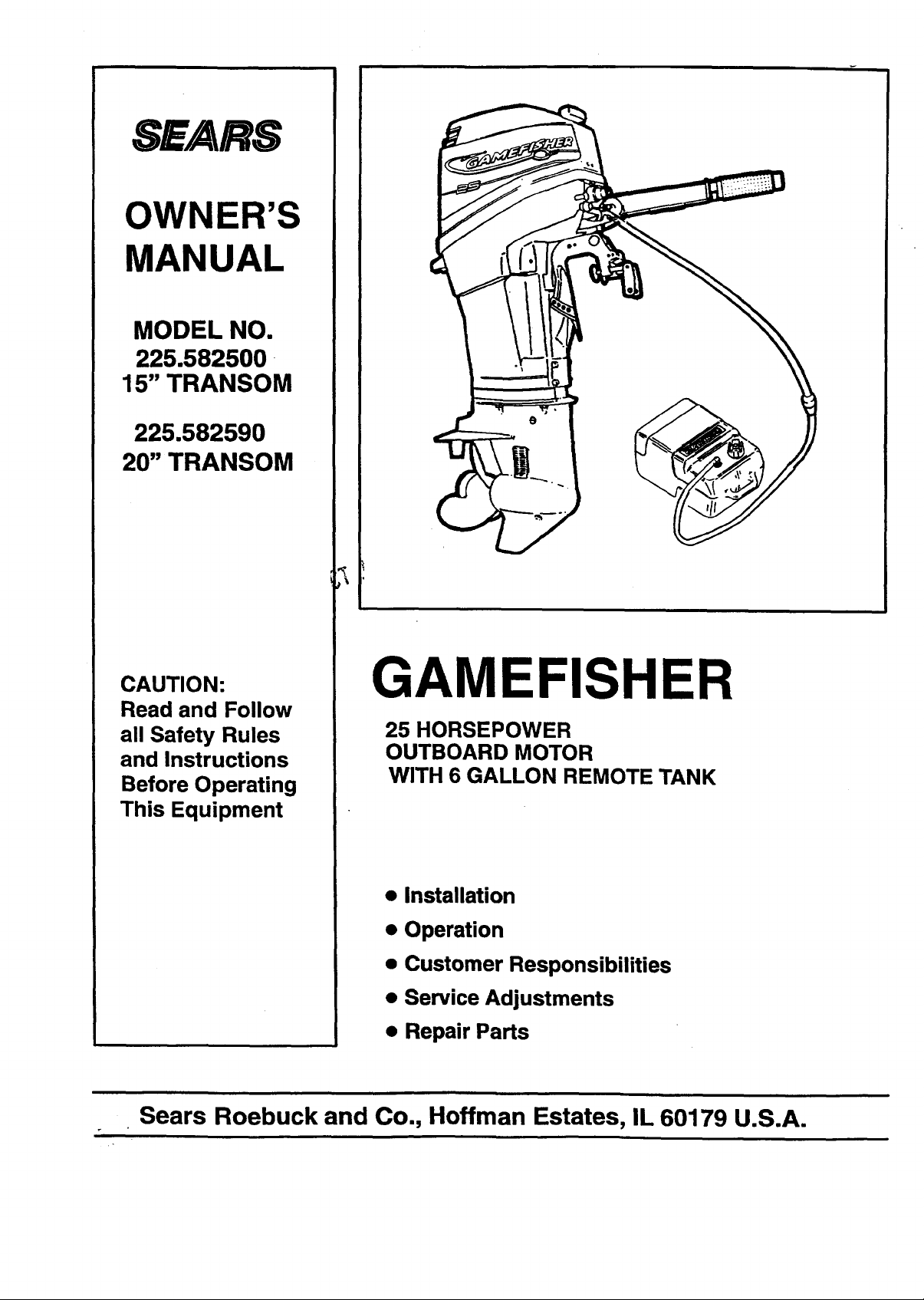

SEARS

OWNER'S

MANUAL

MODEL NO.

225.582500

15" TRANSOM

225.582590

20" TRANSOM

CAUTION:

Read and Follow

all Safety Rules

and Instructions

Before Operating

This Equipment

Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

GAMEFISHER

25 HORSEPOWER

OUTBOARD MOTOR

WITH 6 GALLON REMOTE TANK

• Installation

• Operation

• Customer Responsibilities

• Service Adjustments

• Repair Parts

SAFETY & SAFE PRACTICES

Notice

Throughout this publication, "Warnings" and "Cau-

tions" (accompanied by the international HAZARD

Symbol ) are used to alert the operator to special

instructions concerning a particular operation that

may be hazardous if performed incorrectly. OB-

SERVE THEM CAREFULLY.

HAZARDS OR UNSAFE PRACTICES WHICH

COULD RESULT IN SEVERE PERSONAL

INJURY OR DEATH

HAZARDS OR UNSAFE PRACTICES WHICH

COULD RESULT IN MINOR INJURY OR

PRODUCT OR PROPERTY DAMAGE.

Boaters Responsibilities

The operator (driver) is responsible for the correct

and safe operation of the boat and safety of its occu-

pants and general public. It is strongly recommended

that each operator (driver) read and understand this

entire manual before operating the outboard.

Be sure at least one additional person is instructed in

the basics of starting and operating the outboard and

boat handling in case the driver is unable to operate

the boat.

Before Operating Your Outboard

DO NOT USE A MOTOR WITH A HORSE-

POWER RATING HIGHER THAN WHAT IS

LISTED ON THE CERTIFICATION PLATE ON

YOUR BOAT.

USING AN OUTBOARD THAT EXCEEDS THE

MAXIMUM HORSEPOWER LIMIT OF A BOAT

CAN RESULT IN SERIOUS INJURY, DEATH OR

BOAT DAMAGE.

Fuel

DO NOT STORE YOUR MOTOR OR GAS-

OLINE WHERE FUMES MAY REACH AN OPEN

FLAME AND CAUSE A FIRE.

DRAIN THE GASOLINE from your motor before

transporting your motor inside your car or other

vehicles.

• GASOLINE AND ITSVAPORS ARE EXTREME-

LY FLAMMABLE AND HIGHLY EXPLOSIVE

UNDER CERTAIN CONDITIONS, ALWAYS

STOP THE ENGINE AND DO NOT SMOKE OR

ALLOW OPEN FLAMES OR SPARKS IN THE

AREA WHILE FILLING FUEL TANK(S).

• DO NOT FILLTHE FUELTANKWHEN THE EN-

GINE IS RUNNING. DO NOT FILL THE FUEL

TANK INDOORS.

• REMOVE PORTABLE FUEL TANK FROM

BOAT WHEN REFUELING TO PREVENT SPIL-

LING FUEL IN BOAT, ALWAYS MIX FUEL IN A

WELL VENTILATED AREA.

Read this manual carefully. Learn how to operate

your outboard properly. If you have any ques-

tions, contact your nearest Sears Store which

sells Gamefisher outboard motors.

This manual as well as safety labels posted on the

outboard use safety alerts to draw your attention

to special safety instructions that should be fol-

lowed.

Safety and operating information that is practiced

along with using good common sense can help

prevent personal injury and product damage.

ALWAYS DISCONNECT SPARK PLUG WIRES AND

PLACE WIRES WHERE THEY CANNOT CONTACT

SPARK PLUGS TO PREVENT ACCIDENTAL

STARTING WHEN WORKING ON YOUR OUT-

BOARD.

Operation

DO NOT attempt to make repairs or adjustments

not specifically covered in this manual. Should

you ever need technicalassistance, please con-

tact your Sears Service Center.

NEVER OPERATE YOUR MOTOR AT FULL

THROTTLE WHEN THE ENGINE IS OVER-

LOADED. THIS CAN OCCUR-4JNDER CONDI-

TIONS WHEN A PLANING BOAT IS LOADED

SO IT DOES NOT PLANE OR WHEN TOWING

ANOTHER BOAT.

Some boats are extremely unstable in the water

even when secured to a dock. Do not stand erect.

Stay as close as possible to centerline of boat es-

pecially while installing motor.

SAFETY & SAFE PRACTICES

SERVICE

Neglected inspection and maintenance service of

your outboard or attempting to perform mainte-

nance or repair on your outboard if you are not fa-

miliar with the correct service and safety proce-

dures could cause personal injury, death or

product failure.

Using a replacement part that is inferior to the

original part could result in personal injury, death

or product failure.

Using Lanyard Stop Switch

THE PURPOSE OF THE LANYARD STOP SWITCH

IS TO TURN OFF THE ENGINE IGNITION WHEN-

EVER THE OPERATOR (WHEN AI"FACHED TOTHE

LANYARD) MOVES FAR ENOUGH AWAY FROM

THE OPERATOR'S POSITION TO ACTIVATE THE

SWITCH.

The lanyard is a cord usuallybetween 4 and 5feet

in length when stretched out with an element on

one end made to be inserted into the switchand

a clip on the other end for attaching tothe opera-

tor. It is coiled to make its at-rest condition as

short as possible so as to minimize the likelihood

of the lanyard entanglement with nearby objects.

Itis made as longas it is in itsstretched condition

to minimize the likelihood of accidental activation

should the operator choose to move around in an

area close to the normal operator's position,iffor

any reason ,it is desired to have a shorterfunc-

tionallanyard, this may be accomplishedby using

up length in the way the lanyard and clipare at-

tached to the operator (such as wrappingthe lan-

yardaround the operator's wrist orleg) orbytying

a simple knot in the lanyard.

The following advantages and disadvantages

of a lanyard stop switch should be considered

before electing to use, or not to use such a

switch.

ADVANTAGES: THE PURPOSE OF A LANYARD

STOP SWITCH IS TO STOP THE ENGINE IGNI-

TION WHENEVER THE OPERATOR (WHEN

ATTACHED TO THE LANYARD) MOVES FAR

ENOUGH AWAY FROM THE OPERATOR'S

POSITION TO ACTIVATE THE SWITCH. THIS

WOULD OCCUR IF THE OPERATOR FALLS OR

MOVES WITHIN THE BOAT A SUFFICIENT DIS-

TANCE FROM THE OPERATOR'S POSITION.

THIS TYPE OF ACCIDENT IS MOST LIKELY IN

CERTAIN TYPES OF BOATS SUCH AS LOW

SIDED BASS BOATS, HIGH PERFORMANCE

BOATS AND LIGHT, SENSITIVE-HANDLING

FISHING BOATS OPERATED BY HAND TIL-

LER. IT IS ALSO LIKELY AS A RESULT OF

POOR OPERATING PRACTICES SUCH AS SIT-

"riNG ON THE BACK OF THE SEAT AT PLAN-

ING SPEEDS, STANDING AT PLANING

SPEEDS, OPERATING AT HIGH SPEEDS IN

SHALLOW OR OBSTACLE-INFESTED WA-

TERS, RELEASING YOUR GRIP ON A STEER-

ING WHEEL THAT IS PULLING IN ONE DIREC-

TION, DRINKING AND DRIVING OR DARING,

HIGH-SPEED BOAT MANEUVERS.

DISADVANTAGES: INADVERTENT ACTIVATION

OF THE SWITCH IS A POSSIBILITY. THIS

COULD CAUSE ANY OR ALL OF THE FOL-

LOWING POTENTIALLY HAZARDOUS SITUA-

TIONS:

.

LOSS OF BALANCE AND FALLING FOR-

WARD OF UNSTABLE BOAT PAS-

SENGERS - A PARTICULAR CONCERN

IN BOW RIDER TYPE BOATS.

2. LOSS OF POWER AND DIRECTIONAL

CONTROL IN HEAVY SEAS, STRONG

CURRENT OR HIGH WINDS.

3. LOSS OF CONTROL WHEN DOCKING.

In addition, there are limitations to what the lan-

yard stop switch can do. The boat can continue

to coast for a considerable distance depending on

the velocity at shutdown and the degree of any

turn. However, the boat will not complete a full

circle while the boat iscoasting. It can cause inju-

ryto anyone in the boat's path as seriously as the

boat would when under power.

