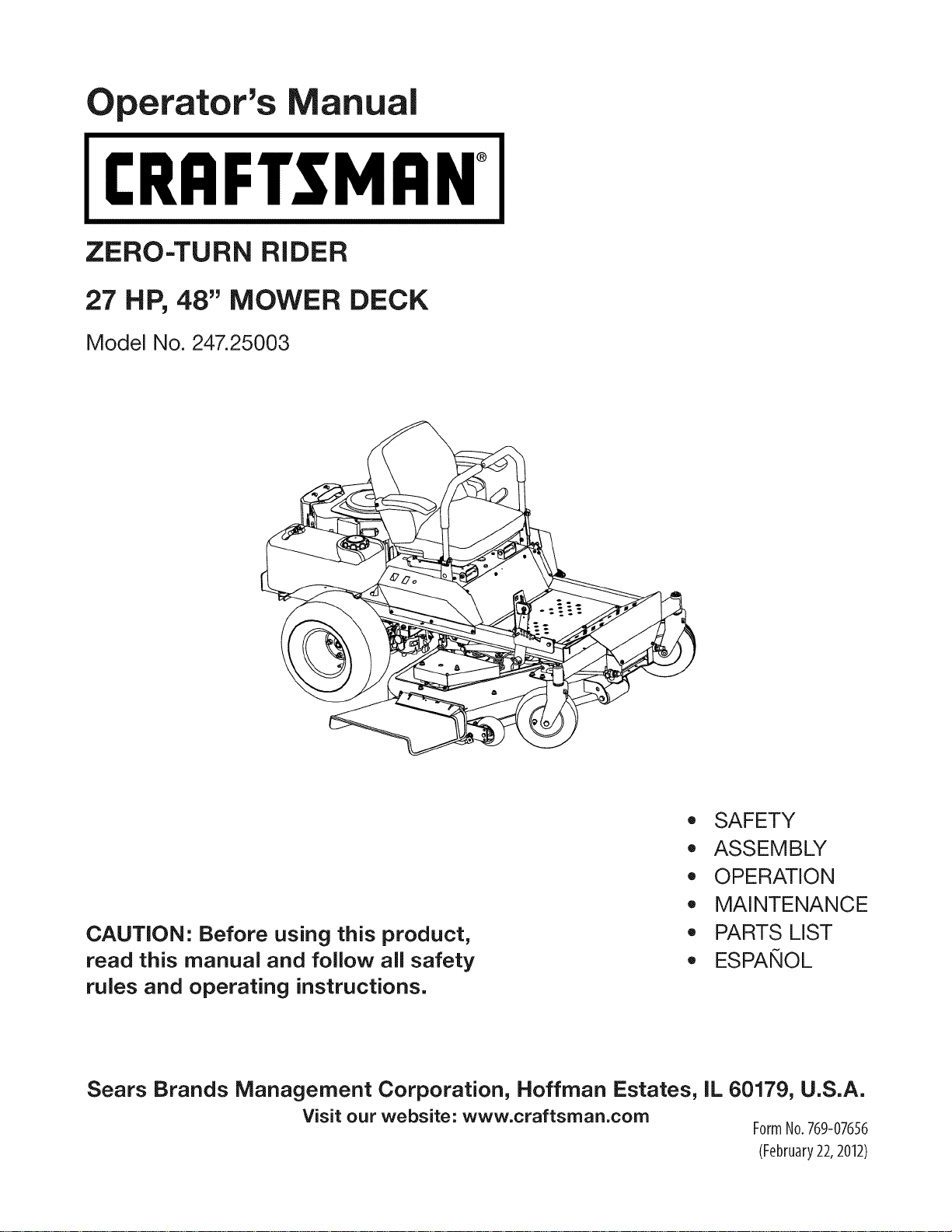

Craftsman 247250030 Owner’s Manual

per'ator's nual

I:RRFrSMRN°

ZERO=TURN RIDER

27 HP, 48" MOWER DECK

Model No. 247,25003

, SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

CAUTION: Before using this product,

read this manual and follow all safety

rules and operating instructions,

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com

PARTS LIST

o ESPANOL

FormNo.769-07656

(February22,2012)

Warranty Statement .................................. Page 2

Safe Operation Practices .......................... Pages 3-8

Assembly .................................................. Pages 9-11

Operation .................................................. Pages 12-21

Service and Maintenance ......................... Pages 22-33

Off-Season Storage .................................. Page 34

Parts List ..................................................... Pages 38-61

Engine Parts List ....................................... Pages 62-75

Labels ....................................................... Page 76

Repair Protection Agreement ................... Page 79

Espafiol ..................................................... Page 84

Service Numbers ...................................... Back Cover

Troubleshooting ........................................ Page 35-36

CRAFTSMAN FULL WARRANTY

FORTHREEYEARSfromthedateof purchase,all non-expendabbpartsofthis ridingequipmentarewarrantedagainstanydefectsinmaterial

orworkmanship.Adefectivenon-expendablepartwill receivefreein-homerepairor replacementif repairis impossible.

FOR90 DAYSfromthe dateof purchase,thebattery(anexpendablepart)of this ridingequipmentiswarrantedagainstanydefectsinmaterialor

workmanship(ourtestingprovesthatit willnotholda charge).A defectivebatterywill receivefreein-homereplacement.

WARRANTYSERVICE

Forwarrantycoveragedetailstoobtainfree repairorreplacement,call 1-800-659-5917or visitthe website: www.craftsman.com

Inallcasesabove,if part repairor replacementis impossible,the ridingequipmentwillbe replacedfreeof chargewiththe sameor anequivalent

model.

Allofthe abovewarrantycoverageisvoid ifthisridingequipmentiseverusedwhileprovidingcommercialservicesor if rentedtoanotherperson.

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.Warrantycoveragedoes NOTinclude:

• Expendableparts(exceptbattery)thatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedtoblades,spark

plugs,air cleaners,belts,andoilfilters.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

Tireor wheelreplacementor repairresultingfromnormalwear,accident,or improperoperationor maintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedto damagecausedbytowingobjectsbeyondthecapabilityofthe

ridingequipment,impactingobjectsthatbendthe frame,axleassemblyor crankshaft,orover-speedingtheengine.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeand amountofengineoil,failuretokeepthedeckclearofflammabledebris,orfailureto maintainthe

ridingequipmentaccordingtothe instructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedto becontaminatedor oxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

Normaldeteriorationandwearof theexteriorfinishes,orproductlabelreplacement.

o

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands ManagementCorporation, Hoffman Estates,IL 60179

EngineOil: 15W-40

Fuel: UnleadedGasoline

SparkPlug: RC12YC

Engine: KohlerSV840-3021

© KCDIRLLC 2

ModelNumber

Serial Number

Dateof Purchase

Recordthemodelnumber,serialnumber,

anddateof purchaseabove.

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron the partof theoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm.

Batteryposts,terminals,and relatedaccessoriescontainleadand

leadcompounds,chemicalsknowntothe Stateof Californiato

causecancerandreproductiveharm.Washhandsafterhandling.

GENERAL OPERATION

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplaceforfutureand regularreference

andfororderingreplacementparts.

• Befamiliarwithall controlsandtheir properoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsofagetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandshouldbetrainedandsupervisedbyan adult.

• Neverallowadultsto operatethismachinewithoutproper

instruction.

• Tohelpavoidbladecontactor a thrownobjectinjury,keep

bystanders,helpers,childrenandpetsatleast75feetfromthe

machinewhileit isin operation.Stopmachineifanyoneenters

thearea.

• Thoroughlyinspecttheareawheretheequipmentistobe used.

Removeallstones,sticks,wire,bones,toys,andotherforeign

objectswhichcouldbe pickedupandthrownbythe blade(s).

Thrownobjectscan causeseriouspersonalinjury.

• Planyourmowingpatterntoavoiddischargeofmaterialtoward

roads,sidewalks,bystandersandthe like.Also,avoiddischarg-

ingmaterialagainstawallorobstructionwhichmaycause

dischargedmaterialto ricochetbacktowardtheoperator.

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperforminganadjustmentorrepairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesandjewelrycan becaughtin movable

parts.Neveroperatethis machinein barefeetor sandals.

Your Responsibility--Restricttheuseof thispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine.

SAVE THESE INSTRUCTIONS!

• Beawareofthemowerandattachmentdischargedirectionand

do notpointitat anyone.Donot operatethemowerwithoutthe

dischargecoverorentiregrasscatcherin its properplace.

• Donotputhandsor feetnearrotatingpartsor underthecutting

deck.Contactwiththe blade(s)can amputatehandsandfeet.

• A missingordamageddischargecovercancausebladecontact

or thrownobjectinjuries.

• Stoptheblade(s)whencrossinggraveldrives,walks,orroads

andwhilenotcuttinggrass.

• Watchfor trafficwhenoperatingnearorcrossingroadways.This

machineisnot intendedforuseonany publicroadway.

• Donotoperatethemachinewhileunderthe influenceofalcohol

or drugs.

• Mowonlyindaylightorgoodartificiallight.

• Nevercarrypassengers.

• Backup slowly.Alwayslookdownandbehindbeforeandwhile

backingtoavoida back-overaccident.Beawareand payatten-

tionto thesafetysystemfunctionthatstopspowertothe blades

whendrivingin reverse.Ifnotfunctioningproperly,contactan

authorizeddealerforsafetysysteminspectionand repair.

• Slowdownbeforeturning.Operatethemachinesmoothly.Avoid

erraticoperationandexcessivespeed.

• Disengageblade(s),setparkingbrake,stopengineandwaituntil

theblade(s)cometo acompletestopbeforeremovinggrass

catcher,emptyinggrass,uncloggingchute,removinganygrassor

debris,or makinganyadjustments.

• Neverleavearunningmachineunattended.Alwaysturnoff

blade(s),placedrivecontrollevers fullyoutwardtoeach sidein

neutral,set parkingbrake,stopengineandremovekeybefore

dismounting.

3

• Useextracarewhenloadingorunloadingthemachineintoa

trailerortruck.Thismachineshouldnotbedrivenupor down

ramp(s),becausethemachinecouldtip over,causingserious

personalinjury.Themachinemustbe pushedmanuallyon

ramp(s)to loador unloadproperly.

• Mufflerandenginebecomehotandcancausea burn.Donot

touch.

• Checkoverheadclearancescarefullybeforedrivingunderlow

hangingtreebranches,wires,dooropeningsetc.,wherethe

operatormaybestruckor pulledfromthe machine,whichcould

resultinseriousinjury.

• Disengageallattachmentclutches,settheparkingbraketothe

'on'positionandmovethe RHand LHdrivecontrolleversfully

outwardto eachsideto theneutralpositionbeforeattemptingto

startthe engine.

• Yourmachineisdesignedto cutnormalresidentialgrassofa

heightnomorethan10".Donotattemptto mowthroughunusually

tall,drygrass(e.g.,pasture)orpilesof dryleaves.Drygrassor

leavesmaycontacttheengineexhaustand/orbuilduponthe

mowerdeckpresentinga potentialfirehazard.

• Useonlyaccessoriesandattachmentsapprovedfor this machine

bythe machinemanufacturer.Read,understandandfollowall

instructionsprovidedwiththeapprovedaccessoryorattachment.

• Dataindicatesthatoperators,age60yearsandabove,are

involvedin a largepercentageofridingmower-relatedinjuries.

Theseoperatorsshouldevaluatetheirabilitytooperatetheriding

mowersafelyenoughto protectthemselvesandothersfrom

seriousinjury.

• If situationsoccurwhicharenotcoveredinthismanual,usecare

andgoodjudgment.ContacttheCraftsmanHelpLineat1-800-

659-5917forassistance.

SLOPE OPERATION

Slopesarea majorfactorrelatedtolossof controlandtip-over

accidentswhichcanresultinsevereinjuryor death.Allslopesrequire

extracaution.Ifyoucannotbackuptheslopeor ifyoufeeluneasyon

it, do notmowit.

Foryoursafety,usetheslopegaugeincludedaspartofthismanual

to measureslopesbeforeoperatingthismachineona slopedor hilly

area.Ifthe slopeis greaterthan15degreesasshownonthe slope

gauge,donot operatethismachineonthatareaor seriousinjurycould

result.

Do:

o

Mowacrossslopes,notupanddown.Exerciseextremecaution

whenchangingdirectionon slopes.

Watchfor holes,ruts,bumps,rocks,orotherhiddenobjects.

Uneventerraincouldoverturnthemachine.Tallgrasscan hide

obstacles.

Useslowspeed.Choosea lowenoughspeedsothatyouwillnot

haveto stopwhileon the slope.Avoidstartingor stoppingon a

slope.Ifthetiresareunableto maintaintraction,disengagethe

bladesandproceedslowlyandcarefullystraightdowntheslope.

Followthemanufacturer'srecommendationsforwheelweightsor

counterweightsto improvestability.

Useextracarewithgrasscatchersorotherattachments.These

canchangethestabilityof the machine.

• Keepallmovementontheslopesslowandgradual.Donot

makesuddenchangesinspeedor direction.Rapidacceleration

or decelerationcouldcausethe frontofthe machinetolift and

rapidlyflipoverbackwards,whichcouldcauseseriousinjury.

DoNot:

• Donotturnonslopesunlessnecessary;thenturnslowlyuphill

and useextracarewhileturning.

• Donotmowneardrop-offs,ditchesorembankments.The mower

couldsuddenlyturnoverif a wheelis overthe edgeofa cliff,

ditch,or if an edgecavesin.

• Donottry tostabilizethemachinebyputtingyourfootonthe

ground.

• Donotuseagrasscatcheron steepslopes.

• Donotmowon wetgrass.Reducedtractioncouldcausesliding.

• Donottowheavypull behindattachments(e.g.loadeddumpcart,

lawnroller,etc.)on slopesgreaterthan5 degrees.Whengoing

downhill,theextraweighttendsto pushthe ridingmowerand

maycauseyouto loosecontrol(e.g.ridingmowermayspeed

up,brakingandsteeringabilityare reduced,attachmentmay

jack-knifeandcauseridingmowertooverturn).

4

CHILDREN

Tragicaccidentscanoccuriftheoperatorisnotalertto thepresence

ofchildren.Childrenareoftenattractedtothe machineandthemowing

activity.Theydo notunderstandthedangers.Neverassumethat

childrenwillremainwhereyoulastsawthem.

• Keepchildrenoutofthe mowingareaand inwatchfulcareof a

responsibleadultotherthanthe operator.

• Bealertandturnmachineoff ifa childentersthearea.

• Toavoidback-overaccidents,alwayslookbehindanddownfor

smallchildren.

• Nevercarrychildren,evenwiththe blade(s)shutoff.Theymay

falloffandbe seriouslyinjuredorinterferewithsafemachine

operation.

• Useextremecarewhenapproachingblindcorners,doorways,

shrubs,treesorotherobjectsthatmayblockyourvisionofa child

whomayrunintothe pathofthe machine.

• Keepchildrenawayfromhotor runningengines.Theycansuffer

burnsfroma hotmuffler.

• Removekeywhenmachineisunattendedtopreventunauthorized

operation.

Neverallowchildrenunder14yearsofageto operatethismachine.

Children14andovershouldreadandunderstandtheinstructionsand

safeoperationpracticesinthismanualandon themachineandshould

betrainedandsupervisedbyan adult.

TOWING

• Towonlywitha machinethathasa hitchdesignedfortowing.Do

notattachtowedequipmentexceptat thehitchpoint.

• Followthemanufacturersrecommendationforweightlimitsfor

towedequipmentandtowingonslopes.

• Neverallowchildrenor othersinoron towedequipment.

• Onslopes,theweightof thetowedequipmentmaycauselossof

tractionandlossof control.

• Travelslowlyandallowextradistanceto stop.

• Donot shiftto neutralandcoastdownhill.

SERVICE

SafeHandlingof Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

on yourselforyour clotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipesandothersourcesofignition.

• Neverfuelmachineindoors.

• Neverremovegascapor addfuelwhiletheengineishotorrun-

ning.Allowengineto coolatleasttwominutesbeforerefueling.

• Neveroverfillfueltank.Filltanktono morethan1/2inchbelow

bottomoffillerneckto allowspaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitofftheengineandequipment.Move

machinetoanotherarea.Wait5 minutesbeforestartingtheengine.

• Toreducefirehazards,keepmachinefreeofgrass,leaves,or

otherdebrisbuild-up.Cleanup oilor fuelspillageandremoveany

fuelsoakeddebris.

• Neverstoreor re-fuelthemachineorfuelcontainerinsidewhere

thereisanopenflame,sparkor pilotlightas on a waterheater,

spaceheater,furnace,clothesdryerorothergasappliances.

• Allowa machineto coolat leastfiveminutesbeforestoring.

• AvoidStaticDischarge.

• Neverfillcontainersinsidea vehicleoron a truckortrailerbed

witha plasticliner.Alwaysplacecontainerson the groundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthetruck

or trailerandrefueliton theground.Ifthis isnotpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthenozzleincontactwiththerimofthefueltankor

containeropeningatall timesuntilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

GeneralService

• Neverrunan engineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an odorless,anddeadlygas.

• Beforecleaning,repairing,or inspecting,makecertainthe

blade(s)andall movingpartshavestopped.Disconnectthespark

plugwireandgroundagainsttheengineto preventunintended

starting.

• Periodicallychecktomakesurethebladescometo completestop

withinapproximately(5) fivesecondsafteroperatingtheblade

disengagementcontrol,ifthe bladesdonot stopwithinthethis

timeframe,aveyourmachineservicedprofessionallybySearsor

anotherqualifieddealer.

• Regularlycheckthesafetyinterlocksystemforproperfunction,as

describedlaterinthis manual.Ifthe safetyinterlocksystemdoes

notfunctionproperly,haveyourmachineservicedprofessionally

bySearsoranotherqualifieddealer.

• Checktheblade(s)andenginemountingboltsatfrequent

intervalsforpropertightness.Also,visuallyinspectblade(s)for

damage(e.g.,excessivewear,bent,cracked).Replacethe

blade(s)withtheoriginalequipmentmanufacturer's(O.E.M.)

blade(s)only,listedinthismanual.Useofpartswhichdonot

meettheoriginalequipmentspecificationsmayleadtoimproper

performanceandcompromisesafety!

Mowerbladesaresharp.Wrapthebladeorweargloves,anduse

extracautionwhenservicingthem.

Keepallnuts,bolts,andscrewstighttobesuretheequipmentis

insafeworkingcondition.

Nevertamperwiththesafetyinterlocksystemorothersafety

devices.Checktheirproperoperationregularly.

Afterstrikingaforeignobject,stoptheengine,disconnectthe

sparkplugwire(s)andgroundagainsttheengine.Thoroughly

inspectthemachineforanydamage.Repairthedamagebefore

startingandoperating.

Neverattempttomakeadjustmentsorrepairstothemachine

whiletheengineisrunning.

Grasscatchercomponentsandthedischargecoveraresubject

towearanddamagewhichcouldexposemovingpartsorallow

objectstobethrown.Forsafetyprotection,frequentlycheck

componentsandreplaceimmediatelywithoriginalequipment

manufacturer's(O.E.M.)partsonly,listedinthismanual.Useof

partswhichdonotmeettheoriginalequipmentspecificationsmay

leadtoimproperperformanceandcompromisesafety!

Donotchangetheenginegovernorsettingsorover-speedthe

engine.Thegovernorcontrolsthemaximumsafeoperatingspeed

oftheengine.

Maintainorreplacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsandregulationsforgas,oil,etc.to

protecttheenvironment.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasanAverageUsefulLifeofseven(7)years,or270hoursof

operation.AttheendoftheAverageUsefulLifehavethemachine

inspectedannuallybySearsoranotherqualifieddealertoensure

thatallmechanicalandsafetysystemsareworkingproperlyand

notwornexcessively.Failuretodosocanresultinaccidents,

injuriesordeath.

DO NOT MODIFY ENGINE

Toavoid seriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

Notice RegardingEmissions

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,andmayinclude

thefollowingemissioncontrolsystems:EngineModification(EM)and

ThreeWayCatalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineisequippedwithan internalcombustionengineand

shouldnot beusedonor nearanyunimprovedforest-covered,

brush-coveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any).

Ifa sparkarrestoris used,it shouldbe maintainedin effectiveworking

orderbythe operator.Inthe Stateof Californiatheaboveis required

bylaw (Section4442of the CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws.Federallawsapplyonfederallands.

