Craftsman 226165291 Owner’s Manual

Operator's Manual

[RRFTSMRN°

Permanently Lubricated

Tank Mounted

AIR COMPRESSOR

Model No.

226.165291

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179LU _

17939.02 Draft (06/19/02)

• Safety Rules

• Operation

• Maintenance

• Parts List

Warranty ....................................... 2

Safety Rules .................................... 2

Glossary ..................................... 2-3

Installation.................................... 3-4

Operation .................................... 4-6

Maintenance .................................. 6-7

Storage ....................................... 7

Troubleshooting ................................ 8-9

Parts Illustration and List ....................... 10-11

FULL ONE YEAR WARRANTY ON CRAFTSMAN

AIR COMPRESSOR

Ifthis Craftsman air compressorfalls due to a defect in materi-

al or workmanship within one full year from the date of pur-

chase, return it to the nearest Sears Service Center in the

United States, and Sears will repair it free of charge.

If this air compressor is used for commercial purposes, this

warranty applies for only 90 days from the date of purchase.

This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL

60179

WARNING: For your own safety read all of the instructions

and precautions before operating tool.

CAUTION: Always follow proper operating procedures as

defined in this manual even if you are familiar with use of this

or similar tools. Remember that being careless for even a

fraction of a second can result in severe personal injury.

• Always operate the compressor in a well ventilated area

free of combustible materials, gasoline or solvent vapors.

• If spraying flammable materials, locate compressor at least

20 feet away from spray area. An additional length of hose

may be required. Store flammable materials in a secure

location away from compressor.

• Never place objects against or on top of compressor.

Operate compressor in an open area at least 12 inches

away from any wall or obstruction that would restrict the

flow of fresh air to the ventilation openings,

• Operate compressor is a clean, dry, well ventilated area.

Do not operate unit indoors or in any confined area.

• Always remain in attendance with the product when it is

operating.

• Drain tank daily or after each use. If tank develops a leak,

replace it immediately with a new tank or replace the

entire compressor.

• Never drill into, weld or make any modifications to the tank

or its attachments.

• The tank is designed to withstand specific operating pres-

sures. Never make adjustments or parts substitutions to

alter the factory set operating pressures.

• For essential control of air pressure, you must install a

pressure regulator and pressure gauge to the air outlet (if

not equipped) of your compressor. Follow the equipment

manufacturers recommendation and never exceed the

maximum allowable pressure rating of attachments. Never

use compressor to inflate small low-pressure objects such

as children's toys, footballs, basketballs, etc.

Always wear ANSI Z87.1 approved safety glasses with

side shields when using the compressor.

Never point any nozzle or sprayer toward any part of the

body or at other people or animals.

Always turn the compressor off and bleed pressure from

the air hose and tank before attempting maintenance,

attaching tools or accessories.

Never operate the compressor outdoors when it is raining

or in wet conditions.

Never operate compressor with protective covers removed

or damaged.

Any electrical wiring or repairs required on this product

should be performed by authorized service center person-

nel in accordance with national and local electrical codes.

• Make certain that the electrical circuit to which the com-

pressor is connected provides proper electrical grounding,

correct voltage and adequate fuse protection.

Air obtained directly from the compressor should never be

used to supply air for human consumption, in order to use

air produced by this compressor for breathing, suitable fil-

ters and in-line safety equipment must be properly

installed. In-line filters and safety equipment used in con-

junction with the compressor must be capable of treating

air to all applicable local and federal codes prior to human

consumption.

• Work in an area with good cross-ventilation. Read and fol-

low the safety instructions provided on the label or safety

data sheets for the material you are spraying. Use a

NIOSH/MSHA approved respirator designed for use with

your specific application.

• Never touch any exposed metal parts on compressor dur-

ing or immediately after operation. Compressor will remain

hot for several minutes after operation.

Do not reach around protective shrouds or attempt mainte-

nance until unit has been allowed to cool.

Always operate compressor in a stable secure position to

prevent accidental movement of the unit. Never operate

compressor on a roof or other elevated position. Use addi-

tional air hose to reach high locations.