As we cannot possibly know of and advise the

boating public of all conceivable boat/motor types

and/or poor operating practices, the final decision

of whether to use a lanyard stop switch rests with

you, the owner/driver.

We strongly recommend that other occupants be

instructed on proper starting and operating proce-

dures should they be required to operate the out-

board and boat in an emergency.

-3-

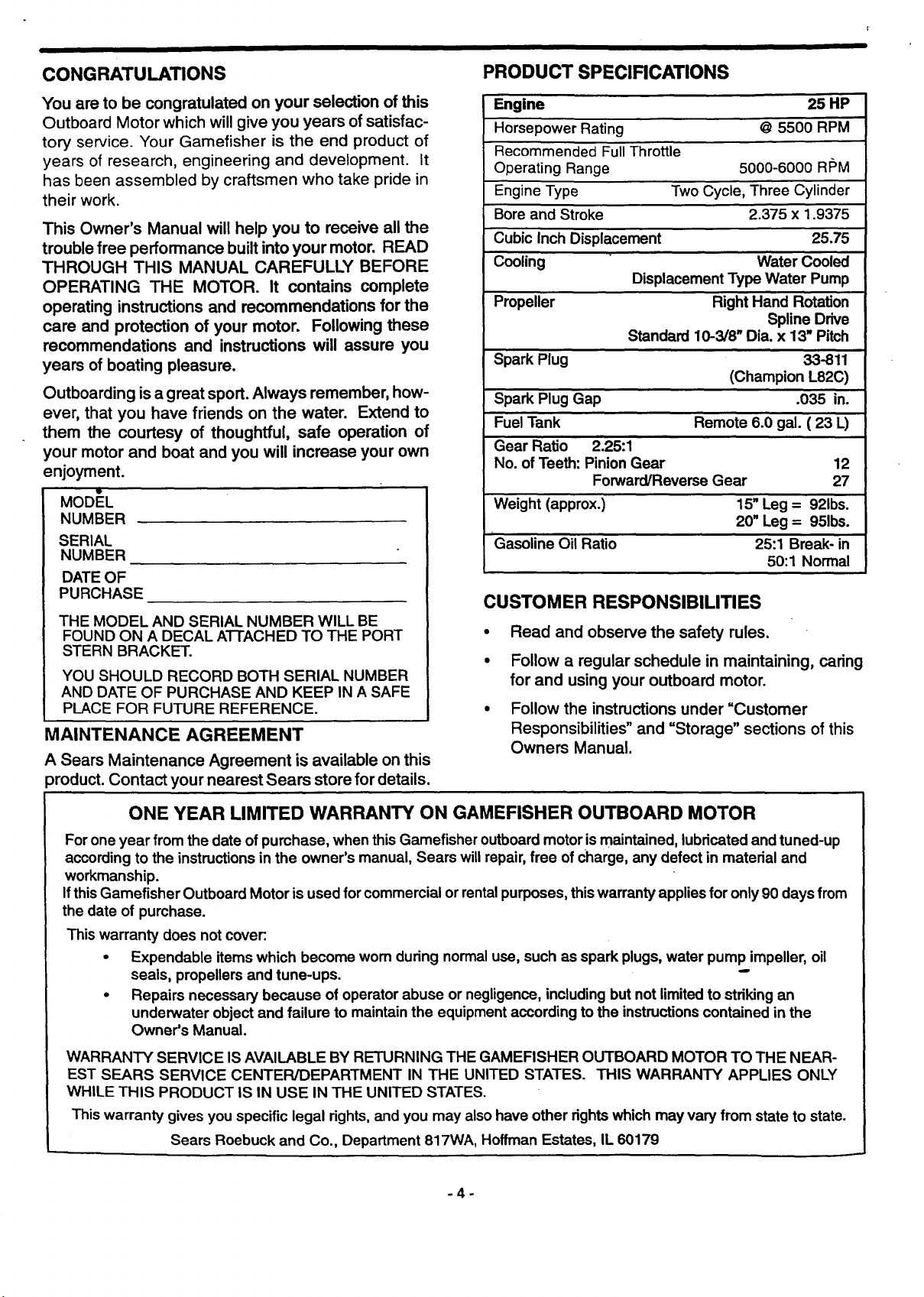

CONGRATULATIONS

PRODUCT SPEClRCATIONS

You are to be congratulated on your selection of this

Outboard Motor which will give you years of satisfac-

tory service. Your Gamefisher is the end product of

years of research, engineering and development. It

has been assembled by craftsmen who take pride in

their work.

This Owner's Manual will help you to receive allthe

trouble free performance built into your motor. READ

THROUGH THIS MANUAL CAREFULLY BEFORE

OPERATING THE MOTOR. It contains complete

operating instructions and recommendations for the

care and protection of your motor. Following these

recommendations and instructions will assure you

years of boating pleasure.

Outboarding is a great sport. Always remember, how-

ever, that you have friends on the water. Extend to

them the courtesy of thoughtful, safe operation of

your motor and boat and you will increase your own

enjoyment.

MODEL

NUMBER

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBER WILL BE

FOUND ON A DECAL ATFACHED TO THE PORT

STERN BRACKET.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

)roduct. Contact your nearest Sears store for details.

Engine 25 HP

Horsepower Rating @ 5500 RPM

Recommended Full Throttle

Operating Range 5000-6000 RIbM

Engine Type Two Cycle, Three Cylinder

Bore and Stroke 2.375 x 1.9375

Cubic Inch Displacement 25.75

Cooling Water Cooled

Displacement Type Water Pump

Propeller Right Hand Rotation

Spline Drive

Standard 10-3/8" Dia. x 13" Pitch

Spark Plug 33-811

(Champion L82C)

Spark Plug Gap .035 in.

Fuel Tank Remote 6.0 gal. ( 23 L)

Gear Ratio 2.25:1

No. of Teeth: Pinion Gear 12

Forward/Reverse Gear 27

Weight (approx.) 15" Leg = 921bs.

20" Leg = 951bs.

Gasoline Oil Ratio 25:1 Break- in

50:1 Normal

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring

for and usingyour outboard motor.

• Follow the instructionsunder =Customer

Responsibilities"and =Storage" sections of this

Owners Manual.

ONE YEAR LIMITED WARRANTY ON GAMEFISHER OUTBOARD MOTOR

For one year from the date of purchase, when this Gamefisher outboardmotor is maintained, lubricated and tuned-up

according to the instructionsin the owner's manual, Sears willrepair,free of Charge, any defect in material and

workmanship.

IfthisGamefisher Outboard Motor is used for commercial or rental purposes, this warranty appliesfor only90 days from

the date of purchase.

This warranty does not cover:.

• Expendable items which become wom during normaluse, such asspark plugs, water pump impeller, oil

seals, propellers and tune-ups.

• Repairs necessary because of operator abuse or negligence, including but not limitedto strikingan

underwater object and failure to maintain the equipment according to the instructionscontained in the

Owner's Manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE GAMEFISHER OUTBOARD MOTOR TO THE NEAR-

EST SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES. THIS WARRANTY APPLIES ONLY

WHILE THIS PRODUCT IS IN USE IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rightswhich may vary from state to state.

Sears Roebuck and Co., Department 817WA, Hoffman Estates, IL 60179

-4-

TABLE OF CONTENTS

SAFETY & SAFE PRACTICES ................ 2

MOTOR SPECIFICATIONS .................. 4

OUTBOARD MOTOR ACCESSORIES ......... 6

INSTALLATION ............................. 7

MOTOR NOMENCLATURE ................... 8

OPERATION ............................. 8-17

G

INDEX

A

Adding/Refilling Lubricants ... 22

B

Before Starting Engine ....... 14

Break-In Procedures ......... 16

C

Carburetor Adjustment ....... 23

Co-Pilot Adjustment ......... 10

Corrosion Anode ............ 22

Customer ResponsibUities .... 18

Customer Responsibilities ..... 4

D

Draining Gear Housing ....... 22

E

Emergency Stopping ........ 15

Engine Overheating ......... 21

Exterior Care ............... 25

F

Filling Fuel Tank ............ 15

Fuel Pump Filter ............ 20

Fuel System Connection ..... 15

FuelTank Filter ............. 20

Gasoline Selection .......... 14

Gasoline/Oil Break In Mixture . 14

Gasoline/Oil Mixing

Ratio Chart ............. 14

General Recommendations ... 18

I

Index ....................... 5

Install Motor Cover .......... 20

L

Lubrication ................. 19

M

Maintenance Schedule ....... 18

Motor Nomenclature .......... 8

Motor'lilt ................... 10

Motor "liltAngle ............. 12

Mounting Motor .............. 7

O

Oil Recommendation ........ 14

Operating Checks ........... 13

Operating In Freezing

Temperatures ........... 17

Operating'lips .............. 16

P

Pre-Operating Check List..... 13

Propeller ............. 6, 13, 21

CUSTOMER RESPONSIBILITIES ......... 18-22

SERVICE AND ADJUSTMENTS ............. 23

STORAGE ................................. 24

TROUBLESHOOTING TIPS ................. 26

REPAIR PARTS .................... Rear Cover

PARTS ORDERING ................ Rear Cover

Remove MotorCover ........ 20

Removing Motor ............. 7

S

Salt Water Operation ........ 17

Service and Adjustments ..... 23

Shallow Water Drive Bar ..... 10

Shift Control ................. 9

Spark Plug ................. 21

Starting Engine ............. 15

Stopping Engine ............ 15

Storage .................... 24

Storage Preparation ......... 24

Submerged Outboard ........ 22

T

Throttle ..................... 9

Tiller Handle ................ 9

Trim Tab Adjustment ......... 11

Troubleshooting Tips ........ 26

u

Use After Storage ........... 25

W

Warranty .................... 4

I

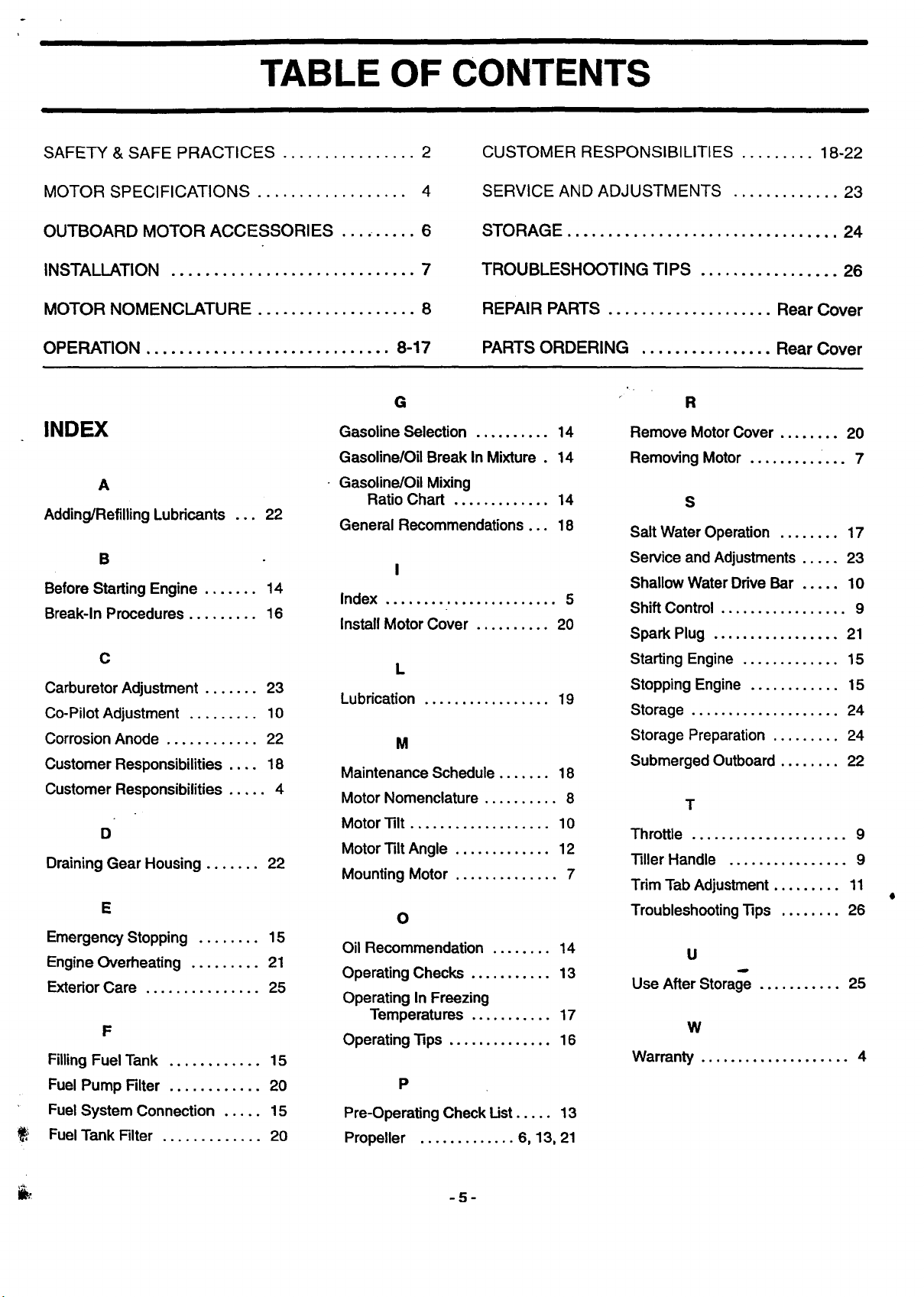

OUTBOARD MOTOR ACCESSORIES

These accessories were available when the outboard motor was purchased. They are also available at most Sears

retail outlets, catalog and service centers. Most Sears stores can order repair parts for you, when you provide the

model number of your outboard motor.

