Craftsman 235.19906 Owner's Manual

Owner ’s Manual

12,000 RPM .2 hp Motor

RANDOM ORBITAL SANDER

Model No.

235.19906

W ARNING:

Before using this Sander,

read this manual and follow all its

Safety and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Owner’s Manual P7368 (1–99) Printed in USA

Safety

Operation

Service and

Adjustments

Parts List

Español

2

TABLE OF CONTENTS PAGE

Two Year Warranty 2

Safety 3–6

Warning Labels

Notice, Warning and Caution

Placing Tool In Service

Using the Tool

Operation 6

Air Supply and Connections

Specifications

Parts List 7–8

Exploded Drawing

Parts for Ordering

Español 9–16

WARRANTY

FULL TWO YEAR WARRANTY ON

CRAFTSMAN AIR–DRIVE TOOLS.

If this Craftsman Air–Drive Tool fails to give complete satisfaction

within two years from the date of purchase, RETURN IT TO THE

NEAREST SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED

SATES, and Sears will repair it, free of charge. If this Craftsman tool

is used for commercial or rental purposes, this warranty applies for

only 90 days from the date of purchase.

This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

If you have any questions about the Model 19906

Random Orbital Sander, call: 1–800–866–5457

3

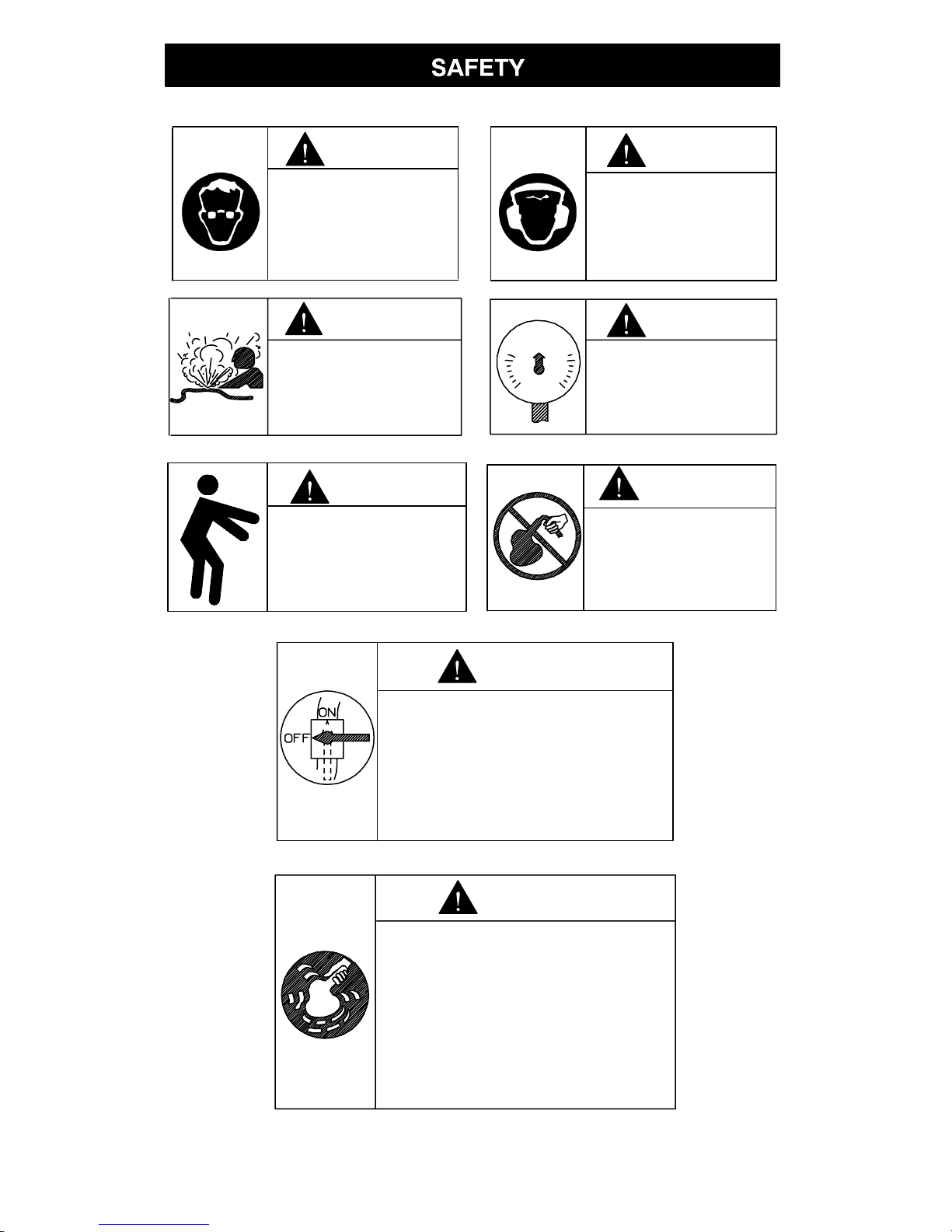

Always wear eye

protection when operating or performing maintenance on

this tool.

Always wear hearing protection

when operating

this tool.

Always turn off the air supply

and disconnect the air supply

hose before installing, removing or adjusting any accessory on this tool, or before

performing any maintenance

on this tool.

Air powered tools can vibrate

in use. Vibration, repetitive

motions or uncomfortable

positions may be harmful to

your hands and arms. Stop

using any tool if discomfort,

tingling feeling or pain occurs.

Seek medical advice before

resuming use.

Do not carry the

tool by the hose.

Do not use damaged, frayed or

deteriorated air

hoses and fittings.

Keep body stance

balanced and firm.

Do not overreach

when operating this

tool.

Operate at 90 psig

(6.2 bar/620 kPa)

Maximum air

pressure.

90 psig

(6.2bar/620kPa)

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

4

WARNING is used to indicate the presence of a hazard which

