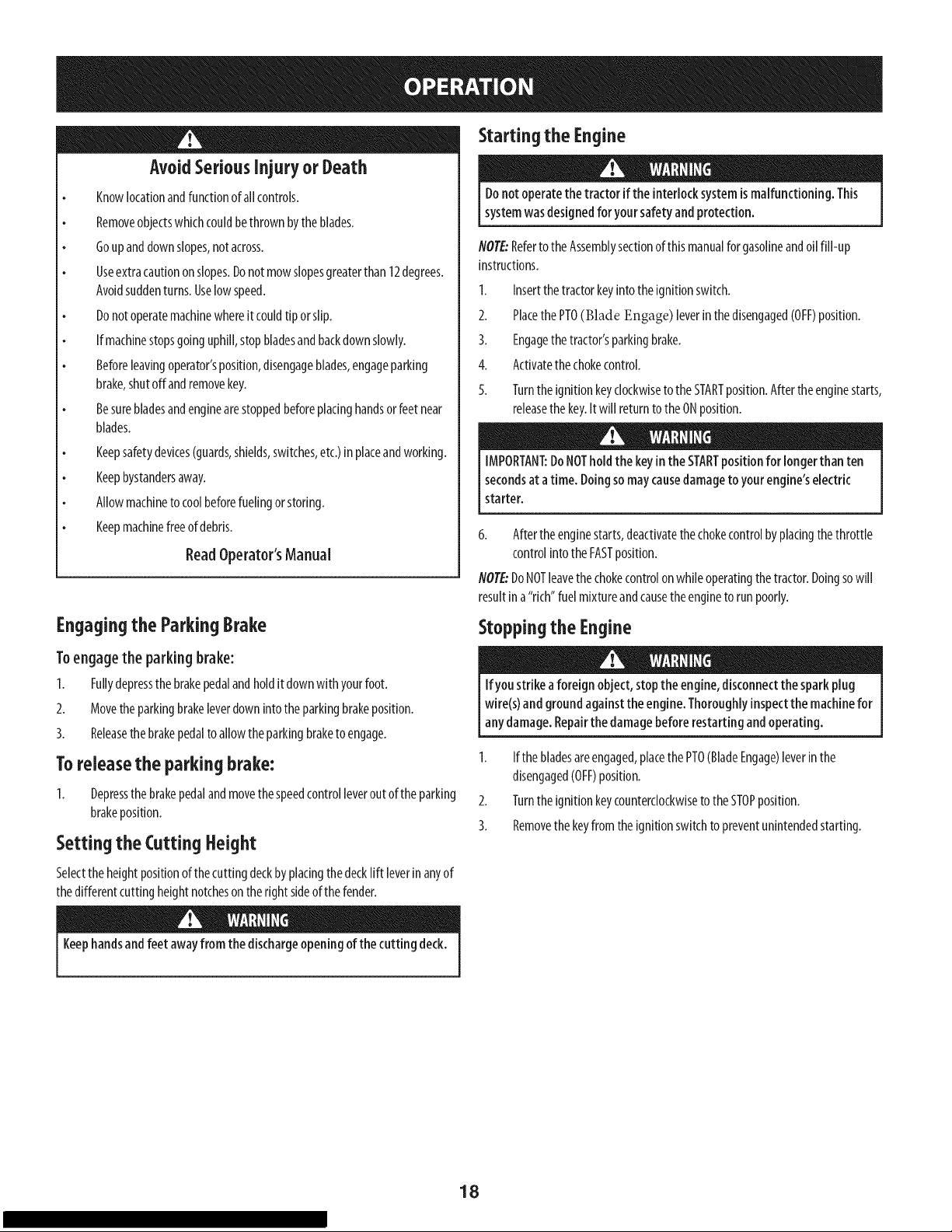

IgnitionSwitch

Theignitionswitchisactivatedtostart theengine.Insertkeyintotheignition

switchandturnclockwisetotheSTARTposition.ReleasethekeyintotheON

positiononceenginehasfired.SeeFigure21.

Tostoptheengine,turntheignitionkeycounterclockwiseto theOFFposition.See

Figure21.

Neverleavearunningmachineunattended.AlwaysdisengagePTO,move

shift leverinto neutralposition,setparking brake,stopengineandremove

keyto prevent unintendedstarting.

On

Start

off

FuelFill Cap

Thegasolinetankislocatedundertheseat.Donotoverfill.

Useextremecarewhen handlinggasoline.Gasolineisextremelyflammable

andthe vaporsareexplosive.Neverfuel machineindoorsorwhile the

engineishotorrunning. Extinguishcigarettes,cigars,pipes,andother

sourcesof ignition.

Fordetailedinformationonaddingfuel,referto FuelRequirementsintheAssembly

sectionofthis manual.

Figure21

17

AvoidSeriousinjuryor Death

Knowlocationandfunctionofallcontrols.

Removeobjectswhichcouldbethrownbytheblades.

Goupanddownslopes,notacross.

Useextracautiononslopes.Donotmowslopesgreaterthan12degrees.

Avoidsuddenturns.Uselowspeed.

Donotoperatemachinewhereitcouldtip orslip.

Ifmachinestopsgoinguphill,stopbladesandbackdownslowly.

Beforeleavingoperator'sposition,disengageblades,engageparking

brake,shutoff andremovekey.

Besurebladesandenginearestoppedbeforeplacinghandsorfeetnear

blades.

Keepsafetydevices(guards,shields,switches,etc.)inplaceandworking.

Keepbystandersaway.

Allowmachinetocoolbeforefuelingorstoring.

Keepmachinefreeofdebris.

ReadOperator'sManual

Starting the Engine

Donotoperatethetractor if the interlocksystemismalfunctioning. This

systemwasdesignedforyour safetyandprotection.

NOTE:RefertotheAssemblysectionofthismanualforgasolineandoilfill-up

instructions.

1. Insertthetractorkeyintotheignitionswitch.

2. PlacethePTO(Blade Engage) leverin thedisengaged(OFF)position.

3. Engagethetractor'sparkingbrake.

4. Activatethechokecontrol.

5. Turntheignitionkeyclockwiseto theSTARTposition.Aftertheenginestarts,

releasethekey.Itwill returntotheONposition.

IMPORTANT:DoNOTholdthe keyintheSTARTpositionfor longerthan ten

secondsat atime. Doingsomaycausedamagetoyourengine'selectric

starter.

6. Aftertheenginestarts,deactivatethechokecontrolbyplacingthethrottle

controlintotheFASTposition.

NOTE:DoNOTleavethechokecontrolonwhileoperatingthetractor.Doingsowill

resultina"rich"fuelmixtureandcausetheenginetorunpoorly.

Engagingthe ParkingBrake

Toengagethe parking brake:

I. Fullydepressthe brakepedalandholdit downwith yourfoot.

2. Movetheparkingbrakeleverdownintotheparkingbrakeposition.

3. Releasethebrakepedalto allowtheparkingbraketo engage.

Toreleasethe parking brake:

1. Depressthebrakepedalandmovethespeedcontrolleveroutof theparking

brakeposition.

Setting the Cuttingfreight

Selecttheheightpositionofthecuttingdeckbyplacingthedecklift leverinanyof

thedifferentcuttingheightnotchesontherightsideofthefender.

Keephandsandfeet awayfrom the dischargeopeningof thecutting deck.

Stopping the Engine

Ifyoustrikeaforeign object,stoptheengine,disconnectthesparkplug

wire(s)andgroundagainsttheengine.Thoroughlyinspectthemachinefor

anydamage.Repairthedamagebeforerestarting andoperating.

1. Ifthebladesareengaged,placethePTO(BladeEngage)leverin the

disengaged(OFF)position.

2. Turntheignitionkeycounterclockwiseto theSTOPposition.

3. Removethekeyfromtheignitionswitchtopreventunintendedstarting.

18

Driving TheTractor

Avoidsuddenstarts,excessivespeedandsuddenstops.

Donotleavethe seatofthe tractorwithout first placingthe PTO(Blade

Engage)leverinthe disengaged(OFF)position,depressingthe brakepedal

andengagingtheparkingbrake.Ifleavingthetractor unattended,also

turn the ignitionkeyoff andremovethe key.

Alwayslookdownandbehindbeforeandwhile backingupto avoidaback-

overaccident.

1. Depressthebrakepedalandmovethespeedcontrolleveroutof theparking

brakeposition,thenletthepedalrelease.

2. Movethethrottle leverintothe FAST(rabbit)position.

3. PlacetheshiftleverineithertheFORWARDorREVERSEposition.

IMPORTA#_DoNOTusetheshiftlevertochangethedirectionoftravelwhenthe

tractorisinmotion.Alwaysusethebrakepedaltobringthetractortoacomplete

stopbeforeshifting.

4. Releasetheparkingbrakebydepressingtheclutch-brakepedaland

positioningthespeedcontrolleverindesiredposition.

IMPOR@N_First-timeoperatorsshouldusespeedpositions1or2.Become

completelyfamiliarwith thetractor'soperationandcontrolsbeforeoperatingthe

tractorinhigherspeedpositions.

5. Releaseclutch-brakepedalslowlyto putunitintomotion.

6. Thelawntractorisbroughttoastopbydepressingtheclutch-brakepedal.

NOTE:Whenoperatingthe unitinitially,therewill belittle differencebetweenthe

highesttwospeedsuntilafterthebeltshaveseatedthemselvesintothepulleys

duringthebreak-inperiod.