PROPELLER

SPARK PLUG

APPLICATION

STANDARD

Average Loads

Very Light Loads

Heavy Loads

Very Heavy Loads

Average Loads

SEARS ULTRA PRE-

MIUM 2 CYCLE OUT-

BOARD OIL

Approx.

Boat

Len_lth

13-17ft.

To 14 ft.

To 17 ft.

17 ft. +

13-17 ft.

I I

1200-2800 Ibs

iFUEL STABILIZER

Approx.

Boat Wt.

700-1700 Ibs

To 900 Ibs.

1800+

700-1700 Ibs,

GEAR LUBE

0

NO. OF DIA. PITCH

BLADES (IN.) (IN.)

3 10-3/8 13

3 10-114 14-1/2

3 10-3/8 11

3 10-3/8 9-112

2 10-3/8 13

MATERIAL

Aluminum

Aluminum

Aluminum

Aluminum

Stainless

Steel

PART NO.

48-19640A40

48-19642A40

48-19638A40

48-19636A10

48-19644A5

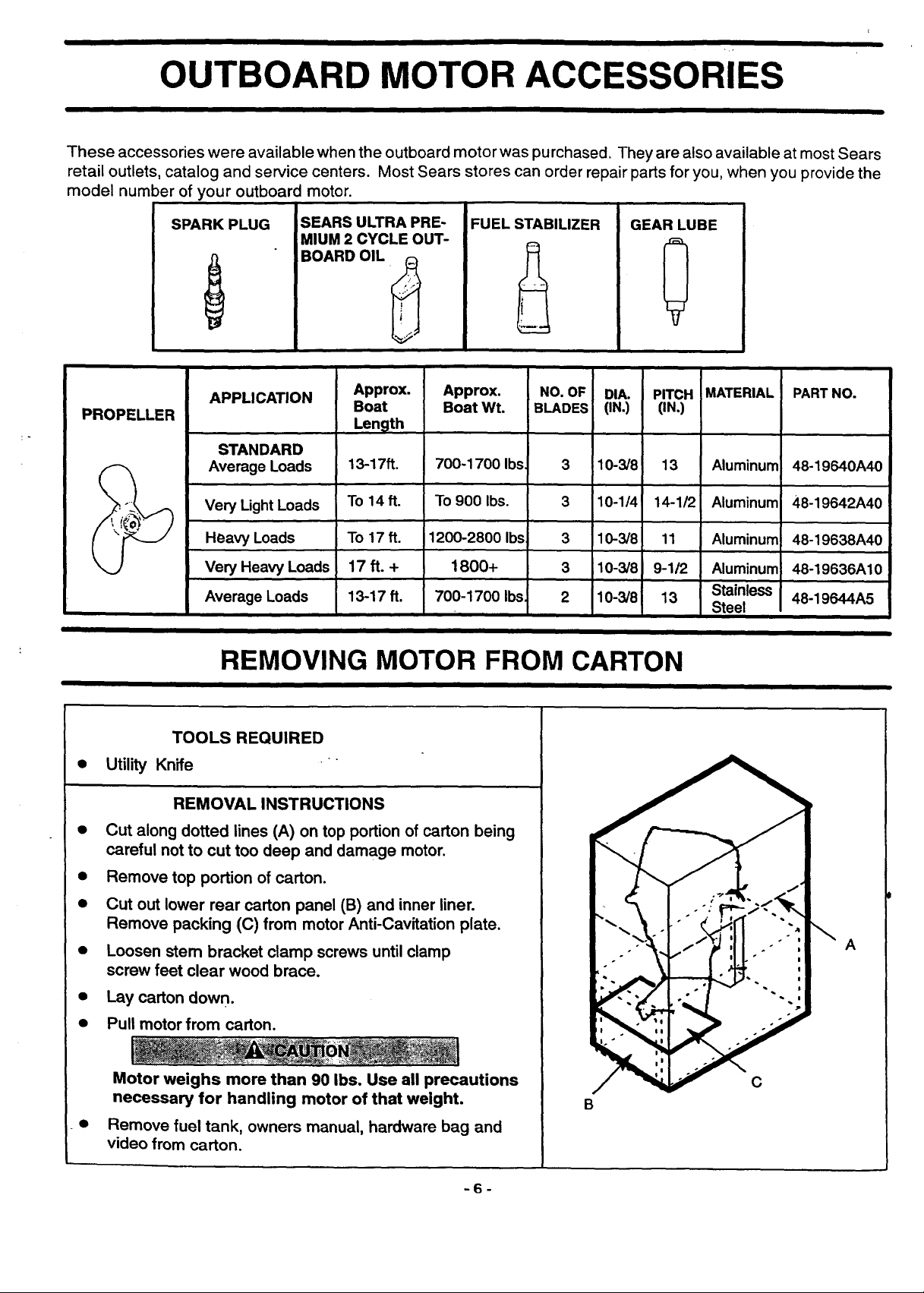

REMOVING MOTOR FROM CARTON

TOOLS REQUIRED

• Utility Knife

REMOVAL INSTRUCTIONS

• Cut along dotted lines (A) on top portion of carton being

careful not to cut too deep and damage motor.

• Remove top portion of carton.

• Cut out lower rear carton panel (B) and inner liner.

Remove packing (C) from motor Anti-Cavitation plate.

• Loosen stem bracket clamp screws until clamp

screw feet clear wood brace.

• Lay carton down.

• Pull motor from carton.

Motor weighs more than 90 Ibs. Use all precautions

necessary for handling motor of that weight.

Remove fuel tank, owners manual, hardware bag and

video from carton.

A

C

B

-6-

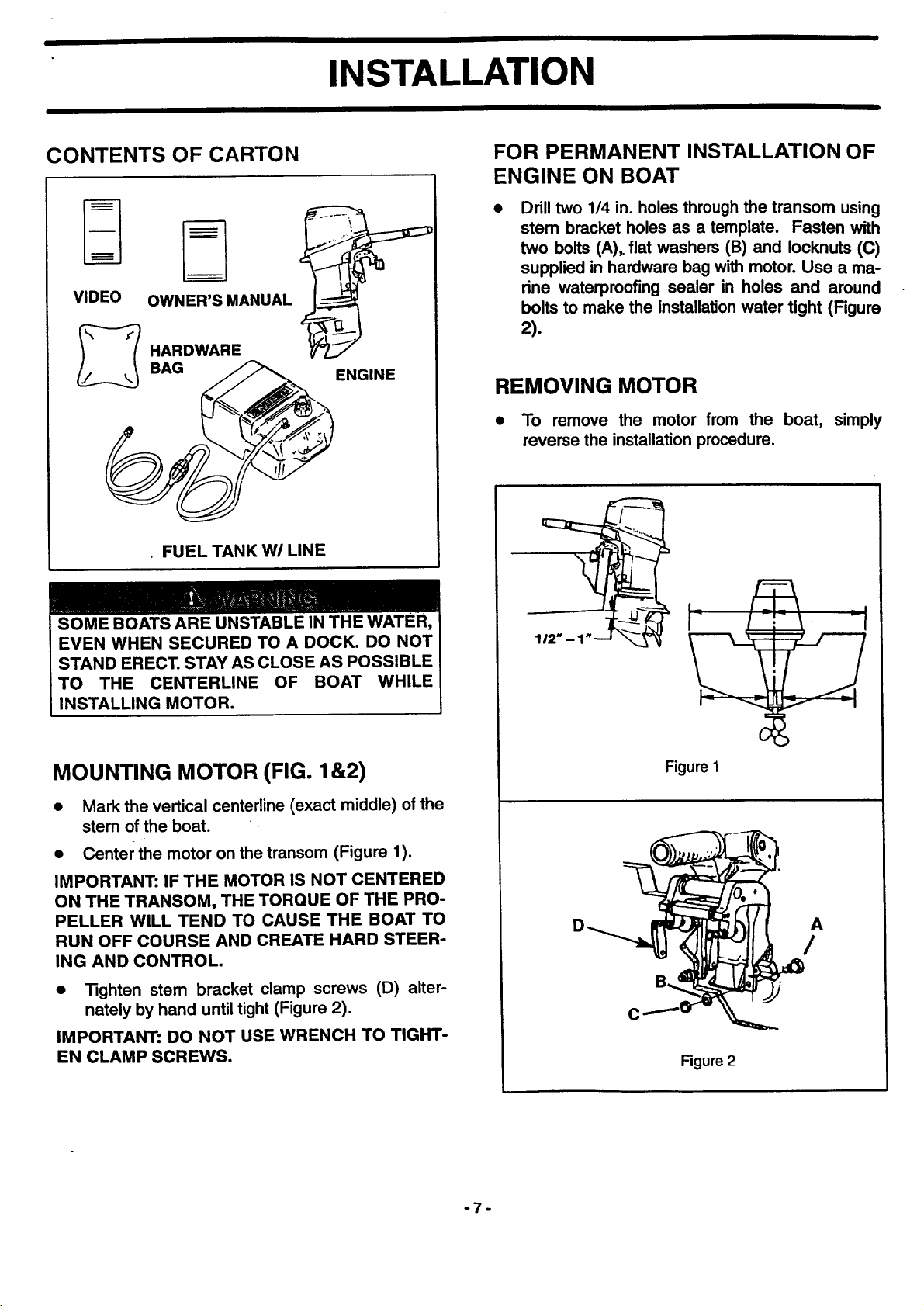

INSTALLATION

CONTENTS OF CARTON

_'_ HARDWARE

J!_._ BAG _ ENGINE

• FUEL TANK W/LINE

FOR PERMANENT INSTALLATION OF

ENGINE ON BOAT

Drill two 1/4 in. holes through the transom using

stem bracket holes as a template. Fasten with

two bolts (A),. flat washers (B) and Iocknuts ((3)

supplied in hardware bag with motor. Use a ma-

rine waterproofing sealer in holes and around

bolts to make the installation water tight (Figure

2).

REMOVING MOTOR

• To remove the motor from the boat,

reverse the installation procedure.

simply

SOME BOATS ARE UNSTABLE IN THE WATER,

EVEN WHEN SECURED TO A DOCK. DO NOT

STAND ERECT. STAY AS CLOSE AS POSSIBLE

TO THE CENTERLINE OF BOAT WHILE

INSTALLING MOTOR.

MOUNTING MOTOR (FIG. 1&2)

• Mark the vertical centerline (exact middle) of the

stem of the boat.