A sparkarrestorforthe muffleris availablefor purchasebycallingSear

Parts& Repairat 1-800-469-4663.

6

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct.Read,understand,andfollowallinstructionson themachine

beforeattemptingto assembleandoperate.

READTHEOPERATOR'SMANUAL(S)

Read,understand,andfollowall instructionsinthemanual(s)beforeattemptingtoassembleand

operate

WARNING--ROTATINGBLADES

Donot puthandsor feetnearrotatingpartsor underthecuttingdeck.Contactwiththe blade(s)can

amputatehandsandfeet.

sJ / _

®

WARNING--THROWNOBJECTS

Thismachinemaypickupandthrowandobjectswhichcancauseseriouspersonalinjury.

WARNING--THROWNOBJECTS

Thismachinemaypickupandthrowandobjectswhichcancauseseriouspersonalinjury.

BYSTANDERS

Keepbystanders,helpers,childrenandpetsatleast75feetfromthemachinewhileit is inoperation.

WARNING--SLOPEOPERATION

Donot operatethismachineona slopegreaterthan15degrees.

DANGER-- ROTATINGBLADES

Toreducetheriskof injury,keephandsandfeetaway.Donotoperateunlessdischargecoveror grass

catcheris in itsproperplace.Ifdamaged,replaceimmediately.

7

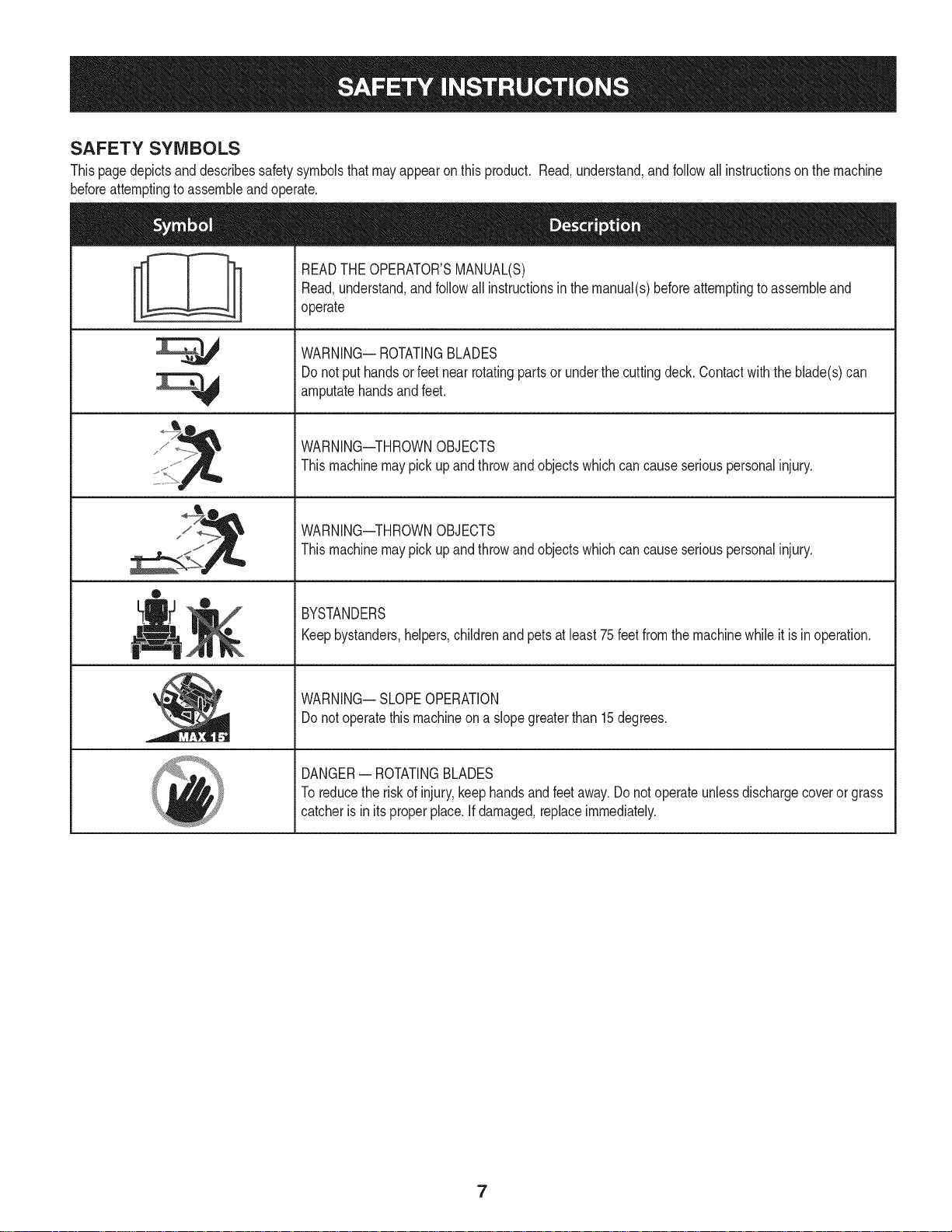

15° Slope

15° Slope

X

(OK)

'_. _ Figure1

(TOO STEEP)

Figure2

15°

dashedline

USETHISSLOPEGAUGETODETERMINE

IFA SLOPEISTOOSTEEPFORSAFEOPERATION!

Tochecktheslope,proceedasfollows:

1. Removethis pageandfoldalongthedashedline.

2. Locateaverticalobject onor behindthe slope(e.g.a pole, building,fence, tree,etc.)

3. Align eithersideoftheslopegaugewiththeobject(SeeFigure1 and Figure2).

4. Adjust gaugeupor down untilthe left cornertouchestheslope(SeeFigure1andFigure2).

5.

If thereis agap belowthe gauge,theslopeis too steepfor safeoperation(SeeFigure2 above).

Slopesare a majorfactor relatedtotip-over and roll-over accidents whichcan resultin severe injury or death. Do not operatemachineonslopes

in excess of 15degrees.All slopes require extra caution. Ifyou cannot backup the slope orif you feel uneasy on it, do not mow it.

Always mow across the face of slopes, never mow upand downthe face of slopes.

RiDiNG MOWER PREPARATION

Removethe uppercratingmaterialfromtheshippingpallet,andcut

anybandsor tiestrapssecuringtheridingmowertothepallet.

1. Usethelift handleto raisethedeckto itshighestposition.

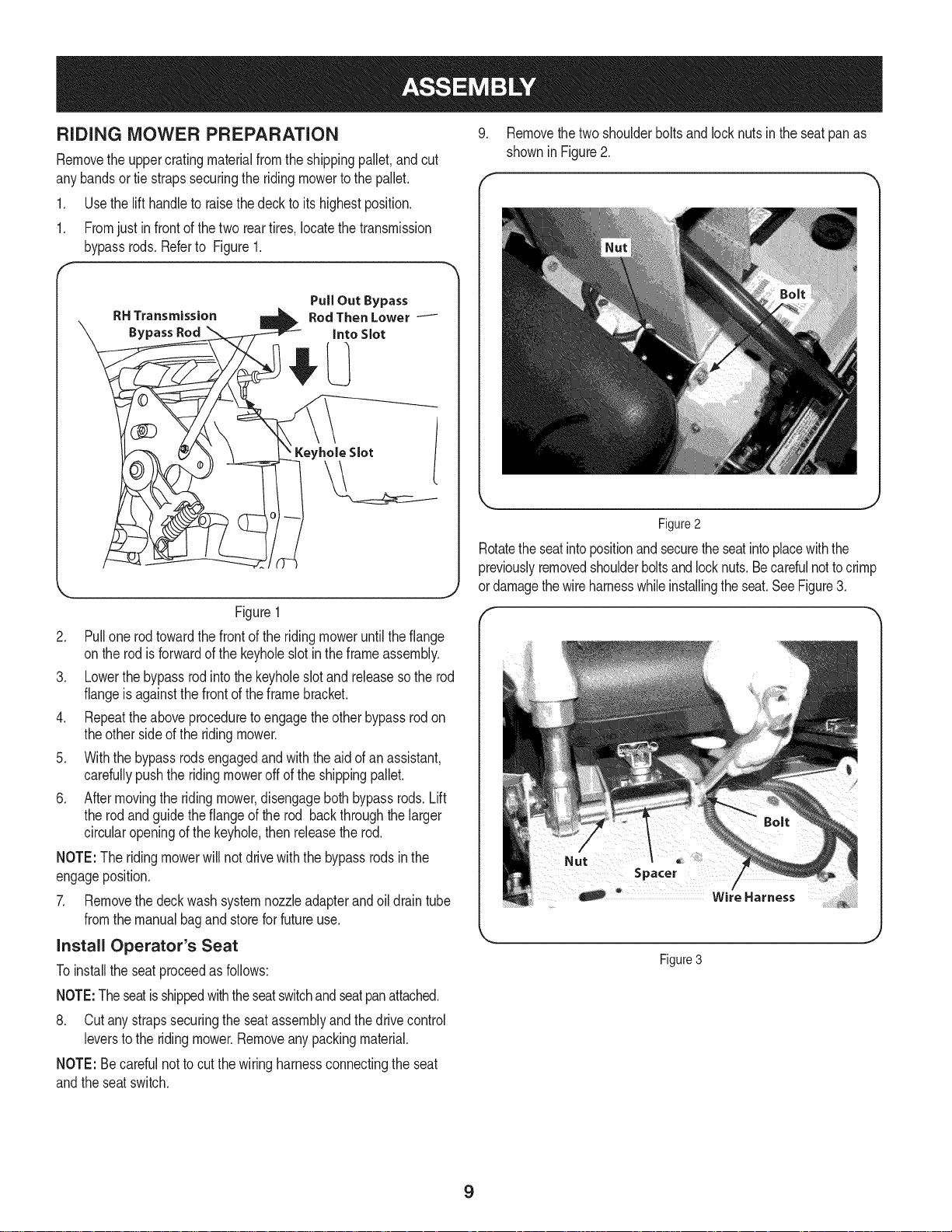

1. Fromjustin frontofthetwo reartires,locatethetransmission

bypassrods.Referto Figure1.

RH Transmission

BypassRod

Figure1

2. Pullonerodtowardthefrontof the ridingmoweruntilthe flange

ontherod is forwardofthe keyholeslotin theframeassembly.

3. Lowerthebypassrodintothekeyholeslotandreleasesothe rod

flangeis againstthefrontof theframebracket.

4. Repeattheaboveproceduretoengagetheotherbypassrodon

theother sideof the ridingmower.

5. Withthe bypassrodsengagedandwiththeaidof anassistant,

carefullypushtheridingmoweroffof theshippingpallet.

6. Aftermovingthe ridingmower,disengagebothbypassrods.Lift

therodandguidethe flangeof therod backthroughthelarger

circularopeningof the keyhole,then releasetherod.

NOTE:The ridingmowerwillnot drivewiththe bypassrodsinthe

engageposition.

7. Removethedeckwashsystemnozzleadapterandoildraintube

fromthemanualbagandstoreforfutureuse.

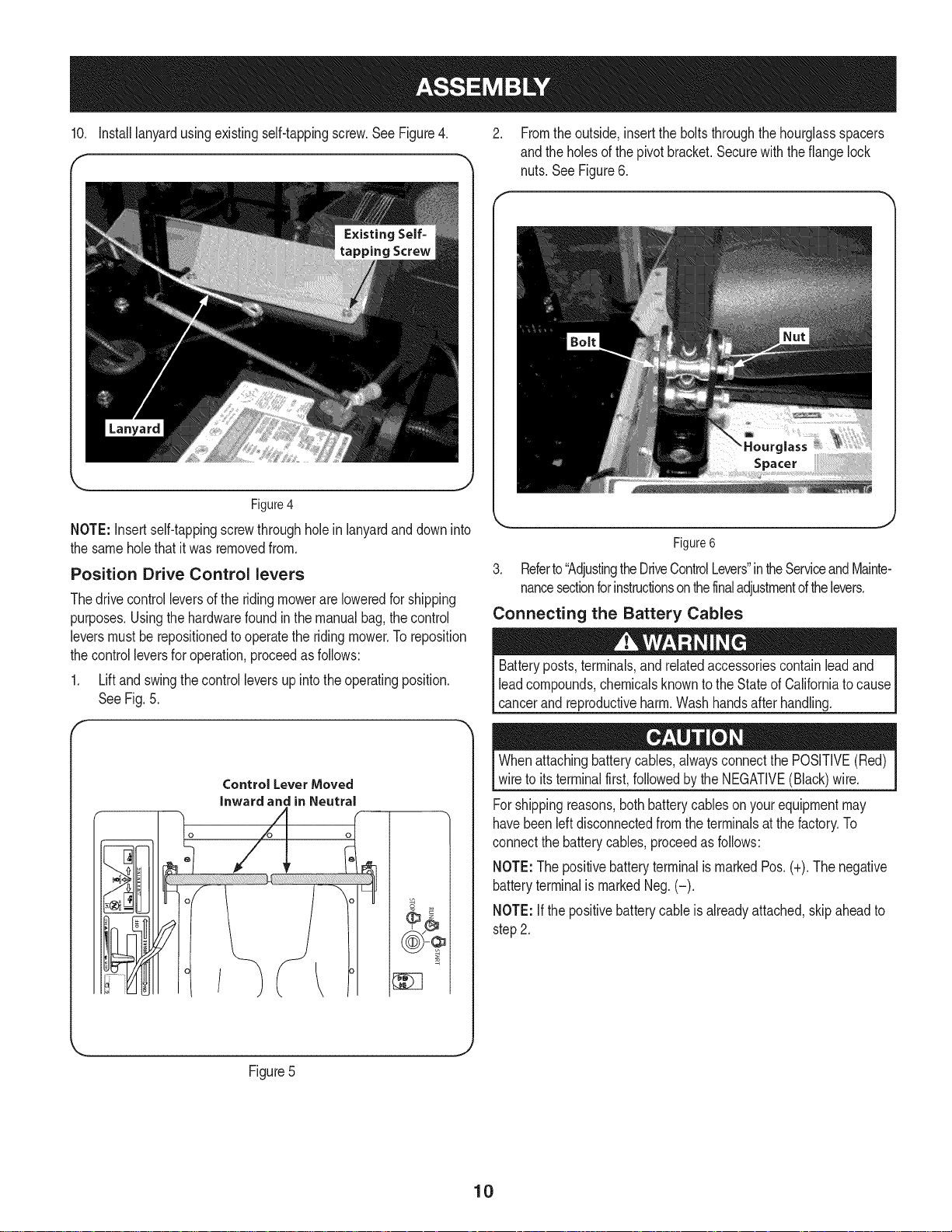

9. Removethe twoshoulderboltsandlocknutsin the seatpanas

showninFigure2.

Figure2

Rotatethe seatintopositionandsecuretheseatintoplacewiththe

previouslyremovedshoulderboltsandlocknuts.Becarefulnottocrimp

or damagethewireharnesswhileinstallingtheseat.SeeFigure3.

install Operator's Seat

Toinstallthe seatproceedasfollows:

NOTE:Theseatisshippedwiththeseatswitchandseatpanattached.

8. Cutanystrapssecuringtheseatassemblyandthedrivecontrol

leverstothe ridingmower.Removeanypackingmaterial.

NOTE:Becarefulnottocut thewiringharnessconnectingtheseat

andtheseatswitch.

Figure 3

9

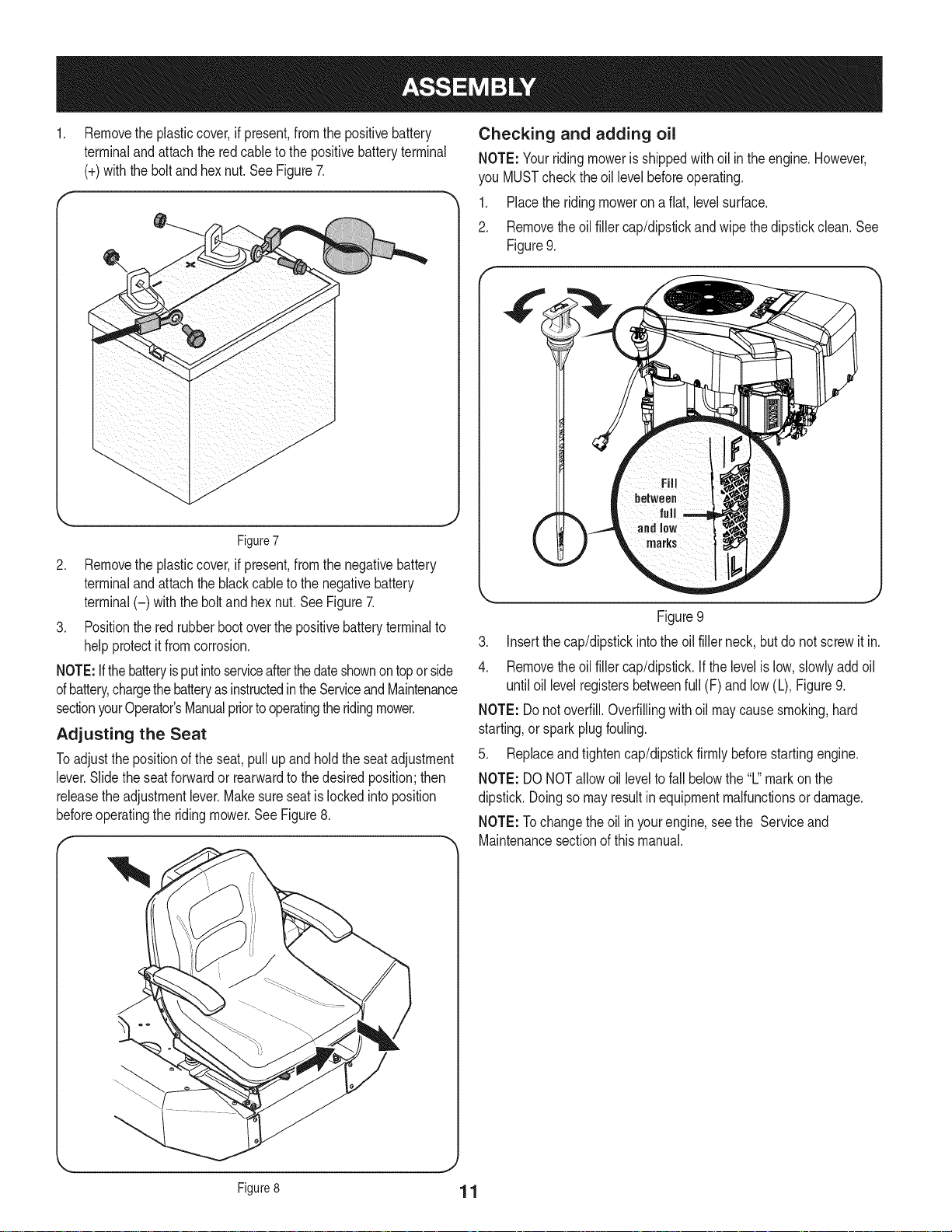

10. Installlanyardusingexistingself-tappingscrew.SeeFigure4. 2. Fromtheoutside,inserttheboltsthroughthehourglassspacers

andtheholesofthe pivotbracket.Securewith theflangelock

nuts.SeeFigure6.

Figure4

NOTE:Insertself-tappingscrewthroughholeinlanyardanddowninto

thesameholethatit was removedfrom.

Position Drive Control levers

Thedrivecontrolleversof the ridingmowerareloweredforshipping

purposes.Usingthehardwarefoundin themanualbag,the control

leversmustbe repositionedto operatethe ridingmower.To reposition

thecontrolleversfor operation,proceedasfollows:

1. Liftand swingthecontrolleversupintotheoperatingposition.

SeeFig.5.

3. Referto"AdjustingtheDriveControlLevers"intheServiceandMainte-

nancesectionforinstructionsonthefinaladjustmentofthelevers.

Connecting the Battery Cables

Batteryposts,terminals,and relatedaccessoriescontainleadand

leadcompounds,chemicalsknowntothe StateofCaliforniatocause

cancerand reproductiveharm.Washhandsafter handling.

Figure6

r

Control Lever Moved

inward and in Neutral

Figure5

Whenattachingbatterycables,alwaysconnectthePOSITIVE(Red)

wireto itsterminalfirst,followedbytheNEGATIVE(Black)wire.

Forshippingreasons,bothbatterycableson yourequipmentmay

havebeenleftdisconnectedfromthe terminalsatthefactory.To

connectthe batterycables,proceedasfollows:

NOTE:ThepositivebatteryterminalismarkedPos.(+).Thenegative

batteryterminalismarkedNeg.(-).