Become familiar with these terms before operating the unit.

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of measure of

air delivery.

PSIG: Pounds per square inch gauge; a unit of measure of

pressure.

Code Certification: Products that bear one or more of the

following marks: UL, CUL, ETL, CETL, have been evaluated

by OSHA certified independent safety laboratories and meet

the applicable Underwriters Laboratories Standards for Safety.

Cut-In Pressure: While the motor is off, air tank pressure

drops as you continue to use your accessory.When the tank

pressure drops to a certain low level the motor will restart

automatically,The low pressure at whichthe motor automati-

cally restartsis called "cut-in"pressure.

2

Cut-OutPressure:Whenanaircompressoristurnedonand

begins to run, air pressure in the air tank begins to build, it

buildsto a certain high pressure before the motor automati-

cally shuts off- protecting your air tank from pressure higher

than its capacity. The high pressure at which the motorshuts

off is called "cut-out" pressure.

Branch Circuit: Cimuit carrying electricity from electrical

panel to outlet.

LOCATION OF THE AIR COMPRESSOR

Locate the air compressor in a clean, dry and well ventilated

area. The air compressor should be located at least 12" away

from the wall or other obstructions that will interfere with the

flow of air. The air compressor pump and shroud are designed

to allow for proper cooling.The ventilation openings on the

compressor are necessary to maintain proper operating tem-

perature. Do not place rags or other containers on or near

these openings.

POWER SOURCE

The motor is designed for operation on the voltage and fre-

quency specified. Normal loads will be handled safely on volt-

ages not more than 10% above or below specified voltage.

Runningthe unit on voltageswhich are not within range may

cause overheating and motor burn-out. Heavy loads require

that voltage at motor terminals be no less than the voltage

specified on nameplate.

• Air compressor requires a 115 volt, 60 Hz power source.

GROUNDING INSTRUCTIONS

WARNING: Improper connection of equipment grounding

conductor can resultin the risk of electrical shock. Equipment

should be grounded while in use to protect operator from

electrical shock.

• Check with a qualified electrician if you do not understand

grounding instructions or if you are in doubt as to whether

the tool is properly grounded,

• This tool is equipped with an approved 3-conductor cord

rated up to 240V and a 3-prong grounding type plug rated

at 115V (See Figure 1) for your protection against shock

hazards.

• Grounding plug should be plugged directly into a properly

installed and grounded 3-prong greunding-type receptacle,

as shown (See Figure 1),

Properly Grounded Outlet

Grounding Prong

3-Prong Plug _

Figure 1 - 3-Prong Receptacle

fit in outlet, have proper outlet installed by a qualified

electrician.

• Inspect tool cords periodically, and if damaged, have

repaired by an authorized service facility.

• Green (or green and yellow) conductor in cord is the

grounding wire. if repair or replacement of the electric cord

or plug is necessary, do not connect the green (or green

and yellow) wire to a live terminal.

• Where a 2-prong wall receptacle is encountered, it must

be replaced with a properly grounded 3-prong receptacle

installed in accordance with National Electric Code and

local codes and ordinances.

WARNING: Any receptacle replacement should be per-

formed bya qualified electrician.

A temporary3-prong to 2-prong grounding adapter (See

Figure2) is available for connecting plugstoa two pole outlet

if it is properly grounded.

Grounding Lug Make Sure This

Adapter \

3-Pron_. _ Greund

2-Prong Receptacle

Figure 2 - 2-Prong Receptacle with Adapter

• Do not use a 3-prong to 2-preng grounding adapter unless

permitted by local and national codes and ordinances. (A

3-preng to 2-preng grounding adapter is notpermitted in

Canada,)

• Where a 3-prong to 2-preng grounding adapter ispermit-

ted, the rigidgreen tab or terminal on the side of the

adapter must besecurely connected to a permanent elec-

trical ground such as a properly grounded water pipe, a

properly grounded outlet box or a properly grounded wire

system.