• Center the motor on the transom (Figure 1).

IMPORTANT: IF THE MOTOR IS NOT CENTERED

ON THE TRANSOM, THE TORQUE OF THE PRO-

PELLER WILL TEND TO CAUSE THE BOAT TO

RUN OFF COURSE AND CREATE HARD STEER-

ING AND CONTROL.

• "13ghten stem bracket clamp screws (D) alter-

nately by hand until tight (Figure 2).

IMPORTANT: DO NOT USE WRENCH TO TIGHT-

EN CLAMP SCREWS.

Figure 1

D

A

/

Figure 2

I

-7-

II I

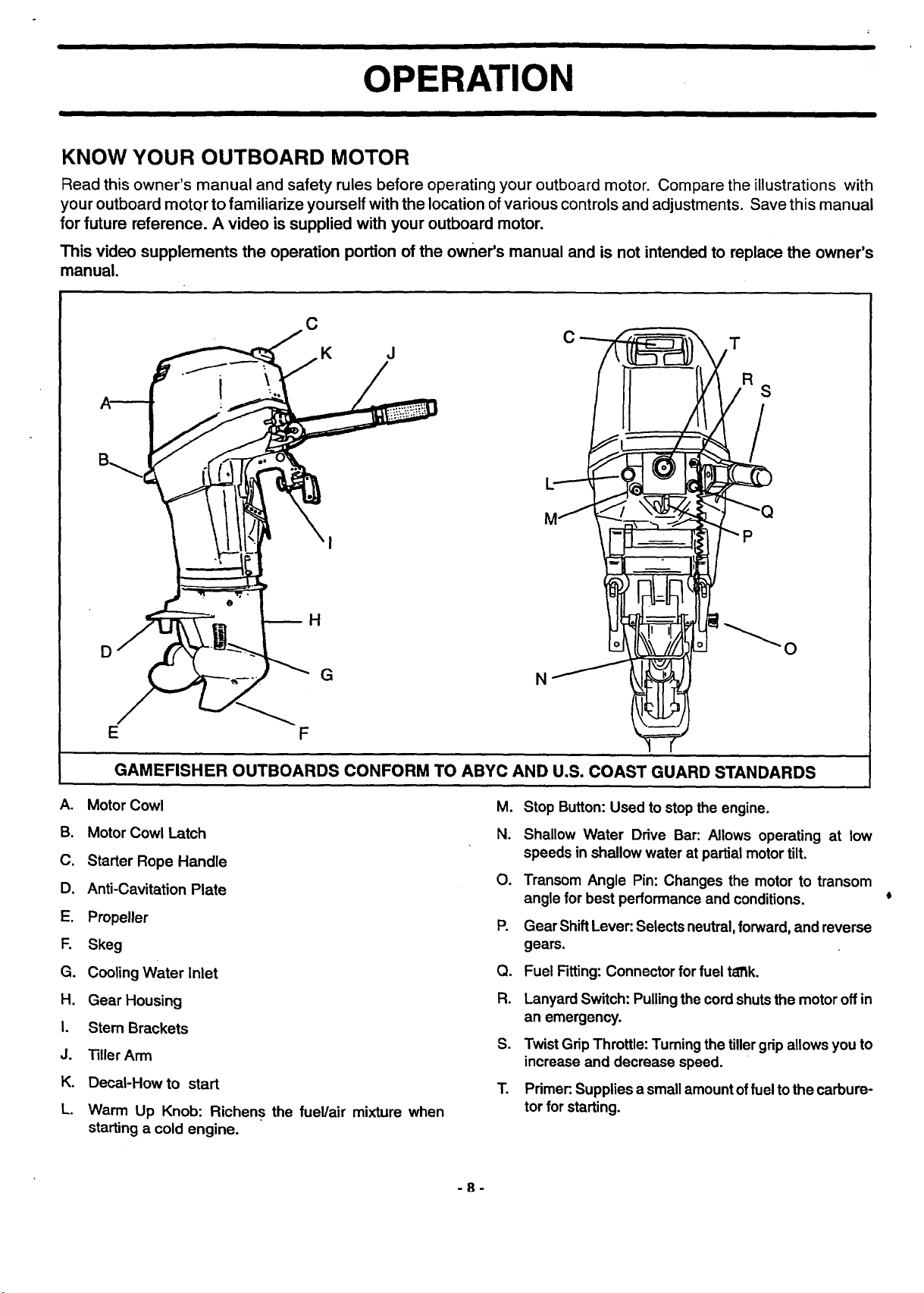

OPERATION

KNOW YOUR OUTBOARD MOTOR

Read this owner's manual and safety rules before operating your outboard motor. Compare the illustrations with

your outboard motQr to familiarize yourself with the location of various controls and adjustments. Save this manual

for future reference. A video is supplied with your outboard motor.

This video supplements the operation portion of the owner's manual and is not intended to replace the owner's

manual.

D

E F

C

K J

H

G N

C

T

S

P

GAMEFISHER OUTBOARDS CONFORM TO ABYC AND U.S. COAST GUARD STANDARDS

A. Motor Cowl

B. Motor Cowl Latch

C. Starter Rope Handle

D. Anti-Cavitation Plate

E. Propeller

F. Skeg

G. Cooling Water Inlet

H. Gear Housing

I. Stem Brackets

J. Tiller Arm

K. Decal-How to start

L. Warm Up Knob: Richens the fuel/air mixture when

starting a cold engine.

M. Stop Button: Used to stop the engine.

N. Shallow Water Drive Bar: Allows operating at low

speeds in shallow water at partial motortilt.

O. Transom Angle Pin: Changes the motor to transom

angle for best performance and conditions.

P. Gear ShiftLever:Selects neutral,forward,and reverse

gears.

Q. Fuel Fitting:Connector for fuel t_fflk.

R. Lanyard Switch: Pullingthe cordshutsthe motoroffin

an emergency.

S. TwistGripThrottle: Turning the tillergripallowsyou to

increase and decrease speed.

3". Primer:.Supplies a small amountoffueltothe carbure-

tor for starting.

-8-

OPERATION

HOW TO USE YOUR OUTBOARD

MOTOR

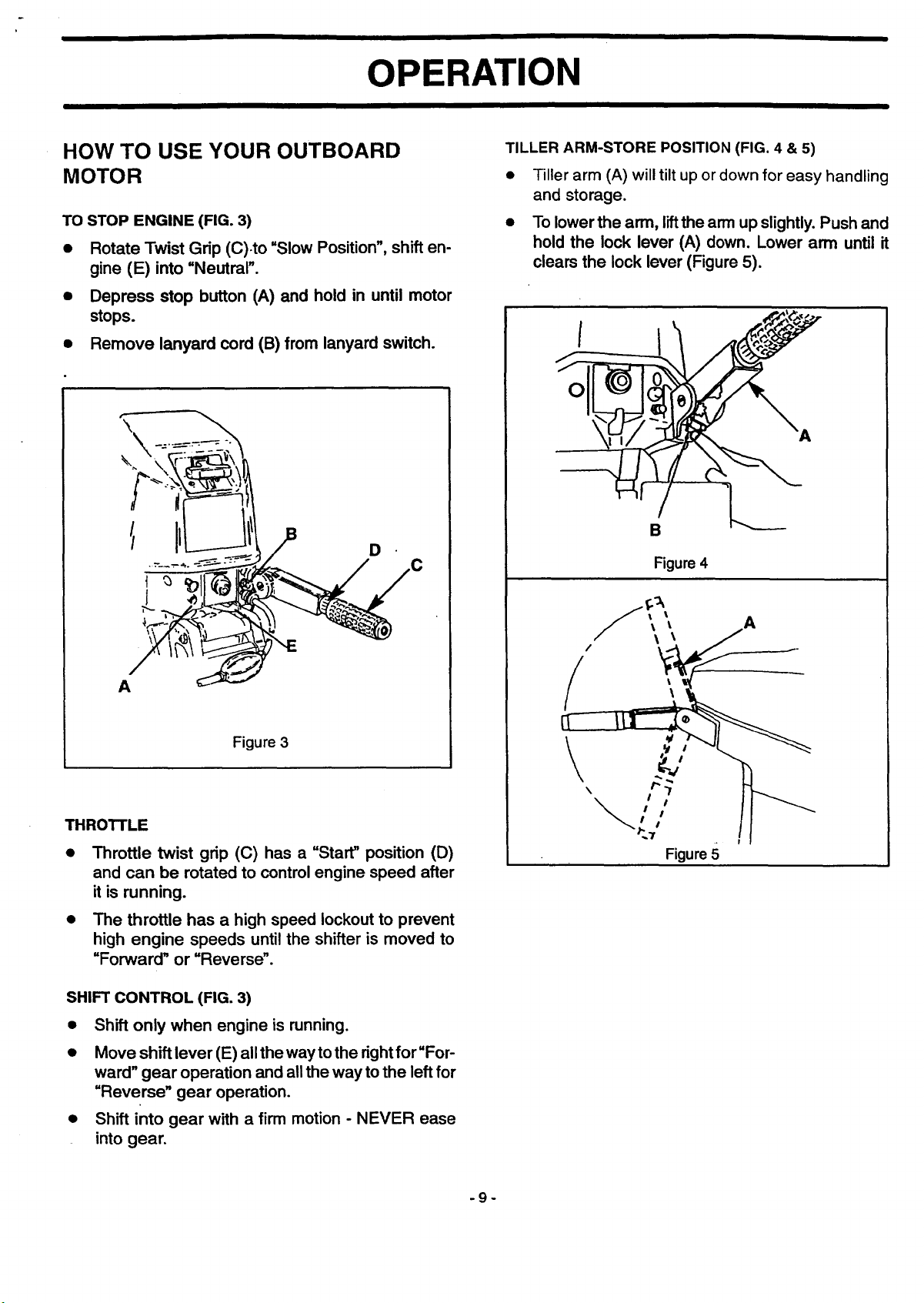

TO STOP ENGINE (FIG. 3)

• Rotate Twist Grip (C).to "Slow Position", shift en-

gine (E) into "Neutral".

• Depress stop button (A) and hold in until motor

stops.

• Remove lanyard cord (B) from lanyard switch.

D

TILLER ARM-STORE POSITION (FIG. 4 & 5)

• Tiller arm (A) will tilt up or down for easy handling

and storage.

• To lower the arm, liftthe arm up slightly. Push and

hold the lock lever (A) down. Lower arm until it

clears the lock lever (Figure 5).

I

O

B

Figure 4

A

Figure 3

THROTTLE

• Throttle twist grip (C) has a "Start" position (D)

and can be rotated to control engine speed after

it is running.

• The throttle has a high speed lockout to prevent

high engine speeds until the shifter is moved to

"Forward" or "Reverse".

SHIFT CONTROL (FIG. 3)

• Shift only when engine is running.

• Move shift lever (E) all the way to the right for"For-

ward" gear operation and all the way to the left for

"Reverse" gear operation.

• Shift into gear with a firm motion - NEVER ease

into gear.