5. Depressclutch-brakepedal.

6. Placespeedcontrolleverindesiredposition.

7. PlaceshiftleverineitherFORWARDorREVERSE,andfollownormaloperating

procedures.

Driving OnSlopes

Referto theSLOPEGAUGEin theSafetyInstructionssectionofthemanualtohelp

determineslopeswhereyoumayoperatethistractorsafely.

Donotmowoninclineswith aslopeinexcessof 12degrees(ariseof

approximately2feetevery10feet). Thetractor couldoverturnandcause

seriousinjury.

Mowupanddownslopes,NEVERacross.

Exerciseextremecautionwhenchangingdirectiononslopes.

Watchforholes,ruts,bumps,rocks,orotherhiddenobjects.Uneventerrain

couldoverturnthemachine.Tallgrasscanhideobstacles.

Avoidturnswhendrivingonaslope.Ifaturn mustbemade,turndownthe

slope.Turningupaslopegreatlyincreasesthechanceof arollover.

Avoidstoppingwhendrivingupa slope.Ifit isnecessarytostopwhile

drivingupa slope,start upsmoothlyandcarefullyto reducethepossibility

offlippingthetractoroverbackward.

Beforeleavingtheoperator'spositionforanyreason,disengagetheblades,place

theshiftleverinneutral,engagetheparkingbrake,shutengineoffand remove

thekey.

IMPORTAN_Whenstoppingthetractorforanyreasonwhileonagrasssurface,

always:

1. Placetheshiftleverinneutral,

2. Engagetheparkingbrake,

3. Shutengineoffandremovethekey.Doingsowill minimizethe possibility

ofhavingyourlawn"browned"byhotexhaustfromyourtractor'srunning

engine.

Ifunitstallswith speedcontrolinhighspeed,or ifunitwill notoperatewith speed

controlleverinalowspeedposition,proceedasfollows:

1. PlaceshiftleverinNEUTRAL.

2. Restartengine.

3. Placespeedcontrolleverinhighestspeedposition.

4. Releaseclutch-brakepedalfully.

19

Engagingthe Blades

Engagingthe PTO(BladeEngage)transferspowertothecuttingdeck.Toengage

theblades,proceedasfollows:

1. Movethethrottle/chokecontrollevertotheFAST(rabbit)position.

2. GraspthePTO(BladeEngage)leverandpivotit allthewayforwardintothe

engaged(ON)position.

3. Keepthethrottleleverinthe FAST(rabbit)positionfor themostefficientuse

ofthecuttingdeck.

NOTE:Theenginewill automaticallyshutoff ifthe PTO(BladeEngage)leveris

movedintotheengaged(ON)positionwith theshiftleverinReverse.

Mulching

Amulchkitisavailableasanattachment.Mulchingisaprocessofredrculating

grassclippingsrepeatedlybeneaththecuttingdeck.Theultra-fineclippingsare

thenforcedbackintothe lawnwheretheyactasanaturalfertilizer.Contactthe

nearestParts& RepairServiceCenterto purchaseamulchkit forthisunit.

TolocatethenearestParts& RepairServiceCenter,contact1-800-4-MY-HOME®.

Using the Deck Lift Lever

Toraisethecuttingdeck,movethedecklift leverto the left,then placeit inthe

notchbestsuitedfor yourapplication.Referto SettingTheCuttingHeightearlierin

thissection.

Mowing

Tohelpavoid bladecontactor athrown object injury,keepbystanders,

helpers,childrenandpetsat least75feet from the machinewhile it isin

operation.Stopmachineif anyoneentersthearea.

Thefollowinginformationwill behelpfulwhenusingthecuttingdeckwithyour

tractor:

Planyour mowing pattern to avoiddischargeof materialstowardroads,

sidewalks,bystandersandthe like.Also,avoiddischargingmaterialagainst

awall or obstructionwhichmaycausedischargedmaterialto ricochetback

towardthe operator.

Donotmowat highgroundspeed,especiallyifa mulchkitorgrasscollector

isinstalled.

Forbestresultsit isrecommendedthatthefirsttwo lapsbecutwiththe

dischargethrowntowardsthecenter.Afterthefirst two laps,reversethe

directiontothrowthedischargetotheoutsideforthebalanceofcutting.

Thiswill giveabetterappearancetothelawn.

Donotcutthegrasstooshort.Shortgrassinvitesweedgrowthandyellows

quicklyindryweather.

Mowingshouldalwaysbedonewiththeengineatfullthrottle.

Underheavierconditionsit maybenecessaryto gobackoverthecutareaa

secondtimeto getacleancut.

DoNOTattemptto mowheavybrushandweedsandextremelytall grass.

Yourtractorisdesignedtomowlawns,NOTclearbrush.

Keepthebladesharpandreplacethebladewhenworn.Referto Cutting

Bladein theMaintenancesectionof thismanualforproperbladesharpening

instructions.

Thelampsturn OFFwhentheignitionkeyismovedtotheSTOPposition.

2O

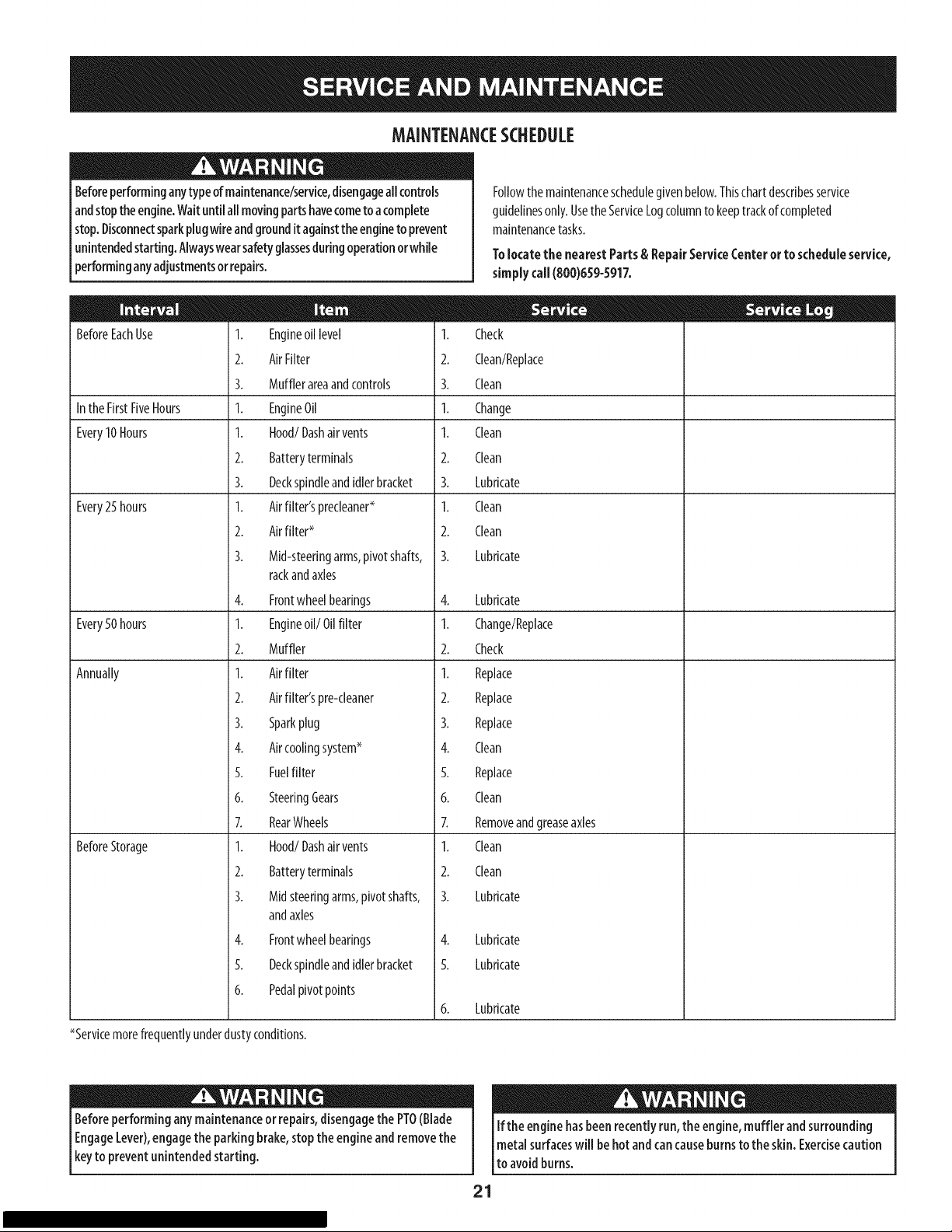

MAINTENANCESCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall controls

andstoptheengine.Waituntilallmovingpartshavecometo acomplete

stop.Disconnectsparkplugwireandgrounditagainsttheengineto prevent

unintendedstarting.AlwayswearsafetyglassesduringoperationorwhUe

performinganyadjustmentsor repairs.

