Craftsman 235199050 Owner’s Manual

Owner's Manual

CRAFTSMIIN"

1/2" Drive Ultra-Duty

PISTOL GRIP IMPACT WRENCH

Model No.

235.199050

• Safety

° Operation

° Maintenance

° Service and

Adjustments

= Parts List

• Espa_oi

_WARNING:

Before using this Impact Wrench

read this manual and follow all its

Safety and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Owner'= M=nual P7360 (1-98) Printed In USA

TABLE OF CONTENTS

PAGE

Two Year Warranty

Safety

Warning Labels

Notice, Warning and Caution

Placing Tool In Service

Using the Tool

Operation

Air Supplyand Connections

Using the Power Management System

Specifications

Maintenance

Lubrication

Service and Adjustment

Disassembly

Assembly

Troubleshooting

Parts List

Exploded Drawing

Parts for Ordering

EspaSol 20-37

3-5

6-7

8-15

17-19

2

16

FULL TWO YEAR WARRANTY

If this product fails due to a defect in material or workmanship within

two years from the date of purchase, Sears will at its option, repair or

replace it free of charge.

Return this product to a Sears Service Center for repair,or to place of

purchase for replacement.

This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

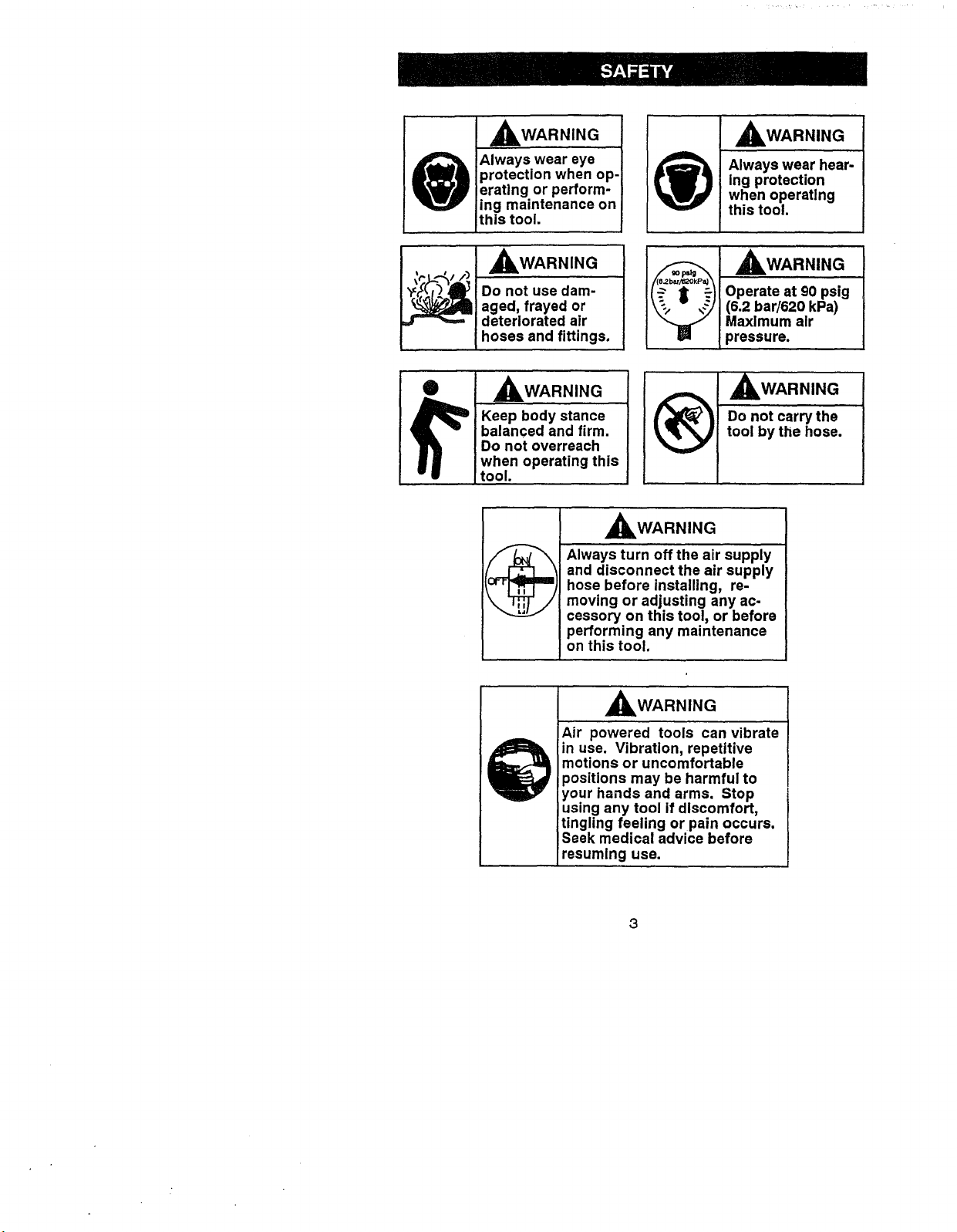

,_WARNING

Always wear eye

protection when op-

erating or perform-

ing maintenance on

this tool.

_WARNING

Always wear hear-

ing protection

when operating

this tool.

_._l_gl_ Do not use dam- Operate at 90 psig

aged, frayed or (6.2 bar/620 kPa)

deteriorated air Maximum air

hoses and fittings, i pressure.

Keep body stance Do not carry the

balanced and firm. tool by the hose.

Do not overreach

when operating this

tool.

,_WARNING

Always turn off the air supply

and disconnect the air supply

hose before installing, re-

moving or adjusting any ac-

cessory on this tool, or before

performing any maintenance

on this tool.

,_WARNING

Air powered tools can vibrate

in use. Vibration, repetitive

motions or uncomfortable

positions may be harmful to

your hands and arms. Stop

using any tool if discomfort,

tingling feeling or pain occurs.

Seek medical advice before

resuming use.

3

_WARNING is used to indicate the presence of a hazard which

can cause severe personal Injury or death if thewarning Is Ignored.

CAUTION is used to indicate the presence of a hazard which will

or can cause minor personal injury or property damage if the cau-

tion is Ignored.