A

-9-

OPERATION

III

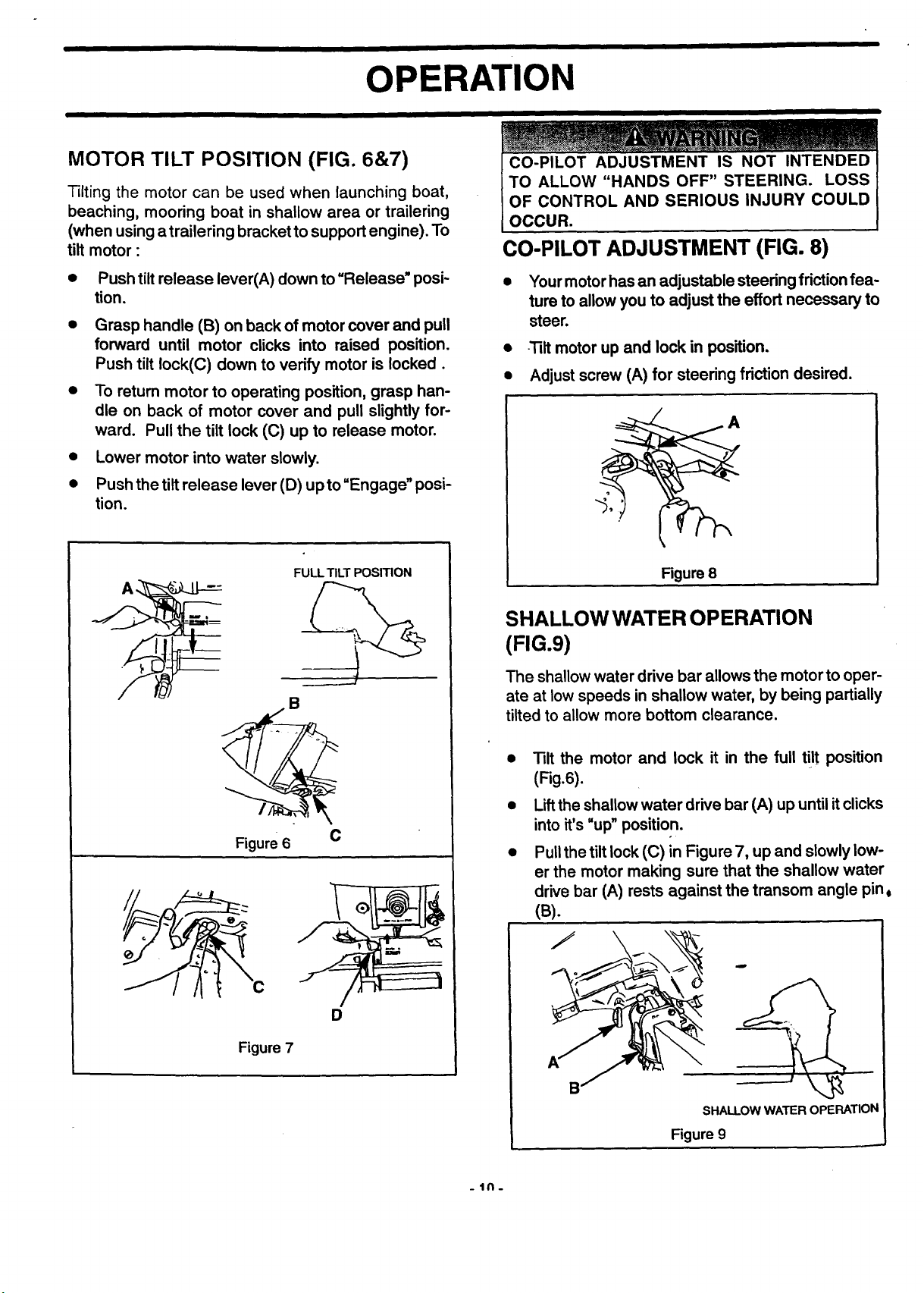

MOTOR TILT POSITION (FIG. 6&7)

Tilting the motor can be used when launching boat,

beaching, mooring boat in shallow area or trailering

(when using a trailering bracket to support engine). To

tilt motor :

Push tilt release lever(A) down to "Release" posi-

tion.

• Grasp handle (B) on back of motor cover and pull

forward until motor clicks into raised position.

Push tilt lock(C) down to verify motor is locked.

• To return motor to operating position, grasp han-

dle on back of motor cover and pull slightly for-

ward. Pull the tilt lock (C) up to release motor.

• Lower motor into water slowly.

• Push the tilt release lever (D) up to"Engage" posi-

tion.

FULL TILT POSITION

CO-PILOT ADJUSTMENT IS NOT INTENDED

TO ALLOW "HANDS OFF" STEERING. LOSS

OF CONTROL AND SERIOUS INJURY COULD

OCCUR.

CO-PILOT ADJUSTMENT (FIG. 8)

• Yourmotorhasan adjustable steeringfriction fea-

ture to allowyou to adjust the effortnecessary to

steer.

• -'_it motor up and lock in position.

• Adjust screw (A) for steering friction desired.

Figure 8

Figure 6 C

Figure 7

SHALLOW WATER OPERATION

(FIG.9)

The shallow water drive bar allows the motor to oper-

ate at low speeds in shallow water, by being partially

tilted to allow more bottom clearance.

Tilt the motor and lock it in the full ti!t position

(Fig.6).

Lift the shallow water drive bar (A) up until it clicks

into it's "up" position.

Pull the tilt lock (C) in Figure 7, up and slowly low-

er the motor making sure that the shallow water

drive bar (A) rests against the transom angle pin 0

(B).

7

D

_IN.

SHALLOW WATER OPERATION

Figure 9

OPERATION

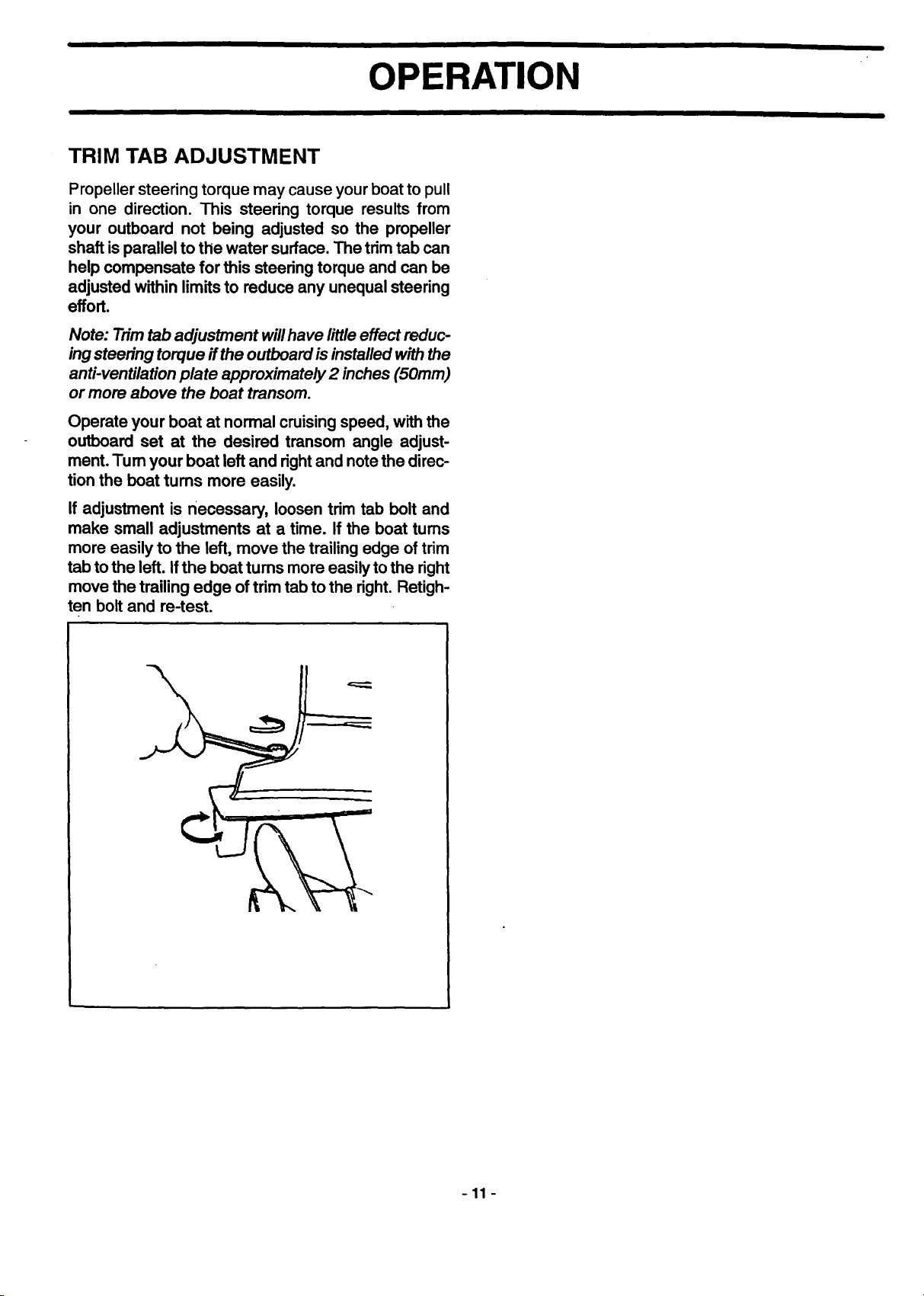

TRIM TAB ADJUSTMENT

Propeller steering torque may cause your boat to pull

in one direction. This steering torque results from

your outboard not being adjusted so the propeller

shaft isparallel to the water surface.The trimtab can

help compensate for this steering torque and can be

adjusted withinlimits to reduce any unequalsteering

effort.

Note: Trim tab adjustment will have little effect reduc-

ing steering torque if the outboard is installed with the

anti-ventilation plate approximately 2 inches (50mm)

or more above the boat transom.

Operate your boat at normal cruisingspeed, with the

outboard set at the desired transom angle adjust-

ment. Tum your boat left and rightand note the direc-

tion the boat tums more easily.

If adjustment is necessary, loosen trim tab bolt and

make small adjustments at a time. If the boat turns

more easily to the left, move the trailing edge oftrim

tab to the left. If the boat turns more easily to the right

movethe trailing edge of trimtab to the right. Retigh-

ten boltand re-test.

-11 -

OPERATION

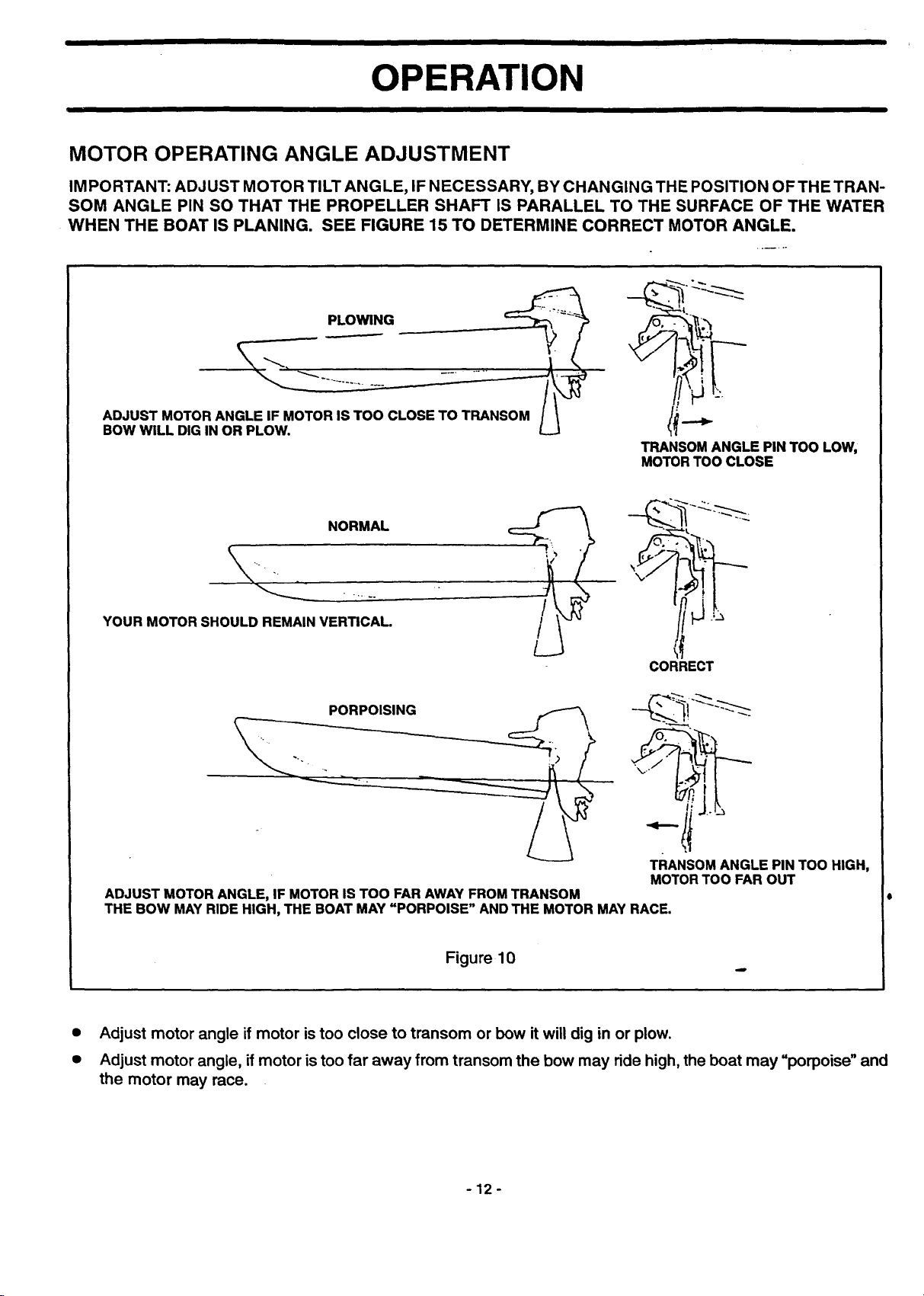

MOTOR OPERATING ANGLE ADJUSTMENT

IMPORTANT: ADJUST MOTOR TILT ANGLE, IF NECESSARY, BY CHANGING THE POSITION OF THE TRAN-

SOM ANGLE PIN SO THAT THE PROPELLER SHAFT IS PARALLEL TO THE SURFACE OF THE WATER

WHEN THE BOAT IS PLANING. SEE FIGURE 15 TO DETERMINE CORRECT MOTOR ANGLE.