NOTE:If the positivebatterycableis alreadyattached,skipaheadto

step2.

J

10

Removethe plasticcover,if present,fromthe positivebattery

terminaland attachthe redcableto thepositivebatteryterminal

(+)withtheboltandhexnut.See Figure7.

Figure7

2. Removethe plasticcover,if present,fromthe negativebattery

terminaland attachtheblackcane to thenegativebattery

terminal(-) withtheboltandhexnut.SeeFigure7.

3. Positionthe redrubberbootoverthepositivebatteryterminalto

helpprotectit fromcorrosion.

NOTE:Ifthe batteryisputintoserviceafterthedateshownontoporside

ofbattery,chargethebatteryasinstructedintheServiceandMaintenance

sectionyourOperator'sManualpriortooperatingtheridingmower.

Adjusting the Seat

Toadjustthe positionofthe seat,pullup andholdthe seatadjustment

lever.Slidetheseatforwardor rearwardtothe desiredposition;then

releasetheadjustmentlever.Makesureseatis lockedintoposition

beforeoperatingtheridingmower.SeeFigure8.

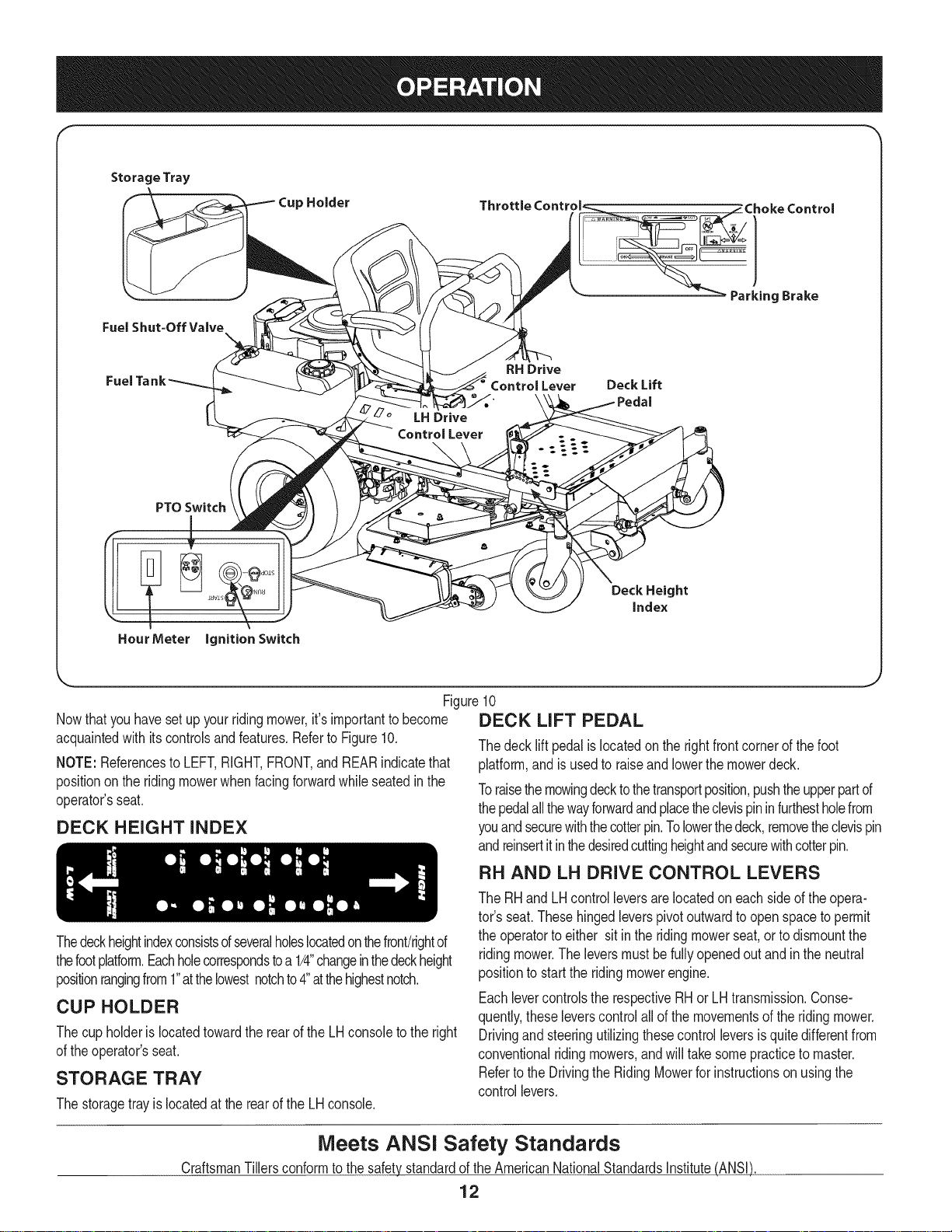

Checking and adding oil

NOTE:Yourridingmowerisshippedwithoil inthe engine.However,

youMUSTcheckthe oil levelbeforeoperating.

1. Placetheridingmoweron a flat,levelsurface.

2. Removethe oilfillercap/dipstickandwipe thedipstickclean.See

Figure9.

Figure9

3. Insertthecap/dipstickintothe oil fillerneck,butdo notscrewit in.

4. Removethe oilfillercap/dipstick.If thelevelislow,slowlyaddoil

untiloil levelregistersbetweenfull (F)andlow (L),Figure9.

NOTE:Do notoverfill.Overfillingwithoilmaycausesmoking,hard

starting,or sparkplugfouling.

5. Replaceandtightencap/dipstickfirmlybeforestartingengine.

NOTE:DO NOTallowoil levelto fall belowthe"L"markonthe

dipstick.Doingsomayresultinequipmentmalfunctionsor damage.

NOTE:Tochangetheoil inyourengine,seethe Serviceand

Maintenancesectionof thismanual.

Figure8 1 1

Storage Tray

FuelShut=Off Valve

PTOSwitch

!

Cup Holder

RH Drive

Control Lever Deck Lift

LHDrive

Control Lever

Deck Height

index

HourMeter ignition Switch

Figure10

Nowthat youhavesetup yourridingmower,it'simportanttobecome

acquaintedwith itscontrolsandfeatures.Referto Figure10.

NOTE:Referencesto LEFT,RIGHT,FRONT,andREARindicatethat

positionontheridingmowerwhenfacingforwardwhileseatedinthe

operator'sseat.

DECK HEIGHT INDEX

Thedeckheightindexconsistsofseveralholeslocatedonthefront!rightof

thefootplatform.Eachholecorrespondstoa1/4"changeinthedeckheight

positionrangingfrom1"atthelowestnotchto4"atthehighestnotch.

CUP HOLDER

Thecup holderis locatedtowardtherearofthe LHconsoleto the right

ofthe operator'sseat.

STORAGE TRAY

Thestoragetrayis locatedatthe rearofthe LHconsole.

DECK LiFT PEDAL

Thedecklift pedalislocatedon therightfrontcornerofthefoot

platform,andisusedto raiseand lowerthemowerdeck.

Toraisethemowingdecktothetransportposition,pushtheupperpartof

thepedalallthewayforwardandplacetheclevispininfurthestholefrom

youandsecurewiththecotterpin.Tolowerthedeck,removetheclevispin

andreinsertitinthedesiredcuttingheightandsecurewithcotterpin.

RH AND LH DRIVE CONTROL LEVERS

TheRHandLH controlleversarelocatedon eachsideofthe opera-

tor'sseat.Thesehingedleverspivotoutwardtoopenspacetopermit

theoperatortoeither sitin the ridingmowerseat,orto dismountthe

ridingmower.Theleversmustbefullyopenedoutand intheneutral

positionto starttheridingmowerengine.

Eachlevercontrolsthe respectiveRHorLHtransmission.Conse-

quently,theseleverscontrolallof themovementsofthe ridingmower.

Drivingand steeringutilizingthesecontrolleversisquitedifferentfrom

conventionalridingmowers,andwill takesomepracticetomaster.

Refertothe Drivingthe RidingMowerforinstructionsonusingthe

controllevers.

Meets ANSI Safety Standards

CraftsmanTillersconformtothe safetystandardofthe AmericanNationalStandardsInstitute(ANSI)

12

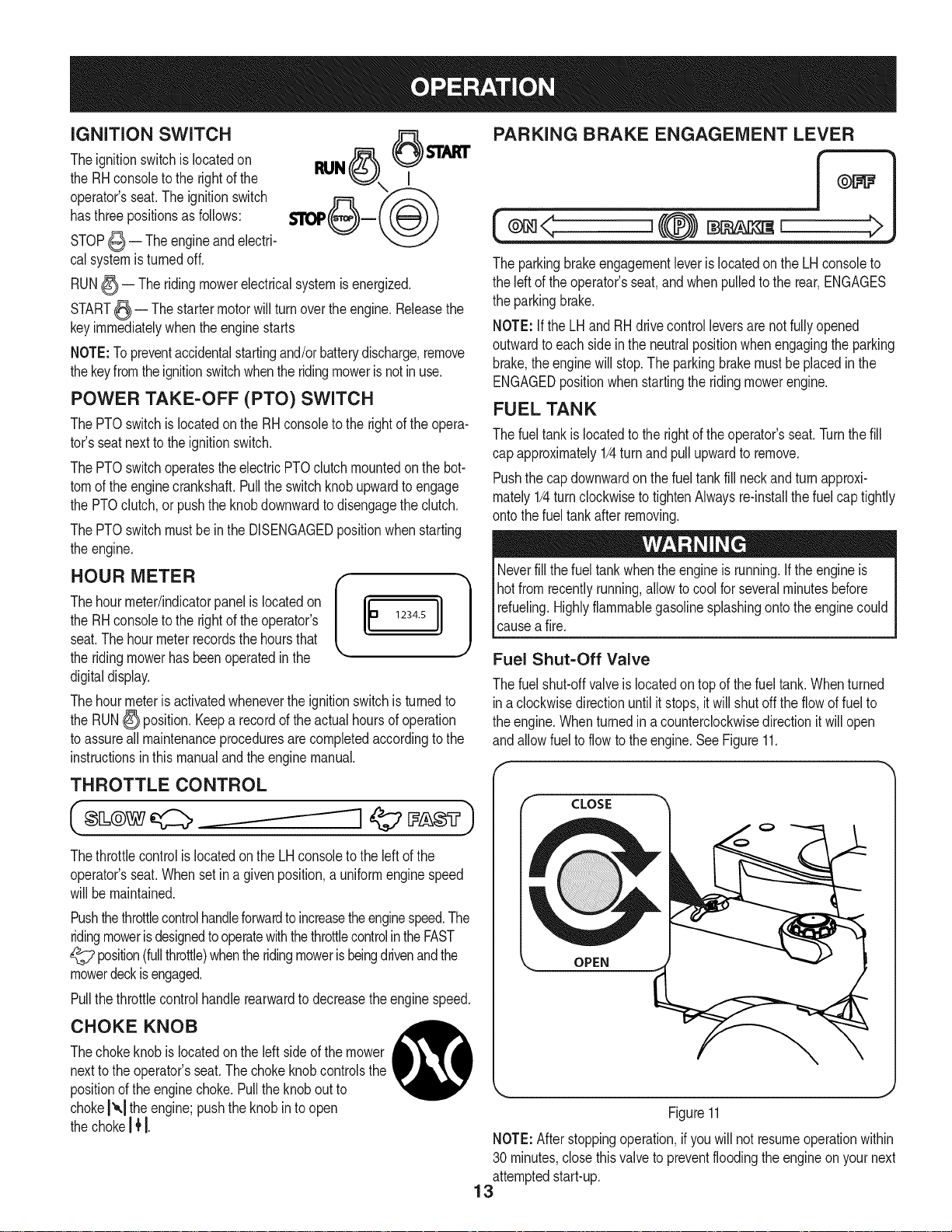

iGNiTiON SWITCH

Theignitionswitchis locatedon

theRHconsoleto therightofthe

operator'sseat.Theignitionswitch

hasthree positionsas follows:

PARKING BRAKE ENGAGEMENT LEVER

(®=< ,{@) =,, >

STOP_ -- Theengineandelectri-

calsystemisturnedoff.

RUN_-- Theridingmowerelectricalsystemisenergized.

START_ -- Thestartermotorwillturn overthe engine.Releasethe

keyimmediatelywhenthe enginestarts

NOTE:Topreventaccidentalstartingand/orbatterydischarge,remove

thekeyfromtheignitionswitchwhentheridingmowerisnotinuse.

POWER TAKE-OFF (PTO) SWITCH

ThePTOswitchislocatedonthe RHconsoletothe rightof theopera-

tot'sseatnexttotheignitionswitch.

ThePTOswitchoperatestheelectricPTOclutchmountedonthebot-

tomofthe enginecrankshaft.Pullthe switchknobupwardtoengage

thePTOclutch,or pushthe knobdownwardto disengagetheclutch.

ThePTOswitchmustbein the DISENGAGEDpositionwhenstarting

theengine.

Thehourmeter/indicatorpanelislocatedon

theRHconsoleto therightofthe operator's 1234.5

HOO.O.T.. '11

seat.The hourmeterrecordsthehoursthat

theridingmowerhas beenoperatedinthe

digitaldisplay.

Thehourmeteris activatedwhenevertheignitionswitchisturnedto

theRUN_ position.Keepa recordofthe actualhoursof operation

toassureall maintenanceproceduresarecompletedaccordingto the

instructionsin thismanualandtheenginemanual.

THROTTLE CONTROL

Theparkingbrakeengagementleverislocatedon the LHconsoleto

theleftof theoperator'sseat,andwhenpulledto the rear,ENGAGES

theparkingbrake.

NOTE:if theLHand RHdrivecontrolleversarenotfullyopened

outwardtoeach sideinthe neutralpositionwhenengagingtheparking

brake,theenginewill stop.Theparkingbrakemustbeplacedin the

ENGAGEDpositionwhenstartingtheridingmowerengine.

FUEL TANK

Thefueltankis locatedto therightofthe operator'sseat.Turnthefill

capapproximately1/4turnandpullupwardto remove.

Pushthecapdownwardon the fueltankfill neckandturnapproxi-

mately1/4turnclockwisetotightenAlwaysre-instalthefuel captightly

ontothefueltankafterremoving.

Neverfillthe fueltankwhentheengineis running,iftheengineis

hotfromrecentlyrunning,allowtocool forseveralminutesbefore

refueling.Highlyflammablegasolinesplashingontotheenginecould

_causea f re.

Fuel Shut=Off Valve

Thefuelshut-offvalveislocatedontop ofthe fueltank.Whenturned

ina clockwisedirectionuntilitstops,itwillshutoffthe flowoffuel to

theengine.Whenturnedinacounterclockwisedirectionitwillopen

andallowfuel toflowto theengine.SeeFigure11.

CLOSE

Thethrottlecontrolis locatedonthe LHconsoleto theleftof the

operator'sseat.Whensetina givenposition,a uniformenginespeed

willbemaintained.

Pushthethrottlecontrolhandleforwardto increasetheenginespeed.The

ridingmowerisdesignedtooperatewiththethrottlecontrolintheFAST

_;? position(fullthrottle)whentheridingmowerisbeingdrivenandthe

mowerdeckisengaged.

Pullthethrottlecontrolhandlerearwardto decreasetheenginespeed.

CHOKE KNOB

Thechokeknobislocatedonthe left sideof themower

nexttothe operator'sseat.Thechokeknobcontrolsthe

positionofthe enginechoke.Pullthe knobout to

chokeI'_,1theengine;pushtheknobintoopen

thechokeI JtI.

OPEN

Figure11

NOTE:Afterstoppingoperation,ifyouwill notresumeoperationwithin

30 minutes,closethisvalveto preventfloodingtheengineonyour next

attemptedstart-up.

13

SEAT ADJUSTMENT LEVER (NOT SHOWN)

Theseatadjustmentleverislocatedbelowthefront/leftof the seat.

Theleverallowsforadjustmentoftheforetoaft positionof the

operator'sseat.RefertotheServiceandMaintenancesectionfor

instructionsonadjustingthe seatposition.

TRANSMISSION BYPASS RODS (NOT SHOWN)

Thetransmissionbypassrods(oneforeachtheRHandLH transmis-

sion)are locatedbeneaththeframeplatform,just insideeachrear

wheel.SeeFigure1on page9.

Whenengaged,thetwo rodsopena bypasswithinthe hydrostatic

transmissions,whichallowsthe ridingmowertobe pushedshort

distancesbyhand. Refertothe Assembly sectionforinstructionson

usingthe bypassfeature.

Nevertowyourridingmower.Towingtheridingmowerwiththe rear

wheelsonthegroundmaycauseseveredamagetothetransmissions.

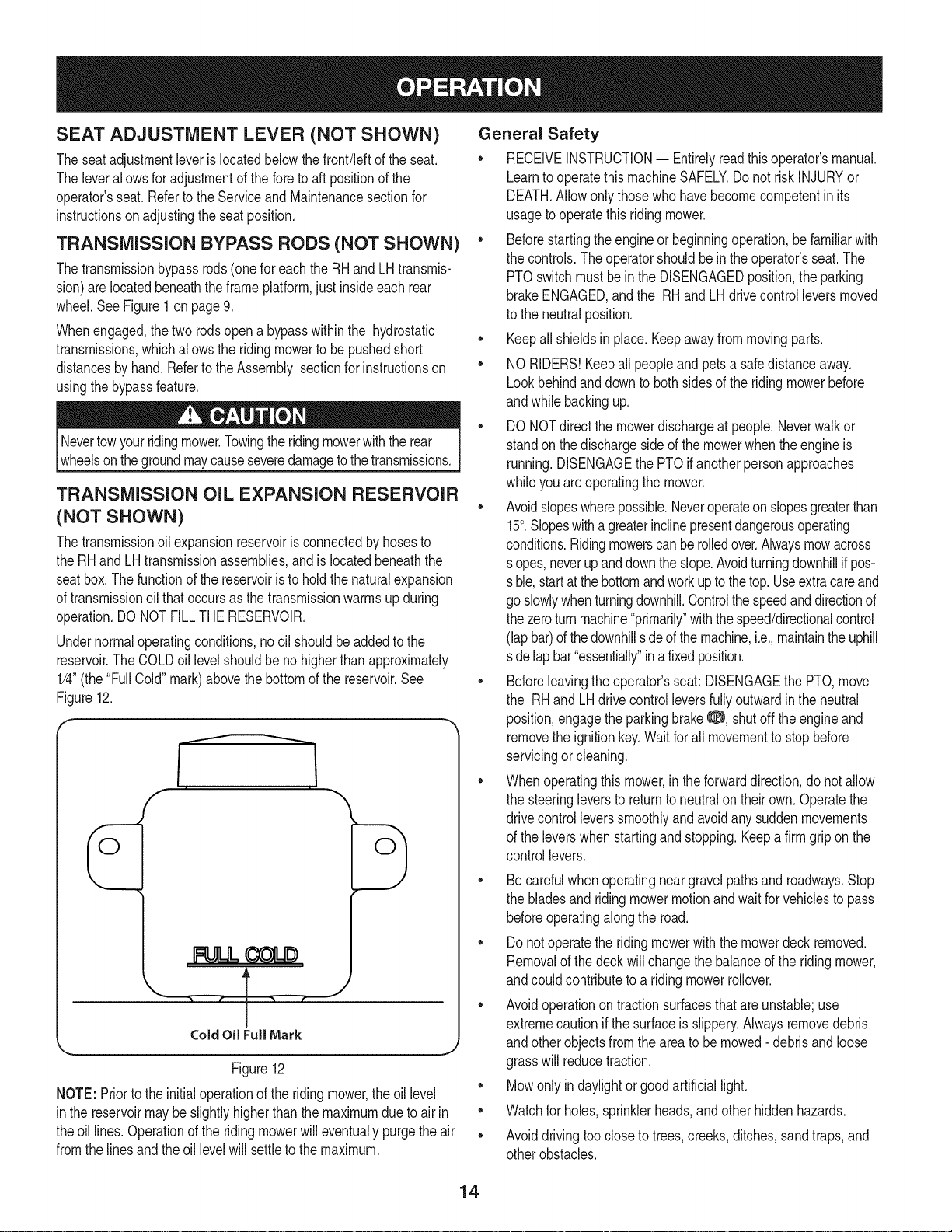

TRANSMISSION OIL EXPANSION RESERVOIR

(NOT SHOWN)

Thetransmissionoil expansionreservoirisconnectedbyhosesto

theRHandLHtransmissionassemblies,and islocatedbeneaththe

seatbox.Thefunctionofthe reservoiristoholdthenaturalexpansion

oftransmissionoilthatoccursas thetransmissionwarmsupduring

operation.DONOTFILLTHE RESERVOIR.