NOTICE is used to notify people of installation, operation or main-

tenance information which is important but not hazard related.

This Craftsman Impact Wrench is

designed for use in general auto-

motive repair, tire service and

heavy duty fleet applications.

,_WARNING:

Important safety information en-

closed.

Read this manual before operating

tool.

It is the responsibility of an em-

ployer to place the information in

this manual into the hands of any-

one who operates this device.

Failure to observe the following

warnings could result in injury.

PLACING TOOL IN SERVICE

• Always operate, inspect and

maintain this tool in accordance

with all regulations (local, state,

federal and country), that may

apply to hand-held/hand-oper-

ated pneumatic tools.

• For safety, top performance,

and maximum durability of

parts, operate this toolat

90 psig (6.2 bar/620 kPa) maxi-

mum air pressure at the inlet

with 3/8" (10 mm) inside diame-

ter air supply hose.

° Always turn offthe air supply

and disconnect the air supply

hose before installing, removing

or adjusting any accessory on

this tool, or before performing

any maintenance on this tool.

• Do not use damaged, frayed or

deteriorated airhoses and fit-

tings.

° Be sure all hoses and fittings

are the correct size and are

tightly secured. See Figure 1 for

a typical piping arrangement.

° Always use clean, dry air at

90 psig maximum air pressure.

Dust, corrosive fumes and/or

excessive moisture can ruin the

motor of an air tool.

° Do not lubricate tools with flamo

mable or volatile liquids such as

kerosene, diesel or jet fuel.

PLACING TOOL IN SERVICE

(continued)

• Do not removeany labels. Re-

place any damagedlabel.

• The use of a hosewhip is rec-

ommended. A couplercon-

nected directlyto the air inletin-

creases tool bulkand de-

creases tool maneuverability.

• For maximum performance, the

coupler on thewallshould be

the next size largerthan the

coupler usedon the tool.The

coupler closesttothe tool

should notbe lessthanthe

proper air supplyhose size.

USING THE TOOL

• Always wear eye protection

when operatingor performing

maintenance on this tool.

• Always wear hearing protection

when operating this tool.

• Keep hands, loose clothing and

long hair away from rotating

end of tool.

• Note the position of the revers-

ing lever before operating the

tool so as to be aware of the

direction of rotation when oper-

ating the throttle.

• Anticipate and be alert for sud-

den changes in motion during

start-up and operation of any

power tool.

• Keep body stance balanced

and firm. Do not overreach

when operating this tool. High

reaction torques can occur at or

below the recommended air

pressure.

• Tool shaft may continue to ro-

tate briefly after throttle is re-

leased.

• Air powered tools can vibrate in

use. Vibration, repetitive mo-

tions or uncomfortable positions

may be harmful to your hands

and arms. Stop using any tool ff

discomfort, tingling feeling or

pain occurs. Seek medical ad-

vice before resuming use.

• Use accessories recommended

by Craftsman.

• Use only impact sockets and

accessories. Do not use hand

(chrome) sockets or accesso-

ries.

• Impact wrenches are not torque

wrenches. Connections requir-

ing specific torque must be

checked with a torque meter af-

ter fitting with an impact

wrench.

• This tool is not designed for

working in explosive atmo-

spheres.

° This tool is not insulated against

electric shock.

NOTICE: The use of other than

genuine Craftsman replacement

parts may result in safety hazards,

decreased tool performance, in-

creased maintenance, and may

invalidate all warranties.

Repairs should be made only by

authorized trained personnel.