PLOWING

ADJUST MOTOR ANGLE IF MOTOR IS TOO CLOSE TO TRANSOM I \

BOW WILL DIG IN OR PLOW. L_J

TRANSOM ANGLE PIN TOO LOW,

MOTOR TOO CLOSE

NORMAL

YOUR MOTOR SHOULD REMAIN VERTICAL

/

L

CORRECT

TRANSOM ANGLE PIN TOO HIGH,

MOTOR TOO FAR OUT

ADJUST MOTOR ANGLE, IF MOTOR IS TOO FAR AWAY FROM TRANSOM

THE BOW MAY RIDE HIGH, THE BOAT MAY uPORPOISE" AND THE MOTOR MAY RACE.

Figure 10

• Adjust motor angle if motor is too close to transom or bow it will dig in or plow.

• Adjust motor angle, if motor is too far away from transom the bow may ride high, the boat may "porpoise" and

the motor may race.

-12-

OPERATION

PRE-OPERATING CHECK LIST

_1 Boat is rated for motor horsepower and load

conditions.

I_1 Operator knows safe navigation, boating and

operating procedures.

I_1 All needed safety equipment is on board, in good

condition and easy to reach.

I_1 Motor is operating normally. If the motor is hard to

start or is not running well, have repairs made

before leaving dockside.

I_ Fuel supply is O.K.

!_1 Use only recommended gasoline and oil and use

only the correct mixture.

I_1 There are no fuel leaks.

I_l Propeller is not fouled or damaged.

I_1 A spare propeller is on board.

I_1 The correct anchor and lines are on board.

I_1 All anchor and mooring lines are neatly coiled out

of the way.

[_l Recreational equipment and fishing gear is

stowed securely.

[_ Bilge is pumped and there are no water leaks.

1_1 Passengers are safely on board.

[_1 The area is clear for operation. Operator is aware

of other boats,skiers,divers,swimmers,etc.

[_ Boat is loaded evenly from front to rear.

[_1 Operator has read and understood the entire

owner's manual

Check tightness of stem bracket clamp screws.

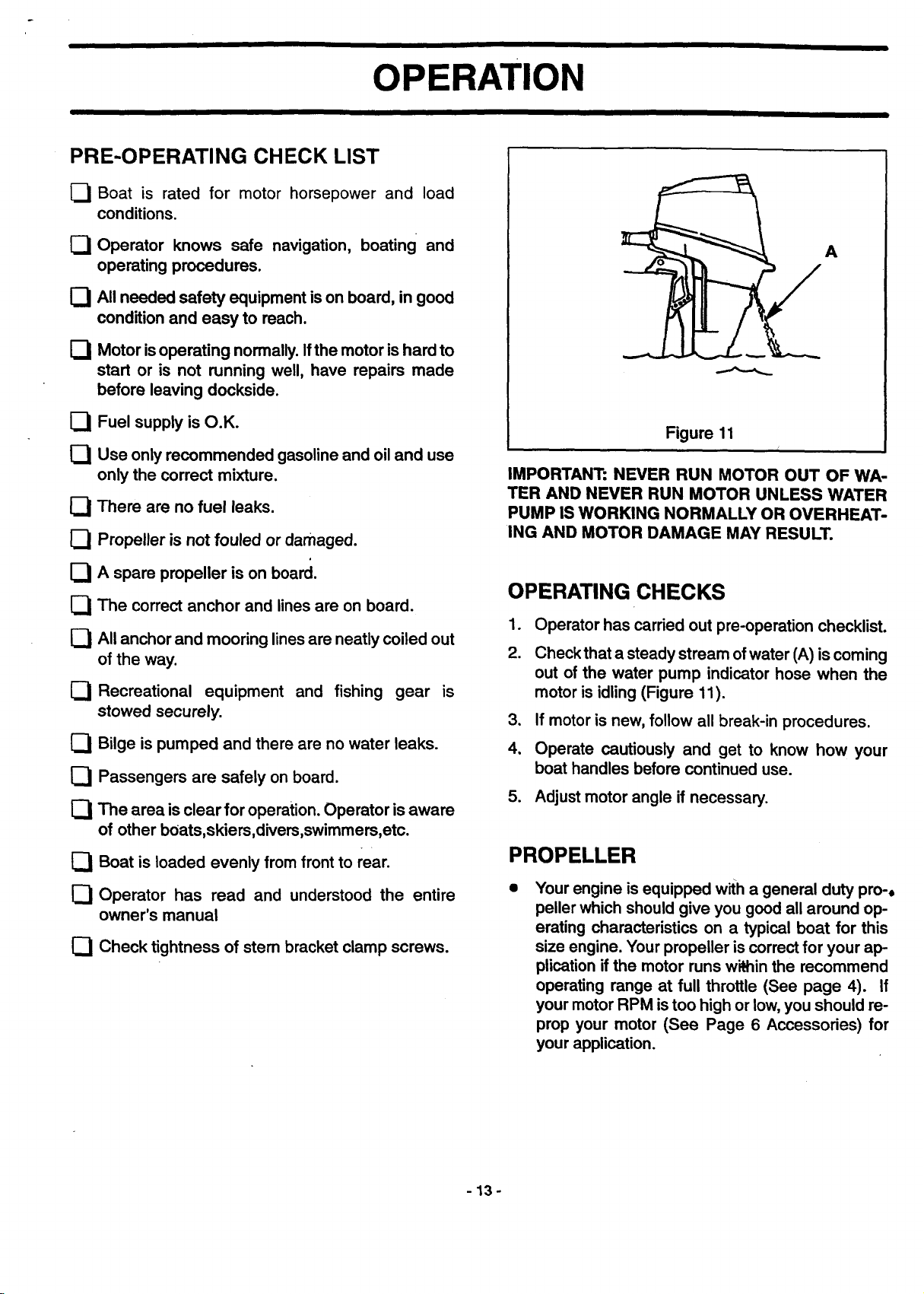

A

Figure 11

IMPORTANT: NEVER RUN MOTOR OUT OF WA-

TER AND NEVER RUN MOTOR UNLESS WATER

PUMP IS WORKING NORMALLY OR OVERHEAT-

ING AND MOTOR DAMAGE MAY RESULT.

OPERATING CHECKS

1. Operator has carried out pre-operation checklist.

2. Checkthat a steadystream of water (A) is coming

out of the water pump indicator hose when the

motor is idling (Figure 11).

3. Ifmotoris new,follow all break-in procedures.

4, Operate cautiously and get to know how your

boat handles before continued use.

5. Adjustmotor angle if necessary.

PROPELLER

Your engine is equipped with a general duty pro-,

peller which should give you good all around op-

erating characteristics on a typical boat for this

size engine. Your propeller is correct for your ap-

plication if the motor runs within the recommend

operating range at full throttle (See page 4). If

your motor RPM is too high or low, you should re-

prop your motor (See Page 6 Accessories) for

your application.

-13-

OPERATION

BEFORE STARTING ENGINE

GASOLINE SELECTION

UNITED STATES AND CANADA

This outboard is designed to operate on any major

brand of automotive unleaded gasoline with a mini-

mum posted octane rating of 87. Mid-grade automo-

tive gasolines that contain fuel injector cleaner are

preferred for added intemal engine cleanliness.

Leaded gasoline is not recommended.

INTERNATIONAL

Use a major brand of automotive unleaded gasoline

with a minimum poster RON of 90. Mid-grade auto-

motive gasoline that contain fuel injector cleaner are

preferred for added intemal engine cleanliness.

Leaded gasoline is acceptable in areas where un-

leaded gasoline is not available. However, exhaust

passageway corrosion may occur due to the accu-

mulation of exhausted lead particles.

IMPORTANT: TO AVOID ENGINE PROBLEMS,

THE FUEL SYSTEM SHOULD BE EMPTIED BE-

FORE STORAGE FOR 30 DAYS OR LONGER.

DRAIN THE FUEL TANK, THEN RUN THE ENGINE

AND LET IT RUN UNTIL IT STOPS. USE FRESH

FUEL NEXT SEASON. SEE STORAGE INSTRUC-

TIONS FOR ADDITIONAL INFORMATION. NEVER

USE ENGINE OR CARBURETOR CLEANER

PRODUCTS IN THE FUEL TANK OR PERMANENT

DAMAGE MAY OCCUR. EXPERIENCE INDI-

CATES THAT ALCOHOL BLENDED FUELS

CALLED GASOHOL (OR USING ETHANOL OR

METHANOL) CAN ATTRACT MOISTURE, WHICH

LEADS TO OIL/GAS SEPARATION AND FORMA-

TION OF ACIDS DURING STORAGE. ACIDIC GAS

CAN DAMAGE THE FUEL SYSTEM OF AN EN-

GINE WHILE IN STORAGE.

If gasoline containing alcohol is used or if you suspect

the presence of alcohol in your gasoline, increase

your inspection of the fuel system, visually checking

for leaks or abnormalities.

stabilizer container. Run engine at least 5 minutes af-

ter adding stabilizer to allow the stabilizer to reach the

carburetor. You do not have to drain the fuel tank for

storage if you are using fuel stabilizer.

OIL RECOMMENDATION

Use SEARS ULTRA PREMIUM Certified TC-W3

2- Cycle Outboard Oil.

Sears Ultra Premium Certified TC-W3 Outboard

Oil is a high grade oilthat provides increased lu-

bricationand extra resistance to carbon buildup

when used with good or varying grades of gaso-

line.

Periodically consult with your Sears store to get the

latest gasoline and oil recommendations. If Sears

2-Cycle Outboard Oil is not available, substitute a 2

Cycle outboard manufacturer's oil or another brand of

2-Cycle outboard oil that is NMMA Certified TC-W3

or TC-WII. The use of an inferior 2-Cycle oil can re-

duce engine durability. Damage from use of an inferi-

or oil may not be covered under the limited warranty.