• Many cover plate screws, water pipes and outlet boxesare

not properly grounded. Toensure proper ground, ground-

ing means must be tested by a qualified electrician,

EXTENSION CORDS

• The use of any extension cord will cause some drop in

voltage and loss of power.

• Wires of the extension cord must be of sufficient size to

carry the current and maintain adequate voltage.

• Use the table to determine the minimum wire size (A.W.G.)

extension cord.

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool

plug.

• Ifthe extension cord is worn, cut or damaged in any way,

replace itimmediately.

• Do not remove oralter grounding preng in any manner. In the

event of a malfunction or breakdown, grounding provides a

path of least resistance for electrical shock.

WARNING: Do not permit fingers to touch the terminals of

plug when installing or removing from outlet.

• Plug must be plugged into matching outlet that is properly

installed and grounded in accordance with all local codes

and ordinances. Do not modify plug provided. If it will not

EXTENSION CORD LENGTH

Wire Size A.W.G.

Up to 50 ff..................................... 12

NOTE: Using extension cords over 50 ft. long is not

recommended.

3

VOLTAGE AND CIRCUIT PROTECTION

This air compressor can be operated on a 15 amp circuit if

the following conditions are met.

• Voltage supply threugh branch circuit is 15 amps.

• Circuit is not used to supply any other electrical needs

(lights, appliances, etc.)

• Extension cords comply with specifications.

• Circuit is equipped with a 15 amp circuit breaker or 15

amp time delay fuse.

NOTE: If compressor is connected to a circuit protected by

fuses, use only time delay fuses marked "D".

If any of the above conditions cannot be met, or if operation of

the compressor repeatedly causes interruption of the power, it

may be necessary to operate it from a 20 amp circuit. It is not

necessary to change the line cord.

DESCRIPTION

The Craftsman permanently lubricated air compressor con-

sists of a one cylinder, single-stage air compressor pump and

air tank. This air compressor requires no oil.Your air compres-

sor can be used for operating paintspray guns, air tools, blow

guns, nailers/staplers, air brushes and inflator kits,An inline

are filter which removes moisture and dirt from compressed

air should be used where applicable. An inline regulator can

be used if a more precise adjustment of air pressure is need-

ed downstream.

SPECIFICATIONS

HP (Max. Developed) ............................. 2

Displacement ............................. 4.6 CFM

Bore ....................................... 1.85"

Stroke ..................................... 0.86"

Voltage-Single Phase .......................... 115 V

Minimum Branch Circuit Requirement .............. 15A.