can cause severe personal injury or death if the warning is ignored.

CAUTION is used to indicate the presence of a hazard which will

or can cause minor personal injury or property damage if the caution is ignored.

NOTICE is used to notify people of installation, operation or main-

tenance information which is important but not hazard related.

This Craftsman Sander is designed to prepare metal and wood

surfaces for painting and finishing

operations.

WARNING:

Important safety information enclosed.

Read this manual before operating

tool.

It is the responsibility of an employer to place the information in

this manual into the hands of anyone who operates this device.

Failure to observe the following

warnings could result in injury.

SANDER SPECIFIC

WARNINGS

• These Sanders will operate at

the free speed specified on the

label if the air supply line furnishes 90 psig (6.2 bar/620

kPa) air pressure at the tool.

Operation at higher air pressure

will result in excessive speed.

• Use only a sanding pad, buffing

wheel or polishing bonnet with

these tools. Do not use any

grinding wheel, bur or metal

removing accessory with these

tools. Never use an accessory

having a maximum operating

speed less than the free speed

of the Sander in which it is

being used.

• When using a pad having a

shank, insert the shank to full

depth in the collet. When using

a pad on a threaded arbor,

make certain the flange nut is

tightened securely. Check the

tightness of the collet nut or

flange nut before operating a

Sander to make certain it will

not loosen during operation.

NOTICE: The use of other than

genuine Craftsman replacement

parts may result in safety hazards,

decreased tool performance, increased maintenance, and may

invalidate all warranties.

Repairs should be made only by

authorized trained personnel.

PLACING TOOL IN SERVICE

• Always operate, inspect and

maintain this tool in accordance

with all regulations (local, state,

federal and country), that may

apply to hand–held/hand–operated pneumatic tools.

• For safety, top performance,

and maximum durability of

parts, operate this tool at

90 psig (6.2 bar/620 kPa) maximum air pressure at the inlet

with 5/16” (8 mm) inside diameter air supply hose.