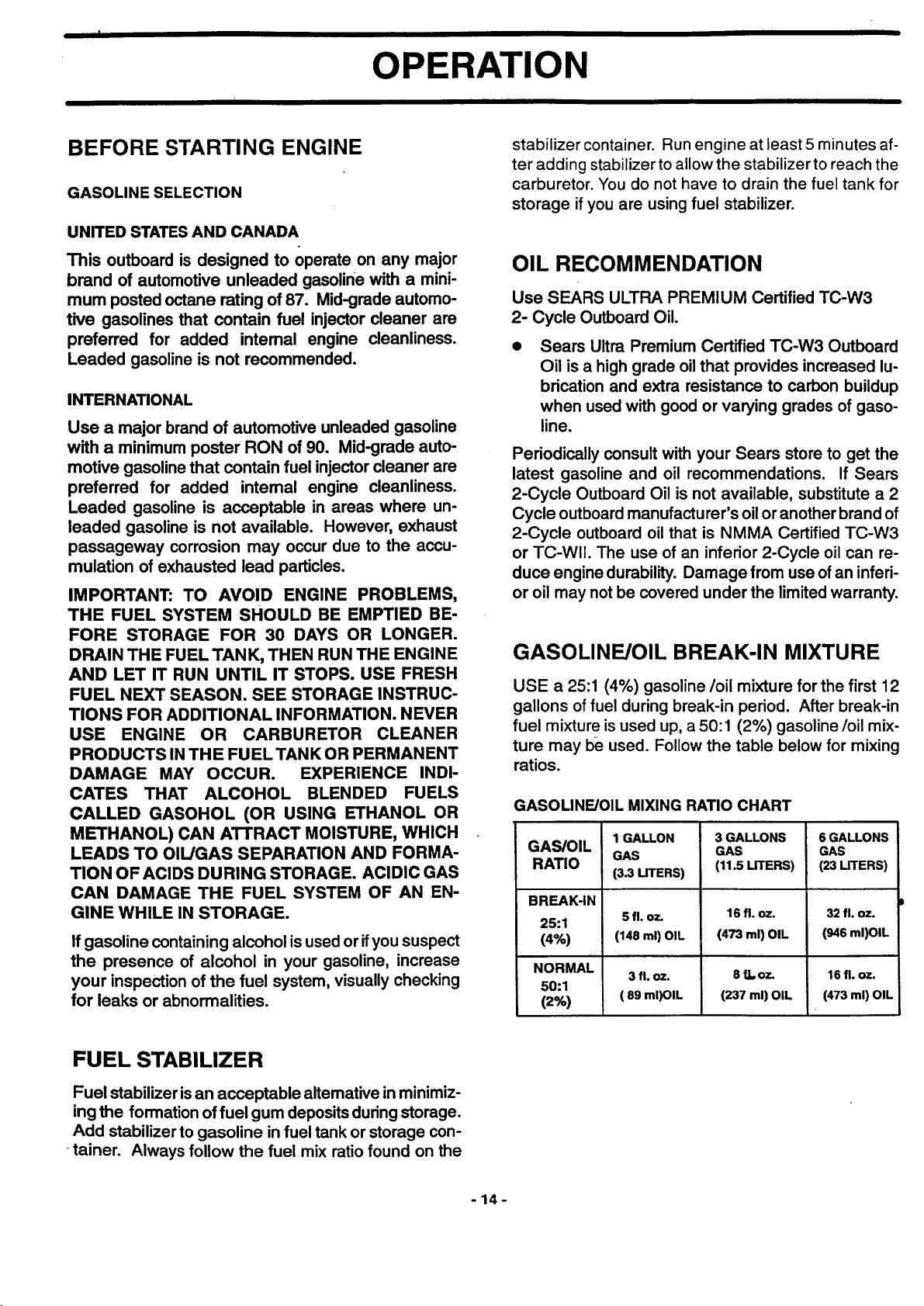

GASOLINE/OIL BREAK-IN MIXTURE

USE a 25:1 (4%) gasoline/oil mixture for the first 12

gallons of fuel during break-in period. After break-in

fuel mixture is used up, a 50:1 (2%) gasoline/oil mix-

ture may be used. Follow the table below for mixing

ratios.

GASOLINE/OIL MIXING RATIO CHART

GAS/OIL

RATIO

BREAK-IN

25:1

(4%)

NORMAL

50:1

(2%)

1 GALLON

GAS

(3.3 UTERS)

5 fl. oz.

(148 ml) OIL

3 fl. oz.

( 89 ml)OIL

3 GALLONS

GAS

(11.5 LITERS)

16fl. oz.

(473 ml) OIL

8 tLoz.

(237 ml) OIL

6 GALLONS

GAS

(23 LITERS)

32 fl. oz.

(946 ml)OIL

16fl. oz.

(473 ml) OIL

FUEL STABILIZER

Fuel stabilizer isan acceptable alternative in minimiz-

ing the formation of fuel gum deposits during storage.

Add stabilizer to gasoline in fuel tank or storage con-

tainer. Always follow the fuel mix ratio found on the

-14-

OPERATION

FILLING FUEL TANK

;!_

gm

AVOID SERIOUS INJURY OR DEATH FROM A

GASOLINE FIRE OR EXPLOSION. ALWAYS

STOP THE ENGINE. DO NOT SMOKE OR

ALLOW OPEN FLAMES OR SPARKS IN THE

AREA WHILE FILLING FUEL TANKS.

• Fill fuel tanks outdoors away from heat, sparks,

and open flames.

• Remove portable fuel tanks from boat to refill

them.

Always stop engine before refilling tanks.

Do not overfill the fuel tank. Fuel will expand in

volume as it's temperature rises and can leak un-

der pressure.

FILLING PORTABLE FUEL TANK

Pour the full amount of oil along with approximately

one gallon of gasoline into the fuel tank. Mix thor-

oughly, then pour the remainder of gasoline into the

tank.

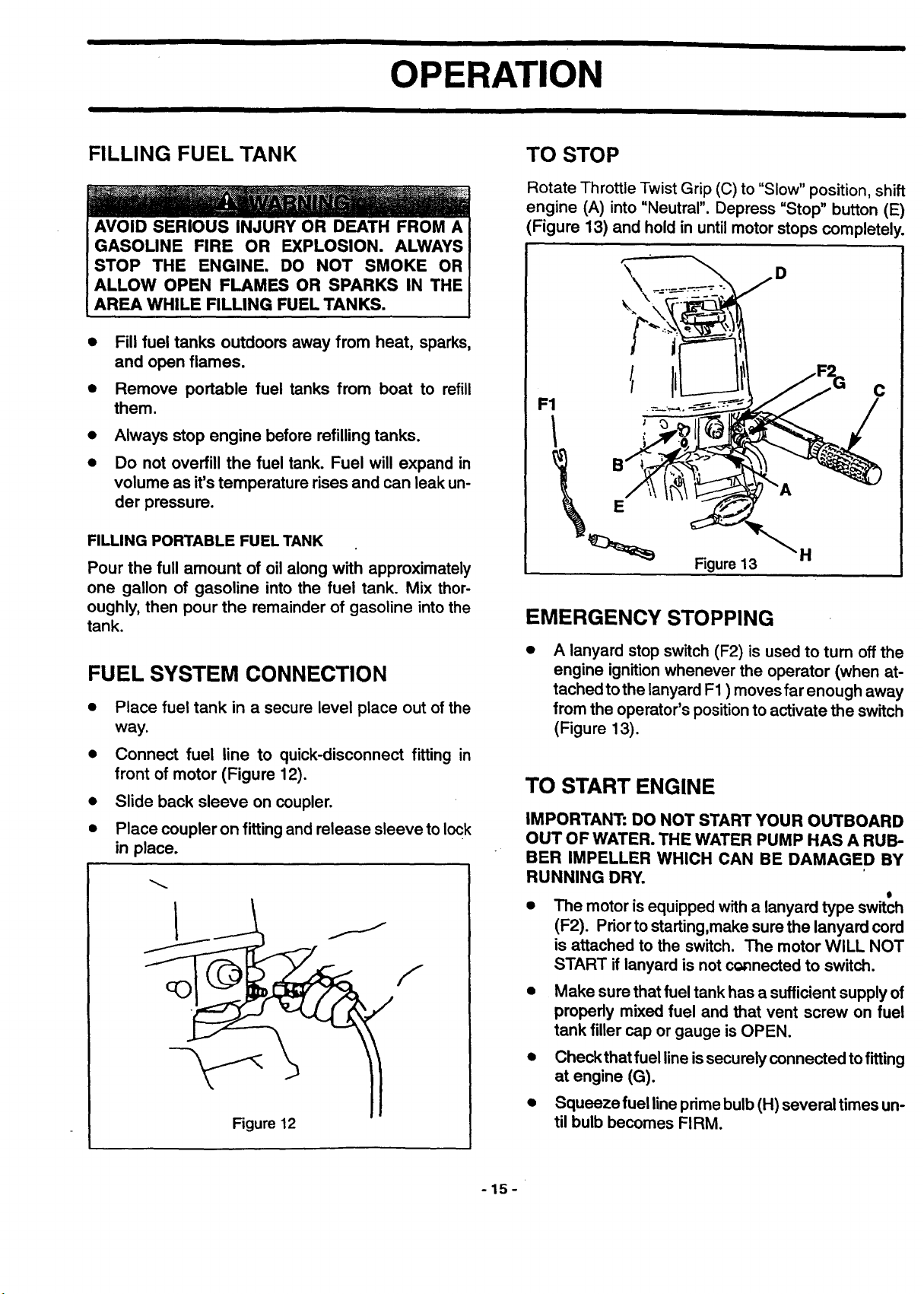

TO STOP

Rotate Throttle Twist Grip (C) to "Slow" position, shift

engine (A) into "Neutral". Depress "Stop" button (E)

(Figure 13) and hold in until motor stops completely.

D

C

F1

E

H

Figure 13

EMERGENCY STOPPING

FUEL SYSTEM CONNECTION

• Place fuel tank in a secure level place out of the

way.

• Connect fuel line to quick-disconnect fitting in

front of motor (Figure 12).

• Slide back sleeve on coupler.

• Place coupler on fitting and release sleeve to lock

in place.

F

A lanyard stop switch (F2) is used to tum off the

engine ignition whenever the operator (when at-

tached tothe lanyard F1 ) moves far enough away

from the operator's position to activate the switch

(Figure 13).

TO START ENGINE

IMPORTANT: DO NOT START YOUR OUTBOARD

OUT OF WATER. THE WATER PUMP HAS A RUB-

BER IMPELLER WHICH CAN BE DAMAGED BY

RUNNING DRY.

0

• The motor is equipped with a lanyard type switch

(F2). Prior to starting,make sure the lanyard cord

is attached to the switch. The motor WILL NOT

START if lanyard is not connected to switch.

• Make sure that fuel tankhas a sufficientsupplyof

properly mixed fuel and that vent screw on fuel

tank filler cap or gauge is OPEN.

• Checkthatfuel line issecurelyconnected tofitting

at engine (G).

Figure 12

• Squeeze fuel line prime bulb (H) several times un-

til bulb becomes FIRM.