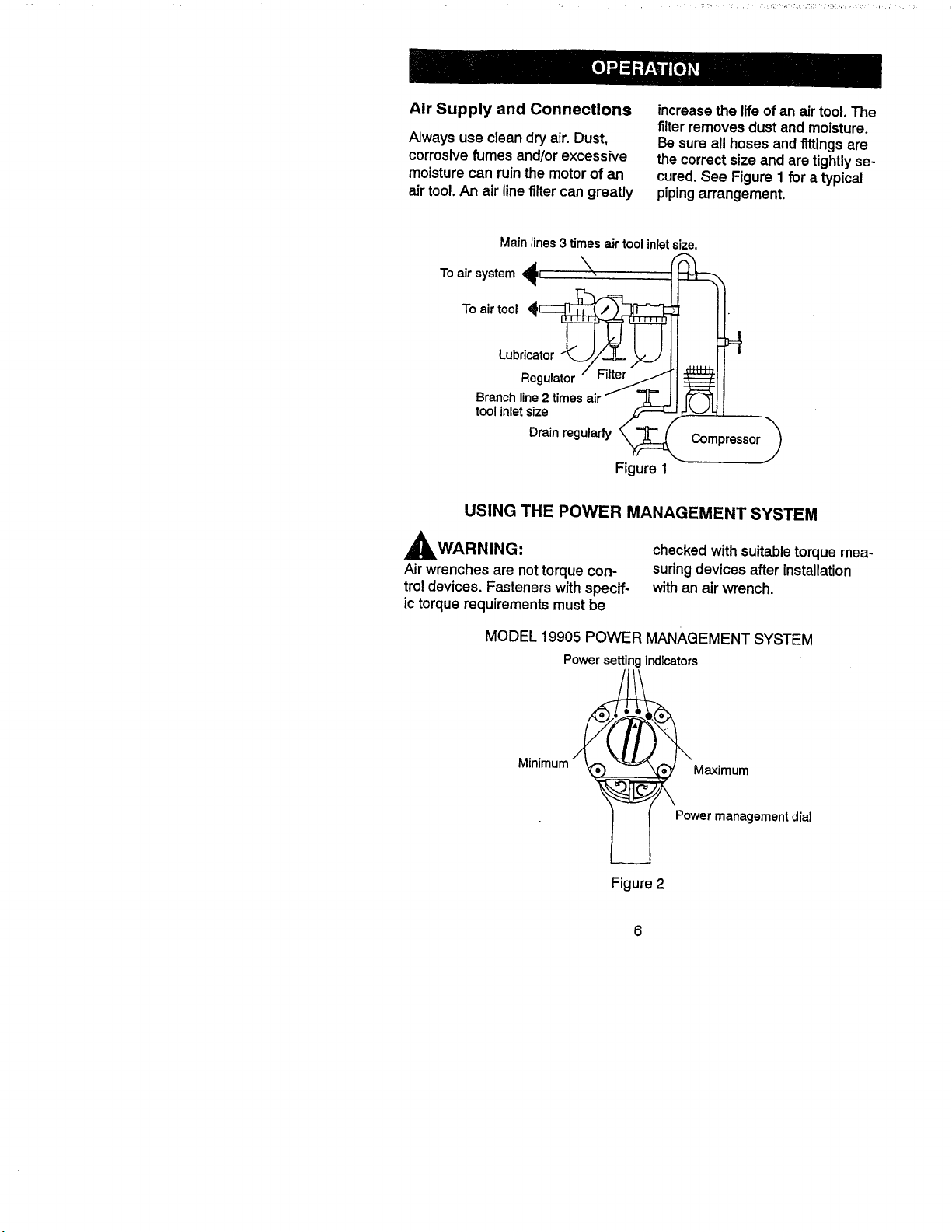

Air Supply and Connections

Always use clean dry air.Dust,

corrosivefumes and/or excessive

moisture can ruinthe motor of an

air tool. An air line filter can greatly

Main lines 3 timesair tool inletsize.

Toairtool

Lubri

Branch line 2 times air - _ I [_ _1 I

toolinletsize _,,//_/-.-,- ,t =

Drainregulady_ Compressor_

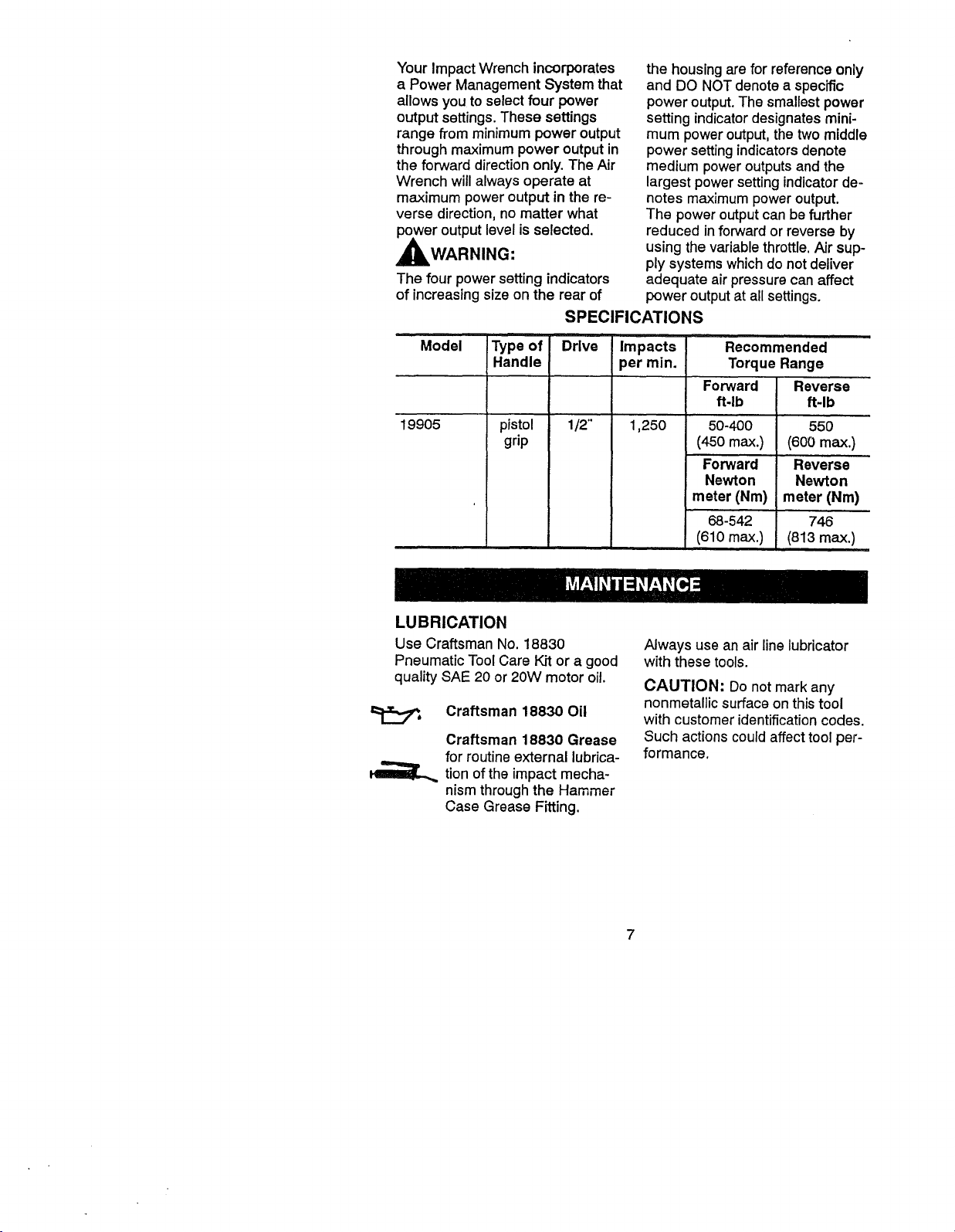

USING THE POWER MANAGEMENT SYSTEM

increasethe life of anair tool. The

filterremoves dustand moisture.

Besure all hoses andfittingsare

the correct sizeand are tightlyse-

cured.See Figure1 for a typical

pipingarrangement.

Figure 1

,_WARNING:

Airwrenches are nottorquecon-

trotdevices. Fastenerswith specif-

ictorquerequirementsmust be

MODEL 19905 POWER MANAGEMENT SYSTEM

Power settingindicators

Minimum

Figure2

checked with suitabletorque mea-

suringdevices afterinstallation

with an air wrench.

Maximum

Power management dial

6

YourImpactWrench incorporates

a Power Management System that

allows you to select four power

output settings. These settings

range from minimum power output

through maximum power output in

the forward direction only. The Air

Wrench will always operate at

maximum power output in the re-

verse direction, no matter what

power output level is selected.