Fuse Type ............................. Amps Delay

Air Tank Capacity .......................... 6 Gallons

Approximate Cut-In Pressure .................. 110 PSI

Approximate Cut-Out Pressure ................. 150 PSI

SCFM@40 psi ................................. 3.9

SCFM@90 psi ................................. 2.7

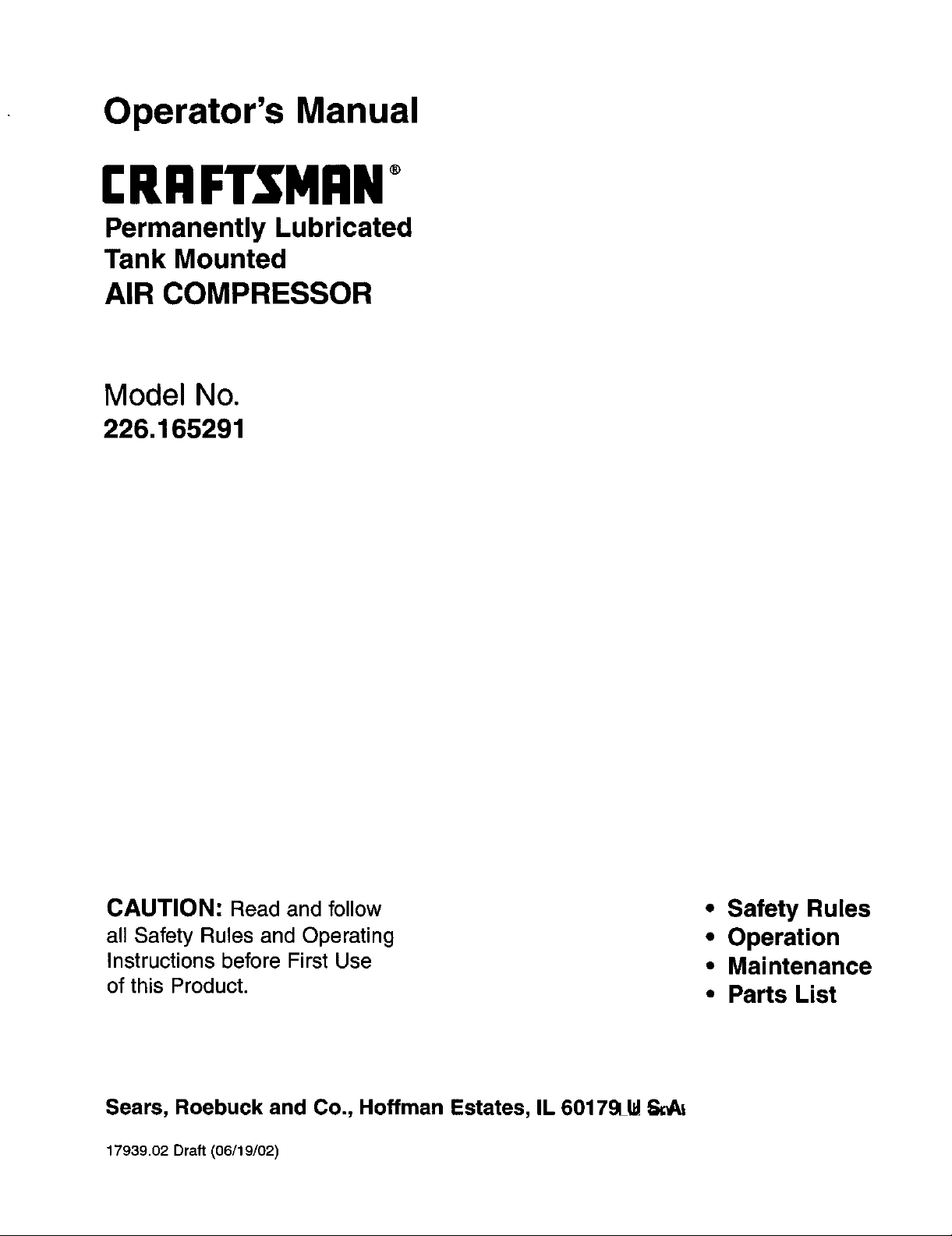

AIR COMPRESSOR CONTROLS

Refer to Figures 3, 4 and 5.

Become familiar with these controls before operating the unit.

• Auto/Off Lever: Turn this lever to "Auto" to provide auto-

matic power to the pressure switchand "OFF" to remove

power at the end of each use.

• Pressure Switch: The pressure switchautomatically

starts the motorwhen the air tank pressure drops below

the factoryset "cut-in"pressure.It stopsthe motor when the

airtank pressure reaches the factoryset "cut-out"pressure,

• Safety Valve: If the pressure switch does not shut off the

air compressor at its"cut-out" pressure setting,the safety

valve will protect against high pressure by "popping out"at

its factory set pressure (Slightlyhigher than the pressure

switch "cut-out" setting).

• Outlet Pressure Gauge: The outlet pressure gauge indi-

cates the air pressure available at the outlet side of the

regulator. This pressure is controlled by the regulator and

is always less than or equal to the tank pressure.

• Tank Pressure Gauge: The tank pressure gauge indi-

cates the reserve air pressure in the tank.

• Regulator: Controls the air pressure shown on the outlet

pressure gauge.Turn clockwise to increase pressure and

counterclockwiseto decrease pressure. Thread nut against

knob to lock in place.