BeforeEachUse

Inthe FirstFiveHours

Every10Hours

Every25hours

Every50hours

Annually

BeforeStorage

1. Engineoil level

2. AirFilter

3. Mufflerareaandcontrols

1. EngineOil

1. Hood/Dashairvents

2. Batteryterminals

3. Deckspindleandidlerbracket

1. Airfilter'sprecleaner*

2. Airfilter*

3. Mid-steeringarms,pivotshafts,

rackandaxles

4. Frontwheelbearings

1. Engineoil/Oil filter

2. Muffler

1. Airfilter

2. Airfilter'spre-cleaner

3. Sparkplug

4. Aircoolingsystem*

5. Fuelfilter

6. SteeringGears

Z RearWheels

1. Hood/Dashairvents

2. Batteryterminals

3. Midsteeringarms,pivotshafts,

andaxles

4. Frontwheelbearings

5. Deckspindleandidlerbracket

6. Pedalpivotpoints

Followthe maintenanceschedulegivenbelow.Thischartdescribesservice

guidelinesonly.UsetheServiceLogcolumnto keeptrackofcompleted

maintenancetasks.

Tolocate the nearestParts& RepairServiceCenteror toscheduleservice,

simply call(800)659-5917.

1. Check

2. Clean/Replace

3. Clean

1. Change

1. Clean

2. Clean

3. Lubricate

1. Clean

2. Clean

3. Lubricate

4. Lubricate

1. Change/Replace

2. Check

1. Replace

2. Replace

3. Replace

4. Clean

5. Replace

6. Clean

7. Removeandgreaseaxles

1. Clean

2. Clean

3. Lubricate

4. Lubricate

5. Lubricate

6. Lubricate

*Servicemorefrequentlyunderdustyconditions.

Beforeperforminganymaintenanceorrepairs,disengagethe PTO(Blade

EngageLever),engagethe parking brake,stopthe engineandremovethe

keyto preventunintendedstarting.

Ifthe enginehasbeenrecentlyrun,the engine,muffler andsurrounding

metalsurfaceswill behot andcancauseburnsto the skin. Exercisecaution

to avoidburns.

21

Engine Maintenance

Shutoff the enginebeforeperforminganymaintenance.Toprevent

accidentalstart-up,disconnectthesparkplug boot.

IMPORTAIV#If enginemustbetippedtotransportequipmentor toinspector

removegrass,keepsparkplugsideofengineup.Transportingortippingengine

sparkplugdownmaycausesmoking,hardstarting,sparkplugfouling,oroil

saturationofaircleaner.

Periodicinspectionandadjustmentoftheengineisessentialifhighlevel

performanceistobemaintained.Regularmaintenancewill alsoensurealong

servicelife.Therequiredserviceintervalsandthekindof maintenancetobe

performedaredescribedinthetableonthepreviouspage.Followthehourlyor

calendarintervals,whicheveroccurfirst.Morefrequentserviceisrequiredwhen

operatinginadverseconditions.

Ifthe enginehasbeenrunning,themuffler will bevery hot. Becarefulnot

totouch the muffler.

Servicingthe EngineOil

Checkthe oillevelregularly.

Besurecorrectoillevelismaintained.Checktheoiieveryfive to tenhoursof

operation,beforestartingtheengine.SeeCheckingOilLevelintheAssembly

section.

OnlyusehighqualitydetergentoilratedwithAPIserviceclassificationSIC,SG,

SH,or SJ.Selecttheoil'sSAEviscositygradeaccordingto theexpectedoperating

temperature.Referto Gas&Oilin theAssemblysectionofthismanual.

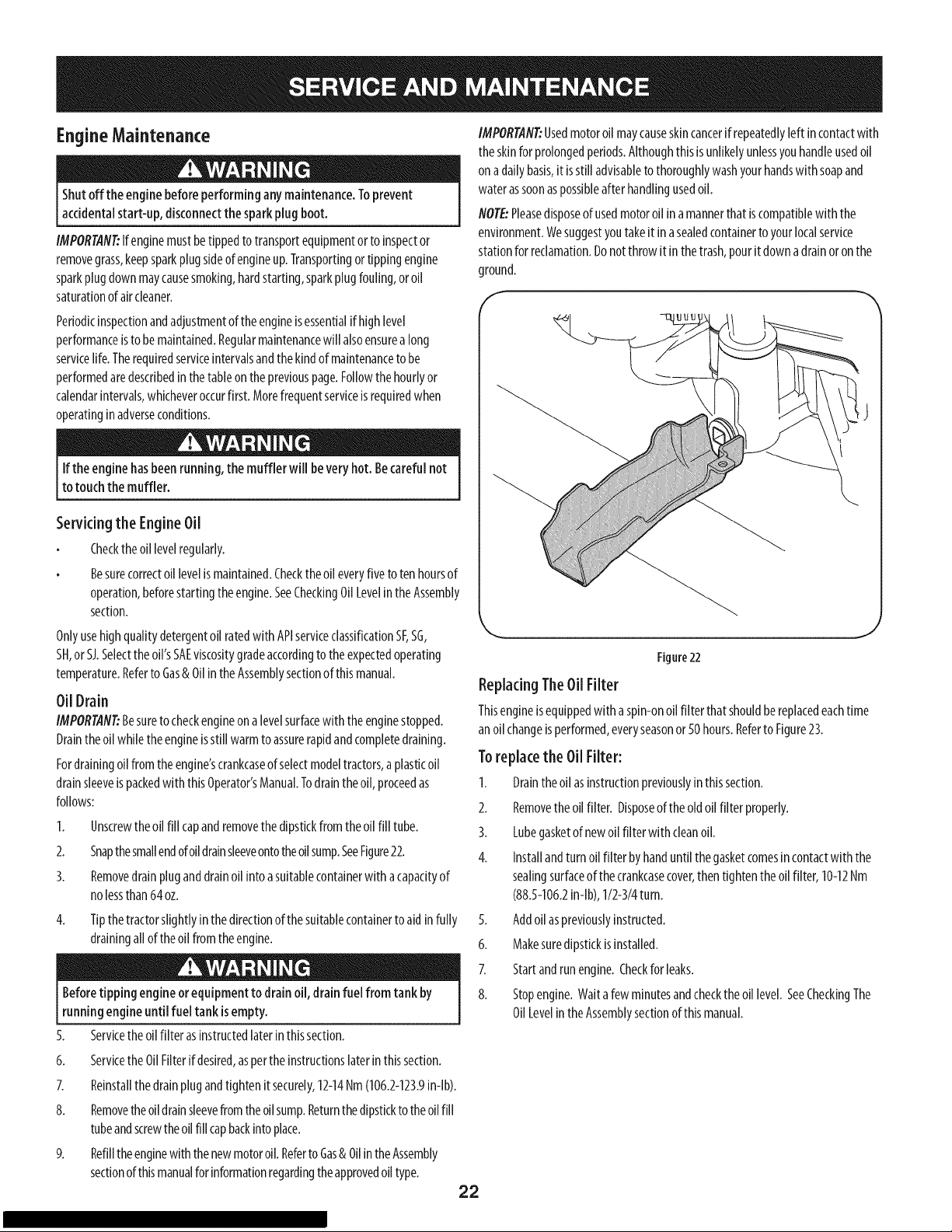

Oil Drain

IMPORTIIfl#Besureto checkengineonalevelsurfacewith theenginestopped.

Draintheoilwhiletheengineisstillwarmtoassurerapidandcompletedraining.

Fordrainingoiifromtheengine'scrankcaseofselectmodeltractors,aplasticoil

drainsleeveispackedwith thisOperator'sManual.Todraintheoil, proceedas

follows:

1. Unscrewtheoilfill capandremovethedipstickfromtheoil fill tube.

2. Snapthesmallendofoildrainsleeveontotheoilsump.SeeFigure22.

3. Removedrainpluganddrainoilintoasuitablecontainerwith acapacityof

nolessthan64oz.

4.

Tipthetractorslightlyinthedirectionof thesuitablecontainerto aidinfully

drainingall oftheoilfromtheengine.

Beforetipping engineor equipmentto drainoil, drain fuelfrom tank by

runningengineuntil fuel tank isempty.

5. Servicetheoilfilter asinstructedlaterinthissection.

IMPORTAIV#Usedmotoroilmaycauseskincancerifrepeatedlyleft incontactwith

theskinforprolongedperiods.Althoughthisisunlikelyunlessyouhandleusedoil

onadallybasis,itisstilladvisabletothoroughlywashyourhandswith soapand

waterassoonaspossibleafterhandlingusedoil.

flOTE:Pleasedisposeof usedmotoroilin amannerthatiscompatiblewith the

environment.Wesuggestyoutakeitinasealedcontainertoyourlocalservice

stationforreclamation.Donotthrowitinthetrash,pouritdownadrainoronthe

ground.

,, j

Figure22

ReplacingTheOil Filter

Thisengineisequippedwith aspin-onoilfilter thatshouldbereplacedeachtime

anoilchangeisperformed,everyseasonor50hours.Referto Figure23.

Toreplace the Oil Filter:

1. Draintheoil asinstructionpreviouslyinthissection.

2. Removetheoilfilter. Disposeof theoldoilfilter properly.

3. Lubegasketof newoilfilterwith cleanoil.

4. Installandturnoilfilter byhanduntilthegasketcomesincontactwiththe

sealingsurfaceofthecrankcasecover,thentightentheoilfilter, 10-12Nm

(88.5-106.2in-lb),1/2-3/4turn.

5. Addoilaspreviouslyinstructed.

6. Makesuredipstickisinstalled.

7. Startandrunengine.Checkfor leaks.

8. Stopengine.Waitafew minutesandchecktheoillevel.SeeCheckingThe

0il LevelintheAssemblysectionofthismanual.