AWARNING:

The four powersettingindicators

of increasingsize onthe rear of

SPECIFICATIONS

the housing are for reference only

and DO NOT denote a specific

power output. The smallest power

setting indicator designates mini-

mum power output, the two middle

power setting indicators denote

medium power outputs and the

largest power setting indicator de-

notes maximum power output.

The power output can be further

reduced in forward or reverse by

using the variable throttle. Air sup-

ply systems which do not deliver

adequate air pressure can affect

power output at all settings.

Model Type of Drive Impacts

Handle per min.

19905

pistol 1/2'" 1,250

grip

LUBRICATION

Use Craftsman No. 18830

Pneumatic Tool Care Kit or a good

quality SAE 20 or 20W motor oil.

Craftsman 18830 Oil

Craftsman 18830 Grease

for routine external lubrica-

tion of the impact mecha-

nism through the Hammer

Case Grease Fitting.

Recomm'ended

Torque Range

Forward

ft.lb

50-400

(450 max.)

Forward

Newton

meter (Nm)

68-542

(610 max.)

Reverse

ft-lb

55O

(600 max.)

Reverse

Newton

meter (Nm)

746

(813 max,)

Always use an air line lubricator

with these tools.

CAUTION: Donot mark any

nonmetallic surface on this tool

with customer identification codes.

Such actions could affect tool per-

formance.

7

DISASSEMBLY

NOTICE: Numbers in paren-

theses in the following instruc-

tons are part illustration num-

bers found on pages 17-19.

General Instructions

1. Do not disassemble the tool any

further than necessary to re-

place or repair damaged parts.

2. Whenever grasping atool or

part in a vise, always use lea-

ther-covered vise jaws to pro-

tect the surface of the part and

help prevent distortion. This is

particularly true of threaded

members and housings.

NOTICE: Always use lea-

ther-covered vise jaws when

clamping the handle in a vise.

Leather will conform to the

shape of the handle and allow

the tool to be held securely. To

prevent damage to the exhaust

diffuser, never clamp only the

bottom of the handle.

3. Do not disassemble the tool

unless you have a complete set

of new gaskets and O-rings for

replacement.

Disassembly of the Impact

Wrench

1. Clamp the handle of the impact

wrench in a vise with leather-

covered jaws withthe square

driver positioned horizontally.

NOTICE: Avoid excessive

clamping pressure which can

damage the Housing and can

cause difficulty when removing

the parts.

2. Unscrew and remove the four

Hammer Case Screws (11).

3. While lightly tapping on the end

of the Anvil (8) with a plastic

hammer, lift off the Hammer

Case (15) and Hammer Case

Gasket (18).

NOTICE: The Front End Plate

(2) might come off during the

removal of the Hammer Case.

Make sure that itdoes not drop

on the floor or strike a hard or

metallic surface since it might

be damaged.

4. Grasp the Hammer Frame (12)

and carefully lift off the entire

impact mechanism, making cer-

tain not to drop the two Ham-

mer Pins (13).

Disassembly of the Impact

Mechanism

1. Set the mechanism, driver end

up, on the workbench.

NOTICE: Note the twin ham-

mers within the Hammer

Frame. These are identical, but

must be placed in the Hammer

Frame in a certain relationship.

Using a felt-tipped pen, mark

the top "Tt" hammer and the

bottom hammer "Bt" with the

arrows pointing upward. Mark

both Hammers on the same

end.

2. With the mechanism sitting up-

right on the workbench, slowly

rotate the Anvil in a clockwise

direction until it comes up solid.

NOTICE: If you continueto ro-

tate the Anvil, it will cam the

Hammers out of engagement.

Don't do this; merely rotate the

Anvil until itcomes up solid.

3. Hold the Hammer Frame firmly

and without disturbing the ham-

mers, gently lift the Anvil while

simultaneously rotating it clock-

wise about 1/8 of a turn from

the Hammer Frame.

4. With the Anvil removed, lift out

the two Hammer Pins. The twin

hammers are now free to slide

from the Hammer Frame, Be

careful do not to drop them.