Tank

Pressure

Gauge

Figure 3 - Controls

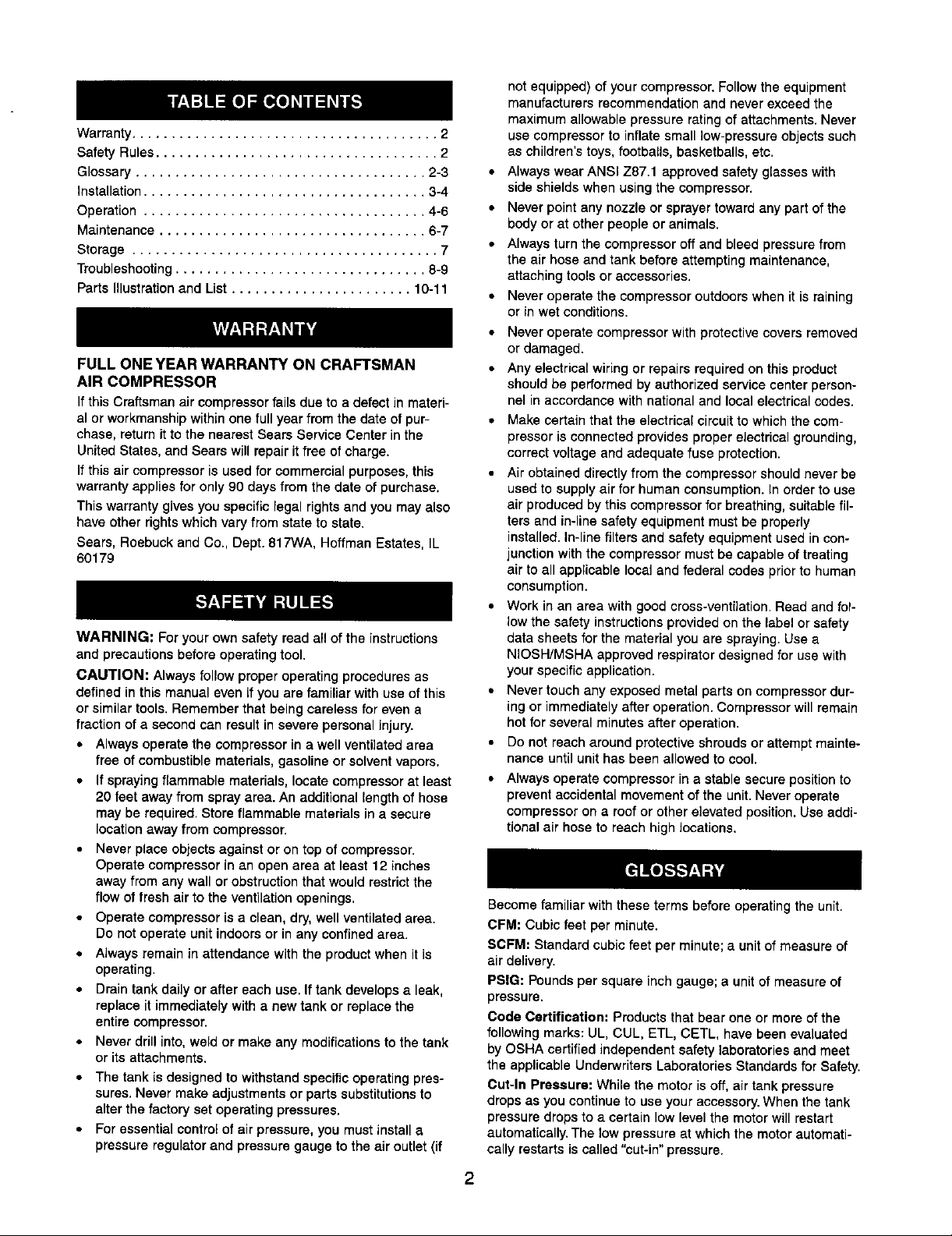

• Drain Valve: The drain valve is located at the base of the

air tank and is used to drain condensation at the end of

each use. Turn counterclockwise to OPEN and clockwise

to close.

Drain Valve

Figure 4 - Drain Valve

4

Loading...

Loading...