6. Servicethe 0il Filterifdesired,aspertheinstructionslaterinthissection.

7. Reinstallthedrainplugandtightenitsecurely,12-14Nm(106.2-123.9in-lb).

8. Removetheoildrainsleevefromtheoilsump.Returnthedipsticktotheoilfill

tubeandscrewtheoilfill capbackintoplace.

9. Refilltheenginewith thenewmotoroil.RefertoGas&OilintheAssembly

sectionofthismanualforinformationregardingtheapprovedoiltype.

22

OilFilter

Air Filter Service

Paperfilterscannotbecleanedandshouldbereplacedevery100operatinghours;

moreoftenif usedinextremelydustyconditions.

Neverusegasolineor lowflashpointsolventsforcleaningtheairfilter

element.Afire or explosioncouldresult.

Donot usepressurizedair orsolventsto cleantheaircleaner

cartridge.

Iffilters, orcoversarenot installedcorrectly seriousinjuryordeath

could resultfrom backfire. Donot attempt to start the enginewith them

removed.

Figure23

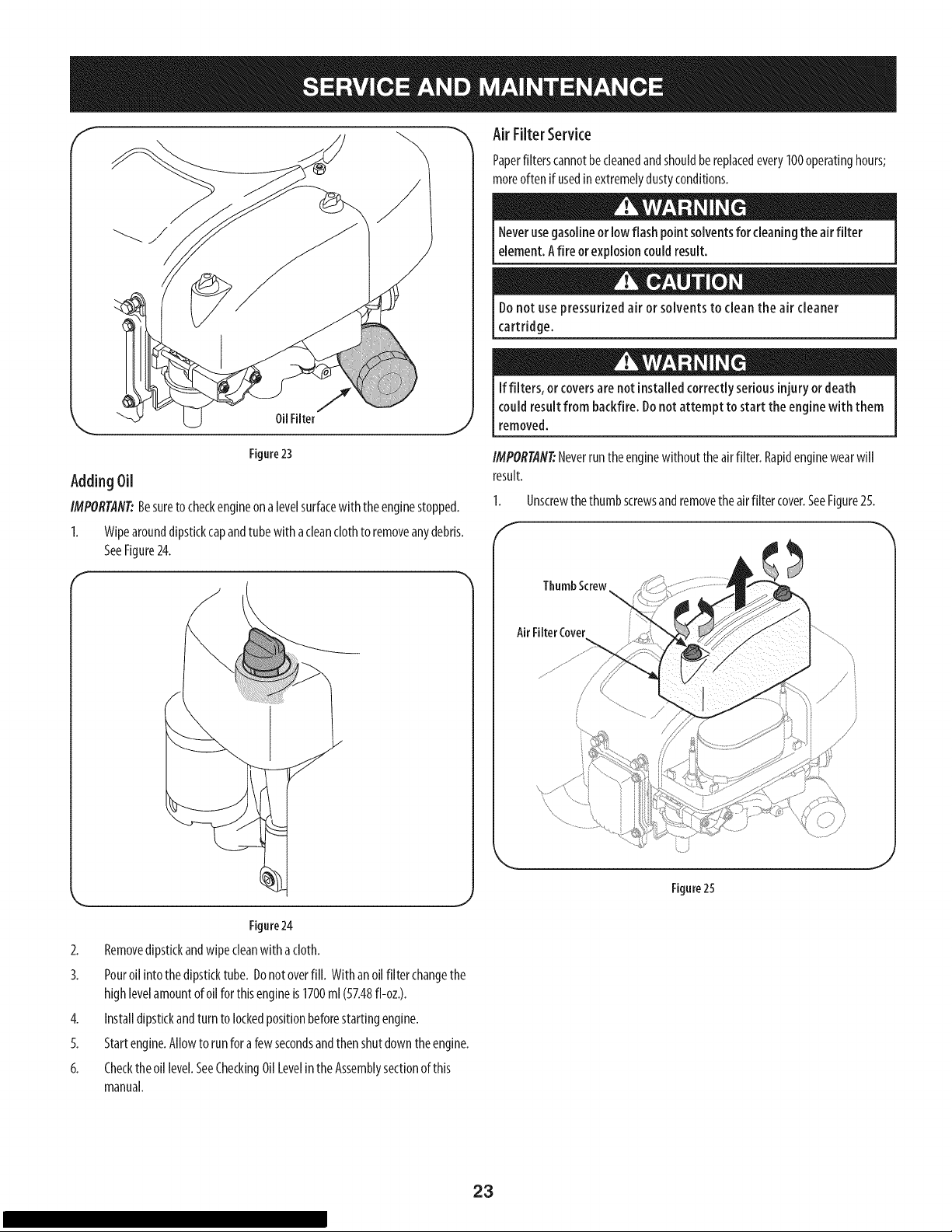

Adding Oil

IMPORTANT:Besuretocheckengineonalevelsurfacewith theenginestopped.

I. Wipearounddipstickcapandtubewith acleanclothto removeanydebris.

SeeFigure24.

f

IMPORTANT:Neverruntheenginewithouttheairfilter.Rapidenginewearwill

result.

1. Unscrewthethumbscrewsandremovetheairfiltercover.SeeFigure25.

\

AirFilter Cover

Figure25

Figure24

2. Removedipstickandwipecleanwith acloth.

3. Pouroilintothedipsticktube. Donotoverfill. Withanoilfilterchangethe

highlevelamountofoilforthisengineis1700ml(57.48fl-oz.).

4. Installdipstickandturnto lockedpositionbeforestartingengine.

5. Startengine.Allowto runforafewsecondsandthenshutdowntheengine.

6. Checktheoil level.SeeCheckingOilLevelintheAssemblysectionofthis

manual.

23

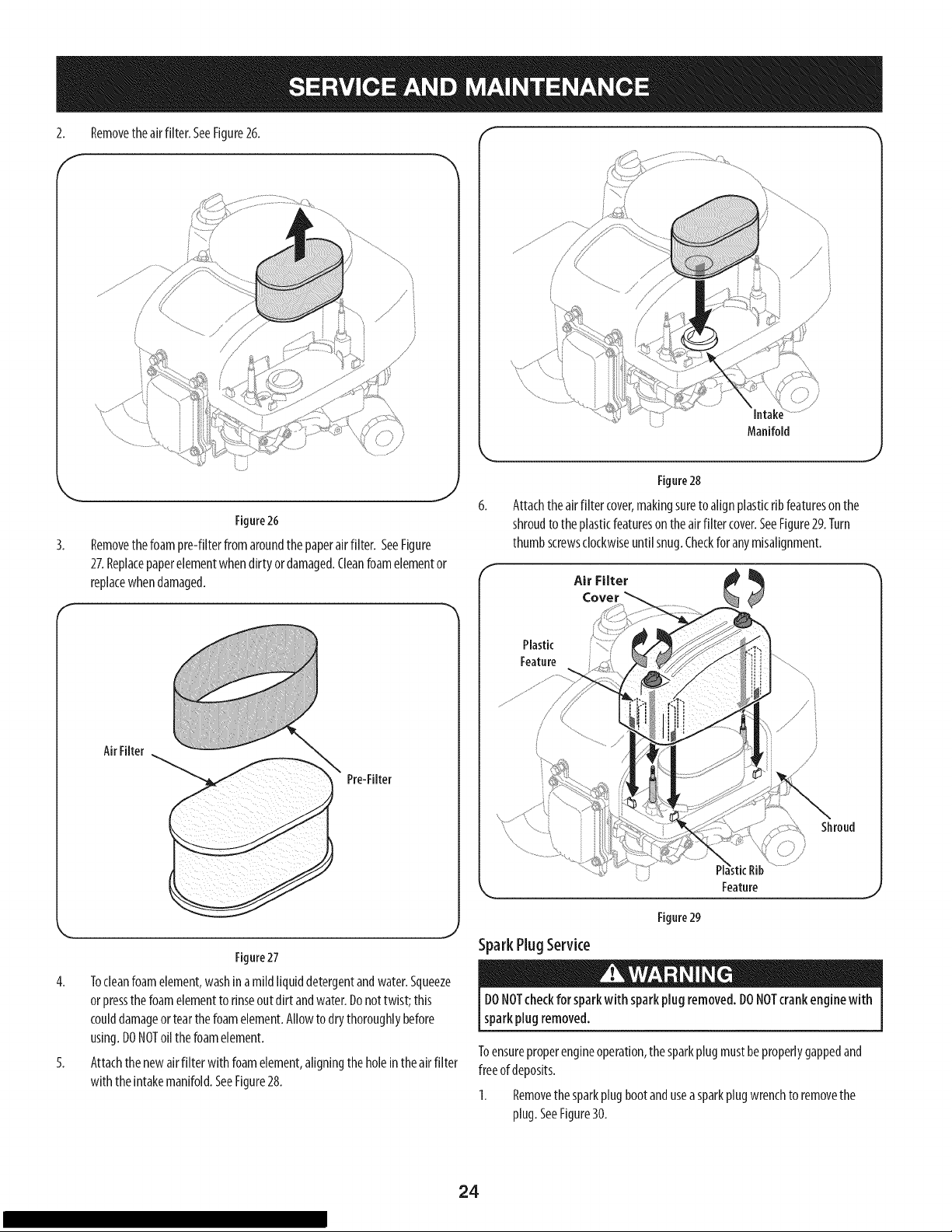

2.

Removetheairfilter.SeeFigure26.

f

._ j

Figure26

Removethefoampre-filterfromaroundthepaperairfilter. SeeFigure

27.Replacepaperelementwhendirtyordamaged.Cleanfoamelementor

replacewhendamaged.