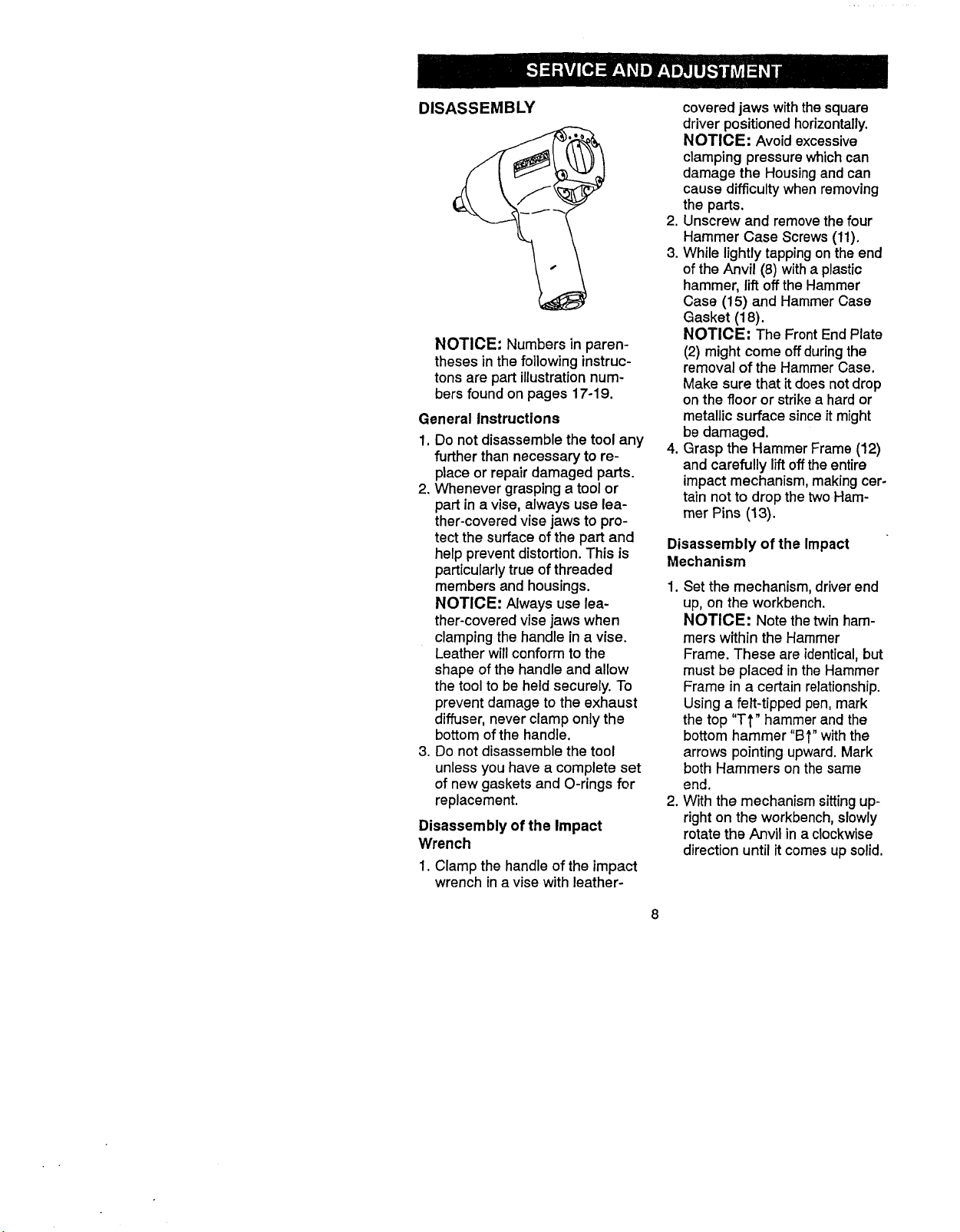

Disassembly of the Motor

NOTICE: When pulling, disas-

sembling or assemblingthe mo-

tor, we recommendreplace-

ment of the MotorGasket (7).

1. Remove the MotorAssembly

from the Housing(19) bypush-

ingon Power Management Dial

(41) from the back ofthe

Housing. See Figure3.

splined end of the Rotor (5) with

a plastic hammer. If the Front

End Plate does not come loose,

secure a center punchin a vise

with the point angled downward

and outward from the vise.

Then, grasp the Cylinder and

Front End Plate in one hand

and position the hole in the end

of the Rotor against the punch.

NOTICE: Be careful not to

drop the Cylinder since it can

be damaged by hitting a hard

surface.

Using the other hand, tap the

punch with a hammer while

pressing the Rotor against the

punch. After a few taps, the

Front End Plate will slide off of

the Cylinder.

NOTICE: To prevent damage

to the Cylinder, do not tap or

strike Cylinder on a hard or me-

tallic surface when removing

the Rotor Bearings (3).

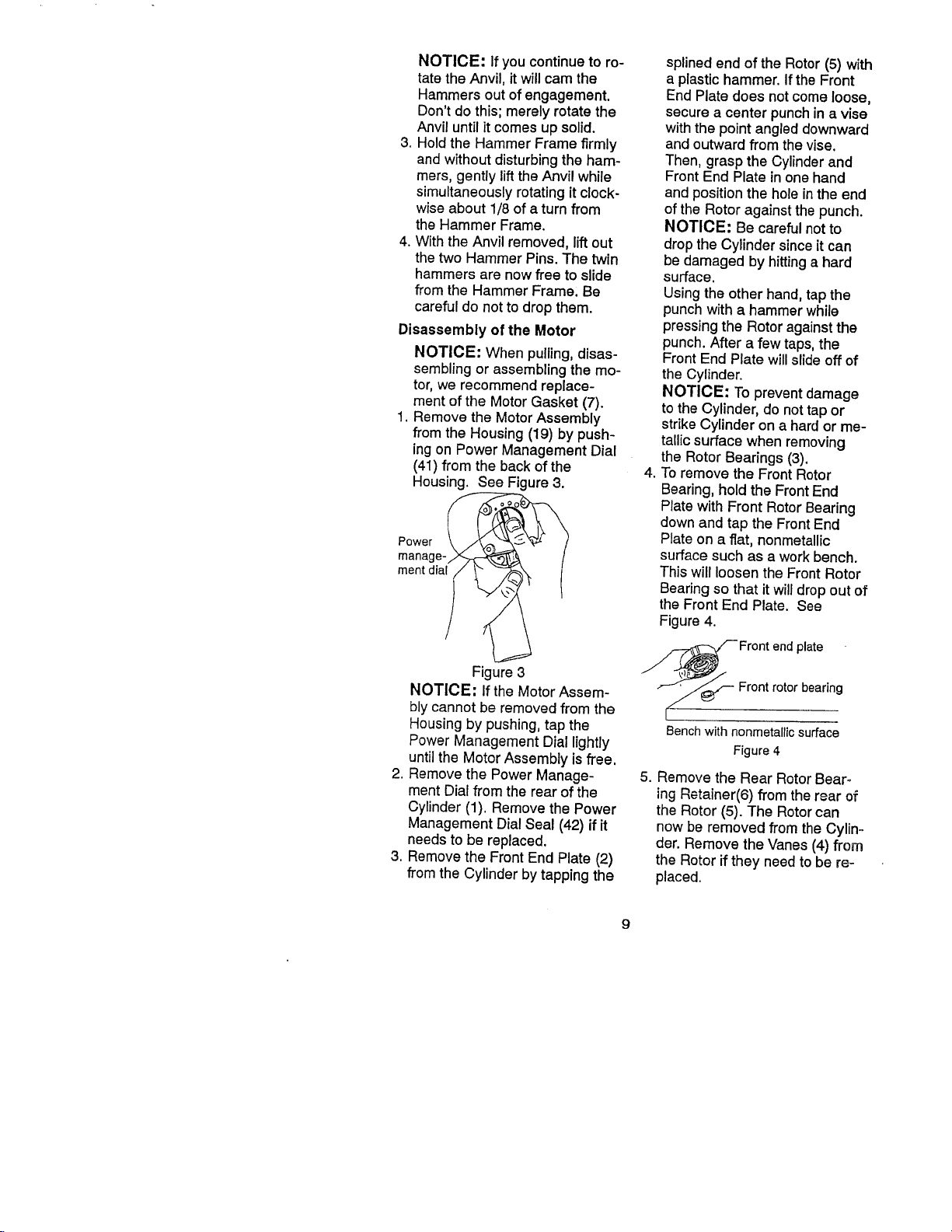

4,

To remove the Front Rotor

Bearing, hold the Front End

Plate with Front Rotor Bearing

down and tap the Front End

Plate on a flat, nonmetallic

surface such as awork bench.