Undernormaloperatingconditions,nooil shouldbeaddedtothe

reservoir.The COLDoil levelshouldbe nohigherthanapproximately

1/4"(the"FullCold"mark)abovethebottomofthe reservoir.See

Figure12.

' • ..... • 3 ..... f

ColdOilFull Mark

Figure12

NOTE:Priorto theinitialoperationoftheridingmower,theoil level

inthe reservoirmaybeslightlyhigherthanthe maximumduetoair in

theoil lines.Operationofthe ridingmowerwilleventuallypurgetheair

fromthelines andtheoil levelwillsettletothe maximum.

General Safety

• RECEIVEINSTRUCTION-- Entirelyreadthisoperator'smanual.

Learnto operatethismachineSAFELY.Do notriskINJURYor

DEATH.Allowonlythosewhohavebecomecompetentin its

usageto operatethisridingmower.

• Beforestartingtheengineorbeginningoperation,befamiliarwith

thecontrols.Theoperatorshouldbein theoperator'sseat.The

PTOswitchmustbein theDISENGAGEDposition,theparking

brakeENGAGED,andthe RHand LHdrivecontrolleversmoved

tothe neutralposition.

• Keepallshieldsin place.Keepawayfrommovingparts.

• NORIDERS!Keepall peopleandpetsa safedistanceaway.

Lookbehindanddowntobothsidesoftheridingmowerbefore

andwhilebackingup.

• DONOTdirectthemowerdischargeatpeople.Neverwalkor

standonthedischargesideofthe mowerwhentheengineis

running.DISENGAGEthePTOifanotherpersonapproaches

whileyou areoperatingthemower.

• Avoidslopeswherepossible.Neveroperateonslopesgreaterthan

15°.Slopeswitha greaterinclinepresentdangerousoperating

conditions.Ridingmowerscanberolledover.Alwaysmowacross

slopes,neverupanddowntheslope.Avoidturningdownhillif pos-

sible,startat thebottomandworkuptothetop.Useextracareand

go slowlywhenturningdownhill.Controlthespeedanddirectionof

thezeroturnmachine"primarily"withthespeed/directionalcontrol

(lapbar)ofthedownhillsideofthemachine,i.e.,maintaintheuphill

sidelapbar"essentially"in afixedposition.

• Beforeleavingtheoperator'sseat:DISENGAGEthePTO,move

the RHand LHdrivecontrolleversfullyoutwardinthe neutral

position,engagetheparkingbrake0, shutoff the engineand

removetheignitionkey.Waitfor all movementto stopbefore

servicingorcleaning.

• Whenoperatingthismower,inthe forwarddirection,donotallow

thesteeringleversto returnto neutralontheirown.Operatethe

drivecontrolleverssmoothlyandavoidanysuddenmovements

ofthe leverswhenstartingandstopping.Keepafirmgripon the

controllevers.

• Becarefulwhenoperatingneargravelpathsandroadways.Stop

thebladesandridingmowermotionandwaitforvehiclesto pass

beforeoperatingalongtheroad.

• Donotoperatetheridingmowerwiththemowerdeckremoved.

Removalof thedeckwillchangethe balanced theridingmower,

andcouldcontributetoa ridingmowerrollover.

Avoidoperationontractionsurfacesthatare unstable;use

extremecautionif thesurfaceis slippery.Alwaysremovedebris

andotherobjectsfromtheareato bemowed- debrisandloose

grasswillreducetraction.

• Mowonlyindaylightorgoodartificiallight.

• Watchfor holes,sprinklerheads,andotherhiddenhazards.

• Avoiddrivingtoocloseto trees,creeks,ditches,sandtraps,and

otherobstacles.

14

• Slowdownbeforeturningandcometoa completestopbefore

anyzeroturnmaneuver.

• If youhit a solidobjectwhilemowing,DISENGAGEthePTO,

placethe steeringleversintheneutral,opened-outposition,

movethethrottleto slowq?::>,settheparkingbrake8, shutoff

theengine,andtakethekeyfromthe ignitionswitch.Inspectfor

damage.Repairthedamage.Makesurethe bladesarein good

conditionandthatthebladeboltsare tightbeforerestartingthe

engine.

• Donot stoptheridingmowerorparktheridingmowerover

combustiblematerialssuchas drygrass,leaves,debris,etc.

• Keepthemowerandespeciallytheengineandhydrauliccompo-

nentscleanandfree ofgrease,grass,and leavesto reducethe

chanceoffire andpermitpropercooling.

• Donotfillthe fueltankwhen theengineis runningorwhilethe

engineishot.Allowtheengineseveralminutestocool before

refueling.Tightenthefuelcapsecurely.

BEFORE OPERATING YOUR RIDING MOWER

1. Beforeyouoperatetheridingmower,studythismanualcarefully

tofamiliarizeyourselfwiththe operationofalltheinstrumentsand

controls.Ithasbeenpreparedtohelpyouoperateandmaintain

yourridingmowerefficiently.

2. Fillthefueltankwithonlyclean,fresh,unleadedgasolinewitha

pumpstickeroctaneratingof87or higher.Whenthe fuelreaches

oneinchfromthe topof thetank,stop.DO NOTOVERFILL.

Spacemustbeleftforexpansion.

3. Checktheengineoil level.Pullouttheoildipstick,wipeitoffand

reinsertit. Pullitout againand readtheoillevel.Ifit is belowthe

operatingrange,addoil throughthefilltube usingafunnelto

bringitupto thetop ofthe operatingrange.

4. Checkthetireinflationpressures-8-10psifor thereartires,

20-25psifronttires.

NOTE:Newtiresareoverinflatedinordertoproperlyseatthebeadto

therim.

5. Checkthatall nuts,boltsandscrewsaretight.

6. Checkthetensionofthe deckdrivebeltsas instructedin the

ServiceandMaintenancesection.

7. Checkif deckislevel.Whencorrectlyadjustedthemowerdeck

shouldbelevelsideto side,andthefrontof thedeckshouldbe

approximately1/4"lowerthantherearofdeck.Ifdeckneedstobe

leveled,refertotheServiceand Maintenancesection.

8. Lubricateall pivotpointslistedin theServiceandMaintenance

section.

9. Adjusttheseatforoperator'smaximumcomfort,visibilityandfor

maintainingcompletecontrolofthe ridingmower.

SAFETY INTERLOCK SYSTEM

• This ridingmowerisequippedwitha safetyinterlocksystemfor

theprotectionofthe operator.Iftheinterlocksystemshouldever

malfunction,do not operatetheridingmower.Call1-800-659-

5917toscheduleservicefromSearsParts& Repair.

• Thesafetyinterlocksystempreventstheenginefromcranking

or startingunlessthe RHandLH drivecontrolleversaremoved

fullyoutwardtoeachsideinthe neutralposition,theparking

brakeis ENGAGED,andthe PTOis DISENGAGED.

• Toavoidsuddenmovementwhendisengagingtheparkingbrake,

thesafetyinterlocksystemwillshutoff theengineif the RHand/

or LHdrivecontrolleversaremovedtoa positionotherthan

thefullyout inthe neutralpositionwhenthe parkingbrakeis

engaged.

• Thesafetyinterlocksystemwillshutoff theengineif theoperator

leavestheseatbeforeengagingtheparkingbrake.

• Thesafetyinterlocksystemwillshutoff theengineif theoperator

leavestheseatwiththe PTOengaged,regardlessofwhetherthe

parkingbrakeisengaged.

NOTE:The PTOswitchmustbemovedtothe DISENGAGEDposition

to restarttheengine.

• Thesafetyinterlocksystemwillshutoff thePTOandthemower

bladeswillstopifbothdrivecontrolleversaremovedintothe

reverseposition.ThePTOwill re-engagewhenoneorbothof the

leversare movedbacktoeithertheneutralor forwardposition.

15

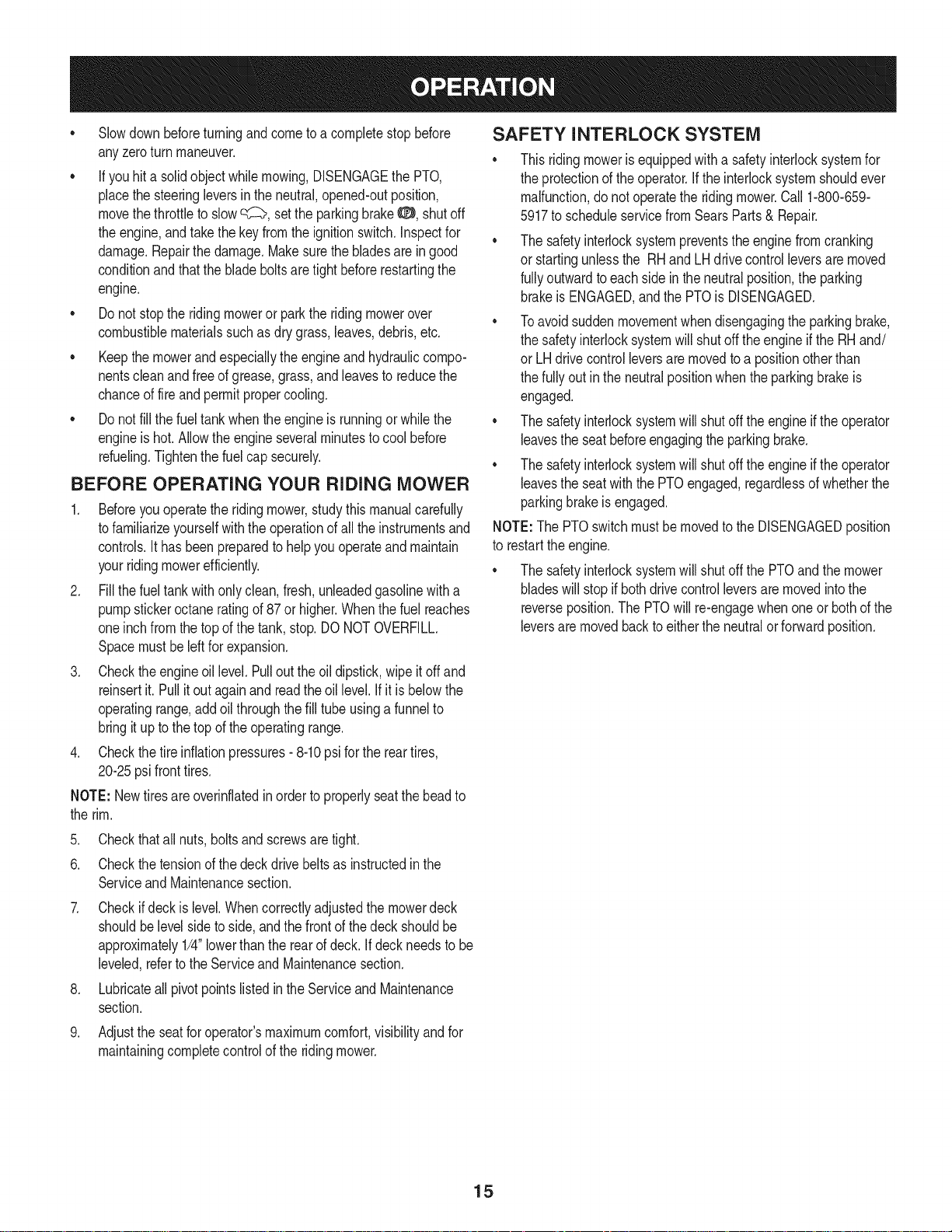

STARTING THE ENGINE

Thisridingmowerisequippedwitha safetyinterlocksystem

designedfortheprotectionofthe operator.Donotoperatetheriding

mowerifany partof theinterlocksystemis malfunctioning.Periodi-

_cay checkthefunctonsofthe nterocksystemforproperoperaton.

Forpersonalsafety,theoperatormustbe sittinginthe ridingmower

seatwhenstartingtheengine.

.

Openthefuel shut-offvalve.

2.

Operatormustbesittingin the tractorseatwith bothdrivecontrol

leversfullyoutwardto eachsideinthe neutral/startposition.See

Figure13.

LHControlLever

Outin !eutral

Parking Break

Engaged

RHControl Lever

Out in Neutral

7. Turnthe ignitionkeyclockwisetotheSTART_ positionand

releaseitassoonasthe enginestarts;however,do notcrankthe

enginecontinuouslyformorethan 10secondsata time. Ifthe

enginedoesnot startwithinthis time,turnthe keytoSTOP

andwaitatleast30 secondstoallowtheengine'sstartermotor

tocool.Tryagainafterwaiting.Ifaftera fewattemptstheengine

failsto start,do not keeptryingto startitwiththe chokeclosedas

this willcausefloodingandmakestartingmoredifficult.

8. Oncetheenginewarmsup, pushthechokeknobdownintothe

OFFI{ !position.

Cold Weather Starting

Whenstartingtheengineat temperaturesnearor belowfreezing,

ensurethecorrectviscositymotoroil is usedinthe engineandthe

batteryis fullycharged.Starttheengineas follows:

1. Besurethe batteryisingoodcondition.Also,awarmbatteryhas

muchmorestartingcapacitythana coldbattery.

2. Usefreshwintergradefuel.Wintergradegasolinehashigher

volatilitytoimprovestarting.Do notuse gasolineleftoverfrom

summer.

3. Followthepreviousinstructionfor Startingthe Engine.

Using Jumper Cables To Start Engine

CHOKE Position

Figure13

3. EngagetheparkingbrakeO.

4. MakecertainthePTOswitchisinthe DISENGAGED(down)

position.

5. Pullthechokeknobup intotheCHOKE!'_.1position.

NOTE:Ifthe engineiswarmedup, itmaynotbe necessarytochoke

theengine.

6. Pushthe throttlecontroltothe FAST_ (full throttle)position.

Batteriescontainsulfuricacidandproduceexplosivegasses.Make

certaintheareais wellventilated,wearglovesandeyeprotection,

land avod sparksorfamesnearthe battery.

Ifthe batterychargeisnotsufficientto cranktheengine,rechargethe

battery.If a batterychargeris unavailableandtheridingmowermust

be started,theaidof a boosterbatterywillbe necessary.Connectthe

boosterbatteryas follows:

1. Connecttheendof one cableto thedisabledridingmowerbat-

J

tery'spositiveterminal;thenconnecttheotherendof thatcableto

theboosterbattery'spositiveterminal.

2. Connectoneendof the othercabletothe boosterbattery's

negativeterminal;thenconnecttheotherendofthatcableto

the frameofthe disabledridingmower,asfar fromthebatteryas

possible.

3. Startthedisabledridingmowerfollowingthenormalstarting

instructionspreviouslyprovided;thendisconnectthejumper

cablesintheexactreverseorderoftheirconnection.

4. Havetheridingmower'selectricalsystemcheckedandrepaired

assoonas possibletoeliminatethe needforjumpstarting.

16

Stopping the Engine

1. PushthePTOswitchdownintotheDISENGAGEDposition.

2. MovetheRHandLH drivecontrolleversoutwardtotheneutral

position.

3. EngagetheparkingbrakeO.

4. MovethethrottlecontroltomidwaybetweentheSLOW_ and

FAST_ positions.

5. Turntheignitionkeyto the STOP6 positionand removethekey

fromtheignitionswitch.

NOTE:Alwaysremovethekeyfromthe ignitionswitchto preventacci-

dentalstartingor batterydischargeiftheequipmentis Idt unattended.

PRACTICE OPERATION (INITIAL USE)

Operatinga zero-turnridingmoweris notlikeoperatinga conventional

typeridingmower.Becausea zeroturnridingmowerismoremaneuver-

able,gettingusedtooperatingthecontrolleverstakessomepractice.

Westronglyrecommendthatyou locatea reasonablylarge,leveland

open"practicearea"wheretherearenoobstructions,pedestrians,or

animals.Youshouldpracticeoperatingtheridingmowerfora minimum

of30 minutes.

Carefullymove-- or haveanexperiencedusermove-- theriding

mowertothe practicearea.Whenperformingthepracticesession,

thePTOshouldnotbeengaged.Whilepracticing,operatetheriding

moweratapproximately1/2to3/4throttleandat lessthanfull speedin

bothforwardandreverse.

Useprotectiveequipmentforeyes,hands,hearing,feet,legs,head

andotherareasofthe bodyif needed-- safetyeyeglasses,gloves,

earplugs,boots,hats,etc.

HearingProtectionisrequiredforalloperatorexposureexceeding

two(2) hours.

Carefullypracticemaneuveringtheridingmowerusingtheinstructions

in thefollowingsection"DrivingtheRidingmower."Practiceuntilyou

areconfidentthatyoucansafelyoperatetheridingmower.

DRIVING THE RIDING MOWER

Avoidsuddenstarts,excessivespeedandsuddenstops.

1. Adjusttheoperator'sseattothemostcomfortablepositionthat

allowsyouto operatethecontrols.Seeseatadjustmentinthe

Assemblysection.

2. ReleasetheparkingbrakeO.

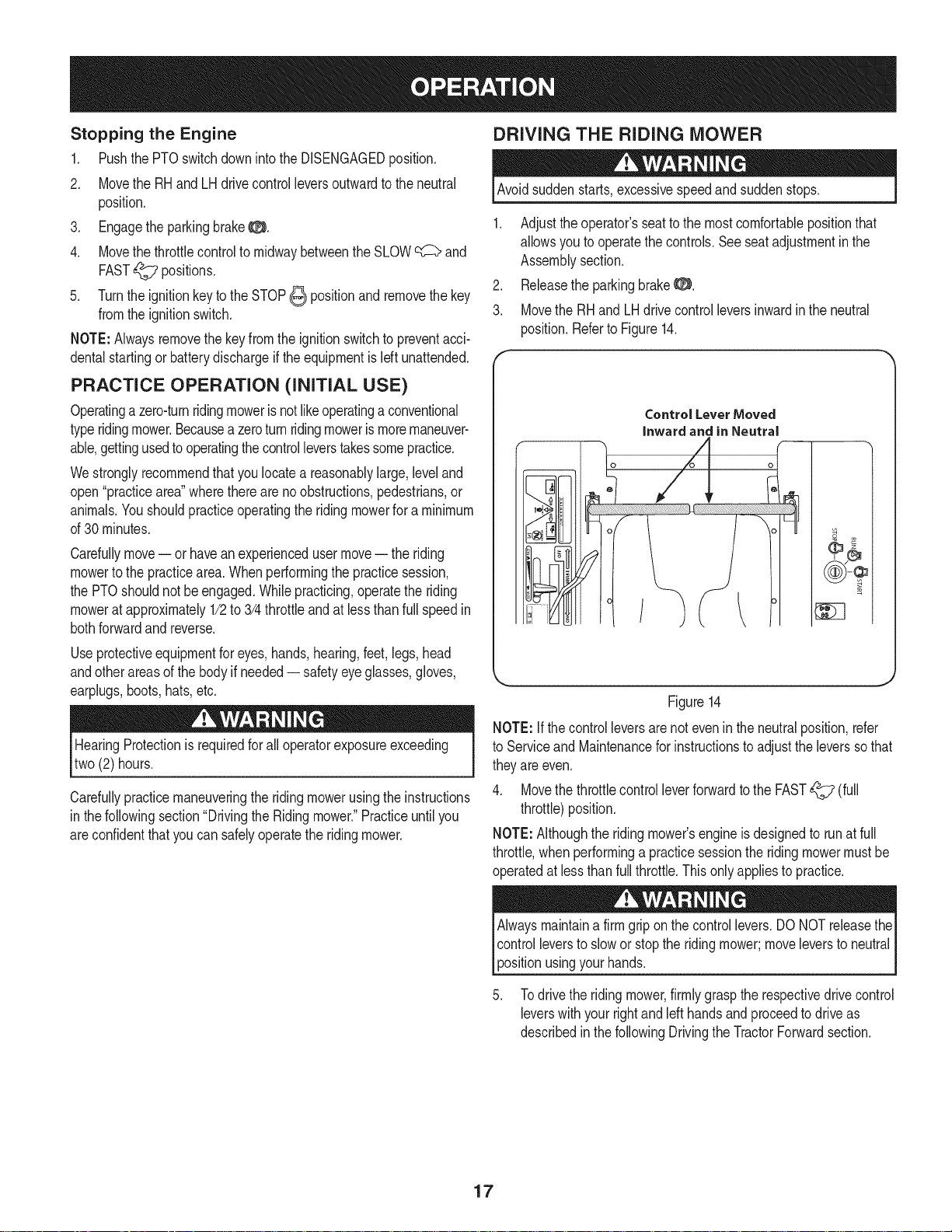

3. Movethe RHand LHdrivecontrolleversinwardin theneutral

position.RefertoFigure14.