• Always turn off the air supply

and disconnect the air supply

hose before installing, removing

or adjusting any accessory on

this tool, or before performing

any maintenance on this tool.

5

• Do not use damaged, frayed or

deteriorated air hoses and fittings.

• Be sure all hoses and fittings

are the correct size and are

tightly secured. See Figure 4,

on page 6, for a typical piping

arrangement.

• Always use clean, dry air at

90 psig maximum air pressure.

Dust, corrosive fumes and/or

excessive moisture can ruin the

motor of an air tool.

• Do not lubricate tools with flammable or volatile liquids such as

kerosene, diesel or jet fuel.

• Do not remove any labels.

Replace any damaged label.

USING THE TOOL

• Always wear eye protection

when operating or performing

maintenance on this tool.

• Always wear hearing protection

when operating this tool.

• Keep hands, loose clothing and

long hair away from rotating

end of tool.

• Anticipate and be alert for sudden changes in motion during

start–up and operation of any

power tool.

• Keep body stance balanced

and firm. Do not overreach

when operating this tool. High

reaction torques can occur at or

below the recommended air

pressure.

• Tool shaft may continue to rotate briefly after throttle is released.

• Air powered tools can vibrate in

use. Vibration, repetitive motions or uncomfortable positions

may be harmful to your hands

and arms. Stop using any tool if

discomfort, tingling feeling or

pain occurs. Seek medical advice before resuming use.

• Use accessories recommended

by Craftsman.

• This tool is not designed for

working in explosive atmospheres.

• This tool is not insulated against

electric shock.

• Every 160 hours of tool operation, remove sanding pad from

spindle and inject 1 or 2 strokes

of multi–purpose bearing

grease through the end of the

spindle to lubricate the needle

bearing in the counter–balance.

• Rotate Knob on the Air Regulator (7) to adjust air flow.

(Figure 2)