This will loosen the Front Rotor

Bearing so that it will drop out of

the Front End Plate. See

Figure 4.

Figure 3

NOTICE; If the Motor Assem-

bly cannot be removed from the

Housing by pushing, tap the

Power Management Dial lightly

until the Motor Assembly is free.

2. Remove the Power Manage-

ment Dial from the rear of the

Cylinder (1). Remove the Power

Management Dial Seal (42) if it

needs to be replaced.

3. Remove the Front End Plate (2)

from the Cylinder by tapping the

Front end plate

Front rotor bearing

Bench with nonmetallic surface

Figure 4

5. Remove the Rear RotorBear-

ingRetainer(6) from the rear of

the Rotor (5). The Rotor can

now be removed from the Cylino

der. Remove the Vanes (4) from

the Rotor if they need to be re-

placed.

e

Rear rotor bearing

_ Cylinder

Bench with nonmetallic surface

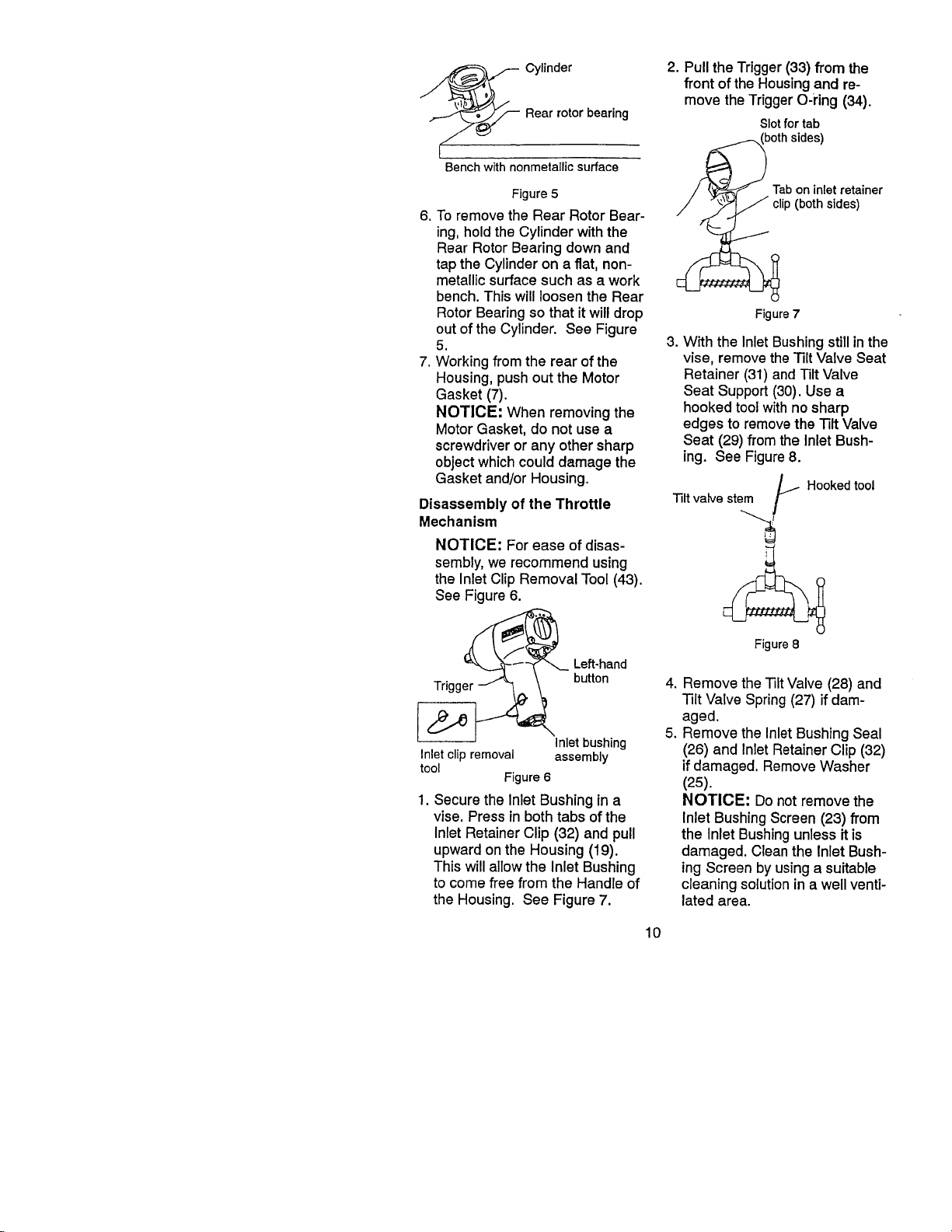

Figure 5

6. To remove the Rear Rotor Bear-

ing, hold the Cylinder with the

Rear Rotor Bearing down and

tap the Cylinder on a flat, non-

metallic surface such as a work

bench. This will loosen the Rear

Rotor Bearing so that it will drop

out of the Cylinder. See Figure

5.

7. Working from the rear of the

Housing, push out the Motor

Gasket (7).

NOTICE: When removing the

Motor Gasket, do not use a

screwdriver or any other sharp

object which could damage the

Gasket and/or Housing.

Disassembly of the Throttle

Mechanism

NOTICE: For ease of disas-

sembly, we recommend using

the inlet Clip Removal Tool (43).

See Figure 6.

2. Pull the Trigger (33) from the

front of the Housing and re-

move the Trigger O-ring (34).

SIotfortab

Tab on inlet retainer

clip (both sides)

Figure 7

3. With the Inlet Bushing stillinthe

vise, remove the Tilt Valve Seat

Retainer (31) and Tilt Valve

Seat Support (30). Use a

hooked tool with no sharp

edges to remove the Tilt Valve

Seat (29) from the Inlet Bush-

ing. See Figure 8.