ControlLeverMoved

inwardand in Neutral

o

/

Figure14

NOTE:If thecontrolleversarenotevenin theneutralposition,refer

to ServiceandMaintenanceforinstructionstoadjustthe leverssothat

theyareeven.

4. Movethethrottlecontrolleverforwardto theFAST_ (full

throttle)position.

NOTE:Althoughtheridingmower'sengineisdesignedto runatfull

throttle,whenperformingapracticesessiontheridingmowermustbe

operatedatlessthanfullthrottle.Thisonlyappliestopractice.

17

usingyourhands.

Todrive theridingmower,firmlygrasptherespectivedrive control

leverswithyourrightandleft handsandproceedtodriveas

describedinthefollowingDrivingtheTractorForwardsection.

Driving the Riding Mower Forward

Turning the Riding mower While Driving Forward

Keepall movementofthe drivecontrolleversslowandsmooth.

Abruptmovementof thecontrolleverscan affectthestabilityof the

ridingmowerandcouldcausethe ridingmowertoflipover,which

mayresultin seriousinjuryordeathtothe operator.

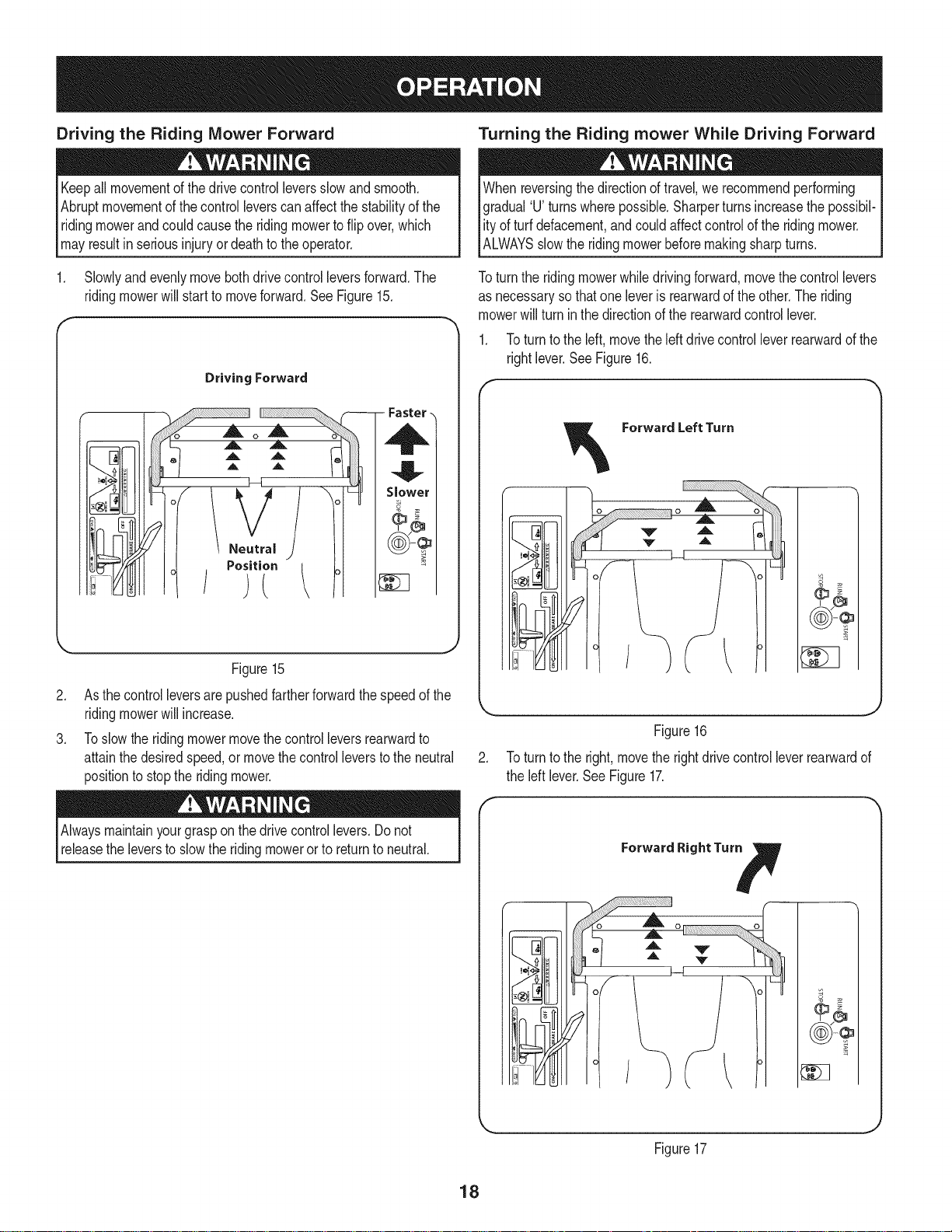

1. Slowlyandevenlymovebothdrivecontrolleversforward.The

ridingmowerwillstart tomoveforward.SeeFigure15.

Driving Forward

- Faster -

o

_. ,A A _'-_/

_,t ,,L A t,,I I I

t A ,,, h

S, w:r

¢

J/A

\ Neutral ) 1

/.o?,.,i°i ,

Whenreversingthe directionoftravel,werecommendperforming

gradual'U turnswherepossible.Sharperturnsincreasethepossibil-

ity ofturfdefacement,andcouldaffectcontrolof the ridingmower.

IALWAYSsow therdngmowerbeforemakng sharpturns.

Toturn theridingmowerwhiledrivingforward,movethecontrollevers

asnecessaryso thatone leveris rearwardoftheother.The riding

mowerwillturn inthedirectionof therearwardcontrollever.

1. Toturnto theleft, movetheleftdrivecontrolleverrearwardofthe

rightlever.SeeFigure16.

Forward Left Turn

o

Figure15

.

Asthecontrolleversarepushedfartherforwardthespeedofthe

ridingmowerwillincrease.

.

Toslowthe ridingmowermovethecontrolleversrearwardto

attainthedesiredspeed,ormovethecontrolleverstothe neutral

positiontostopthe ridingmower.

Alwaysmaintainyourgraspon the drivecontrollevers.Donot

releasetheleverstoslowthe ridingmowerorto returnto neutral.

Figure16

.

Toturn tothe right,movetherightdrivecontrolleverrearwardof

theleft lever.SeeFigure17.

Forward Right Tur_

0 '

J

_ J

Figure17

18

NOTE:The greaterthefore-to-aftdistancebetweenthetwolevers,the

sharpertheridingmowerwillturn.

3. Toexecutea "zeroturn,"movetheturnsidedrivecontrolleverto

theneutralposition,whilemovingtheothercontrolleverforward.

NOTE:Makinga"zeroturn"on grasswillgreatlyincreasethepotential

fordefacementof theturf.

Driving the Riding mower in Reverse

Turning While Driving Rearward

Toturn theridingmowerwhiledrivingrearward,movethe control

leversas necessarysothatoneleverisforwardofthe other.Theriding

mowerwillturn inthedirectionoftheforwardcontrollever.

1. Toturnto theleftwhiletravelingin reverse,movetheleftdrive

controlleverforwardoftheright lever.See Figure19.

Alwayslookbehindanddownonbothsidesoftheridingmowerbefore

backingup.Alwayslookbehindwhiletravelinginthereversedirection.

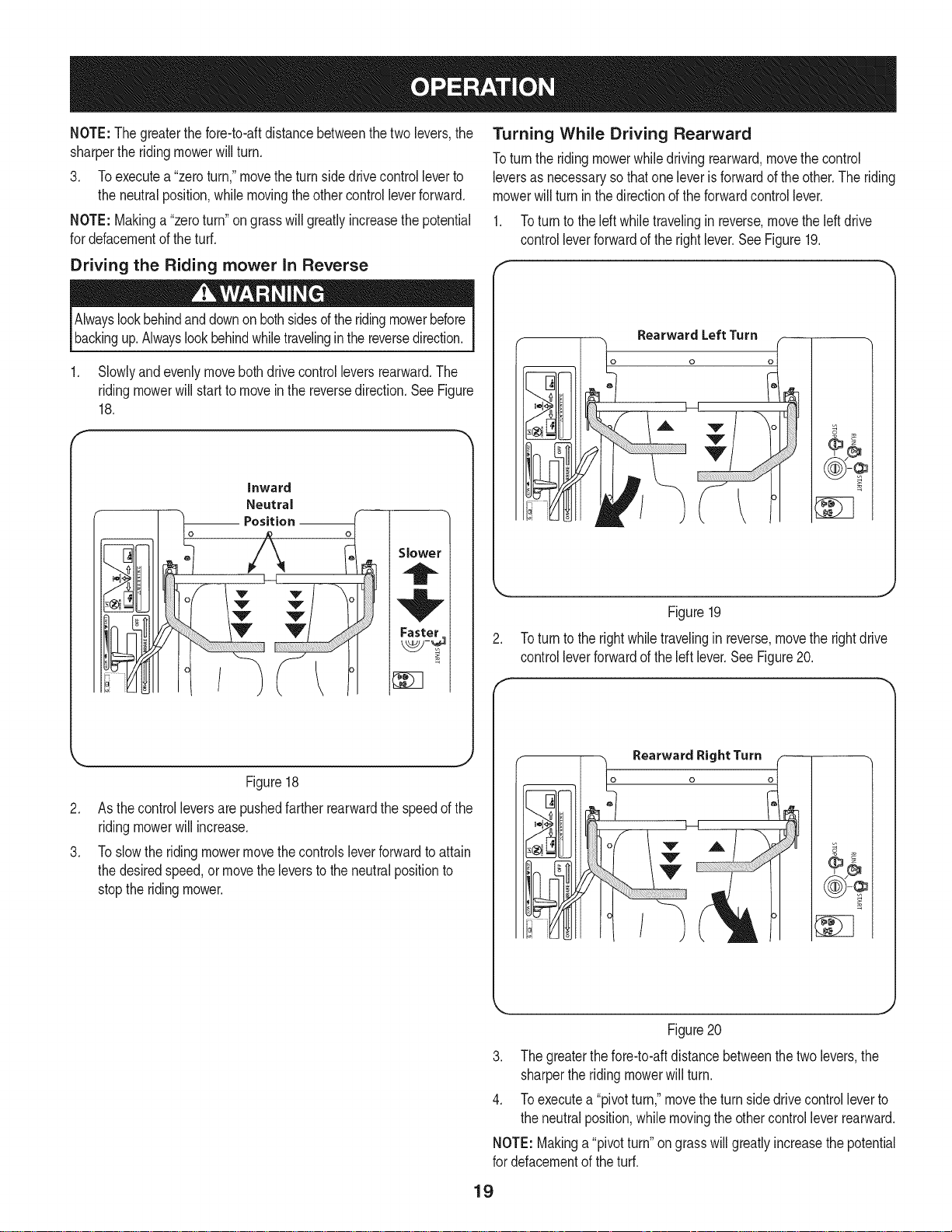

1. Slowlyandevenlymovebothdrive controlleversrearward.The

ridingmowerwillstartto movein the reversedirection.SeeFigure

18.

inward

o

Neutral

_ Position o_

Slower

Faster

RearwardLeftTurn

o

Figure19

2. Toturntothe rightwhiletravelingin reverse,movetherightdrive

controlleverforwardoftheleft lever.SeeFigure20.

Figure18

.

Asthecontrolleversarepushedfartherrearwardthespeedofthe

ridingmowerwillincrease.

.

Toslowthe ridingmowermovethecontrolsleverforwardto attain

thedesiredspeed,or movetheleversto theneutralpositionto

stoptheridingmower.

m

II ,.-,'qII

J

Figure20

3. Thegreaterthefore-to-aftdistancebetweenthetwolevers,the

sharpertheridingmowerwillturn.

4. Toexecutea "pivotturn,"movetheturnsidedrivecontrolleverto

theneutralposition,whilemovingtheothercontrolleverrearward.

NOTE:Makinga"pivotturn"on grasswill greatlyincreasethe potential

fordefacementof theturf.

19

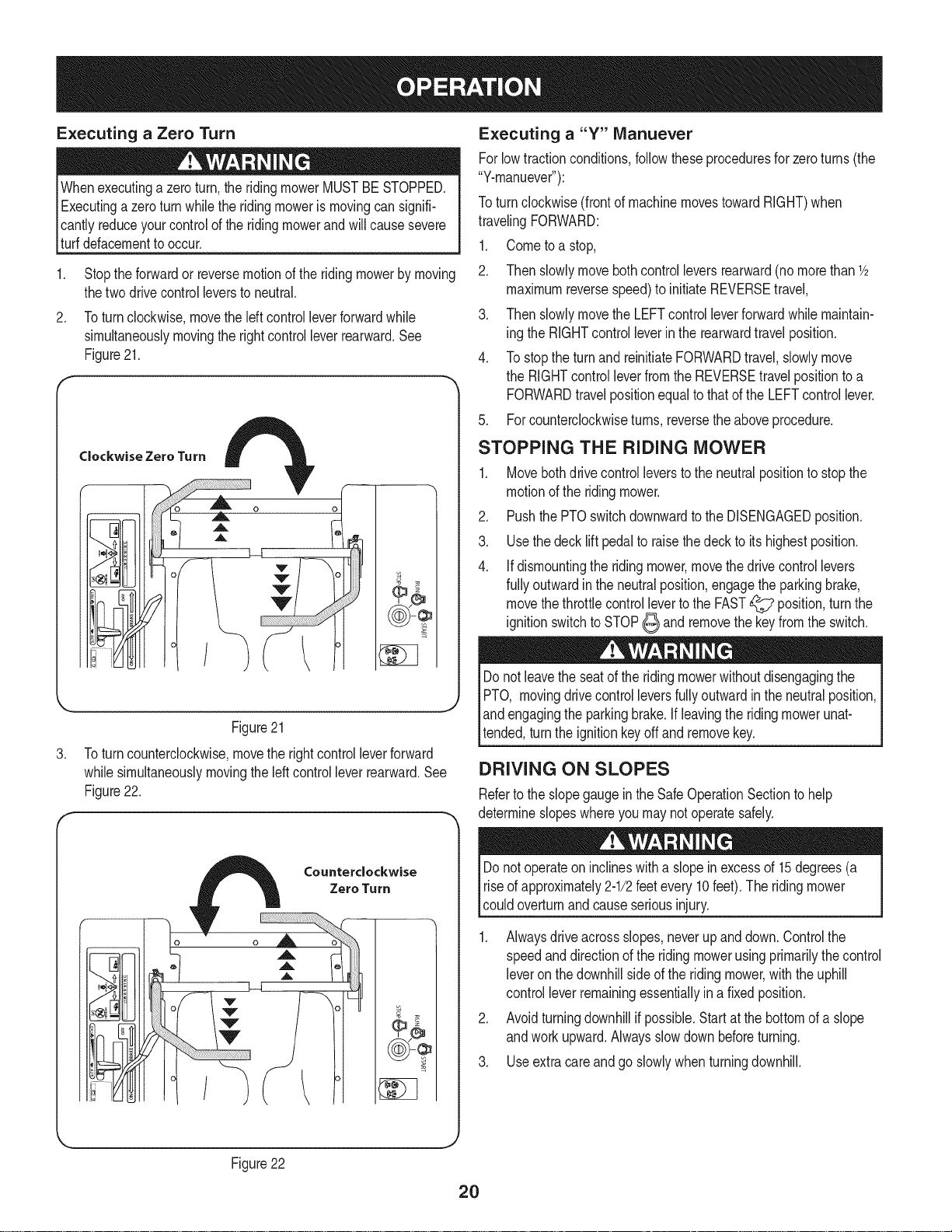

Executing a Zero Turn

Whenexecutinga zeroturn,the ridingmowerMUSTBESTOPPED.

Executinga zeroturnwhiletheridingmoweris movingcansignifi-

Icantlyreduceyourcontrolofthe ridingmowerandwillcausesevere

[turfdefacementto occur.

1. Stopthe forwardor reversemotionoftheridingmowerbymoving

thetwo drivecontrolleverstoneutral.

2. Toturnclockwise,movetheleftcontrolleverforwardwhile

simultaneouslymovingthe rightcontrolleverrearward.See

Figure21.

Clockwise Zero Turn

Executing a "Y" Manuever

Forlowtractionconditions,followtheseproceduresfor zeroturns(the

"Y-manuever"):

Toturn clockwise(frontof machinemovestowardRIGHT)when

travelingFORWARD:

1. Cometoa stop,

2. Thenslowlymovebothcontrolleversrearward(nomorethan 1/2

maximumreversespeed)to initiateREVERSEtravel,

3. Thenslowlymovethe LEFTcontrolleverforwardwhilemaintain-

ingthe RIGHTcontrolleverinthe rearwardtravelposition.

4. TostoptheturnandreinitiateFORWARDtravel,slowlymove

the RIGHTcontrolleverfromtheREVERSEtravelpositionto a

FORWARDtravelpositionequalto thatofthe LEFTcontrollever.

5. Forcounterclockwiseturns, reversetheaboveprocedure.

STOPPING THE RIDING MOWER

1. Movebothdrivecontrolleverstothe neutralpositionto stopthe

motionofthe ridingmower.

2. PushthePTOswitchdownwardtotheDISENGAGEDposition.

3. Usethedecklift pedalto raisethedecktoitshighestposition.

4. Ifdismountingthe ridingmower,movethe drivecontrollevers

fullyoutwardin theneutralposition,engagetheparkingbrake,

movethethrottlecontrolleverto theFAST_ position,turnthe

ignitionswitchtoSTOP_ and removethekeyfromtheswitch.

Figure21

.

Toturncounterclockwise,movethe rightcontrolleverforward

whilesimultaneouslymovingtheleftcontrolleverrearward.See

Figure22.

Counterclockwise

Zero Turn

o

_uL

I 1 _'-III

((¢))-@

/

Donot leavetheseatofthe ridingmowerwithoutdisengagingthe

PTO, movingdrivecontrolleversfullyoutwardinthe neutralposition,

land engagingthe parkingbrake.Ifleavingtheridingmowerunat-

ltended,turnthe ignitionkeyoffand removekey.

DRIVING ON SLOPES

Refertothe slopegaugeinthe SafeOperationSectiontohelp

determineslopeswhereyou maynotoperatesafely.

Donot operateoninclineswitha slope inexcessof 15degrees(a

riseof approximately2-1/2feetevery 10feet).Theridingmower

couldoverturnandcauseseriousinjury.

1. Alwaysdriveacrossslopes,neverup anddown.Controlthe

speedanddirectionof theridingmowerusingprimarilythecontrol

leveron thedownhillsideofthe ridingmower,withthe uphill

controlleverremainingessentiallyina fixedposition.

2. Avoidturningdownhillif possible.Startatthebottomofa slope

andworkupward.Alwaysslowdown beforeturning.