/

Manifold

Figure28

Attachtheairfilter cover,makingsuretoalignplasticribfeaturesonthe

shroudtotheplasticfeaturesontheairfiltercover.SeeFigure29.Turn

thumbscrewsclockwiseuntilsnug.Checkforanymisalignment.

Air Filter

AirFilter

Pre-Filter

Figure27

4. Tocleanfoamelement,washinamildliquiddetergentandwater.Squeeze

orpressthefoamelementto rinseoutdirt andwater.Donottwist; this

coulddamageortearthefoamelement.Allowtodrythoroughlybefore

using.DONOToilthefoamelement.

5. Attachthenewairfilter with foamelement,aligningtheholeintheairfilter

with theintakemanifold.SeeFigure28.

Plastic

Feature

Shroud

PI,

Feature

Figure29

SparkPlugService

DONOTcheckfor sparkwith sparkplugremoved.DONOTcrankenginewith

sparkplug removed.

Toensureproperengineoperation,thesparkplugmustbeproperlygappedand

freeofdeposits.

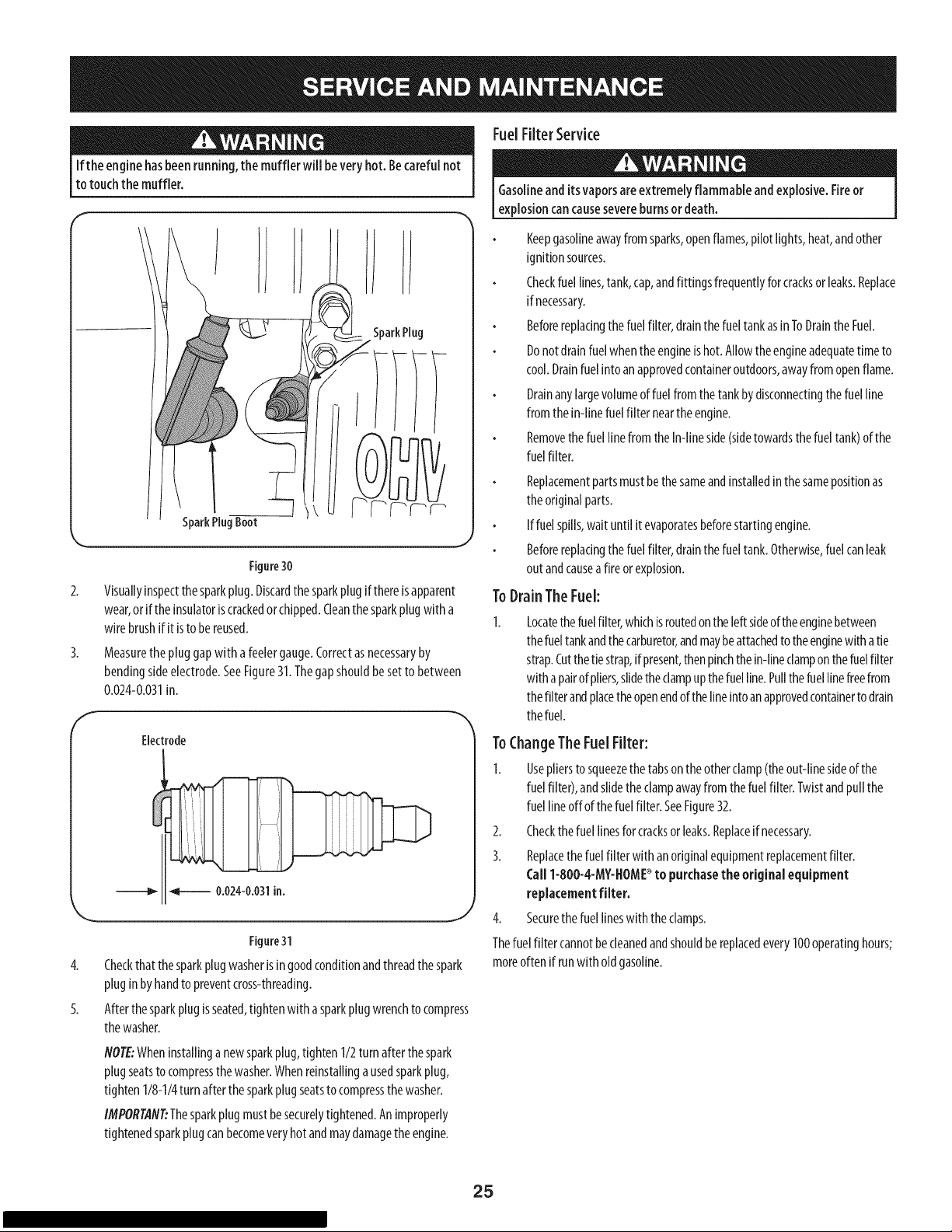

1. Removethesparkplugbootanduseasparkplugwrenchtoremovethe

plug.SeeFigure30.

24

ifthe enginehasbeenrunning,the mufflerwii[ beveryhot.Becarefulnot

to touchthe muffler.

SparkPlug

SparkPlugBoot

Figure30

2.

Visuallyinspectthesparkplug.Discardthesparkplugif thereisapparent

wear,orif theinsulatoriscrackedorchipped.Cleanthesparkplugwitha

wirebrushifit istobe reused.

3.

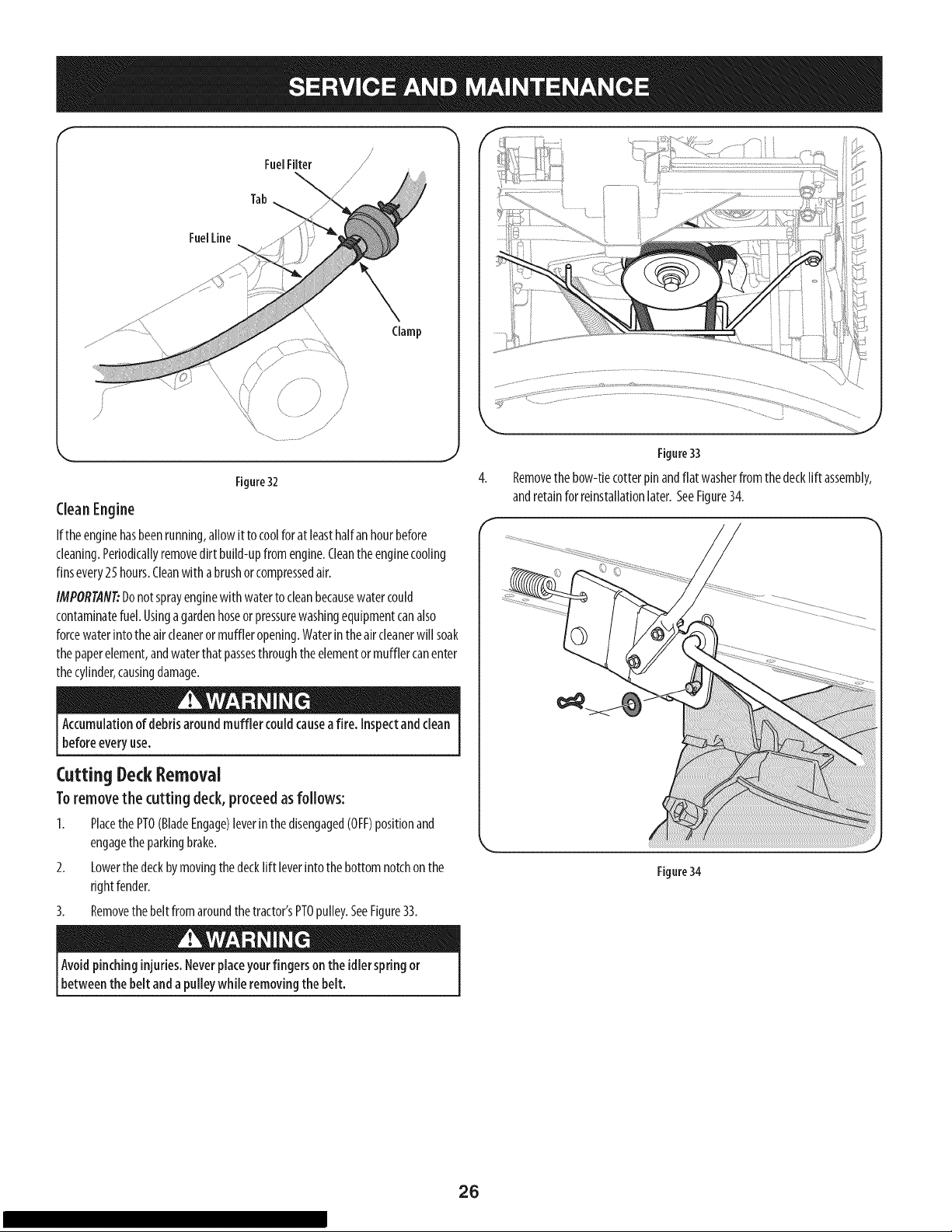

Measurethepluggapwithafeelergauge.Correctasnecessaryby

bendingsideelectrode.SeeFigure31.Thegapshouldbesettobetween

0.024-0.031in.

f

Electrode

Figure31

4. Checkthatthesparkplugwasherisingoodconditionandthreadthespark

pluginbyhandtopreventcross-threading.

5. Afterthesparkplugisseated,tightenwith asparkplugwrenchtocompress

thewasher.