-15-

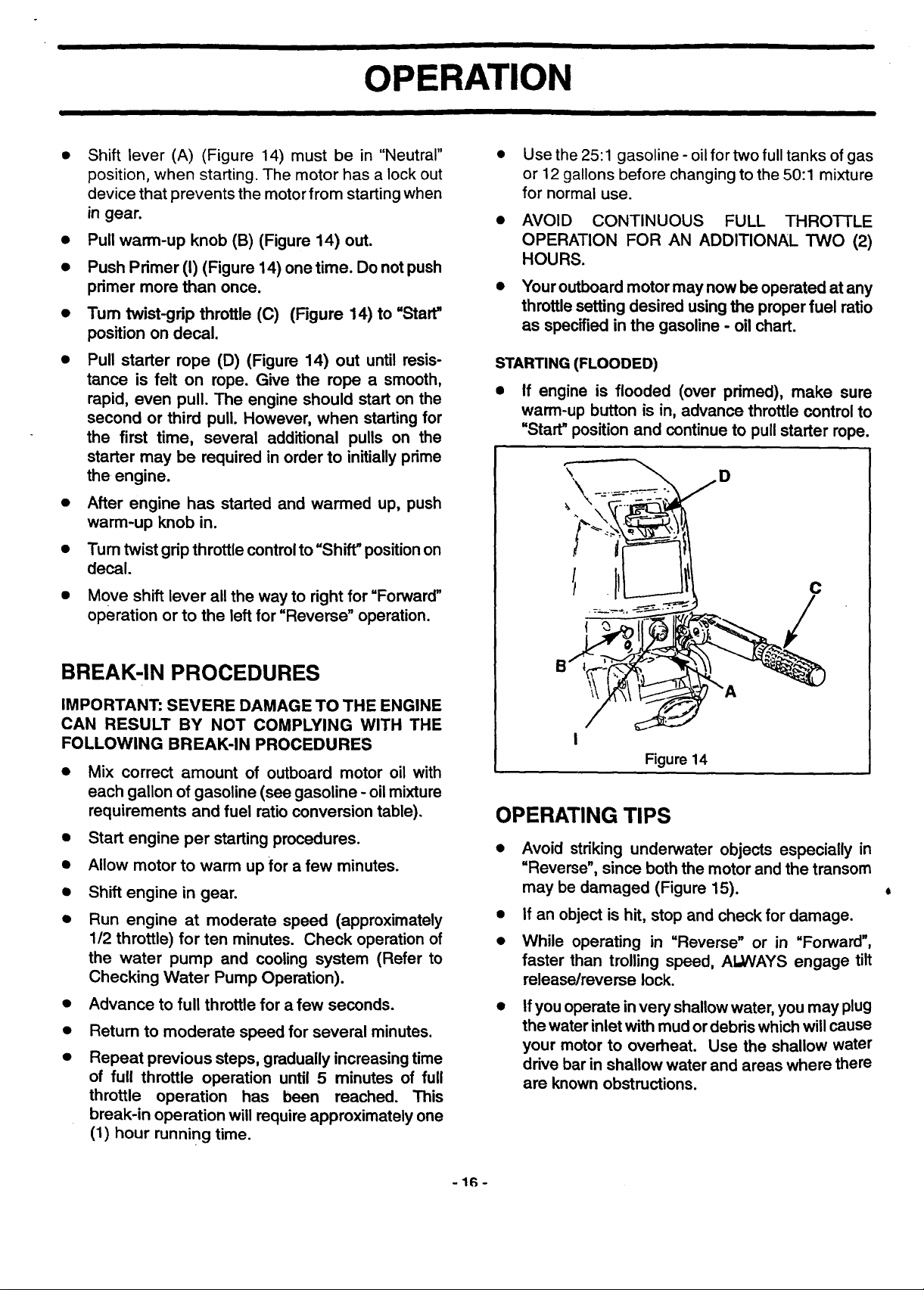

OPERATION

• Shift lever (A) (Figure 14) must be in "Neutral"

position, when starting. The motor has a lock out

device that prevents the motor from starting when

in gear.

• Pull warm-up knob (B) (Figure 14) out.

• Push Primer (I) (Figure 14) one time. Do not push

primer more than once.

• Turn twist-grip throttle (C) (Figure 14) to "Start"

position on decal.

• Pull starter rope (D) (Figure 14) out until resis-

tance is felt on rope. Give the rope a smooth,

rapid, even pull. The engine should start on the

second or third pull. However, when starting for

the first time, several additional pulls on the

starter may be required in order to initially prime

the engine.

• After engine has started and warmed up, push

warm-up knob in.

• Tum twist grip throttle control to"Shift" position on

decal.

Use the 25:1 gasoline - oil for two full tanks of gas

or 12 gallons before changing to the 50:1 mixture

for normal use.

AVOID CONTINUOUS FULL THRO'I-I'LE

OPERATION FOR AN ADDITIONAL TWO (2)

HOURS.

Youroutboardmotormay nowbe operated at any

throttlesetting desired usingthe properfuel ratio

as specifiedinthe gasoline - oil chart.

STARTING (FLOODED)

• If engine is flooded (over primed), make sure

warm-up button is in, advance throttle controlto

"Start" position and continue to pull starter rope.

D

Move shift lever allthe way to rightfor "Forward"

operation or to the left for "Reverse" operation.

BREAK-IN PROCEDURES

IMPORTANT: SEVERE DAMAGE TO THE ENGINE

CAN RESULT BY NOT COMPLYING WITH THE

FOLLOWING BREAK-IN PROCEDURES

• Mix correct amount of outboard motor oil with

each gallon of gasoline (see gasoline - oil mixture

requirements and fuel ratio conversion table).

• Start engine per starting procedures.

• Allow motor to warm up for a few minutes.

• Shift engine in gear.

• Run engine at moderate speed (approximately

112 throttle) for ten minutes. Check operation of

the water pump and cooling system (Refer to

Checking Water Pump Operation).

Advance to full throttle for a few seconds.

Return to moderate speed for several minutes.

Repeat previous steps, gradually increasing time

of full throttle operation until 5 minutes of full

throttle operation has been reached. This

break-in operation will require approximately one

(1) hour running time.

I

Figure 14

OPERATING TIPS

Avoid striking underwater objects especially in

"Reverse", since both the motor and the transom

may be damaged (Figure 15).

If an object is hit, stop and check for damage.

While operating in "Reverse" or in "Forward",

faster than trolling speed, AI,,WAYS engage tilt

release/reverse lock.

If you operate in very shallow water, you may plug

the water inlet with mud or debris which will cause

your motor to overheat. Use the shallow water

drive bar in shallow water and areas where there

are known obstructions.

-16-

OPERATION

OPERATING TIPS, CONT.

If while operating your boat the propeller comes

in contact with fishing line, stop motor. Visually

inspect and remove any fishing line that is

wrapped around prop. As soon as possible,

remove engine from water and check gear hous-

ing for water which would indicate a damaged

seal.

OPERATING IN FREEZING TEMPERATURES

• When operating the motor in freezing or near

freezing temperature, keep the gear housing in

the water. When launchingthe boat/motor innear

freezing temperature, letthe rigsoak for 20 to 30

minutes before startingto allowwater inthe water

pick-up, water pump orwater tube to thaw.

IMPORTANT: IF OUTBOARD IS STORED TILTED

UP IN FREEZING TEMPERATURE, TRAPPED

COOLING WATER OR RAIN WATER THAT MAY

HAVE ENTERED THE EXHAUST OUTLET IN THE

GEAR CASE COULD FREEZE AND CAUSE DAM-

AGE TO THE OUTBOARD.

AND CHECK

Figure 15

IMPORTANT: IF THE MOTOR IS TILTED OUT OF

THE WATER, WATER REMAINING IN THE COOL-

ING SYSTEM AND GEAR HOUSING MAY FREEZE

AND CAUSE PARTS TO BREAK.

• Do not start a motor that might be frozen.

SALT WATER OPERATION

Although all motor parts that contact water have been

chemically treated to resist salt water corrosion, you

should take some special steps after running your

motor in salt water.

• Always tilt the motor out of the water when not in

use.

• From time to time run the motor in fresh water to

flush out salt deposits.

• Wash motor down with fresh water and soap:

rinse.

Apply a marine type wax to protect the finish.

• Periodically remove propeller and lubricate pro-

peller shaft.

• Replace water pump impeller every year.

• Remove gear housing and apply anti-seize com-

pound to the driveshaft/crankshaft splines.

_4"/

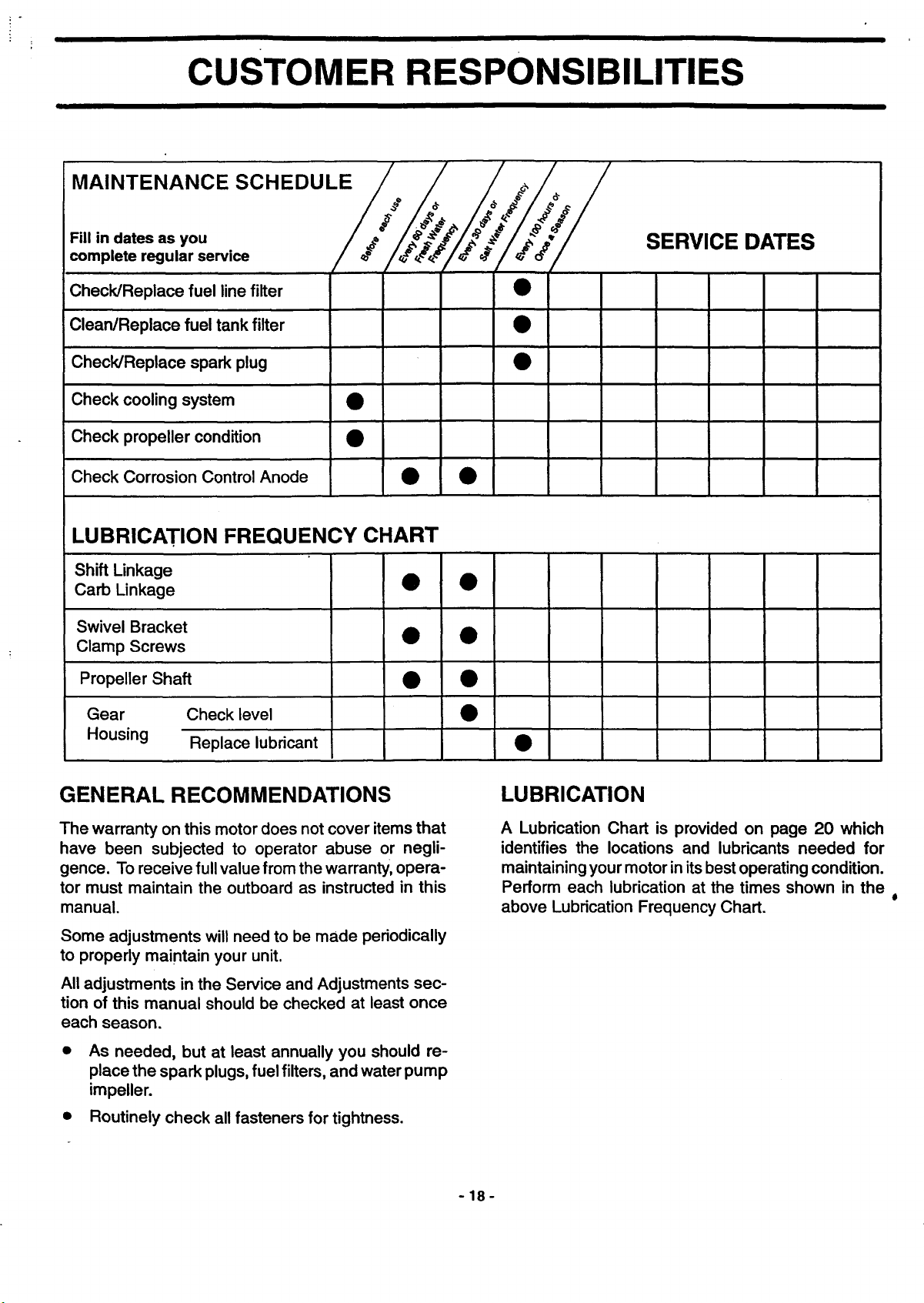

CUSTOMER RESPONSIBILITIES

' / /

,,,,,n°°,o°°,

complete regular service // _

Check/Replace fuel line filter •

Clean/Replace fuel tank filter •

Check/Replace spark plug •

Check cooling system •

Check propeller condition •

Check Corrosion Control Anode • •

LUBRICATION FREQUENCY CHART

Shift Linkage

Carb Linkage • •

Swivel Bracket • •

Clamp Screws

Propeller Shaft • •

SERVICE DATES

Gear Check level •

Housing Replace lubricant •

GENERAL RECOMMENDATIONS

The warranty on this motor does not cover items that

have been subjected to operator abuse or negli-

gence. To receive full value from the warranty, opera-

tor must maintain the outboard as instructed in this

manual.

Some adjustments will need to be made periodically

to properly maintain your unit.

All adjustments in the Service and Adjustments sec-

tion of this manual should be checked at least once

each season.

As needed, but at least annually you should re-

place the spark plugs, fuel filters, and water pump

impeller.

Routinely check all fasteners for tightness.

LUBRICATION

A Lubrication Chart is provided on page 20 which

identifies the locations and lubricants needed for

maintaining your motor in its best operating condition.

Perform each lubrication at the times shown in the

above Lubrication Frequency Chart.

-18-