3. Useextracareandgo slowlywhenturningdownhill.

Figure22

2O

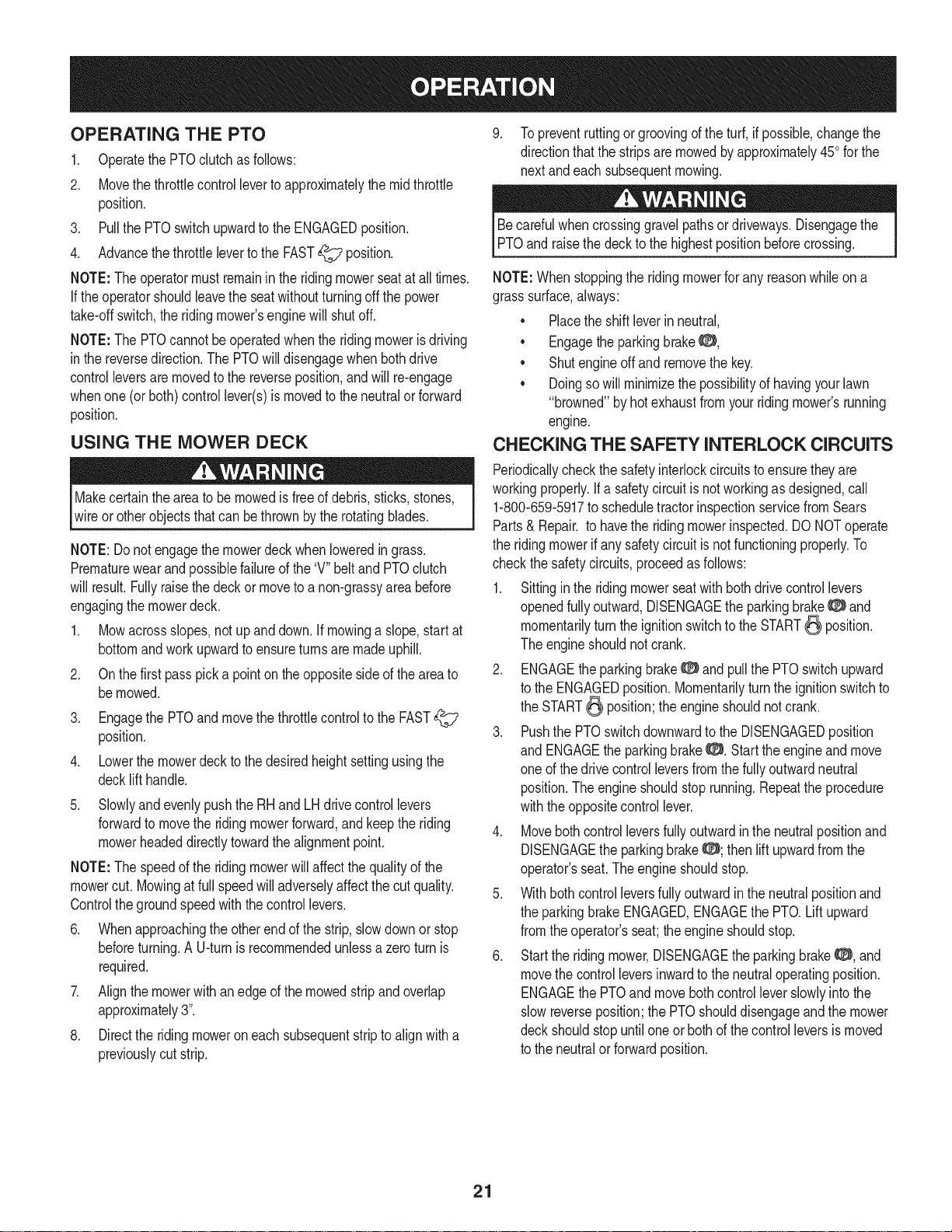

OPERATING THE PTO

1. OperatethePTOclutchasfollows:

2. Movethethrottlecontrolleverto approximatelythemidthrottle

position.

3. PullthePTOswitchupwardtotheENGAGEDposition.

4. Advancethethrottleleverto theFAST_ position.

NOTE:The operatormustremaininthe ridingmowerseatatall times.

If theoperatorshouldleavetheseatwithoutturningoffthe power

take-offswitch,the ridingmower'senginewill shutoff.

NOTE:The PTOcannotbeoperatedwhenthe ridingmowerisdriving

in thereversedirection.ThePTOwilldisengagewhenbothdrive

controlleversaremovedtothe reverseposition,and will re-engage

whenone(or both)controllever(s)ismovedto theneutralor forward

position.

USING THE MOWER DECK

Makecertaintheareato be mowedisfree ofdebris,sticks,stones,

wireor otherobjectsthatcan bethrownbythe rotatingblades.

NOTE:Do notengagethe mowerdeckwhenloweredingrass.

Prematurewearandpossiblefailureofthe 'V" beltandPTOclutch

willresult.Fullyraisethe deckor moveto anon-grassyareabefore

engagingthemowerdeck.

1. Mowacrossslopes,notup anddown.Ifmowinga slope,startat

bottomandworkupwardtoensureturnsare madeuphill.

2. Onthefirst passpicka pointon theoppositesideofthe areato

bemowed.

3. Engagethe PTOandmovethethrottlecontrolto the FAST

position.

4. Lowerthemowerdecktothe desiredheightsettingusingthe

decklift handle.

5. Slowlyandevenlypushthe RHandLHdrivecontrollevers

forwardtomovethe ridingmowerforward,andkeepthe riding

mowerheadeddirectlytowardthealignmentpoint.

NOTE:The speedof theridingmowerwill affectthequalityof the

mowercut.Mowingatfullspeedwilladverselyaffectthecut quality.

Controlthegroundspeedwiththecontrollevers.

6. Whenapproachingtheotherendofthe strip,slowdownor stop

beforeturning.AU-turnis recommendedunlessazeroturnis

required.

7. Alignthemowerwithanedgeof themowedstripandoverlap

approximately3".

8. Directtheridingmoweroneachsubsequentstriptoalignwitha

previouslycut strip.

9. Topreventruttingorgroovingoftheturf,ifpossible,changethe

directionthatthestripsaremowedbyapproximately450forthe

nextandeachsubsequentmowing.

Becarefulwhencrossinggravelpathsordriveways.Disengagethe

PTOandraisethedeckto thehighestpositionbeforecrossing.

NOTE:Whenstoppingtheridingmowerforanyreasonwhileon a

grasssurface,always:

• Placetheshiftleverinneutral,

• Engagetheparkingbrake8,

• Shutengineoffandremovethekey.

• Doingsowillminimizethepossibilityofhavingyourlawn

"browned"byhotexhaustfromyour ridingmower'srunning

engine.

CHECKING THE SAFETY INTERLOCK CIRCUITS

Periodicallycheckthe safetyinterlockcircuitstoensuretheyare

workingproperly.Ifa safetycircuitis notworkingas designed,call

1-800-659-5917to scheduletractorinspectionservicefromSears

Parts& Repair.to havethe ridingmowerinspected.DONOToperate

theridingmowerif anysafetycircuitisnot functioningproperly.To

checkthe safetycircuits,proceedasfollows:

1. Sittinginthe ridingmowerseatwithbothdrivecontrollevers

openedfullyoutward,DISENGAGEthe parkingbrake_ and

momentarilyturnthe ignitionswitchto theSTART_ position.

Theengineshouldnotcrank.

2. ENGAGEtheparkingbrake0 and pullthe PTOswitchupward

tothe ENGAGEDposition.Momentarilyturntheignitionswitchto

theSTART_ position;theengineshouldnotcrank.

3. Pushthe PTOswitchdownwardto theDISENGAGEDposition

and ENGAGEthe parkingbrake0. Starttheengineand move

oneof thedrivecontrolleversfromthe fullyoutwardneutral

position.The engineshouldstoprunning.Repeatthe procedure

withtheoppositecontrollever.

4. Movebothcontrolleversfullyoutwardinthe neutralpositionand

DISENGAGEtheparkingbrake0; thenliftupwardfromthe

operator'sseat.Theengineshouldstop.

5. Withbothcontrolleversfullyoutwardinthe neutralpositionand

theparkingbrakeENGAGED,ENGAGEthe PTO.Liftupward

fromtheoperator'sseat;theengineshouldstop.

6. Starttheridingmower,DISENGAGEtheparkingbrake0, and

movethecontrolleversinwardtothe neutraloperatingposition.

ENGAGEthe PTOandmovebothcontrolleverslowlyintothe

slowreverseposition;thePTOshoulddisengageandthe mower

deckshouldstopuntiloneor bothof thecontrolleversis moved

tothe neutralorforwardposition.

21

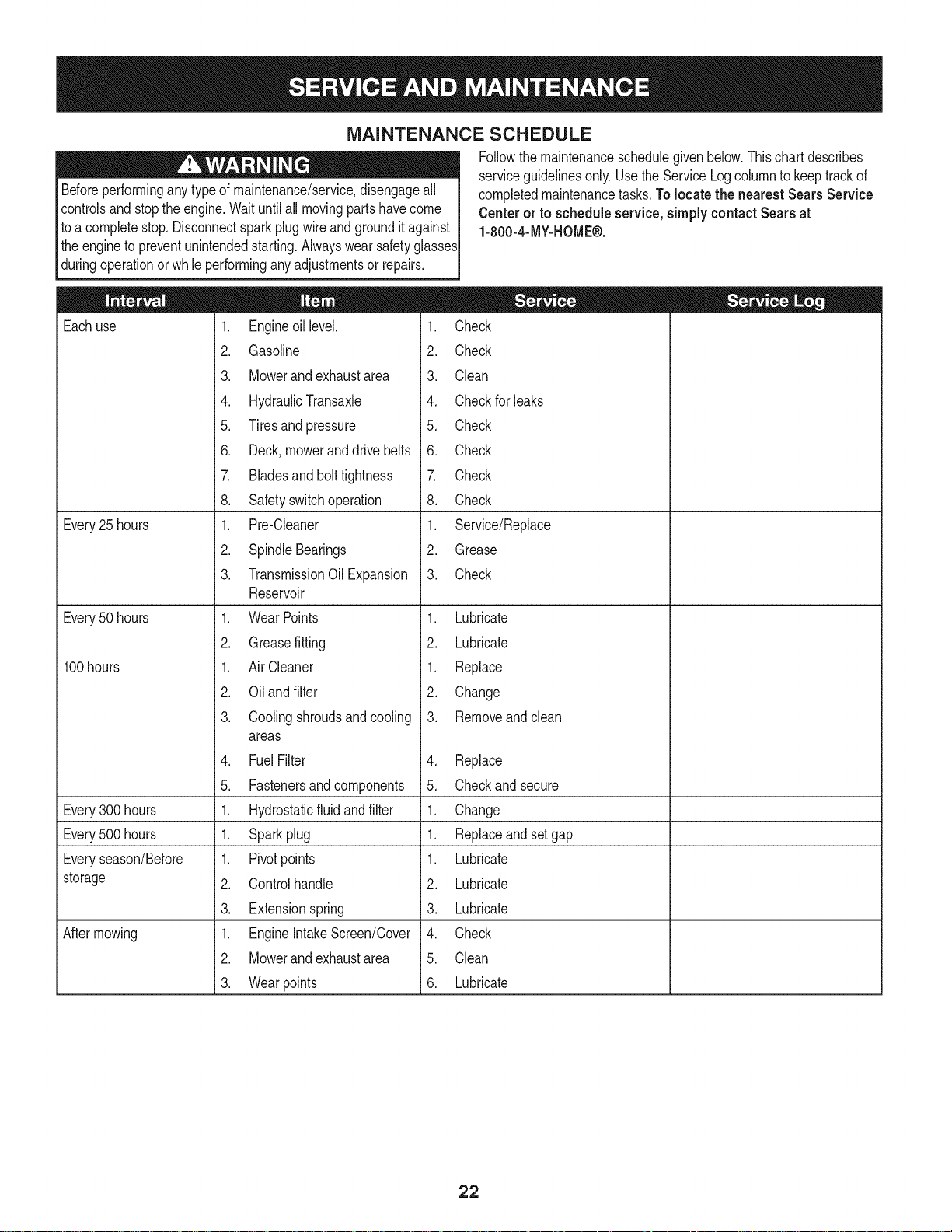

MAINTENANCE SCHEDULE

Beforeperformingany typeofmaintenance/service,disengageall

controlsandstopthe engine.Waituntilall movingpartshavecome

toa completestop.Disconnectsparkplugwireandgroundit against

theengineto preventunintendedstarting.Alwayswearsafetyglasses

duringoperationorwhile performinganyadjustmentsor repairs.

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.Tolocatethe nearest Sears Service

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

Eachuse

Every25 hours

Every50 hours

100hours

Every300 hours

Every500 hours

Everyseason/Before

storage

Aftermowing

1. Engineoillevel.

2. Gasoline

3. Mowerand exhaustarea

4. HydraulicTransaxle

5. Tiresand pressure

6. Deck,moweranddrivebelts

7. Bladesandbolttightness

8. Safetyswitchoperation

1. Pre-Cleaner

2. SpindleBearings

3. TransmissionOilExpansion

Reservoir

1. WearPoints

2. Greasefitting

1. AirCleaner

2. Oilandfilter

3. Coolingshroudsandcooling

areas

4. FuelFilter

5. Fastenersand components

1. Hydrostaticfluidandfilter

1. Sparkplug

1. Pivotpoints

2. Controlhandle

3. Extensionspring

1. EngineIntakeScreen/Cover

2. Mowerand exhaustarea

3. Wearpoints

1. Check

2. Check

3. Clean

4. Checkfor leaks

5. Check

6. Check

7. Check

8. Check

1. Service/Replace

2. Grease

3. Check

1. Lubricate

2. Lubricate

1. Replace

2. Change

3. Removeandclean

4. Replace

5. Checkandsecure

1. Change

1. Replaceandsetgap

1. Lubricate

2. Lubricate

3. Lubricate

4. Check

5. Clean

6. Lubricate

22

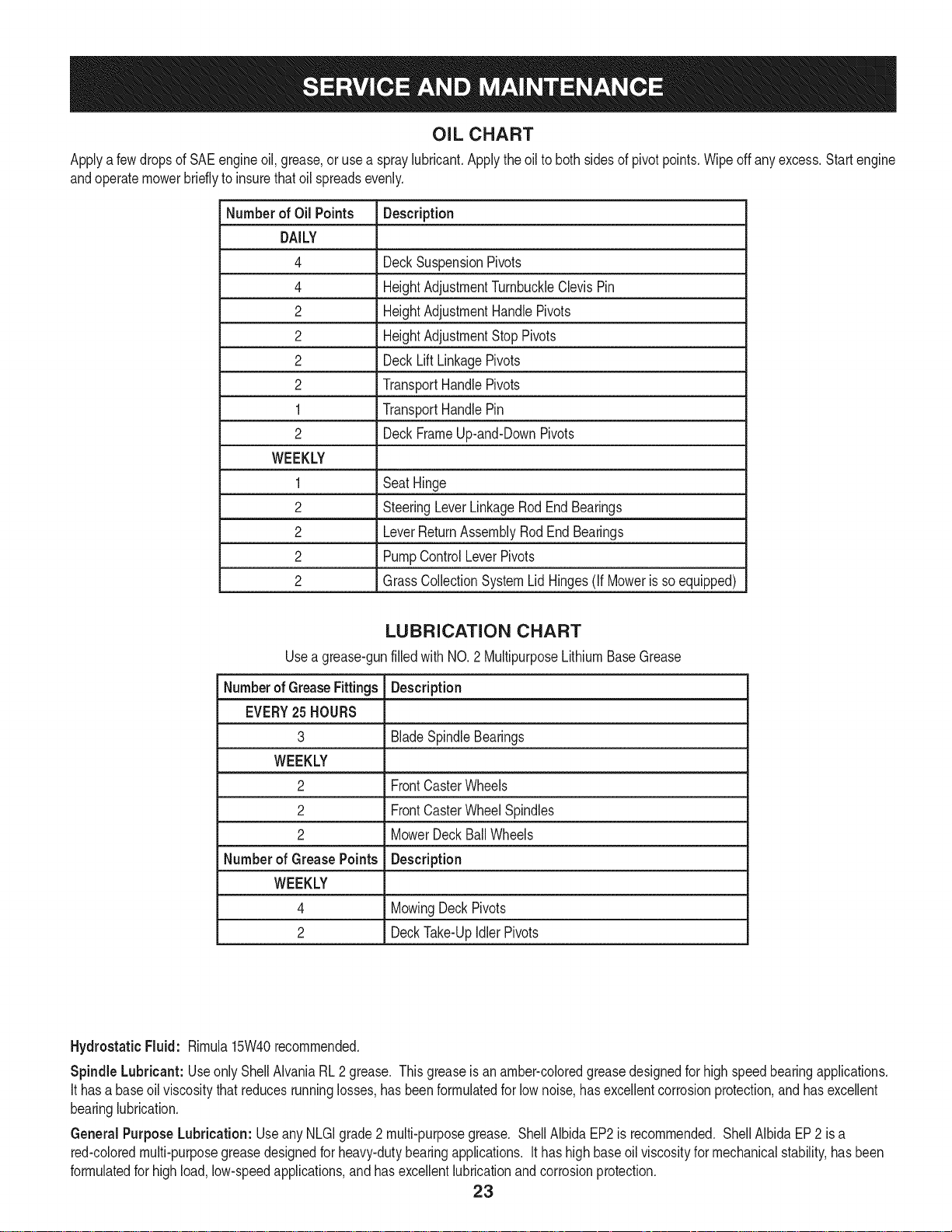

OIL CHART

Applya fewdropsofSAEengineoil,grease,or usea spraylubricant.Applythe oil tobothsidesofpivotpoints.Wipeoffanyexcess.Startengine

andoperatemowerbrieflytoinsurethatoil spreadsevenly.

Number of Oil Points Description

DALLY

4 DeckSuspensionPivots

4 HeightAdjustmentTurnbuckleClevisPin

2 HeightAdjustmentHandlePivots

2 HeightAdjustmentStopPivots

2 DeckLiftLinkagePivots

2 TransportHandlePivots

1 TransportHandlePin

2 DeckFrameUp-and-DownPivots

WEEKLY

1 SeatHinge

2 SteeringLeverLinkageRodEndBearings

2 LeverReturnAssemblyRodEndBearings

2 PumpControlLeverPivots

2 GrassCollectionSystemLidHinges(IfMoweris soequipped)

LUBRICATION CHART

Usea grease-gunfilledwith NO.2 MultipurposeLithiumBaseGrease

Numberof GreaseFittings Description

EVERY25 HOURS

3 BladeSpindleBearings

WEEKLY

2 FrontCasterWheels

2 FrontCasterWheelSpindles

2 MowerDeckBallWheels

Numberof Grease Points Description

WEEKLY

4 MowingDeckPivots

2 DeckTake-UpIdlerPivots

Hydrostatic Fluid: Rimula15W40recommended.

Spindle Lubricant:UseonlyShellAlvaniaRL2grease.Thisgreaseisanamber-coloredgreasedesignedforhighspeedbearingapplications.

It hasa baseoil viscositythatreducesrunninglosses,hasbeenformulatedforlownoise,hasexcellentcorrosionprotection,andhasexcellent

bearinglubrication.

General PurposeLubrication: UseanyNLGIgrade2 multi-purposegrease.ShellAlbidaEP2is recommended.ShellAlbidaEP2 is a

red-coloredmulti-purposegreasedesignedforheavy-dutybearingapplications.Ithashighbaseoil viscosityfor mechanicalstability,hasbeen

formulatedfor highload,low-speedapplications,andhas excellentlubricationandcorrosionprotection.