FuelFilter Service

Gasolineand itsvaporsareextremely flammable andexplosive.Fireor

explosioncancausesevereburnsor death.

Keepgasolineawayfromsparks,openflames,pilotlights,heat,andother

ignitionsources.

Checkfuellines,tank,cap,andfittingsfrequentlyforcracksorleaks.Replace

if necessary.

Beforereplacingthefuelfilter,drainthefueltankasinToDrainthe Fuel.

Donotdrainfuelwhentheengineishot.Allowtheengineadequatetimeto

cool.Drainfuelinto anapprovedcontaineroutdoors,awayfromopenflame.

Drainanylargevolumeoffuelfromthetankbydisconnectingthefuelline

fromthein-linefuelfilterneartheengine.

RemovethefuellinefromtheIn-lineside(sidetowardsthefueltank)ofthe

fuelfilter.

Replacementpartsmustbethesameandinstalledinthesamepositionas

theoriginalparts.

Iffuelspills,waituntilit evaporatesbeforestartingengine.

Beforereplacingthefuelfilter,drainthefueltank.Otherwise,fuelcanleak

outandcauseafireorexplosion.

ToDrainTheFuel:

Locatethefuelfilter,whichisroutedontheleftsideoftheenginebetween

thefueltankandthecarburetor,andmaybeattachedtotheenginewithatie

strap.Cutthetiestrap,ifpresent,thenpinchthein-lineclamponthefuelfilter

with apairofpliers,slidetheclampupthefuelline.Pullthefuellinefreefrom

thefilterandplacetheopenendofthelineintoanapprovedcontainertodrain

thefuel.

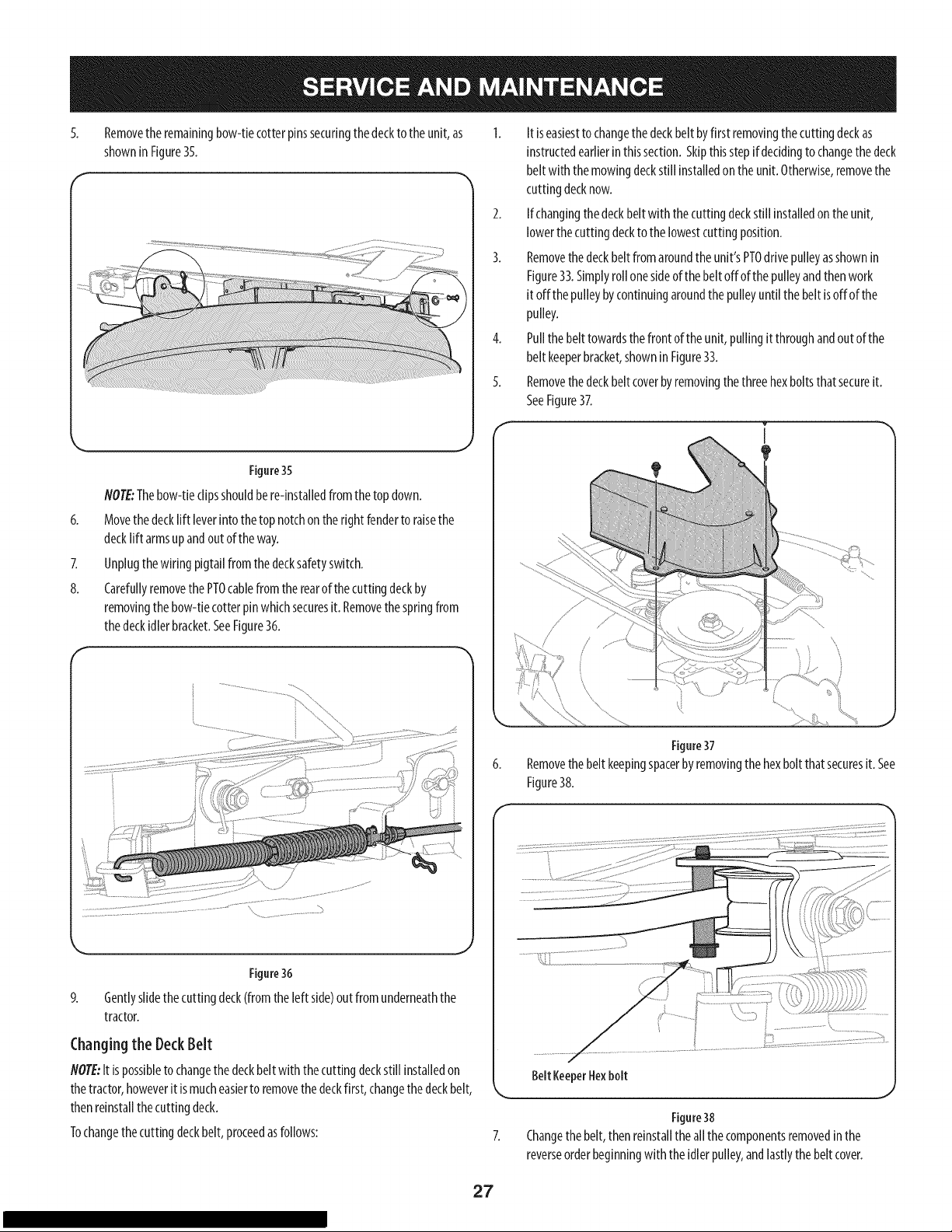

ToChangeTheFuelFilter:

I. Usepliersto squeezethetabsontheotherclamp(theout-linesideofthe

fuelfilter),andslidetheclampawayfromthefuelfilter.Twistandpullthe

fuellineoffofthefuelfilter. SeeFigure32.

2. Checkthefuellinesforcracksorleaks.Replaceifnecessary.

3. Replacethefuelfilter with anoriginalequipmentreplacementfilter.

Call1-800-4-MY-HOME_to purchasethe original equipment

replacementfilter.

4. Securethefuellineswith theclamps.

Thefuelfilter cannotbecleanedandshouldbereplacedevery100operatinghours;

moreoftenif runwitholdgasoline.

NOTE:Wheninstallinganewsparkplug,tighten1/2turnafterthespark

plugseatstocompressthewasher.Whenreinstallingausedsparkplug,

tighten1/8-1/4turnafterthesparkplugseatstocompressthewasher.

IMPORTANT:Thesparkplugmustbesecurelytightened.Animproperly

tightenedsparkplugcanbecomeveryhotandmaydamagetheengine.

25

F

FuelLine

Figure32

CleanEngine

Iftheenginehasbeenrunning,allowittocoolforatleasthalfanhourbefore

cleaning.Periodicallyremovedirt build-upfromengine.Cleantheenginecooling

finsevery25hours.Cleanwith a brushorcompressedair.

IMPORTANT:Donotsprayenginewith watertocleanbecausewatercould

contaminatefuel.Usingagardenhoseorpressurewashingequipmentcanalso

forcewaterintotheaircleanerormuffleropening.Waterintheaircleanerwill soak

thepaperelement,andwaterthatpassesthroughtheelementormufflercanenter

thecylinder,causingdamage.

Figure33

Removethebow-tiecotterpinandflatwasherfromthedecklift assembly,

andretainforreinstallationlater.SeeFigure34.

Accumulationof debrisaroundmuffler couldcausea fire. Inspectandclean

beforeeveryuse.

Cutting DeckRemoval

Toremovethe cutting deck,proceedas follows:

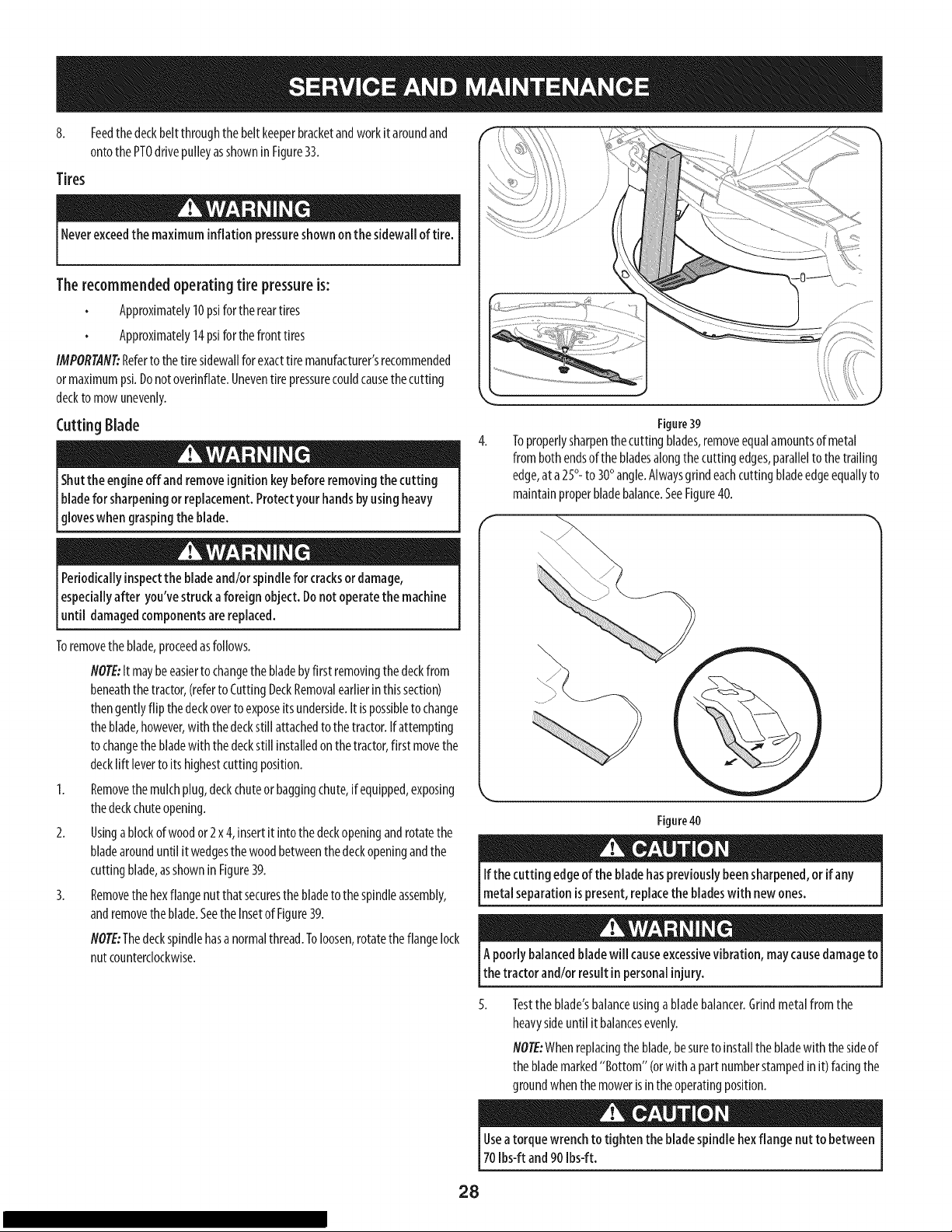

1. PlacethePTO(BladeEngage)leverinthedisengaged(OFF)positionand

engagethe parkingbrake.

2. Lowerthedeckbymovingthedecklift leverintothe bottomnotchonthe

rightfender.

3. Removethebeltfromaroundthetractor'sPTOpulley.SeeFigure33.

Avoidpinchinginjuries.Neverplaceyourfingersonthe idler spring or

betweenthebelt anda pulleywNle removingthe belt.

Figure34

26

5.

Removetheremainingbow-tiecotterpinssecuringthedeckto theunit,as

shownin Figure35.

k. j

Figure35

NOTE:Thebow-tieclipsshouldbere-installedfromthetopdown.

6. Movethedeckliftleverintothetopnotchontherightfendertoraisethe

deckliftarmsupandoutoftheway.

7. Unplugthewiringpigtailfromthedecksafetyswitch.

8. CarefullyremovethePTOcablefromtherearof thecuttingdeckby

removingthebow-tiecotterpinwhichsecuresit.Removethespringfrom

thedeckidlerbracket.SeeFigure36.

f

1. Itiseasiestto changethedeckbeltbyfirst removingthecuttingdeckas

instructedearlierinthissection.Skipthisstepifderidingtochangethedeck

beltwith themowingdeckstill installedontheunit.Otherwise,removethe

cuttingdecknow.

2. Ifchangingthedeckbeltwith thecuttingdeckstillinstalledontheunit,

lowerthecuttingdecktothelowestcuttingposition.

3. Removethedeckbeltfromaroundtheunit'sPTOdrivepulleyasshownin

Figure33.Simplyrollonesideofthebeltoffof the pulleyandthenwork

itoffthe pulleybycontinuingaroundthepulleyuntil the beltisoffof the

pulley.

4. Pullthebelttowardsthefrontof theunit,pullingitthroughandoutof the

beltkeeperbracket,showninFigure33.

5. Removethedeckbeltcoverbyremovingthethreehexboltsthat secureit.

SeeFigure37.

Figure36

9. Gentlyslidethecuttingdeck(fromtheleft side)outfromunderneaththe

tractor.

Changingthe DeckBelt

NOTE:Itispossibletochangethedeckbeltwiththecuttingdeckstillinstalledon

thetractor,howeveritismucheasiertoremovethedeckfirst,changethedeckbelt,

thenreinstallthecuttingdeck.

Tochangethecutting deckbelt,proceedasfollows:

Figure37

Removethebeltkeepingspacerbyremovingthe hexboltthatsecuresit. See

Figure38.

BeltKeeperI-lexbolt

Figure38

Changethebelt,thenreinstalltheallthecomponentsremovedinthe

reverseorderbeginningwith theidlerpulley,andlastlythebeltcover.

27

8.

Feedthedeckbeltthroughthebeltkeeperbracketandworkit aroundand

ontothePTOdrivepulleyasshownin Figure33.

Tires

Neverexceedthe maximum inflationpressureshownonthe sidewallof tire.

Therecommendedoperatingtire pressureis:

Approximately10psiforthereartires

Approximately14psiforthefronttires

IMPORTANT:Refertothetiresidewallforexacttiremanufacturer'srecommended

ormaximumpsi.Donotovednflate.Uneventirepressurecouldcausethecutting

deckto mowunevenly.

CuttingBlade

Shutthe engineoffand removeignitionkeybeforeremovingthe cutting

bladefor sharpeningorreplacement.Protectyourhandsbyusingheavy

[g oveswhengraspngthe bade.

Periodicallyinspectthe bladeand/orspindleforcracksordamage,

[especiallyafter you'vestruckaforeign object.Donot operatethe machine

[until damagedcomponentsarereplaced.

Toremovetheblade,proceedasfollows.

NOTE:Itmaybeeasierto changethebladebyfirst removingthedeckfrom

beneaththetractor,(refertoCuttingDeckRemovalearlierinthissection)

thengentlyflip thedeckovertoexposeitsunderside.It ispossibletochange

theblade,however,with thedeckstillattachedto thetractor.Ifattempting

tochangethebladewith thedeckstillinstalledonthetractor,firstmovethe

decklift levertoitshighestcuttingposition.

1. Removethemulchplug,deckchuteorbaggingchute,ifequipped,exposing

thedeckchuteopening.

2. Usingablockofwoodor2x4,insertit intothedeckopeningandrotatethe

bladearounduntilitwedgesthewoodbetweenthedeckopeningandthe

cuttingblade,asshownin Figure39.

3. Removethehexflangenutthatsecuresthe bladetothespindleassembly,

andremovetheblade.SeetheInsetofFigure39.

NOTE:Thedeckspindlehasanormalthread.Toloosen,rotatetheflangelock

nutcounterclockwise.

Figure39

Toproperlysharpenthecuttingblades,removeequalamountsofmetal

frombothendsofthebladesalongthecuttingedges,paralleltothetrailing

edge,at a25°-to 30°angle.Alwaysgrindeachcutting bladeedgeequallyto

maintainproperbladebalance.SeeFigure40.

Figure40

Ifthe cuttingedgeofthebladehaspreviouslybeensharpened,orif any

metalseparationispresent,replacethe bladeswith newones.

Apoorlybalancedbladewill causeexcessivevibration, maycausedamageto

the tractor and/orresultin personalinjury.

Testtheblade'sbalanceusingabladebalancer.Grindmetalfromthe

heavysideuntilit balancesevenly.

NOTE:Whenreplacingthe blade,besuretoinstallthebladewith thesideof

the blademarked"Bottom" (orwitha partnumberstampedin it)facingthe

groundwhenthemowerisintheoperatingposition.

Useatorquewrenchto tighten the bladespindlehexflange nut to between

70Ibs-ftand 90Ibs4t.

28

Adjustments

ParkingBrakeAdjustment

Neverattempt to makeanyadjustmentswhiletheengineisrunning,except

wherespecifiedinthe operator'smanual.

Levelingthe Deck

NOTE:Checkthetractor'stire pressurebeforeperforminganydeckleveling

adjustments.Referto Tires,inthisServiceAndMaintenancesectionformore

informationregardingtire pressure.

Front ToRear

Itispossibleto adjustthepitchofthecuttingdeck.Thefrontofthedeckshouldbe

between0" (level)and1_,,lowerthantherearofthedeck.Adjustif necessaryas

follows:

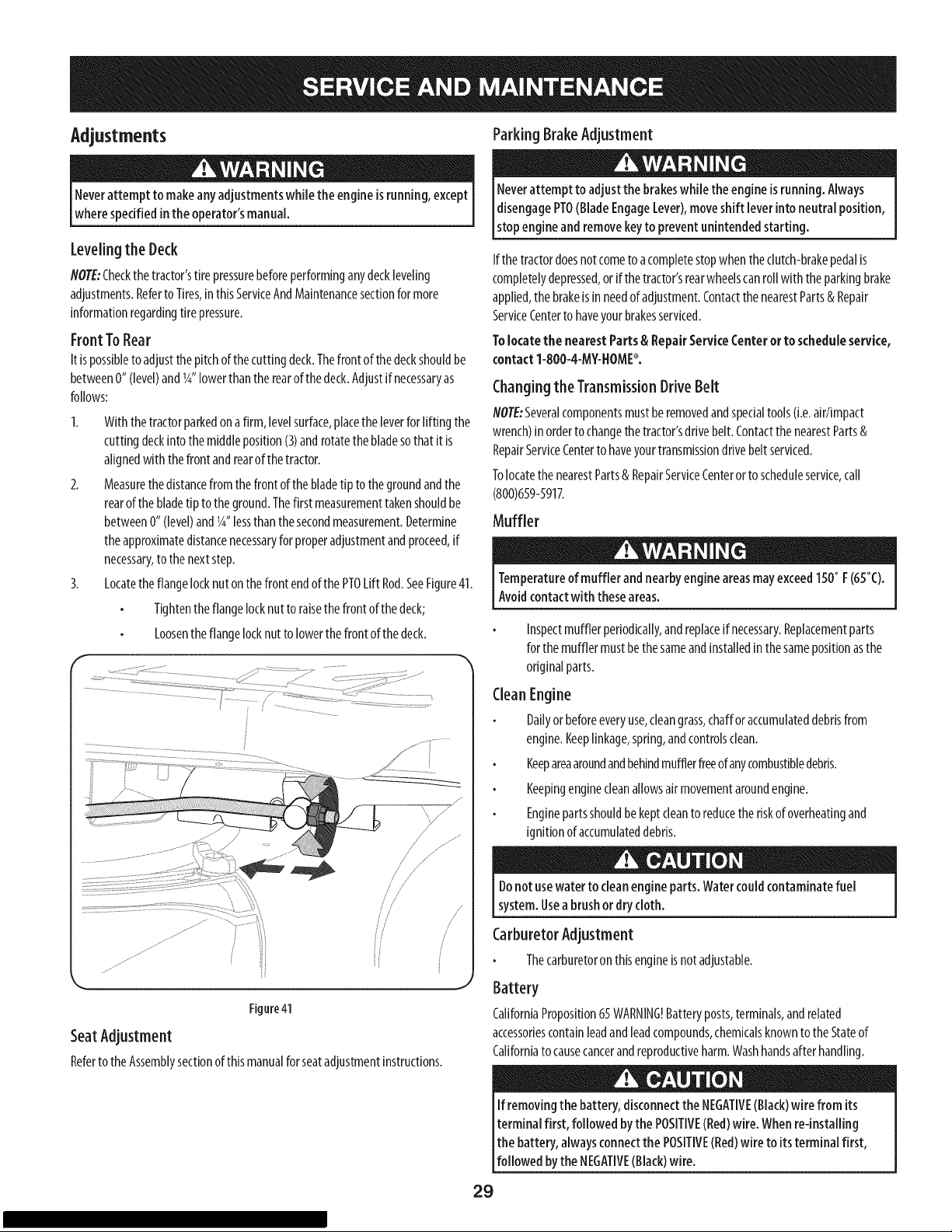

Withthetractorparkedona firm, levelsurface,placetheleverforliftingthe

cuttingdeckintothemiddleposition(3)androtatethebladesothat it is

alignedwith thefrontandrearofthetractor.

2.

Measurethedistancefromthefrontofthe bladetiptothegroundandthe

rearofthe bladetip totheground.Thefirstmeasurementtakenshouldbe

between0" (level)and1_,,lessthanthesecondmeasurement.Determine

theapproximatedistancenecessaryfor properadjustmentandproceed,if

necessary,to thenextstep.

3.

LocatetheflangelocknutonthefrontendofthePTOLiftRod.SeeFigure41.

Tightentheflangelocknutto raisethefrontofthedeck;

Loosentheflangelocknutto lowerthefrontofthedeck.

Neverattempt to adjustthe brakeswhile the engineisrunning.Always

disengagePTO(BladeEngageLever),moveshift leverinto neutralposition,

stopengineandremovekeyto preventunintendedstarting.

Ifthetractordoesnotcometoacompletestopwhentheclutch-brakepedalis

completelydepressed,or ifthetractor'srearwheelscanrollwiththe parkingbrake

applied,thebrakeisinneedofadjustment.ContactthenearestParts& Repair

ServiceCentertohaveyourbrakesserviced.

Tolocate the nearestParts&Repair ServiceCenteror toscheduleservice,

contact 1-800-4-MY-HOME_.

Changingthe TransmissionDriveBelt

NOTE:Severalcomponentsmustberemovedandspecialtools(i.e.air/impact

wrench)inordertochangethetractor'sdrivebelt.ContactthenearestParts&

RepairServiceCentertohaveyourtransmissiondrivebeltserviced.

TolocatethenearestParts& RepairServiceCenterorto scheduleservice,call

(800)659-5917.

Muffler

Temperatureofmuffler and nearbyengineareasmayexceed150° F(65°C).

Avoidcontactwith theseareas.

Inspectmufflerperiodically,andreplaceif necessary.Replacementparts

forthe mufflermustbethesameandinstalledinthesamepositionasthe

originalparts.

/ ....

/ /

/ /

....................... / /

Figure41

/ / /

, /

SeatAdjustment

RefertotheAssemblysectionofthismanualforseatadjustmentinstructions.

Clean Engine

Dailyorbeforeeveryuse,cleangrass,chafforaccumulateddebrisfrom

engine.Keeplinkage,spring,andcontrolsclean.

Keepareaaroundandbehindmufflerfreeofanycombustibledebris.

Keepingenginecleanallowsairmovementaroundengine.

Enginepartsshouldbekeptcleantoreducetheriskofoverheatingand

ignitionof accumulateddebris.

Donotusewater tocleanengineparts.Watercouldcontaminatefuel

system.Useabrushor drycloth.

CarburetorAdjustment

Thecarburetoronthisengineisnotadjustable.

Battery

CaliforniaProposition65WARNING!Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,chemicalsknownto theStateof

Californiatocausecancerandreproductiveharm.Washhandsafterhandling.

Ifremovingthebattery, disconnecttheNEGATIVE(Black)wire from its

terminalfirst, followed bythePOSITIVE(Red)wire. Whenre-installing

the battery,alwaysconnectthe POSITIVE(Red)wire to itsterminal first,

followedbythe NEGATIVE(Black)wire.

29

Thebatteryissealedandismaintenance-free.Acidlevelscannotbechecked.

Alwayskeepthebatterycablesandterminalscleanandfreeof

corrosivebuild-up.

Aftercleaningthe batteryandterminals,applyalight coatof

petroleumjellyorgreasetobothterminals.

Alwayskeeptherubberbootpositionedoverthepositiveterminalto

preventshorting.

IMPORTAIV_If removingthe batteryforanyreason,disconnecttheNEGATIVE

(Black)wirefromitsterminalfirst, followedbythePOSITIVE(Red)wire.When

re-installingthebattery,alwaysconnectthePOSITIVE(Red)wiretoitsterminal

first, followedbytheNEGATIVE(Black)wire.Becertainthat thewiresareconnected

tothecorrectterminals;reversingthemcouldchangethepolarityandresultin

damageto yourengine'salternatingsystem.

CleaningBattery

Cleanthebatterybyremovingit fromthetractorandwashingwith abakingsoda

andwatersolution.If necessary,scrapethebatteryterminalswith awirebrushto

removedeposits.Coatterminalsandexposedwiringwith greaseorpetroleumjelly

topreventcorrosion.

Battery Failures

Somecommoncausesforbatteryfailureare:

Incorrectinitialactivation

Overcharging

Freezing

Undercharging

Corrodedconnections

ThesefailuresareNOTcoveredbyyourtractor'swarranty.

Jump Starting

Charging

Batteriesgive off anexplosivegaswhile charging.Chargethe battery in

awell ventilated areaand keepawayfrom anopenflame or pilot light

ason awater heater,spaceheater,furnace,clothesdryer or other gas

appliances.

Whenchargingyour tractor'sbattery, useonlyachargerdesignedfor 12V

lead-addbatteries.Readyour battery charger'sOwner'sManualpriorto

chargingyour tractor'sbattery. Alwaysfollow itsinstructionsandheedits

warnings.

Ifyourtractorhasnotbeenputintouseforanextendedperiodoftime,chargethe

batteryasfollows:

1. Setyourbatterychargerto delivera maxof 10amperes.

Ifyourbatterychargerisautomatic,chargethebatteryuntilthechargerindicates

thatchargingiscomplete.Ifthechargerisnotautomatic,chargefor nofewerthan

eighthours.

Fuse

One15AMPfuseisinstalledinyourtractor'swiringharnessto protectthetractor's

electricalsystemfromdamagecausedbyexcessiveamperage.

Iftheelectricalsystemdoesnotfunction,oryourtractor'senginewill notcrank;

first checkto becertainthatthefusehasnot blown.Itcanbefoundunderthe

fenderontheleftsideoftheunit,onthewiringharnessjustabovethe battery.

Alwaysuseafusewith thesameamperagecapacityfor replacement.

Lubrication

Neverjump start adamaged or frozen battery. Be certain the vehicles

do not touch, and ignitions areoff. Donot allow cable clamps to

touch.

1. Connectpositive(+) cabletopositivepost(+)ofyourtractor'sdischarged

battery.

2. Connecttheotherendofthecableto thepositive(+) postofthejumper

battery.

3. Connectthesecondcablenegative(-) to thenegativepost(-) ofthejumper

battery.

4. Connecttheotherendofthenegativecabletotheengineblockofthe

tractor,awayfromthebattery.Attachtoanunpaintedpartto assureagood

connection.

Ifthejumper batteryis installedonavehicle(i.e.car,truck),doNOTstart

the vehicle'senginewhenjump starting your tractor.

5. Startthetractor(asinstructedintheOperationsectionofthismanual).

6. Setthetractor'sparkingbrakebeforeremovingthejumpercables,inreverse

orderofconnection.

Beforelubricating, repairing,or inspecting,alwaysdisengagePTO(Blade

EngageLever),moveshift leverinto neutral position,setparking brake,stop

engneandremovekeyto preventun ntendedstart ng.

Pivot Points& Linkage