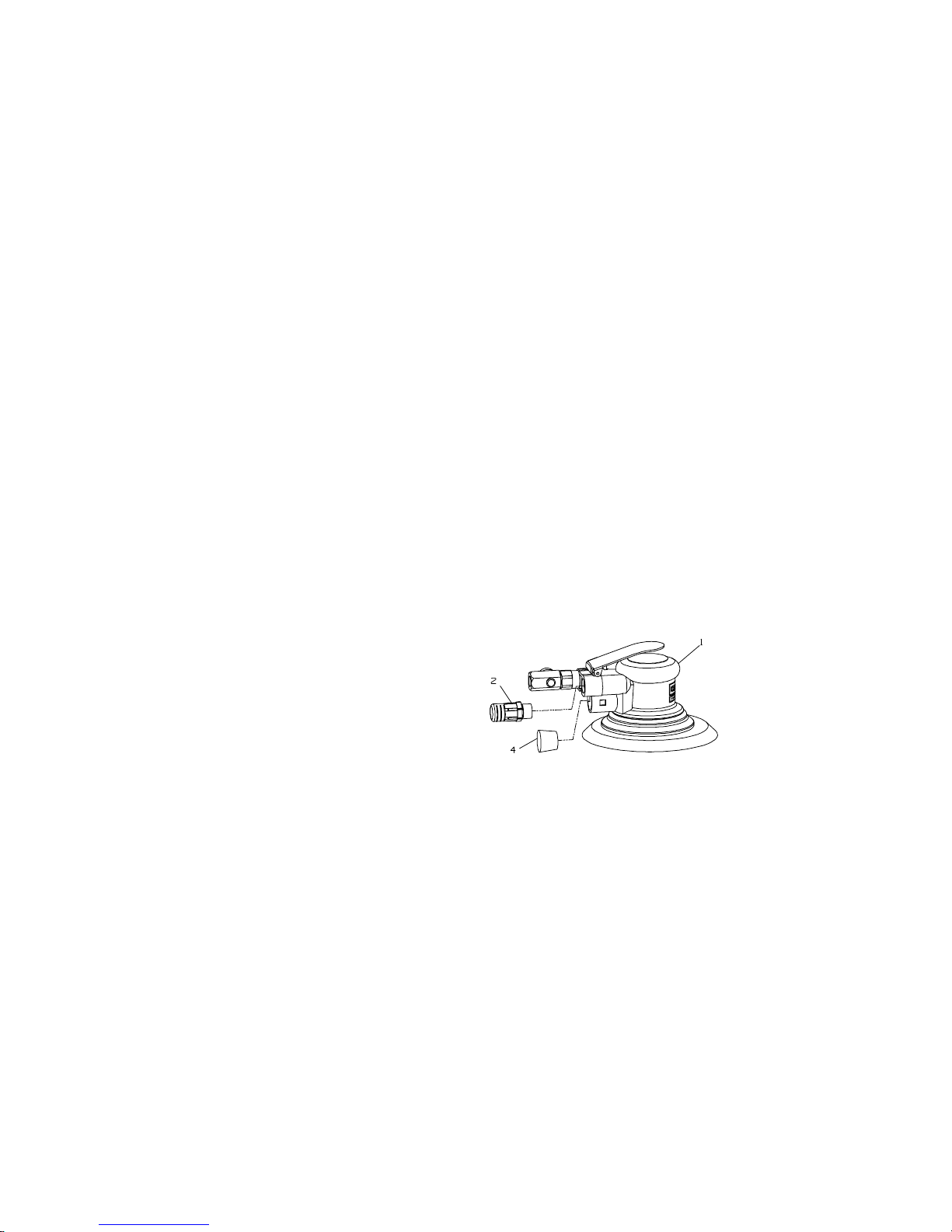

Standard Equipment

(Figure 1)

This Random Orbital Sander

comes with the Muffler (2) and

Plug (4) installed. Before using

optional equipment, one or all of

these parts must be removed.

See Figure 1 and instructions

below .

Figure 1

Optional Equipment

(Figures 1, 2 and 3)

For Use With Central Vacuum:

1.Remove the Muffler (2) and

Plug (4).

2.Install the Eductor Assembly

(5). Insert the tapered section

of the Eductor Assembly into the

Housing (1) while aligning the

threaded section with the

Housing. Using a wrench on

the flats, tighten the threaded

section securely. The tabs will

snap into slots in the Housing.

6

3.Install the central vacuum on

Eductor Assembly (5).

See Figure 2.

Figure 2

5

7

For Use With Vacuum Bag:

1.Remove Muffler (2) and Plug

(4).

2.Install the Eductor Assembly

(5). Insert the tapered section

of the Eductor Assembly into the

Housing (1) while aligning the

threaded section with the

Housing. Using a wrench on

the flats, tighten the threaded

section securely. The tabs will

snap into slots in the Housing.

3.Install the Vacuum Bag (6) on

the Eductor Assembly (5).

See Figure 3.

Figure 3

65

7

NOTICE: Before installing the

Eductor Assembly, make sure that

the Air Regulator (7) is installed

with the adjustment knob facing

away from the ports in the Housing. If the Air Regulator is not

installed in this manner, the adjustment knob will block the installation of the Eductor Assembly.