23

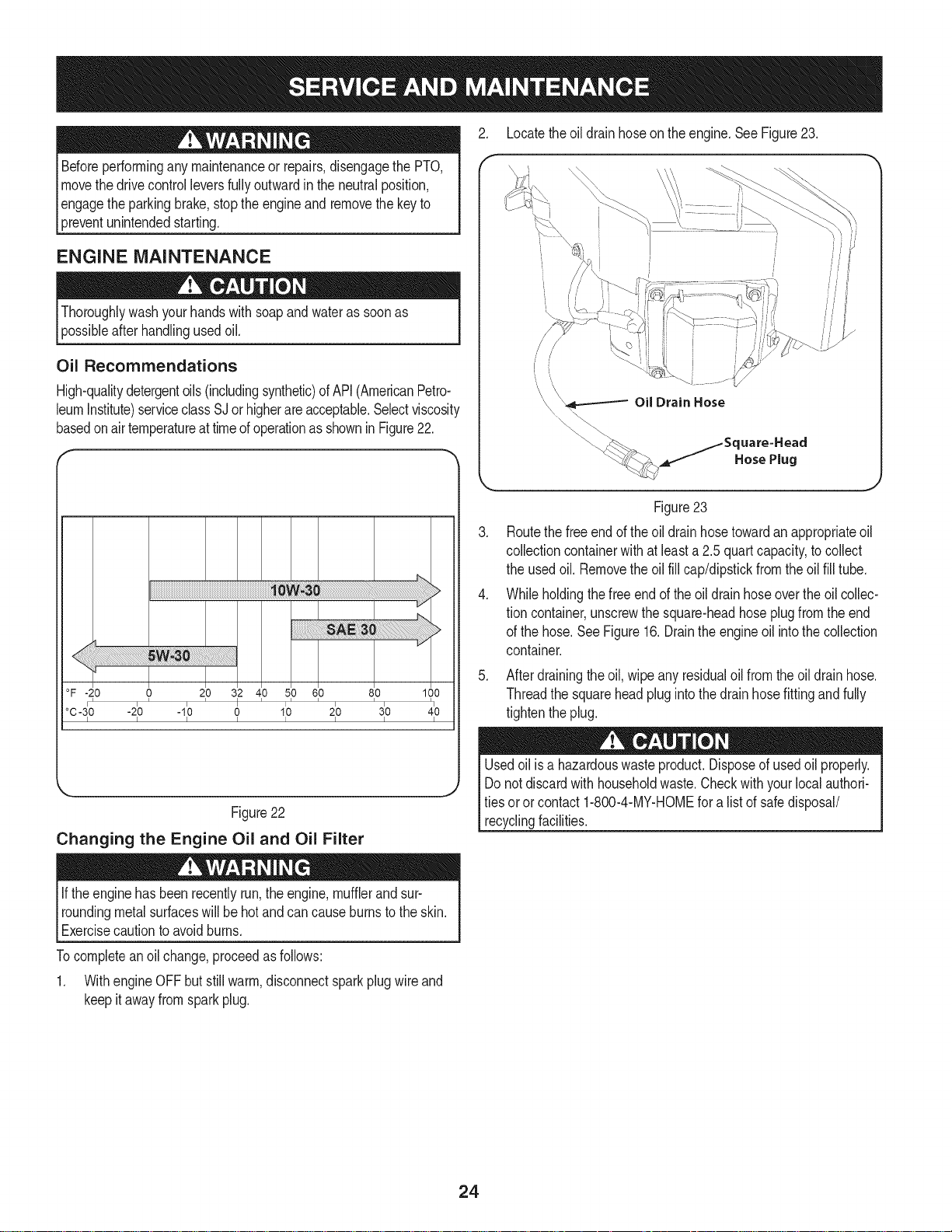

2. Locatetheoil drainhoseon theengine.SeeFigure23.

Beforeperforminganymaintenanceorrepairs,disengagethePTO,

movethedrivecontrolleversfullyoutwardintheneutralposition,

Iengagetheparkingbrake,stoptheengineandremovethekeyto

[preventunintendedstarting.

ENGINE MAINTENANCE

usedoil.

Oil Recommendations

High-qualitydetergentoils (includingsynthetic)ofAPI(AmericanPetro-

leumInstitute)serviceclassSJorhigherareacceptable.Selectviscosity

basedonairtemperatureat timeofoperationasshowninFigure22.

\

i,

/

Oil Drain Hose

._:_ j_Square=Heacl

HosePlug

Figure23

.

Routethefree endofthe oildrainhosetowardanappropriateoil

collectioncontainerwithat leasta 2.5quartcapacity,tocollect

theusedoil.Removetheoilfill cap/dipstickfromtheoil fill tube.

.

Whileholdingthe freeendof theoil drainhoseoverthe oilcollec-

tioncontainer,unscrewthesquare-headhoseplugfromtheend

ofthe hose.SeeFigure16.Draintheengineoil intothe collection

container.

°F-20 0 210 312 410 510 610 810 100

°C-3_0 -2_0 -1_0 0 1_0 2_0 3_0 4_0

I I I I I I I I

Figure22

Changing the Engine Oil and Oil Filter

If theenginehasbeenrecentlyrun,theengine,mufflerandsur-

roundingmetalsurfaceswillbe hotandcancauseburnstothe skin.

Exercisecautiontoavoidburns.

Tocompleteanoil change,proceedasfollows:

1. WithengineOFFbutstillwarm,disconnectsparkplugwireand

keepit awayfromsparkplug.

5. Afterdrainingtheoil, wipeanyresidualoilfromtheoil drainhose.

Threadthe squareheadpluginto thedrainhosefittingandfully

tightentheplug.

Usedoilisa hazardouswasteproduct.Disposeof usedoilproperly.

Donot discardwithhouseholdwaste.Checkwithyourlocalauthori-

J

tiesor orcontact1-800-4-MY-HOMEfora listof safedisposal/

recyclingfacilities.

24

.

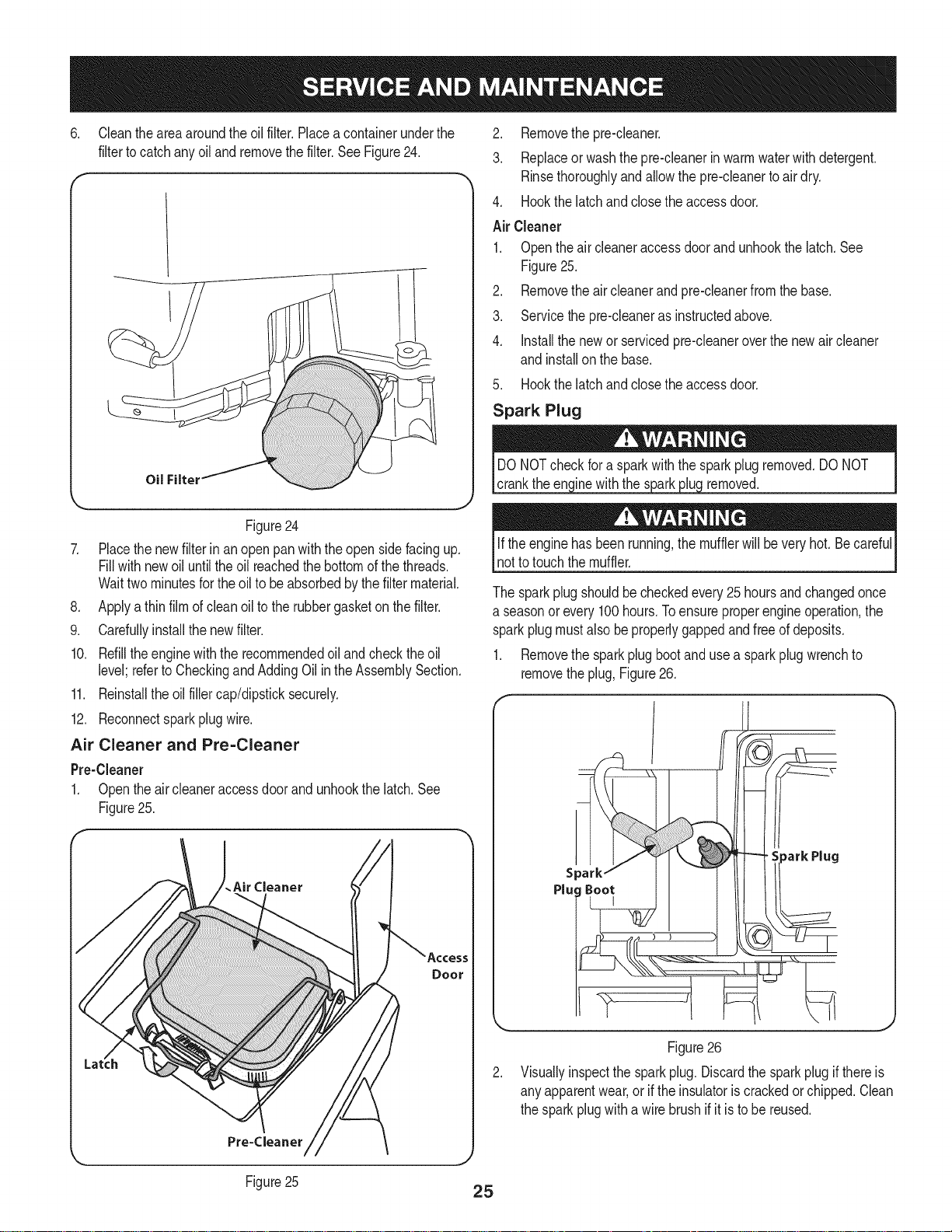

Cleantheareaaroundtheoilfilter. Placeacontainerunderthe

filtertocatchanyoil andremovethefilter.SeeFigure24.

f

2. Removethepre-cleaner.

3. Replaceor washthepre-cleanerin warmwaterwithdetergent.

Rinsethoroughlyandallowthe pre-cleanerto airdry.

4. Hookthelatchandclosethe accessdoor.

AirCleaner

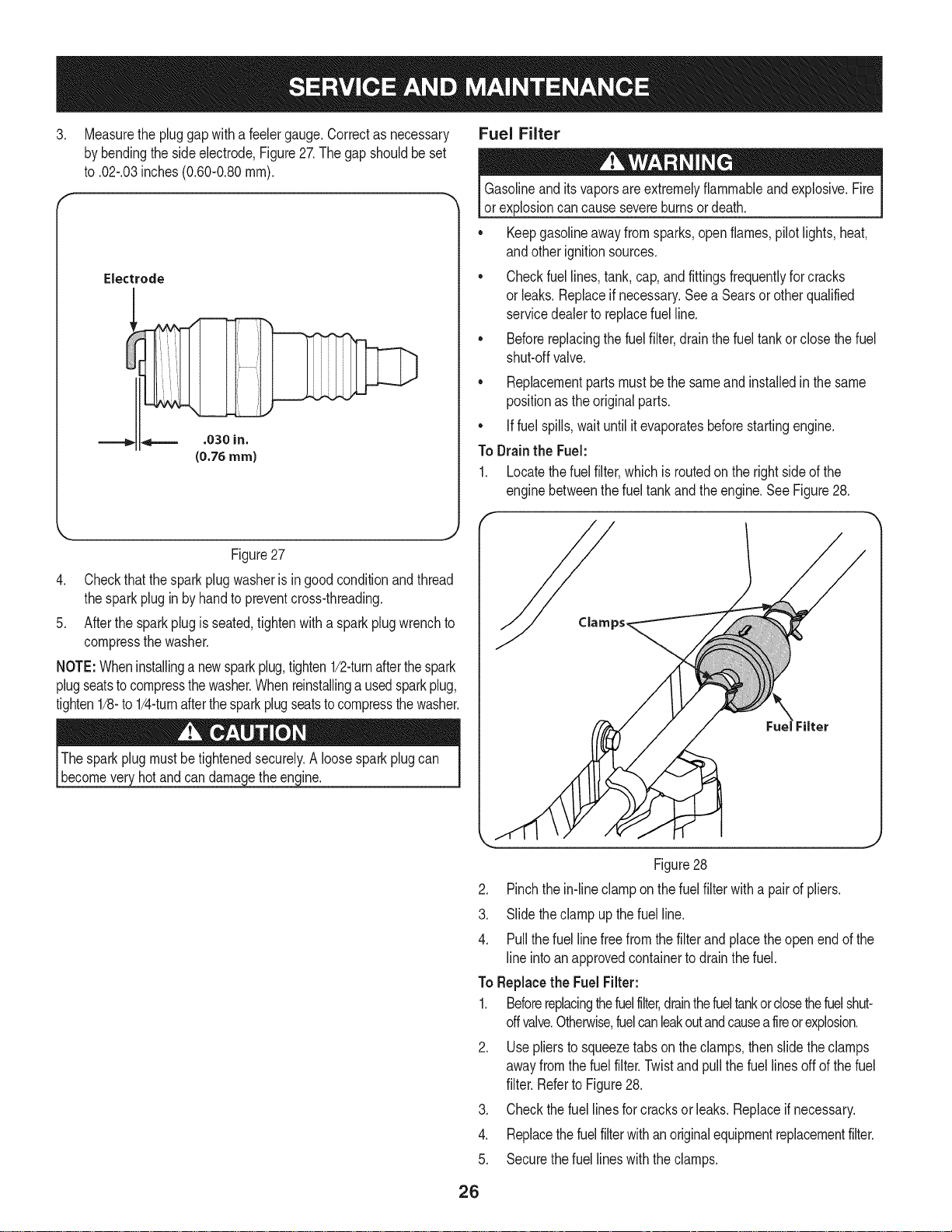

1. Opentheaircleaneraccessdoorand unhookthelatch.See

Figure25.

2. Removethe aircleanerandpre-cleanerfromthebase.

3. Servicethepre-cleanerasinstructedabove.

4. Installthenewor servicedpre-cleaneroverthenewaircleaner

and installonthebase.

5. Hookthelatchandclosethe accessdoor.

Spark Plug

Oil Filter

Figure24

7. Placethe newfilterinanopenpanwiththeopensidefacingup.

Fillwithnewoil untilthe oil reachedthe bottomofthethreads.

Waittwo minutesfortheoil to beabsorbedbythefiltermaterial.

8. Applya thinfilmof cleanoilto therubbergasketonthefilter.

9. Carefullyinstallthenewfilter.

10. Refilltheenginewiththe recommendedoil andcheckthe oil

level;referto CheckingandAddingOilin theAssemblySection.

11. Reinstalltheoilfillercap/dipsticksecurely.

12. Reconnectsparkplugwire.

Air Cleaner and Pre=Cleaner

Pre-Cleaner

1. Openthe aircleaneraccessdoorandunhookthelatch.See

Figure25.

.Air Cleaner

cranktheen( inewiththe s_ removed.

ifthe enginehasbeenrunning,the mufflerwillbeveryhot. Becareful

notto touchthemuffler.

Thesparkplugshouldbecheckedevery25hoursandchangedonce

a seasonor every100hours.Toensureproperengineoperation,the

sparkplugmustalso beproperlygappedandfreeof deposits.

1. Removethesparkplugbootand usea sparkplugwrenchto

removetheplug,Figure26.

Figure25

Figure26

Visuallyinspectthe sparkplug.Discardthe sparkplugif thereis

anyapparentwear,or ifthe insulatoriscrackedorchipped.Clean

thesparkplugwitha wire brushif it isto be reused.

25

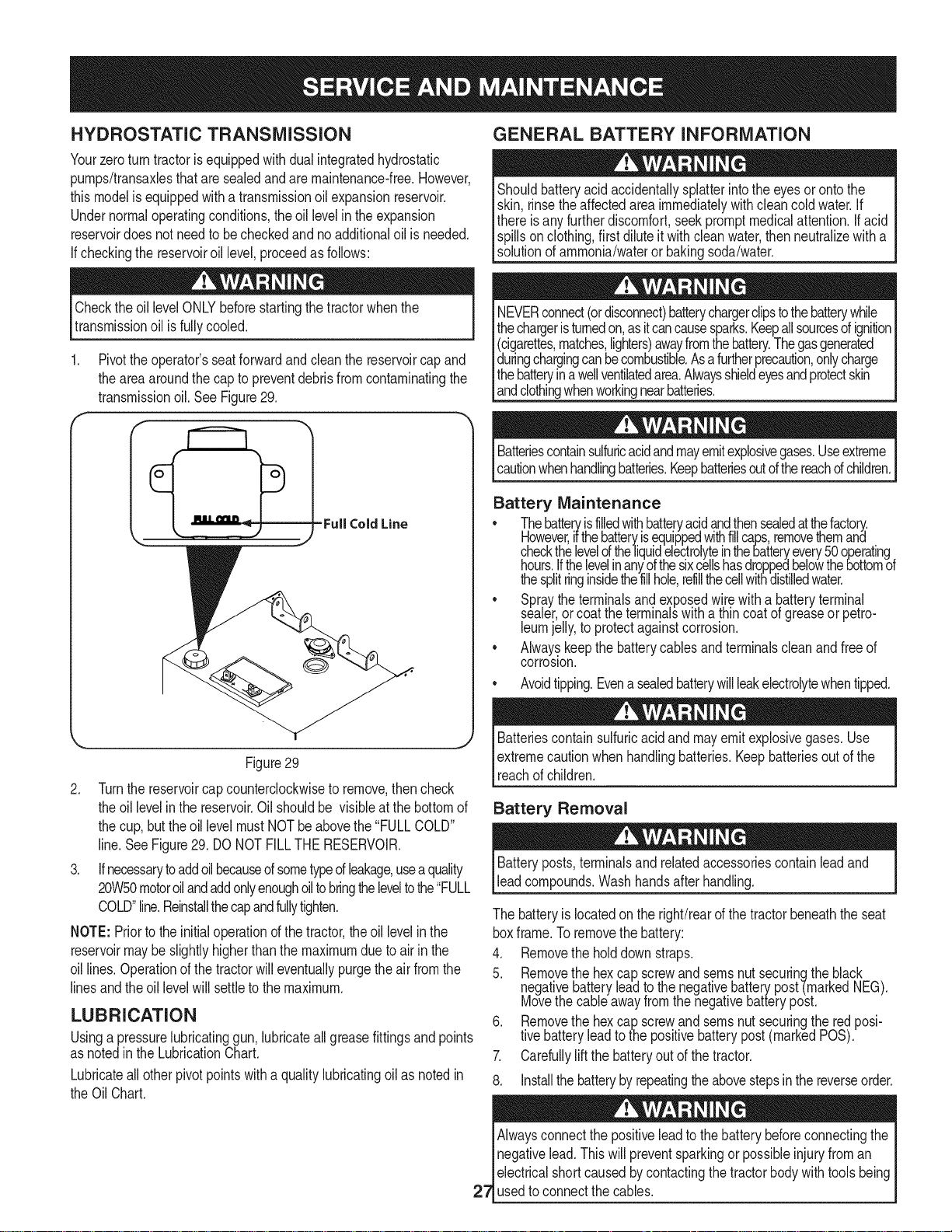

3. Measurethepluggapwitha feelergauge.Correctas necessary Fuel Filter

bybendingthesideelectrode,Figure27.Thegap shouldbe set

to.02-.03inches(0.60-0.80ram).

Gasolineandits vaporsareextremelyflammableand explosive.Fire

or explosioncancausesevereburnsordeath.

• Keepgasolineawayfromsparks,openflames,pilotlights,heat,

andotherignitionsources.

Electrode

• Checkfuel lines,tank,cap,andfittingsfrequentlyforcracks

or leaks.Replaceif necessary.Seea Searsor otherqualified

servicedealerto replacefuelline.

• Beforereplacingthefuelfilter,drainthefueltankorclosethefuel

shut-offvalve.

• Replacementpartsmustbethesameandinstalledinthesame

positionasthe originalparts.

• Iffuelspills,waituntilitevaporatesbeforestartingengine.

ToDrainthe Fuel:

1. Locatethefuel filter,whichisroutedontherightsideofthe

enginebetweenthefueltankandtheengine.SeeFigure28.

Figure27

4. Checkthatthesparkplugwasherisingoodconditionandthread

thesparkplugin by handtopreventcross-threading.

5. Afterthe sparkplugisseated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthespark

plugseatstocompressthewasher.Whenreinstallingausedsparkplug,

tighten1/8-to1/4-turnafterthesparkplugseatstocompressthewasher.

Thesparkplugmustbetightenedsecurely.A loosesparkplugcan

becomeveryhotandcan damagetheengine.

J

Figure28

2. Pinchthein-lineclamponthefuel filterwitha pairof pliers.

3. Slidetheclampup thefuel line.

4. Pullthefuel linefreefromthe filterand placetheopenendofthe

line intoanapprovedcontainertodrainthe fuel.

ToReplacethe Fuel Filter:

1. Beforereplacingthefuelfilter,drainthefueltankorclosethefuelshut-

offvalve.Otherwise,fuelcanleakoutandcauseafireorexplosion.

2. Usepliersto squeezetabsontheclamps,thenslidetheclamps

awayfromthefuel filter.Twistandpullthe fuellinesoffofthe fuel

filter.Referto Figure28.