Hooked tool

Tilt valve stem

Left-hand

button

Inlet clip removal assembly

tool

Figure 6

Inlet bushing

1. Secure the Inlet Bushing in a

vise. Press in both tabs of the

Inlet Retainer Clip (32) and pull

upward on the Housing (19).

This will allow the Inlet Bushing

to come free from the Handle of

the Housing. See Figure 7.

Figure 8

.

Remove the TiltValve (28) and

-lilt Valve Spring (27) if dam-

aged.

5°

Remove the inlet Bushing Seal

(26) and Inlet Retainer Clip (32)

if damaged. Remove Washer

(25).

NOTICE: Do not remove the

Inlet Bushing Screen (23) from

the Inlet Bushing unless it is

damaged. Cleanthe Inlet Bush-

ing Screen by using a suitable

cleaning solution in a well venti-

lated area.

10

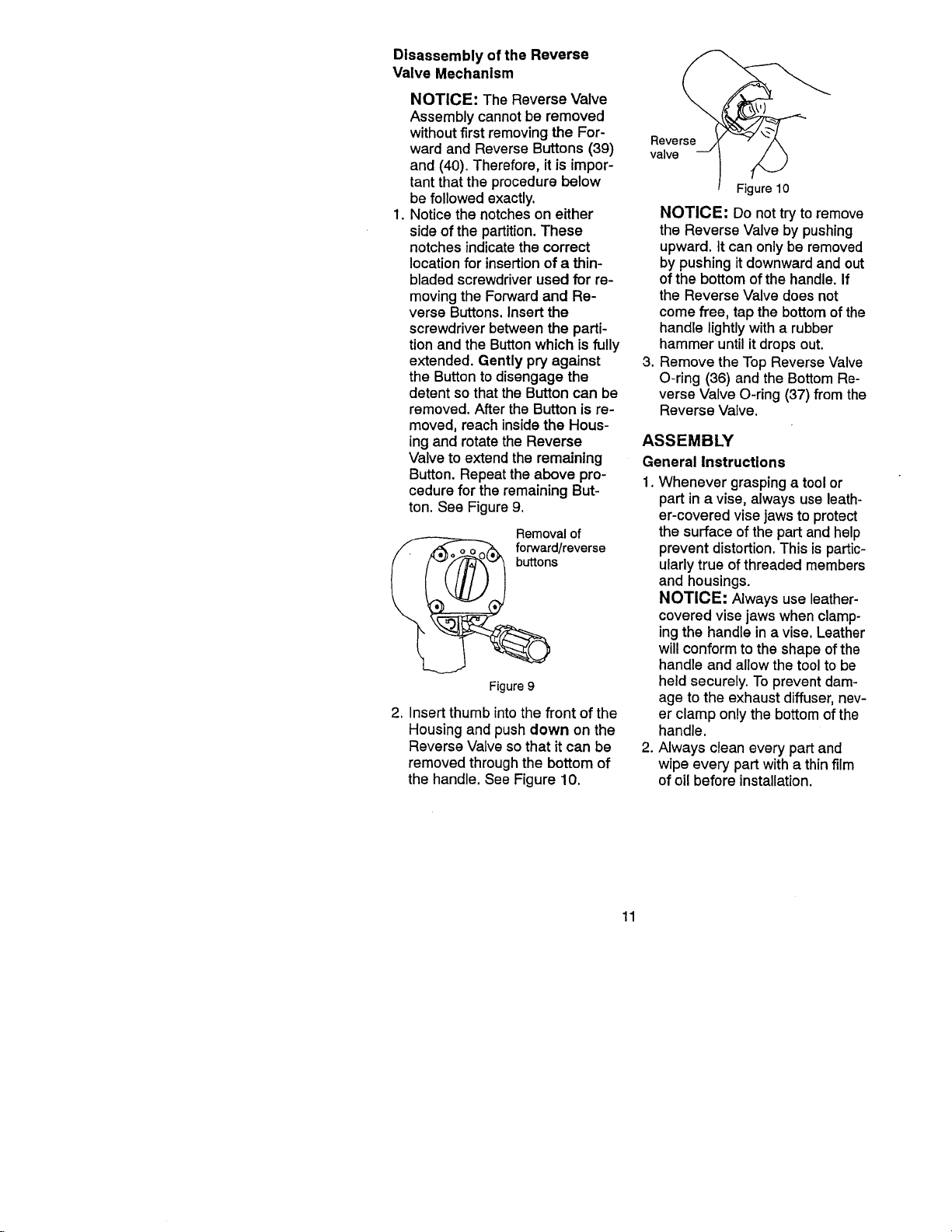

Disassembly of the Reverse

Valve Mechanism

NOTICE: The Reverse Valve

Assembly cannot be removed

without first removing the For-

ward and Reverse Buttons (39) valve

and (40). Therefore, it is impor-

tant that the procedure below

be followed exactly.

1. Notice the notches on either

side of the partition. These

notches indicate the correct

location for insertion of a thin-

bladed screwdriver used for re-

moving the Forward and Re-

verse Buttons. Insert the

screwdriver between the parti-

tion and the Button which is fully

extended. Gently pry against 3.

the Button to disengage the

detent so that the Button can be

removed. After the Button is re-

moved, reach inside the Hous-

ing and rotate the Reverse

Valve to extend the remaining

Button. Repeat the above pro-

cedure for the remaining But-

ton. See Figure 9.

Removal of

_ _°uttrWoard/reverse

Figure 9

2. Insert thumb into the front of the

Housing and push down on the

Reverse Valve so that it can be

removed through the bottom of

the handle. SeeFigure 10.

Reverse

Figure 10

NOTICE: Do not try to remove

the Reverse Valve by pushing

upward. It can only be removed

by pushing it downward and out

of the bottom of the handle. If

the Reverse Valve does not

come free, tap the bottom of the

handle lightly with a rubber

hammer until it drops out.

Remove the Top Reverse Valve

O-ring (36) and the Bottom Re-

verse Valve O-ring (37) from the

Reverse Valve.

ASSEMBLY

General Instructions

1. Whenever grasping a tool or

part in a vise, always use leath-

er-covered vise jaws to protect

the surface ofthe part and help

prevent distortion.This ispartic-

ularlytrue of threadedmembers

and housings.