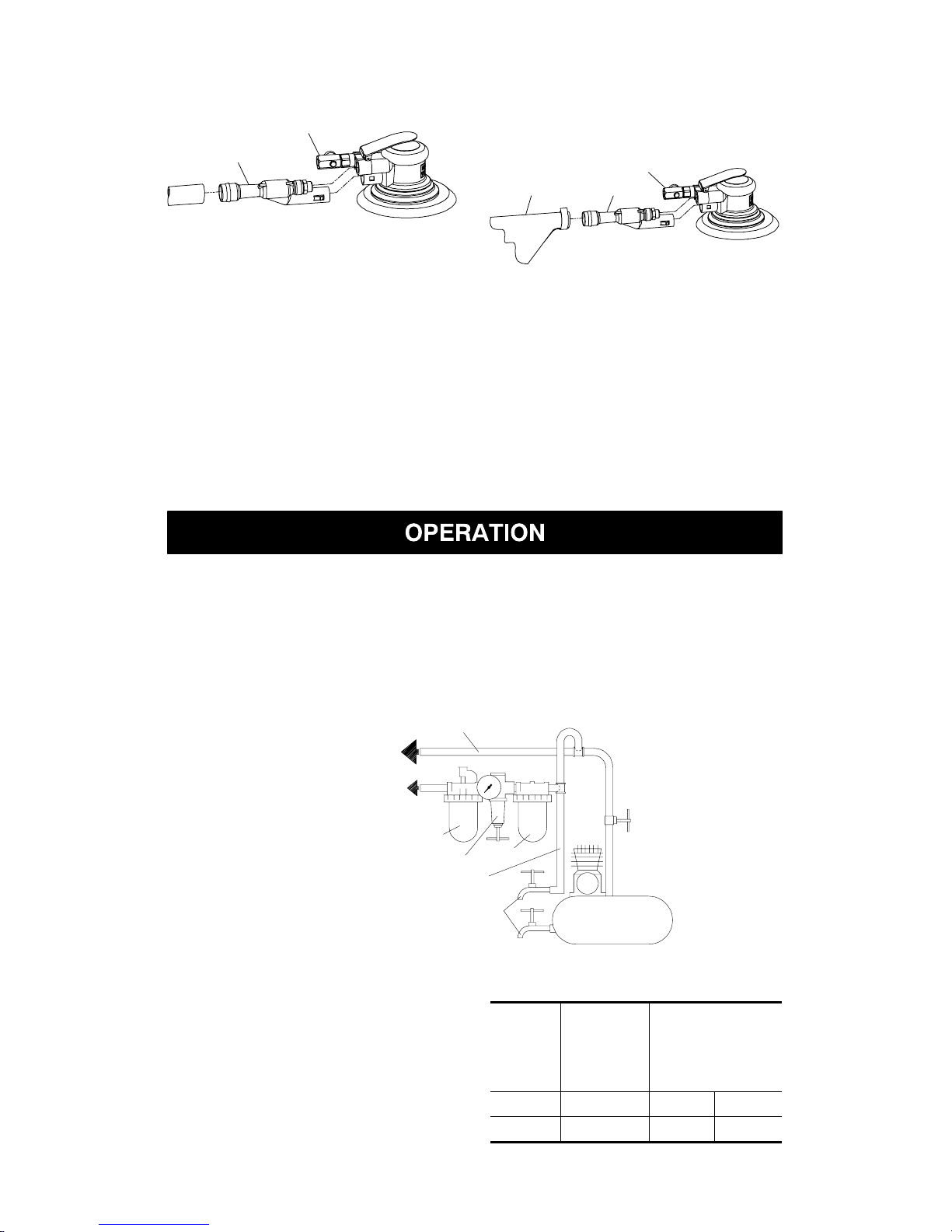

Air Supply and Connections

Always use clean dry air. Dust,

corrosive fumes and/or excessive

moisture can ruin the motor of an

air tool. An air line filter can greatly

increase the life of an air tool.

The filter removes dust and moisture. Be sure all hoses and fittings

are the correct size and are tightly

secured. See Figure 4 for a typical

piping arrangement.

Main lines 3 times air tool inlet size.

To air system

To air tool

Lubricator

Filter

Regulator

Branch line 2 times air

tool inlet size

Drain regularly

Compressor

Figure 4

Operating the Sander – With the

Sanding Pad on the work to be

sanded, grasp the Sander by the

Grip Ring with the palm of your

hand over the Lever. To begin

Sanding, apply pressure to the

Lever. To stop Sanding, release

the pressure on the Lever.

SPECIFICATIONS

Model Free

Speed

RPM

Pad Diameter

in mm

19906 12,000 6 152

Loading...

Loading...