3. Checkthe fuellinesforcracksorleaks.Replaceifnecessary.

4. Replacethefuelfilterwithanoriginalequipmentreplacementfilter.

5. Securethefuellineswiththeclamps.

26

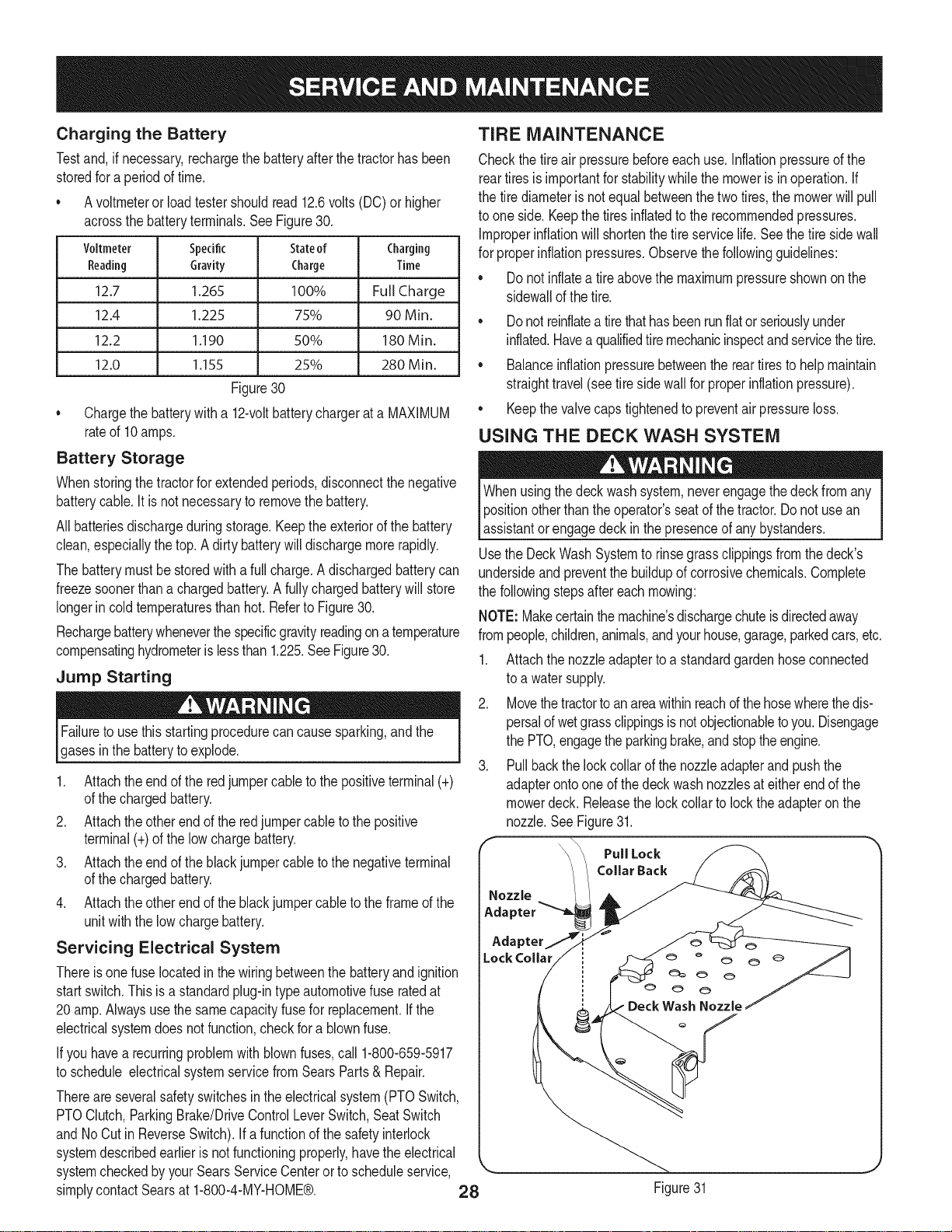

HYDROSTATIC TRANSMiSSiON

Yourzeroturntractoris equippedwithdualintegratedhydrostatic

pumps/transaxlesthataresealedandaremaintenance-free.However,

thismodelis equippedwitha transmissionoil expansionreservoir.

Undernormaloperatingconditions,the oillevelin the expansion

reservoirdoesnot needtobecheckedand noadditionaloilis needed.

If checkingthereservoiroil level,proceedasfollows:

GENERAL BATTERY INFORMATION

Shouldbatteryacidaccidentallysplatterintotheeyesor ontothe

skin,rinsetheaffectedareaimmediatelywithcleancoldwater.If

thereisanyfurtherdiscomfort,seekpromptmedicalattention.Ifacid

spillsonclothing,firstdiluteit withcleanwater,thenneutralizewitha

solutionofammonia/wateror bakingsoda/water.

Checktheoil levelONLYbeforestartingthetractorwhenthe

transmissionoil is fullycooled.

1. Pivotthe operator'sseatforwardandcleanthereservoircapand

theareaaroundthe capto preventdebrisfromcontaminatingthe

transmissionoil. SeeFigure29.

-Full Cold Line

k,_ [ j

Figure29

2. Turnthe reservoircapcounterclockwisetoremove,thencheck

theoillevelin thereservoir.Oil shouldbe visibleatthebottomof

thecup,buttheoillevel mustNOTbe abovethe"FULLCOLD"

line.SeeFigure29.DONOTFILLTHERESERVOIR.

3. Ifnecessarytoaddoilbecaused sometypeofleakage,useaquality

20W50motoroilandaddonlyenoughoiltobringtheleveltothe"FULL

COLD"line.Reinstallthecapandfullytighten.

NOTE:Priorto theinitialoperationd thetractor,theoil levelinthe

reservoirmaybe slightlyhigherthanthemaximumdueto airin the

oil lines.Operationof thetractorwilleventuallypurgetheair fromthe

linesandthe oil levelwill settletothemaximum.

LUBRICATION

Usinga pressurelubricatinggun,lubricateallgreasefittingsandpoints

asnotedinthe LubricationChart.

Lubricateall otherpivotpointswithaqualitylubricatingoilas notedin

theOilChart.

NEVERconnect(ordisconnect)batterychargerclipstothebatterywhile

thechargeristurnedon,asitcancausesparks.Keepallsourcesofignition

(cigarettes,matches,lighters)awayfromthebattery.Thegasgenerated

duringchargingcanbecombustible.Asafurtherprecaution,onlycharge

thebatteryinawellventilatedarea.Alwaysshieldeyesandprotectskin

[andc othngwhenworkngnearbatteries.

Batteriescontainsulfuricacidandmayemitexplosivegases.Useextreme

cautionwhenhandlingbatteries.Keepbatteriesoutofthereachofchildren.

Battery Maintenance

• Thebatte_isfilledwithbatteryacidandthensealedatthefactory.

However,ifthebatteryisequippedwithfillcaps,removethemant

checkthelevelof the]iquidelectroly!einthebatteryevery50operating.

hours.Ifthelevelinanyofthesixcellshasdroppetbelowthebottomot

thesplitringinsidethefillhole,refillthecellwithdistilledwater.

• Spraytheterminalsandexposedwirewitha b.atteryterminal

sealer,orcoattheterminalswitha thincoatot greaseorpetro-

leumjelly,to protectagainstcorrosion.

• Alwayskeepthebatterycablesandterminalscleanandfreeof

corrosion.

• Avoidtipping.Evenasealedbatterywillleakelectrolytewhentipped.

Batteriescontainsulfuricacidandmayemitexplosivegases.Use

extremecautionwhenhandlingbatteries.Keepbatteriesoutof the

reachofchildren.

Battery Removal

Batteryposts,terminalsand relatedaccessoriescontainleadand

leadcompounds.Washhandsafterhandling.

Thebatteryislocatedonthe right/rearofthe tractorbeneaththeseat

boxframe.Toremovethebattery:

4. Removethe holddownstraps.

5. Remove!he hexcap screwandseresnut securingtheblack

negativebatteryleadto thenegativebatterypost-(markedNEG).

Movethecableawayfromthenegativebatterypost.

6. Removethe hexcap screwandsernsnut securingtheredposi-

tivebatteryleadto thepositivebatterypost(markedPOS).

7. Carefullyliftthebatteryoutofthetractor.

8. Installthe batterybyrepeatingtheabovestepsinthereverseorder.

Alwaysconnectthepositiveleadtothe batterybeforeconnectingthe

Inegativelead.Thiswillpreventsparkingorpossibleinjuryfroman

| electricalshortcausedbycontactingthetractorbodywithtoolsbeing

27_usedtoconnectthecables.

Chargingthe Battery

Testand,ifnecessary,rechargethebatteryafterthetractorhasbeen

storedforaperiodoftime.

• Avoltmeteror loadtestershouldread12.6volts(DC)or higher

acrossthebatteryterminals.SeeFigure30.

Voltmeter Specific Charging

Reading Gravity Time

12.7 1.265 Full Charge

12.4 1.225 90 Min.

12.2 1.190 180 Min.

12.0 1.155 280 Min.

Figure30

* Chargethebatterywitha 12-voltbatterychargerata MAXIMUM

rateof 10amps.

Battery Storage

Whenstoringthetractorfor extendedperiods,disconnectthenegative

batterycable.It is notnecessaryto removethebattery.

All batteriesdischargeduringstorage.Keeptheexteriorof thebattery

clean,especiallythetop.Adirty batterywilldischargemorerapidly.

Thebatterymustbe storedwitha full charge.A dischargedbatterycan

freezesoonerthana chargedbattery.A fullychargedbatterywillstore

longerin coldtemperaturesthan hot.RefertoFigure30.

Rechargebatterywheneverthespecificgravityreadingona temperature

compensatinghydrometerislessthan 1.225.SeeFigure30.

Jump Starting

Failuretousethisstartingprocedurecan causesparking,andthe

gasesinthebatterytoexplode.

1. Attachtheendof theredjumpercableto thepositiveterminal(+)

ofthe chargedbattery.

2. Attachtheotherend ofthe redjumpercabletothe positive

terminal(+)ofthelowchargebattery.

3. Attachtheendof theblackjumpercableto thenegativeterminal

ofthe chargedbattery.

4. Attachtheotherend ofthe blackjumpercabletothe frameofthe

unitwiththe lowchargebattery.

Servicing Electrical System

Thereis onefuselocatedinthewiringbetweenthe batteryandignition

startswitch.Thisisa standardplug-intypeautomotivefuse ratedat

20amp.Alwaysusethesamecapacityfusefor replacement.Ifthe

electricalsystemdoesnotfunction,checkfor a blownfuse.

Ifyouhavea recurringproblemwithblownfuses,call 1-800-659-5917

toschedule electricalsystemservicefromSearsParts& Repair.

Thereareseveralsafetyswitchesintheelectricalsystem(PTOSwitch,

PTOClutch,ParkingBrake/DriveControlLeverSwitch,SeatSwitch

andNoCutin ReverseSwitch).Ifa functionofthe safetyinterlock

systemdescribedearlieris notfunctioningproperly,havethe electrical

systemcheckedbyyourSearsServiceCenterorto scheduleservice,

simplycontactSearsat 1-800-4-MY-HOME®. 28

Stateof

Charge

100%

75%

50%

25%

TIRE MAINTENANCE

Checkthe tireair pressurebeforeeachuse.Inflationpressureofthe

reartiresisimportantforstabilitywhilethemoweris in operation.If

thetire diameteris notequalbetweenthetwotires,themowerwill pull

toone side.Keepthetiresinflatedtothe recommendedpressures.

Improperinflationwillshortenthe tireservicelife.Seethetire sidewall

forproperinflationpressures.Observethe followingguidelines:

• Donotinflatea tireabovethemaximumpressureshownonthe

sidewallofthe tire.

• Donotreinflateatirethathasbeenrunflatorseriouslyunder

inflated.Havea qualifiedtiremechanicinspectandservicethetire.

• Balanceinflationpressurebetweenthereartiresto helpmaintain

straighttravel(seetiresidewallfor properinflationpressure).

• Keepthevalvecapstightenedto preventair pressureloss.

USING THE DECK WASH SYSTEM

Whenusingthedeckwashsystem,neverengagethedeckfromany

positionotherthan theoperator'sseatofthetractor.Donotusean

assistantorengagedeckinthe presenceof anybystanders.

UsetheDeckWashSystemtorinsegrassclippingsfromthedeck's

undersideandpreventthe buildupof corrosivechemicals.Complete

thefollowingstepsaftereachmowing:

NOTE:Makecertainthemachine'sdischargechuteisdirectedaway

frompeople,children,animals,andyourhouse,garage,parkedcars,etc.

1. Attachthenozzleadaptertoa standardgardenhoseconnected

toa watersupply.

2. Movethetractortoanareawithinreachofthe hosewherethedis-

persalofwetgrassclippingsisnotobjectionabletoyou.Disengage

thePTO,engagethe parkingbrake,andstoptheengine.

3. Pullbackthelockcollarofthe nozzleadapterandpushthe

adapterontooneofthe deckwashnozzlesateitherendof the

mowerdeck.Releasethelockcollarto locktheadapteronthe

nozzle.SeeFigure31.

CollarBack

PullLock

Adapter

Lock Collar

Figure31

4. Turnonthewatersupply.

5. Fromthetractoroperator'sseat,starttheengineandengagethePTO.

Allowtorunasneeded.DisengagethePTOandstoptheengine.

6. Turnoffthewatersupply.

7. Pullbackthelockcollarofthenozzleadaptertodisconnectthe

adapterfromthenozzle.

8. Repeatthepreviousstepstocleanthedeckusingthenozzleat

theotherendofthedeck.

CLEANING THE SPINDLE PULLEYS

Oncea monthremovethe beltcoversto removeanyaccumulationof

grassclippingsfromaroundthespindlepulleysandV-belt.Cleanmore

oftenwhenmowingtall,dry grass.

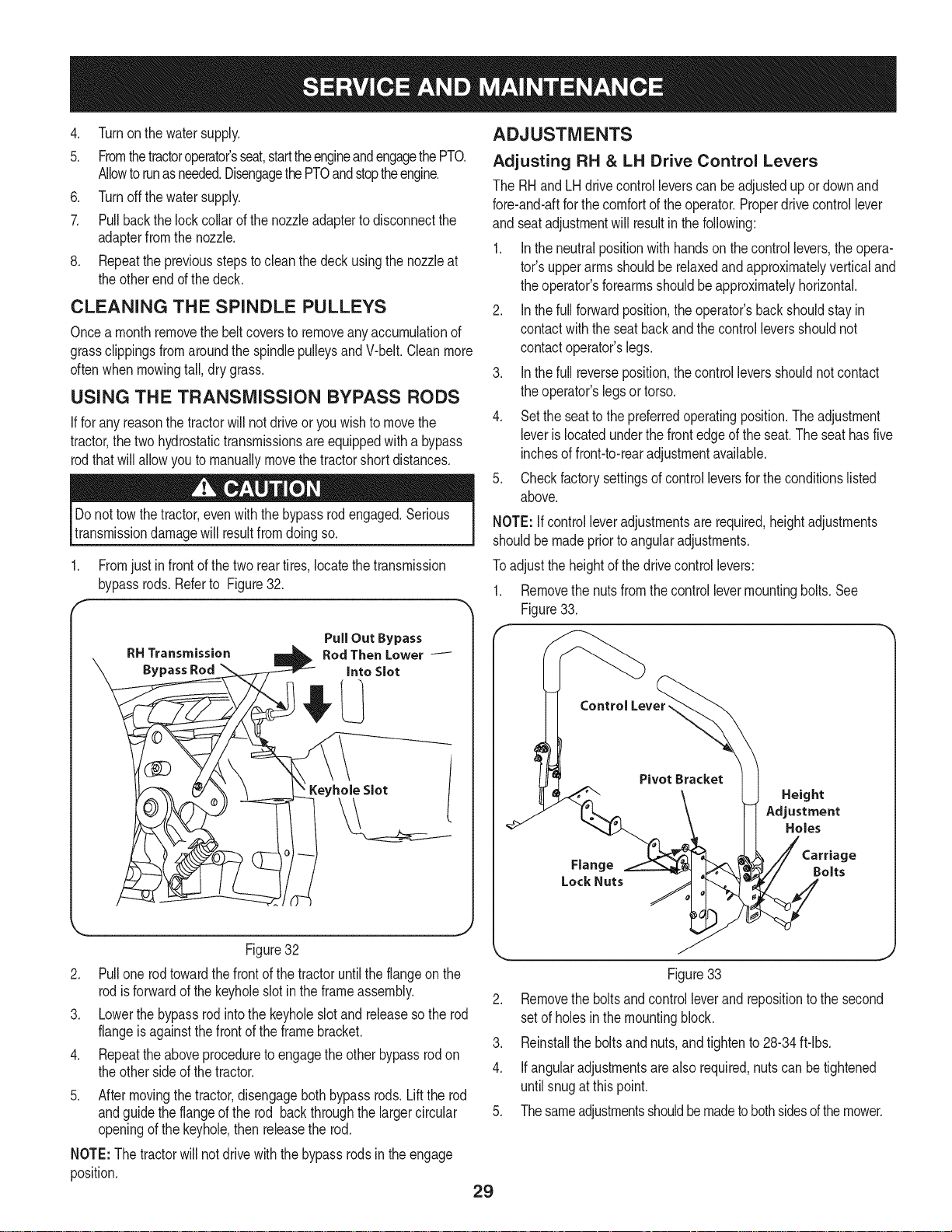

USING THE TRANSMISSION BYPASS RODS

If forany reasonthetractorwill notdriveor youwishtomovethe

tractor,thetwo hydrostatictransmissionsareequippedwitha bypass

rodthatwillallowyouto manuallymovethetractorshortdistances.

Donottowthetractor,evenwith thebypassrodengaged.Serious

transmissiondamagewillresultfromdoingso.

1. Fromjustin frontof the tworeartires,locatethe transmission

bypassrods.Referto Figure32.

f

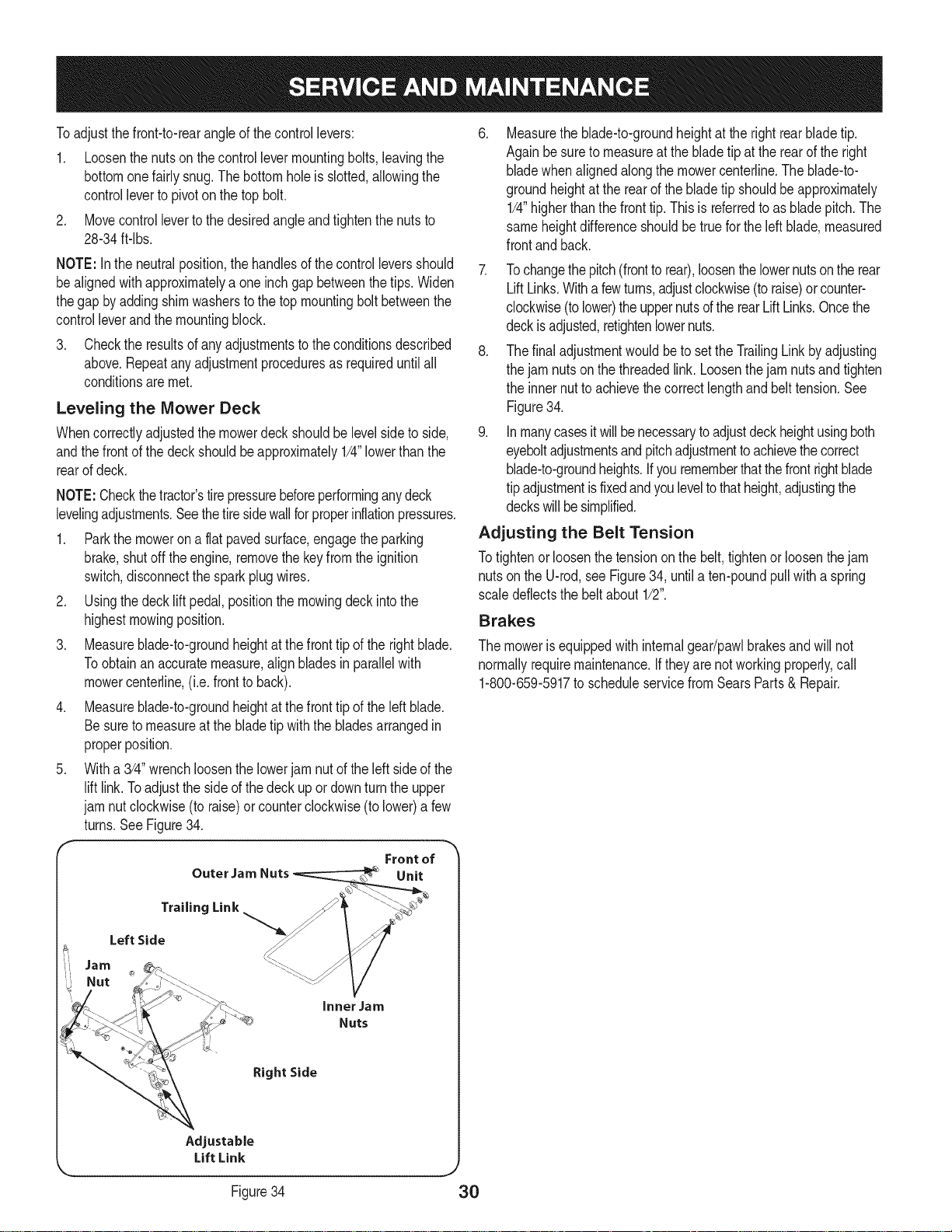

ADJUSTMENTS