NOTICE: Always use leather-

covered visejaws when clamp-

ingthe handle ina vise, Leather

willconformto the shapeofthe

handle and allowthetoolto be

heldsecurely.To prevent dam-

age to the exhaust diffuser, nev-

er clamp only the bottom of the

handle.

2. Always clean every part and

wipe every part with a thin film

of oil before installation.

11

NOTICE: Do not remove

grease from the impactmecha-

nismor Hammer Case (15). If

the impactmechanism has not

been disassembled,inject

Craftsman No. 18830 Grease

throughthe Hammer Case

Grease Fitting(17). When dis-

assemblingand assemblingthe

impactmechanism,remove all

grease from the impactmecha-

nism and Hammer Case and lu-

bricatethe impactmechanism

and Hammer Case Bushing

(16) with Craftsman No. 18830

Grease.

3. Apply a filmof o-ringlubricantto

all O-rings beforefinal assem-

bly.

Assembly of the Reverse Valve

Mechanism

1. Install the Bottom Reverse

Valve O-ring (37) (color-coded

blue) and theTop Reverse

Valve bring(36) on the Reverse

Valve (35).

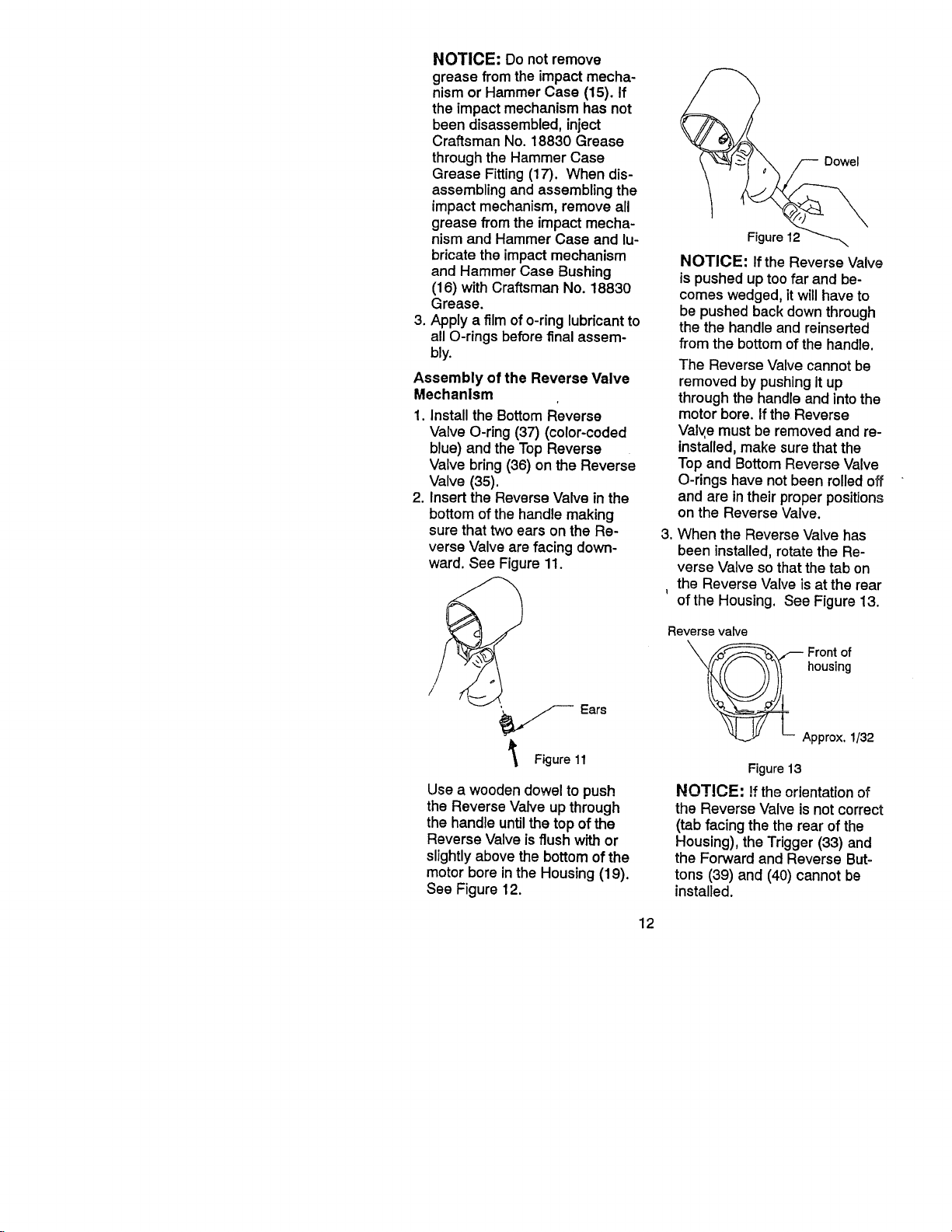

2. Insert the ReverseValve in the

bottomof the handlemaking

sure thattwoears on the Re-

verseValve are facing down-

ward.See Figure 11.

Dowel

Figure12

NOTICE: If the Reverse Valve

is pushed up too far and be-

comes wedged, itwillhave to

be pushed backdownthrough

the the handleand reinserted

from the bottomof the handle.

The Reverse Valve cannot be

removed by pushing it up

through the handle and into the

motor bore. If the Reverse

Valve must be removed and re-

installed, make sure that the

Top and Bottom Reverse Valve

O-rings have not been rolled off

and are in their proper positions

on the Reverse Valve.

3. When the Reverse Valve has

been installed, rotate the Re-

verse Valve so that the tab on

the Reverse Valve is at the rear

I

of the Housing. See Figure 13.

/_ Ears

Figure 11

Use a wooden dowel to push

the Reverse Valve up through

the handle until the top of the

Reverse Valve is flush with or

slightly above the bottom of the

motor bore in the Housing (19).

See Figure 12.

Reverse valve

housing

__ Front of

Approx, 1/32

Figure13

NOTICE: !f the orientation of

the Reverse Valve is not correct

(tab facing the the rear of the

Housing), the Trigger (33) and

the Forward and Reverse But-

tons (39) and (40) cannot be

installed.

12

Loading...

Loading...